Patents

Literature

645results about How to "Effective drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Droplet extraction from a liquid column for on-chip microfluidics

InactiveUS8304253B2Effective drainageAvoid distortionSemi-permeable membranesWithdrawing sample devicesMicrofluidicsDistortion

Owner:ADVANCED LIQUID LOGIC

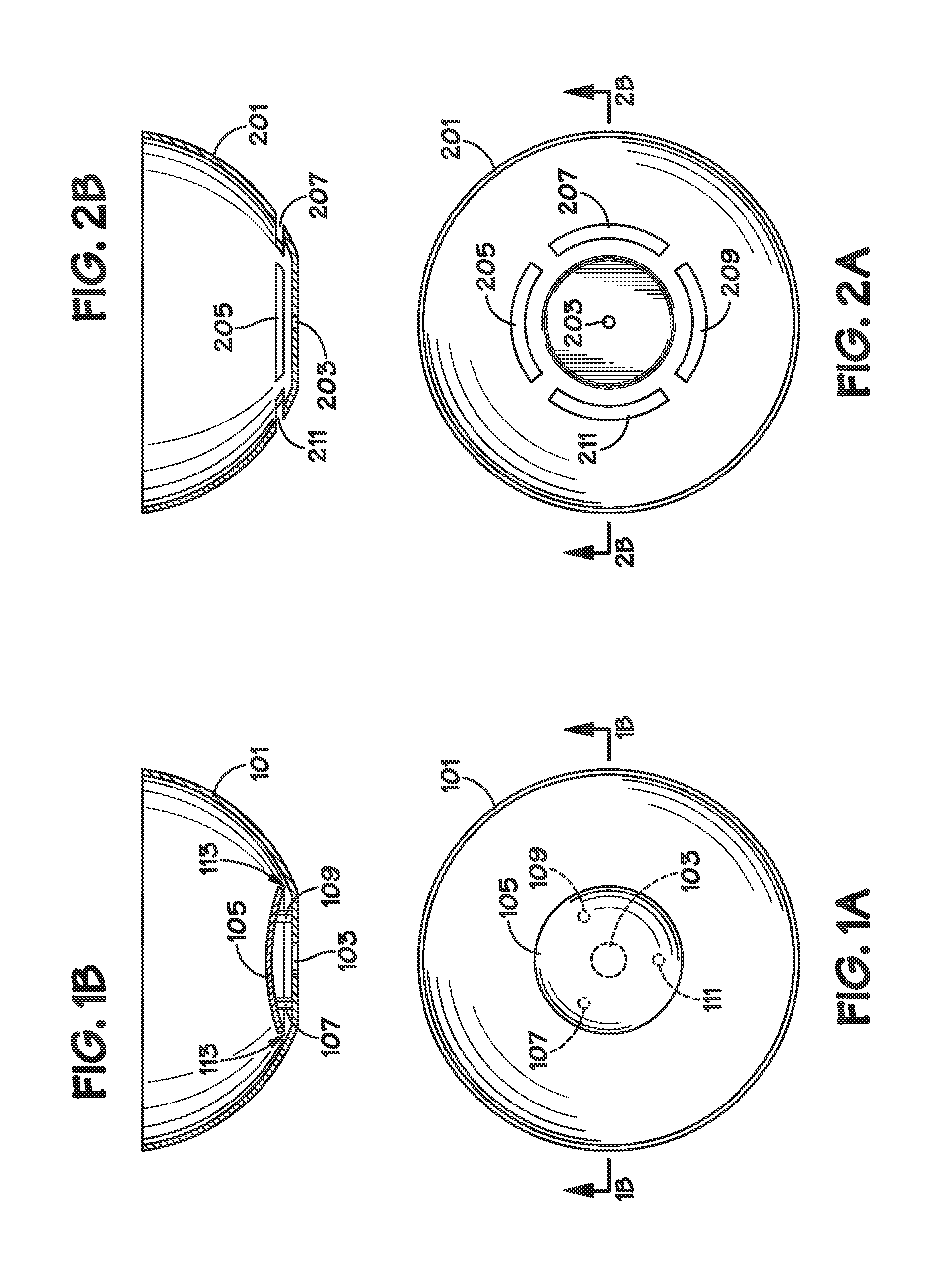

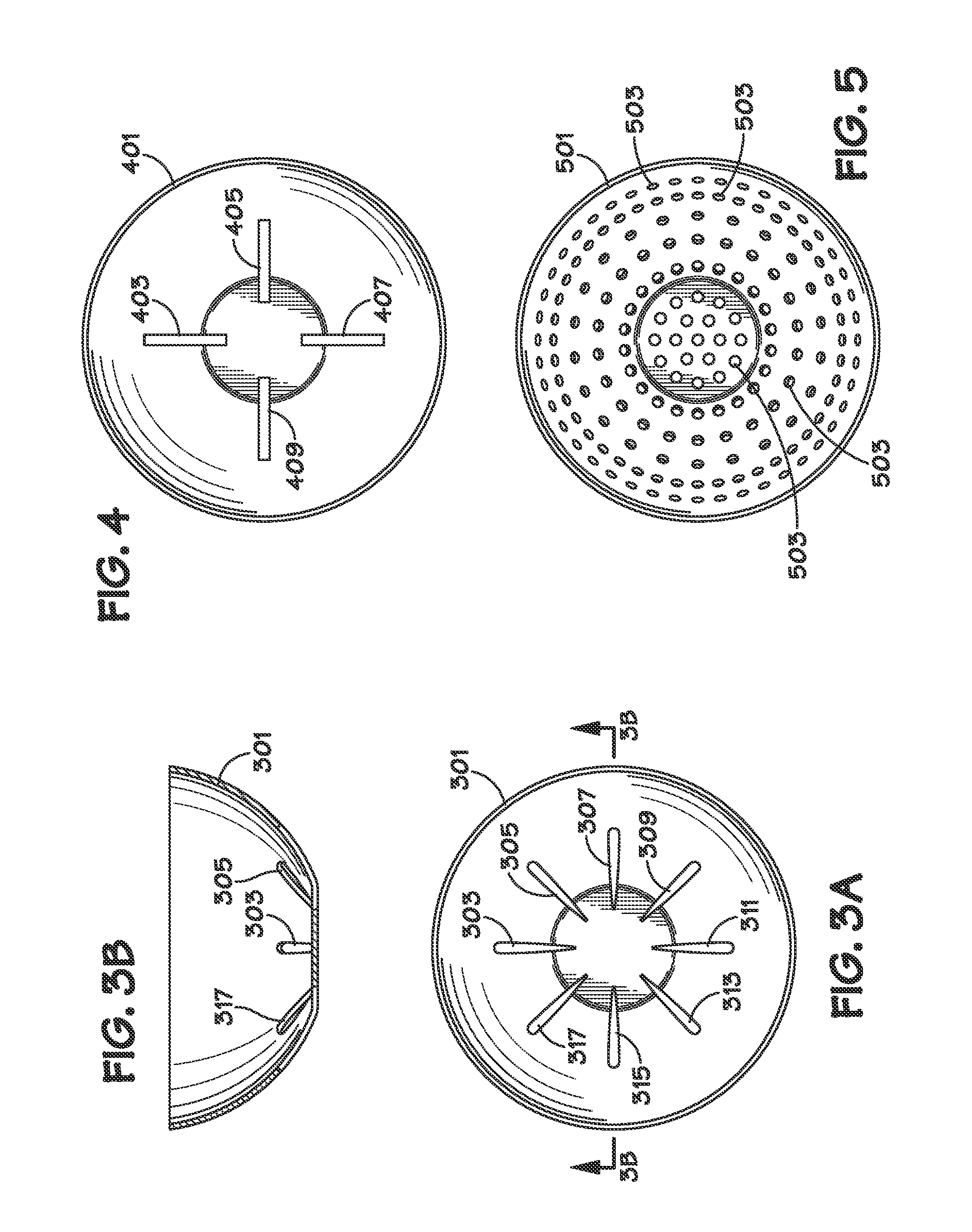

Droplet extraction from a liquid column for on-chip microfluidics

InactiveUS20090014394A1Effective drainageAvoid distortionSemi-permeable membranesWithdrawing sample devicesMicrofluidicsDistortion

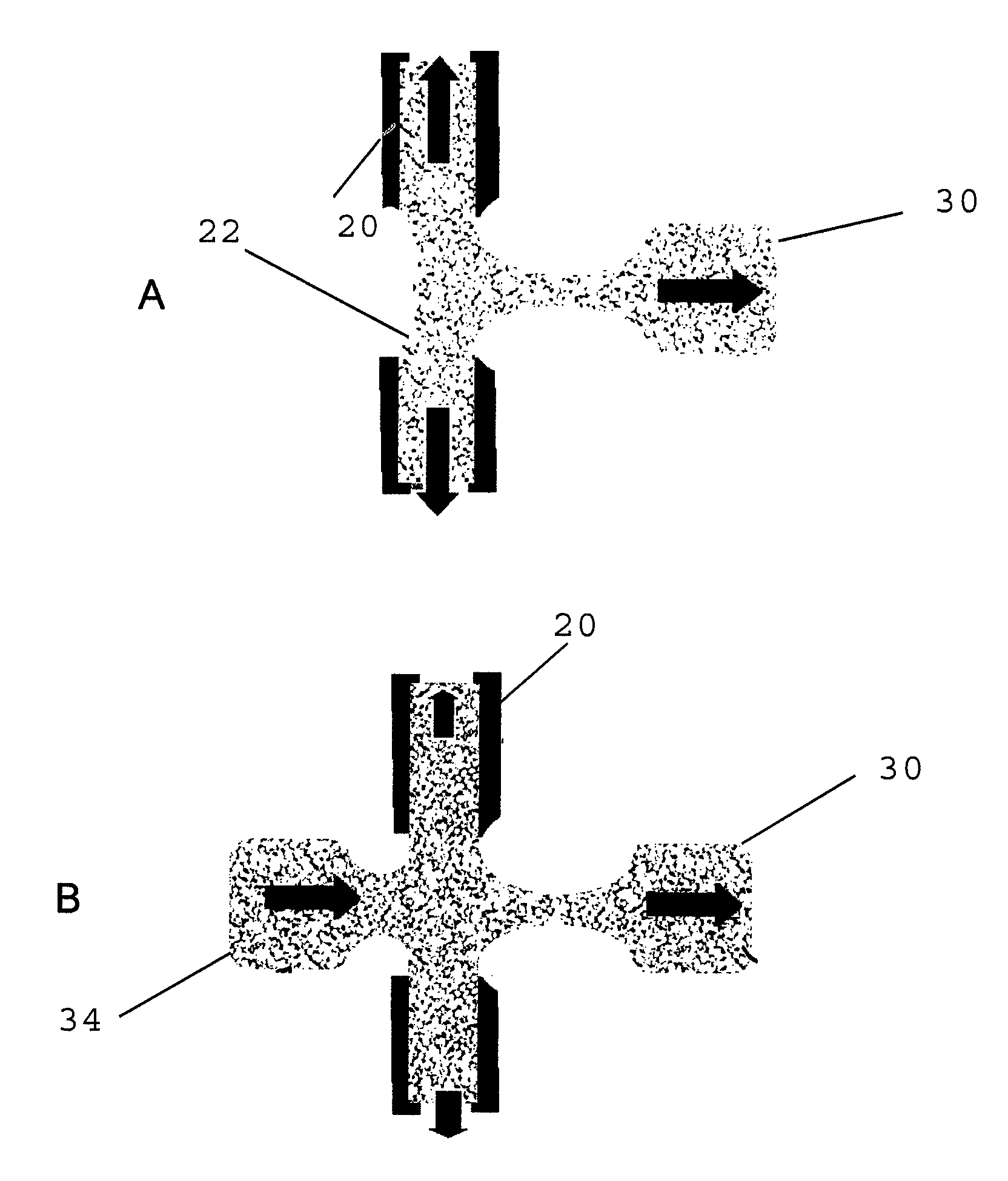

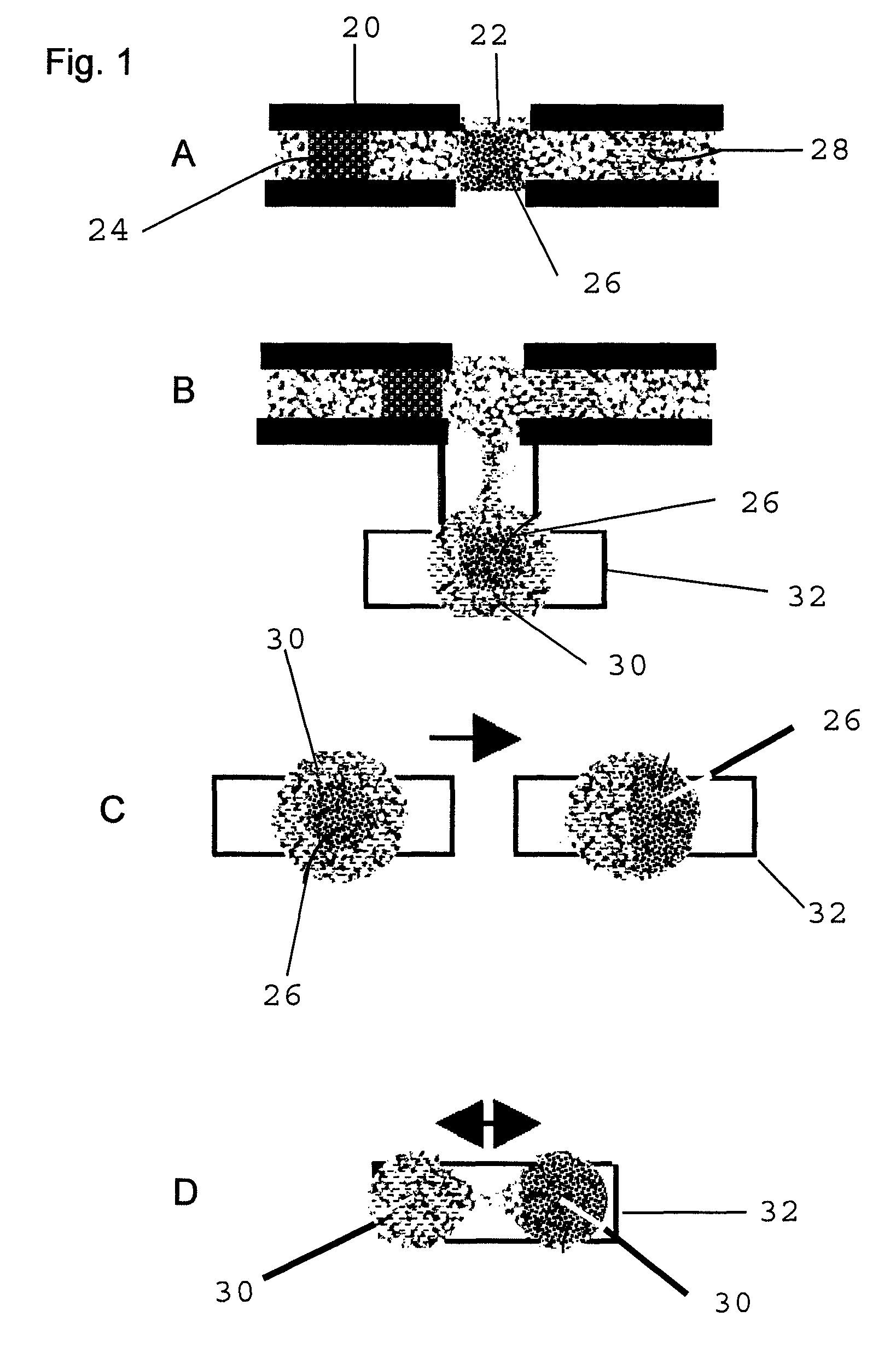

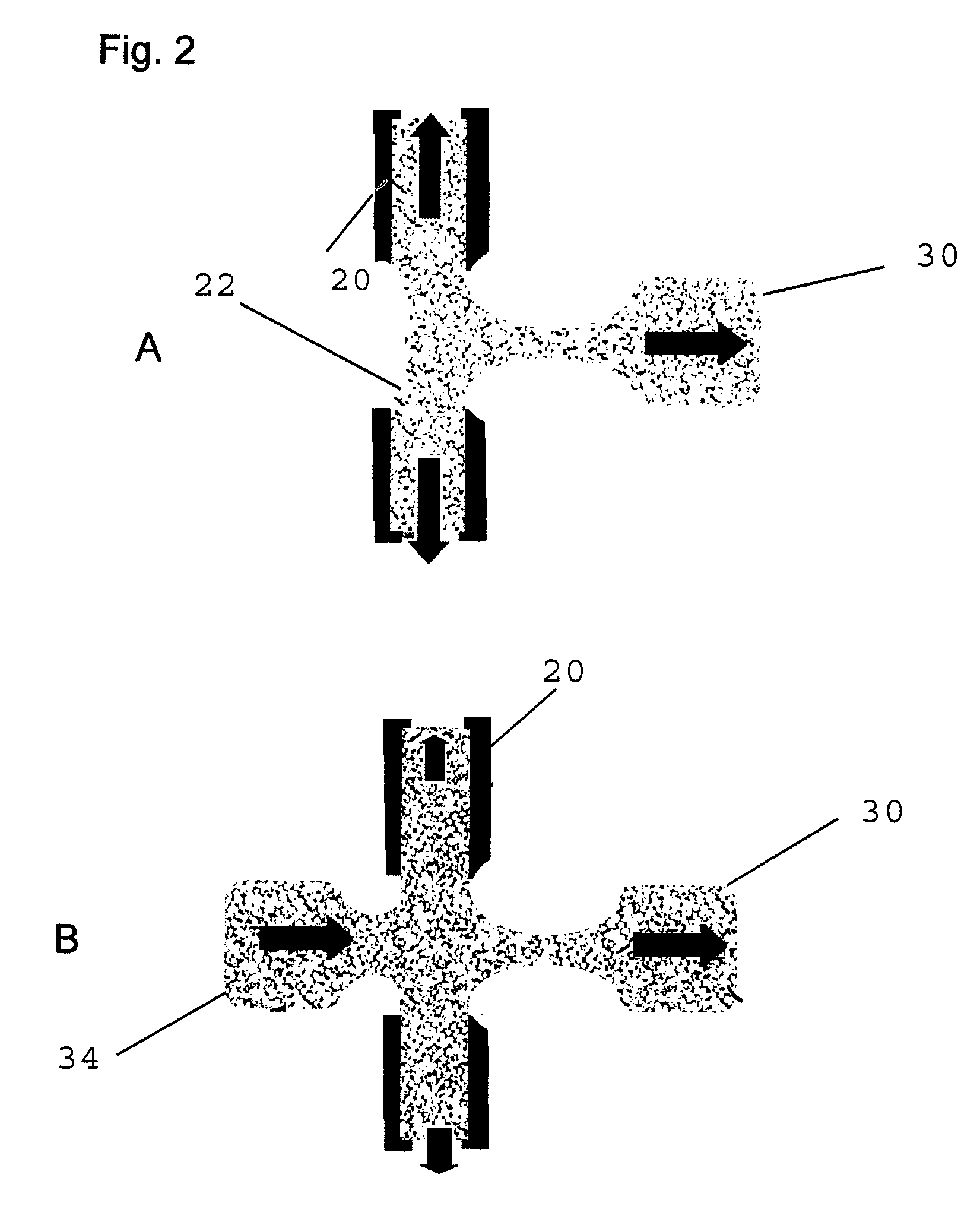

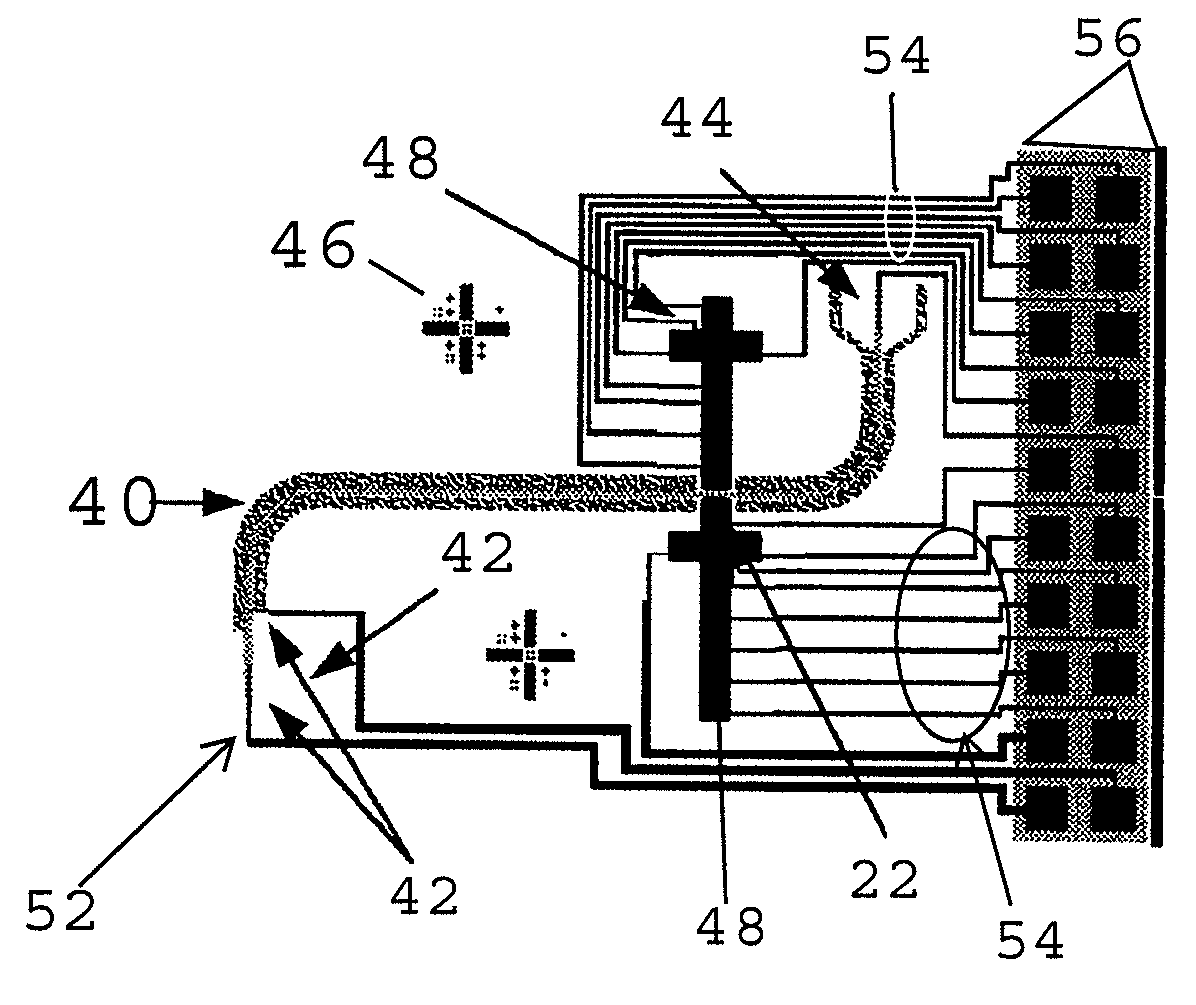

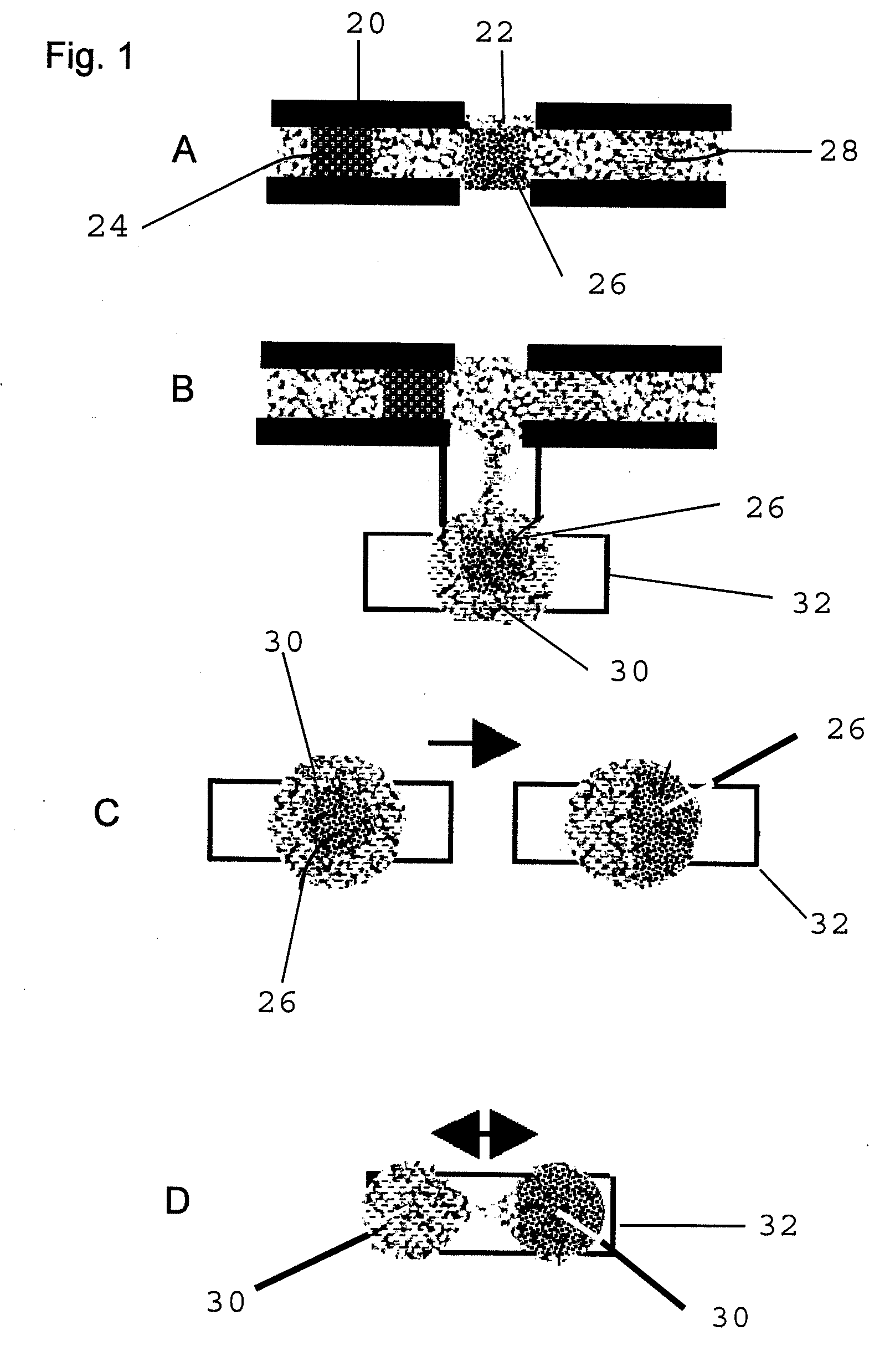

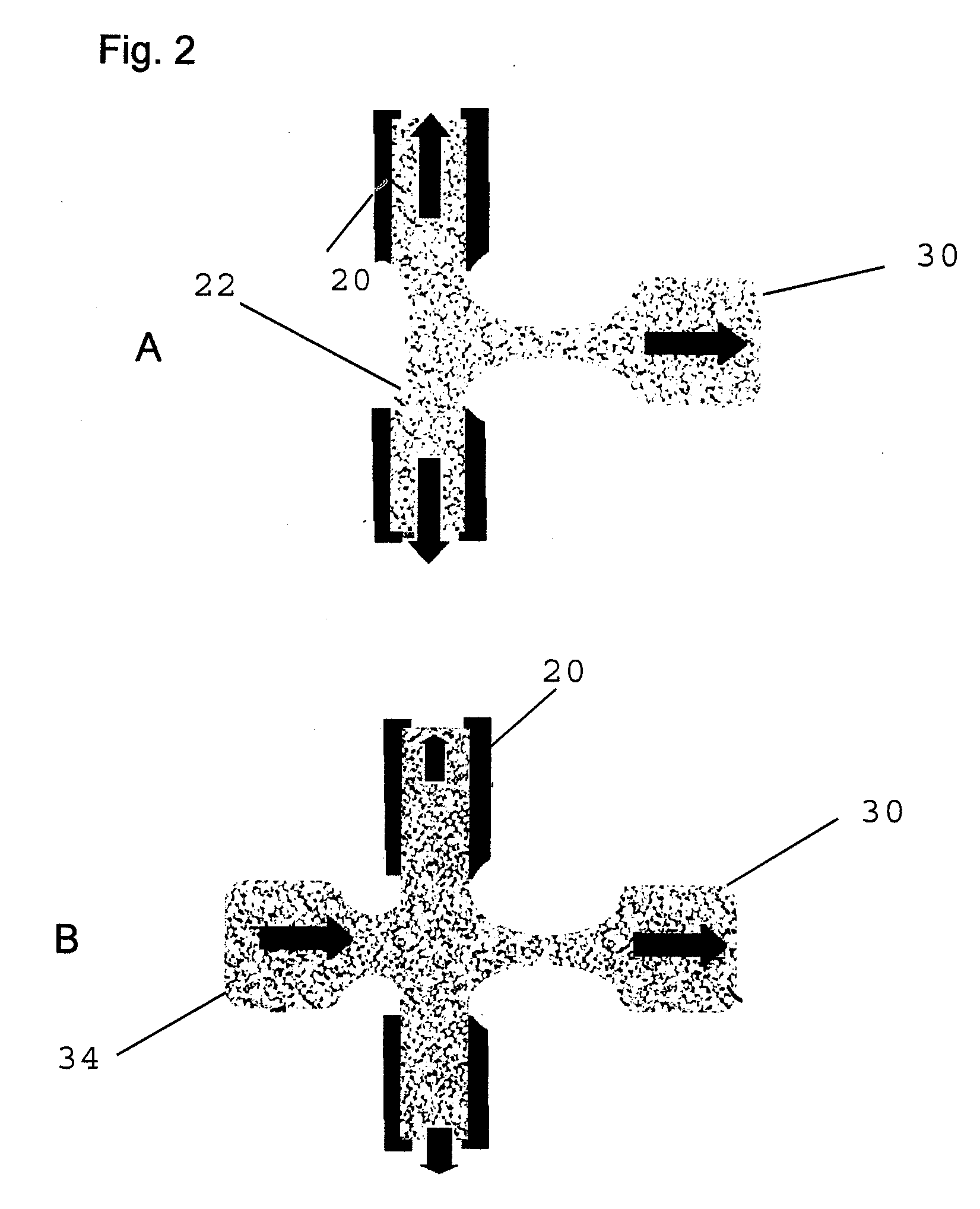

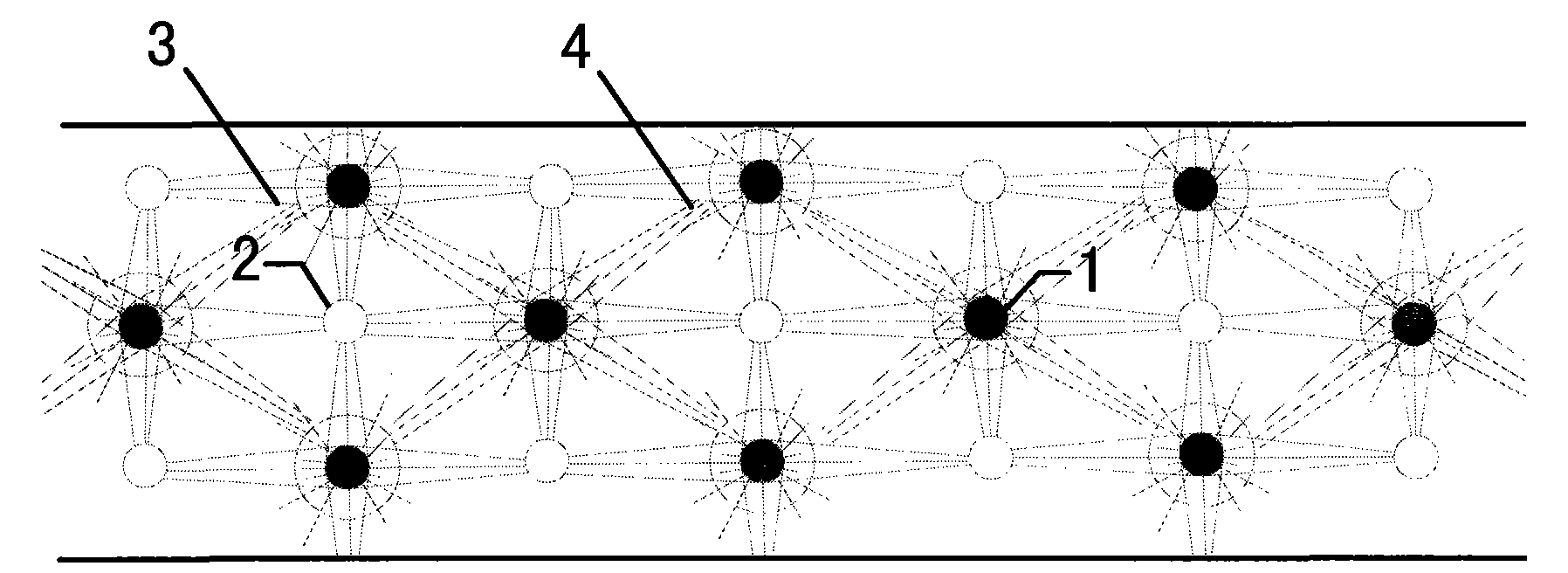

A refill droplet facilitates the extraction of a droplet laterally from a channel in a microfluidic apparatus. Such extraction allows a discrete band of separated particles or solute molecules to be excised from a fluid stream and processed and analyzed separately. An extraction point is located along the length of the channel and includes an EWOD surface or similar microfluidic technology to extract a droplet. An opening in the channel opposite the extraction means is equipped with microfluidic technology to transport a refill droplet to the opening. The refill droplet is moved into the channel or column to occupy the area previously occupied by the extracted droplet. This prevents distortion or mixing of the bands of particles or molecules within the channel and prevents the draining of any portion of the fluidic system.

Owner:ADVANCED LIQUID LOGIC

Bathroom floor panel

InactiveUS20080190048A1Prevent slippingReduce the average velocityTreadsFlooringWater flowEngineering

A bathroom floor panel for use in an airtight and water tight space is configured to be efficiently dried in a few hours under ambient conditions. When water drops onto the floor panel, the surface tension of the water is broken by irregular-shaped portions and the water spreads without forming waterdrops. Also, the irregular-shaped portions reduce the flow velocity of the water due to a gradient of the panel, so as to prevent the water flowing in channels to a drain from being discontinued. With this, although the drain velocity of the water is low, substantially no water remains as isolated drops. Further, even if some water remain on the irregular-shaped portions after the water flows out the channels to the drain, any amount of water remaining in the channels is evaporated in a relatively short period of time because the amount of the remaining water is very small.

