Patents

Literature

112 results about "Overhead camshaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Overhead camshaft, commonly abbreviated to OHC, is a valvetrain configuration which places the camshaft of an internal combustion engine of the reciprocating type within the cylinder heads ("above" the pistons and combustion chambers) and drives the valves or lifters in a more direct manner compared with overhead valves (OHV) and pushrods.

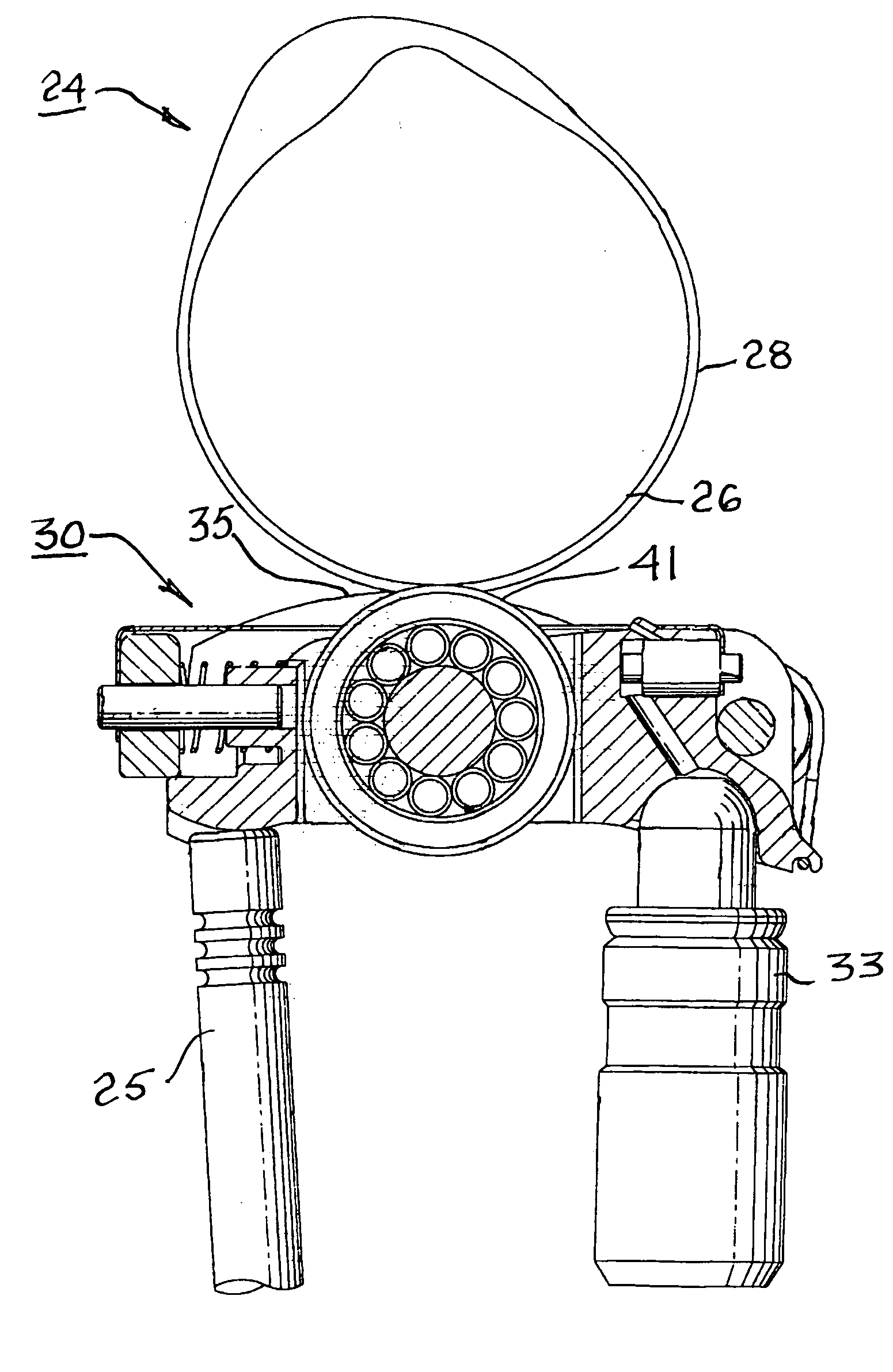

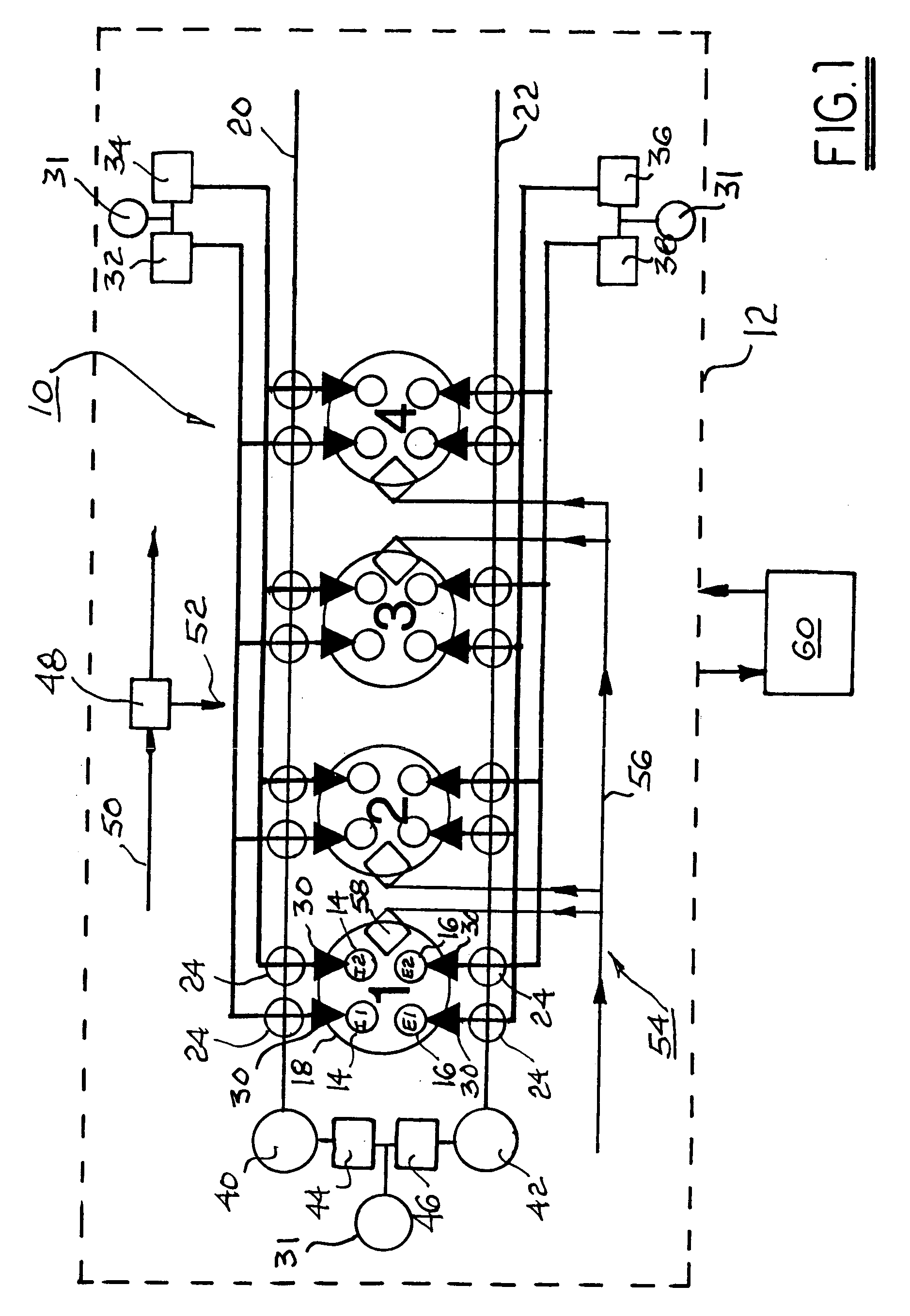

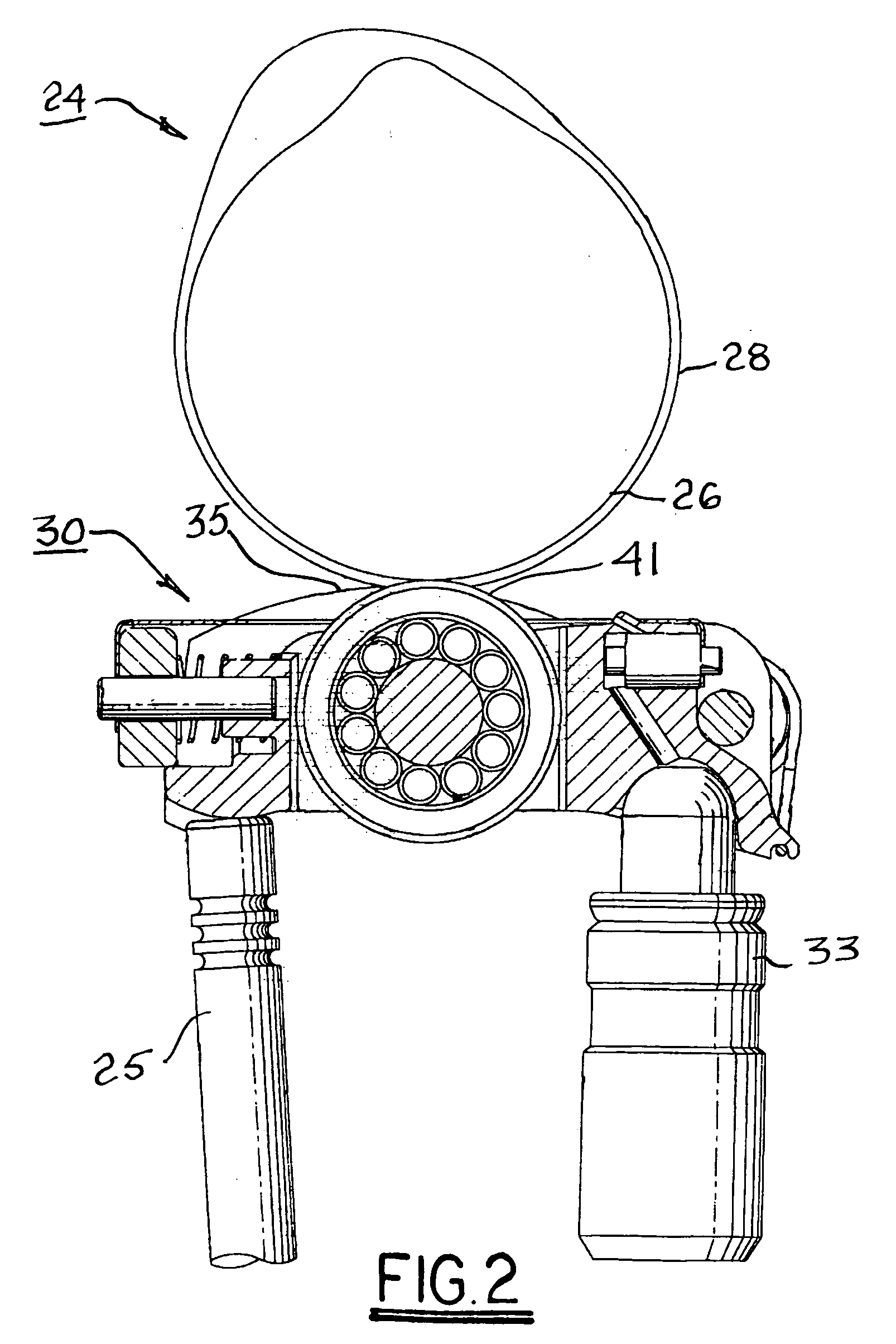

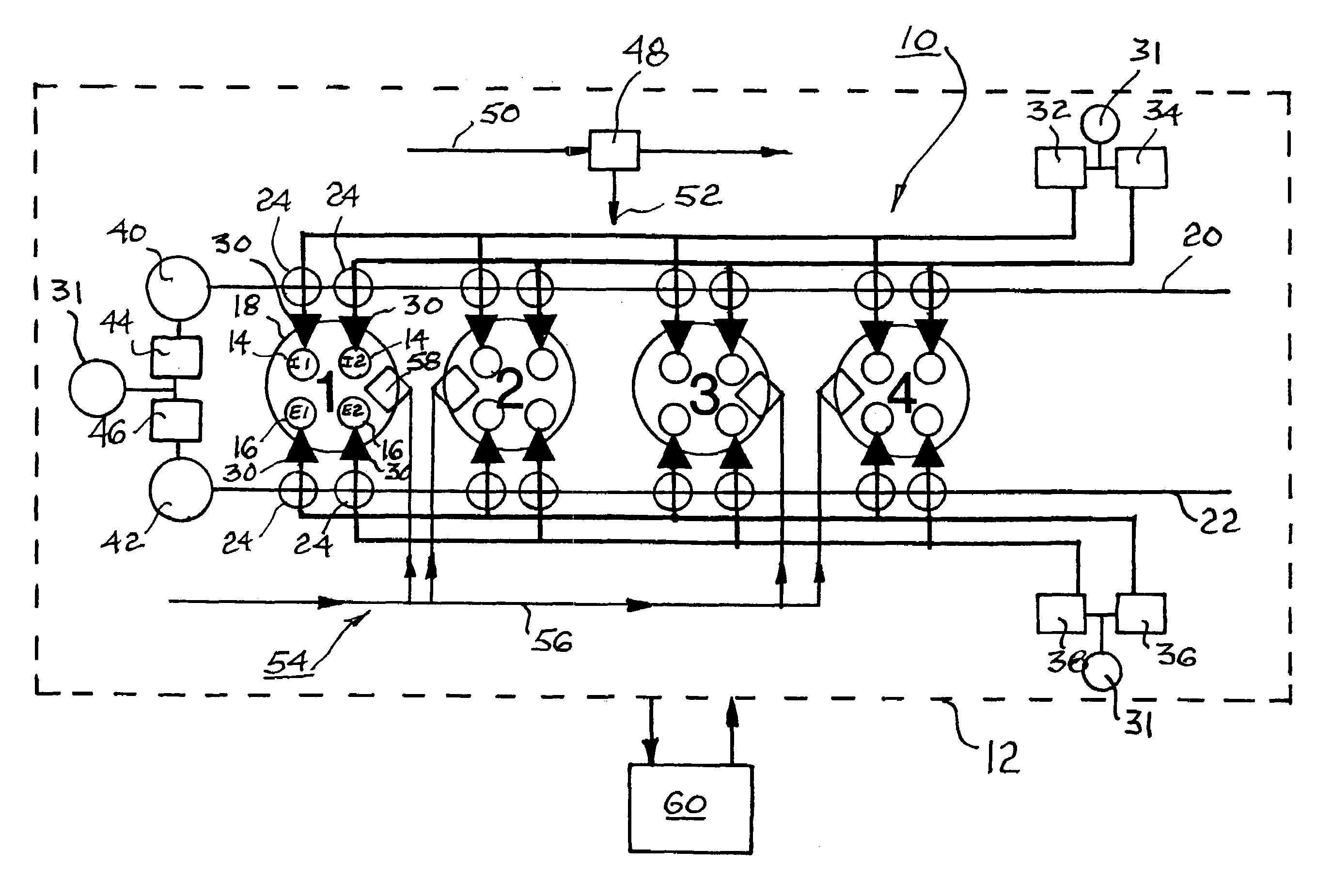

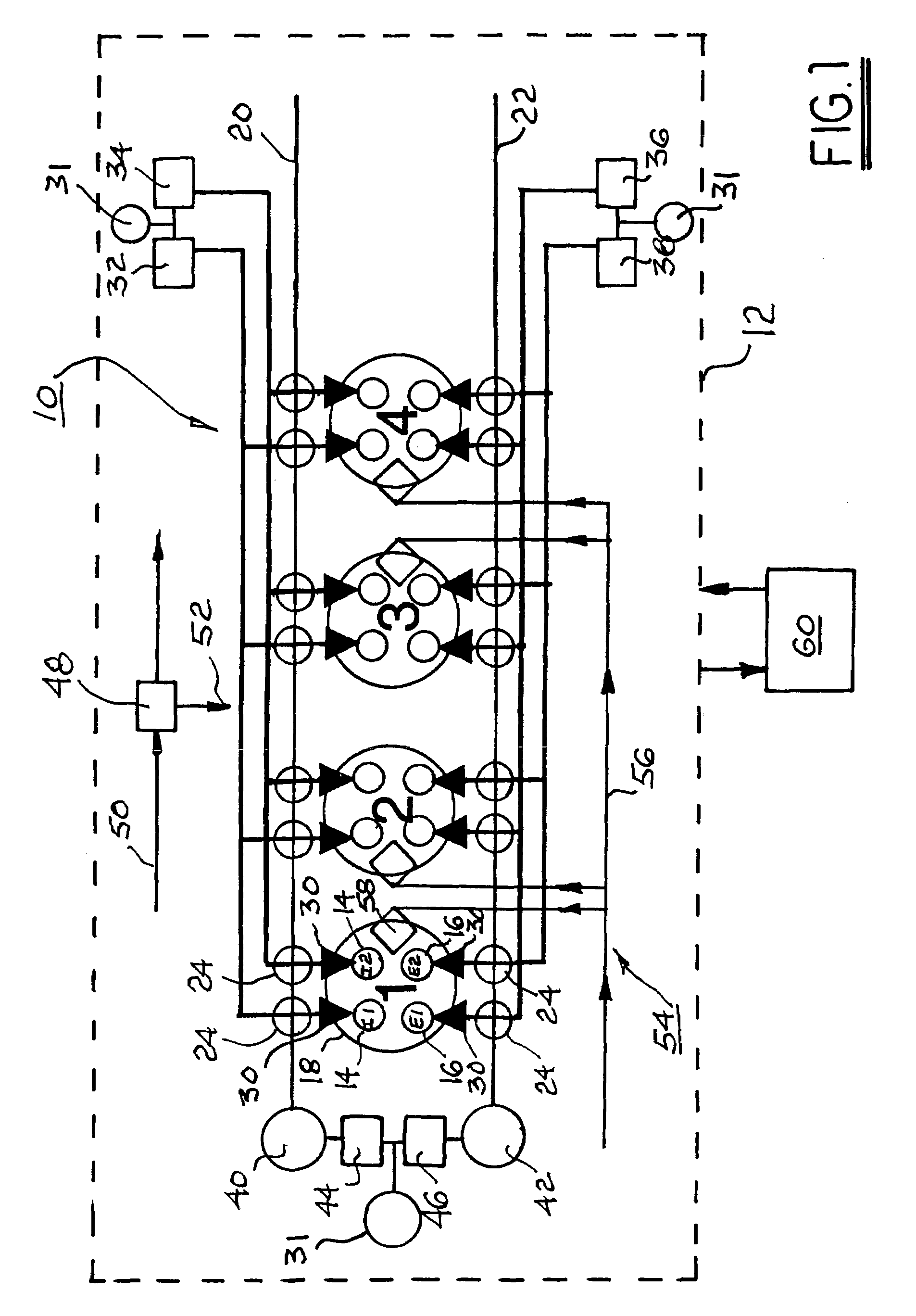

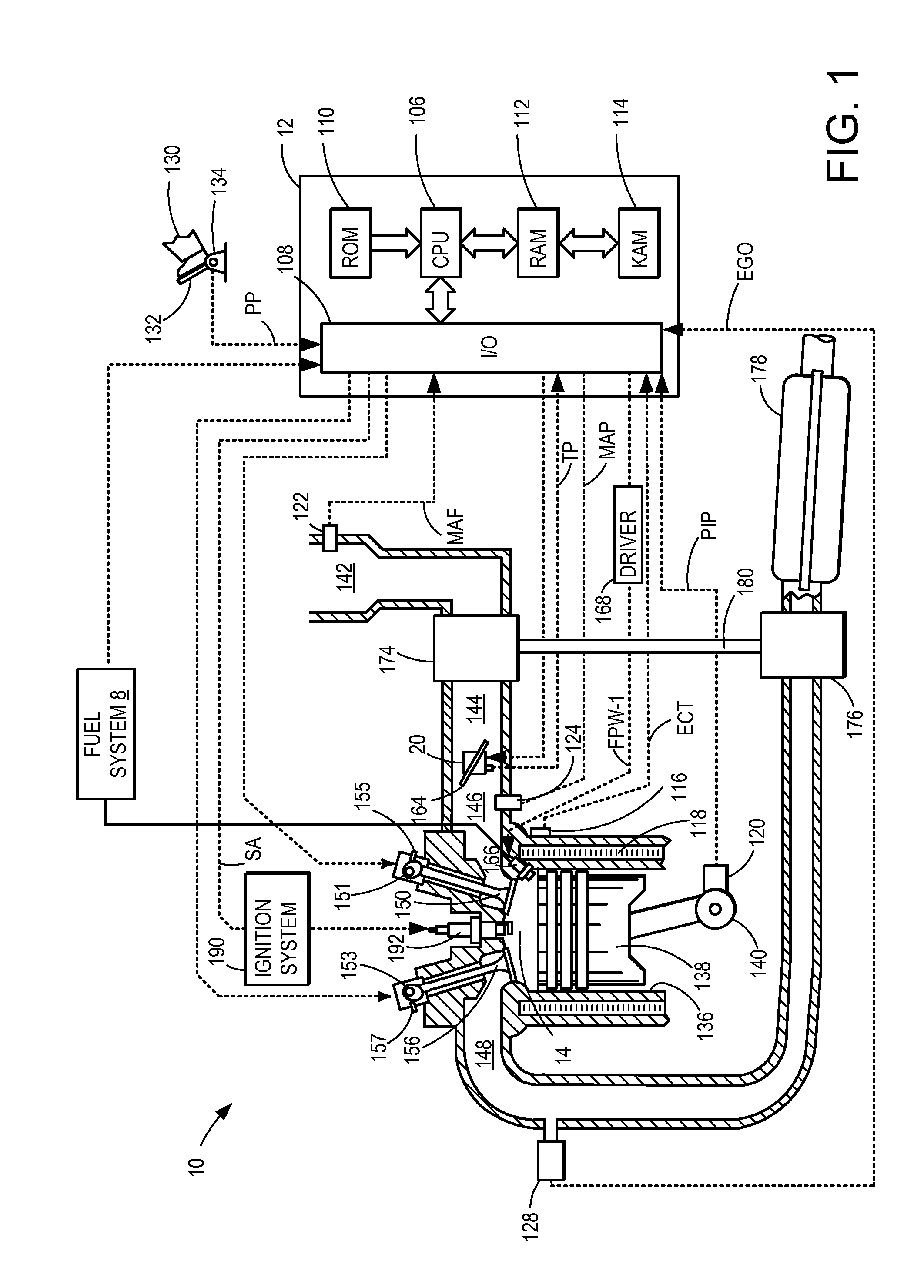

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS20060144356A1Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

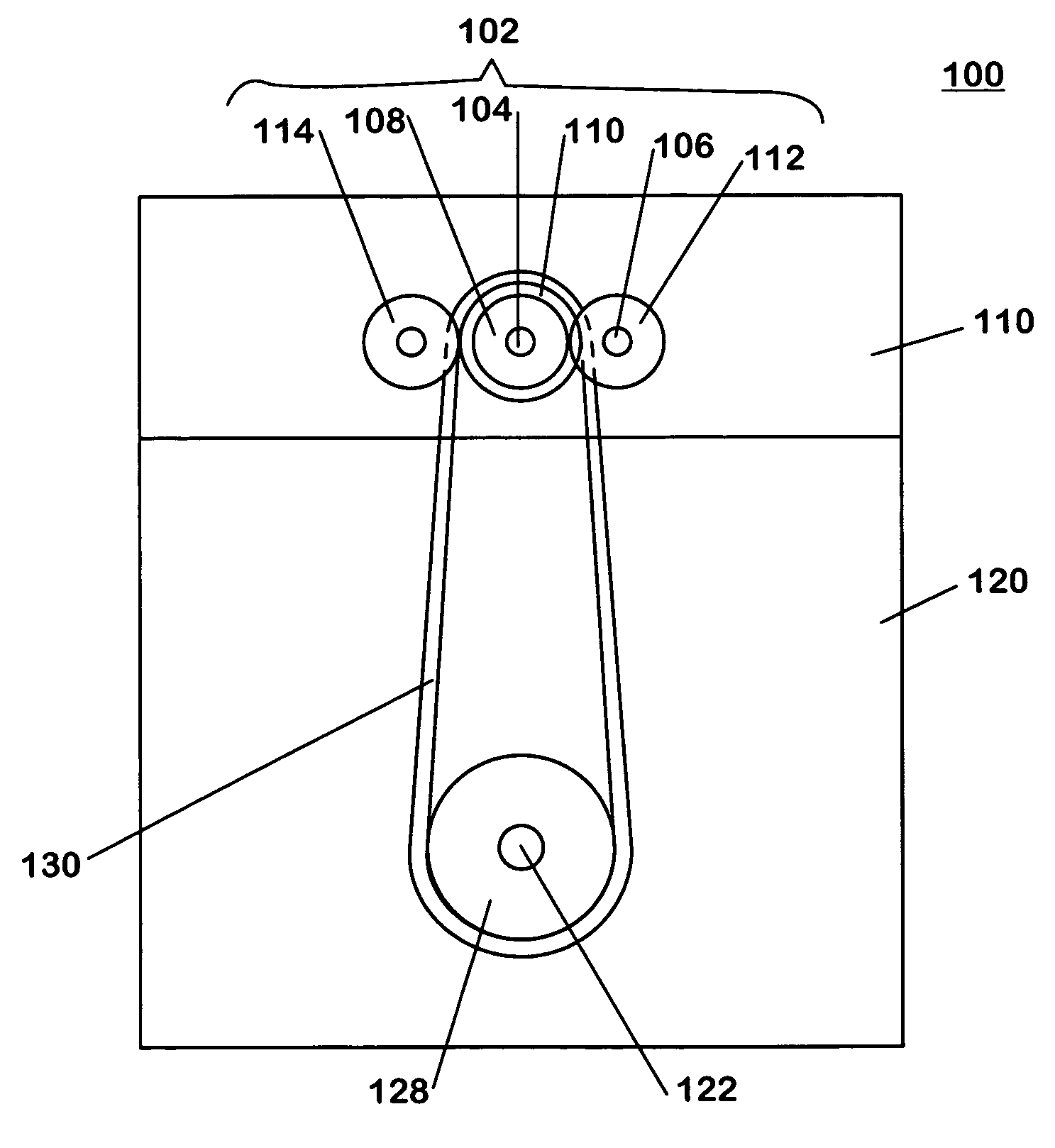

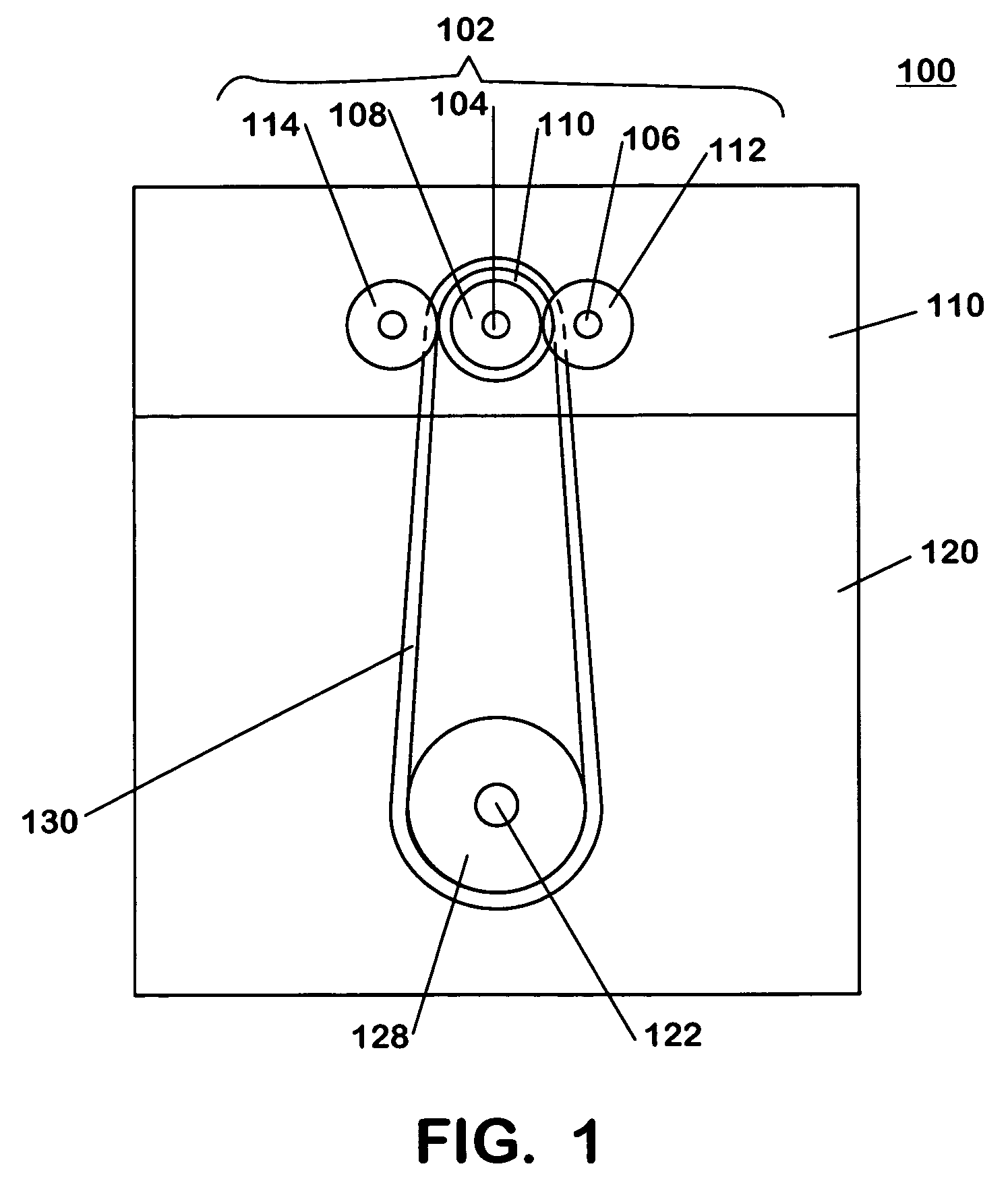

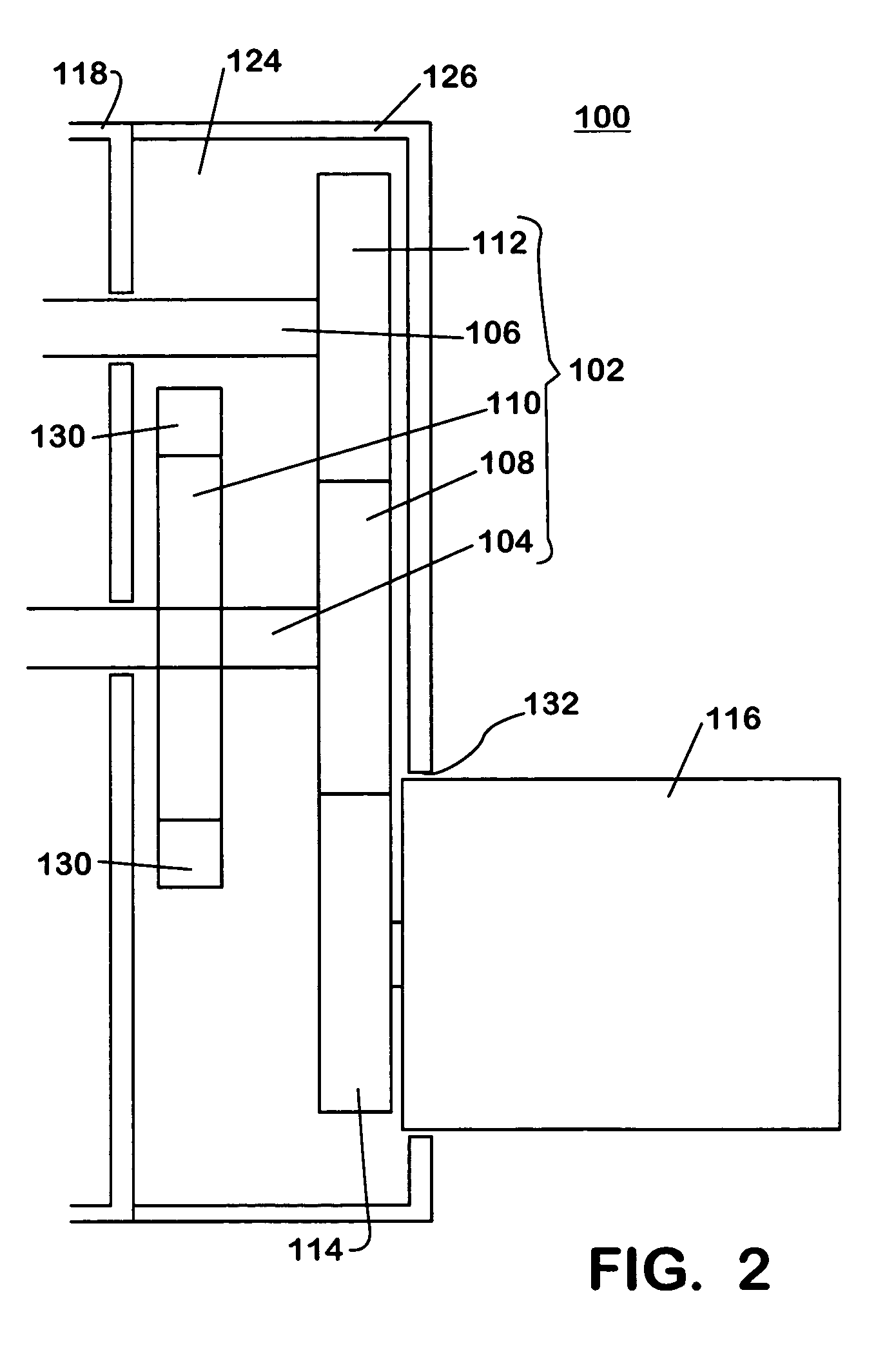

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

Method and apparatus for optimized combustion in an internal combustion engine utilizing homogeneous charge compression ignition and variable valve actuation

InactiveUS7308872B2Electrical controlInternal combustion piston enginesHomogeneous charge compression ignitionExhaust valve

A valvetrain system mechanization for an internal combustion engine using compression ignition, including homogeneous charge compression ignition, having two intake and one or more exhaust valves per cylinder. The valves are operated by dual overhead camshafts having two-step cams. The intake and exhaust camshafts are provided with phasers for varying the opening and closing of the intake and exhaust valves. A two-step roller finger follower is disposed for each valve between the cam lobes and the valve stem. The two sets of intake and exhaust valves are controlled by separate oil control valves. Swirl of gases may be introduced by mismatching the lifts of the valves. The valve opening times, closing times, lifts, fuel injection, compression ratio, and exhaust gas recirculation may be varied to optimize combustion conditions for a range of engine operating modes.

