Patents

Literature

179results about How to "The extraction process is smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

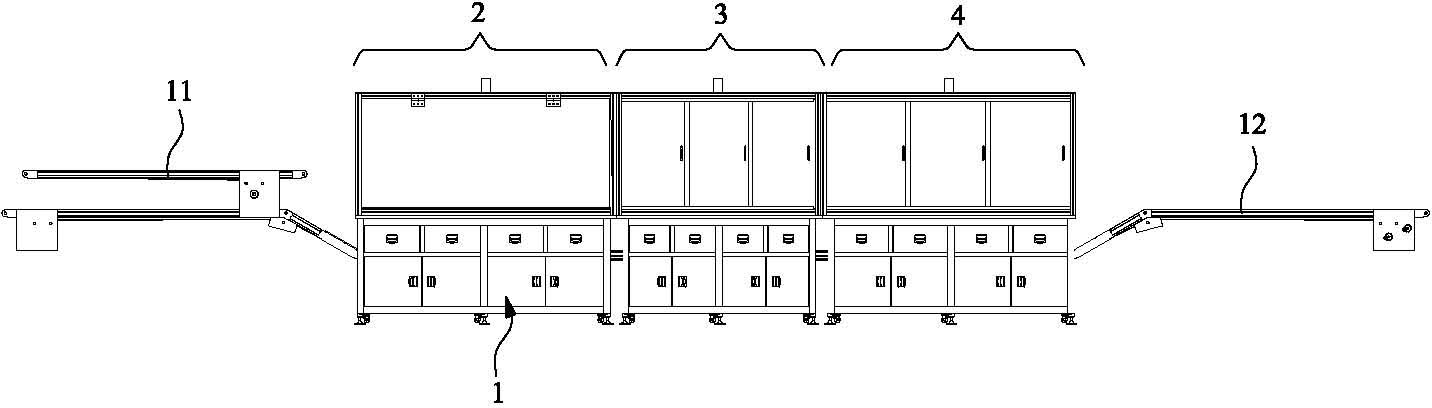

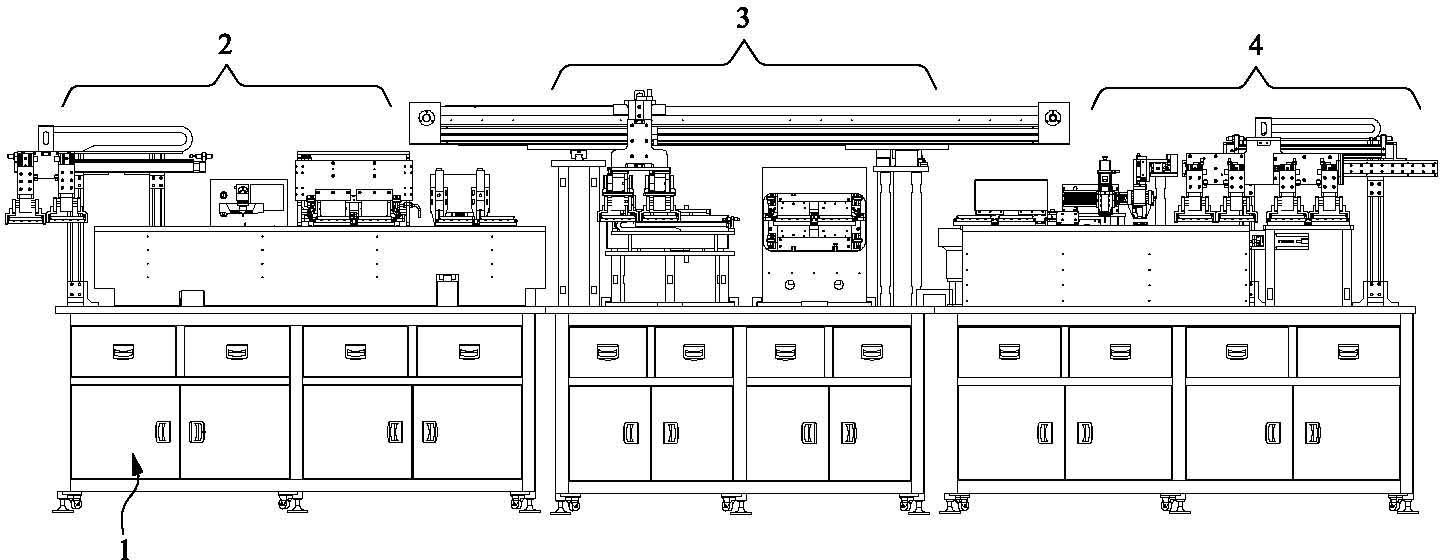

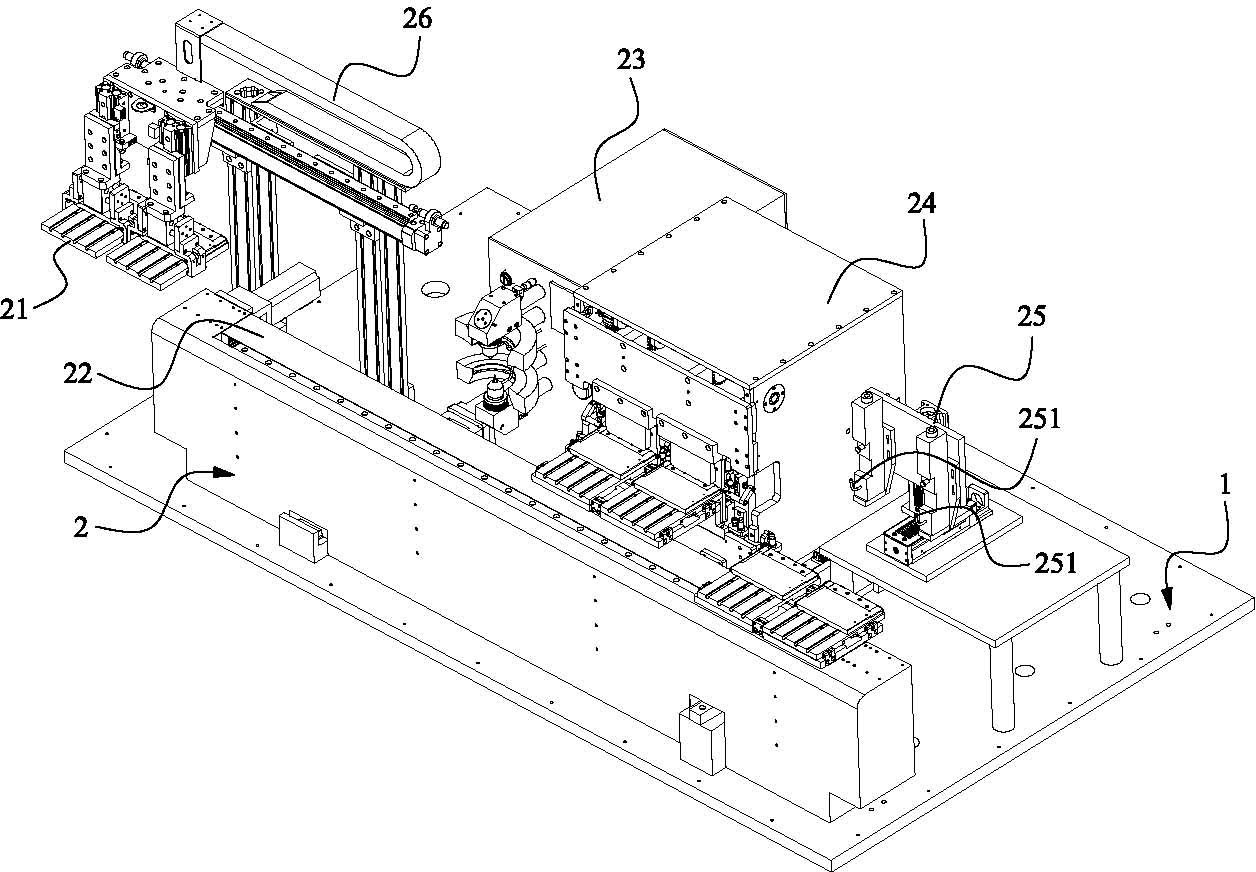

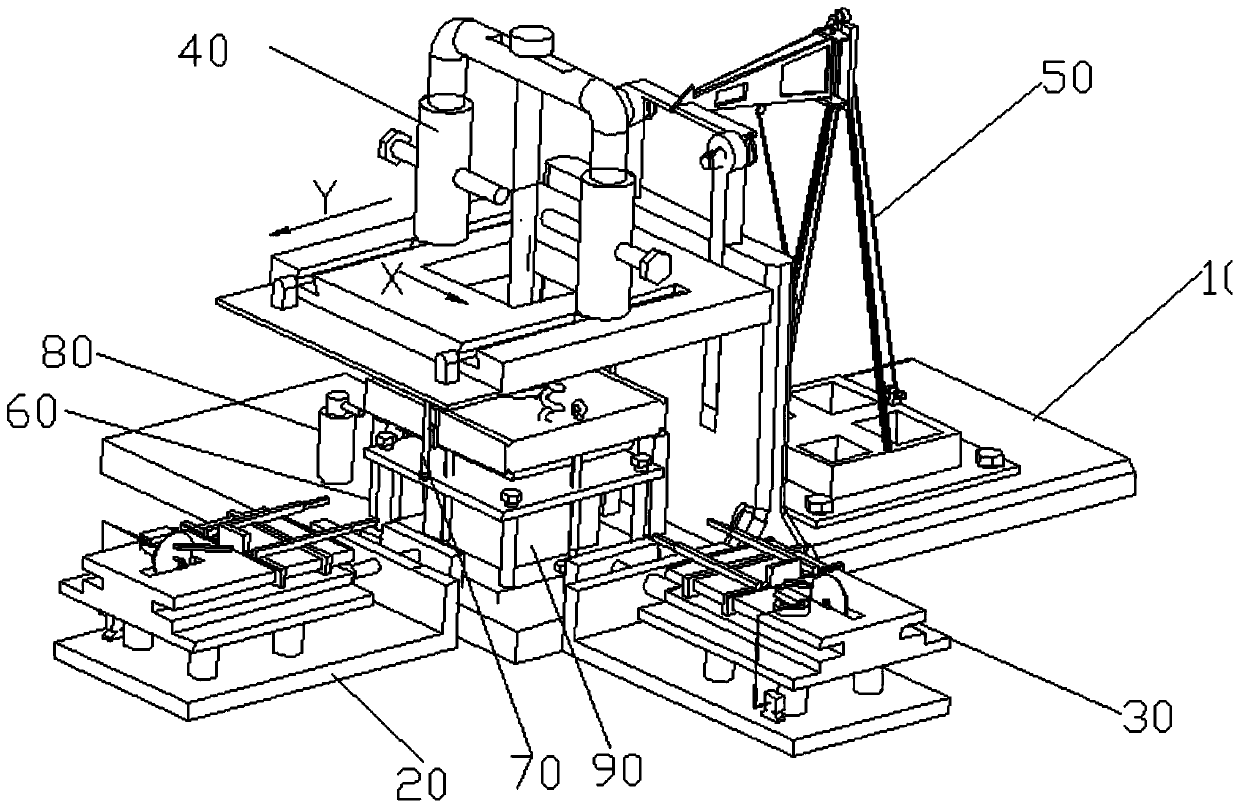

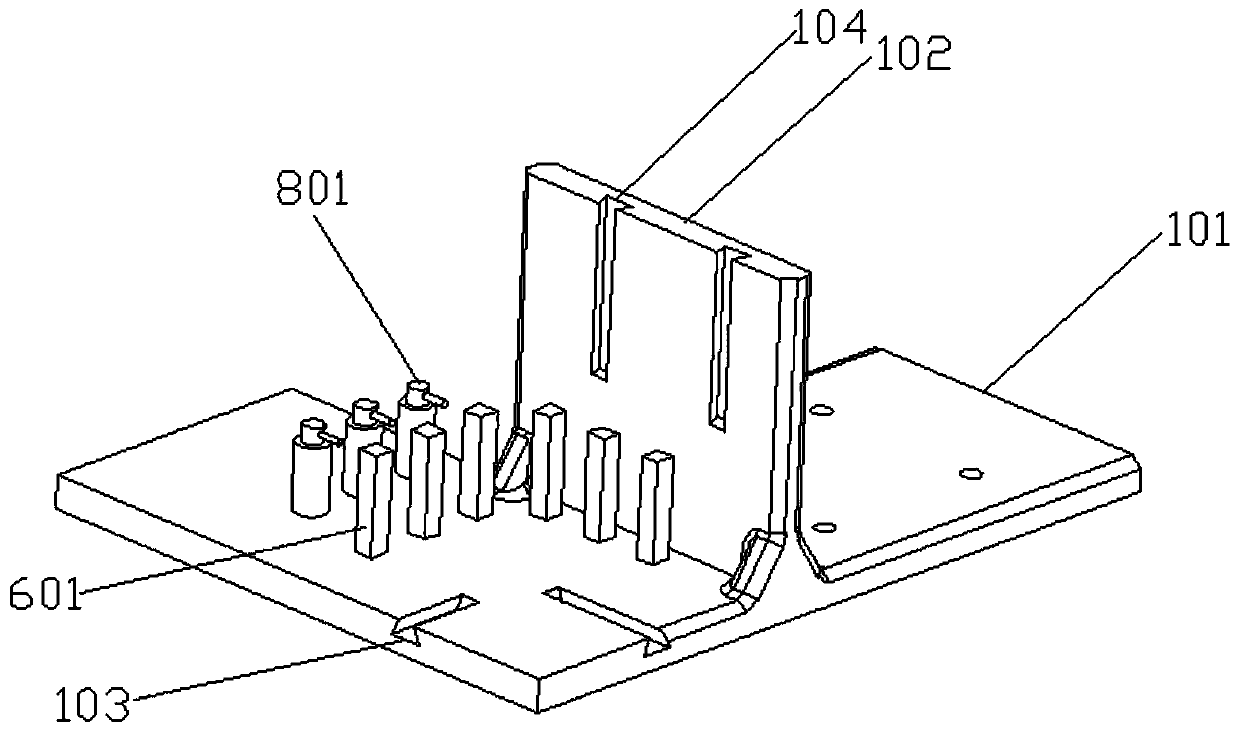

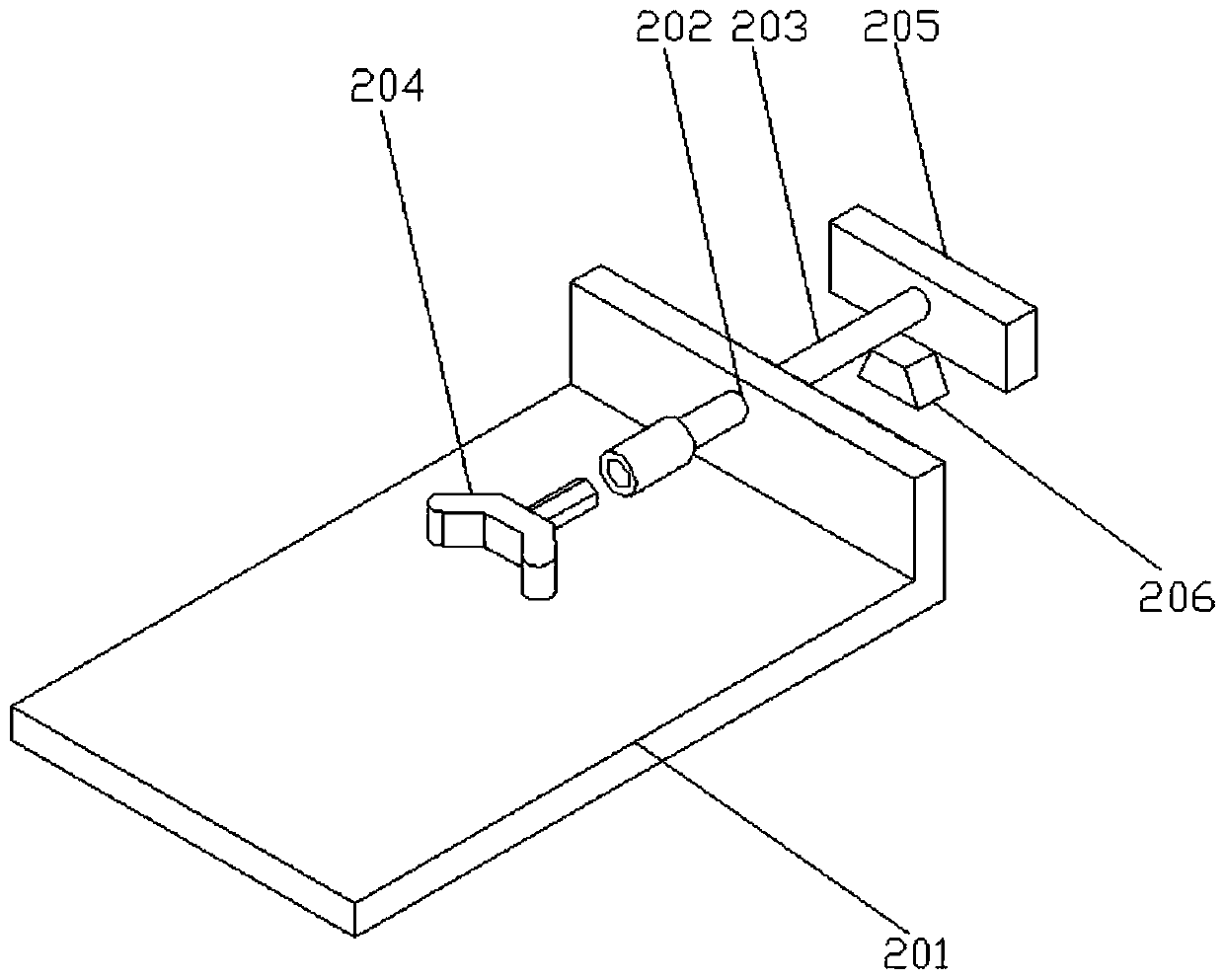

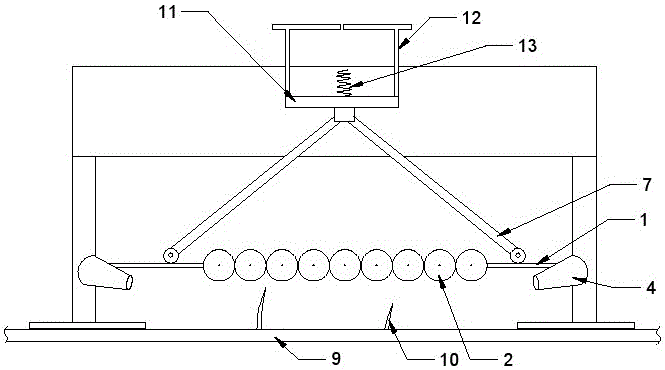

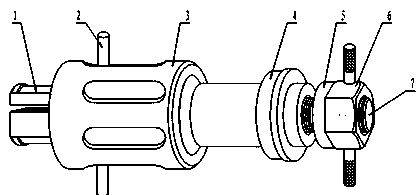

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

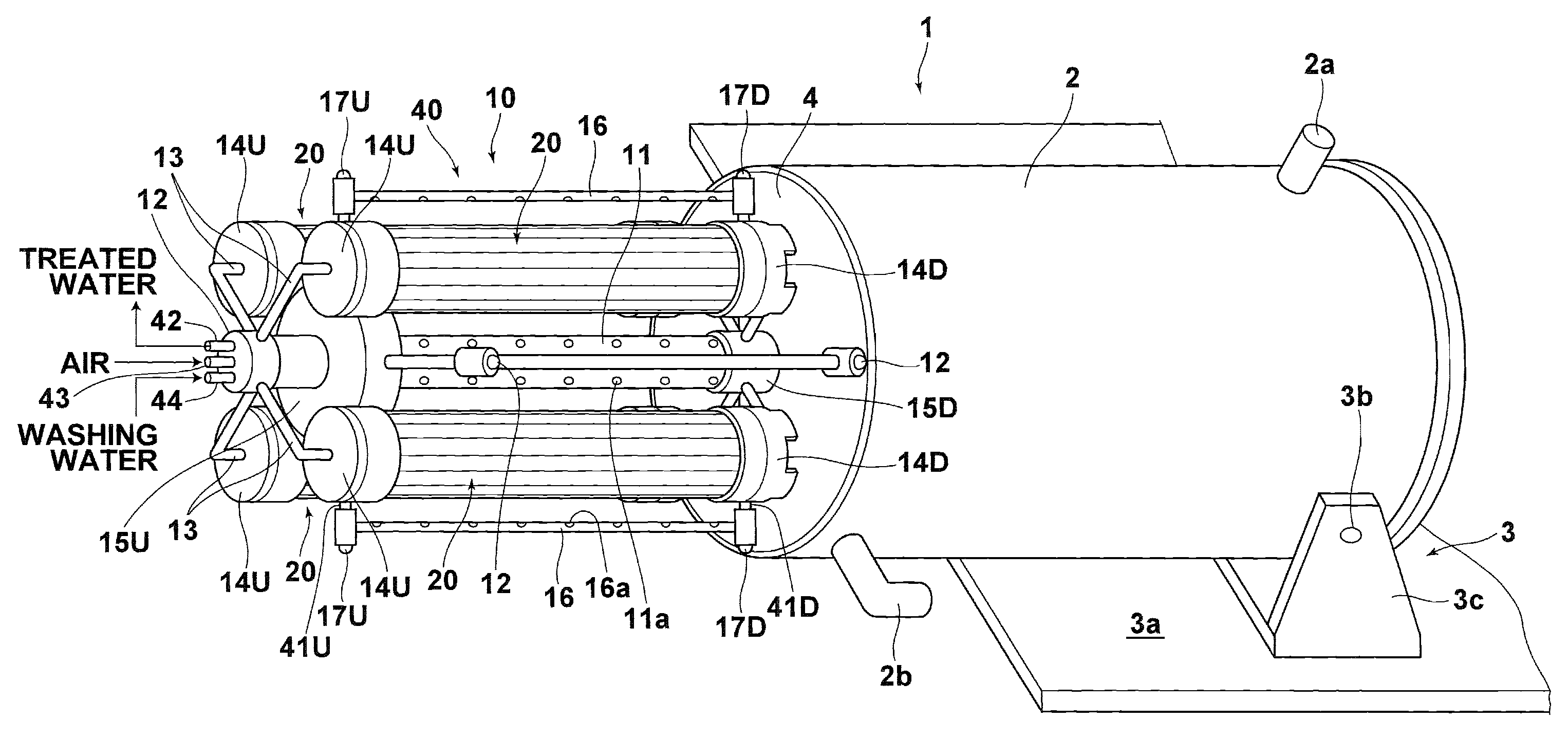

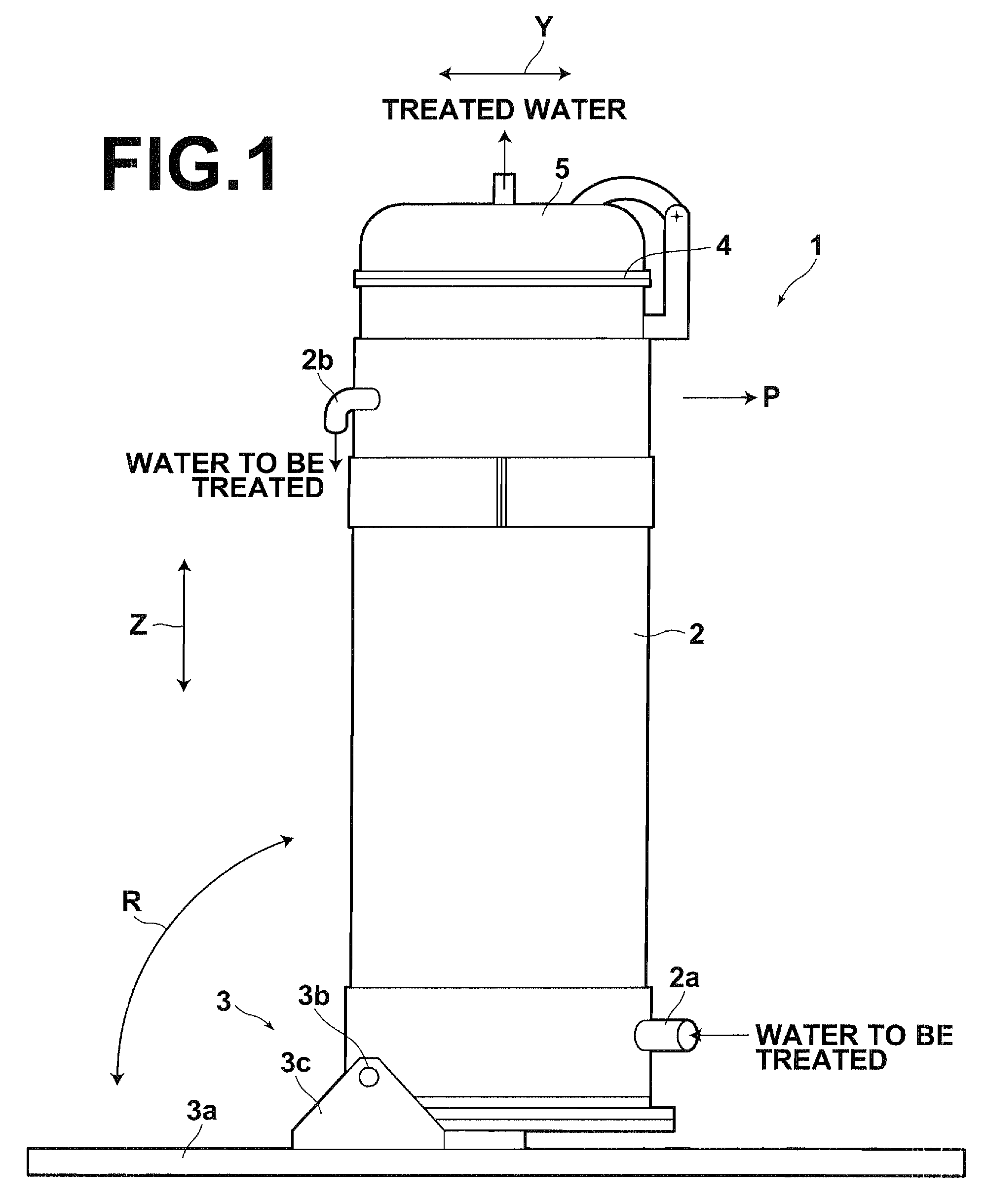

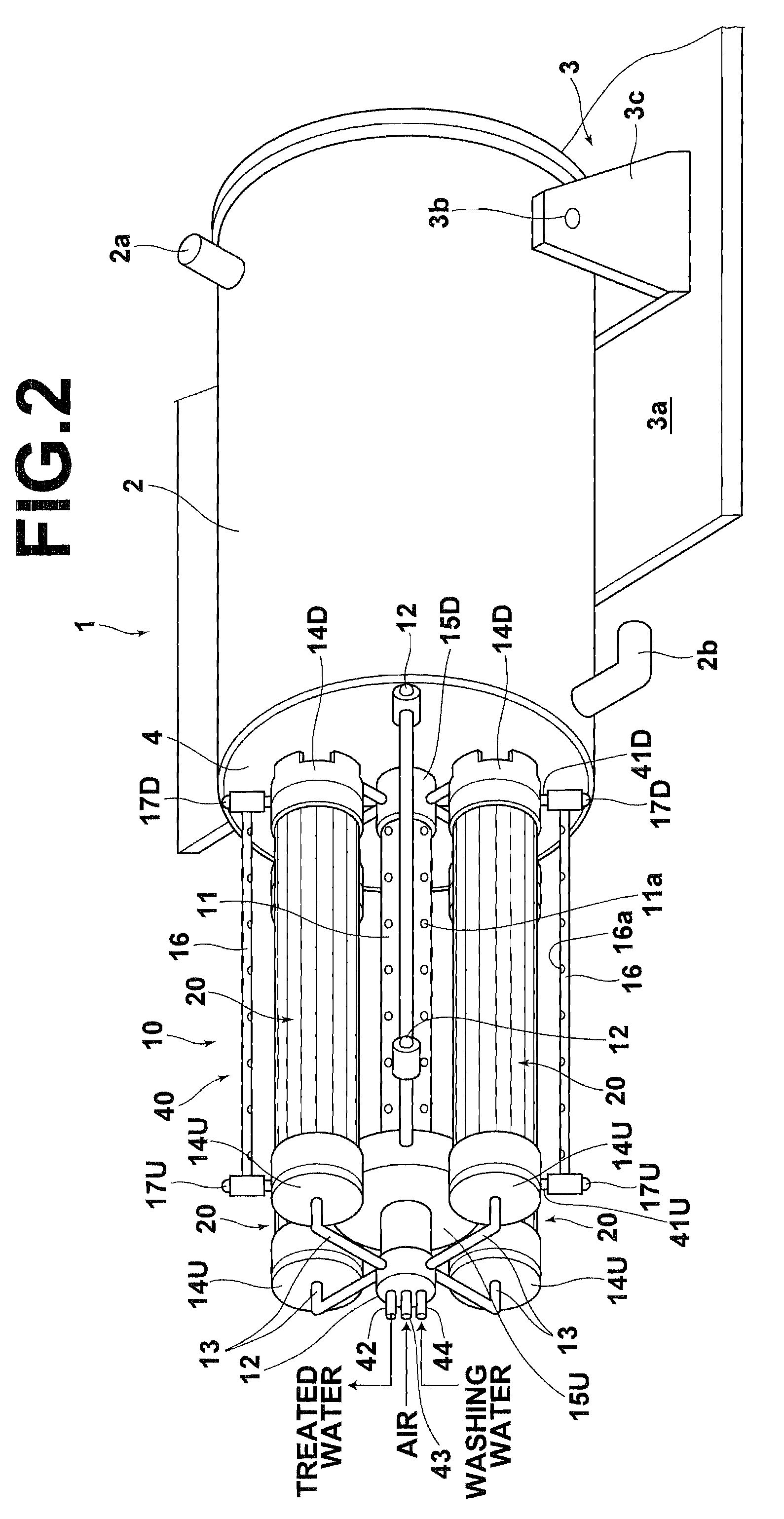

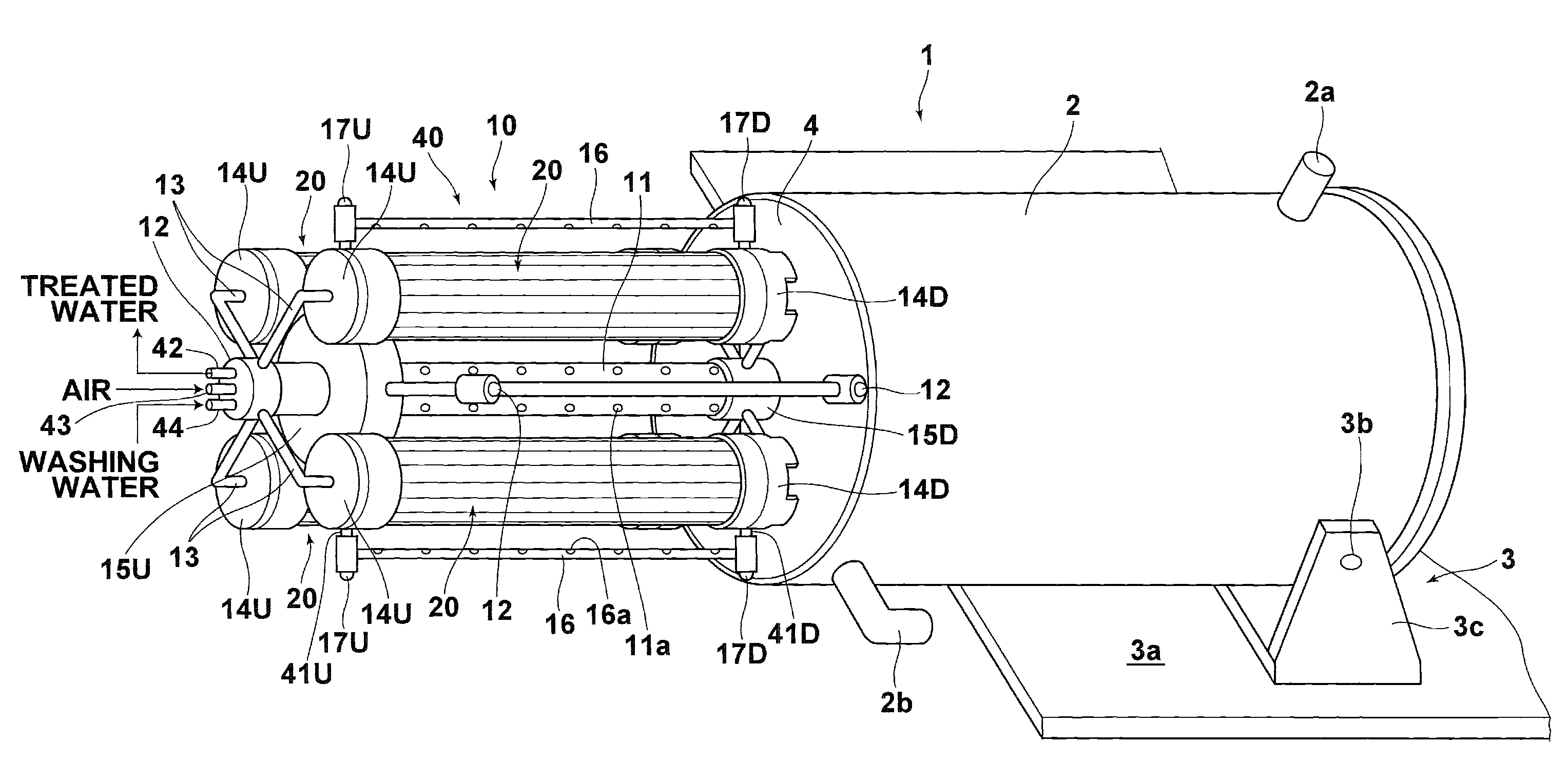

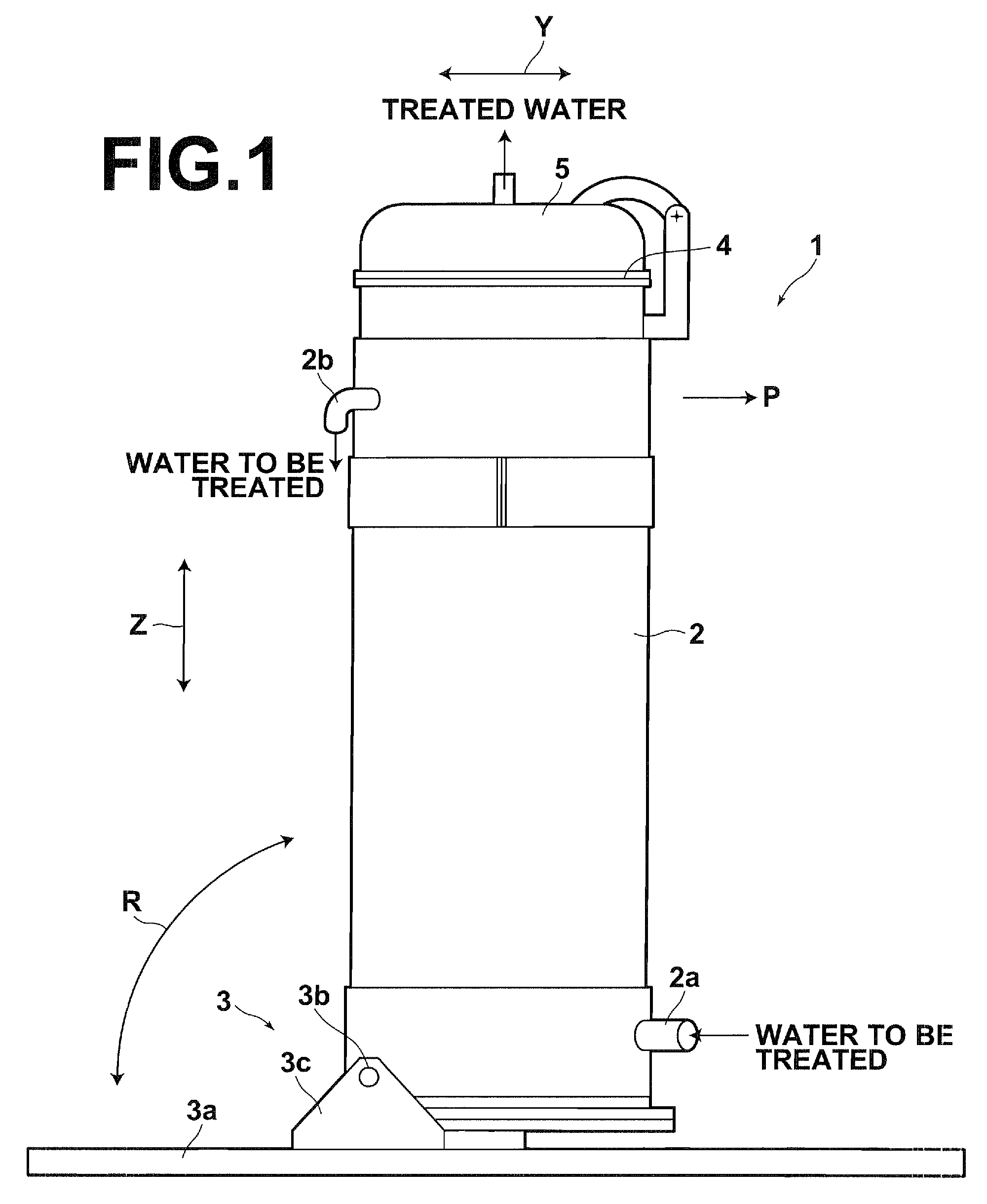

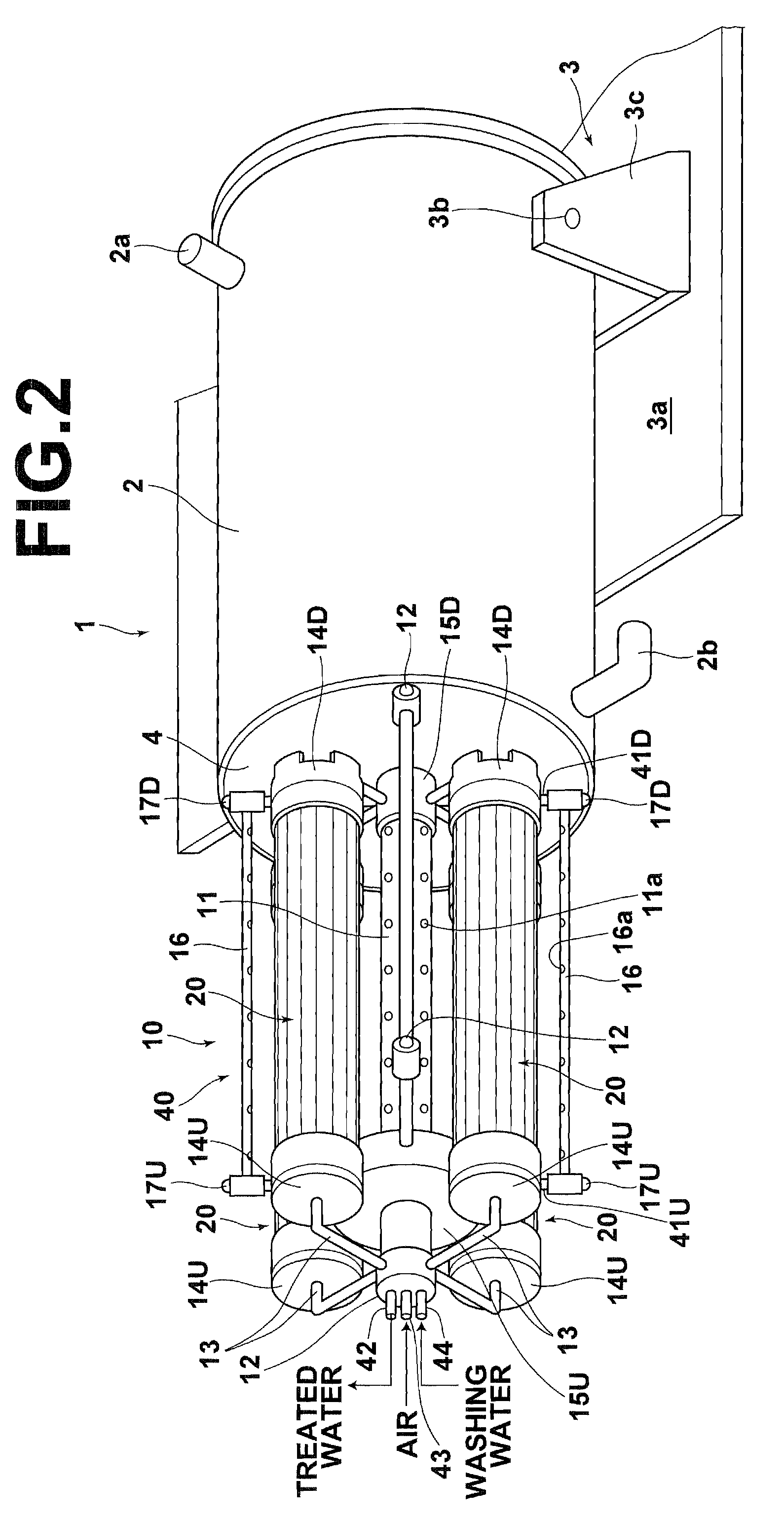

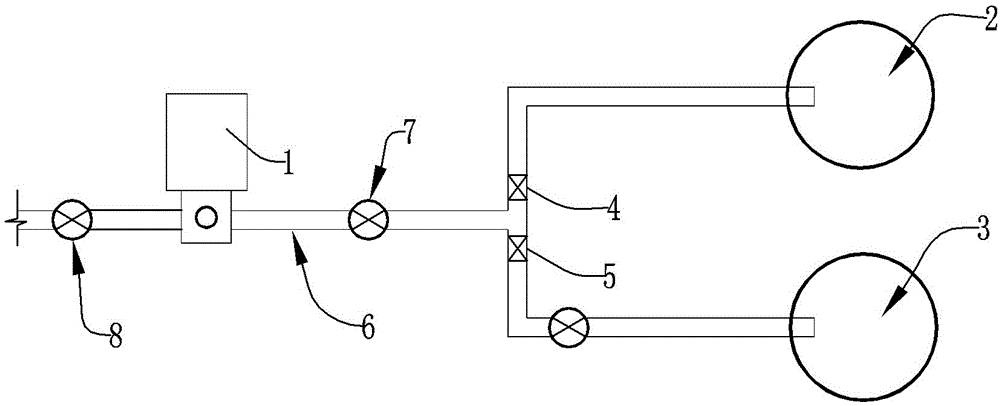

