Patents

Literature

56results about How to "Improve the sealing level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

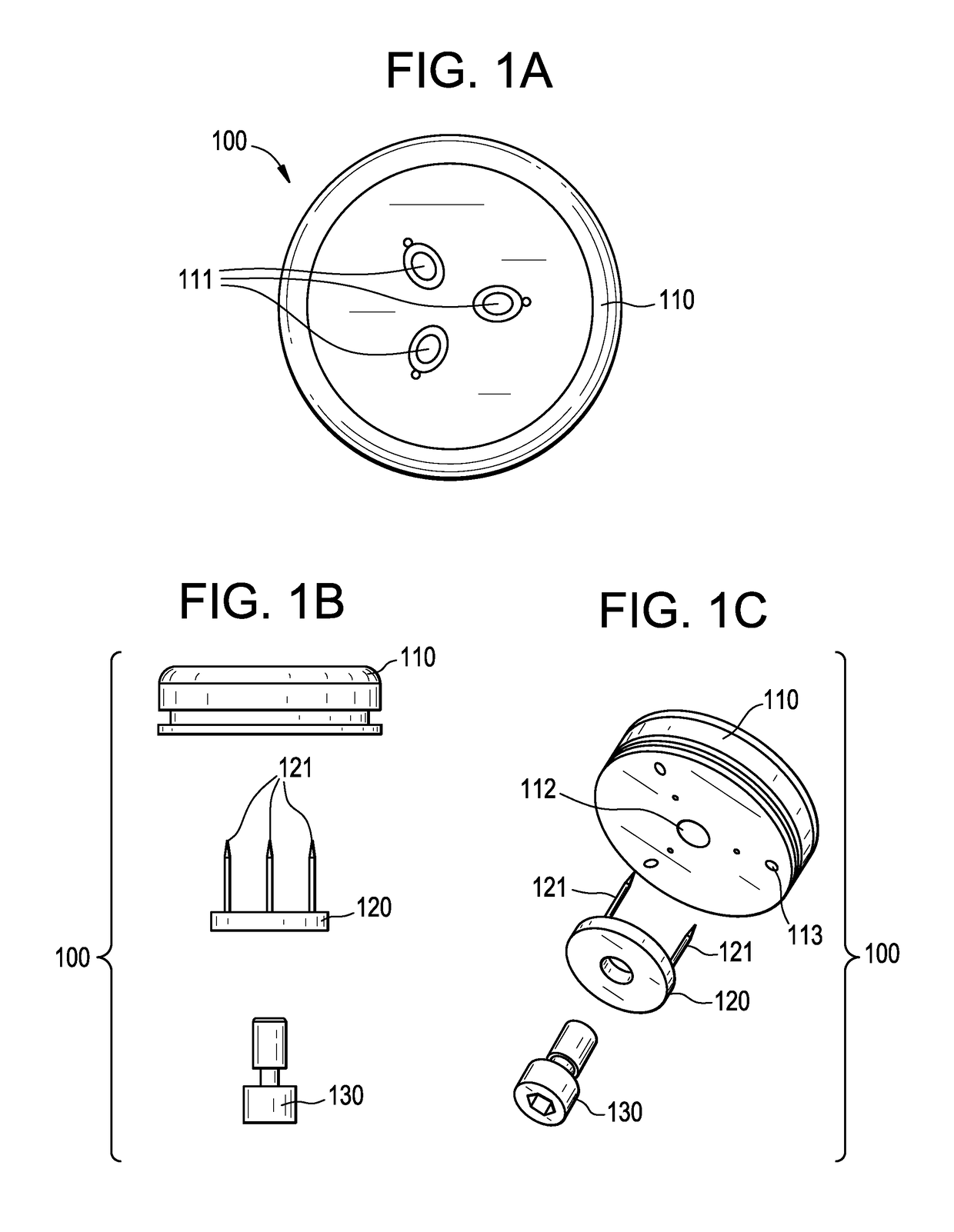

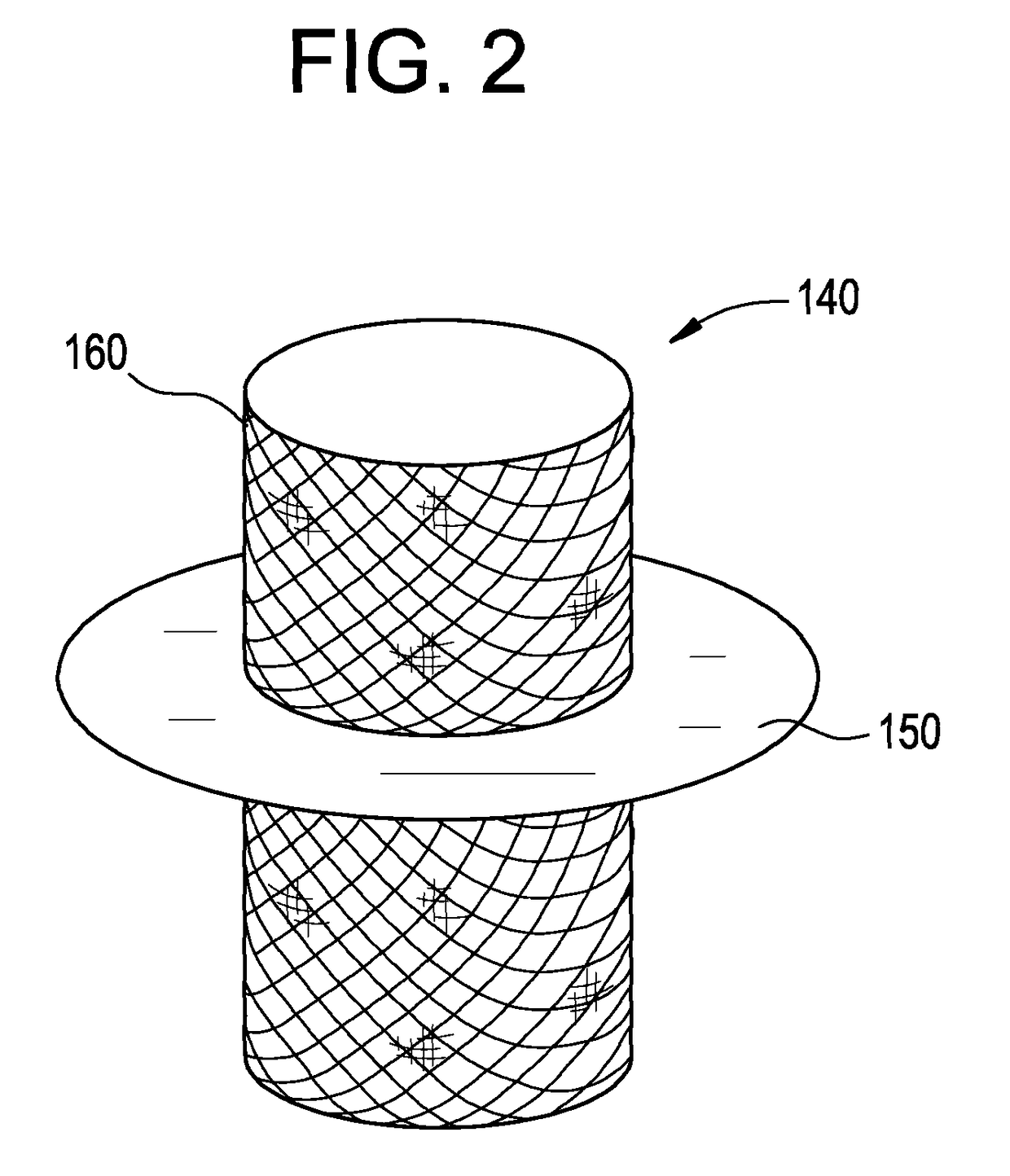

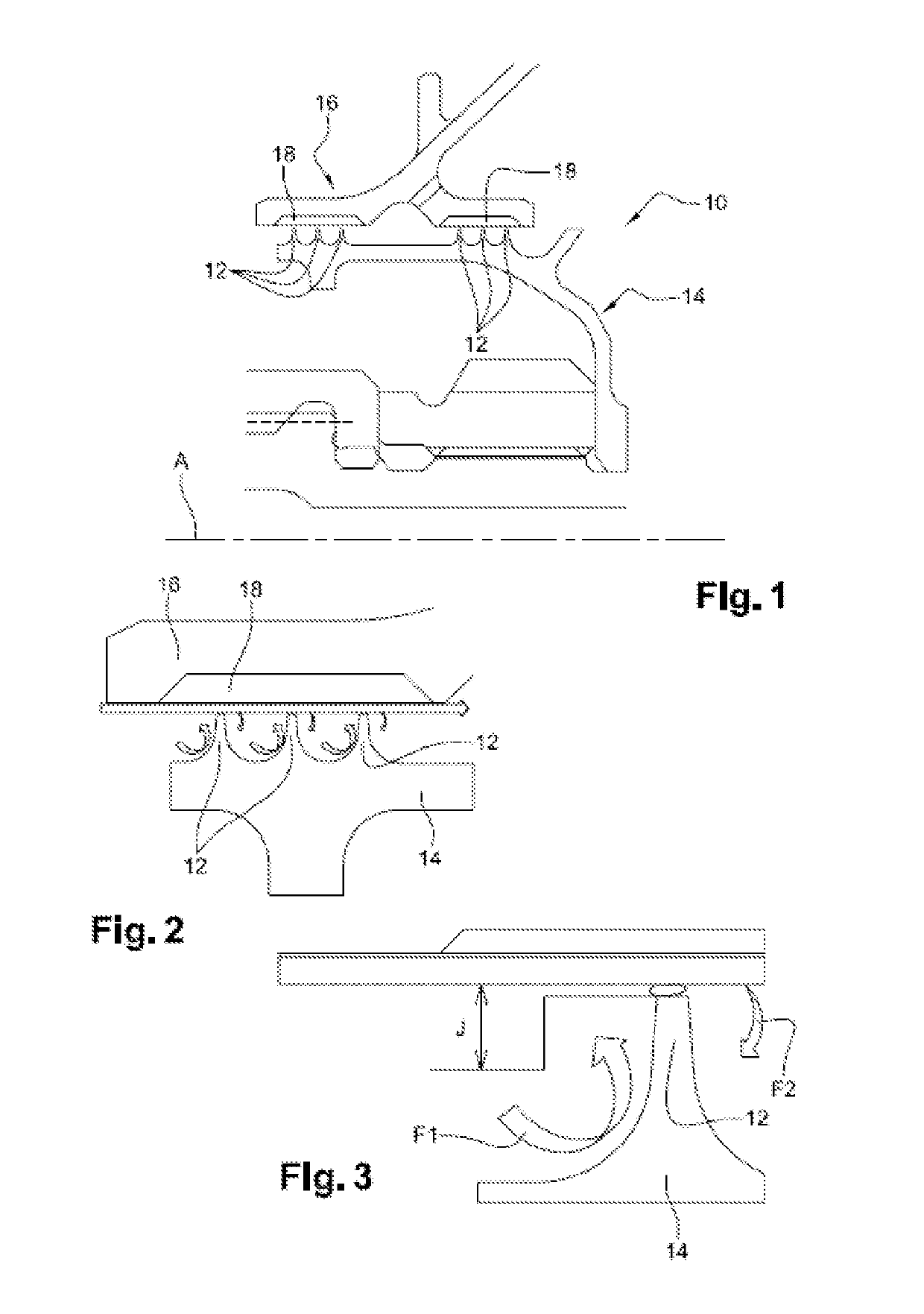

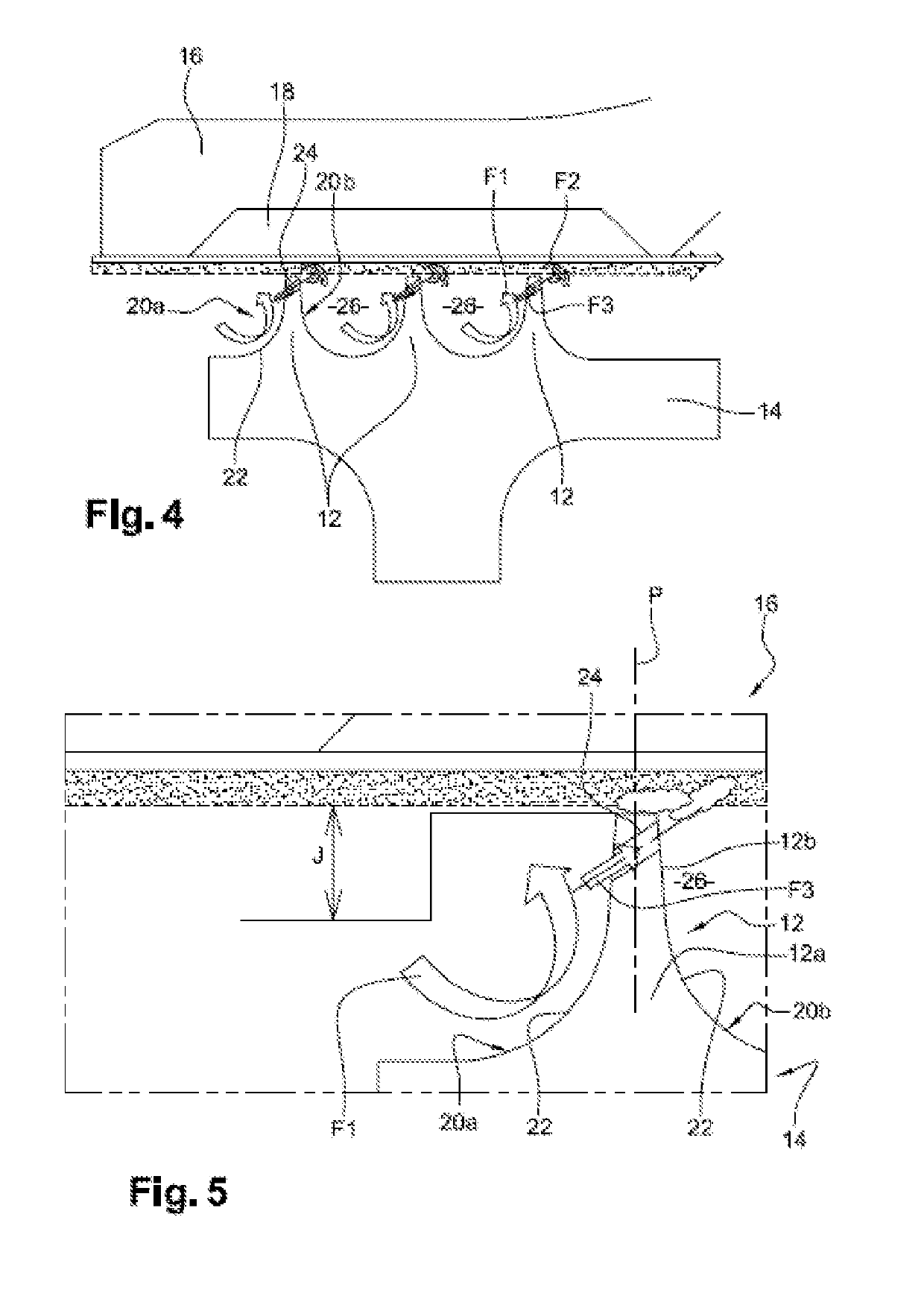

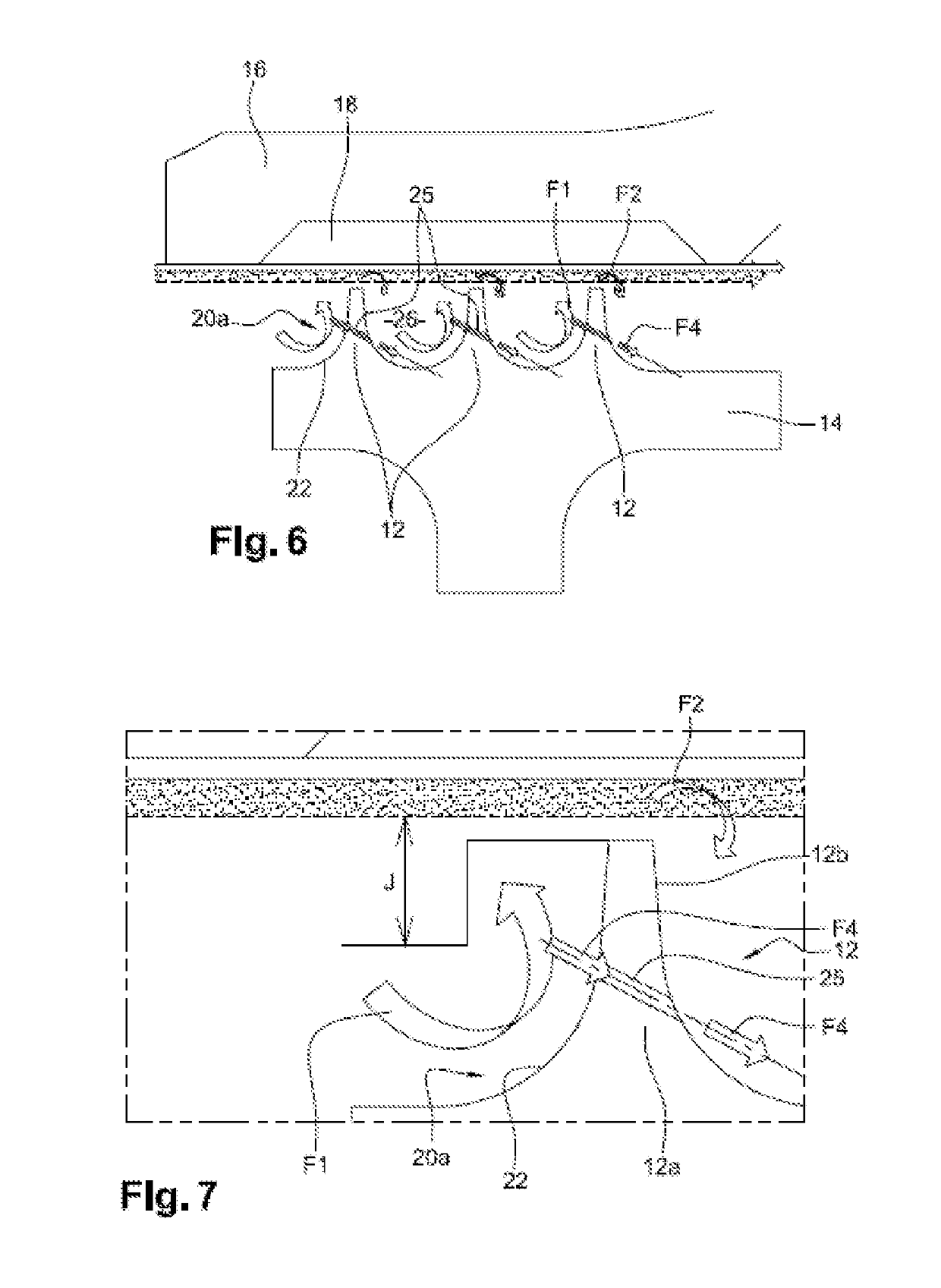

Tethers for Prosthetic Mitral Valve

ActiveUS20130172978A1Improve the sealing levelSuture equipmentsHeart valvesExtracorporeal circulationInsertion stent

