Patents

Literature

313results about How to "Improve crop quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

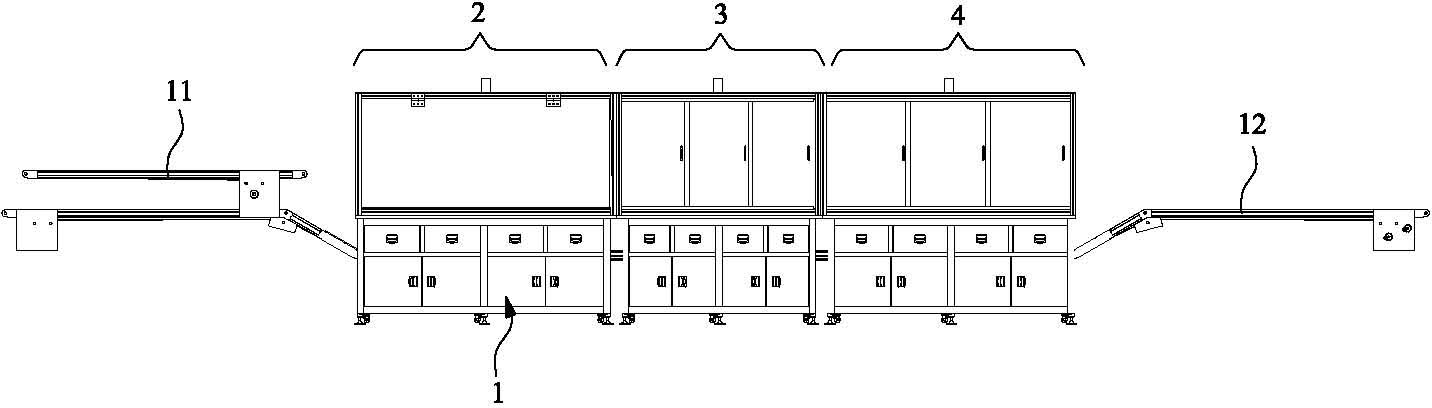

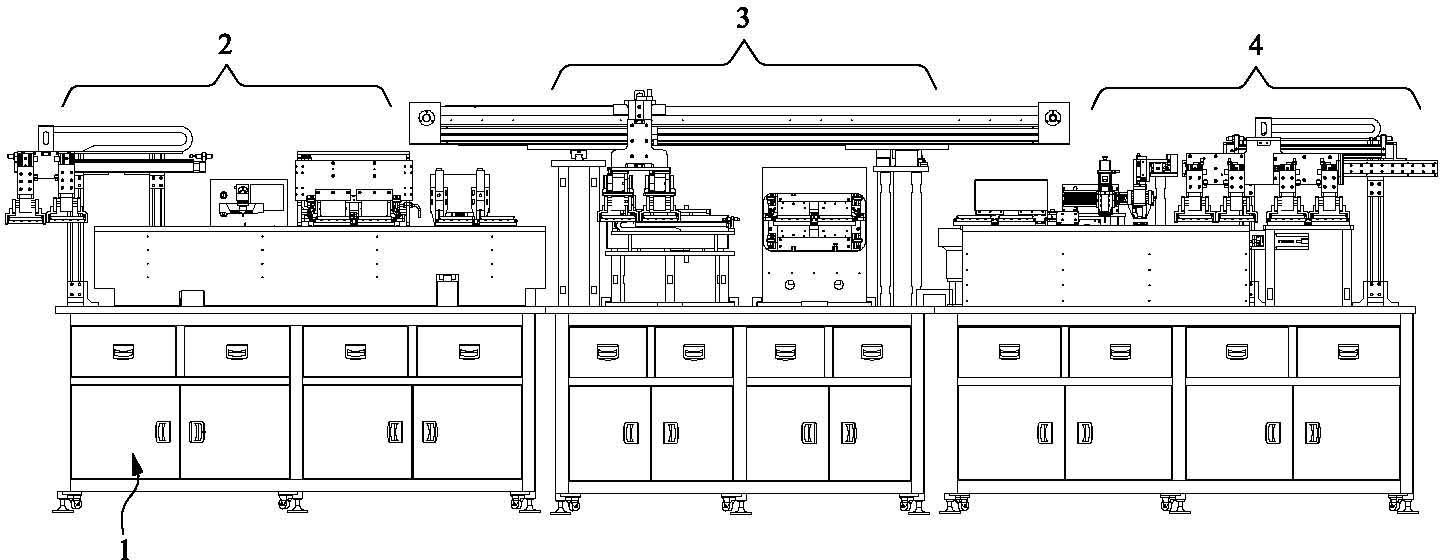

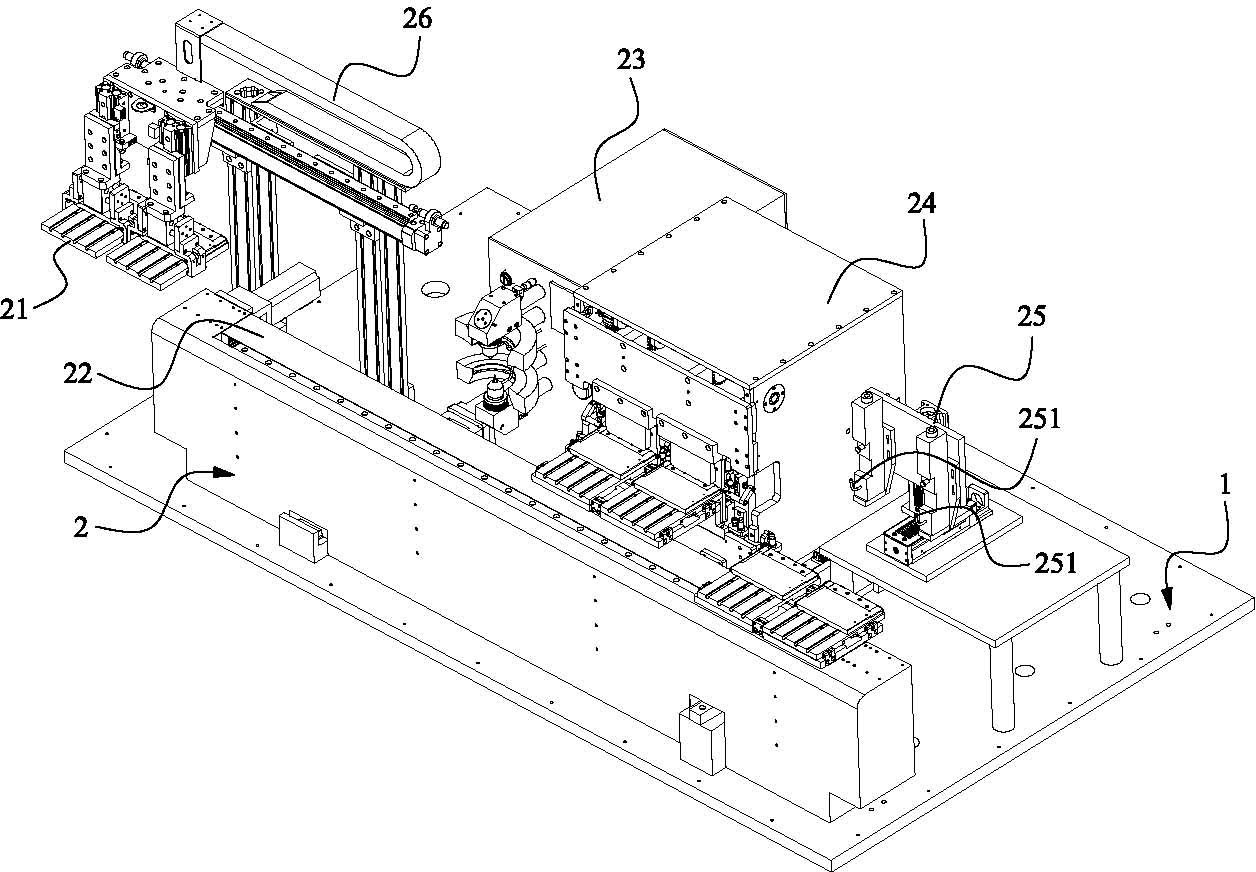

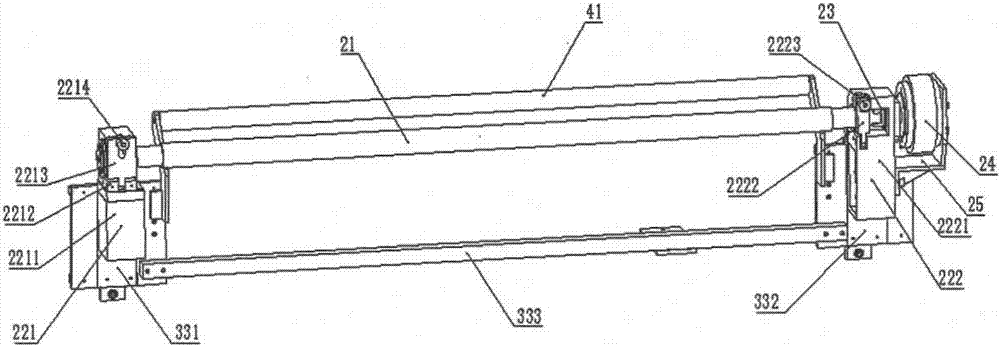

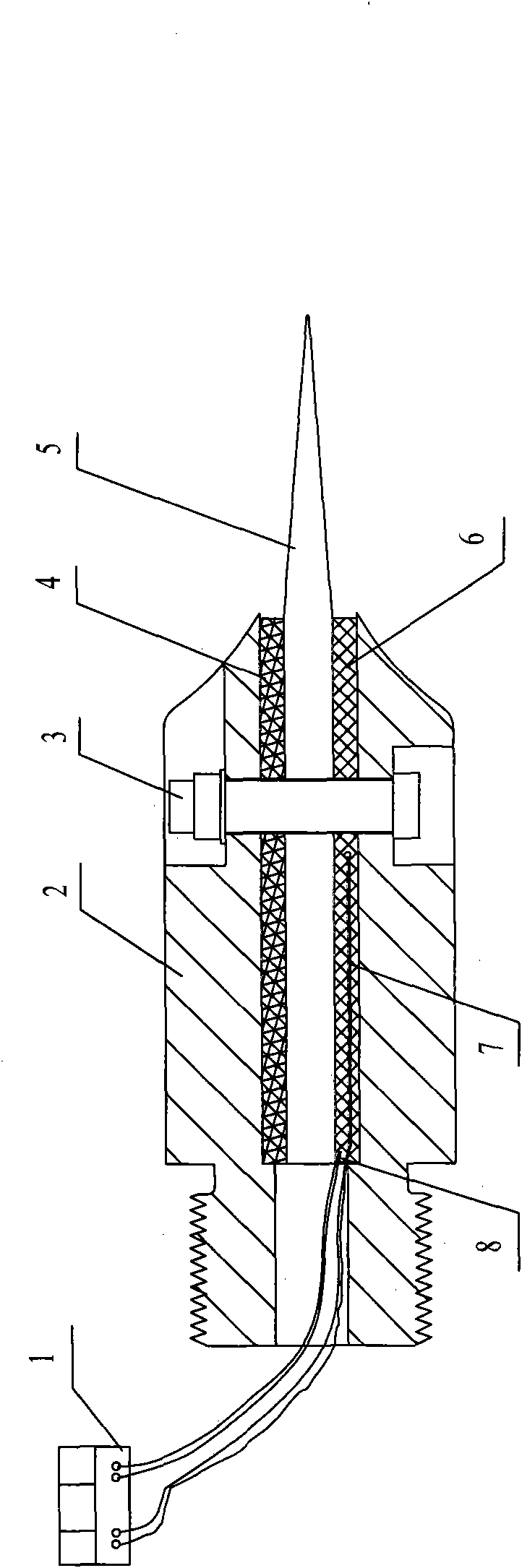

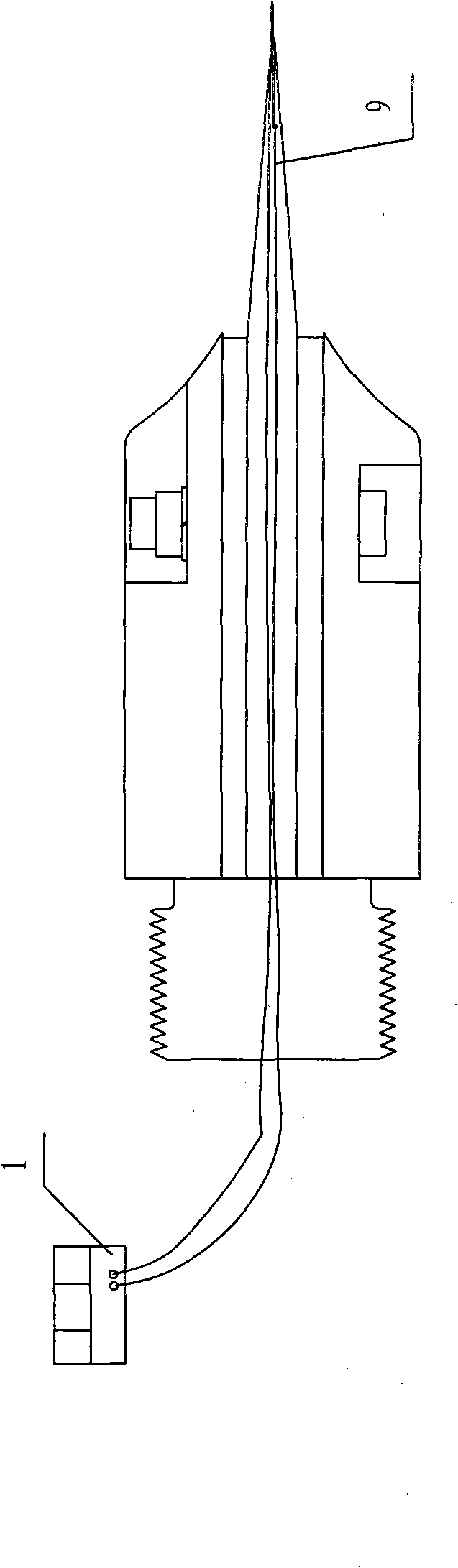

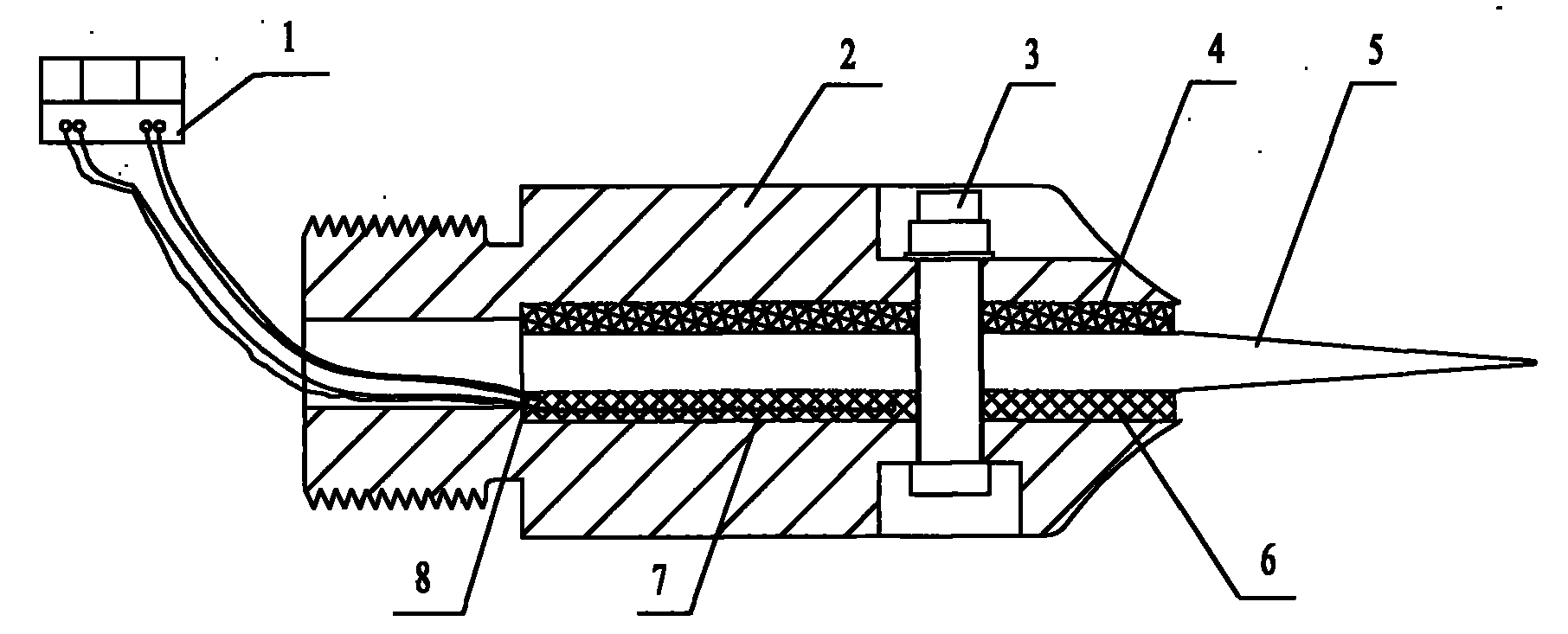

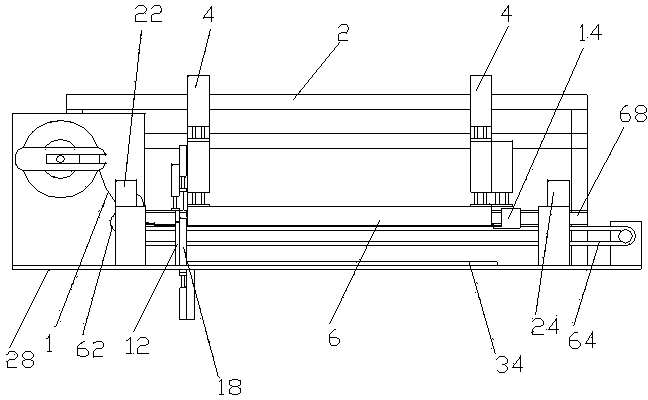

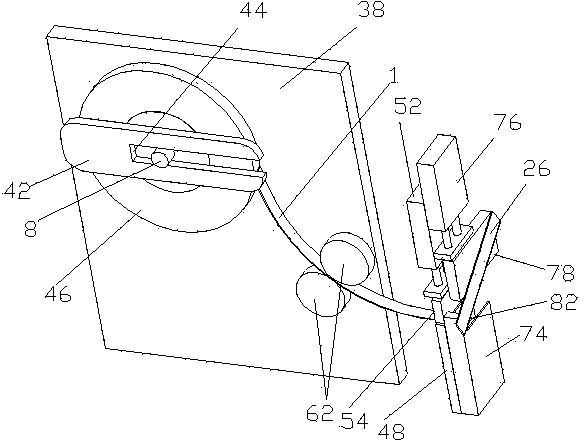

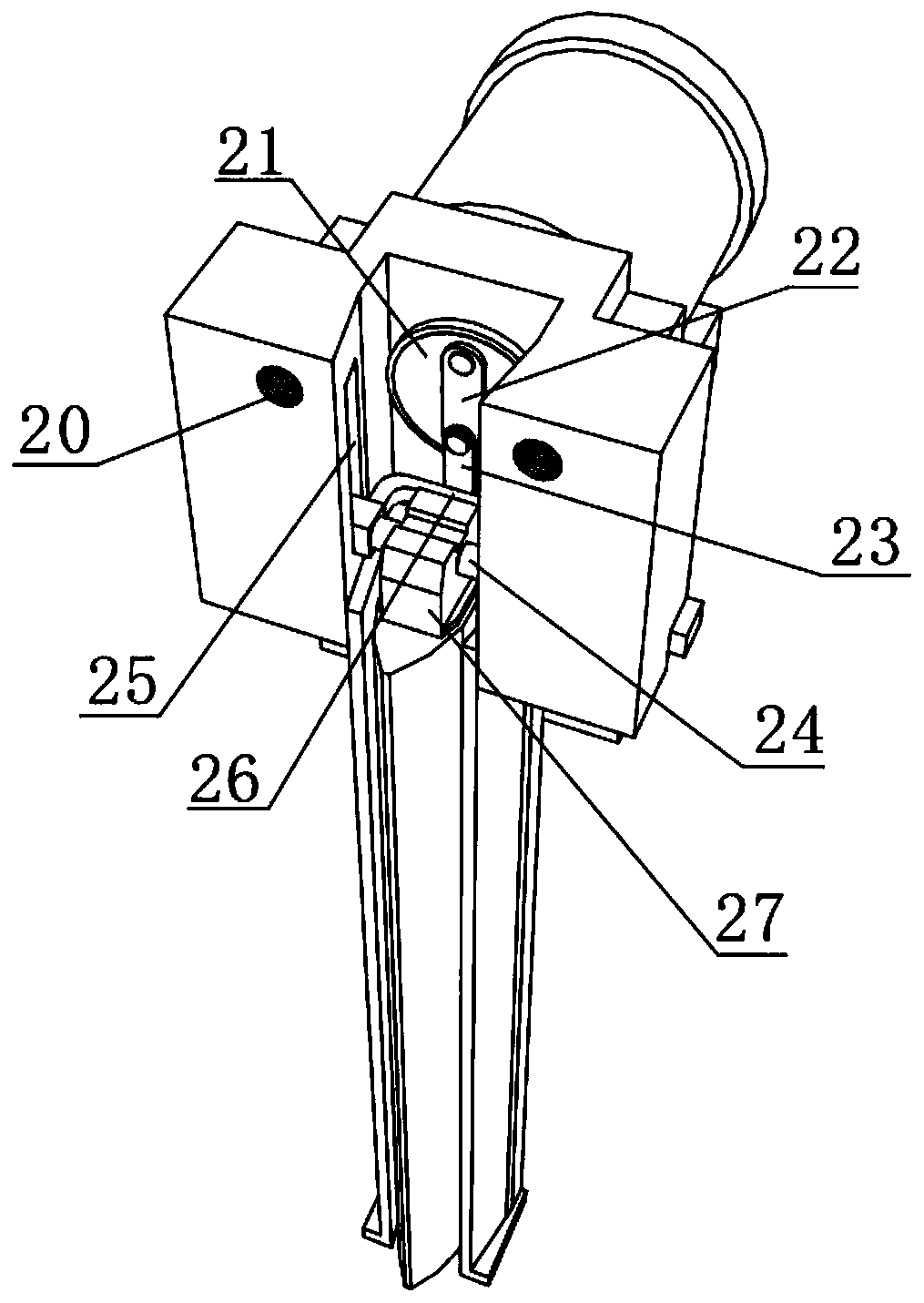

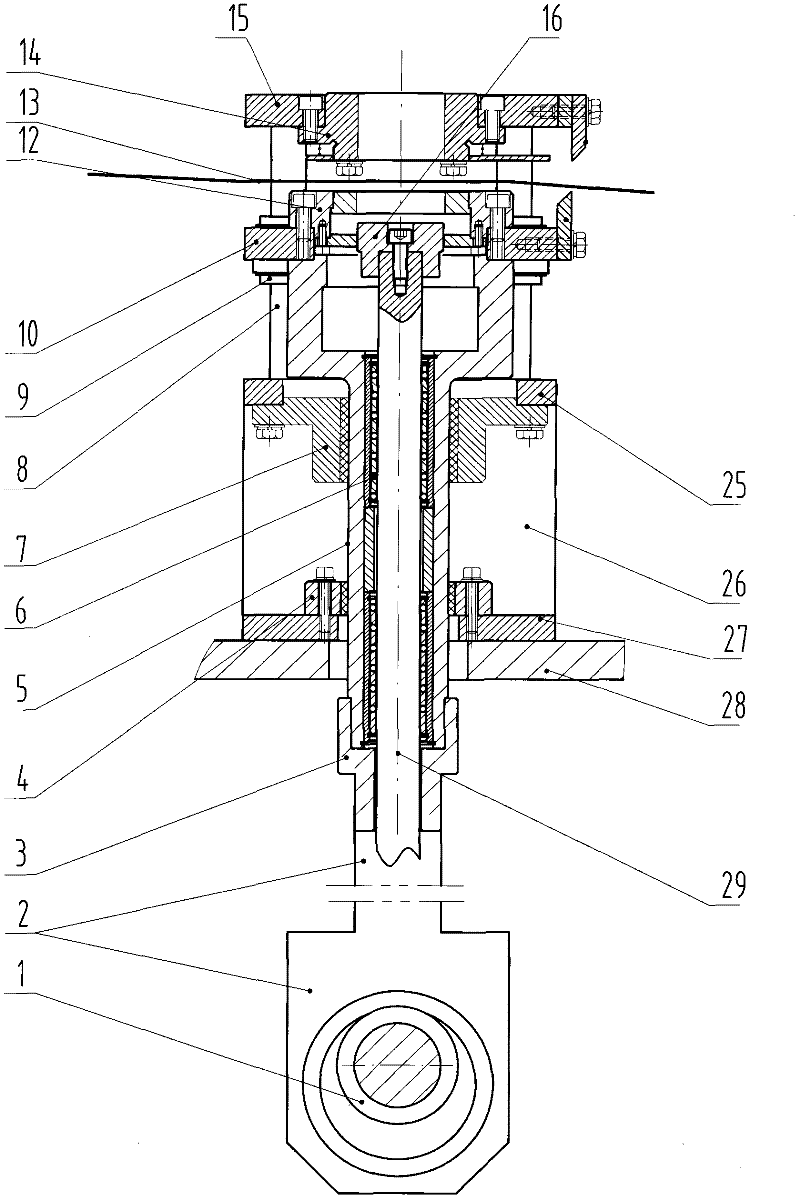

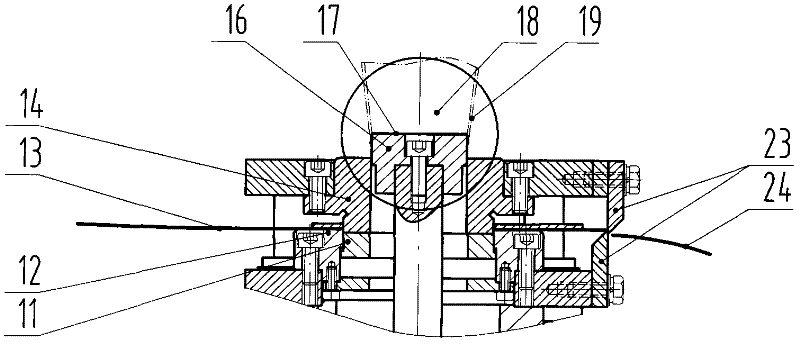

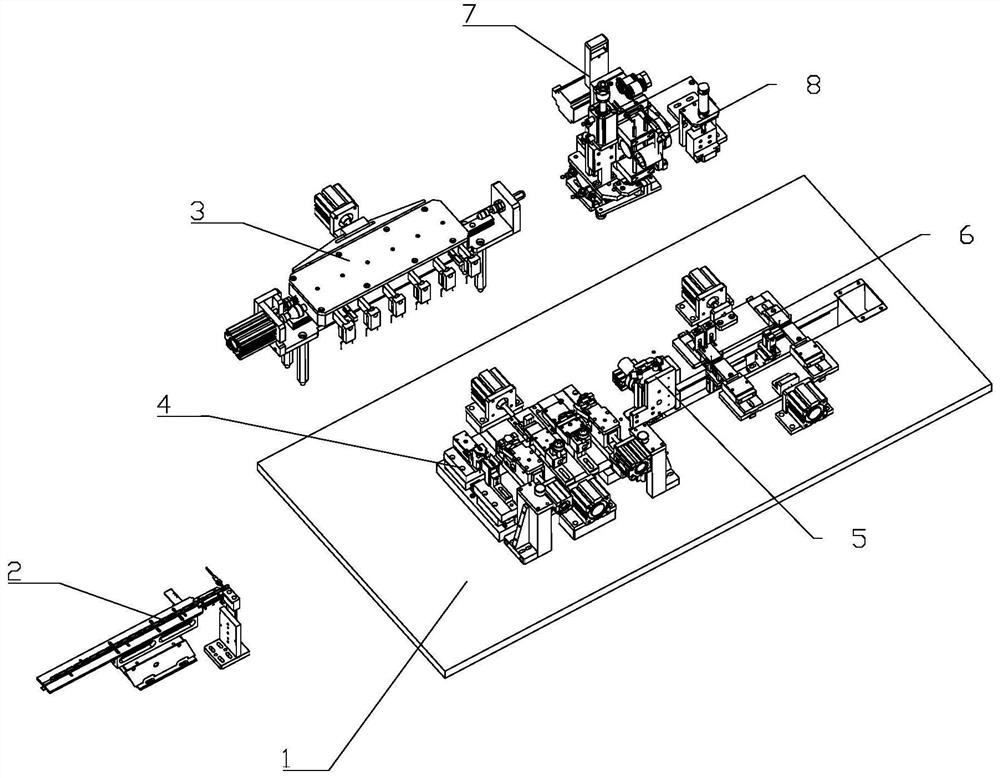

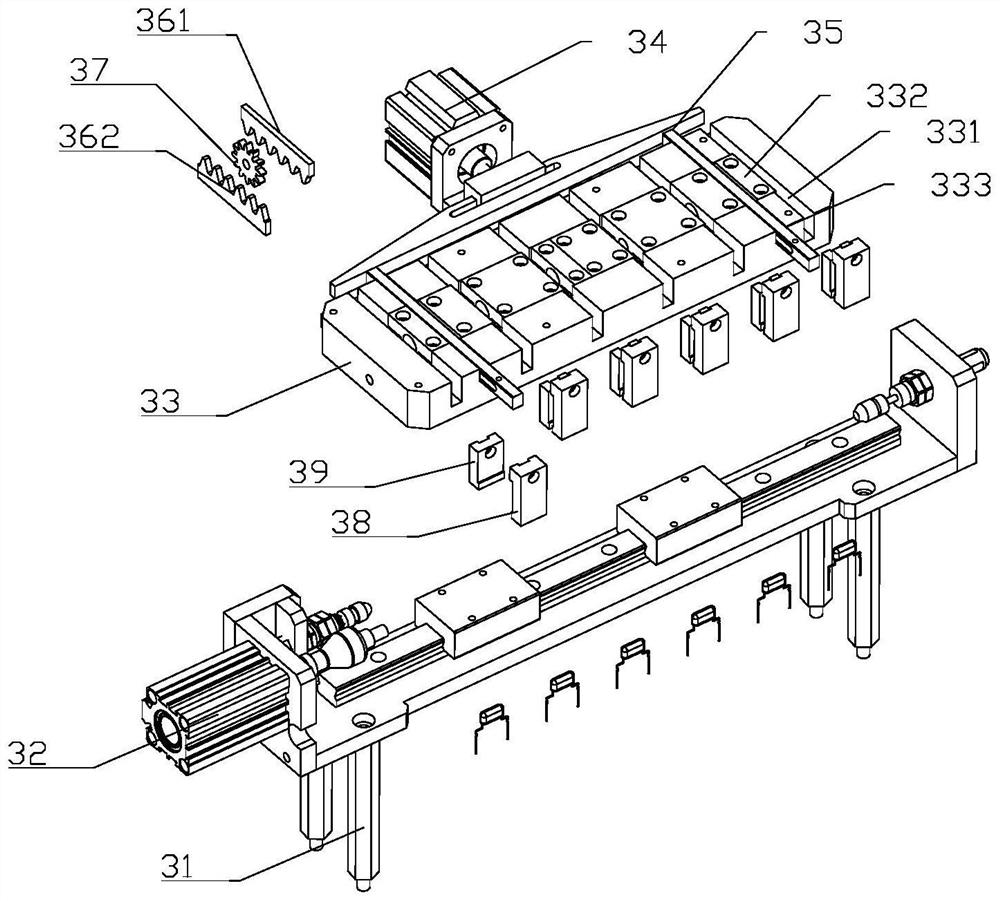

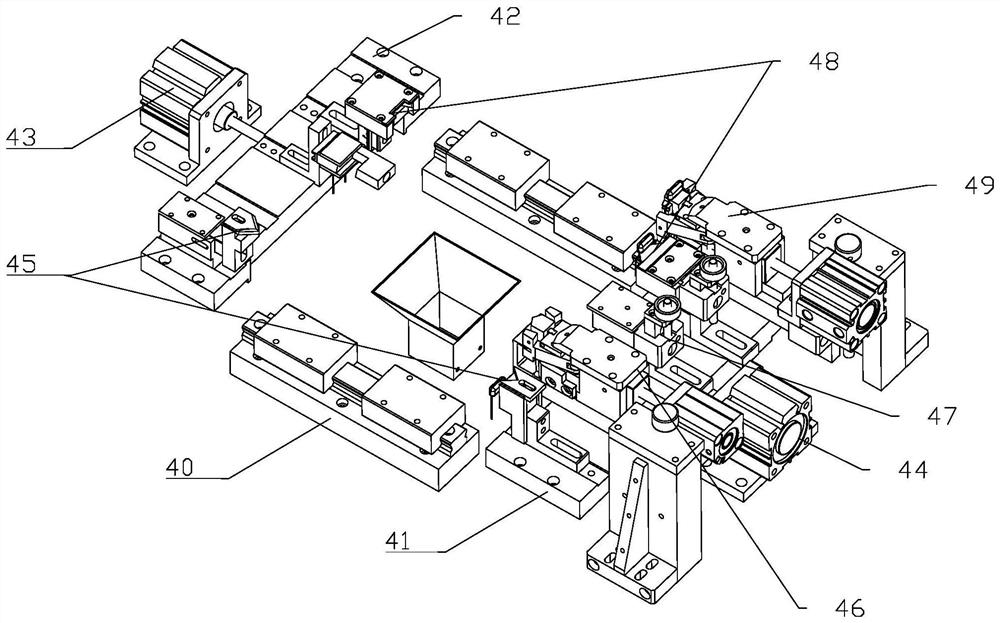

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

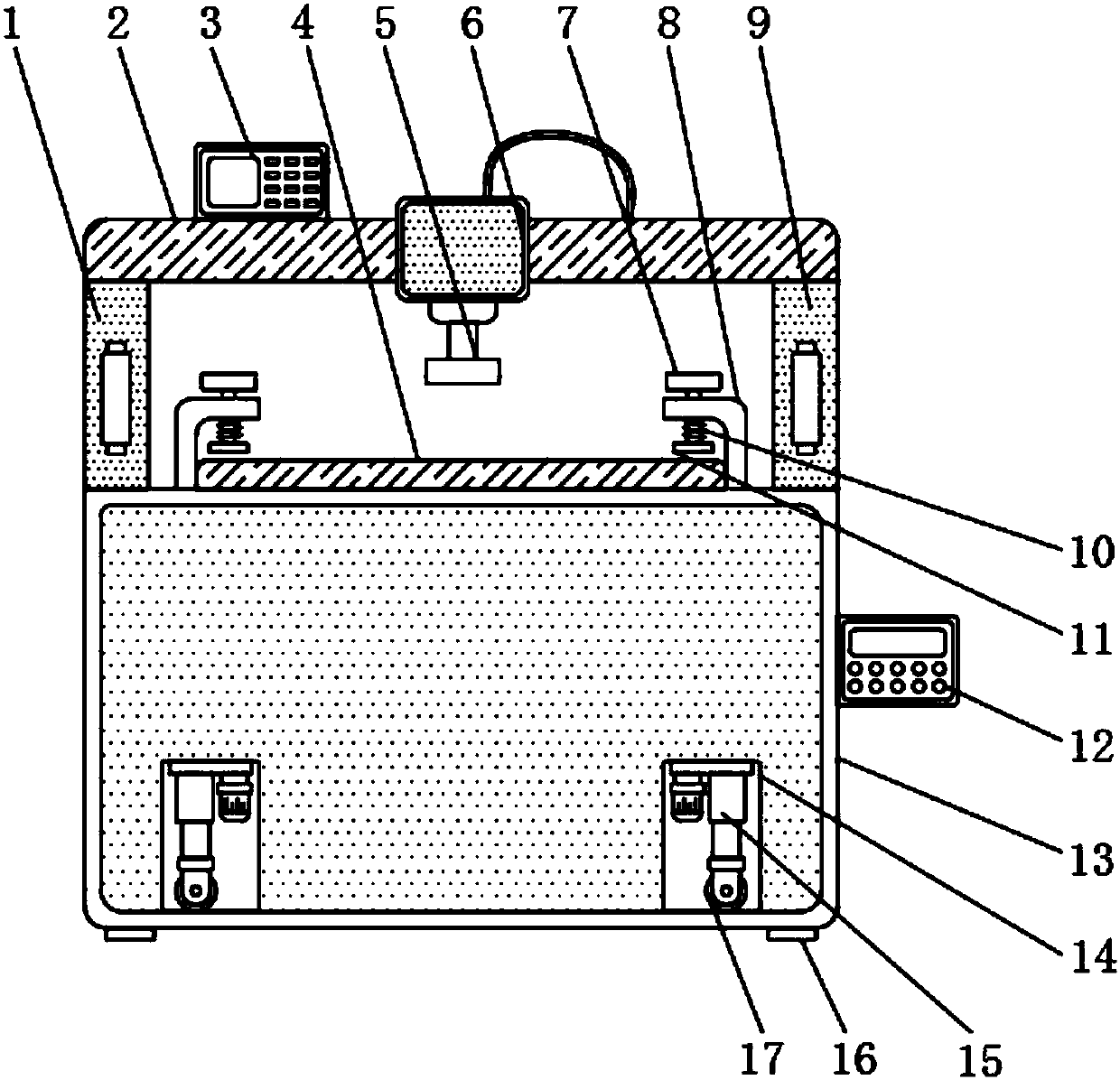

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

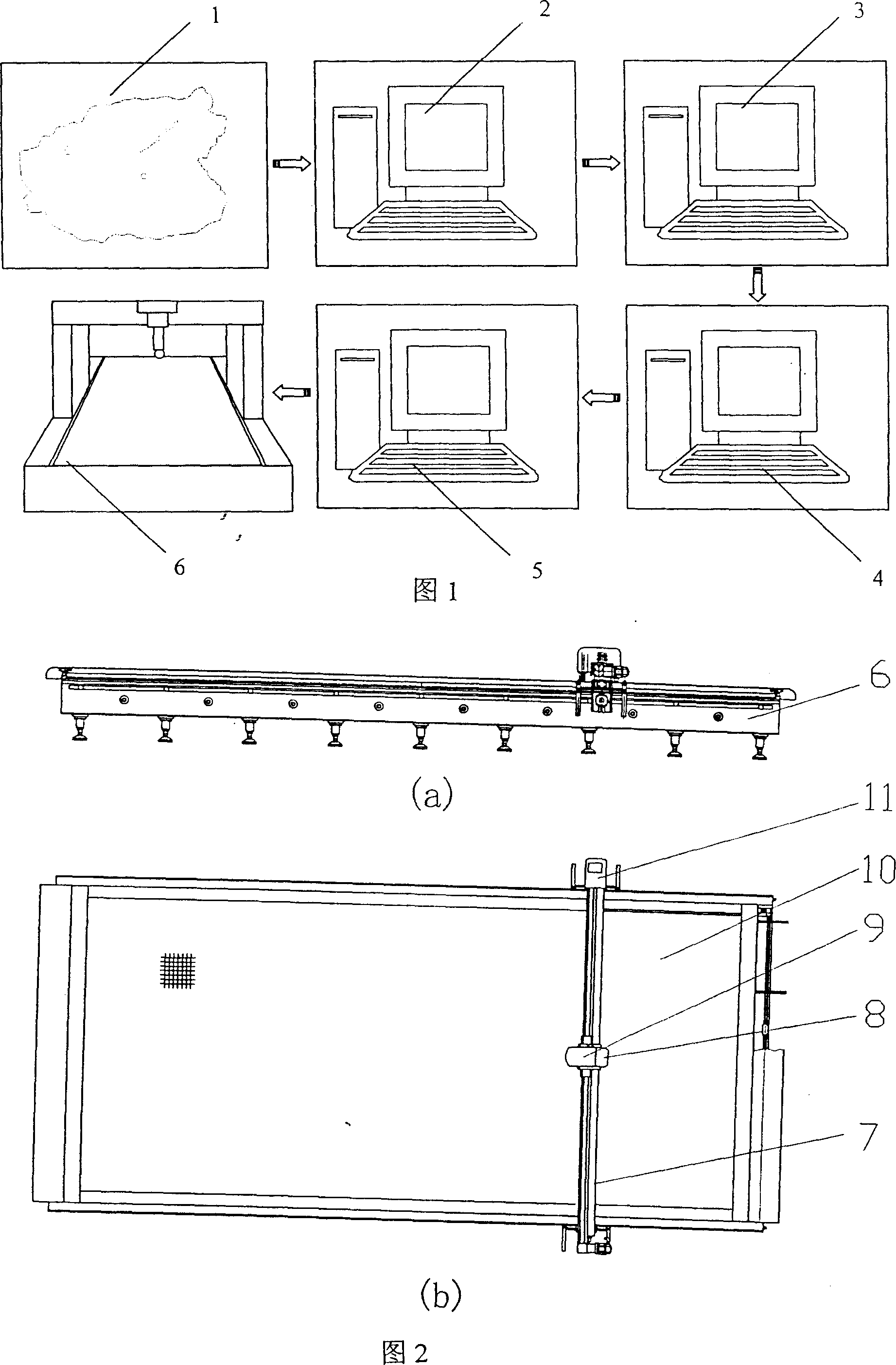

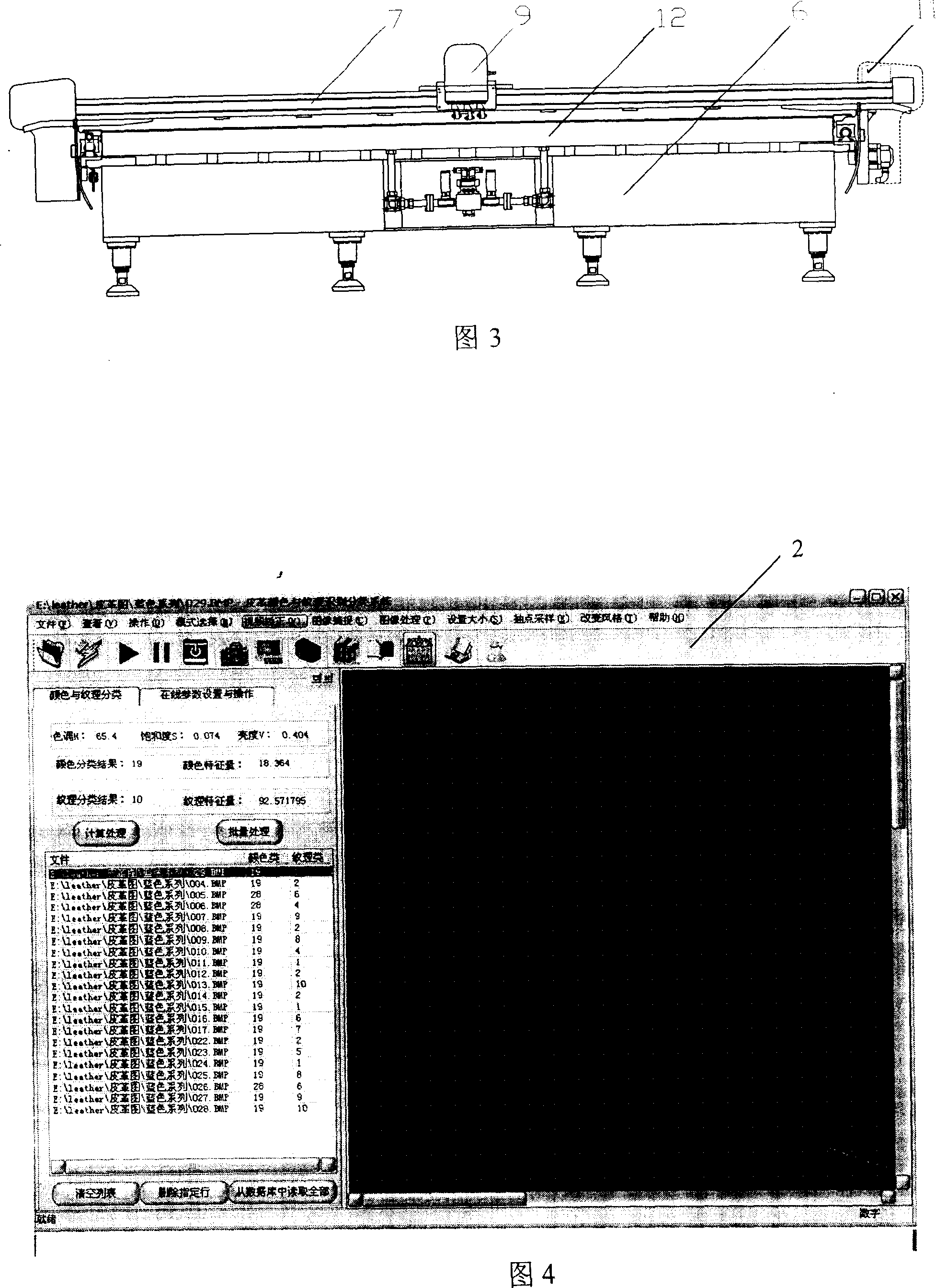

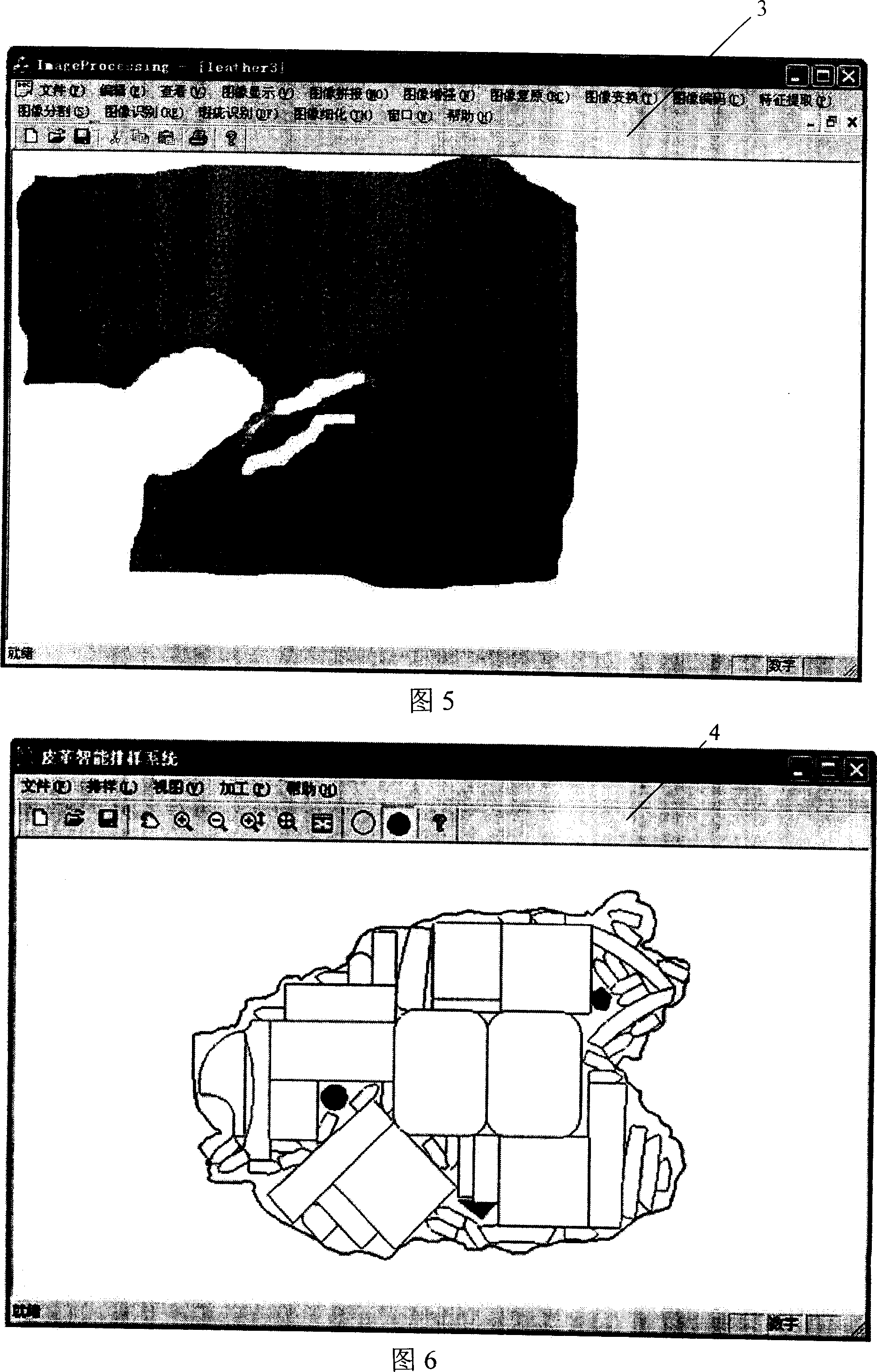

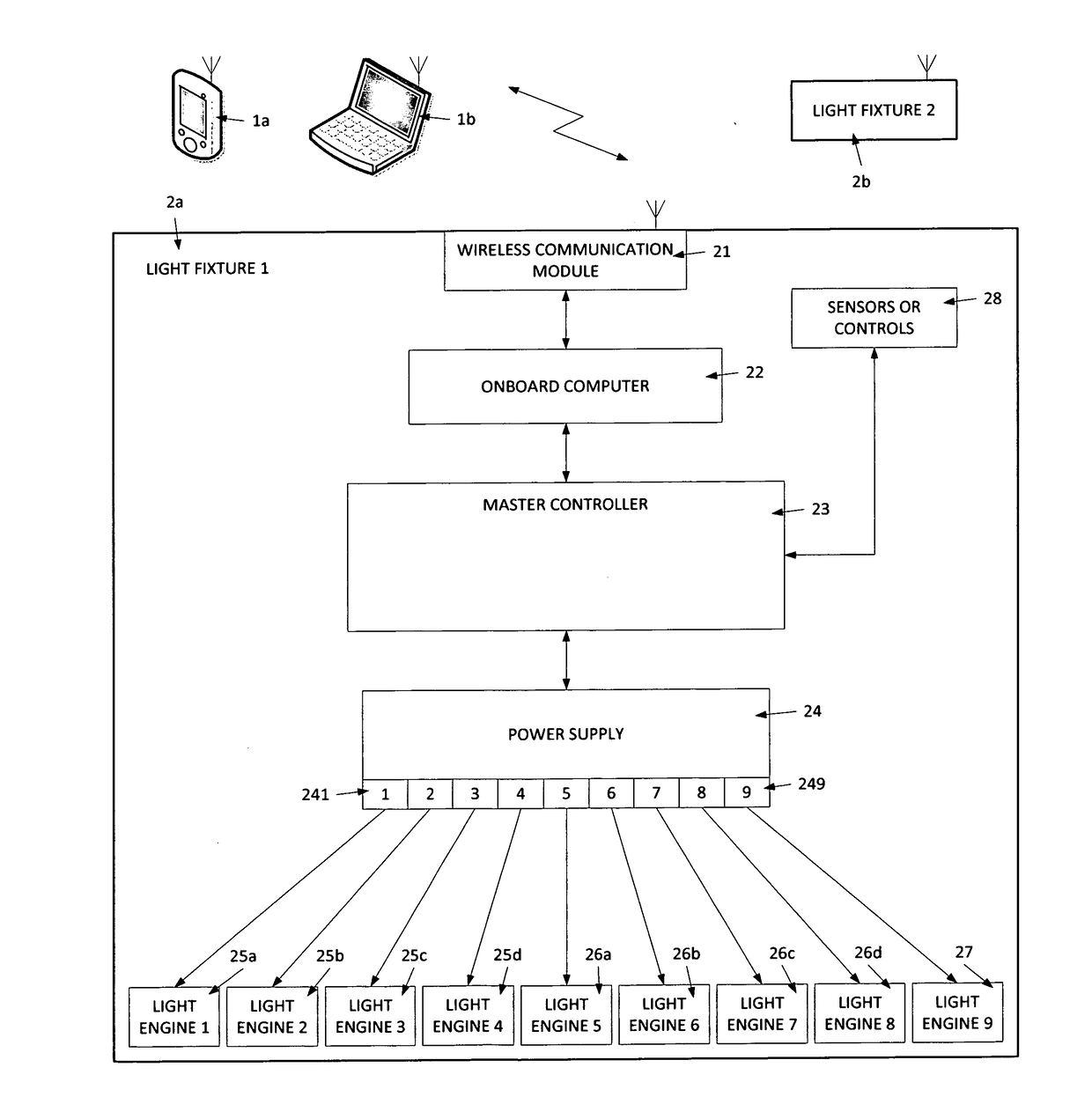

Function integrated numerically controlled automatic leather cutting method

InactiveCN1986835AQuick responseChange typeLeather clicking/perforating/clickingNumerical controlPattern recognitionSystem identification

The function integrated numerically controlled automatic leather cutting method includes four parts, automatic leather color and grain identification and classification, automatic leather flaw detection and boundary recognition, automatic optimized template layout and numerically controlled cutting. The automatic leather color and grain identification subsystem completes the leather color and grain matching, the automatic leather flaw detection and boundary recognition subsystem provides the available region information of the leather, the automatic optimized template layout subsystem arranges the optimized cutting template on the available region of the leather to reach maximum leather material utilization rate, and the numerically controlled cutting subsystem completes leather cutting automatically.

Owner:ZHEJIANG UNIV

Process for preparing seaweed urea

ActiveCN101486619AImprove Absorption and UtilizationImprove crop qualityBiocideAnimal repellantsChemistryDecomposition