Owner:TOTO LTD

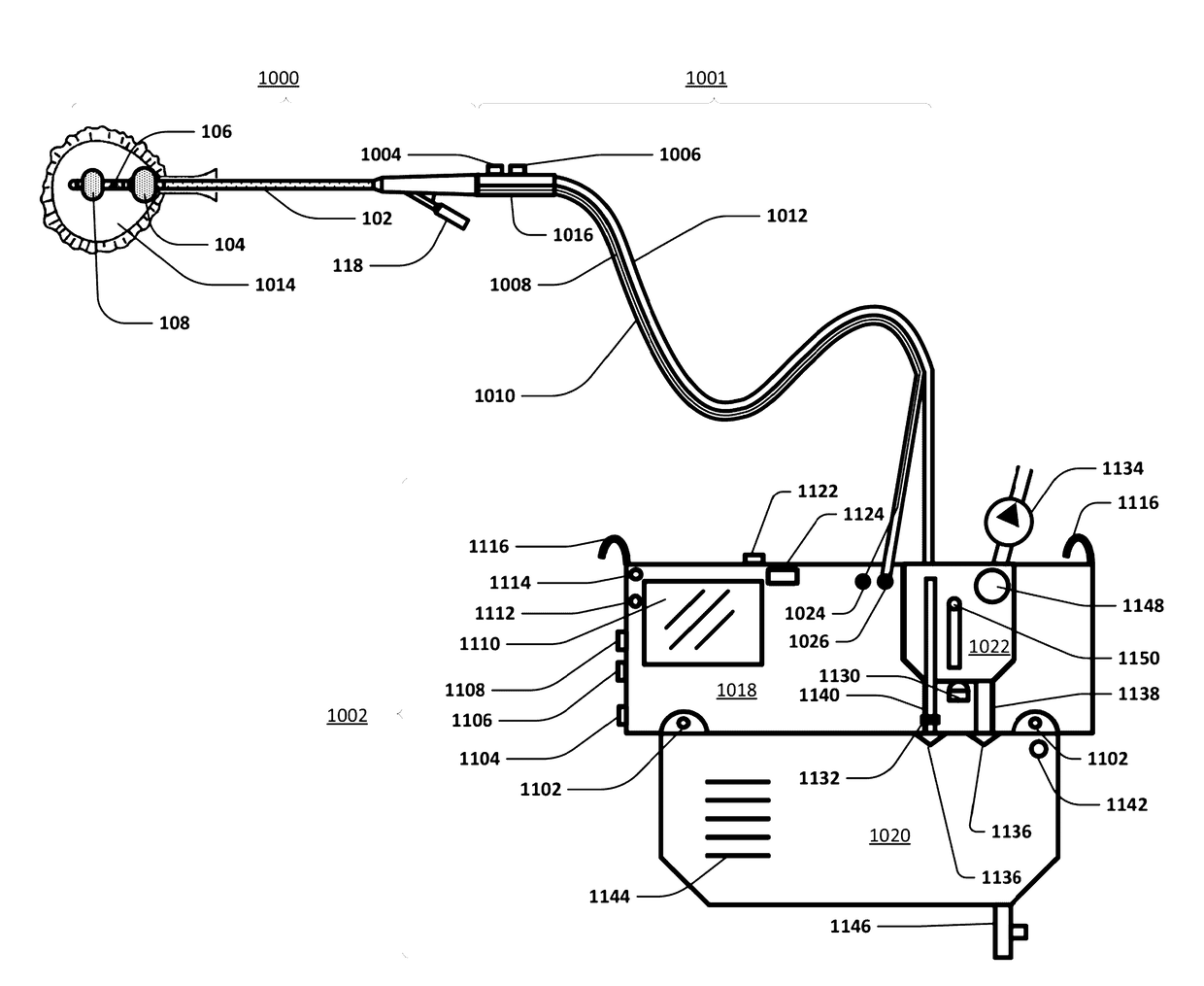

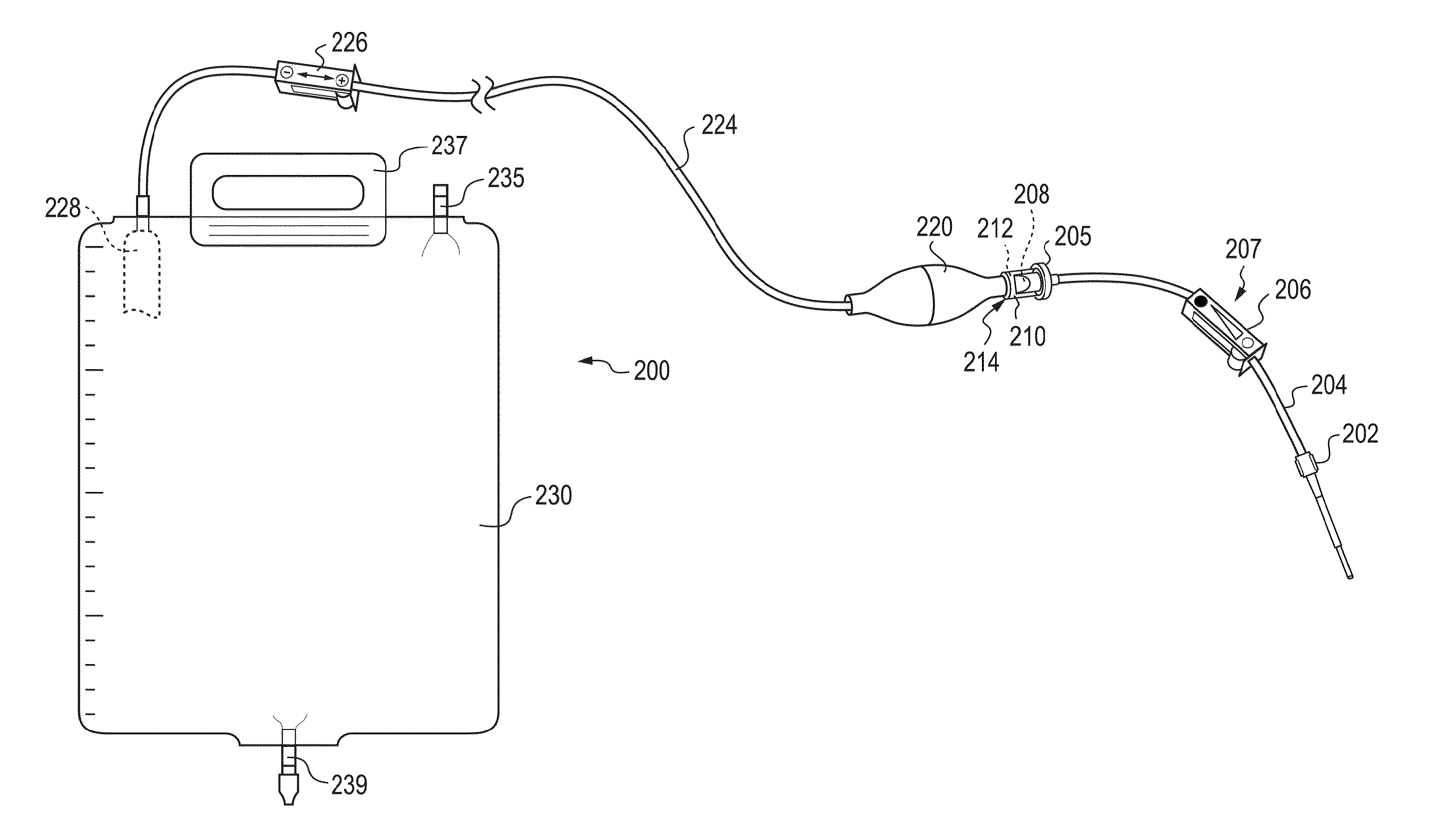

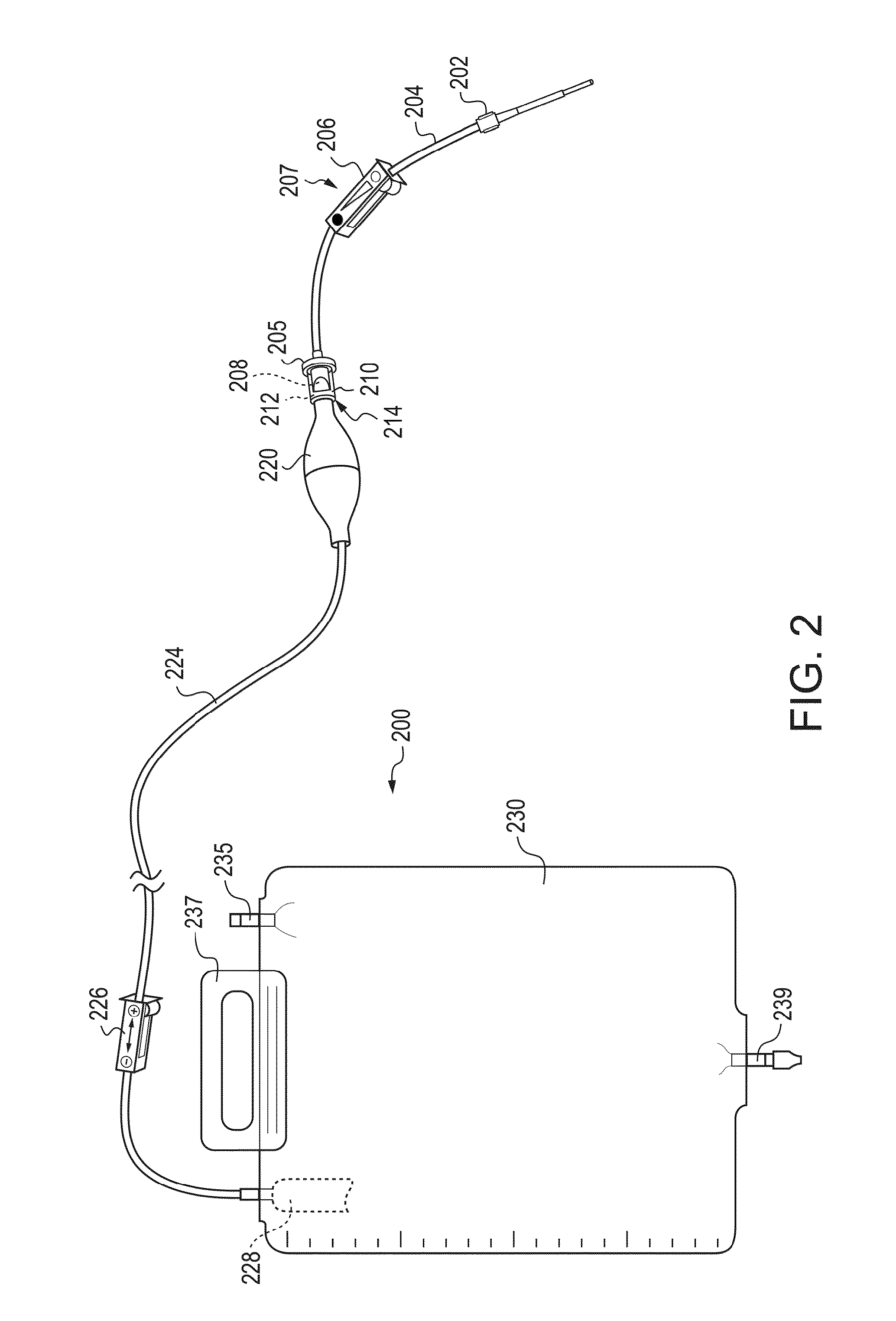

Systems, devices and methods for draining and analyzing bodily fluids

ActiveUS20170136209A1Avoid problemsUseful in detectionWound drainsMedical devicesPositive pressureEngineering

Systems, devices and methods for draining and analyzing bodily fluids are disclosed in which a drainage assembly is configured to prevent negative pressure build-up. The drainage assembly generally includes a catheter which may include a drainage lumen, a reservoir, a venting mechanism in fluid communication with the drainage lumen and a positive pressure lumen, and a controller. The venting mechanism may further include a valve which is configured to maintain a closed position, as well as a vent in fluid communication with the valve, where the venting mechanism is configured to inhibit wetting of the vent from fluid within the drainage lumen

