Fastening device used for fixing cable

A technology for fastening devices and fixing wires, which is applied in the direction of electrical components, etc., can solve the problems of low assembly efficiency, lengthened working hours, and increased manufacturing costs, and achieve the effects of saving costs, high assembly efficiency, and avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

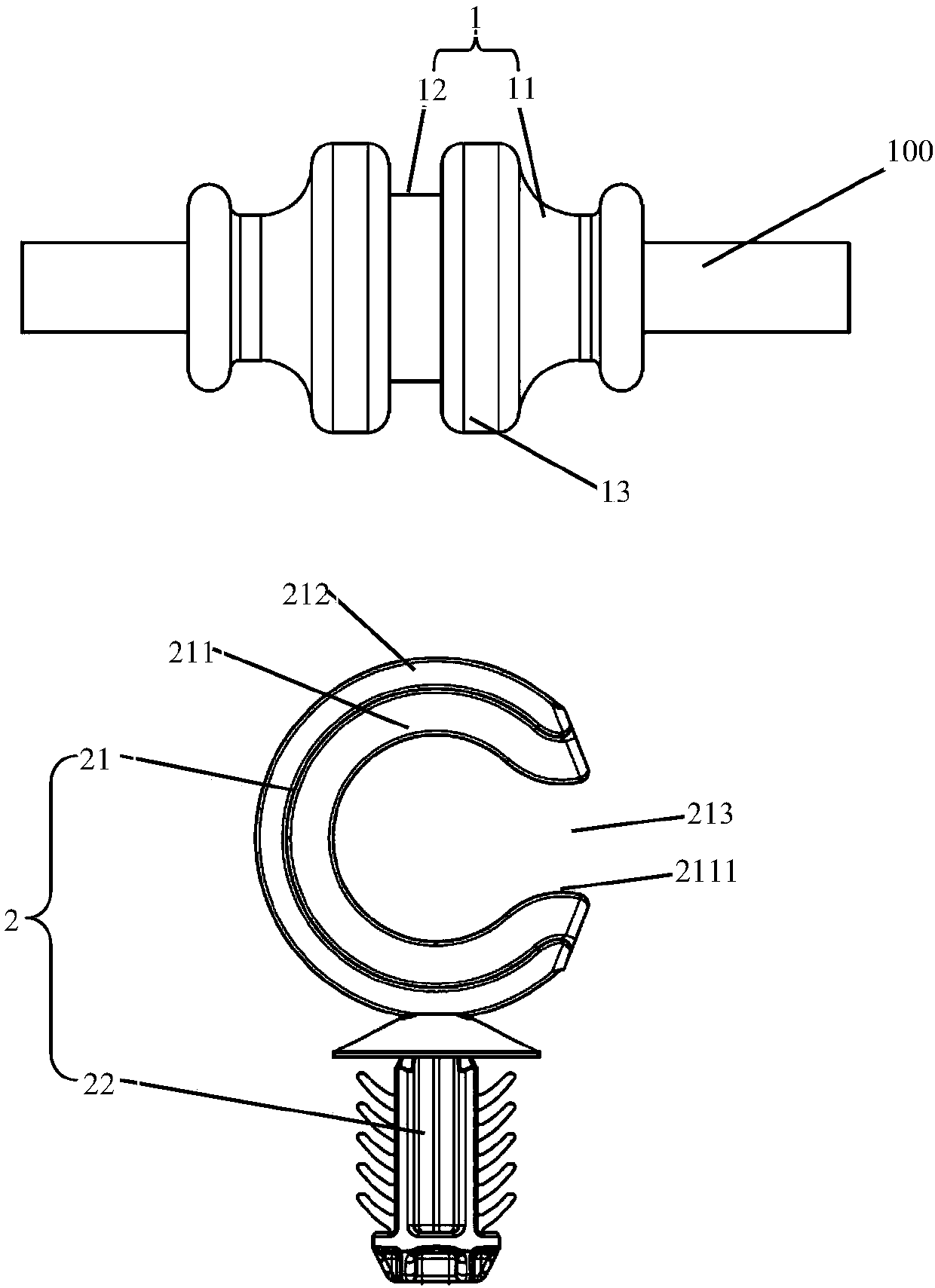

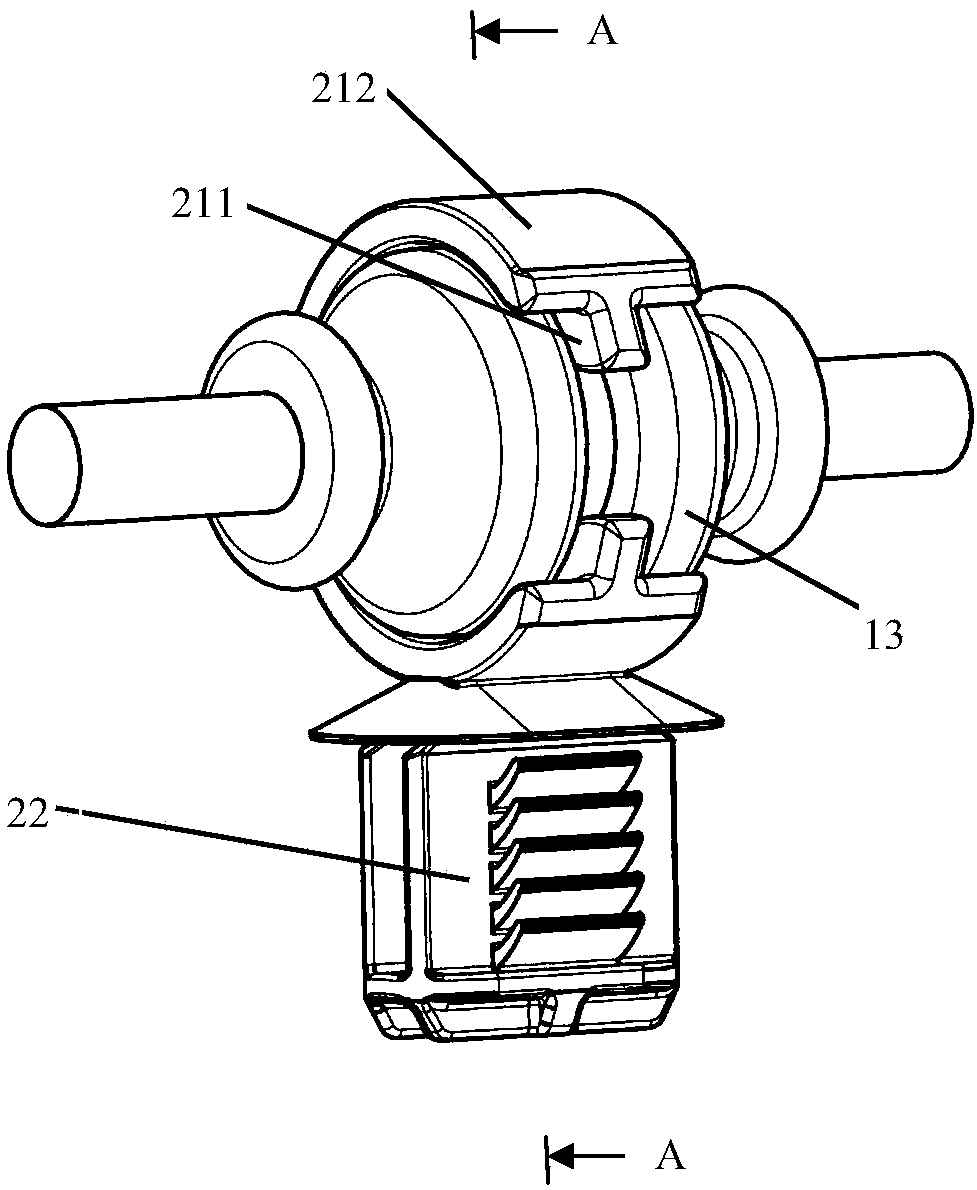

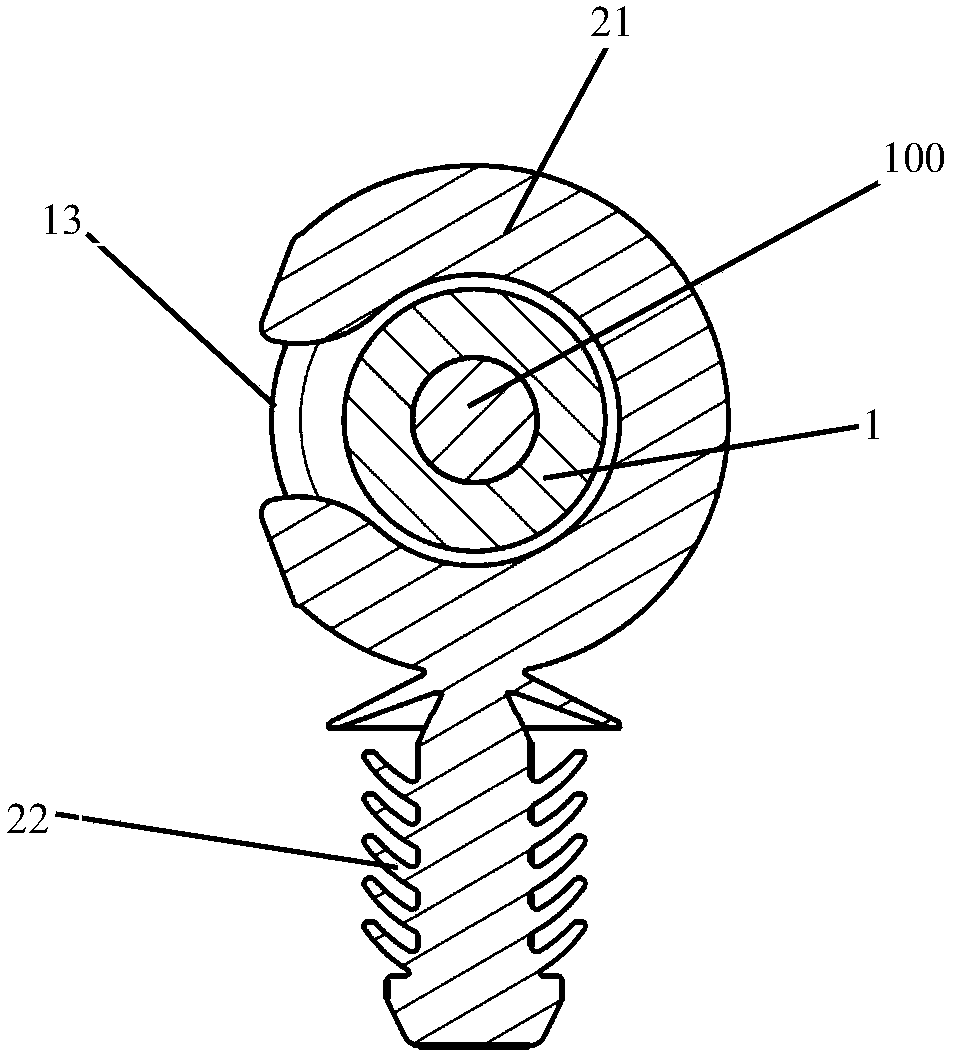

[0024] see Figure 1 to Figure 3 , the fastening device for fixing the wire harness 100 includes a locking piece 1 and a fixing piece 2 , the locking piece 1 is made of rubber, and is fixed to the wire harness 100 by injection molding. The fixing part 2 is one piece and is injection molded from nylon. The locking part 1 includes a