The invention provides a method for preparing seaweed urea. Firstly, a concentrated seaweed extract is prepared; during the prilling process of urea, the concentrated seaweed extract and a fused urea solution are evenly mixed, wherein, the weight proportion of the concentrated seaweed extract and the urea added is 50 to 200:1000; then prilling is conducted in a prilling tower to prepare seaweed urea products. After the prilling of the concentrated seaweed extract and the fused urea, the concentrated seaweed extract exists in the form of solid seaweed extract, wherein, the weight percentage of the solid seaweed extract in the seaweed urea is 0.5 percent to 2 percent and the weight percentage of the urea is 98 percent to 99.5 percent. The combination of seaweed and urea can greatly improve the absorption and utilization ratio of urea, and meanwhile has the function of restraining the fast decomposition of urea contents and slowing down loss, thus effectively solving the problem of soil deterioration in current fertilization.

Owner:青岛海大生物集团股份有限公司

Morinda citrifolla based antifungal formulations and methods

InactiveUS20050181082A1Improve crop qualityImprovement in resistance againstBiocideOrganic active ingredientsAntifungalOrganic farming

The present invention provides a formulation which may be utilized in agricultural practice that is eco-friendly and effective as plant growth promotion agent, soil improvement agent, bactericide and insecticide agent, disease and harmful insect prevention agent, and is suitable for organic farming. The formulation of the present invention is comprised of a Morinda citrifolia product or extract. The formulation of the present invention may be applied to fruit vegetables, leafy vegetables, root vegetables, grains as well as flowers and shrubs, increasing the amount of yield and extending freshness period after harvest. Further, the present invention relates to antifungal and antibacterial activity of processed Morinda citrifolia products, as well as from various fractions of extracts from these processed products and the Morinda citrifolia L. plant, and related methods to determine mean inhibitory concentrations. In particular, the present invention relates to ethanol, methanol and ethyl acetate extracts from Morinda citrifolia L. and their inhibitory activities on common fungi and bacteria and the identification of mean inhibitory concentrations.

Owner:TAHITIAN NONI INT INC

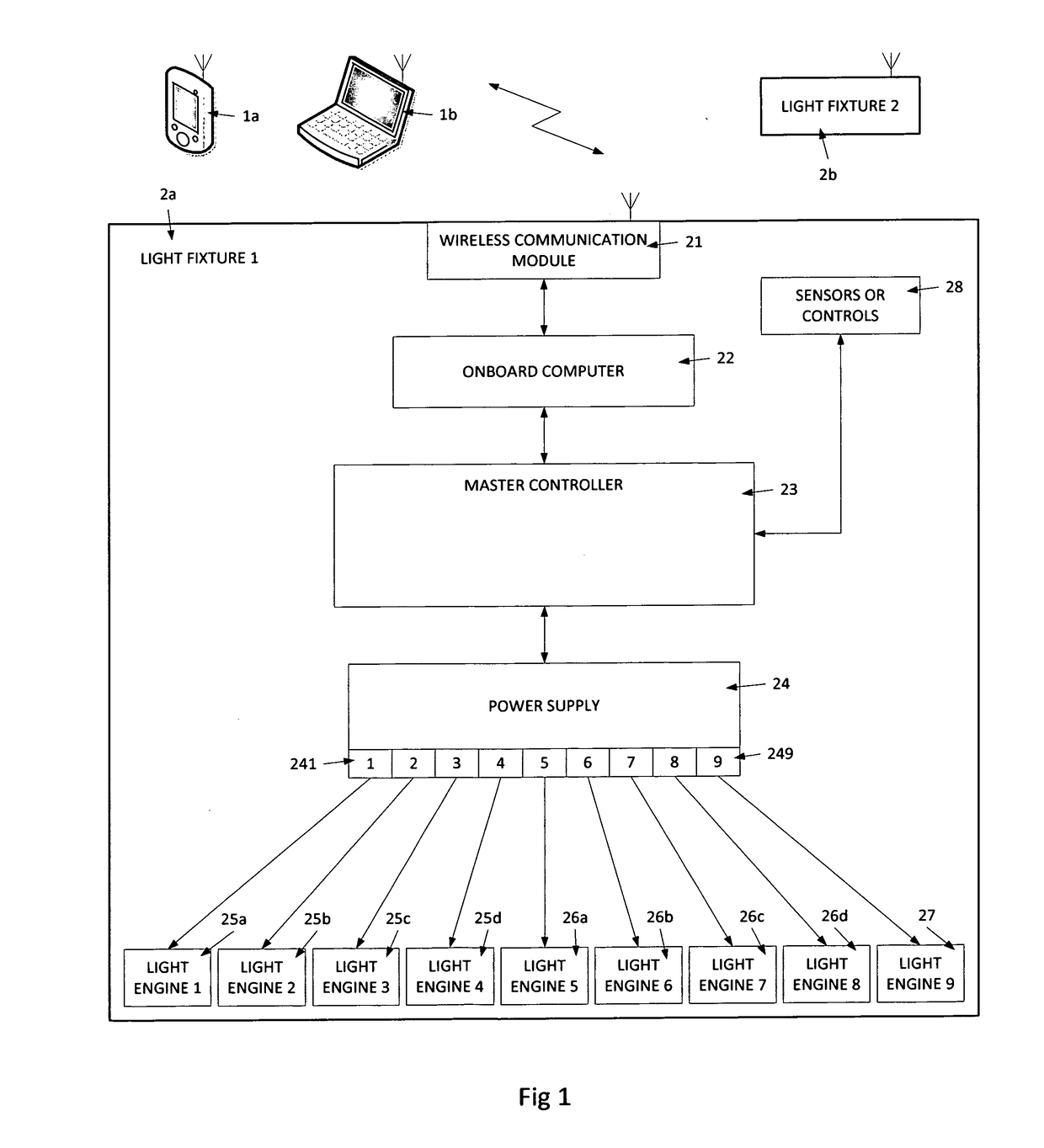

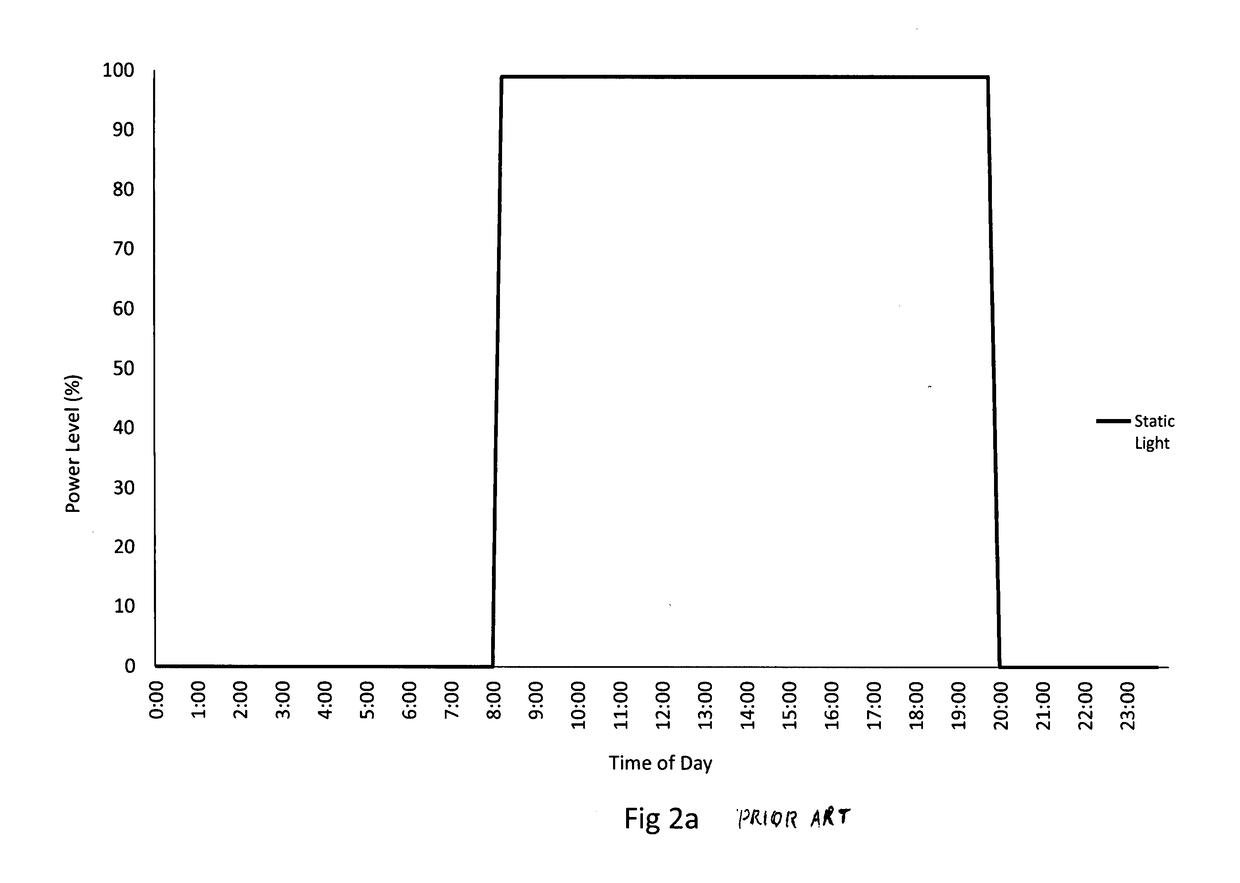

Multiple colors, and color palettes, of narrowband photosynthetically active radiation (PAR) time-staged over hours, days, and growing seasons yields superior plant growth

ActiveUS20180007838A1Lower energy requirementsImprove welfareElectrical apparatusElectroluminescent light sourcesPeak valueGrowing season