Owner:POTRERO MEDICAL

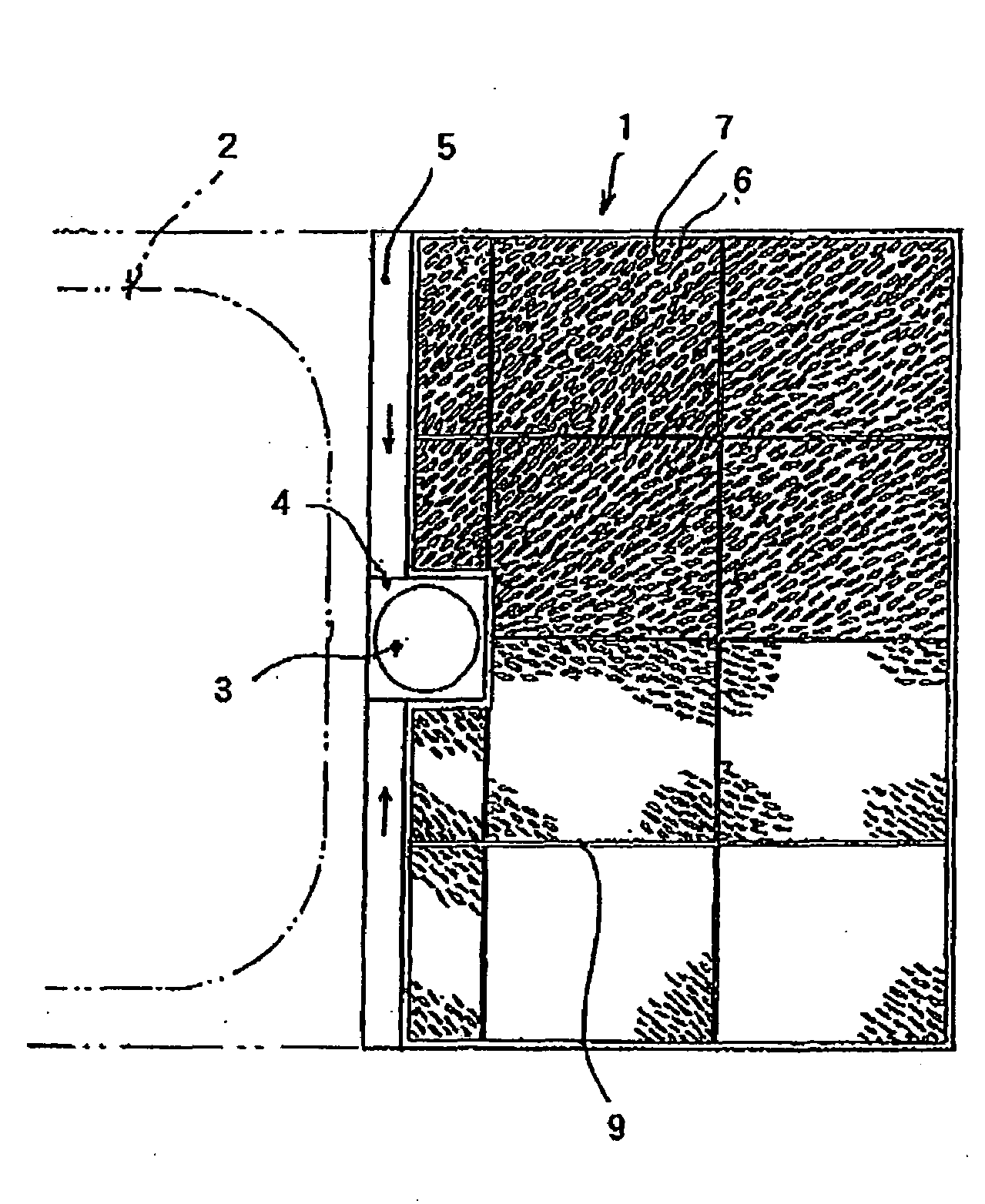

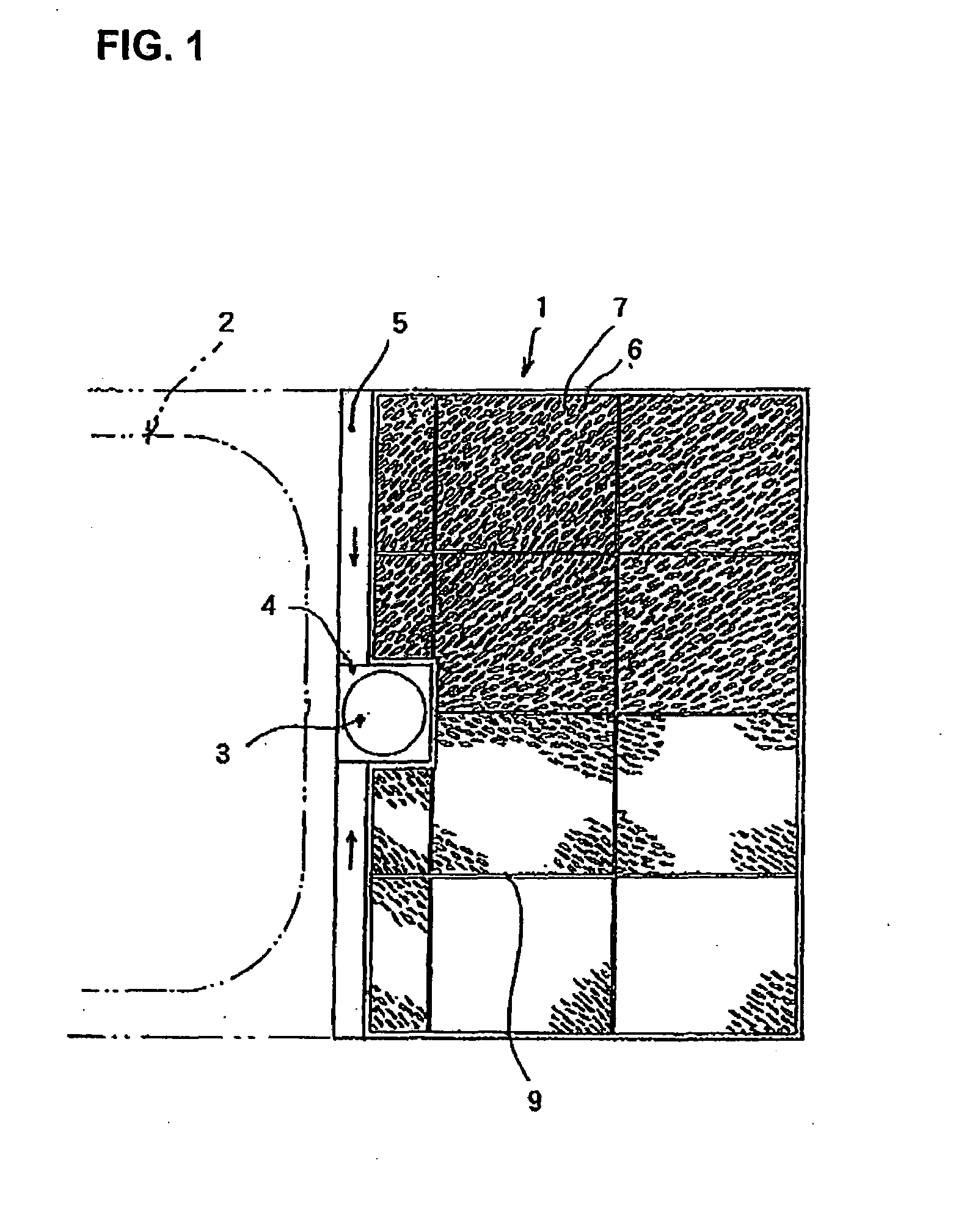

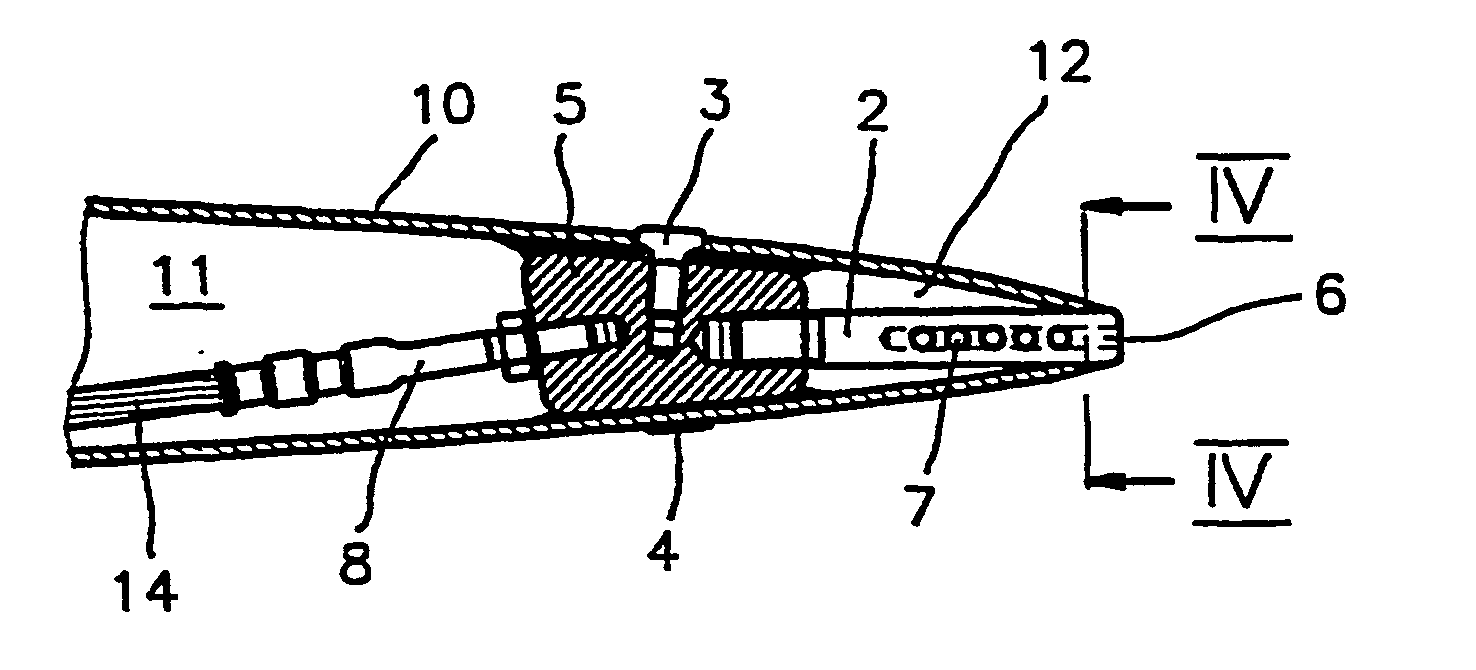

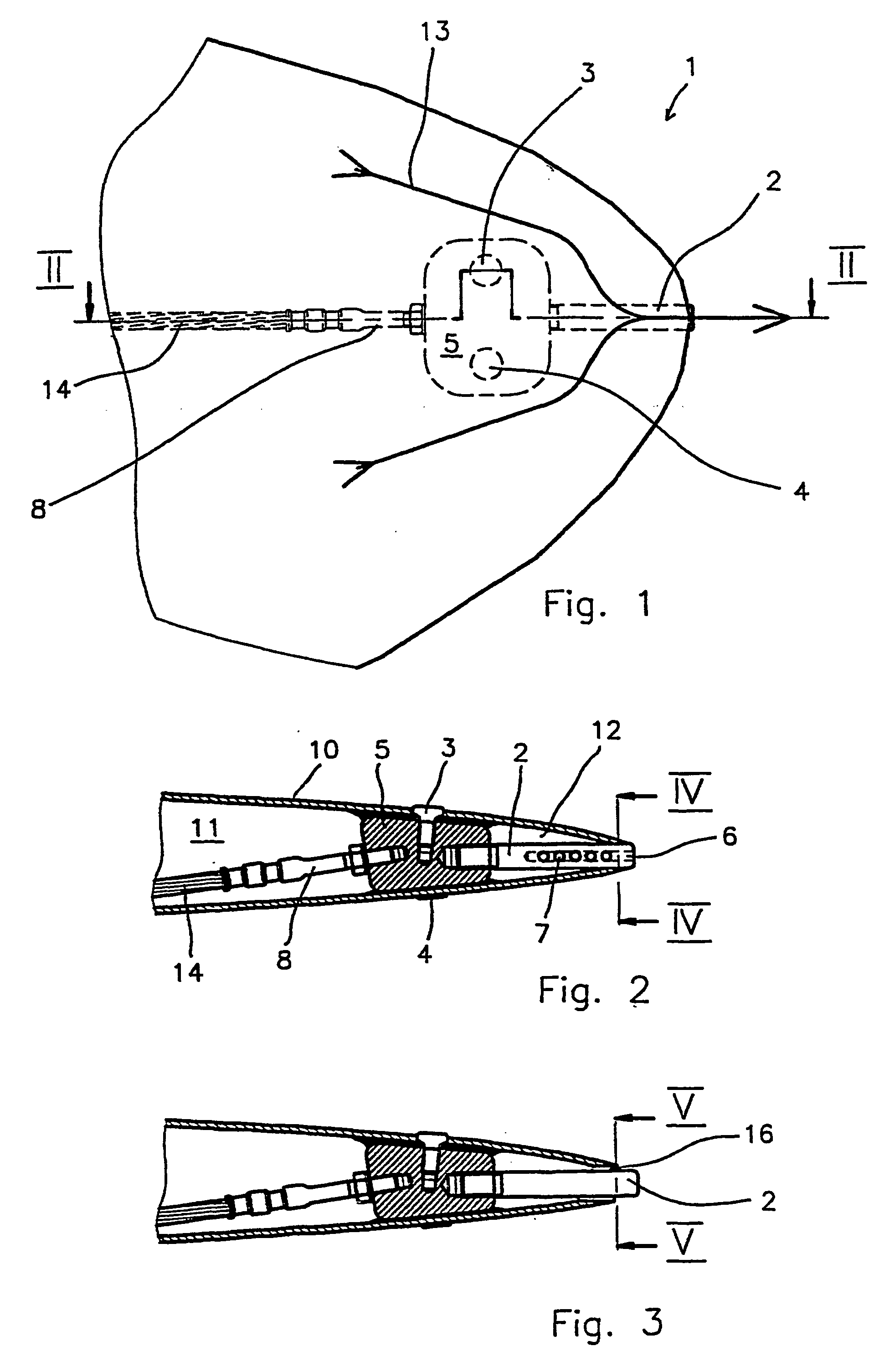

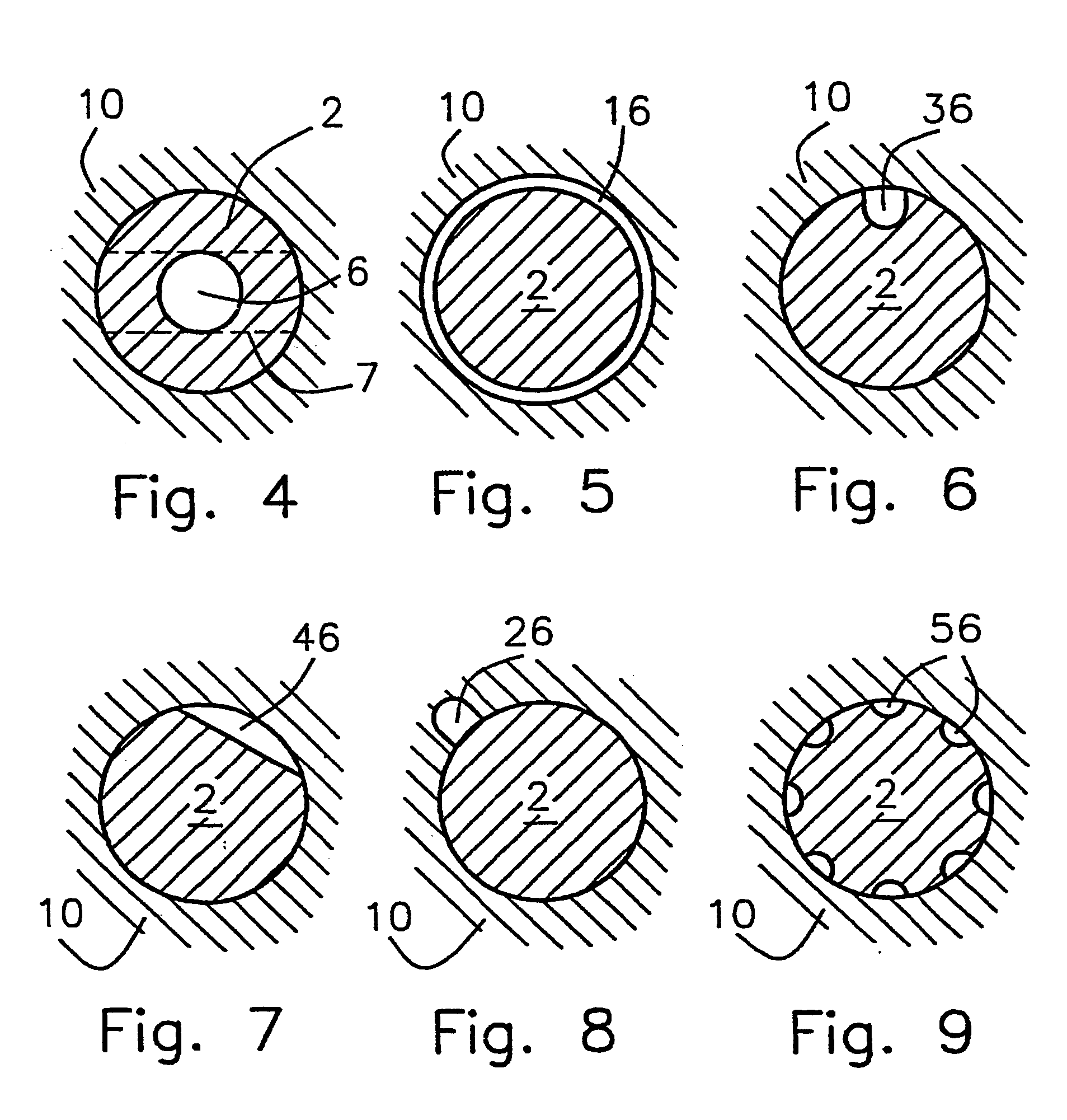

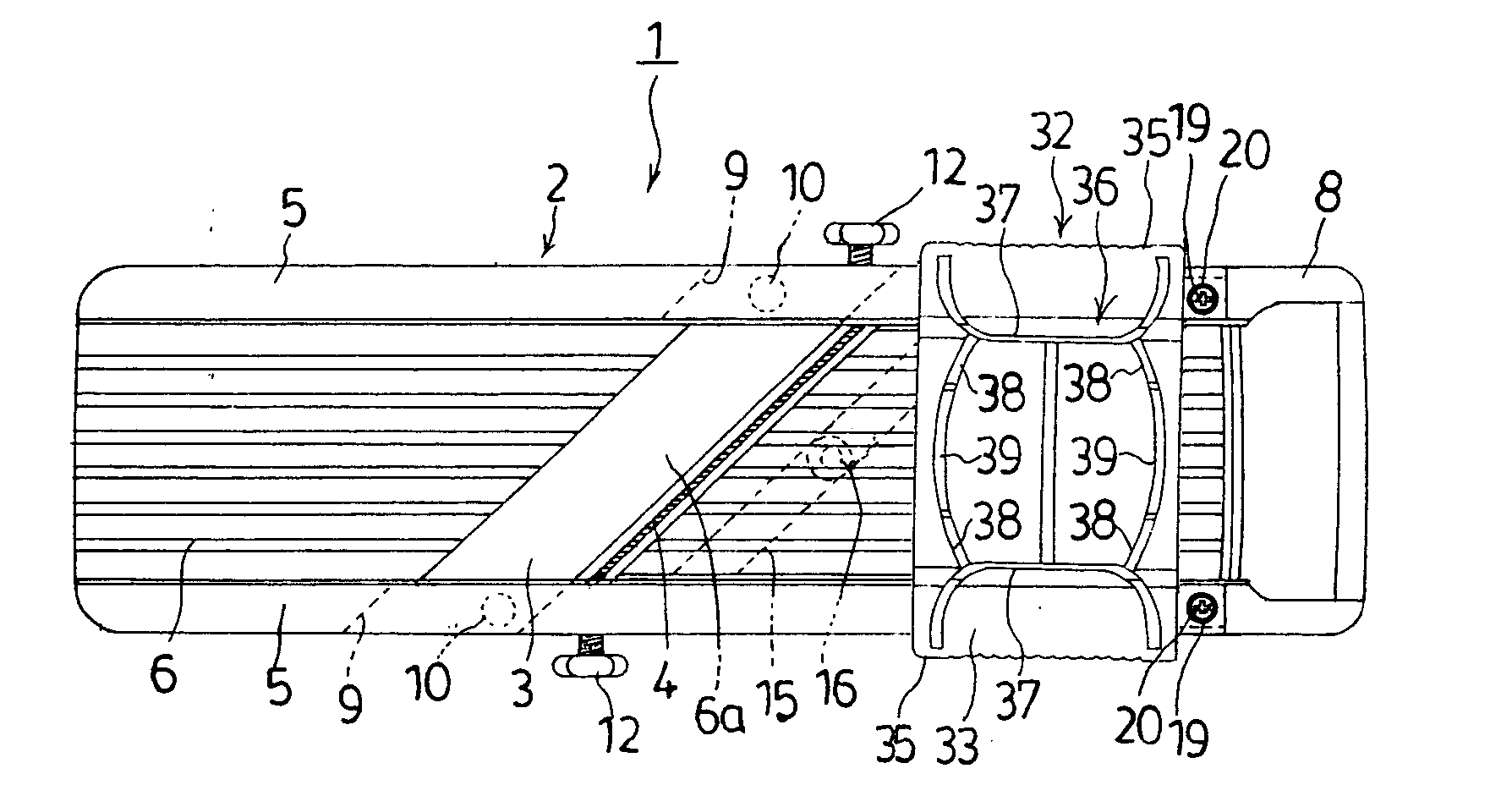

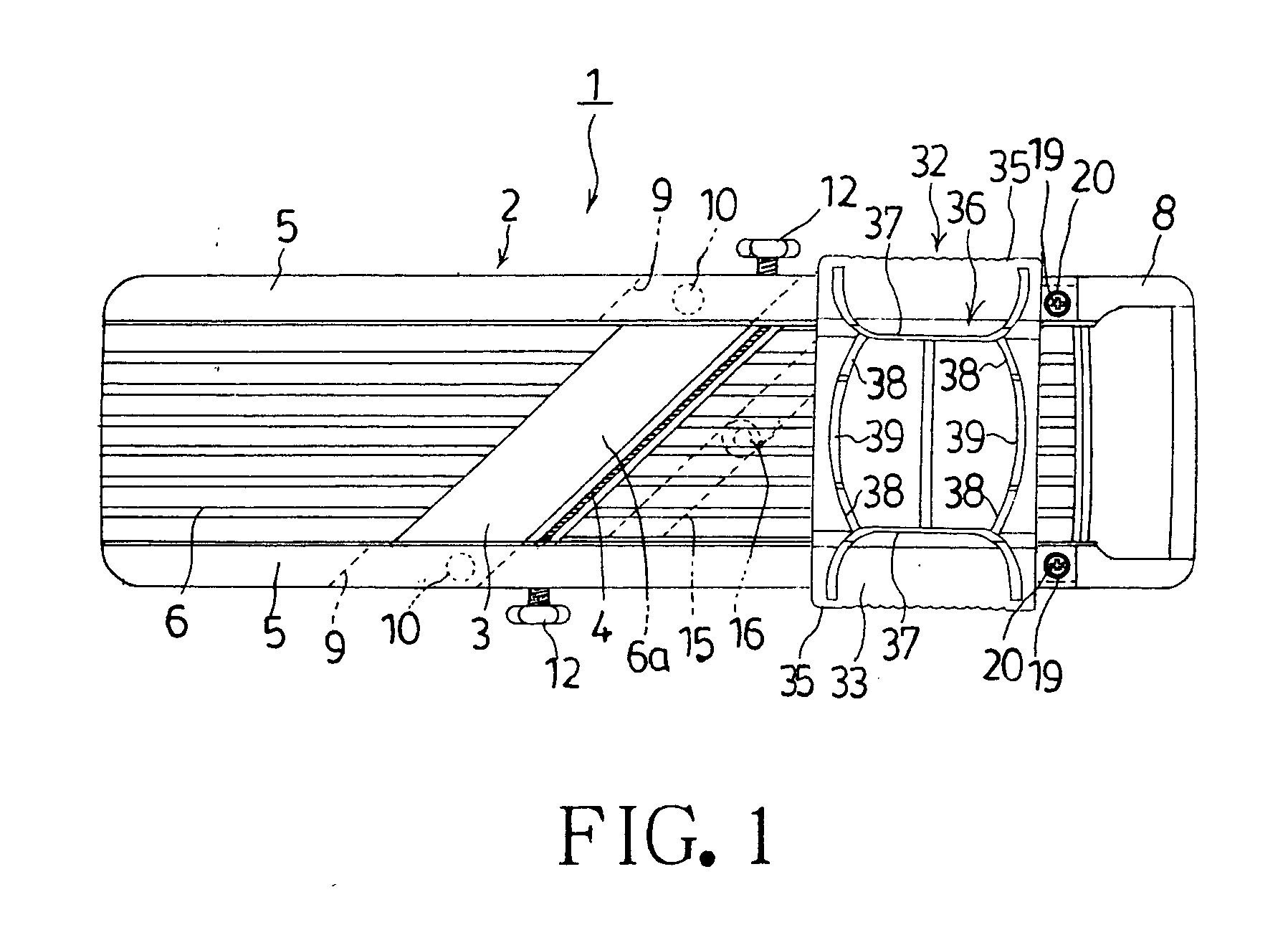

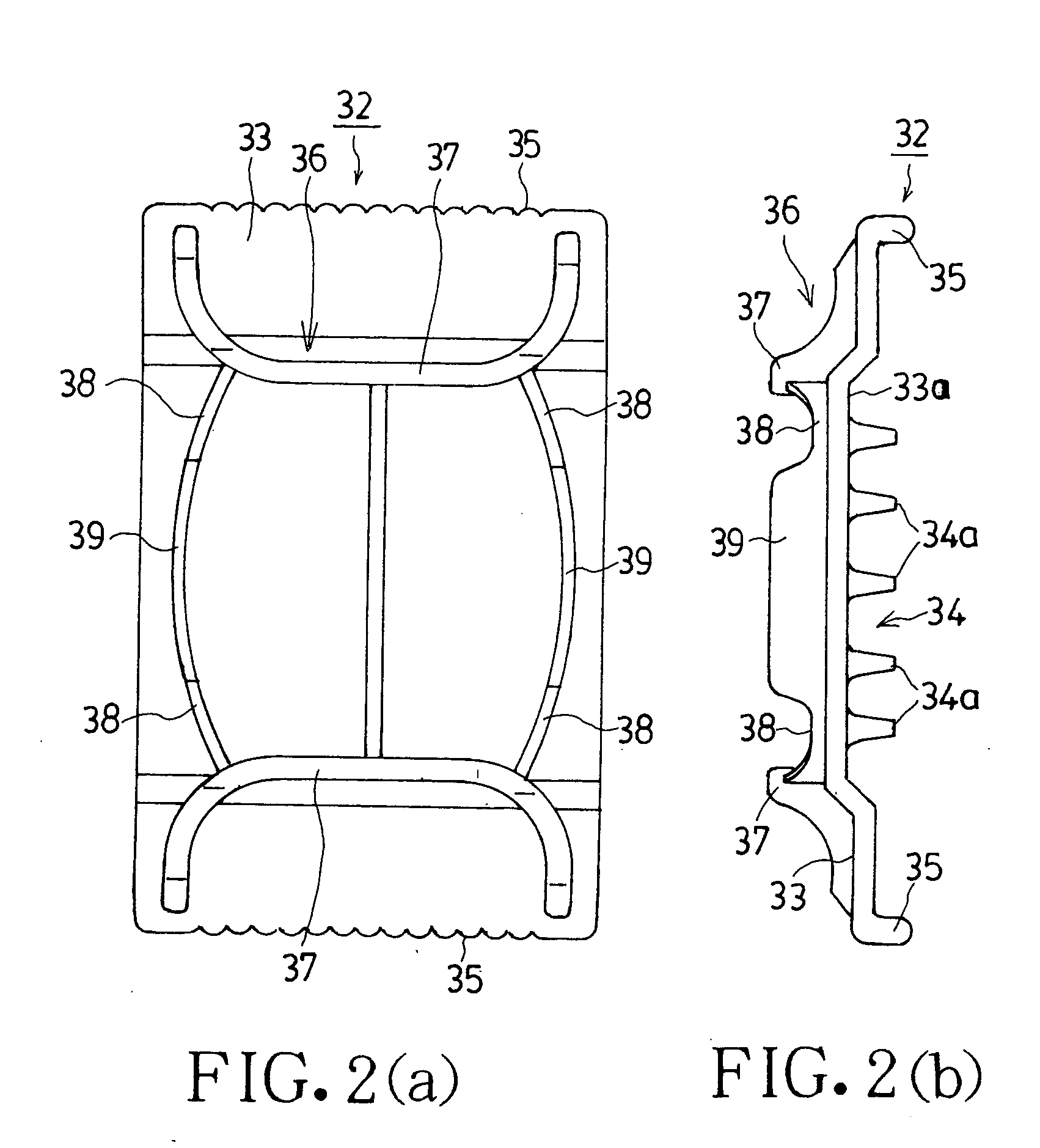

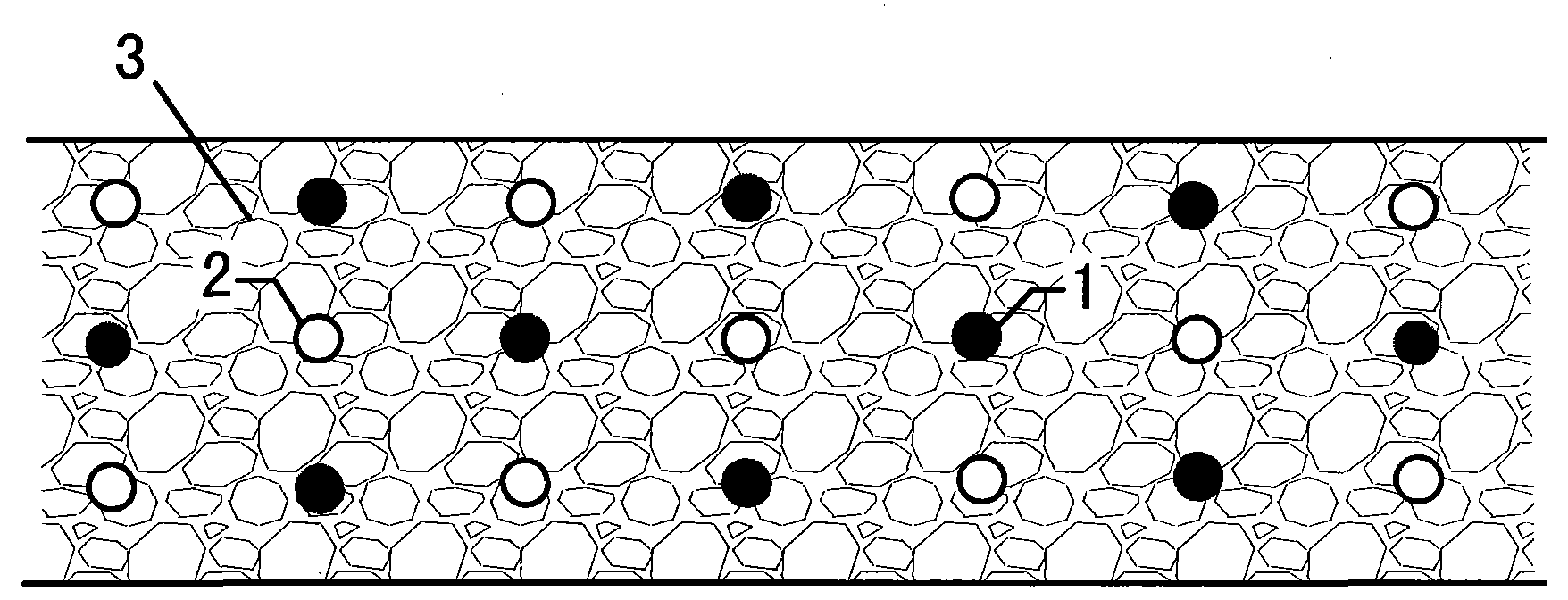

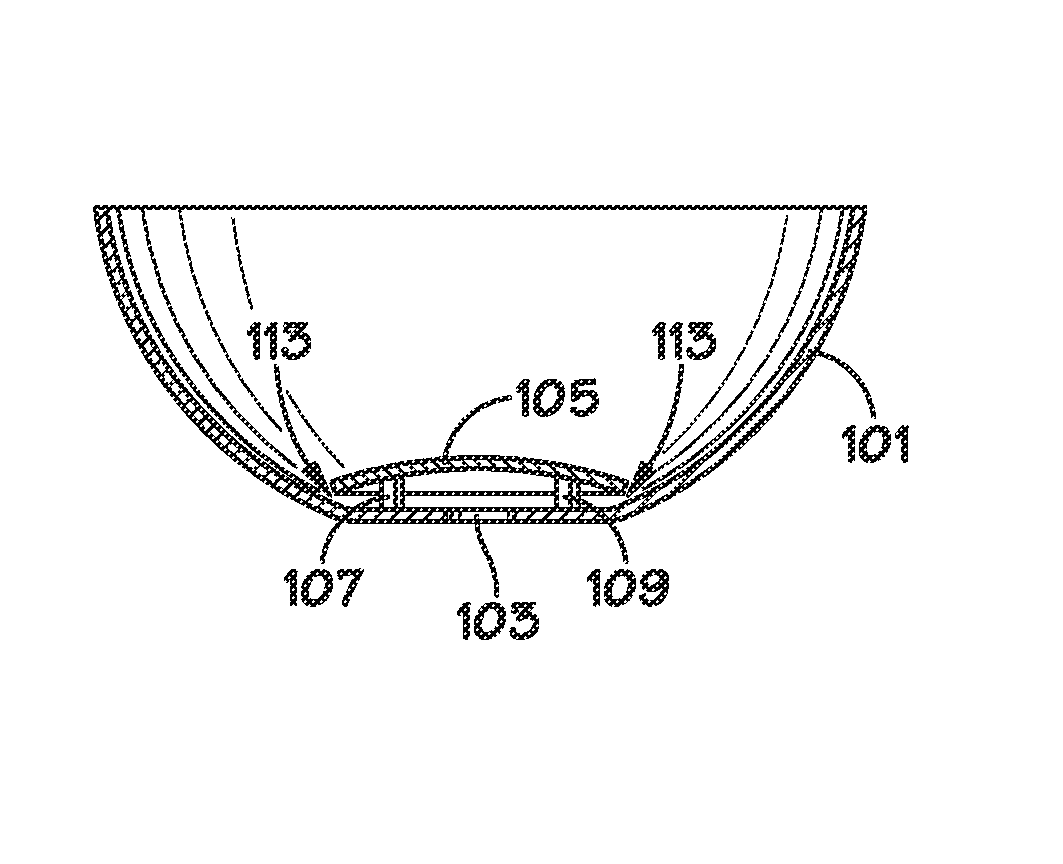

Wind turbine rotor blade with combined lighting receptor and drain passage and lighting receptor with drain passage

The invention relates to a wind turbine rotor blade which in its tip (1) is provided with a lightning receptor (2) and a drain passage (6; 16; 26; 36; 46; 56) connecting the blade interior (11, 12) with the blade exterior, the drain passage (6; 16; 26; 36; 46; 56) and the lightning receptor (2) having a common interface. The invention further relates to a lightning receptor provided with a drain passage (6; 36; 46; 56).

Owner:LM GLASSFIBER

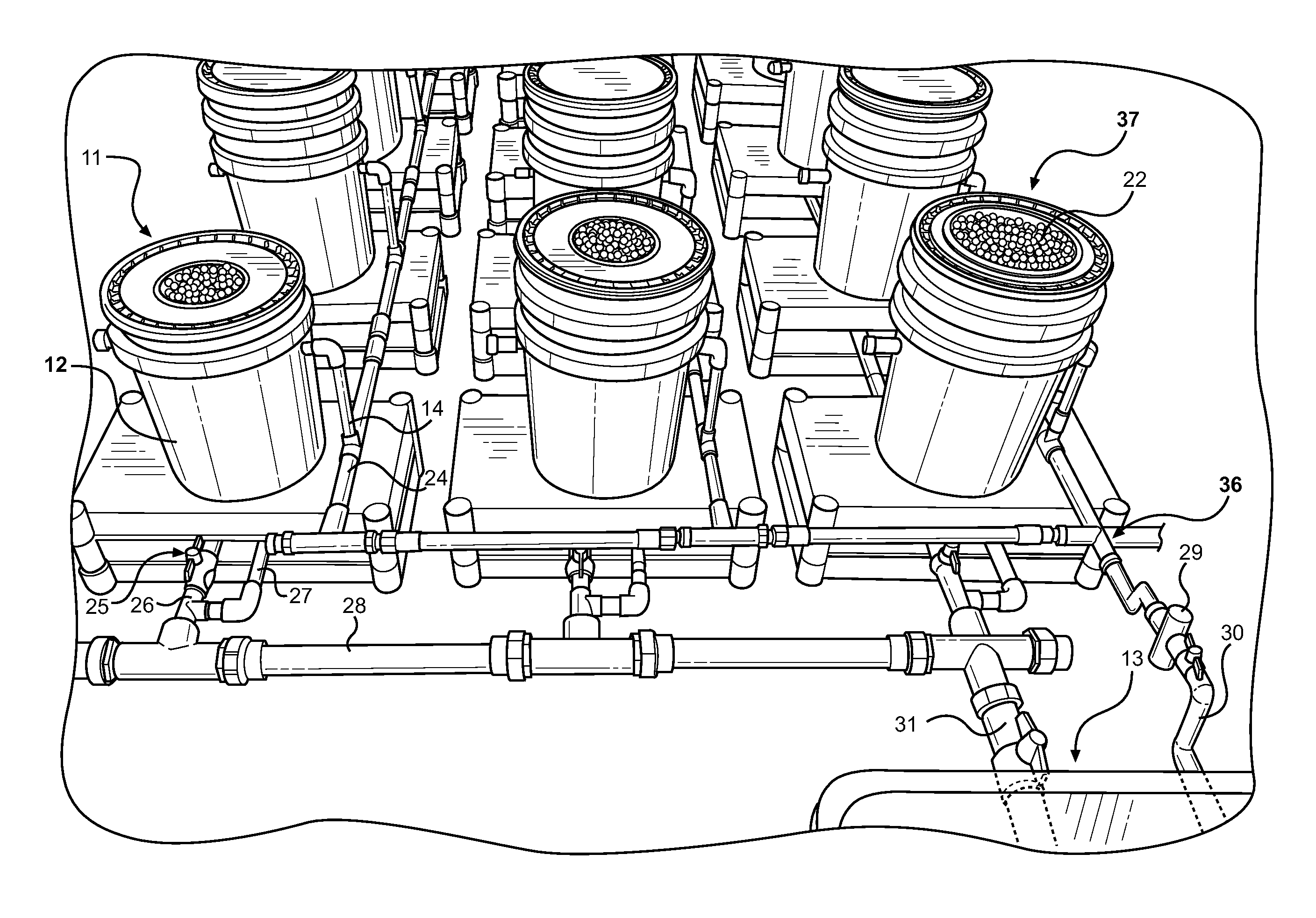

Aeroponic System and Sprayer Device for Improved Plant Growth and Aeration

ActiveUS20120005957A1Effective drainageReduce heat transferDust removalFire preventionPlant rootsSprayer

An aeroponic growing system, double T-shaped sprayer design and method for cultivating larger plant crops and increasing harvest frequency. The system comprises a series of aeroponic growing units, each of which supports a plant's roots within an enclosure. The enclosure houses a sprayer, an interior volume of plant nutrient solution and a plumbing system for accepting and distributing the aqueous water-nutrient solution. The internal sprayer is a double T-shaped mister that sprays an atomized mist directed from a first set of nozzles onto the plant roots, along with a second set of nozzles directed toward the base of the enclosure to aerate the interior volume of plant nutrient solution. The T-shaped mister provides circumferential coverage of the plant roots, while the aeration of the plant nutrient solution provides an aerated solution that accelerates plant growth through a hybrid process of Nutrient Film Technique (NFT) called a Hyperactive Aeroponic Shallow Water Culture (HAS Culture). Several interconnected aeroponic growing units may be stationed in a parallel grid to provide ample space for rapid growth of crops, while supplying the water and nutrient solution through a network of pipes and tubes between units.

Owner:DOWNS SR THOMAS J

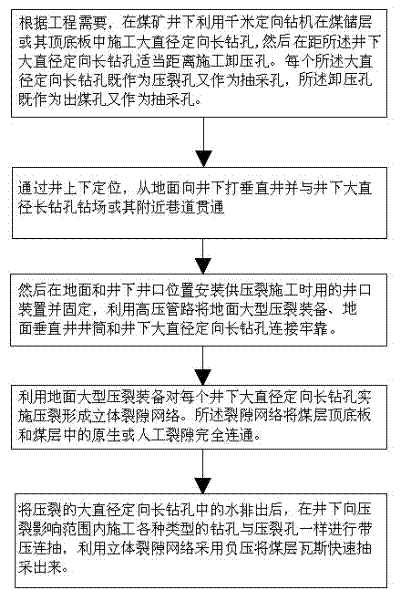

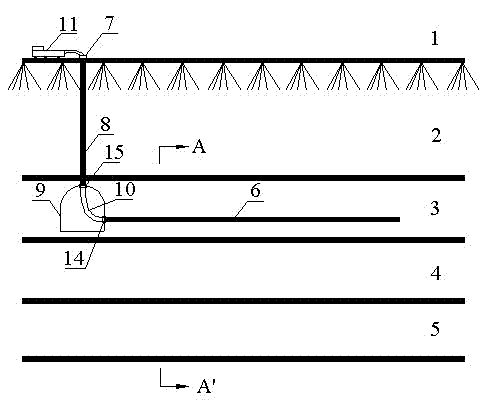

Gas drainage method combining surface and underground fracturing and permeability improvement

InactiveCN102392678AAvoid the disadvantages of unfrackableFirmly connectedFluid removalGas removalMining engineeringCoal

The invention relates to a gas drainage method combining surface and underground fracturing and permeability improvement, and the method comprises the following steps: building underground large-diameter directional long boreholes in a coal reservoir or the top and bottom plates thereof under a coal mine by using a drilling machine; then building pressure relief holes in a coal bed having an appropriate distance with the large-diameter directional long boreholes; building vertical wells communicated with an underground large-diameter directional long borehole filed or nearby roadways thereof from the ground to the underground; firmly connecting large ground fracturing equipment, a ground vertical well shaft and the underground large-diameter directional long boreholes by using high pressure pipelines; carrying out fracturing on each underground large-diameter directional long borehole by using the large ground fracturing equipment to form a three-dimensional fracture network; discharging water in the underground large-diameter directional long boreholes and then carrying out continuous pressure extraction on fracturing holes and the pressure relief holes; and quickly extracting out the coal bed gas through negative pressure by using the three-dimensional fracture network. According to the invention, the coal bed gas can be extracted out quickly with high efficiency by using the three-dimensional fracture network and negative pressure, thereby providing a technical guarantee for safe and high-efficiency production of mines; and the method has the advantage of wide application prospect.

