Device and method for applying a preparation to threads

A technology of filament and oil agent, which is applied in the direction of filament/thread forming, textile and papermaking, and textile material treatment, etc. It can solve the problem of oil mist escaping, oily yarn monofilament mixing, and inability to fully absorb oiling agent, etc. problems, to avoid pollution, save the effect of oiling agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

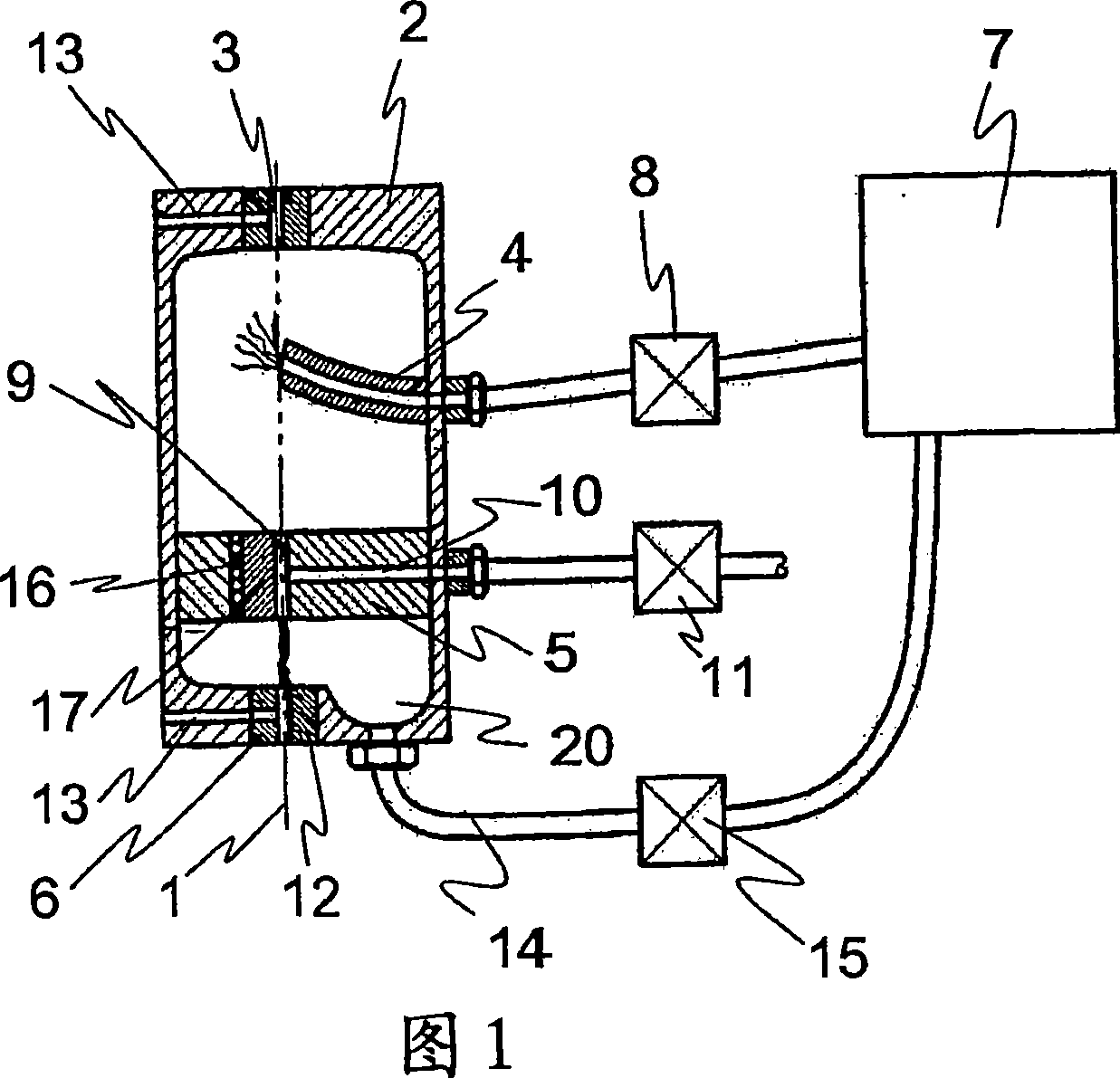

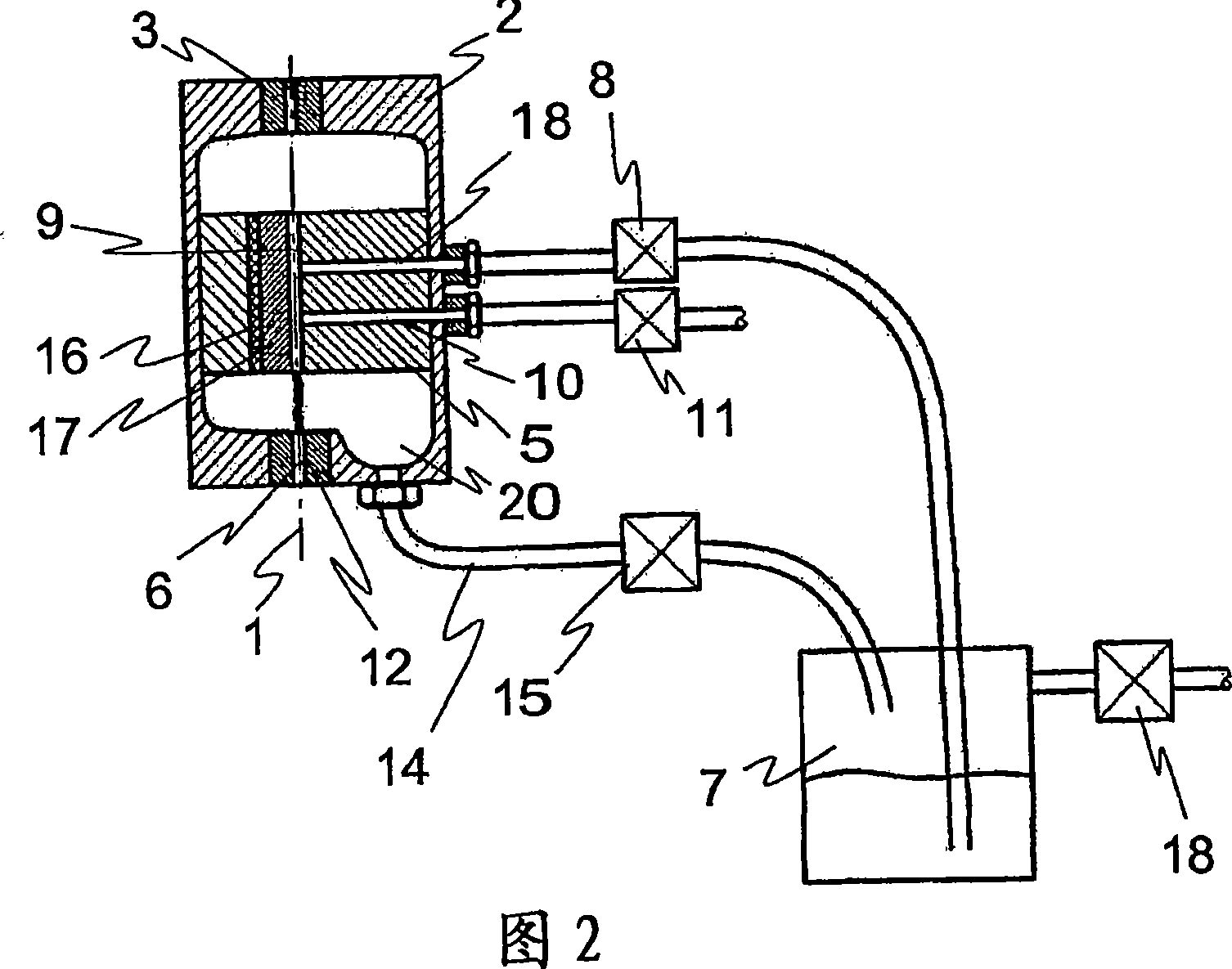

[0040]FIG. 1 shows a complete device according to the invention for applying a finish. The filament 1 passes through the filament inlet 3 of the housing 2, is moistened with oil as oiling agent in the oiling device 4 of a rod-shaped oiler here, and is then air-jet deformed