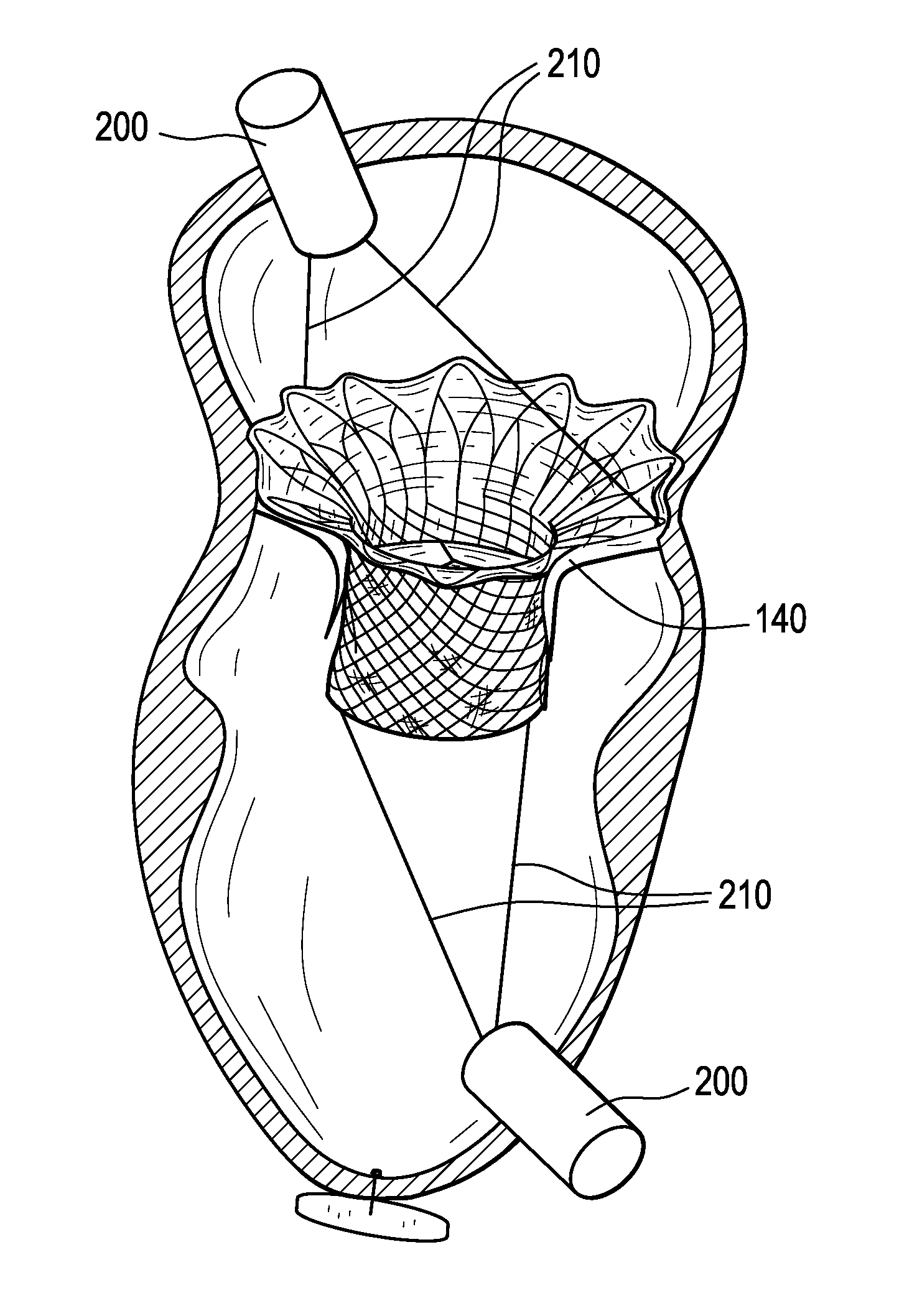

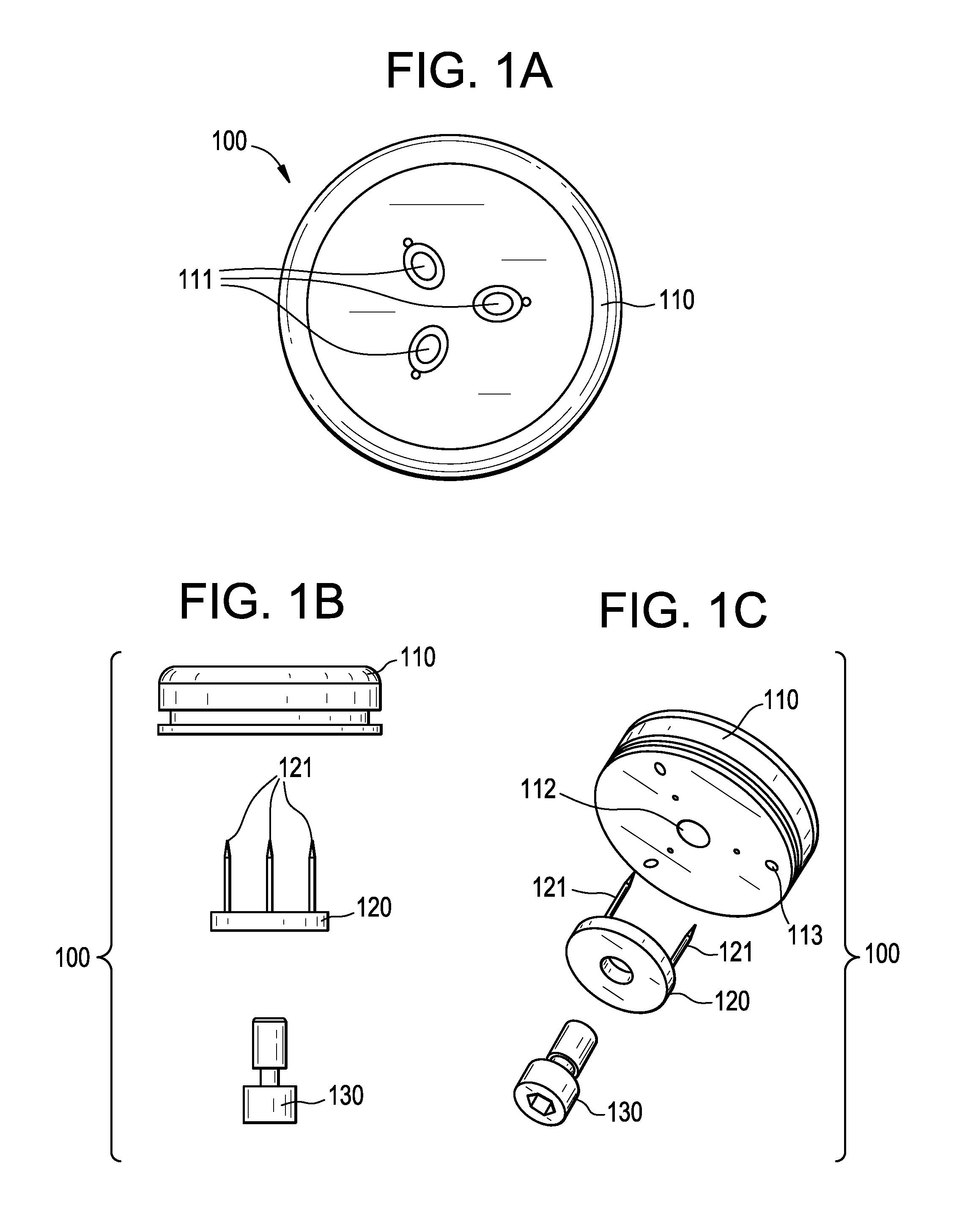

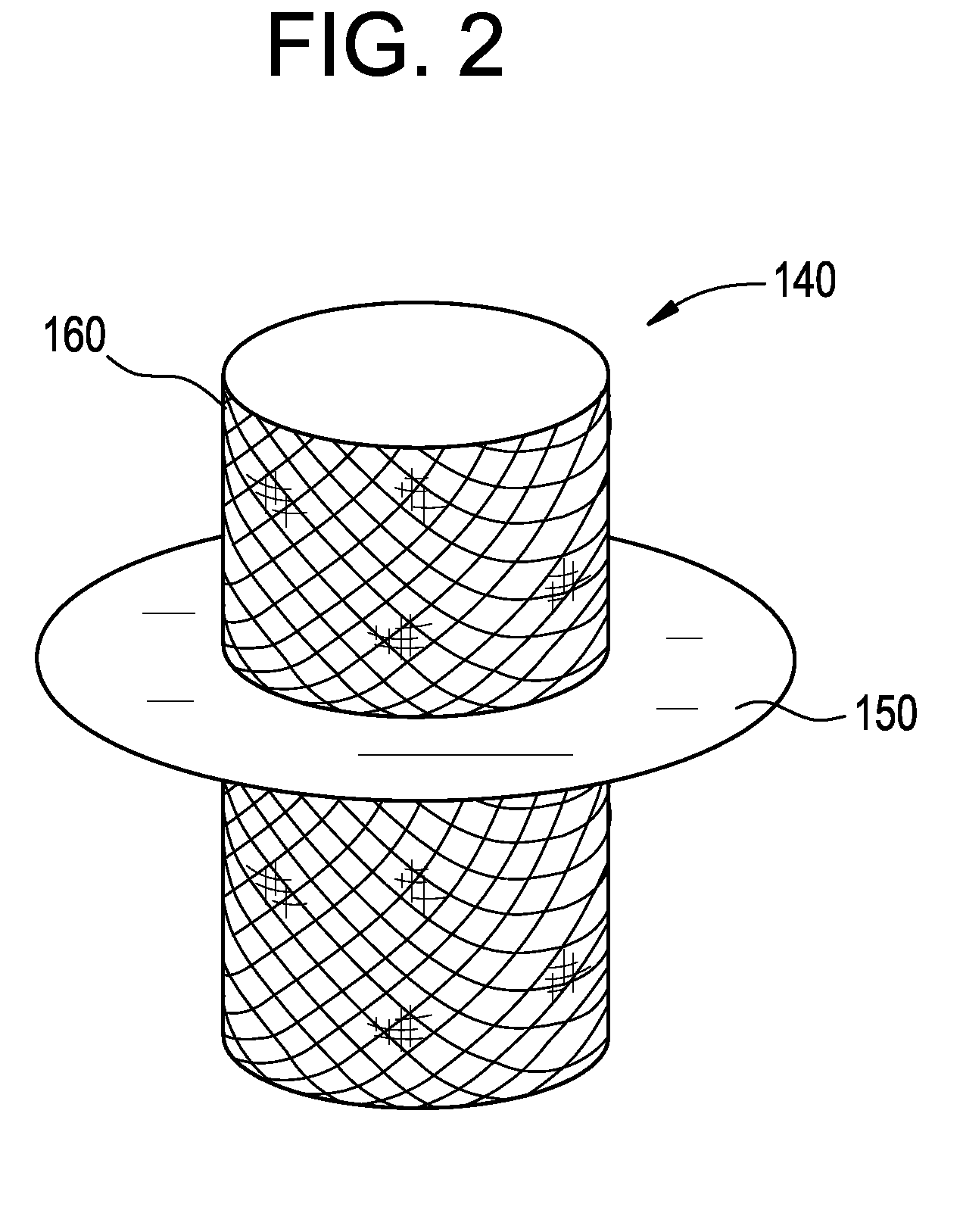

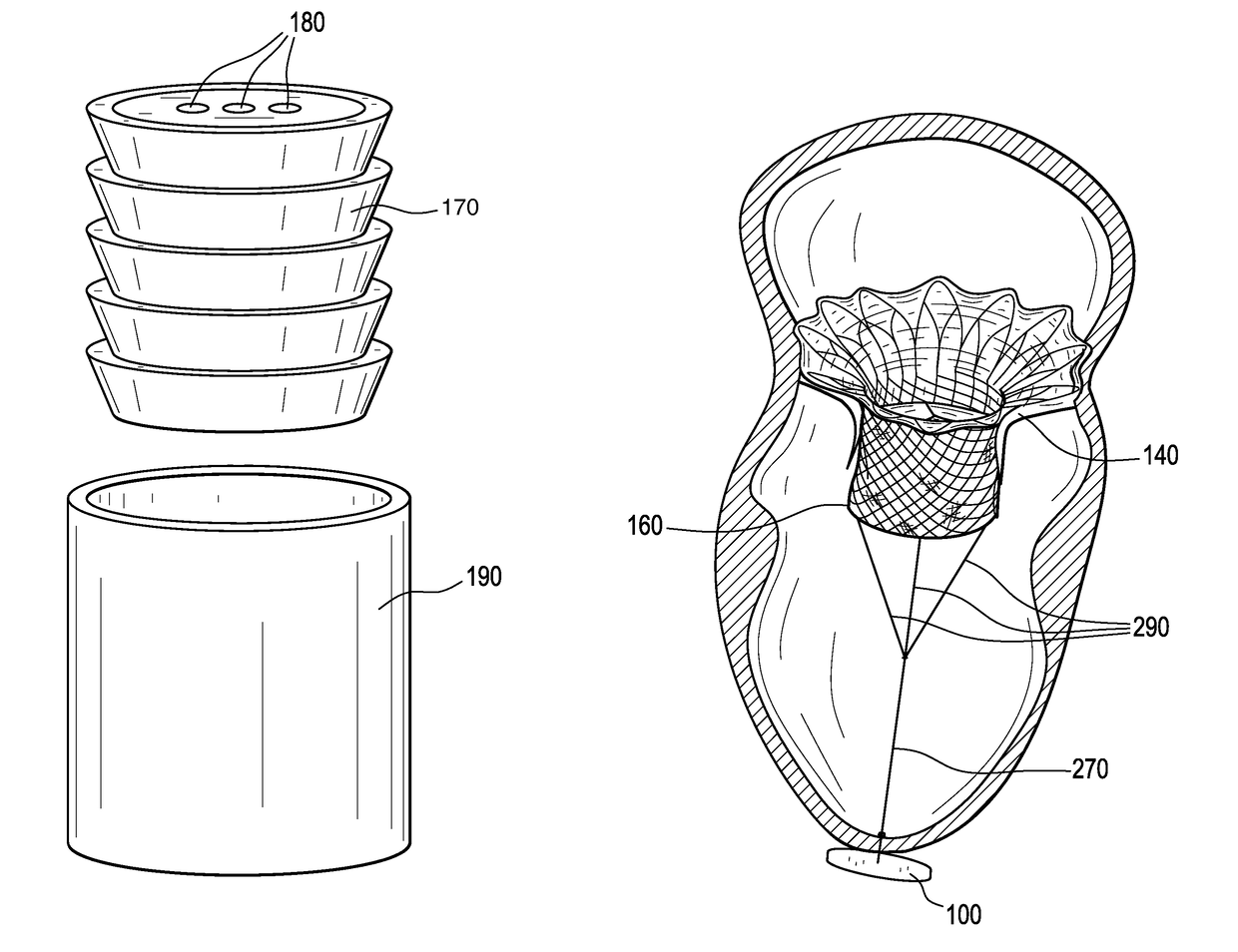

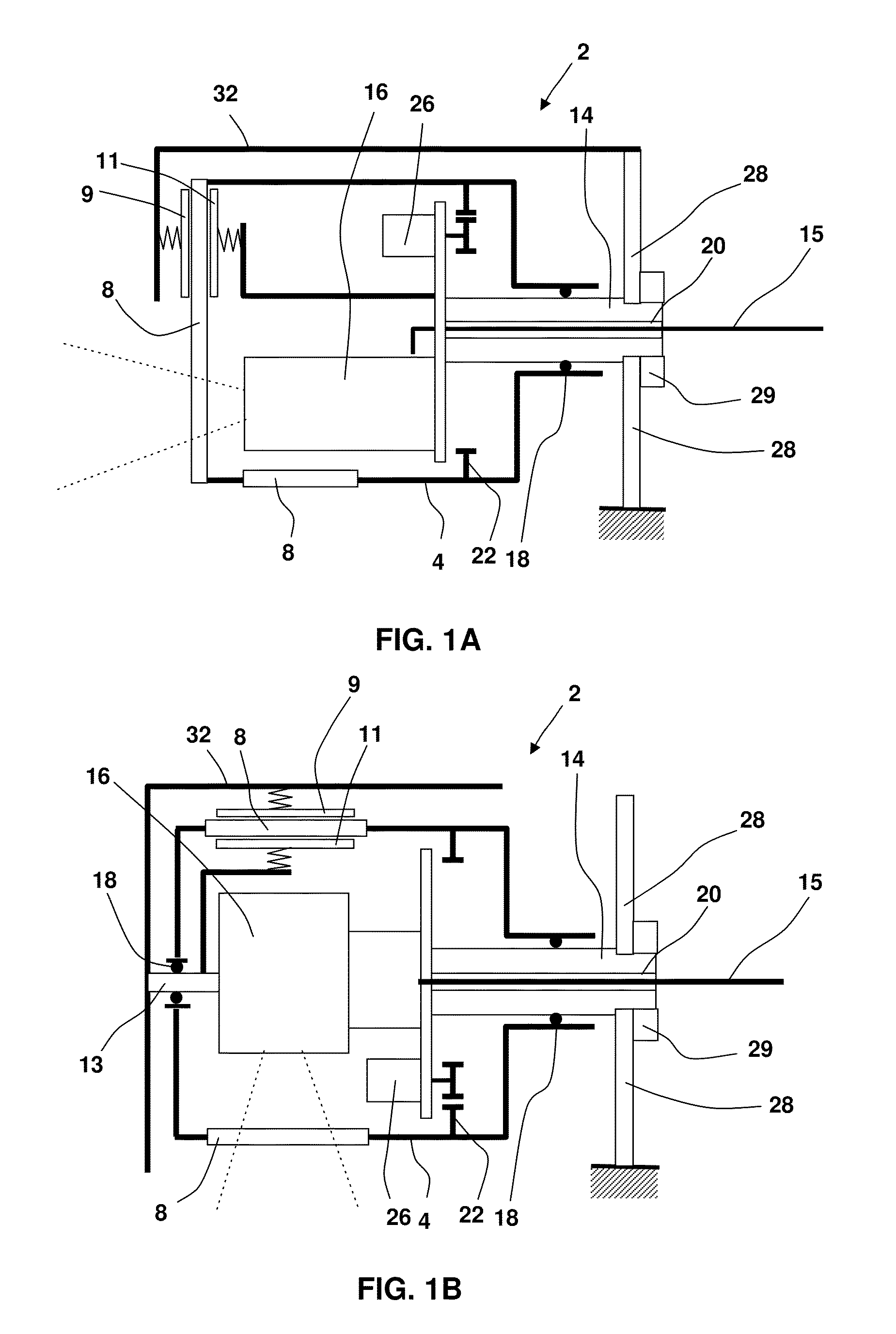

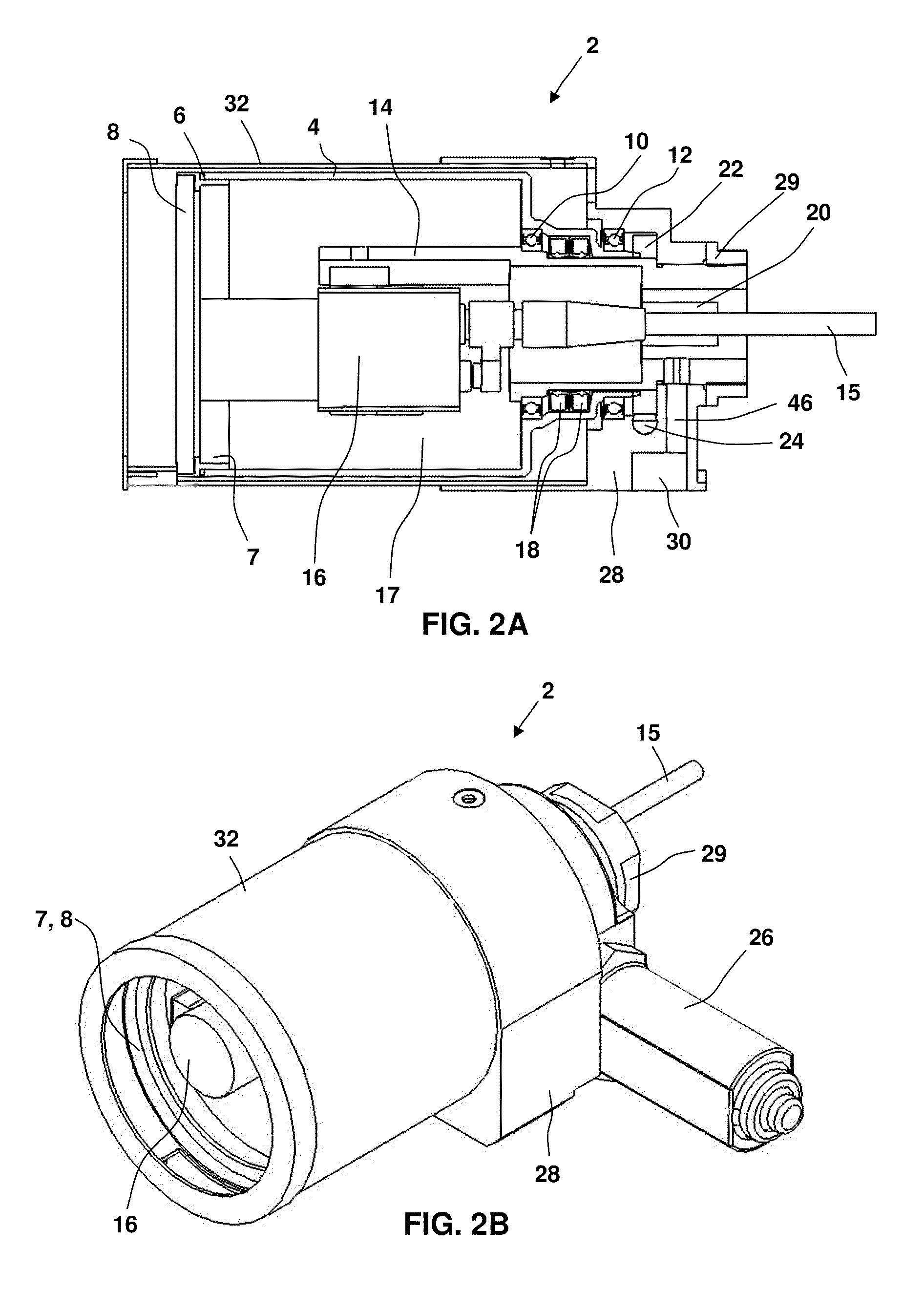

This invention relates to the design and function of a single-tether compressible valve replacement prosthesis which can be deployed into a beating heart without extracorporeal circulation using a transcatheter delivery system. The design as discussed combats the process of wear on anchoring tethers over time by using a plurality of stent-attached, centering tethers, which are themselves attached to a single anchoring tether, which extends through the ventricle and is anchored to a securing device located on the epicardium.

Owner:TENDYNE HLDG

Tethers for prosthetic mitral valve

ActiveUS9827092B2Improve the sealing levelSuture equipmentsHeart valvesExtracorporeal circulationInsertion stent

This invention relates to the design and function of a single-tether compressible valve replacement prosthesis which can be deployed into a beating heart without extracorporeal circulation using a transcatheter delivery system. The design as discussed combats the process of wear on anchoring tethers over time by using a plurality of stent-attached, centering tethers, which are themselves attached to a single anchoring tether, which extends through the ventricle and is anchored to a securing device located on the epicardium.

Owner:TENDYNE HLDG

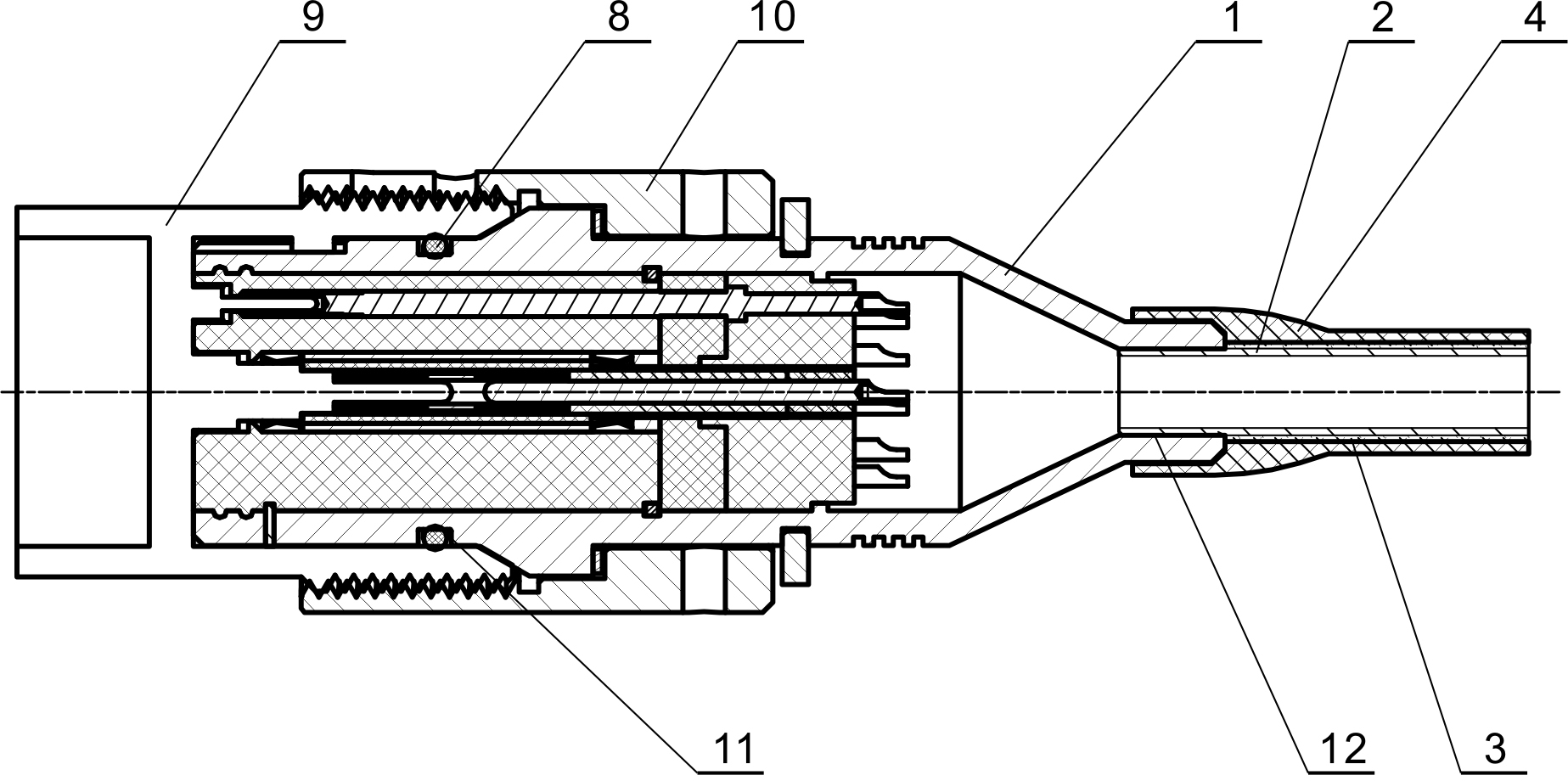

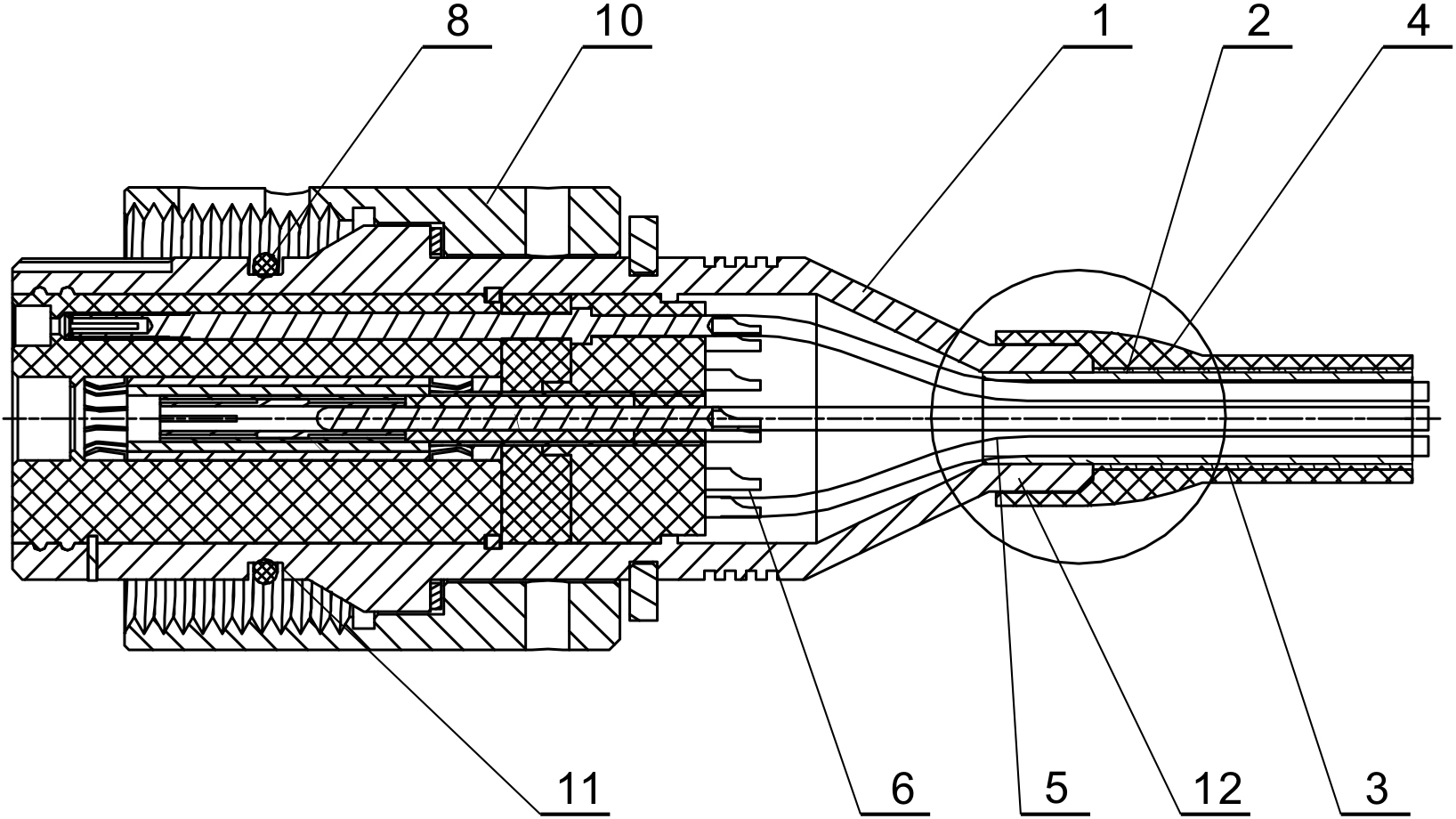

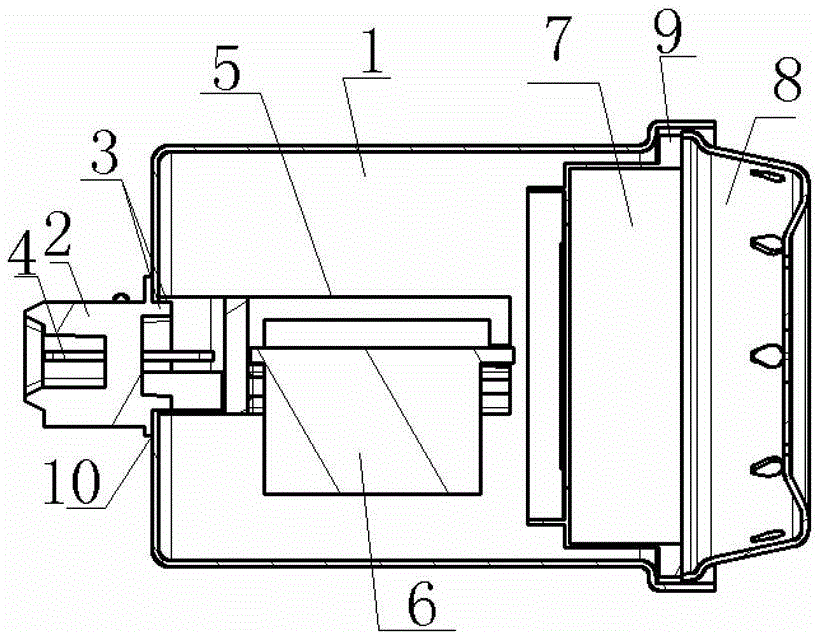

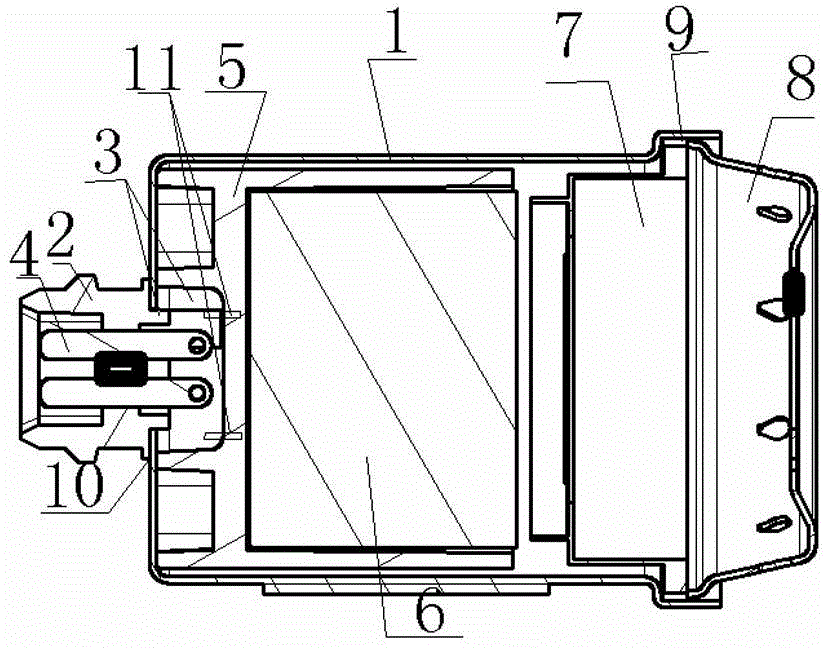

Electric connector sealing structure

InactiveCN102593655ASimple structureEasy constructionCouplings bases/casesElectricityWorking environment

The invention discloses an electric connector sealing structure, which comprises a plug shell, a copper tube, a shrinkable tube, a rubber sleeve, a sealing ring, a socket and a connecting nut, wherein the copper tube is locally inserted in a cable socket and is welded with the cable socket; the shrinkable tube is coated on an exposed surface of the copper tube; the rubber sleeve is coated on outer surfaces of the plug shell and the shrinkable tube; the sealing ring is arranged in a sealing groove of the plug shell; the socket is sleeved at one end of the plug shell; and the connecting nut is sleeved at the other end of the plug shell and is meshed with external threads of the socket. The invention has the advantages that: the electric connector sealing structure has a simple structure, high sealing degree and high reliability and is convenient to construct; and moreover, the electric connector sealing structure is suitable for a high-temperature high-pressure working environment and a working environment with a wide temperature difference range and is also suitable for a working environment with an explosion-proof requirement, and a high sealing level between the interior of the connector and the outside is guaranteed after the electric connector is connected with a cable.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