Owner:HENAN COAL CHEM IND GROUP INST

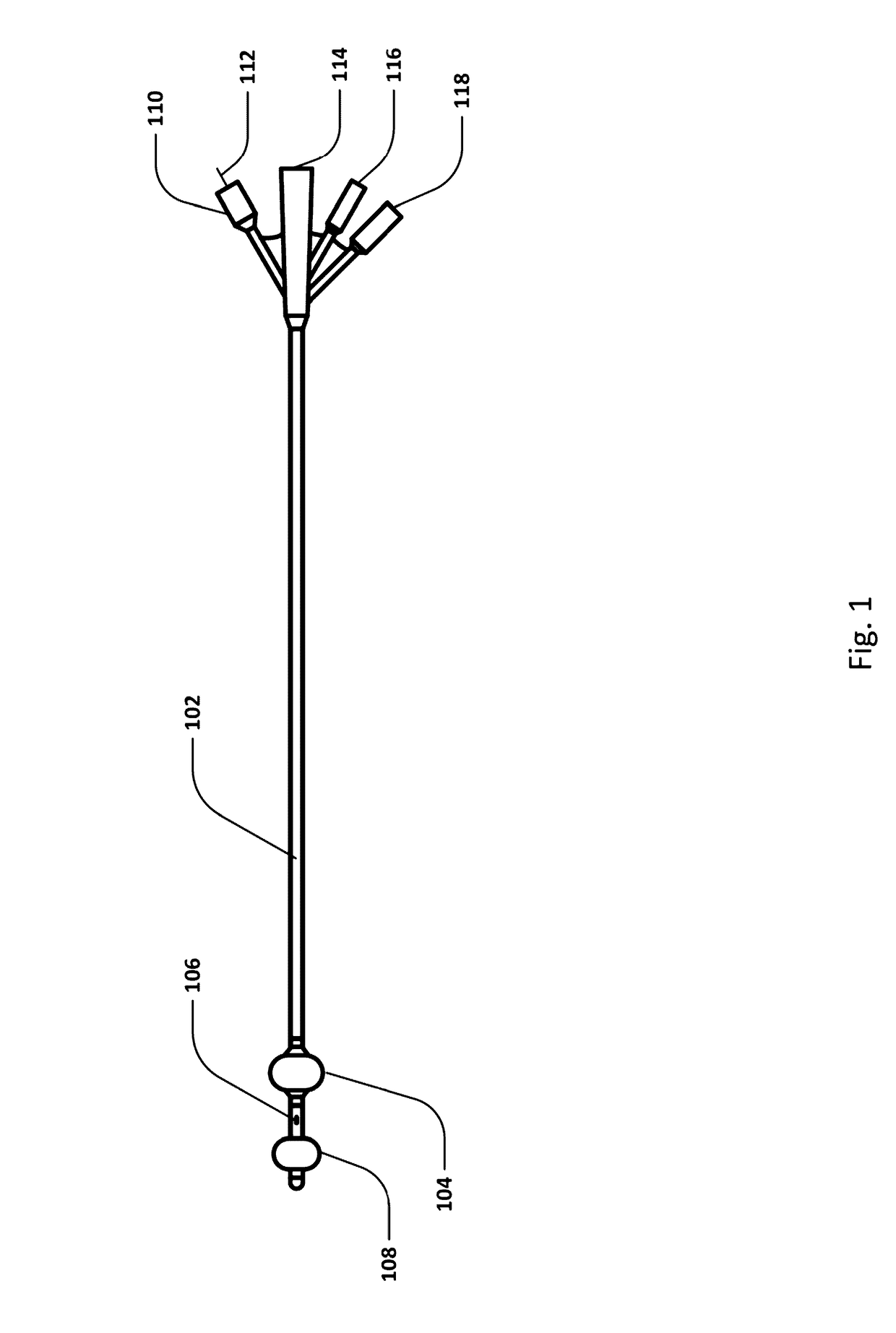

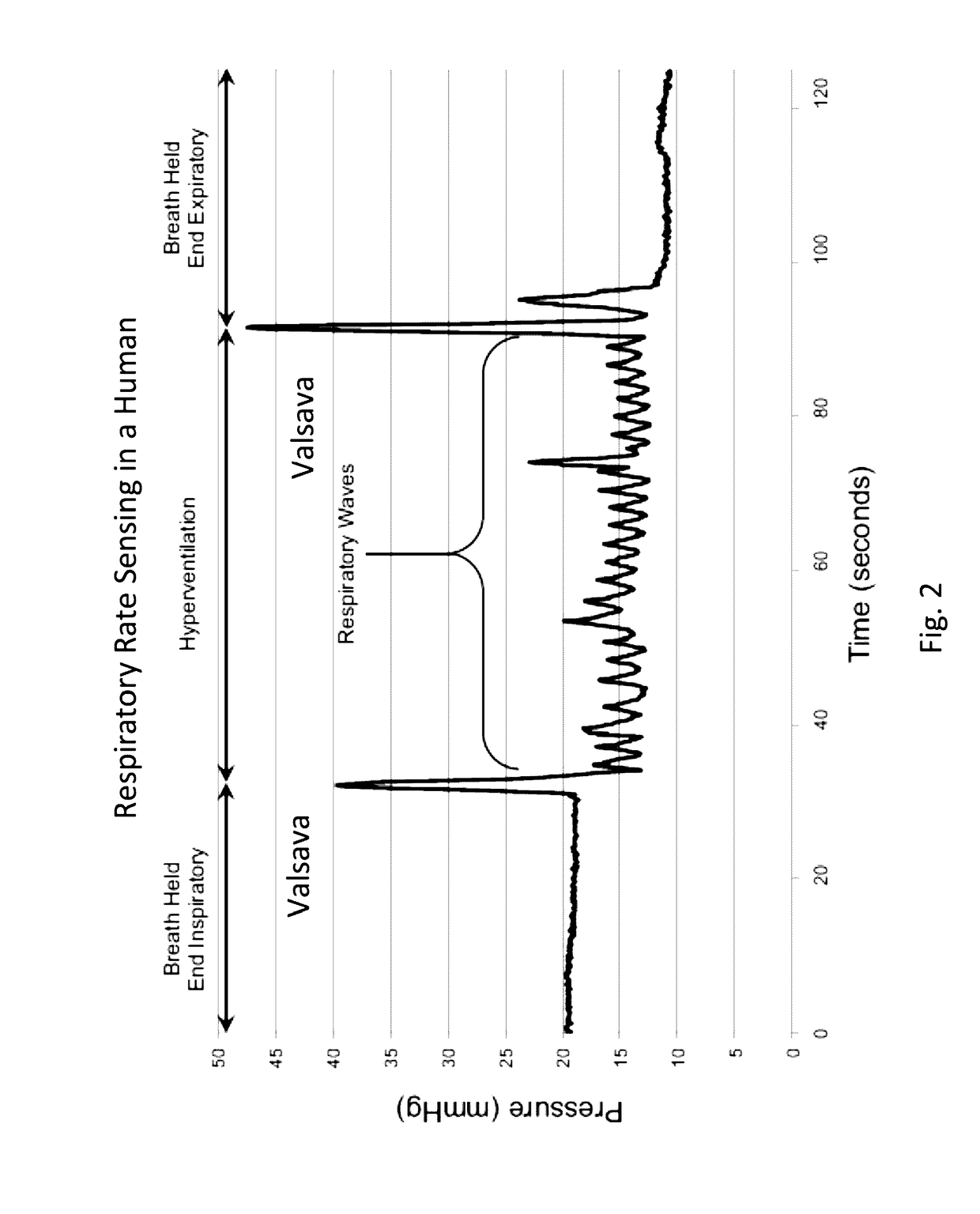

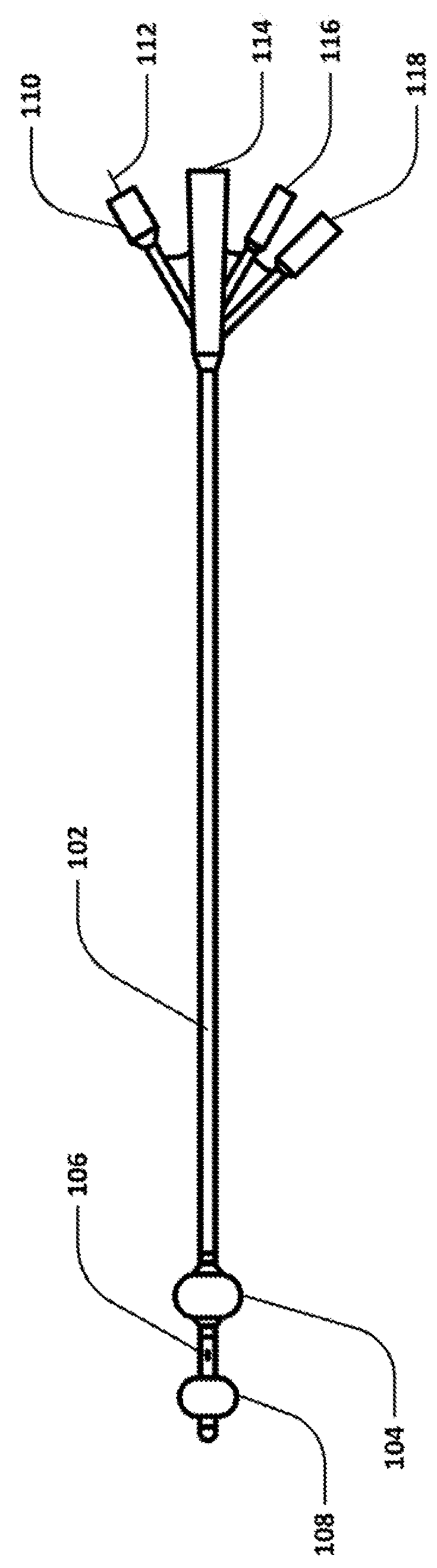

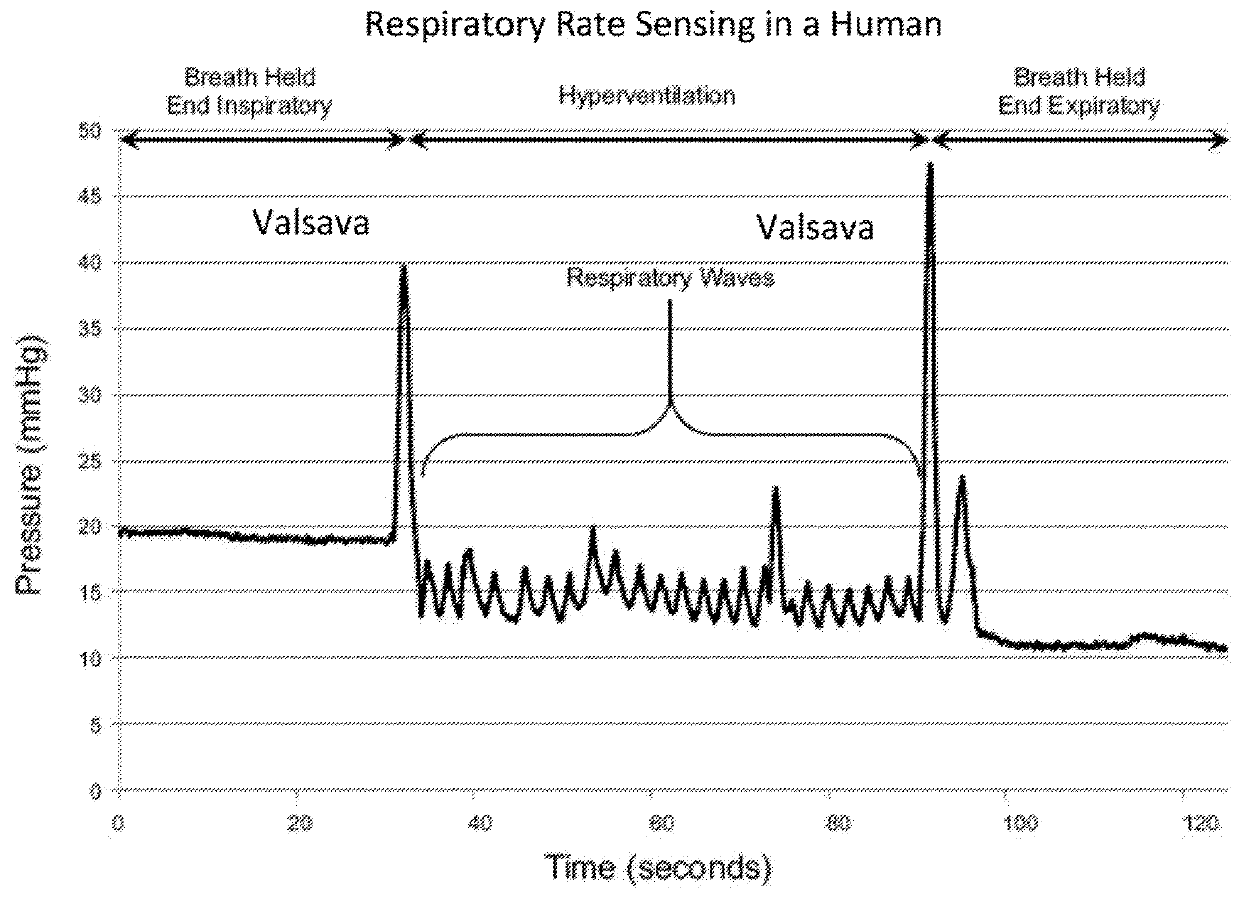

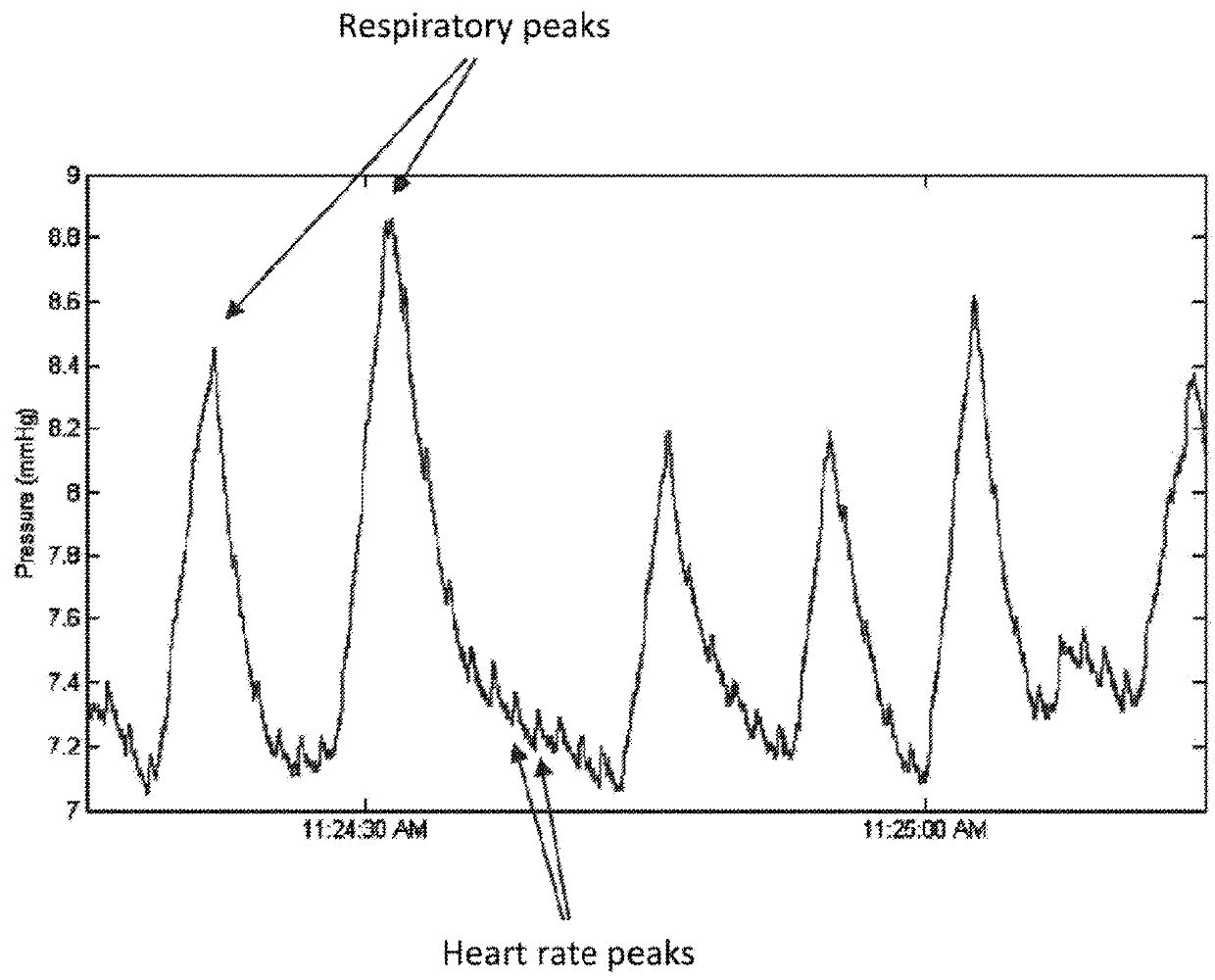

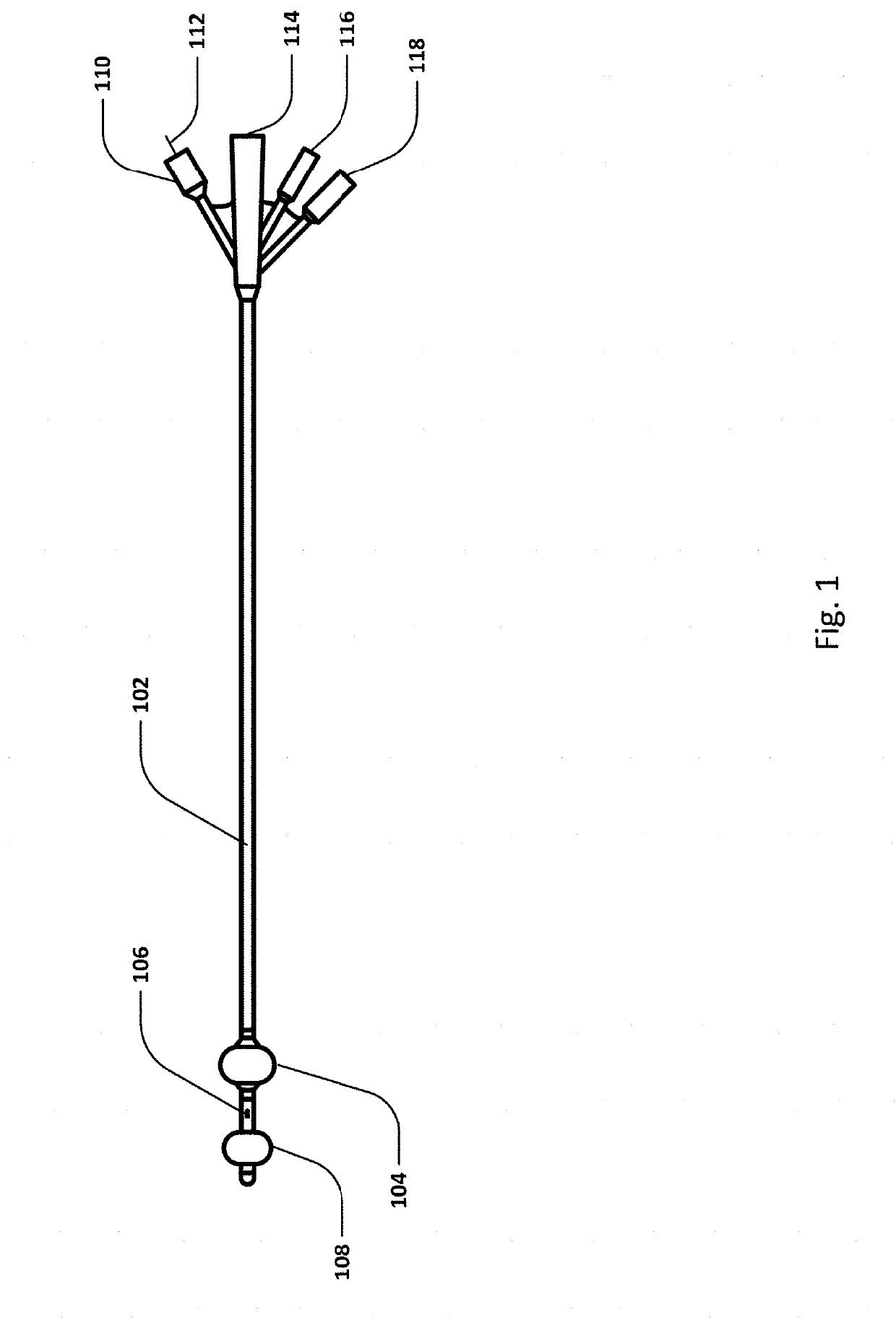

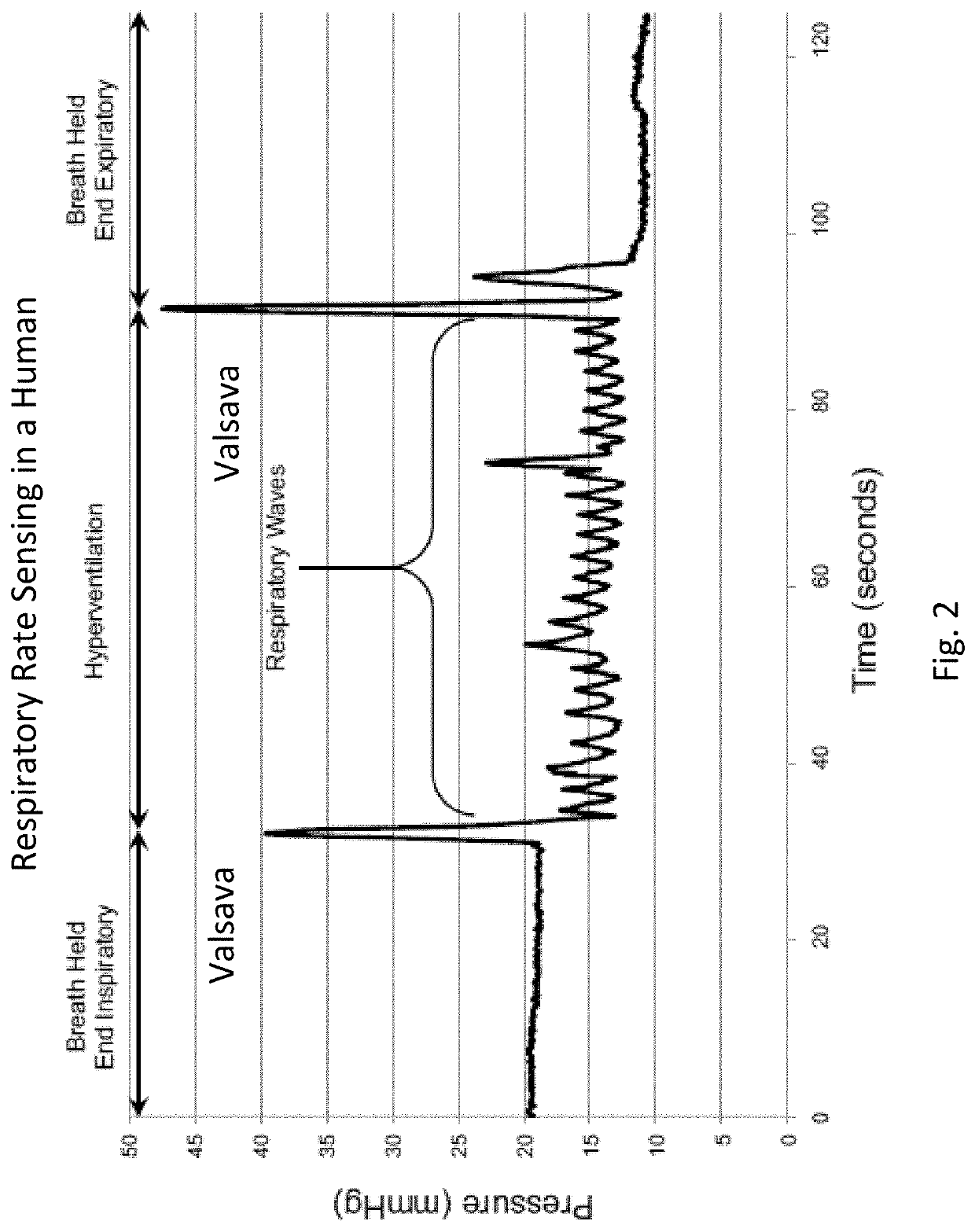

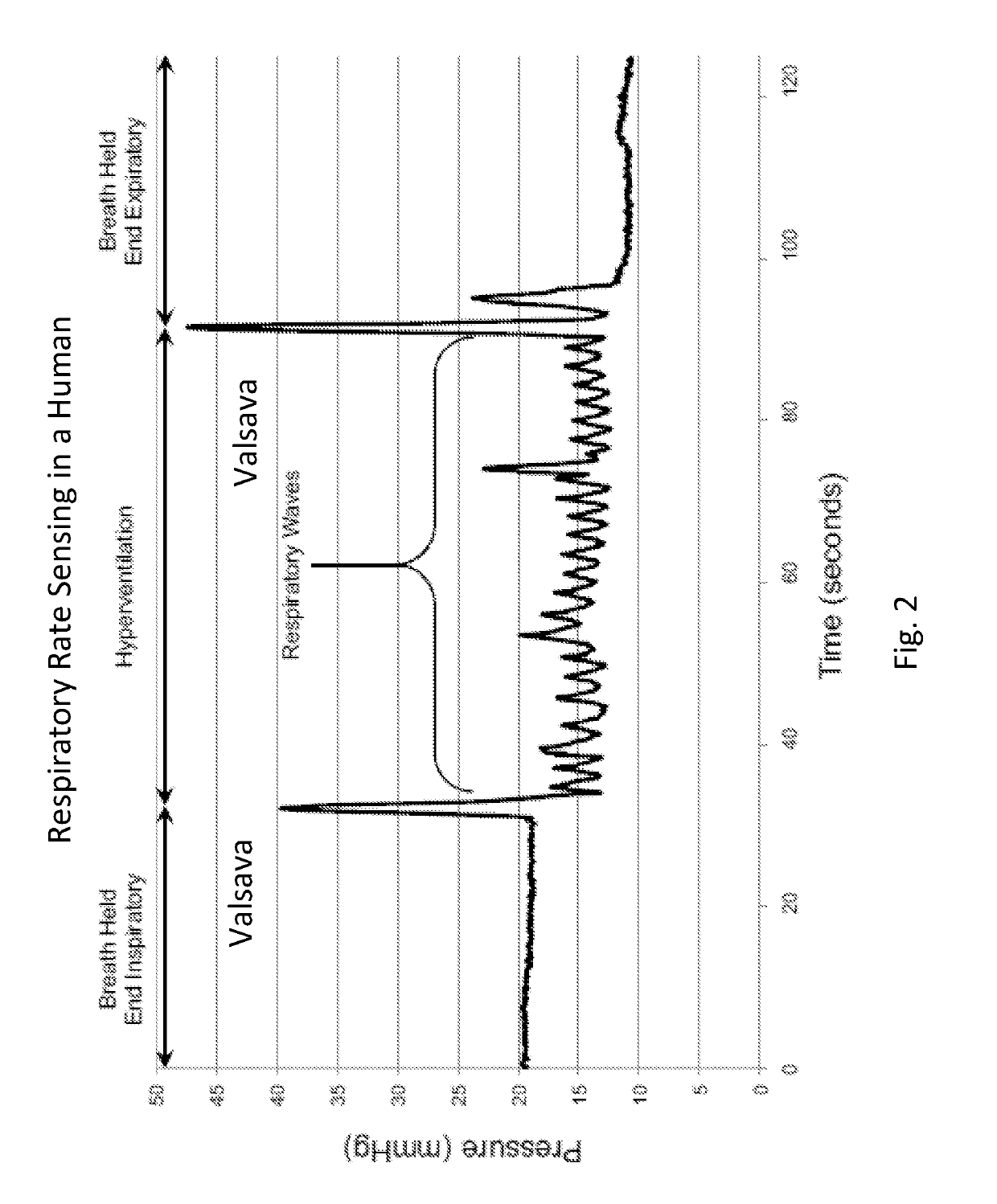

Systems, devices and methods for sensing physiologic data and draining and analyzing bodily fluids

ActiveUS20180177458A1Avoid problemsUseful in detectionMedical devicesCatheterEngineeringPleural spaces

Systems, devices and methods for sensing physiologic data and draining and analyzing bodily fluids are described which are capable of sensing physiologic data based on sensors incorporated into a catheter adapted to reside in any of a urinary tract, gastrointestinal tract, rectal location, pre-peritoneal, pleural space or other body cavity. The devices aid emptying of the bladder, measure urine output and various urine parameters such as oxygen tension, urine conductance and urine specific gravity, monitor renal function, analyze urine parameters, including urine content, including the presence of infection, and track and / or control fluid administration.

Owner:POTRERO MEDICAL

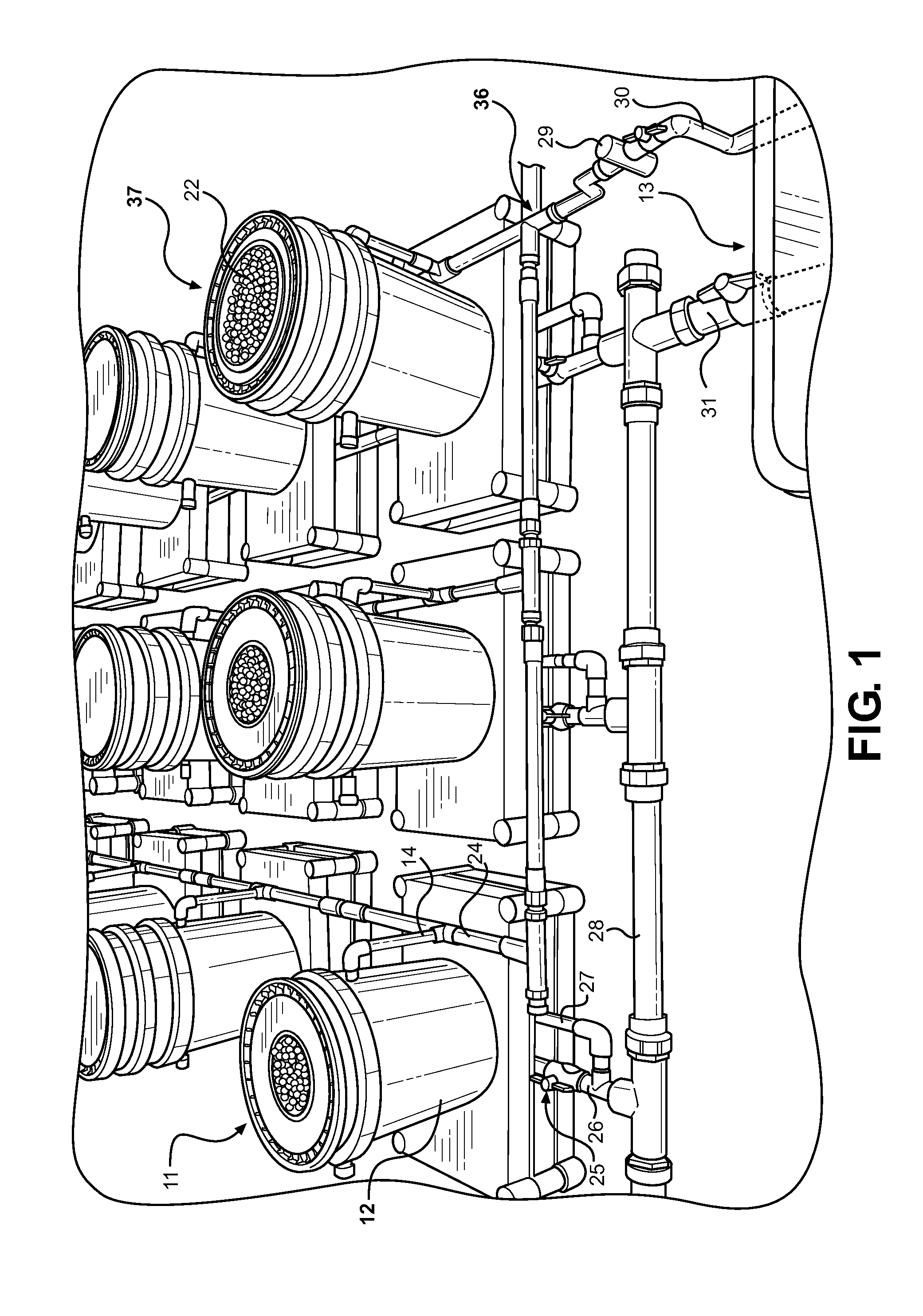

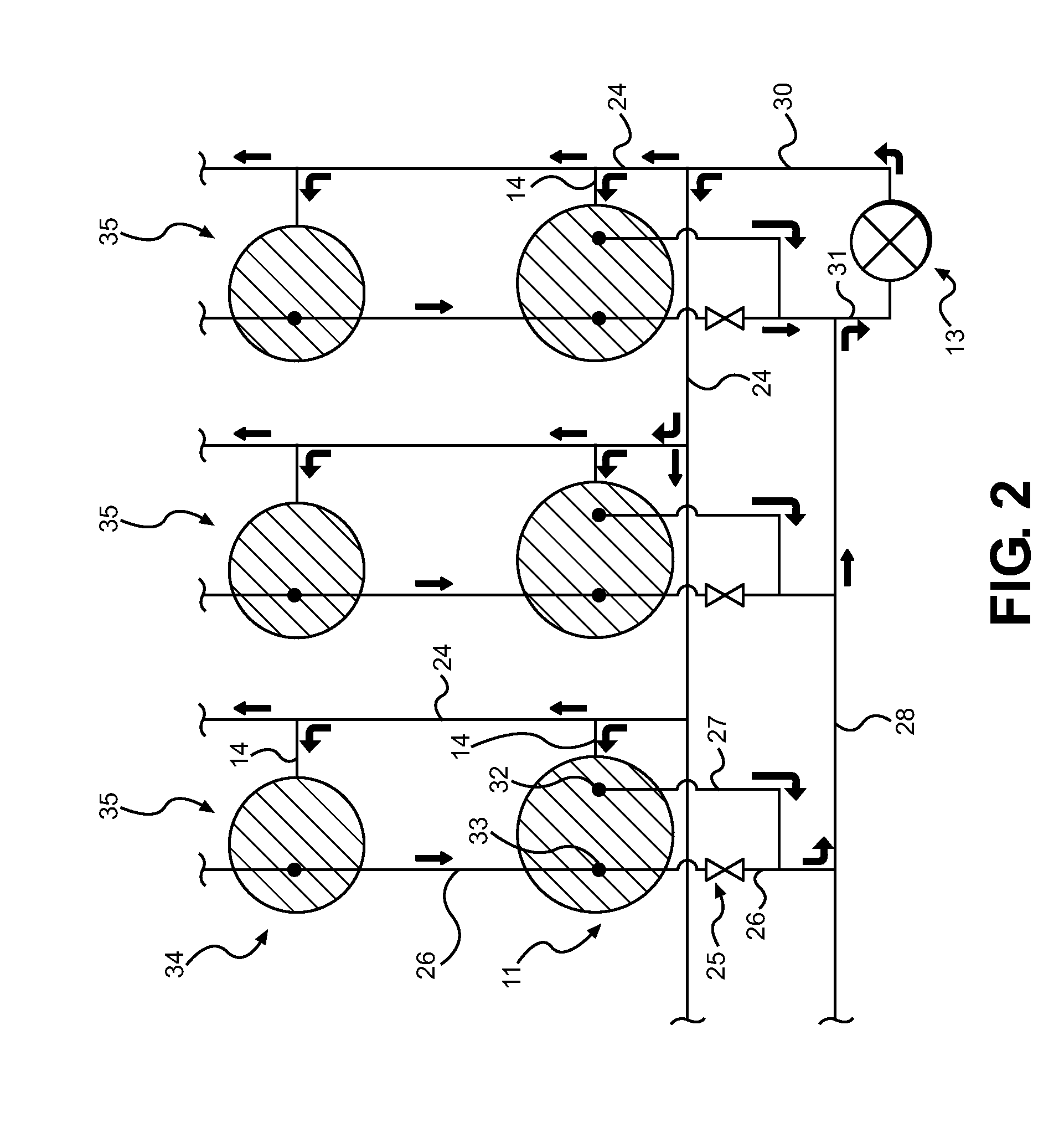

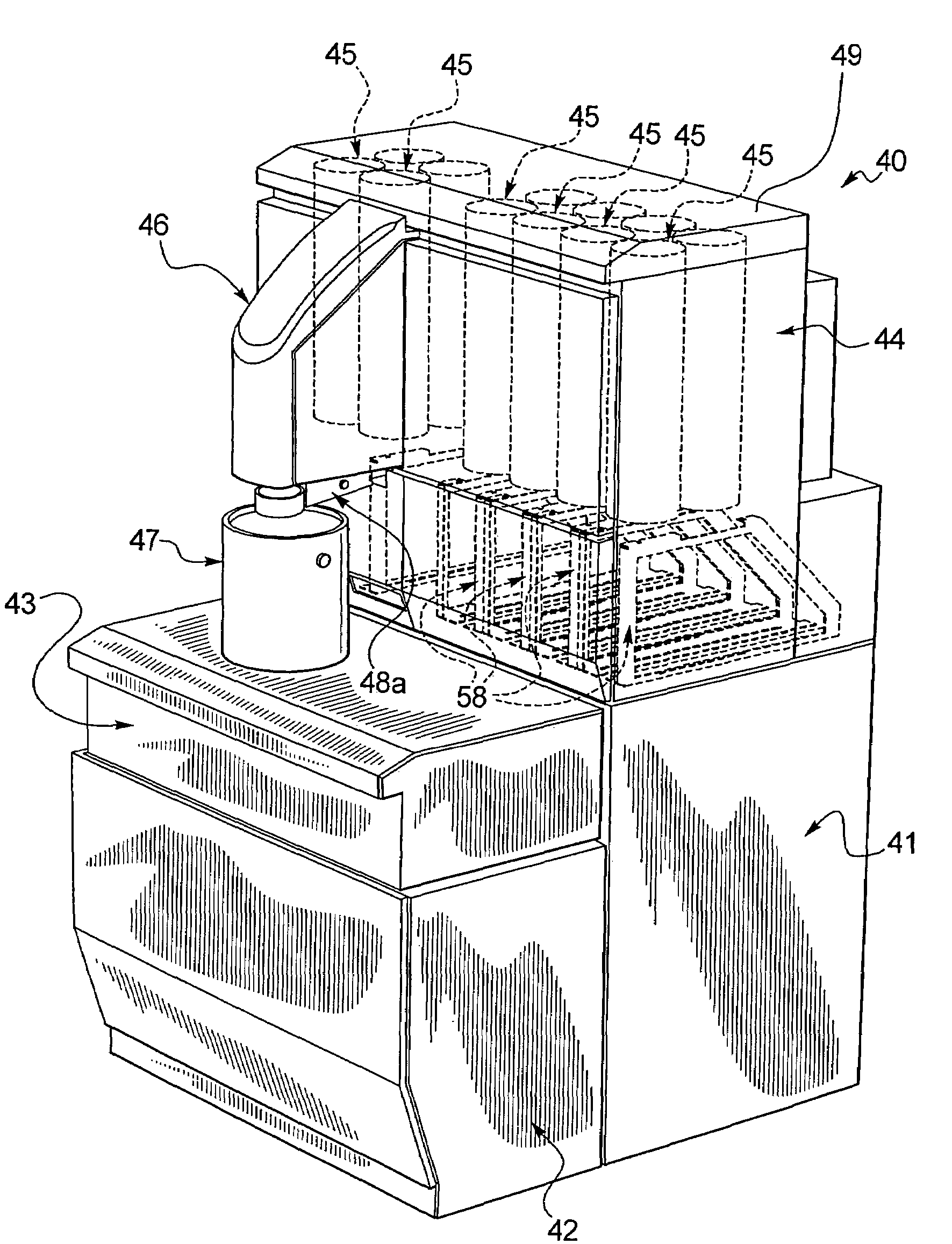

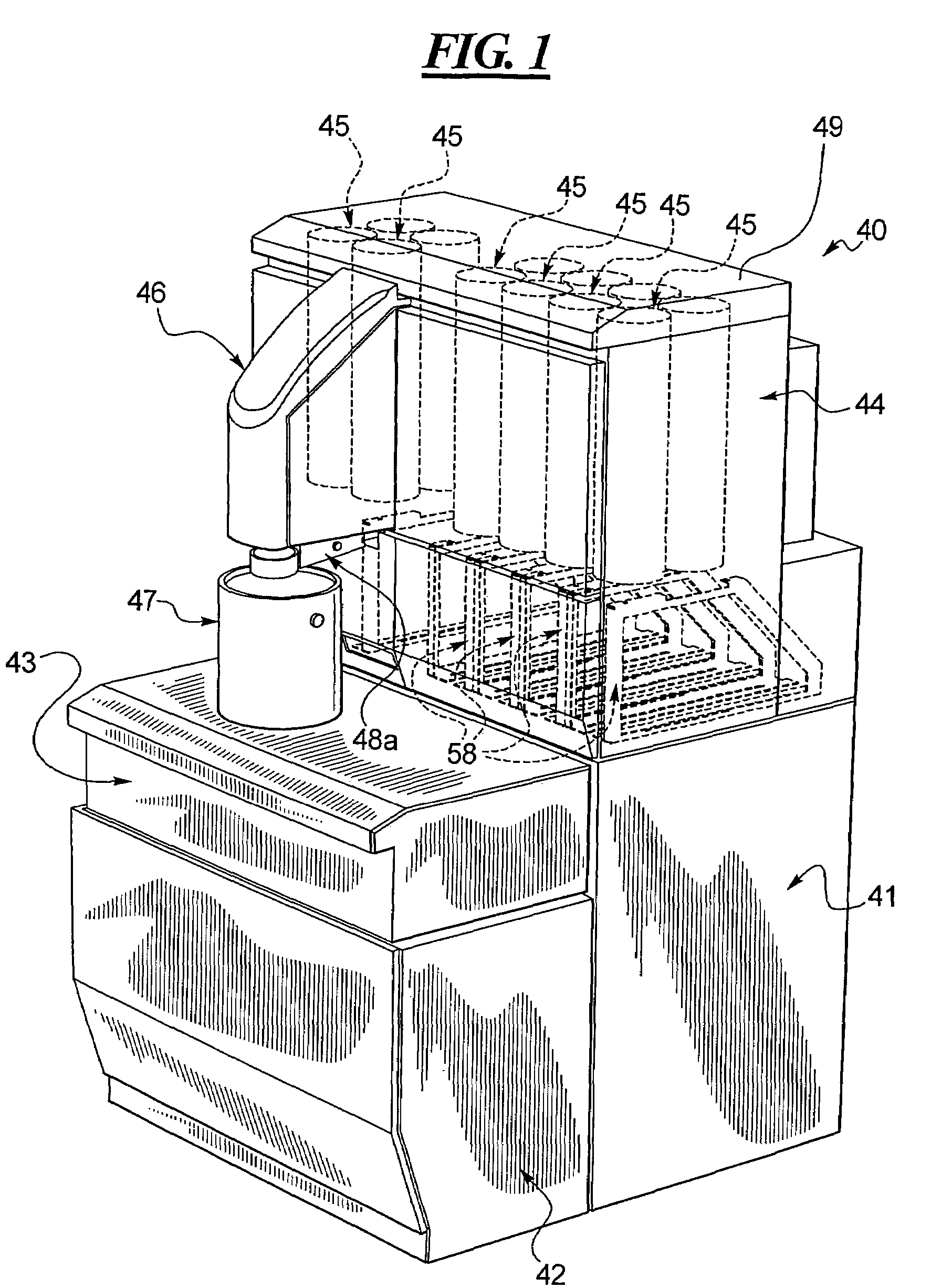

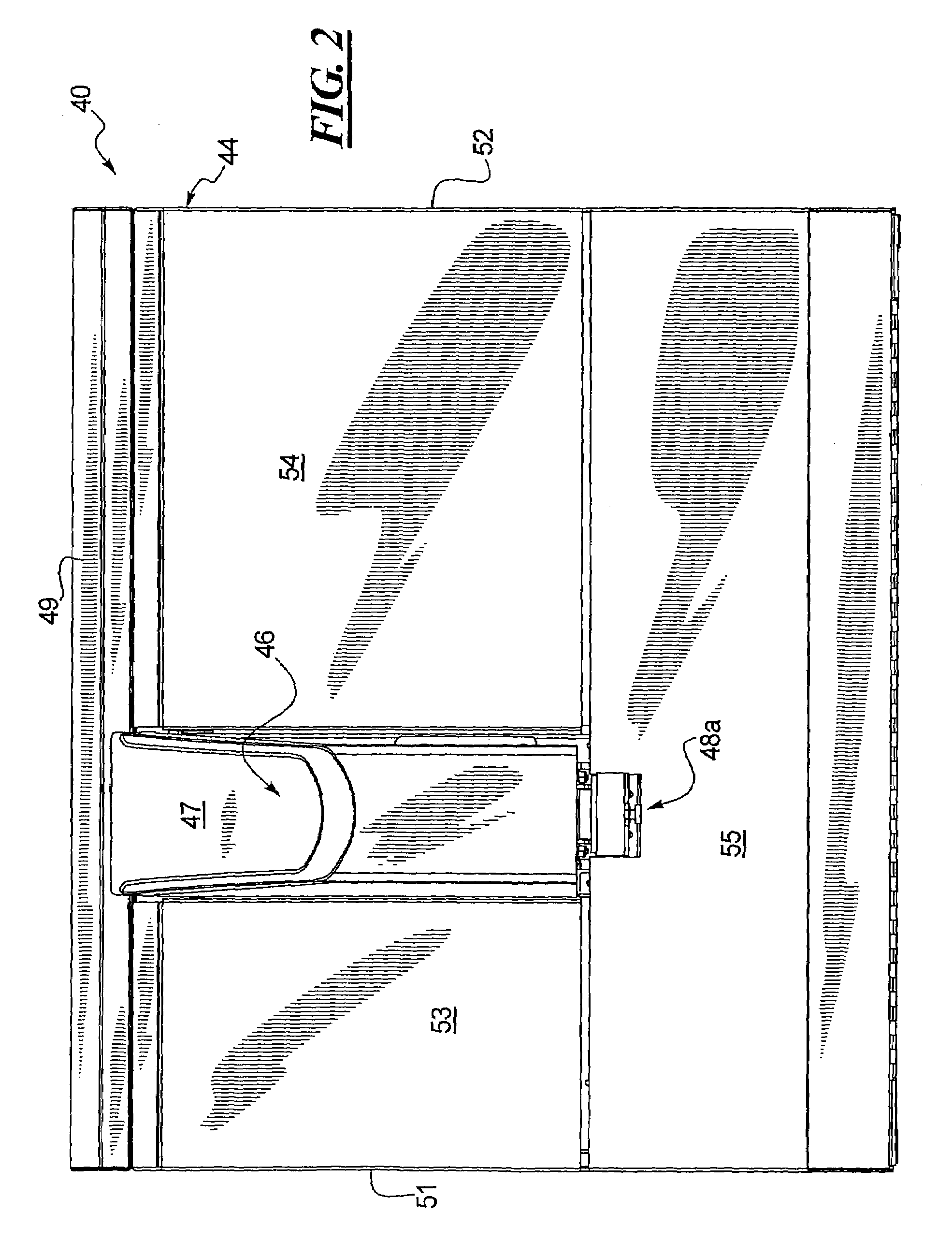

Multiple fluid dispenser

InactiveUS7690405B2Promote exchangeEasy to replaceLiquid fillingRotary stirring mixersEngineeringElectrical and Electronics engineering

Owner:FLUID MANAGEMENT LLC

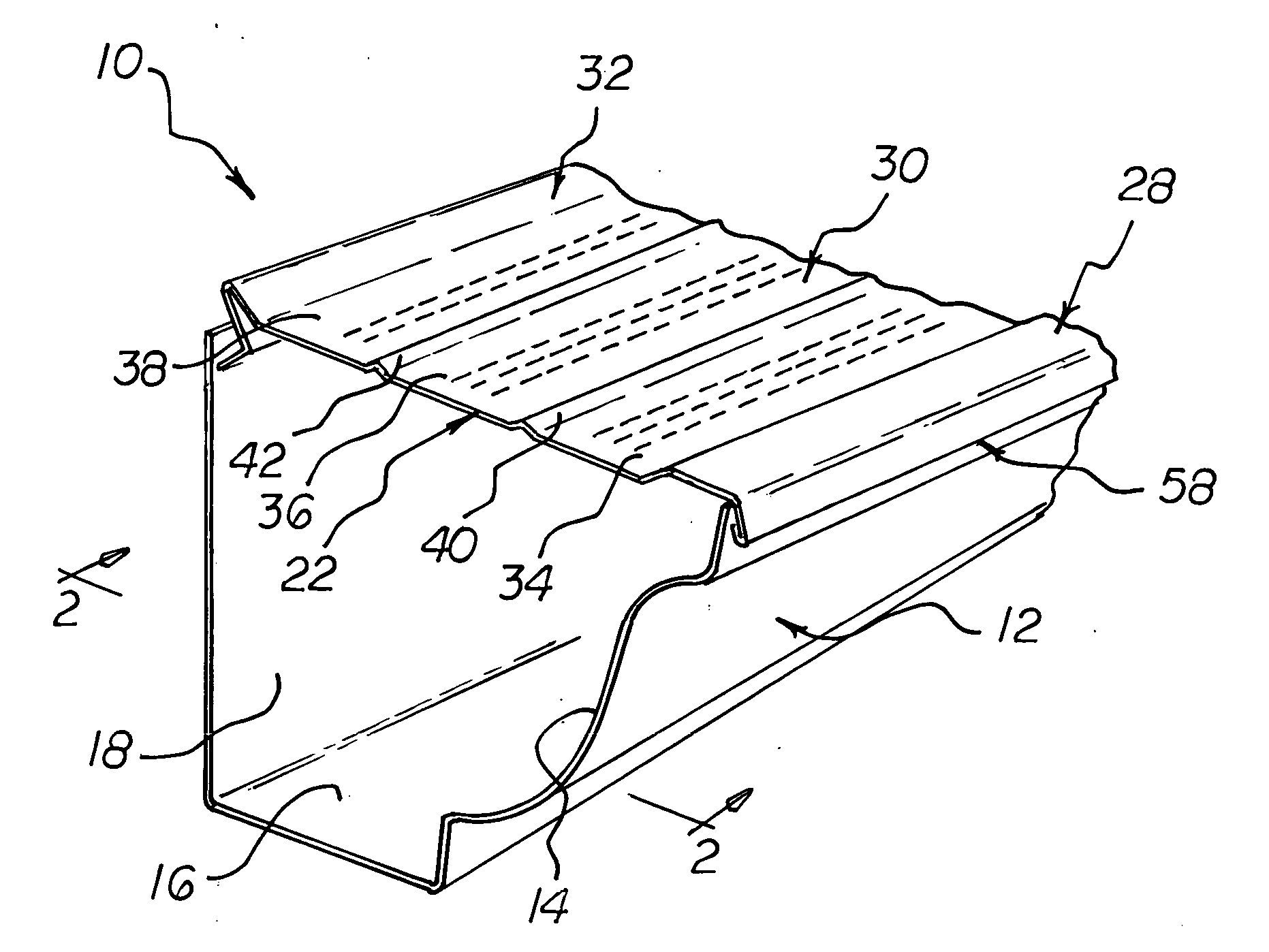

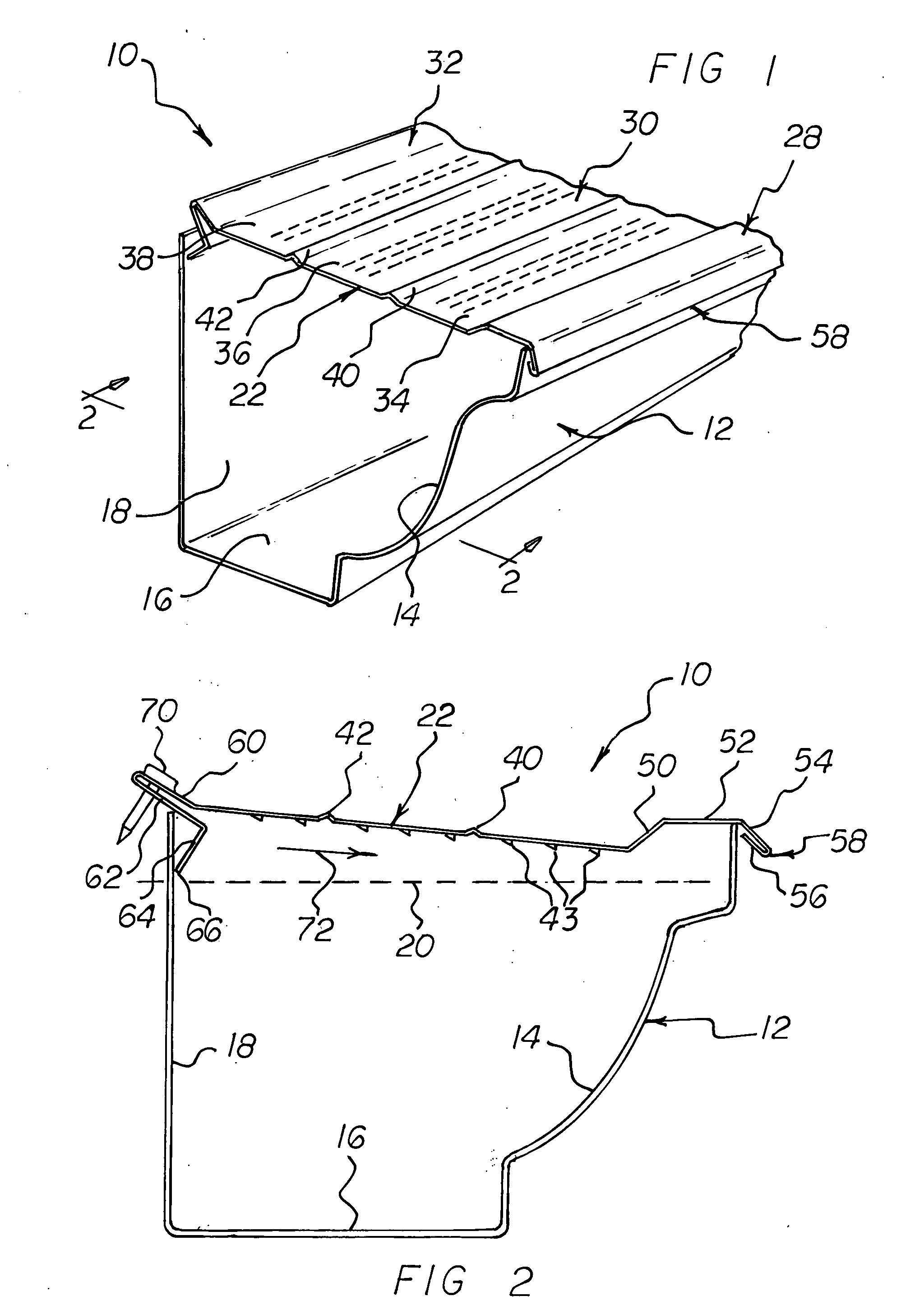

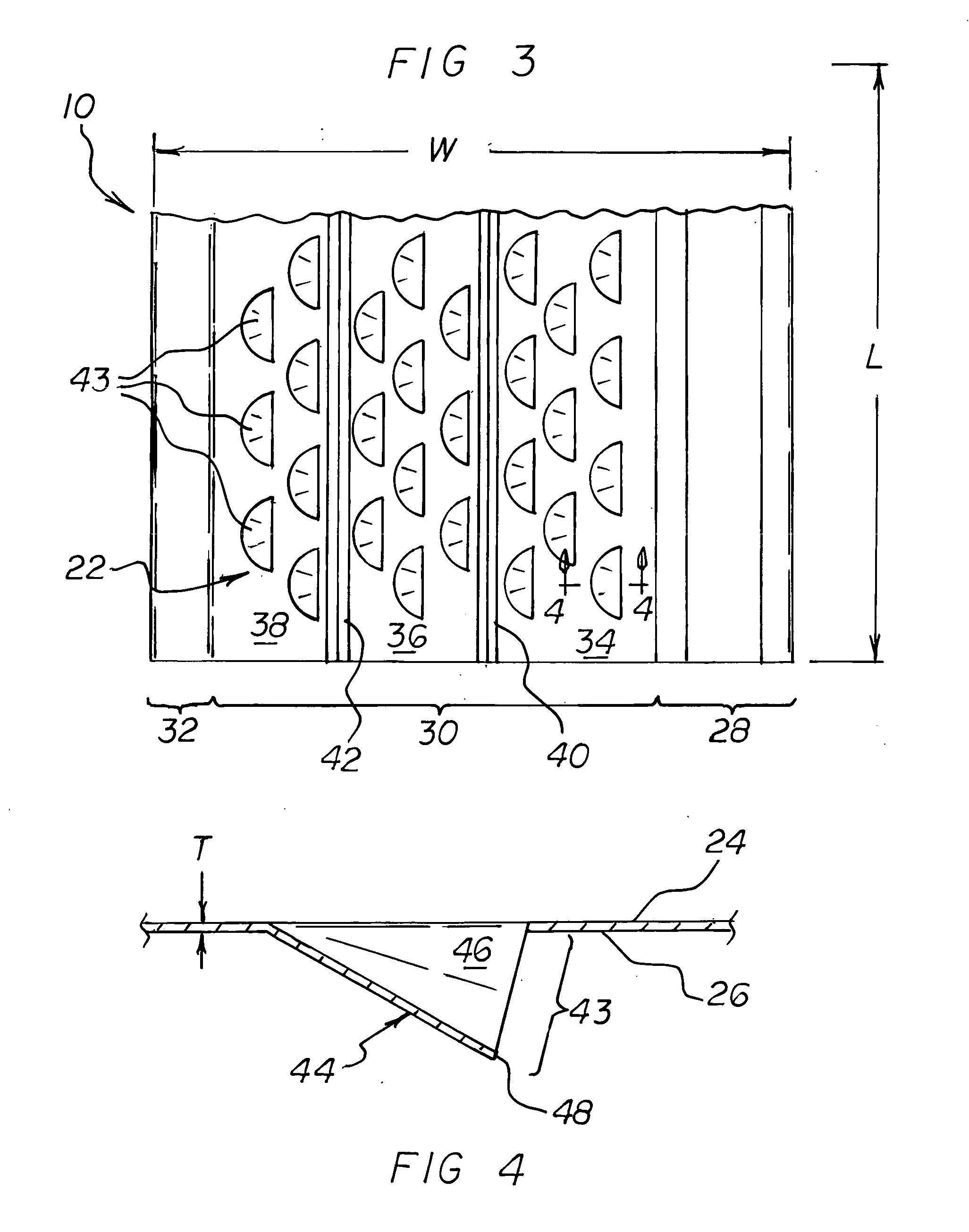

Gutter cover apparatus

A gutter cover apparatus a comprising a relatively thin, elongated generally planar sheet member, preferably of metallic material, suitably sized and configured to fit over and cover the top of a conventional roof gutter. The elongated sheet member has a longitudinal front edge portion, a longitudinal rear edge portion, and a generally planar intermediate portion therebetween. The intermediate portion, in turn, is characterized by first and second upstanding longitudinal spaced ridges or protuberances, spaced from each other and extending generally parallel to each other and to the front edge portion and the rear edge portion of the sheet member, substantially the full length thereof. The first and second upstanding spaced ridges define first, second and third drainage zones each containing a pattern of staggered rows of openings, each one of which opening is in the form of downwardly depending semi-cylindrical or other arcuate-shaped spout opening below the bottom surface of the sheet member and facing forwardly thereof. The rear longitudinal edge portion of the sheet member is bent suitably to form an upstanding “spoiler” or debris blocking section downwardly terminating in a longitudinally extending distal edge defining a bearing surface for the rear portion of the sheet member. The forward longitudinal edge portion of the sheet member is raised upwardly with respect to the drainage zones on the intermediate portion of the sheet member to define a downwardly directed “drip lip” and a bearing surface for the front of the sheet member with respect to the front edge of the gutter to which operatively it may be attached.

