Patents

Literature

258results about How to "Realize sliding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

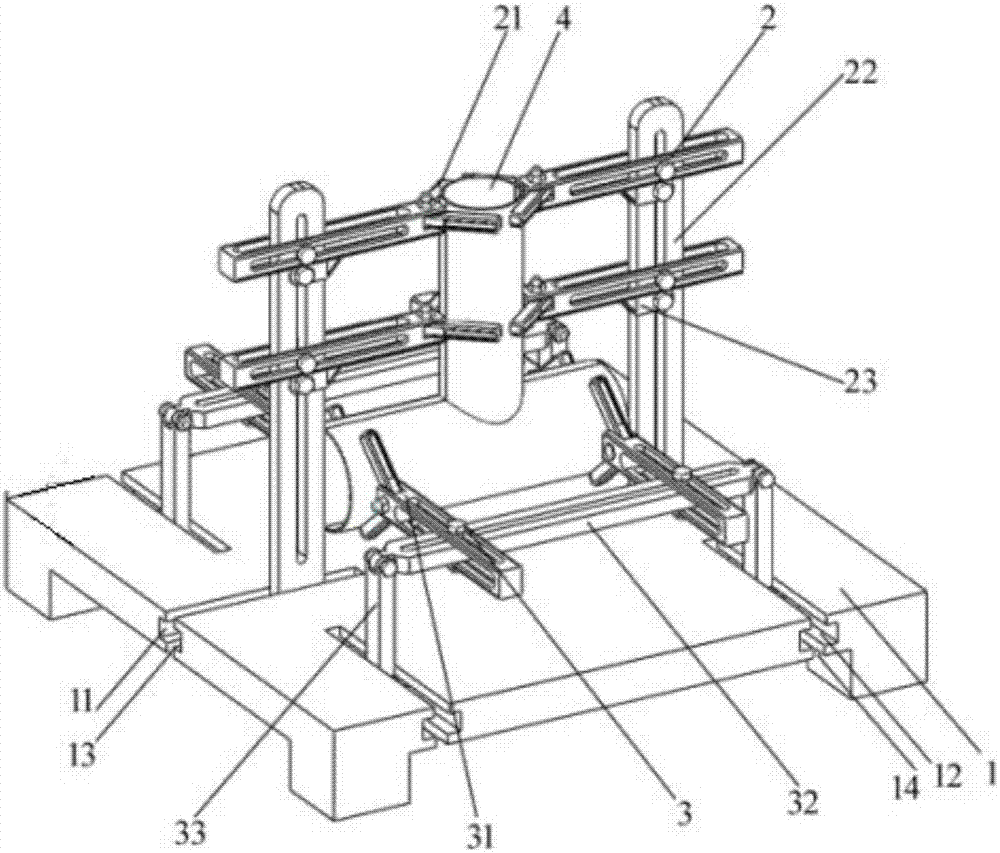

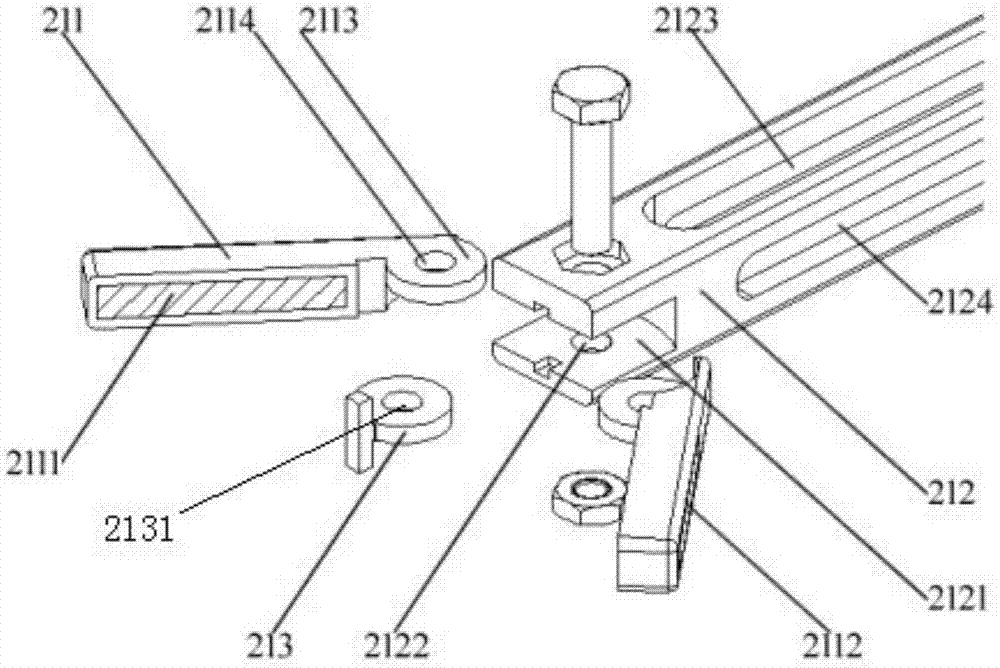

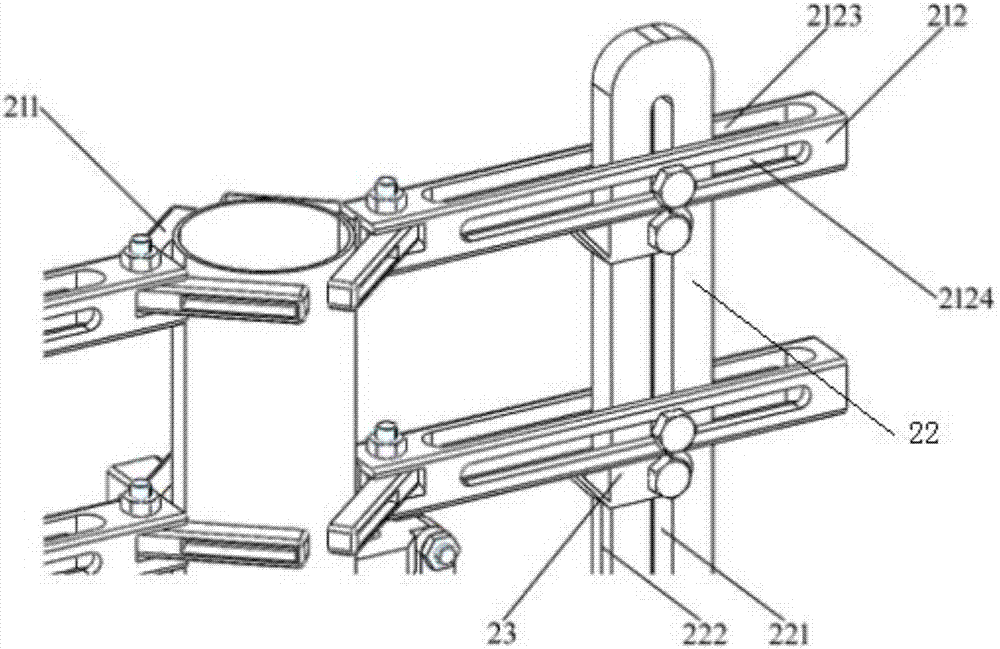

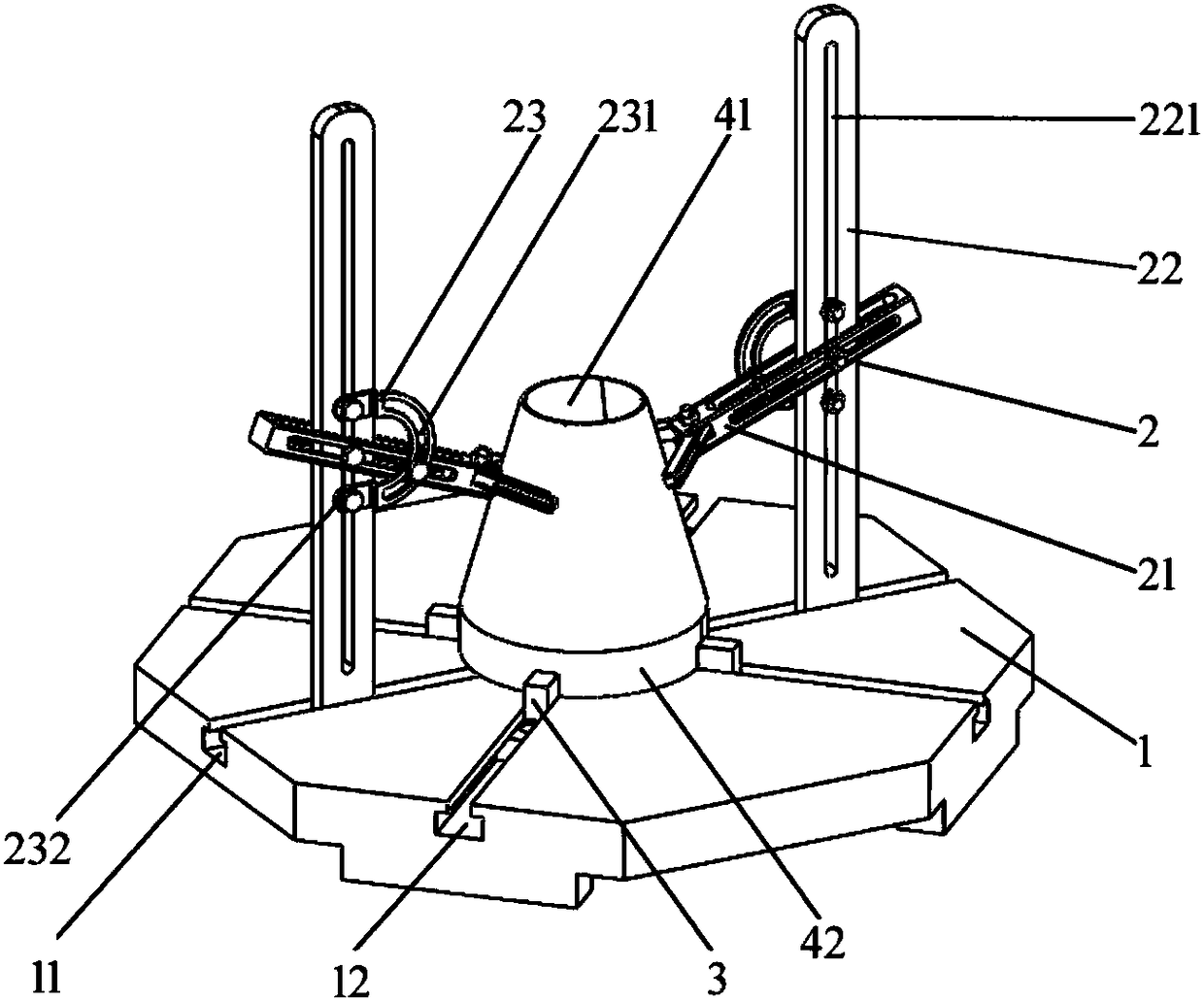

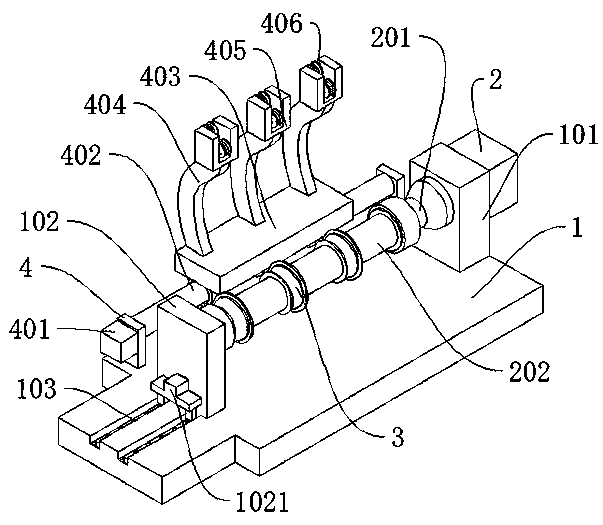

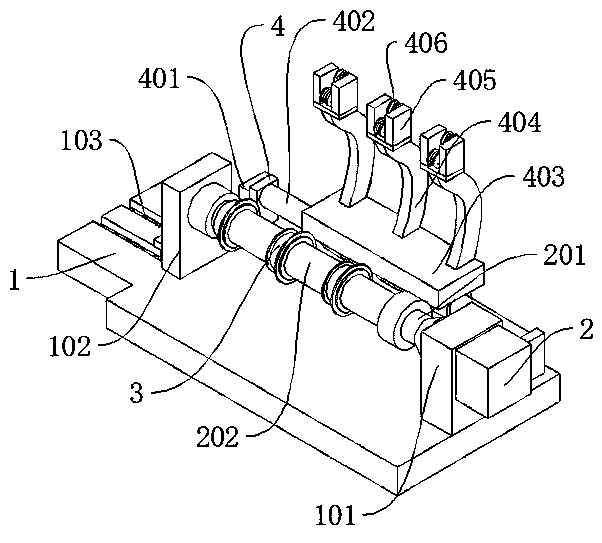

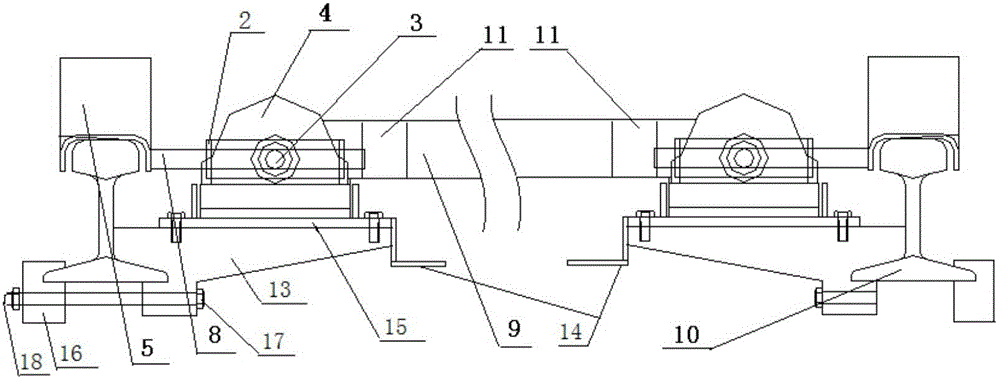

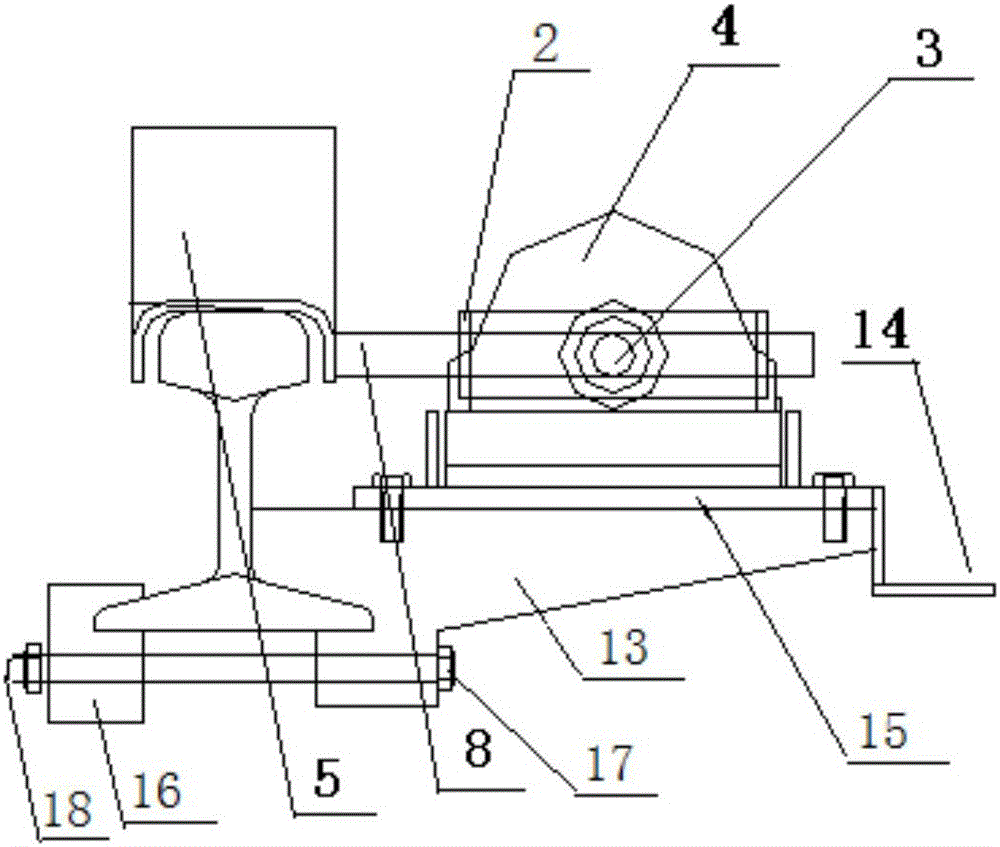

Thin-wall three-way pipe clamping device

PendingCN108000047AImprove stabilityAvoid pinchingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

