Patents

Literature

72results about How to "Large amount of atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

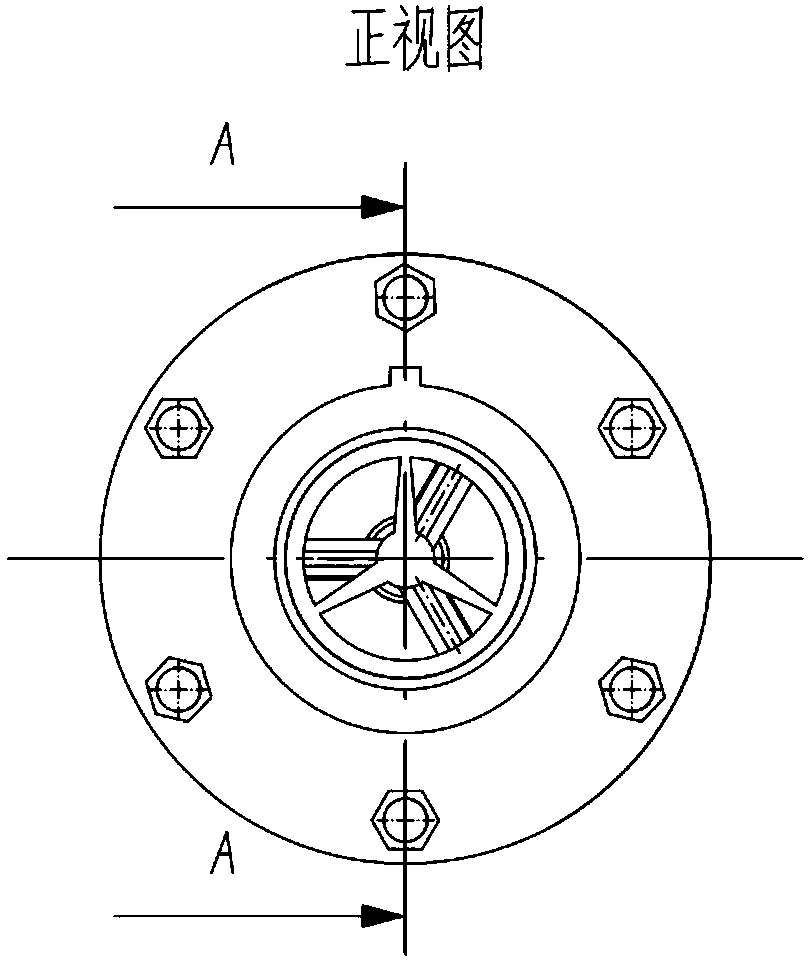

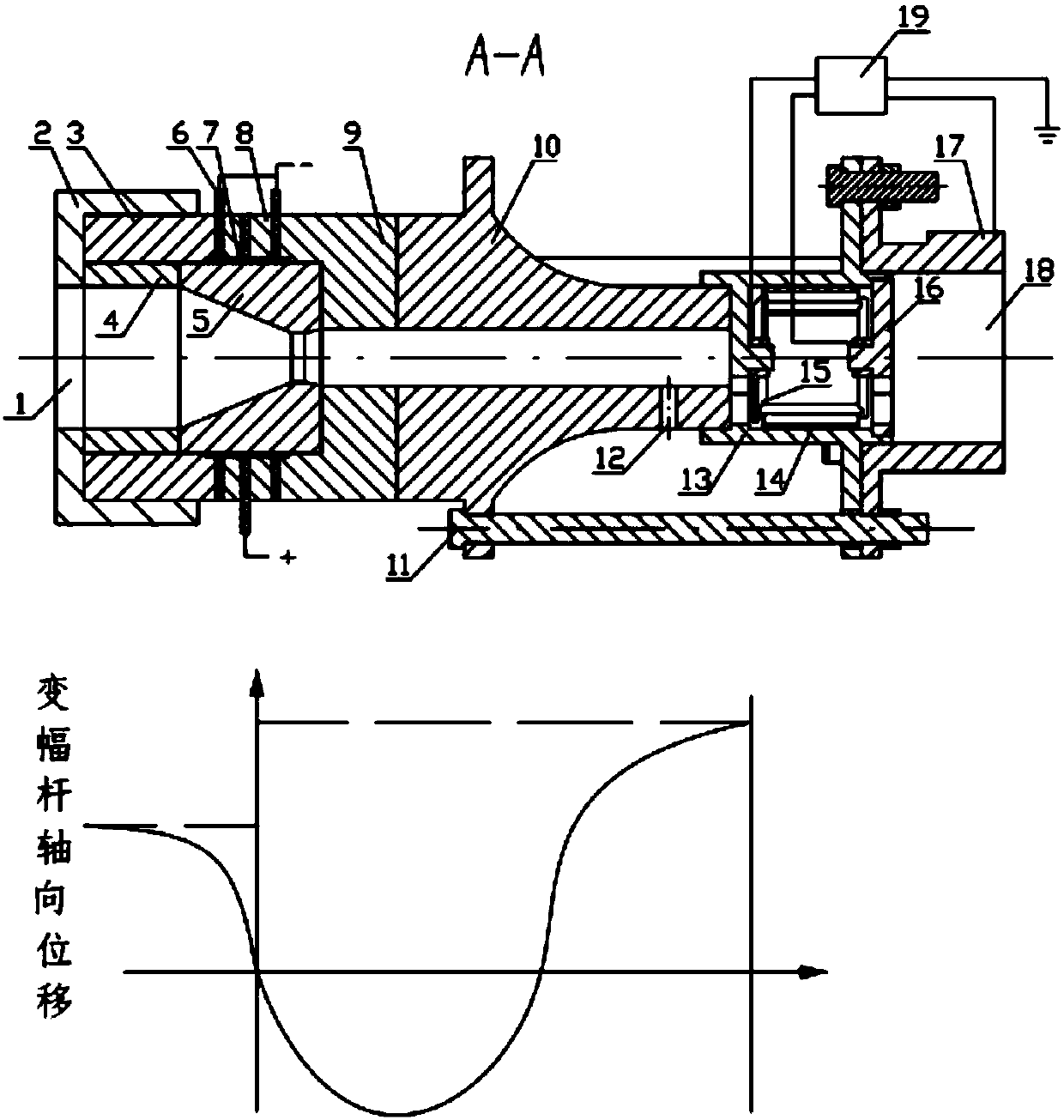

Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

InactiveCN105834054ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricitySpray nozzle

