Submersible pump device with filtering function

A submersible pump, functional technology, applied to pump devices, parts of pumping devices for elastic fluids, pumps, etc., can solve the problems of sediment blocking filter holes, poor pumping and drainage, etc., to prevent blockage of filter plates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

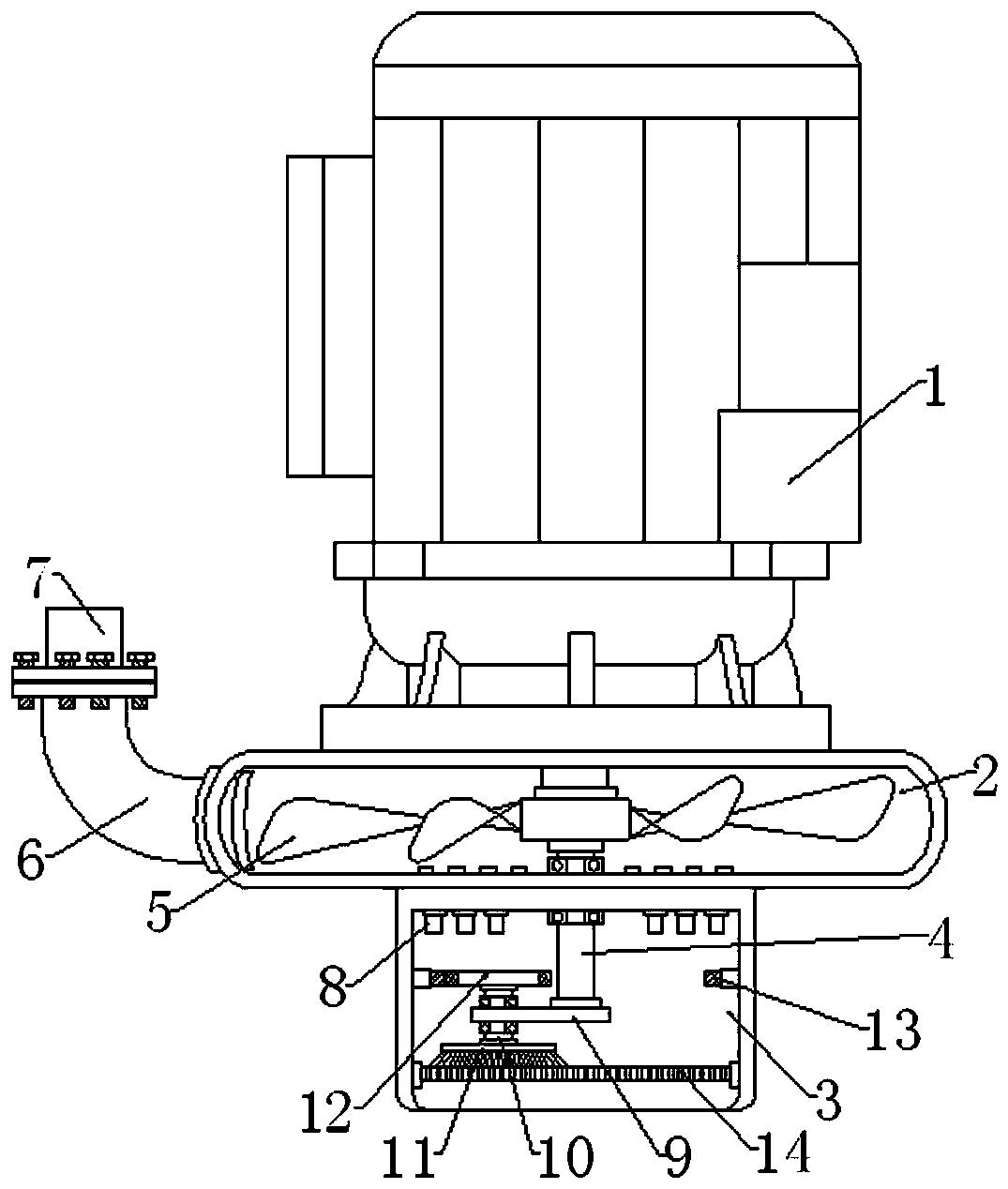

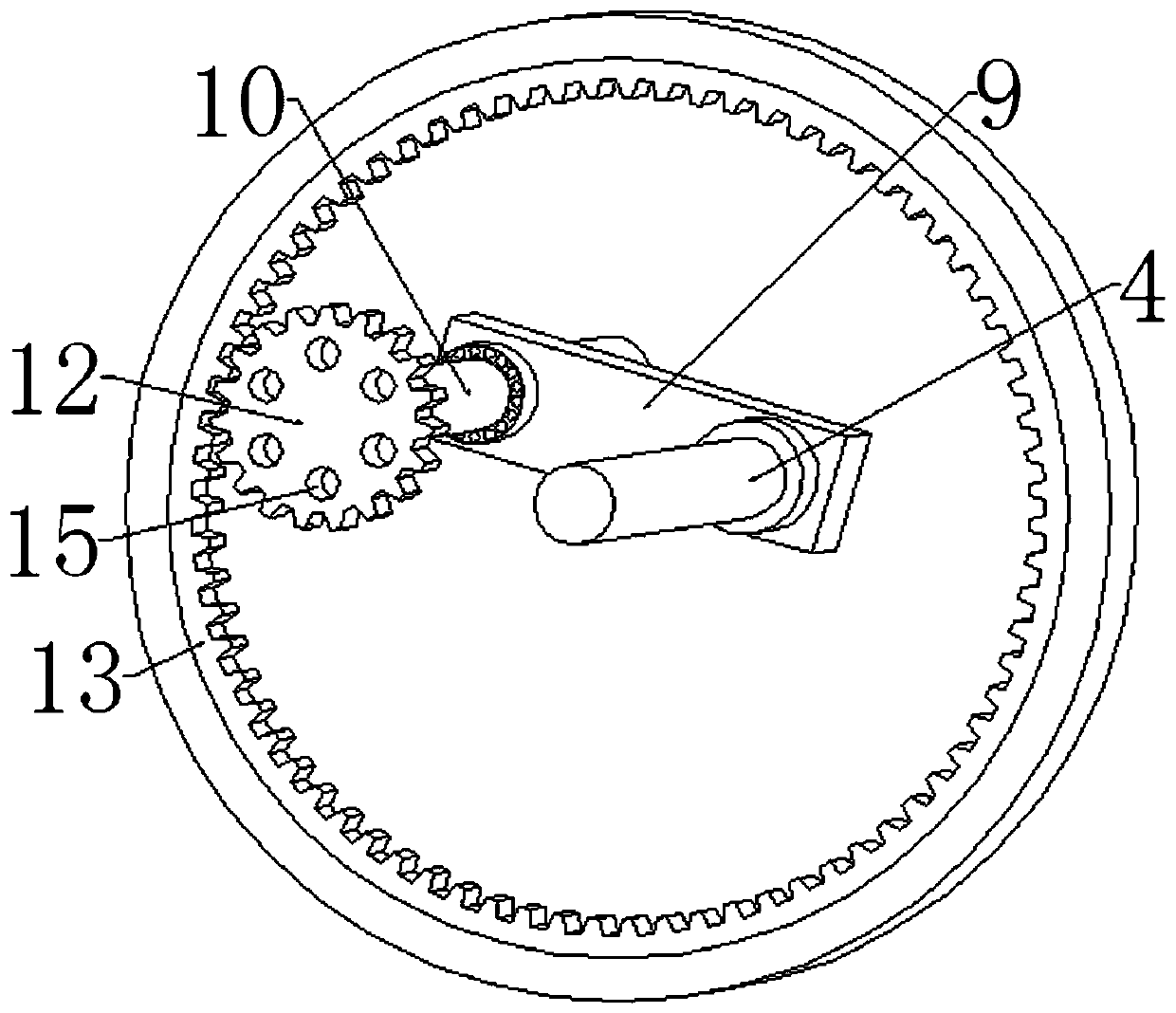

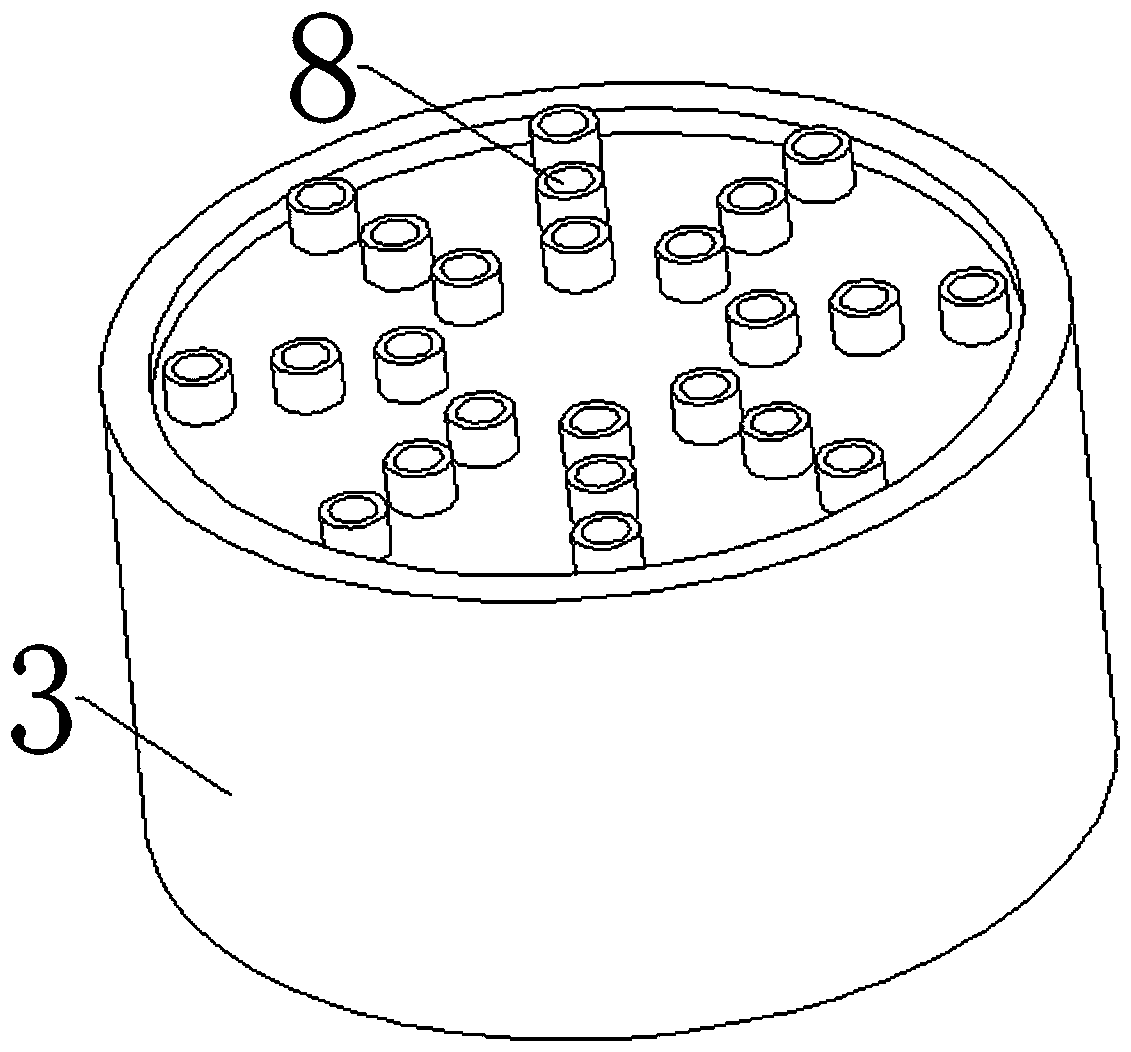

[0021] see Figure 1~3 , in an embodiment of the present invention, a submersible pump device with filtering function includes a device body, and the device body is respectively provided with a drive motor 1 for powering the device body, a pump body 2 for pumping water, and a pump body for filtering impurities. the filter;

[0022] Specifically, the upper flange of the device body is equipped with a drive motor 1 connected to a power supply and a switch through wires, the lower part of the drive motor 1 is fixedly connected to the pump body 2, and a filter 3 is fixed below the pump body 2, wherein the pump body 2 The impeller 5 is provided for rotation, and the impeller 5 is fixed on the rotating shaft 4 connected to the output end of the driving motor 1. It should be noted that the rotating shaft 4 passes through the pump body 2 and is connected with the bearing in rotation. When the driving motor 1 is energized, it drives The rotating shaft 4 rotates to drive the impeller 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com