Automobile cutting detection machine for positive plate and negative plate of mobile phone battery

A technology for positive and negative pole pieces and mobile phone batteries, which is applied in the direction of electrode manufacturing, other manufacturing equipment/tools, lamination devices, etc., and can solve the problem of backward detection of cutting size and edge tread, low efficiency, and poor control Cutting quality and other issues, to achieve the effect of increasing production capacity and saving cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

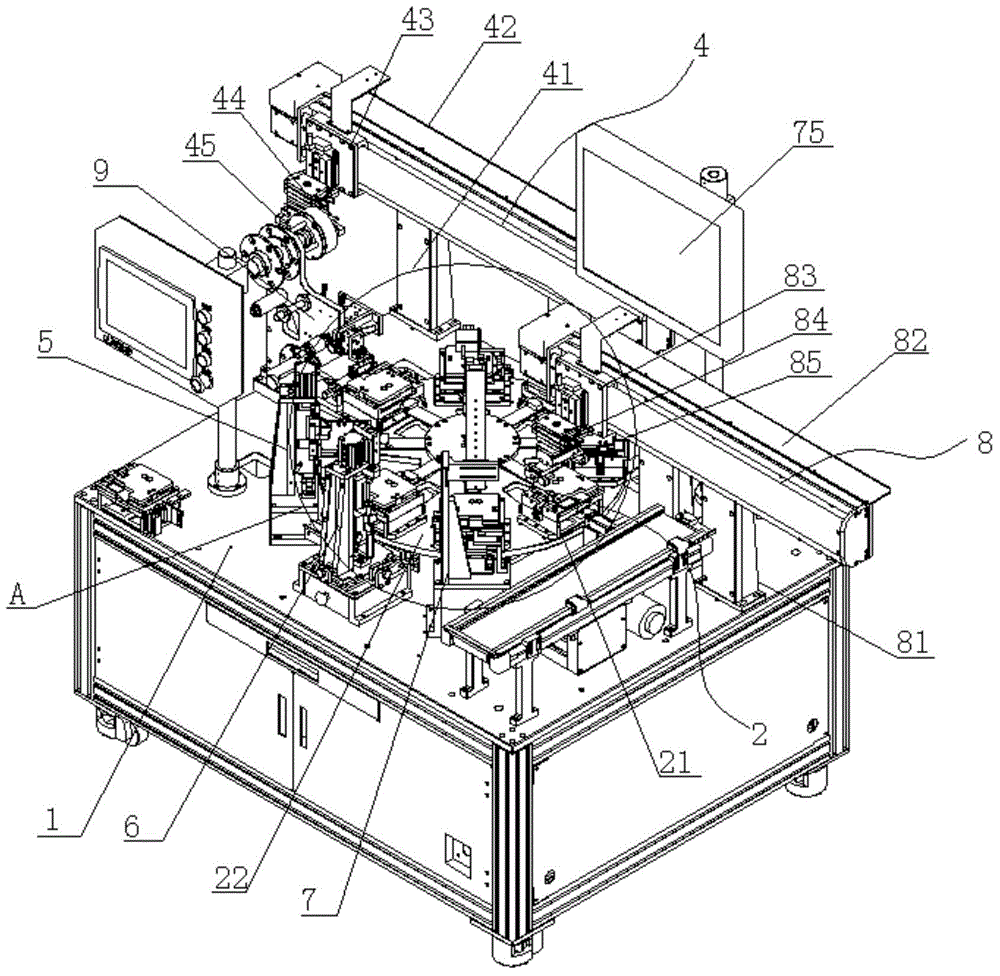

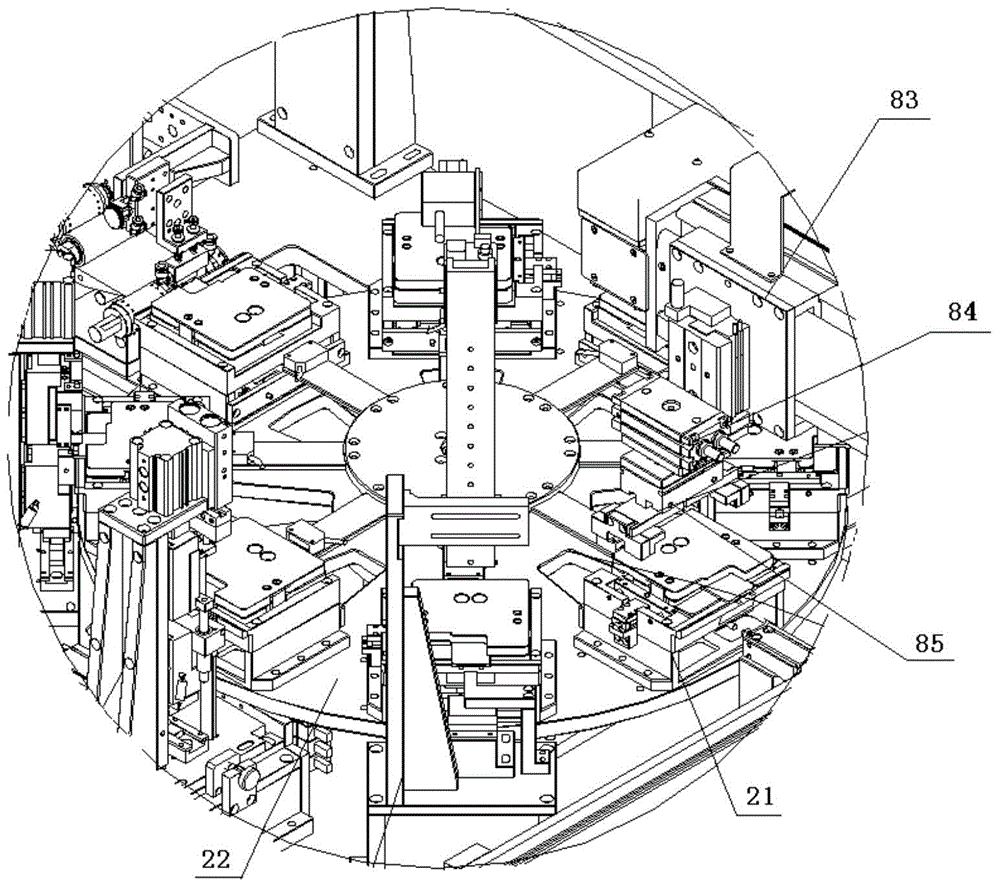

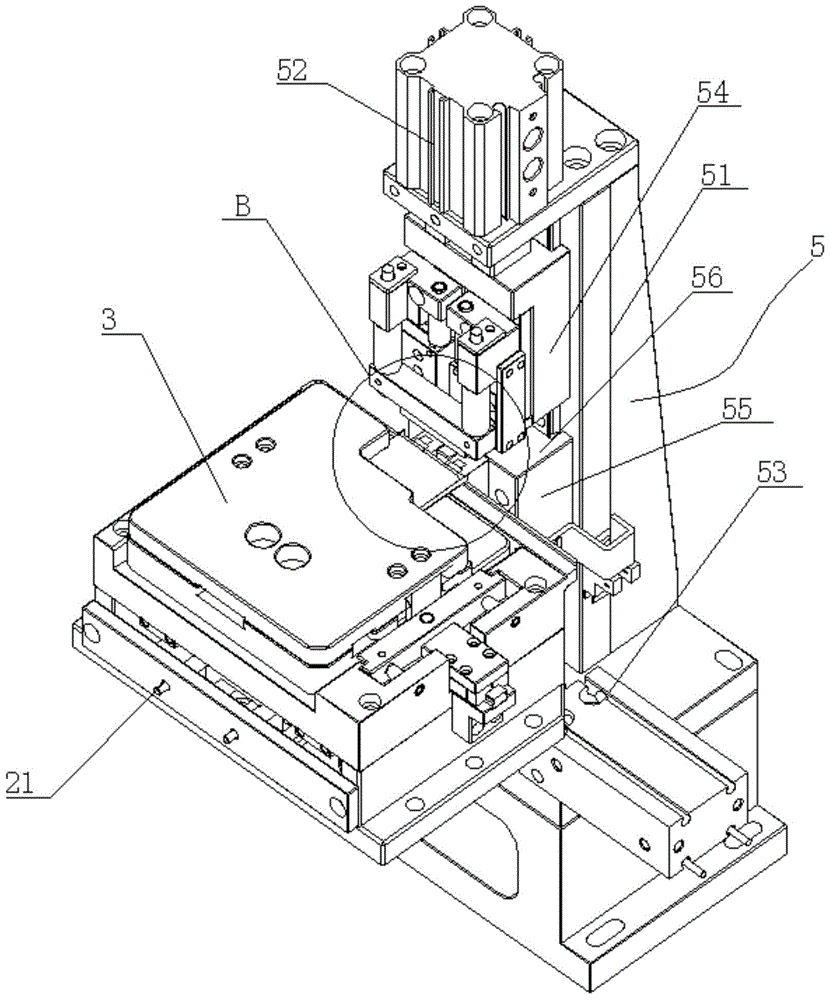

[0049] Such as figure 1 and figure 2 As shown, an automatic cutting and testing machine for positive and negative pole pieces of mobile phone batteries includes a working platform 1 and a turntable mechanism 2 that is arranged in the middle of the working platform and can rotate and position in the circumferential direction. There are at least five rotary stations 21, corresponding to each rotary station, a carrier 3 for positioning the battery 31 with positive and negative pole pieces 311 is provided, and a feeding and conveying mechanism is provided in sequence on the periphery of the turntable mechanism 4. Shaping mechanism 5, cutting mechanism 6, AOI detection mechanism 7 and unloading and conveying mechanism 8; the loading and conveying mechanism can automatically grab and carry the carrier and place it on one of the rotating stations. The rotary station can automatically position the carrier; the shaping mechanism can flatten and shape the positive and negative pole pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com