Bathroom floor panel

a floor panel and bathroom technology, applied in the direction of flooring, treads, constructions, etc., can solve the problems of large amount of water drops remaining on the floor surface, user discomfort, and water used in the shower room or the unit bathroom to be repelled, so as to prevent slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

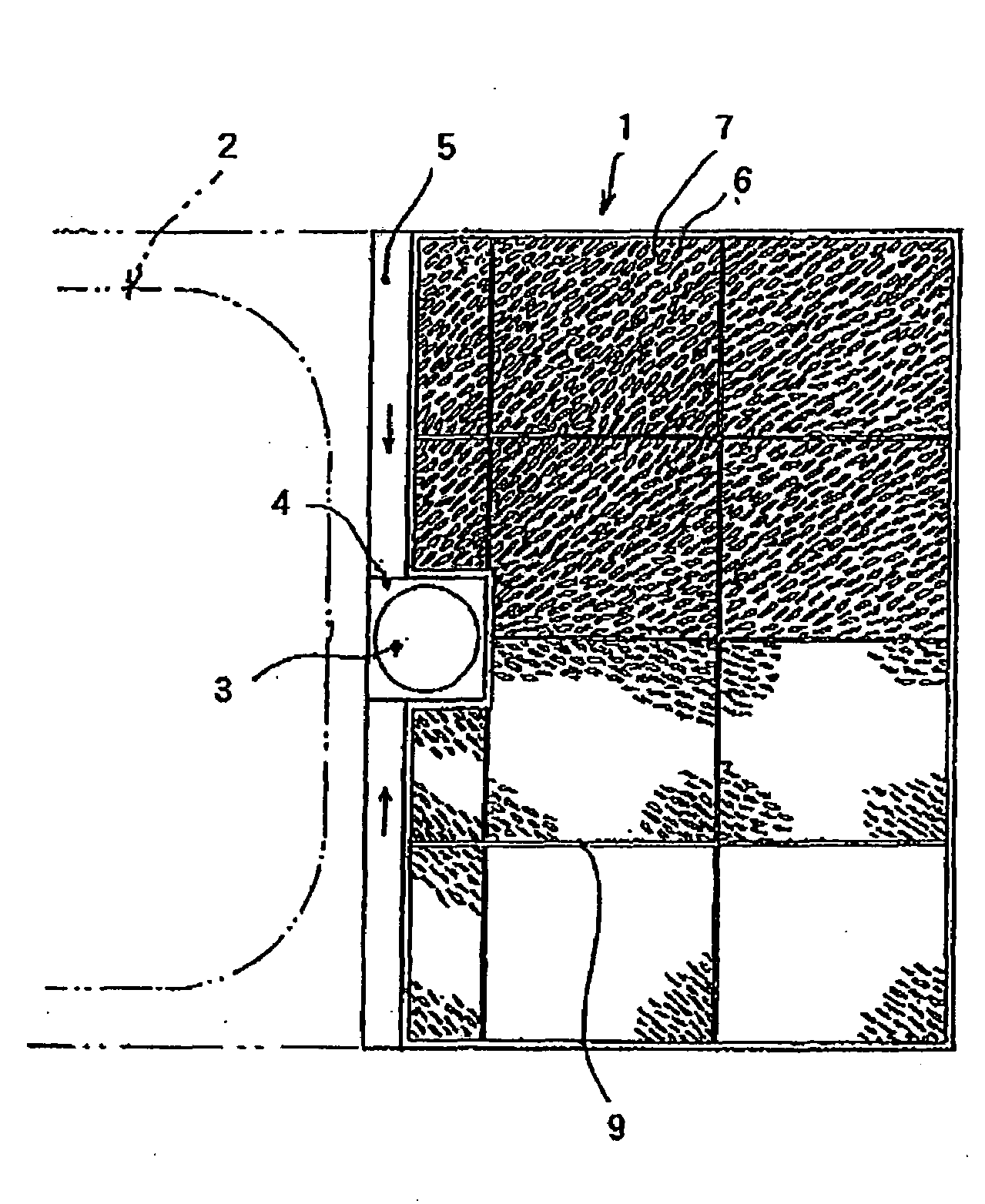

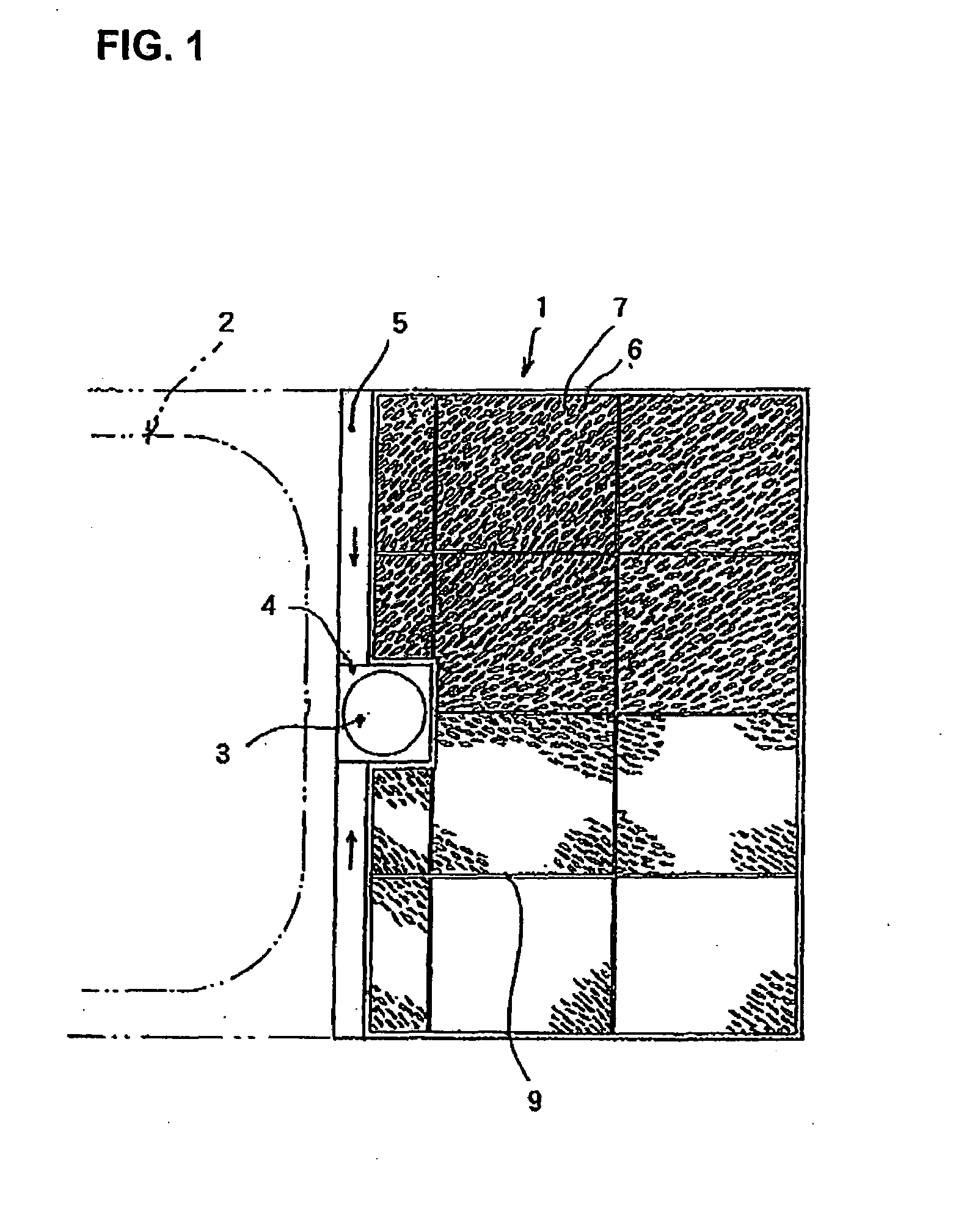

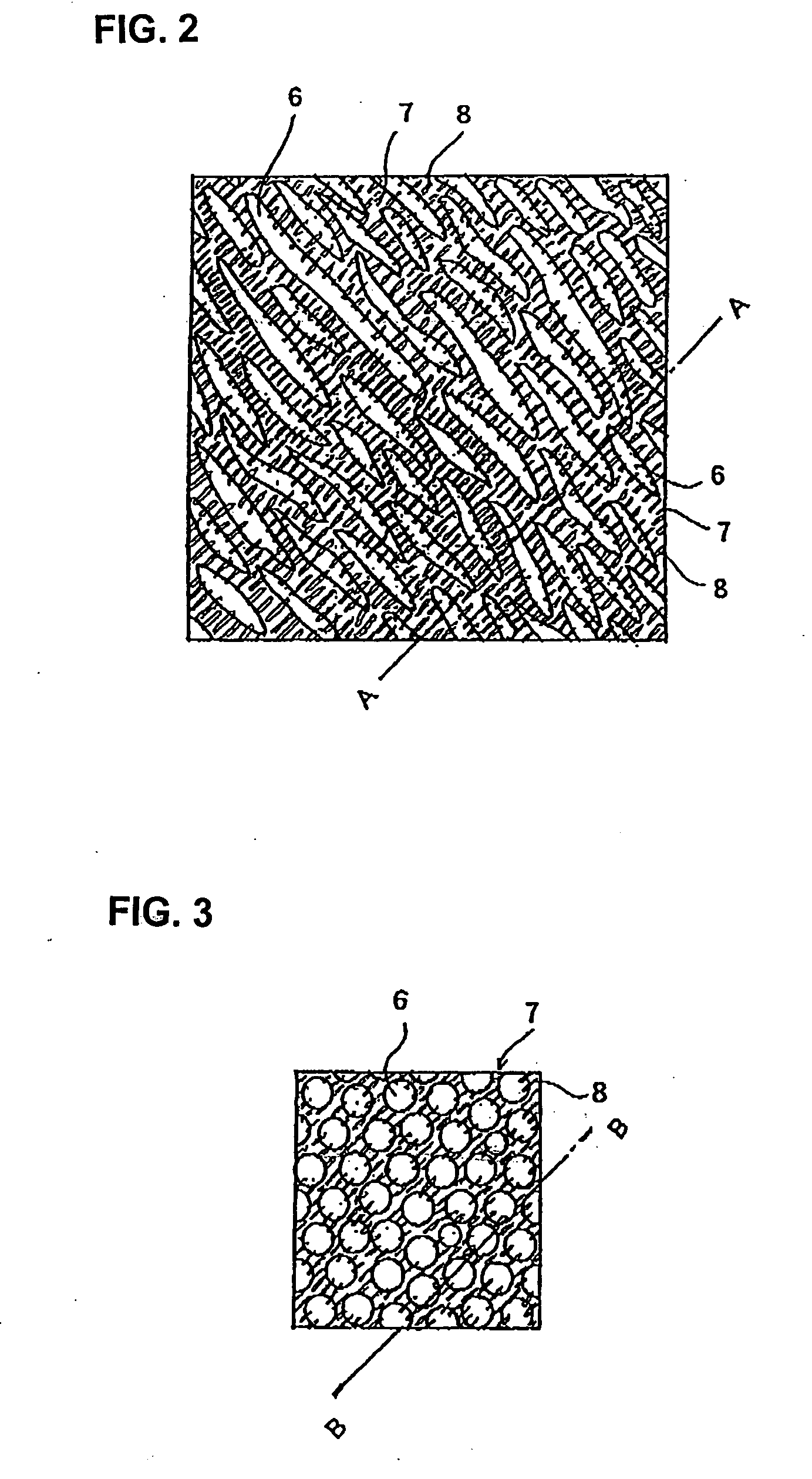

[0056]The embodiments of the present invention will now be described with reference to the appended drawings. FIG. 1 is a plan view of a bathroom floor panel according to a first aspect of the present invention; FIG. 2 is an enlarged plan view of the bathroom floor panel; FIG. 3 is an enlarged plan view of a bathroom floor panel according to another embodiment of the first aspect of the present invention; FIG. 4 is an enlarged sectional view taken along line A-A of FIG. 2; FIG. 5 is an enlarged sectional view taken along line B-B of FIG. 3; and FIGS. 6(a) to (c) show the behavior of water on a floor panel.

[0057]A floor panel 1 is prepared by molding a resin material (for example FRP) and comprised of a bathtub installing portion 2 and a water place portion adjacent thereto. The bathtub installing portion 2 may be a split type in which it is formed as a separate member from a water place side floor panel and these are connected afterwards, or a bathtub with a water place in which a b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com