Patents

Literature

147 results about "Retaining harness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

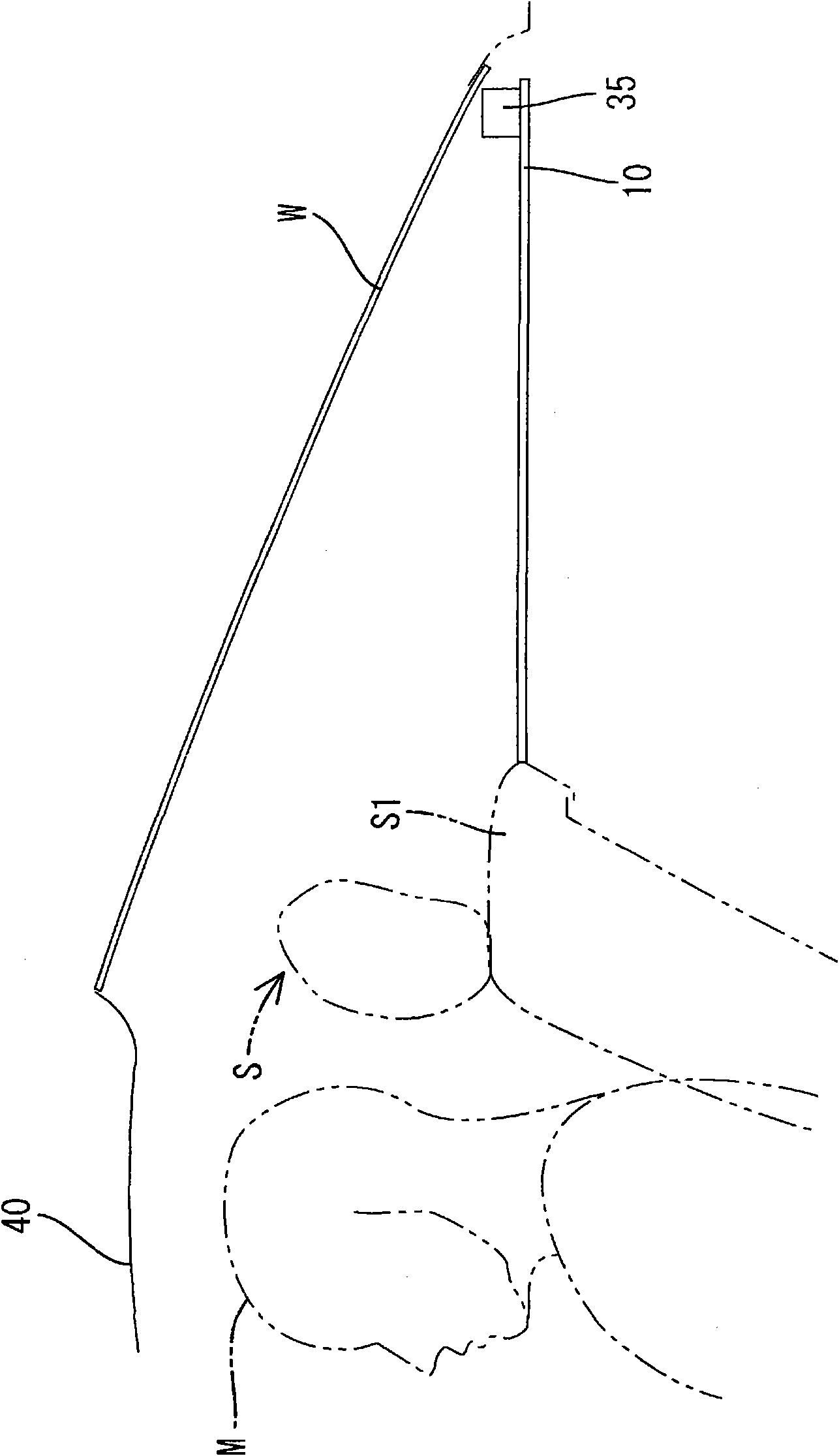

Methods of forming prostheses

A breast prosthesis may be formed by forming an outer layer on a mold, and filling the mold with a polymerizable foaming composition. The mold may be formed by forming a computer model of the prosthesis based on scanning a patient. The computer model may be used to form a solid model. A prosthesis may be coupled to the patient by coupling at least one metallic insert to the prosthesis and at least one magnet to the patient. Alternately, the prosthesis may be formed with a retaining harness integral to the prosthesis. In still another method, the prosthesis may be coupled to a retaining device surgically implanted in the patient.

