Road plastic film attaching device for road construction

A road construction and plastic film technology, applied in the field of film sticking equipment, can solve problems such as low efficiency, plastic film is easily blown away by wind, and plastic film cannot be closely attached to the road surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

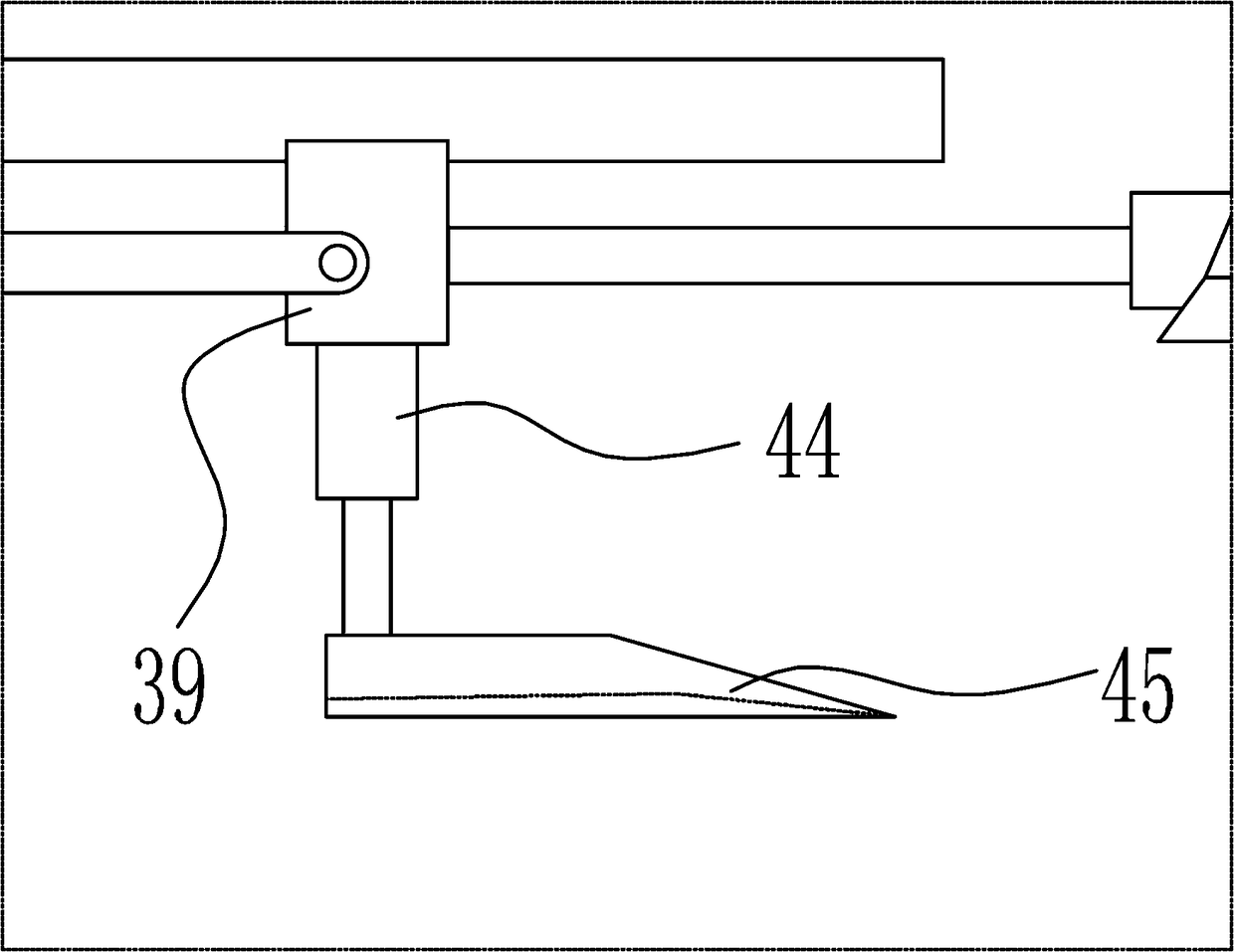

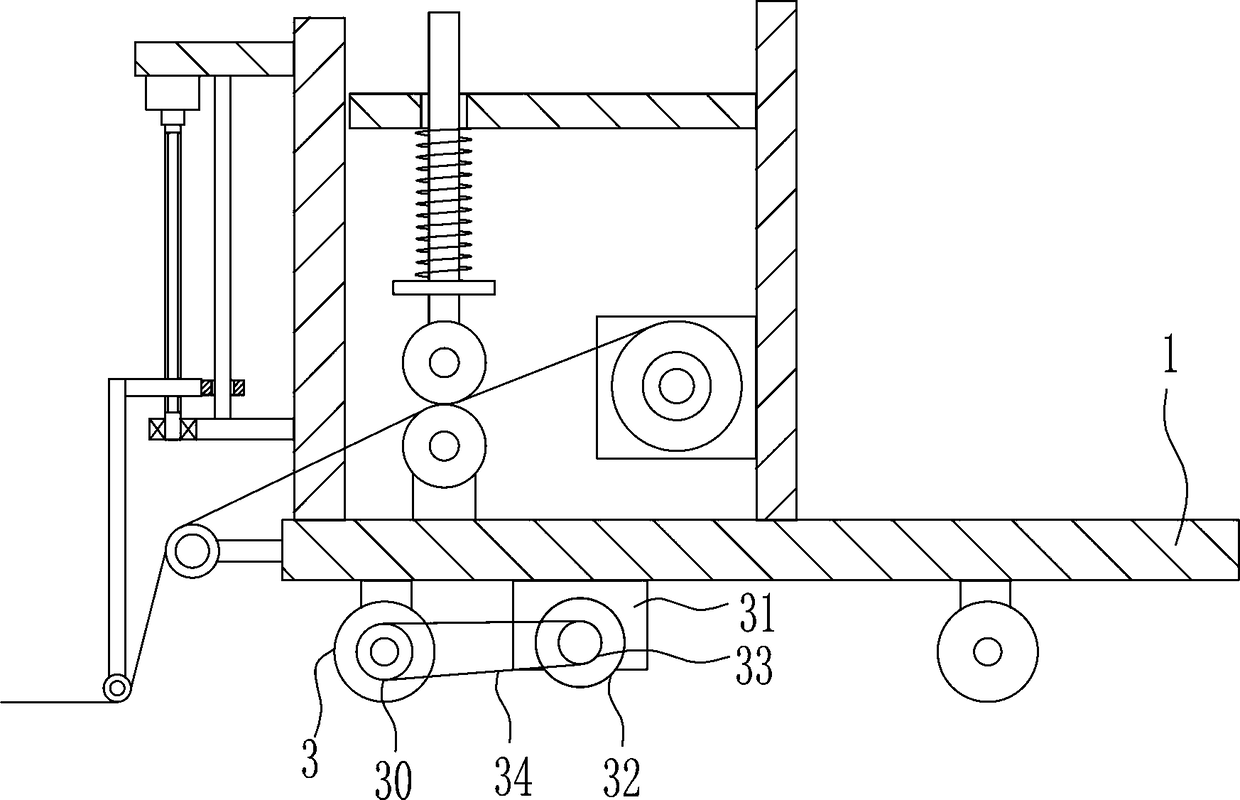

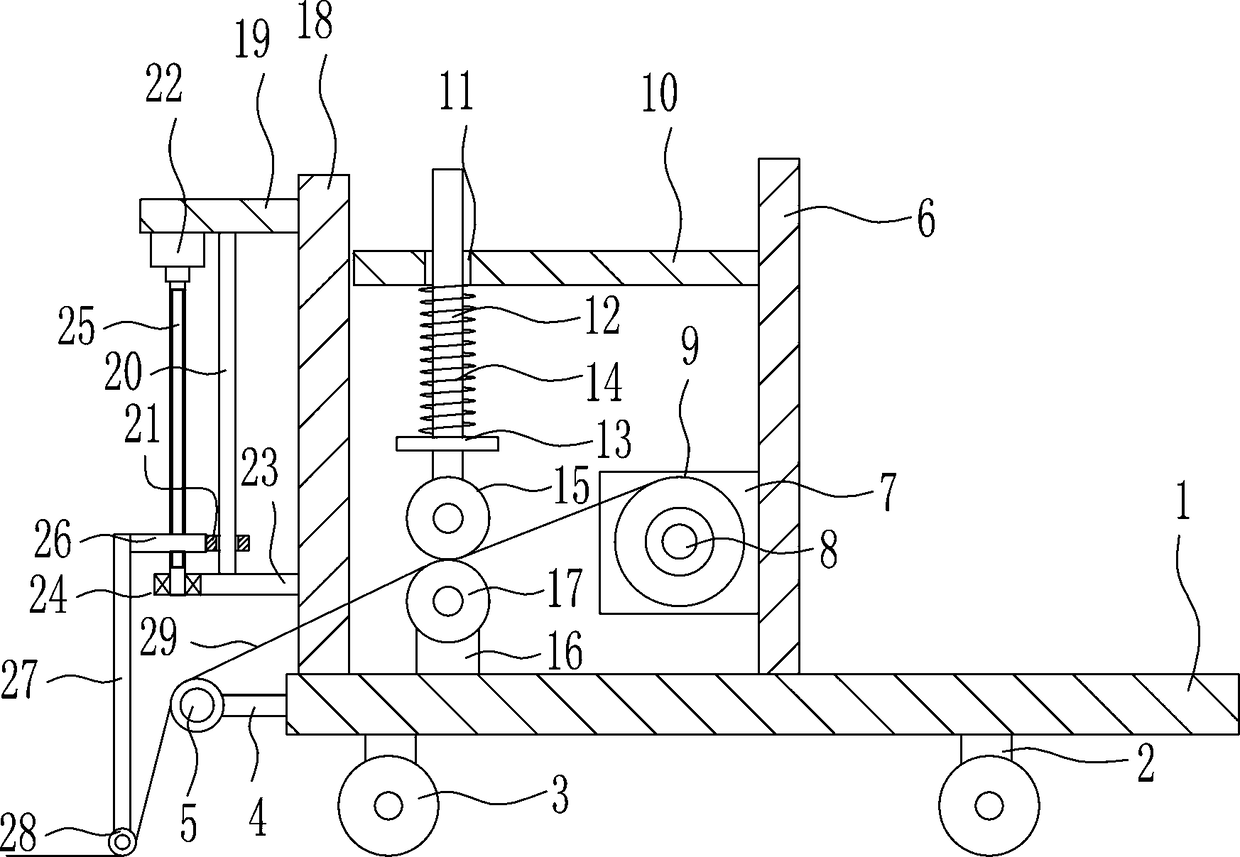

[0026] A kind of road construction is used for sticking plastic film equipment on the road, such as Figure 1-5As shown, it includes a vehicle frame 1, a first pole 2, a wheel 3, a second pole 4, a first roller 5, a first bracket 6, a first fixing plate 7, a pin rod 8, a roller 9, and a second bracket 10. Guide rod 12, baffle plate 13, first spring 14, second roller 15, third pole 16, third roller 17, third bracket 18, fourth bracket 19, slide bar 20, sliding sleeve 21, the first A motor 22, the fourth pole 23, the first bearing 24, the screw rod 25, the nut 26, the fifth pole 27 and the fourth roller 28 are fixedly connected with the first pole 2 at the bottom of the vehicle frame 1. The