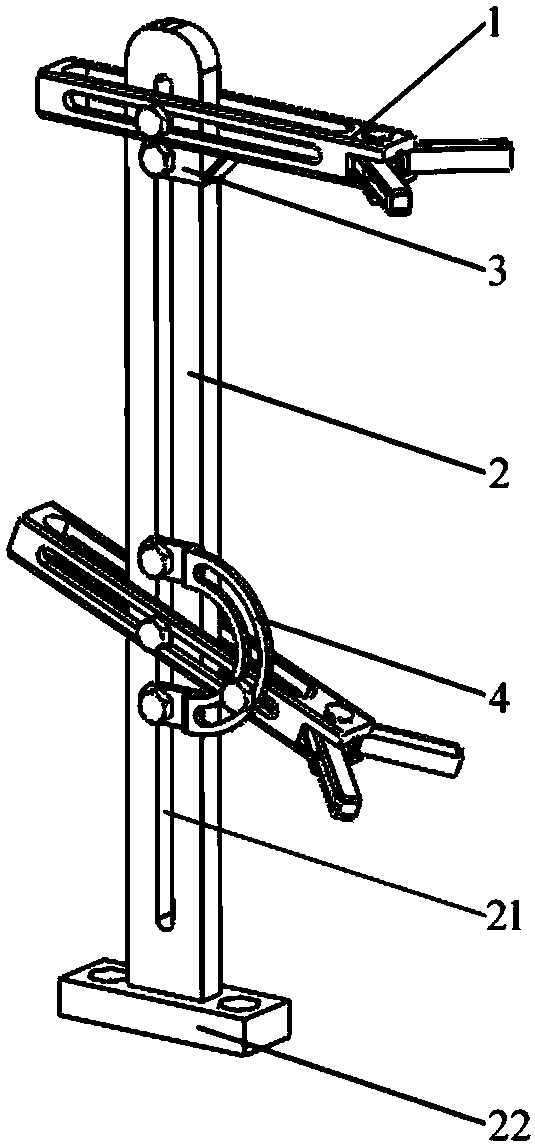

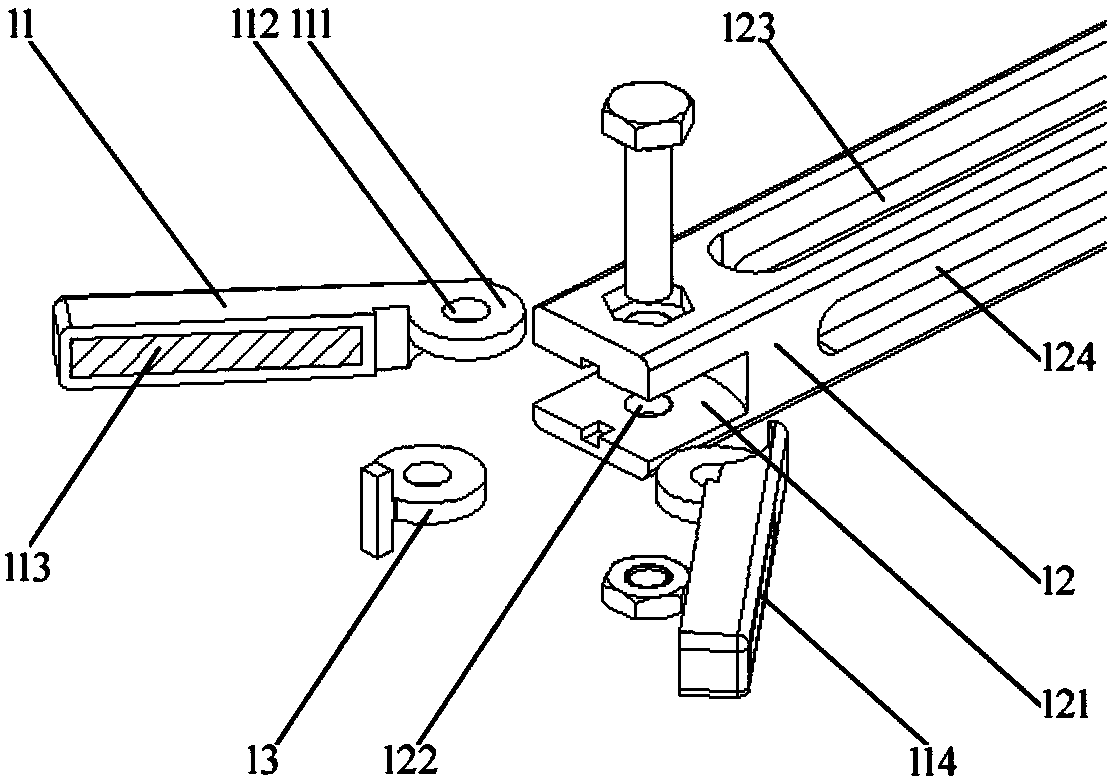

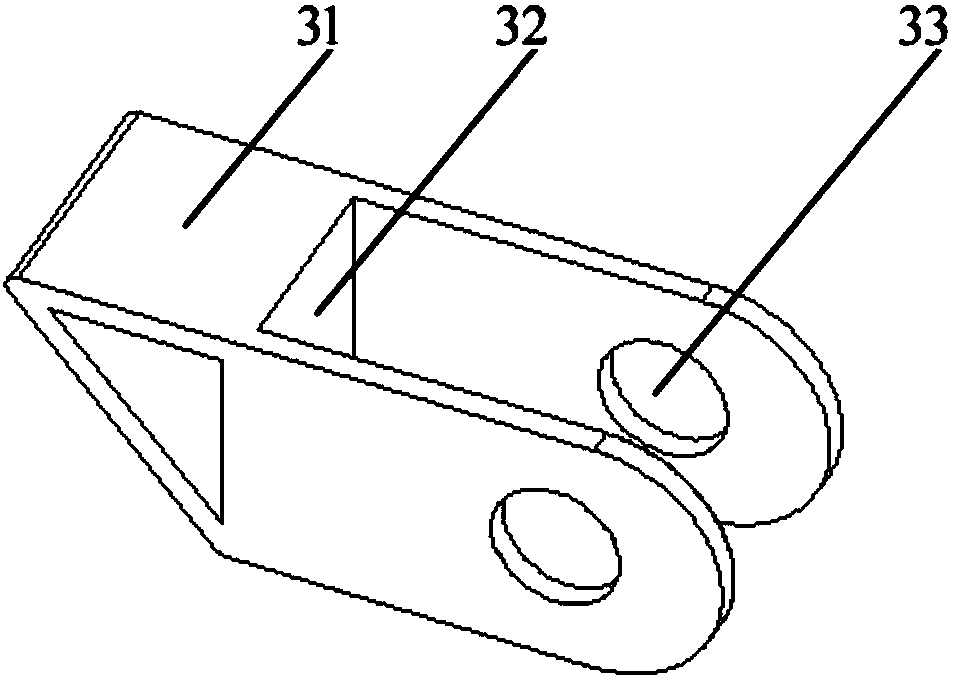

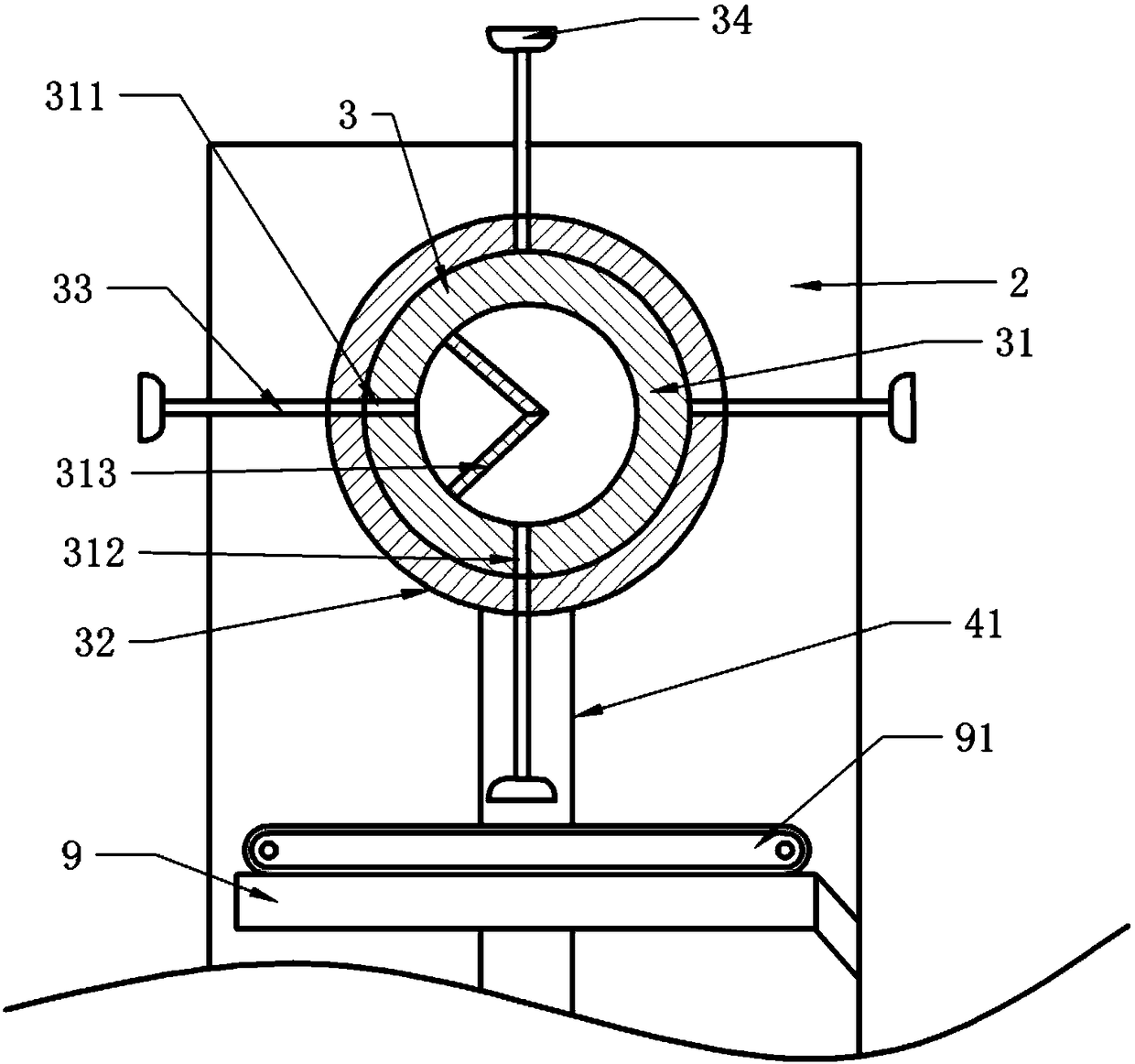

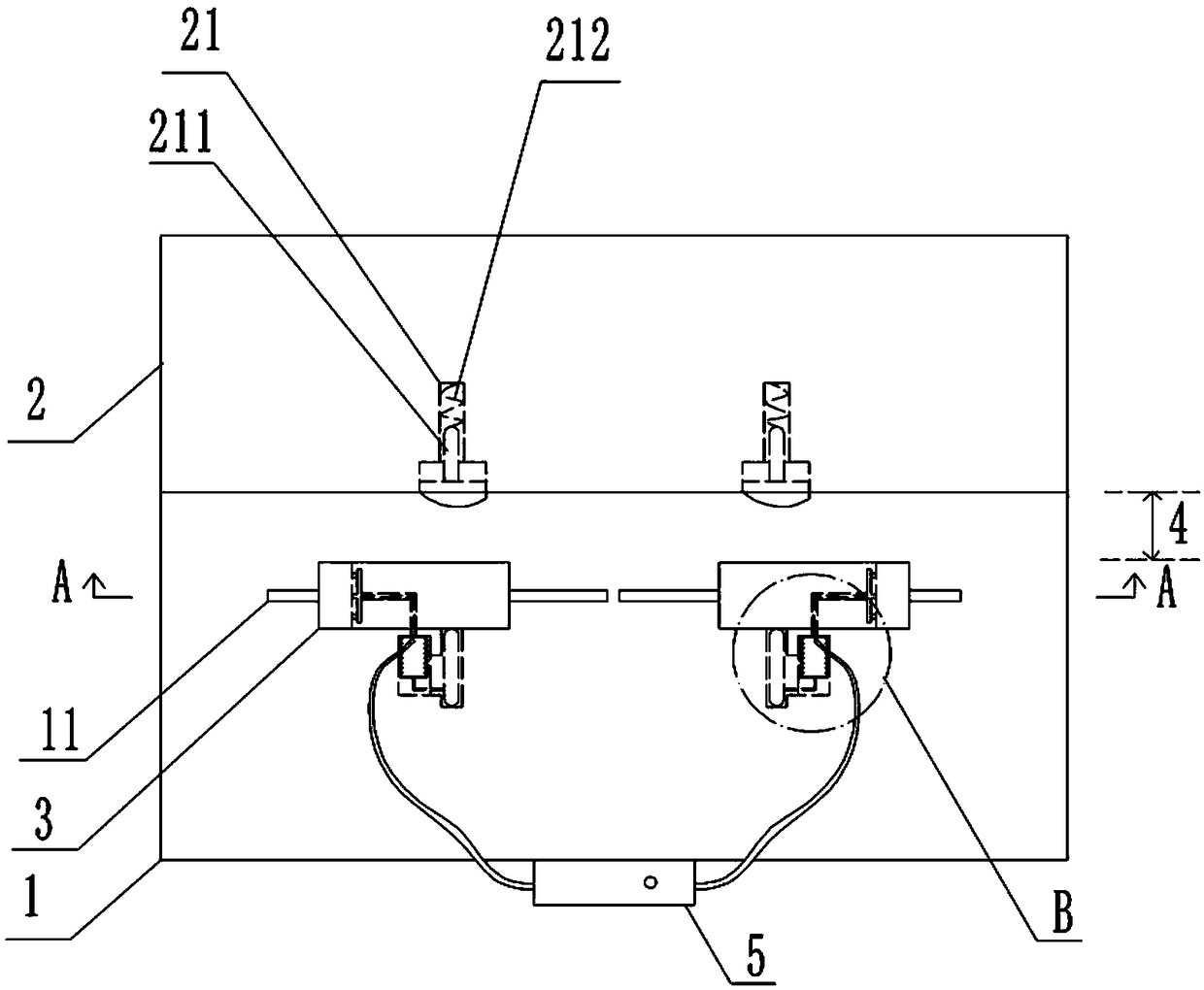

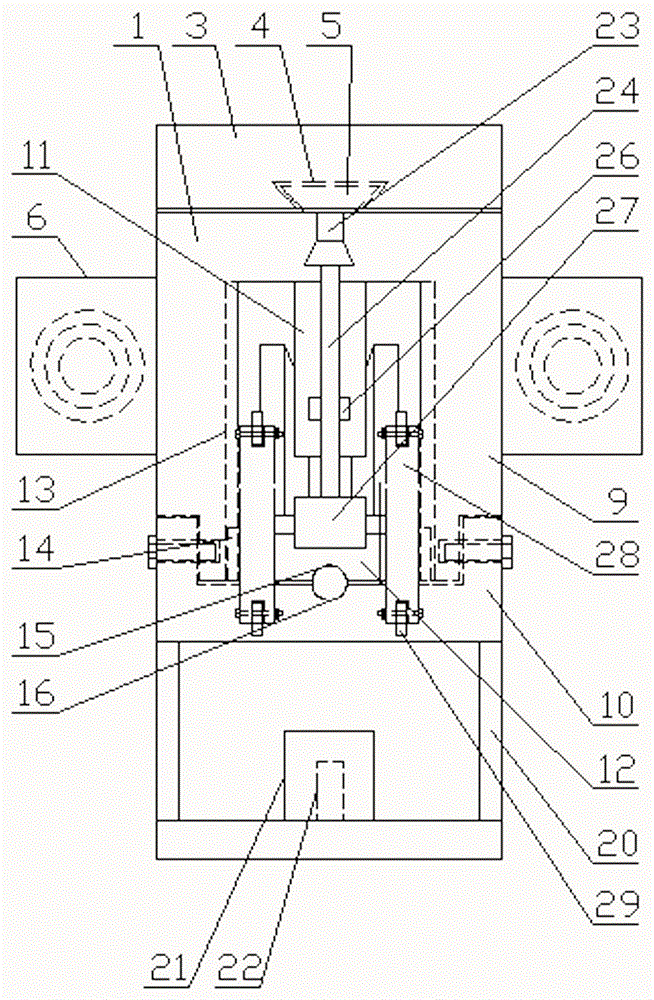

The invention discloses a thin-wall three-way pipe clamping device. The thin-wall three-way pipe clamping device comprises a base plate. A thin-wall three-way pipe vertical segment clamping module anda thin-wall three-way pipe horizontal segment clamping module are mounted on the base plate. The thin-wall three-way pipe vertical segment clamping module comprises vertical sliding rods which are movably mounted on the base plate. Vertical segment V-shaped clamping mechanisms are movably mounted on the vertical sliding rods. A trapezoids support frame for locating is mounted between each vertical sliding rod and each vertical segment V-shaped clamping mechanism. The thin-wall three-way pipe horizontal segment clamping module comprises a horizontal sliding rod support frame which is movably mounted on the base plate. A horizontal sliding rod is mounted on the horizontal sliding rod support frame. Horizontal segment V-shaped clamping mechanisms are movably mounted on the horizontal slidingrod. The thin-wall three-way pipe clamping device has universality and is precise in locating and capable of improving welding precision and operation efficiency.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

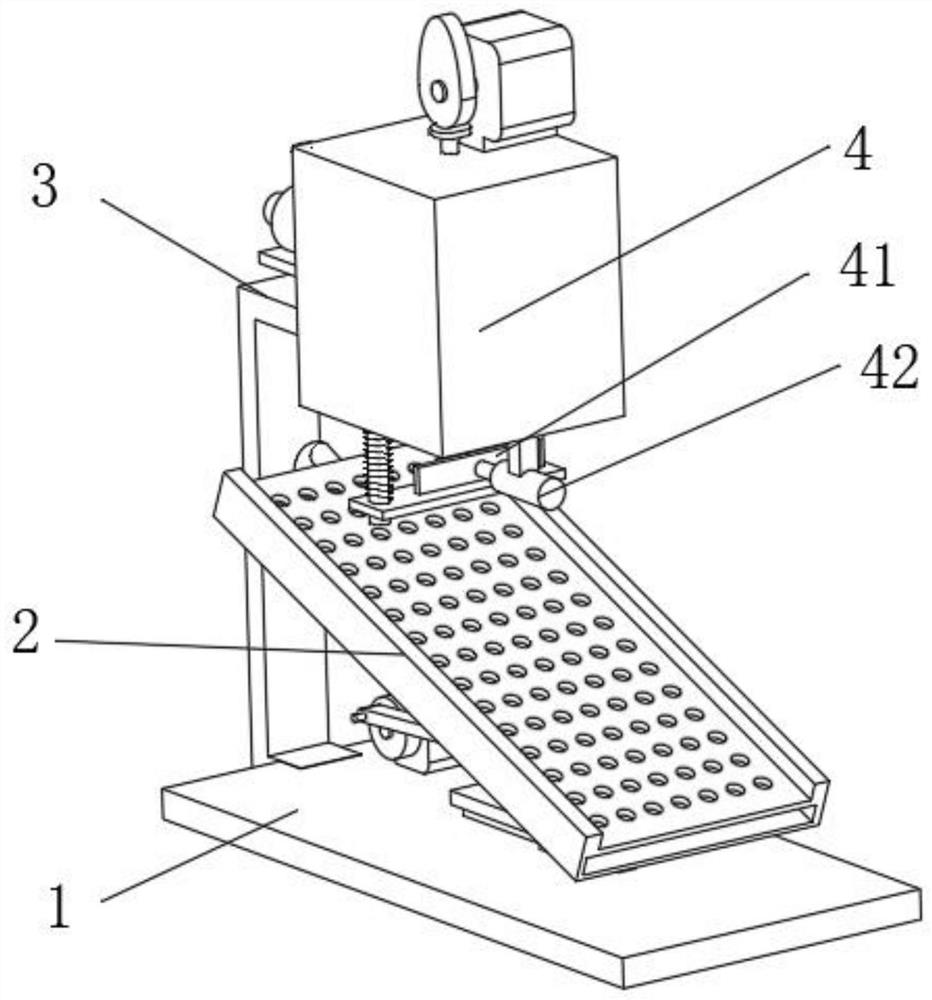

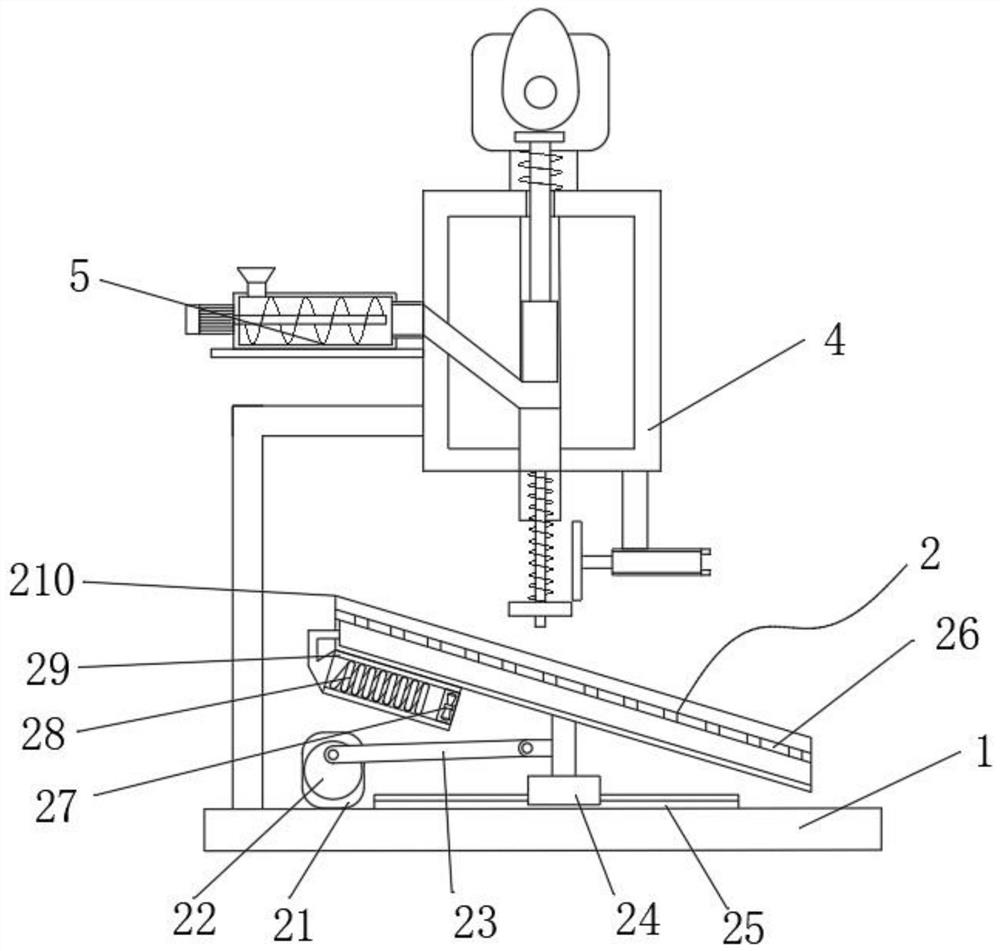

Reshaping device for metal steel processing

ActiveCN111545604ANot easy to moveGuaranteed stabilityMetal-working feeding devicesPositioning devicesElectric machineGear wheel

The invention discloses a reshaping device for metal steel processing. The reshaping device for metal steel processing comprises a workbench. A support is fixedly connected to the workbench. An installation groove is formed in the upper end of the workbench, multiple conveying rollers are connected with the interior of the installation groove in a rotating mode, and a transmission mechanism is arranged among the multiple conveying rollers. A driving motor is installed on the front side of the workbench, a first gear is fixedly connected with the output end of the driving motor, a second gear is installed on the workbench, and the second gear and the first gear mesh with each other. An adjusting mechanism is fixedly connected to the second gear, the adjusting mechanism and the second gear are coaxial, and the adjusting mechanism and the transmission mechanism are connected with each other through a transmission belt. The reshaping device for metal steel processing is reasonable in structure, cutters can be bent into a whole, and therefore the steel plate bending efficiency is greatly improved, the labor workload of a worker is also reduced, steel plates can be subjected to adjustable equal-length cutting operation, the practicability is high, the steel plate bending angle can also be adjusted, and the function is powerful.

Owner:浙江星筑科技有限公司

Bracket mounting device and bracket mounting method

Owner:GUANGZHOU FUYAO GLASS GRP

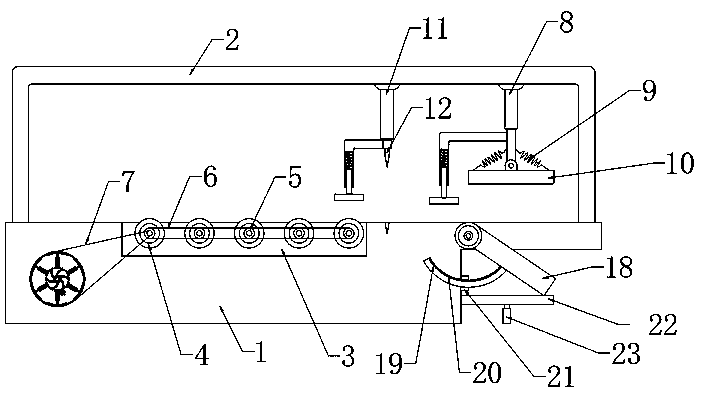

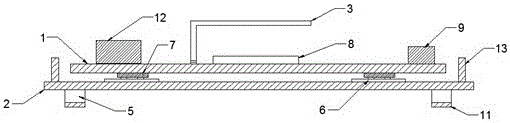

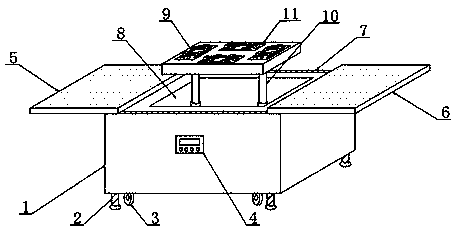

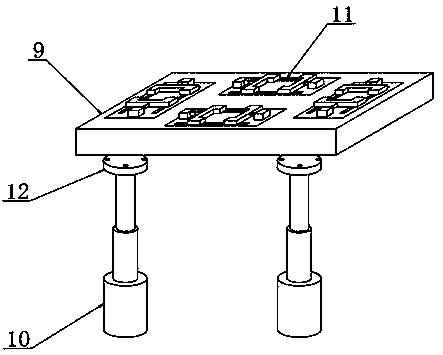

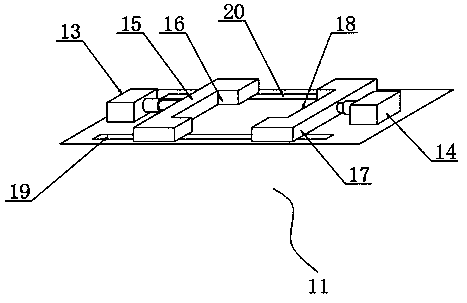

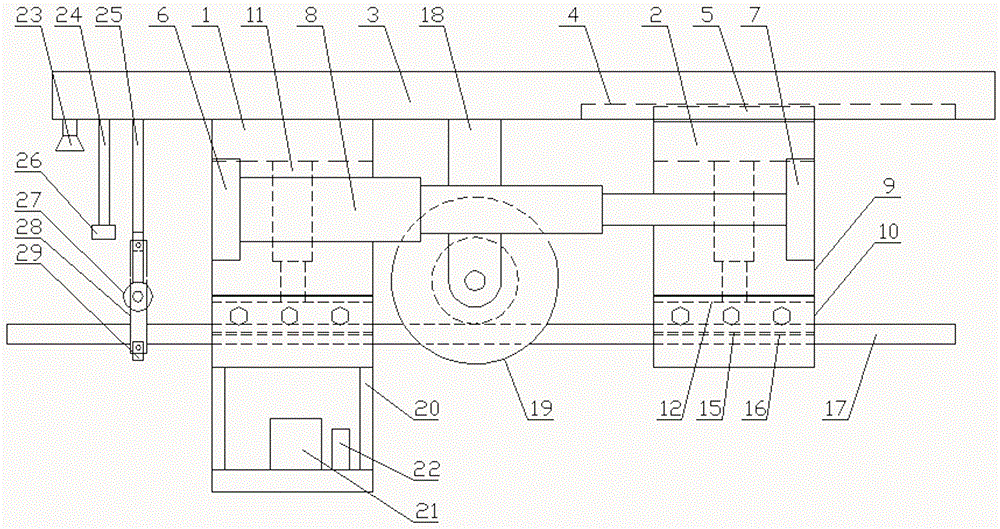

Automobile cutting detection machine for positive plate and negative plate of mobile phone battery

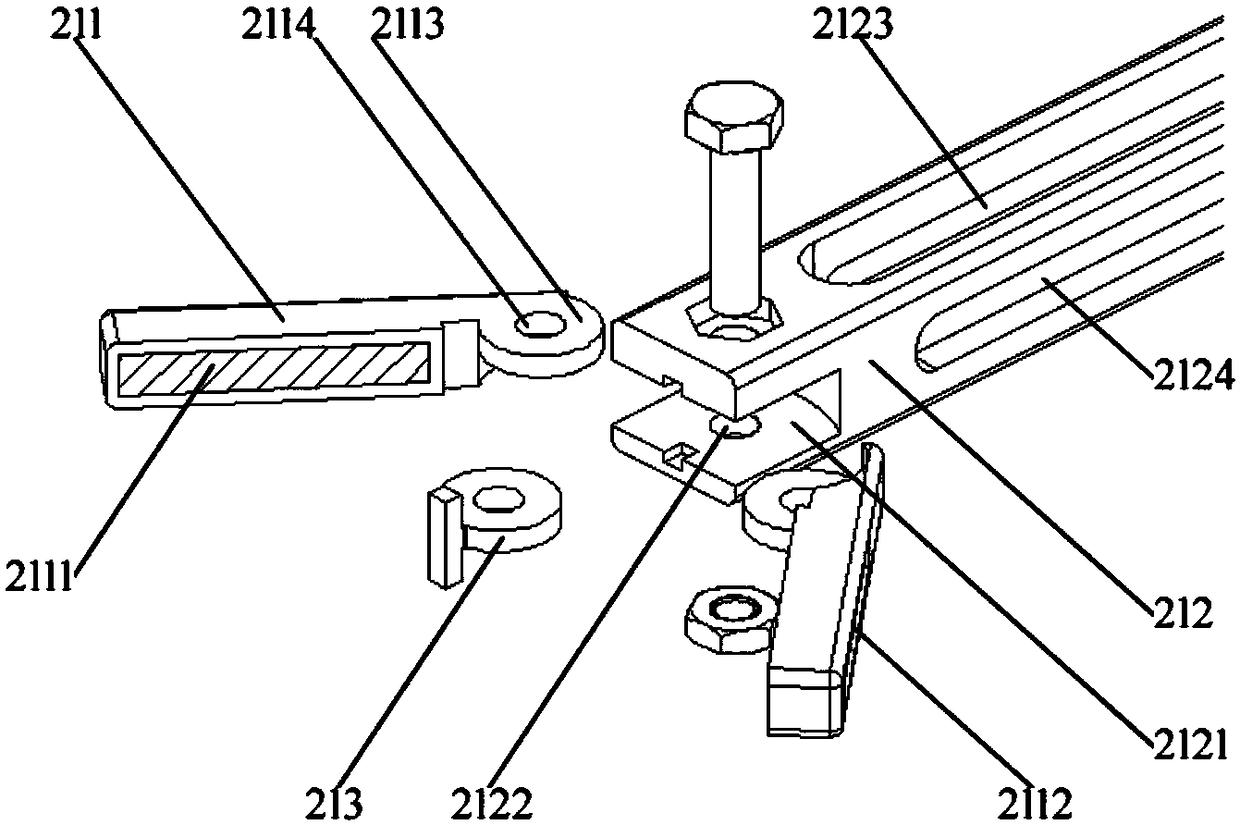

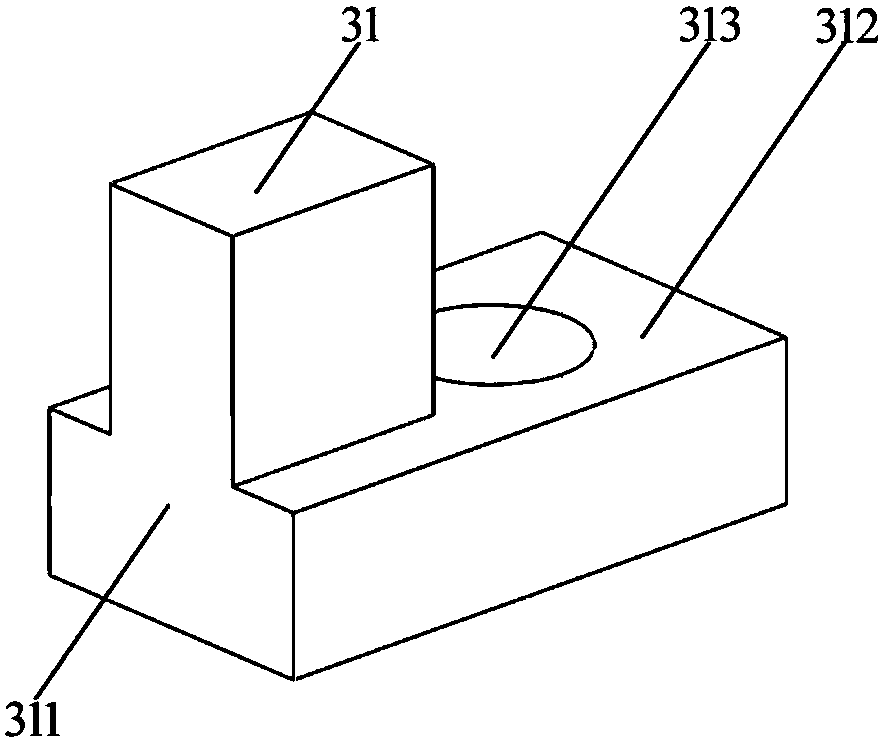

ActiveCN104942594AFully automatedRealize slidingElectrode manufacturing processesLaminationMobile phoneAutomation

