Back ward water draining system of face plate rock-fill dam dam body and its construction method

A face rockfill dam and reverse drainage technology, which is applied in water conservancy projects, dams, barrages, etc., can solve the problems of affecting the quality of the project, pumping and drainage, inconvenient sealing of holes, and high cost, so as to achieve good response and effective drainage of the dam body and the effect of plugging design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

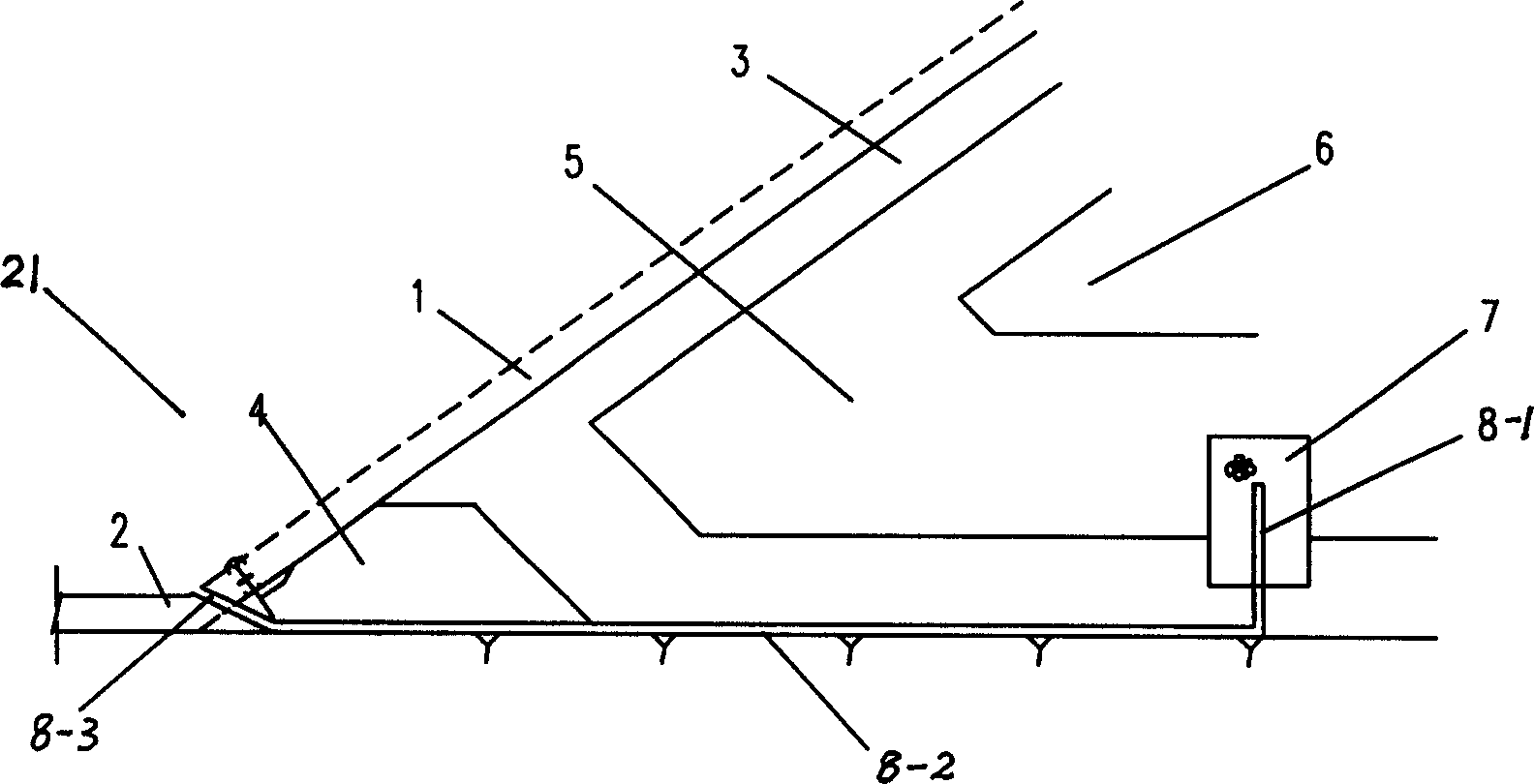

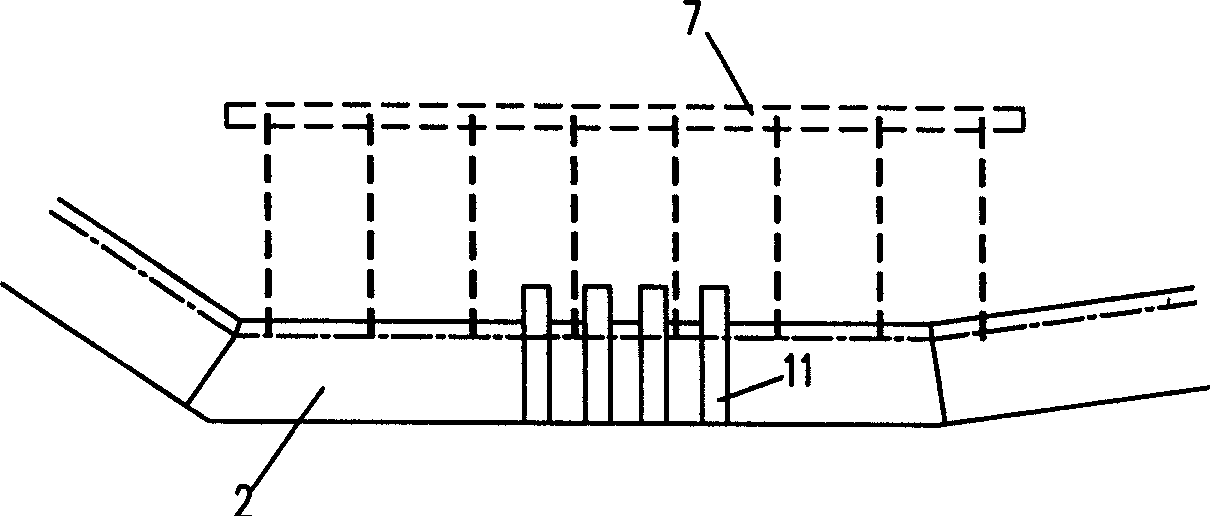

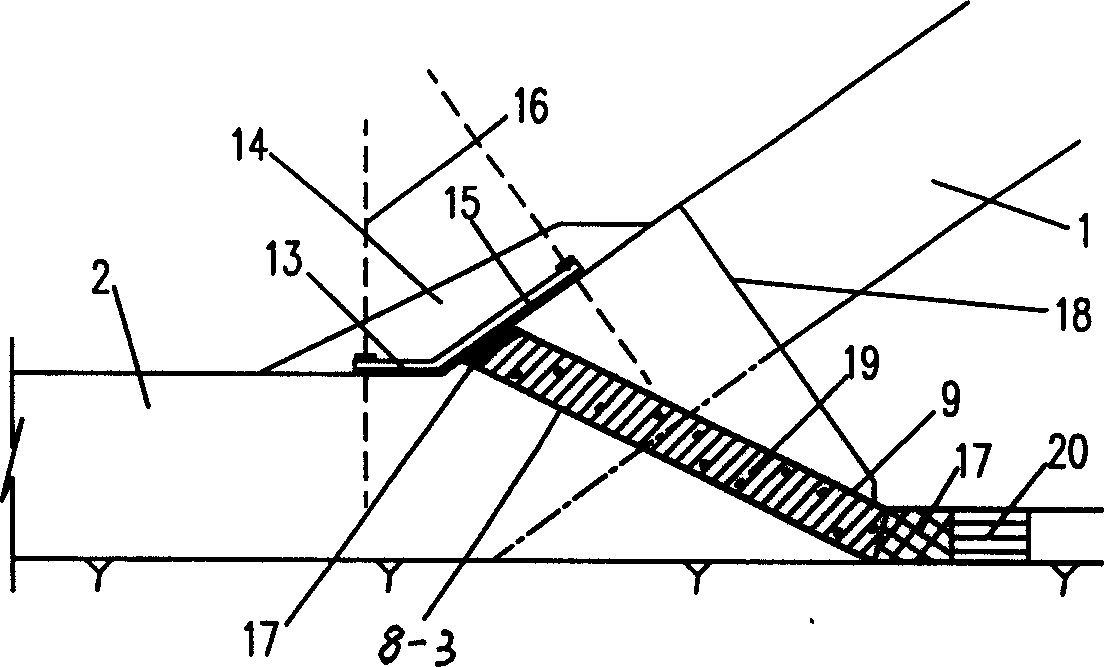

[0022] During the construction period, the reverse drainage system of the concrete face rockfill dam is set up. The system has concrete face 1, toe slab 2, cushion material 3, plot material 4, transition layer material 5, and rockfill material 6. Estimate the design frequency of the dam during the construction period In order to ensure that the seepage water in the dam body can concentrate and effectively seep freely from the drainage holes, a certain distance from the plinth 2 The water collecting body 7 is set in the dam body, and the water collecting body is made of pebbles of a certain volume, and 8 drainage pipes 8 leading to the pebble water collecting body (blind ditch) 7 are arranged from the toe plate 2 of the upstream sump pit 21, and the drainage pipes The vertical section is a perforated steel pipe 8-1, surrounded by a stainless steel filter to prevent clogging of the steel pipe and facilitate smooth drainage; the part passing through the toe plate 2 is an inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com