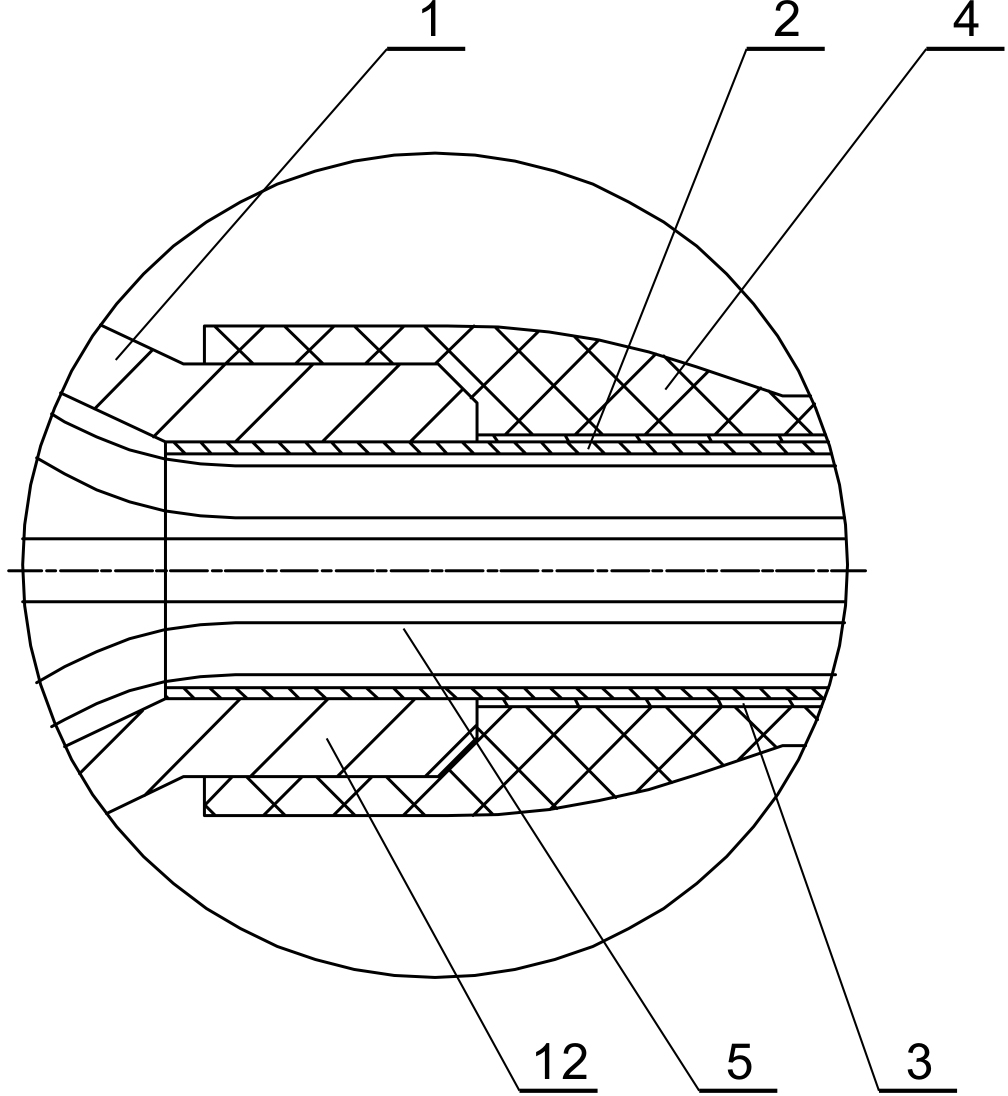

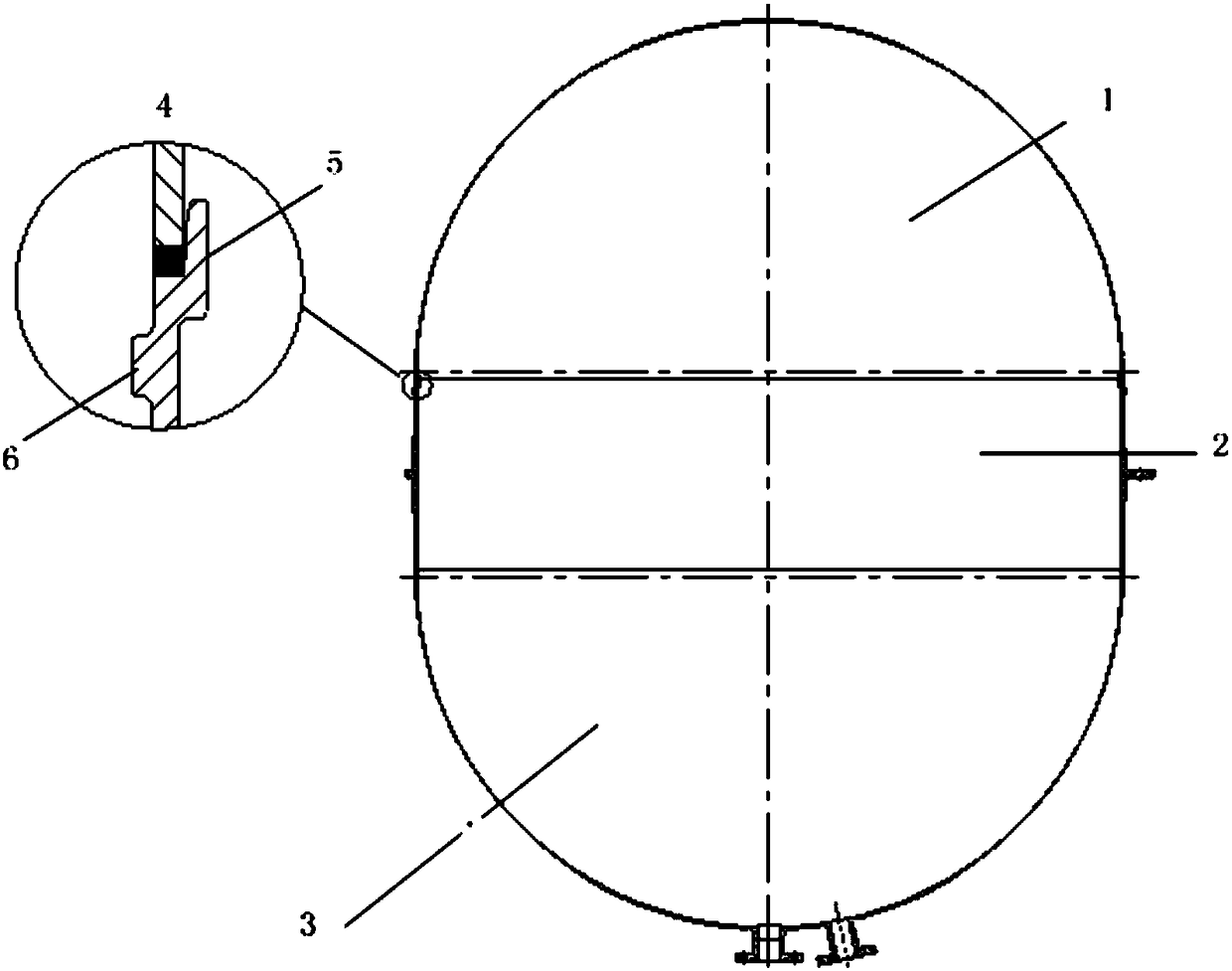

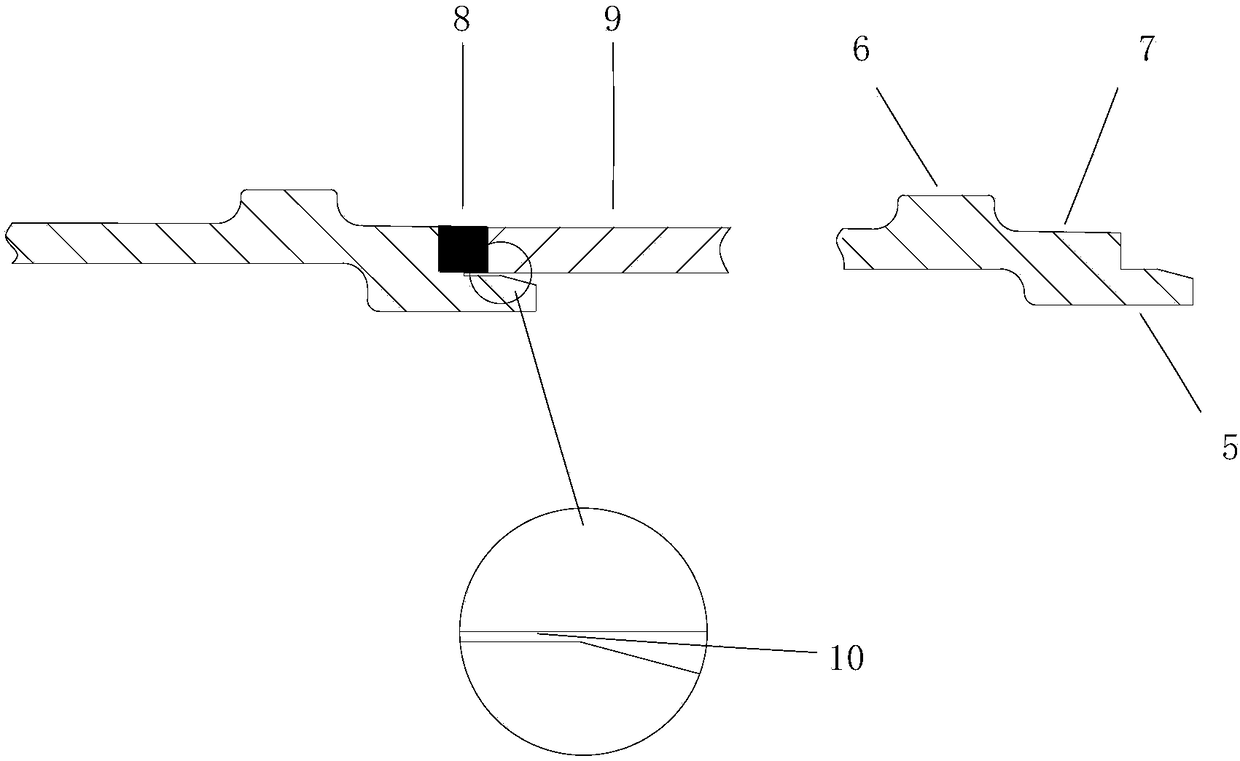

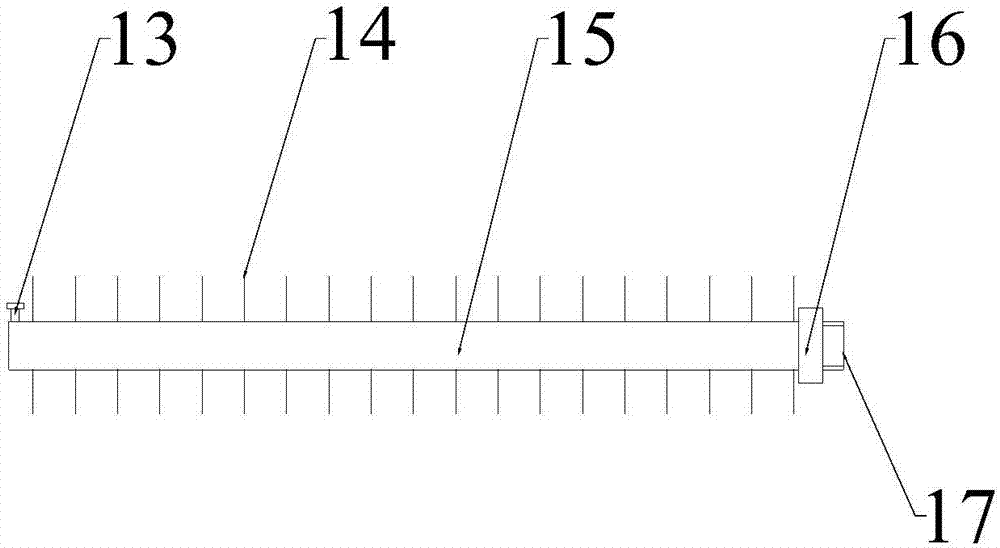

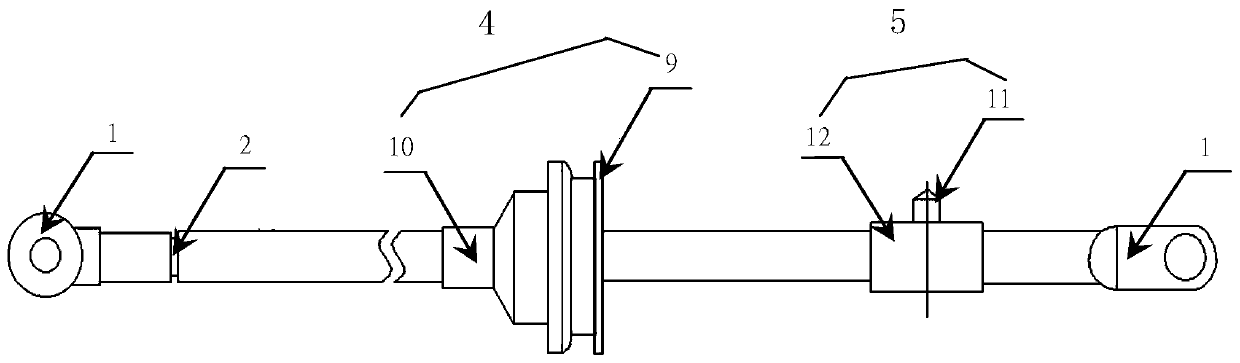

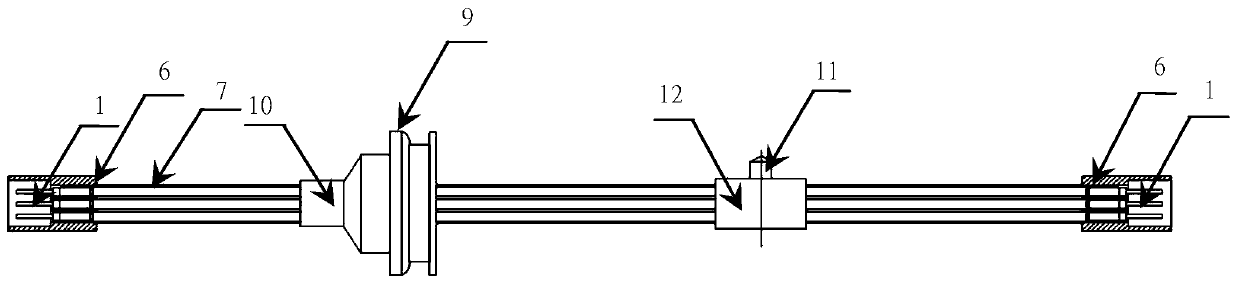

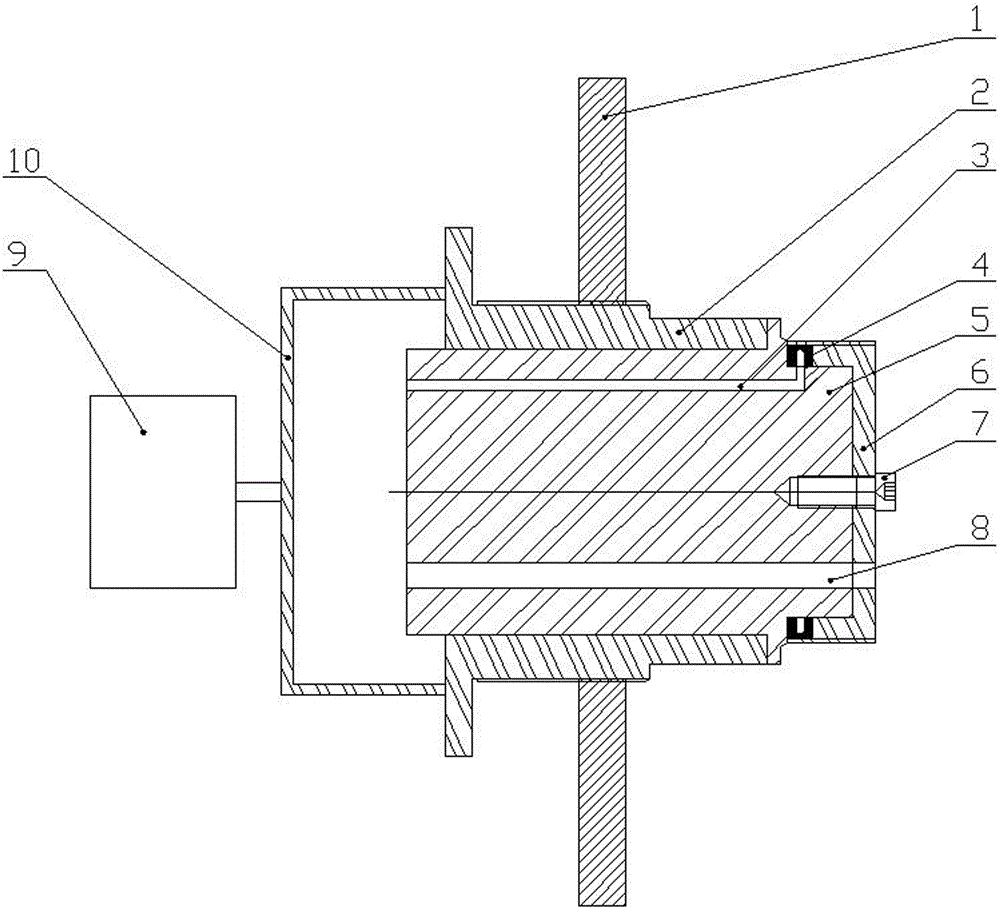

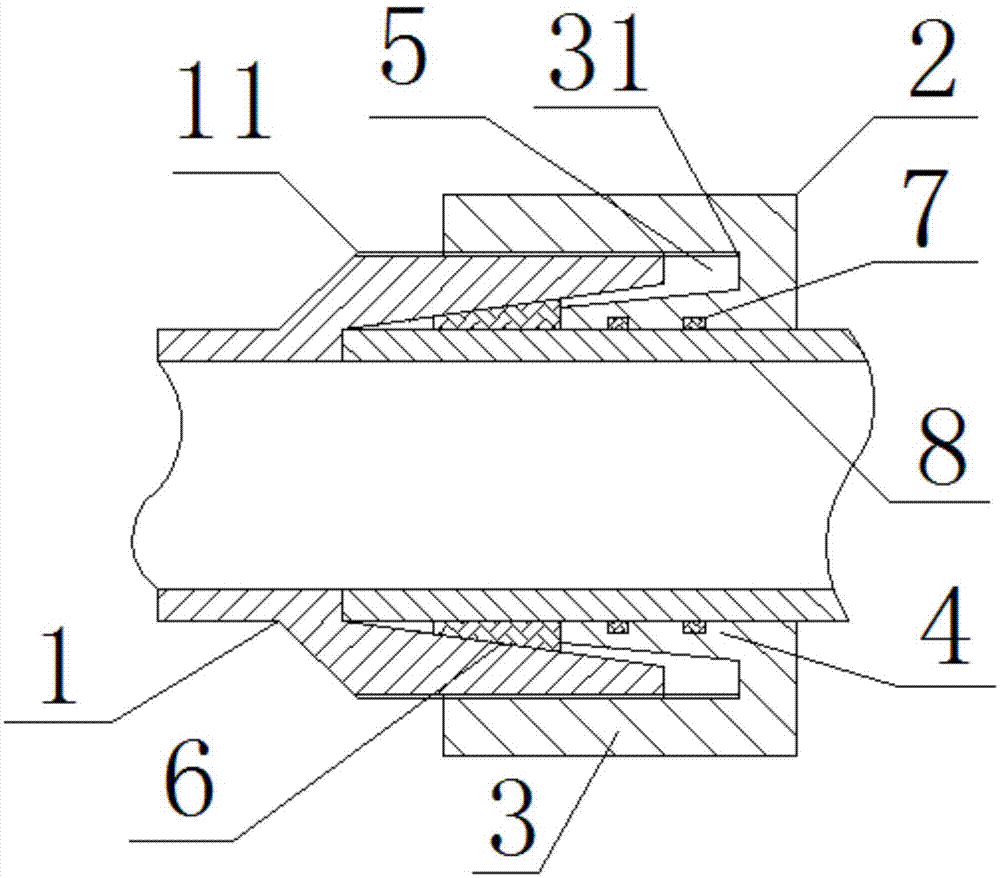

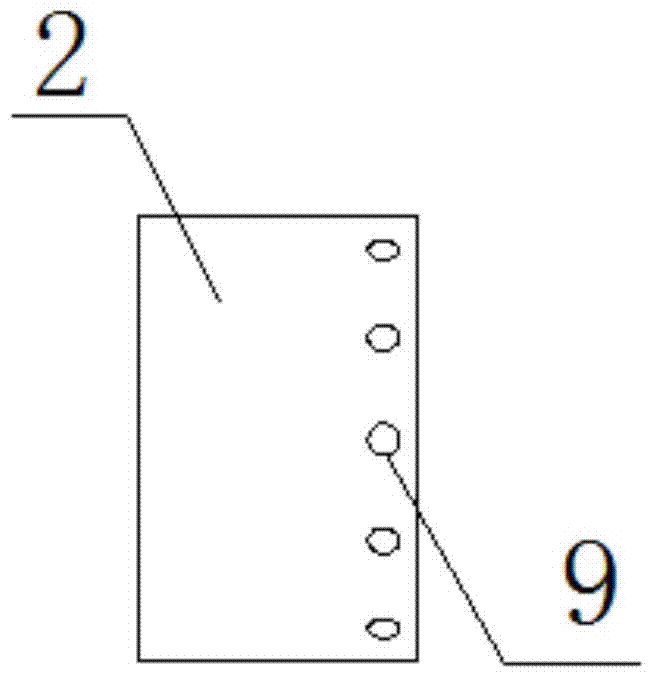

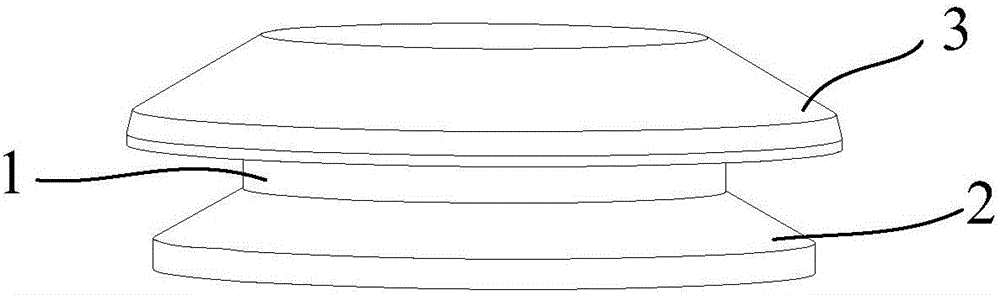

All-welded ultra thin-walled storage tank and welding structure suitable for all welding

InactiveCN108488006AIncrease stiffnessImprove welding qualityCosmonautic vehiclesCosmonautic propulsion system apparatusMechanical engineeringElectron bunches

The invention discloses an all-welded ultra thin-walled storage tank and a welding structure suitable for all welding. The all-welded ultra thin-walled storage tank comprises a front bottom (1), a cylinder segment (2) and a rear bottom (3). The welding structure comprises a lock bottom (5), a reinforcing boss (6) and a middle connection structure (7). The welding structure is connected with the cylinder segment (2) through the middle connection structure (7). The front bottom (1) comprises a front bottom welding edge (9) or the rear bottom (3) comprises a rear bottom welding edge (9). The welding edge (9) and the middle connection structure (7) are connected through electron beam welding. According to the all-welded ultra thin-walled storage tank and the welding structure suitable for allwelding, the technical effects that the welding process is simplified, the welding quality is improved, the sealing level reaches the limit and the storage box wall is ultra thin are achieved, and thetechnical purpose of designing the storage box with the leak rate reaches the limit is achieved.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

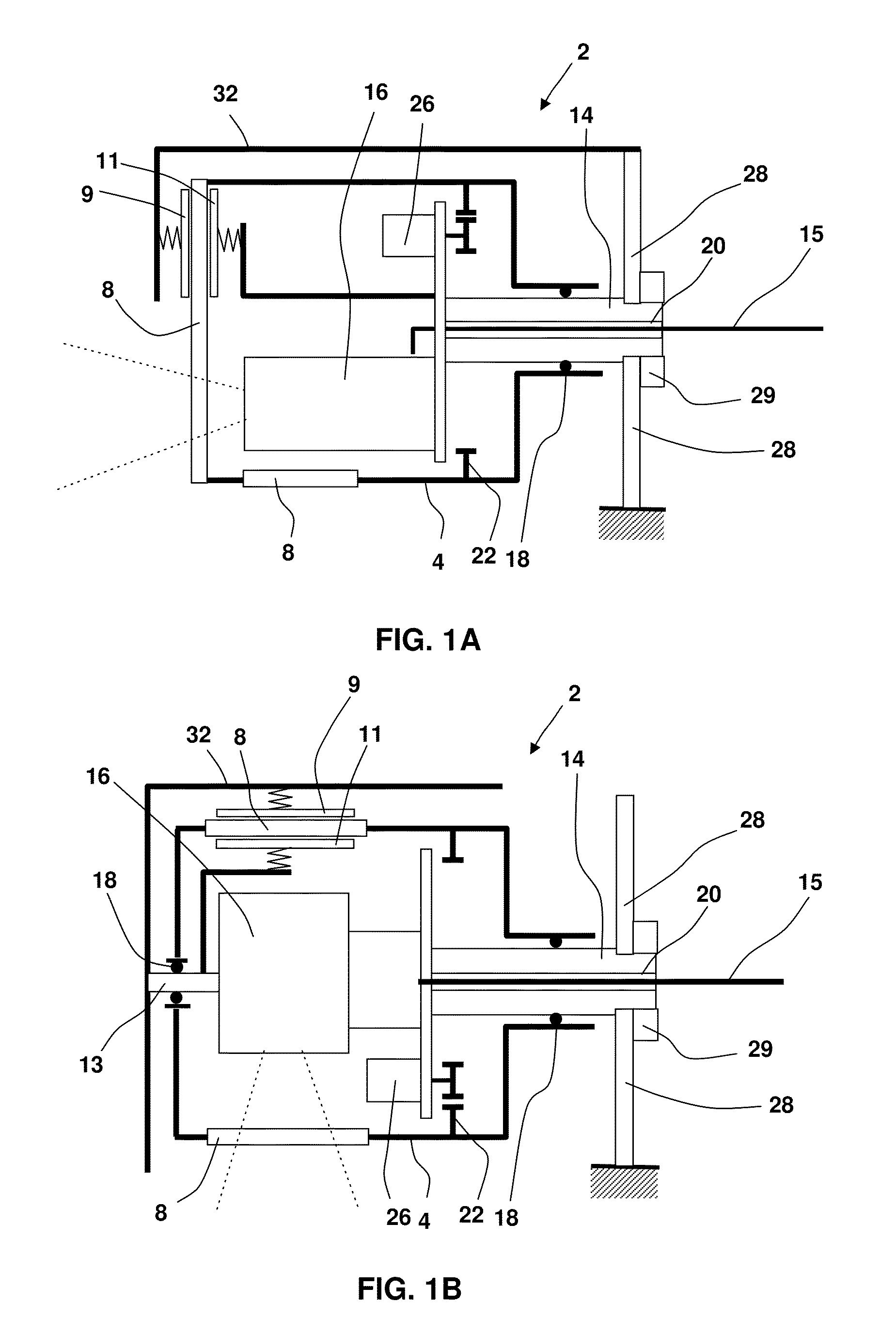

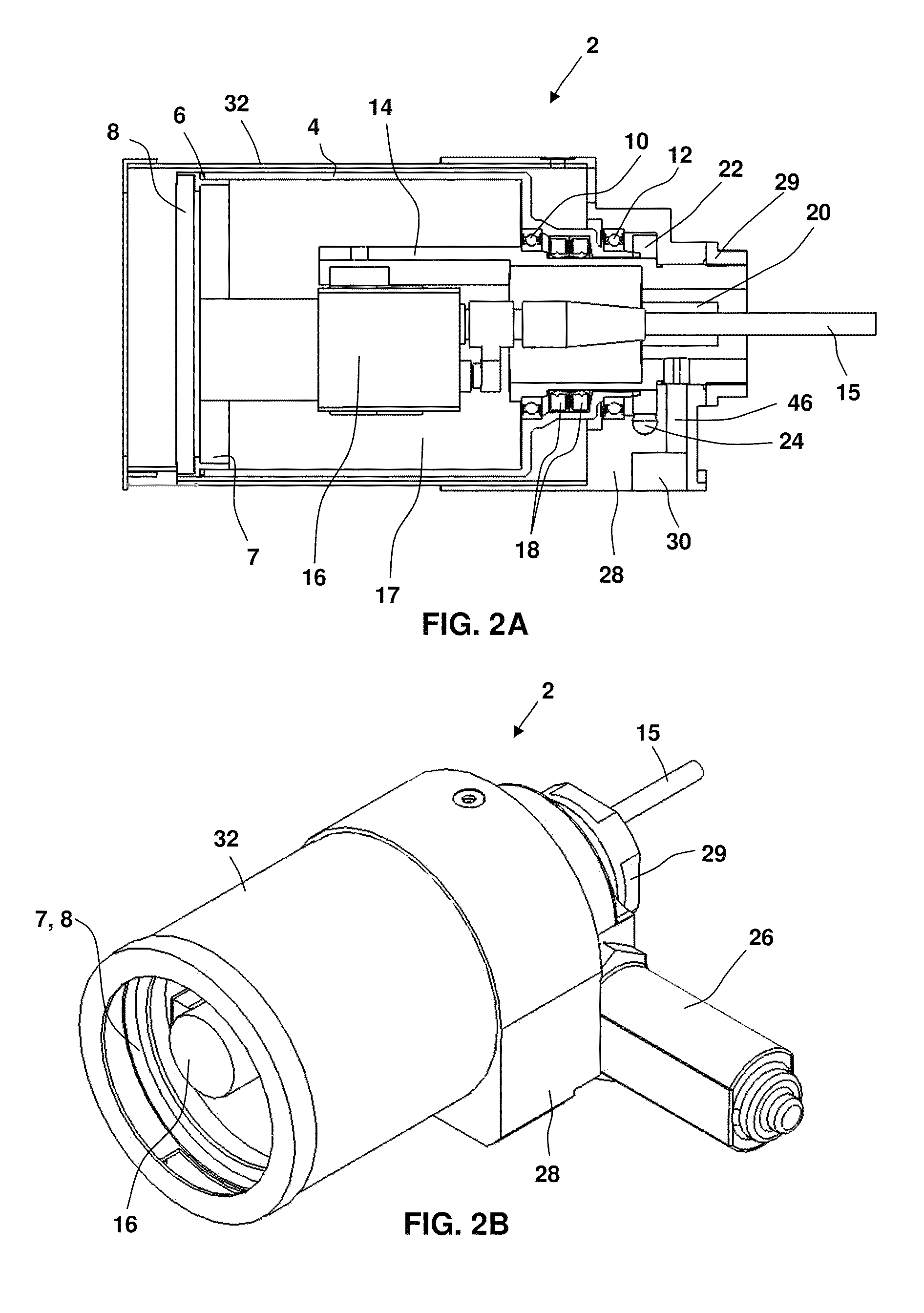

Moisture barrier breathing device

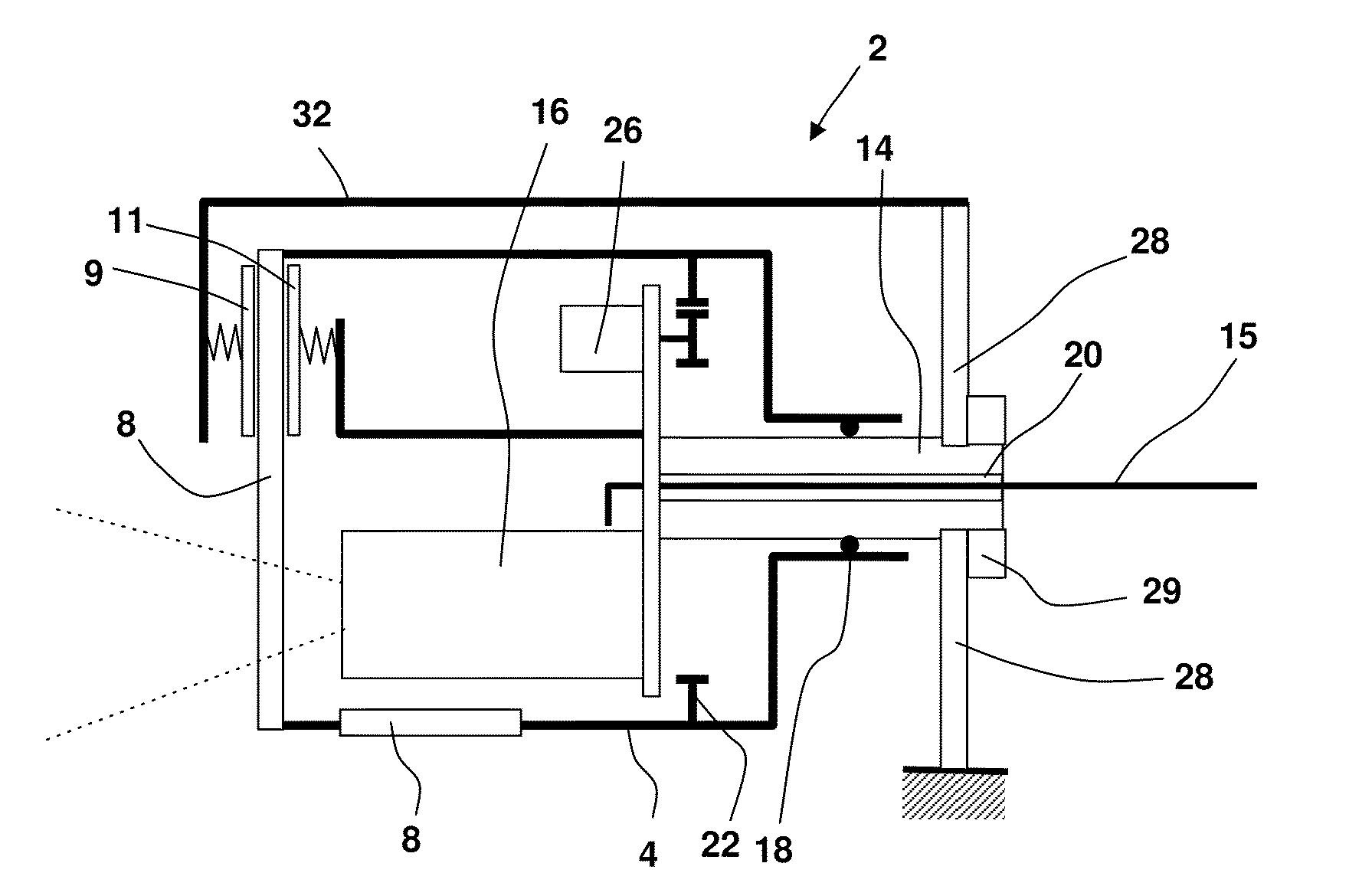

ActiveUS20100071150A1Effective barrierImprove the sealing levelLiquid processingReconditioning/cleaning record carriersEngineeringMoisture barrier

A cleaning assembly (2) for an optical device (16) includes a shaft (14) configured for supporting the optical device within an enclosure (4) that is adapted for rotation about the shaft. At least one first sealing element (18) is disposed between the shaft and a mating surface of the enclosure for preventing fluid leakage therethrough. At least one optically transparent window (8) is mounted in association with the enclosure (4), and at least one cleaning element (9, 11) is coupled to the shaft for cleaning a surface of the window (8). The cleaning assembly may include a moisture barrier in the form of a pressure-influenced member (58) such as a bellows (40) having a body of expandable and retractable-volume for containing air that diffuses therein, while equalizing pressure on opposite sides of the barrier.