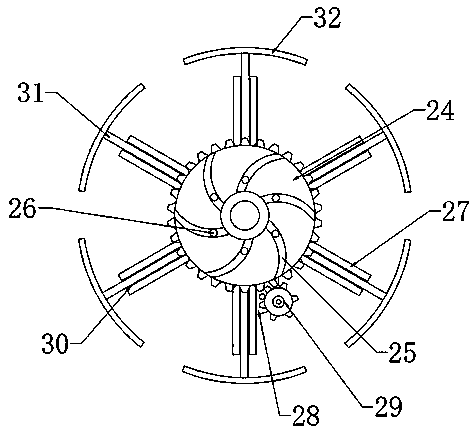

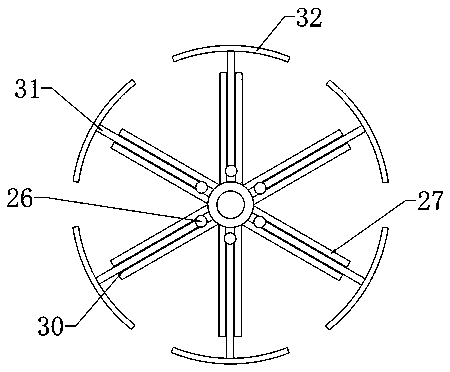

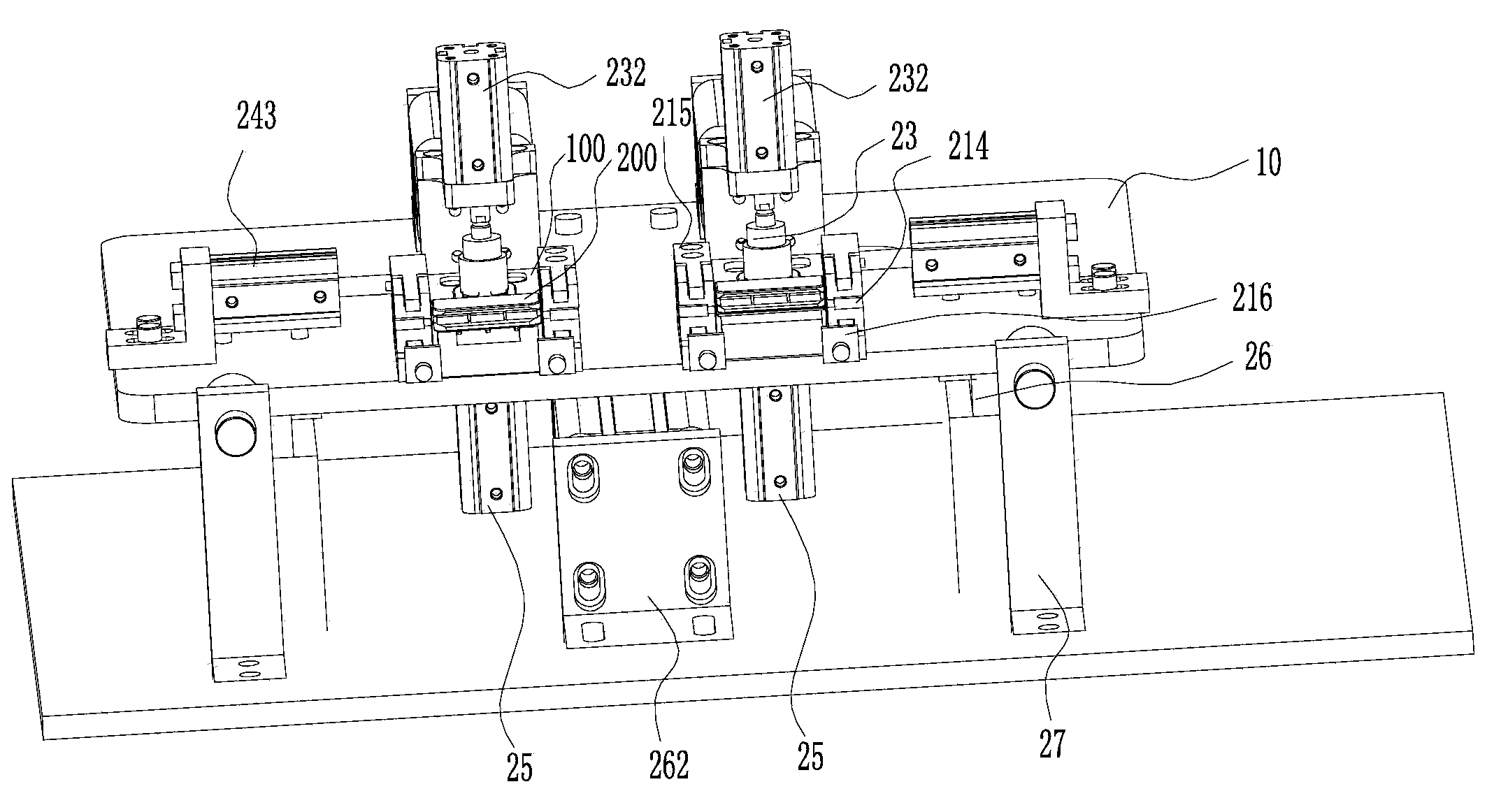

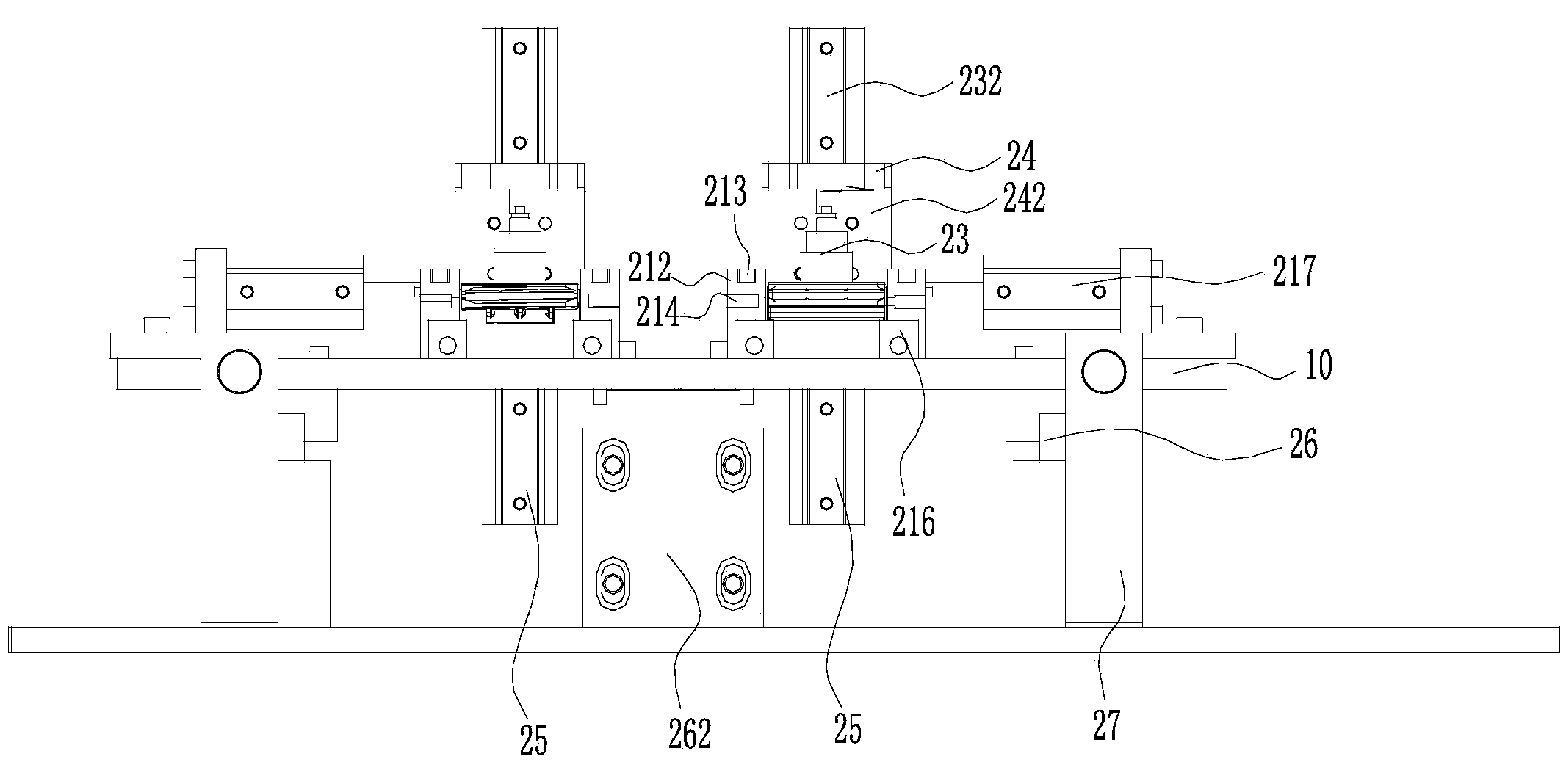

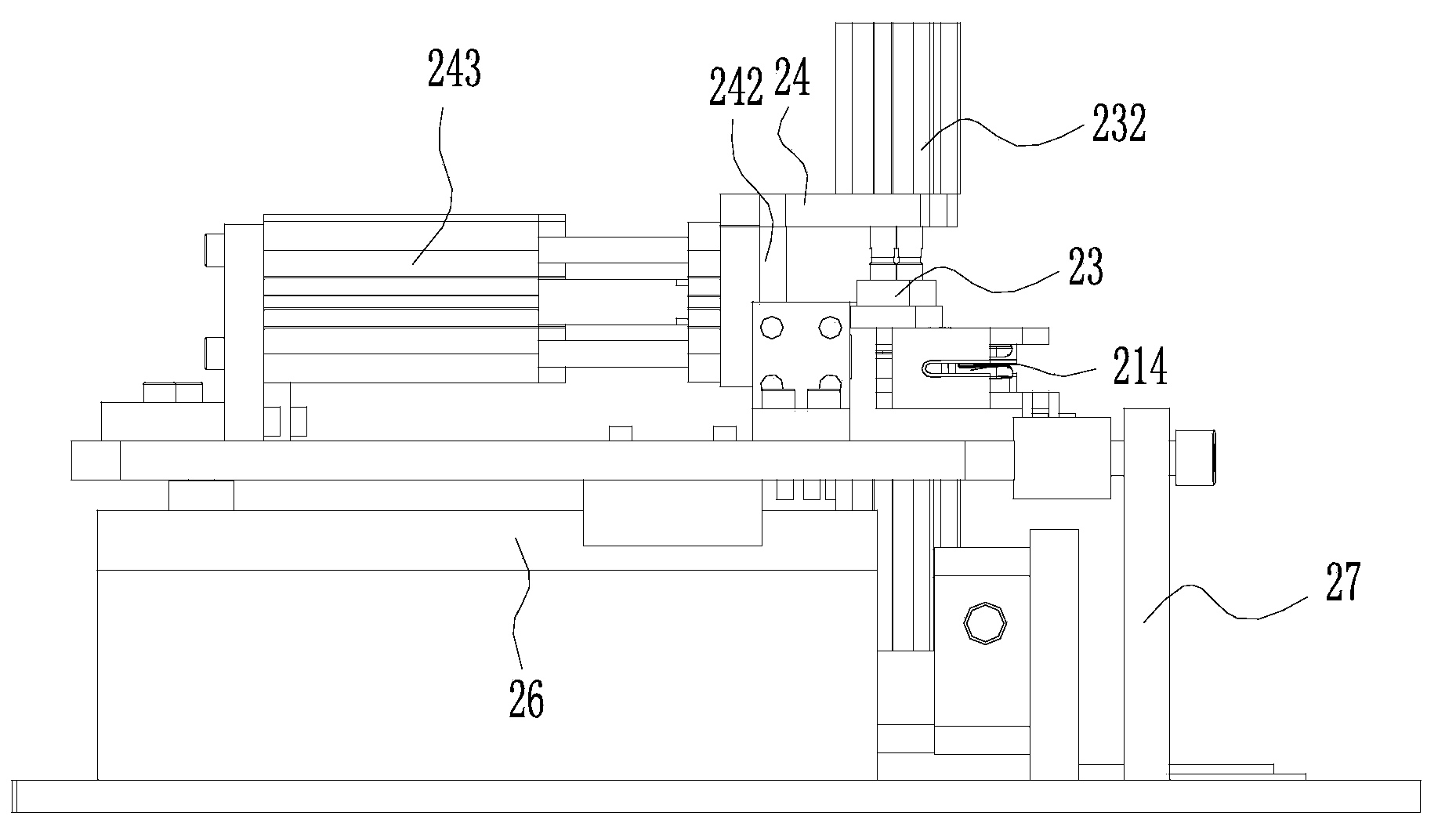

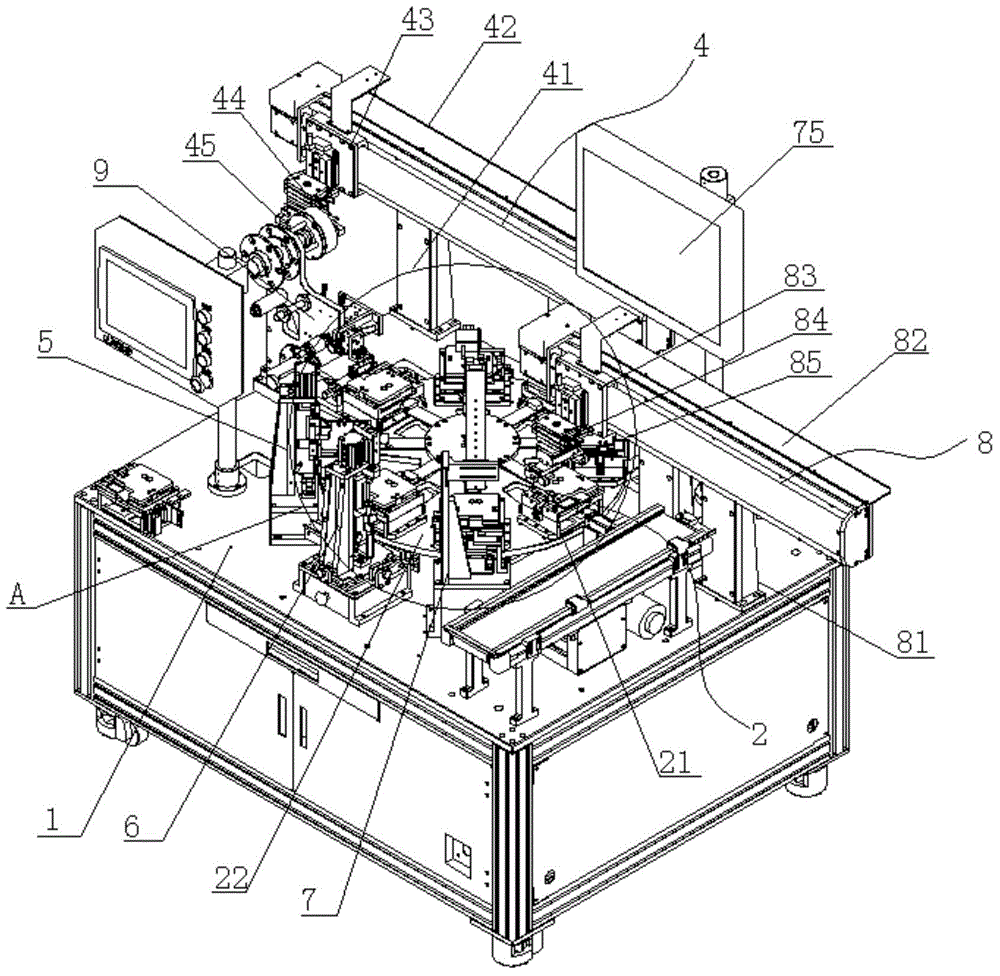

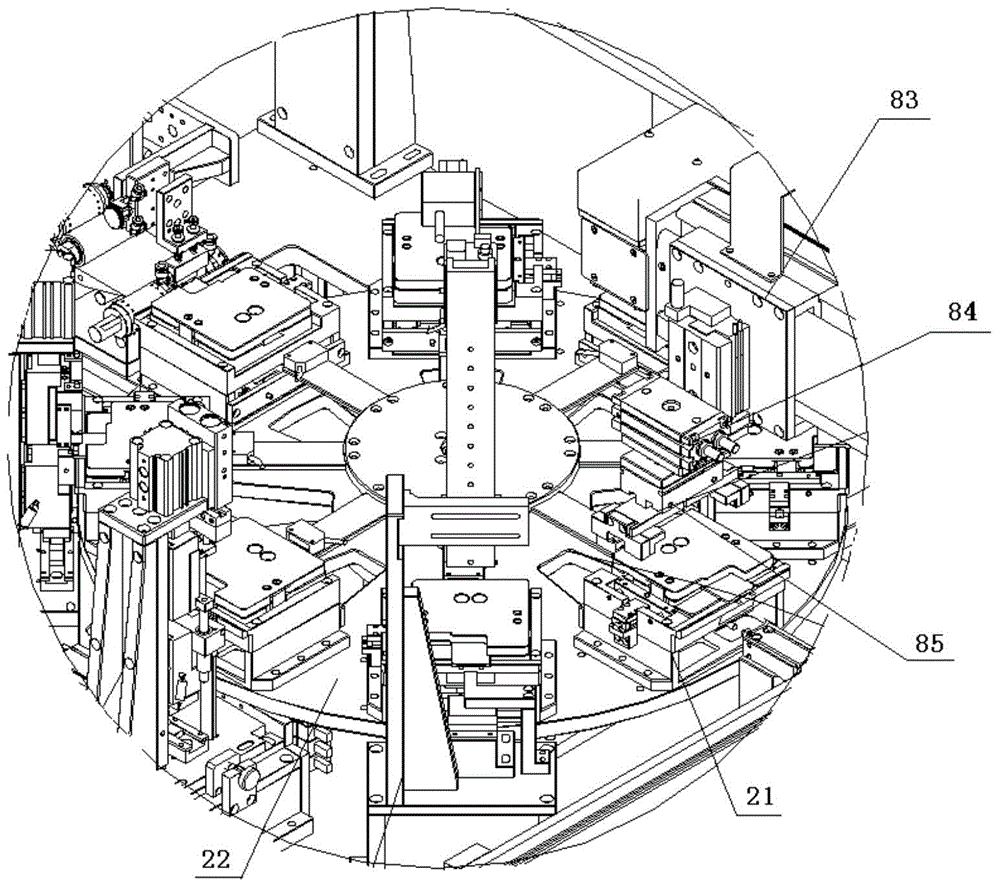

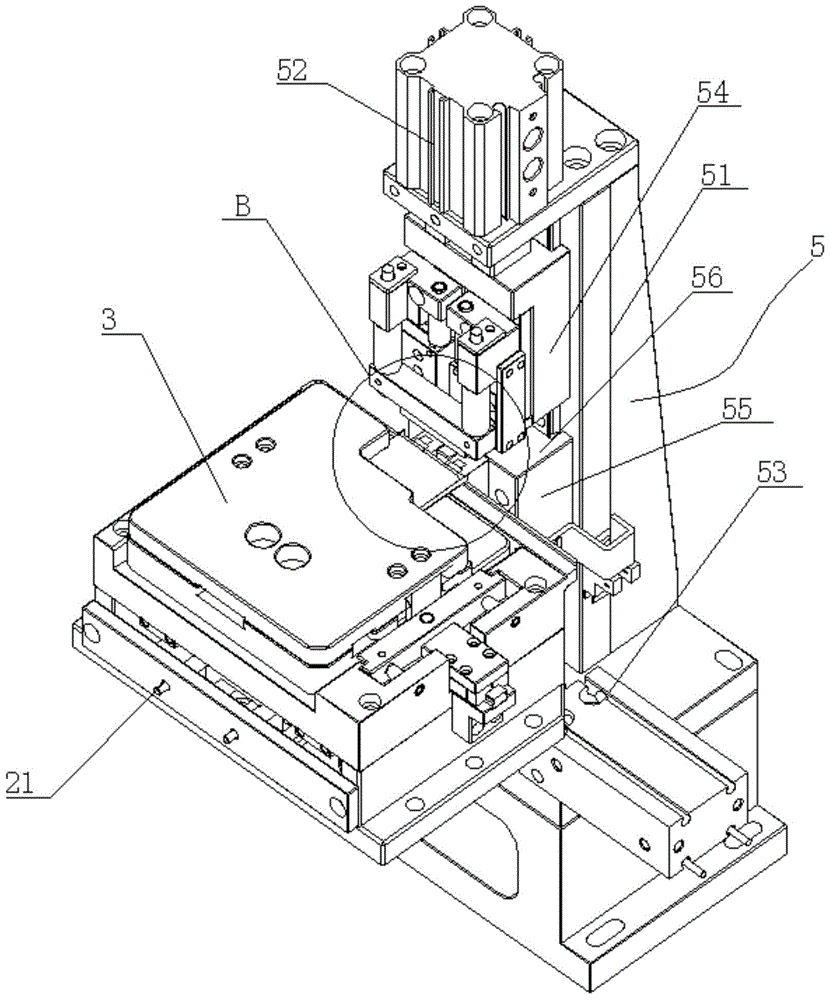

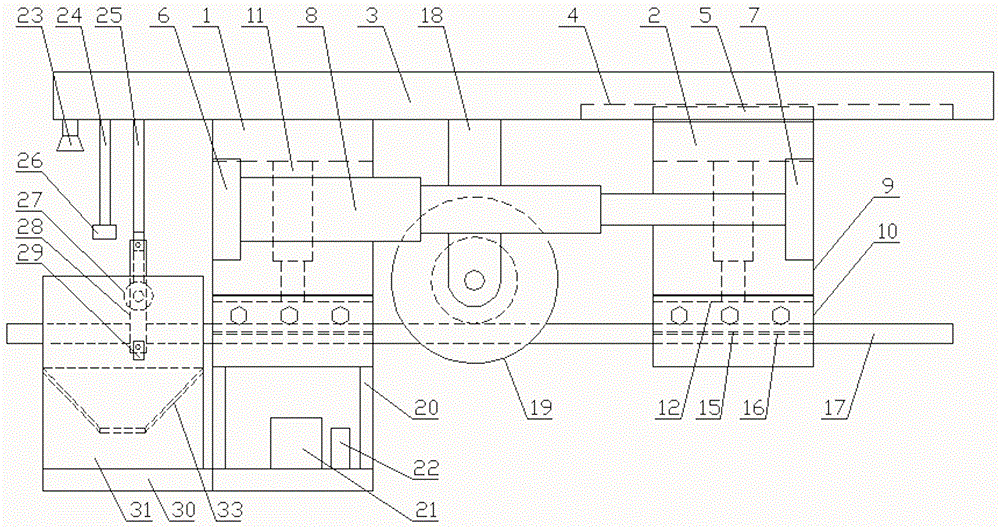

The invention discloses an automobile cutting detection machine for a positive plate and a negative plate of a mobile phone battery. The machine comprises a work platform and a rotary plate mechanism which can circumferentially rotate and is used for positioning. The rotary plate mechanism is provided with at least five rotation stations and a carrier used for positioning a battery provided with the positive plate and the negative plate. A fed material carrying mechanism, a shaping mechanism, a cutting mechanism, an AOI detection mechanism and a discharged material carrying mechanism are arranged on the peripheral side of the rotary plate mechanism. The fed material carrying mechanism can automatically grab and carry the carrier, and the carrier can be automatically positioned through the rotation stations. The shaping mechanism can flatten and shape the positive plate and the negative plate. The cutting mechanism can cut off the flattened and shaped positive plate and the flattened and shaped negative plate. The AOI detection mechanism can detect whether the cutting size of the cut positive and negative plates is qualified. The discharged material carrying mechanism can automatically grab and convey the carrier. Manual operation is not needed, full automation of shaping, cutting and cutting size detecting of the positive plate and the negative plate of the mobile phone battery can be achieved, productivity and cutting quality are greatly improved, and labor cost is reduced.

Owner:JIANGSU JUSTECH PRECISION IND CO LTD

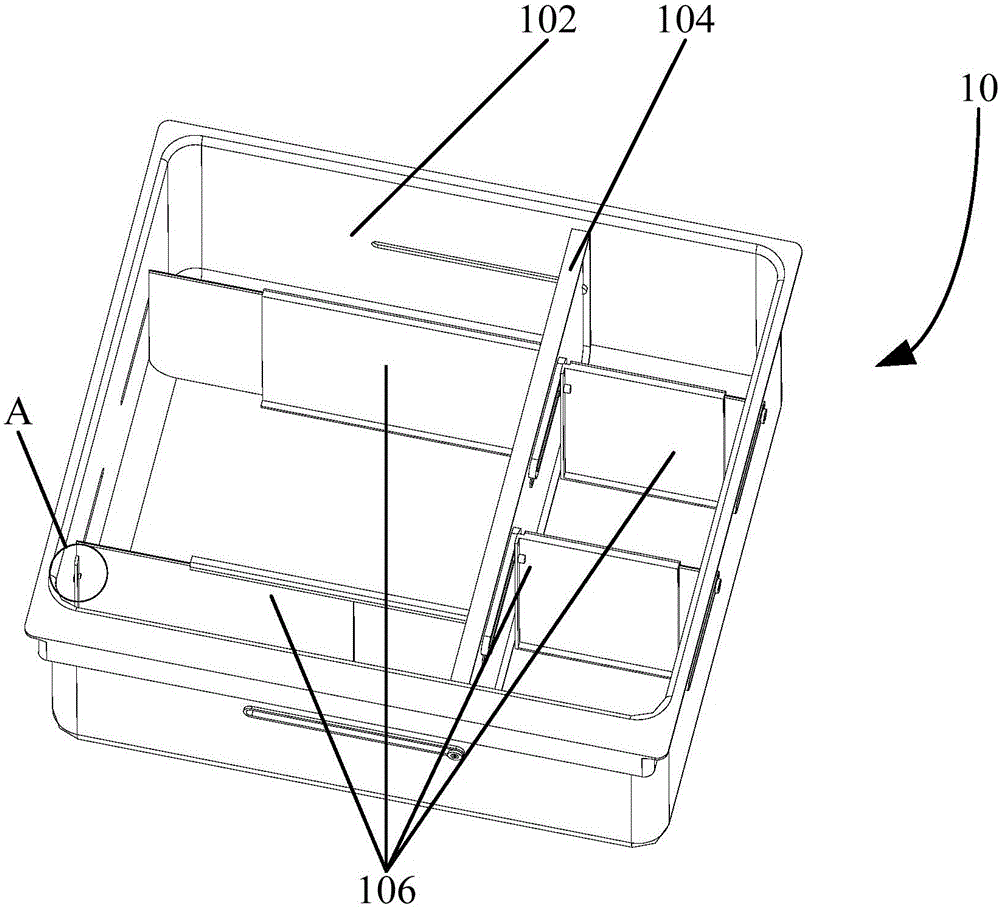

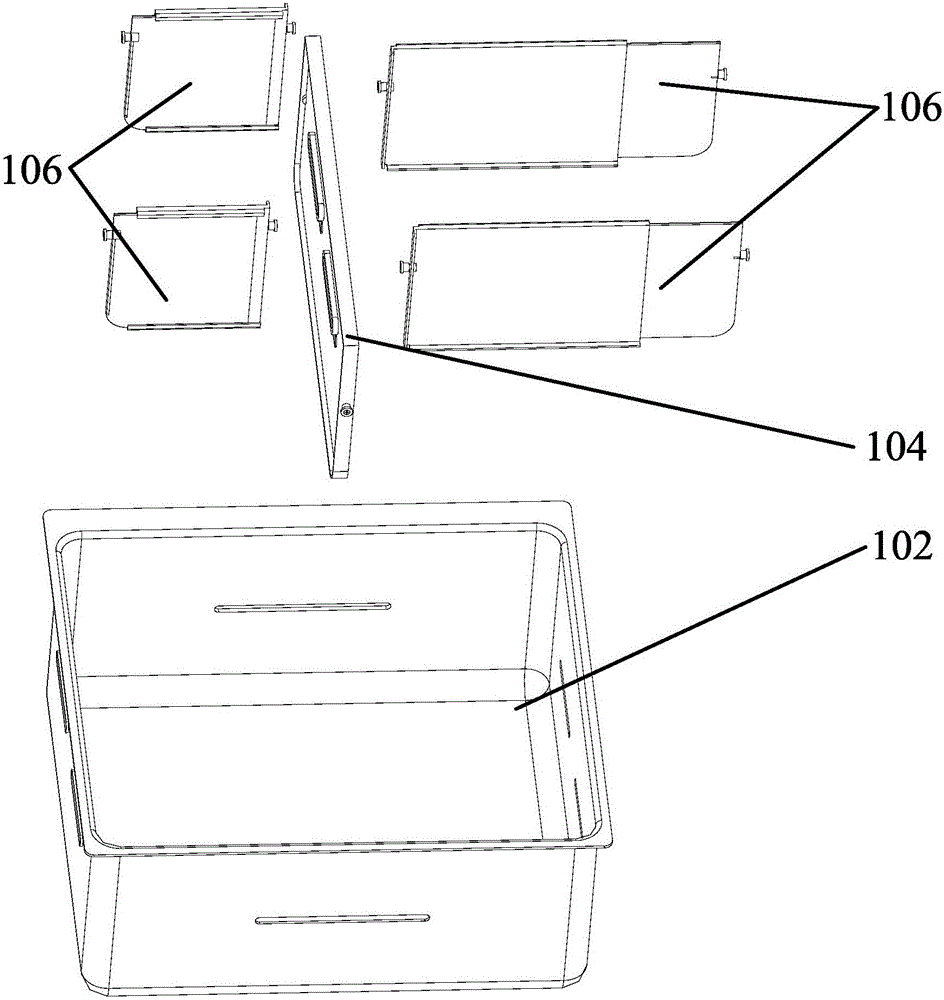

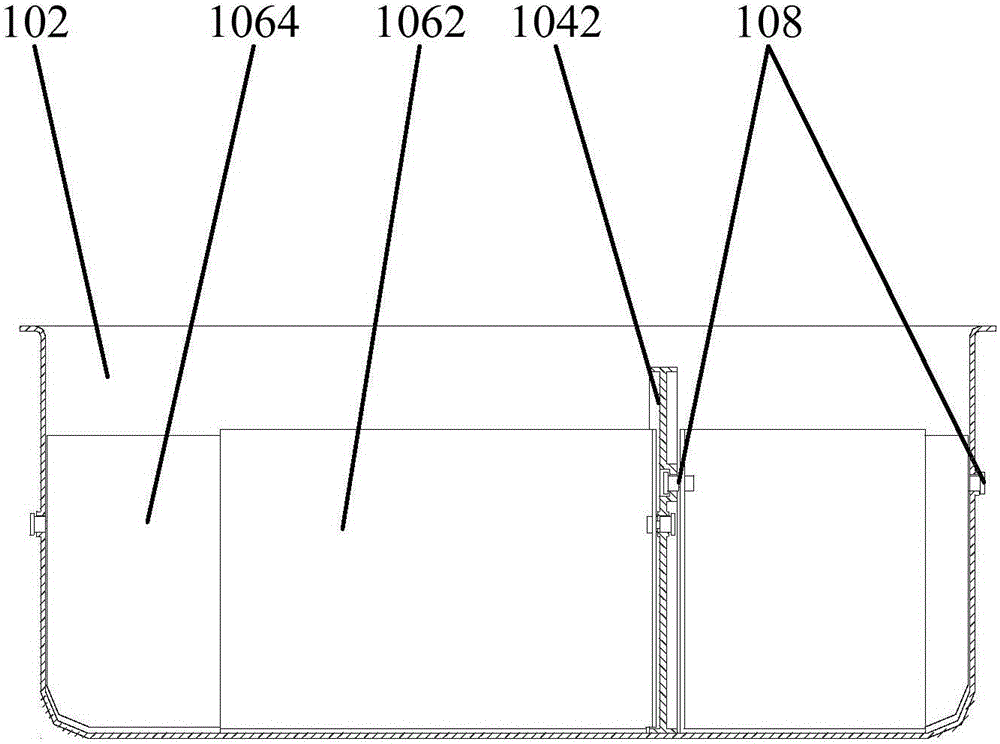

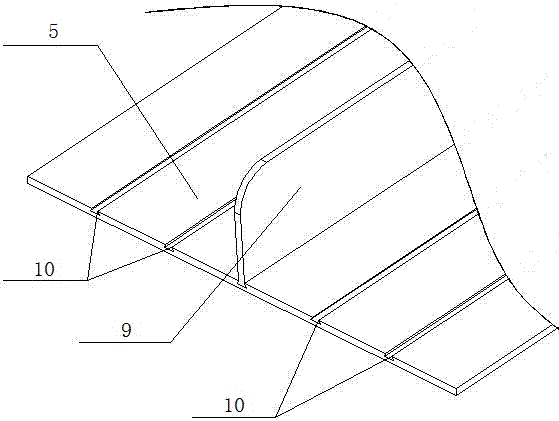

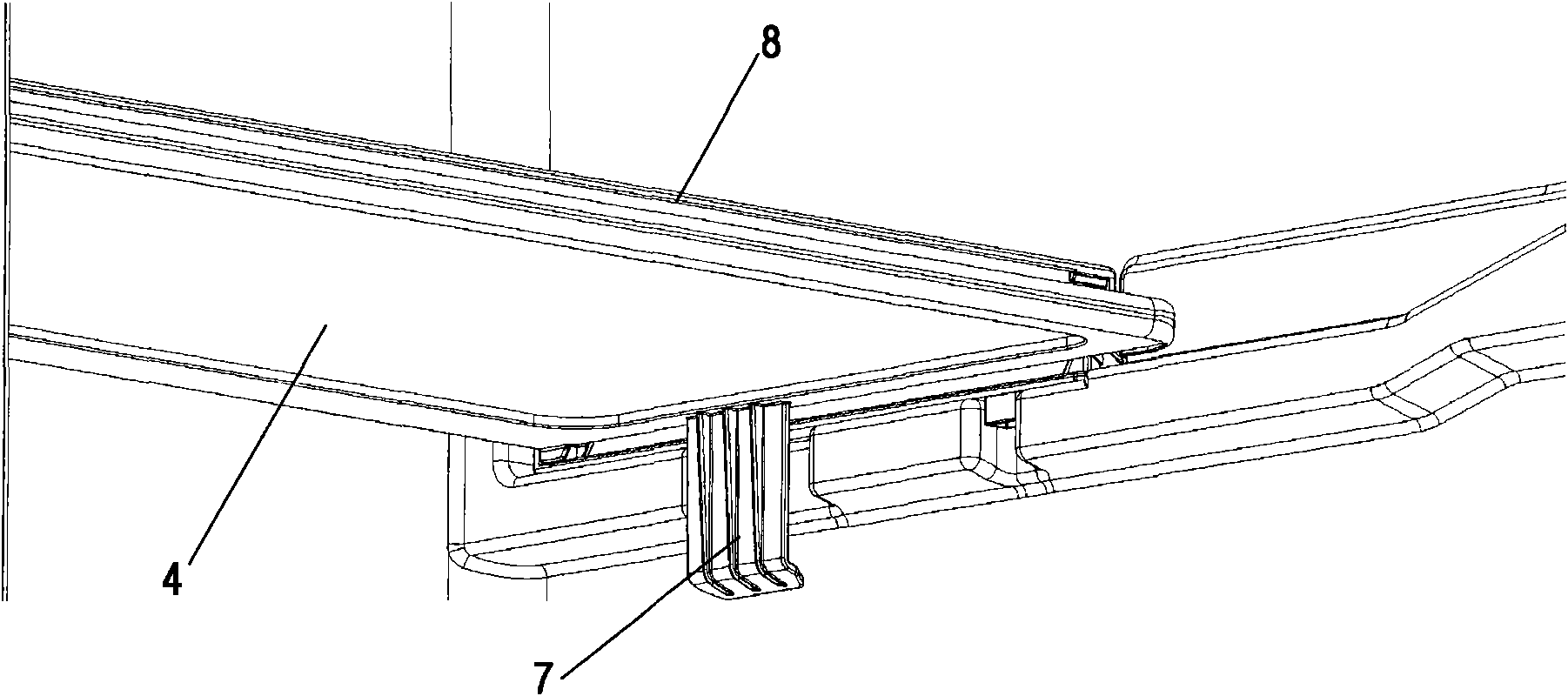

Adjustable drawer and refrigerator

ActiveCN106705559AEasy to operateFirmly connectedLighting and heating apparatusSupportRefrigerated temperatureMechanical engineering

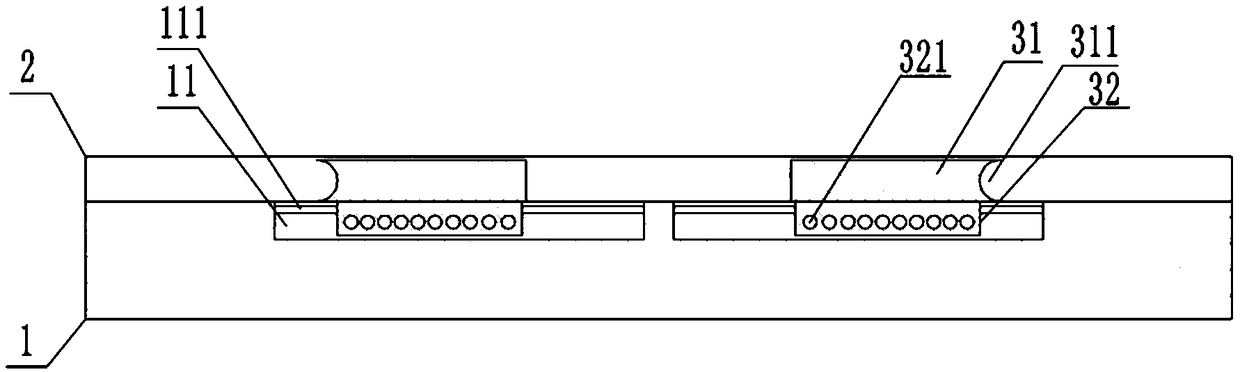

The invention provides an adjustable drawer and a refrigerator, wherein, the adjustable drawer comprises a drawer body, one or more first partition plate assemblies and one or more second partition plate assemblies. First sliding grooves are formed in the side wall of the drawer body; the one or more first partition plate assemblies are arranged in the drawer body; each first partition plate assembly comprises a first partition plate and first rolling parts arranged at the two ends of the first partition plate; second sliding grooves are formed in the first partition plates; and the first rolling parts and the first sliding grooves are mounted in a matched mode. The one or more second partition plate assemblies are arranged inside the drawer body. Each second partition plate assembly comprises a retractable partition plate and second rolling parts arranged at the two ends of the retractable partition plate. The second rolling parts and the first sliding grooves and / or the second sliding grooves are mounted in a matched mode correspondingly. According to the technical scheme, the positions of the first partition plate assemblies can be adjusted, the positions and the lengths of the second partition plate assemblies can further be adjusted, and partitioned space can be arbitrarily adjusted according to the size and the type of placed goods, on the other hand, by arranging the sliding grooves and the matched rolling parts, the partition plates can smoothly slide, and adjustment is convenient.