Owner:SNELL TODD

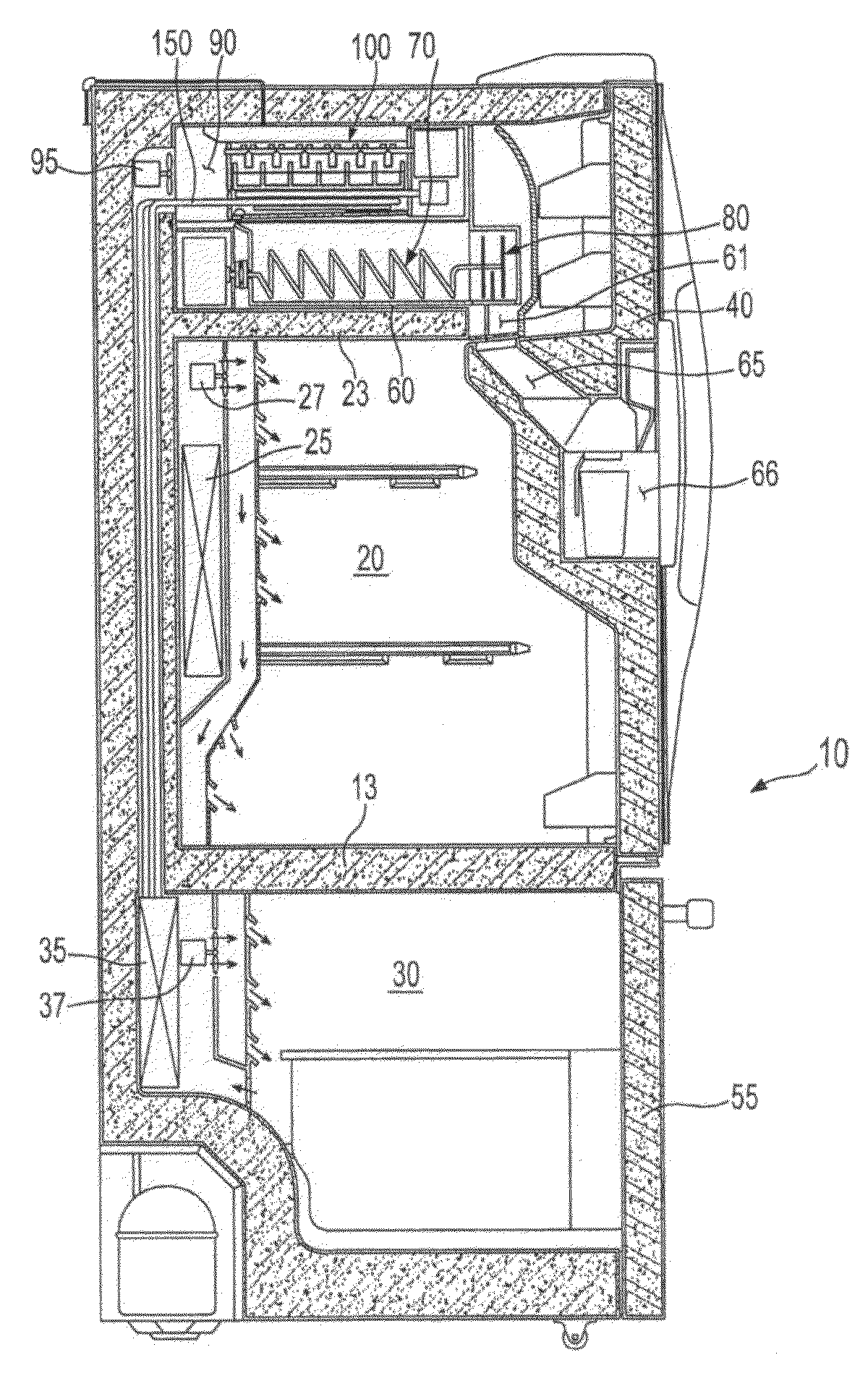

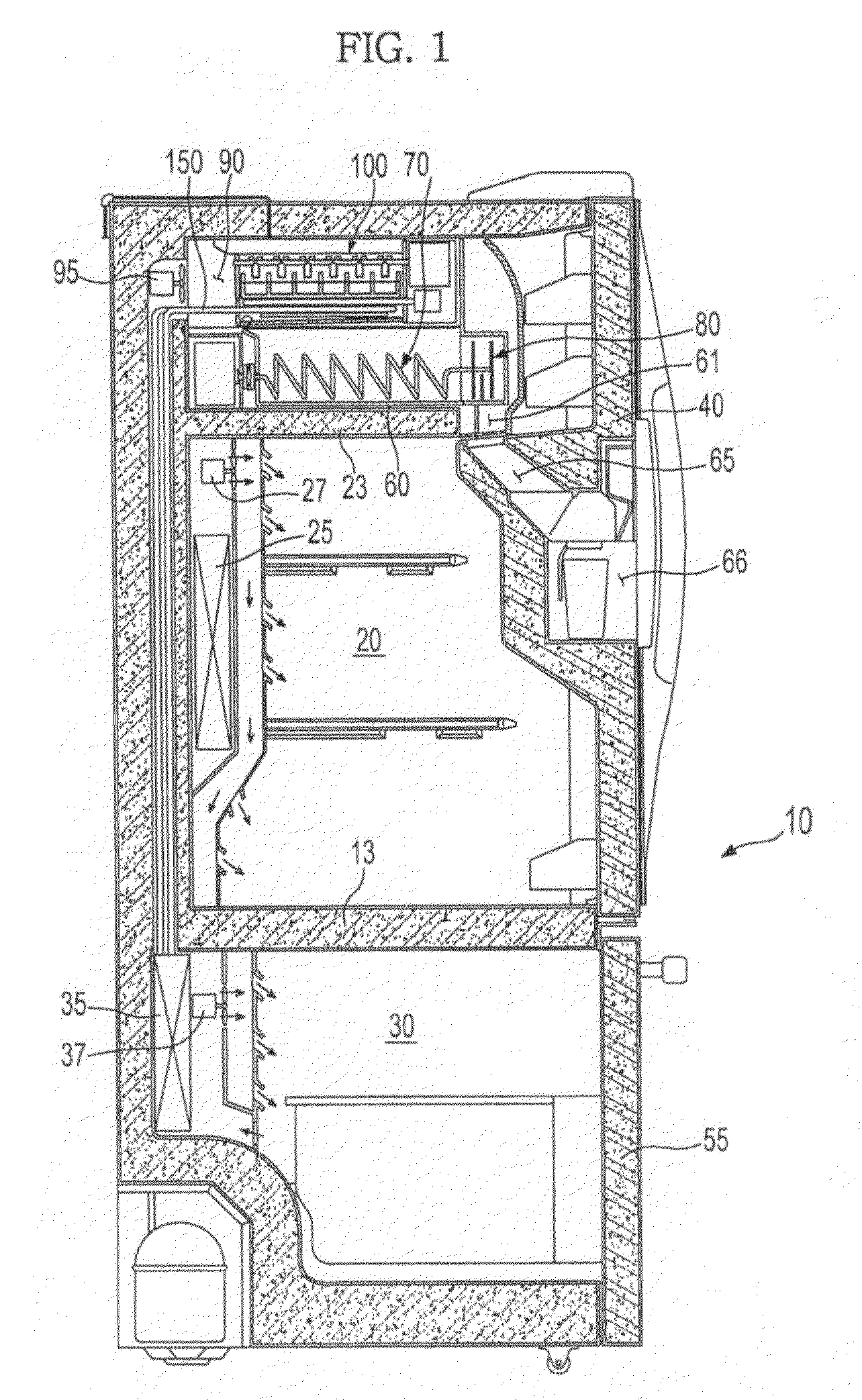

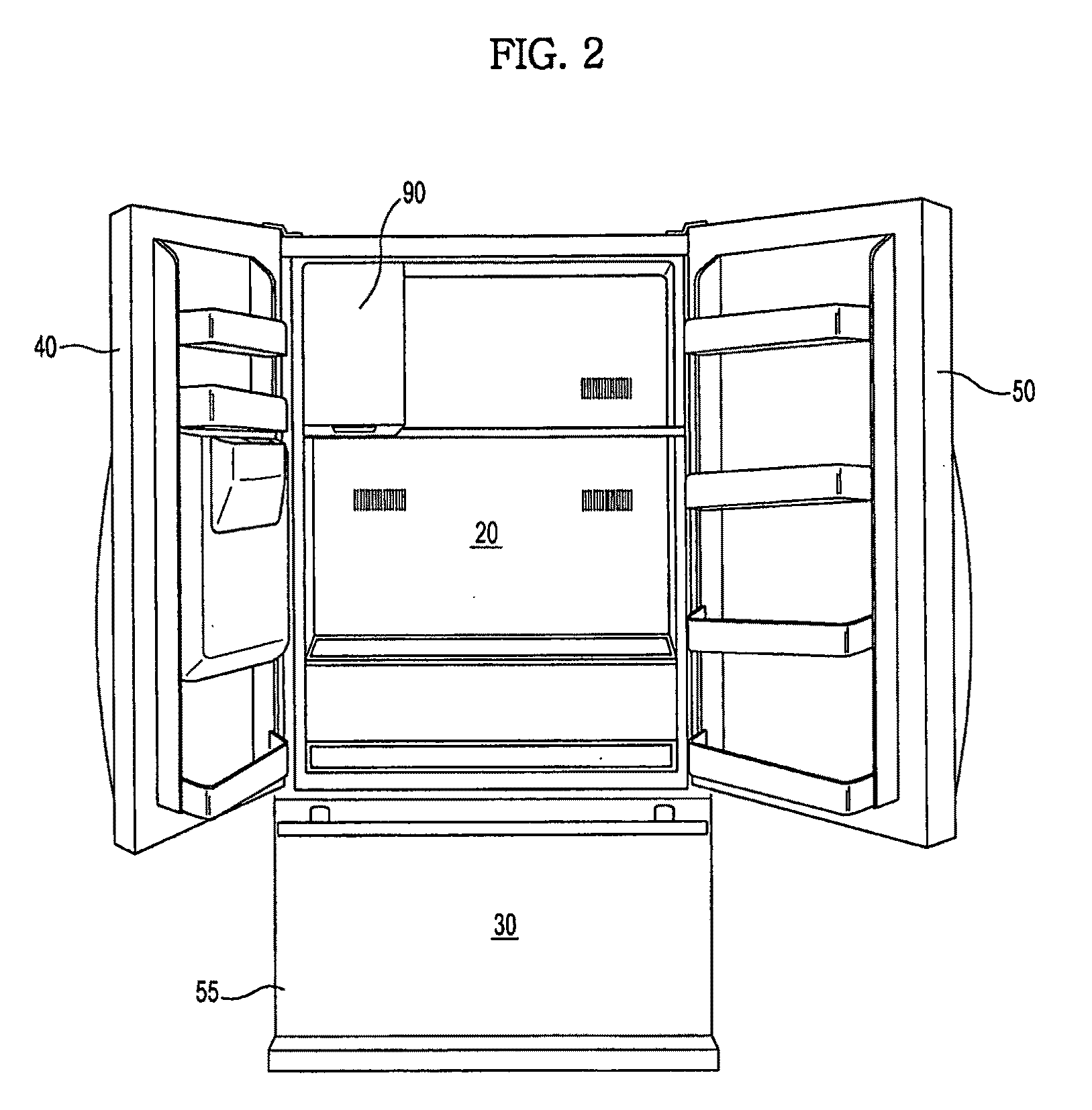

Icemaker unit and refrigerator having the same

ActiveUS20110000248A1Effective drainageImprove efficiencyLighting and heating apparatusIce productionEngineeringRefrigerated temperature

An icemaker unit and a refrigerator having the same. A drainage duct is provided to the icemaker unit, including a longitudinally inclined structure, a laterally inclined structure, and drainage holes to enhance drainage of the water. An upper part of the drainage duct is formed of a high heat-conductivity material and a lower part of the drainage duct of a low heat-conductivity material.

Owner:SAMSUNG ELECTRONICS CO LTD

Vegetable retainer for vegetable cooking utensil

InactiveUS20050028685A1Prevent projectionSatisfy safety performance requirementsJuice extractionFruit stoningCookerEngineering

In a vegetable retainer employed for a vegetable cooling utensil which is provided with a flat blade and a comb blade on a roughly central portion in a longitudinal direction of a vegetable cooking utensil main body of a roughly rectangle in a plan view to shred a vegetable and the like, in order that the vegetable retainer can be held reliably and that a finger tip is prevented from coming into contact with a cooking blade so that safety performance is improved, the vegetable retainer comprises an approximately flat plate-like retainer main body portion whose central portion underside is recessed to form a recess, a vegetable retaining portion which protrudes from the recess and which is constructed of a plurality of comb teeth bodies for being stuck into a vegetable and the like to retain it, sliding portions which extend vertically on both side portions of the retainer main body portion and which are guided by both side portions of the vegetable cooking utensil main body to slide, and a holding portion which extends upwardly from an upper surface of the retainer main body portion and by which a cooking person holds the vegetable retainer.

Owner:BENRINER

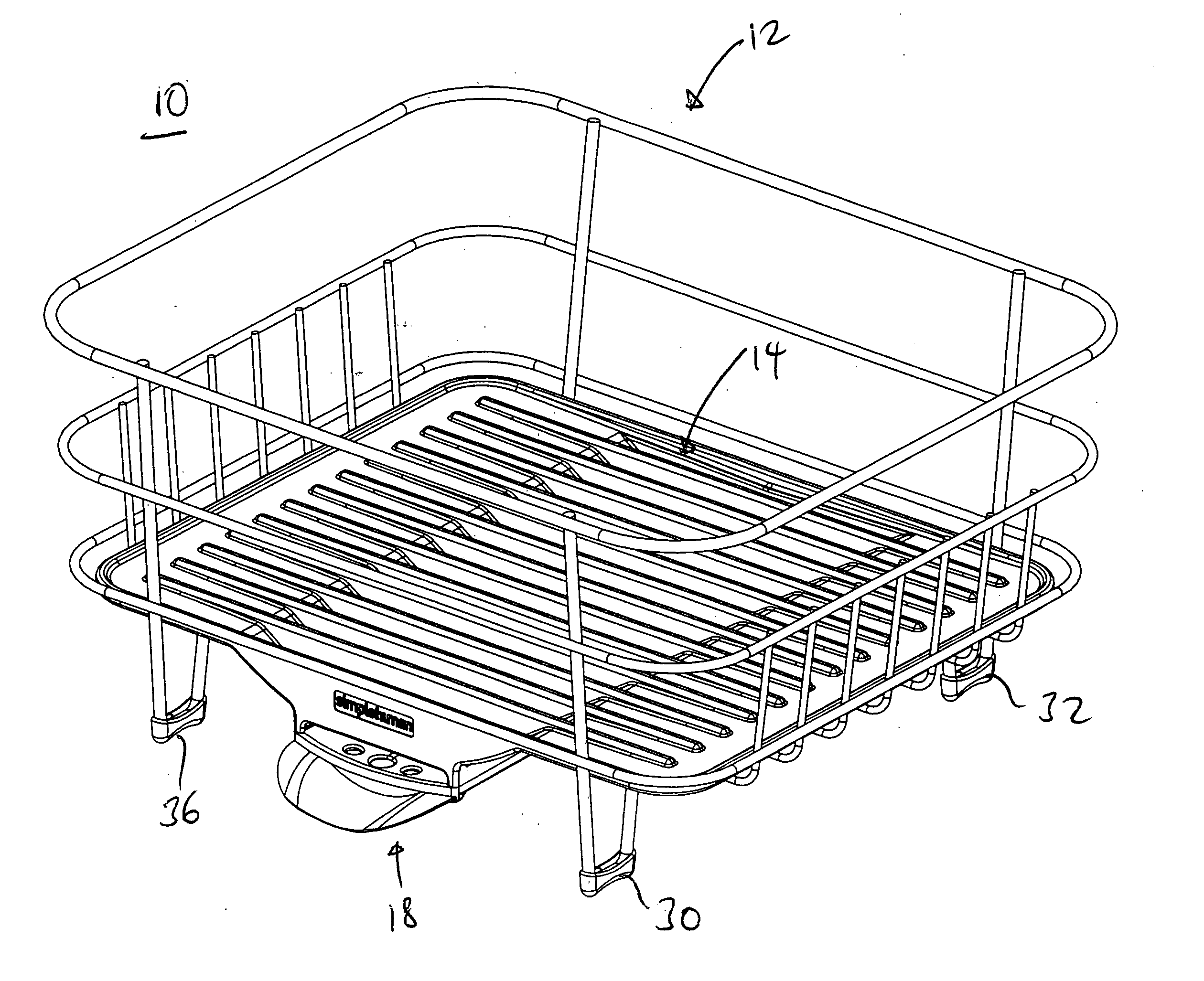

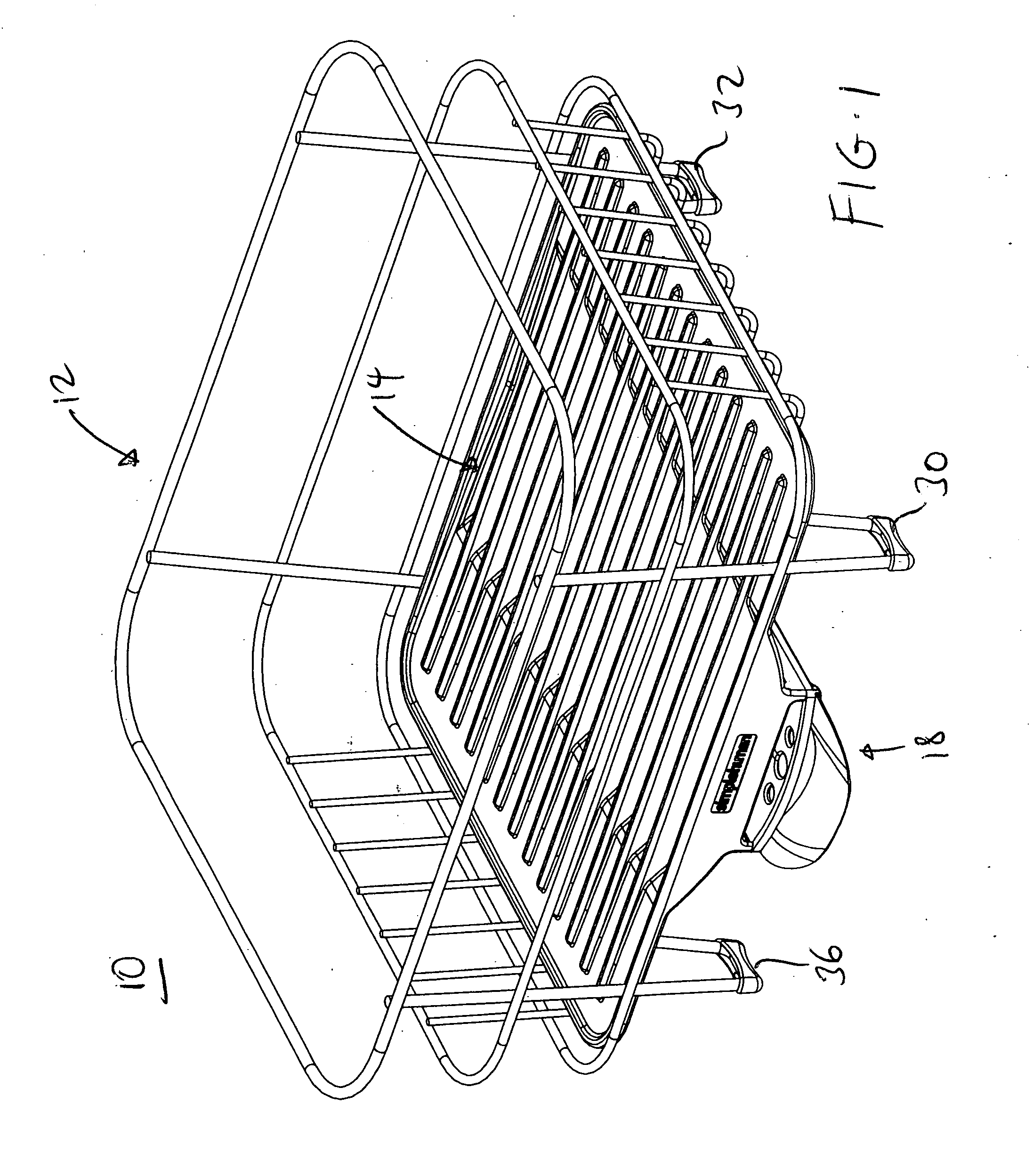

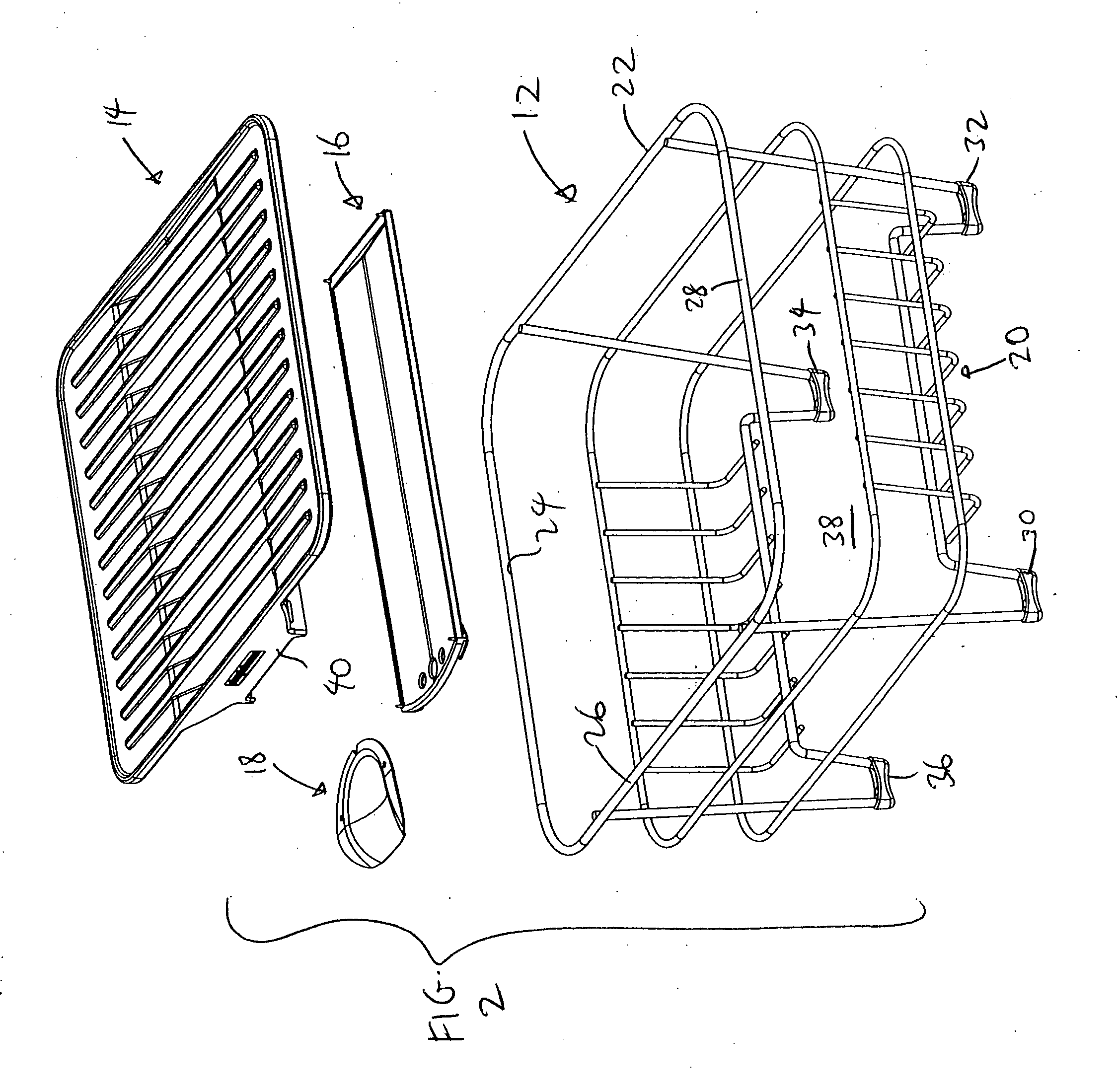

Dish rack with water drainage mechanism

ActiveUS20060283817A1Efficiently drainedEffective drainageKitchenware cleanersKitchen equipmentOutfallMechanical engineering

Owner:SIMPLEHUMAN

Drilling-explosion-pumping triadic gas extraction method

The invention relates to a drilling-explosion-pumping triadic gas extraction method, which is most suitable for regional gas extraction of a high gas and low permeability coal seam. The method comprises the following steps: alternately arranging hole positions of drainage holes and blast holes of an along bed or a cross seam on a coal seam in front of a coal mining or tunneling working surface; and performing construction work on the drainage holes one by one, and performing blasting operation, wherein through the edgetone effect of denotation gas in the blast holes, a columnar compression crushing circle and a crack body which passes through and blasts in the direction of a line of centers of the blast holes and the extraction holes are generated on the periphery of a blasting hole to transfer the ground stress, improve the gas permeability of a coal body, relieve the pressure in a coal body and facilitate for drainage of gas in the coal body. The gas permeability of the coal body can be improve by around 20 to 50 times, the gas extraction quantity of haplopore can be increased by 5 to 10 times averagely, the gas extraction concentration is more than or equal to 50 percent, and the gas extraction rate of a robbing working surface is more than or equal to 80 percent. After pressure releasing and permeability improving of drilling, explosion and pumping, the gas pre-extraction time can be shortened by half, and the number of drilling holes of gas extraction is decreased by 20 to 30 percent; and the method achieves safe, high-efficiency and uniform extraction of the gas in the high gas and low permeability outburst coal seam.

Owner:CHINA UNIV OF MINING & TECH

Heating plate for vacuum filter press

InactiveUS20060032805A1Efficient heatingAssist in removingStationary filtering element filtersFiltrationFilter press

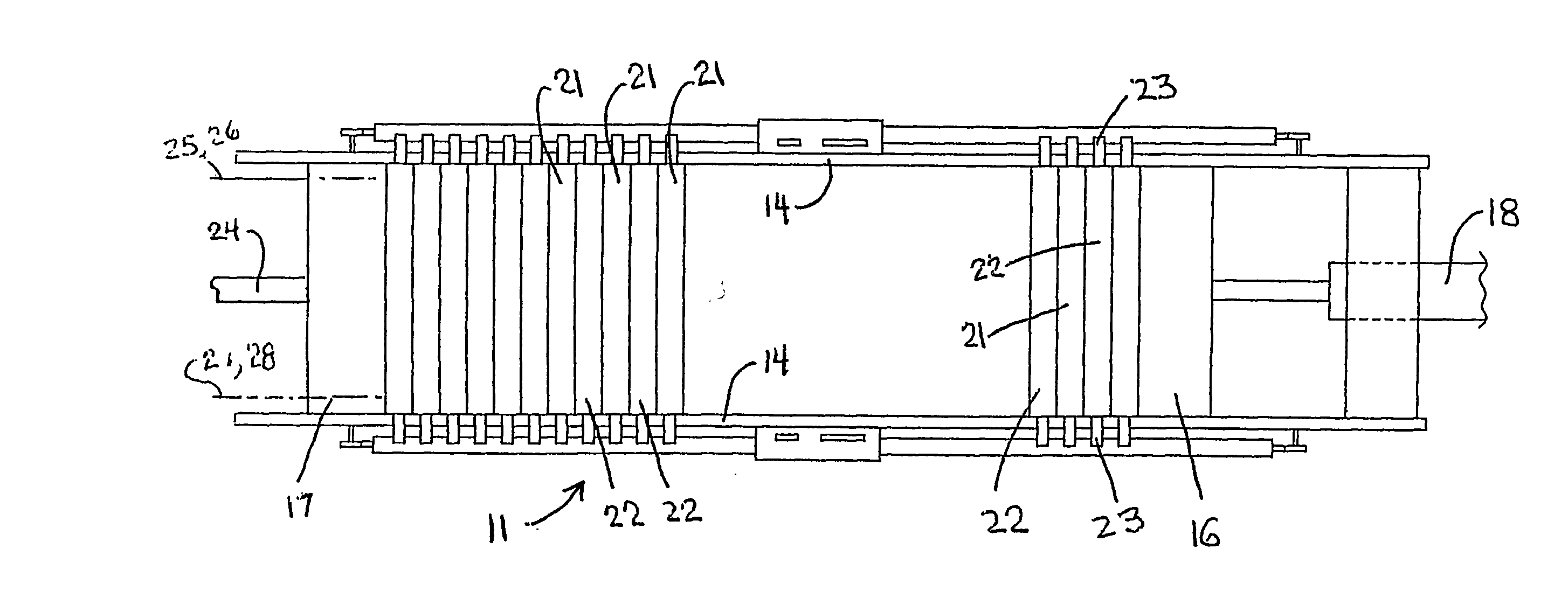

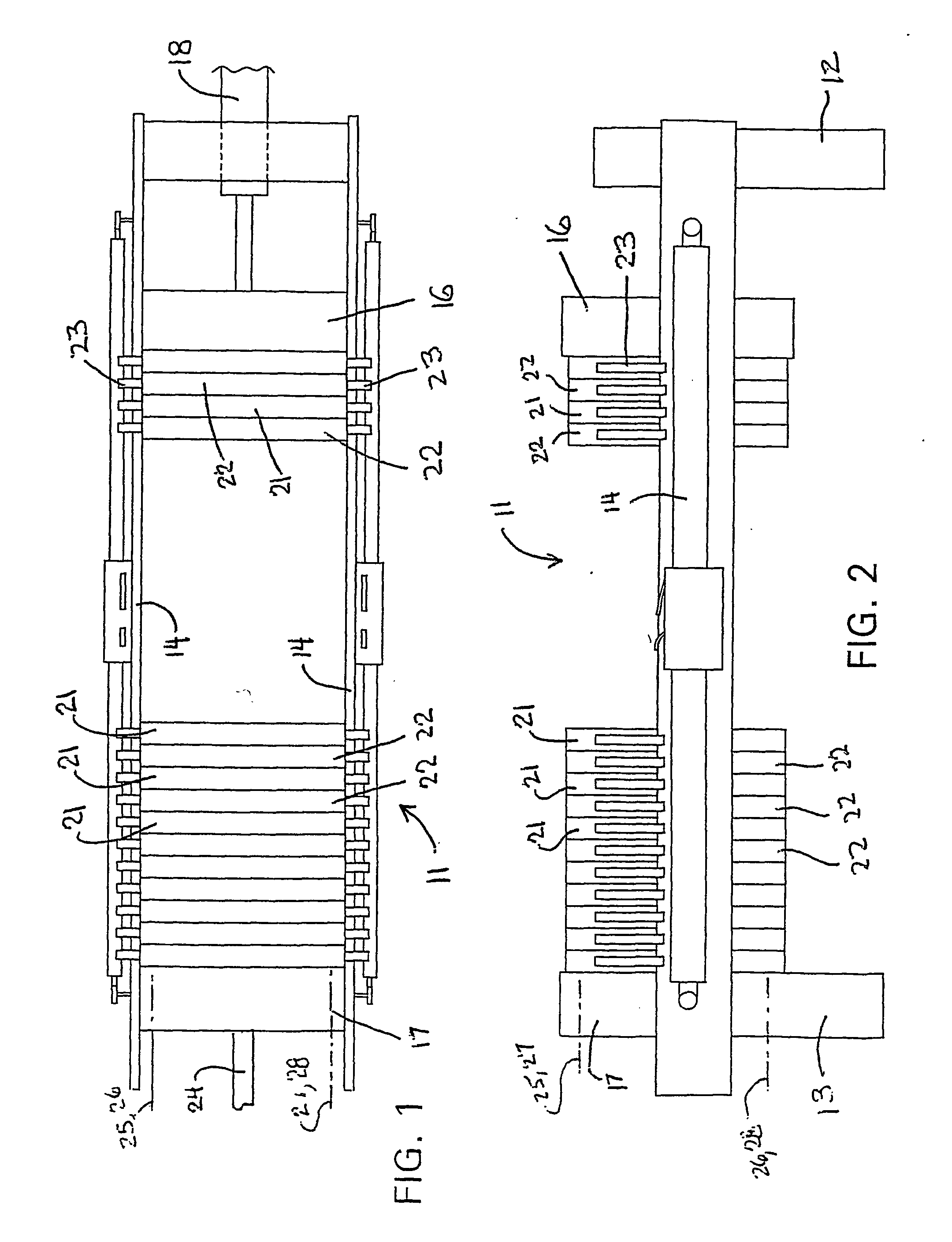

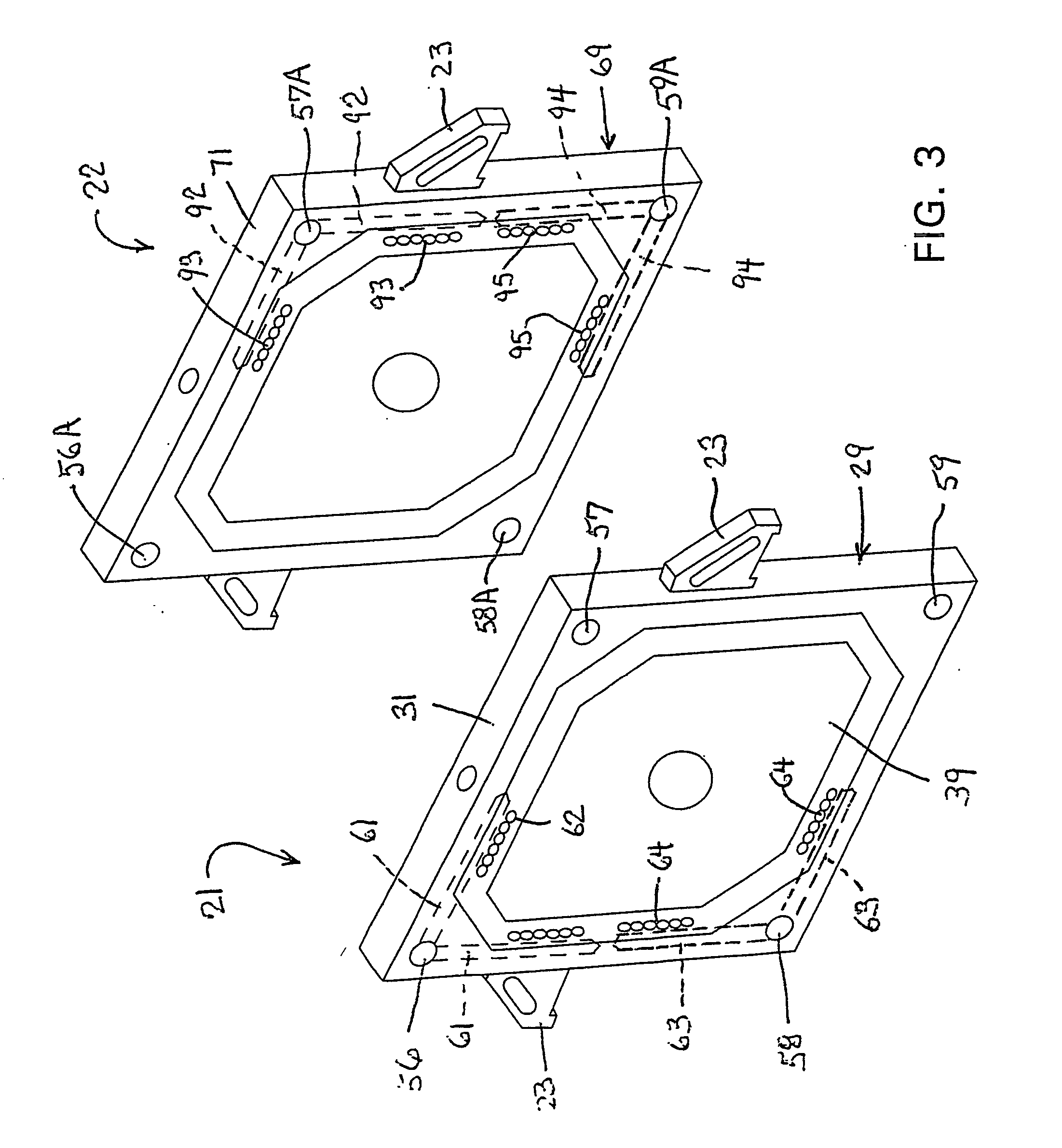

A filter press (11) defined by a closable stack of filter plates defined by a first plurality of membrane filter plates (21) alternately disposed with a second plurality of heating-type filter plates (22). The membrane plates (21) have chamber-defining recesses on opposite sides thereof, with each recess (36) having a flexible membrane (39) associated therewith which can be pressurized from the rearward side so as to effect squeezing of the cake in the filtration chamber. Each heating plate (22) also has chamber-defining recesses (74) on opposite sides thereof, and the main center bottom wall (76) of each recess (74) has a metal heat transfer surface (77) associated therewith, the rear side of which is in intimate contact with a chamber or passage (79) which receives therein a high-temperature heat transfer fluid.