Owner:CONTOURMED

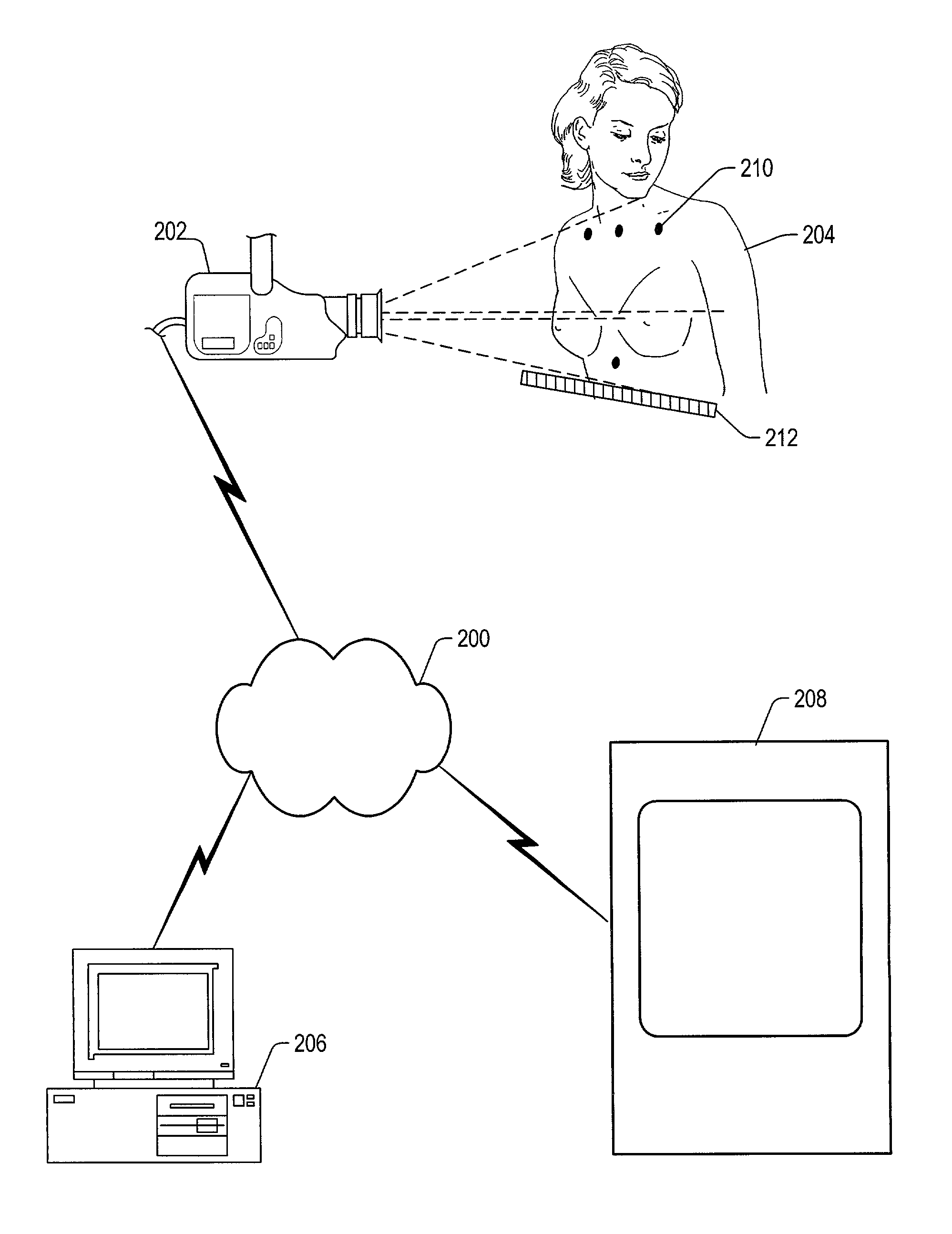

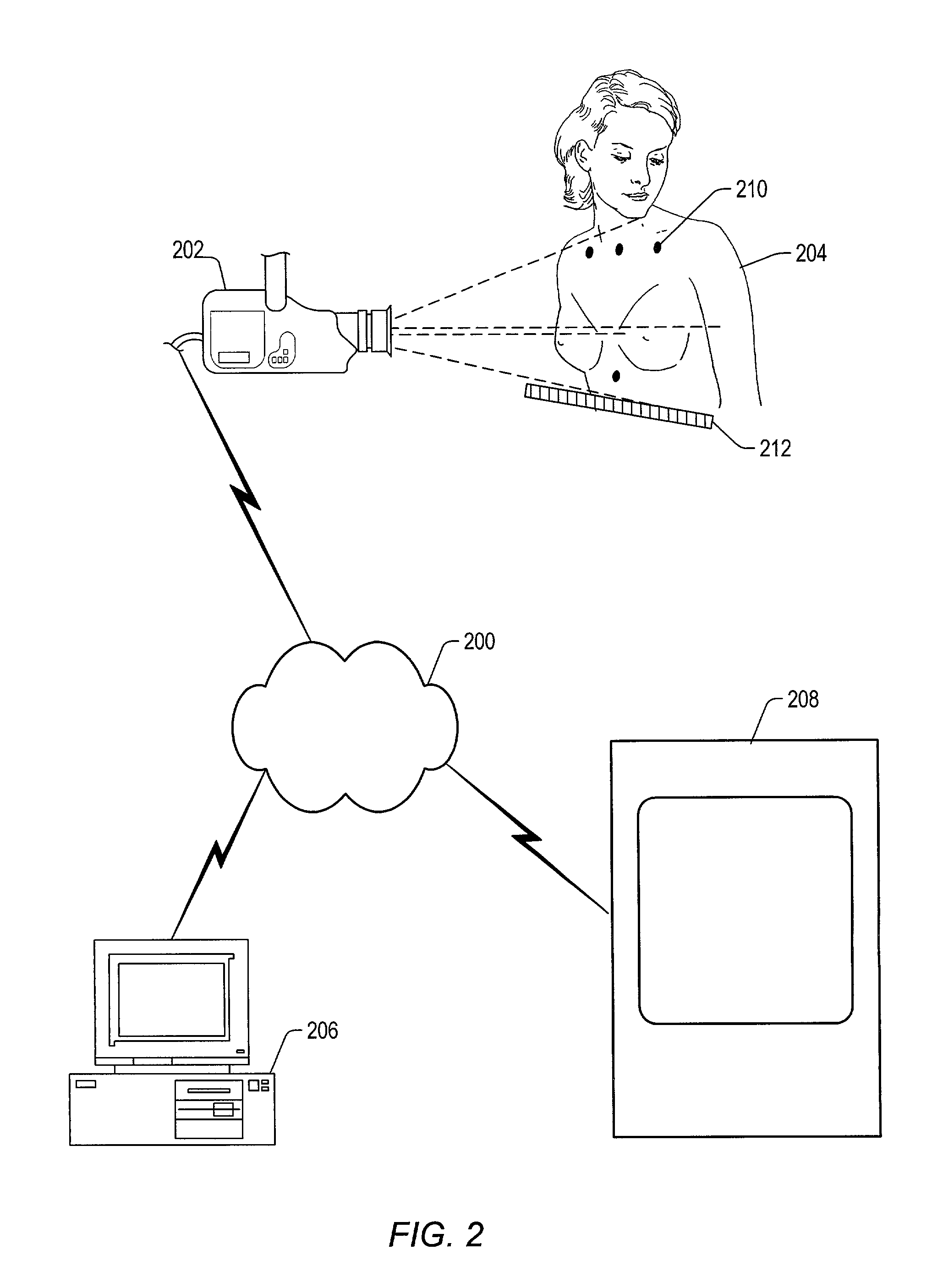

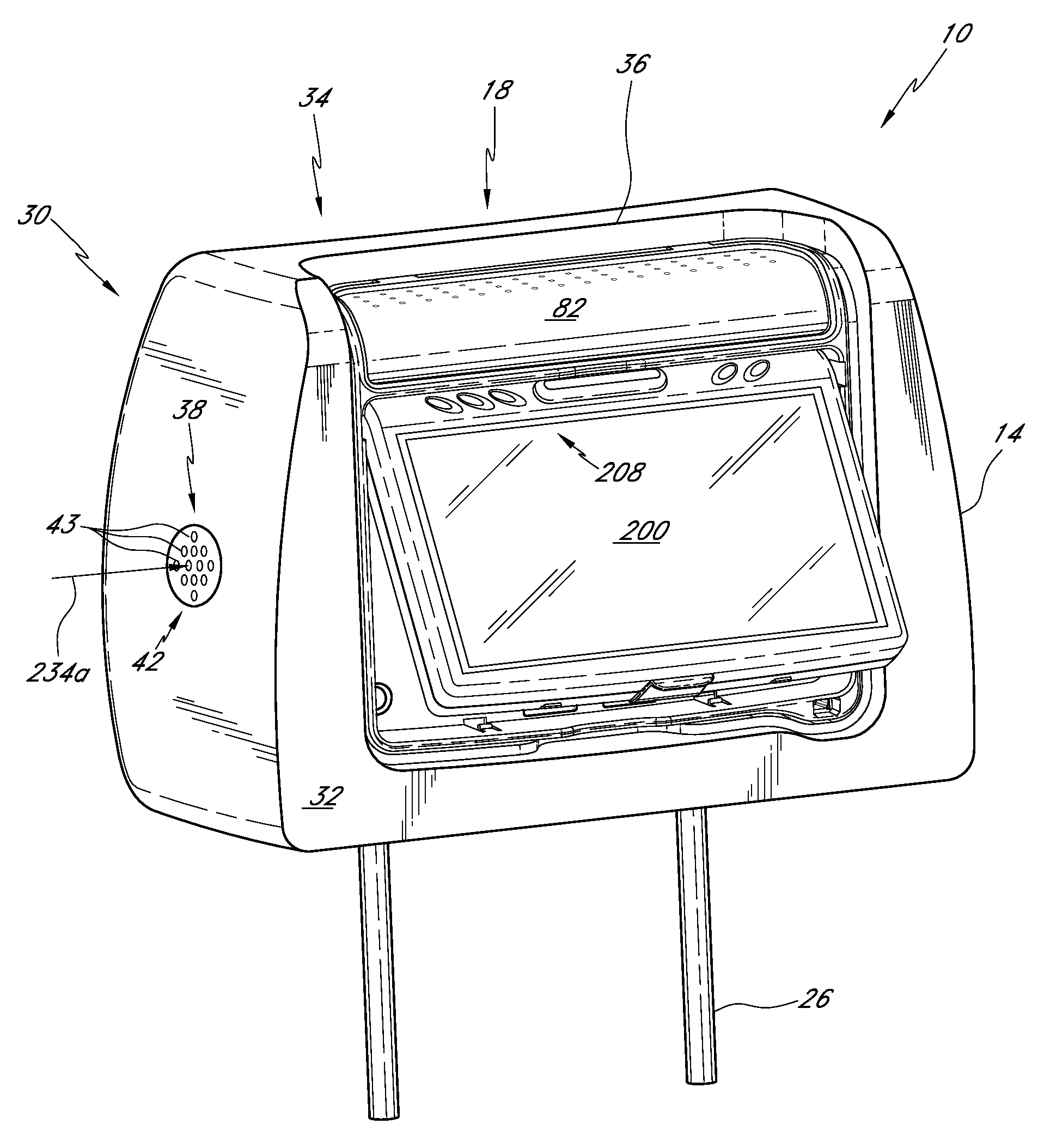

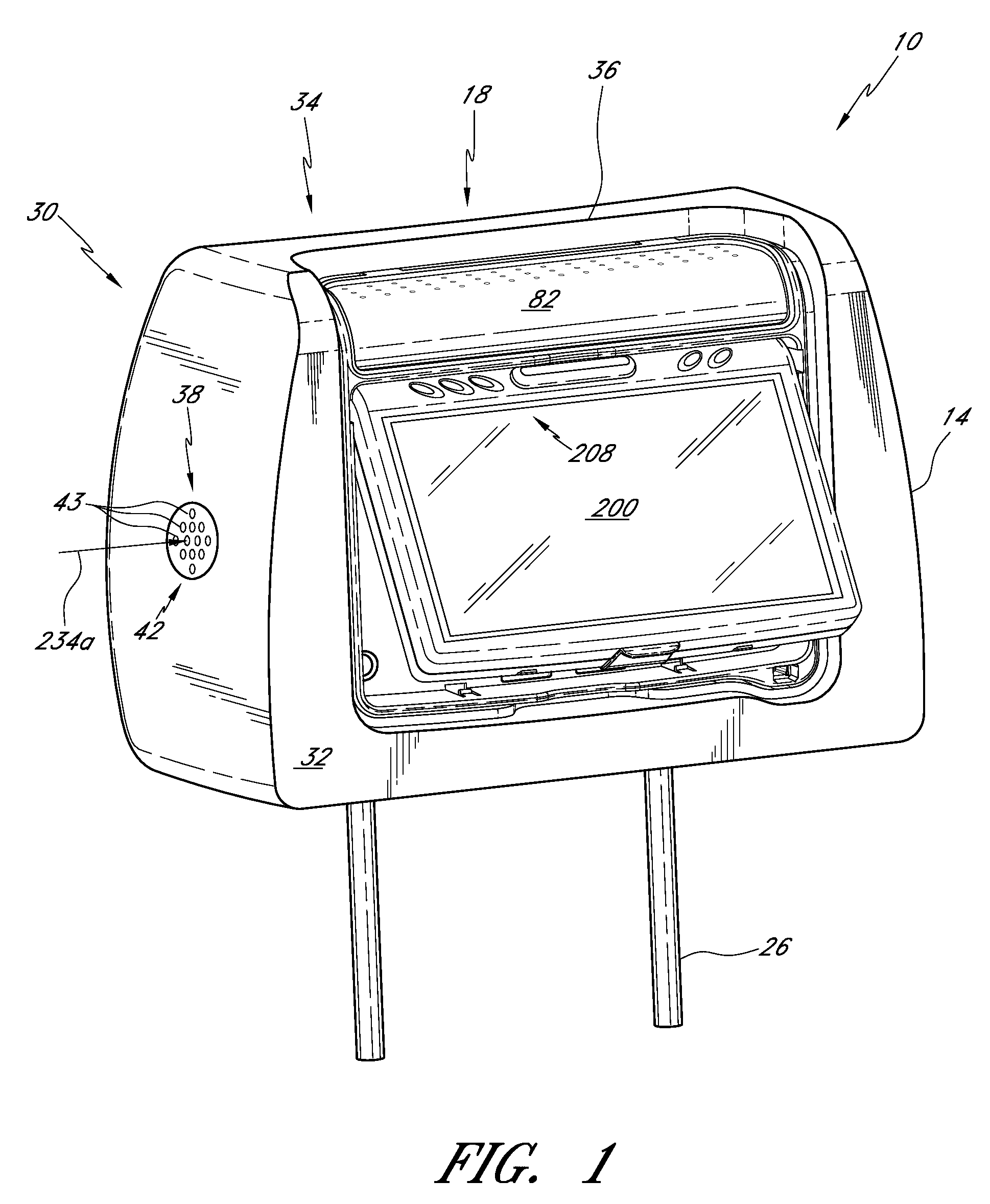

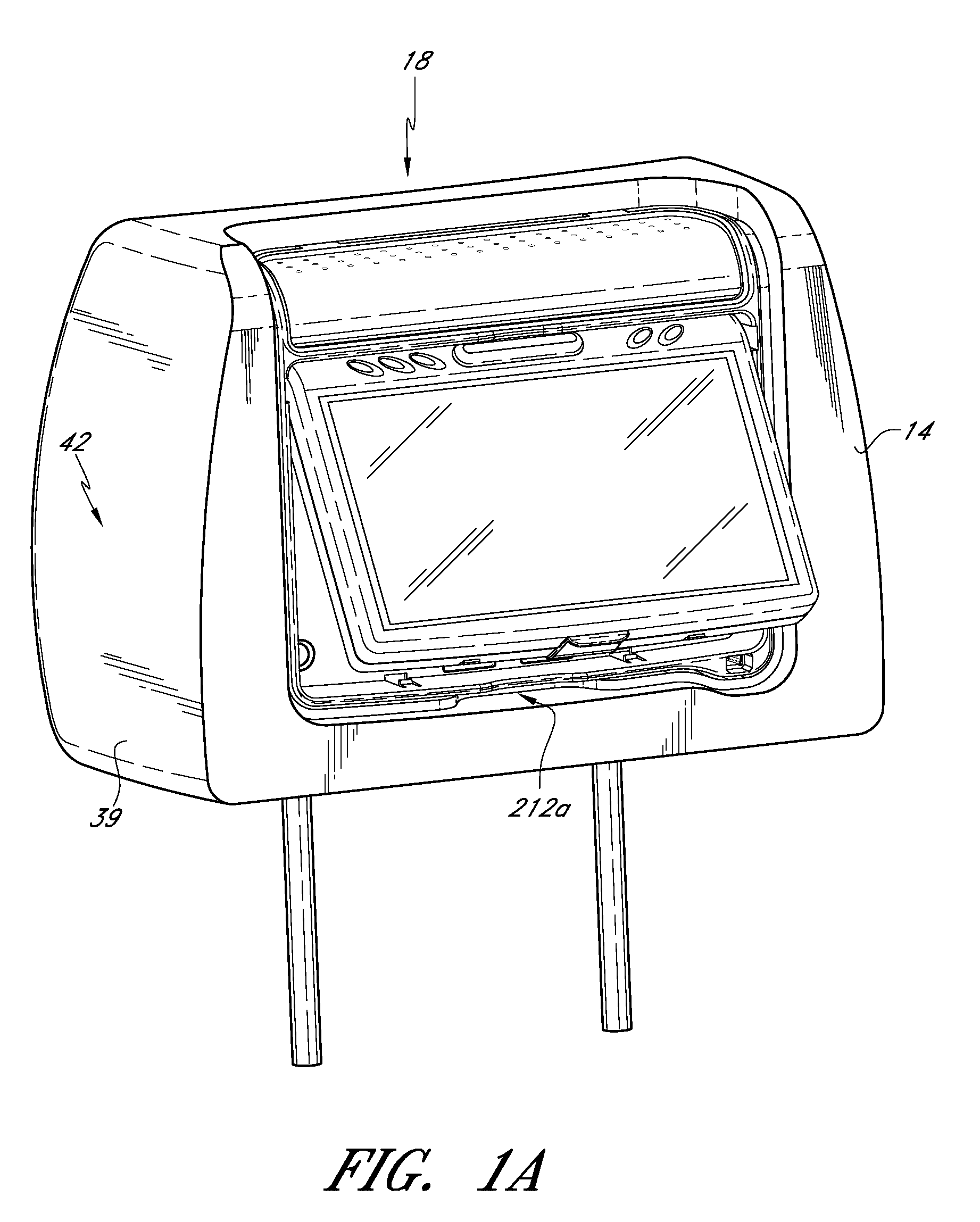

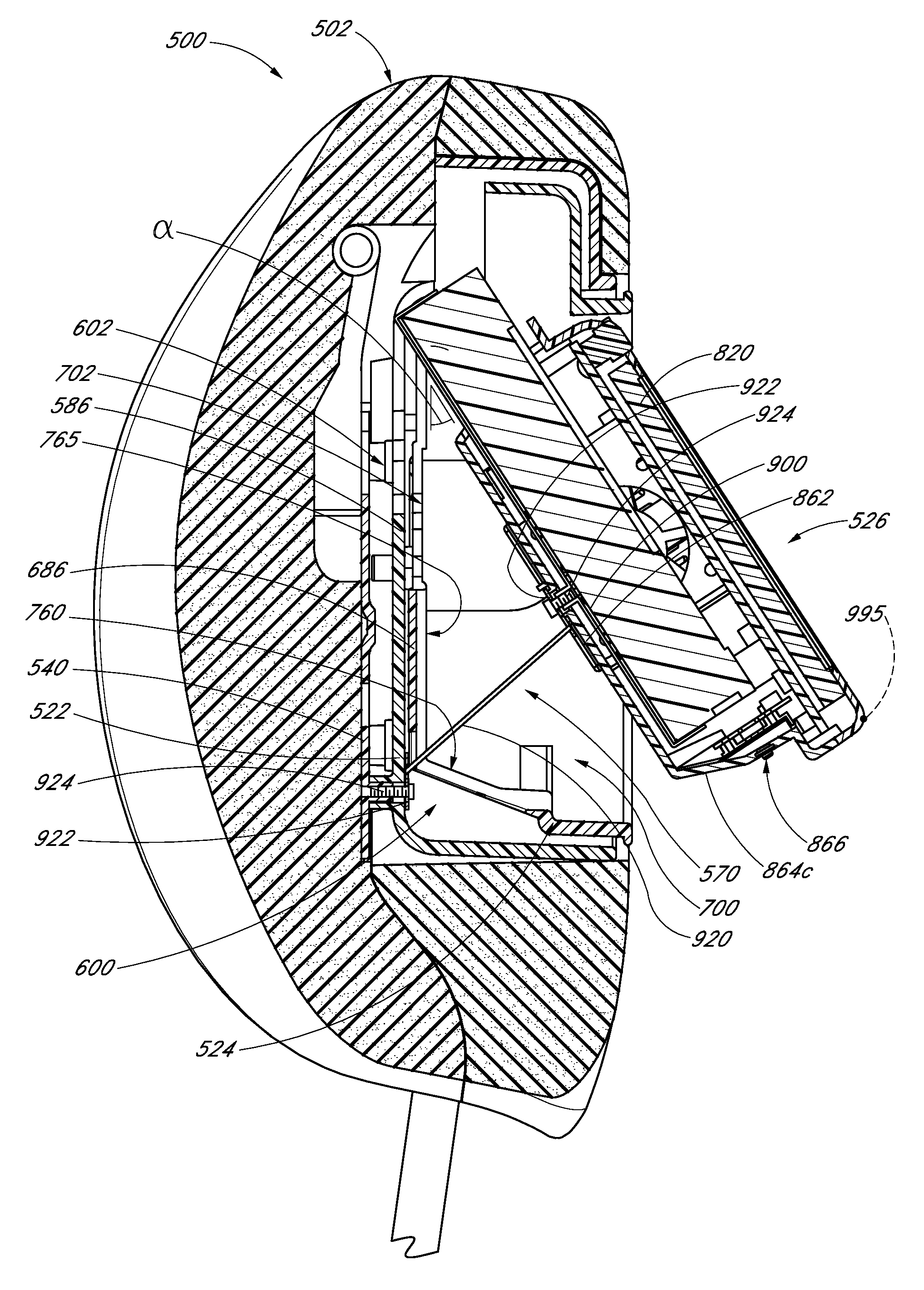

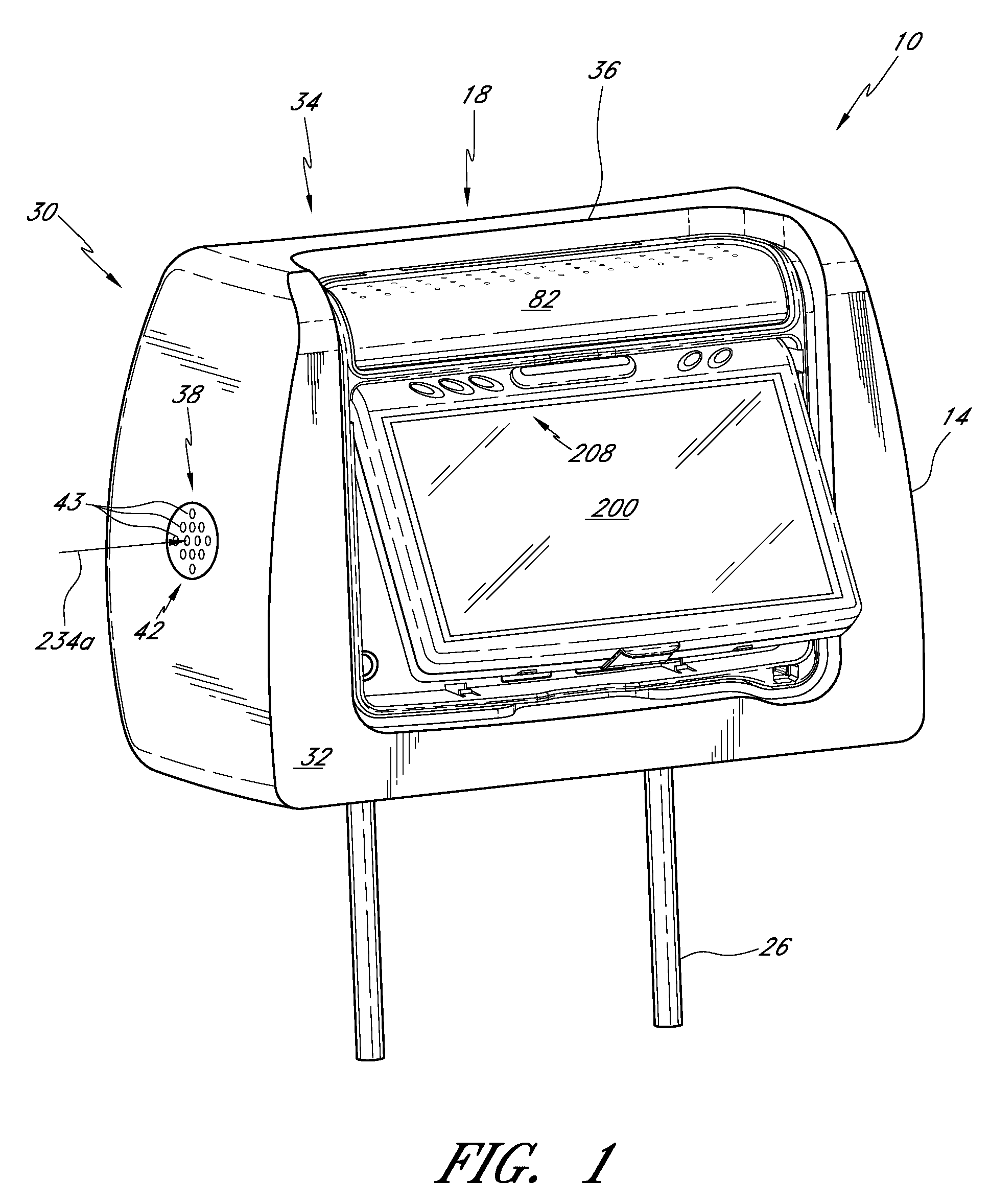

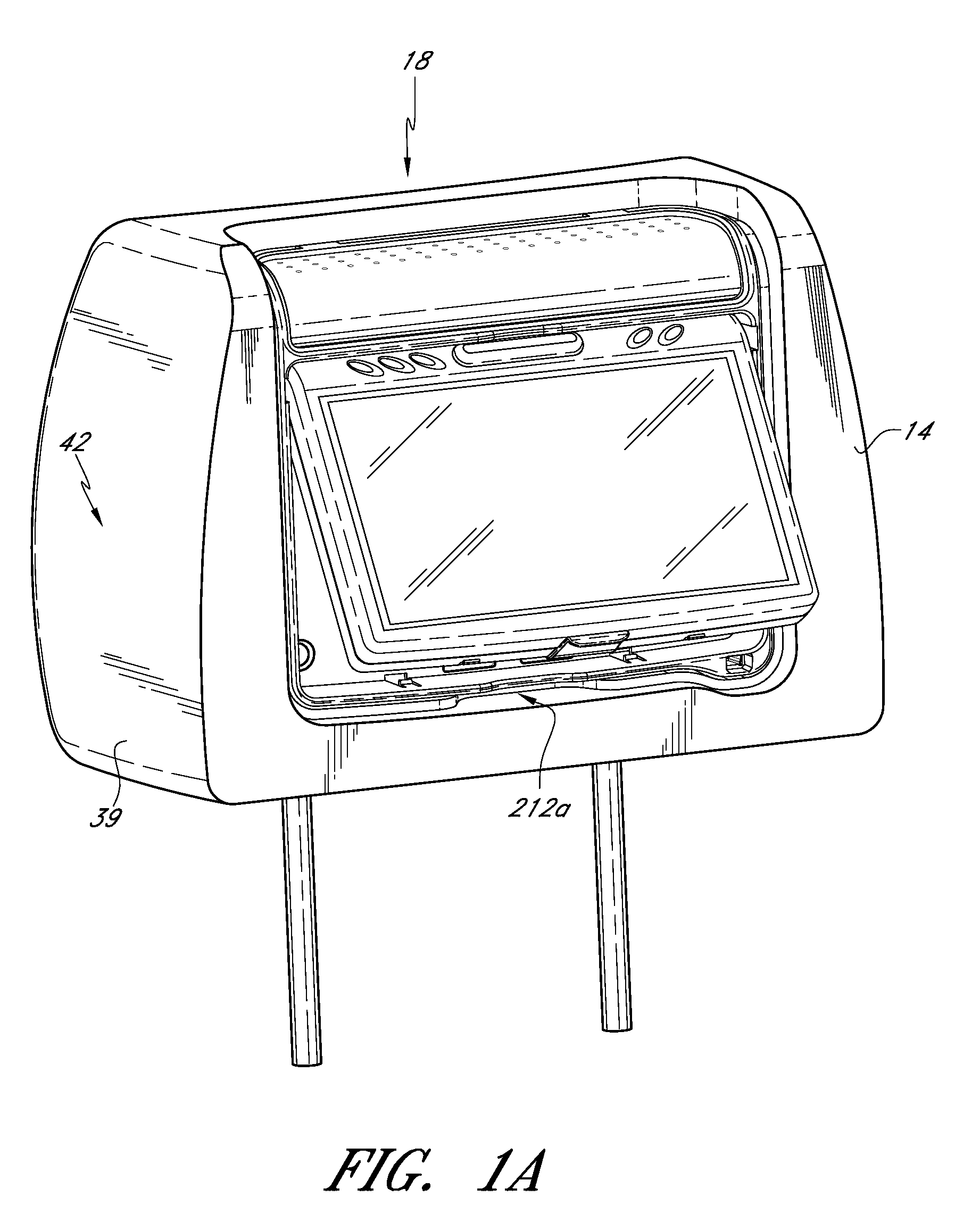

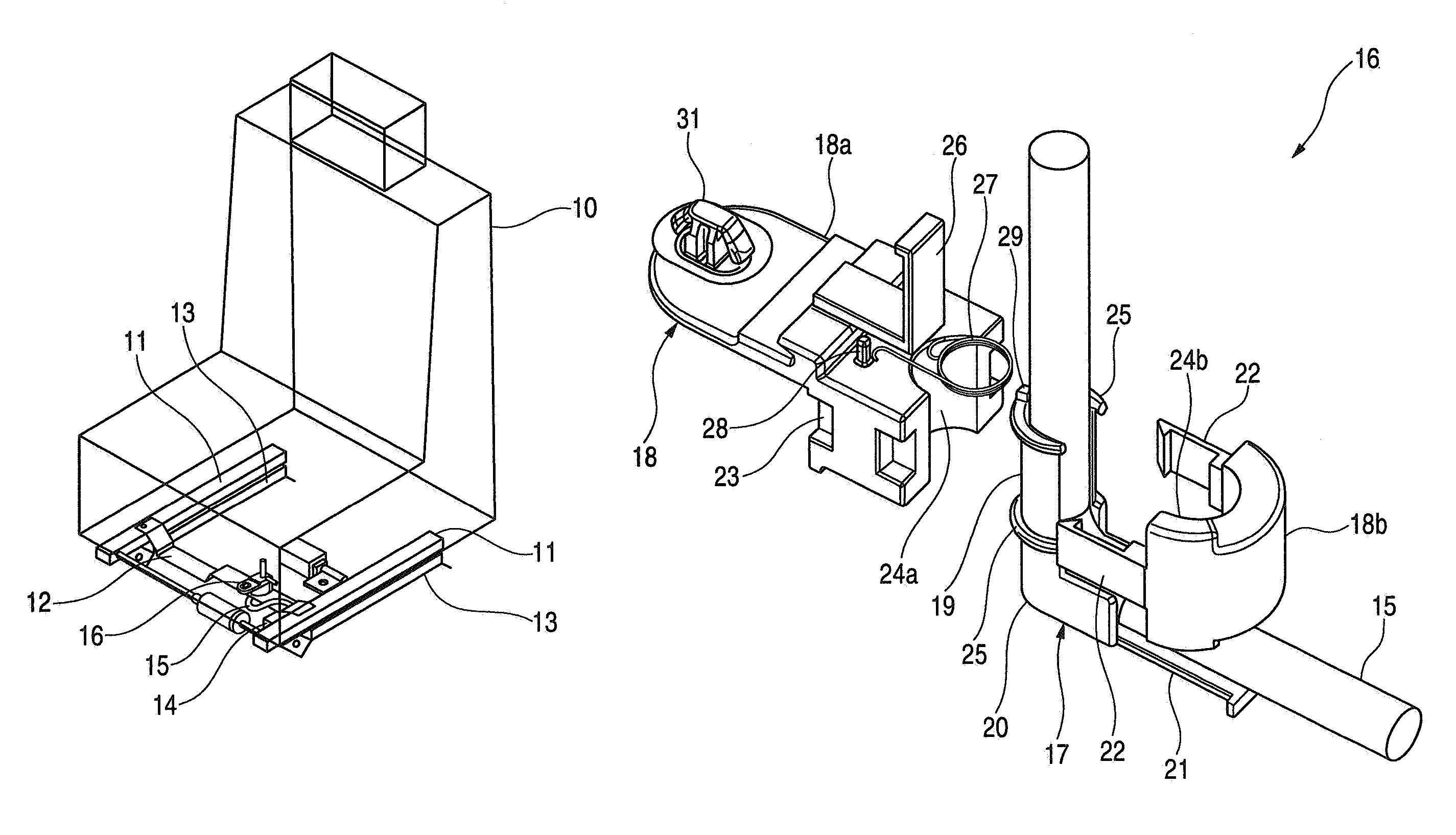

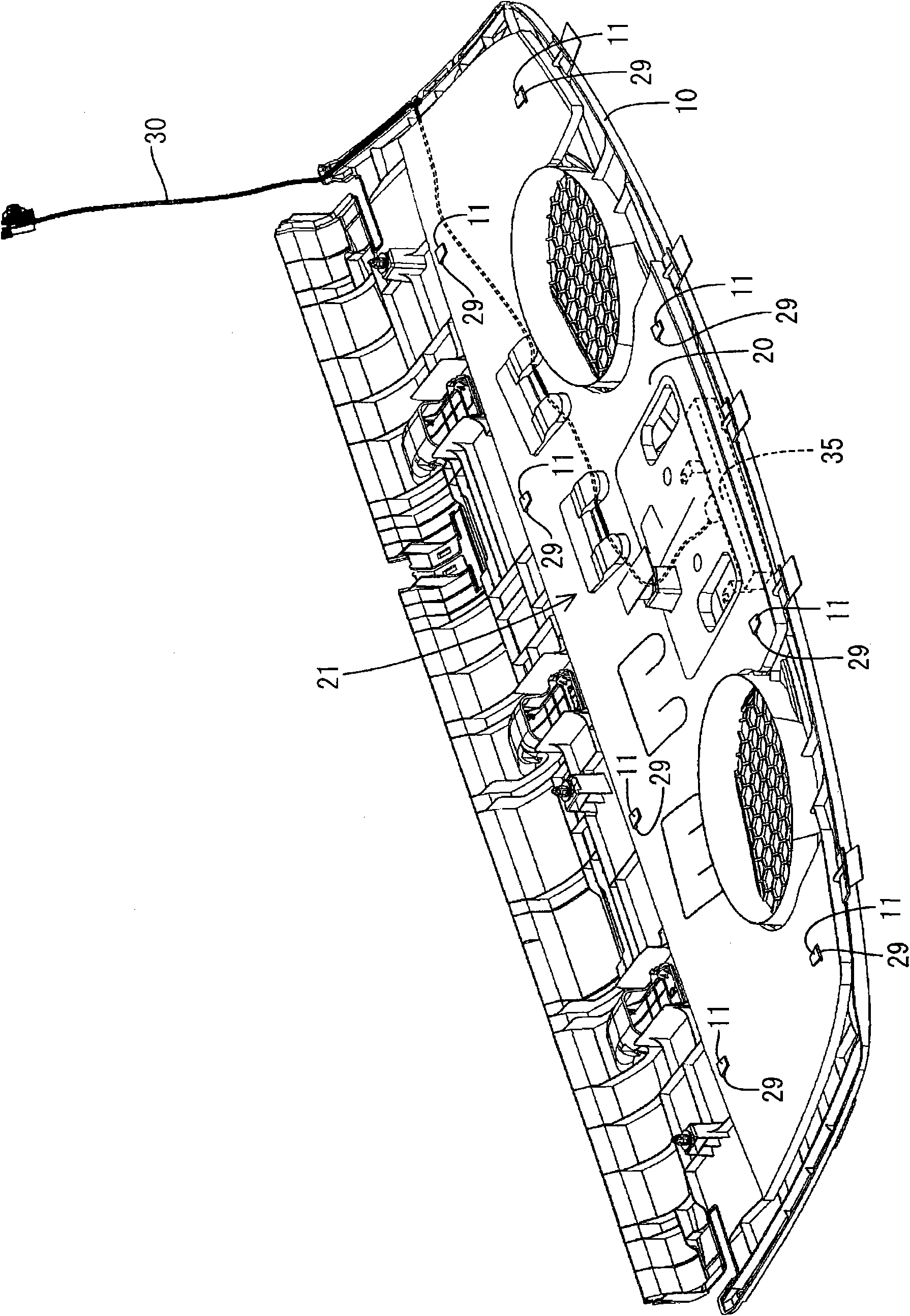

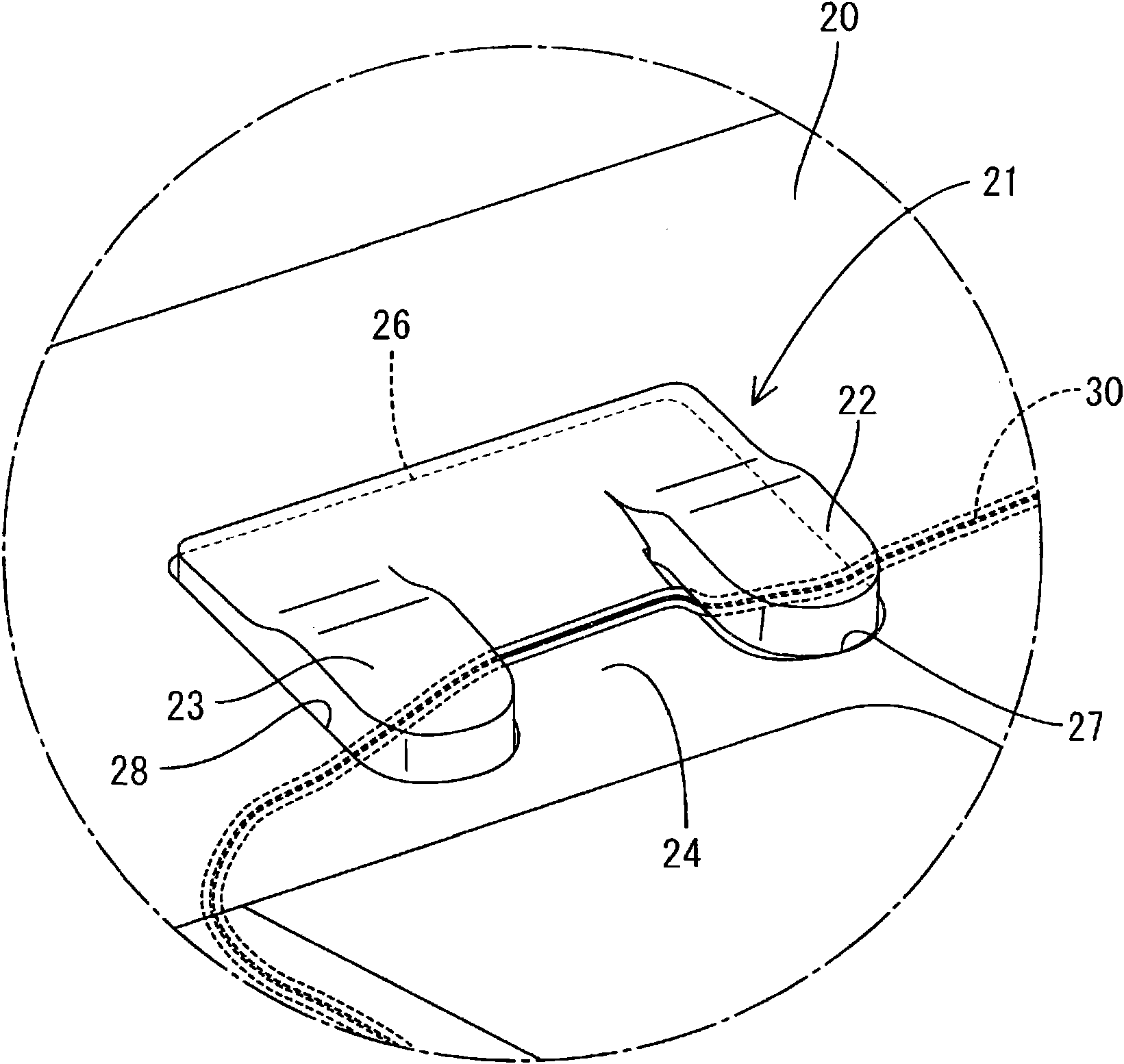

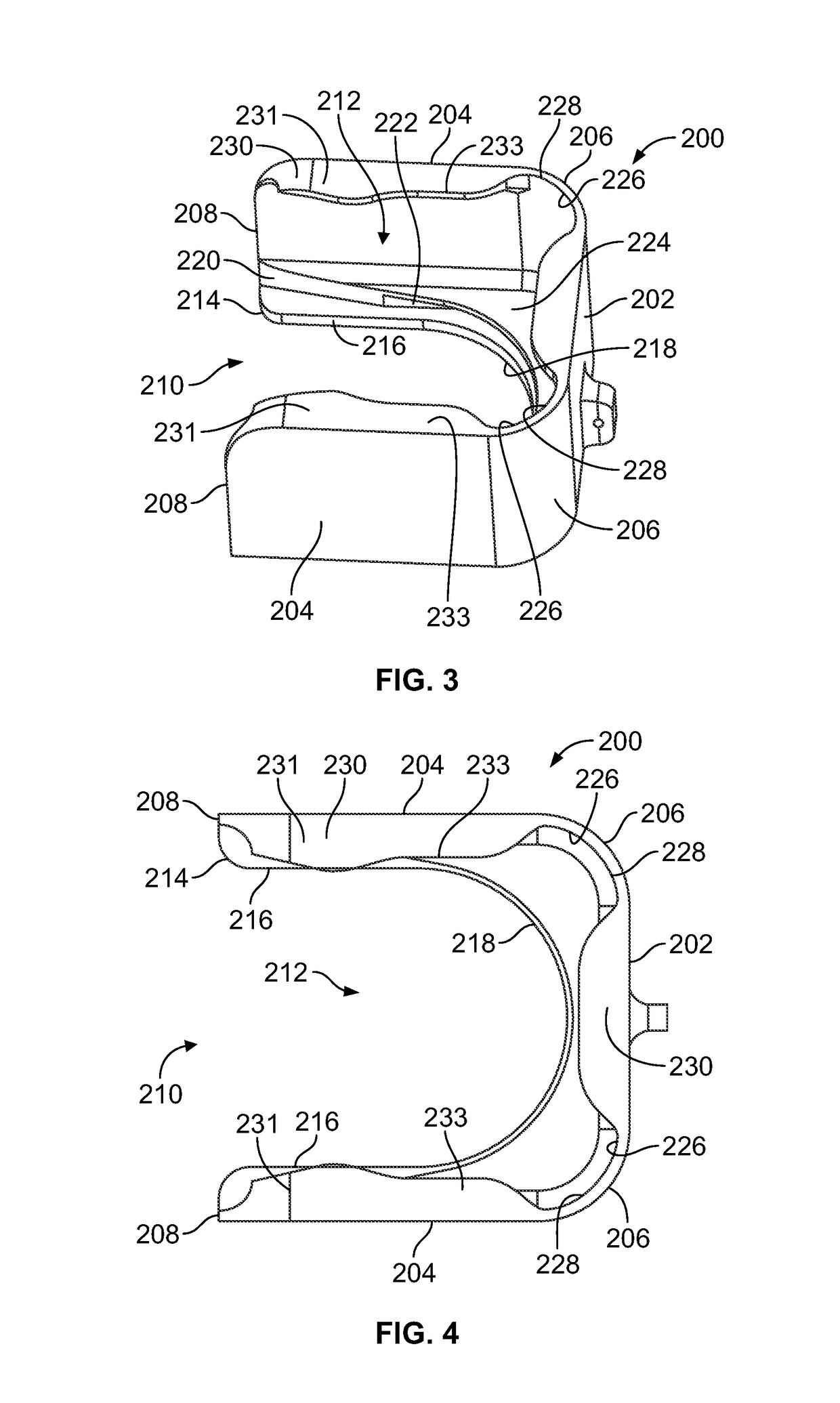

Headrest-mounted entertainment systems

InactiveUS20080246320A1Television system detailsColor television detailsEngineeringRetaining harness

In certain embodiments, a mobile entertainment system includes a housing configured to be coupled with a mounting plate of a headrest. The housing can define a first hinge portion. In some embodiments, the system further includes a screen assembly. The screen assembly can define a second hinge portion that cooperates with the first hinge portion to pivotally couple the screen assembly with the housing such that the screen assembly can rotate relative to the housing. In some embodiments, the system further includes a retaining harness fixedly attached to the mounting plate at a first end and fixedly attached to the screen assembly at a second end. The retaining harness can be configured to limit rotation of the screen assembly relative to the housing. Optionally, in some embodiments, the system includes a headrest configured to be installed in a vehicle. The headrest can include a mounting plate.

Owner:VOXX INT CORP

Headrest-mounted entertainment systems

Owner:VOXX INT CORP

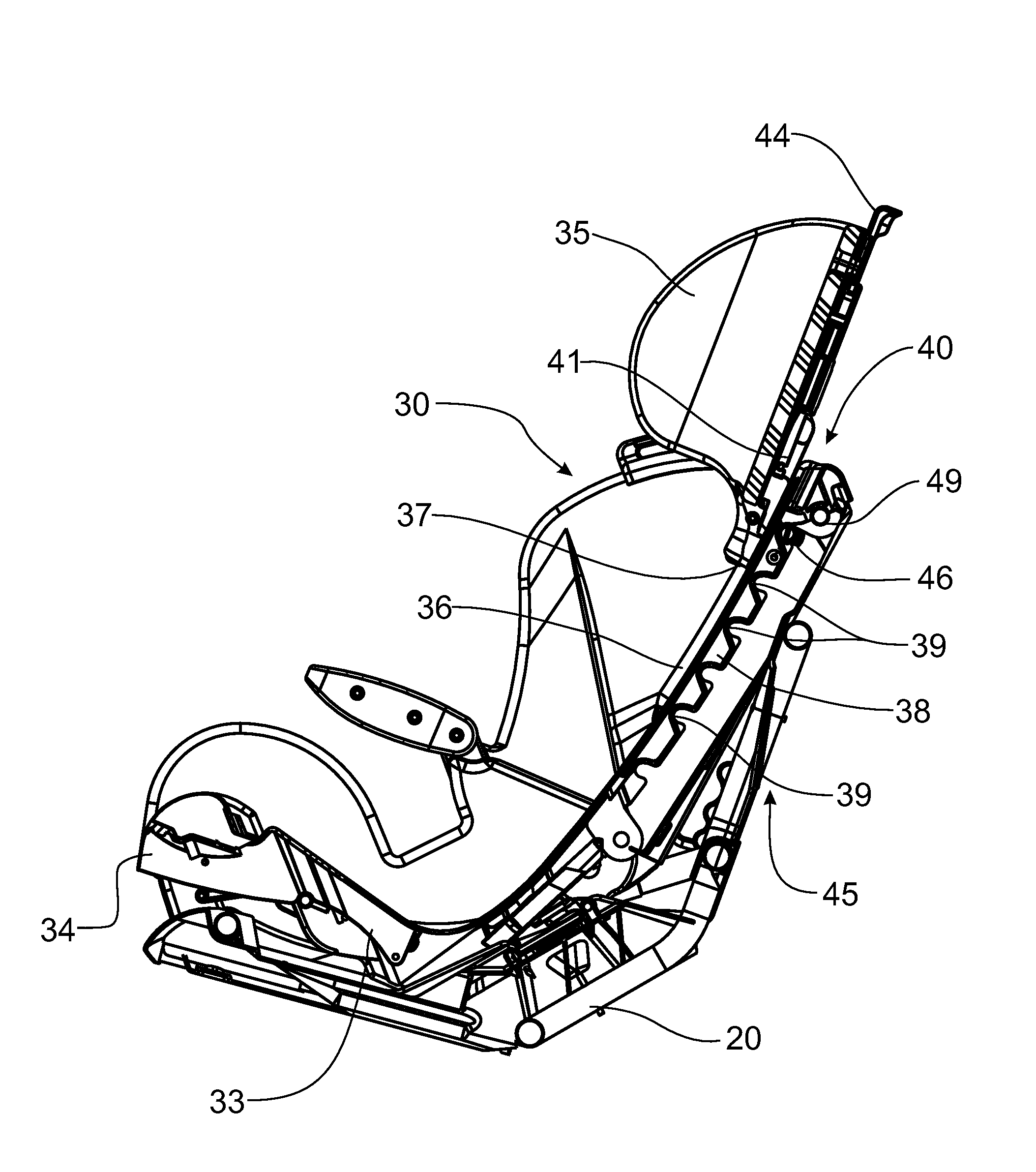

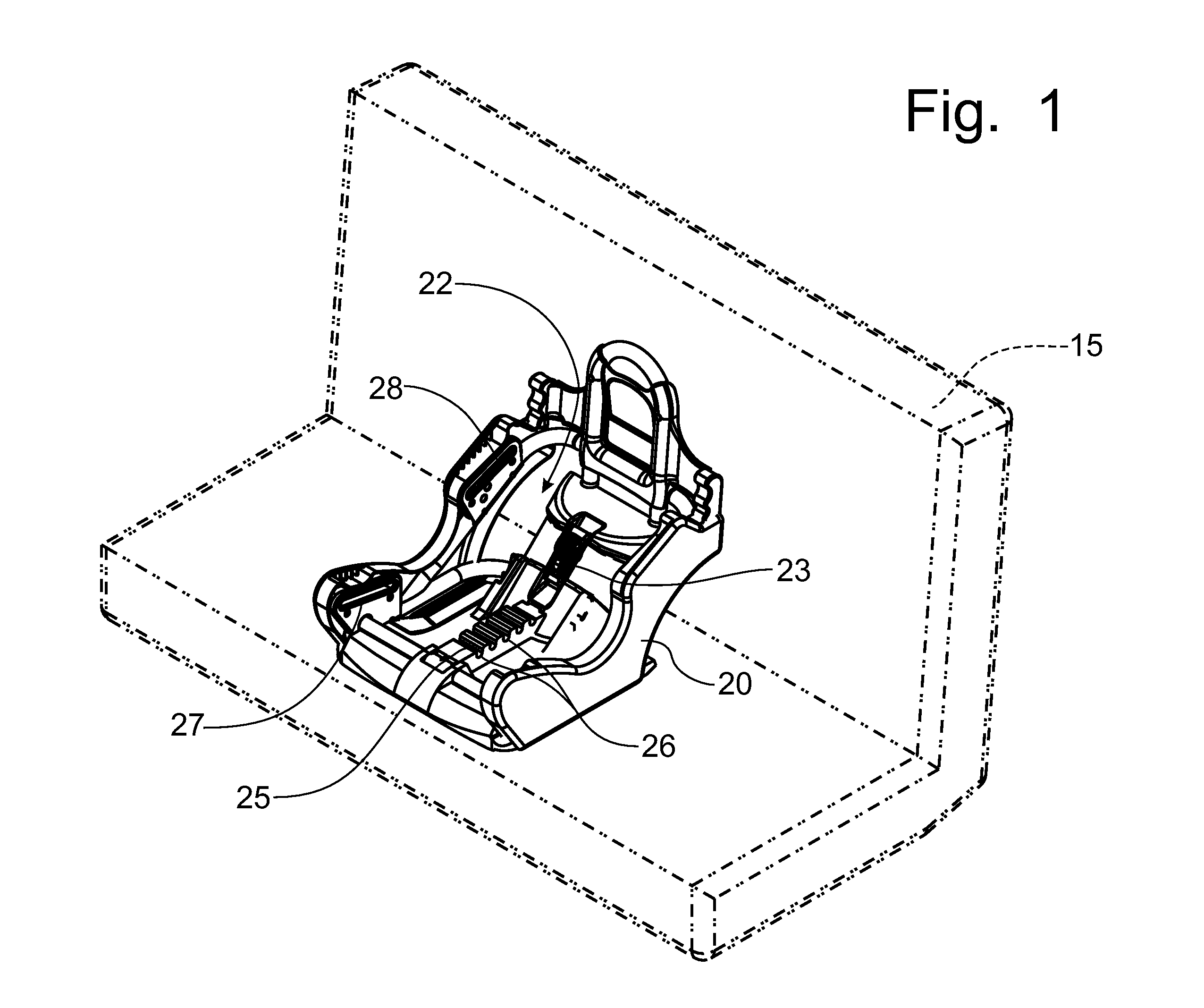

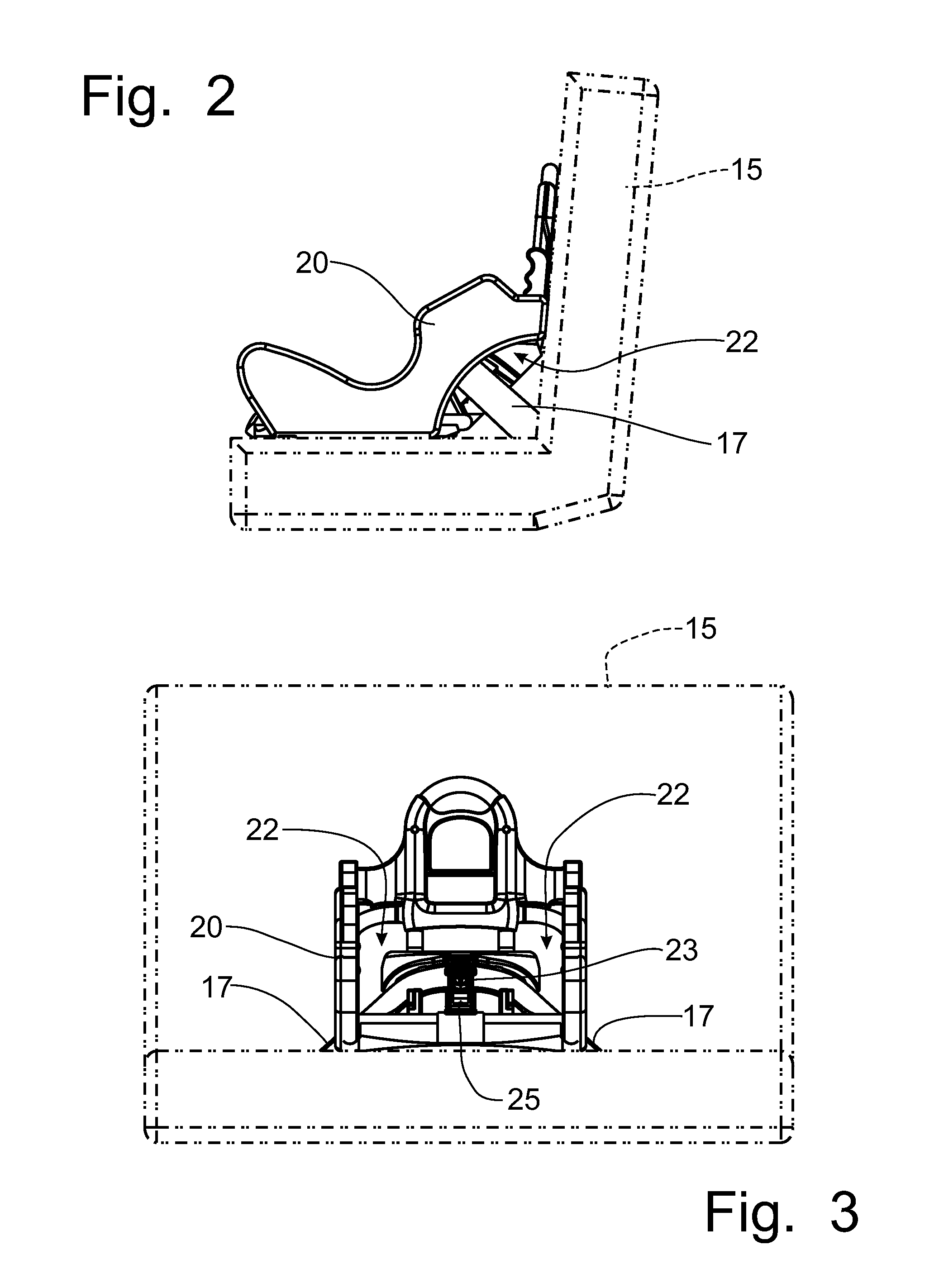

Head rest and harness adjustment for child car seat

ActiveUS20080136232A1Reduce the possibilityReliable constructionVehicle seatsOperating chairsCar seatEngineering

A car seat includes a vertically adjustable head rest and harness support apparatus that will properly locate the position of the harness relative to the child in response to the positioning of the head rest. The head rest is movable along a curved track to provide horizontal clearance with respect to the vehicle head rest when in a fully raised position. The harness belt is trapped in a length adjustment lock and follows a path that extends around a fixed guide bar at the top of the car seat frame then downwardly through a guide member that directs the belt through an opening in the seat back for engagement with the child. The guide member is supported on a harness control tube that engages a rack device to fix the position of the harness control tube when the position of the head rest is selected.