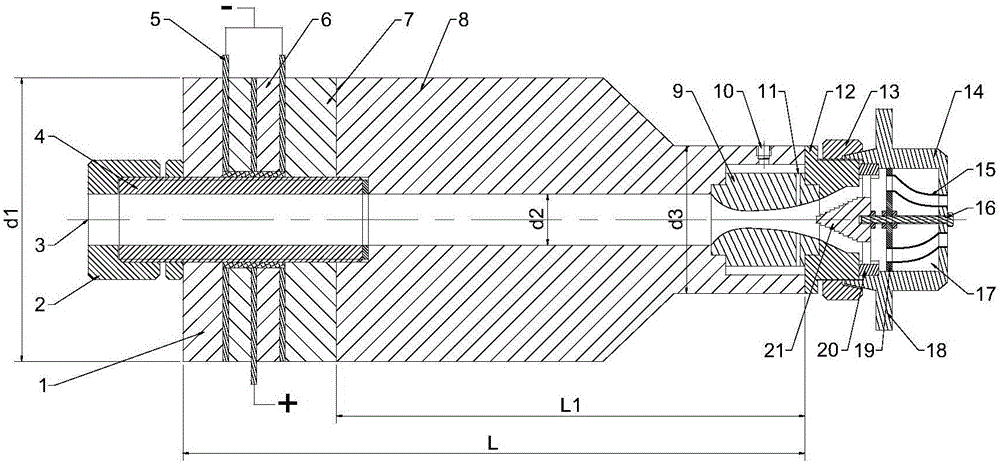

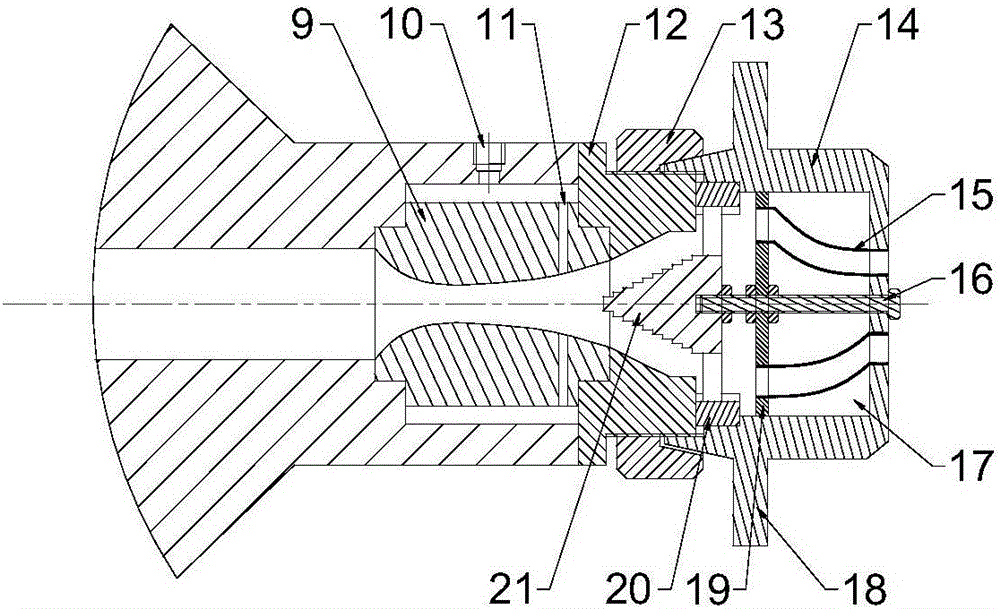

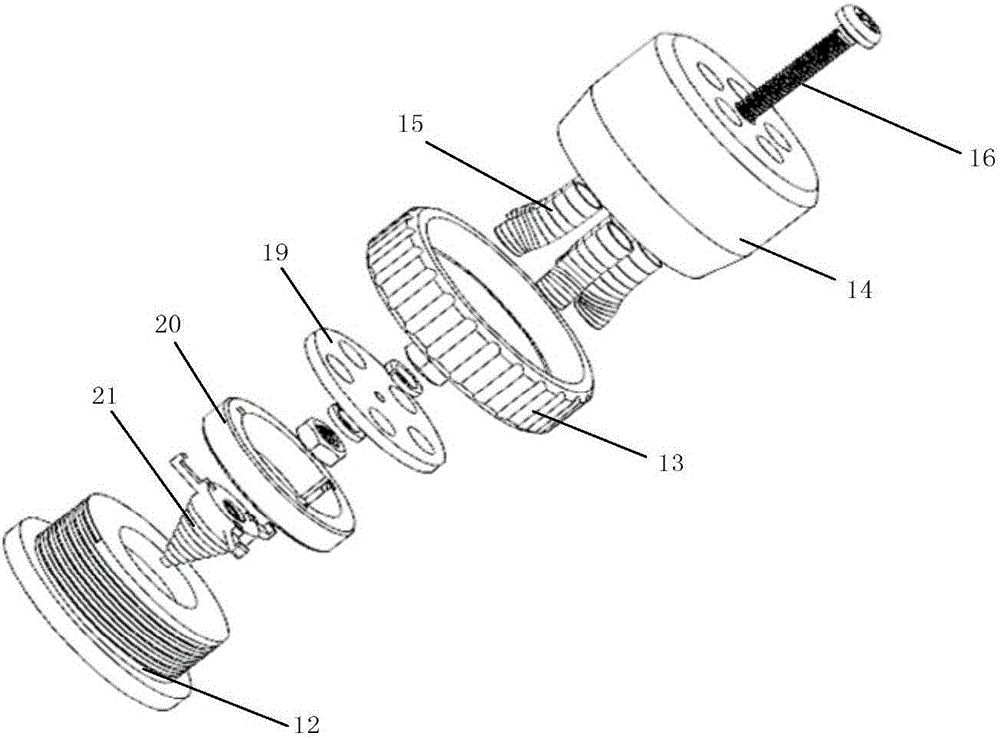

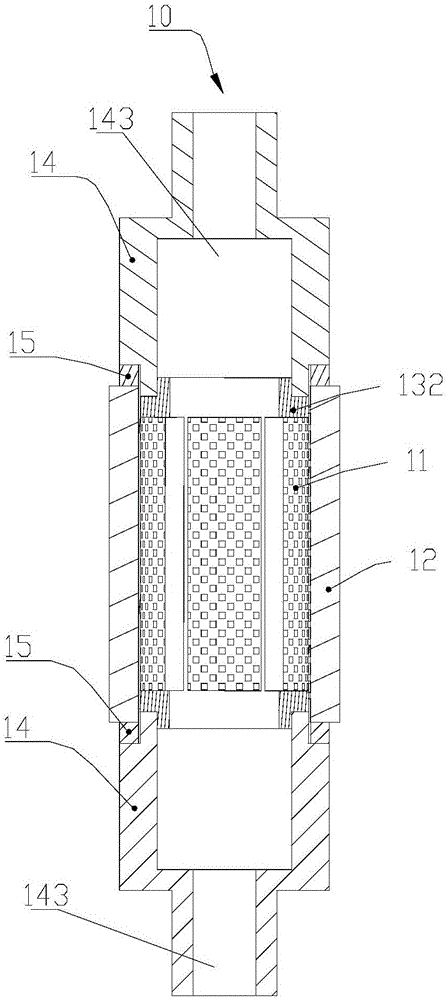

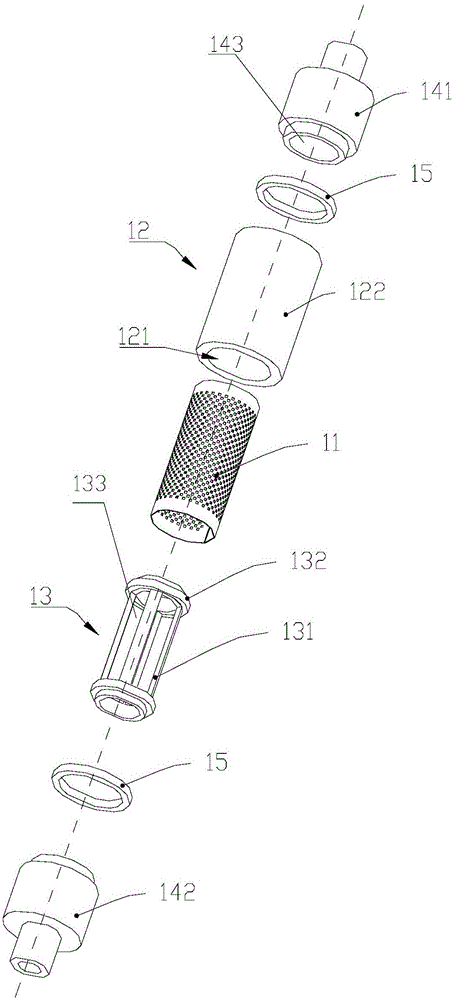

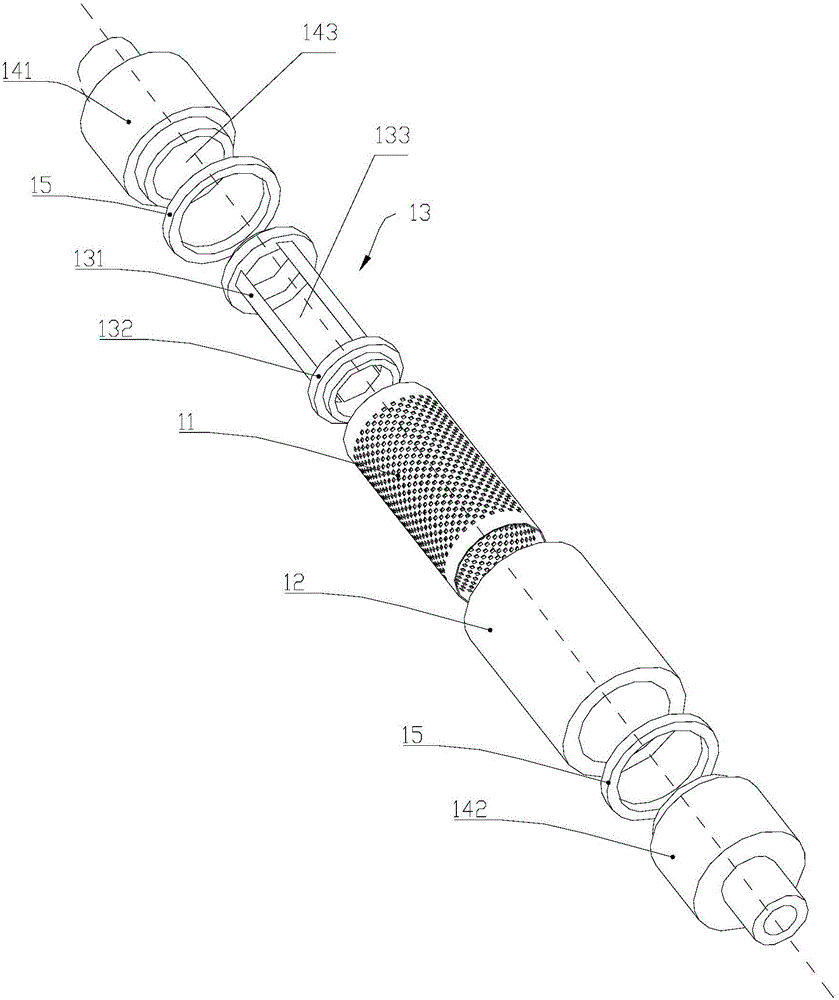

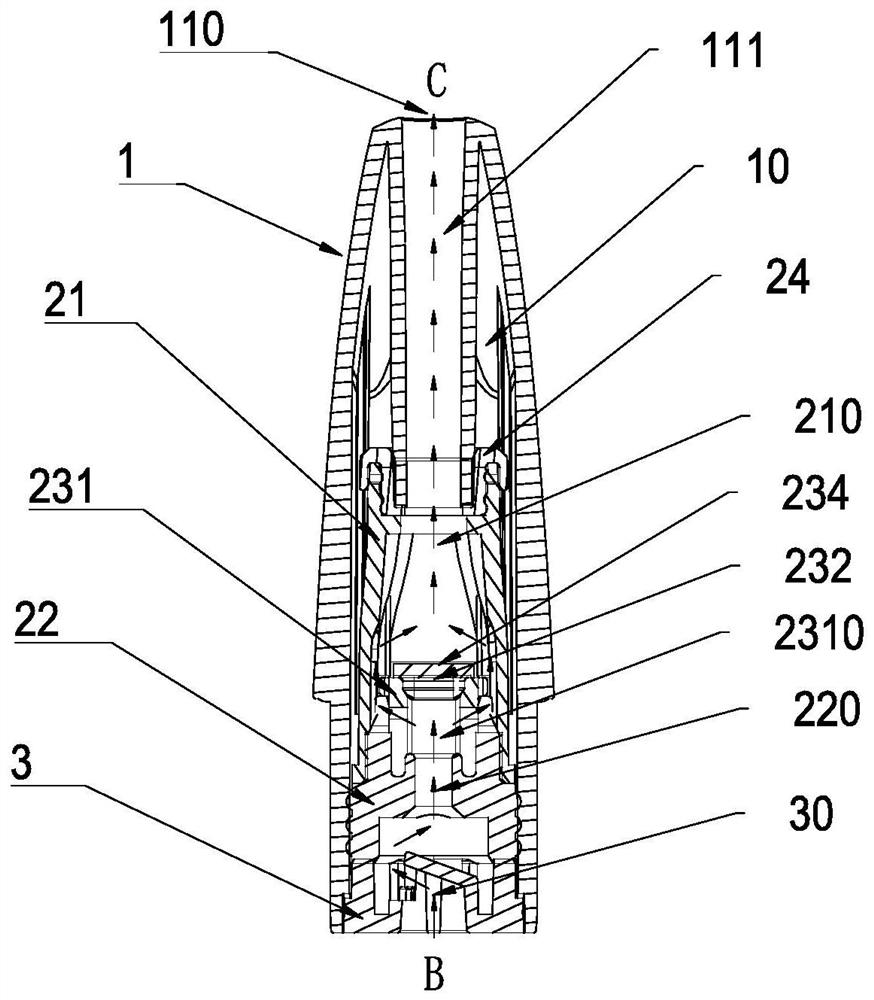

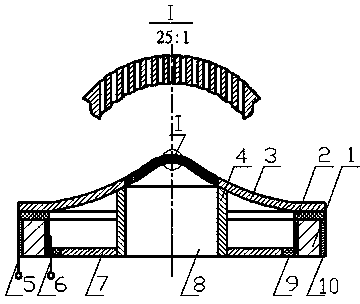

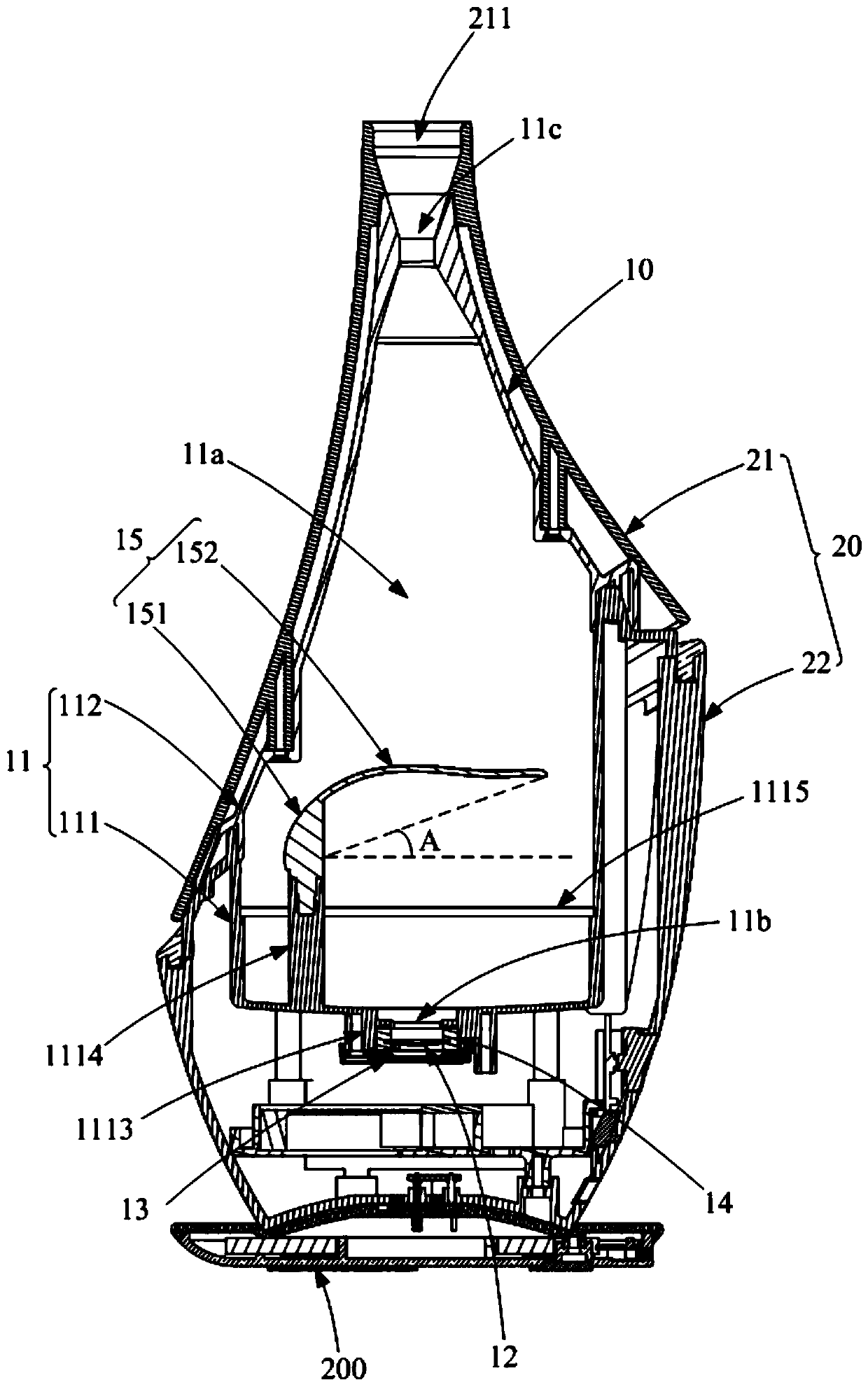

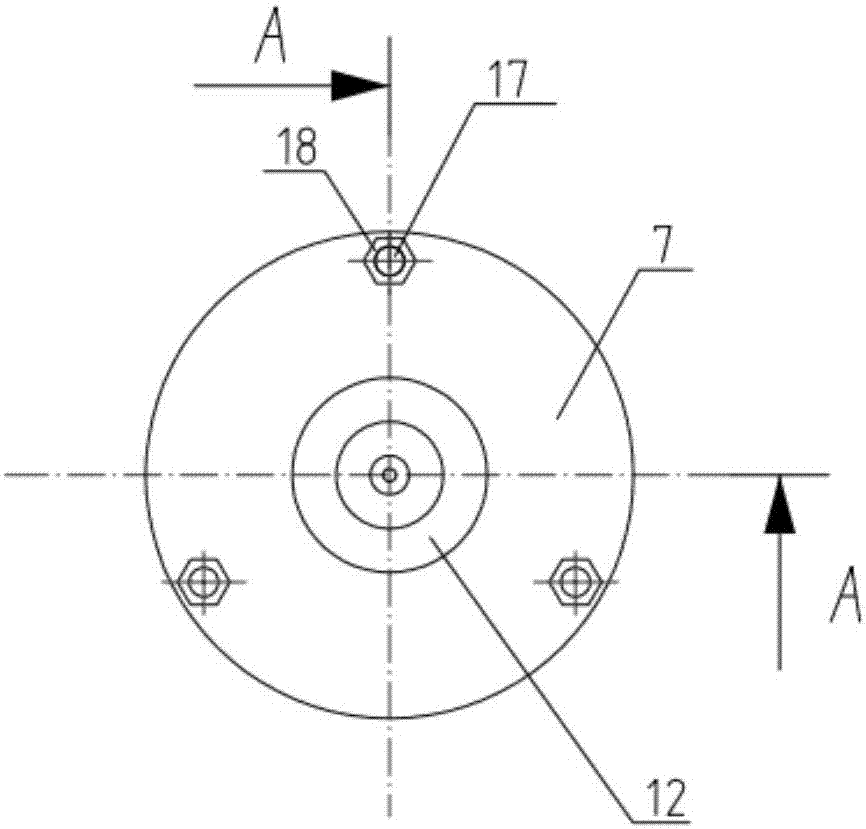

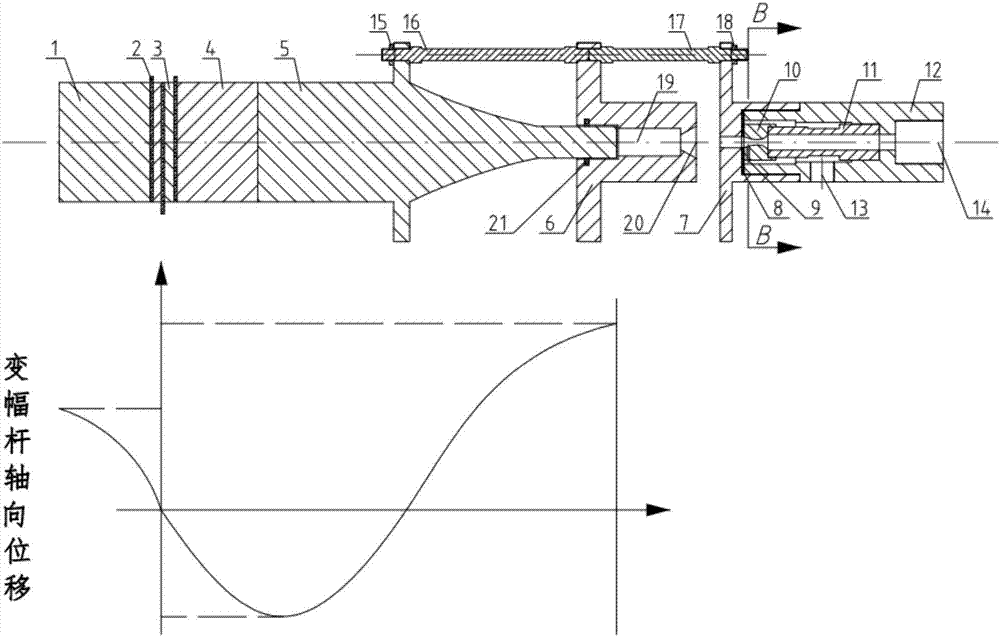

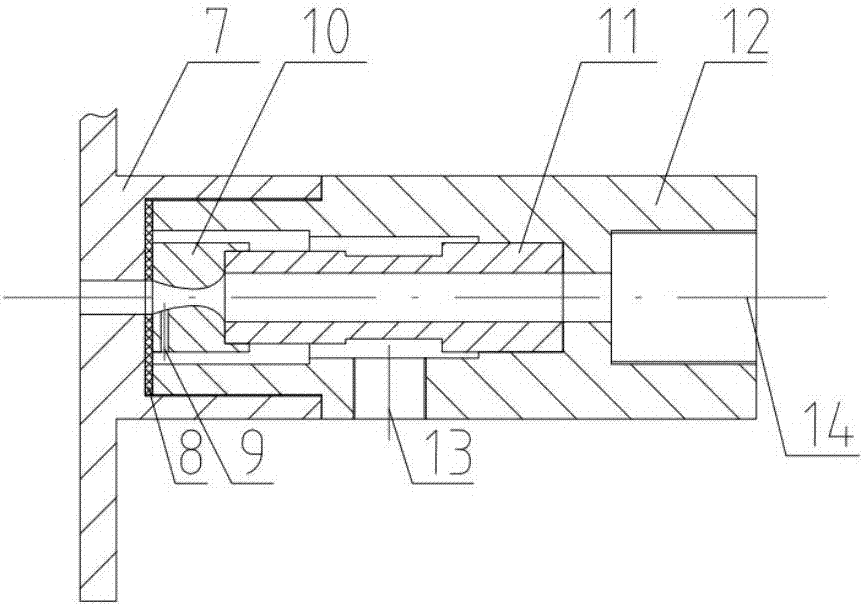

The invention provides a piezoelectric two-phase flow ultrasonic atomization spraying nozzle. The piezoelectric two-phase flow ultrasonic atomization spraying nozzle comprises a piezoelectric vibrator, an amplitude-change pole, a second end cover and a first end cover; the piezoelectric vibrator and the amplitude-change pole are connected through a connecting bolt; an air inlet connector is installed at the tail of the connecting bolt; the second end cover is fixed to the front end of the amplitude-change pole; a laval type valve element is fixed into a step hole of the amplitude-change pole and a groove of the second end cover; a liquid inlet hole is formed in the hole wall face of the step hole of the amplitude-change pole; a plurality of flow guide holes are formed in the positions, close to an outlet, of the laval type valve element in the radial direction; the first end cover is threaded connection to the second end cover; a radial positioning ring is arranged at the position of a clamping groove in the back end of the first end cover; a step type taper valve is installed on the radial positioning ring; the step type taper valve and a vibration separating plate are connected through an adjusting bolt; a resonance chamber is formed between the vibration separating plate and the top end of the first end cover; and a plurality of flexible pipes are arranged in the resonance chamber. According to the piezoelectric two-phase flow ultrasonic atomization spraying nozzle, a large number of superfine fog drops are generated under the low-energy working condition, and the shortcoming that large pulverization amount, small grain size, low power dissipation and directed spraying cannot be considered at the same time through in the traditional technology is overcome.

Owner:JIANGSU UNIV

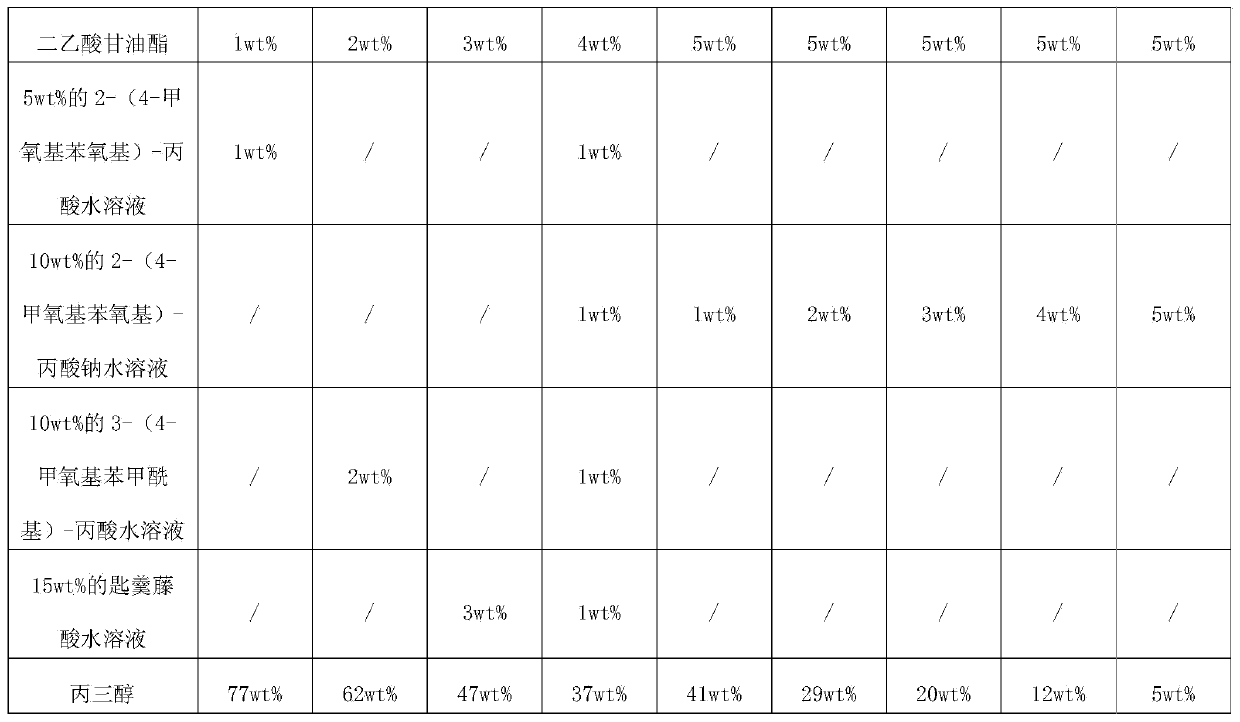

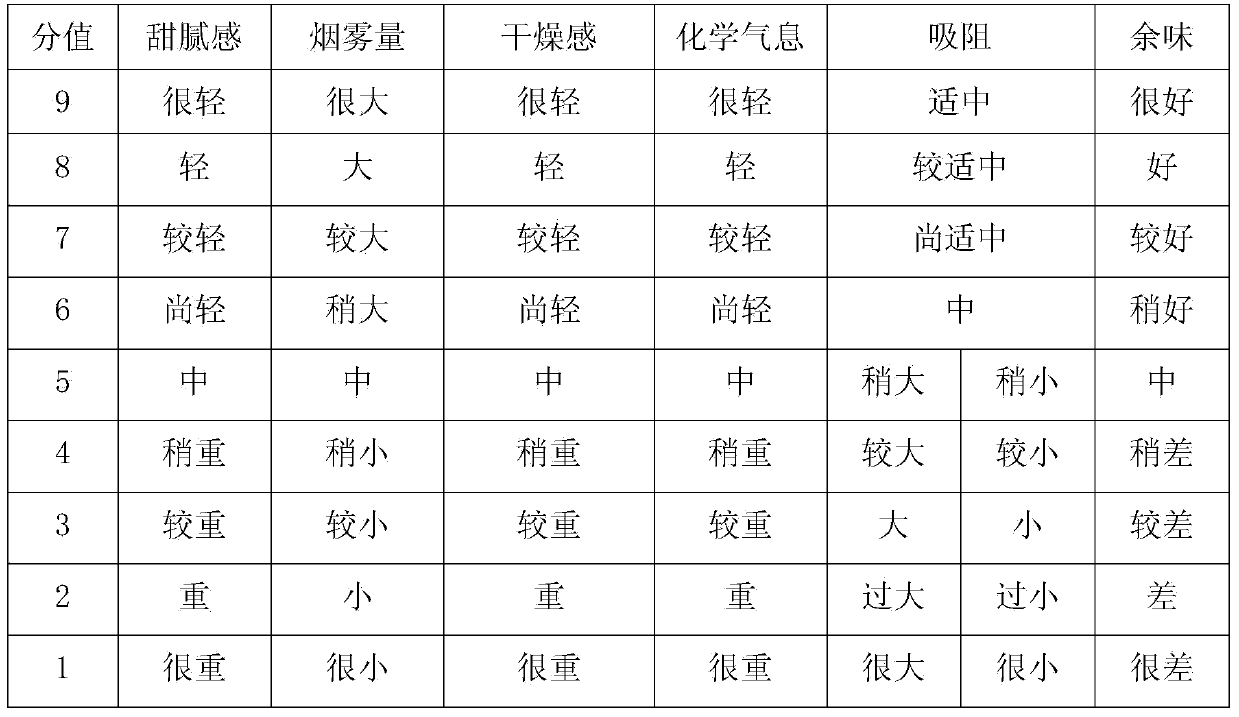

Tobacco juice solvent for electronic cigarette

ActiveCN104256885ASolve the problem of heavy sweetnessGreat tasteTobacco treatmentTobacco devicesMedicinePolyethylene glycol

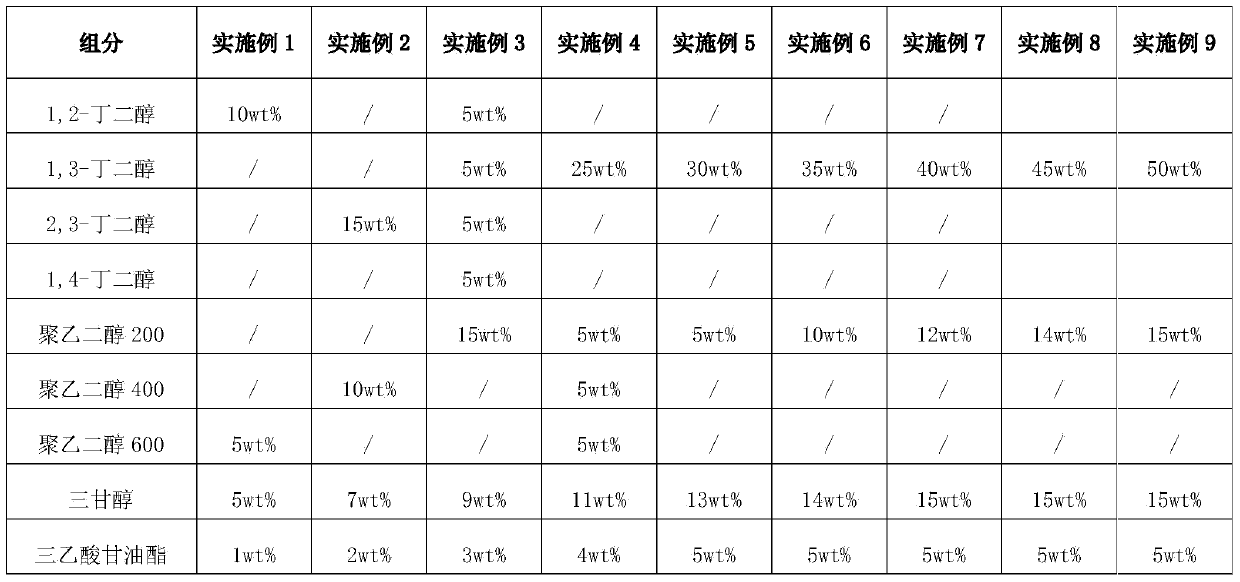

The invention discloses a tobacco juice solvent for an electronic cigarette. The tobacco juice solvent for the electronic cigarette comprises 10wt%-50wt% of butanediol, 5wt%-15wt% of polyethylene glycol, 5wt%-15wt% of triethylene glycol, 1wt%-5wt% of triacetin, 1wt%-5wt% of diacetin, 1wt%-5wt% of sweet taste inhibitor solutions and the balance glycerin, wherein the sweet taste inhibitor solutions are sweet taste inhibitor aqueous solutions or propylene glycol solutions, and the concentration of the sweet taste inhibitor solutions is 5wt%-15wt%. When the electronic cigarette prepared from the tobacco juice solvent is smoked, sweet greasy is avoided, the drying feeling is light, the taste is bitter, and a good application prospect in the development of the tobacco juice solvent of the electronic cigarette is achieved.

Owner:CHINA TOBACCO YUNNAN IND

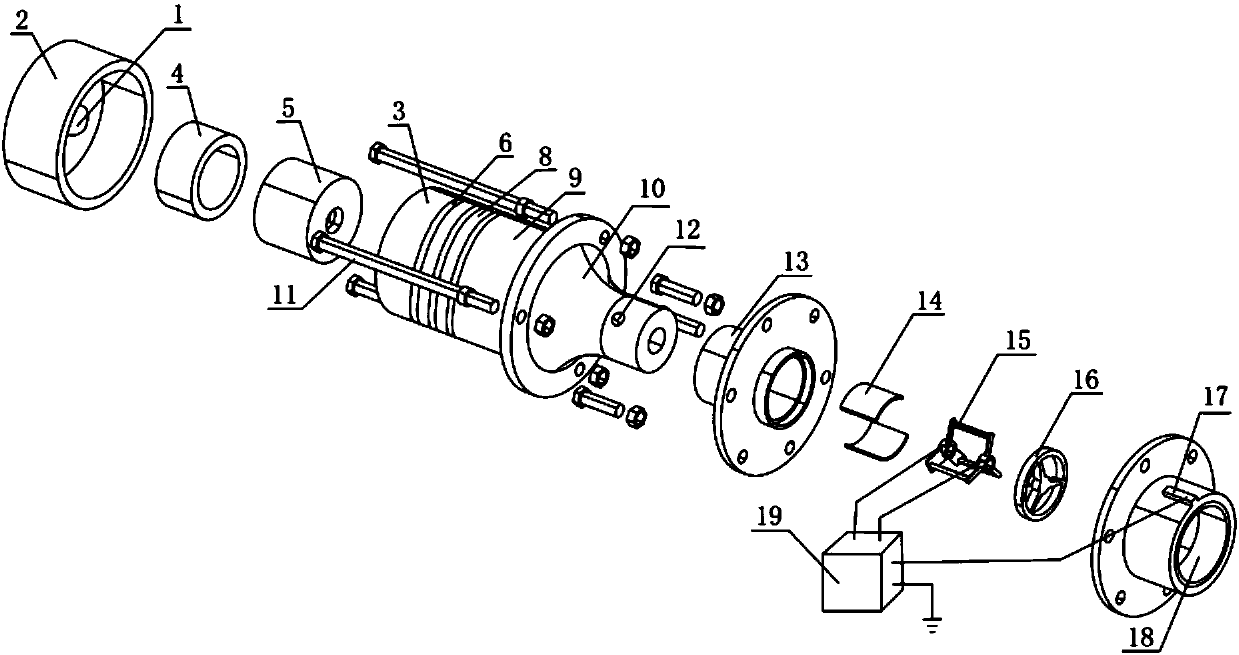

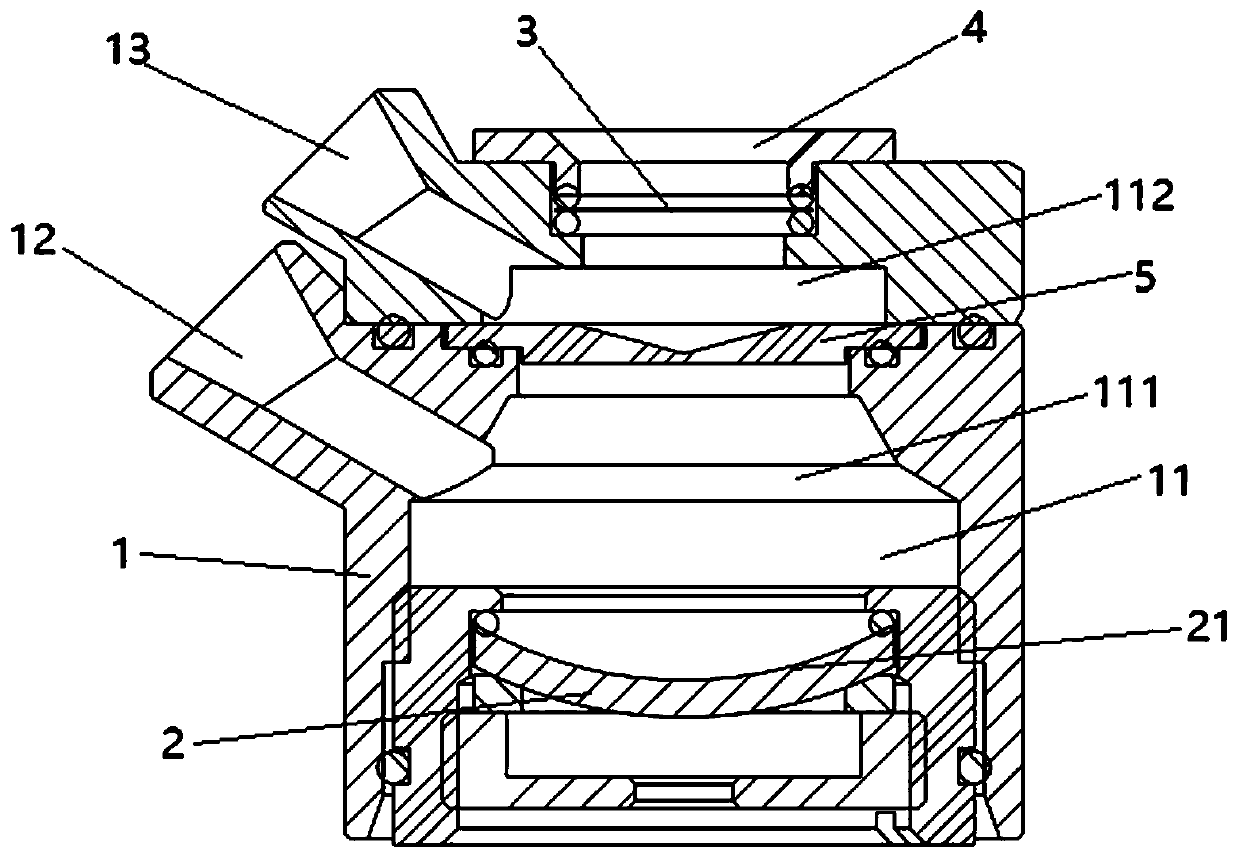

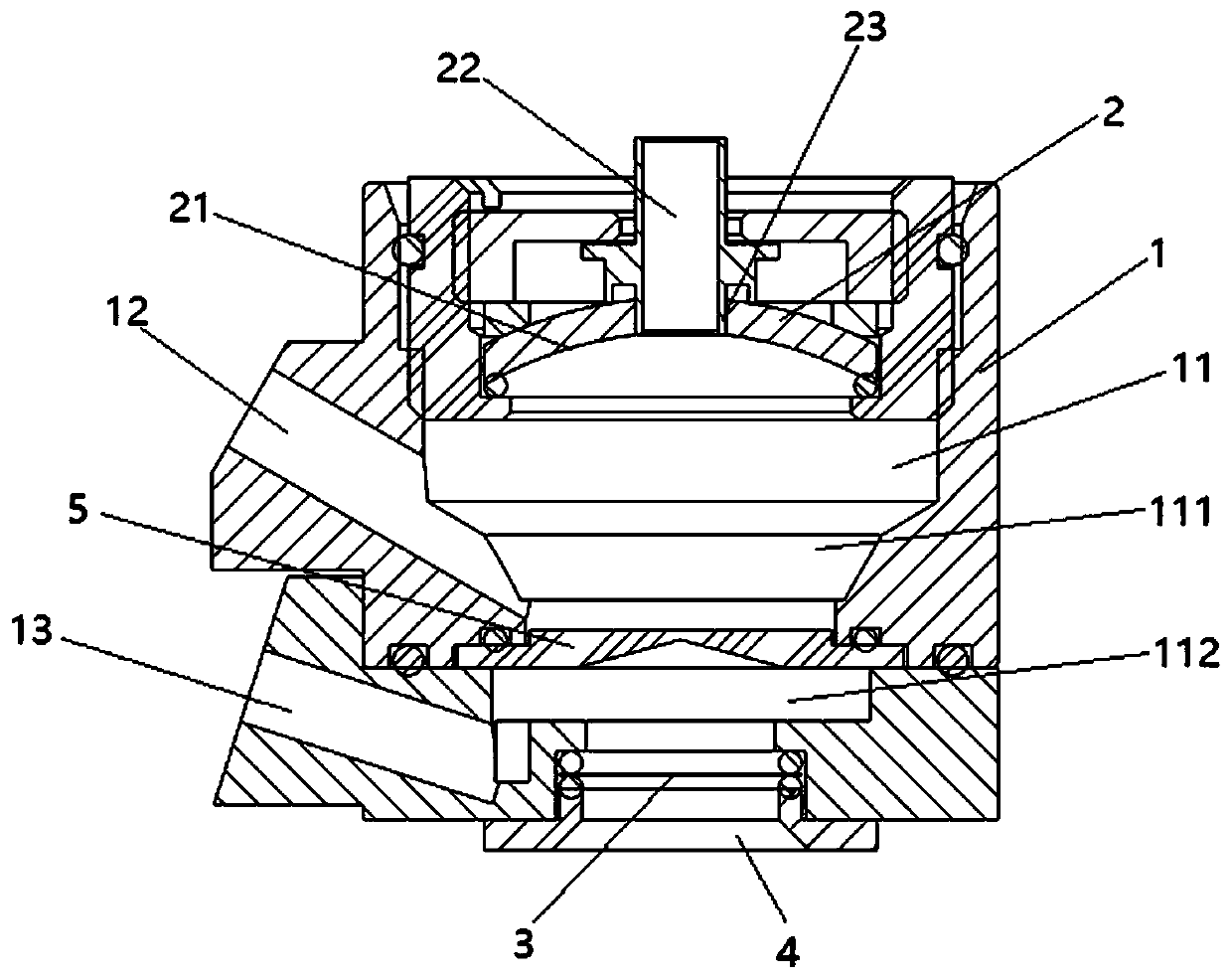

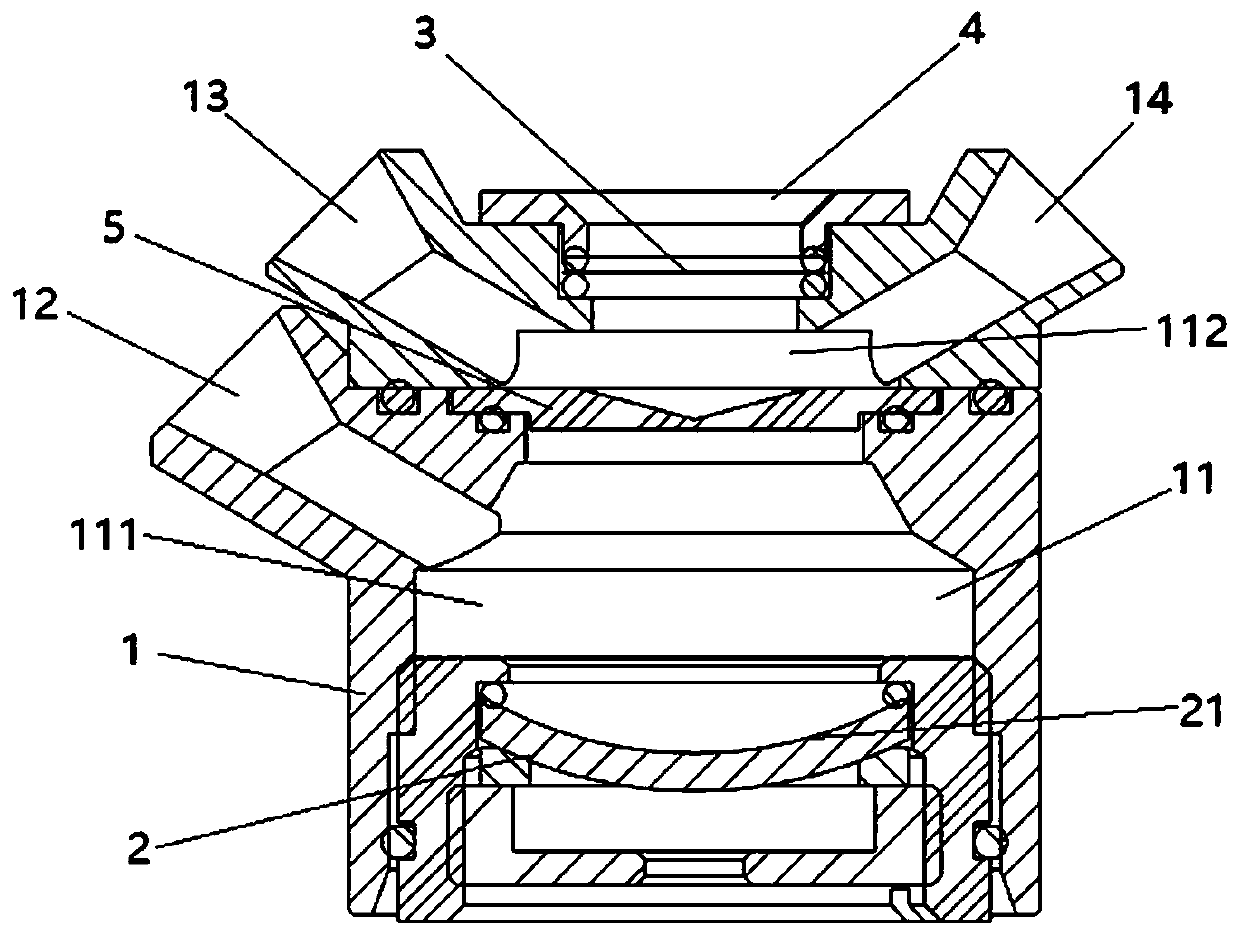

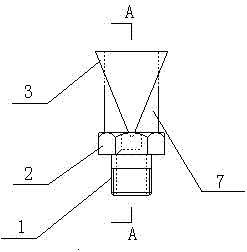

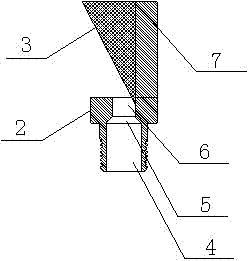

Laval-low frequency static and ultrasonic composite atomizing saying head

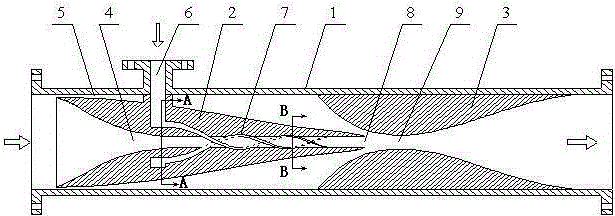

ActiveCN107670893ASmall particle sizeImprove adhesionSpraying power supplyLiquid spraying apparatusElectricityTransformer