Owner:KERETH YEFIM

Closed type optical fiber pass-through device and processing method thereof

InactiveCN106340372AImprove the sealing levelGood sealing effectTransformers/inductances casingsCoupling light guidesFlangeScrew thread

The invention relates to the technical field of communication and provides a closed type optical fiber pass-through device and a processing method thereof. The device comprises a flange, an installation plate and optical fiber pass-through devices, wherein each of the optical fiber pass-through devices comprises a main body with a through hole, a ceramic inserted core, and two sleeves; the ceramic inserted core is bonded inside the through hole; the ceramic inserted core is provided with a light-permeable bare optical fiber encapsulated with glue; the two sleeves are positioned inside the through hole and sleeve on two ends of the ceramic inserted core. According to the device, the airtightness of the optical fiber pass-through device inside is guaranteed through glue binding sealing mode inside the optical fiber pass-through device; threaded connection is adopted between the optical fiber pass-through device main body and the installation plate, and screw thread assembling play the role of sealing so that the sealing grade of the closed type optical fiber pass-through device is increased, and the sealing effect is good; meanwhile, due to the simple overall structure of the closed type optical fiber pass-through device, less space occupation, simple processing method and small cost, large scale production and application are facilitated.

Owner:SHENZHEN INST OF ADVANCED TECH

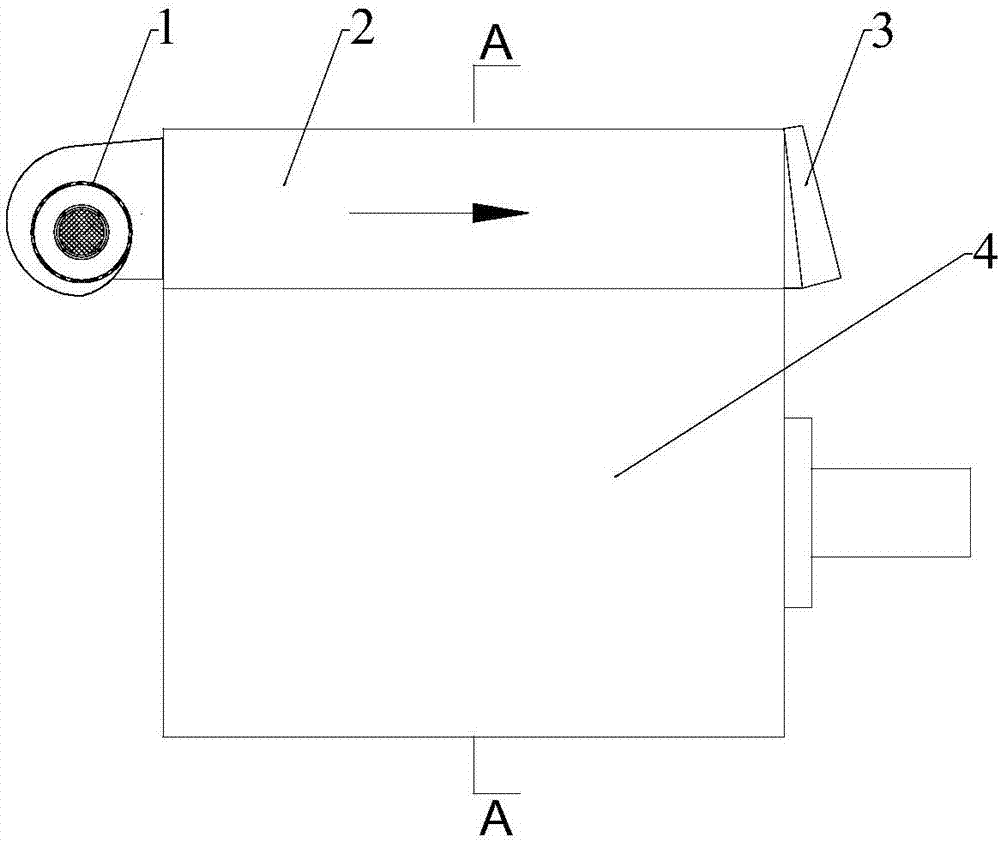

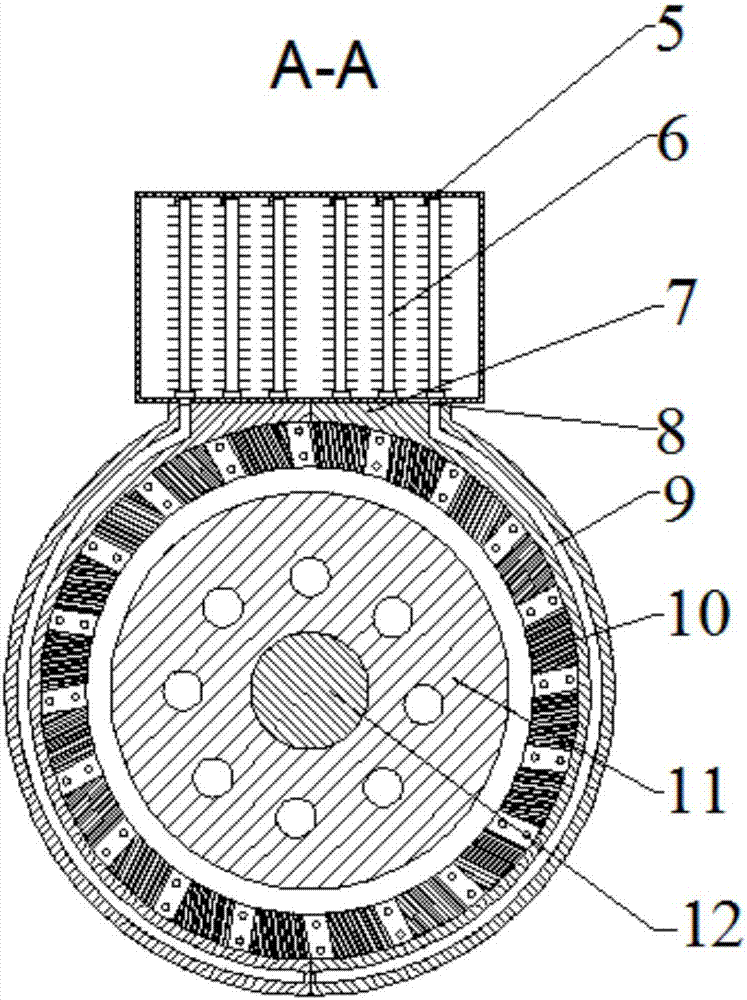

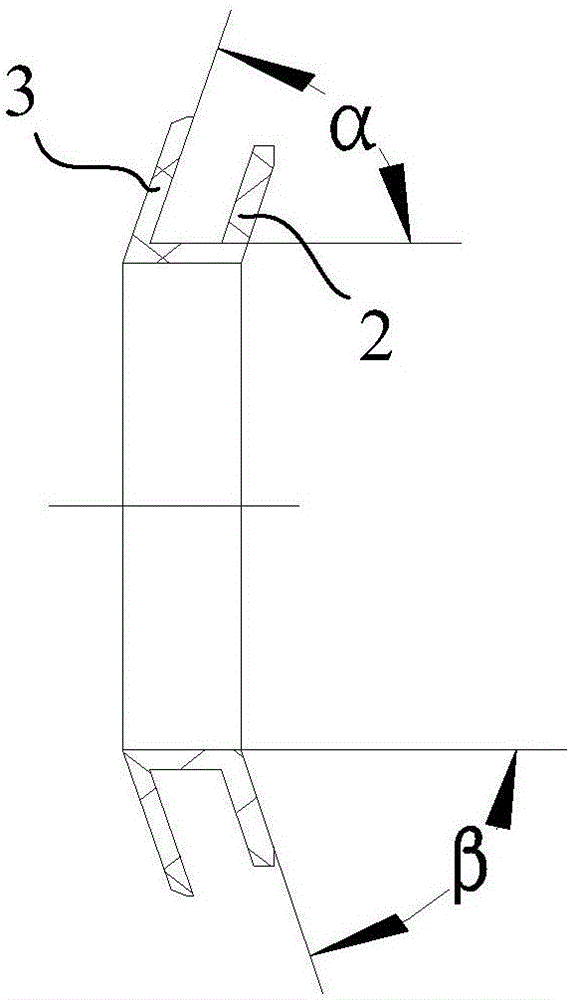

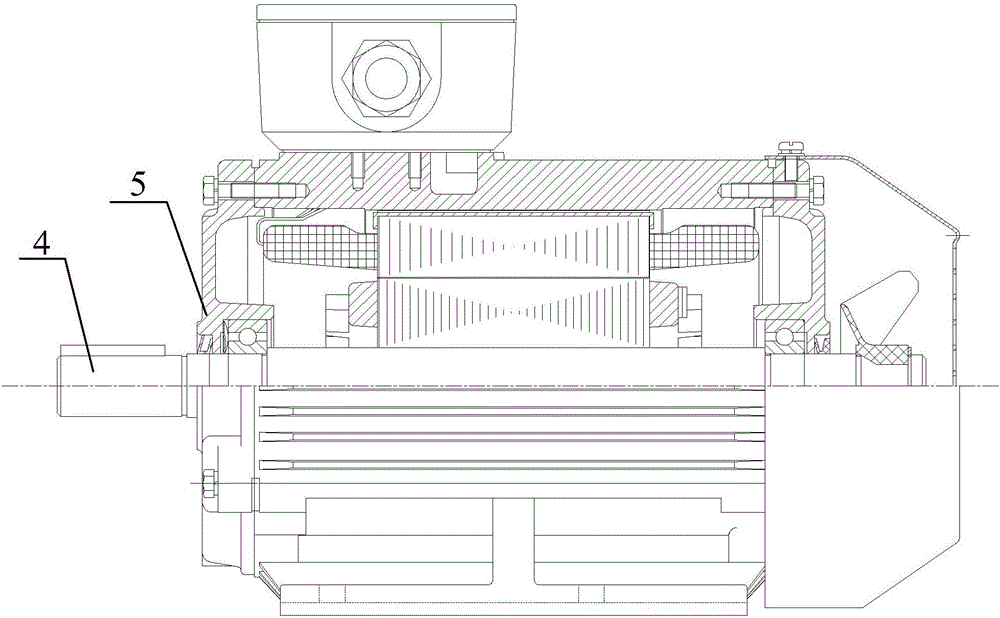

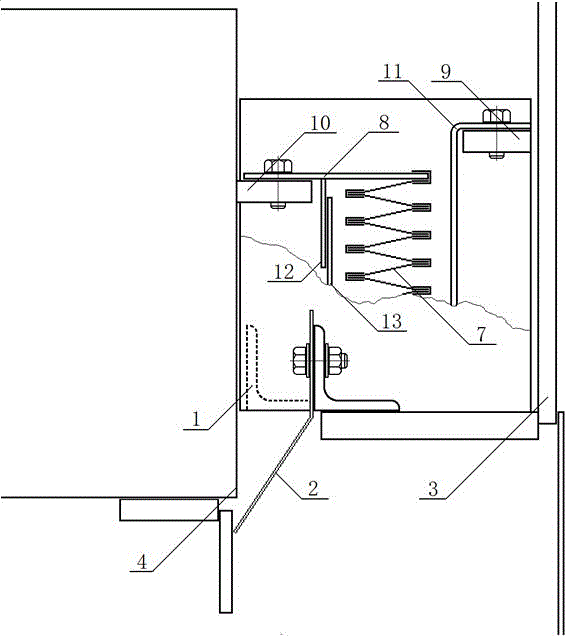

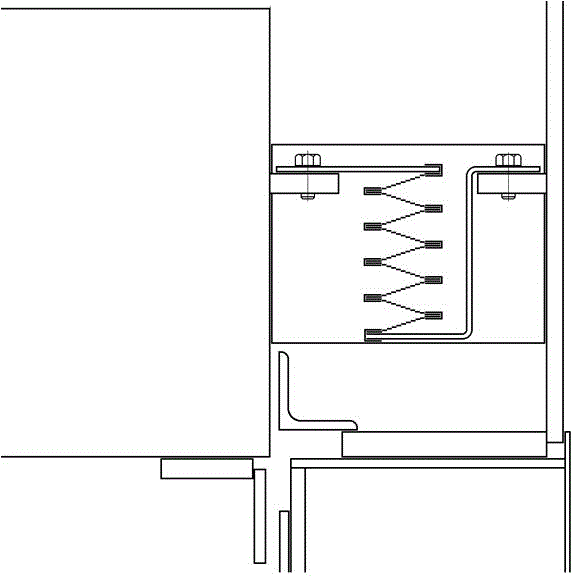

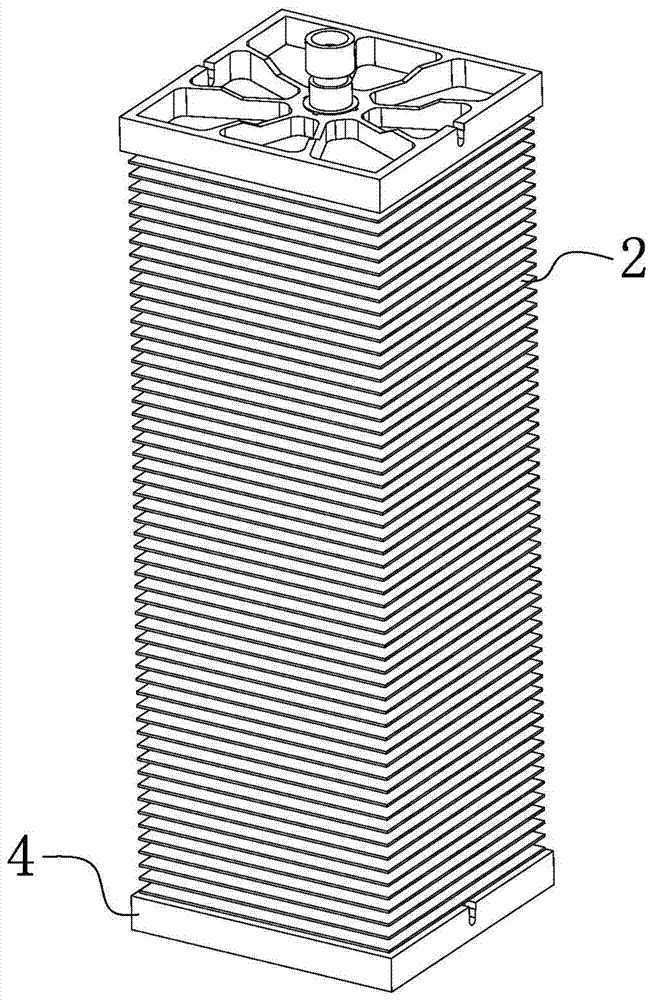

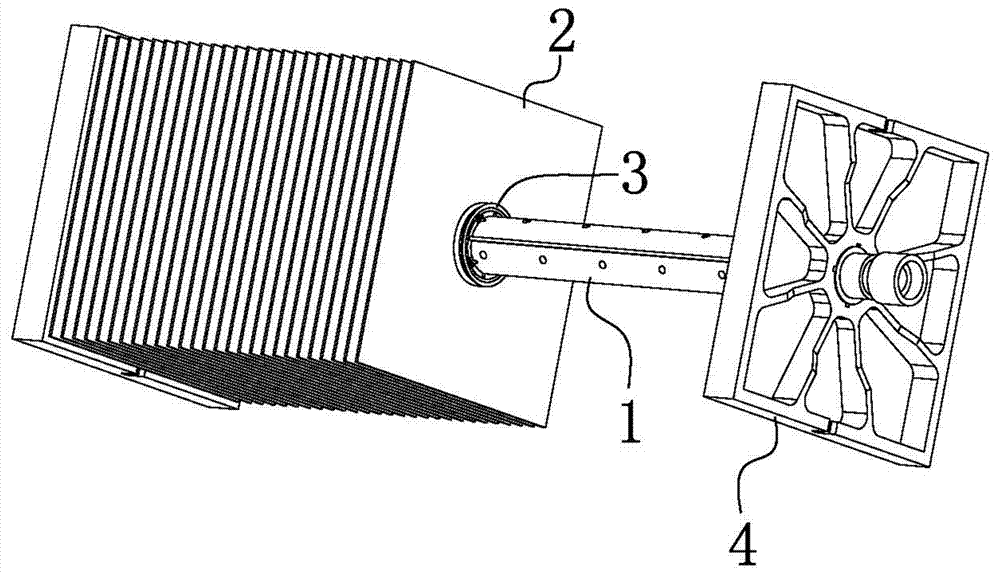

Heat pipe generator air-cooling cooling device

PendingCN107294291ASimple internal structureImprove the sealing levelCooling/ventillation arrangementSupports/enclosures/casingsElectric generatorHeat pipe

The invention relates to a heat pipe generator air-cooling cooling device which comprises a generator, and the generator comprises a stator, a rotator and a rotating shaft; the innovation point is in that: the generator also comprises a fan, a heat exchanger assembly, a wind guide cover and a cooling assembly, the cooling assembly is arranged on the periphery of the stator of the generator, the outlet of the fan is communicated with one end of the heat exchanger assembly, and the wind guide cover is communicated with the other end of the heat exchanger assembly; the heat exchanger assembly comprises a heat exchanger shell and condenser pipes, a plurality of condenser pipes are arranged in the heat exchanger shell, and the condenser pipe has a liquid inlet and a liquid outlet; the cooling assembly comprises a cooling shell and evaporating pipes, a plurality of evaporating pipes are arranged in the cooling shell, and the cooling shell is fixedly connected with the periphery of the stator of the generator; and the liquid outlets of the condenser pipes of the heat exchanger assembly are respectively communicated with corresponding evaporating pipes in the cooling shell. According to the invention, the device provided by the invention has advantages of simple structure, high cooling efficiency and low energy consumption.