Plants are optimally grown under artificial narrowband Photosynthetically Active Radiation (“PAR”) of multiple colors, and color palettes, applied in but partially time-overlapping cycles. As well as a long, growing season, cycle, the colored lights are cyclically applied on a short, diurnal, cycle that often roughly simulates a peak-season sunny day at the earth latitude native to the plant. Bluer lights are applied commencing before redder lights, and are likewise terminated before the redder lights. Infrared light in particular, is preferably first applied at a time corresponding to early afternoon, and is temporally extended past a time corresponding to sunset. The colored lights and light palettes preferably rise to, and fall from, different peak intensities over periods from 10 minutes to 2 hours, and relative peak intensities of even such different colors as are used at all vary up to times two (×2) in response to differing PAR requirements of different plants. Computer-controlled colored LED lights realize all.

Owner:SYMBIOTIC SYST INC

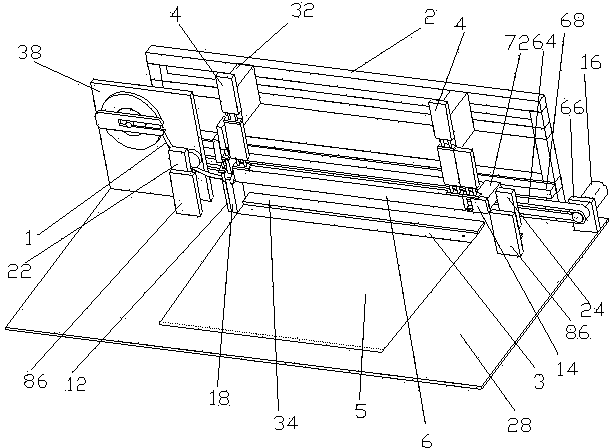

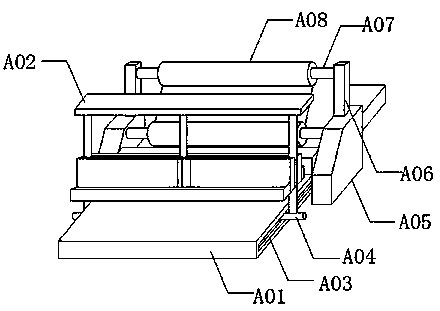

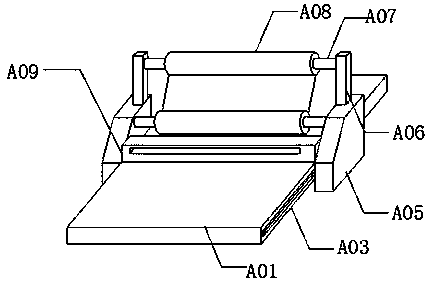

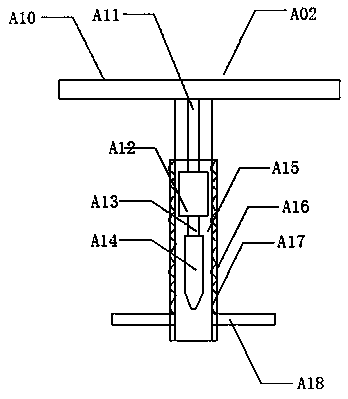

A cutting machine used for necktie fabric processing

InactiveCN105316928AImplement automatic transferIncrease transfer rateTextile selvedgesSevering textilesEngineeringMechanical engineering

The invention provides a cutting machine used for necktie fabric processing. The cutting machine comprises a material holding stand, a material feeding device, a cutting platform and a cutter device. The material feeding device comprises an upper clamping roller and a lower clamping roller. A driving lever device is arranged below the upper clamping roller and comprises a driving lever and a driving lever cylinder. The top surface of the cutting platform is provided with a material falling groove and a protecting plate. The cutter device comprises a horizontal guide rail and a cutting knife. A heating device is arranged in the cutter device and comprises a heater, a heat conduction plate and a heat conduction tube. The cutting machine is simple in structure and highly practical; with the material feeding device, fabric can be conveyed more conveniently; with a gear assembly, the length of fabric cutting can be controlled and the transmission is more stable; with the heating device, the temperature of the cutting knife can be made to rise and through high temperature cutting, cut fabric has the advantages of high quality, smooth cuts and zero burr and the processing of the next procedure is facilitated; energy consumption is reduced and the comprehensive utilization rate is increased.

