Patents

Literature

425results about How to "Realize the cleaning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

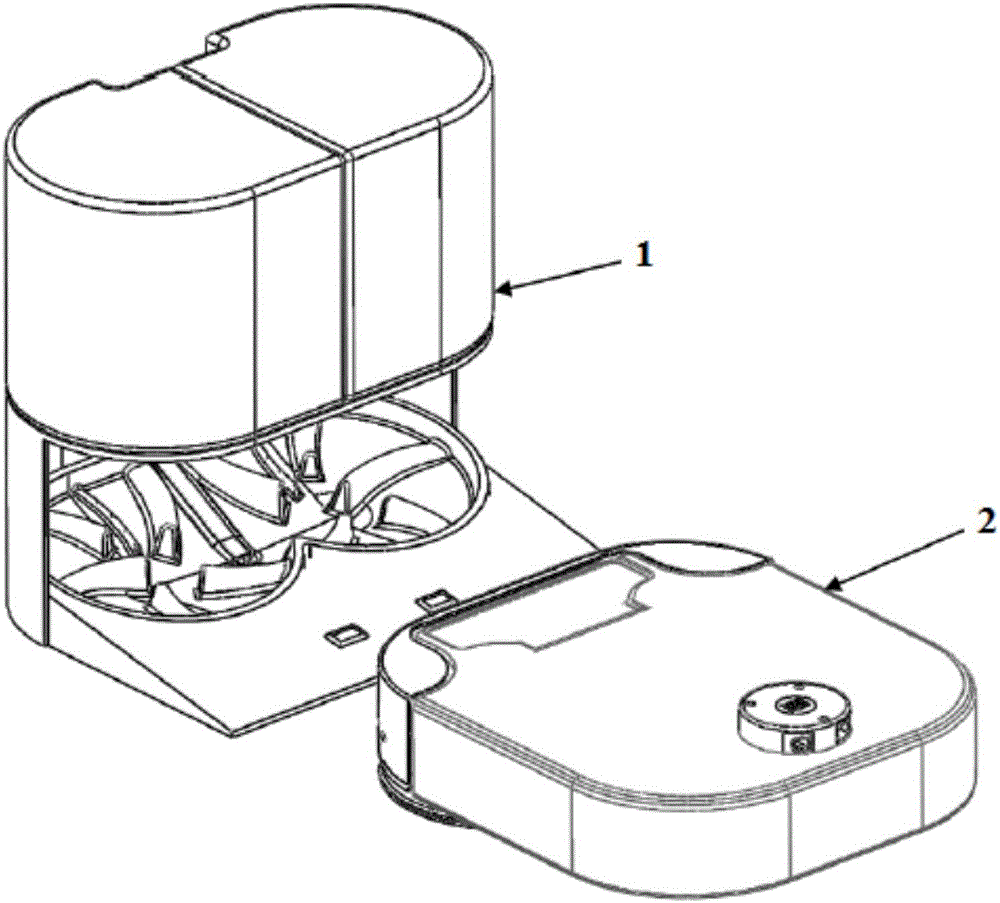

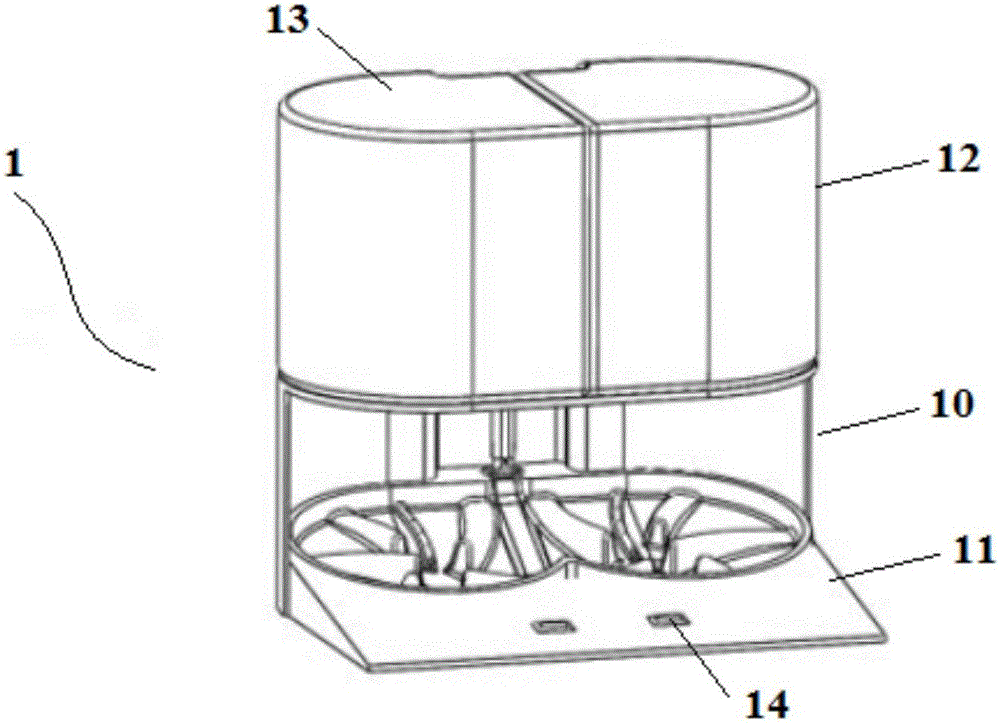

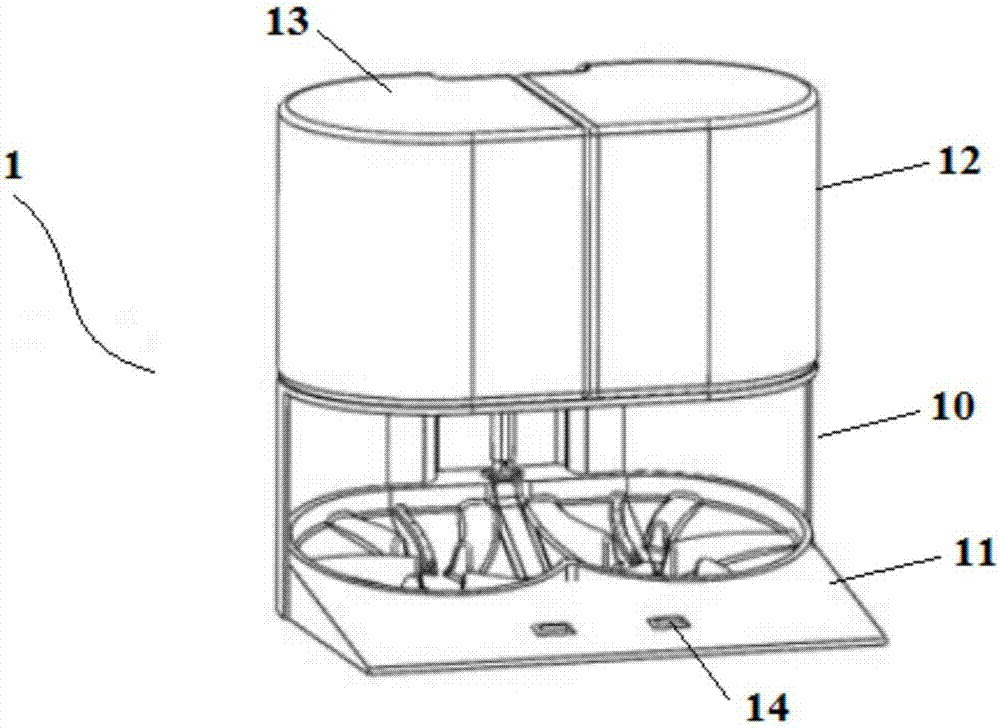

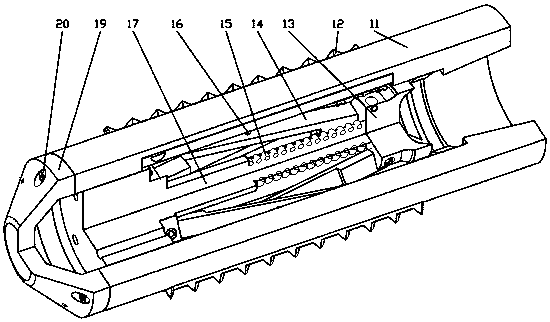

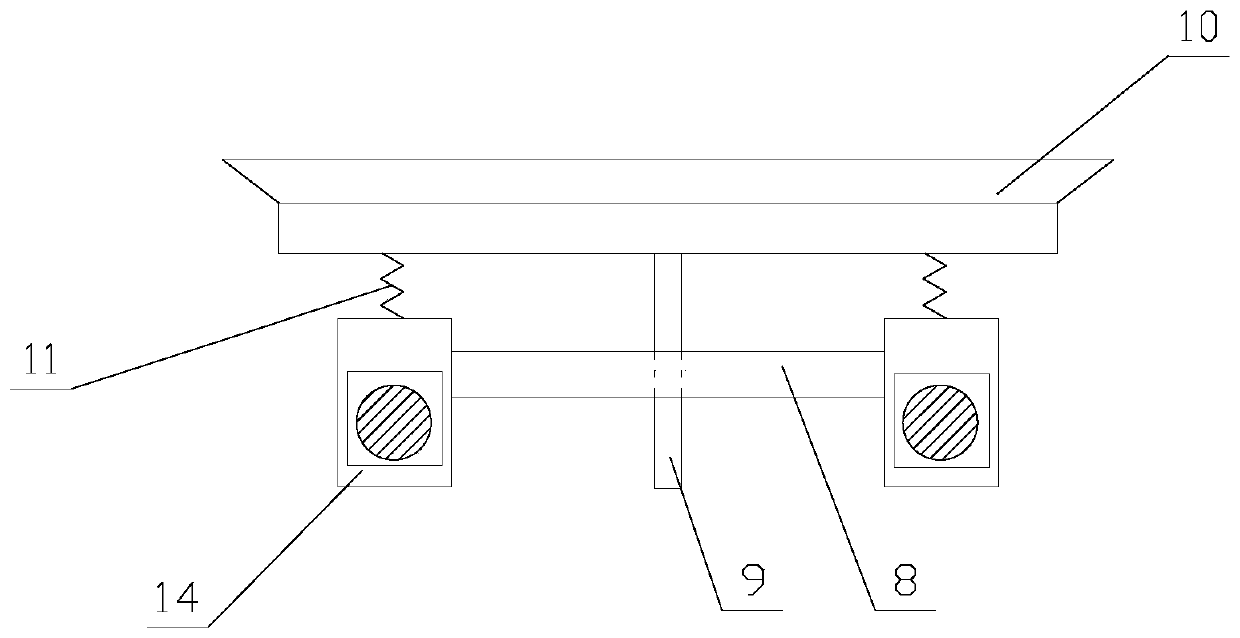

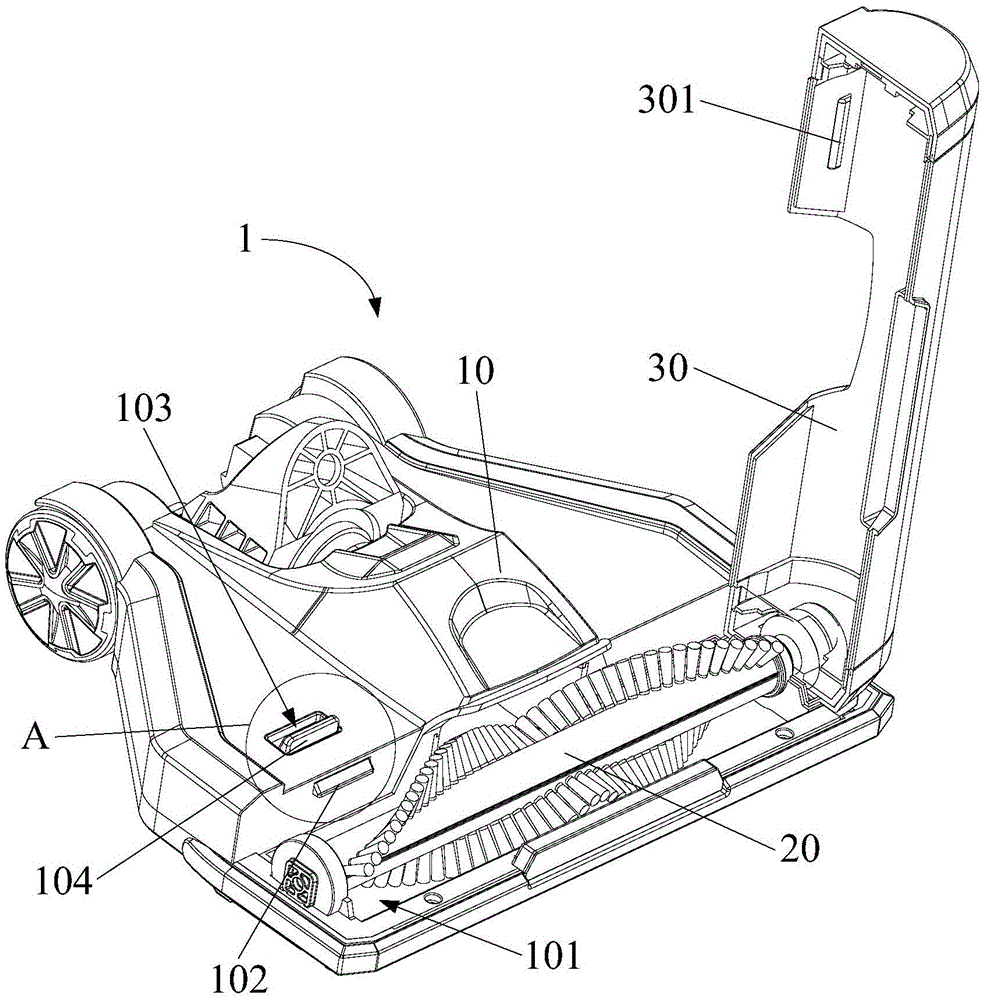

Robot cleaner and cleaning robot system

ActiveCN106510556ASimple structureReduce volumeCarpet cleanersFloor cleanersRobotic systemsControl theory

The invention relates to the technical field of a cleaning robot, and especially relates to a robot cleaner and a cleaning robot system. According to the cleaning robot provided by the invention, two mopping pieces on a mopping unit can rotate in the same direction or reverse direction around a vertical axial line in relative to a chassis of the cleaning robot, and a collecting opening of a garbage collecting device is arranged in the middle of two mopping units. Thus the relative movement between the mopping piece and the ground during the mopping process includes movement of the whole cleaning robot on the ground and also includes rotating movement of the mopping piece in relative to the ground, thus the mopping force is enhanced, and the mopping effect of the mopping piece is further improved. Besides, the rotating mopping piece can sweep large particles, dust and other garbage on the ground, so that the garbage collecting device can collect garbage collected by the mopping piece of two mopping unit rotated around the vertical axial line, namely, the rotating mopping piece can play the sweeping function at the same time, and the cleaning robot becomes the integrated robot of sweeping and mopping.

Owner:YUNJING INTELLIGENCE TECH (DONGGUAN) CO LTD

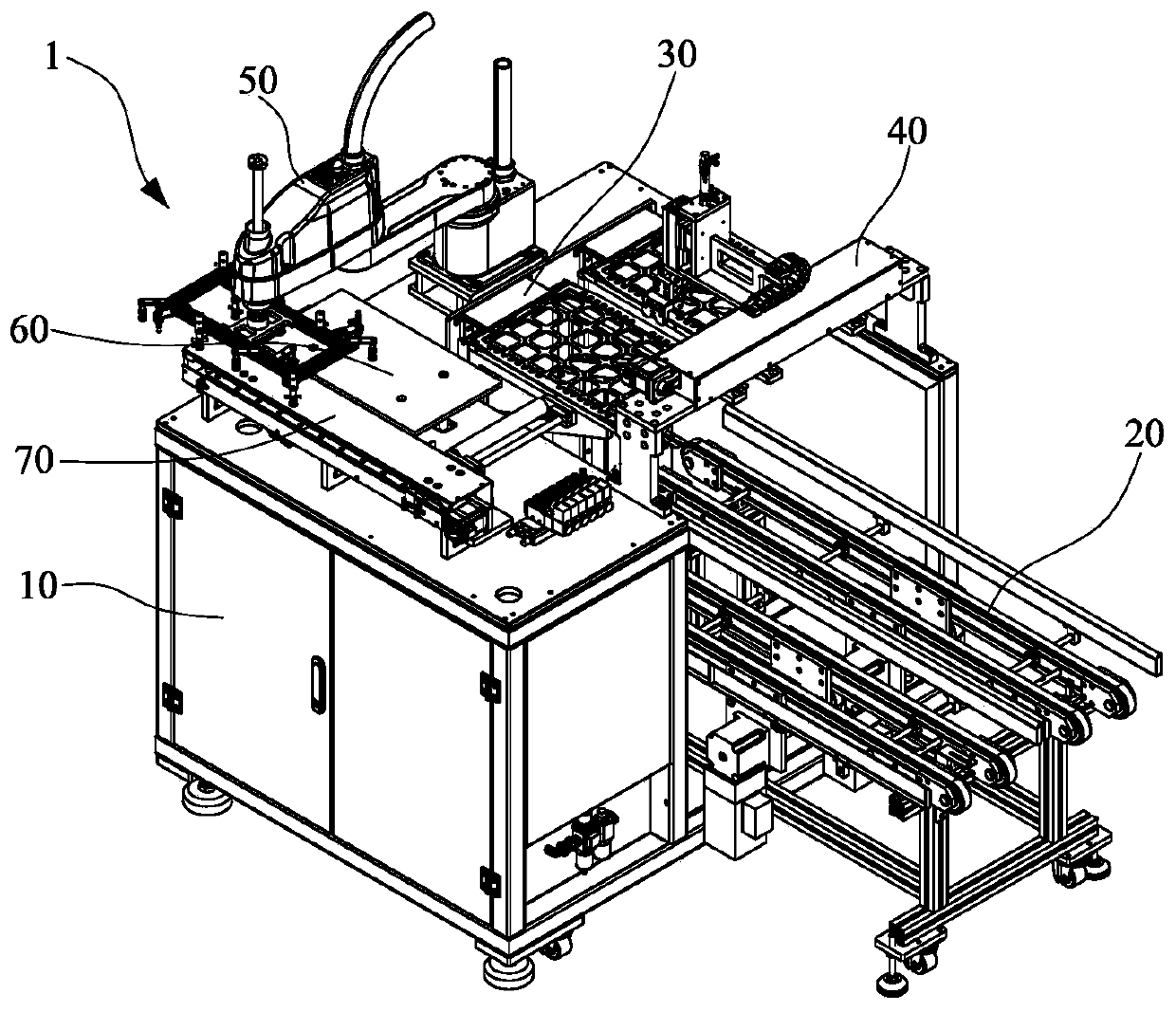

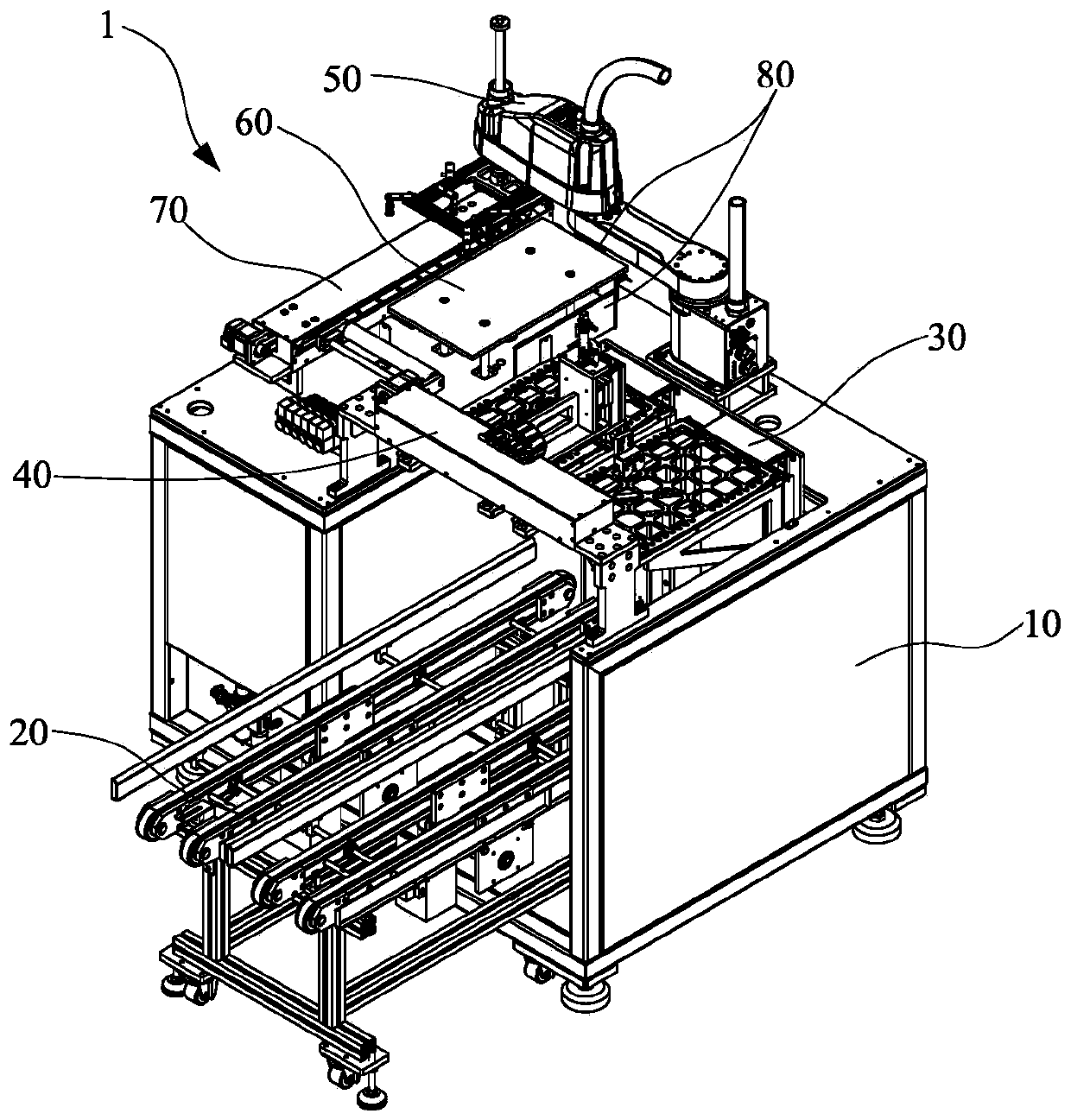

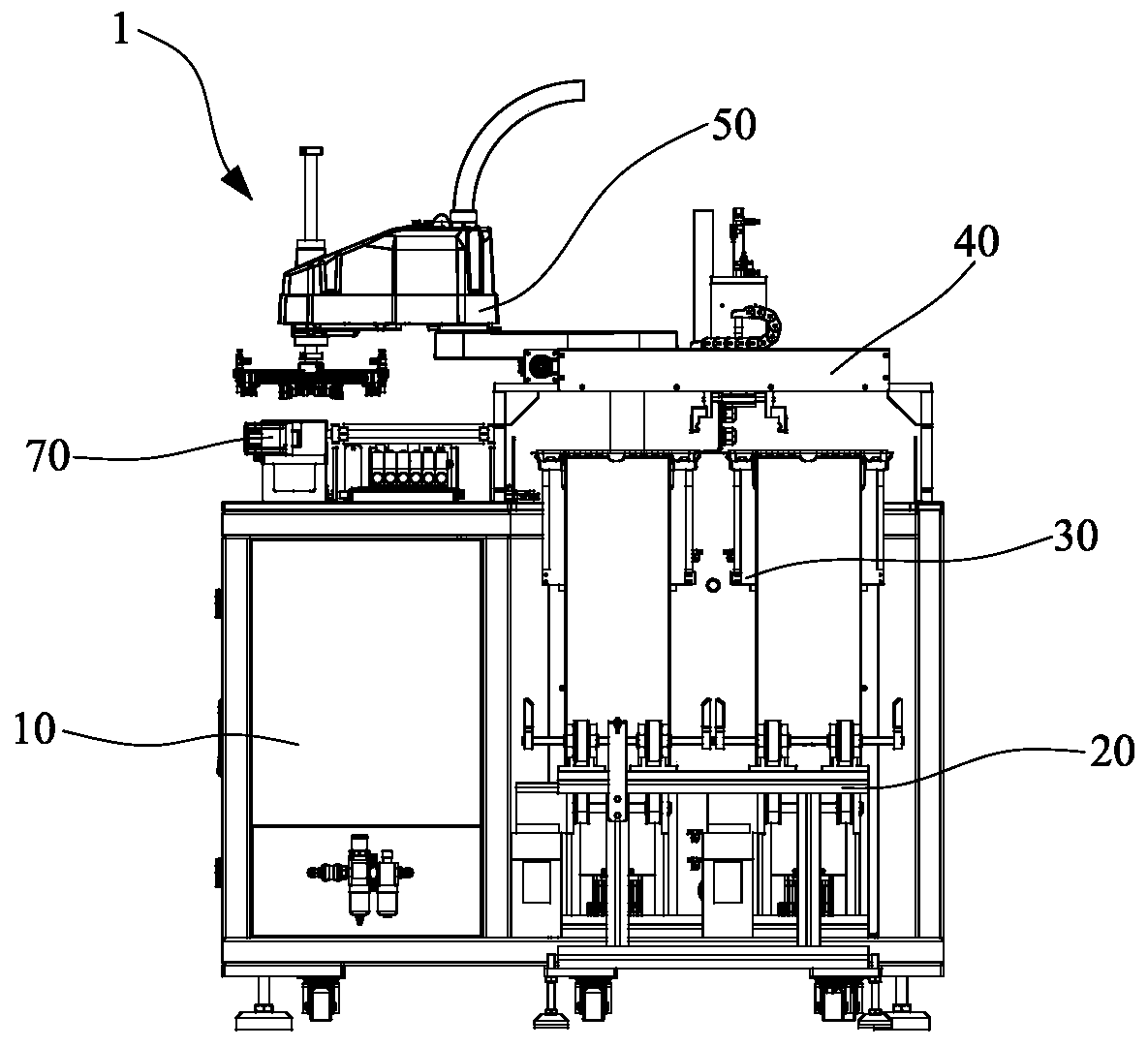

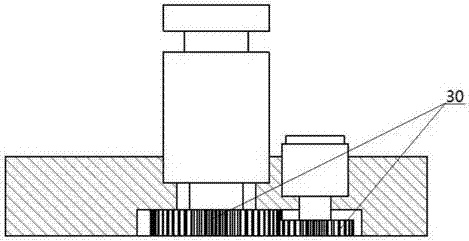

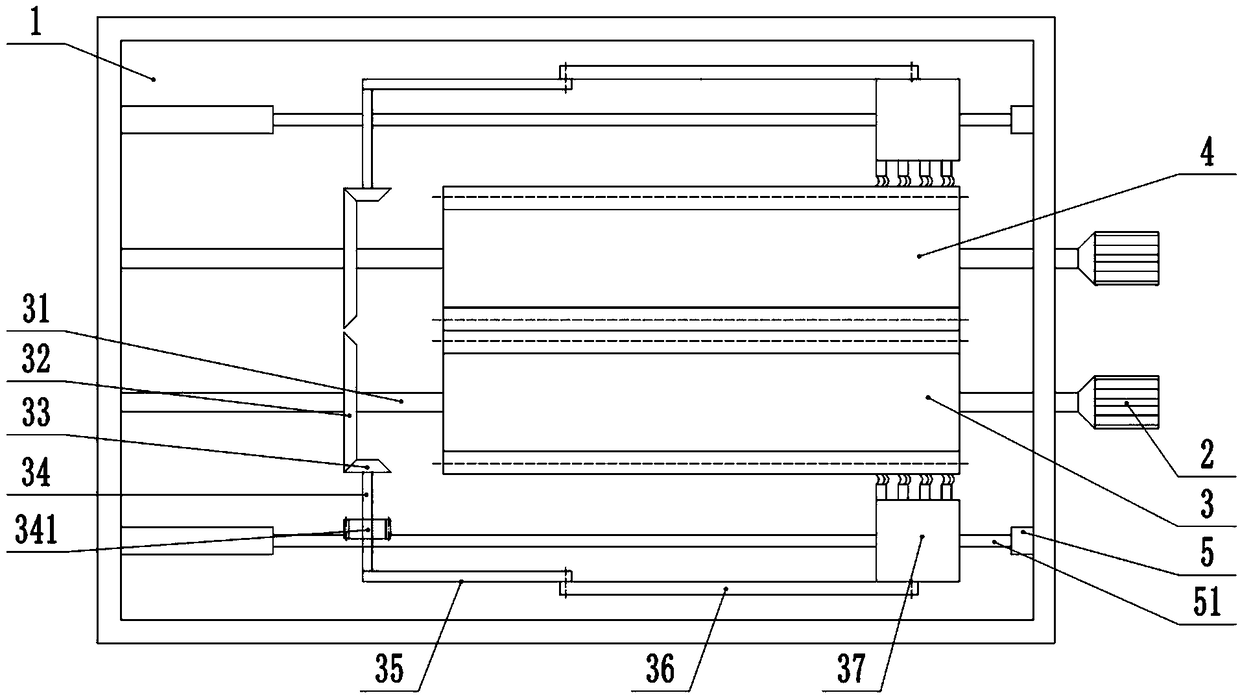

Silk-screen feeding and discharging device

PendingCN111252491ARealize handoverReduce waiting timeControl devices for conveyorsStacking articlesScreen printingEngineering

The invention discloses a silk-screen feeding and discharging device. The silk-screen feeding and discharging device comprises a rack, a tray conveying and buffering mechanism, a tray feeding and discharging mechanism, a tray carrying mechanism, a material moving manipulator and a feeding platform mechanism, wherein a workbench and a tray feeding and discharging space are arranged on the rack; thetray conveying and buffering mechanism penetrates through the tray feeding and discharging space of the rack; the tray feeding and discharging mechanism can move up and down relative to the tray conveying and buffering mechanism; the tray carrying mechanism is transversely erected on the portion, above the corresponding tray conveying and buffering mechanism, of the rack and moves in the space above the tray feeding and discharging mechanism; the material moving manipulator is arranged on the portion, on one side of the tray feeding and discharging mechanism, of the rack and rotates and movesin the space above the rack at multiple stations; and the feeding platform mechanism is arranged on the workbench of the rack and is close to the side, close to the tray feeding and discharging mechanism, of the material moving manipulator. The silk-screen feeding and discharging device can be matched with an existing semi-automatic silk-screen printing machine and transformed into a full-automatic silk-screen printing machine, existing equipment resources are fully utilized, and automation of silk-screen printing of products is achieved.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

