Patents

Literature

86results about How to "Prevent Consolidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

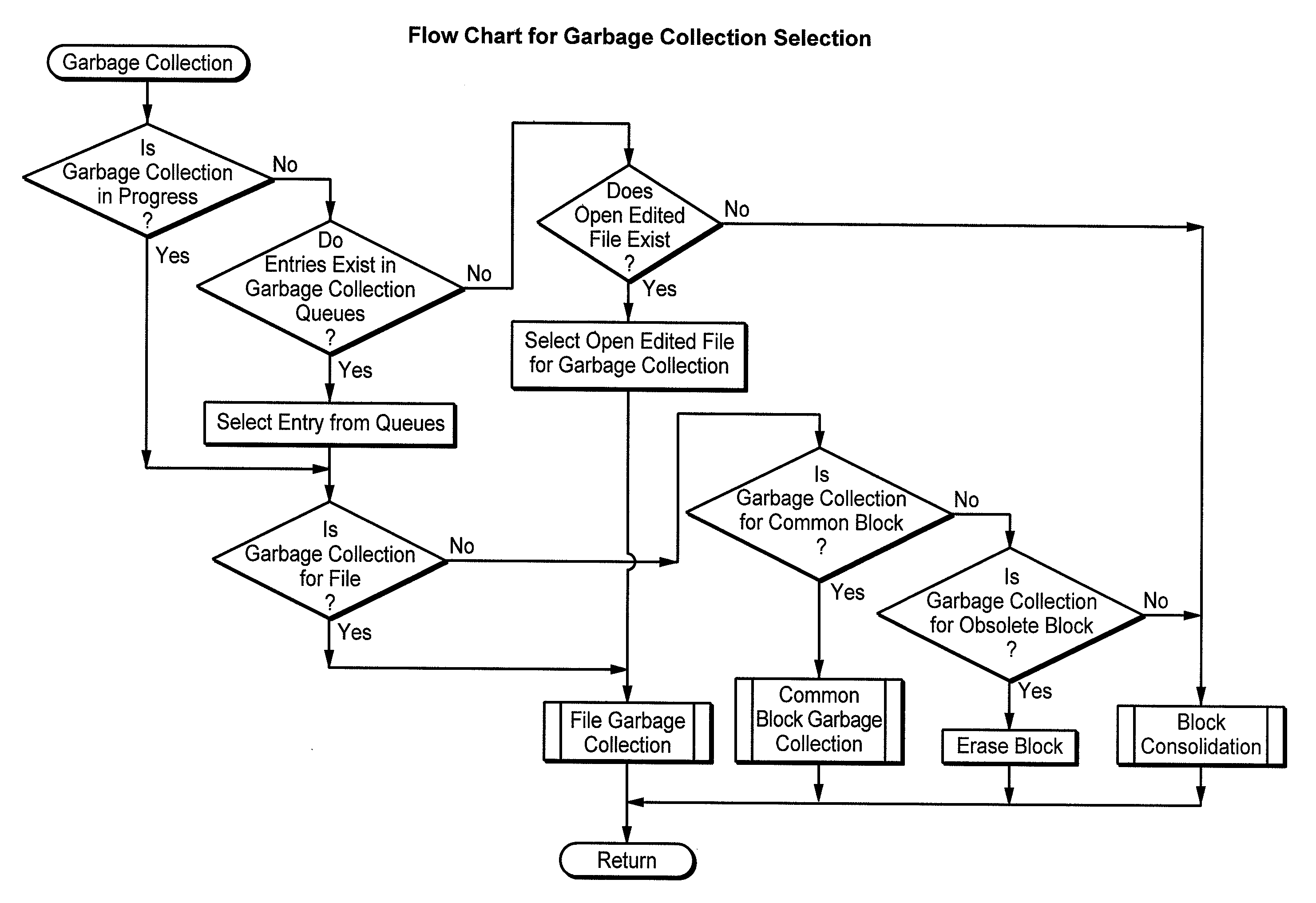

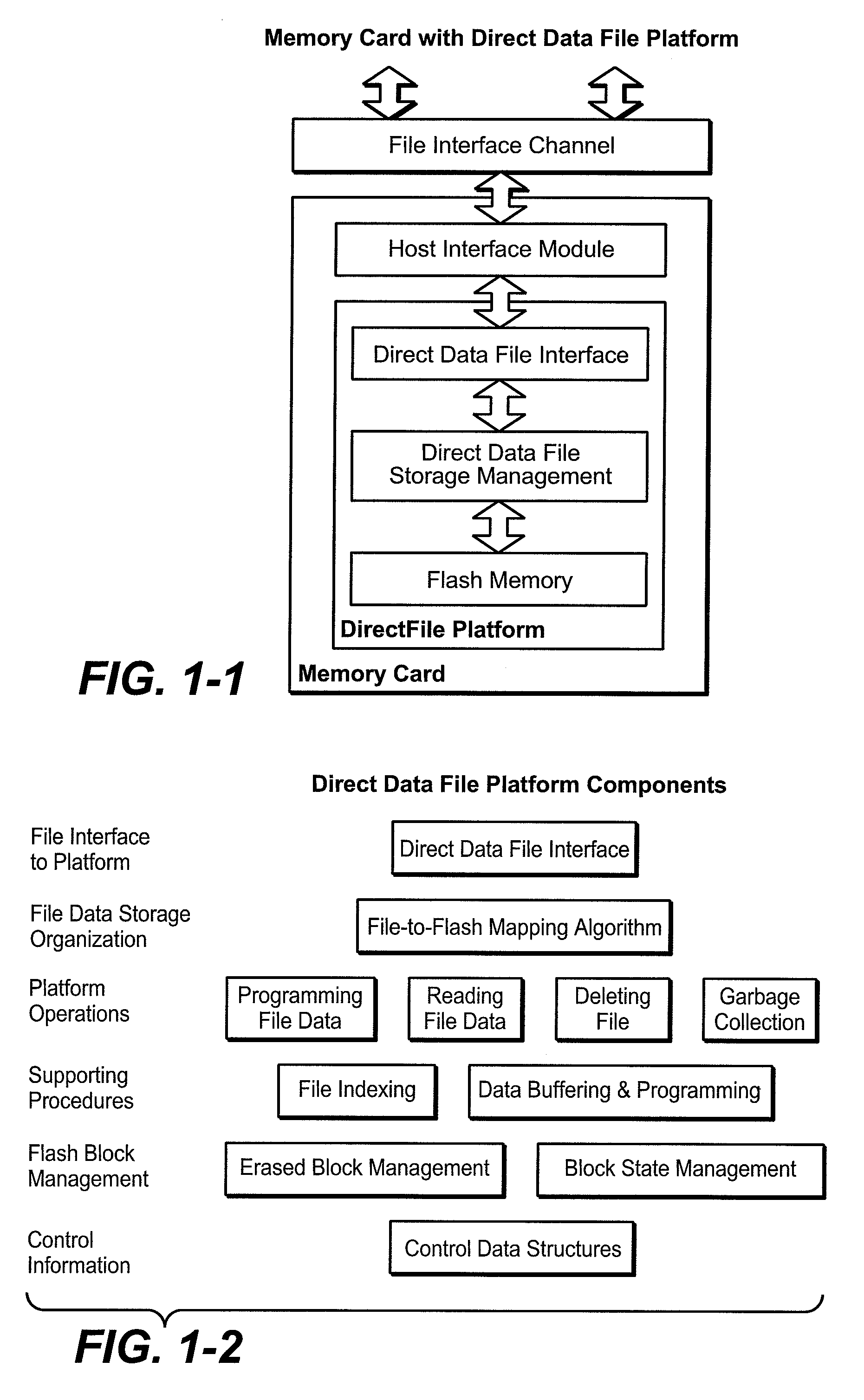

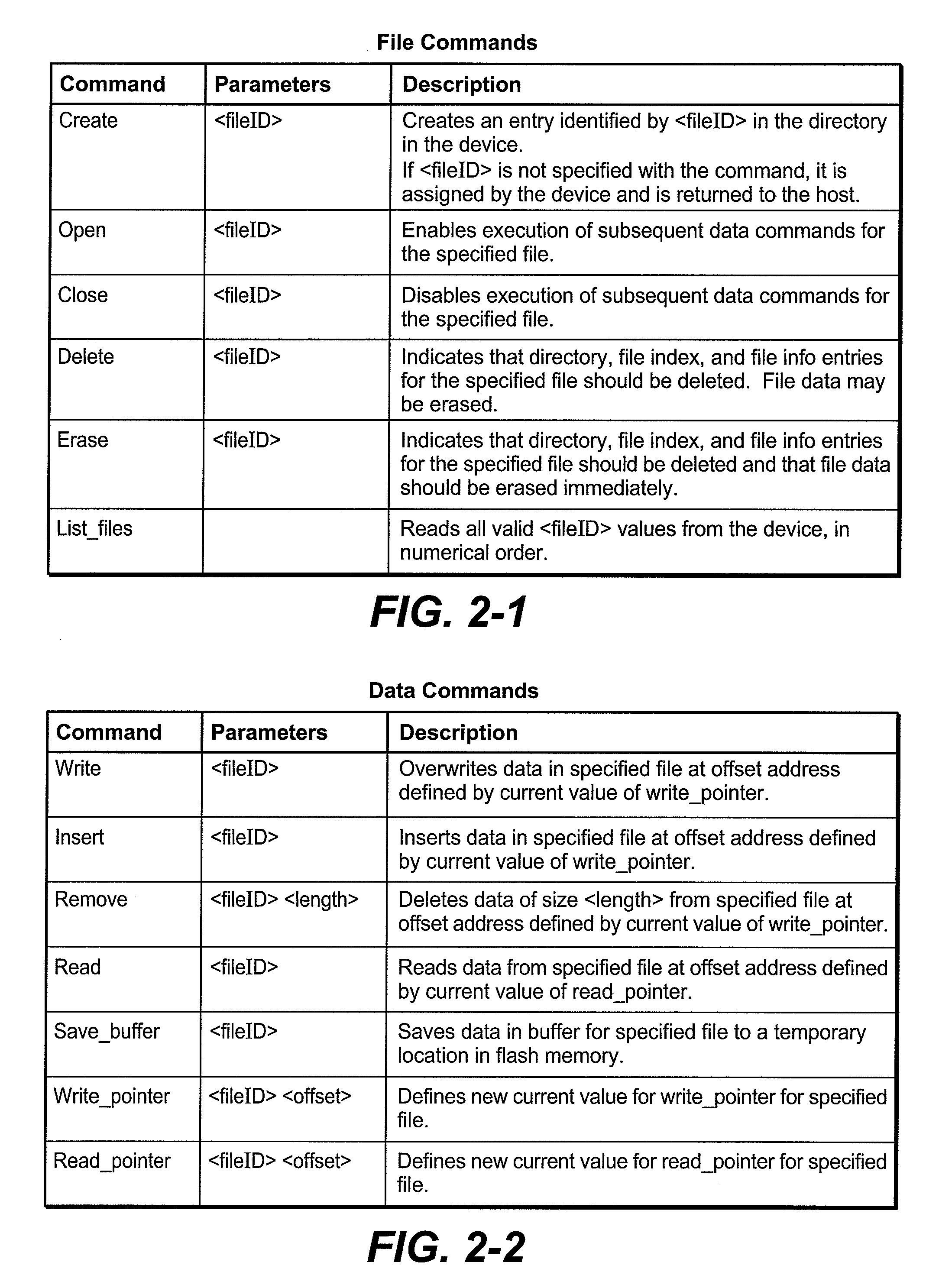

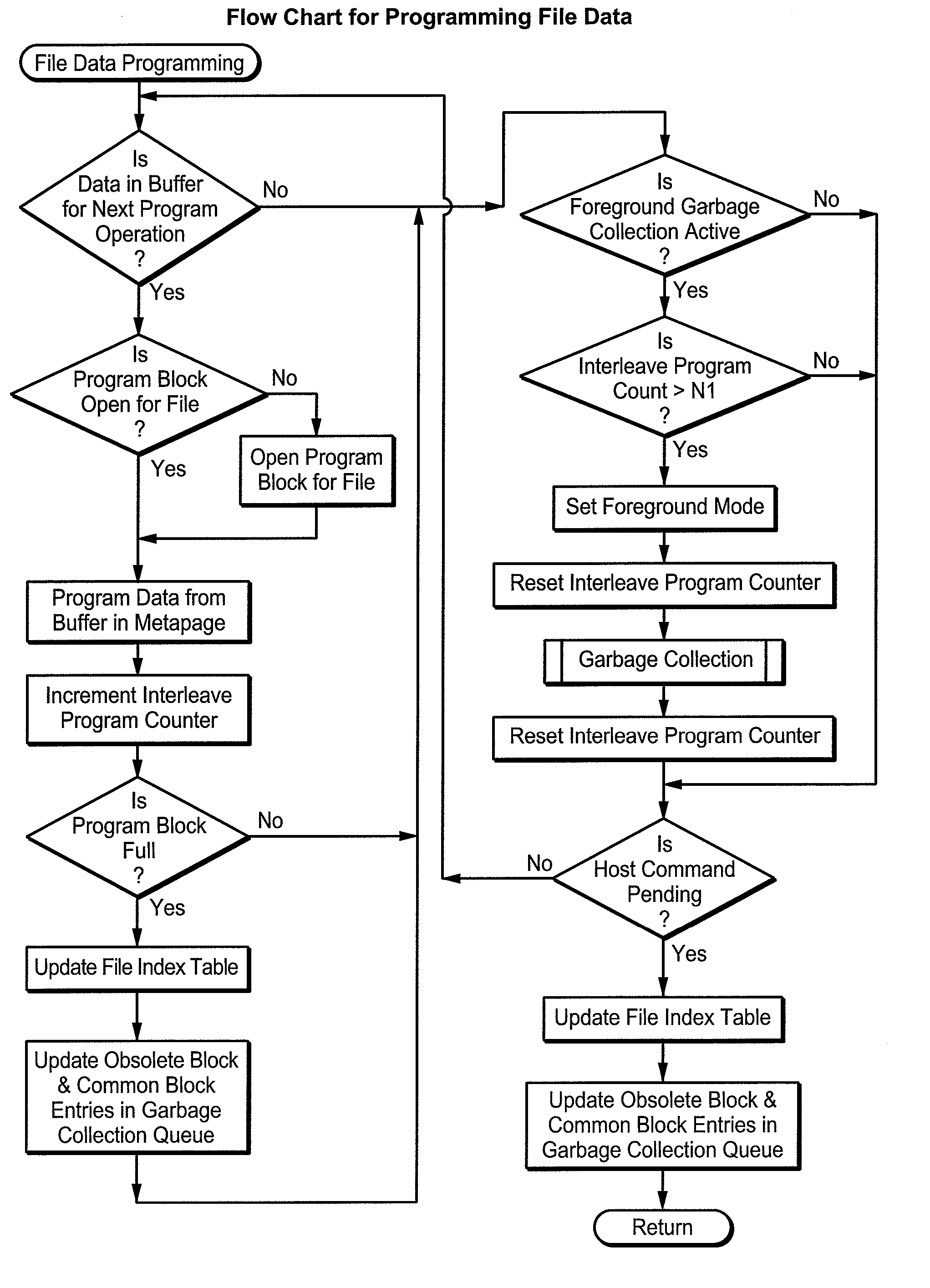

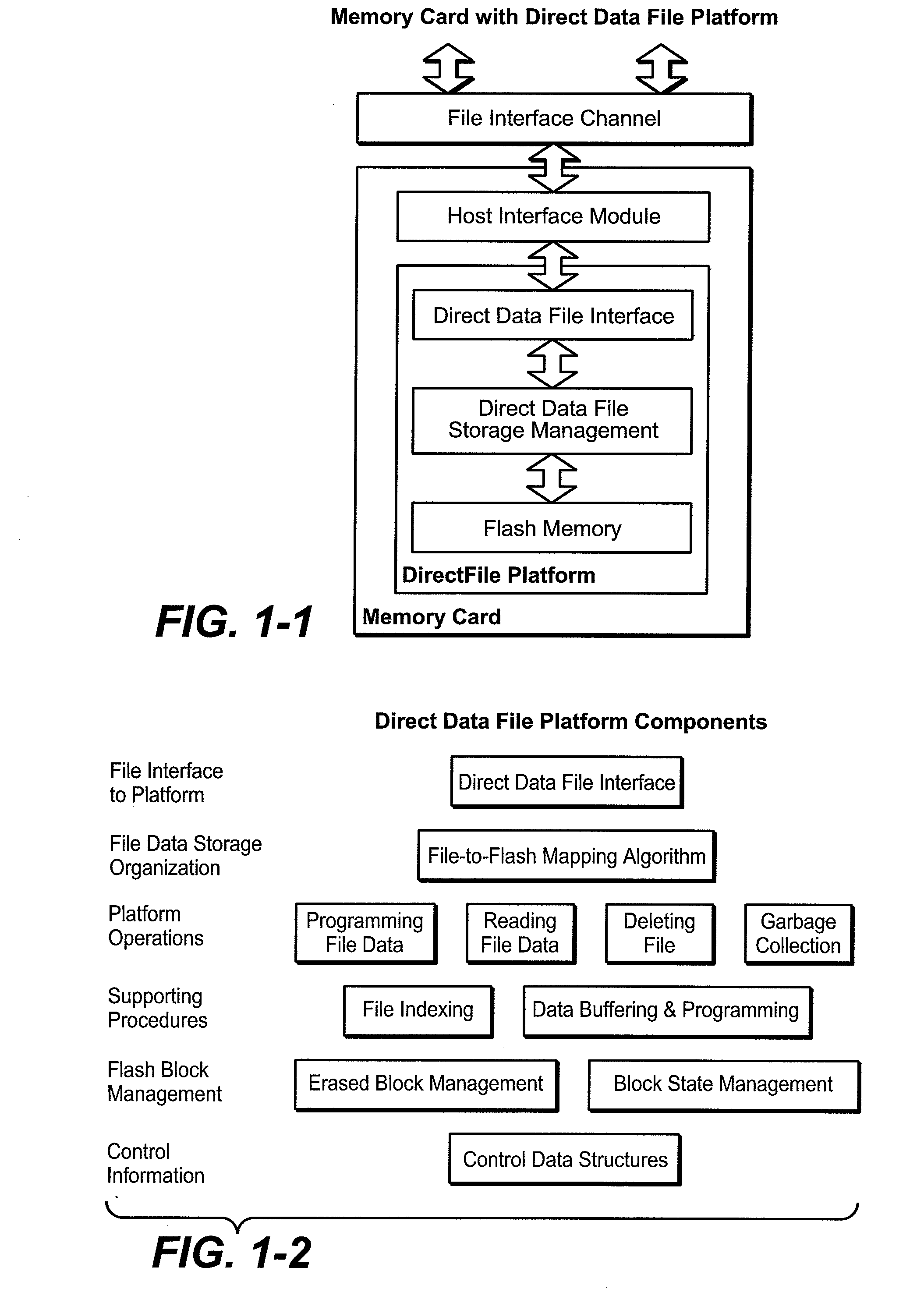

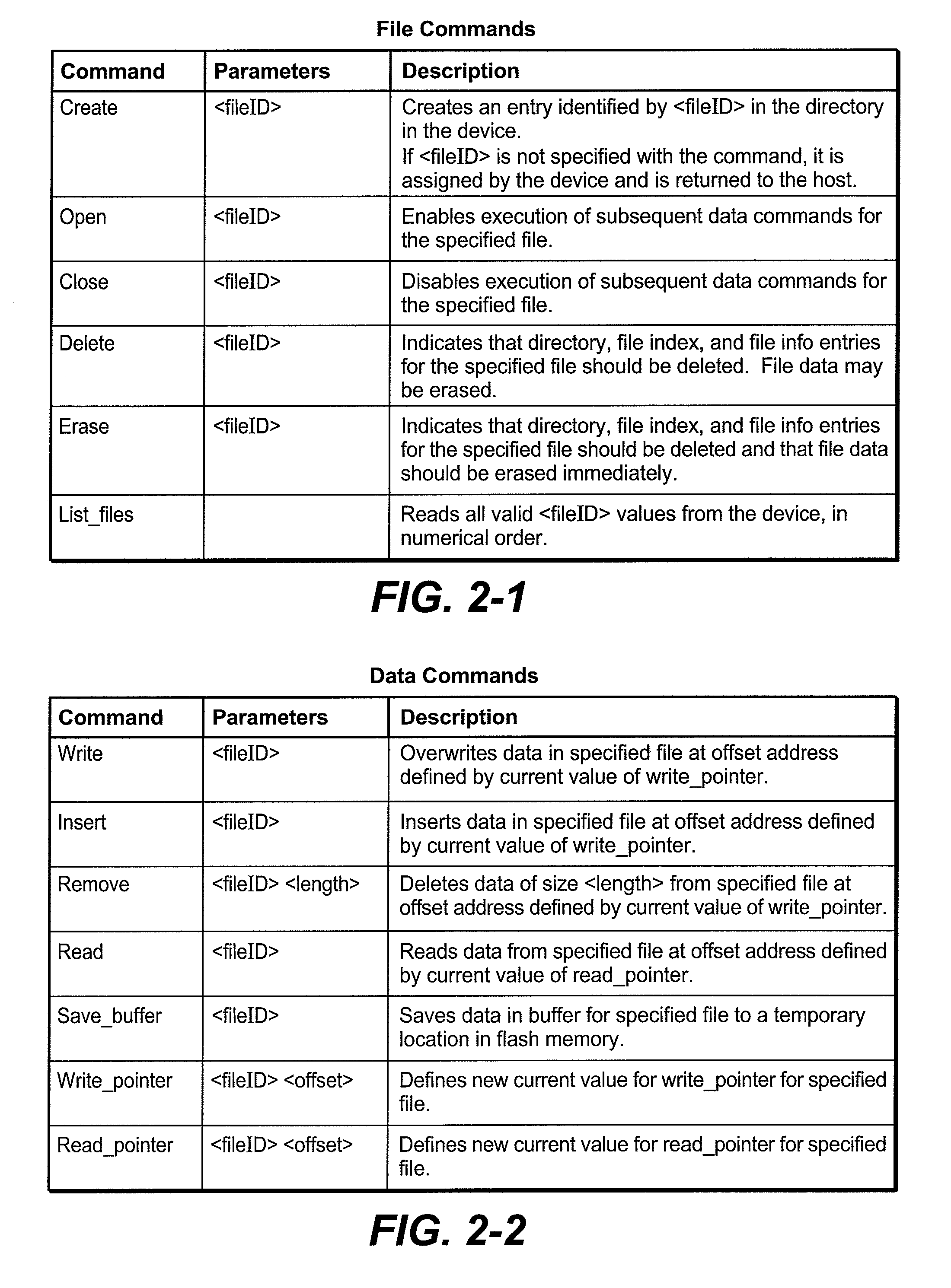

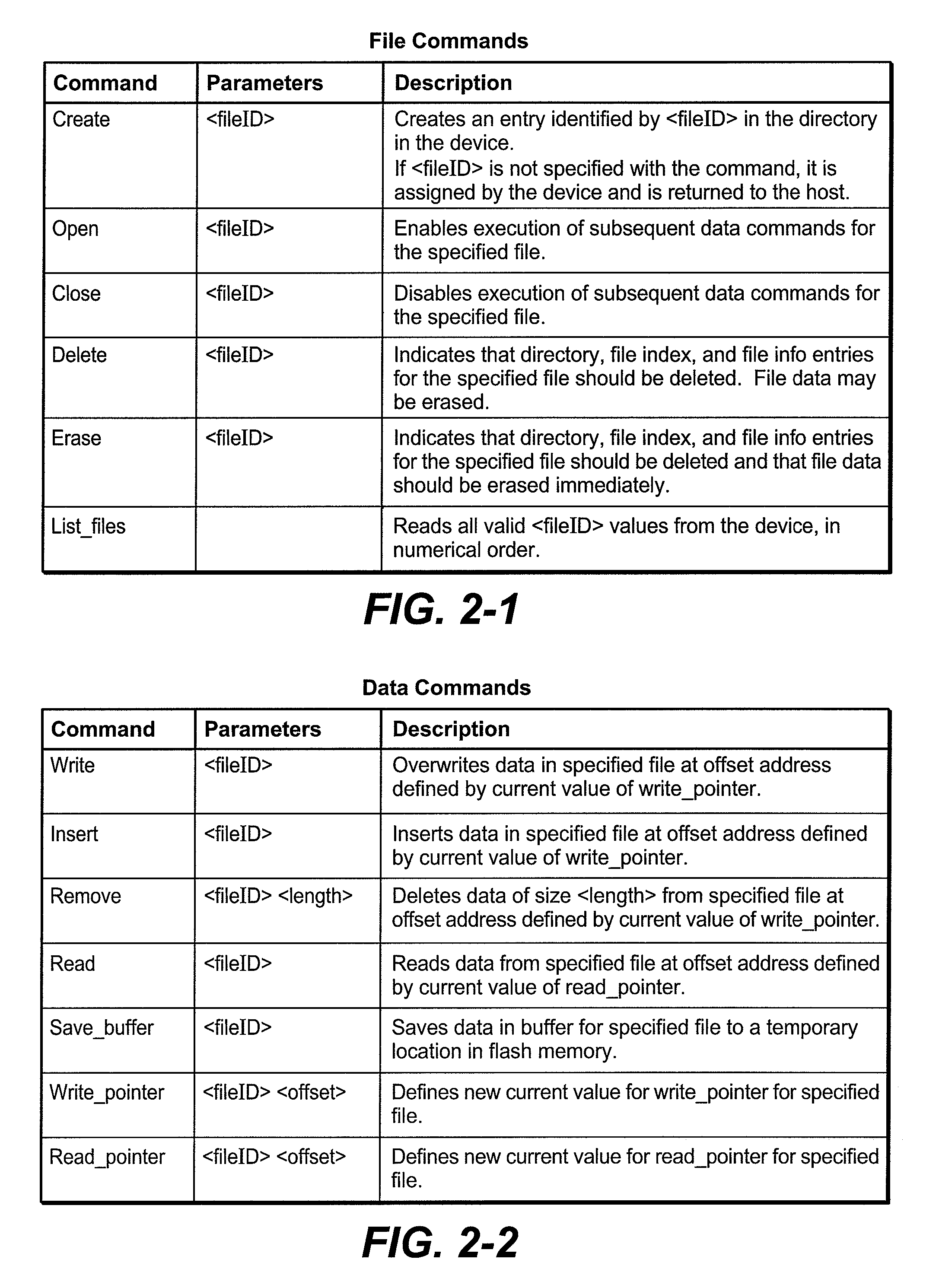

Flash Memory Systems With Direct Data File Storage Utilizing Data Consolidation and Garbage Collection

ActiveUS20070186032A1Prevent ConsolidationImprove memory performanceMemory architecture accessing/allocationDigital data information retrievalData fileTerm memory

Host system data files are written directly to a large erase block flash memory system with a unique identification of each file and offsets of data within the file but without the use of any intermediate logical addresses or a virtual address space for the memory. Directory information of where the files are stored in the memory is maintained within the memory system by its controller, rather than by the host.

Owner:SANDISK TECH LLC

Flash Memory Systems Utilizing Direct Data File Storage

ActiveUS20070033378A1Prevent movementPrevent ConsolidationMemory architecture accessing/allocationDigital data information retrievalData fileTerm memory

Host system data files are written directly to a large erase block flash memory system with a unique identification of each file and offsets of data within the file but without the use of any intermediate logical addresses or a virtual address space for the memory. Directory information of where the files are stored in the memory is maintained within the memory system by its controller, rather than by the host.

Owner:SANDISK TECH LLC

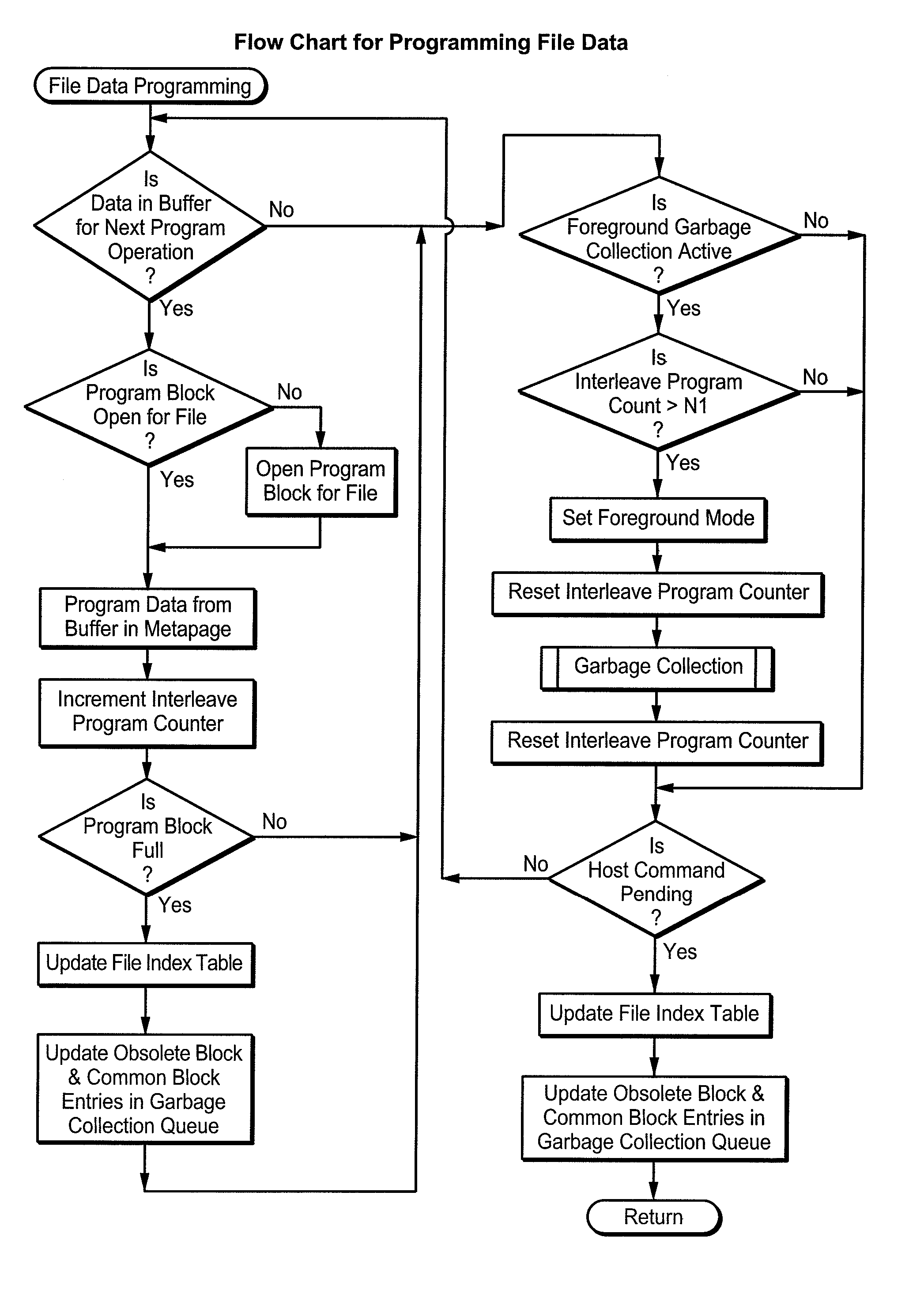

Data Operations in Flash Memories Utilizing Direct Data File Storage

ActiveUS20070033377A1Prevent ConsolidationImprove memory performanceMemory architecture accessing/allocationDigital data information retrievalData operationsData file

Host system data files are written directly to a large erase block flash memory system with a unique identification of each file and offsets of data within the file but without the use of any intermediate logical addresses or a virtual address space for the memory. Directory information of where the files are stored in the memory is maintained within the memory system by its controller, rather than by the host.

Owner:SANDISK TECH LLC

Heavy oil thermal recovery method using foamed gel to inhibit bottom water coning

ActiveCN106150466APrevent intrusionPlay the role of heat insulation protectionFluid removalSealing/packingNitrogenNitrogen gas

The invention discloses heavy oil thermal recovery method using foamed gel to inhibit bottom water coning and belongs to the technical field of oilfield exploitation and oilfield chemistry. The method includes the steps of firstly, injecting nitrogen into a producing well to form a front nitrogen slug when the period comprehensive water content of the producing well is larger than 90%; secondly, injecting a mixed system of nitrogen and a foamed gel solution to form a nitrogen-foamed gel main slug; thirdly, injecting nitrogen into the producing well to form a replacing nitrogen slug; fourthly, injecting steam, wherein the front nitrogen slug can push water of a shaft and a stratum in an area near the well to an oil layer and balance stratum pressure, the