Owner:SHAOXING HENRY TIE FASHION

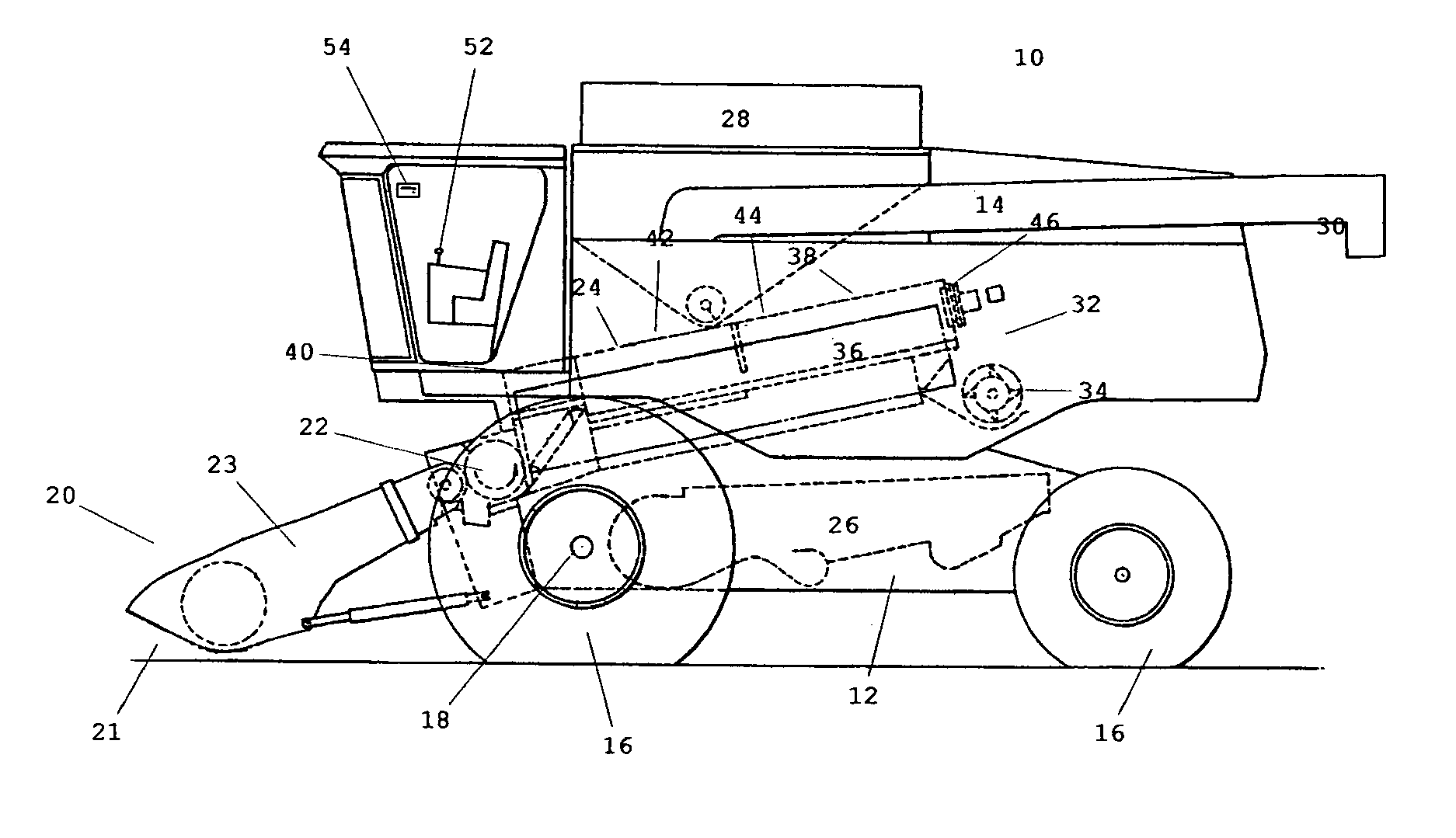

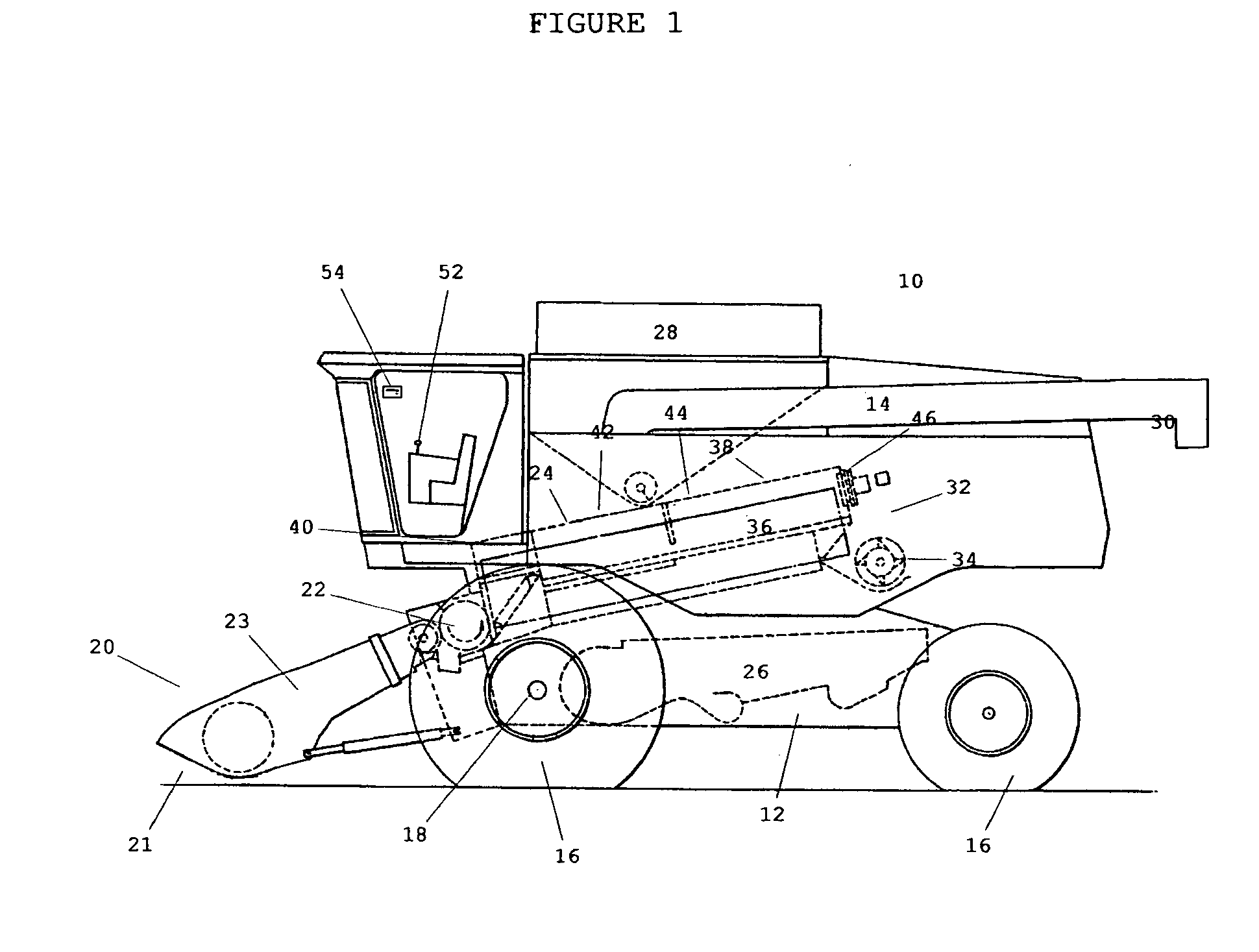

Engine load control for hydrostaticaly driven equipment

InactiveUS20080034720A1Mitigate damage to cropsReduce crop lossMowersPicking devicesAutomatic controlGround speed

A harvester load control that increases the efficiency of the harvester and its operator by providing a automatic control unit that monitors minute engine RPM's caused by varying crop and transport load effects, automatically adjusting the harvester's ground speed to provide a consistent operational RPM including thrashing, separating and other conditioning services.

Owner:HELFRICH JAMES C +1

Fertilizer Containing Yaeyama Aoki Extract

InactiveUS20070204510A1Promote growthImprove crop qualityBiocideDead plant preservationDiseaseGrowth plant

An eco-friendly fertilizer that acts as a plant growth promotion agent, soil improvement agent, bactericide and insecticide agent, disease and harmful insect prevention agent and the like, and is suitable for organic farming. The fertilizer contains extract from fruits, leaves, stems, seeds and / or roots of the Yaeyama Aoki and increases the amount of yield and extends the freshness period after harvest when applied to fruits, vegetables, leafy vegetables, root vegetables, grains as well as flowers and shrubs.

Owner:TAHITIAN NONI INT INC +1

Fertilizer containing Yaeyama Aoki extract

InactiveUS7144439B2Promote growthImprove crop qualityBiocidePlant growth regulatorsDiseaseGrowth plant

An eco-friendly fertilizer that acts as a plant growth promotion agent, soil improvement agent, bactericide and insecticide agent, disease and harmful insect prevention agent and the like, and is suitable for organic farming. The fertilizer contains extract from fruits, leaves, stems, seeds and / or roots of the Yaeyama Aoki and increases the amount of yield and extends the freshness period after harvest when applied to fruits, vegetables, leafy vegetables, root vegetables, grains as well as flowers and shrubs.

Owner:TAHITIAN NONI INT INC

Foliar fertilizers

InactiveUS6328780B1Improve featuresQuality improvementLiquid fertilisersFertilizer mixturesTrace elementManganese

A foliar fertiliser composition providing for an enhanced crop characteristic in a crop. The composition is made of soluble compounds of the following trace elements in the following ranges of relative proportions of the respective element by weight, 0.5 to 4.0 copper, 2.0 to 10.0 zinc, 2.5 to 12 manganese, 5 to 14.0 iron, 0.5 to 6.5 boron, 0 to 0.3 molybdenum.

Owner:SPRINGBROOK NOMINEES

Microorganisms, microbial phosphate fertilizers and methods for preparing such microbial phosphate fertilizers

ActiveUS20110100078A1Promote formationIncrease capacityFungiBacteriaBacillus licheniformisMicroorganism

The present invention relates to a microorganism, a microbial phosphate fertilizer and a method for manufacturing said microbial phosphate fertilizer, wherein said microorganism is Streptomyces cellulosae with Accession number CGMCC No. 2167 or Aspergillus versicolor with Accession number CGMCC No. 2171. The microbial phosphate fertilizer of the present invention comprises a fermentation product of the microbial composition consisting of the following four microorganisms: Bacillus subtilis strain WH2, Bacillus licheniformis strain WH4, Streptomyces cellulosae strain WH9 and Aspergillus versicolor strain WH13. A method for manufacturing said microbial phosphate fertilizer is also provided, wherein the manufacture of said microbial phosphate fertilizer may involve the use of ground phosphate rock having 8%-12% P2O5.