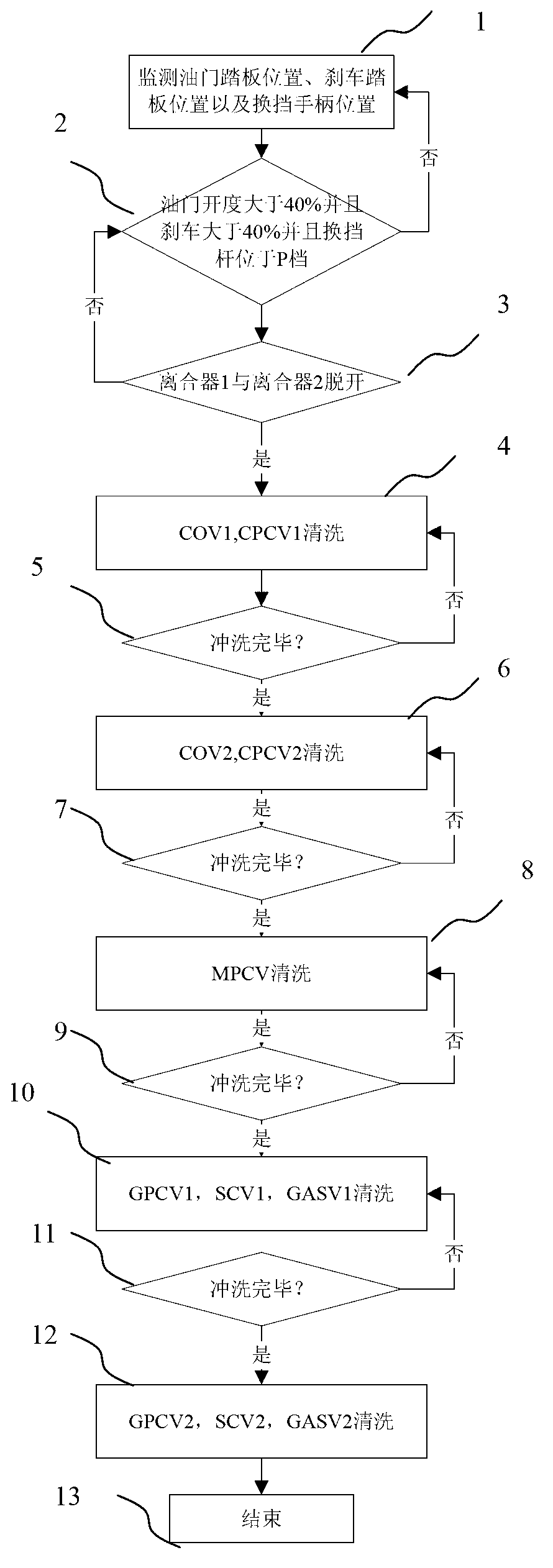

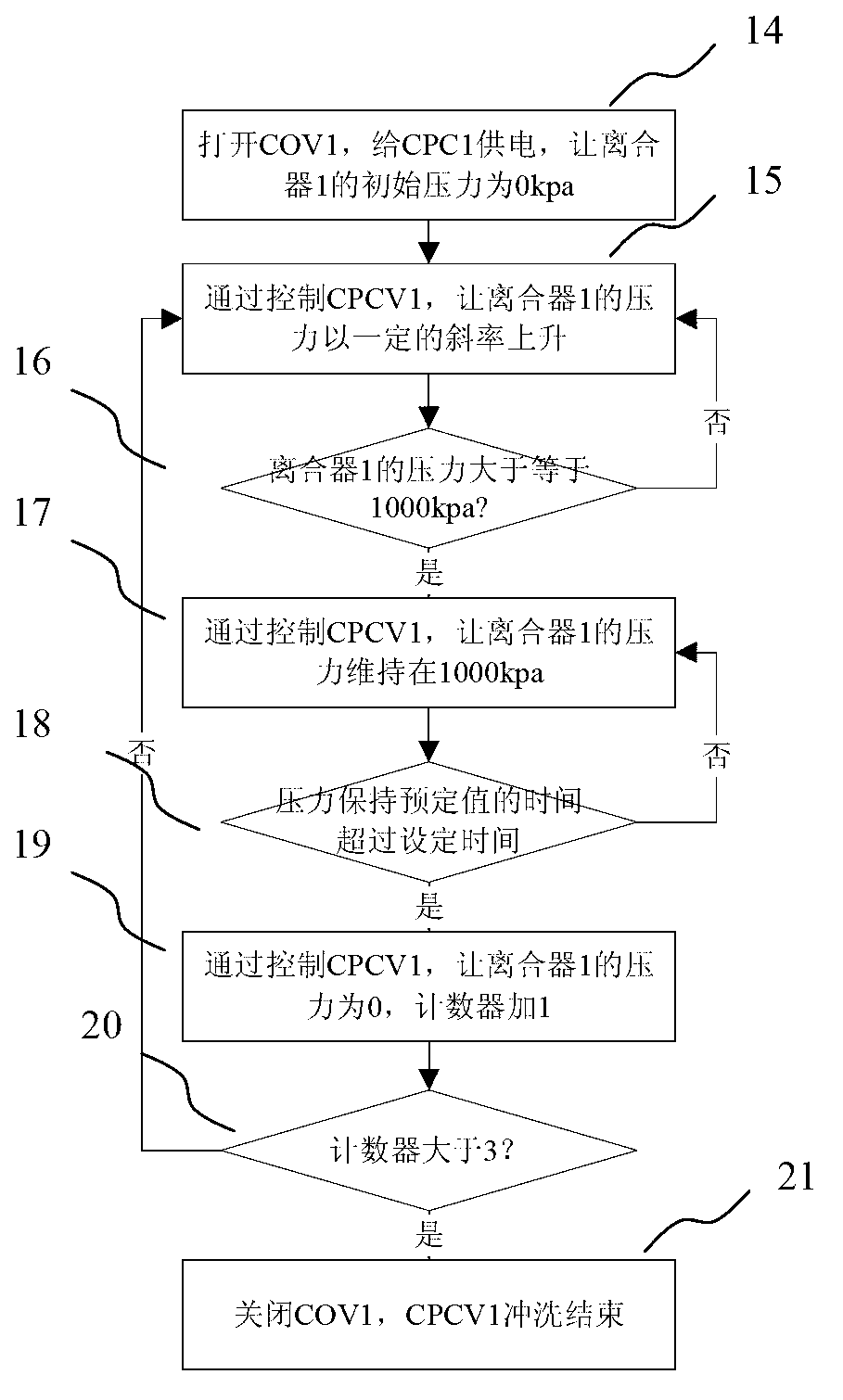

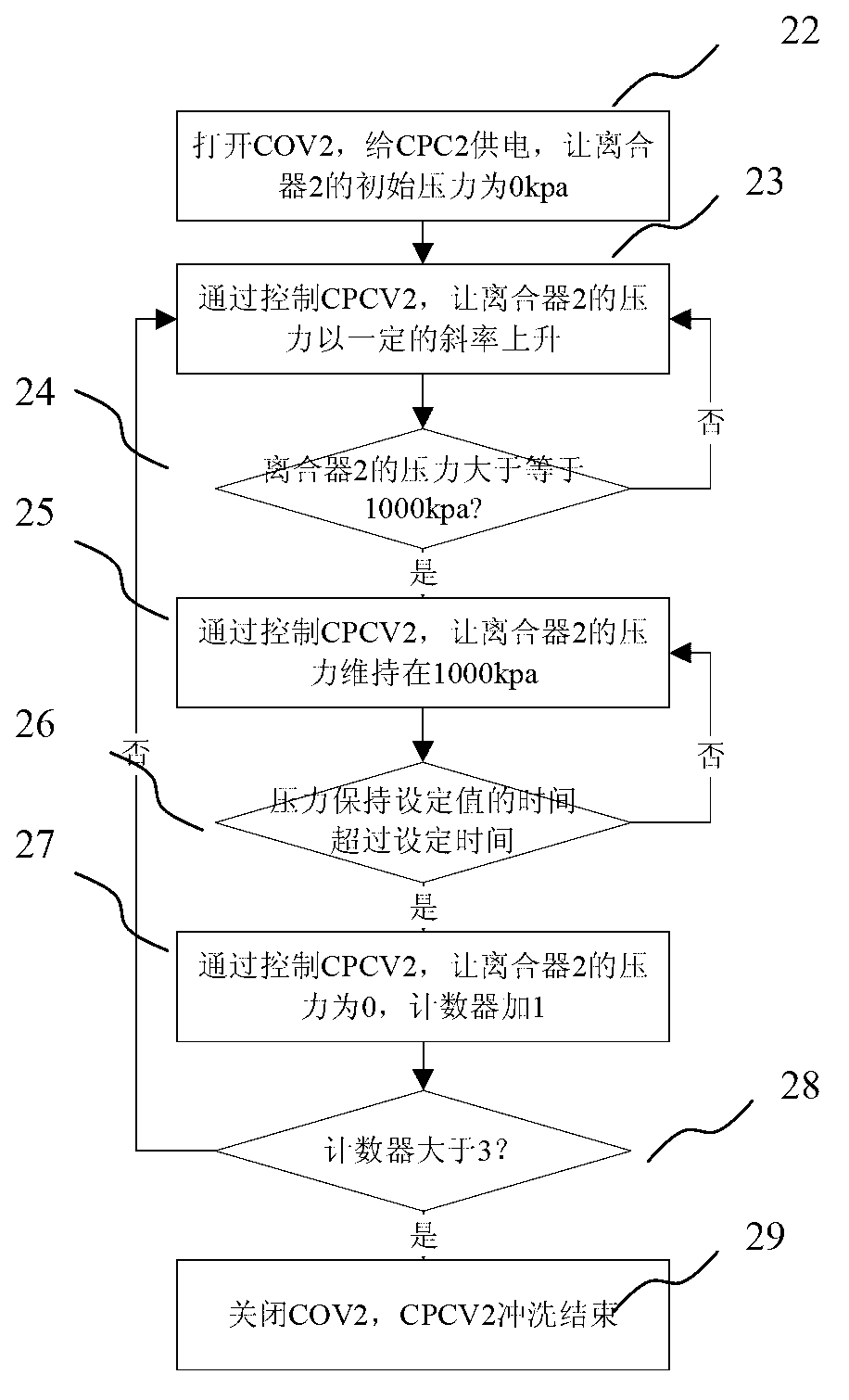

Washing control system for double-clutch automatic gearbox

ActiveCN102841550AEasy to collectEasy to operateVehicle cleaningProgramme control in sequence/logic controllersSolenoid valveControl system

The invention relates to an electric control system for a double-clutch automatic gearbox. In the electric control system, a washing set for a solenoid valve of a wet type double-clutch automatic gearbox mainly comprises a solenoid valve, a clutch 1 pressure control valve (CPCV1), a clutch 2 pressure control valve (CPCV2), a switch valve 1 (COV1), a switch valve 2 (COV2), a main oil pressure control valve (MPCV), a gear pressure control valve 1 (GPCV1), a gear fork direction control valve 1 (GASV1), a position selecting valve 1 (SCV1), a gear pressure control valve 2 (GPCV2), a gear fork direction control valve 2 (GASV2) and a position selecting valve 2 (SCV2). According to the electric control system, the algorithm is easy to realize, the data collection is convenient and the maneuverability is strong; compared with the other domestic wet type double-clutches, the electric control system has the advantages that a washing control function for the solenoid valve is added, the fault occurrence rate of the gearbox is reduced and the safety is increased; and the routine maintenance and preservation for the gearbox are easy to perform.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

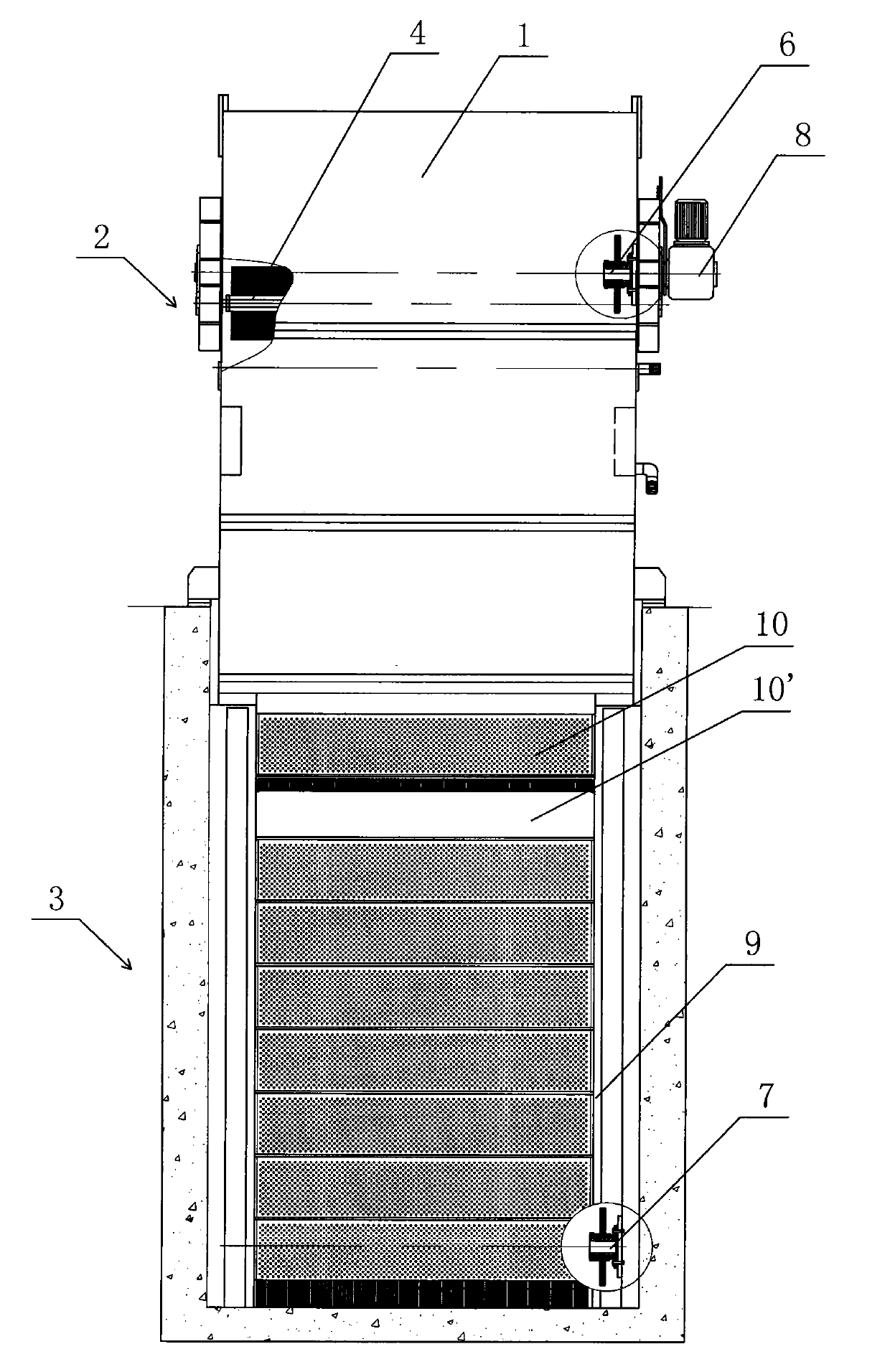

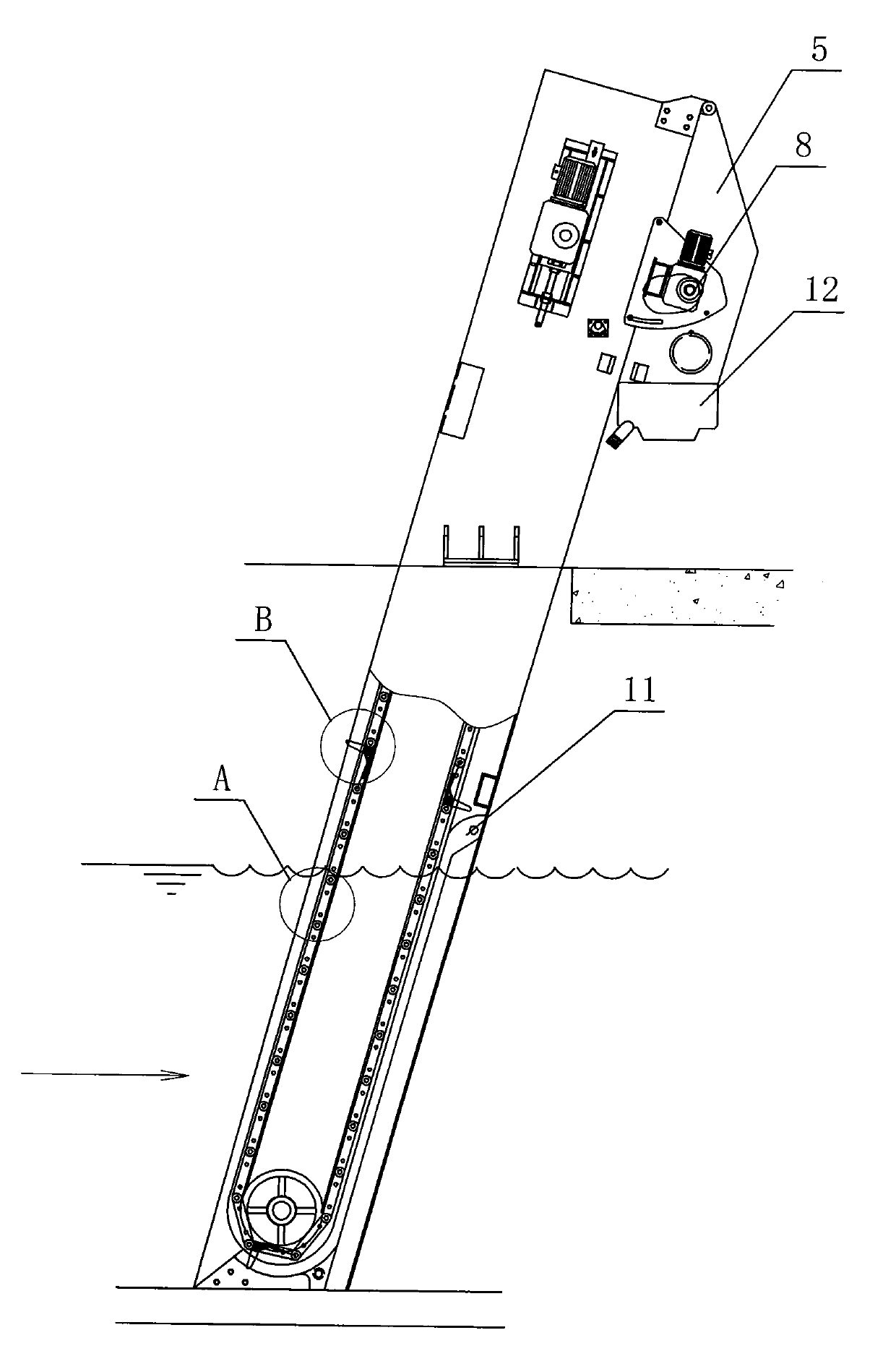

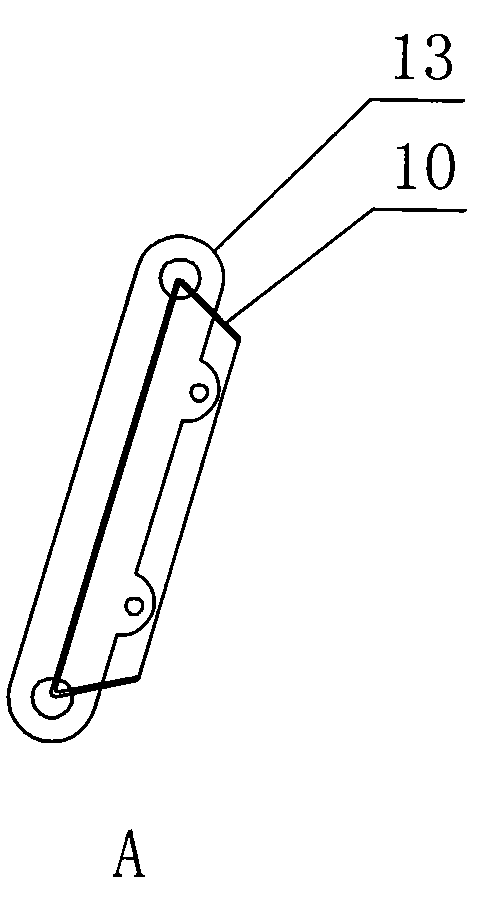

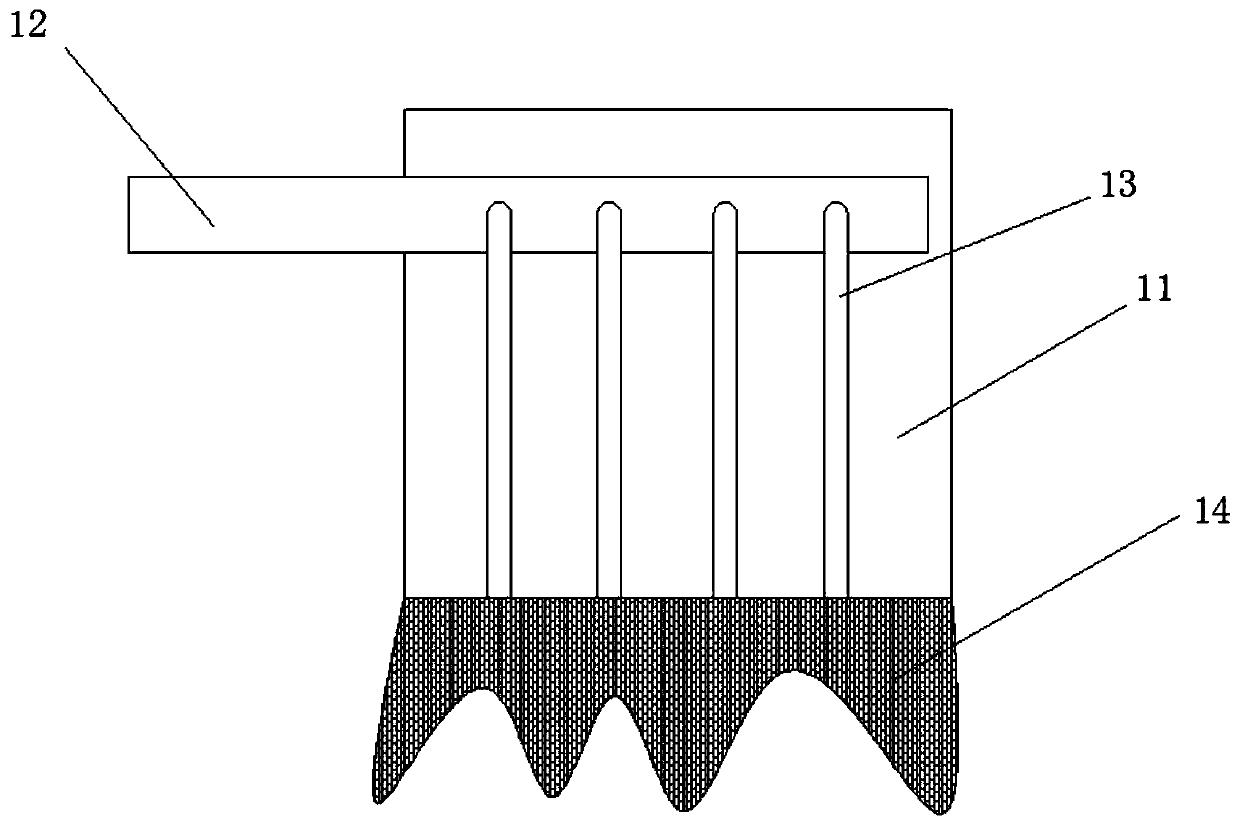

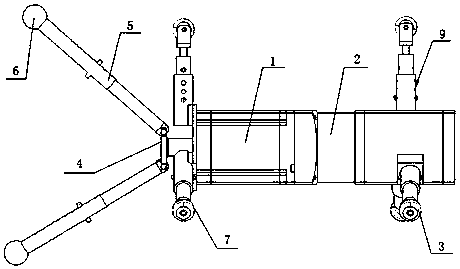

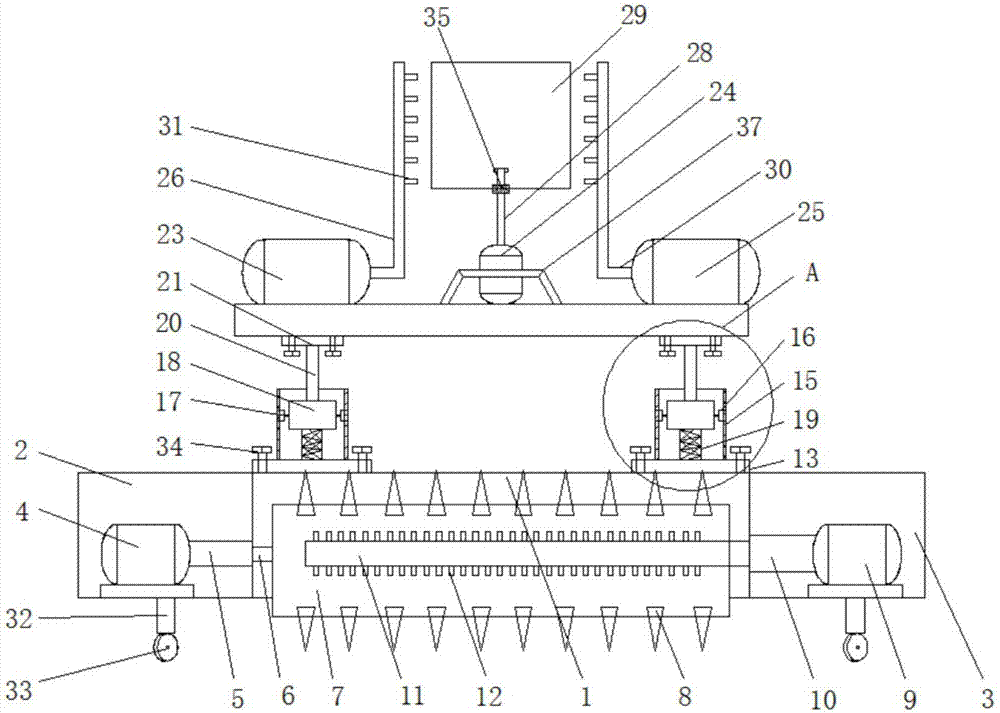

Trash cleaning device for grating of plane sieve plate

ActiveCN102000456AStop stuckImprove sealingWater cleaningMoving filtering element filtersGratingDrive motor

The invention relates to a trash cleaning device for a grating of a plane sieve plate. The trash cleaning device comprises a frame type machine rack arranged in a titling mode, and a rotating device and a rotating hairbrush device which are arranged in the machine rack. The rotating hairbrush device comprises a hairbrush roller arranged at the upper part of inner side of the machine rack and a rotating hairbrush driving motor connected with the hairbrush roller. The rotating device comprises an upper guide wheel and a lower guide wheel. The upper guide wheel is connected with a sieve plate driving motor. Chains and sieve plates are arranged between two guide wheels. The trash cleaning device for the grating of the plane sieve plate is characterized in that: the surface of each sieve plateis plane; the sieve plates are connected to form a plane; and a rabble blade is arranged on one of a plurality of sieve plates. The device can enhance solid floater so as to effectively solve the problem of trash clamped in the centre joint of the sieve plates, clean the dead corner and improve the grating trash rate.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

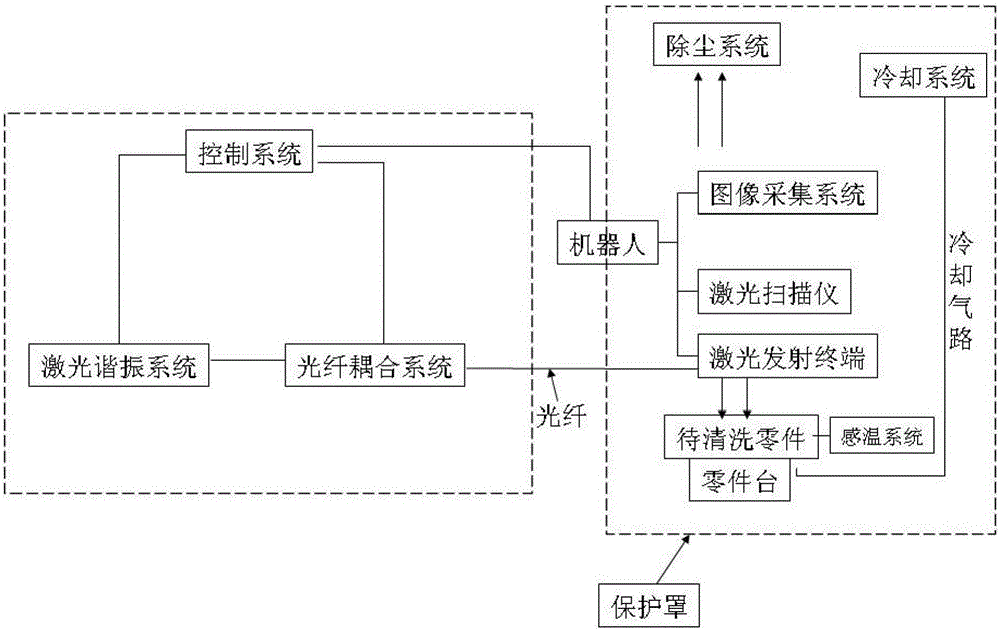

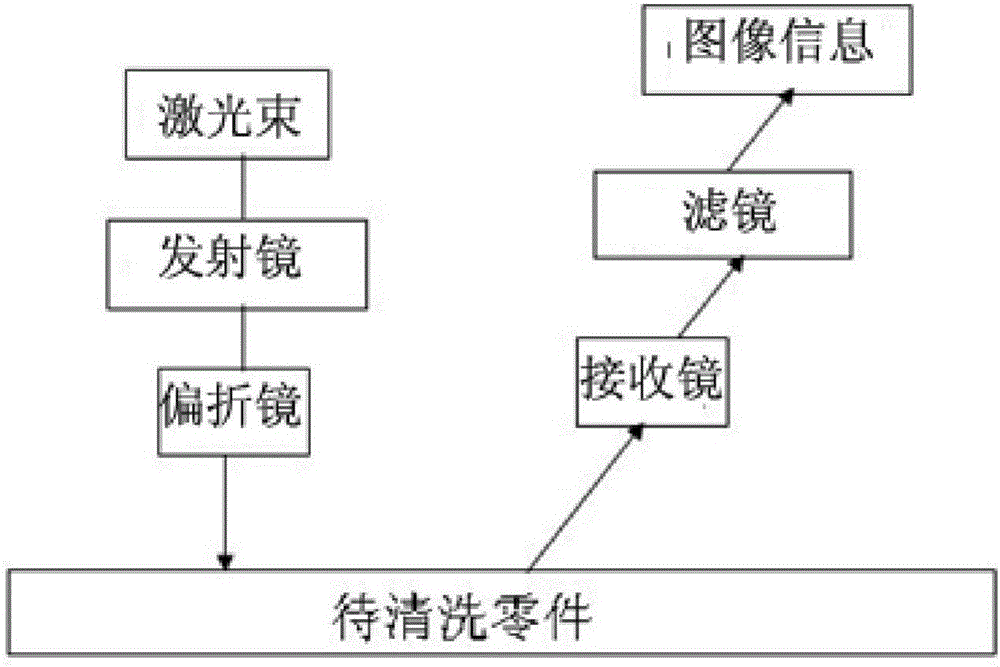

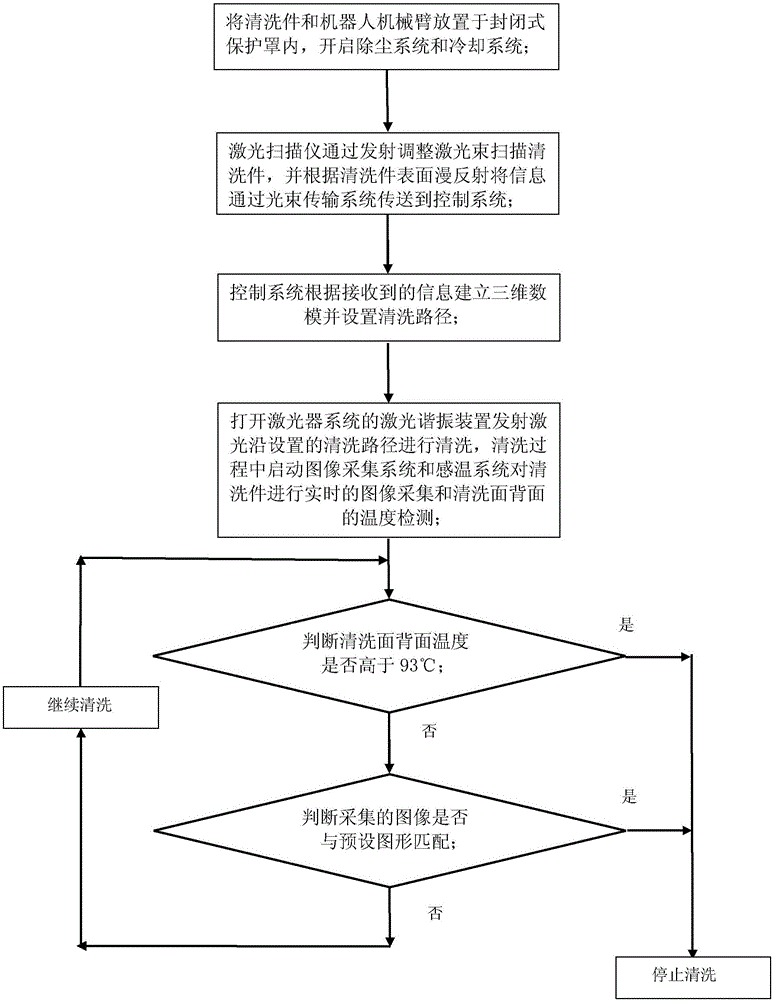

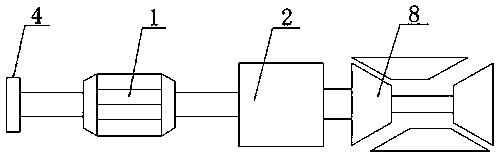

Composite material surface coating laser cleaner and cleaning method thereof

PendingCN106824923ARealize the cleaning functionImprove removal efficiencyCleaning processes and apparatusMathematical modelLacquer

The invention relates to a composite material surface coating laser cleaner and a cleaning method thereof. The composite material surface coating laser cleaner comprises a control system, a beam transmission system, a laser system, a laser scanner, and an image acquisition system, and the laser system, the laser scanner and the image acquisition system are arranged on the mechanical arm of a robot. The laser scanner scans a cleaned part by emitting and adjusting a laser beam, and transmits information to the control system via the beam transmission system according to diffuse reflection by the surface of the cleaned part; the control system creates a three-dimensional mathematical model and sets a cleaning path according to the received information, and the laser system cleans the cleaned part according to the cleaning path; and in the process of cleaning, the image acquisition system acquires images in real time and transmits the images to the control system so as to compare the images with preset images for adjustment. The composite material surface coating laser cleaner achieves a full-automatic high-efficiency cleaning and removing function for composite material surface coatings, can remove and recover pyrolysis products produced by paint removal, and has the advantages of high removal efficiency, uniform removing effect and environmental pollution prevention.

