Patents

Literature

579results about How to "Won't flow out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

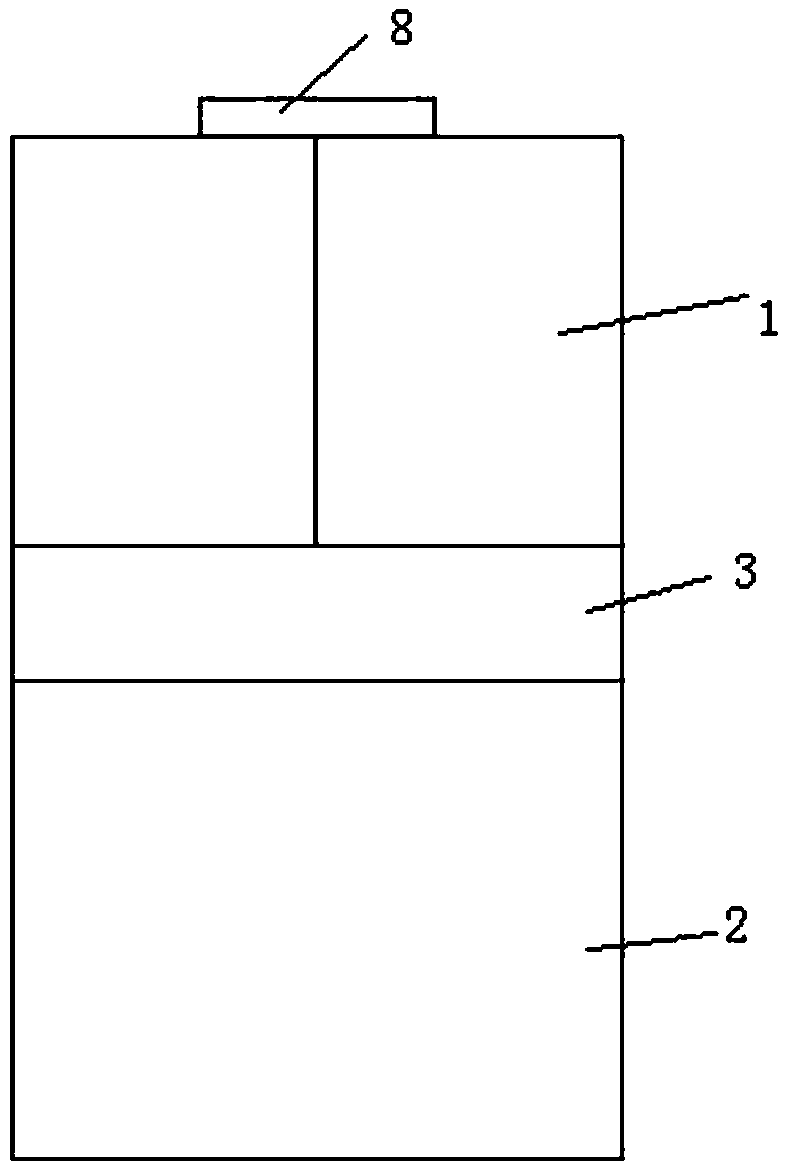

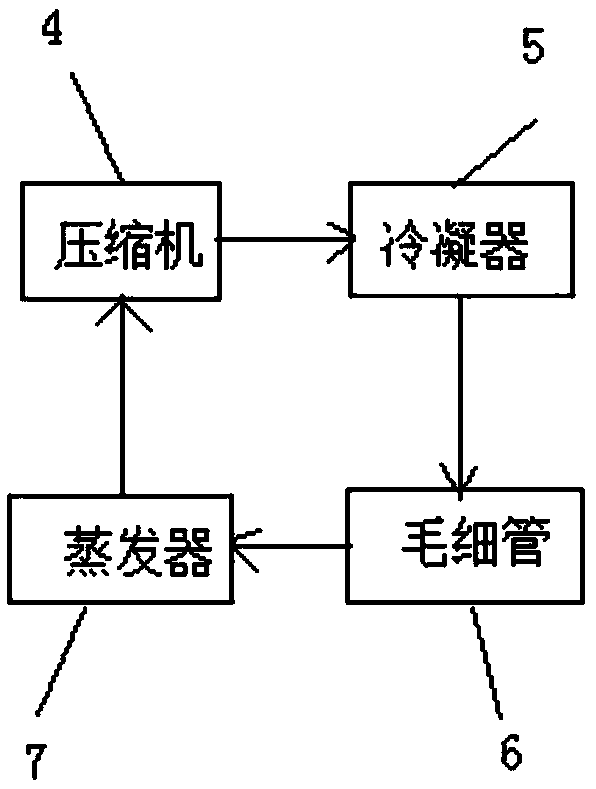

Refrigeration equipment capable of achieving undercooling preservation and control method of equipment

InactiveCN109253572AWon't flow outWon't be lostLighting and heating apparatusDomestic refrigeratorsThree stageProcess engineering

The invention discloses refrigeration equipment capable of achieving undercooling preservation and a control method of the equipment. The refrigeration equipment comprises an undercooling chamber, theundercooling chamber is provided with an air inlet and an air return port, and the air inlet of the undercooling chamber is provided with an air door; a temperature sensor for detecting real-time temperature in the undercooling chamber is arranged in the undercooling chamber, and a control device is further arranged on the refrigeration equipment. The rotation speed and of a compressor and opening and closing of the air door are controlled by the control device, the temperature of the undercooling chamber is controlled accordingly, after food is put into the undercooling chamber, the undercooling chamber is subjected to the three stages including primary cooling, secondary cooling and low-temperature maintenance in sequence, and the average cooling speed of the primary cooling stage is larger than that of the secondary cooling stage. The refrigeration equipment has the advantages that undercooling preservation of the food is achieved, and accordingly the food quality is guaranteed.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

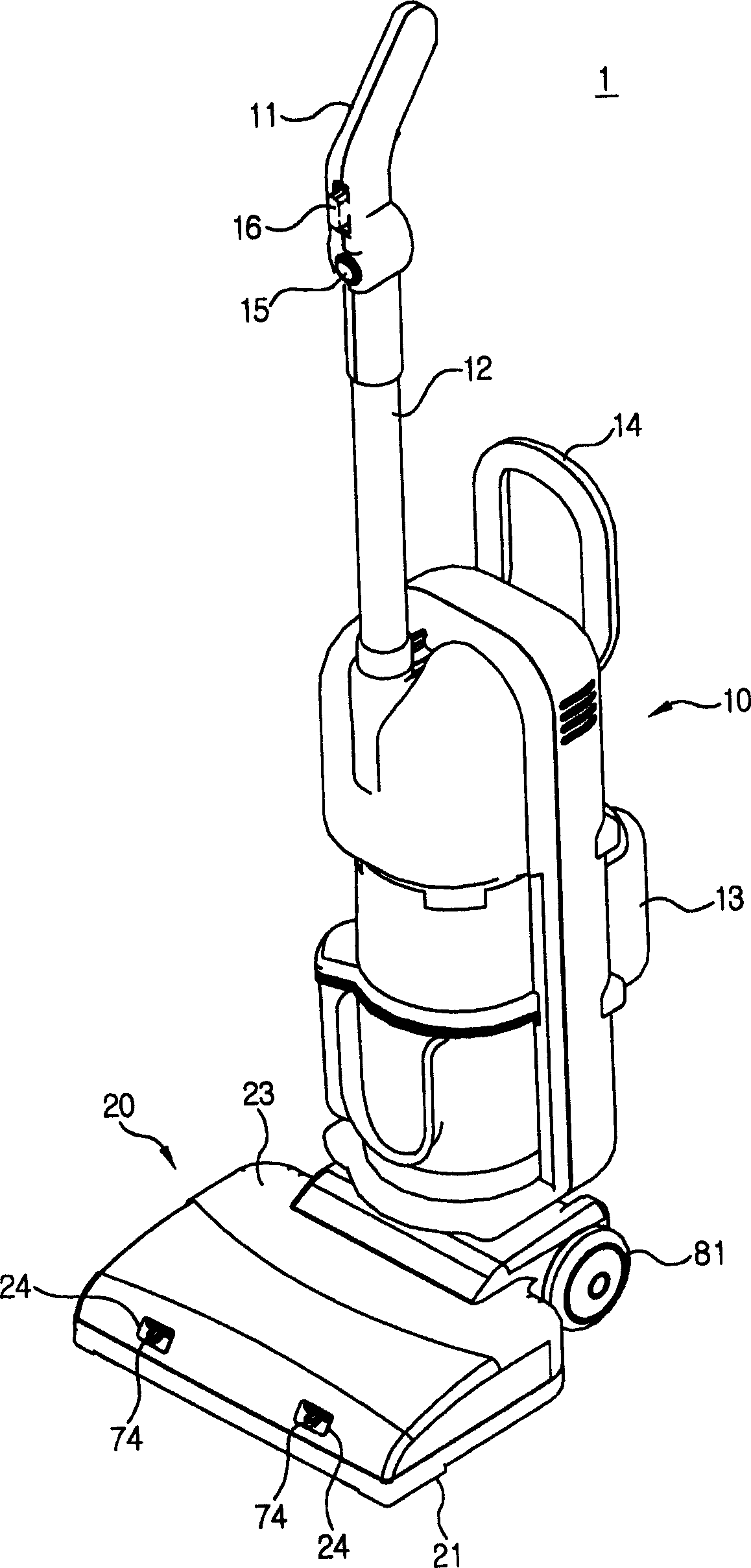

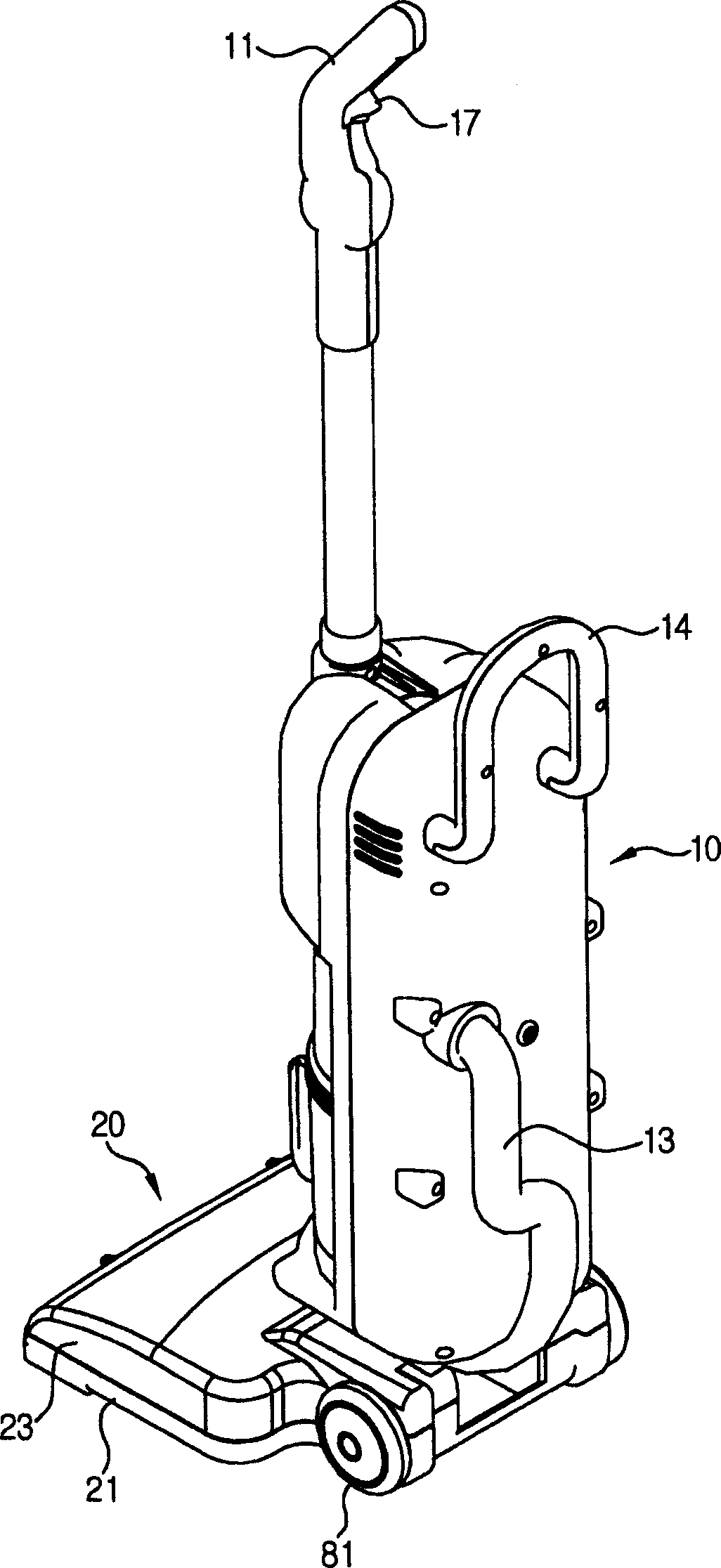

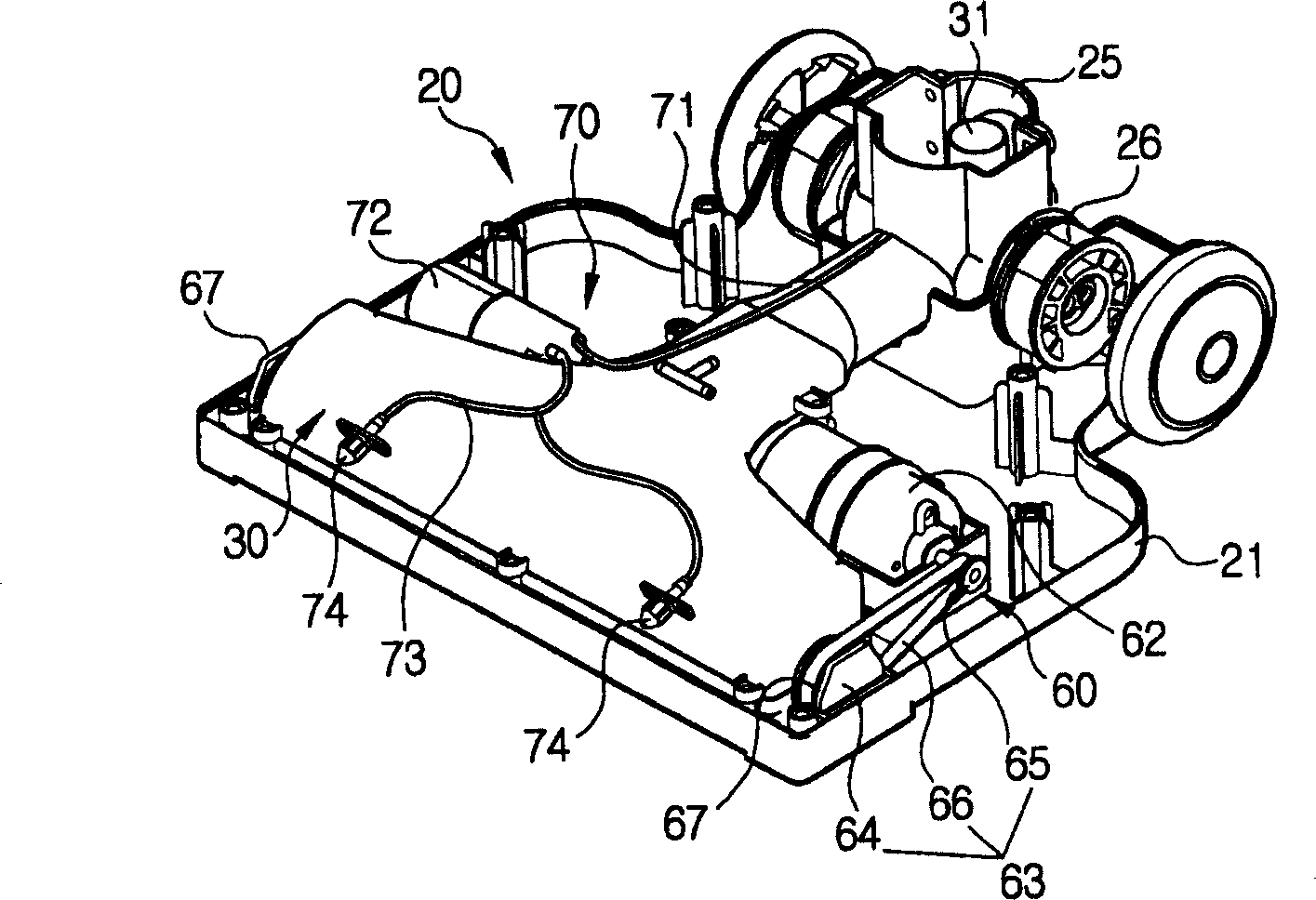

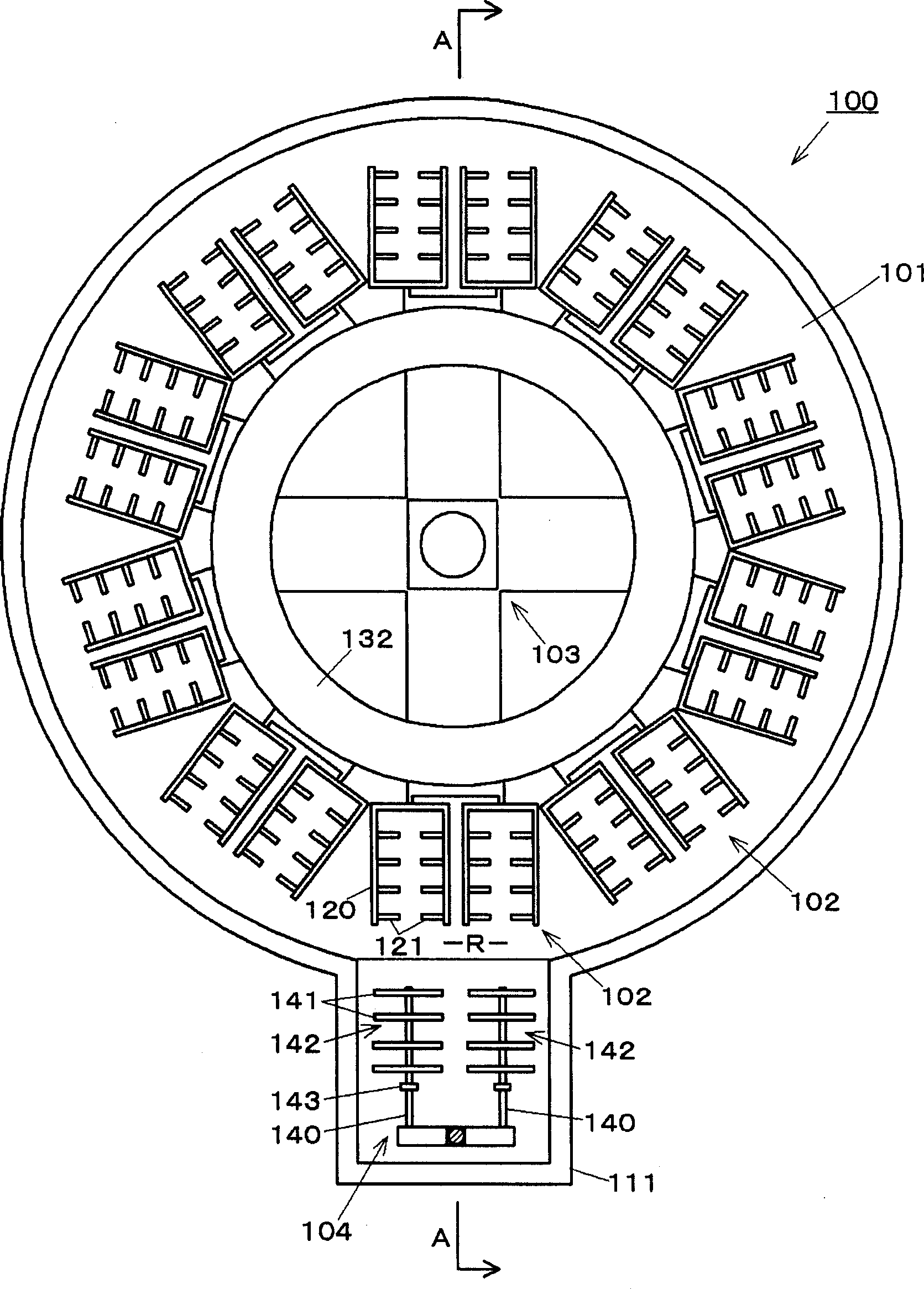

Vacuum cleaner with wet method cleaning function

InactiveCN1883354ASimple structureSave cleaning timeCarpet cleanersFloor cleanersEngineeringFriction force

A vacuum cleaner with a wet cleaning function comprises a main body, a brush assembly having a contaminant suction port facing a cleaning surface, a brush of the contaminant suction port to rotate in contact with the cleaning surface, and a water exhaust nozzle, the contaminants suction port is fluidly communicated with the main body, and a front and a rear block parts formed at a front and a rear of the brush on a bottom surface of the brush assembly to selectively open or block a contaminant suction path by a friction force against the cleaning surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