Owner:JINKUIZI BIO&ENVIRONMENTALINTLTD +1

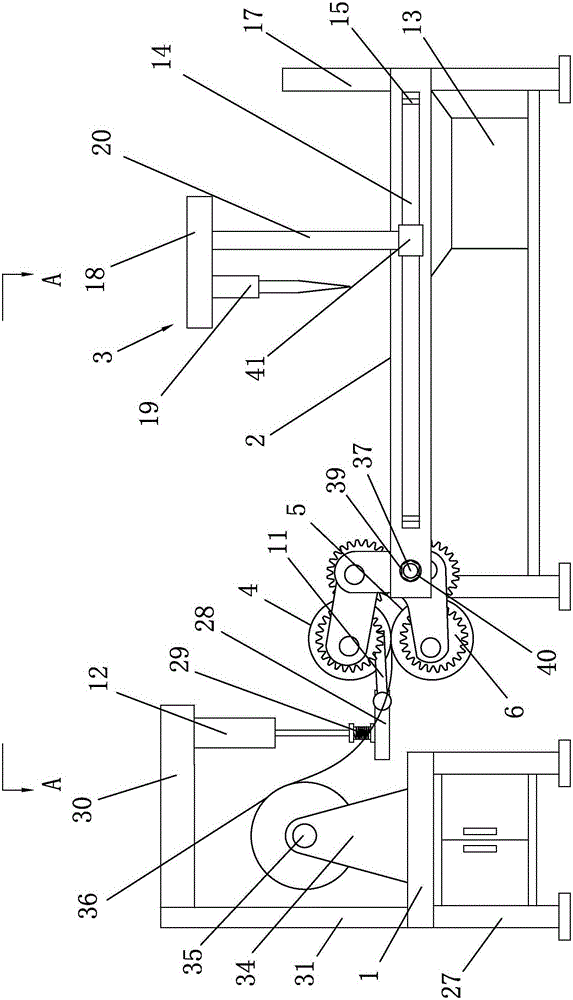

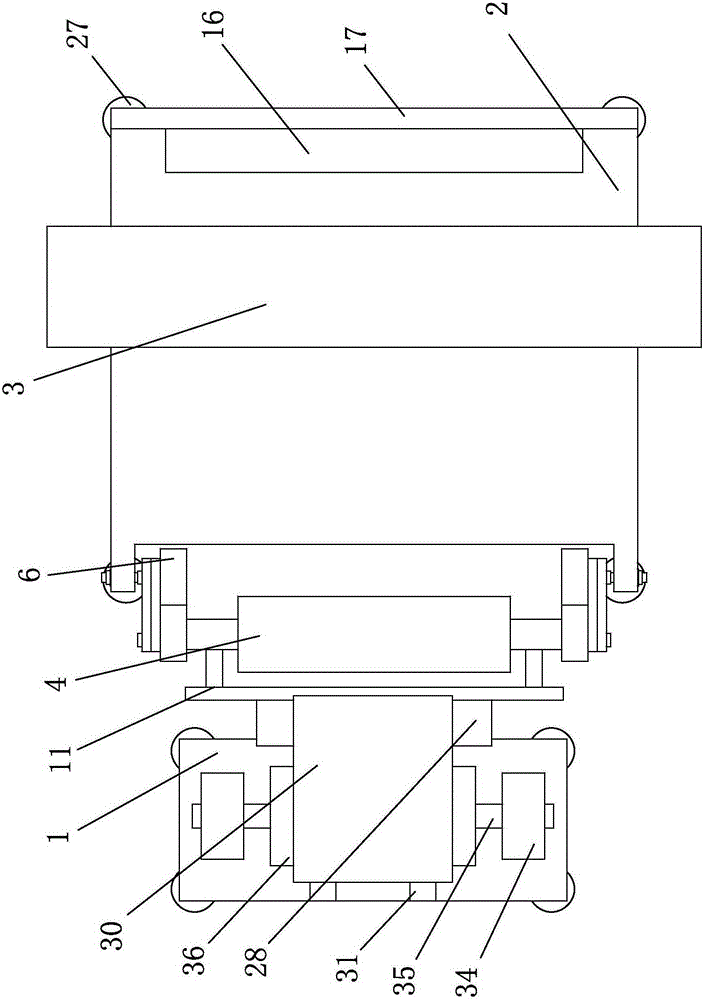

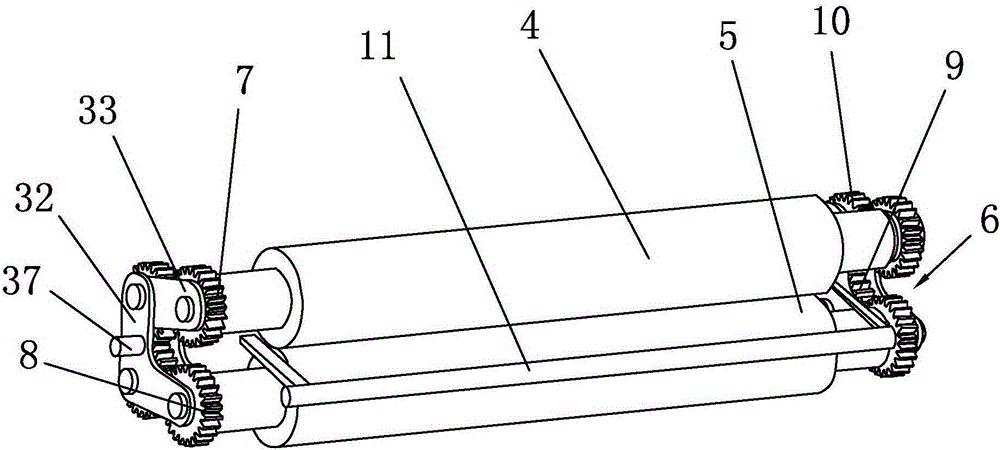

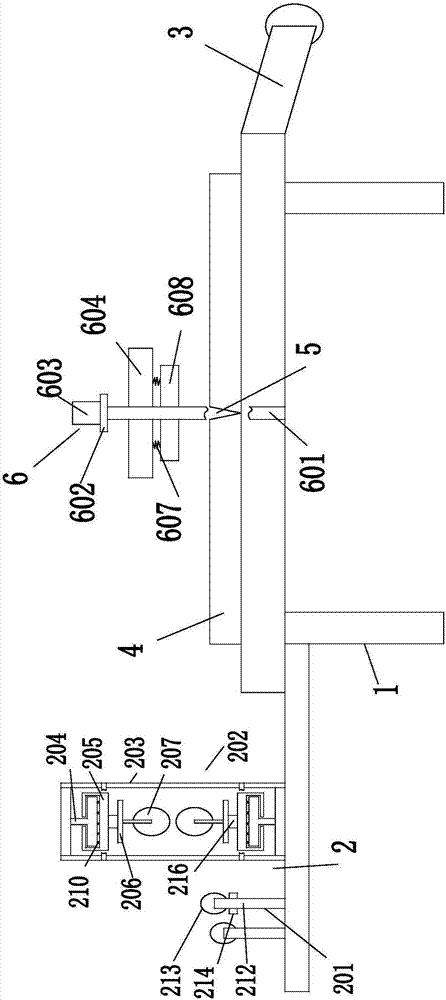

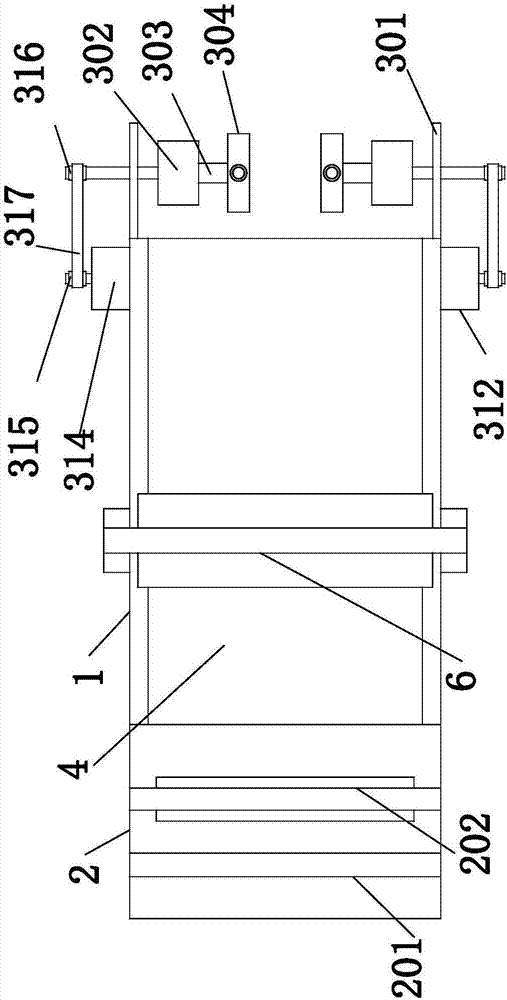

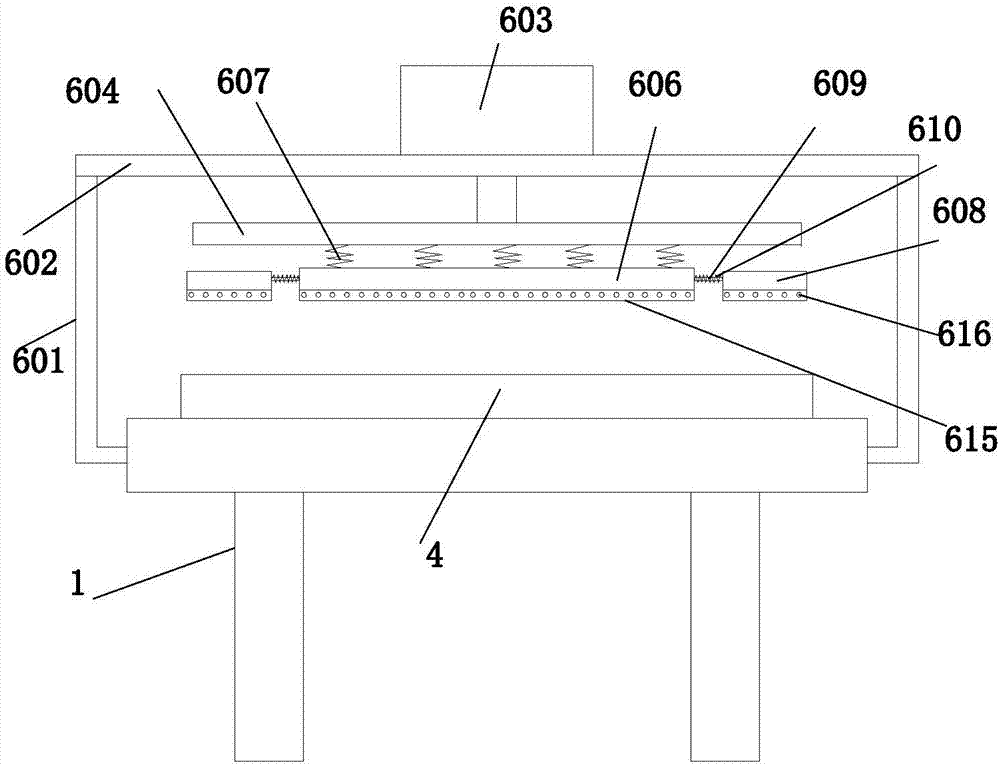

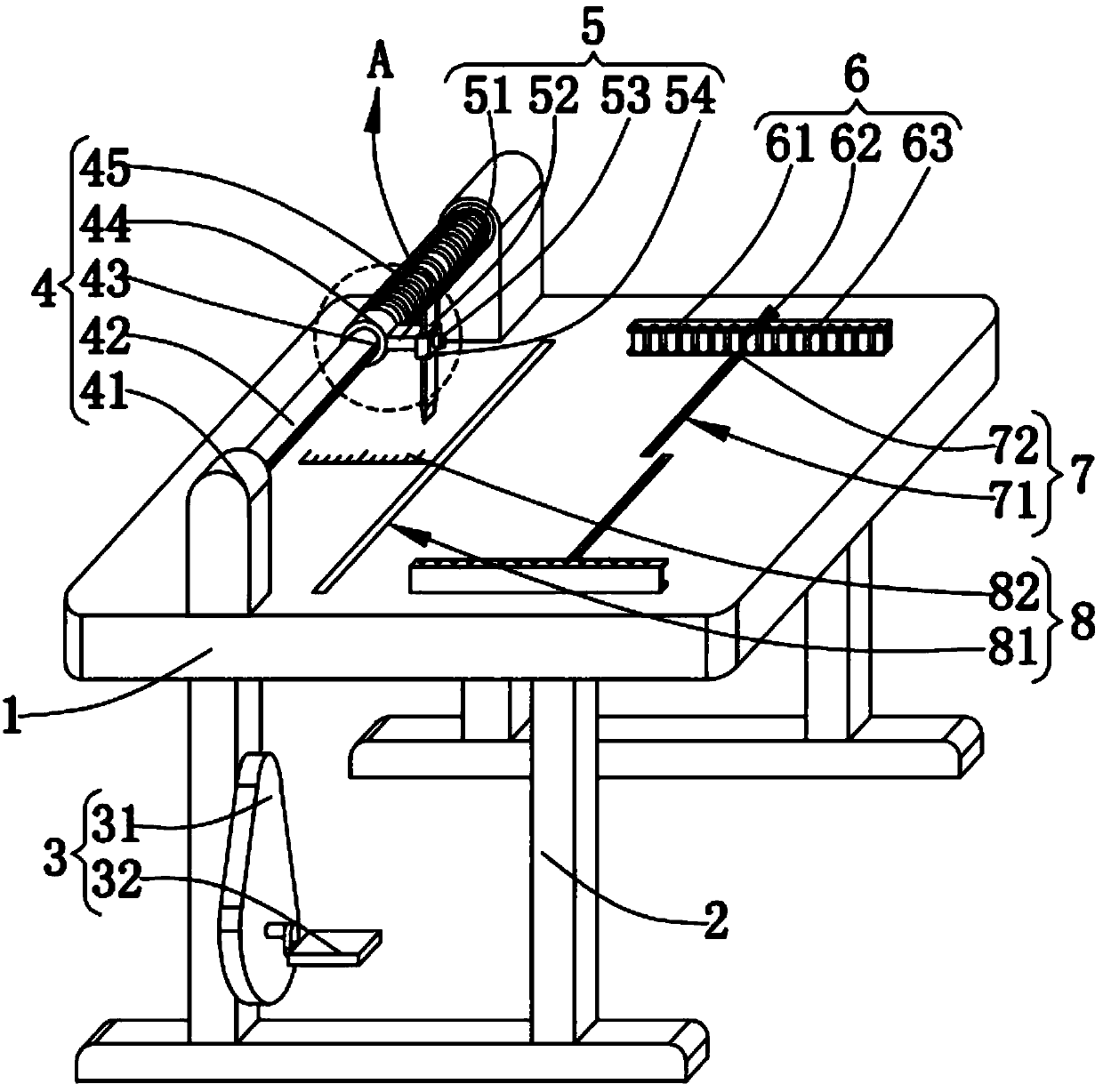

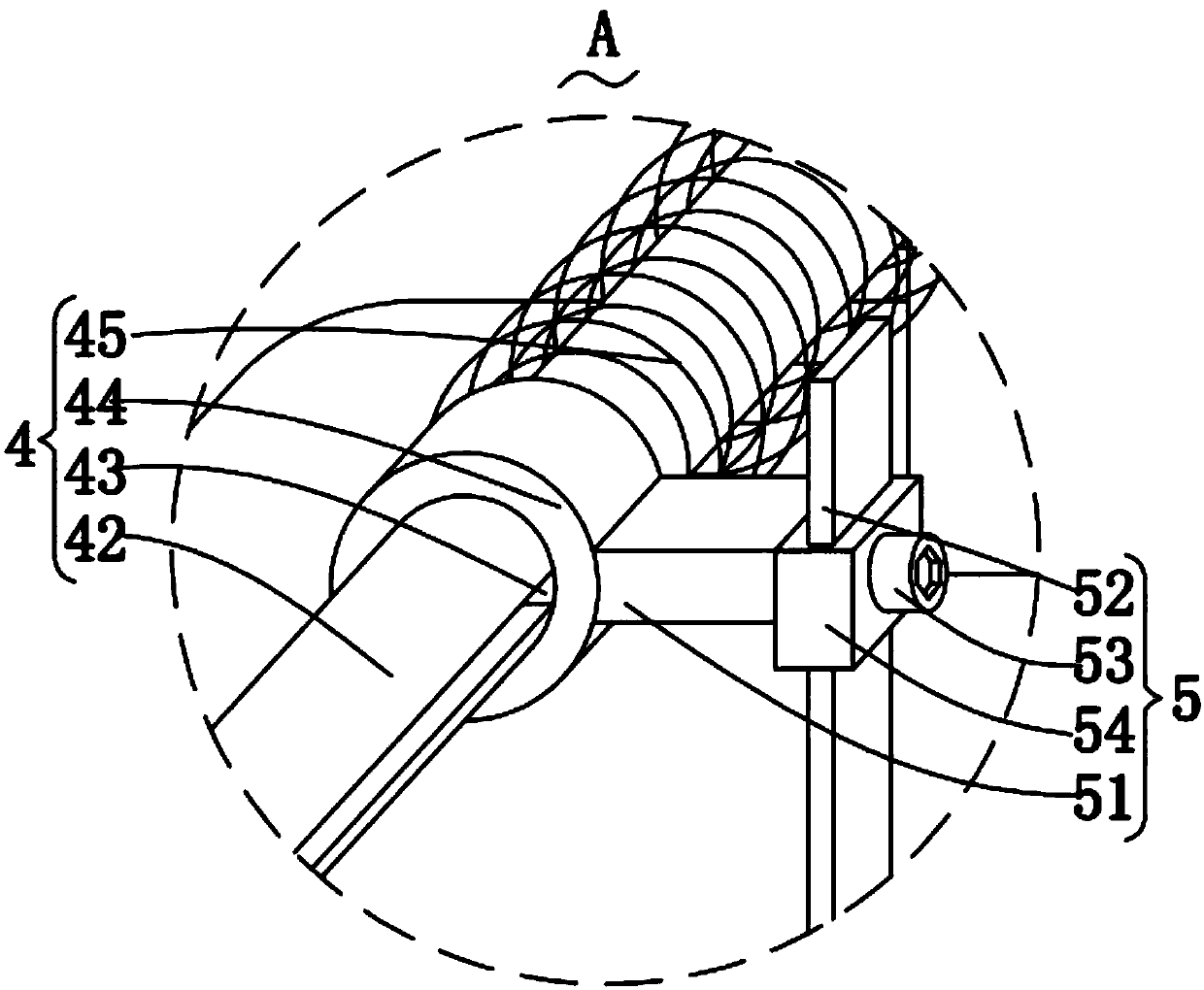

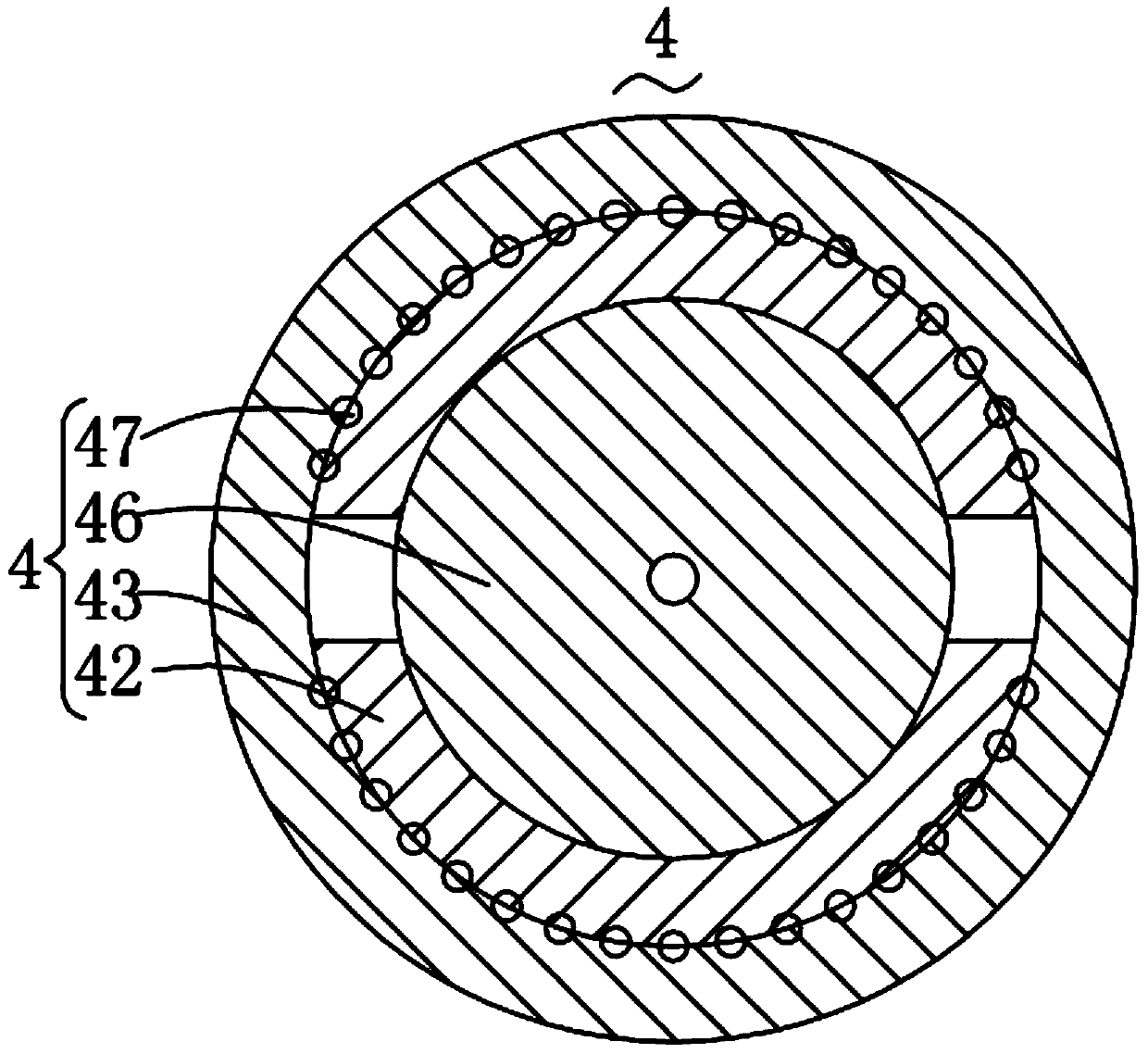

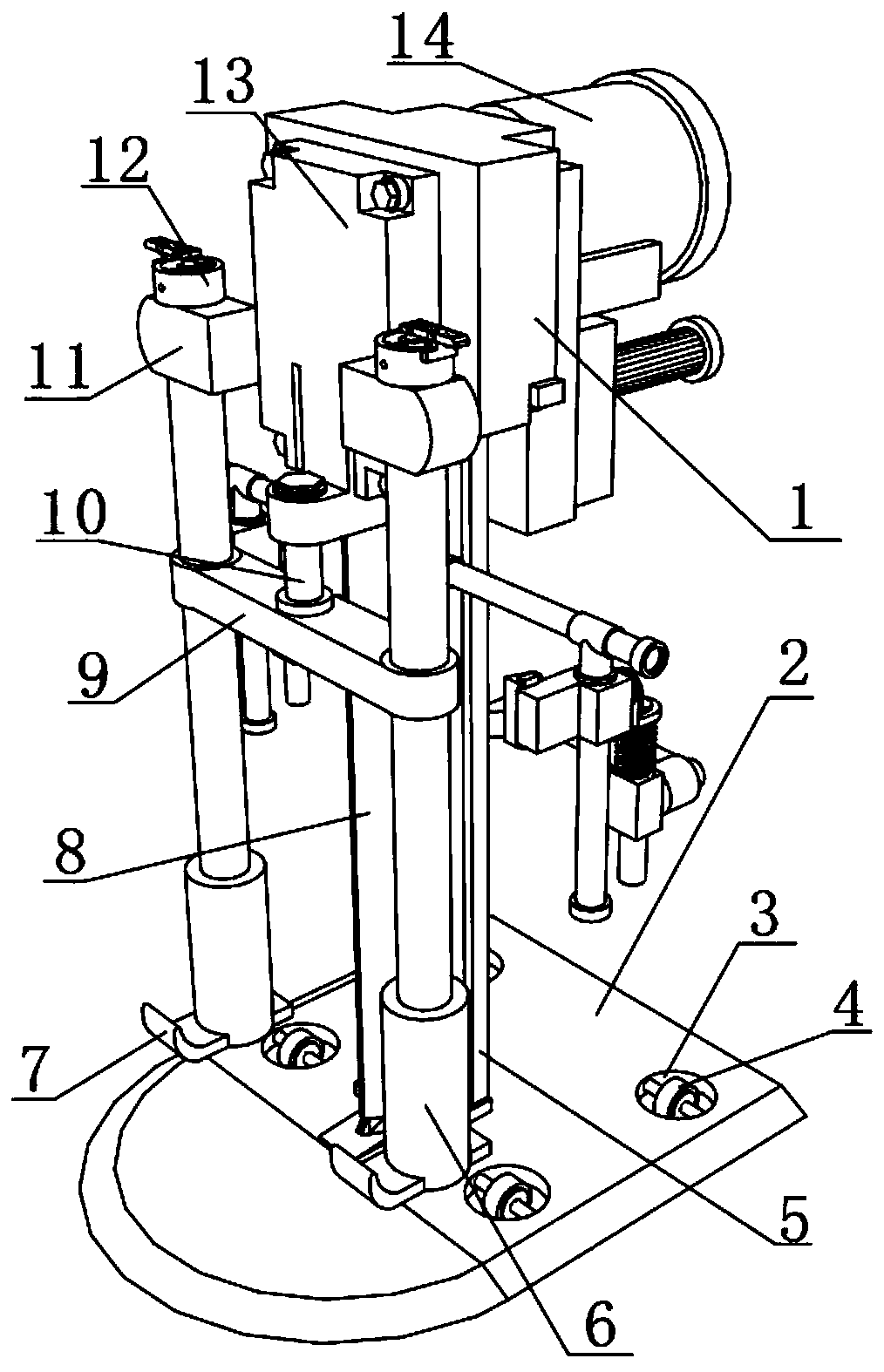

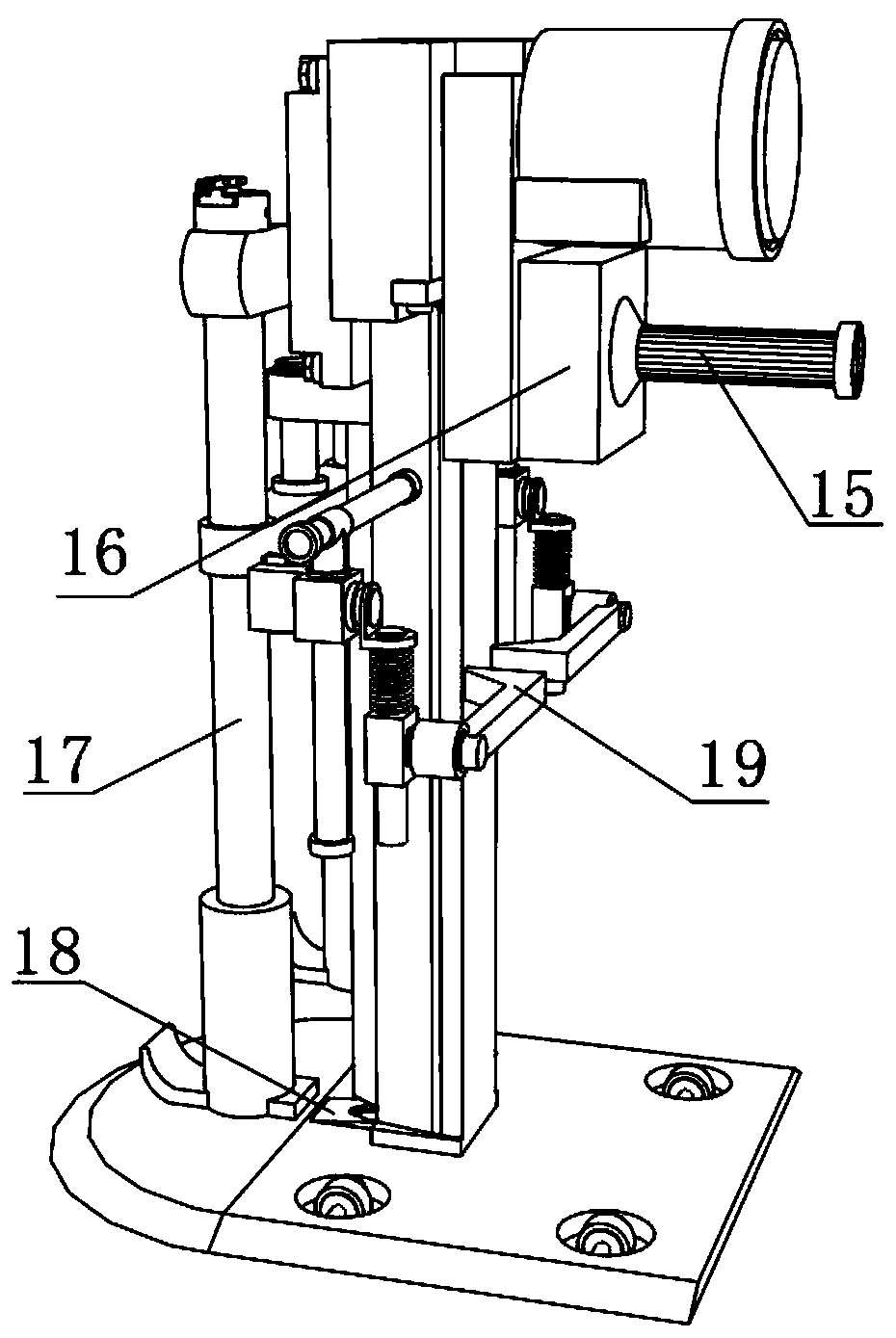

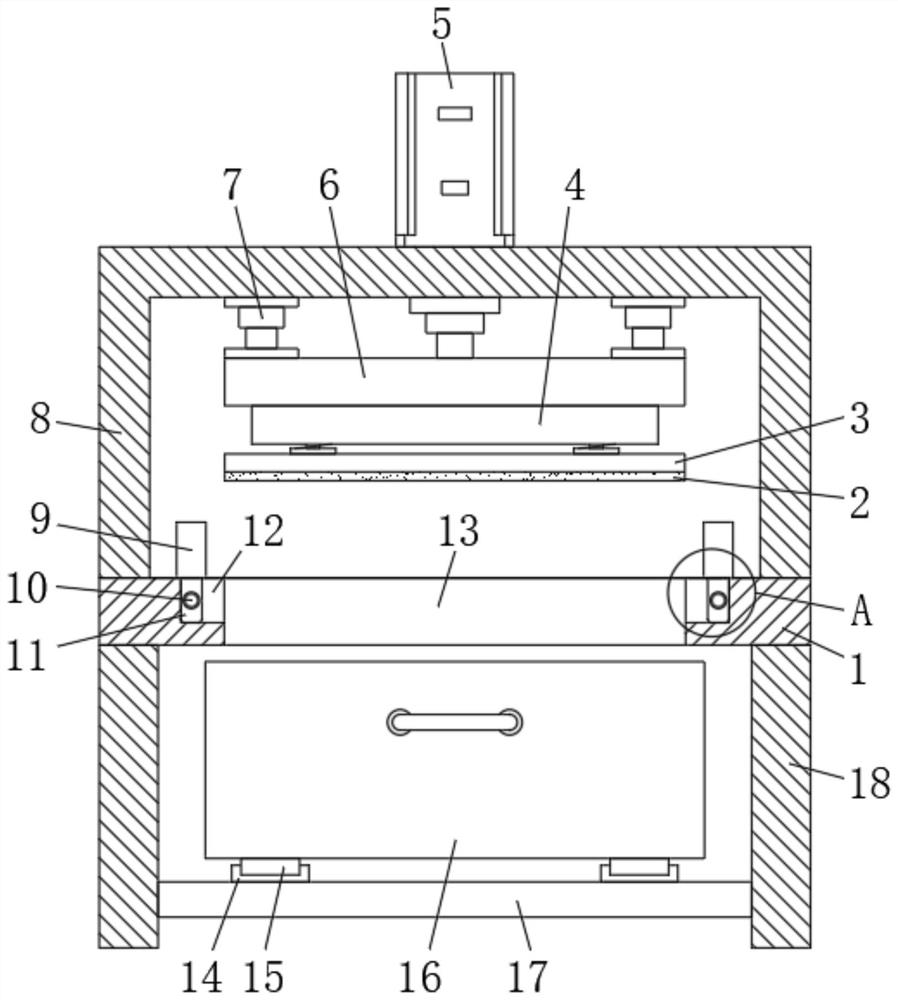

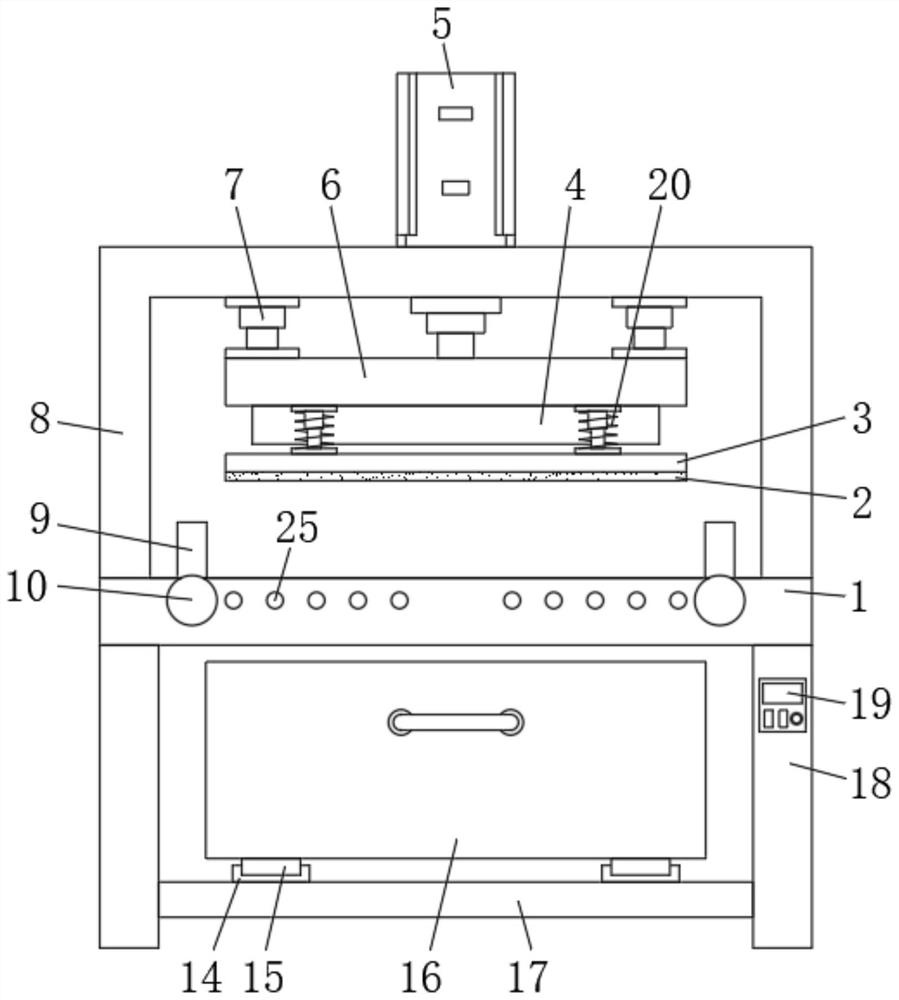

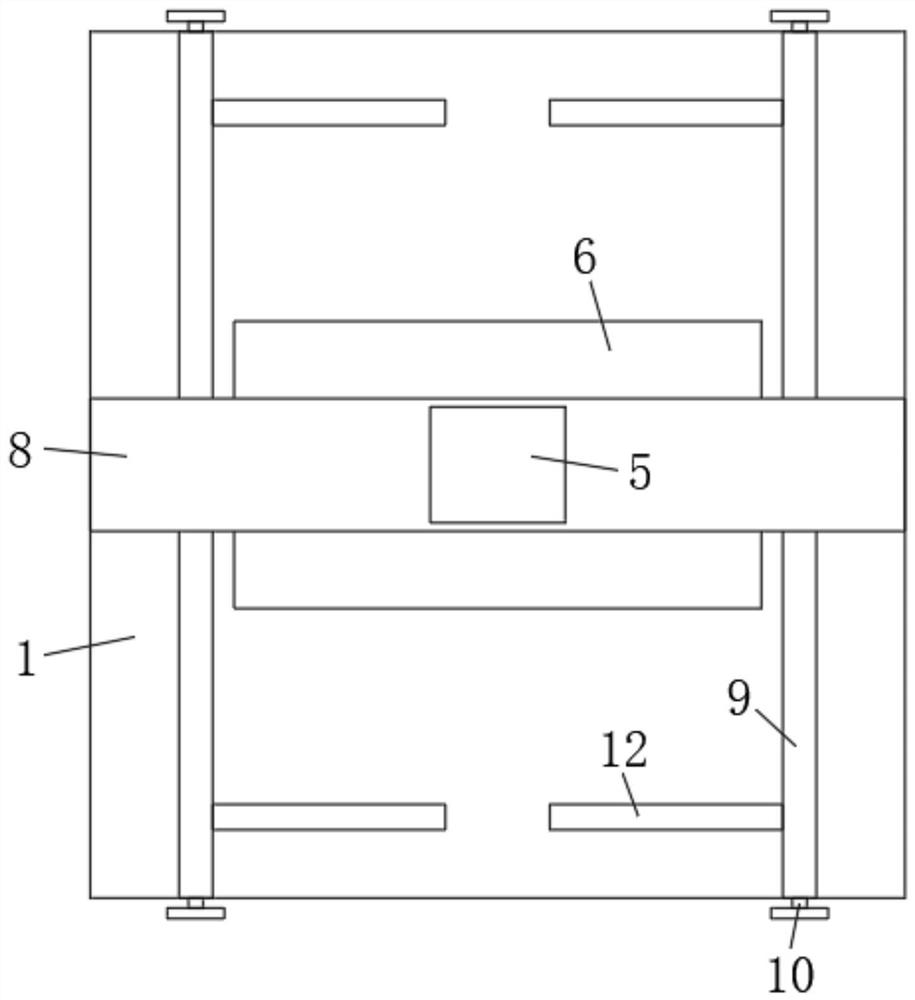

Equipment for rapidly cutting silk

InactiveCN107364756AImprove crop qualityImprove cutting uniformitySevering textilesArticle deliveryEngineeringMechanical engineering

The invention discloses a silk rapid cutting device, which comprises a frame (1), the feed end of the frame (1) is provided with a pressing roller group (2), and the discharge end of the frame (1) is provided with a cloth rolling device (3), a cutting platform (4) fixed on the top of the frame (1) is provided between the pressing roller group (2) and the cloth rolling device (3), and the cutting platform (4) is provided with a cutting groove ( 5), the top of the cutting groove (5) is provided with a cutting device (6) fixed on the frame (1); the cutting device (6) is connected with a controller (7), and the controller (7) is connected with the pressing The roller group (2) is connected with the cloth rolling device (3). The invention has the characteristics of being able to improve the cutting quality of the silk fabric, increase the cutting efficiency and reduce the waste of the silk fabric.

Owner:HUZHOU JINTELAI SILK WEAVING

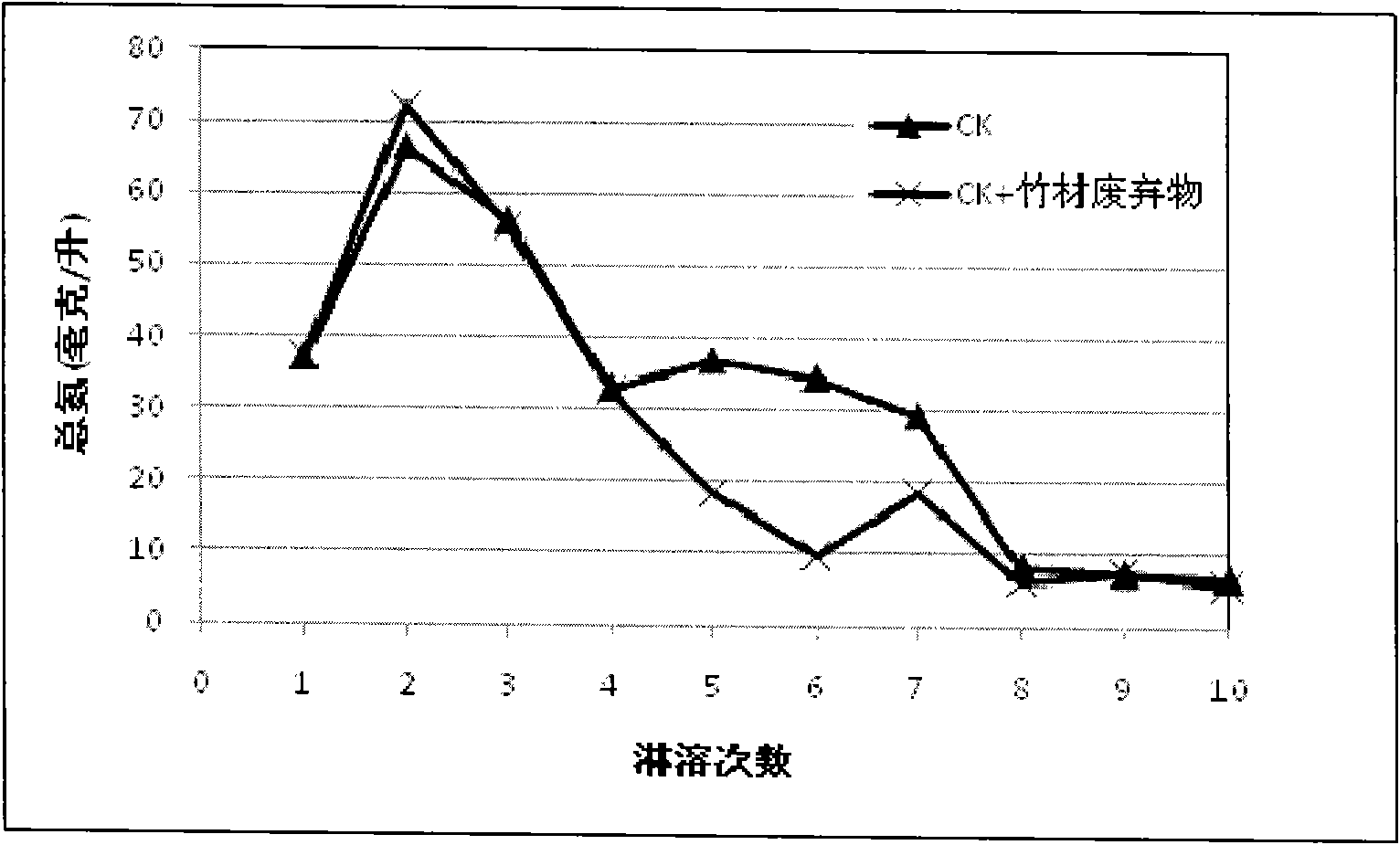

Method for improving soil by using bamboo wastes

InactiveCN101843186AImprove soil propertiesImprove crop qualitySoil-working methodsFertilizerSoil acidification

Owner:ZHEJIANG UNIV

Cloth cutting machine

ActiveCN107587341AGuarantee personal safetyImprove personal safetySevering textilesFixed frameThreaded rod

The invention discloses a cloth cutting machine which comprises a cutting machine main body and a fixing frame; a rotating handle is arranged at the top end of a threaded rod; an anti-sliding pad is arranged at the bottom end of the threaded rod; a photoelectric protector is arranged at the top end of a cross beam; a fixing base sleeves on the exterior of the cross beam; an electric hydraulic rodis arranged in a slide slot; a bidirectional gear pump is arranged on a position on one side close to the electric hydraulic rod in the slide slot. According to the invention, the photoelectric protector is arranged for guaranteeing the personal safety of the user in the working process and avoiding the problem of hazardous conditions caused by the arm of the user in contact with the cutter; the electric hydraulic rod is arranged for using and hiding the pulley by the user in the manner of stretching the electric hydraulic rod; the rotating handle and the anti-sliding pad are arranged for theuser to contact the anti-sliding pad with a cutting platform by rotating the rotating handle, so that the extensibility of the cloth can be promoted and the problem of inaccurate cutting caused by theincapability of fixing the cloth can be avoided.

Owner:鹤山冠东制衣有限公司

Foam plastic board cutting equipment

ActiveCN109676659ALabor savingImprove processing efficiencyMetal working apparatusMechanical engineeringEngineering

The invention relates to the field of foam plastic board production and processing equipment, in particular to foam plastic board cutting equipment comprising a base, support legs, a rotating structure, a sliding structure, a cutting structure, a guide structure, a regulating structure and a limiting structure; the sliding structure which can be used for ensuring that the cutting structure is moved right and left is fixed to the end, far away from the support legs, of the base; and one end of the corresponding support leg is provided with the rotating structure which can be used for providingsliding power for the sliding structure. Through cooperative application of the rotating structure and the sliding structure, the cutting structure can be moved by stepping, and does not need to be pulled by hand, so that both hands are freed and can be used for other works; labors are saved, and the processing efficiency can be improved; the sliding structure can be reset automatically upon completion of cutting, and the processing cycle is shortened; and the production efficiency is improved.

Owner:中山市长盈包装材料有限公司

Method for producing organic manure through harmless treatment of fowl, livestock feces