Owner:WONDERLAND SWITZERLAND AG

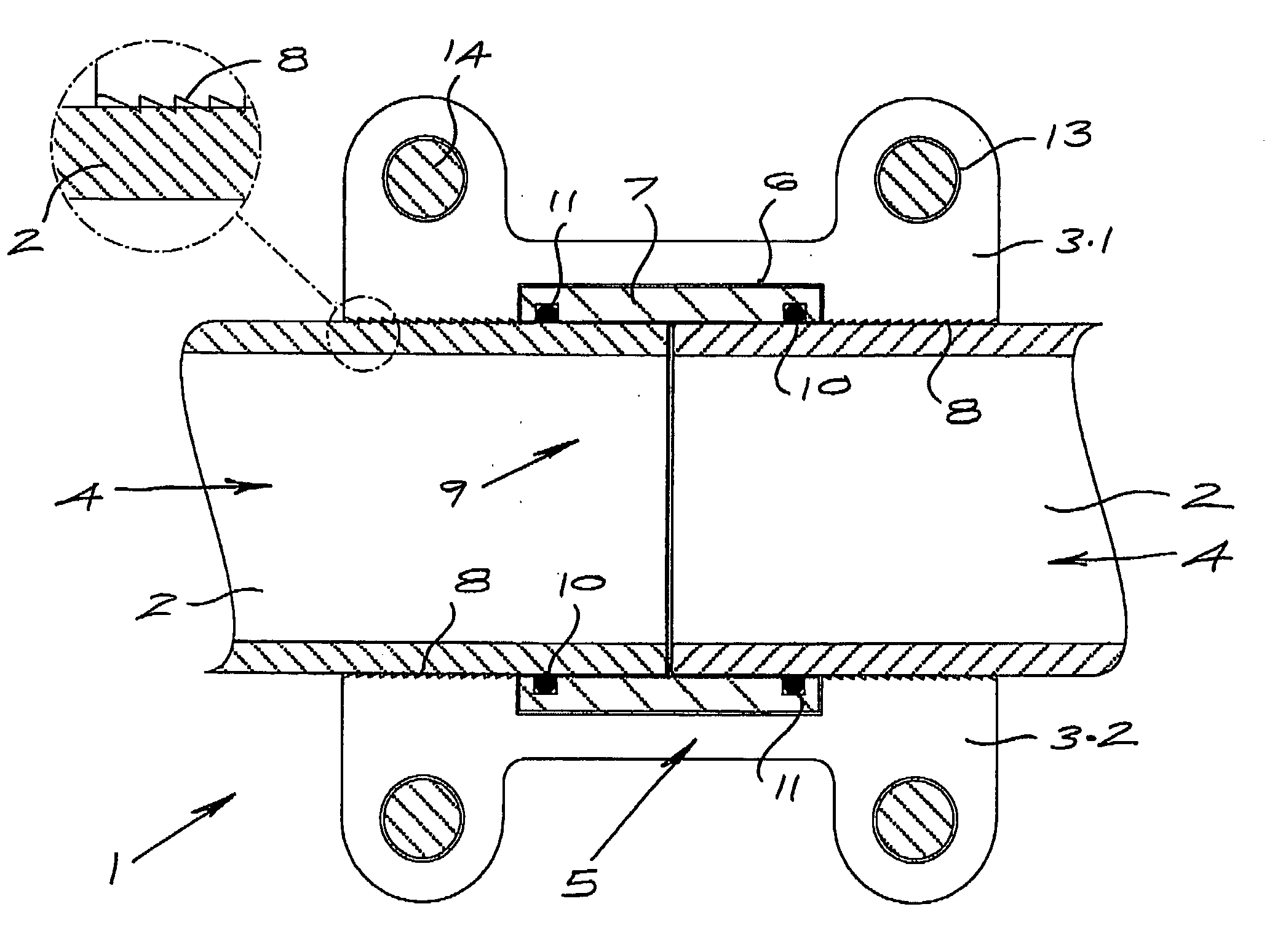

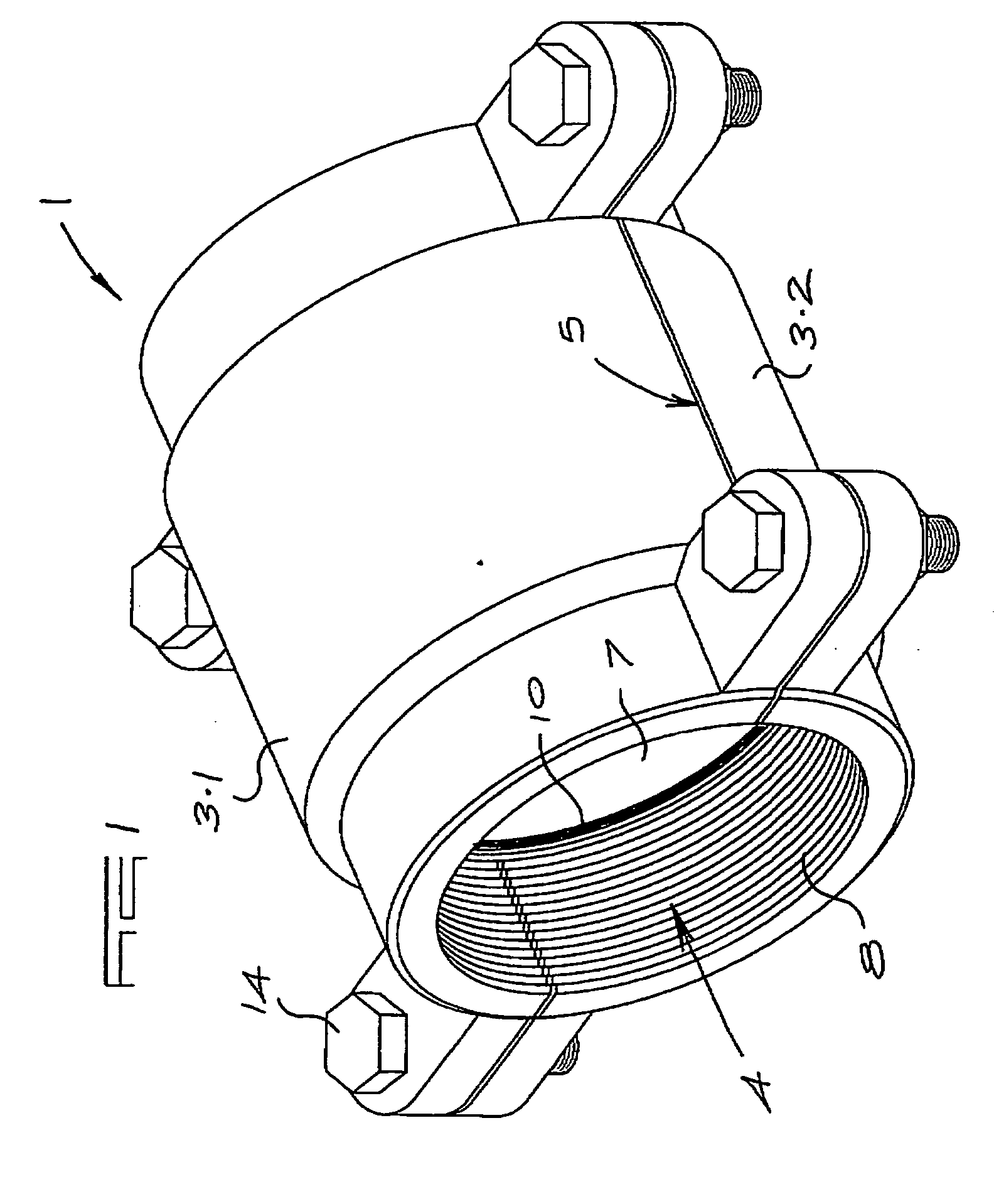

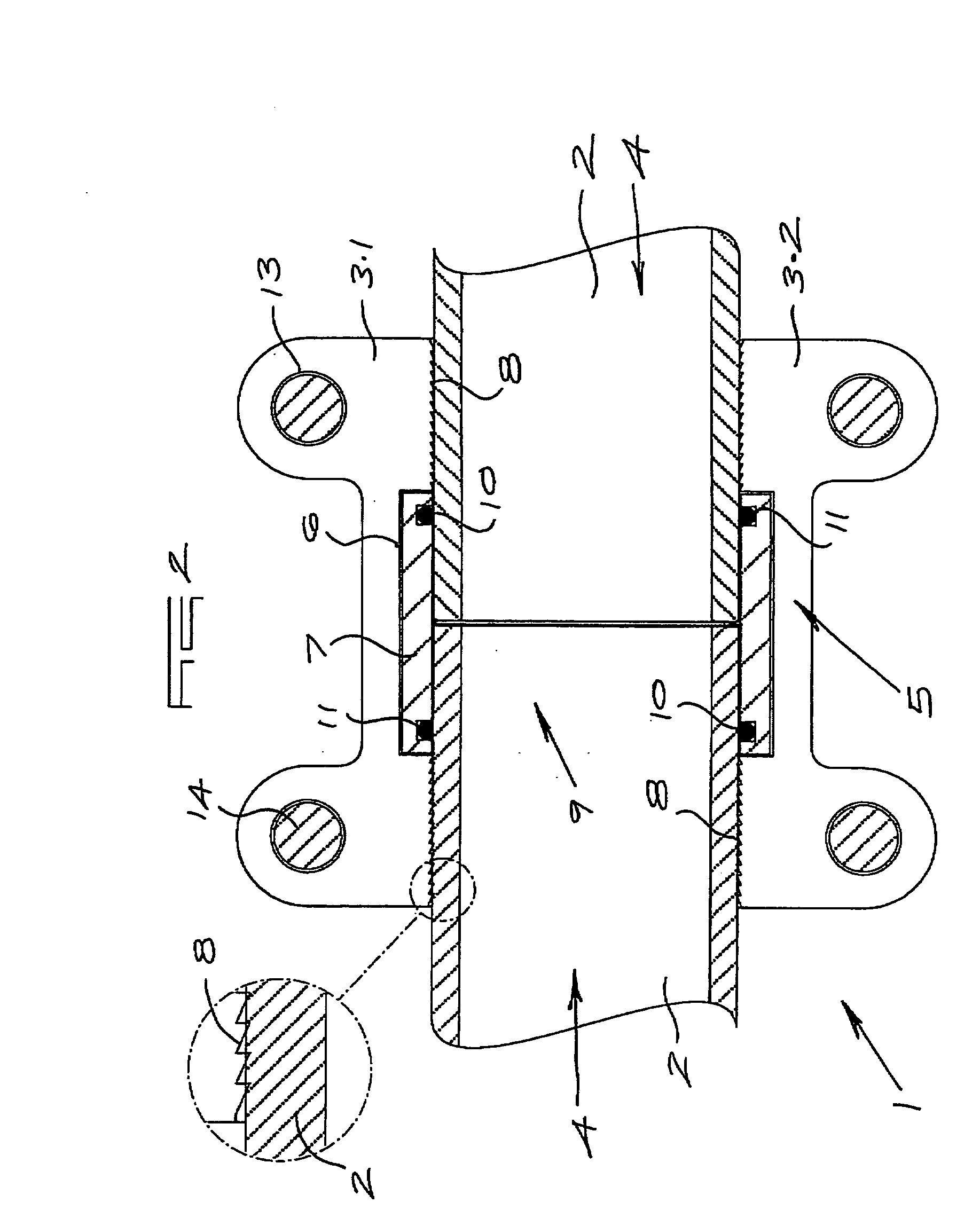

Pipe coupling

InactiveUS20060267343A1Easy to installActive connectionSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

The invention relates to a pipe coupling for rigid plastics pipes having smooth cylindrical ends. The coupling includes a rigid sleeve having a longitudinal bore. Two spaced apart annular grooves are provided in the bore to respectively house deformable annular seals adjacent the ends of the sleeve. O-rings will be used as seals. A harness is securable over the sleeve with pipe engaging teeth adjacent each of the opposite ends. The harness is split longitudinally with a cylindrical passage having an annular recess to receive the sleeve. The teeth are formed by serrated ridges, preferably screw threads, in the passage extending from the recess to the outer ends of the passage. Corresponding lateral lugs on each half of the harness have bolt holes for assembly of the harness over the sleeve. The coupling is particularly suited for connecting plastics pipes used to convey backfill, normally in underground mining operations.

Owner:WRIGHT JOHN PETER

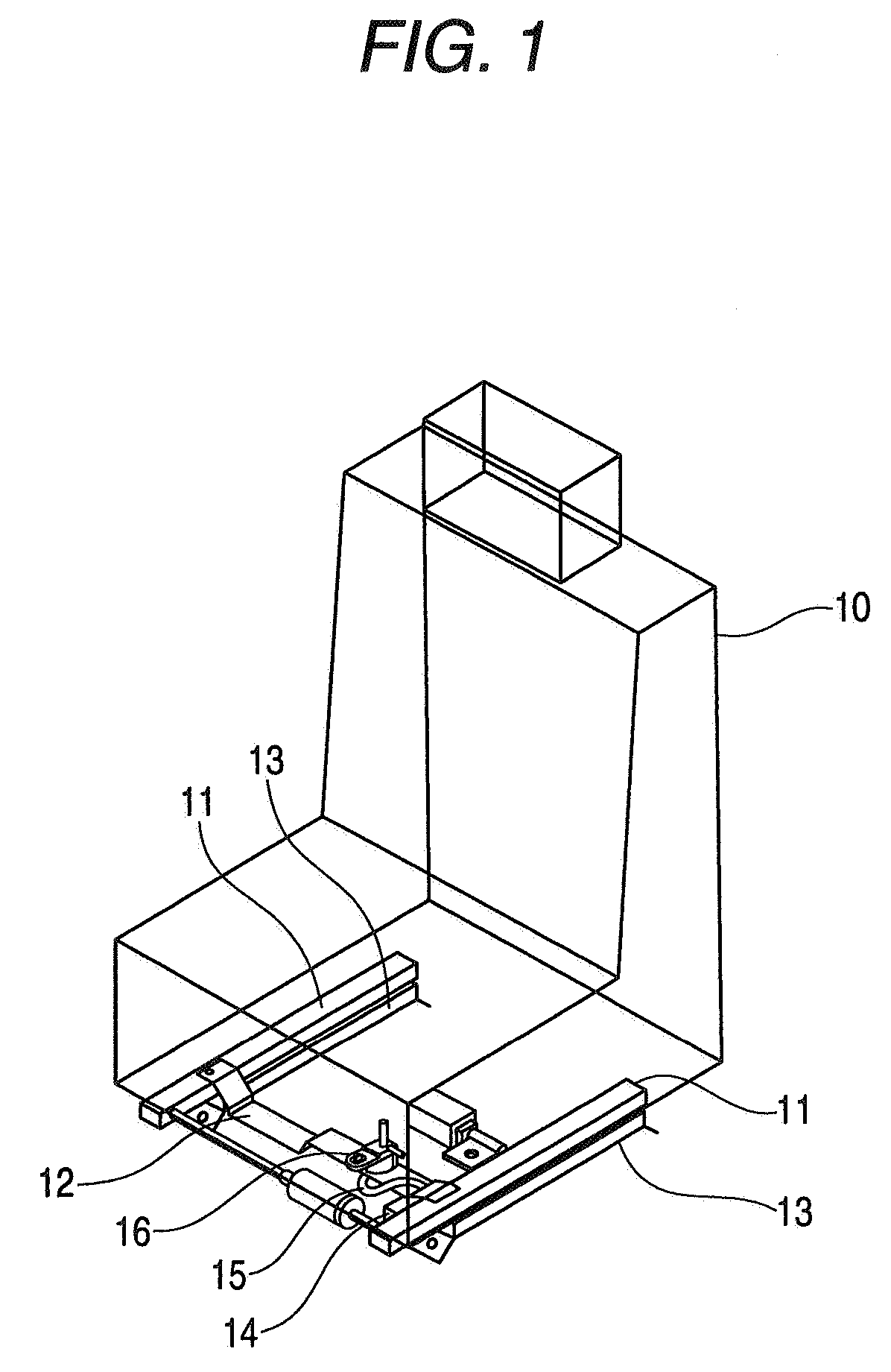

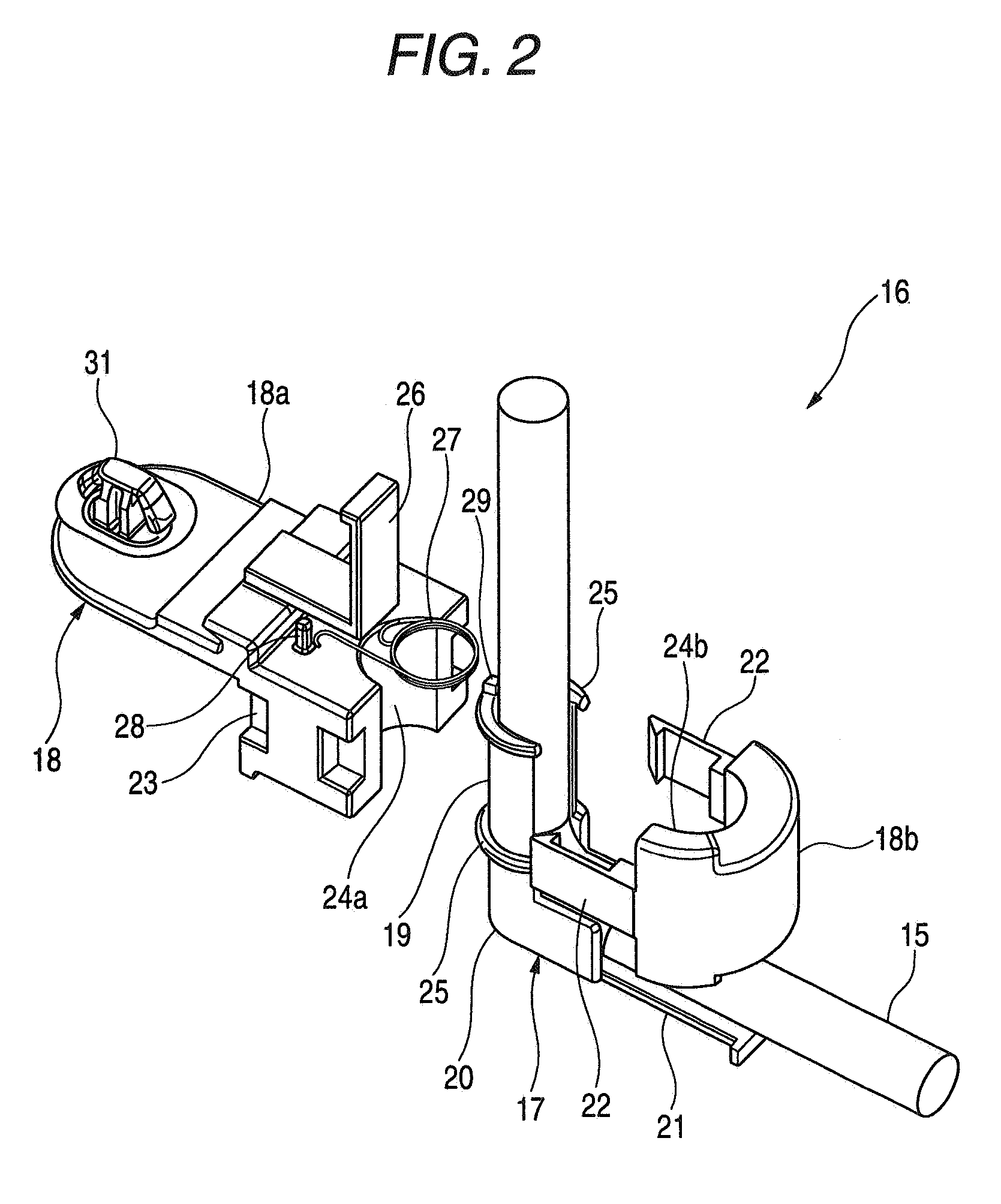

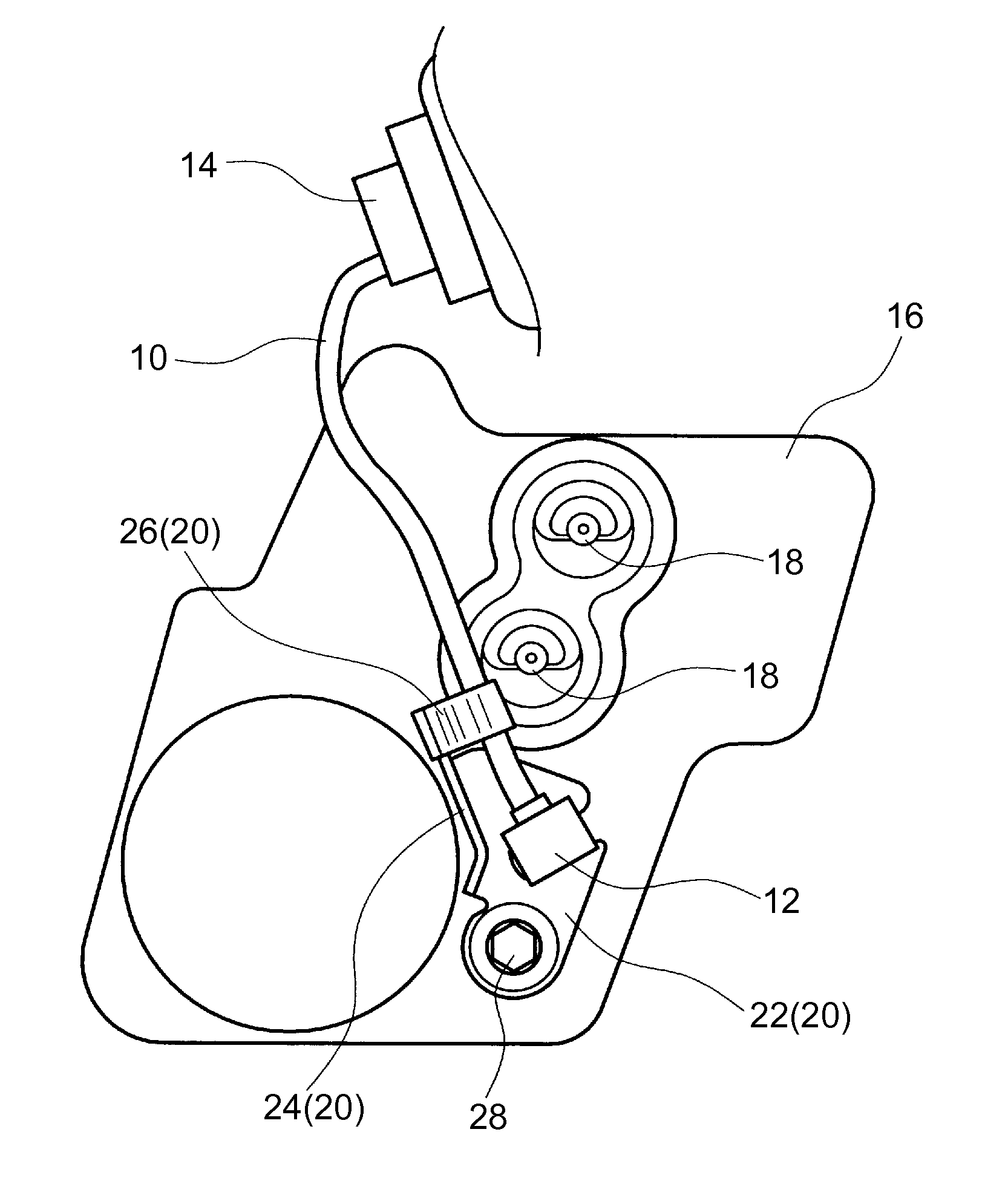

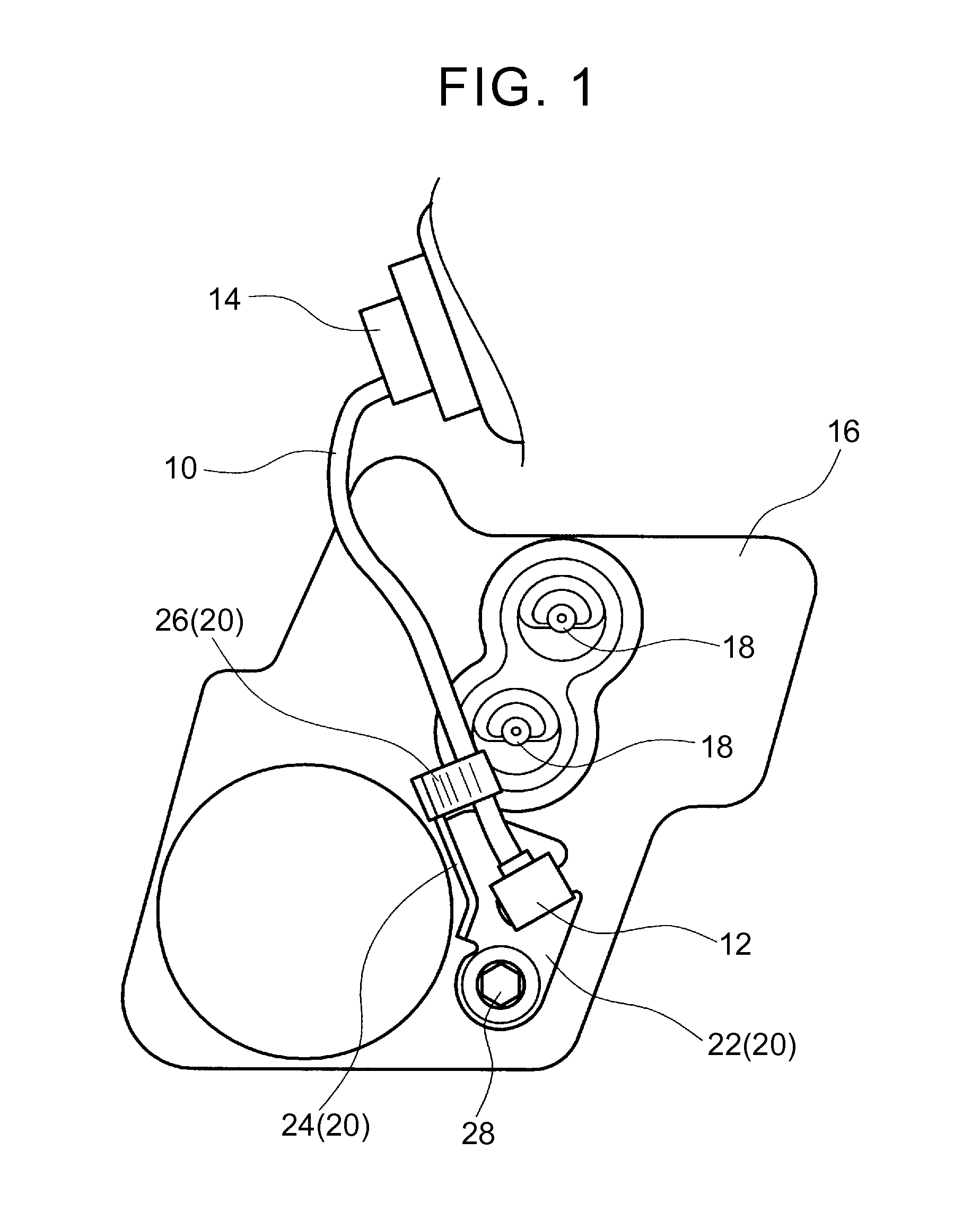

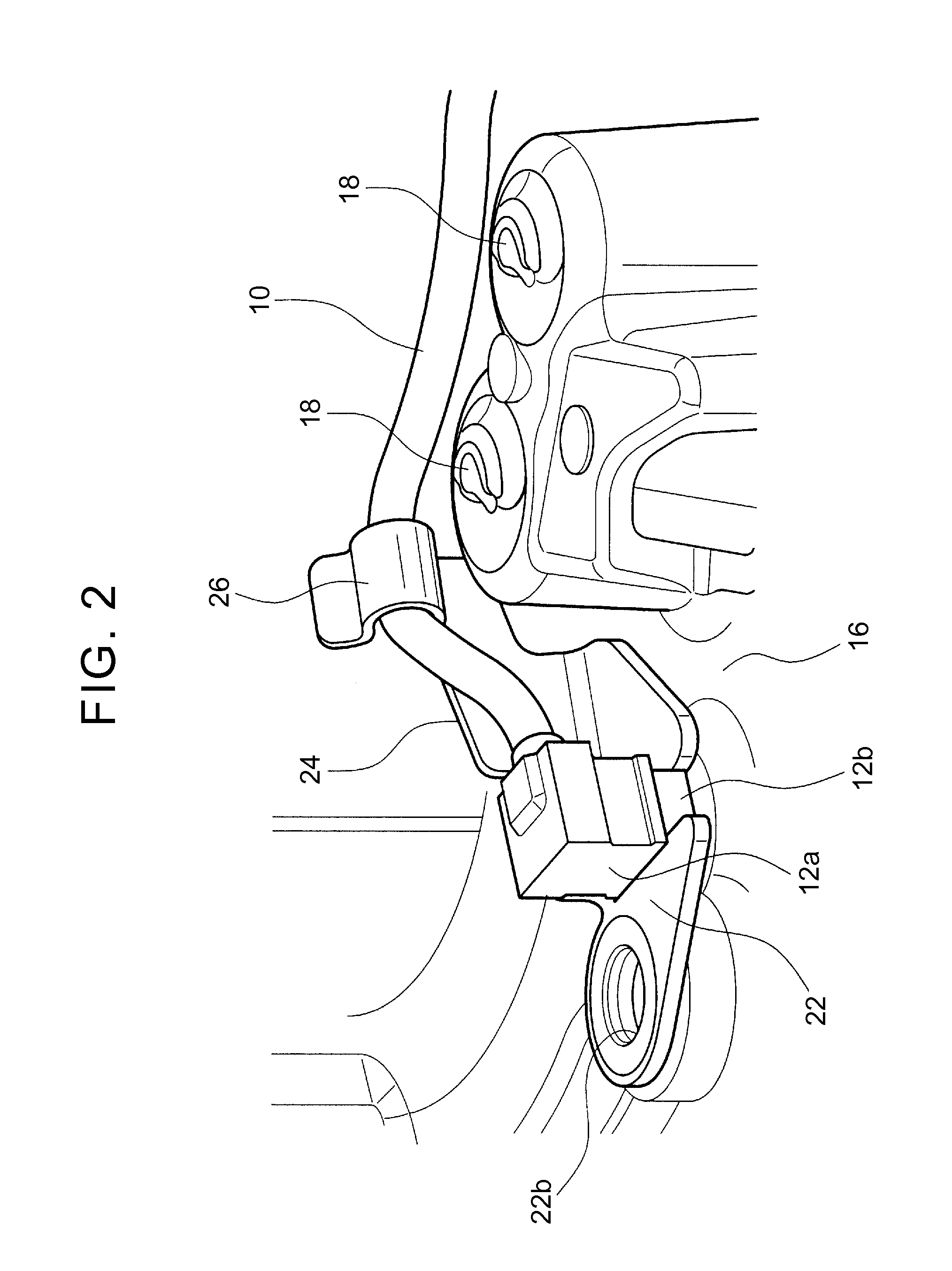

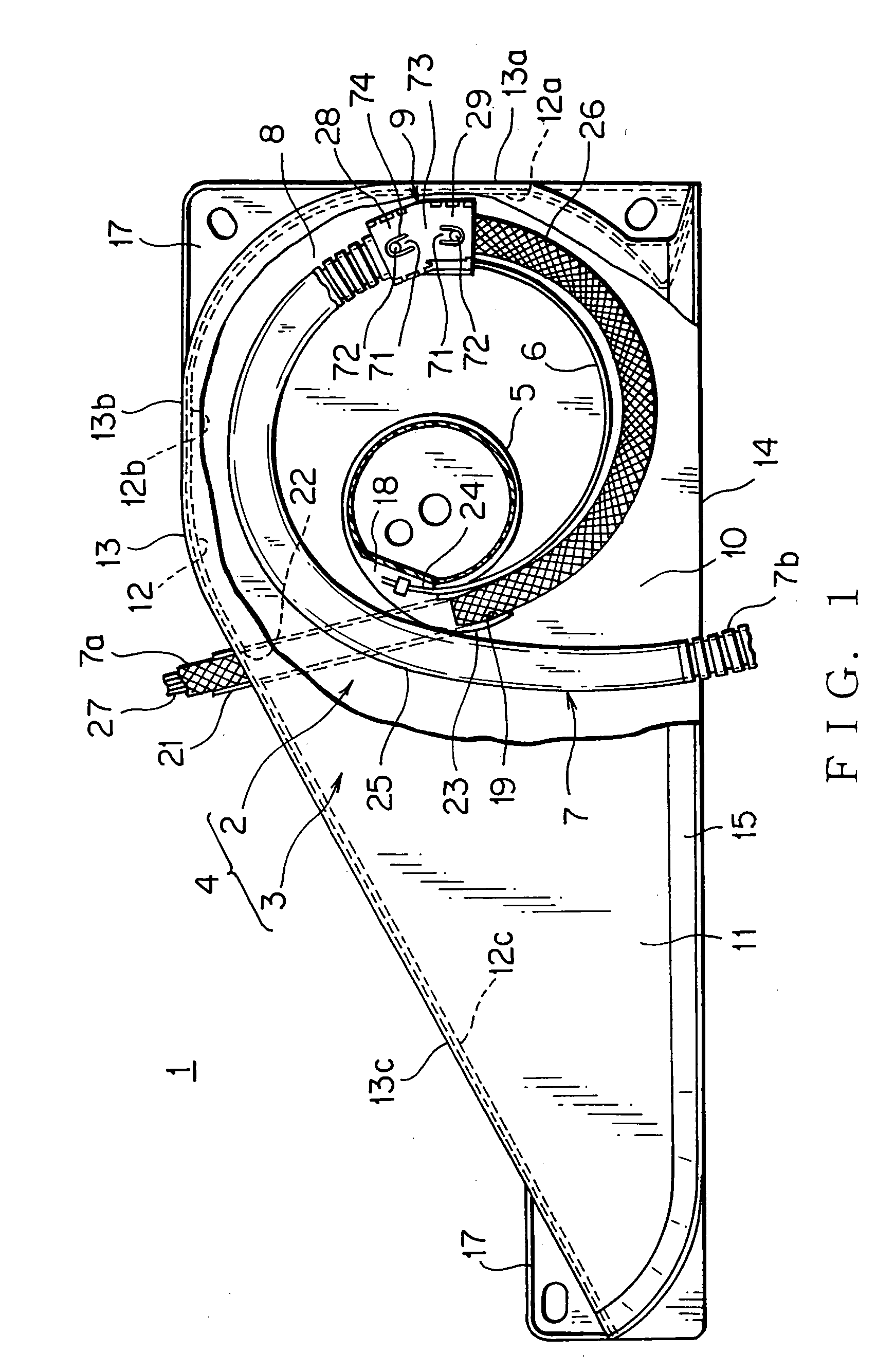

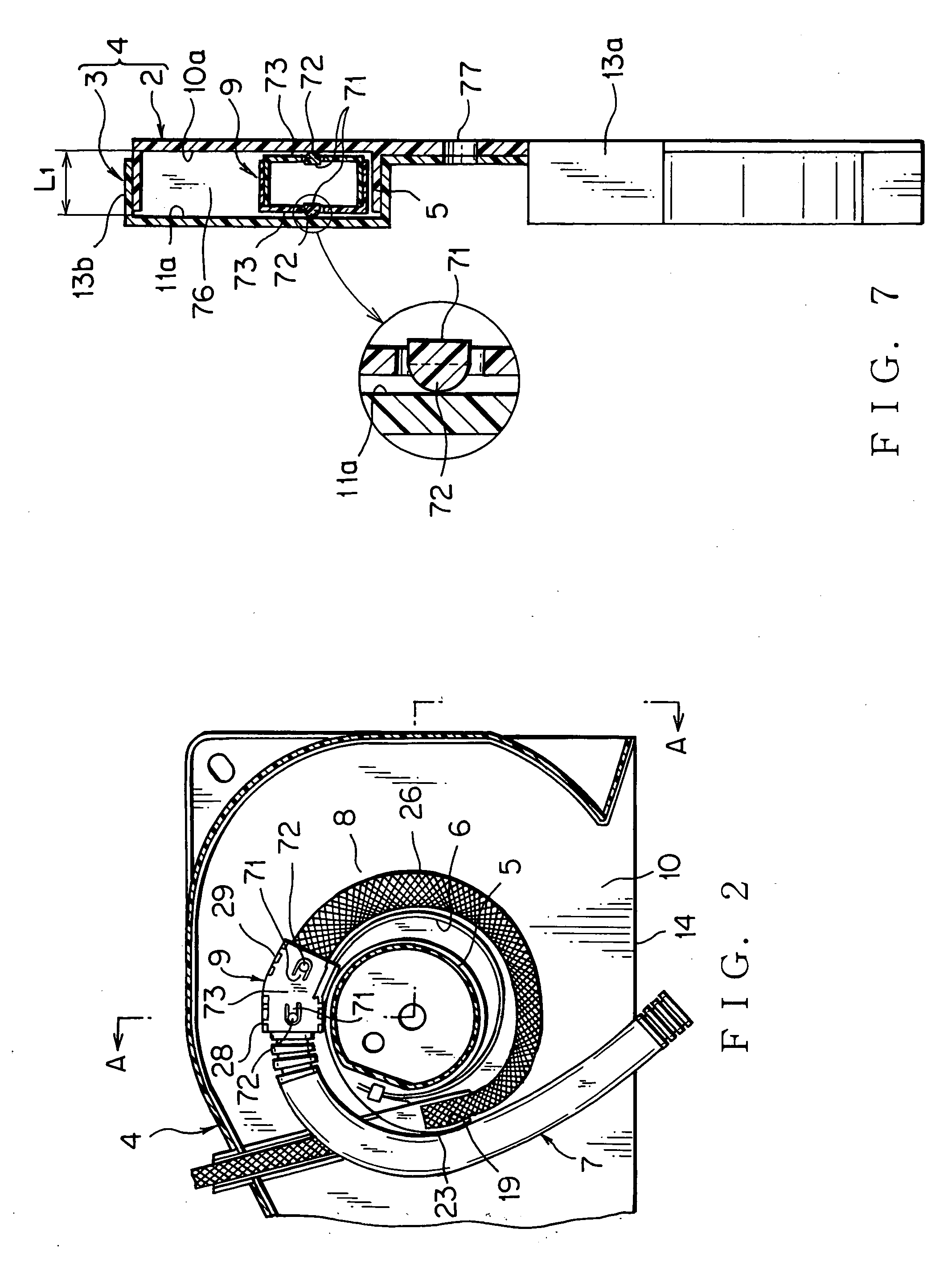

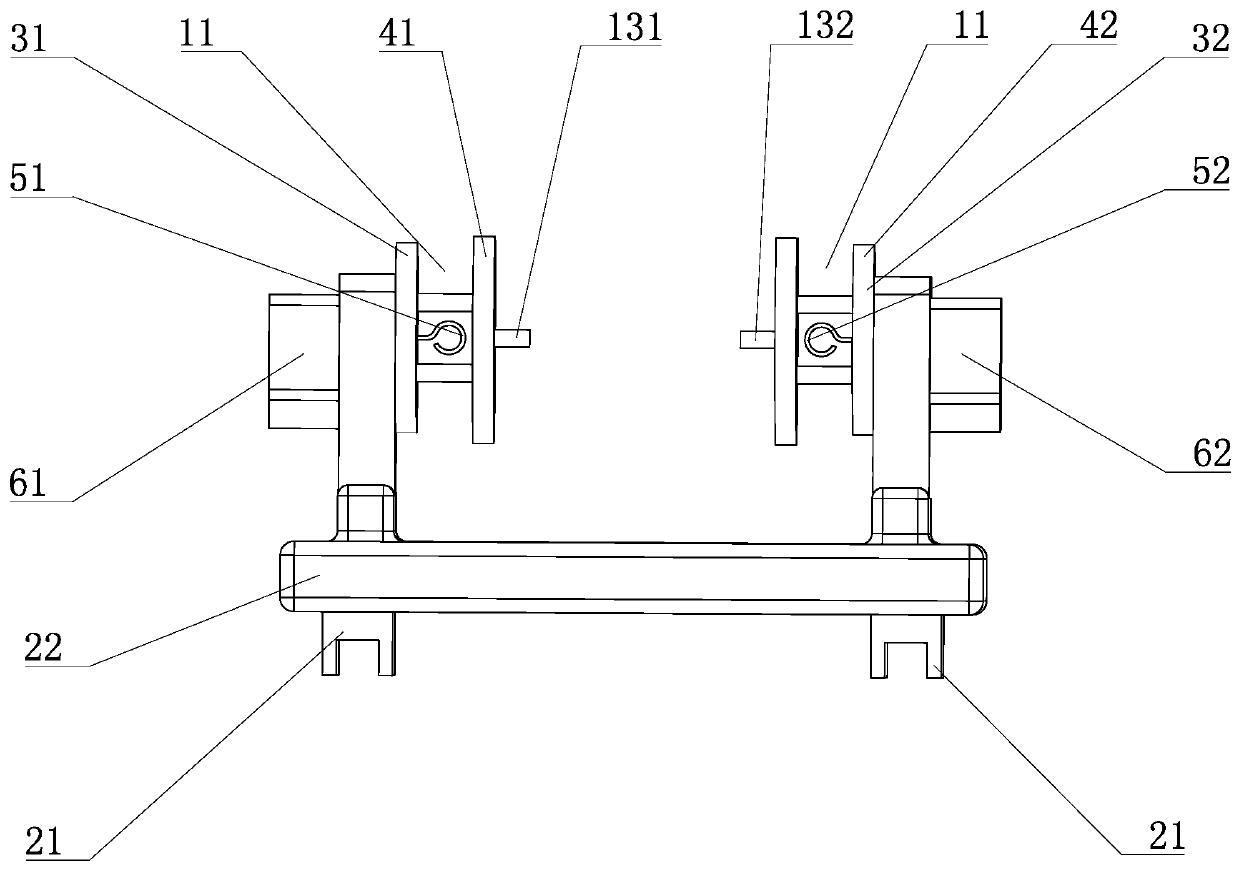

Wiring harness holding device

InactiveUS7369381B2Excessive lengthMaintain good propertiesInsulated cablesElectric/fluid circuitEngineeringRetaining harness