Owner:常州优谷新能源科技股份有限公司

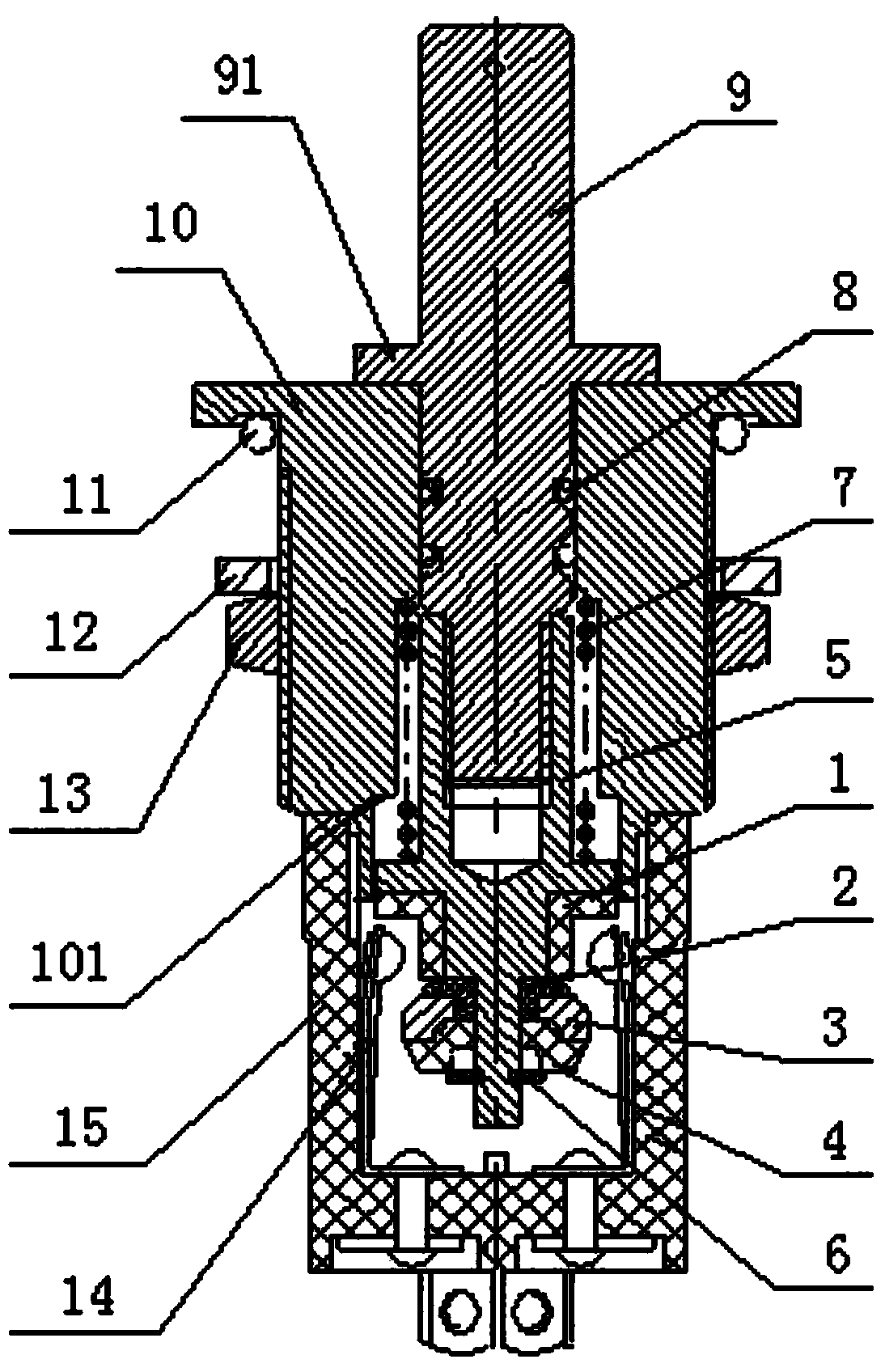

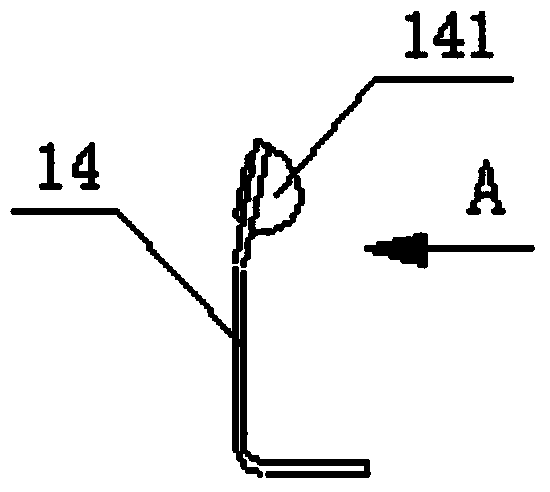

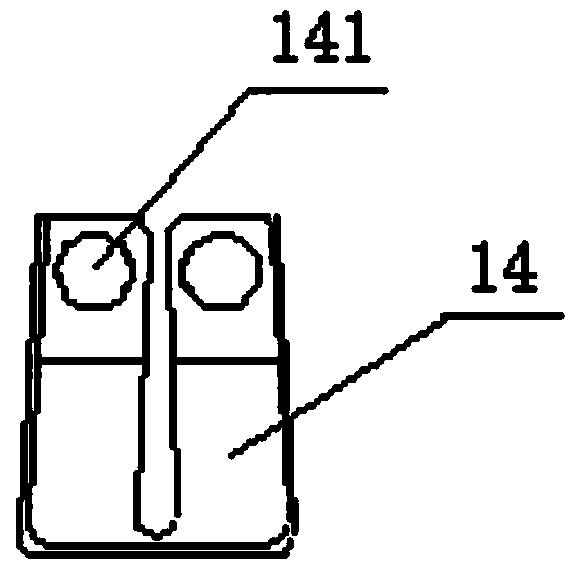

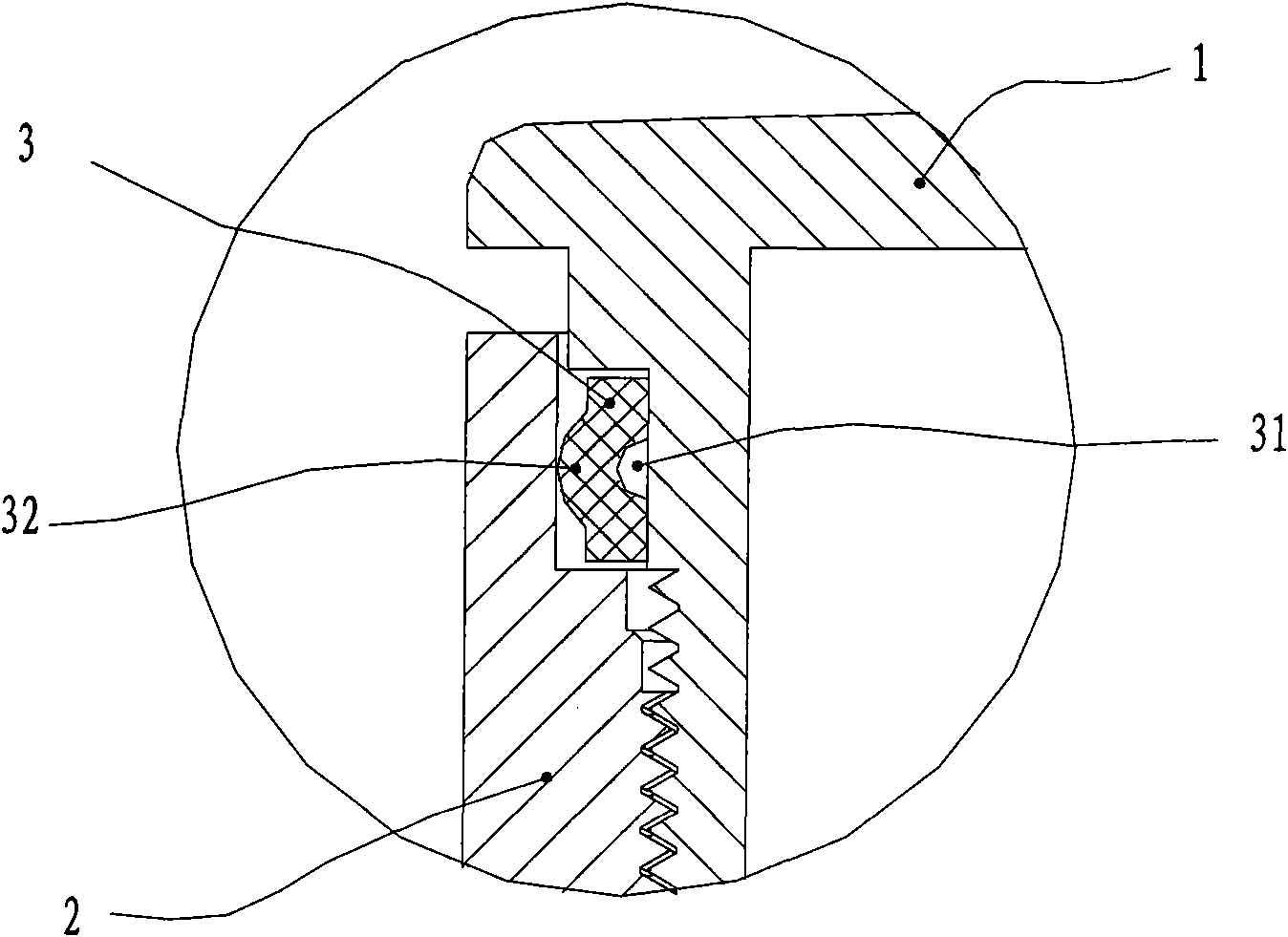

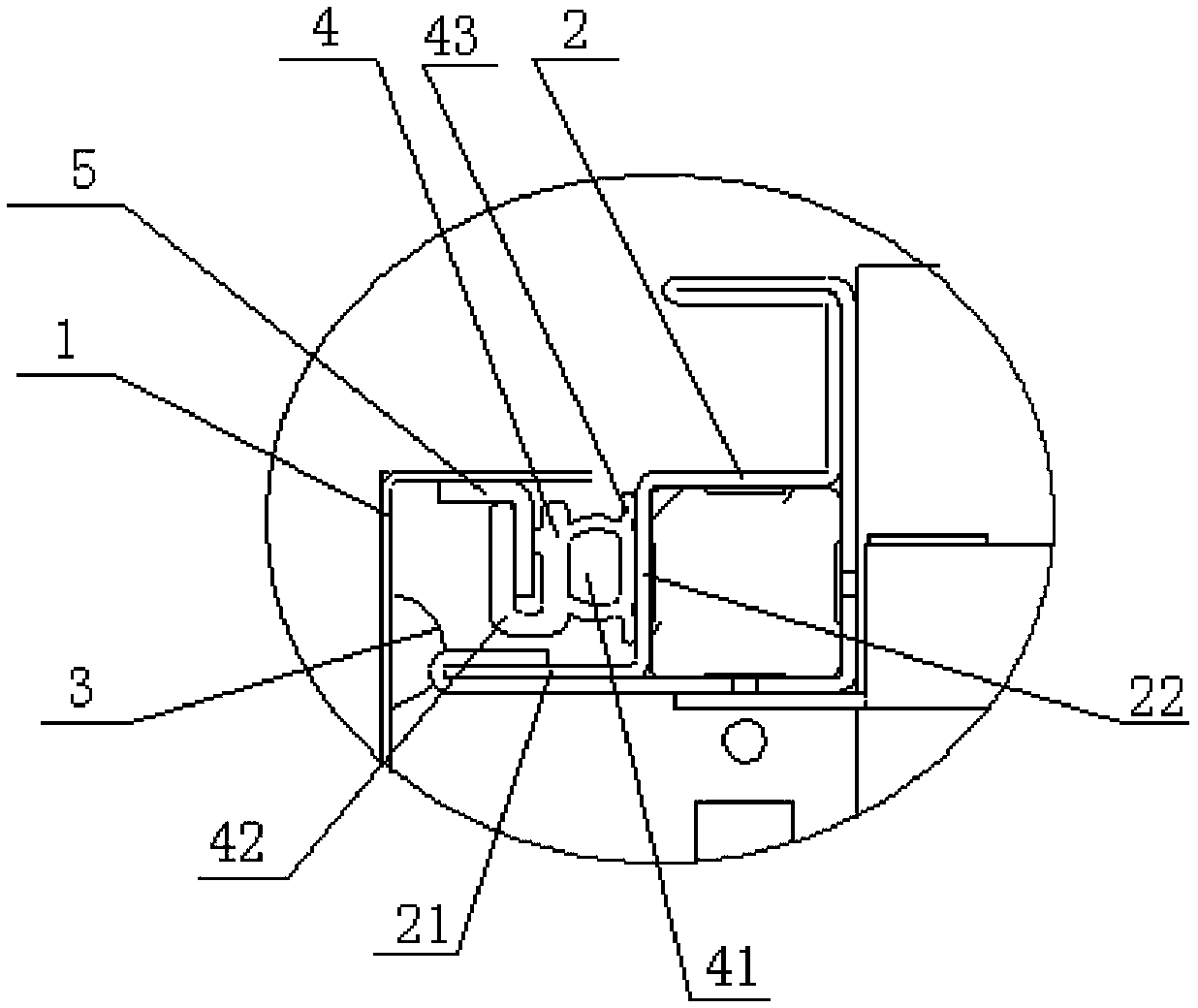

Reverse pulling type switch

ActiveCN103871765ARealize reverse pull operationReliable contactElectric switchesWorking temperatureEngineering

The invention discloses a reverse pulling type switch. The reverse pulling type switch comprises a base, an outer shell, a nut and a gasket, wherein the base is connected with the outer shell through threads, the nut and the gasket are respectively installed on the outer shell in a sleeved mode through threads, an operation mechanism, a sealing mechanism and a switching circuit part are arranged inside the base and the outer shell, the operation mechanism comprises an insulating sleeve, an insulator A, an insulator B, a clamping ring and a compression spring, the insulating sleeve, the insulator A, the insulator B and the clamping ring are sequentially installed at the lower end of a handle in a sleeved mode, the compression spring is installed at the upper end of the handle in a sleeved mode, the sealing mechanism is composed of a waterproof ring, a pulling handle and an O-shaped sealing gasket, the waterproof ring is installed inside an annular groove in the pulling handle, the O-shaped sealing gasket is installed on the outer shell, the switching circuit part is composed of a contact chip assembly and a contact circular ring, the contact chip assembly is installed inside the base, and the contact circular ring is installed at the lower end of the handle in a sleeved mode and located between the insulator A and the insulator B. The reverse pulling type switch has the advantages of being high in sealing level, wide in working temperature range, reliable in contact and the like, thereby being widely used for instruments and equipment in a deep water environment.

Owner:GUIZHOU ZHENHUA HUALIAN ELECTRONICS

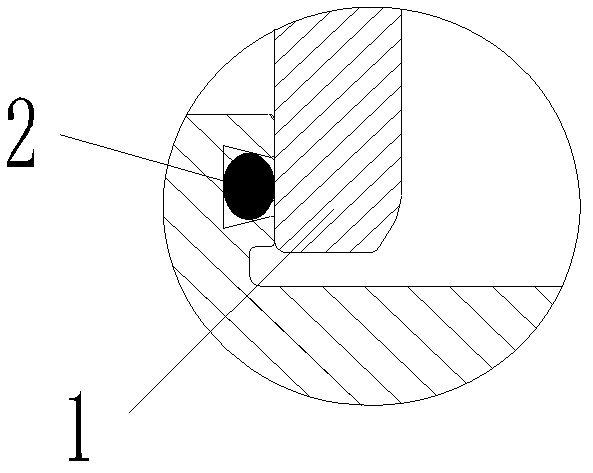

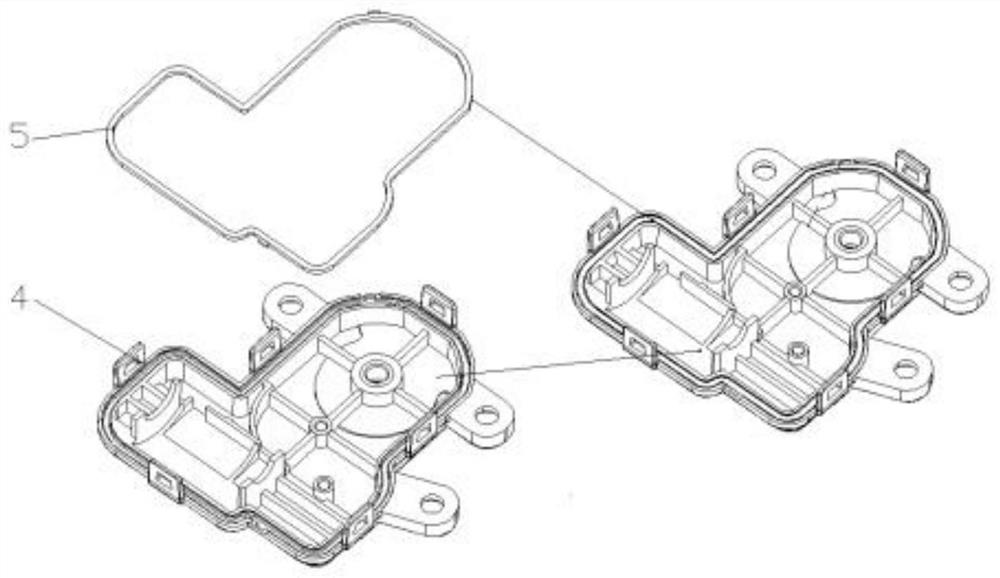

Fixed radial sealing piece

InactiveCN101922697ALarge deformationReduce friction damageGas-tight/water-tight arrangementsInterference fitMachining

The invention discloses a fixed radial sealing piece. The fixed radial sealing piece is arranged between an upper shell and a lower shell which are correspondingly matched and connected with each other, comprises a body made of a flexible material, and is characterized in that: at least one first groove capable of tolerating the body to be deformed by force in the axial direction is formed on the body; and the section of the first groove can be a concave arc, a triangle, a trapezoid, a wooden club, a square or a rectangle. By using the structural design of the sealing piece of the invention, relatively large axial deformation can be tolerated, so that relatively large clearance fit between the upper shell and the lower shell is not needed, assembly is convenient, meanwhile, the machining precision of the fitting surfaces of the upper and lower shells can be reduced, and the machining cost can be saved; and the abrasive damage of the sealing piece in the rotational locking process of the upper and lower shells is relatively small, so that sealing reliability is further improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

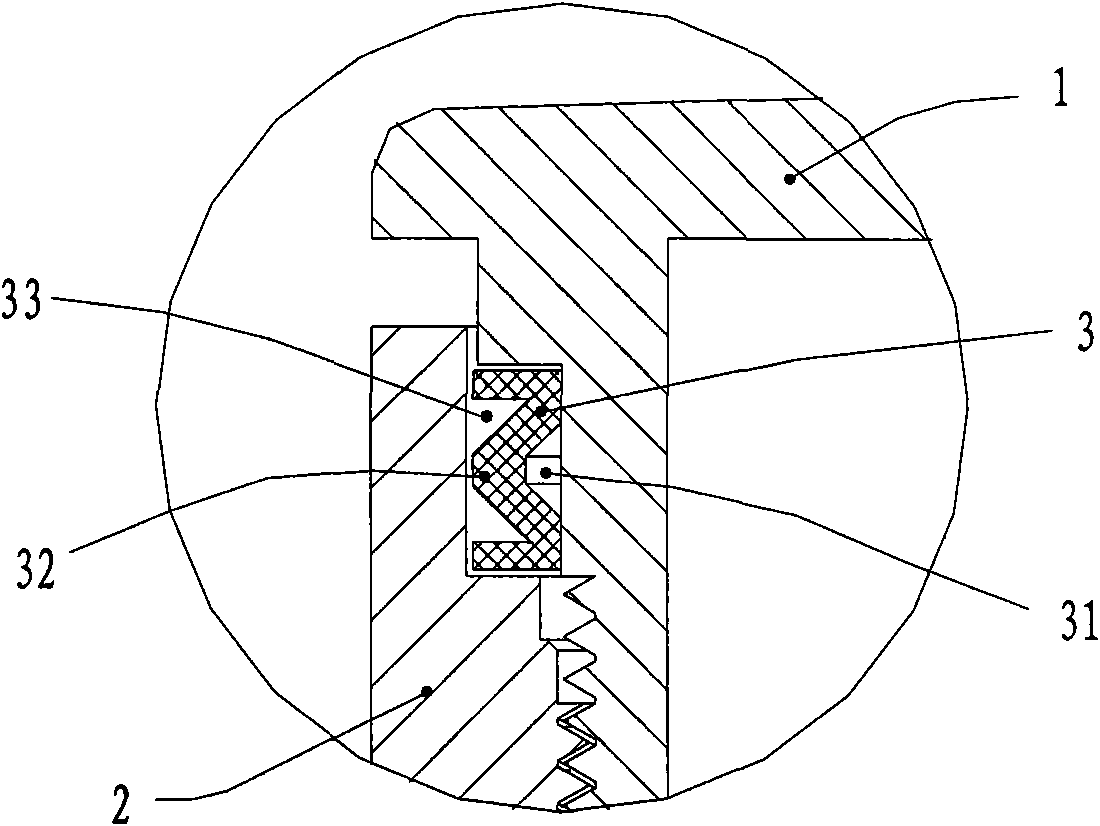

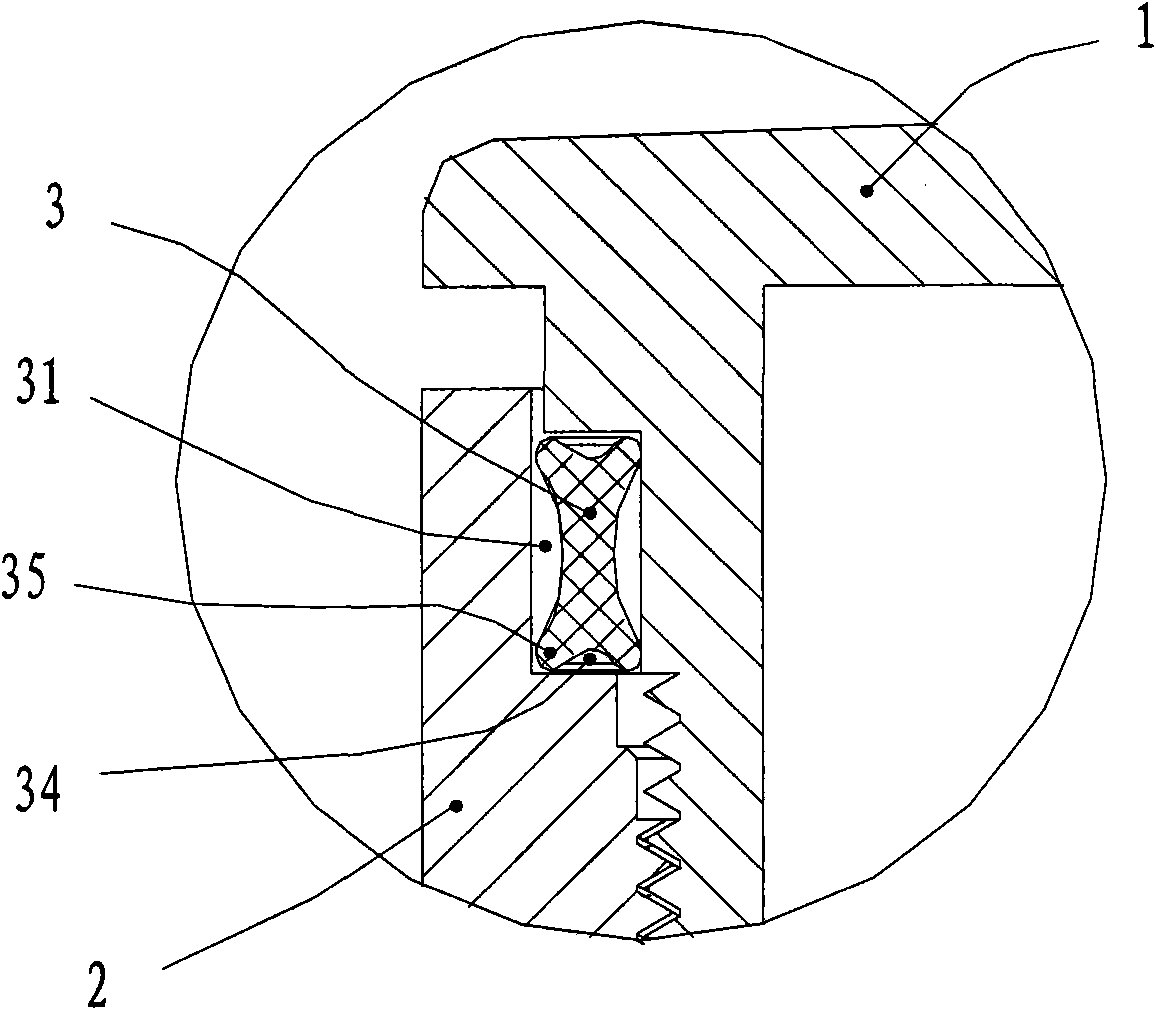

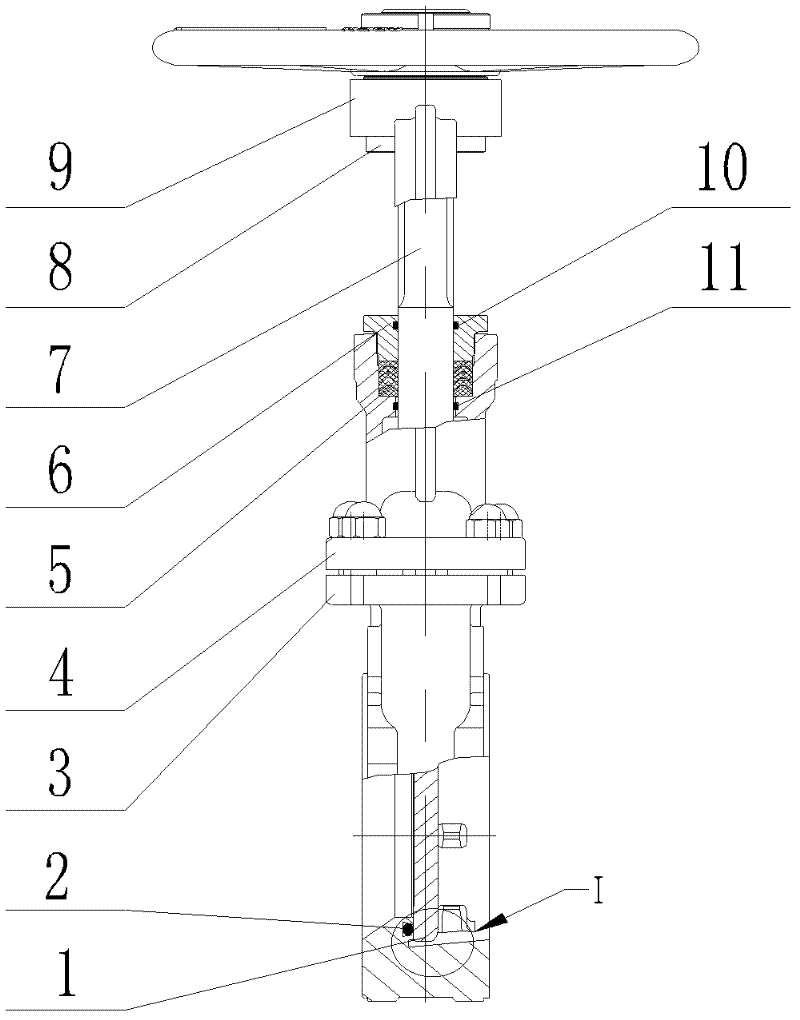

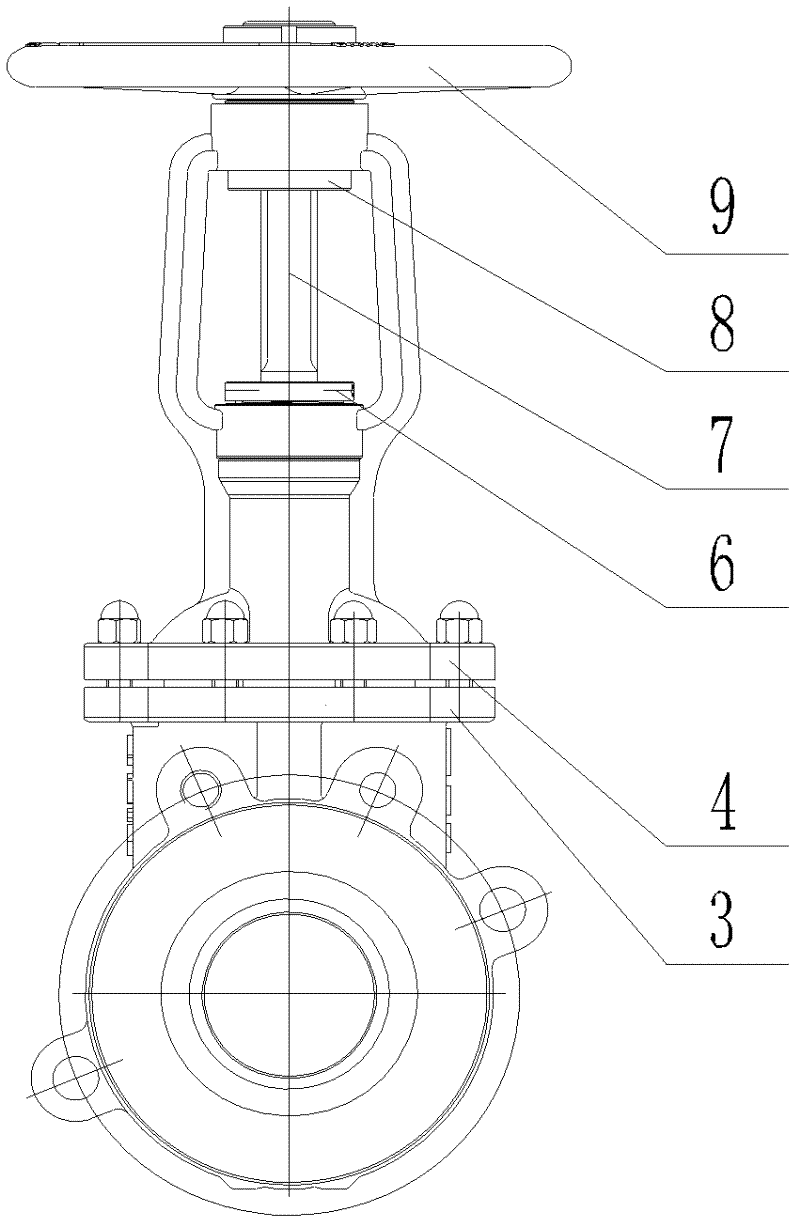

Slurry gate valve

The invention relates to a slurry gate valve and relates to a valve. The slurry gate valve is provided with a cutting board, a valve body, a valve cover, a stuffing, a stuffing gland, a valve rod, a shaft sleeve and a hand wheel, wherein the valve body is fixedly connected with the valve cover, the cutting board is arranged on an inner cavity of the valve body and the valve cover, the motion of the cutting board is driven by the valve rod, and the motion trail of the cutting board is determined by a guide groove in the valve body; the valve rod and the cutting board are connected by a hinge, the valve rod is provided with a notch, the cutting board is inserted into the notch, the valve cover is provided with a valve cover stuffing box, and the valve cover stuffing box is filled with the stuffing and is compacted by the stuffing gland; the valve rod passes through the valve cover stuffing box and the stuffing gland, the shaft sleeve is arranged on the valve cover, the shaft sleeve and the valve rod are in T-shaped thread fit and are fixed on the valve cover; and the hand wheel is arranged at the top of the valve rod. The slurry gate valve provided by the invention has the advantages of compact structure, small volume, light weight, convenience in transportation and installation, and effectively reduced material cost and the like; the slurry gate valve solves the serious problem that the conventional transporting-discharging paper pulp valve circulating channel is provided with a groove, is easily sitcked, is easy to scab, and is easily stuck by material; and the slurry gate valve is mainly used for papermaking slurry.

Owner:BRAD XIAMEN IND STOCK

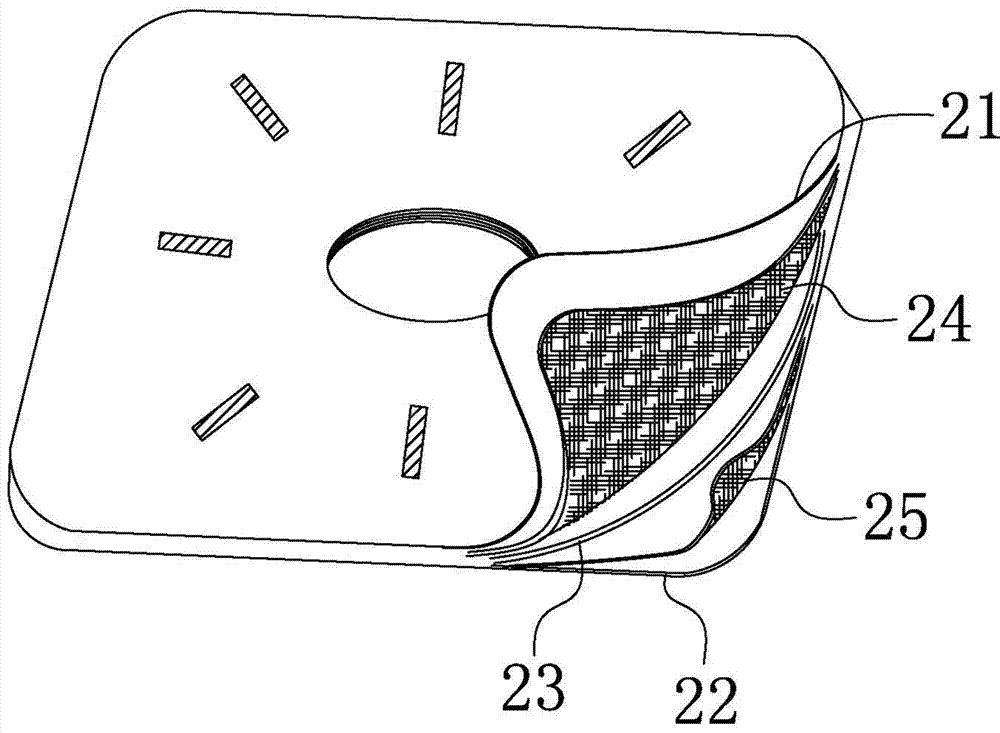

Injection-molded wire harness and molding method

PendingCN111478060ANo mutual wearThe relative positioning size is accurateContact member assembly/disassemblyCoupling contact membersElectrical conductorInjection moulding

The invention relates to an injection-molded wire harness and a molding method. The wire harness comprises a terminal and at least one conductor, wherein one end of the terminal is connected with an electrical loop of an electric device, the other end of the terminal is connected with the conductor, and the wire harness is provided with a protection layer which is formed by injection molding and wraps the conductor, and at least one positioning device which is formed by injection molding and is used for fixing the position of the wire harness or / and a sealing device for water prevention. According to the invention, manual operation can be reduced, the consistency of wire harness products is improved, the production cost of the wire harness products is reduced, and the service life of the wire harness is prolonged.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