InactiveCN1800109AImprove crop qualityIncrease crop yieldClimate change adaptationExcrement fertilisersSalmonella danWater content

The invention discloses a method for using transit fecal harmless treatment to make organic endorse fertilizer in the field of fecal harmless treatment and fertilizer making method. It uses methyphrrolidine and the high temperature of the fermenting course to kill the colicin, Salmonella and parasite ovum to achieve the fecal harmless treatment. It uses the fecal and the urine as basic material and the abandon cigar to adjust the PH value, the abandon tea clinker to adjust the porosity degree and the abandon material to adjust the water content. The fertilizer component is that the organic material >=35, the azophoska total content >=4, PH value 7.5-9.0, the water 26-35, the product PH value 7.5-9.0.

Owner:何炎森

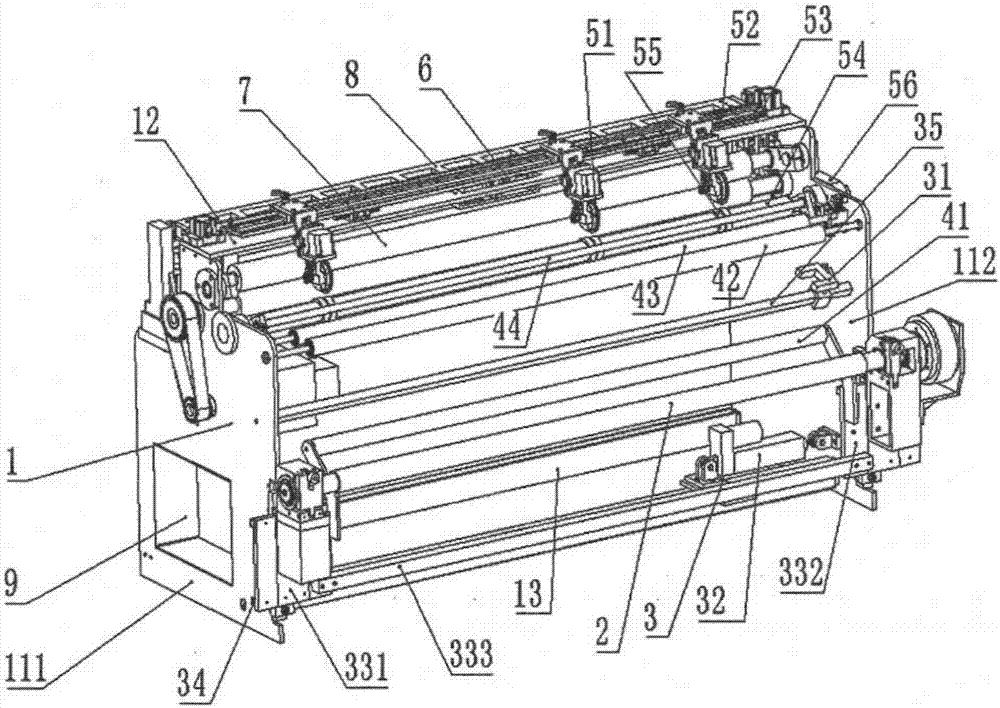

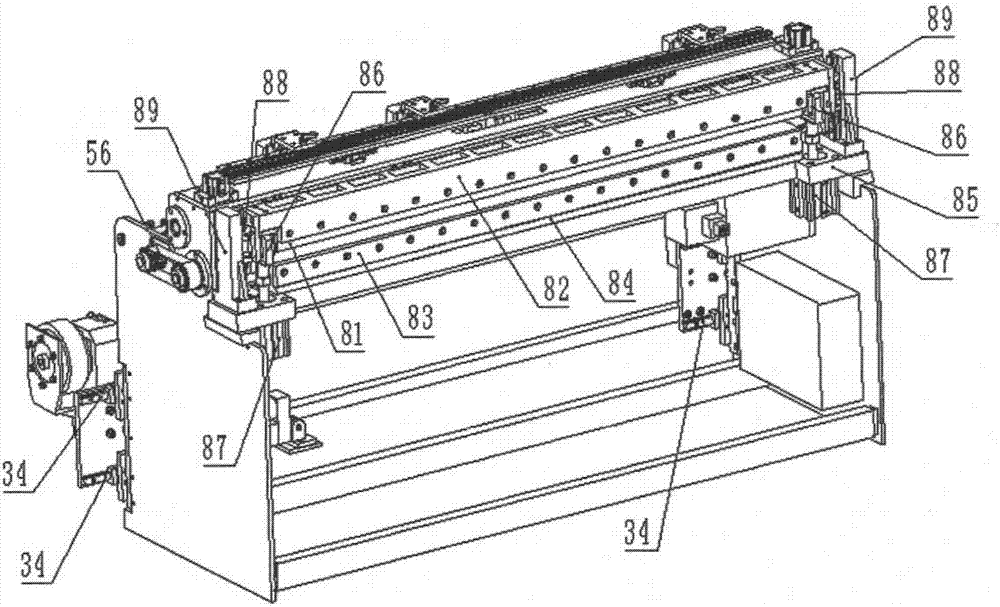

Slicing machine

InactiveCN107128732AChange manual cutting modeSolving automation problemsArticle deliveryWebs handlingEngineeringTension control

The invention relates to a slicing machine. The slicing machine is characterized in that the slicing machine comprises a rack, a depolarized part, a feeding part, a tension roller part, a traction roller part, a longitudinal knife part, a longitudinal knife transverse moving part, a transverse knife part and a control cabinet. A picture medium is spread out of a material roll, makes feeding conveying movement under the effect of a traction roller assembly, is longitudinally sliced when passing through the longitudinal knife part, continues moving and is transversely sliced when passing through the transverse knife part, and therefore picture partition slicing is completed. The depolarized part achieves the condition that the picture medium cannot skew during slicing operation. The slicing machine has the advantages that automatic slicing operation for the picture medium is achieved, and the slicing machine can also be applicable to slicing for picture media of large thicknesses. The problems of picture medium conveying skewing and tension control are solved, so that picture slicing is more orderly, and slicing quality is improved.

Owner:DONGHUA UNIV +1

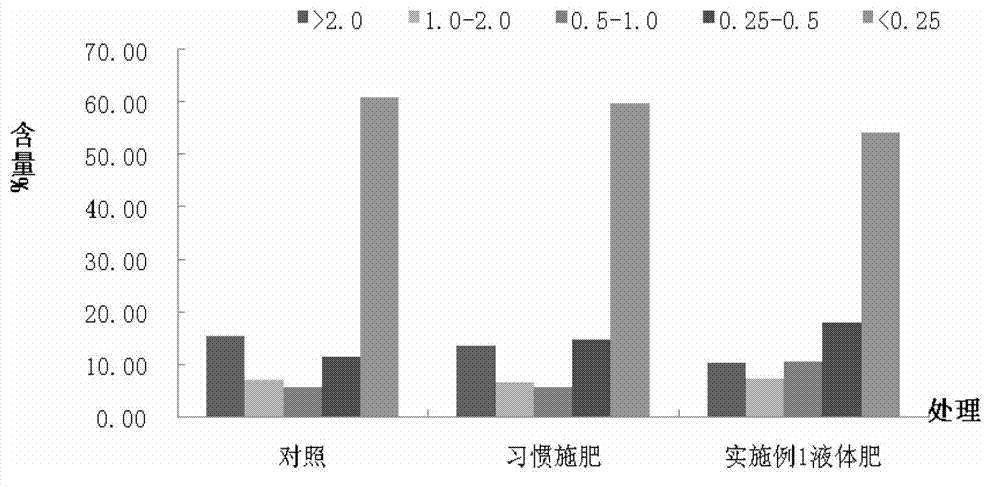

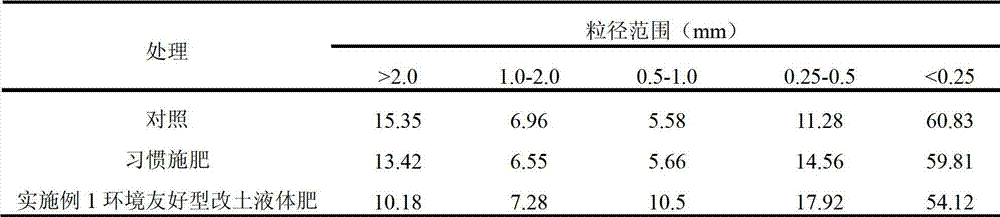

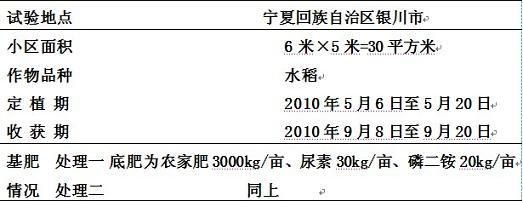

Environment-friendly soil-improving liquid fertilizer and preparing method thereof

The invention relates to environment-friendly soil-improving liquid fertilizer and a preparing method thereof. The environment-friendly soil-improving liquid fertilizer is prepared by the following raw materials in part by weight: 15 to 25 parts of lignosulfonate, 10 to 20 parts of potassium humate, 10 to 20 parts of urea, 2 to 5 parts of microelements, 1 to 5 parts of sodium alginate and 70 to 100 parts of water, wherein lignosulfonate and potassium humate are dissolved in water and sufficiently and uniformly mixed and dissolved; 40 to 60wt% of nitric acid is used to adjust the pH value of the solution to be from 6.0 to 7.5; urea is added into the solution to be mixed and dissolved; the solution is heated to 50 to 70 degrees C and then added with the microelements to be mixed and dissolved; and sodium alginate is added into the cooled solution to be dissolved, so as to obtain the environment-friendly soil-improving liquid fertilizer. The environment-friendly soil-improving liquid fertilizer integrates the functions of growth promoting, stress resisting and active soil improving, comprehensively utilizes the waste, and finally realizes the comprehensive development of circular economy.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Organic mineral fertilizer and preparation method thereof

The invention relates to an organic mineral fertilizer comprising the following components in percentage by weight: 15%-60% of zeolite powder with granularity of less than or equal to 60 meshes, 20%-30% of humic acid (salt), 10%-30% of calcium magnesium phosphate fertilizer and 10%-25% of plant ash. A preparation method of the organic mineral fertilizer comprises the following steps of: respectively weighing the zeolite powder with the granularity of less than or equal to 60 meshes, the humic acid (salt), the calcium magnesium phosphate fertilizer and the plant ash in the percentage by weight; placing into a stirrer for stirring and mixing; granulating through a granulator; baking at the temperature of 200-400 DEG C through a baking machine for 20-50 minutes; and screening through a screening machine so as to prepare the organic mineral fertilizer. The invention has the advantages of promoting the crop yield increase, enhancing the crop quality, improving the soil structure and ensuring that the crops can be safely eaten.