Owner:YAZAKI CORP

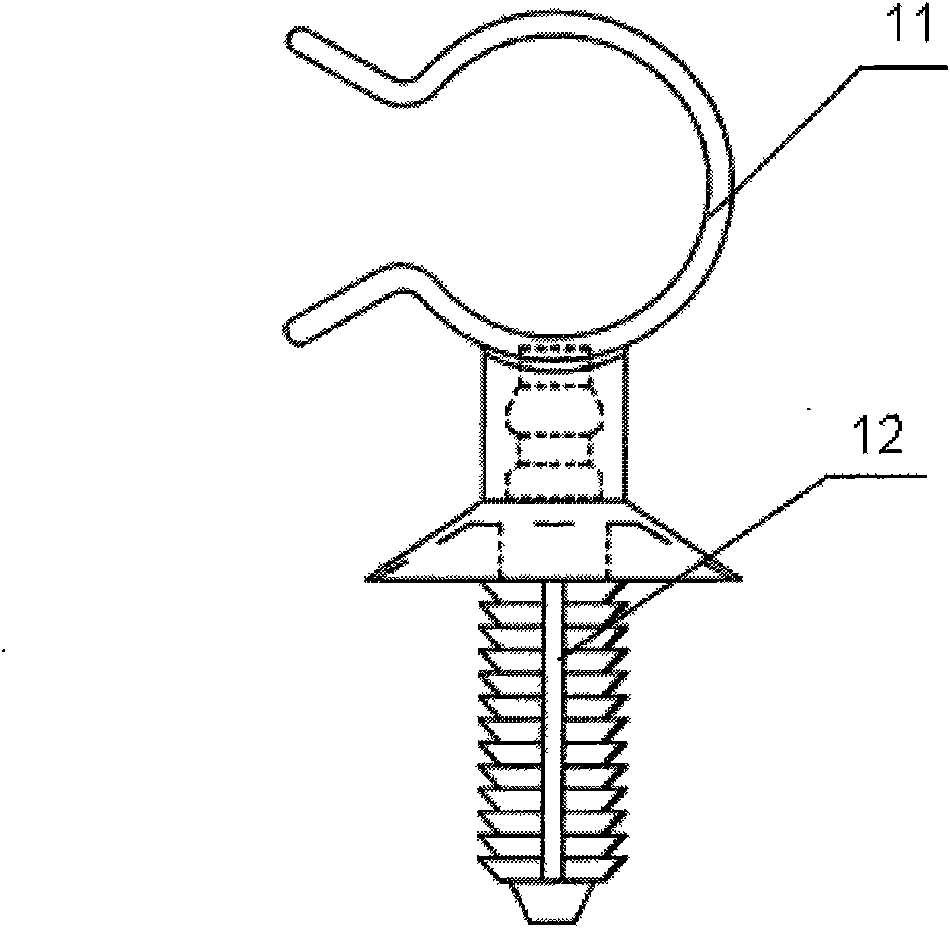

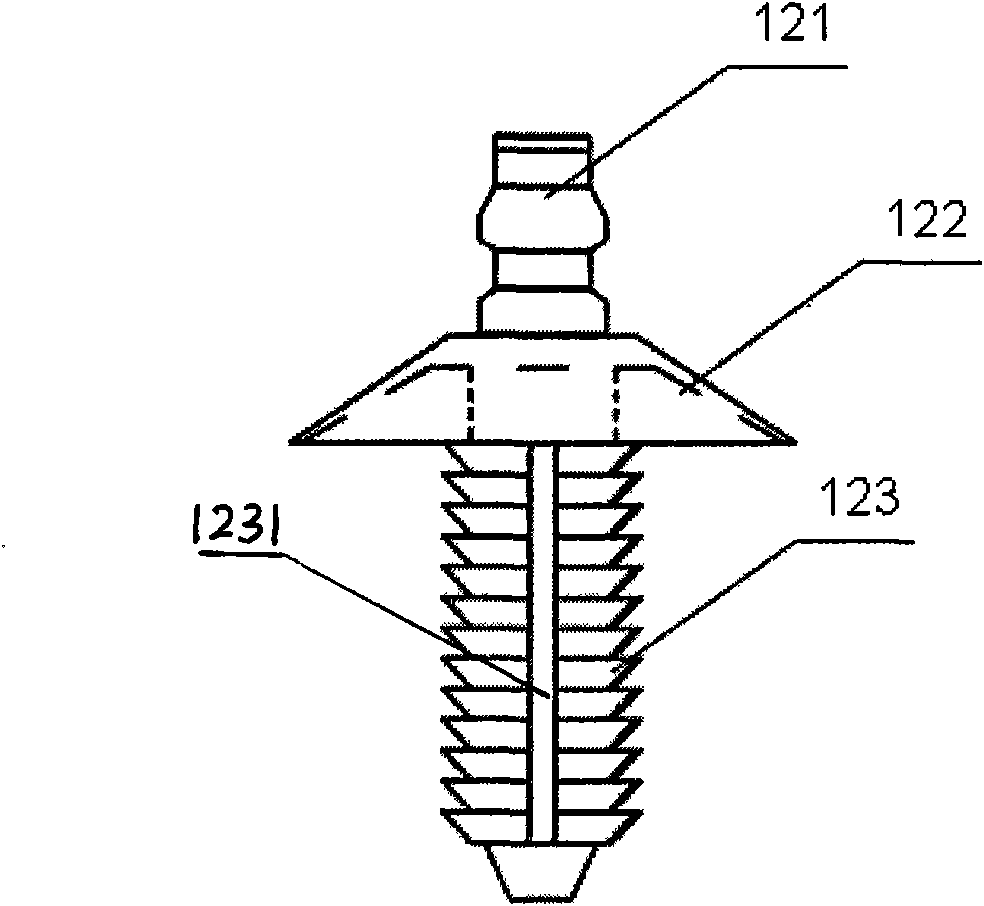

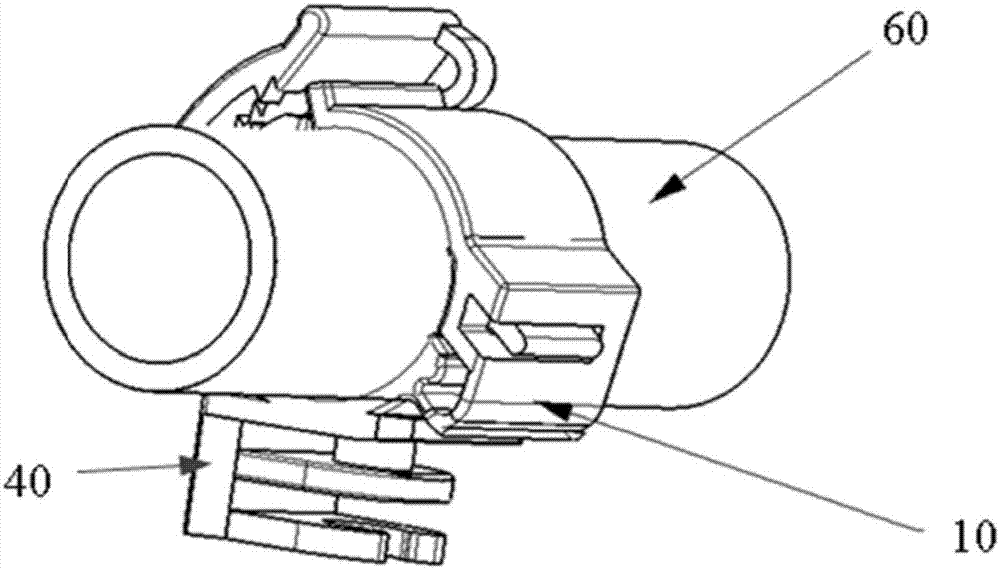

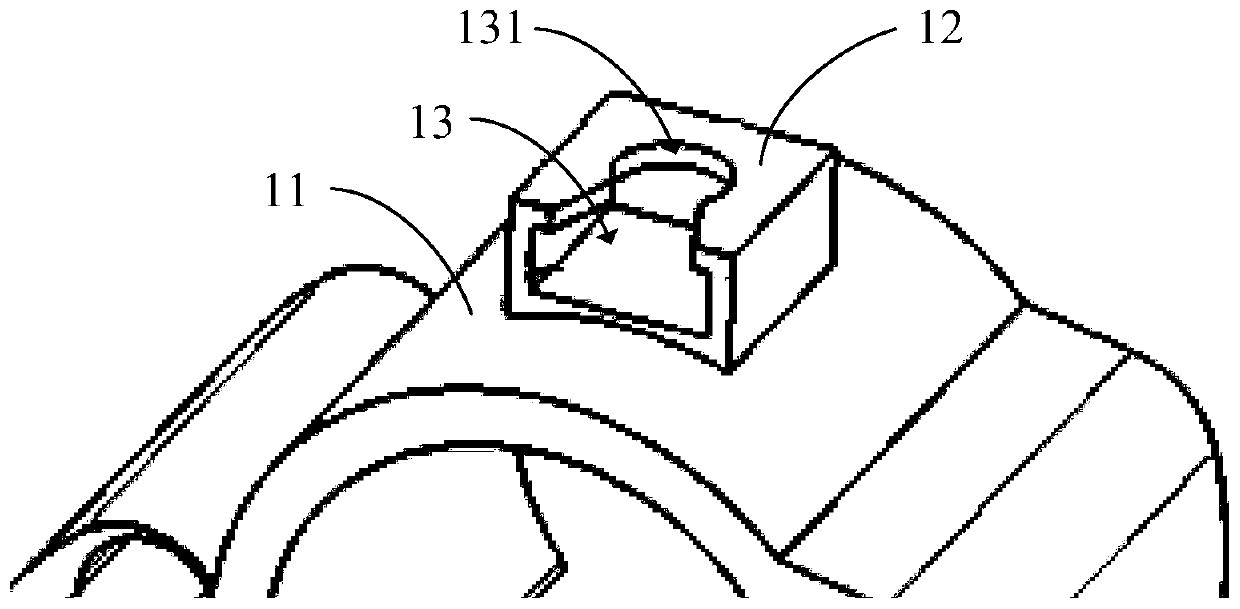

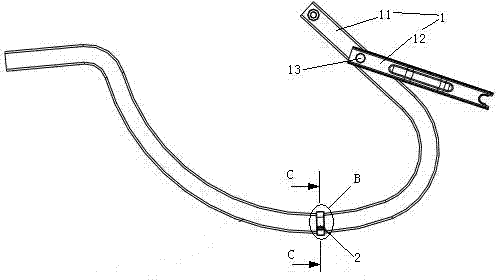

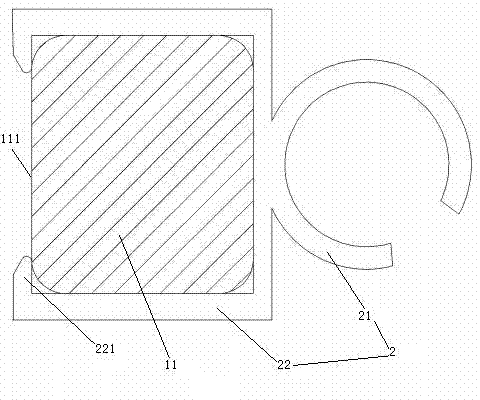

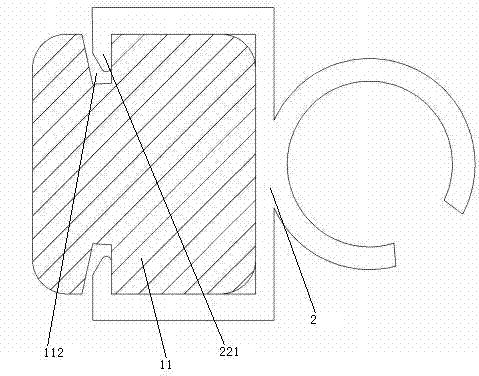

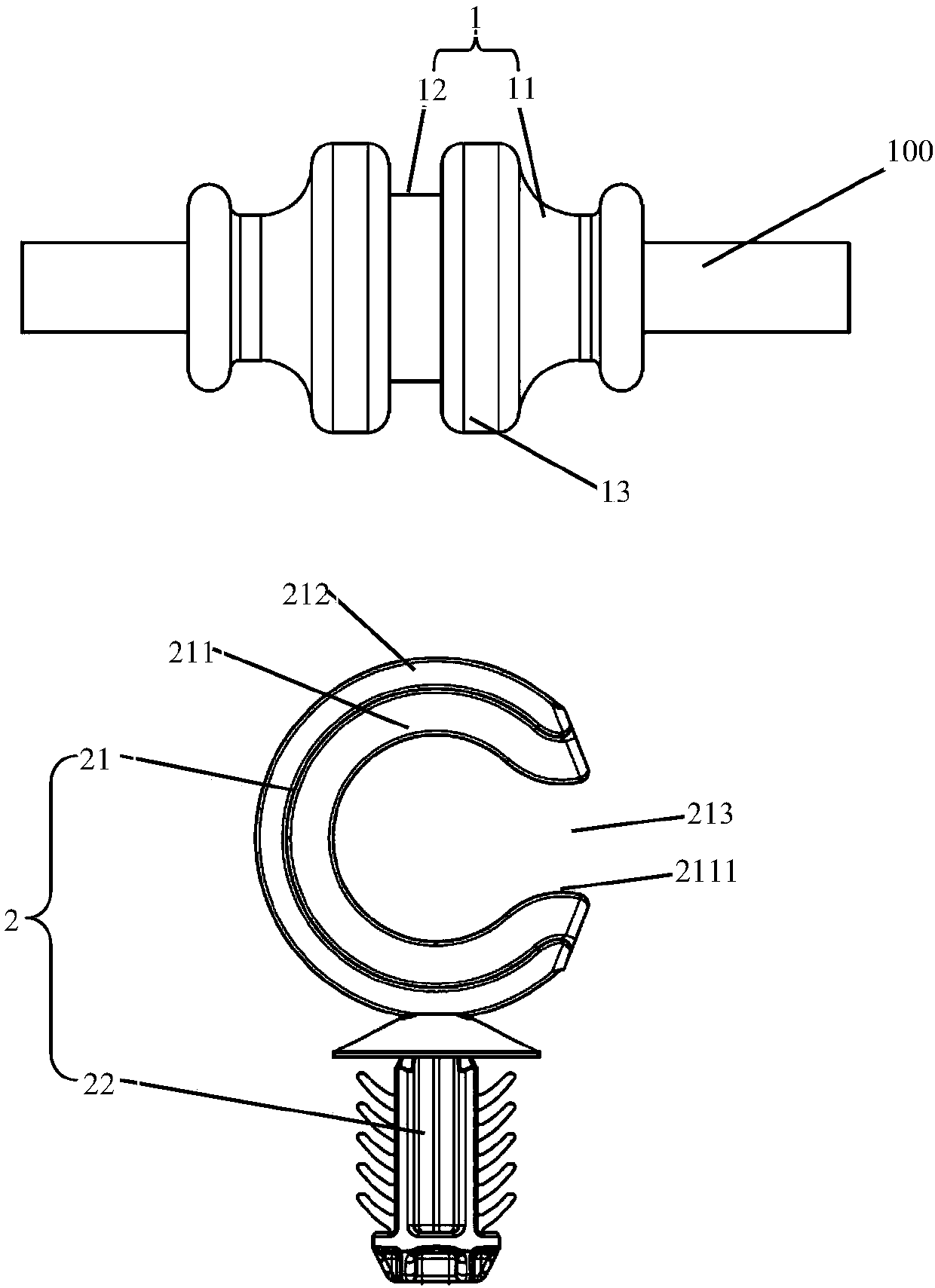

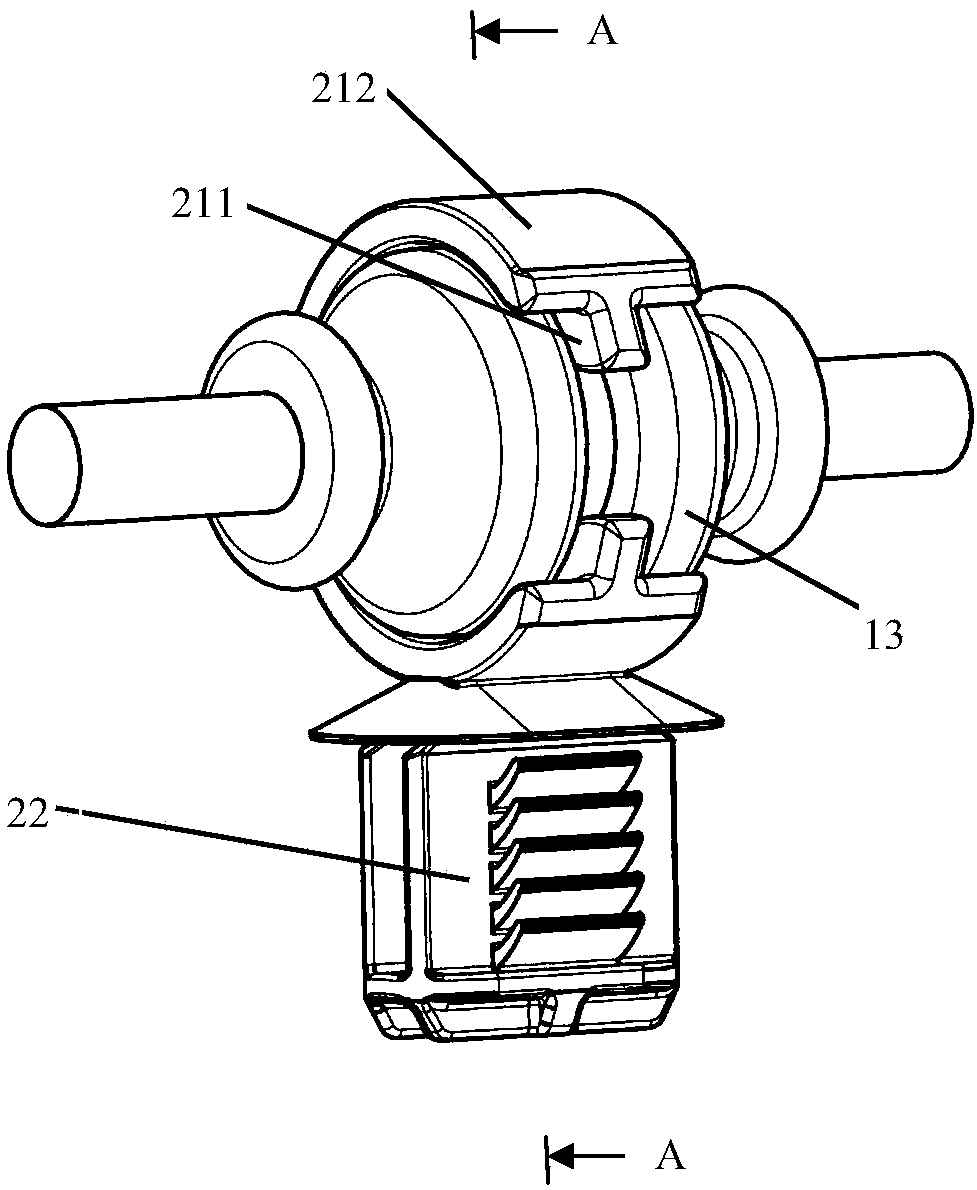

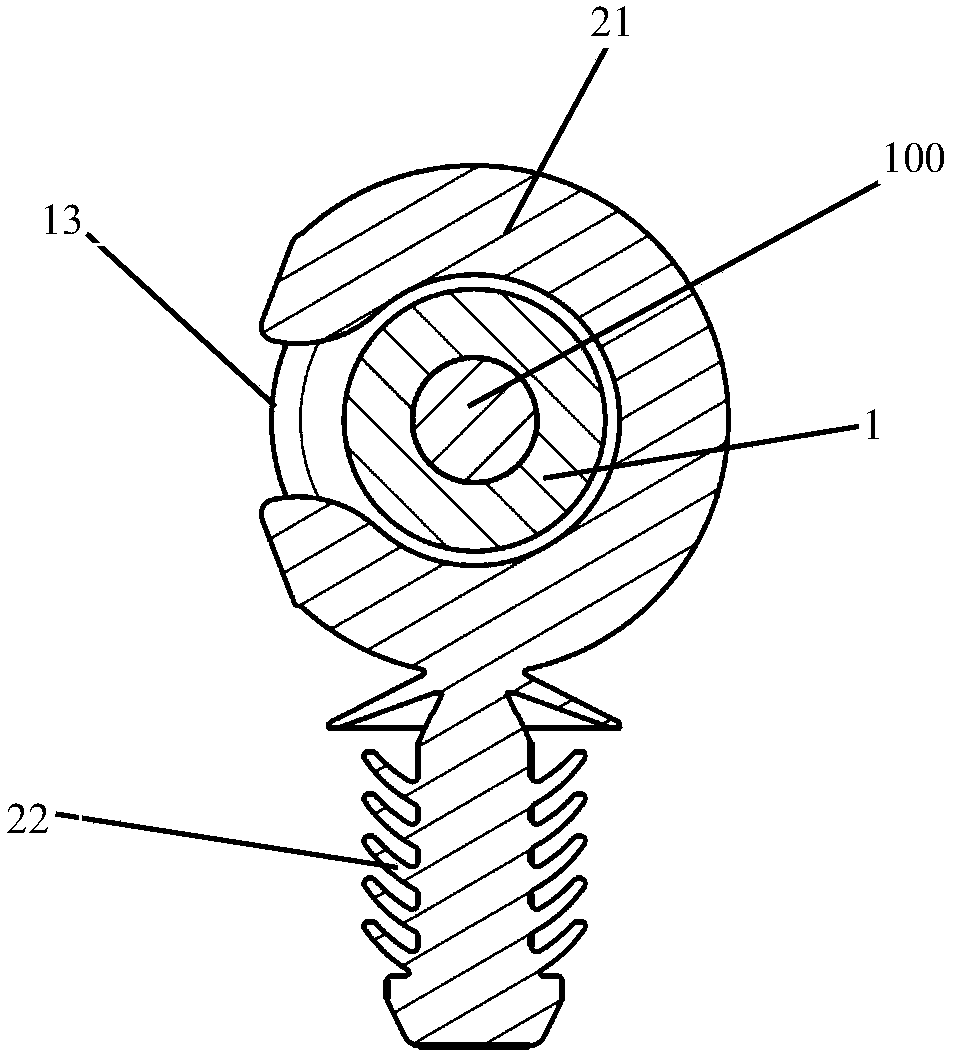

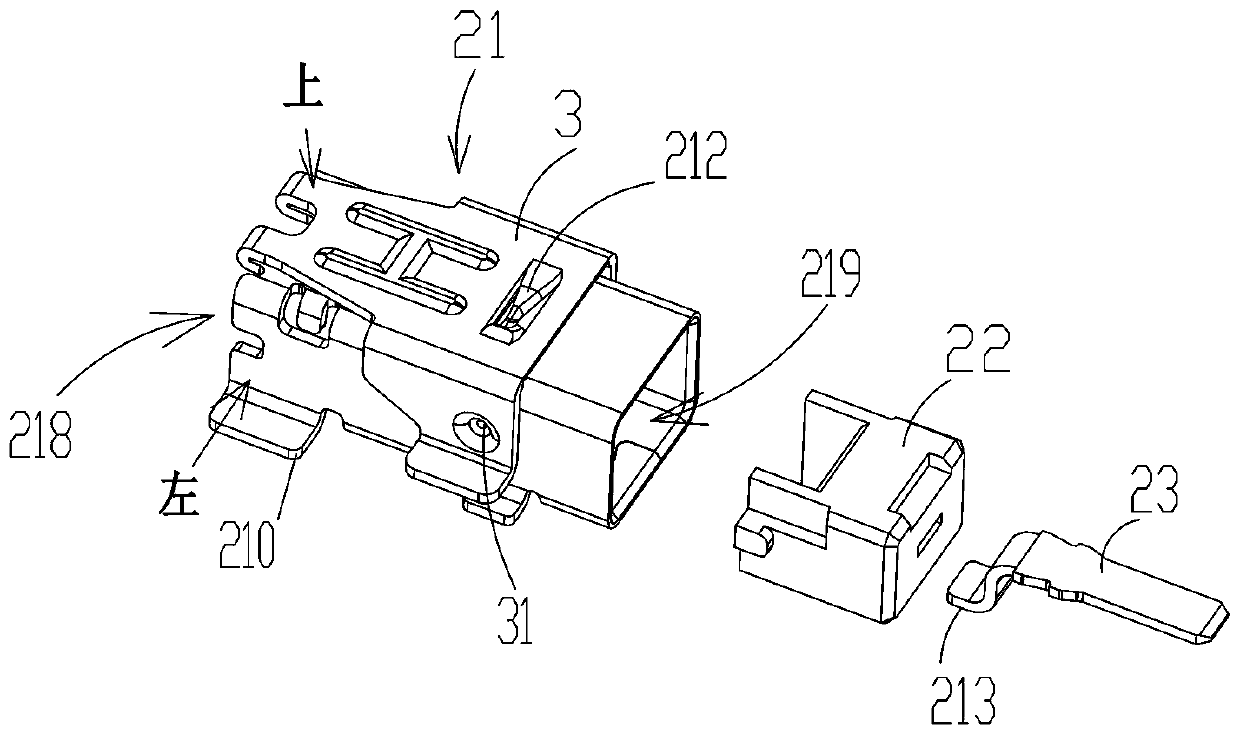

Combined lathedog for fixing harnesses and pipelines

The invention discloses a combined lathedog which is used for fixing pipelines or wires in an automobile engine. The lathedog comprises two parts, i.e. a retaining ring and a buckle; the retaining ring is circular, is provided with an opening on the positive side surface, and clamps the harnesses or the pipelines; a connecting tube is fixed at the lower part of the retaining ring, and the inner wall of the connecting tube is provided with a ladder-shaped slot; the buckle comprises three parts, i.e. a clamping head, a lampshade-type clamping cap and an installation pawl; the clamping head is provided with a ladder-shaped structure which corresponds to the ladder-shaped slot of the connecting tube, the clamping head and the ladder-shaped structure are mutually matched and clamped; the lampshade-type clamping cap is connected on the lower end of the clamping head, and is matched with an installation surface to play a limiting role; and the installation pawl is in a pagoda shape, and is matched with an installation hole. The combined lathedog for fixing harnesses and pipelines has the advantages of simple structure, convenient installation and low manufacturing cost, and can meet the requirements on the fixation of the harnesses and hoses of the automobile engines.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

