Construction technology and equipment for cement mixing pile

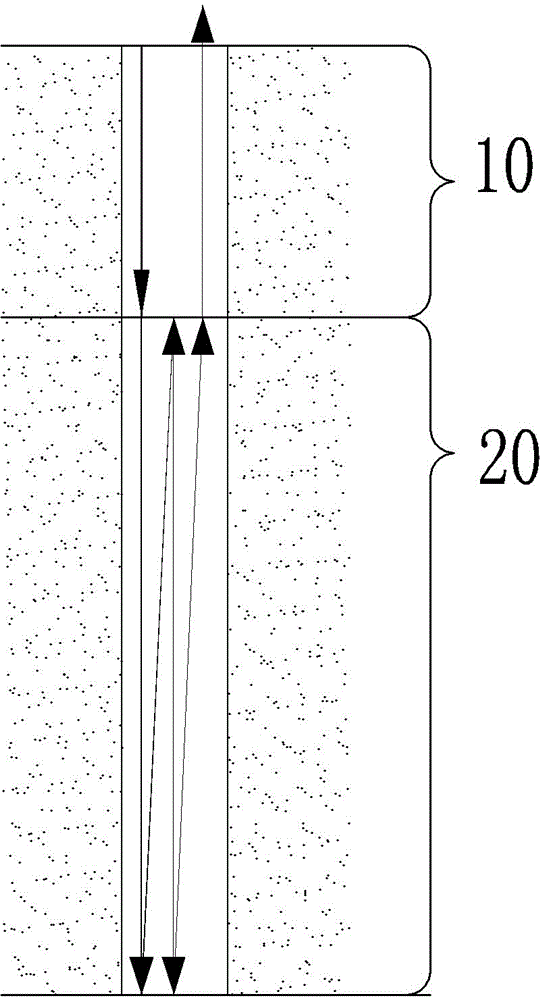

A technology of cement mixing piles and construction equipment, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of insufficient grouting of solid pile sections, poor pile quality of solid pile sections, poor pile quality, etc. To achieve the effect of facilitating soil disturbance, improving bearing capacity and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

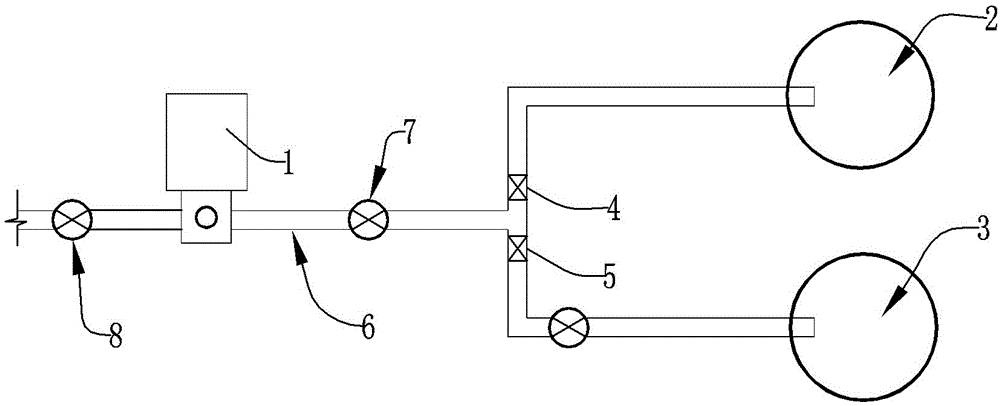

[0018] Such as figure 1 , figure 2 , a cement mixing pile construction equipment, including a slurry pump 1, a cement slurry tank 2 and a clean water tank 3, the cement slurry tank and the clean water tank are respectively connected to the slurry pump inlet pipeline 6 through their own pipelines, and the cement slurry tank and the clean water tank are respectively Valves 4 and 5 for controlling the opening and closing of the pipelines are respectively arranged on the pipelines connected to the inlets of the slurry pumps, and the outlets of the slurry pumps are connected to pile drivers through pipelines.

[0019] By selecting the opening and closing of valve 4 and valve 5, the slurry pump 1 can be controlled to communicate with the cement slurry tank 2 or with the clean water tank 3, so as to deliver different liquids to the pile driver to meet the needs of cement mixing pile construction.

[0020] When the valve 4 is opened and the valve 5 is closed, the inlet pipe 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com