Patents

Literature

218results about How to "Uniform atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

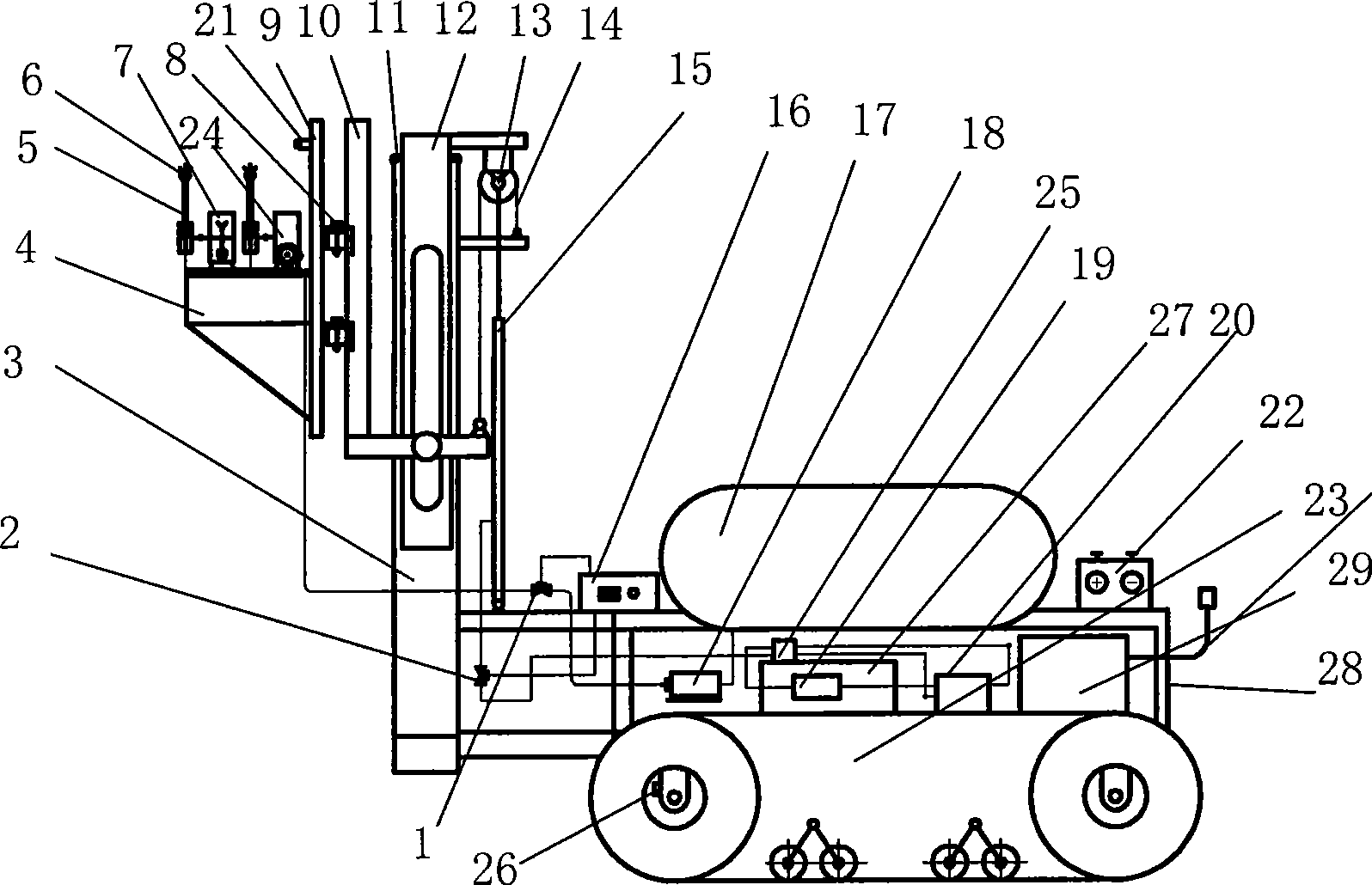

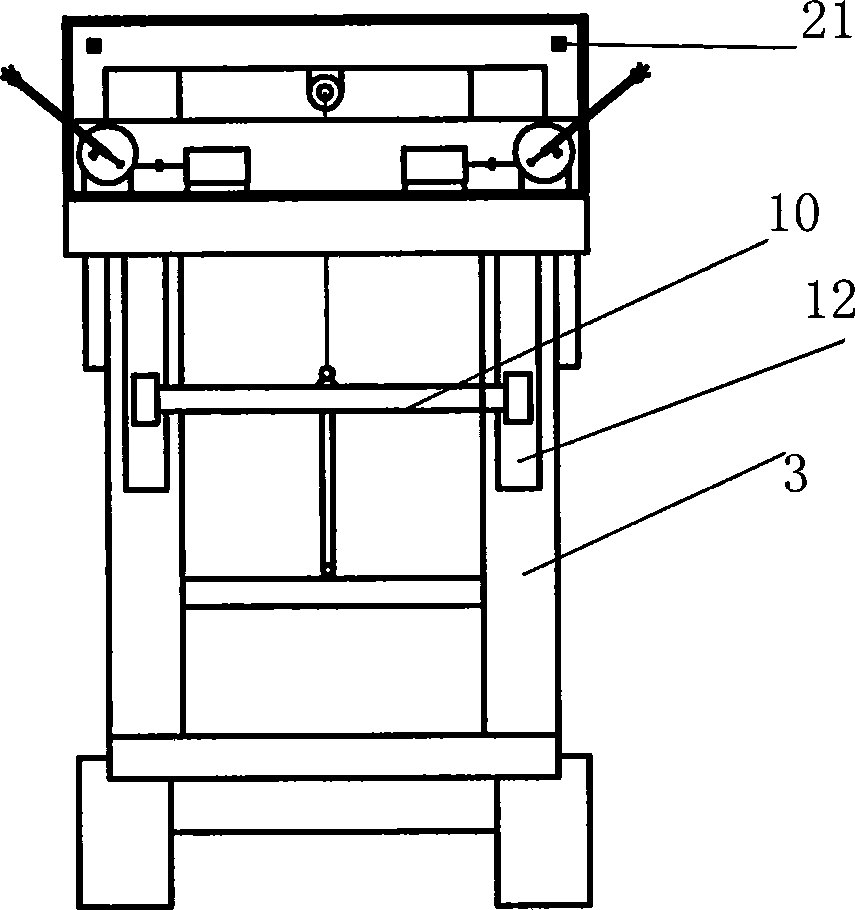

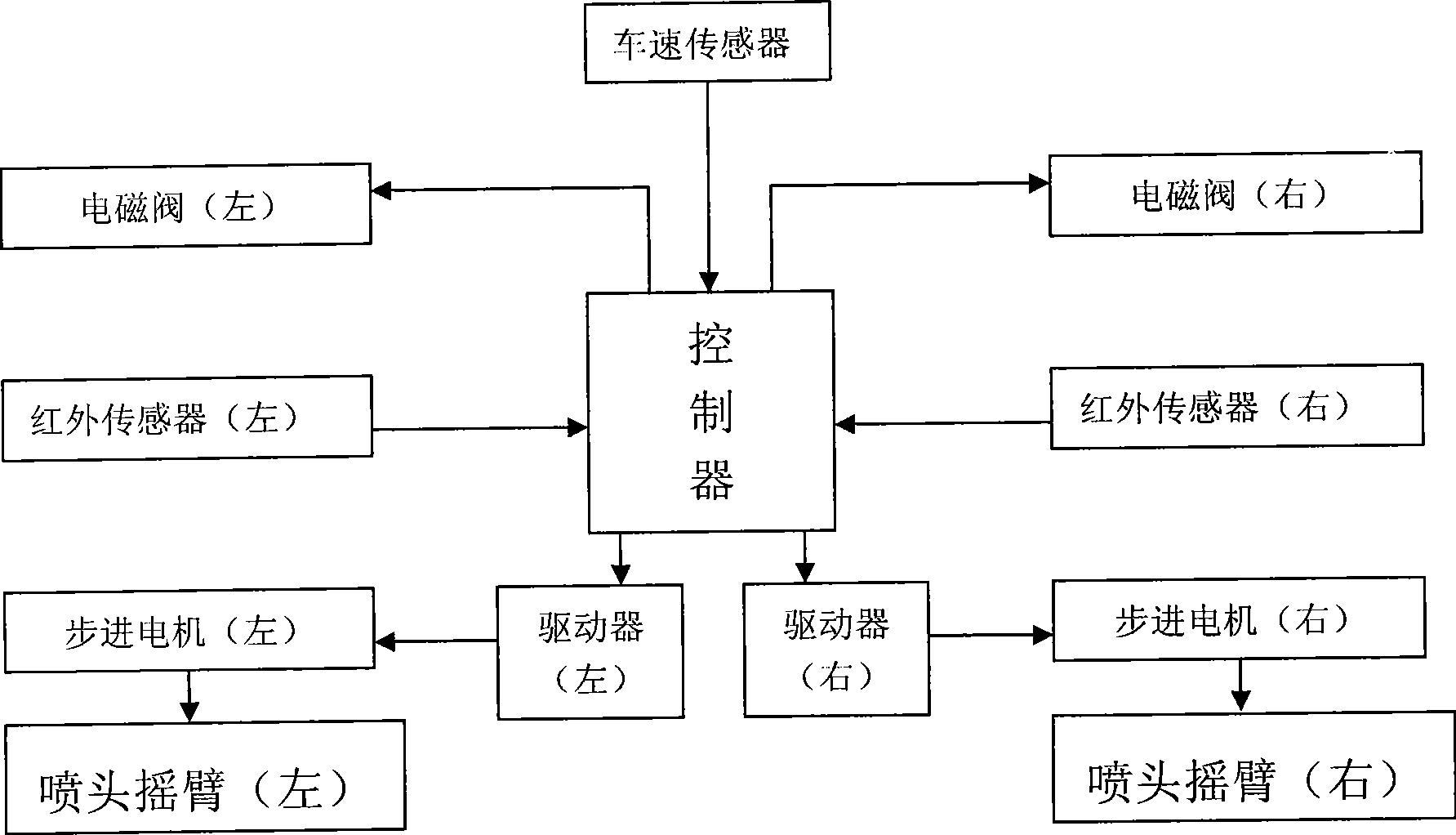

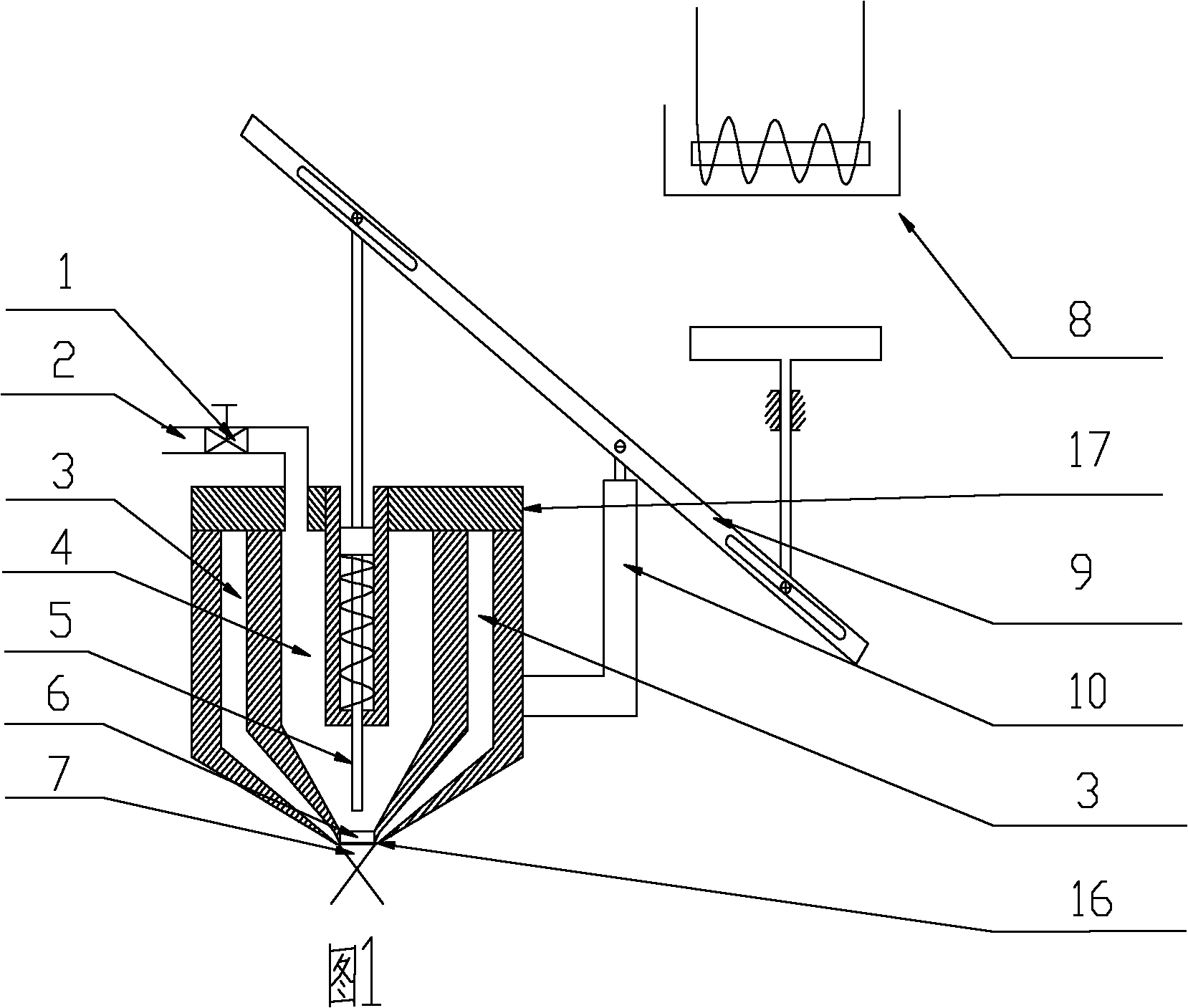

Self-propelled remote control spraying machine

The invention discloses a self-propelled remote control spraying machine, which comprises a remotely-controllable caterpillar tractor and a controller, wherein the controller is connected with a step motor connected with an input shaft of a worm gear reducer; an output shaft of the worm gear reducer is connected with a spray nozzle oscillating arm; an agricultural chemical spray pump, a chemical tank, the spray nozzle oscillating arm and a nozzle are connected, and an electromagnetic valve I is arranged between a water outlet pipe and the spray nozzle oscillating arm; the worktable is provided with an infrared sensor; a driving wheel of the tractor is provided with a vehicle speed measuring sensor; a return oil pipe of an oil pipe of a hydraulic oil tank is connected with an electronic distributor; an oil pipe of a hydraulic oil pump is connected with the hydraulic oil tank and the electronic distributor; and the output end of the electronic distributor is connected with the hydraulic oil cylinder, and an electromagnetic valve II is arranged between the electronic distributor and the hydraulic oil tank. The remote control spraying machine effectively solves the problem of harm caused to a human body during chemical spraying, avoids resource waste, has high working efficiency, and can adjust the spraying amount of the chemical and realize accurate amount-variable chemical application.

Owner:NORTHWEST A & F UNIV

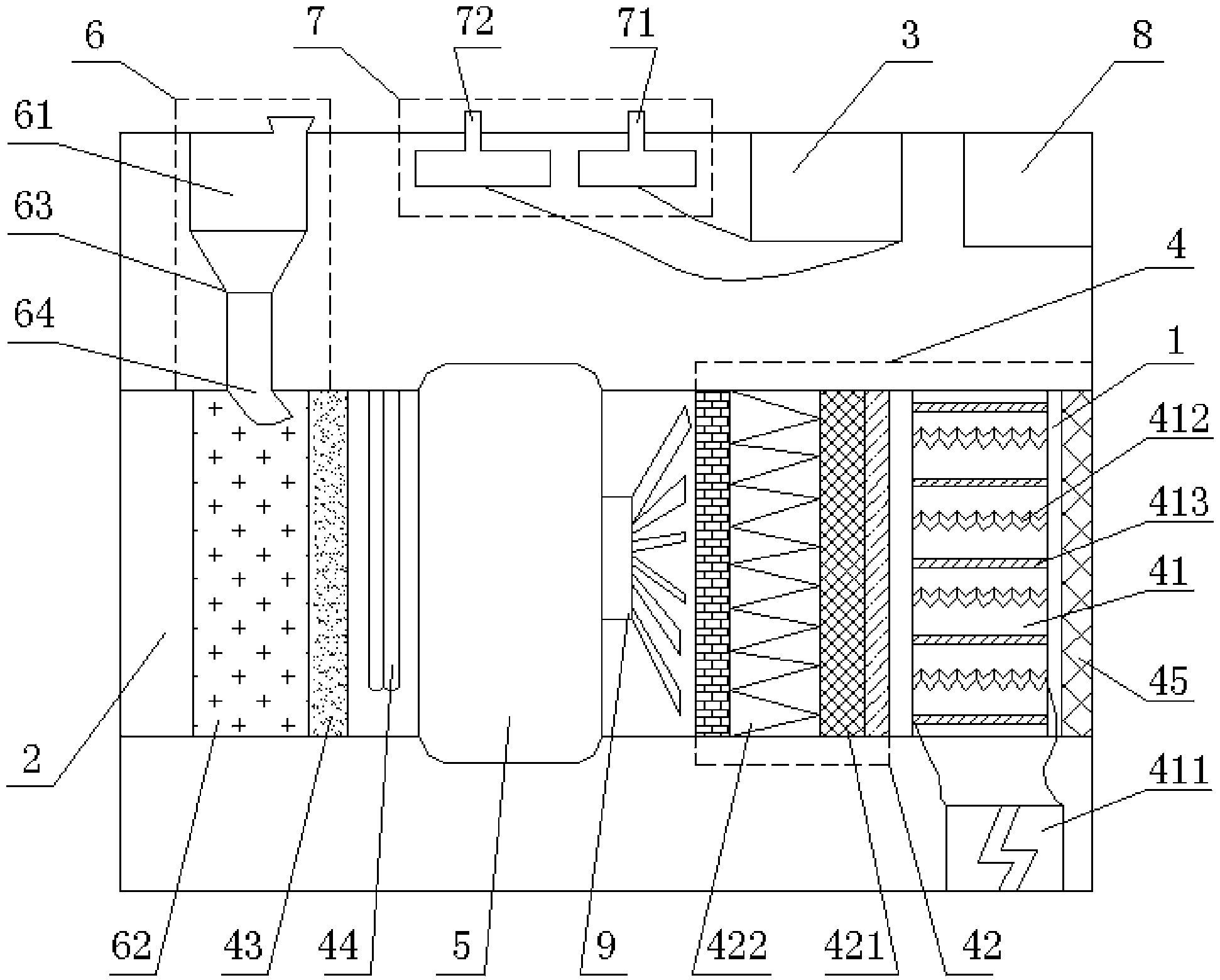

Air conditioner capable of purifying air

InactiveCN103727600AKeep coolingKeep the heating functionSpace heating and ventilation safety systemsLighting and heating apparatusTemperature conditioningControl system

The invention discloses an air conditioner capable of purifying air. The air conditioner comprises a control system, an air purification system, a temperature conditioning system, an air humidification system, an air detection device and a display screen, wherein the air purification system is arranged in an air conditioner air inlet channel at the front part of the temperature conditioning system; the air purification system comprises a plasma discharging device and a PM2.5 (Particulate Matter 2.5) filtering device; the air humidification system is arranged in an air conditioner air outlet channel in the rear part of the temperature conditioning system; the air detection device comprises a PM2.5 sensor and an air humidification sensor; the PM2.5 sensor and the air humidification sensor are used for transmitting collected data to the control system; the data received by the control system is displayed on the display screen in real time; meanwhile, the air humidification system is turned on or off according to the received data. The air conditioner can be used for conditioning the indoor air temperature and removing harmful particles in air, and solving the problem that the indoor air is dried if the air conditioner is turned on in winter.