Water treating apparatus

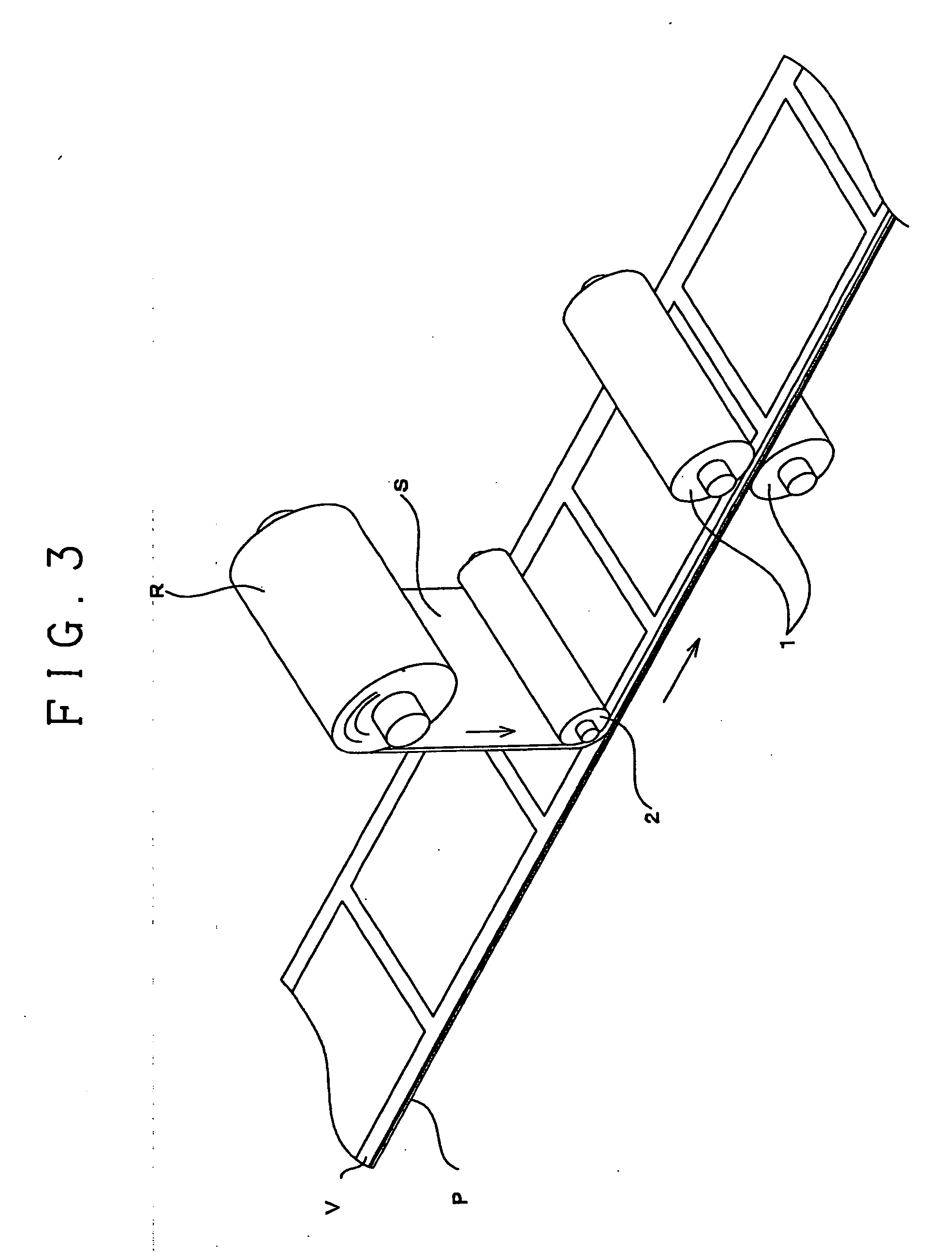

InactiveUS20080105605A1Effective installationThe extraction process is smoothUltrafiltrationSolid sorbent liquid separationEngineeringTreated water

A vertical membrane module unit is allowed to be installed even at a place with a low ceiling. A housing containing a vertical membrane module unit is held by a housing holder. The housing holder holds the housing tiltably such that the housing can be positioned with the longitudinal direction of the membrane module unit being substantially vertical when treated water is extracted, and the housing can be positioned with the longitudinal direction of the membrane module unit being substantially horizontal when the membrane module unit is removed from the housing.