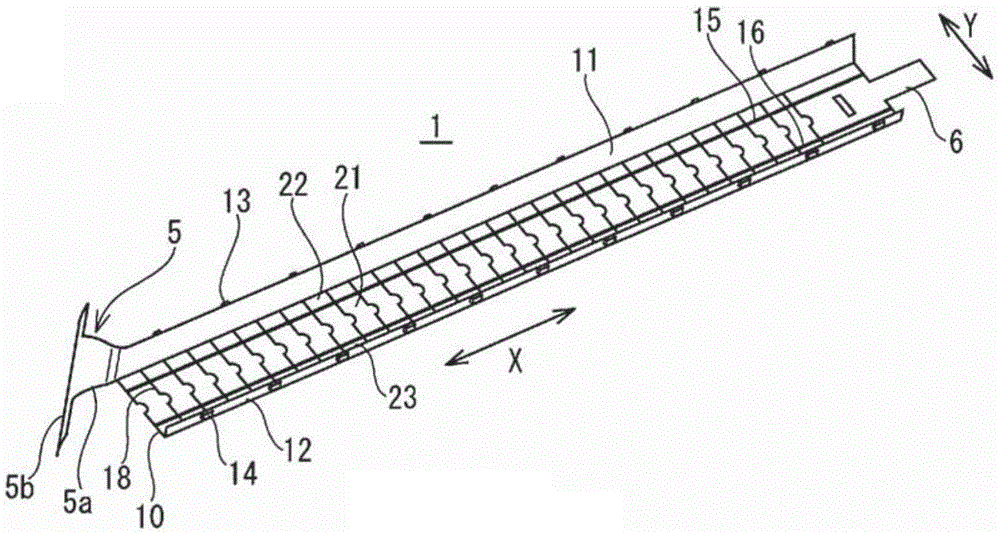

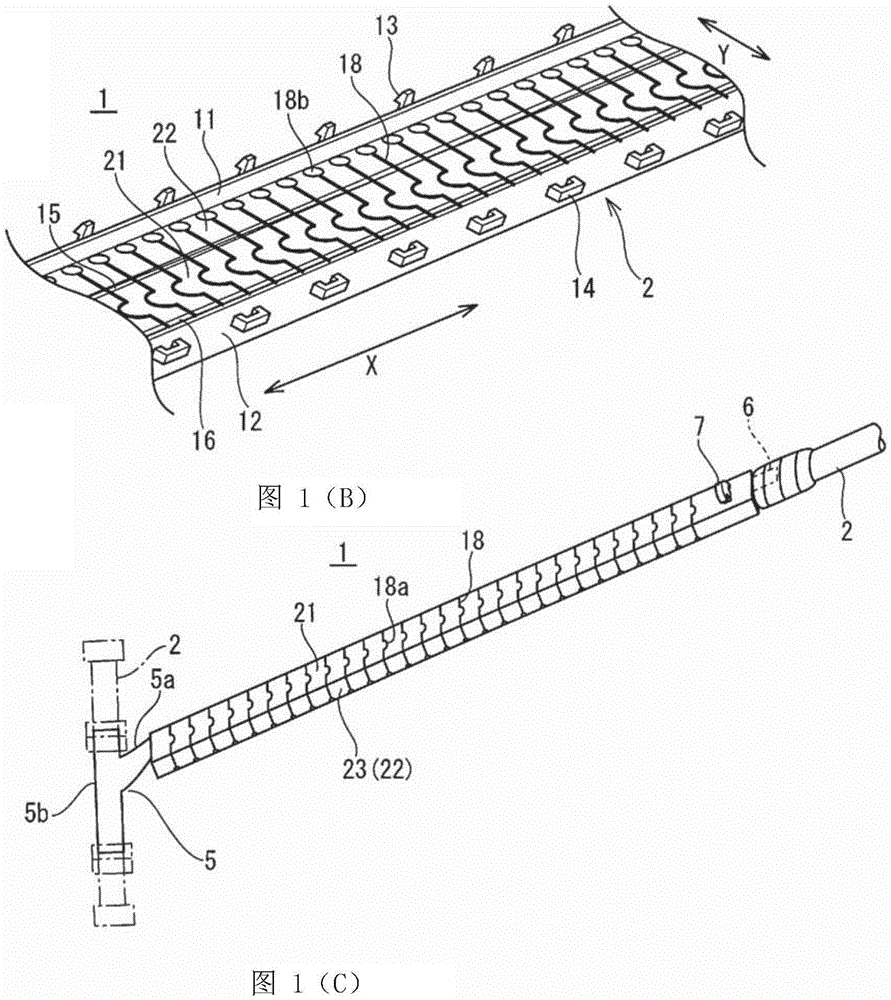

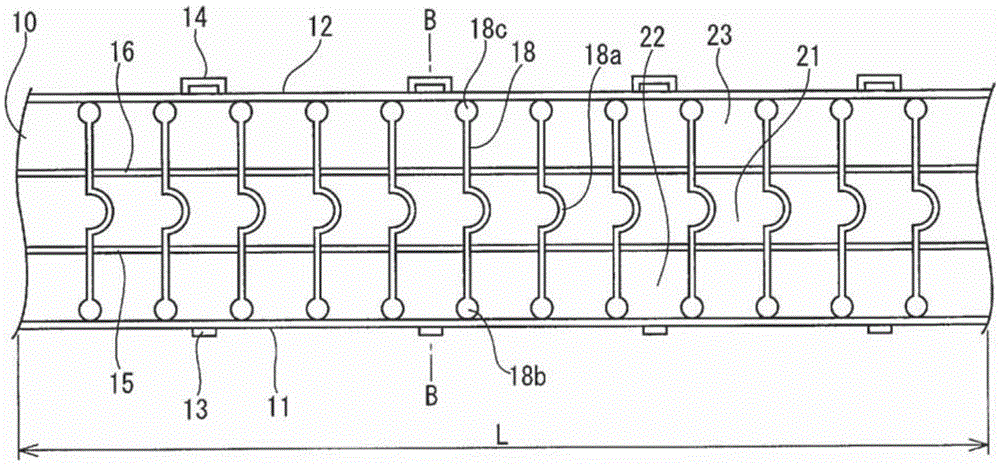

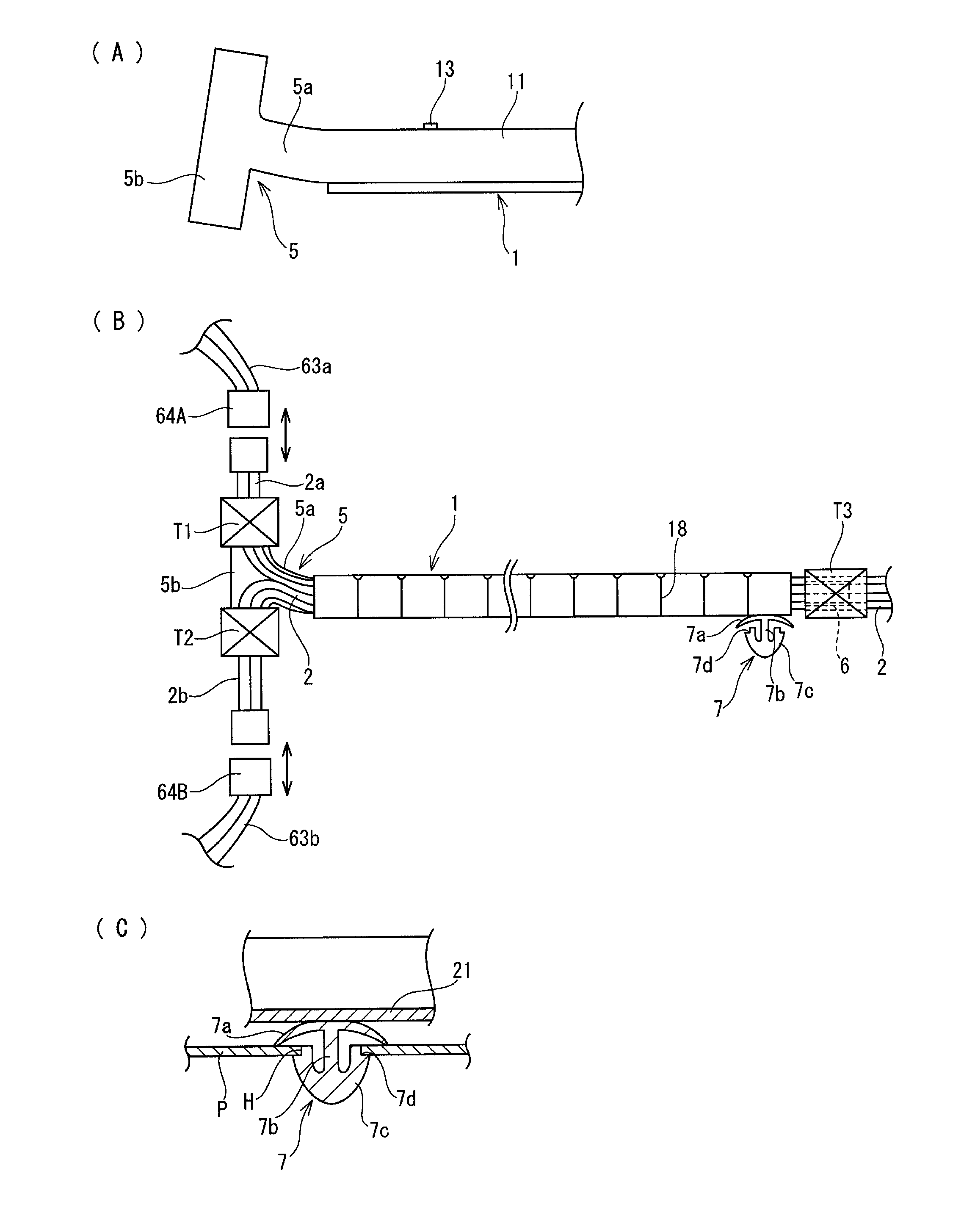

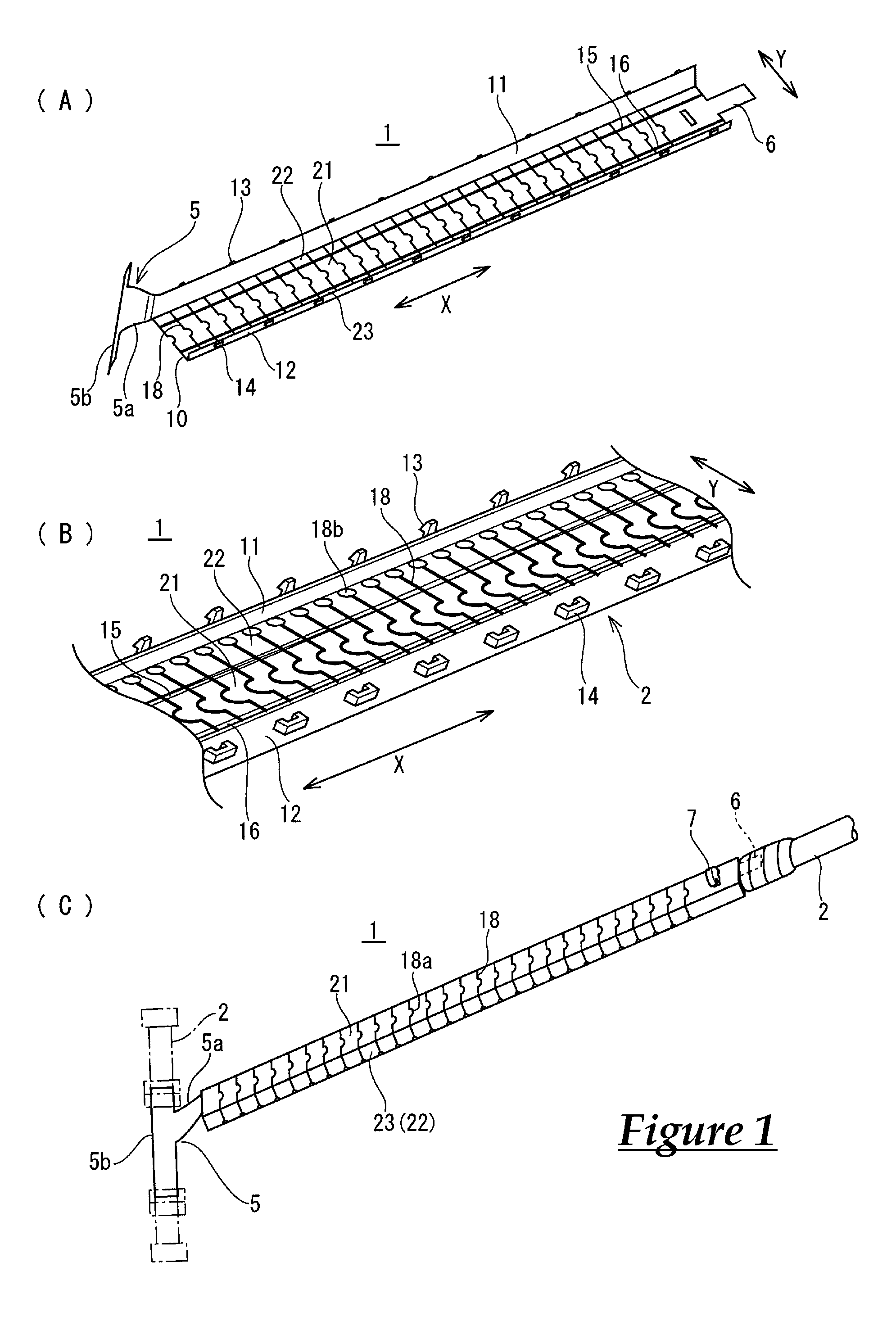

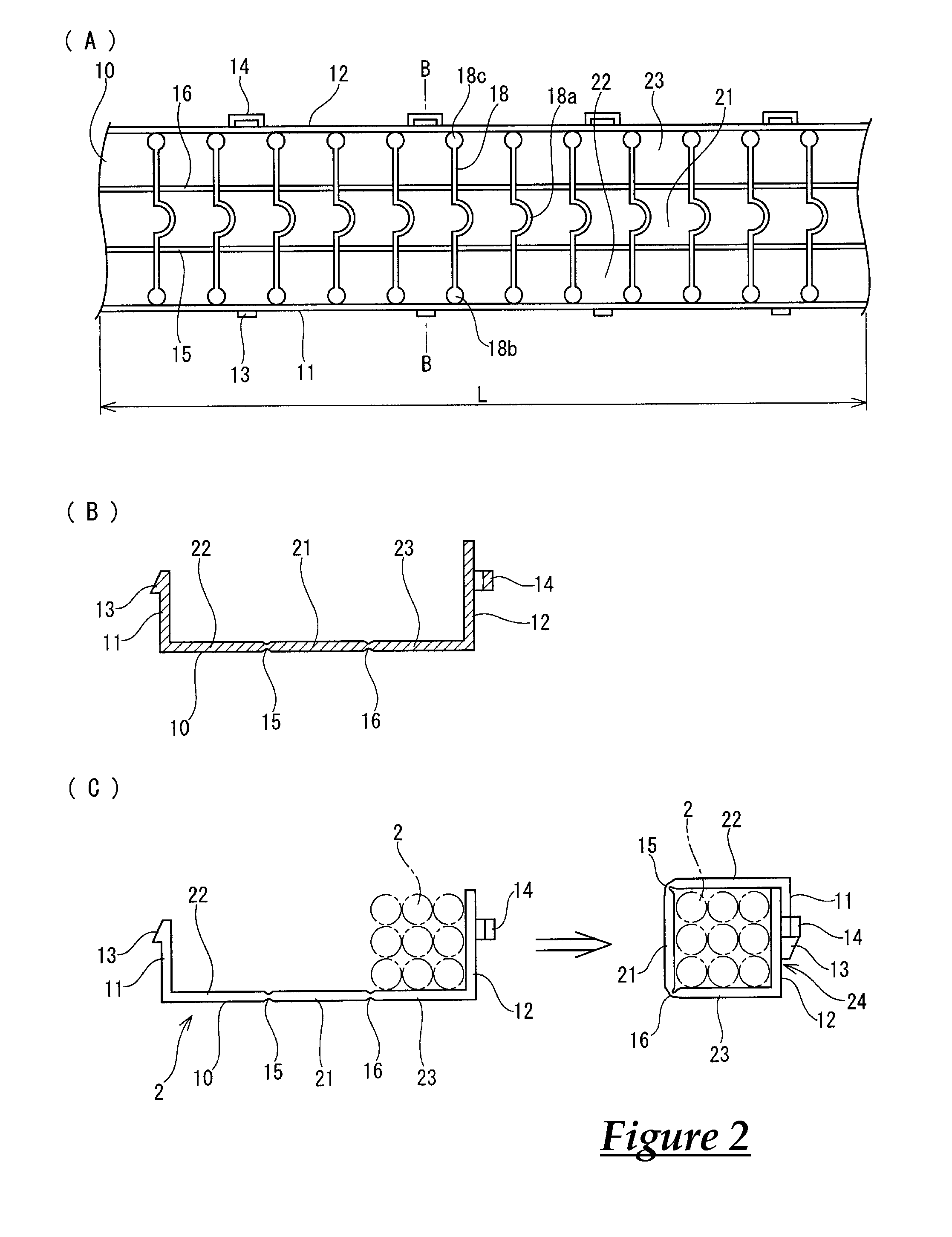

Outer cover material for wire harness, and routing structure for wire harness

InactiveCN105474488AEasy positioningImprove manufacturing efficiencyHauling chainsHoisting chainsBand shapeEngineering

Provided is an improved caterpillar-shaped outer cover material for a wire harness. A caterpillar-shaped outer cover material for a wire harness comprises an injection molded article. Joining plates are provided parallel to each other along both edges of a band-like center plate in the width direction thereof so as to protrude from the edges. Locking claws are provided at the front end of one of the joining plates so as to protrude therefrom and so as to be located at a distance from each other in the longitudinal direction, and locking frames to which the locking claws are joined and locked are provided at the front end of the other joining plate so as to protrude therefrom. Two folding lines consisting of grooves and extending in the longitudinal direction are provided in the center plate at a distance from each other in the width direction, and slits extending in the width direction are provided in the center plate at a distance from each other in the longitudinal direction. A tape wrapping section for affixing a wire harness is provided either at the one joining plate or at one end and / or the other end, in the longitudinal direction, of a side of the center plate, the side being sandwiched between the folding lines of the center plate, and a clip to be engaged with an affixation material is provided at at least the other end so as to protrude therefrom.

Owner:SUMITOMO WIRING SYST LTD

Outer cover material for wire harness, and routing structure for wire harness

A caterpillar-shaped outer cover material for a wire harness is improved. An outer cover material for a wire harness that is made of an injection molded article and is caterpillar-shaped includes coupling plates that are provided along two edges of a band-shaped central plate in a width direction so as to protrude in parallel to each other. One of the coupling plate has locking claws that are provided at intervals in a length direction protruding from an end of that coupling plate, the other of the coupling plates has locked frames to which the locking claws are respectively locked and coupled, and that protrude from an end of that coupling plate, and the central plate has folding lines constituted by two grooves that extend in the length direction at a distance in the width direction, and has slits extending in the width direction that are provided at intervals in the length direction. Furthermore, a tape wound piece to which a wire harness is to be fixed is provided at least one of two ends, in the length direction, of the one coupling plate or a member arranged between the folding lines of the central plate, and a clip for being latched to a fixation material protrudes from at least the other end.

Owner:SUMITOMO WIRING SYST LTD

Electrical control cabinet terminal strip

ActiveCN110838626AFirmly connectedPrevent slippingElectrically conductive connectionsElectrical controlRetaining harness

The invention provides an electrical control cabinet terminal strip. The electrical control cabinet terminal strip comprises a fixing plate, a fixing component, a limiting component and a terminal connecting component. Thus, the problems that the existing wire harness is inconvenient to be inserted into the terminal strip for fixation, the existing wire harnesses are mostly inserted into a terminal strip in a one-to-one correspondence mode and are fixed by screwing fixing bolts, however, time and labor are consumed when connected wires are fixed by screwing single bolts, wire slipping is proneto occurring when the bolts are screwed in a rotating mode, and therefore the ends of the wire harnesses are not firmly fixed and are prone to loosening, the use is influenced, and moreover, the outer wall of the wire harness needs to be fixed through a buckle after a conventional wire is connected to the terminal strip, thereby preventing the wire harness from being separated from a connection hole of the terminal strip when the wire harness is pulled by an external force, however, existing fixing mostly adopts single fixing and is inconvenient to use, and an existing mode of fixing the outer wall of the wire harness easily causes damage to the outer wall of the wire harness and affects the conductivity of the wire can be solved.

Owner:杭州铭伟斯电气有限公司

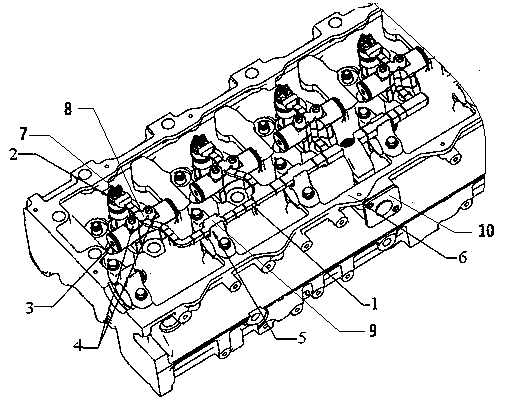

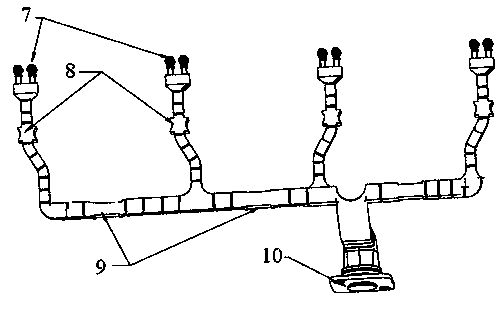

Fixing structure of engine cylinder internal wire harness assembly and method for fixing wire harness assembly

The invention provides a fixing structure of an engine cylinder internal wire harness assembly and a method for fixing the wire harness assembly. The fixing structure of the engine cylinder internal wire harness assembly comprises the wire harness assembly, a wire harness sheath matched with the wire harness assembly wraps the wire harness assembly, and at least one fixing part is arranged on the wire harness sheath. The wire harness assembly is fixed through the following steps that one end of the wire harness assembly is connected with a binding post of an engine cylinder internal oil atomizer through a wire harness terminal, the other end of the wire harness assembly is fixed in a mounting hole in the front end of an engine cylinder cover through an inserting connector, and the fixing parts of the wire harness sheath are fixed to the cylinder cover in sequence in a matching mode. According to the scheme, the assembling and fixing positions of wire harnesses are made to be clear through a reasonable wire harness distribution mode, and the design space is utilized effectively; meanwhile, the wire harness sheath performs protecting and guide fixing functions on the wire harnesses, and the performance of resistant to high temperature, resistant to corrosion, resistant to vibration and resistant to abrasion is achieved.

Owner:SINO TRUK JINAN POWER

Wire harness fixing structure

ActiveUS20160066473A1Avoid reliabilityInsulated cablesElectric/fluid circuitEngineeringRetaining harness

A wire harness fixing structure includes a cooling medium tank provided with a cooling medium relief valve; a sensor that is installed in the cooling medium tank; a connection terminal that is located beyond the cooling medium relief valve as viewed from a position where the sensor is installed; a wire harness that electrically connects the sensor to the connection terminal; and a bracket that is fastened to the cooling medium tank and that fixes the wire harness. The bracket includes a fastened portion that is fastened to the cooling medium tank, and a retention portion that has a substantially U-shaped form closed at a side facing the cooling medium relief valve and that retains the wire harness in the U-shaped form.

Owner:TOYOTA JIDOSHA KK +1

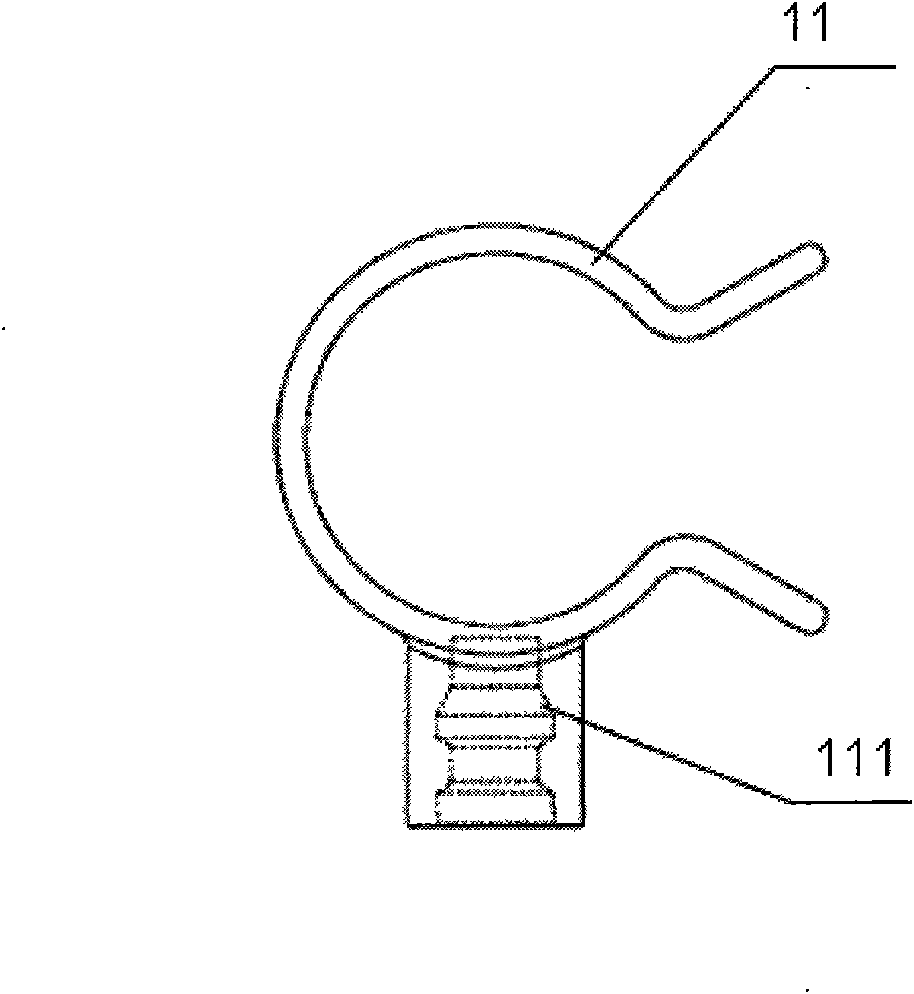

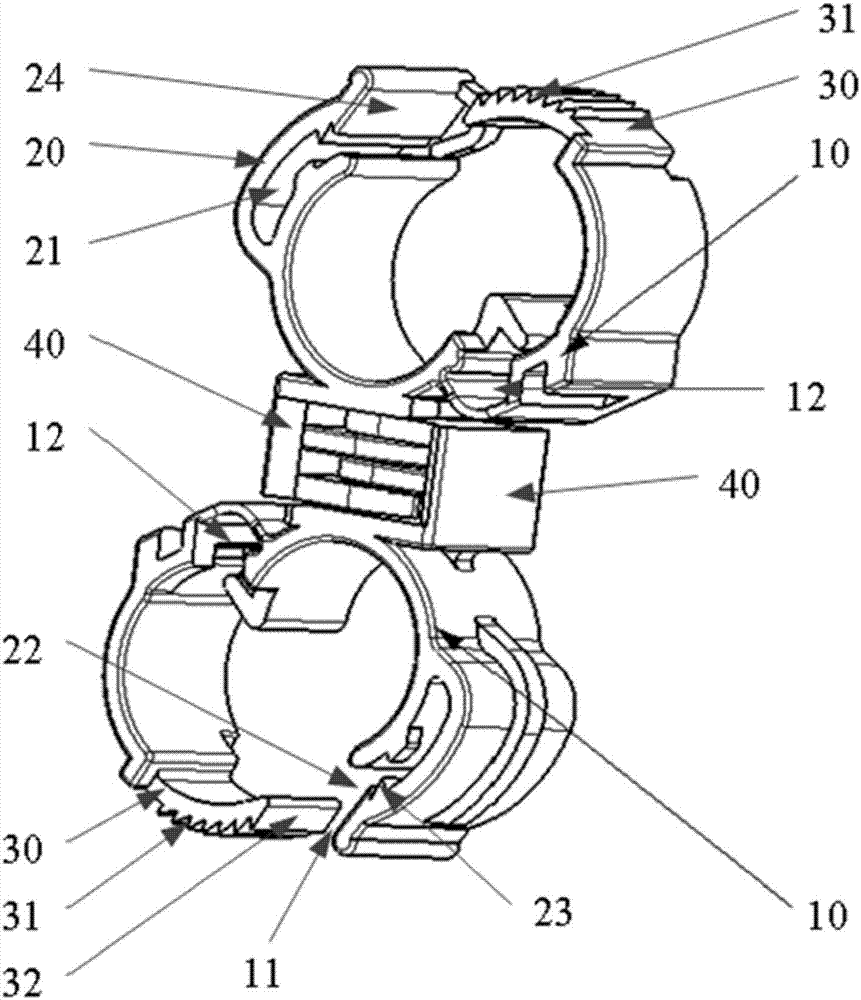

Wiring harness fixing and limiting pipe clamp

InactiveCN107196248AImprove reliabilityImprove versatilityElectrical apparatusEngineeringRetaining harness

The invention discloses a wiring harness fixing and limiting pipe clamp. The wiring harness fixing and limiting pipe clamp comprises two pipe clamp bodies which are both circular rings with openings; a locking part is arranged at one end of each opening while a clamping part is arranged at the other end of the opening; the clamping part can be clamped in the locking part; the two pipe clamp bodies are both rotationally connected with connecting pieces; and the two connecting pieces can be buckled and fixed mutually. The pipe clamp bodies are circular rings with openings, so that when a wiring harness needs to be fixed, the wiring harness is put into the circular rings of the pipe clamp bodies from the opening positions; next, the clamping parts are clamped in the corresponding locking parts to complete fixation of the wiring harness; by virtue of the matching mode of the clamping parts and the locking parts, the openings of the pipe clamp bodies are locked tightly, so that wiring harness fixation reliability is greatly improved; when two strands of wiring harnesses are fixed, two wiring harness fixing and limiting pipe clamps are fixedly connected through respective connecting pieces; and the connecting pieces are rotationally connected with the pipe clamp bodies, so that the angle between the two wiring harness fixing and limiting pipe clamps can be adjusted optionally, so as to be suitable for different spaces, thereby improving universality of the wiring harness fixing and limiting pipe clamp.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

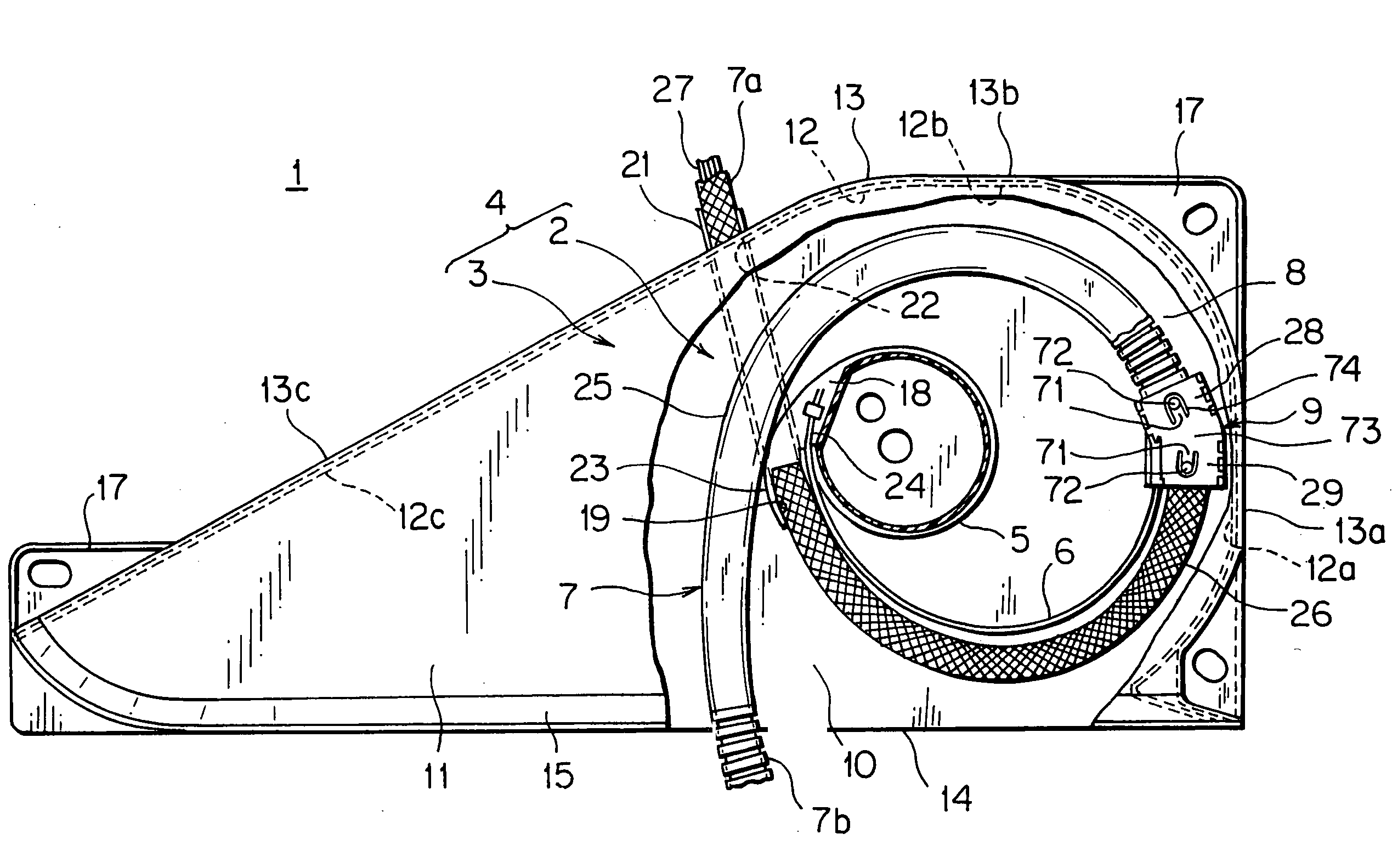

Continuous power supply device

ActiveUS20060131049A1InterferenceIncrease freedomCable arrangements between relatively-moving partsInsulated cablesMiniaturizationEngineering

Miniaturizing a protector receiving a wiring harness in height, and preventing sound noise caused by interference between a spring holder for holding the wiring harness and an inner surface of the protector, a continuous power supply device includes a wiring harness to be bent into a loop within a protector, a spring holder fixed at the loop of the wiring harness, a front end of a flat spring fixed at the spring holder to energize the loop to expand in radius, an elastic arm provided at the spring holder to be continuously and elastically in contact with inner surfaces of the protector.