Owner:DELPHI TECH INC

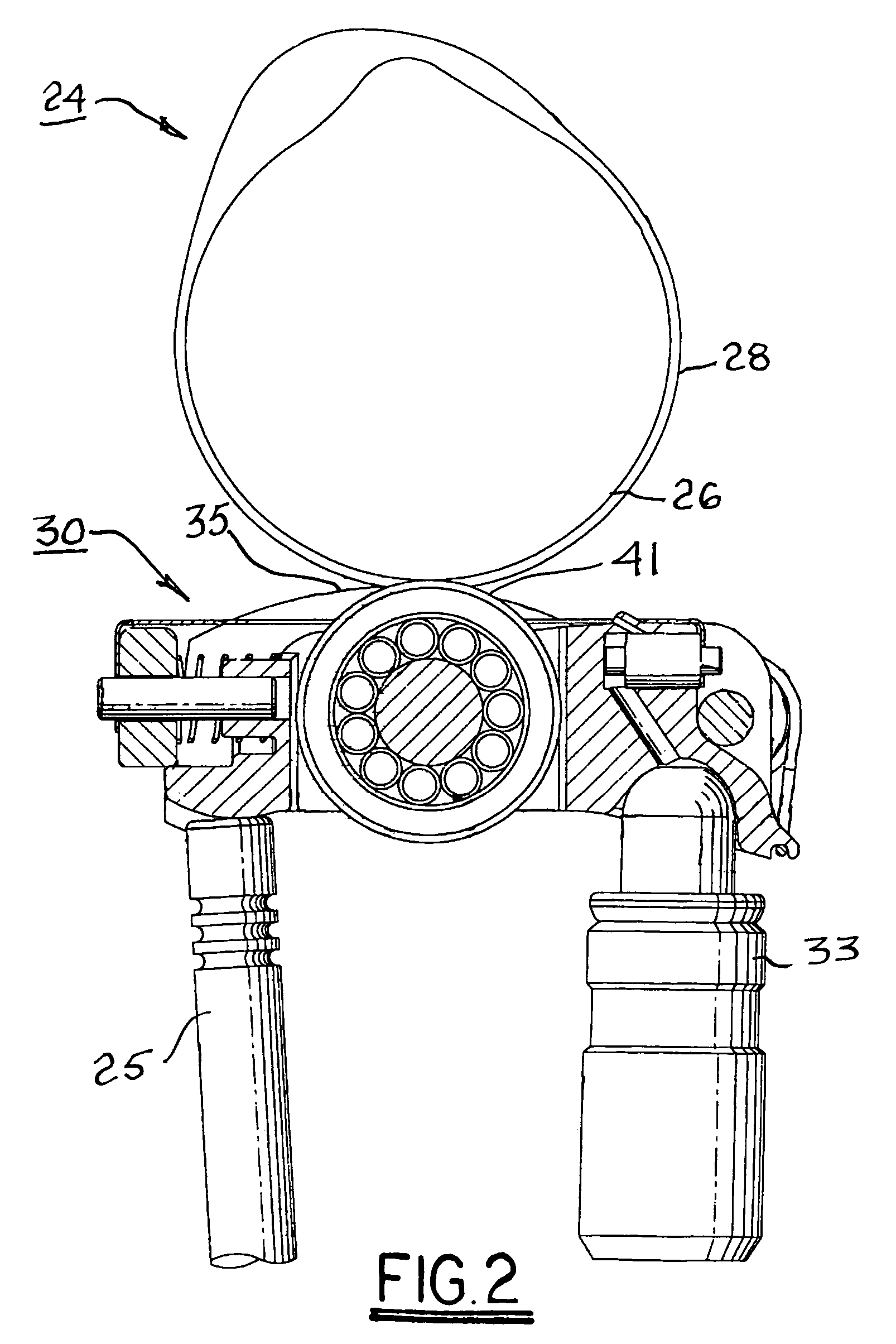

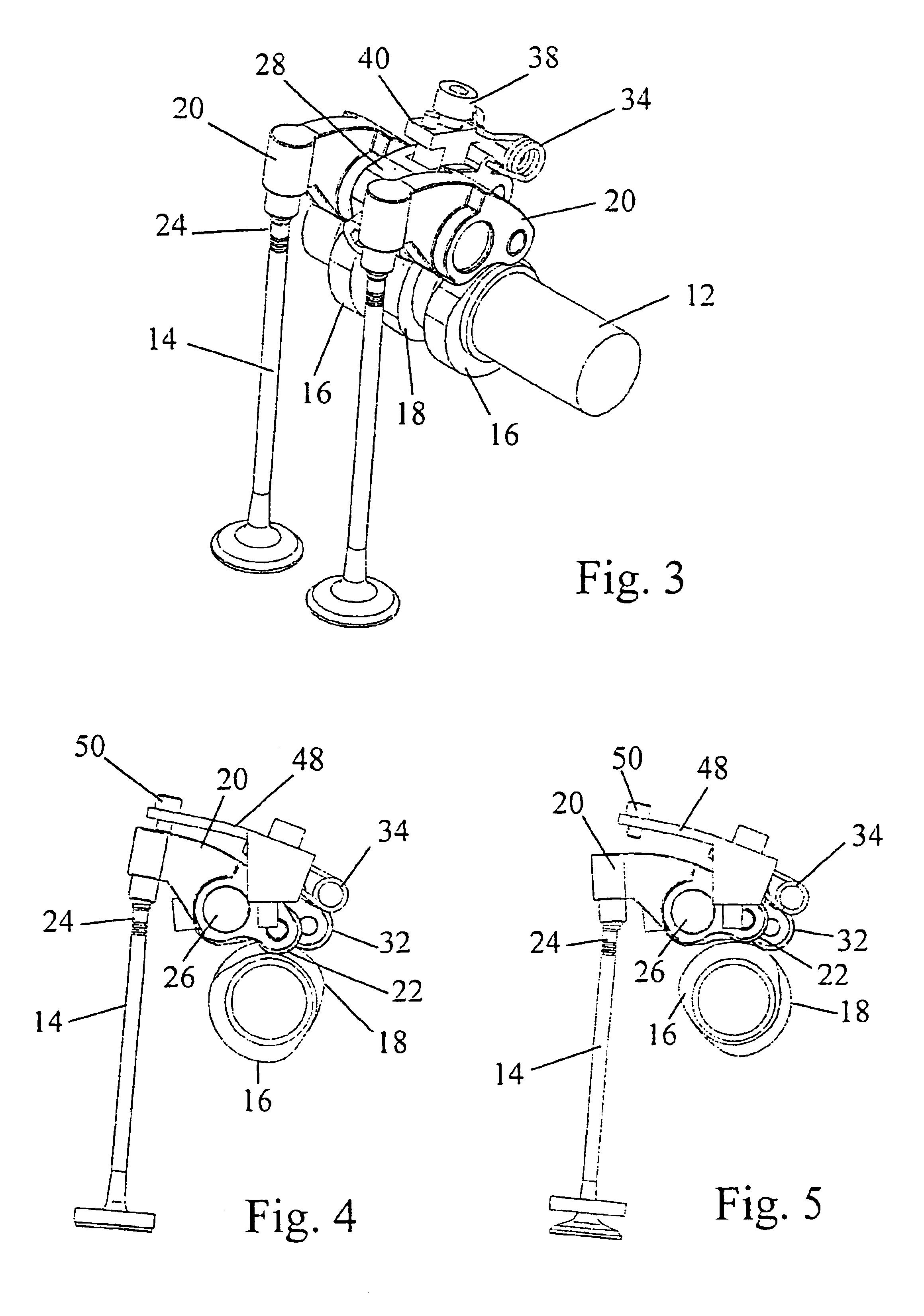

Engine with variable valve mechanism

An overhead camshaft internal combustion engine is disclosed having a valve mechanism which comprises an intake or exhaust poppet valve 14 having a valve stem operated by two cams 16 and 18 mounted for rotation about a common axis. A first rocker 20 mounted on a pivot shaft 26 acts between the first cam 16 and the valve 14. A second rocker 28 is mounted in the engine on a fixed pivot shaft 30 and acts between the second cam 18 and the pivot shaft 26 of the first rocker 20, to raise and lower the pivot point 26 of the first rocker 20 cyclically in synchronism with the rotation of the second cam 18.

Owner:MECHADYNE INT

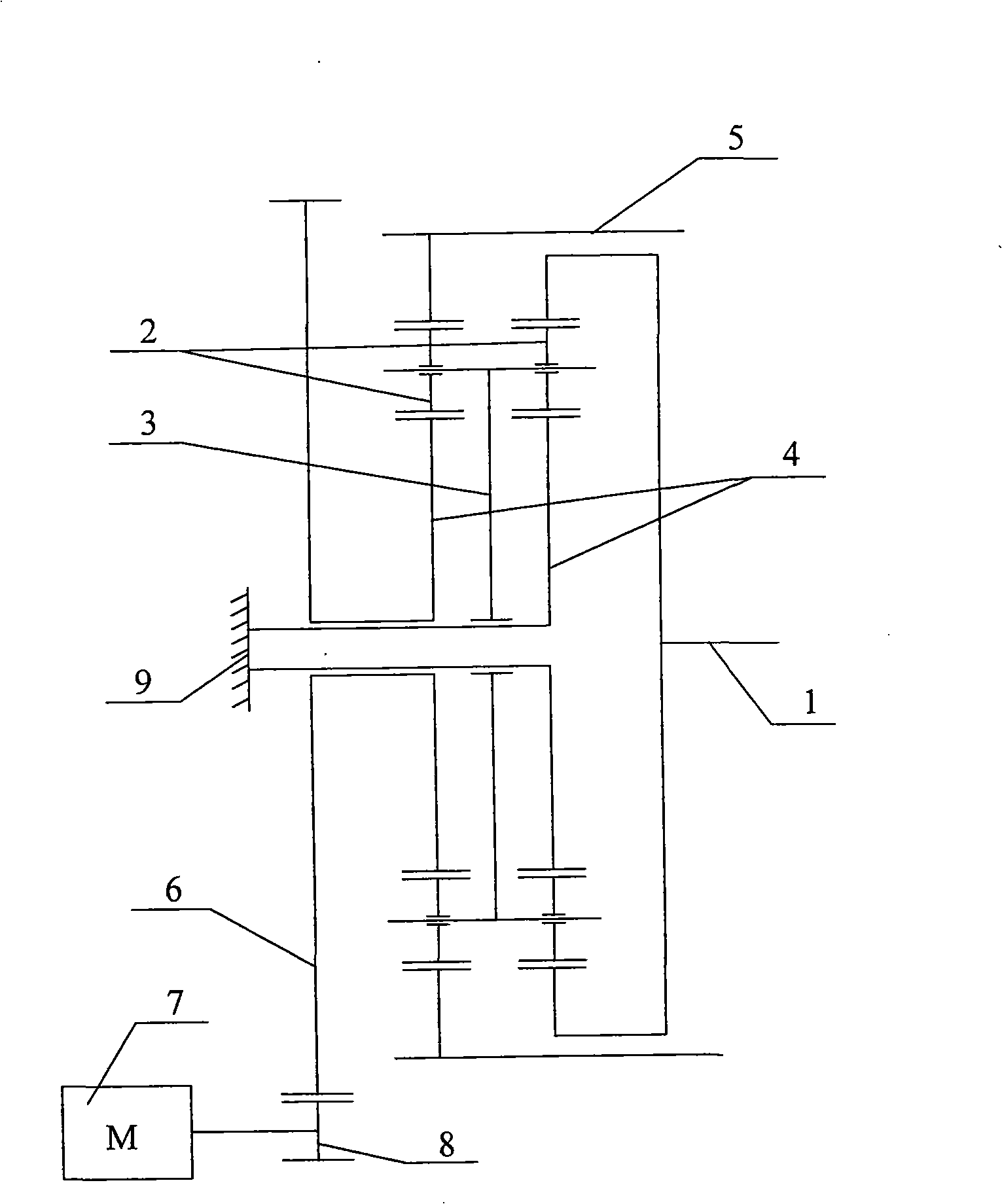

Car engine air valve variable phase device

ActiveCN101338689ASimple structureControl phaseValve arrangementsMachines/enginesGear wheelEngine valve

The present invention provides an automobile engine valve changeable phase mechanism which comprises a camshaft and is characterized by also comprising two sets of planet wheels and sun wheels, a planet carrier, a controlling and adjusting wheel, a step motor and a belt pulley. The mechanism combination is as follows: the camshaft and the belt pulley are internally meshed with two sets of planet wheels; the sun wheel which is externally meshed with one set of planet wheels at left is integrated with the controlling and adjusting wheel as a whole; the sun wheel which is externally meshed with one set of planet wheels at right is connected with an engine casing; the rotating shaft of the planet carrier of two sets of planet wheels is arranged at the shaft of the sun wheel for connecting with the engine casing; a gear ring which is internally meshed with one set of planet wheels at right is connected with the camshaft directly; a gear which is connected with the step motor is meshed with the controlling and adjusting wheel. The automobile engine valve changeable phase mechanism uses a planet gear mechanism, has simpler structure, can control a best cams shaft phase at any rotating speed and can change directly on a produced non-VVT double overhead camshaft engine without changing a engine body.