nitrogen-foamed gel main slug can effectively inhibit bottom water invasion, and the replacing nitrogen slug can replace a foamed gel blocking agent in a screen pipe and an area in near the shaft to prevent the blocking agent from solidifying near the shaft and blocking a steam injecting pipeline and an oil extraction pipeline. By the method, bottom water coning speed can be reduced, steam wave coefficient and utilization rate can be increased, and oil reservoir exploitation effect can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reinforcement method for combined part of shield tunnel and mining-method tunnel

InactiveCN102400694AHigh strengthImprove the water-stop effectUnderground chambersTunnel liningShotcreteGrating

The invention discloses a reinforcement method for a combined part of a shield tunnel and a mining-method tunnel. The reinforcement method is used for using a shield machine to propel and enter the mining-method tunnel and comprises the following steps of: 1) primarily spraying concrete on a working face of the mining-method tunnel so as to prevent local collapse of the tunnel; 2) horizontally placing gratings at the positions of end walls of the mining-method tunnel and spraying the concrete after being fixed; 3) adopting a plurality of grouting pipes for injecting slurry at the end walls of the mining-method tunnel so as to carry out reinforcement; and 4) adopting plain concrete to block the full cross sections at the two end walls of the mining-method tunnel and the shield tunnel.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

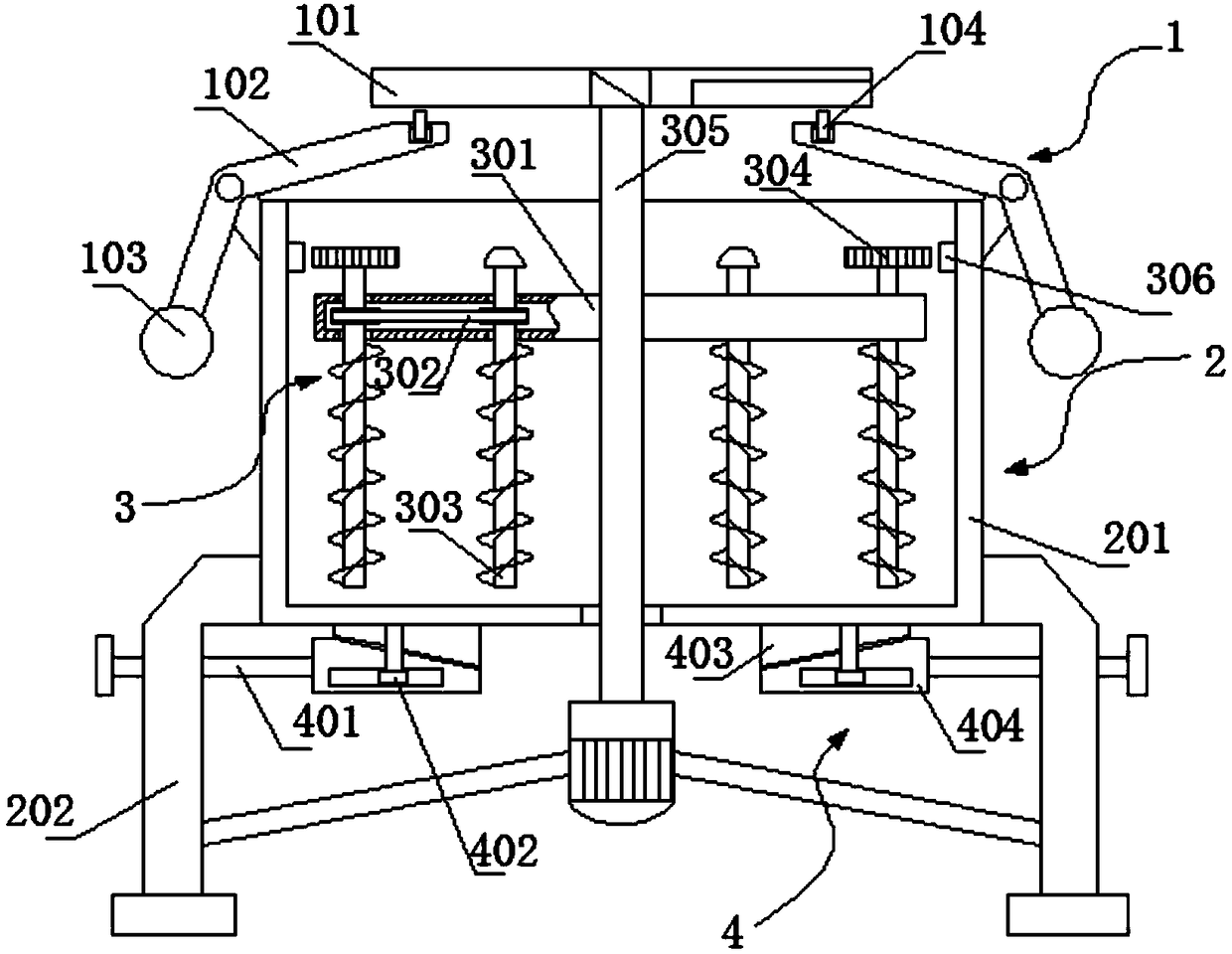

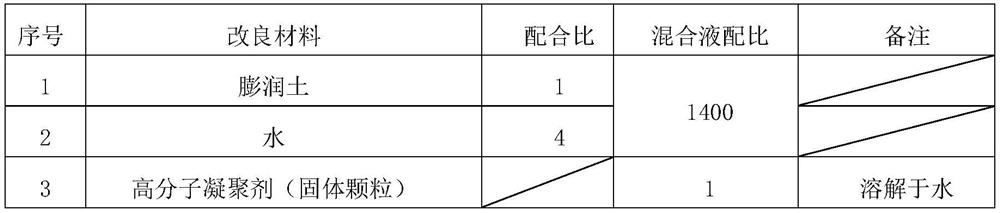

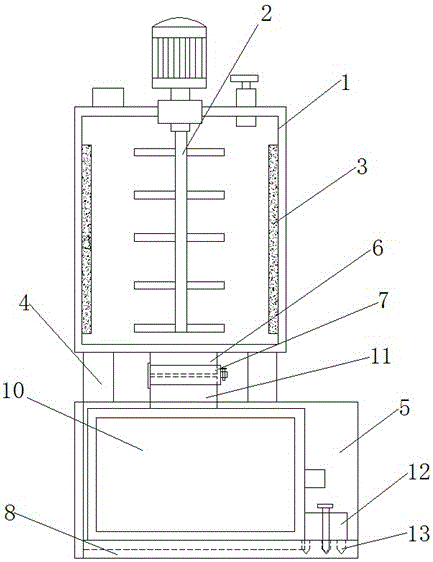

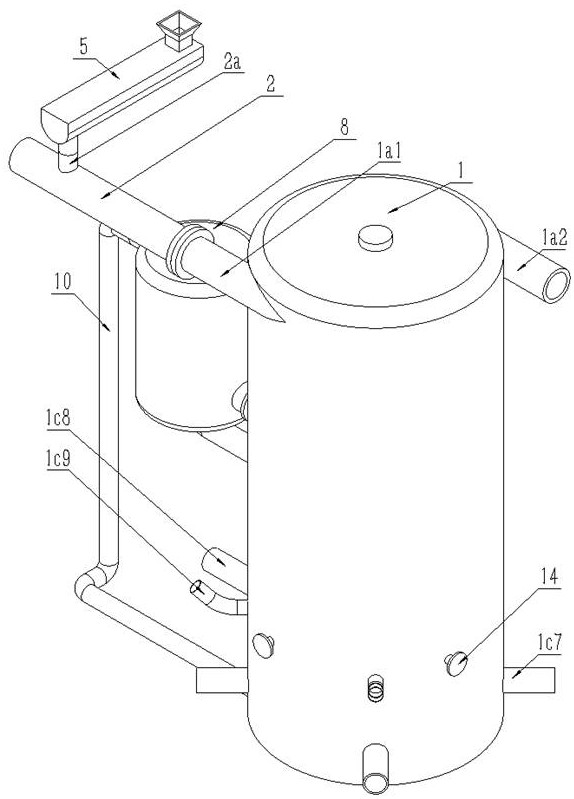

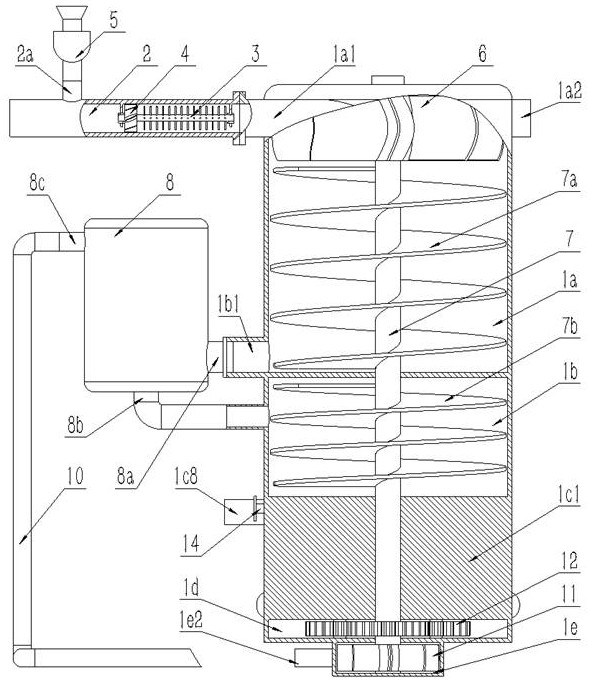

Wall-adhesion-preventing building material-mixing equipment

InactiveCN108890888AImprove mixing uniformityEasy to unloadTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention discloses wall-adhesion-preventing building material-mixing equipment. The wall-adhesion-preventing building material-mixing equipment comprises a material-mixing container, wherein a stirring portion is arranged in the material-mixing container; and a discharging valve is arranged on the bottom of the material-mixing container. Spiral stirring shafts carry out revolution and rotation around a spindle, because the screwing directions of blades of the two spiral stirring shafts are opposite, one spiral stirring shaft drives material to ascend while the other spiral stirring shaftdrives the material to descend, and thus, the stirring uniformity is improved; a cross-shaped pressure lever rotates, a curved bar is extruded intermittently by an inclined plane on the cross-shaped pressure lever, the curved bar is driven to swing in a reciprocating manner, and a ball hammer on the curved bar continuously beats the wall of a stirring barrel to prevent powder from being solidifiedon the inner wall of the stirring barrel; and discharging is facilitated, a screw rotates to drive a wedge-shaped cover to move horizontally, at the moment, a wedge-shaped discharging tube and a wedge-shaped cover are staggered from each other, materials flow out from a gap, the screw rotates reversely, the wedge-shaped discharging tube and the wedge-shaped cover are closed to seal the gap, opening and closing are facilitated, pressuring force is large, and the sealing property is good.