Owner:YAZAKI CORP

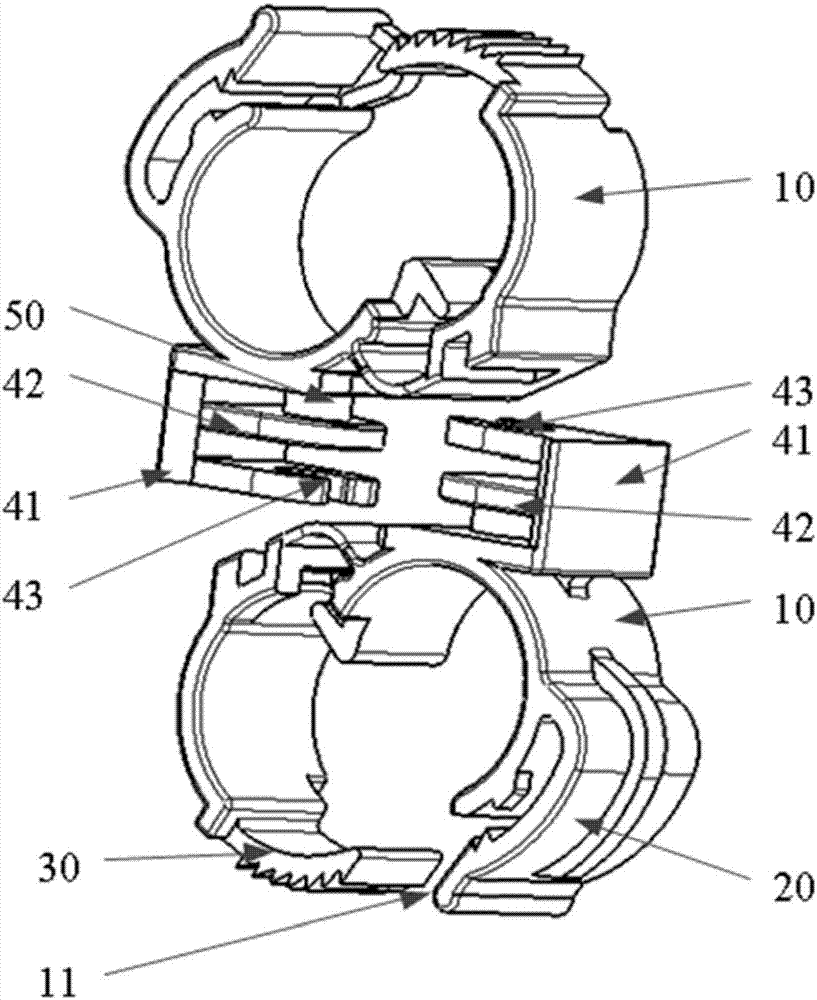

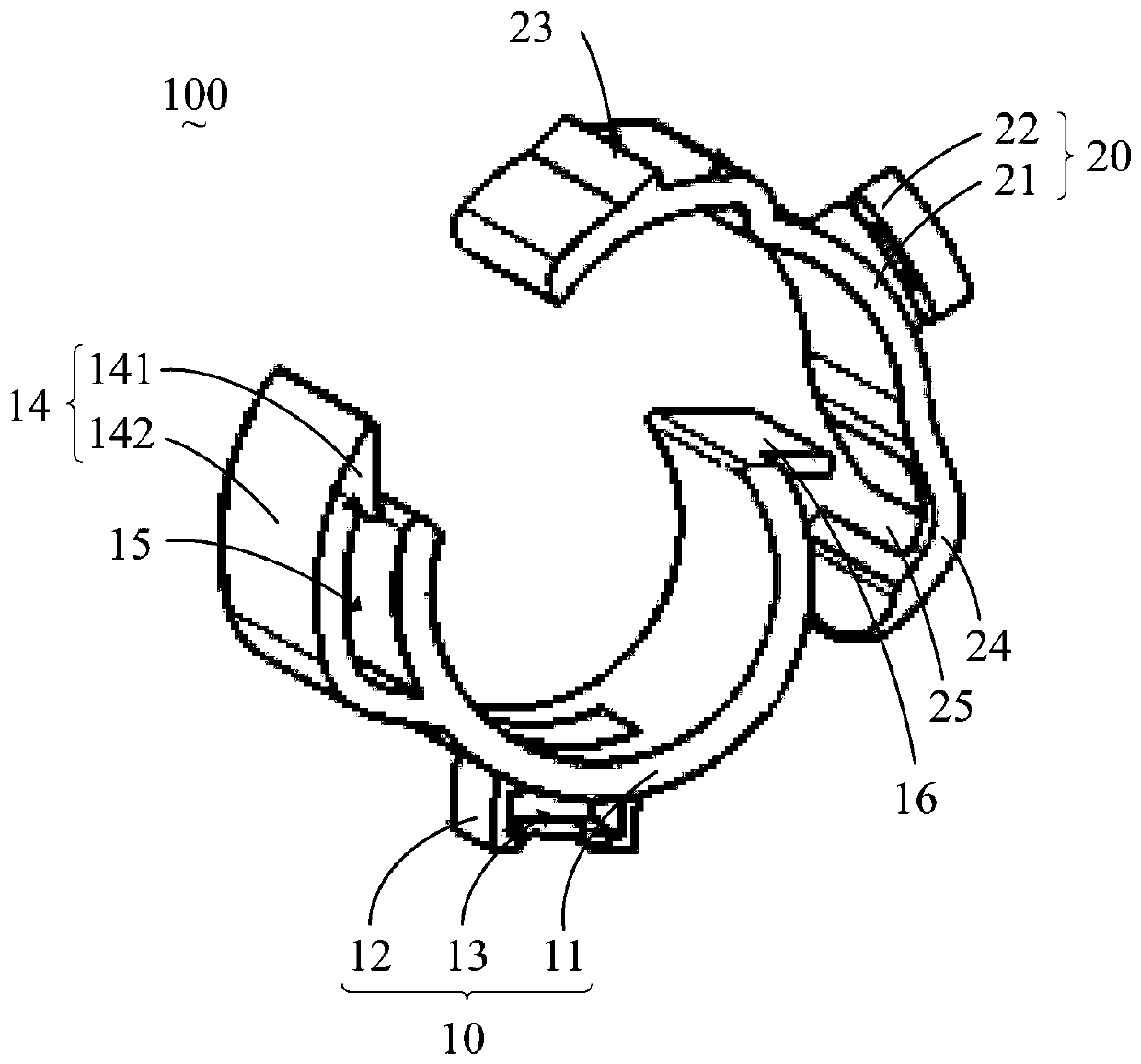

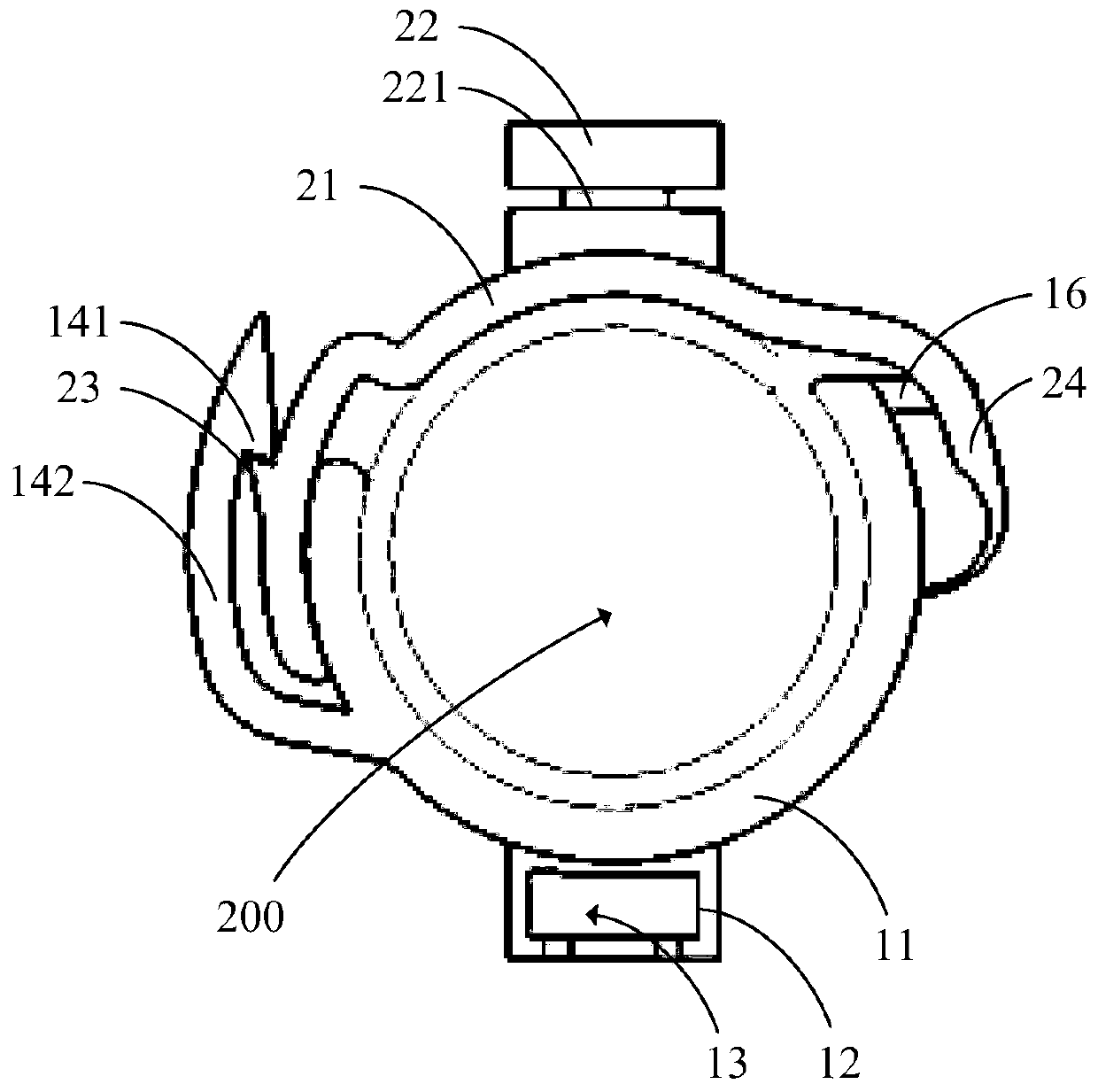

Wire harness pipe clamp and wire harness device

The invention provides a wire harness pipe clamp and a wire harness device. The wire harness pipe clamp comprises a wire harness ring and a hasp, wherein a first accommodating ring is arranged on thewire harness ring, a second accommodating ring is arranged on the hasp, and the hasp is used for being buckled on the wire harness ring, so that the first accommodating ring and the second accommodating ring define an accommodating cavity for fixing wire harnesses; a second boss is arranged on the buckle, a first boss is arranged on the wire harness ring, and a limit groove is formed in the firstboss, and can be matched with the second boss. According to the technical scheme, the hasp is buckled on the wire harness ring, and the accommodating cavity is formed between the hasp and the wire harness ring so as to fix the wire harnesses or wire pipes. Meanwhile, the second boss is arranged on the harness ring and the first boss is arranged on the hasp, so that fastening connection between a plurality of harness pipe clamps is achieved by the cooperative relationship between the second boss and the first boss, and a plurality of groups of wire pipes or harnesses in different directions canbe fixed simultaneously.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

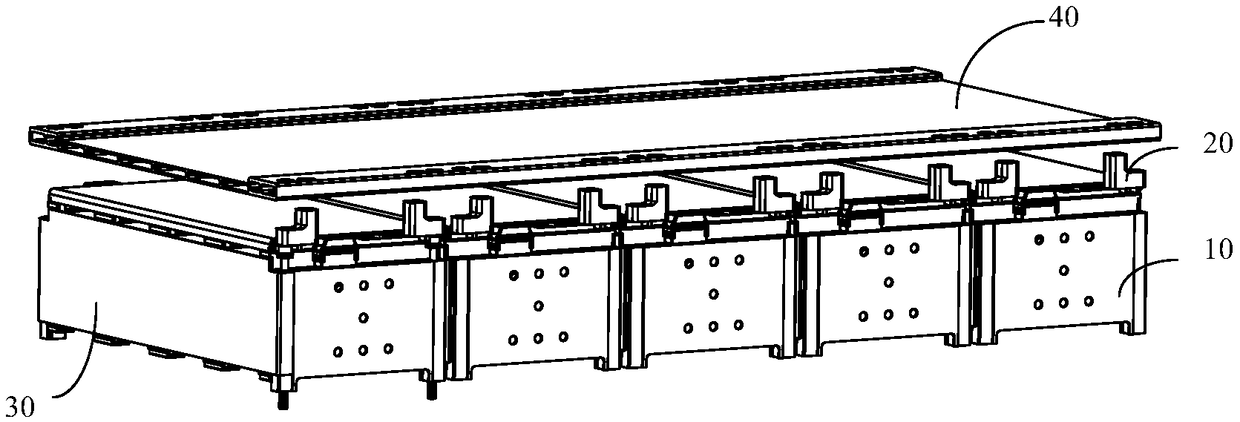

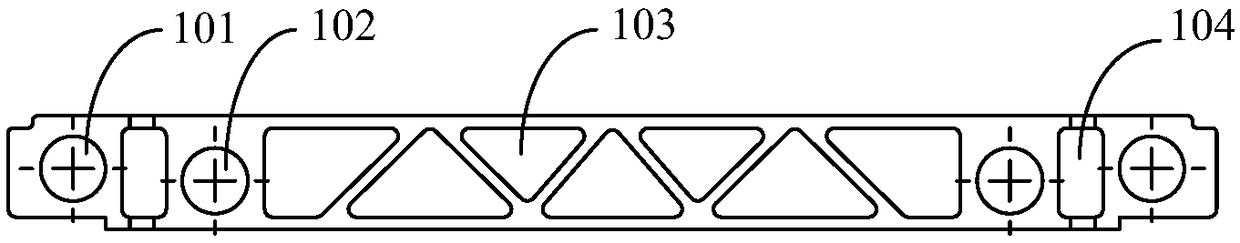

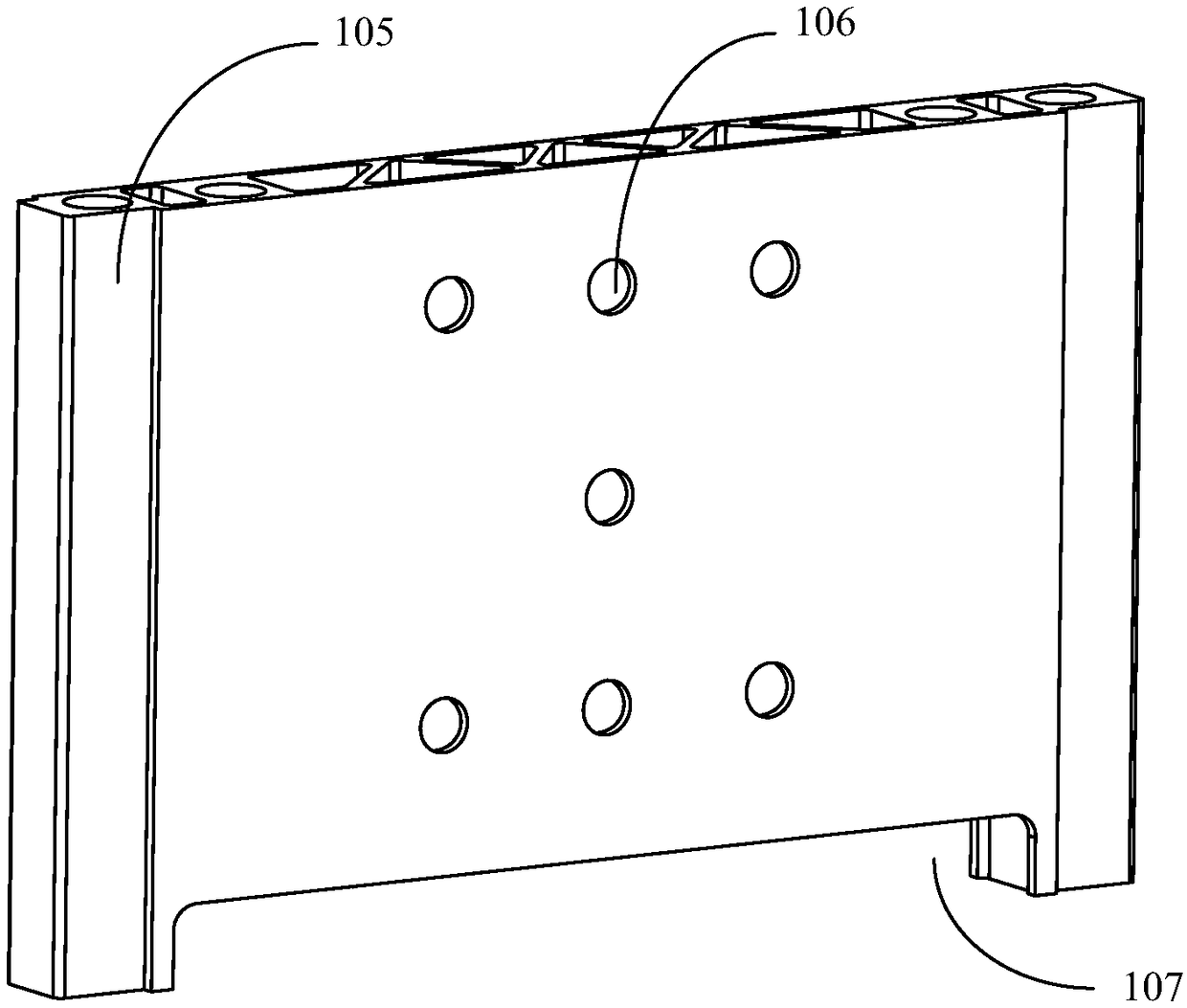

Battery module and manufacturing method

PendingCN108899456ASolve the problem of not being able to pre-pinImprove assembly efficiencyAssembling battery machinesFinal product manufactureMortise and tenonLiquid cooling system

The invention discloses a battery module and a manufacturing method. The battery module mainly comprises batteries, vertical columns, end plates and lateral plates, wherein the vertical columns are fixed and limited to the end plates through tenon-and-mortise structures in advance, and the vertical columns are tightly installed on the end plate through bolts; the vertical columns are used for fixing at least one of a tray on the upper layer and a top plate on the lower layer. Because the tenon-and-mortise structures are adopted between the vertical columns and the end plates, the problem thatin the prior art, when placed, the vertical columns cannot be pre-fixed is solved, great convenience is brought to subsequent assembly, the calibration time is reduced during installation, and the PACK efficiency is effectively improved. Liquid cooling system installation grooves are reserved in the end plates, and a liquid cooling system is conveniently designed. Wire binding holes used for fixing a wire group and mortise holes used for connection are formed in the surface of the module. Lateral plate connecting grooves are reserved in the lateral sides of the end plates of the modules, and after being bent, the lateral plates of the module can be connected with the end plates of the module so that a shell of the module can bear larger battery swelling force.

Owner:江苏和中普方新能源科技有限公司

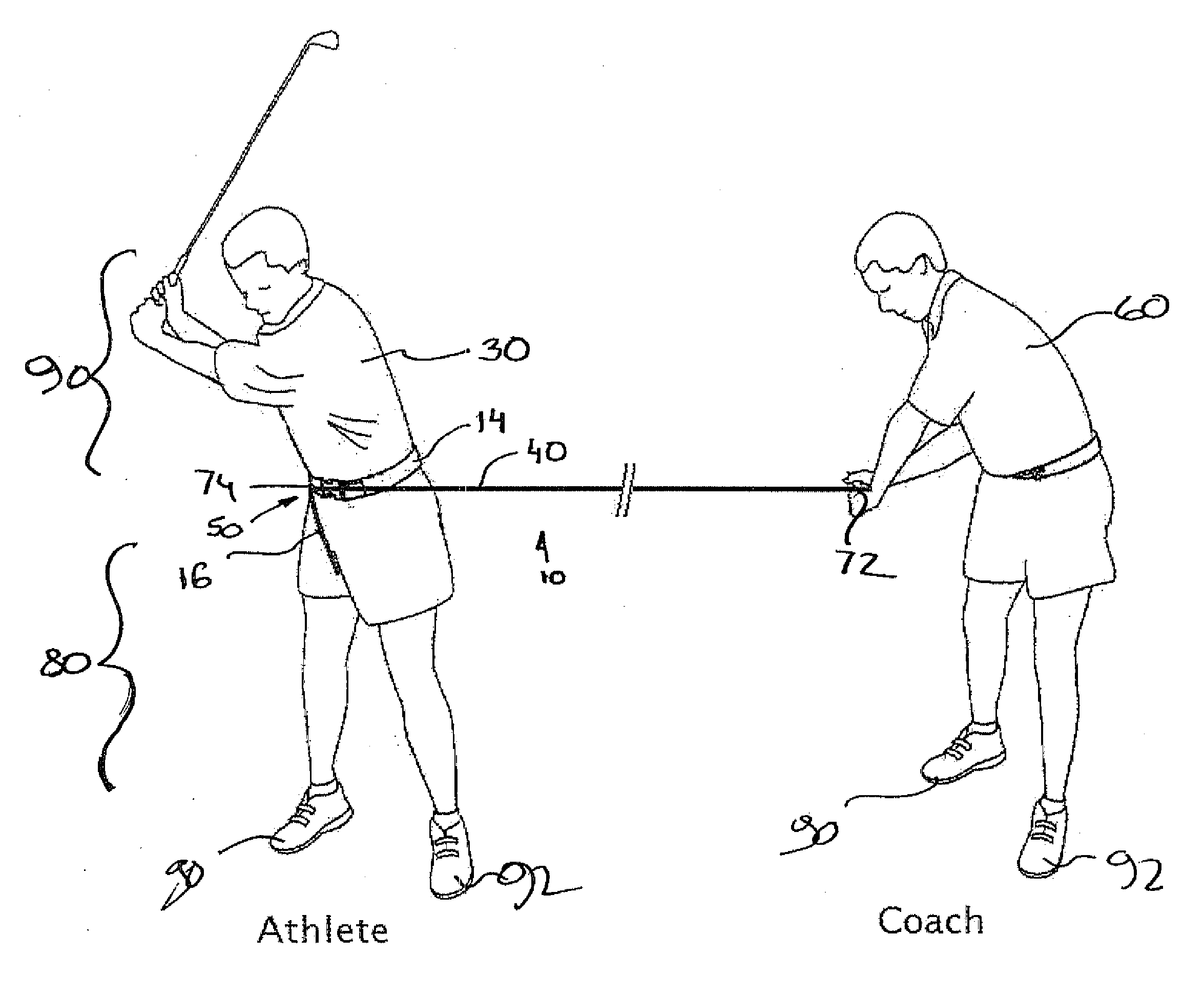

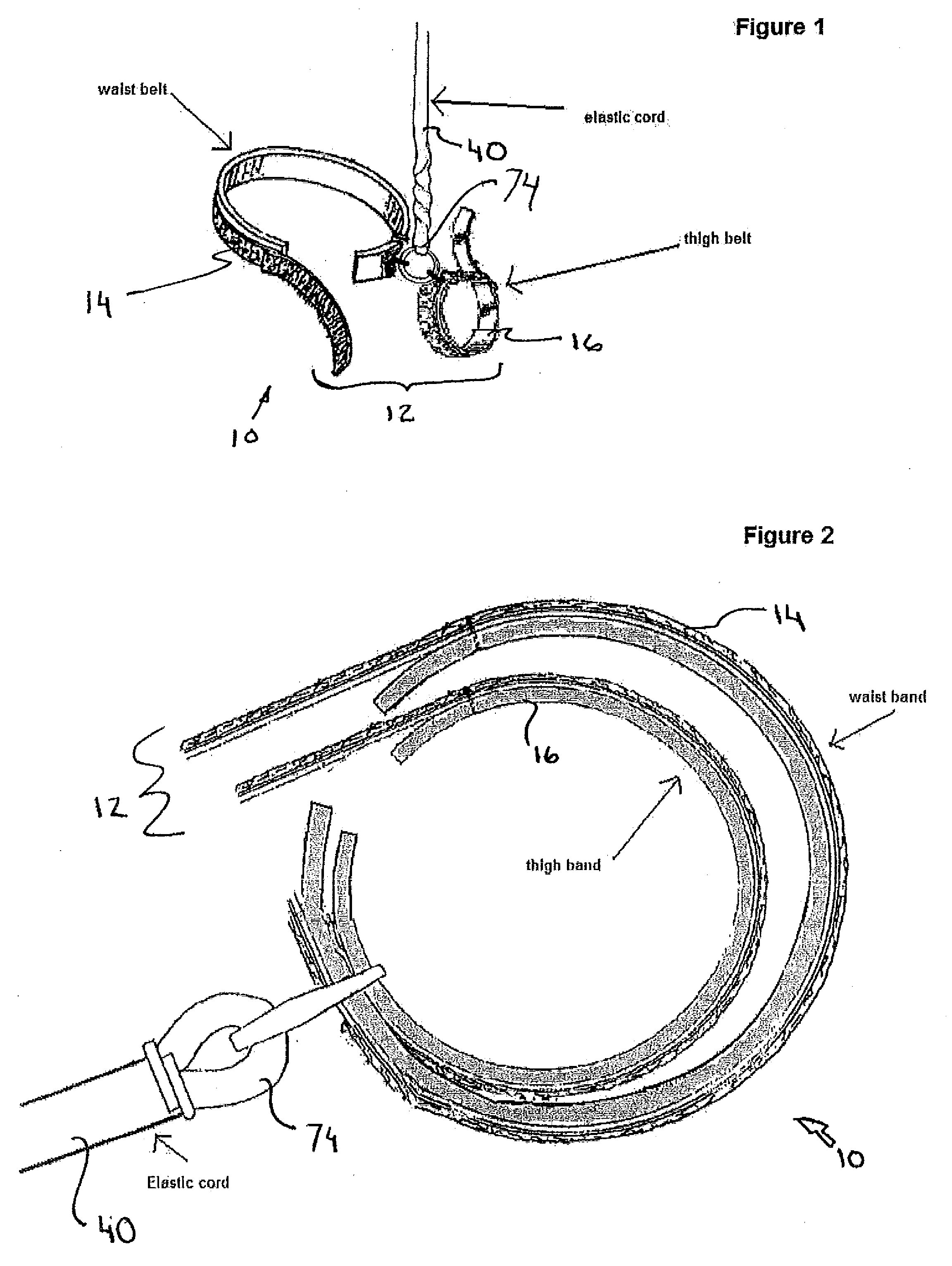

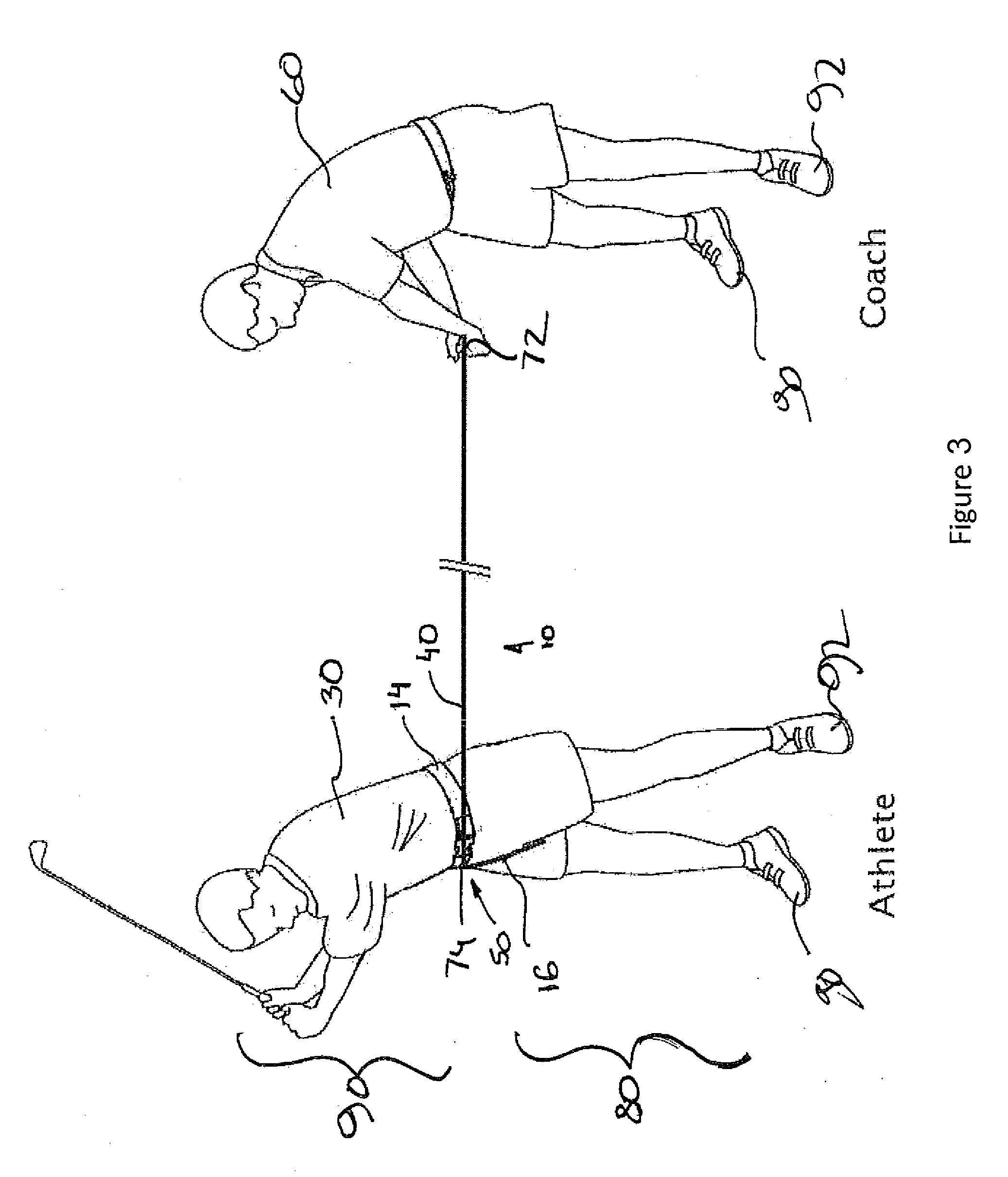

Sport training apparatus and method of use

A training apparatus having a harness mountable about a user's waist and thigh and a pull securable to the harness at a region corresponding to the iliac of a crest of the user for pulling the harness to encourage or resist turning of the user's hips to respectively teach or strengthen weight transfer from a back foot to a front foot of the user. A method is provided for training a person in an activity requiring transfer of weight and momentum from a lower area to an upper area of a person.

Owner:DANBREE CORP

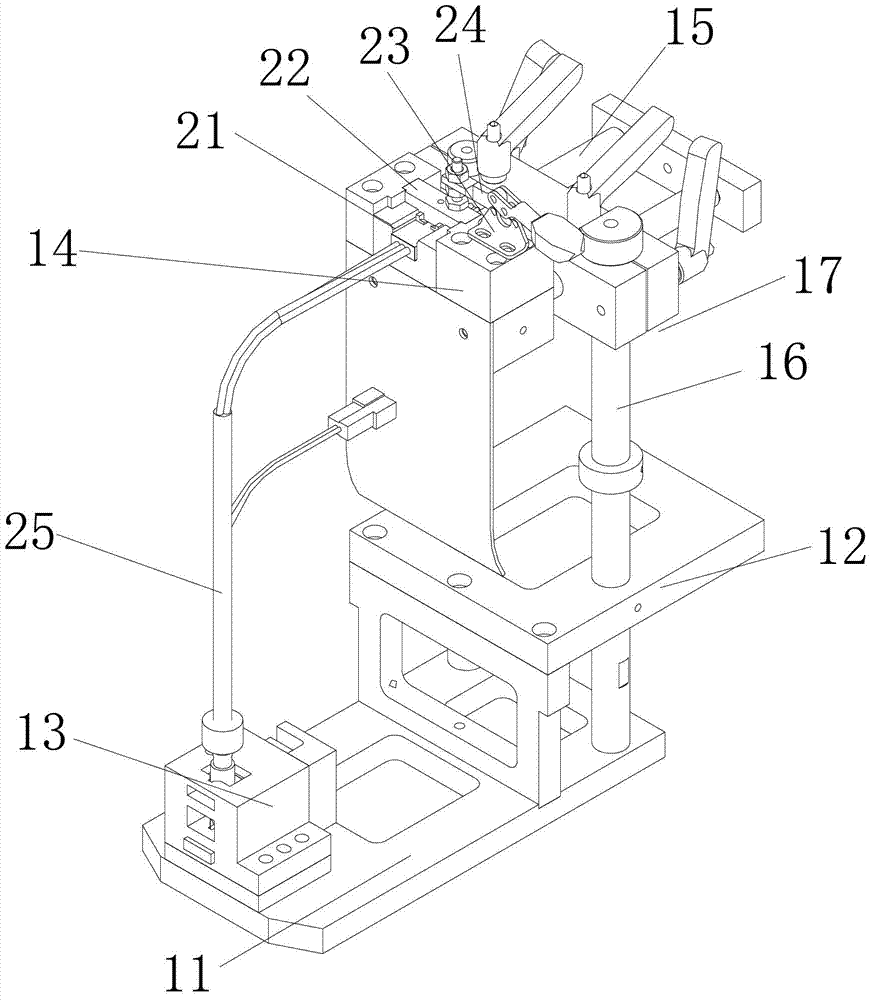

Wire harness clamping mechanism

The invention discloses a wire harness clamping mechanism which comprises a base and a bracket. The wire harness clamping mechanism is characterized by further comprising a transverse guide rail, a vertical guide rail, a sliding block, a wiring harness inserting block and a wiring harness fixing block, wherein the wiring harness inserting block is arranged at the rear end of the base; a bracket is arranged at the front end of the base; the wiring harness fixing block is arranged above the bracket; the sliding block is arranged in front of the wiring harness fixing block; the transverse guide rail transversely penetrates through the sliding block and is connected with the wiring harness fixing block; and the vertically guide rail sequentially penetrates through the sliding block and the bracket and is connected with the base. According to the wire harness clamping mechanism disclosed by the invention, the problems that the wire harness clamping mechanism in the prior art has a clamping function only and cannot be used for adjusting the position of a wire harness, and the subsequent detection of the wire hardness is influenced due to the fact that the wire harness clamping mechanism cannot be used for better fixing the end part of the wire harness are solved. The invention provides the wire harness clamping mechanism which is simple in structure and convenient in use and can be used for clamping the wire harness quickly and accurately and adjusting the position of the wire harness.