Owner:HEFEI HUALING CO LTD +2

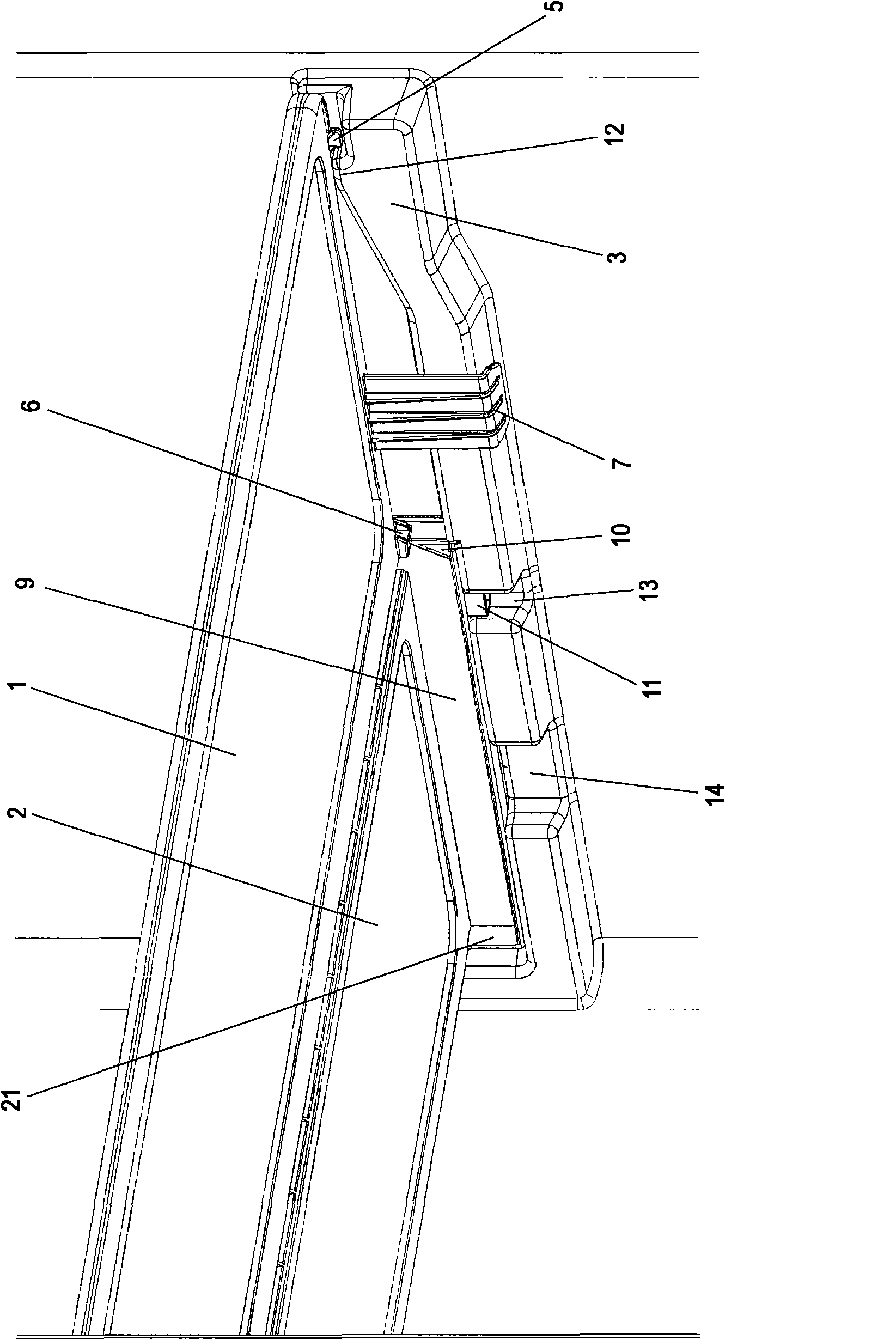

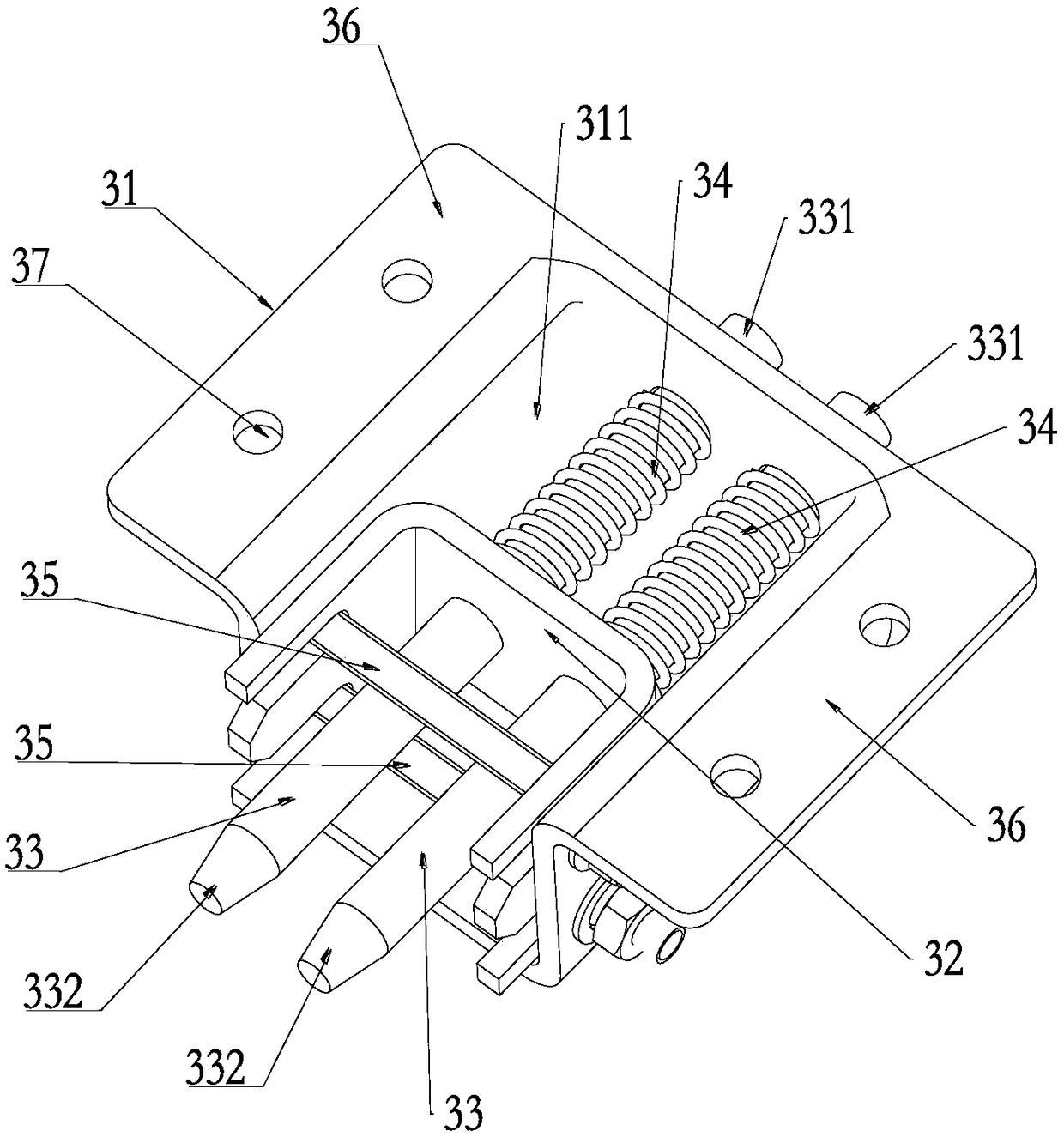

Clamping device for thin-wall variable-section pipe

PendingCN108188649AImprove stabilityAvoid pinchingWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringLinear section

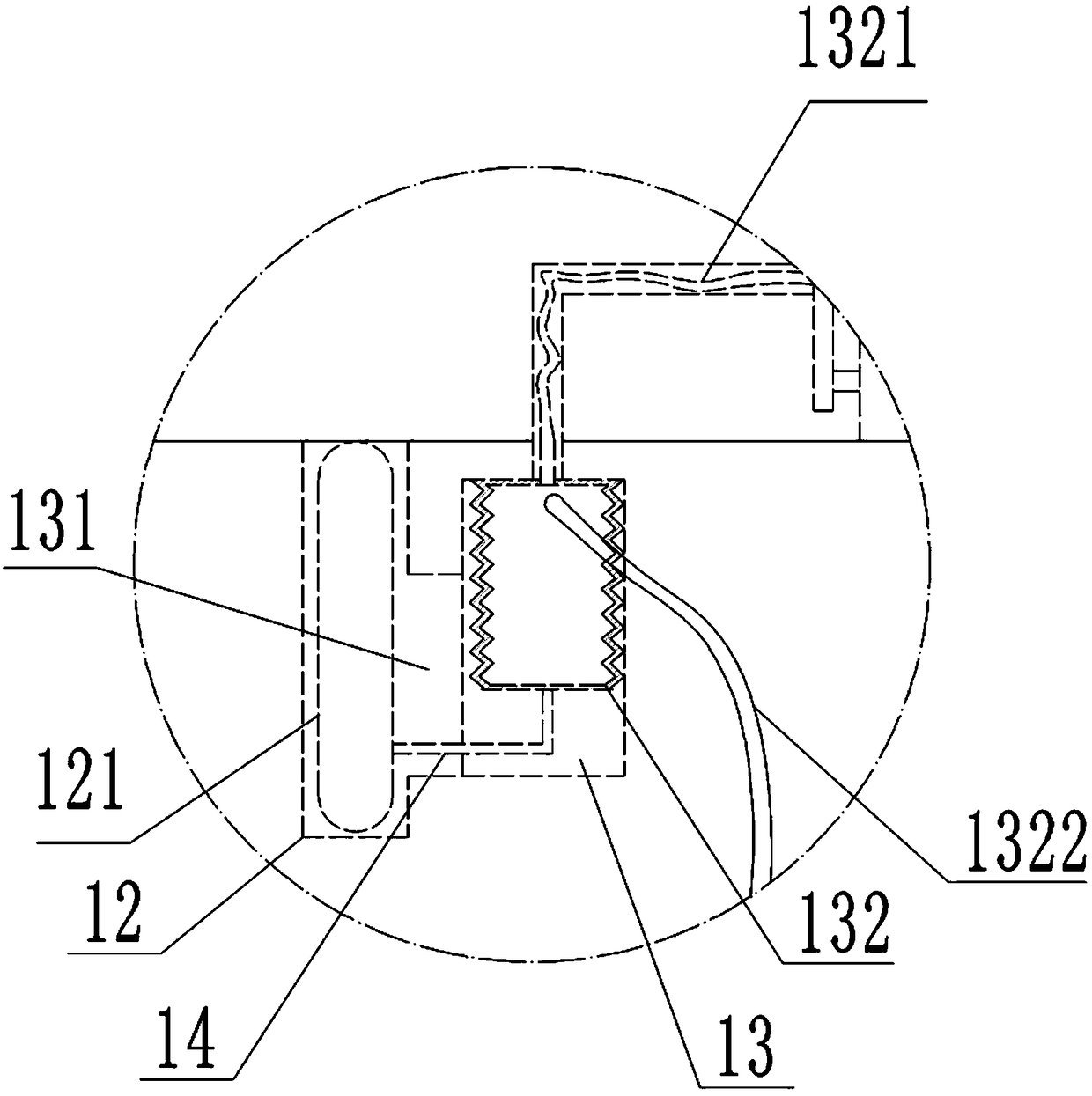

The invention discloses a clamping device for a thin-wall variable-section pipe. The clamping device comprises a bottom plate, a first clamping module and a second clamping module, wherein the first clamping module is installed on the bottom plate and used for clamping a variable-section section thin-wall pipe, and the second clamping module is used for clamping a linear section thin-wall pipe; first sliding grooves used for allowing the first clamping module to be installed and second sliding grooves used for allowing the second clamping module to be installed are formed in the bottom plate;the first clamping module comprises V-shaped clamping mechanisms, vertical sliding rods and U-shaped mounting frames, wherein the vertical sliding rods are installed in the first sliding grooves, theU-shaped mounting frames are fixed on the vertical sliding rods, one ends of the V-shaped clamping mechanisms are connected to the vertical sliding rods, the middles of the V-shaped clamping mechanisms are connected to the U-shaped mounting frames, and V-shaped claws of the V-shaped clamping mechanisms are used for clamping the outer periphery of the variable-section section thin-wall pipe; and the second clamping module comprises a plurality of clamping sliding blocks, the clamping sliding blocks are installed in the second sliding grooves and are used for clamping the linear section thin-wall pipe. The clamping device has certain universality, and is accurate in positioning, and high in welding precision and operation efficiency.