Owner:融之航信息科技(苏州)有限公司

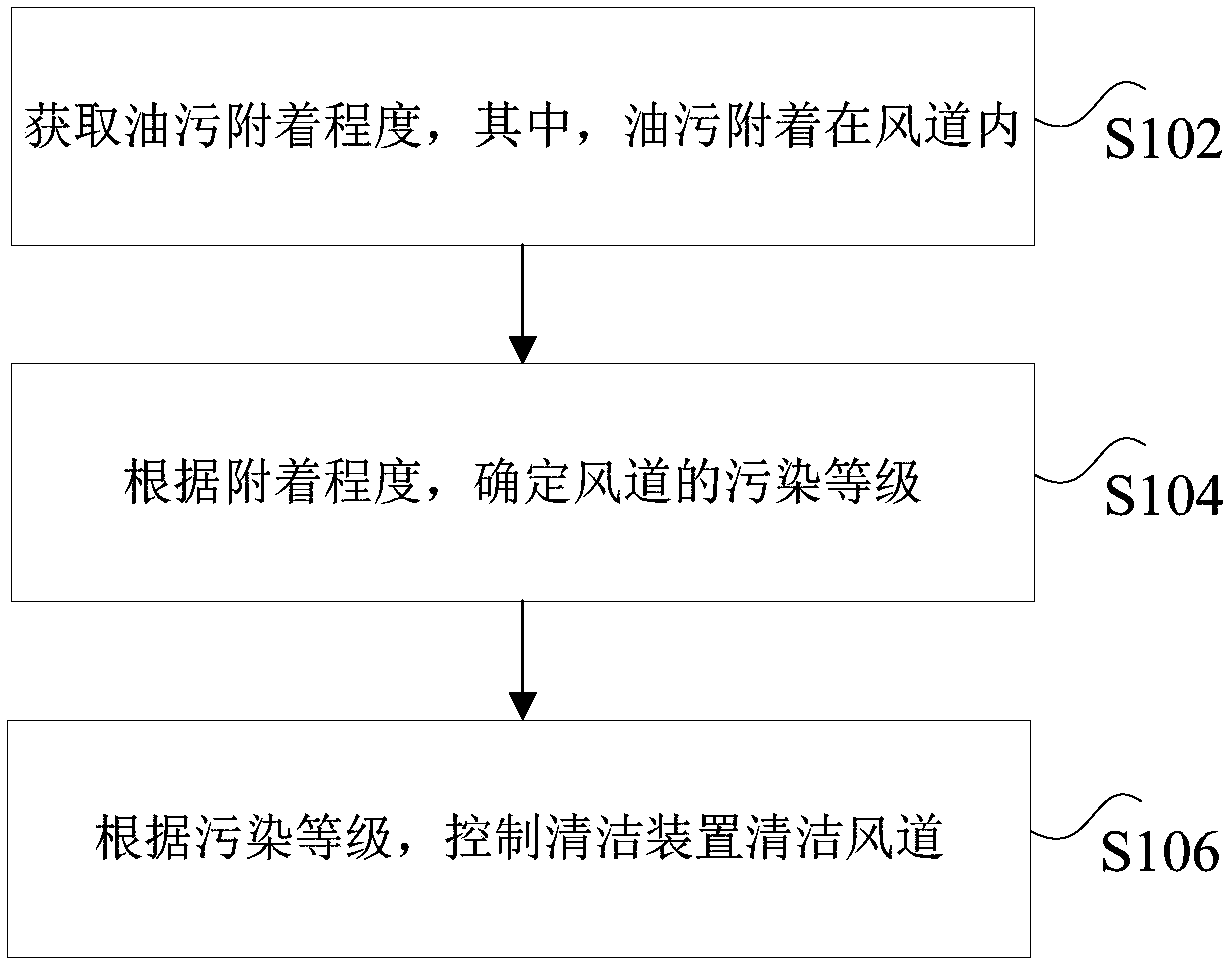

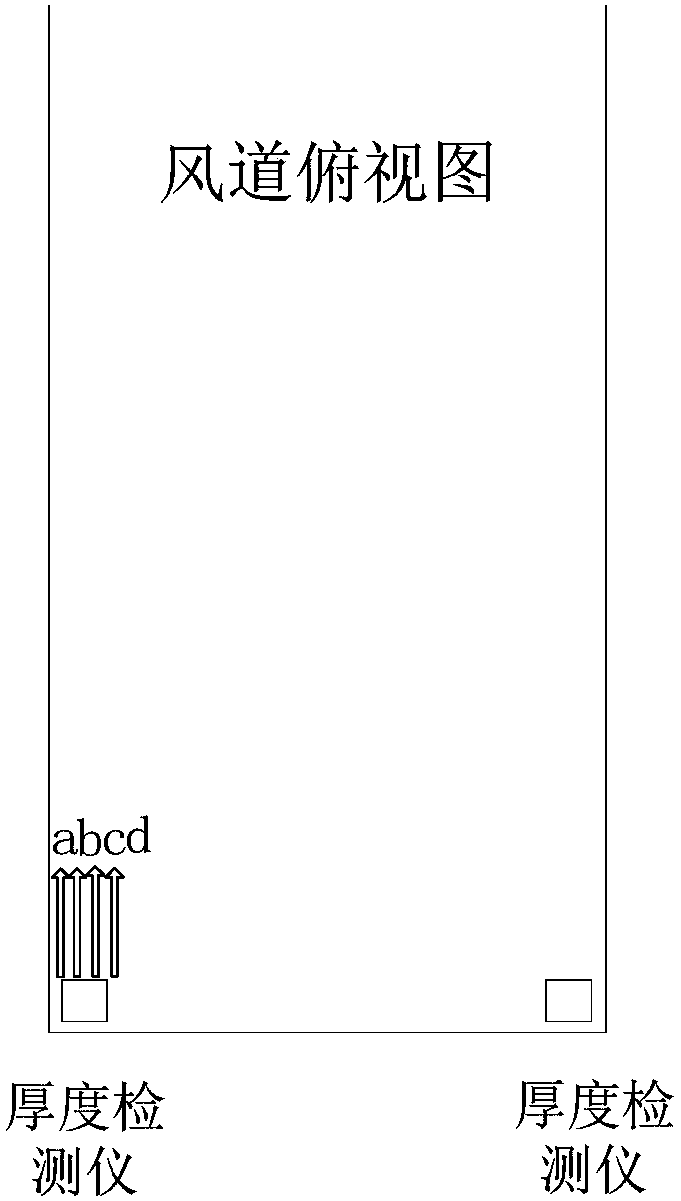

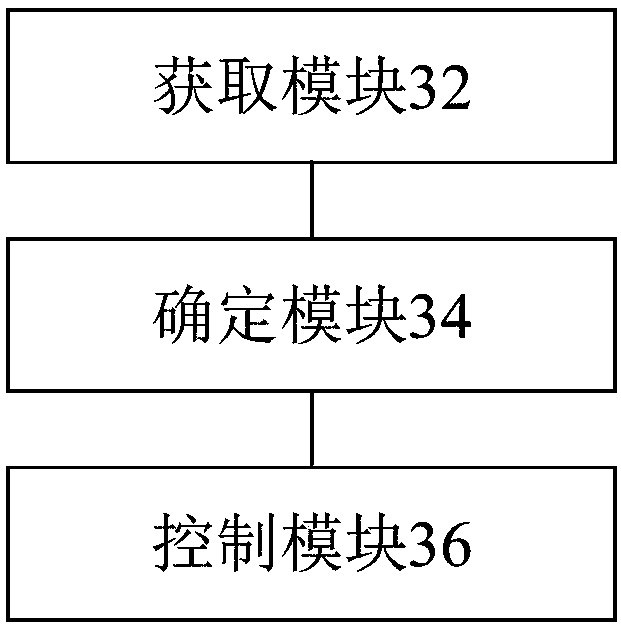

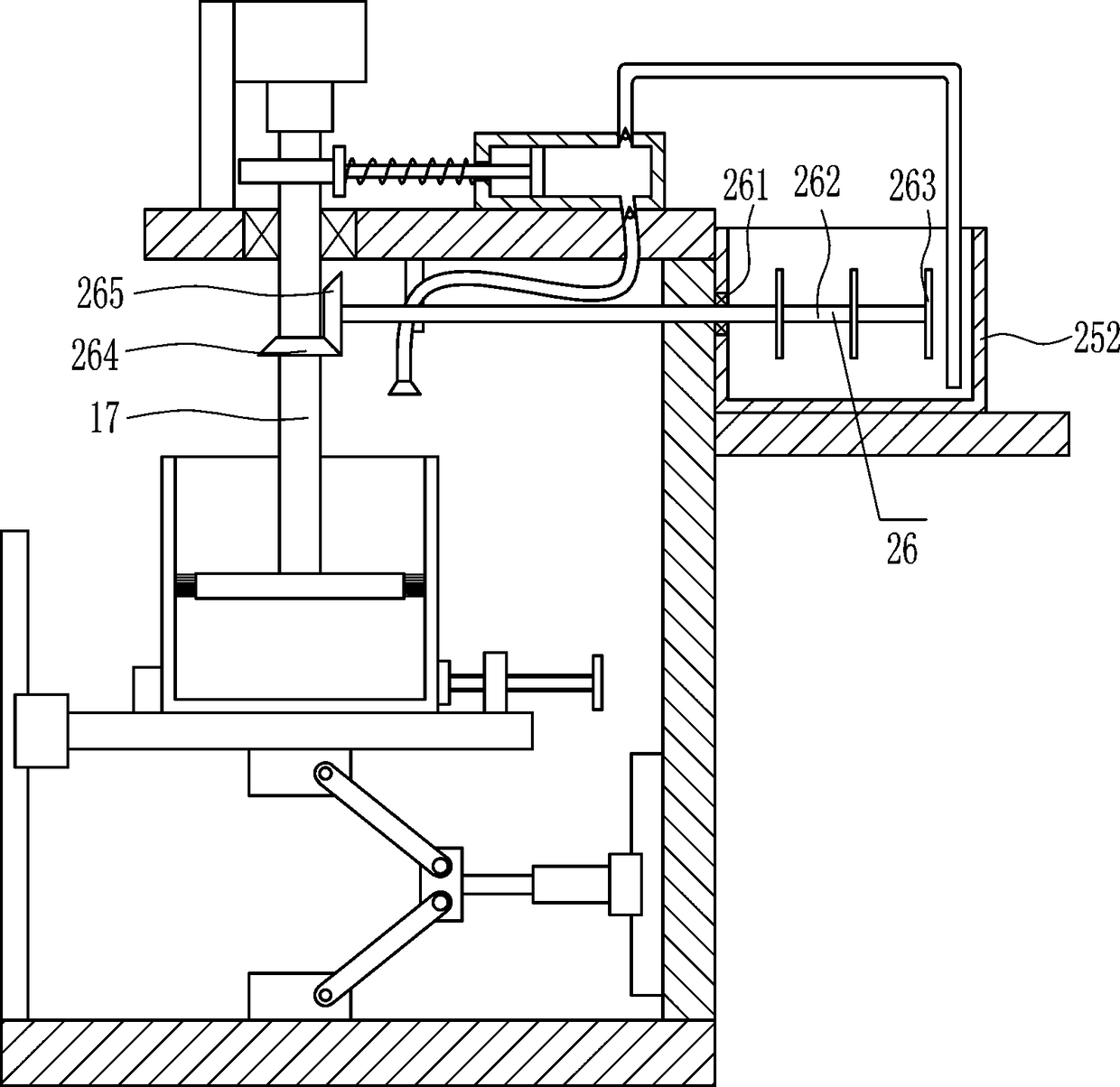

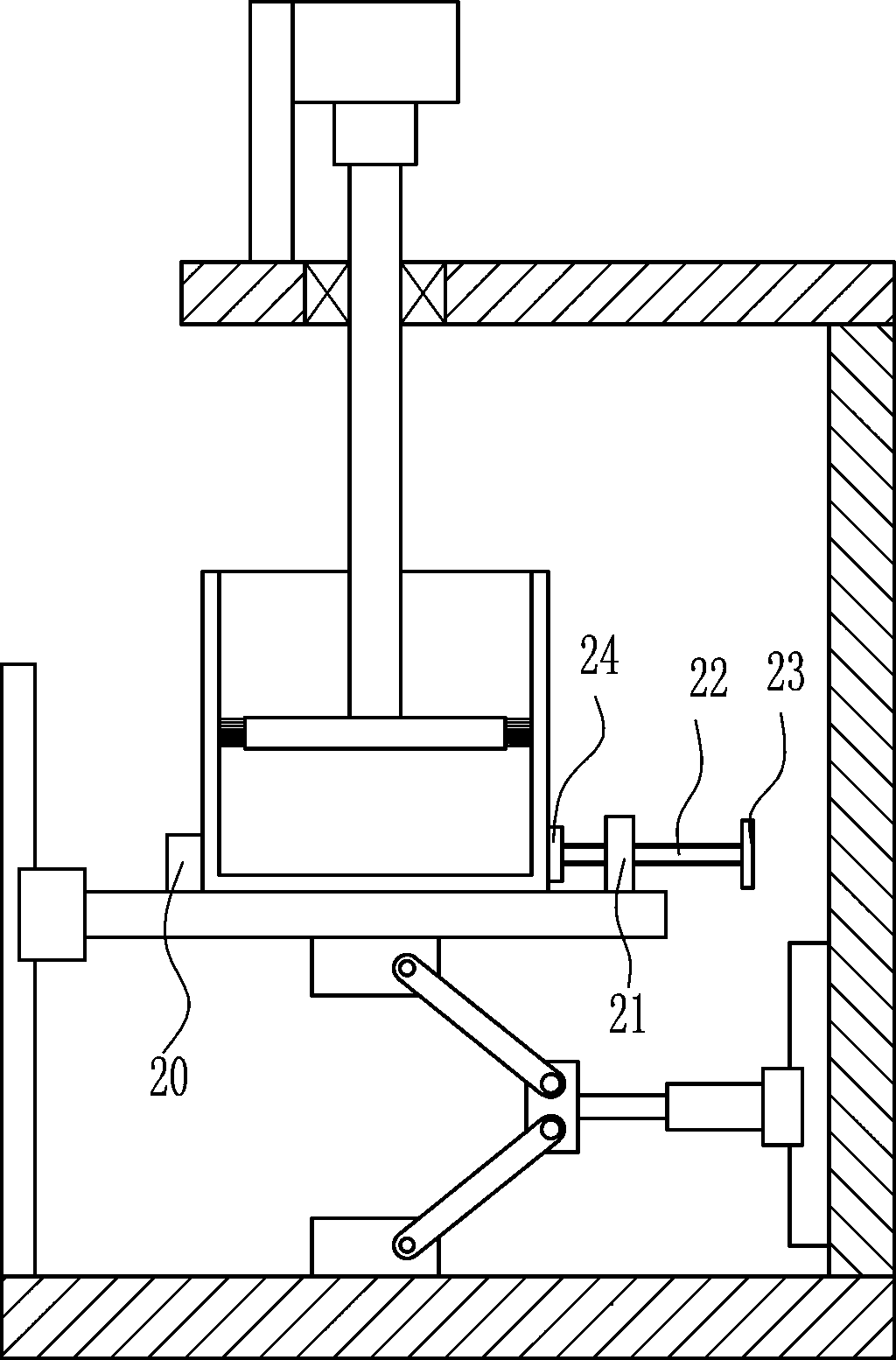

Method and device for cleaning air channels, and air conditioner

PendingCN108119985ARealize the detection functionRealize the cleaning functionMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir channel

The invention discloses a method and a device for cleaning air channels, and an air conditioner. The method includes acquiring attachment degrees of oil stain; determining pollution grades of the airchannels according to the attachment degrees; cleaning the air channels by the aid of the device under the control according to the pollution grades. The oil stain is attached into the air channels. The method, the device and the air conditioner have the advantage that the technical problem of influence on the air outlet quality of existing air conditioners due to the fact that existing air channels are easy to get dirty and are difficult to detach and clean can be solved by the aid of the method, the device and the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

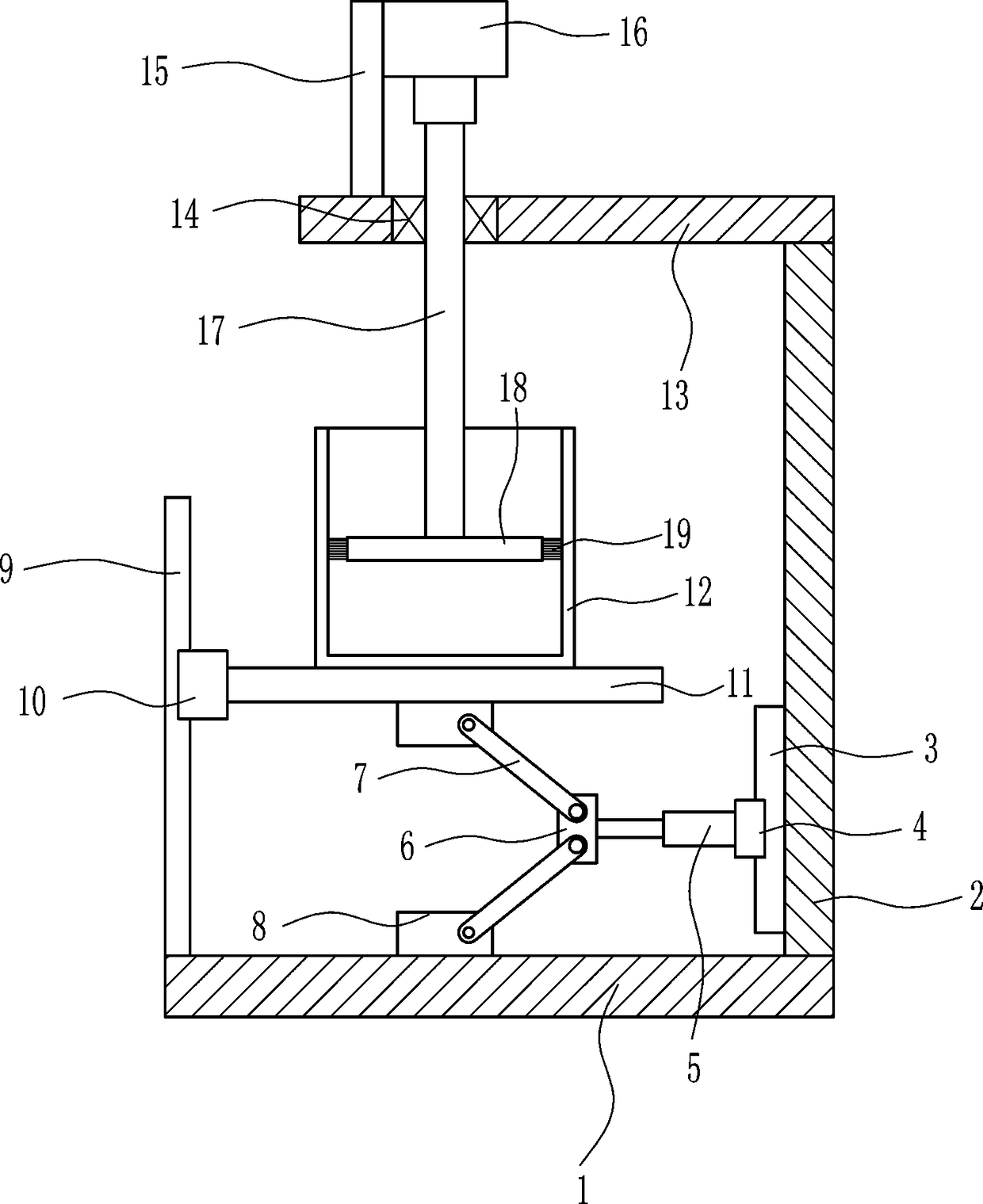

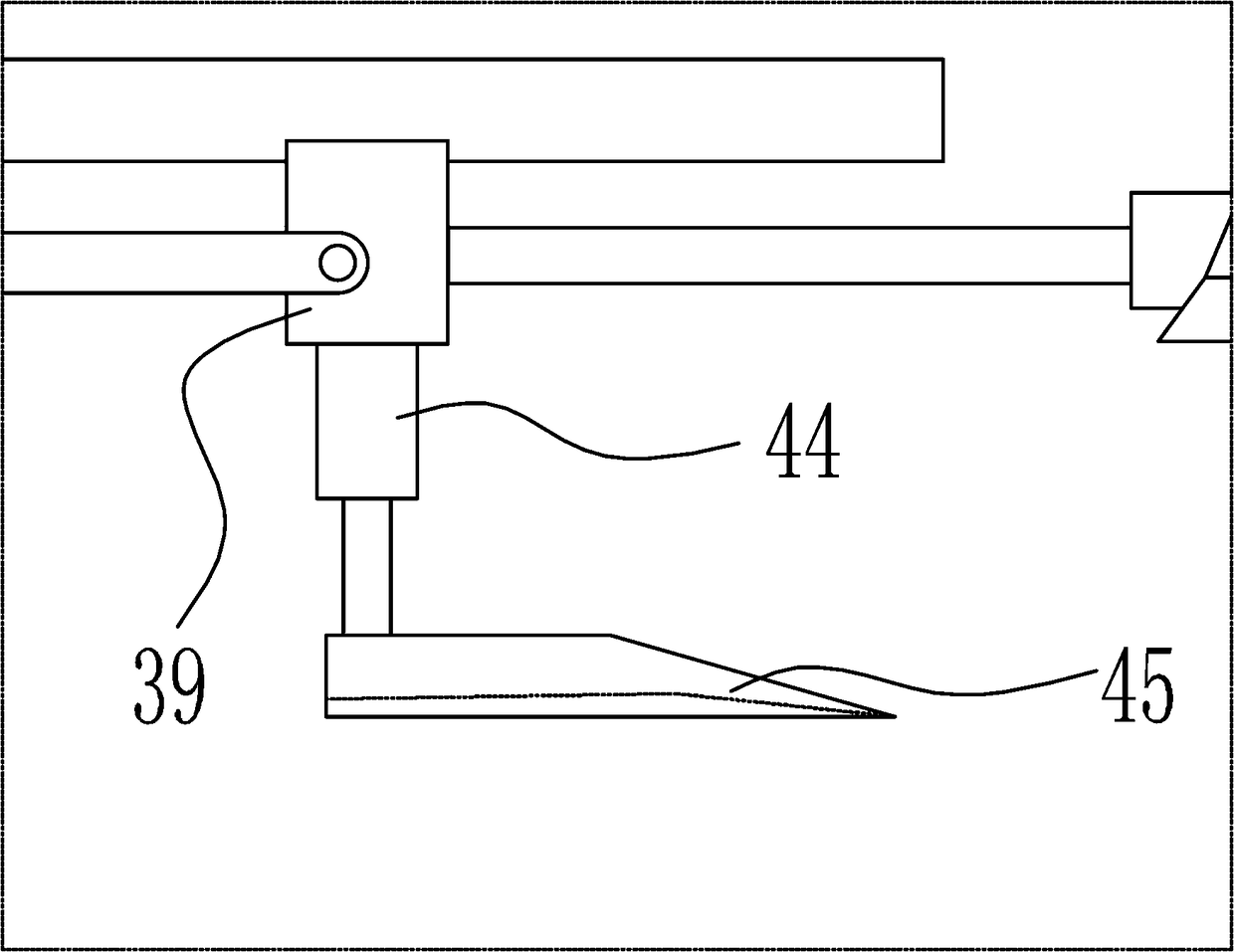

Cleaning equipment special for interior of chemical raw material barrel

InactiveCN108325967ARealize the cleaning functionRealize the function of lifting and cleaningHollow article cleaningCleaning using toolsRaw materialCivil engineering

The invention relates to cleaning equipment, in particular to cleaning equipment special for interior of a chemical raw material barrel. The cleaning equipment special for the interior of the chemicalraw material barrel is convenient to use and easy to operate. The cleaning equipment special for the interior of the chemical raw material barrel comprises a base, a first bracket, a first sliding rail, a first sliding block, a cylinder, a first fixing block, first connecting rods, a second fixing block, a second sliding rail, a second sliding block and the like. The first bracket is fixedly connected to the upper right side of the base, the first sliding rail is fixedly connected to the lower left side of the first bracket, and the first sliding block is slidably connected to the first sliding rail. The cleaning equipment special for the interior of the chemical raw material barrel realizes the function of cleaning the interior of the barrel, the function of quickly cleaning the interiorof the barrel is realized, and the function of lifting cleaning of the barrel is realized. The cleaning equipment special for the interior of the chemical raw material barrel has the characteristicsof convenient use, safe use, simple operation, low manufacturing cost and the like.

Owner:深圳高佳研机械研究设计有限公司

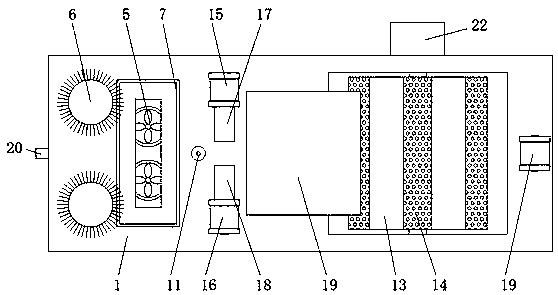

Floor mopping robot for laboratory

InactiveCN108606736AAbsorb moreThorough dust removalCarpet cleanersFloor cleanersDrive motorEngineering

The invention discloses a floor mopping robot for a laboratory. The floor mopping robot for the laboratory comprises a bottom plate; a dust removing mechanism, a watering mechanism and a floor moppingmechanism are arranged on the bottom plate, wherein the dust removing mechanism comprises a support fixed at one end of the top face of the bottom plate, a first driving motor is installed at the topof the support, and the output end of the first driving motor penetrates through the bottom plate and is connected with a dust removing brush; the dust removing mechanism also comprises negative-pressure draught fans embedded into the top face of the bottom plate, dust collecting boxes are arranged at the tops of the negative-pressure draught fans, and a dust suction box is arranged at the bottoms of the negative-pressure draught fans; the watering mechanism comprises a water tank fixed in the middle of the top face of the bottom plate, and a spraying head and a water collecting tank are installed on the bottom face of the bottom plate; the floor mopping mechanism comprises rolling wheels rotationally connected on a base, and multiple cleaning cotton slivers are installed on the circumferential faces of the rolling wheels. According to the floor mopping robot for the laboratory, water is only filled one time, a series of work such as automatic dust moving, watering, floor mopping andcotton-sliver self-cleaning can be achieved, and the cleaning effect is good.

Owner:苏州奥科莱实验室仪器有限公司

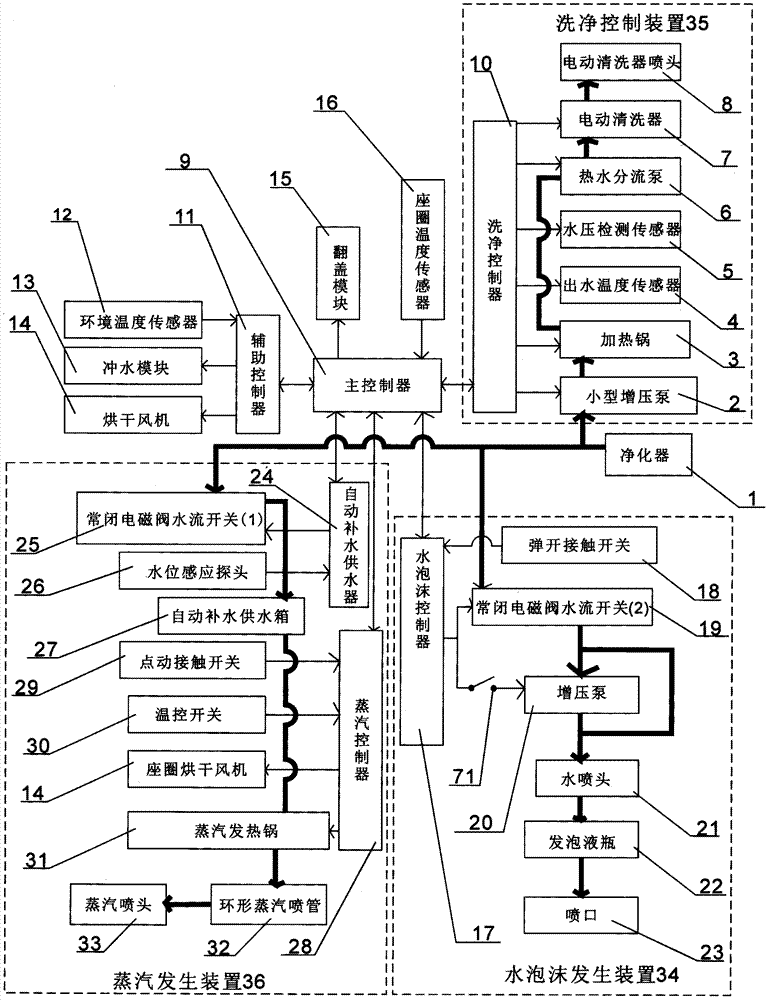

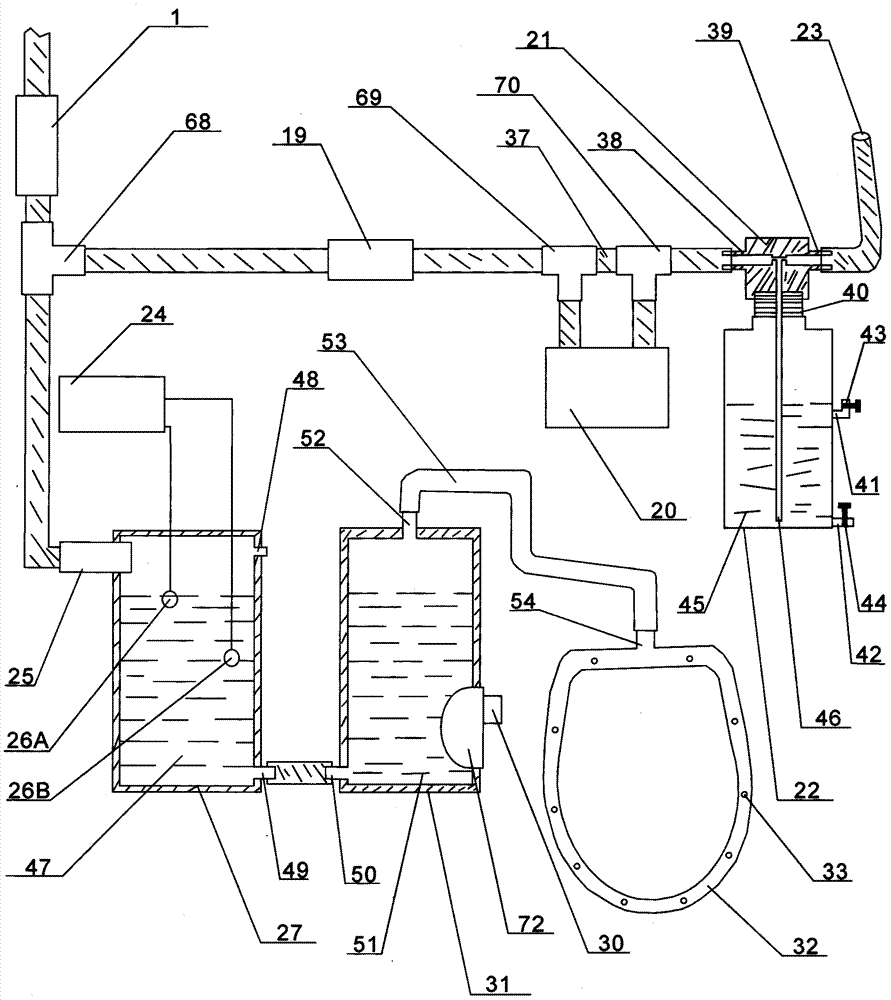

Intelligent pedestal pan cleaning device

InactiveCN107165242ARealize the cleaning functionPrevent splashLavatory sanitoryHigh pressure waterEngineering

An intelligent toilet cleaning device, comprising a purifier, a toilet body, a seat ring temperature sensor, a main controller, an auxiliary controller, a cleaning control device, a steam generating device, a water The foam generating device and flip cover module are composed. When the upper cover of the toilet is opened, the normally closed solenoid valve water flow switch and the booster pump are simultaneously activated to energize the water, and the high-pressure water flows through the water nozzle to suck out the foaming liquid from the foaming liquid bottle and mix it with water The water foam formed is sprayed in the toilet bowl, which plays the role of easy flushing of toilet dirt, no smell, and splash prevention. In the toilet, it can realize the function of intelligent buttock washing, women's washing, electric washer nozzle cleaning, and drying fan to dry the buttocks. After defecation, close the top cover of the toilet, turn on the steam heating pot to generate steam to clean and sterilize the toilet seat at high temperature, and then start the drying fan to blow hot air to dry the water marks on the toilet seat. The invention completes the waterway function application through circuit control, and realizes the whole cleaning process of the toilet before, during and after defecation.