Owner:TIANRUN LVYE BEIJING ENVIRONMENTAL PROTECTION TECH

Thermal cutting shear and cutting method thereof

InactiveCN101992473ATemperature is directly measured and controlledTemperature measurement and controlMetal working apparatusRubber materialTemperature control

The invention relates to a thermal cutting shear and a cutting method thereof, and a flat arrangement type heating mode in fixture bodies is adopted to enhance the heating efficiency and the heat transfer speed and effectively control the operating temperature when the front end of a cutting edge carries out the cutting so as to enhance the cutting quality of the rubber material, and the quality of the joint and the stitching among various materials. The cutting shear comprises a group of the fixture bodies and shear bodies clamped and fixed among the fixture bodies, wherein at least one flat plate type heating plate is lined among the fixture bodies and the bases of the shear bodies; a heat source temperature sensor is arranged in the heating plate and is connected with an external power supply and a temperature control meter through a power supply wire; and a shear body temperature sensor is arranged in the cutting edge part of the shear bodies.

Owner:MESNAC

Device for attaching double-faced adhesive tape to cloth curtain

ActiveCN103625978AFitting position is accurateHigh precisionArticle deliveryVertical planeAdhesive belt

The invention relates to a device for attaching double-faced adhesive tape to a cloth curtain. The device comprises a rack and a press fit mechanism arranged on the rack. The press fit mechanism comprises a press fit cylinder which is perpendicularly arranged on the rack, and a cloth curtain pressing plate which is arranged at the bottom end of the press fit cylinder. The device is characterized in that a positioning mechanism is arranged on one side of the cloth curtain pressing plate, wherein the positioning mechanism comprises a supporting shaft which is longitudinally arranged on the rack, and a movable clamping piece which is arranged between the supporting shaft and the cloth curtain pressing plate; a feeding mechanism is arranged on the side, facing the press fit mechanism, of the positioning mechanism, wherein the feeding mechanism comprises a first clamping piece which can move transversely in the extension direction of the cloth curtain pressing plate. The device further comprises a cutting mechanism, wherein the cutting mechanism comprises a cutting piece which is arranged between the movable clamping piece and the cloth curtain pressing plate, and two second clamping pieces which are arranged on the two transverse sides of the cloth curtain pressing plate respectively, and the cutting piece comprises a cutter which can move in a vertical plane to cut the adhesive tape; the movable clamping piece, the first clamping piece and the second clamping pieces can clamp and release the adhesive tape respectively. The device is good in adhesive tape attaching quality and high in adhesive tape attaching efficiency.

Owner:KUSN HUANGTIAN AUTO PARTS INDAL

Cloth cutting device for clothing manufacture

ActiveCN110685144APlay a cutting roleLow costGrinding carriagesGrinding drivesStructural engineeringKnife holder

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cloth cutting, aiming to solve the problem that conventional bench type cutting devices are not adaptable to mass cutting of cloth. The cloth cutting device comprises a rack and a lower cutting plate; a blade carrier is arranged on the outer wall of the bottom of the rack, and the outer wall of the bottom of the blade carrier is welded to the outer wall of the top of the lower cutting plate; four mount holes are formed on the outer wall of the top of the lower cutting plate, and four rollers are respectively arranged inside the four mount holes; slide slots are respectively formed on the inner walls of two sides of the rack, two first sliders are slidably connected to the inner walls of two sides of the two slide slots respectively, the two first sliders are the same, mounting shafts are welded to outer walls of opposite sides of the two first sliders respectively, and holderssleeve the outer peripheral walls of the mounting shafts respectively; a cutting blade is fastened to the outer wall of the bottom of the holder, a U-shaped connecting frame is welded to the outer walls of backs of the two first sliders, and a second connecting plate is rotationally connected to the outer wall of the back of the U-shaped connecting frame. In application of the cloth cutting device, squeezing and fixing to single-layer or multi-layer cloth are facilitated, and accordingly, the cutting quality of the cutting blade is improved.

Owner:湖南浚林服饰有限公司

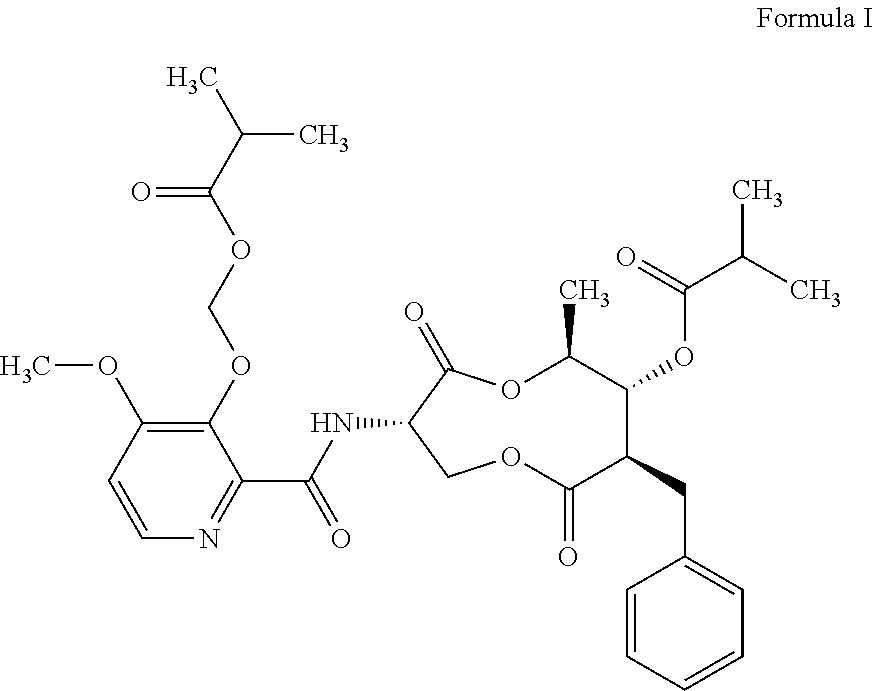

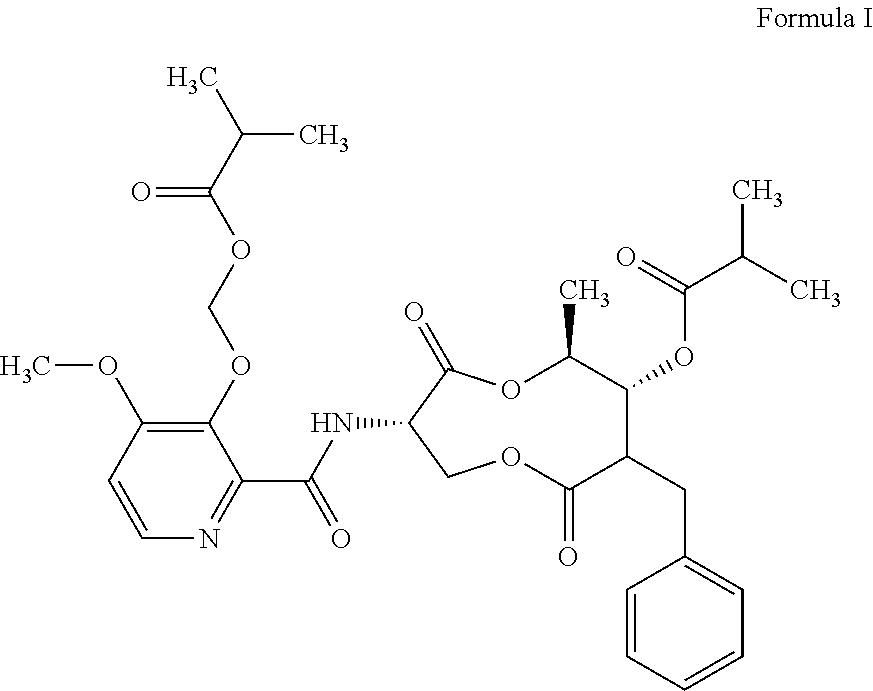

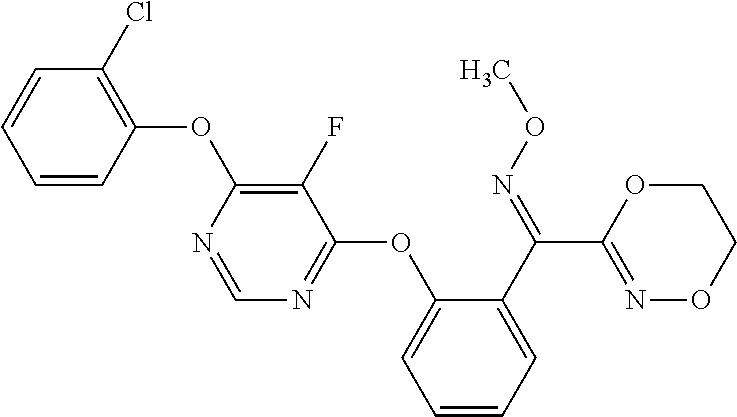

Synergistic fungicidal mixtures for fungal control in cereals

A fungicidal composition containing a fungicidally effective amount of a compound of Formula I:(3S,6S,7R,8R)-8-benzyl-3-(3-((isobutyryloxy)methoxy)-4-methoxypicolinamido)-6-methyl-4,9-dioxo-1,5-dioxonan-7-yl isobutyrate, and at least one fungicide selected from the group consisting of fluoxastrobin, trifloxystrobin, and picoxystrobin, provides synergistic control of selected fungi.

Owner:CORTEVA AGRISCIENCE LLC

Cutting device used for producing cloth of knapsack of baby carriage and use method of cutting device

InactiveCN107904913AEasy to cutImprove cutting efficiencySevering textilesTextile shapingHydraulic pumpEngineering

The invention discloses a cutting device used for a cutting device used for producing cloth of a knapsack of a baby carriage and a use method of the cutting device. The device includes a cutting table, a cutting frame, slide grooves, a slide rod, a fixation table, a support, a rotating shaft, a cloth rack, a clamping block, a fixation base, a support column, a hydraulic pump, a hydraulic rod, a blade, a support rod, a baffle, a spring supporting frame, a press plate, a metal plate and an electromagnet. The cutting device has the advantages that the side walls of the two sides of the cutting table are provided with slide grooves, the position of the cutting frame can be adjusted in a sliding mode, cloth of different positions of the knapsack is convenient to cut, and the cutting efficiencyand the cutting quality are effectively improved. By arranging the electromagnet in the cutting table and magnetizing the metal plate, the metal plate is magnetized. The metal plate can be used for adsorbing the press plate, the press plate thus can tightly press the cloth, the cloth is fixed more stably in the cutting process, no skewing occurs, and the cloth cutting quality is effectively ensured. The device has the advantages that the cutting efficiency is high and the cutting quality is good.