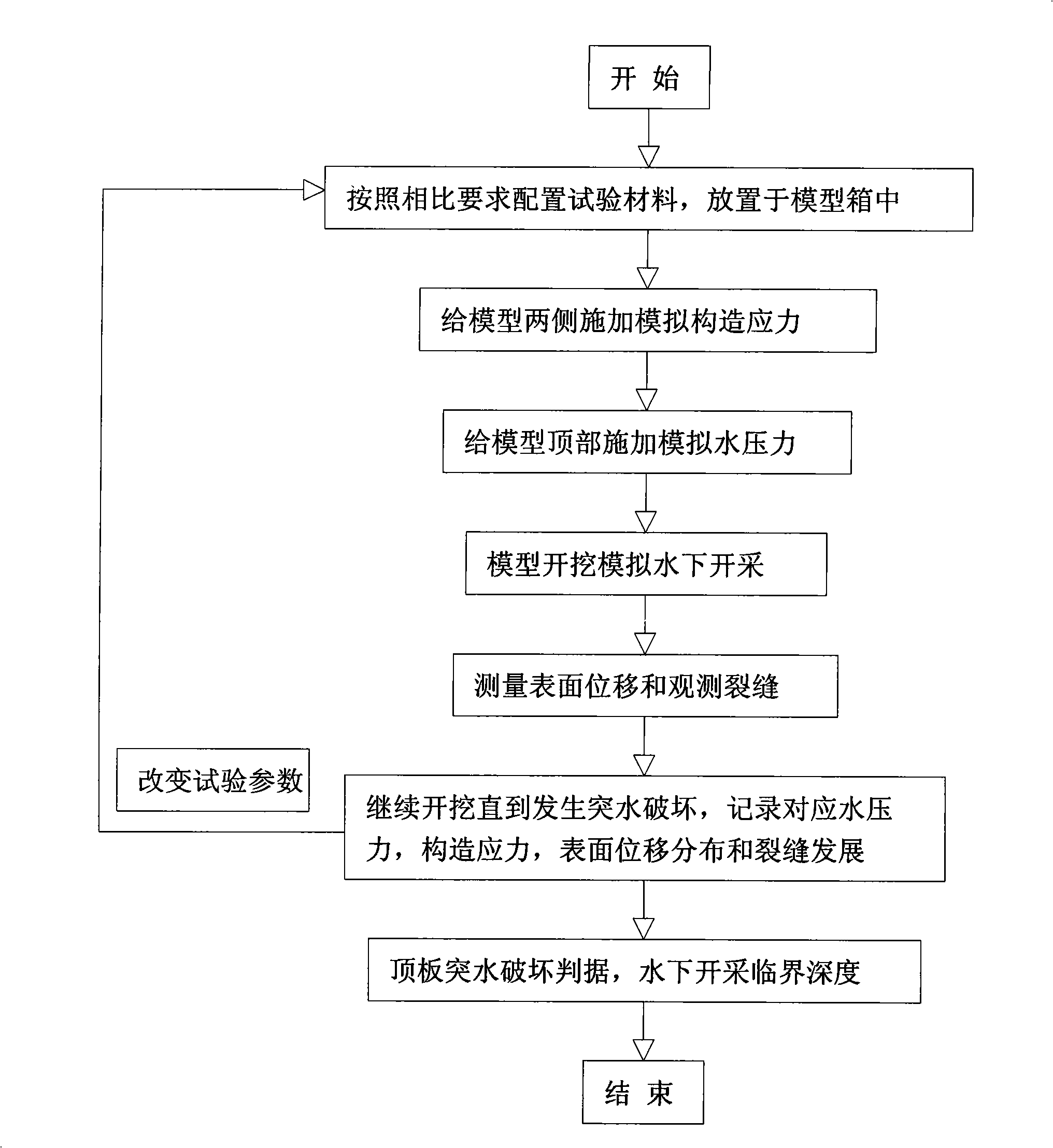

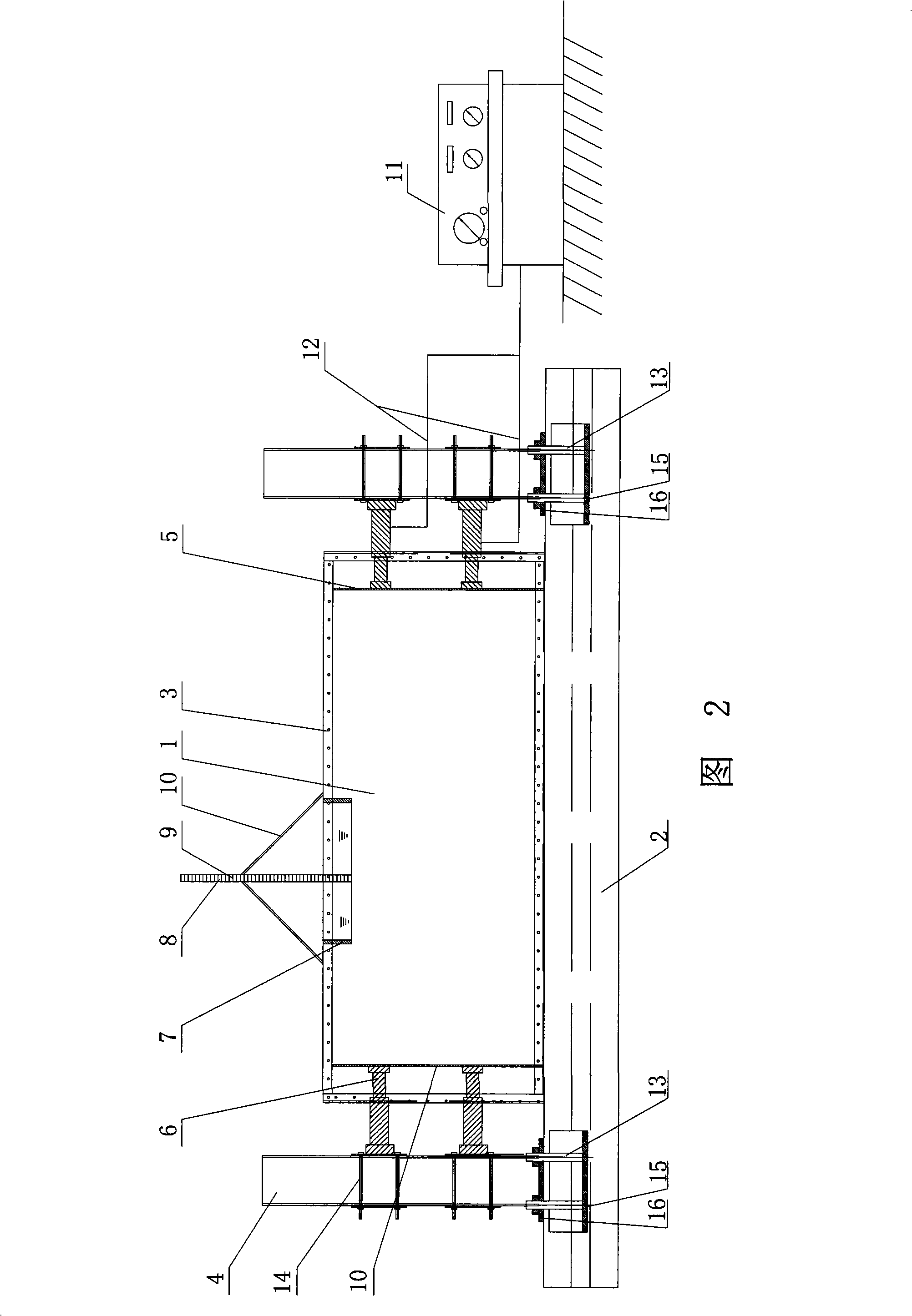

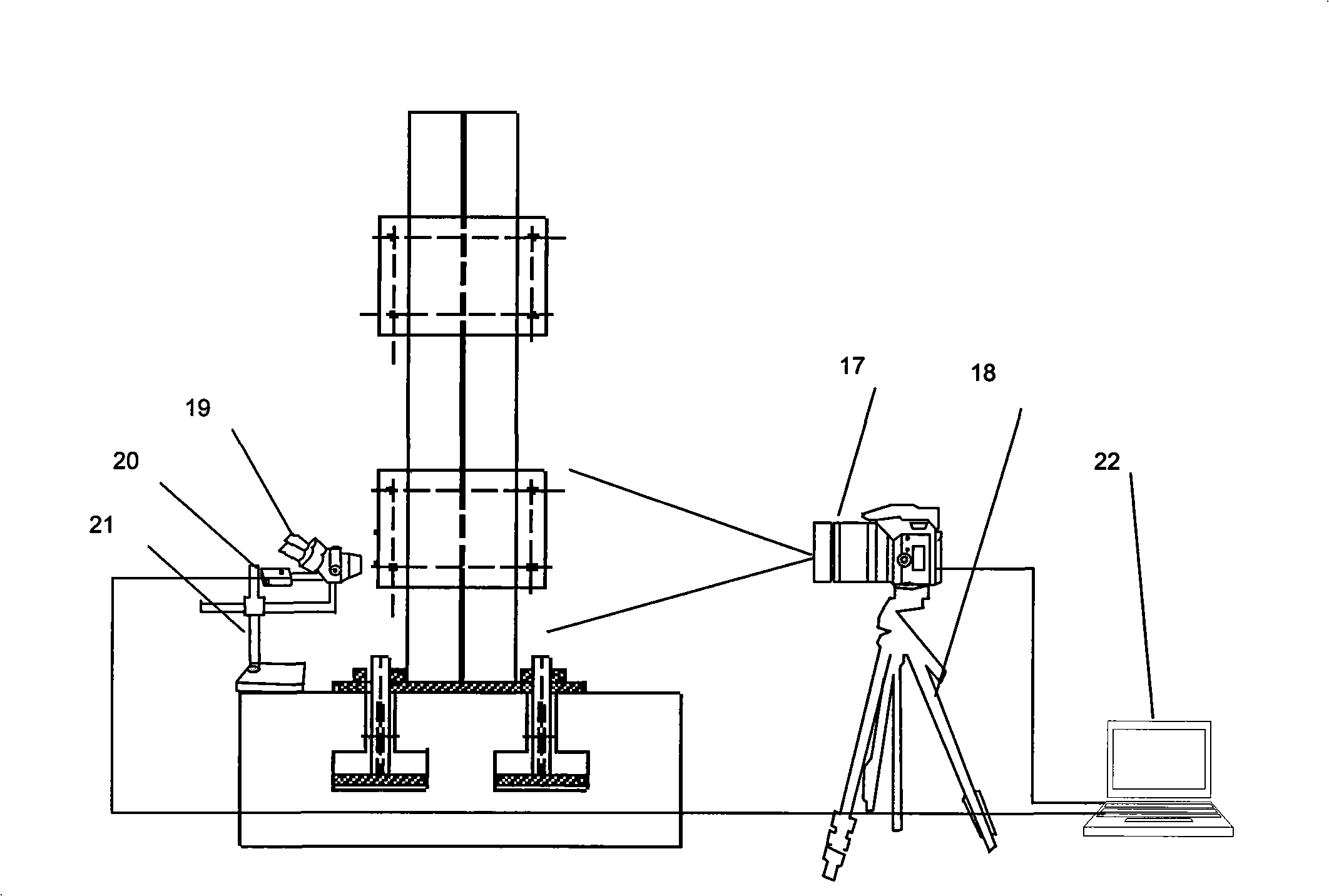

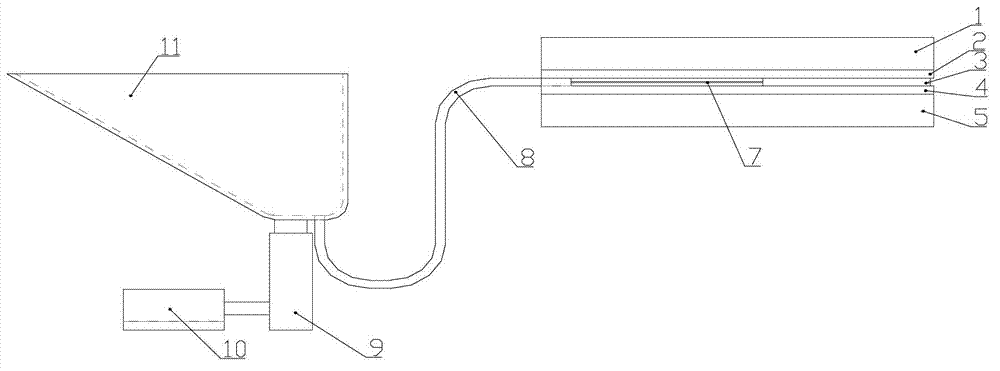

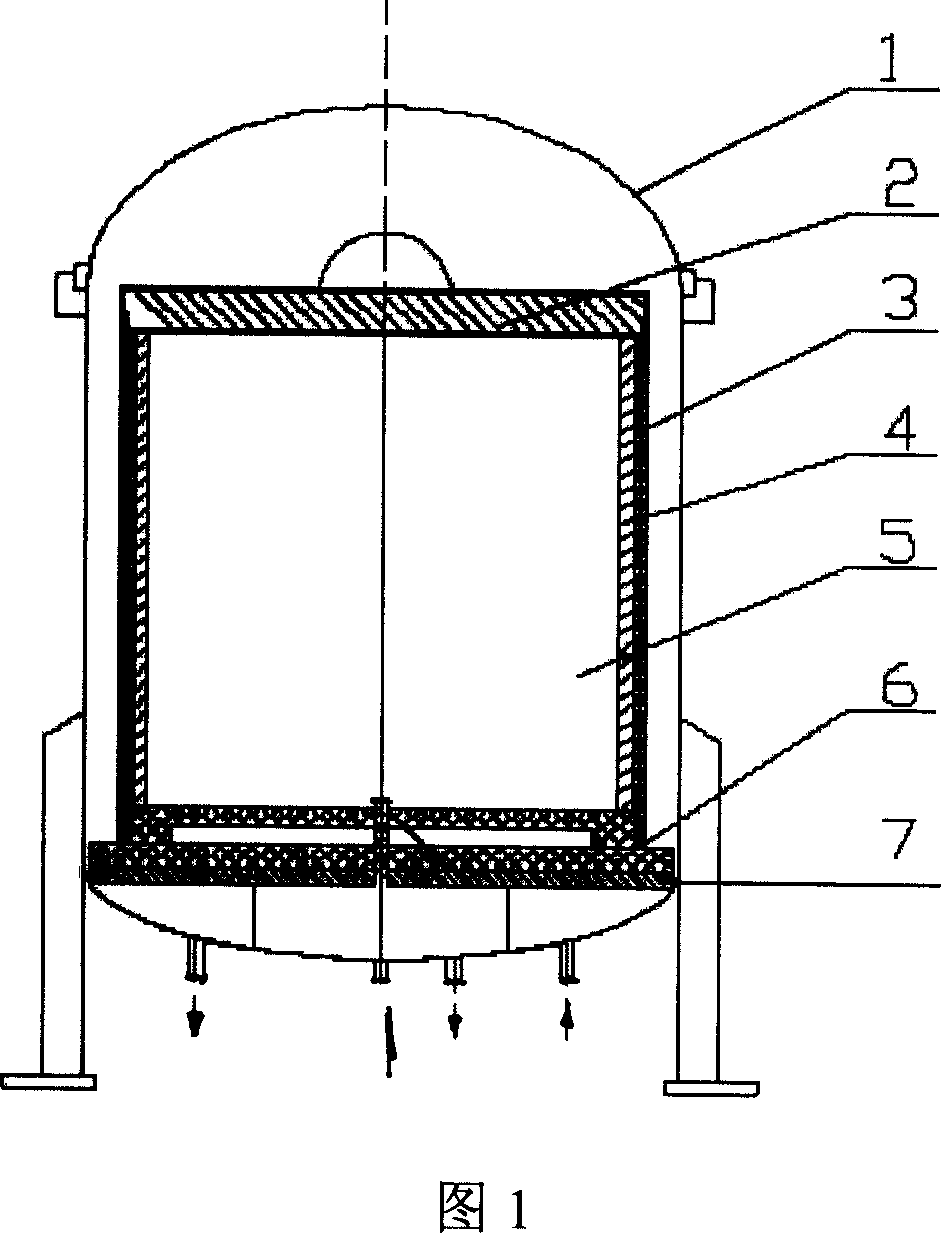

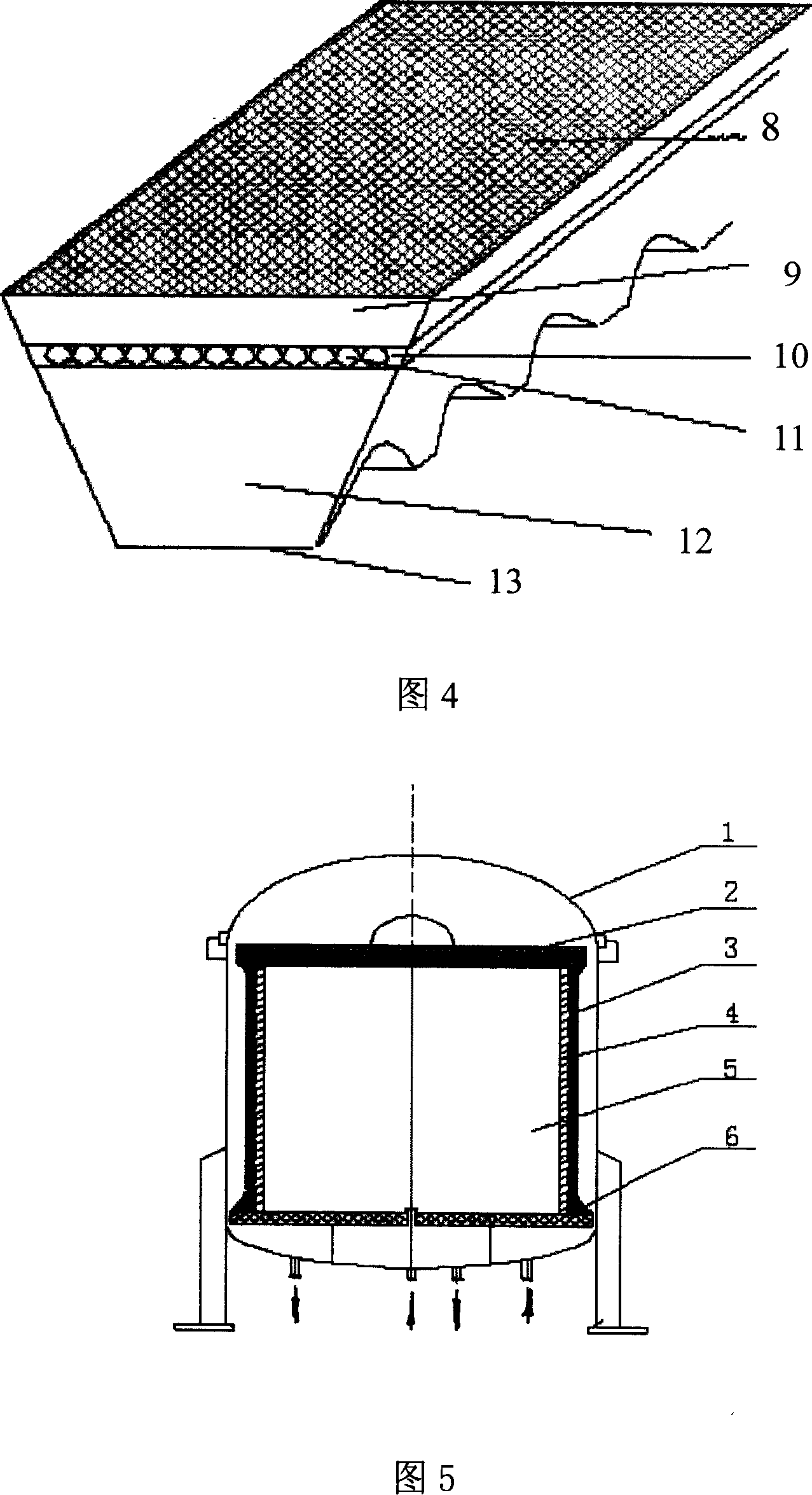

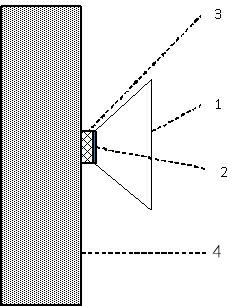

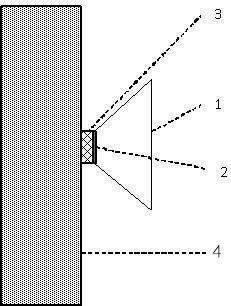

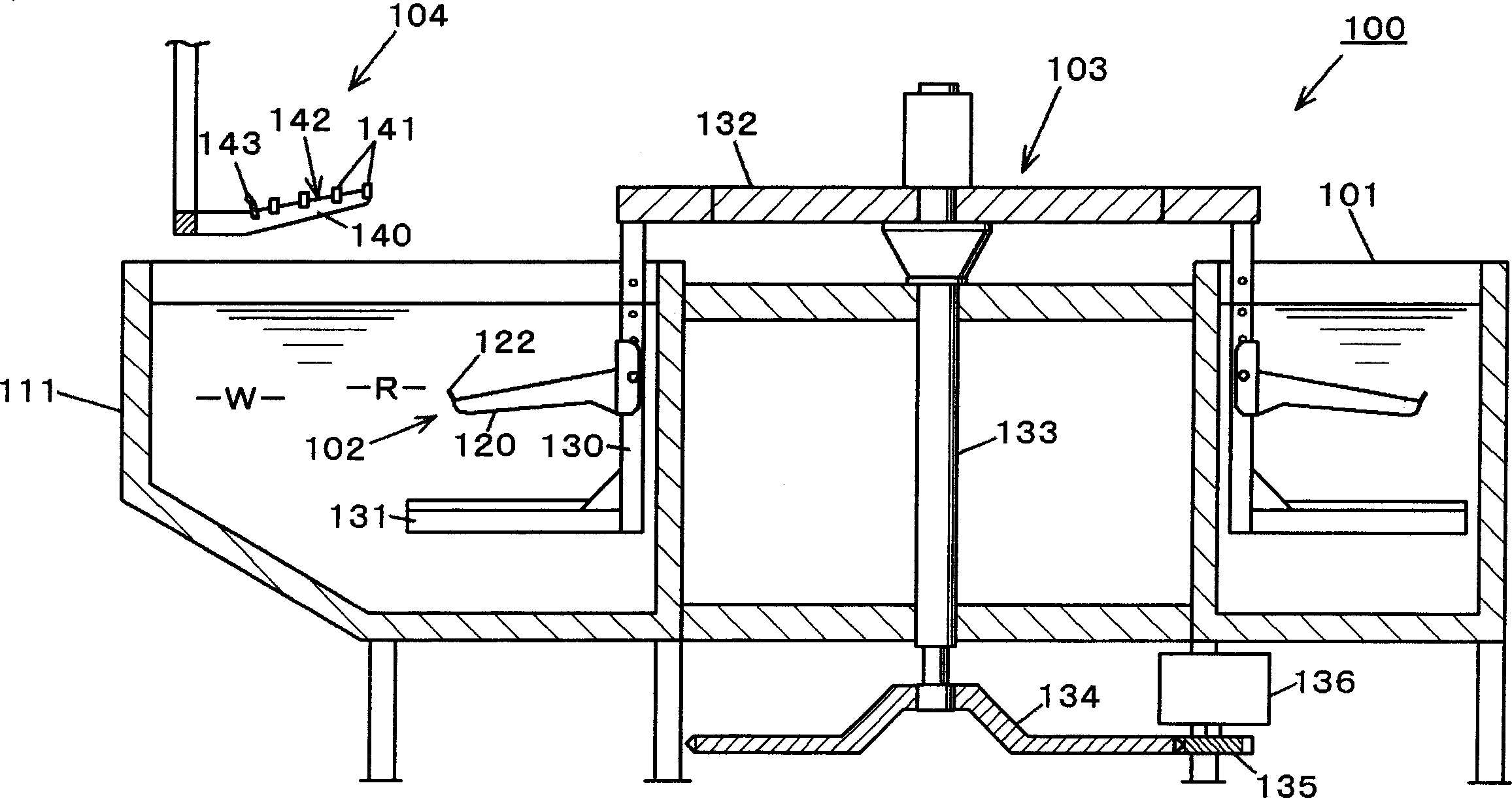

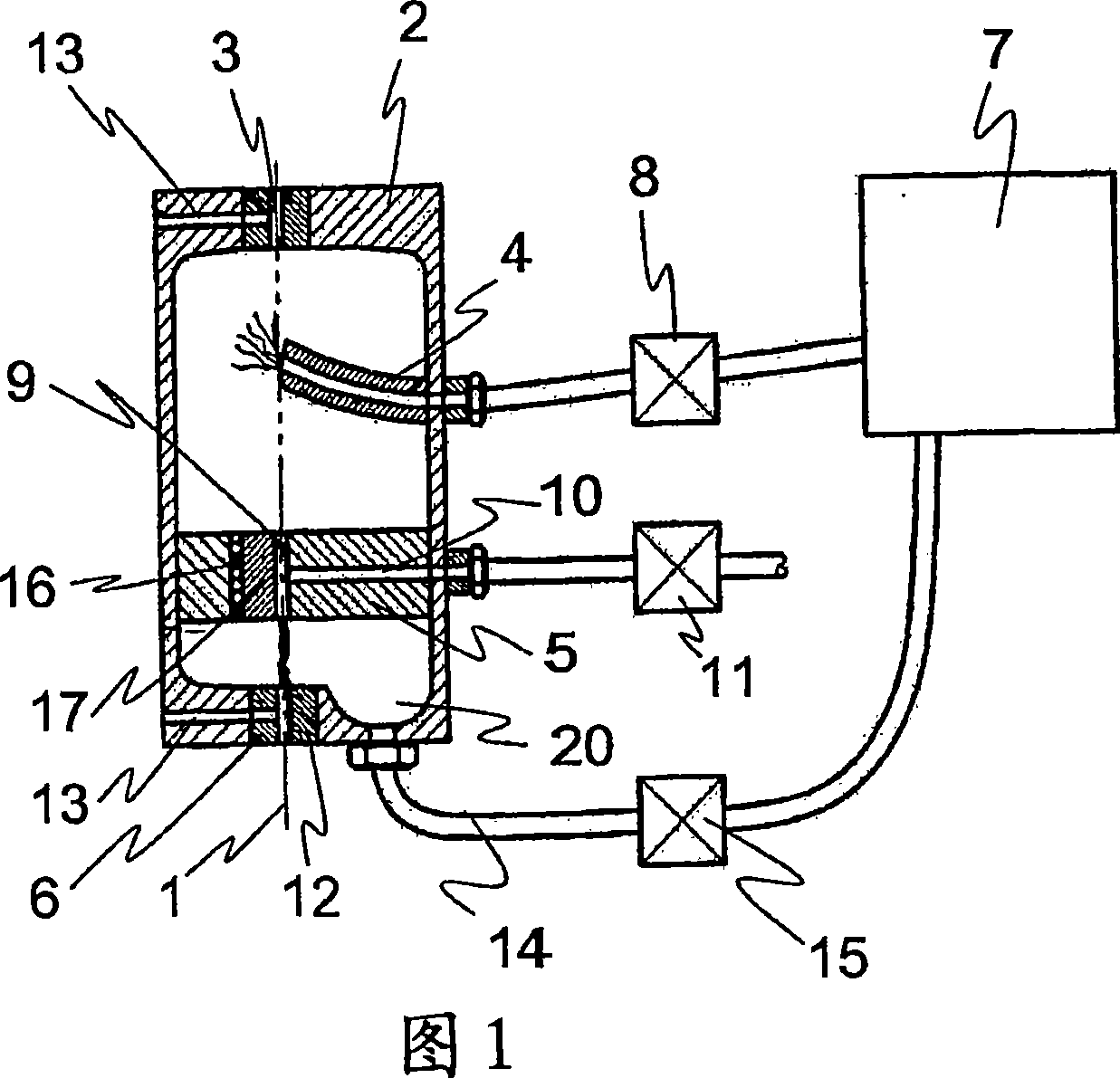

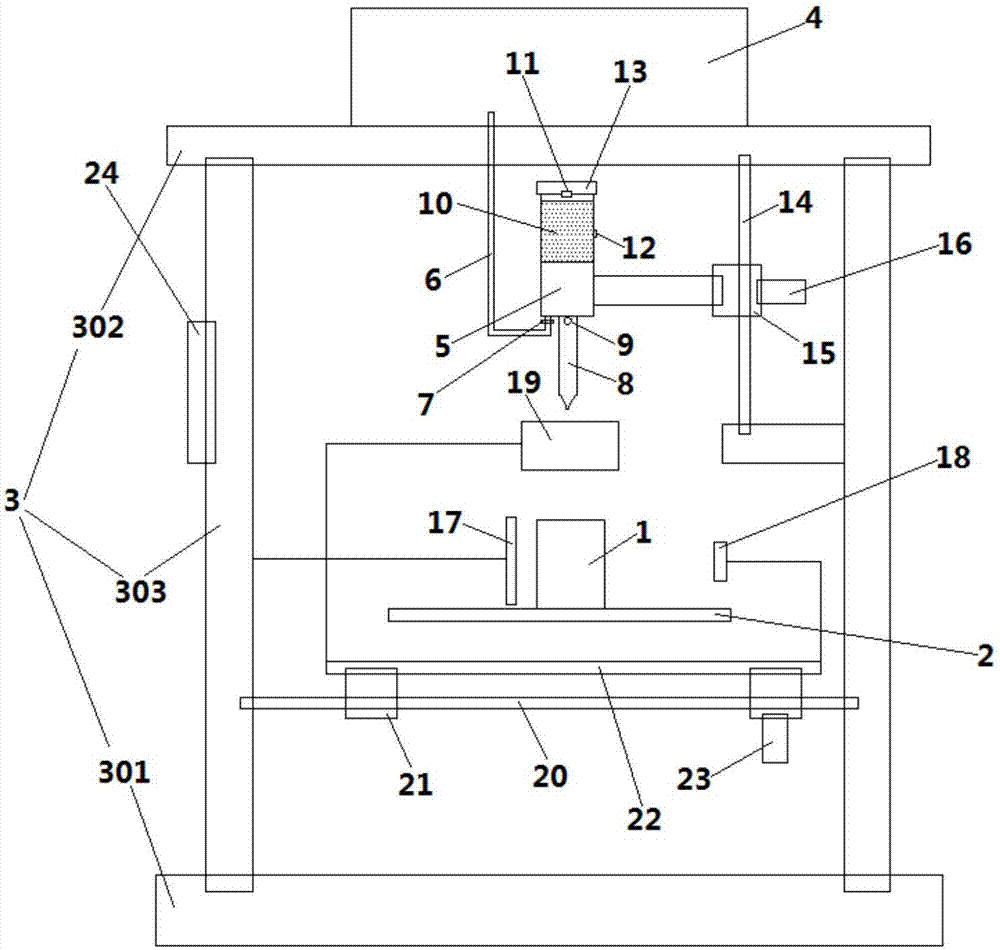

Offshore mining top board seepage flow sudden inflow test method and device

ActiveCN101308126ATo achieve the purpose of waterproofingWon't flow outMaterial analysisTectonic stressExperimental methods

The invention discloses an experimental method for top plate seepage and water inrush when in underwater exploitation as well as an apparatus thereof, comprising the steps of: (1) putting a configured experimental material in a model box according to the practical relative position; (2) exerting lateral pressure on the model material in the model box; (3) sealing the top part of the model box and exerting the stated water pressure on the top part of the model; (4) acquiring water pressure data, tectonic stress data, displacement digital photos and crack digital photos magnified by certain times at regular intervals in the exploitation process until the water inrush destruction takes place; (5) repeating the steps of (1), (2) and (3) to change lateral pressure and water pressure parameters, and repeating the step (4); and (6) obtaining the relation between the water pressure at the top part, the tectonic stress and the model surface displacement, model surface crack. The method and apparatus can embody the combined action of tectonic stress and water pressure at the top part and deadweight function of cover layer more factually, thereby improving the testing precision.

Owner:CENT SOUTH UNIV

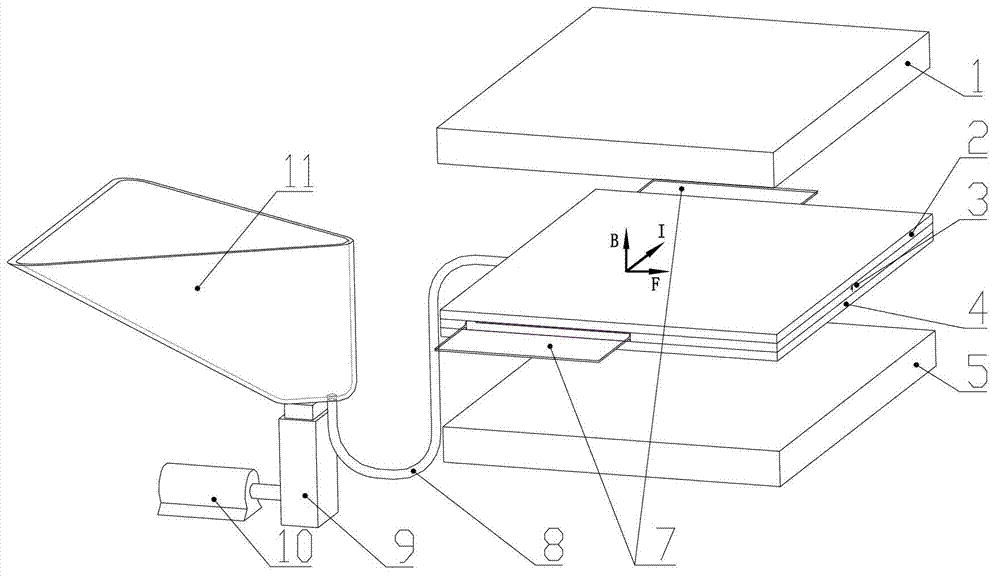

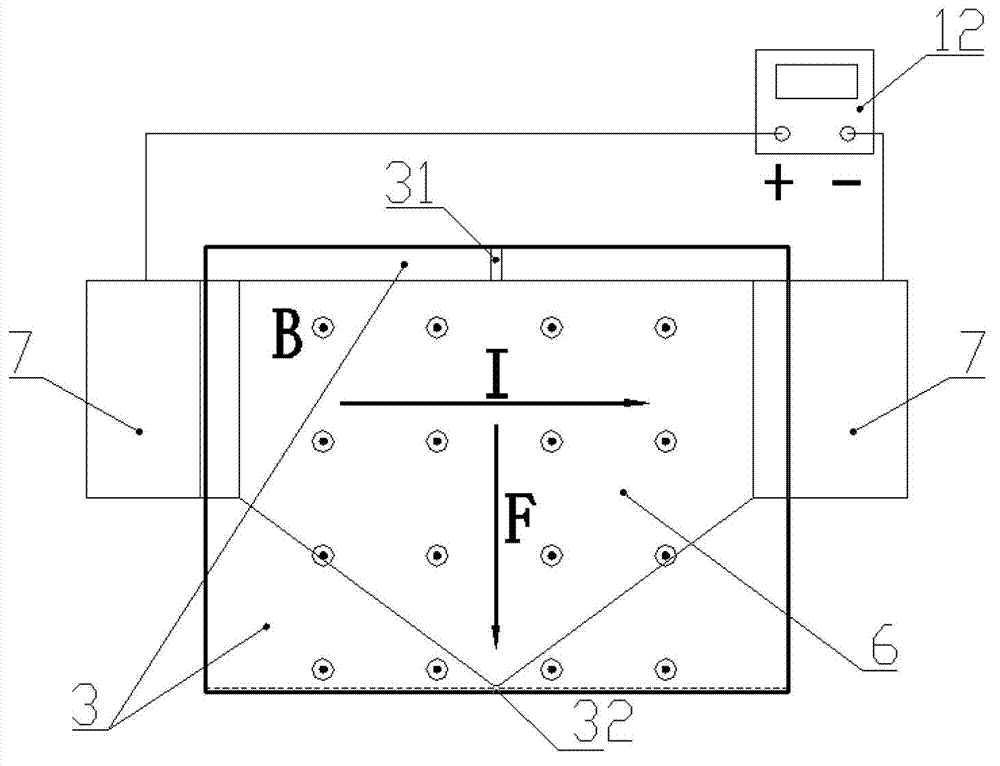

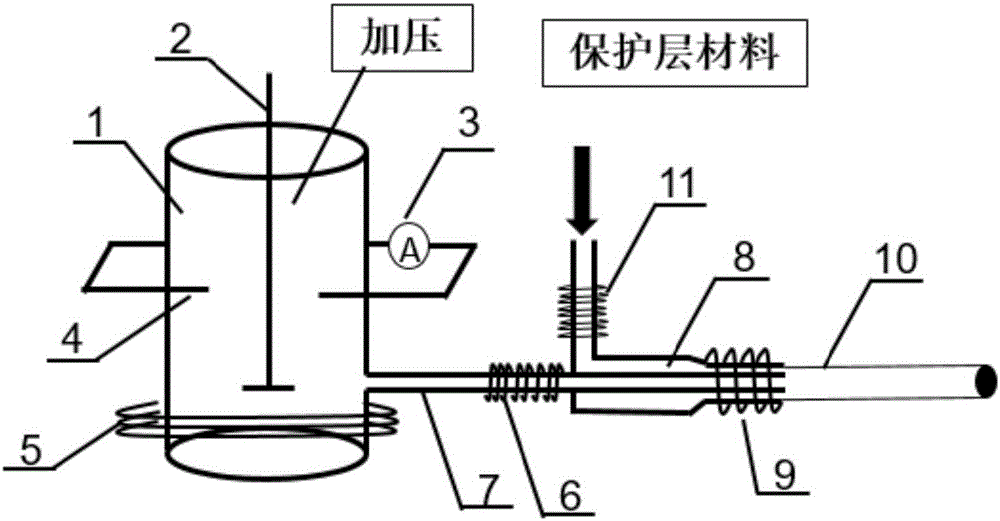

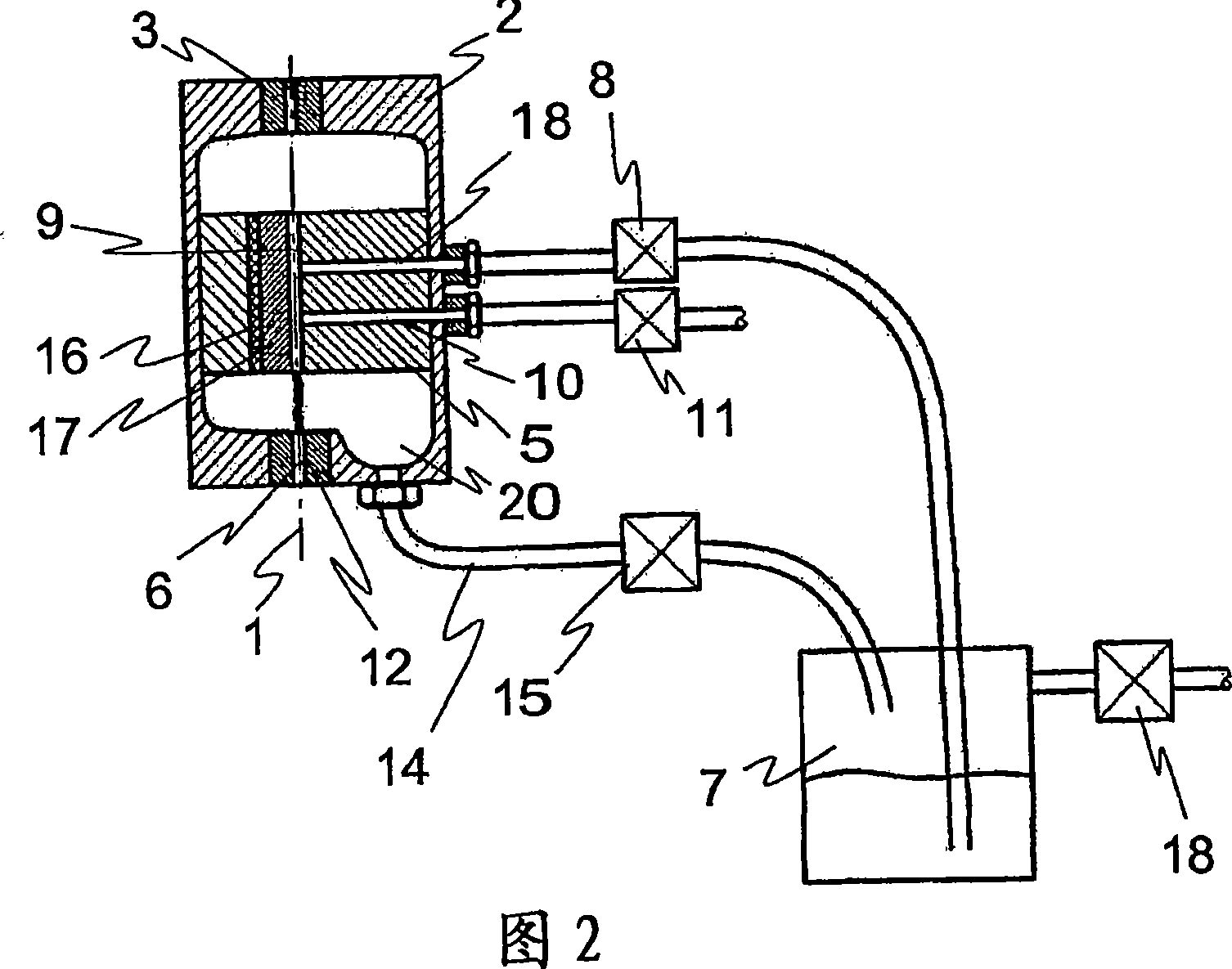

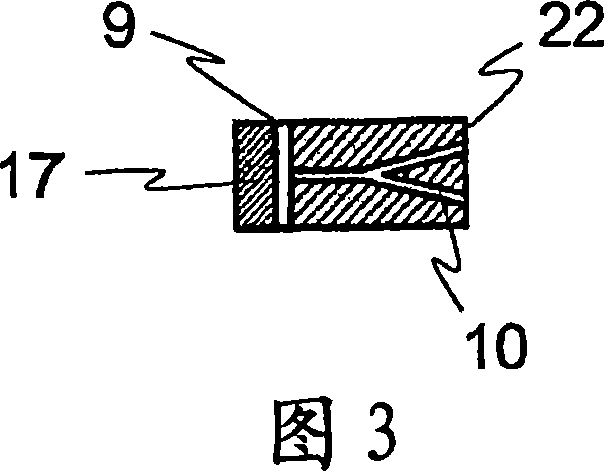

Electromagnetic micro jet device

ActiveCN103203294ASimple mechanical structureSupply pressure is stableElectrostatic spraying apparatusEngineeringMagnet