Owner:王凯丽

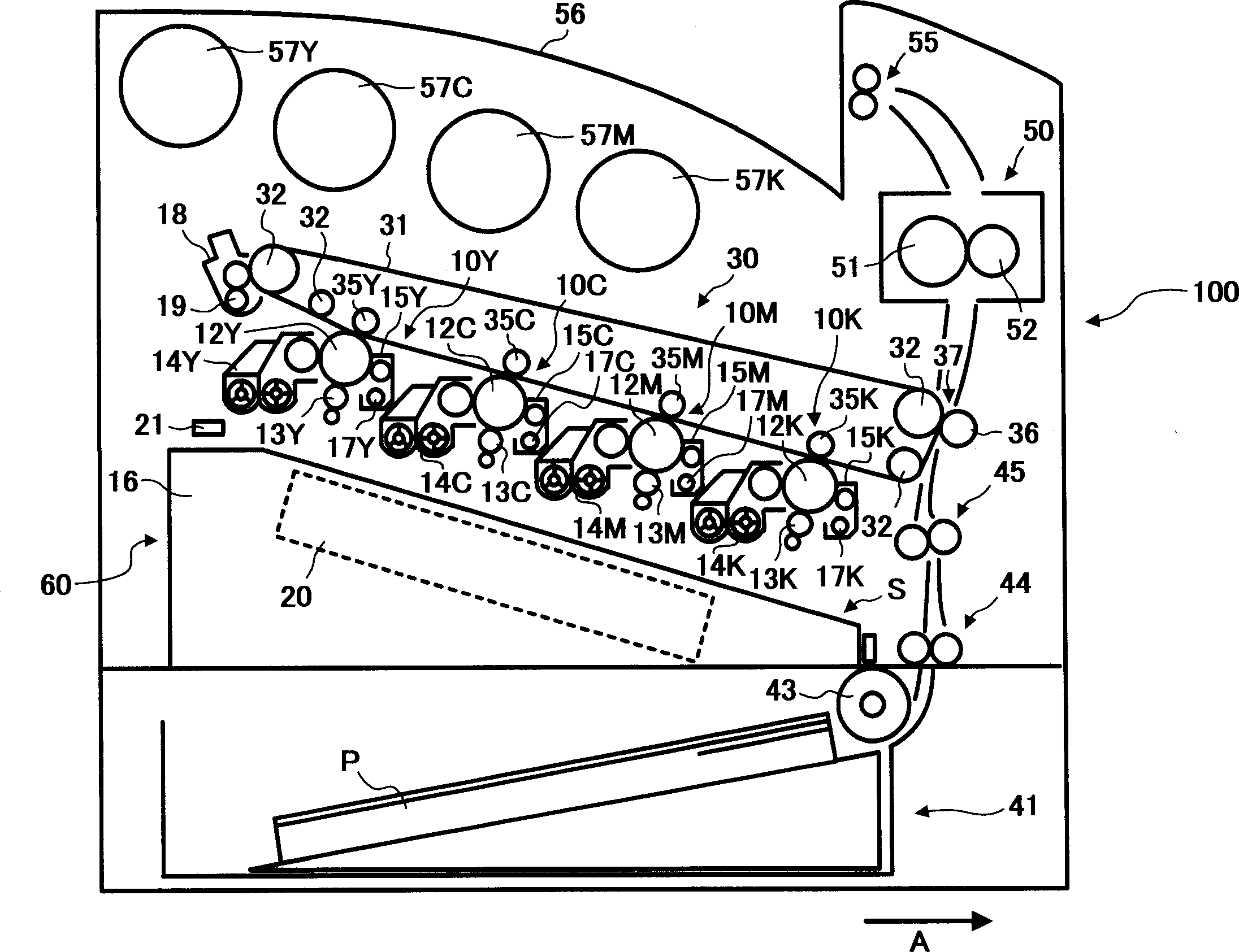

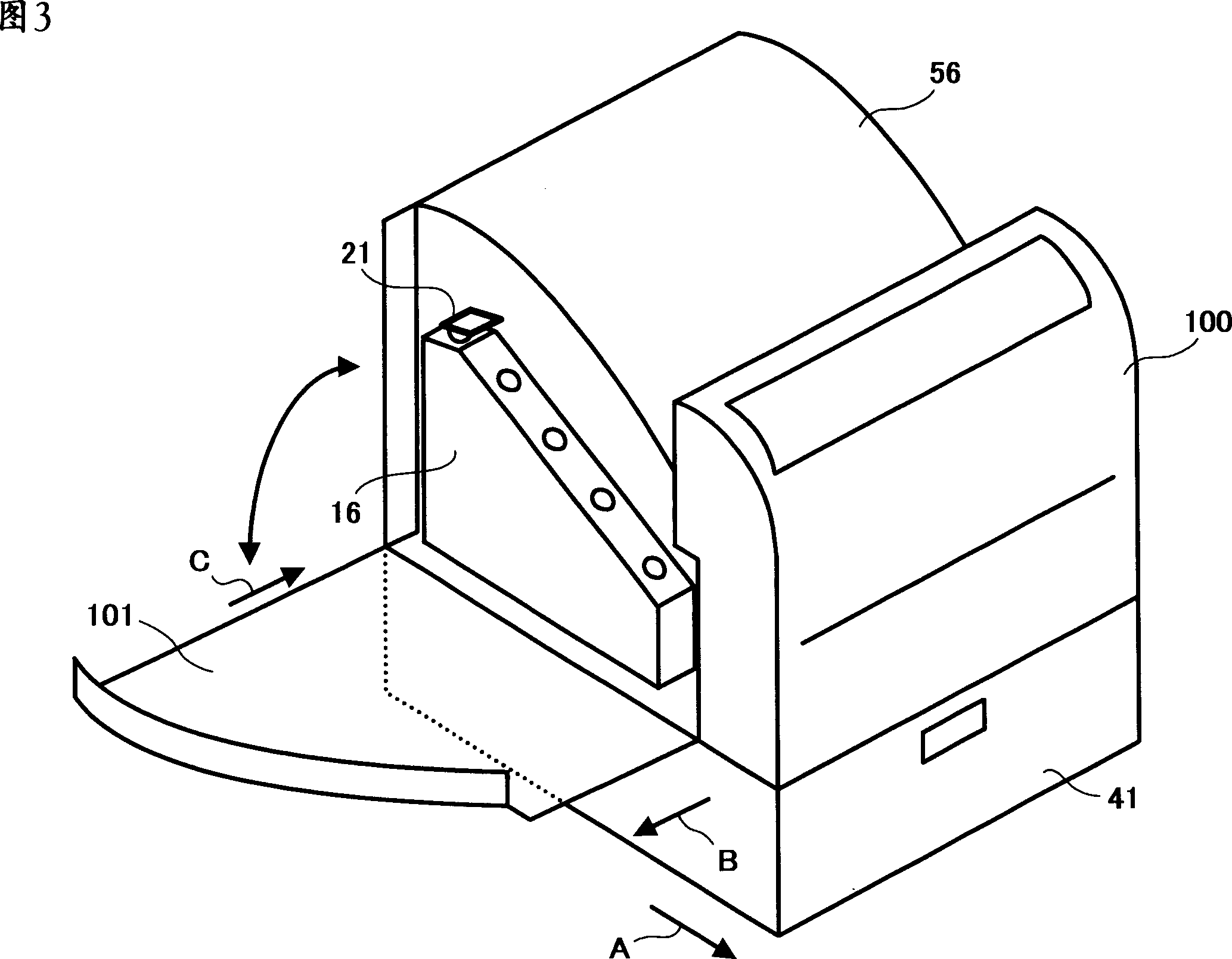

Waste toner recovering apparatus and image forming apparatus

InactiveCN1493932AEfficient fillingExtended replacement cycleElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

Stabilized milnacipran formulation

ActiveUS20090049935A1Prevent adhesionPrevent coagulationBiocideOrganic active ingredientsMilnacipranChemistry

It is intended to provide a milnacipran formulation which is more stable than a conventionally known milnacipran formulation, and a method of stabilizing a milnacipran formulation. The object could be achieved by using a milnacipran-containing composition in which milnacipran or a salt thereof is allowed to exist in a porous carrier, packing a powder containing milnacipran or a salt thereof in an HPMC capsule, or combining an additive which does not cause an interaction with milnacipran with time.

Owner:PIERRE FABRE MEDICAMENT SAS

Road repairing and breaking device

InactiveCN109629386AWeight increaseImprove repair qualityRoads maintainenceCrushed stoneRoad surface

The invention belongs to the field of road equipment, and particularly discloses a road repairing and breaking device. The road repairing and breaking device comprises a cart body, a breaking mechanism, a dust collection pump and a pouring mechanism, wherein the breaking mechanism, the dust collection pump and the pouring mechanism are located in the cart body; a lever is arranged in the cart body, the dust collection pump and the pouring mechanism are fixedly connected to the two ends of the level respectively, an elastic piece is fixedly connected to the bottom of the level on one side of the dust collection pump, the dust collection pump is communicated with a sucker for absorbing road gravel particles, the sucker penetrates through the bottom of the cart body, and a sucker opening faces the lower portion of the cart body; the pouring mechanism comprises a discharging hopper containing padding, the side wall, towards one side of the dust collection pump, of the discharging hopper iscommunicated with a discharging pipe, and the discharging pipe penetrates through the bottom of the cart body to face the lower portion of the cart body. After the technical scheme is adopted, the road repairing and breaking device can automatically pour padding into road surface cracks in the road repairing process.

Owner:CHONGQING VOCATIONAL INST OF ENG

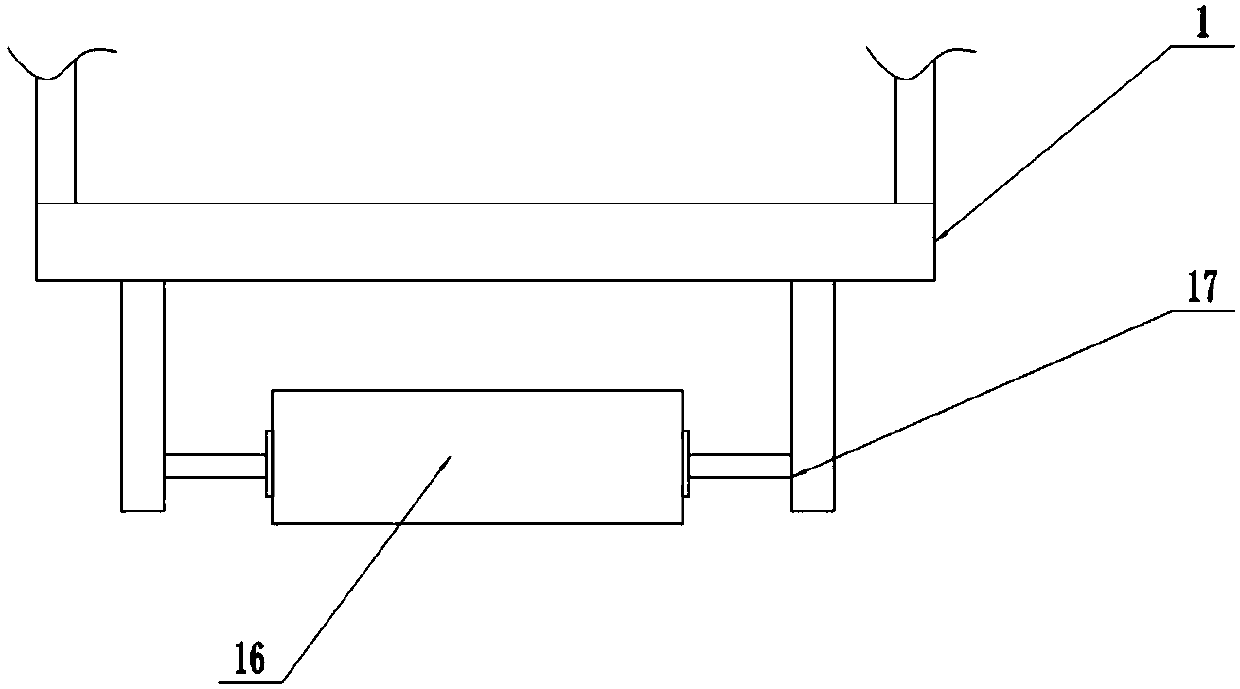

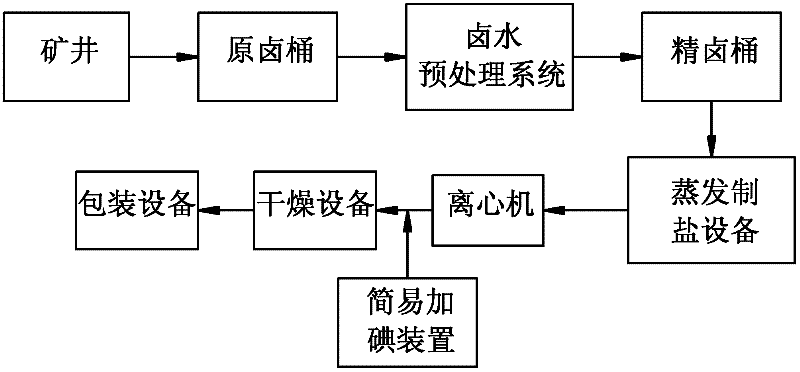

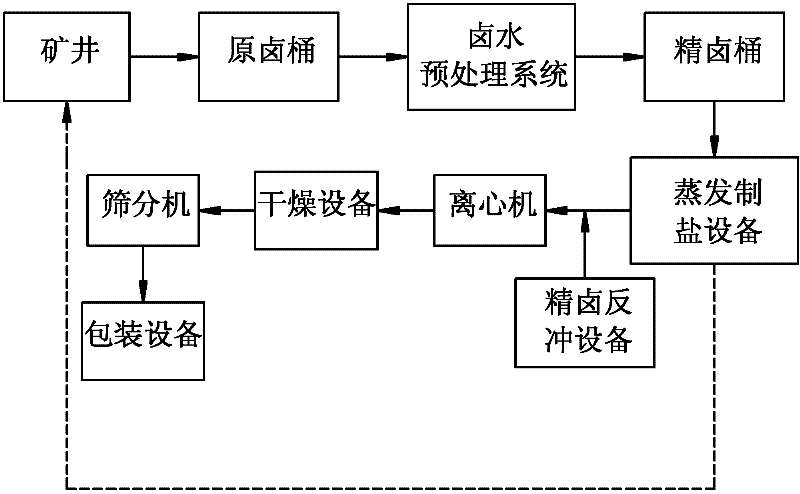

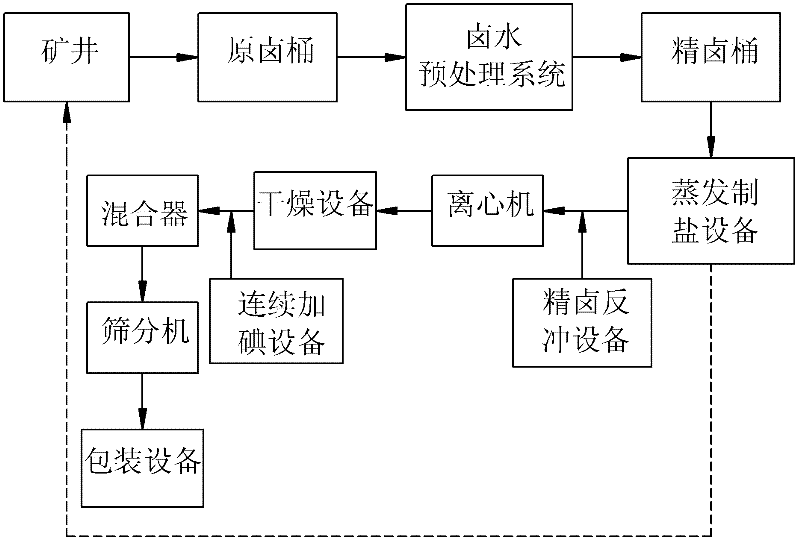

Preparation process and special device for salt with green food label

InactiveCN102502711AQuality improvementEvenly distributedAlkali metal chloridesAnticaking agentIodide

The invention relates to a preparation process and a special device for salt with green food label. The device comprises mine brine mining equipment, an original brine barrel, a brine pretreatment system, a refined brine barrel and evaporation salt-making equipment, which are sequentially arranged. A salt slurry outlet of the evaporation salt-making equipment is sequentially provided with a centrifugal machine and a drying device, while a condensed water outlet of the evaporation salt-making equipment is communicated with the mine brine mining equipment; a refined brine countercurrent device for refined brine countercurrent backwashing salt slurry is arranged between the evaporation salt-making equipment and the centrifugal machine; and an outlet of the drying device is provided with a sieving machine, and a sieving machine outlet is provided with packaging equipment. The salt is prevented from caking by physical molecular structure of sodium chloride through improving production process and production equipment, optimizing process indexes and obviating potassium ferrocyanide and other anticaking agent. Qualification rate of iodized salt manufactured with the invention is 100%, the utilization rate of potassium iodate is 95%, the iodide content of finished product salt is steady and reliable; and the fluctuation range is within 5 mg / L.