Owner:ZHEJIANG UNIV OF TECH

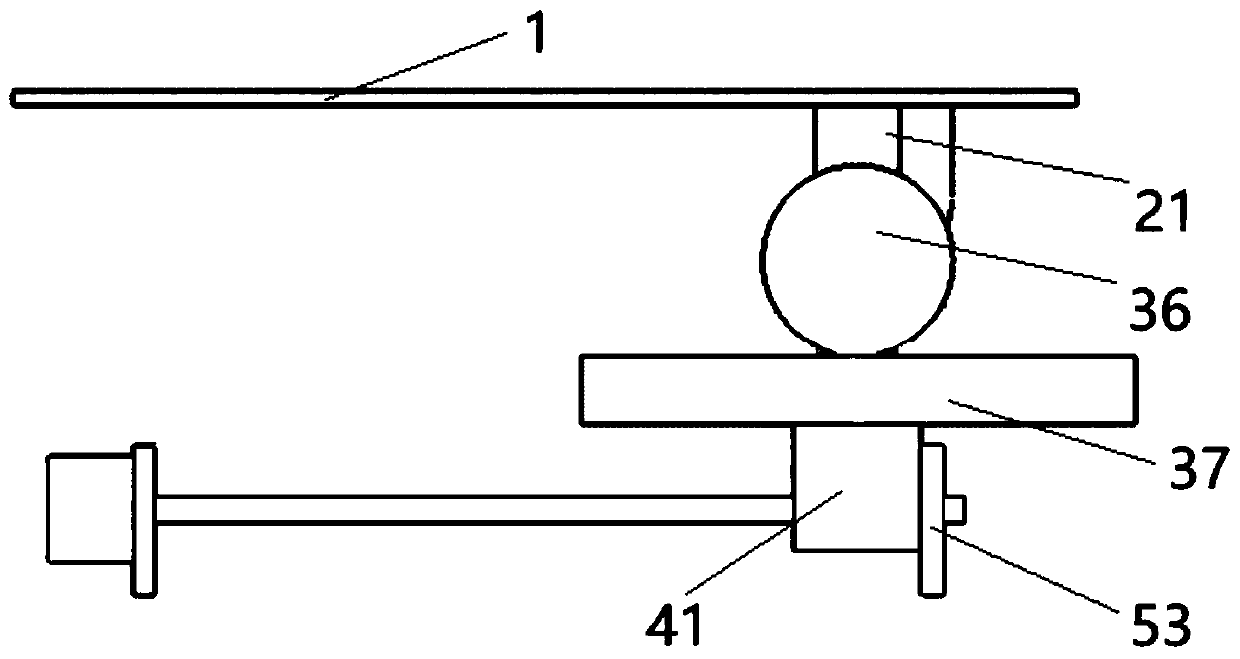

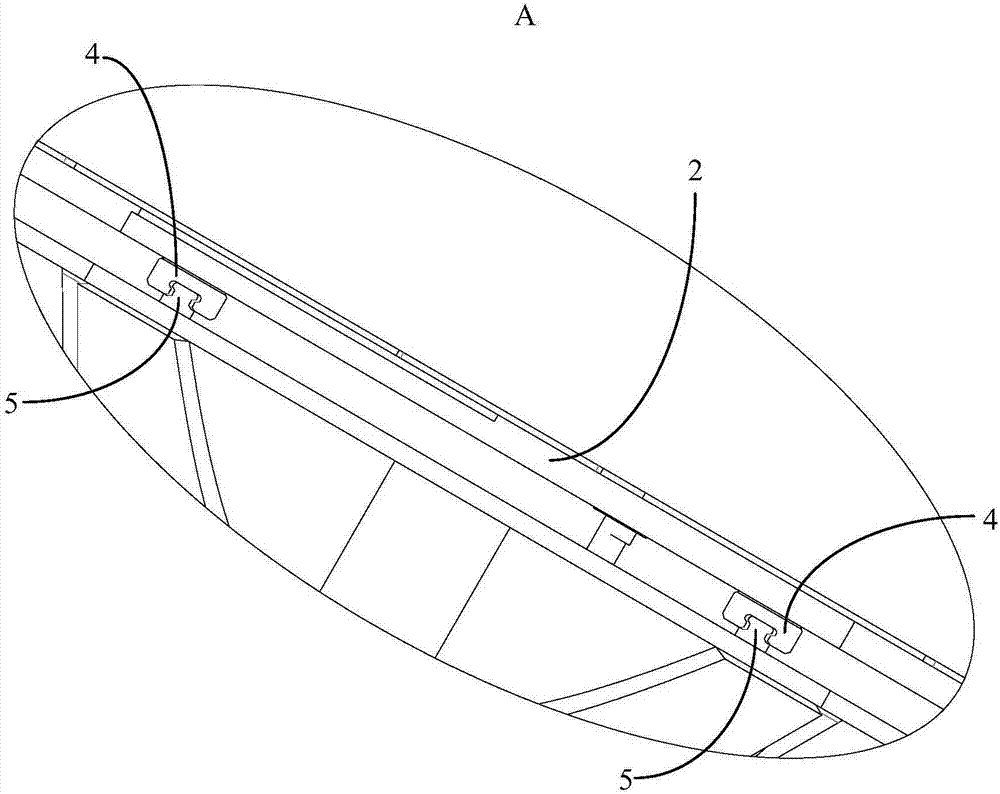

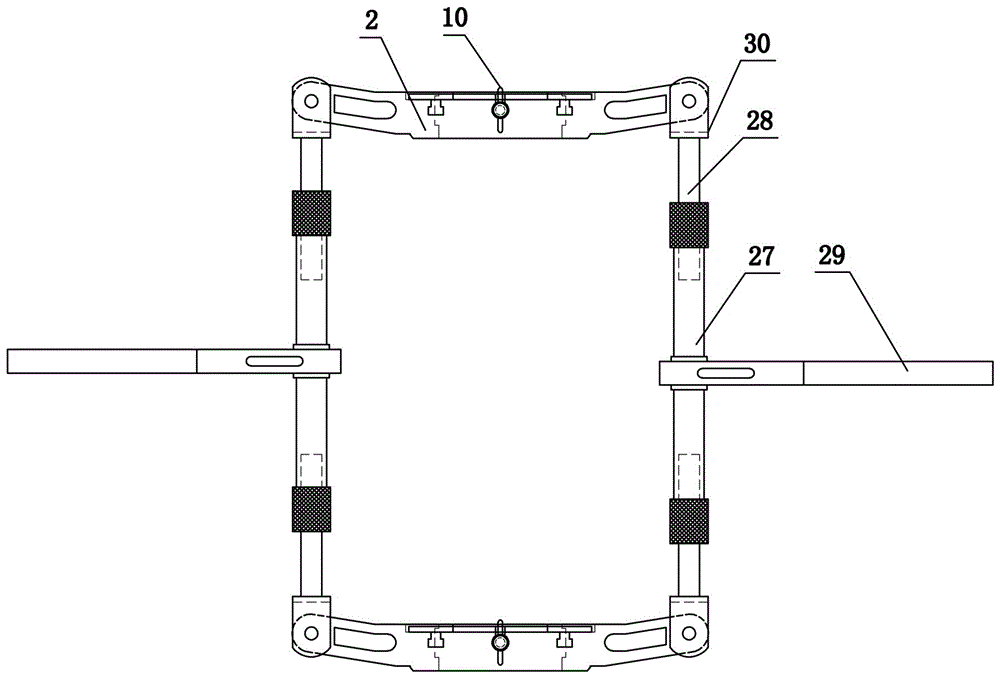

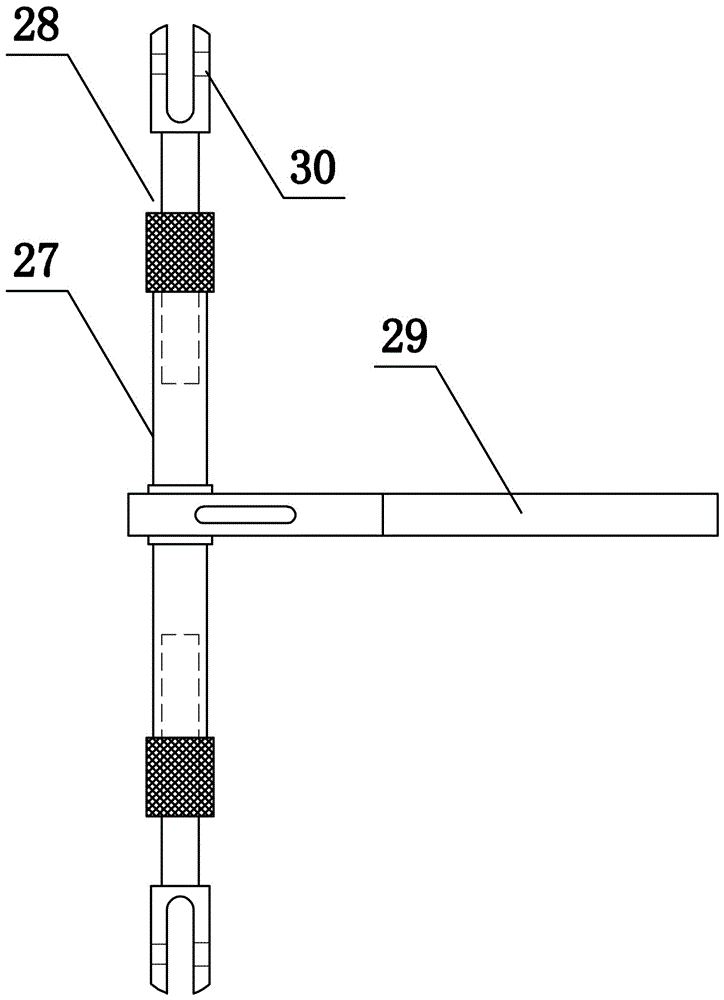

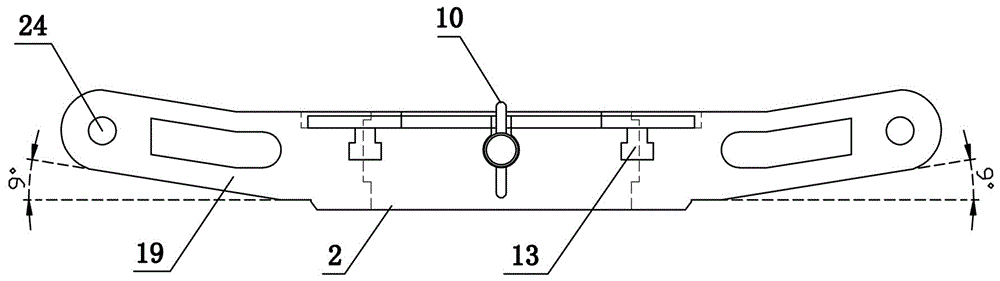

Adjustable automobile central control large screen assembly

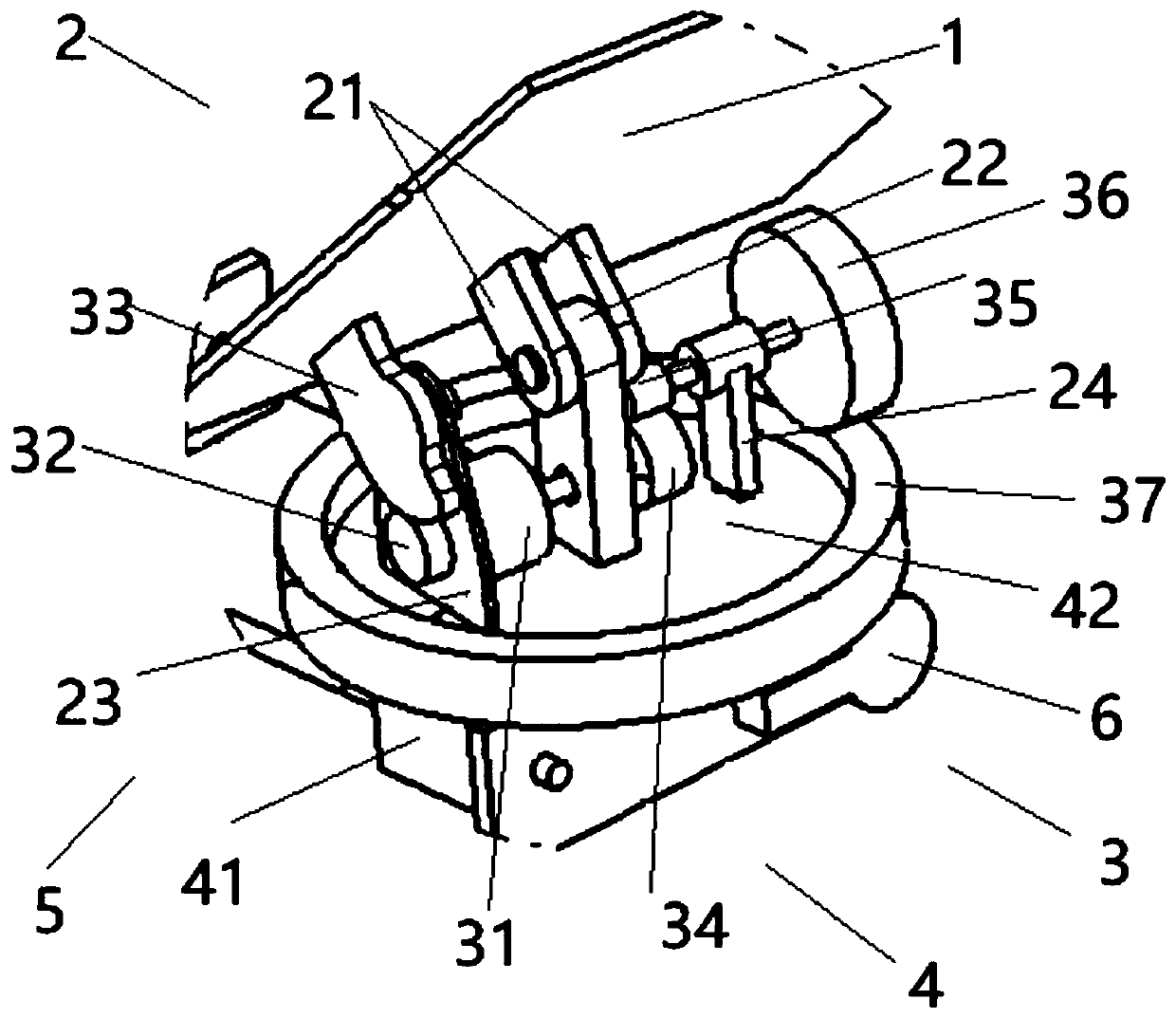

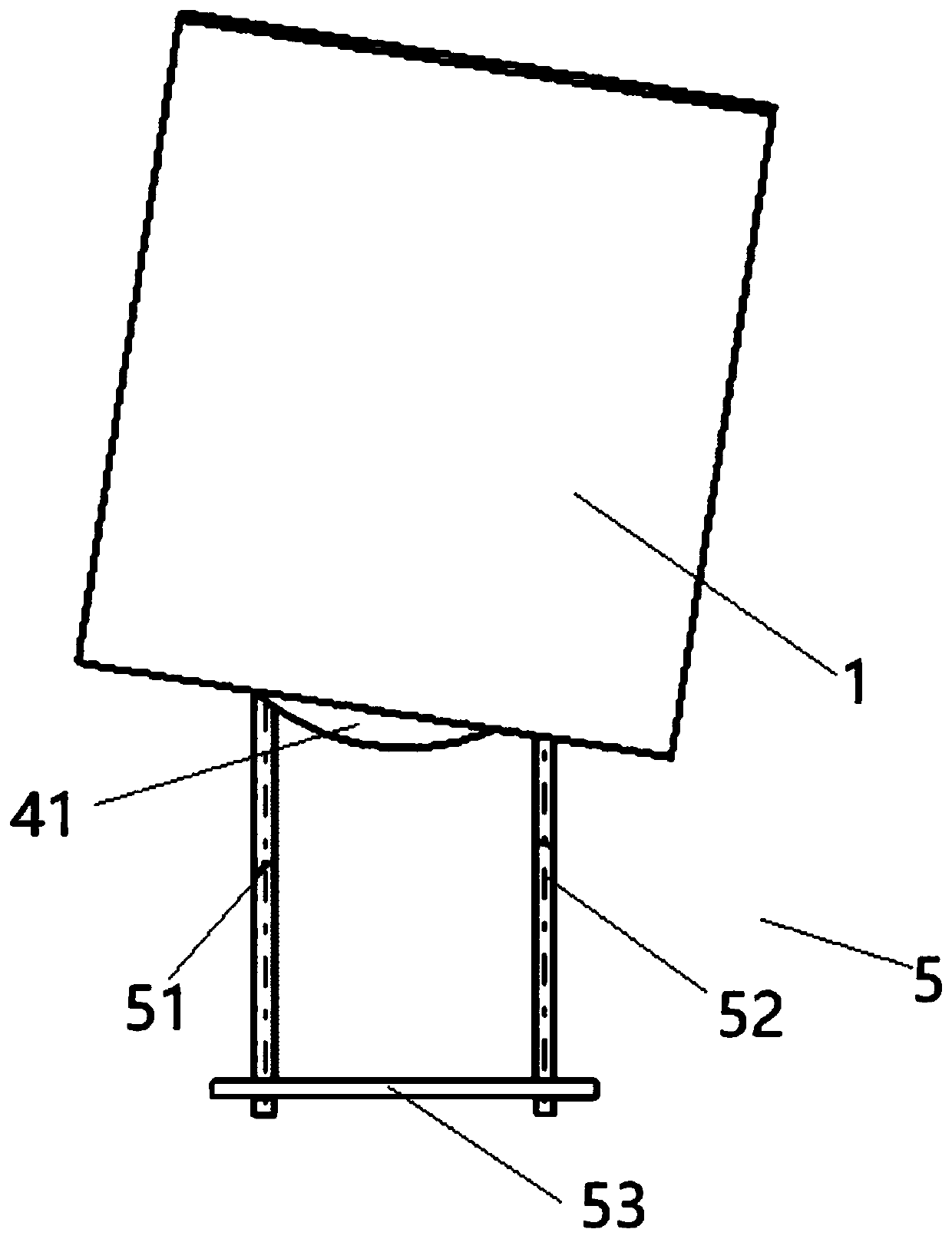

ActiveCN110254362ARealize slidingAchieve rotationVehicle componentsLarge screenAutomotive engineering

The invention discloses an adjustable automobile central control large screen assembly. The adjustable automobile central control large screen assembly comprises a central control large screen, a fixing component, a rotating component, an adjusting component and a guiding component; the fixing component comprises a mounting bracket and a central column; one end of the mounting bracket is fixedly connected with the central control large screen; the other end of the mounting bracket is rotationally connected with the upper end of the central column; the rotating component comprises a rotating piece; the rotating piece drives the central control large screen to rotate; the central column is fixedly connected with the adjusting component; and the adjusting component is connected with the guiding component and moves relative to the guiding component. According to the adjustable automobile central control large screen assembly, through coordination of the rotating component and the adjusting component, the central control large screen can be automatically adjusted to a state of facing towards a driver to a flatly laid state by realizing sliding, rotating and rotating of the central control large screen; and meanwhile, the fixing component fixes the central control large screen so as to effectively avoid the sliding of the central control large screen of the running process and guarantee the running safety.

Owner:WUHAN LOTUS CARS CO LTD

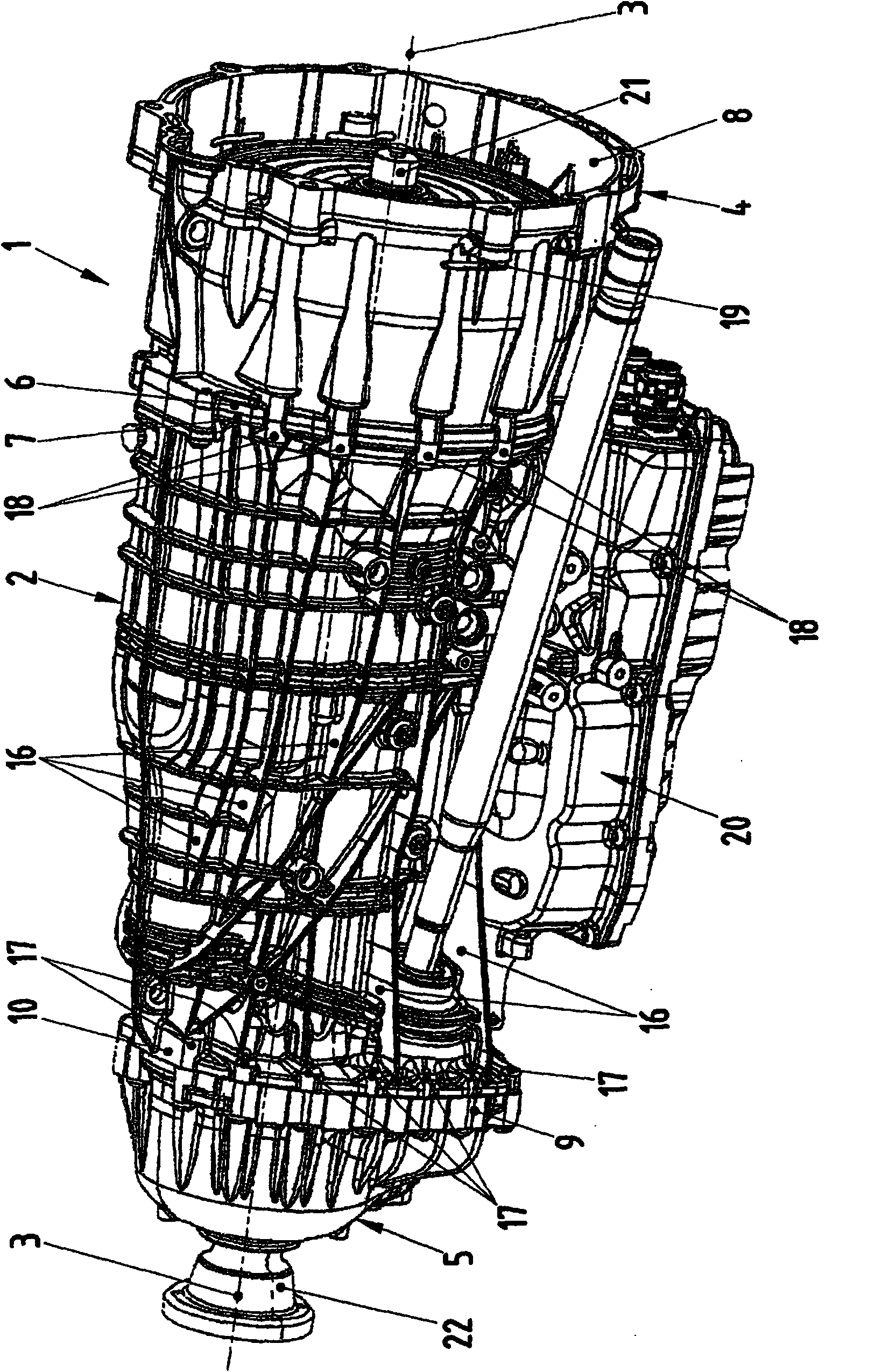

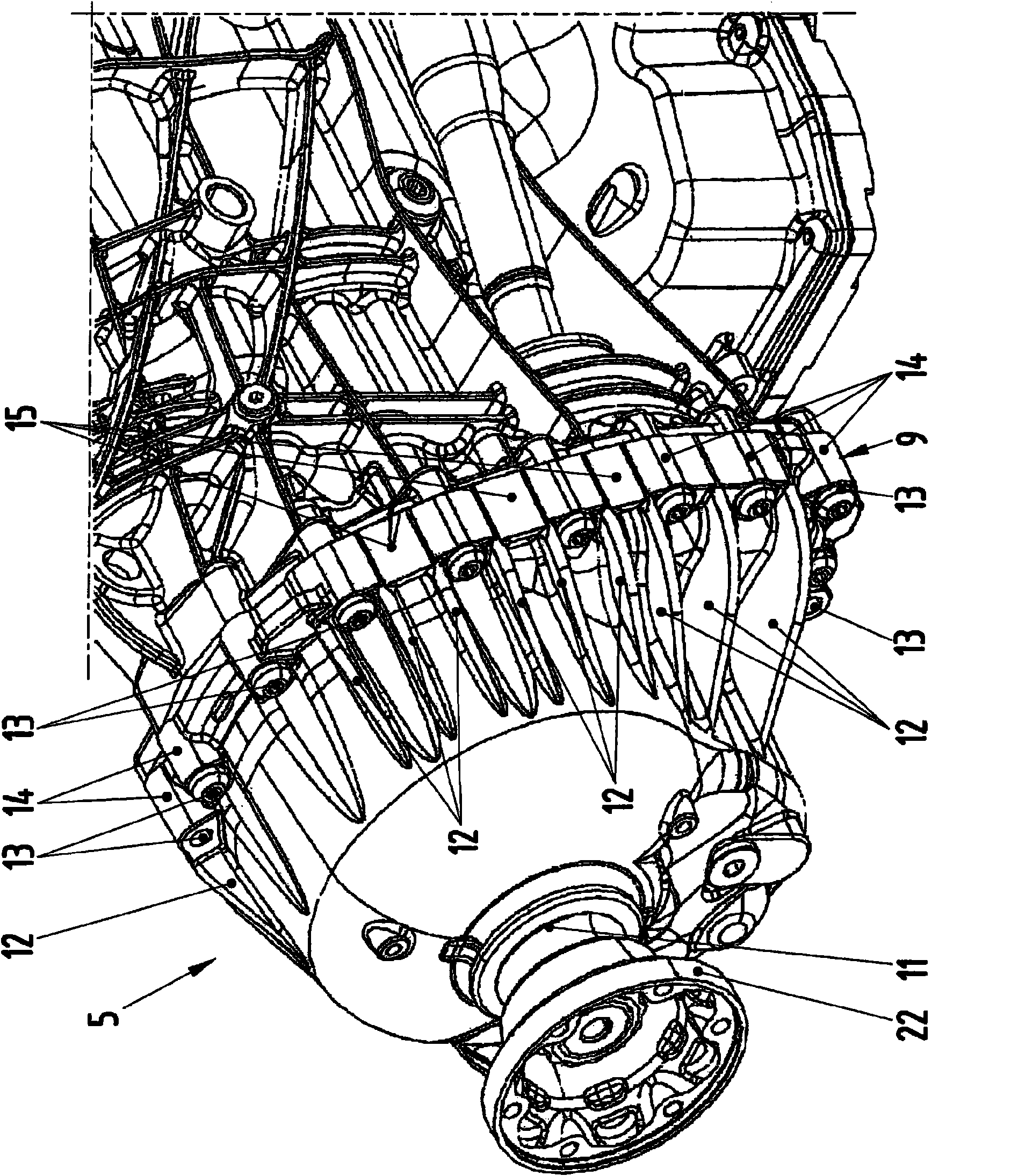

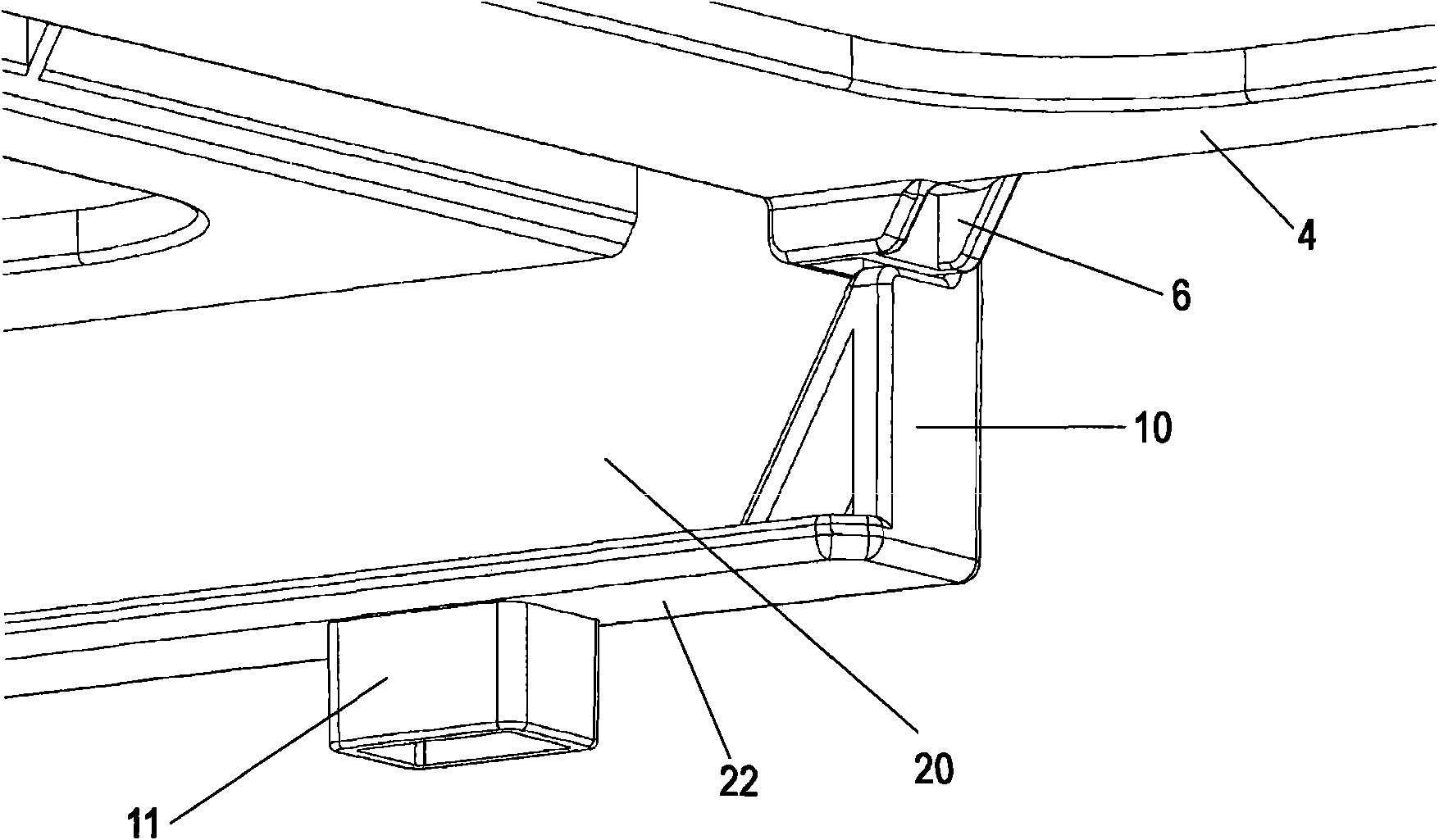

Housing used for vehicle transmission

InactiveCN101566222AEasy to passAvoid breakingGearboxesGearing detailsInternal combustion engineFlange

The invention relates to a housing used for transmission of motor vehicle, especially car. The housing has: a main housing used for receiving the transmission; and a transmission cover used for receiving the torque-converter of the transmission and / or the clutch of the transmission. One end of the transmission cover is connected on the main housing by a flange, the other end can be connected on the cylinder of the internal combustion engine of the vehicle by a flange; if the flange of the end cover is equipped with longitudinal ribs, the end cover is connected onto the main housing by the flange, and the longitudinal ribs are arranged on both sides of the screw holes; and if the flange of the end cover is provided with bump bridges, the bump bridges can connect the adjacent longitudinal ribs between the adjacent screw holes to each other in circumference direction; thereby, the failure properties of the transmission housing can be improved.

Owner:DR ING H C F PORSCHE AG

Movable automobile repairing creeper

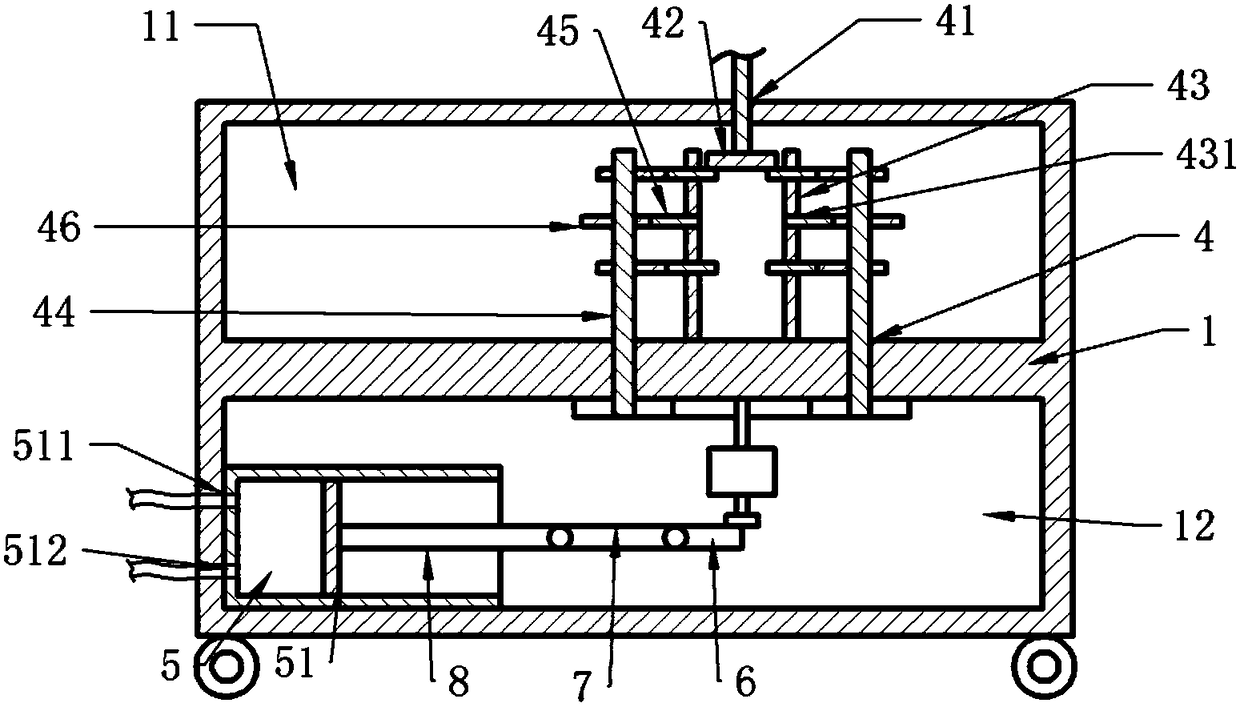

InactiveCN105751190ARealize slidingAvoid influenceOther workshop equipmentEngineeringHuman engineering

The invention relates to a movable automobile repairing creeper which comprises a creeper body, a bottom plate, a face protecting plate, universal wheels and support feet, wherein the creeper body meets human engineering; horizontal sliding tracks are arranged on the bottom plate; sliding blocks are fixedly screwed at the bottom of the creeper body; a sponge lying pillow is adhered to the head part of the creeper body; a storage battery is fixedly connected with one side of the middle of the creeper body; the face protecting plate is arranged right above the sponge lying pillow; one end of the face protecting plate is hinged with the creeper body; a plurality of lighting lamps are arranged around the sponge pillow and are connected with the storage battery through wires; the two universal wheels are fixedly connected below the head part of the bottom plate; the two support feet are fixedly connected below the tail part of the bottom plate. The movable automobile repairing creeper can be operated by a repairer independently to control the position of the creeper, the consequence that the repairer is affected by dirt falling from a chassis can be avoided, and the movable automobile repairing creeper is good in lighting effect, low in production cost, simple in structure, convenient to operate and easy to popularize.

Owner:赵健

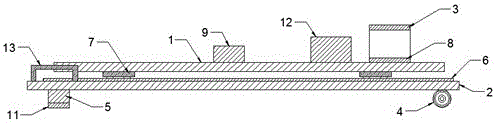

Simple type dining cart

Owner:赵康钦

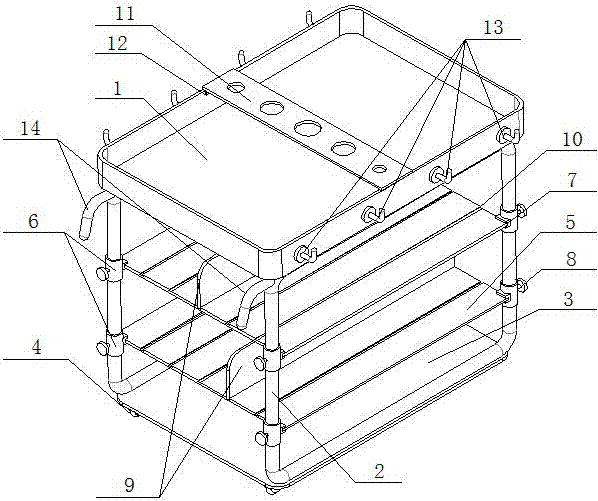

Telescopic rack

InactiveCN101581529ARealize slidingLighting and heating apparatusSupportEngineeringMechanical engineering

Owner:HAIER GRP CORP +1

Automatic fallen yarn coiling system for polyester production

The invention discloses an automatic fallen yarn coiling system for polyester production, and belongs to the technical field of polyester production. The automatic fallen yarn coiling system for polyester production comprises a base, a first baffle is fixedly connected to the base, and the end, away from the first baffle, of the base is slidably connected with a second baffle; the side wall of thefirst baffle is connected with a first motor, the output end of the first motor is connected with a first rotating shaft, and the end, away from the first motor, of the first rotating shaft is rotationally connected with the second baffle; the first rotating shaft is connected with a winding disc, and the first rotating shaft is connected with a clamping sleeve matched with the winding disc; a second rotating shaft is slidably connected with a thread distributing mechanism corresponding to the winding disc. The second baffle is slid to be connected with the first rotating shaft, so that the function of supporting the first rotating shaft is achieved; then polyester threads are wound on the winding disc through the thread distributing mechanism, then the first motor is started to make thefirst rotating shaft rotate to drive the winding disc to rotate, and winding and coiling effects are achieved.

Owner:HUAXIANG (CHINA) HIGH FIBER CO LTD

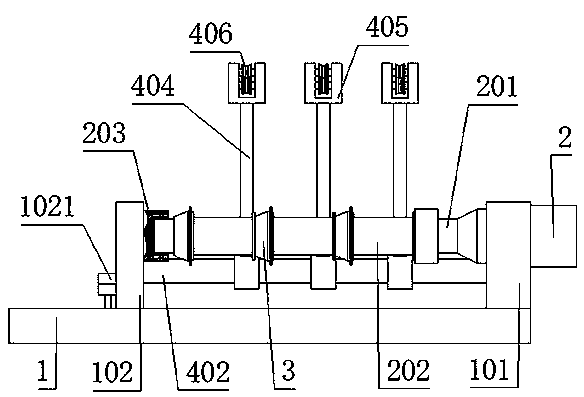

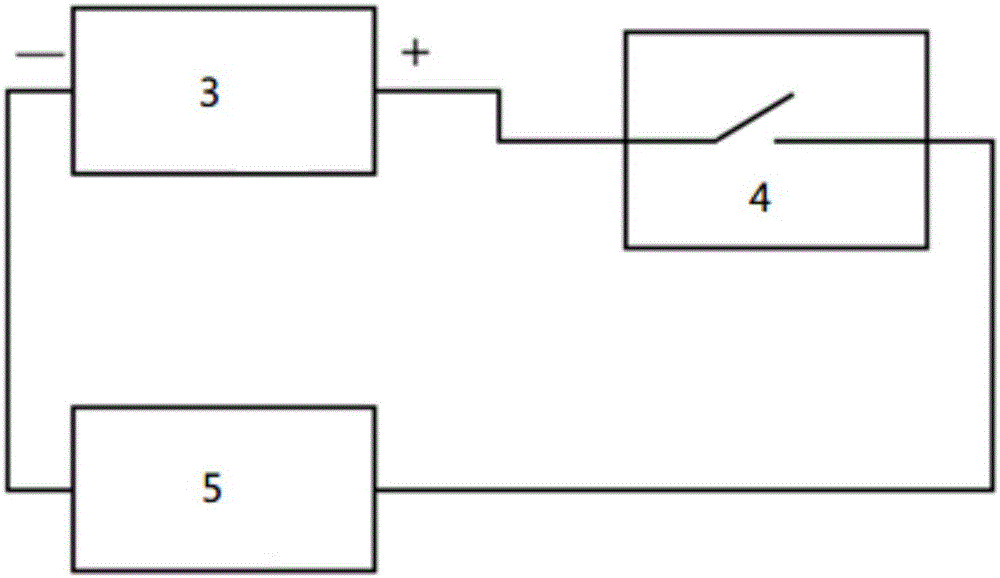

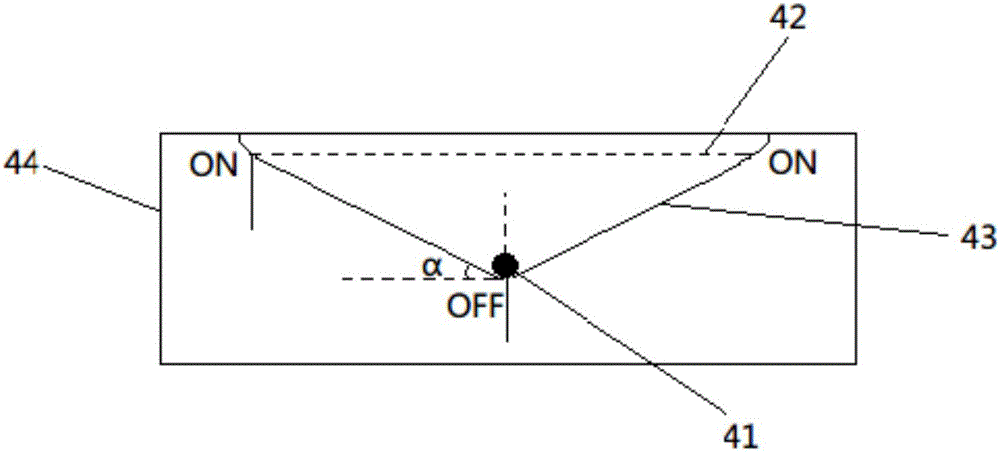

Electronic scale tilt alarm device

InactiveCN105136119ARealize slidingRealize inclination detectionIncline measurementElectric energyAlarm device

The present invention discloses an electronic scale tilt alarm device comprising a tilt detection device and a fixed assembly, the fixed assembly is used for horizontally fixing the tilt detection device on an electronic scale bottom plate, the tilt detection device includes a power source, a tilt switch and an alarm device, the power source, the tilt switch and the alarm device are connected in series into a closed circuit, and are mounted in the tilt detection device, the tilt switch is used for detecting whether an electronic scale is tilted, when the electronic scale tilt angle is over the set value of the tilt switch, the tilt switch is in a closed state, the circuit comprising the tilt detection device is closed, the power source provides power to the alarm device, the alarm device sends an alarm signal, and the electronic scale tilt alarm device solves the unfair competition phenomenon caused by electronic scale tilting in competition in the market, and is simple in operation, low in cost, and high in sensitivity.