Owner:黄贤斌

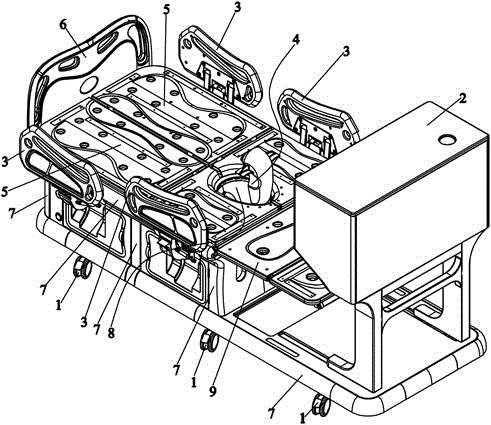

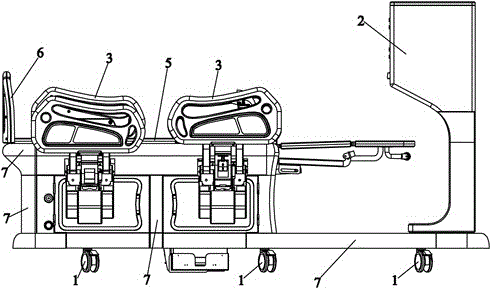

Multifunctional bed

InactiveCN106491292APrevent leakageWith left and right turning functionNursing bedsAmbulance serviceOlder peopleEngineering

The invention discloses a multifunctional bed, comprising a urine collecting and guiding device. The multifunctional bed is arranged by adopting a combination integrating a bedstead, a bed board, a complete intelligent closestool assembly and a feces collection box, wherein defecation of a human body, carried out by sitting on the bed board or lying on the bed board, is realized by detachably arranging the urine collecting and guiding device at the front end of a closestool, so that possible secondary injury to a patient or an old person caused by off-bed defecation is avoided, pain of the patient or the old person during defecation is greatly relieved, trouble and inconvenience of defecation assisted by others are also avoided, convenience of the defecation directly performed on the bed by the human body is greatly improved, and an indoor living environment, especially the living environment in a hospital ward is improved; a cleaning device is used for automatically cleaning the human body after the defecation, and a drying device is used for drying the cleaned human body, so that a human body cleaning function and a dampness removal function after directly performing the defecation on the bed are realized; the multifunctional bed is ingenious in structural design, is high in practicability, is energy-saving and environment-friendly, and is suitable for popularization and application.

Owner:HANGZHOU SHUNSHI HARDWARE MACHINERY

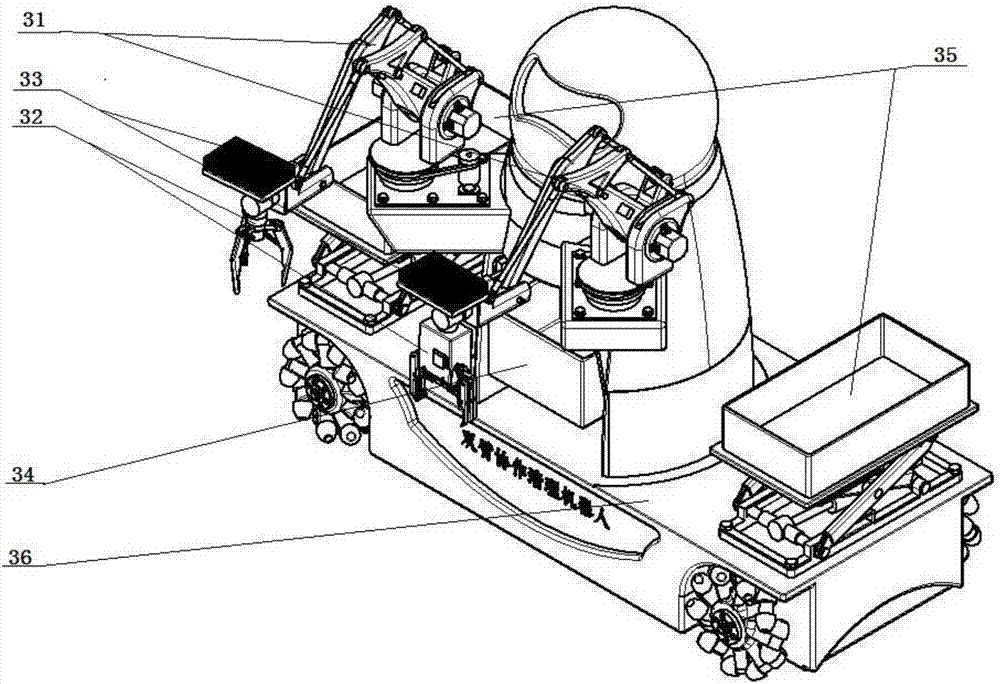

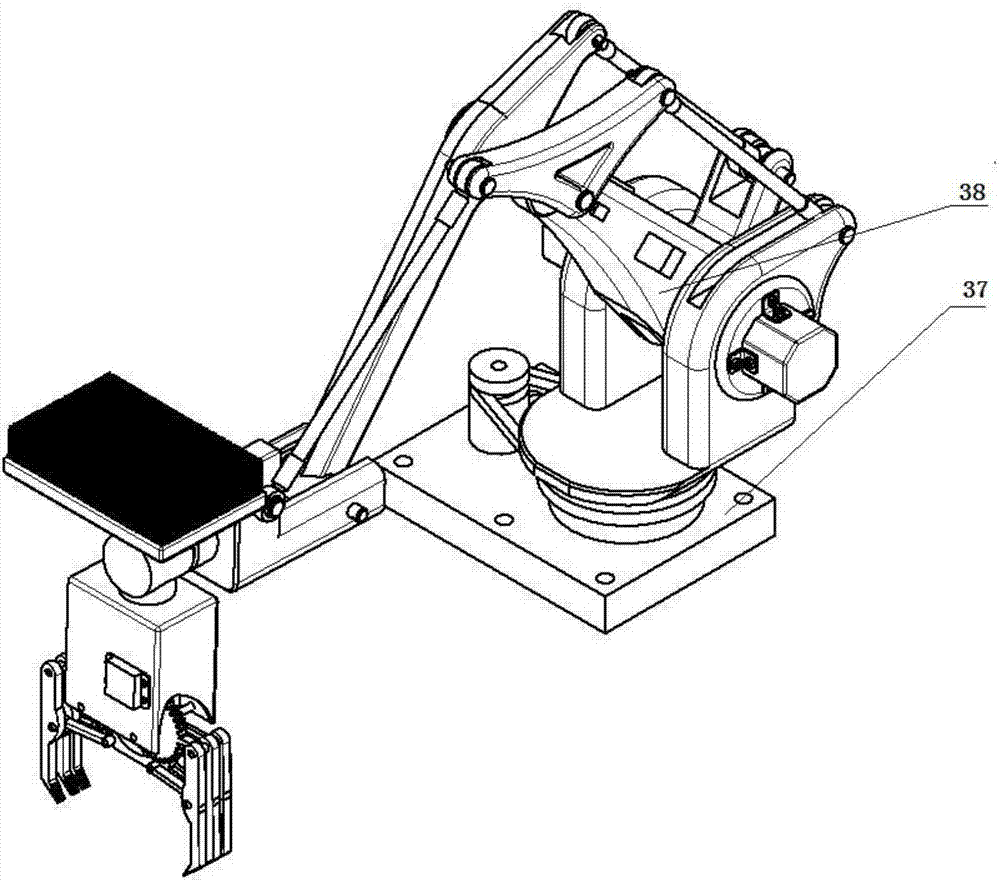

Double-arm-cooperative cleaning robot

InactiveCN106881722AEasy multi-directional movementImprove efficiencyManipulatorEngineeringMechanical engineering

The invention discloses a double-arm-cooperative cleaning robot. The double-arm-cooperative cleaning robot comprises a grabbing and sweeping module composed of mechanical arms, grabbing grippers and cleaning brushes, a trash can for collecting trash, lifting platforms for containing tableware and a bottom plate for moving. The robot is of a double-arm rotating structure. The two four-shaft mechanical arms are arranged on two bases. The three-claw gripper on one mechanical arm is driven by an air cylinder to grip bowls and dishes and convey the bowls and dishes into the corresponding lifting platform for containing the tableware through the waist rotation; and meanwhile the two-claw gripper on the other mechanical arm is driven by gears to grip chopsticks and spoons, convey the chopsticks and spoons into the corresponding lifting platform for containing the tableware through the waist rotation and then exchange the mechanical grippers with the cleaning brushes through the wrist rotation, and residues on a dinning table are swept and put into the trash can through the cooperation of the two mechanical arms. By the adoption of the technical scheme of the double-arm-cooperative cleaning robot, the tableware is collected quickly and conveniently, and the dining table is swept.

Owner:BEIJING UNIV OF TECH

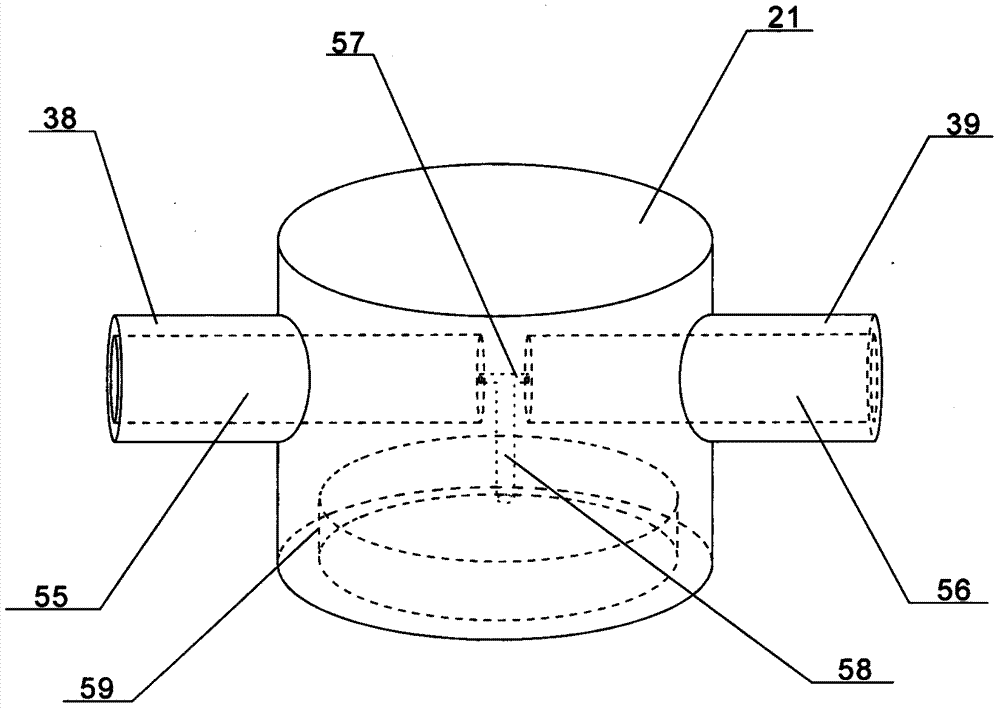

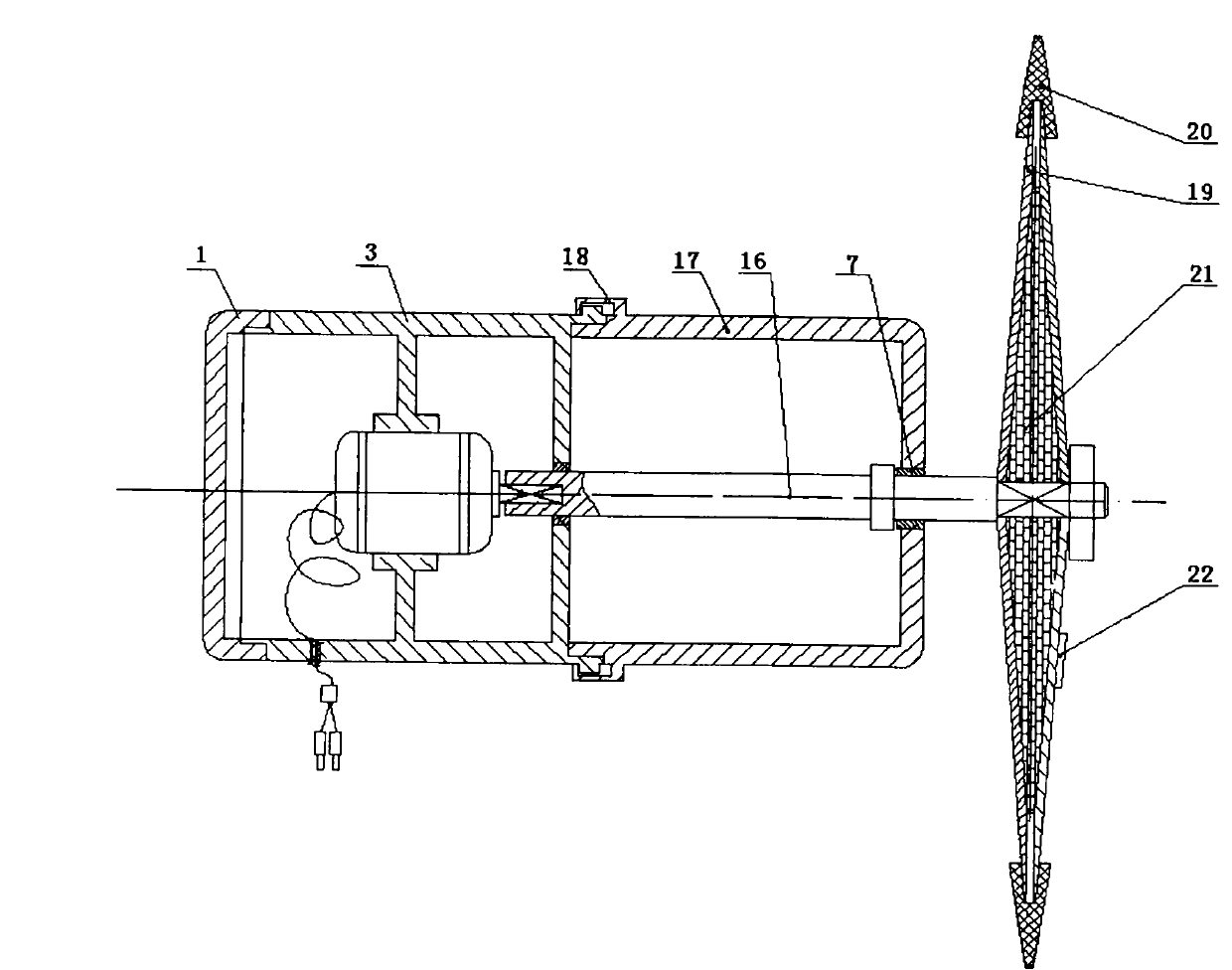

Rotary reversing valve and rotary heat-accumulation waste gas incinerator

ActiveCN105509072AReduced power ratingReduce energy consumptionIncinerator apparatusPositive pressureEngineering

The invention provides a rotary reversing valve which comprises a valve body and a valve core, wherein a clearance is left between the valve body and valve core; the valve core is driven by a drive unit to rotate; a gas inlet region, a gas discharge region, a purging region and at least two distribution regions are arranged between the valve core and valve body; the valve body is provided with a plurality of inlet / outlet ports respectively communicated with all the regions; the distribution regions are respectively a to-be-treated gas distribution region and a treated gas distribution region; the to-be-treated gas distribution region is communicated with the gas inlet region to form a to-be-treated gas passage; the treated gas distribution region is communicated with the gas discharge region to form a treated gas passage; the valve core is in a hollow structure and is communicated with the purging region to form a purging gas passage; and when the purging gas passage is under positive pressure or negative pressure, the purging region obstructs the mutual communication between the to-be-treated gas passage and the treated gas passage. The rotary reversing valve has the advantages of simple structure, low energy consumption, favorable sealability, low cost and the like. The invention also provides a rotary heat-accumulation waste gas incinerator using the rotary reversing valve.

Owner:VERBOCA ENERGY SAVING TECH CO LTD

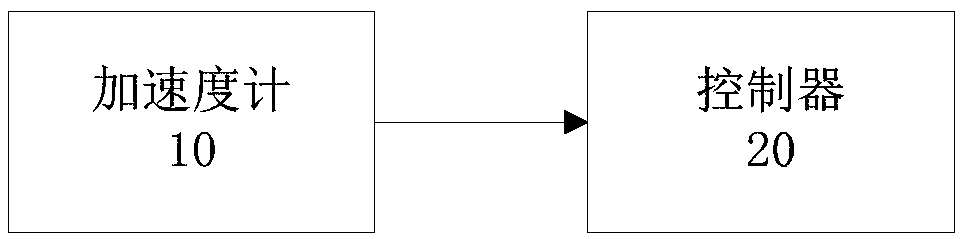

Floor sweeping robot and control system and control method thereof

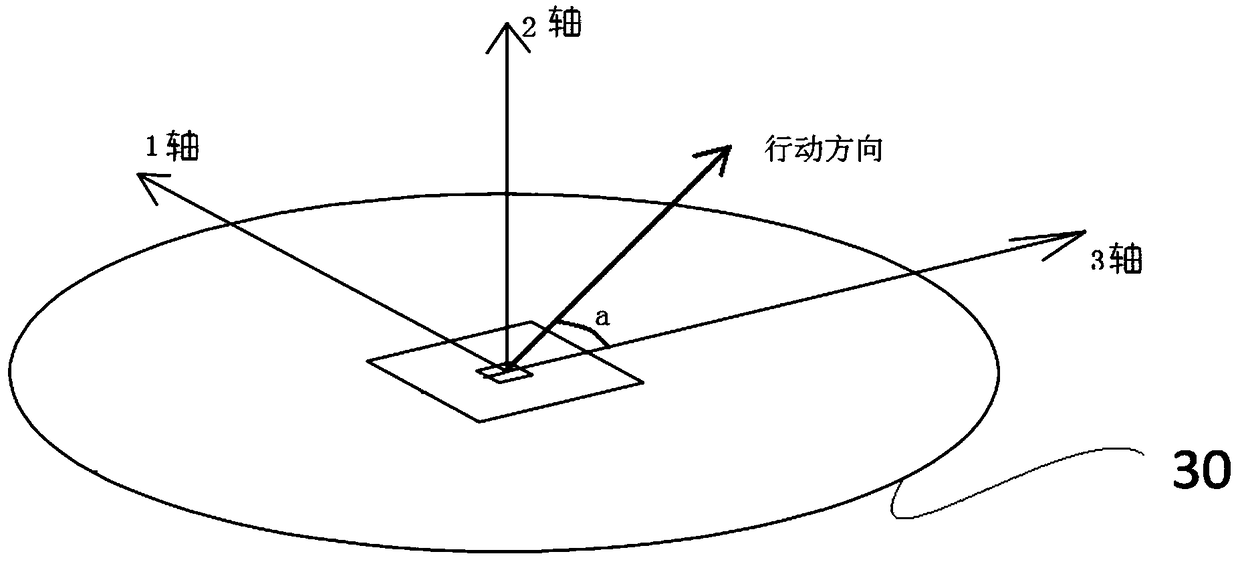

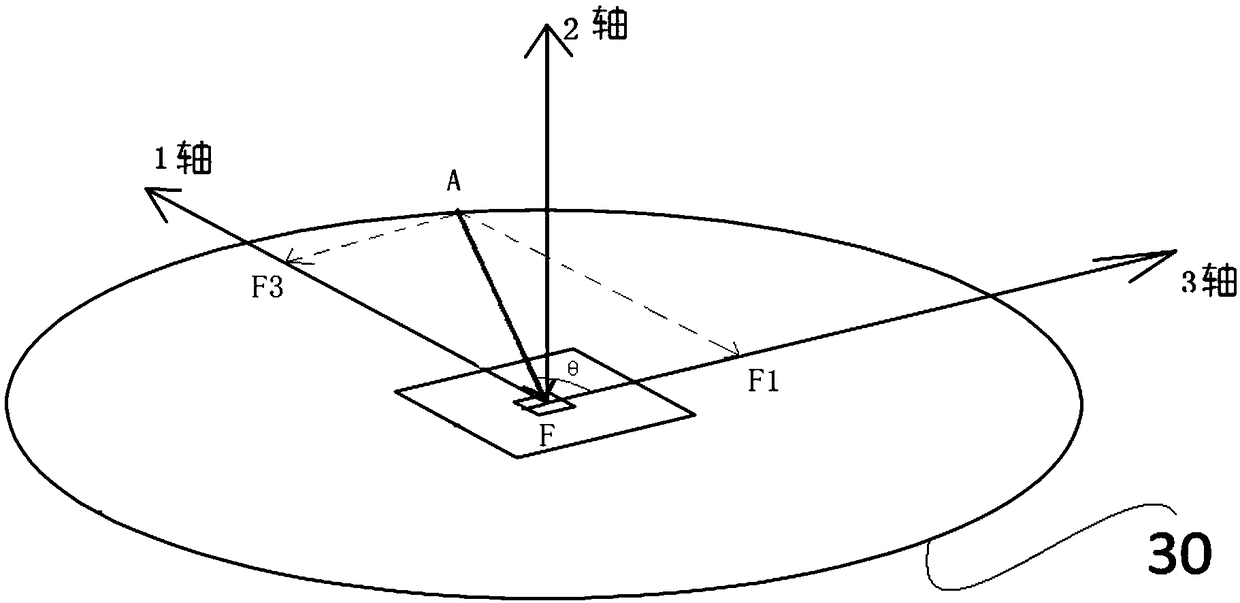

ActiveCN109381125ASmart obstacle avoidanceEfficient obstacle avoidanceAutomatic obstacle detectionTravelling automatic controlAccelerometerControl system

The embodiment of the invention provides a floor sweeping robot and a control system and control method used for the floor sweeping robot. The system comprises an accelerometer and a controller, wherein the accelerometer is used for detecting the acceleration of the floor sweeping robot in at least two directions in a movement plane of the floor sweeping robot; the controller is used for determining a movement mode in which the floor sweeping robot is currently located; according to the movement mode, the current expected acceleration of the floor sweeping robot in at least two directions is determined; according to the current expected acceleration of the floor sweeping robot in the at least two directions and the acceleration of the floor sweeping robot in the at least two directions detected by the accelerometer, whether or not the floor sweeping robot collides is determined; under the situation that the floor sweeping robot collides, the collision direction and / or collision strength are determined; according to the collision direction and / or collision strength, a sweeping strategy of the floor sweeping robot is determined. The floor sweeping robot and the control system and control method used for the floor sweeping robot have the advantages that the collision direction and / or collision strength of an obstacle can be accurately judged.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

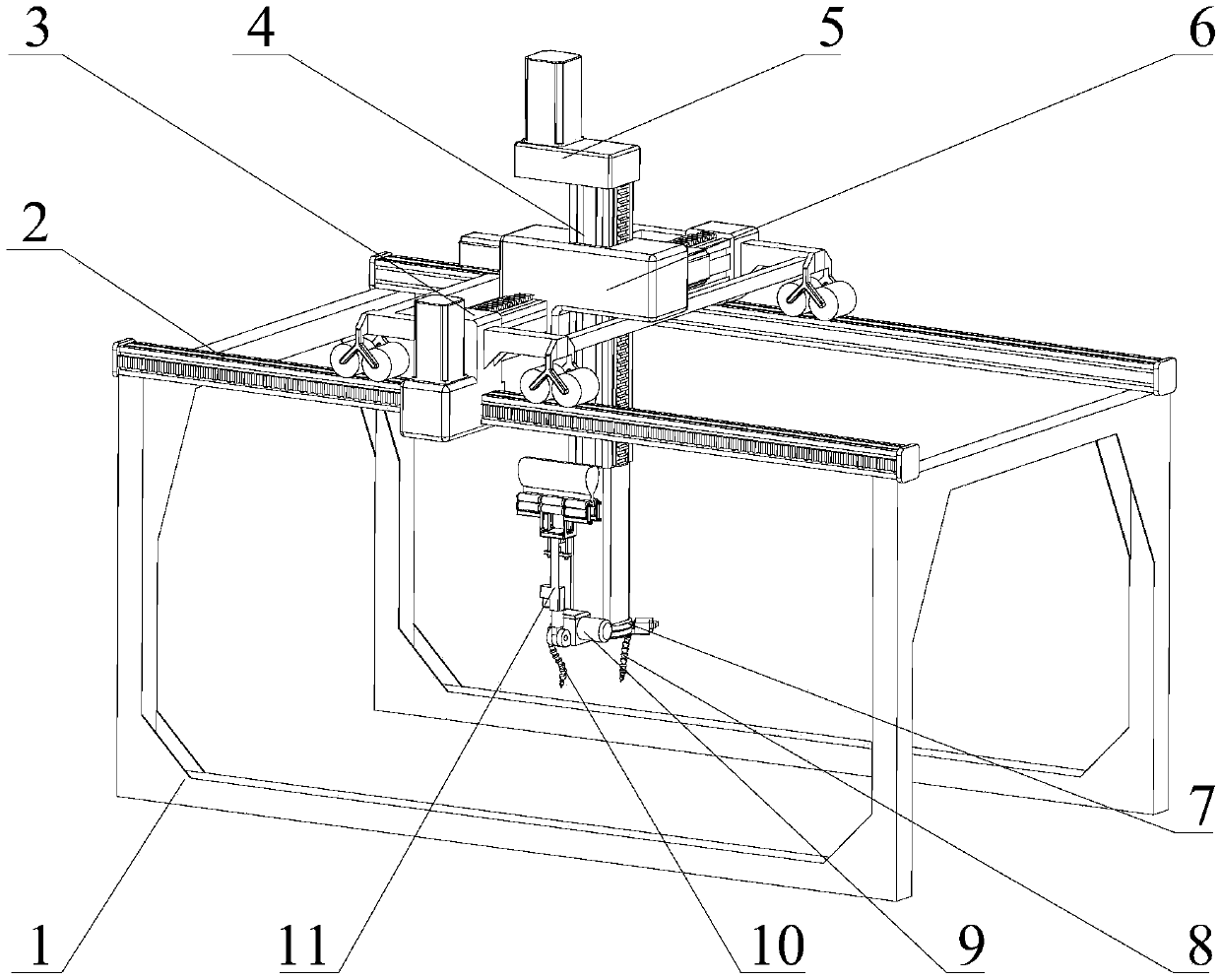

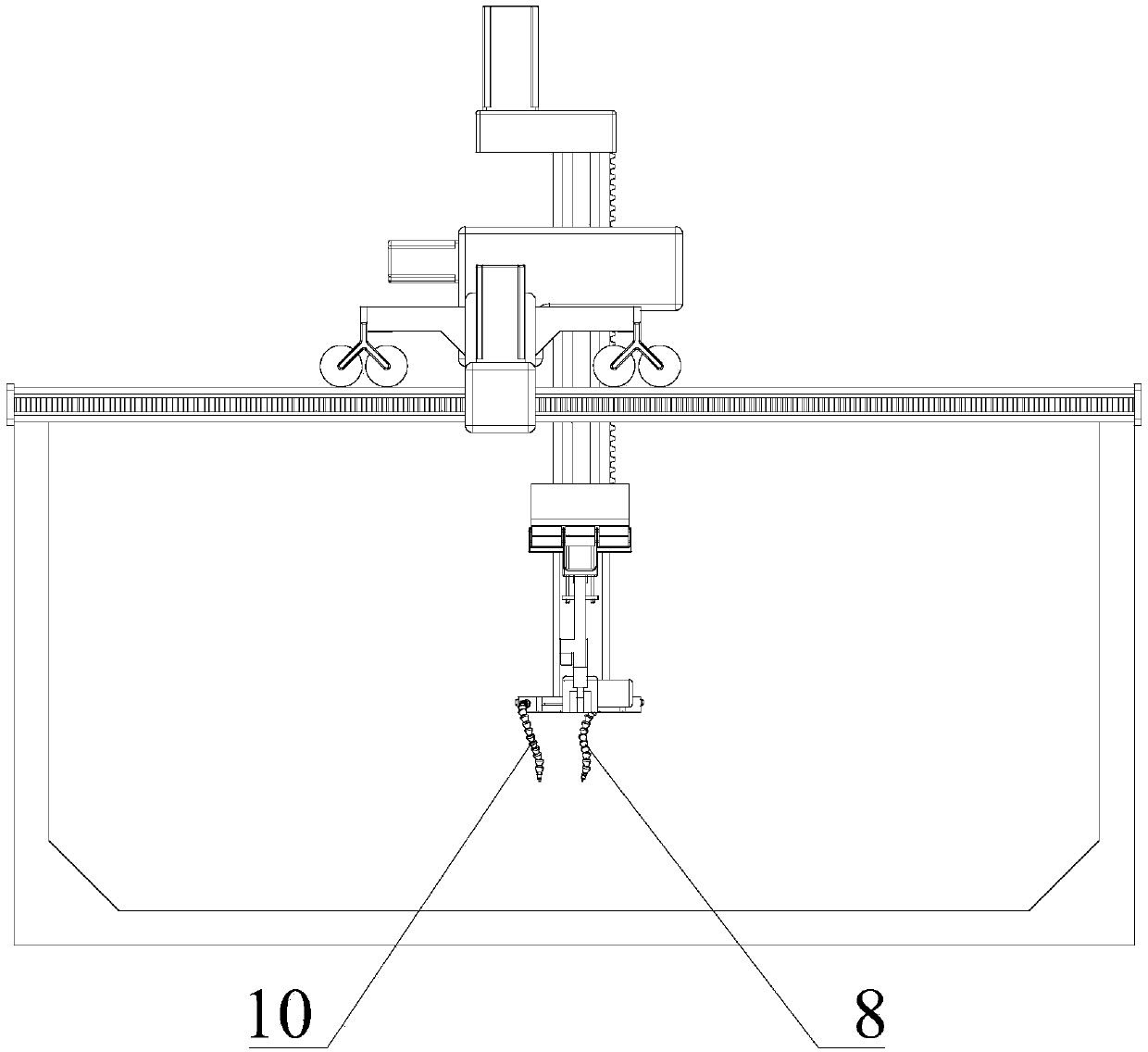

Plane equipment cleaning robot

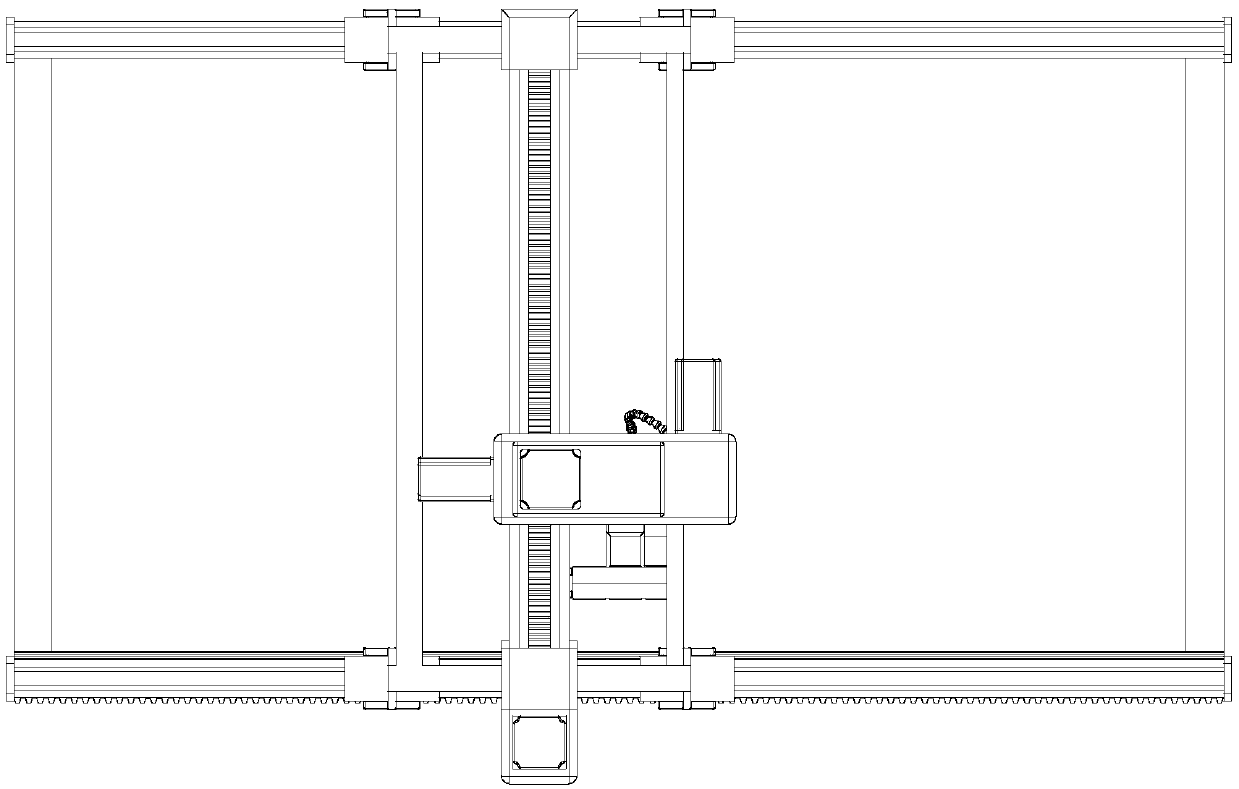

PendingCN109530305ARealize the cleaning functionAchieve dryingCleaning using liquidsMechanical conveyorsRectangular coordinatesInjection air

The invention discloses a plane equipment cleaning robot. The plane equipment cleaning robot comprises a machine frame, a jet liquid spraying device I, a jet liquid spraying device II and a rectangular coordinate positioning mechanism, wherein the rectangular coordinate positioning mechanism is fixed on the machine frame, the air injection liquid spraying device I, the air injection liquid spraying device II is arranged at an output end of the rectangular coordinate positioning mechanism. According to the plane equipment cleaning robot, the rectangular coordinate positioning mechanism can be used for carrying out linear movement in three directions, so that the output end can be positioned in space; through separate application of the two air injection liquid spraying devices, and one airinjection and one liquid spraying cleaning function can be realized at the same time; and wiping after cleaning and drying after wiping can be realized through a wiping device.

