Patents

Literature

149results about How to "Quick paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

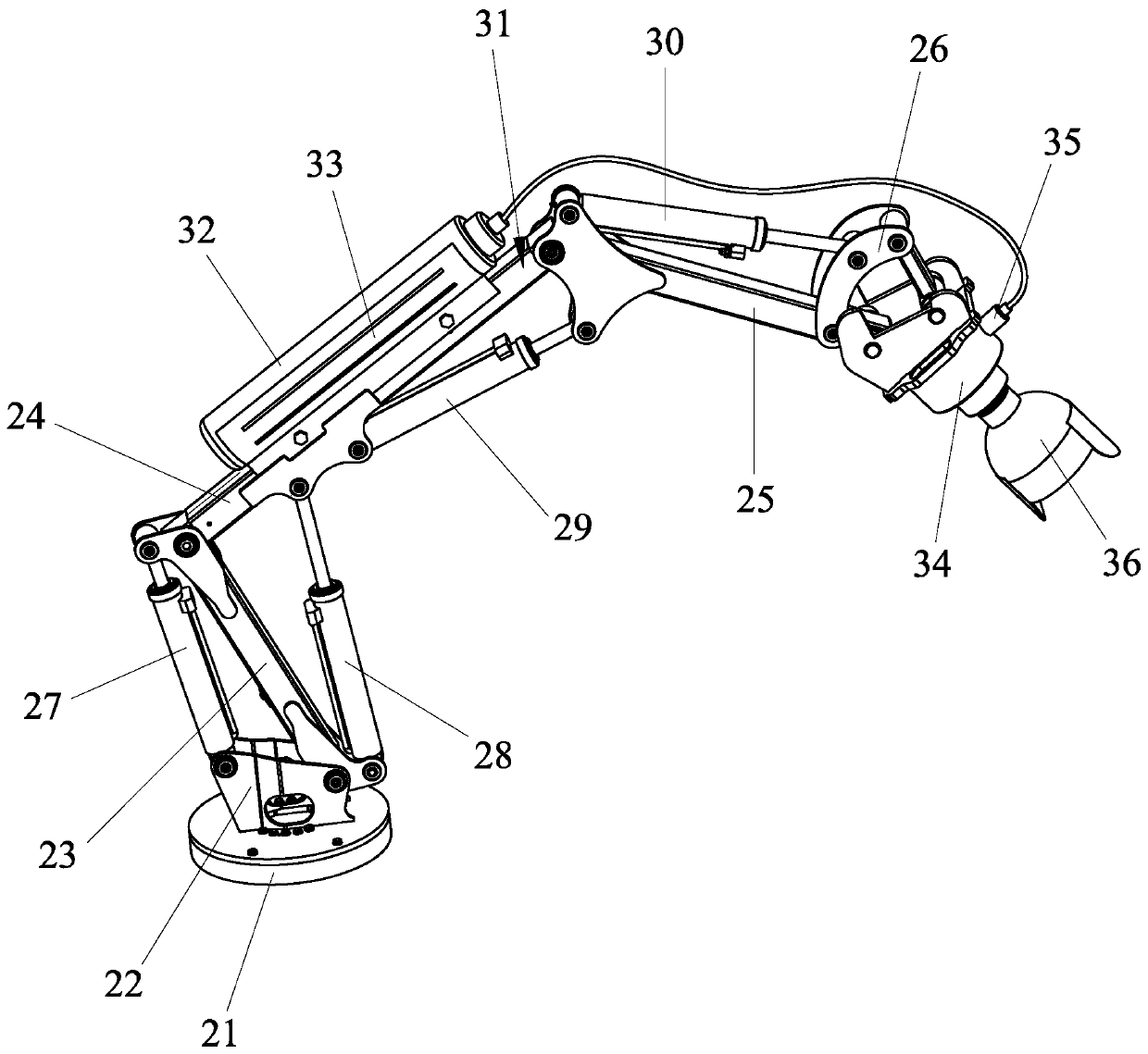

Method For Controlling A Robot Tool Center Point

InactiveUS20090074979A1Uniform thicknessCarry-out quicklyProgramme-controlled manipulatorComputer controlProgram planningEngineering

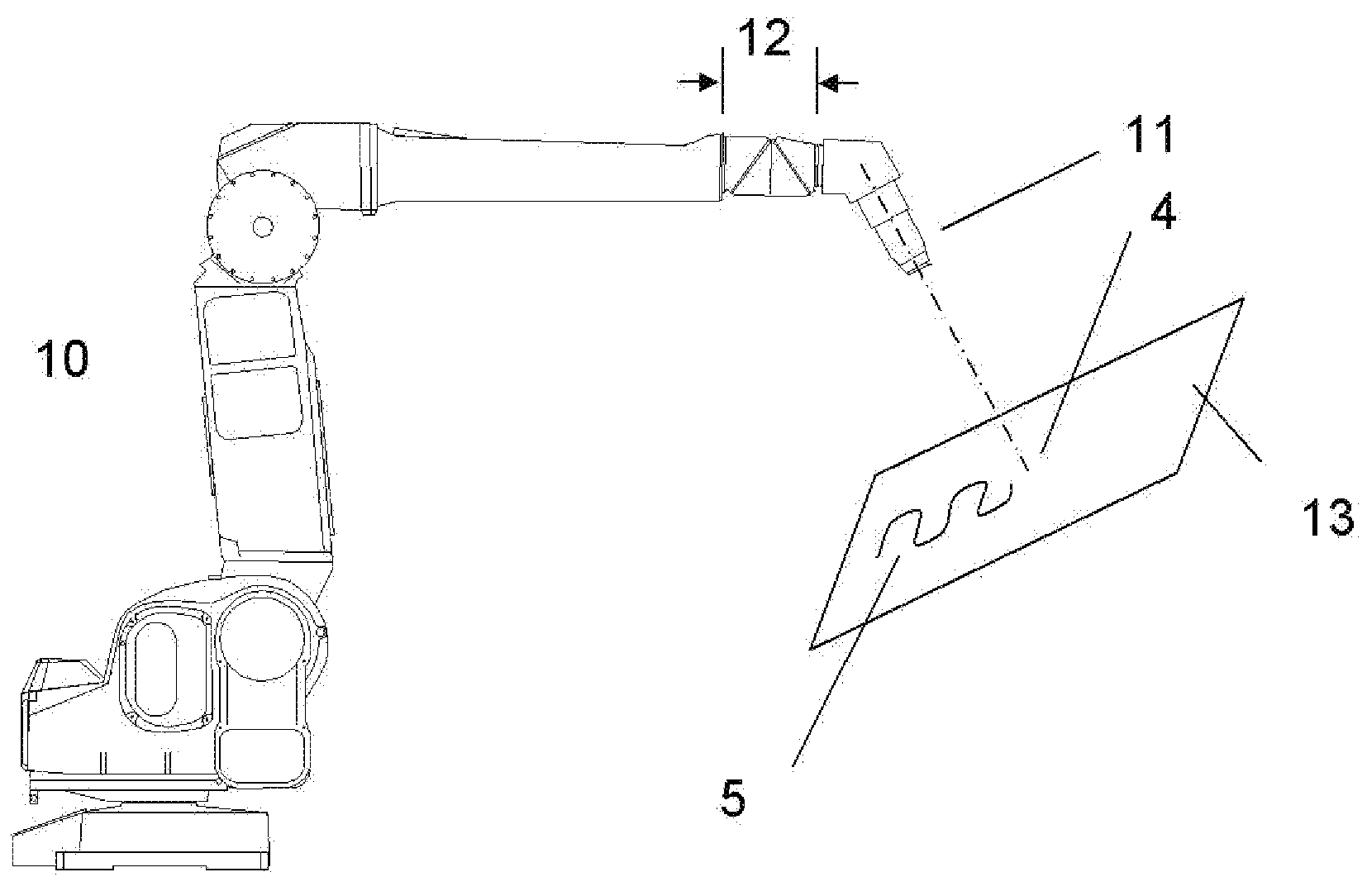

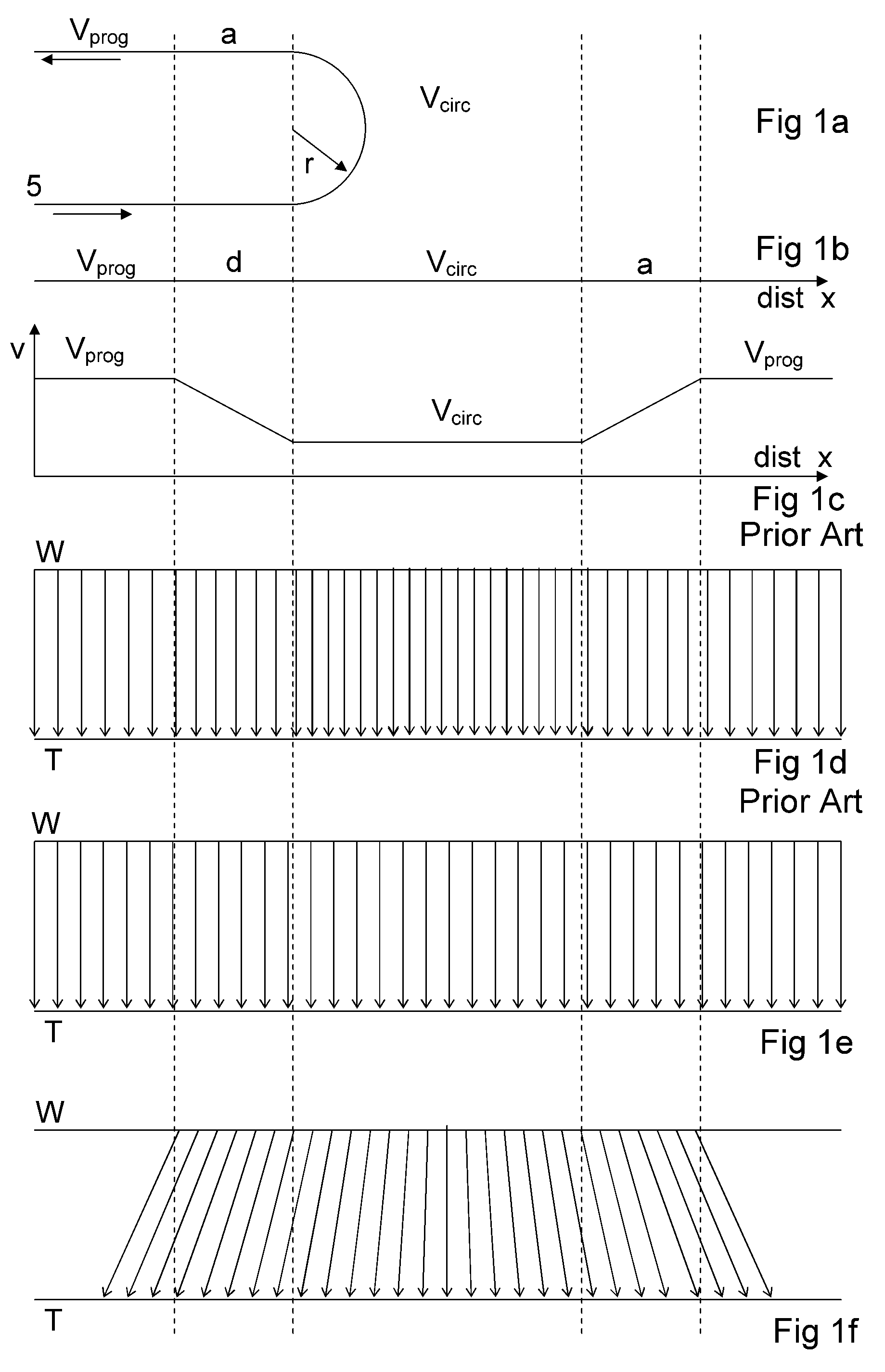

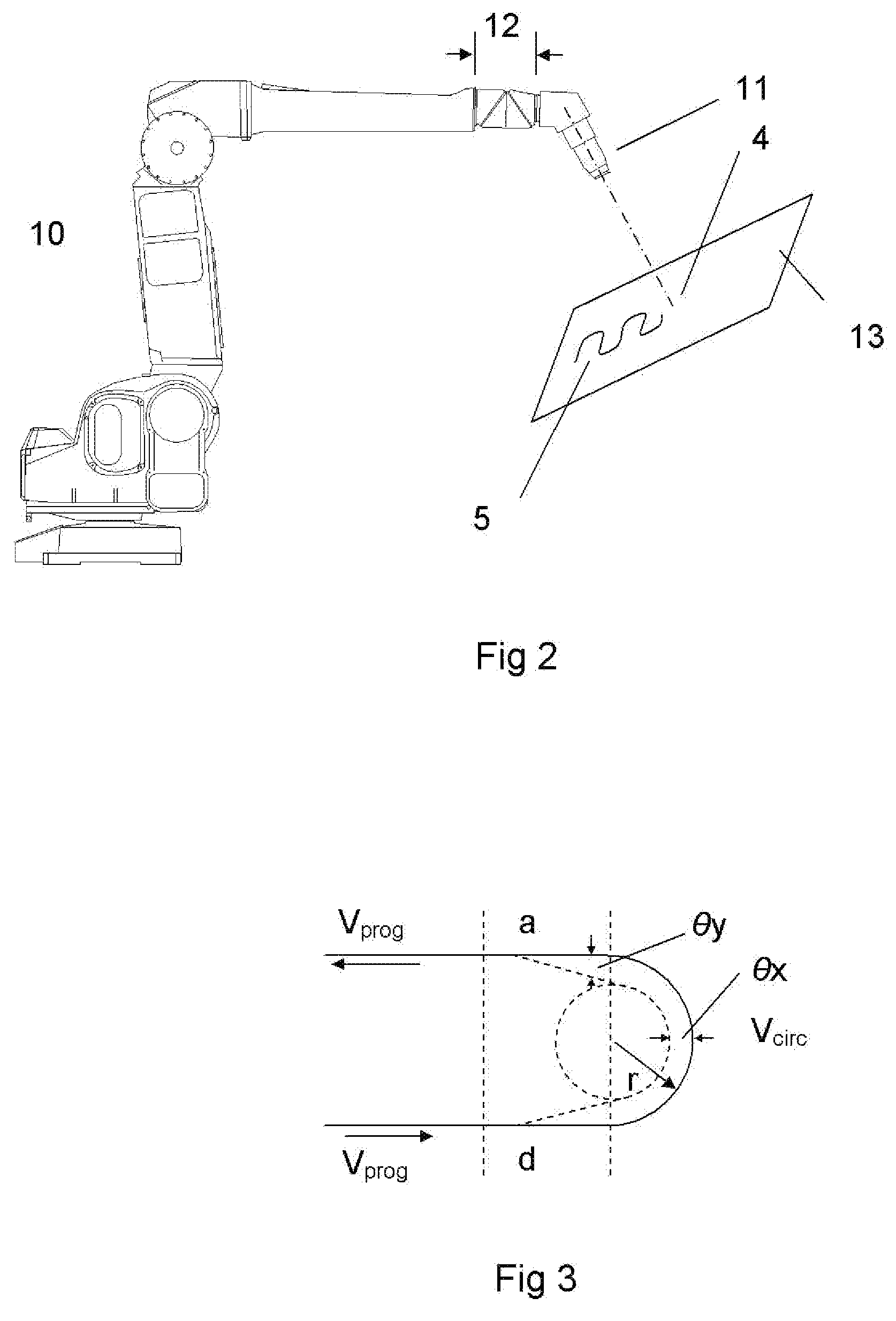

A method for controlling a painting system including an industrial robot or manipulator arm arranged with a wrist section and carrying a paint applicator arranged on the robot wrist is described. Paint is applied by the applicator to a substantially circular or elliptical area on the surface, the center of the area being defined as a Tool Center Point. The wrist section is arranged capable of moving and orienting the paint applicator. In the method, the paint applicator is moved by the manipulator arm so that the Tool Center Point moves along a planned path so coating a part of the surface. The planned path may include one or more bends. The path taken by the robot wrist may be controlled to follow a different path from the path taken by the Tool Center Point. A system and a computer program for carrying out the method are also described.

Owner:ABB AS

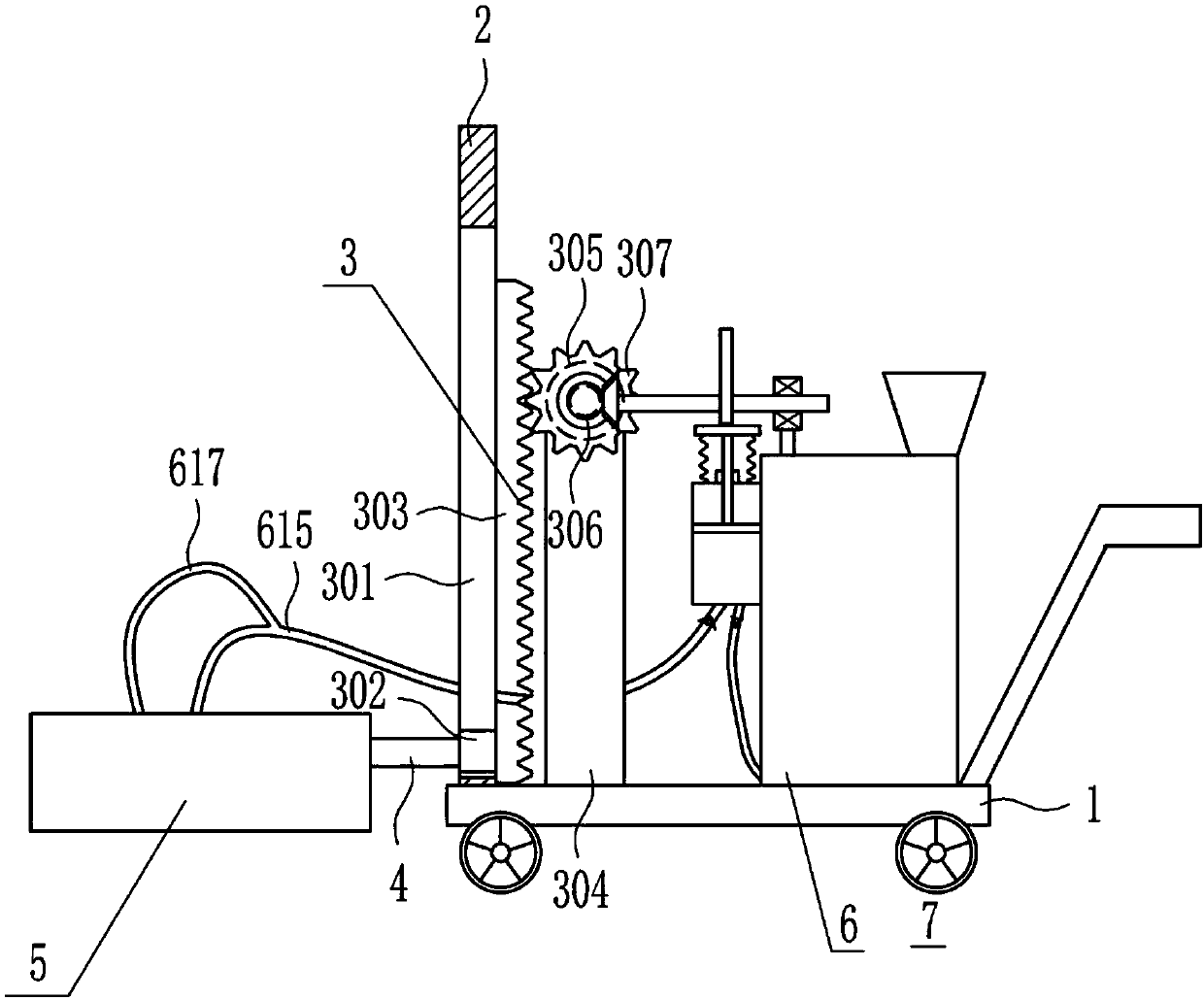

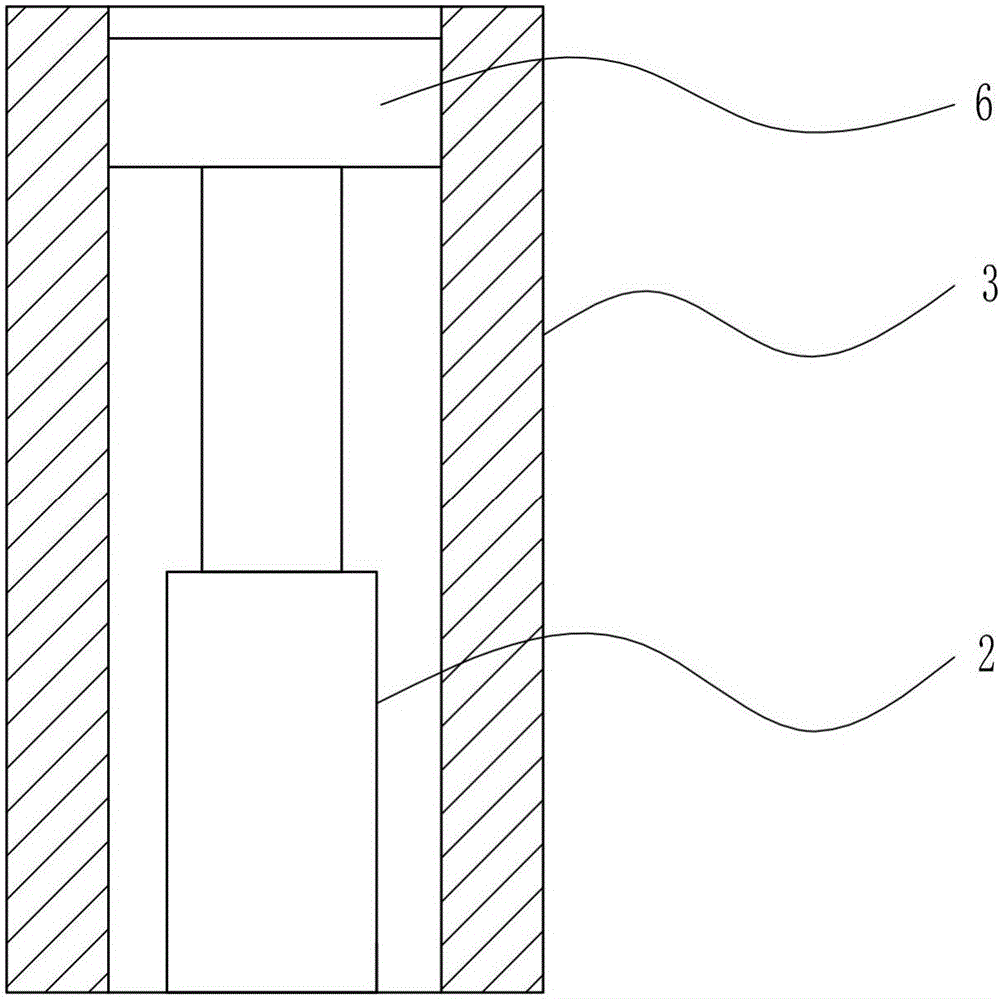

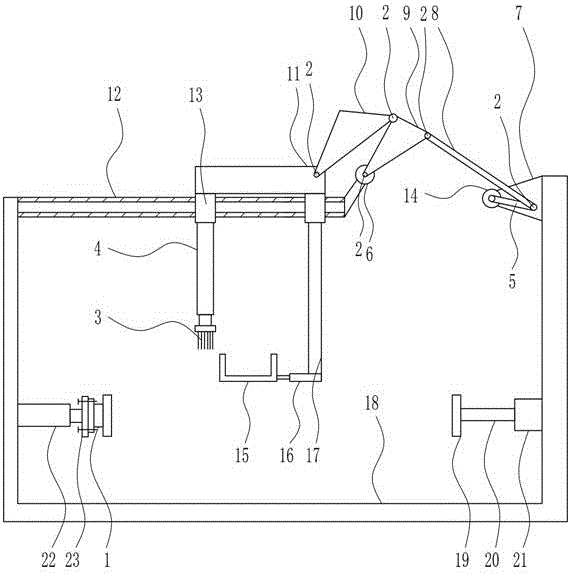

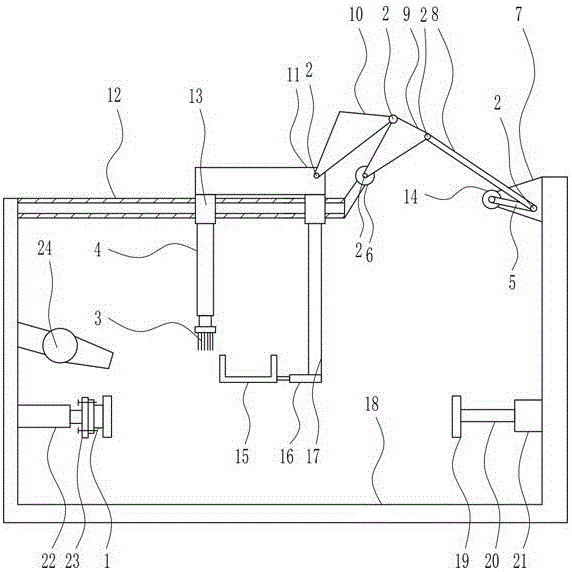

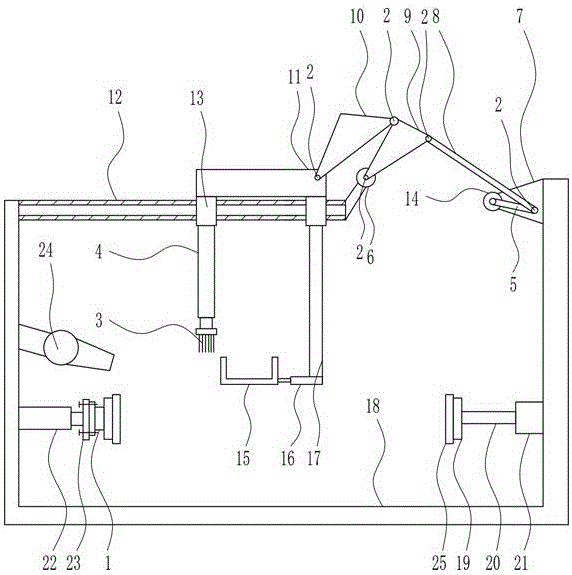

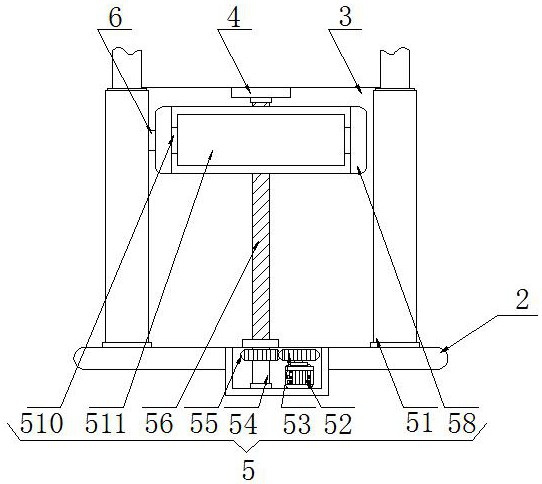

Trunk whitewashing machine for landscaping

InactiveCN107638972AWhite evenlyWhitewash fastLiquid surface applicatorsLiquid spraying apparatusWhitening AgentsLandscaping

The invention relates to a whitewashing machine for landscaping, in particular to a trunk whitewashing machine for landscaping. The invention aims to provide a trunk whitewashing machine for landscaping, which reduces the labor intensity of workers, increases the coating speed, and is convenient to use and simple in operation. In order to solve the above technical problem, the trunk whitewashing machine for landscaping includes a trolley and the like. The left side of the top of the trolley is vertically connected with a supporting plate, and the supporting plate is provided with a vertical moving device. The vertical moving device is connected with a transverse plate, and a whitewashing device is arranged on the left side of the transverse plate. The trunk whitewashing machine for landscaping can spray the whitening agent on the trunk through a liquid spraying device, and can evenly coat the whitening agent by moving the whitewashing device up and down by the vertical moving device soas to reduce the labor intensity of the workers, increase the coating speed, and achieve easy use and simple operation effects.