The invention provides a Laval-low frequency static and ultrasonic composite atomizing saying head which is used for atomization cultivation in the field of agricultural engineering. The Laval-low frequency static and ultrasonic composite atomizing saying head mainly includes a Laval type spool, a piezoelectric vibrator front cover plate, a piezoelectric vibrator, a copper chip electrode, a piezoelectric vibrator rear cover plate, an amplitude-change pole, a permanent magnet, a rotor, an induction static electrode ring and a transformer. Metal glue bonding connecting is conducted between the piezoelectric vibrator front cover plate, the piezoelectric vibrator rear cover plate and the copper chip electrode as well as between the copper chip electrode, the piezoelectric vibrator and the amplitude-change pole. Through holes are formed in the amplitude-change pole. A liquid inlet hole is formed in the atomizing end part of the amplitude-change pole. A rotor supporting frame is connected with the zero-amplitude surface of the amplitude-change pole through bolts. The Laval-low frequency static and ultrasonic composite atomizing saying head uses a mode that Laval principle technique, a piezoelectric ultrasonic atomization technology and a static spraying technology are combined, so that droplets have the high energy and the high speed, therefore, the spraying head can realize high efficiency and accurate spraying, enhances the atomization quantity and realizes long-distance spraying.

Owner:徐州馨予康建材有限公司

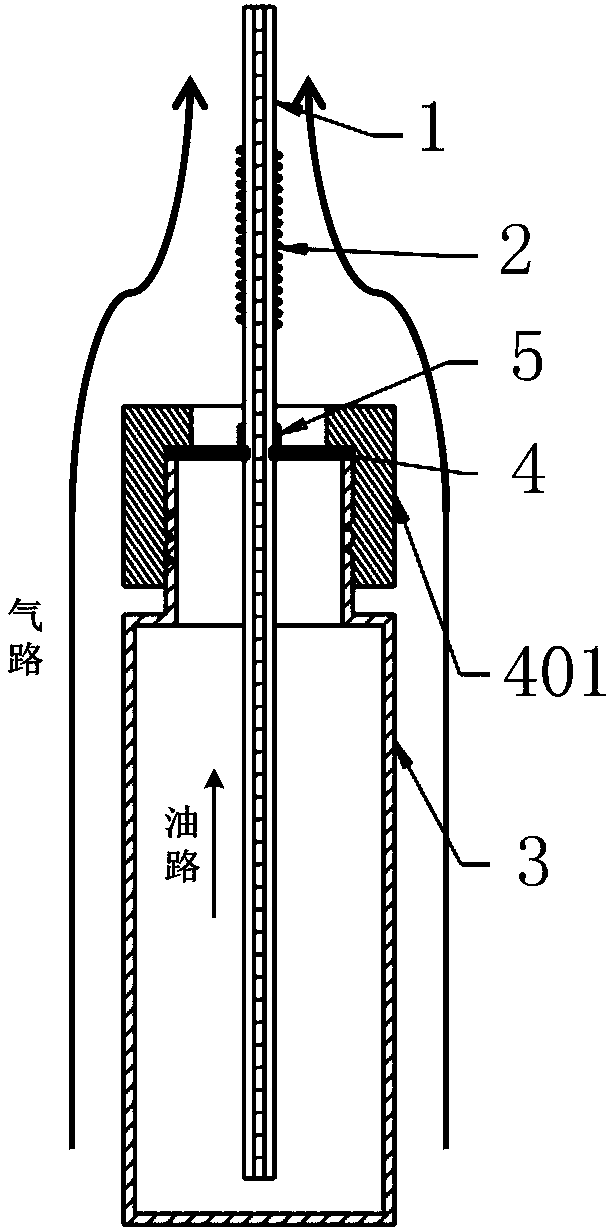

Electronic cigarette having nanometer sized hyperfine space warming atomizing functions

ActiveCN100593982CLarge amount of atomizationConcentrated use of energy and high efficiencyMedical devicesTobacco devicesElectricityLiquid core

An electric-cigarette undertaking nanometer dimension fineness space heating pulverization to nicotine solution comprises a cigarette pole and a cigarette holder connected with the front end of the cigarette pole. The cigarette pole is a hollow rod shape cigarette pole welded with a plug at the back end. The intracavity of the cigarette pole is provided with a rechargeable battery, a liquid storage tank for storing nicotine solution, an imbibition liquid core arranged at the front end of the liquid storage tank and contacted with the nicotine solution, and a heater of space heating pulverization arranged inside the heating cavity positioned in the front part of the cigarette pole. The wall of the cigarette pole corresponding to the liquid storage tank is provided with a liquid inlet communicated with the liquid storage tank. Any place of the wall of the cigarette pole is provided with an electric heating switch. The center of the cigarette holder is provided with a hollow pipe which extends into the cigarette pole. The wall of front part of the cigarette holder is provided with a piezoelectric press sensor. The back end of the cigarette pole is provided with a recharging connectiondevice which can charge the rechargeable battery through outer power. The piezoelectric press sensor is communicated with the rechargeable battery all the time. The electric heating switch, the piezoelectric press sensor and the rechargeable battery constitute a circuit loop. The invention has the advantages of convenient assembly and installation, easy carry, wide application and convenient use.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

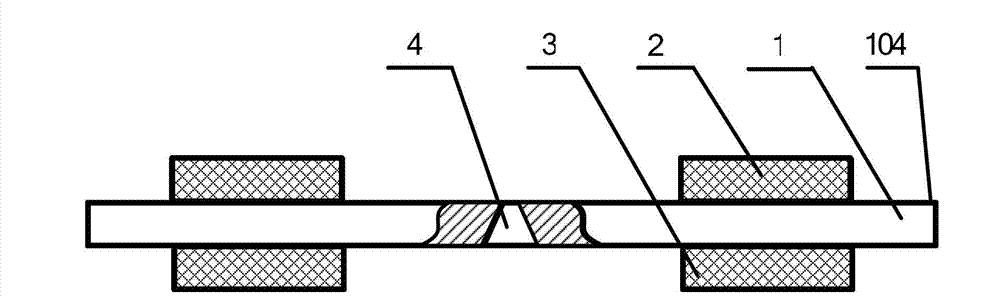

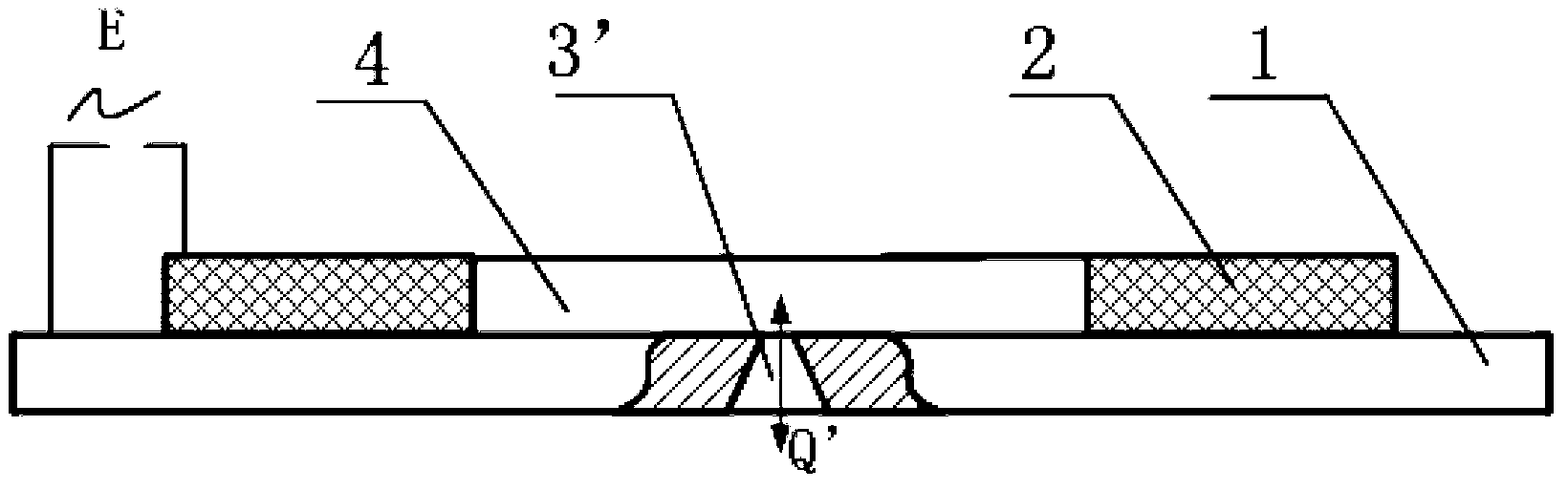

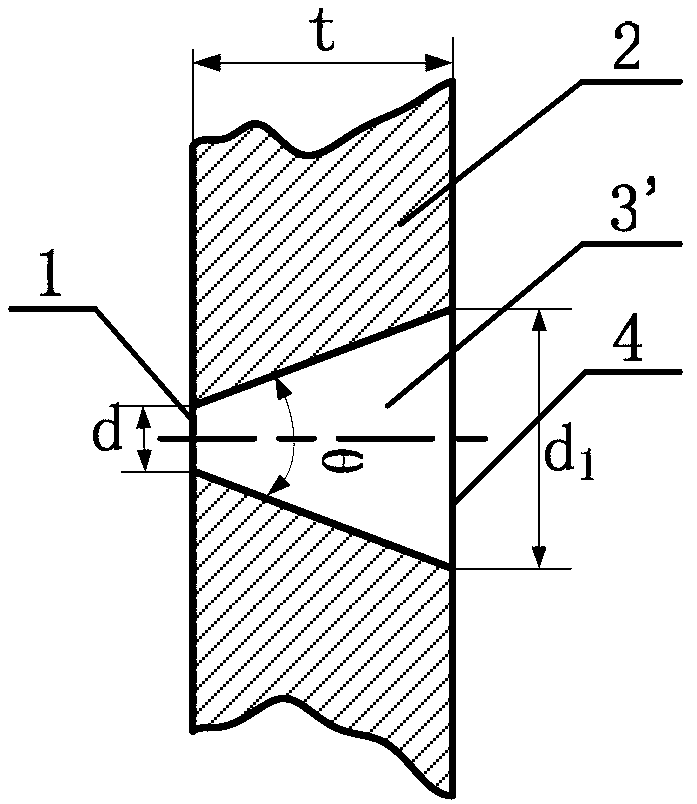

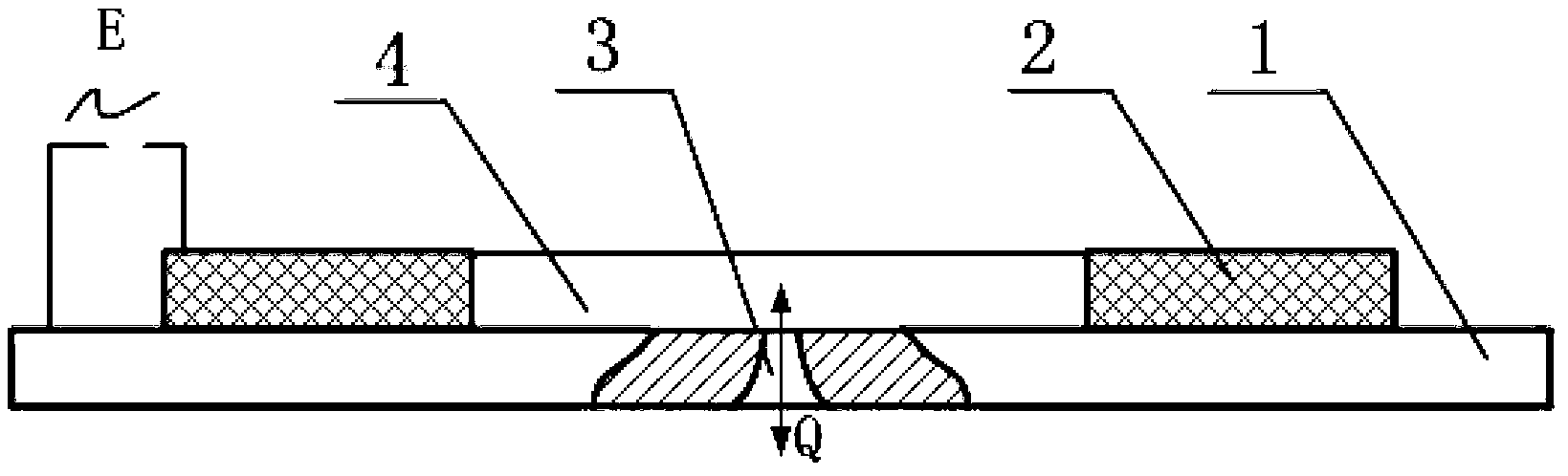

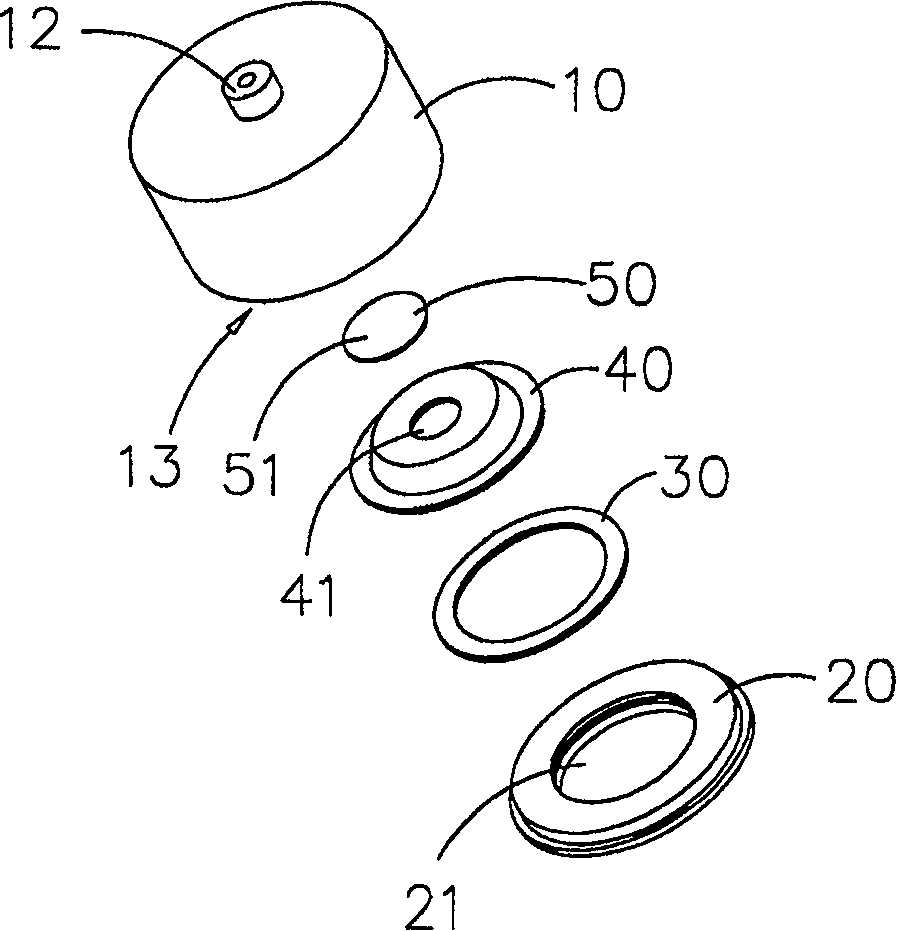

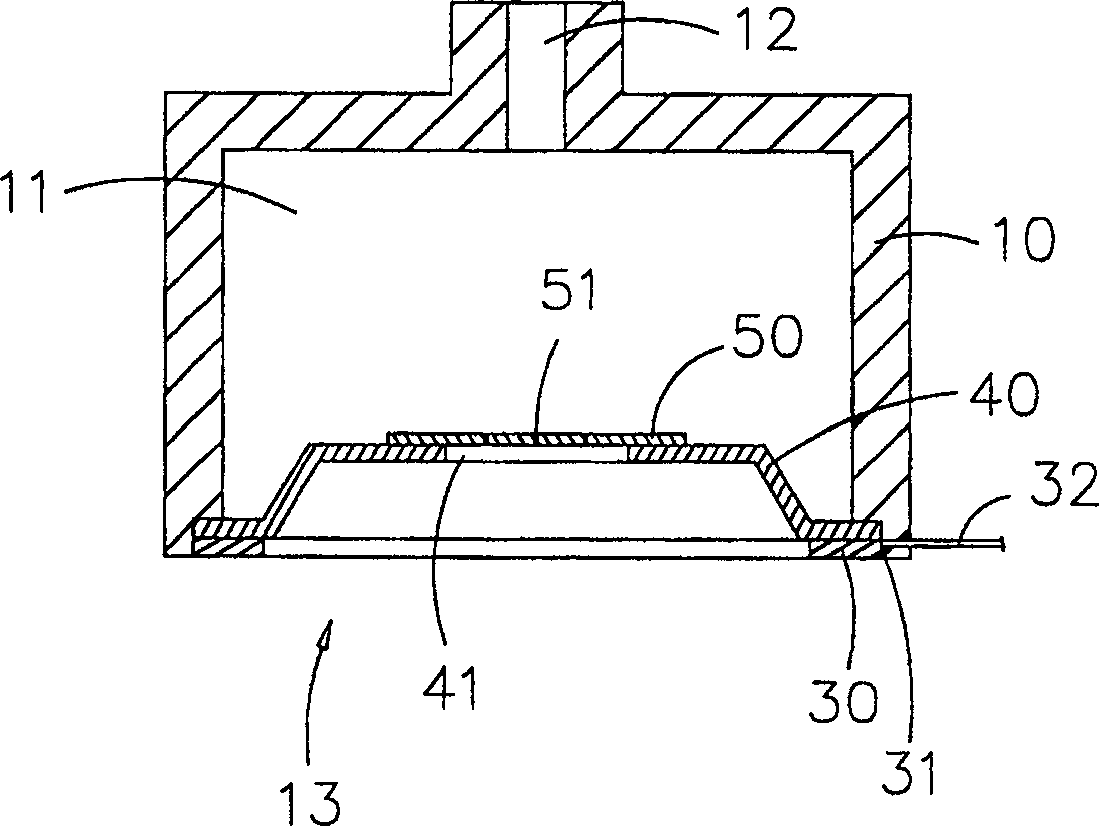

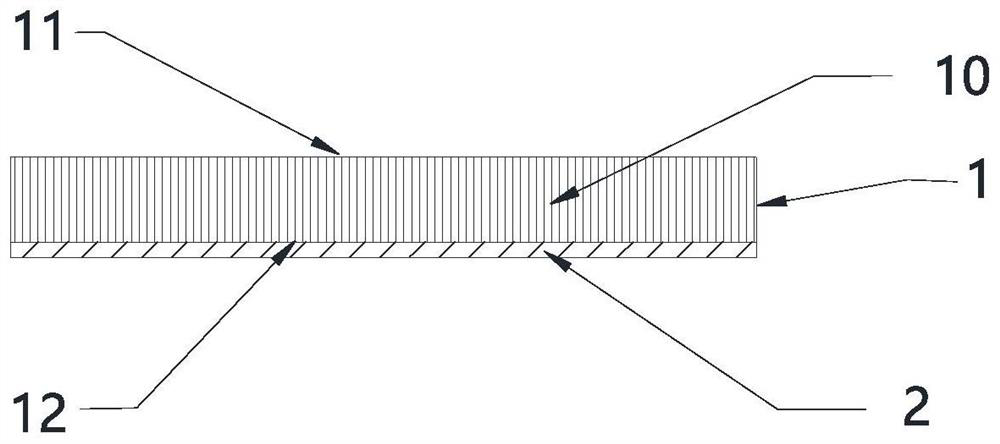

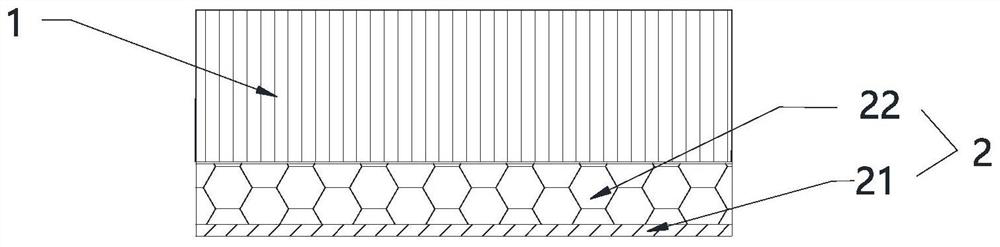

Piezoelectric ceramic ultrasonic atomization sheet

InactiveCN102896064ALow costIncreasing the thicknessLiquid spraying apparatusElastomerUltrasonic atomization

The invention discloses a piezoelectric ceramic ultrasonic atomization sheet, which adopts two atomization units, in each atomization unit, one piezoelectric ceramic sheet is bonded with one metal membrane, and dense conical atomization holes are arranged in each metal membrane. One group of piezoelectric ceramic sheet is arranged on the small diameter end of the conical holes, and the other group of the ceramic sheet of the piezoelectric ceramic sheet is arranged on the large diameter end of the conical holes. The two piezoelectric ceramic sheets are stacked together so as to form the structure of the piezoelectric ultrasonic atomization sheet, the thickness of the metal membrane is correspondingly increased, the cavity volume of each conical atomization hole is enlarged, thus the improvement of the atomization amount is facilitated, and the atomization effect is improved. Meanwhile, by the adoption of the micro and thin absorption elastomer between metal membranes, a large noise caused by direct contact when the metal membranes deform is prevented, and the sealing function is realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