locking part 11 and a first guiding part 12 for fixing the wire harness 100, and the fixing part 2 includes a second guiding part 21 and a holding part for connecting the fastening device to a fixed position 22 , the first guide part 12 is slidingly matched with the second guide part 21 so as to guide the fixing part 2 to rotate axially around the wire harness 100 . When assembling, rotating the fixing part 2 according to the actual situation can effectively avoid twisting of the wire harness, and the cost is low and the assembly is convenient.

[0025] The first guide part 12 is a guide groove extending circumferentially along the locking member 1...

Embodiment 2

[0028] see Figures 4 to 6 , the difference between this embodiment and Embodiment 1 is that the second guide part 21 has two sections 210, one side of the two sections 210 is connected by a hinge part 215, and the other side is connected by an open or The locking latch mechanism 216 is connected. The locking mechanism 216 includes a buckle part 217, two position-limiting parts 218 cooperating with the buckle part 217, and a buckle slot 219 for accommodating the buckle part 217. The buckle part 217 has a guide surface 2171, and two position-limiting parts The part 218 is oppositely disposed and has a guide surface 2181. The locking mechanism 216 also includes an elastic arm 214, wherein a limiting part 218 is arranged at the end of the elastic arm 214. When the elastic arm 214 is not elastically deformed, the two The spacing between each limiting portion 218 is smaller than the width of the locking portion 217 . When assembling, the fixing part 2 is sleeved on the locking pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com