Owner:CHINASALT JINTAN

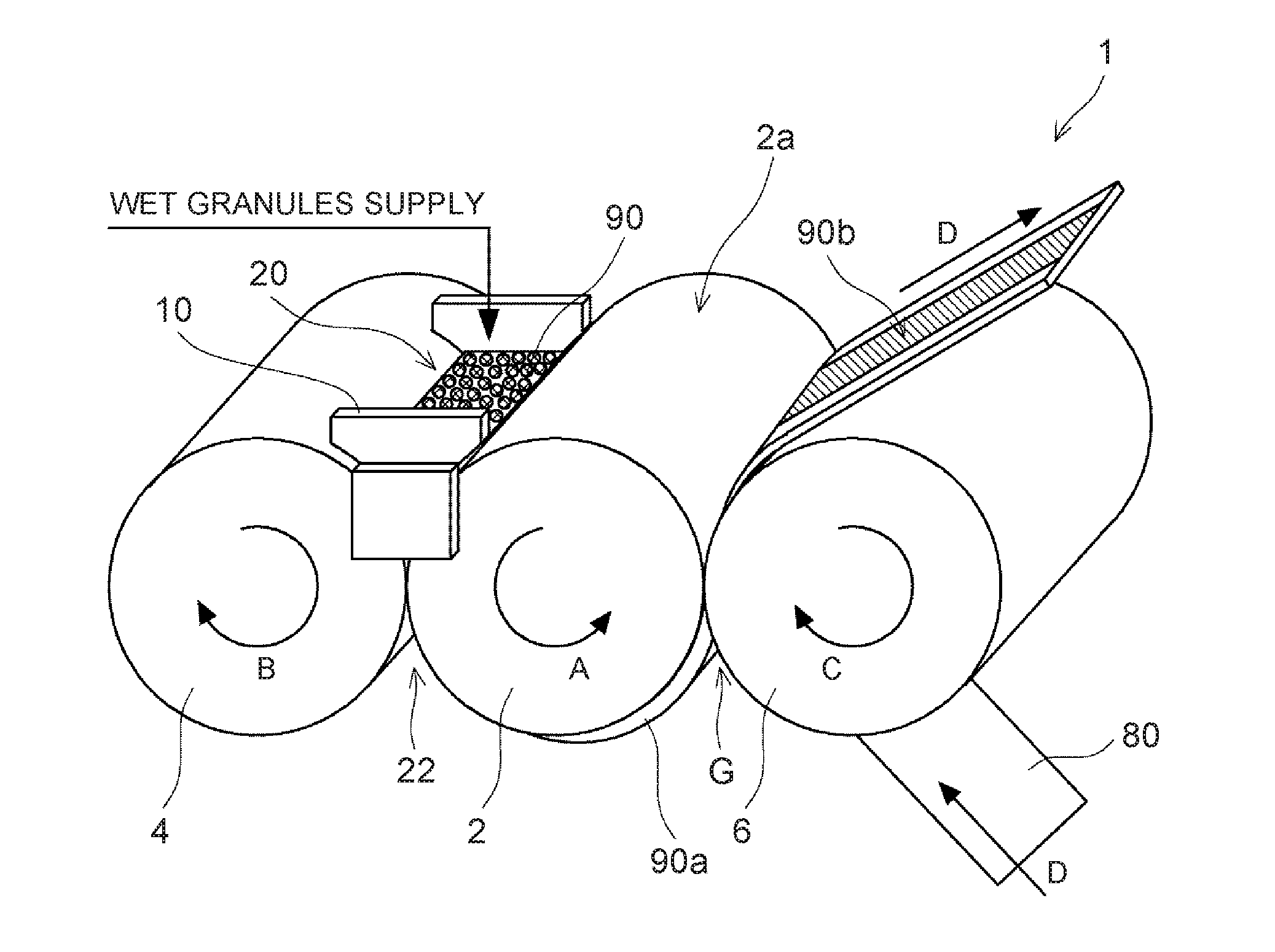

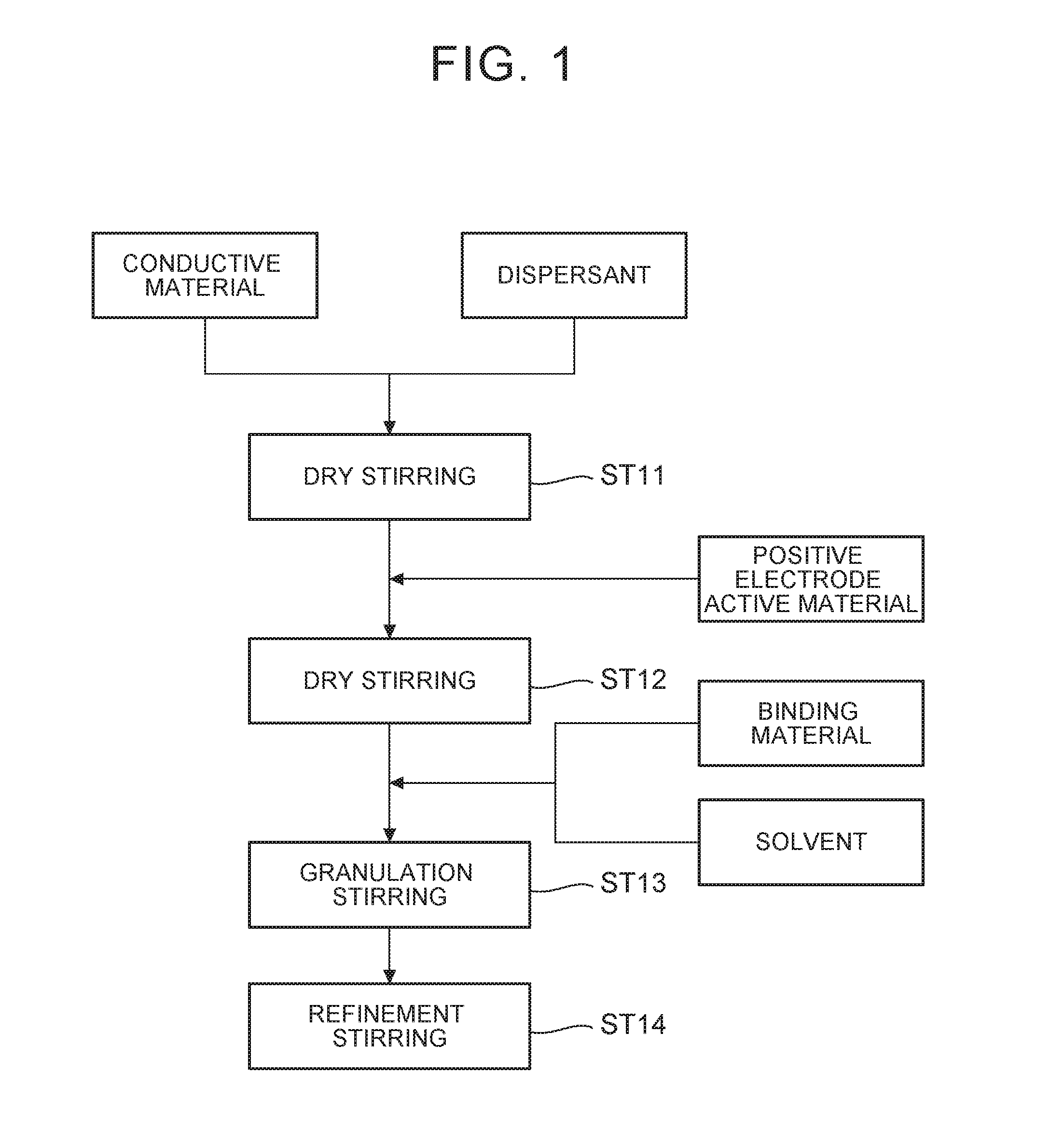

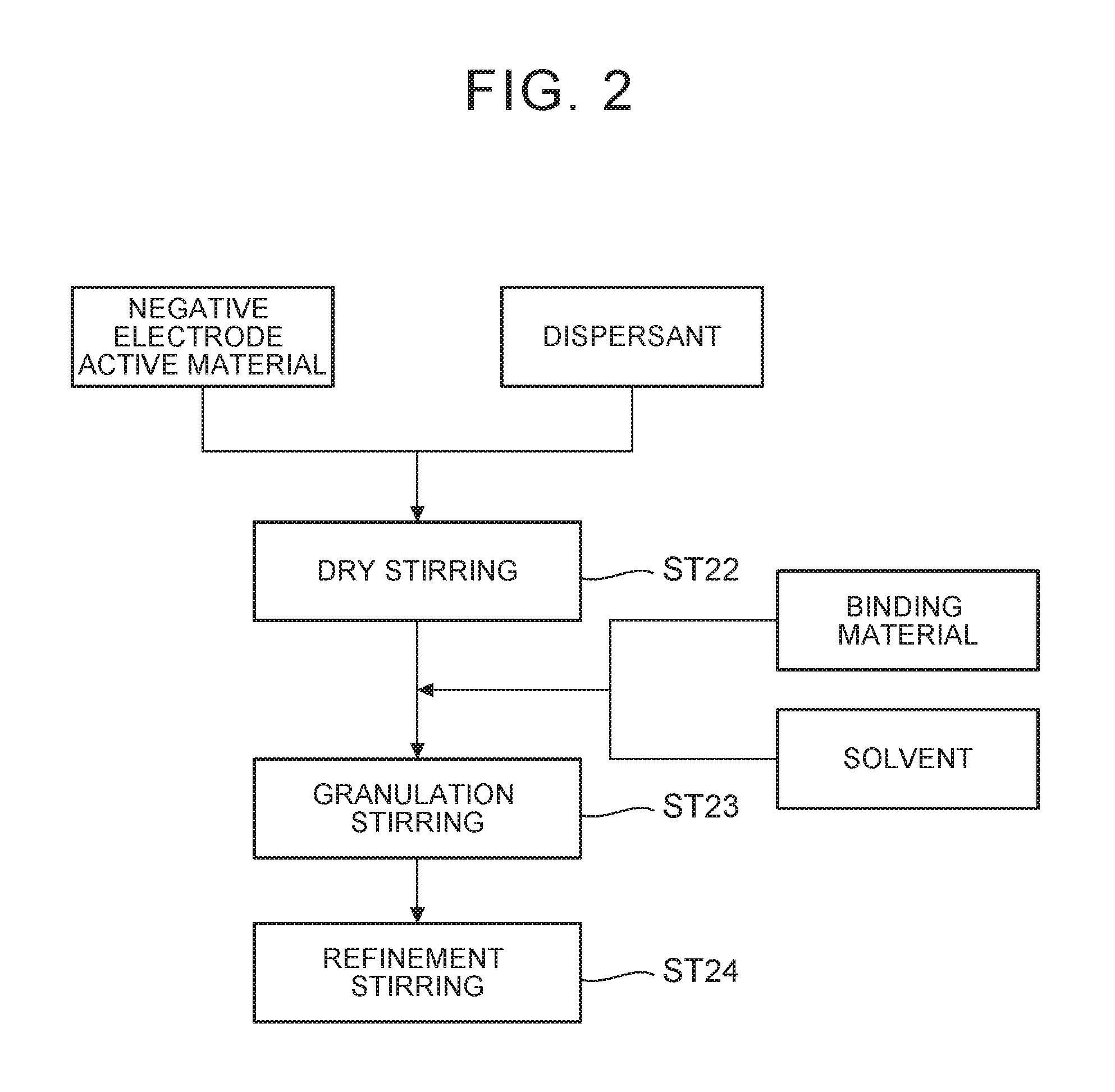

Manufacturing method of electrode and wet granules

ActiveUS20160204434A1Reduce materialConsolidation of wet can be preventedElectrode rolling/calenderingSecondary cellsPolymer scienceSolvent

A manufacturing method of an electrode according to the invention includes: a process of forming wet granules by stirring a mixture of an electrode active material, a binding material, and a solvent; and a process of forming an electrode material layer on a current collector by rolling the wet granules. The process of forming the wet granules includes: a process of granulating the electrode active material by stirring the mixture at a first stirring speed; and a process of stirring the granulated electrode active material at a second stirring speed that is faster than the first stirring speed so as to be refined to an average particle size of 400 μm or smaller. A stirring time at the second stirring speed is shorter than a stirring time at the first stirring speed and is shorter than 5 seconds.

Owner:TOYOTA JIDOSHA KK

Method for using gel foaming agent for suppressing bottom water coning of heavy oil thermal recovery

InactiveCN109025953APrevent intrusionPlay the role of heat insulation protectionFluid removalSealing/packingOil productionNitrogen gas

The invention discloses a method for using a gel foaming agent for suppressing the bottom water coning of heavy oil thermal recovery, and belongs to the field of oilfield exploitation and oilfield chemical technology. The method comprises the following steps: 1) when the periodic comprehensive water content of a production well is greater than 90%, injecting nitrogen into the production well to form a front nitrogen slug; 2) continuing injecting a mixed system of nitrogen and a gel foaming agent solution into the production well to form a nitrogen-gel foam main slug; 3) injecting nitrogen intothe production well to form a replacing nitrogen plug; and 4) injecting steam. The front nitrogen slug can push the water in a wellbore and in the immediate vicinity of the wellbore to an oil layer to balance formation pressure, the nitrogen-gel foam main slug can suppress the bottom water intrusion, and the replacing nitrogen slug can push a gel foam plugging agent out of a screen tube and a near-wellbore zone so as to prevent the plugging agent from consolidating in the vicinity of the wellbore and blocking the steam injection and oil production passages. The method can delay the bottom water coning speed, improves a steam wave sweep coefficient and a utilization rate, and improves the development effect of a reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

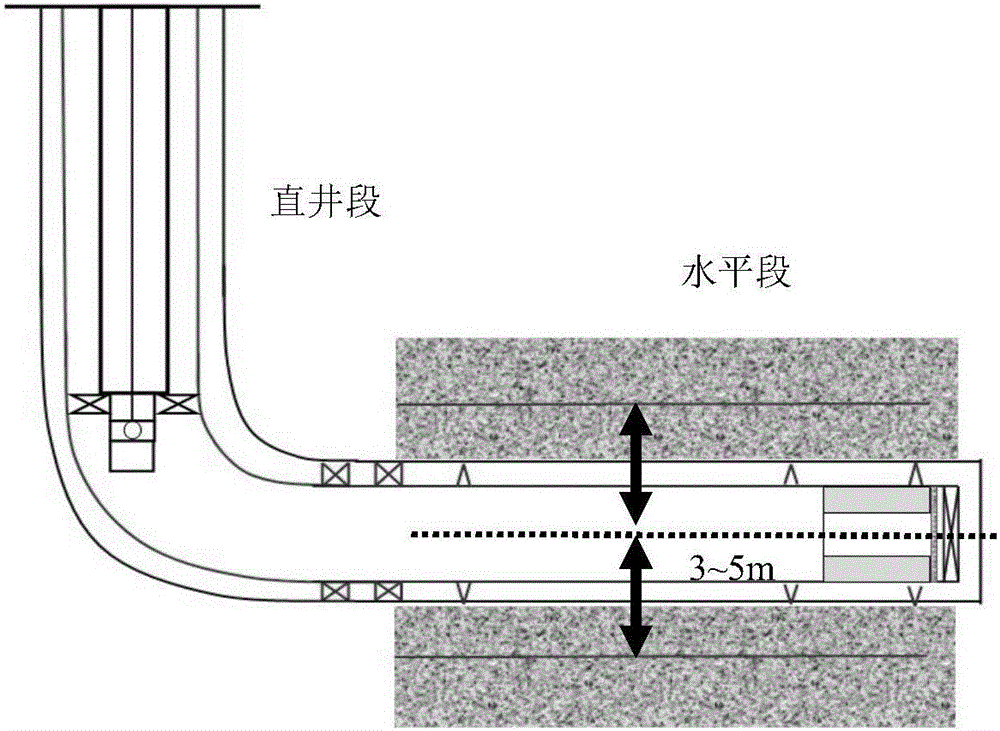

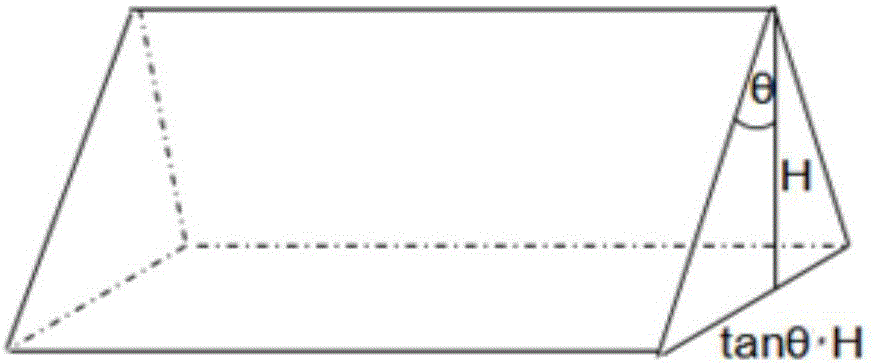

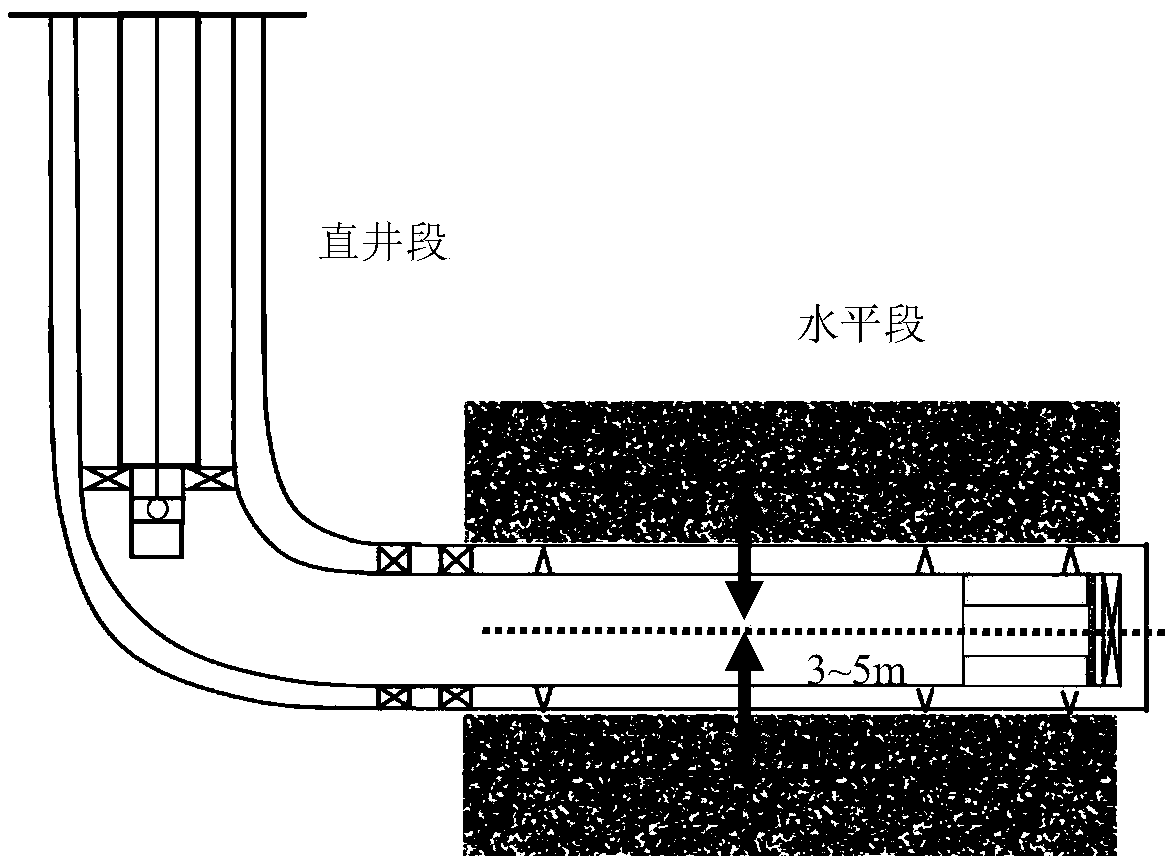

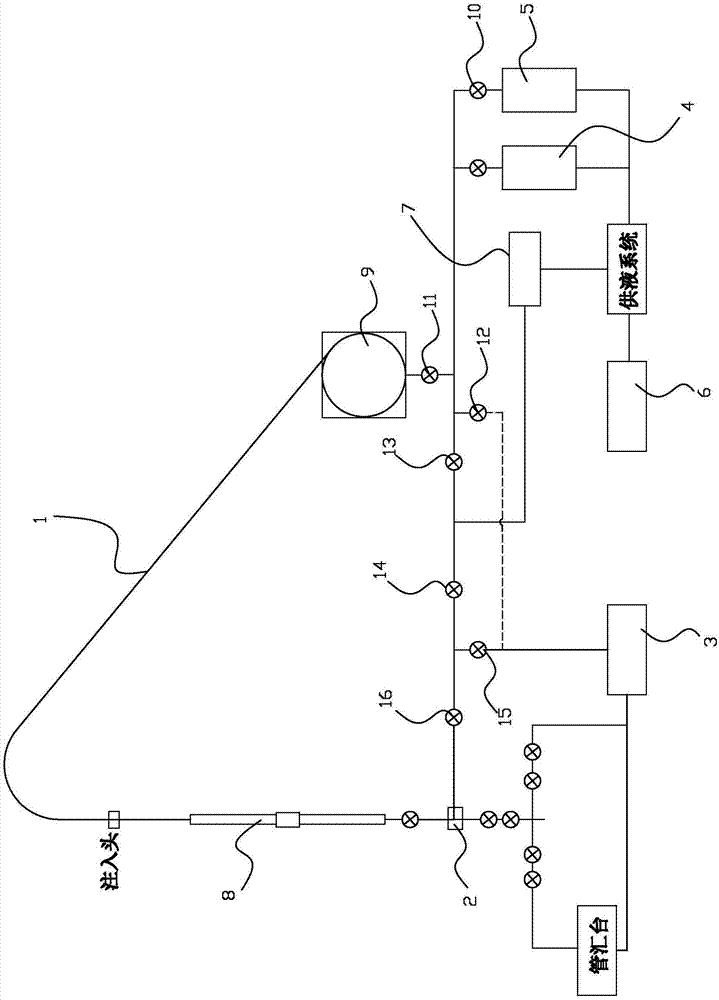

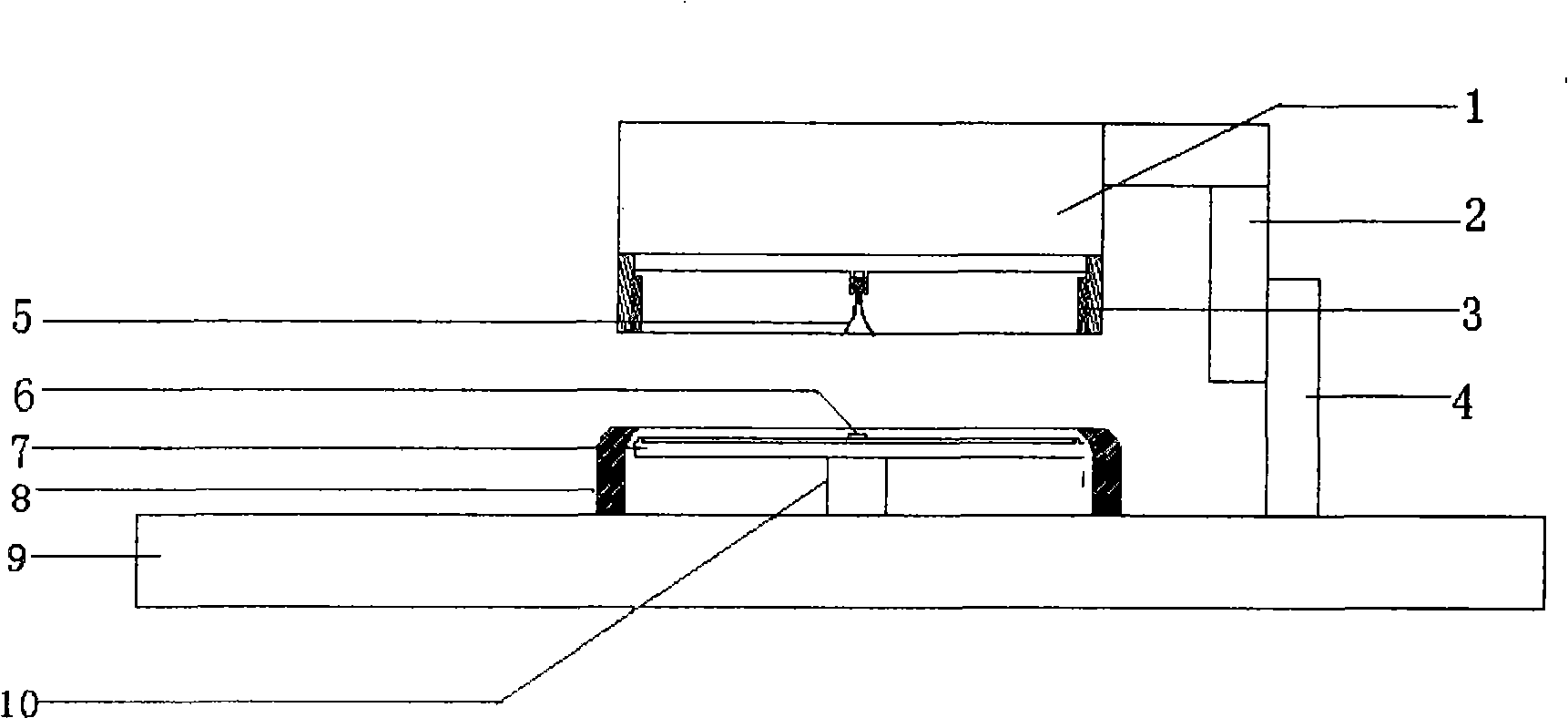

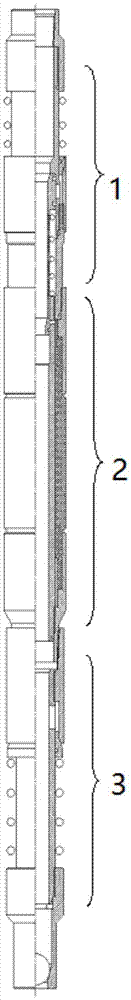

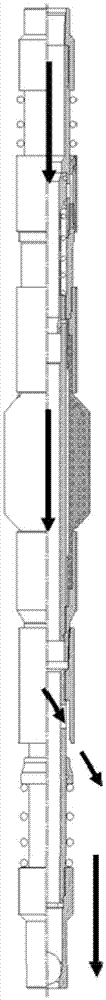

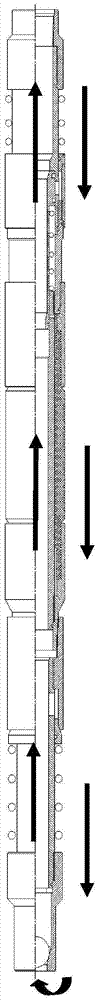

Device assembly for horizontal well temporary well plugging operation through coiled tubings and use method

InactiveCN107120093APrevent ConsolidationReduce security risksDrilling rodsSealing/packingControl systemCoiled tubing

The invention discloses a device assembly for horizontal well temporary well plugging operation through coiled tubings and a use method. According to the main points of the technical scheme, the device assembly comprises a coiled tubing vehicle, and a single-machine well cementation vehicle or a double-machine well cementation vehicle. The coiled tubing vehicle comprises a vehicle head, a control cabinet, a power system, a roller, the 2-inch coiled tubing, the 2.375-inch coiled tubing, an injection head and corresponding parts, wherein the injection head and the corresponding parts are connected to the 2.375-inch coiled tubing. The single-machine well cementation vehicle or the double-machine well cementation vehicle comprises a vehicle head, a power system, an instrument control system and a metering liquid tank. The coiled tubing vehicle is matched with the single-machine well cementation vehicle or the double-machine well cementation vehicle for the temporary well plugging operation process including the steps of well tripping, bridge plug running, continuous cement plug injection and reverse circulation well flushing. By adoption of the device assembly and the use method, one-time continuous cement plug injection (the vertical thickness is larger than 200 m, and the along hole depth length is larger than 300 m) for a horizontal well can be achieved, the construction period is greatly shortened, the process complexity degree is lowered, the well control safety risk is reduced, and operation cost is saved.

