Low-frequency ultrasonic atomization device with large atomization amount

An ultrasonic atomization, low-frequency technology, applied in spray devices, liquid spray devices, etc., can solve the problem of large droplet diameter, and achieve the effect of large atomization, small droplets, and uniform droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

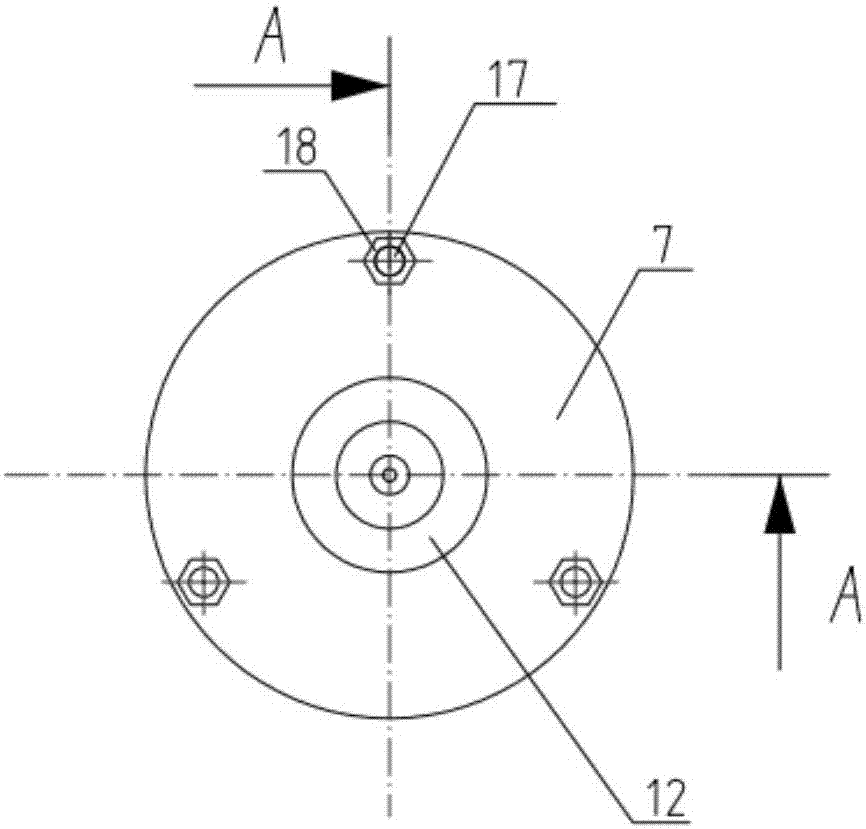

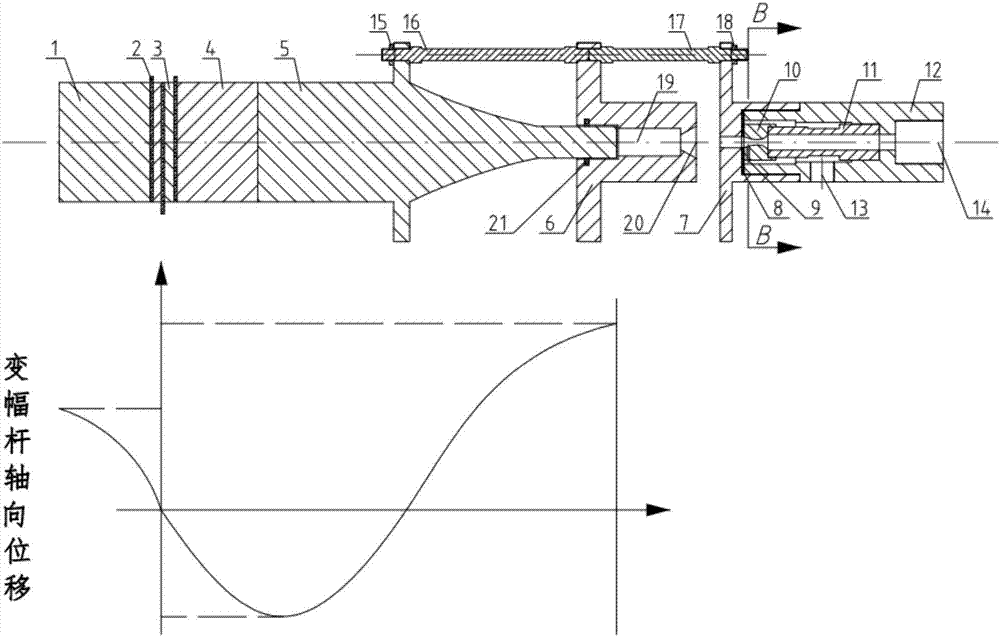

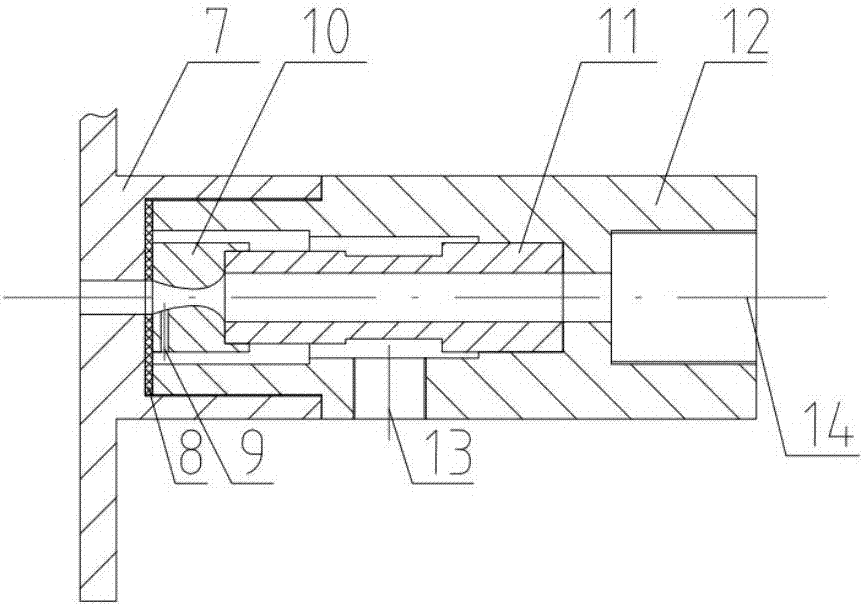

[0034] Such as figure 1 , figure 2 As shown, the main body length of the large atomization volume low-frequency ultrasonic atomization device is 110mm, the length of the ultrasonic atomization nozzle part is 70mm, the length of the secondary atomization cavity is 15mm, and the distance between the gas-liquid inlet end surface of the secondary atomization cavity and the gas-liquid valve The end face distance of the end cover is 3mm, and the length of the gas-liquid valve body is 28mm. The low-frequency ultrasonic atomization device with a large atomization amount according to the present invention includes a piezoelectric vibrator 3, a horn 5, a secondary atomization chamber 6, a gas-liquid valve end cover 7, a sealing ring 8, and a Laval valve core 10. Step valve core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com