Owner:中能建城市投资发展有限公司

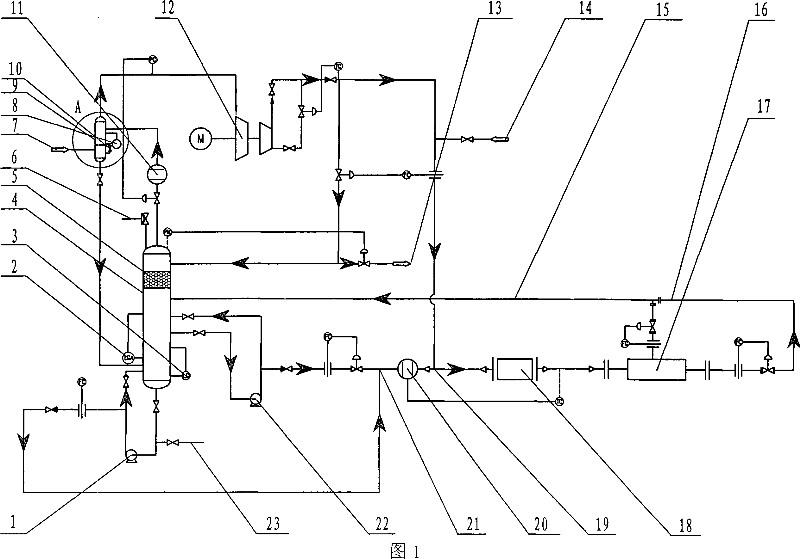

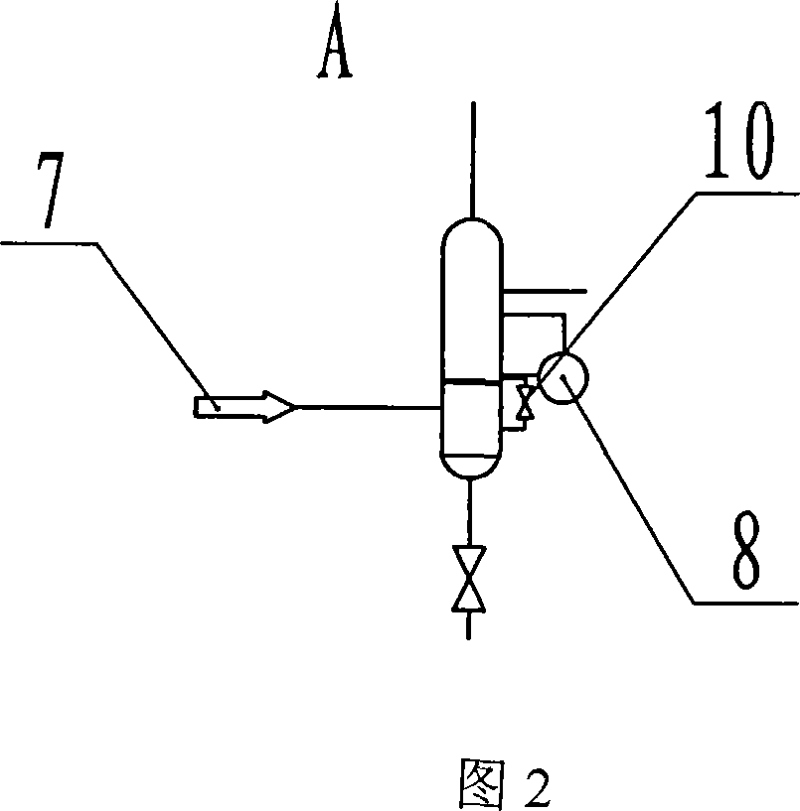

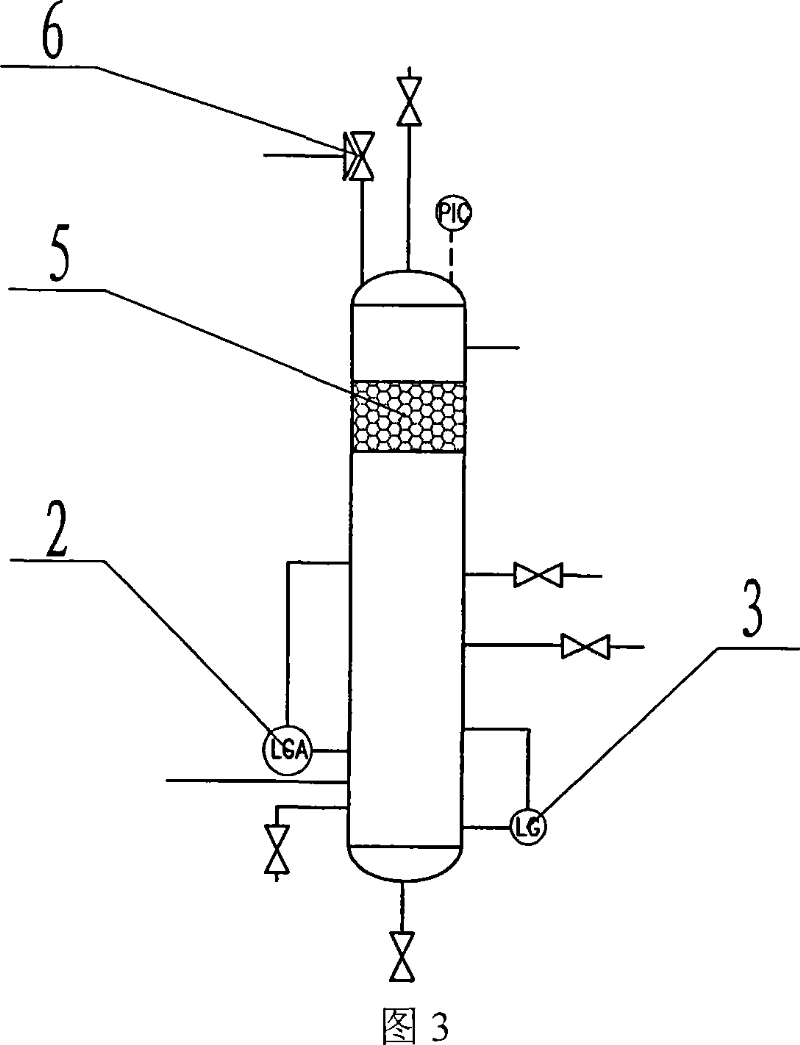

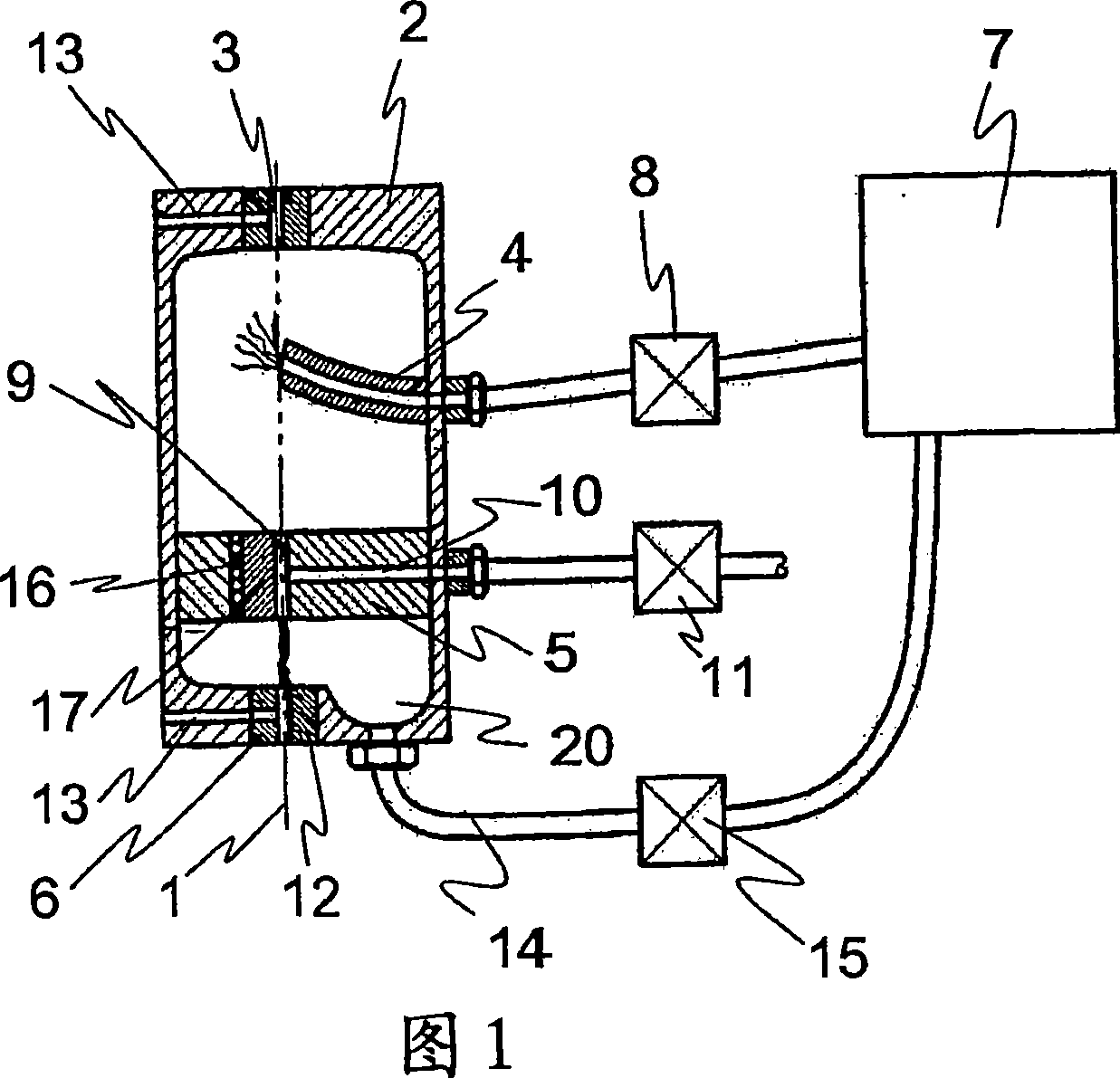

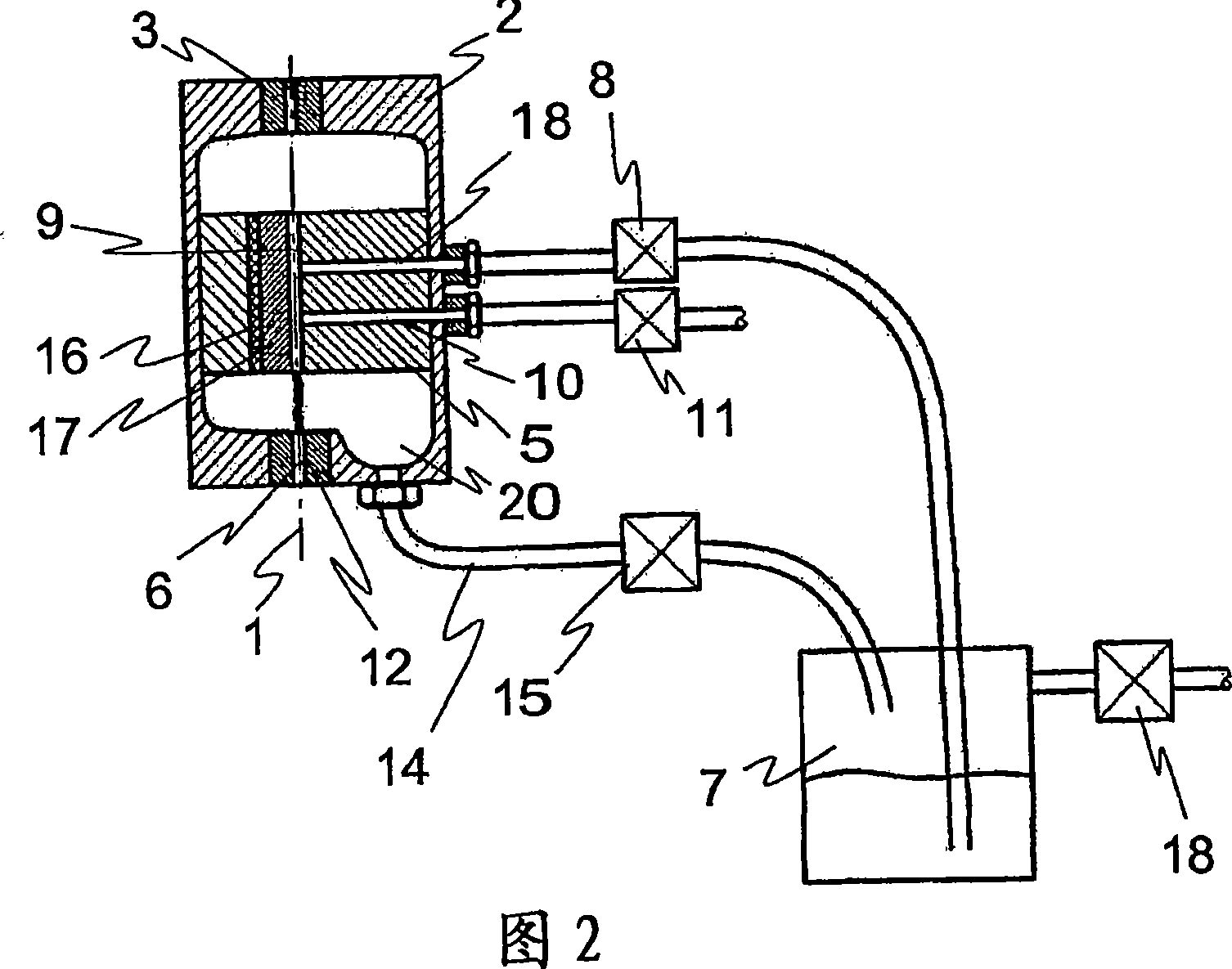

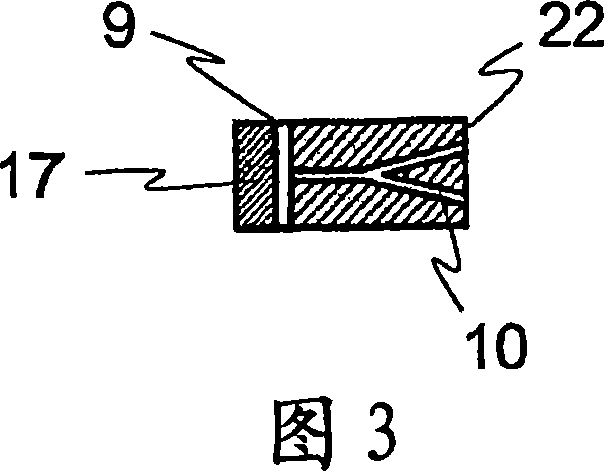

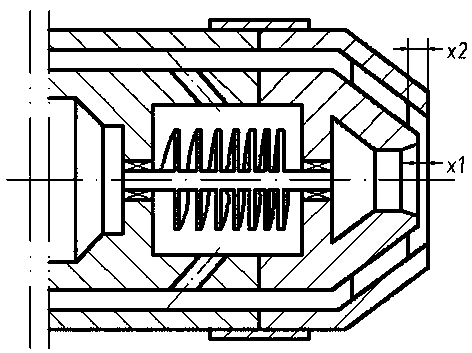

Loop-type multi-phase flow erosion test device

InactiveCN101038250AUniform atomizationEnsure balanceWeather/light/corrosion resistancePipeline systemsPipe fittingGas phase

The present invention discloses a ring-road type multi-phase flow erosion tester comprising a gas, oil and water three-phase separation tank and pipe circulating systems of said three phases including, in detail, a gassy system ranging from an export at the top part of the three-phase separation tank, a cooler and a cyclone separator, a circulating gas screw compressor to the pipe filter; an oil phase system ranging from an export at the middle part of the three-phase separation tank, a diesel magnetic drive pump, a heater to the pipe filter; and a water phase system ranging from an export at the bottom part of the three-phase separation tank, a wastewater metering pump, a heater to the pipe filter. After mixing, the three phases are connected to the three-phase separation tank through the pipe filter and a testing platform for pieced to be tested. The present invention is capable of simulating erosion study cases in practical pipe fittings such as tee joints, bend pipes, transition pipes and liner pipes to perform a transient characteristics prediction study of gas, oil and water multi-phase flow erosion destruction.