The invention discloses an electromagnetic micro jet device, and relates to a micro jet device. The electromagnetic micro jet device is suitable for jet of metal liquid as required, and is provided with an upper magnet, a jet cavity, a lower magnet, electrodes, a liquid feed pipe, a liquid feed tank, a lifting mechanism, a stepping motor and a pulse current device, wherein the upper magnet and the lower magnet are fixed on the upper surface and the lower surface of the jet cavity respectively; the jet cavity is provided with a liquid inlet and a liquid nozzle; the electrodes are arranged on the two sides of the jet cavity and stretch into the jet cavity; one end of the liquid feed pipe is communicated with an inner cavity of the jet cavity; the other end of the liquid feed pipe is communicated with the liquid feed tank; an input end of the lifting mechanism is connected with the stepping motor; an output end of the lifting mechanism is connected with the liquid feed tank; and the two ends of the pulse current device are connected with the electrodes.

Owner:XIAMEN UNIV

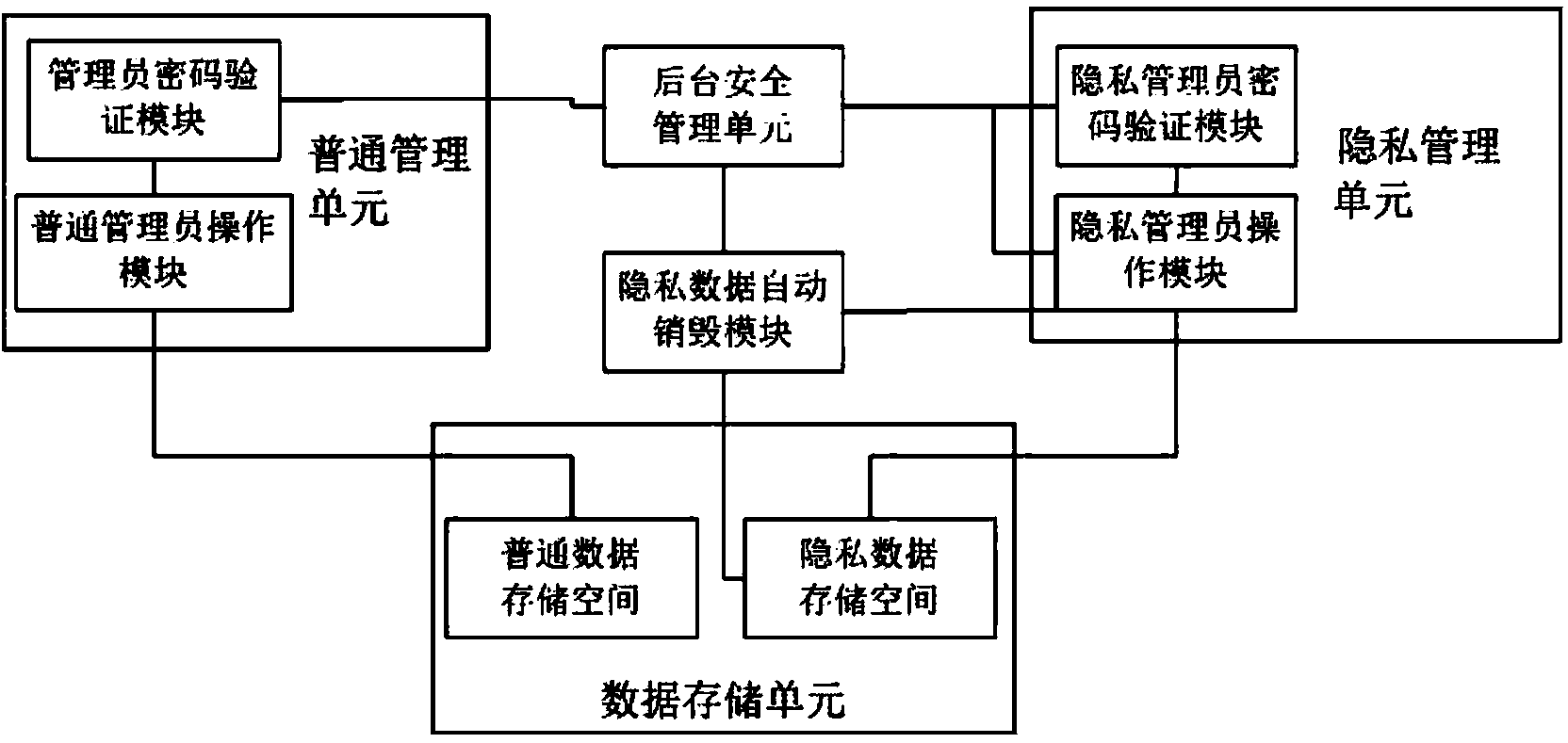

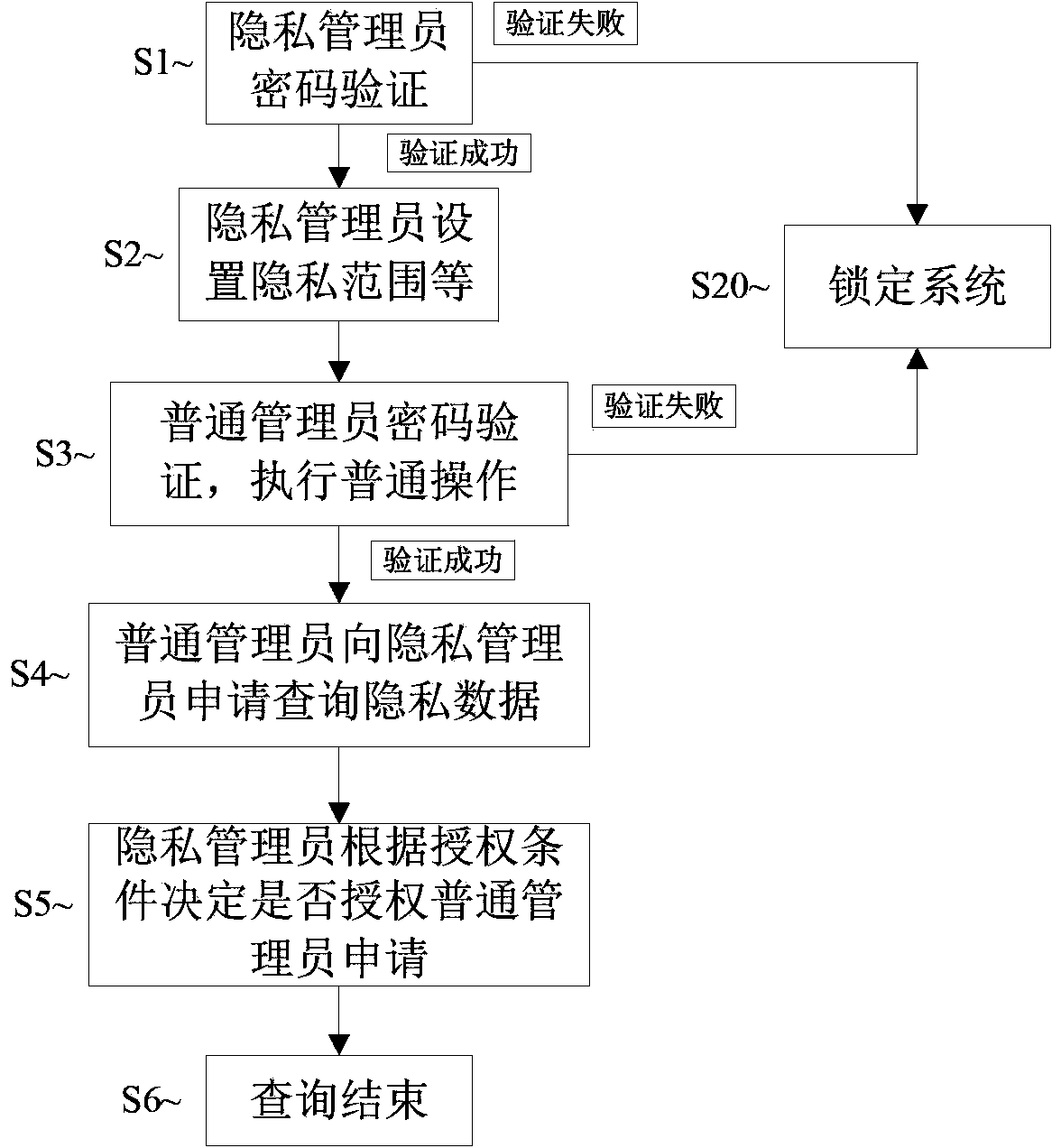

Internet surfing log recording system and method capable of protecting personal privacies of users

InactiveCN103455763AImprove confidentialityAchieve securityDigital data protectionDigital data authenticationManagement unitInternet privacy

The invention discloses an Internet surfing log recording system and method capable of protecting personal privacies of users. The system comprises a general management unit responsible for general management operation, a privacy management unit responsible for authorization and operation, a background safety management unit connected with the general management unit and the privacy management unit and responsible for safety of a monitoring system, and a data storage unit used for storing data. Therefore, the method is good in safety and less prone to data leakage of the personal privacies of the users, and can achieve joint administration by administrators in different levels through combination of software encryption and hardware encryption.