Owner:韦政鸿

Multi-station machining device for pressure sensor manufacturing

The invention discloses a multi-station machining device for pressure sensor manufacturing. The multi-station machining device comprises a rack. Adjusting supporting legs are fixedly installed at thebottom end of the rack, and universal wheels are arranged at the positions, located on one sides of the adjusting supporting legs, of the rack. A control panel is arranged on the front side of the rack in an embedded manner, a first panel is arranged on one side of the top of the rack, and a second panel is installed on the other side of the top of the rack. The multi-station machining device is scientific and reasonable in structure and convenient to operate, due to the fact that electric telescopic rods are arranged, height adjustment of a machining table can be achieved, and corresponding adjustment is conducted according to the height of an actual user; due to the fact that sliding rails are arranged, sliding of the first panel and the second panel can be achieved, and a certain protection effect is achieved on the machining table; and due to the fact that a first adjusting air cylinder and a second adjusting air cylinder are arranged to act, a first clamp and a second clamp can bedriven to slide to work on a first sliding groove and a second sliding groove, and the multi-station machining device can be suitable for various sizes of pressure sensors.

Owner:芜湖凯兴汽车电子有限公司

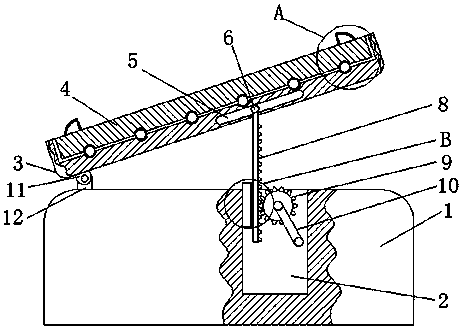

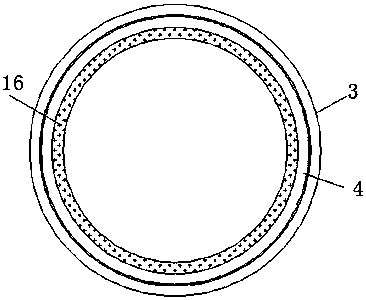

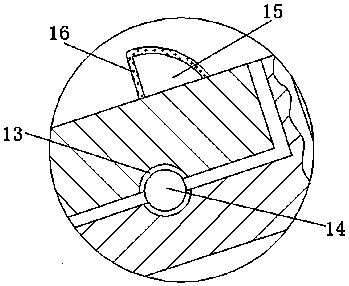

Clamping device of thin-walled tube

PendingCN108188648AImprove stabilityAvoid pinchingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

Owner:ZHEJIANG UNIV OF TECH

Stone clamping device for excavating robot

The invention belongs to the technical field of excavating aids, and discloses a stone clamping device for an excavating robot. The stone clamping device comprises a base and a support plate as well as a clamping mechanism and an adjusting mechanism; the clamping mechanism comprises a mounting shaft and a rotating roller which are hollow; the mounting shaft is slidably connected to the support plate, and provided with a first through hole and a second through hole; the mounting shaft is provided with two baffles, and divided into a negative pressure chamber and a pressure relief chamber by thetwo baffles; the rotating roller is connected to four connecting rods which are provided with industrial vacuum chucks; the base is internally provided with a cavity which is internally provided witha motor, a piston barrel and a piston, and the stone clamping device further comprises a first support rod, a second support rod and a third support rod which are hinged in sequence; the motor is connected to a rotating disk, and the first support rod is fixed to the rotating disk; the third support rod is hinged to the piston; and the piston barrel is provided with an air inlet and an air outlet. According to the stone clamping device disclosed by the invention, the problem that the stone clamping efficiency is low since stones can be clamped one by one only in the prior art is solved.

Owner:CHONGQING UNIV OF ARTS & SCI

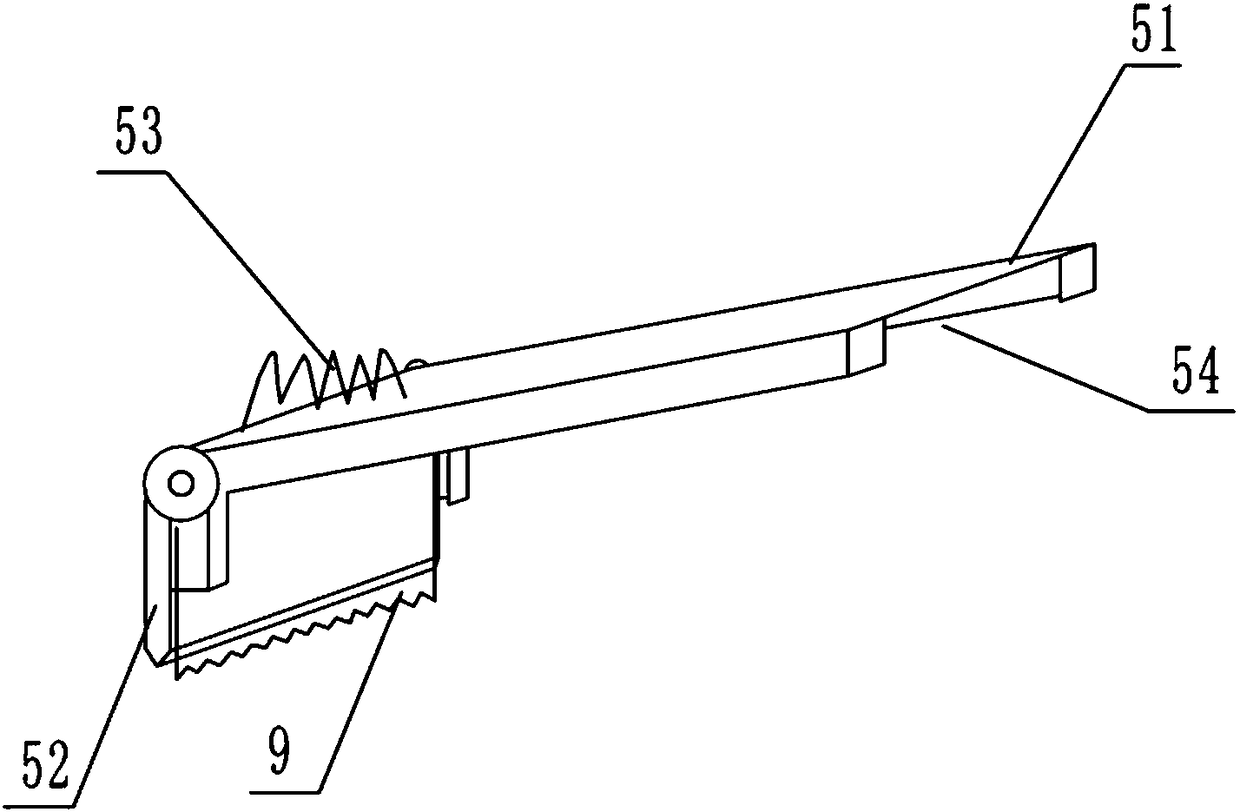

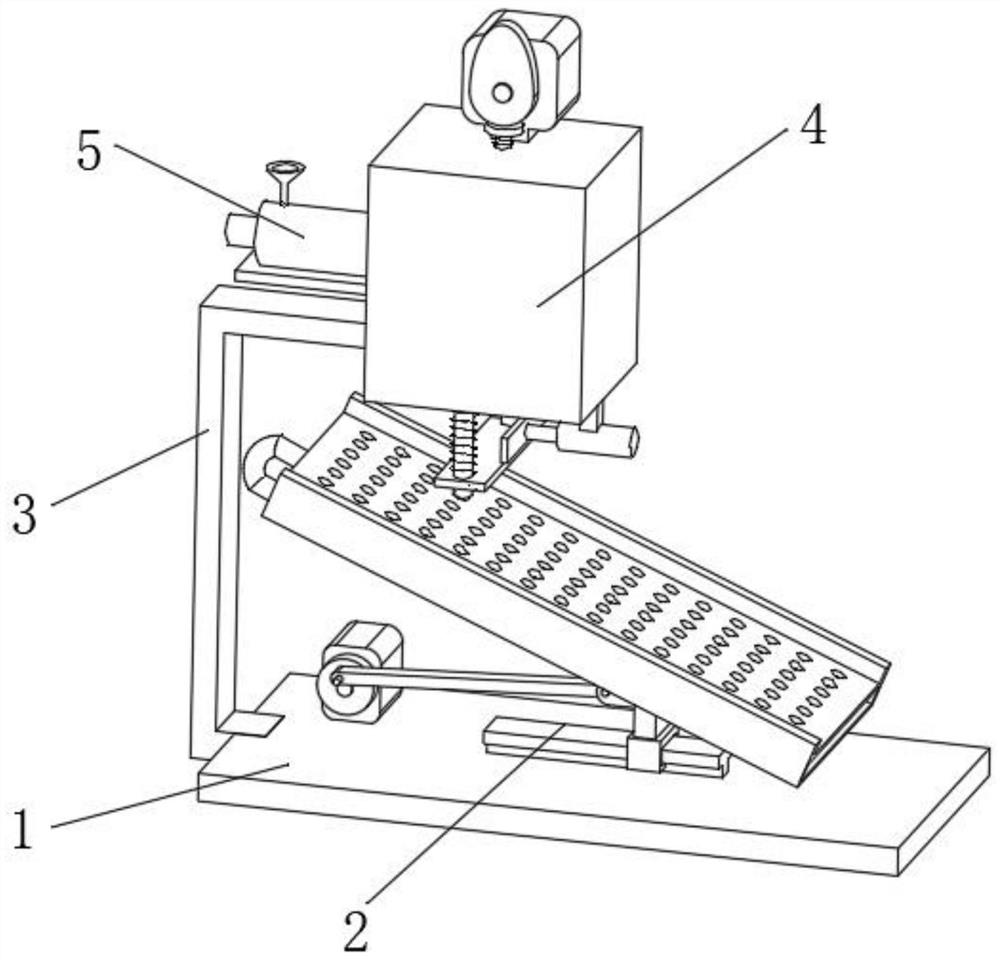

Pipe bending tooling

The invention relates to the technical field of pipe processing, and particularly discloses a pipe bending tooling, which comprises a processing table, a positioning table and adjusting blocks are arranged on the processing table, and a placing channel for placing a pipe is formed between the adjusting blocks and the positioning table; the number of the adjusting blocks is two, and the two adjusting blocks are in sliding connection with the processing table; a positioning hole is formed in the lower part of each adjusting block; the end part of each adjusting block is provided with an arc-shaped groove; a sliding hole is arranged in the positioning table, a sliding block is slidably connected in the sliding hole, and a spring is fixed between the sliding block and the sliding hole wall; asliding cavity and a positioning cavity are arranged in the processing table; a positioning column used for being inserted in a positioning hole is slidably connected in the positioning cavity, the two ends of the sliding cavity are respectively communicated with the sliding hole and the positioning cavity; a push rod is slidably connected in the sliding cavity, the two ends of the push rod are bent and fixedly connected with the sliding block and the positioning column. According to the scheme, the problem that the distance between the two bending parts of the pipe is difficult to control when the two ends of the pipe are bent in the prior art, which causes low qualification rate of the bent pipe, is solved.

Owner:重庆祥越管道配件制造有限公司

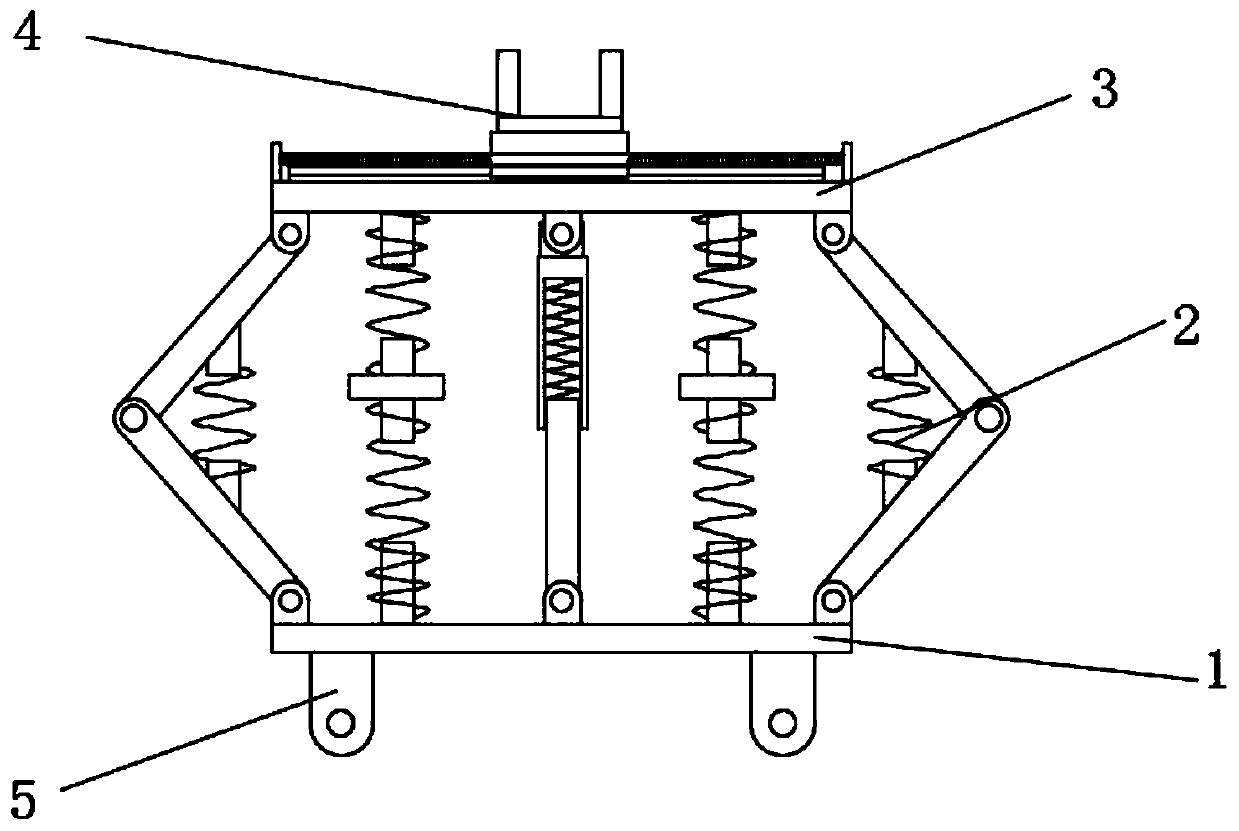

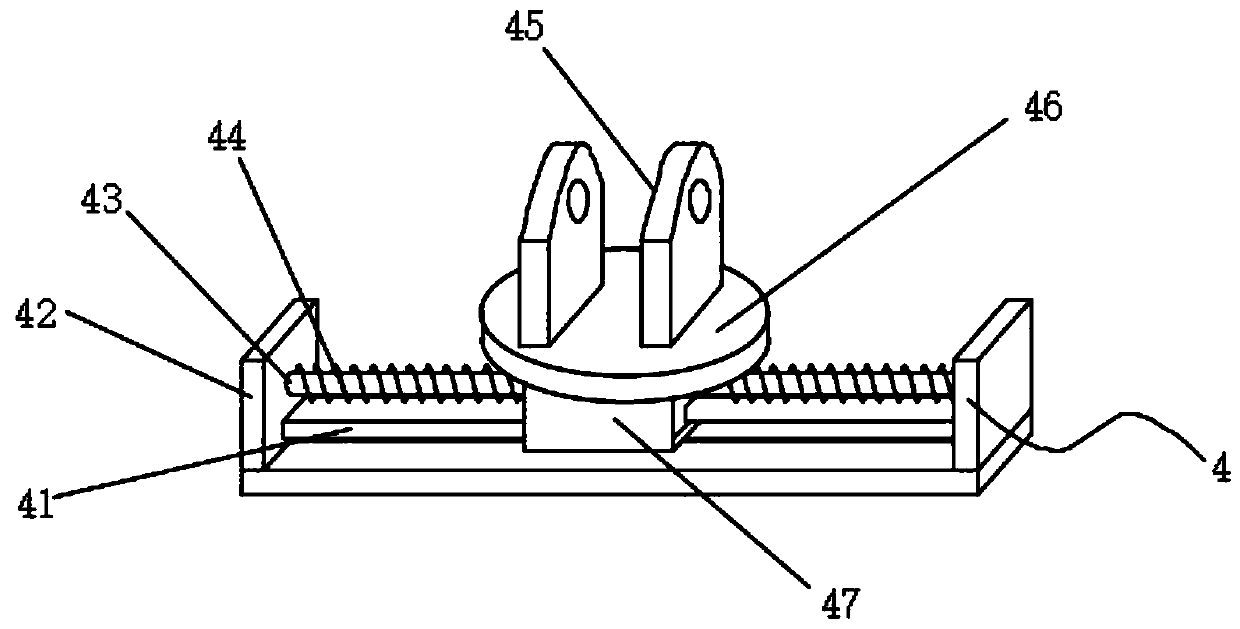

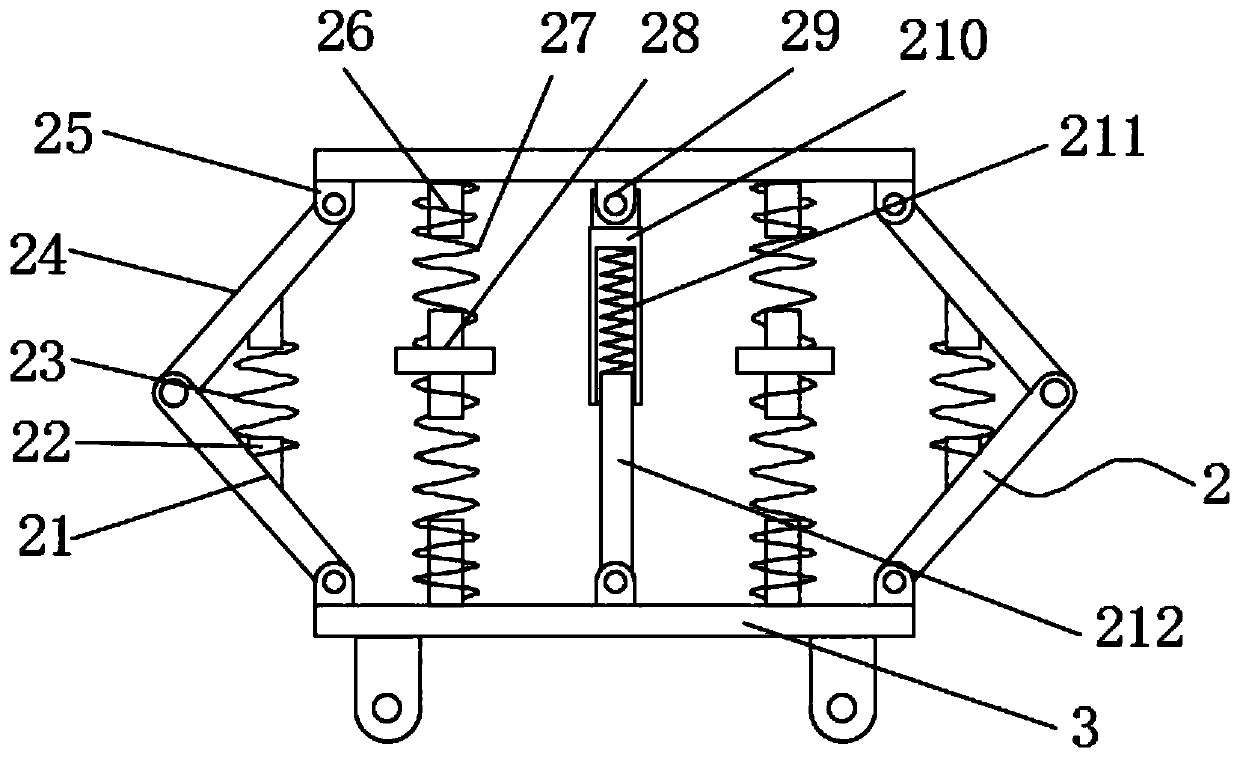

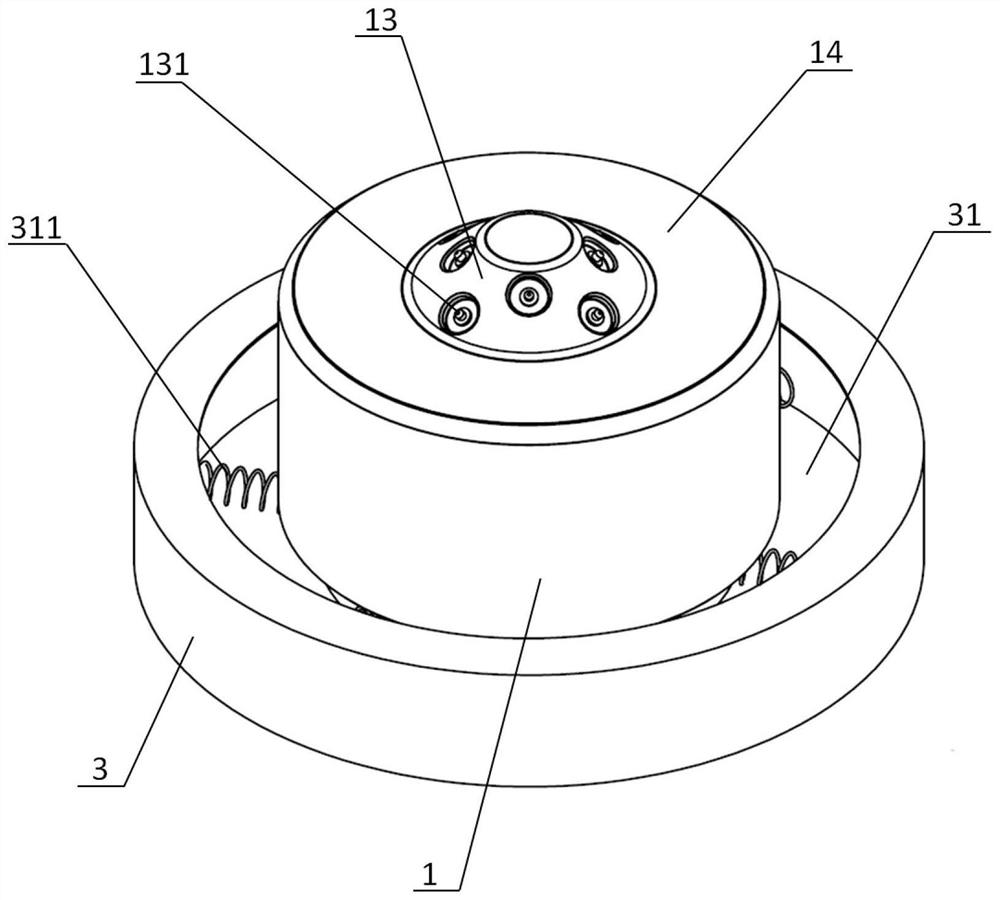

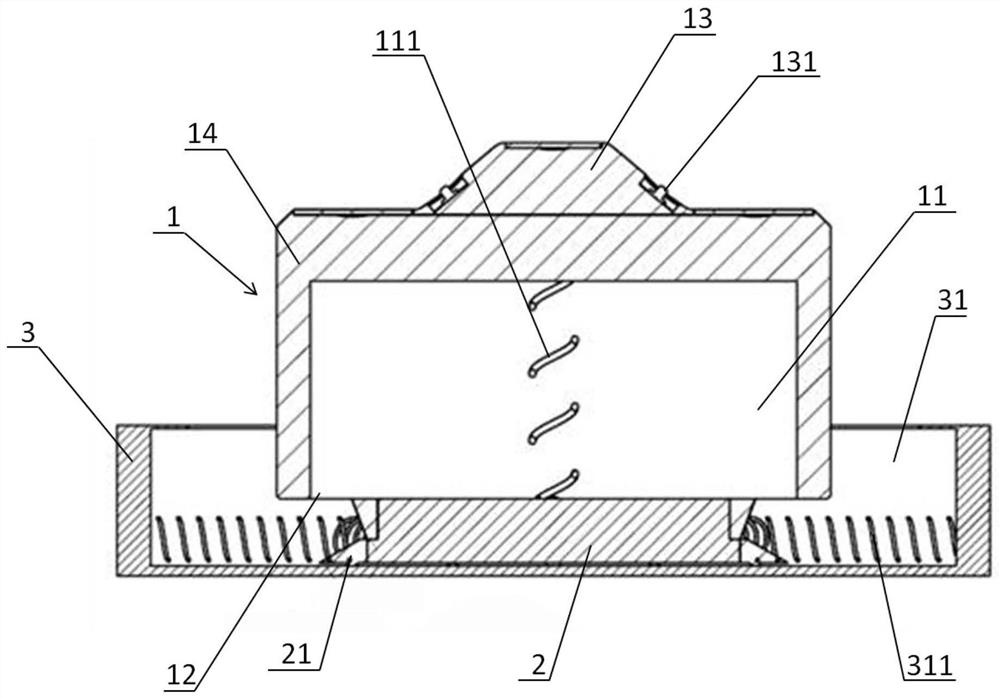

Multifunctional damper

InactiveCN110821998AAvoid breakingImprove shock absorptionWound springsLow internal friction springsEngineeringDamper

The invention provides a multifunctional damper, and relates to the technical field of dampers. The damper comprises a fixing plate, a damping structure, a supporting plate, a sliding structure and afixing support, wherein the supporting plate is arranged right above the fixing plate. According to the damper, a first side connecting rod and a second side connecting rod are arranged in a matched mode through a first connecting support, a damping sleeve and a damping inserting rod are arranged in a matched mode through a second connecting support, and damping joints are all of movable structures, so that twisting buffering can be randomly carried out; when the supporting plate bears extrusion and vibration in different directions, a good damping effect can be achieved under the action of alimiting spring, a damping spring and a returning spring, and the situation that when the fixing structure is used, the damper is broken if the fixing structure bears extrusion and vibration in different directions is avoided; and a rotating face plate can rotate under the cooperation of a shaft rod and a bearing, meanwhile a sliding buckle can slide along a sliding rail to be matched with the displacement of a connecting piece, so that the situation that the damper is broken when the connecting piece is displaced is avoided.

Owner:西安科技成果转化工程有限公司

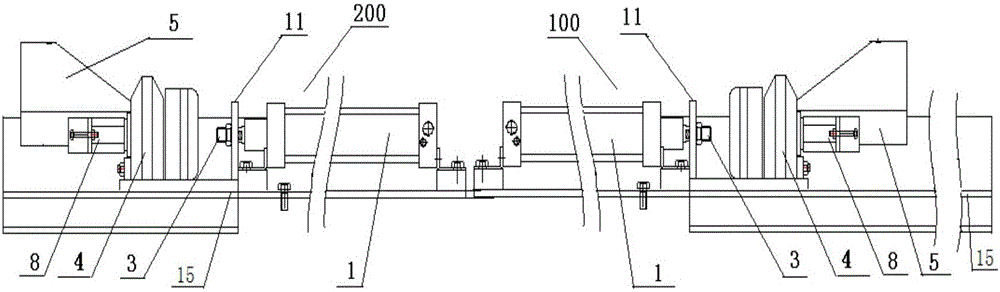

Parking method for two-way braking anti-rolling system on railway line

The invention discloses a parking method for a two-way braking anti-rolling system on a railway line, and belongs to the field of railway safety anti-rolling parking facilities. According to the parking method for the two-way braking anti-rolling system, four anti-rolling devices and two square bars are included, and the four anti-rolling devices are two anti-forward-rolling devices and two anti-backward-rolling devices; the two anti-forward-rolling devices are arranged at the front part, and the two anti-backward-rolling devices are arranged at the rear part; the two ends of the square bars are fixedly connected with supports of the anti-rolling devices respectively, so that a rigid synchronous mechanism is formed. Each anti-rolling device further comprises a linear cylinder, an oscillating cylinder, an iron shoe, a supporting mechanism and an air path mechanism. By adopting the parking method for the two-way braking anti-rolling system on the railway line, the mechanical and pneumatic technologies are combined, the purposes that rigid synchronous two-way braking of two wheels on the two sides of a train is achieved, and the iron shoes will not damage steel rails and not be easily lost during fixation can be achieved, the service life is prolonged through the pneumatic technology, and the using operation risk is effectively lowered.