Owner:ZHEJIANG SCI-TECH UNIV

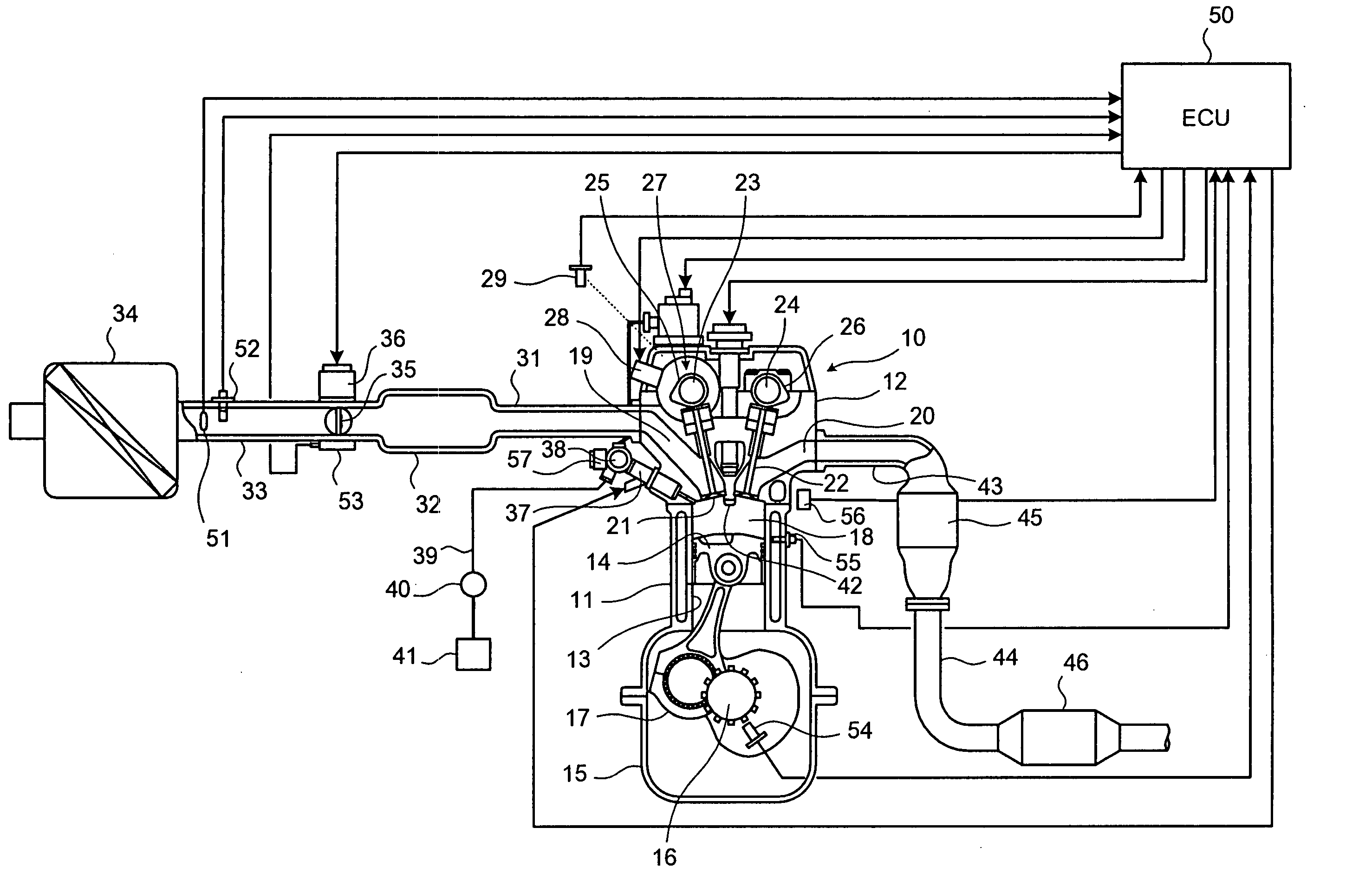

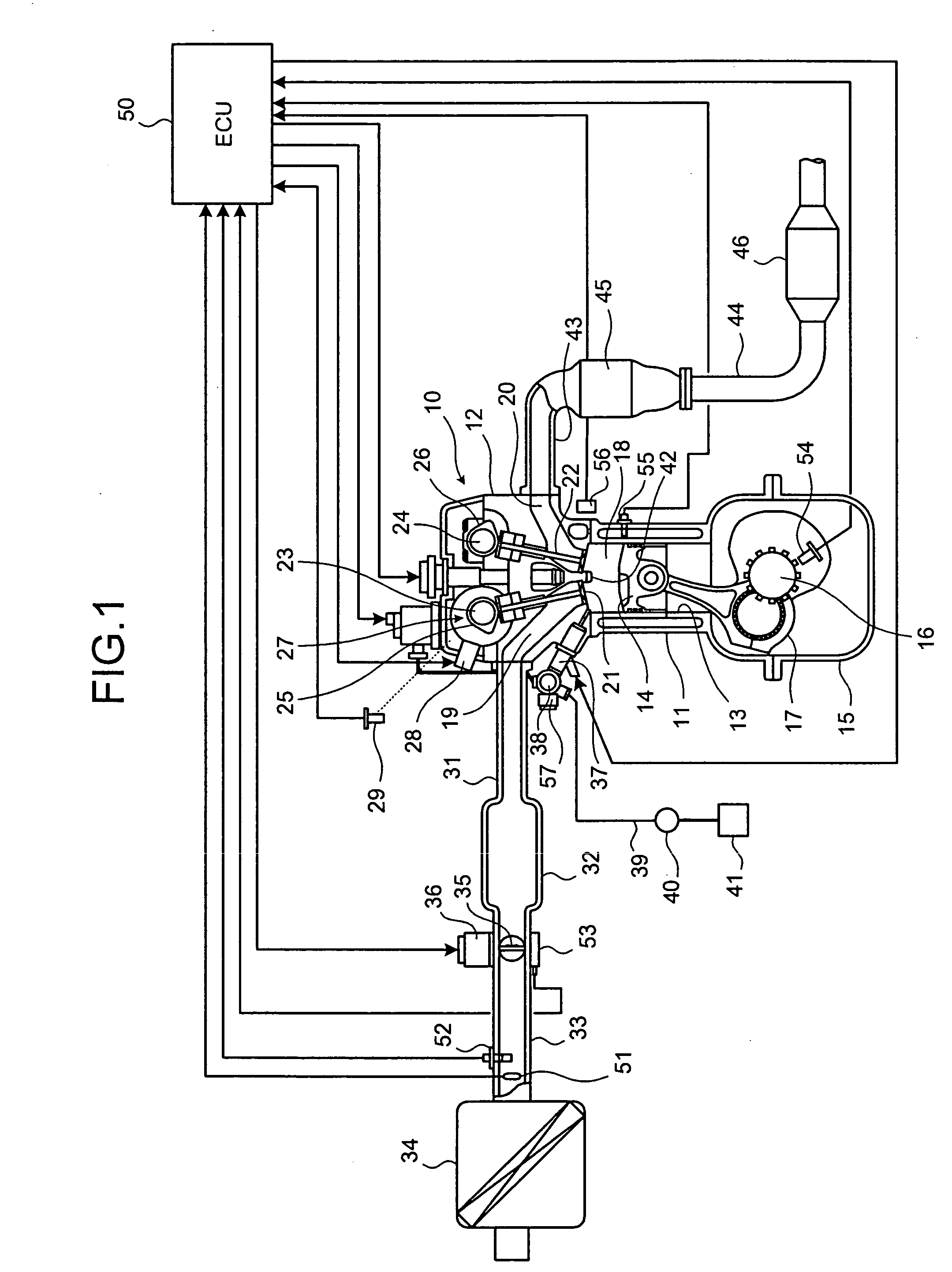

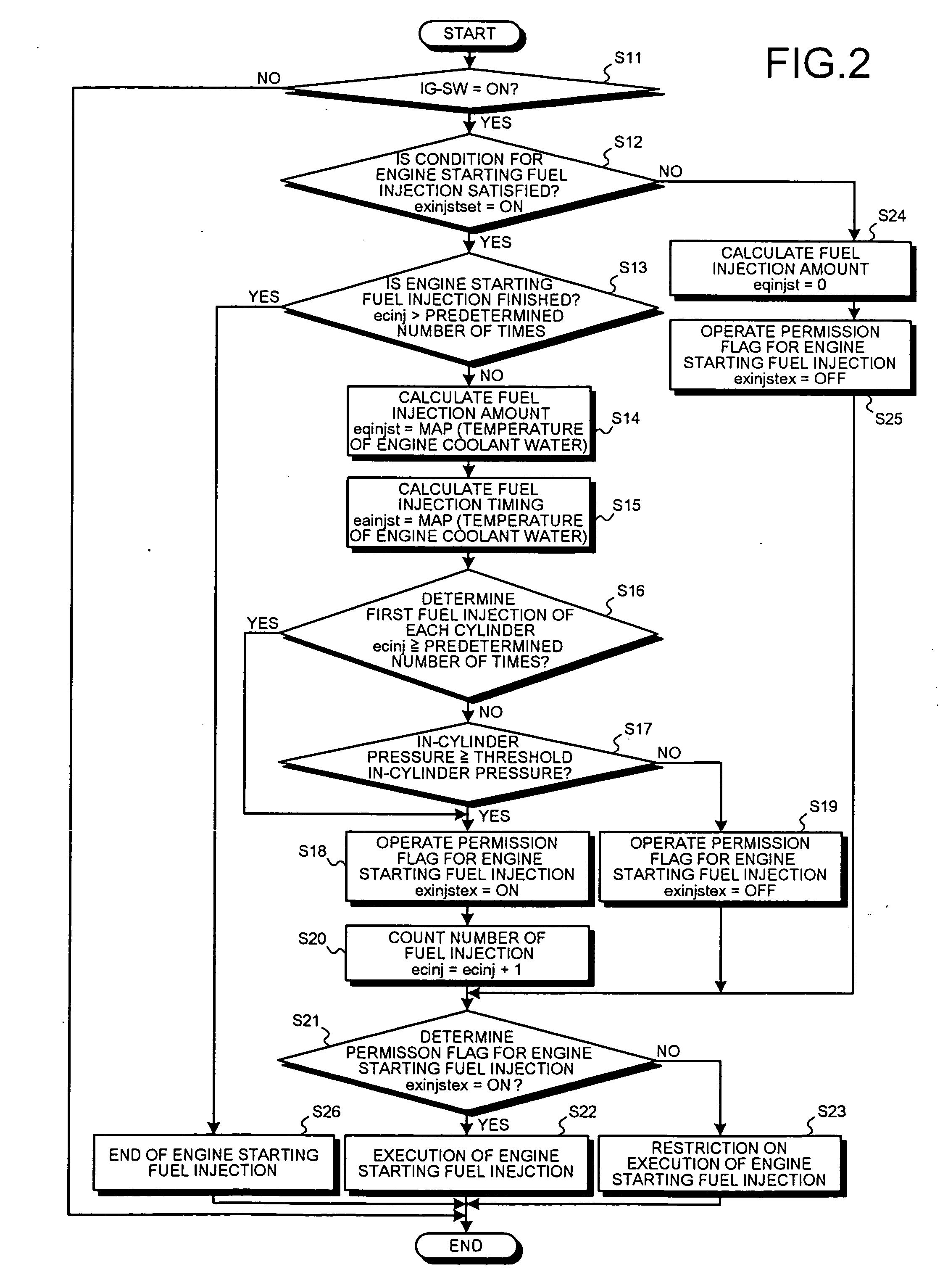

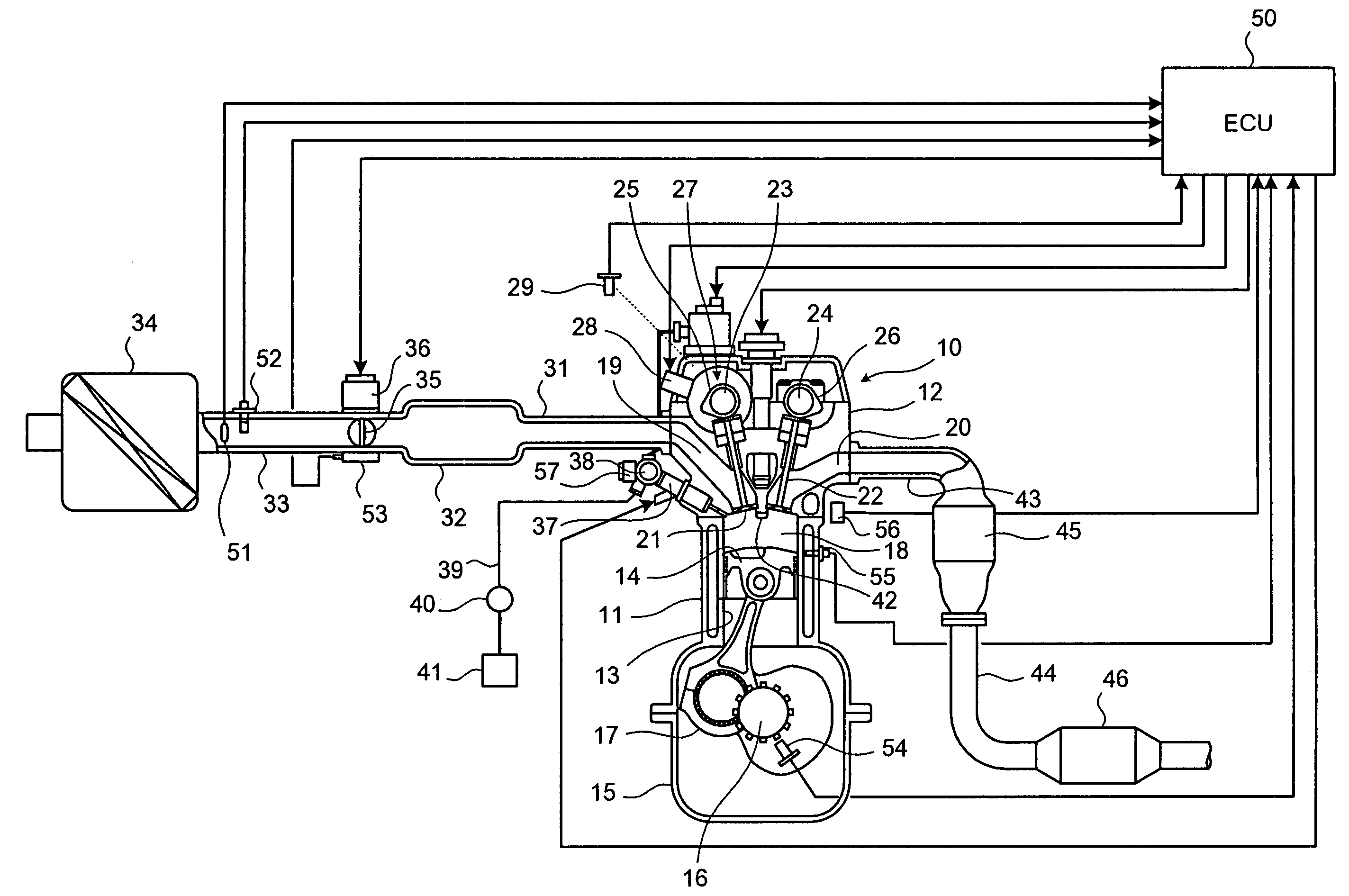

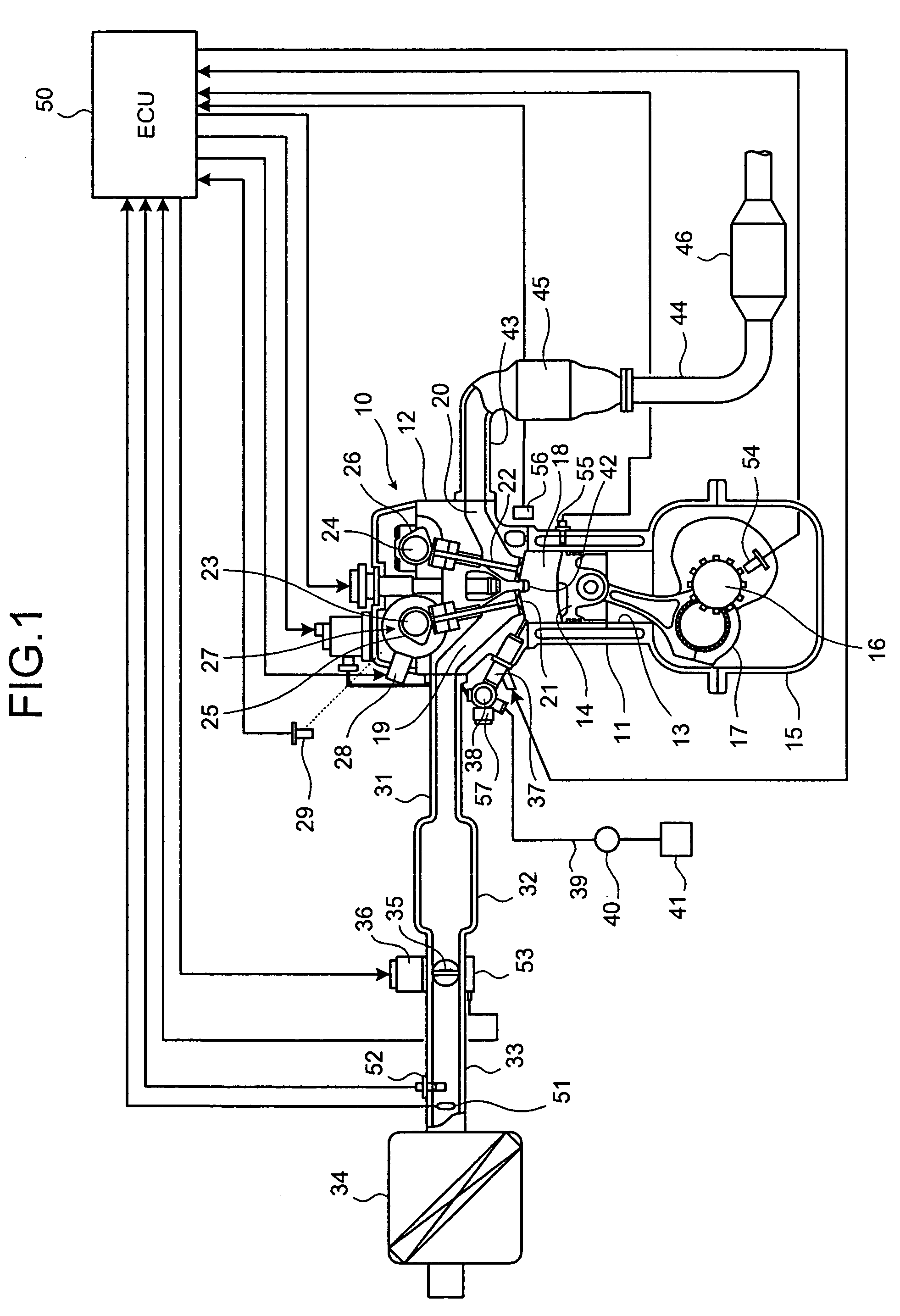

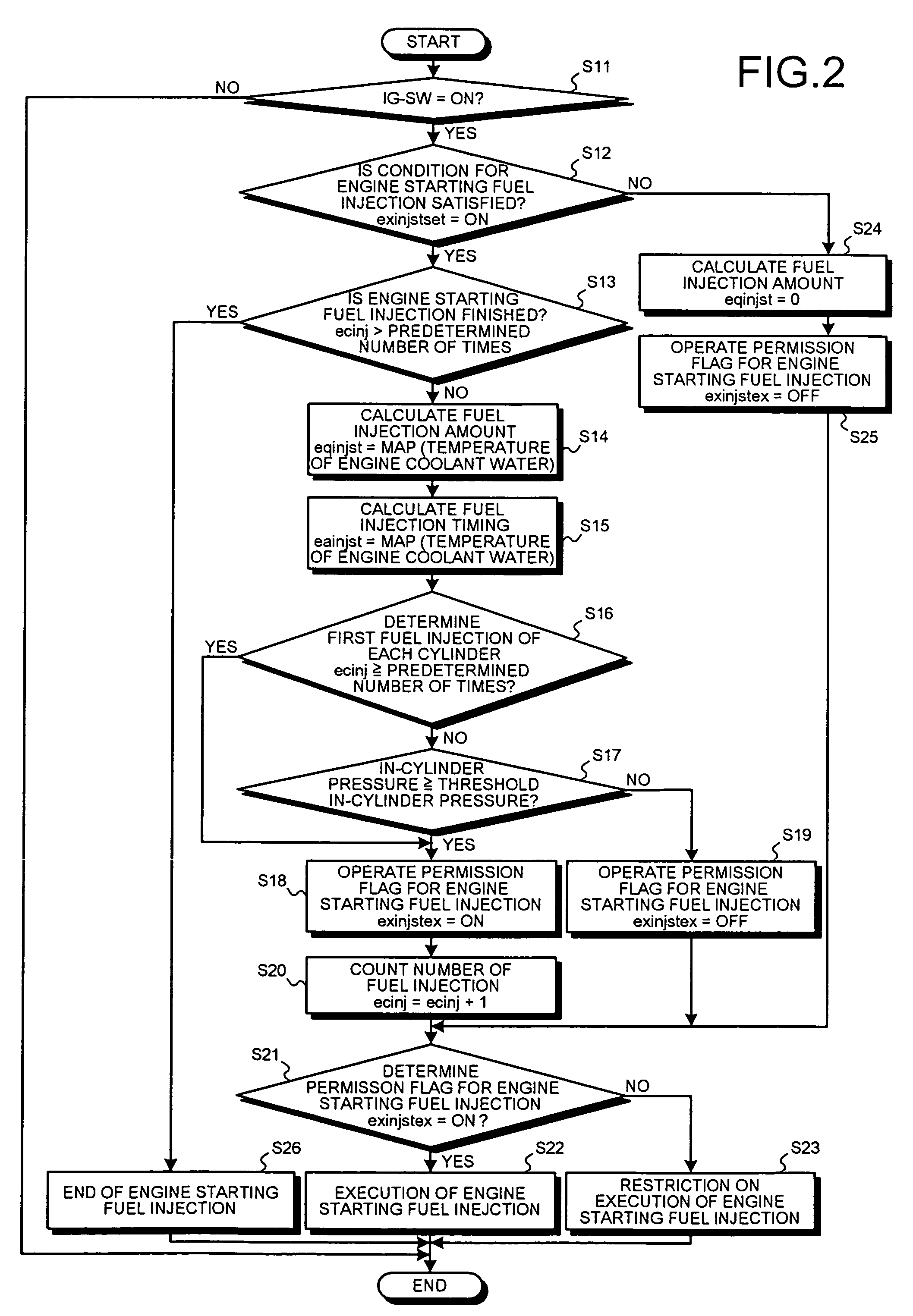

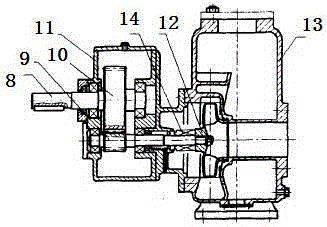

Control apparatus of internal combustion engine

InactiveUS20060231066A1Engine startability can be improvedUniform atomizationElectrical controlCombustion enginesCombustion chamberInternal combustion engine

A control apparatus of an internal combustion engine includes a fuel pressure sensor to detect the pressure of the fuel supplied from a fuel pump to an injector; an in-cylinder pressure sensor, which serves as a combustion chamber temperature detecting unit that detects the temperature in the combustion chamber or the parameter depending on the temperature, to detect in-cylinder pressure (combustion chamber pressure); and an ECU that controls to execute the first fuel injection of each cylinder by the injector when the fuel pressure detected by the fuel pressure sensor is not less than a predetermined threshold fuel pressure and when the in-cylinder pressure detected by the in-cylinder pressure sensor is not less than a threshold in-cylinder pressure.

Owner:TOYOTA JIDOSHA KK +1

Control apparatus of internal combustion engine

InactiveUS7150262B2Engine startability can be improvedUniform atomizationElectrical controlCombustion enginesExternal combustion engineInternal combustion engine

Owner:TOYOTA JIDOSHA KK +1

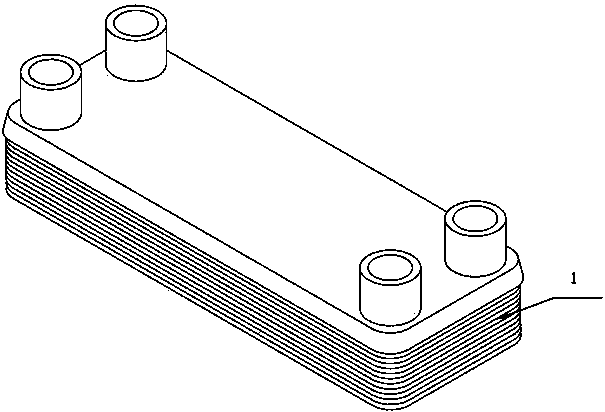

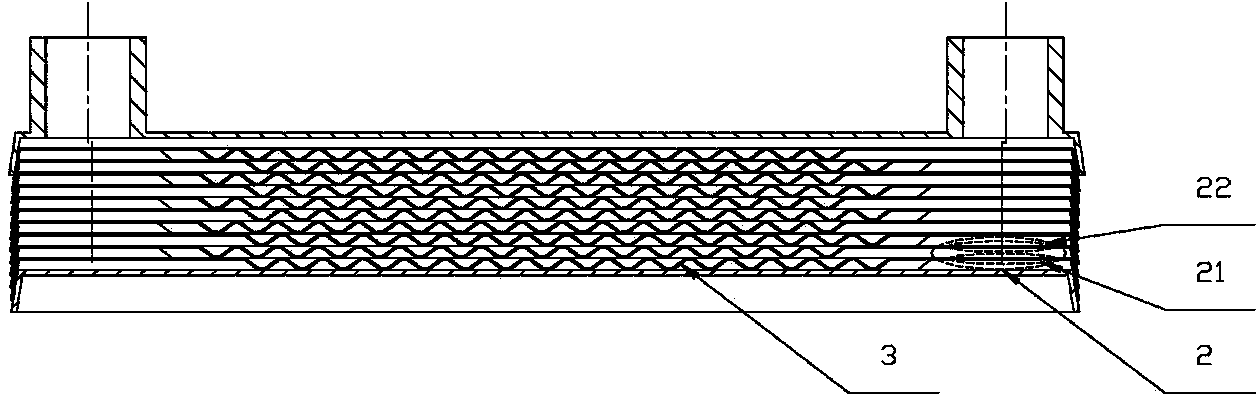

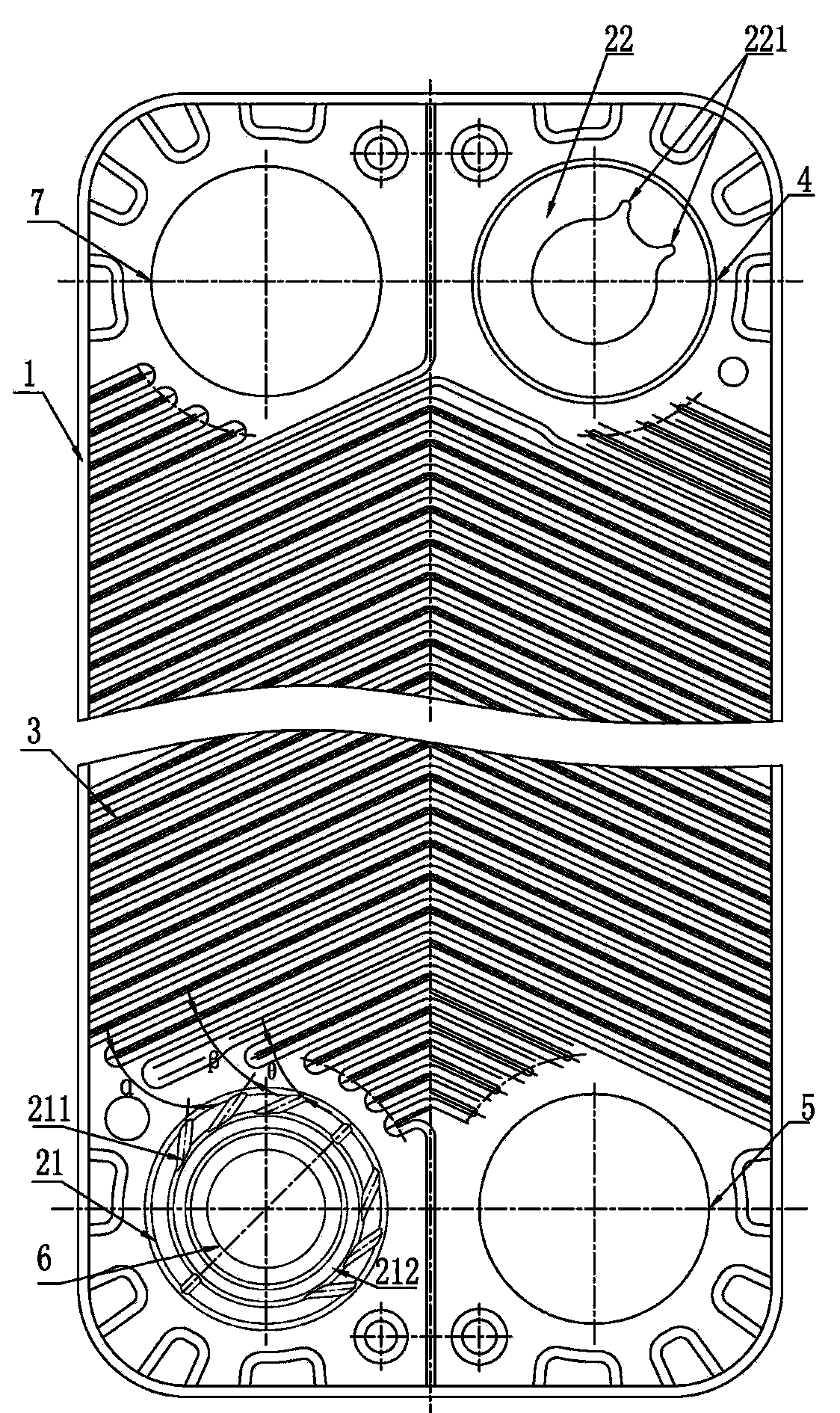

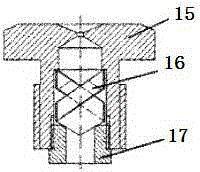

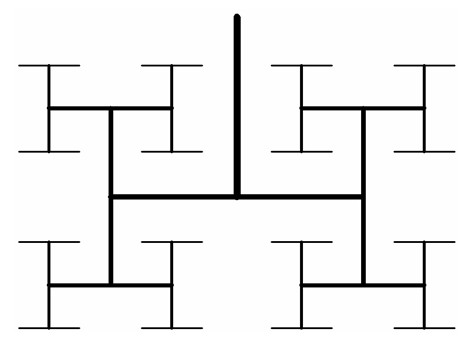

Plate heat exchanger and fluid distributers and plates thereof

ActiveCN103940267AUniform atomizationImprove evaporation and vaporization efficiencyHeat exchanger casingsLaminated elementsInter layerEngineering

The invention discloses a plate heat exchanger and fluid distributers of the plate heat exchanger. A plate heat exchanger comprises a plurality of plates in a stacked mode, wherein the plates are provided with a plurality of layers of herringbone corrugations, and the four corners of each plate are provided with corner holes. Each plate is provided with one fluid disturber. Each fluid distributer comprises a plurality of stacked inter-layer fluid distributers. Each inter-layer fluid distributer includes a fluid distribution structure and a fluid inlet structure, wherein each fluid distribution structure is arranged on the peripheral side of the corresponding first corner hole of the corresponding plate; each fluid inlet structure is arranged on the side wall of the corresponding third corner hole of one corresponding stacked and adjacent plate; the fluid distribution structures and the fluid inlet structures are coaxially and vertically matched, and at least one inter-layer fluid distributer is formed between any two adjacent plates. The fluid distributers can effectively lower fluid resistance, so that uniform atomization is performed on high-pressure fluid, and flow distribution of fluid in inter-plate flow channels is more uniform. In this way, the utilization rate of the plates is increased, and the heat exchange efficiency of the heat exchanger is effectively improved.

Owner:ZHEJIANG FORWON PLATE HEAT EXCHANGER

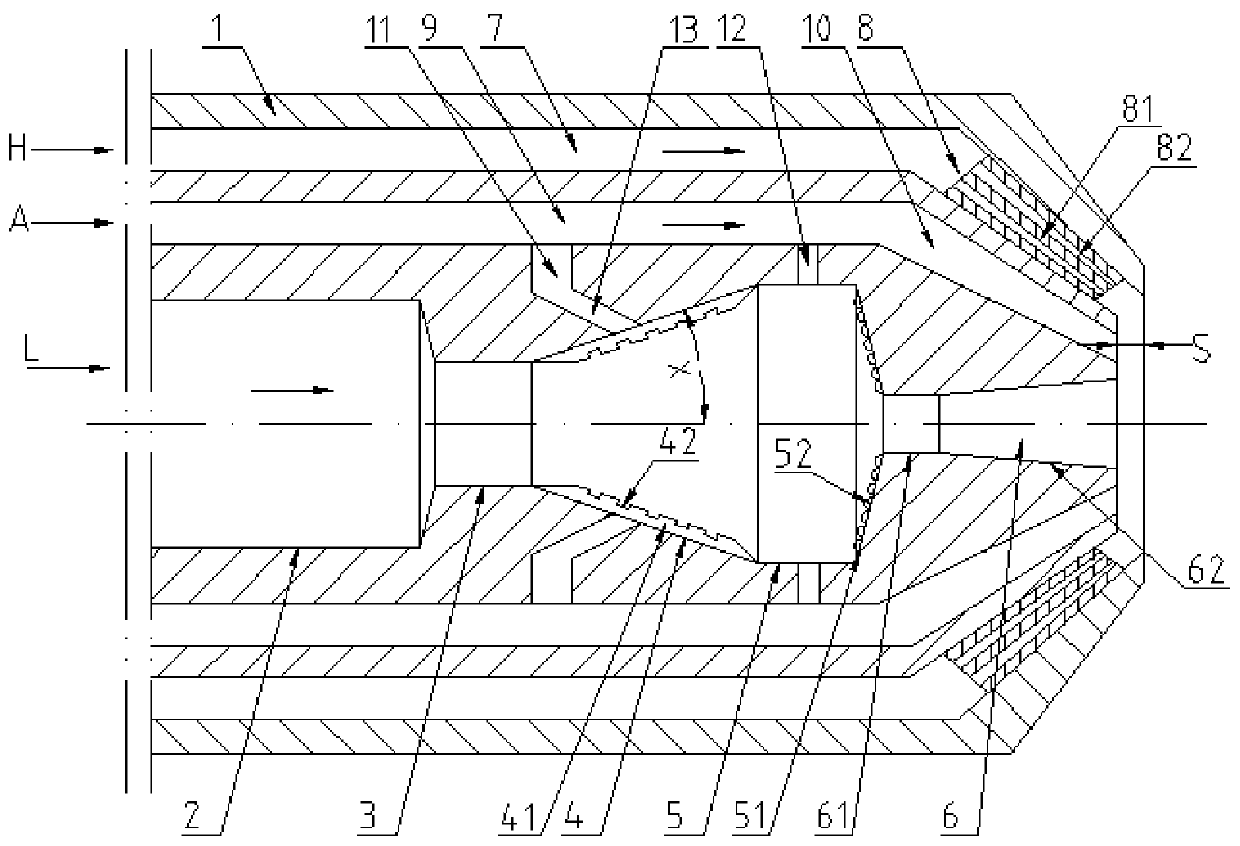

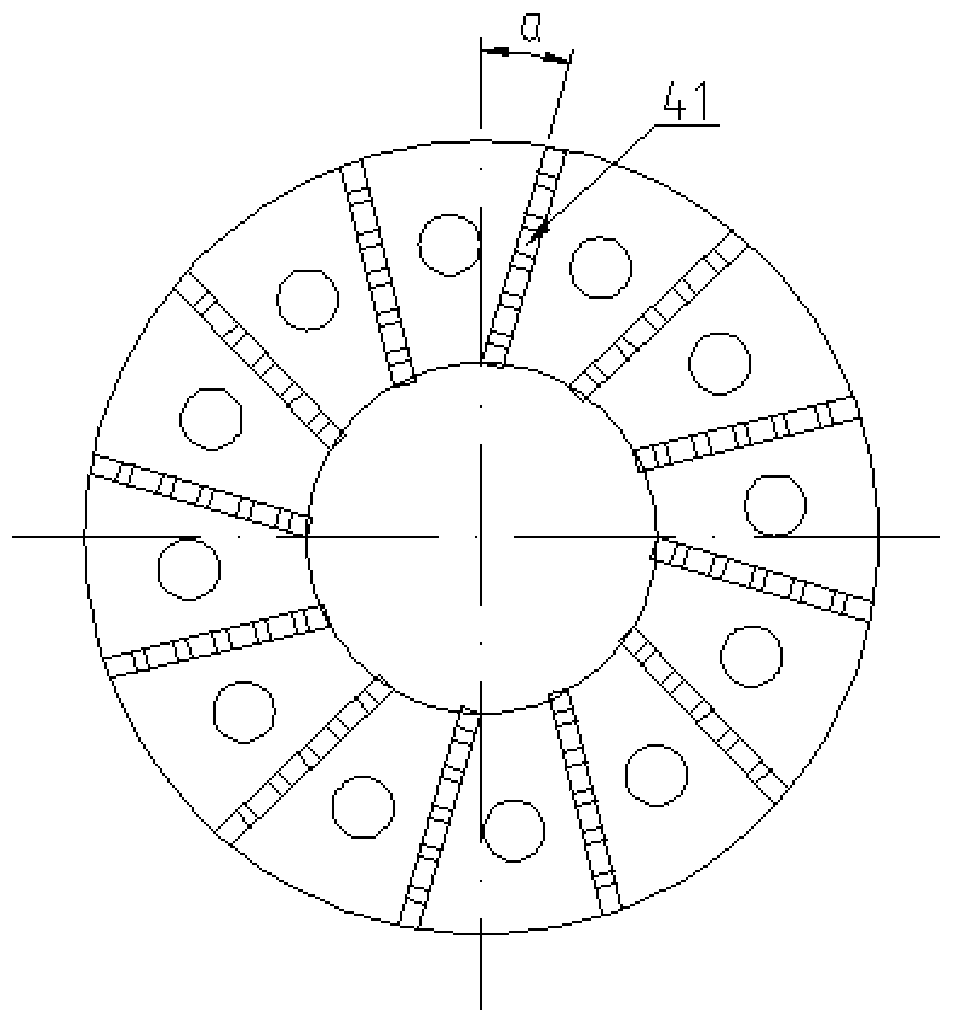

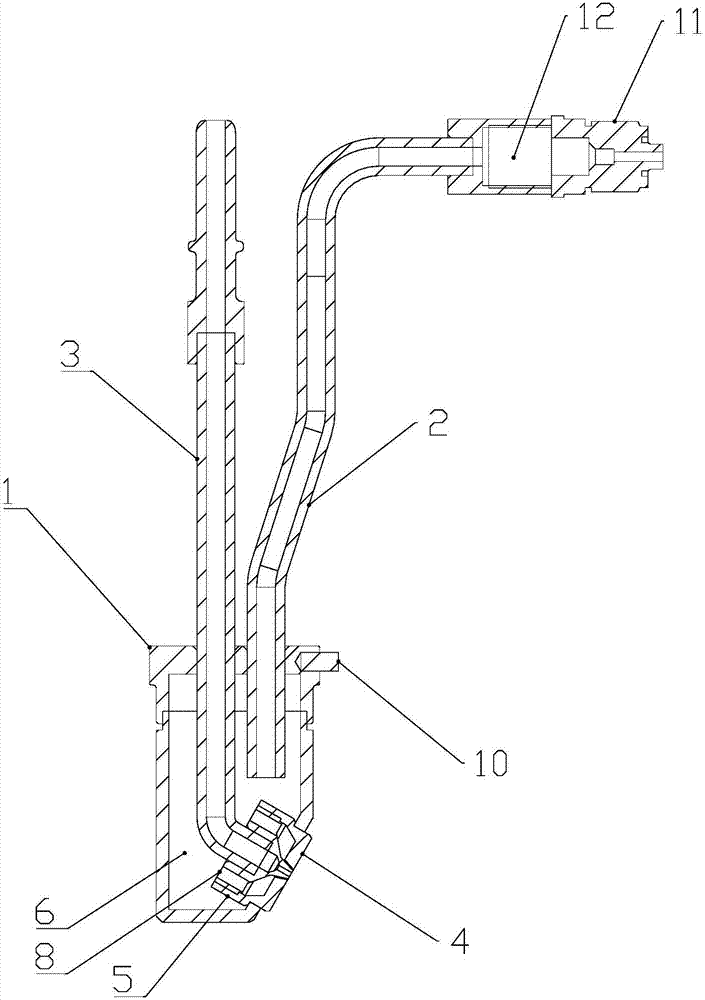

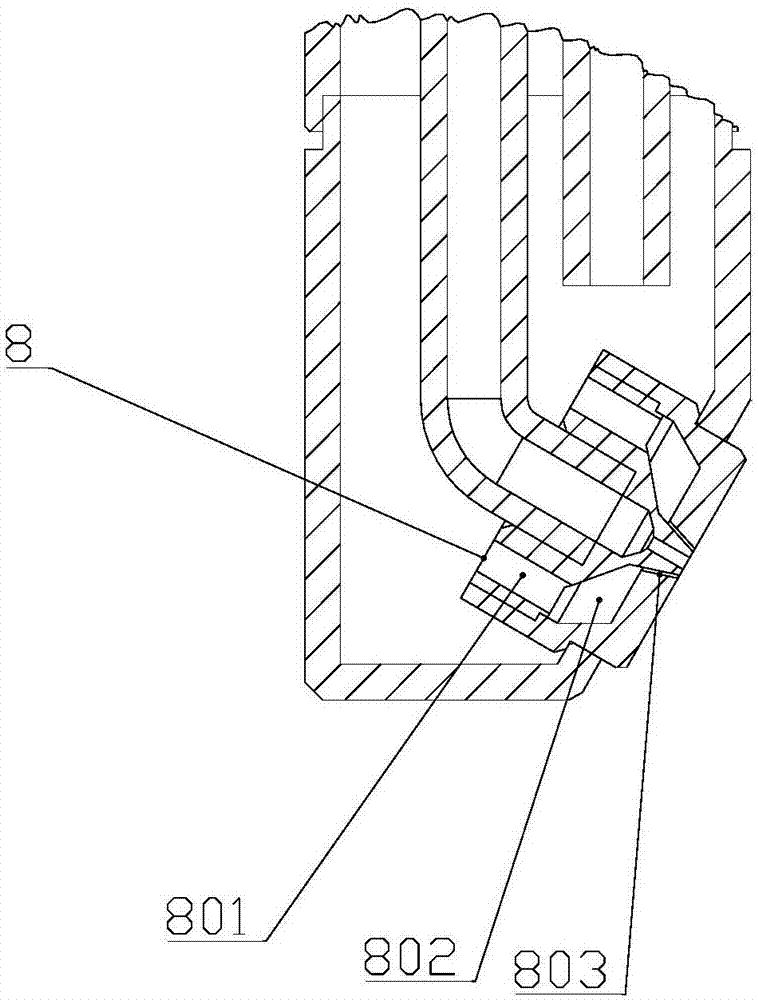

Injection device for surface treatment or coloring

InactiveCN110449282AIncrease rotational kinetic energy/tangential velocityImprove the mixing effectLiquid spraying apparatusSpray nozzleSurface finishing

The invention provides an injection device for surface treatment or coloring. The injection device comprises a nozzle body, and the nozzle body is internally provided with a liquid channel, a gas channel and a temperature regulating gas channel; the liquid channel is located at the center position of the nozzle body, and the gas channel is located on the radial outer side of the liquid channel; the temperature regulating gas channel is located on the radial outer side of the gas channel, and the liquid channel comprises a first diameter part (1), a second diameter part (2), a first tapered part (3), a diffusion cavity (5) and an outlet part (6); the injection device is characterized in that the inner peripheral surface of the first tapered part is provided with a plurality of swirl plates(41) uniformly distributed in the circumferential direction; and the radial inner edges of the swirl plates are provided with a plurality of swirl slots (42) distributed in the axial direction of theswirl plates. According to the injection device, the rotational kinetic energy / tangential speed of fluid can be increased, and the mixing effect of the fluid is improved; the injection device has theadvantages of a pressurization effect, uniform atomization of the nozzle, small size of droplets, and an excellent injection / atomization effect; the temperature regulating gas flow direction is controllable and accurate, and the flow is stable; and the subsequent drying time is shortened.

