Ultrasonic spray generator special for preparing large-area transparent conductive film

A transparent conductive film, ultrasonic spray technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of unsuitable preparation of large-area transparent conductive films, low fogging efficiency, low power of ultrasonic spray generator, etc. Large, no power loss, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

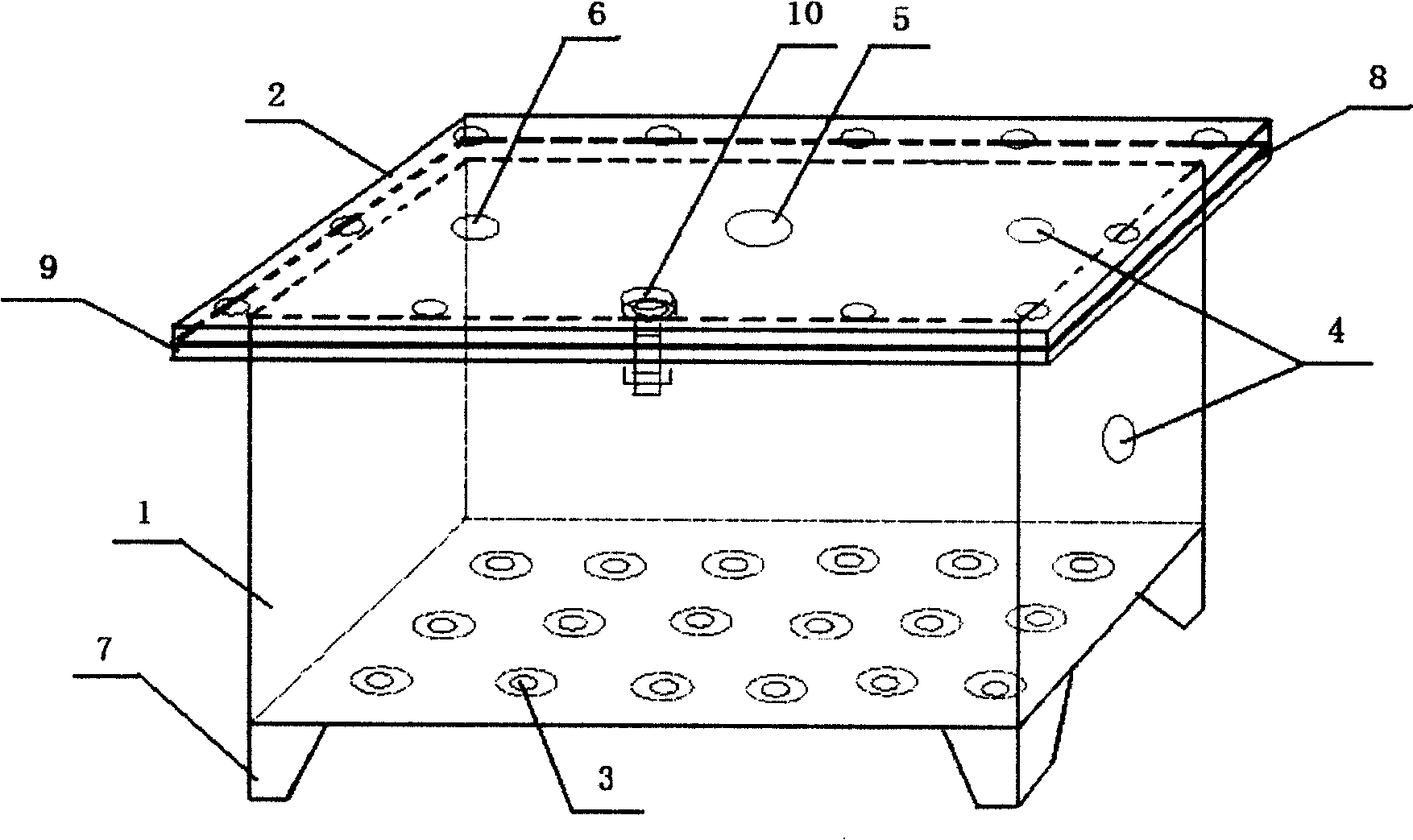

[0018] figure 1 It is a perspective view of a special ultrasonic spray generator for preparing large-area transparent conductive films provided by the present invention, see figure 1 , the large-area transparent conductive film ultrasonic spray generator provided by the present invention includes: a box body 1 and 18 ultrasonic atomizers 3 installed on the bottom floor of the box body 1, and an outer wall around the top of the box body 1. Flange 9, the upper cover 2 installed on the outer flange 9, the corrosion-resistant rubber pad 8 between the outer flange 9 of the box body 1 and the upper cover 2, in the box body 1 The side surface and the carrier gas inlet 4 provided on the upper cover 2, the spray outlet 6 and the solution inlet 5 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com