Owner:ECO CREATIVE JAPAN

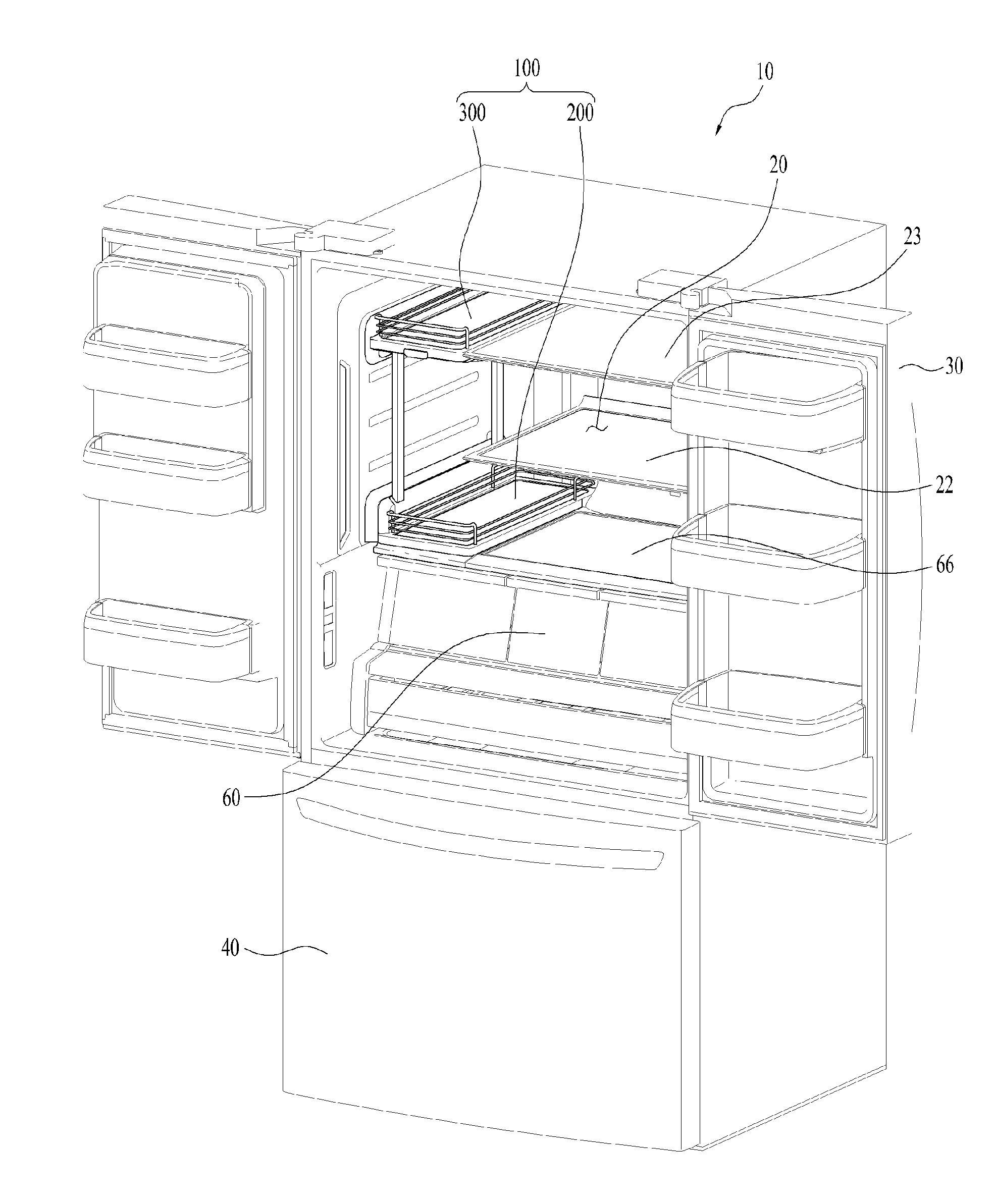

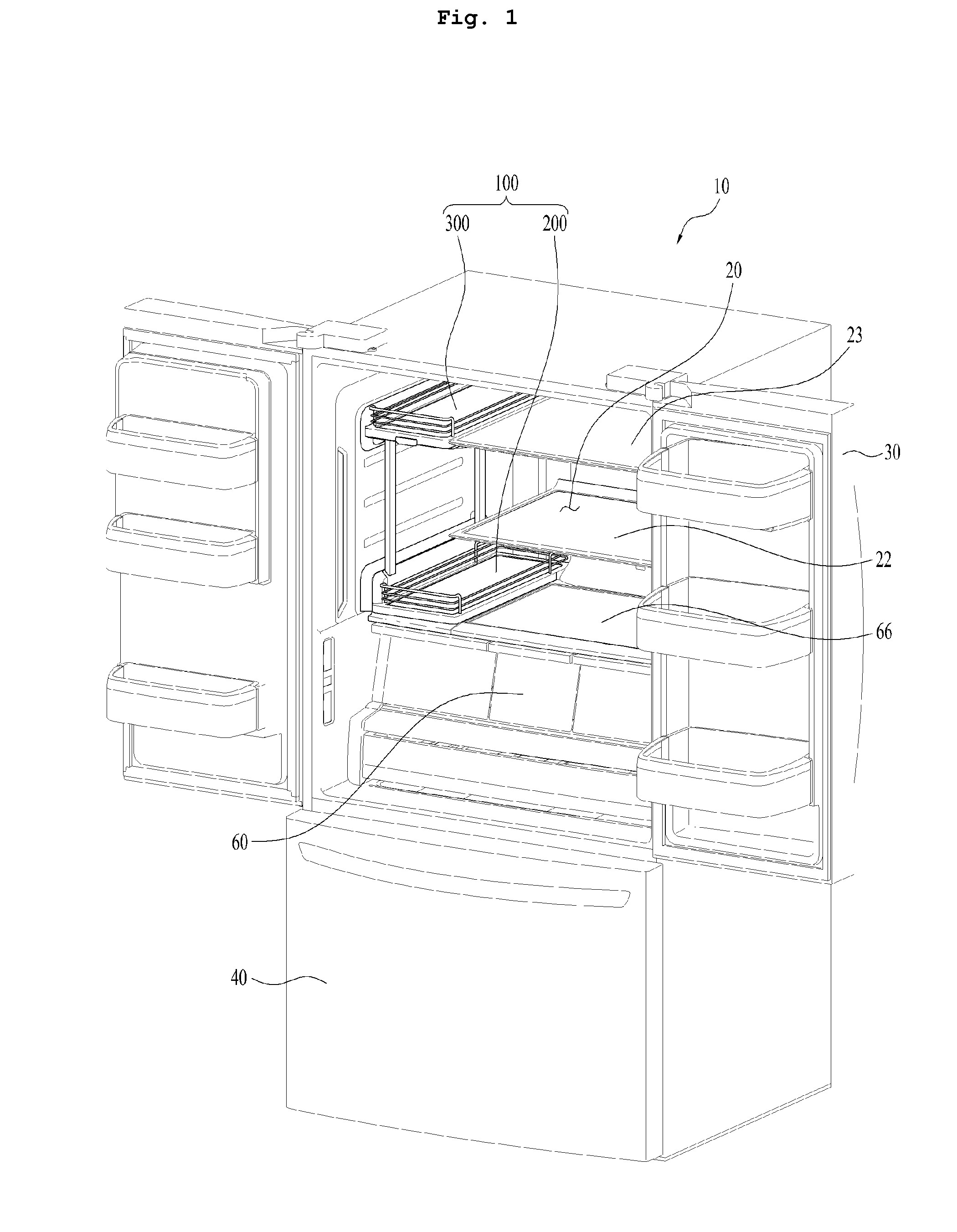

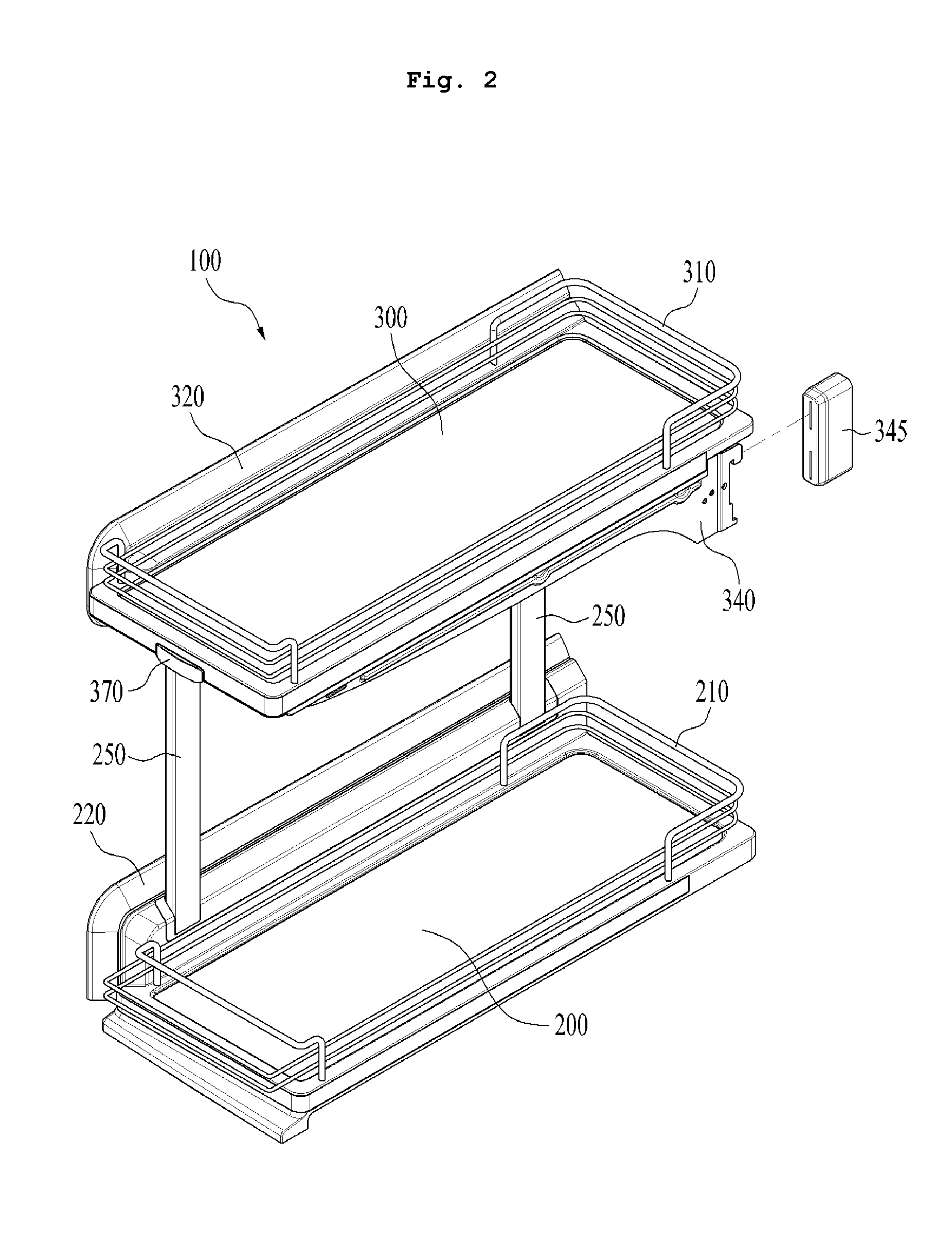

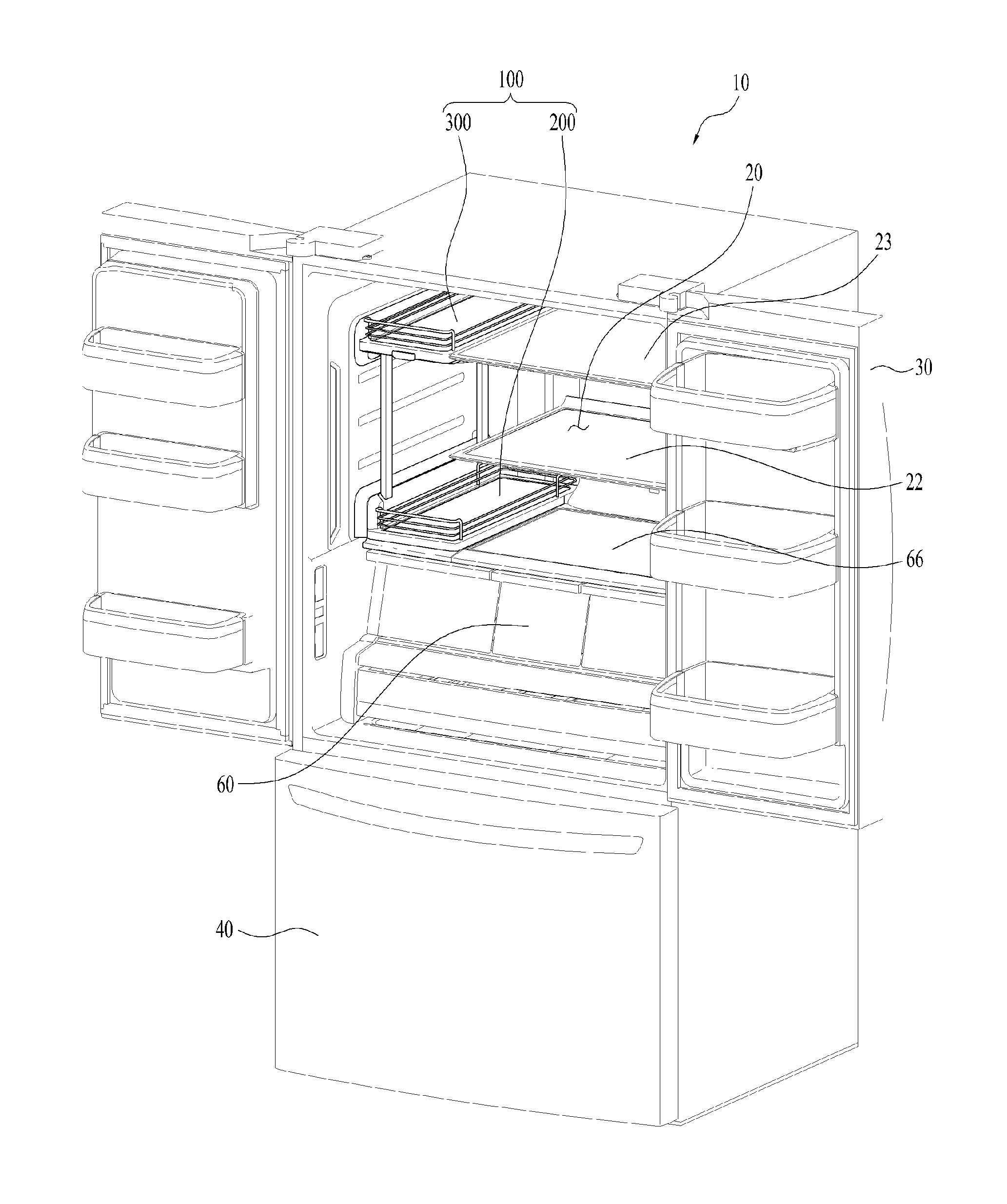

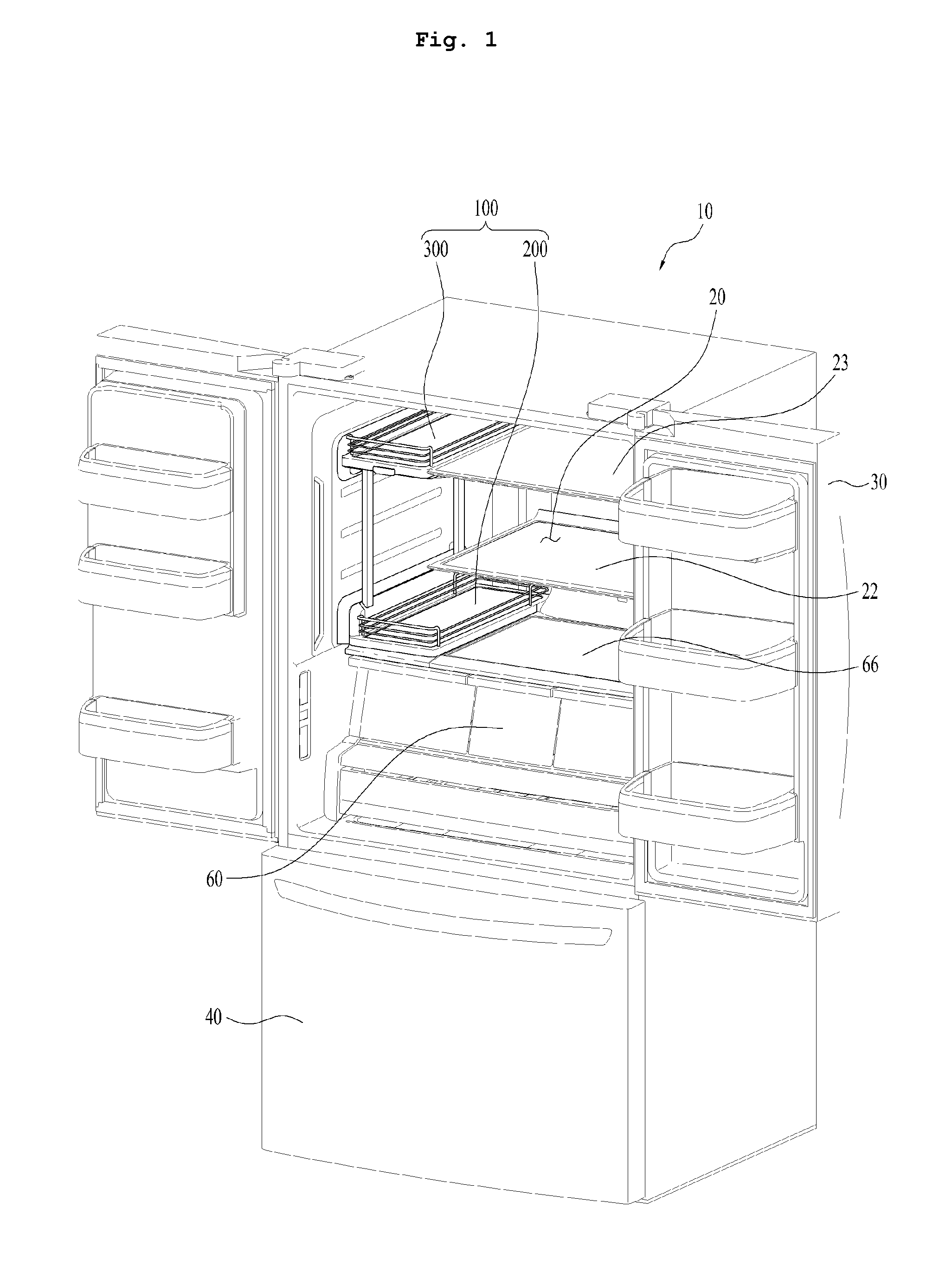

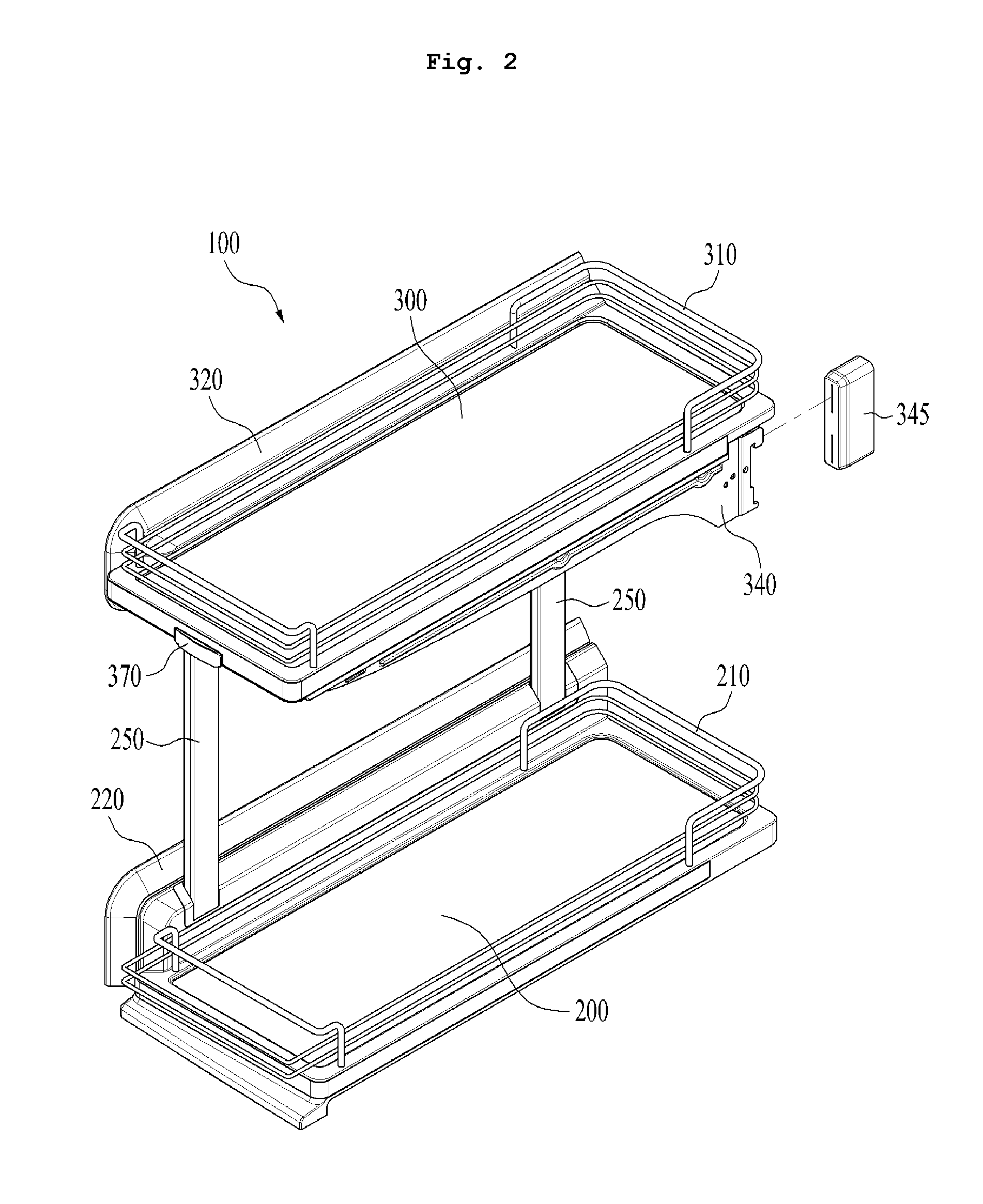

Refrigerator

ActiveUS20140252937A1The extraction process is smoothIncrease the use of spaceLighting and heating apparatusFurniture partsEngineeringRefrigerated temperature

Disclosed is a refrigerator including a main body, a storage chamber provided within the main body, a drawer assembly provided in the lower portion of the storage chamber, a cover shelf covering at least a part of the upper surface of the drawer assembly, a lower shelf disposed between the cover shelf and the sidewall of the storage chamber and provided with one side supported by the sidewall of the storage chamber so as to be pulled out and the other side supported by the upper surface of the drawer assembly so as to be pulled out, and an upper shelf disposed above the lower shelf and provided with one side supported by the sidewall of the storage chamber so as to be pulled out and the other side supported by a shelf frame mounted on the rear wall of the storage chamber so as to be pulled out.

Owner:LG ELECTRONICS INC

Refrigerator

ActiveUS9217602B2The extraction process is smoothIncrease the use of spaceLighting and heating apparatusSupportEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

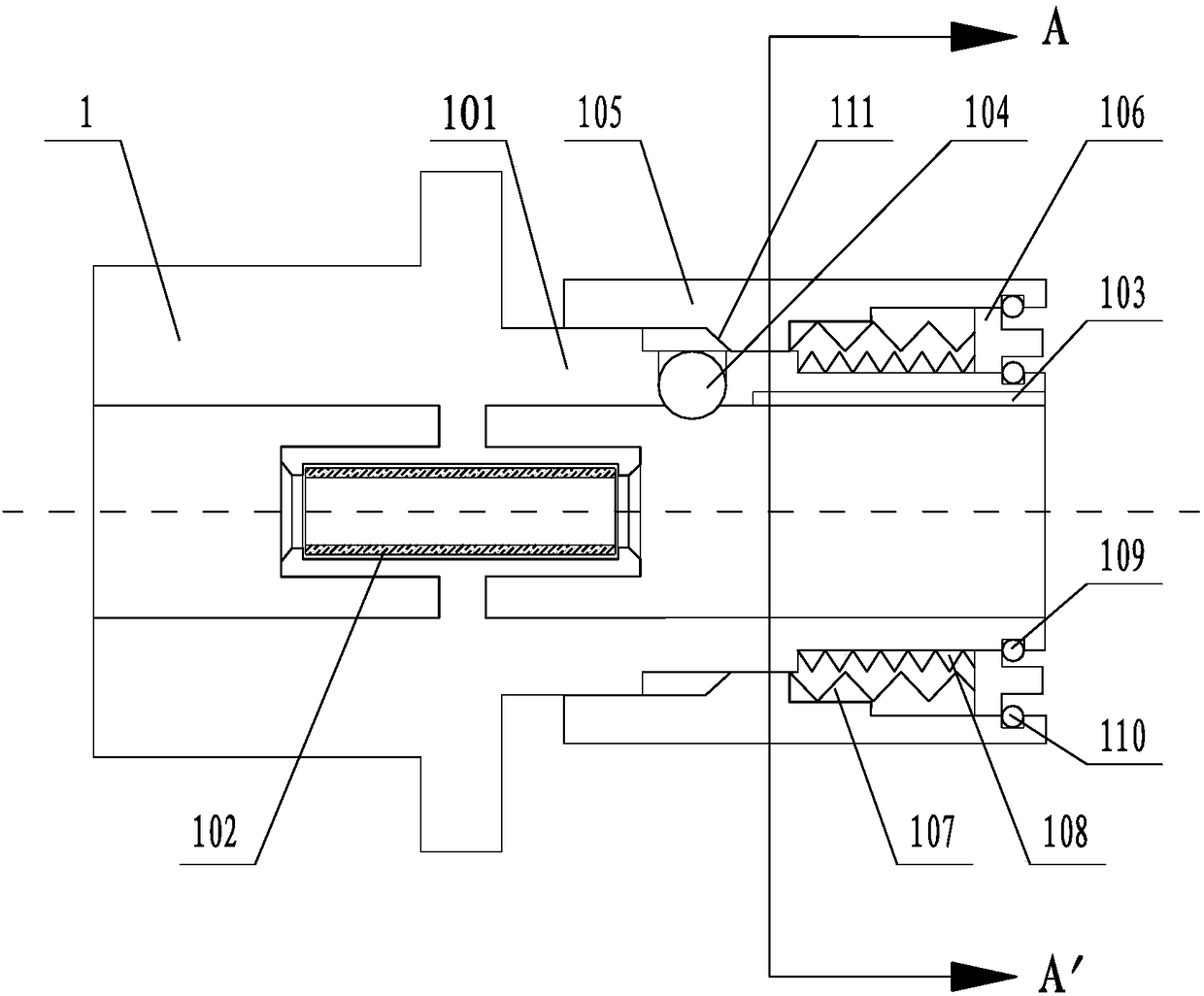

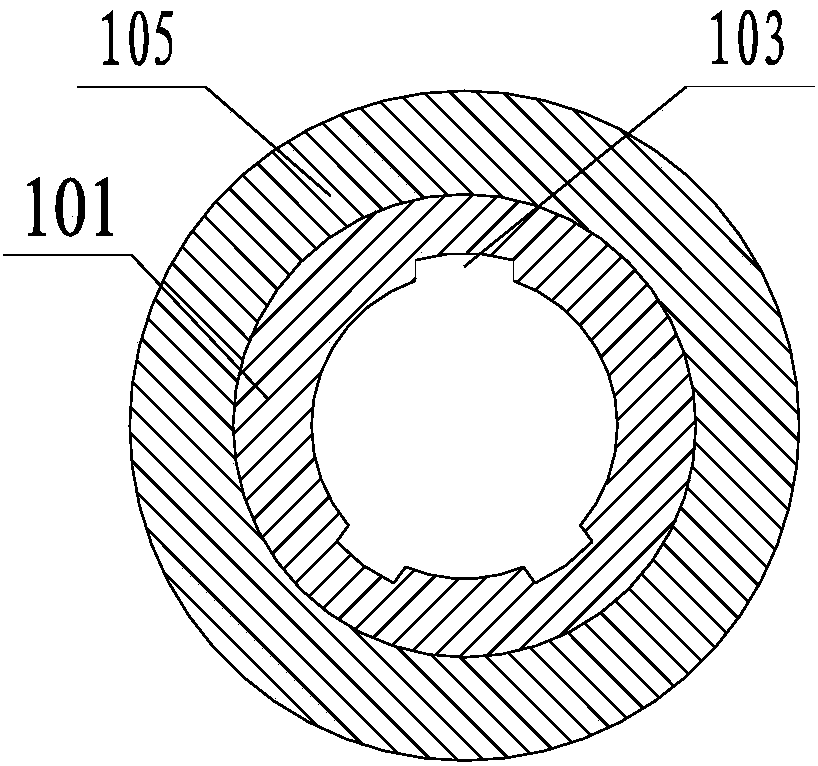

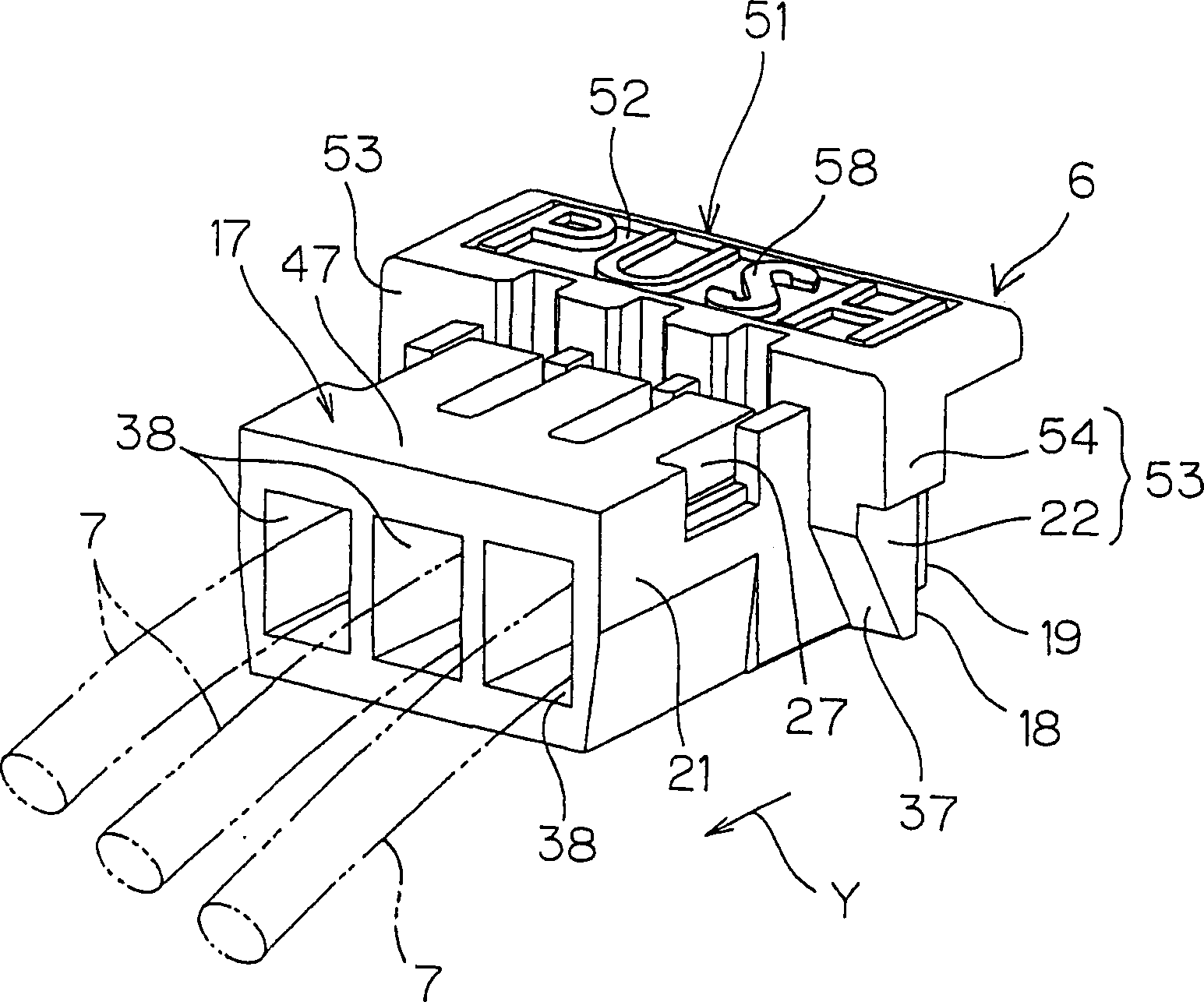

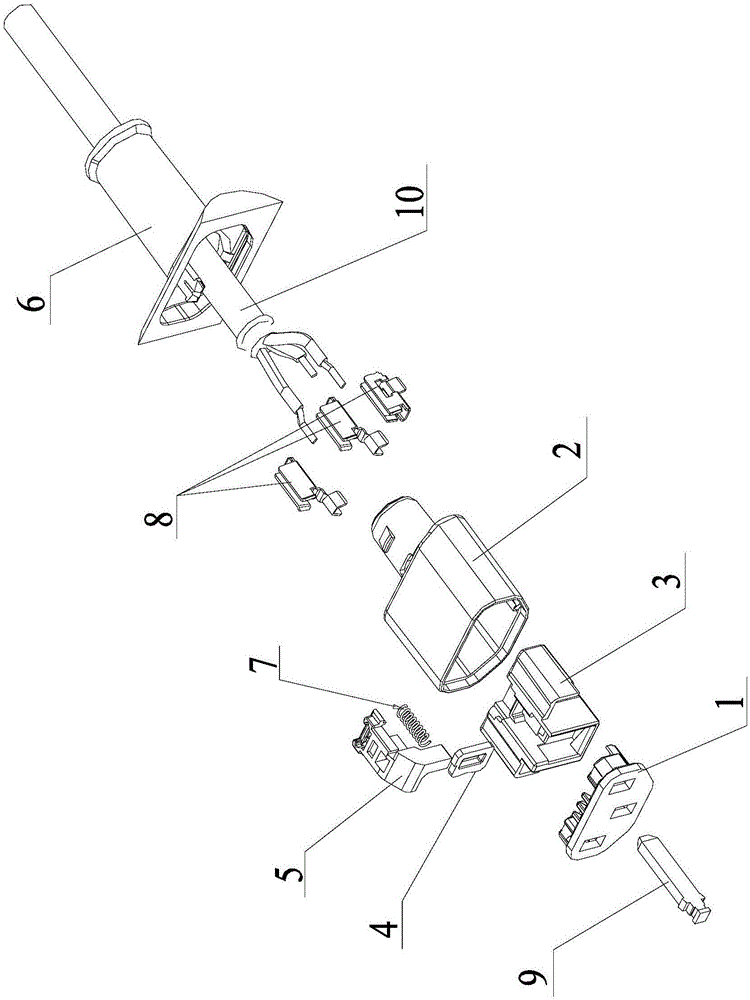

Connector, adapter and quick-plug optic fiber connection component

Owner:FENGHUO COMM SCI & TECH CO LTD

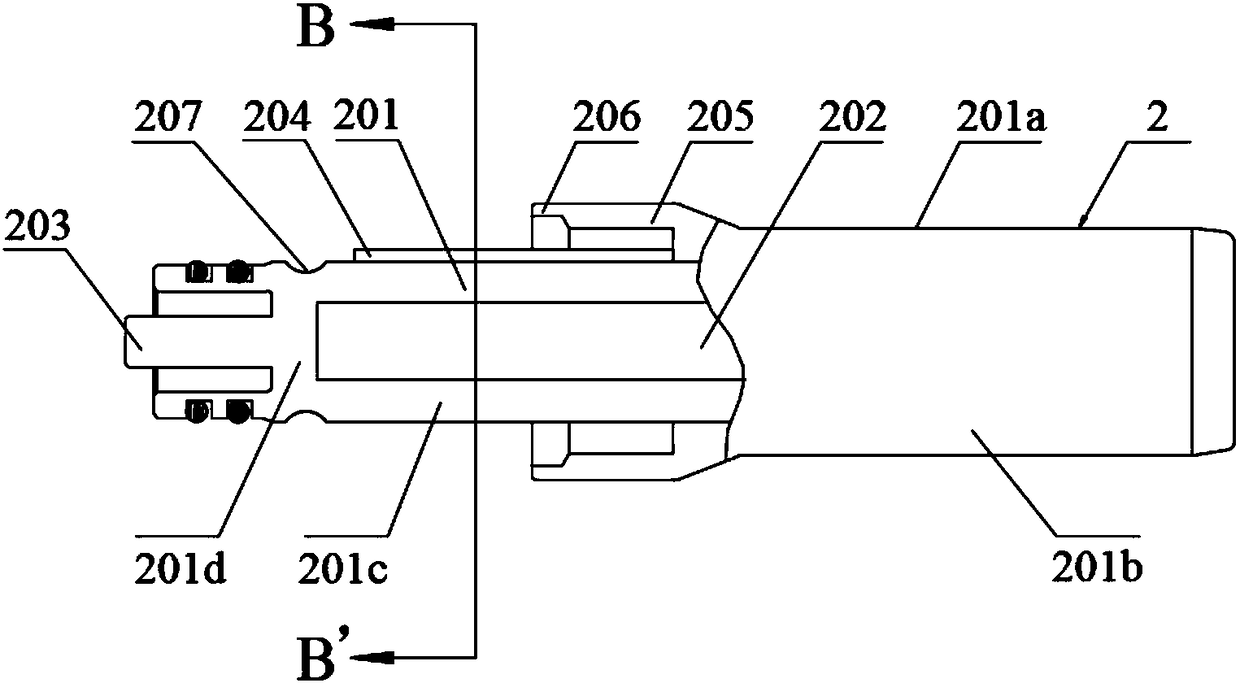

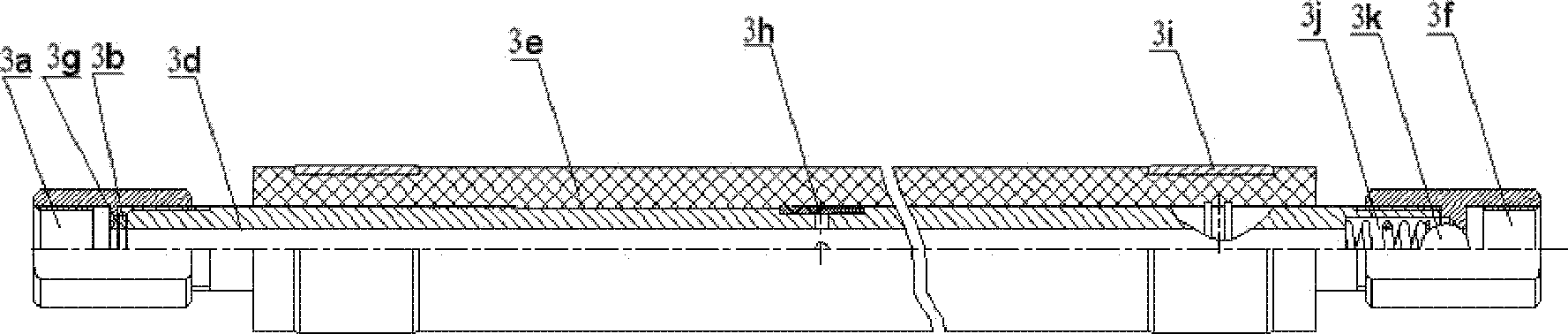

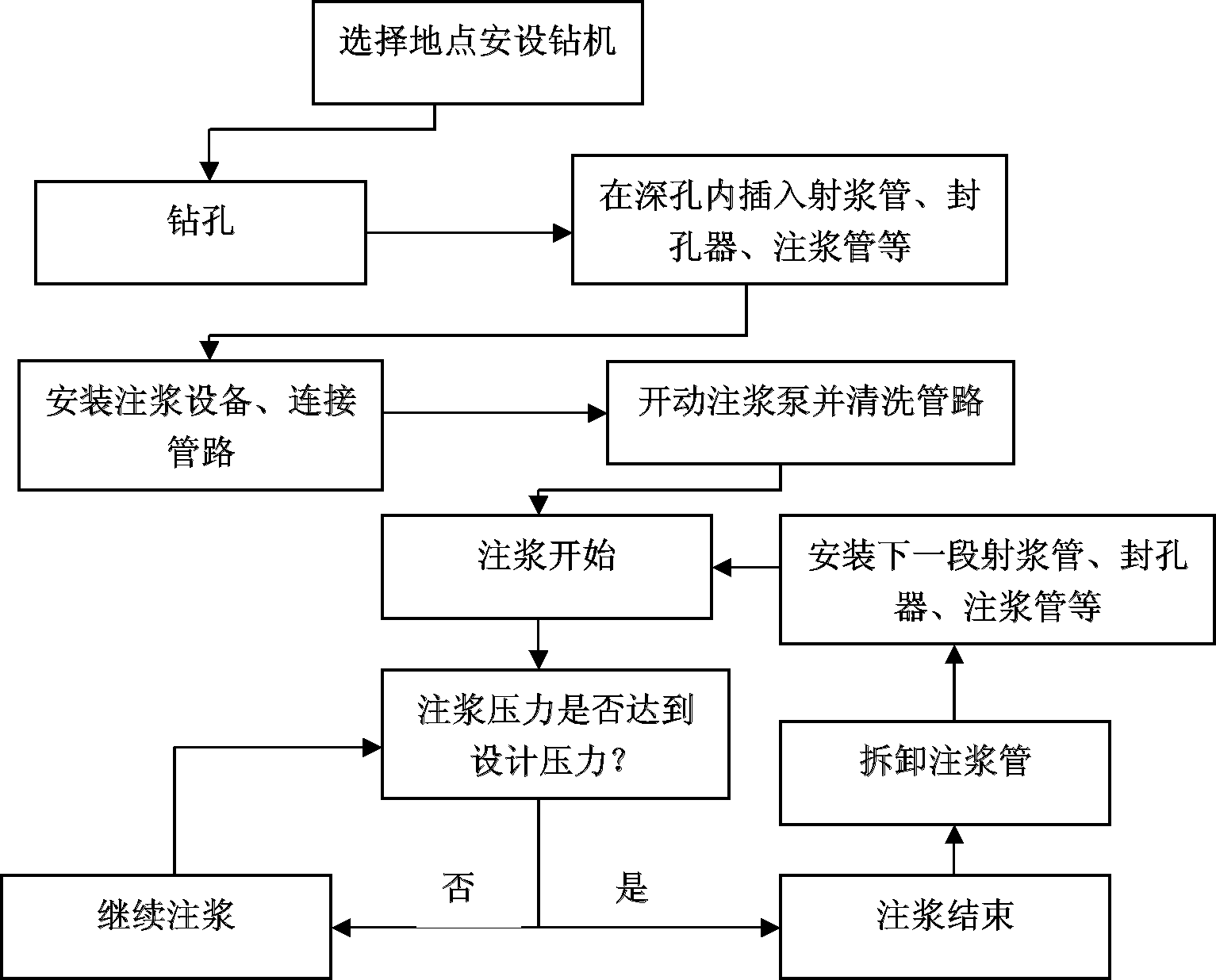

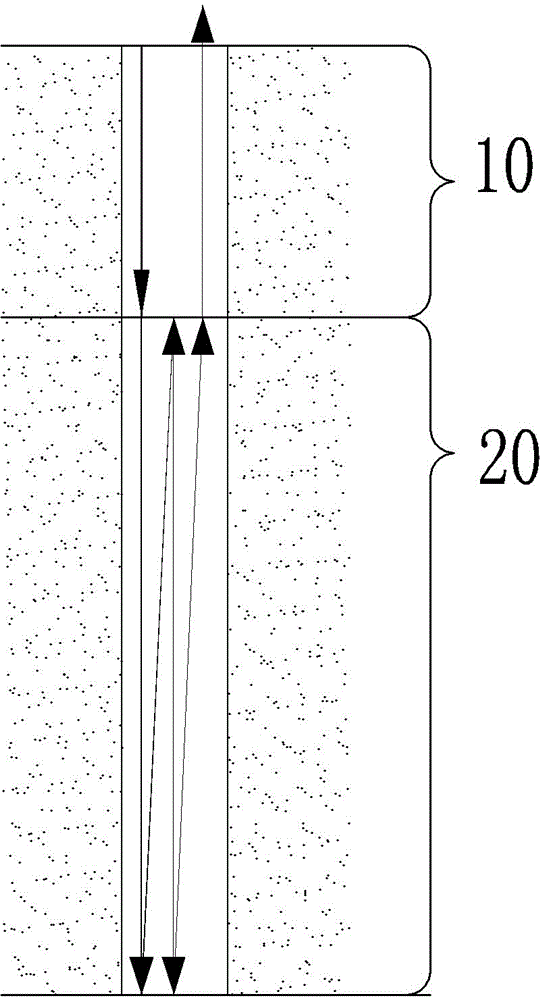

Grouting method and system of cracked coal rock mass

InactiveCN102635327AInhibit sheddingThe extraction process is smoothSealing/packingChemical groutingSlurry

The invention relates to the technical field of coal mine exploitation and discloses a grouting method and system of cracked coal rock mass. The grouting procedure is performed on the cracked coal rock mass of a back production gateway in front of a back production face, and the grouting method comprises the following steps: step 1. drilling a deep hole in the cracked coal rock mass by using a drill bit; step 2. inserting a hole packer connected with a slurry injection pipe and a grouting pipe in the deep hole, wherein the slurry injection pipe is connected with the front end of the hole packer, the grouting pipe is connected with the tail end of the hole packer, and the other end of the grouting pipe is connected with a chemical grouting machine; and step 3. sealing the hole and grouting section by section according to the depth of the deep hole, starting the chemical grouting machine to pressurize the hole packer to seal the hole, wherein a blocking piece is pushed away when a pressure value under which the blocking piece can be pushed away is reached, and then the slurry injection pipe grouts the deep hole. According to the invention, a hole is drilled in the cracked coal rock mass of the back production gateway in front of the back production face and grouting is performed section by section,the technique is simple, the low is low and the operation at the coal mining face is not affected.

