Water cutting automatic disassembling device for waste mattresses

A mattress and waste technology, applied in metal processing, etc., can solve the problems that cannot be recycled, products can only be sent to incineration plants for incineration, and it is difficult to separate metals and non-metals, so as to reduce the cost of manual dismantling and improve dismantling work The effect of maximizing efficiency and resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

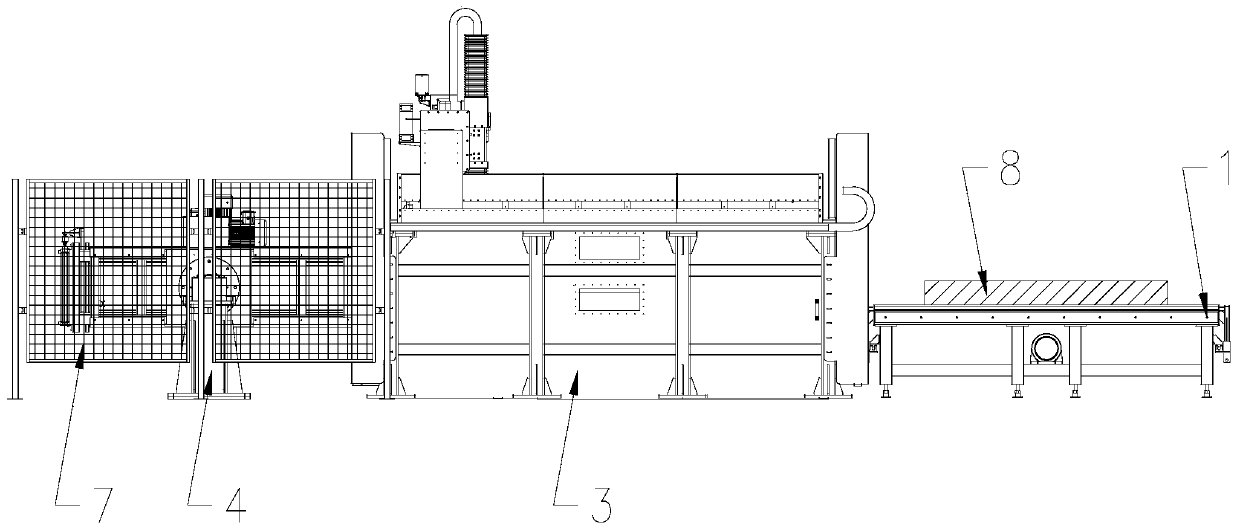

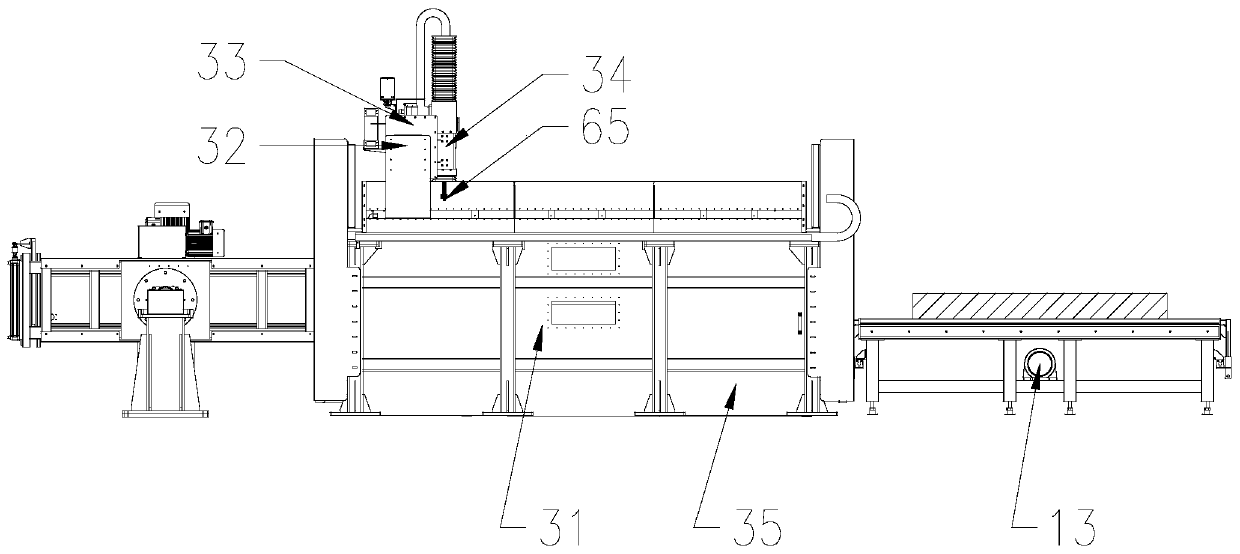

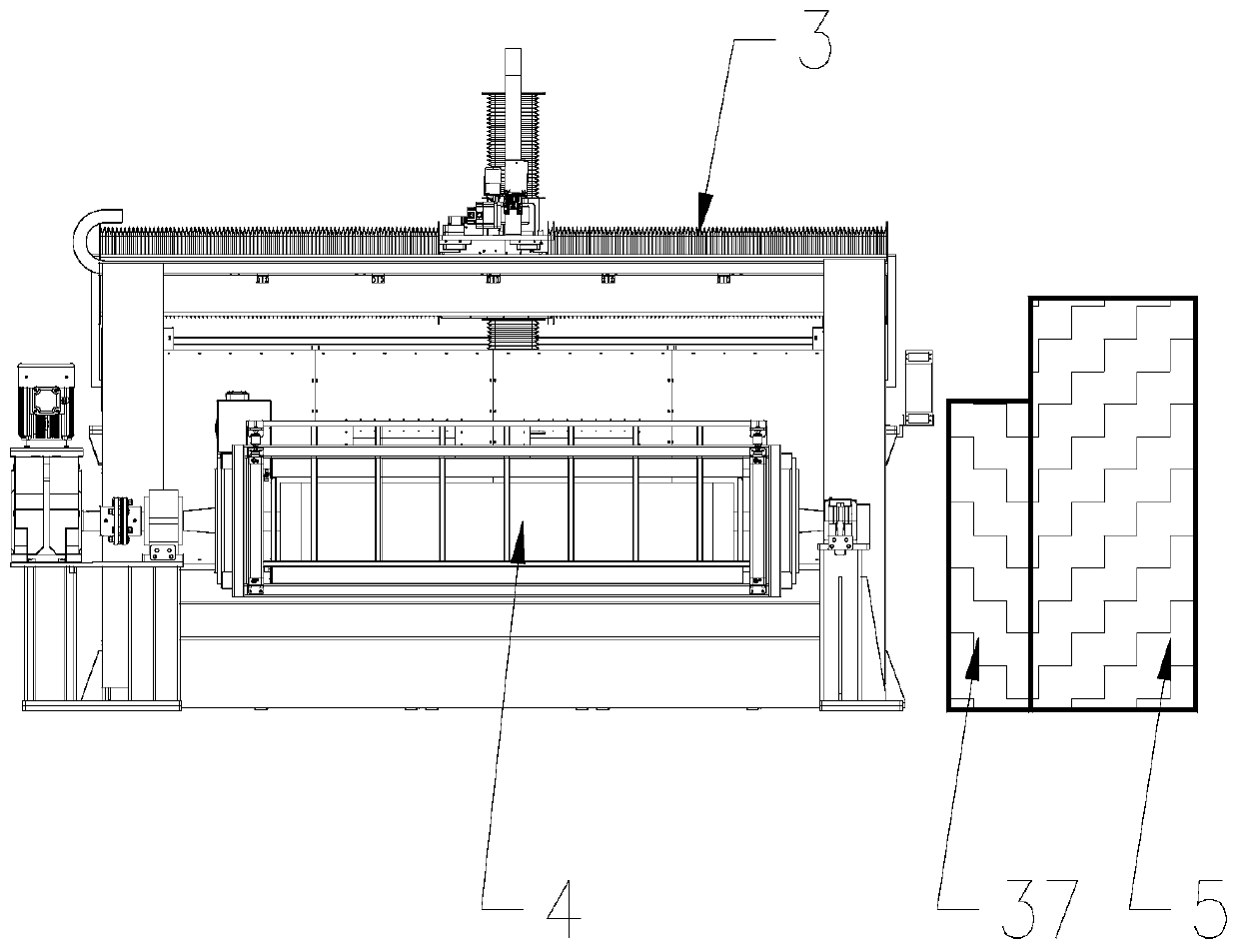

[0024] refer to Figure 1 to Figure 4 , a kind of automatic dismantling device of water-cutting waste mattresses of the present invention, comprises five-axis water jet cutting machine 3, the narrow roller conveyor 2 that is fixed in five-axis water jet cutting machine 3, is respectively arranged on five-axis water jet cutting machine 3 Turning roller conveyor 4 and feeding roller conveyor 1 at the left and right ends, size measurement sensor group 6 located on the narrow roller conveyor 2 and respectively connected with feeding roller conveyor 1, narrow roller conveyor 2, five-axis water Knife cutting machine 3, flipping roller conveyor 4 and electric control main cabinet 5 electrically connected with measurement sensor group 6, said size measurement sensor group 6 includes the first sensor 61 fixed on the front and rear sides of the top of narrow roller conveyor 2, several A second sensor 62 and a third sensor 63 fixed on the top front side of the narrow roller conveyor 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com