Owner:郭昌磊

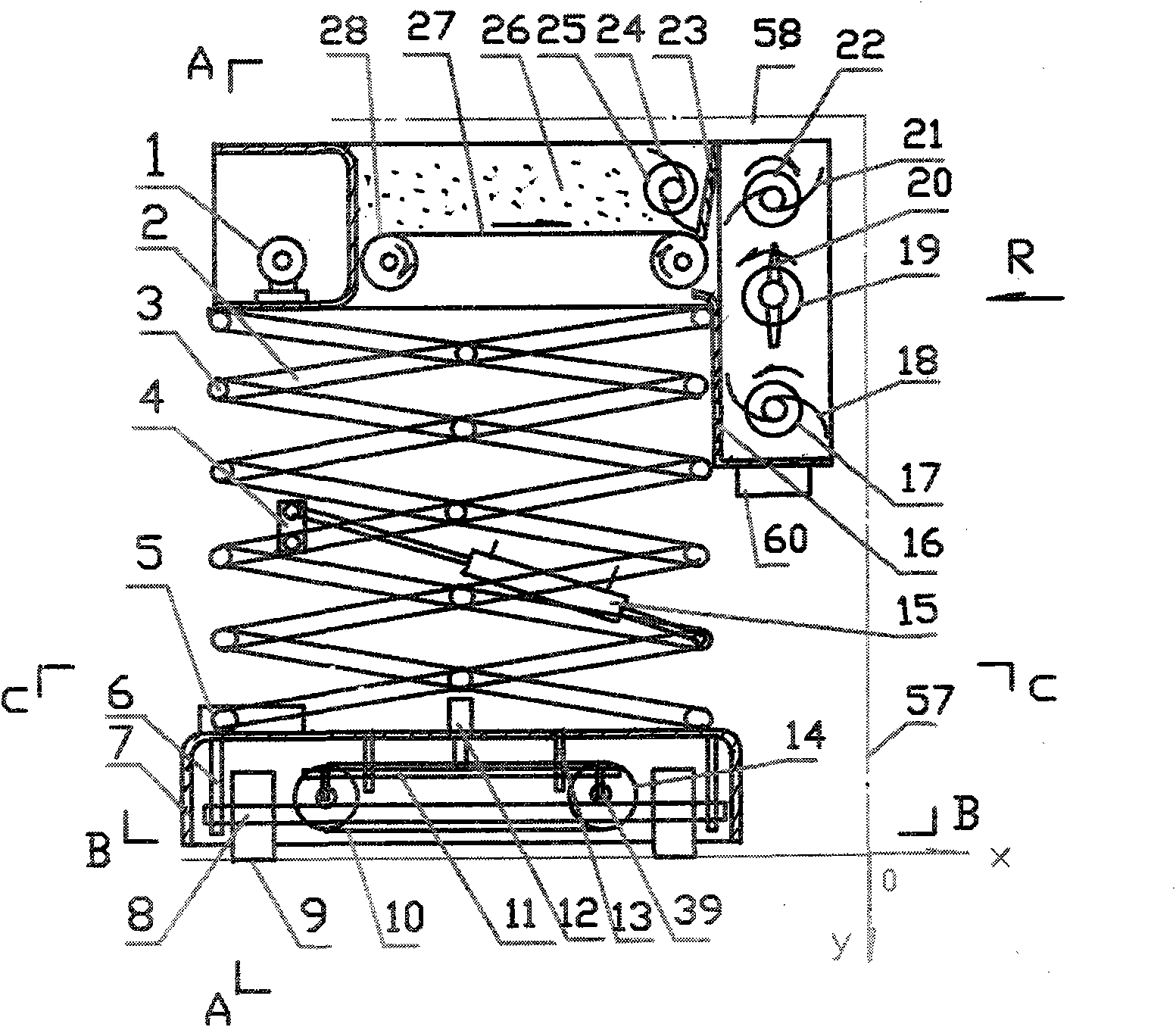

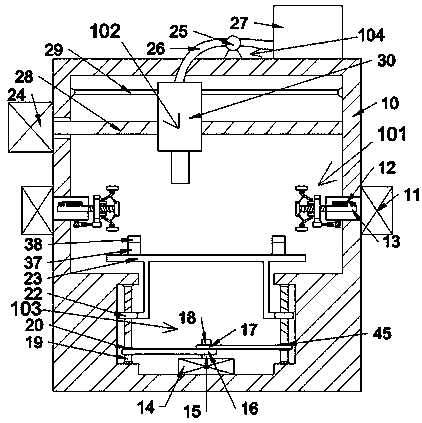

Full-automatic multifunctional wall plastering machine

InactiveCN102011482AEasy to operateHumanized operationBuilding constructionsWorking environmentEngineering

The invention discloses a full-automatic multifunctional wall plastering machine comprising a control mechanism, a power mechanism, a transmission mechanism, a lifting mechanism, a working mechanism and a crawler-type traveling positioning mechanism, wherein the crawler-type traveling positioning mechanism can enable the working mechanism to realize horizontal and vertical synchronous movement positioning; the crawler-type traveling positioning mechanism comprises a horizontal crawler (9) and a longitudinal crawler (10), wherein the horizontal crawler (9) can synchronously travel, and the longitudinal crawler (10) can synchronously travel, lift and veer; and a wall corner plastering roller (21) capable of plastering a wall corner, a wall surface plastering wheel (18) and a roof plastering roller (24) capable of plastering an indoor roof are arranged below the top surface of the working mechanism. The invention can not only save the non-operation time and enhance the wall plastering work efficiency, but also ensure a plastered wall surface to be flat, thereby enhancing the plastering quality of the wall surface; the wall plastering machine has the advantages of compact and reasonable structure, convenience in operation, good work environment, low work labor intensity, strong applicability and high use safety and automation degree, can not only fast plaster the wall surface, but also plaster the wall corners, pillars, the roofs and outer walls with certain height.