Owner:UNITED STATES FILTER CORPORATION

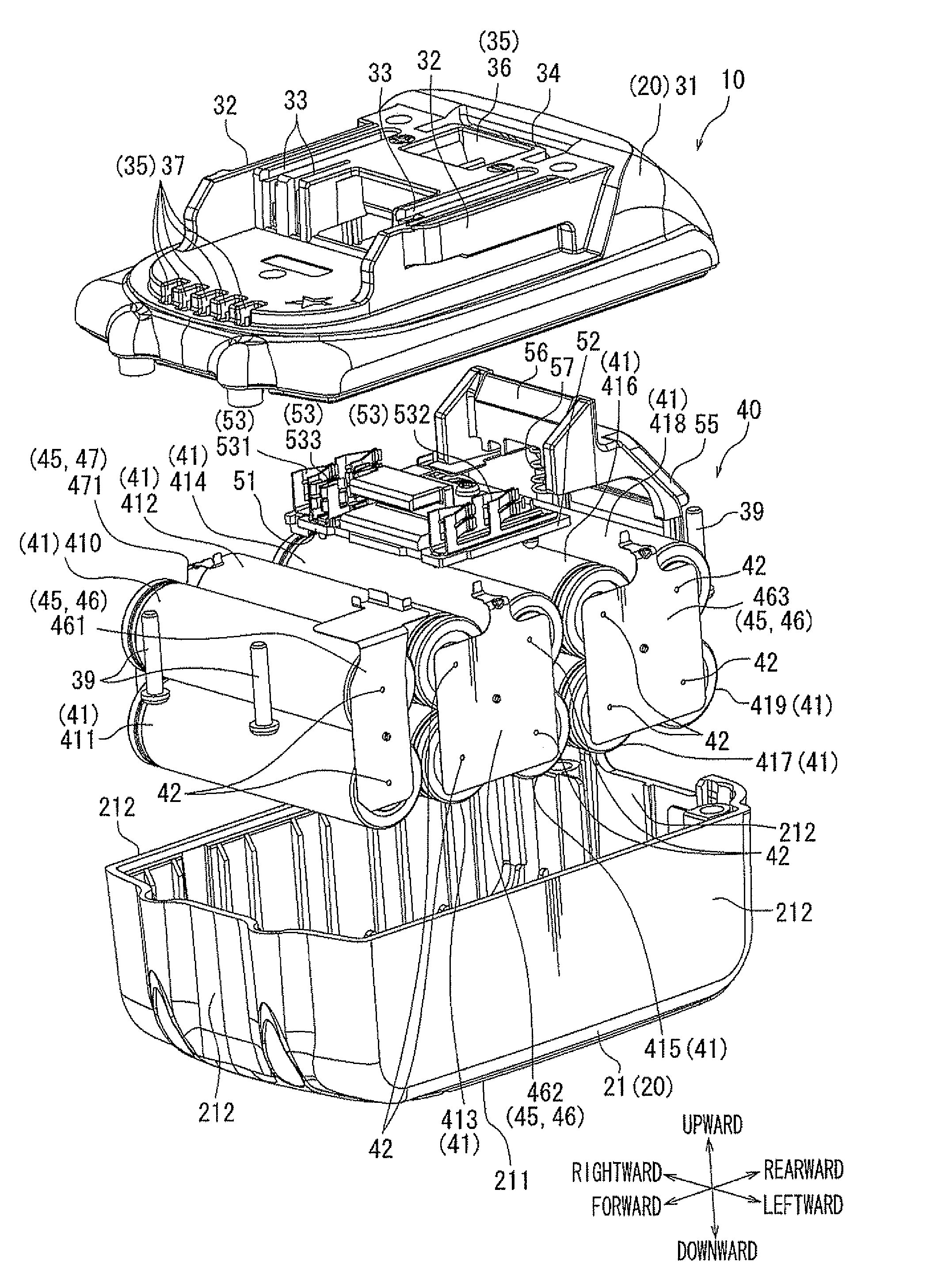

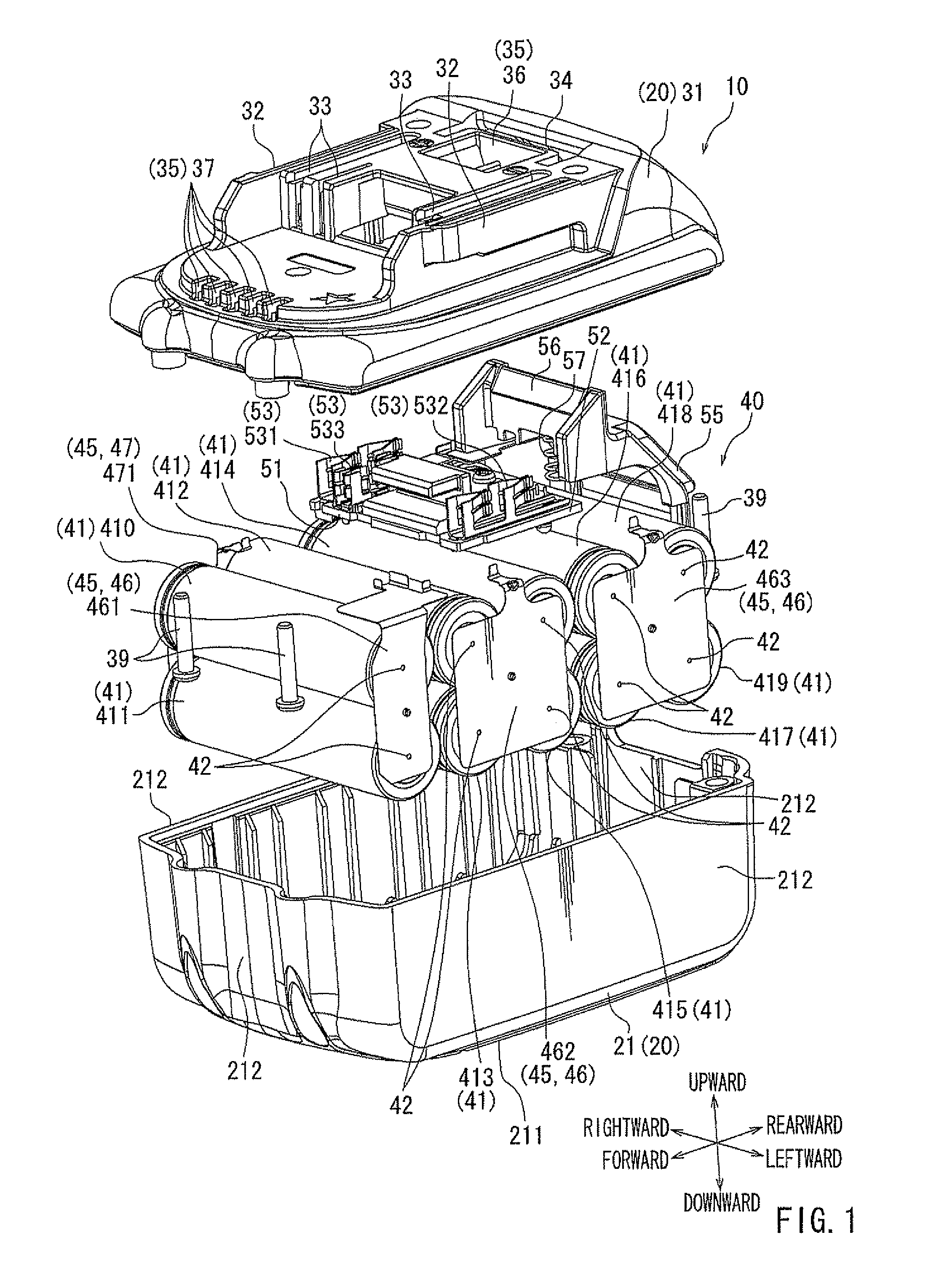

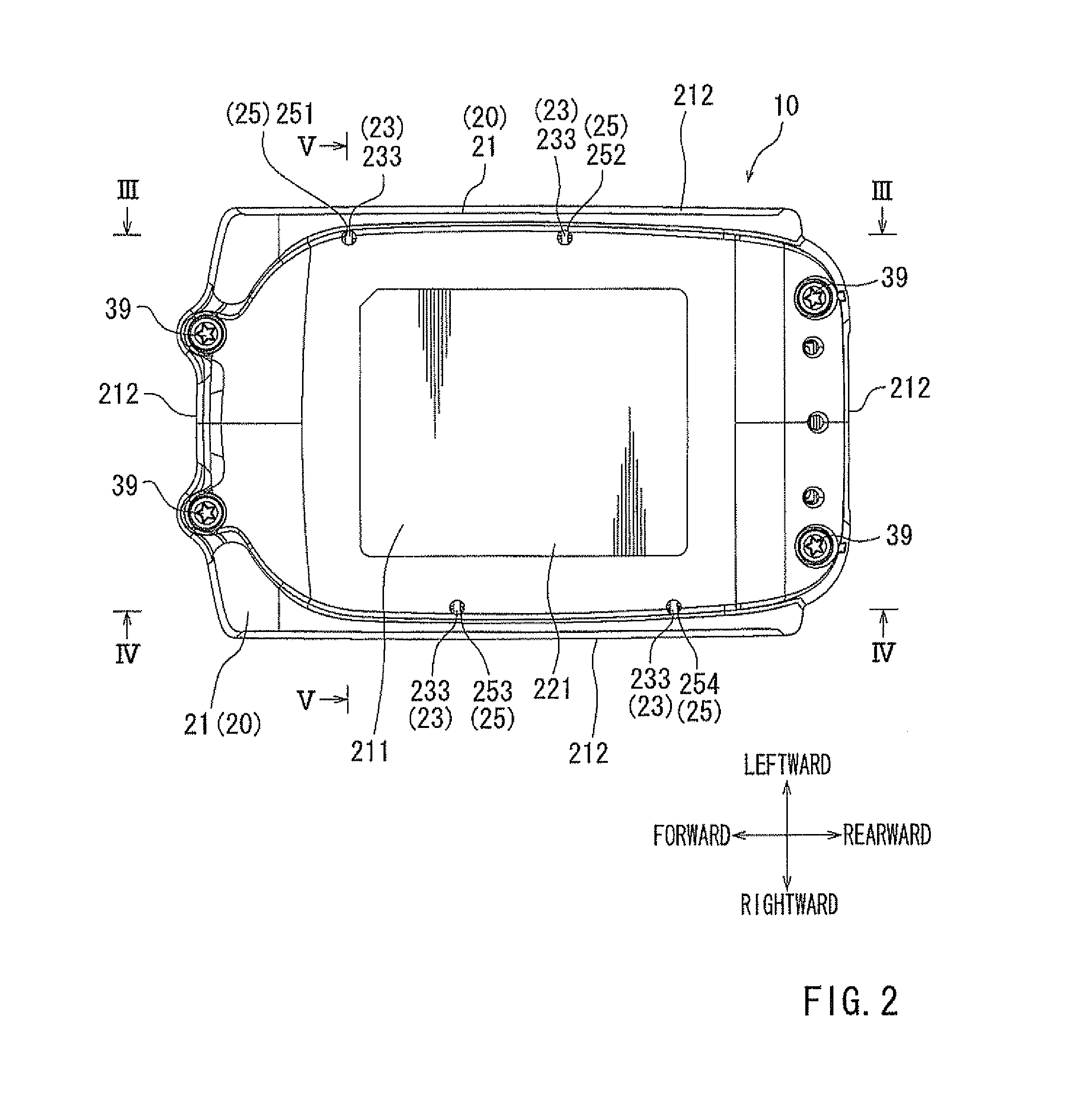

Battery pack

ActiveUS20130224539A1Prevent leakageReduce the numberBattery isolationBatteriesEngineeringBattery cell

A battery pack may include a drainage device provided at a bottom portion of the housing case. The drainage device may include a drain hole communicating between the inside and the outside of the housing case, so that water introduced into the housing case is discharged to the outside of the housing case. The drainage device may be disposed between two of the terminal members that are connected to electrodes of the battery cells.

Owner:MAKITA CORP

Animal feeding bowl

InactiveUS8381684B2Easy to cleanEasy maintenanceAnimal feeding devicesAnimal housingEngineeringIndividual animal

An animal feeding structure can include one or more openings to drain water that is sprayed into the feeding structure in order to clean it. By draining the incident water, the remaining dirt, food and other particles are drained and removed from the feeding structure, thereby cleaning the structure without direct handling. Also, because the water is drained, water bounce back onto the person cleaning the bowl can be greatly reduced. The feeding structure can include an opening covered by a raised cap whose clearance from the bottom of the bowl can be adjusted. The feeding bowl can also include lateral and / or longitudinal slits of various sizes and shapes. The size and shape of openings can be designed to prevent food from falling out while allowing water, food crumbs, dirt, and debris to drain out. The effective size of the openings can be adjusted.

Owner:CRAWFORD STEPHEN W

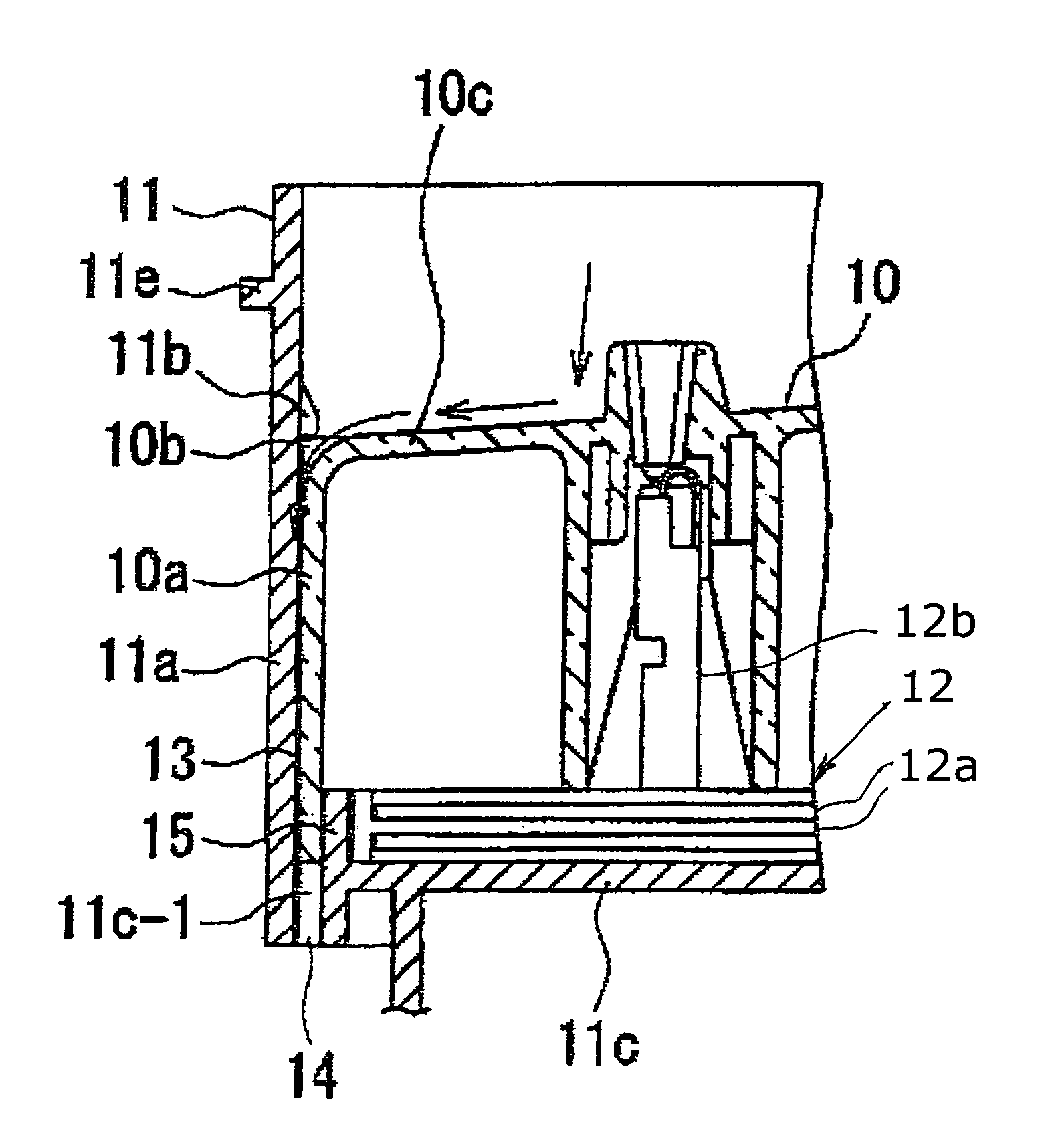

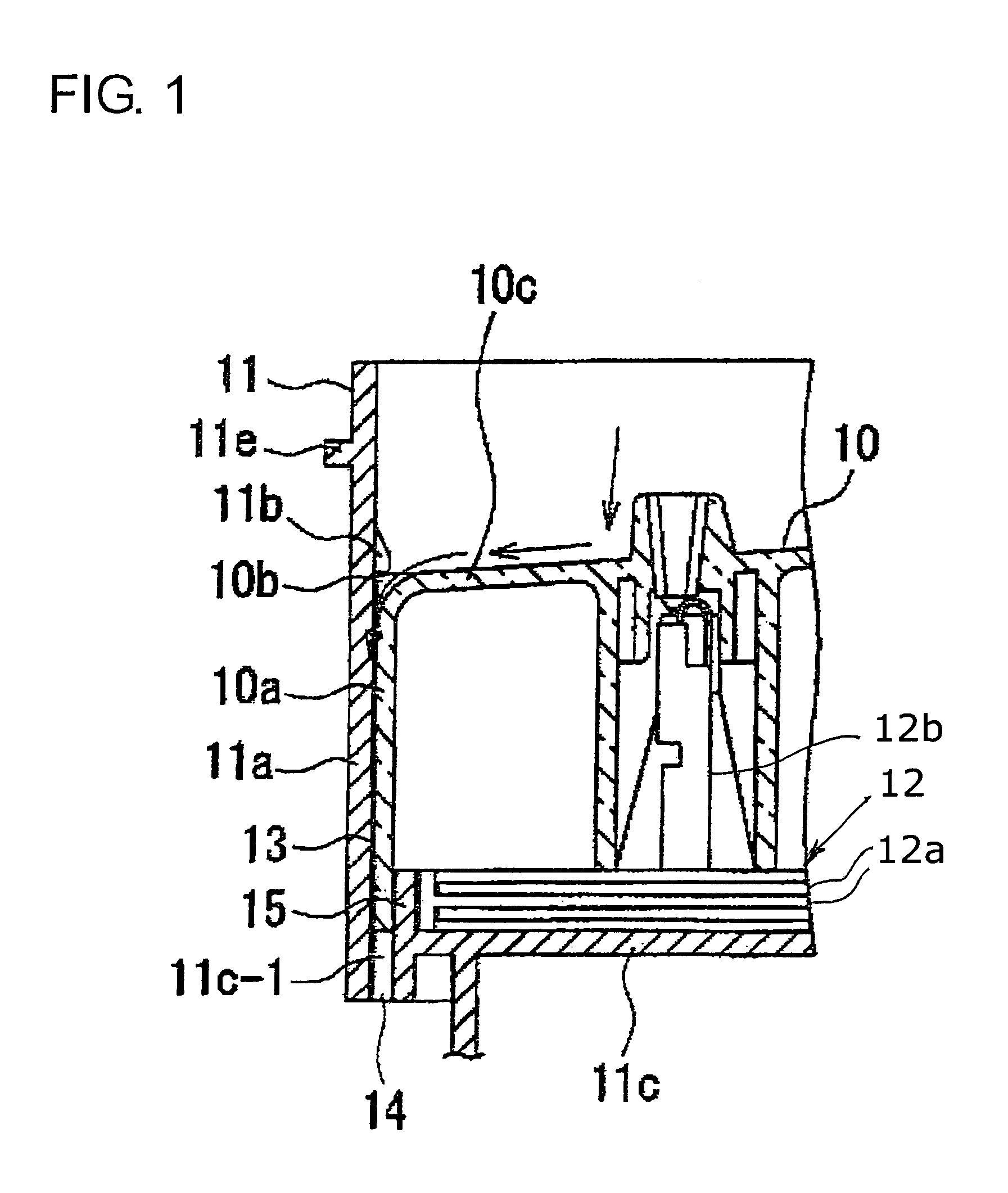

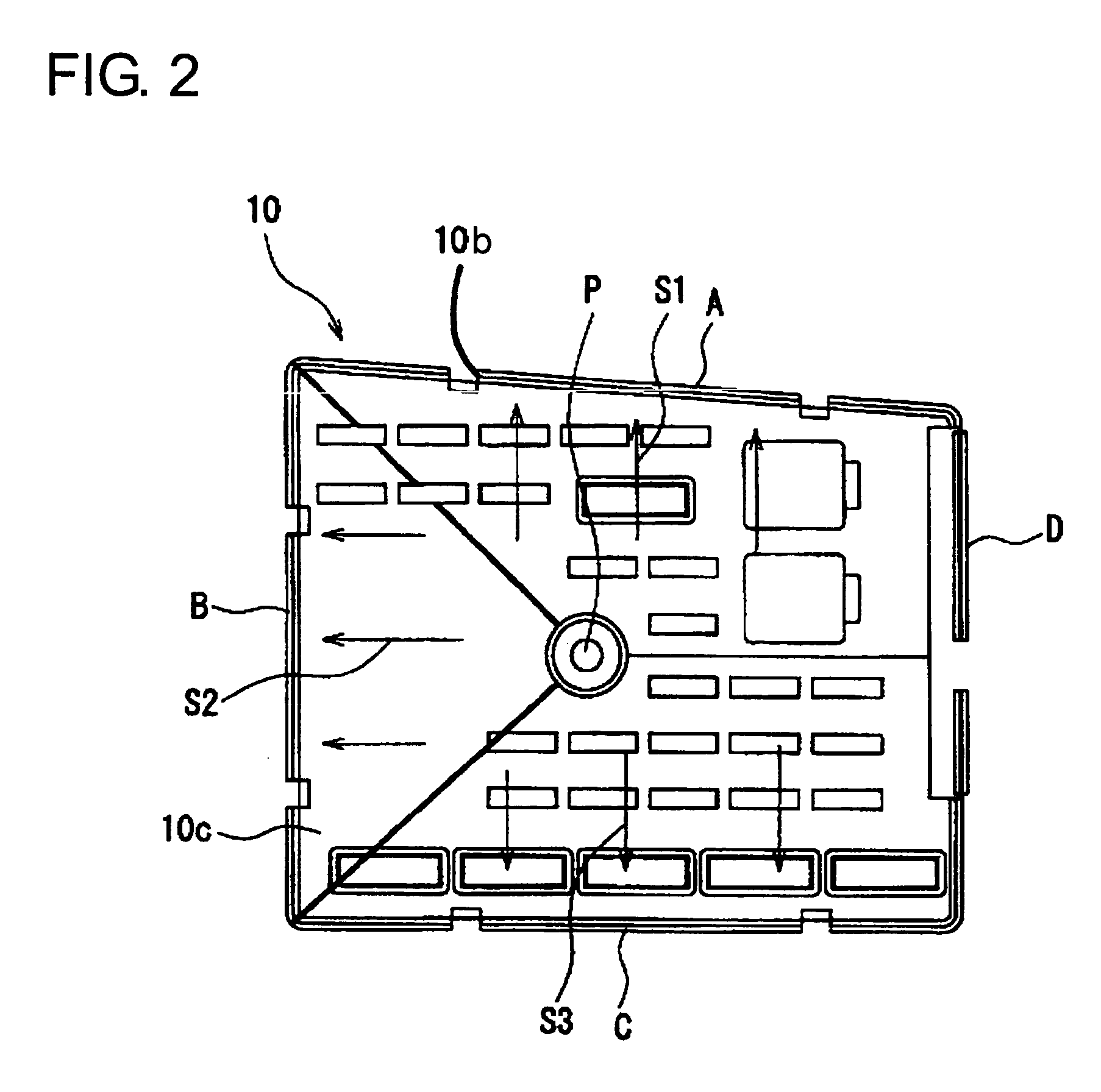

Automotive electrical connection box and a method of mounting it

InactiveUS6982379B2Effective drainageConstructionsTransformers/inductances coils/windings/connectionsElectrical connectionEngineering

An electrical connection box has upper and lower casings (10, 11) for accommodating circuitry. A surrounding wall (10a) of the upper casing (10) fits inside a surrounding wall (11a) of the lower casing (11). Engaging locking claws (10b, 11b) project from the outer surface of the surrounding wall (10a) of the upper casing (10) and from the inner surface of the surrounding wall (11a) of the lower casing (11). An upper wall of the upper casing (10) is inclined down from a center portion to three peripheral edges. A drainage path (13) is defined by a clearance between the surrounding walls (10a, 11a) of the upper and lower casings (10, 11). A bottom wall of the lower casing (11) has drainage holes (14) at the bottom end of the drainage path (13).

Owner:SUMITOMO WIRING SYST LTD

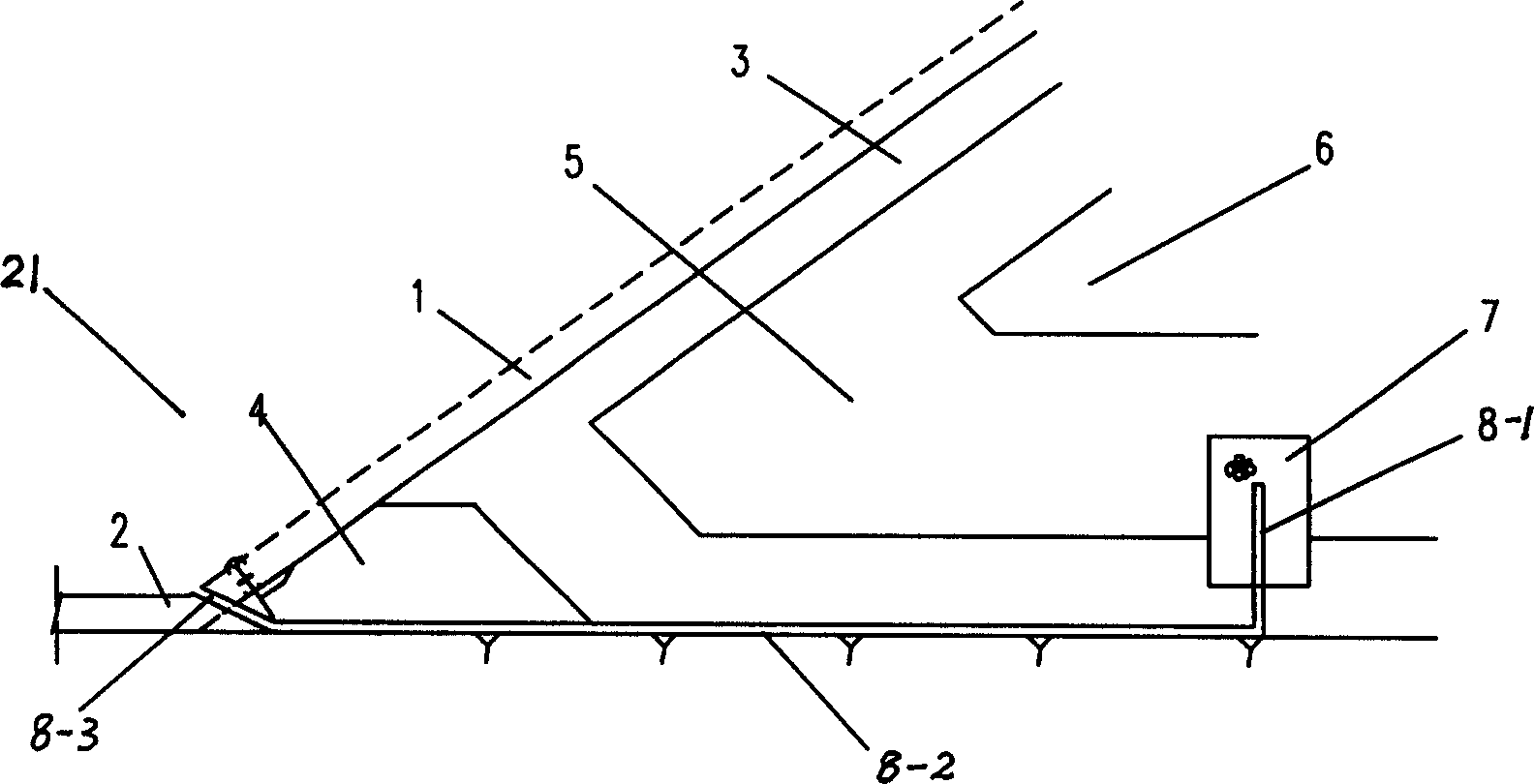

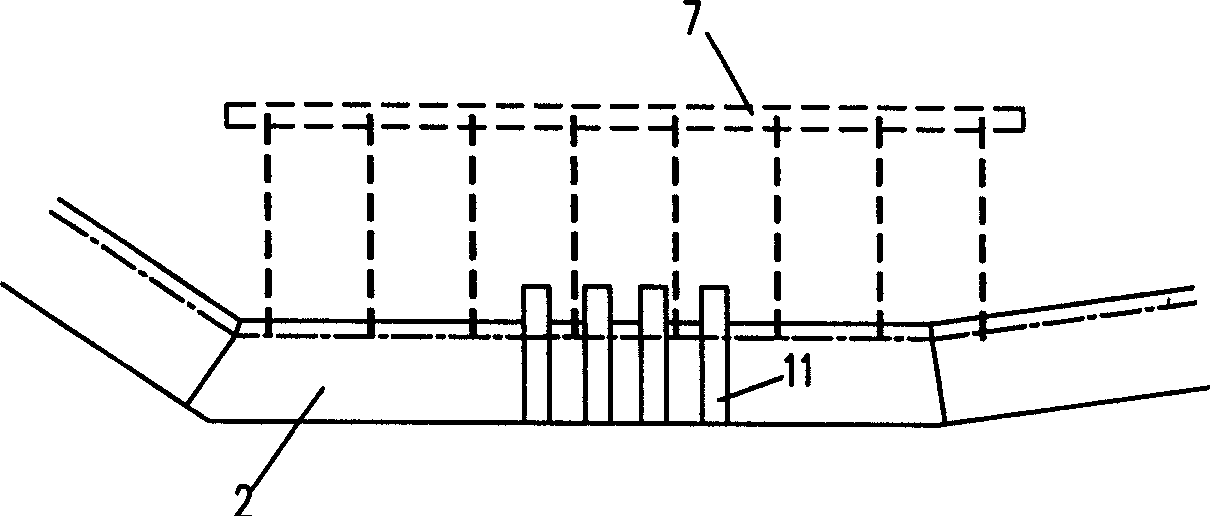

Power-free reverse-water-pressurizing self-recovery slope high-lift siphon drainage system and drainage method

ActiveCN104196047AOvercome accumulationDischarge in real timeFoundation engineeringWater storageSiphon

The invention relates to a power-free reverse-water-pressurizing self-recovery slope high-lift siphon drainage system and drainage method adaptive to accumulation member slope drainage of rich rainfall areas. The system includes an automatic drainage system and an automatic recovery system. The automatic drainage system comprises a siphon drainage hole, a high-lift siphon drainage tube and a siphon water storage tube; the automatic recovery system comprises a water collecting blind groove, a water collecting case, a water feeding pipe,a two-way water incoming and draining valve and the like. The high-lift siphon drainage system with the lift more than 5cm is utilized, and the excessive underground water in the slope can be drained automatically, efficiently and timely; reverse water feeding is performed on the automatic drainage system by the automatic recovery system to start siphon, the air accumulated in the siphon pipe can be exhausted, and long effective period of a forward siphon system is guaranteed; the system is simple in structure, the power is omitted, the discharging effect is fine, the continuity and applicability are high, and the maintaining cost is low.