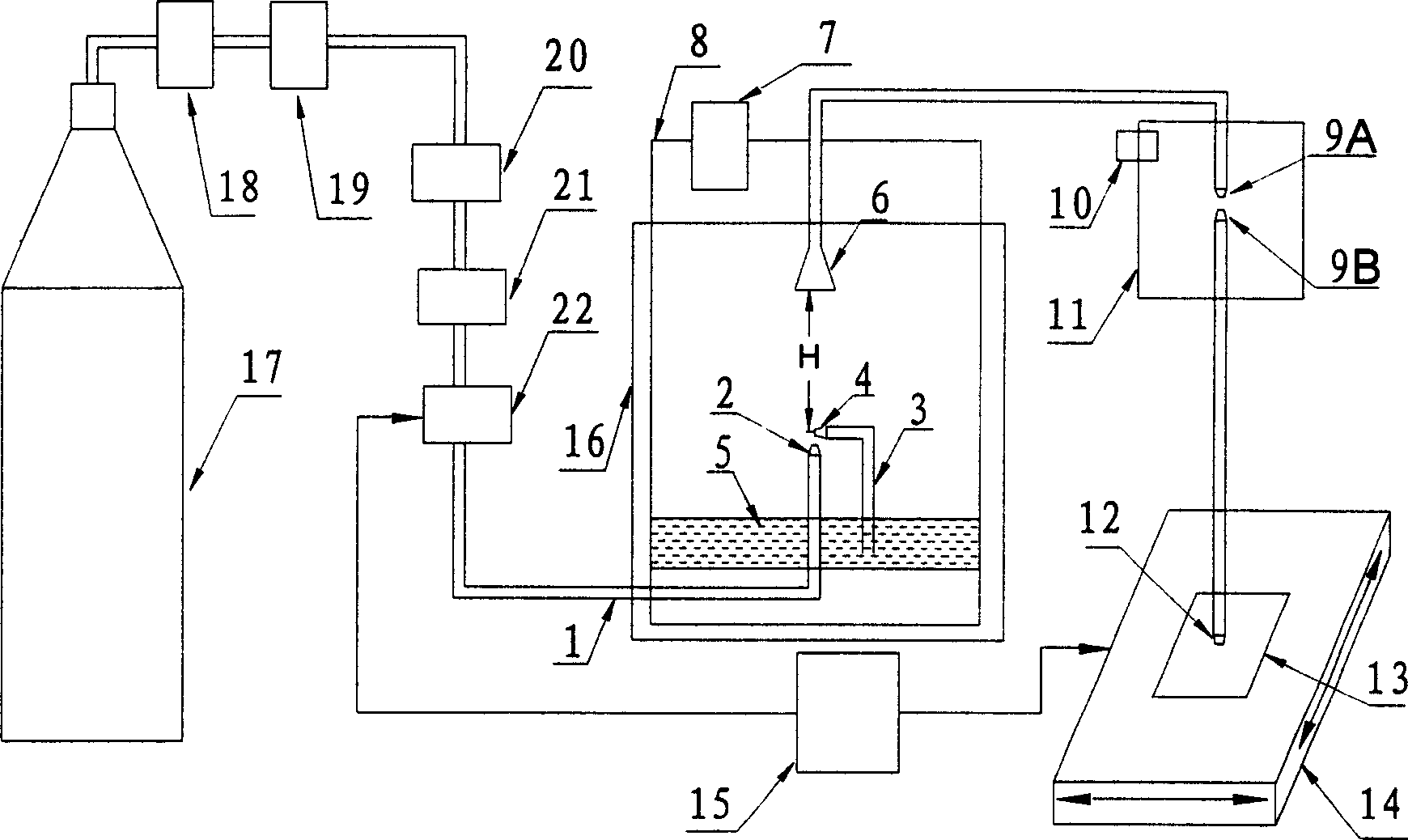

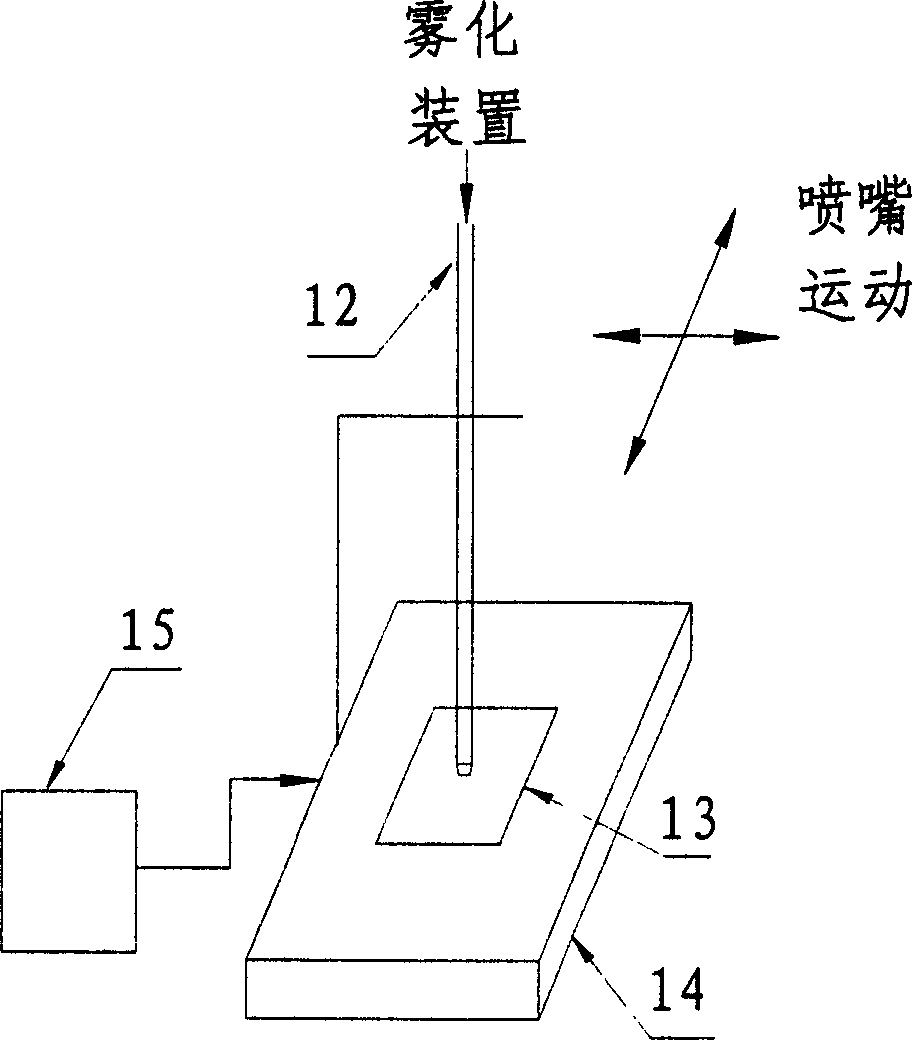

Electronic device for direct slurry atomization and deposition

ActiveCN1876244ASmall inner diameterIncrease air velocityLiquid surface applicatorsSpraying apparatusButt jointSlurry

The disclosed electronic slurry atomization deposition direct-write device comprises: a deposition nozzle, a base plate, a work bench controlled by a controller, two atomizing nozzles every with a gas nozzle connected to gas source and a liquid nozzle connected to slurry pipe end both in the atomization cavity, and a butt-joint jet pipe with co-axial upper and lower jet pipes, wherein arranging a micro-pressure gauge in the cavity, arranging a adjustable valve in the decompression recovery cavity. This invention has well atomization effect, and runs stably and conveniently.

Owner:HUAZHONG UNIV OF SCI & TECH

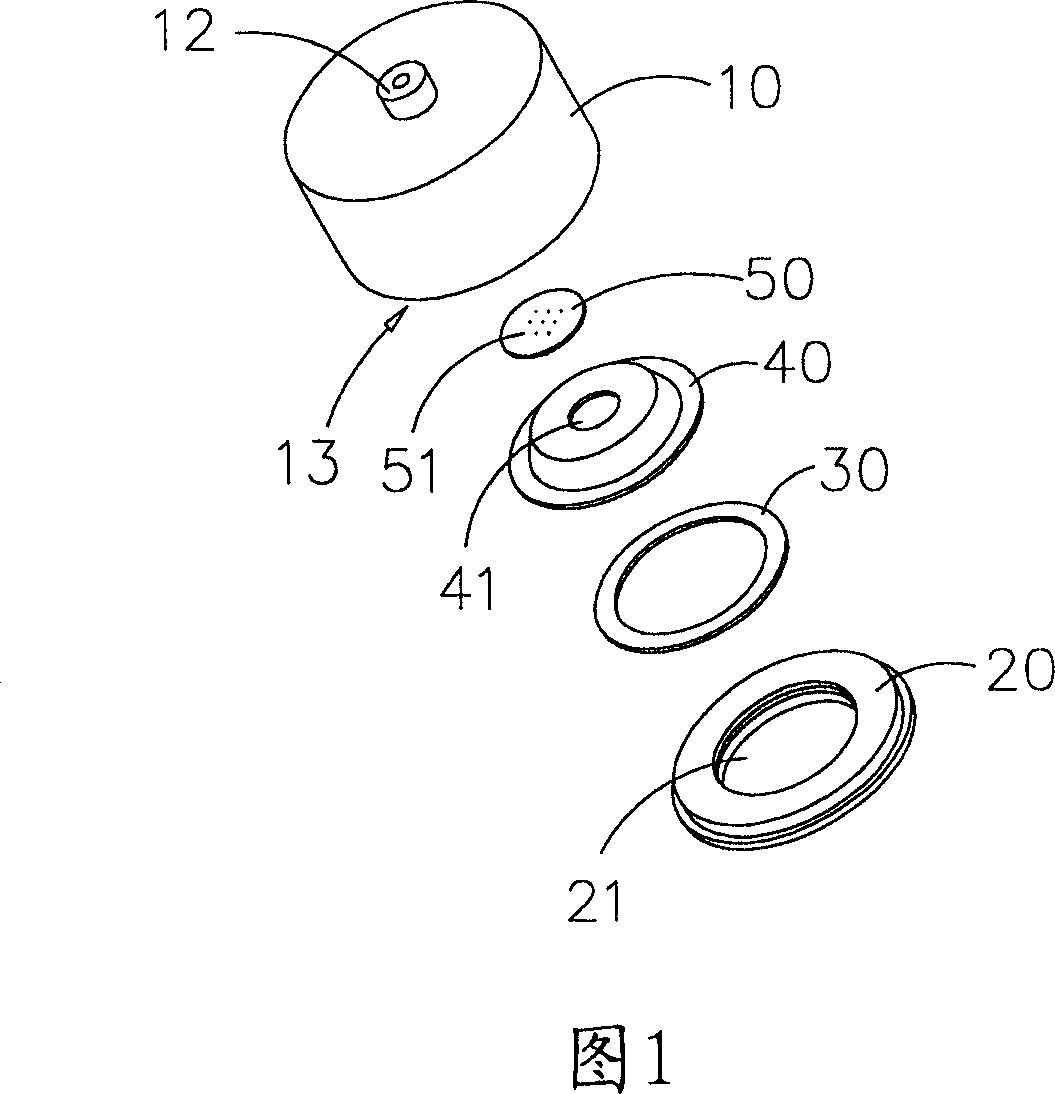

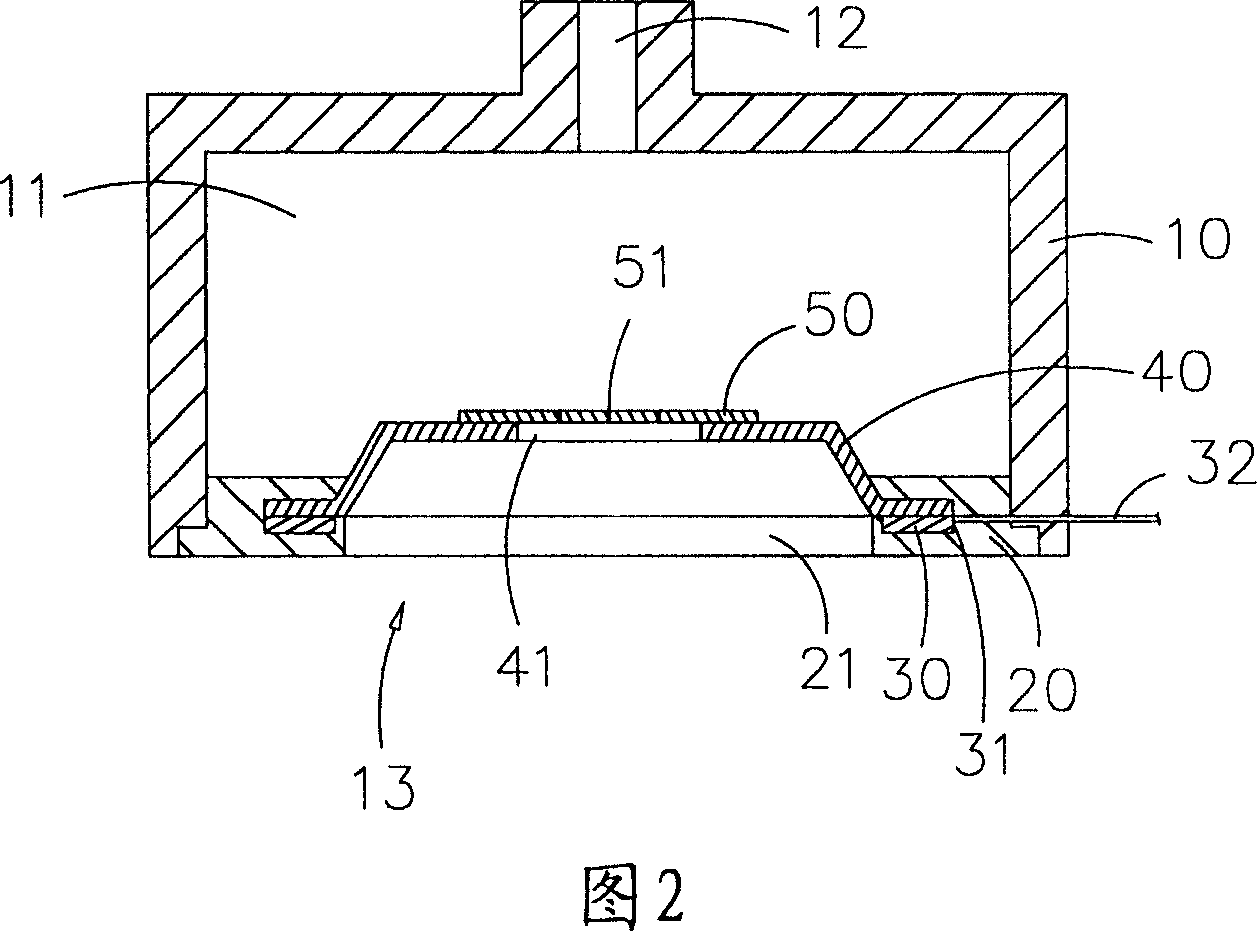

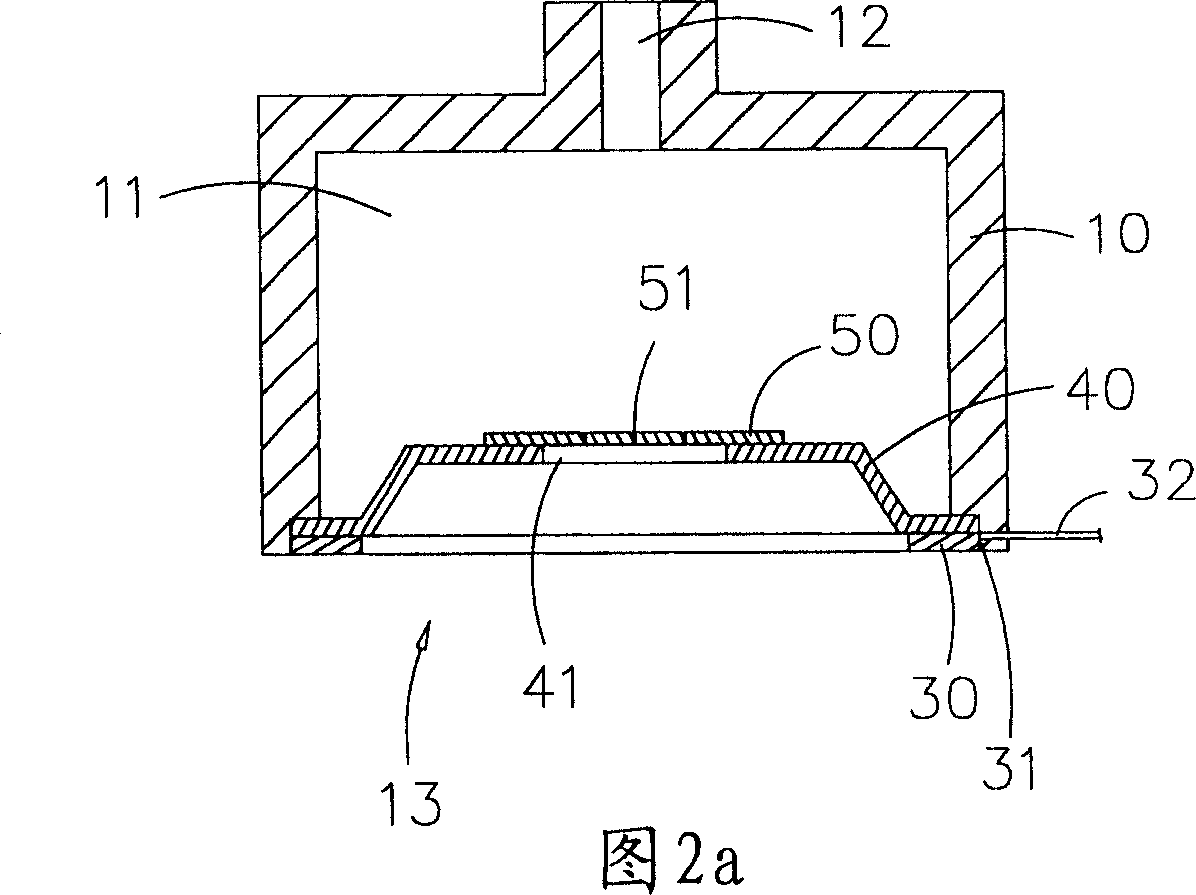

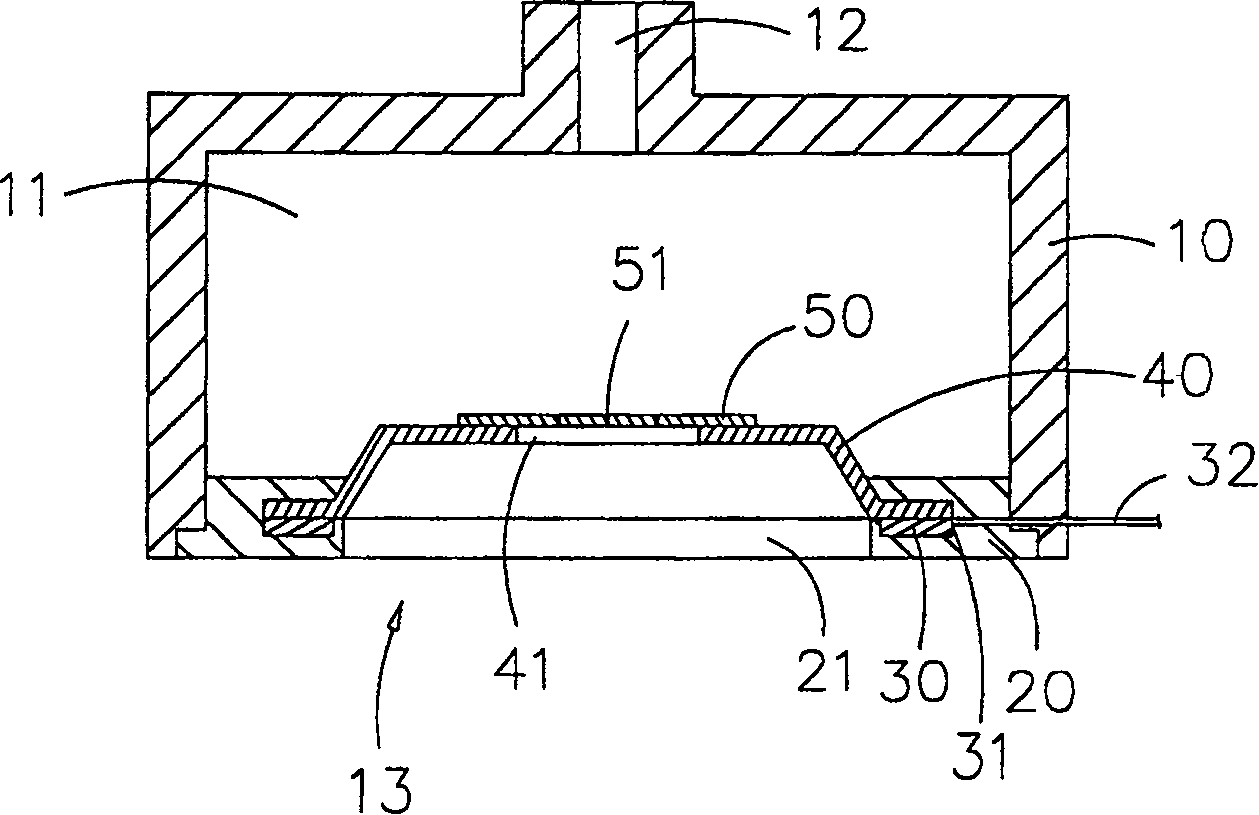

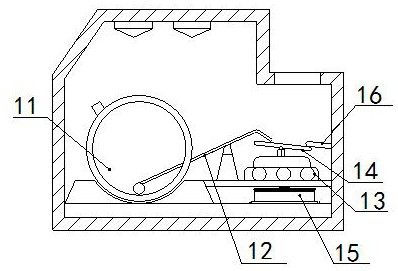

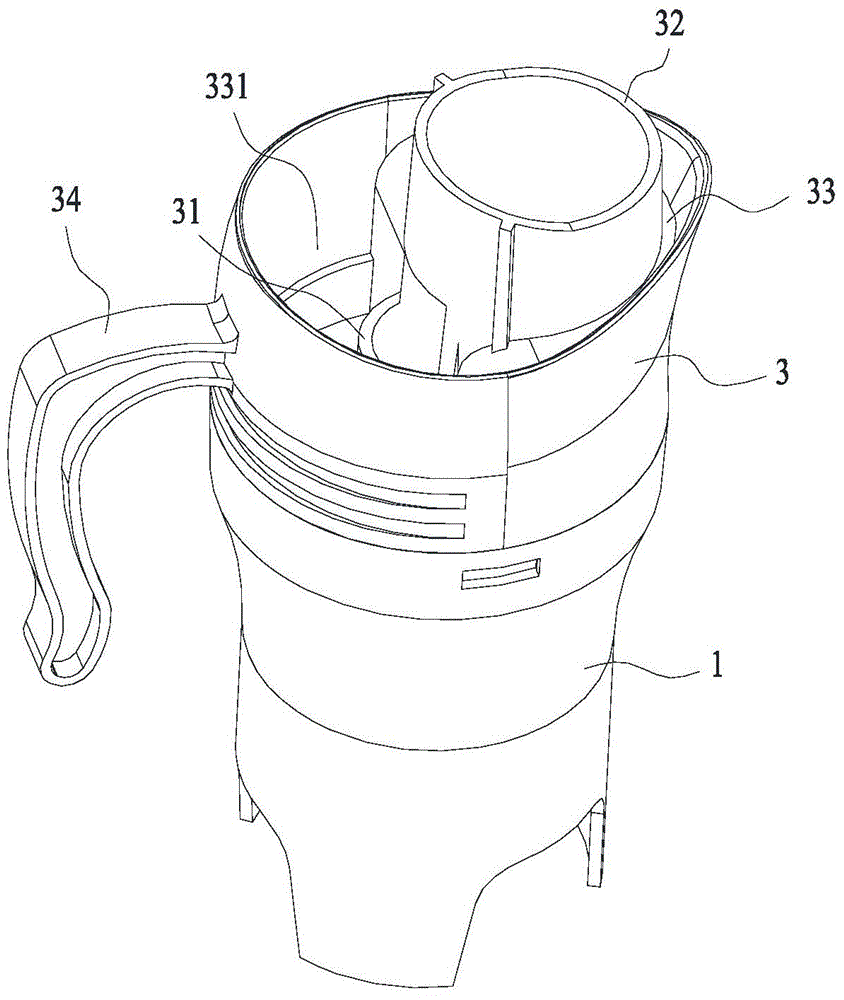

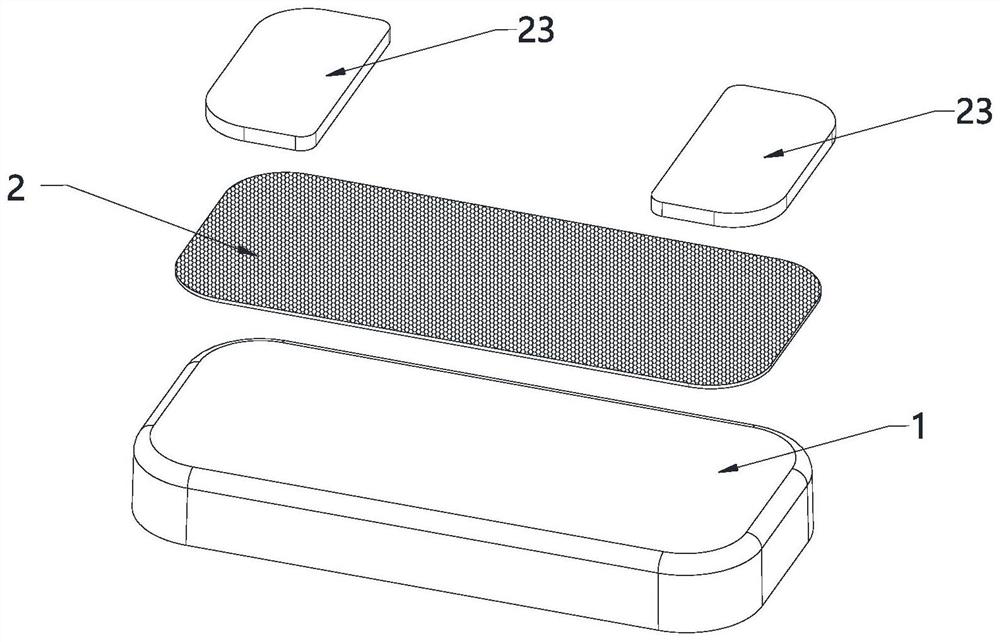

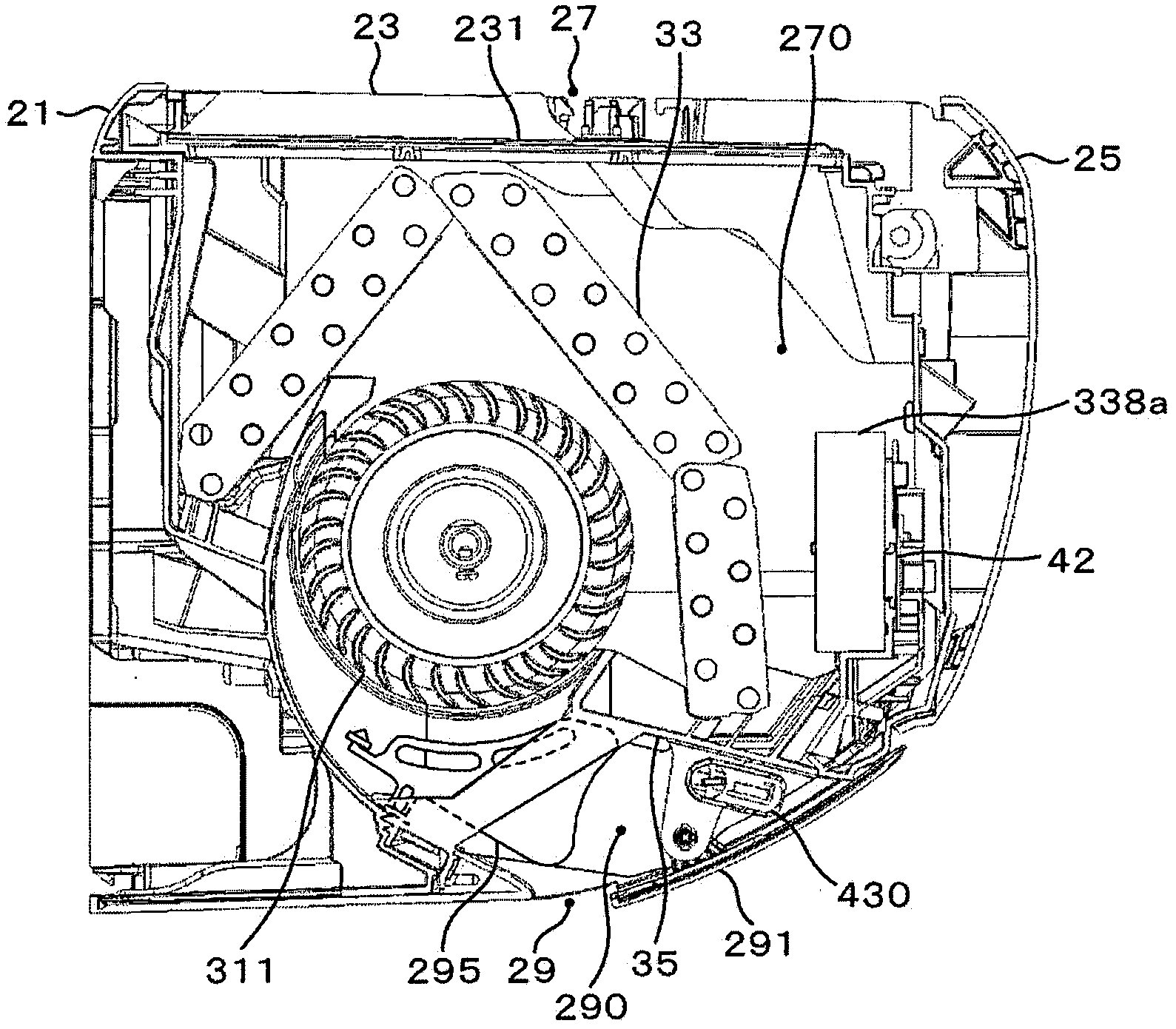

Atomizer structure

ActiveCN1923377AReduce use costLarge amount of atomizationLiquid spraying apparatusElectrical and Electronics engineeringLiquid storage