Owner:LIYANG SHENGJIE MACHINE

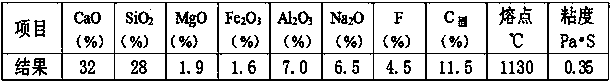

Square billet low-medium carbon steel continuous casting crystallizer mold powder and production method thereof

ActiveCN103785805AIncrease profitReduce bulk buildupMicroballoon preparationMicrocapsule preparationSpray GranulationSlag

The invention discloses square billet low-medium carbon steel continuous casting crystallizer mold powder and a production method thereof. The mold powder is composed of 29-32Wt% of CaO, 28-31Wt% of SiO2, 1.6-2.2Wt% of MgO, 1.6-2.5Wt% of Fe2O3, 6.5-8.5Wt% of Al2O3, 4.5-6.5Wt% of Na2O, 4.5-6.5Wt% of F and 11.5-13.5Wt% of solid C. The production method includes raw material pretreatment and detection, mold powder formula designing, burdening and pulping, spray granulation, screening dedusting and product detection. The production method is low in production cost, quality of the mold powder and utilization efficiency of yellow phosphorus slag can be improved, and contribution to environment is great; tests show that compared with using of conventional raw materials, due to adopting the yellow phosphorus slag as a raw material, cost can be lowered by 256-309 RMB / ton, and primary qualified rate of casting blanks is increased by 2.4-2.9% after being used for production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

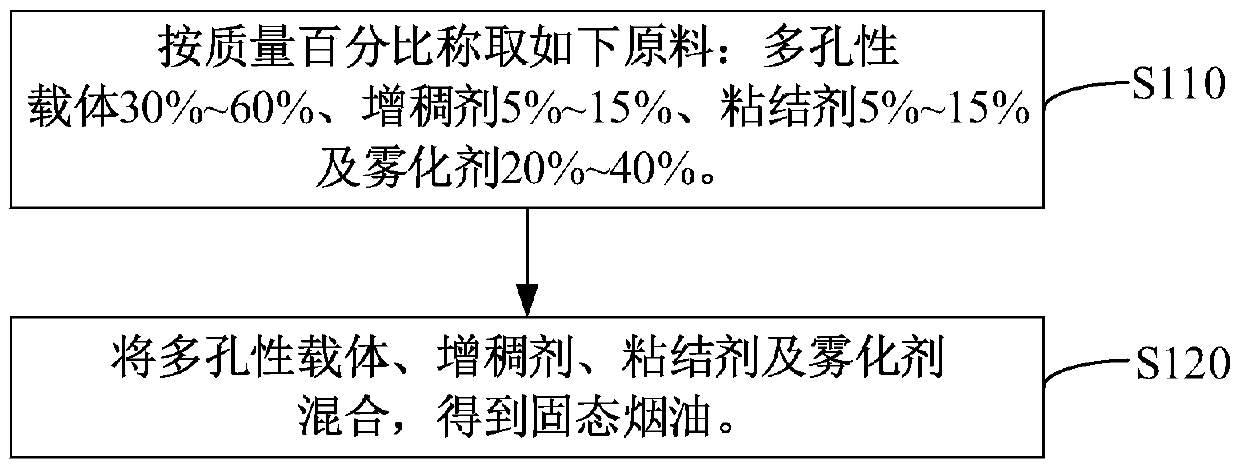

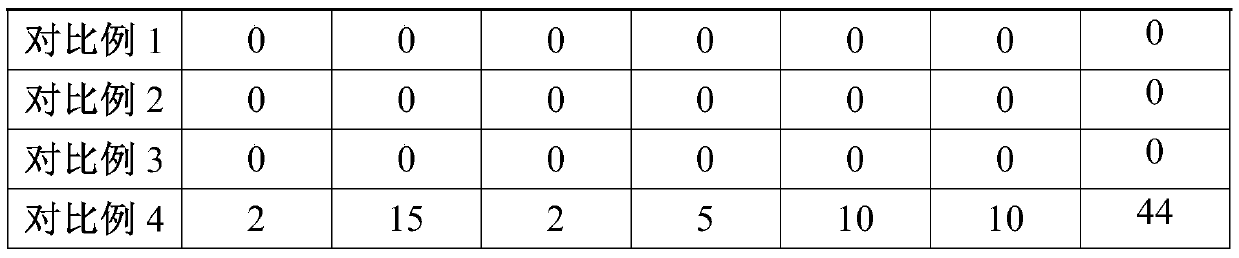

Solid tobacco tar and preparation method and application thereof

InactiveCN110150725AUniform atomizationLoose internal structureTobacco treatmentTarMaterials science

The invention relates to solid tobacco tar and a preparation method and application thereof. The solid tobacco tar is prepared from the raw materials in percentage by mass: 30-60% of a porous carrier,5-15% of a thickening agent, 5-15% of a binder and 20-40% of an alevaire aer. According to the solid tobacco tar, the raw materials can cooperate with one another, and the obtained solid tobacco tarcan be atomized evenly when being used.

Owner:SMISS TECH

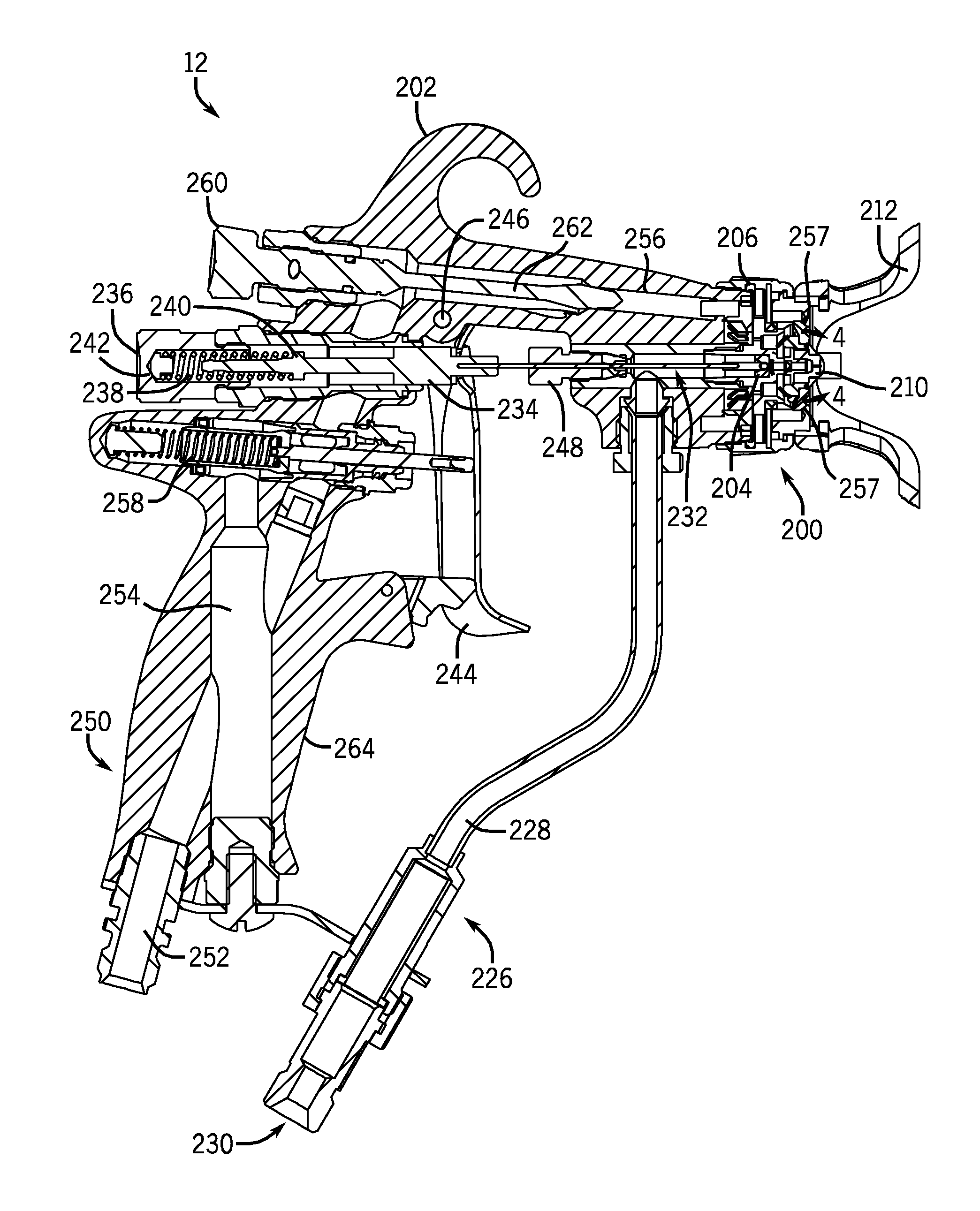

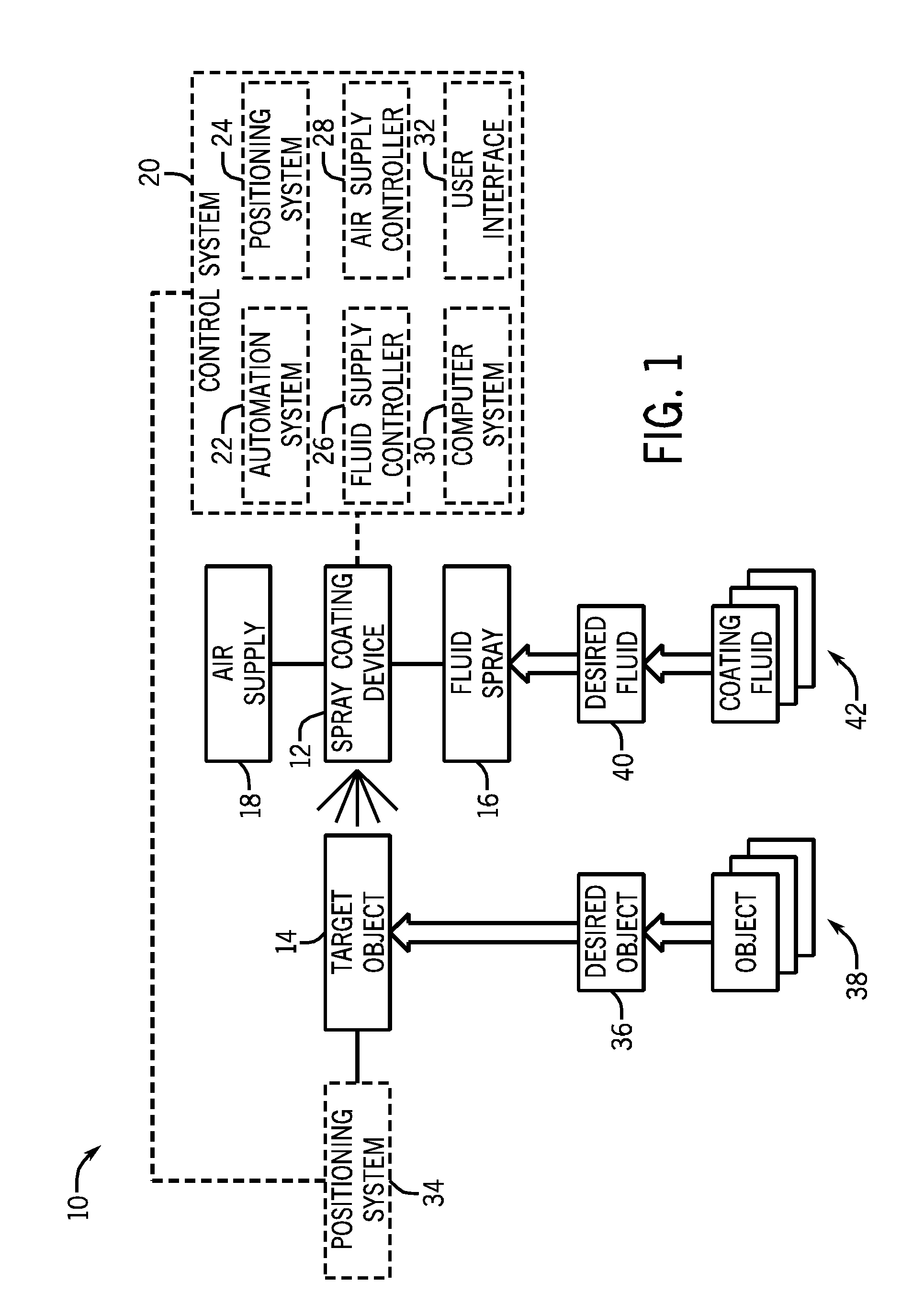

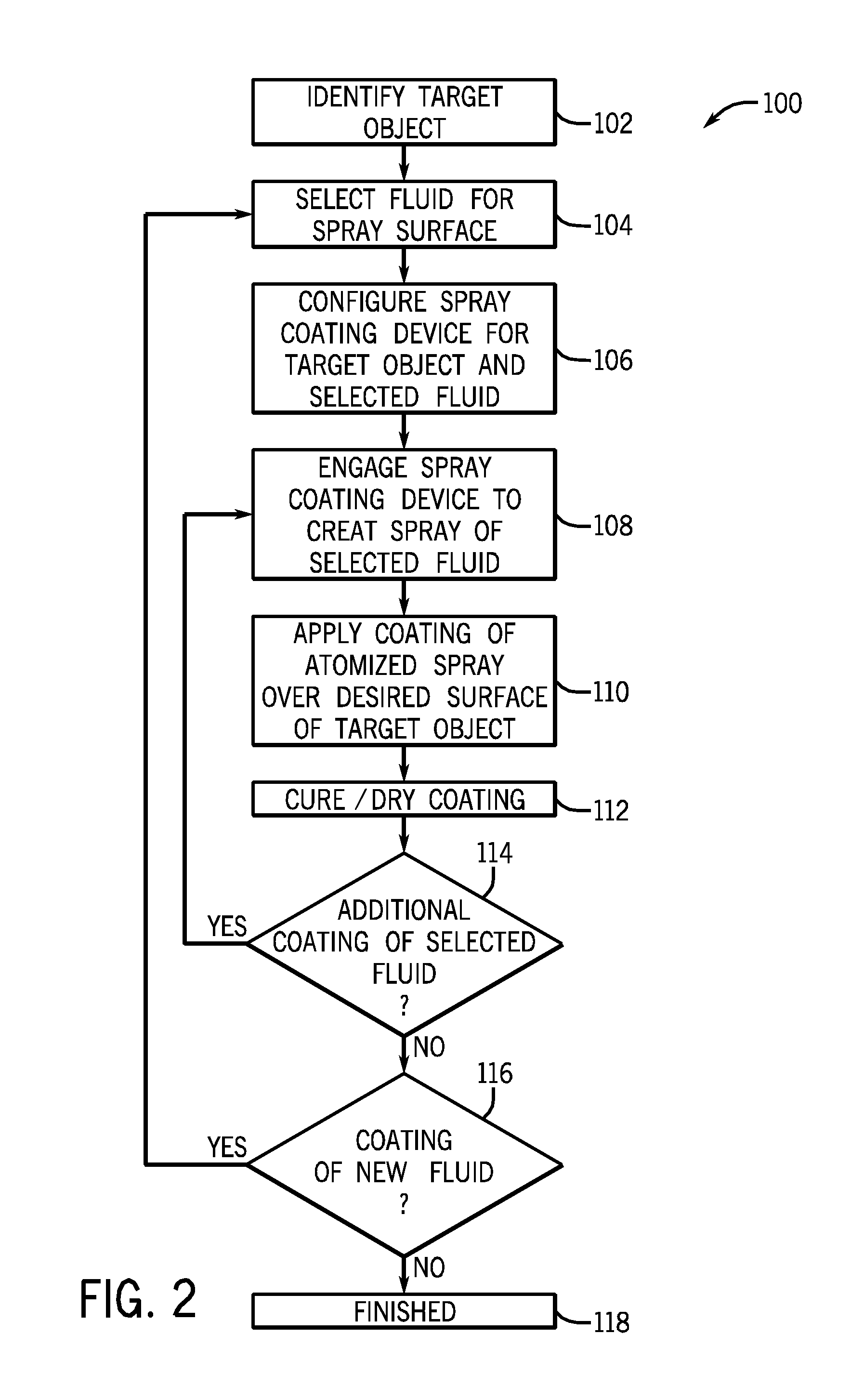

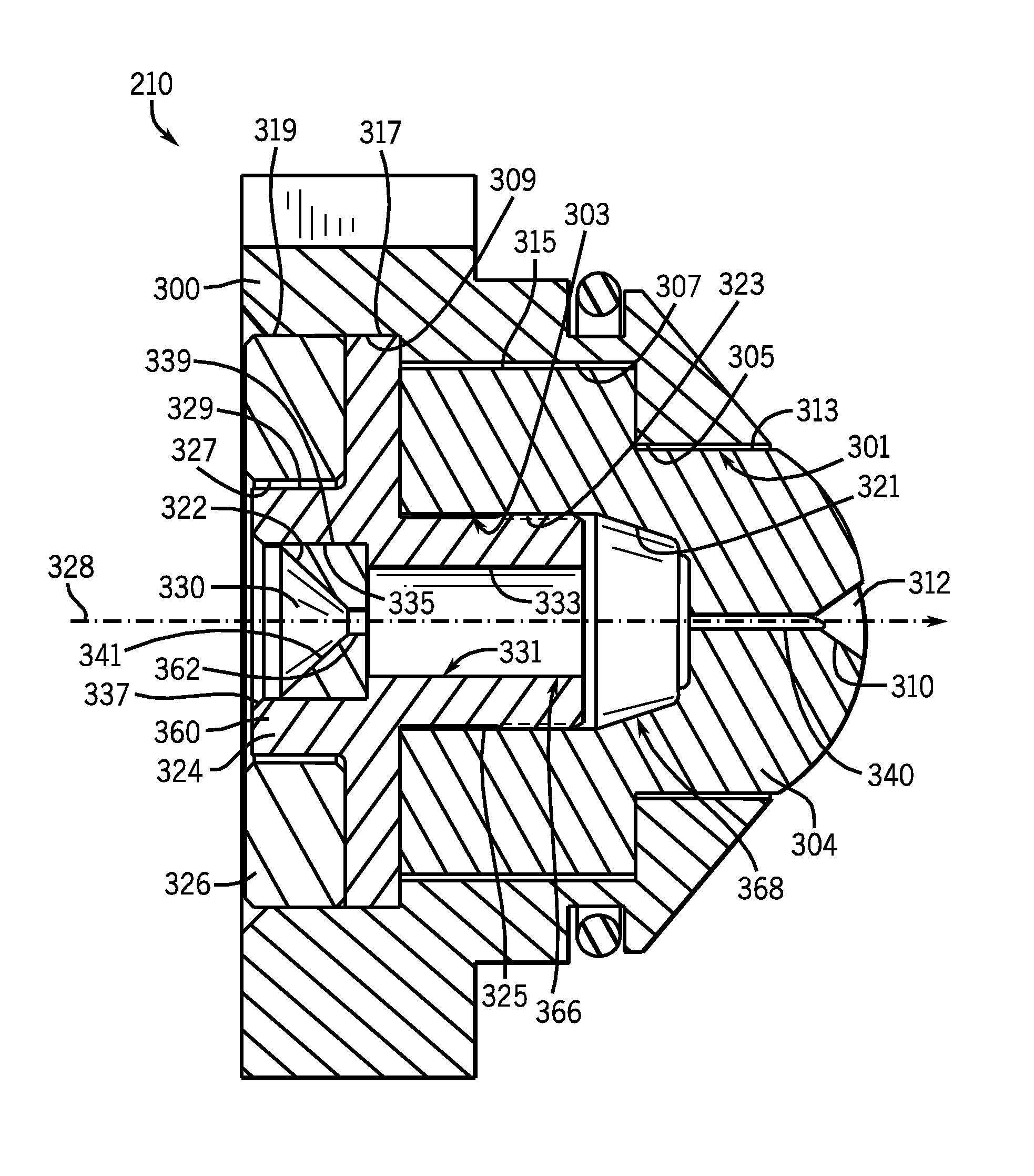

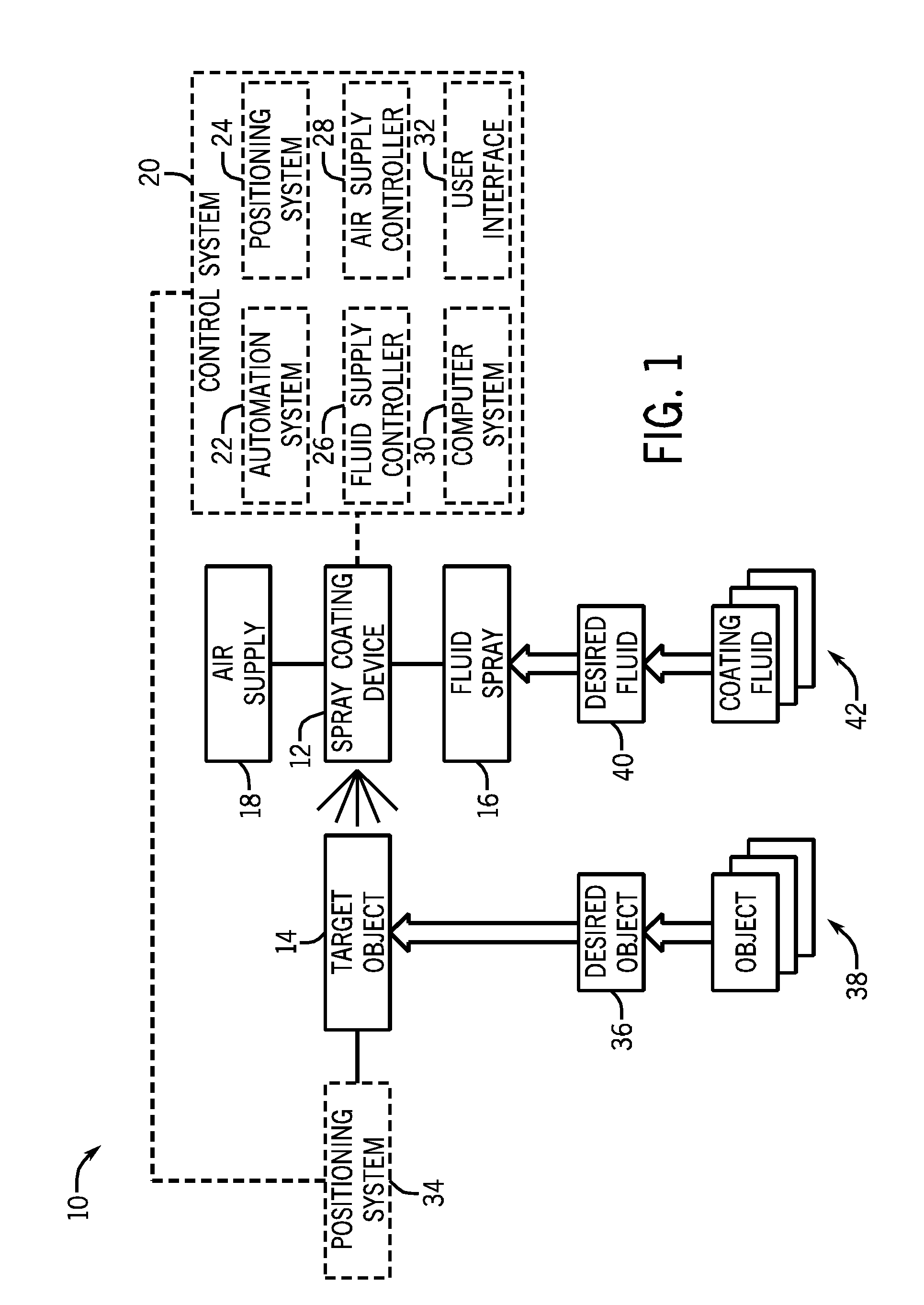

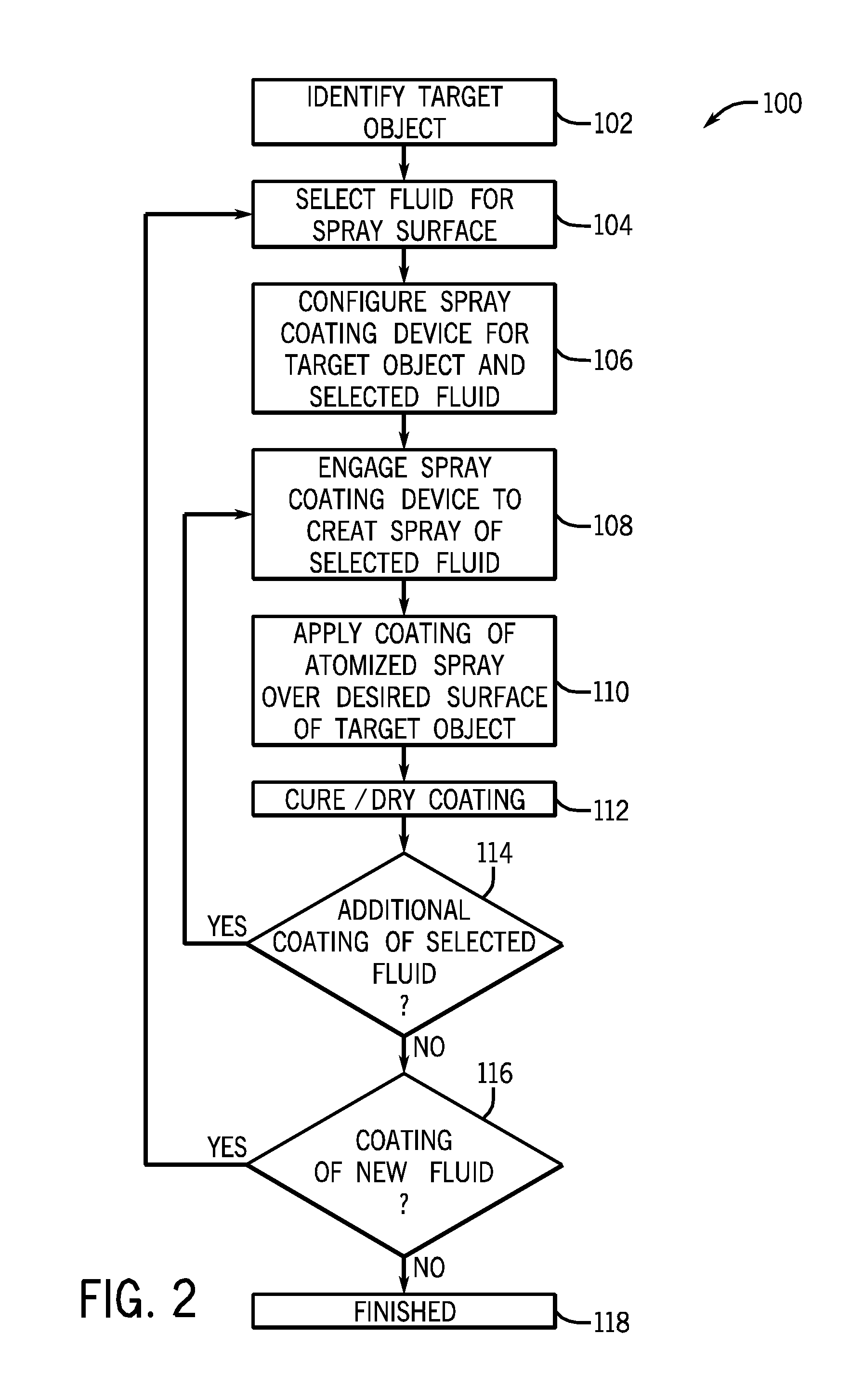

Fine Finish Airless Spray Tip Assembly for a Spray Gun

InactiveUS20120097765A1Easy to understandPromote atomizationSpray nozzlesFire rescueSpray coatingEngineering

The present technique provides a system and method for improving atomization in a spray coating device. An exemplary spray coating device of the present technique has a fine finish tip with an atomization section comprising a first fluid impingement orifice, i.e., a pre-orifice, angled toward an expansion chamber and a subsequent second fluid impingement orifice. The fine finish tip is provided as a unitary assembly that may be applied to a spray gun and that provides a fixed relationship between the pre-orifice, the expansion chamber, and the second orifice, which results in refined spray characteristics, such as uniform particle distribution and uniform fan pattern shapes.