Owner:何干清

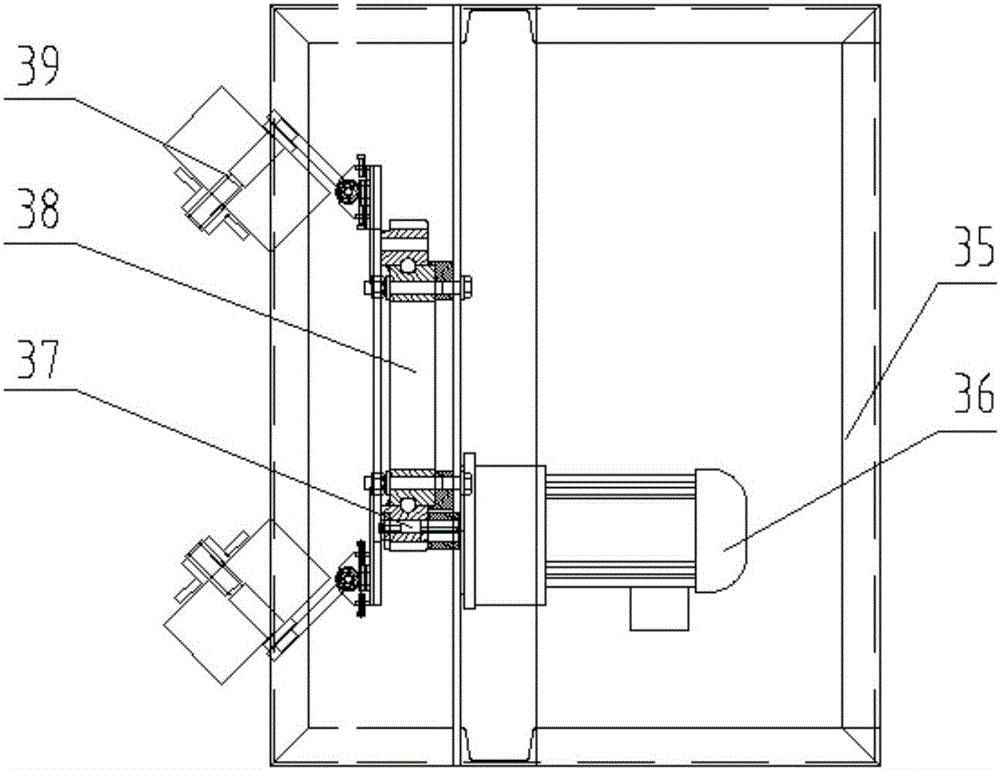

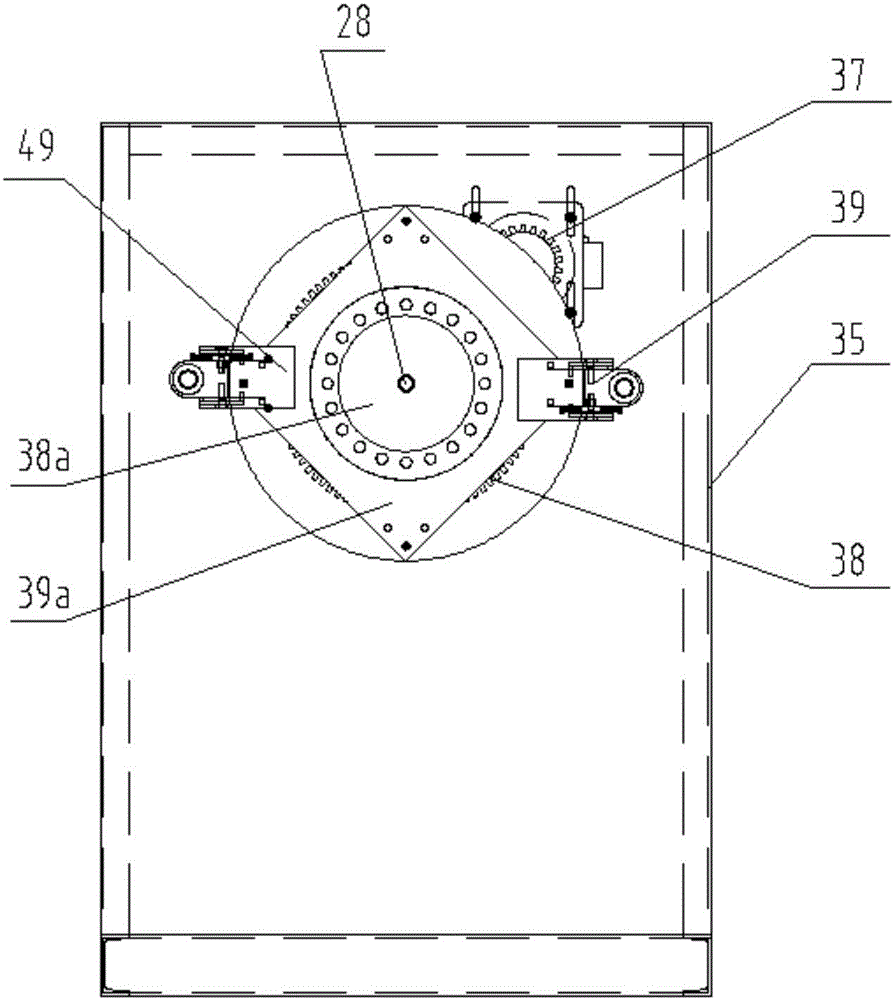

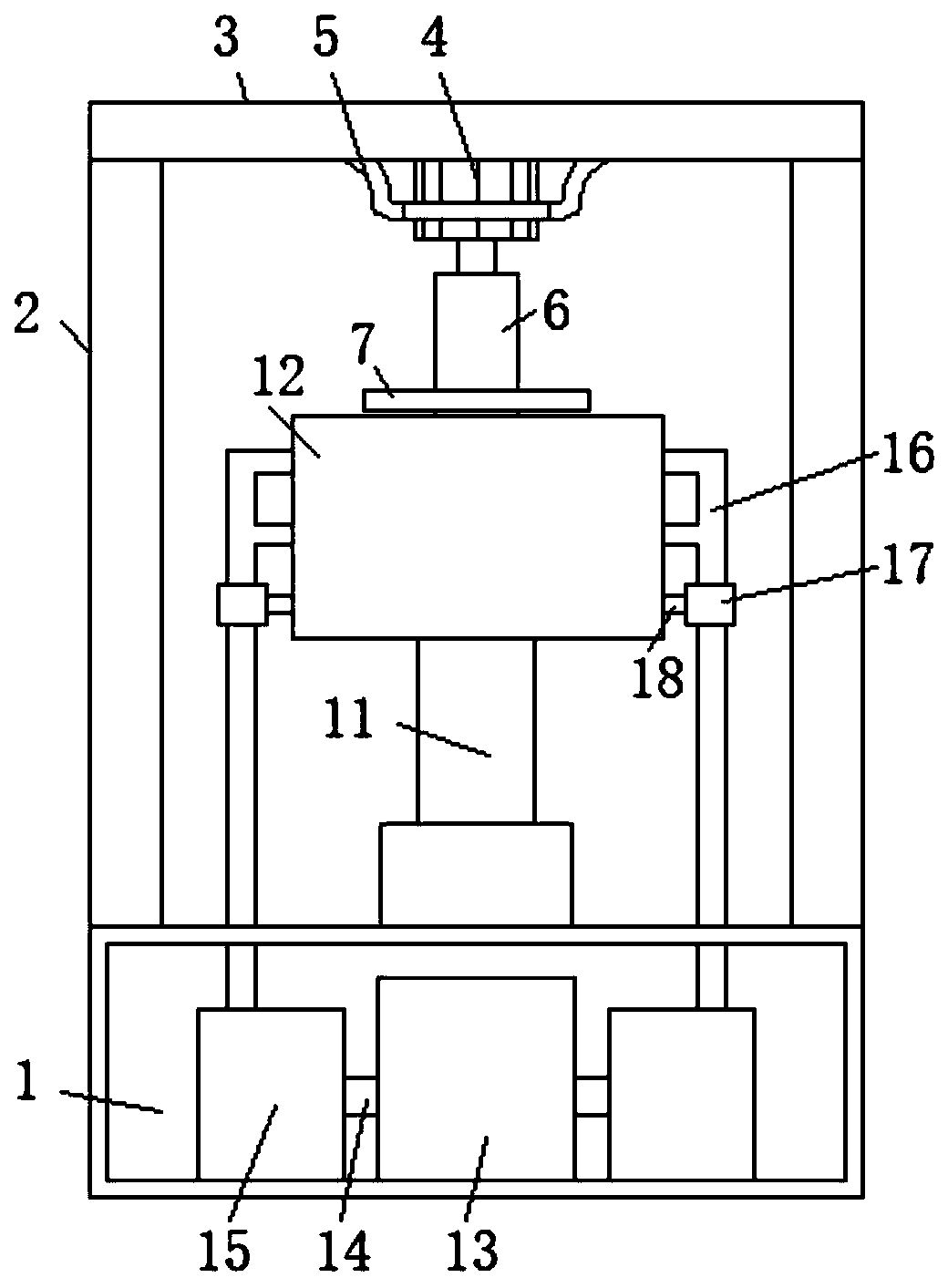

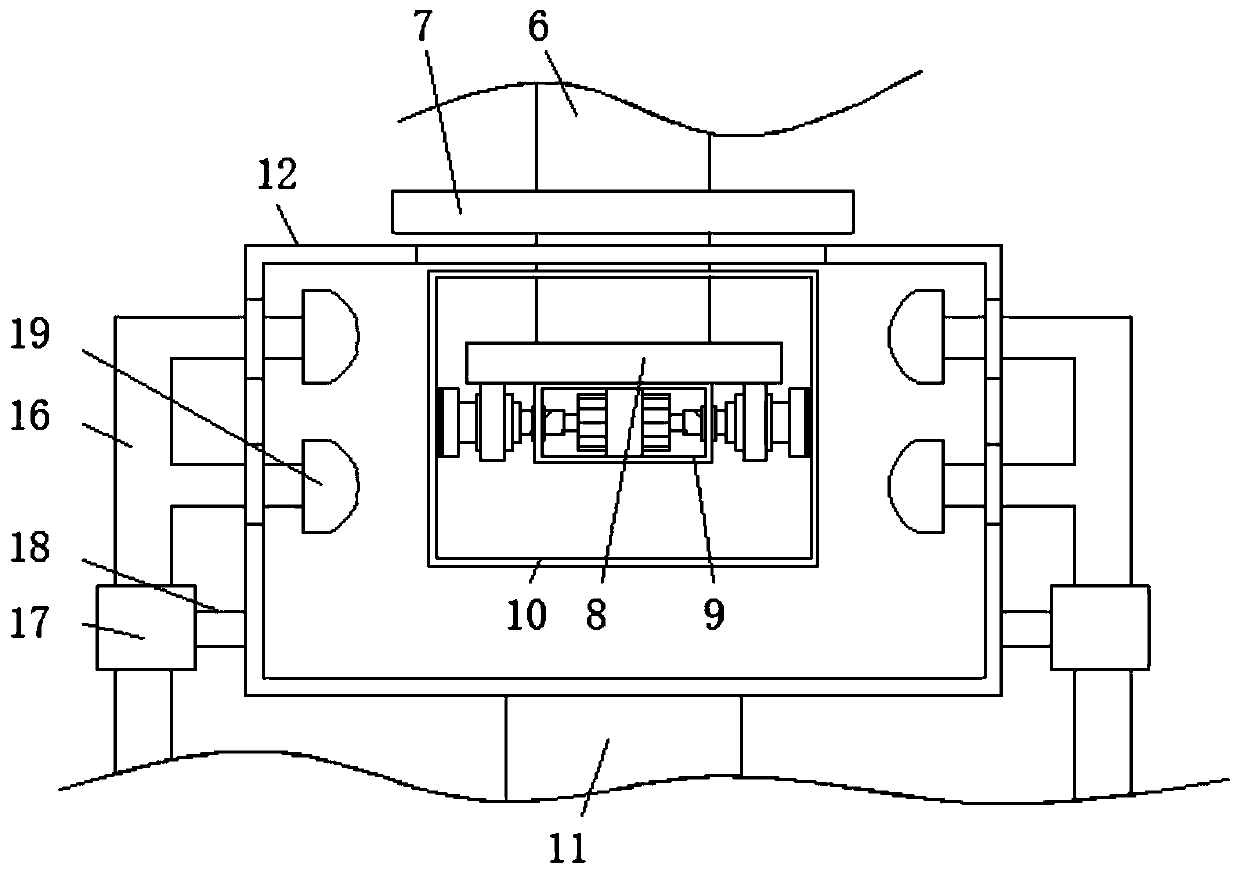

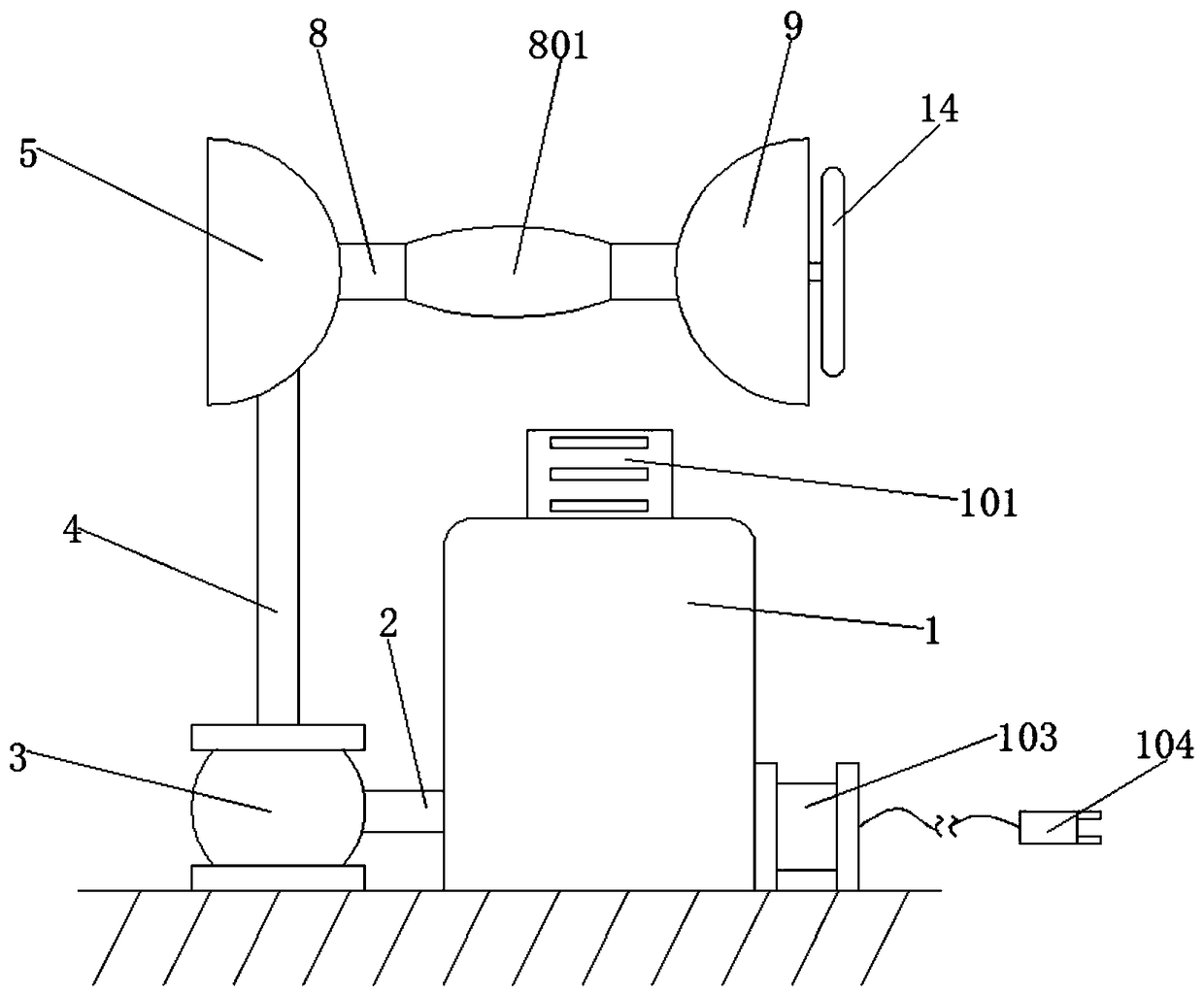

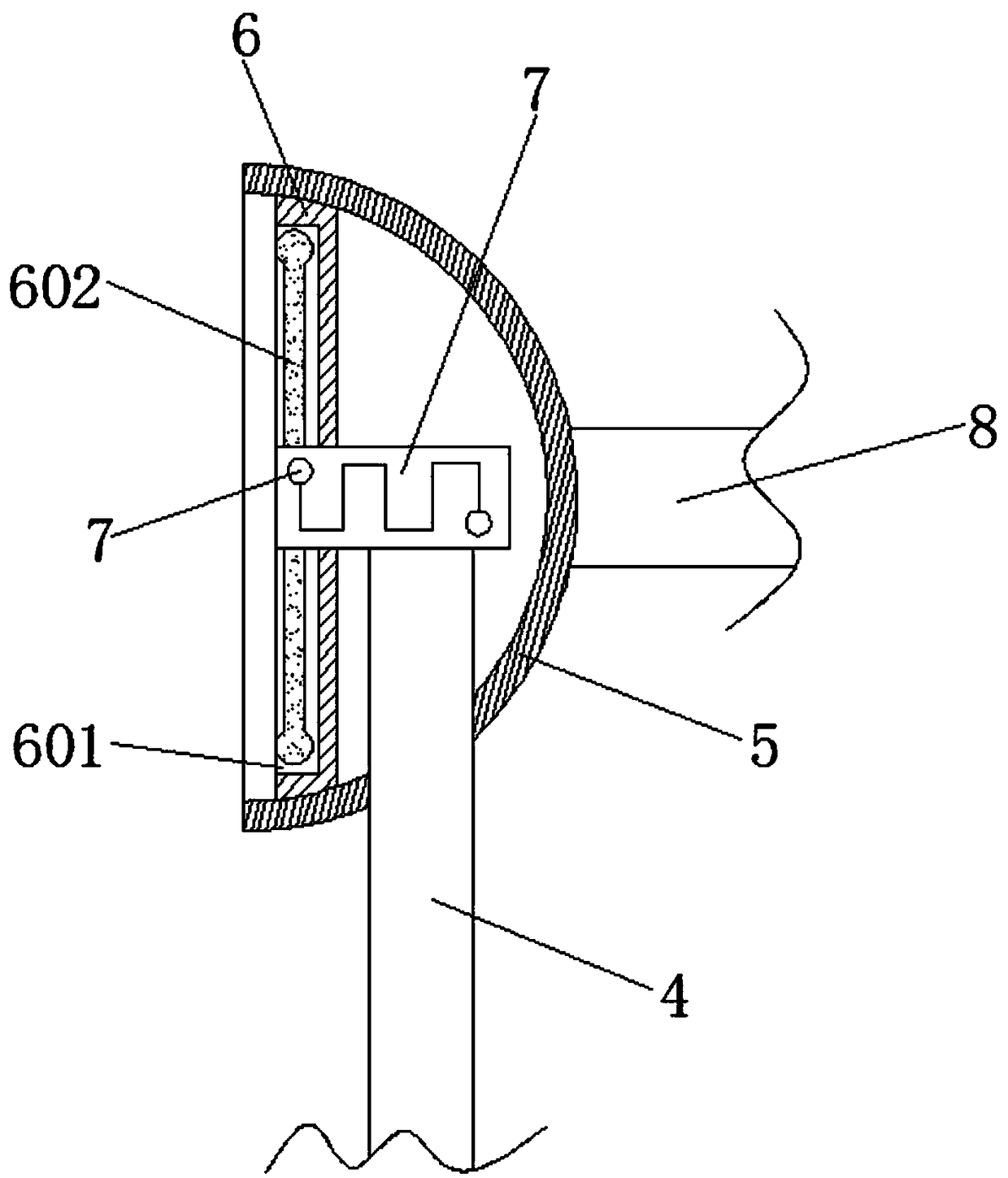

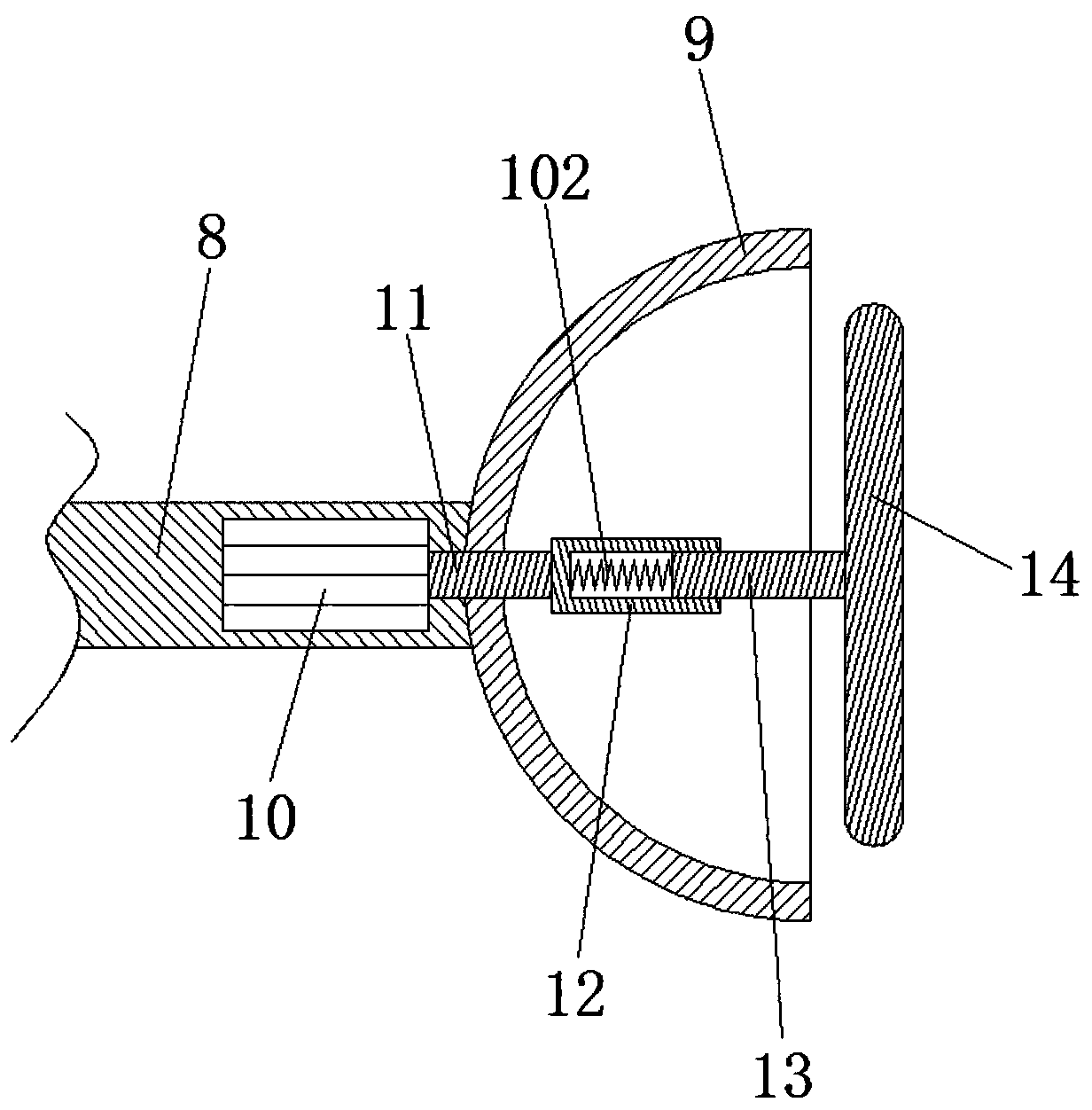

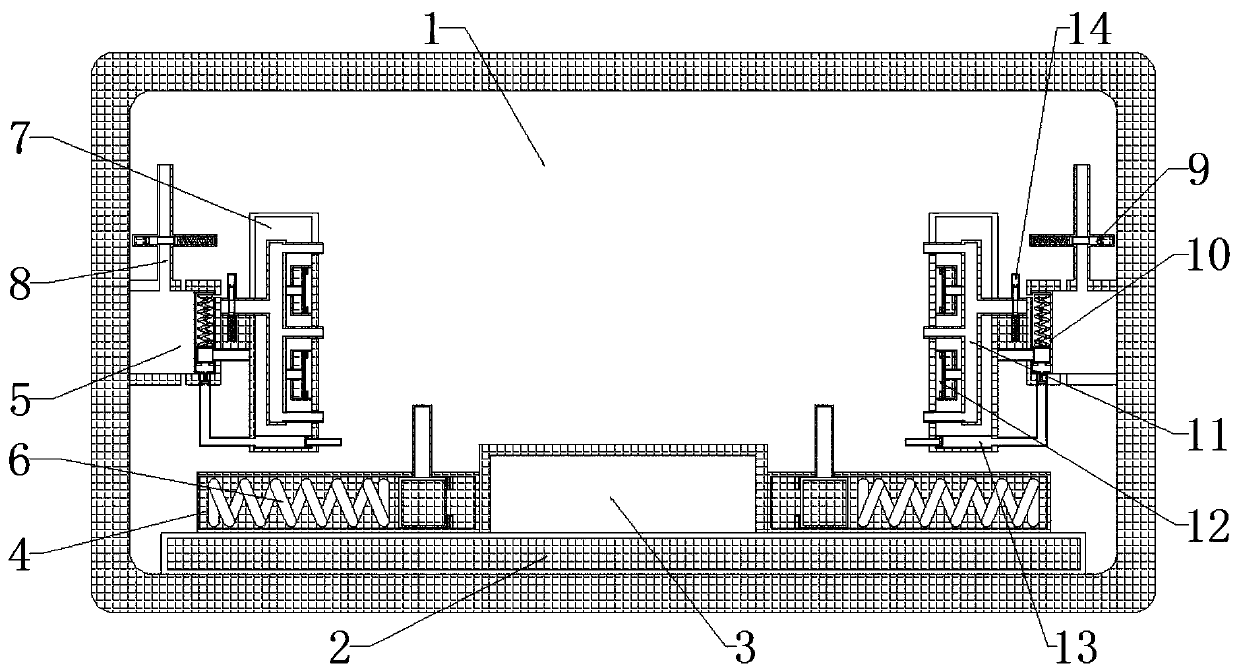

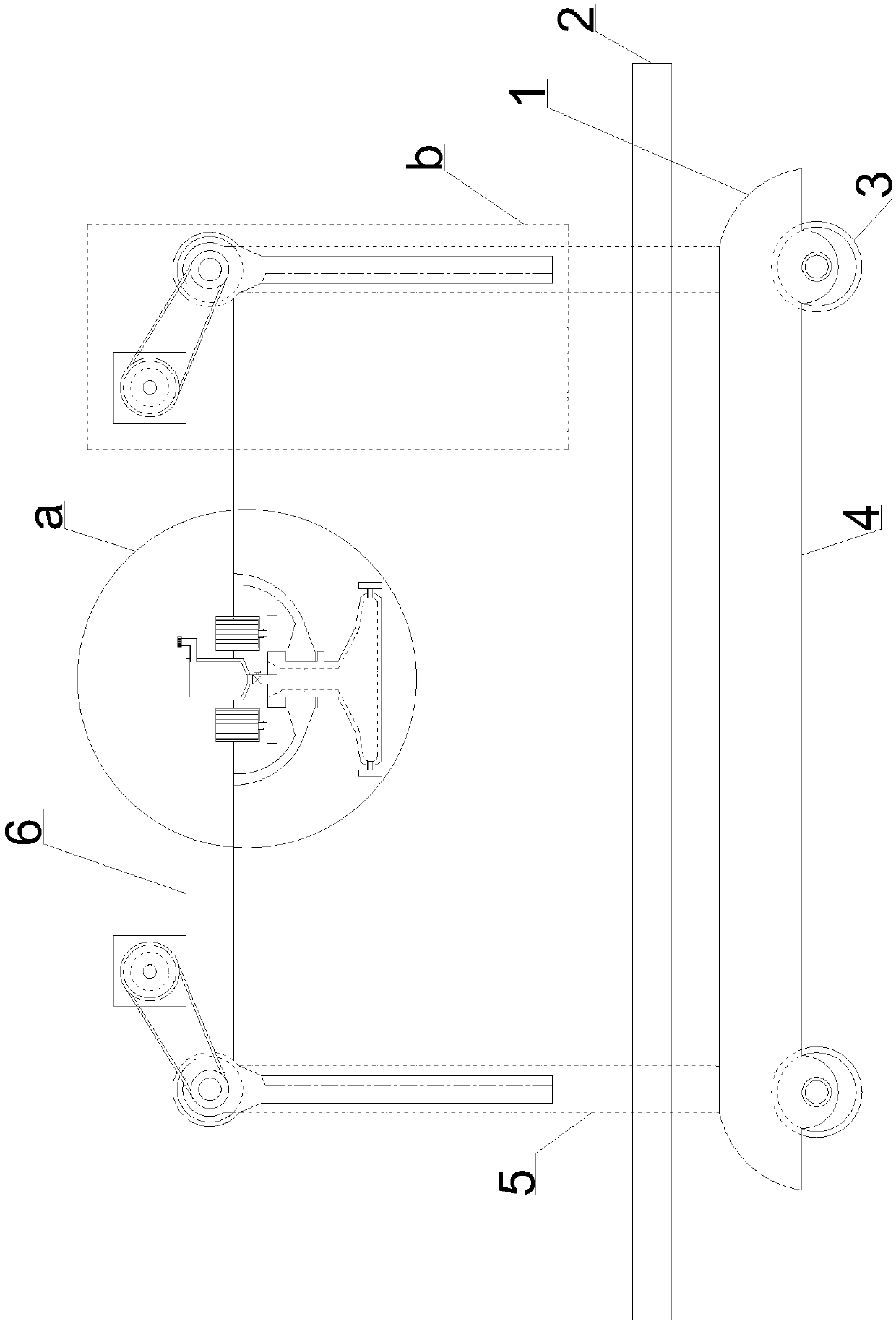

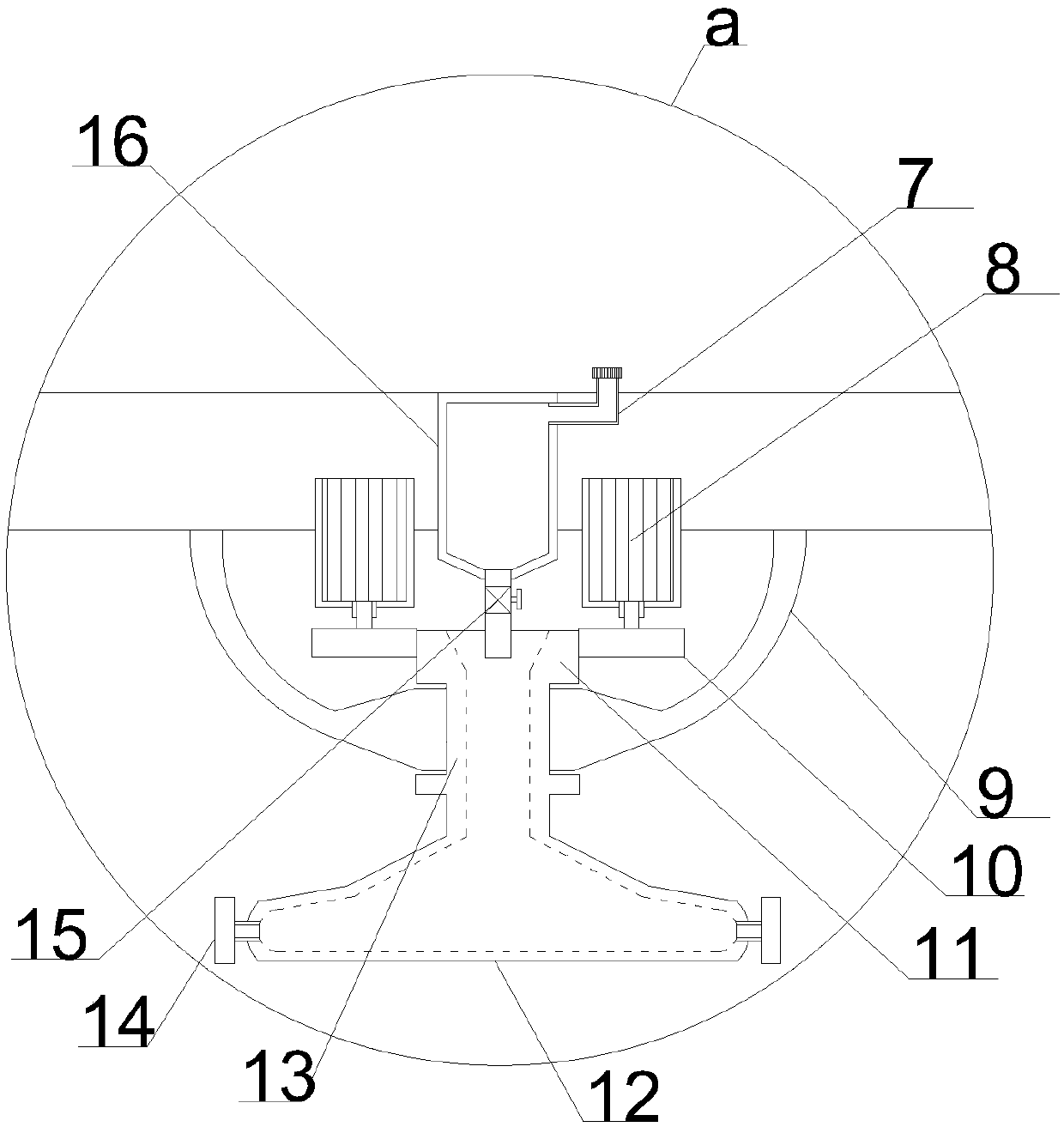

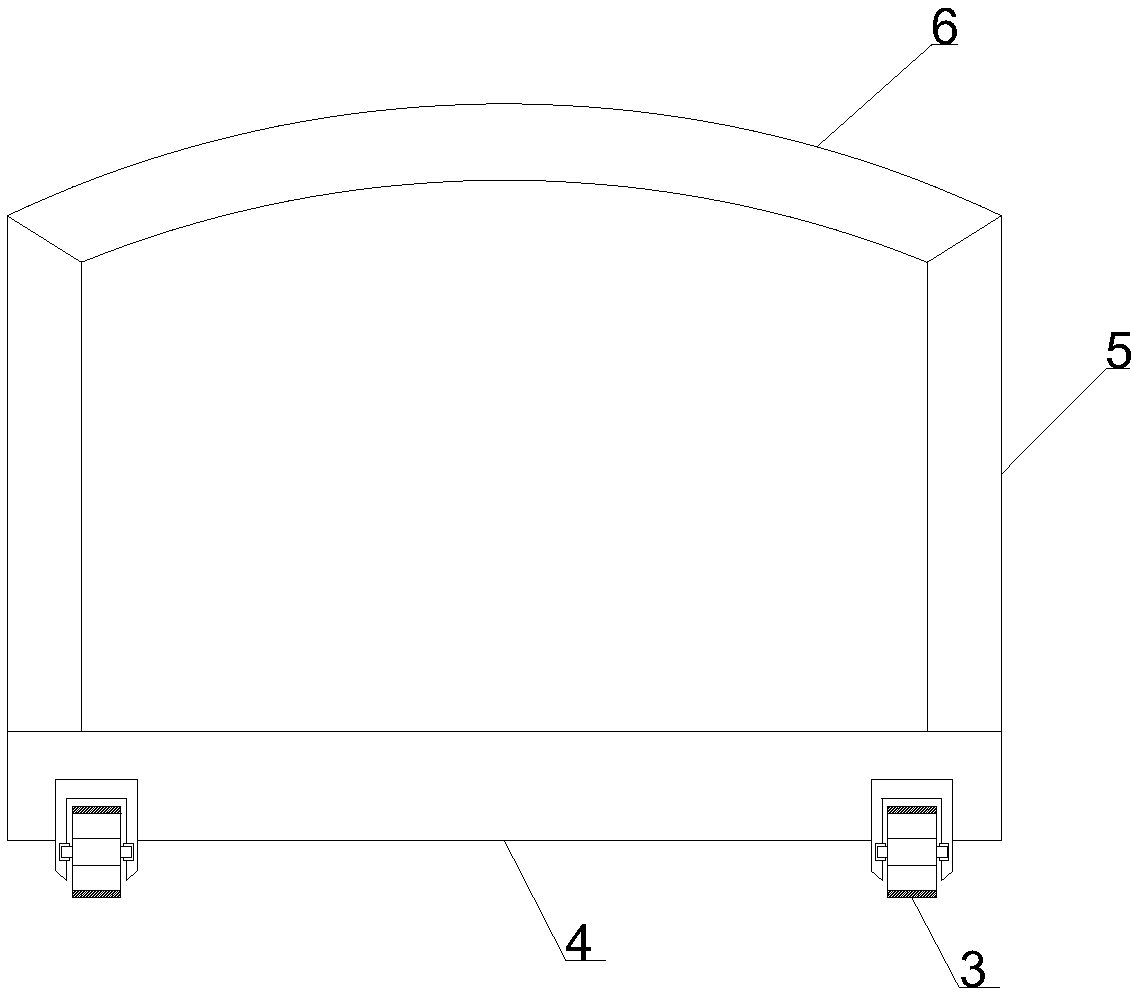

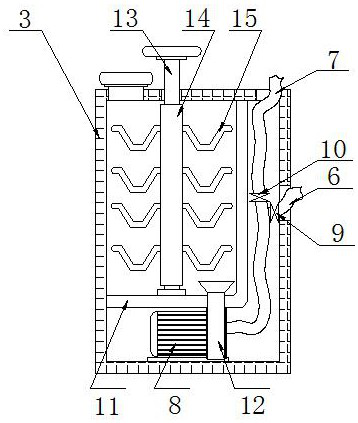

Rust removing and paint spraying device for metal pipes

InactiveCN111167655AEasy to holdNot easy to looseGrinding drivesGrinding machinesMetallurgyElectric machinery

The invention discloses a rust removing and paint spraying device for metal pipes. The rust removing and paint spraying device for the metal pipes comprises a rust removing and paint spraying machinebody arranged on the ground; the rust removing and paint spraying machine body is provided with a fixing rod and a first threaded rod which can be used for installing the rust removing and paint spraying device; a clamping device and a lifting platform are arranged in the rust removing and paint spraying machine body; the clamping device comprises second motors which are symmetrically arranged outside the left side wall and the right side wall; and the lifting platform comprises a third motor which is arranged on the lower portion of the inside of the rust removing and paint spraying machine body. The lifting platform is controlled by the third motor, the metal pipes with different diameters on rollers are collinear with the clamping device, and the clamping effect on the metal pipes is good; and a rust removing device can make a rust removing sheet be in full contact with the metal pipes, and therefore the rust removing effect on the metal pipes is improved; and the metal pipes can besubjected to paint spraying treatment after rust removing is completed, and the production efficiency of the metal pipes is improved.

Owner:PAN AN AIKEN MECHANICAL EQUIP CO LTD

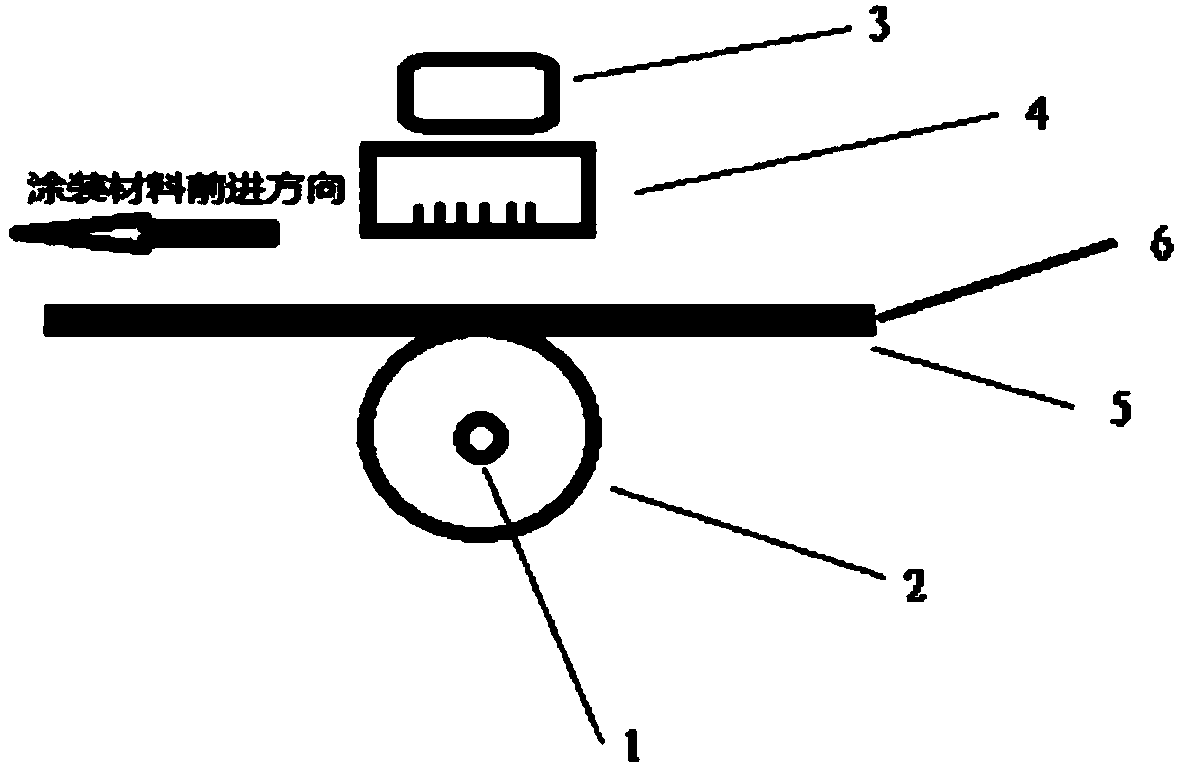

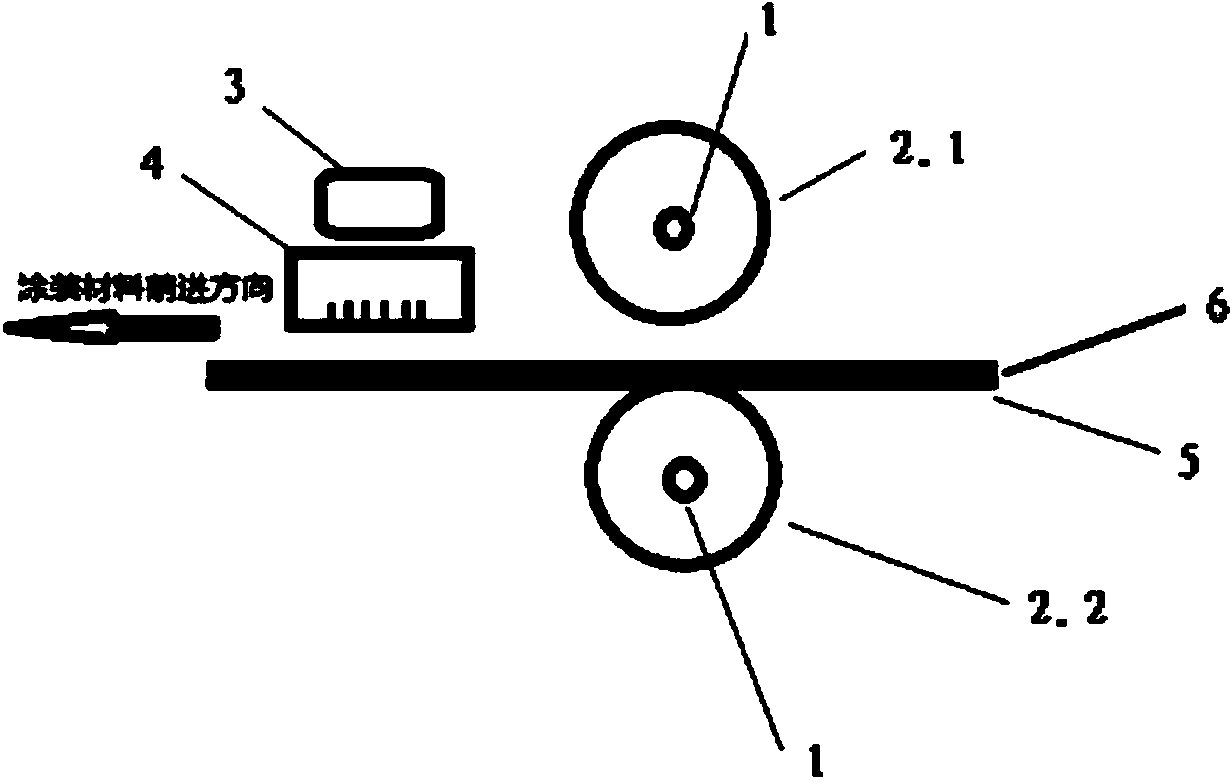

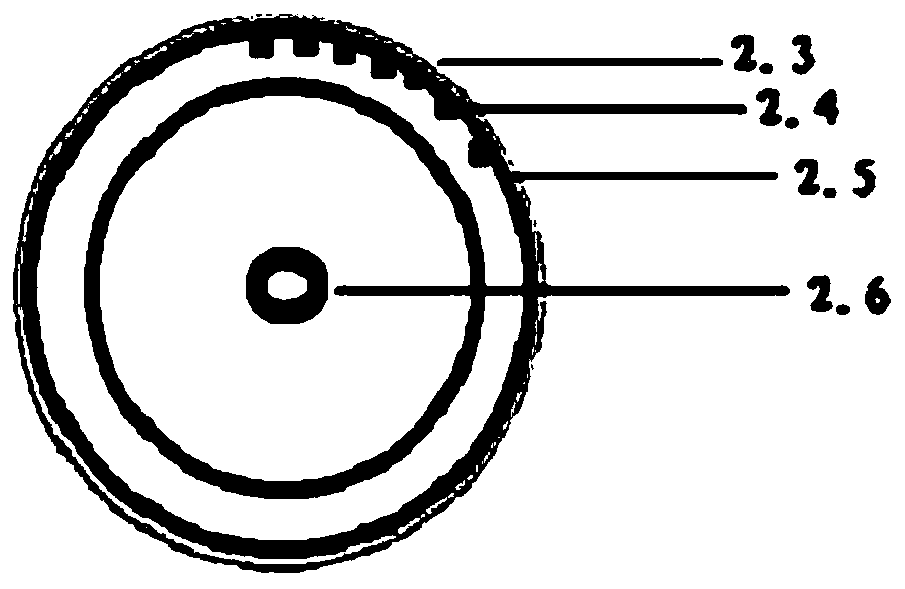

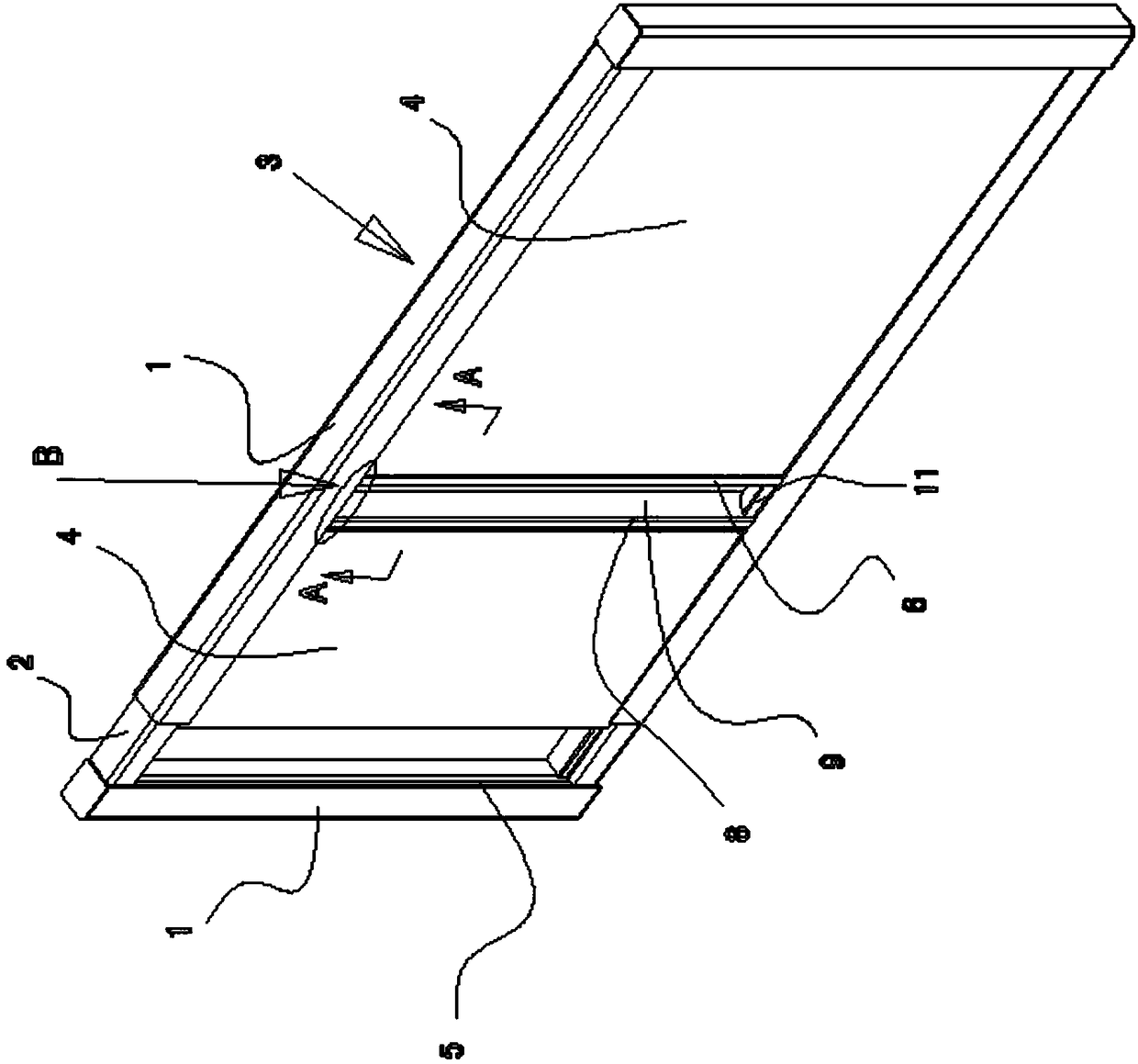

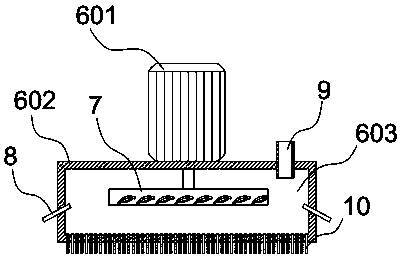

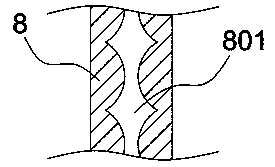

Painting equipment and technology of magnetic pigment

The invention discloses painting equipment of magnetic pigment. A painting device, a magnetic orienting device and a magnetic setting device used for setting of the magnetic pigment are sequentially arranged in the forward direction of magnetic pigment painting material, wherein the painting device is used for continuously painting the painting material with the magnetic pigment, and the magnetic orienting device is used for orienting the magnetic pigment. According to the painting equipment, the magnetic pigment can be continuously and rapidly painted and can be continuously, rapidly and magnetically oriented and set, production efficiency is improved, accuracy of magnetic patterns is improved, and product cost is reduced. The invention further discloses a painting technology, a sheet coated with the magnetic pigment is sequentially magnetically oriented and set and completely solidified through a drying oven, and the sheet having a stereoscopic and dreamlike visual effect is formed. The method can greatly increase production speed of the magnetic pigment and reduce production cost, and the manufactured sheet is excellent in magnetic stereoscopic effect, the magnetic patterns are distinct, and accuracy is high.