Owner:TIANDI SCI & TECH CO LTD

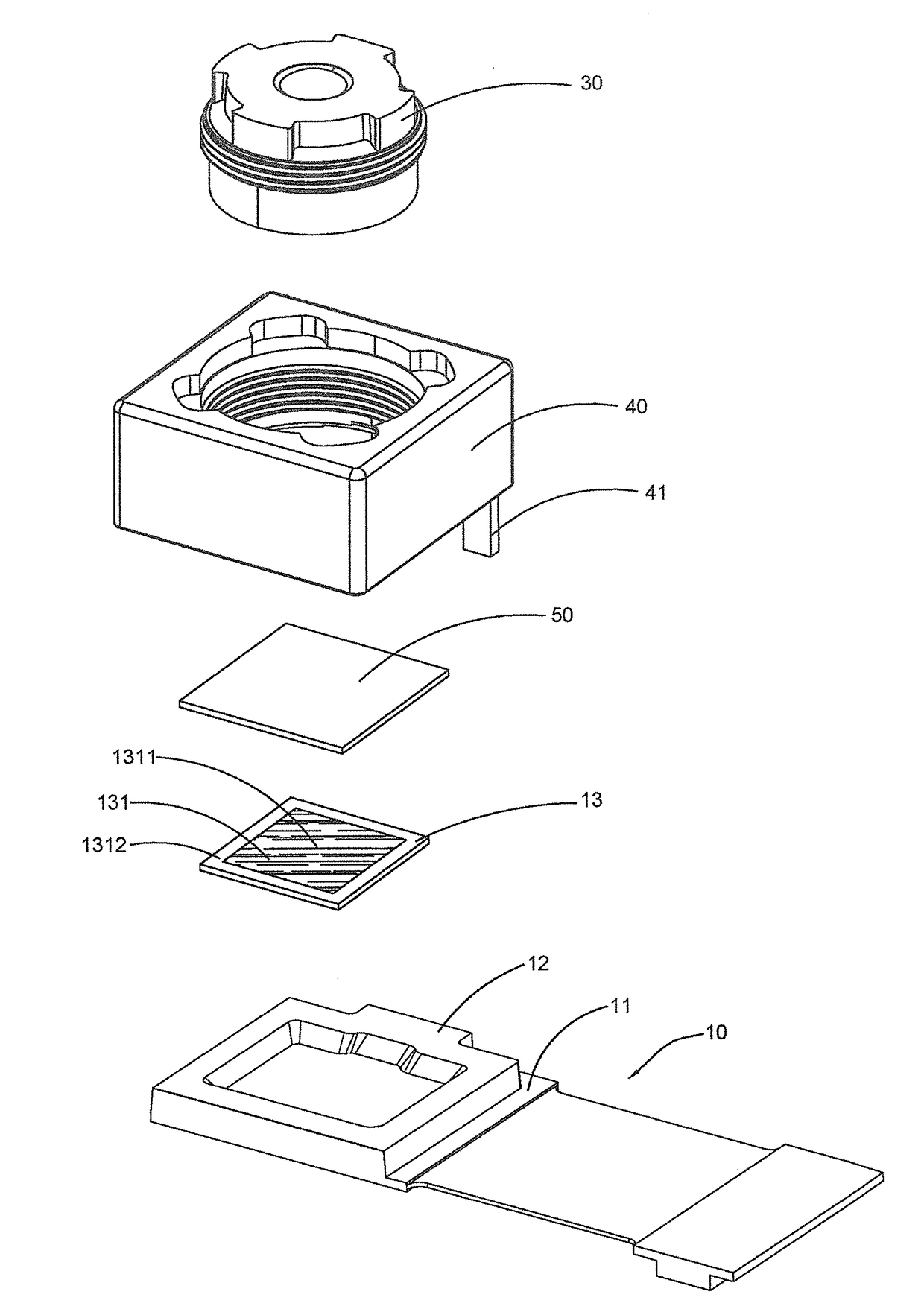

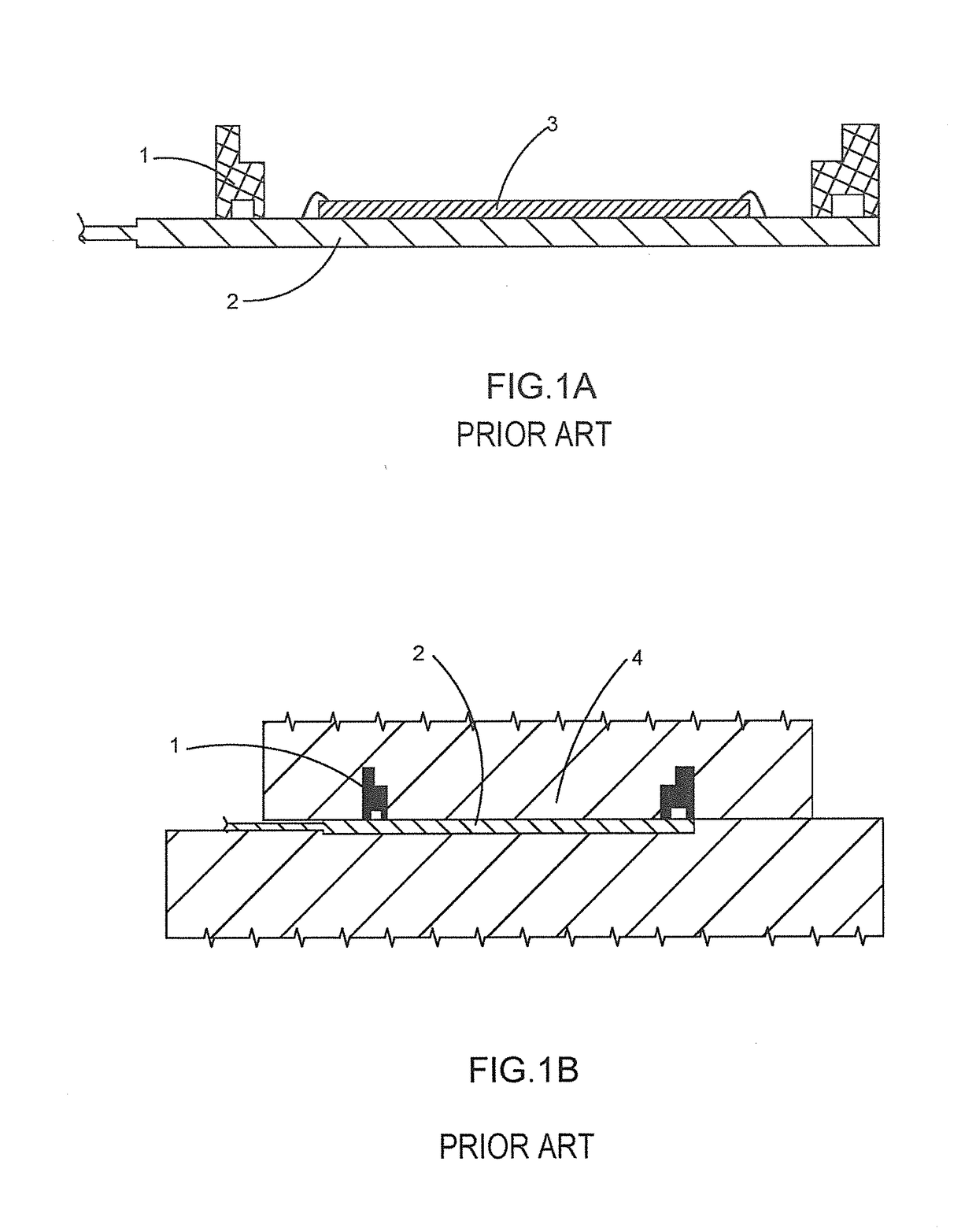

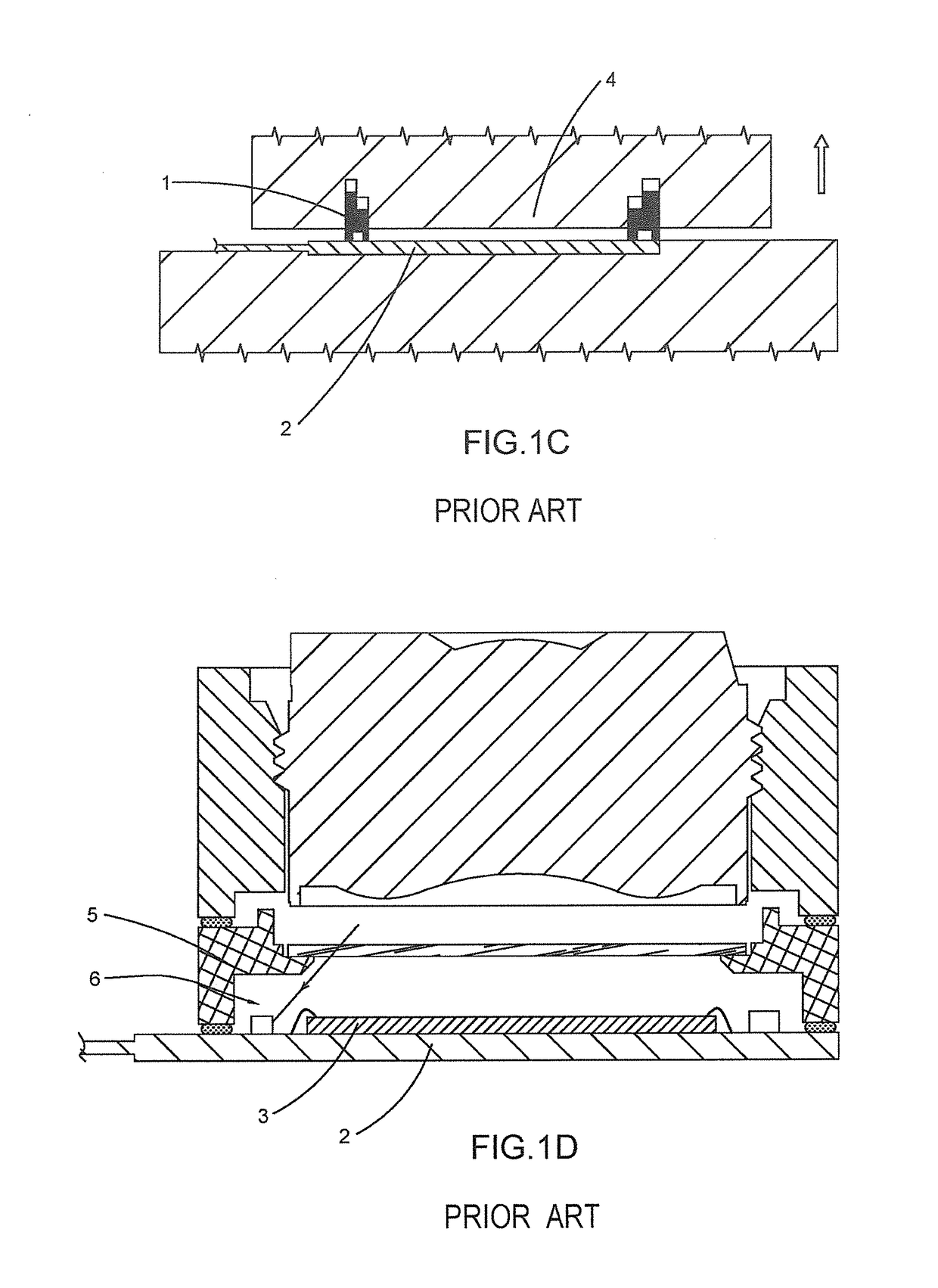

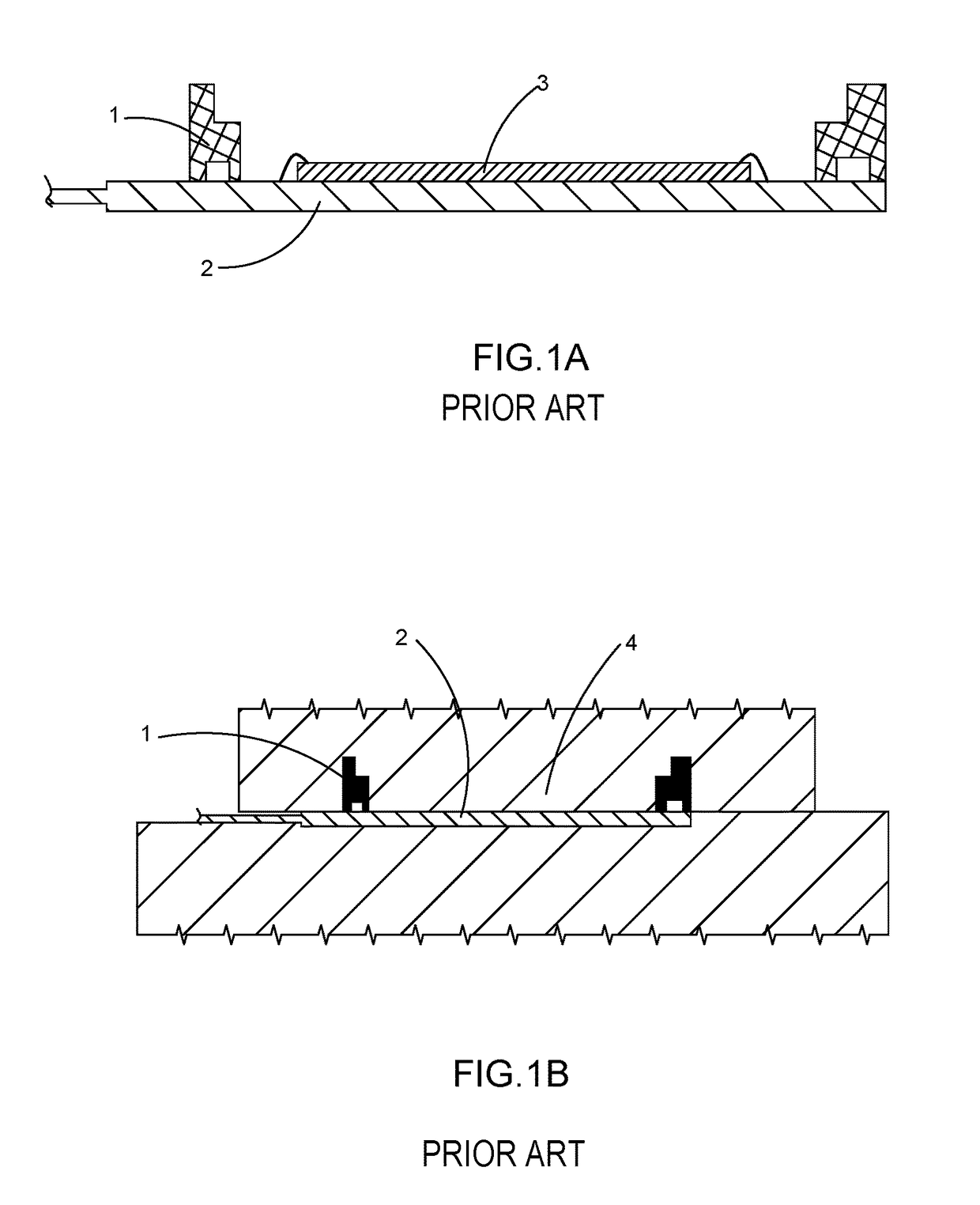

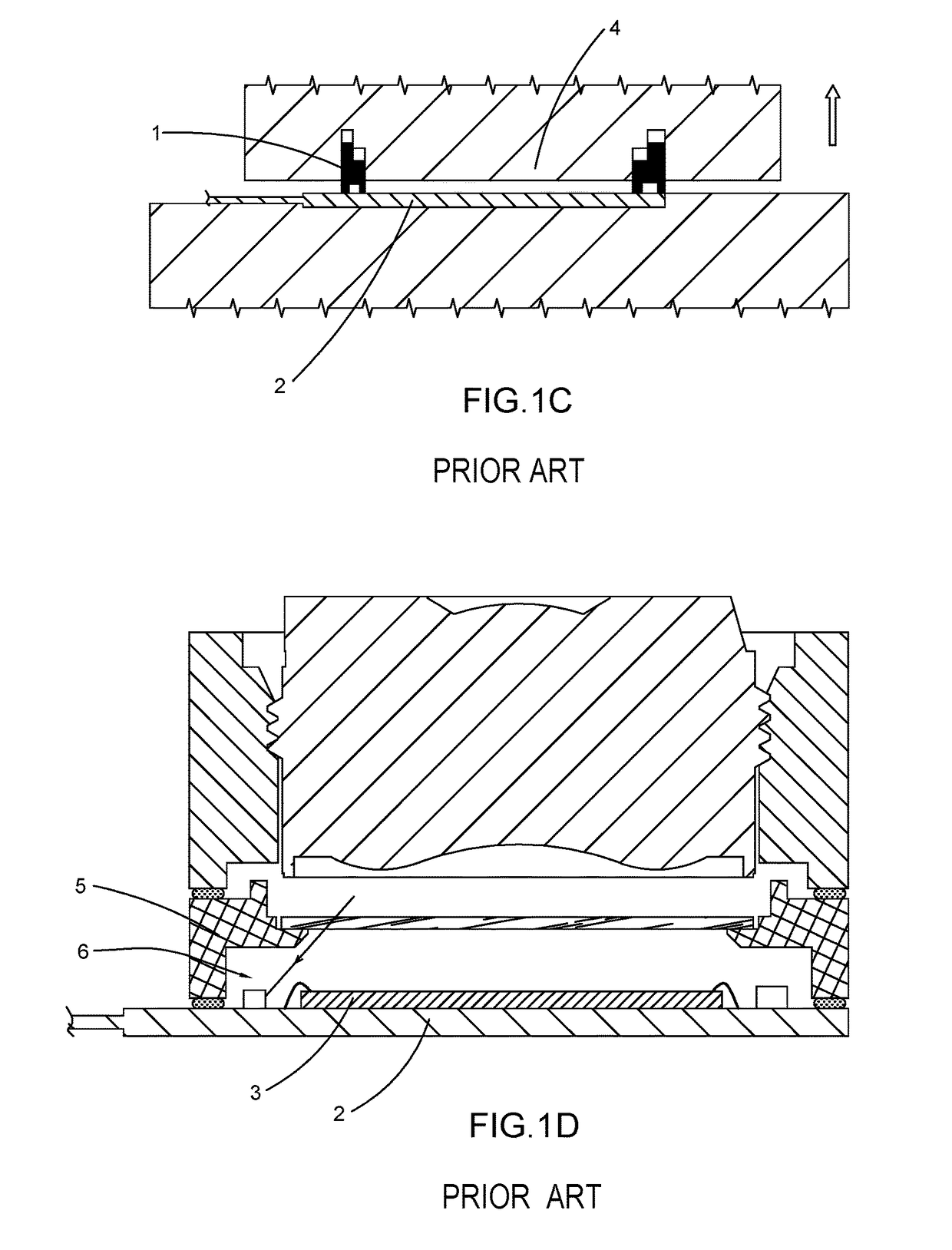

Camera Module, Molded Circuit Board Assembly, Molded Photosensitive Assembly and Manufacturing Method Thereof

ActiveUS20180035022A1Reduce harmConveniently removedTelevision system detailsFinal product manufactureSize increaseComputer module

A camera module, a molded circuit board assembly, a molded photosensitive assembly and manufacturing method thereof are disclosed. The camera module includes a molded base which is integrally formed with a circuit board through a molding process, wherein a photosensitive element may be electrically connected on the circuit board and at least a portion of a non-photosensitive area portion of the photosensitive element is also connected by the molded base through the molding process. A light window is formed in a central portion of the molded base to provide a light path for the photosensitive element, wherein a cross section of the light window is configured to have a trapezoidal or multi-step trapezoidal shape which has a size increasing from bottom to top to facilitate demolding and avoiding stray lights.

Owner:NINGBO SUNNY OPOTECH CO LTD

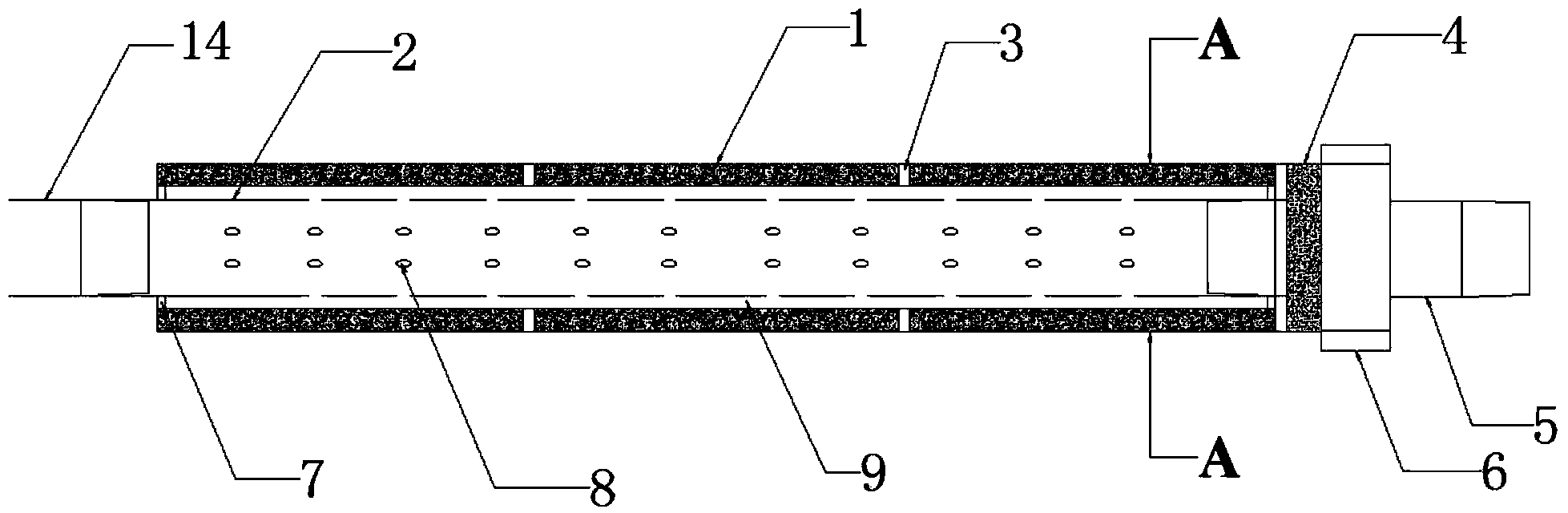

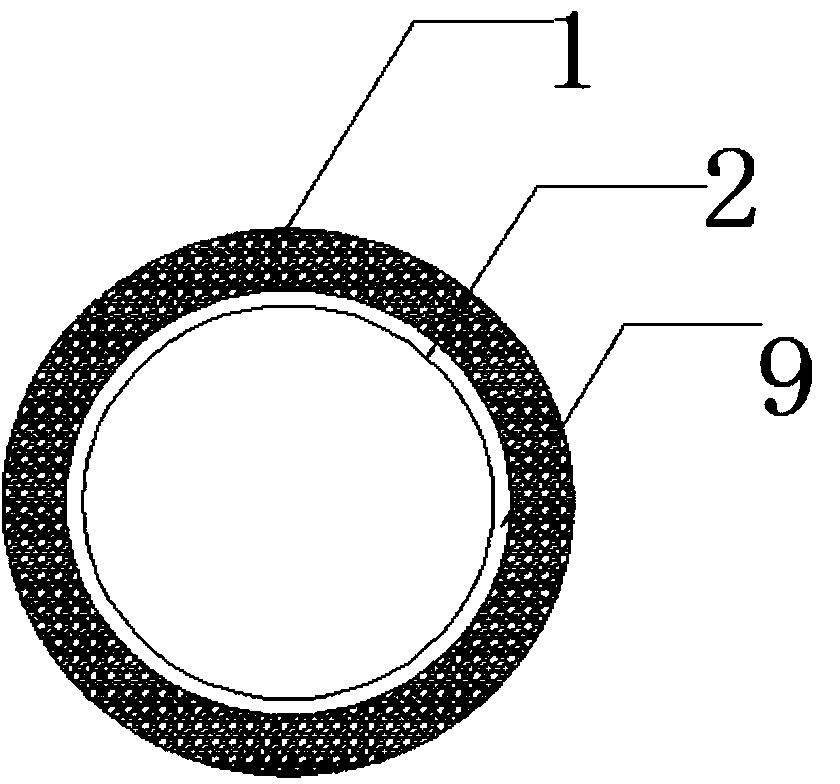

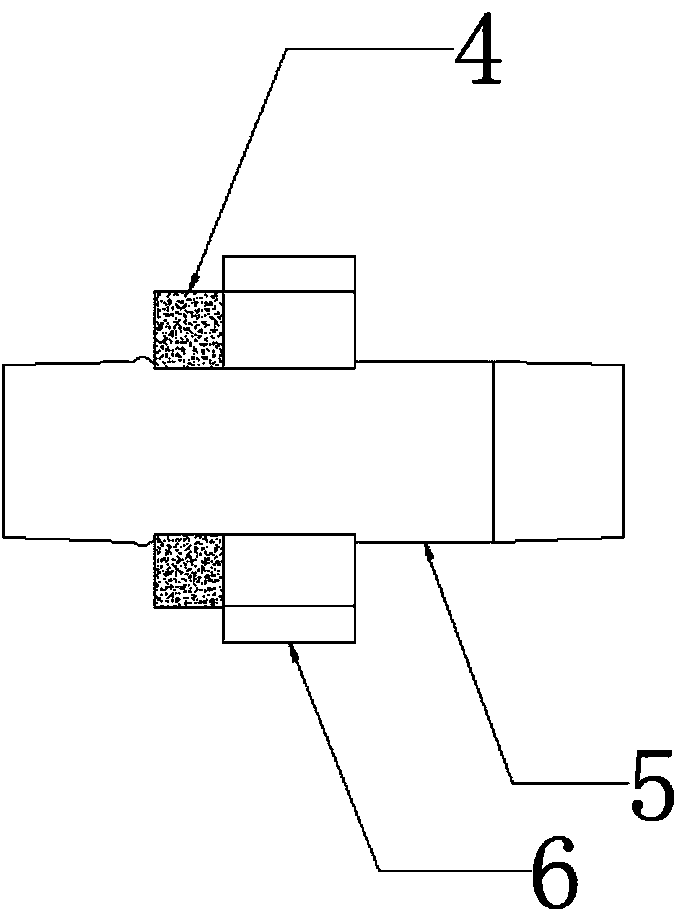

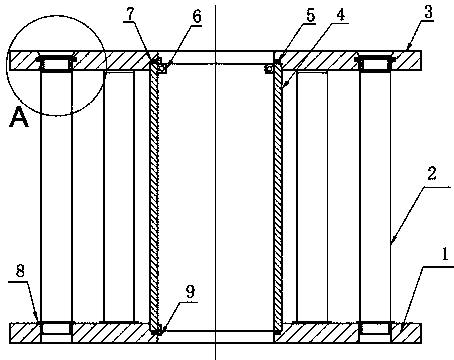

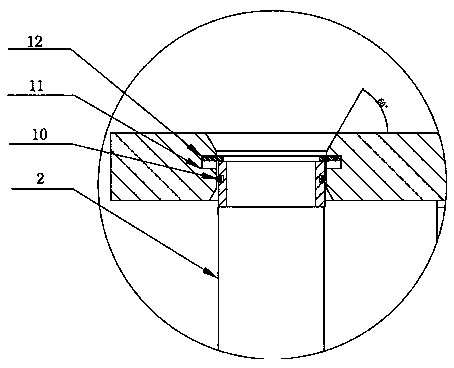

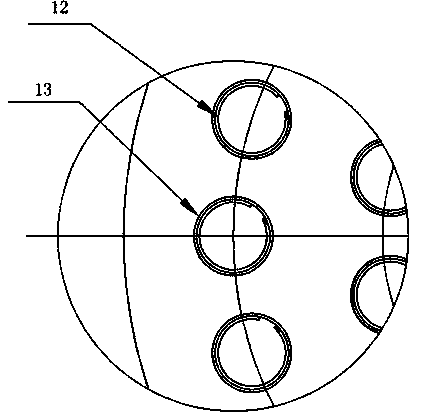

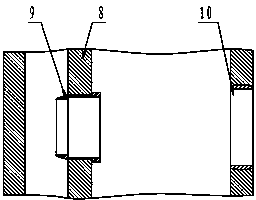

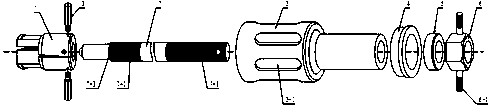

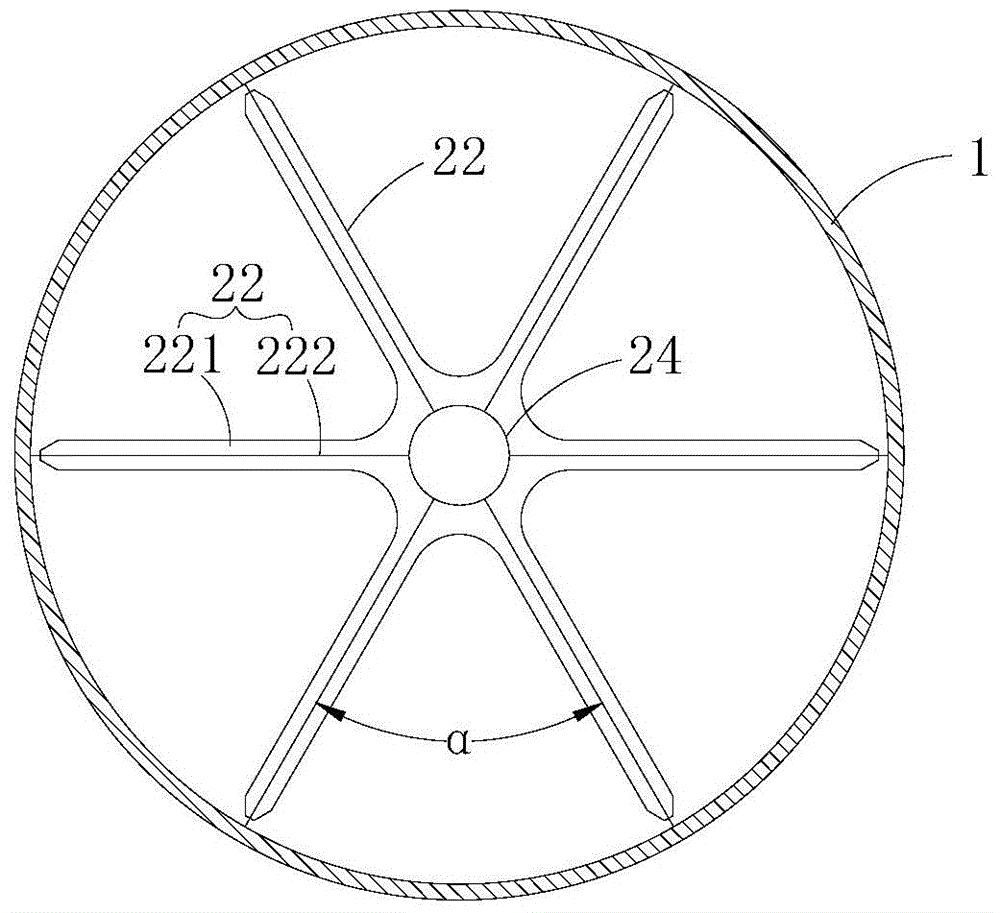

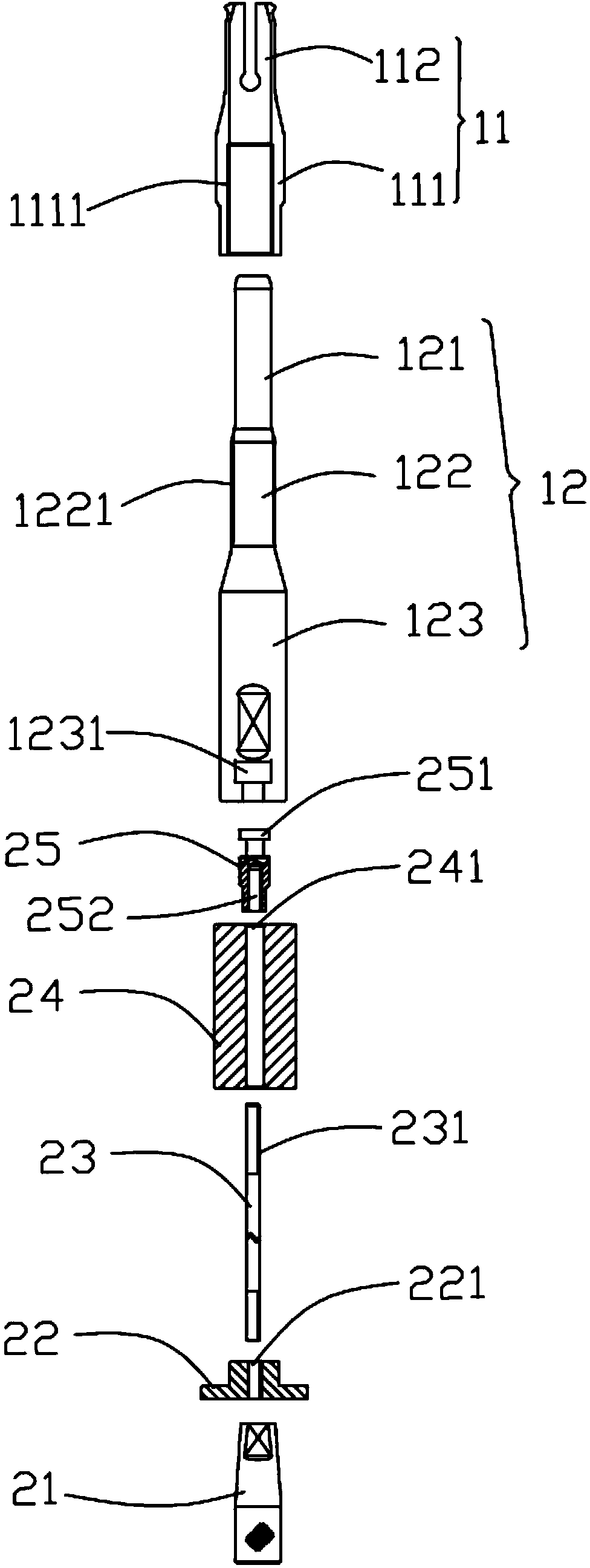

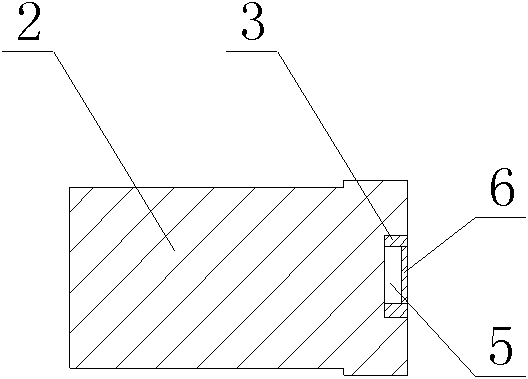

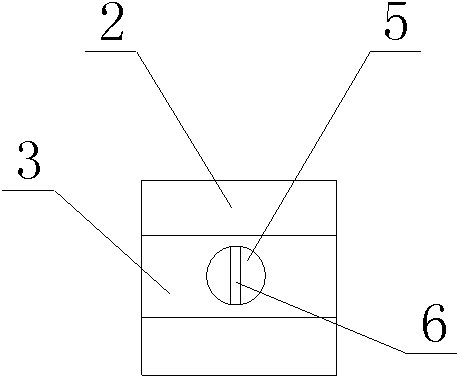

Sand protection matching pipe string for high-throughput sand filter pipe

ActiveCN103470229AIncrease the effective oil passing areaOvercoming the drawbacks of clogging and reducing oil production efficiencyDrilling rodsFluid removalHigh fluxCoupling

The invention relates to a sand protection matching pipe string for a high-throughput sand filter pipe. The sand protection matching pie string comprises a packer, a conversion coupling, a high-throughput sand filter pipe and a time delay self-locking valve or plug, wherein the conversion coupling is connected with the packer and is arranged at the back end of the high-throughput sand filter pipe, and the time delay self-locking valve or plug is arranged at the front end of the high-throughput sand filter pipe; high-throughput sand filter units are sequentially connected by a double-male left-hand coupling end to end to form the high-throughput sand filter pipe, and a high-temperature resistant broken centralizer is arranged on the outer surface of the middle of the double-male left-hand coupling; and a broken bracket is arranged between the high-temperature resistant broken centralizer arranged on the outer surface of the double-male left-hand coupling and the high-throughput sand filter unit. The high-temperature resistant broken centralizer can ensure that the high-throughput sand filter pipe is positioned at the center of a shaft, so that formation fluid evenly supplies fluid to a sand filter from the shaft, and meanwhile, the wear of the shaft to the sand filter in the logging process is reduced, the success rate of logging is ensured, the breaking is easy, and the replacement operation is not affected.