Owner:CARLISLE FLUID TECH INC

Device and method for applying a preparation to threads

InactiveCN1969069AWill not polluteUniform atomizationTextile treatment containersFilament/thread formingEngineeringBiomedical engineering

Owner:天科部件有限公司

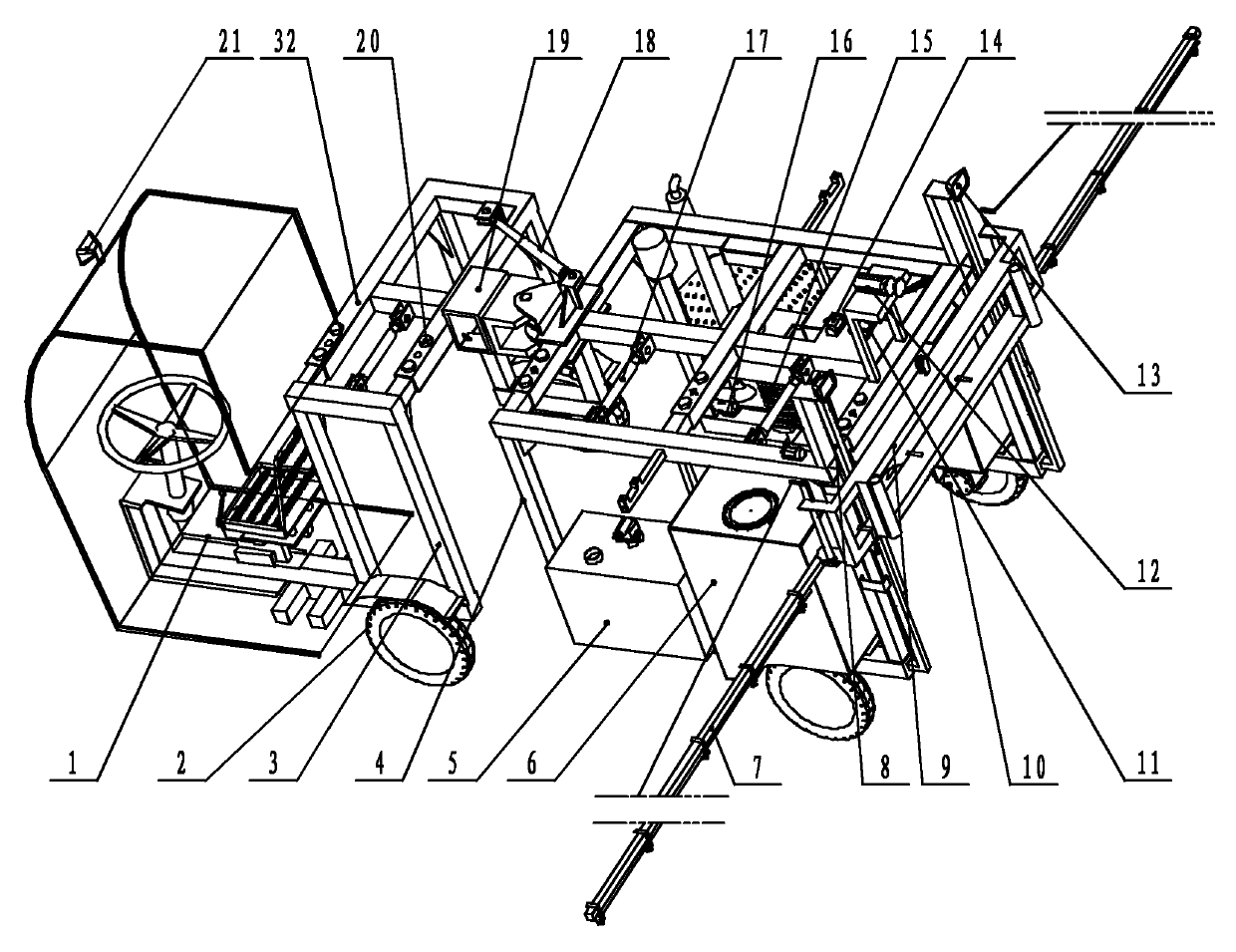

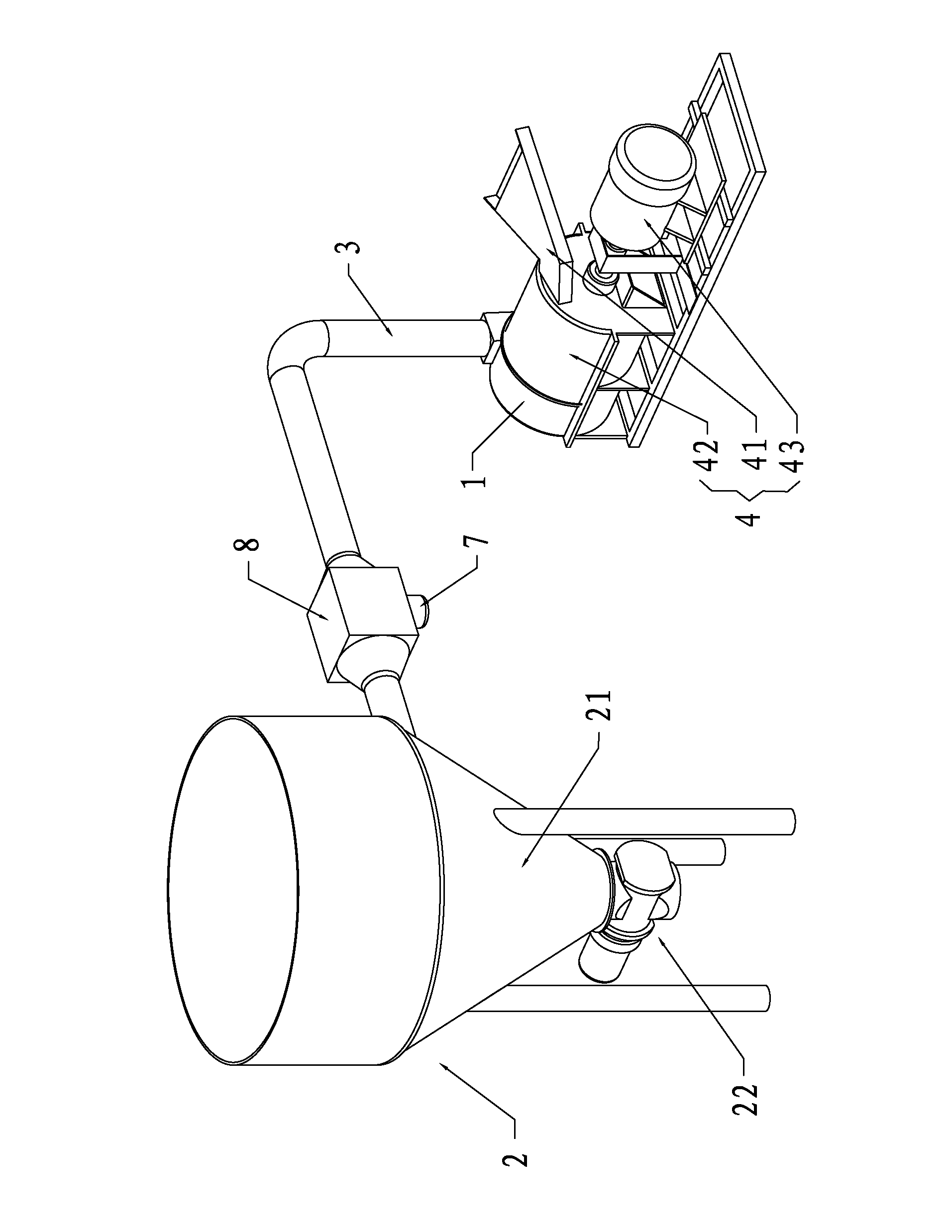

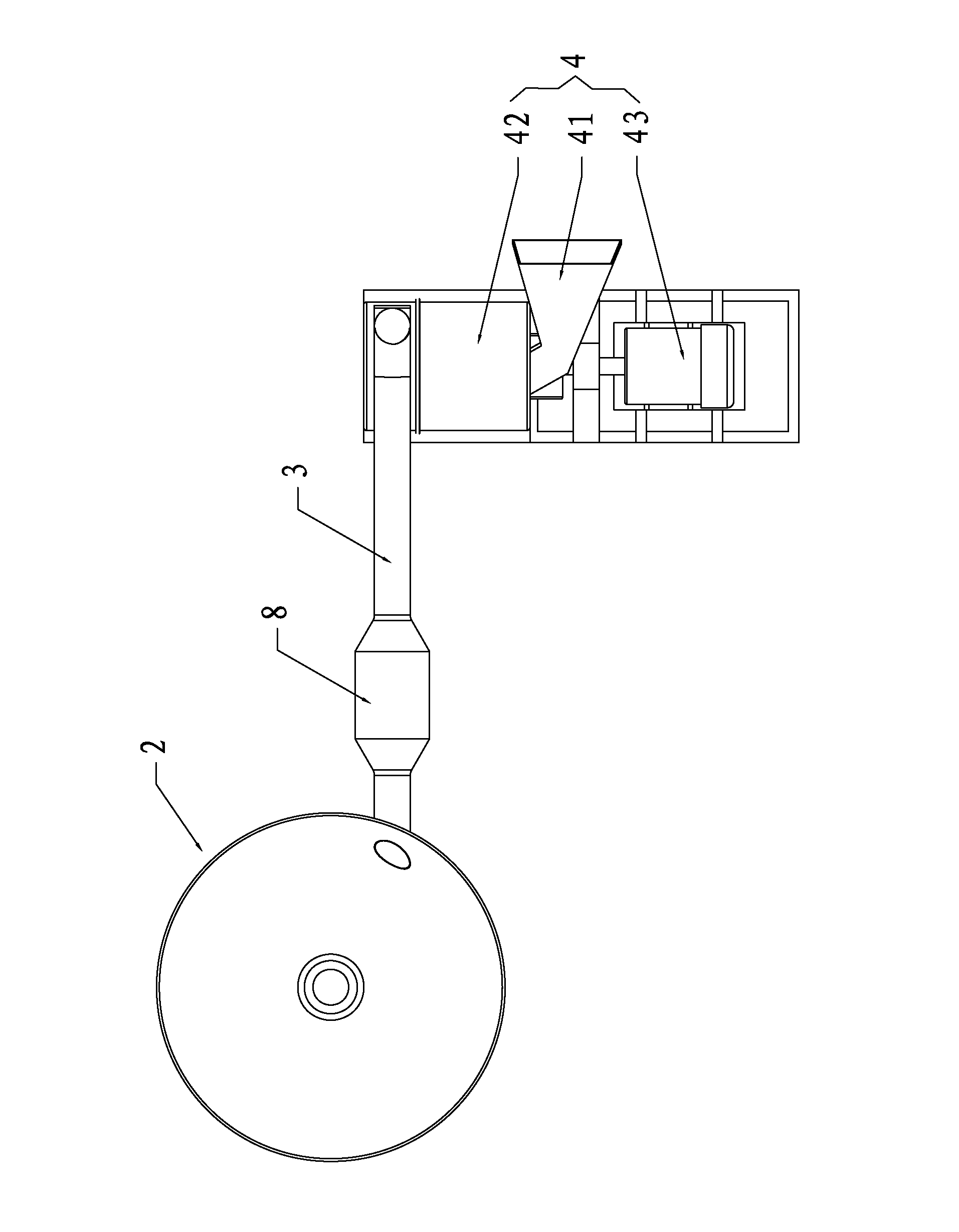

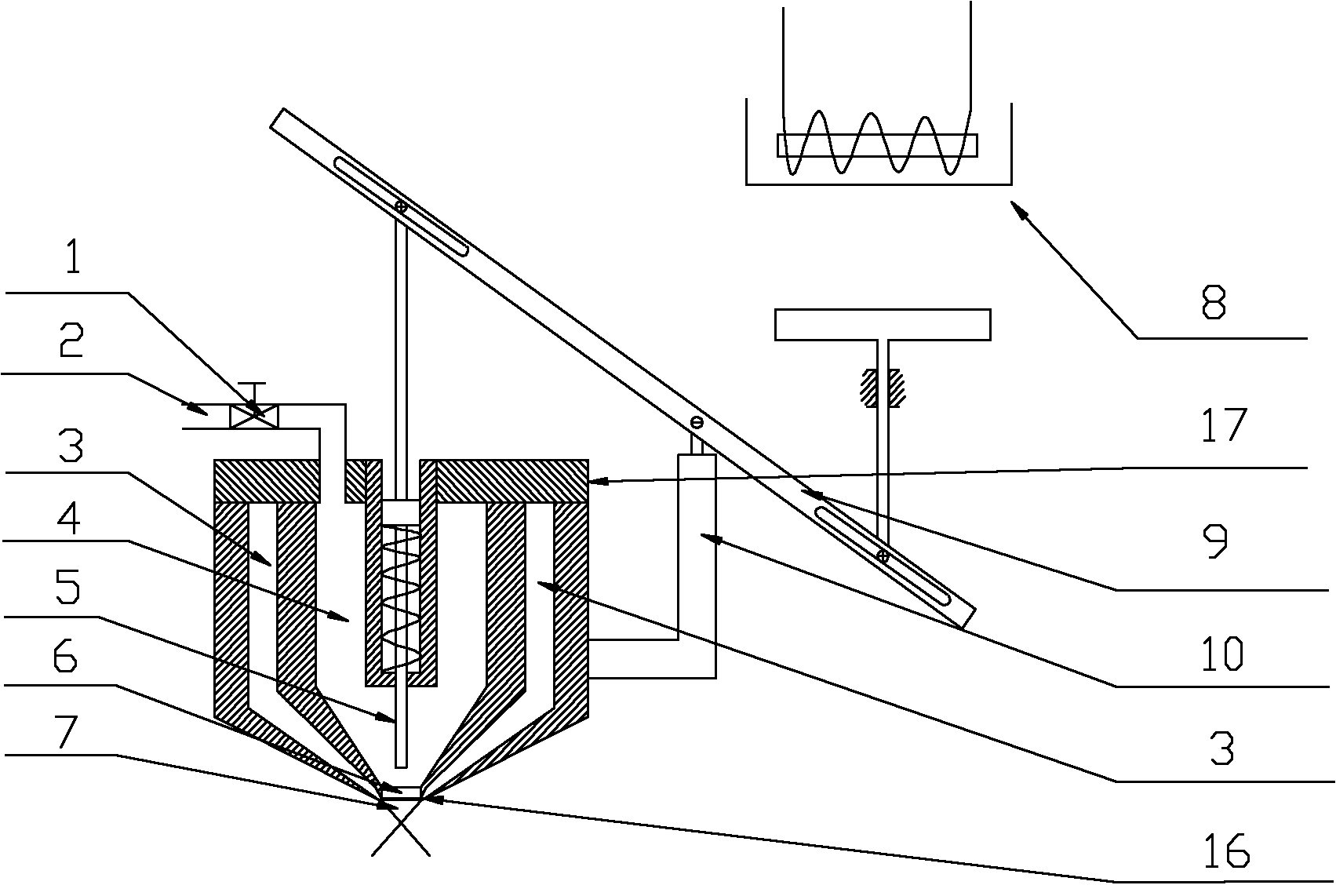

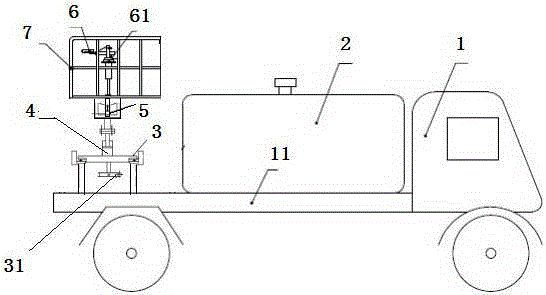

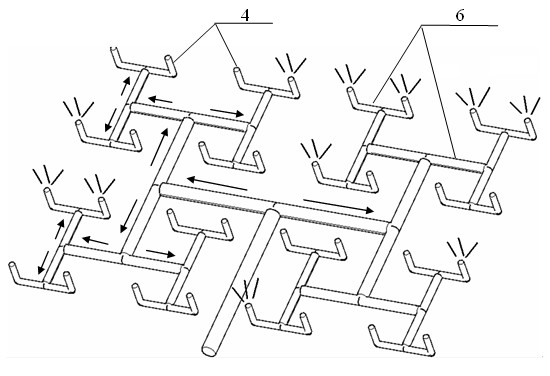

High-clearance self-propelled lance boom spraying device

InactiveCN101946756AReduce expensive equipmentAutomatic height adjustmentInsect catchers and killersVehicle frameAgricultural engineering

The invention discloses a high-clearance self-propelled lance boom spraying device, which belongs to a planting machine. The invention solves the drawbacks of low ground clearance, poor liquid medicament spraying effect, large volume, high weight and incompetence of meeting requirements of modern agriculture of the lance boom spraying device in the prior art. The high-clearance self-propelled lance boom spraying device mainly comprises a vehicle frame, and a cab, a power system, a spray system, a spray system suspending bracket, an oil tank, a medical tank, a headlight and tail lamps, which are arranged on the vehicle frame; the power system comprises a motor, a duplicate gear pump, a hydraulic driving device and wheels; the spray system comprises a spray pump and a spray lance, and a spray lance is provided with a nozzle; the spray system is arranged on the spray system suspending bracket; and the vehicle frame comprises a front vehicle frame and a rear vehicle frame which are connected by a steering and hinging device. The high-clearance self-propelled lance boom spraying device is mainly used for spraying liquid medicament on crops and particularly preventing and controlling pests in long-stalk crops such as corn, broomcorn and the like.

Owner:LINYI SANHE YONGJIA POWER

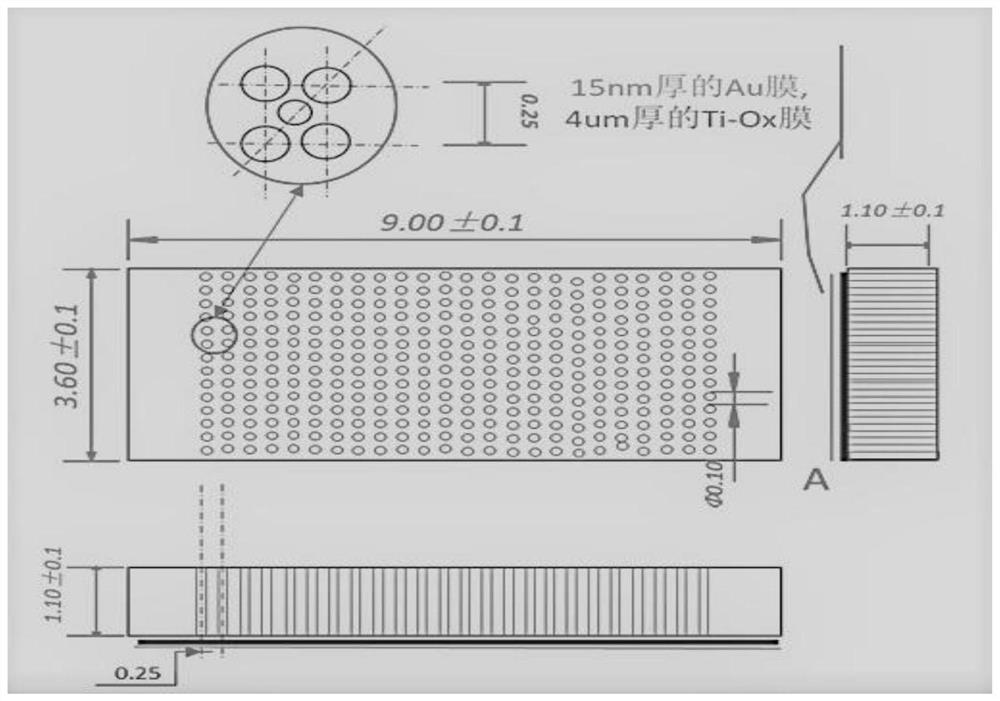

Novel atomizing core

PendingCN112385898APlay the effect of quantum atomizationUniform atomizationTobacco devicesMedical atomisersHazardous substanceAerosolize

Owner:SHANGHAI QV TECH CO LTD

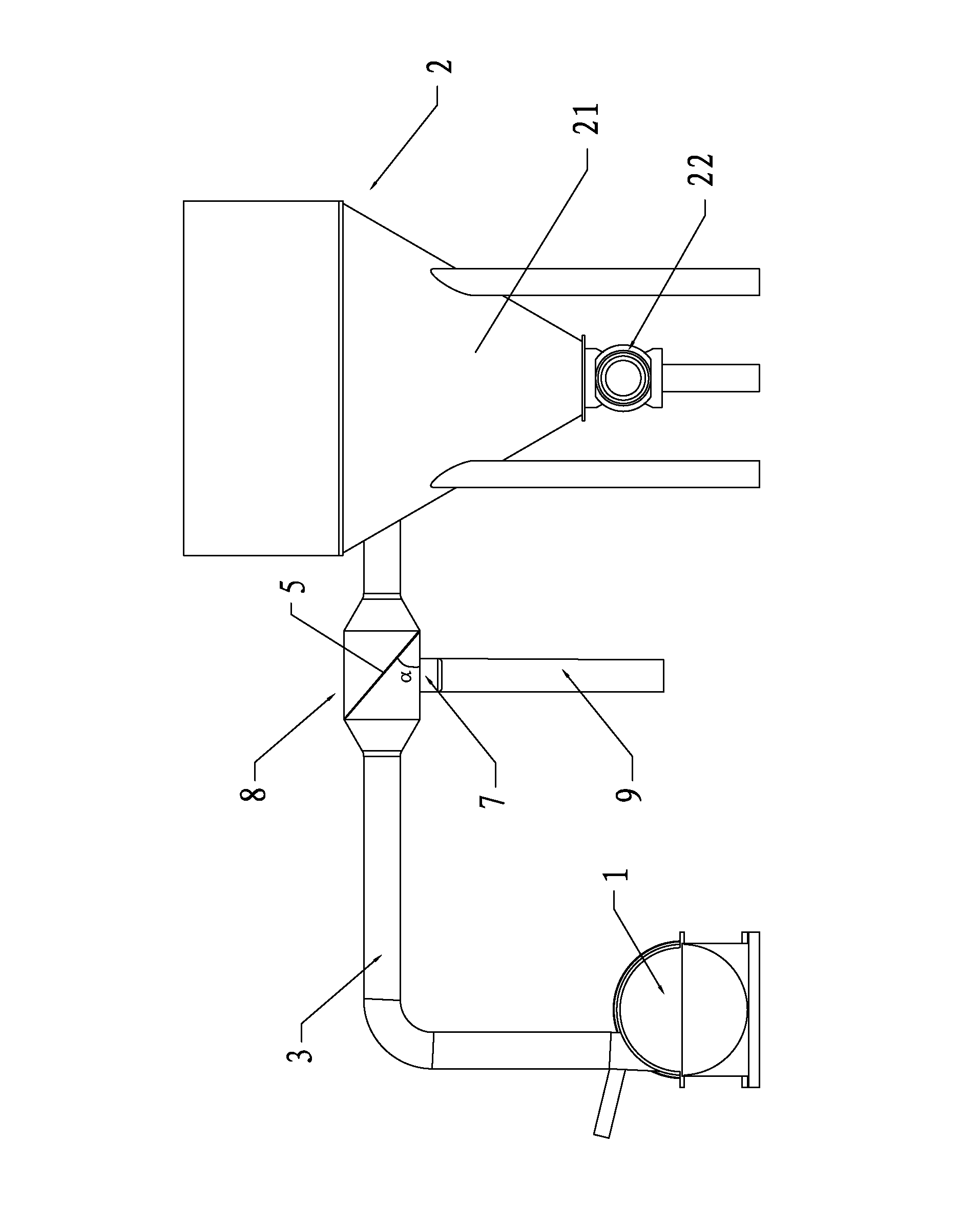

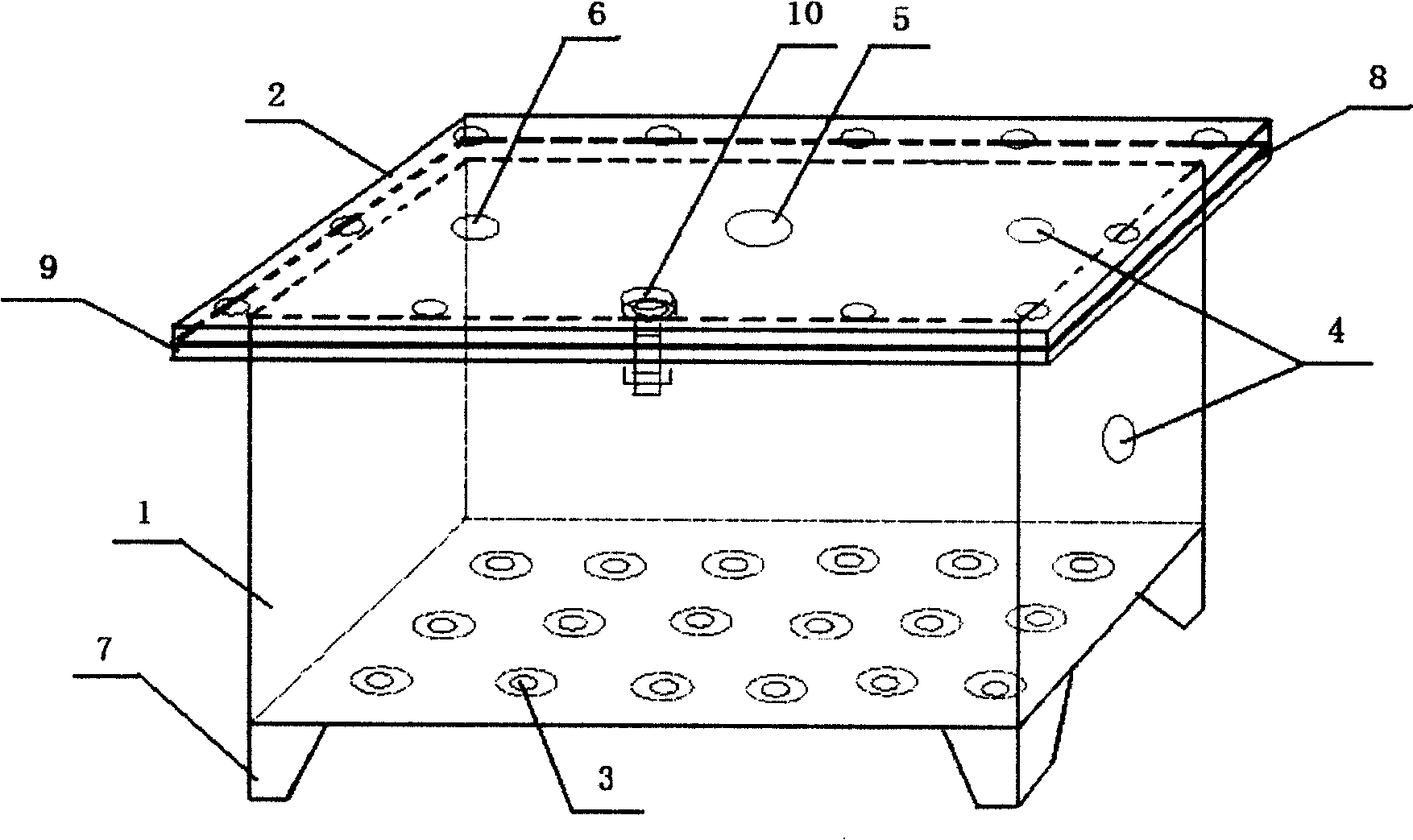

Micron-level powder material sieving equipment and sieving method

ActiveCN102430520ASimple structureReduce manufacturing costGas current separationProcess engineeringMaterials science

The invention relates to the technical field of sieving equipment, in particular to micron-level powder material sieving equipment and a sieving method thereof. The micron-level powder material sieving equipment comprises an air supply device, a material collecting device and an airflow pipeline arranged between the air supply device and the material collecting device; the air supply device is connected with a feeding device; the position of the airflow pipeline near the material collecting device is provided with a sieve screen slot; the sieve screen inserting slot is arranged obliquely; theinclined angle is 20-80 degrees; the sieve screen inserting slot is provided with a sieve screen inserting plate which is matched with the sieve screen inserting slot; a sieve screen is detachably paved on the sieve screen inserting plate; and the position of the airflow pipeline near the lower end of the sieve screen inserting slot is provided with a coarse material outlet. According to the invention, the airflow and powder materials are mixed uniformly, and the powder materials are fully atomized; moreover, the micron-level powder material sieving equipment has the characteristics of simplified technique, low production cost, high sieving efficiency, good sieving effect, high efficiency, energy saving, and convenience for widespread popularization and application.

