Residual water drainage and water suction non-return mechanism

A technology of residual water and non-return, which is applied in the direction of spraying device, spraying device, liquid spraying device, etc., to achieve the effect of increasing sealing performance and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

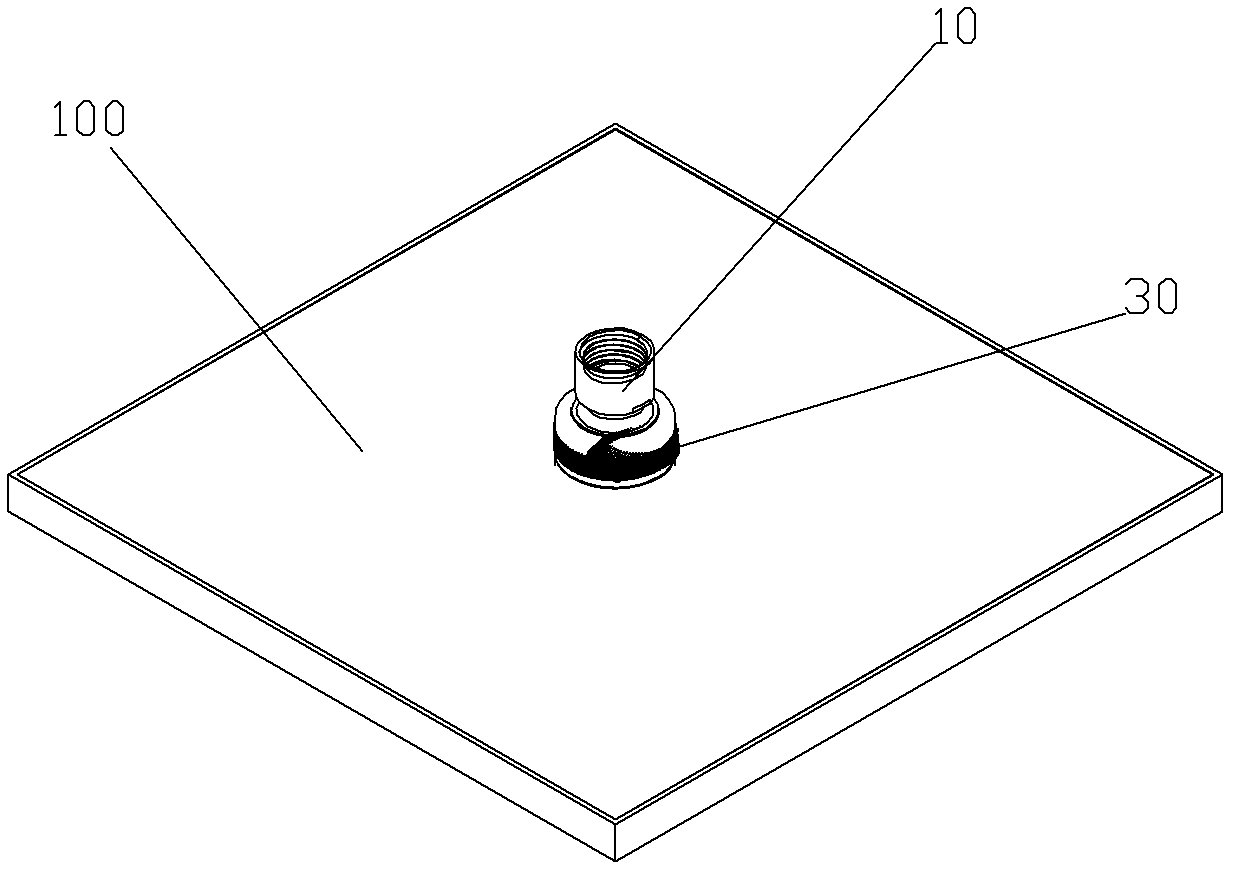

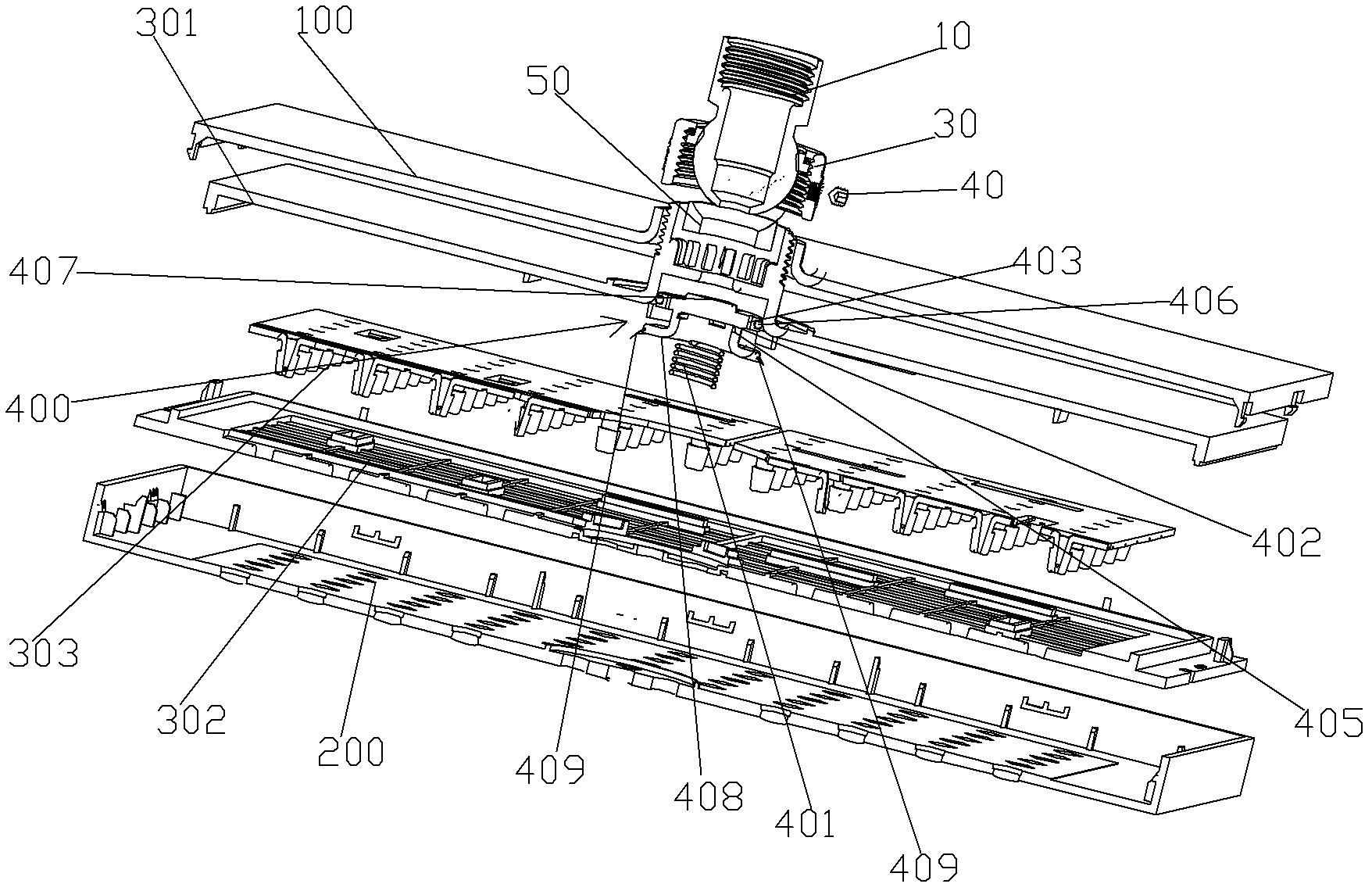

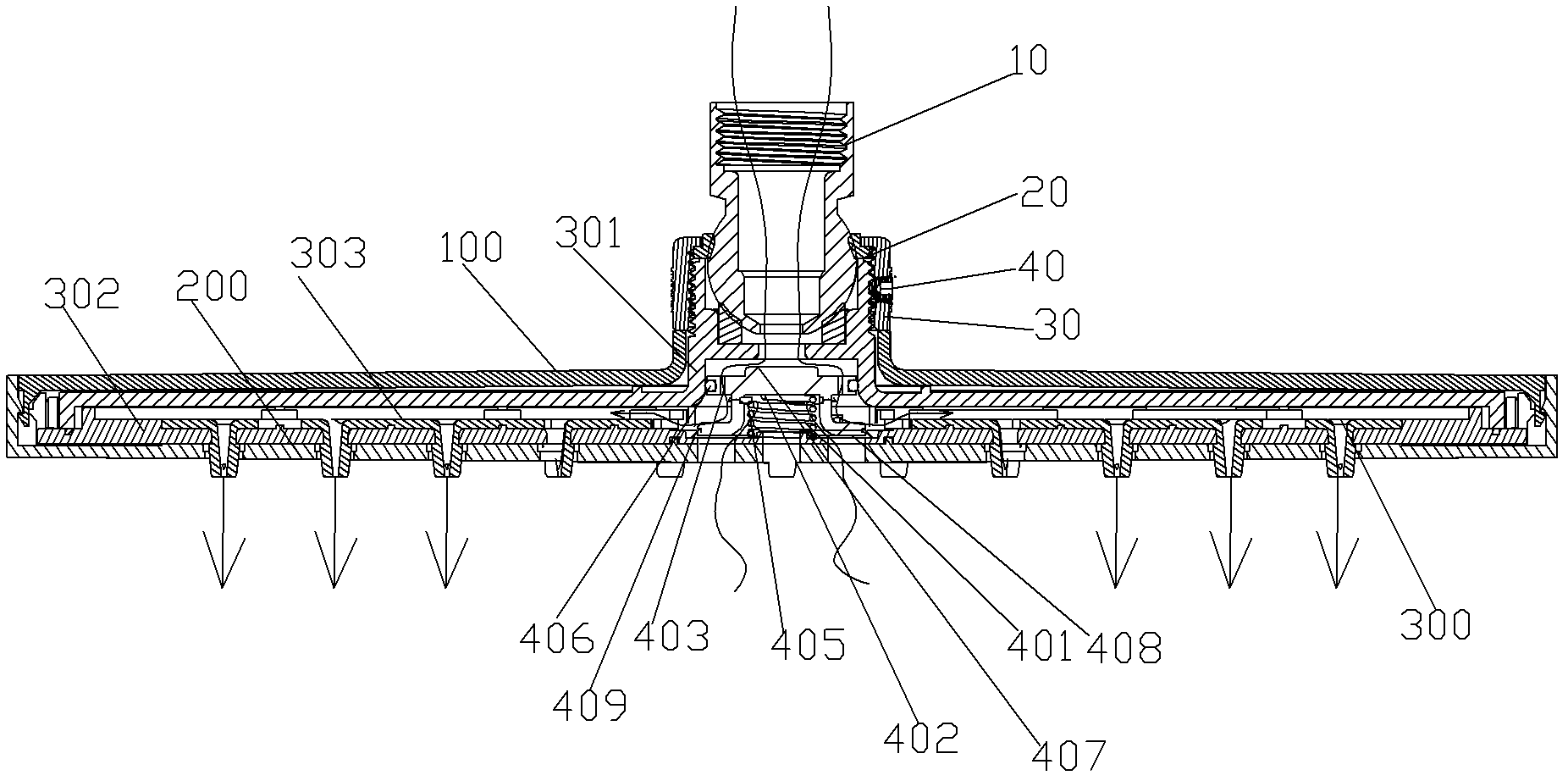

[0036] Please check Figure 1 to Figure 5 , The first embodiment of the residual water drainage and air suction check mechanism, which includes a fixed part and a drainage suction assembly 400.

[0037] The fixed part includes an upper part, a lower part and an assembly cavity. The upper part includes an upper cover 100 provided with a through hole and an upper water body 301 fixed under the upper cover 100. The center of the bottom surface of the upper water body 301 is recessed to form a cavity, and the top surface of the cavity is provided with a through hole , Connect the through hole. The lower part includes a lower cover 200 and a lower water body 302 fixedly connected to the lower cover 200, and the lower part is provided with water outlet holes and drainage suction holes 201. The upper part and the lower part are fixed together so that the cavity forms an assembly cavity, so that a gap is formed between the upper part and the lower part, that is, between the upper water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com