Owner:孙伟力

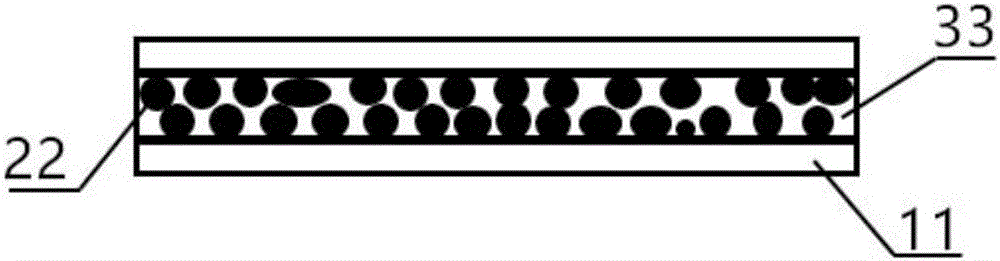

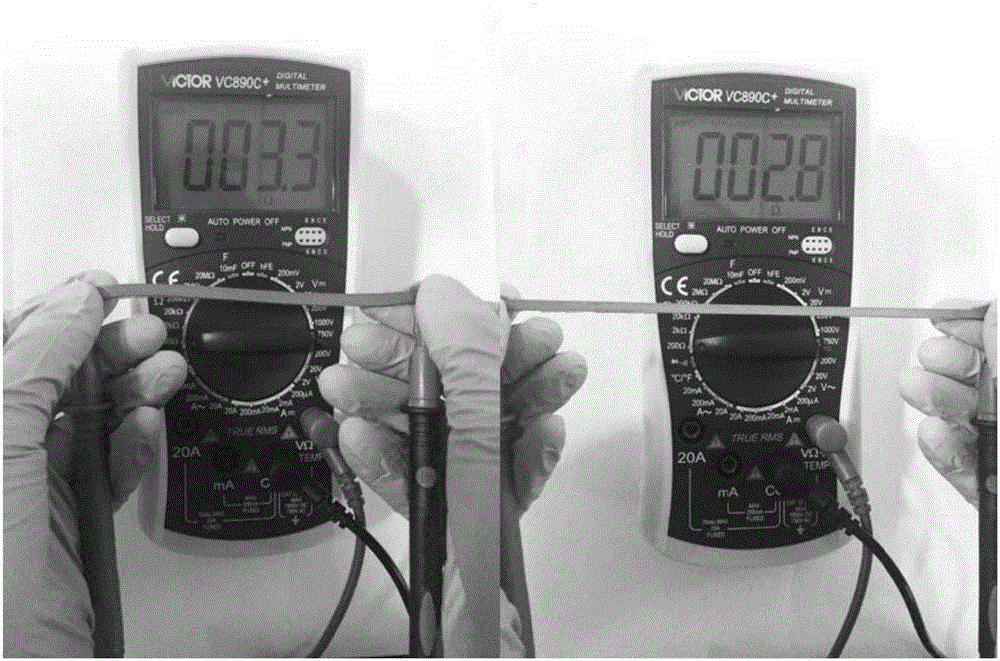

Cuttable flexible wire and preparation device and preparation method thereof

ActiveCN106328262AFlow restrictionWon't flow outLiquid conductorsFlexible cablesTensile strainElastomer

The invention provides a cuttable flexible wire which is composed of liquid metal and an elastomer, wherein liquid metal particles are dispersed in the elastomer. The liquid metal material will not flow out after the flexible wire is cut, and can bear stretching, bending and other deformation. When the liquid metal material produces stretching, bending or other deformation, the resistance will not change. The invention further provides a device for large-scale preparation of the cuttable flexible wire, comprising a mixing device, a current detection device, a conductor pipe, a protective layer pipe, and a heating device. The cuttable flexible wire prepared using the device has stable performance and large tensile strain, can be recovered after stretching, and can be cut. The cuttable flexible wire has potential application value in the flexible electronic technology.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

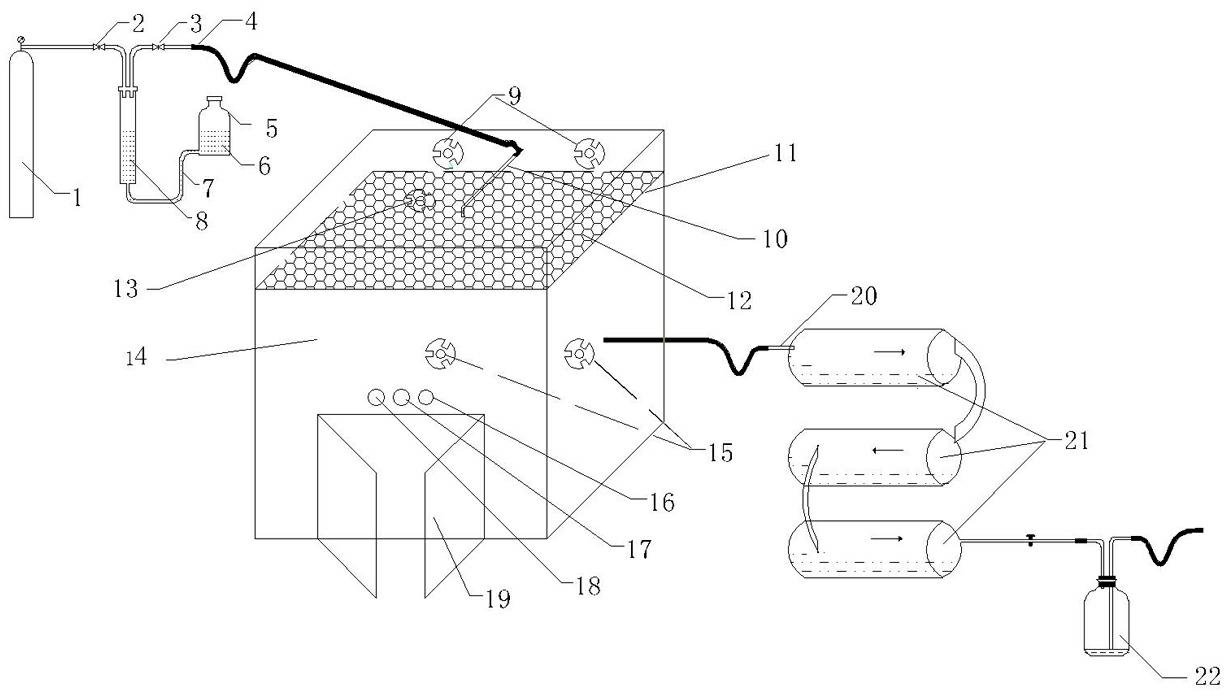

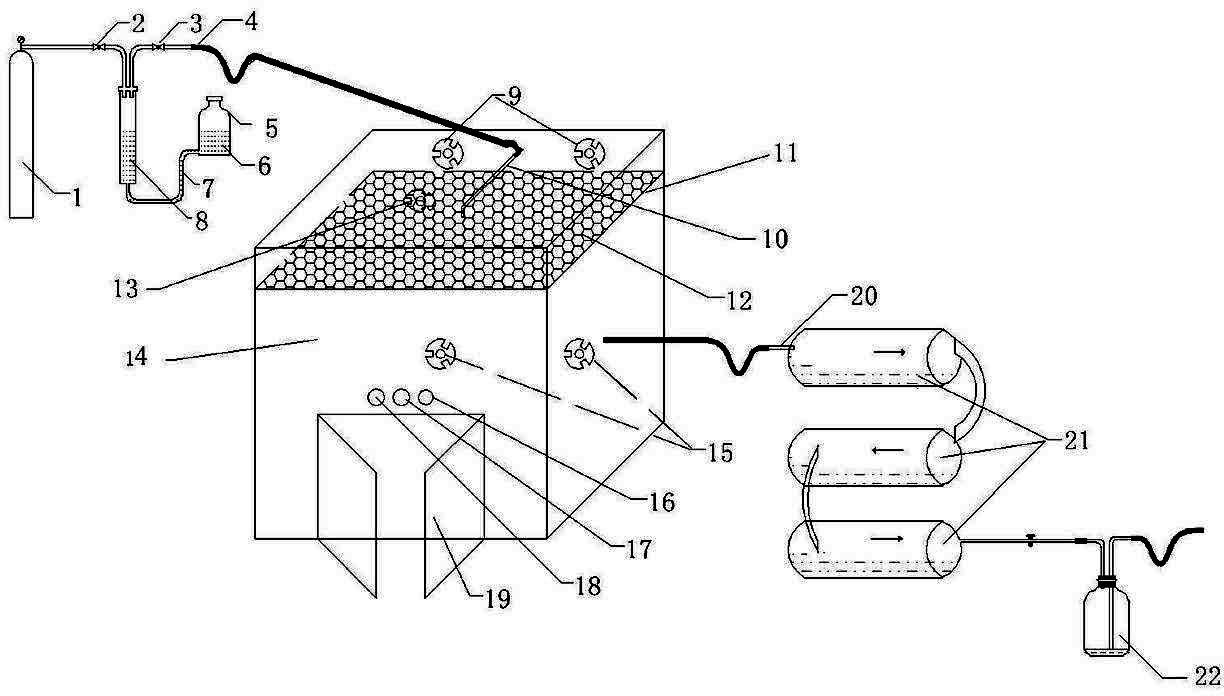

Simple dynamic sulfur dioxide gas toxicant exposure experimental device

InactiveCN102172336AAchieving decompression earlyQuantitative control in advancePreparing sample for investigationBiological testingToxic gasToxicant

The invention provides a simple dynamic sulfur dioxide gas toxicant exposure experimental device. The device consists of a gas decompression dosing device, a dynamic gas toxicant exposure cabinet / chamber and a waste gas absorption and discharge device, wherein the gas decompression dosing device has functions of directly decompressing and quantifying high-purity sulfur dioxide gas, thus omitting assembly of a special decompression gauge and a flow gauge and realizing quantitative control on toxic gas in advance; the dynamic gas exposure cabinet / chamber ensures that a simulated toxicant exposure environment is closer to a natural exposure environment and concentration of the toxic gas is uniform and accurate and can be regulated and controlled in real time; and the discharged gas meets thesafe discharge standard through the waste gas absorption and discharge device. The overall device has the advantages that operation method is simple, the manufacturing expense is low, and the continuous long-time toxicant exposure can be realized, thus solving the difficulty of continuous dynamic toxic gas exposure for a large number of animals, and realizing sulfur dioxide fumigation for variousfood and industrial materials and the like.

Owner:SHANXI AGRI UNIV

Bone-china exquisite glaze and method for fabricating bone-china exquisite products by using bone-china exquisite glaze

The invention relates to a bone-china exquisite glaze. The glaze comprises the following components in parts by weight: 16-24 parts of silica, 0-8 parts of clay, 28-38 parts of feldspar, 12-18 parts of borax, 0-7 parts of boric acid, 10-17 parts of barium carbonate, 0-5 parts of strontium carbonate, 0-8 parts of lithium carbonate, 2-12 parts of zinc oxide, 0-6 parts of aluminum hydroxide, 0-3 parts of talc, 0-12 parts of calcite and 0-1 part zirconium silicate. The glaze has the advantages of good transmittance and no opaque phenomenon and is exquisitely carved and glittering and translucent like jewels; the invention also provides a method for fabricating bone-china exquisite products from bone-china exquisite glaze, according to the method, residual bubbles can be eliminated, at the same time, the expansion coefficients of the glaze and the bone china are matched, quick heating and cooling resistance of products are improved and the cracking problem is avoided.

Owner:潮州市雅森陶瓷实业有限公司

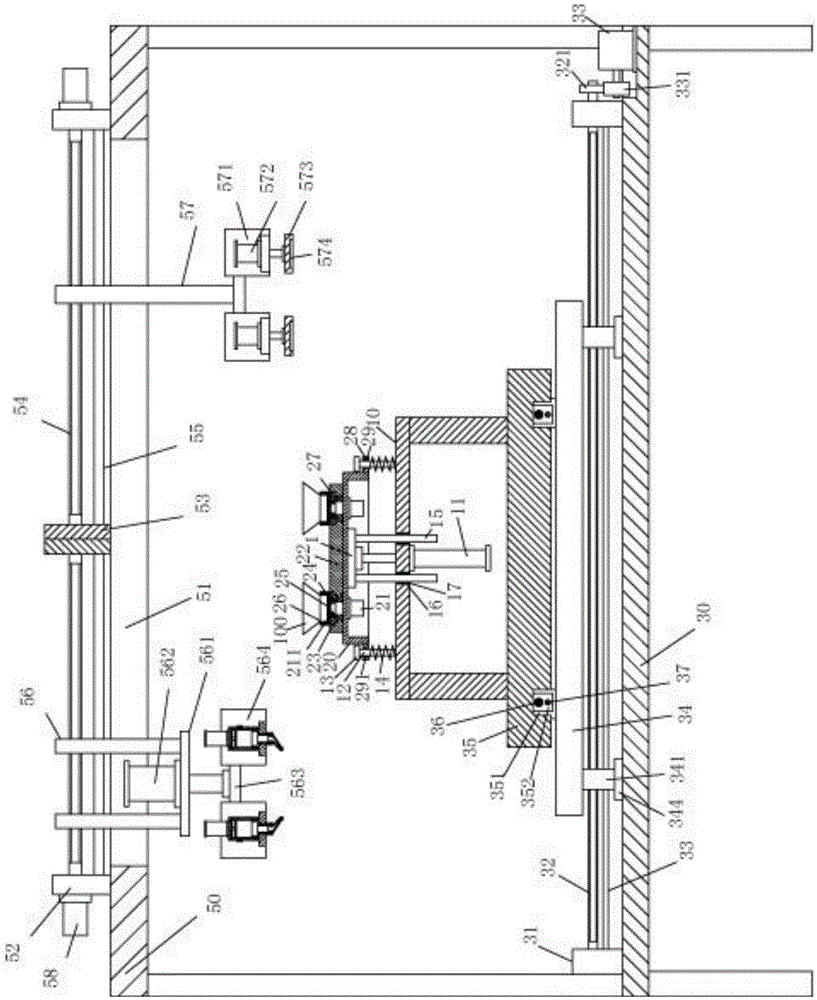

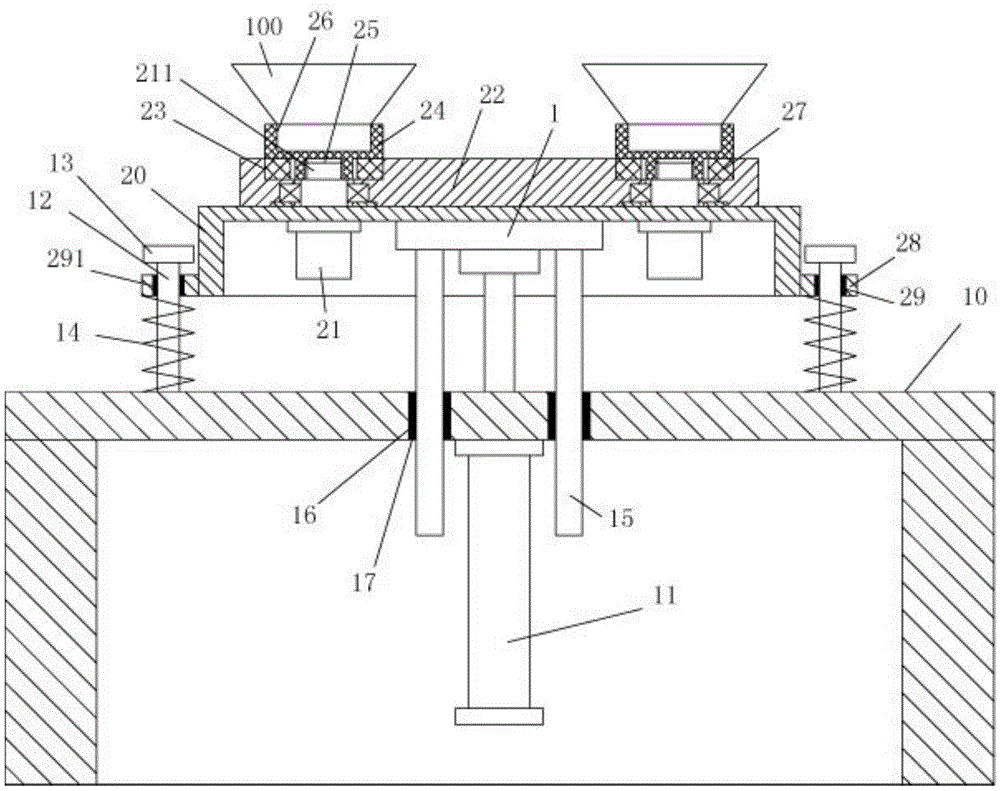

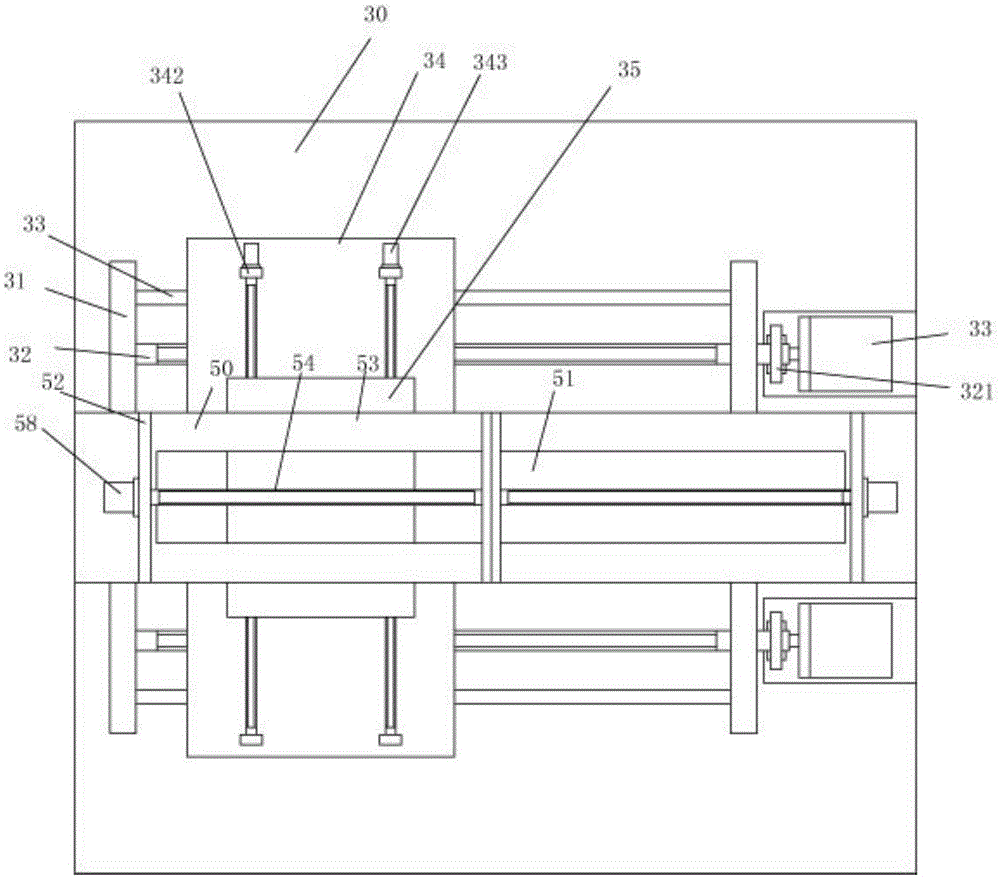

Material loading, gluing and piece pressing integrated manufacturing device of basin stand for assembling horn

The invention discloses a material loading, gluing and piece pressing integrated manufacturing device of a basin stand for assembling a horn. The material loading, gluing and piece pressing integrated manufacturing device comprises a movable main frame, a main rack, a gluing supporting frame and an automatic grabbing frame. The gluing supporting frame and the automatic grabbing frame are arranged side and side and fixed to the main rack. The gluing supporting frame is provided with a gluing mechanism and a pressing cylinder. A grabbing adjustment through groove is formed in a top plate body of the automatic grabbing frame. Two vertical grabbing supporting plates are fixed to the top face of the top plate body of the automatic grabbing frame. By means of the material loading, gluing and piece pressing integrated manufacturing device, the basin stand can be automatically placed and is made to automatically rotate, lift and move, and therefore automatic gluing, elastic piece placement and pressing can be performed, no manual operation is needed in all procedures, and operation is quite convenient; meanwhile, the position of the gluing mechanism and the position of the pressing cylinder can be automatically adjusted as required, the adjustment effect is good, glue can be uniformly squeezed out of a discharge head by the gluing mechanism as required to drop on the basin stand, the discharge head is automatically sealed when the material loading, gluing and piece pressing integrated manufacturing device is not used, glue will not flow out, and operation is quite convenient.