Owner:李文胜

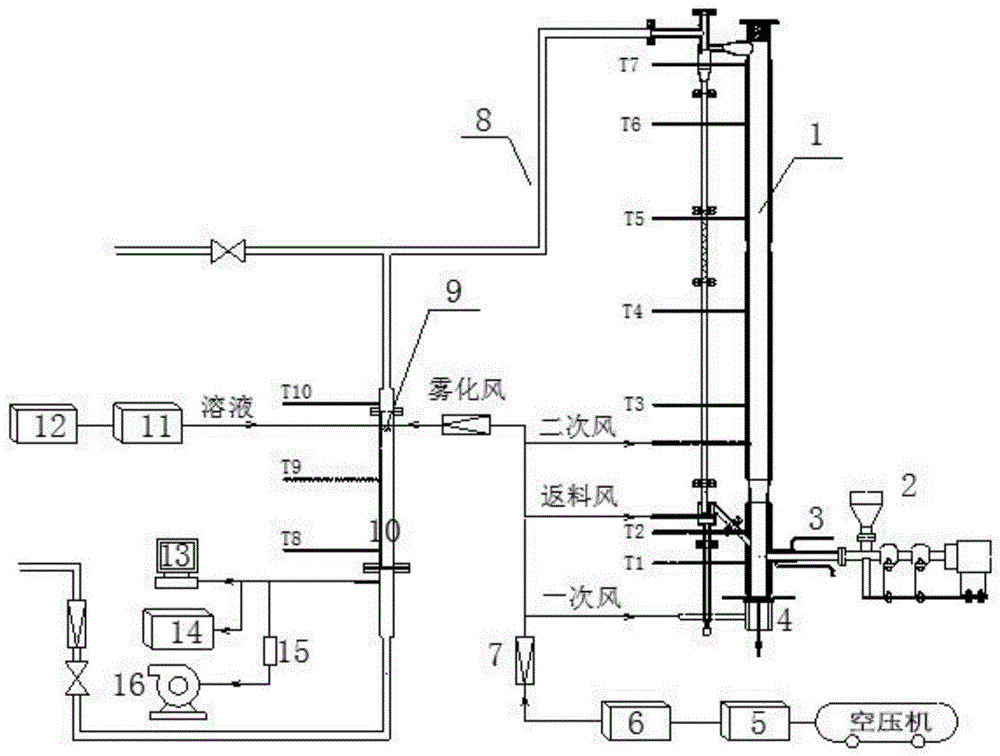

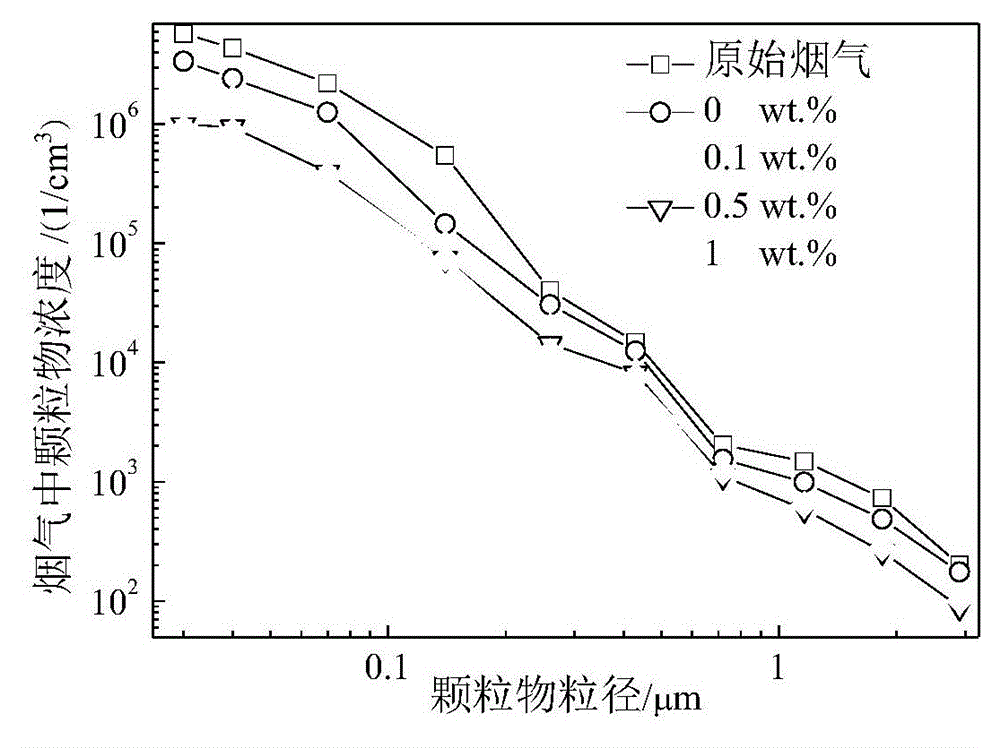

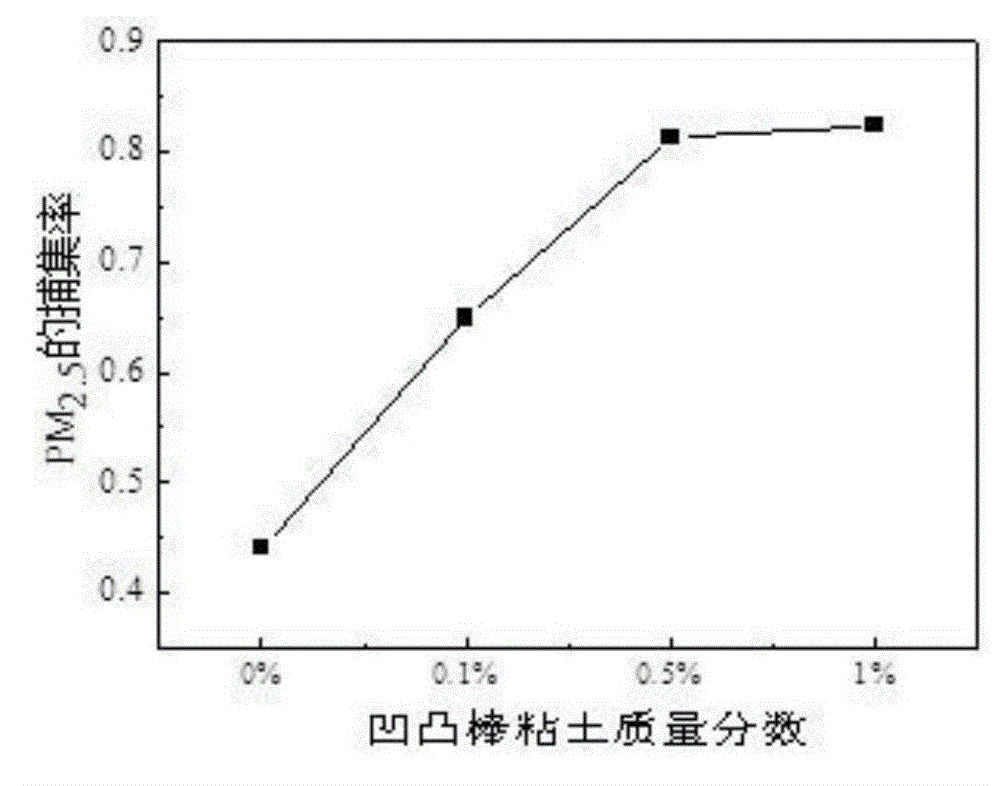

Method for trapping coal-fired PM2.5 by using agglomeration of attapulgite turbid liquid

ActiveCN104147890AImprove exchange capacityHigh specific surface areaAuxillary pretreatmentActive agentFlue gas

The invention discloses a method for trapping coal-fired PM2.5 by using agglomeration of an attapulgite turbid liquid. The method comprises the steps of grinding attapulgite into particles with diameters smaller than those of a 200-mesh sieve; adding the attapulgite particles into water according to a mass percentage concentration of 0.1-1% to form a turbid liquid; and at the same time, adding a surfactant in the turbid liquid and controlling a pH value of the turbid liquid to 5-7 while stirring the turbid liquid continuously. The turbid liquid is pumped into a flue with a temperature of 110-350 DEG C in front of a deduster according to a volume flow rate of the turbid liquid accounting for 0.01-0.1% of a flue flow volume by a liquid pump; a mass ratio of atomized air to the attapulgite turbid liquid is 0.25-0.5; the turbid liquid is atomized into 20-50 [mu]m fog drops through a two-fluid spray nozzle; the fog drops are mixed with the coal-fired flue gas to make fine particles in the flue gas to grow by agglomeration, thereby facilitating subsequent trapping of a conventional deduster and greatly reducing emission of PM2.5 in the flue gas.

Owner:SOUTHEAST UNIV

Preparation method of tungsten carbide coating layer sprayed on surface of aluminum base material through explosion

InactiveCN104213064AReduce overheatingHigh hardness and bonding strengthMolten spray coatingPropellerAluminum matrix composites

The invention discloses a preparation method of a tungsten carbide coating layer sprayed on a surface of an aluminum base material through explosion. The preparation method comprises the following steps: (1) the surface of an in-situ synthesis TiB2 particle-reinforced aluminum base material is pretreated by adopting an oil removing and shot blasting process; (2) a wear resisting and corrosion resisting WC-10Co4Cr coating layer is prepared on the surface of the in-situ synthesis TiB2 particle-reinforced aluminum base material by adopting a pulse explosion spraying method; and the temperature of the aluminum base material is controlled within 60-120 DEG C; (3) after the spraying is finished, the coating layer is grinded and finished by adopting a diamond grinding wheel; and (4) the coating layer is closed by adopting epoxy resin sealant. The method can prepare the coating layer on the surface of a composite material of a propeller hub plywood of a connecting piece of a helicopter rotor system so as to improve the corrosion resistance of the surface of the TiB2 particle-reinforced aluminum base composite material, and can effectively prevent the invalidation caused by fretting wear and surface scratching so as to prolong the fatigue fracture resisting service life of the material above 3 times.

Owner:KING STRONG MATERIAL ENG LTD +1

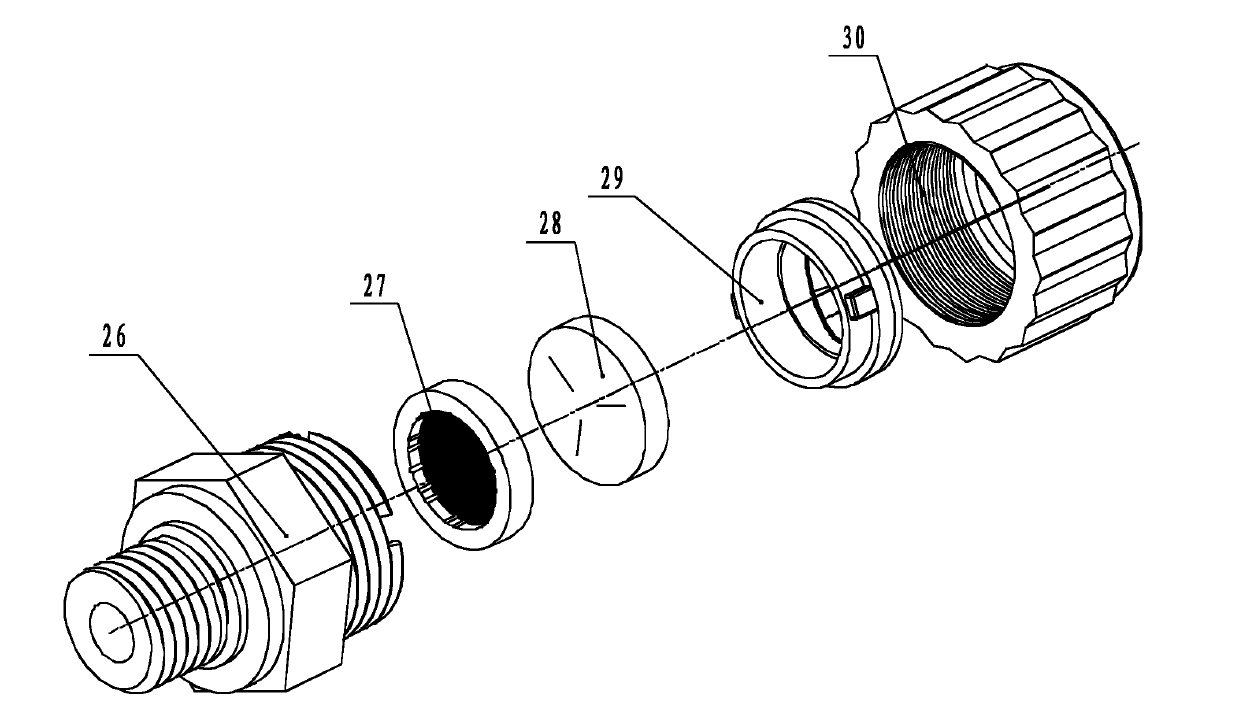

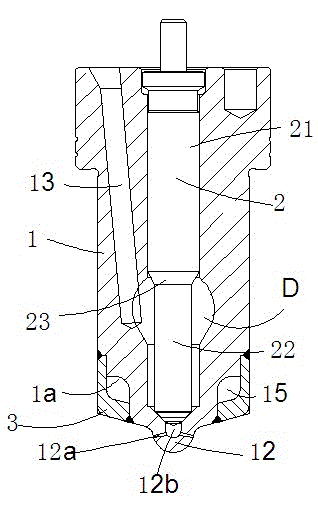

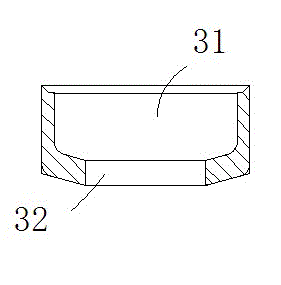

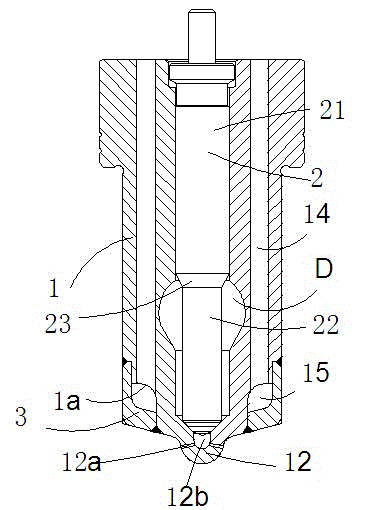

Cooling-type needle valve coupling with carbon deposition prevention effect

ActiveCN102979654ASlow coolingImprove cooling effectFuel injection apparatusMachines/enginesCouplingCooling chamber

The invention discloses a cooling-type needle valve coupling with a carbon deposition prevention effect. The cooling-type needle valve coupling comprises a needle valve body and a needle valve, which are assembled with each other. The needle valve is assembled in a valve chamber which is machined in the needle valve body; an annular clearance passage, through which a high pressure fuel passes, is formed between the outer circumference of the lower rod body of the needle valve and the inner wall of the valve chamber; and the annular clearance passage is communicated with an oil inlet passage. The cooling-type needle valve is characterized in that a cooling water jacket is fixedly mounted to the lower part of the needle valve body, a cooling chamber is formed between the cooling water jacket and the needle valve body, the needle valve body is provided with at least one group of cooling annular passages, the cooling annular passages are communicated with the cooling chamber, the opening at the two ends of each cooling annular passage are formed in the upper surface of the needle valve body; at least two jet holes are formed in the front end of the needle valve body and are communicated with the annular clearance passage. The cooling-type needle valve coupling has the advantages of smart structure, good performance, low oil consumption, less carbon deposition in the nozzle and long service life and can meet the needs for oil-fuel injector needle-valve couplings in marine diesel engines.

Owner:YUYAO SHUCHUN MACHINERY

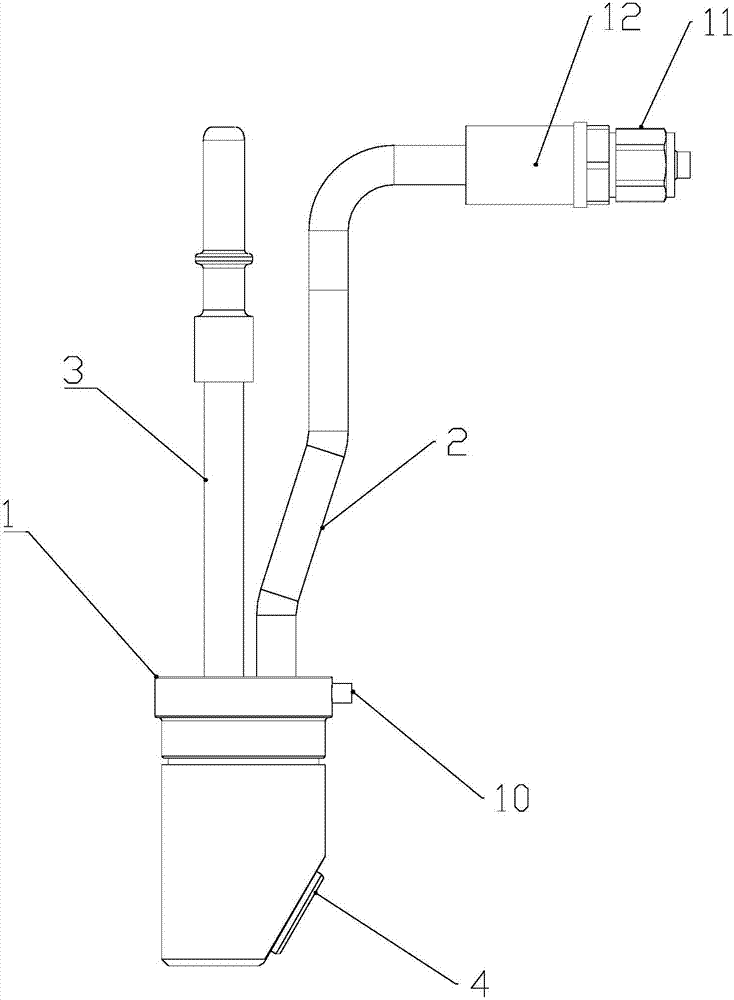

Efficient anti-crystallization urea spray nozzle

InactiveCN106870073AStrong tendon dischargePrevent crystallizationExhaust apparatusSilencing apparatusSpray nozzleEngineering

The invention relates to a high-efficiency anti-crystallization urea nozzle, comprising a nozzle housing, an air guide pipe and a urea guide pipe connected to the top of the nozzle housing, the nozzle housing is cylindrical, and a spray surface is provided on one side of the lower end of the nozzle housing. The spraying face extends inside the nozzle housing to form a spraying seat; the nozzle housing is provided with a cavity, and the cavity is connected to the air guide tube; the center of the spraying seat is connected to the urea guide tube, and the urea guide tube is arc-shaped transition to the center of the spraying seat, and the urea The guide tube extends to the injection surface to form the outlet of the urea solution; the injection seat forms an air ring cavity around the periphery of the urea guide tube, and the air ring cavity includes an air introduction section, an air buffer section, and an air injection section, and the air introduction section is set in the air ring cavity At the edge, the end of the air introduction section communicates with the air buffer section, the air buffer section communicates with the air injection section, and the air injection section extends to the injection surface to form an air outlet. The invention has smooth ejection, uniform atomization, and better effect of catalytic reduction of tail gas.

Owner:北京凯德斯环保科技有限公司

Preparation method of detonation-sprayed tungsten carbide wear-resistant coatings

The invention discloses a preparation method of detonation-sprayed tungsten carbide wear-resistant coatings which can be applied to connecting pieces of helicopter rotor systems. The method comprises the following steps: carrying out cleaning and sand blowing treatment on the surface of a substrate of a workpiece; preparing a tungsten carbide wear-resistant coating on the surface of the substrate of the workpiece by using a detonation spraying method, and controlling the temperature of the substrate of the workpiece at 60-120 DEG C; and after the detonation spraying is completed, carrying out grinding finish-machining on the coating by using a diamond or cubic boron nitride grinding wheel until the surface of the coating on the substrate of the workpiece has no burn and crack; the microhardness HV0.3 of the coating is 1000-1400; the bonding strength of the coating and the substrate of the workpiece is greater than or equal to 70 MPa; the porosity is less than or equal to 1.0; and the oxygen content is less than or equal to 2%. Once the method provided by the invention is adopted for carrying out spraying treatment on the surface of a connecting piece of a helicopter rotor system, the failure of parts caused by fretting wear and surface tear can be effectively avoided, so that the service life of the coating can be increased by 5-8 times.

Owner:KING STRONG MATERIAL ENG LTD +1

Lime slurry atomizing method and device for treating household waste incineration smoke

ActiveCN102000493AConcentration control onlineAvoid cloggingDispersed particle separationLitterEngineering

The invention relates to a lime slurry atomizing method and device for treating household waste incineration smoke, used for removing acid gaseous pollutants of HCl, SOx and the like in the smoke in the household waste incineration industry and belonging to the field of smoke treatment. A double-fluid atomizing step is adopted, one path of fluid passes through a lime slurry solution and two paths of fluid pass through a water path, water is pumped in a feeding pipe by the pressurization of a pressurizing pump along a tangential direction of an inlet, lime slurry concentrated liquid is dispersed and atomized under the action of pressure and speed after sprayed from an annular narrow hole to obtain fine particles, and a mixture is obtained while the atomization is carried out; and supply of the slurry and the water is regulated through an automatic flow control valve, and on-line regulation is realized according to the quantity of the acid gaseous pollutants and the change of the smoke temperature. For example, a nozzle is blocked, an electromagnet is controlled to be powered on or off through pressure detection, and a needle core is driven by a connecting rod to move up and down along the axial direction for getting through the blockage.

Owner:BMEI

Preparation method of tourmalinite fuel oil activator

ActiveCN103980964AStrong NMR propertiesImprove conductivityLiquid carbonaceous fuelsWater useCombustion

The invention discloses a preparation method of a tourmalinite fuel oil activator. The tourmalinite fuel oil activator comprises tourmalinite nano-powder as a main functional component. The preparation method comprises the following steps of compounding the tourmalinite nano-powder and spinel ferrite, mixing the compound and an additive according to a mass ratio of the tourmalinite nano-powder, the spinel ferrite to the additive of 87-93: 5-9: 2-4, carrying out sintering to obtain a solid mixture, and adding water and a surfactant into the mixture, wherein the amount of the used mixture is 1-5% the total amount of the solid-liquid mixture, a water use ratio is in a range of 5-98% and a surfactant use ratio is in a range of 2-30%. The tourmalinite fuel oil activator obtained by the preparation method can improve fuel oil quality, promote full combustion of fuel oil, improve combustion efficiency, save fuel oil, improve fuel oil atomization quality, and realize full combustion of fuel oil thereby reducing discharge of harmful gas so that energy saving and emission reduction are realized.