Owner:苏州市洁优卫生材料科技有限公司

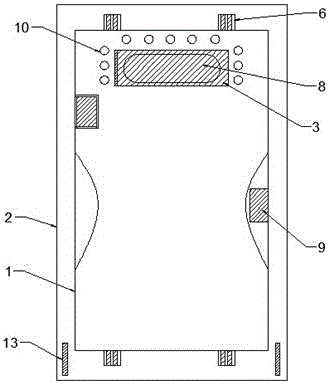

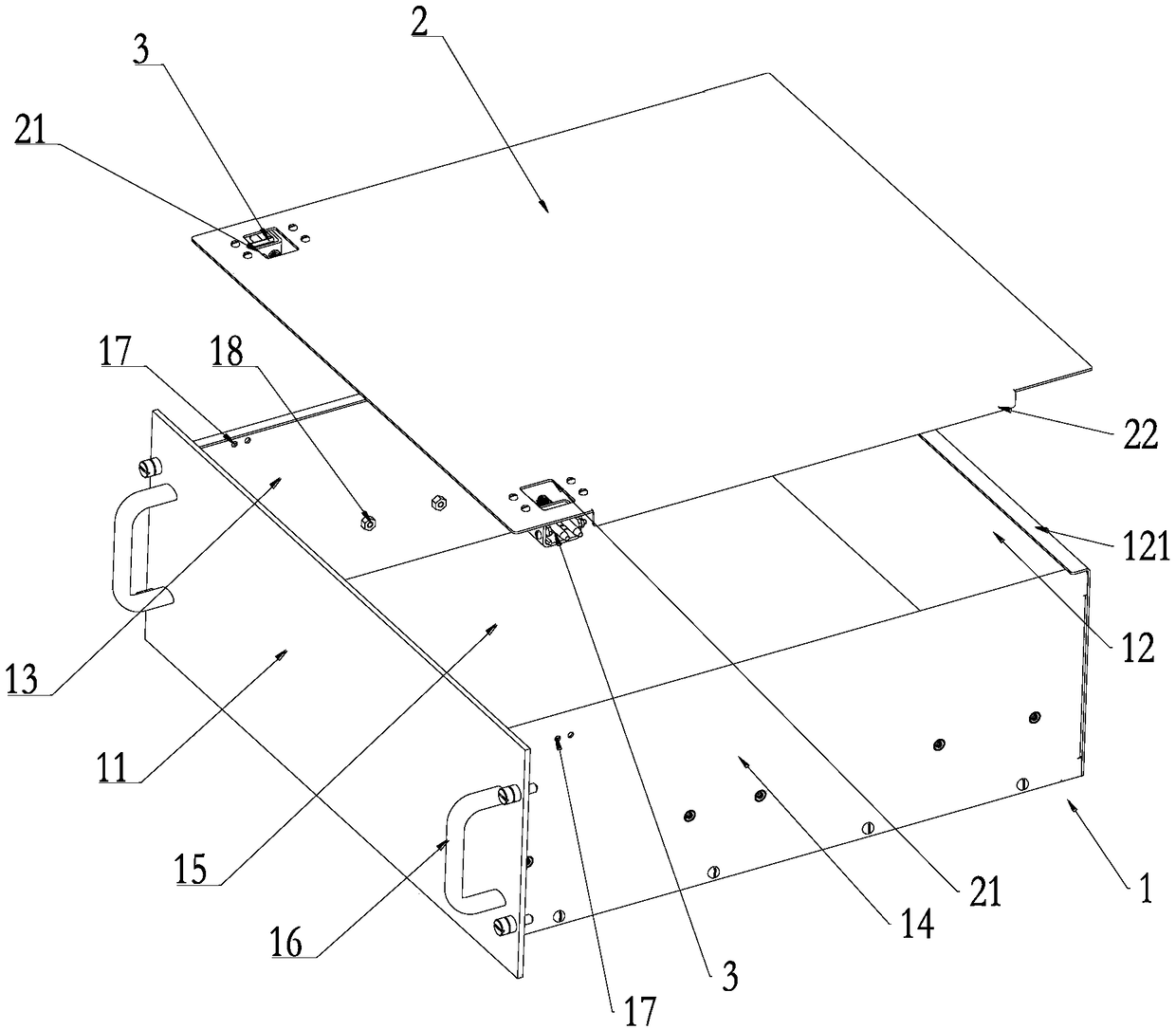

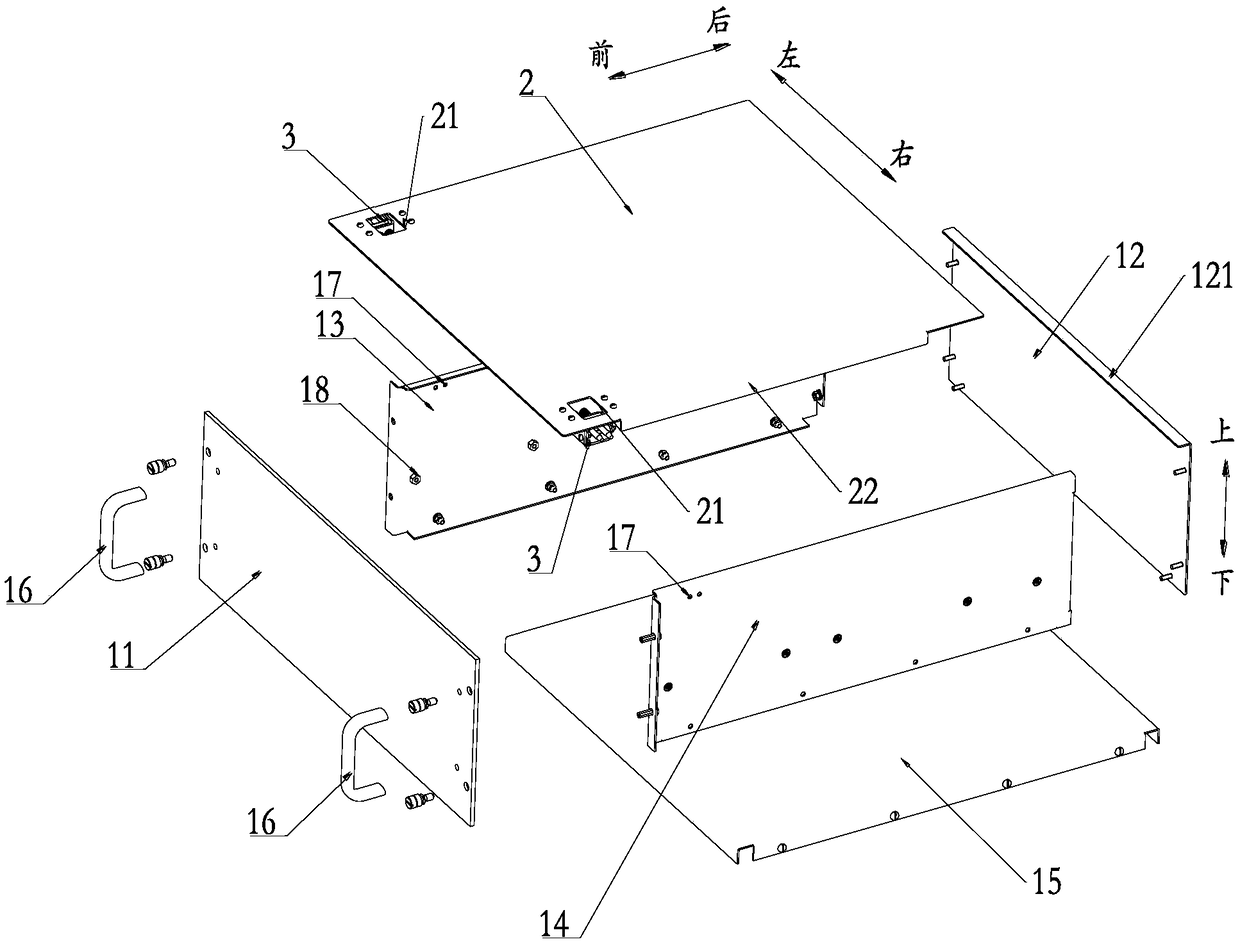

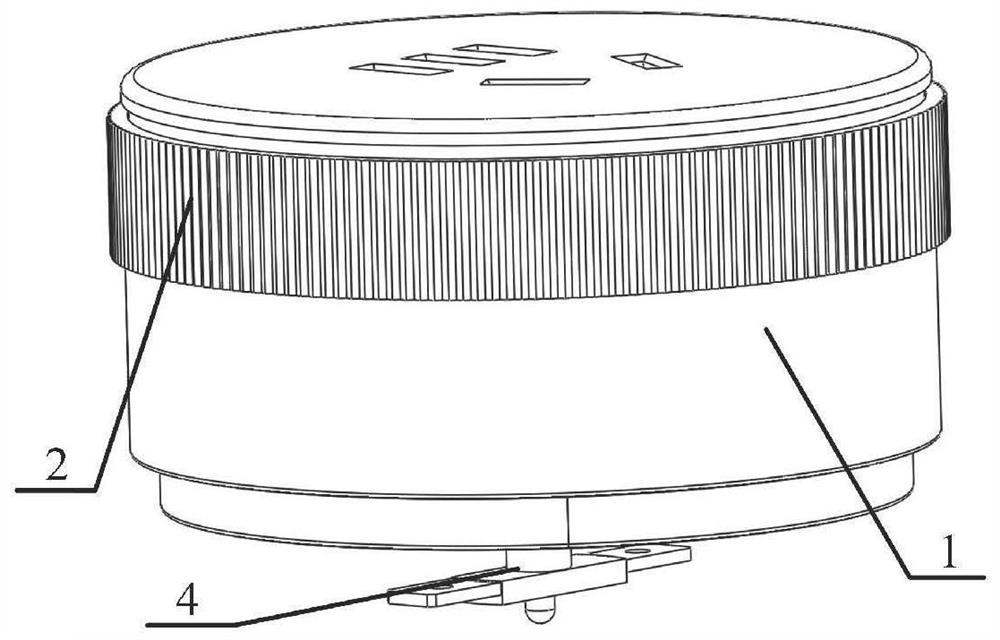

A spare part combination for quick disassembly and assembly of a top cover

ActiveCN109041491AQuick disassemblyEasy to operateCasings/cabinets/drawers detailsEngineeringSpare part

The invention relates to a spare part assembly for quick disassembly and assembly of a top cover, comprising a box body with an open top end and a top cover detachably covering the open end of the boxbody, wherein one side of the open end of the box body is formed with a clamping groove, one end of the top cover is inserted into the clamping groove, and the other end is clamped on the side wall of the box body through a plurality of elastic clamping mechanisms. Wherein, when the top cover is removed, the elastic clamping mechanism is squeezed out of the box body, and the top cover is withdrawn from the clamping groove; When the top cover is installed, one end of the top cover is inserted into the clamping groove, the elastic clamping mechanism is pressed to correspond to the clamping point on the side wall of the box body, and the elastic clamping mechanism is released to be clamped on the corresponding clamping point. The spare part combination of the invention can first position thetop cover through the clamping groove and then realize clamping and fixing of the top cover through the elastic clamping mechanism by arranging the clamping groove and the elastic clamping mechanismat the open end of the box body, and the spare part combination top cover can be quickly disassembled and assembled without additional tools, and the operation is simple and convenient and the cost islow.

Owner:BEIJING INST OF RADIO MEASUREMENT

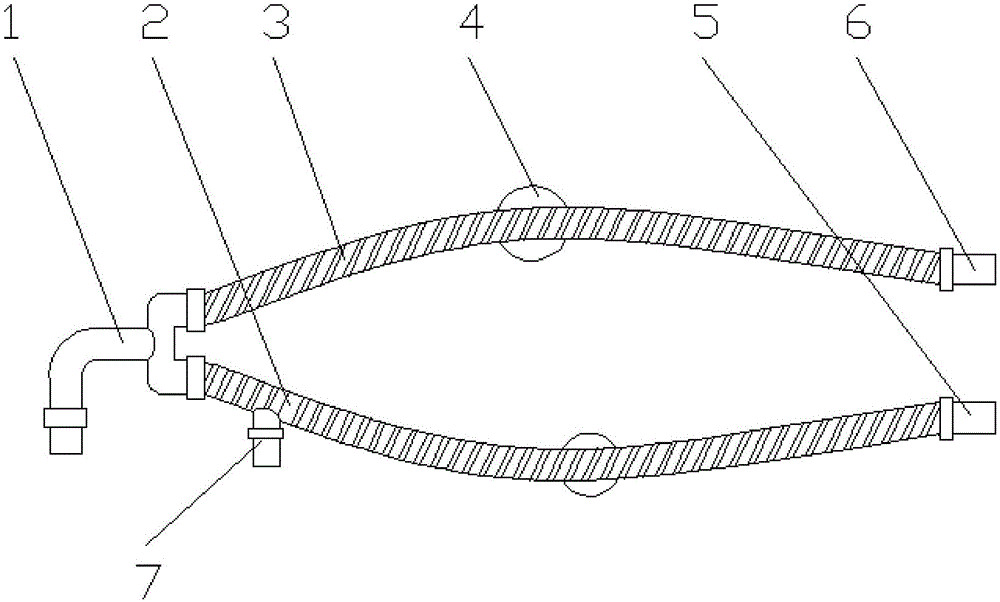

Respirator pipeline

The invention discloses a respirator pipeline, and belongs to the field of medical equipment. The respirator pipeline comprises a Y-shaped connector, an aspirating pipe, an exhaling pipe and two water collecting cups; the aspirating pipe and the exhaling pipe are both threaded pipes, the water collecting cups are communicated with the aspirating pipe and the exhaling pipe respectively, the inner side wall of the aspirating pipe and the inner side wall of the exhaling pipe are each provided with a water collecting ditch guiding water into the corresponding water collecting cup, the water collecting ditches are arranged in the axial direction, and the bottom of each water collecting ditch is lower than the thread bottom of the corresponding threaded pipe. The respirator pipeline can adjust the positions of the water collecting cups to be always located at the lowest part of the respirator pipeline, and collection of condensated water is guaranteed, and pipeline rupture and disengagement can be avoided; meanwhile, drugs can be prevented from being aspirated to contaminate a respirator; the condensated water can be prevented from being left at the thread bottoms, and the condensated water can completely flow into the water collecting cups.

Owner:成都欧赛医疗器械有限公司

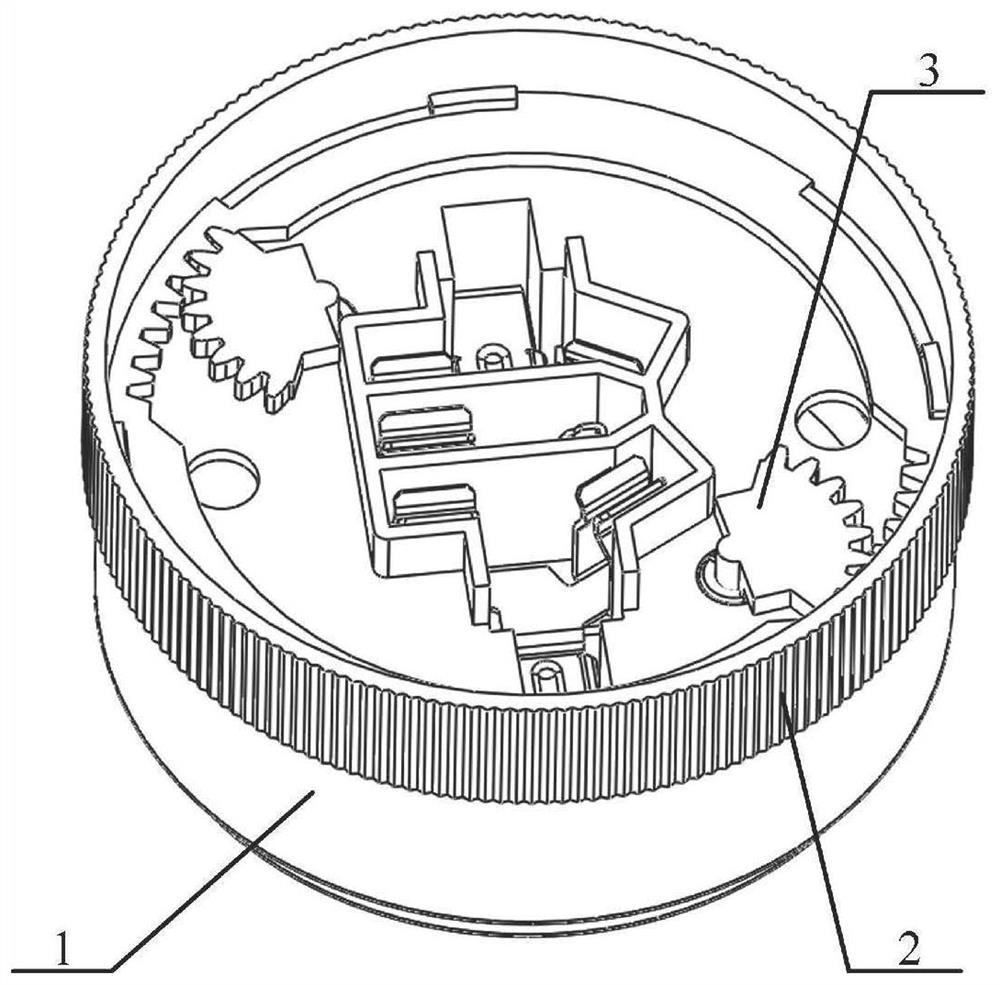

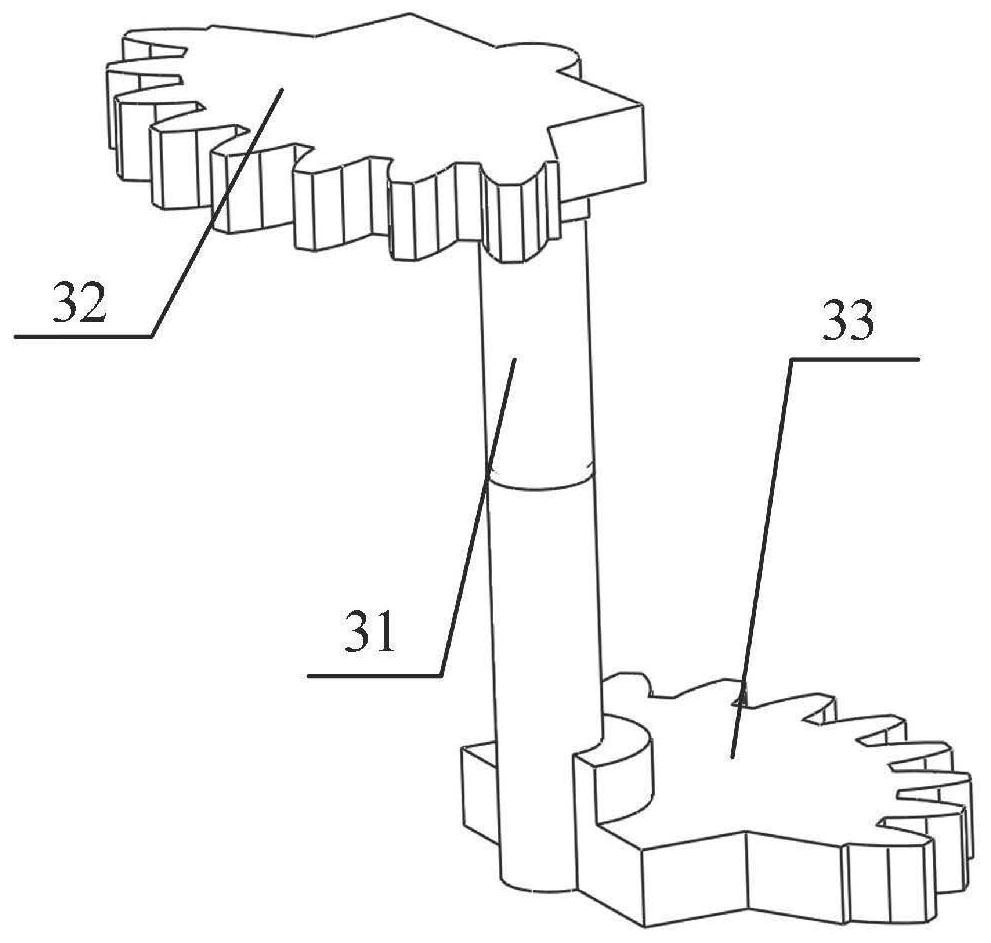

Adapter and rail socket

ActiveCN111786186ARealize slidingRealize uncharged slidingCoupling device detailsComputer hardwareTrackway

The invention relates to an adapter and a rail socket, and belongs to the technical field of sockets. The adapter comprises an adapter main body, a rotating piece, a transmission assembly and a conducting strip assembly. The rotating piece is rotationally connected with the adapter main body; and one end of the transmission assembly is matched with the inner wall of the rotating piece, and the other end of the transmission assembly is matched with the conducting strip assembly. The conducting strip assembly penetrates through the bottom of the adapter main body and can rotate relative to the adapter main body. By adoption of the adapter provided by the embodiment of the invention, when the adapter needs to slide on a track, the rotating part can be rotated to control the conducting strip assembly to be in the power-off position, so that the conducting strip assembly is separated from a track plug bush, and then the adapter slides, thereby realizing uncharged sliding of the adapter in the track.

Owner:BULL GRP CO LTD

Overhead line entanglement removing apparatus

ActiveCN106684762AEasy to installRealize slidingApparatus for overhead lines/cablesAgricultural engineeringFuel tank

The invention discloses an overhead line entanglement removing apparatus. The overhead line entanglement removing apparatus comprises a walking mechanism and a removing mechanism arranged on the walking mechanism, wherein the walking mechanism comprises a left walking bracket and a right walking bracket; a cross beam is arranged on the upper part of the left walking bracket; a first dovetail groove is formed in the bottom surface of the cross beam; a first dovetail joint matched with the first dovetail groove is arranged on the top of the right walking bracket; a pulley bracket is arranged in the middle part of the cross beam; a pulley is arranged on the lower part of the pulley bracket; the pulley presses on an overhead line; the removing mechanism used for removing overhead line entanglement is arranged at the bottom of the lower bracket of the left walking bracket; and the removing mechanism comprises a bearing bracket arranged at the bottom of the lower bracket of the left walking bracket and a fuel tank and a CPU module arranged on the bearing bracket. By adoption of the overhead line entanglement removing apparatus, the problems of retreating or even falling off in climbing can be effectively avoided, and in addition, high entanglement removing efficiency and a good effect are realized.

Owner:HENAN POLYTECHNIC INST

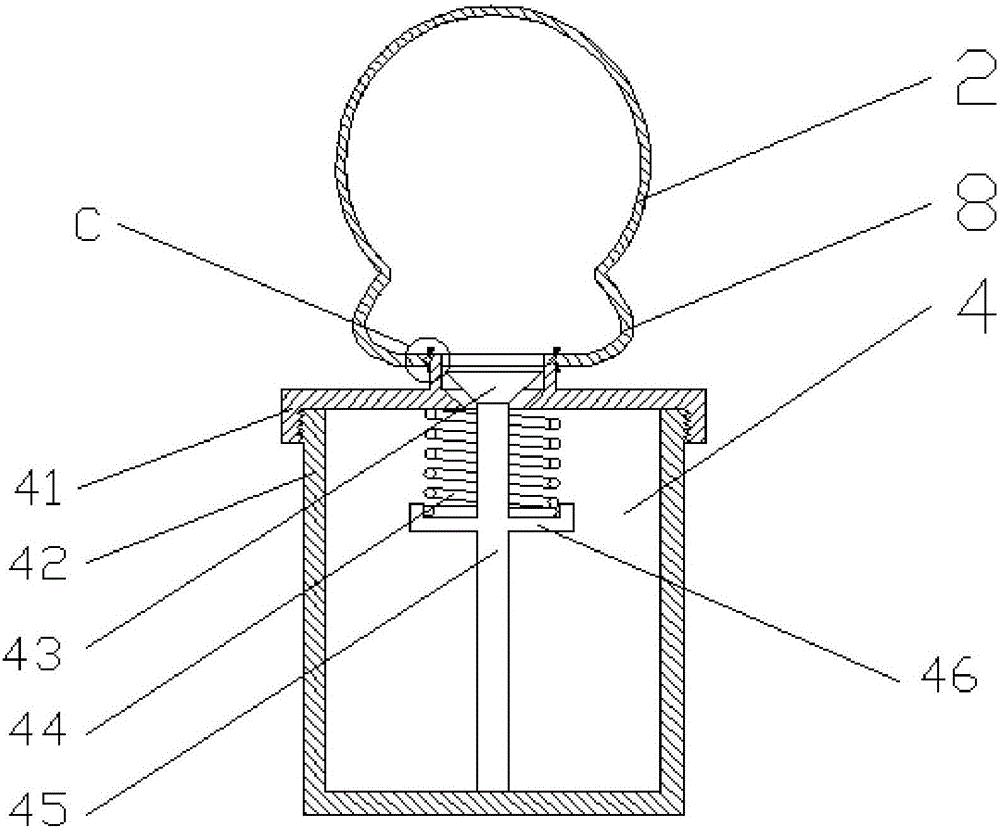

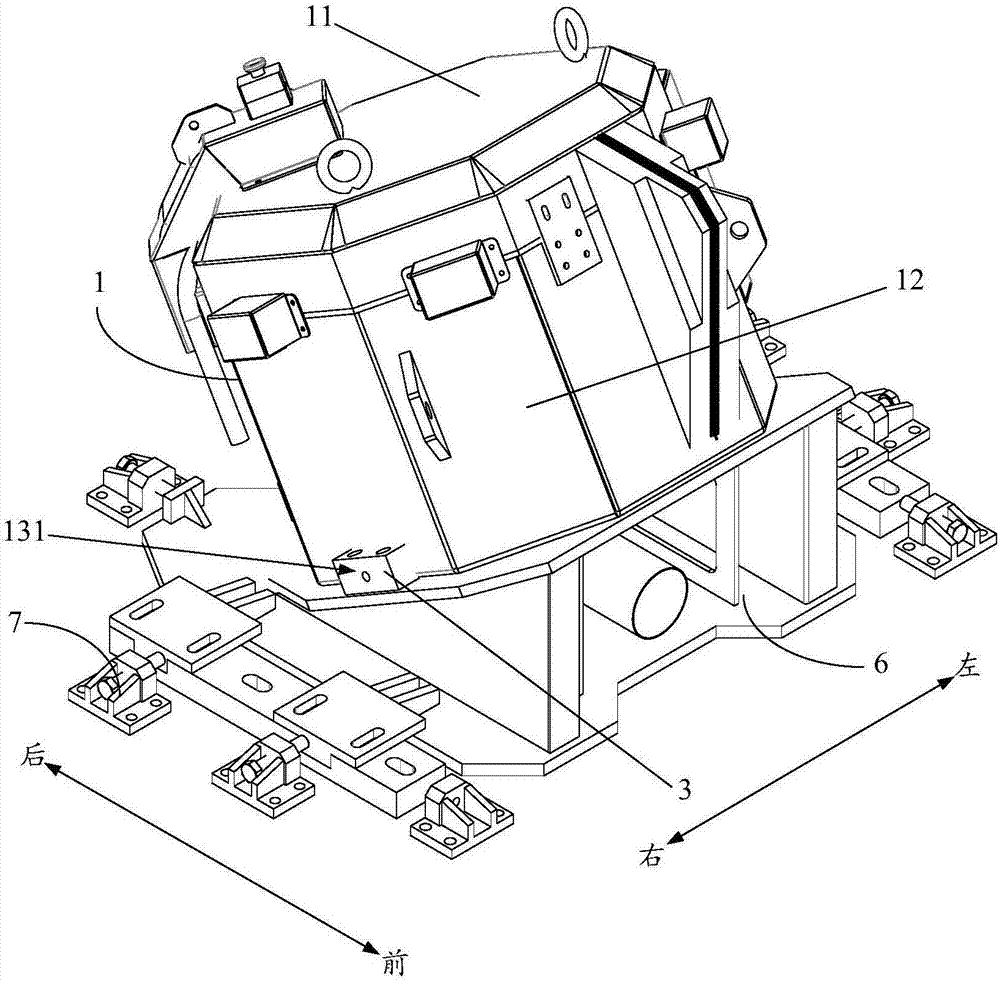

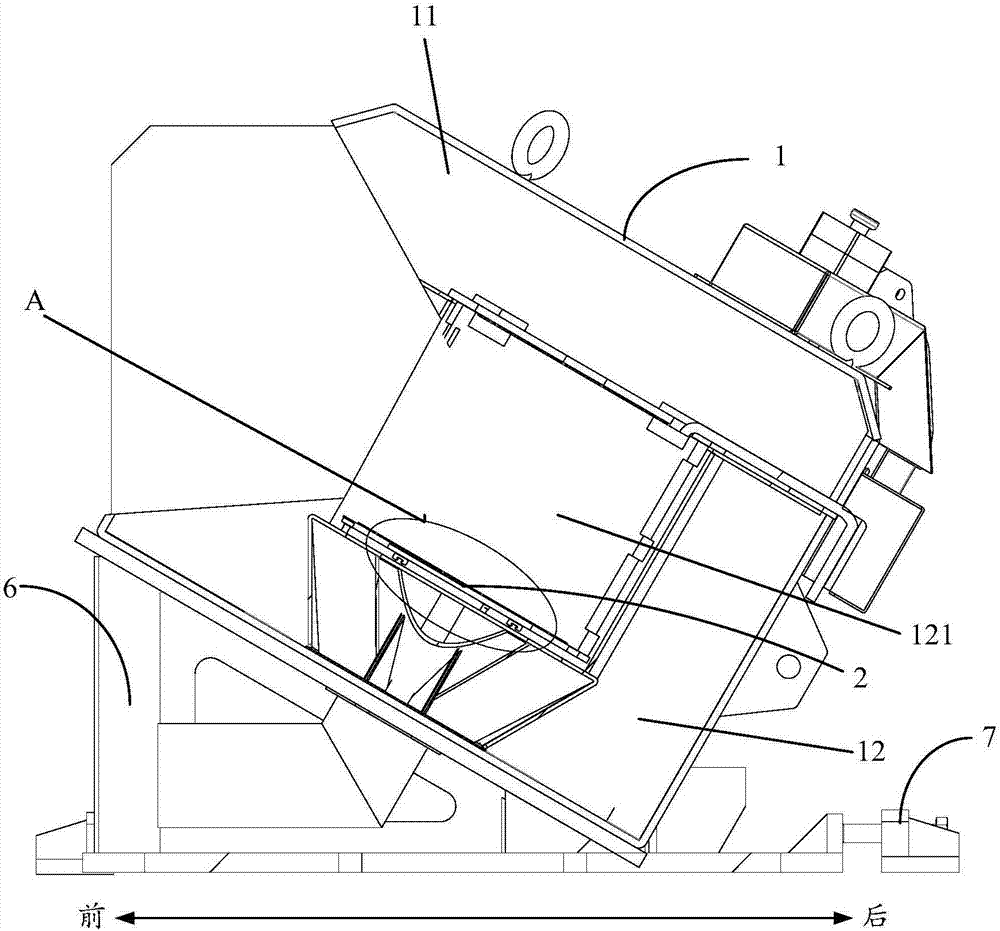

Accelerator position adjusting mechanism and electronic induction accelerator shielding container

PendingCN106879156AEasy to pushReduced maximum static frictionPortable shielded containersAcceleratorsStructural engineeringMechanical engineering

The invention provides an accelerator position adjusting mechanism and an electronic induction accelerator shielding container. The adjusting mechanism comprises a fixing plate and an operation piece. The fixing plate is installed on the base wall of an accommodation cavity of the electronic induction accelerator shielding container, is capable of sliding in the left and right directions relative to the base wall of the accommodation cavity and is used for fixing an electronic induction accelerator. A through hole is arranged in the left end and / or the right end of the side wall of the accommodation cavity. The first end of the operation piece passes through the through hole and is matched with the fixing plate. The second end of the operation piece is arranged outside the electronic induction accelerator shielding container, and used for driving the fixing plate to slide in the left and right directions relative to the base wall of the accommodation cavity. According to the invention, positions of the electronic induction accelerator can be easily adjusted outside the shielding container without disassembling an upper cover of the shielding container, so difficulty level of position adjustment work of the accelerator is greatly reduced, workload is reduced and time consumed for adjusting the position of the accelerator can be shortened.