Owner:SHANDONG UNIV +1

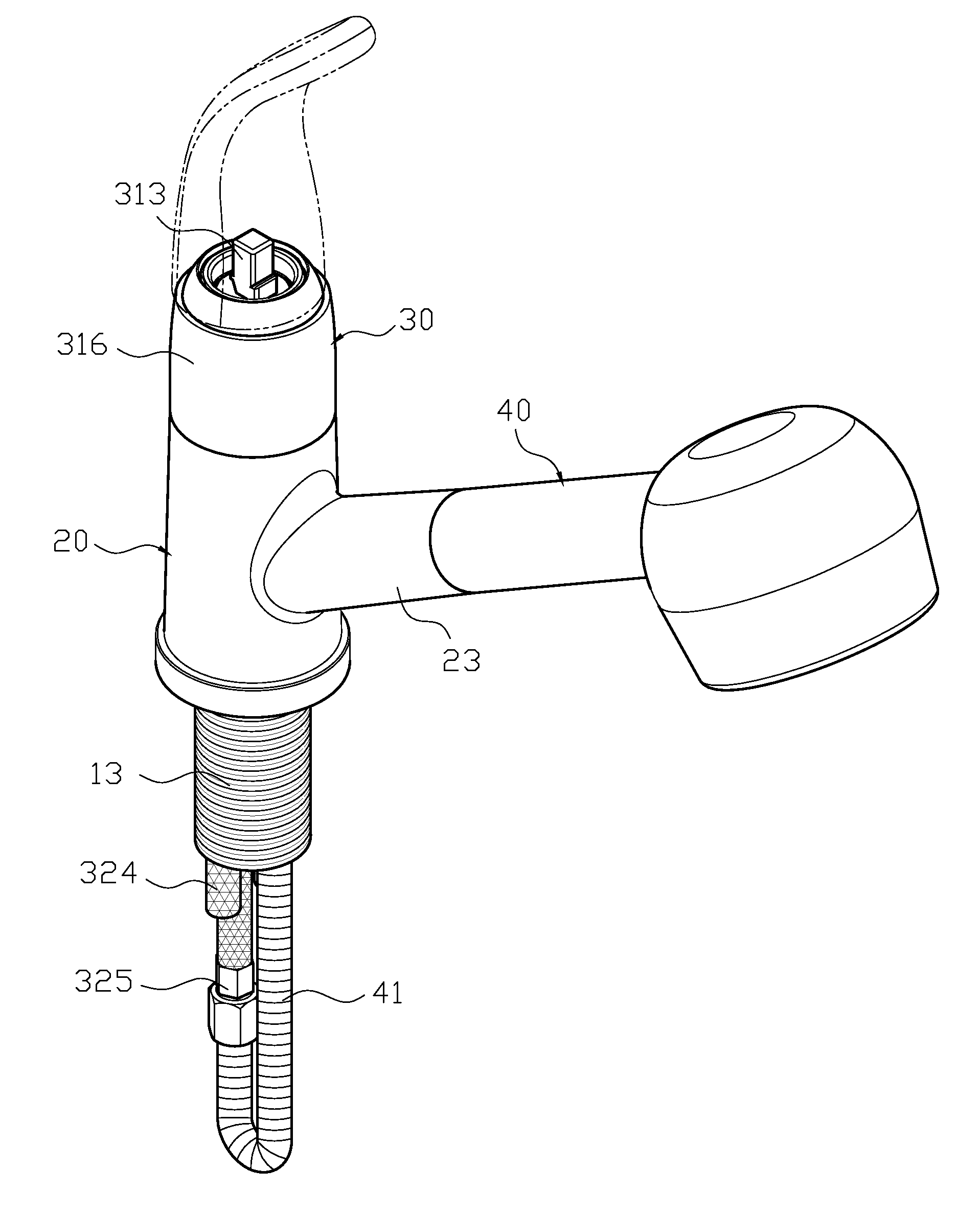

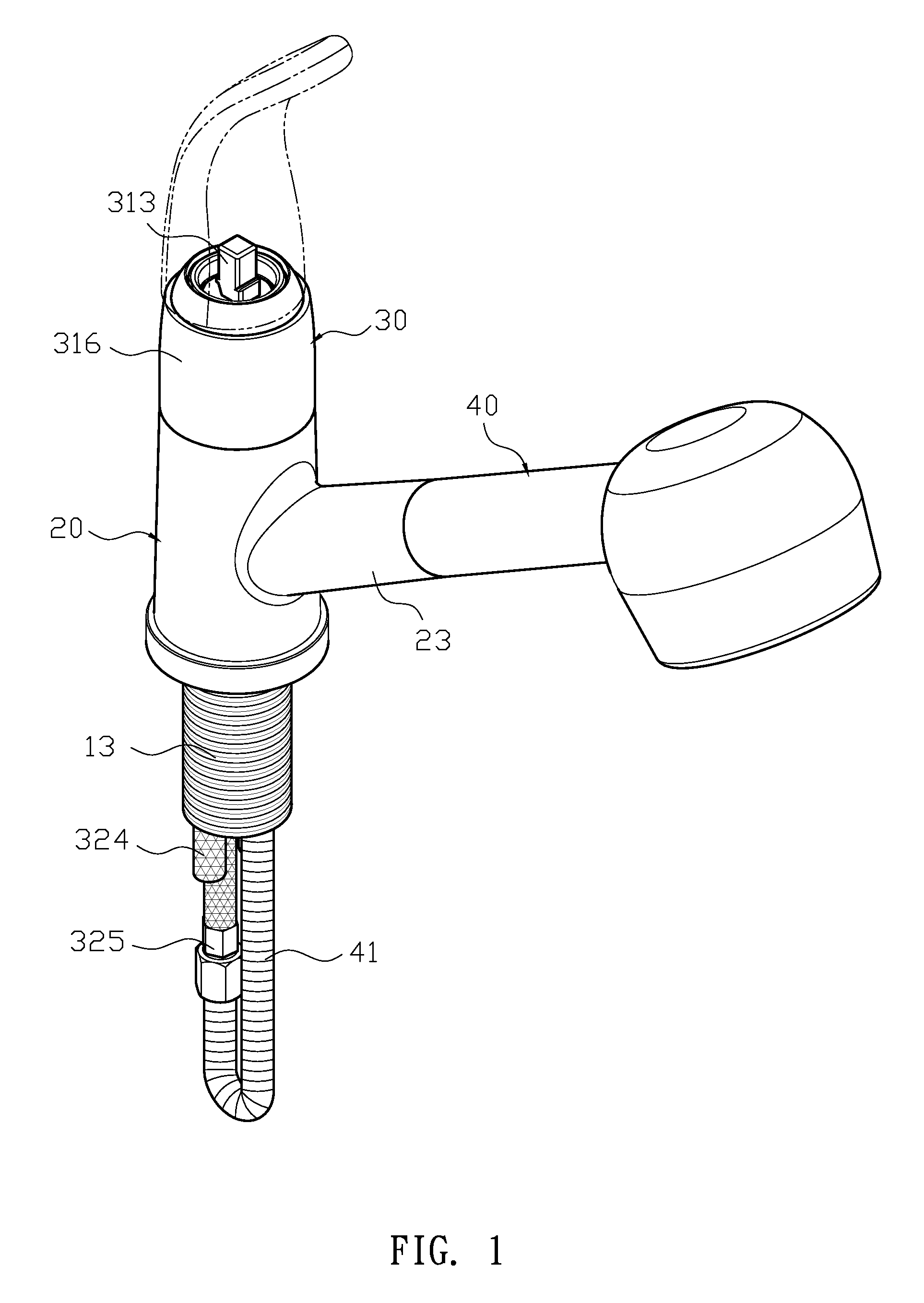

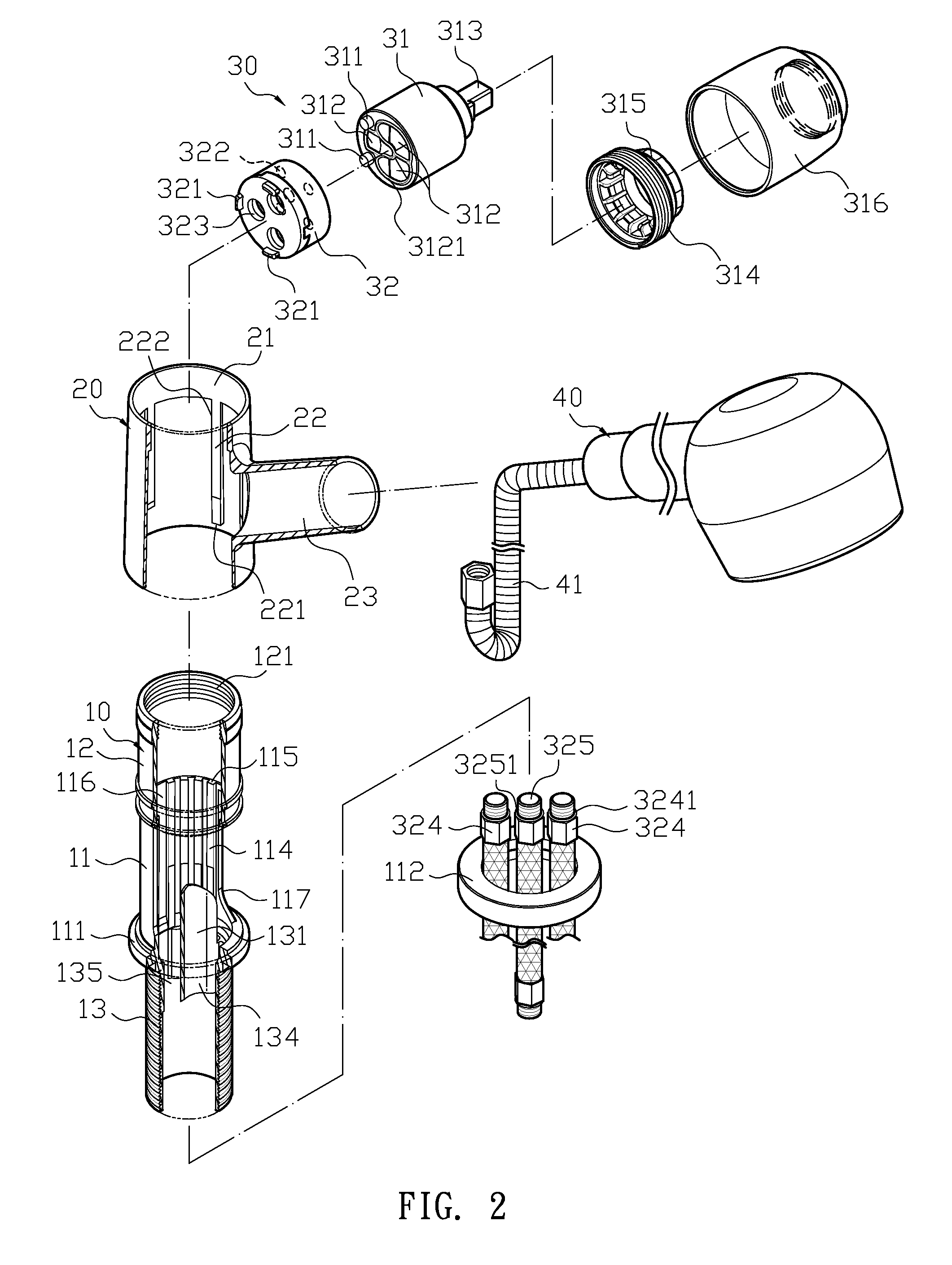

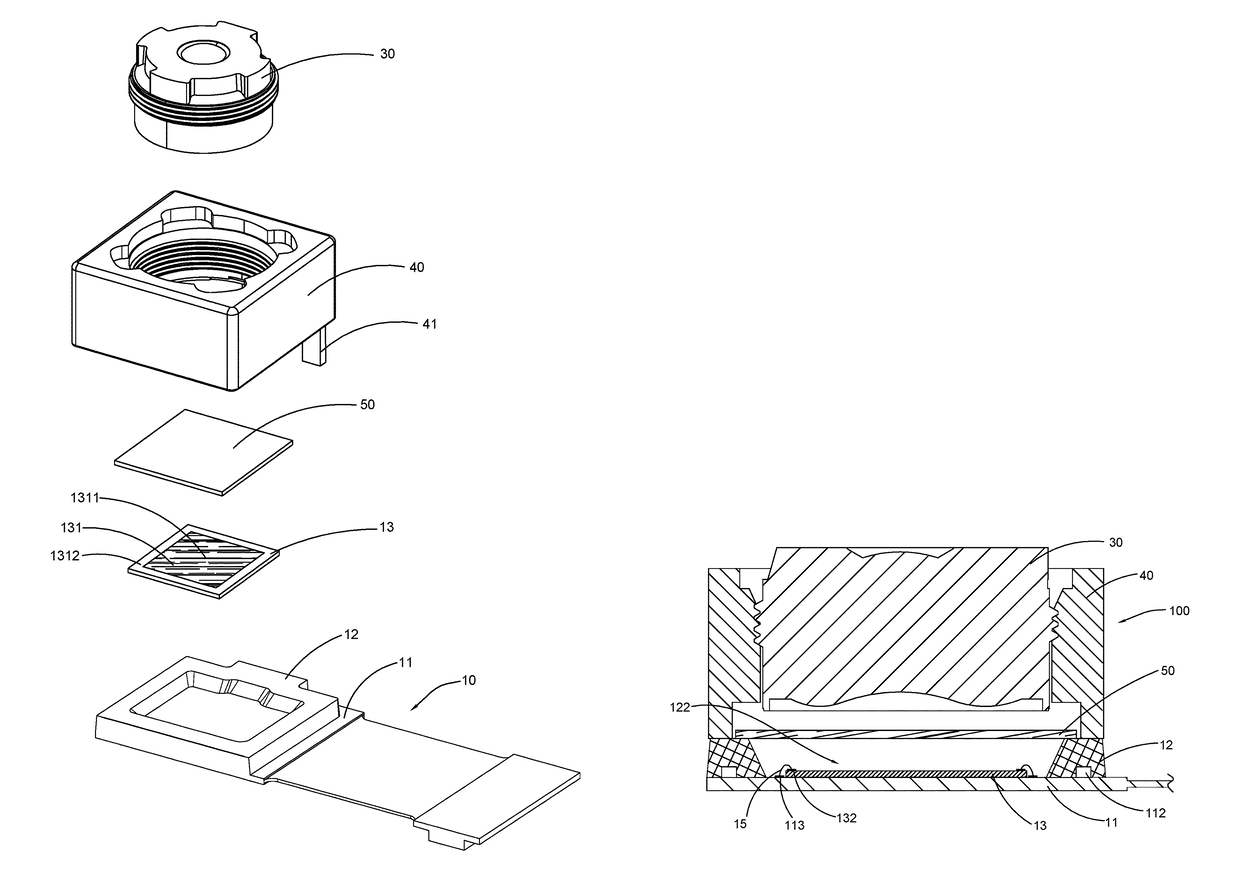

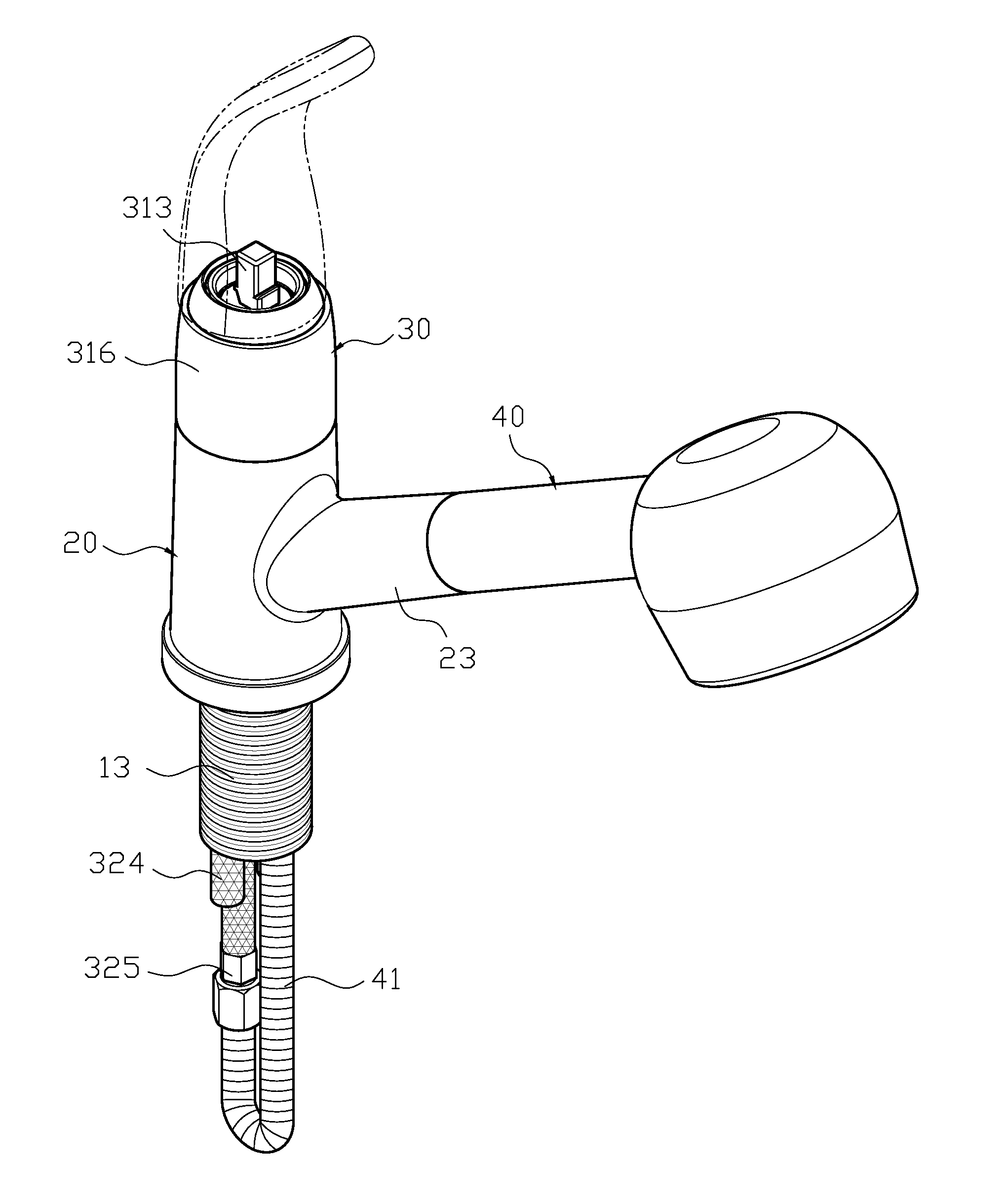

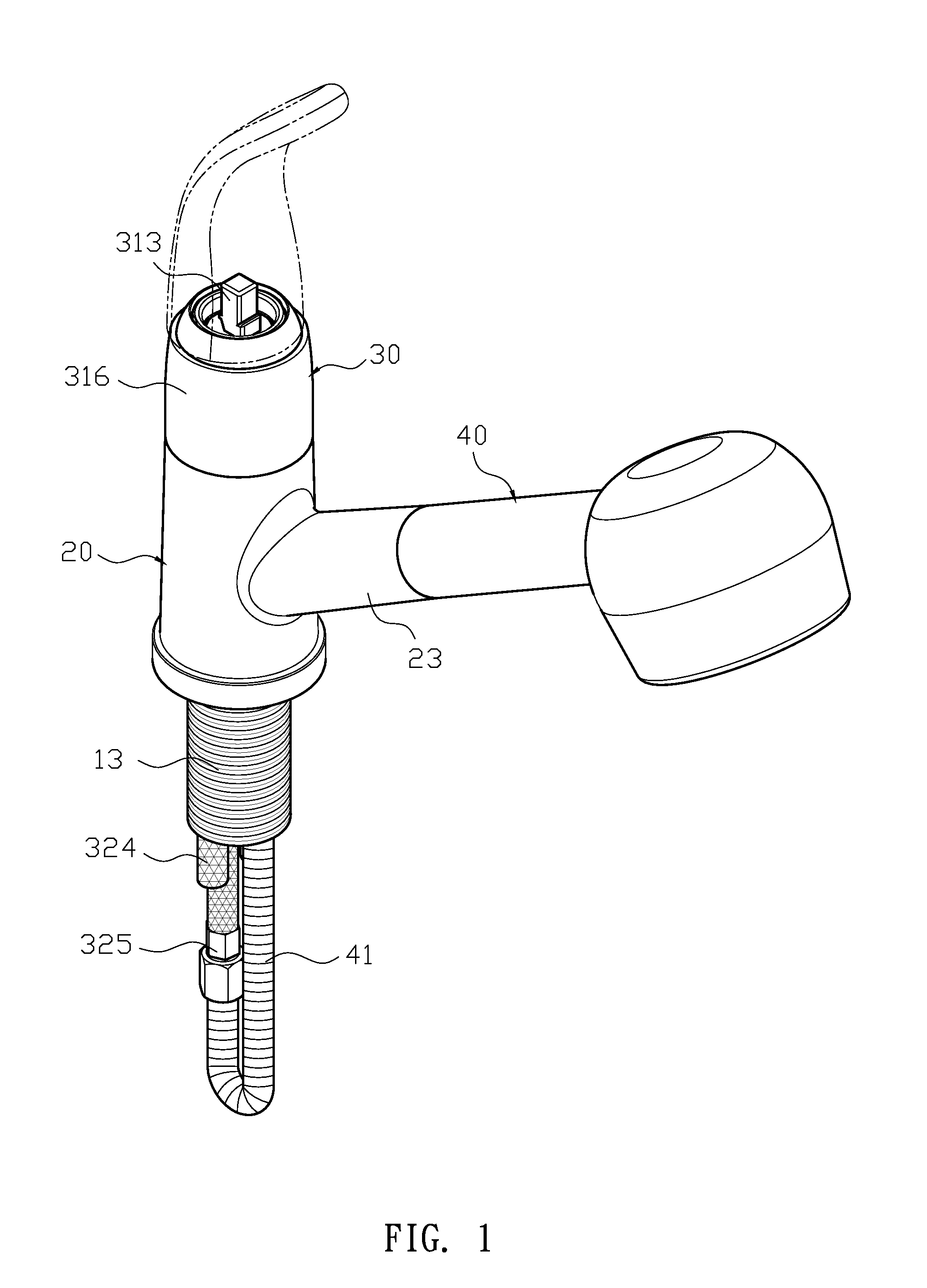

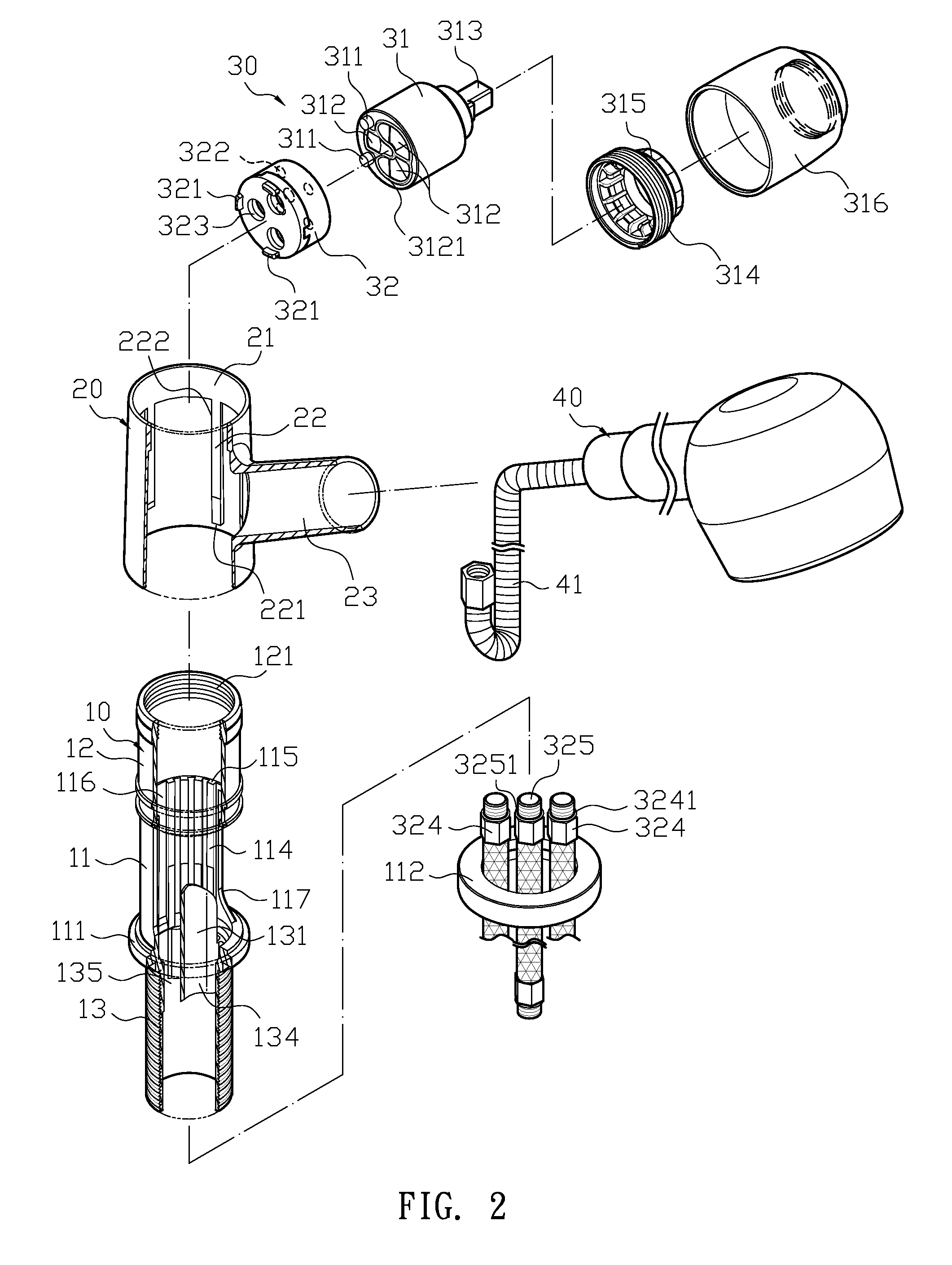

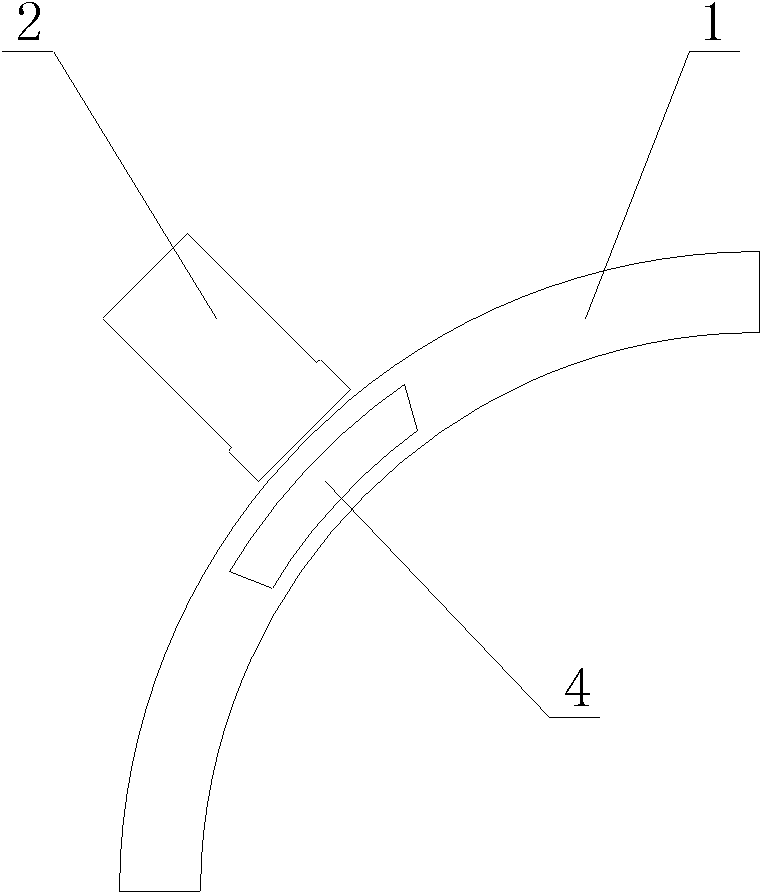

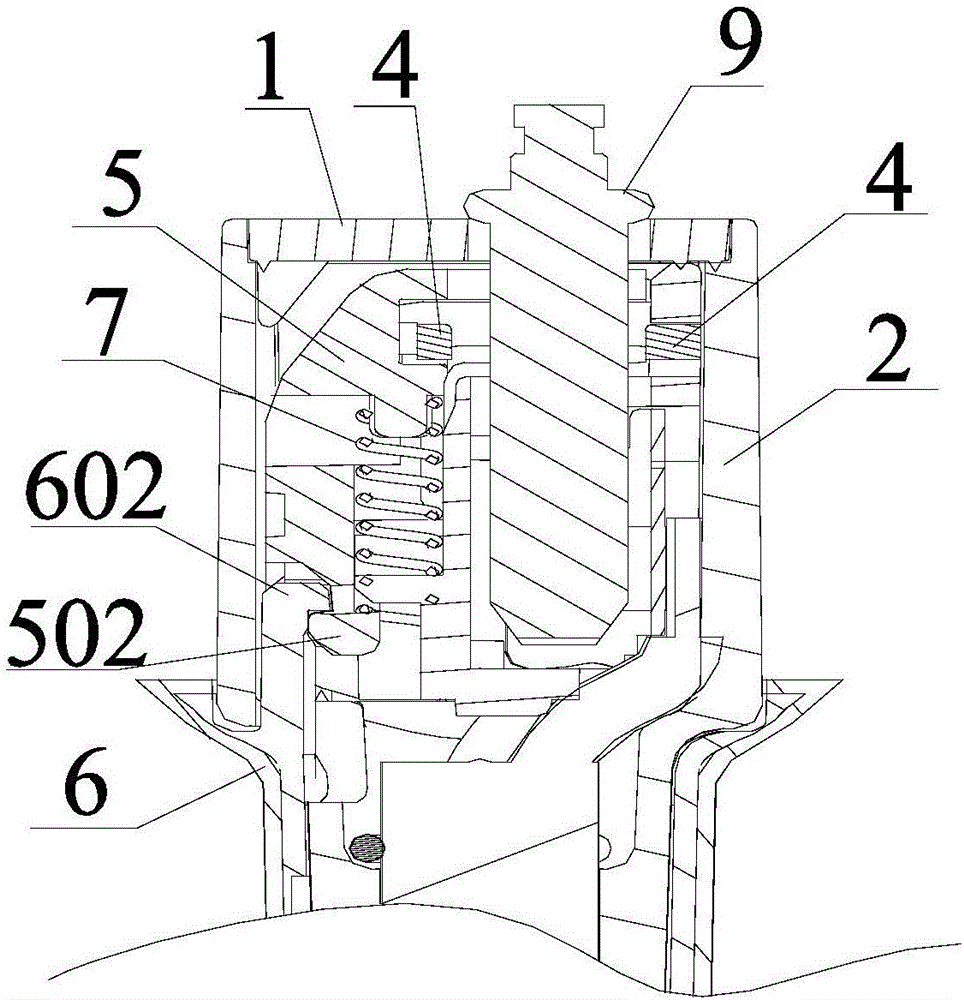

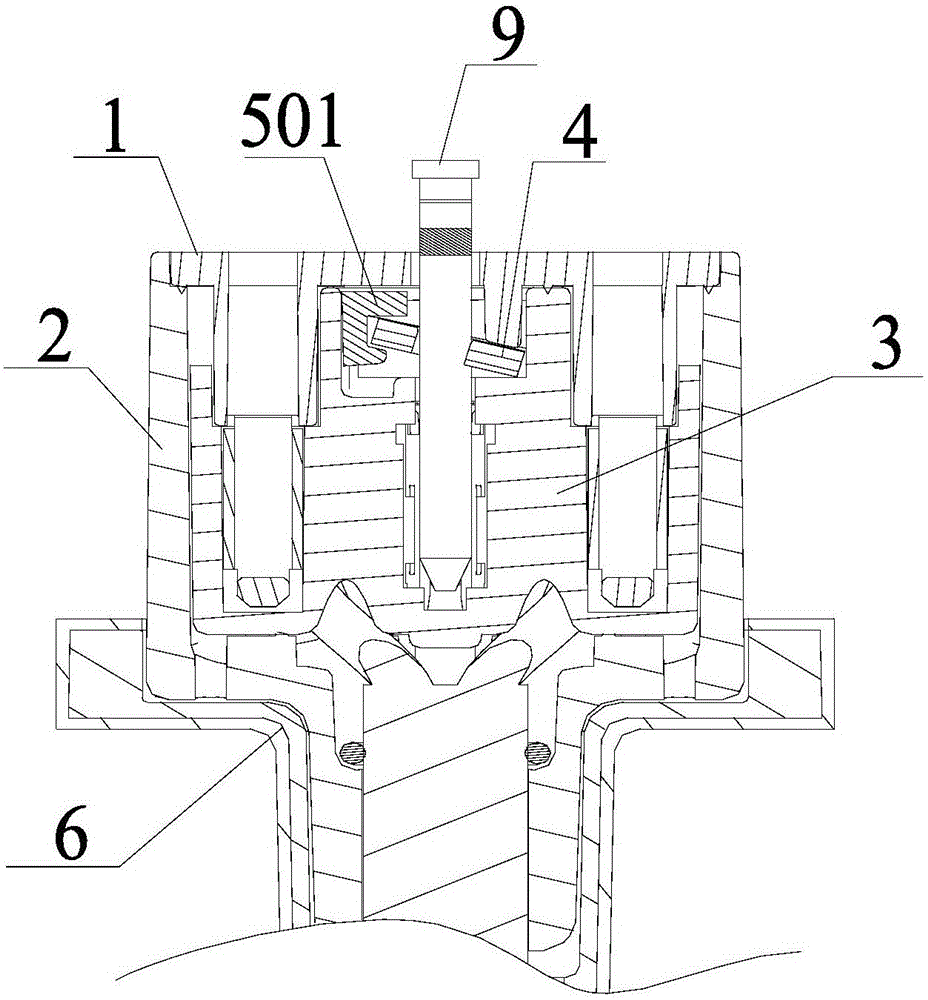

Faucet structure

InactiveUS8584697B2The extraction process is smoothSimplify the installation processPlug valvesServomotor componentsControl unitHead parts

An easy-to-install faucet structure includes an inner tube, a main body, a water control unit and a water outlet head. The inner tube is disposed in a through space of the main body, and has a tube base that has a plurality of rib units at an inner periphery thereof. A plurality of guiding slots are formed between each rib unit, so that when water inner tubes and a water outlet of the water control unit pass through the inner tube, they can be guided to directly pass through a second path of the connecting portion without further bundling to achieve the goal of easy tube connection and installation to simplify the assembly process.