Owner:ZHEJIANG UNIV

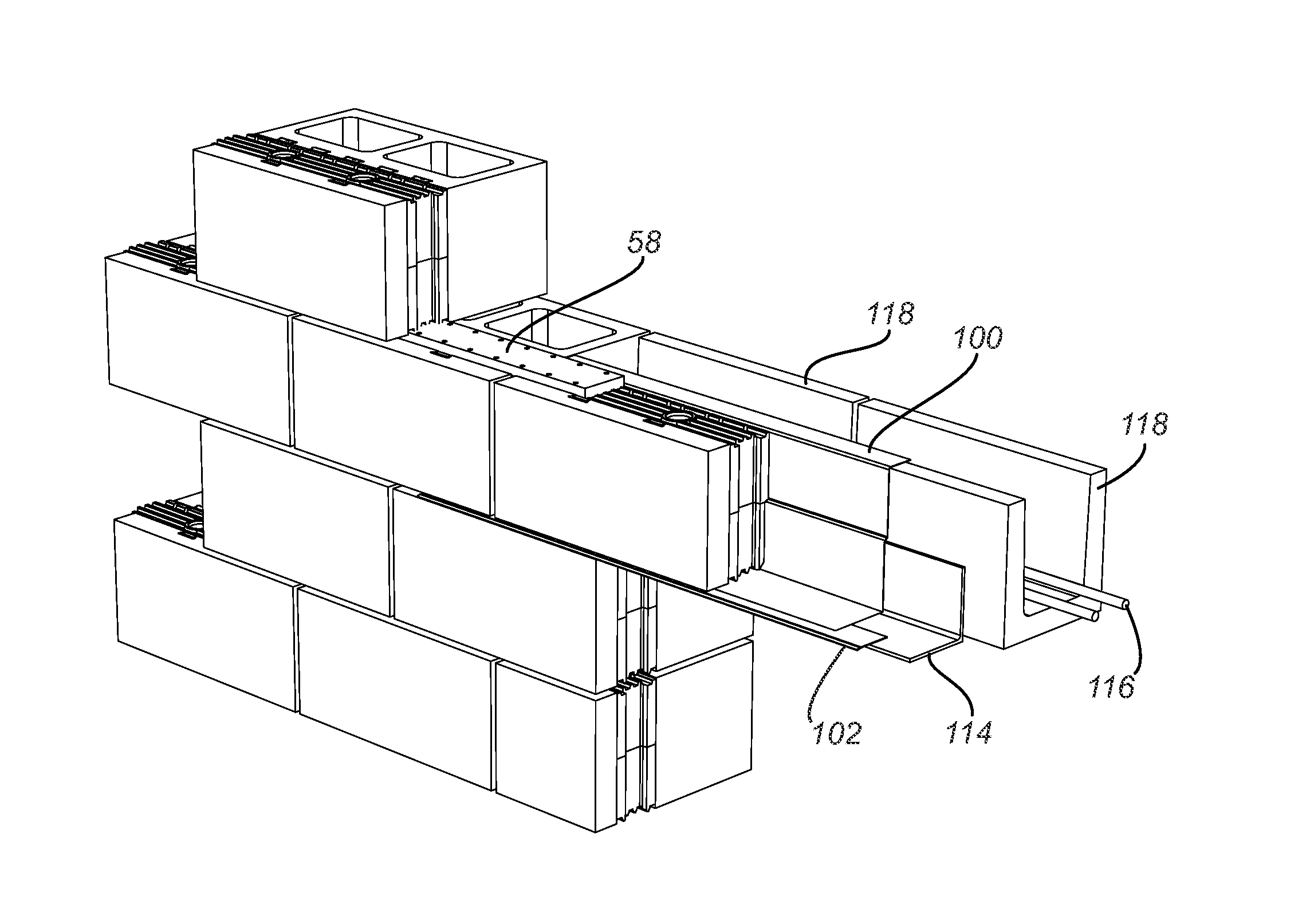

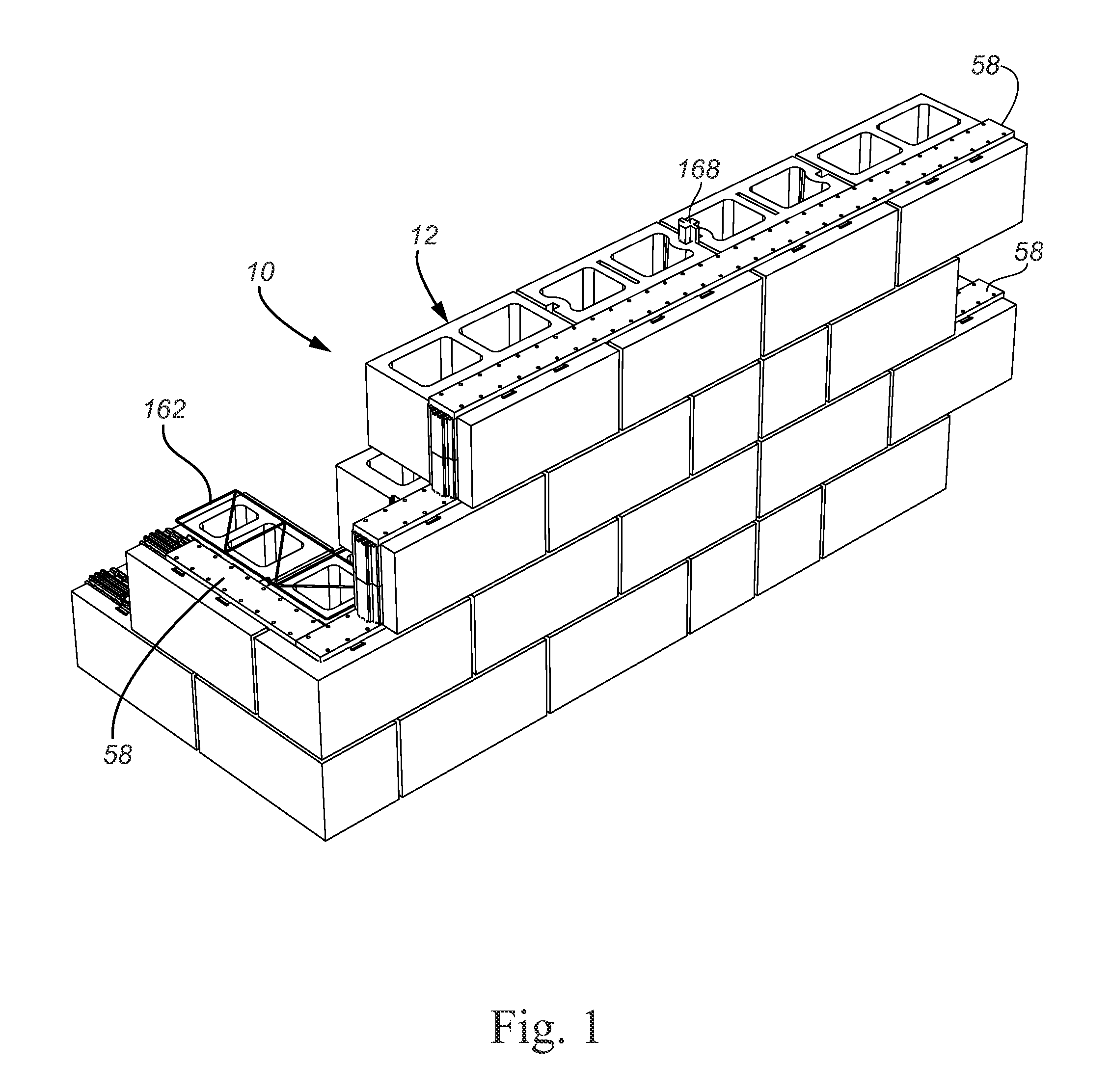

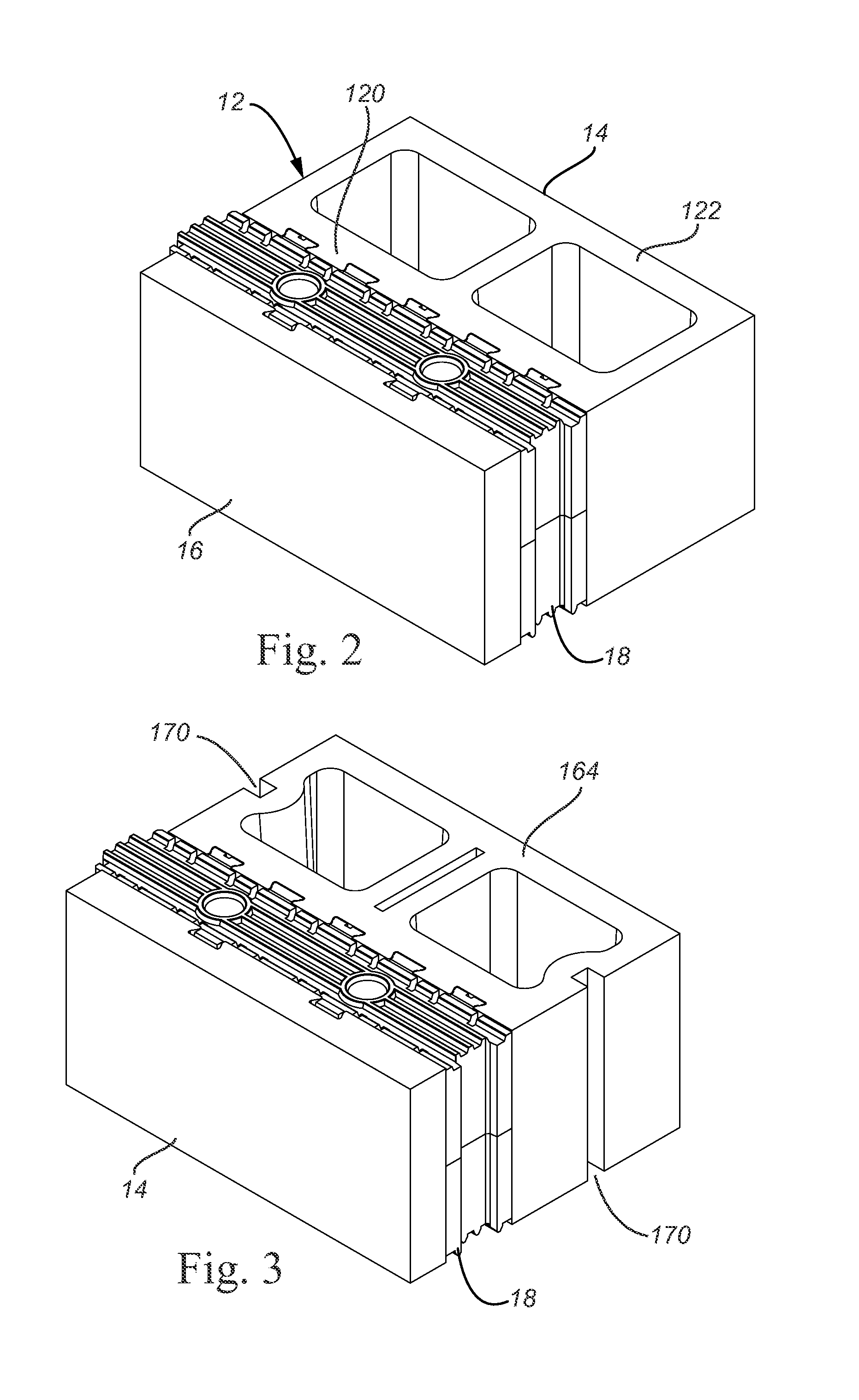

Insulated concrete masonry system

ActiveUS20140260029A1Strong and inexpensiveAvoid thermal bridgeStrutsConstruction materialStructural engineering

A insulated masonry wall system having insulation blocks between structural and face blocks to provide structures that are strong, inexpensive, avoid thermal bridges, and resist transmission of heat. The walls are attractive and versatile, and an enormous variety of decorative face members may be utilized. The face blocks are attached to the structural blocks to prevent facing materials from falling even if fire destroys the insulation blocks between the structural blocks and the facing. The system resists water penetration and effectively drains water that does penetrate any portion of the system.

Owner:OLDCASTLE ARCHITECTURAL

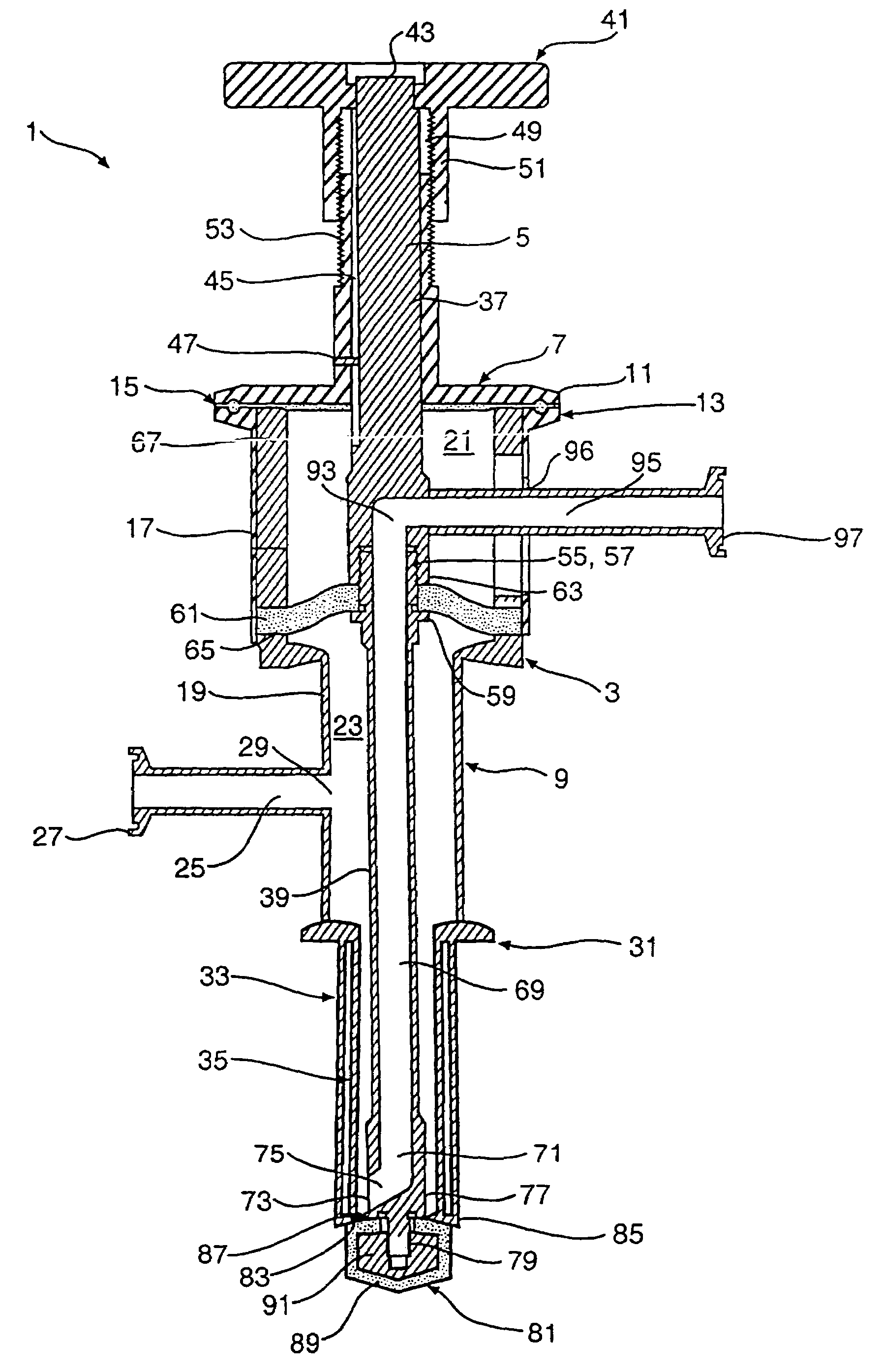

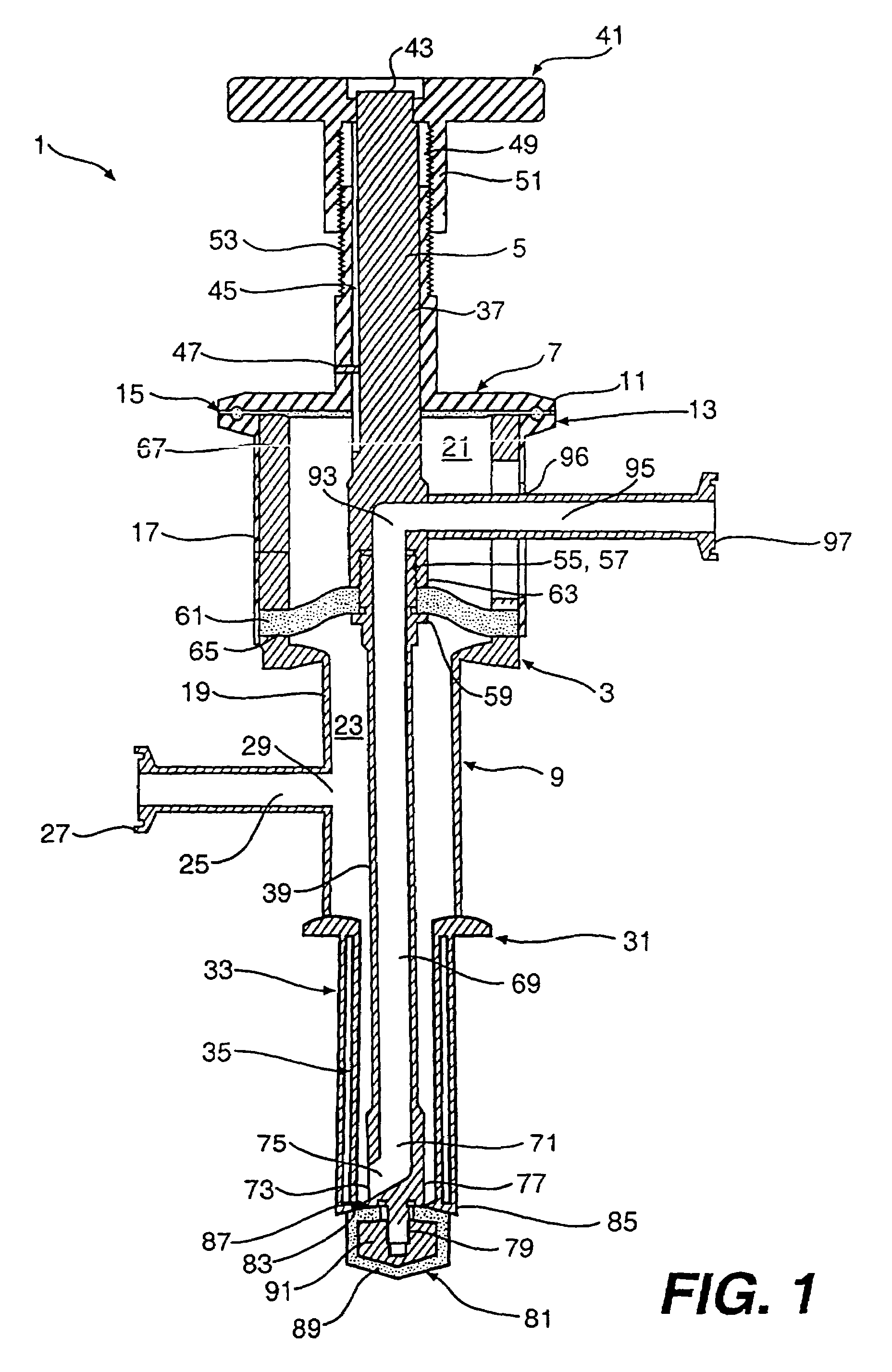

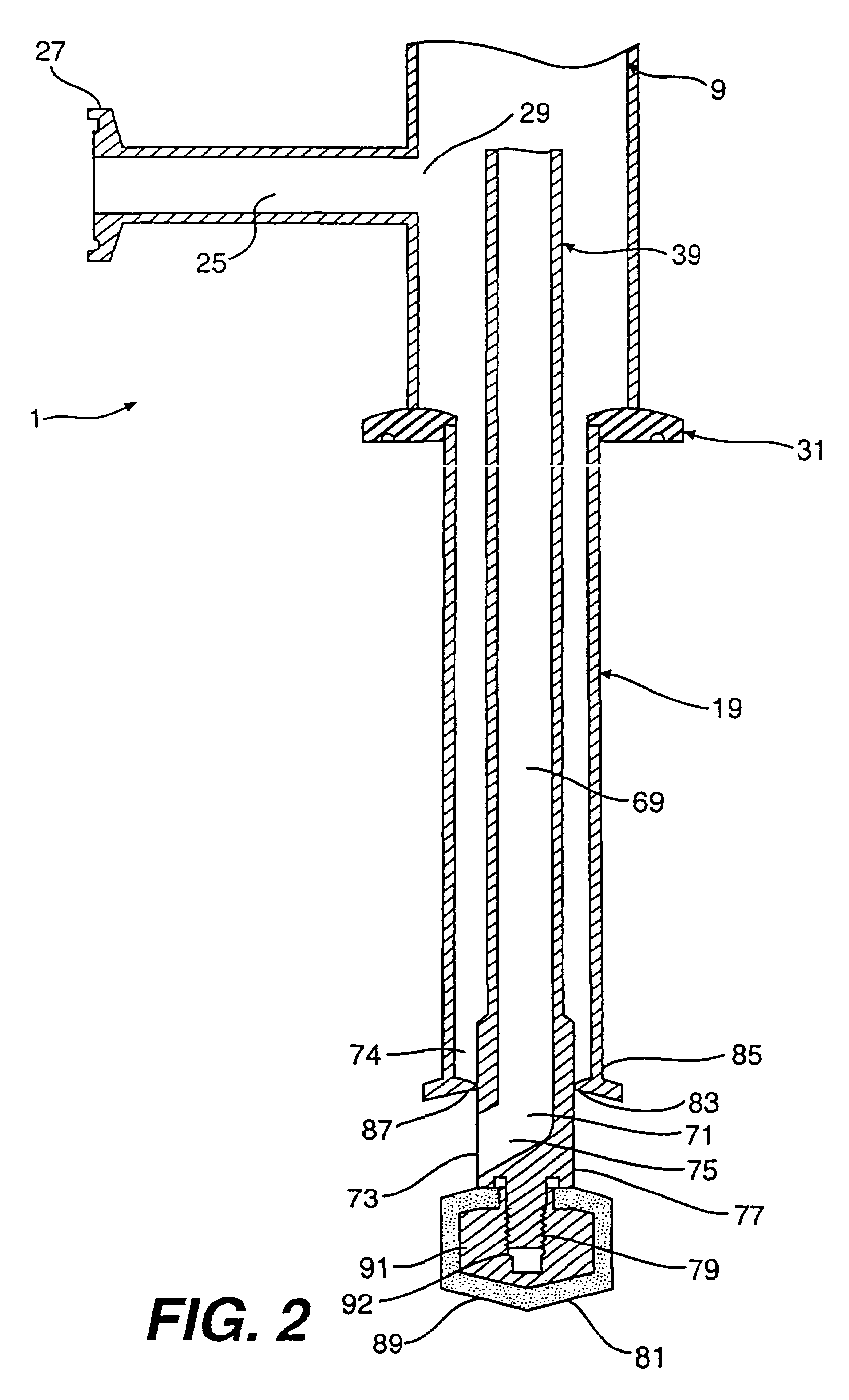

Dip tube valve assembly

Owner:NL TECH

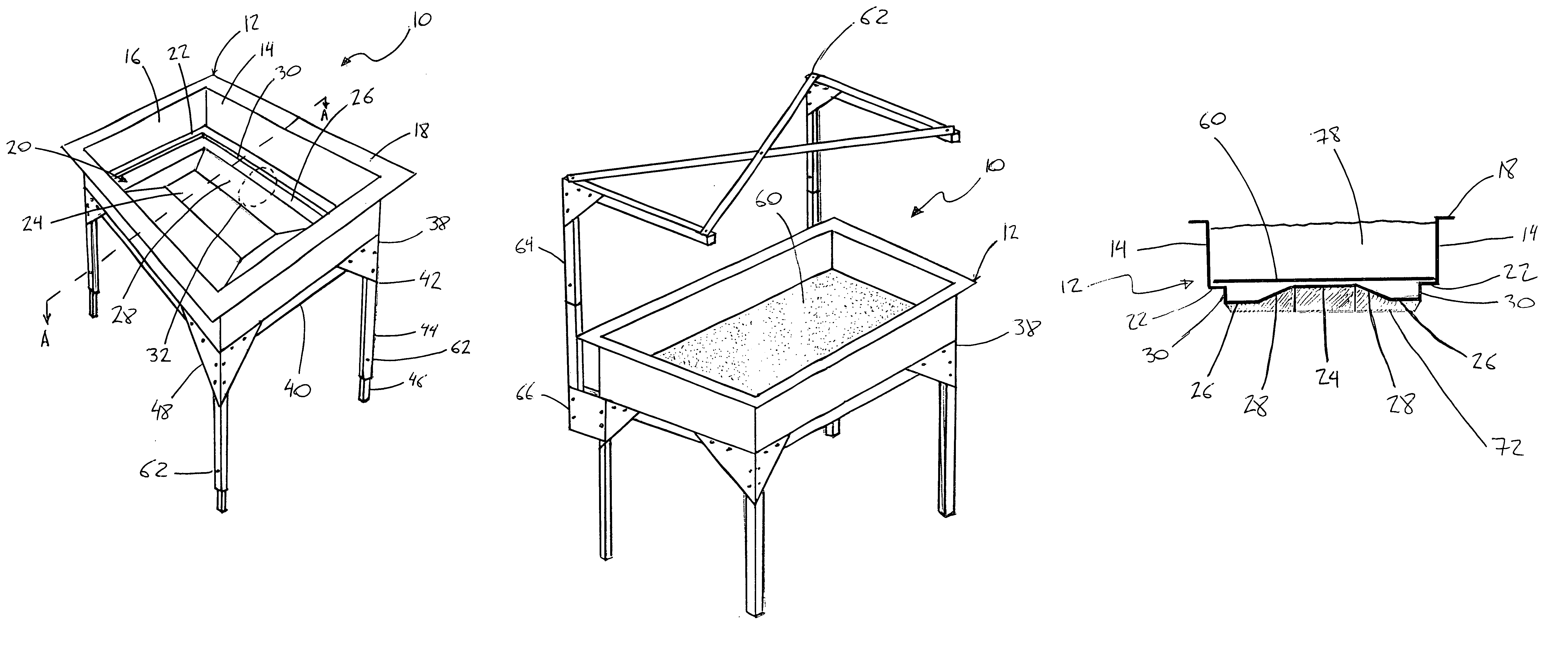

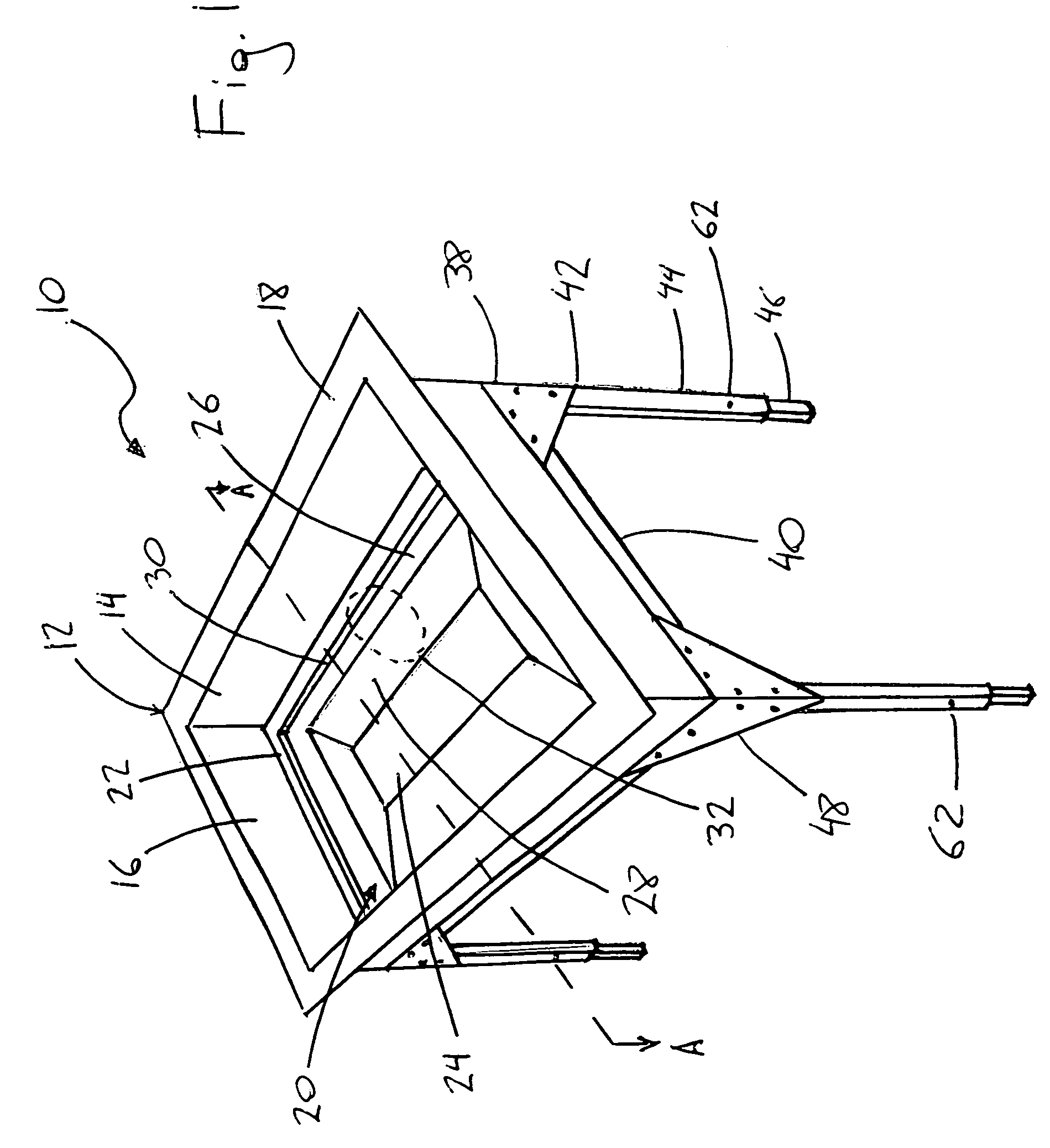

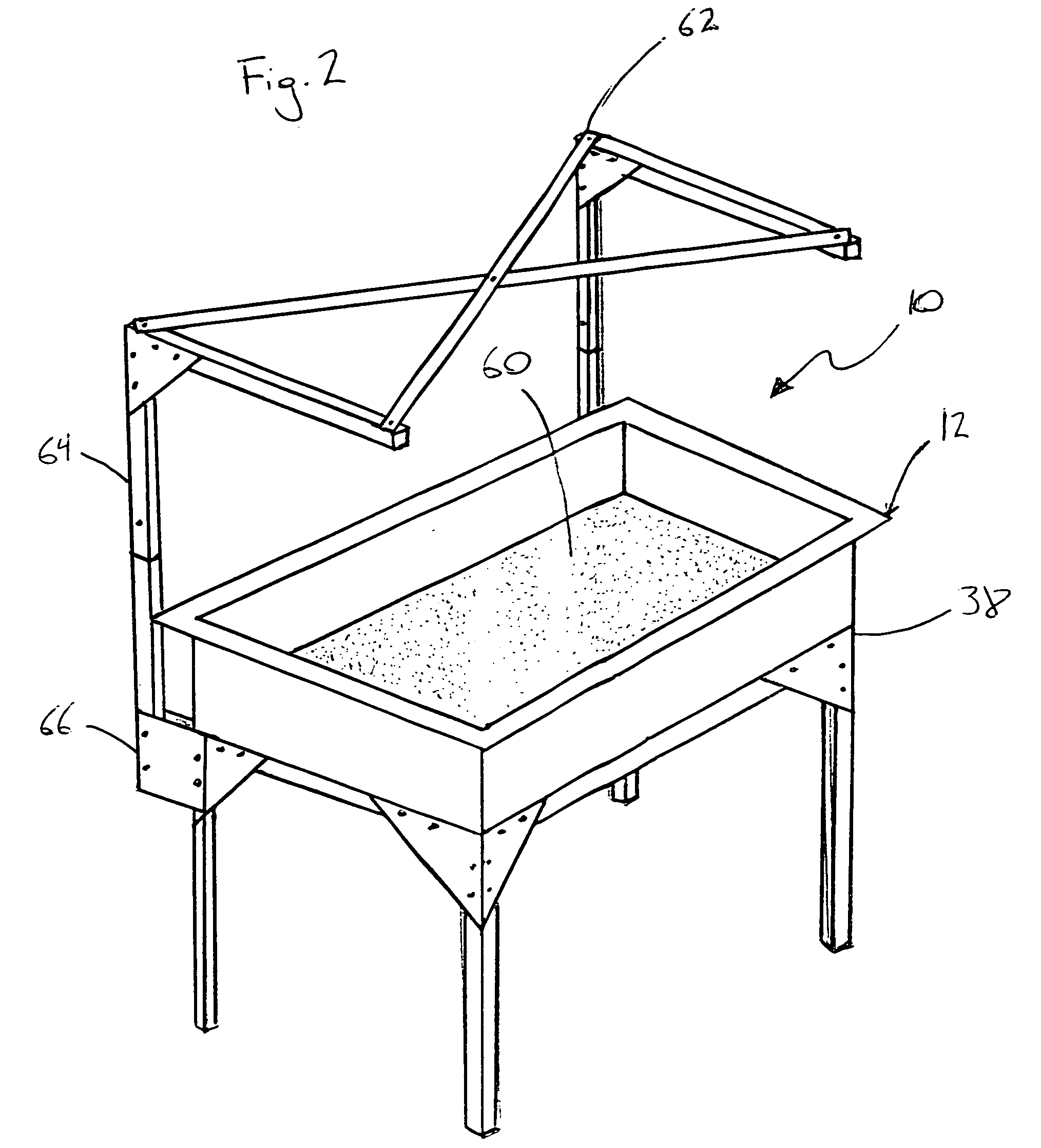

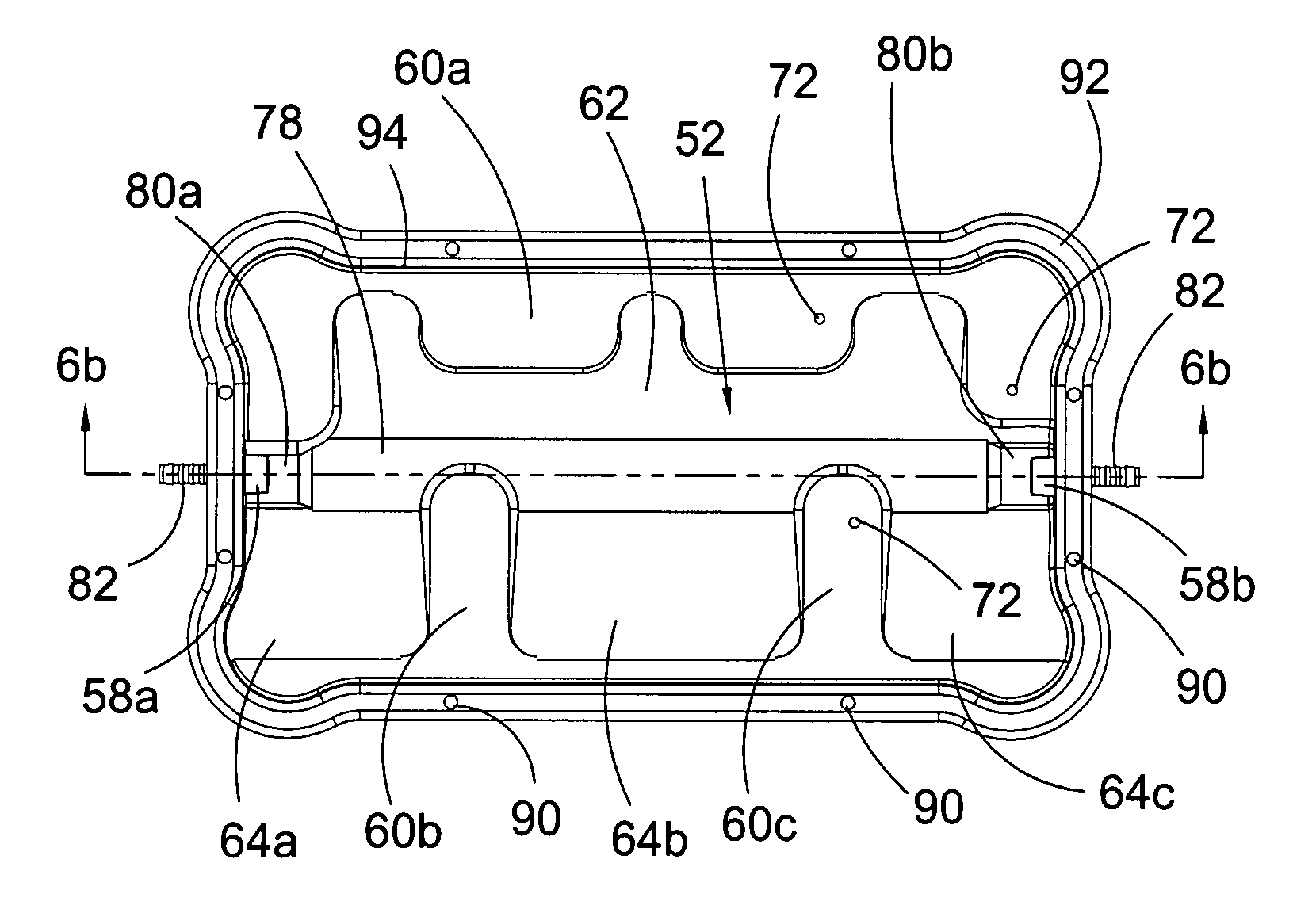

Portable gardening station

ActiveUS6907693B1Rigid enoughEffective drainageCultivating equipmentsSoilless cultivationEngineeringStructural component

A portable gardening station comprising a bed for containing a growing medium. The bed has a base comprising a shoulder, a trough, and a raised center portion, wherein the trough is lower than the shoulder and raised center portion. The underside of the bed is reinforced with structural ribs to provide sufficient rigidity so that the base does not deflect under the weight of the growing medium. The gardening station has a perforated growing medium baseplate which is supported by the shoulder and raised center portion of the base. The baseplate is operative to support the growing medium and to allow water to drain from the growing medium through the baseplate and into the trough. The trough has a drain to allow water from the growing medium to exit the gardening station. The gardening station is supported by a structural assembly.