in an air-jet texturing device 5 . Each individual filament of the filament 1 is uniformly mixed and moistened with oil by air-jet texturing, after which the filament 1 exits the housing 2 through an outlet 6 at the other end.

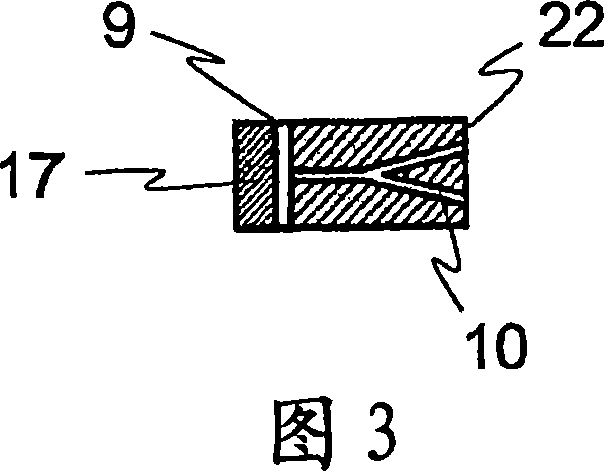

[0041] Input oil from fuel tank 7 with an oil quantity regulator 8 control. The filament 1 is tangential to the oiling device 4 and is acted upon with oil flowing out of an inlet opening of the oiling device 4 . The structure of the oiling device 4 can be known (designed) according to the current prior art. An air jet texturing device 5 is arranged behind the oiling device 4 along the filament running direction. The filament 1 passes through the closed yarn channel 9 of the air-je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com