Fixing structure of engine cylinder internal wire harness assembly and method for fixing wire harness assembly

A wire harness assembly and engine cylinder technology, applied in electrical components and other directions, can solve the problems of poor corrosion resistance and anti-fouling ability of the wire harness, affecting the reliability of the wire harness, easy oil penetration, etc., to achieve outstanding substantive features, easy operation, The effect of saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

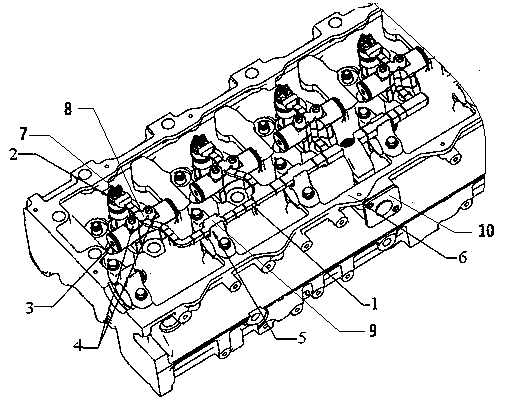

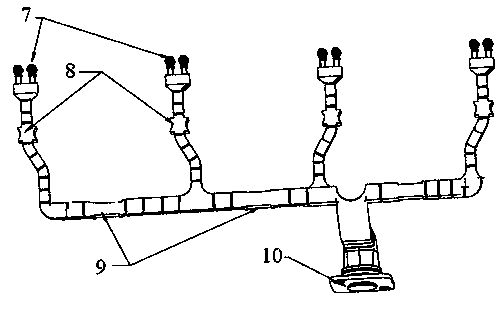

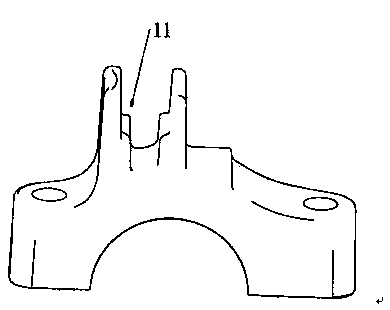

[0024] It can be seen from the accompanying drawings that a fixed structure of a wire harness assembly in an engine cylinder includes a wire harness assembly, and the outside of the wire harness assembly is wrapped with a wire harness protective sleeve 1 that matches the wire harness assembly. The wire harness protective sleeve 1 There is at least one fixing piece arranged on it. The wire harness assembly includes a main wire and four branch wires connected to the main wire. The end of the main wire is connected to the connector 10 , and the end of each branch wire is connected to a wire harness terminal 7 . The wire harness protective sleeve 1 outside the branch line is provided with a first fixing part 8, in order to adapt to the shape of the hexagon socket head cap screw 4 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com