Owner:SINOPEC CHONGQING FULING SHALE GAS EXPLORATION & DEV

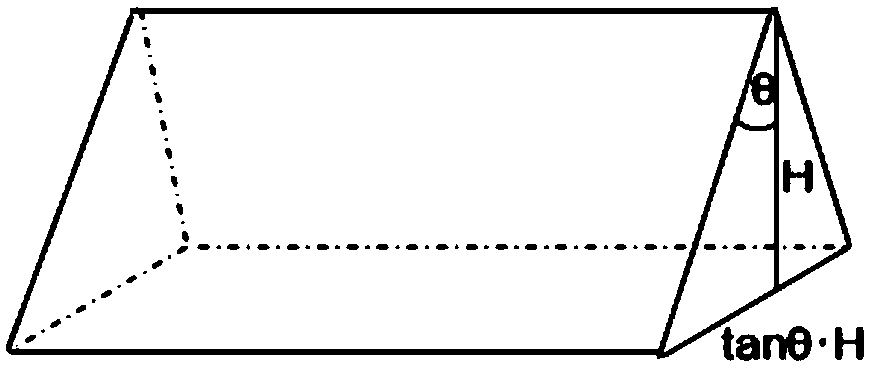

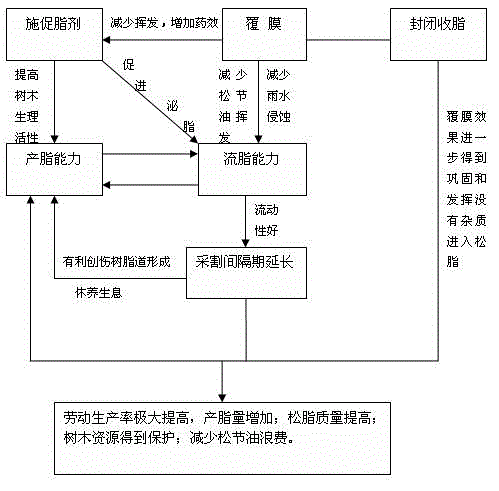

Ultralow-frequency resin tapping method

The invention discloses an ultralow-frequency resin tapping method. The method includes the following steps that a shaved face is made in advance; a middle groove is formed; a resin guiding device and a resin receiving device are installed, namely, the resin guiding device and a resin receiving bag are installed at the tail end of the middle groove; the top of the middle groove is cut towards the left and right sides in an upward inclined mode to form a first pair of cut grooves respectively; afterwards, every 12-20 days, a trunk continues to be cut from top to bottom in sequence from the lower edges of the tapping cut grooves formed last time; a resin accelerator is sprayed on cutting faces; the part between the tops of the first pair of cut grooves and the upper portion of the resin receiving bag is covered with a film in a closed mode. The method has the advantages that the tapping frequency is reduced, the tapping period is prolonged, and the resin tapping time limit of each pine reaches above 30 years; meanwhile, the quality of resin is improved, the impurity removal process is omitted for subsequent processing of resin, and therefore the subsequent processing cost is lowered.

Owner:郭志文

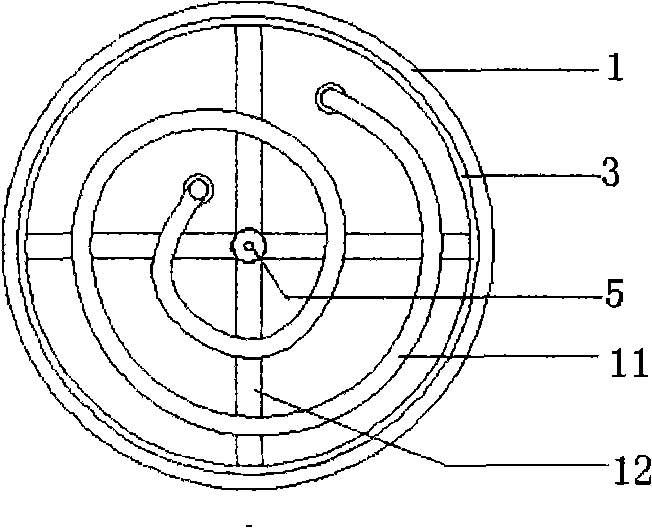

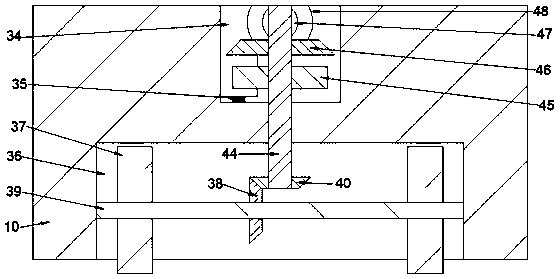

Method and device for resolving nonuniformity of thickness of retaining layer in production of blue ray disc

InactiveCN101359491APrevent ConsolidationAvoid ChuckingOptical record carrier manufactureProtection layerIrradiation

A method and a device for solving the problem of thickness unevenness of the protective layer in the production of a blue-ray disc are disclosed. After being spin-coated with protective glue, the disc is placed on a tray in a whirl coating bowl and is irradiated by an uviol lamp when a whirl coating rotating shaft drives the tray to rotate. The device is characterized in that a fixed arm and the whirl coating bowl are fixed on a pedestal; the whirl coating rotating shaft is arranged at the center of the whirl coating bowl and the tray is fixed at the upper end of the whirl coating rotating shaft; the moveable arm on which the uviol lamp is fixed can move up and down along the fixed arm. Due to the irradiation of the uviol lamp, the viscidity of the glue on the disc can be increased and the elastic shrinkage of the glue layer can be reduced, thus effectively controlling the evenness of the thickness of the protective layer of the disc.

Owner:HENAN KAIRUI DIGITAL

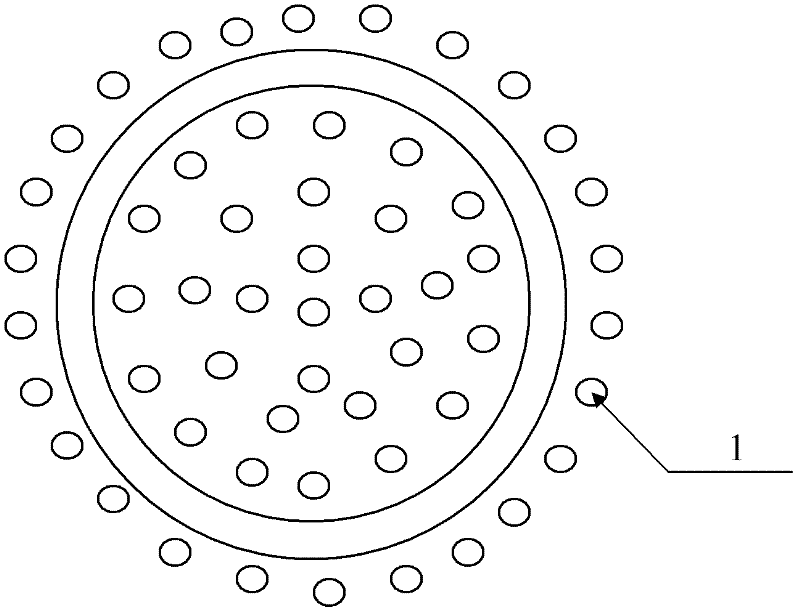

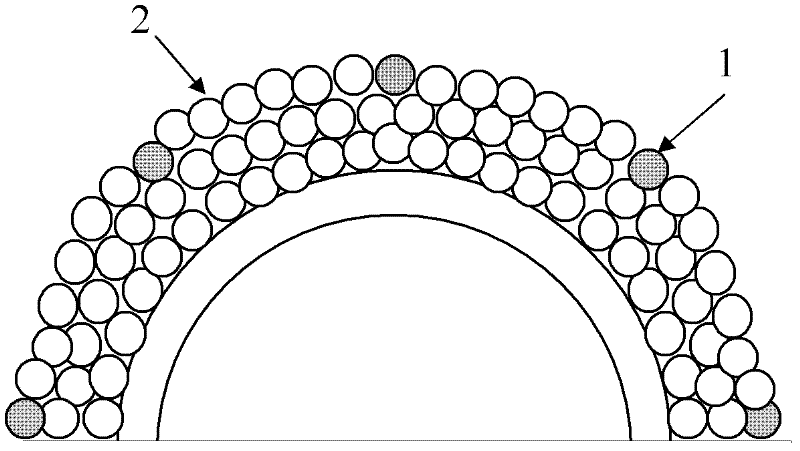

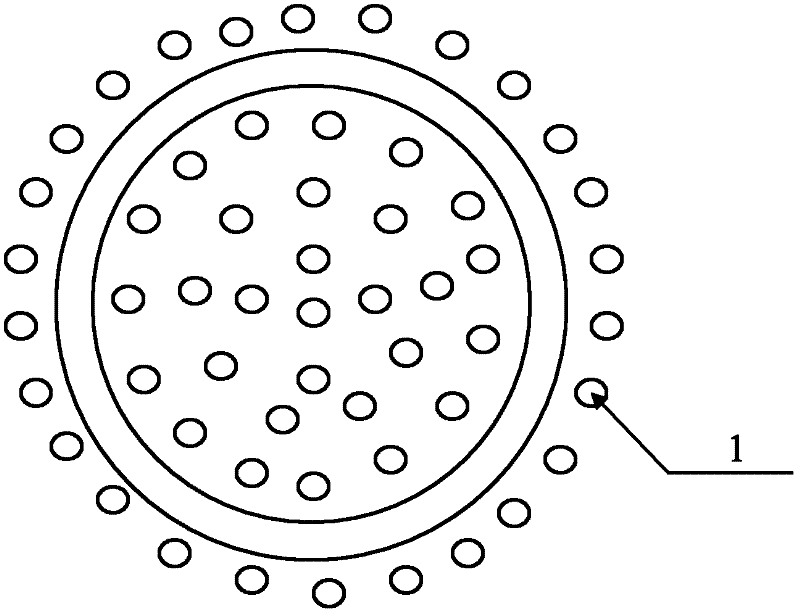

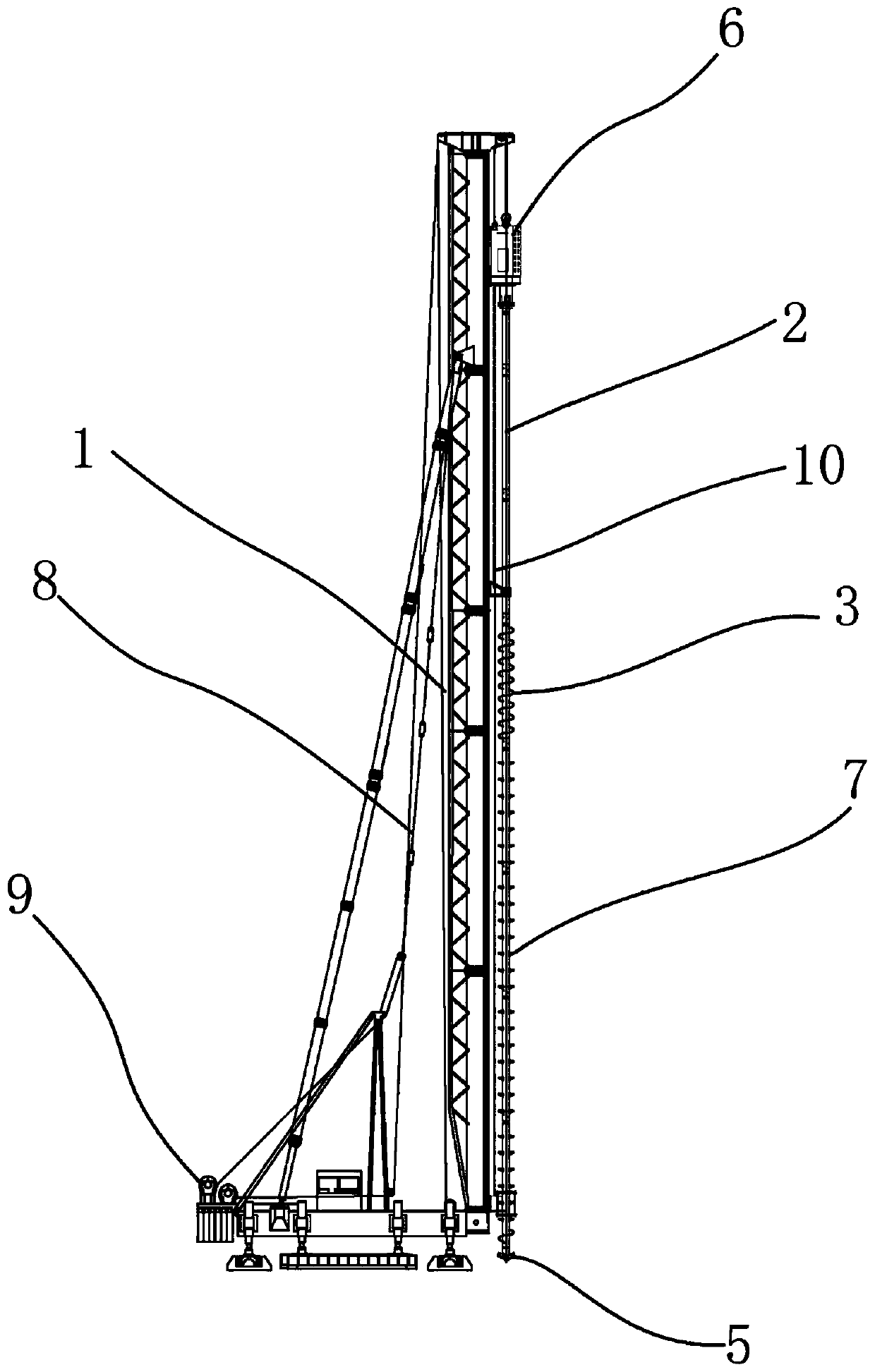

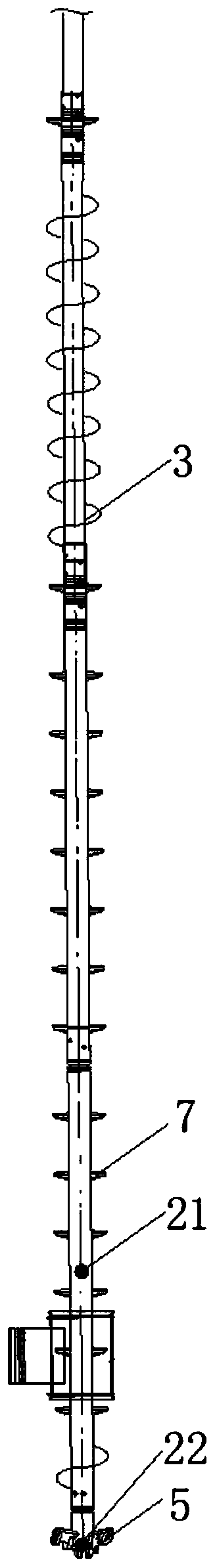

Construction technology and equipment for cement mixing pile

The invention discloses a construction technology and equipment for a cement mixing pile. The construction technology comprises the steps that when the hollow pile section is constructed, clear water is ejected from a grout ejecting opening, the clear water is also ejected by the grout ejecting opening in the first sinking process of the solid pile section, a mixing head is lifted and sunk for many times in the lifting process of the solid pile section, and cement grout is ejected from the grout ejecting opening. According to the construction technology for the cement mixing pile, the cement is distributed in the solid pile section uniformly, and the cement grout is combined with soil body in the solid pile section, so that the pile forming quality of the solid pile section is guaranteed, waste of the cement grout is avoided, and follow-up digging work of the hollow pile section is convenient.

Owner:中国能源建设集团广东电力工程局有限公司

Concrete mixer for building

InactiveCN107053478APrevent ConsolidationImprove pore structureCement mixing apparatusBall valveEngineering

The invention discloses a concrete mixer for construction, which comprises a cylinder body, a linkage shaft, a stirring drive device, a humidity controller and a temperature controller. There is a feed inlet, and a feed hopper is fixedly installed on the feed inlet. The linkage shaft passes through the cylinder body and is fixedly installed on the top of the cylinder body. An insulation layer is fixedly installed outside the outer surface of the cylinder body. There is an isolation layer, and a hanging plate is fixedly installed on the top of the cylinder. The hanging plate is a symmetrical distribution structure and is independently separated in the middle of the hanging plate. There is a suspension bar, and the combination of the humidity controller and the temperature controller forms an integral structure and is fixedly installed on the suspension bar. The invention overcomes the defects that the traditional stirring drive device supplies water regularly and quantitatively, and cannot control temperature and real-time adjustment, thereby improving the applicable surface and functionality of the stirring drive device.

Owner:CHENGDU GUANYU TECH

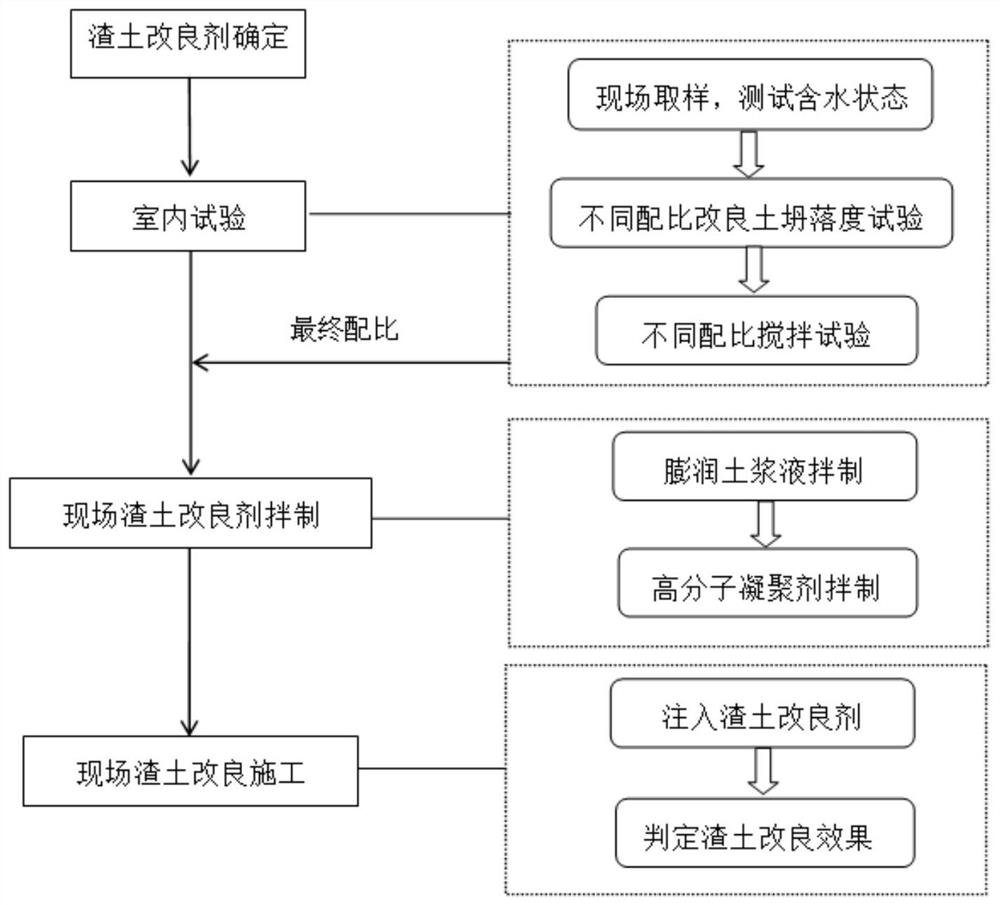

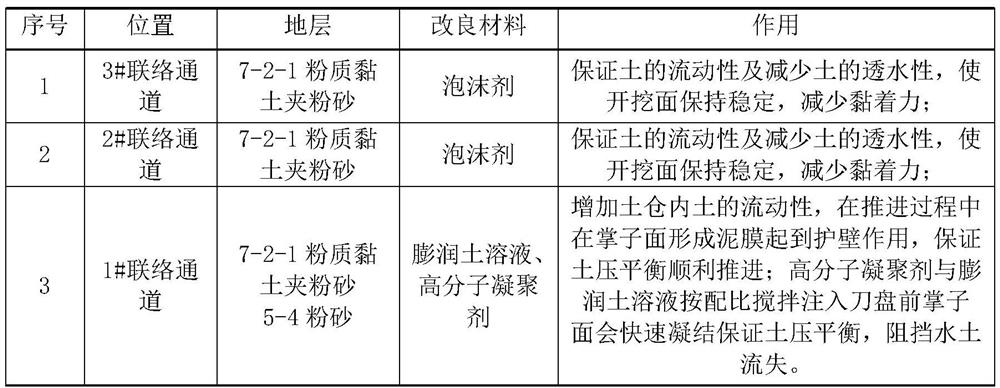

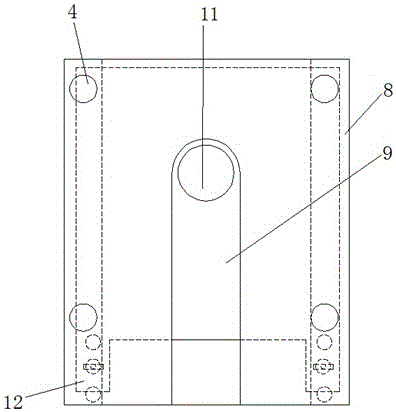

Method for improving full-section muck in silt soil layer during construction of contact channel pipe jacking machine

PendingCN113775345AChange the permeability coefficientNot easy to gushSilicon compoundsTunnelsSoil sciencePolymer solution

The invention relates to a method for improving full-section muck in a silt soil layer during construction of a contact channel pipe jacking machine. The method comprises the following steps of: S1, determining a muck improver; S2, performing an indoor test; S3, mixing the muck improver on site; and S4, performing site construction. The method has the beneficial effects that the muck is improved by adopting a bentonite improver (a bentonite solution and a high-molecular flocculant), a high-molecular polymer solution has relatively high adhesion and can well absorb soil moisture, and the permeability coefficient of the muck is changed through cutter head cutting and screw machine stirring, so that the muck is fully improved. The improved muck is not easy to gush and cake, the permeability of the muck in a soil bin is effectively reduced, and the gushing is further inhibited, so that shield tunneling is smooth and efficient, the shutdown time is shortened, the muck in a screw machine is prevented from being solidified, and the construction safety and smoothness are guaranteed.