The invention relates to an atomizer which comprises a frame with liquid storage room, a water inlet and a water outlet; a support on the frame; a vibrator on the support; an auxiliary vibrator protruded on the support; an ejection plate with several ejectors on the auxiliary vibrator. Wherein, when the vibrator vibrates, the energy will be transmitted to the auxiliary vibrator, to vibrate the auxiliary one repeatedly; the ejection plate will fluctuate to compress the liquid of liquid storage room, to discharge the liquid via ejection hole into atom. The invention can reduce element cost, improve atomization and reduce noise.

Owner:IND TECH RES INST

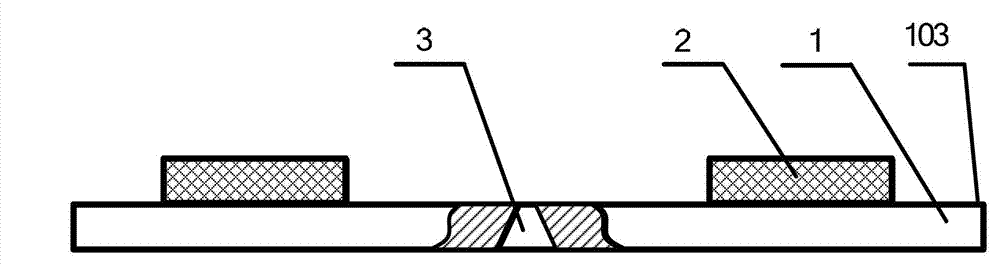

Piezoceramic ultrasonic atomizer

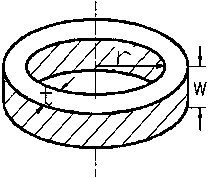

InactiveCN103223390ASmall rate of changeReduce lossesLiquid spraying apparatusEngineeringMetal membrane

The invention discloses a piezoceramic ultrasonic atomizer. The piezoceramic atomizer comprises a metallic membrane and a piezoceramic ring piece which are connected, wherein the outer diameter of the piezoceramic ring piece is smaller than or equal to the diameter of the metallic membrane; a through hole is formed in the center of the piezoceramic ring piece; a group of dense atomizing holes are formed in an area where the metallic membrane corresponds to the central area of the piezoceramic ring piece; the diameter of each first opening, facing to the piezoceramic ring piece, of each atomizing hole is smaller than that of each second opening, deviating from the piezoceramic ring piece, of each atomizing hole; and the contour line of the wall of each atomizing hole is a curve. Each atomizing hole with the structure can reduce the change rate of a cross section of each atomizing hole in an axis direction of the hole, and reduce the energy loss caused by bigger change of the cross section; and besides, the atomization amount of the atomizer is increased, and the atomizing effect is improved remarkably.

Owner:张建辉

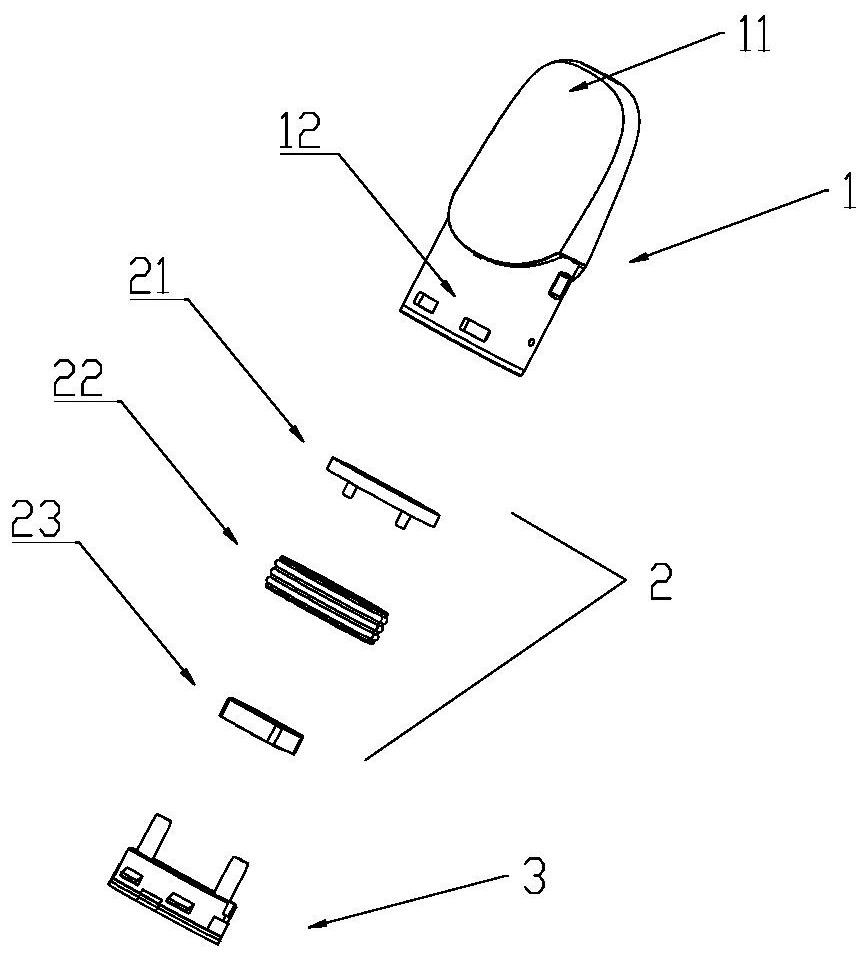

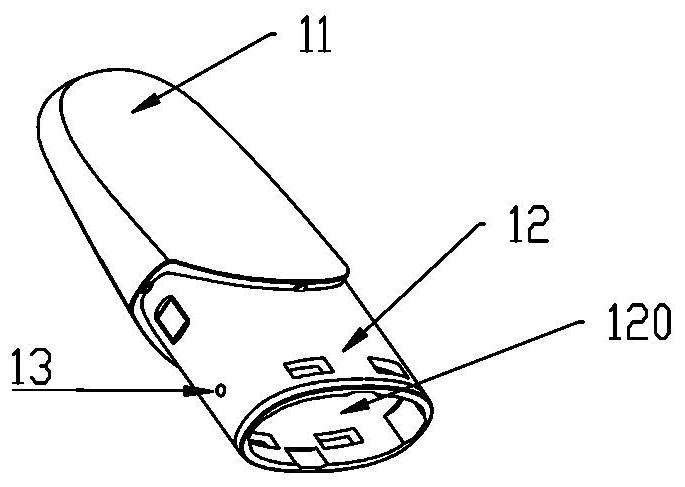

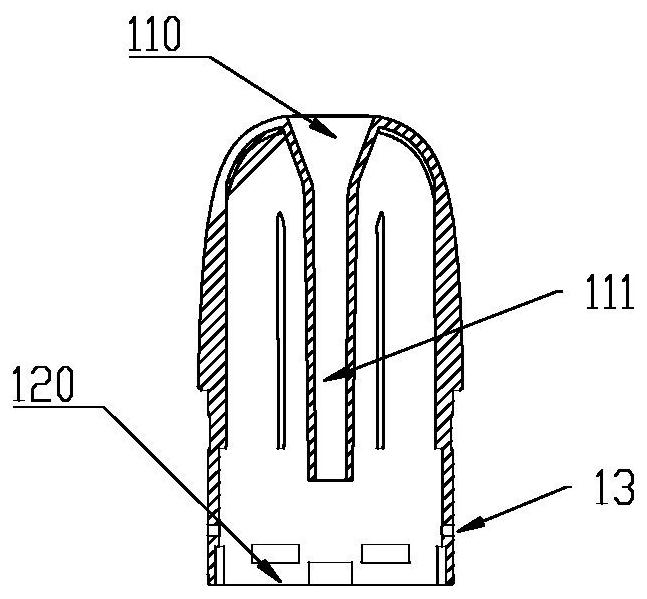

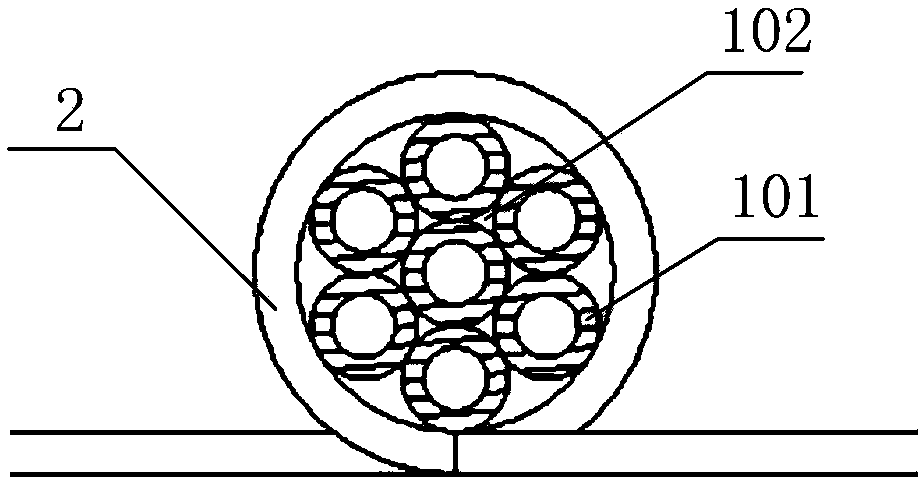

Atomization core, atomizer and electronic cigarette

InactiveCN105054307AIncrease contact areaLarge amount of atomizationTobacco devicesElectronic cigaretteEngineering

The invention discloses an atomization core used for an electronic cigarette atomizer. The atomization core comprises a heating wire assembly, and the heating wire assembly comprises a heating net and an oil guiding body attached to the surface of the heating net. By means of the atomization core, the contact area of the oil guiding body and the heating net is increased through the heating net, net design is beneficial to air ventilation, the smoking oil atomization time can be shortened accordingly, and the smoking oil atomization amount can be increased. The invention further discloses the atomizer comprising the atomization core and an electronic cigarette.

Owner:SHENZHEN HANGSEN STAR TECH +1

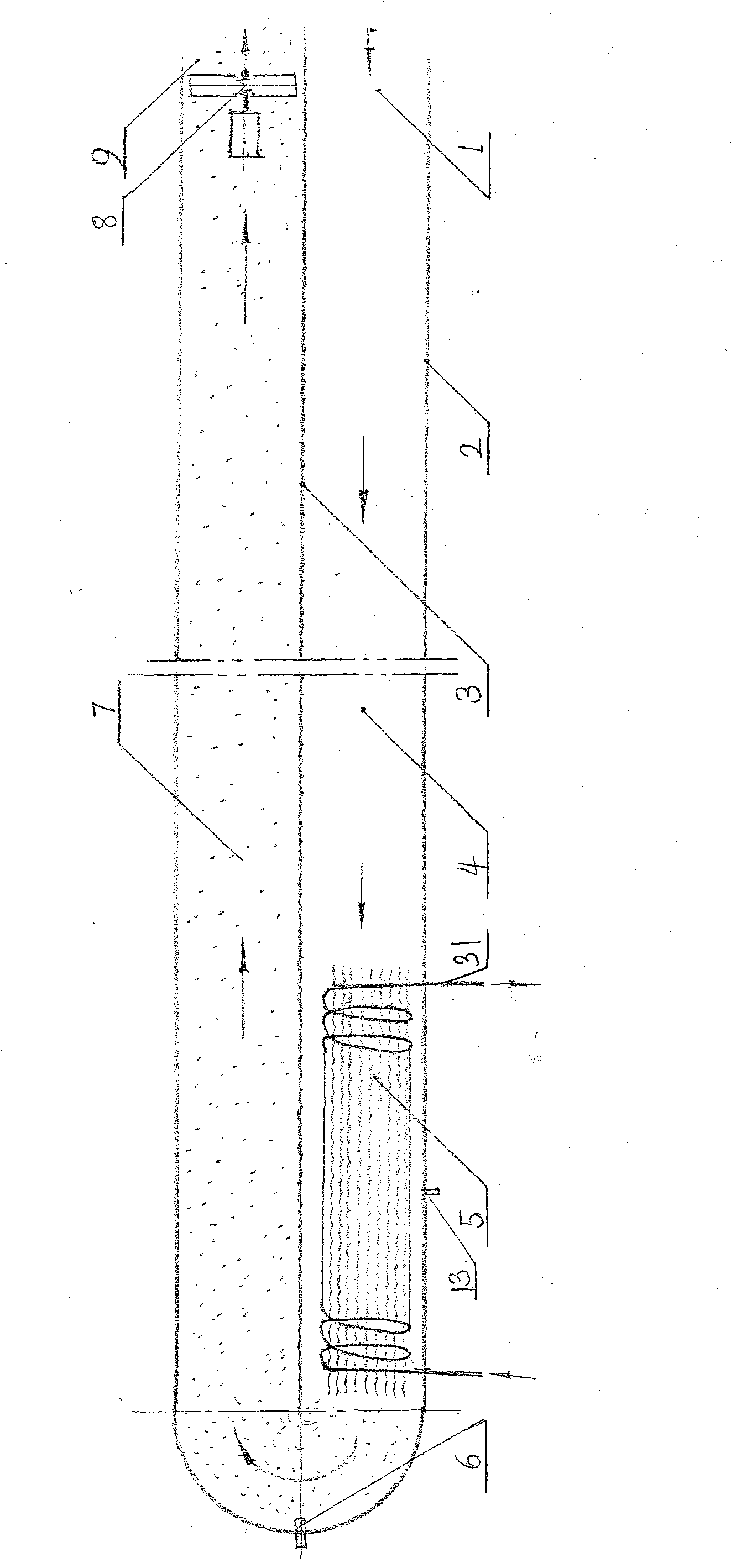

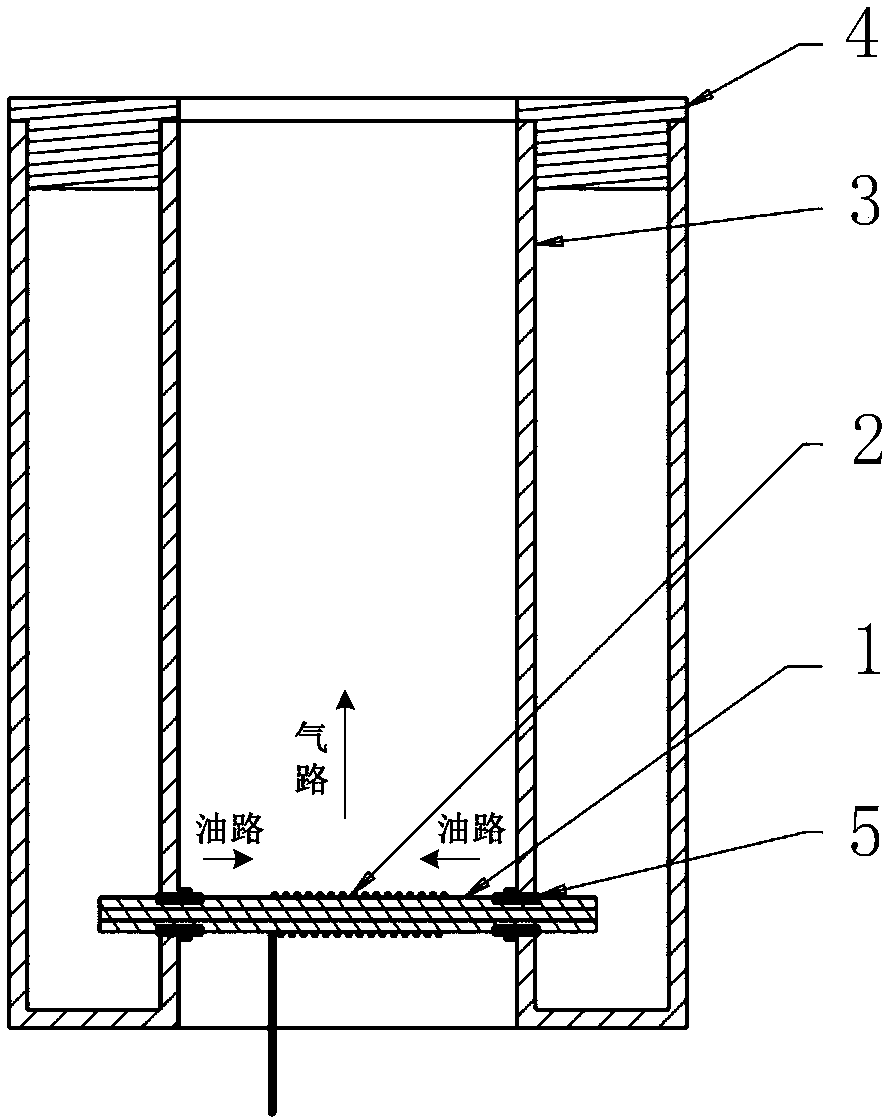

Liquid addition and atomization device for mine nitrogen-filling process

ActiveCN103195462BStable nebulized nitrogen flowReduce excessive resistanceDust removalFire preventionViscous liquidInlet channel

The invention discloses a liquid addition and atomization device for a mine nitrogen-filling process. A flow-guide atomization device is arranged at the front end of a barrel body of the liquid addition and atomization device. A reducing gas-guide channel is reserved in the interior of the flow-guide atomization device. A bypass channel is arranged between the exterior of the flow-guide atomization device and the barrel body. A flow inlet channel is arranged on a lateral side of the flow-guide atomization device, and is communicated with a liquid-guide groove. A Venturi mixer is arranged at the rear end of the barrel body; and an injection orifice of the flow-guide atomization device is opposite to a mixture channel of the Venturi mixer. The liquid addition and atomization device is simple in structure, large in atomization amount, small in occupied space, flexible in movement, convenient to assemble, capable of effectively preventing blocking and working continuously, suitable for viscous liquid, free of electric elements, safe, reliable, and wide in practicability, is applicable to fire preventing and suppression in gob area of a mine or a closed space, and especially is applicable to adding fire-proof inhibitor solution in a mine nitrogen-filling process for fire preventing and suppression.

Owner:CHINA UNIV OF MINING & TECH

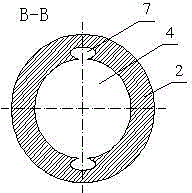

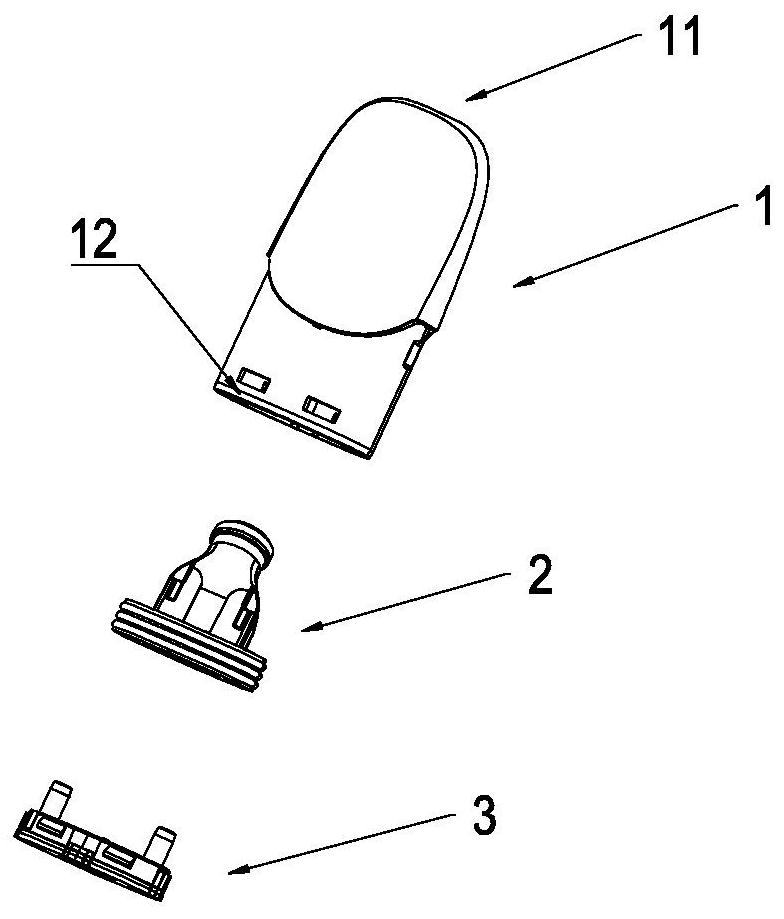

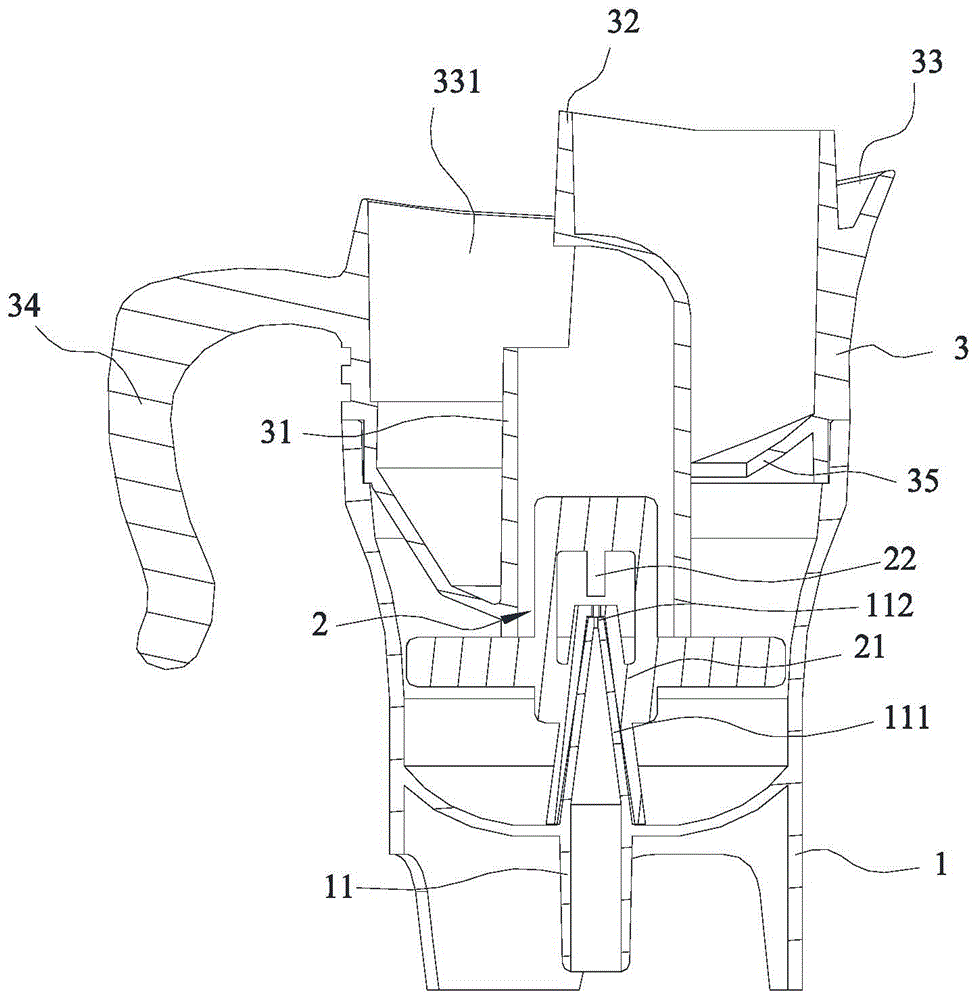

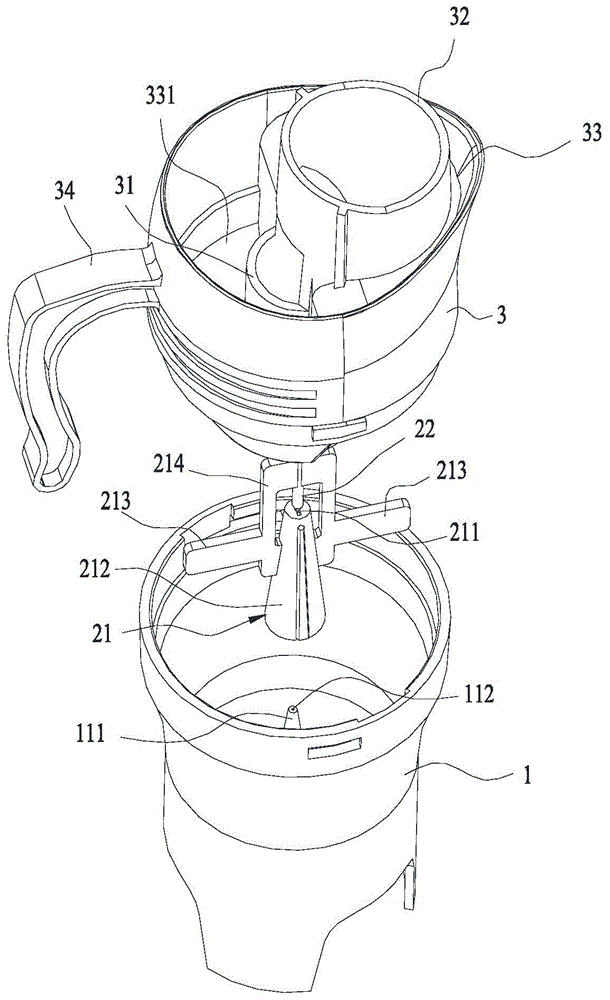

Atomizer having atomization cavity arranged in atomization core bracket

PendingCN112690501AAvoid inhalationImprove user experienceMedical atomisersTobaccoEngineeringBattery pack