Owner:KUNMING UNIV OF SCI & TECH

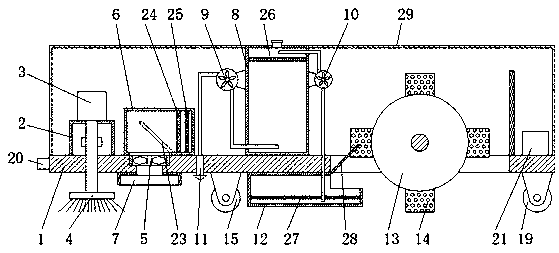

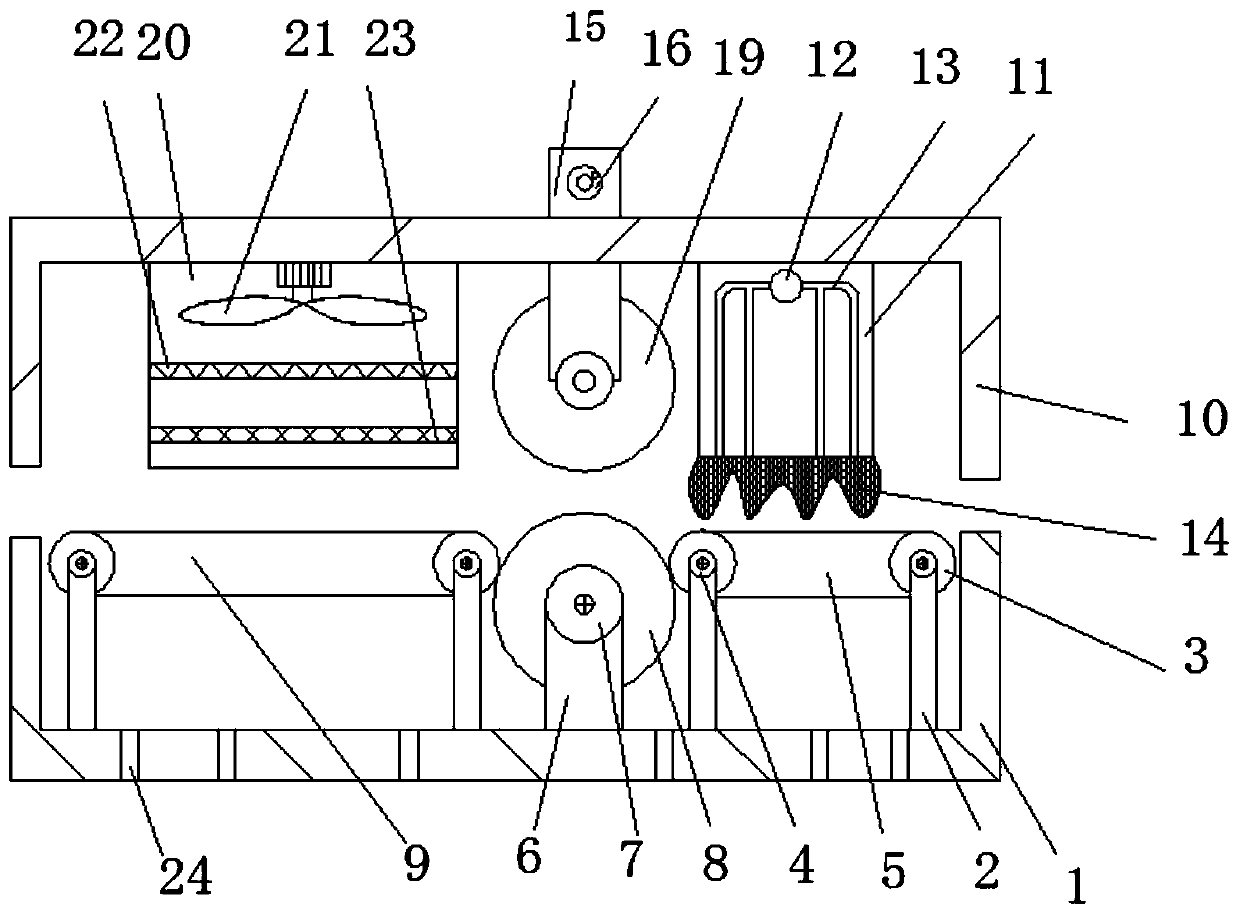

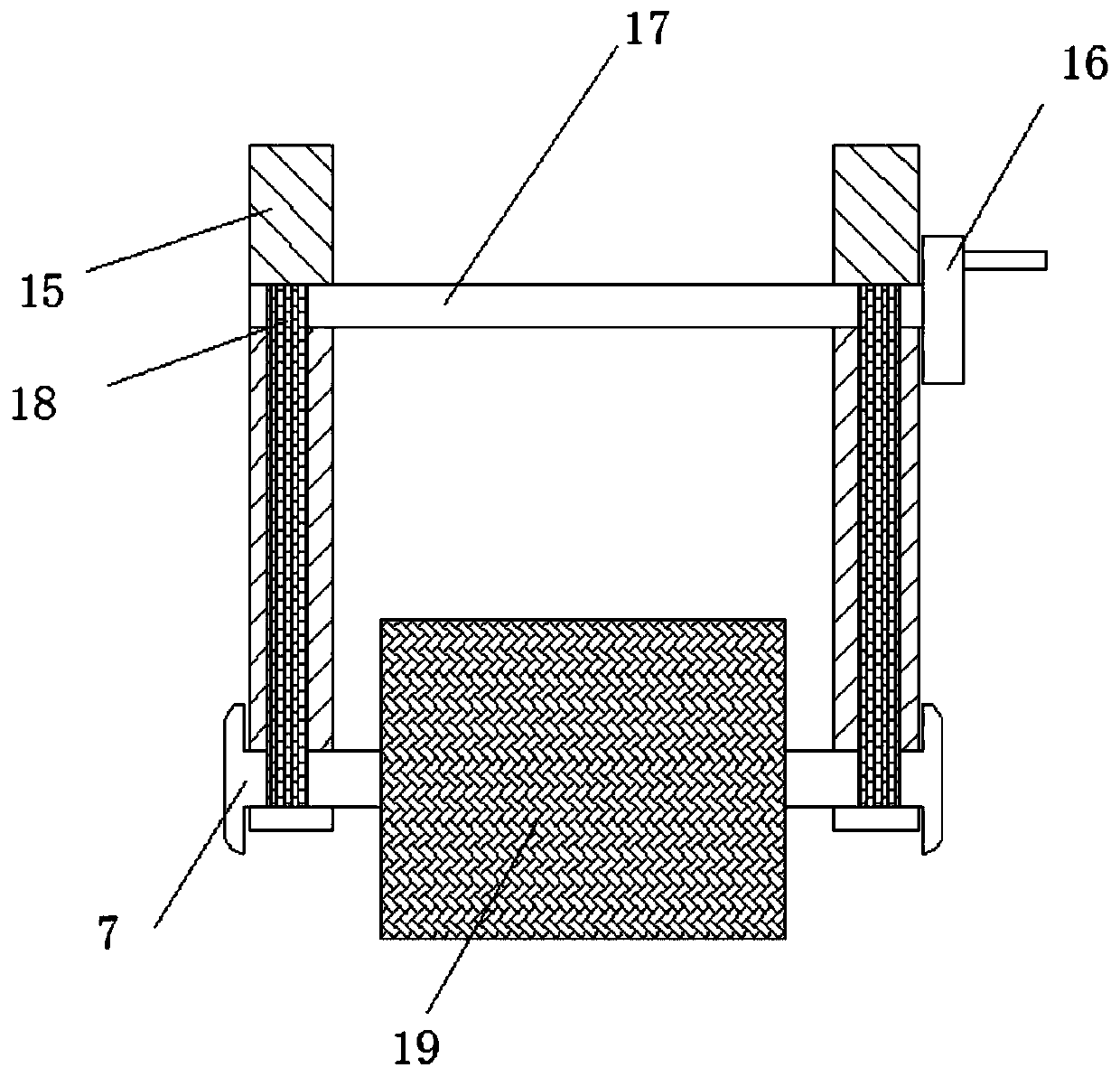

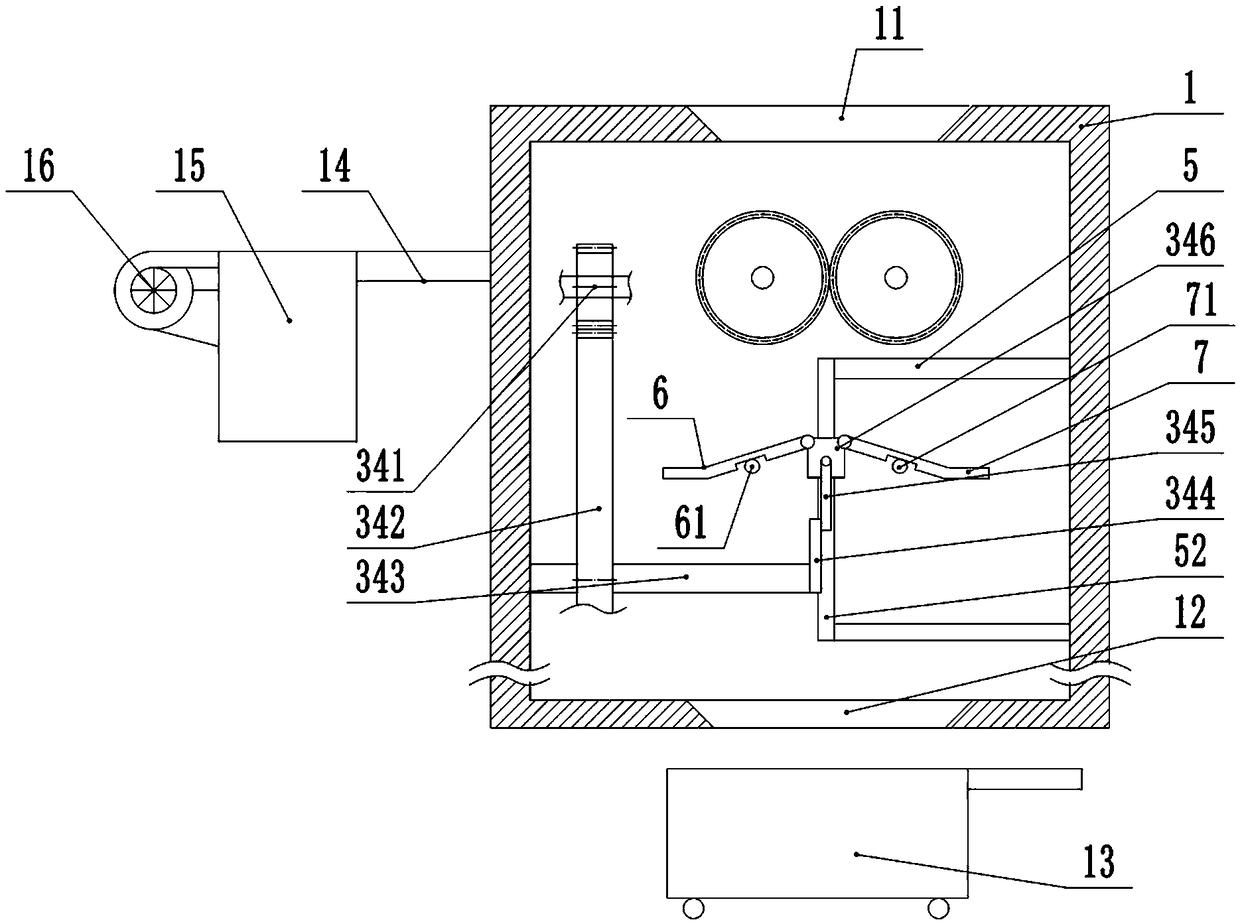

Large-batch natural emulsion mattress cleaning equipment

InactiveCN110479661AHas a cleaning effectRealize the cleaning functionDrying gas arrangementsCleaning using toolsEmulsionAssembly line

The invention relates to the field of mattress correlation techniques, and discloses assembly line type natural emulsion mattress cleaning equipment. The assembly line type natural emulsion mattress cleaning equipment comprises a lower base, and a supporting seat is fixedly connected in the lower base. The top end of the supporting seat is movably connected with rolling wheels. According to the assembly line type natural emulsion mattress cleaning equipment, a mattress enters the equipment from a first conveying belt, cleaning cloth is arranged above the first conveying belt, and the cleaningcloth can be kept wet all the time through a water dividing pipe in a water pipe cavity and has a cleaning effect. After the mattress is cleaned by the cleaning cloth, water in the mattress can be squeezed out through the cooperation of an upper squeezing wheel and a lower squeezing wheel, then the mattress enters a second conveying belt, and a drying chamber is arranged above the second conveyingbelt. Under pushing of an exhaust fan, air is heated by two heating screens and reaches the mattress to dry the mattress. After drying is completed, the mattress is discharged out of the equipment accordingly, the equipment successfully achieves an assembly line type cleaning function, and the natural emulsion mattress can be efficiently cleaned in large batch.

Owner:杭州盟韵科技有限公司

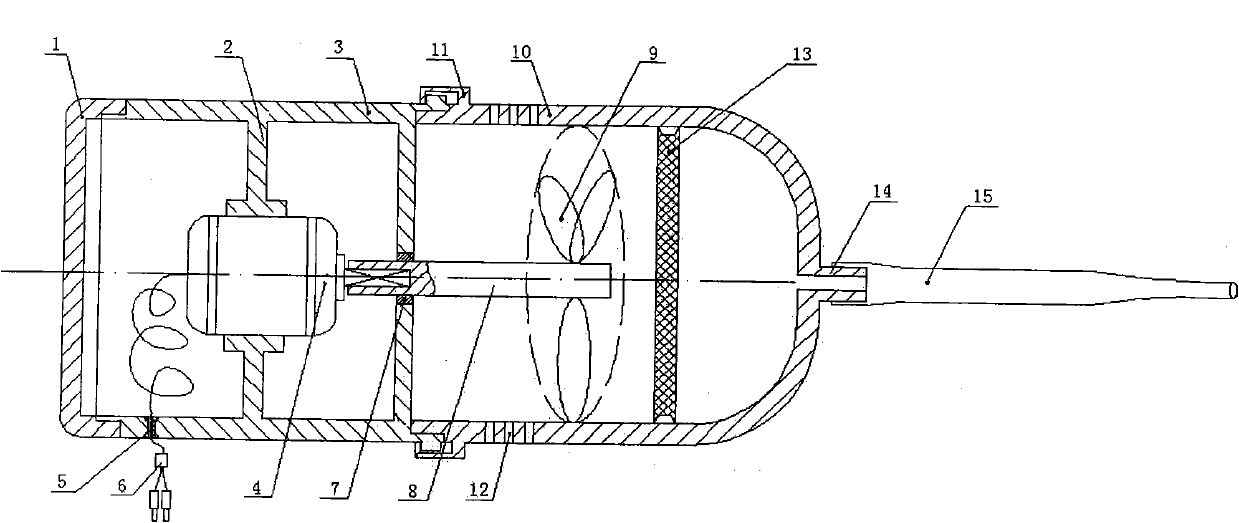

Pipeline cleaning robot

InactiveCN111112251ASimple structureSave resourcesHollow article cleaningDrive wheelElectric machinery

The invention discloses a pipeline cleaning robot which comprises a stepping motor and a planet wheel speed reducer, wherein the stepping motor is a left-right double-shaft synchronous output motor; the stepping motor is fixedly connected with the outside of the planet wheel speed reducer through a case; an output shaft at the right end of the stepping motor is in transmission connection with theplanet wheel speed reducer; the planet wheel speed reducer is in transmission connection with a driving wheel through a reversing mechanism; an output shaft at the left end of the stepping motor is transmission connection with a turntable; the turntable is movably connected with centrifugal rotating rods through plug pin structures; a cleaning ball is fixedly arranged at the tail end of each centrifugal rotating rod; and the left end of the case is fixedly connected with a driven wheel. The pipeline cleaning robot has the beneficial effects that the structure is simple; the resources are saved; the driving and cleaning functions can be realized by the single stepping motor; and the adjustment can be performed according to the inner diameter of a pipeline so as to adapt to pipelines of different specifications.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Computer keyboard cleaner

InactiveCN101905225AWill not flow out automaticallyWon't flow outCleaning using toolsCleaning using gasesImpellerEngineering

The invention discloses a computer keyboard cleaner, which comprises a dust absorption device and a cleaning device. The dust absorption device comprises a base and a dust absorber. The cleaning device comprises a base and a cleaning head. The dust absorption device and the cleaning device share the same base. Different functions can be realized by replacing different working heads. A motor is arranged in the base. The dust absorber comprises a dust absorbing shell connected to the base; a side wall of the dust absorbing shell is provided with an air vent; a filter screen is arranged in the shell; the front end of the shell is sleeved with a dust absorbing soft tube; an impeller connected to the motor is arranged in the dust absorbing shell; the cleaning head comprises a rotating shaft connected to the motor; a rotating box is arranged on the end of the rotating shaft; the rotating box is provided with a transparent cavity; sponge is filled in the cavity in order to absorb cleaning liquid; an annular brush is sleeved on the edge of the rotating box; a plug seals the cavity of the rotating box; and a liquid adding hole is arranged in the side wall of the rotating box. Through replacing different working heads, the invention can realize the functions of dust absorption and cleaning and the working heads can be conveniently replaced.