Owner:ANHUI HAPPYANG CHILDRENS ARTICLES

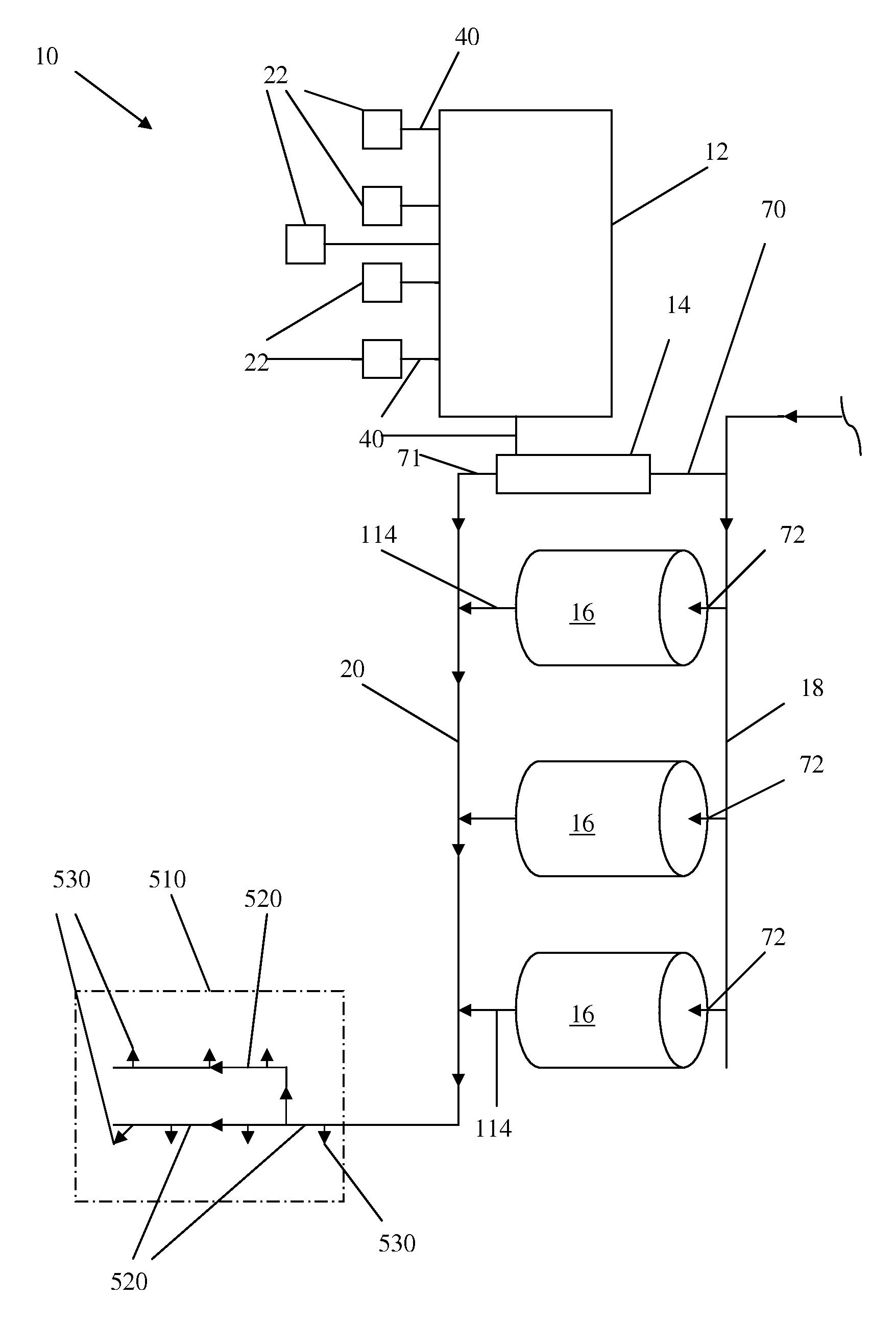

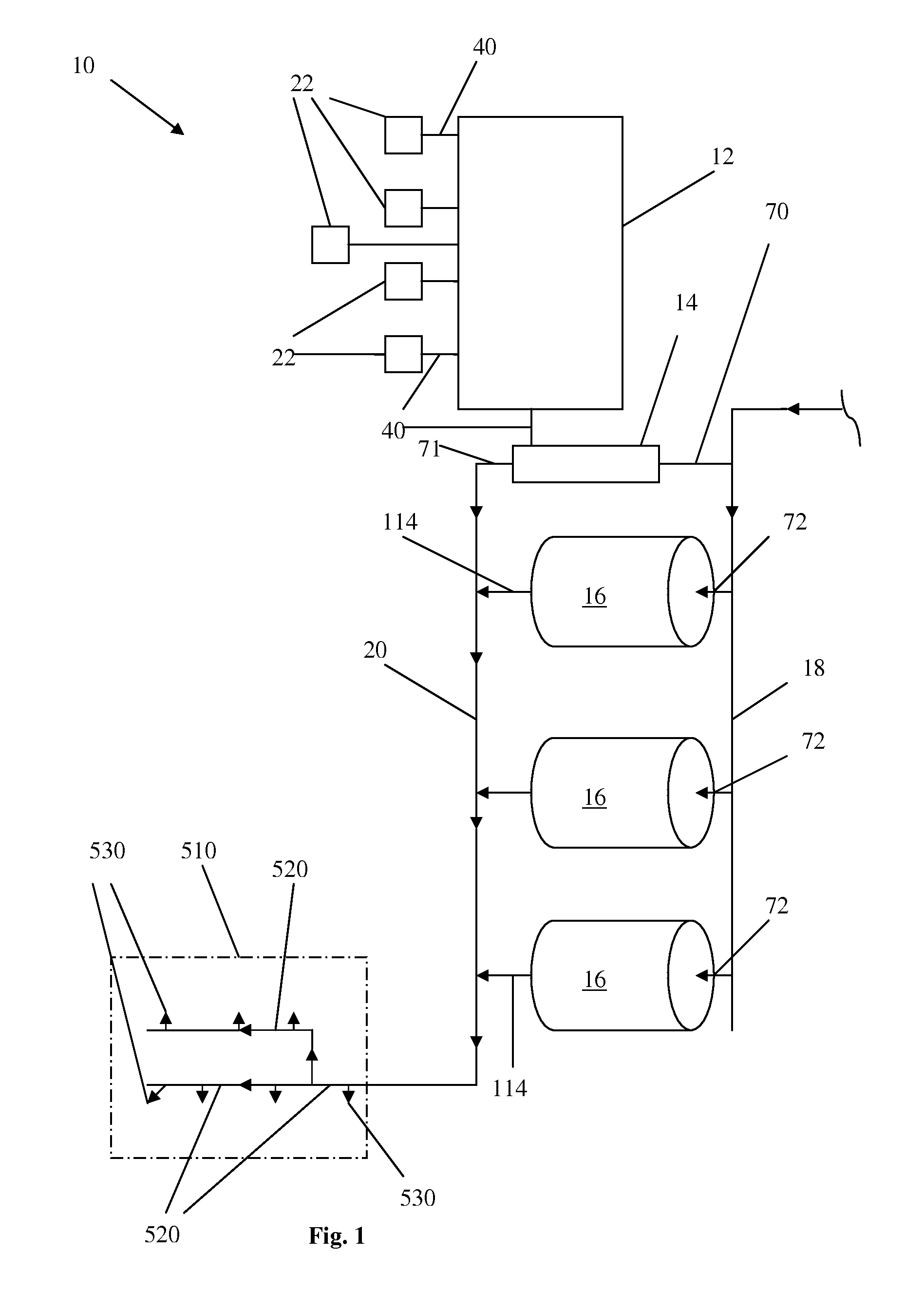

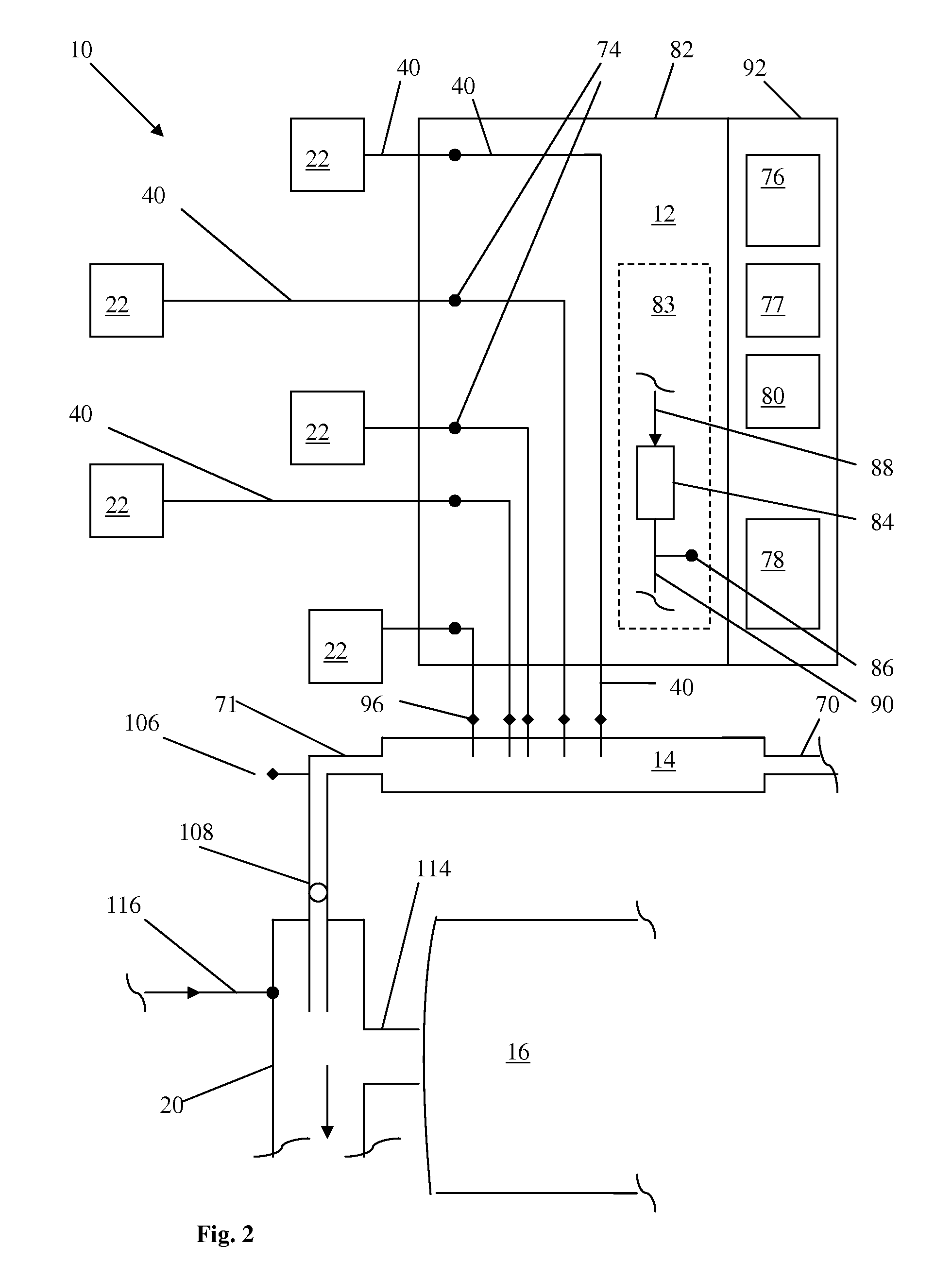

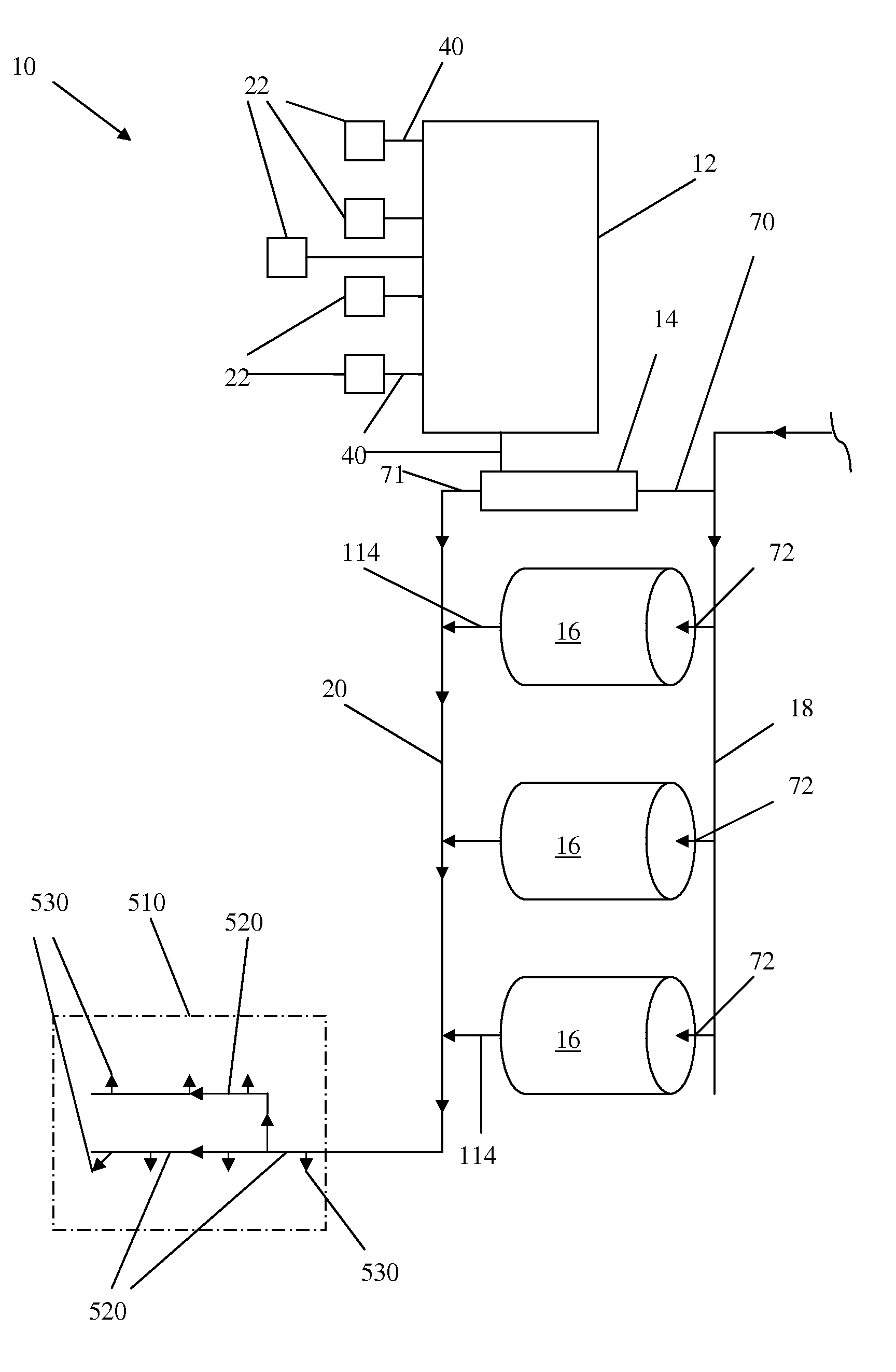

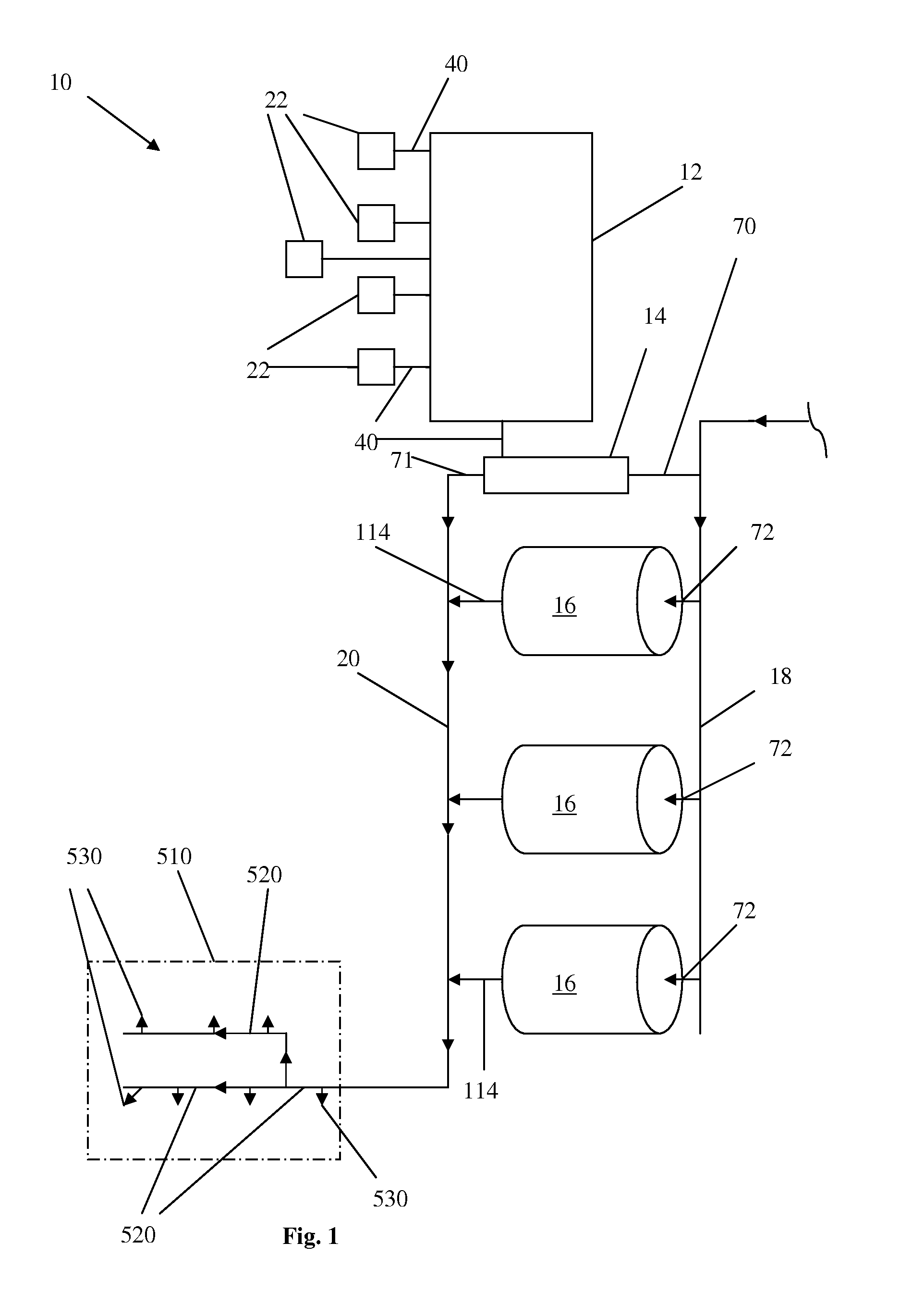

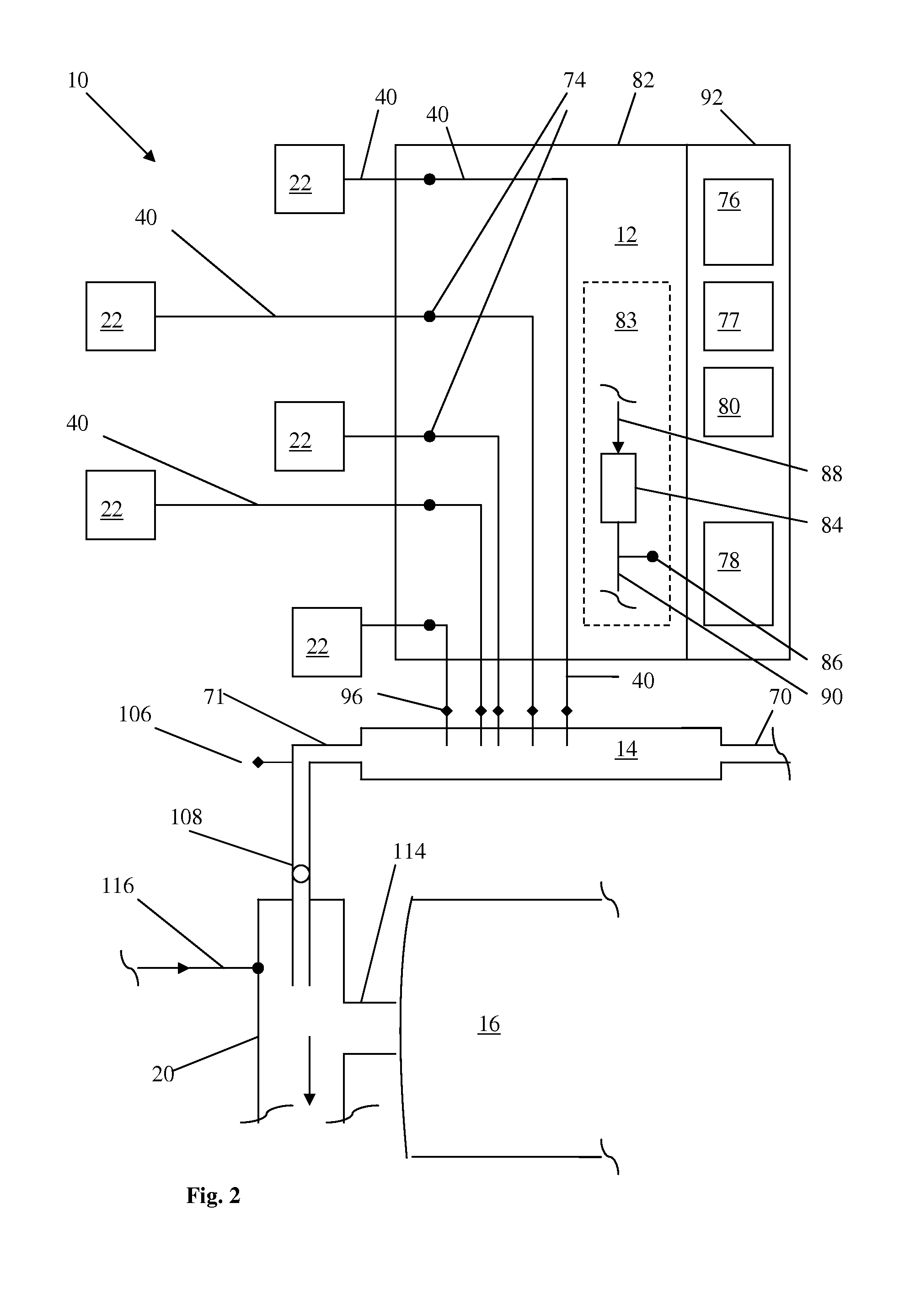

Method and system for agricultural fertigation

ActiveUS8986417B1Improve crop qualityPromotes crop healthCalcareous fertilisersMagnesium fertilisersSolubilityAgricultural engineering

An agricultural fertigation method includes the continuous charging of crop-quality-enhancer-feedstock comprised of one or more crop-quality enhancers (fertilizers, soil amendments and the like) to an irrigation system upstream of the agricultural field being irrigated. The crop-quality-enhancer-feedstock is diluted upon so charging to a level within the system solubility limits and the stream of flowing irrigation water dampens the resultant dissolution exotherm. A system wherein crop-quality enhancers are efficiently continuously fed to the irrigation system main line or a side-arm mixing chamber efficiently implements the method.

Owner:MILLER JOHN C +1

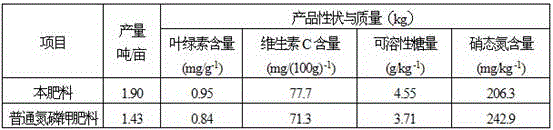

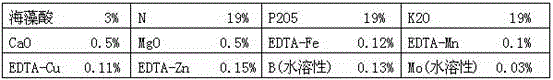

Water-soluble fertilizer containing alginate and various nutrients and preparation method of water-soluble fertilizer

InactiveCN105777263AImprove crop qualityImprove plant resistanceMagnesium fertilisersAlkali orthophosphate fertiliserNutrientChemistry

The invention relates to water-soluble fertilizer containing alginate and various nutrients and a preparation method of the water-soluble fertilizer. The water-soluble fertilizer comprises alginate, macro-elements N, P2O5 and K2O, medium elements Ca and Mg and trace elements Cu, Fe, Mn, Mo, Zn and B, wherein the weight percentage of the alginate is 3%., the total weight percentage of the macro-elements is 57%, the total weight percentage of the medium elements is 1%, and the total weight percentage of the trace elements is 0.64%. The preparation method includes: weighing the raw materials according to the weight percentage, and crushing and sieving; weighing the alginate, and evenly mixing with nitrogen fertilizer for standby; weighing the trace elements, and mixing with calcium and magnesium fertilizer for standby; weighing phosphorus fertilizer and potassium fertilizer, evenly mixing, adding the mixture, and sufficiently mixing to obtain the water-soluble fertilizer. By the water-soluble fertilizer, fruit yield can be increased by 20-30%, vegetable yield can be increased by 25-35%, and flower quality can be increased evidently.

Owner:董礼

Method and system for agricultural fertigation

ActiveUS8979969B1Improve crop qualityPromotes crop healthCalcareous fertilisersMagnesium fertilisersSolubilityAgricultural irrigation

An agricultural fertigation method includes the continuous charging of crop-quality-enhancer-feedstock comprised of one or more crop-quality enhancers (fertilizers, soil amendments and the like) to an irrigation system upstream of the agricultural field being irrigated. The crop-quality-enhancer-feedstock is diluted upon so charging to a level within the system solubility limits and the stream of flowing irrigation water dampens the resultant dissolution exotherm. A system wherein crop-quality enhancers are efficiently continuously fed to the irrigation system main line or a side-arm mixing chamber efficiently implements the method.

Owner:MILLER JOHN C +1

High-precision wallpaper cutting device for indoor decoration design

InactiveCN113021445AImprove crop qualityReduce scrap rateMetal working apparatusEngineeringSupport plane

The invention discloses a high-precision wallpaper cutting device for interior decoration design, and relates to the technical field of wallpaper cutting devices for interior decoration design. The high-precision wallpaper cutting device for interior decoration design comprises a cutting table, and a supporting frame is mounted in the middle of the top of the cutting table; supporting rods are mounted at the four corners of the bottom end of the cutting table, an air cylinder is fixed to the middle of the top end of the supporting frame, and a mounting plate is arranged in the supporting frame; and the telescopic end of the air cylinder extends into the supporting frame and is connected with the top of the mounting plate, and a cutting knife is mounted in the middle of the bottom end of the mounting plate. According to the high-precision wallpaper cutting device for interior decoration design, by arranging a pressing plate, wallpaper can be pressed, so that the cutting position of the wallpaper is smooth, cutting edges are prevented from appearing at the cutting position of the wallpaper, the cutting quality of the wallpaper is effectively improved, the rejection rate of wallpaper cutting can be reduced, then efficient and high-quality cutting of the wallpaper is achieved, and the wallpaper cutting benefit is increased.

Owner:TAIZHOU POLYTECHNIC COLLEGE

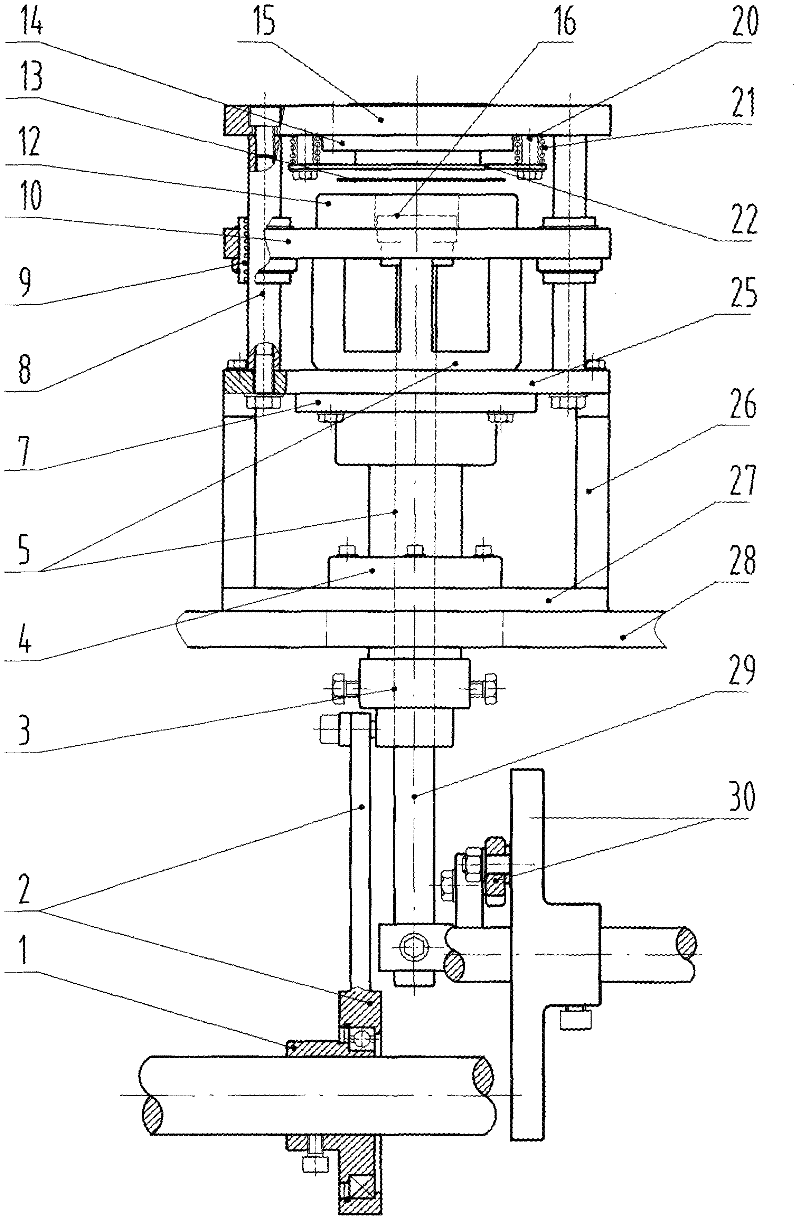

Cup bottom paper cutting and delivering mechanism of high-speed paper cup machine

ActiveCN102653103AExtended service lifeImprove crop qualityMetal working apparatusSlide plateEngineering

The invention relates to a cup bottom paper cutting and delivering mechanism of a high-speed paper cup machine. Guide sleeves are respectively arranged in the inner holes of a lower guide holder and a middle guide holder and are in clearance fit with a sliding seat in outer diameter, a sliding plate is square, upper guide sleeves are arranged in the inner holes of four corners and are in clearance fit with guide pillars, and an eccentric wheel is driven by a driving mechanism to enable the sliding plate to move vertically; and the guide pillars are used for positioning while the sliding plate is used for guiding, and the middle and lower guide holders are used for positioning while the sliding seat is used for guiding, so that a tri-positioning-guiding cup bottom cutting structure is formed. The inner hole of the sliding seat is provided with push rod guide sleeves which are in clearance fit with a push rod, the lower end of the push rod is connected with a cam rocking bar transmission device, and the push rod moves vertically so as to form a double-positioning-guiding propelling structure by virtue of the vertically distributed push rod guide sleeves. A tri-positioning-guiding mode is adopted by the cup bottom cutting structure for cutting a cup bottom so that the service life of a cutting die is prolonged and the cutting quality is improved. A double-positioning-guiding mode is adopted by the cup bottom propelling structure, so that the cup bottom is directly propelled into a cup body, not only is the service life of the push rod and a cup bottom propelling die prolonged, but also a cup bottom transmitting link is omitted.

Owner:瑞安市胜利机械有限公司

Thin-film capacitor and automatic production equipment and method thereof

InactiveCN111627706AHigh precisionRealize synchronous handlingThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention relates to the technical field of capacitor production. Automatic production equipment of a thin-film capacitor comprises a rack, and a feeding conveying device, a clamping and transferring device, a multifunctional forming device, a rotary material overturning device, an inverted conveying device, a pipe penetrating device and a pipe pressing device which are mounted on the rack, the feeding conveying device is connected with the clamping and transferring device, and the multifunctional forming device is located under the clamping and transferring device. The multifunctional forming device is connected with the inverted conveying device through the rotary material overturning device. The pipe penetrating device and the pipe pressing device are located over the inverted conveying device, the rack is further provided with a discharging barrel, and the discharging barrel is connected with the discharging side of the inverted conveying device. According to the invention, movement between film capacitor stations is efficient and positional accurate, the pins are flat and uniform in length, twice bending is completed by one action, and the forming and bending efficiency ishigh; the mobile capacitor is inverted to position a capacitor pin, so that pipe penetration is facilitated; and the heat shrink tube is integrally assembled, and the success rate of pipe penetrationis high.

Owner:温州源利智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com