The present invention discloses an atomizer having an atomization cavity arranged in an atomization core bracket. The atomizer comprises a shell, a suction port is formed in the suction nozzle end of the shell, a suction port pipe is downwards and integrally formed at the suction port, an opening is formed in the connecting end, a bottom cover is arranged at the opening to block the opening, and the connecting end can be connected with a battery assembly to form electronic atomization equipment. An atomization assembly is connected between the suction port pipe and the bottom cover, a liquid storage cavity is formed between the atomization assembly and the inner wall of the shell, the atomization assembly comprises a throttling cover and an atomization base which are connected up and down, cavities are formed in the throttling cover and the atomization base and used for installing an atomization core, the atomization core comprises a support, a heating piece and a liquid guide plate, and the support comprises a support plane and a support wall. The support wall is vertically arranged on the periphery of the lower portion of the support plane, the lower portion of the support plane and the support wall define an atomization cavity, an atomization through hole leading to the atomization cavity is downwards formed in the support plane, the heating piece is arranged on the support plane and the atomization through hole of the support plane, electrode leads are arranged at the two ends of the heating piece, and a liquid guide plate is tightly attached to the heating piece.

Owner:HUIZHOU HAPPY VAPING TECH LTD

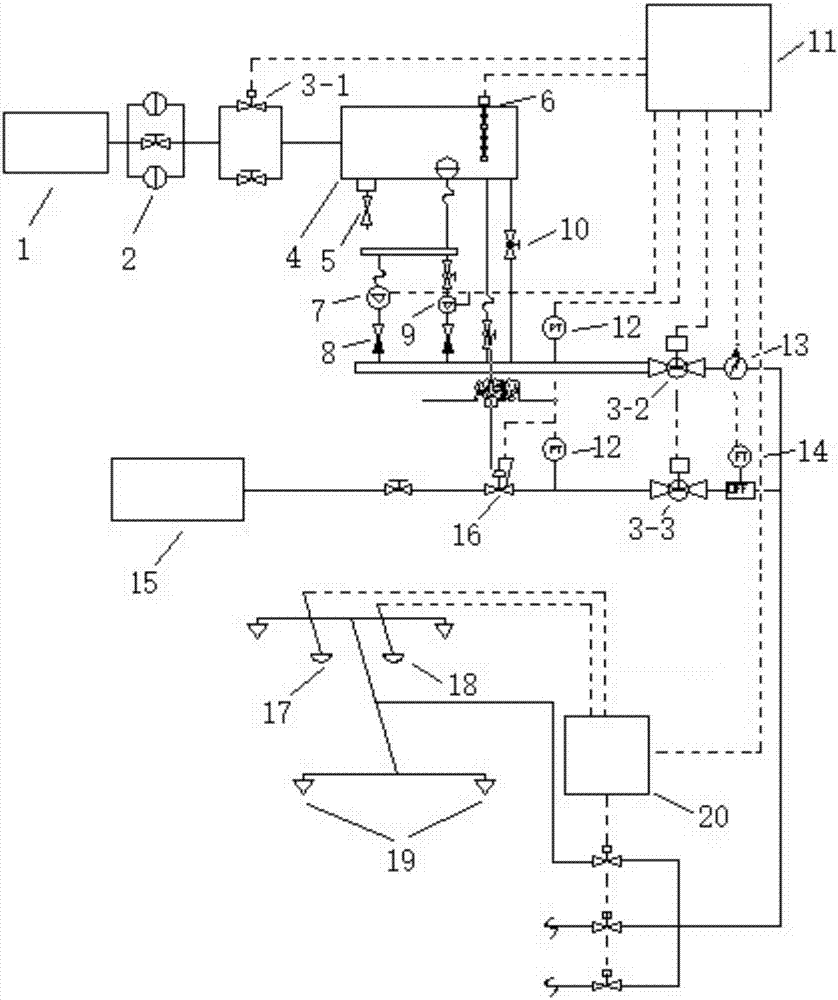

High-pressure gas mist linkage automatic fire extinguishing system

The invention discloses a high-pressure gas mist linkage automatic fire extinguishing system. A high-pressure water supply system comprises a water path connecting a water source, a filter, a first electric control valve and a water tank in sequence; a primary water supply pipeline is connected to the bottom of the water tank and connected with a secondary water supply pipeline through a pipeline provided with a high-pressure pump and a check valve; the secondary water supply pipeline provided with a pressure sensor is connected with a main pipeline of a flow sensor through a second electric control valve; a high-pressure nitrogen system comprises a gas path connecting a high-pressure gas source, a pressure regulating valve, a third electric control valve and a mass flow meter in sequence; the tail end of the gas path is connected with the main pipeline; a plurality of nozzles are connected to the tail end of the main pipeline through a plurality of branch pipes; a smoke sensor and a temperature sensor which are connected with an alarming device are mounted at the tail end of the main pipeline; and a drain valve and a liquidometer are mounted in the water tank. Large-particle-size water drops are prevented from being formed when fire extinguishing with high-pressure fine water mist is completed, secondary disasters to protected substances are reduced, and the environment pollution is avoided.

Owner:天津神封科技发展有限公司

Atomizer having atomizing core with protective cover

PendingCN112690500AAvoid being susceptible to external forcesAvoid the problem of cracking under the immersion of the liquid to be atomizedMedical atomisersInhalatorsEngineeringStructural engineering

The present invention discloses an atomizer having an atomizing core with a protective cover. The atomizer comprises a shell, a suction port and a suction port pipe are arranged at the suction nozzle end of the shell, an opening and a bottom cover for blocking the opening are arranged at the connecting end of the shell, an atomization assembly is connected between the suction port pipe and the bottom cover, and a liquid storage cavity is formed between the atomization assembly and the inner wall of the shell; the atomization assembly comprises an isolation piece, an atomization base and an atomization core, the isolation piece is arranged on the upper plane of the atomization base, a center containing cavity is formed in the bottom of the atomization base, the atomization core is arranged in the center containing cavity, the isolation piece and the atomization base are each provided with a vertically-through liquid through hole in the same position, the liquid through holes are communicated with the liquid storage cavity, and the atomization base is arranged on the bottom cover. The atomization core comprises a flat liquid guide body used for adsorbing and conducting liquid to be atomized, a protective cover is tightly attached to the upper face and the side face of the liquid guide body, the liquid guide body and the protective cover are provided with a vertically-through mist outlet channel, the mist outlet channel is communicated with the suction port pipe, a throttling hole is further formed in the protective cover and communicated with the liquid through hole, and a heating body is arranged at the bottom of the liquid guide body.

Owner:HUIZHOU HAPPY VAPING TECH LTD

Focused ultrasound atomization device

The invention relates to the technical field of liquid atomization, in particular to a focused ultrasonic atomization device. The focused ultrasound atomization device comprises a shell, an ultrasonictransducer and a microporous mesh, the inside of the shell is provided with a through cavity, the ultrasonic transducer is arranged at one end of the through cavity, the other end of the through cavity is provided with the microporous mesh, the ultrasonic transducer comprises a piezoelectric ceramic body, the piezoelectric ceramic body is in a spherical crown shape, the concave surface of the piezoelectric ceramic body is opposite to the microporous mesh, and the through cavity is filled with a liquid medium. According to the ultrasound atomization device, a combined structure combining the high-intensity focusing ultrasonic action and the microporous mesh is adopted, ultrasonic waves emitted by the spherical crown shaped piezoelectric ceramic body with the side facing the microporous mesh being the concave surface are high-intensity focusing ultrasounds and are not a conventional parallel-launched ultrasonic sound field, the energy of the ultrasonic waves is greatly increased, the atomization amount is larger, the atomization efficiency is higher, and higher-viscosity liquid can be atomized.

Owner:SIANSONIC TECH CO LTD

Intermediate-frequency ultrasonic atomizer

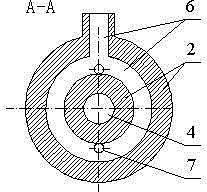

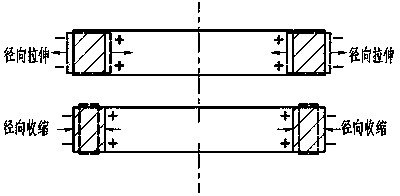

InactiveCN103769337AIncrease axial displacementWon't breakLiquid spraying apparatusChemical structureIntermediate frequency

The invention discloses an intermediate-frequency ultrasonic atomizer. The intermediate-frequency ultrasonic atomizer comprises piezoelectric ceramics, an upper end insulating ring, a metallic end cap, a central metal ring, a negative wire, a positive wire, a lower end metal ring, a liquid inlet, a lower end insulating ring and silver, wherein the metallic end cap is in the shape of a cycloid curve, the polarization direction of the piezoelectric ceramics is radial thickness direction, the atomization amount is high, the reliability is high, and the service life is long; the working frequency of the intermediate-frequency ultrasonic atomizer can reach to 300-500 KHz. The intermediate-frequency ultrasonic atomizer can obtain smaller fog drops without destroying the chemical structure of nutrient solution, and overcomes the defects that the chemical structure of the nutrient solution is destroyed by a high-frequency ultrasonic atomizer and larger fog drops are produced by a low-frequency ultrasonic atomizer. The intermediate-frequency ultrasonic atomizer can be applied to the field of atomization cultivation.

Owner:JIANGSU UNIV

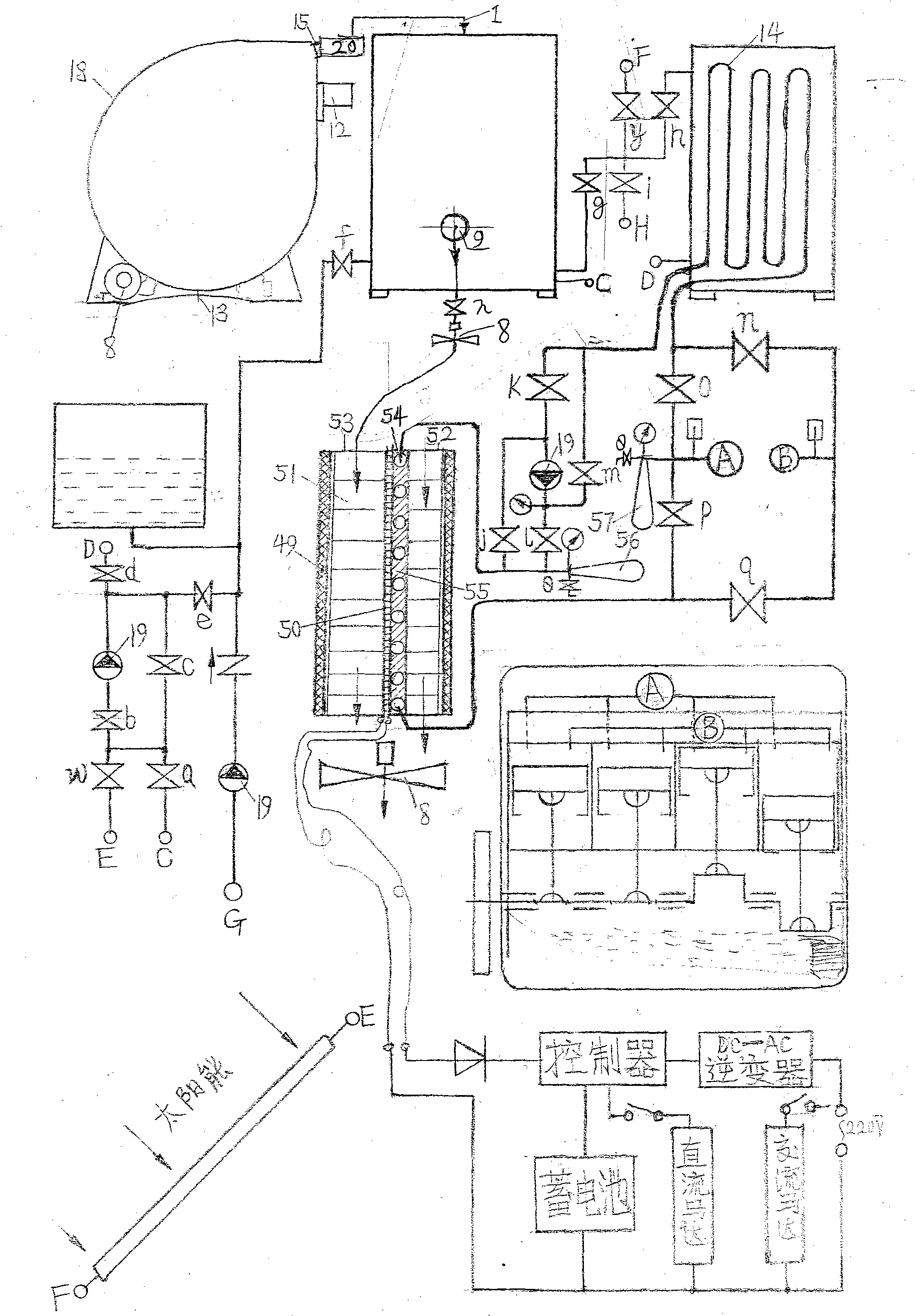

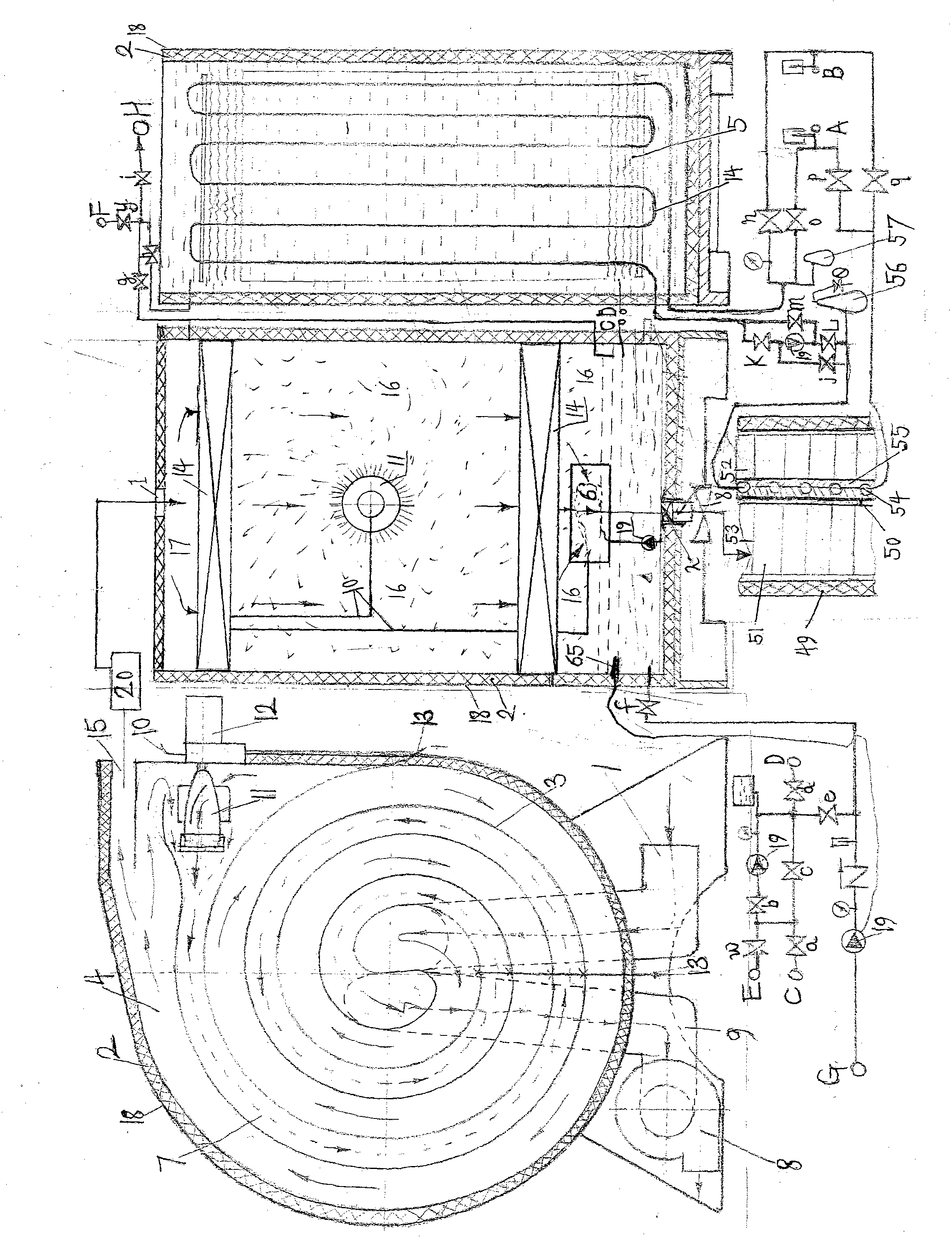

Freezing point indirect evaporation cooling type natural low-phase energy engine taking water as raw material

InactiveCN102635523AReduce peak electricity usageCompact structureFrom solar energyInternal combustion piston enginesThermal energyAtmospheric air

The invention discloses a freezing point indirect evaporation cooling type natural low-phase energy engine taking water as a raw material and aims to provide an indirect evaporation cooler which can dehumidify and reduce the temperature to the temperature close to a freezing point; the indirect evaporation cooler is used as a cold source of an air conditioner or an engine and also can collect solar energy; and atmosphere heat energy is used as a hot source to drive a piston type engine and a thermoelectric engine to work so as to output mechanical energy and electric energy. The technical points are as follows: the freezing point indirect evaporation cooler takes finished air and cold medium water which are close to the freezing point and are generated by carrying out heat-insulating dehumidification and heat exchange on primary air until d is more than or equal to 3.5 grams steam in each kilogram of dry air as a cold source, and takes an atmosphere heat energy solar low-phase energy heat exchanger as a hot source; a circulating work medium refrigerating agent is subjected to heat exchange and expansion with a heat source in a heat collector coiled pipe (14) to drive a piston engine to output mechanical energy; and the refrigerating agent is subjected to heat exchange with the cold source in a thermoelectric engine coiled pipe (54) to be converted into electric energy; and meanwhile, the refrigerating agent is subjected to temperature reduction and is retracted and circulated.

Owner:刘国利

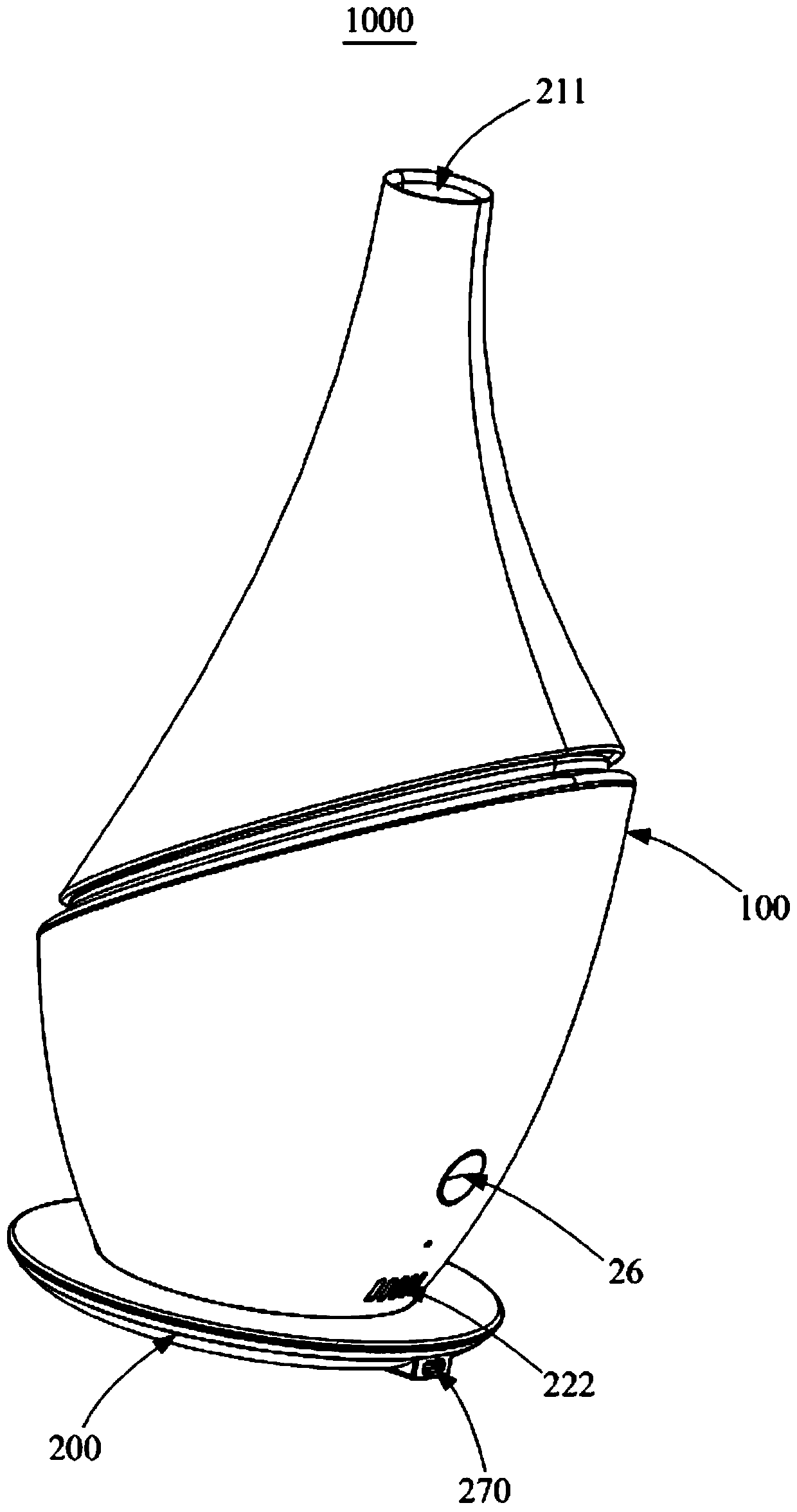

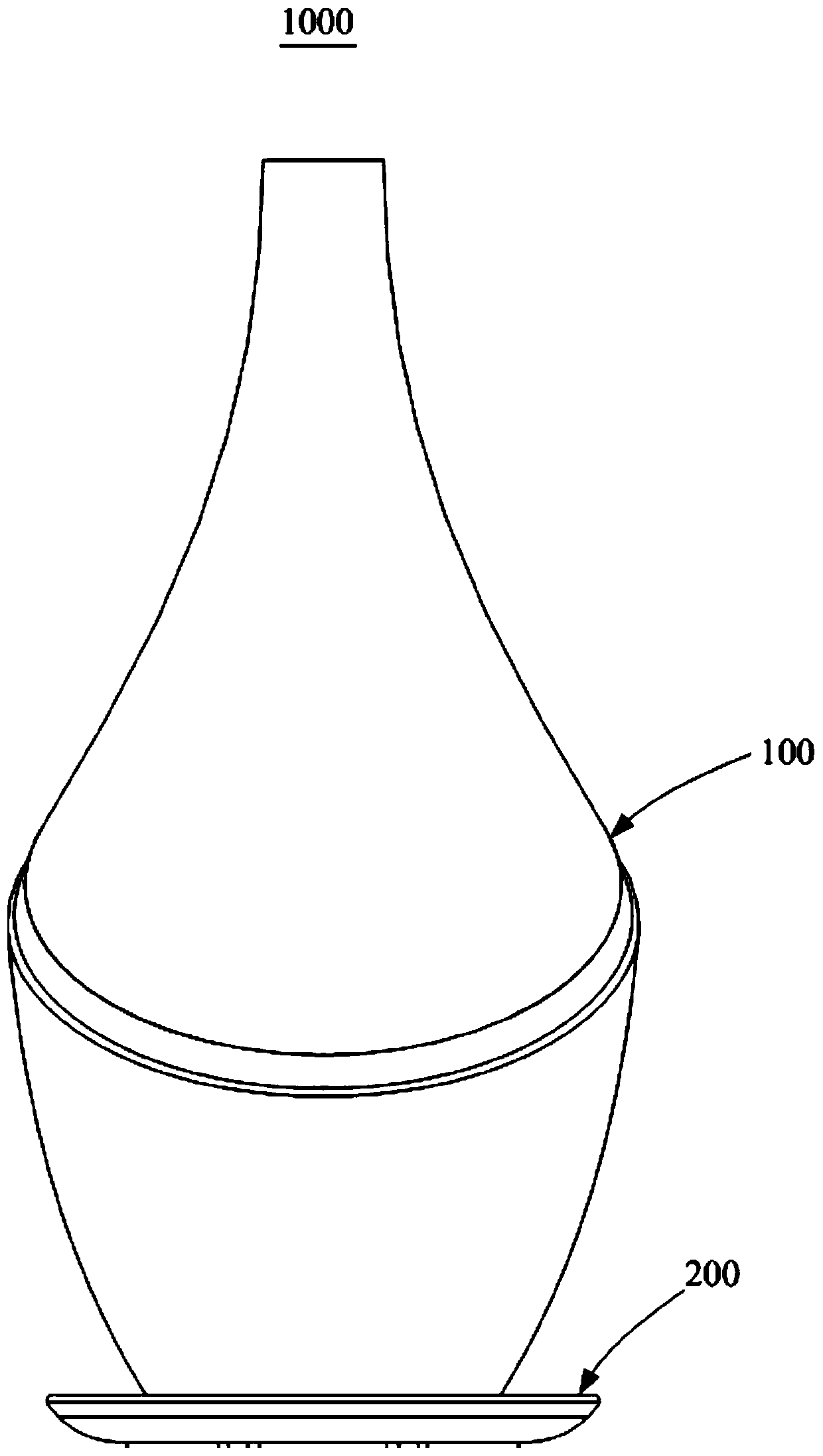

Atomization device and mobile portable charging atomization aromatherapy machine

PendingCN111594963AHigh energyImprove atomization efficiencyMechanical apparatusSpace heating and ventilation safety systemsAromatherapyProcess engineering

The invention discloses an atomization device and a mobile portable charging atomization aromatherapy machine. The atomization device comprises a water tank and an atomization piece, wherein the watertank is provided with an atomization cavity, a through hole communicating with the atomization cavity is formed in the bottom of the water tank, and a mist outlet communicating with the atomization cavity is formed in the top of the water tank; and the atomization piece is installed at the bottom of the water tank and covers the through hole, and the surface, facing the water tank, of the atomization piece is concave. By means of the technical scheme, the atomization efficiency and atomization capacity can be improved, and therefore energy consumption is reduced.