Owner:昆山艾博机器人股份有限公司

Hinge wiring harness buckling structure

ActiveCN102856845ADoes not affect strengthImprove convenienceElectrical apparatusRetaining harnessCable harness

The invention relates to wiring harness buckling and particularly relates to a hinge wiring harness buckling structure. The structure comprises a hinge and a wiring harness fastener, the hinge comprises a first connecting portion and a second connecting portion which can rotate relative to the first connecting portion, the wiring harness fastener comprises a wiring harness fixing portion, the first connecting portion is provided with a wiring harness buckling installation section, the wiring harness also comprises a chuck which can be opened or closed, and the chuck is clamped on the wiring harness installation section. According to the hinge wiring harness buckling structure, a hole is not required to be arranged on a hinge, the structure can be installed on the hinge and is convenient to adjust the installation position, and the problem that the strength of the hinge is affected due to the fact that an existing wiring harness fastener is installed on the hinge, and a hole is required to be installed on the hinge and the problem that the wiring harness fastener is difficult to adjust the installation position on the hinge are solved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

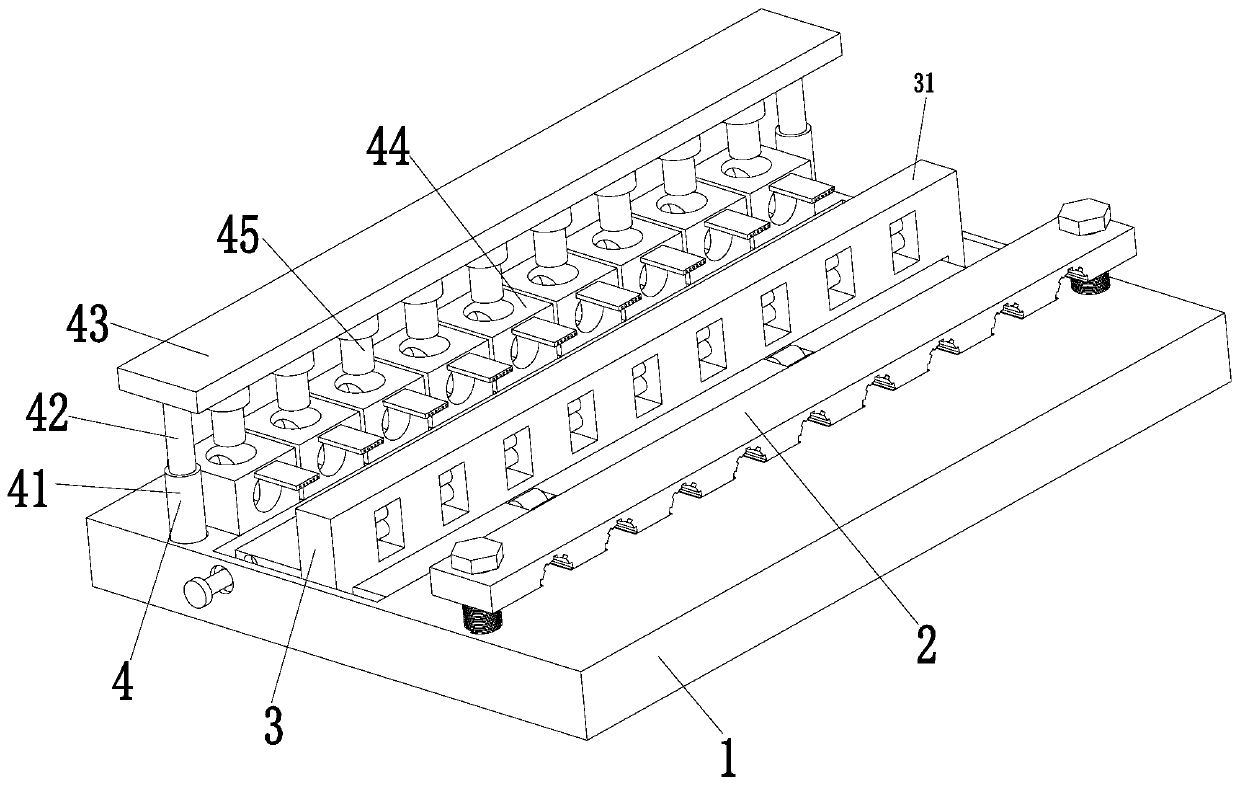

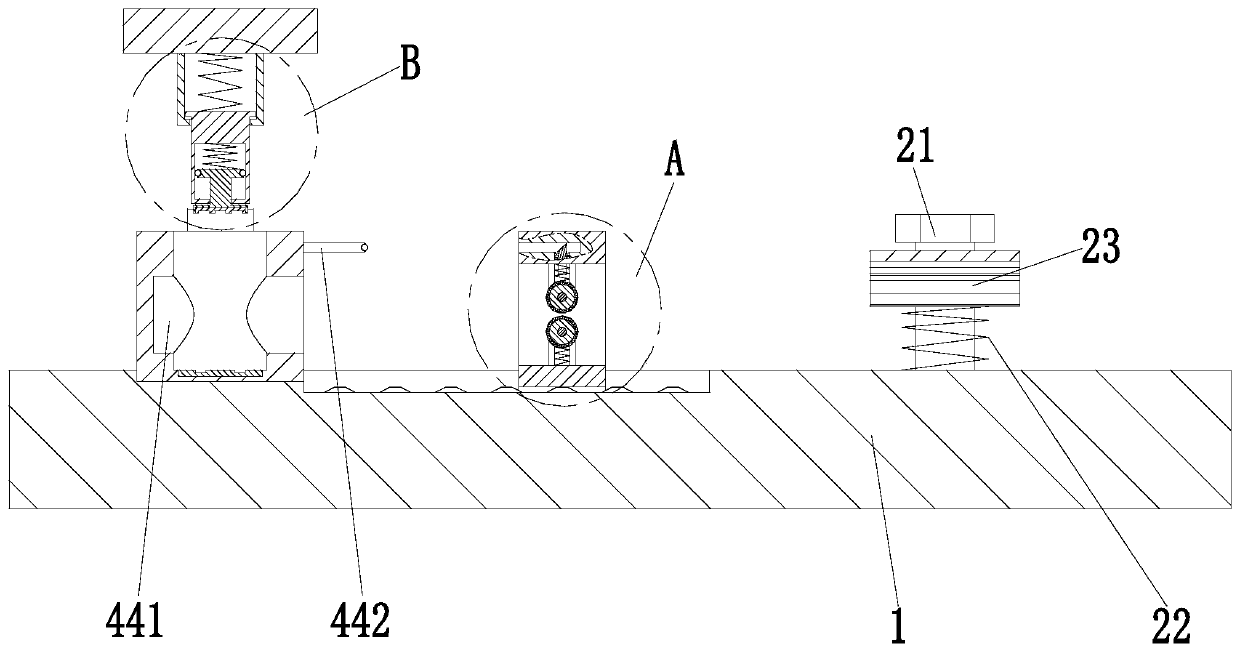

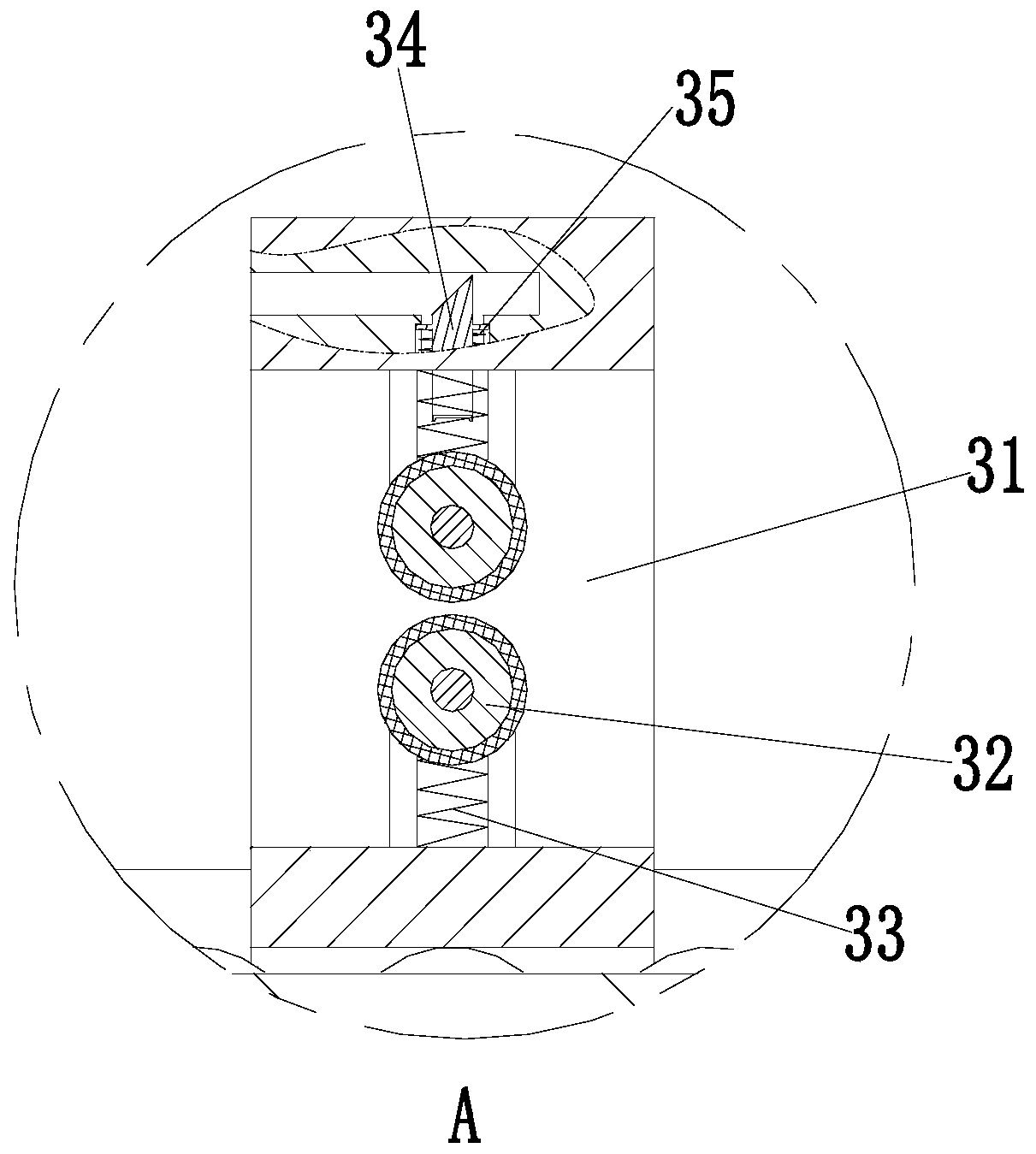

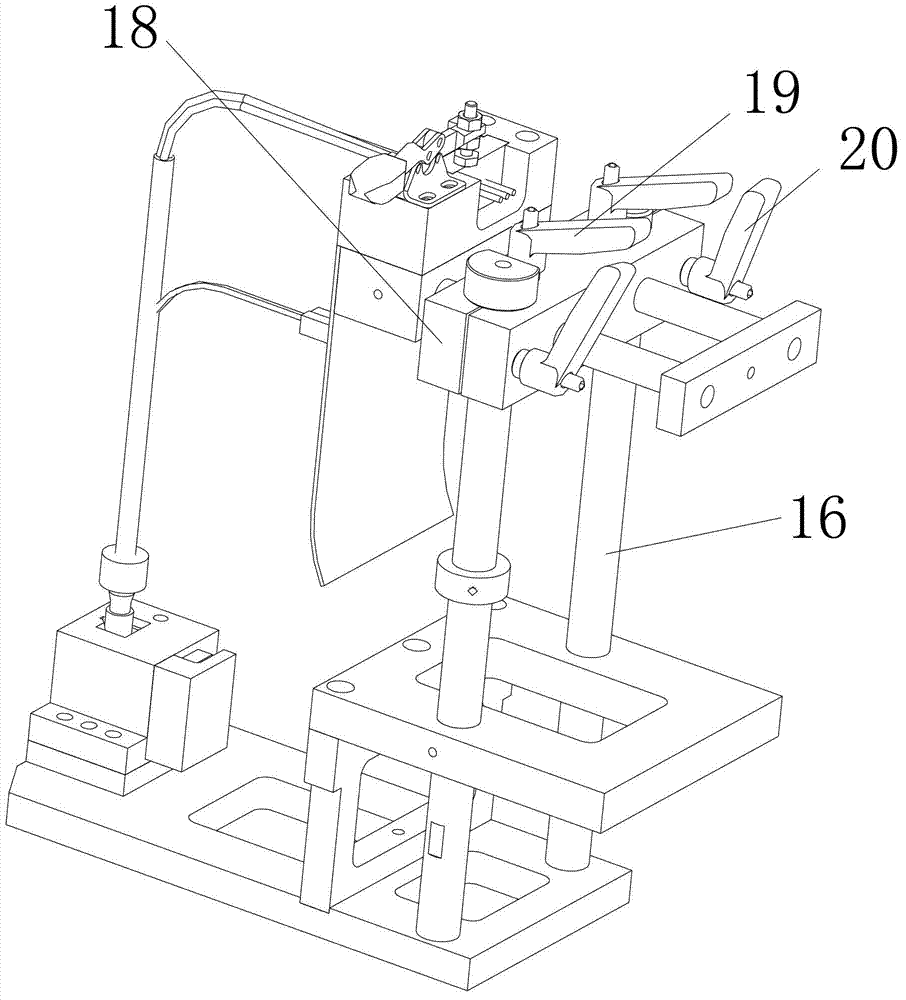

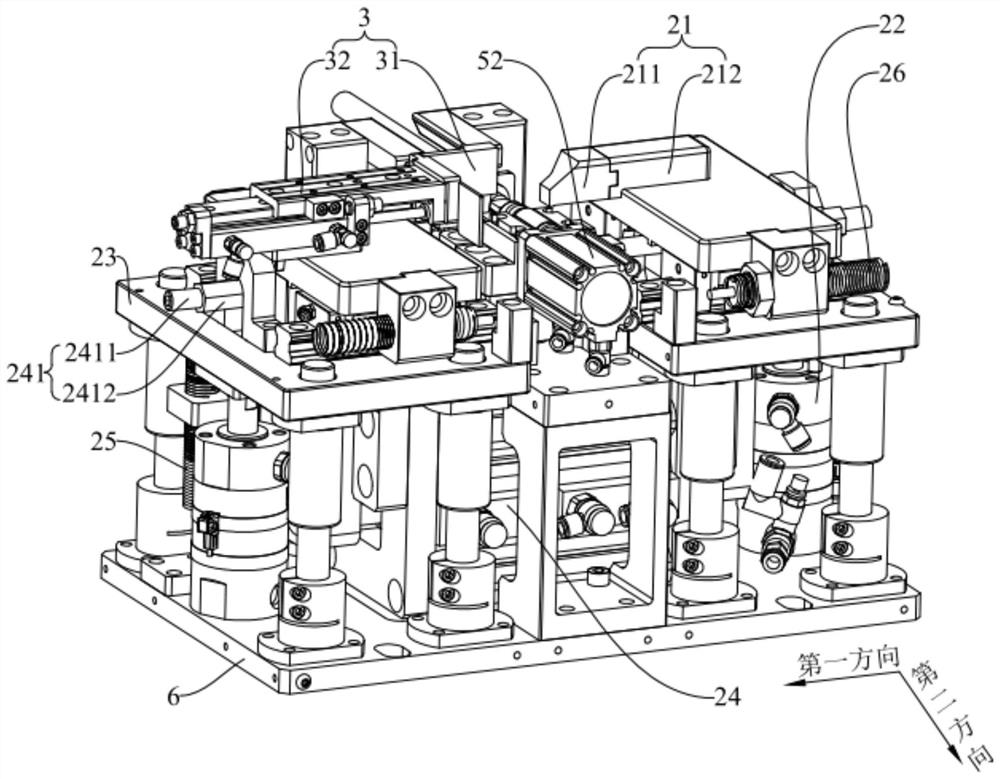

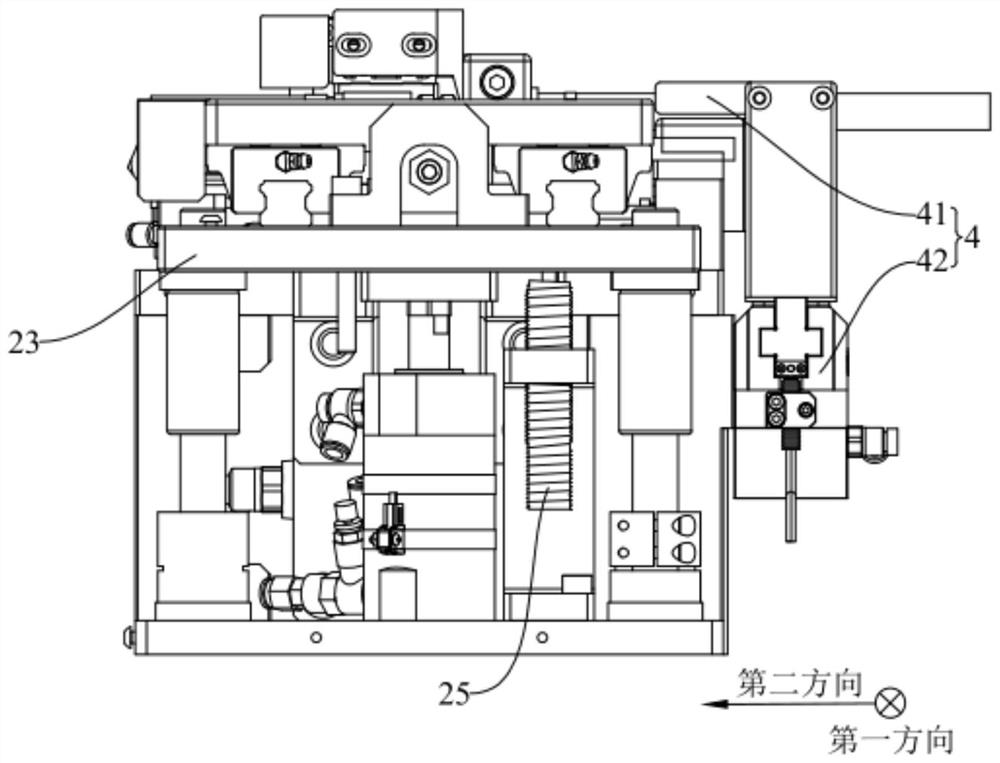

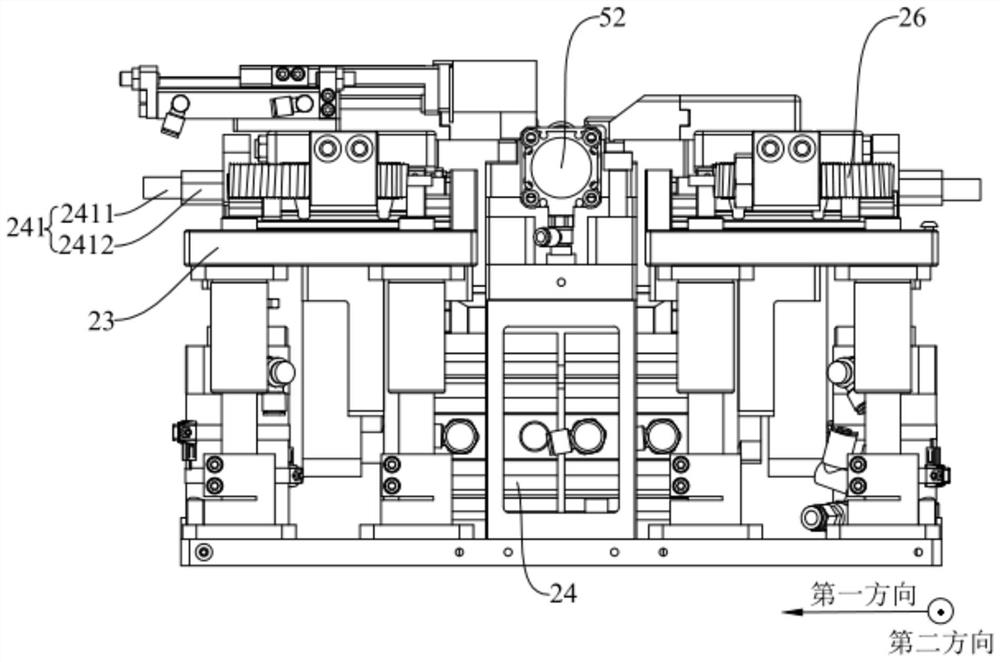

Welding tool

PendingCN112692485AAvoid misalignmentAvoid affecting welding resultsLine/current collector detailsWelding/cutting auxillary devicesEngineeringRetaining harness

The invention belongs to the technical field of welding, and discloses a welding tool. The welding tool comprises a carrying table, a first positioning mechanism, a second positioning mechanism and a clamping mechanism; the carrying table is provided with a first profiling groove used for carrying a terminal; and the first positioning mechanism can move towards the carrying table so as to abut against and fix the terminal to the carrying table. The second positioning mechanism and the first positioning mechanism can form a second profiling groove in an enclosing mode, and the second profiling groove is used for limiting the carrying position of wire harness so that the to-be-welded portion of the terminal placed in the first profiling groove can be attached to the to-be-welded portion of the wire harness placed in the second profiling groove; the clamping mechanism is configured to fix the wire harness. The first positioning mechanism and the second positioning mechanism are arranged, the terminal and the wire harness are placed in sequence, the first positioning mechanism forms the carrying position of the wire harness with the second positioning mechanism while fixing the terminal so as to position the terminal and the wire harness at the same time, and dislocation between the wire harness and the terminal during wire harness placement is prevented.

Owner:SBT ULTRASONIC TECH CO LTD

Fixing structure of wire harness

A hard-to-fall fixing structure of wire harness contributive to cost reduction in which VOC is not generated and flapping sound (noise) of wire harness is hard to occur. In the fixing structure of wire harness (30) to an interior material (10) for vehicle, a silencer pad (acoustical material) (20) is fixed to the interior material (10), the silencer pad (20) is provided with a latching piece (21)formed by cutting a portion of the silencer pad (20), and the wire harness (30) is latched to the latching piece (21).

Owner:TOYOTA BOSHOKU KK

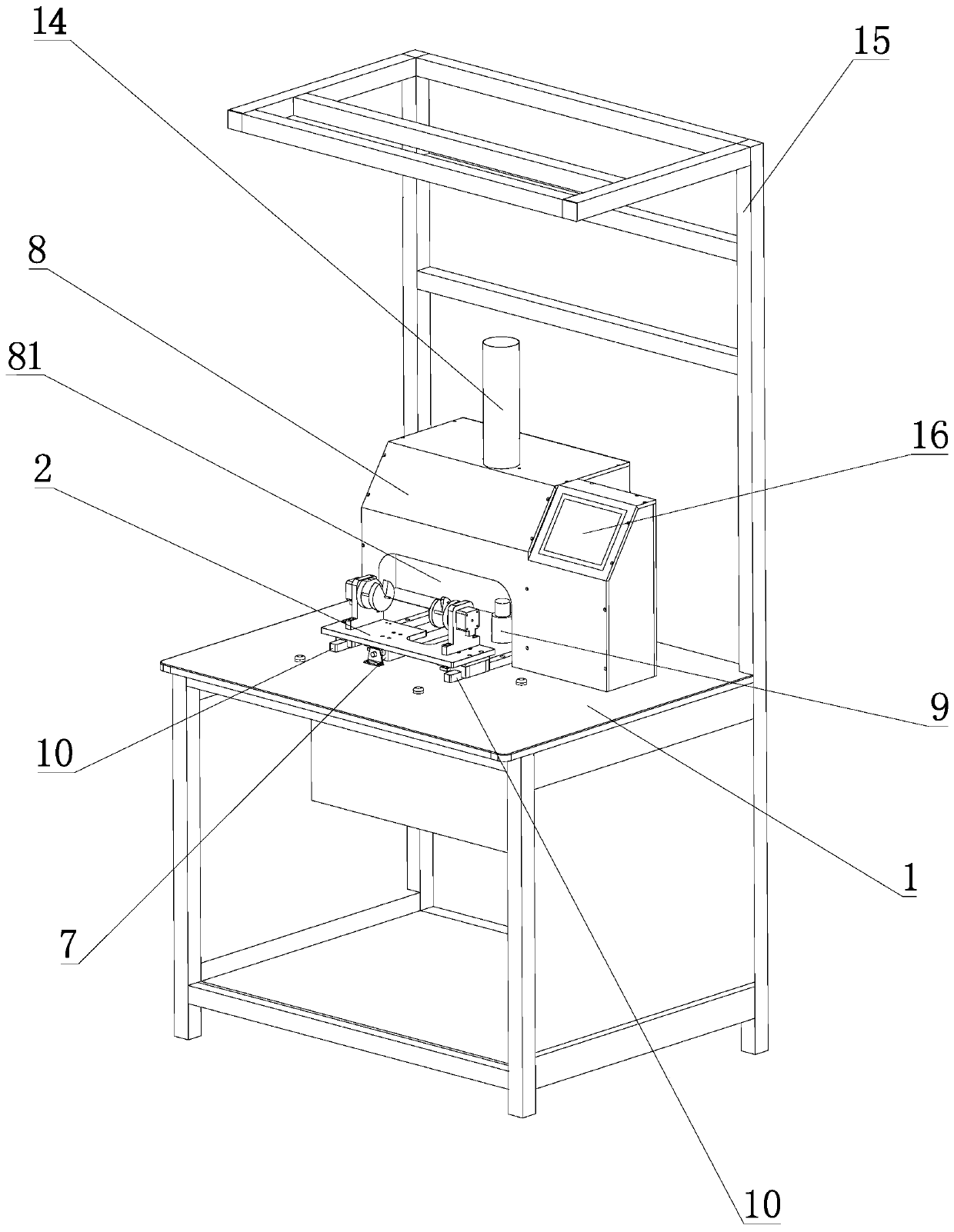

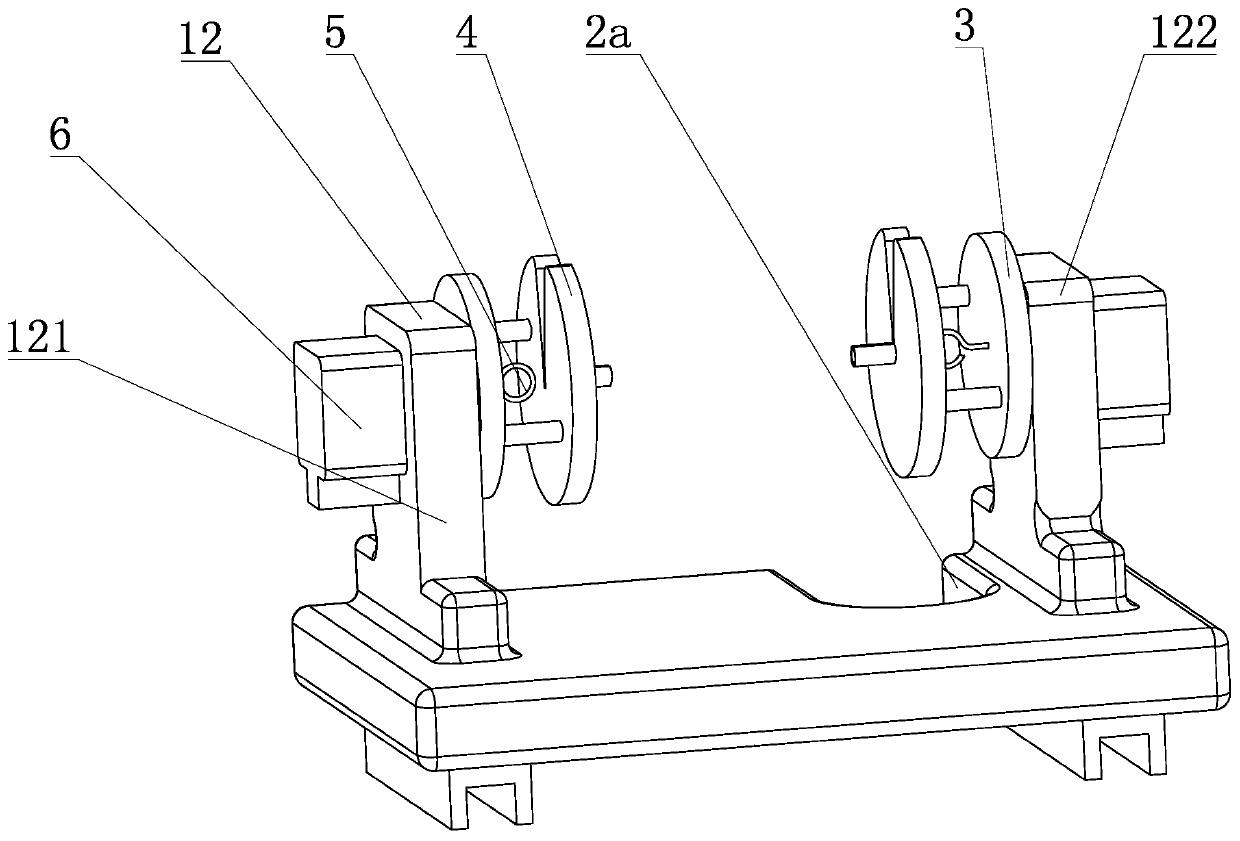

Device and method for sleeving wire harness with heat-shrinkable tube

The invention relates to a device and method for sleeving a wire hardness with a heat-shrinkable tube, and aims at solving the technical problem that in the prior art, the use performance of a heat-shrinkable tube is greatly reduced due to poor coating quality of the heat-shrinkable tube on the wire harness. The device comprises a rack, wherein the rack is movably connected with a movable rack, the movable rack is connected with two rotating discs, the two rotating discs are arranged in parallel and opposite to each other, the two rotating discs are each fixedly connected with a heat-shrinkable tube fixing block used for fixing the heat-shrinkable tube, the two heat-shrinkable tube fixing blocks are arranged in parallel and opposite to each other, the two rotating discs are each connectedwith a wire harness fixing device used for fixing the wire harness, the rotating discs are driven by a motor, the rack is connected with a driving mechanism, the movable rack can slide in and slide out of a heating box under the driving of the driving mechanism, the rack is connected with a hot air gun, an air outlet of the hot air gun is aligned with the gap between the two heat-shrinkable tube fixing blocks, and the hot air gun is positioned inside the heating box. The sleeved heat-shrinkable tube has good service performance and smoothness.

Owner:宁波拓普电器有限公司

Injection-molded wire harness and molding method

PendingCN111478060ANo mutual wearThe relative positioning size is accurateContact member assembly/disassemblyCoupling contact membersElectrical conductorInjection moulding

The invention relates to an injection-molded wire harness and a molding method. The wire harness comprises a terminal and at least one conductor, wherein one end of the terminal is connected with an electrical loop of an electric device, the other end of the terminal is connected with the conductor, and the wire harness is provided with a protection layer which is formed by injection molding and wraps the conductor, and at least one positioning device which is formed by injection molding and is used for fixing the position of the wire harness or / and a sealing device for water prevention. According to the invention, manual operation can be reduced, the consistency of wire harness products is improved, the production cost of the wire harness products is reduced, and the service life of the wire harness is prolonged.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

Fastening device used for fixing cable

The invention relates to a fastening device used for fixing a cable. The fastening device comprises a locking component and a fixing component, the locking component comprises a locking part used forfixing wiring harness and a first guide part, the fixing component comprises a second guide part and a keeping part used for connecting the fastening device to a fixed position, and the first guide part and the second guide part are in sliding fit to guide the fixing component in rotating in the axial direction around the wiring harness. Due to the fact that the first guide part and the second guide part are in sliding fit to guide the fixing component in rotating in the axial direction around the wiring harness, during assembly, the fixing component can be rotated according to actual conditions, and torsion of the wiring harness can be effectively avoided.

Owner:CONTINENTAL AUTOMOTIVE CORP LIANYUNGANG CO LTD

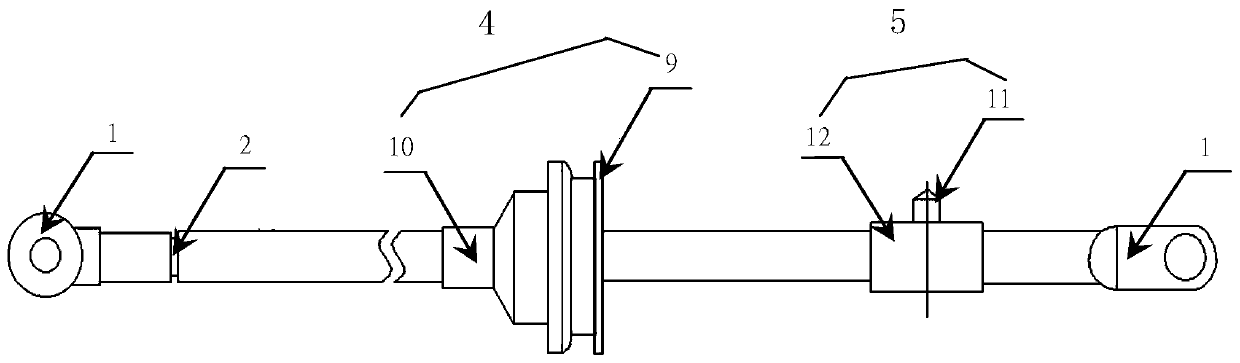

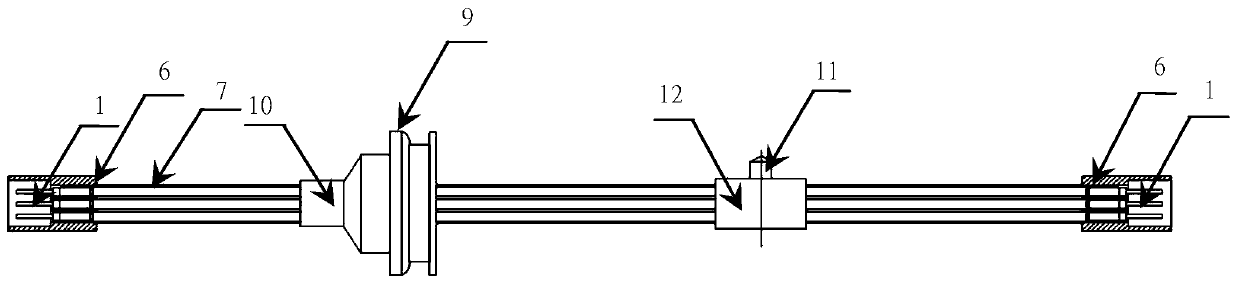

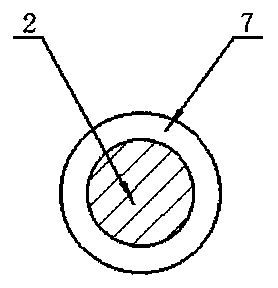

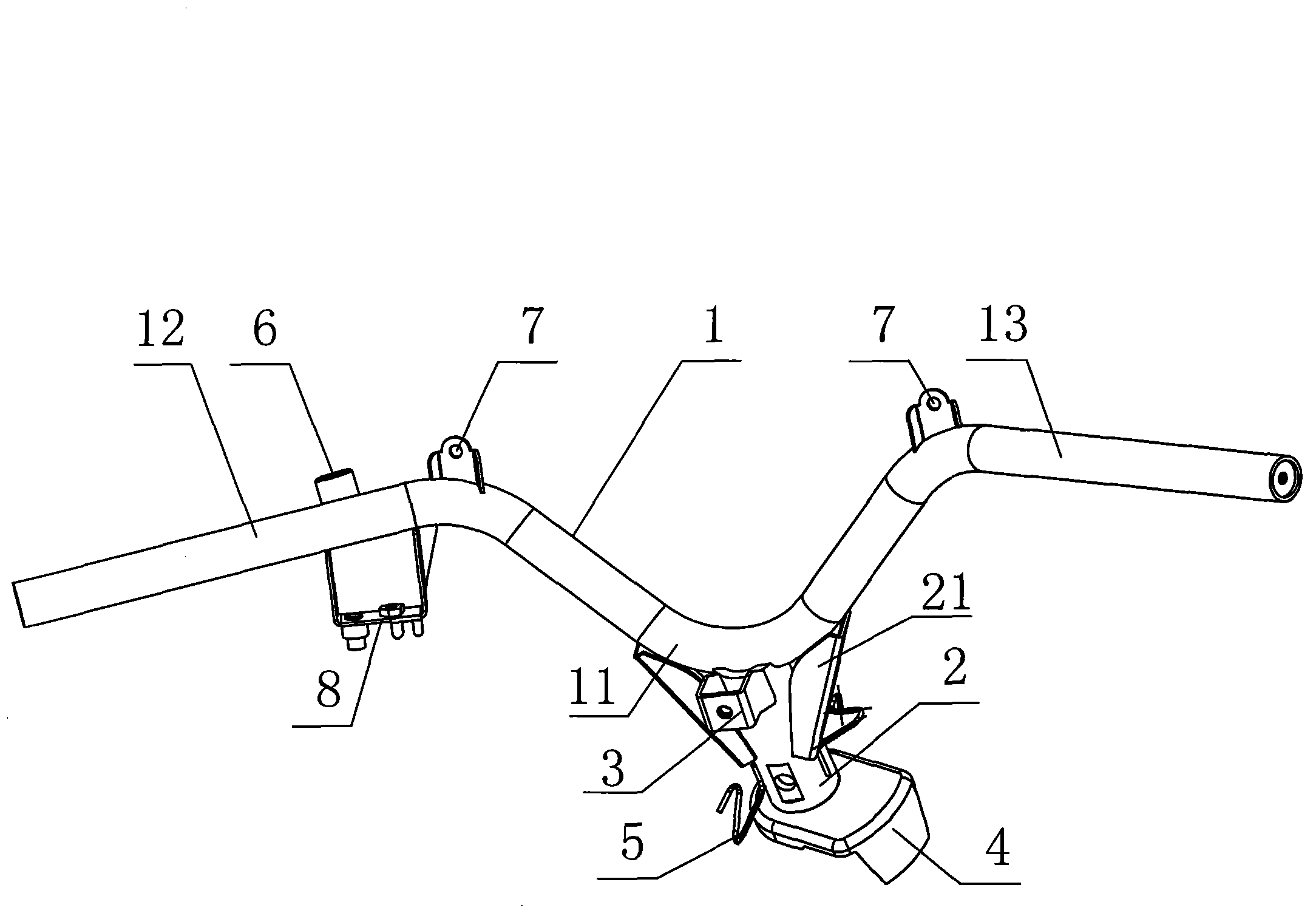

Motorcycle handlebar pipe structure

InactiveCN103847896AHigh strengthImprove axial fixation strengthSteering deviceVehicle frameEngineering

The invention discloses a motorcycle handlebar pipe structure. The motorcycle handlebar pipe structure comprises a handlebar pipe body, wherein the handlebar pipe body is a round steel pipe; a left handlebar and a right handlebar are arranged at the two ends of the handlebar body; a bent part which is bent frontwards and downwards is arranged in the middle position of the handlebar body; a frame vertical pipe is fixedly connected below the bent part; reinforcing ribs are welded among the two sides of the frame vertical pipe and the bent part; the upper part of the frame vertical pipe is welded with an instrument shell mounting supporting lug with a mounting hole; a handlebar lock seat for supporting a locking direction is fixedly arranged below the frame vertical pipe; a rearview mirror mounting seat is fixedly arranged above the left handlebar and an air door fixing bracket is fixedly arranged below the left handlebar; two headlamp shell mounting supporting lugs with mounting holes are arranged above the bent part; wire hooks for fixing a wiring harness or a pull cable are fixedly arranged below the instrument shell mounting supporting lug. The motorcycle handlebar pipe structure has the advantages that the structure has the strength of the connection of a handlebar pipe, all the parts is firm and reliable, the function is great, the manufacturing cost is low, the detachment is simple, and the like.