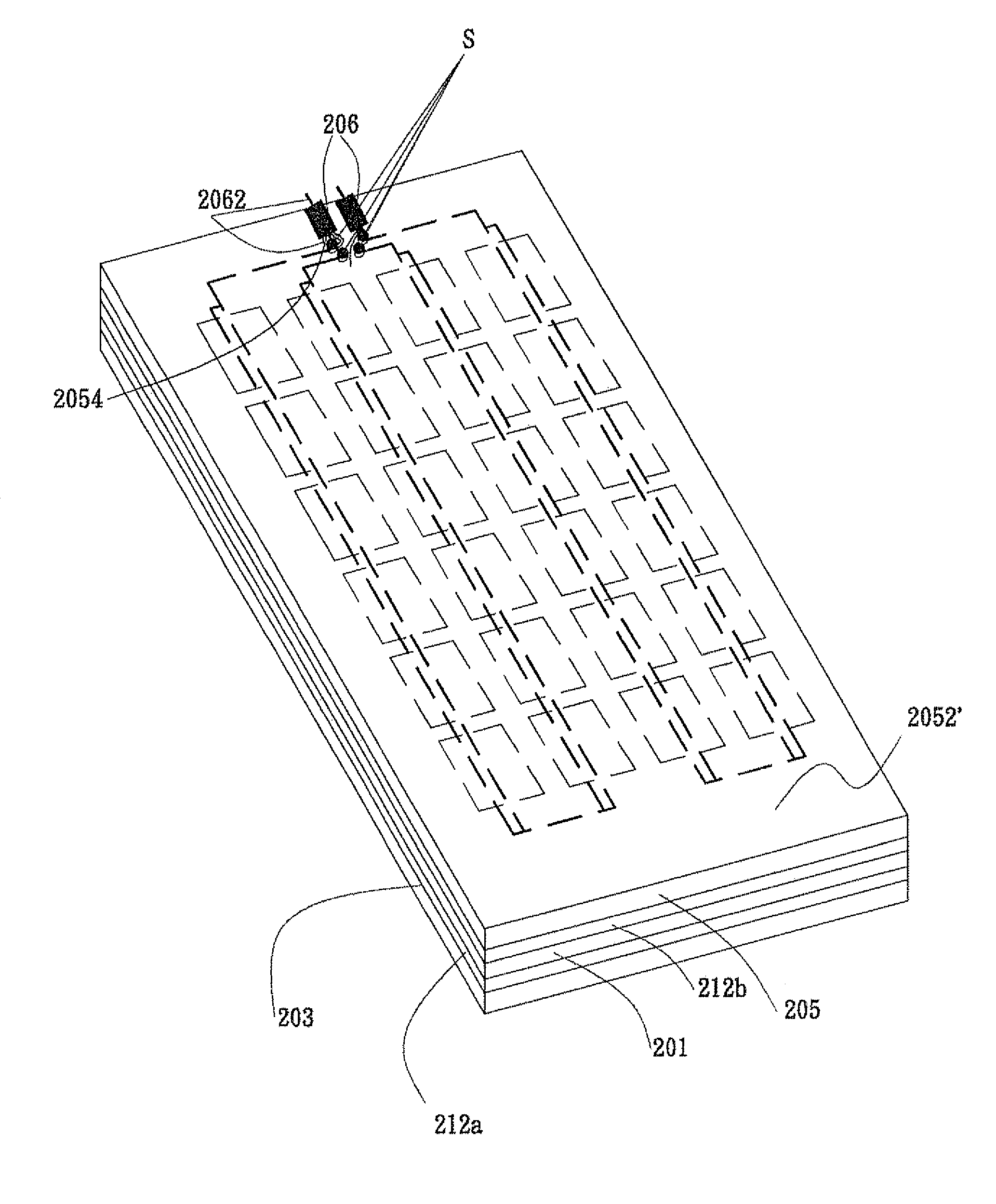

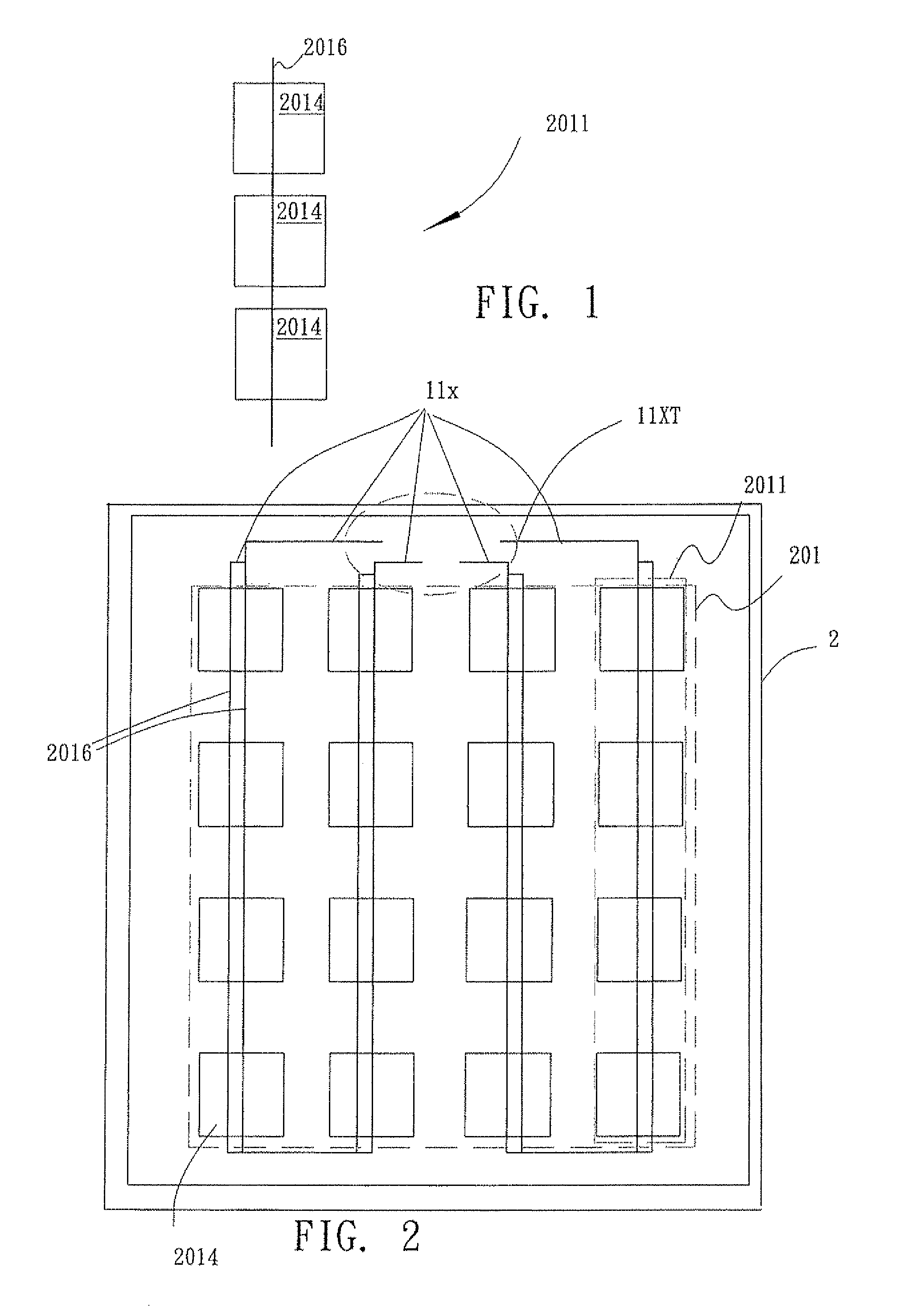

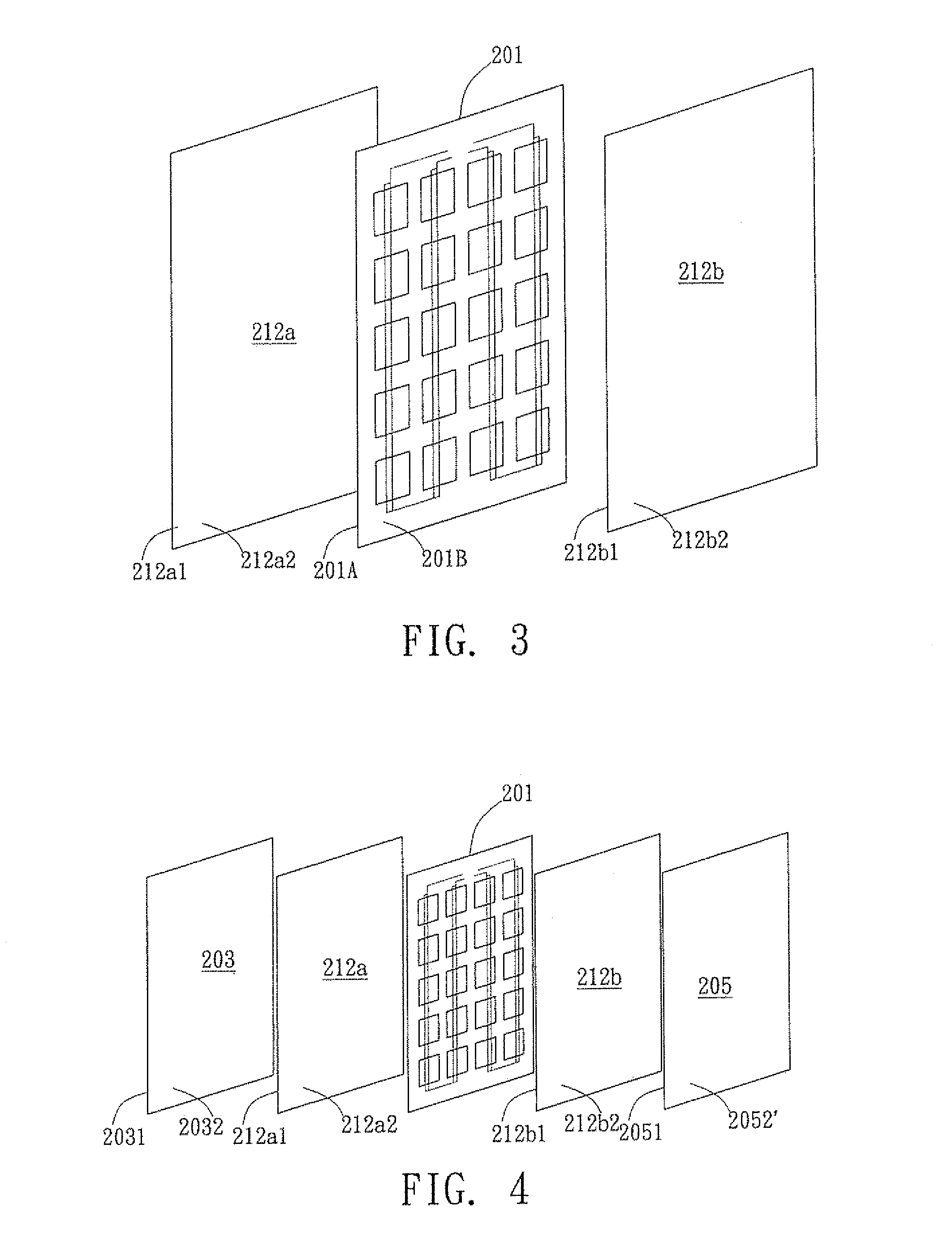

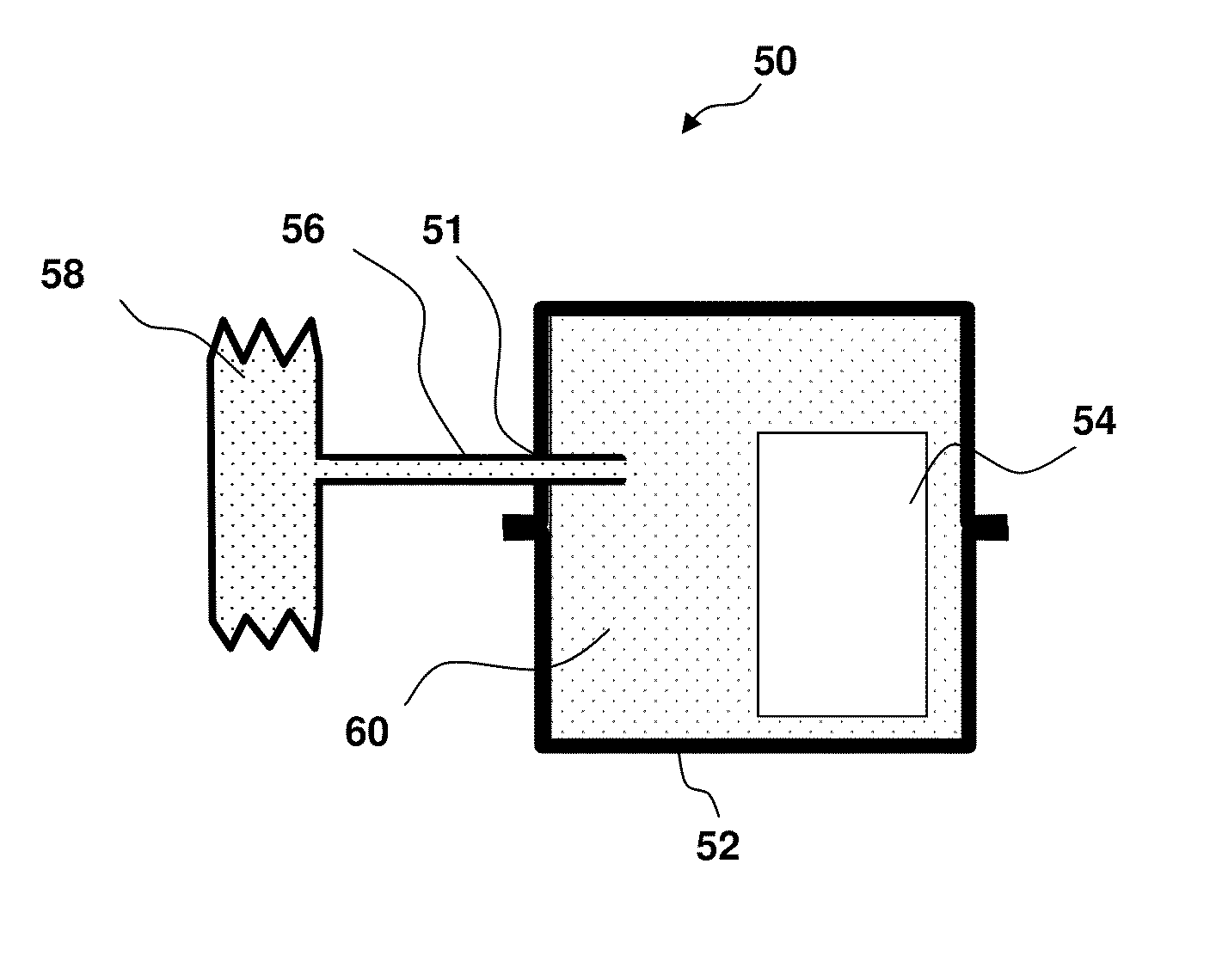

Method for manufacturing improved solar cell module

InactiveUS8722450B1Increase seal level of sealImprove the sealing levelSolid-state devicesPhotovoltaicsEngineeringSolar cell

The present invention generally relates to a method for manufacturing an improved solar cell module, more particularly to a method for manufacturing the improved solar cell module that may not happen problems of power leakage and short circuit and save the cost to manufacturing.

Owner:PERFECT SOURCE TECH CORP

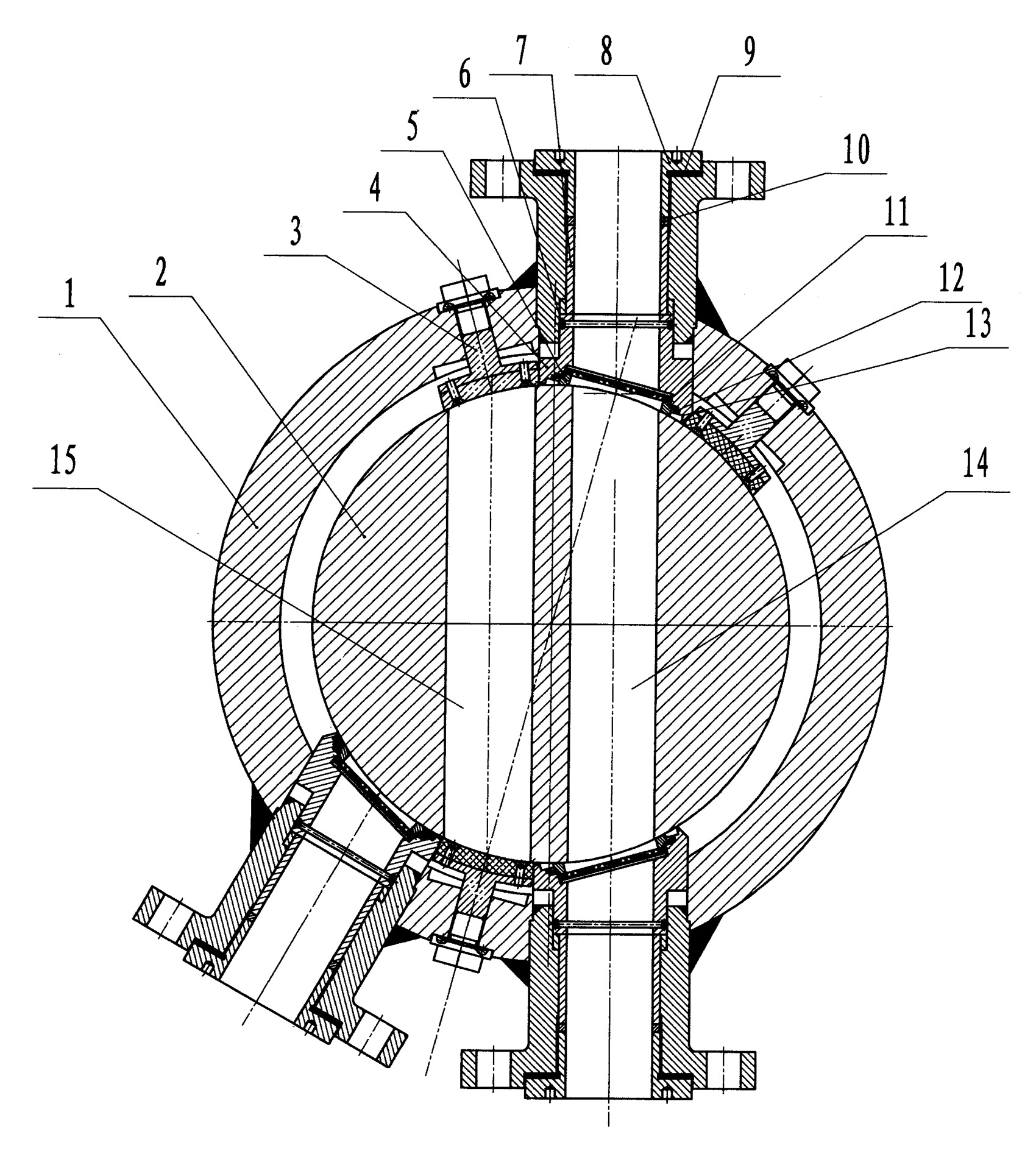

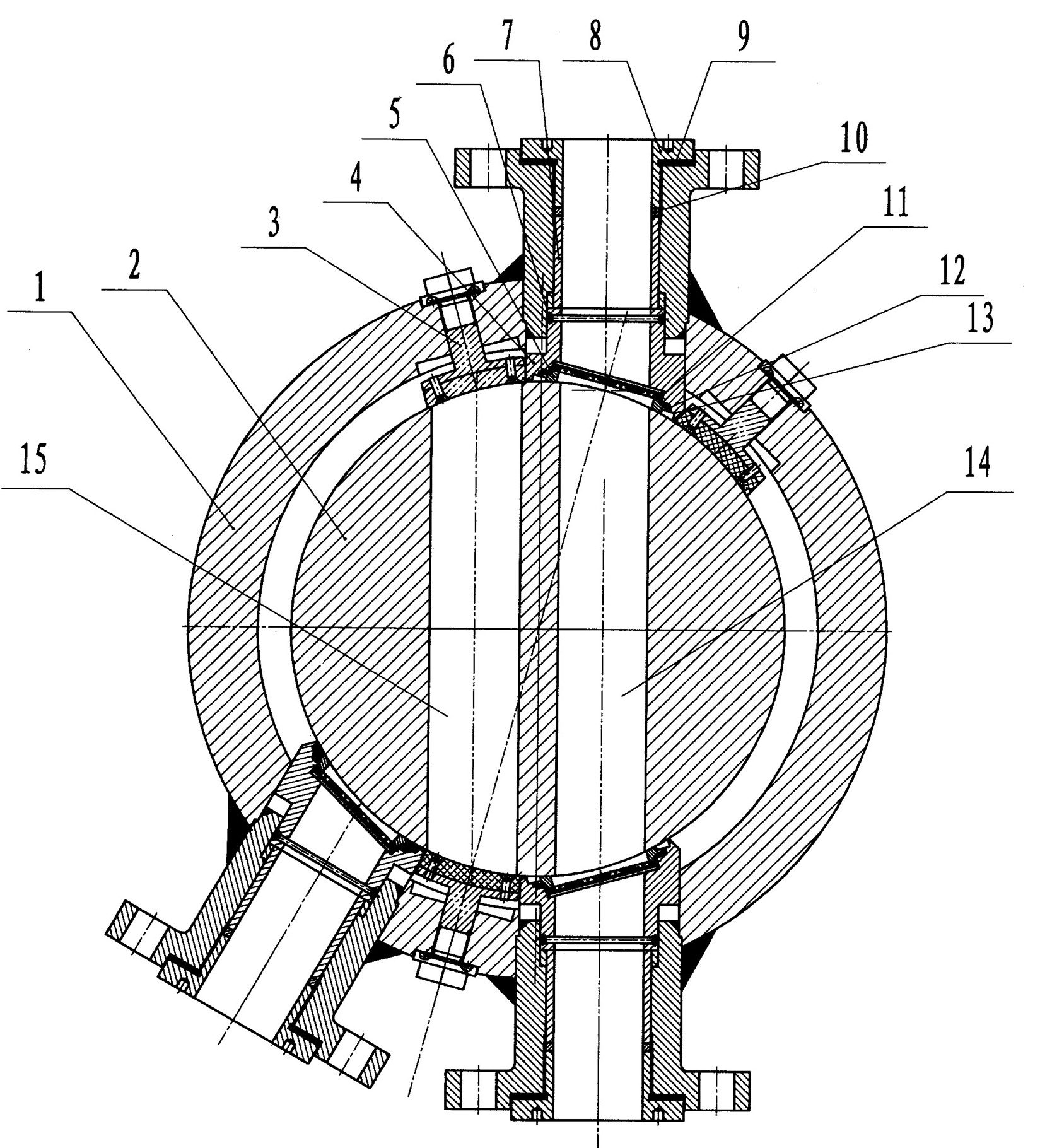

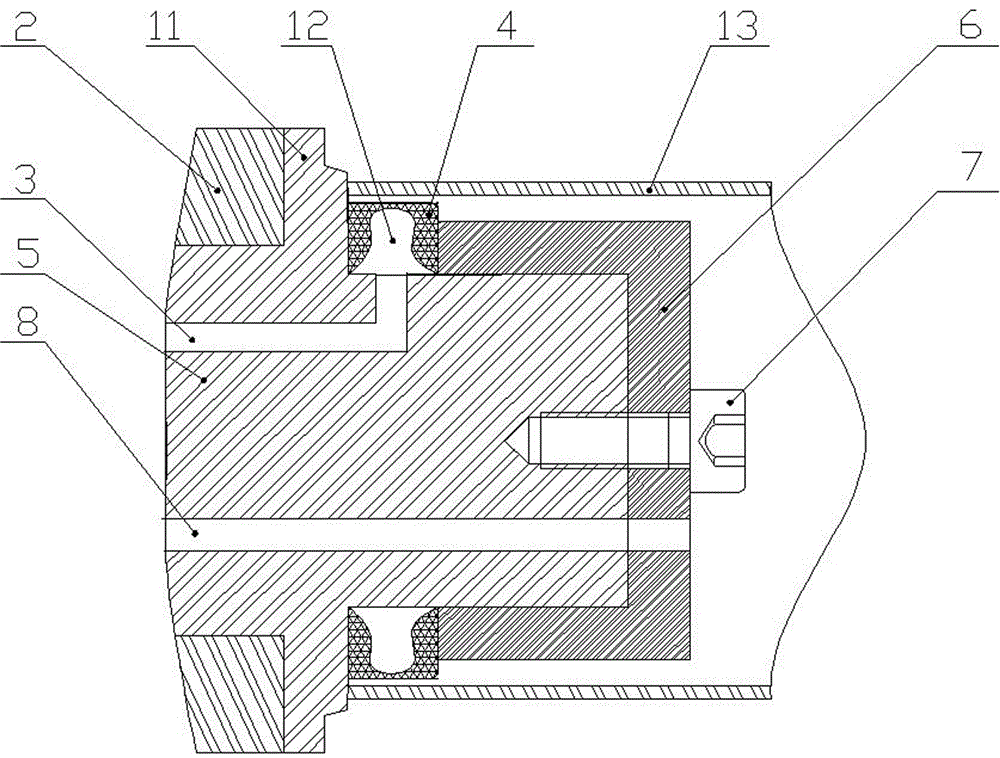

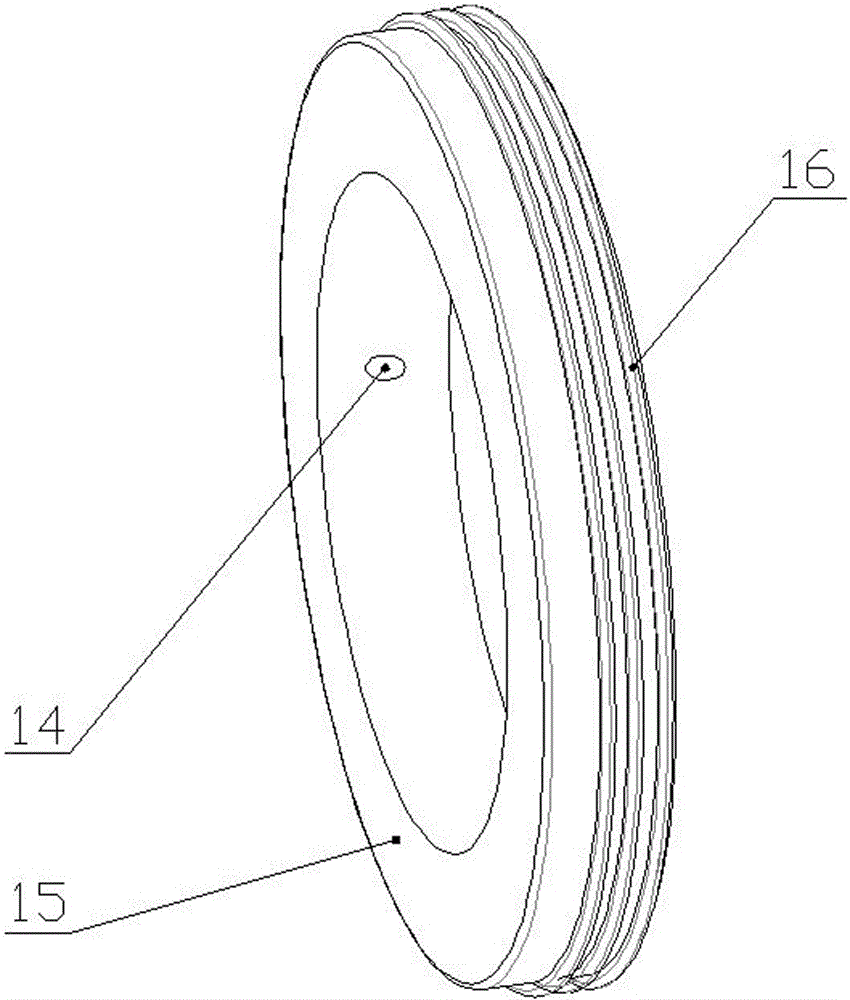

Eccentric/concentric combined sealing valve seat

ActiveCN101886708AImprove the sealing levelEliminate stuckPlug valvesMultiple way valvesEngineeringLine tubing

The invention relates to an eccentric / concentric combined sealing valve seat which is arranged in the body channel mouth of a three-way change valve comprising a valve body, a spherical double-channel valve plug, a valve cap and a start-stop shaft. The eccentric / concentric combined sealing valve seat is formed by concentric sealing valve seats and eccentric sealing valve seats which are arranged at the two ends of the channel mouths of the valve body and the valve plug. The valve seat and the valve plug are fit and sealed by spring pre-tightening force and medium pressure. The eccentric / concentric combined sealing valve seat comprises eccentric sealing valve seat bodies, concentric sealing valve seat bodies, plate springs, bearing rings, eccentric sealing rings, valve seat pressure caps, sealing gaskets, adjusting gaskets, eccentric soft seals and concentric sealing rings. The eccentric / concentric combined sealing valve seat ensures high valve sealing grade, can achieve zero leakage, thoroughly eliminates the problems of valve blocking and inflexible opening, has the service life as long as more than 200000 times, has good use effect on the chemical pipelines and does not have faults till now.

