Axial force balancing structure of centrifugal closed impeller

A technology of centrifugal closed type and impeller shaft, which is applied in non-variable pumps, parts of pumping devices for elastic fluids, machines/engines, etc., which can solve the problem of impeller inlet flow and limited use of balance discs , complex processing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

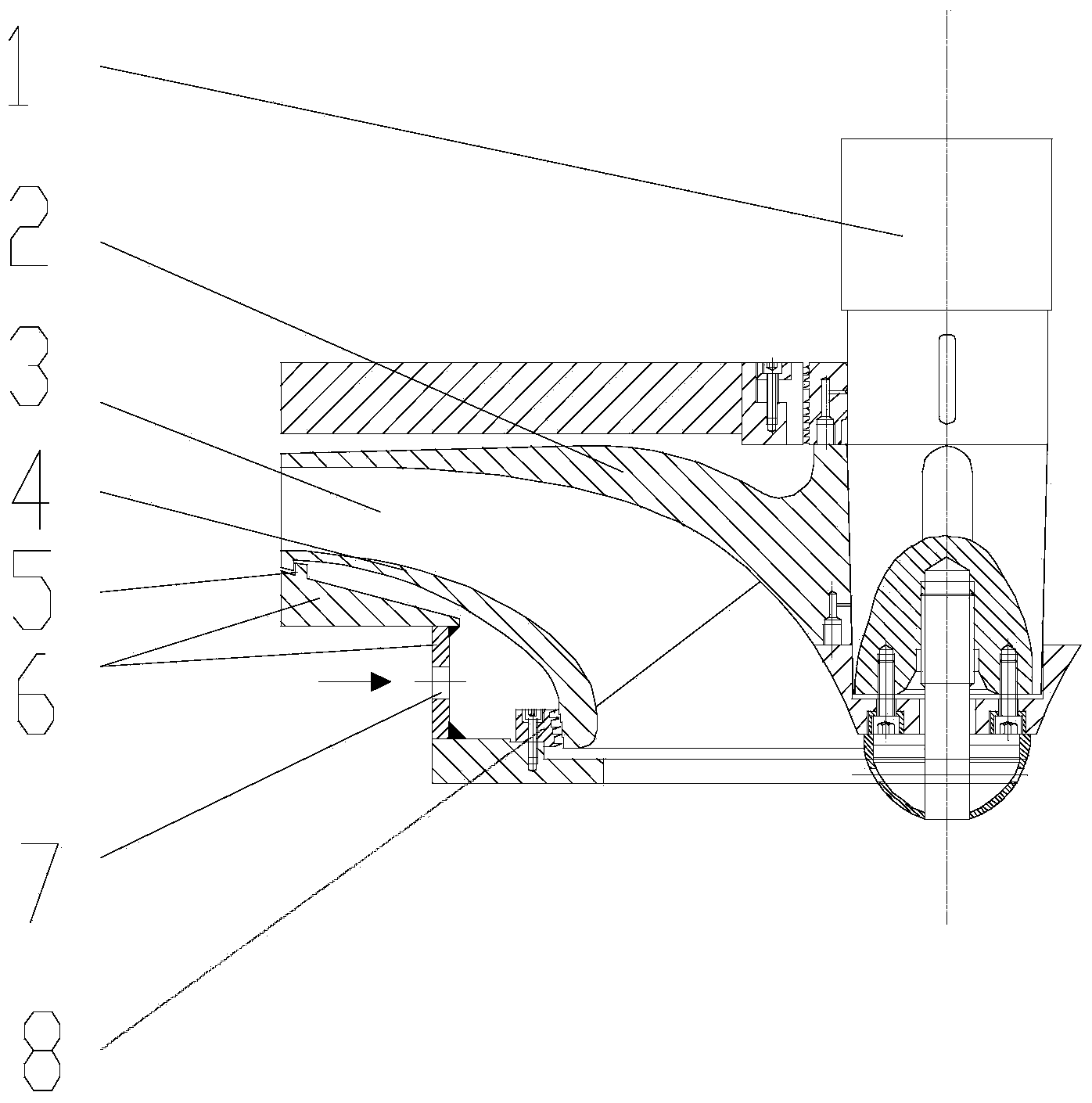

[0015] The axial force balance structure of the centrifugal closed impeller of the present invention is shown in the accompanying drawings. On the basis of the common centrifugal closed impeller structure, the following structure is added: between the impeller wheel cover 4 and the casing 6 near the outlet of the centrifugal closed impeller 3 Set the sealing ring 5, and set the casing inlet hole 7 on the casing 6 at the same time. The casing 6 is the casing part corresponding to the impeller wheel cover 4 here. The sealing ring 5 is arranged near the outlet of the centrifugal closed impeller 3, and the corresponding radius value is less than or equal to the outlet radius of the centrifugal closed impeller 3, so as to ensure that the external high-pressure medium introduced from the casing inlet hole 7 acts on the impeller cover 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com