Owner:吕嘉明 +1

Automatically sprayed ultraviolet curing paint and preparation method thereof

InactiveCN102372935AShorten the construction periodGood anti-corrosion effectAnti-corrosive paintsSolventPhotoinitiator

The invention relates to an ultraviolet curing paint, and concretely relates to an automatically sprayed ultraviolet curing paint and a preparation method thereof. A disadvantage of present ultraviolet curing paints is that: the curing process is completed in several seconds, and the large contraction makes the formation of the thick coating to be impossible, so the usage of the paints in the anticorrosion field is restricted. The ultraviolet curing paint comprises the following substances, by weight, 100 parts of an oligomer, 20-50 parts of a monomer, 10-30 parts of a coupling agent, 2-10 parts of an acid anhydride, 1-2 parts of a mixed assistant, 10-30 parts of nanometer silica, 3-10 parts of a photoinitiator, 80-200 parts of a solvent and 100-200 parts of a propellent. The ultraviolet curing paint of the invention, which allows a technical problem of ultraviolet curing paints for the equipment anticorrosion to be solved, has the advantages of good anticorrosion effect, convenient construction, no need of compressed air, realization of the automatic spray, simple preparation method, safety, no pollution, fast curing speed, high production efficiency, high film quality, and excellent coating performance.

Owner:SHANGHAI TITANOS IND

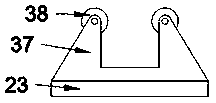

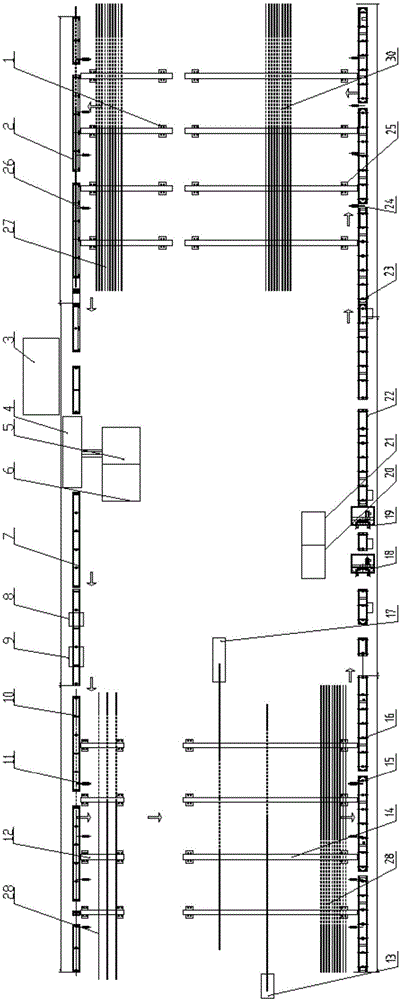

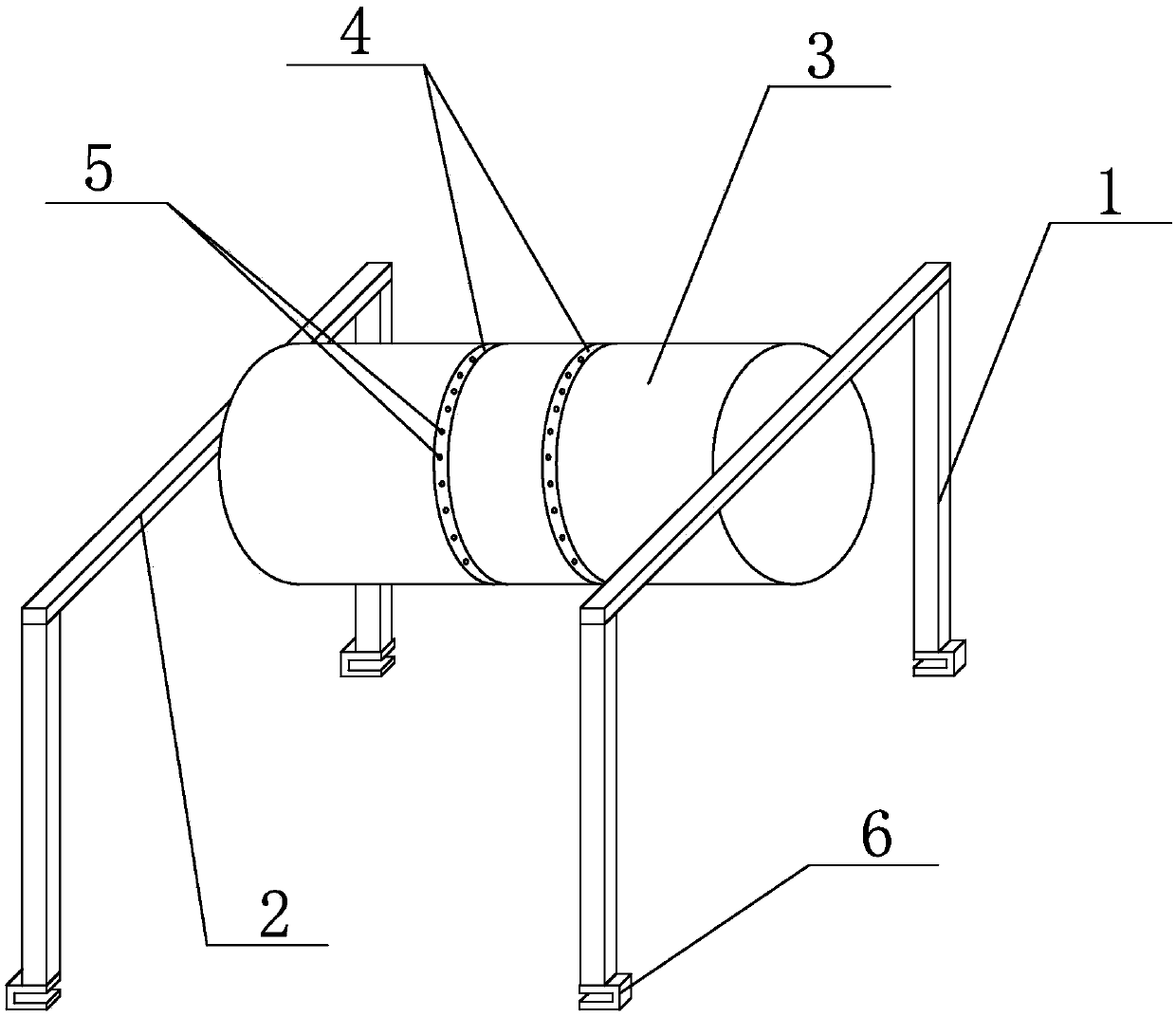

Automatic production line and production method for anti-corrosion steel tubes

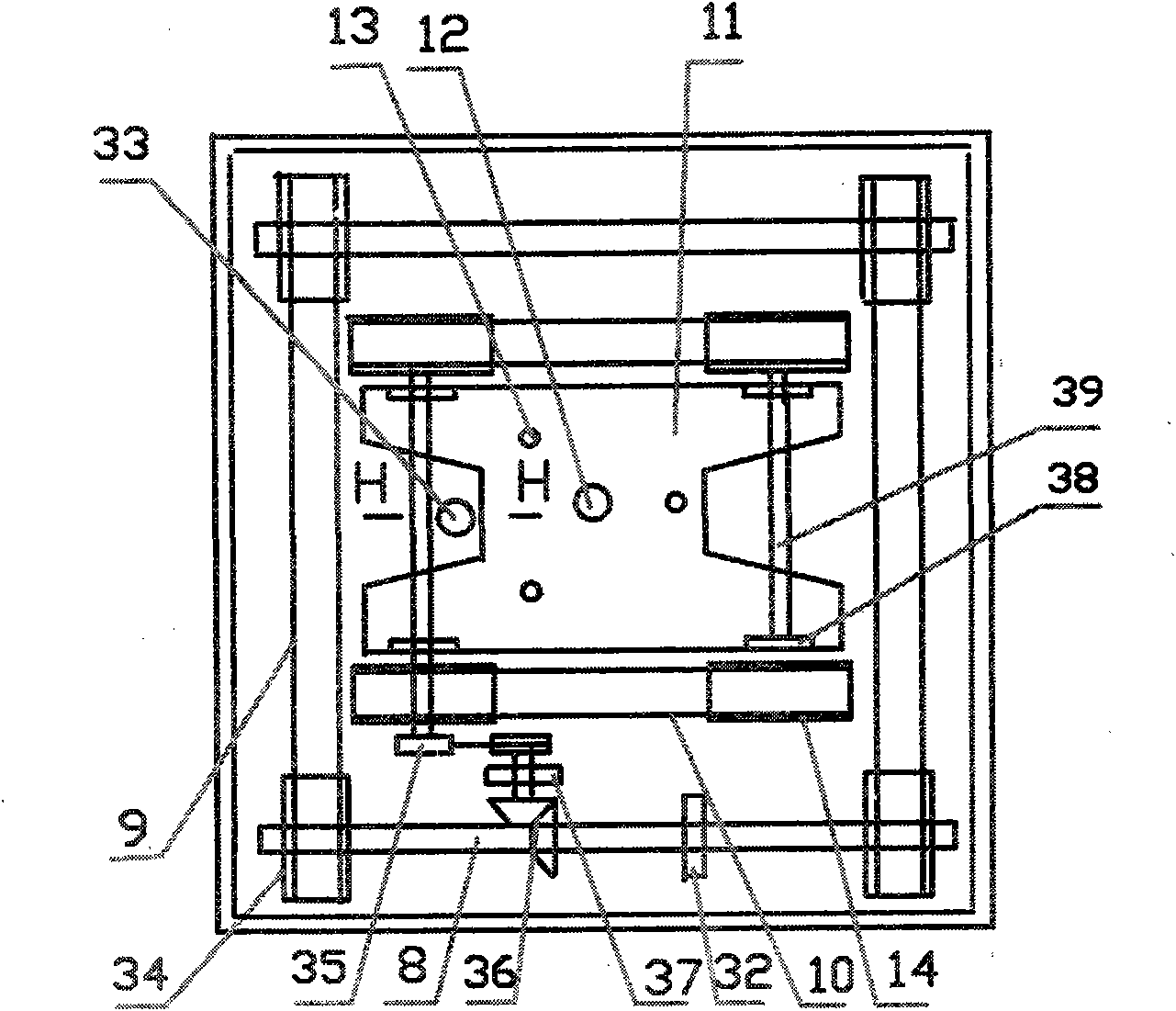

PendingCN106345662AReduce labor intensityImprove production efficiency and product qualityPretreated surfacesCoatingsSteel tubeEngineering

The invention discloses an automatic production line and a production method for anti-corrosion steel tubes. The production method for anti-corrosion steel tubes includes the steps that steel tubes are turned into the front section of a derusting conveying line, and tube-tracking conveying is carried out towards the middle section of the derusting conveying line; the steel tubes are subjected to derusting in the middle section of the derusting conveying line; when the steel tubes obtained after derusting are conveyed to the rear section of the derusting conveying line, tube-separating conveying is carried out; the steel tubes are turned into the front section of a winding conveying line, tube-tracking conveying is carried out towards the middle section of the winding conveying line, and connection is carried out through tube connectors; the steel tubes are subjected to strip winding in the middle section of the winding conveying line; the steel tubes obtained after strip winding are conveyed to the rear section of the winding conveying line for tube-separating conveying. By using the speed-adjustable automatic conveying lines in coordination and cooperation with automatic derusting treatment equipment and automatic strip winding treatment equipment, the purpose of automatic flow production is achieved, the labor intensity is relieved, and the product quality and production efficiency are improved.

Owner:中油管道防腐工程有限责任公司 +1

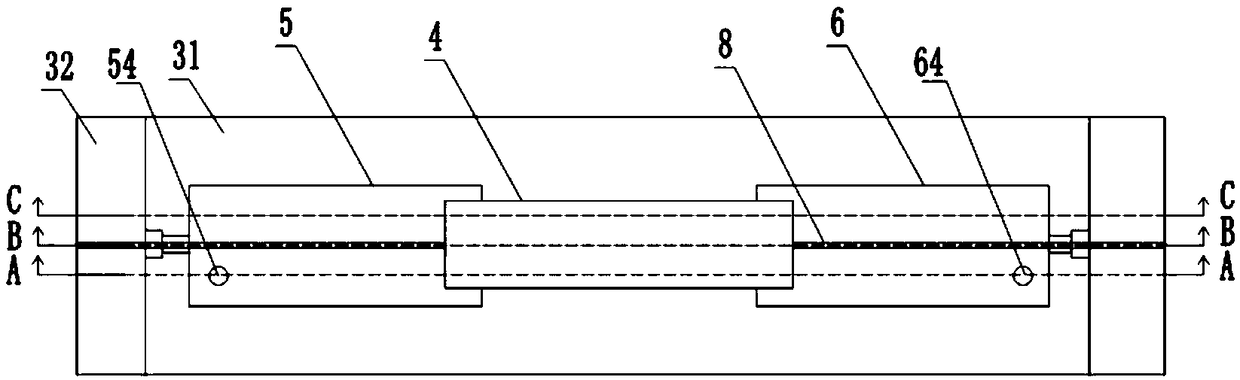

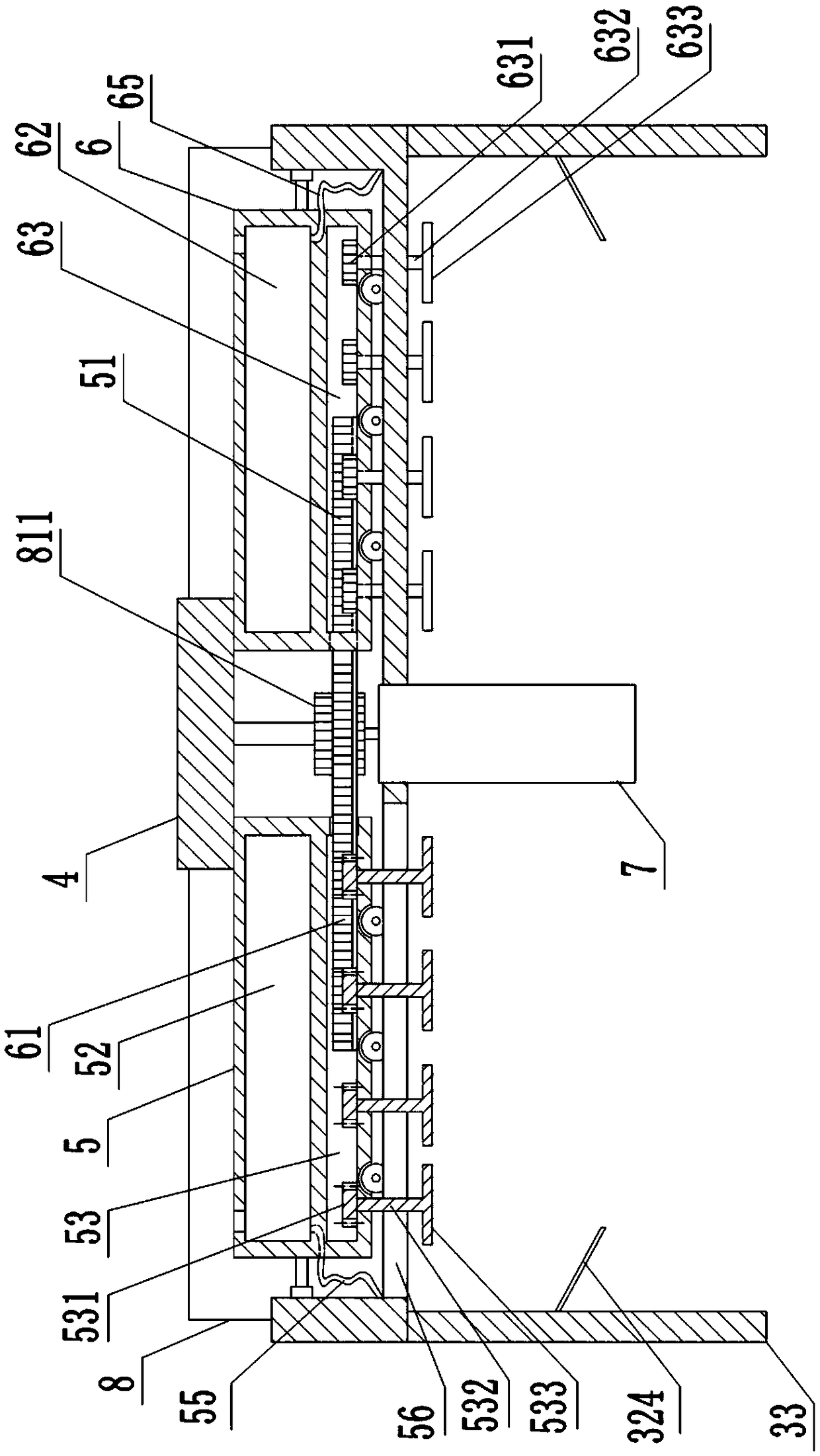

Quick paint spraying device for propeller of unmanned aerial vehicle

ActiveCN106583105AImprove work efficiencyEasy to operateSpraying apparatusAircraft assemblyPropellerUncrewed vehicle

The invention belongs to the technical field of unmanned aerial vehicle equipment, and particularly relates to a quick paint spraying device for a propeller of an unmanned aerial vehicle. The technical problem to be solved by the invention is to provide the quick paint spraying device for the propeller of the unmanned aerial vehicle, which is convenient to operate, quick in paint spraying, time-saving and labour-saving. In order to solve the technical problem, the invention provides the quick paint spraying device for the propeller of the unmanned aerial vehicle, which comprises a right frame, a first electric push rod, a first sliding rail, a clamping device, a bottom plate, a first sliding block, a paint spraying device, pulling wires, a movable plate, second sliding blocks, a second sliding rail and the like; the centre of the top of the bottom plate is connected with the first sliding rail in a bolt connecting mode; the first sliding rail is connected with the first sliding block in a sliding manner; and the first sliding block is in sliding fit with the first sliding rail. The quick paint spraying device for the propeller of the unmanned aerial vehicle achieves the effects of convenient operation, quick paint spraying, time conservation and labour conservation, and moreover, is low in manufacturing cost, reasonable in structure, easy to maintain and repair and convenient to use; the investment of manpower and material resources is reduced; the work efficiency is improved.