Owner:CHINA AGRI UNIV

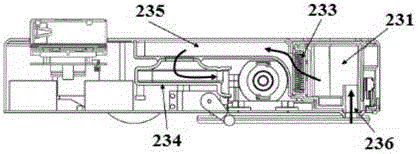

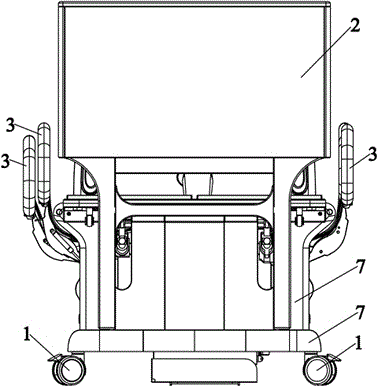

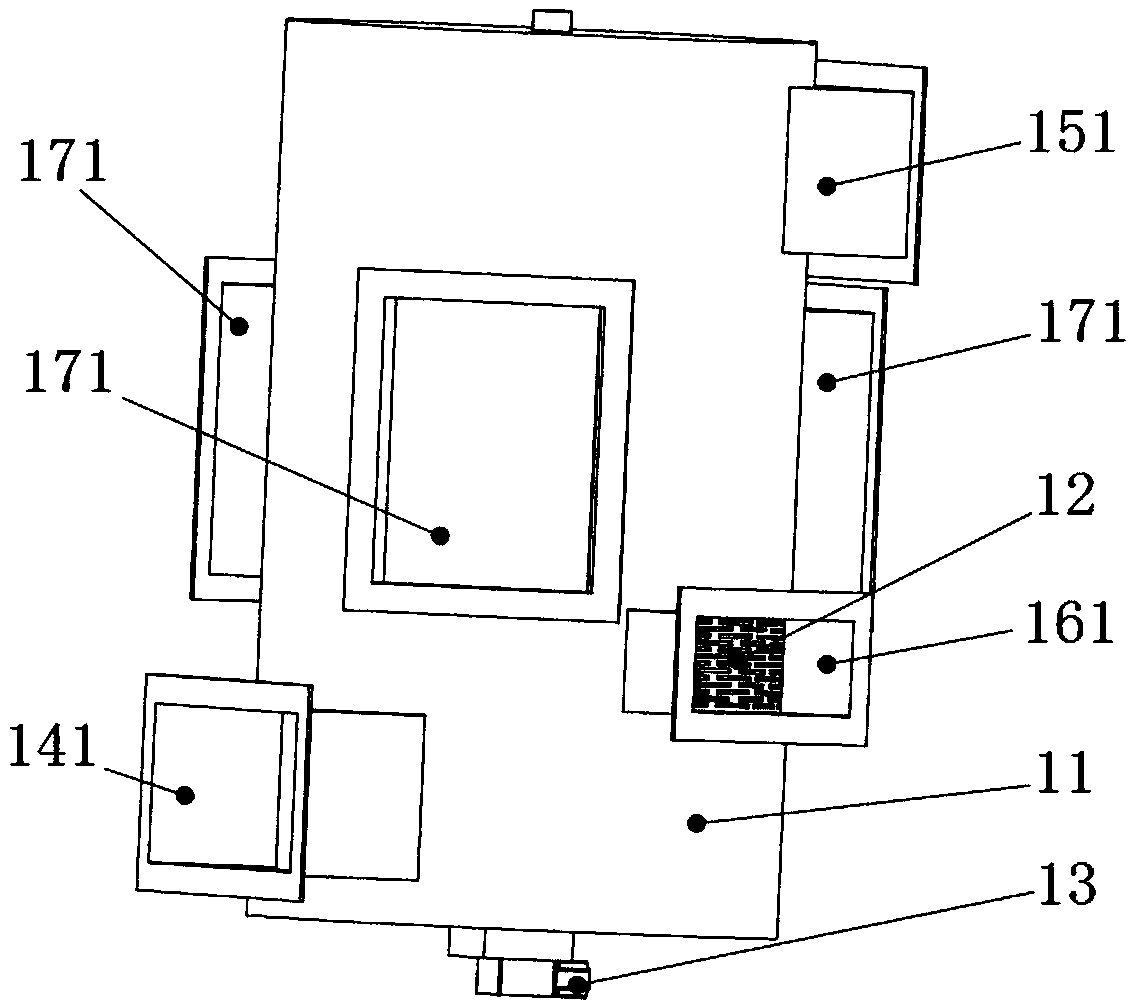

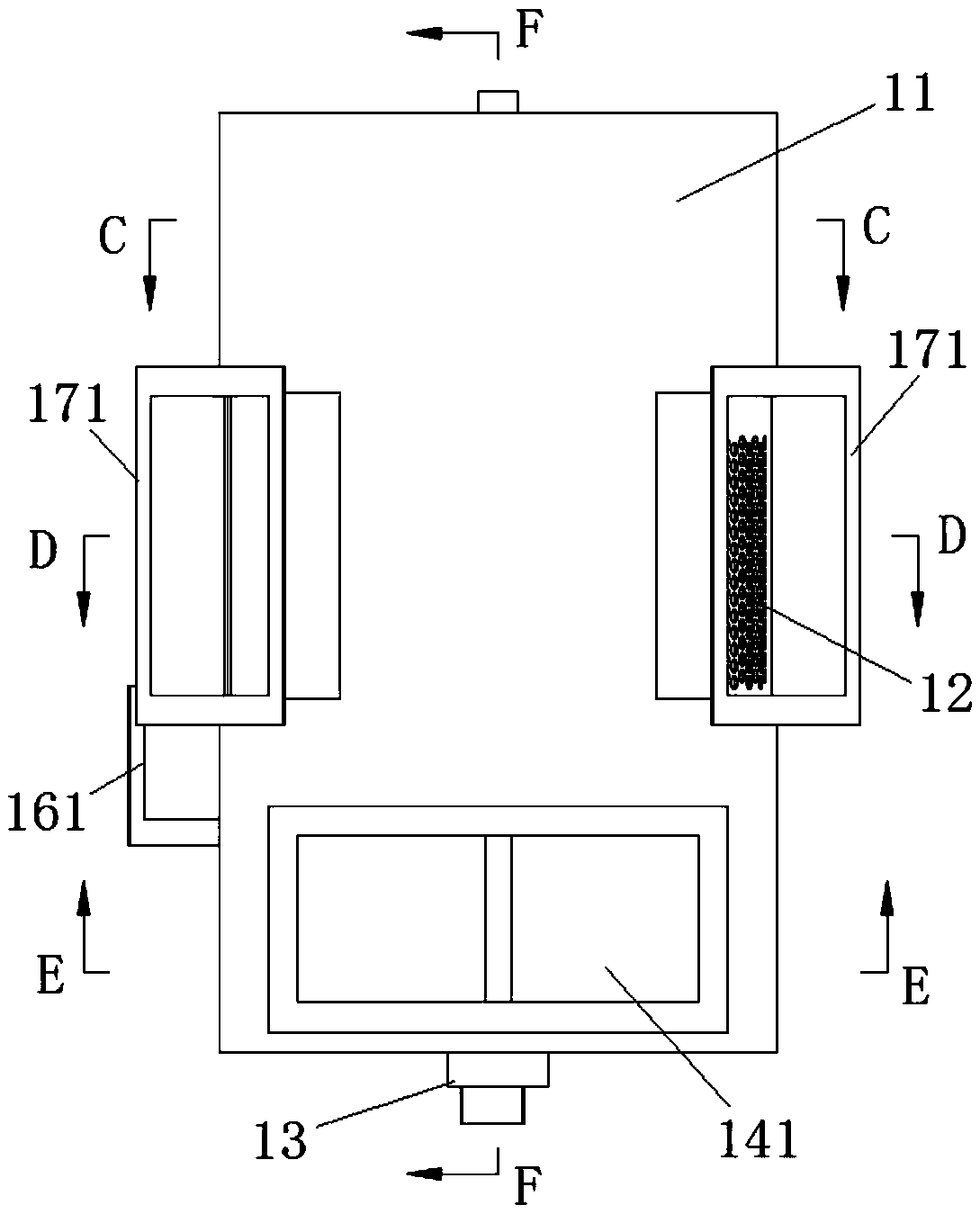

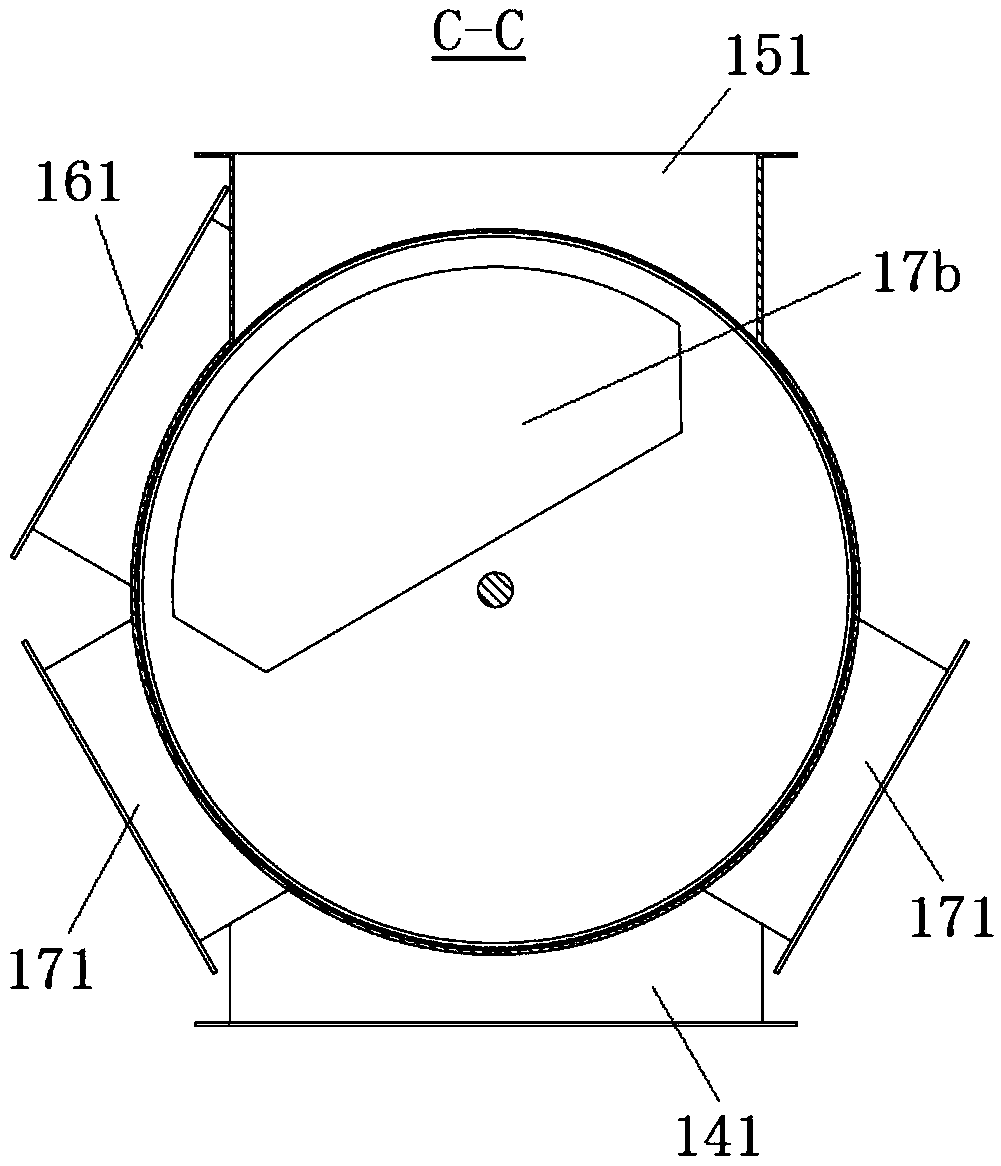

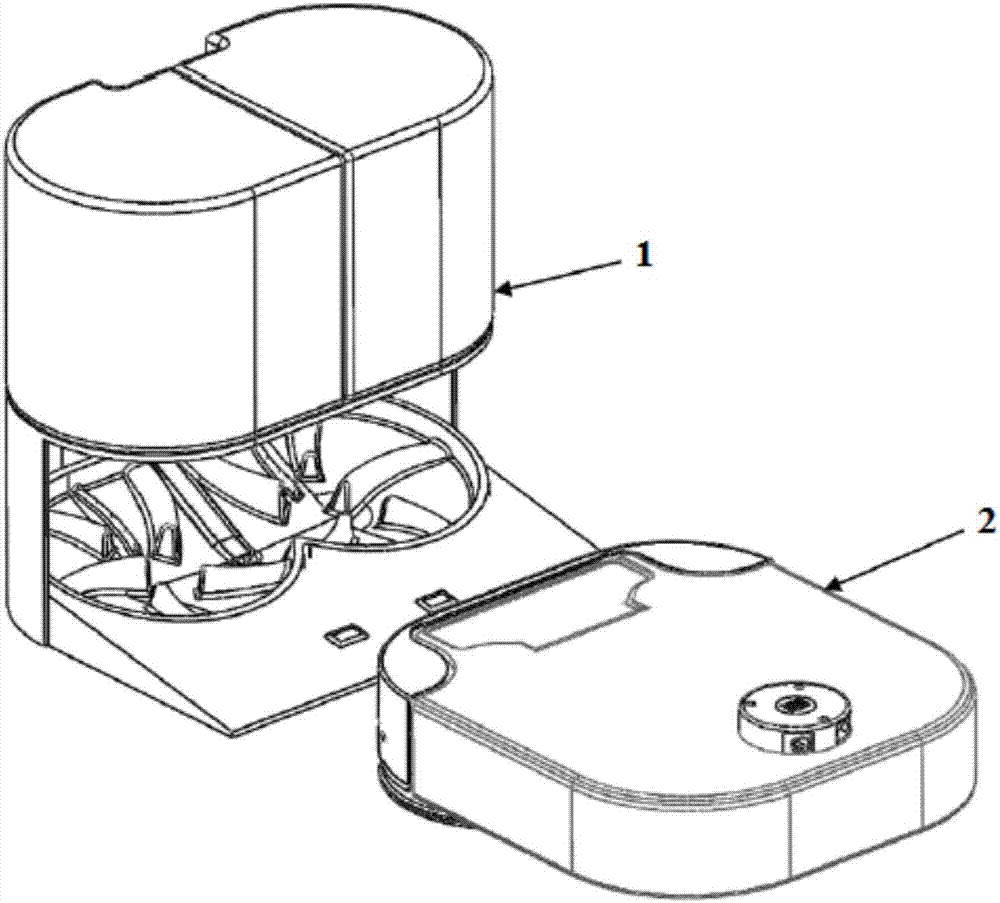

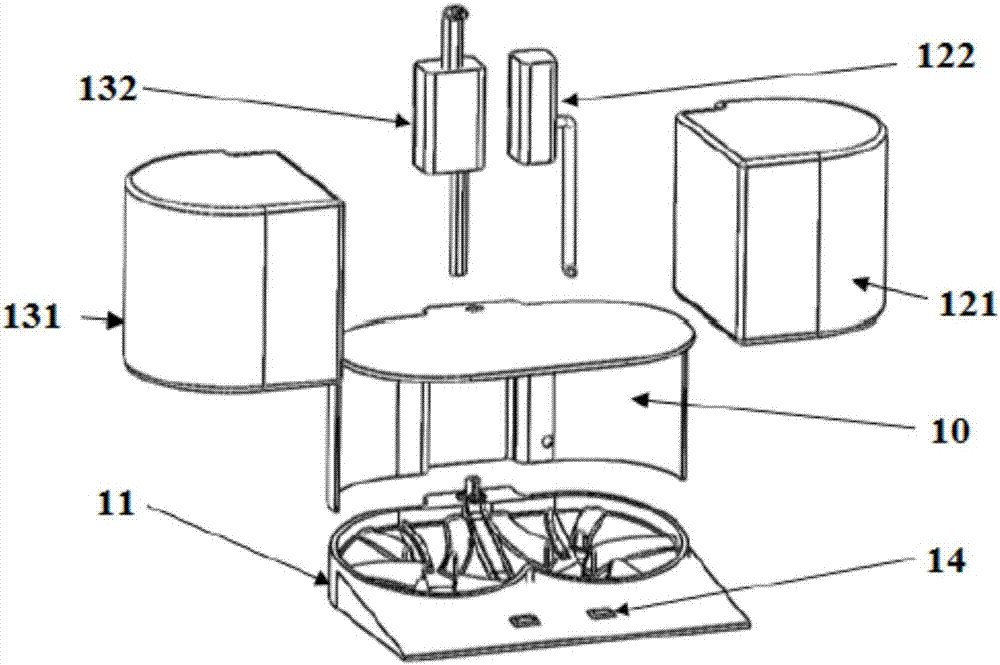

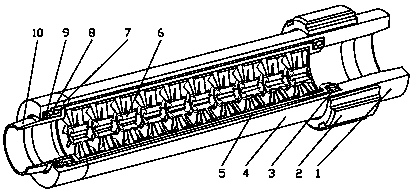

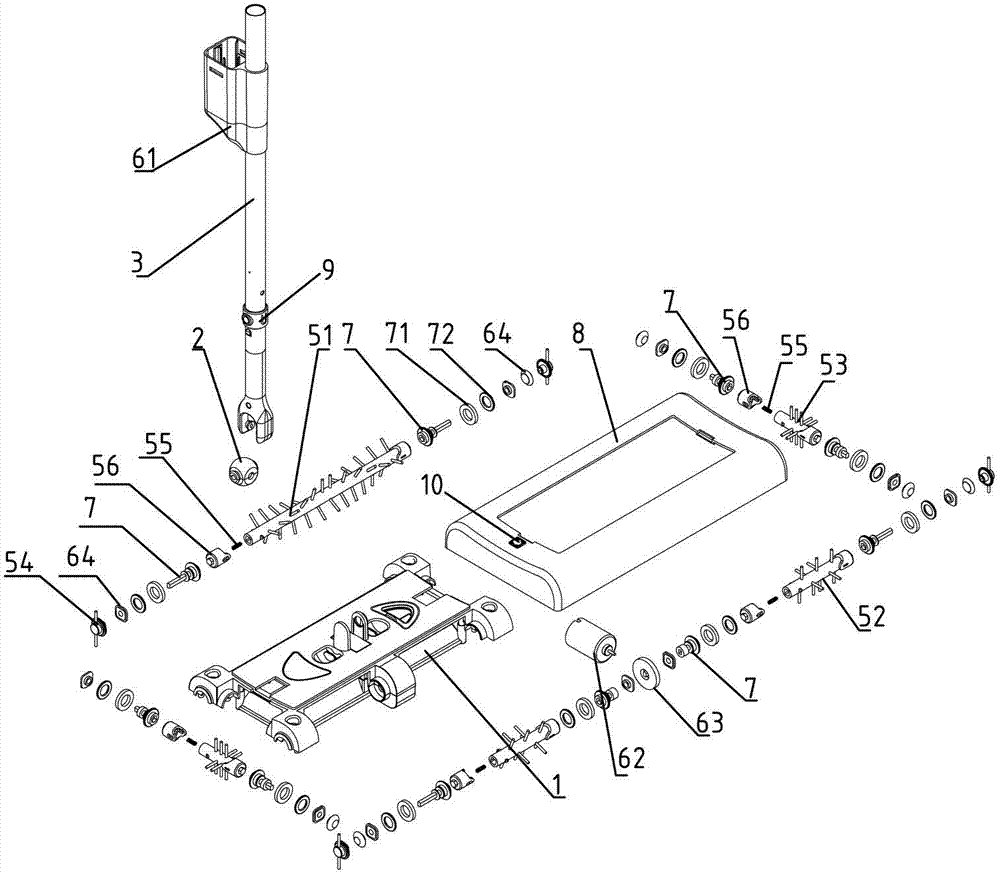

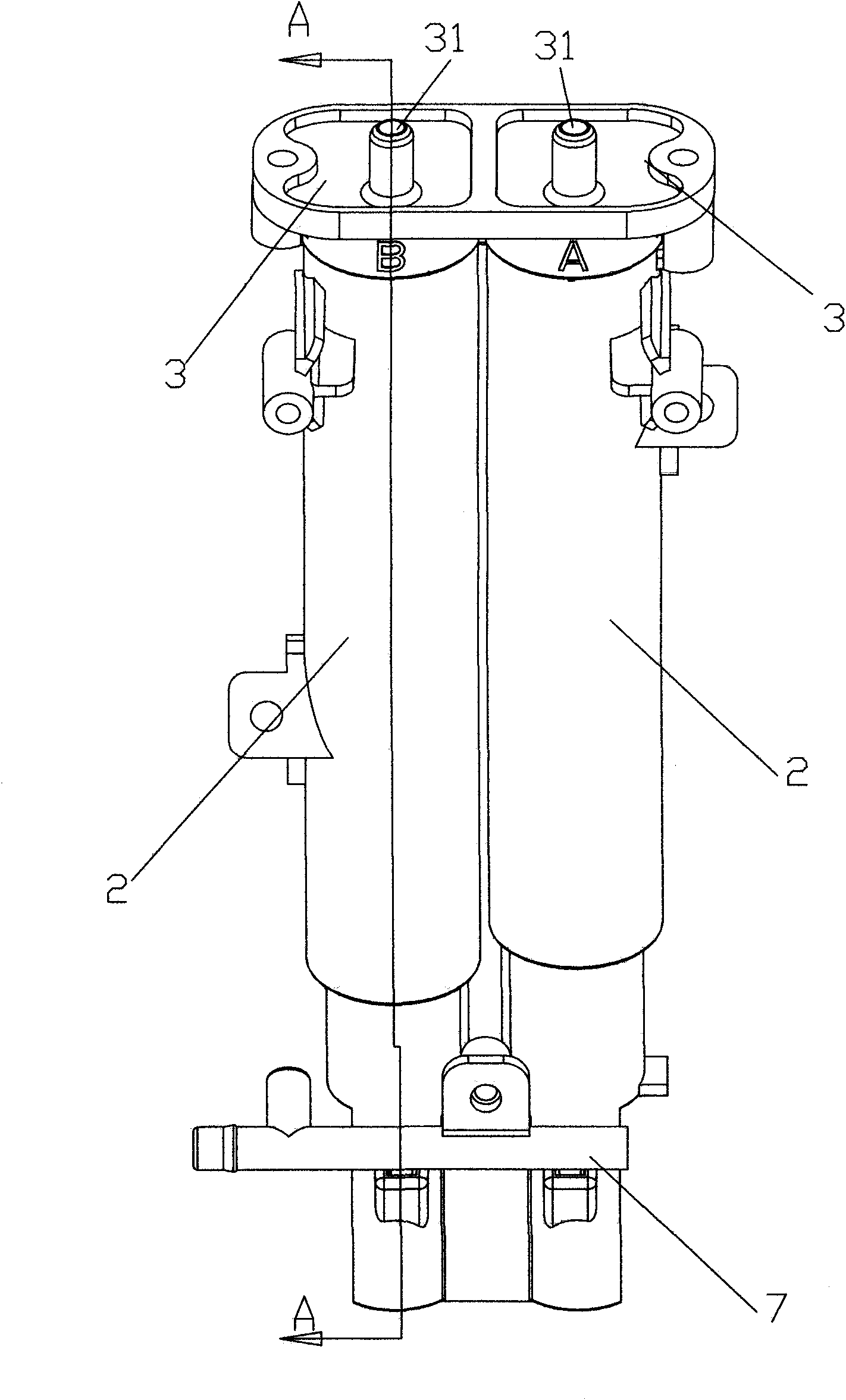

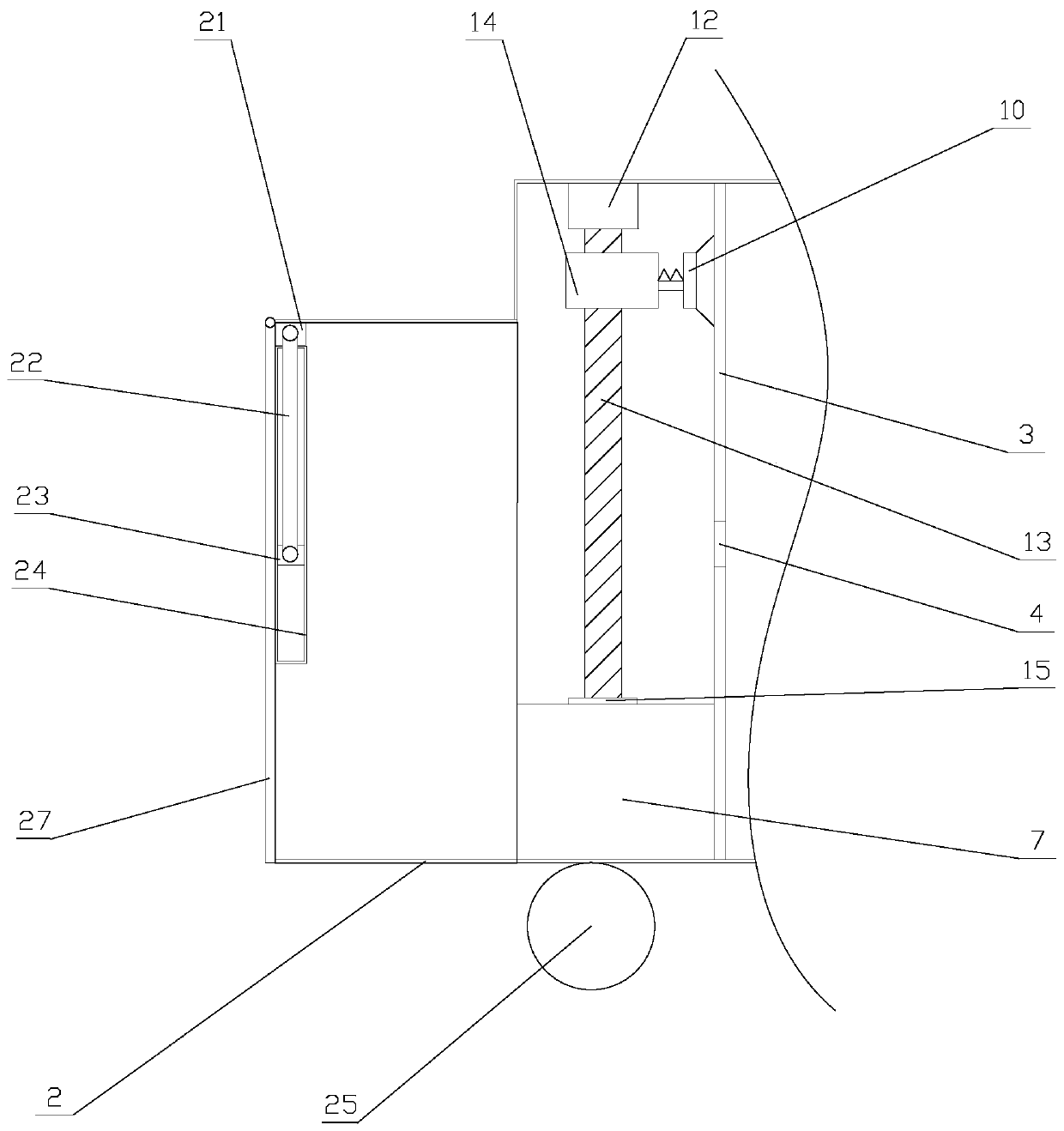

Cleaning robot and cleaning robot system

InactiveCN107049153ASimple structureReduce volumeCarpet cleanersFloor cleanersRobotic systemsControl theory

The invention relates to the technical field of cleaning robots, in particular to a cleaning robot and a cleaning robot system. According to the cleaning robot, a mopping and wiping part on a mopping and wiping unit can rotate around a vertical axis relative to a chassis of the cleaning robot, a collecting port of a garbage collection device is formed in the outer side of the edge of the mopping and wiping unit, relative movement between the mopping and wiping part and the ground in the mopping and wiping process includes integral movement of the cleaning robot on the ground and rotary movement of the mopping and wiping part relative to the ground, so that mopping and wiping strength can be improved, mopping and wiping effect of the mopping and wiping part can be improved, garbage such as large particulate matters on the ground and dust can be swept up by the rotary mopping and wiping part, so that garbage gathered by the mopping and wiping part of the mopping and wiping unit is collected by the garbage collection device, namely, the rotary mopping and wiping part has a sweeping function, and the cleaning robot is a mopping and wiping integrated robot.

Owner:YUNJING INTELLIGENCE TECH (DONGGUAN) CO LTD

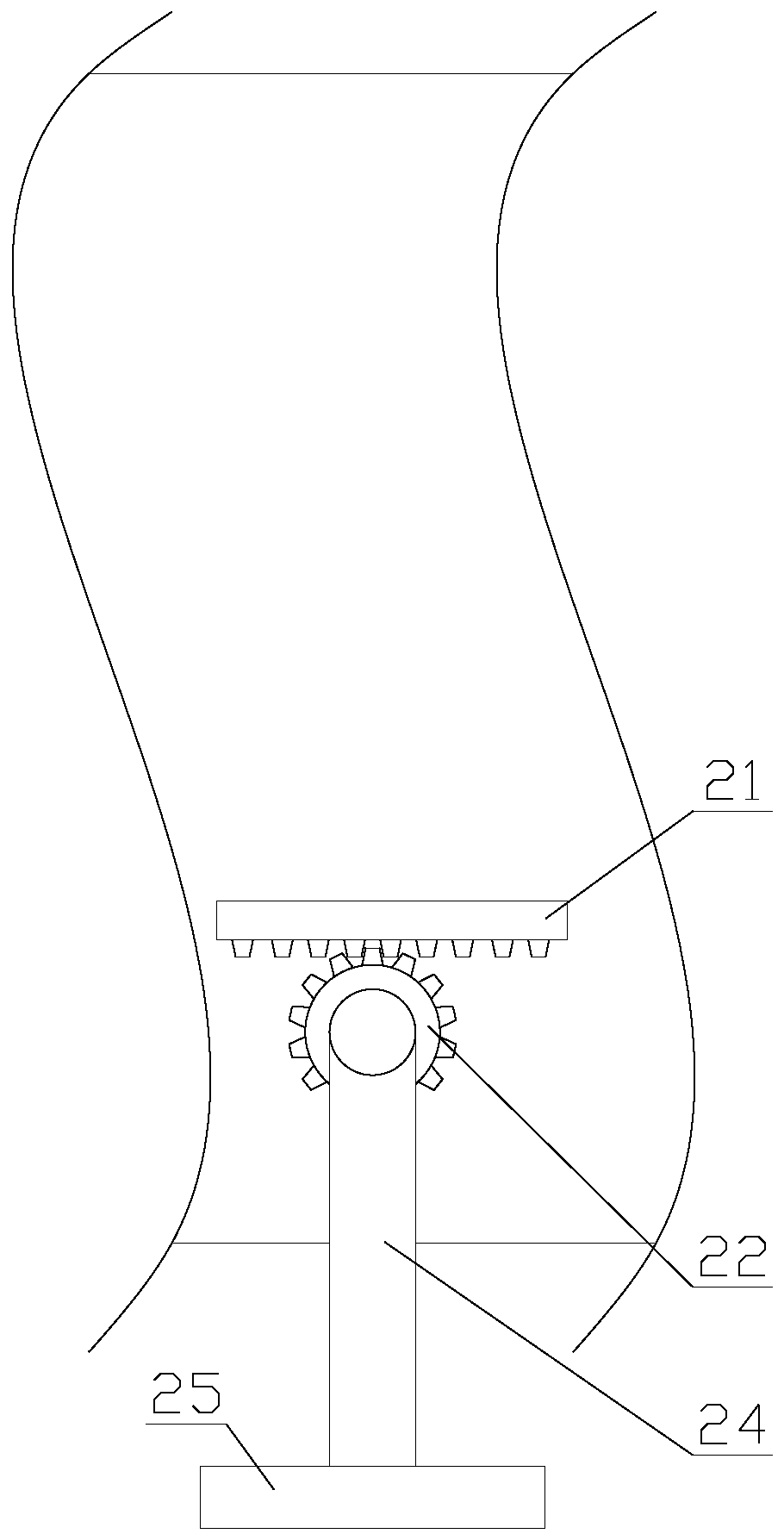

Gear type effective crushing device for solid wastes

ActiveCN108889374ARealize the cleaning functionReduce broken areaDirt cleaningGrain treatmentsEngineeringBevel gear

The invention relates to the technical field of crushing devices, and particularly discloses a gear type effective crushing device for solid wastes. The gear type effective crushing device for solid wastes comprises a motor and a crushing chamber, wherein the crushing chamber comprises a first tooth roller, a second tooth roller and a rack; the first tooth roller is fixedly connected to the motor;one end of the first tooth roller is fixedly connected with a first straight rod; the first straight rod is fixedly connected with a first bevel gear; the first bevel gear is engaged with a second bevel gear; the bottom of the second bevel gear is fixedly connected with a second straight rod; the bottom of the second straight rod is fixedly connected with a first crank; one end of the first crankis hinged to a first connecting rod; one end of the first connecting rod is hinged to a first sliding block; the rack is fixedly connected with a first guiding rod; the first sliding block is slidably connected to the first guiding rod; and one side of the first sliding block is fixedly connected to a plurality of cleaning brushes. The invention aims to provide the gear type effective crushing device for the solid wastes so as to solve the problems that solid wastes remain on the tooth roller, and thus, the crushing efficiency of the device is low.