Owner:浙江杭海城际铁路有限公司 +2

Casting device for box body type casting of refrigerator liner mold

InactiveCN106424606AAvoid it happening againPrevent ConsolidationMolten metal conveying equipmentsHoopingEngineering

The invention discloses a casting device for a box body type casting of a refrigerator liner mold. The casting device comprises a feed bin which is of a hollow structure; stirring paddles are vertically installed inside the hollow structure; the inner walls of the two sides of the feed bin are each provided with a heating plate; four supporting columns are arranged at the lower end of the feed bin; a part, between the supporting columns, of the feed bin is provided with a material charging hole; a hooping device is arranged at one side of the material charging hole; the hooping device comprises a rotating shaft; the rotating shaft is fixedly installed at one side of the material charging hole and is connected with a first hooping arc and a second hooping arc. The casting device disclosed by the invention is provided with the feed bin so that casting materials are remained inside the feed bin and are uniformly stirred to release air, and thus generation of air bubbles inside a finished product after casting formation is ended can be prevented; casting parts are movably installed inside a casting bin, and a feeding hole communicates with the material charging hole through the hooping device so that the cast parts can be changed by replacing the casting parts, and thus the production cost of a manufacturer can be lowered.

Owner:CHUZHOU XINDING MACHINERY MOLD MFG

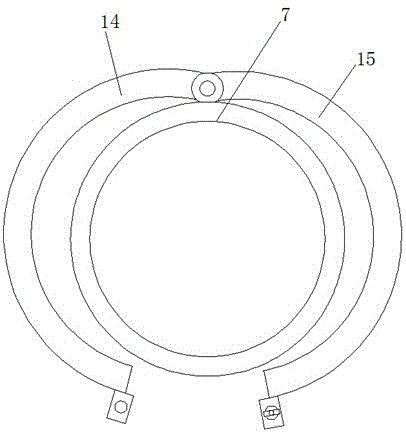

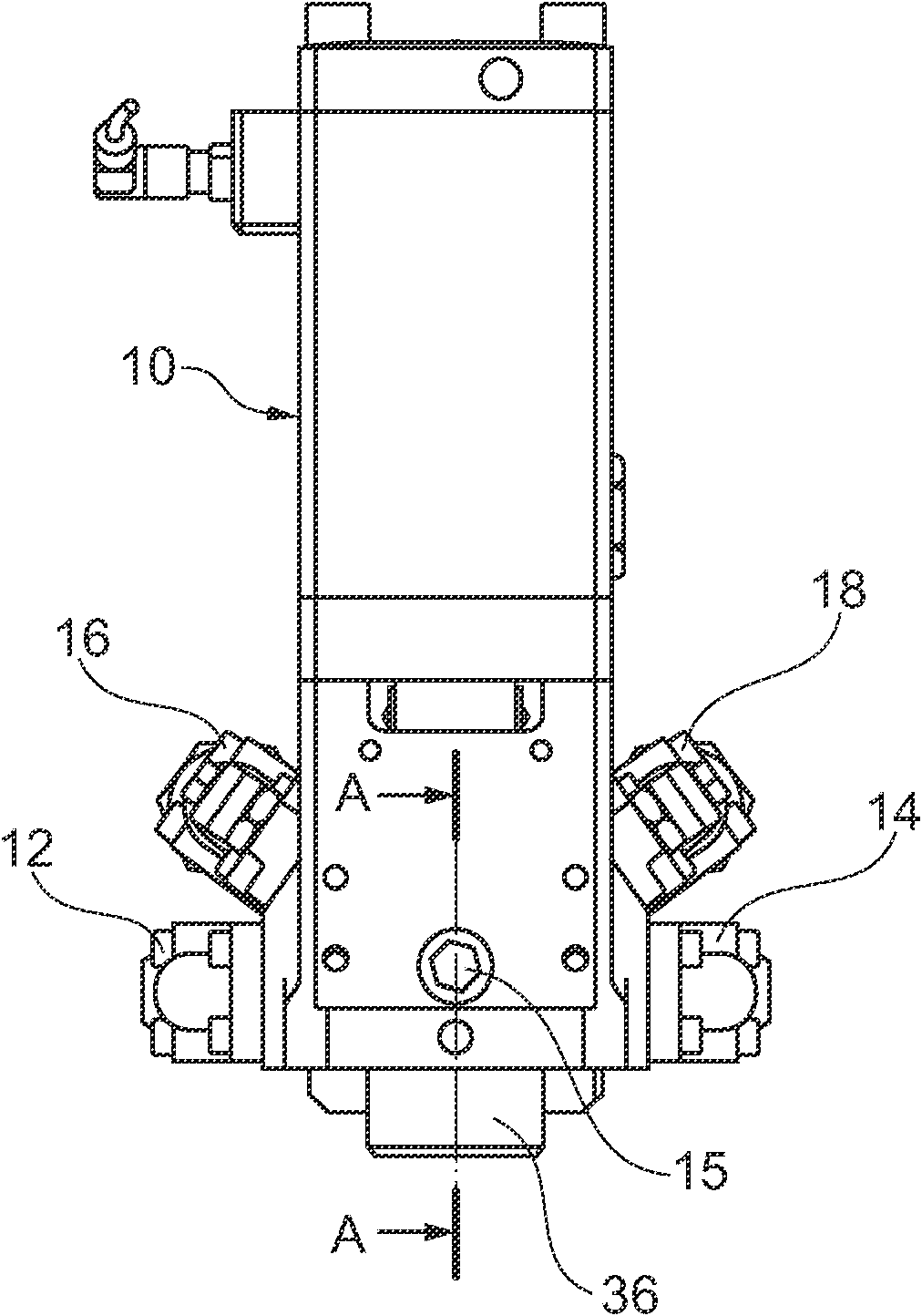

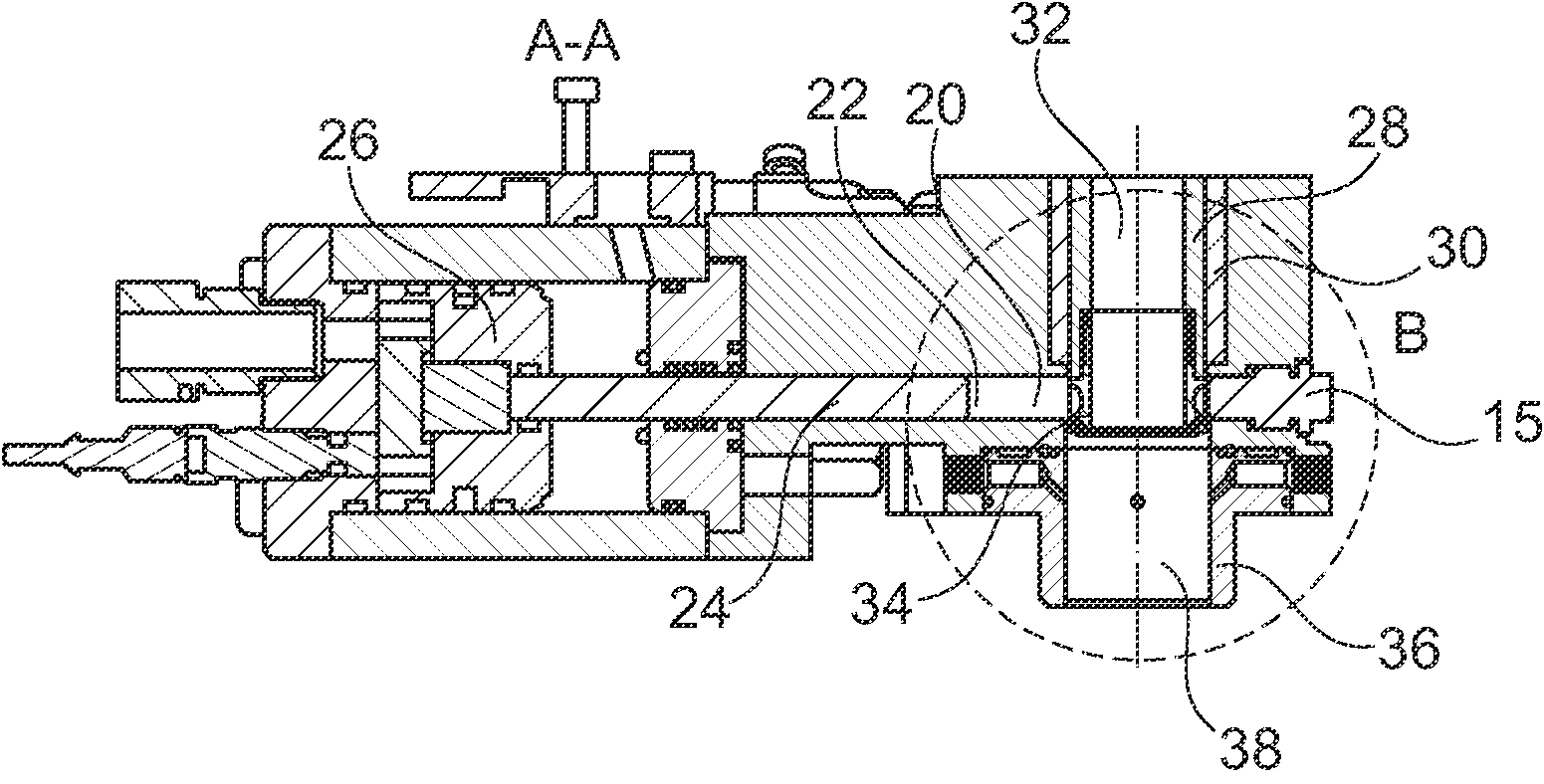

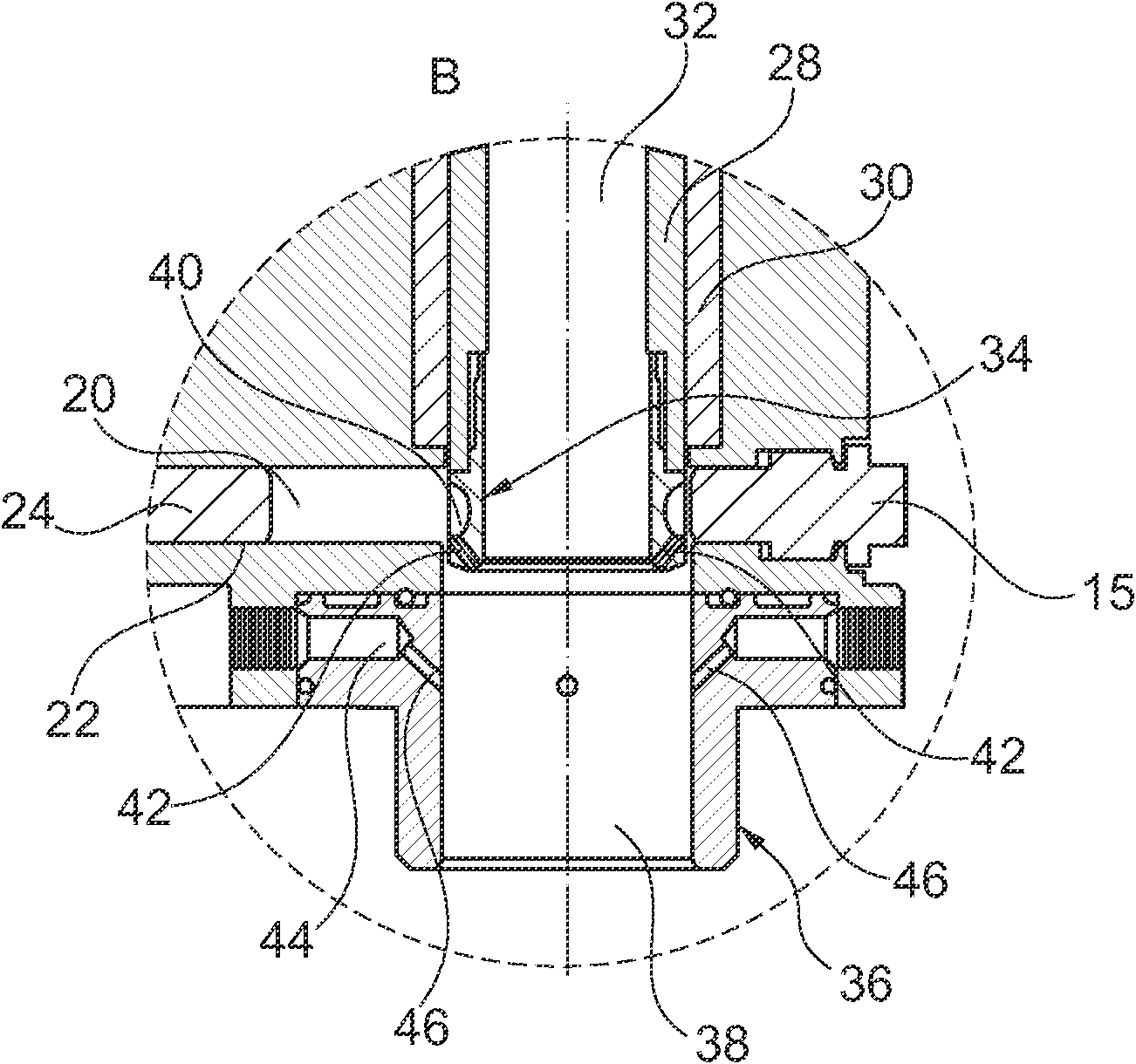

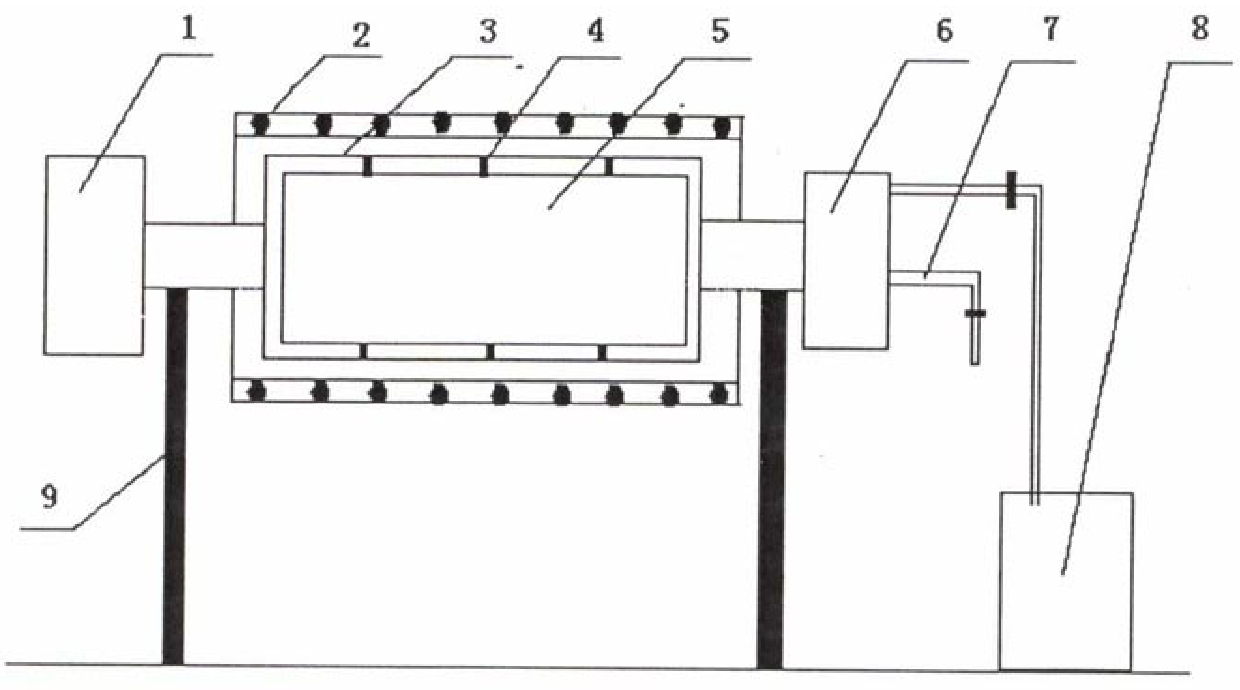

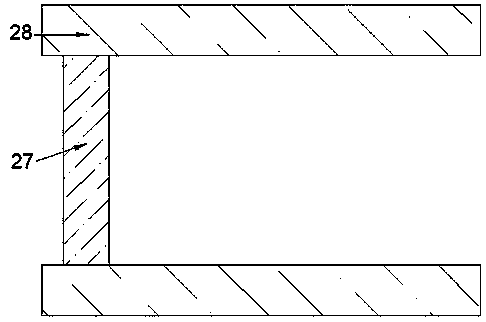

Apparatus for producing plastic parts interspersed with reinforcing fibres

InactiveCN102341224AWell mixedPrevent ConsolidationFlow mixersTransportation and packagingFiberChemical reaction

The present invention relates to an apparatus for producing plastic parts interspersed with reinforcing fibres, with a mixing chamber (20) for producing a mixture of chemically reactive polymer components, with an outlet chamber (38), which is arranged downstream of the mixing chamber and in which a cleaning ram (28) in which a fibre conveying channel (32) is formed is guided in a reciprocatingly movable manner. The invention is characterized in that the end face of the cleaning ram is provided with a die (34), through which the fibre conveying channel (32) extends and arranged on the outer circumference of which there is an annular groove (40), which is at a distance from the end of the die (34) and can be positioned in such a way that, in a first working position, a flow connection between the mixing chamber (20) and the annular groove (40) is formed and, in another working position of the cleaning ram (28), the flow connection between the mixing chamber (20) and the annular groove (40) is interrupted and in that at least one die channel (42), preferably a plurality of die channels (42), is / are formed between the annular groove (40) and the outlet-side end of the die (34), said channel(s) opening at the end face into the outlet chamber (38).