Owner:BEMBEN KELLY

Systems, devices and methods for draining and analyzing bodily fluids

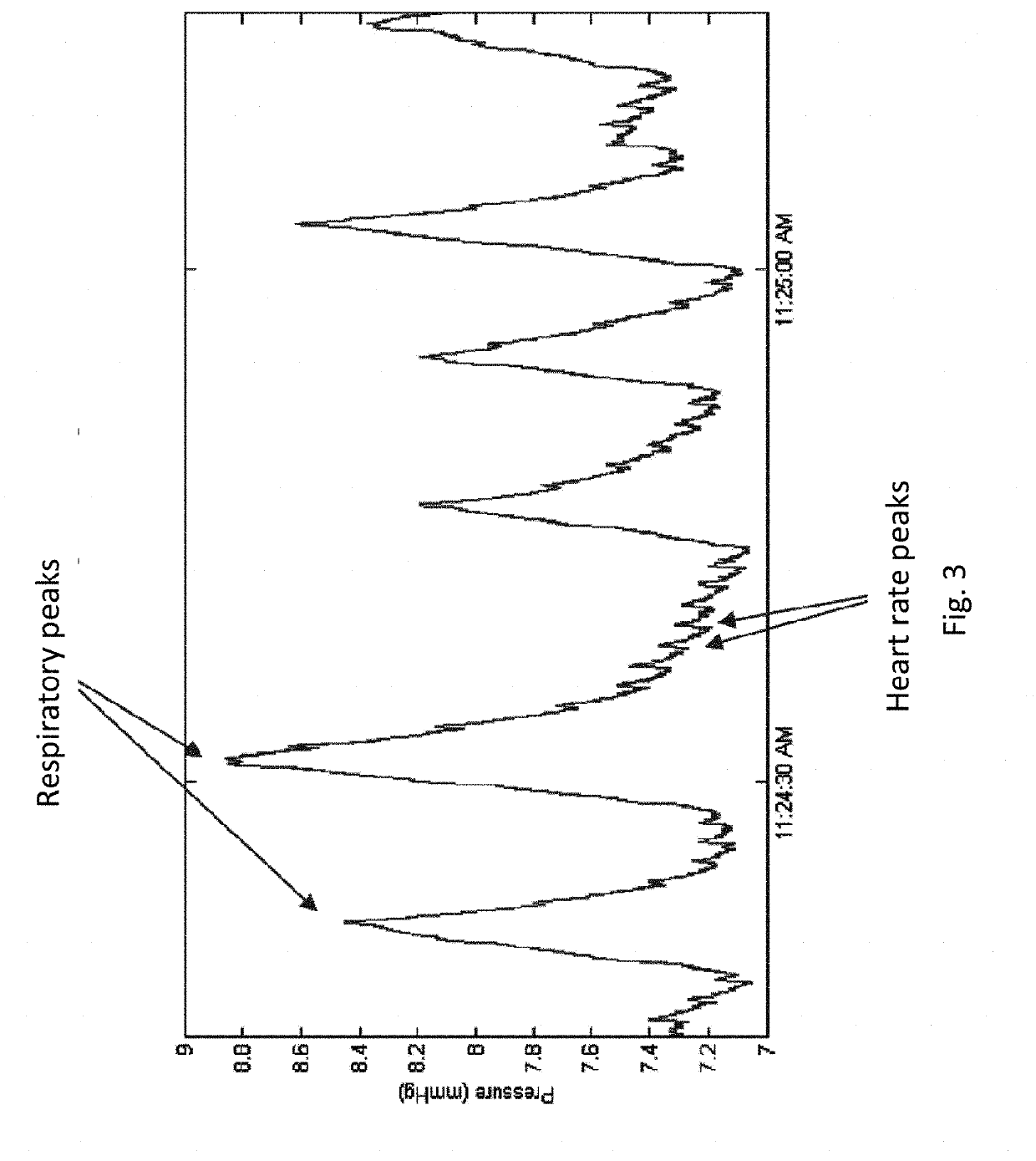

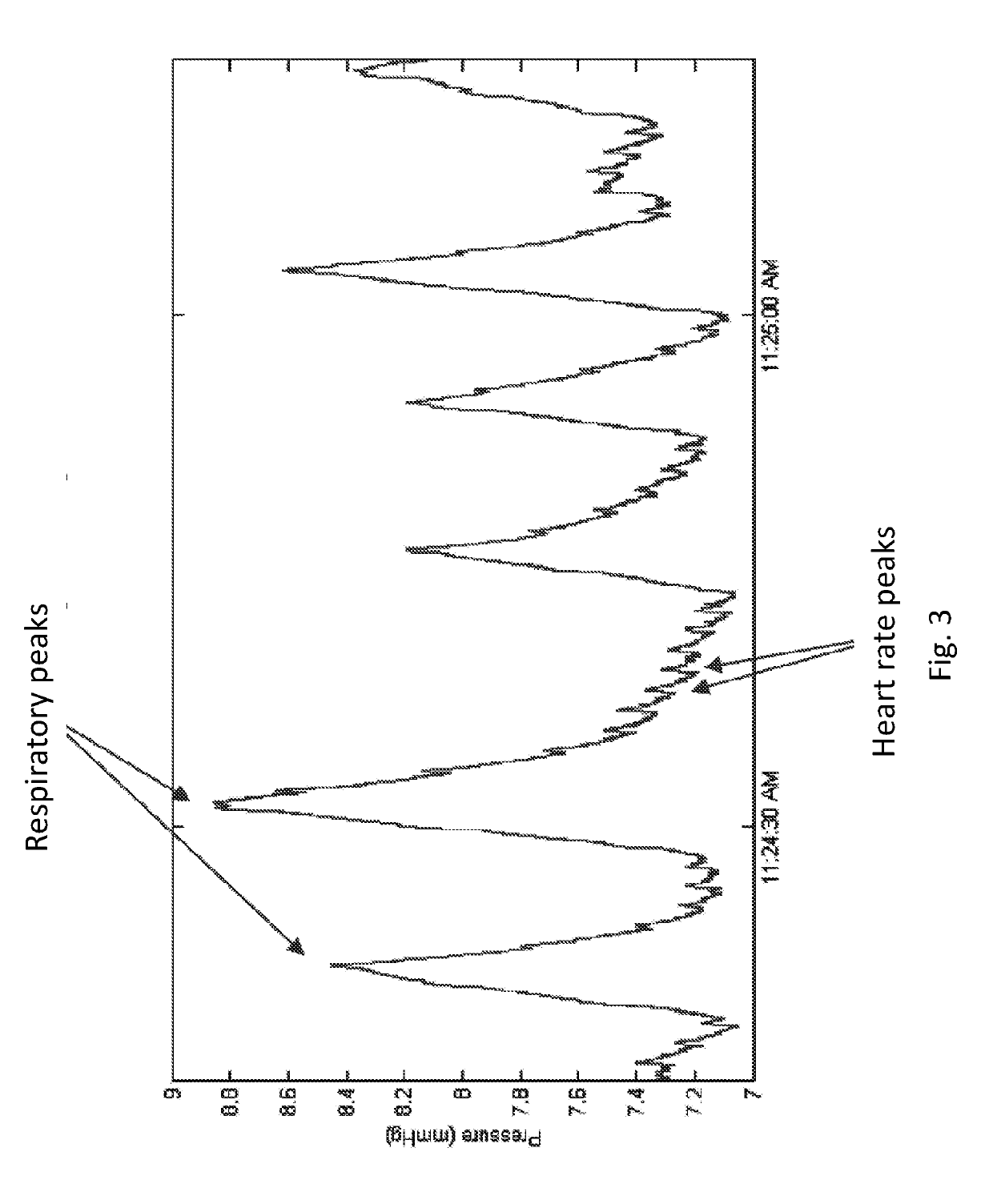

PendingUS20190343445A1Low costEasy to placeElectrocardiographyBalloon catheterCatheterDrainage tubes

Systems, devices and methods for draining and analyzing bodily fluids are disclosed where one variation of the catheter system may generally comprise a catheter having at least one opening near or at a distal end of the catheter, a barb in fluid communication with a proximal end of the catheter, a drainage tube in fluid communication with the at least one opening, and a vent tube in fluid communication with the barb. A one-way valve may be positioned in-line with the vent tube and at a location proximal to the barb and a controller may be in communication with the one-way valve, wherein the controller is programmed to apply a negative pressure to the drainage tube resulting in the one-way valve being opened and fluid passing through the vent tube.

Owner:POTRERO MEDICAL

Systems, devices and methods for draining and analyzing bodily fluids

ActiveUS20190321588A1Low costEasily put in placeWound drainsMedical devicesPositive pressureEngineering

Systems, devices and methods for draining and analyzing bodily fluids are disclosed in which a drainage assembly is configured to prevent negative pressure build-up. The drainage assembly generally includes a catheter which may include a drainage lumen, a reservoir, a venting mechanism in fluid communication with the drainage lumen and a positive pressure lumen, and a controller. The venting mechanism may further include a valve which is configured to maintain a closed position, as well as a vent in fluid communication with the valve, where the venting mechanism is configured to inhibit wetting of the vent from fluid within the drainage lumen

Owner:POTRERO MEDICAL

Multiuse, solid cleaning device and composition

InactiveUS20070232517A1Reduce solubilityIncrease brightnessInorganic/elemental detergent compounding agentsFlow mixersSolubilityAdditive ingredient

A multiuse cleaning device in a solid state containing a homogeneous quantity of cleaning agent configured to dissolve and release a substantially consistent quantity of cleaning agent over a plurality of wash and rinse cycles. The cleaning agent includes a gas-releasing component and potassium silicate as a solubility control component to limit the solubility of the cleaning agent. The cleaning agent may include other ingredients such as an alkalinity agent as a pH regulator, a water softener to solvate metal ions in a solution of water, an optical brightener, an anti-redeposition agent, fragrances, surfactants, and other ingredients. Controlled dissolution of the cleaning agent composition releases a desired quantity of cleaning agent in each cleaning cycle over a plurality of cycles. A porous enclosure may be disposed around the solid cleaning agent.

Owner:ECO SAFE TECH L L C

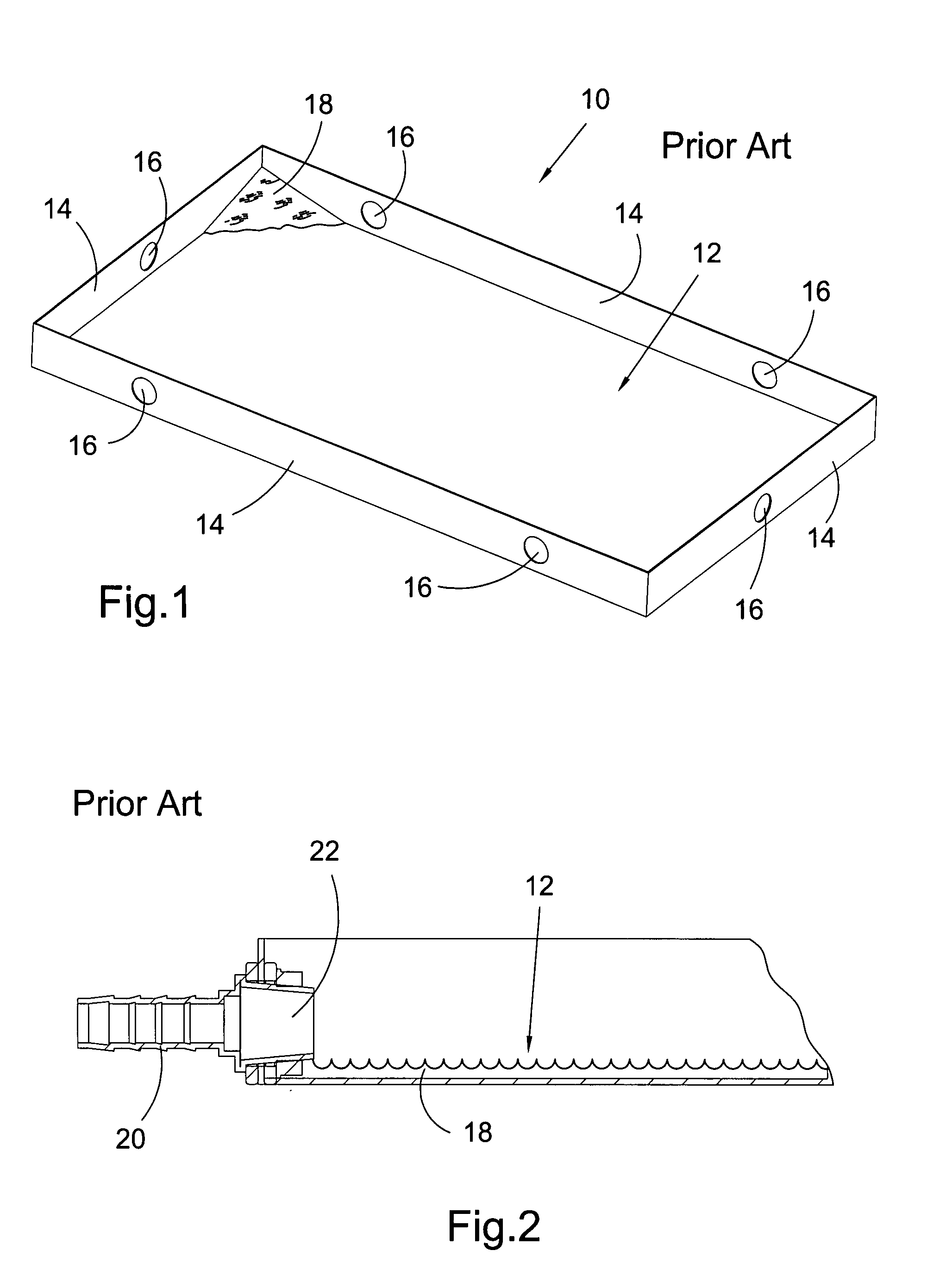

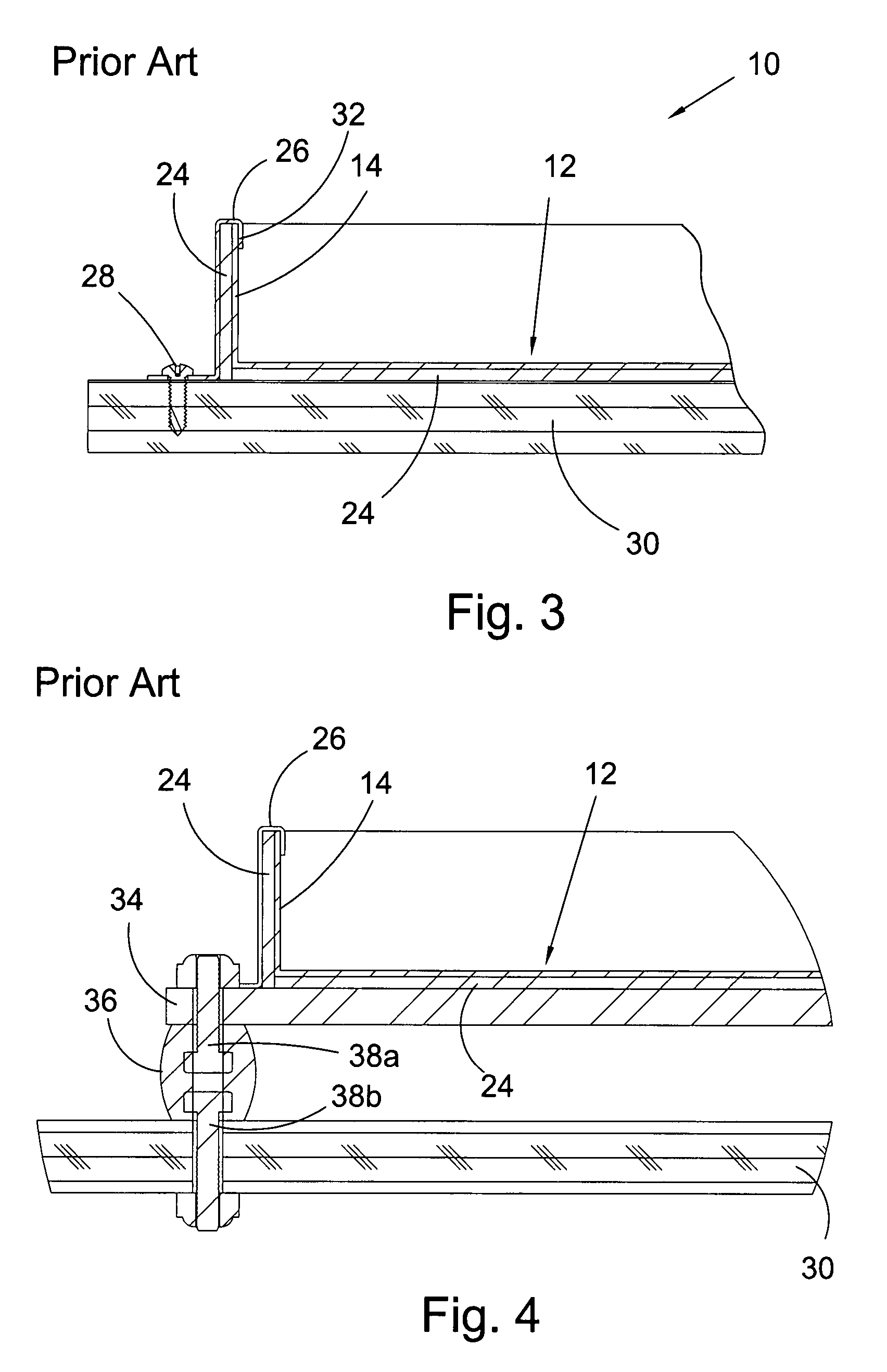

Air conditioning unit support pan

InactiveUS20080047289A1Reduce vibrationFacilitate transmissionAuxillariesLighting and heating apparatusEngineeringAir conditioning

A mounting and collection pan for an air conditioning unit including a bottom portion having a perimeter and a first flow surface, a sidewall extending upwardly from the perimeter and a first portal arranged in the sidewall. The air conditioning unit is secured to the bottom portion and the first flow surface is angled to direct a liquid condensate collected from the air conditioning unit to the first portal via gravity. The bottom portion may further include a first substantially horizontal mounting surface having a first means for securing the air conditioner unit thereto and is elevationally higher than the first flow surface.

Owner:POMPANETTE

Back ward water draining system of face plate rock-fill dam dam body and its construction method

The present invention relates to backward draining system of face plate rock-fill dam body and its construction process, and aims at preventing backward water head caused damage of mat base and concrete plate seam. During construction of the dam, backward draining system is set, which includes water collecting body comprising pebbles in certain volume set inside the dam and in certain distance to the toe board, and water draining pipe connected between the toe board and the water collecting body and comprising vertical section of pored steel pipe, inclined pipe in the toe board and horizontal pipe in between. After finishing the construction, the water draining pipe is blocked. The present invention is used in the concrete face plate dam and asphalt concrete face plate dam engineering under construction.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

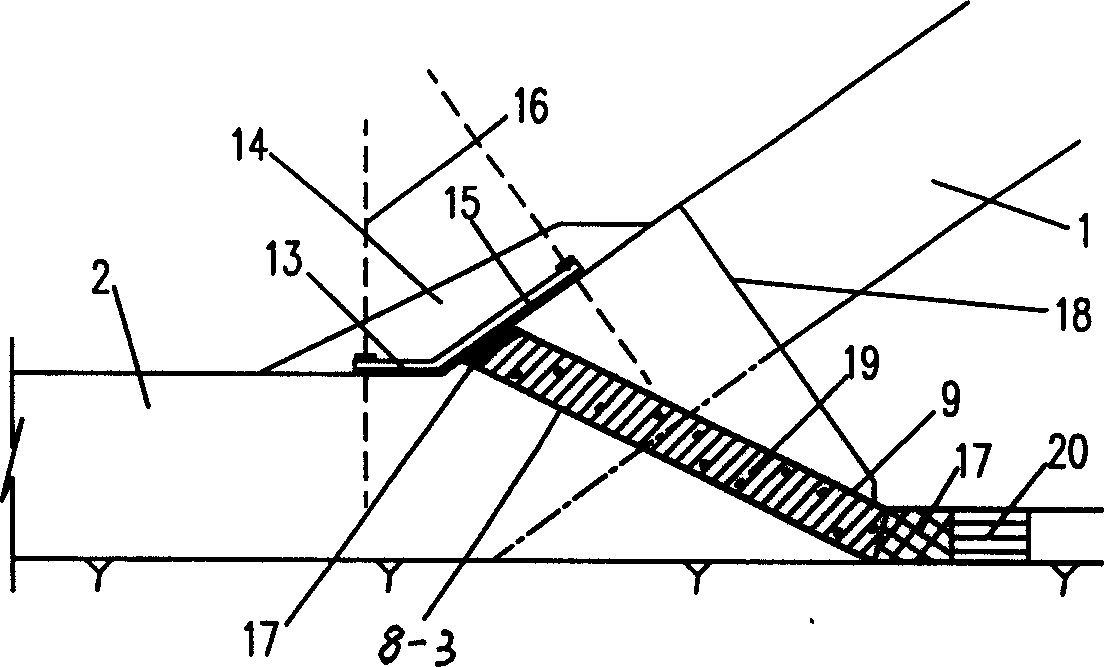

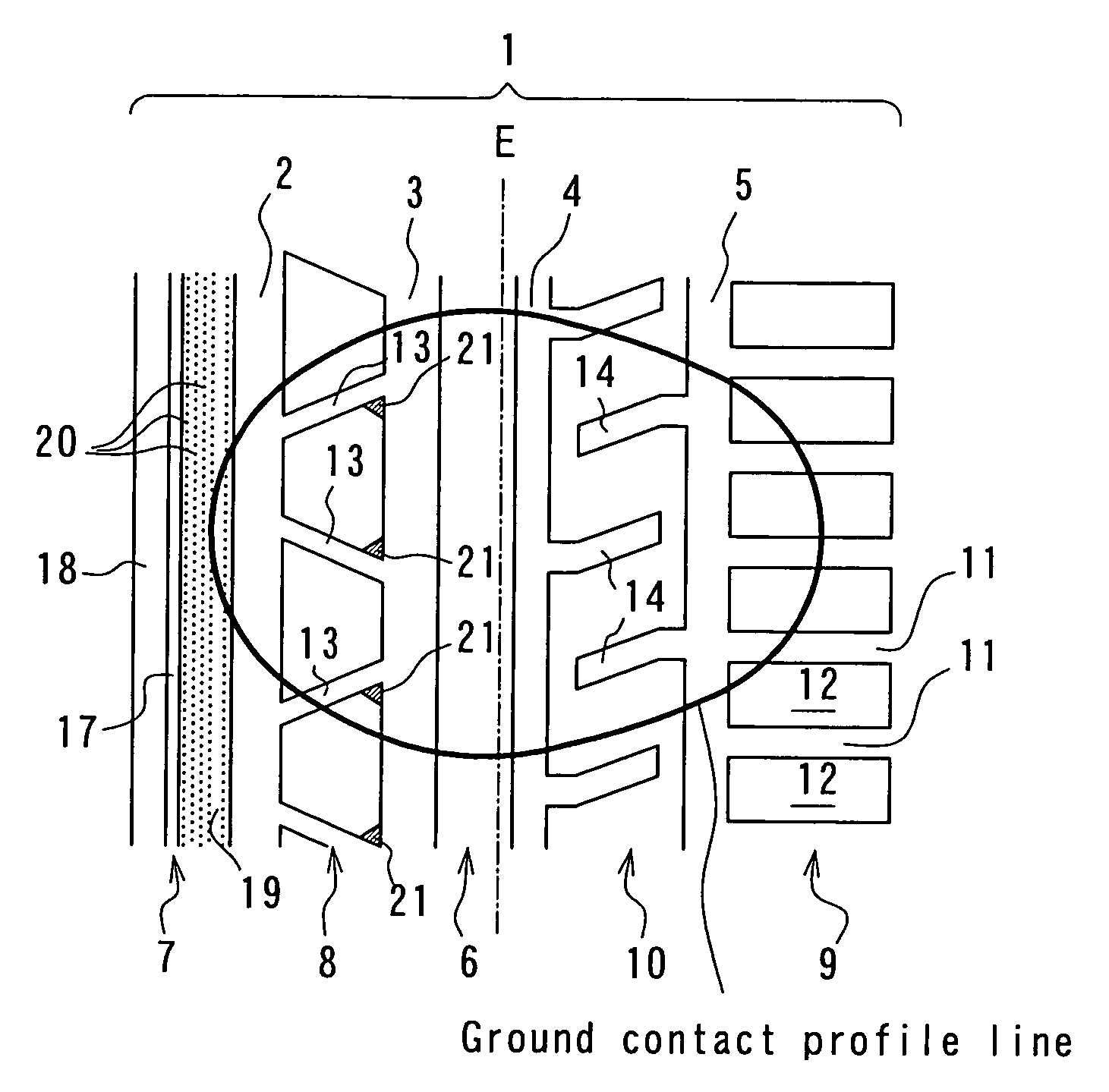

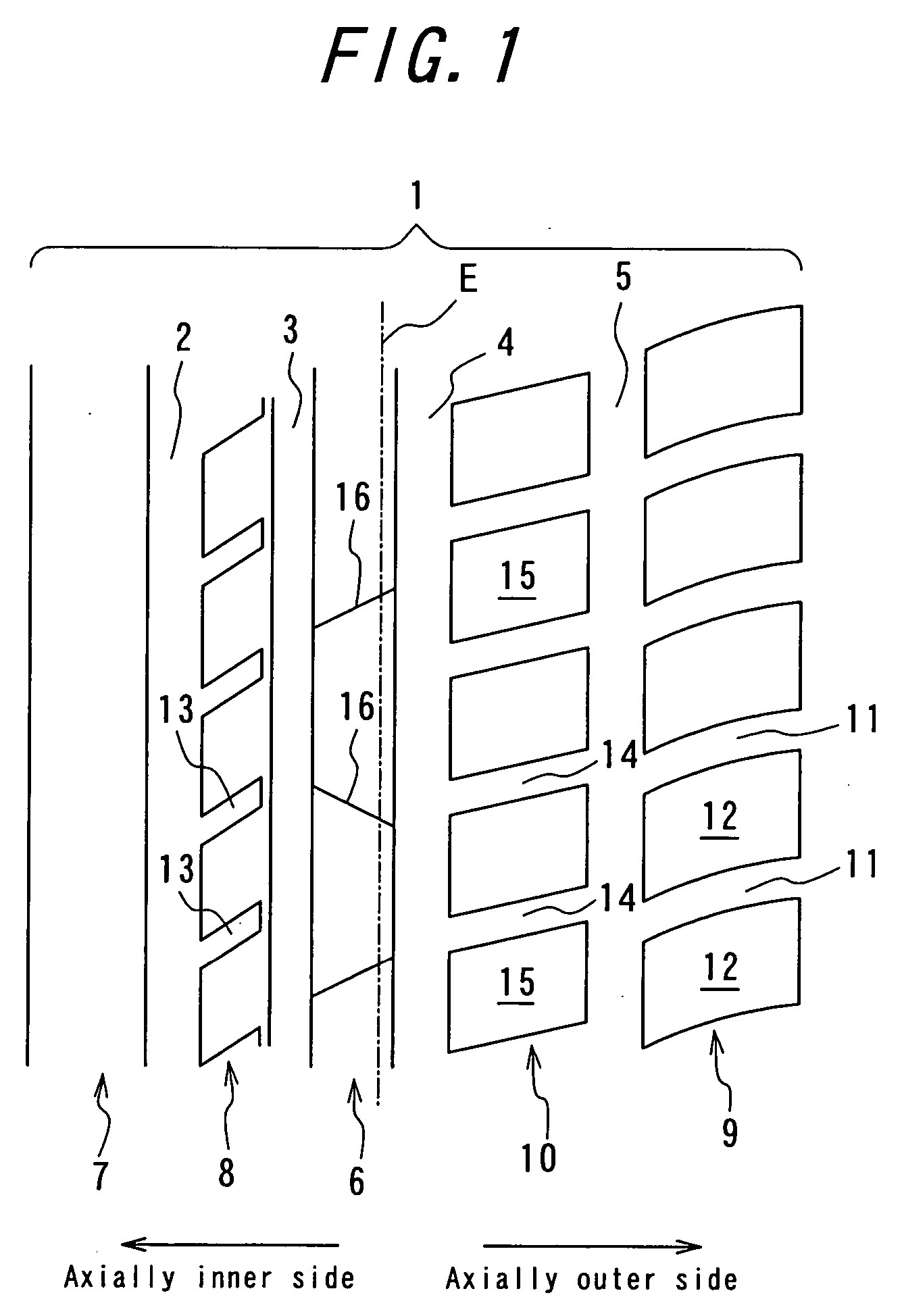

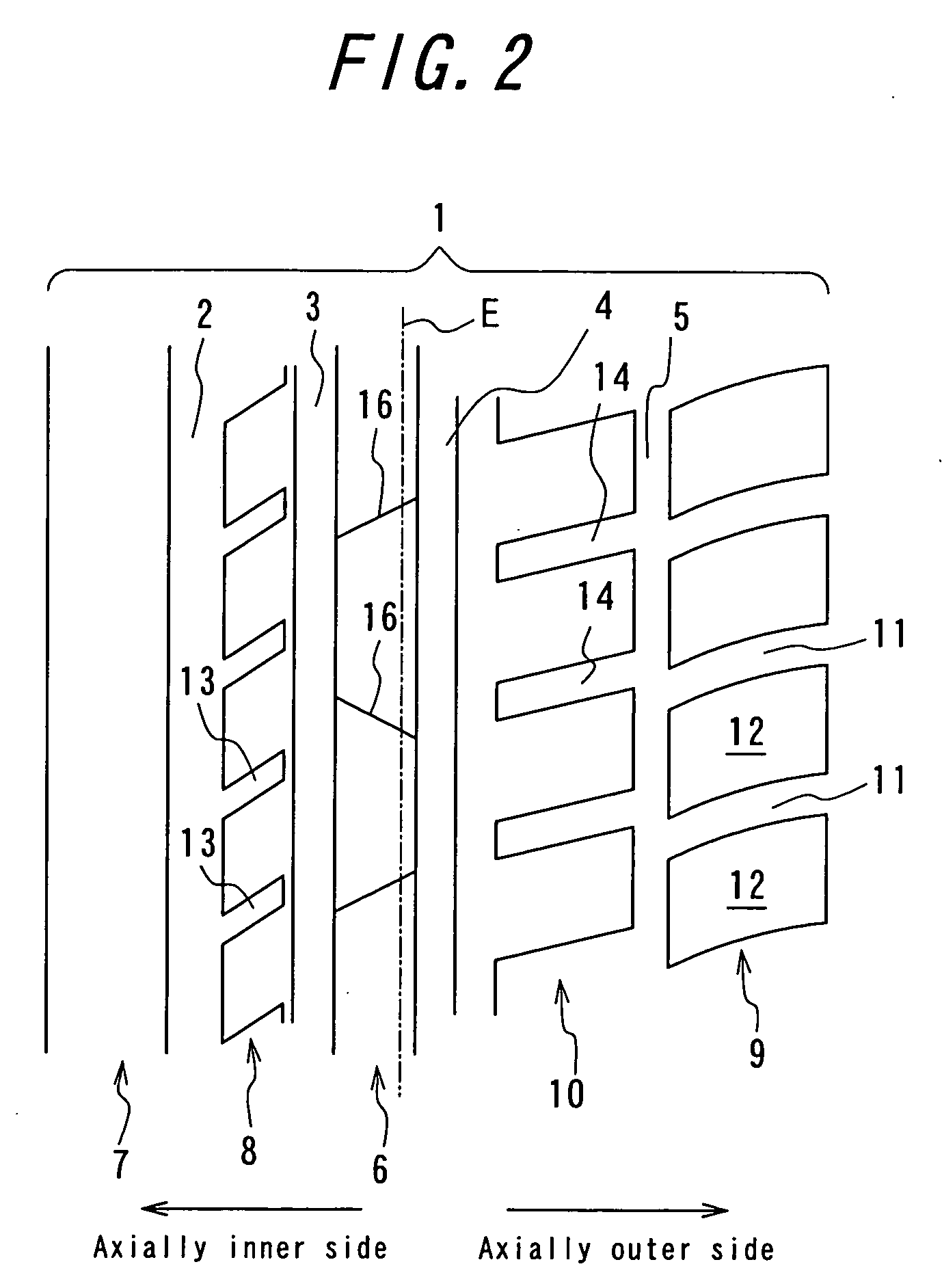

Pneumatic tire and tire wheel assembly

InactiveUS20050257870A1Enhancing silentnessEasily causedSpecial tyresInflatable tyresEngineeringTread

The reduction of noise in the rotation of the tire and the improvement of resistance to hydroplaning are established and also the resistance to uneven wear is improved, in which four circumferential main grooves 2-5 are formed asymmetrically, and a sum of groove volume in a circumferential direction in lateral grooves formed in a shoulder land part row 7 as a portion of an axially inner side per unit width is made smaller than a sum of groove volume in the circumferential direction in lateral grooves 11 formed in a shoulder land part row 9 as a portion of an axially outer side and a land part row 6 in a central region is rendered into a rib, and slant grooves 13 extending at an average inclination angle of not less than 45° with respect to a widthwise direction of the tread are arranged in a second inner land part row 8 located at a side of an equatorial line adjacent to the shoulder land part row 7 at the axially inner side and these slant grooves 13 are opened to the circumferential main groove located adjacent to the second inner land part row 8 of the axially inner side.

Owner:BRIDGESTONE CORP

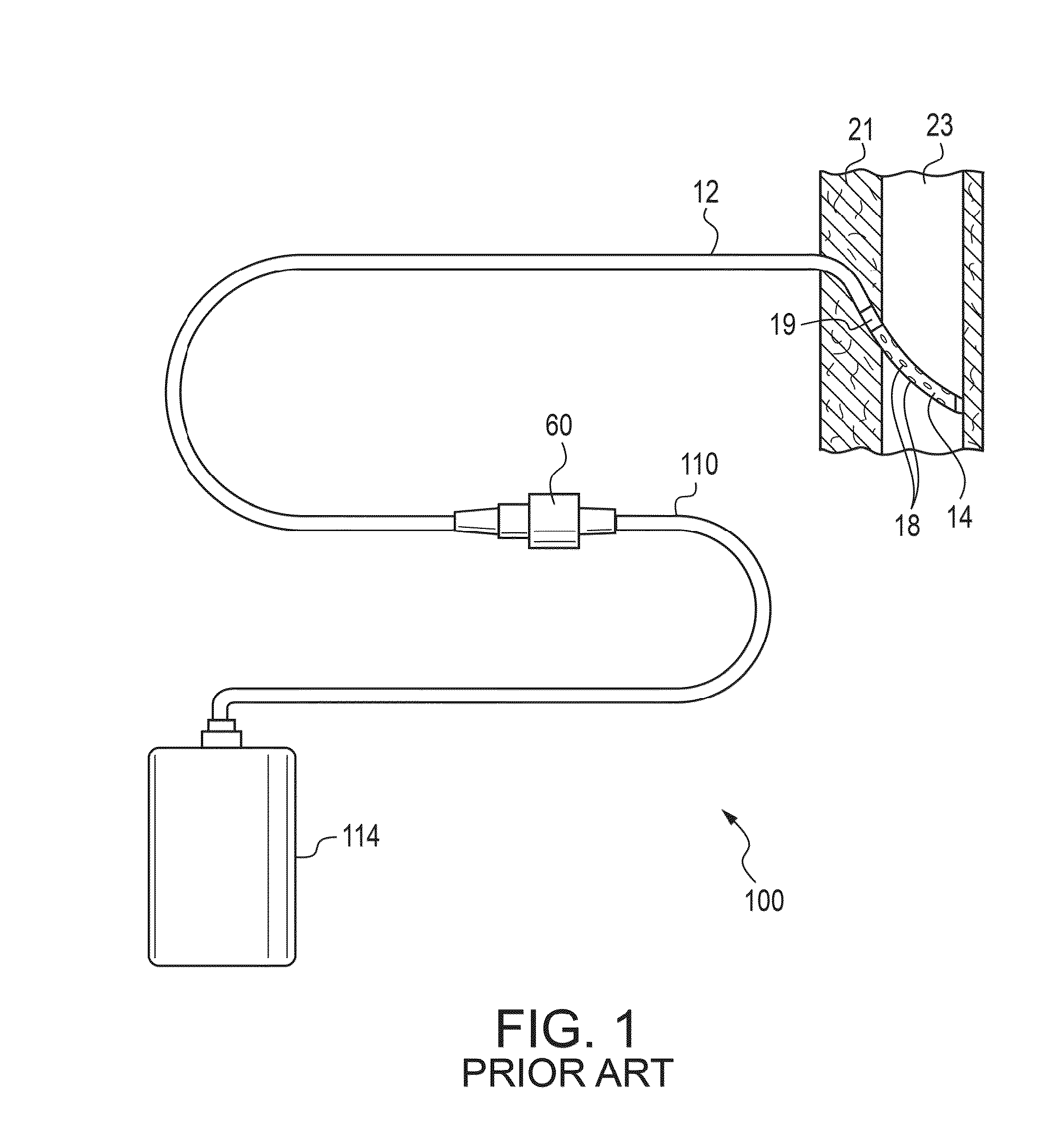

Drainage system

A medical drainage system may include a pair of inlet tubes separated by a pump bulb and a valve chamber, where the valve chamber is in fluid communication with a first inlet tube across a one way valve. A second one-way valve may be provided in the entrance to a drainage container at an inlet tube end opposite the pump bulb. The drainage container may be rigid or flexible and may be equipped with emptying means such as a drain valve, connector for suction source, or other emptying / draining means that can be used to partially or wholly void the container contents (e.g., for sampling, testing, or disposal).

Owner:CAREFUSION 2200 INC

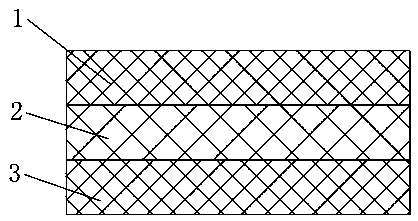

Lightweight high-strength water permeable brick with photocatalysis effect

ActiveCN105507103AGood photocatalytic effectEasy to handleSolid waste managementSingle unit pavingsPorosityBrick

The invention discloses a lightweight high-strength water permeable brick with a photocatalysis effect. The lightweight high-strength water permeable brick comprises a reverse osmosis layer, a water permeable layer and a photocatalysis layer in sequential distribution from bottom to top. The photocatalysis layer is coated with a cement-based material with a photocatalysis property; the water permeable layer is formed by pouring of ceramsite-doped regenerated lightweight aggregate concrete; the reverse osmosis layer is also formed by pouring of ceramsite-doped regenerated lightweight aggregate concrete. The lightweight high-strength water permeable brick structurally comprises three layers, namely the photocatalysis layer, the water permeable layer and the reverse osmosis layer, from top to bottom, and each of the three layers has certain porosity. The photocatalysis layer is capable of effectively treating motor vehicle exhaust; the water permeable layer is effective in water drainage; the reverse osmosis layer is effective in reduction of influences of the heat island effect on the environment.

Owner:河北华固科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com