Owner:南京扬子环保科技有限公司

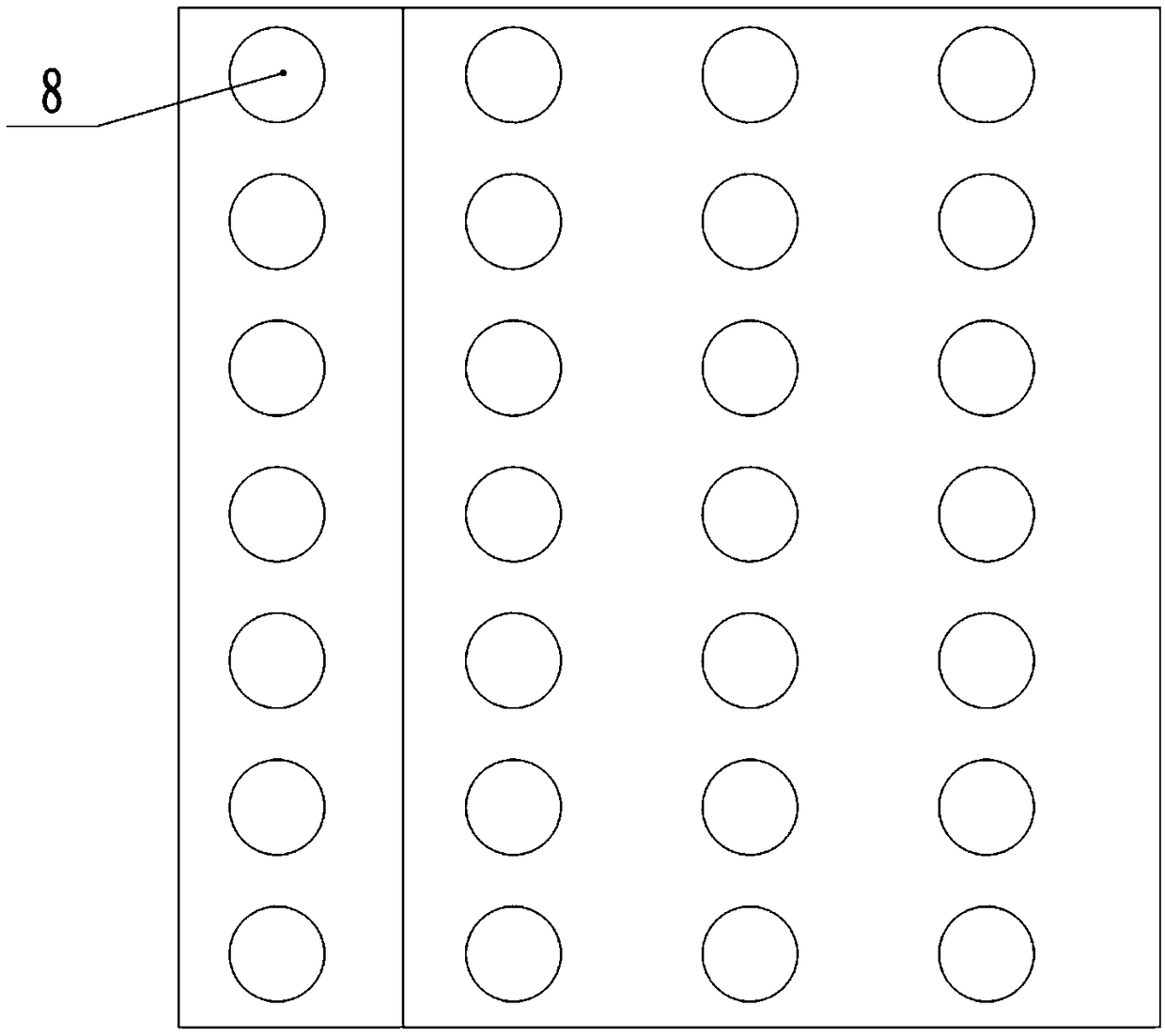

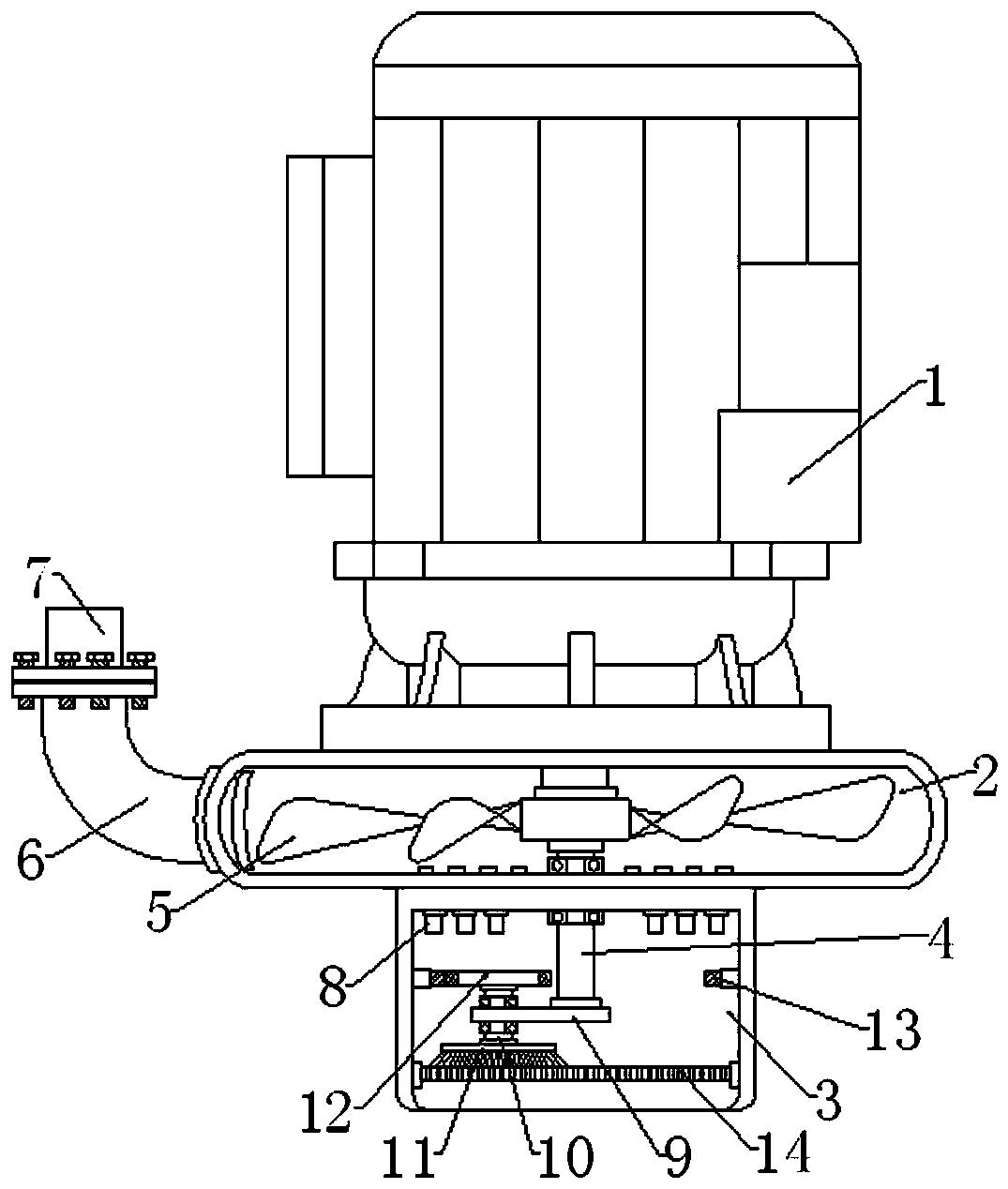

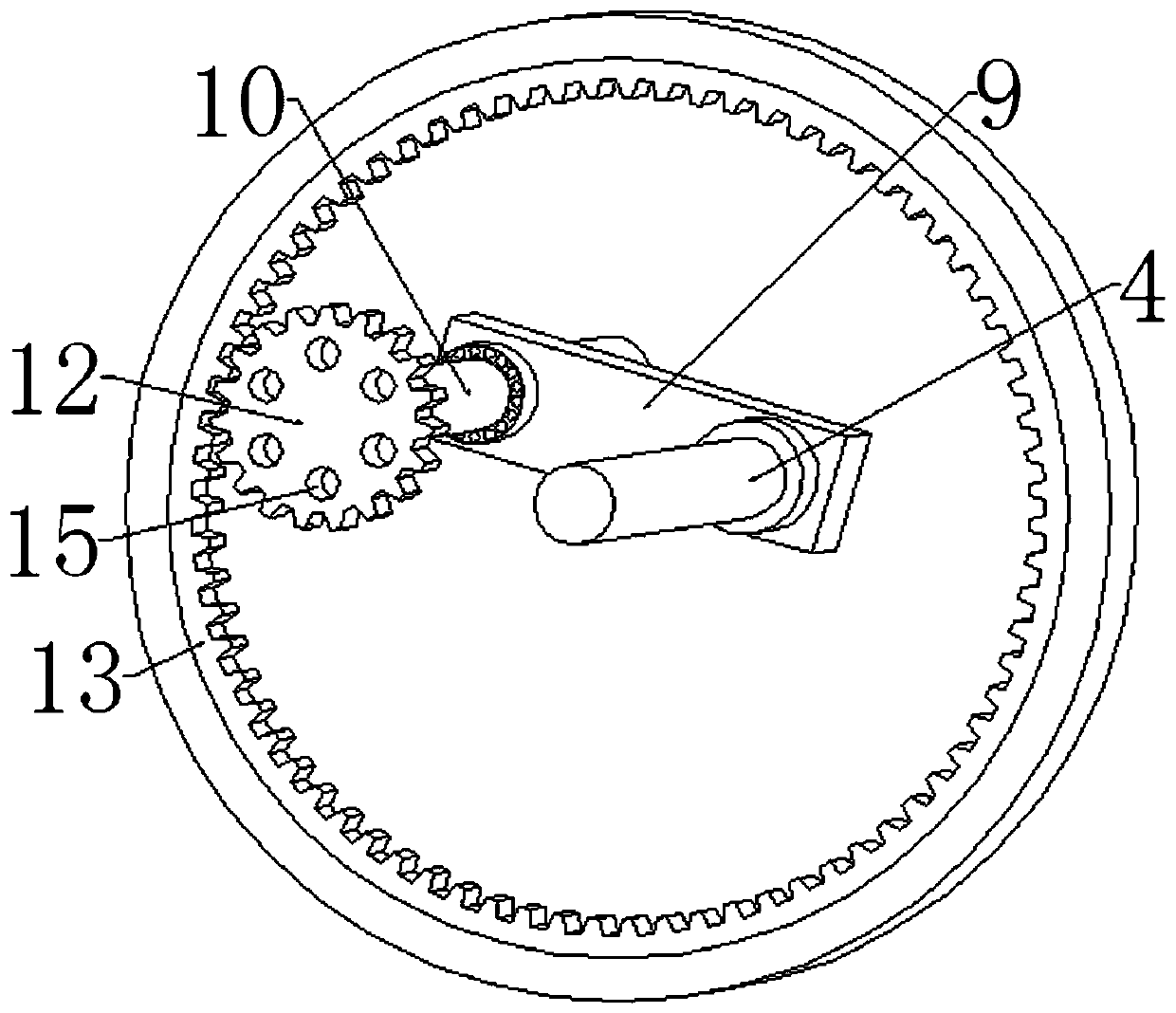

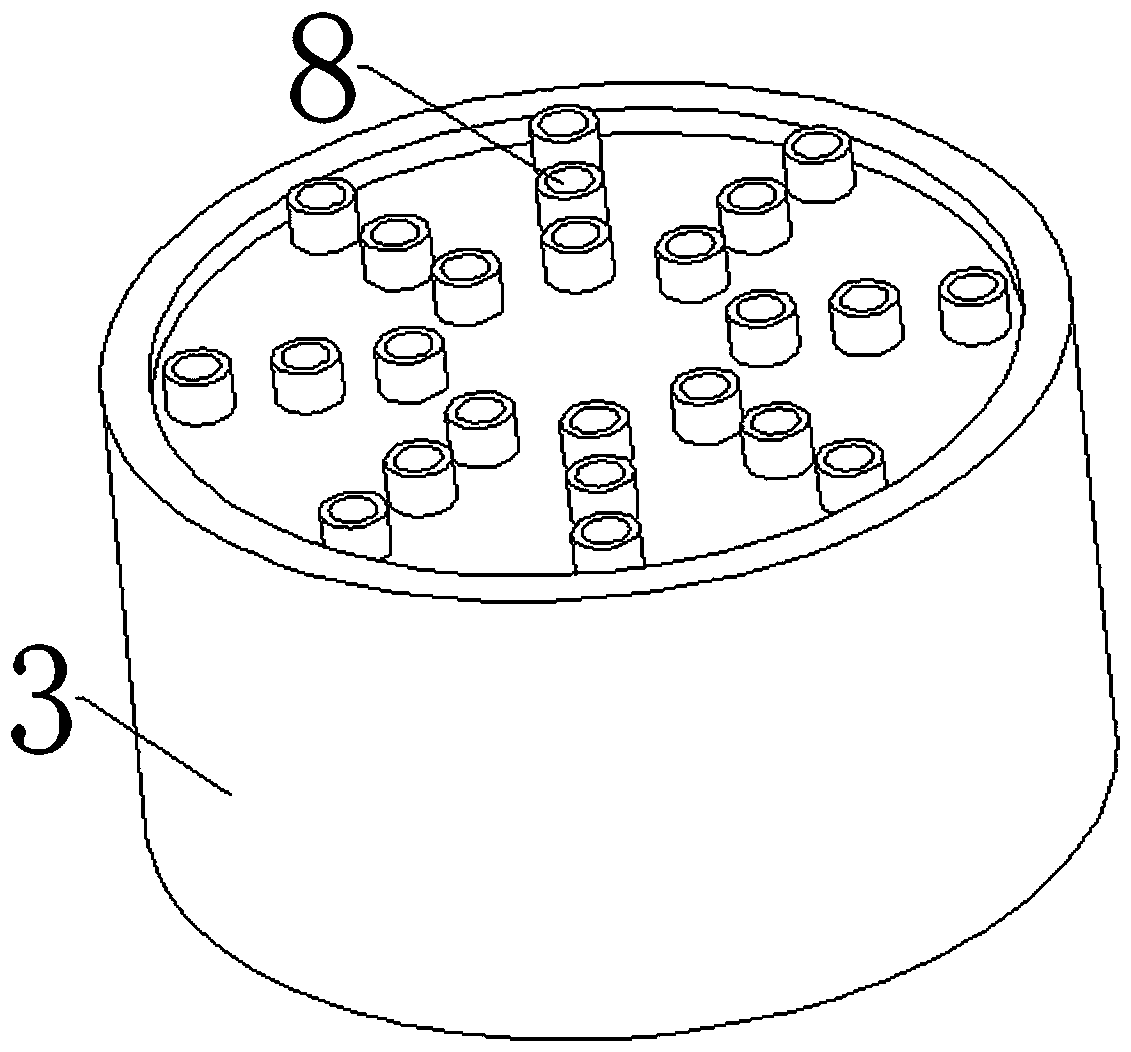

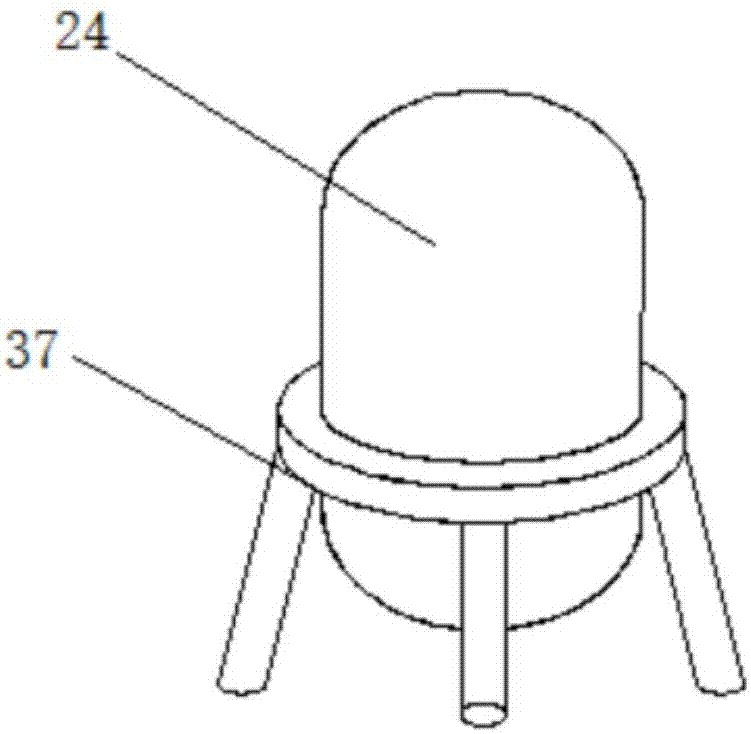

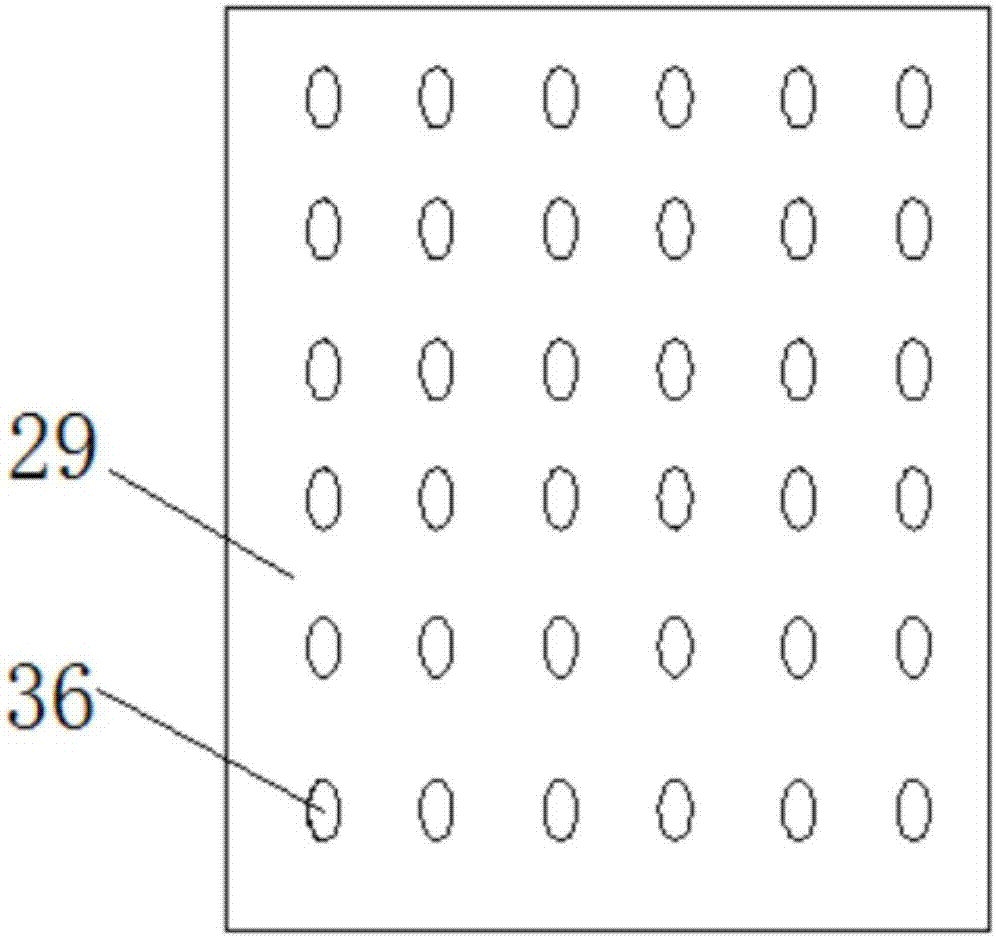

Submersible pump device with filtering function

InactiveCN110185630ARealize the cleaning functionAvoid cloggingPump componentsPump installationsImpellerDraining tube

The invention discloses a submersible pump device with a filtering function. Particularly, the submersible pump device is capable of filtering water and provided with an anti-blocking mechanism, a filter is effectively prevented from being blocked, and the problem that a filtering part in an existing submersible pump is blocked after long-time use is solved. A driving motor is installed on an upper flange of a device body. A pump body is fixedly connected to the lower portion of the driving motor. The filter is fixed below the pump body. An impeller is rotationally arranged in the pump body and is fixed to a rotating shaft connected to the output end of the driving motor. The upper portion of the filter communicates with the lower portion of the pump body through a through pipe. A drainagepipe is fixed to the side wall of the pump body in a communicating mode. An anti-blocking mechanism is arranged at the lower end of the rotating shaft. A filtering plate is fixedly connected to an inner wall of the lower portion of the filter. A plurality of filtering holes used for filtering the water liquid are uniformly formed in the surface of the filtering plate.

Owner:LIMING VOCATIONAL UNIV

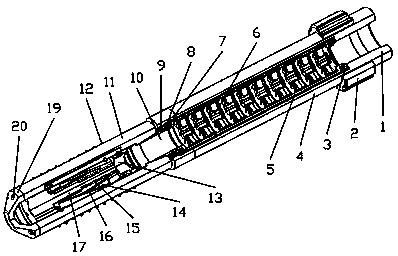

Novel rotary casing scraper

The invention relates a novel rotary casing scrapper. The scrapper comprises a hydraulic drive assembly and a scrapping cutter assembly, the inner wall of an inner tube of the scrapper is fixedly connected with turbines, the inner tube of the scrapper is driven to rotate by the turbines which are impacted by high-pressure water flow, so that the scrapping cutter assembly is further driven to rotate. Every two scissor rods are connected through pins as a group to form a scissor frame structure, a function of radial and straight expanding of scrapping blades is achieved through axial movement ofthe scissor frame. Six oblique holes are formed in the scrapping blades, which are used for jetting out the high-pressure flow in a scrapping process and cleaning the cutter and the inner wall of a casing. A base is connected with a housing of the scrapping cutter through screws, six oblique holes are formed in the base, the holes are used for jetting out the remaining high-pressure water flow and flushing an inner tube of the casing at the lower portion in advance to achieve pretreatment of scrapping. Compared with the traditional casing scrapper, while the function of radial expanding of the scrapping blade is achieved and the diameter of scrapping is increased, the scissor frame structure is more stable, the scrapping efficiency is more significant, the novel rotary casing scrapper also has a cleaning function, and the scrapping capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

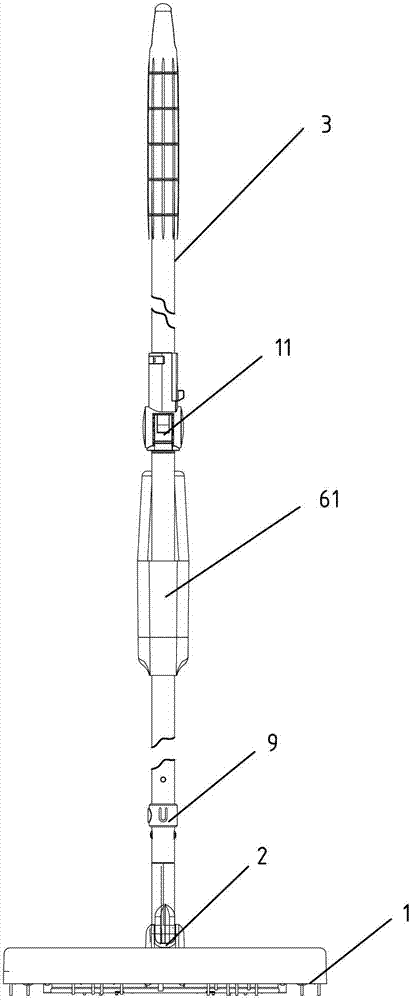

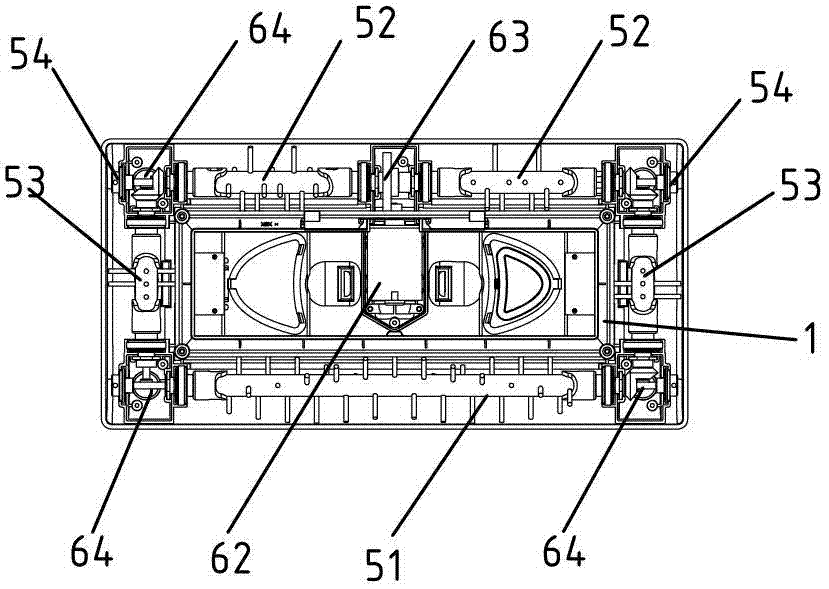

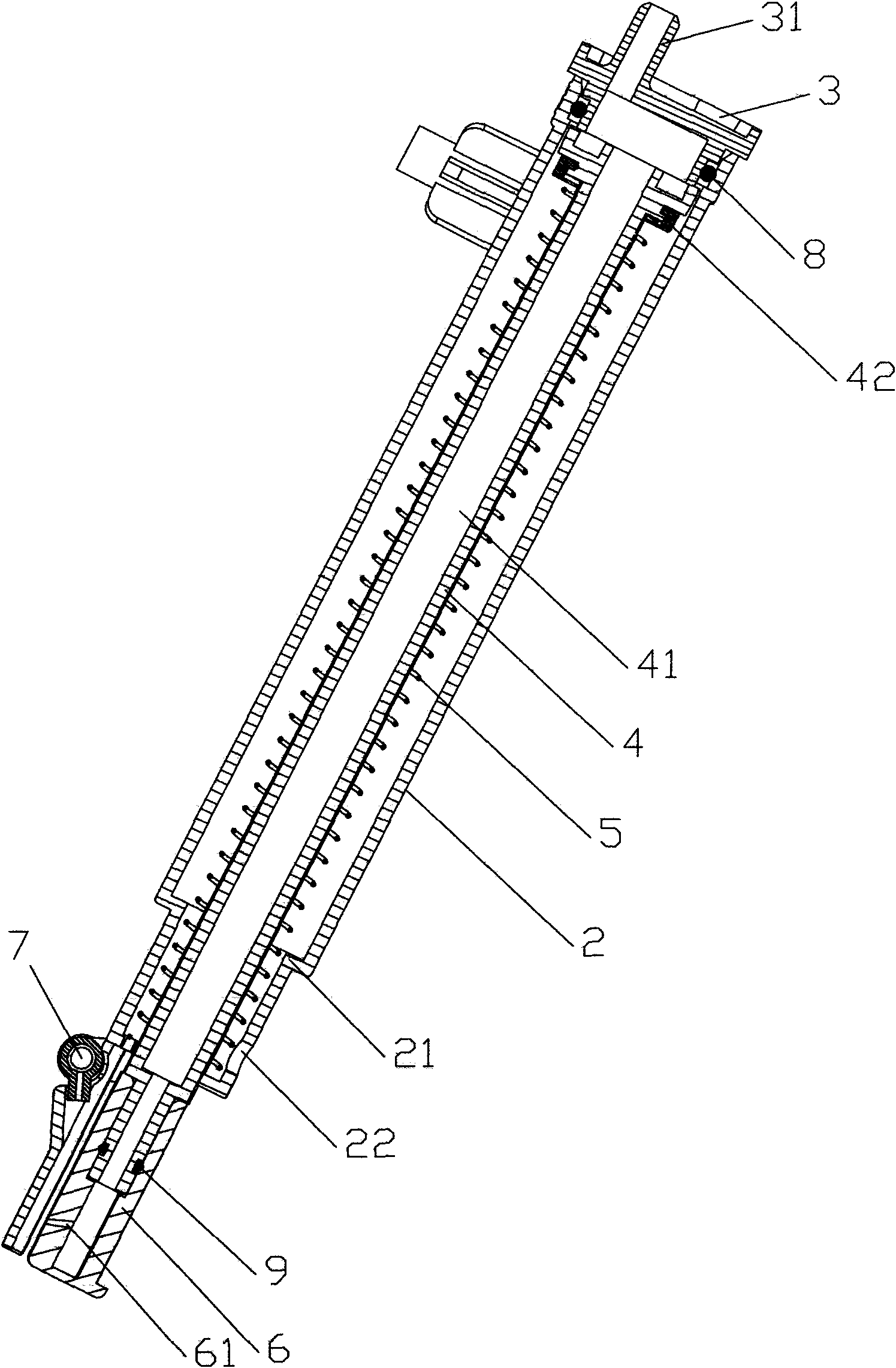

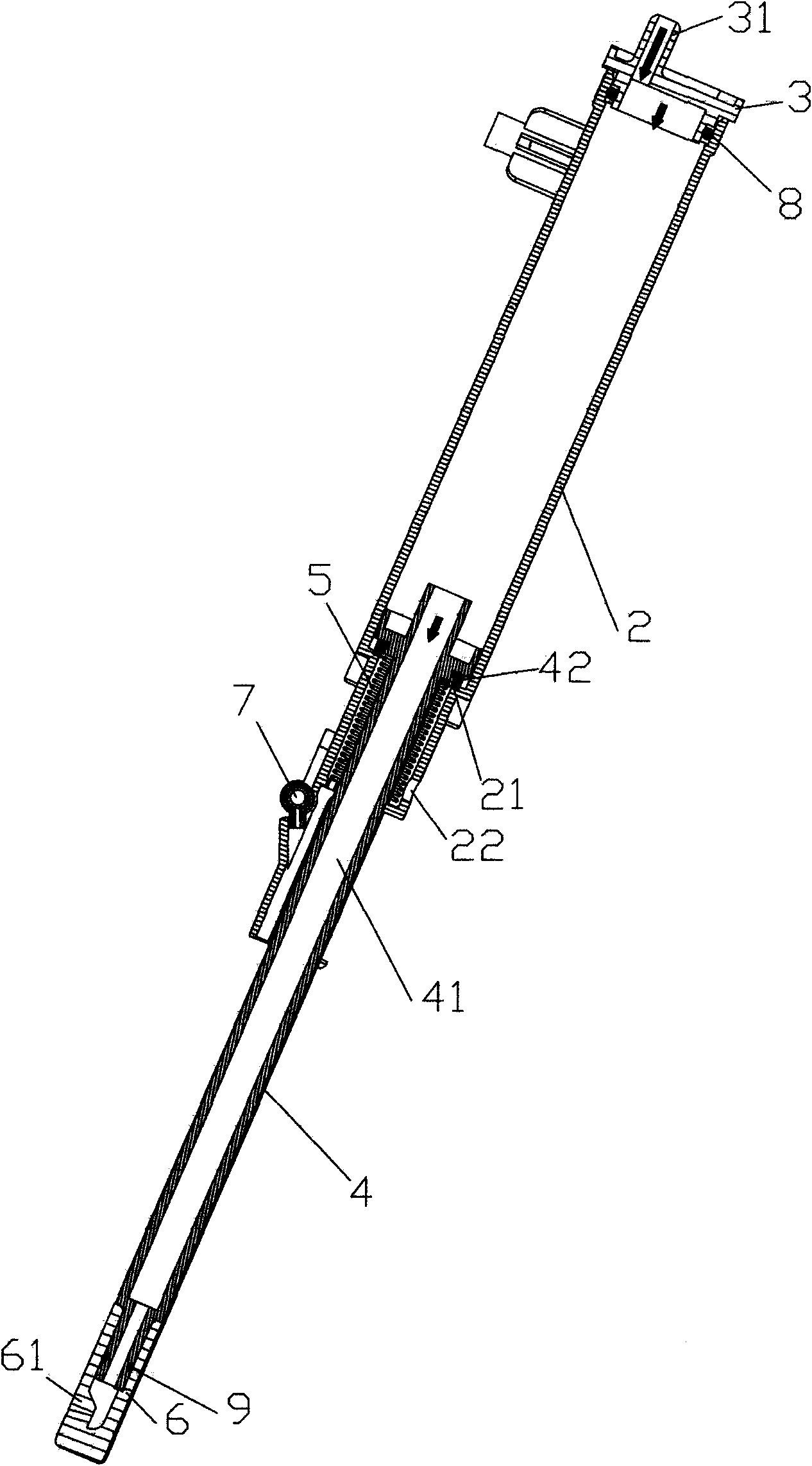

Indoor sweeper

InactiveCN102764099AAchieving aggregation and inductionRealize the cleaning functionMachine detailsFloor sweeping machinesUniversal jointTransmitted power

The invention discloses an indoor sweeper, which comprises a brush base 1, a universal joint 2, an operating handle 3, a dust chamber 4, a rotating brush component and a transmission device, wherein the operating handle 3 is connected with the brush base 1 through the universal joint 2; the dust chamber 4 is arranged on the lower middle part of the brush base 1; the rotating brush component is arranged in the periphery of the bottom surface of the brush base 1, and consists of rotating brushes 51, 52 and 53, a brush binding spring 55 and a brush binding shaft sleeve 56; and a micro motor 62 transmits power to the rotating brushes for rotating work application through transmission gears 63 and 64. The indoor sweeper has the advantage that the brush binding component can be disassembled for washing or replacement.

Owner:NINGBO FUDA ELECTRIC APPLIANCE

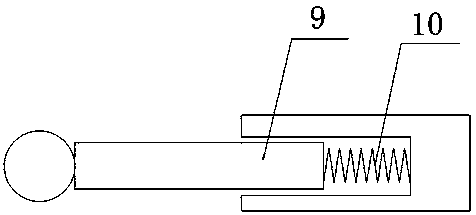

Private-anus flusher of seat type toilet

The invention discloses a private-anus flusher of a seat type toilet, which comprises two hollow sliding sleeves mounted on the toilet, the tail of each sliding sleeve is connected with a sliding sleeve cap with a water inlet tube connector, a sliding rod and a restoring spring are mounted in each sliding sleeve, the sliding rod can be extended out of the front end of the sliding sleeve under the pressure of influent water, the restoring spring can push the sliding rod into the sliding sleeve when no water flows in, the front ends of the sliding rods are provided with nozzles which are provided with flushing water spouts, and the sliding rods are provided with water flow passages communicated with the sliding sleeves and the nozzles. The purpose of the invention is to provide the private-anus flusher which has a simple structure and is used for flushing the privates and anuses of people after using the toilet.