Owner:SHANGHAI SICAR VEHICLE TECH DEV

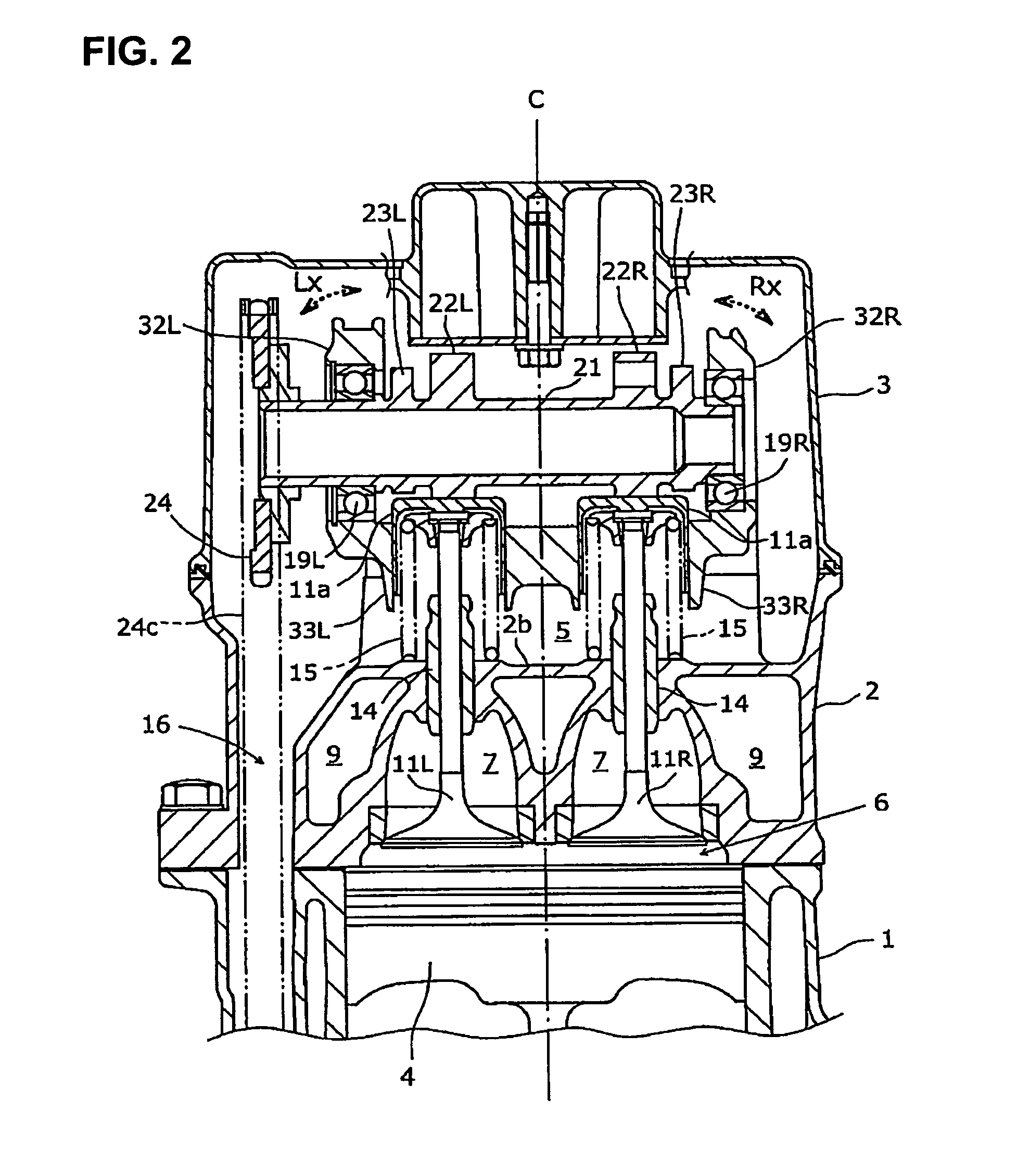

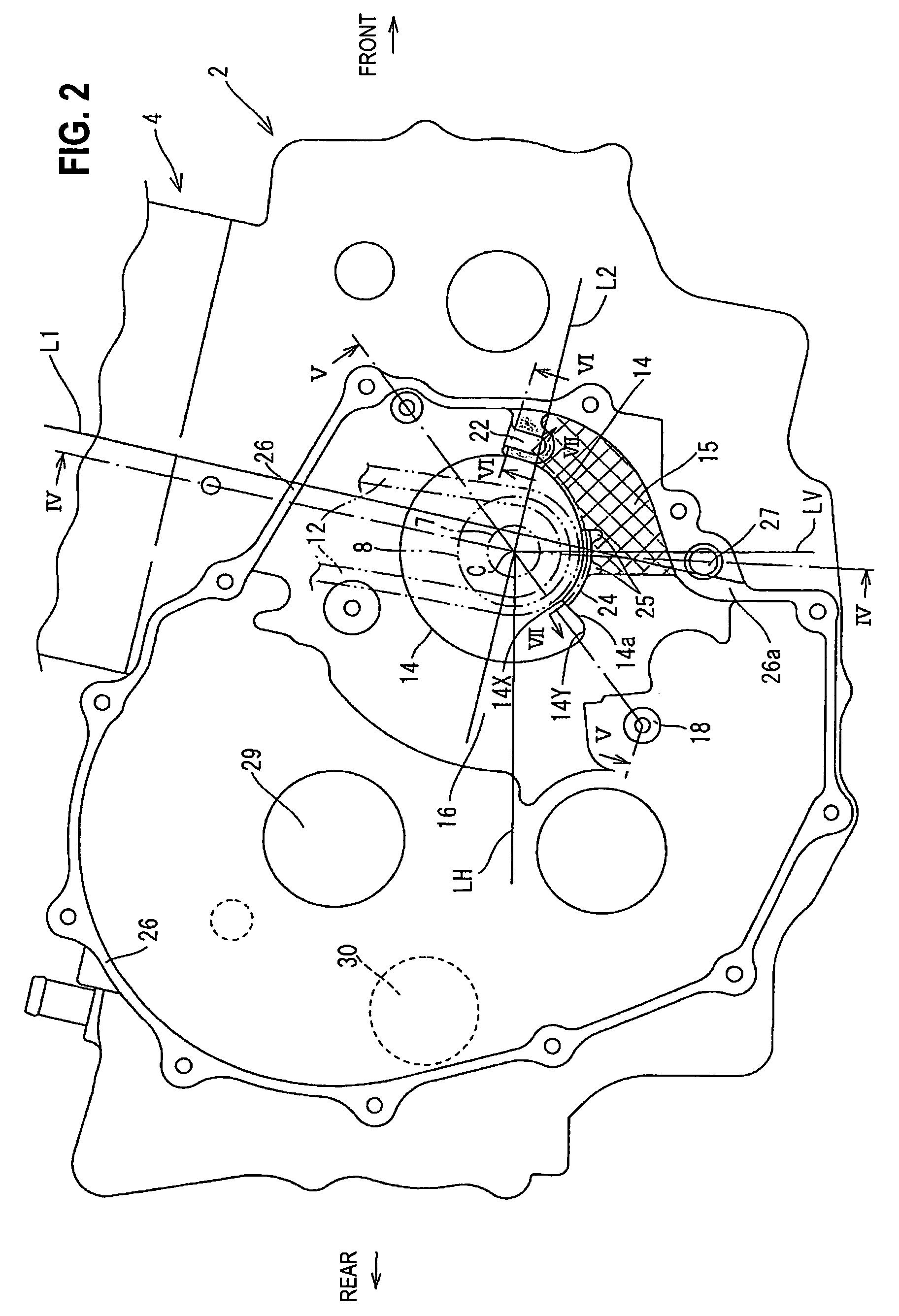

Valve system for overhead-camshaft-type internal combustion engine, and engine incorporating same

A valve system of an overhead-camshaft-type internal combustion engine includes a cam holder fastened to a cylinder head having a combustion chamber formed therein. The cam holder supports a camshaft, and is disposed above the combustion chamber. The cam holder includes a bottom wall, a pair of oppositely-facing support walls having lower sides thereof joined with each other by the bottom wall, and a rib joining predetermined oppositely-facing portions of respective upper side portions of the support walls with each other. The support walls of the cam holder pivotally support the cam shaft. The rib may be integrated with the cam holder, or may be separately formed and fastened to the support walls of the cam holder.

Owner:HONDA MOTOR CO LTD

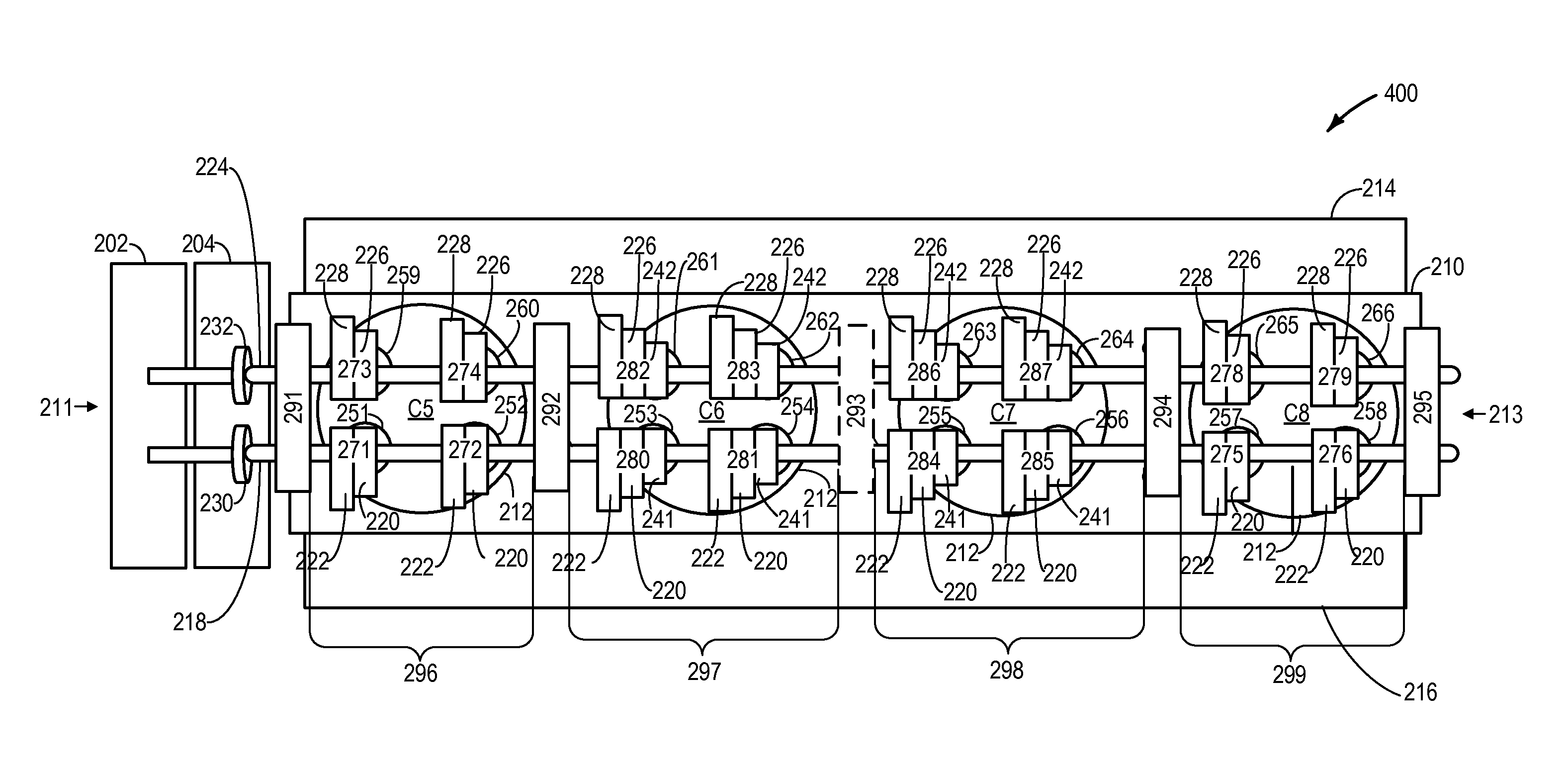

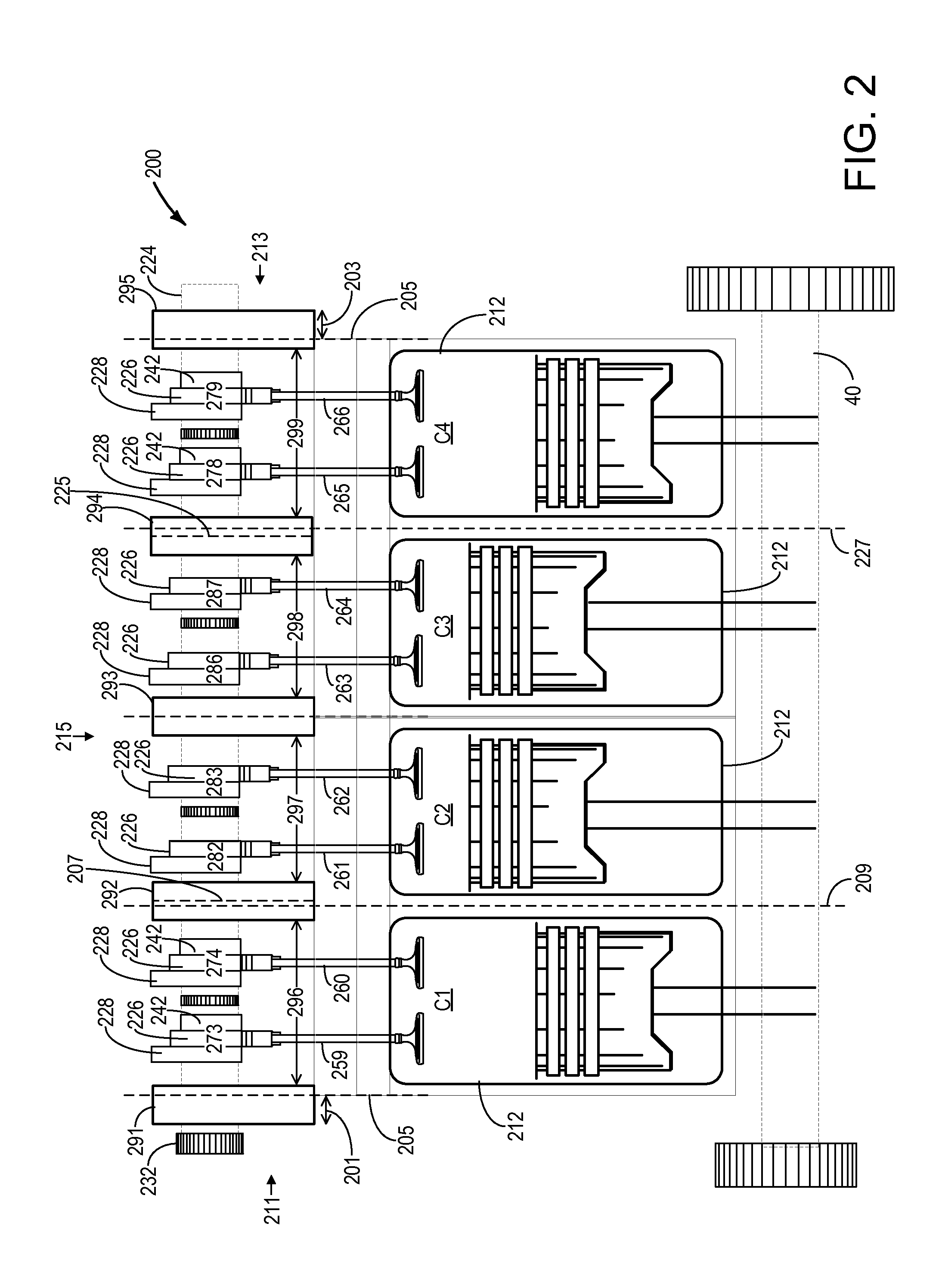

Head packaging for cylinder deactivation

ActiveUS8931444B2Improve fuel efficiencyReduce outputValve arrangementsInternal combustion piston enginesEngineeringCam

Systems and methods for an overhead cam shaft coupled to an inline engine with inner cylinders and outer cylinders are disclosed. In one example approach, an engine bank comprises inner cylinders each having only first and second lift profiles, both being non-zero lift profiles, and outer cylinders each having first, second, and third lift profiles, two being non-zero lift profiles and one being zero lift.

Owner:FORD GLOBAL TECH LLC

Fuel pump drive system in an internal combustion engine

A fuel pump drive system for an internal combustion engine uses a cam-to-cam gear from a double overhead camshaft to rotate a fuel pump gear. The fuel pump drive system may have a primary camshaft, a secondary camshaft, and the fuel pump. The primary camshaft has a camshaft gear and the cam-to-cam gear. The secondary camshaft has a cam gear. The cam gear engages the cam-to-cam gear. The fuel pump has a fuel pump gear that engages the cam-to-cam gear. The fuel pump gear drives the fuel pump.