Owner:SHAOXING UNIVERSITY

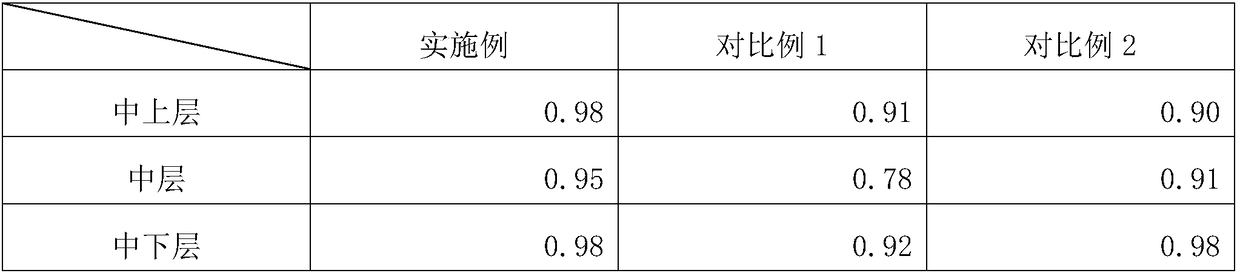

Method for preparing dense fine-grain neodymium iron boron sintering magnet

ActiveCN103489619AConsistent shrinkageConsistent performanceInorganic material magnetismInductances/transformers/magnets manufactureIngot castingRare earth

The invention belongs to the field of rare earth permanent magnetic materials, and particularly provides a method for preparing a dense fine-grain neodymium iron boron sintering magnet. The method for preparing the dense fine-grain neodymium iron boron sintering magnet is characterized in that vacuum pre-sintering is conducted before high-pressure argon hot isostatic pressure sintering, the sintering temperature is kept between +5 DEG C and 50 DEG C of the eutectic temperature of a 2:14:1 phase and a phase rich in neodymium, and the pressure range is between 2MPa to 20MPA in the isostatic pressure sintering process. The method particularly comprises the steps that after ingot casting, powder preparation and orienting profiling are sequentially conducted on neodymium iron boron alloy, the neodymium iron boron alloy is placed in a sintering furnace, after the high vacuum condition is met, the neodymium iron boron alloy is heated, the sintering furnace is vacuumized continuously, the high vacuum environment is created through stage heating and control over the heating speed, when the required sintering temperature and the required vacuum degree are achieved, the neodymium iron boron alloy is pre-sintered for a certain time in a vacuum mode, then, vacuumization is stopped, high-purity argon is gradually conveyed to the sintering furnace so that isostatic pressure can be exerted, the temperature is continuously kept for a certain time, rapid cooling is conducted, and therefore the product is obtained. The method for preparing the dense fine-grain neodymium iron boron sintering magnet has the advantages that a dense and fine-crystalline structure can be sintered, shrinkage of the product is even, properties are identical, operation is simple, and the method is suitable for industrialized production.

Owner:UNIV OF SCI & TECH BEIJING

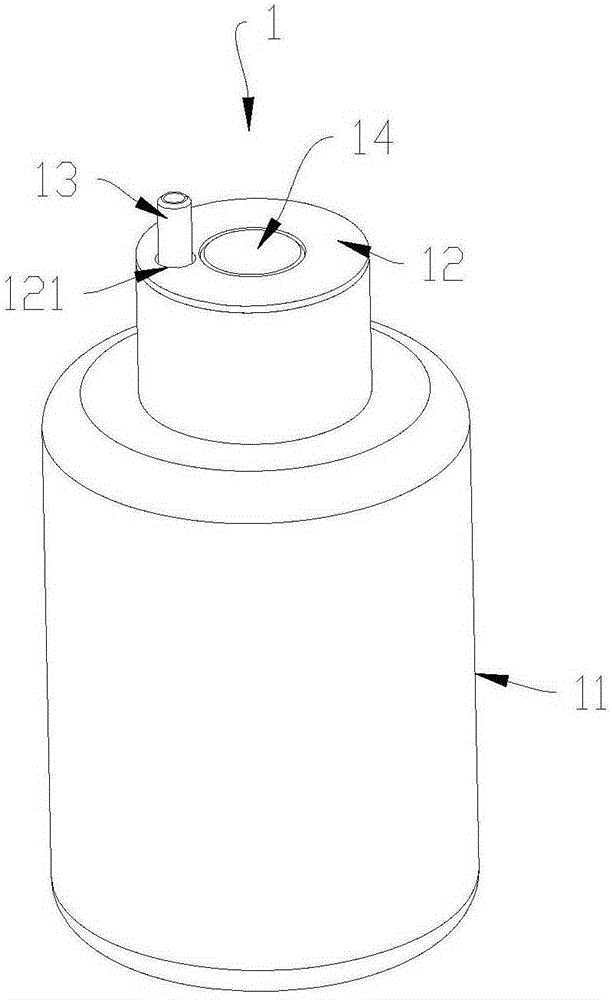

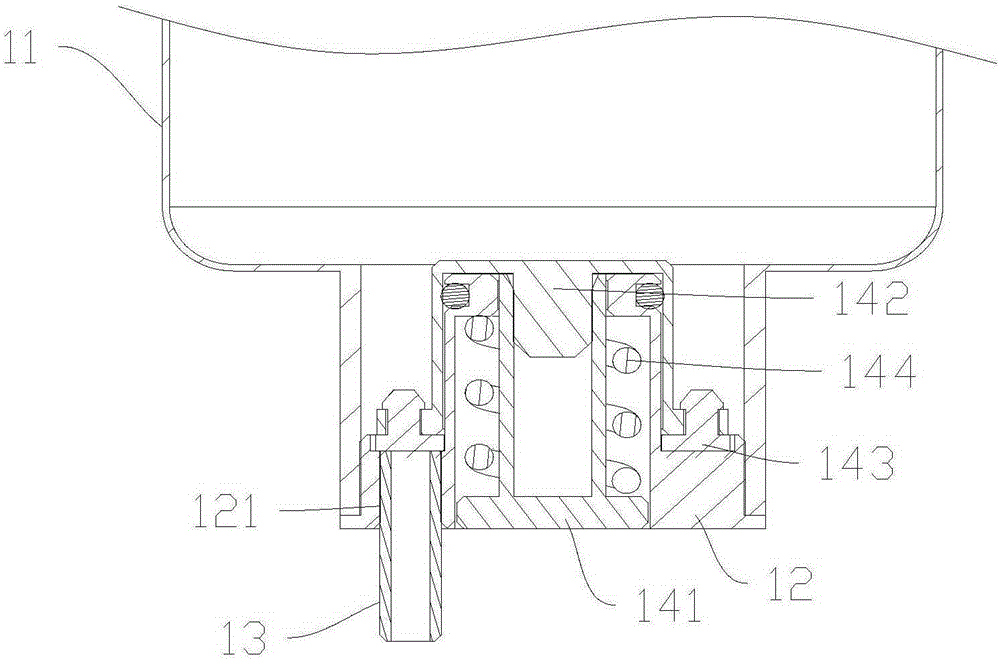

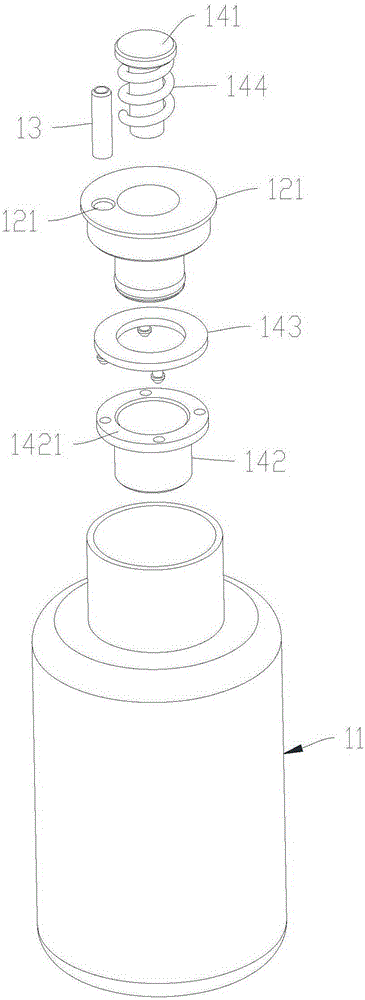

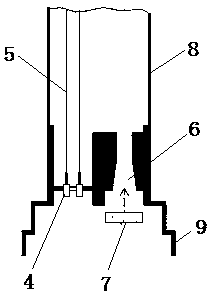

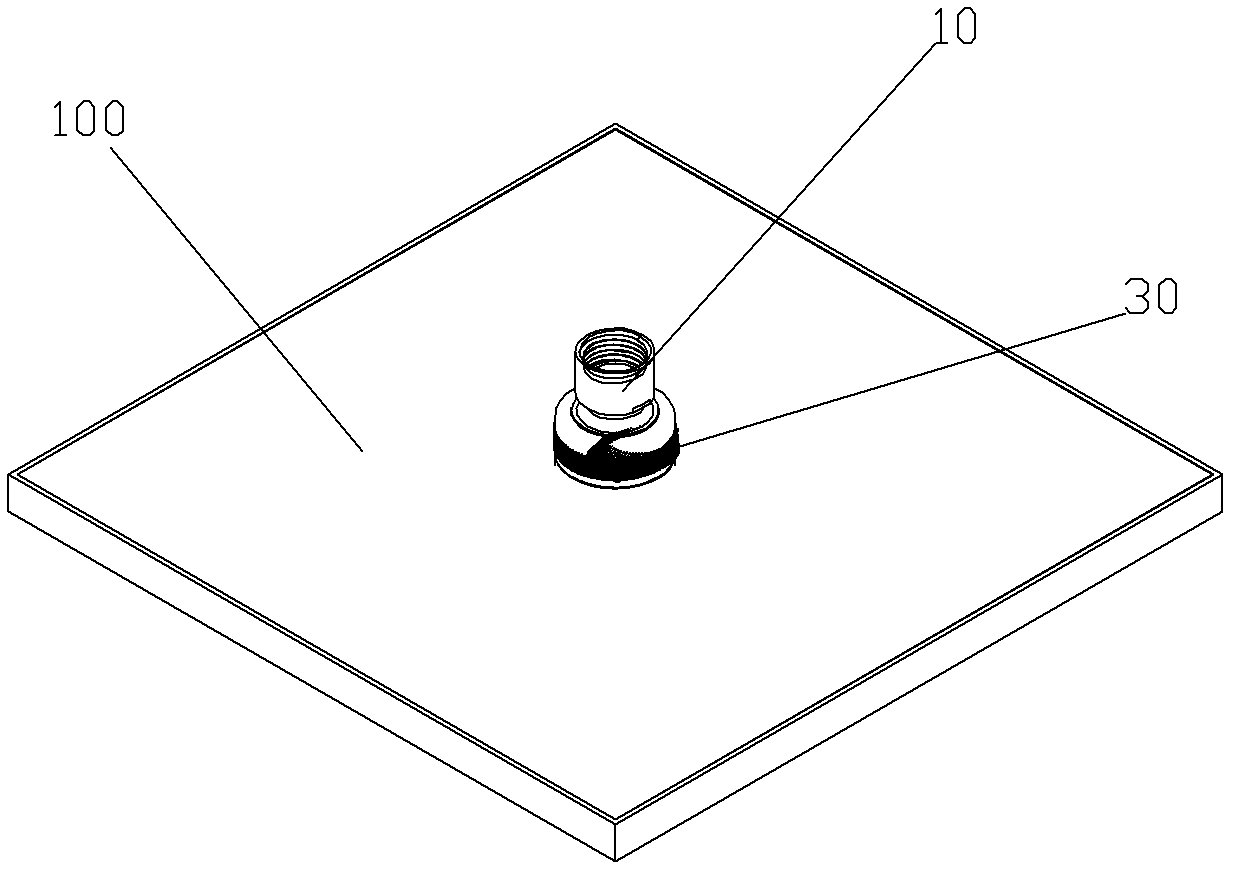

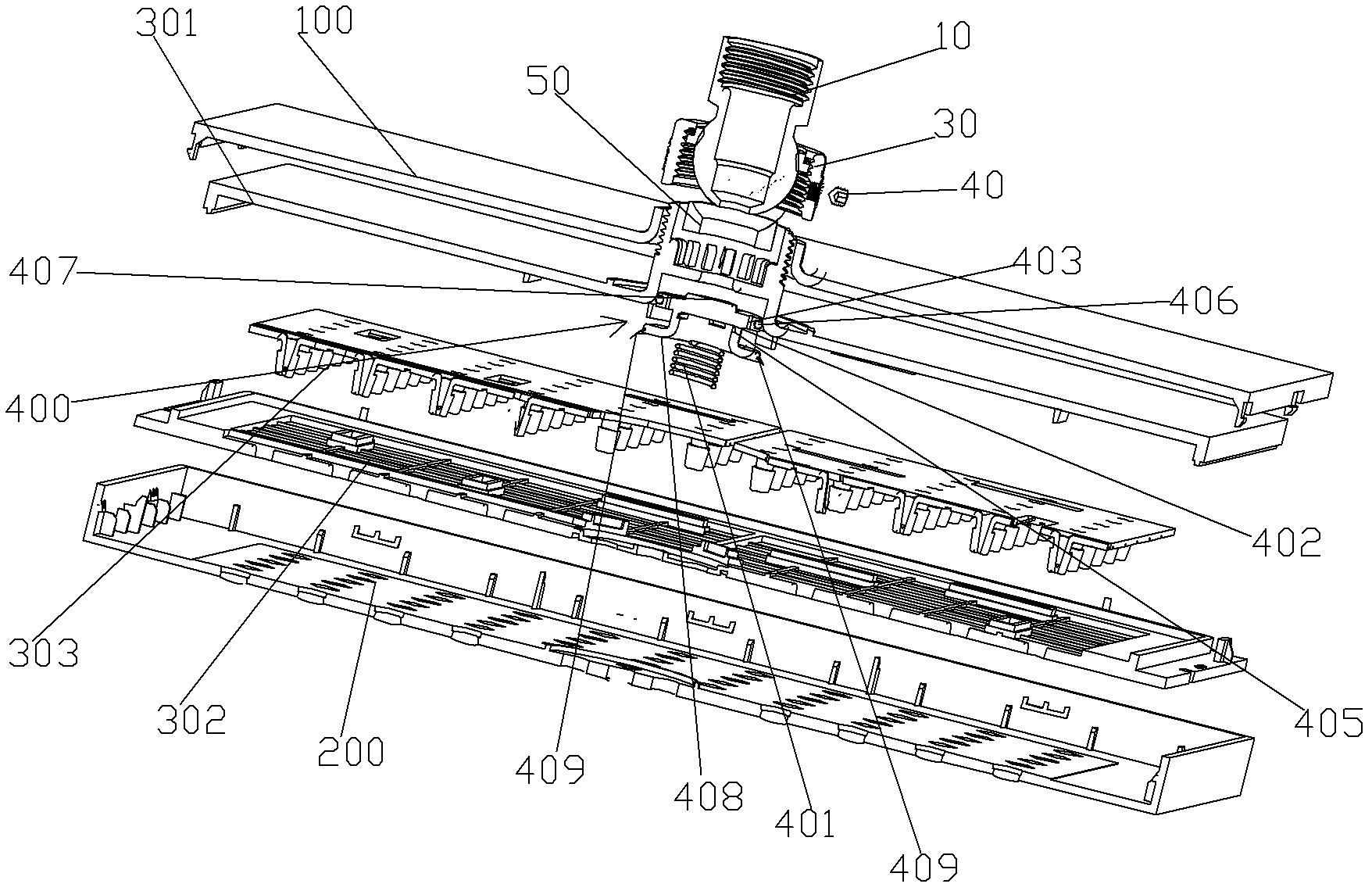

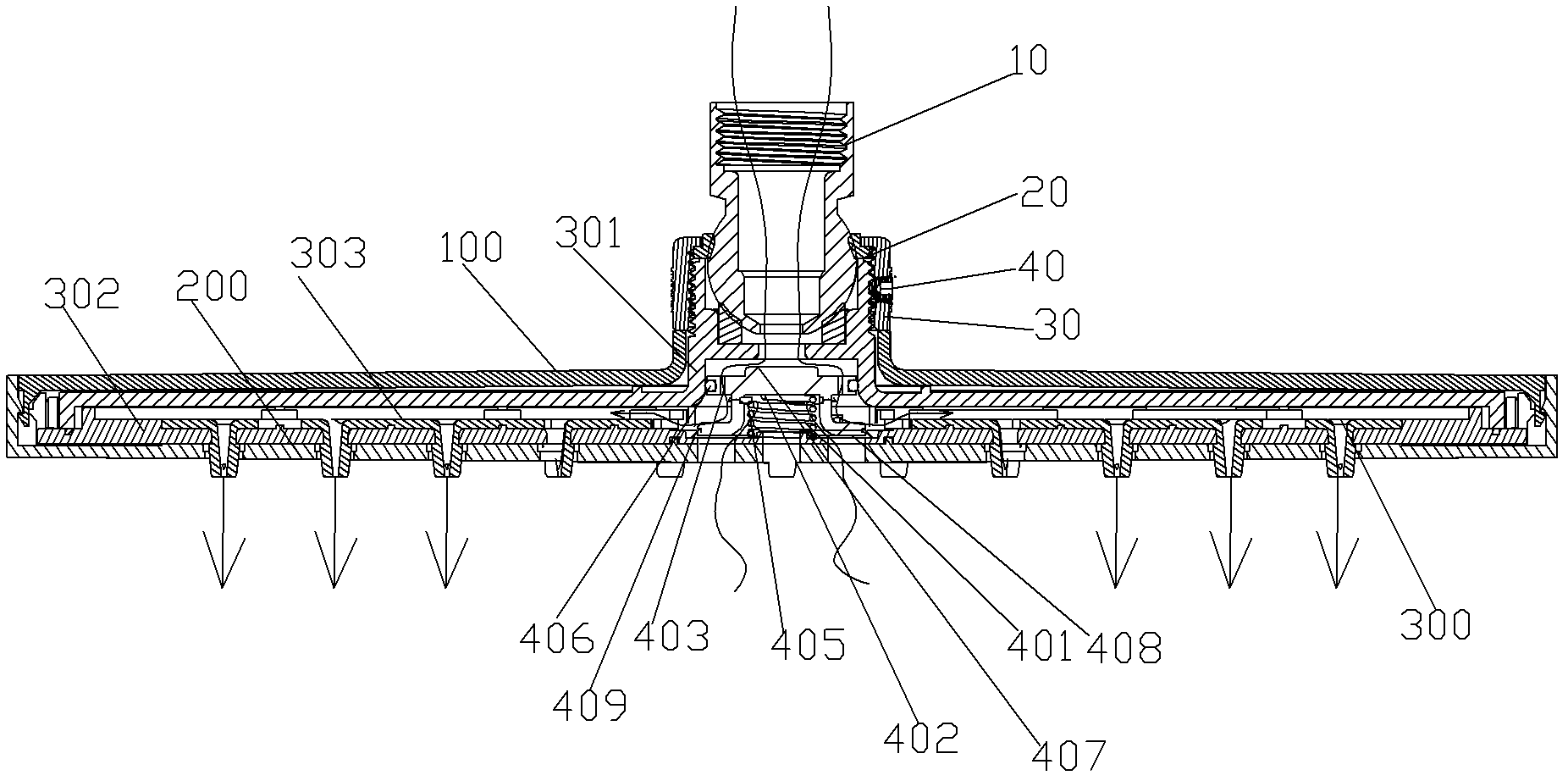

Tobacco tar bottle and electronic cigarette

The invention relates to a tobacco tar bottle and a matched electronic cigarette. The tobacco tar bottle comprises a bottle body, a bottle cover and a control switch, wherein the bottle cover is provided with a juice outlet, and the control switch is arranged on the bottle cover. The electronic cigarette comprises a smoke cartridge pipe and a juice injection device; the interior of the smoke cartridge pipe forms a juice storage chamber, one end surface of the smoke cartridge pipe forms an end wall and a second operation part axially protruding outside. Juice injection ports are formed in the end wall, and the second operation part corresponds to the position of a press switch. The juice injection device is arranged at the end where the end wall is located, juice injection passages respectively corresponding to the juice outlet and the juice injection ports are formed on the juice injection device, the juice injection passages are spaced from the juice storage chamber, and first juice inlets are formed in the juice injection passages. When the tobacco tar bottle is used for injecting juice to the electronic cigarette, the tobacco tar bottle presses the juice injection device to open the juice injection ports, the second operation part presses the control switch to open the juice outlet, so as to communicate the tobacco tar bottle with the juice storage chamber to inject juice into the juice storage chamber; when the tobacco tar bottle is separated from the electronic cigarette, the juice injection ports and the juice outlet are closed, and tobacco juice cannot flow out during a juice injection process, and the safety of juice injection is guaranteed.

Owner:SHENZHEN SMOORE TECH LTD

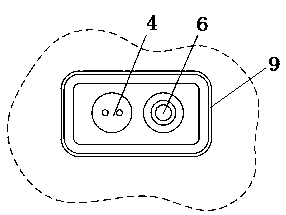

Electric car lithium-ion power battery box fire extinguishing mechanism and implementation method

The invention relates to an implementation method of an electric car lithium-ion power battery box fire extinguishing mechanism. The implementation method comprises the following steps that when thermal runaway occurs to lithium-ion power batteries in a lithium-ion power battery box and a fire is caused, drivers and conductors open a car body sealing cover and a blocking end cover of a fire extinguishing agent filling port to connect a fire extinguishing device containing a fire extinguishing agent with the fire extinguishing agent filling port and starts the fire extinguishing device. The fire extinguishing agent is fed into the lithium-ion power battery box from the fire extinguishing agent filling port via a fire extinguishing agent filling pipe under the action of a driving medium of the fire extinguishing agent and covers the spaces between the multiple lithium-ion power batteries and the interior of the lithium-ion power battery box totally to achieve the purposes of fire extinguishing and battery thermal runaway suppression. Through the implementation method, and the lithium-ion fire can be effectively put out in time to provide a guarantee for people escape and vehicle safety protection. Meanwhile, the measures and the method for putting out the electric car lithium-ion power battery fire are provided for electric car production units, electric car marketing units, electric car users and rescuers.

Owner:TIANJIN FIRE RES INST

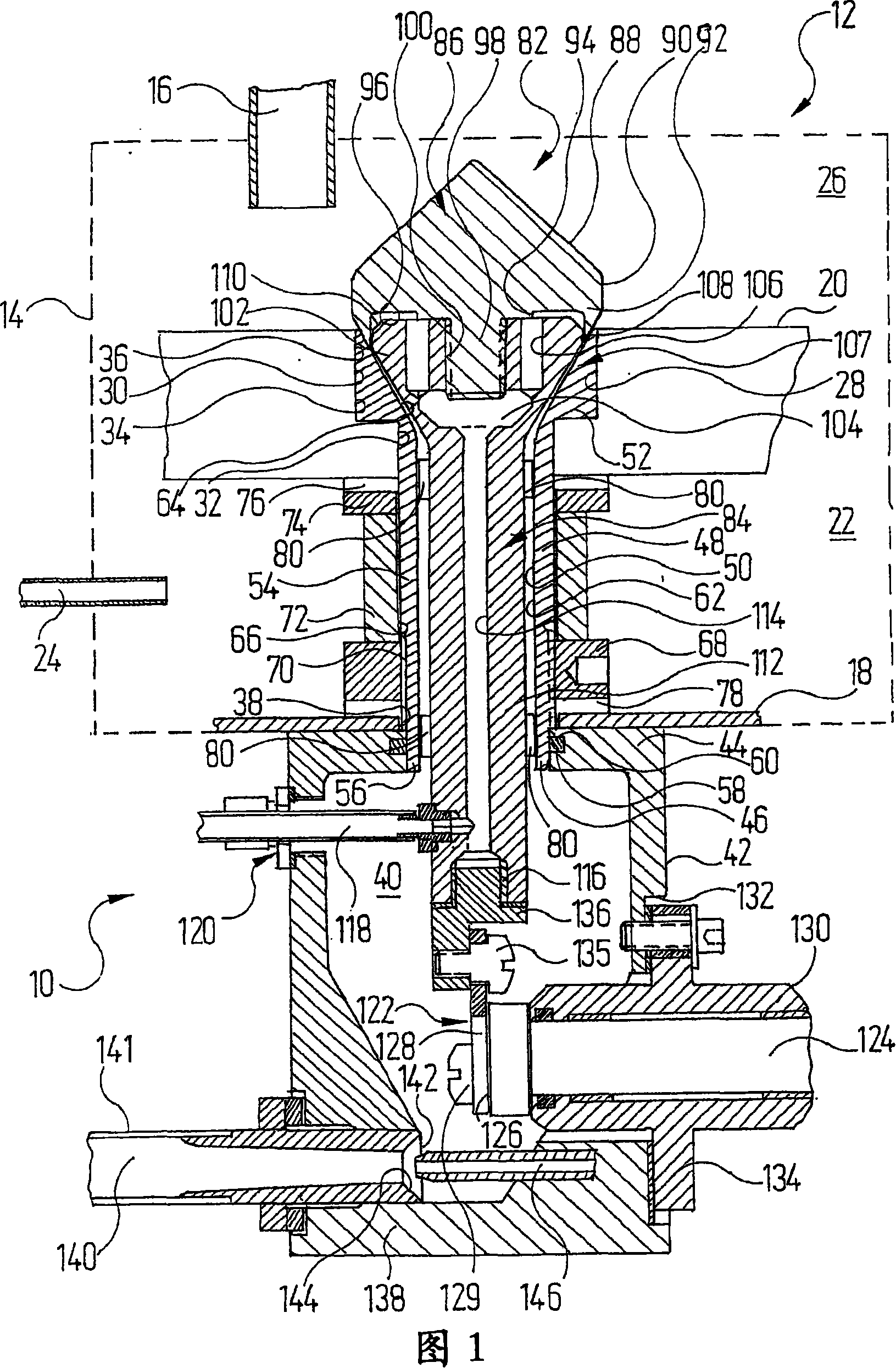

Device for guiding powdery fluidic media

The invention relates to a device for guiding powdery fluidic media, in particular powder paint, comprising a receptacle (12) which is provided with an inner chamber (26) for the media which is to be guided, and from where the medium is suctioned via a connection channel (48) which can be closed by a valve body (82). The connection channel (48) and the valve body (82) comprise, respectively, an upper end area (64, 102). Said upper end areas are formed in such a manner that an annular Venturi nozzle (107) is formed therebetween which is used as a pump. The valve body (82) is inserted in a sealed manner in the end region (64) of the connecting channel (48) by means of a sealing section (92) when in the closed position thereof and comprises a conveyor gas channel (114, 104, 106, 108) which can be impinged upon by conveyor gas, through which the conveyor gas can be guided to the connection channel (48) in the vicinity of the sealing section (92), essentially, in the direction of flow of the medium.