Owner:深圳市本原生活科技有限公司

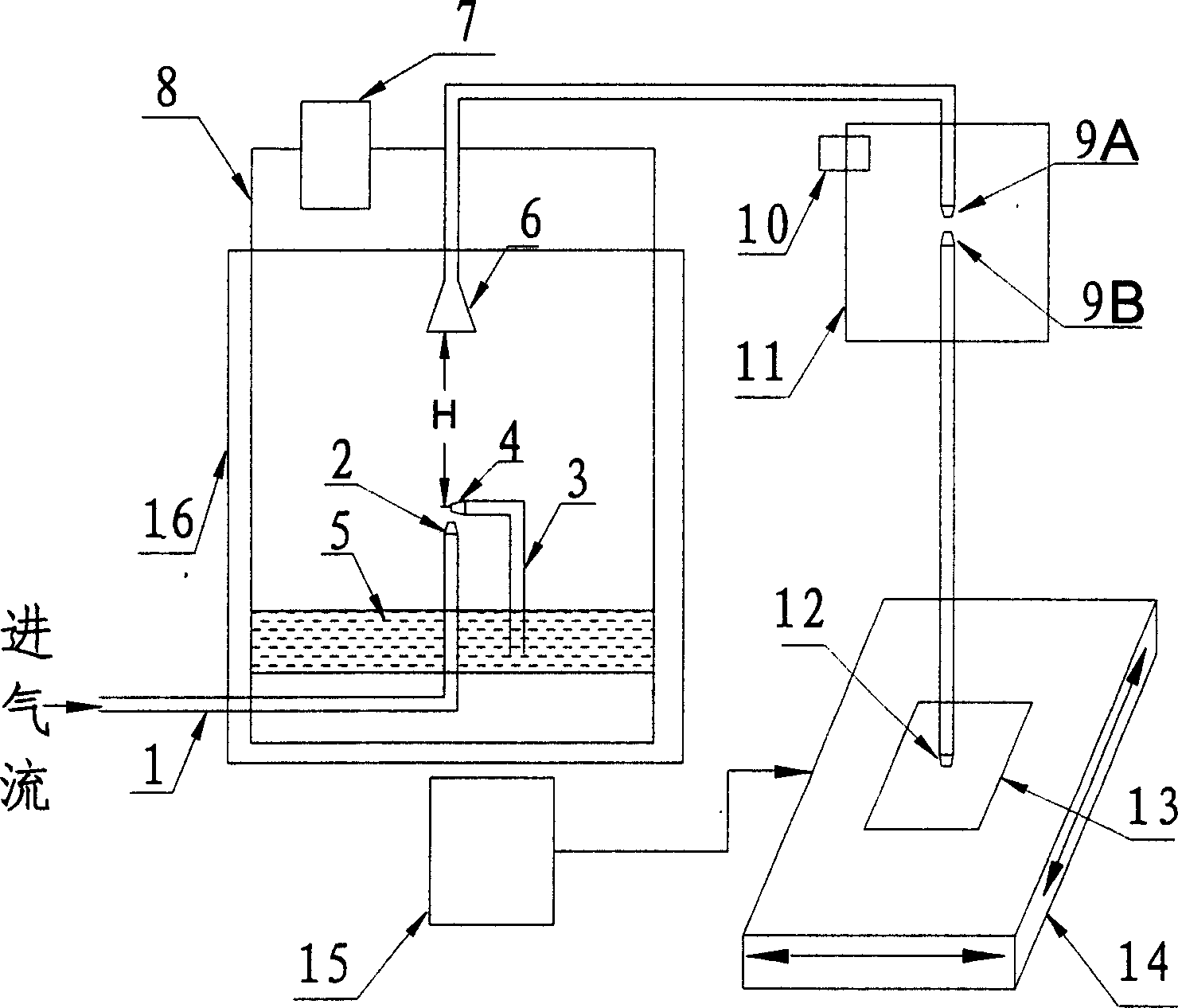

Ultrasonic atomization dust fall device for mine mining working face

InactiveCN103878084ASolve the problem that the diameter is large and cannot fully absorb finer coal dustLarge amount of atomizationSlitting machinesLiquid spraying apparatusWater sourceSolenoid valve

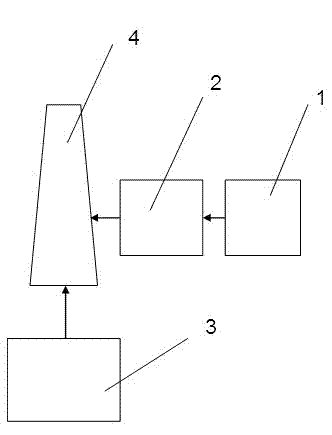

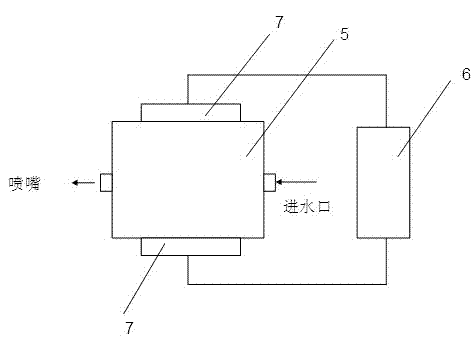

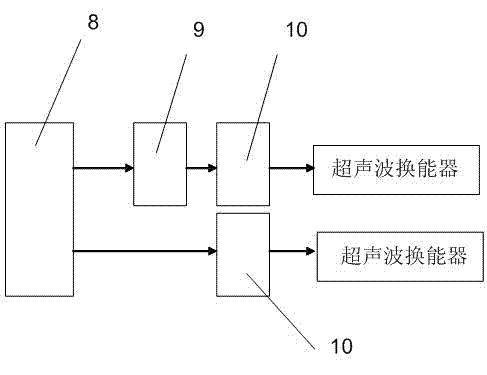

The invention discloses an ultrasonic atomization dust fall device for a mine mining working face. The ultrasonic atomization dust fall device is suitable for being used in a special environment under a mine. The ultrasonic atomization dust fall device comprises a dustproof air compressor and a jet nozzle, wherein the jet nozzle is connected to the dustproof air compressor, and an ultrasonic atomizer is arranged on the jet nozzle and connected with a water source. The ultrasonic atomizer comprises a water container connected with the water source, and an ultrasonic unit is arranged on the water container. Two ultrasonic energy converters are arranged on the two sides of the water container, and a phase inverter is arranged between one ultrasonic energy converter and a signal generator, so that the two ultrasonic energy converters arranged on the two sides of the water container generate high-frequency vibration in an inverted frequency mode, and the ultrasonic atomizing effect in the water container is enhanced; a stainless steel dust filter net is arranged on an air inlet of the air compressor and used for filtering dust on the air inlet, meanwhile, a solenoid valve B and a dust blowing nozzle are arranged on an air outlet, and coal dust accumulating on the stainless steel filter net is cleared through opening the solenoid valve B at regular intervals, so that the dustproof air compressor continuously works normally. The ultrasonic atomization dust fall device is simple in structure, convenient to use and high in dust fall efficiency.

Owner:CHINA UNIV OF MINING & TECH

Atomization assembly, atomizer and aerosol generating device

The invention relates to an atomization assembly, an atomizer and an aerosol generating device, a heating body is at least partially embedded in an atomization part, and the atomization part is fixed in a guide part; the guide part is in contact with the atomizing medium and transmits the atomizing medium to the atomizing part; the inner wall of the atomizing part forms a first atomizing surface and a first air channel, and the outer wall forms a second atomizing surface and a second air channel. On one hand, a physical interval is formed between the atomizing surface and the liquid absorbing surface, and the heating body indirectly contacts with the atomizing medium in the liquid storage cavity through the guide part, so that a long distance exists between the heating body and the atomizing medium in the liquid storage cavity, heat transfer is effectively isolated, and the atomizing medium in the liquid storage cavity can be prevented from deteriorating due to high temperature; due to heat concentration, the heating efficiency of the whole atomization assembly is high; on the other hand, the atomization part and the oil guide part are connected, the guide part obtains the atomization medium through the liquid suction face, the oil guide area is large, oil is guided in all directions, and sufficient oil supply can be effectively guaranteed.

Owner:深圳市大迈发展有限公司

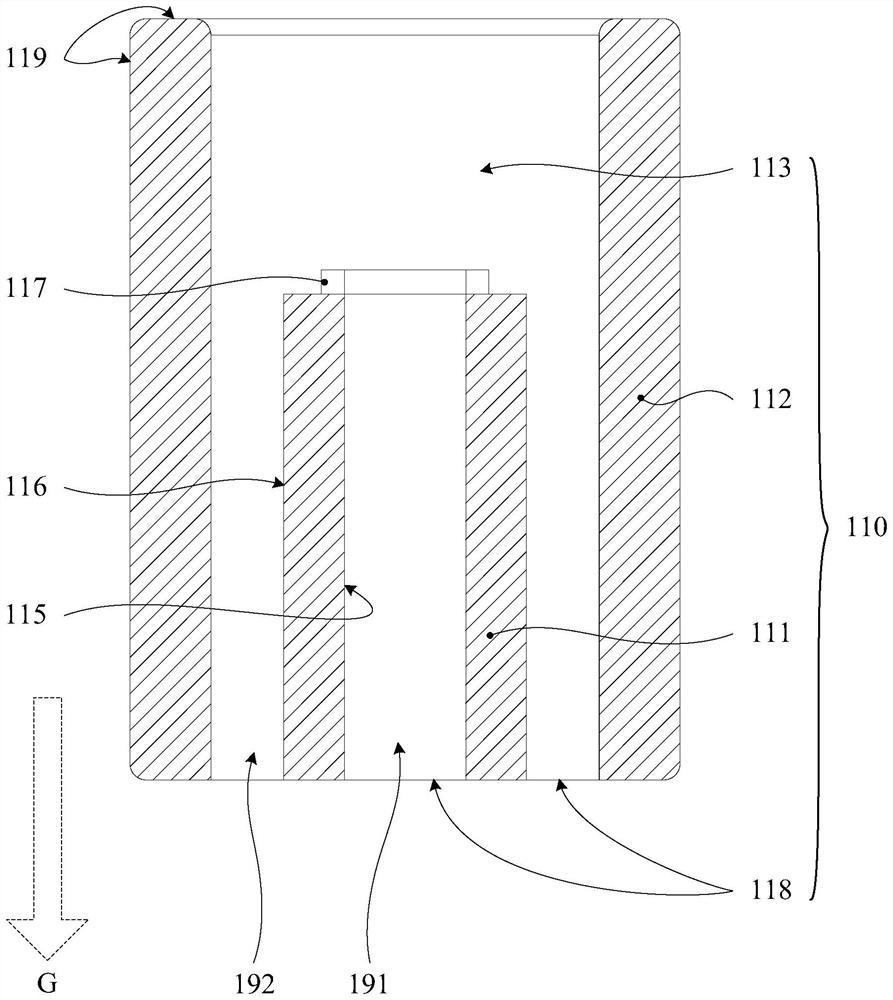

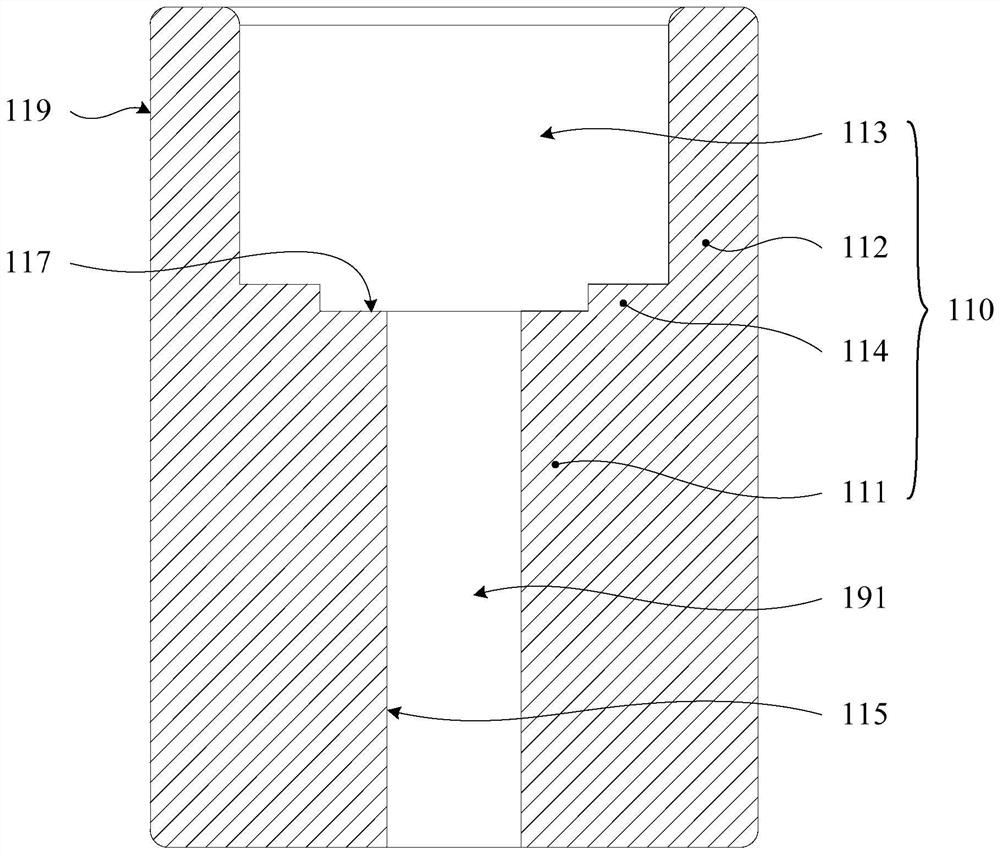

Atomizer structure

ActiveCN100404141CReduce use costLarge amount of atomizationLiquid spraying apparatusEngineeringElectrical and Electronics engineering

The invention relates to an atomizer which comprises a frame with liquid storage room, a water inlet and a water outlet; a support on the frame; a vibrator on the support; an auxiliary vibrator protruded on the support; an ejection plate with several ejectors on the auxiliary vibrator. Wherein, when the vibrator vibrates, the energy will be transmitted to the auxiliary vibrator, to vibrate the auxiliary one repeatedly; the ejection plate will fluctuate to compress the liquid of liquid storage room, to discharge the liquid via ejection hole into atom. The invention can reduce element cost, improve atomization and reduce noise.

Owner:IND TECH RES INST

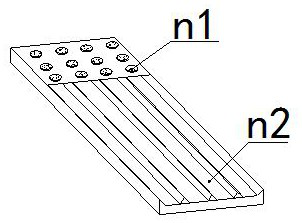

Air purification, sterilization and humidification device

InactiveCN111829122AReduce gravityHigh vibration frequencyLighting and heating apparatusCleaning using toolsEngineeringMachine

The invention discloses an air purification, sterilization and humidification device which structurally comprises a machine body, rolling wheels, a front cover, a control panel and a spray pipe. The rolling wheels are vertically fixed to the edge of the bottom of the machine body. The front cover is mounted on the front face of the machine body. The control panel is arranged on the front face of the machine body and is located on the front portion of the front cover. The spray pipe is embedded and fixed to the top of the machine body. A liquid storage chamber and a liquid conveying pipe are arranged on the machine body. For water scales left on the surface of an atomization sheet in a water solution, the water scales on the surface of the atomization sheet are brushed away through a removal roller of a descaling plate, water scales of the atomization sheet are cleaned away in time, the bearing gravity of the atomization sheet is reduced, the vibration frequency is improved, atomizationof the atomization sheet to the water solution is accelerated, and the atomization quantity is increased. For part of impurities left on the surface of a brush plate and the bottoms of clamping plates, impurities on the surface of the brush plate are removed through a convex block of a push block, impurities accumulated on the surface of the brush plate are reduced, impurities of main brush headscan be brushed away sufficiently, and by means of mutual extrusion between inclined rods, impurities brushed away from secondary brush heads are accelerated to fall off.

Owner:广州德程智能科技股份有限公司

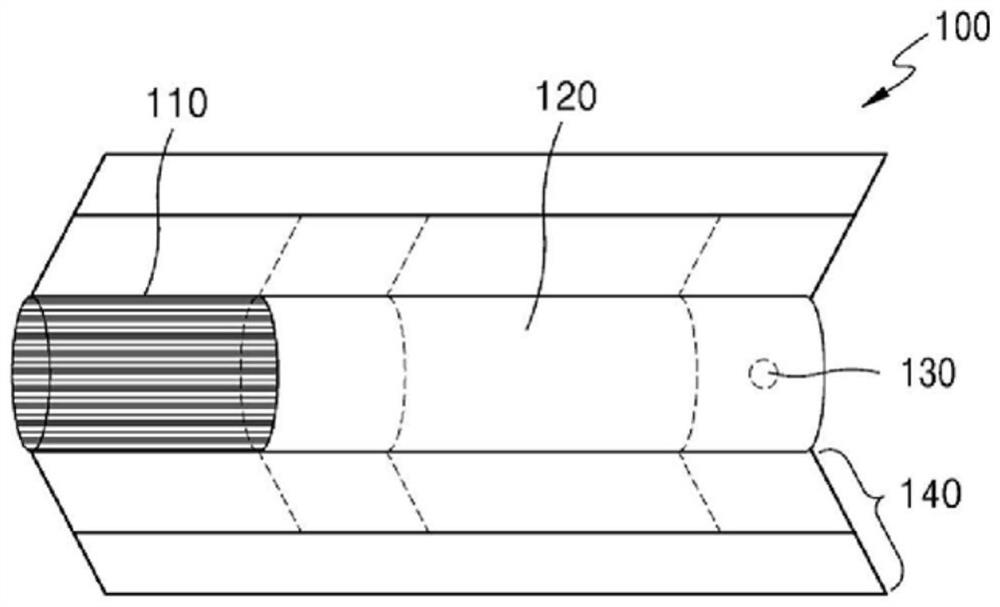

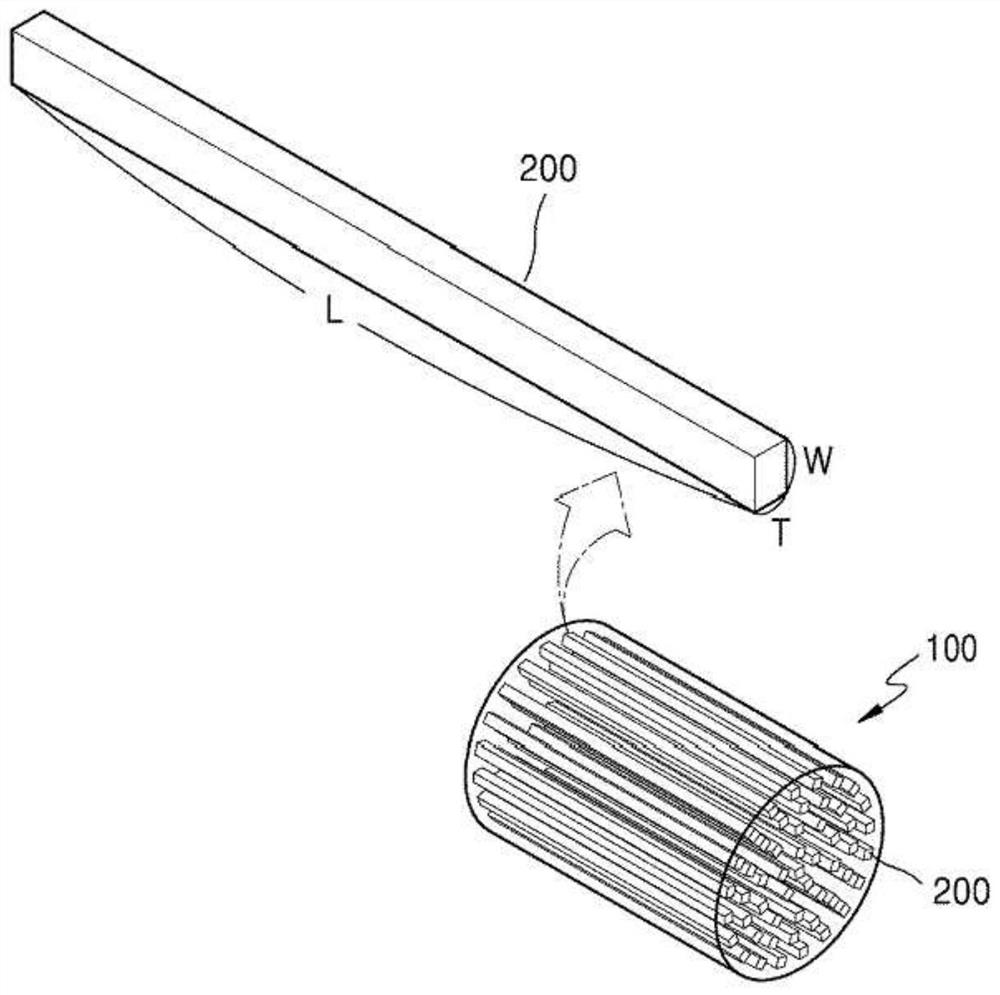

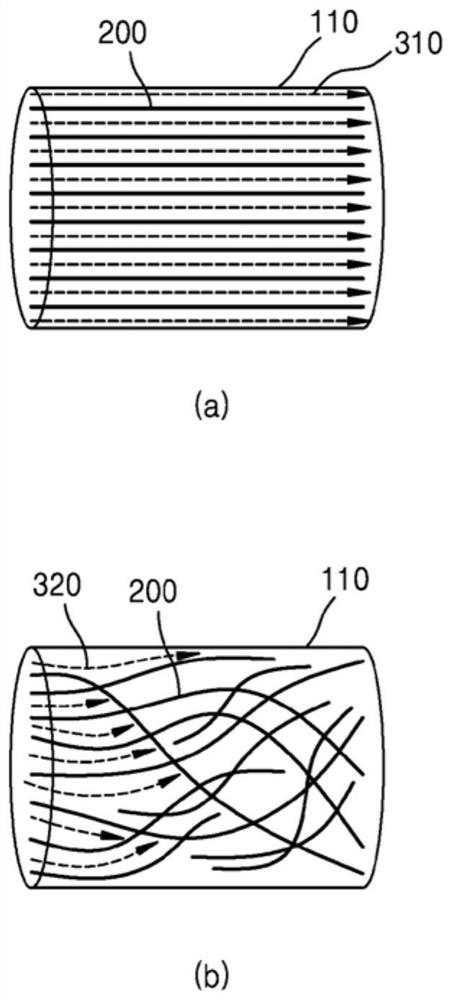

Aerosol-generating rod comprising tabacco strands arranged in parallel

PendingCN112040794ASmooth circulationReduce carbonizationTobacco preparationTobacco treatmentMechanical engineeringPhysics