Owner:INT ENGINE INTPROP CO LLC

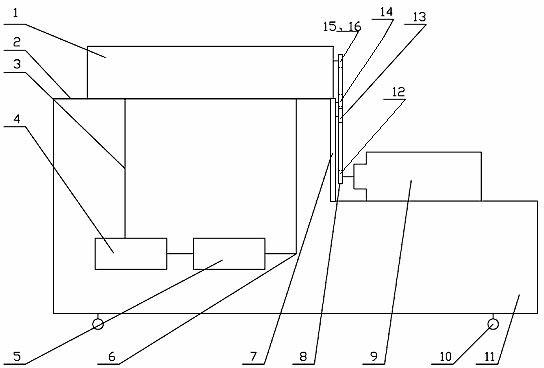

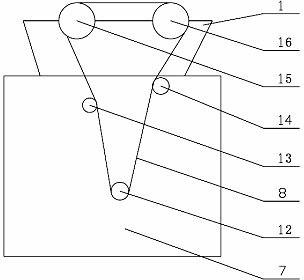

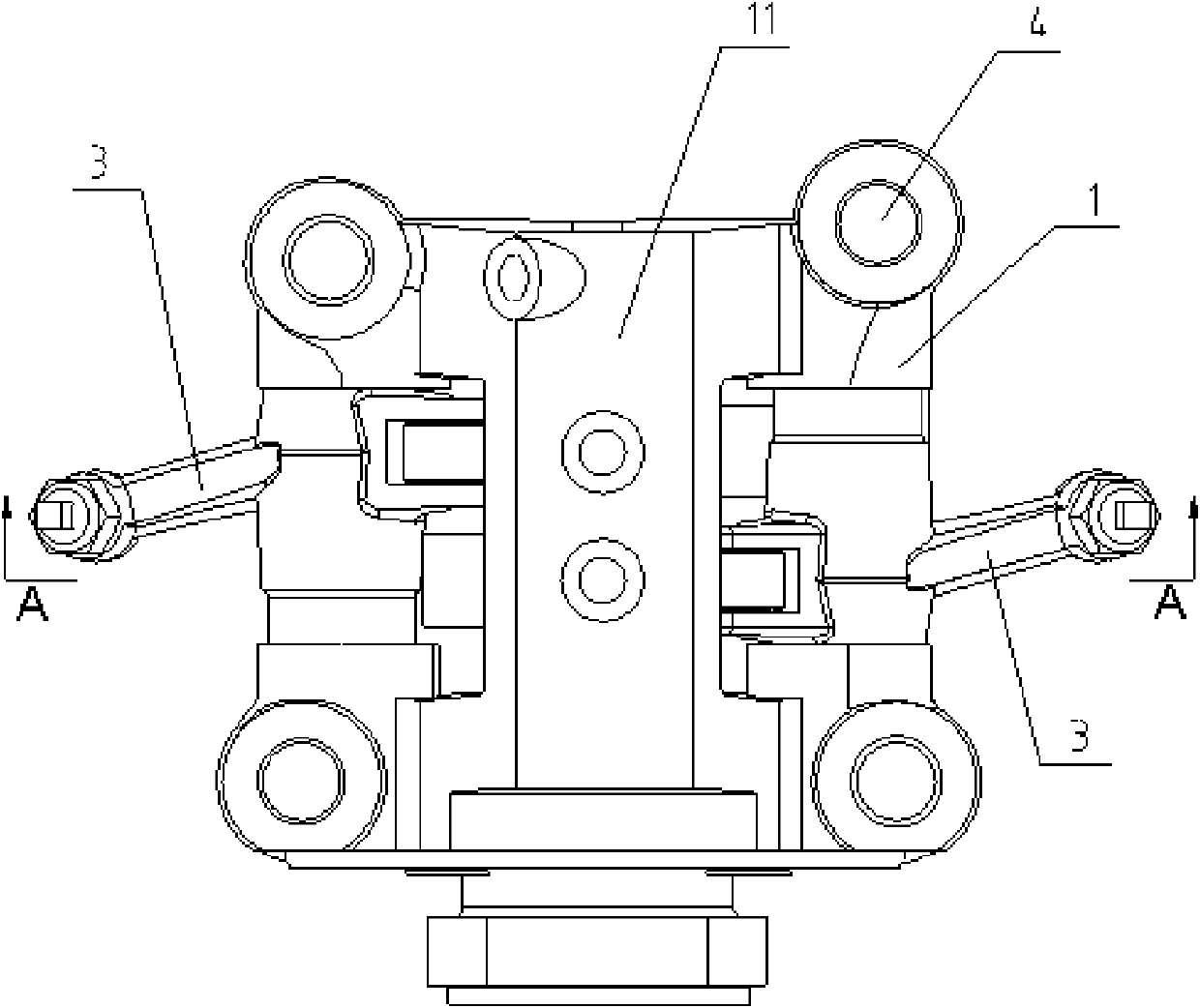

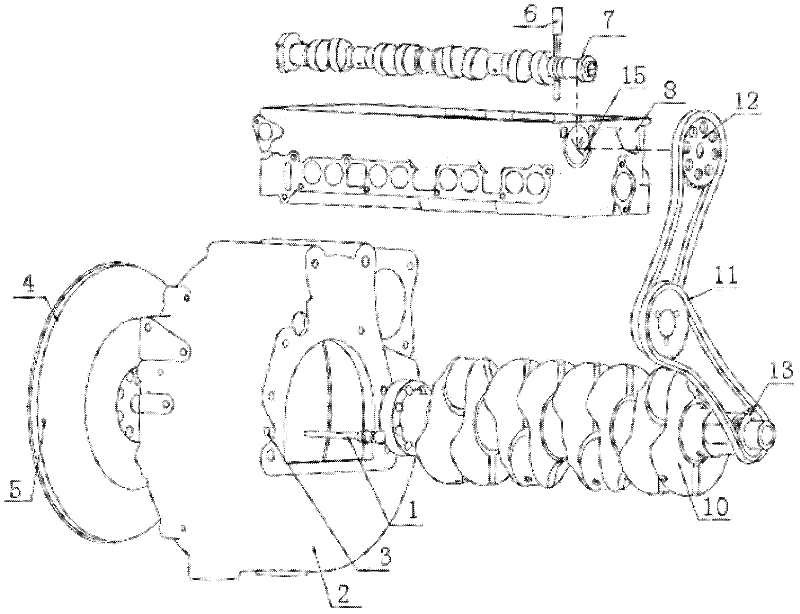

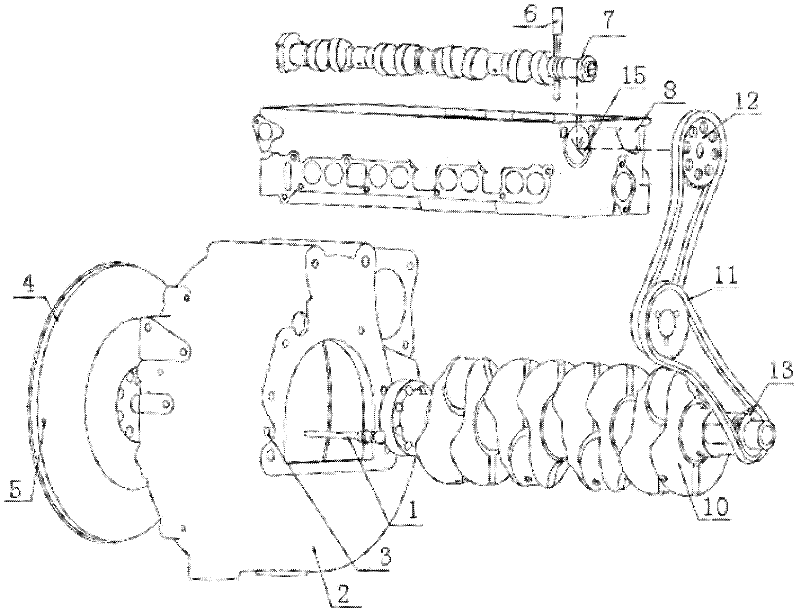

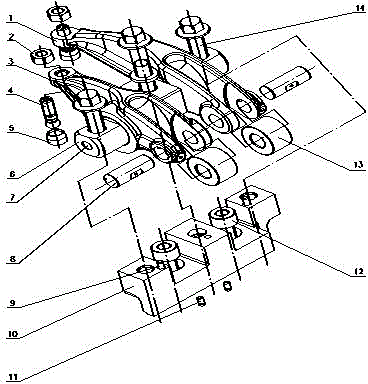

Test bed for valve actuating mechanism of engine with top-mounted cam shafts

The invention relates to a test bed for a valve actuating mechanism of an engine with top-mounted cam shafts. The test bed comprises a test bed supporting trolley, and a cylinder-cover connection board, a front-end gear board and a motor which are fixed on the test bed supporting trolley, as well as a circulation oil path and an engine front-end gear. The motor simulates the rotating speed of theengine; and a front-end panel which is the same as a timing gear of the engine is designed and used for installing various tension wheels and idle wheels which are needed by the timing gear, so that an arrangement state of an actual working gear of the engine can be simulated. The motor is used as a power source, and a crank shaft timing wheel arranged on the motor drives a timing belt or chain so as to drive an admission cam shaft and an exhaustion cam shaft to work; and an actual working state of the valve actuating mechanism of the engine with two top-mounted cam shafts can be represented really, so that the performance test of the valve actuating mechanism of the engine can be performed. The test bed has the advantages that: the equipment is simple, the actual working state of the valve actuating mechanism of the engine with the two top-mounted cam shafts can be simulated effectively and really, and the accuracy of a test result can be guaranteed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

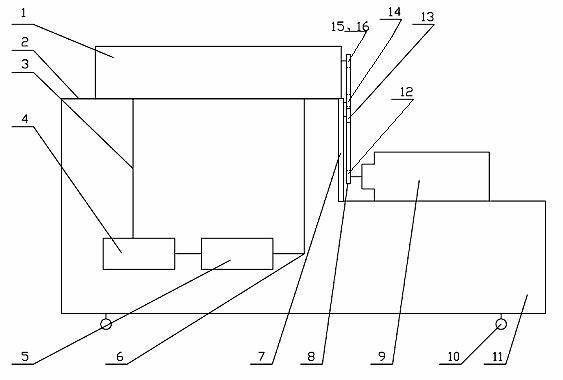

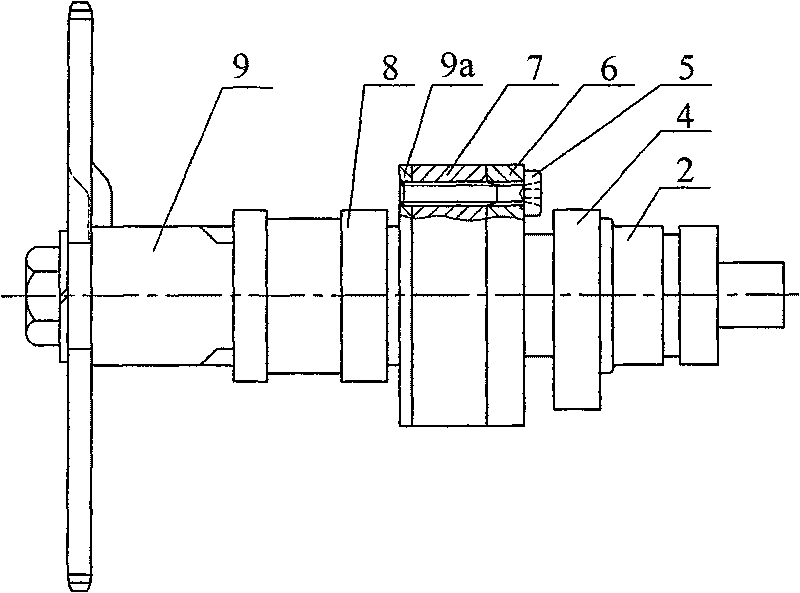

Engine correct-timing drive system mounting method and positioning tool

InactiveCN1936281APrecise positioningSimple and fast operationValve arrangementsMachines/enginesEngineeringScrew thread

This invention relates to an installation method for timing drive system of engines including: 1, setting phase of a crank by a crank location pin to mount a timing gear, 2, rotating two camshafts to the required phase and bolting a locating tool on a cap end and mounting the camshaft timing gear without screw down, 3, mounting a tension wheel and a timing belt and adjusting the adjuster of the wheel and screwing down the timing gear, 4, removing the locating tool and the pin, 5, calibrating position of the tension wheel. Two clamp blocks are set corresponding to the grooved position of the dual-camshaft on the long edge of a ruler body and more than two fixed screw holes are set on the body to form a locating tool of the invented method.

Owner:CHERY AUTOMOBILE CO LTD

Lubricating system for OHC engine

A scraper is provided in a large end portion of a connecting rod in an inclined type of overhead camshaft engine to lubricate a timing system by dipping a lubricating oil stored in a lower portion of a crank case up. The scraper includes a bottom wall and a side wall set up on the bottom wall, and have a substantially L-shaped cross-section. An angle between the bottom wall and the side wall is set in a range of 60.degree. to 90.degree.. Thus, the droplets of the oil can be splashed to the side direction of scraper also in three-dimensional inclined direction, so that oil can be securely supplied to and lubricate the timing system which is offset from the scraper in a longitudinal direction of the crankshaft.

