Pipe column and method used for layered chemical sand prevention

A sand control and chemical technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of anti-ejection of sand consolidation agent, difficulty in achieving uniform reconstruction of small layers, and inability to realize backwashing of wells without moving the pipe string, etc. , to achieve the effect of preventing consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

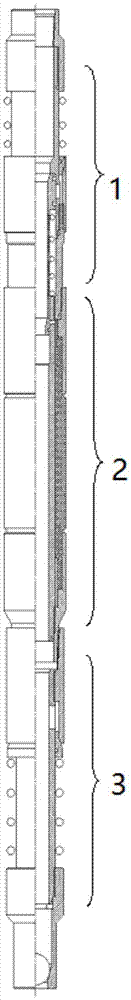

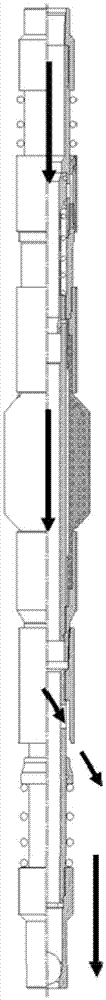

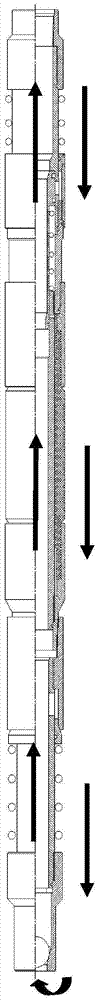

[0017] according to Figure 1-4 , a pipe string that can be used for layered chemical sand control, including an upper layer packing assembly 1, an interlayer packer 2 and a lower layer packing assembly 3 connected sequentially from top to bottom. The upper end of the upper filling assembly is connected to the upper joint, and the lower end of the lower filling assembly is connected to the lower joint. The upper filling assembly includes an upper inner sliding sleeve and an upper outer sliding sleeve, the lower end of the upper inner sliding sleeve is connected to the upper inner compression spring, and the upper end of the upper outer sliding sleeve is connected to the upper outer compression spring. The upper inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com