Owner:吴军

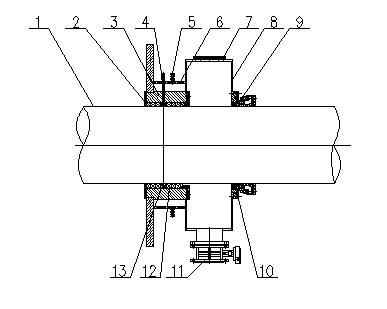

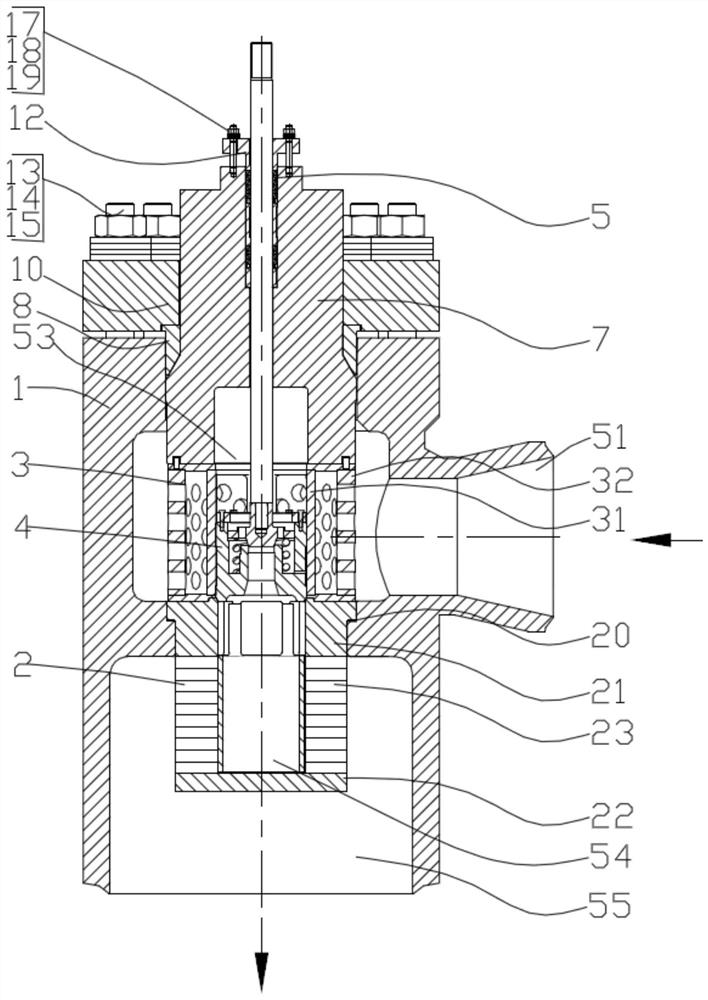

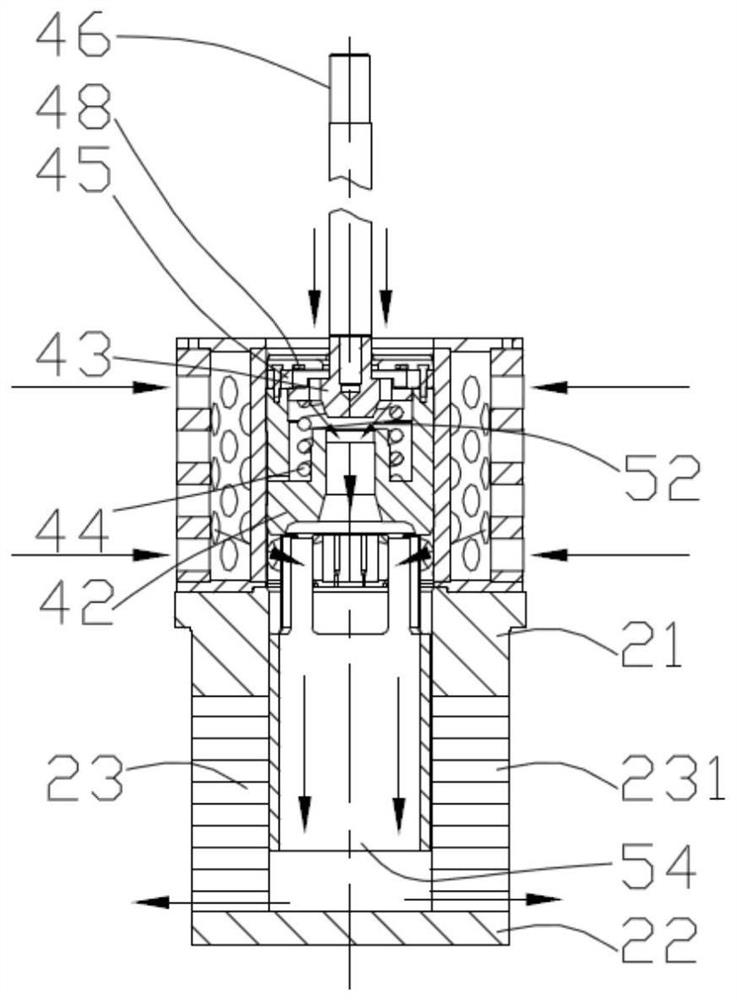

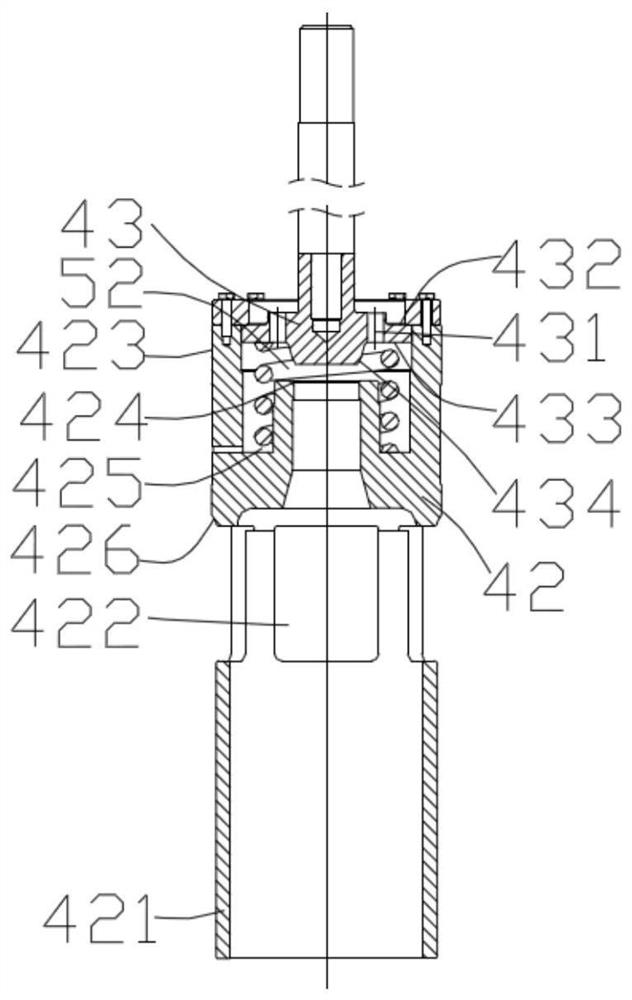

Internal high-pressure forming pushing and pressing device

The invention discloses an internal high-pressure forming pushing and pressing device. The device comprises a pushing head assembly and a driving device used for driving the pushing head assembly to move in the axial direction of the pushing head assembly; the pushing head assembly comprises a pushing head and a plugging head, wherein the pushing head is a sleeve part with an outer thread, the plugging head is partially arranged in the pushing head in a sleeved mode, a shaft collar is arranged on the exposed portion of the plugging head, the back side of the shaft collar is matched with the front end face of the pushing head, a working surface used for pushing and pressing a pipe blank is formed on the front side of the shaft collar, a probing sealing portion is arranged on the portion, at the front side of the shaft collar, of the plugging head, and the axial diameter of the probing sealing portion is smaller than the inner diameter of the pipe blank, so that a seal ring with a bag cavity is arranged on the probing sealing portion in a sleeving mode; the plugging head is provided with a hydraulic pipe used for enabling a medium channel to be formed and an air pipe used for communicating with the bag cavity to supply compressed air. According to the device, the sealing capability of the pushing head and a pipe opening of the pipe blank are good, and demolding is not influenced.

Owner:UNIV OF JINAN

Mobile terminal

PendingCN111225085ASmooth liftStructural balanceDevices with rotatable cameraDigital data processing detailsComputer hardwareElectrical and Electronics engineering

Owner:HUAWEI TECH CO LTD

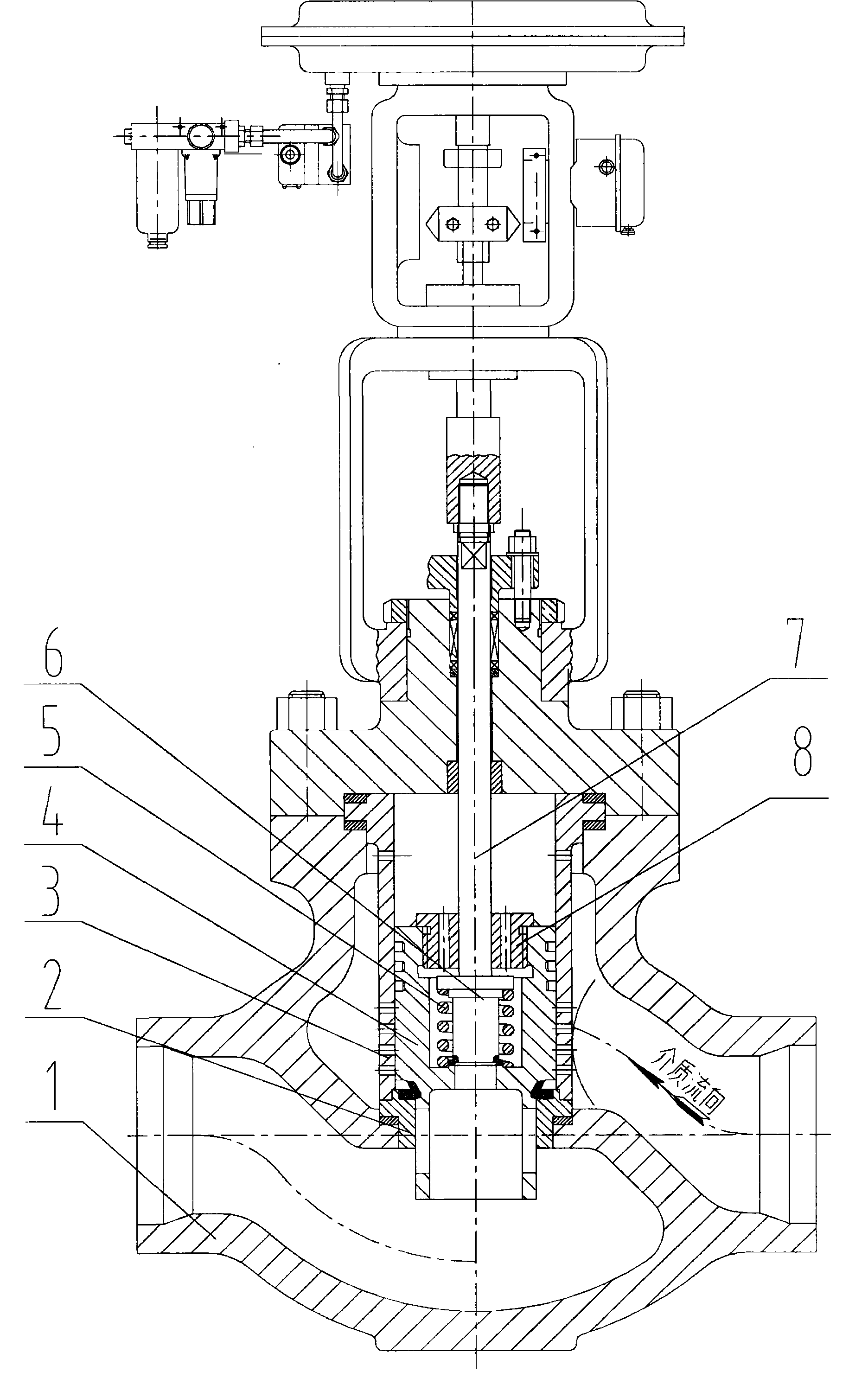

Cascading valve clack type adjusting valve

InactiveCN103821949AReduce valve operating forceImprove valve sealing levelPressure relieving devices on sealing facesSlide valveWater vaporVALVE PORT

The invention relates to a cascading valve clack type adjusting valve, and belongs to the field of thermal power and nuclear power valves. The cascading valve clack type adjusting valve is arranged on a water vapor system pipeline of a thermal power and nuclear power unit and is important equipment for adjusting flow, pressure and temperature of media. The cascading valve clack type adjusting valve is composed of a valve clack, a spring, an auxiliary valve clack, a valve rod, a valve clack pressing cover and the like, and the auxiliary valve clack and the valve rod are of an integral structure. When the valve is opened, the auxiliary valve clack is firstly opened, an upper cavity and a lower cavity of the valve clack are communicated, the valve clack is changed to be of a balance structure, and the valve rod drives the valve clack to move vertically through the valve clack pressing cover and the spring. When the valve is closed, the valve rod compresses the spring, the auxiliary valve clack compresses the inner sealing face of the valve clack, the sealing face on the lower portion of the valve clack compresses the sealing face of a valve seat, the two sealing faces are sealed, and the valve clack is changed to be of an unbalance structure. Opening force of the valve is effectively reduced, and sealing performance in the valve closing process is improved.

Owner:HARBIN HBC VALVE

Hollow blade shaft-end sealing mechanism

The invention relates to a hollow blade shaft-end sealing mechanism which comprises a packing seal and a mechanical seal arranged in the rear of the packing seal. A material collection box is arranged between the packing seal and the mechanical seal and communicated with the same, and a dust ring is arranged at the communicating position of the tail end of the material collection box and the mechanical seal. The material collection box is arranged between the packing seal and the mechanical seal, a traditional integral combination mode is changed to a split mode, the purpose is to separate the packing seal from the mechanical seal by the material collection box, the probability that solid granular matters such as dust enter the mechanical seal is lowered greatly by the aid of the material collection box, and accordingly sealing performance of the mechanical seal is improved, reliability of two-stage seal is improved, and sealing class is increased; meanwhile, by the aid of the material collection box, emptying time is prolonged, operation amount of workers is decreased, the workers can view material level in the material collection box through a sight glass hole, an empty valve is turned on to discharge excess materials after the material level reaches a certain height, and the hollow blade shaft-end sealing mechanism has high practicality.

Owner:PENGFEI CHEM EQUIPS FACTORY JIANGDU CITY +2

Moisture barrier breathing device

ActiveUS8234740B2Improve the sealing levelPower complexityLiquid processingReconditioning/cleaning record carriersEngineeringMoisture barrier

A cleaning assembly (2) for an optical device (16) includes a shaft (14) configured for supporting the optical device within an enclosure (4) that is adapted for rotation about the shaft. At least one first sealing element (18) is disposed between the shaft and a mating surface of the enclosure for preventing fluid leakage therethrough. At least one optically transparent window (8) is mounted in association with the enclosure (4), and at least one cleaning element (9, 11) is coupled to the shaft for cleaning a surface of the window (8). The cleaning assembly may include a moisture barrier in the form of a pressure-influenced member (58) such as a bellows (40) having a body of expandable and retractable-volume for containing air that diffuses therein, while equalizing pressure on opposite sides of the barrier.

Owner:KERETH YEFIM

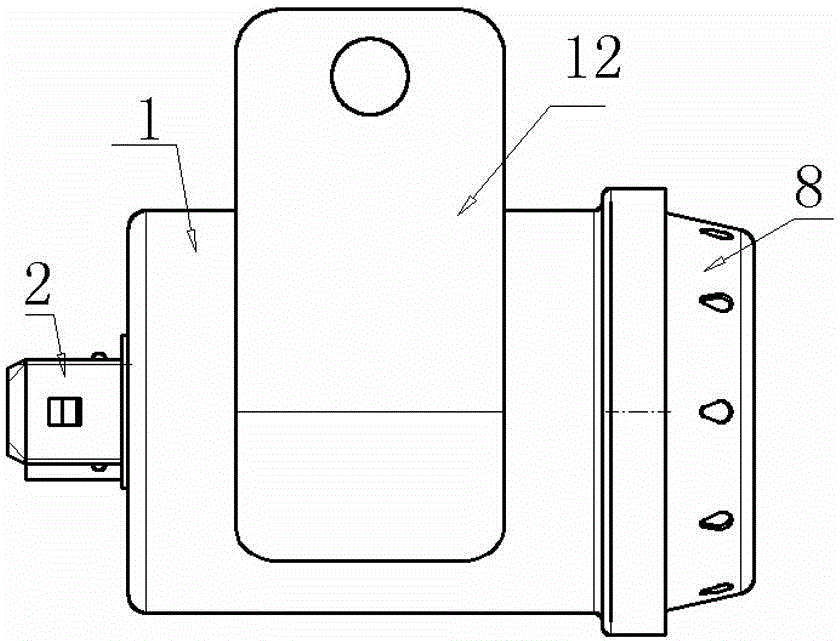

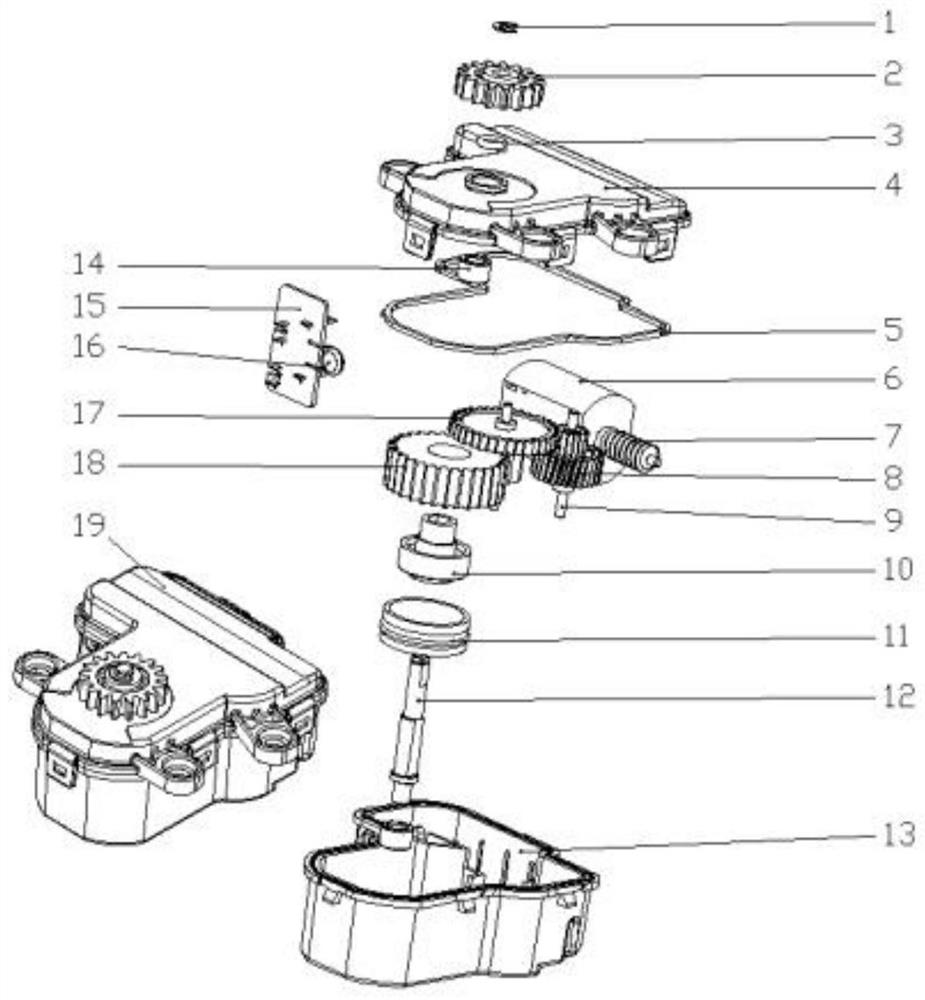

Back-up buzzer assembly

InactiveCN105564302AAvoid enteringDust-proofAcoustic signal devicesCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention relates to a back-up buzzer assembly; a connector is plugged in a plug port of a housing; the connector and the plug port are plugged in a snap fastener mode; a power plug pin of the connector is an embedded or injection molding integrated structure; the connector is plugged with a fixed seat through a snap fastener in the housing; the fixed seat is provided with a circuit control board, and fasteners can combine the connector, the housing with the fixed seat; the power plug pin is connected with the circuit control board through a power line, and connected with a buzzer; a shield is embedded through a seal ring. The connector is plugged with the plug port through the snap fastener, and the power plug pin of the connector is the embedded or injection molding structure, thus forming a first defense line; the connector is plugged with the fixed seat through the snap fastener in the housing, so a second defense line is formed to provide dustproof and waterproof effects; the two defense lines can generate a protection level as IP6K7, which is higher than same type products.

Owner:SHIYAN GUANGHAI IND & TRADE CO LTD

Sealing inspection well socket

ActiveCN104264774AEasy to maintainStrong sealingSewerage structuresEngineeringMechanical engineering

The invention discloses a sealing inspection well socket and relates to the field of sealing connection devices of plastic inspection well sockets. The sealing inspection well socket comprises a socket body. The socket body comprises a fixed socket body and a removable socket body. The removable socket body is composed of an outer sleeve, an inner sleeve and an annular groove formed between the inner sleeve and the outer sleeve. The outer wall of the fixed socket body is provided with external threads. The inner wall of the outer sleeve is provided with internal threads corresponding to the external threads. The inner diameter of the fixed socket body is larger than the outer diameter of the inner sleeve. The sealing inspection well socket can compress a sealing ring between a pipe and the socket through the threads to reduce the gap between the pipe and the socket. The sealing inspection well socket is good in sealing performance and easy to operate.

Owner:JIAXING HUICHANG PLASTIC IND CO LTD

Demonstrator shell and robot demonstrator

InactiveCN109041493AAffecting workImprove convenienceProgramme-controlled manipulatorCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention discloses a demonstrator shell and a robot demonstrator, comprising a first shell, an annular sealing seat is arranged in the first shell, and a sealing groove is arranged on the end face of the sealing seat; an inner sealing ring arranged in the sealing groove; a second shell arranged on the first shell, the second shell and the first shell forming a cavity, and an annular fin corresponding to the sealing seat being arranged in the second shell, and the fin being pressed on the inner sealing ring, so that the sealing ring is lower than or equal to the end face of the sealing seat; the fins and the sealing seat separating the cavity into a receiving cavity and a water retaining cavity. Since the inner sealing ring is installed in the sealing groove of the sealing seat, when the second shell is installed on the first shell, the torsional bending of the inner sealing ring does not occur, and the assembly does not need to be carefully adjusted for many times, so that the installation process of the first shell and the second shell becomes simple; and in addition, even if the external water enters the water retaining cavity, it will be resisted by the sealing seat or finsfirst, and then blocked by the inner sealing ring, thereby achieving a relatively high level of sealing.

Owner:GREE ELECTRIC APPLIANCES INC

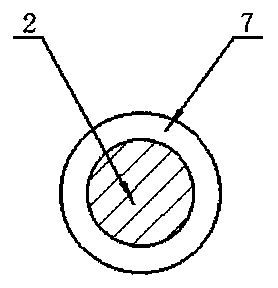

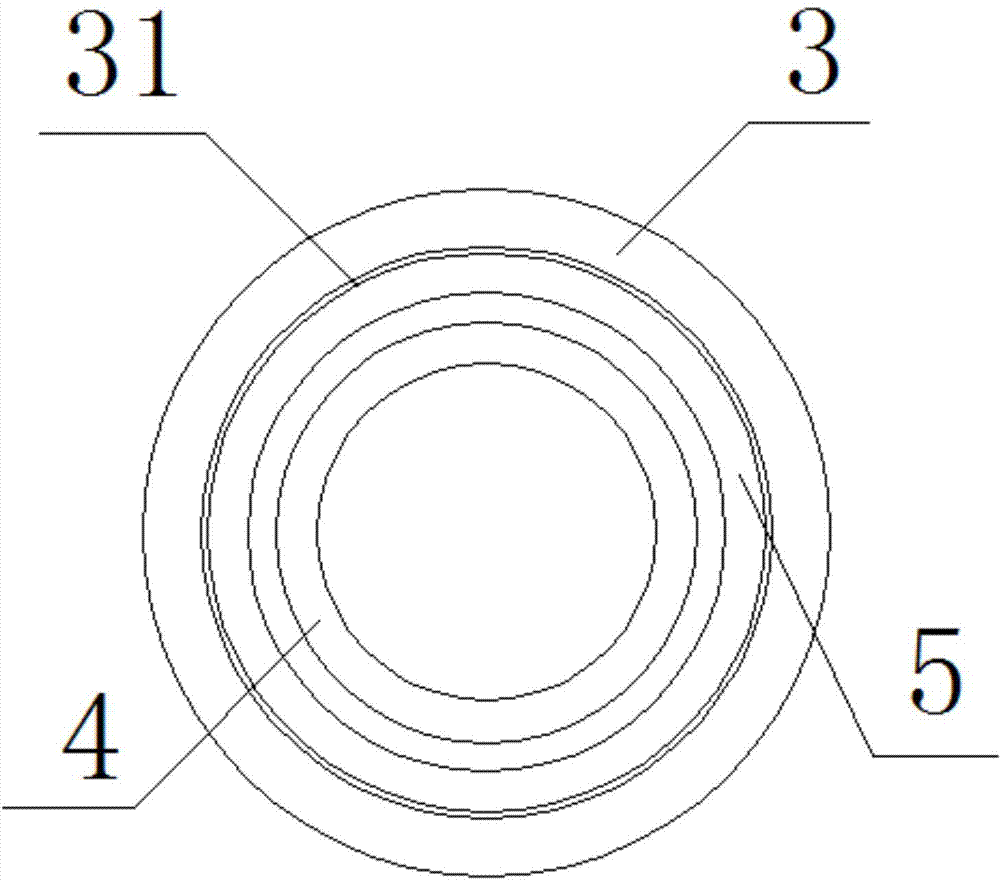

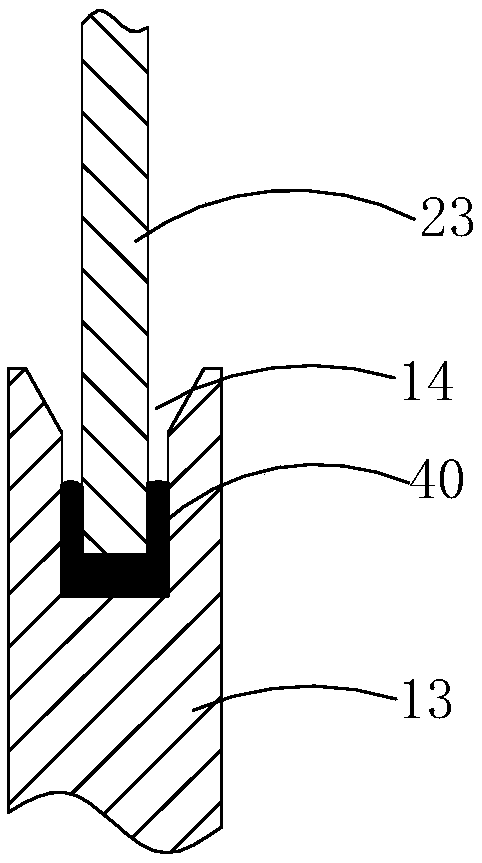

Rotating shaft sealing structure and sealing ring for rotating shaft seal

ActiveCN106286841AImprove the level of sealing protectionImprove the sealing levelEngine sealsInterference fitAcute angle

The invention relates to a sealing ring for rotating shaft seal. The sealing ring is used for being mounted on a rotating shaft and embedded into a sealing ring groove of a shell, and comprises a rubber main body, wherein a sleeving hole through which the rotating shaft is in interference fit is formed in the center of the rubber main body; the root is connected with the rubber main body; a first circular sealing lip and a second circular sealing lip are arranged along the axial direction of the rubber main body at an interval; an included angle between a lip surface of each of the first circular sealing lip and the second circular sealing lip and the axis of the rubber main body is an acute angle; an outer edge of the first circular sealing lip is a first sealing part in squeeze fit with the groove bottom of the sealing ring groove; and an outer edge of the second circular sealing lip is a second sealing part in squeeze fit with the side wall of the sealing ring groove. According to the sealing ring for rotating shaft seal, the sealing property of a shaft extension position can be effectively improved. The invention also relates to a shaft sealing structure adopting the sealing ring for shaft seal.