Owner:DA YUAN SHENG IND

Camera Module, Molded Circuit Board Assembly, Molded Photosensitive Assembly and Manufacturing Method Thereof

ActiveUS20180035032A1Reduce harmConveniently removedTelevision system detailsFinal product manufactureElectricitySize increase

A camera module, a molded circuit board assembly, a molded photosensitive assembly and manufacturing method thereof are disclosed. The camera module includes a molded base which is integrally formed with a circuit board through a molding process, wherein a photosensitive element may be electrically connected on the circuit board and at least a portion of a non-photosensitive area portion of the photosensitive element is also connected by the molded base through the molding process. A light window is formed in a central portion of the molded base to provide a light path for the photosensitive element, wherein a cross section of the light window is configured to have a trapezoidal or multi-step trapezoidal shape which has a size increasing from bottom to top to facilitate demoulding and avoiding stray lights.

Owner:NINGBO SUNNY OPOTECH CO LTD

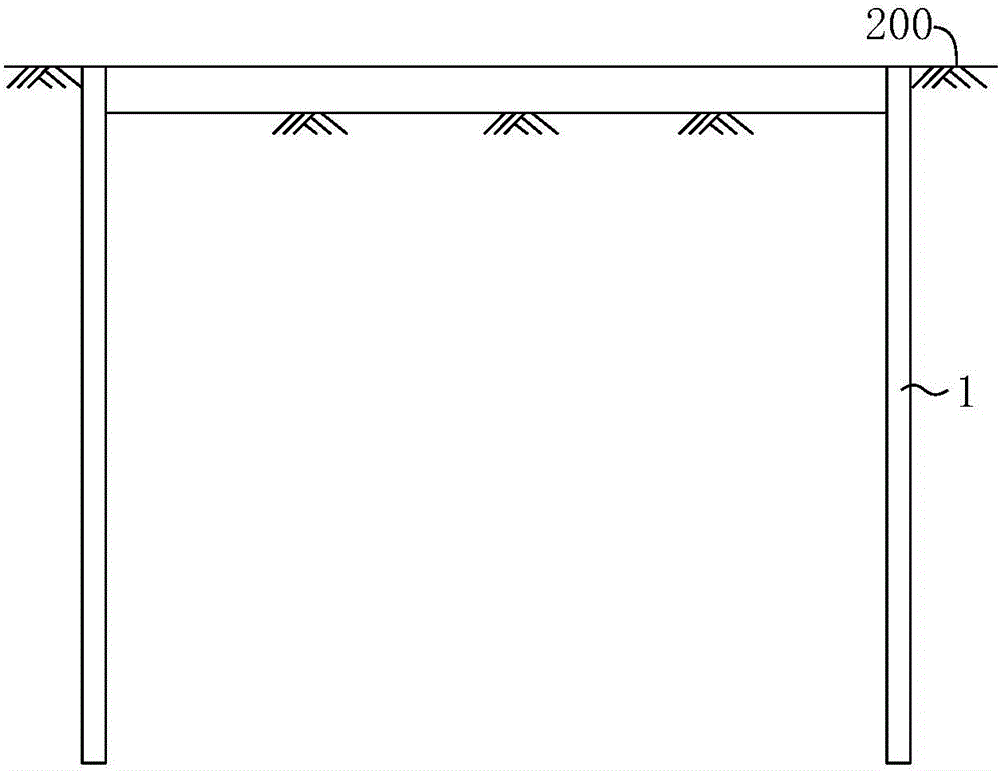

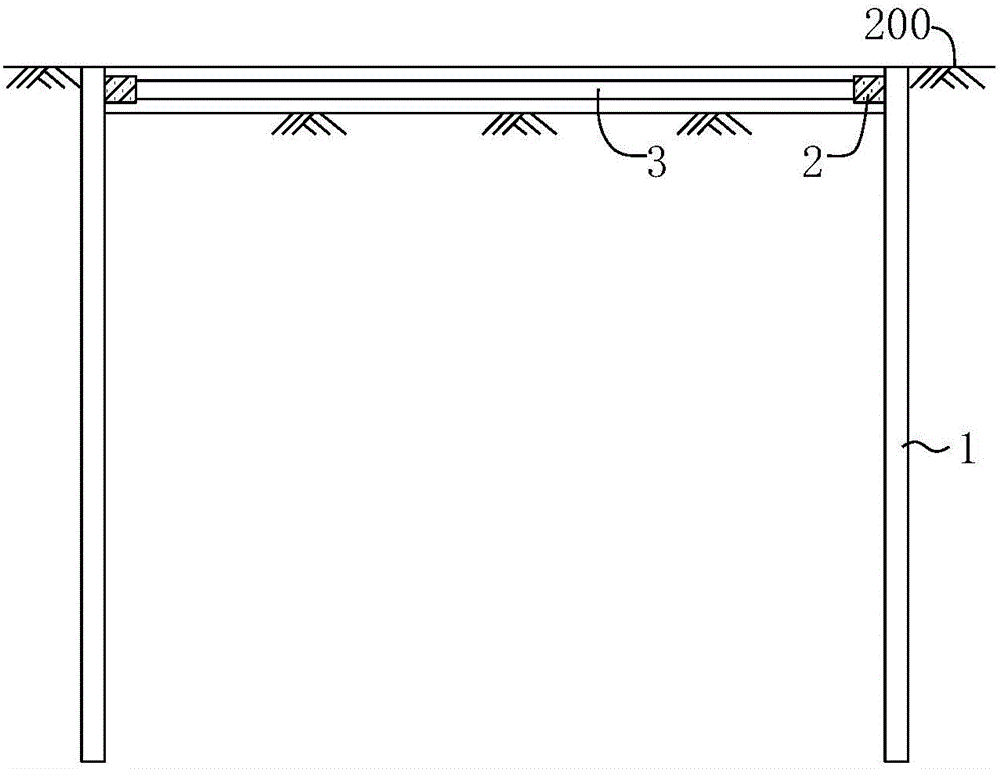

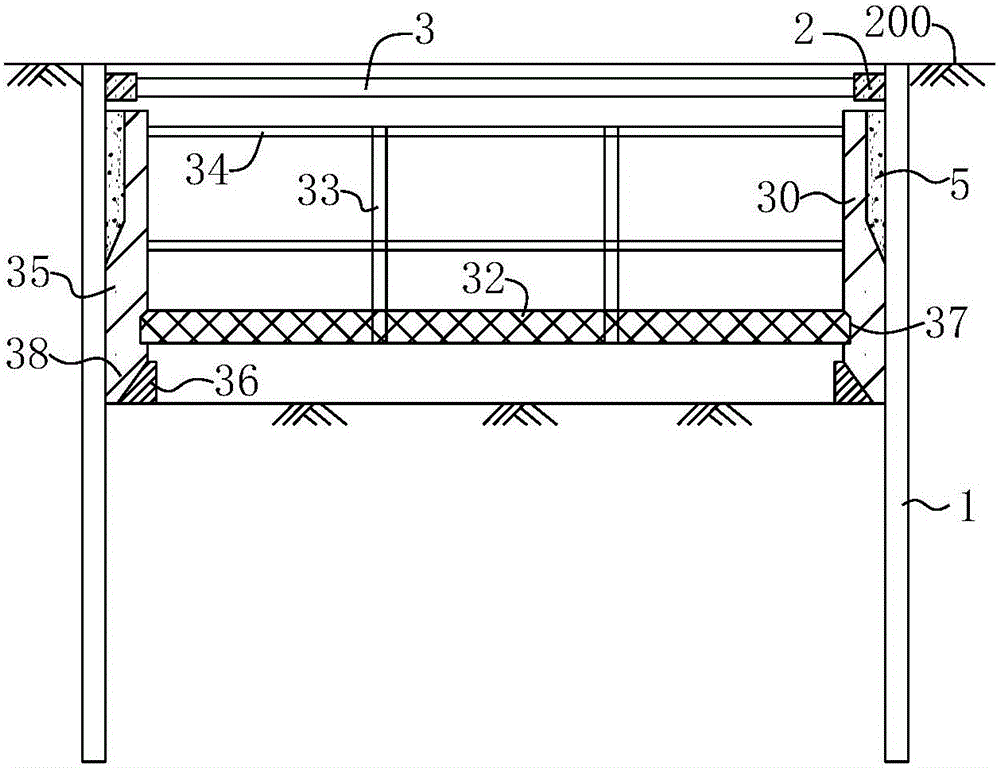

Steel sheet pile support construction method for building underground garage open caisson

ActiveCN106013053AReduce the risk factorAvoid cumbersomeArtificial islandsExcavationsPurlinArchitectural engineering

The invention discloses a steel sheet pile support construction method for building an underground garage open caisson to reduce the construction complexity and improve the construction efficiency during open caisson building and reduce the building expenditure for the open caisson. According to the construction method, open caisson construction is carried out in an area defined by a steel sheet wall, wherein building of a wall of the open caisson is carried out in a manner of segment-by-segment construction from bottom to top. The building method comprises the steps that steel sheet piles are sunk, and the continuous steel sheet pile wall is formed; a certain of earthwork is excavated in the area defined by the steel sheet pile wall, then, a pile block enclosure purlin is erected on the top of the steel sheet pile wall, and horizontal braces are built on the inner side of the pile block enclosure purlin; and then, open caisson building is finished through a method that earthwork is excavated segment by segment, the wall is poured segment by segment and sinking is carried out.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Faucet structure

InactiveUS20130199645A1Simplify the installation processThe extraction process is smoothPlug valvesServomotor componentsEngineeringHead parts

An easy-to-install faucet structure includes an inner tube, a main body, a water control unit and a water outlet head. The inner tube is disposed in a through space of the main body, and has a tube base that has a plurality of rib units at an inner periphery thereof. A plurality of guiding slots are formed between each rib unit, so that when water inner tubes and a water outlet of the water control unit pass through the inner tube, they can be guided to directly pass through a second path of the connecting portion without further bundling to achieve the goal of easy tube connection and installation to simplify the assembly process.

Owner:DA YUAN SHENG IND

Water treating apparatus

InactiveUS7708882B2Effective installationThe extraction process is smoothUltrafiltrationSolid sorbent liquid separationEngineeringTreated water

Owner:ECO CREATIVE JAPAN

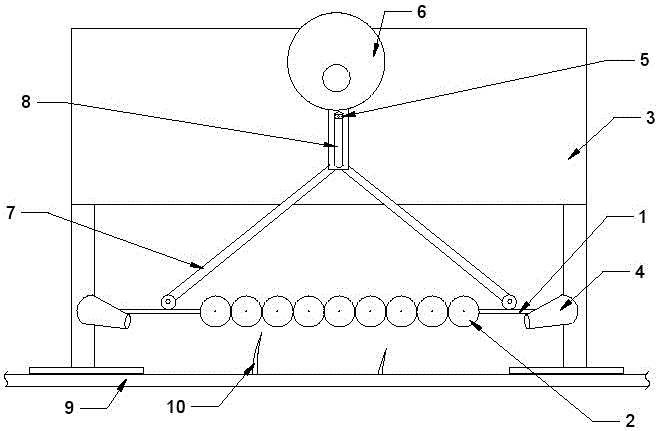

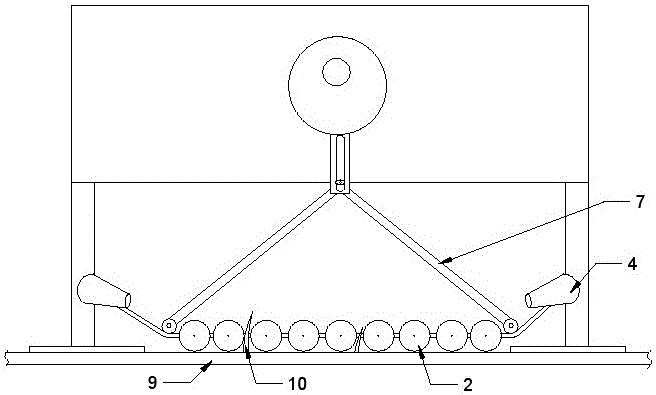

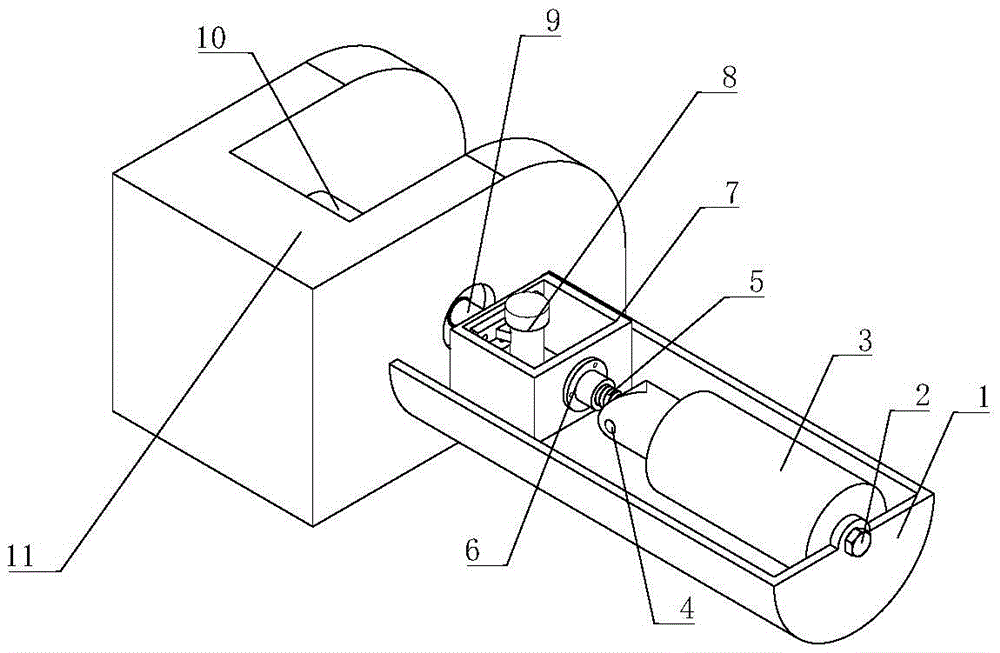

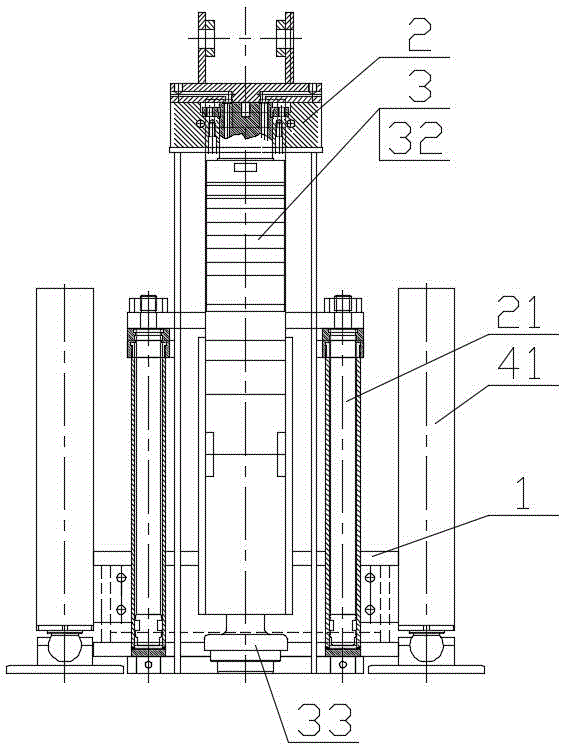

Automatic fuel cell stack assembling and detecting device

The invention discloses an automatic fuel cell stack assembling and detecting device, which comprises a rack, a material conveying assembly used for conveying different assemblies forming an electricpile to a designated position, an electric pile output assembly used for outputting assembled electric piles, a pressing assembly used for providing stable and accurate pressure for the electric piles, an automatic lifting assembly used for enabling a hydraulic workbench of the pressing assembly to be located at different heights so as to adapt to electric piles of different specifications, a limiting assembly used for limiting the stacking position of an electric pile assembly on the bottom plate of the rack, an automatic tightening assembly comprising an electric screwdriver, and an air tightness detecting assembly comprising an air cylinder, a connecting pipeline of the air cylinder and a quick-screwing plug and used for detecting the air tightness of the electric piles. The device is high in automation degree, manpower is greatly saved, and the phenomenon that the parts of an electric pile are stressed unevenly is avoided. A positioning pin can be pulled out stably by an automaticpin pulling device, and damage to the electric pile assembly in the manual pin pulling process is avoided.

Owner:WUHAN UNIV OF TECH

Device for clearing pig hair with cereals

ActiveCN106305947AAvoid slipperyPrevents the problem of not being able to pull it out easilySlaughtering accessoriesHair rootsArray data structure

The invention discloses a device for clearing pig hair with cereals. The device comprises a rack and is characterized by further comprising steamers and multiple hair pulling mechanisms arranged on the rack horizontally, wherein each hair pulling mechanism comprises elastic ropes and multiple rice grains, the multiple rice grains are transversely arranged on the elastic ropes in a penetrating manner, when the elastic ropes reach 20%-50% of the maximum stretching length, the two adjacent rice grains are butted against each other, two ends of each elastic rope are detachably connected onto the rack, outlets of the steamers face the space below the hair pulling mechanisms, and a reciprocating drive mechanism for pushing the hair pulling mechanisms to move up and down is arranged on the rack. With the implementation of the technical scheme, the problem that hair roots are prone to be left in pig skin with an existing hair pulling technology is solved.

Owner:CHONGQING GUANGHENG FOOD DEV

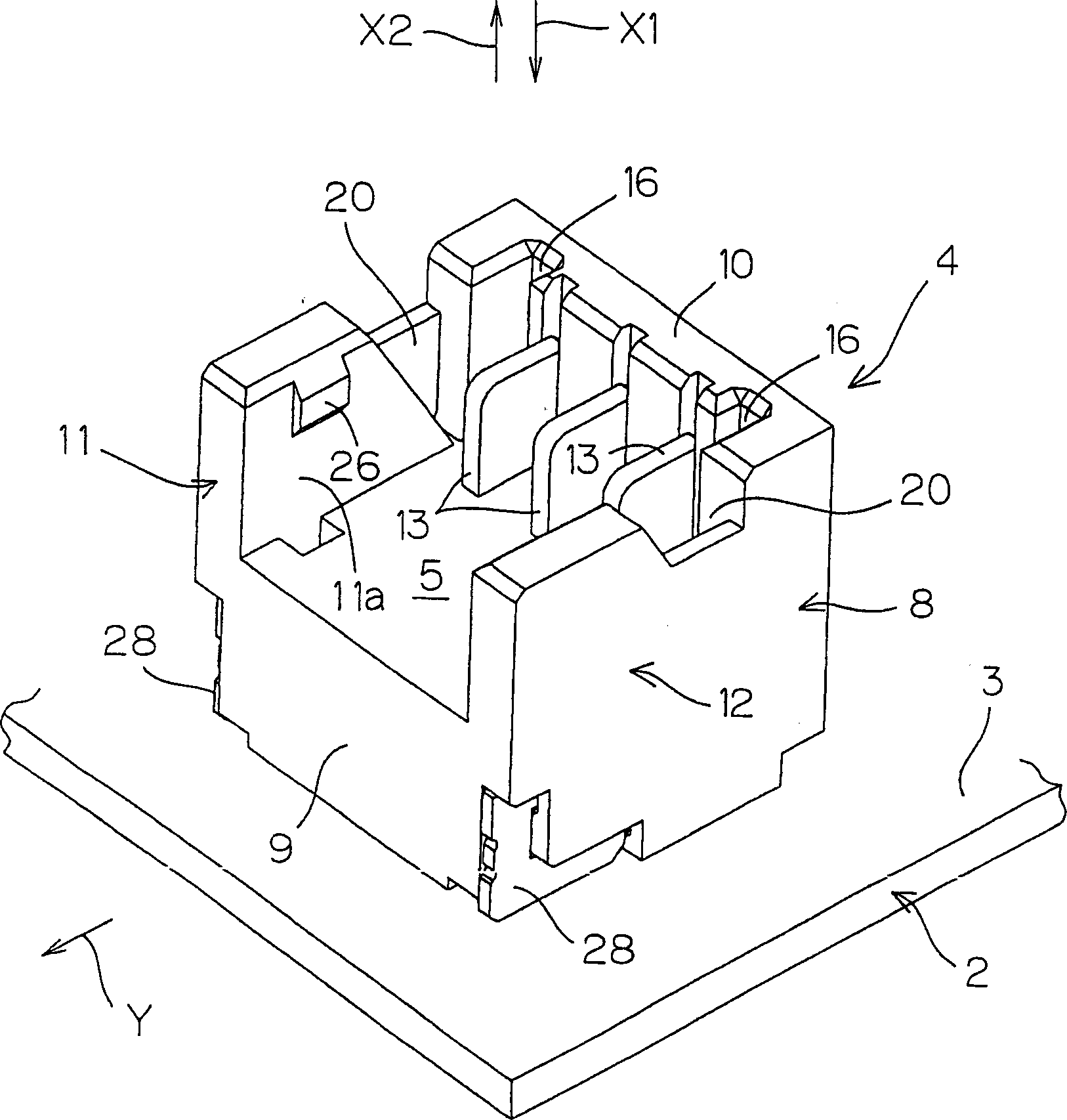

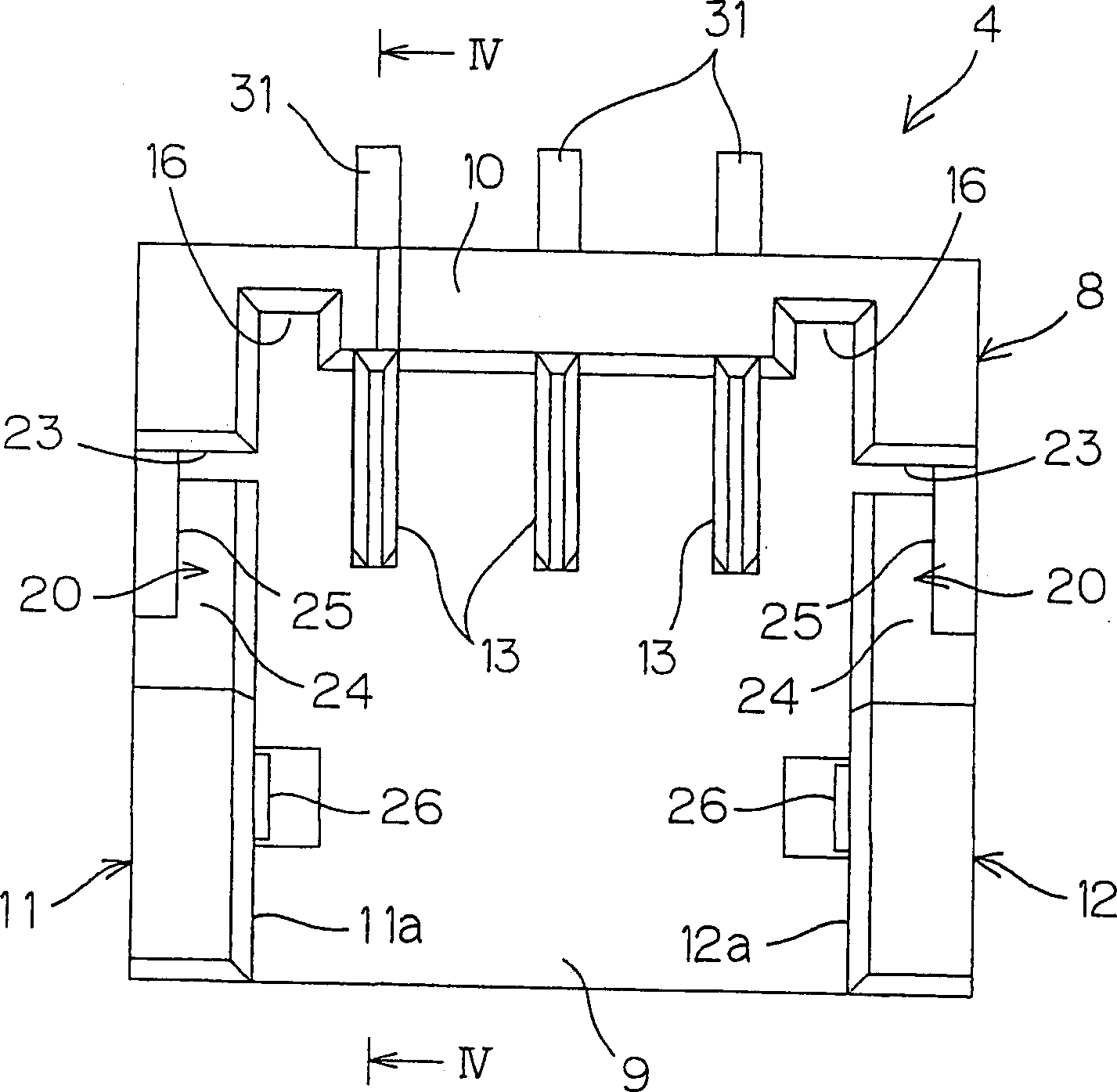

Electric connector and socket connector

InactiveCN1440577AThe extraction process is smoothEnsure that the plug-in is in placeCoupling contact membersCouplings bases/casesCamMechanical engineering

Owner:JST MFG CO LTD

Quick mounting and dismounting structure for filter cores of filter

ActiveCN104043283ALow costThe extraction process is smoothFiltration separationUltimate tensile strengthFriction force

The invention discloses a quick mounting and dismounting structure for filter cores of a filter. The quick mounting and dismounting structure includes an upper tray, a support cylinder and a lower tray which are connected in sequence, and also includes a plurality of filter cores fixing between the upper tray and the lower tray through filter core mounting holes arranged on the upper tray and the lower tray; the filter core mounting holes of the upper tray are each internally provided with an annular groove, and each annular groove is internally provided with an earless elastic hole baffle ring. The quick mounting and dismounting structure is low in cost, and adopts simple tools during dismounting; hand pushing is performed during mounting, no dedicated tools are required, bolts are not required to be mounted or dismounted, and mounting and dismounting save time and labor and are convenient and fast; the diameter of the earless elastic hole baffle rings is larger than the diameter of the filter core mounting holes, so that the baffle rings do not fall into the interior of the filter; two faces of each filter core mounting hole are each processed with a 60-degree chamfer, so that pulling-out and mounting-in of the filter cores are smooth, the work efficiency is greatly improved, and the labor intensity is reduced; the working surface of the upper tray is flat and smooth, the friction force is small, and reliable, smooth and steady operation of the automatic backwashing filter is ensured.

Owner:QINGDAO HEADWAY TECH

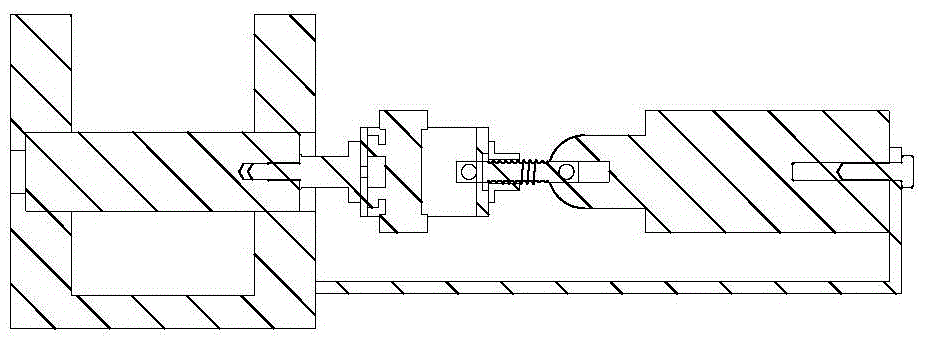

Tightly-propping pulling type detaching device for bearing neck bush

ActiveCN104015157ARealize the tightening effectThe extraction process is smoothMetal-working hand toolsMechanical engineeringEngineering

The invention discloses a tightly-propping pulling type detaching device for a bearing neck bush. The tightly-propping pulling type detaching device is used for achieving zero-damage detaching work of the bearing neck bush in the narrow space of a machine body and comprises a tightly-propping sleeve, a guiding supporting sleeve, an annular supporting seat, a pressing plate, a rotation nut assembly and a pull rod. The tightly-propping sleeve is of a split type hinged structure and is assembled with the left end of the pull rod, and the right end of the pull rod is assembled with the rotation nut assembly. The pull rod is sequentially sleeved with the guiding supporting sleeve, the annular supporting seat and the pressing plate from left to right, and the annular supporting seat is assembled with a bearing hole of the machine body. The tightly-propping pulling type detaching device solves the problem that the structural space of the machine body is small and a general tool cannot get into the machine body, damage to the structure of the machine body and the bearing neck bush is avoided, especially, the tightly-propping sleeve is of the hinged split structural design, the bearing neck bush can be accurately and tightly propped and positioned, and the detaching work efficiency of the bearing neck bush is improved.