Owner:KRAUSSMAFFEI TECH GMBH

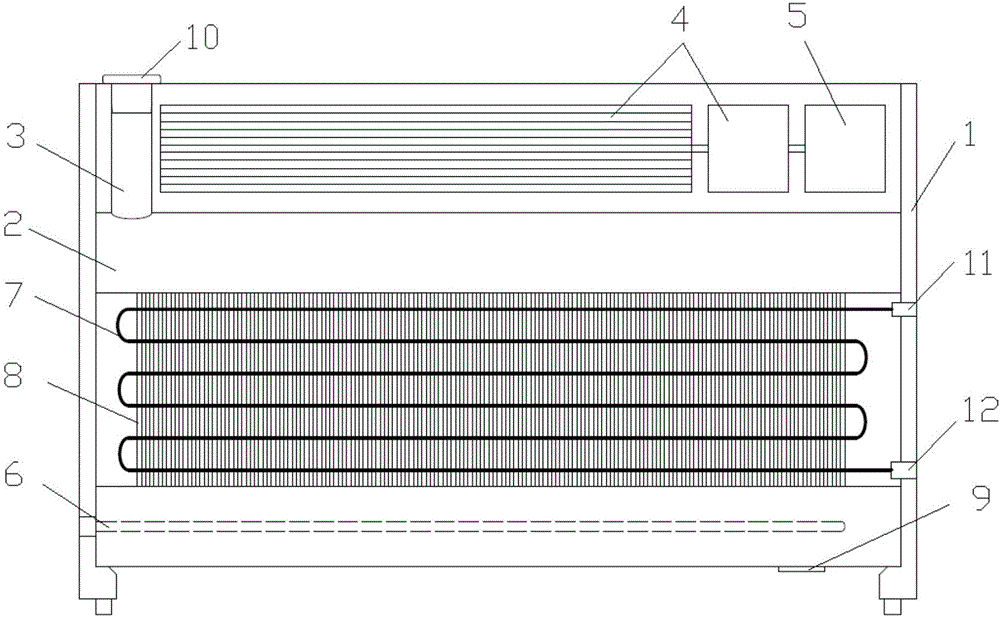

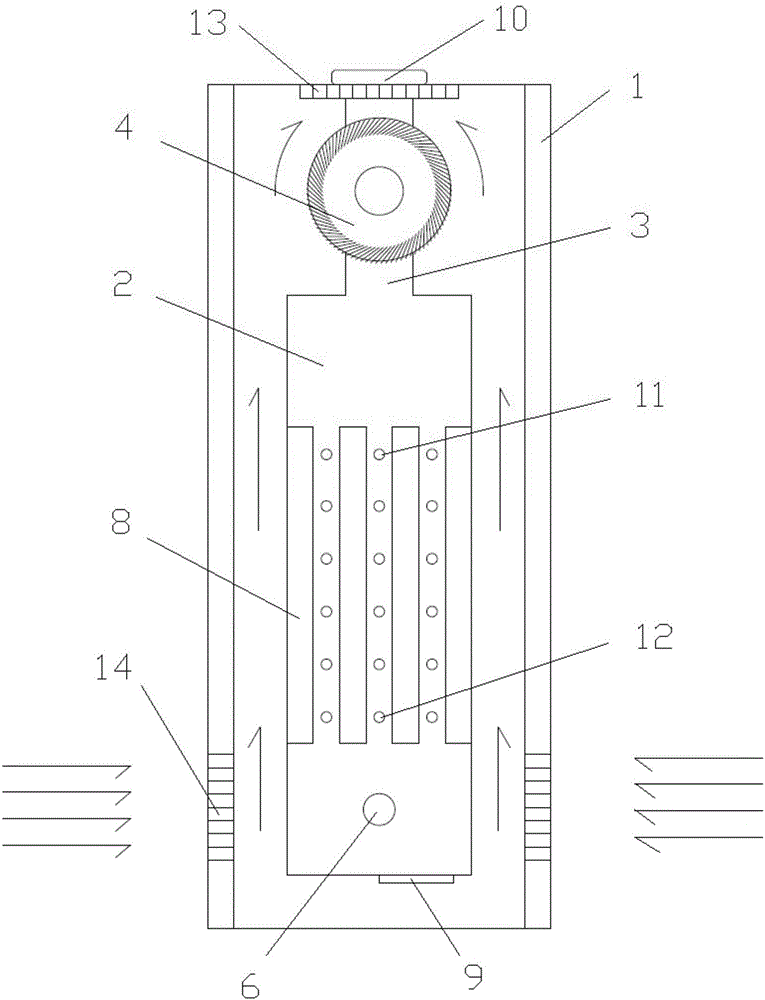

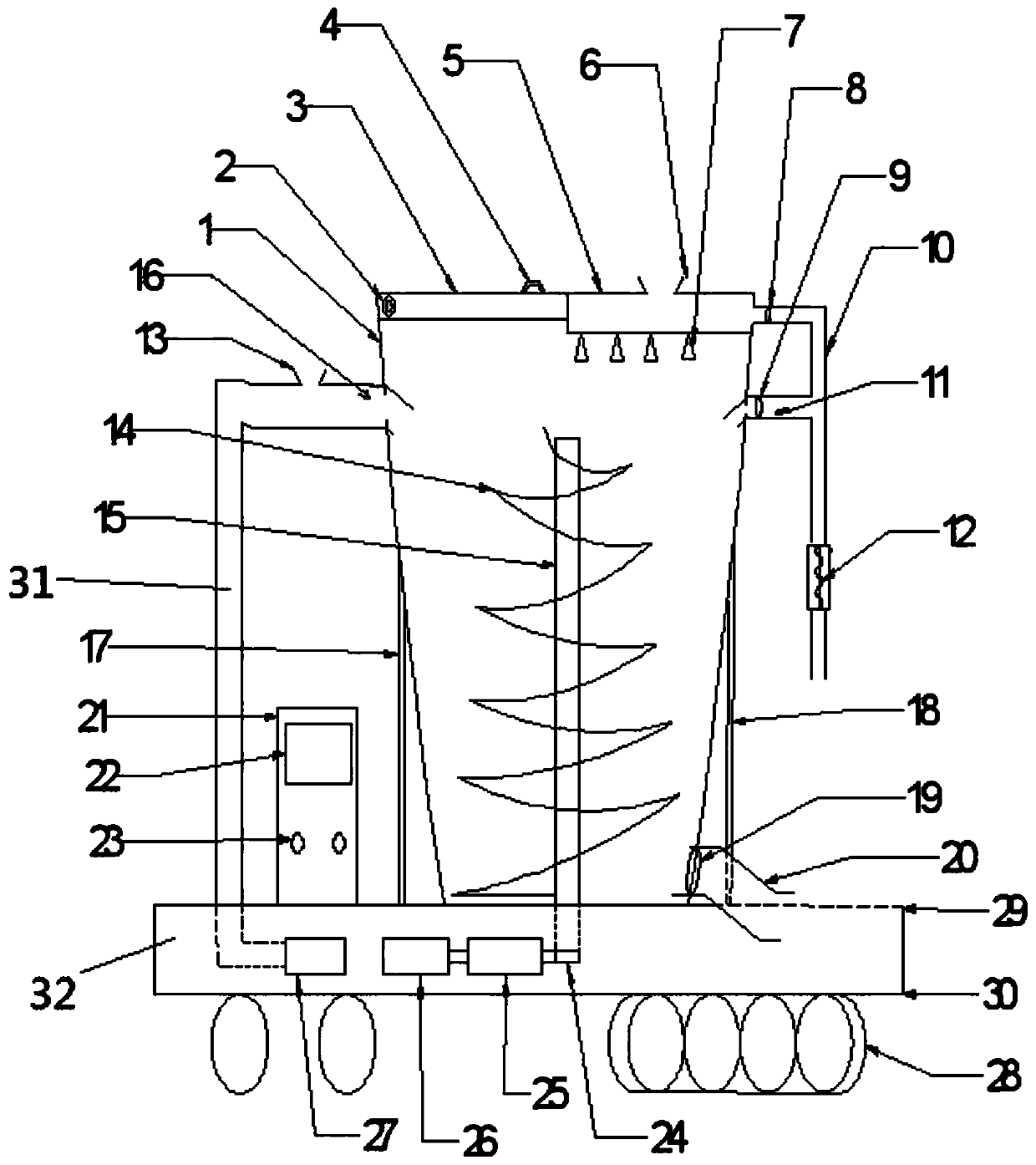

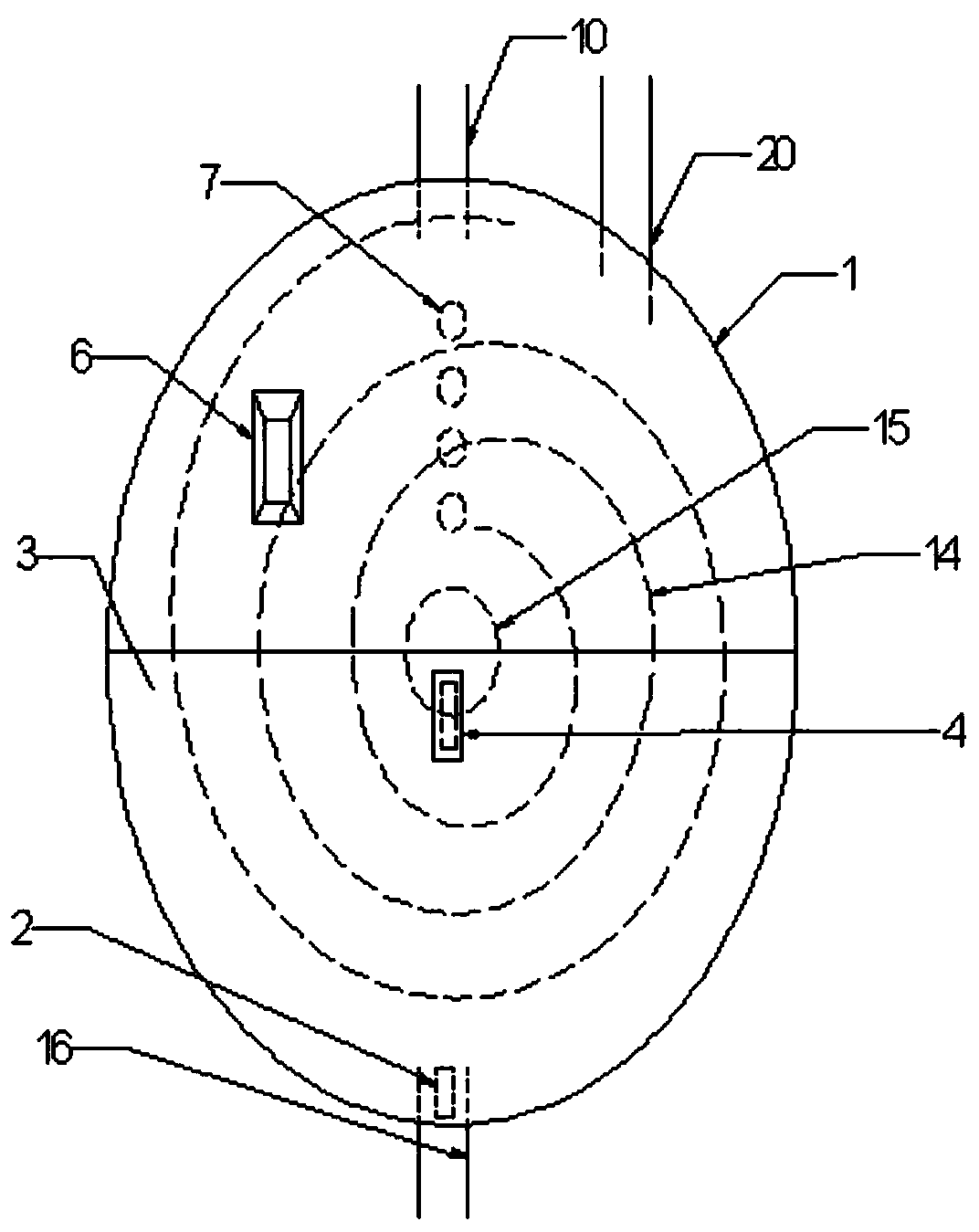

Heat accumulating type intelligent warm air blower

InactiveCN106524509AMonitor temperatureMonitor ambient temperatureStorage heatersWater vaporEngineering

The invention discloses a heat accumulating type intelligent warm air blower. The heat accumulating type intelligent warm air blower comprises a shell, air outlets and air inlets in the shell, and a cross-flow fan which is positioned inside the shell and communicates with the air outlets, and is characterized by further comprising a heat accumulator, wherein the heat accumulator is arranged inside the shell; and an air flow layer is arranged between the heat accumulator and the shell. The heat accumulating type intelligent warm air blower has the effects that 1) the heat accumulator is arranged, so that the heat accumulating type intelligent warm air blower has the beneficial effects of firstly accumulating heat and releasing heat at other periods through accumulated heat; 2) when a heat accumulation medium in the heat accumulator is water, a cover of a water inlet can be opened, and the environment can be humidified through water vapor; 3) an intelligent temperature controller is arranged, so that the temperature of the heat accumulator and the temperature of the environment can be monitored, and heating of the heat accumulator is intelligently controlled to be started or stopped; 4) auxiliary heating coils are arranged, so that the heat supply effect is strengthened; and 5) the structure is simple, and popularization is easy.

Owner:郝勇

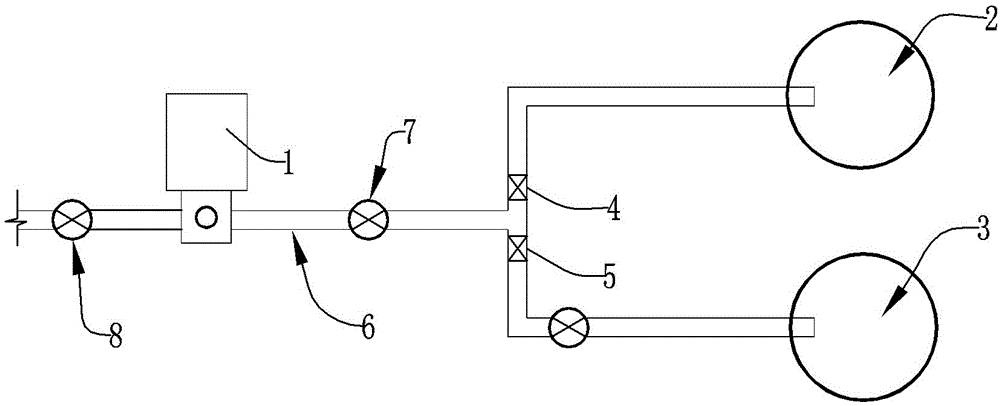

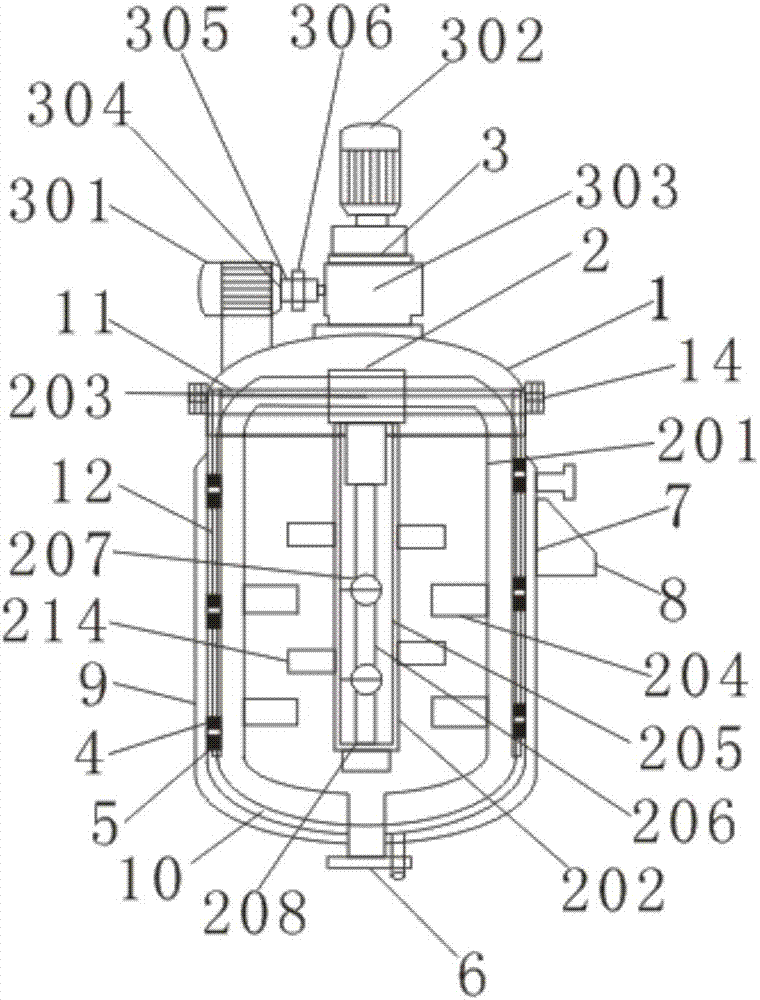

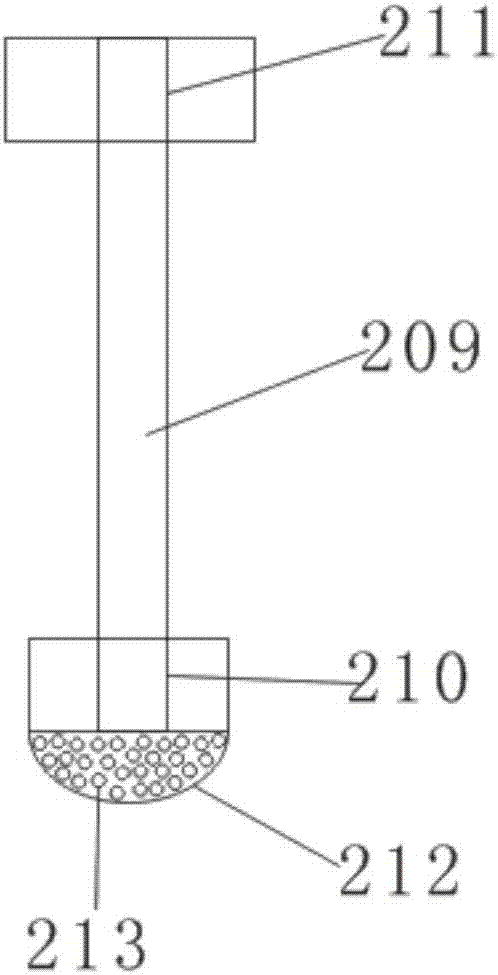

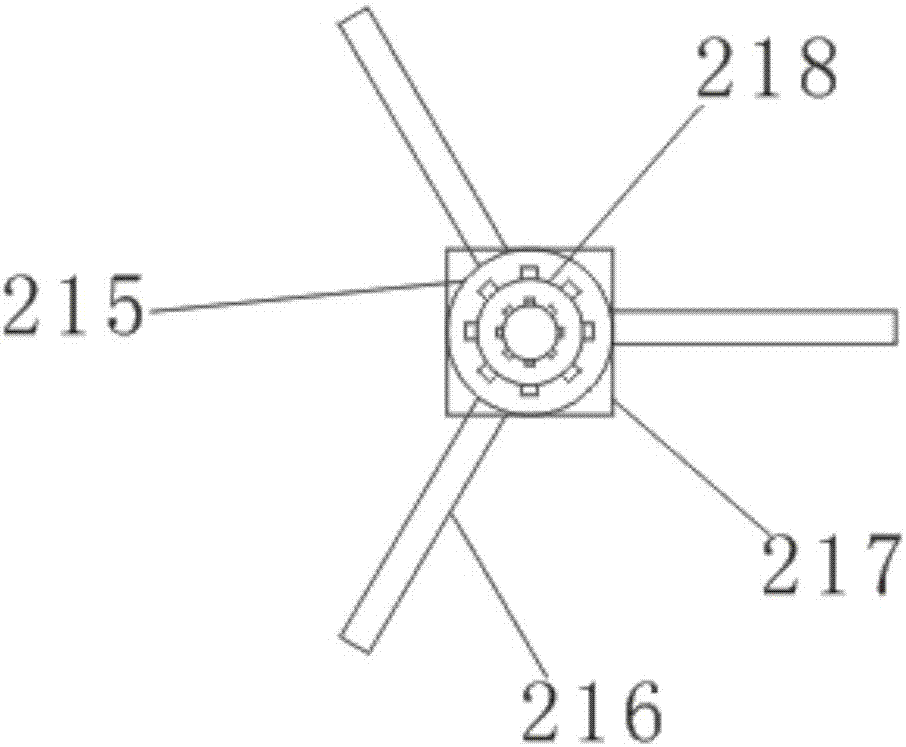

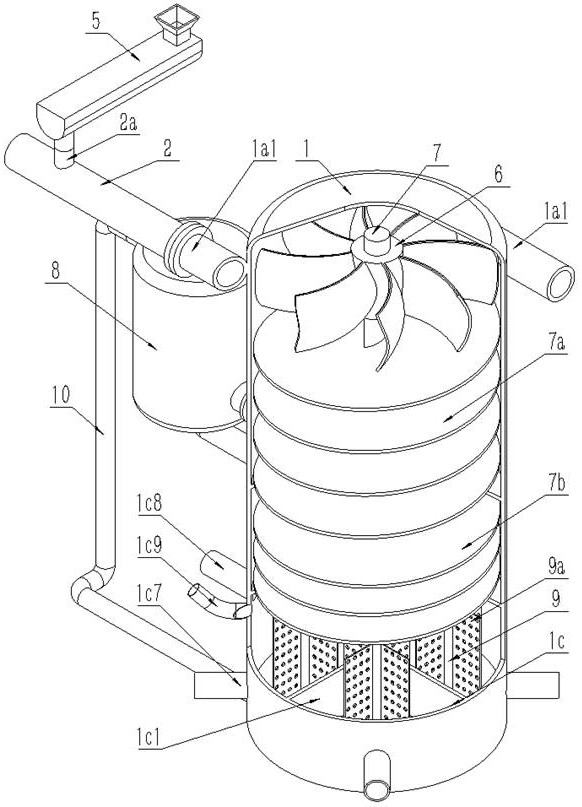

Suspending agent blending device for profile control of water injection well

ActiveCN111905628AUniform particle distributionIncrease productivityTransportation and packagingMixer accessoriesImpellerVapor–liquid separator

The invention provides a suspending agent blending device for profile control of a water injection well, belongs to the technical field of profile control suspending agent production equipment, and isused for solving the technical problems that the existing suspending agent production cannot meet continuous and serialized production at the same time and often employs a motor for driving the stirring, wherein the energy consumption is high, and the efficiency is low. The device comprises a graded mixing box, a high-pressure air channel and a gas-liquid separator; an adjusting valve, a main stirring shaft and a distributing stirring shaft are arranged on the graded mixing box; an impeller, a rotating wheel and a large gear are fixed to the main stirring shaft; a small gear is fixed to the distributing stirring shaft; an auger feeding channel and a gas stirring shaft are arranged on the high-pressure air channel; and a fan wheel is fixed to the gas stirring shaft. According to the invention, continuous and serialized output of different products of the suspending agent can be met through different batching chambers, so that the production efficiency is high, different stirring shaftsare driven to rotate and stir by taking liquid flow and circulating air flow as power, solution particles can be uniformly distributed, the stirring efficiency is high, the energy is saved, the environment is protected, and the energy consumption is low.

Owner:甘肃中科聚合石油科技有限公司

A kind of method for preparing titanium powder

A method for preparing titanium powder relates to a method for producing metal powder, in particular a method for preparing titanium metal powder by using a dynamic hydrogenation dehydrogenation process. It is characterized in that the whole process of its preparation is carried out in a furnace body with the functions of air extraction, air filling, heating and rotation. During the preparation, the furnace is heated to 450°C to start the hydrogenation reaction in the furnace, and the furnace body is rotated so that The hydrogenated titanium layer formed on the surface of the titanium block collides with the steel ball and the titanium block, and is broken and separated until the hydrogenated sponge titanium is broken into powder; the hydrogenation and crushing process is completed, stop the rotating furnace body, and vacuumize the furnace body to make the vacuum less than 5×10-2Pa Afterwards, the temperature is raised to 600-850°C to dehydrogenate the titanium hydride powder, and finally obtain titanium powder. The method of the present invention directly carries out the processes of hydrogenation, crushing, dehydrogenation and crushing continuously in the dynamic hydrogenation dehydrogenation equipment without separating several processes independently, thereby producing high-quality and low-cost titanium powder.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Building cement transport vehicle capable of preventing cement solidification

InactiveCN111214977APrevent ConsolidationFree laborRotary stirring mixersMixer accessoriesArchitectural engineeringStructural engineering

The invention discloses a building cement transport vehicle capable of preventing cement solidification. The vehicle comprises a working box and a supporting block located on the lower cavity wall ofthe right side of the working box, a rectangular cavity with a downward opening is formed in the supporting block, a fixing device capable of supporting the vehicle is fixedly arranged in the rectangular cavity, and the fixing device comprises a supporting plate capable of abutting against the ground to play a supporting role. The building cement transport vehicle is cement transportation equipment. A moving device can be started when cement is transported, so the labor force of conveying personnel is liberated, and the transport efficiency is greatly increased; by means of a supporting device, the vehicle can stably stay on the ground with different gradients; a stirring roller can intermittently rotate to prevent cement in the vehicle from being solidified; and a closing plate can closea working cavity in the conveying process, so the cement on the upper surface of the working cavity is prevented from making contact with outside air.