Owner:GREE ELECTRIC APPLIANCES INC

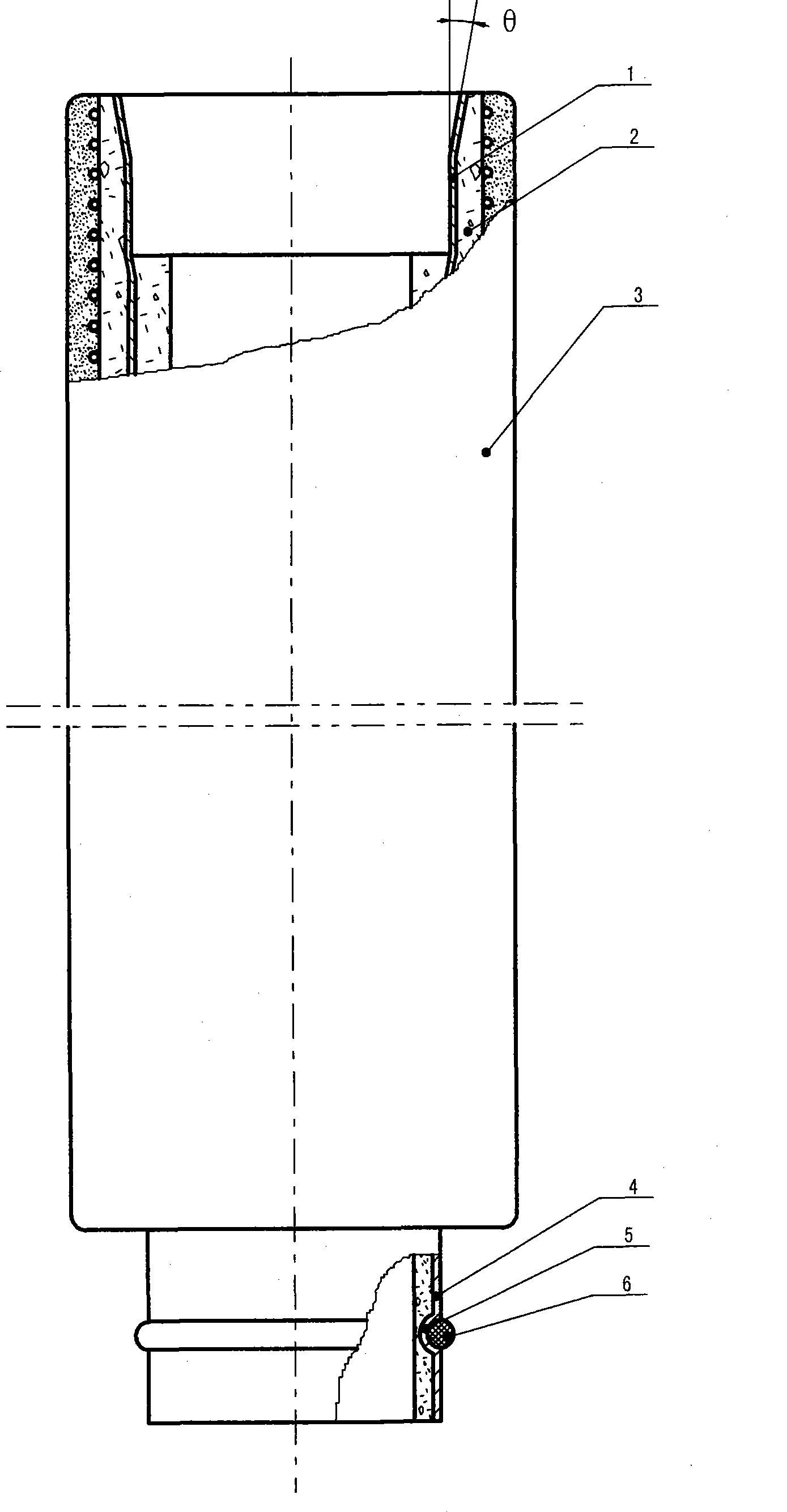

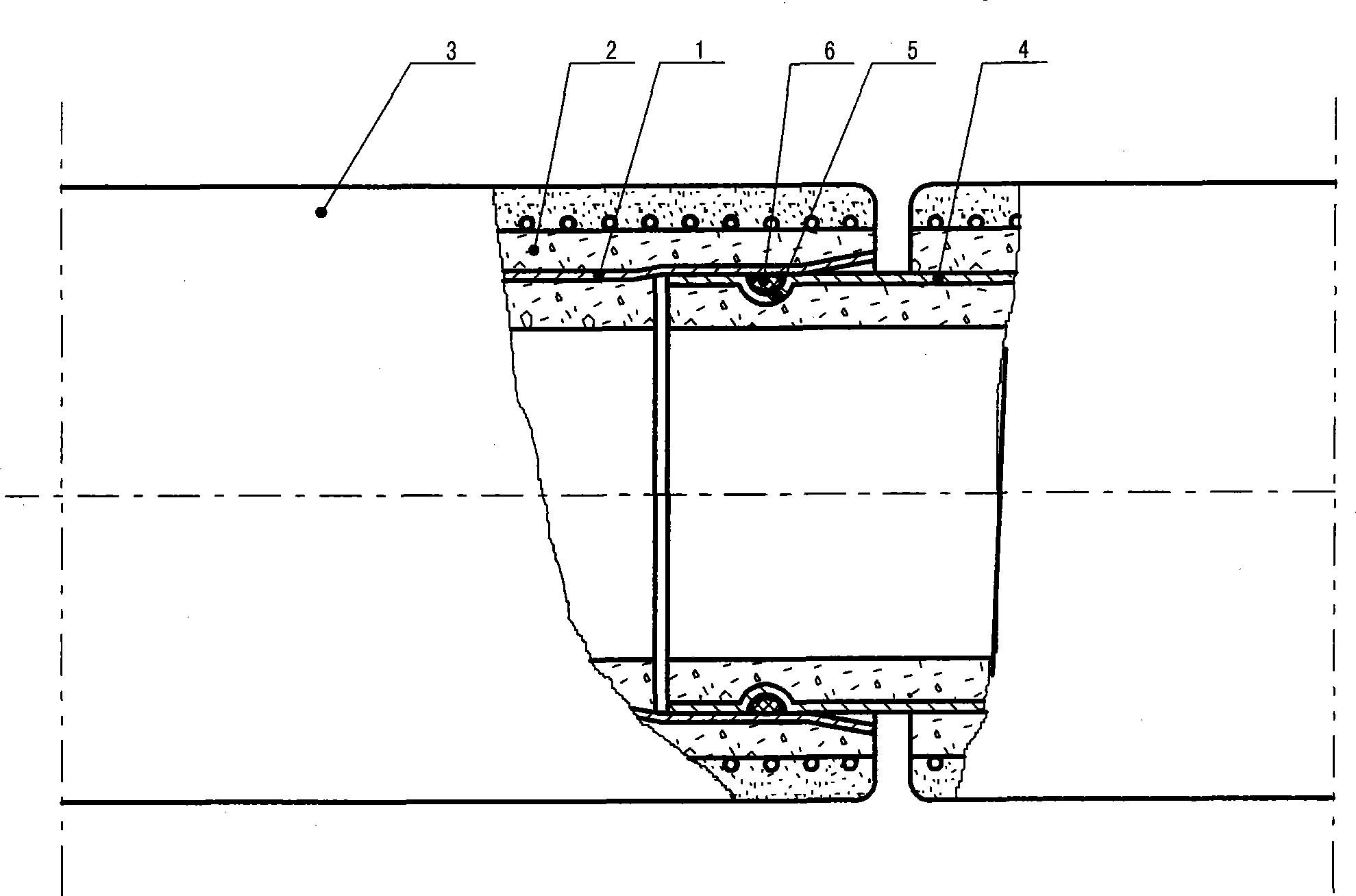

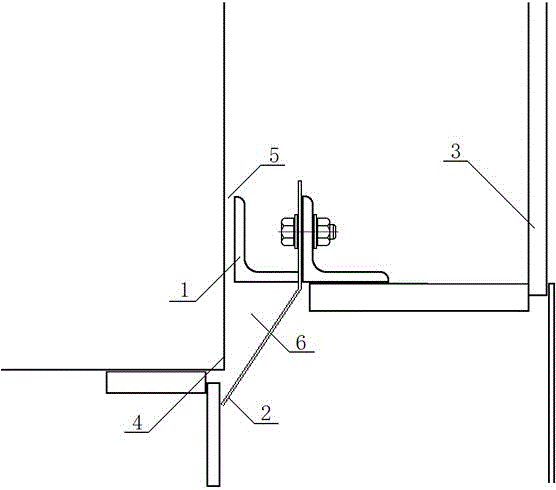

Sealing structure of pipe faucet of concrete

InactiveCN101363563AImprove output efficiencySimple preparation processSleeve/socket jointsRing typeBuilding construction

The invention relates to a sealing structure in a concrete reinforced pipe bell and faucet. The concrete reinforced pipe consists of a bell mouth, a faucet and a pipe; the bell mouth and the faucet are fixedly arranged in a pipe core at the two ends of the pipe; wherein, an outer wall of the concrete reinforced pipe faucet is coaxially provided with a ring socket along the radial direction. The invention has the advantages of simple integral structure, scientific and reasonable design, low construction cost and simple technique; the ring socket structure can increase the sealing property between concrete reinforced pipes and raise the integral sealing level of concrete reinforced pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Pressurizing pilot-operated type high-temperature and high-pressure labyrinth valve

PendingCN111609146AImprove the sealing levelReduce noiseSpindle sealingsPressure relieving devices on sealing facesPhysicsEngineering

The invention belongs to the technical field of pipeline engineering, and particularly relates to a pressurizing pilot-operated type high-temperature and high-pressure labyrinth valve. According to the technical scheme, a pressurizing type pilot structure is introduced, a pilot valve is closed, unbalanced force acts on the upper surface of a main valve element when the valve is in a closed state,the sealing specific pressure of a sealing pair is increased, and the sealing grade is improved; by opening the pilot valve, pressure balance of the upper and lower surfaces of a main valve element inan adjusting state is achieved, the size of an executing mechanism is reduced, and action time is shortened; a flow equalizing sleeve is introduced to realize uniform circumferential flow of a mediumand prevent the medium from directly impacting a valve rod; and the flow equalizing sleeve and a valve element guide face form guiding, and the valve is stable in action and free of jamming.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Labyrinth seal for a turbine engine of an aircraft

InactiveUS20190106999A1Reduce trafficIncrease airflowEngine fuctionsBlade accessoriesEngineeringTurbine

Labyrinth seal for a turbine engine, in particular of an aircraft, including a rotor element rotating about an axis of rotation (A), and a stator element extending around the rotor element (14), the rotor element including a series of annular lip(s) extending radially outwards and surrounded by at least one abradable element carried by the stator element, each lip comprising an inner peripheral body portion, an outer peripheral body portion, an upstream annular face of impact of an air flow during operation and a downstream annular face, wherein at least one lip includes, on the inner peripheral body portion thereof and / or the outer peripheral body portion thereof, through-orifices for the passage of air extending between the upstream and downstream annular faces.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

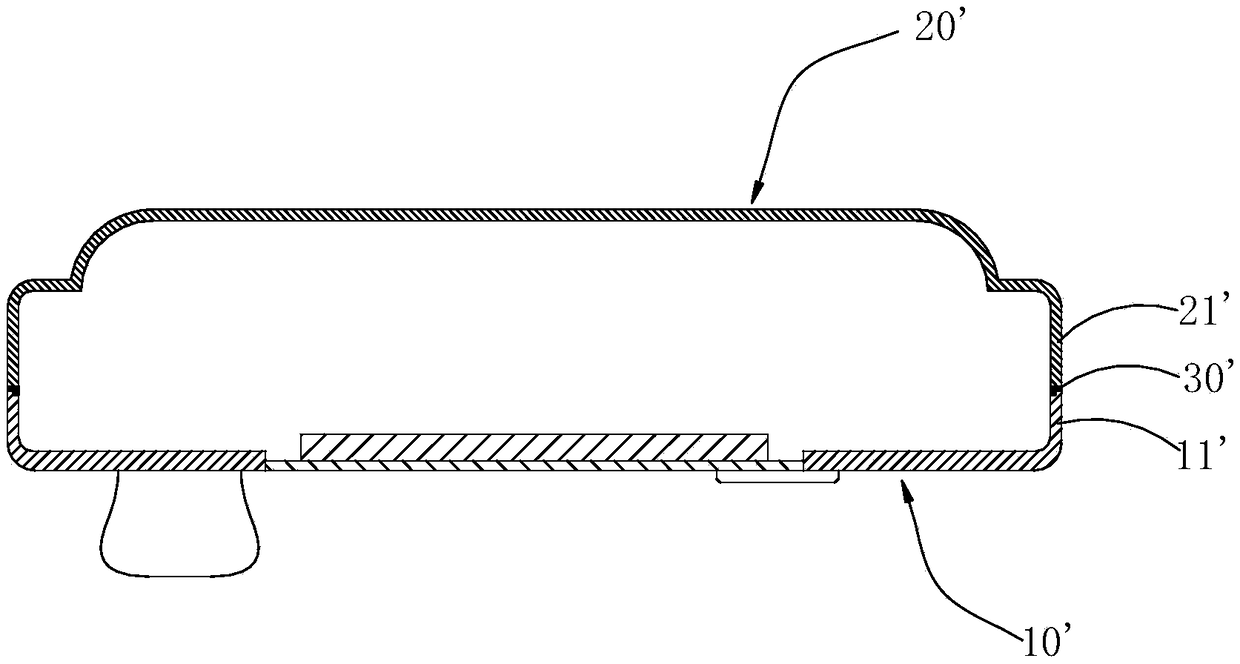

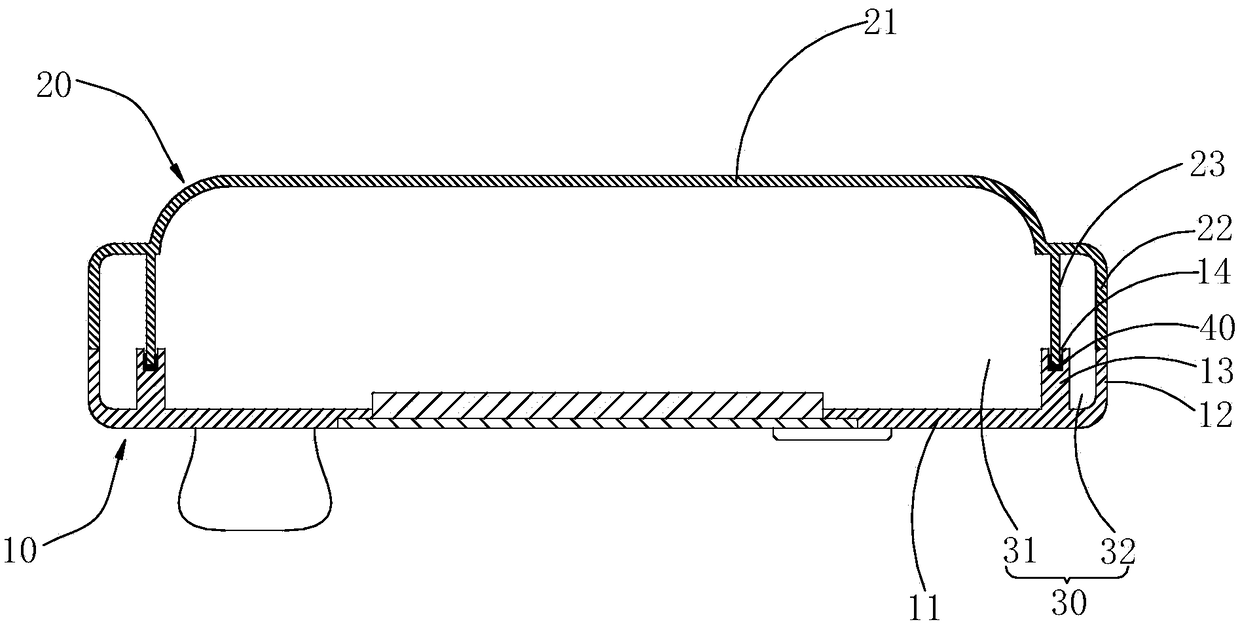

A double-stage sealed cabinet and an air conditioner using the same

ActiveCN106028730BIncrease the degree of sealingImproves sealing reliabilityHermetically-sealed casingsDouble stageMechanical engineering

Owner:GREE ELECTRIC APPLIANCES INC

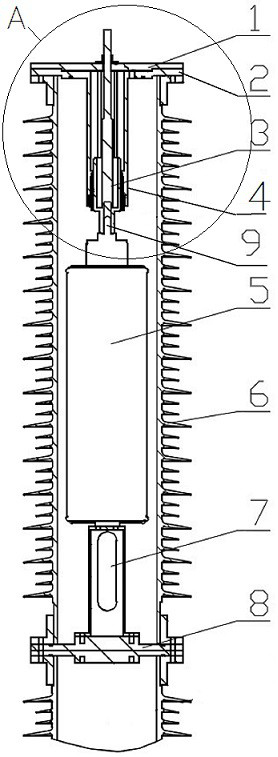

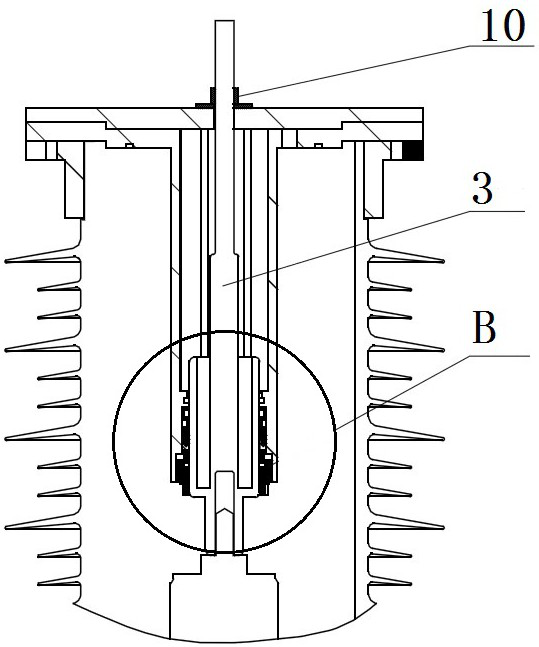

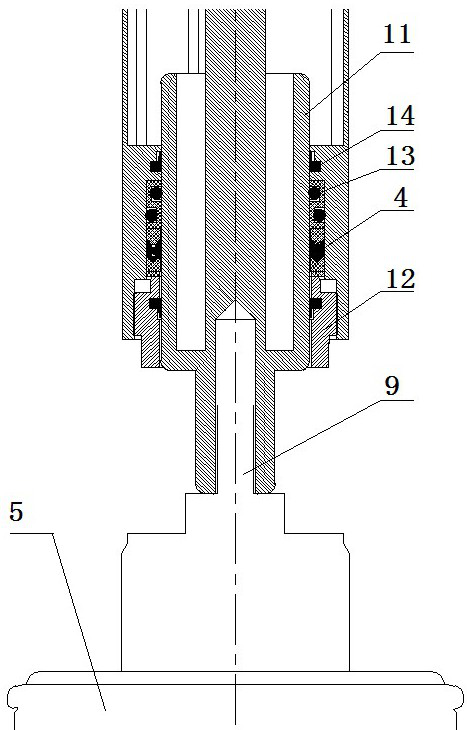

Aging and insulation testing device for vacuum arc-extinguishing chamber

ActiveCN112951647AImprove the sealing levelMeet sealing requirementsTesting dielectric strengthHigh-tension/heavy-dress switchesElectrical connectionEngineering

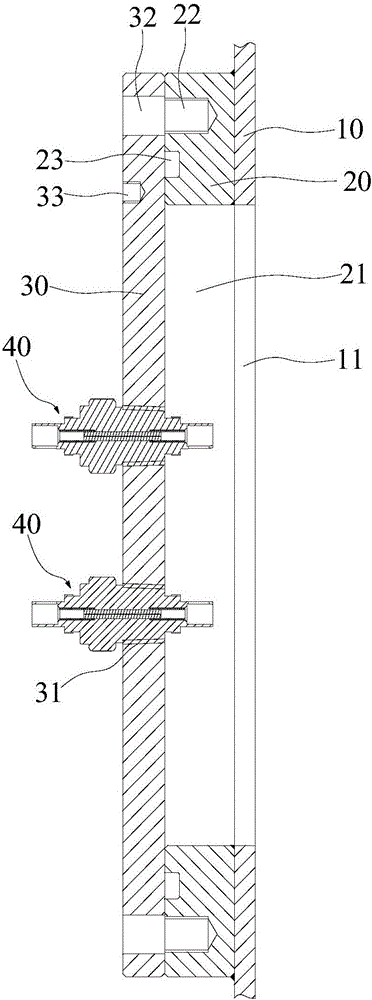

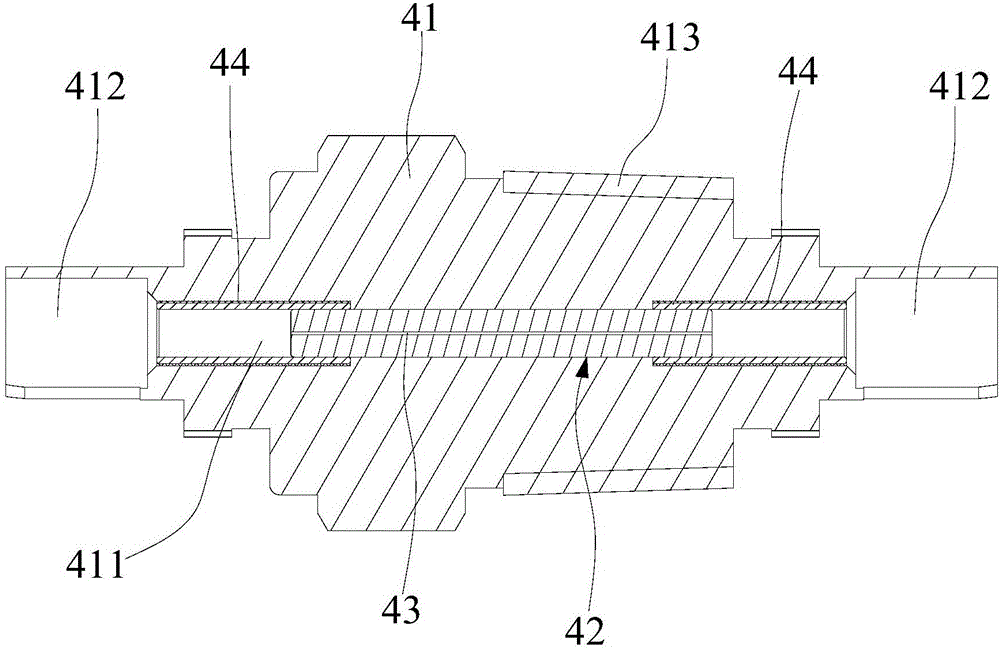

The invention relates to an aging and insulation testing device for a vacuum arc-extinguishing chamber. The aging and insulation testing device for the vacuum arc-extinguishing chamber comprises a shell, the shell is provided with an inflation cavity for accommodating the vacuum arc-extinguishing chamber to be aged or subjected to insulation testing, a conductive connecting rod is used for being fixedly connected with a movable conductive rod of a vacuum arc-extinguishing chamber to be aged, the shell is provided with a connecting rod penetrating-out channel for the conductive connecting rod to penetrate out, and a direct-acting sealing structure is arranged between the connecting rod penetrating-out channel and the peripheral surface of the conductive connecting rod. The sealing peripheral surface of the conductive connecting rod is processed according to high-grade surface processing precision, so that the sealing grade between the sealing peripheral surface and the direct-acting sealing structure is relatively high, the sealing requirement when a relatively large pressure difference exists inside and outside the inflation cavity is met, and the inflation cavity can be filled with compressed gas with relatively high pressure; therefore, the aging and insulation testing device for the vacuum arc-extinguishing chamber has a relatively high insulation grade, thereby being suitable for aging or insulation testing of the vacuum arc-extinguishing chamber with a high voltage grade.

Owner:TIANJIN PINGGAO INTELLIGENT ELECTRIC +2

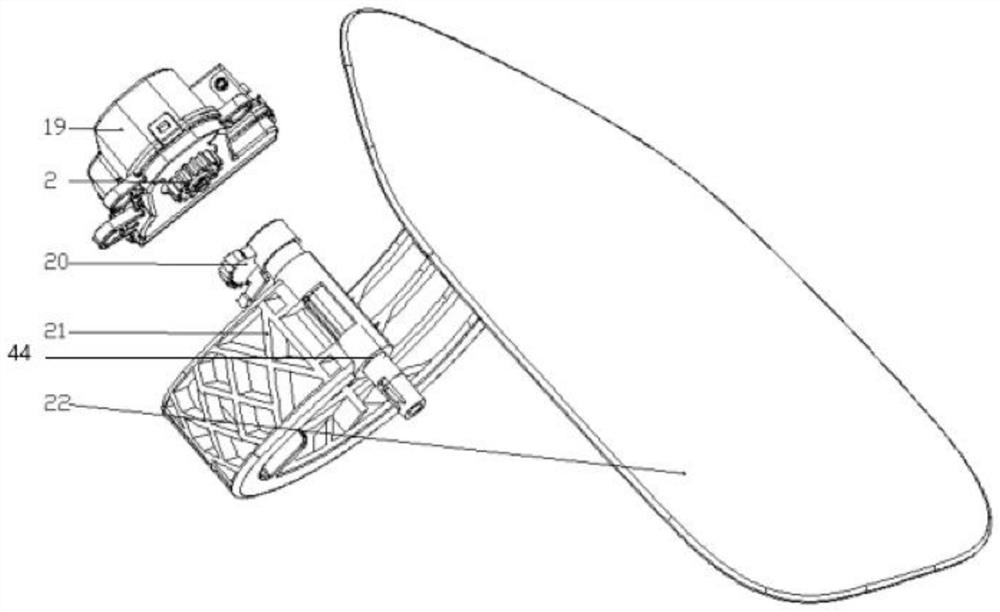

Charging port cover and port cover assembly

PendingCN113184058AImprove the sealing levelBeautiful appearanceCharging stationsSuperstructure subunitsStructural engineeringMechanical engineering

The invention discloses a charging port cover and a port cover assembly. The charging port cover comprises an actuator assembly, a positioning assembly, a gooseneck, a port cap and a port pipe, wherein the port pipe is installed in the automobile body metal plate in an embedded mode. The port cap is mounted on the gooseneck in a clamping manner; through holes are formed in the upper surface of the port pipe; the other end of the gooseneck penetrates through the through hole to be installed in the port pipe; an actuator assembly is installed at the joint of the gooseneck and the port pipe; the positioning assembly is arranged on one side of the port cap; a limiting assembly used for fixing the positioning assembly is installed on the surface of the port pipe in an embedded mode; and a shielding rib is mounted on the back of the gooseneck. According to the invention, the covering cap is driven to operate through the actuator assembly, intelligent application of a product is improved, and use of a customer is facilitated; by adding a decorative structure on the back of the gooseneck, after the port cap is opened, the port cap covers the through hole and is integrated with the gooseneck, a mold does not need to be developed independently, and the product development and production cost is reduced; a positioning structure is additionally arranged between the port cap and the port pipe, so that the surface difference and the gap value between the port cap and the automobile body metal plate are ensured.

Owner:重庆峻基汽车部件有限公司

Sealing device of circular arc section of fan-shaped plate of air preheater

ActiveCN105805773ASpill Area IsolationReduced isolationEngine sealsCombustion processAir preheaterEngineering

The invention relates to the field of air preheaters, in particular to a sealing mechanism. A sealing device of a circular arc section of a fan-shaped plate of an air preheater comprises fan-shaped plate sealing angle steel and a bypass sealing piece, wherein one end of the bypass sealing piece is fixedly connected on a hot end connecting ring through a bracket; the other end of the bypass sealing piece is leaned on a sealing surface of the circular arc section of the fan-shaped plate through elastic restoring force; a hot end lug plate and a fan-shaped plate lug plate are respectively arranged on the hot end connecting ring and the sealing surface of the circular arc section of the fan-shaped plate; a corrugated pipe is arranged on the sealing surface of the circular arc section of the fan-shaped plate in a sleeving manner; one end of the corrugated pipe is fixedly connected on the fan-shaped plate lug plate through a movable connecting annular plate; and the other end of the corrugated pipe is fixedly connected on the hot end lug plate through a static connecting annular plate. According to the sealing device, the corrugated pipe is arranged between the circular arc section of the fan-shaped plate and the connecting ring, and an air flow channel of an original leakage interval is covered by the corrugated pipe, so that a leakage zone is completely isolated, the smoke leakage is reduced, and the entire sealing level is improved.

Owner:上海尚甸电站设备有限公司

Small square soft sheet membrane module

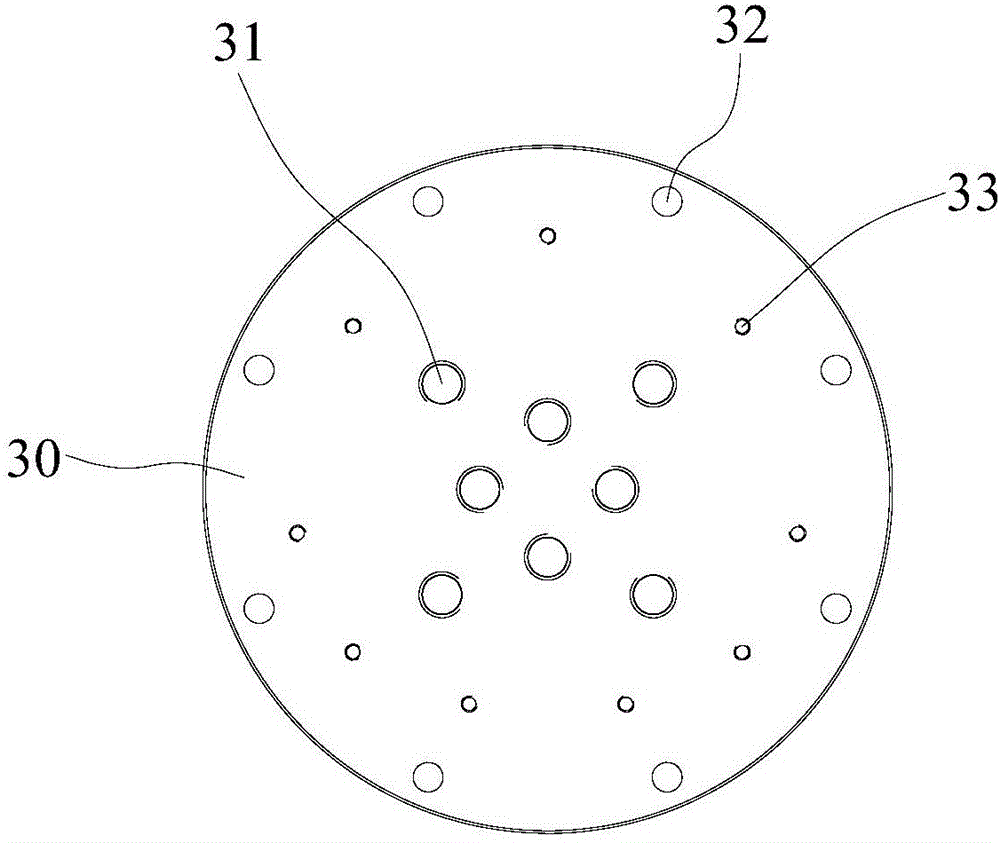

ActiveCN107051209AReduce manufacturing costSave membrane materialMembranesUltrafiltrationWater flowFilter media

The invention discloses a small square soft sheet membrane module, belonging to the technical field of water treatment filtering mediums. The small square soft sheet membrane module comprises a percolating water guide pipe provided with water permeable holes, soft sheet membranes and locking plates which are arranged on the percolating water guide pipe in a staggered way, and end plates respectively arranged at the two ends of the percolating water guide pipe, wherein through holes, through which the percolating water guide pipe can pass, are respectively formed in the middle parts of the locking plates; the inner wall of each locking plate is provided with a convex part, and the convex parts enable a percolating water flow channel to be formed between the percolating water guide pipe and the inner walls of the locking plates. The small square soft sheet membrane module is provided with the stable percolating water converging flow channel, thus being basically constant in outlet water resistance and stable in permeant flux; furthermore, sealing rings arranged in the locking plates do not fall off, so that a membrane filtration component structure which is stable in all the directions and firm in sealing can be formed.

Owner:湖州鼎泰软片膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com