Owner:SUBARU CORP

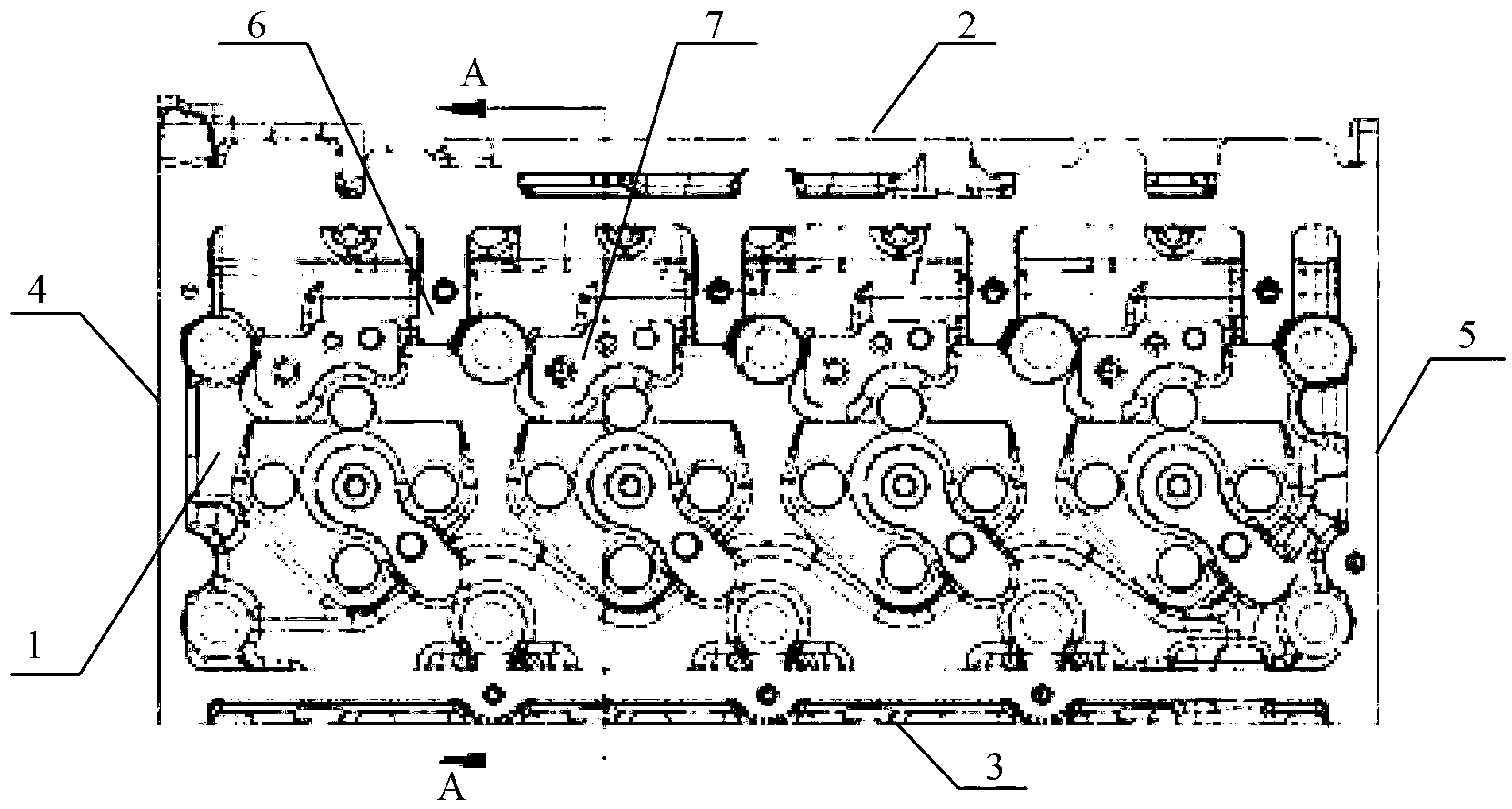

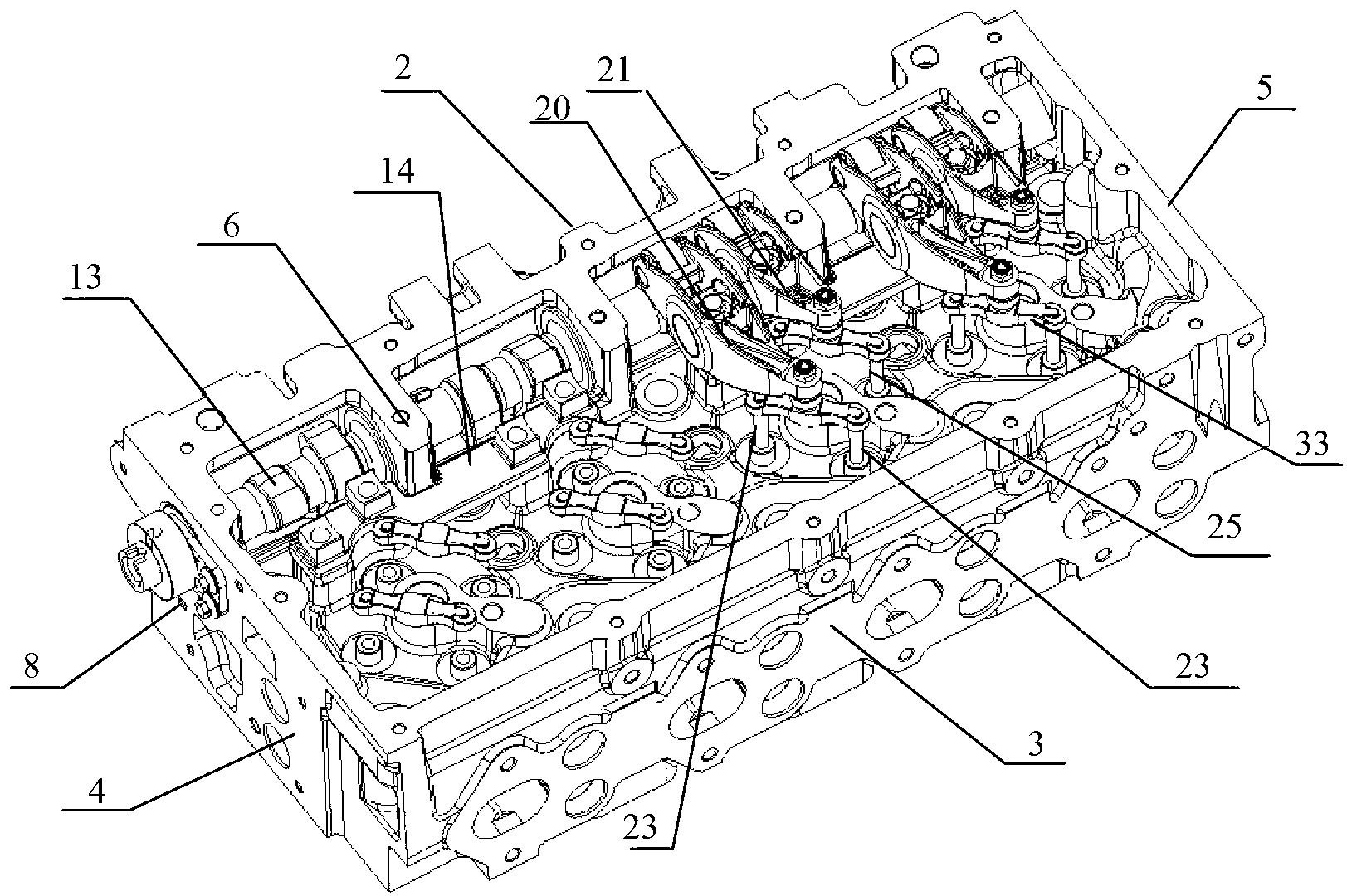

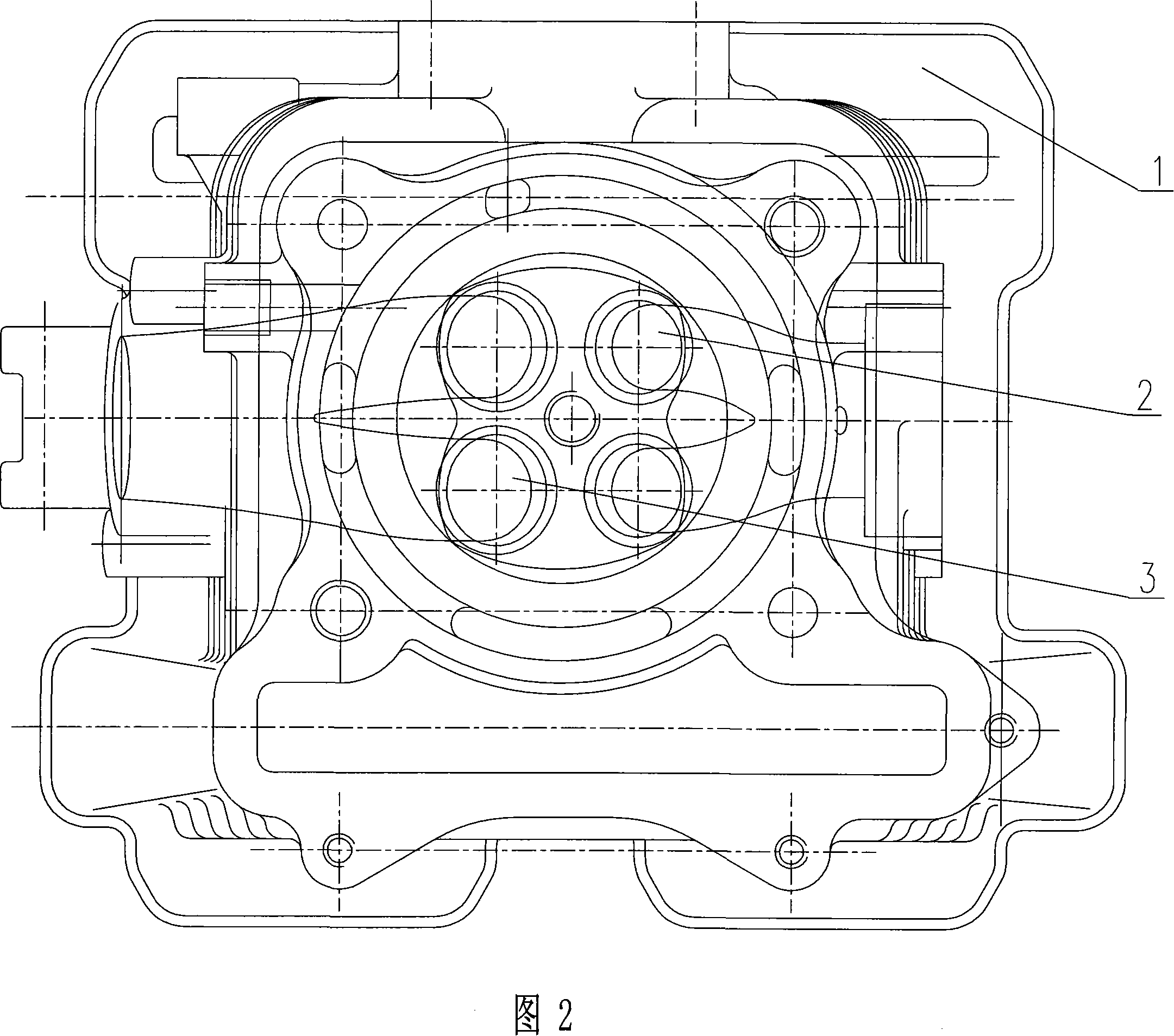

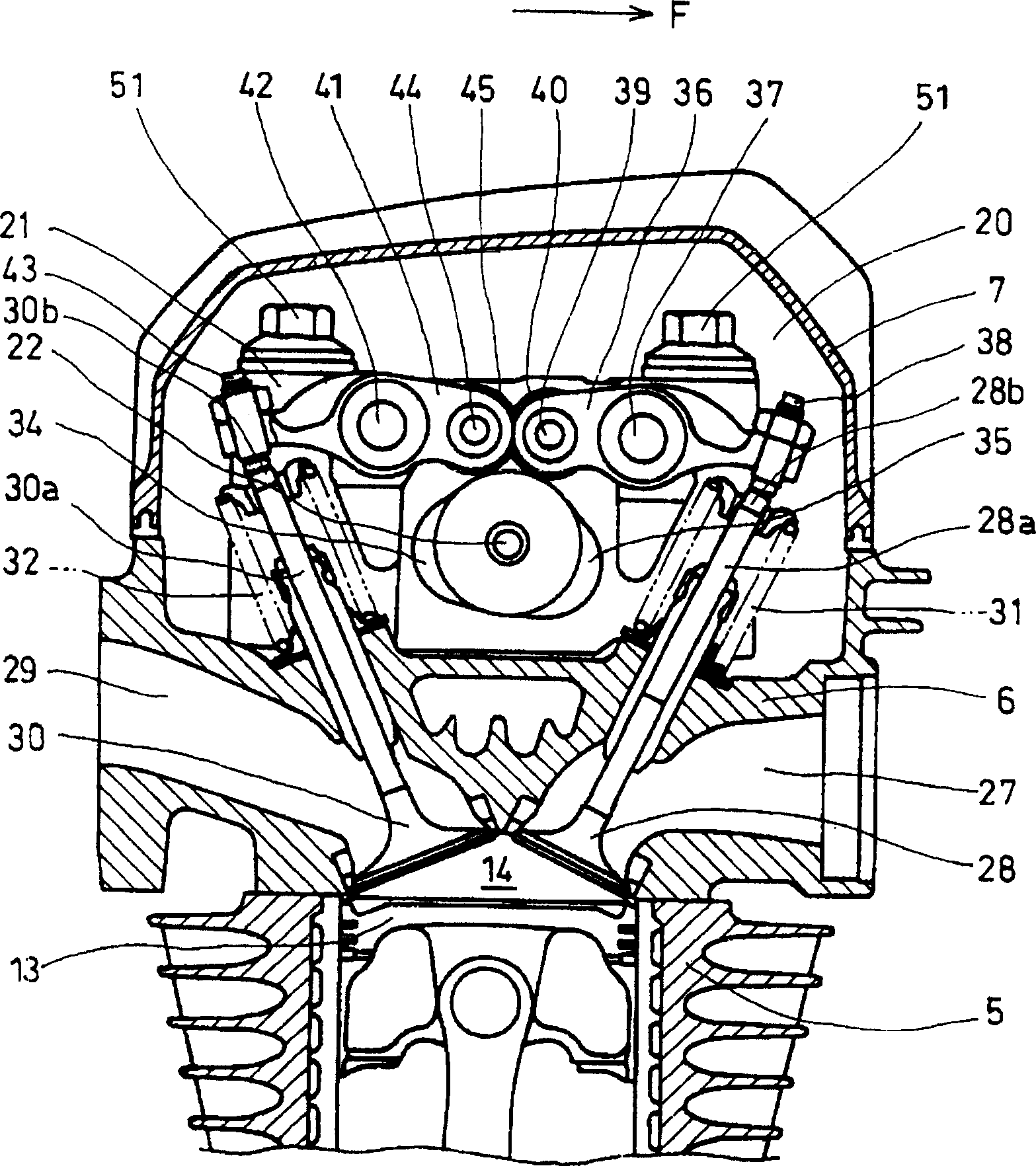

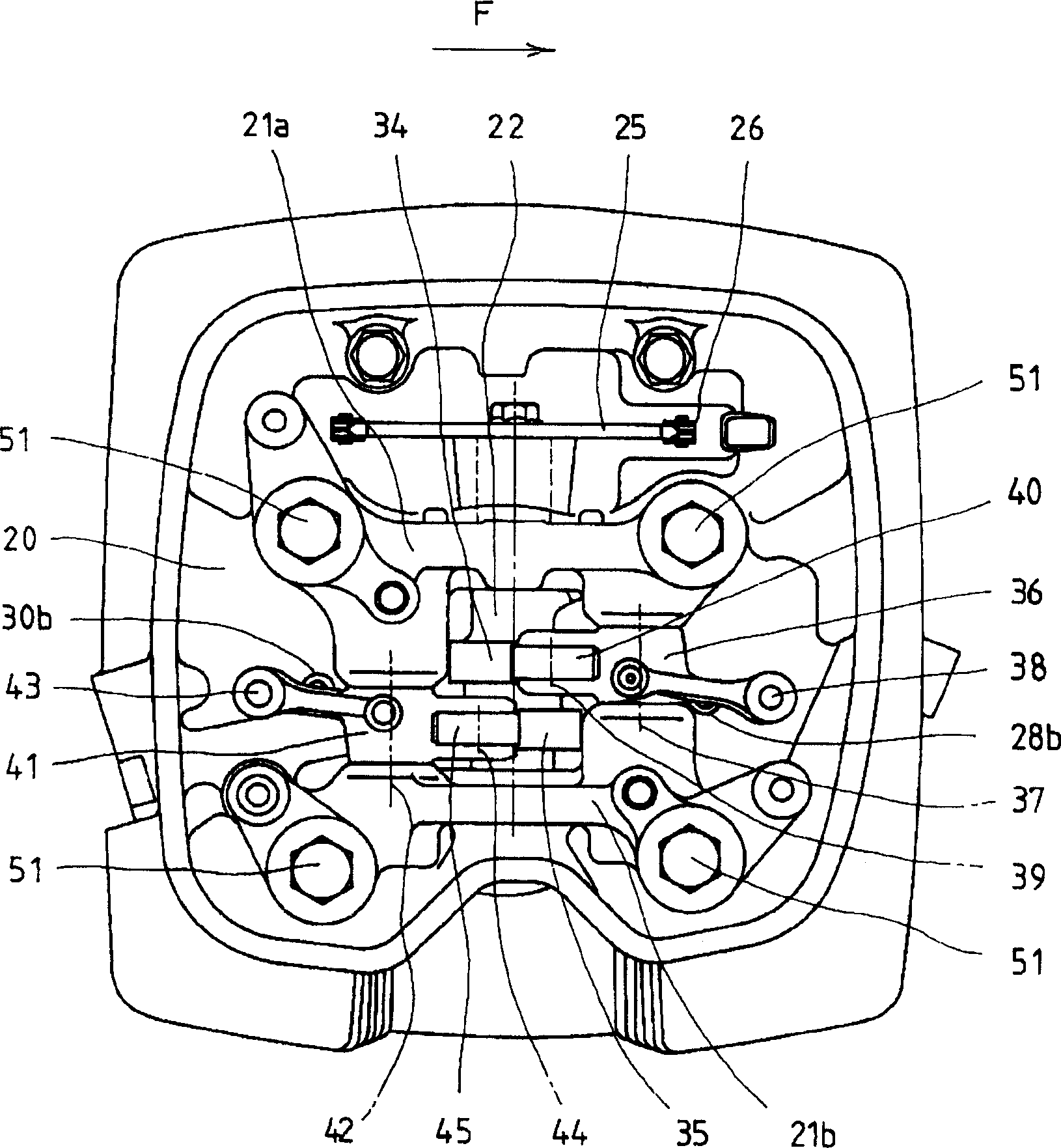

Cylinder head and overhead camshaft engine

ActiveCN103195602ASmall sizeCompact layoutValve arrangementsCylinder headsMiniaturizationOverhead camshaft

The invention provides a cylinder head which comprises a top face, an air inlet side face, a exhaust side face, a front end face, and a rear end face. A camshaft mounting seat and a rocker support mounting boss are distributed on the top face. A through oil return passage is arranged between the front end face and the rear end face. The cylinder head is provided with a first straight oil hole vertically downwardly extending from the rocker support mounting boss and a second straight oil hole horizontally extending from the air inlet side face. The first straight oil hole is communicated with the second straight oil hole which is communicated with the oil return passage. The invention further provides an overhead camshaft engine with the cylinder head. By the cylinder head, the engine structure is compacter to further achieve miniaturization.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