Owner:南通市通州区宏峰机械有限公司

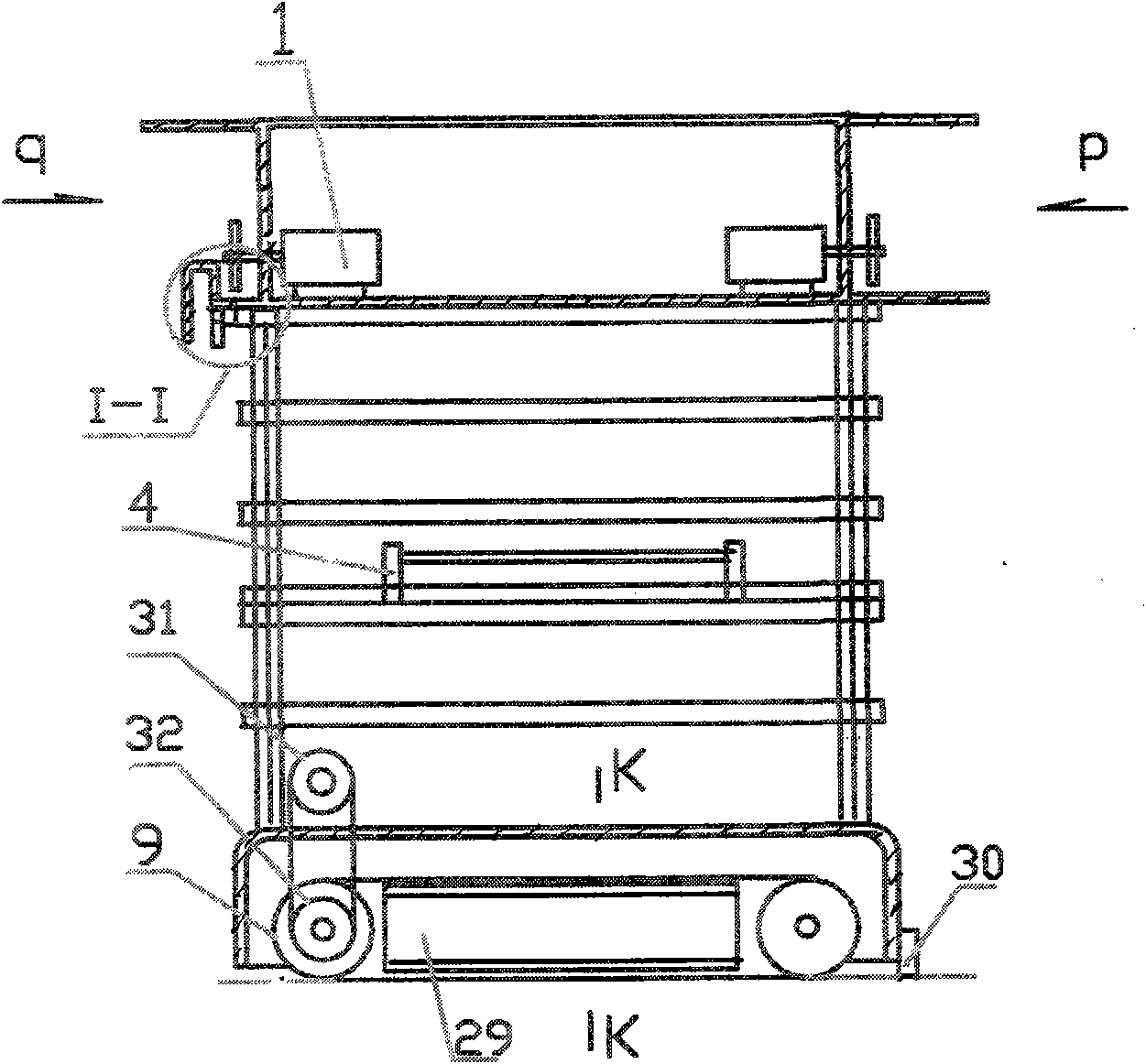

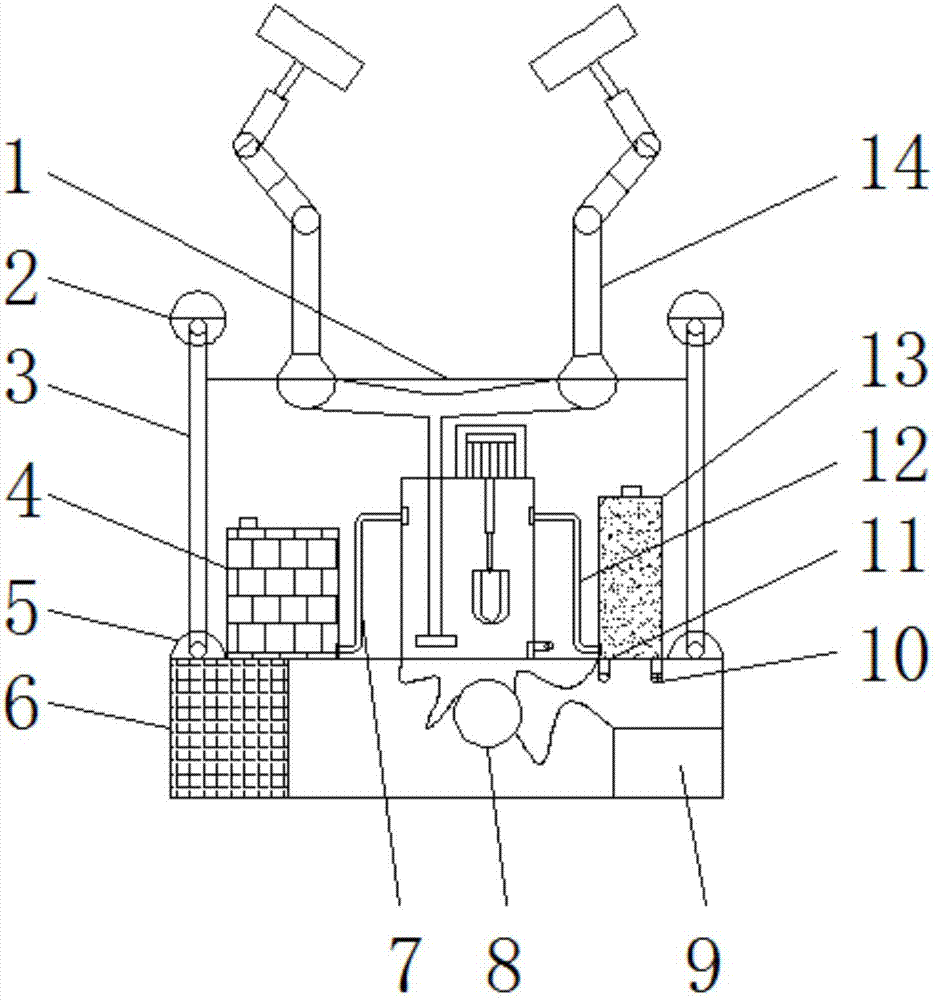

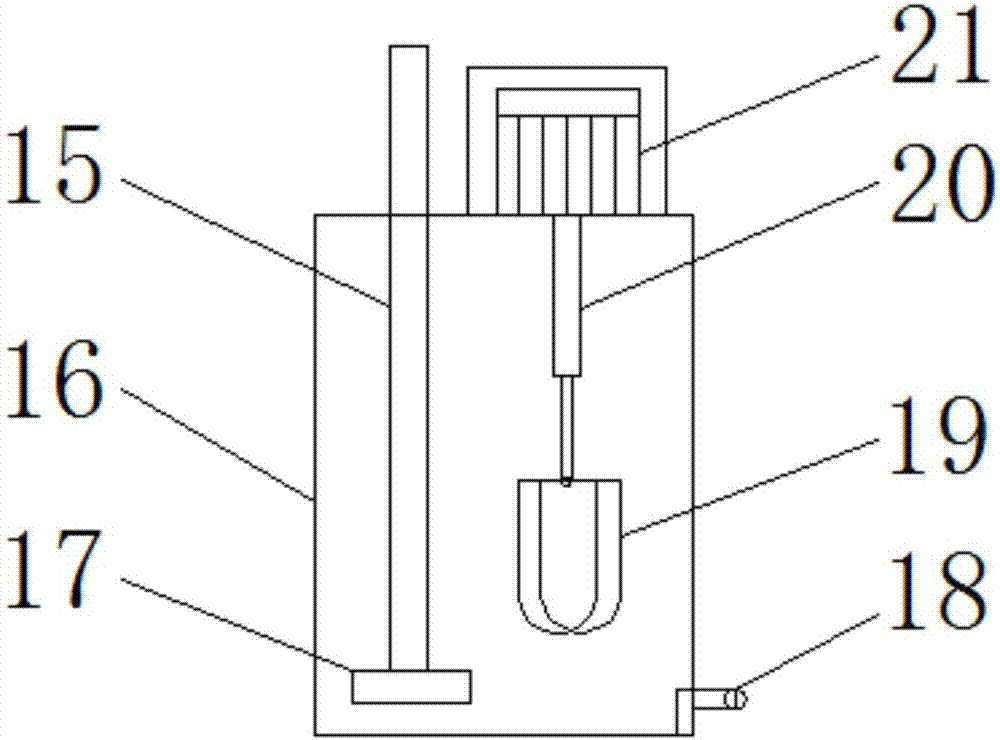

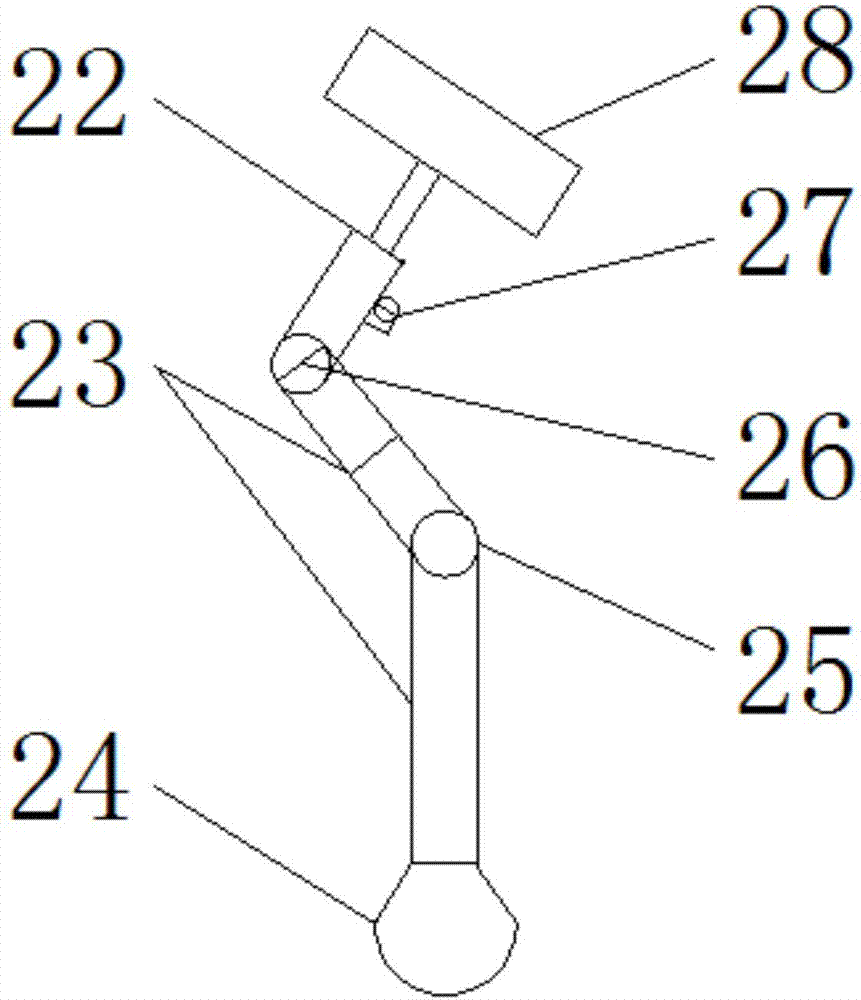

Intelligent robot external wall plastering machine

InactiveCN107060289AScientific and reasonable structureEasy to use and efficientBuilding constructionsIntelligent robotsElectric motor

The invention discloses an intelligent robot external wall plastering machine. The intelligent robot external rendering machine comprises a working main body, a machine arm and a material stirring bucket. The machine arm is installed at the upper end of the working main body. A roller is installed at the upper end of the machine arm. The lower portion of the roller is provided with a rotating shaft. The stirring material bucket is installed at the lower portion of a QC200 data processor. The QC200 data processor is connected with the stirring material bucket through a suction pipe. An electromotor is arranged at the upper end of the stirring material bucket. A rising and falling rotating rod is arranged at the lower end of the electromotor. A stirrer is arranged at the lower end of the rising and falling rotating rod. The two ends of the working main body are both provided with suspending rods. A PLC controller is arranged at one side of a heat dissipation device. One side of the PLC controller is provided with an accumulator. A TDX-328X signal transceiver is arranged at the upper portion of the accumulator. According to the intelligent robot external wall rendering machine, integrated control technology is adopted, a building is remotely controlled, an outer wall of plastered, and the robot plastering machine is high in efficiency.

Owner:吴俊

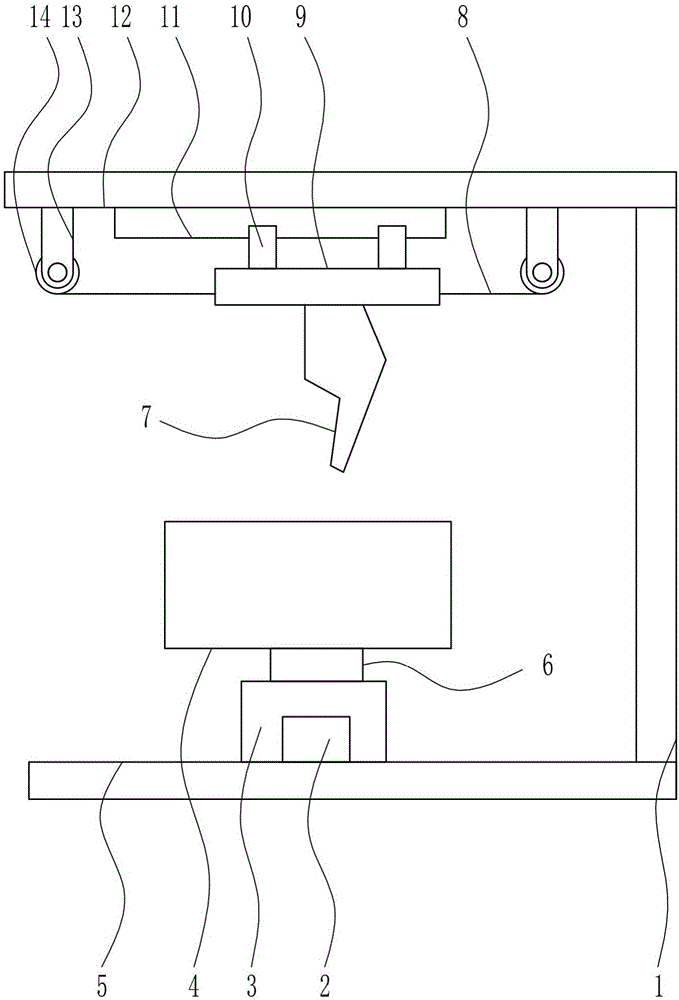

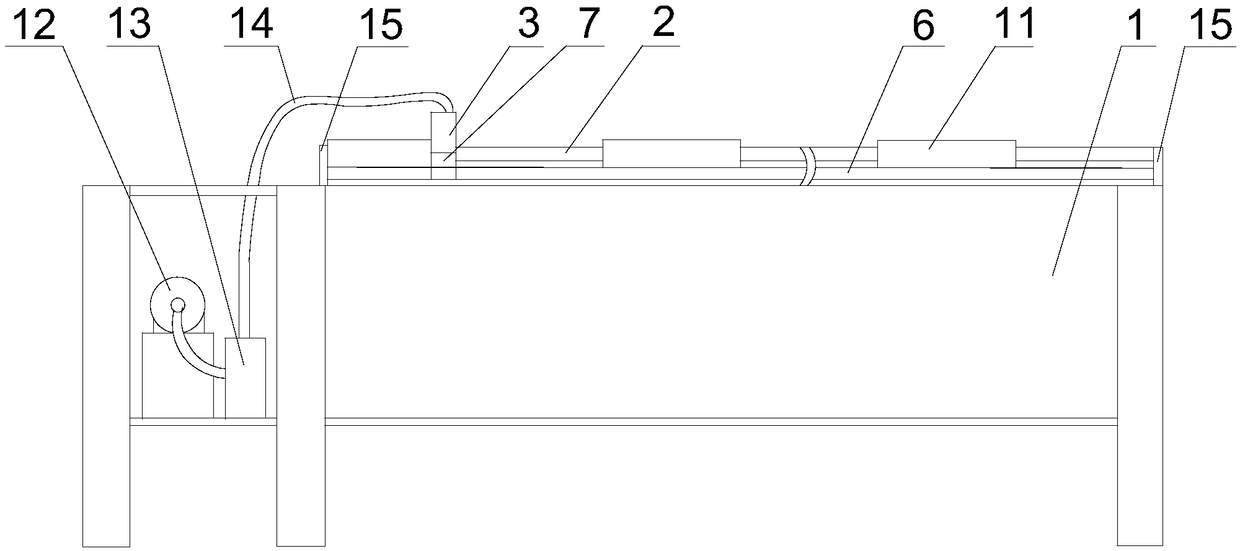

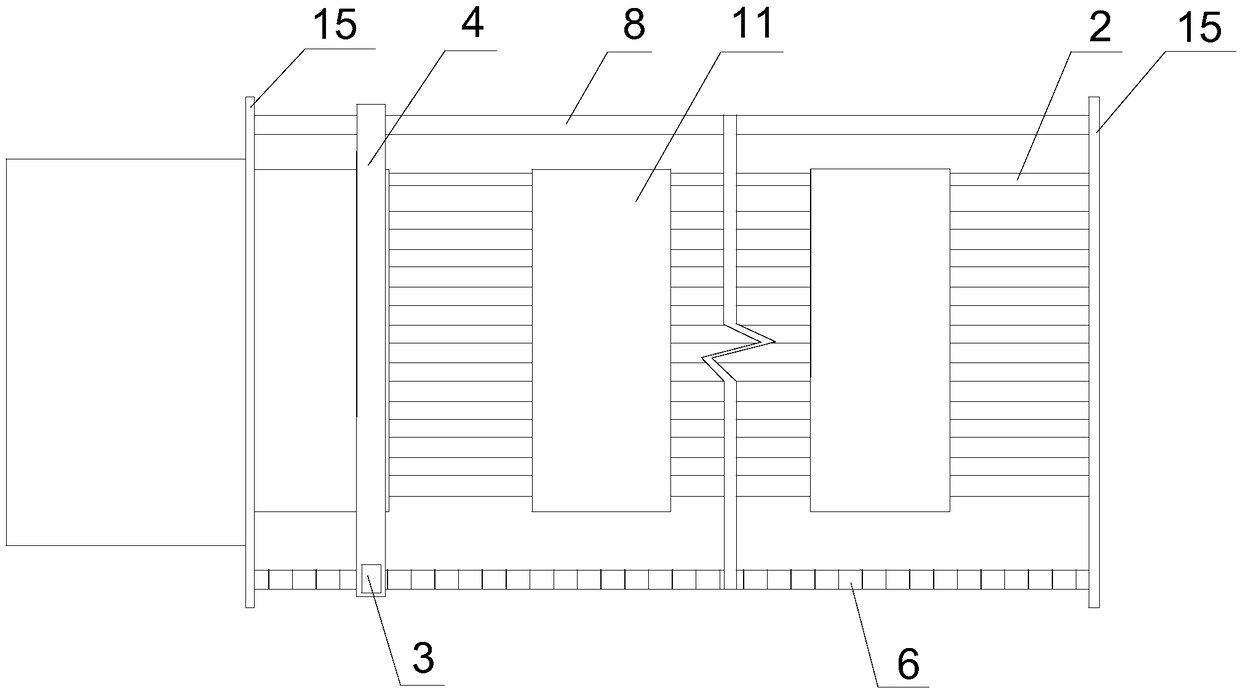

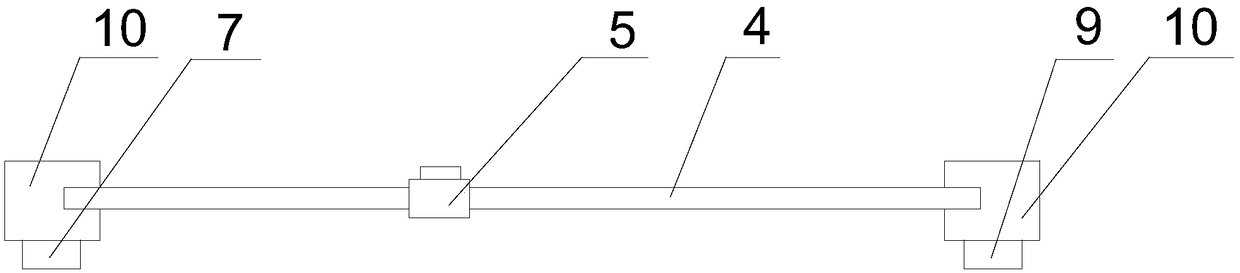

Novel paint spraying equipment for steel pipes

PendingCN109433466AImprove spraying effectColor seams are straight and beautifulSpraying apparatusEngineeringMechanical engineering

The invention discloses novel paint spraying equipment for steel pipes. The equipment comprises a workbench; a plurality of the steel pipes are laid on the workbench in parallel; the equipment furthercomprises a moving mechanism I moving in the axial direction of the steel pipes and a moving mechanism II moving in the radial direction of the steel pipes; and a paint spraying gun is arranged on the moving mechanism I or the moving mechanism II and is driven to move in the axial direction and the radial direction of the steel pipes through cooperation with the moving mechanism I or the moving mechanism II. The equipment is applicable to spraying of the steel pipes with two colors alternating with each other and is the efficient and automatic paint spraying equipment capable of meeting requirements of the steel pipes with the two colors alternating with each other.

Owner:CHINA NUCLEAR IND 24 CONSTR

Efficient paint spraying method for furniture

InactiveCN107774550AEnhanced adhesionPrevent falling offSpraying apparatusPretreated surfacesFingerprintSandpaper

The invention discloses a high-efficiency paint spraying method for furniture, which comprises the following steps: drying; grinding; removing dust and small particles; putting it into a sealed cabin and steaming with high-temperature steam; spraying primer, and then irradiating and heating with ultraviolet light , curing the coated primer; using fine sandpaper to polish the cured primer once; after polishing, the surface of the primer is coated with a topcoat by a spraying device; the coated topcoat furniture is dried in a gradient heating method, And irradiated with ultraviolet light to cure the topcoat. The paint spraying method of the present invention can quickly remove the moisture in the paint, and at the same time ensure that the paint "penetrates" into the furniture, improves the adhesion between the paint and the surface of the furniture, avoids falling off, and has good curing effect, less paint volatilization, safety and environmental protection , can effectively improve the brightness and color of the furniture surface, and has good scratch resistance, and is not easy to leave fingerprints.

Owner:张杰

Medical functional coating applying method and application

PendingCN109622344AEvenly distributedImprove adaptabilityPretreated surfacesCoatingsPolysilazaneProduct gas

The invention discloses a medical functional coating applying method and application, and relates to the technical field of functional materials. The medical functional coating applying method comprises the steps that surface pretreatment is conducted, two steps are divided, mixed gas of fluorine-carbon gas and inorganic oxygen containing gas and mixed gas of alkyl containing gas and inorganic oxygen containing gas are sequentially used, and plasma surface pretreatment is conducted on medical materials; and aftertreatment is conducted, the medical material subjected to two-step plasma surfacepretreatment is coated with a functional polysilazane solution, and a medical functional coating is formed through curing. The prepared functional coating has the advantages that curing is easy, baseselectivity does not exist, the bonding force between the functional coating and a base is high, the coating is dense and transparent, curing products are free of toxicity, and the coating is durable;and the defects of a traditional medical functional coating are overcome.

Owner:INST OF MEDICAL DEVICES (SUZHOU) SOUTHEAST UNIV

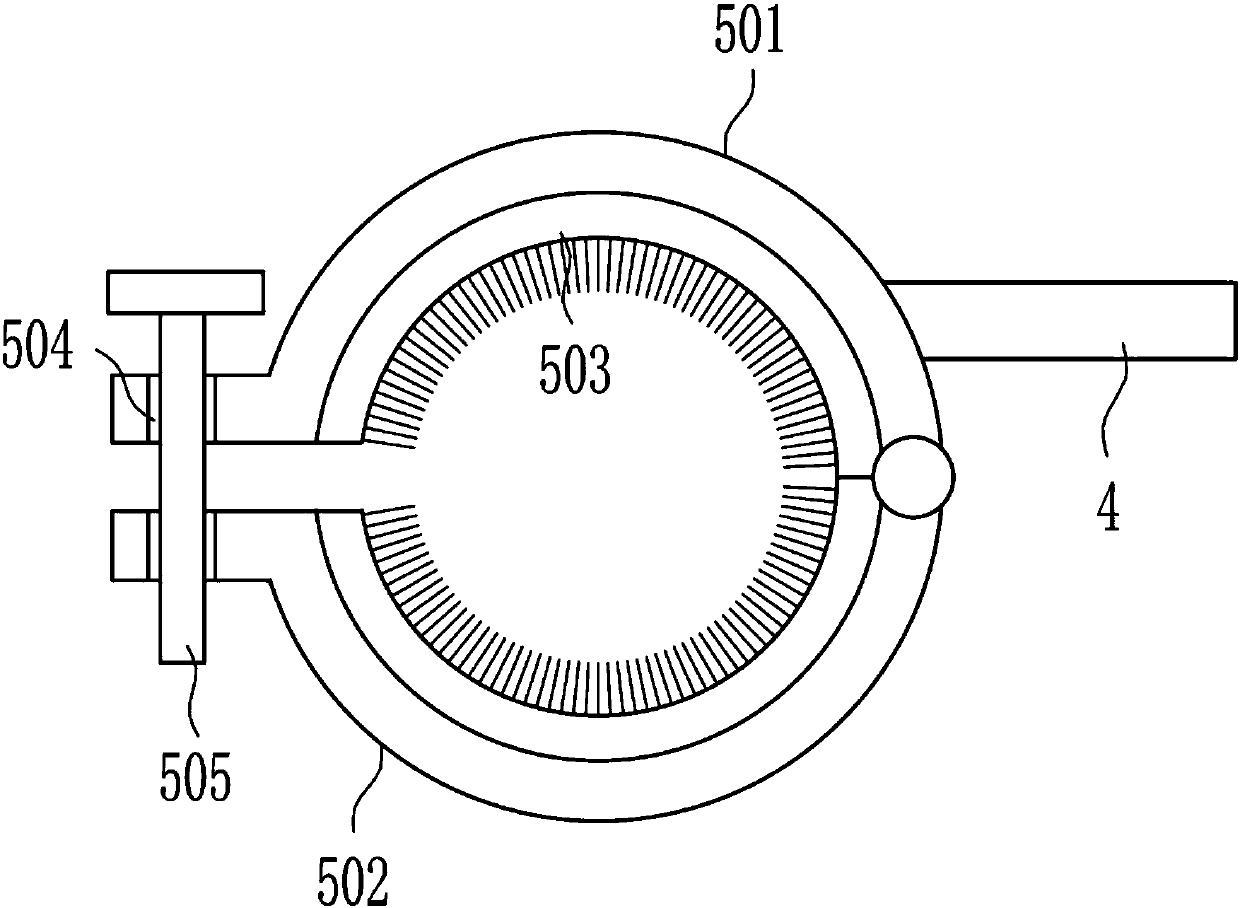

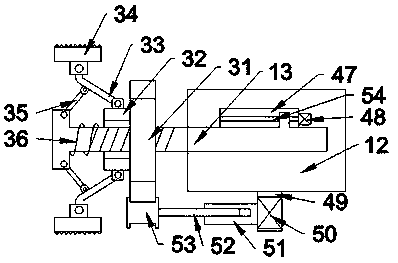

Efficient stainless steel pipe paint brushing device used for hardware tool production

InactiveCN106362905AEasy to operateEasy to useLiquid surface applicatorsCoatingsLacquerHardware tool

The invention relates to a stainless steel pipe paint brushing device used for hardware tool production, in particular to an efficient stainless steel pipe paint brushing device used for hardware tool production. In order to solve the technical problems, the invention provides the efficient stainless steel pipe paint brushing device for hardware tool production, which is convenient to operate, is quick in paint brushing, and saves time and labor. The efficient stainless steel pipe paint brushing device comprises a first motor, a hinged part, a brush, a first electric pushing rod, a first connecting rod, a swing base, a mounting base, a second connecting rod, a first triangular plate, a second triangular plate and the like, wherein the upper part of the left wall in a mounting frame is connected with a slide rail in a bolt connecting mode. The efficient stainless steel pipe paint brushing device achieves the effects of being simple to operate, quick in paint brushing, and saving time and labor, is low in manufacturing cost, is reasonable in structure, is easy to maintain and repair and is convenient to use, reduces investment of manpower and material resources and improves working efficiency.

Owner:PHST CORP

Contactless powder coating method for small metal workpiece

InactiveCN1460560AStrong adhesionUniform thicknessLiquid surface applicatorsCoatingsCoated surfaceContact free

The present invention relates to a contact-free powder coating mathod for small metal workpiece. The workpiece coating process is implemented in vibration-type fluidized bed, the fluidized layer is made of high-molecular powder material whose grain size is less than 80 meshes, in the course of that the preheated workpiece is passed through the fluidized layer from top to bottom a high-molecular coating laeyr can be formed on the surface of the workpiece, and the thickness of said coating layer is 100-300 micrometers. Said invention can adopt coloured powder material to implement two-colour coating and obtain colour mark function.

Owner:杭州五源科技实业有限公司

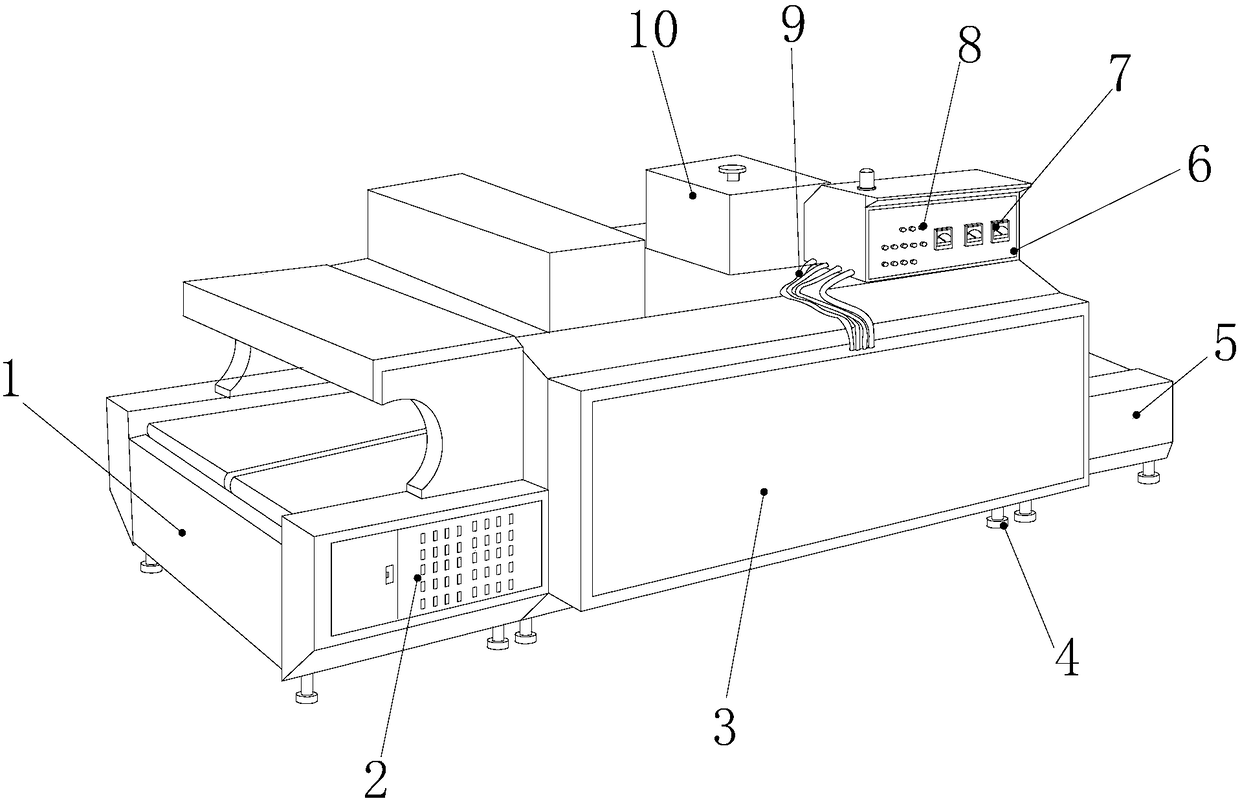

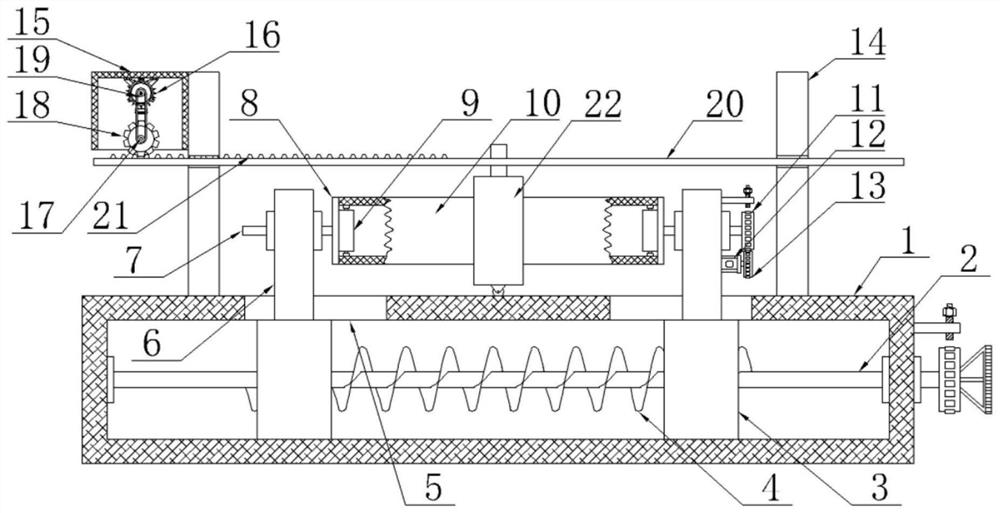

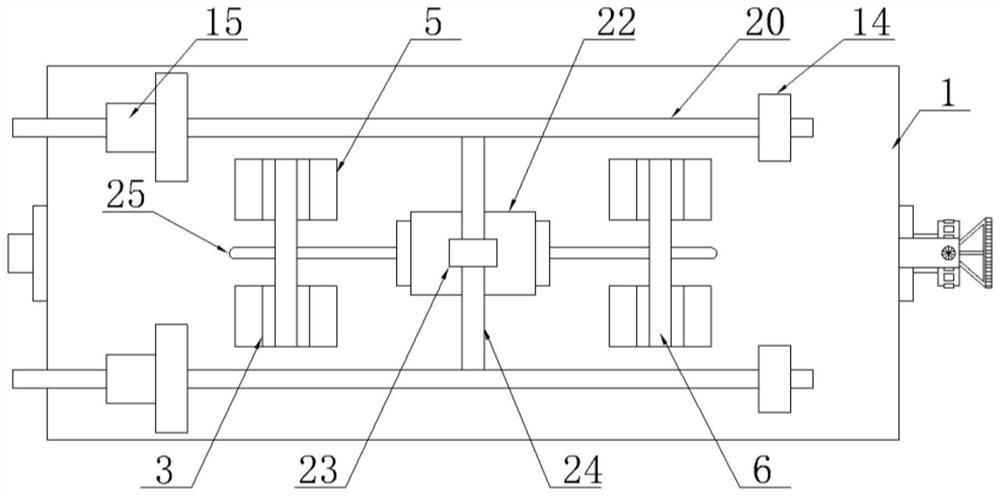

Rapid paint spraying equipment for elevator plate

InactiveCN108480094AExtended service lifeQuick paintGearingLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses rapid paint spraying equipment for an elevator plate. The rapid paint spraying equipment structurally comprises a front conveying seat, a heat dissipation grid, a main body device, supporting foot cups, a rear conveying seat, a control box, a display screen, operating buttons, connection wires and a paint liquid box; the main body device comprises a paint liquid runner pipe, a pressure pump, an upper paint spraying disc, a manual adjustment mechanism, a screw transmission mechanism, a rust removal mechanism, a driving mechanism, a geneva wheel mechanism, a lower paint spraying disc, a paint spraying chamber, an iron rust collecting groove and an iron rust discharge tube. According to the rapid paint spraying equipment for the elevator plate, the manual adjustment mechanism, the screw transmission mechanism, the rust removal mechanism, the driving mechanism, the geneva wheel mechanism and the lower paint spraying disc are arranged in the main body device, rust removal can be carried out on the elevator plate before paint spraying, the paint spraying quality is improved, and the service life of the elevator plate is prolonged; and meanwhile, the rapid paint spraying equipment can carry out paint spraying on the two surfaces of the plate simultaneously, so that the purpose of rapid paint spraying is realized.