Owner:嵊州摩天自动化设备有限公司

Movable solid-liquid feed mixing and stirring machine

PendingCN110605050ASimple structureEasy to operateFeeding-stuffRotary stirring mixersLiquid tankProcess engineering

The invention discloses a movable solid-liquid feed mixing and stirring machine. The mixing and stirring machine comprises a movable base and a stirring tank arranged on the movable base; the top endof the stirring tank is fixedly connected with a liquid tank; the bottom of the liquid tank is provided with a plurality of sprinkler heads; the top of the liquid tank is provided with a liquid feed inlet; the liquid tank is connected with a water supply pipeline, the water supply pipeline is connected with a water supply branch, and the water supply branch is fixedly connected to the side wall ofthe stirring tank; an electric heating device is arranged at a water inlet of the water supply pipeline; a granular powder feed box is further fixedly connected to the side wall of the stirring tank,a granular powder feed inlet is formed in the top of the granular powder feed box, and the granular powder feed box is connected with an air blowing pipeline and connected with an air blower throughthe air blowing pipeline; a rotating shaft is arranged in the stirring tank, and a spiral conical auger is arranged on the rotating shaft. The movable solid-liquid feed mixing stirrer provided by theinvention is simple in structure, convenient to use, more uniform and sufficient in stirring and high in stirring efficiency.

Owner:HEBEI AGRICULTURAL UNIV. +1

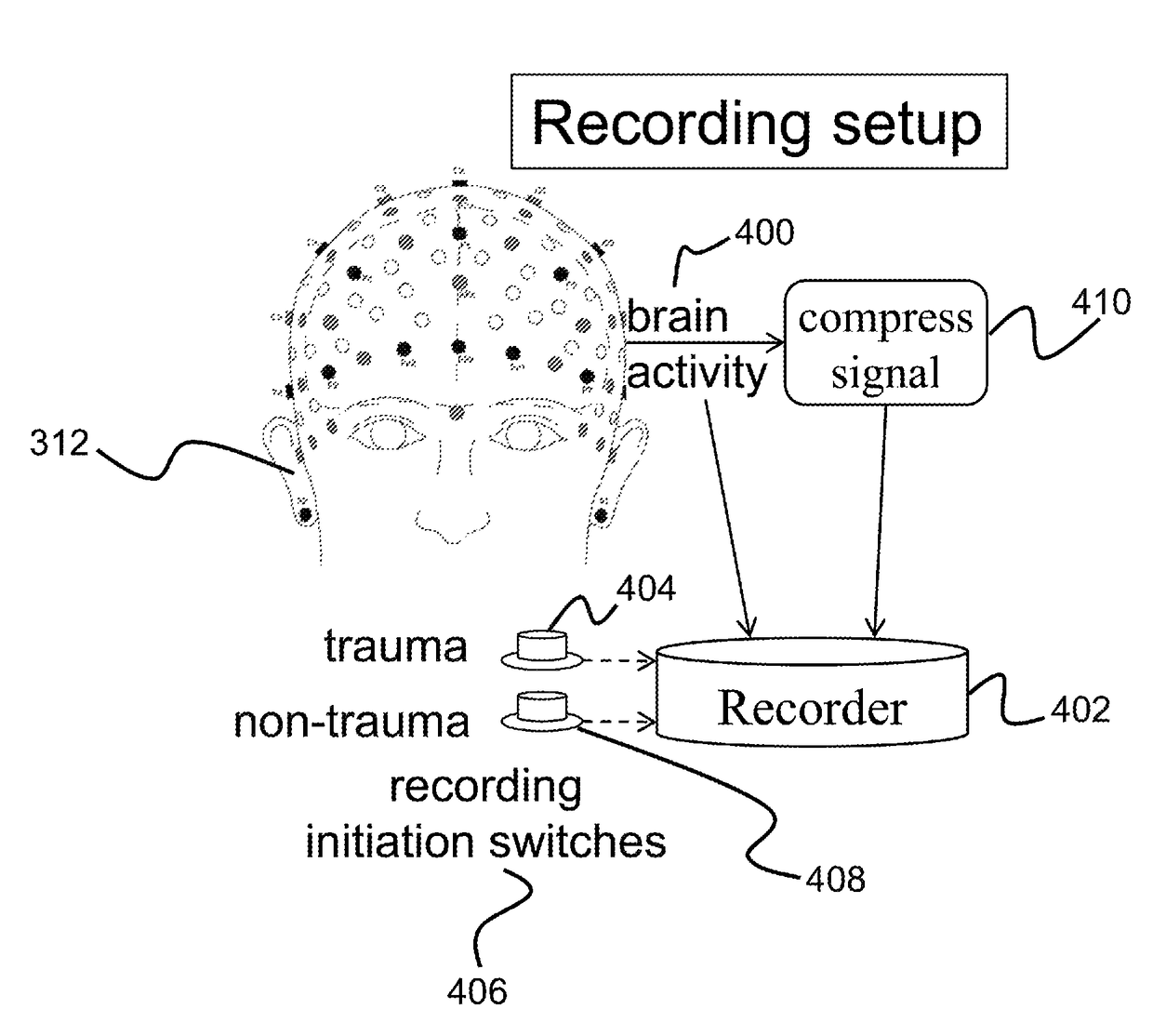

Transcranial intervention to weaken traumatic memories

ActiveUS10046162B1Prevent ConsolidationDiagnostics using spectroscopySensorsAntidoteElectro stimulation

Described is a system for weakening traumatic memories using transcranially-applied electro-stimulation. The system uses a recording of spatiotemporally distributed brain activity of a human subject experiencing a traumatic memory to generate a traumatic pattern. Additionally, the system uses a recording of spatiotemporally distributed brain activity of the human subject experiencing a non-traumatic memory to generate an antidote pattern. A required transcranially-applied electro-stimulation is determined to recreate the antidote pattern to block consolidation and reconsolidation of the traumatic memory in the human subject.

Owner:HRL LAB

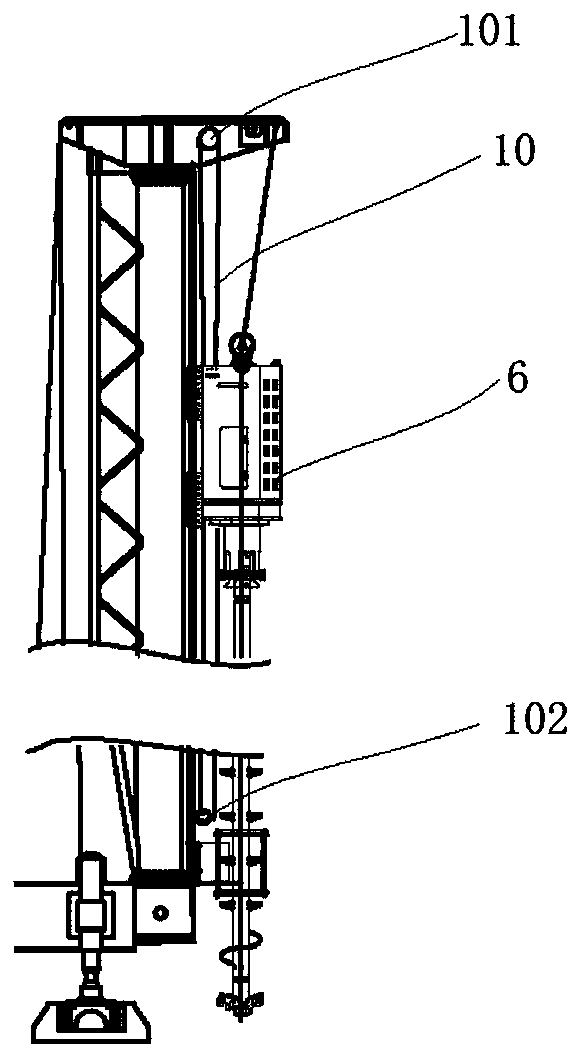

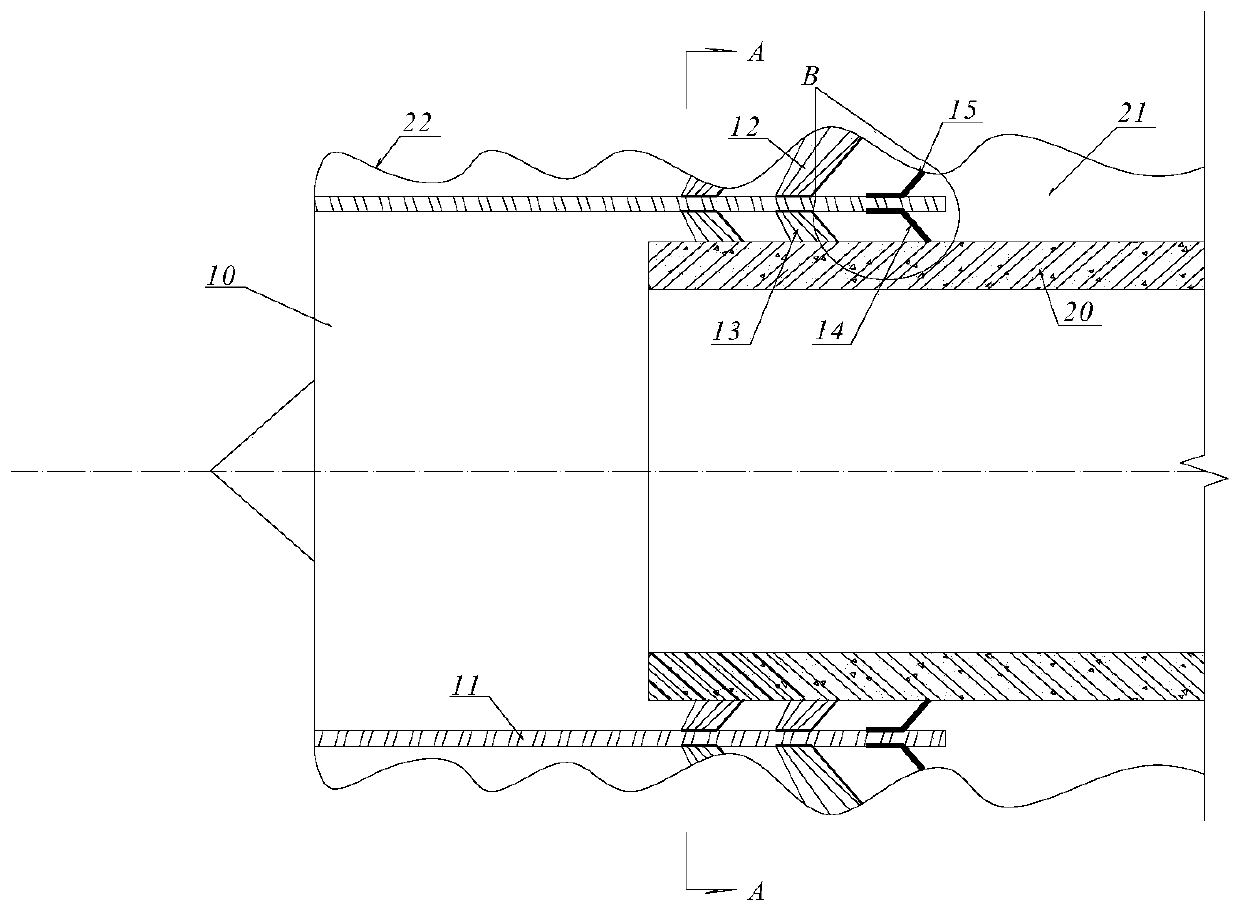

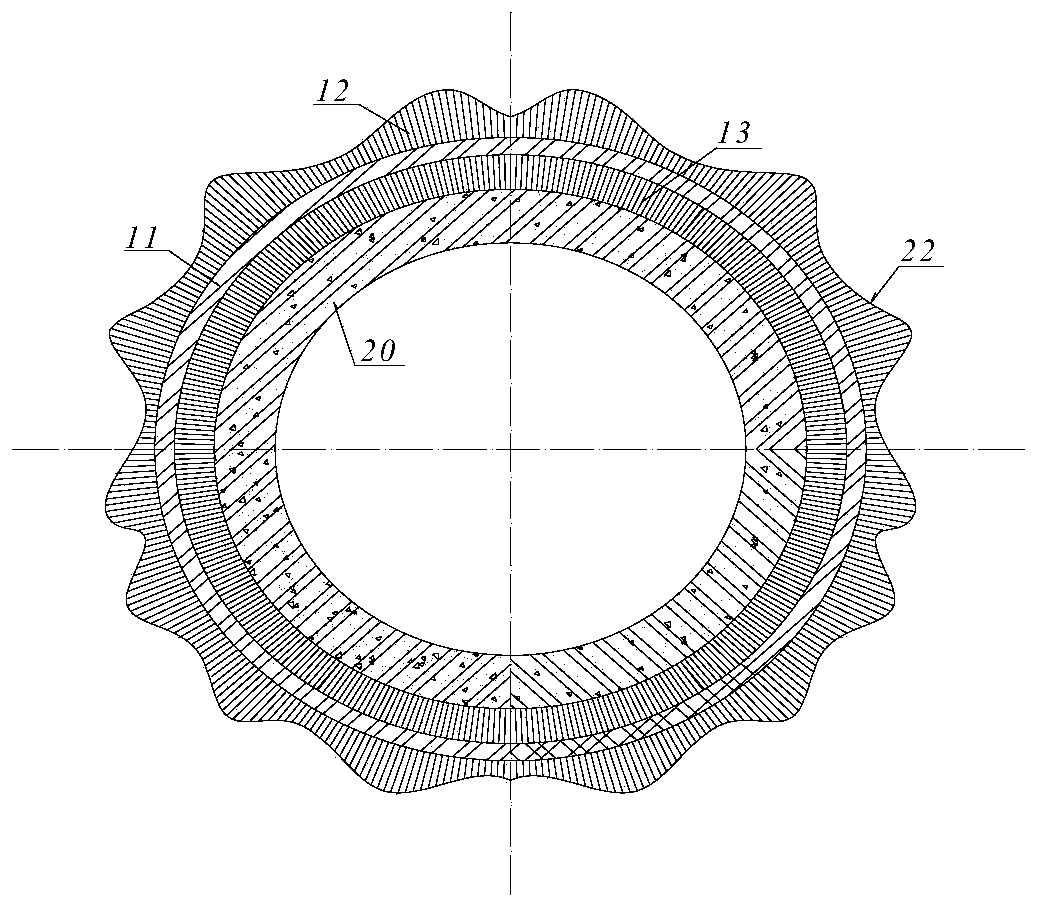

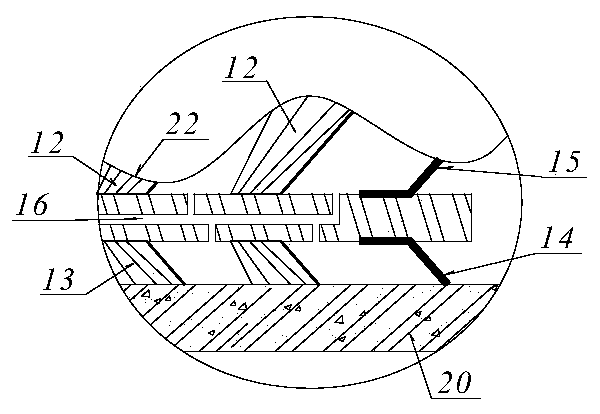

Intelligent construction equipment for pile foundations

PendingCN110185029AAdd automatic flushing devicePrevent ConsolidationBulkheads/pilesFully automaticWire rope

The invention provides intelligent construction equipment for pile foundations. The intelligent construction equipment comprises a pile frame. A drill rod is arranged on the pile frame. A power deviceis arranged at the top of the drill rod. According to the scheme, a drill rod speed measuring scheme is improved, a speed measuring steel wire rope is directly connected with the power device, the speed of the drill rod can be directly obtained, and the speed of the speed measuring steel wire rope can be directly obtained by a fixed pulley, so that pulley speed measuring is free of error and timedifference, and speed measuring is timely, accurate and reliable. An automatic drill rod washing device is additionally arranged. After construction, the drill rod can be washed, cement consolidationis effectively prevented, the washing process is carried out in a fully automatic manner, and time and labor are saved. All operations can be visually implemented on a touch screen, the performance is stable, the construction efficiency is high, and safety and reliability are realized.

Owner:SHANGHAI STRONG FOUND ENG

External sealing structure for tunnel heading machine

PendingCN110056364AEffective barrierGuaranteed drilling efficiencyUnderground chambersTunnel liningTunnel boring machineTunnel wall

The invention provides an external sealing structure for a tunnel heading machine. Filled grout channeling to a cutterhead of the heading machine is effectively avoided, and the tunneling efficiency of the tunnel heading machine is ensured. The external sealing structure is arranged at the tail part of a steel shell of the tunnel heading machine, a tunnel lining structure extends a certain distance into the tail part of the steel shell, an annular gap between the peripheral wall of the tunnel lining structure and the newly-excavated tunnel wall after excavation of a tunnel is filled with the grout, and the external sealing structure has the characteristics that outer annular spring steel plates are fixedly arranged on the positions, on the peripheral wall, of the tail end of the steel shell, one or more outer-layer annular wire brushes with the tail ends being in contact with the newly-excavated tunnel wall after excavation of the tunnel are fixedly arranged on the positions, on the peripheral wall of the steel shell, behind the outer annular spring steel plates, sealing grease is injected into an outer annular cavity between the outer annular spring steel plates and the outer-layer annular wire brushes as well as between every adjacent outer-layer annular wire brushes to form sealing, and the grout is prevented from channeling into the gap between the peripheral wall of the steel shell and the newly-excavated tunnel wall after excavation of the tunnel.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

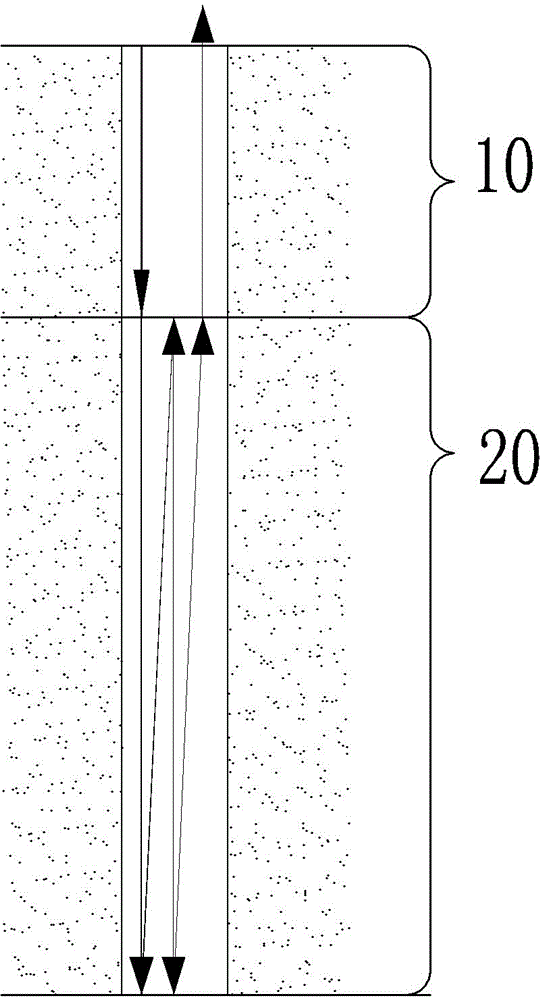

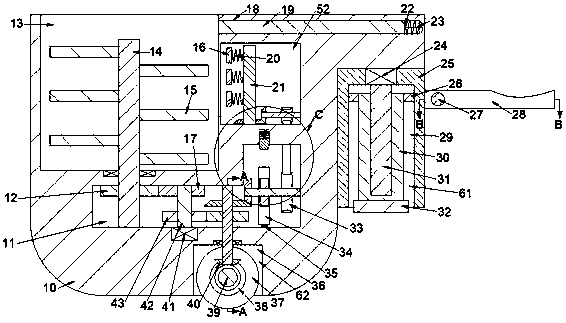

Pipe column and method used for layered chemical sand prevention

PendingCN106978992APrevent ConsolidationImplement injectionFluid removalSealing/packingGeotechnical engineeringStructural engineering

The invention discloses a pipe column and a method used for layered chemical sand prevention. The pipe column comprises an upper layer filling assembly, an interlayer packer and a lower layer filling assembly which are connected in sequence from top to bottom; the upper end of the upper layer filling assembly is connected with an upper connector; the lower end of the lower layer filling assembly is connected with a lower connector; the upper layer filling assembly comprises an upper inner sliding sleeve and an upper outer sliding sleeve which are arranged in an internal-external sleeving mode; the lower end of the upper inner sliding sleeve is connected with an upper inner pressure spring; the upper end of the upper outer sliding sleeve is connected with an upper outer pressure spring; and an upper layer filling channel is formed between the upper inner sliding sleeve and the upper outer sliding sleeve. The lower layer filling assembly comprises a lower inner pipe and a lower outer sliding sleeve which are arranged in an internal-external sleeving mode; the lower end of the lower outer sliding sleeve is connected with a lower outer pressure spring; and a lower layer filling channel is formed between the lower inner pipe and the lower outer sliding sleeve. Layered sand consolidating agent injection of the immovable pipe column can be achieved, and the immovable pipe column can completely conduct reverse well washing at any time according to the needs, so that a sand consolidating agent is prevented from being regurgitated and solidified in the well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chromizing agent and technology of chromizing coating of chromizing agent

ActiveCN107881462APrevent ConsolidationIncrease productivitySolid state diffusion coatingSodium fluorideMetallic coating

The invention discloses a chromizing agent and a technology of a chromizing coating of the chromizing agent, and belongs to the field of metallic coatings. The chromizing agent comprises a chromium supply agent, an activating agent and an inert filler, and further comprises a foamed inorganic material, wherein the chromium supply agent is chromium powder and / or ferrochromium; the activating agentis ammonium chloride and / or sodium fluoride, the inert filler is aluminum oxide and / or magnesium oxide and the foamed inorganic material is foamed asbestos and / or expanded perlite. By taking corresponding measures like adding the high temperature resistant foamed inorganic material or the high temperature calcination inert filler to an existing chromizing agent, the defects that the chromizing agent in a traditional technology is solidified, the production efficiency is low, the chromizing agent is difficult to clean and the like are overcome.

Owner:SINOPEC YANGZI PETROCHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com