External sealing structure for tunnel heading machine

A tunnel boring machine and sealing structure technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of reducing excavation cutting efficiency, increasing cutter head torque, and increasing the advancing resistance of roadheaders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

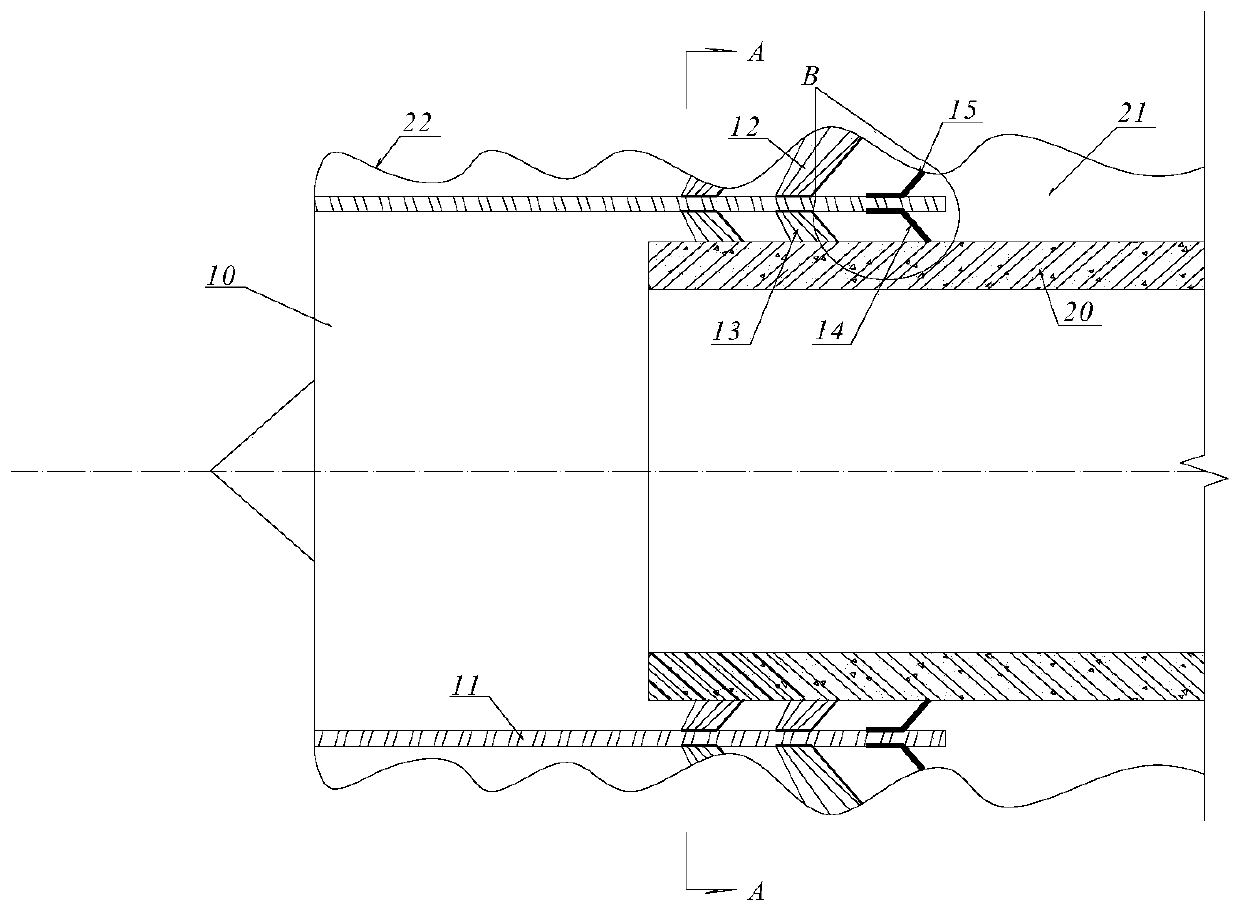

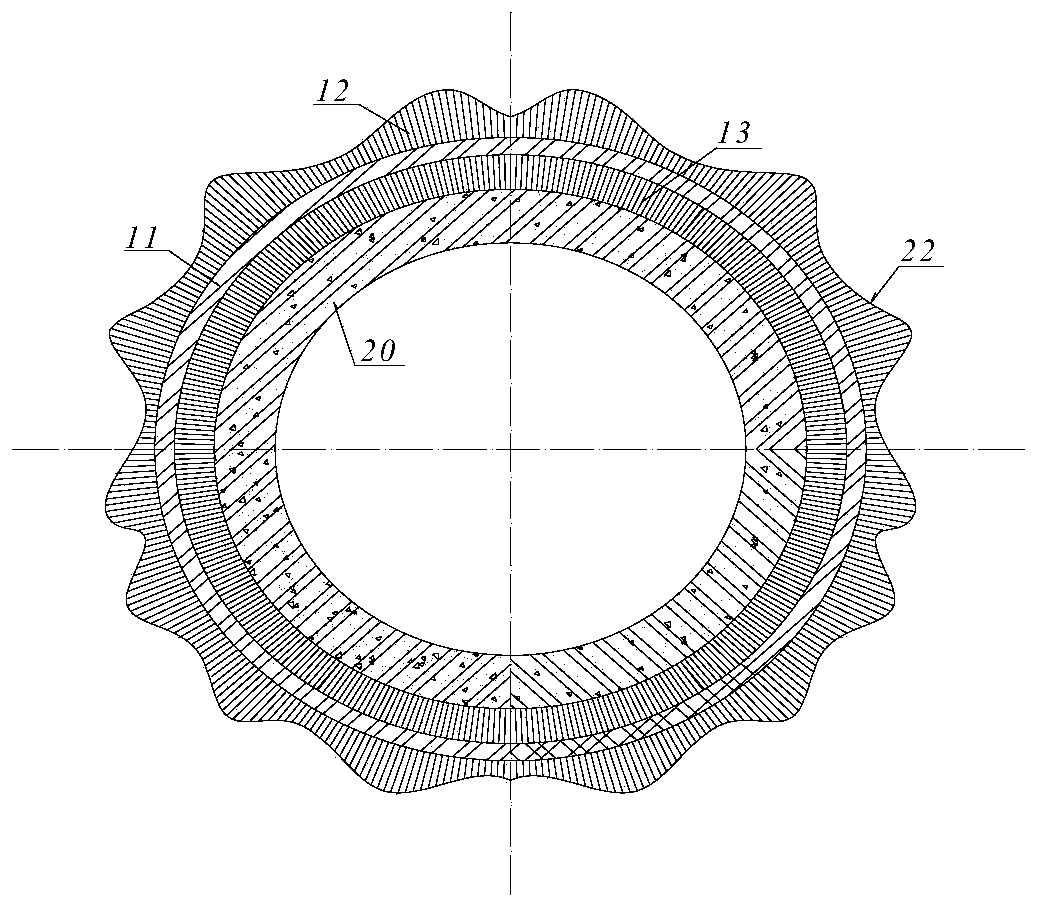

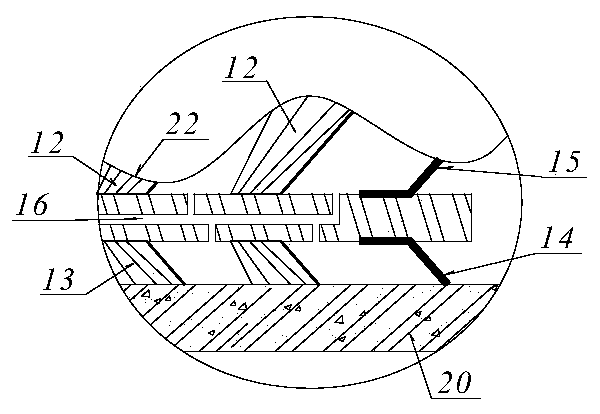

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] refer to Figure 1 to Figure 5 , an external sealing structure for a tunnel boring machine of the present invention is arranged at the tail of the steel shell 11 of the tunnel boring machine 10, the tunnel lining structure 20 extends into the steel shell 11 tail for a certain distance, and the outer peripheral wall of the tunnel lining structure 20 is connected to the After excavation of the tunnel, the annular space 21 between the cavern walls 22 is filled with slurry 31 . The tail end of the steel housing 11 is fixedly provided with an outer annular spring steel plate 15 on its outer peripheral wall, and behind the outer annular spring steel plate 15, at least one end is fixedly arranged on the outer peripheral wall of the steel housing 11 to connect with the tunnel wall after excavation. 22 keep in contact with the outer ring wire brush 12, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com