Owner:莆田市华赢建材有限公司

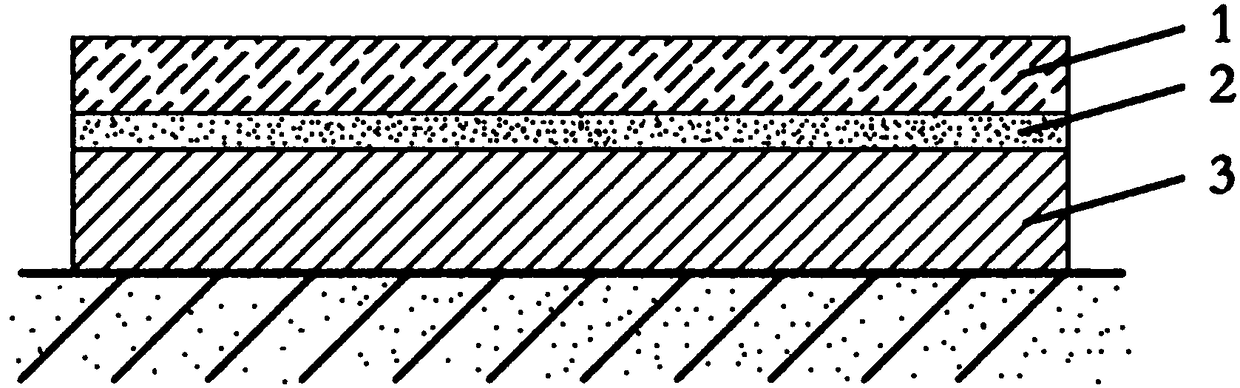

Manufacturing method of green and environment-friendly solid wood multilayer decorative board

InactiveCN108661267AIncrease packing densityHigh tensile strengthCovering/liningsLamination ancillary operationsEnvironmental resistanceFiber

The invention relates to a manufacturing method of a green and environment-friendly solid wood multilayer decorative board, and belongs to the technical field of heat preservation decorative board forming technology. The manufacturing method comprises the following five steps that 1, materials are mixed; 2, the mixed materials are put in an extruder to being extruded; 3, shaping is carried out; 4,bonding is carried out; and 5, cutting and packaging are carried out. According to the manufacturing method, the process conditions are relatively mild, and continuous production can be realized; anda bottom layer uses cheap PP and PE as a waterproof and moisture-proof layer, the cost is reduced, and the reinforcing effect of wood fibers enables a board to be not prone to cracking. The bonding performance of a flame-retardant decorative board prepared by the manufacturing method meets the requirements of national standards, and base materials have flame retardant performance; moreover, the mechanical properties of the base materials are not affected, the formaldehyde emission is further above E1 level, and safety and environmental protection are achieved; and at the same time, the natural texture of wood is maintained, and the decorative effect is good.

Owner:肖桂云

Anti-splashing equipment for paint spraying of aluminum alloy motor shell

ActiveCN110237978AImprove efficiencyImprove uniformityLiquid spraying apparatusSpray boothsEngineeringAlloy

The invention relates to the technical field of paint spraying of motor shells, in particular to anti-splashing equipment for paint spraying of an aluminum alloy motor shell. The anti-splashing equipment comprises a storage box, wherein the top of the storage box is fixedly connected with a fixing plate through a supporting frame, the top of the fixing plate is movably connected with a rotary motor through a rotating rod, the bottom of the rotating rod penetrates through the anti-splashing plate and is fixedly connected with the anti-splashing plate, the bottom of the rotating rod is fixedly connected with a position limiting mechanism through a connecting plate, the position limiting mechanism is movably connected with a machine shell, the bottom of the inner cavity of the storage box is fixedly connected with a paint storage tank, the side surface of the paint storage tank fixedly communicates with a paint pumping pump through a paint pumping pipe, a paint spraying pipe fixedly communicates with the top of the paint pumping pump, and an atomizing nozzle is fixedly connected to one end, located in a protective box, of the paint spraying pipe. According to the anti-splashing equipment, compared with a handheld paint spraying device, the anti-splashing equipment has the advantage that the labor intensity is reduced, sprayed paint is prevented from being diffused into the air and falls onto the skin of a paint sprayer and the discomfort of a body is caused in the nose.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

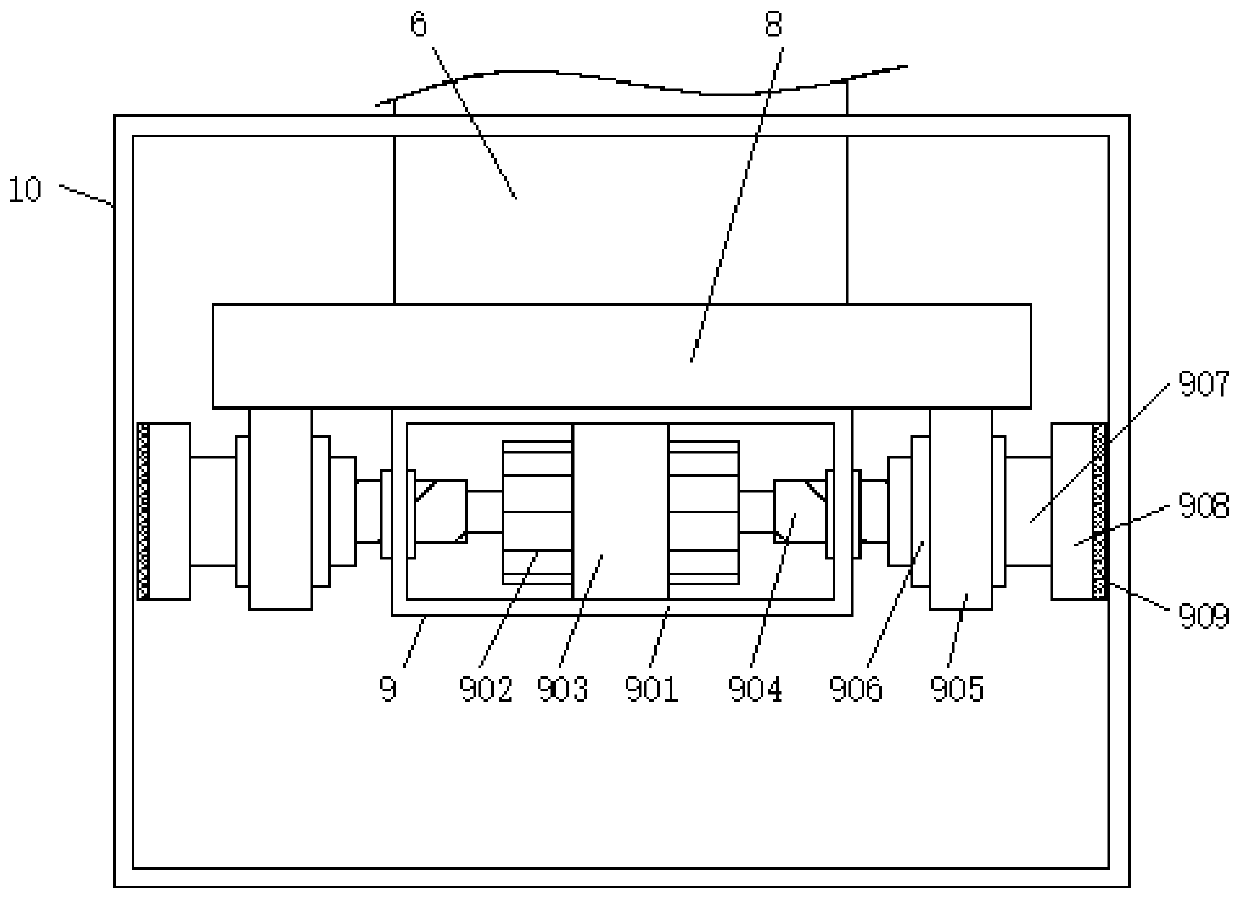

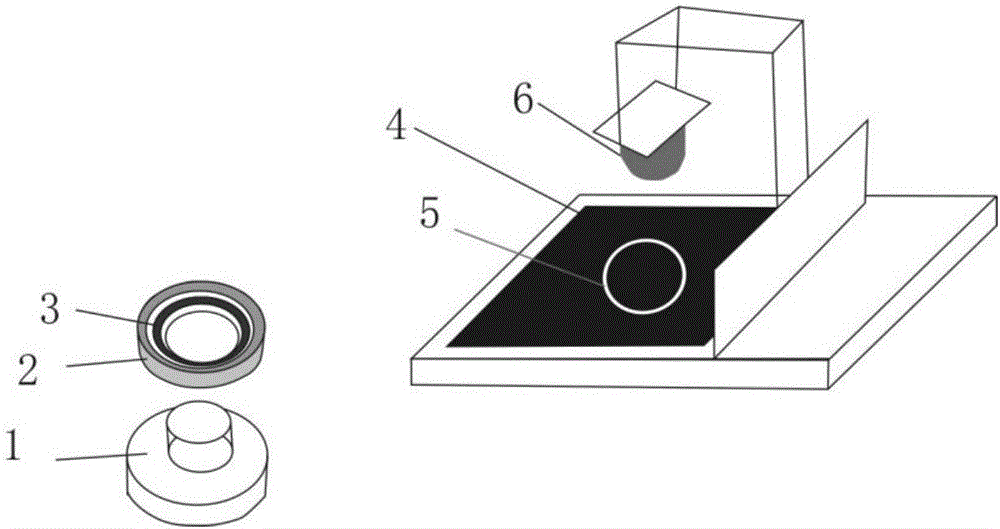

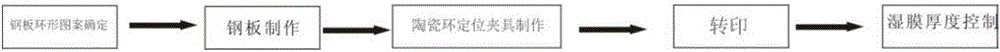

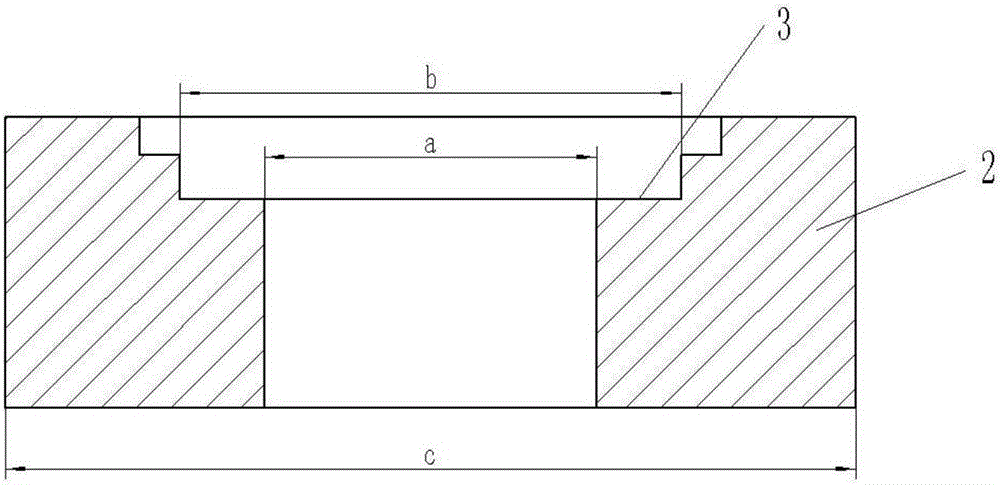

Preparation method for safety electrode of ceramic sealing ring of power battery

ActiveCN106739606AFast printQuality assuranceDuplicating/marking methodsCell sealing materialsPower batterySlurry

The invention discloses a preparation method for a safety electrode of a ceramic sealing ring of a power battery. The preparation method includes the following steps that (1) a ring-shaped pattern is manufactured on a steel plate; (2) the ring-shaped pattern is subjected to the procedures of film making, plate burning, corrosion, cleaning and polishing in sequence; (3) a matched silicone printing pad is manufactured; (4) a ceramic sealing ring positioning clamp is manufactured; (5) the ceramic sealing ring positioning clamp is sleeved with the ceramic sealing ring, a transfer printing power switch is pressed down, and the ring-shaped pattern on the steel plate is filled with molybdenum-manganese slurry under the action of a covering blade and a scraping blade of a transfer printing machine; and (6) the matched silicone printing pad is pressed downwards until the molybdenum-manganese slurry in the ring-shaped pattern is bonded on the matched silicone printing pad, and the molybdenum-manganese slurry bonded on the matched silicone printing pad is transferred onto a ceramic sealing ring groove step surface. By means of the preparation method, the problems that ink brushes are used for coating ceramic sealing ring groove step surfaces with molybdenum-manganese slurry at present, consequently, working efficiency is low, molybdenum-manganese layers of ceramic sealing ring groove step surfaces are not uniform in thickness, and packaging air tightness is poor are solved.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

Car paint spraying and polishing integration device for local parts of car body

ActiveCN108747743APractice soft touchIngenious structureGrinding drivesPretreated surfacesAutomotive engineeringNozzle

The invention discloses a car paint spraying and polishing integration device for the local parts of a car body. The integration device comprises a storing box, a first connecting pipe, a paint spraying pump, a second connecting pipe, a first protecting cover, a supporting plate, an atomizing nozzle, a handle, a second protecting cover, a motor, a rotating shaft, a connecting sleeve, a connectingrod and a polishing sheet. The car paint spraying and polishing integration device for the local parts of the car body is ingenious in structure, powerful in function and easy to operate, by using thedevice, a paint spraying device and a polishing device can be connected into a whole, maintainers can carry out paint spraying and polishing treatment on the local parts of the car body convenientlyand fast, and the car maintenance progress of the maintainers is improved effectively.

Owner:平湖市穗丰五金有限公司

Rapid paint spraying and drying and high-temperature rapid grinding device

ActiveCN111346768APrevent the effect of incomplete processingQuick paintGrinding drivesPretreated surfacesThermodynamicsIndustrial engineering

The invention relates to the technical field of industrial automation, and further discloses a rapid paint spraying and drying and high-temperature rapid grinding device. The rapid paint spraying anddrying and high-temperature rapid grinding device comprises a processing machine. The bottom of the interior of the processing machine is movably connected with a rotating plate. The upper portion ofthe rotating plate is movably connected with a heating plate. The upper portion of the rotating plate is movably connected with a clamping rail. The interior of the processing machine is movably connected with a telescopic rod. The interior of the clamping rail is movably connected with a reset spring. The right side of the telescopic rod is movably connected with a grinding plate. The upper portion of the telescopic rod is movably connected with a constant pressure pipe. Along with the working of the heating plate, the temperature inside the clamping rail movably connected with the interior of the processing machine rises, and meanwhile, clamping sliding blocks movably connected inside the clamping rail are increased to move towards two sides and simultaneously compress clamping springs,so that the heating plate is used to clamp a workpiece under high temperature, and the workpiece is prevented from moving in the processing process and being processed incompletely.

Owner:浙江波鹰机械制造有限公司

Gypsum-based self-humidity-control ceiling decoration material

InactiveCN108237609AIncrease packing densityHigh tensile strengthCeramicwareWood impregnation detailsEnvironmental resistanceThermal insulation

The invention relates to a gypsum-based self-humidity-control ceiling decoration material which comprises a water-soluble non-combustible ceramic protective layer, an organic-inorganic composite toughening layer and a flame-retardant thermal insulation layer, wherein the organic-inorganic composite toughening layer is flame-retardant thermal insulation polymer mortar and comprises the following components: a binding material S, ceramic beads, hydroxyethylmethylcellulose, redispersible emulsion powder, limestone flour and modified expansible graphite; and the flame-retardant thermal insulationlayer comprises the components of modified expandable polystyrene and modified expansible graphite. The flame-retardant thermal insulation board is mounted on the wall space in a manner of combining bonding and anchoring. The bonding performance of the flame-retardant decorative board prepared by the method disclosed by the invention meets the national standard requirement, and the base material is endowed with flame-retardant properties. Moreover, the mechanical property of the base material is not influenced, the formaldehyde release amount is on a level E1 or higher, and the material is safe and environmental-friendly. Meanwhile, the natural texture of wood is maintained, and the decorative effect is excellent.