Owner:丘寿勇 +1

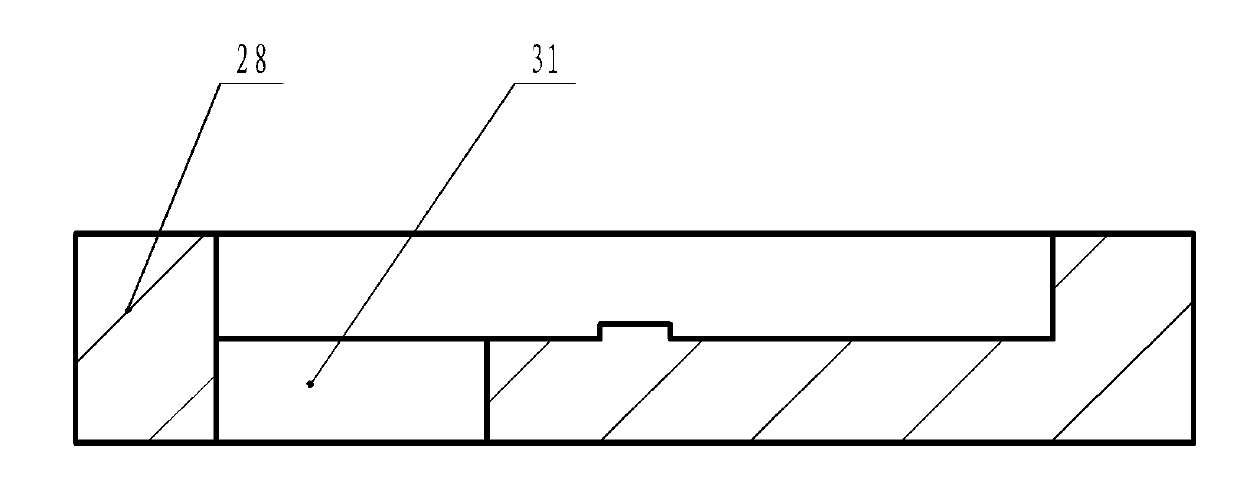

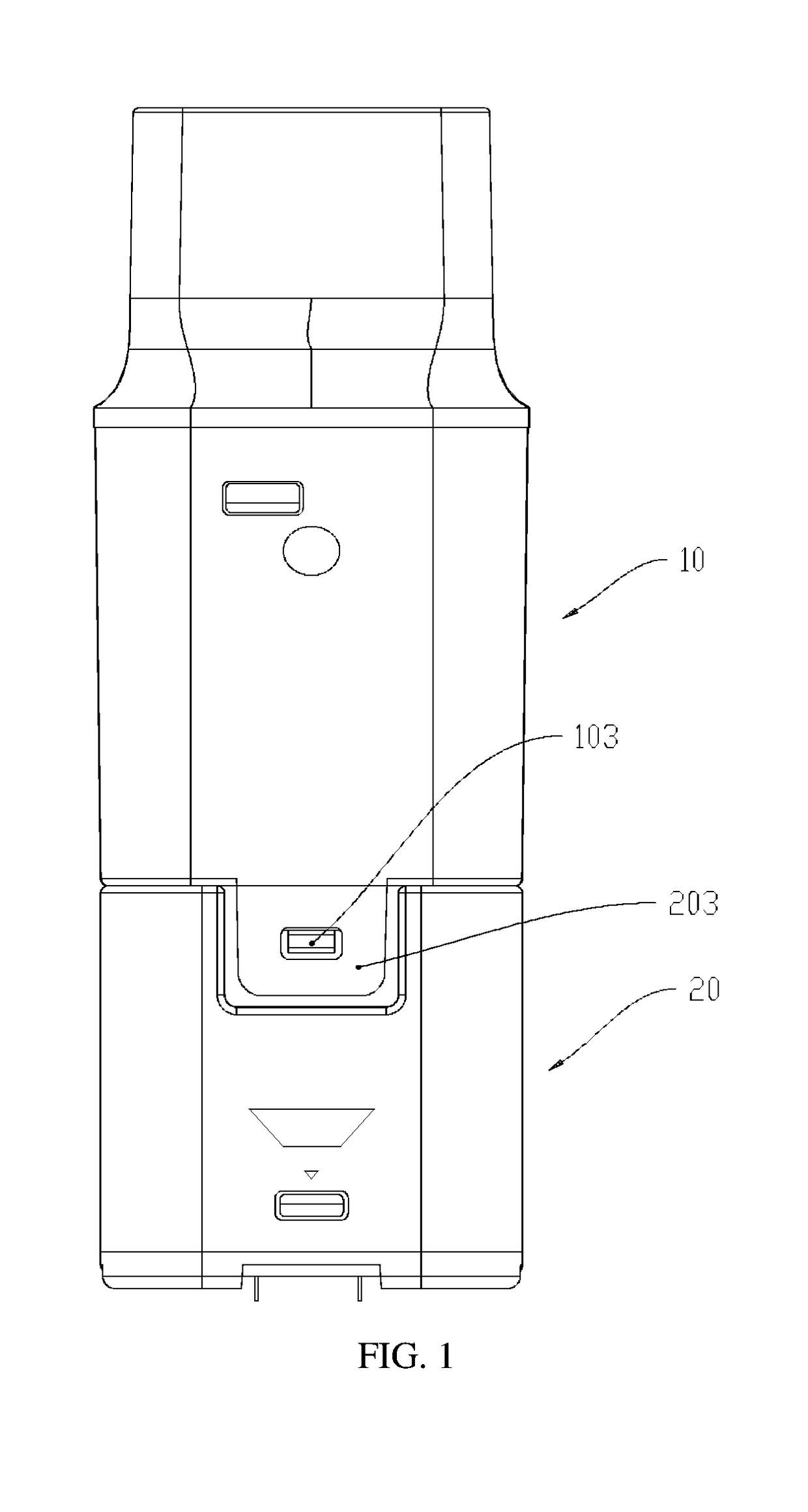

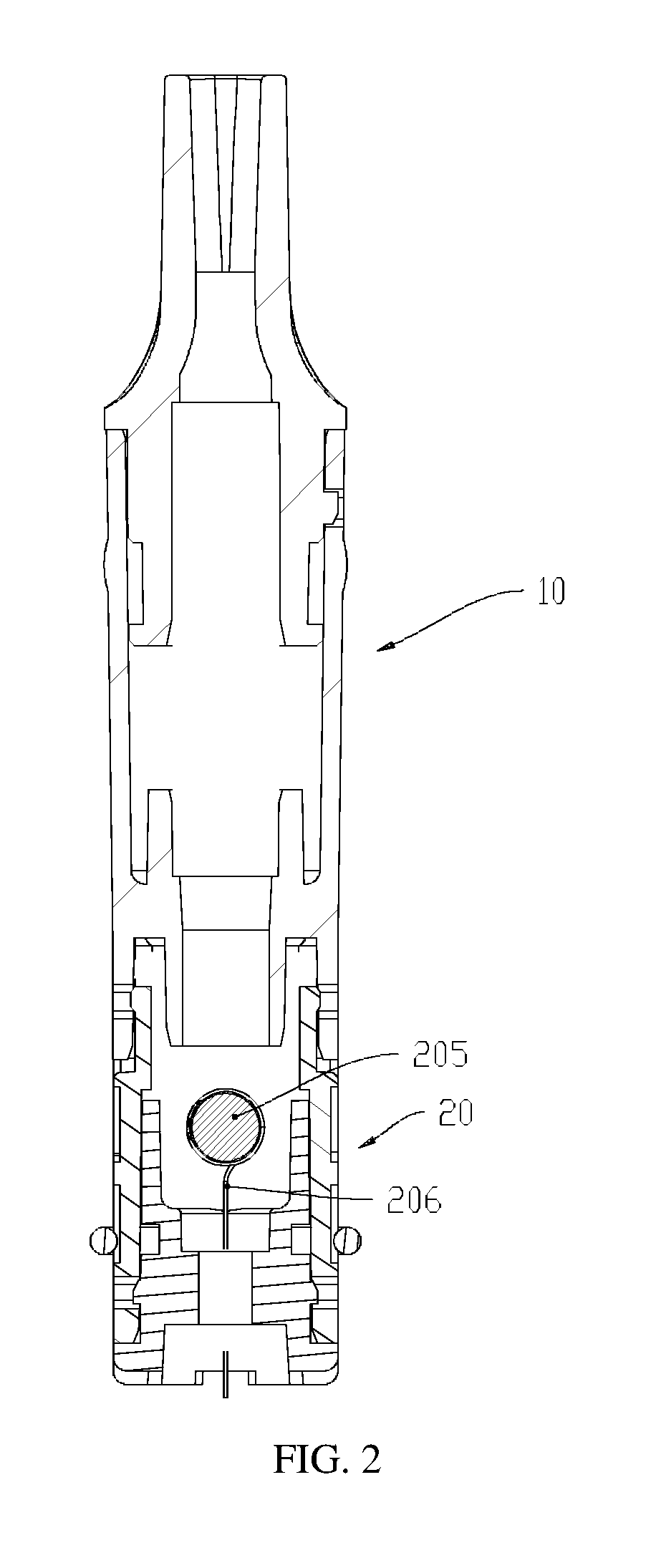

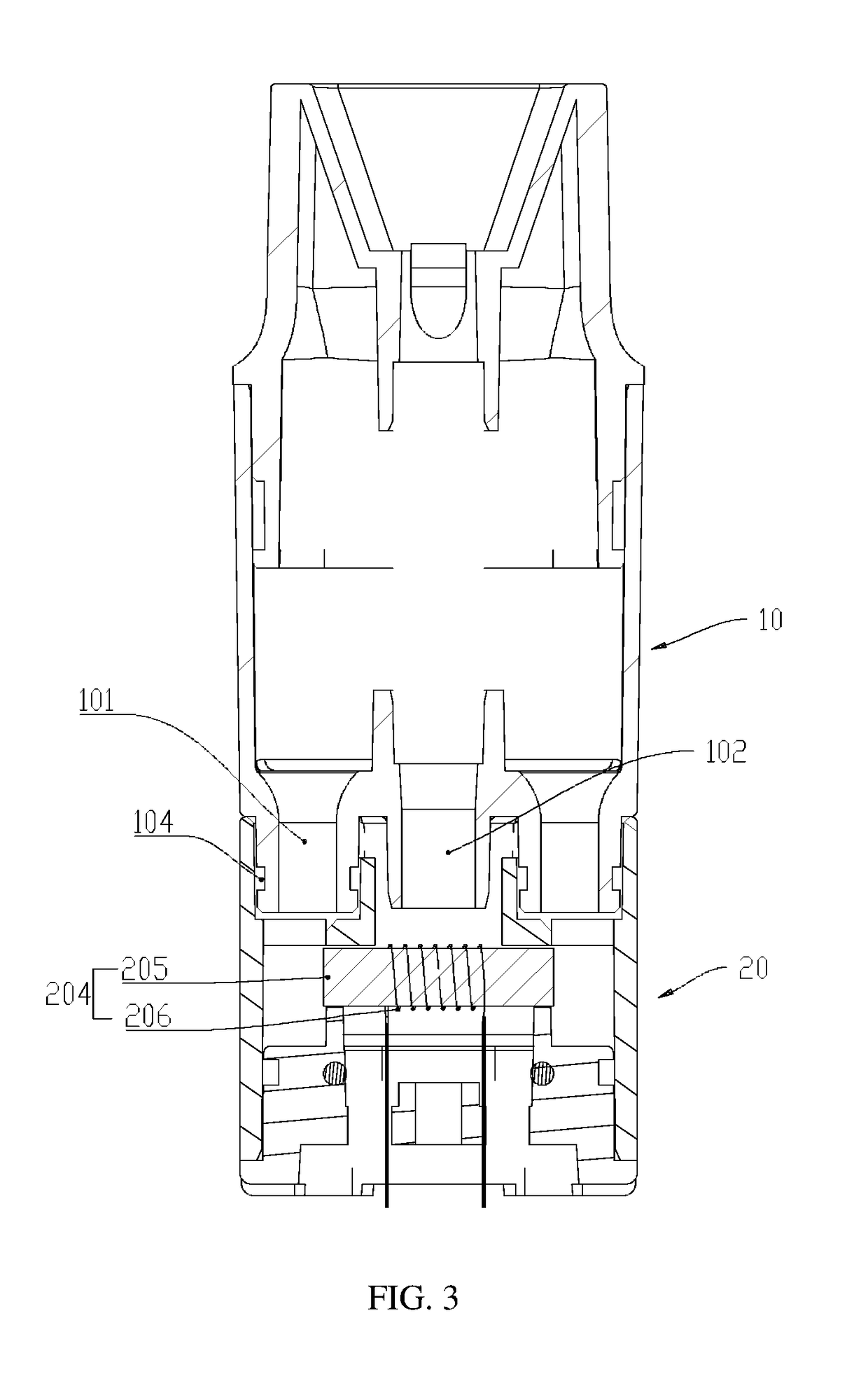

Atomizer compartment structure

ActiveUS10219547B2Simple structureLow production costOhmic-resistance waterproof/air-tight sealsHeater elementsStorage tankOil storage

An atomizer compartment structure includes an oil storage compartment and a heating core support. The upper end of the oil storage tank is a closed end, and the lower end of the oil storage tank has a tubular oil conduit and an air conduit, and the external wall of the oil storage compartment has a latch buckle disposed at an end near the air conduit. The upper end of the heating core support has an oil filling hole corresponsive to the oil conduit and an air guide hole corresponsive to the air conduit, and the external wall of the heating core support has an engaging slot for engaging the latch buckle. When the oil storage compartment and the heating core support are latched tightly, the oil conduit extends into the oil filling hole and the air conduit extends into the air guide hole.

Owner:SHENZHEN YIYOU INT TECH

Fine finish airless spray tip assembly for a spray gun

InactiveUS8814070B2Promote atomizationImprove featuresSpray nozzlesFire rescueSpray coatingEngineering

The present technique provides a system and method for improving atomization in a spray coating device. An exemplary spray coating device of the present technique has a fine finish tip with an atomization section comprising a first fluid impingement orifice, i.e., a pre-orifice, angled toward an expansion chamber and a subsequent second fluid impingement orifice. The fine finish tip is provided as a unitary assembly that may be applied to a spray gun and that provides a fixed relationship between the pre-orifice, the expansion chamber, and the second orifice, which results in refined spray characteristics, such as uniform particle distribution and uniform fan pattern shapes.

Owner:CARLISLE FLUID TECH INC

Road water spraying vehicle

InactiveCN105200951AAdjustable spray angleLarge diffusion surfaceWatering devicesRoad cleaningHydraulic cylinderWater spray

The invention provides a road water spraying vehicle which comprises a vehicle body and a water tank, wherein the water tank is fixedly mounted on a chassis of the vehicle body; a water spraying pump communicated with the water tank is fixedly mounted on a gearbox of the vehicle body; a rotary table is fixedly mounted on the chassis at the tail part of the vehicle body; a lifting hydraulic cylinder and a swinging hydraulic cylinder which are connected are arranged on the rotary table in sequence; the road water spraying vehicle further comprises a water gun communicated with the water spraying pump; a supporting device of the water gun is connected with the swinging hydraulic cylinder; a rectangular protective device is arranged above the rotary table; the protective device comprises a fixed guardrail and a detachable movable guardrail. The spraying position of the water gun can be lifted and rotated, the flexibility and mechanization levels are better, and manual participation is reduced.

Owner:HUZHOU ZHONGHENG GARDEN CONSTR

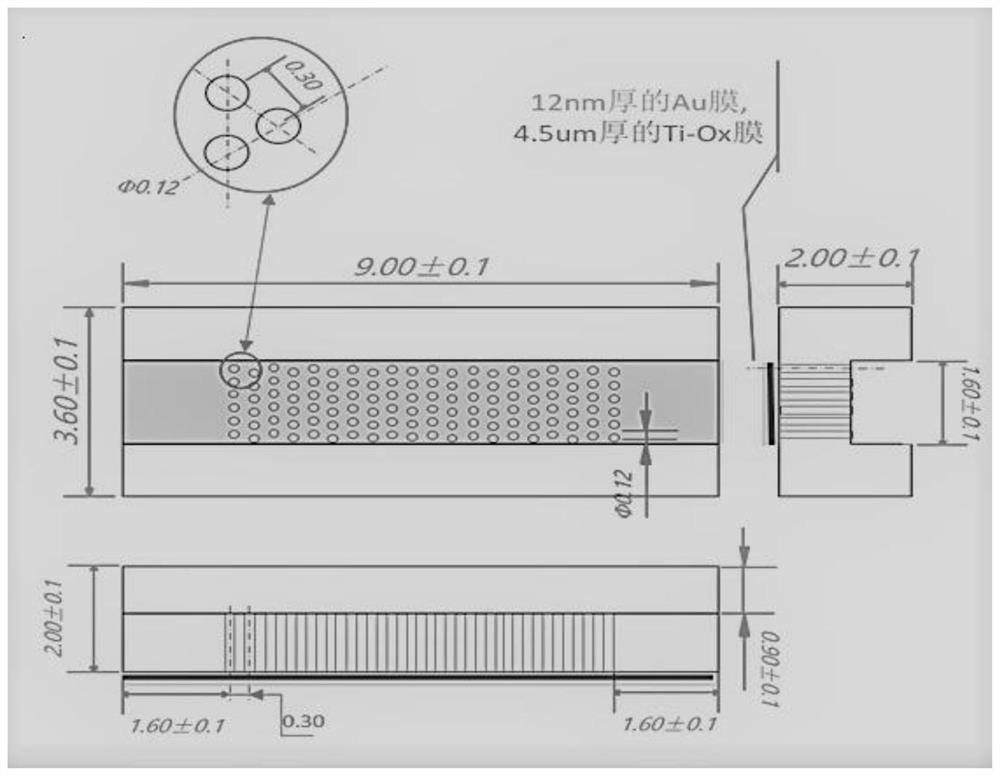

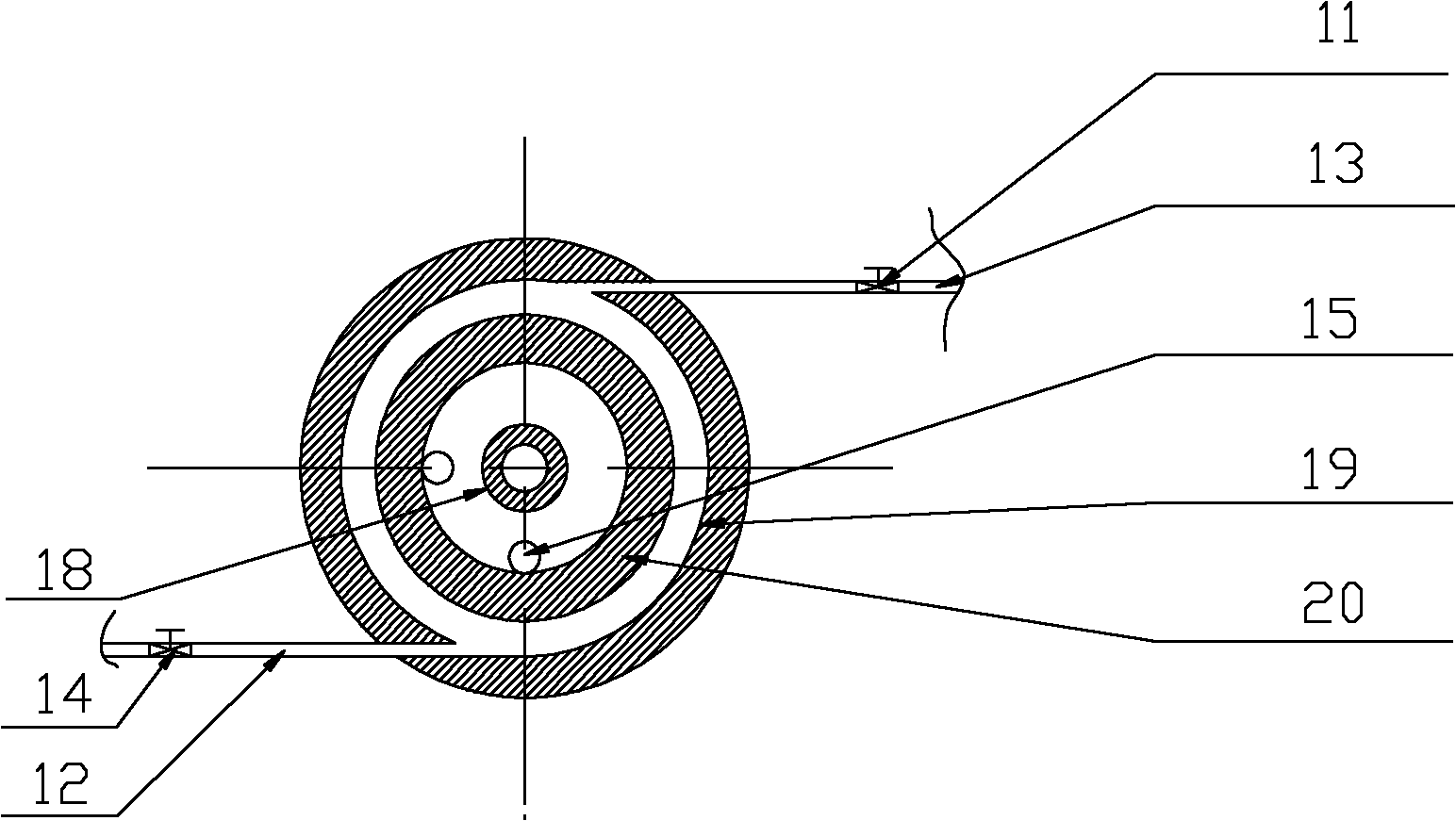

Ultrasonic spray generator special for preparing large-area transparent conductive film

InactiveCN101318166AThe solution is atomized evenlyUniform atomizationFinal product manufactureLiquid spraying apparatusElectrically conductiveCorrosion resistant

The invention discloses a special ultrasonic spray generator for preparing large-area transparent conductive membrane, comprising a case and a plurality of ultrasonic atomizers arranged on the soleplate at the bottom of the case; outer flange is arranged at periphery of the top of the case; an upper cover is arranged on the outer flange at the top of the case; at the same time a corrosion-resistant rubber insert is arranged between the upper cover and the outer flange of the case; a carrier gas inlet is arranged on a side of the case; besides, foundation bolts are arranged at the four sides at the bottom of the case; the upper cover of the case is hermetically connected with the case through bolts and the corrosion-resistant rubber insert; the carrier gas inlet, a solution inlet and a spray outlet are respectively arranged on the upper cover of the case; the plurality of ultrasonic atomizers are corrosion-resistant ultrasonic atomizers. The ultrasonic spray generator provided by the invention arranges a plurality of corrosion-resistant atomizers in the case to be directly contacted with chemical solution, has the advantages of even solution pulverization and high spray efficiency, and can meet the requirements for preparing the large-area transparent conductive membrane effectively and stably.

Owner:NANKAI UNIV

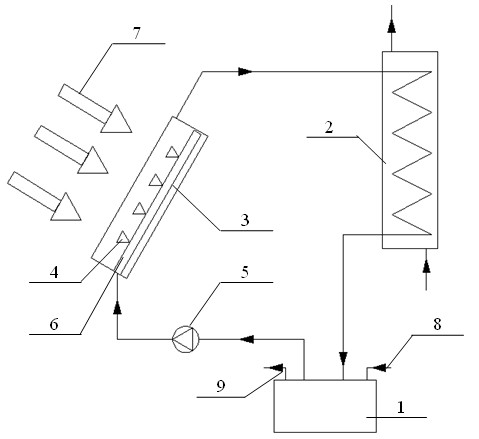

Spray cooling device for cooling heat source with high heat flux

ActiveCN102322751AEfficient take awayTake away quicklyStationary conduit assembliesEngineeringSpray cooling

The invention discloses a spray cooling device for cooling a heat source with high heat flux. The spray cooling device comprises a spray cooler, a pump, a liquid storage drum and a condenser, wherein one end of the spray cooler is connected with the liquid storage drum through the pump, the other end of the spray cooler is connected with the inlet of the condenser, the outlet of the condenser is connected to the liquid storage drum, the spray cooler is internally provided with a transmission pipeline with a configuration characteristic, the inlet of the transmission pipeline with the configuration characteristic is connected with the liquid storage drum through the pump, and the outlet of the transmission pipeline with the configuration characteristic is provided with an atomizer. According to the spray cooling device provided with the transmission pipeline with the configuration characteristic, the transport optimal allocation of a working medium in the spray cooling device is realized, the evenness level of fluid atomization is improved, and the cooling performance of the spray cooler is intensified.

Owner:SOUTHEAST UNIV

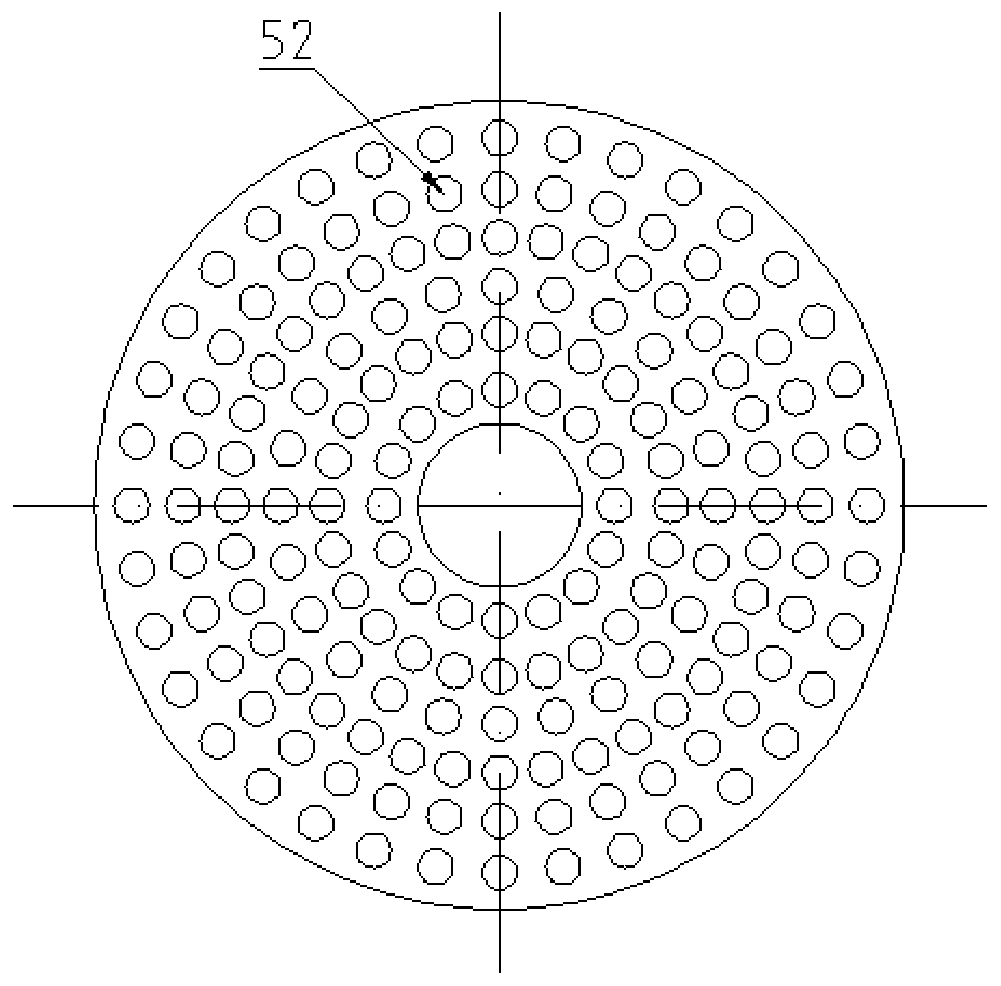

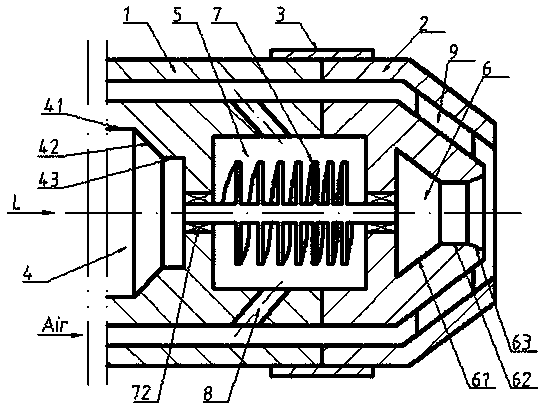

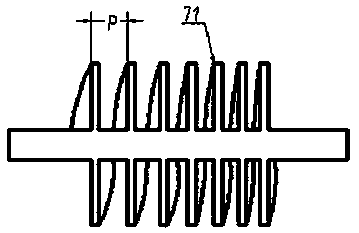

Glazing device for tile production equipment

ActiveCN109940746ACollision uniformCollision stabilizationCeramic shaping apparatusSpray nozzleEngineering

The invention discloses a glazing device for tile production equipment. The glazing device for tile production equipment comprises a spray gun, wherein the spray gun is provided with a nozzle; the nozzle comprises a first body (1), a second body (2), a connecting element (3), a fluid channel (4), a mixing oscillation cavity (5), an outlet part (6), a spiral rotor (7), a gas channel, wherein the fluid channel, the mixing oscillation cavity and the outlet part are sequentially arranged in the fluid flow direction, the glazing device is characterized in that the mixing oscillation cavity (5) is internally provided with the spiral rotor (7), the spiral rotor comprises spiral blades (71) and a rotating shaft, the spiral blades are arranged on the periphery of the rotating shaft, the two ends ofthe rotating shaft are connected with guide frames (10) through bearings (72), the two guide frames are positioned on the first body and the second body respectively. Through the design of the spiralrotor and air inlet holes, the glaze liquid / the liquid is atomized into smaller atomized spray in the mixed oscillation cavity, the atomization refinement degree is high, the atomization is uniform and stable, the glaze spraying yield is improved, and the raw material utilization rate is improved.

Owner:JIANGXI CIMIC CERAMICS +1

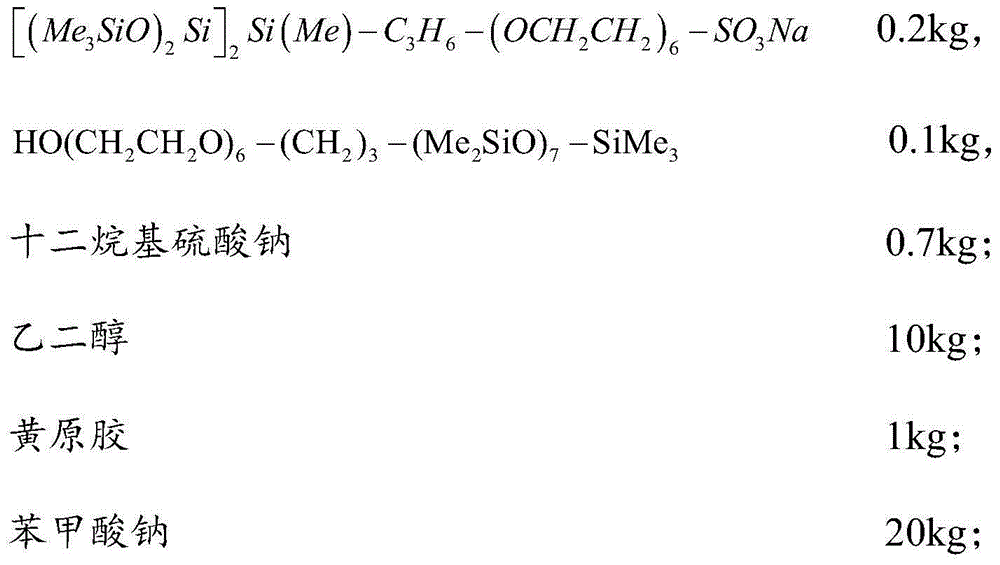

Fluoride-free additive easy to degrade and preparing method and application thereof

InactiveCN105126290ANo aggregationNo suspended solidsFire extinguisherOrganic solventSurface-active agents

The invention relates to the technical field of fire extinguishing and particularly discloses a fluoride-free additive easy to degrade and a preparing method and application thereof. The fluoride-free additive easy to degrade is composed of, by weight, 1%-10% of surface active agents, 10%-20% of organic solvent, 1%-10% of anti-burning agents, 10%-20% of alkali metal salt and the balance water. According to the fluoride-free additive easy to degrade, the surface active agents, the organic solvent, the anti-burning agents and the alkali metal salt serve as the important components of the fluoride-free additive easy to degrade, the four components cooperate with one another to improve a micro fine water mist fire extinguishing environment together, in this way, the fire extinguishing effect is improved, and the phenomenon of accelerated corrosion of metal products on a fire scene after a disaster can be avoided; in addition, the fluoride-free additive easy to degrade is nontoxic, harmless and environment-friendly and can be widely applied to fine water mist fire extinguishing systems on various occasions.