Owner:KT&G CO LTD

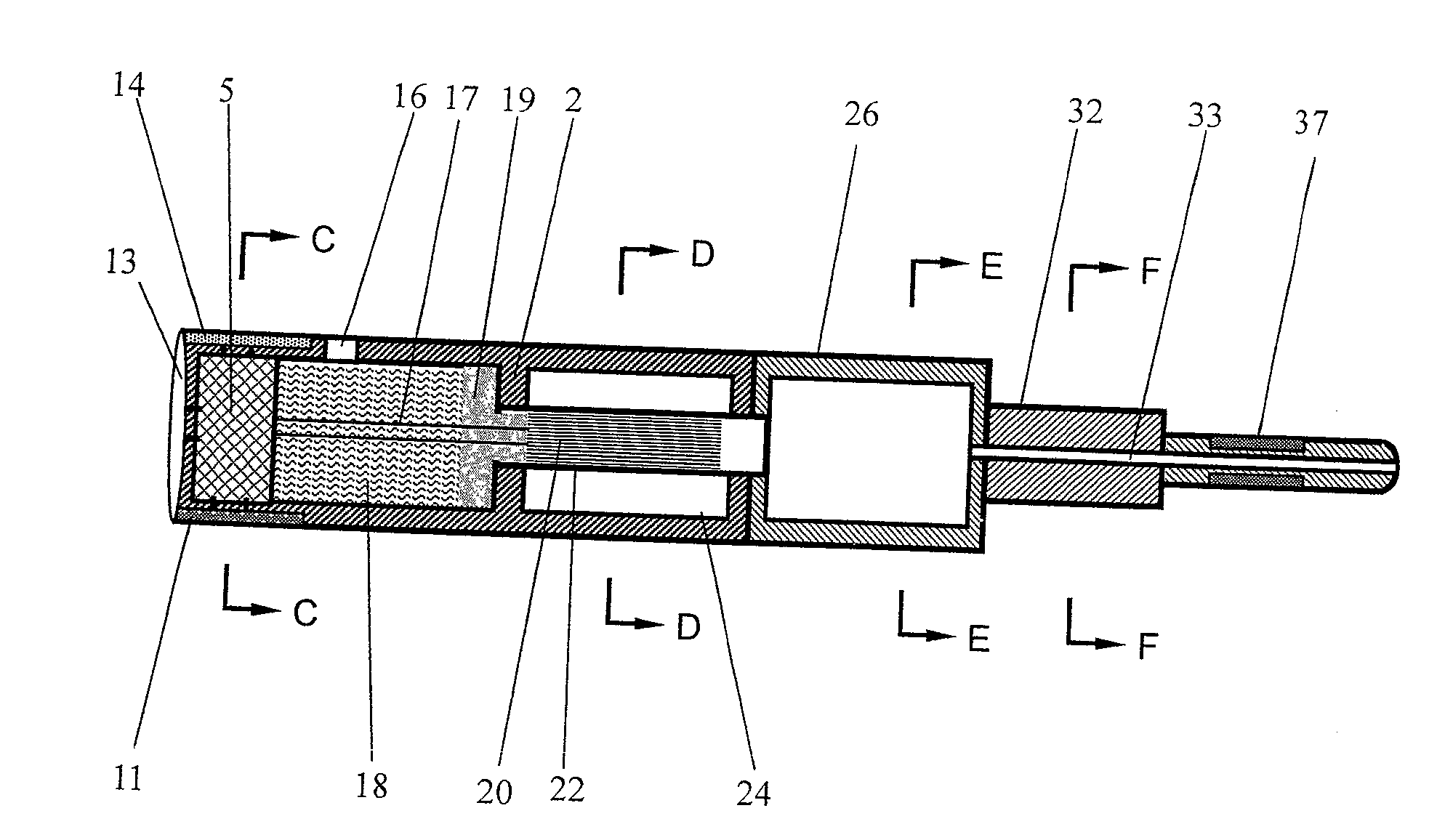

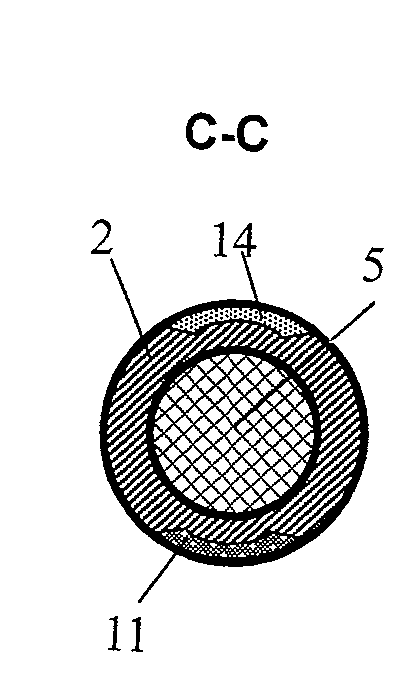

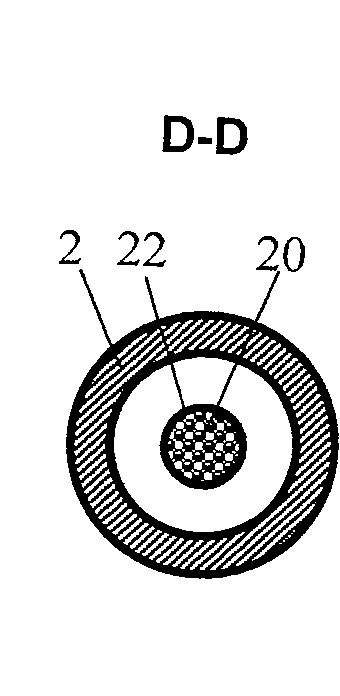

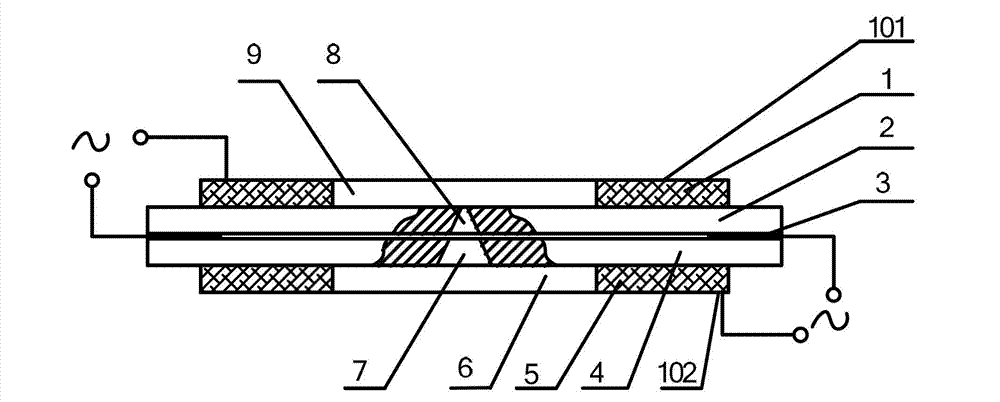

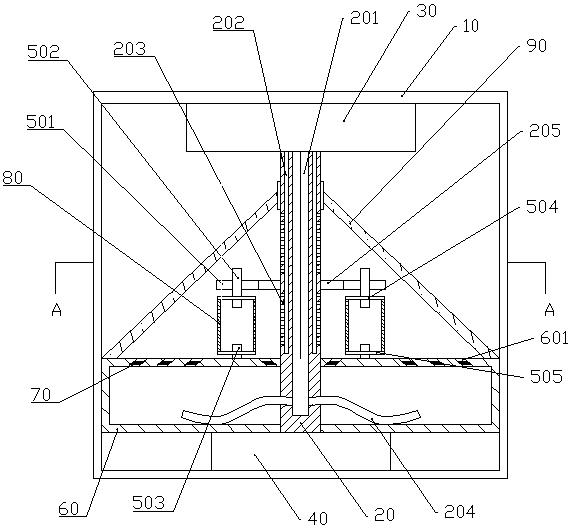

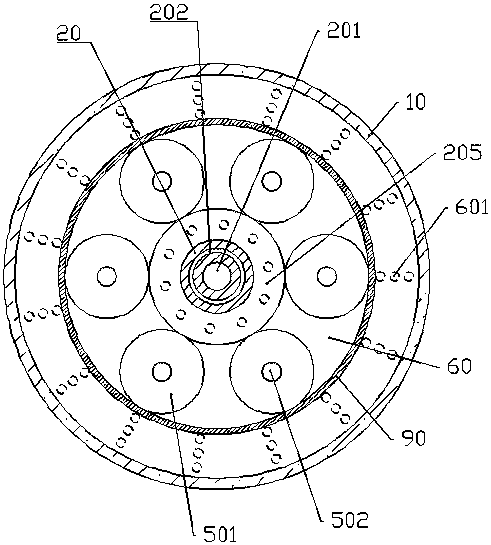

Low-frequency ultrasonic atomization device with large atomization amount

InactiveCN107096677ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricityUltrasonic atomization

The invention provides a low-frequency ultrasonic atomization device. The device is mainly applied to atomization cultivation in the agricultural engineering field. The device comprises a piezoelectric vibrator, an amplitude-change pole, a secondary atomization cavity, a gas and liquid valve end cover, a Laval valve element, a ladder type valve element and a gas and liquid valve body. The piezoelectric vibrator is bonded on the amplitude-change pole, the gas and liquid valve end cover is connected with the gas and liquid valve body through a thread, the ladder type valve element and the Laval valve element are both arranged in a cylindrical cavity in the valve body, one end of the Laval valve element sleeves one end of the ladder type valve element, the amplitude-change pole is connected with the secondary atomization cavity through a stud and a nut, and the secondary atomization cavity is connected with the gas and liquid valve end cover through a stud and a nut. Multistage atomization of fog drops can be achieved, the atomization amount of the atomization device can be improved, the diameter of the fog drops is smaller than that of the fog drops formed through atomization of a single ultrasonic atomization spraying head, and the long-distance atomization can be achieved.

Owner:JIANGSU UNIV

Medical vaporizer

The invention discloses a medical vaporizer comprising a cup body, a jet retaining part and a cover cap, wherein the bottom of the cup body is fixedly connected with an air connecting tube in a perforated way; the end, extending into the cup body, of the air connecting tube, is provided with a circular cone head in which an air outlet is formed, and the other end of the air connecting tube extends out of the bottom of the cup body to be used for introducing external compressed gas; the jet retaining part comprises a mushroom head annularly sleeving the circular cone head and a jet baffle fixedly arranged on the top of the mushroom head, a first spray outlet communicated with the air outlet is formed in the middle of the mushroom head, and the jet baffle is dead against the spray outlet; the cover cap covers the opening edge of the cup body, a negative-pressure hole and a second spray outlet are formed in the cover cap, one end of the negative-pressure hole annularly sleeves outside the jet baffle and supports against the mushroom head, and the other end of the negative-pressure hole is communicated with the outside; one end of the second spray outlet is communicated with the inside of the cup body in a sealing way, and the other end of the second spray outlet is abutted with an external nipple. The medical vaporizer can provide relatively small atomized particles on the basis of ensuring high atomization quantity and avoid side leakage.

Owner:GUANGZHOU DEMI MEDICAL EQUIP +1

Atomizing core with directional micropores

The atomizing core comprises a liquid guiding body and a heating body, the liquid guiding body comprises a liquid absorbing surface and an atomizing surface, the heating body is arranged on the atomizing surface of the liquid guiding body, and the liquid guiding body is provided with a plurality of directional micropores which are directly communicated with the atomizing surface from the liquid absorbing surface. The atomization device has the advantages that components of atomization liquid cannot cause blockage in the directional micropores, the atomization amount can be increased, the aerial fog reduction degree can be improved, scorched smell is not prone to being generated at the high temperature, in addition, the atomization liquid is made of monocrystalline silicon and glass materials, purity is high, impurities are few, and components such as heavy metal which are not beneficial to health cannot be separated out.

Owner:HUIZHOU HAPPY VAPING TECH LTD

Arc fan nozzle used for reducing dust

The invention relates to an arc fan nozzle used for reducing dust. The arc fan nozzle comprises a nozzle body with a thread connector, and a flow-guiding body arranged at an outlet of the nozzle body. An inner bore of the nozzle body is divided into an inlet section, a gradient throat section and an outlet section. The flow-guiding body is of a fan-shaped cone, and the height of the fan-shaped cone is of 1-10cm. Dust reducing media at the outlet of the nozzle form into arc fan spray through the flow-guiding body, and drill cutting components such as drills, cutting heads and the like can be preferably wrapped. The diffusing range is wide, and meanwhile, the using quantity of the dust reducing media can be reduced so as to greatly improve the utilizing rate of the dust reducing media. The arc fan nozzle not only can be used for the dust prevention of drills, cutting heads and the like in the drilling and cutting operations, but also can be used on other occasions where the arc fan nozzle is needed. The arc fan nozzle has the advantages of simple structure, uniform spray, small flow quantity, high impact force, high medium utilizing rate and wide practical applicability.

Owner:CHINA UNIV OF MINING & TECH

Fitting coating device

The invention relates to the field of machining parts and fittings, and particularly disclosed a fitting coating device. When the fitting coating device coats a pipe fitting, the pipe fitting rotatesat a constant speed under the effects of a clamp mechanism, a first gear and a spraying shaft, at the same time, all the side faces of the pipe fitting can be in full contact with air with paint, andtherefore the outer wall of the pipe fitting can be uniformly and fully coated; during coating, paint in a containing box can be supercharged, the spray amount of the paint is increased, a suction port enables air mixed with the paint to flow in the direction close to the pipe fitting, and the coating speed of the pipe fitting can be effectively increased. By the adoption of the technical scheme,the pipe fitting can be uniformly and fully coated.

Owner:CHONGQING YOUBO MACHINERY MFG

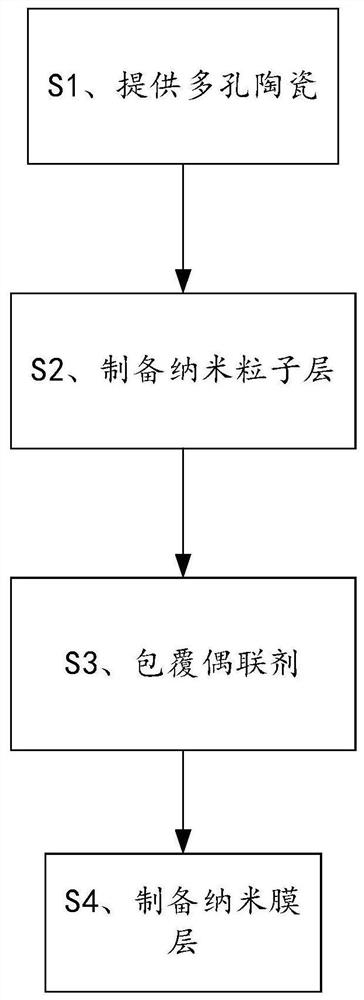

Porous ceramic atomizing core and preparation method thereof

PendingCN113292354AImprove lipophilicityImprove experienceTobacco devicesCeramicwareOrganic solventElectronic cigarette

The invention provides a preparation method of a porous ceramic atomizing core. The preparation method comprises the following steps: porous ceramic for preparing the atomizing core is provided; and the porous ceramic is soaked in a solution, the soaked porous ceramic is taken out and placed in water vapor to be subjected to an in-situ hydrolysis reaction, the porous ceramic subjected to the in-situ hydrolysis reaction is sintered, and the porous ceramic atomization core with the surface covered with a nano particle layer is obtained, wherein the solution is prepared by dissolving a first substance in an organic solvent, and the first substance comprises at least one of organic silicon, trimethyl aluminum or diethyl zinc, and the nano particle layer comprises at least one of SiO2, Al2O3 or ZnO. The invention also provides the porous ceramic atomizing core prepared by the preparation method. The porous ceramic atomizing core provided by the invention is simple in structure, the preparation method of the porous ceramic atomizing core is very simple, effective penetration of tobacco tar can be realized without additionally arranging a pneumatic structure, the atomizing amount of the electronic cigarette is increased, and the user experience feeling is better.

Owner:SHENZHEN TAOTAO TECH CO LTD

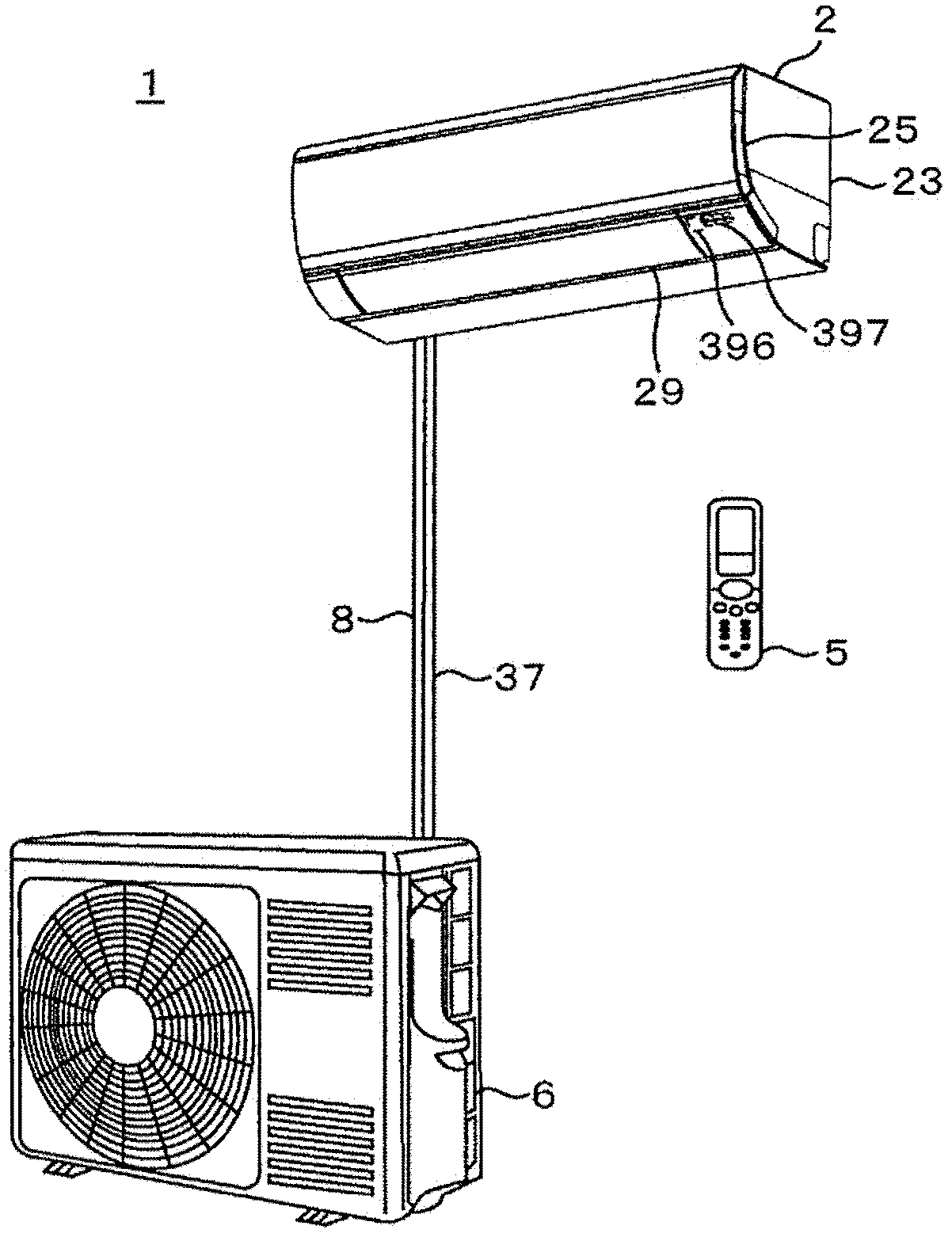

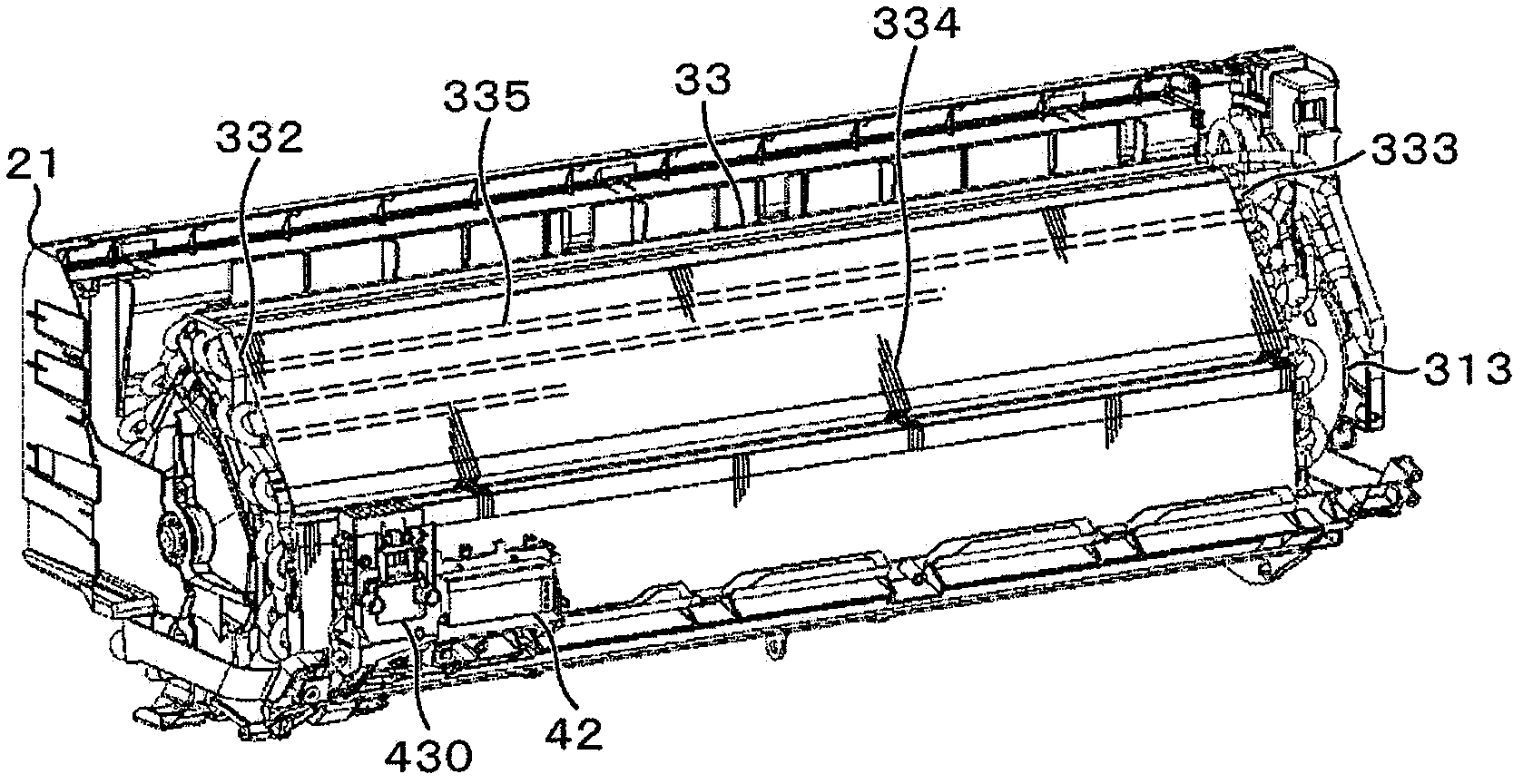

Air conditioner

ActiveCN102650454ALarge amount of atomizationReduce input powerLighting and heating apparatusAir conditioning systemsIndoor airEngineering

The invention relates to an air conditioner. The object of the invention is to provide the light-weighted air conditioner provided with a static atomization device capable of making the indoor environment more comfortable, saving resource and energy. The air conditioner is provided with the static atomization device used for taking the indoor air for the atomization. A heat adsorption part and a heat dissipation part of an electronic cooling device used for taking the water used for the atomization are disposed in a take-in air channel closer to the upstream than a heat exchanger, and a atomized particle discharging part is disposed in a discharging air channel. According to the invention, the light-weighted air conditioner provided with the static atomization device can be used to make the indoor environment more comfortable, save the resource and energy.

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Electronic cigarette atomizer

PendingCN109259325AAvoid the risk of easily carbonized wicksStable and sufficient oil guide volumeTobacco devicesCarbonizationCapillary channel

The invention relates to an electronic cigarette atomizer which comprises an oil storage part and an oil guide part, the oil storage part includes an opening; the oil guide portion is inserted into the oil storage portion through the opening; the oil guide part comprises a thin tube bundle composed of a plurality of thin tubes, wherein the thin tube bundle is inserted into a cigarette liquid chamber and immersed in the cigarette liquid, a plurality of thin tubes in the thin tube bundle are fixed as a whole, and a plurality of capillary gaps are formed between the thin tubes, and the cigaretteliquid in the cigarette liquid chamber can enter the capillary gaps through capillary action. The invention utilizes the gap between the tubes to form a plurality of capillary channels, can carry outlarge-area heat exchange with the outside, and utilizes capillary action to conduct oil, which has sufficient oil supply and rapid oil replenishment, and avoids the risk of carbonization of the oil conducting parts.

Owner:SHANGHAI NEW TOBACCO PRODUCTS RESEARCH INSTITUTE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com