Owner:秦春玉

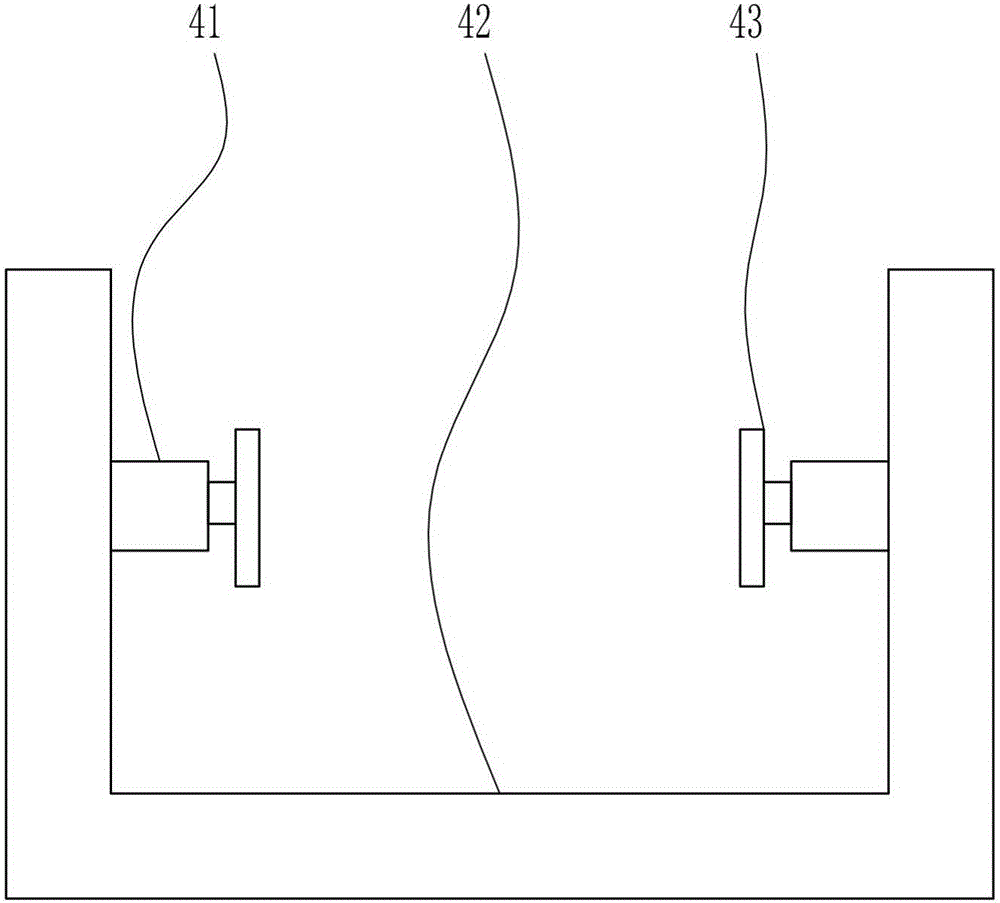

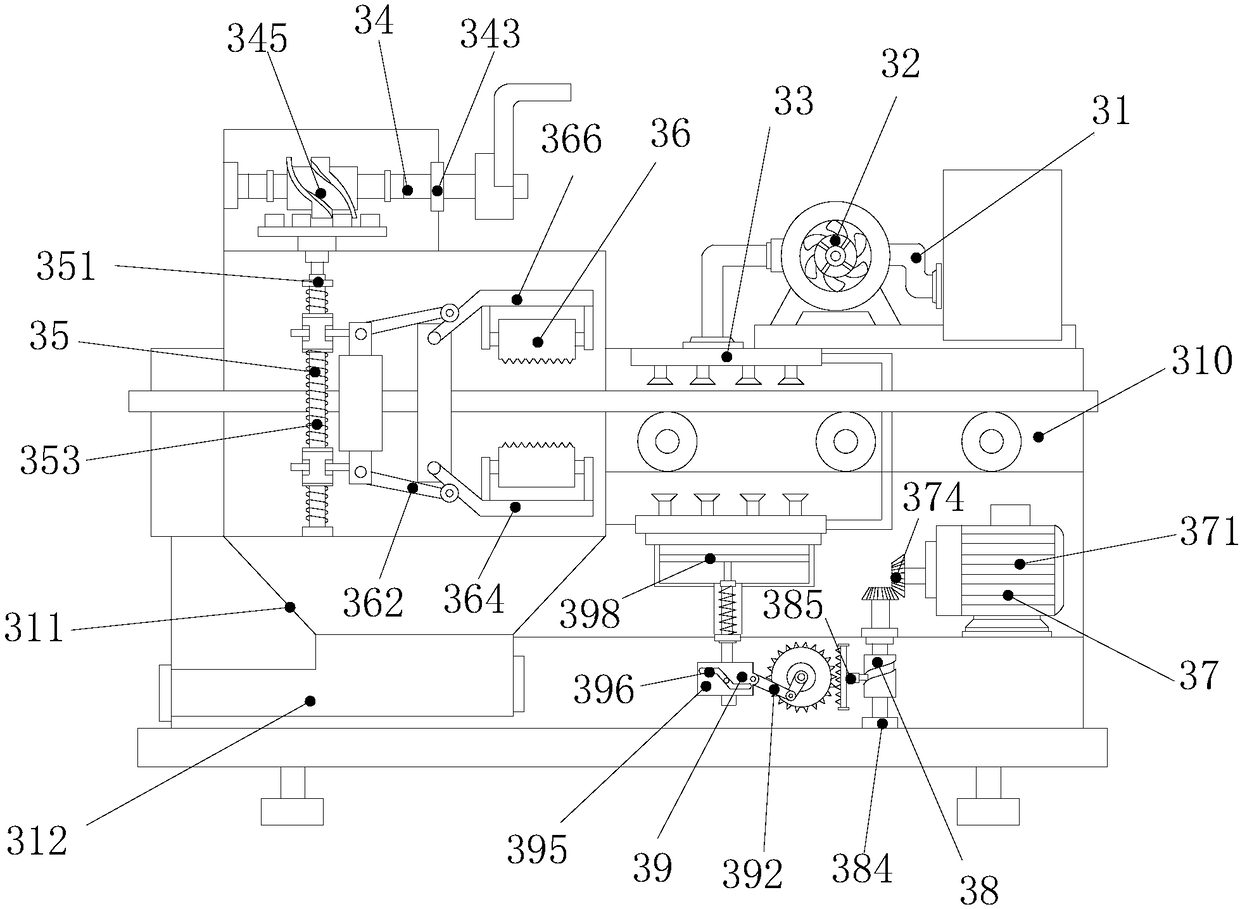

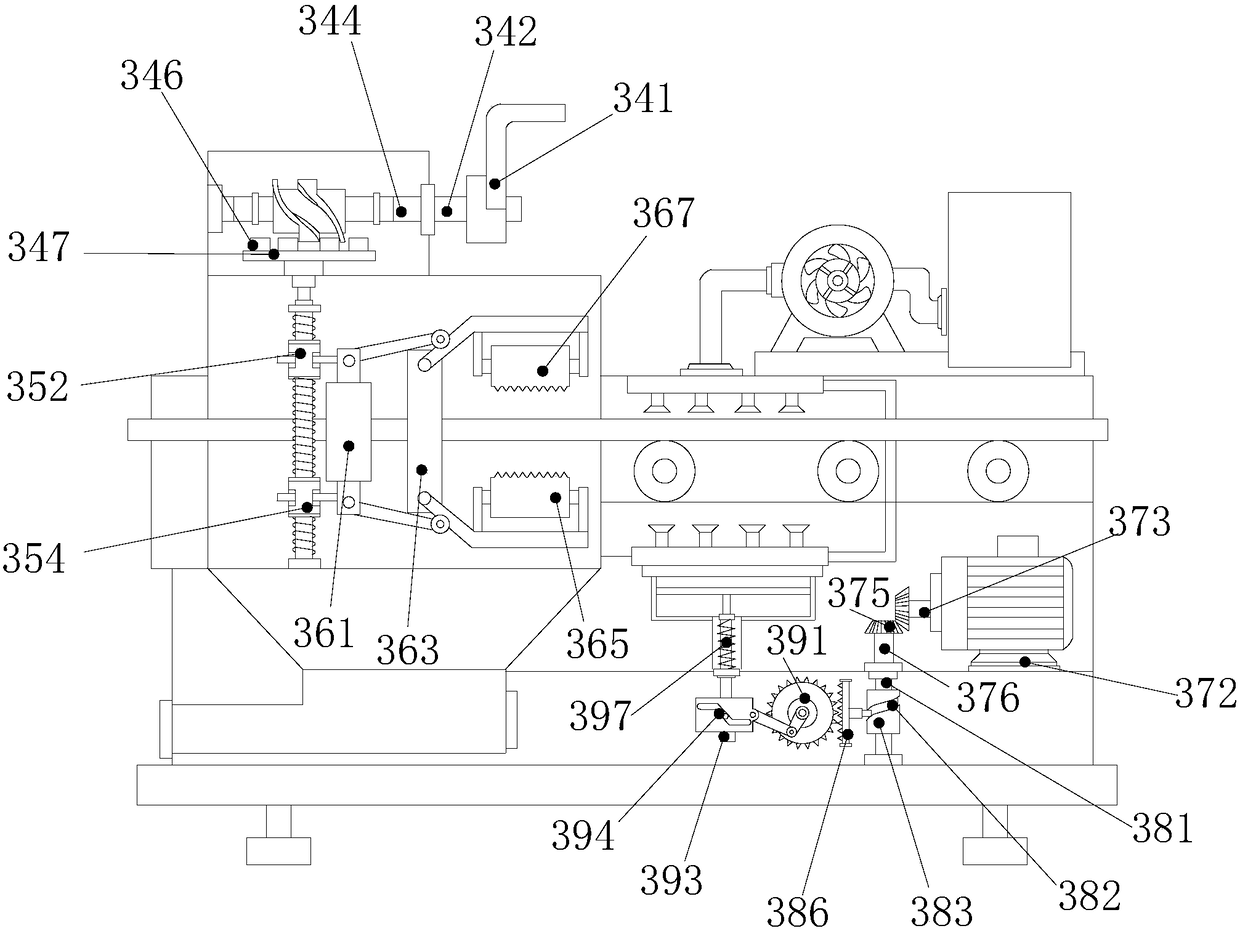

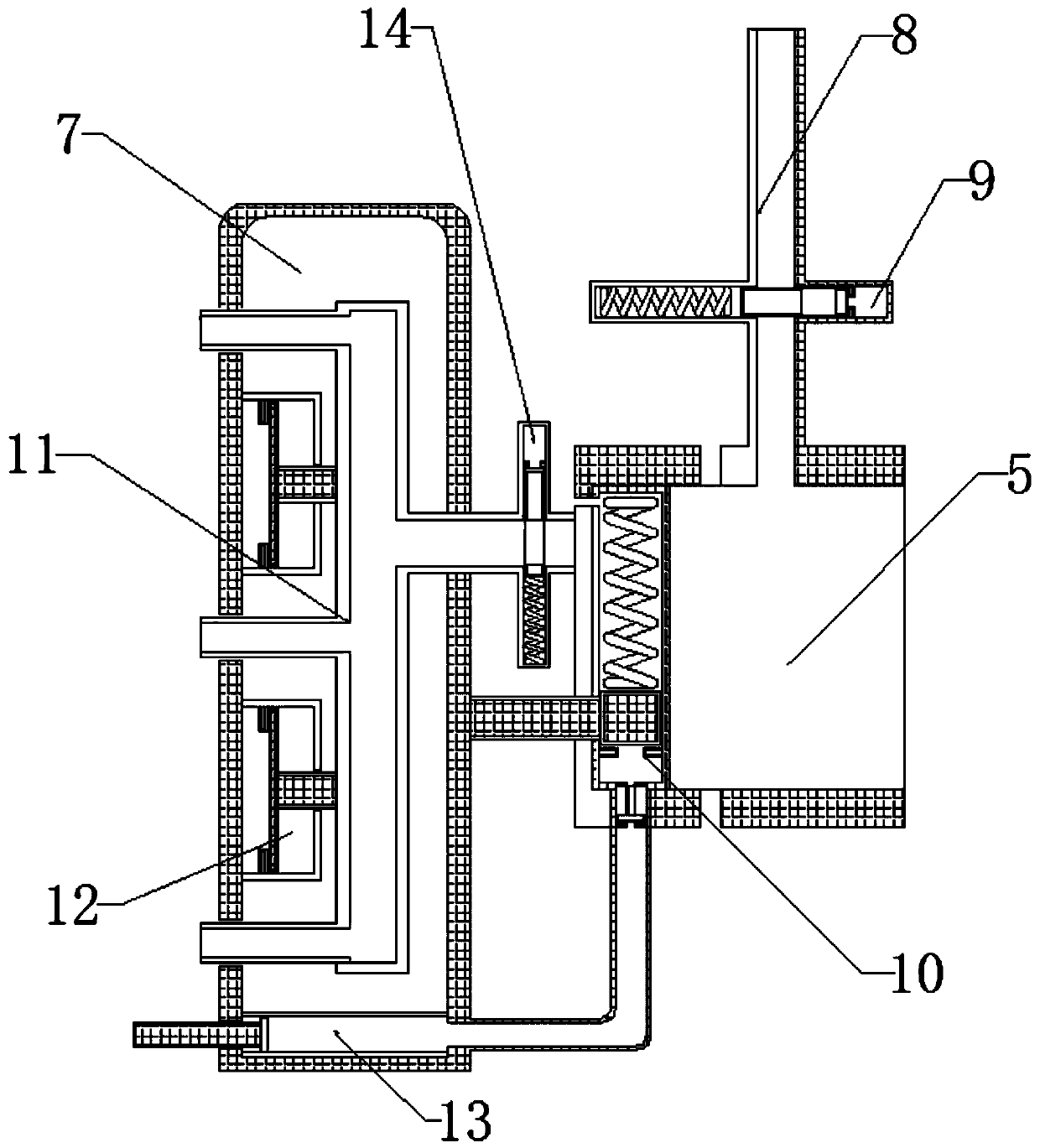

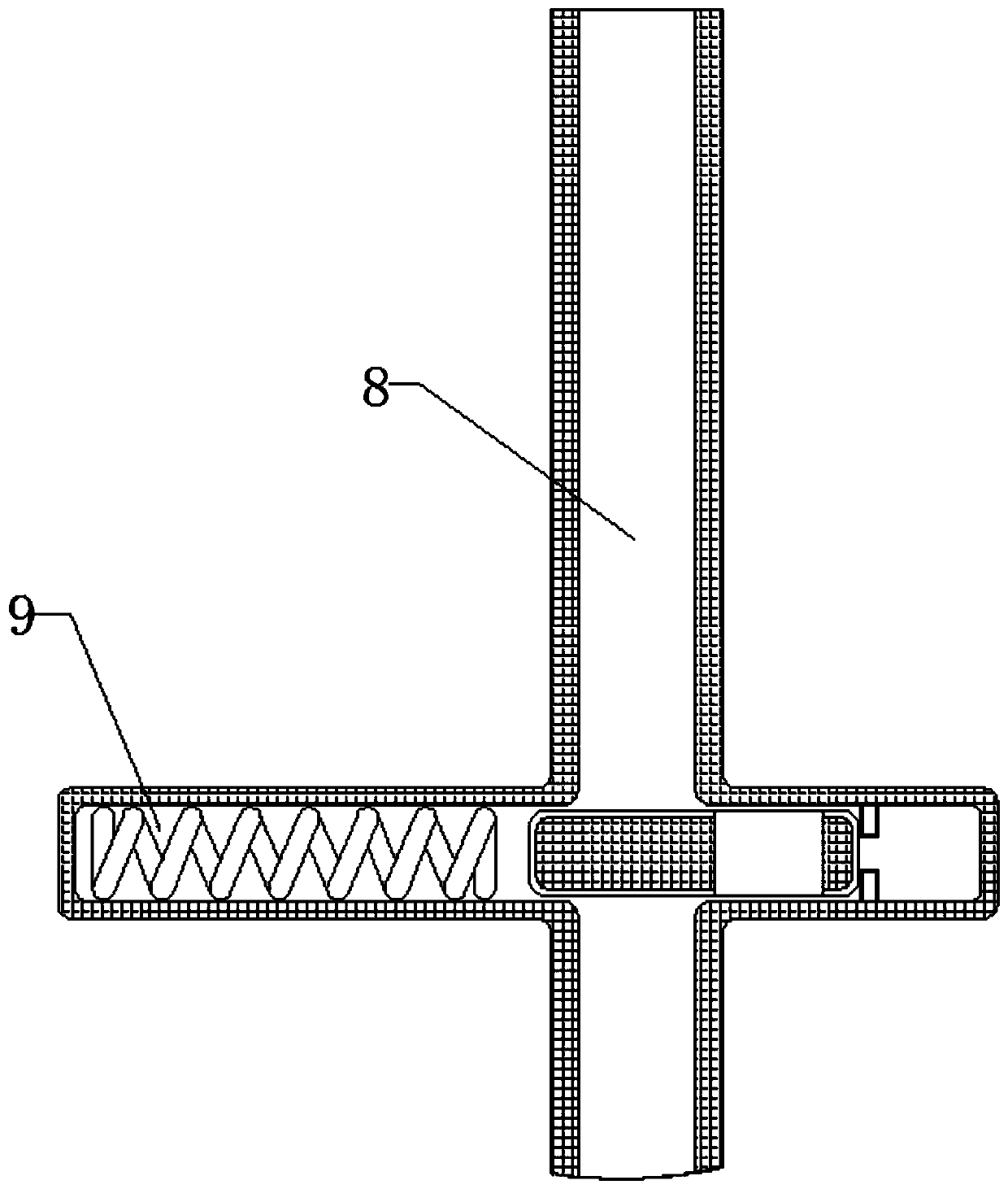

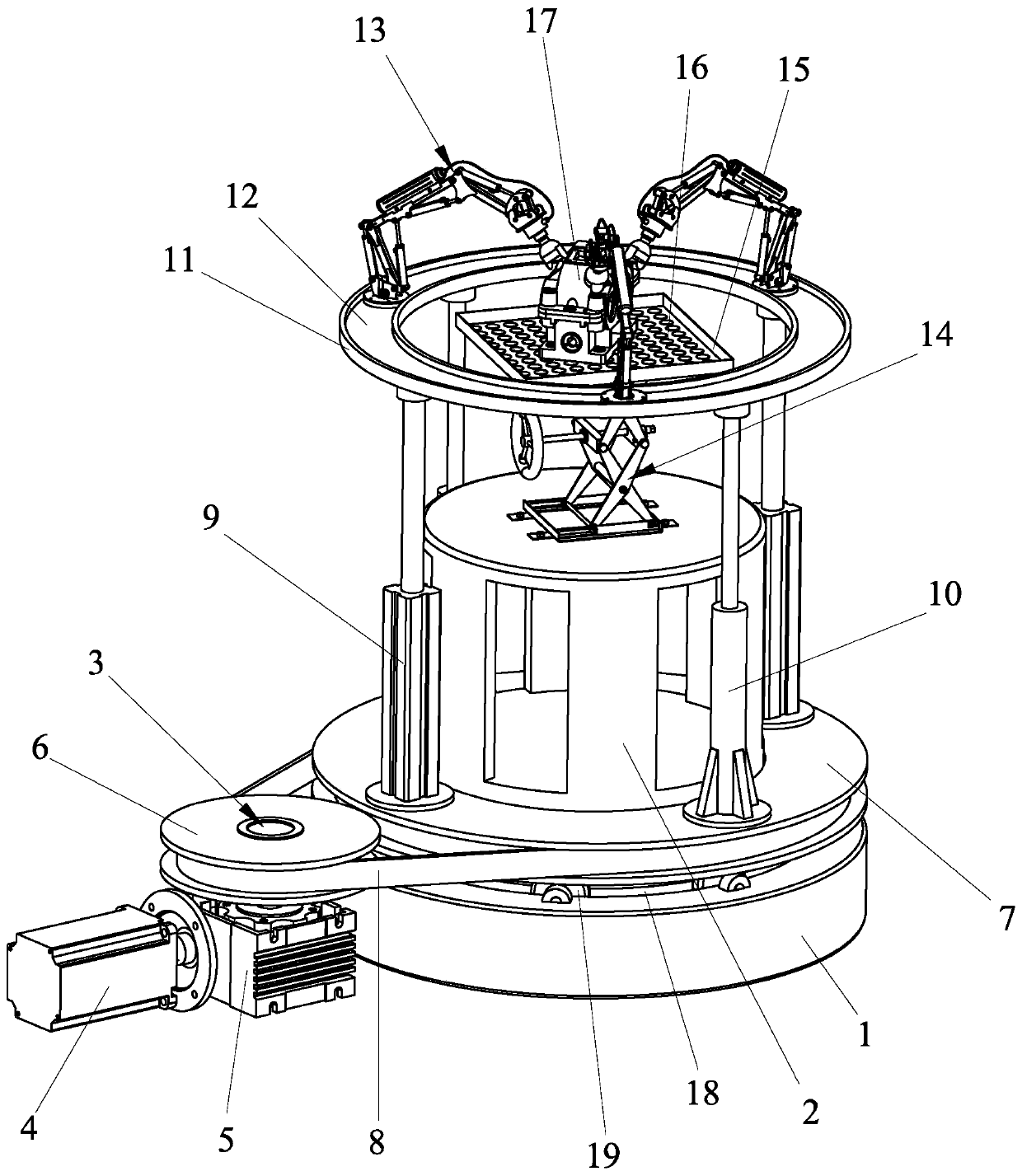

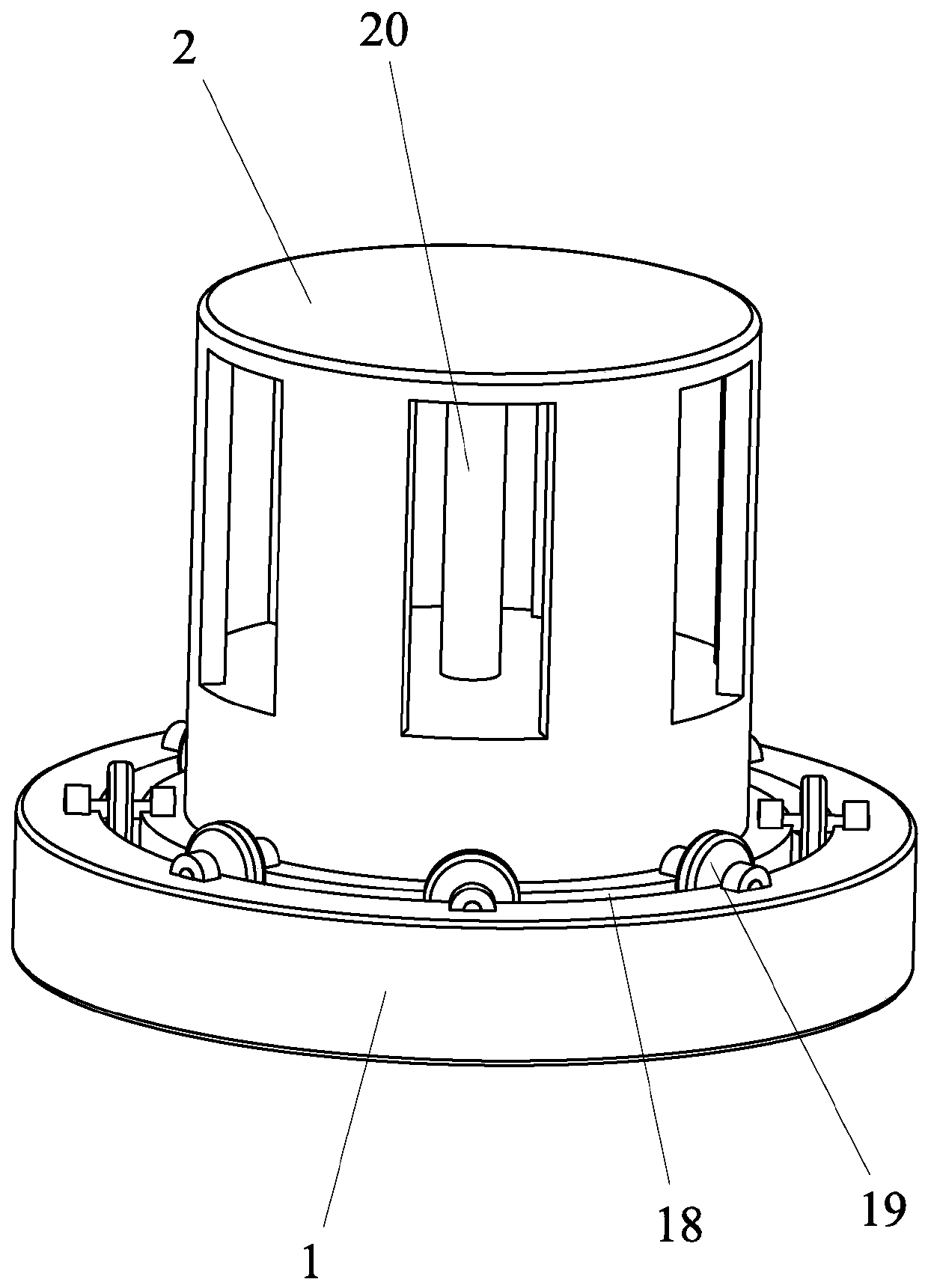

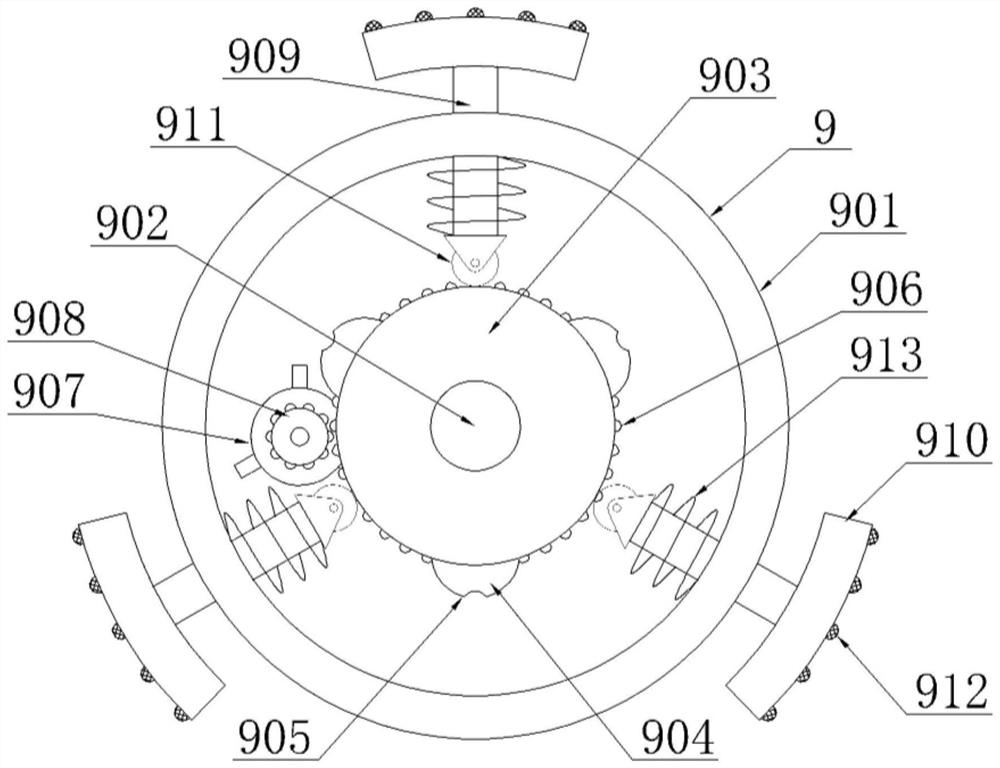

Paint spraying device for submerged speed reducer

InactiveCN110538745AImprove corrosion resistanceAchieve sprayingSpraying apparatusManipulatorReducerManipulator

The invention discloses a paint spraying device for a submerged speed reducer. The paint spraying device comprises a base, wherein a fixing table and a rotating lifting device are arranged on the base; an operating platform used for allowing the submerged speed reducer to be placed thereon is arranged on the fixing table; a plurality of paint spraying manipulators acting on the submerged speed reducer are arranged on the rotating lifting device, and the rotating lifting device drives the paint spraying manipulators to perform spiral ascending or spiral descending; and each paint spraying manipulator comprises a bottom plate, wherein a pneumatic connecting rod mechanism is arranged on the bottom plate, a paint spraying pressure tank is fixed on the pneumatic connecting rod mechanism, a spray head is connected to the tail end of the pneumatic connecting rod mechanism, a nozzle is arranged at the front end of the spray head, an electromagnetic valve is arranged on the side wall of the spray head, the input end of the electromagnetic valve is connected with the paint spraying pressure tank through a guide pipe, and the output end of the electromagnetic valve communicates with the nozzle through a flow passage inside the spray head. The paint spraying device can achieve rapid paint spraying on the surface of the submerged speed reducer, has the advantages of being high in efficiencyand low in labor cost, and has high paint spraying quality, thereby greatly improving the corrosion resistance of the submerged speed reducer surface.

Owner:WENZHOU POLYTECHNIC

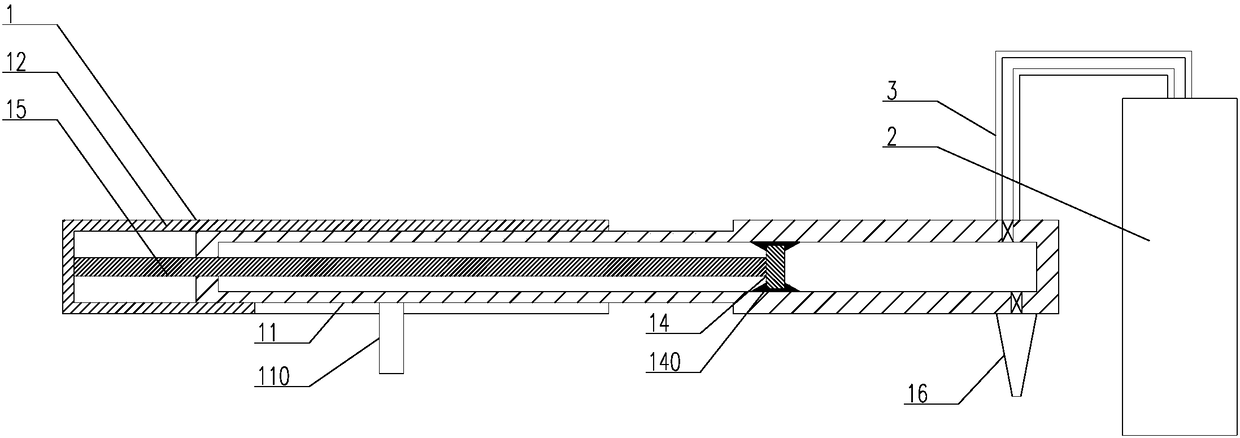

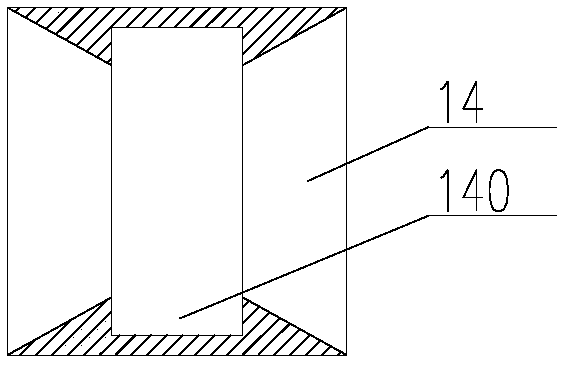

Round pipeline paint sprayer with quick drying function for round hollow pipe

ActiveCN112756167AAvoid drippingQuick paintPretreated surfacesCoatingsStructural engineeringManufacturing engineering

The invention discloses a round pipeline paint sprayer with a quick drying function for round hollow pipe in the technical field of pipe paint sprayers. The round pipeline paint sprayer comprises a case, wherein pipe fitting locking assemblies are mounted at the opposite ends of two rotating rods, and the outer walls of the two pipe fitting locking assemblies are sleeved with a pipeline; a paint sprayer for rapidly drying a paint layer is arranged in a sliding groove in a sliding mode, a pump body is started to suck external air into an air drying pipeline through an air inlet nozzle, air blocks in the air drying pipeline can slow down the air circulation speed, the air in the air drying pipeline is fully heated, then hot air is sprayed out through nozzles, and rapid paint spraying and drying operation of the pipeline is realized; and meanwhile, a rotating motor drives a swing arm to rotate, at the moment, a swing rod drives a sliding block to slide left and right on a sliding rod, a transmission rack drives an arc-shaped rack and a circular air pipe to rotate, the air sprayed out of the nozzles is evenly sprayed to the pipeline and is matched with the pipeline rotating in the reverse direction, and the paint layer on the outer wall of the pipeline is uniformly air-dried.

Owner:辽宁联通管业有限公司

Supporting frame paint spaying device

The invention discloses a supporting frame paint spaying device comprising a supporting mounting plate. Supporting mounting columns are vertically and upwards arranged at the four corners of the upperend of the supporting mounting plate, partition plates are connected between the supporting mounting columns on the front side as well as the between the supporting mounting columns on the rear side,and a supporting mounting frame is horizontally arranged at the upper ends of the supporting mounting columns. Rotating partitioning structures comprise rotating mounting cylinders arranged at the left end and the right end of the supporting mounting frame, matched with the supporting mounting columns on the front side and the right side and coaxially embedded through rotary shafts, rotating partitioning plates are arranged at the lower ends of rotating mounting cylinders and matched with the supporting mounting columns on the front side and the rear side, the front sides of the rotating mounting cylinders are coaxially provided with transmission belt wheels through the rotary shafts extending out of the supporting mounting frames, and driving motors are symmetrically arranged at the leftend and the right end of the supporting mounting frame. The supporting frame paint spaying device has the advantages that the structural design is compact, paint spraying atomization is rapid and sufficient, the partitioning operation protection effect is good, environmental friendliness is achieved, and paint spraying is even, and the quality is high.

Owner:长沙双合盛企业管理有限公司

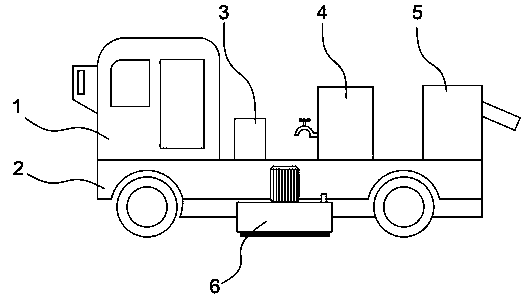

Mobile floor brushing device

ActiveCN108999061AReduce operating labor intensityEvenly distributedRoads maintainenceMobile vehicleBrush device

The invention provides a mobile floor brushing apparatus which comprises a vehicle body, a bottom plate mounted on the bottom of the vehicle body, and brushers respectively mounted on both sides of the bottom plate, wherein the brushers comprise a brushing box provided with a stirring chamber inside, a feed pipe connected to the brushing box, a brush passing through the bottom surface of the brushing box, a stirring body arranged in the stirring chamber, and the stirring body is connected with a rotating shaft of a motor installed on the outside of the brushing box. The device of the inventiondrives the brusher to brush on the ground by using the moving vehicle body, has high brushing flexibility, effectively reduces the labor intensity of personnel, and has high brushing uniformity and brushing quality.