Owner:EISENMANN CORP

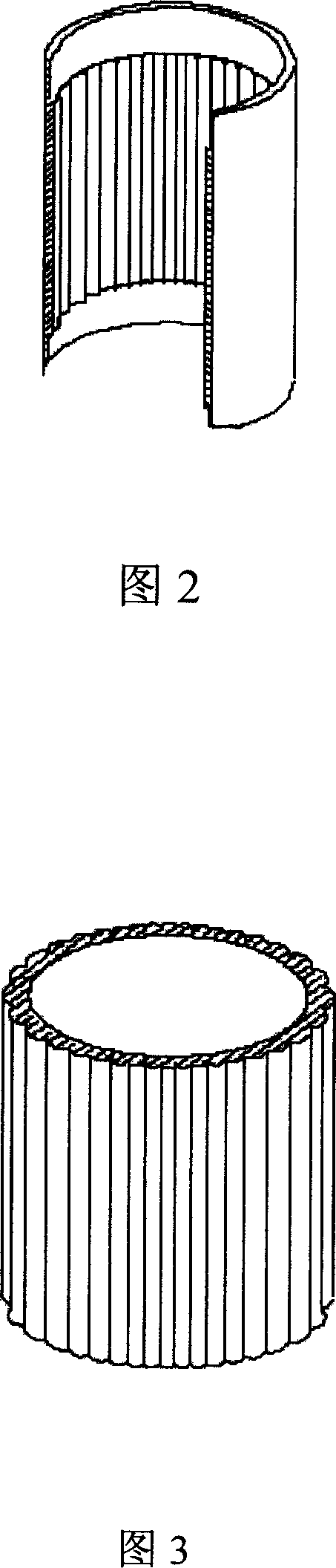

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

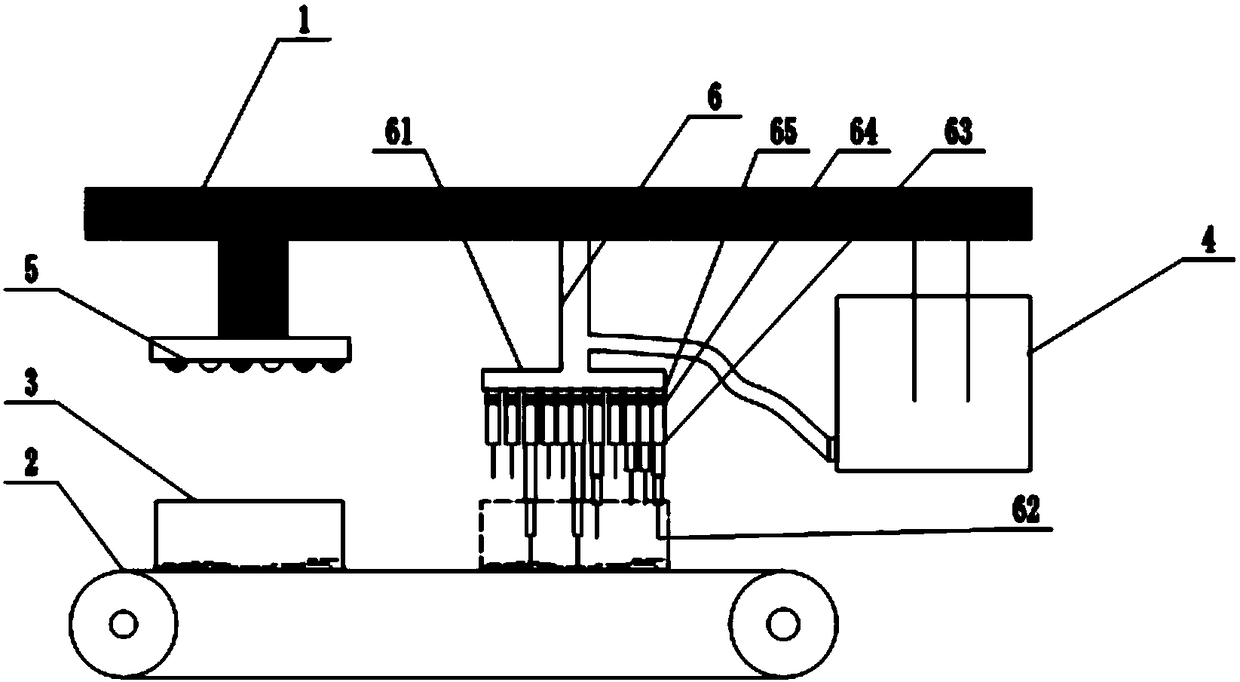

Injection pickling device for spiced beef

The invention discloses an injection pickling device for spiced beef. The injection pickling device comprises a machine frame and a conveying belt, wherein the machine frame is positioned right abovethe conveying belt, a pickling box is arranged on the conveying belt, a color sensor and a marinade injection matrix are sequentially arranged on the machine frame along the direction of advance of the conveying belt, the marinade injection matrix comprises a plurality of queued marinade injection needles, through holes for injecting the marinade are formed in the front ends of the marinade injection needles, a marinade pot is also arranged on the machine frame, the marinade injection matrix is connected with the marinade pot by virtue of a feed pipe, a controller is also arranged on the machine frame, and the controller controls each marinade injection needle in the marinade injection matrix to singly perform injection according to output results of the color sensor. The injection pickling device for spiced beef performs color detection on beef by the color sensor to discriminate the muscles (red) from fat (white) of the beef and inject the fat, and by virtue of drainage effects of blood capillaries, the marinade is drained to everywhere in the beef, thereby achieving the effects uniform pickling and uniform flavor.

Owner:重庆市长寿区田哥食品有限公司

Graphite phase-change thermal conduction silicone grease and preparation method thereof

InactiveCN102504541AImprove heat transfer efficiencyGood heat transfer functionHeat-exchange elementsParaffin oilsGraphite

The invention discloses graphite phase-change thermal conduction silicone grease and a preparation method thereof. The preparation method comprises the steps as follows: heating and melting high-precision paraffin; adding nano porous graphite into the molten high-precision paraffin and stirring to obtain nano porous graphite encapsulated in the high-precision paraffin; and mixing the nano porous graphite encapsulated in the high-precision paraffin with organosilicon oil to obtain high thermal conductivity silicone grease taking a nano porous graphite based phase-change material as the filling material. The preparation method provided by the invention is simple and feasible; and the obtained high thermal conductivity silicone grease product has an excellent temperature reduction effect when used on light-focusing cells, can be used repeatedly, and has a relatively service life.

Owner:SHANGHAI MINGYUAN NEW ENERGY TECH

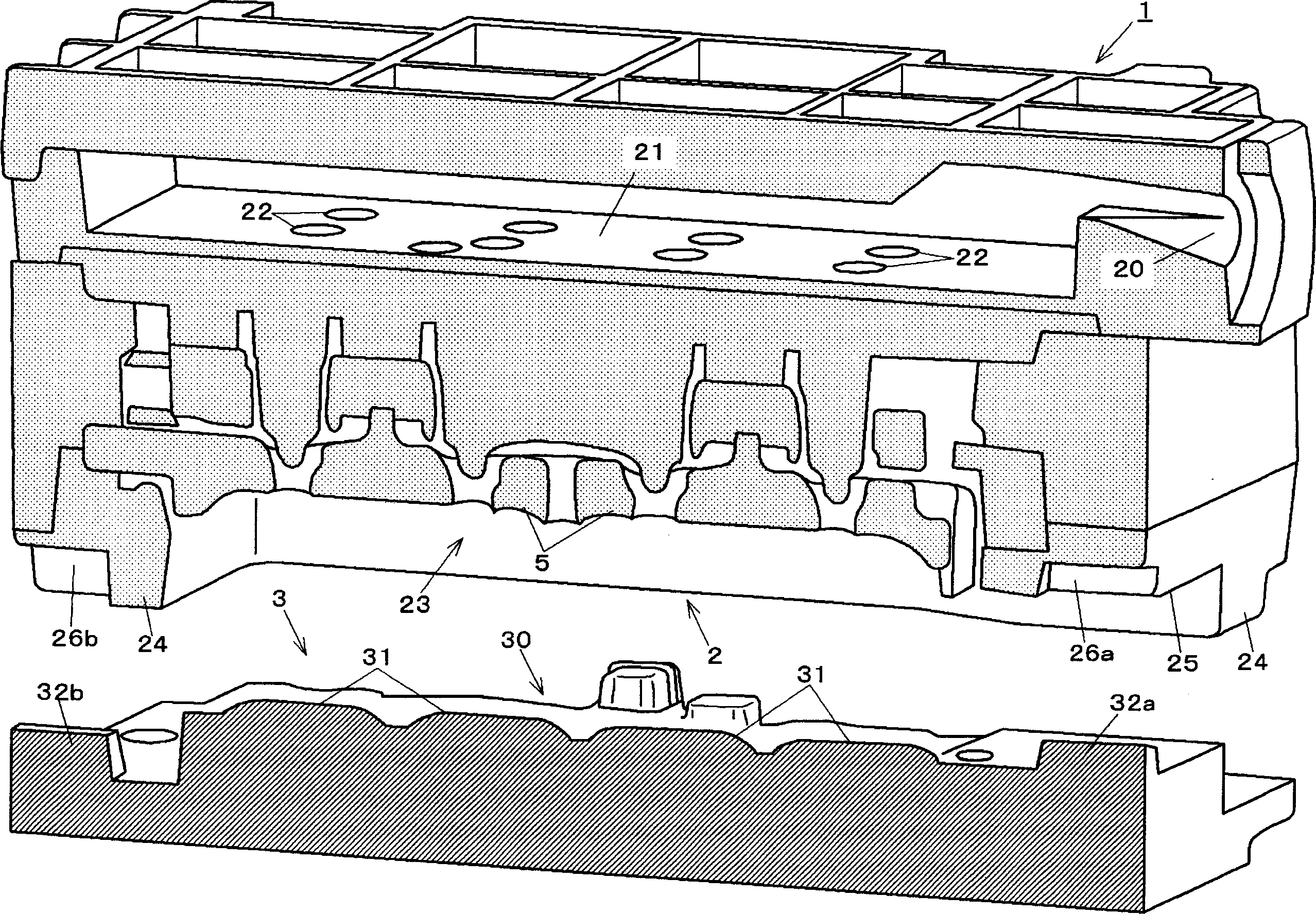

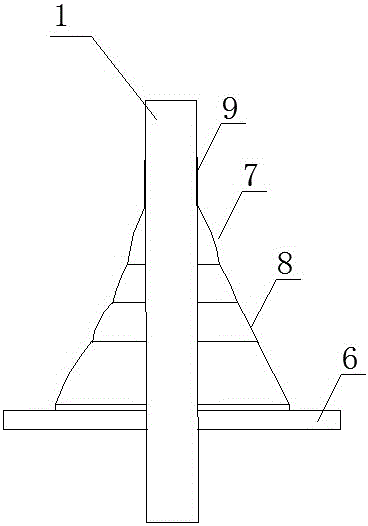

Casting mold device and method producing cast

InactiveCN1833796AWon't flow outExcellent mechanical propertiesFoundry mouldsFoundry coresCooling bathMolding sand

The invention provides a casting mold device and a method for manufacturing castings using the casting mold device. The casting mold device includes a metal mold and a sand mold (2), wherein the sand mold has: a riser formed on the opposite side of the metal mold. One side; the opening (25), which is sealed by a metal mold to form a mold cavity when forming a mold; The surface of the surrounding wall protrudes more toward the metal mold side, wherein a notch is provided on the surrounding wall to make the inner part (S) of the surrounding wall communicate with the outer part. The casting method includes the following steps: a molding process, The sand mold and the metal mold are combined to form a mold cavity; the casting process is to pour molten metal into the mold cavity; the mold opening process is to leave the casting (7) on one side of the sand mold and separate the sand mold from the metal mold; and In the cooling step, the sand mold with the casting left is immersed in a cooling tank with the opening side positioned on the lower side. With this method, when the sand mold and casting are immersed in cooling water in the cooling process, air bubbles (X) remaining in the inner portion (S) are discharged through the notch portion (25), and cooling or quenching can be efficiently performed.

Owner:MAZDA MOTOR CORP

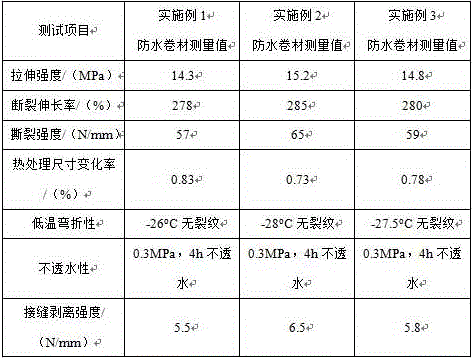

Environment-friendly PVC (Polyvinyl Chloride) waterproof roll and preparation method thereof

The invention provides an environment-friendly PVC (Polyvinyl Chloride) waterproof roll. The waterproof roll is prepared from the following raw materials: PVC resin, a plasticizer, a heat stabilizer, epoxy soybean oil, fillers, an antioxidant and a light stabilizer. The content of the raw materials of the waterproof roll are as follows in parts by mass: 98 to 102 parts of the PVC resin, 45 to 55 parts of the plasticizer, 2 to 2.5 parts of the heat stabilizer, 5 to 6 parts of t he epoxy soybean oil, 20 to 30 parts of the fillers, 0.2 to 0.6 part of the antioxidant and 0.2 to 0.6 part of the light stabilizer. The waterproof roll provided by the invention has no lead and is environmentally friendly; no lead flows out in construction and application processes; the waterproof roll has high mechanical strength and good weather resistance and stability.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

Intelligent automatic air sampling device used for occupational health

InactiveCN105203713AWon't flow outNot easy to mixTransmission systemsWithdrawing sample devicesElectricityGas compressor

The invention discloses an intelligent automatic air sampling device used for occupational health. The intelligent automatic air sampling device comprises a sampling device shell, wherein an air quality sensor is embedded on the surface of the sampling device shell; the sampling device shell is internally provided with a main pipe and a secondary pipe; one end of the main pipe is communicated with an air inlet pipe at the outer part of the sampling device shell; the other end of the main pipe is connected with one end of the secondary pipe; a gas analyzer is mounted at the connection part of the main pipe and the secondary pipe; the secondary pipe is provided with a gas compressor and the other end of the secondary pipe is connected with a flow distribution pipe; a plurality of sampling tanks are mounted at a flow distribution hole of the flow distribution pipe; solenoid valves are mounted at the connection parts of the flow distribution hole of the flow distribution pipe and the sampling tanks; a wireless communication device is further mounted in the sampling device shell; a controller is mounted on the side face of the wireless communication device; the controller is electrically connected with the air quality sensor, an exhaust fan, the gas analyzer, the gas compressor, the solenoid valves and the wireless communication device; and the wireless communication device is wirelessly and electrically connected with a remote control terminal.

Owner:张雪梅

Device and method for applying a preparation to threads

InactiveCN1969069AWill not polluteUniform atomizationTextile treatment containersFilament/thread formingEngineeringBiomedical engineering

Owner:天科部件有限公司

Novel fuel tank for automobile

The invention provides a novel fuel tank for an automobile. The fuel tank comprises a tank body, a fuel filler, a fuel return pipe, a fuel supply pipe, a fuel pump, a gasoline steam output pipe and a fuel level sensor, wherein the tank body comprises an inner layer and an outer layer, the fuel pump is mounted at the lower part in the tank body and connected with the fuel supply pipe, the fuel level sensor is mounted at the top in the tank body, the fuel return pipe is mounted on the left side of the fuel supply pipe, the gasoline steam output pipe is mounted on the left side of the fuel return pipe, a check valve is mounted in the gasoline steam output pipe, the fuel filler is mounted on the right side of the fuel supply pipe, a fuel tank cover is mounted at the top of the fuel filler, and the fuel filler is mounted at the top of the tank body. The fuel tank has the benefits as follows: a vacuum interlayer is arranged between the outer layer and the inner layer, has insulation and heat isolation functions, can prevent fuel from freezing and can play roles in preventing burning of the fuel tank and explosives due to fuel temperature rise; the fuel tank is simple in structure, convenient to use, higher in safety, convenient to mount and capable of reducing environmental pollution.

