Replaceable universal atomizing head

a universal, atomizing head technology, applied in the field of electronic cigarettes, can solve the problems of high use cost, poor taste, and small amount of smoke, and achieve the effects of preventing dry combustion, simple structure, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Now, the present invention will be further described combining with the drawings and specific embodiments.

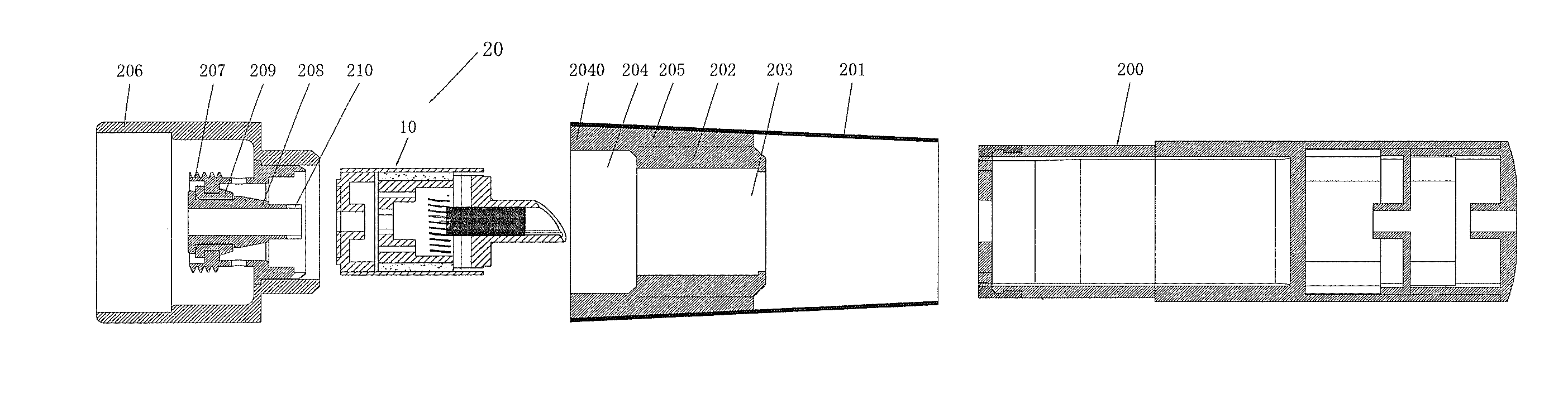

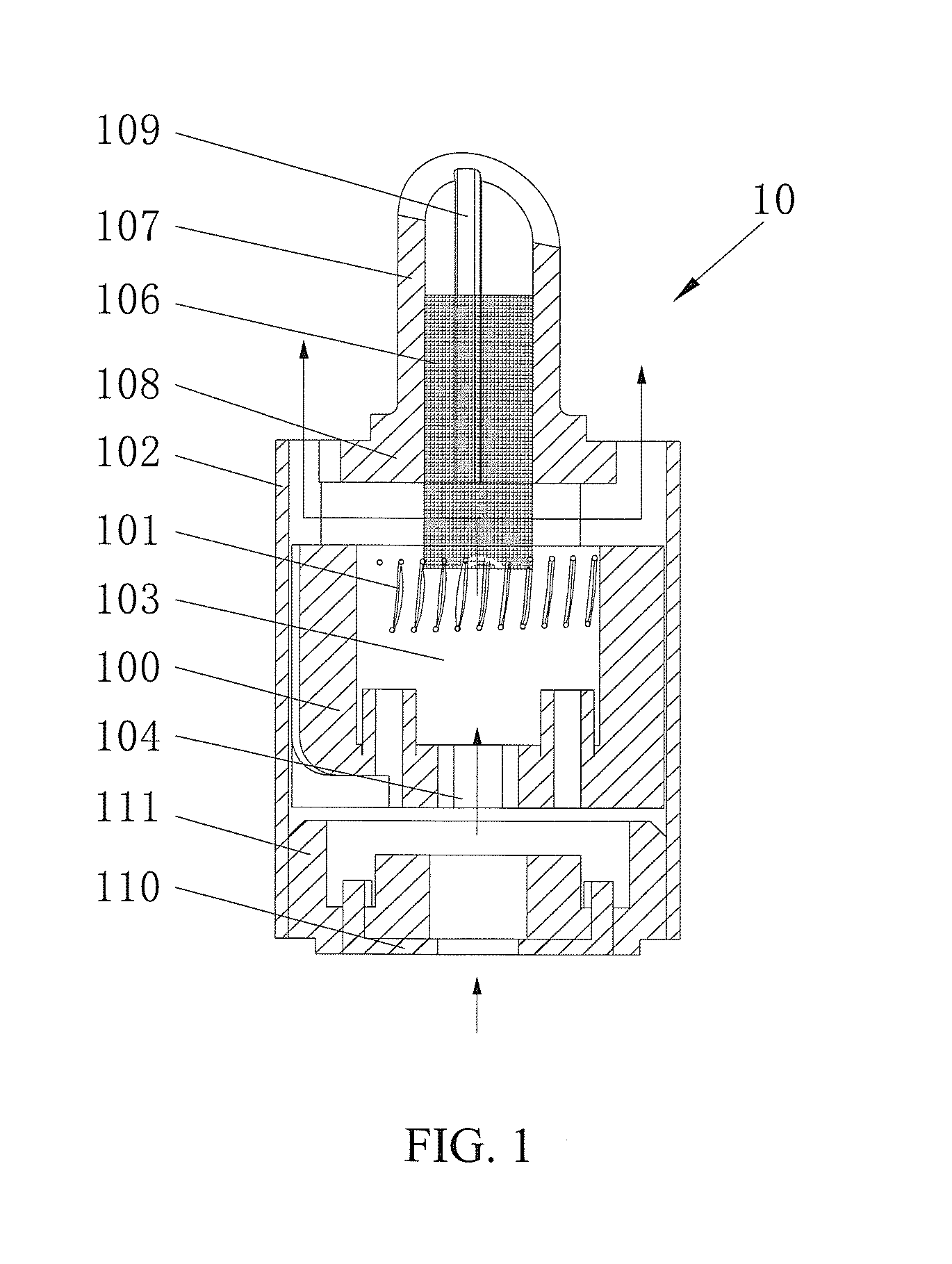

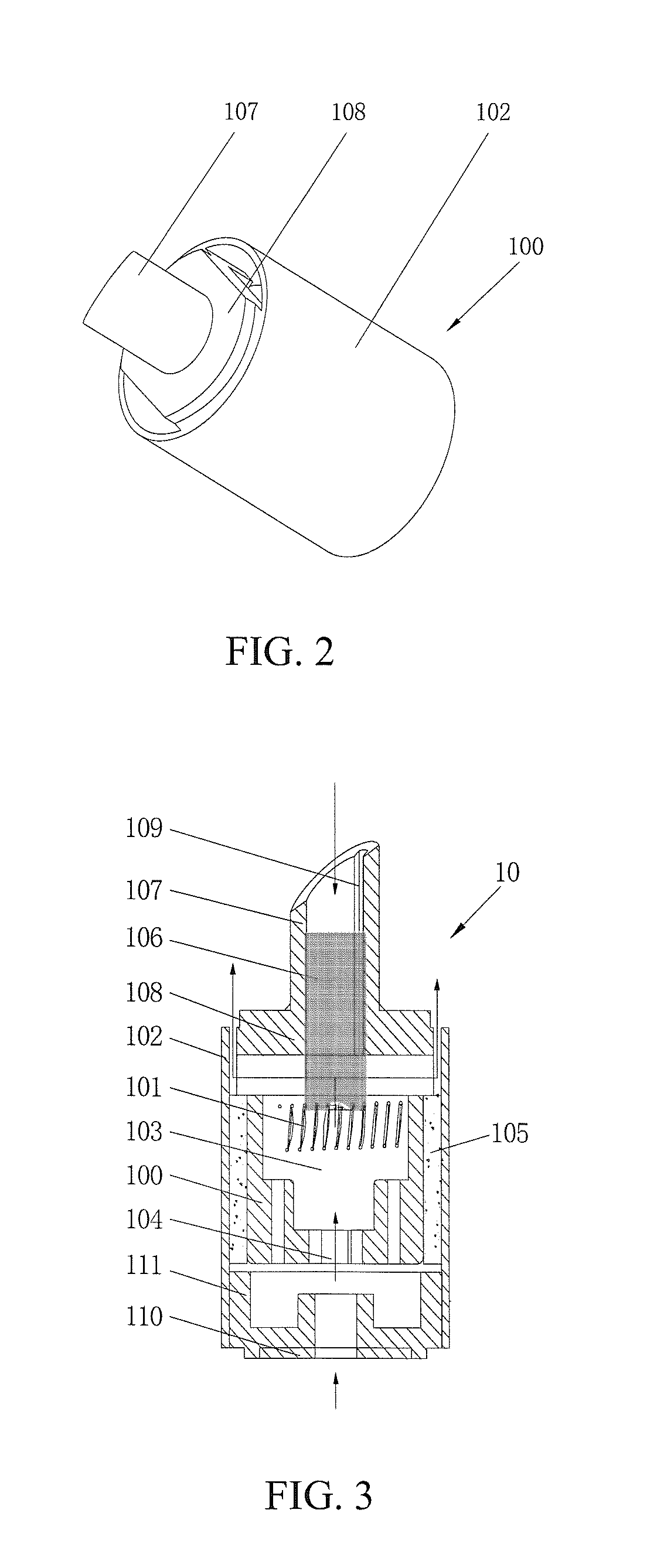

[0034]Referring to FIGS. 1 to 3, a universal atomizing head 10 of the present invention, which comprises a support base 100 with an atomizing chamber, a heating device 101, a conductive ring 102, and a liquid guiding member. The support base 100 is made of ceramic, in order to install the heating device101, an atomizing chamber 103 is provided in the support base 100. In order to permit the gas to enter into the atomization chamber 103, a vent hole 104 is provided in the bottom of the support base 100. The heating device 101 is a heating wire made of the metal, fixed to the atomizing chamber 103 of the support base 100; both ends of the heating device before assembled into a universal atomizing head are welded with the wire. On one hand, the conductive ring 102 is a conductive negative of the universal atomizing head; on the other hand is used to mount other components.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com