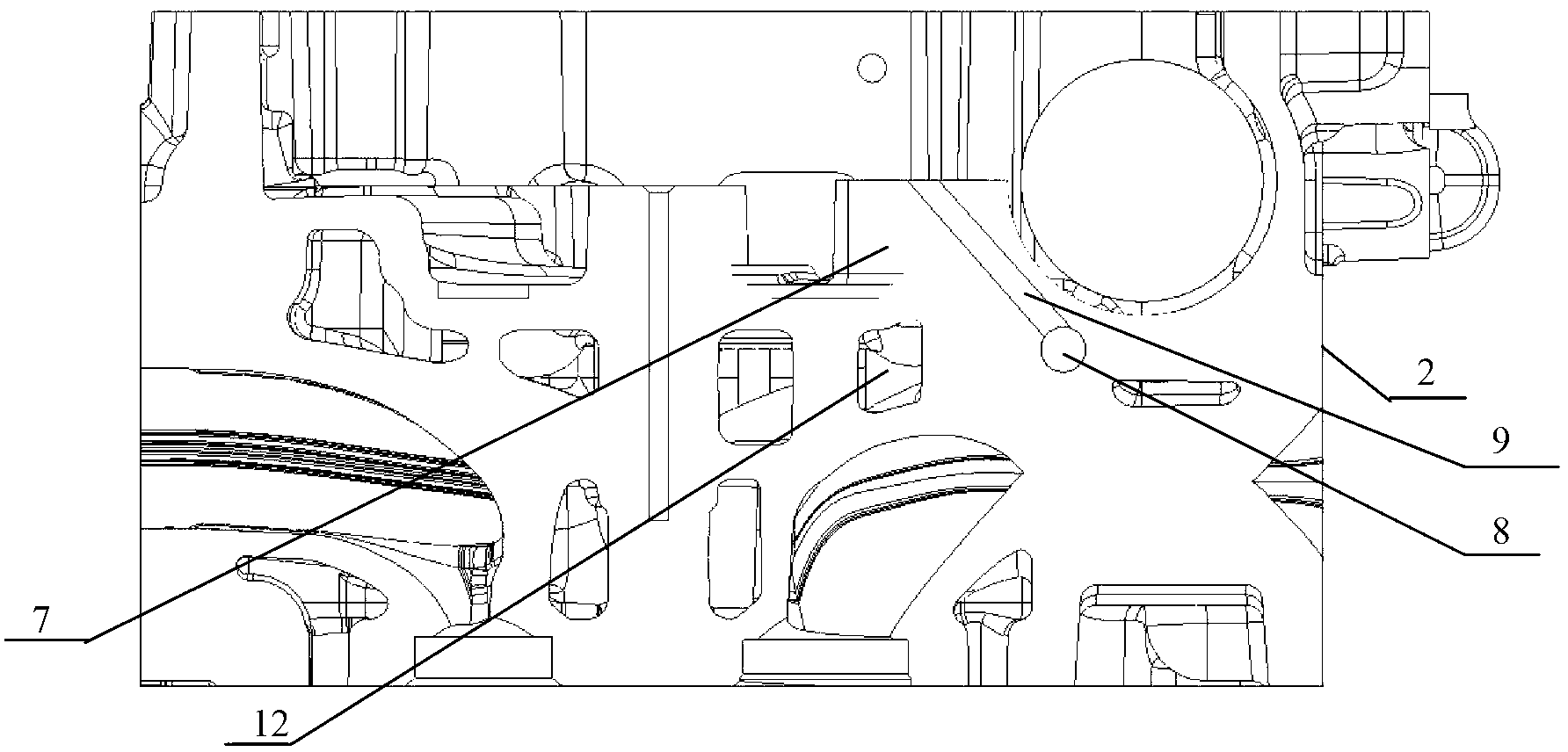

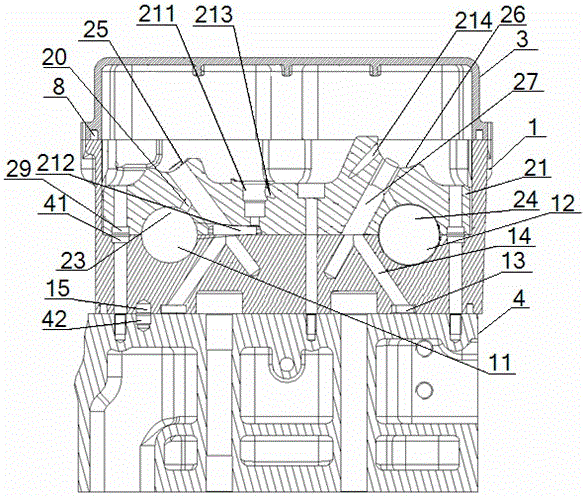

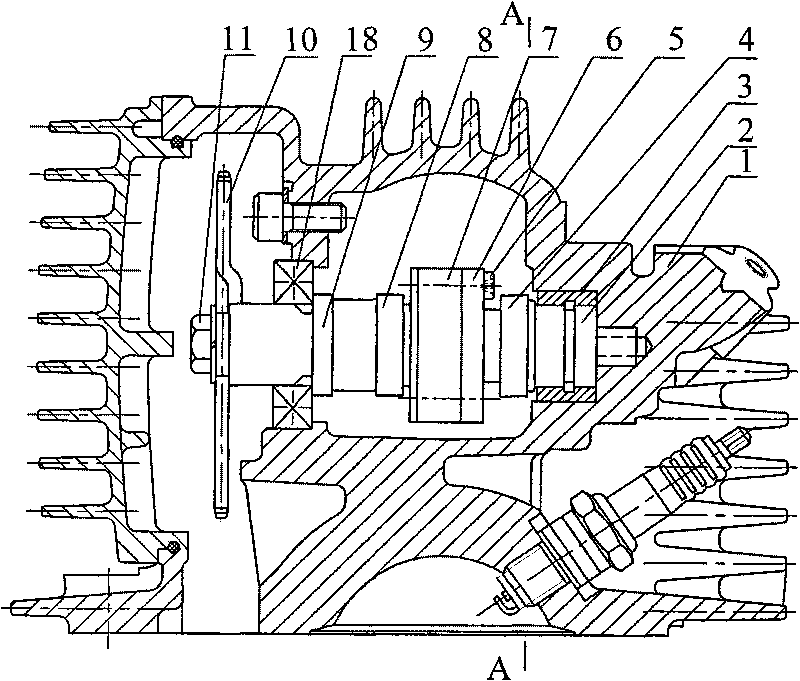

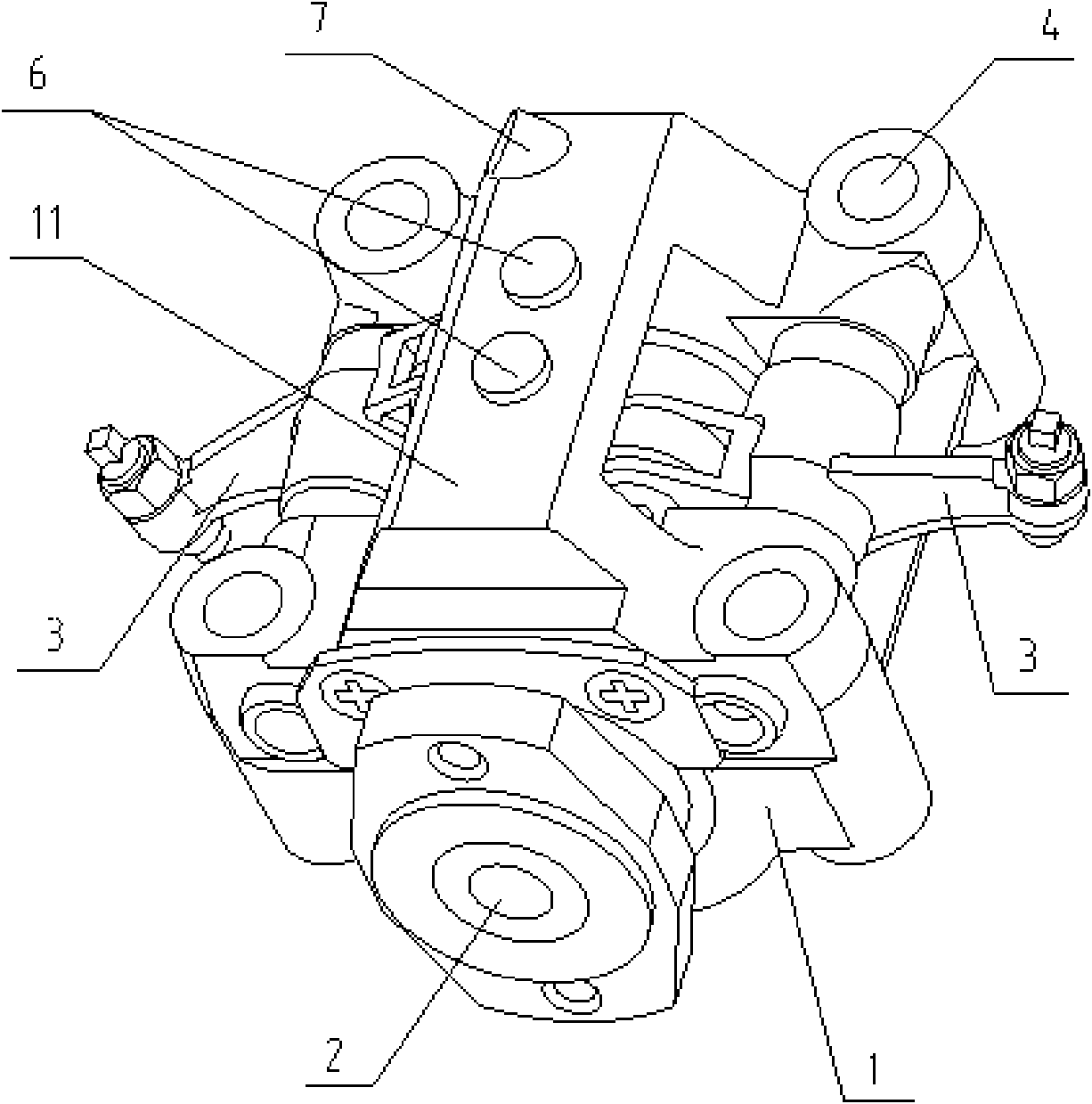

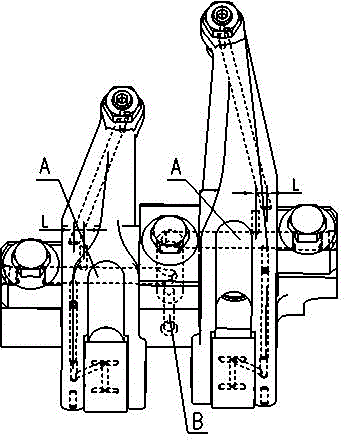

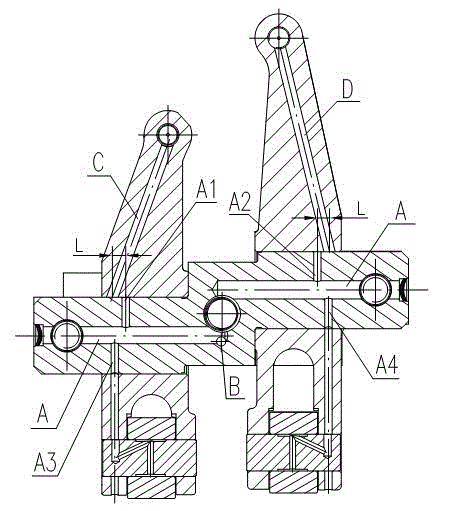

Rocker arm compartment assembly for heavy-duty diesel engine

ActiveCN104989546ARealize installation positioningReduce in quantityCasingsLubrication of auxillariesCamHeavy duty diesel

A rocker arm compartment assembly for a heavy-duty diesel engine comprises a rocker arm compartment and a cam bearing cap. The top of the rocker arm compartment is connected with a cylinder head cover. The bottom of the rocker arm compartment is connected with a cylinder head. A first intake camshaft installation groove and a first exhaust camshaft installation groove are symmetrically formed in the rocker arm compartment. The cam bearing cap comprises first cam bearing cap bodies and second cam bearing cap bodies. The top of each first cam bearing cap and the top of each second cam bearing cap are each provided with an intake rocker arm shaft installation arc surface matched with an intake rocker arm shaft and an exhaust rocker arm shaft installation arc surface matched with an exhaust rocker arm shaft. The bottom of each first cam bearing cap and the bottom of each second cam bearing cap are each provided with a second intake camshaft installation groove matched with the first intake camshaft installation groove and a second exhaust camshaft installation groove matched with the first exhaust camshaft installation groove. The rocker arm compartment assembly is applicable to the engine with double overhead camshafts and double rocker arm shafts; besides, part distribution is simplified while step-by-step braking of the engine is achieved.

