Injection-molded wire harness and molding method

An injection molding and wire harness technology, applied in the field of wire harnesses, can solve problems such as combustion accidents, unprotected cables, short circuits, etc., and achieve the effects of reducing processing time, improving product quality, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

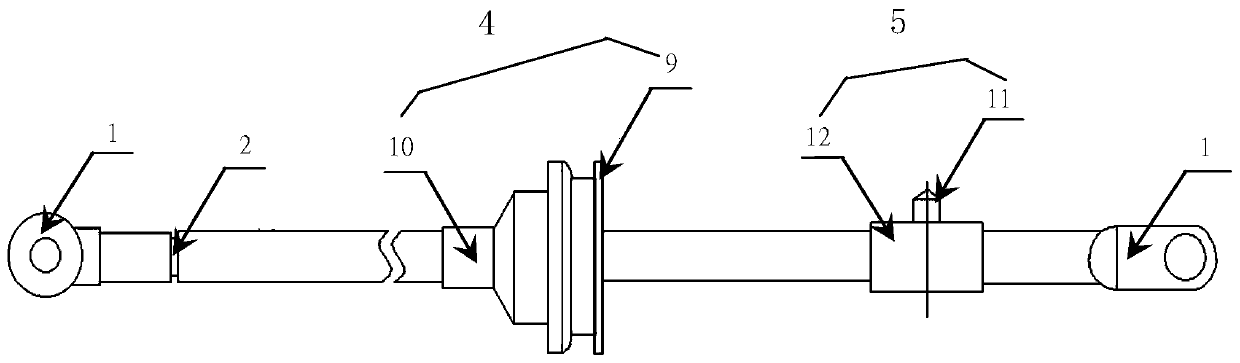

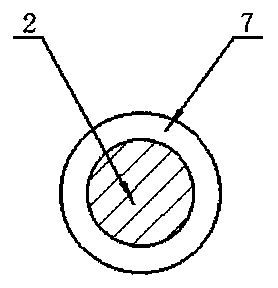

[0077] Such as figure 1 , Figure 3-1 As shown, the wiring harness is composed of a single conductor, and the two ends of the conductor 2 are respectively connected to the terminals 1 . The terminal 1 is a copper terminal, and the copper terminal is made of a copper alloy with a copper content of 60%, which can ensure good electrical conductivity and workability of the copper terminal. The surface of the terminal 1 is plated with nickel, and can also be plated with one of cadmium, zirconium, chromium, cobalt, manganese, aluminum, tin, titanium, zinc, copper, silver or gold. The coating can slow down the corrosion of the terminal and prolong the service life of the terminal . One end of the terminal 1 is connected to the conductor 2, and the other end of the terminal 1 is used to connect the electrical circuit of the electric device when in use. In this embodiment, the conductor 2 is composed of multi-core wires, and the cross-section of the multi-core wires is circular. In o...

Embodiment 2

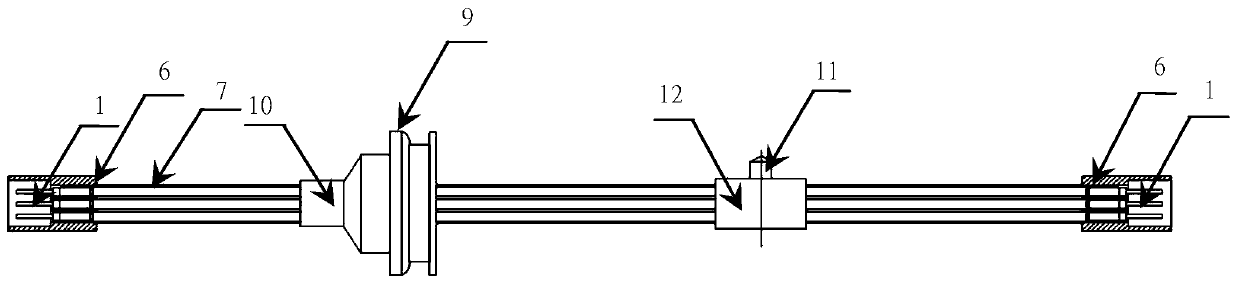

[0087] Such as figure 2 , Figure 3-2 , Figure 3-3 As shown, the wiring harness is composed of more than one conductor 2, and each of the conductors 2 is connected to the terminal 1 at both ends, and the surface of the terminal 1 is galvanized, and nickel, cadmium, zirconium, chromium, cobalt can also be plated , manganese, aluminum, tin, titanium, copper, silver or gold. The conductor 2 and the terminal 1 are the same as those in Embodiment 1, and will not be repeated here. The difference from Embodiment 1 is that the wire harness is also provided with at least one sheath 6 that is plugged into the electrical device. After the conductor 2 is connected to the terminal 1, the terminal 1 is assembled in the sheath 6. The terminals 1 are corresponding to different holes of the sheath 6 according to design requirements, so as to function together with different circuits, and at the same time, protect the terminals 1 from damage. The sheath 6 is integrally injection molded on...

Embodiment 3

[0097] Such as Figure 4 As shown, the wiring harness is composed of more than one conductor 2, one part of the conductor 2 is connected to the terminal 1, and the other part of the conductor 2 is connected to the conductor connection point according to the circuit requirements by crimping or welding. . The surface of the terminal 1 is plated with silver, and may also be plated with one of nickel, cadmium, zirconium, chromium, cobalt, manganese, aluminum, tin, titanium, zinc or gold. After the conductor 2 is connected to the terminal 1, the terminal 1 is assembled into a sheath 6 that is plugged in with the electrical device, and different terminals 1 correspond to different holes in the sheath 6 according to design requirements. During the preparation, the entire connection point of the conductor is sealed as a wire harness protection device 8; the wire harness protection device 8 is a rubber or plastic part processed by injection molding. Such as Figure 3-4 As shown, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com