Owner:FACTORY 5721 OF PLA

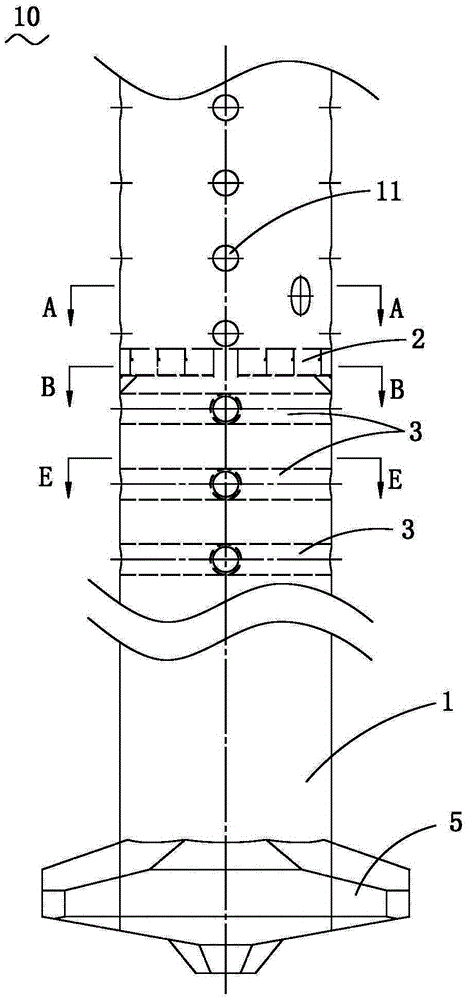

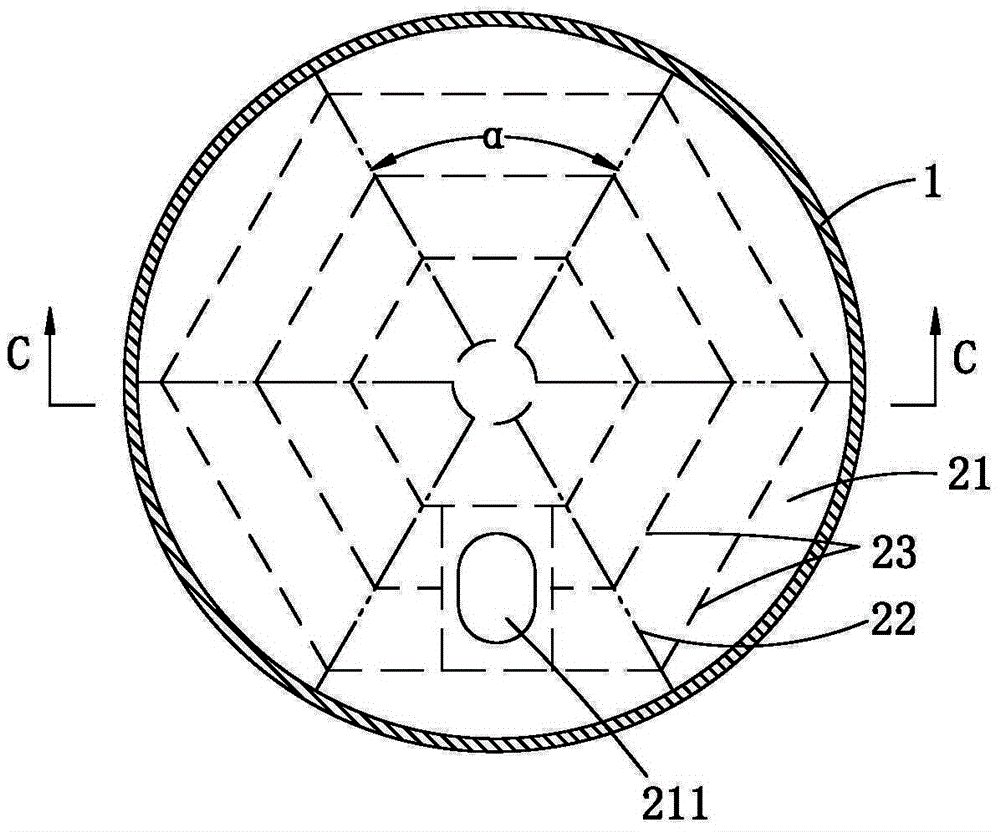

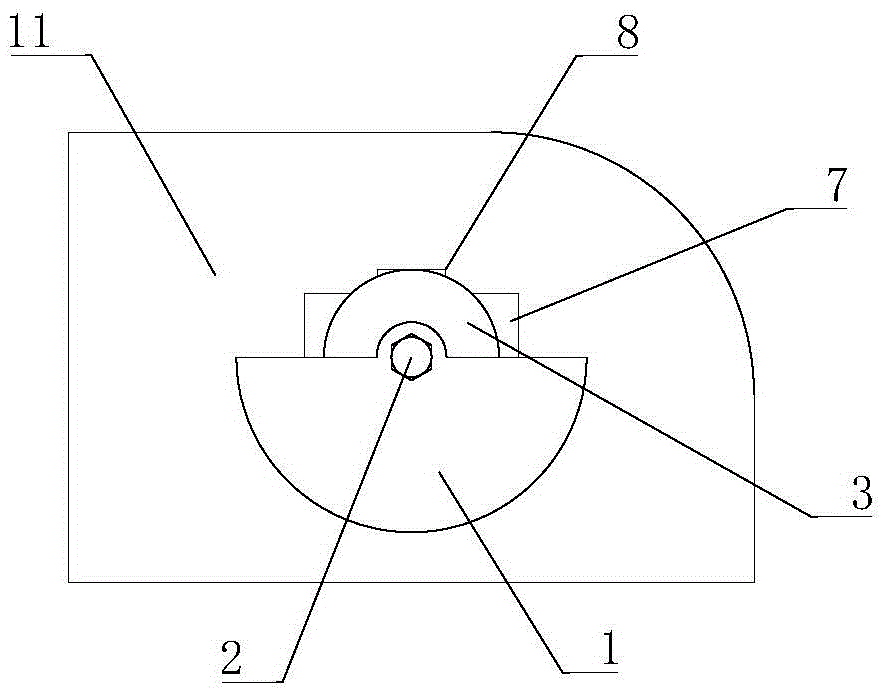

Self-elevating platform pile leg and ocean platform with same

ActiveCN104805858AThe extraction process is smoothSmall sizeFoundation engineeringStructural engineeringEngineering

The invention provides a self-elevating platform pile leg and an ocean platform with the same. The pile leg comprises a hollow columnar pile leg body, a separator and at least one communicating part, a group of pin holes are circumferentially formed in different positions of the pile leg body along the height direction, the separator is mounted at a set position in the pile leg body, the shape of the separator is matched with that of an internal section of the pile leg body, the internal space of the pile leg body is divided into an upper cavity and a lower cavity which are mutually independent, the communicating parts are mounted at the pin holes in the lower cavity in a one-to-one corresponding manner and provided with a group of mutually communicated openings, and the openings of each communicating part are fixedly connected with the inner wall of the pile leg body and communicated with the pin holes in a one-to-one corresponding manner, so that the pin holes are communicated with each other and isolated from the lower cavity. Insertion and extraction operations of pins cannot be affected, soil cannot enter the pile leg, and pile extracting difficulty is reduced.

Owner:CIMC OFFSHORE ENG INST +2

Hydraulic support hinge pin detaching device

ActiveCN105459013AImprove disassembly work efficiencyStable jobMetal-working hand toolsBall screwMental detachment

The invention discloses a hydraulic support hinge pin detaching device. The hydraulic support hinge pin detaching device comprises an axial cylinder, a pneumatic vibrator, a welding rack and a ball screw, wherein a semi-cylindrical sleeve serves as an axial pulling fulcrum, and axial movement, integral vibration and local rotation can be realized simultaneously. The pneumatic vibrator is mounted on the welding rack, the welding rack is welded with a stepped dowel, the stepped dowel is mounted at an end of the hinge pin, the ball screw is connected with the welding rack through a lead screw nut, the effect of rotating the hinge pin automatically is achieved while axial tension is provided through the axial cylinder, the semi-cylindrical sleeve is fixed with the outer wall of the cylinder, the other end of the semi-cylindrical sleeve is propped against the surface of the hydraulic support during operation, and the axial pulling fulcrum is provided. Compressed air serves as a power source, the hinge pin detaching efficiency can be improved obviously, one-step detaching success rate can be improved by pulling, reversing and vibrating combination operation, destructive detachment is avoided effectively, and the problem that an existing hydraulic support hinge pin is difficult to detach and the like is solved.

Owner:YANCHENG SHENGHUA COAL MASCH CO LTD

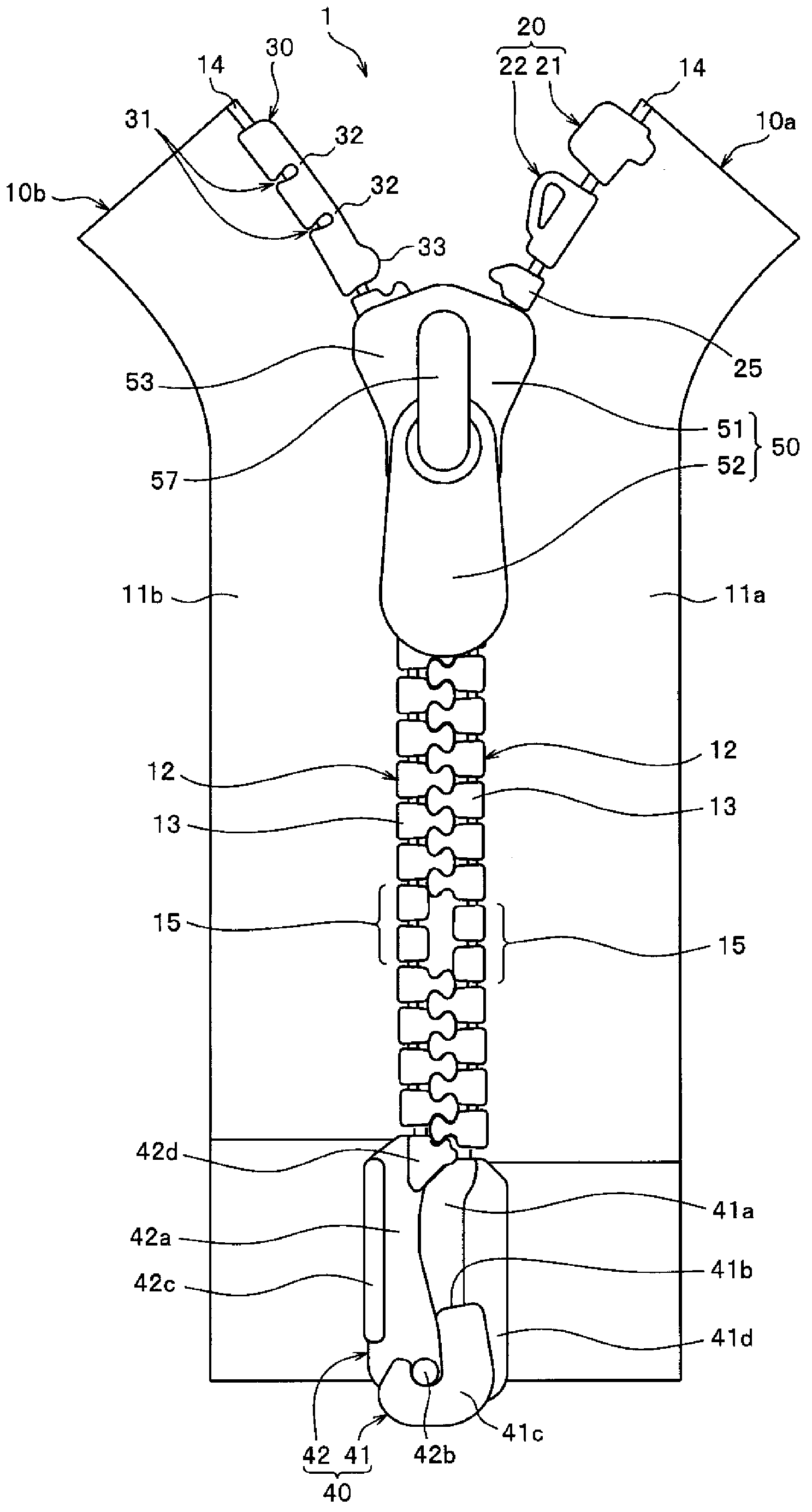

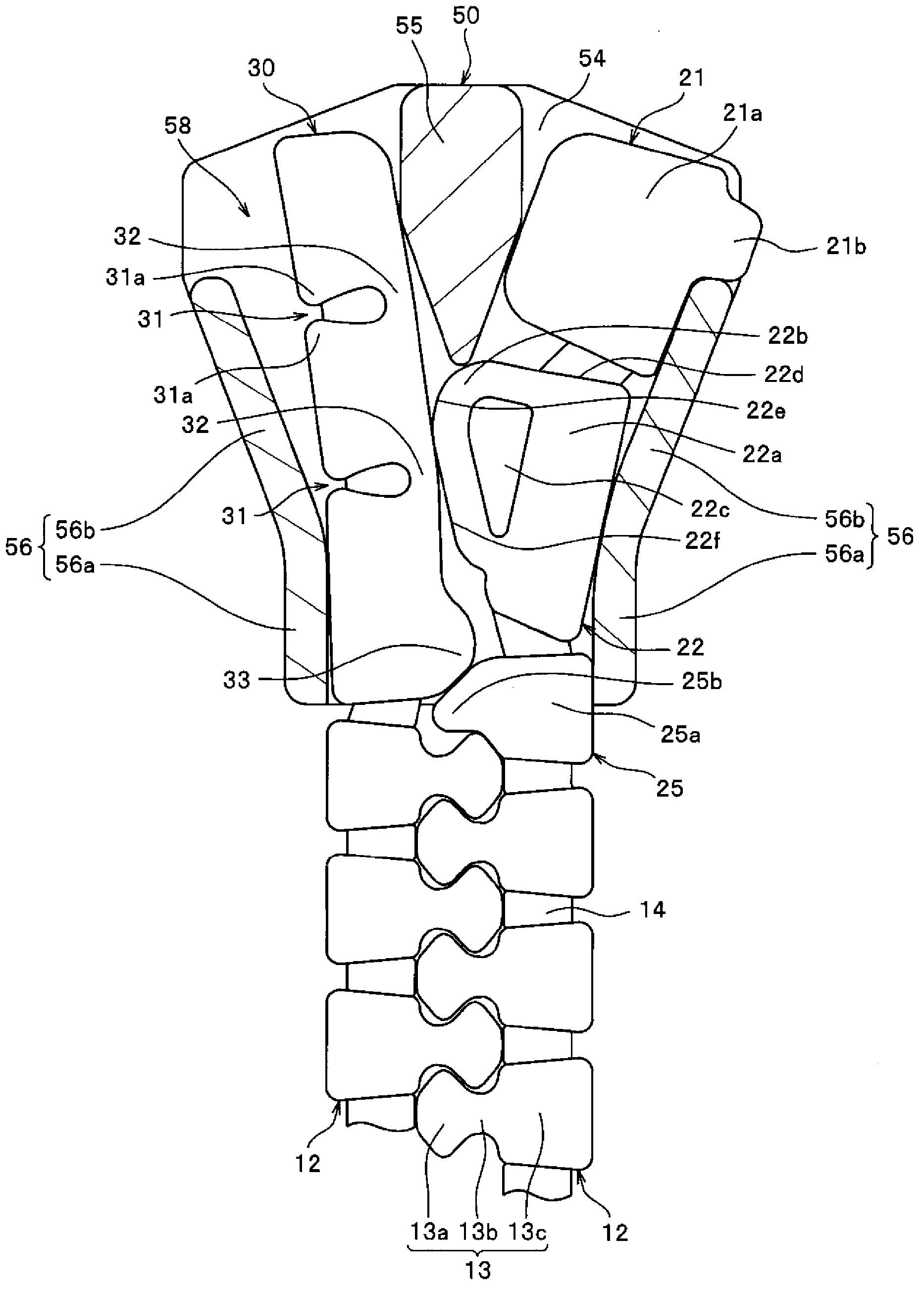

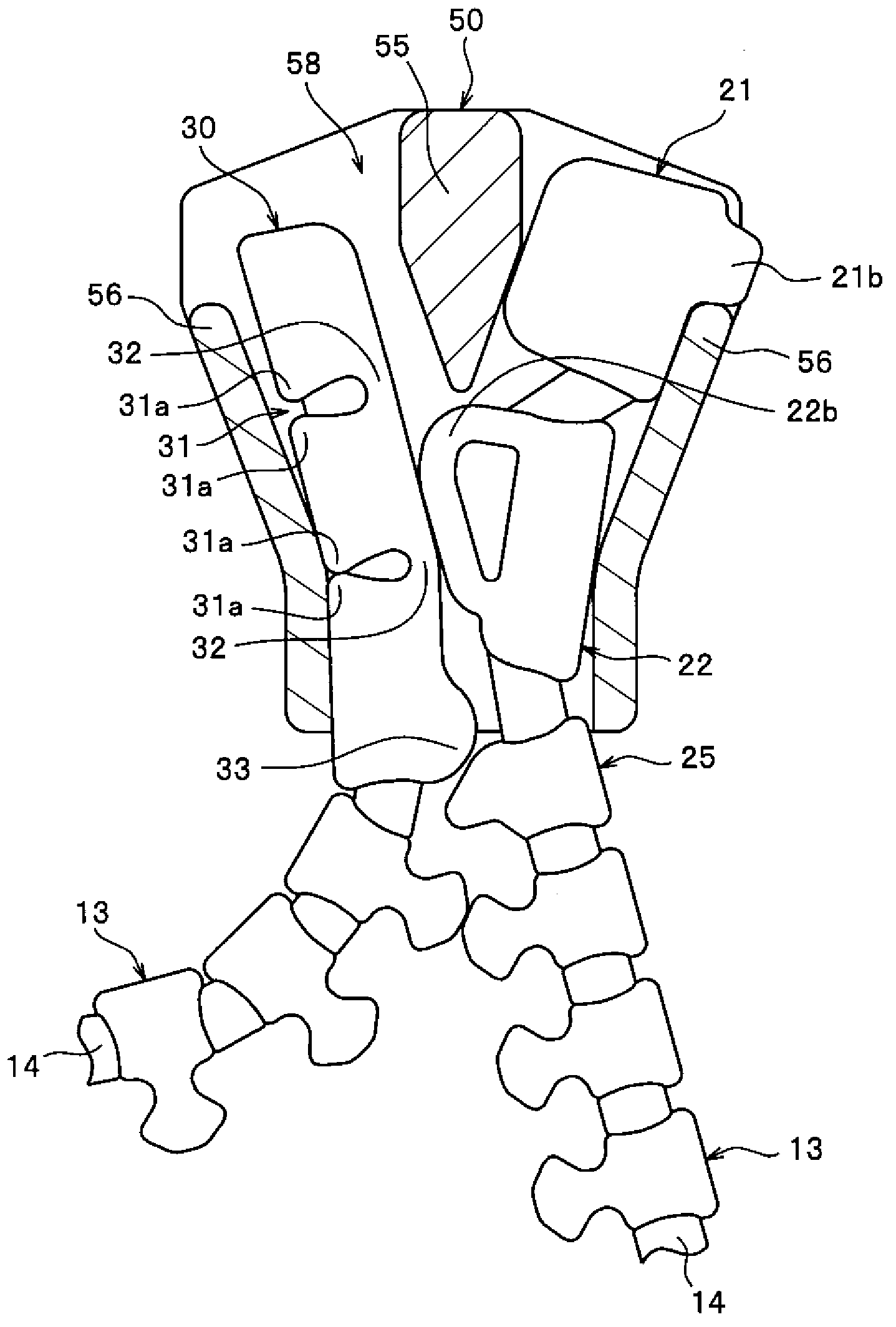

Slide fastener

In this slide fastener (1, 80), a fragile section (15, 86) is provided to an element row (12), and it is possible to detach the element row (12) in an engaged state from the fragile section (15, 86) and to separate first and second fastener stringers (10a, 10b). Lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) are arranged on the second fastener stringer (10b). The lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) have a larger thickness, for preventing lateral withdrawal, than the spacing of a tape insertion and passage gap of a slider (50). The lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) have at least one small-width section (32, 71b, 72b, 72d, 73b, 74b) at a portion provided with a thickness for preventing lateral withdrawal. Even when the slide fastener (1, 80) receives a lateral pulling force, the lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) are thereby held in the slider (50), and a closed state can be maintained. It is also possible, when the element row (12) is detached from the fragile section (15, 86), to pull out the lateral withdrawal prevention sections (30, 71, 72, 73, 74, 84) from the slider (50) in a smooth manner.

Owner:YKK CORP

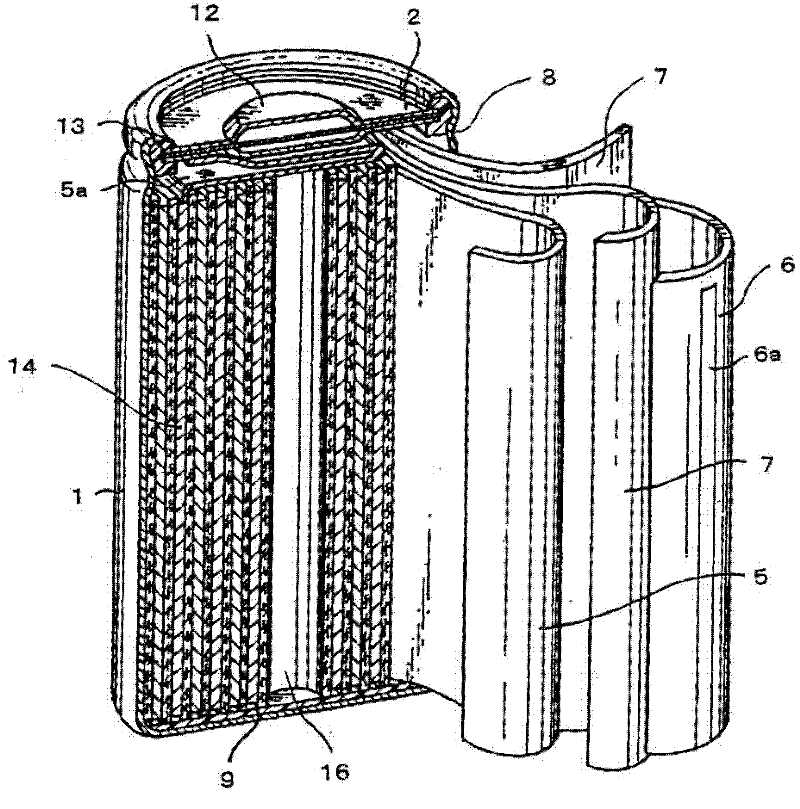

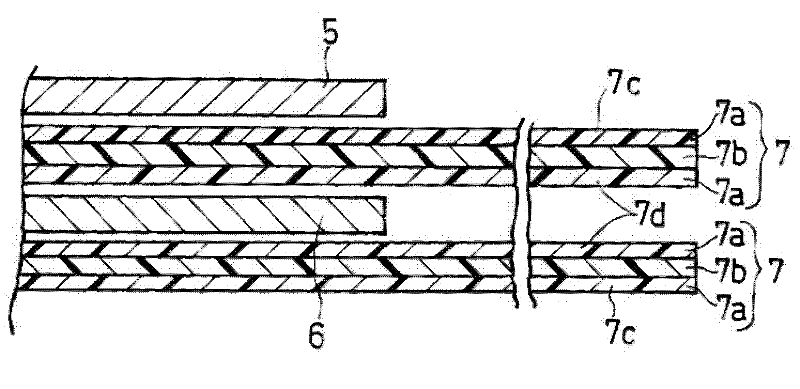

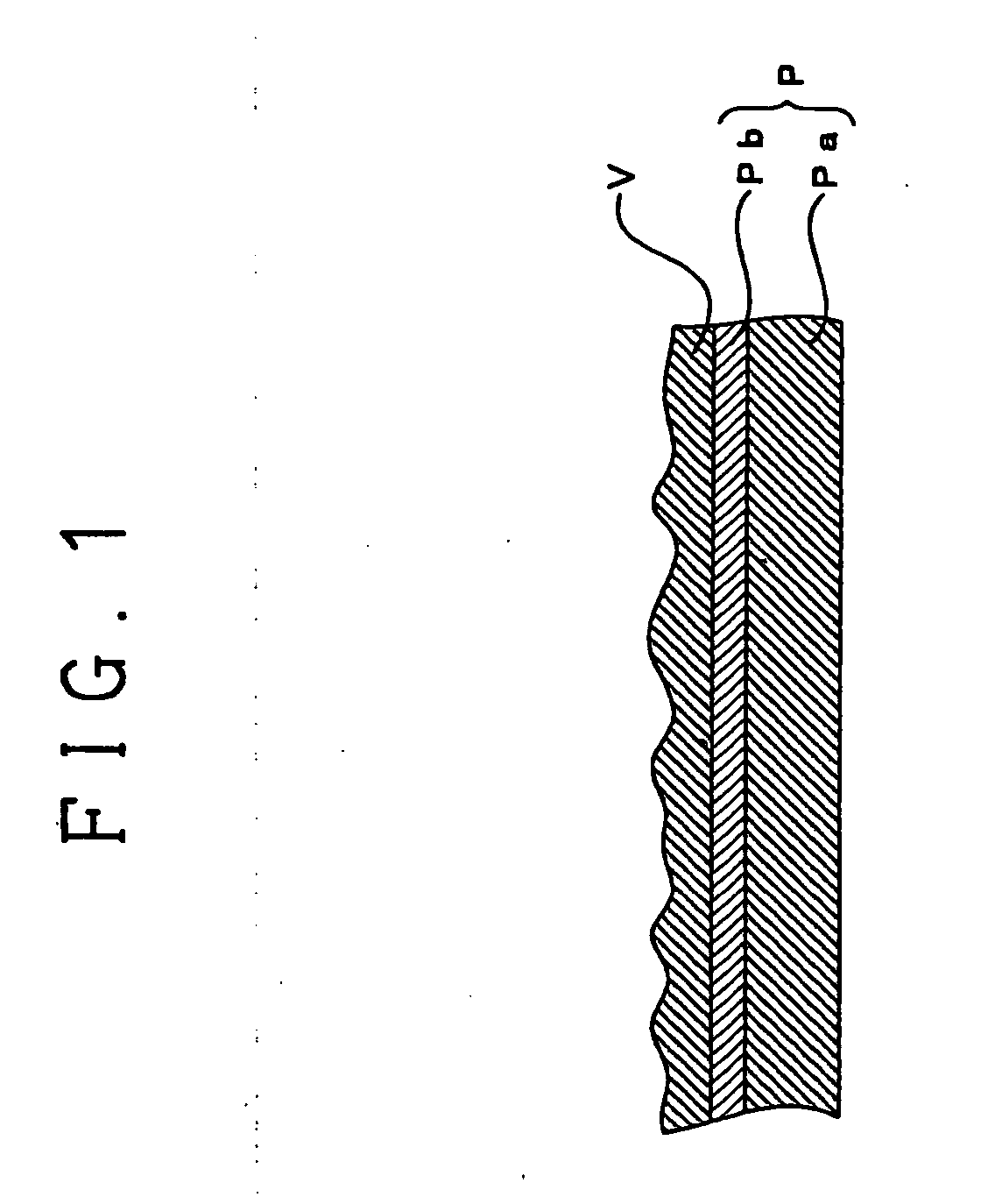

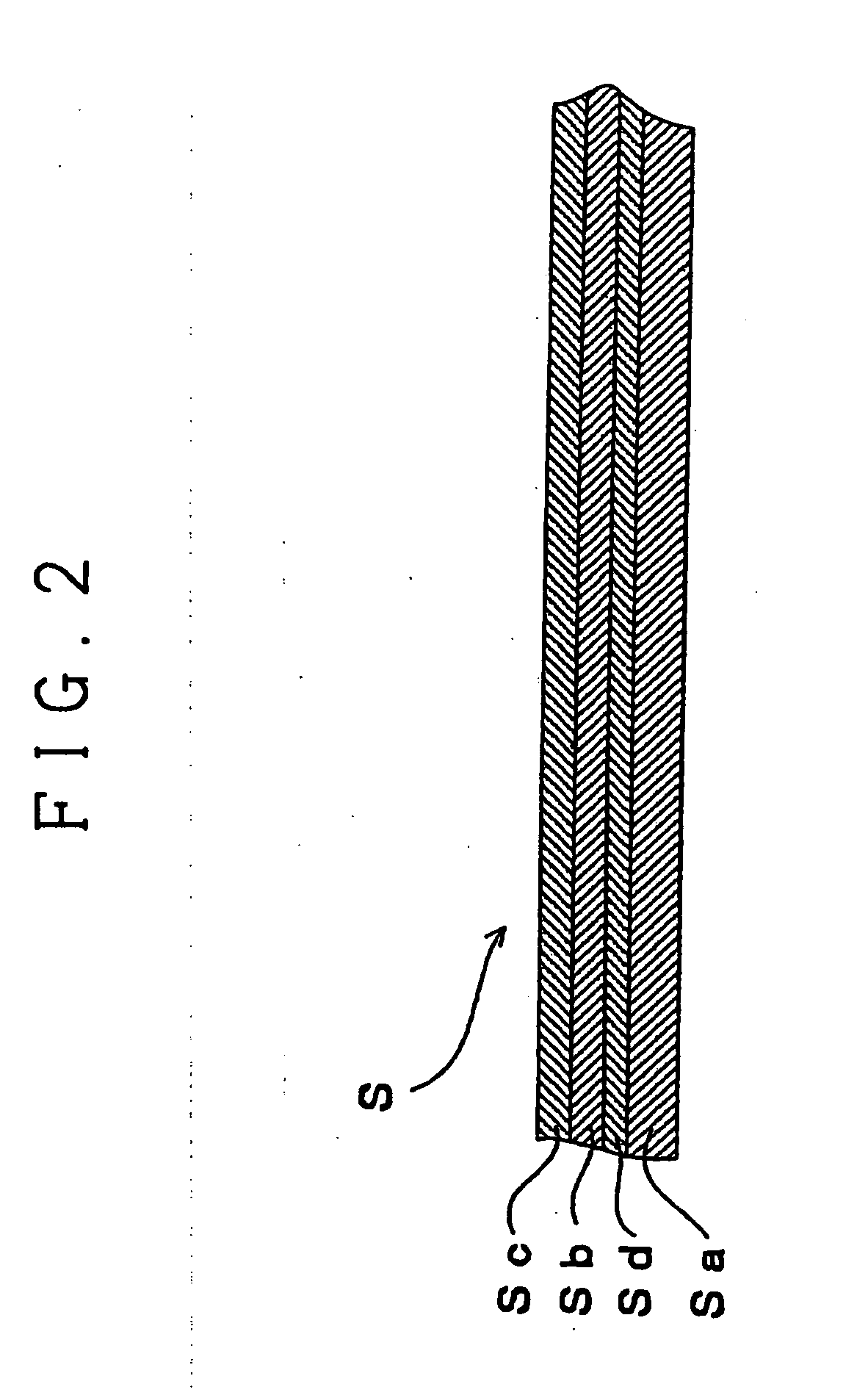

Separator for battery, battery using same and method for producing battery

ActiveCN102341937AReduce frictionThe extraction process is smoothFinal product manufactureSecondary cellsPolymer scienceElectrical battery

Disclosed is a separator for a battery comprising a porous polymer film having a first surface and a second surface that is located on the opposite side of said first surface, wherein openings interconnecting pores in the porous polymer film are distributed in the first surface and the ratio of the total area of the openings to the area of the first surface is 89-96% inclusive. The opening diameter may range from 0.8 to 40 [mu]m inclusive. It is preferred that a part with a definite thickness of the porous polymer film, at least on the first surface side, contains at least one component selected from the group consisting of polypropylene and copolymers of propylene with other copolymerizable monomer(s).