Owner:CHONGQING ZHONGKE SCI & TECH

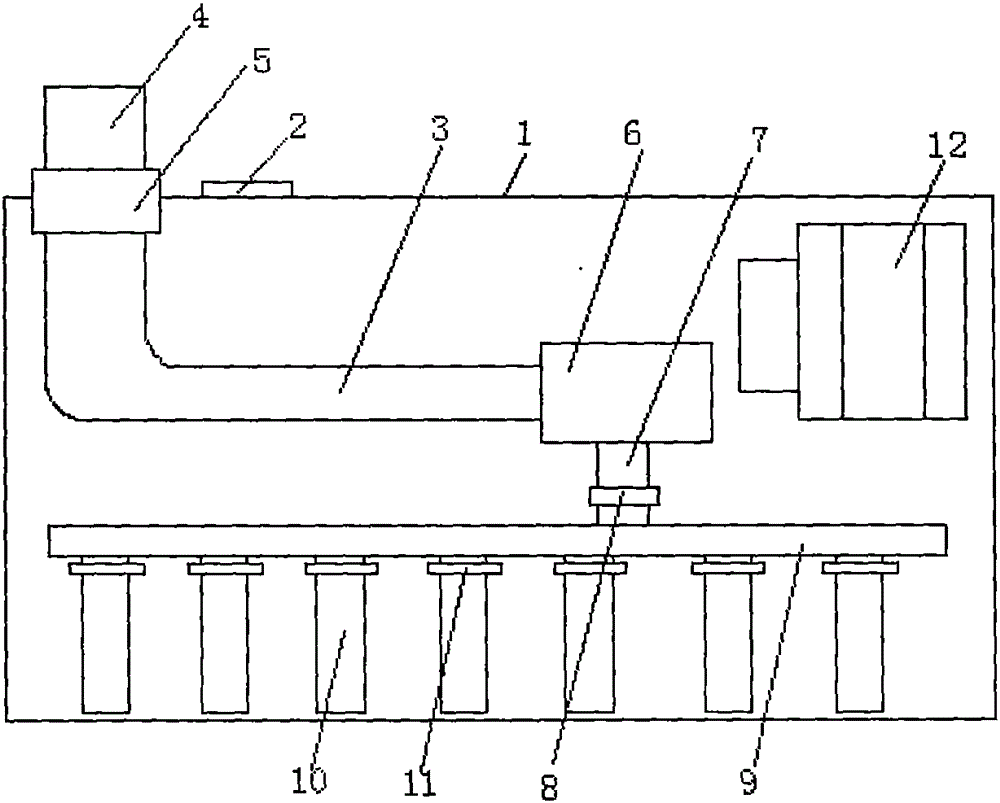

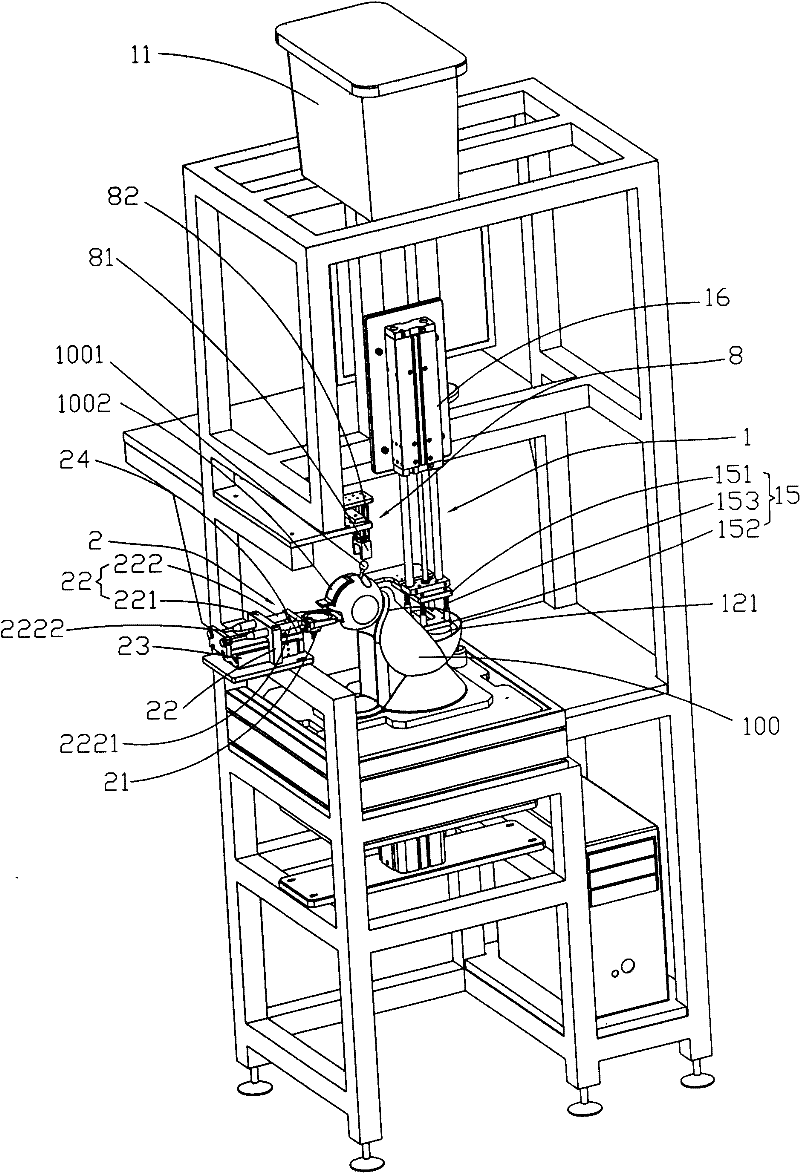

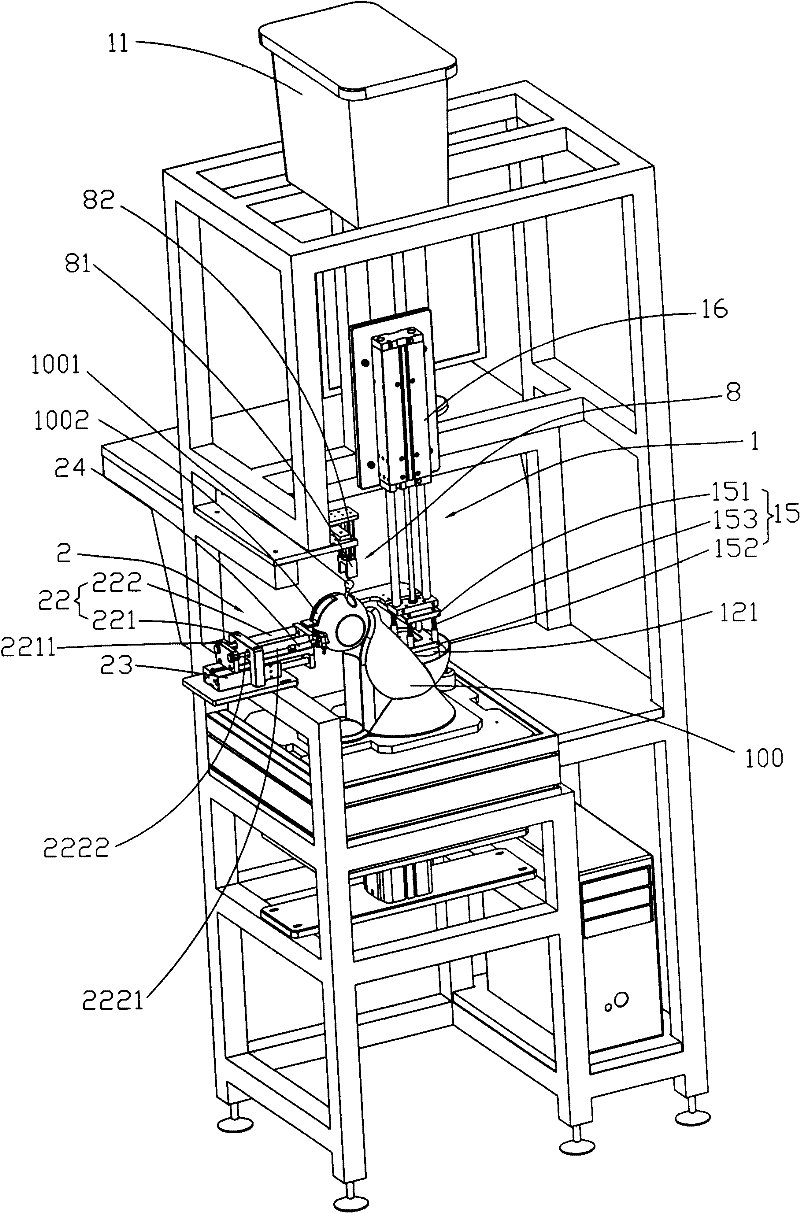

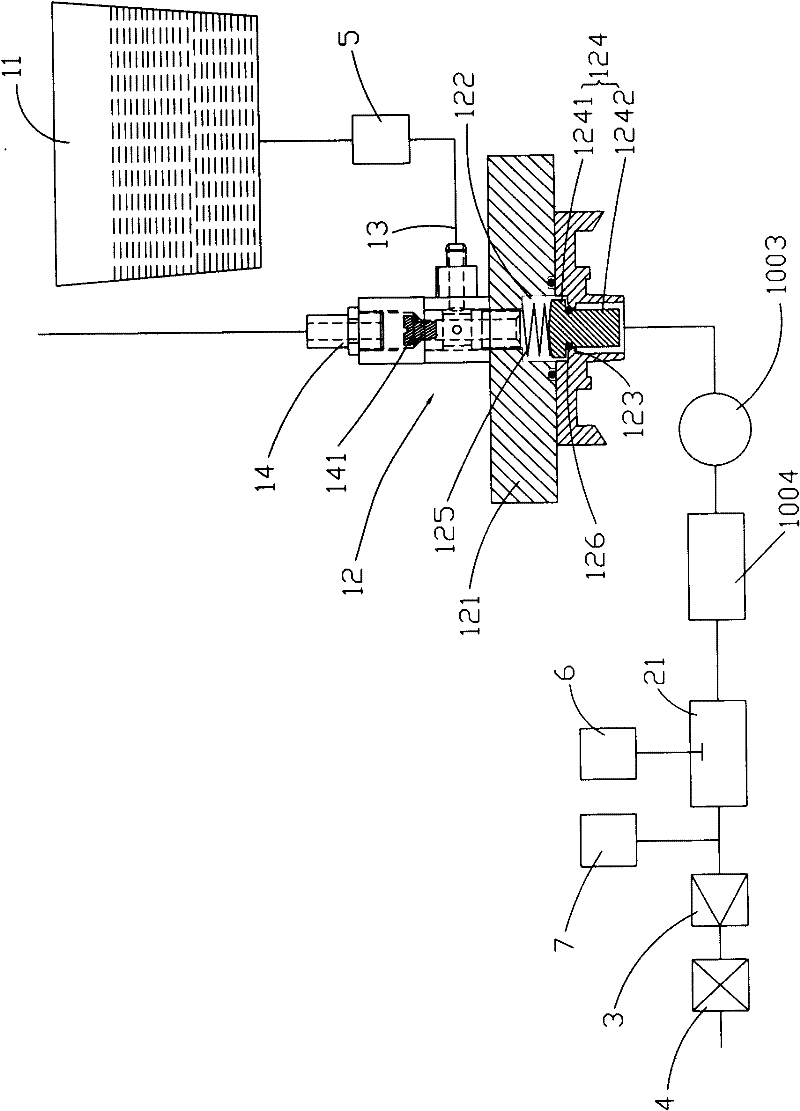

Automatic functional test device of coffee maker

ActiveCN102680026AWon't flow outImprove automated testing efficiencyVolume/mass flow measurementFluid pressure measurementTest efficiencyControl system

The invention relates to an automatic functional test device of a coffee maker. The automatic functional test device comprises a water supply mechanism, a coffee bag prosthesis supply mechanism, a needle valve, a water outlet valve, a flow meter, a temperature sensor, a pressure sensor and a control system. The water supply mechanism is used for filling water into the coffee maker to be tested and comprises a water tank and a port connected with the water tank. The coffee bag prosthesis supply mechanism is used for placing a coffee bag prosthesis into the coffee maker to be tested. On a test water path of the coffee maker to be tested, the needle valve is located on the downstream of the coffee bag prosthesis, the water outlet valve is located on the downstream of the needle valve, the flow meter is located on the upstream of the coffee maker to be tested and arranged between the water tank and the port, the temperature sensor is located on the coffee bag prosthesis, and the pressure sensor is located between the coffee bag prosthesis and the needle valve. The control system controls the water supply mechanism and the coffee bag prosthesis supply mechanism to act, receives signals emitted by the flow meter, the temperature sensor and the pressure sensor and outputs the signals after processing the signals. The test device is high in test efficiency, low in labor intensity and capable of ensuring the quality of products which are massively produced.

Owner:SHENZHEN YUCHEN AUTOMATION EQUIP CO LTD

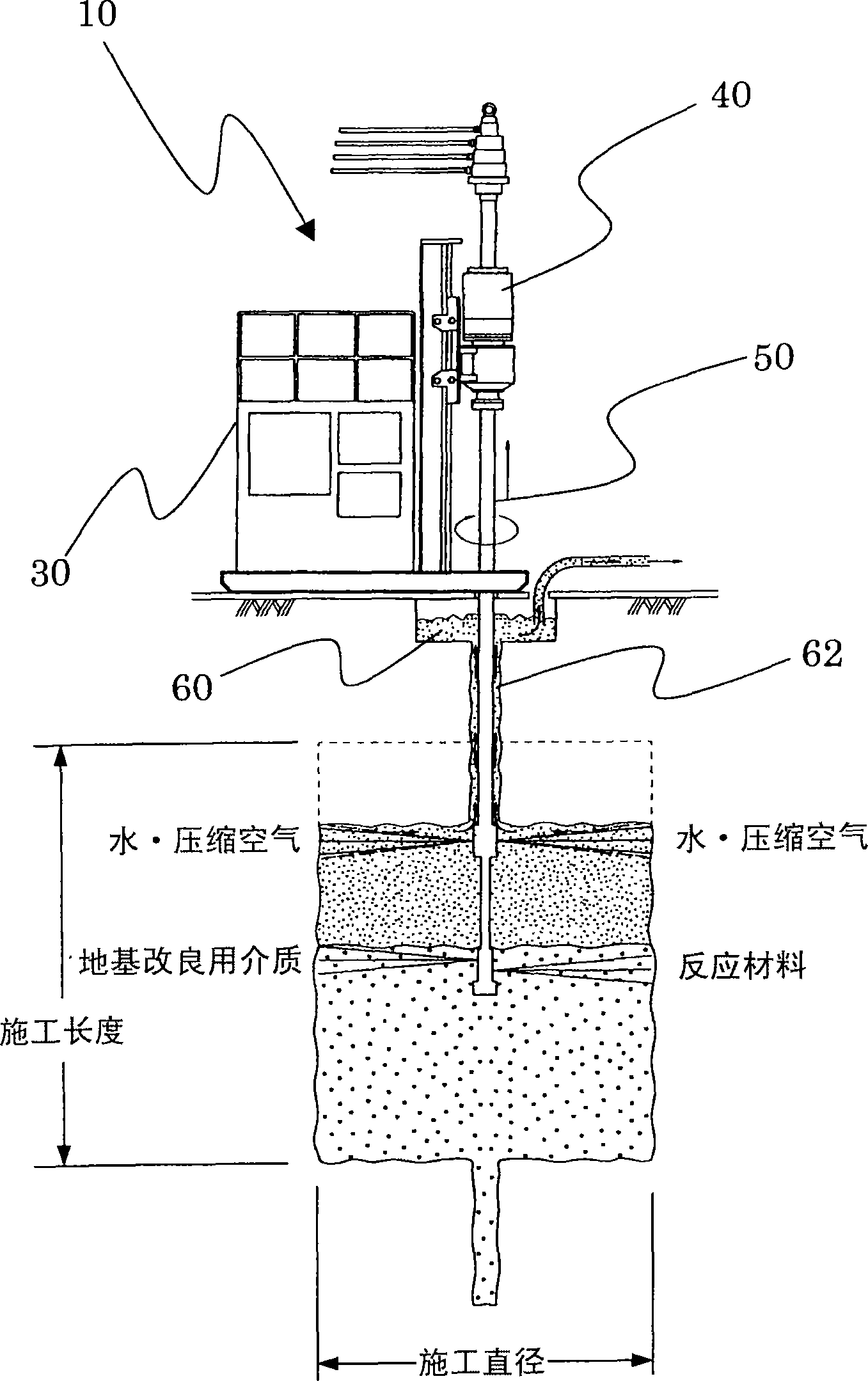

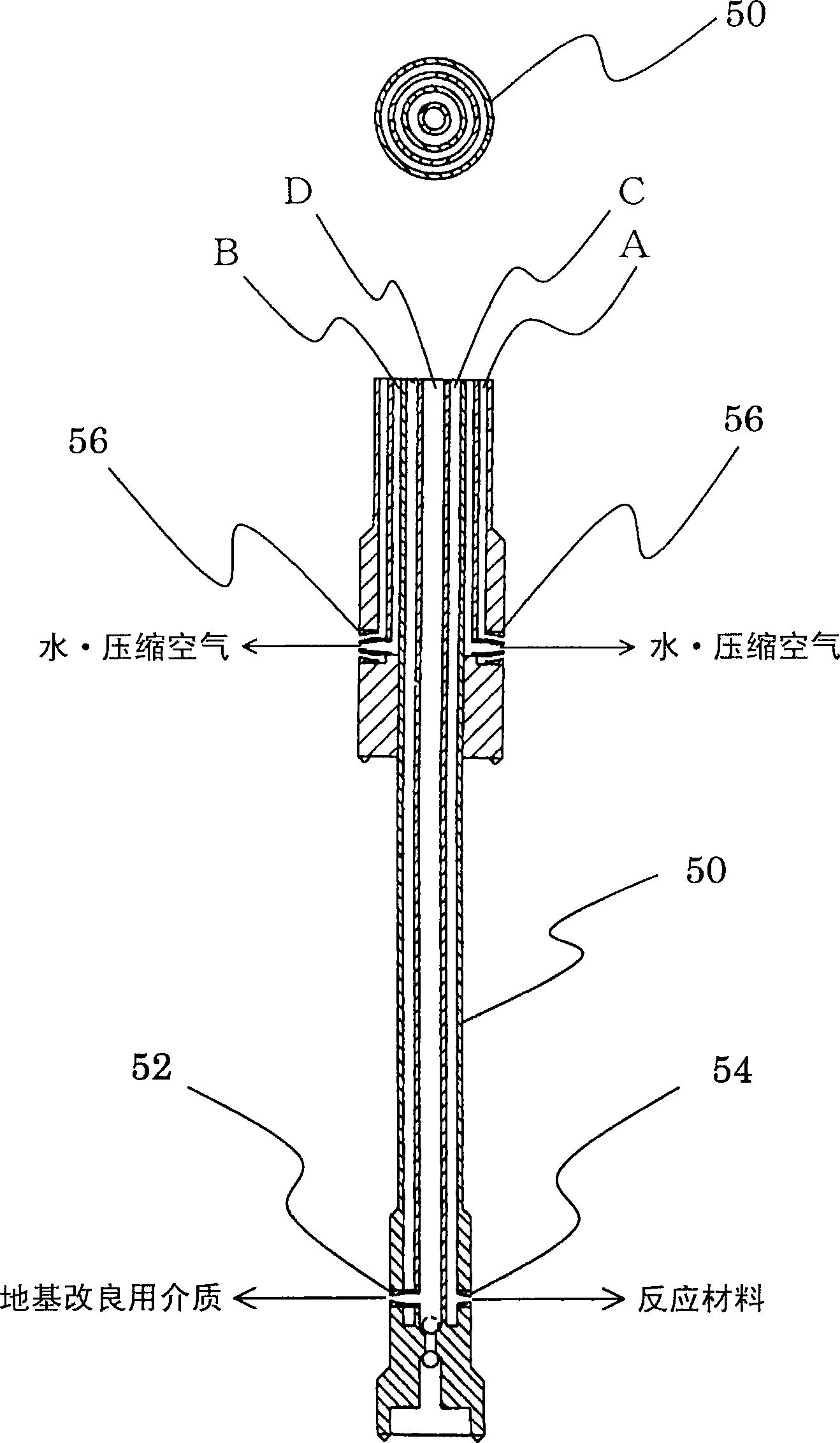

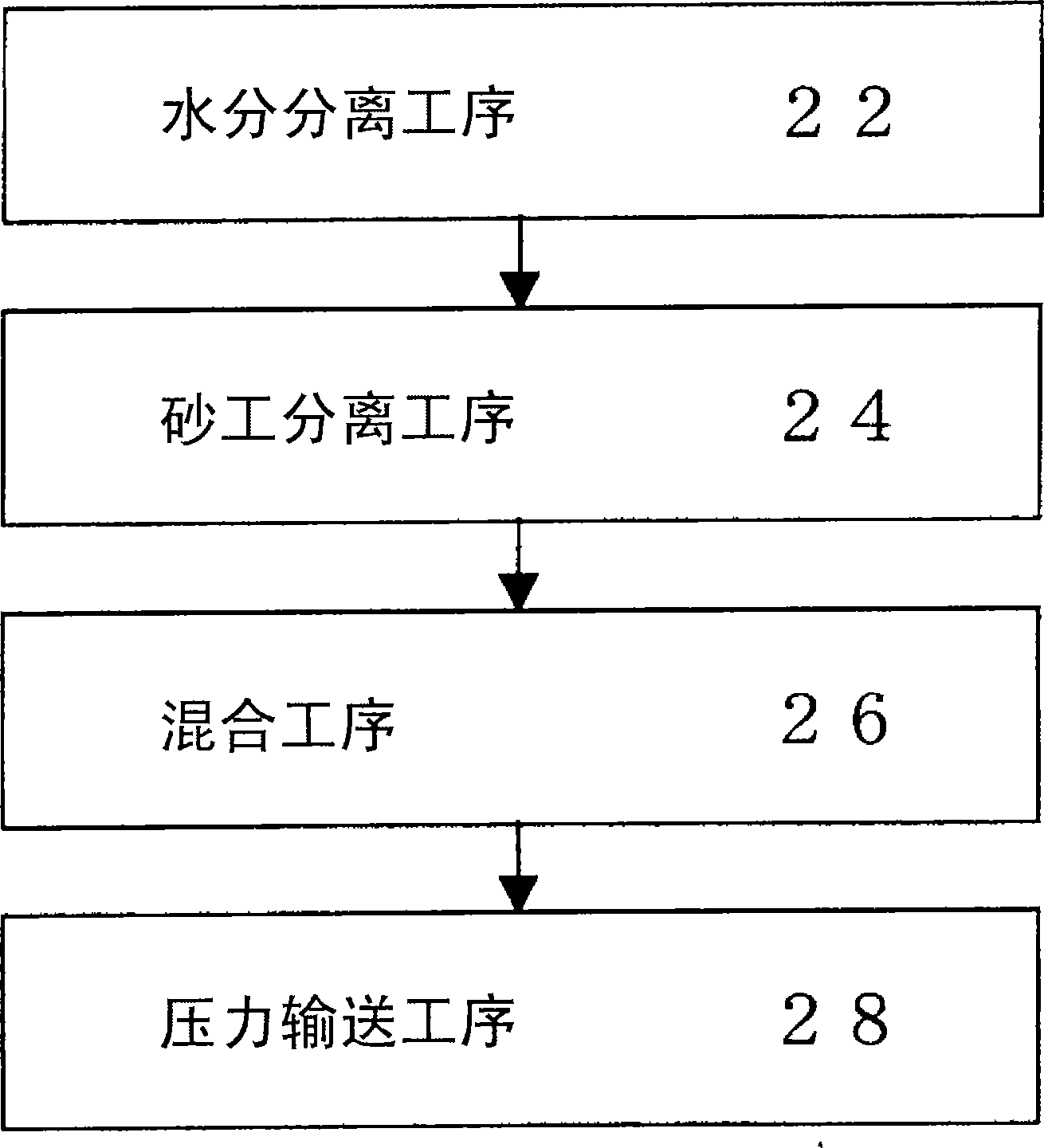

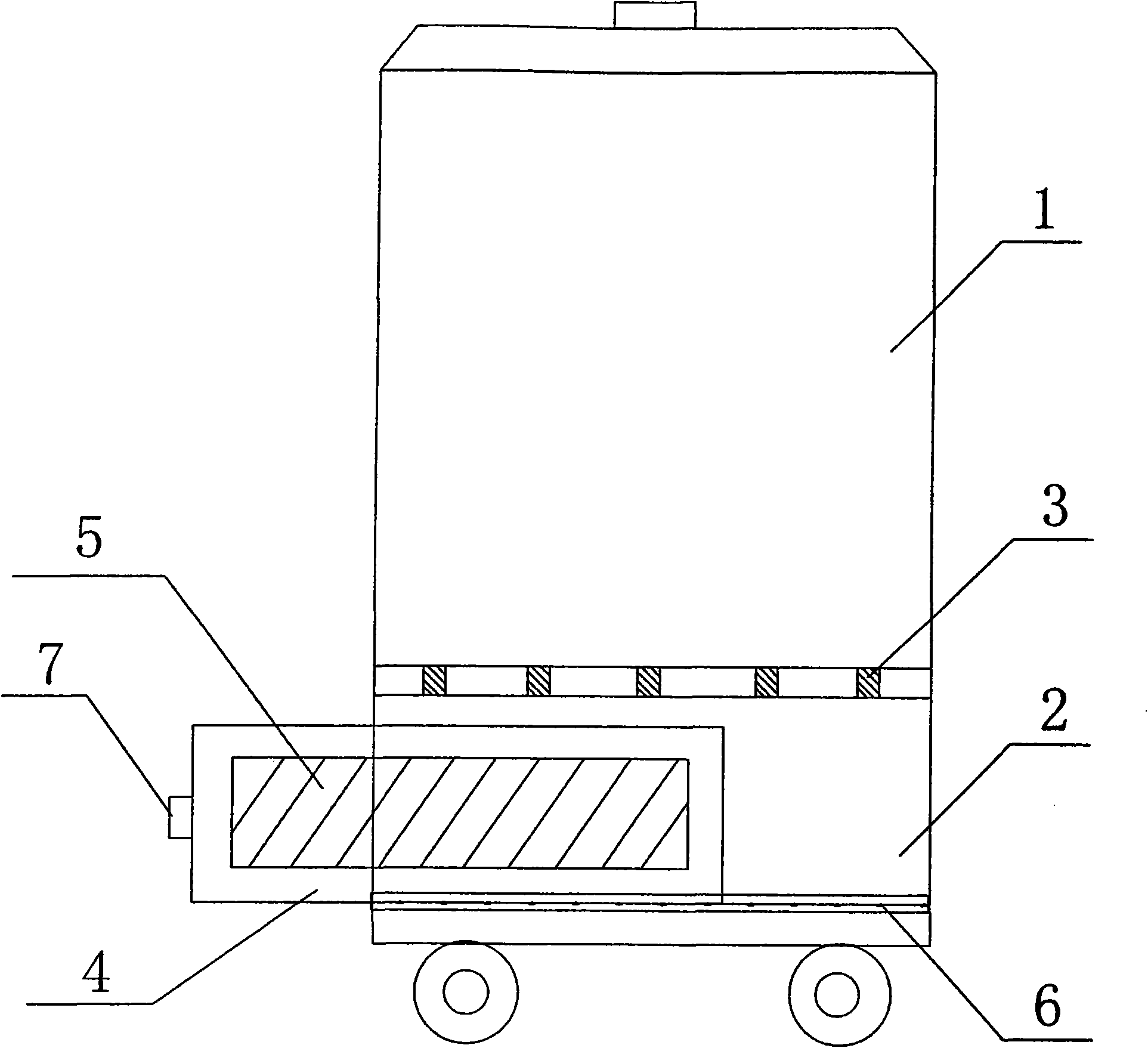

Jetting and agitating construction method and jetting and agitating device

The invention provides a jetting and agitating construction method and a jetting and agitating device for a pile formed by reusing, as a construction material, a sludge mixed with a medium for improving a ground such as a hardener after excluding solid matters with large grain sizes without treating the sludge as an industrial waste or a general surplus soil. In this jetting and agitating construction method, a compressed air and a water are jetted from a third jetting part while rotating and pulling up a multi-tube rod with a plurality of jetting parts from the ground to cut the improved area of the ground in a cylindrical shape by jetting, the cut sludge is discharged to the surface of the ground through an excavated hole, the medium for improving the ground is jetted from the nozzle of the first jetting part, and a reaction material solidifying the medium for improving the ground is jetted from the nozzle of the second jetting part to construct the pile with a specified diameter. The solid matters with the specified grain size or larger are separably removed from the sludge discharged to the surface of the ground, mixed with the medium for improving the ground to form a mixed medium, force-fed by a force-feed pump, and jetted from the first jetting part.