Owner:SHENZHEN HENG XING SECURITY TESTING TECH

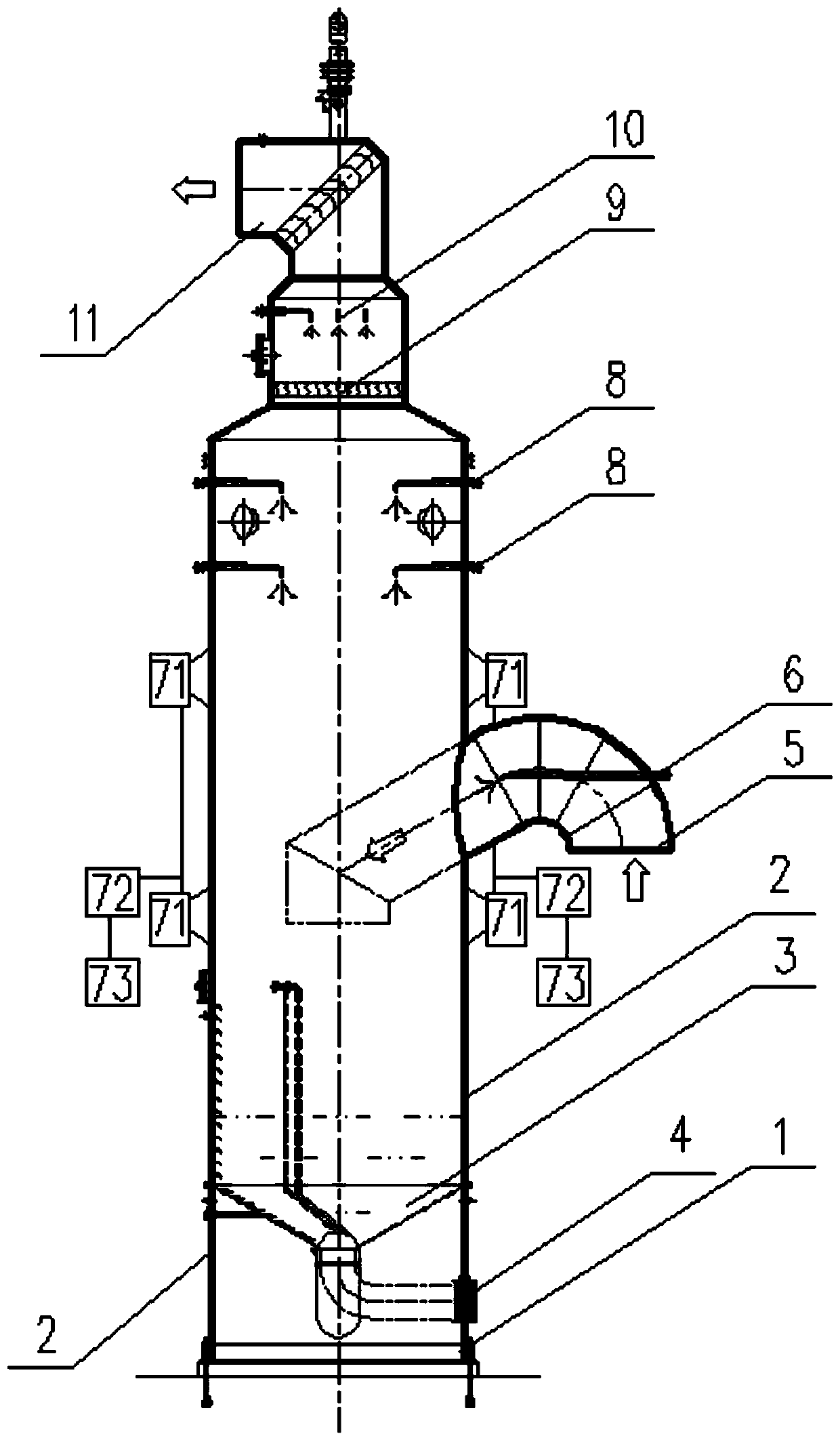

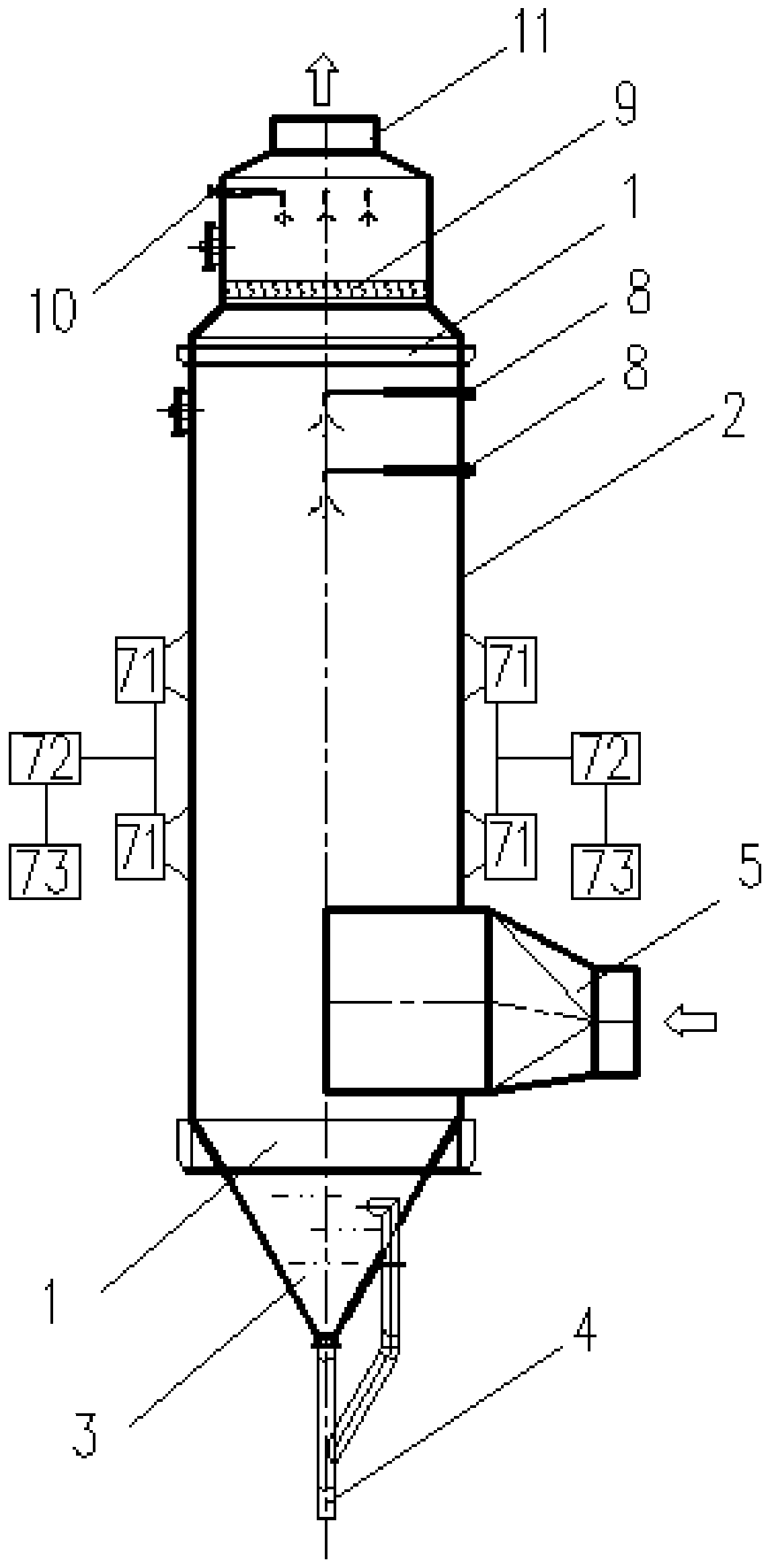

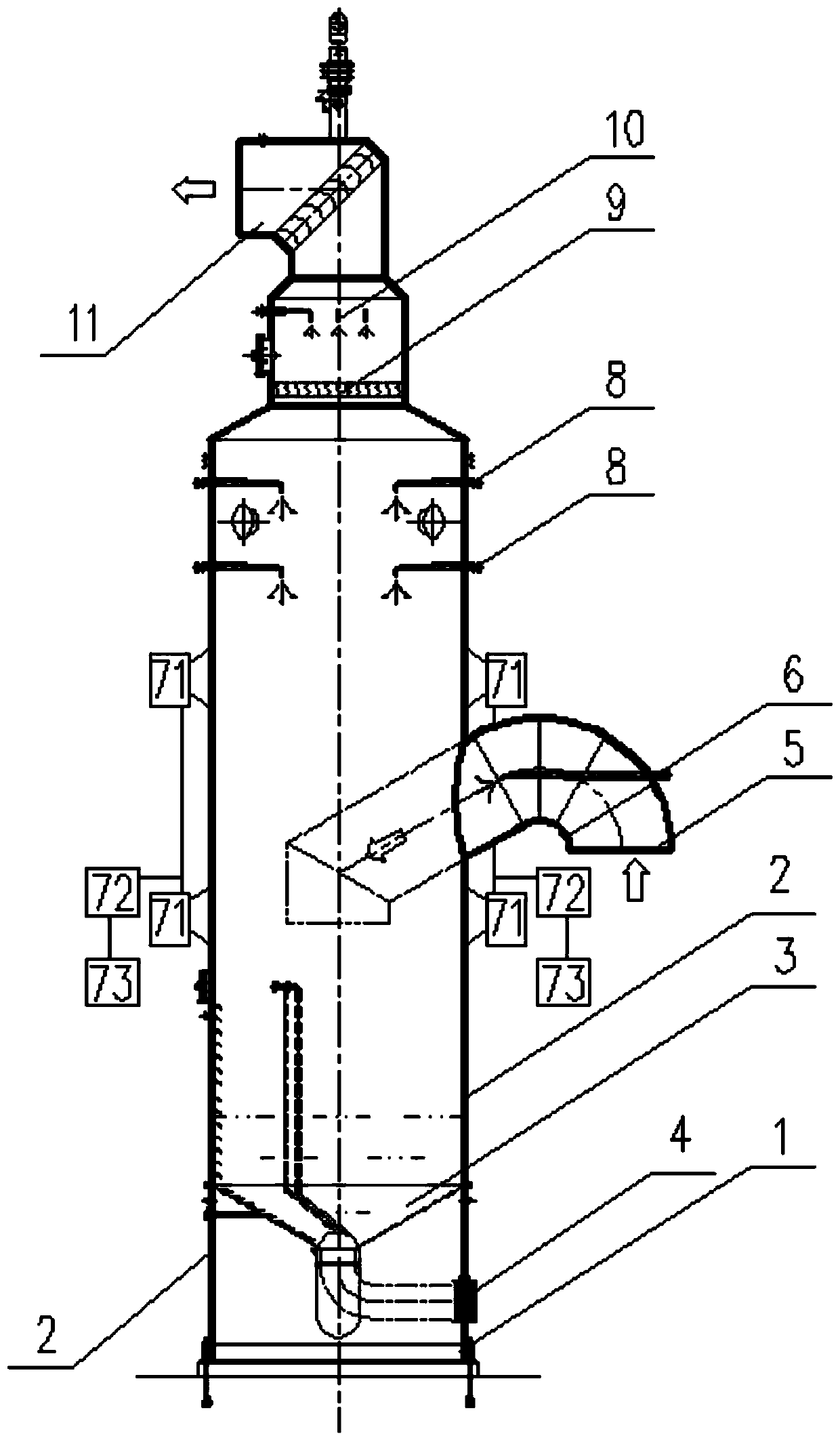

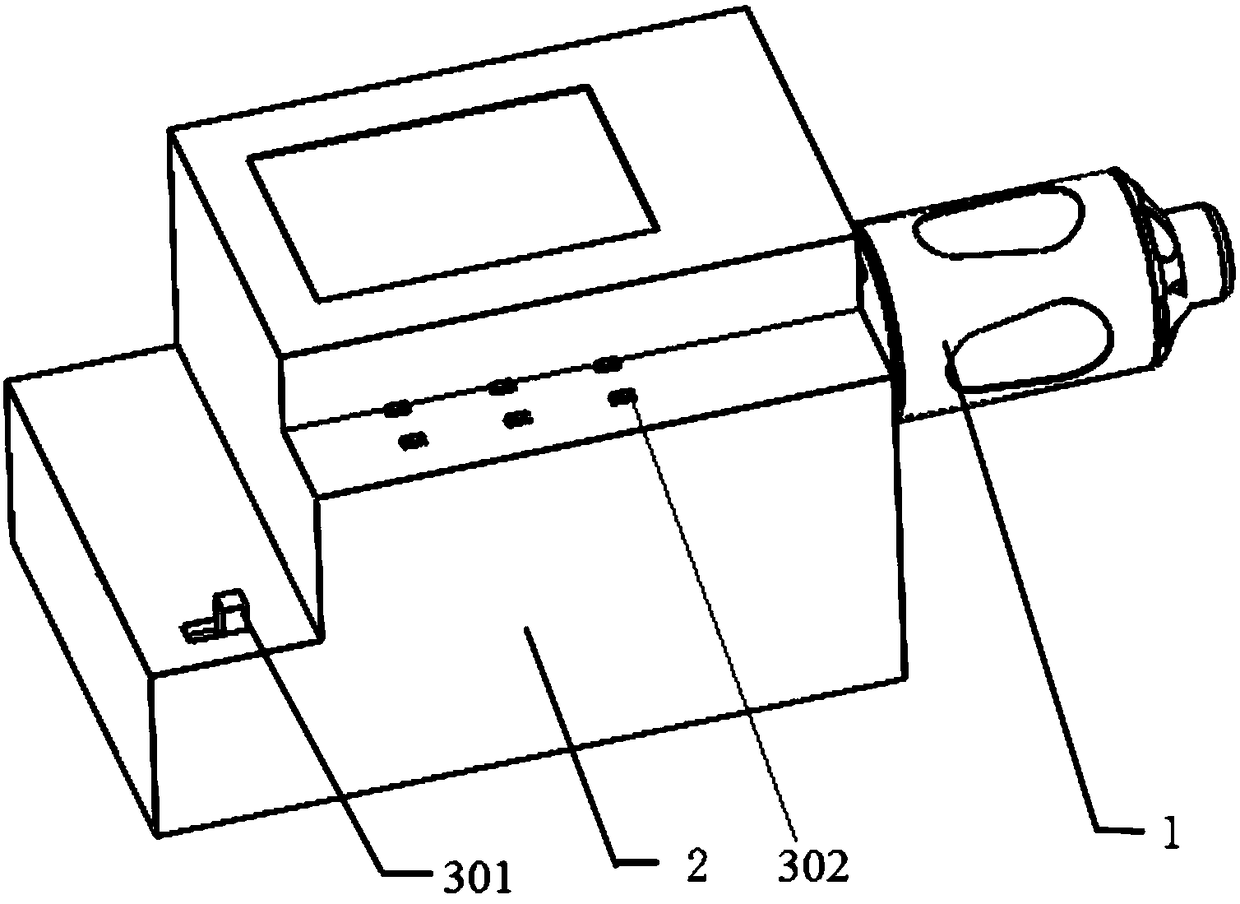

Sound wave agglomeration-based dust removal and ultralow emission device applicable to converter gas

PendingCN109833705AFunctionalSimple structureCombination devicesIncreasing energy efficiencyFlue gasEngineering

The invention relates to a sound wave agglomeration-based dust removal and ultralow emission device applicable to converter gas, and belongs to the technical field of process dust removal in the metallurgical industry, the sound wave agglomeration-based dust removal and ultralow emission device applicable to the converter gas comprises a support; a cylinder body is arranged on the support; a coalgas inlet pipe and a plurality of groups of sound wave agglomeration devices are arranged on the cylinder body, a water mist dust removal nozzle, a dewatering demister and a flushing nozzle are sequentially arranged in the cylinder body above the sound wave agglomeration devices, a gas outlet pipe is arranged at the top of the cylinder body, a gas inlet pipe is used for guiding flue gas into the inner part of the cylinder body, the flue gas enters the cylinder body, passes through the steps of sound wave agglomeration, water mist dust removal and dehydration and demisting from bottom to top, and then enters a dust removal system pipeline, the sound wave agglomeration-based dust removal and ultralow emission device can be used for replacing a coal gas cooler of a converter gas dry-process dust removal system, and can also be used for replacing a dehydrator of a converter gas wet-process dust removal system, the structure is simple, no extra mounting space is needed, the dust concentration of the converter gas can be reduced to be less than or equal to 10 mg / Nm3 from 10-100 mg / Nm3, and ultralow emission of the dust removal system of the converter coal gas can be realized.

Owner:CISDI ENG CO LTD

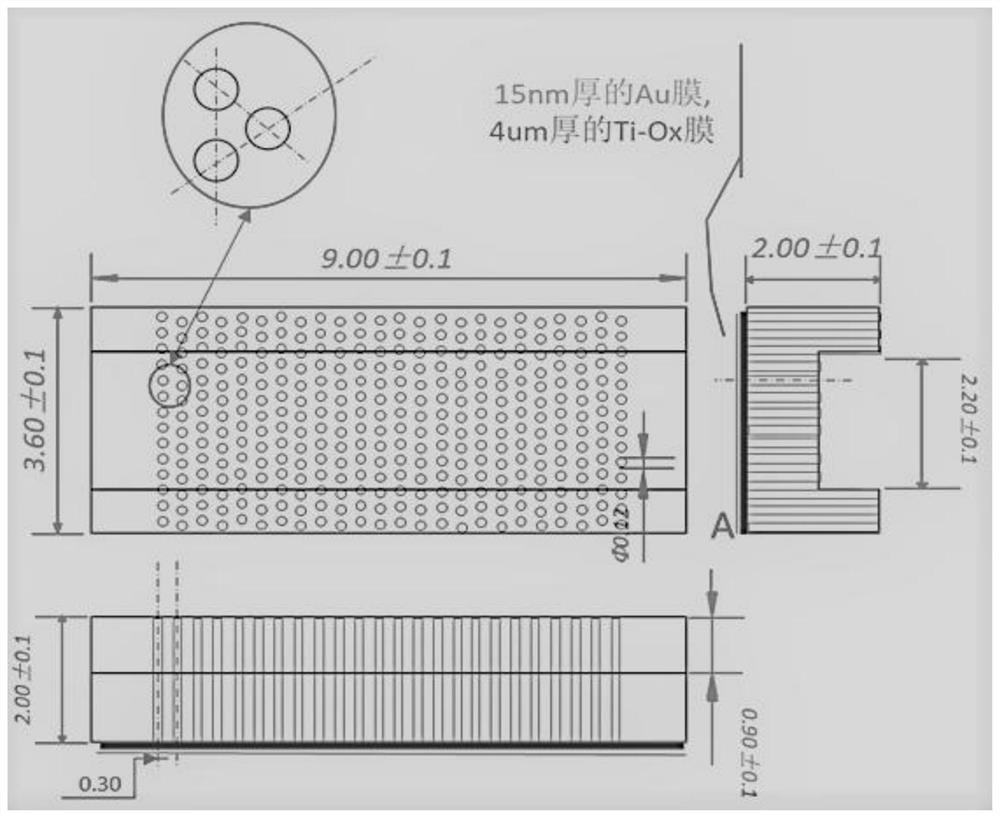

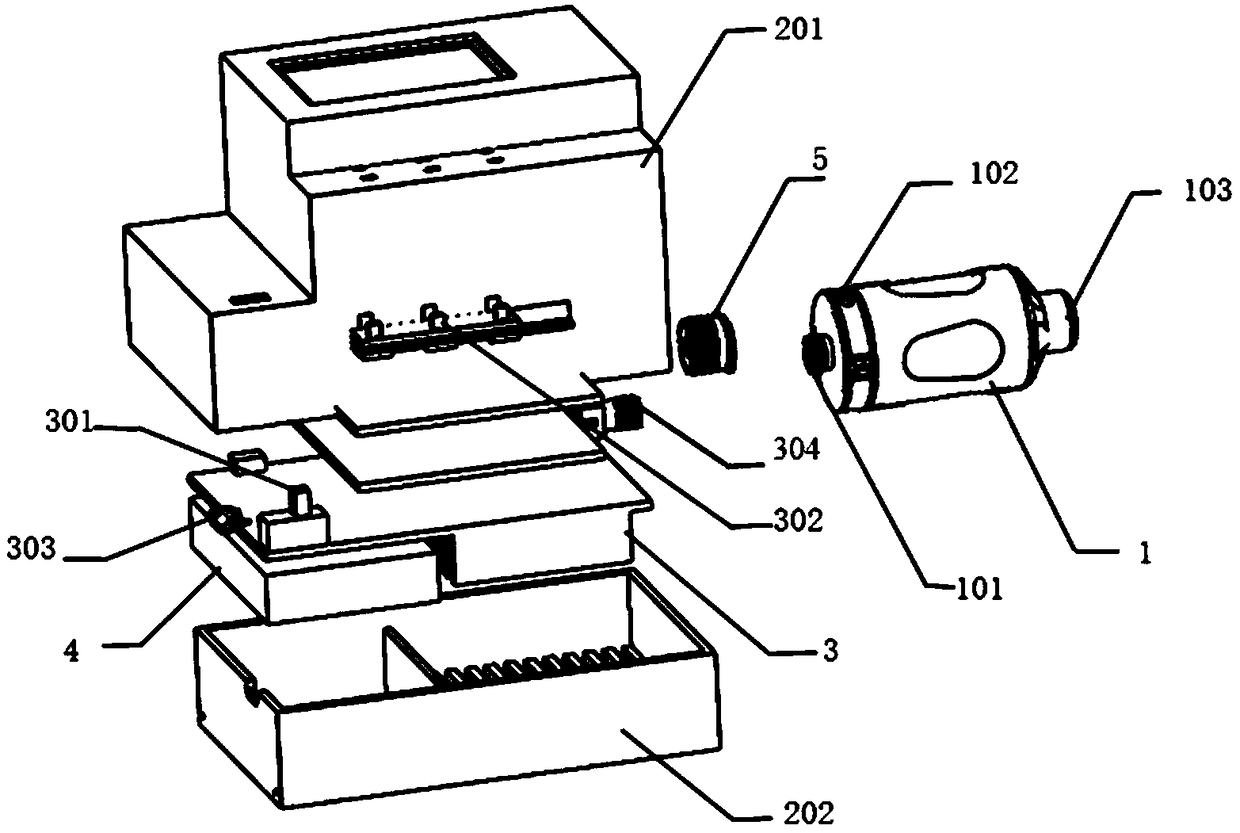

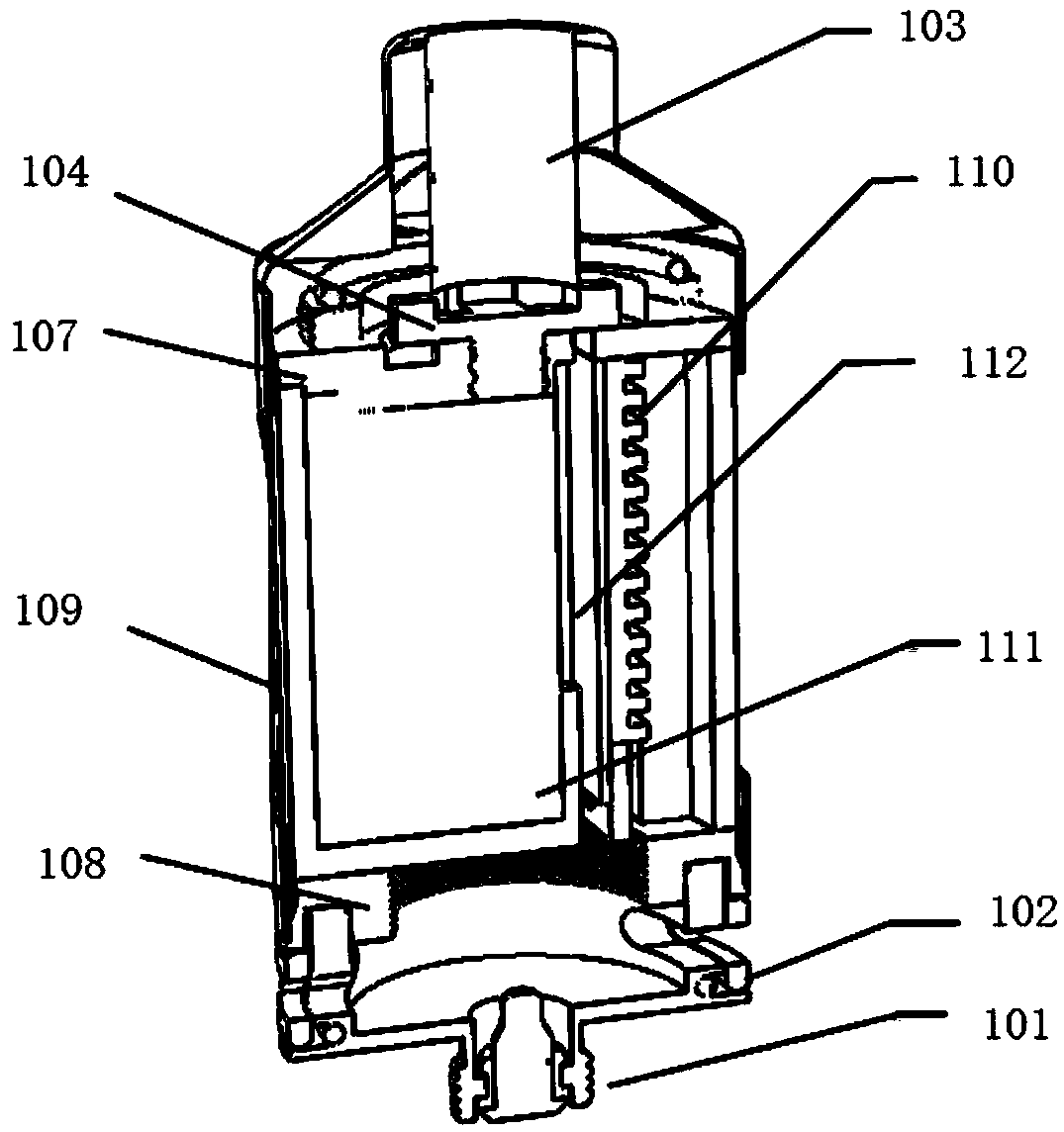

Electronic smoking set capable of outputting smoke with different particle sizes and method for applying electronic smoking set

PendingCN109480335AUniform atomizationImprove atomization qualityTobacco devicesNebulizerEngineering

The invention discloses an electronic smoking set which comprises an atomizer (1), a shell (2), a radiofrequency signal source (3) and a threaded shaft sleeve (5). The radiofrequency signal source (3)is positioned in the shell (2); an atomization chip (110) and oil guide cotton (112) are arranged in the atomizer (11), the oil guide cotton (112) clings onto the atomization chip (110), and a plurality of interdigital transducers (1102) with different wavelengths are arranged on the atomization chip (110) and can be driven by radiofrequency signals to generate traveling waves and acoustic surface waves, so that cigarette liquid on the oil guide cotton (112) can be atomized; the atomizer (1) and the radiofrequency signal source (3) are connected with each other by the threaded shaft sleeve (5). The invention further discloses a method for applying the electronic smoking set.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com