Owner:ZHONGSHAN MEITU PLASTIC IND

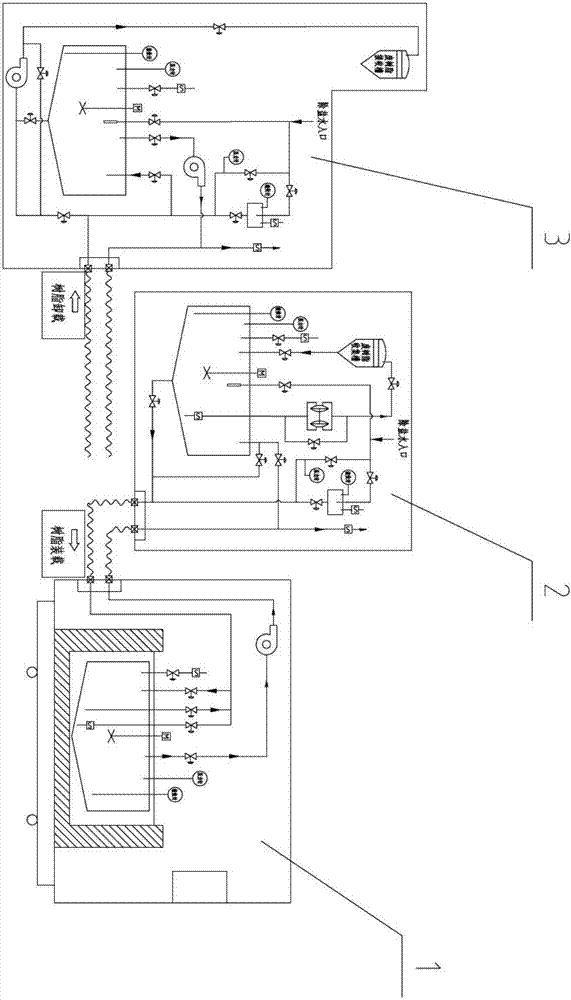

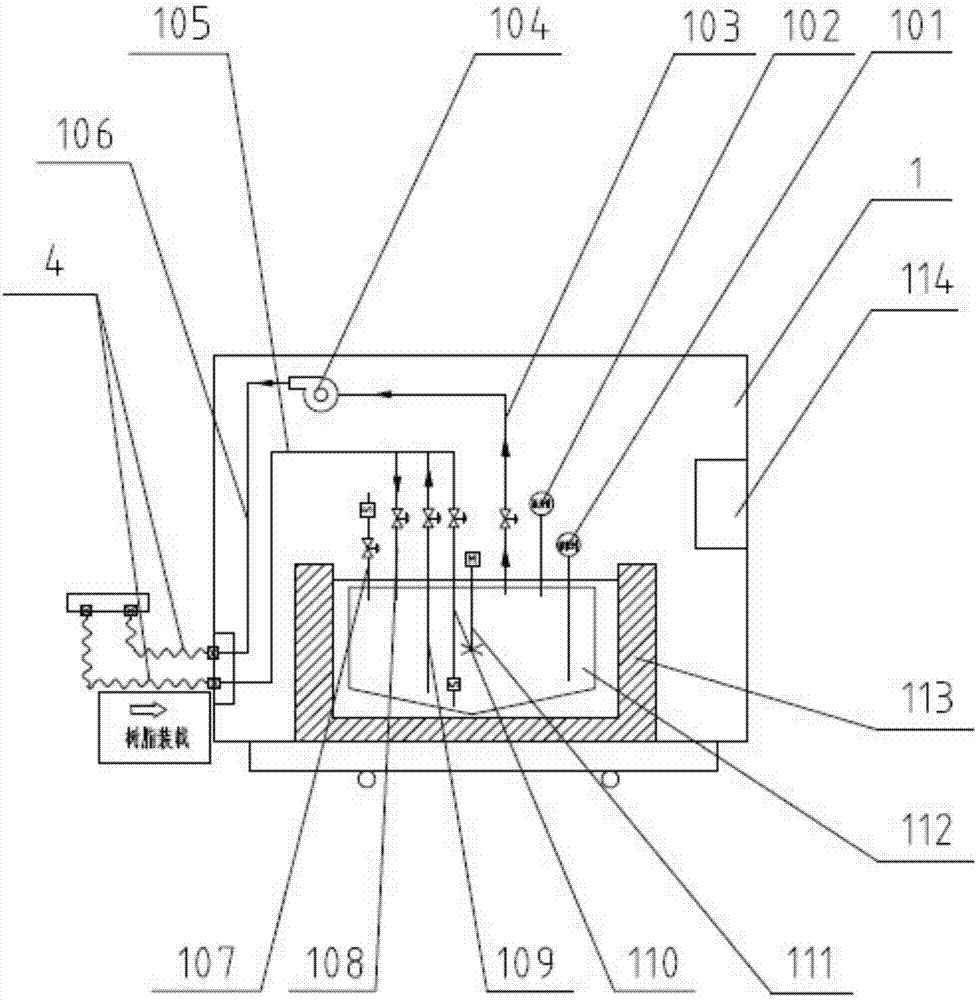

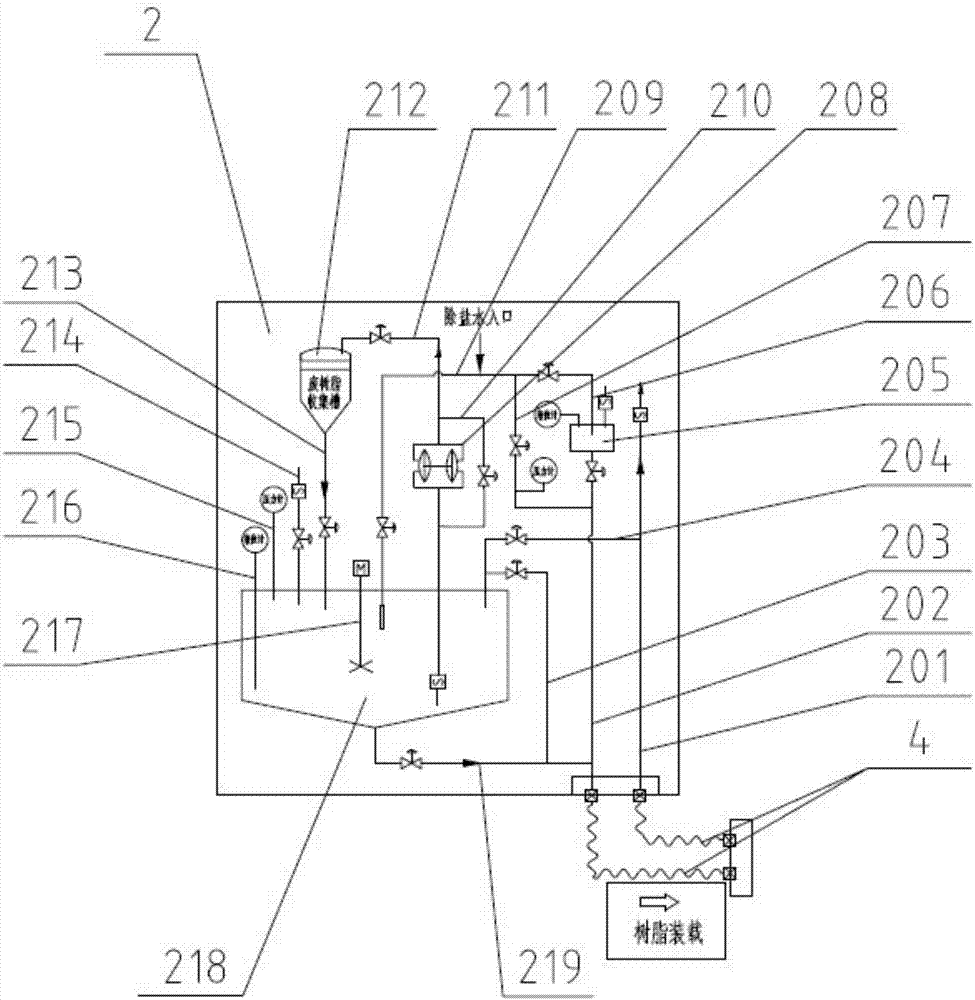

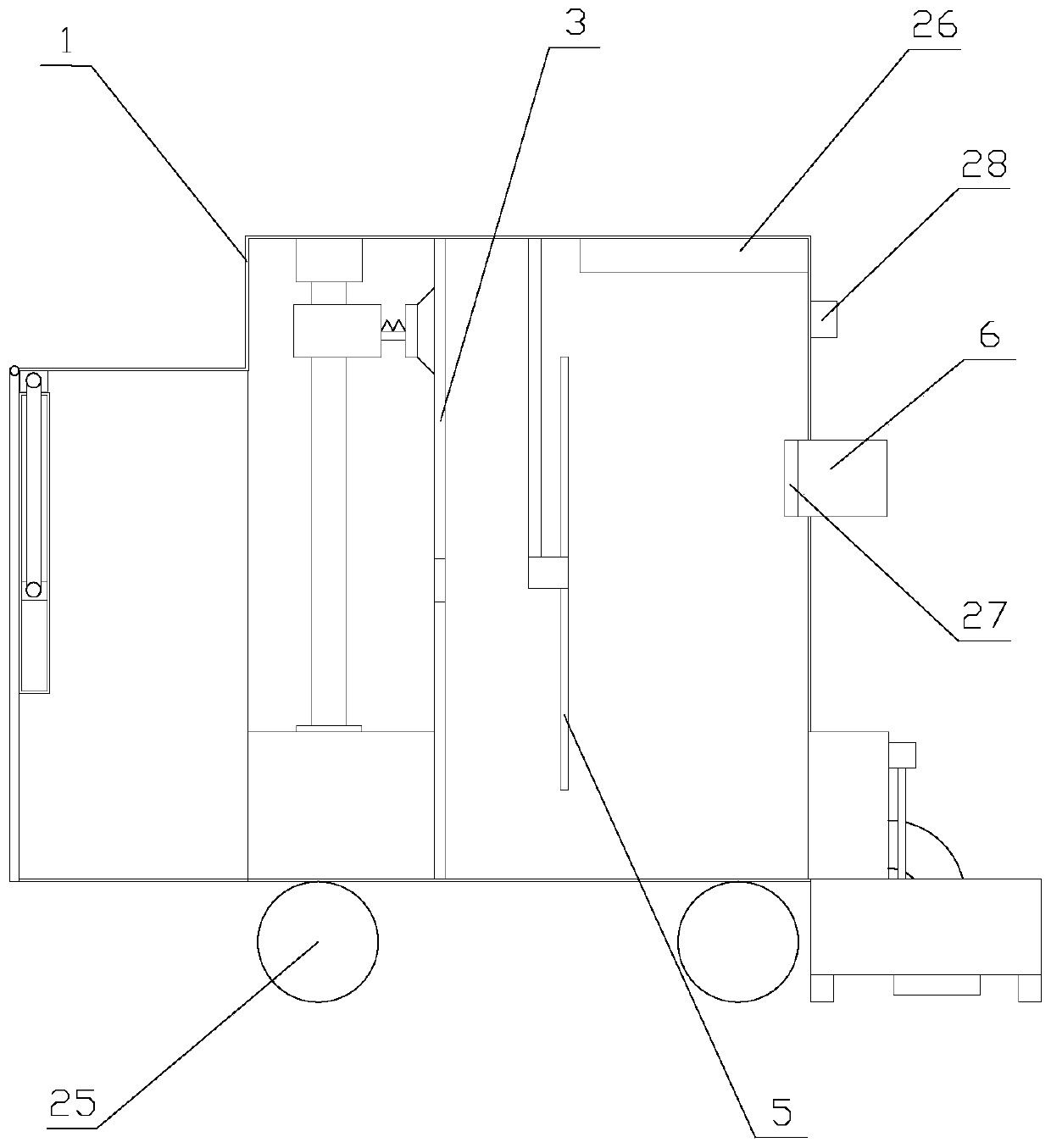

Loading, unloading and transferring apparatus for nuclear power plant spent resin and transferring method thereof

ActiveCN107293343AAvoid depositionReduce the risk of radiationPortable shielded containersNuclear engineeringRadioactive waste

The invention discloses a loading, unloading and transferring apparatus for nuclear power plant spent resin and a transferring method thereof, and belongs to the technical field of safety transfer of radioactive wastes. The loading, unloading and transferring apparatus for nuclear power plant spent resin comprises a shielding transporter, a loading connector device and an unloading connector device; in unloading, the shielding transporter is connected with the loading connector device through a hose; in unloading, the shielding transporter is connected with the unloading connector device through a hose. The loading, unloading and transferring method for nuclear power plant spent resin is good in safety and high in efficiency, and enables the pollution risk due to leakage and radiation danger in personnel's operation to be effectively decreased.

Owner:AEROSUN CORP

Easy-to-clean air purification device using electrostatic precipitator technology

InactiveCN109939828AReduce troubleHealth hazardHuman health protectionElectrodes cleaningAir pumpEngineering

The invention relates to an easy-to-clean air purification device using an electrostatic precipitator technology. The air purification device comprises a main body, an air intake pipe, a filter screen, an electrode, a draught fan, an air outlet pipe, a cleaning mechanism and a decomposing mechanism, wherein the cleaning mechanism comprises a collecting box, a connection a rod, a stopping rod, a cleaning plate, two springs and two moving components; each moving component comprises a first motor, a lead screw and a moving block; the decomposing mechanism comprises an air pump, an air guiding tube, a reaction tank, a heater and four support blocks. The easy-to-clean air purification device using the electrostatic precipitator technology cleans the dust on the filter screen by the cleaning mechanism, alleviates the trouble of the user, improves the practicability of the device, decomposes the excess ozone by the decomposing mechanism, to prevent excessively high ozone concentration from endangering human health, and improves the safety of the device.

Owner:陆光川

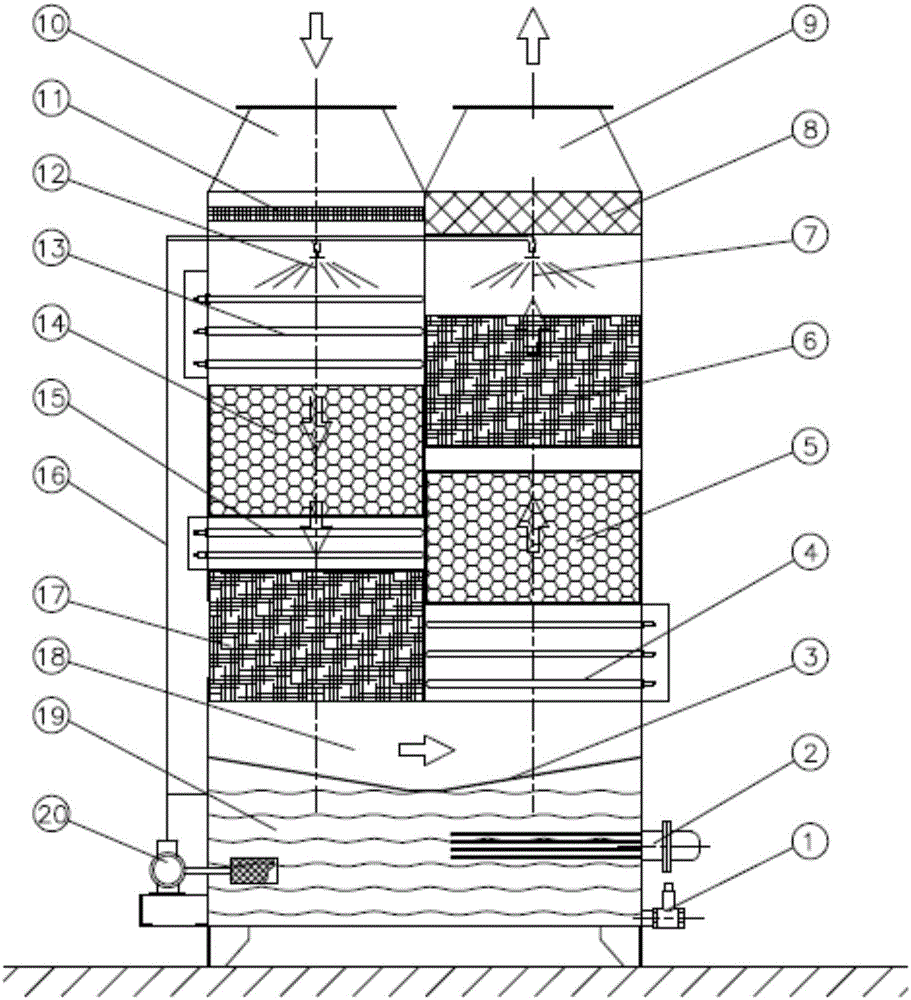

Waste gas purification equipment with stink removal and VOCs (volatile organic compounds) degradation functions

PendingCN106621749ARealize the cleaning functionPrevent freezingCombination devicesGas treatmentWater useThree level

The invention discloses waste gas purification equipment with stink removal and VOCs (volatile organic compounds) degradation functions. The waste gas purification equipment comprises a gas flow channel, a three-level oxidation section, a two-level spherical filler purification section, a two-level composite filler purification section, a circulating spray outlet, a demister, a reducing outlet, a reducing inlet, a flow equalizing device, a circulating spray inlet, a primary oxidation section, a one-level spherical filler purification section, a two-level oxidation section, a spray pipeline, a one-level composite filler purification section, an equipment shell body, a water tank and a circulating pump. The waste gas purification equipment with the stink removal and VOCs degradation functions has the advantages that oxidation and biological synergistic effects are combined with inertial dust removal principles, accordingly, stinky molecules and volatile organic compounds (VOCs) can be removed, dust in waste gas can be removed, and the gas can be thoroughly and effectively purified; water used in all procedures can be recycled, and accordingly the waste gas purification equipment is extremely low in water consumption; discarded circulating water can reach standards and can be discharged after being pertinently easily treated, and accordingly the problem of secondary pollution can be solved.

Owner:上海恒奕环境科技有限公司

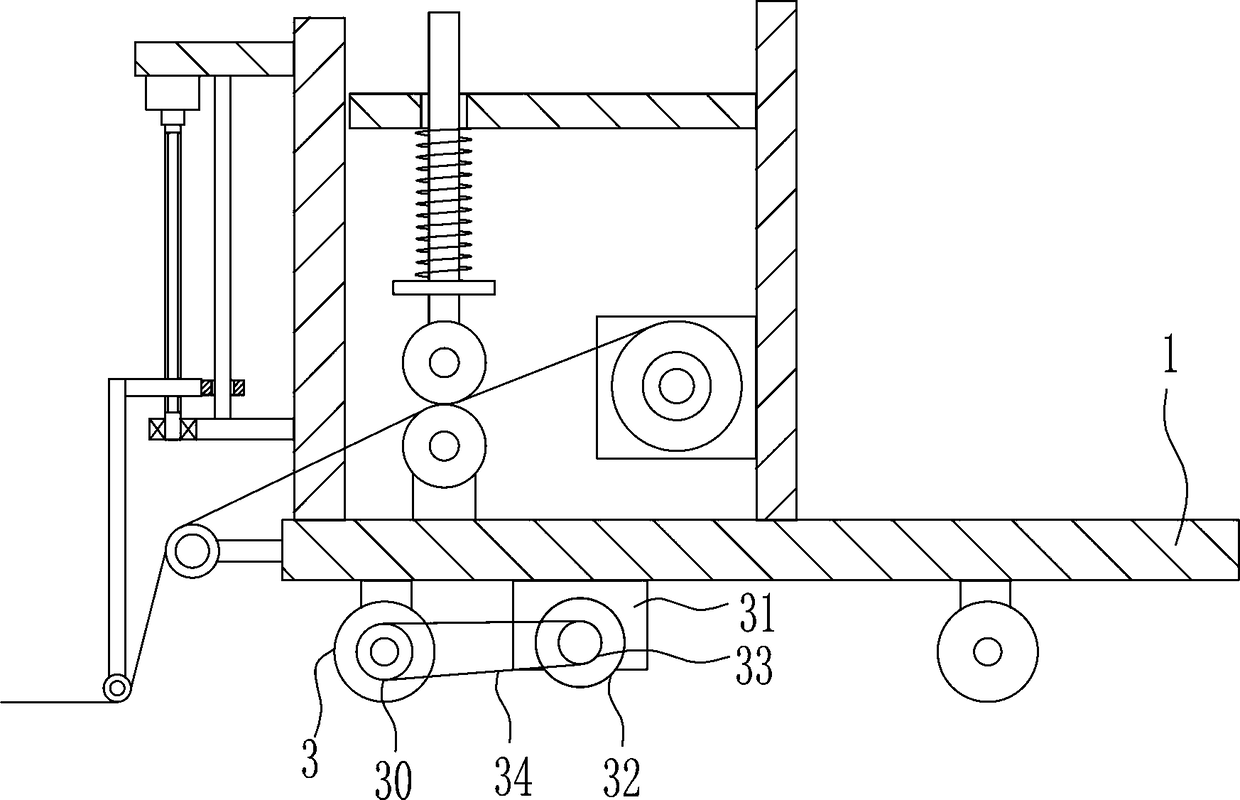

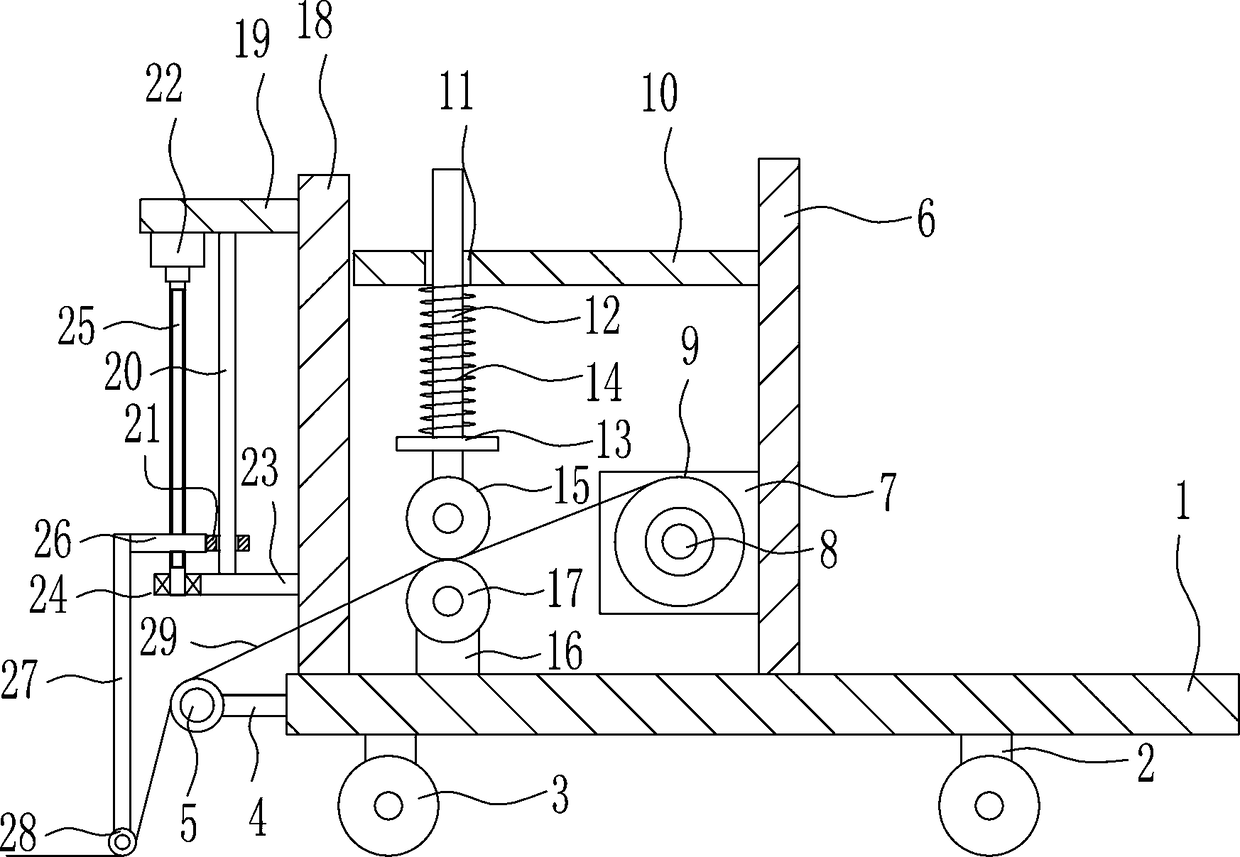

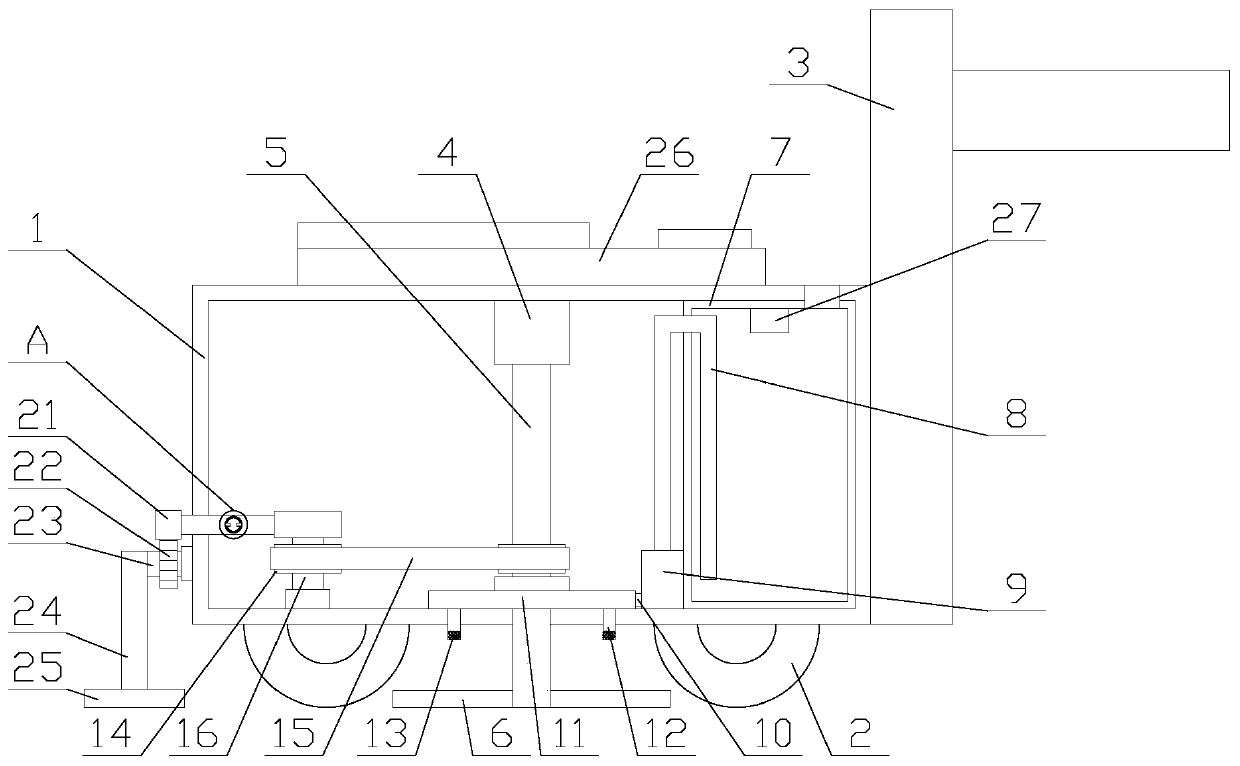

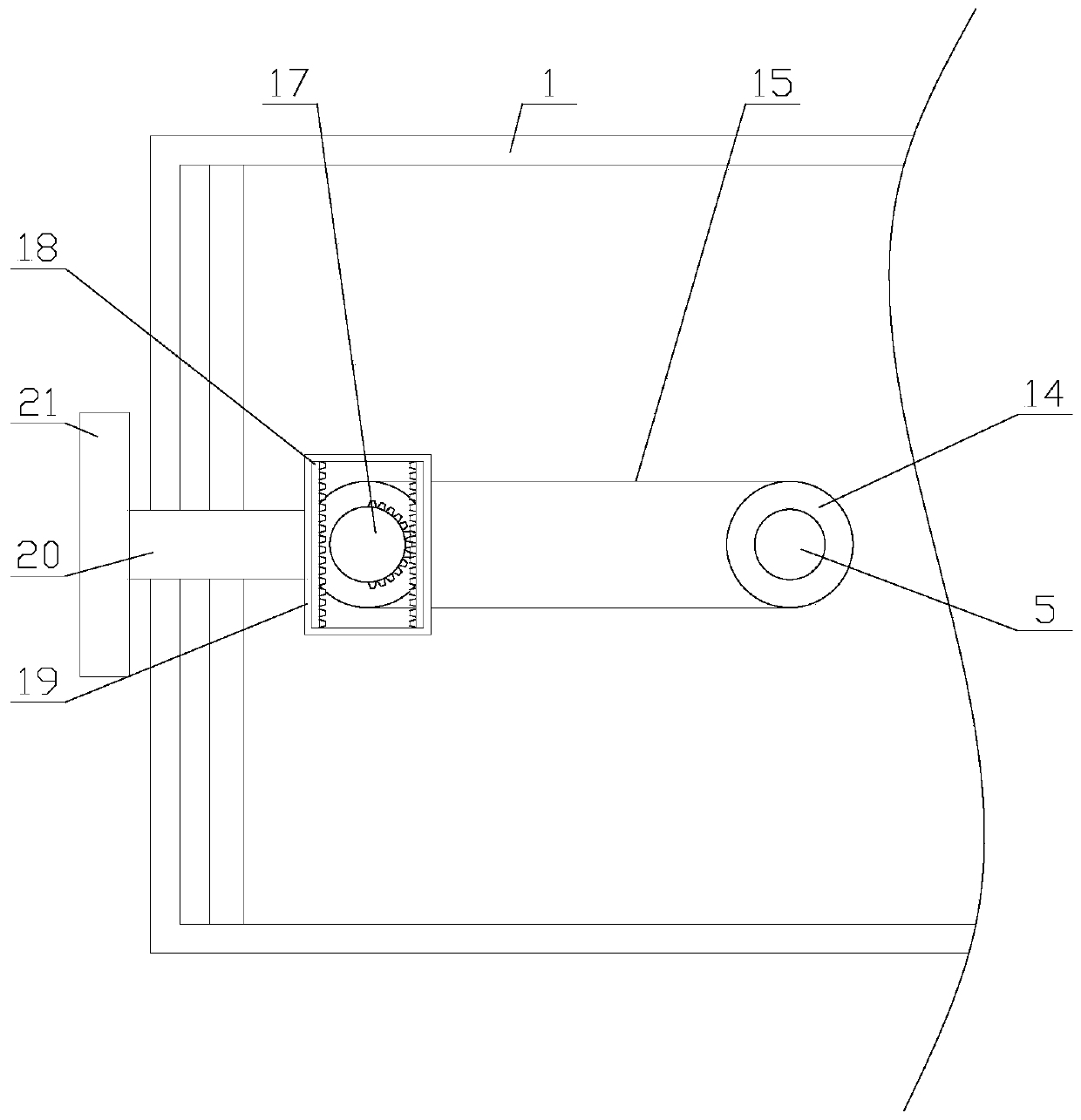

Road plastic film attaching device for road construction

ActiveCN108342962AReach the cleaning functionRealize the cleaning functionRoads maintainenceVehicle frameRoad surface

The invention relates to a film attaching device, and in particular relates to a road plastic film attaching device for road construction. The technical problem to be solved by the present invention is to provide the road plastic film attaching device for road construction, and the road plastic film attaching device for road construction has high film attaching speed and high film attaching efficiency. In order to solve the above technical problem, the road plastic film attaching device for road construction is provide, the road plastic film attaching device for road construction comprises a frame, first poles, wheels, a second pole, a first roller, a first bracket, a first fixing plate, a pin, a roller, a second bracket, a guide rod, and the like; the first poles are fixedly connected tothe bottom of the frame, the wheels are rotatably connected to the front sides of the first poles, the left end of the bracket is fixedly connected the second pole, and the left front side of the second pole is rotatably connected with the first roller. The road plastic film attaching device realizes the function of attaching a plastic film to a road surface, not only realizes the function of quickly attaching the plastic film to the road surface, but also realizes the function of cleaning the road surface.

Owner:祁门县城市建设投资开发有限公司

Mowing equipment with high safety and reliability for garden gardening

InactiveCN110809993AImprove practicalityRealize the cleaning functionMowersCleaning using liquidsGear wheelStone particle

The invention relates to mowing equipment with high safety and reliability for garden gardening, which comprises a vehicle body, a handle, a motor, a rotary shaft, a first bearing, four moving wheels,a plurality of blades, a protection mechanism and a cleaning mechanism, wherein the cleaning mechanism comprises a water tank, a suction pump, a water inlet pipe, a water outlet pipe, a connecting box and a plurality of water spraying pipes; and the protection mechanism comprises a transmission component, a reciprocating component, a connecting block, a first rack, a first gear connecting shaft,a second bearing, a connecting rod and a scraper. The mowing equipment with high safety and reliability for garden gardening realizes the function of cleaning the blades through the cleaning mechanism, and does not need manual cleaning, so that the cleaning convenience is improved; and stone particles on the ground are pushed away through the protection mechanism, and the contact probability between the blades and the stone particles is reduced, so that the damage probability of the blades is reduced, and the safety and reliability of the equipment are improved.

Owner:GUANGZHOU JIAJIANPAI ELECTRONICS TECH CO LTD

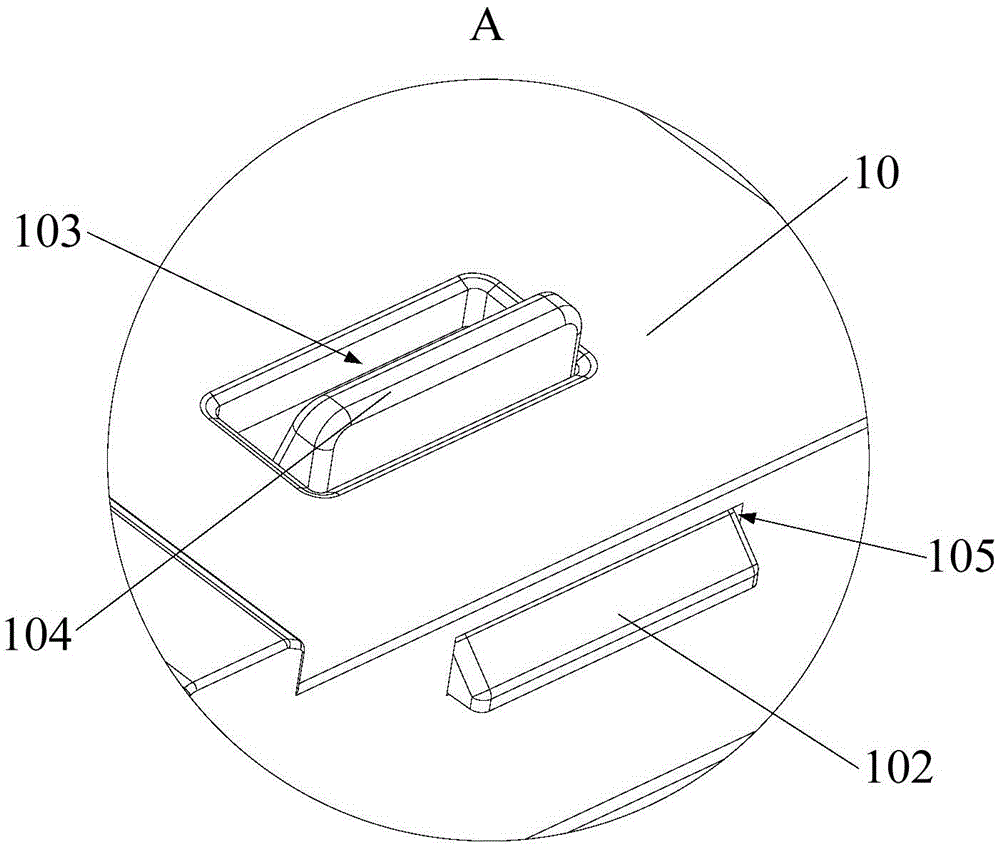

Ground brush and dust collector

InactiveCN105615771ARealize the cleaning functionEasy to cleanSuction nozzlesEngineeringDust collector

The invention provides a ground brush and a dust collector. The ground brush comprises a ground brush body, a rolling brush and a rolling brush cover, wherein a mounting groove is formed in the ground brush body; the mounting groove is provided with an opening running from top to bottom; the rolling brush is rotatably mounted in the mounting groove; the rolling brush cover covers the rolling brush; one end part of the rolling brush cover is rotatably connected with the ground brush body; the other end part of the rolling brush cover is in clamping joint with the ground brush body. According to the ground brush provided by the invention, when the rolling brush needs to be washed or replaced, only the other end part of the rolling brush cover needs to be released from the clamping joint of the ground brush body; then rolling brush cover is rotated and opened; the rolling brush is taken out from the opening formed in the upper end of the mounting groove, so that the rolling brush can be conveniently washed or replaced; the ground brush is simple to operate and convenient to use, so that time and labor are saved; the problems in the prior art that the rolling brush can be replaced only if the ground brush is overturned so that the operation is troublesome and the utilization is inconvenient are solved, and the use feeling of users is improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

Cleaning device for traffic roadblocks

ActiveCN107988937ARealize the cleaning functionReduce shockCleaning using toolsCleaning using liquidsEngineeringBooster pump

The invention discloses a cleaning device for traffic roadblocks. The device comprises a first shell, a second shell and a third shell which are symmetrically distributed are fixedly connected to thetwo sides of the first shell, and cavities are formed in the first shell, the second shell and the third shell; a supporting plate is arranged on the bottom wall of the second shell, a first motor isarranged on the top of the supporting plate, and a first main shaft is arranged at the output end of the first motor; a first rotation shaft is arranged at the end, away from the first motor, of the first main shaft and fixedly sleeved with a sleeve, multiple evenly distributed through holes are formed in the outer wall of the sleeve, and strip-shaped flexible brushes are clamped into the throughholes; a booster pump is arranged on the bottom wall of the second shell. According to the cleaning device for the traffic roadblocks, the defects when the traffic roadblocks are cleaned in the priorart are overcome, automatic cleaning for the traffic roadblocks is achieved, multiple kinds of inconvenience caused by manual operation are avoided, the fixed roadblocks can be cleaned, and the movable roadblocks can also be cleaned.

Owner:山东远腾环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com