Automatic fallen yarn coiling system for polyester production

An automatic and doffing technology, which is applied in the field of polyester production, can solve the problems of not being able to wind more wires, and the efficiency of winding coils is low, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

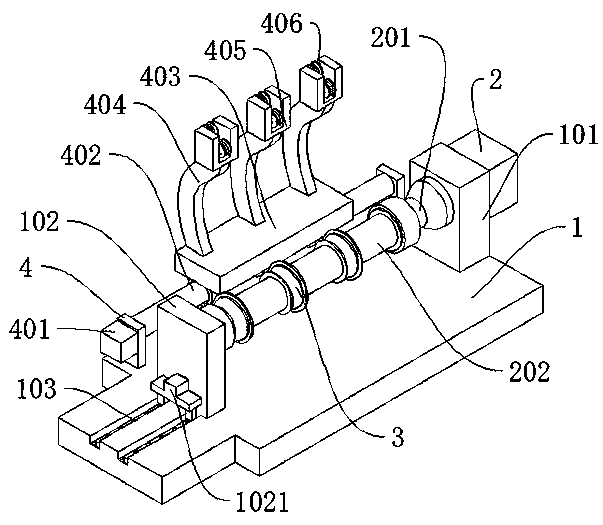

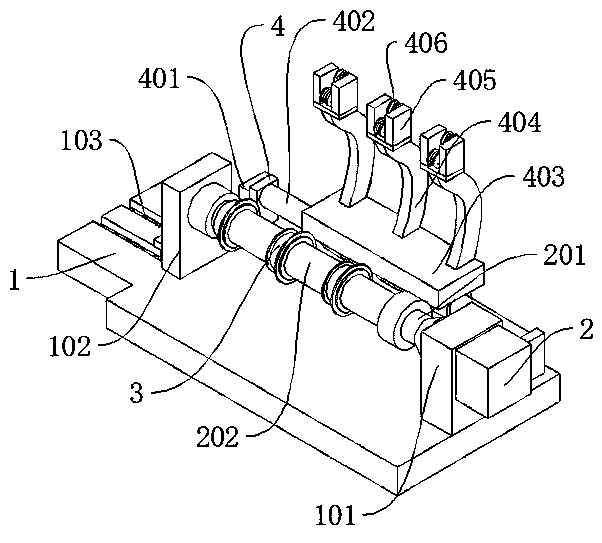

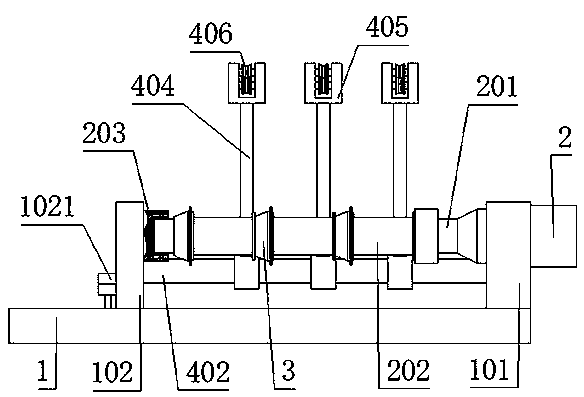

[0032] refer to Figure 1-5 An automatic doffing and rolling system for polyester production, comprising a base 1, a first baffle 101 is fixedly connected to the base 1, a second baffle 102 is slidably connected to the end of the base 1 away from the first baffle 101, the first The side wall of the baffle plate 101 is connected with the first motor 2, the output end of the first motor 2 is connected with the first rotating shaft 201, and the end of the first rotating shaft 201 away from the first motor 2 is connected to the second baffle plate 102 for rotation, and the first rotating shaft 201 The upper part is connected with the reel 202, the ferrule 3 which cooperates with the reel 202 is connected with the first rotating shaft 201, two third baffles 4 are symmetrically connected on the base 1, and the two third baffles 4 rotate The second rotating shaft 402 is connected, and the second rotating shaft 402 is slidably connected with a wire branching mechanism corresponding to...

Embodiment 2

[0034] refer to Figure 1-5 An automatic doffing and rolling system for polyester production, comprising a base 1, a first baffle 101 is fixedly connected to the base 1, a second baffle 102 is slidably connected to the end of the base 1 away from the first baffle 101, the first The side wall of the baffle plate 101 is connected with the first motor 2, the output end of the first motor 2 is connected with the first rotating shaft 201, and the end of the first rotating shaft 201 away from the first motor 2 is connected to the second baffle plate 102 for rotation, and the first rotating shaft 201 The upper part is connected with the reel 202, the ferrule 3 which cooperates with the reel 202 is connected with the first rotating shaft 201, two third baffles 4 are symmetrically connected on the base 1, and the two third baffles 4 rotate The second rotating shaft 402 is connected, and the second rotating shaft 402 is slidably connected with a wire branching mechanism corresponding to...

Embodiment 3

[0037] refer to Figure 1-5, an automatic doffing and rolling system for polyester production, which is basically the same as Embodiment 2, furthermore, the second rotating shaft 402 is provided with external threads, and the bottom of the slide seat 403 is provided with internal threads, by controlling the second motor 401 The positive and negative rotation of the sliding seat 403 is driven to reciprocate on the second rotating shaft 402 through threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com