front side of strut 2 is all rotatably connected with wheel 3, is fixedly connected with second strut 4 at the left end of support, is connected with first roller 5 rotatably at the left front side of second strut 4, on vehicle frame 1 is fixedly connected with the first bracket 6 in the mid...

Embodiment 2

[0028] A kind of road construction is used for sticking plastic film equipment on the road, such as Figure 1-5 As shown, it includes a vehicle frame 1, a first pole 2, a wheel 3, a second pole 4, a first roller 5, a first bracket 6, a first fixing plate 7, a pin rod 8, a roller 9, and a second bracket 10. Guide rod 12, baffle plate 13, first spring 14, second roller 15, third pole 16, third roller 17, third bracket 18, fourth bracket 19, slide bar 20, sliding sleeve 21, the first A motor 22, the fourth pole 23, the first bearing 24, the screw rod 25, the nut 26, the fifth pole 27 and the fourth roller 28 are fixedly connected with the first pole 2 at the bottom of the vehicle frame 1. The front side of strut 2 is all rotatably connected with wheel 3, is fixedly connected with second strut 4 at the left end of support, is connected with first roller 5 rotatably at the left front side of second strut 4, on vehicle frame 1 is fixedly connected with the first bracket 6 in the mi...

Embodiment 3

[0031] A kind of road construction is used for sticking plastic film equipment on the road, such as Figure 1-5 As shown, it includes a vehicle frame 1, a first pole 2, a wheel 3, a second pole 4, a first roller 5, a first bracket 6, a first fixing plate 7, a pin rod 8, a roller 9, and a second bracket 10. Guide rod 12, baffle plate 13, first spring 14, second roller 15, third pole 16, third roller 17, third bracket 18, fourth bracket 19, slide bar 20, sliding sleeve 21, the first A motor 22, the fourth pole 23, the first bearing 24, the screw rod 25, the nut 26, the fifth pole 27 and the fourth roller 28 are fixedly connected with the first pole 2 at the bottom of the vehicle frame 1. The front side of strut 2 is all rotatably connected with wheel 3, is fixedly connected with second strut 4 at the left end of support, is connected with first roller 5 rotatably at the left front side of second strut 4, on vehicle frame 1 is fixedly connected with the first bracket 6 in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com