Owner:来安县好士特化工有限公司

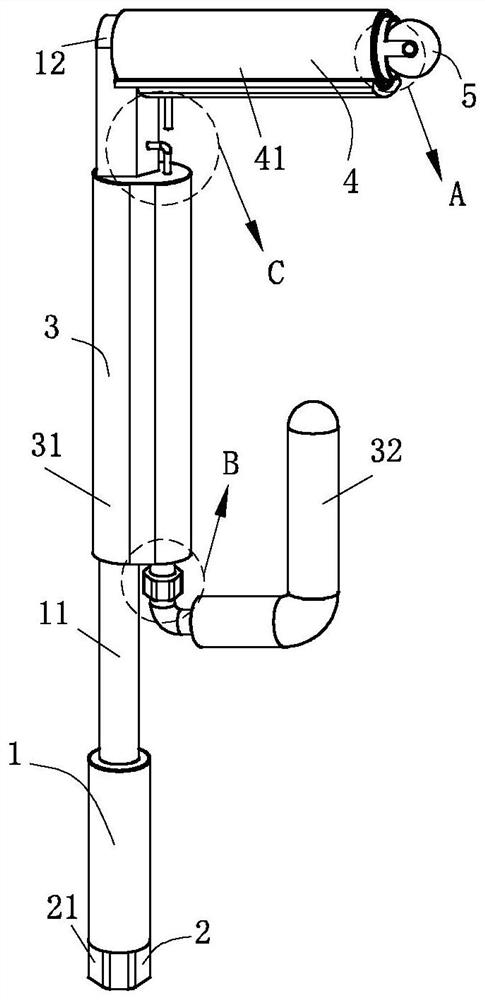

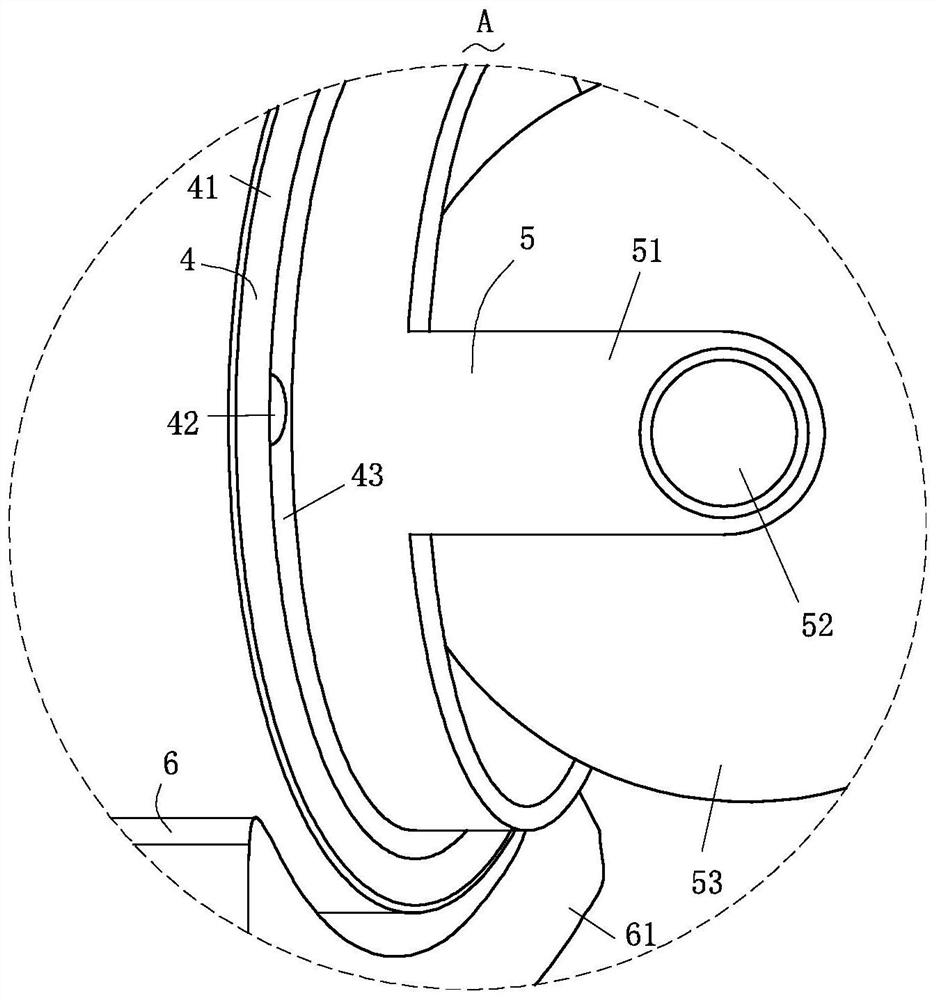

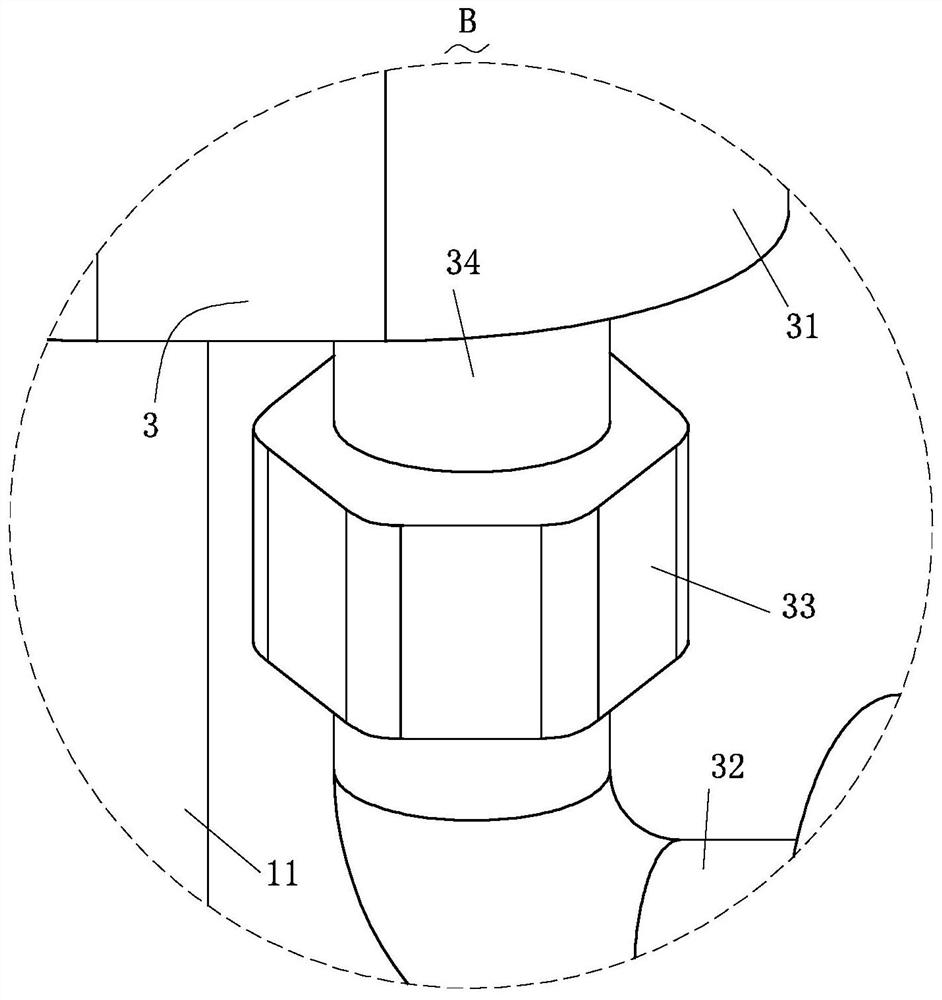

Wall painting device

The invention discloses a wall painting device, and relates to the field of decoration tools. The wall painting device is delicate in structure, easy to operate, and good in sealing effect. The wall painting device comprises a handrailing, a roller and a connecting assembly, and the roller is connected to one side of the handrailing through the connecting assembly and is perpendicular to the handrailing. The handrailing includes an inner rod body, an outer sleeve body, a piston, a sealing pad, a connecting rod and a suction nozzle, wherein the inner rod body is hollow, and a connecting assembly is connected with one end of the inner rod body; the end, away form the connecting assembly, of the inner rod body is sleeved with the outer sleeve body; and the piston is slidably connected into the inner rod body, and the sealing pad is arranged between the piston and the inner rod body. When the wall painting device is used, an operator can first put the suction nozzle into a paint barrel andpull the outer sleeve body outwards, so that paint is drawn into the inner rod body, then the outer sleeve body is extruded while the outer sleeve body is repeatedly swung in the same direction on awall surface, and the automatic ejection of the paint and rapid painting of the wall surface can be realized.

Owner:顾东海

Paint coating tool convenient to work at wall corner

InactiveCN112196228AQuick paintImprove painting efficiencyBuilding constructionsStructural engineeringBrush device

The invention relates to the field of paint brushing devices, and particularly relates to a paint coating tool convenient to work at a wall corner. The paint coating tool comprises a supporting structure, a driving structure, a storage structure, a first smearing structure, a second smearing structure and a spraying structure, wherein the first smearing structure used for smearing the wall surfaceis arranged at the top end of the supporting structure used for supporting and taking an integral assembly; the spraying structure used for spraying paint coating to the first smearing structure is arranged on the supporting structure; the second smearing structure used for smearing the wall corner is slidably connected into the first smearing structure; and the supporting structure can be held by hand conveniently, the right angle of the wall corner is directly and quickly smeared with the paint through the second smearing structure sliding out of the first smearing structure, then the painton the wall corner is integrally formed, the situation that the paint smeared on the wall corner generates irregular lines and even protruding blocks is effectively prevented, then the wall surfaceson the two sides of the wall corner are smeared with the paint coating through cooperation of the first smearing structure, and thus the wall corner brushing efficiency and quality are greatly improved.

Owner:按钮科技(杭州)有限公司

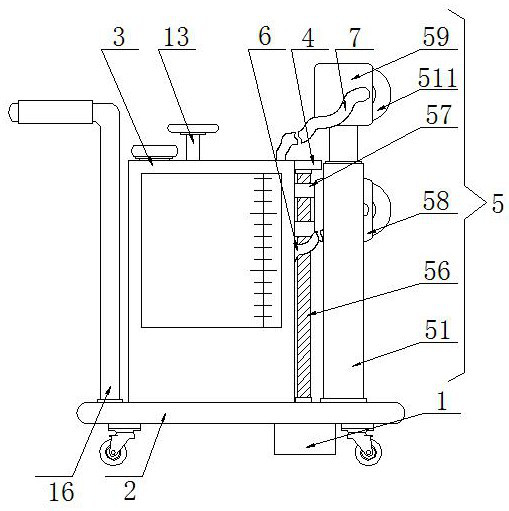

Tree trunk smearing device for park maintenance

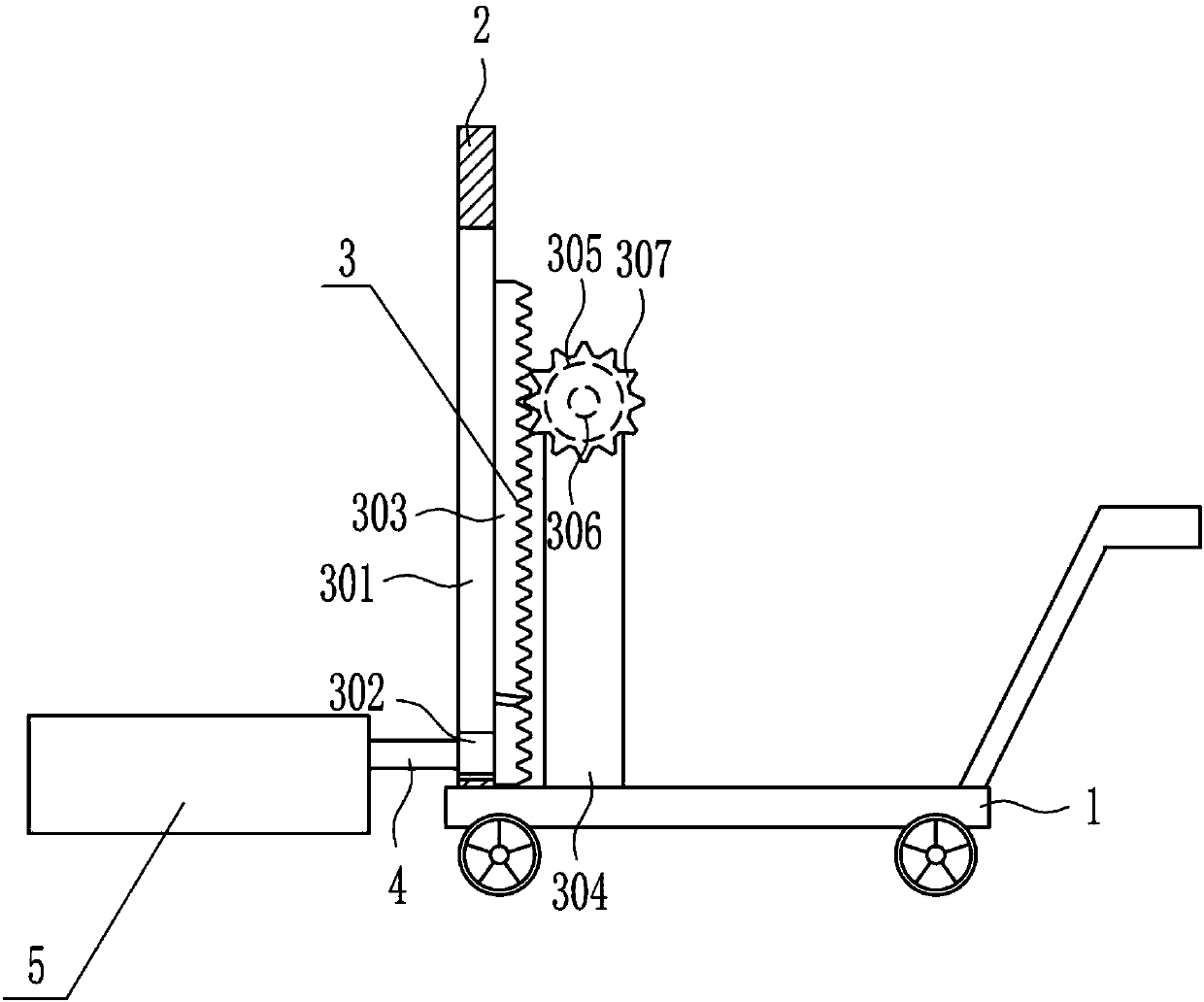

InactiveCN111672694AEasy to moveEasy to operateLiquid surface applicatorsTransportation and packagingTree trunkGear wheel

The invention relates to the technical field of park maintenance, and discloses a tree trunk smearing device for park maintenance. The device comprises a bottom plate, a fixing frame fixedly connectedto one side of the bottom of the bottom plate and a liquid storage tank fixedly connected to one side of the top of the bottom plate. The top of one side of the liquid storage tank is fixedly connected with a fixing plate, and the other side of the top of the bottom plate is provided with a driving assembly; and the driving assembly comprises an electric push rod and a motor, wherein the bottom end of the electric push rod is fixedly connected with the other side of the top of the bottom plate, and one end of the output end of the motor is fixedly connected with a first gear through a coupler. According to the tree trunk smearing device for park maintenance, the smearing device can quickly smear the to-be-smeared part of a tree trunk, slurry leaks out through smearing rollers, slurry is saved, the slurry can be prevented from being easily sprayed to other parts, the top and the bottom of the surface of the tree trunk can be uniformly smeared through the arrangement of the two smearingrollers respectively, manual smearing operation is not needed, and the smearing efficiency of the tree trunk is improved.

Owner:韵敏

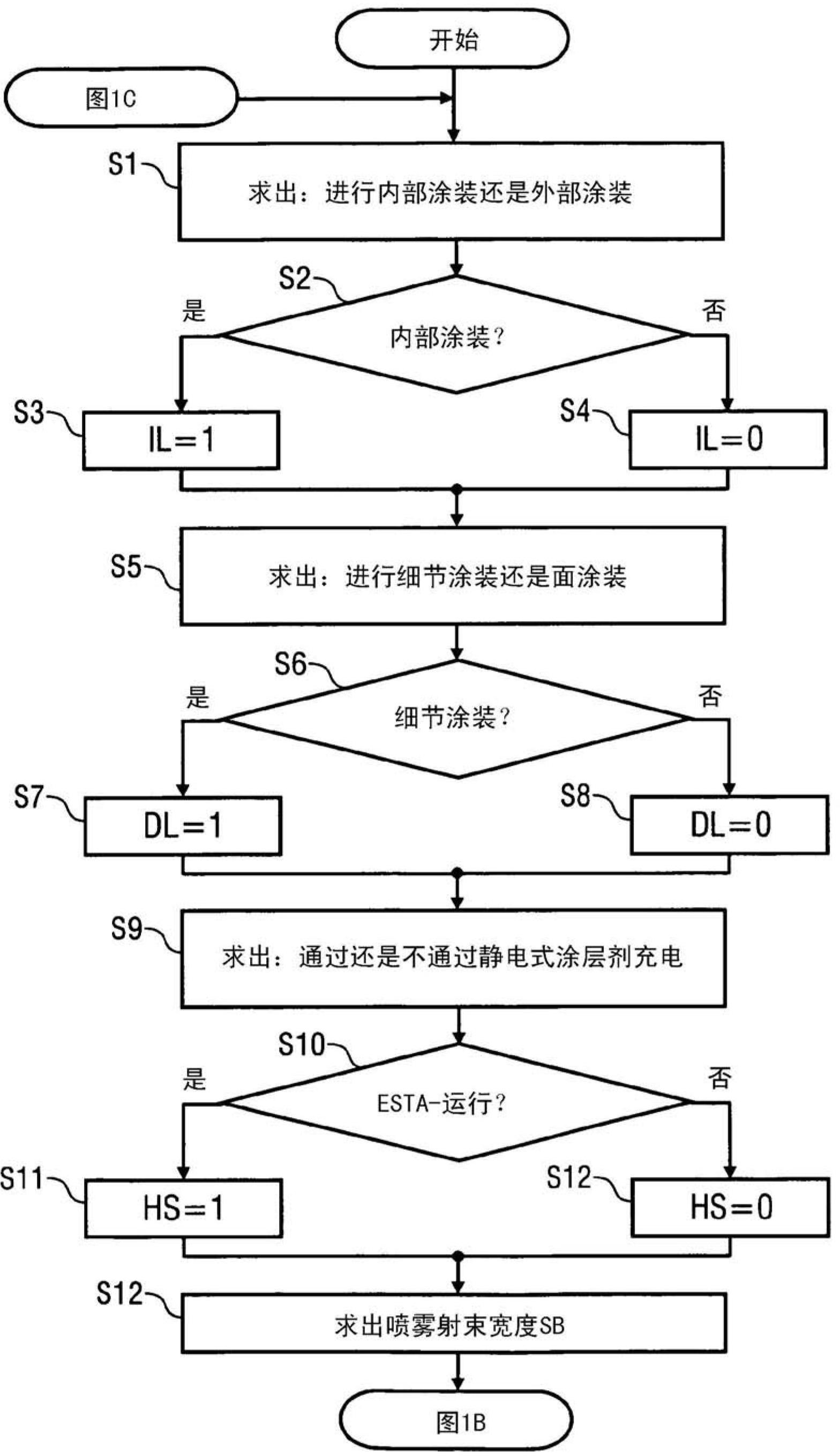

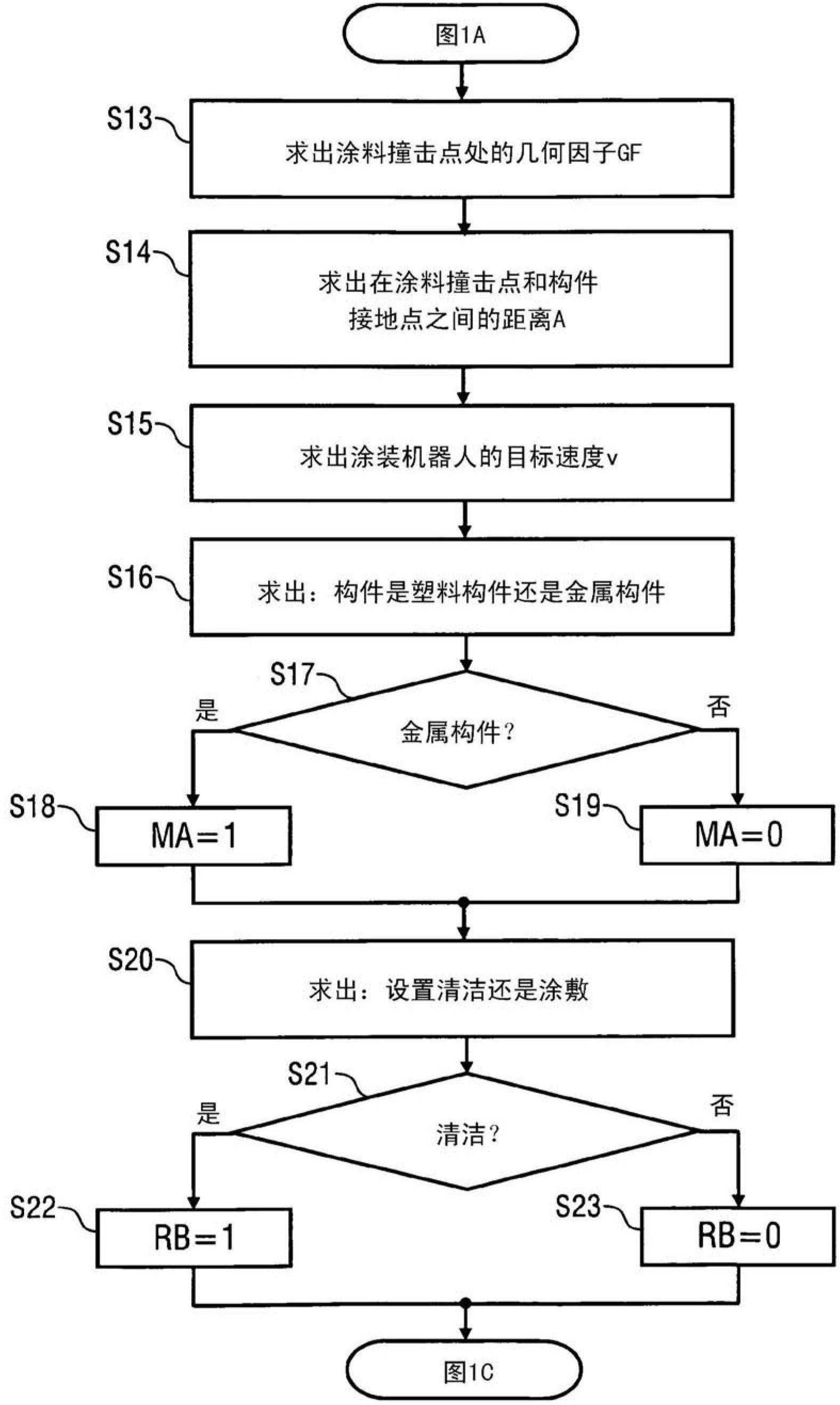

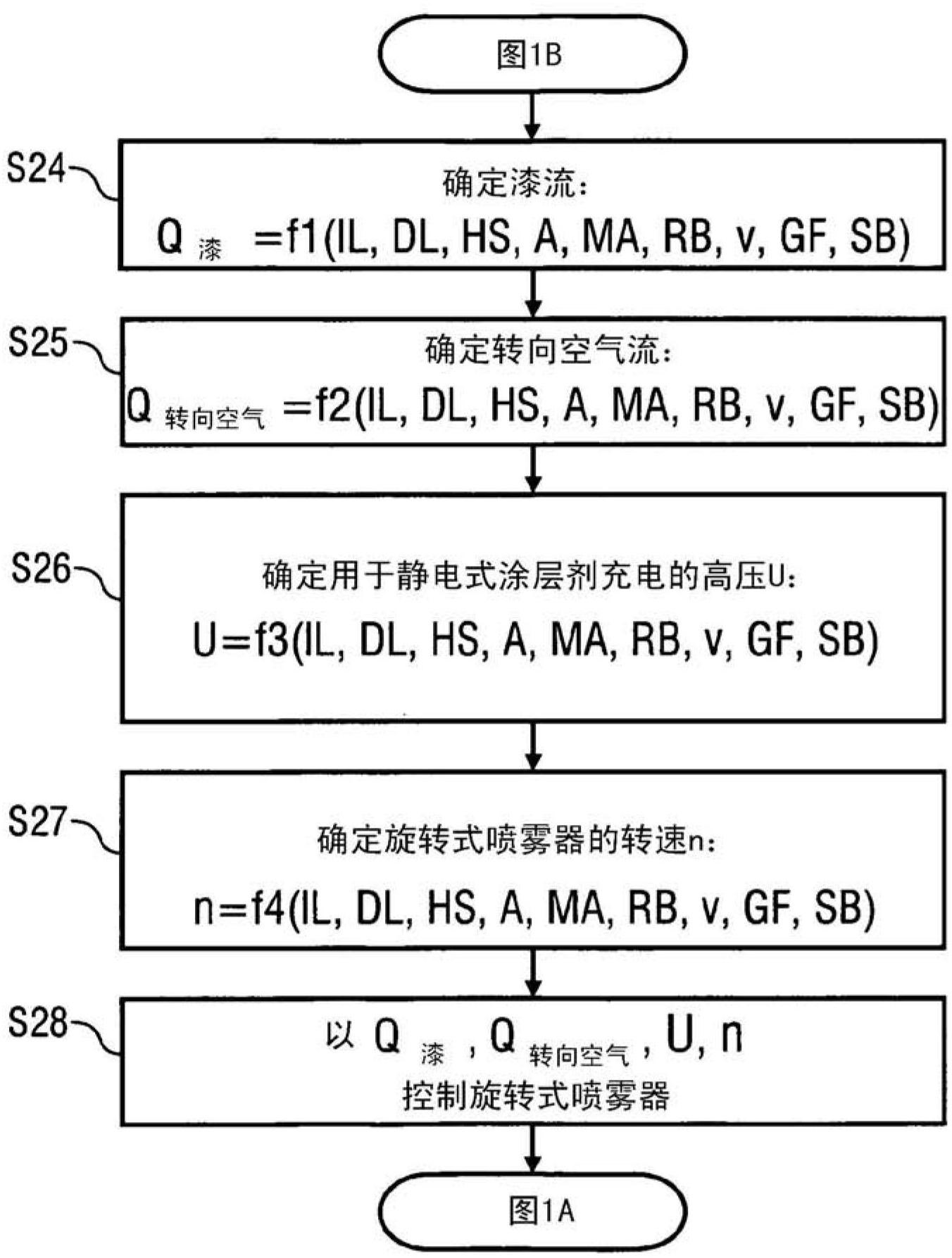

Coating method and coating system having dynamic adaptation of the atomizer rotational speed and the high voltage

ActiveCN102596422ALow costImprove dynamic performanceLiquid spraying plantsLiquid surface applicatorsElectricityLacquer

Owner:DUERR SYST GMBH

Balance shaft support spraying device

ActiveCN108654874AAchieve sprayingAvoid enteringPretreated surfacesLiquid spraying apparatusEngineeringPiston

The invention relates to the technical field of spraying, in particular to a balance shaft support spraying device which comprises a support, a fixed block, a first rolling vehicle, a second rolling vehicle and a spraying barrel. A motor is fixed to the fixed block, a gear is fixed to an output shaft of the motor, a first rack and a second rack are engaged to the gear, push rods are fixed to the ends of the first rolling vehicle and the second rolling vehicle, a cavity is formed in the support, a piston is in sliding connection with the interior of the cavity, the piston is fixed to the push rods, an electric heating wire is arranged in the cavity, an air blowing pipe communicates with the cavity, a rotary table is in threaded connection with the interior of the spraying barrel, a positioning barrel is fixed to the upper surface of the rotary table, a fixed rod is in sliding connection with the interior of the positioning barrel, the upper end of the fixed rod is fixed to the gear, anelastic sealing layer is arranged below the rotary table, the side wall of the spraying barrel is provided with a spraying hole, and a piston column is in sliding connection with the interior of the spraying barrel. By means of the scheme, the problems that anti-rust paint is likely to be sprayed into a shaft hole, and the anti-rust paint on the surface of the balance shaft support cannot be immediately dried after spraying of the anti-rust paint are solved.

Owner:重庆市铭鼎机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com