Owner:DAIEI SANGYO

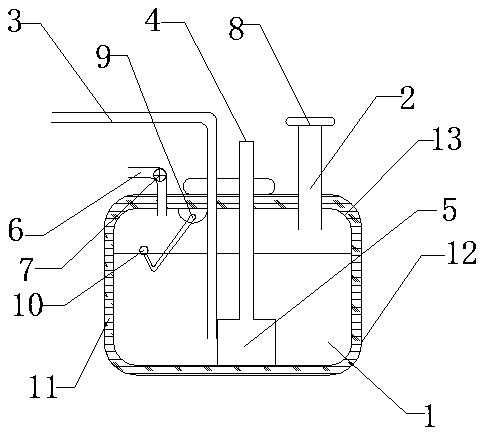

Novel environment-friendly garbage bin with sewage collecting box

The invention relates to a novel environment-friendly garbage bin with a sewage collecting box, which comprises a bin body, and is characterized in that the bin body is divided into an upper part and a lower part, the upper part is a garbage storing bin (1), and the lower part is the sewage collecting box (2); the bottom of the garbage storing bin is provided with a plurality of pores (3), so that sewage in the garbage storing bin (1) can flow into the sewage collecting box (2) through the pores (3); a storage case (4) is arranged in the sewage collecting box (2); and the storage case (4) is withdrawn from an opening of the sewage collecting box (2), and a sewage absorption bag (5) which is filled with powdery or fine granular absorbing substances is arranged in the storage case (4). The garbage can collect the sewage in the garbage bin, so that the sewage cannot flow out of the garbage bin; the garbage bin not only can protect the environment, but also is convenient to clean; and the garbage bin has the advantages of simple structure, convenient modification, and easy implementation and popularization.

Owner:陆洪兴

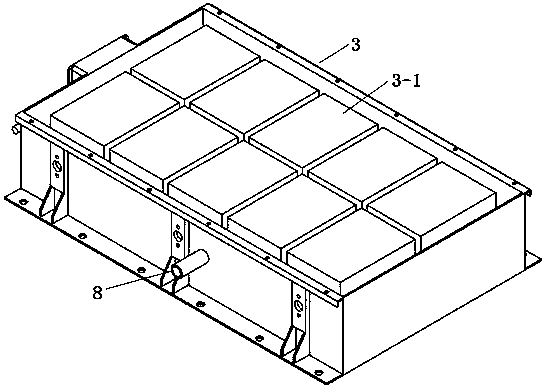

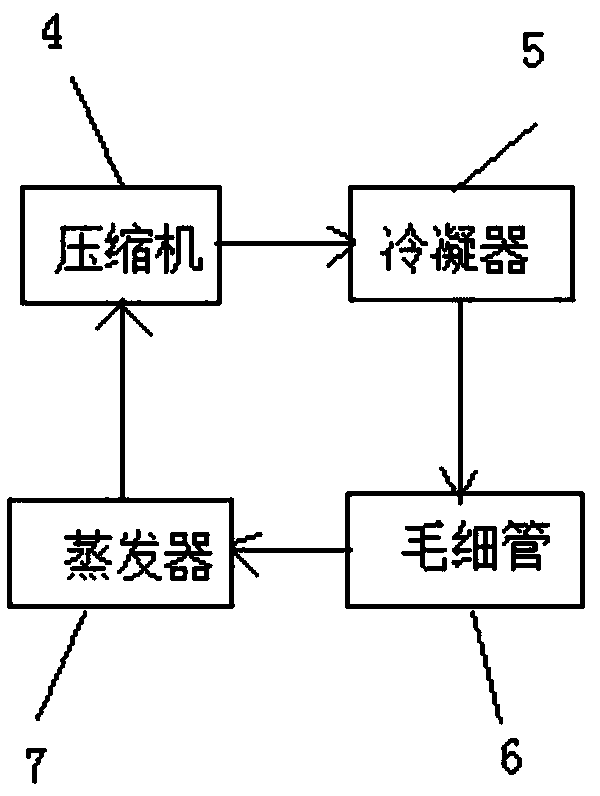

Refrigerating equipment with universal application function and control method thereof

InactiveCN109253570AWon't flow outNot prone to corruptionLighting and heating apparatusDomestic refrigeratorsProcess engineeringRefrigeration

The invention discloses refrigerating equipment with a universal application function and a control method thereof. A refrigeration circulating system is arranged in the refrigerating equipment. The refrigerating equipment comprises a temperature varying chamber. The temperature varying chamber is provided with an independent air door. A temperature sensor for detecting the real-time temperature in the temperature varying chamber is arranged in the temperature varying chamber. A control device is further arranged on the refrigerating equipment, the temperature of the temperature varying chamber is controlled by controlling the rotating speed of a compressor and opening and closing of the air door through the control device, and after food is put in the temperature varying chamber, the temperature varying chamber sequentially suffers from a first cooling stage, a second cooling stage, a third cooling stage and a fourth cooling stage, wherein the average cooling speed of the first cooling stage is higher than that of the second cooling stage, and the average cooling speed of the third cooling stage is higher than that of the second cooling stage. Compared with the prior art, the refrigerating equipment and the control method thereof have the advantages that the function that the food is easy to cut after being frozen is achieved, and the quality of the frozen food can be guaranteed.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

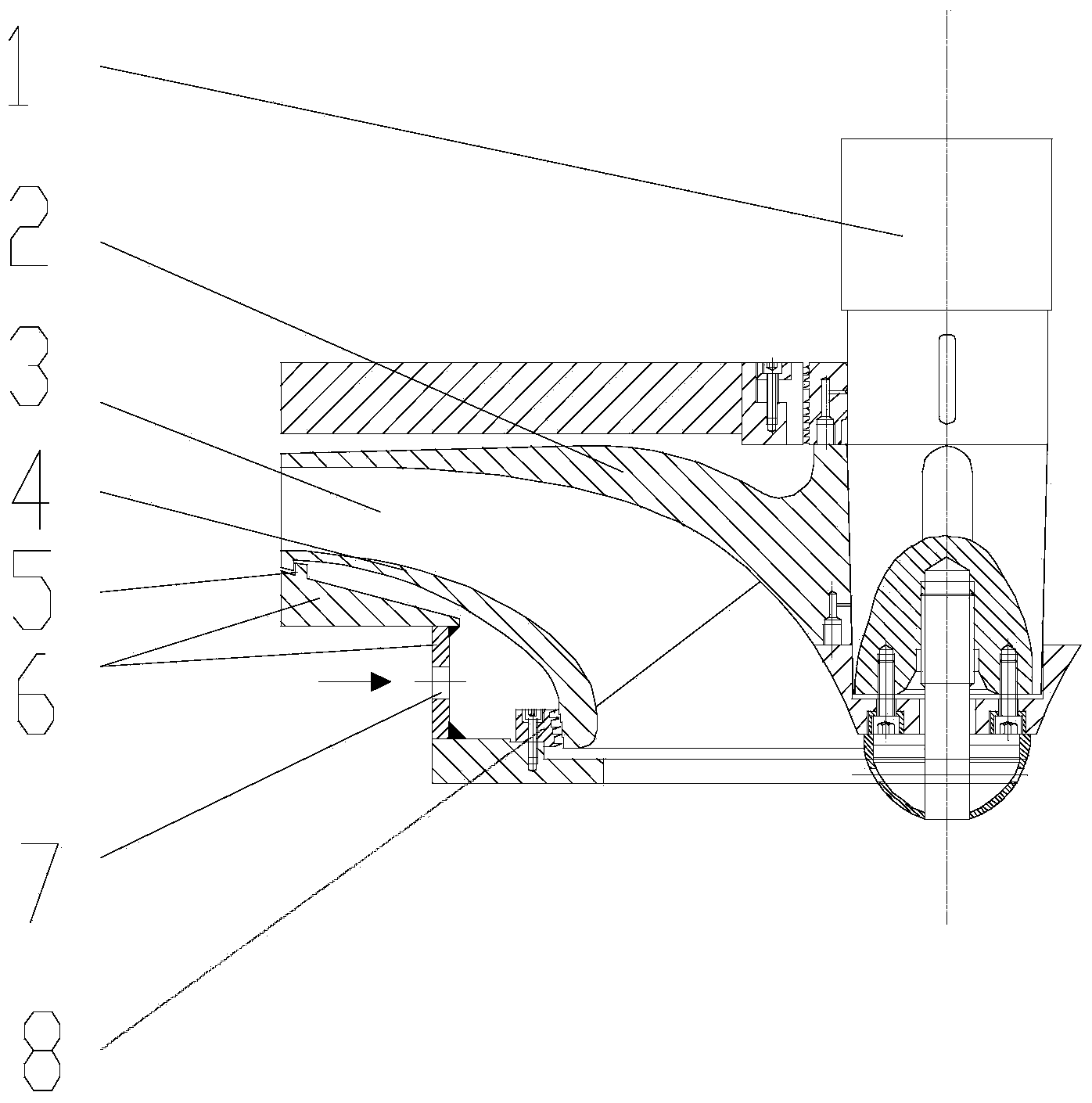

Axial force balancing structure of centrifugal closed impeller

ActiveCN104343747ANo effect on efficiencyShorten shaft lengthPump componentsPumpsImpellerEngineering

An axial force balancing structure of a centrifugal closed impeller comprises a sealing ring which is arranged between an impeller cover and a housing and near the outlet of the centrifugal closed impeller, an impeller inlet seal arranged near the inlet of the centrifugal closed impeller, and a housing inlet formed in the housing, wherein the impeller cover, the housing, the sealing ring and the impeller inlet seal form a cavity; a high pressure medium is introduced into the cavity from the outside through the housing inlet; the pressure of the high pressure medium is higher than the medium pressure at the outlet of the centrifugal closed impeller. The axial force balancing structure can balance an existing axial force from an impeller disc to the impeller cover of the centrifugal closed impeller; the axial force balancing structure does not affect flowing of the medium inside the centrifugal closed impeller, so that the efficiency of an impeller is not affected; the axial force balancing structure does not increase the axial length; the high pressure medium can be from the medium at an outlet of a pressure expander behind the centrifugal closed impeller, so that a risk of medium leakage is avoided; the axial force balancing structure is simple in structure and easy to implement.

Owner:TSINGHUA UNIV

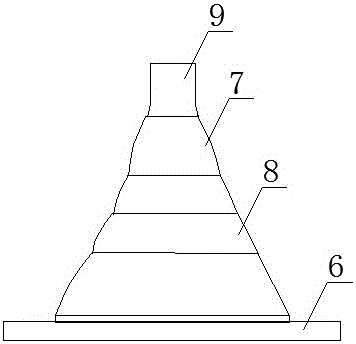

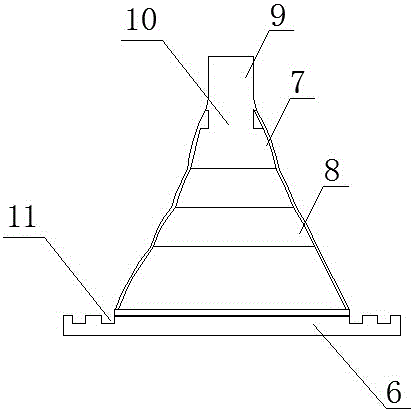

Collection device for fecal incontinence

ActiveCN105749364AWon't flow outFit tightlyMedical devicesIntravenous devicesFecal incontinenceEngineering

The invention provides a collection device for fecal incontinence. The device comprises a drainage tube, wherein an air bag is arranged on the periphery of the front end of the drainage tube, and a full-filling pipeline communicated with the air bag is arranged on the wall of the drainage tube; an in-vitro drainage bag is connected to the tail end of the drainage tube; an air injection connector communicated with the full-filling pipeline is formed in the tail end of the drainage tube; a silica gel anus plug made of a silica gel material sleeves the outer side of the drainage tube, and comprises a base, a nipple, an areola and a seal cartridge; the areola is arranged on the base, the nipple is positioned at the upper part of the areola, a through hole is formed at the center of the nipple, and the seal cartridge is arranged at the upper part of the nipple; and the drainage tube runs through the through hole and the seal cartridge, and the outer wall of the drainage tube is closely attached to the seal cartridge. According to the collection device, the problem that defecation flows out along the drainage tube can be solved.

Owner:浙江康德药业集团股份有限公司

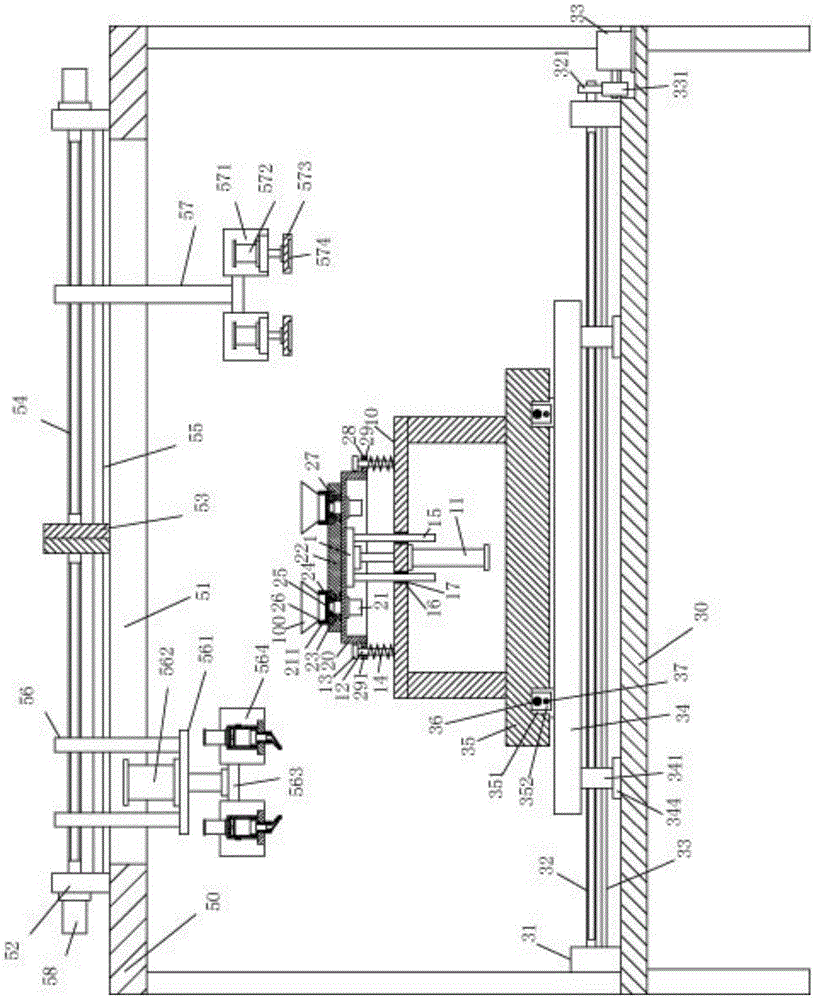

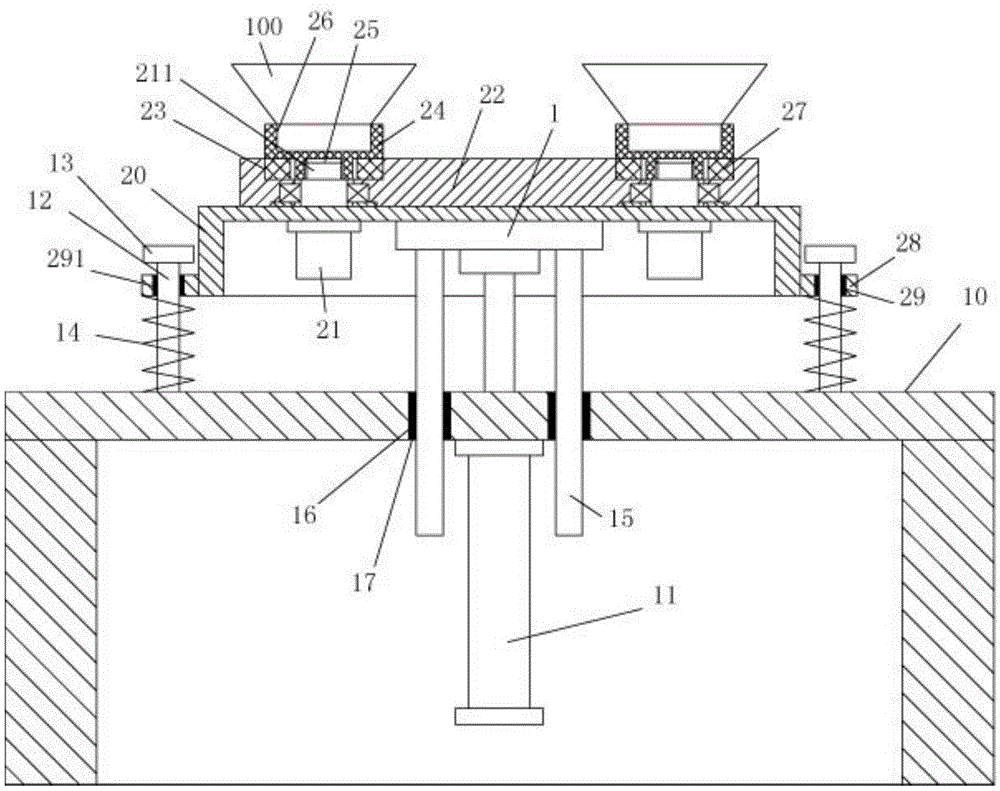

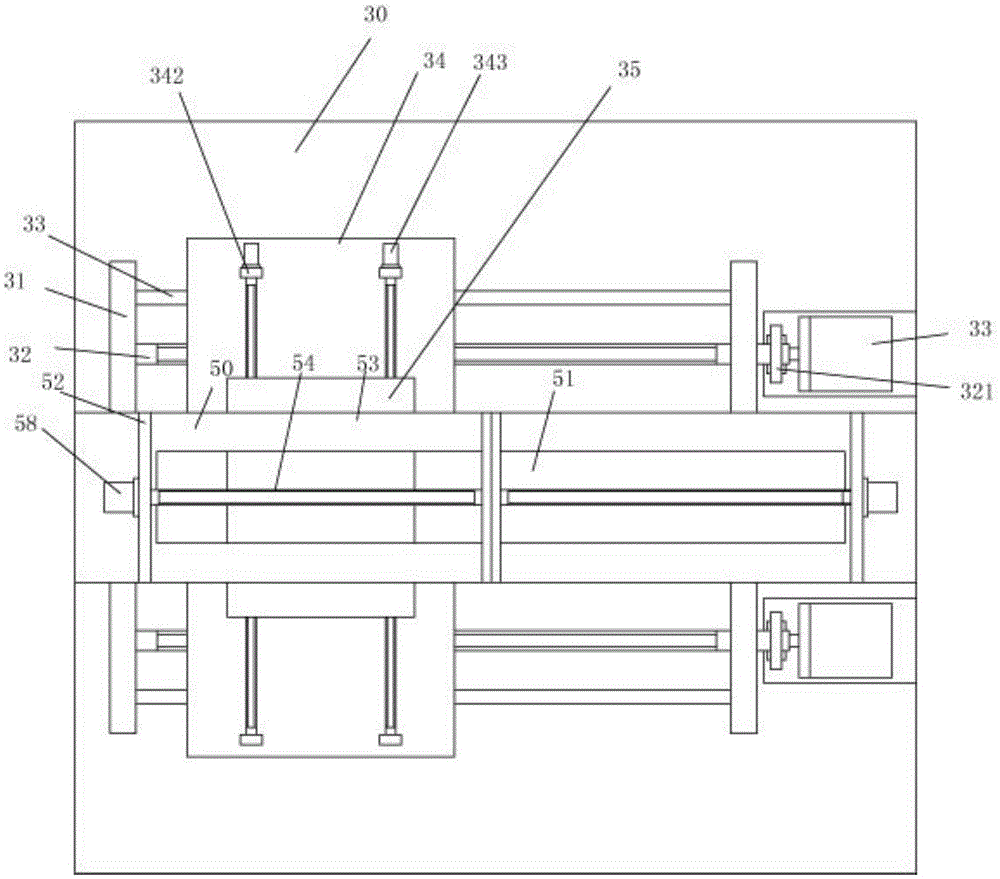

Frame gluing and tabletting device applied to assembly of speaker

The invention discloses a frame gluing and tabletting device applied to the assembly of a speaker. The frame gluing and tabletting device comprises a movable body frame, a main rack and a gluing support, wherein the gluing support is fixed on the main rack, and a gluing mechanism and a compression cylinder are arranged on the gluing support; a transverse movable support plate is fixed on each of left and right sides of the top surface of the main rack, and two ends of a plurality of transmission screws and guide rods are hinged to the two corresponding transverse movable support plates. According to the frame gluing and tabletting device, the frame placed into a frame holder can be automatically rotated, lifted and moved, and thereby gluing is automatically performed and elastic sheets are automatically placed and compressed, and manual operation is not needed in each process, thus being very convenient; and meanwhile, the positions of the gluing mechanism and the compression cylinder can be automatically adjusted according to requirements, the adjustment effect is good, and glue can be uniformly extruded out by the gluing mechanism from the discharge head to drip to the frame according to the requirements, and the discharge head can be automatically sealed to prevent the glue from flowing out when not in use, thus being very convenient.

Owner:SHAOXING UNIVERSITY

Residual water drainage and water suction non-return mechanism

ActiveCN102366739AAvoid enteringPrevent outflowSpray nozzlesLiquid spraying apparatusWater sourceWater flow

The invention discloses a residual water drainage and water suction non-return mechanism, which comprises a fixed part and a water drainage and air suction assembly, wherein the fixed part comprises an upper part provided with a through hole, a lower part provided with a water outlet hole and a water drainage and air suction hole, and an assembly cavity; the water drainage and air suction assembly comprises a body, a ring part formed by extending outwardly from the upper circumference of the body, and a jacking spring; the outer circumference of the ring part and the inner wall of the assembly cavity are sealed; the ring part is provided with small holes; and the body can be covered and connected to the water drainage and air suction hole, and is provided with a cut-through ventilation hole. When a water source is switched on, running water impacts the body through the through hole, the body slides downwardly till the body hermetically leans on the lower part and is hermetically covered and connected outside the water drainage and air suction hole, running water flows inwards from the small holes on the ring part for generating strong negative pressure, air is sucked inwards alongthe water drainage and air suction hole and the ventilation hole under the action of the negative pressure, and the air is fully mixed with the running water in the assembly cavity, so that bubble water is formed; and when the water source is switched off, the body slides upwards under the action of the jacking spring, and the body moving upwards is prevented from returning, so that residual water in a sprinkler is prevented from increasing, and is quickly drained along the space between the body and the lower part as well as the water drainage and air suction hole.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Filling robot suitable for liquid filling production lines

InactiveCN107311097AAvoid pollutionAvoid corrosionSafety device in filling machineryProduction lineReciprocating motion

The invention discloses a filling robot suitable for liquid filling production lines. The robot is erected at two sides of a conveying belt for conveying filling bottles and comprises a filling device and a positioning and leakage catching device, wherein the filling device is driven by a motor to do reciprocating motion in the vertical direction to carry out filling; the positioning and leakage catching device is driven by a motor do the reciprocating motion in the horizontal direction to carry out pabam positioning and leakage catching; and a pabam positioning mechanism and a leakage catching mechanism are linked. The filling bottles are sequentially cycled under the driving of a motor to reach a working position on the conveying belt; the filling device is driven through gas pressure; and the filled liquid quantifying is realized through the balance between the gas pressure and the hydraulic pressure. The filling robot disclosed by the invention has the advantages that the pabam positioning, the automatic filling and the automatic quantifying which are carried out on the filling bottles and the leakage catching after the filling is completed in the filling production can be automatically completed and the manual intervention is not needed, so that the production efficiency is increased by a large margin; and the problems that the conveying belt is polluted by the leaked liquid and multiple filling amounts are not uniform are solved.

Owner:LIUZHOU FUNENG ROBOT DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com