Owner:曾治忠

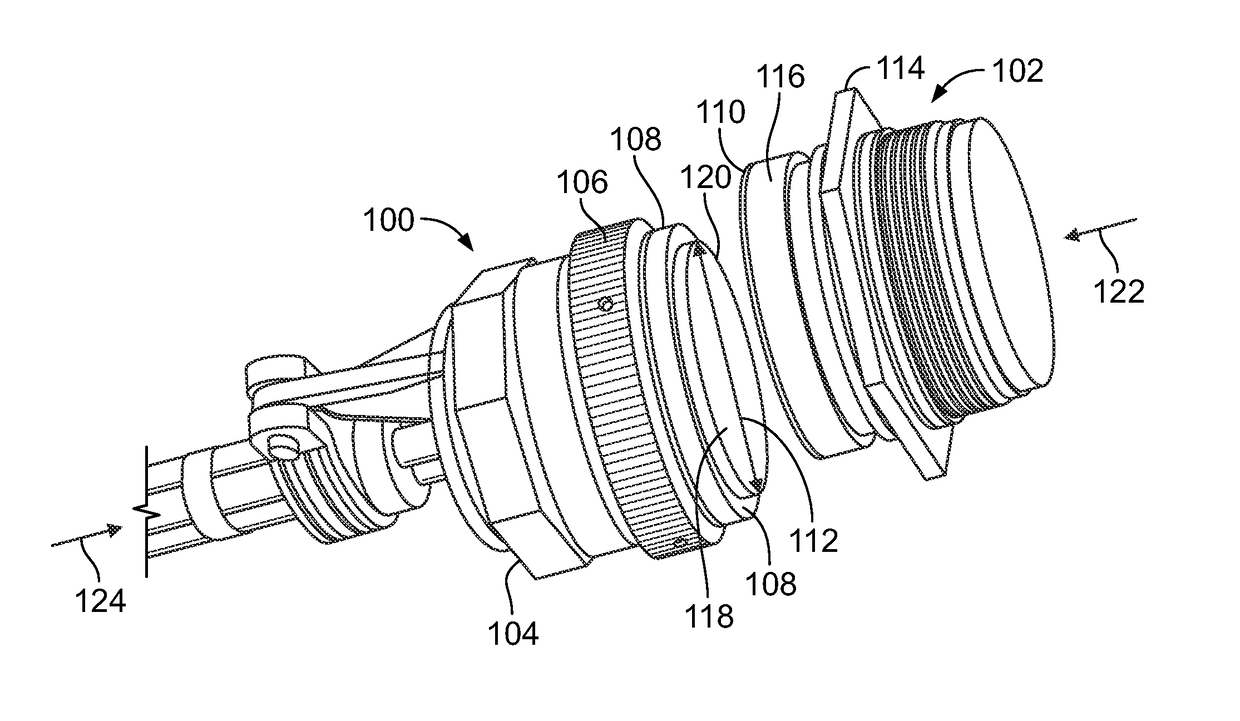

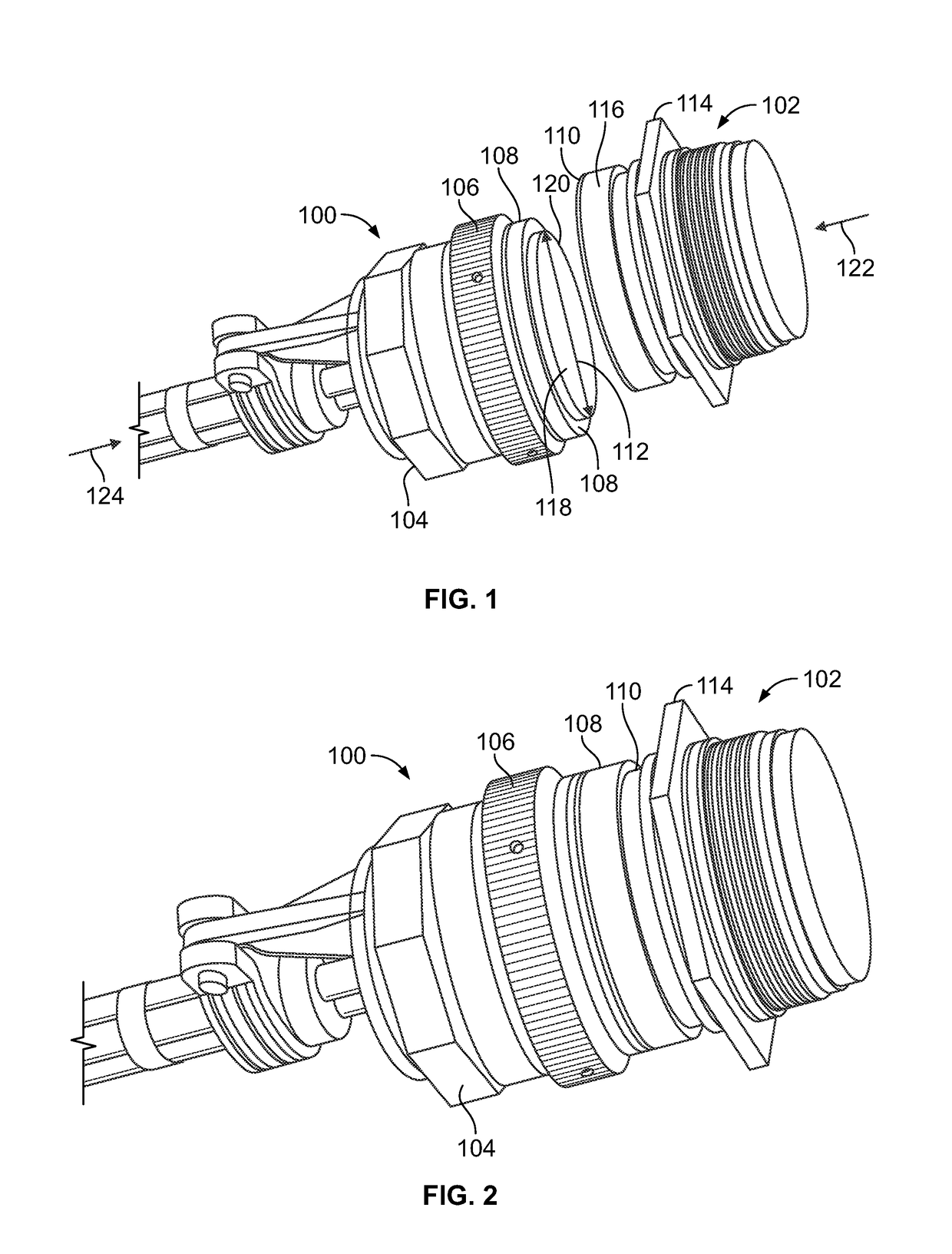

Test connector retaining harness assembly

ActiveUS9689895B2Engagement/disengagement of coupling partsVehicle connectorsEngineeringElectrical connector

An electrical system may include a first electrical connector configured to be coupled to an electrical panel, a second electrical connector configured to be coupled to a testing device that is configured to test components coupled to the electrical panel, and a retaining harness assembly that removably connects to the first and second electrical connectors to maintain a secure mating relationship between the first and second electrical connectors.

Owner:THE BOEING CO

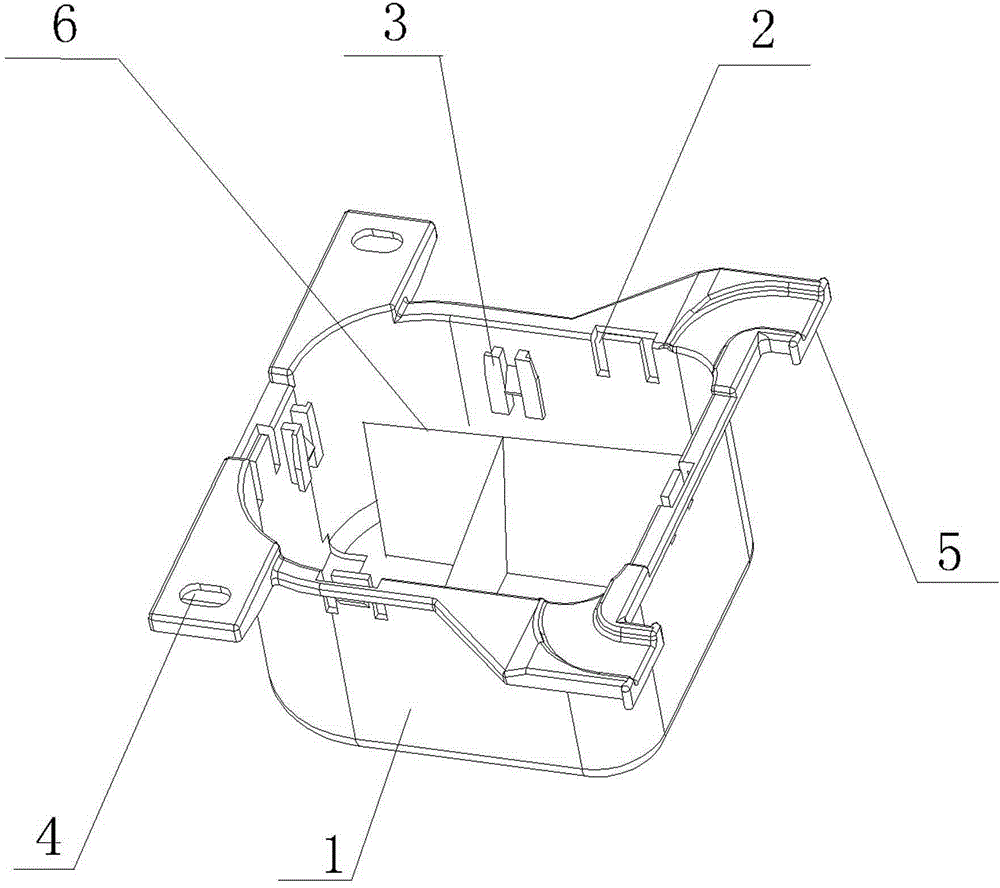

Concentrator for vehicle

InactiveCN104577897AShorten the lengthOptimized use of spaceElectrical apparatusButt jointEngineering

The invention relates to a concentrator for a vehicle. The concentrator specifically comprises a wire concentration box body. The wire concentration box body is a main box body with the upper end open. Wire harness guide slots are formed in the two adjacent corners of the wire concentration box body. The other two corners of the wire concentration box body are each provided with a supporting lug outwards. The two supporting lugs are provided with locating holes used for fixing the wire concentration box body. The edge of the inner side of the wire concentration box body is provided with locating buckles used for fixing the wire concentration box body. The inner side edge of the wire concentration box body is provided with assembling buckles used for fixing wire harness butt joint sockets. Partition plates used for separating wire harnesses are arranged in the wire concentration box body. According to the concentrator designed and matched for placing the wire harness, wire cables are isolated from the external environment and do not need to bypass the area when designed, the wiring difficulty is simplified, the length of the wire harnesses is reduced, the multiple wire harness butt joint sockets are centralized in a unified mode, and therefore the vehicle body space utilization is optimized.

Owner:杭州乐荣工业精密组件有限公司

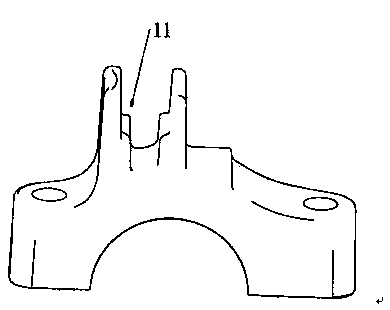

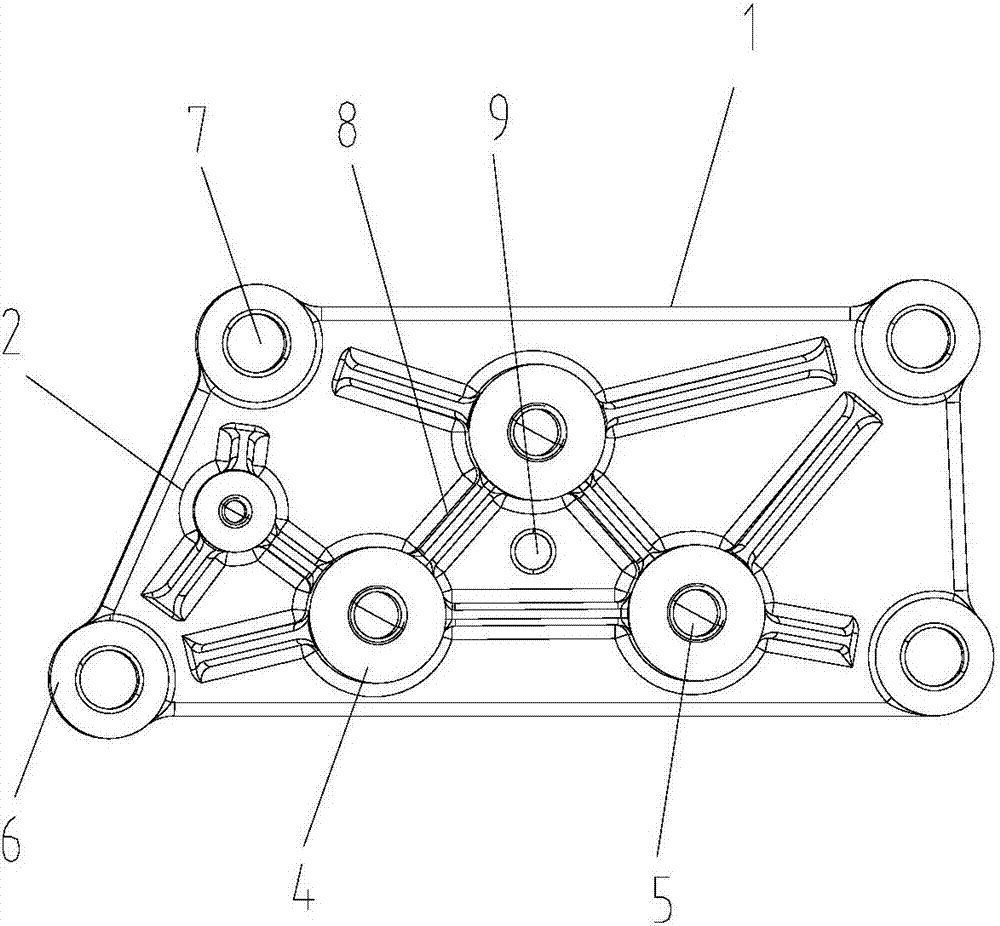

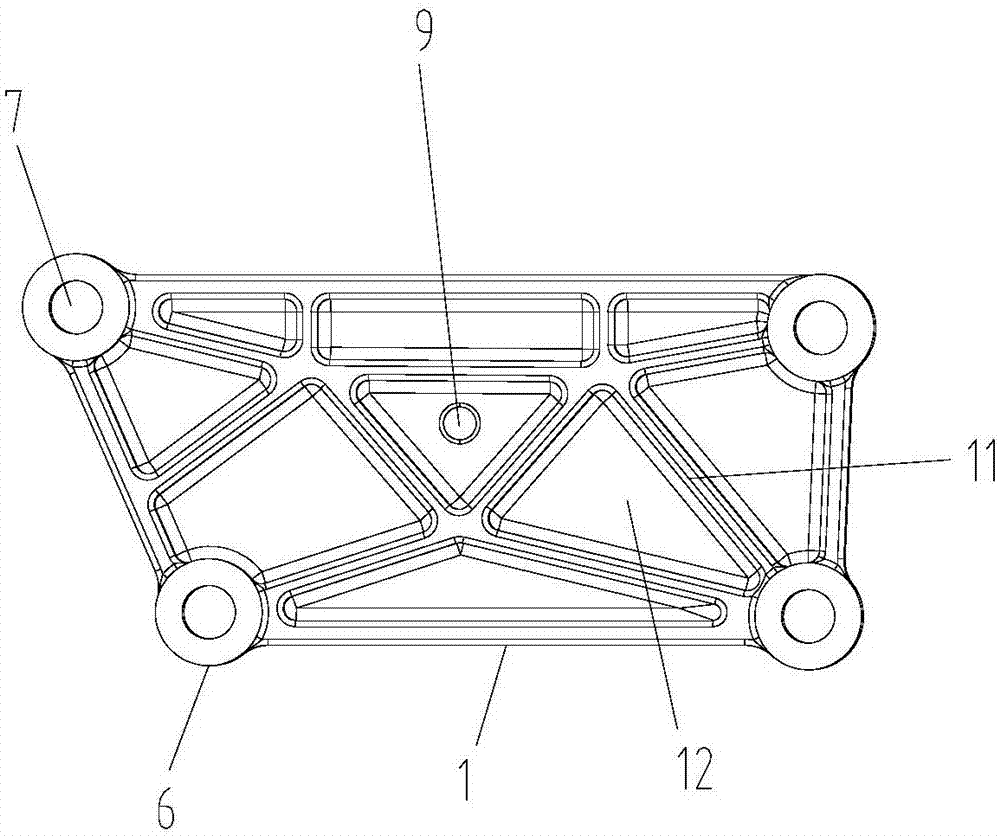

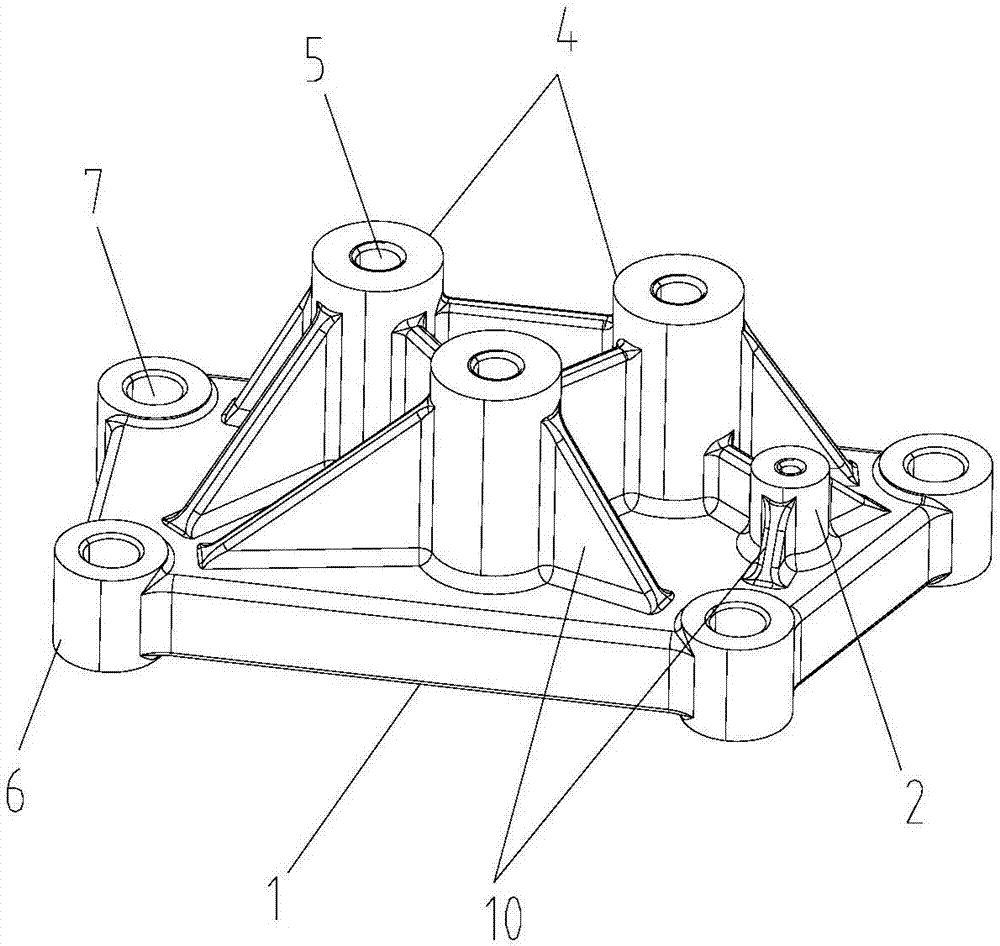

Automobile left suspension bracket capable of fixing wiring harness holder

PendingCN107962947AImprove connection stabilityHigh strengthJet propulsion mountingInternal combustion mountingRetaining harnessCable harness

The invention discloses an automobile left suspension bracket capable of fixing a wiring harness holder. The automobile left suspension bracket capable of fixing the wiring harness holder comprises asupport plate. The support plate is provided with an engine connecting part used for connecting with an engine and a cushion connecting part used for connecting with a left suspension cushion component. The support plate is further provided with a wiring harness holder connecting part used for connecting with the wiring harness holder. The automobile left suspension bracket capable of fixing the wiring harness holder is provided with the wiring harness holder connecting part. The bracket can be used for fixing the wiring harness holder. Structures of the engine and the wiring harness holder can be simplified, the number of engine parts is thereby effectively reduced, and the engine structure is more compact. The automobile light weight can be conveniently realized, and the manufacturing cost of the engine is reduced. In addition, the automobile left suspension bracket capable of fixing the wiring harness holder has the higher strength, and is capable of improving the connection stability of the wiring harness holder.

Owner:CHONGQING SOKON IND GRP CO LTD

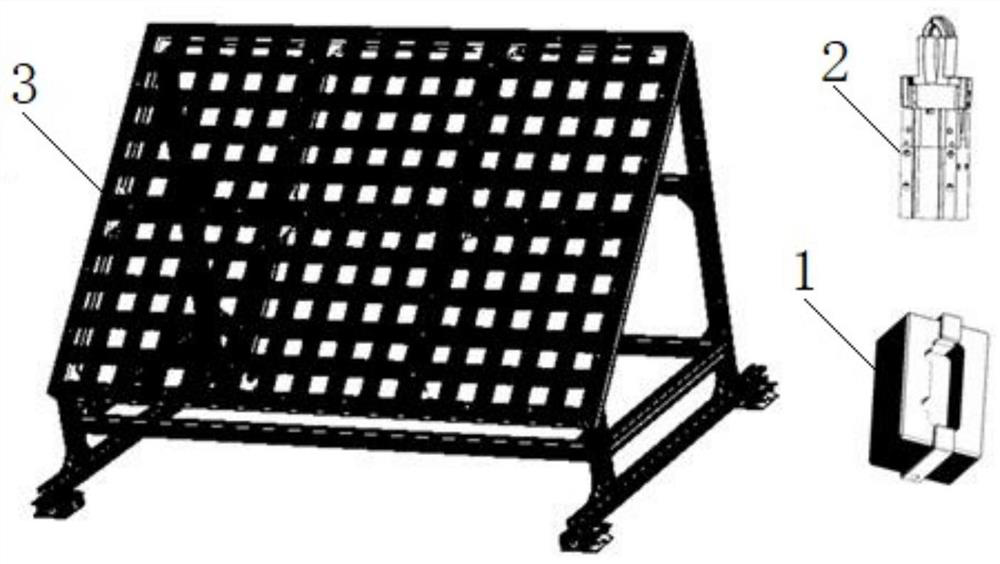

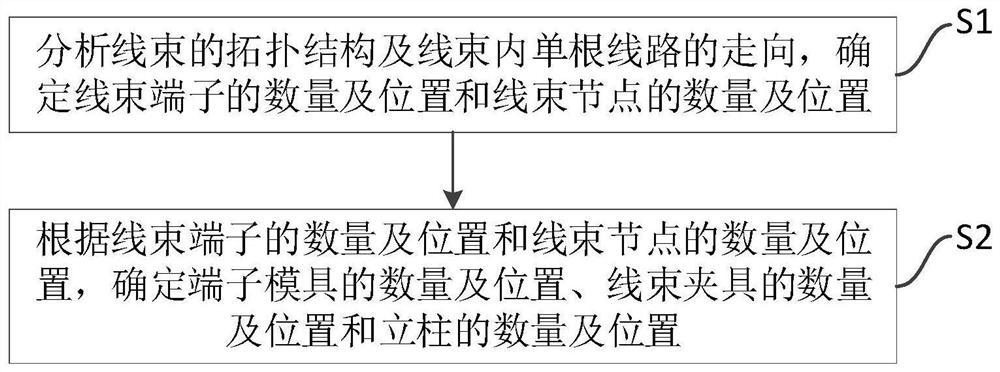

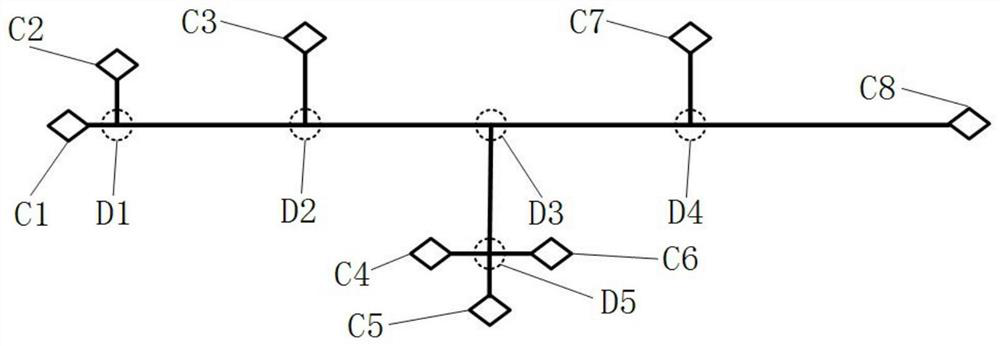

Route planning method for automatic wiring of wiring harnesses

InactiveCN112038971AIncrease productivityHigh product consistencyLine/current collector detailsCable installation apparatusRoute planningIndustrial engineering

The invention discloses a path planning method for automatic wiring of a wire harness, and the method comprises the steps: S1, analyzing the topological structure of the wire harness and the trend ofa single line in the wire harness, and determining the number and positions of wire harness terminals and the number and positions of wire harness nodes; and S2, determining the number and the positions of terminal molds, the number and the positions of wiring harness clamps and the number and the positions of stand columns according to the number and the positions of wiring harness terminals andthe number and the positions of wiring harness nodes. The terminal mold for fixing the wiring harness terminal is arranged at the position of the corresponding wiring harness terminal; At least one wire harness clamp for clamping a wire harness is arranged at a position between two adjacent wire harness nodes; and a stand column used for gathering the wire harnesses towards a preset direction is arranged at the position of each wire harness node. The method has the advantages of being simple in process and high in universality in advance, a manual installation mode can be replaced, and the wire harness production efficiency and the product consistency are improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

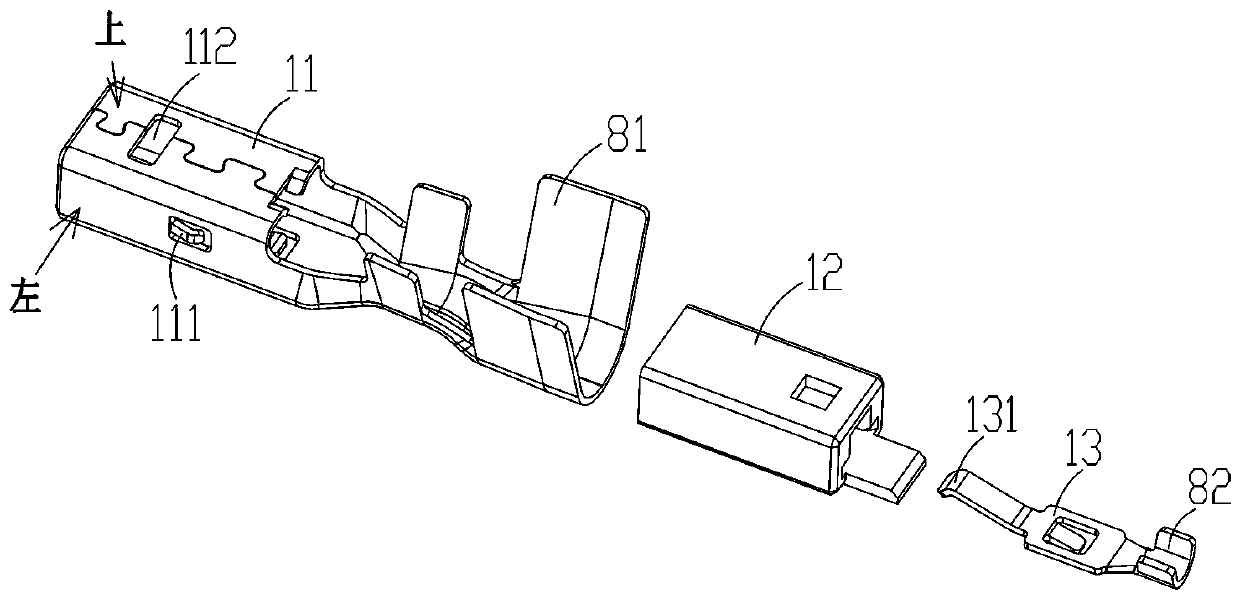

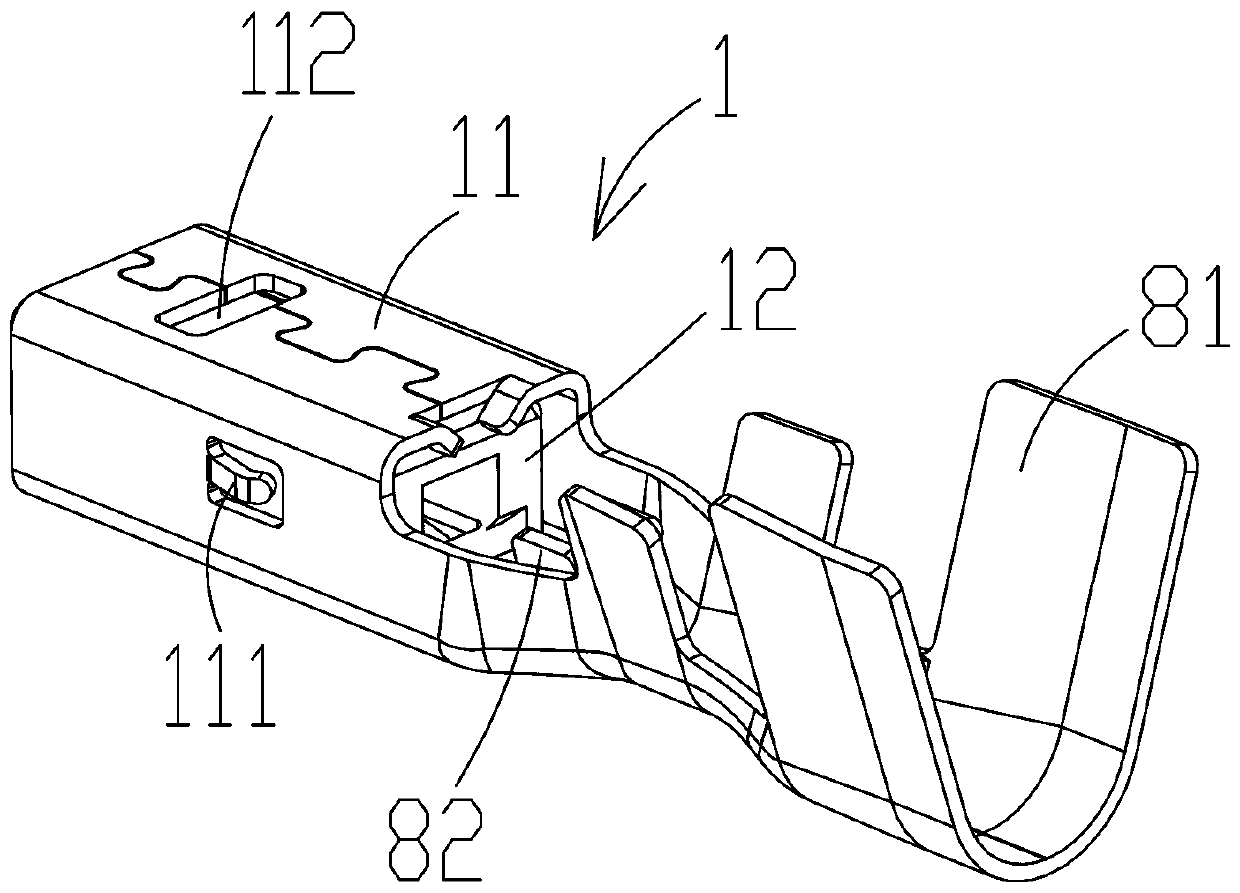

Automotive RF male connector and female connector and connector assembly

PendingCN107834255AFirmly connectedFixed connection, in the present invention, the RF antenna is connected byCoupling device detailsTwo-part coupling devicesCable harnessElectrical and Electronics engineering

The invention discloses an automotive RF male connector and female connector and a connector assembly. The male connector comprises a male seat housing, male seat plastic and a male seat terminal, wherein a first U-shaped fixing structure for accommodating a wire harness and fixing the wire harness is arranged at one end of the male seat housing; the front end and the rear end of the male seat plastic are penetrated; the male seat plastic is arranged in the male seat housing; the male seat terminal stretches into the male seat plastic; a second U-shaped fixing structure for accommodating the wire harness and fixing the wire harness is arranged at one end, corresponding to the first U-shaped fixing structure, of the male seat terminal; the male seat terminal is electrically connected with awire core; and a first contact end which is used for being in contact with a female seat terminal and being electrically connected with the female seat terminal is arranged at the other end of the male seat terminal. The automotive RF male connector has the advantages that connection between an RF antenna and a PCB is more firm and the automotive RF male connector is small in insertion force, large in drawing force and more convenient to assemble and disassemble.

Owner:深圳市百莲科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com