Owner:PANASONIC CORP

Bowl-shaped plug dismantling tool

The invention provides a bowl-shaped plug dismantling tool which comprises a bowl-shaped plug tightly-sleeving assembly and a pulling-poking device assembly, wherein the bowl-shaped plug tightly-sleeving assembly comprises an expansion sleeve and an expansion rod matched with the expansion sleeve; the expansion sleeve comprises a threaded connection section and an expansion section; a run-through matching hole is formed in the shaft center of the expansion sleeve; an internal thread is formed in the matching hole at the threaded section; the end opening, adjacent to the expansion section, of the matching hole gradually shrinks; a plurality of separation grooves are axially formed in the part adjacent to the end opening of the expansion section; the end part of the expansion section is correspondingly divided into a plurality of clamping bars with stretching elasticity; a clamping cone is formed on the outer side surface of each clamping bar; the expansion rod comprises a matching section and a propping section; an external thread is formed in the periphery of the matching section; the expansion rod penetrates into the expansion sleeve; the external thread of the matching section is matched with the internal thread of the expansion sleeve; the propping section is matched into the matching hole; after the expansion rod is screwed by a preset distance, the propping section is propped against the inner sides of the clamping bars at the end opening of the expansion section to enable the clamping bars to be propped to unfold. The bowl-shaped plug dismantling tool is simple in structure and can ensure that a bowl-shaped plug is conveniently dismantled.

Owner:KETENG IND PANYU CITY

Construction technology and equipment for cement mixing pile

The invention discloses a construction technology and equipment for a cement mixing pile. The construction technology comprises the steps that when the hollow pile section is constructed, clear water is ejected from a grout ejecting opening, the clear water is also ejected by the grout ejecting opening in the first sinking process of the solid pile section, a mixing head is lifted and sunk for many times in the lifting process of the solid pile section, and cement grout is ejected from the grout ejecting opening. According to the construction technology for the cement mixing pile, the cement is distributed in the solid pile section uniformly, and the cement grout is combined with soil body in the solid pile section, so that the pile forming quality of the solid pile section is guaranteed, waste of the cement grout is avoided, and follow-up digging work of the hollow pile section is convenient.

Owner:中国能源建设集团广东电力工程局有限公司

Wood pattern with loose piece

InactiveCN102139345ANot easy to dropThe extraction process is smoothFoundry moulding apparatusPulp and paper industryDrop out

The invention provides a wood pattern with a loose piece, comprising a wood pattern main body and the loose piece arranged on the wood pattern main body, wherein an iron plate is arranged at the center of the back end of the loose piece and a magnet corresponding to the iron plate is arranged in the wood pattern main body. The wood pattern with the loose piece has the advantages that the loose piece is not easy to drop out; the pattern drawing is convenient; the accuracy of sizes of castings can be guaranteed; and the working efficiency is improved.

Owner:SUFA HENGDIAN MACHINERY CNNC

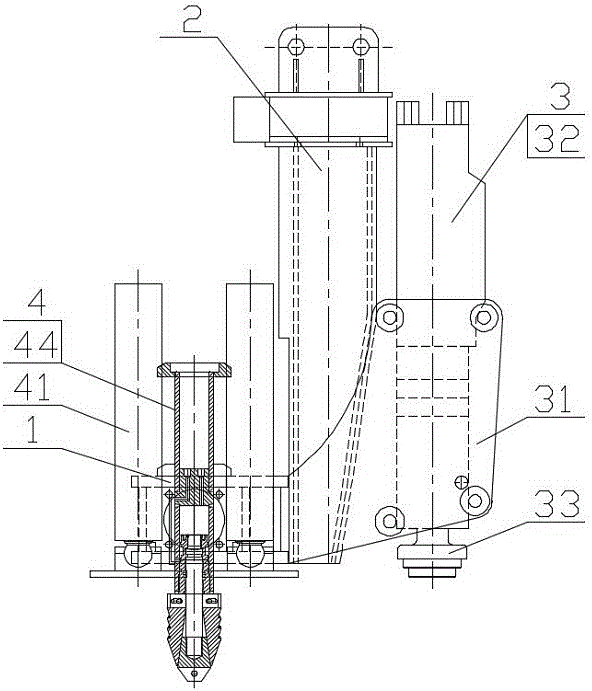

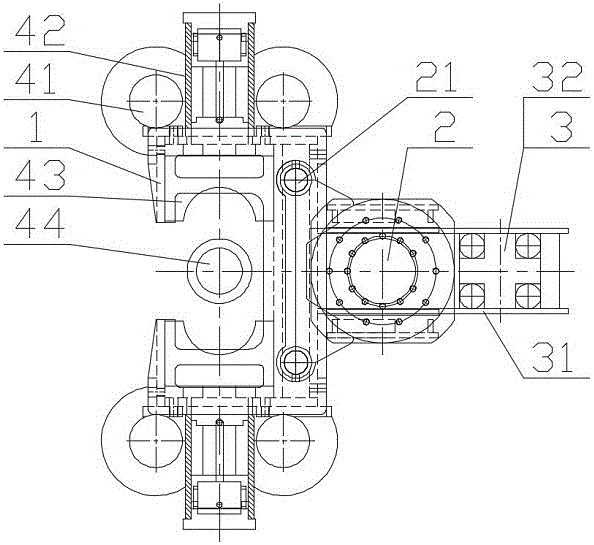

Hydraulic pile driving and extracting device of highway anti-collision guardrail

The invention discloses a hydraulic pile driving and extracting device of a highway anti-collision guardrail. The device comprises an opening box body (1), an up-down floating guide part (2), a pile driving part (3) and a pile extracting part (4); the pile extracting part includes a pile extracting hydraulic oil cylinder (41), a clamping hydraulic cylinder (42), a locking chuck (43) and an inner diameter expansion mechanism (44); the inner diameter expansion mechanism includes an expansion hydraulic cylinder (441), an expansion head (442) and a clamping sleeve (443); the expansion head is mounted on an extension end of the expansion hydraulic cylinder (441), and includes a translation guide ring (4421), a clamping jaw (4422) and a connecting head (4423); and big end down conical surface structures are arranged on the inner surface of the clamping jaw and the outer surface of the connecting head. The hydraulic pile driving and extracting device can effectively extract out broken piles above or below pavements without needing excavation when realizing a pile driving function, and in particular, is suitable for the repair and maintenance work of stand columns of the highway anti-collision guardrail.

Owner:周详淞

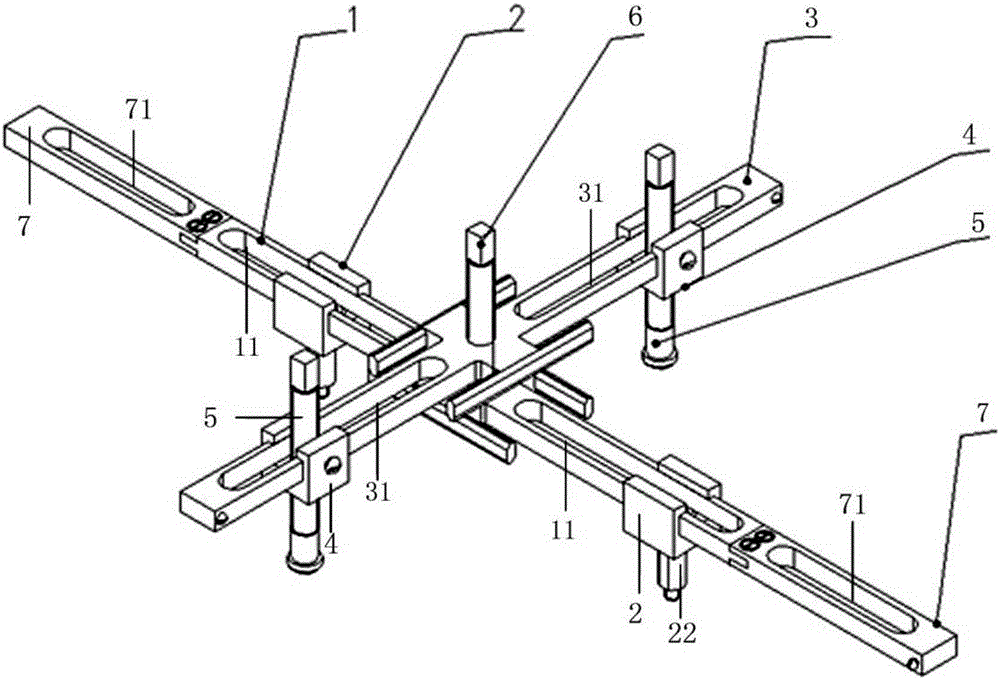

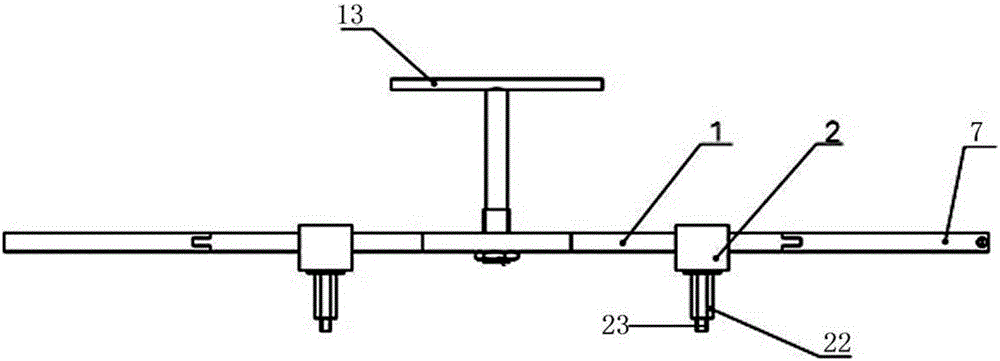

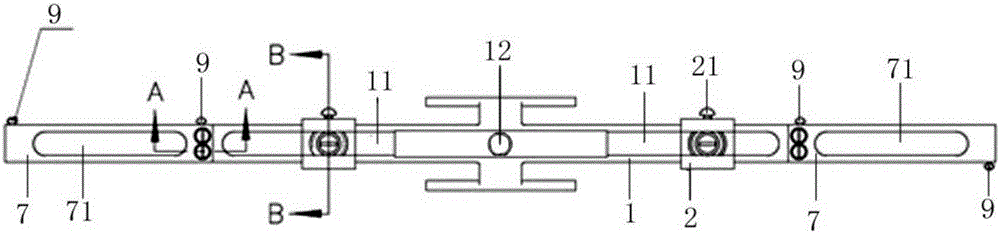

Inserting and pulling device

ActiveCN105171668ARealize plugging requirementsImplement socketMetal-working hand toolsMechanical engineeringTransmitter

The invention relates to an inserting and pulling device. The inserting and pulling device comprises an inserting and pulling guide rail and first sliding blocks. The inserting and pulling guide rail is in a long strip shape. First long holes are formed in the inserting and pulling guide rail. A first inserting and pulling hole is formed in the middle of the inserting and pulling guide rail. The inserting and pulling guide rail is sleeved with the first sliding blocks. A first fastening screw is inserted in one side wall of each first sliding block. Each first sliding block can be locked to the outer wall of the inserting and pulling guide rail by tightening the corresponding first fastening screw. A connecting post is fixed to the bottom of each first sliding block. A second fastening screw is inserted in each connecting post. The second fastening screws are inserted into an object to be inserted and pulled and tightened so that the first sliding blocks and the object to be inserted and pulled can be fixed. The inserting and pulling device can meet the inserting and pulling requirements of transmitter and receiver (TR) modules of different sizes due to the arrangement of the inserting and pulling guide rail and the first sliding blocks.

Owner:BEIJING INST OF RADIO MEASUREMENT

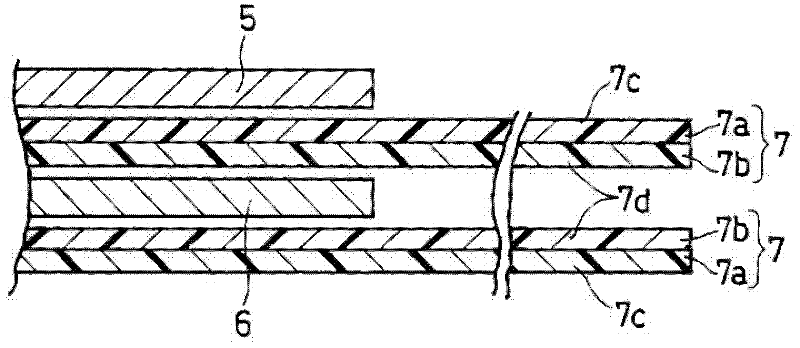

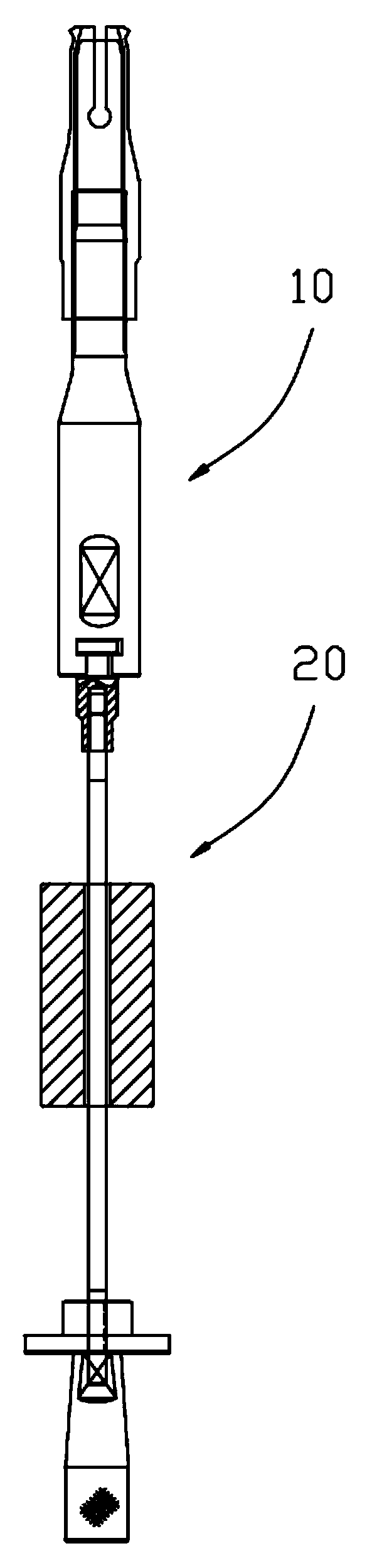

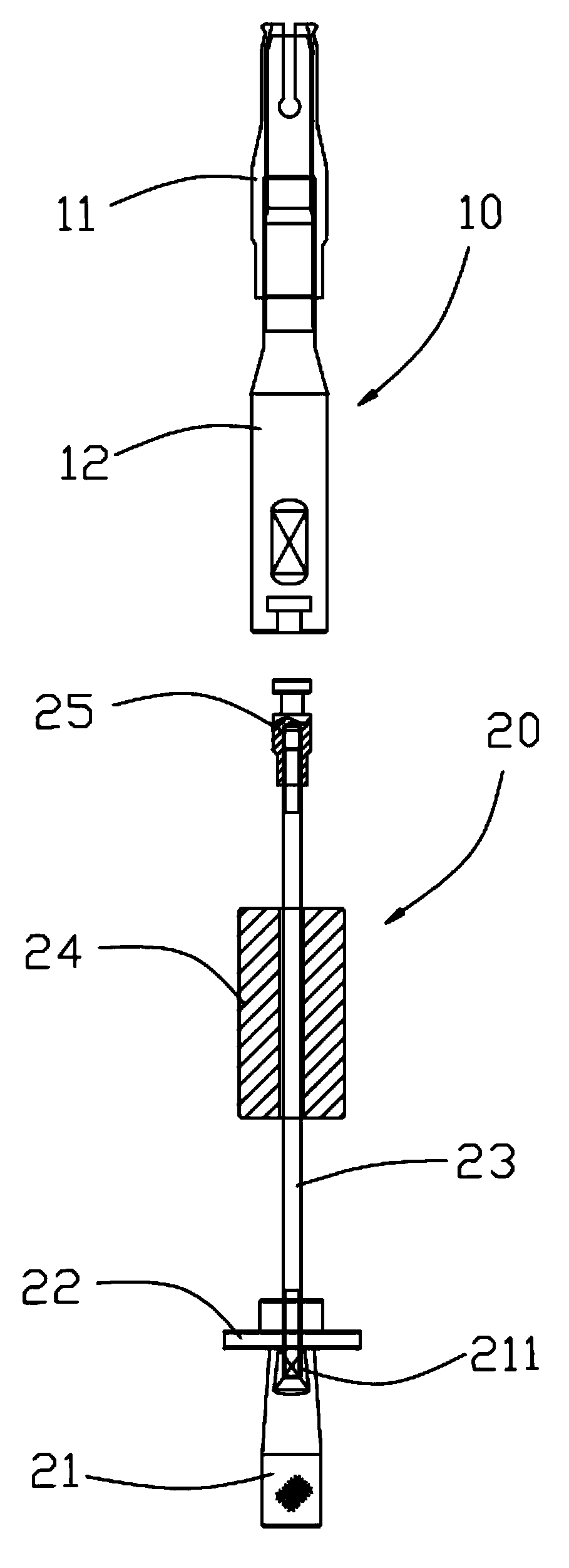

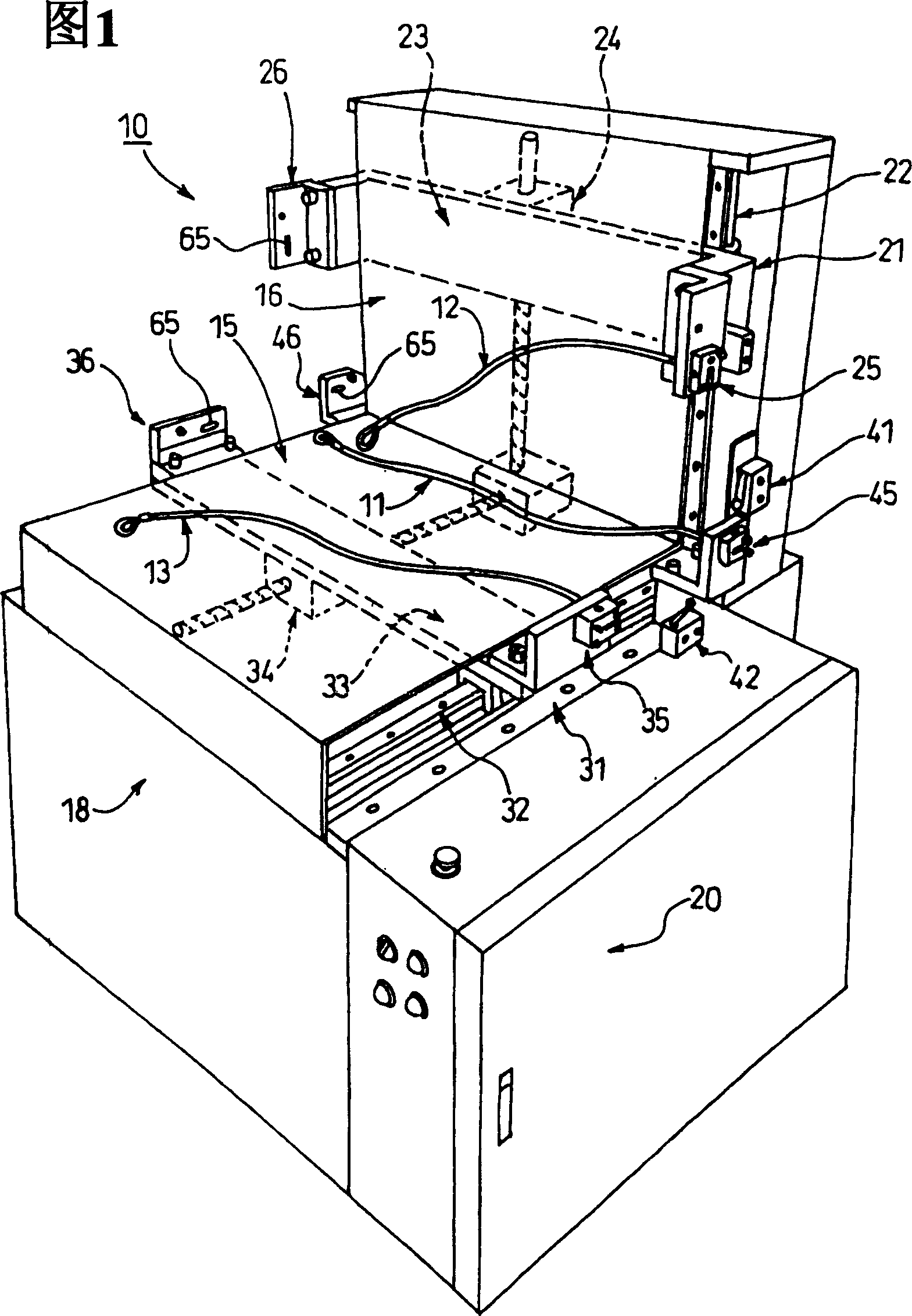

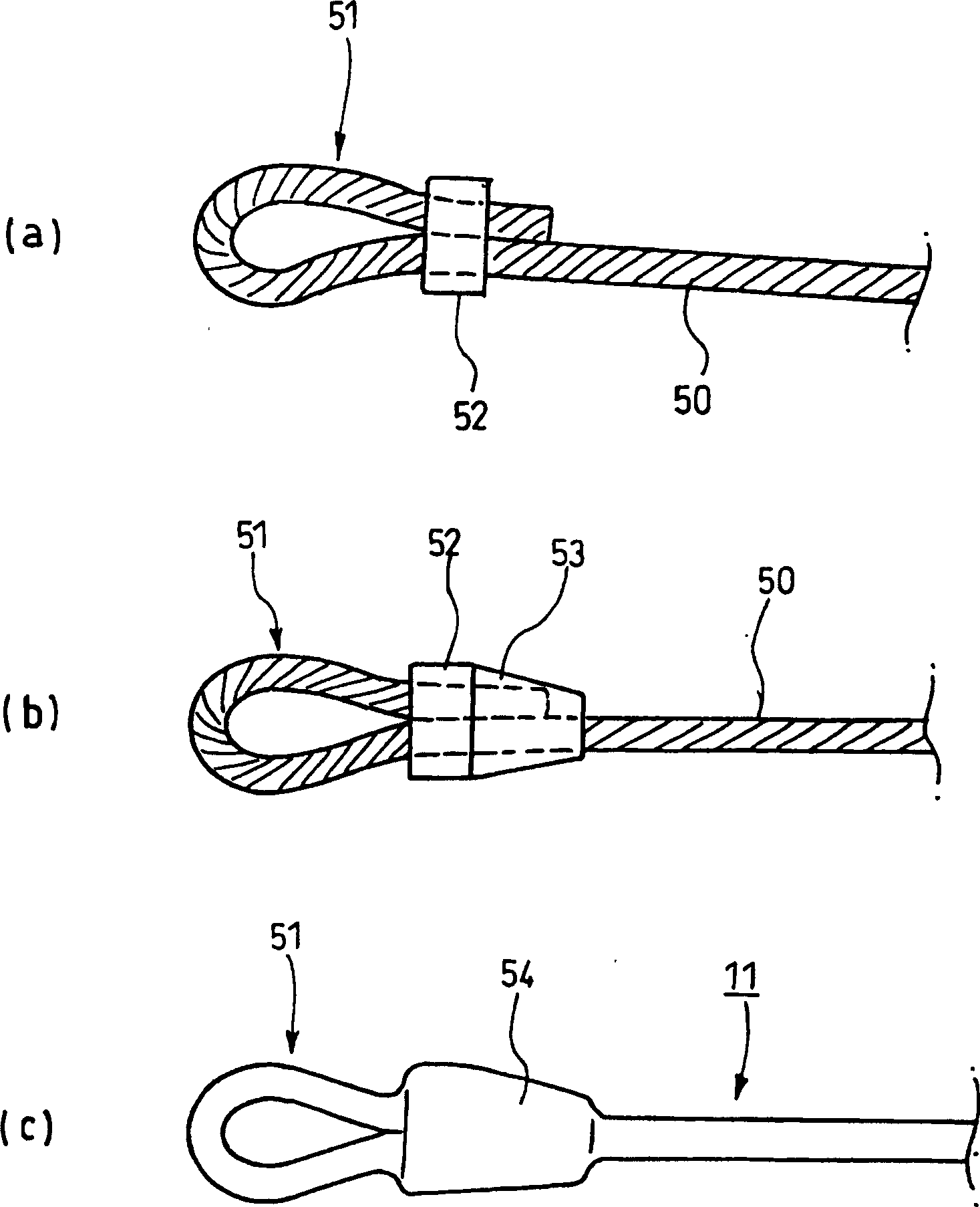

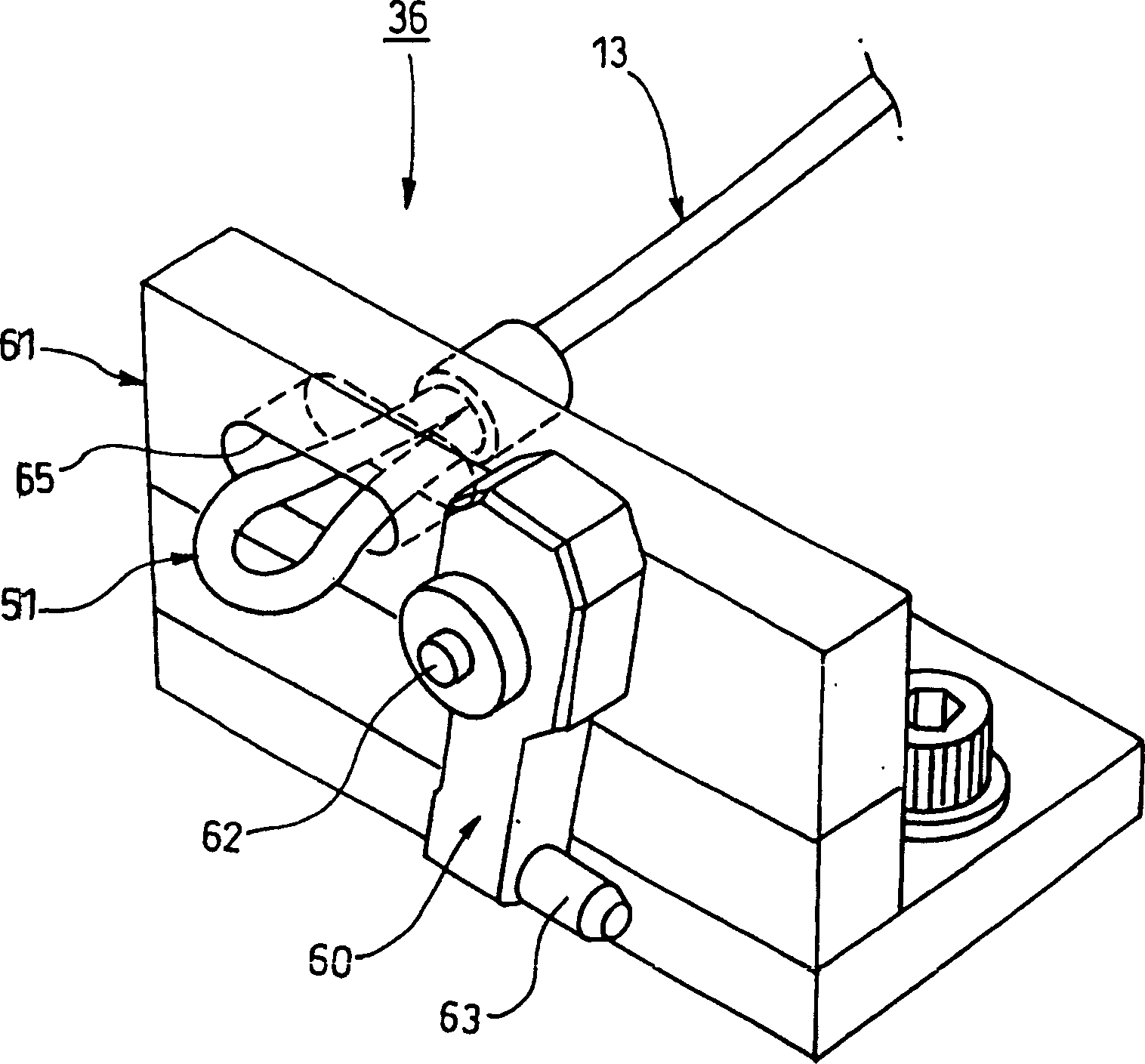

Method of inserting wire in rubber sleeving and rubber sleeving expander

Provided is a good cable threading method to a grommet, which can improve the threading work efficiency at the time of threading a cable into a long grommet, and to provide a grommet expander. The grommet expander 10 is equipped with three pieces of first to third flexible long members 11, 12, and 13 for diameter expansion, which are to be passed into the hole of the long grommet, drive means 21 and 31, which displace these second and third flexible long members 12 and 13 for diameter expansion with both their ends supported into far positions, a frame 18, and a controller 20. The grommet is brought up near the center while expanding it to shrink the longitudinal dimensions by displacing these first to third flexible long members 11, 12, and 13 for diameter expansion into mutually far positions and flexing the centers of the first to third flexible long members 11, 12, and 13 for diameter expansion with both their ends supported.

Owner:YAZAKI CORP

Self-locking plug and power line

ActiveCN106207563AThe extraction process is smoothEliminate interferenceCoupling contact membersSelf lockingEngineering

The invention relates to the technical field of power lines, and especially relates to a self-locking plug for a power line, and the power line. The plug comprises a plug main body, and the plug main body is provided with jacks, wherein the interior of at least one jack is provided with a self-locking assembly. The self-locking assembly comprises a card, and the card is provided with a through hole. The plug main body is provided with a platform, and one side, of the card, is provided with a first pulling plate. One side, located at the jack, of the plug main body is provided with a cavity, and the first pulling plate is disposed in the cavity. The first pulling plate is connected with one end of the card. The interior of the cavity is provided with a spring, and the platform is provided with an inclined limiting baffle plate. The first pulling plate is connected with a second pulling plate. According to the invention, the plug can achieve the locking of a terminal during connection, thereby enabling the plug not to be plugged out easily. The plug has a self-locking function, is simple and quick in operation, further avoids the misoperation and self-falling, can guarantee the normal operation of corresponding equipment, can avoid electric shock accidents, and is higher in safety.

Owner:WELL SHIN ELECTRONICS KUNSHAN

Laminate sheet and lamination method

InactiveUS20060029780A1The extraction process is smoothAvoid damageDecorative surface effectsDuplicating/marking methodsEngineeringHardness

A laminate sheet for giving gloss finish to an image layer that is formed on a printing surface of a substrate by squirting small jets of ink in tiny droplets onto the substrate is provided. The laminate sheet includes a seal layer being transparent and laminated on the image layer, and a gloss layer being transparent and laminated on the seal layer. The seal layer exhibits stickiness to the image layer at least when the seal layer is laminated to the image layer, and is designed to be flexibly deformed so as to conform to a surface configuration of the image layer. The gloss layer has at least one of the opposite surfaces smoothly finished and has such a degree of stiffness as not to allow itself to be deformed due to deformation of the seal layer. The thus structured laminate can keep its smooth surface and give gloss finish to the image layer without an influence of an uneven surface of the image layer.

Owner:KIMURA YASUTO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com