Owner:BEIJING HUALIXING SCI TECH DEV

Insulator replacement device

ActiveCN106786172AIncrease contact areaImprove securityApparatus for overhead lines/cablesEngineeringElectrical and Electronics engineering

The invention discloses an insulator replacement device which comprises a clamp apparatus and a length regulation mechanism. The clamp apparatus comprises a first clamping plate and a second clamping plate which are fixedly connected; the first clamping plate and the second clamping plate are enclosed to form a cylindrical cavity; a first accommodating groove is formed on the upper end face of the first clamping plate; a second accommodating groove is formed on the upper end face of the second clamping plate; a first regulating ring is arranged in a sliding mode in the first accommodating groove; a second regulating ring is arranged in a sliding mode in the second accommodating groove; the center lines of arc holes interact with the center lines of the ring-shaped accommodating grooves; through slots are arranged on the side end faces of the first clamping plate and the second clamping plate; extension directions of the through slots point to the central axis of the cylindrical cavity; the upper ends of the through slots are communicated with the ring-shaped accommodating grooves; limiting pillars are arranged in a sliding mode in the through slots; limiting pins are vertically arranged at the upper end faces of the limiting pillars; the upper ends of the limiting pins extend out of the arc holes. According to the insulator replacement device disclosed by the invention, by regulating the positions of the arc holes, sliding of the limiting pillars in the through slots is implemented; and the insulator replacement device can be used for the replacement work of all types of suspended insulator strings in a substation.

Owner:国网河南省电力公司超高压公司 +1

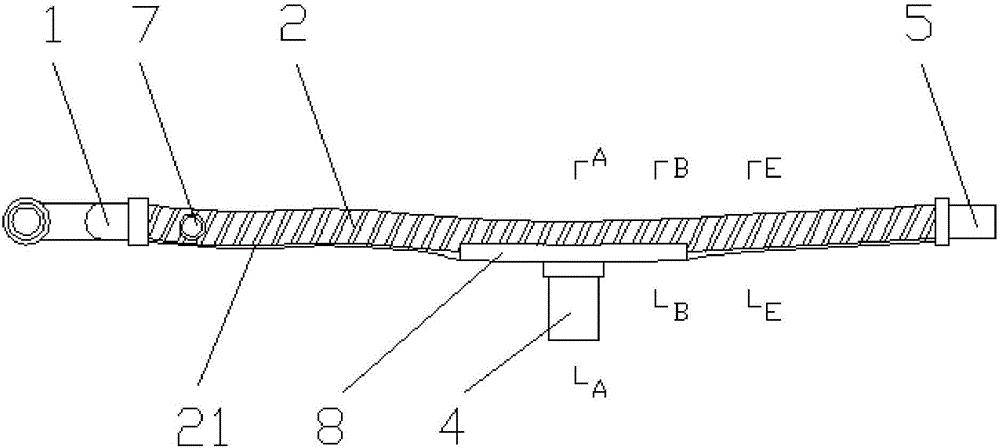

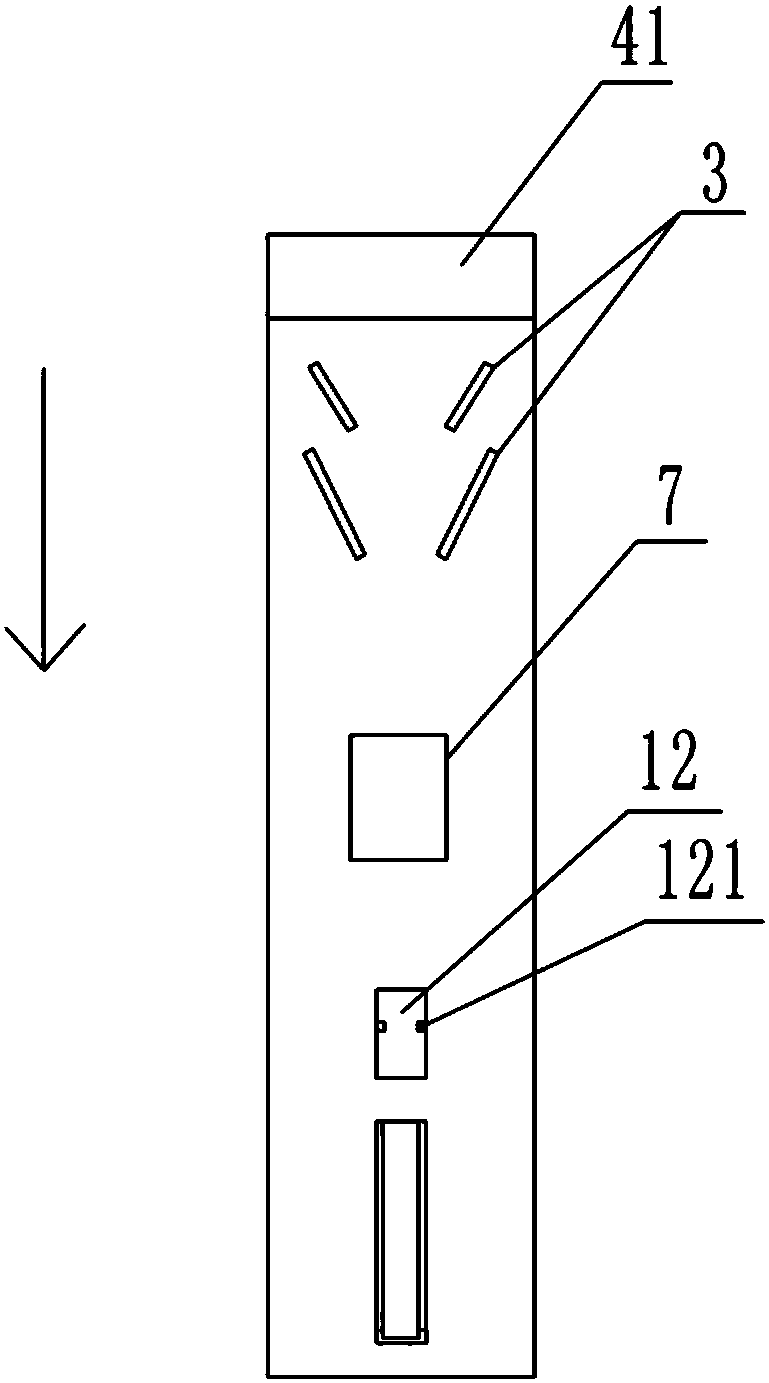

Charging pile of foot-type robot

InactiveCN112134109ARealize slidingAchieve floatingCoupling device connectionsElectric discharge tubesSlide plateControl theory

The invention discloses a charging pile of a foot-type robot, which is used for charging the foot-type robot, and comprises a charging pile body, a first base and a second base, wherein the charging pile body is connected with the foot-type robot to charge the foot-type robot; the first base is connected with the charging pile body; an accommodating groove is formed in the second base, and the first base is slidably connected with the bottom surface of the accommodating groove; and a sliding groove is formed in the bottom surface of the charging pile body, the charging pile body comprises a sliding plate arranged at a groove opening of the sliding groove, the sliding plate is slidably connected with the side wall of the sliding groove, and the outer side of the sliding plate is fixedly connected with the first base. By the adoption of the technical scheme, the charging pile body and the first base achieve floating of the charging pile of the foot-type robot in the vertical direction through a first spring, the first base and the second base are connected in a sliding mode, and sliding of the charging pile of the foot-type robot in the horizontal direction is achieved through sliding of the first base and the second base.

Owner:德鲁动力科技(海南)有限公司

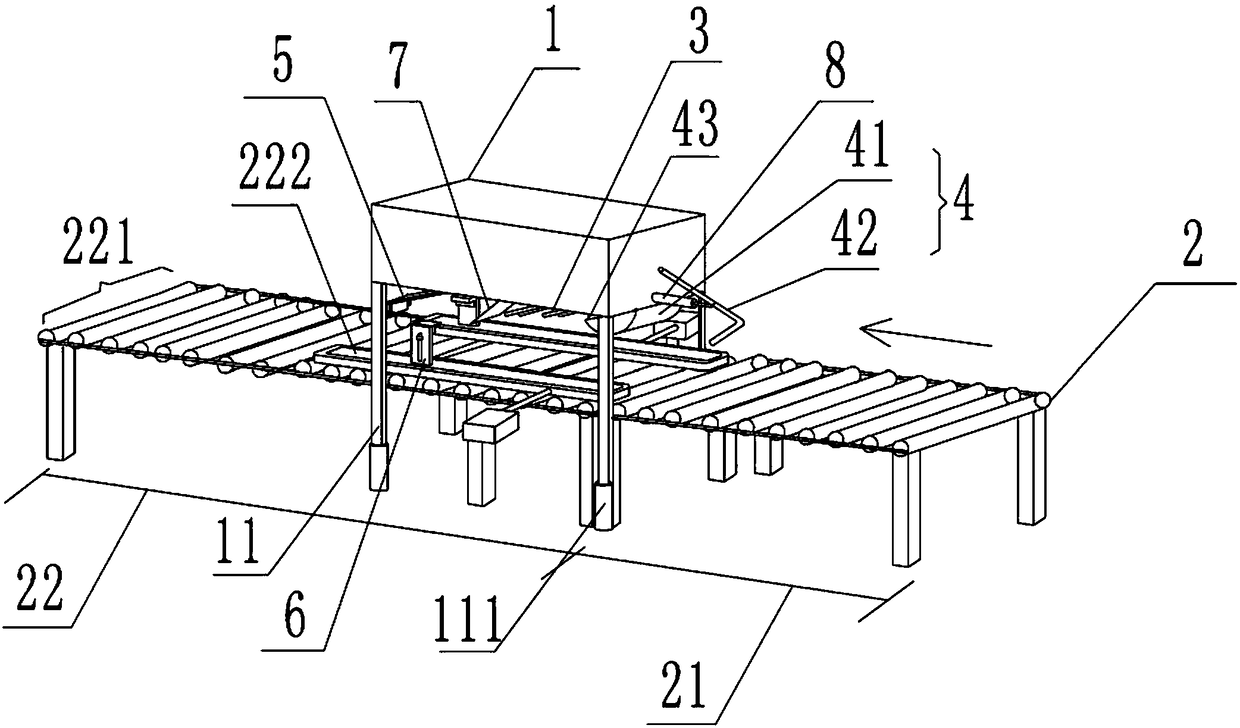

Electronic product container packing method

InactiveCN108100330AImprove sealing efficiencyQuality assuranceWrapper twisting/gatheringEngineeringPacking method

The invention relates to the technical field of shifting mechanisms, in particular to an electronic product container packing method. The electronic product container packing method comprises a framebody, a conveying part, a side plate leveling part, an end plate leveling part and an adhesive tape bonding part; the end plate leveling part, the side plate leveling part and the adhesive tape bonding part are arranged in a conveying direction of the conveying part in sequence; an extension part is arranged at the bottom of the frame body; the conveying part comprises a back conveying part, and afront conveying part consisting of a chain transmission roller way; the back conveying part comprises a conveying frame; the upper surface of the conveying frame is a conveying plane consisting of multiple cylinders; the two sides of the cylinders are connected with the two sides of the conveying frame; the conveying plane is provided with slide bars capable of oppositely moving along the conveying plane and clamping packing containers; conveying belts are arranged on the side surfaces of the slide bars; the slide bars are provided with extrusion parts for extruding the upper parts of the packing containers; and limiting parts for preventing side plates and end plates of the leveled packing containers from upwards turning are arranged at the bottom of the frame body. The electronic product container packing method not only can seal the packing containers with multiple specifications, but also can prevent generation of gaps in seals.

Owner:重庆市长寿区普爱网络科技有限公司

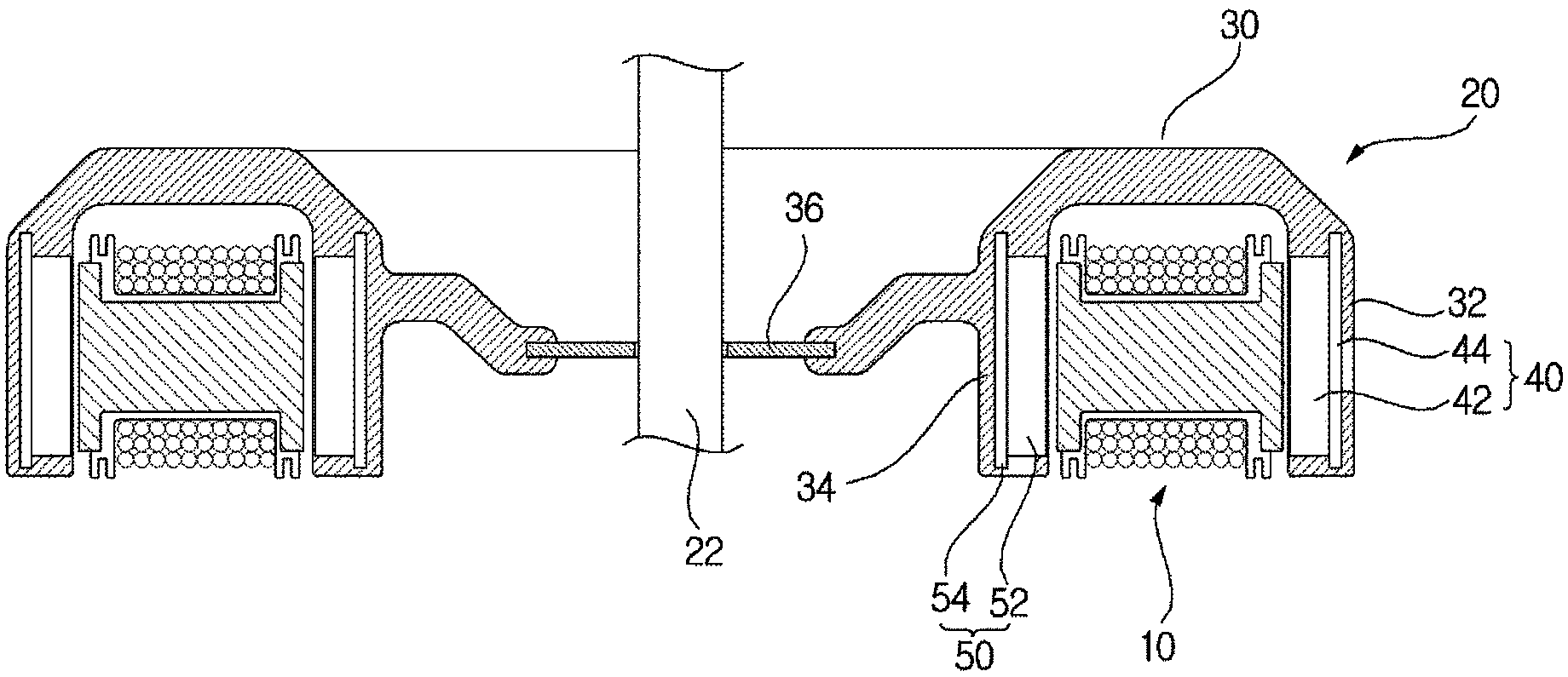

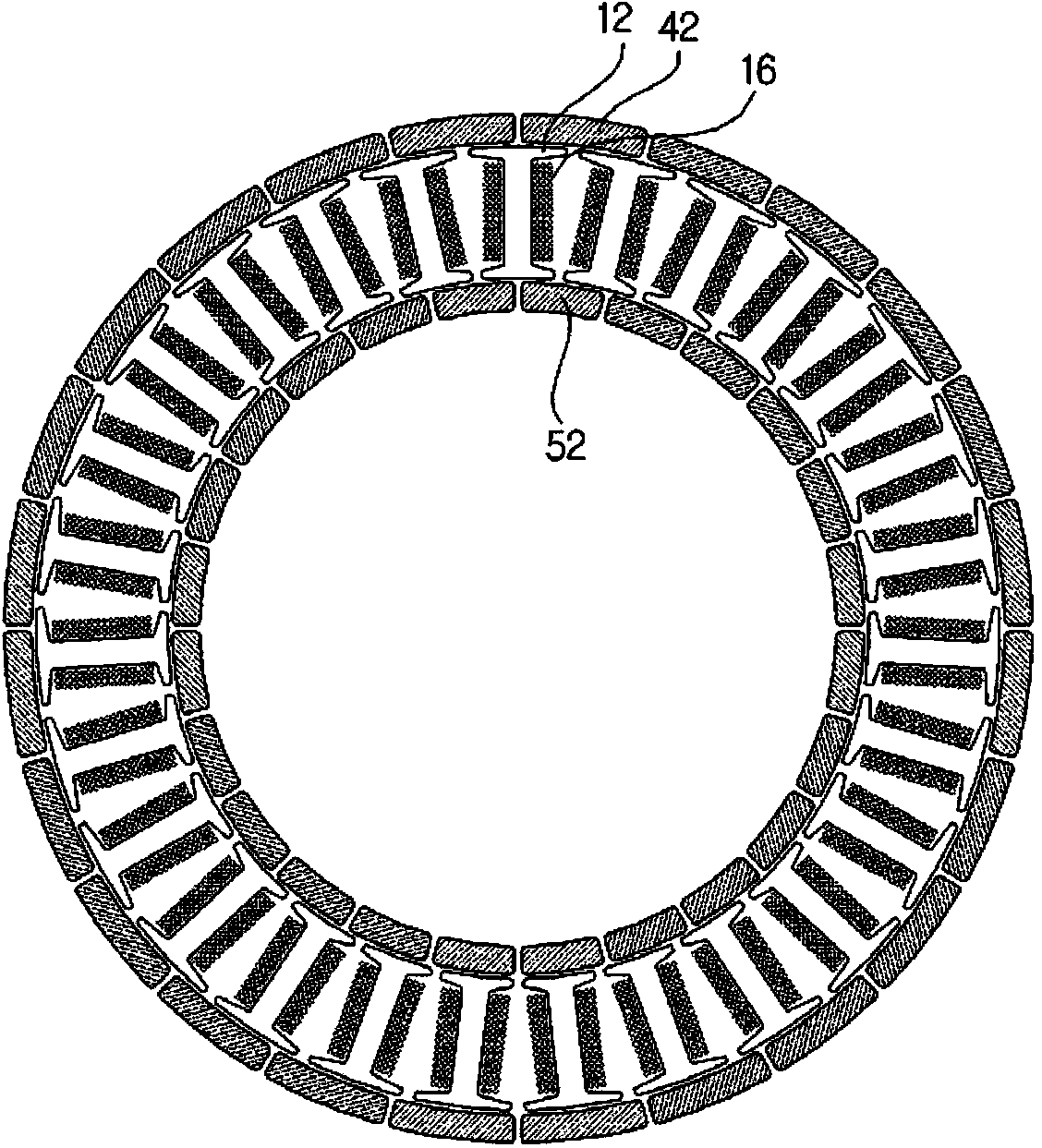

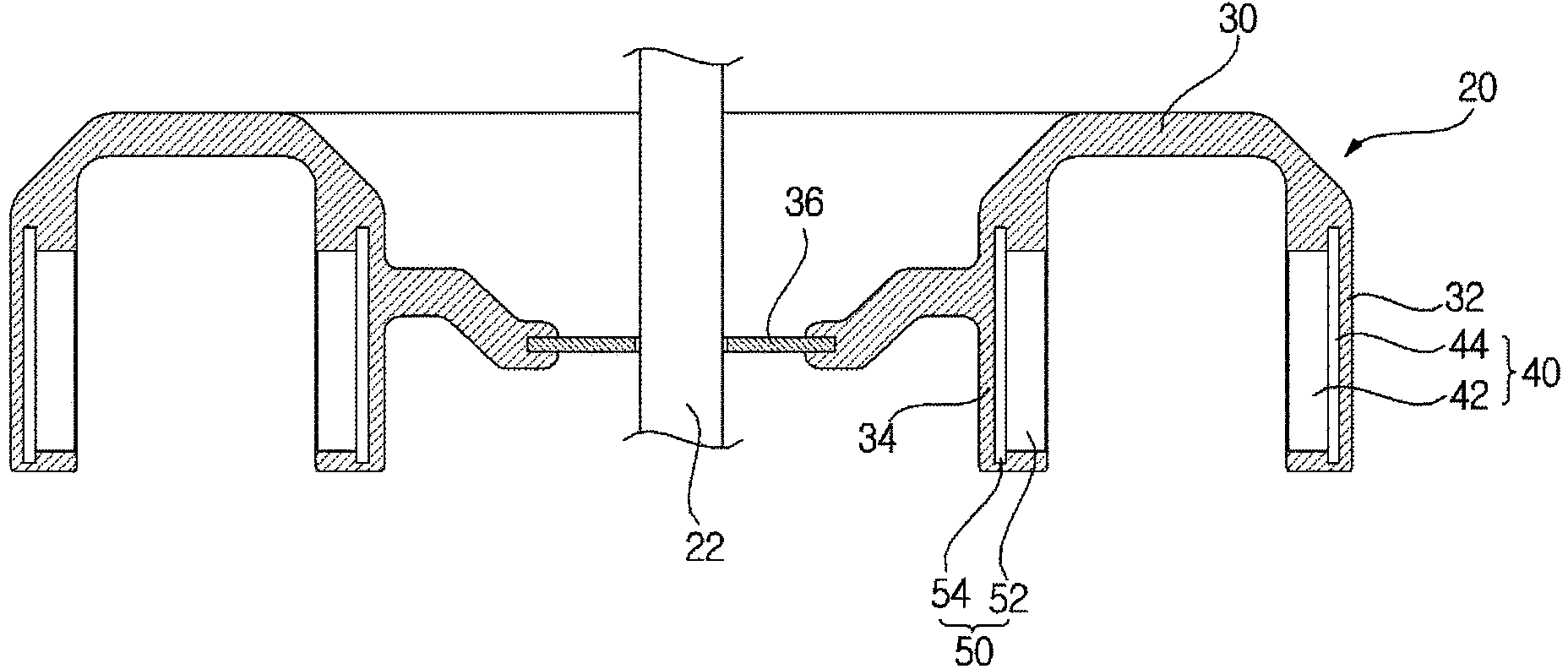

Motor having one-body type stator core

InactiveCN103999326AReduce lossesReduce manufacturing costsMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsBobbinEngineering

A motor having an amorphous core according to the present invention comprises: a stator core which is divided in a plural manner and is arranged in an annular shape; a bobbin surrounding an outer peripheral surface of the stator core; a stator which includes a coil wound around an outer peripheral surface of the bobbin; and a rotor which is disposed separately from the stator. The stator core is formed as a single unit, and comprises a yoke around which the coil is wound, and a first flange and a second flange that are disposed at both ends of the yoke. On upper and lower surfaces of the yoke, a coil winding groove is disposed, the height of which is lower than the heights of the upper and lower surfaces of the first flange and the second flange, so that a height of the stator core can be reduced. Thereby, slippage of the motor is allowed.

Owner:AMOTECH

Electric soldering iron welding working table

InactiveCN107855625AEasy to move up and downRealize slidingWork benchesSoldering auxillary devicesArchitectural engineeringEngineering

The invention discloses an electric soldering iron welding workbench, comprising a base, a workbench body is arranged above the base, a first groove is arranged on the base, and a fixing plate is connected to the left side of the first groove. A tooth plate is provided on one side of the fixed plate, a gear is connected to the right side of the tooth plate, and the gear is rotatably connected to both sides of the first groove, and a support seat is provided above the workbench body. By turning the crank handle, the crank drives the gear to rotate, and the gear rotates to drive the tooth plate to realize the slider sliding inside the slide rail and realize the lifting of the workbench body. The up and down movement of the board can realize the rotation of the support seat on the workbench body through the setting of the steel ball and the second groove, and the slight push of the support seat by touching with hands, and the circuit board and electrical components can be realized on the support seat through the limit plate. It won't slip off.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

Production method and production equipment of special compound fertilizer for lotus roots.

InactiveCN112250504AImprove decomposition abilityImprove toughnessSievingBio-organic fraction processingAgricultural engineeringPoultry manure

The invention discloses a production method of a special compound fertilizer for lotus roots. The method comprises the following steps: S1, uniformly mixing livestock and poultry manure and crushed straw according to a mass ratio of 2: 1 to obtain an organic matter mixture; placing microbial strains into a culture medium and comprising saccharomycetes, photosynthetic bacteria, rhizobium and sporebacteria, wherein the content of microorganisms in lotus root growth sludge is supplemented, the decomposition capacity of nutrient substances is improved, absorption of lotus roots is facilitated, and phosphorus-potassium fertilizer, urea, microelements, hexaurea ferric trinitrate and plant ash are mixed into a fermentation product; fully stirring and mixing the raw materials, then adding the radix puerariae powder and the tapioca flour, and fully and uniformly stirring to obtain a viscous mixed material, so that the toughness of the fertilizer can be improved, the loose texture of the fertilizer can be avoided, and slowly decomposing the fertilizer, continuously and efficiently providing nutrients for lotus roots, bysetting the extrusion granulation components, it is possible to push thefertilizer after molding, preparing fertilizer particles with uniform texture and balanced compactness , and realizing high-quality production of the fertilizer.

Owner:ANHUI SIERTE FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com