Hydraulic support hinge pin detaching device

A technology of hydraulic support and dismantling device, which is applied in the field of mining machinery, and can solve problems such as difficulty in pulling out the inner blind hole, serious corrosion of the pin shaft, and corrosion of the pin shaft, so as to improve the success rate of disassembly, improve work efficiency, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

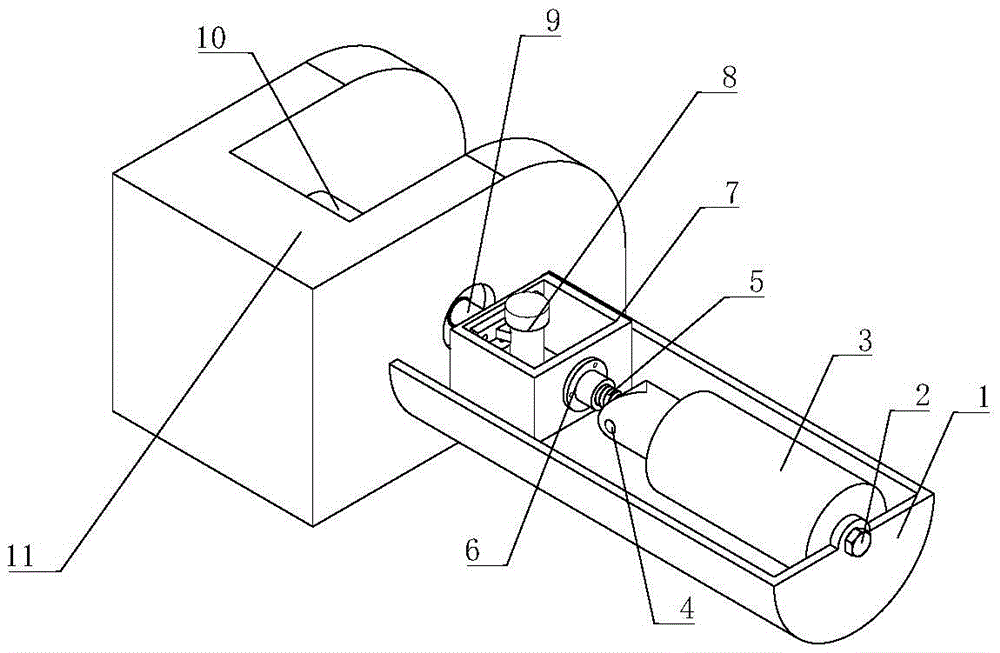

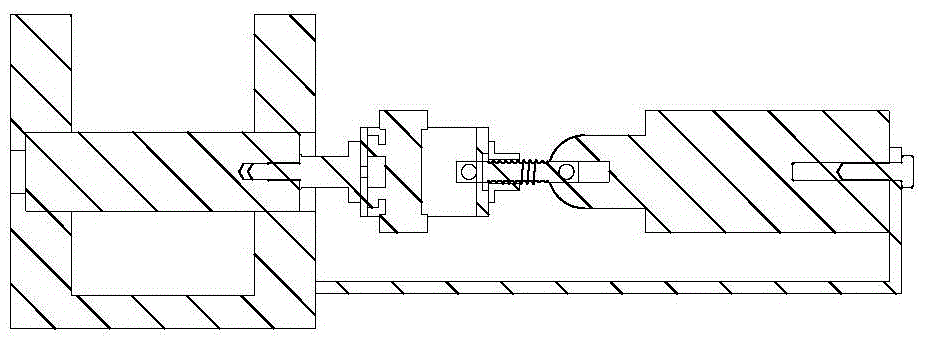

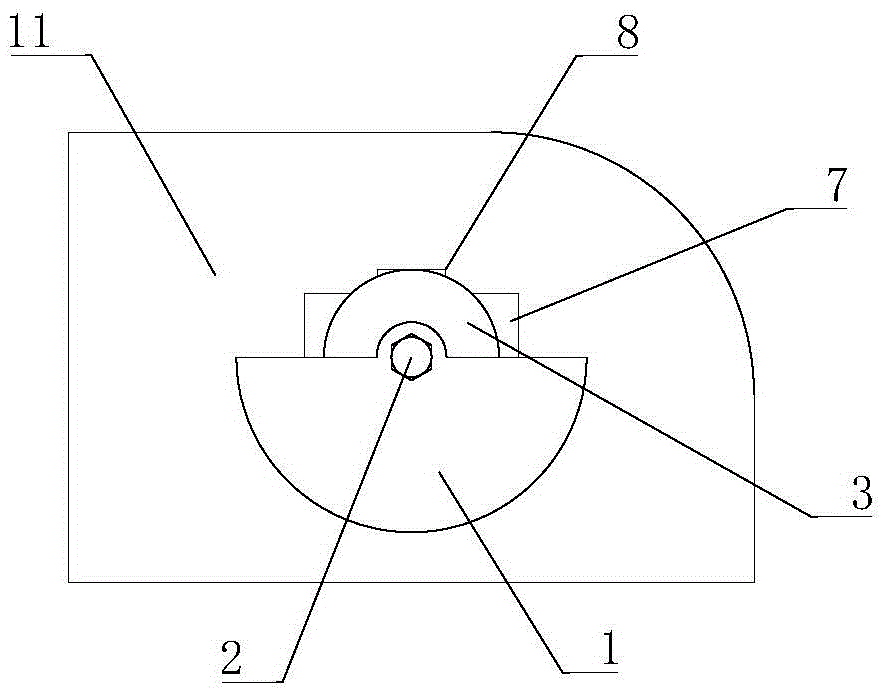

[0032] see figure 1 , a hydraulic support pin removal device provided by the present invention uses compressed air as a power source, includes an axial cylinder 3, a pneumatic vibrator 8, a welding frame 7, and a ball screw 5, and uses a semi-cylindrical sleeve 1 as a The fulcrum is pulled axially, and the axial movement, overall vibration and local rotation can be realized simultaneously during the disassembly process of the pin shaft. The pneumatic vibrator 8 is installed on the welding frame 7, the welding frame 7 is welded with the stepped pin 9, the stepped pin 9 is installed at the end of the pin shaft 10, the ball screw 5 is connected with the welding frame 7 through the screw nut 6, During the disassembly process of the pin shaft 10, the axial cylinder 3 provides the axial pulling force and at the same time plays the role of automatically rotating the pin shaft 10. The semi-cylindrical sleeve 1 is fixed to the outer wall of the axial cylinder 3 by the set screw 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com