Frame gluing and tabletting device applied to assembly of speaker

A tablet pressing device and gluing technology, applied in the direction of electrical components, sensors, etc., can solve the problems of manual handling, troublesome, low efficiency, etc., and achieve good adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

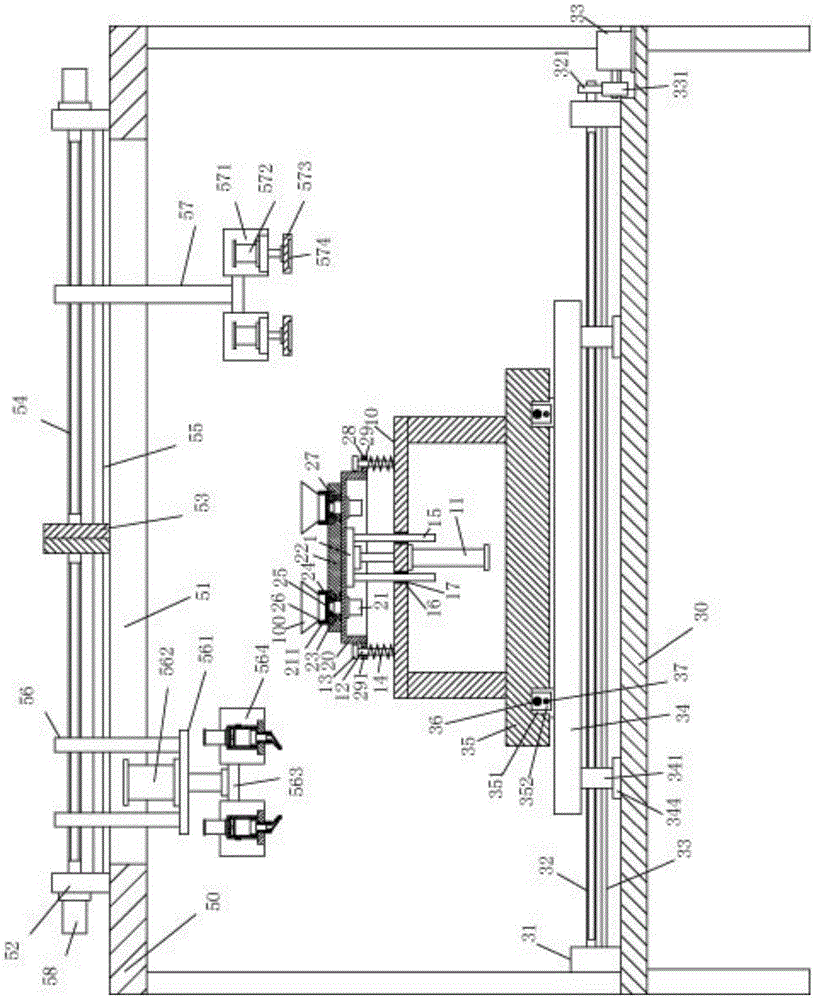

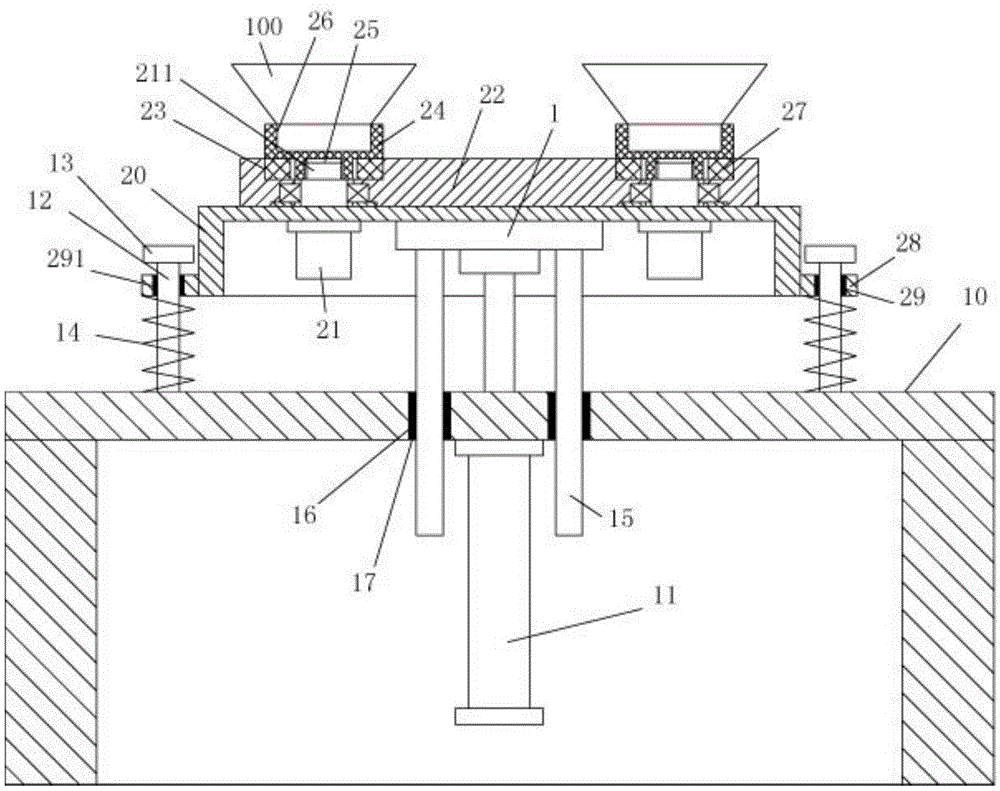

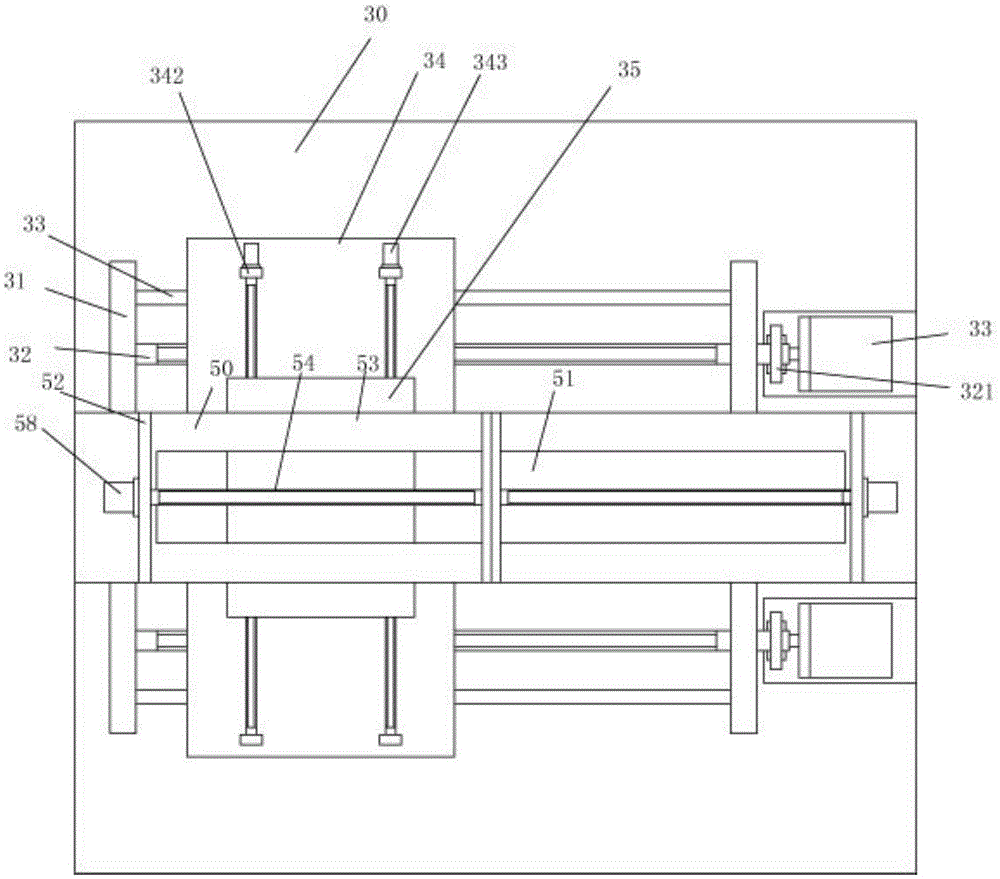

[0028] Examples, see e.g. Figure 1 to Figure 5 As shown, a pot frame gluing and sheeting device for speaker assembly includes a mobile main frame 10, a main frame 30 and a gluing support frame 50, the gluing support frame 50 is fixed on the main frame 30, and the gluing The support frame 50 is provided with a gluing mechanism and a pressing cylinder 572;

[0029] The left and right sides of the top surface of the main platform 30 are fixed with laterally movable support plates 31, and the two ends of a plurality of transmission screws 32 and guide rods 33 are hinged on the corresponding two laterally movable support plates 31, and one end of the transmission screw rods 32 Stretch out one of them lateral movement support plate 31 and be fixed with transmission gear 321, the left side of main platform 30 or the top surface of right side are fixed with lateral movement motor 33, and the output shaft of lateral movement motor 33 is fixed with drive gear 331, drives The gear 331 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com