Gas drainage method combining surface and underground fracturing and permeability improvement

A technology of gas drainage and fracturing, which is applied in the field of fracturing and anti-reflection gas drainage, and can solve problems such as low permeability, poor drainage effect, and insufficient capacity of fracturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

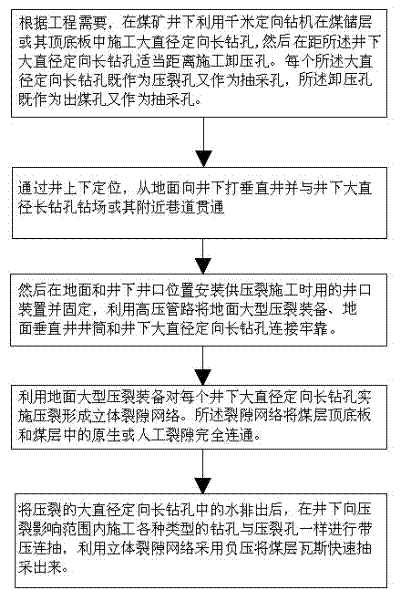

Method used

Image

Examples

Embodiment 1

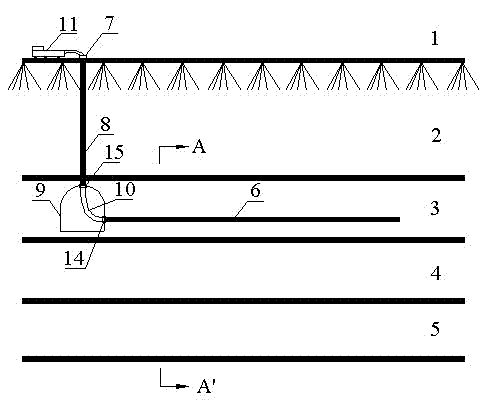

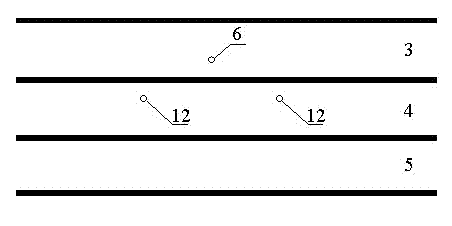

[0027] Such as figure 2 , 3 , Shown in 4, a kind of method that implements the combination of upper and lower fracturing in a single coal seam roof to increase permeability and extract gas. There is a single coal seam 4 with a thickness of 6m and a burial depth of 120m. The soft layer is located at the bottom of the coal seam 4, and the water content in the coal seam roof 3 is small. Adopting the present invention utilizes a kilometer directional drilling rig in the drilling field 9 to the coal seam roof In 3, an underground large-diameter directional long borehole 6 was constructed, two pressure relief holes 12 were arranged in the coal seam 4, and a ground vertical well 8 was arranged downward on the ground 1, and the vertical well 8 passed through the overlying formation 2 and the Drill field 9 through.

[0028] The specific fracturing extraction steps are as follows:

[0029] (1) Firstly, use a special hole sealing device to seal and solidify a large-diameter directi...

Embodiment 2

[0035] Such as Figure 5 , 6 , 7, a method of implementing combined fracturing and anti-permeability drainage of gas in a single coal seam floor. There is a single coal seam 4 with a thickness of 6m and a burial depth of 120m. The soft layer is located at the top of the coal seam 4, and the water content in the coal seam floor 5 is small. Adopt the present invention to utilize the kilometer directional drilling rig to drill to the coal seam floor in the roadway 9. In 5, an underground large-diameter directional long borehole 6 was constructed, two pressure relief holes 12 were arranged in the coal seam 4, and a ground vertical well 8 was arranged downward on the ground 1, and the vertical well 8 passed through the overlying formation 2 and the The roof of the roadway 9 runs through.

[0036] The specific fracturing extraction steps are as follows:

[0037] (1) Firstly, use a special hole sealing device to seal and solidify a large-diameter directional long borehole 6 in t...

Embodiment 3

[0043] Such as Figure 8 , 9 , 10, a method for gas drainage in a single coal seam that implements combined fracturing up and down the well. There is a single coal seam 4 with a thickness of 6m and a burial depth of 120m. The structural types of the coal are mainly primary structural coal and fragmented coal, and the structural coal is not developed. Adopt the present invention to utilize a kilometer directional drilling machine in the drilling site 9 An underground large-diameter directional long borehole 6 was constructed in the coal seam 4, and two pressure relief holes 12 were arranged in the coal seam 4, and a ground vertical well 8 was arranged downward on the ground 1, and the vertical well 8 passed through the overlying Formation 2 connects with drilling field 9 .

[0044] The specific fracturing extraction steps are as follows:

[0045] (1) Firstly, use a special hole sealing device to seal and solidify a large-diameter directional long borehole 6 in the well, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com