Balance shaft support spraying device

A technology of balance shaft support and spraying device, which is applied in the direction of spraying device, liquid spraying device, and device for coating liquid on the surface, etc., which can solve the problems of easy spraying of anti-rust paint into the shaft hole and inability to dry the anti-rust paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below by means of specific embodiments:

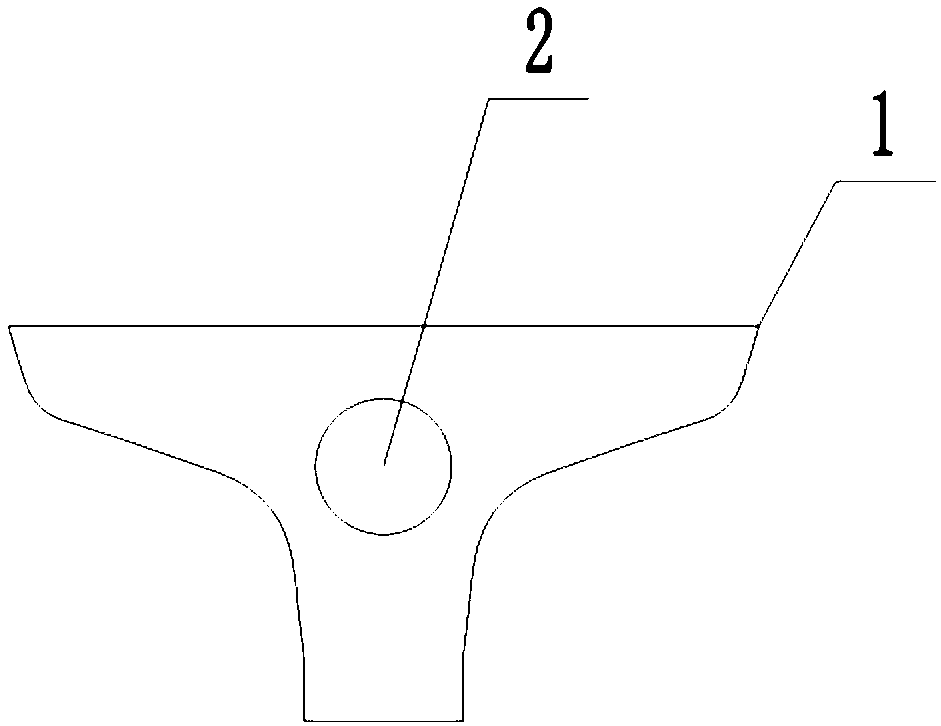

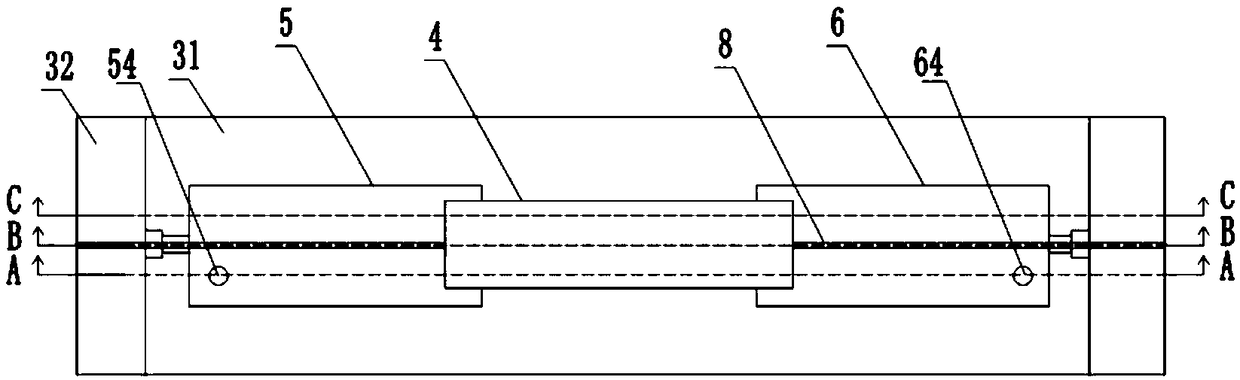

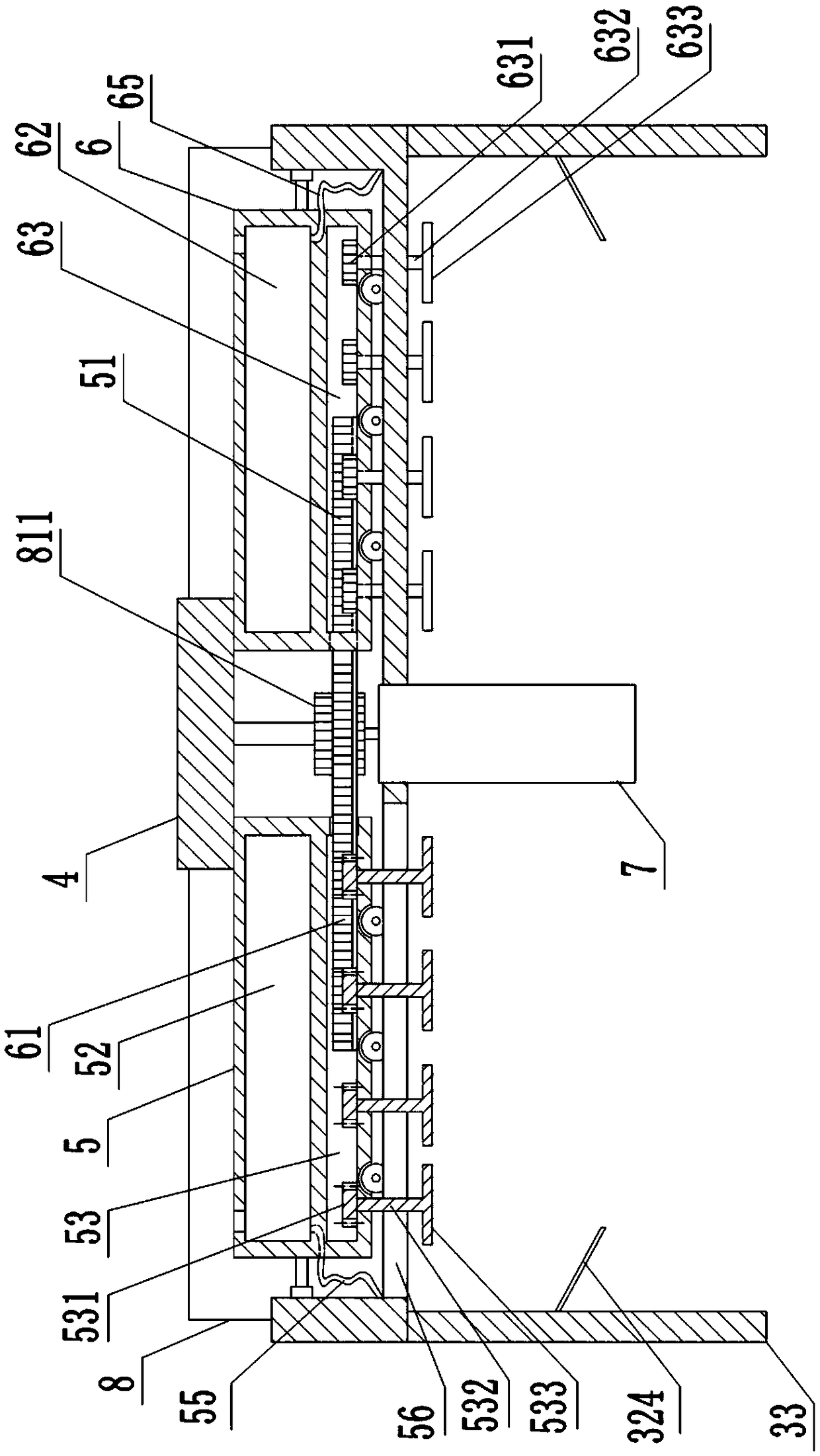

[0034]The reference signs in the drawings of the description include: balance shaft bracket 1, shaft hole 2, bracket 3, support plate 31, side plate 32, cavity 321, piston 322, heating wire 323, air blowing pipe 324, support foot 33, fixing Block 4, the first rolling car 5, the first rack 51, the first material chamber 52, the first power chamber 53, the first driven gear 531, the first rotating shaft 532, the first blade 533, the first feeding port 54, The first connecting pipe 55, the first bar-shaped port 56, the second rolling car 6, the second rack 61, the second material chamber 62, the second power chamber 63, the second driven gear 631, the second rotating shaft 632, the second Two blades 633, the second feeding port 64, the second connecting pipe 65, the second bar-shaped port 66, the spraying cylinder 7, the turntable 71, the boss 711, the threaded section 712, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com