Owner:DONGFENG COMML VEHICLE CO LTD

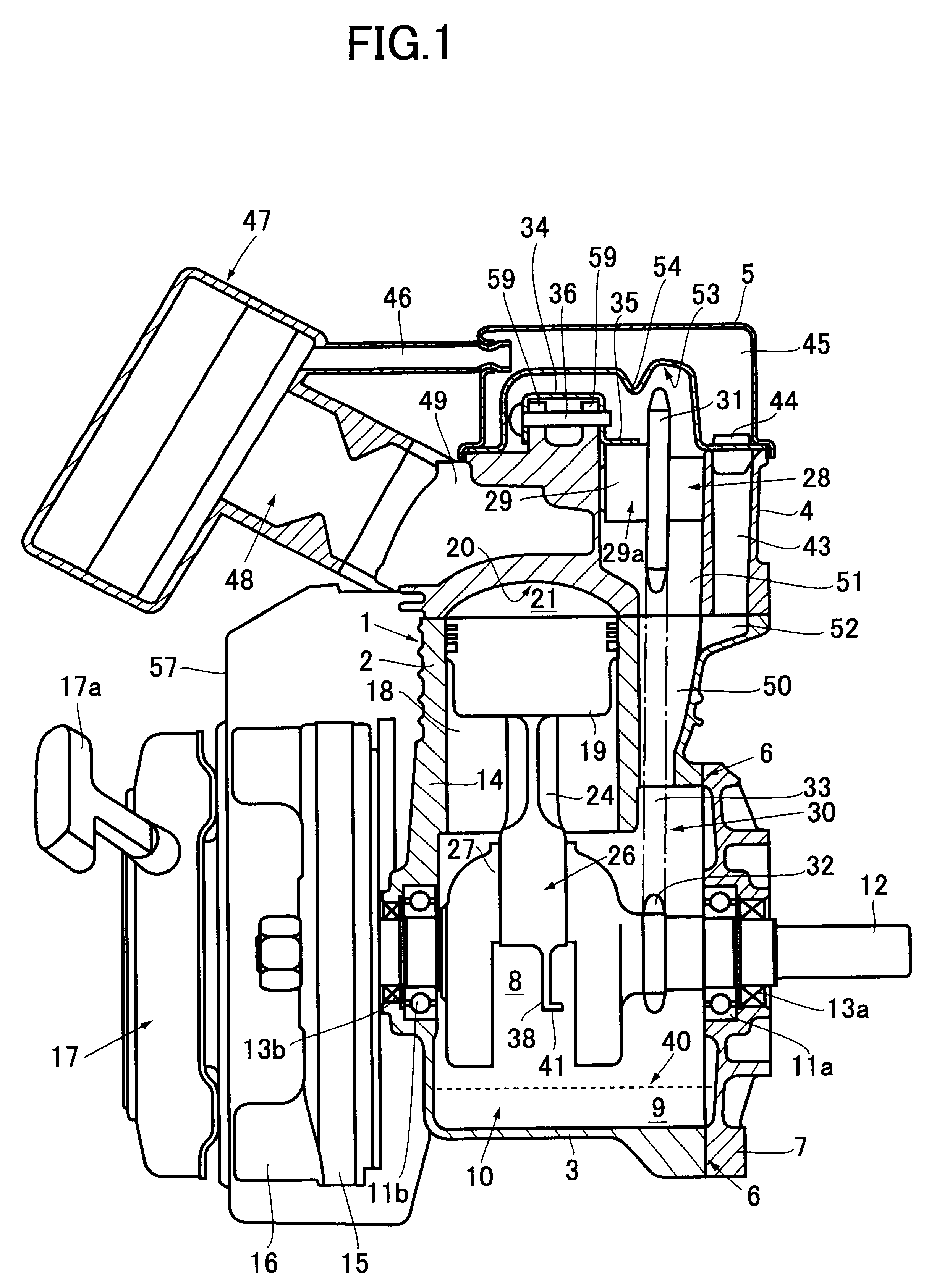

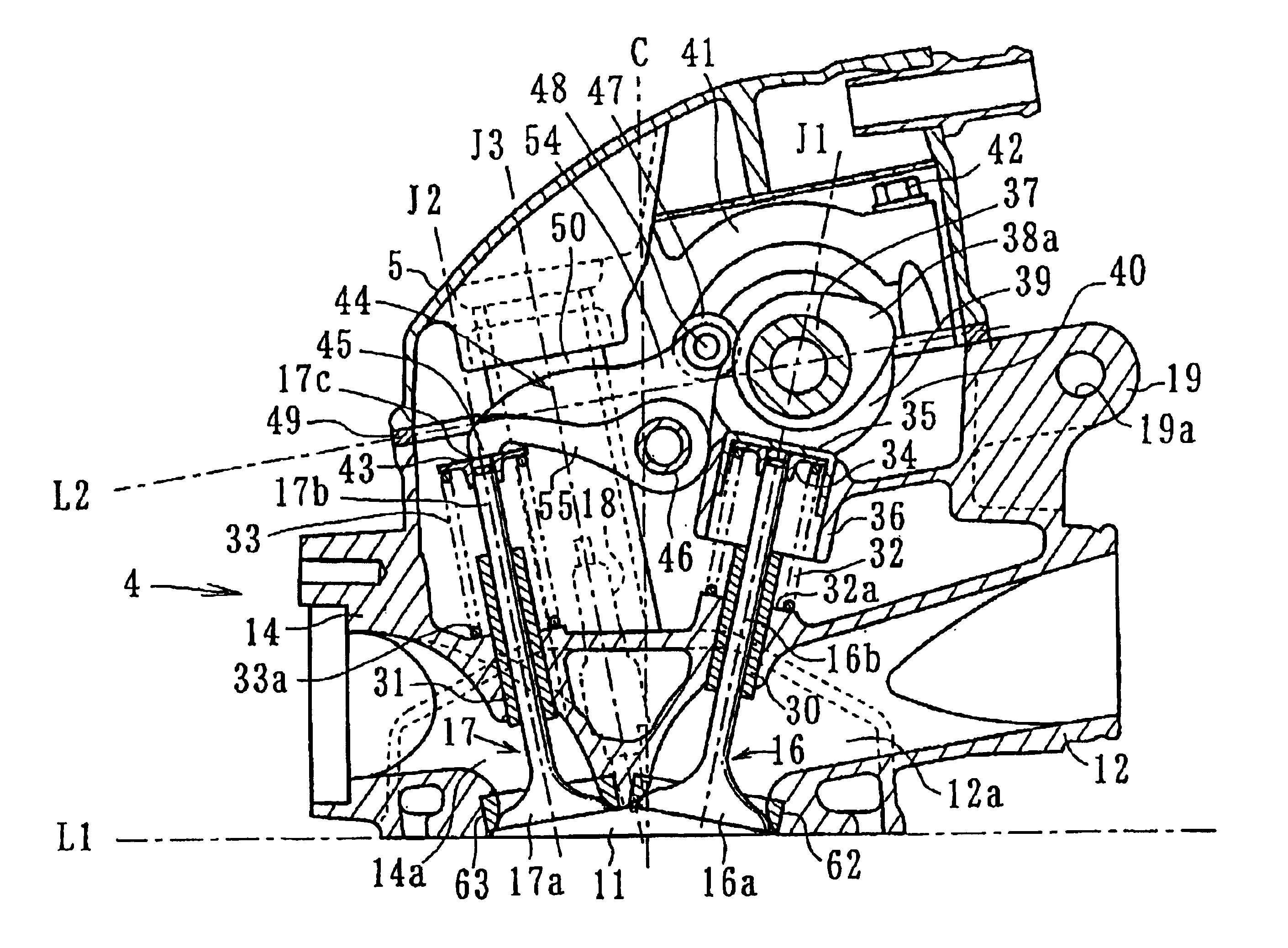

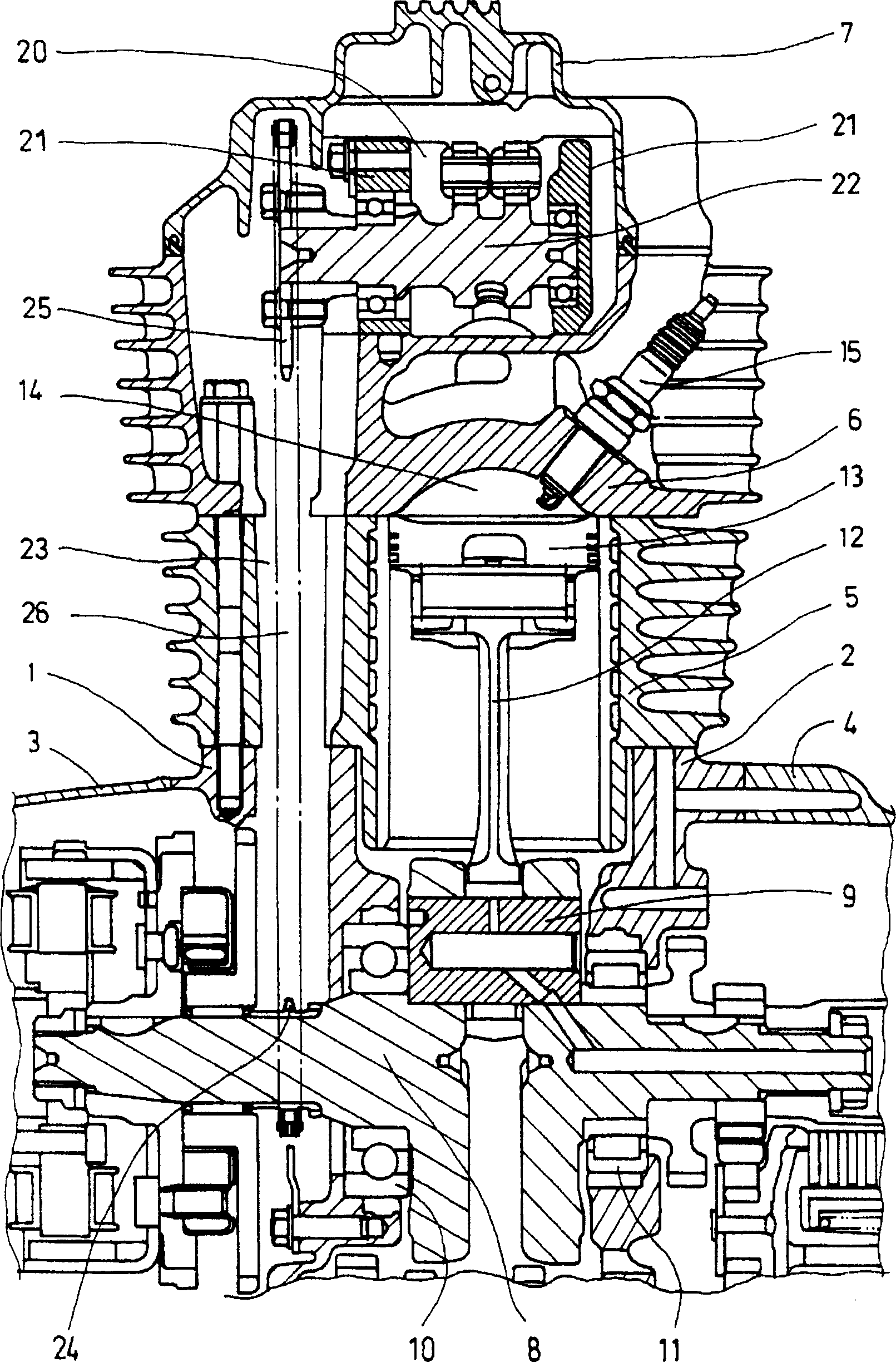

Four-cycle engine

InactiveUS6948470B2Convenience to workOvercomes shortcomingValve arrangementsCasingsExhaust valveLine tubing

A cylinder block, a cylinder head and a cylinder head cover are stacked in order to form a four-cycle engine. A valve train of a single overhead camshaft (SOHC) type provided with an intake valve and an exhaust valve is provided in the cylinder head. A line extending parallel with a joint between the cylinder head and the cylinder head cover is inclined forward and downward toward a line parallel with a joint between the cylinder block and the cylinder head. An axis of an exhaust valve and / or an axis of a plug tube is / are perpendicular to the line extending parallel with the joint between the cylinder head and the cylinder head cover. A cylinder head hanger is integrally formed at an uppermost end of a rear portion of the cylinder head over an intake port.

Owner:HONDA MOTOR CO LTD

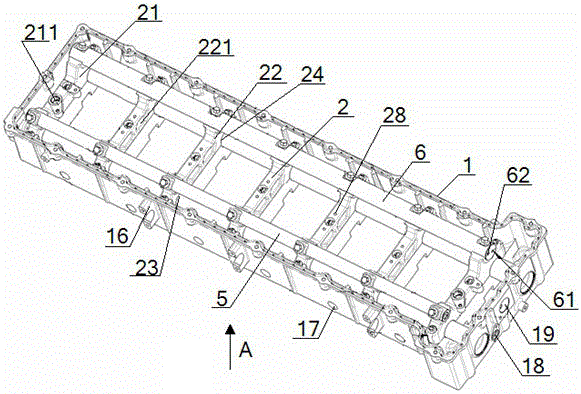

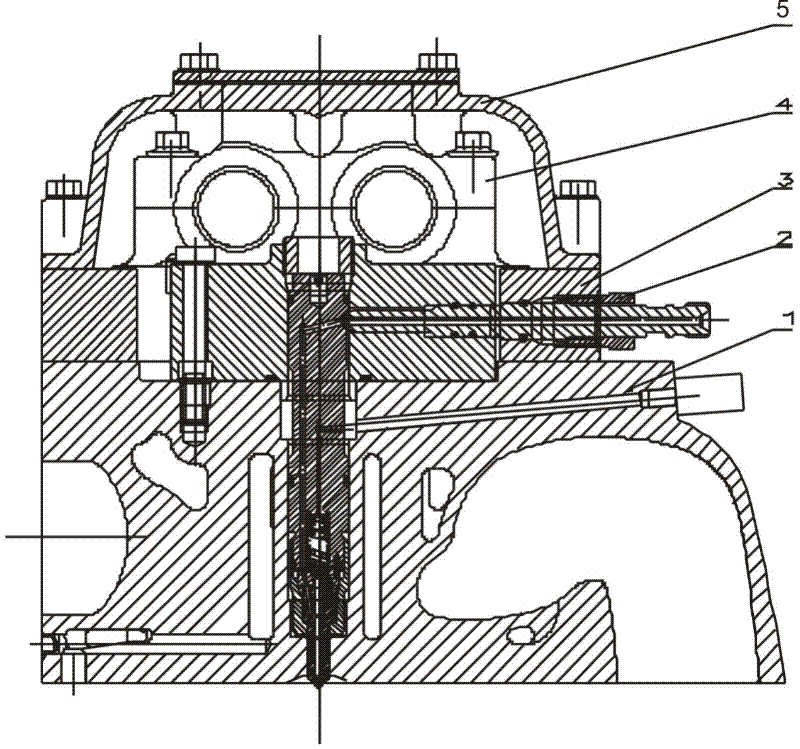

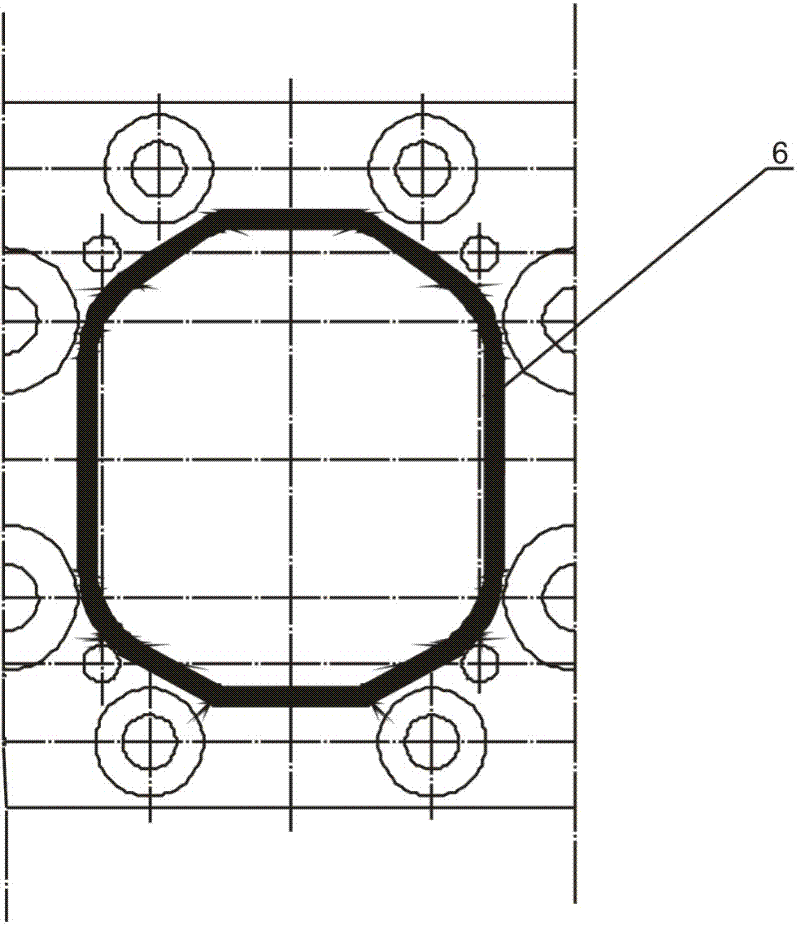

Engine cam shaft bearing frame

InactiveCN102392708AMeet the requirements of high speed useValve arrangementsMachines/enginesEngineeringCam

The invention relates to an engine and particularly relates to an engine cam shaft bearing frame. The device consists of a cam shaft frame body (3) and a cam bearing cover (4), wherein the cam bearing cover (4) is tightly fixed on the cam shaft frame body (3) through a bolt, a cylinder head cover (5) and a fuel injector compact bolt sleeve (2) are arranged on the cam shaft frame body (3), and the cam shaft bearing frame is installed on a cylinder cover (1). The engine cam shaft bearing frame provided by the invention has the advantages that a double overhead cam shaft can be applied to a single cylinder cover, the use requirement of high rotating speed of the engine can be satisfied, the bearing cover can be independently replaced, and an oil supply hole and a lubricating oil channel are designed on the bearing frame, thus the part structure can be fully utilized.

Owner:CHINA NORTH IND GRP NO 70 RES INST

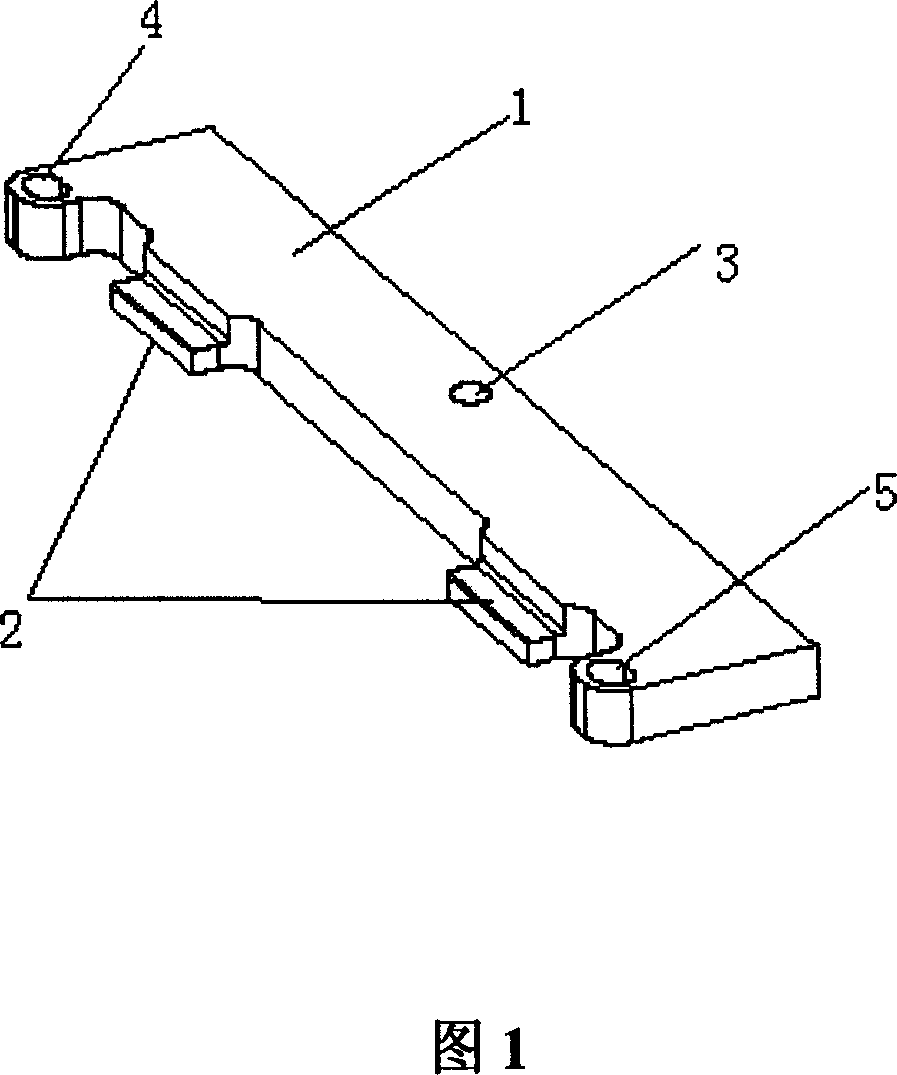

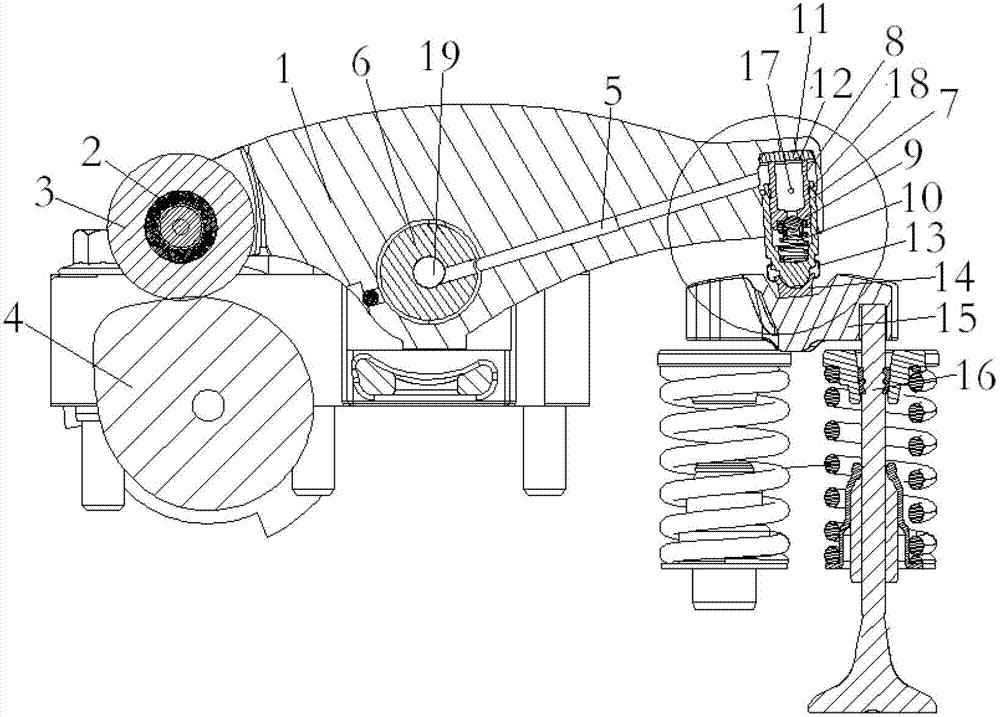

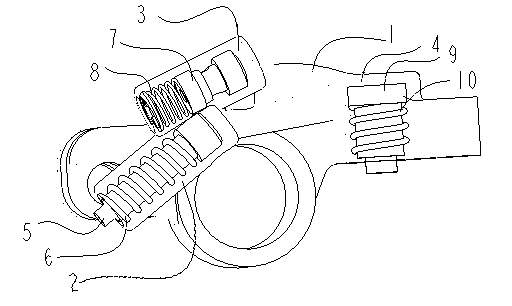

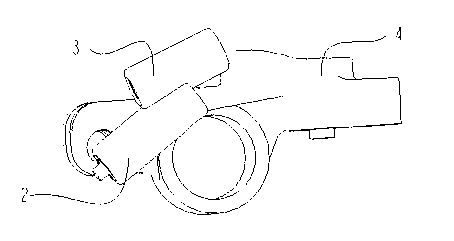

Single overhead camshaft air inlet phase continuous variable mechanism of motorcycle engine

InactiveCN101737110AImprove powerImprove fuel economyValve drivesMachines/enginesImpellerEngineering

The invention discloses a single overhead camshaft air inlet phase continuous variable mechanism of a motorcycle engine, which comprises a camshaft, an air inlet cam and an exhaust cam, wherein the camshaft is supported in a cylinder head; the air inlet cam and the exhaust cam are arranged on the camshaft; and a timing chain wheel is fixed at one end of the camshaft. The single overhead camshaft air inlet phase continuous variable mechanism of a motorcycle engine is characterized in that the camshaft is divided into two coaxial sections, one section is an air inlet cam section comprising the air inlet cam, and the other section is an exhaust cam section comprising the exhaust cam and the timing chain wheel; the two cam sections are connected by a VVT controller; the VVT controller comprises a seal cavity which contains an impeller; and a first oil cavity and a second oil cavity are arranged in the cavity and respectively connected with an engine oil control valve by a first oil passage and a second oil passage. The invention can change a phase angle of the air inlet cam, has simple structure, compact distribution and low manufacture cost and can effectively improve the dynamic property, economy and emission characteristic of the single overhead camshaft engine of the motorcycle in the whole ranges of rotating speed and load working condition.

Owner:CHONGQING UNIV

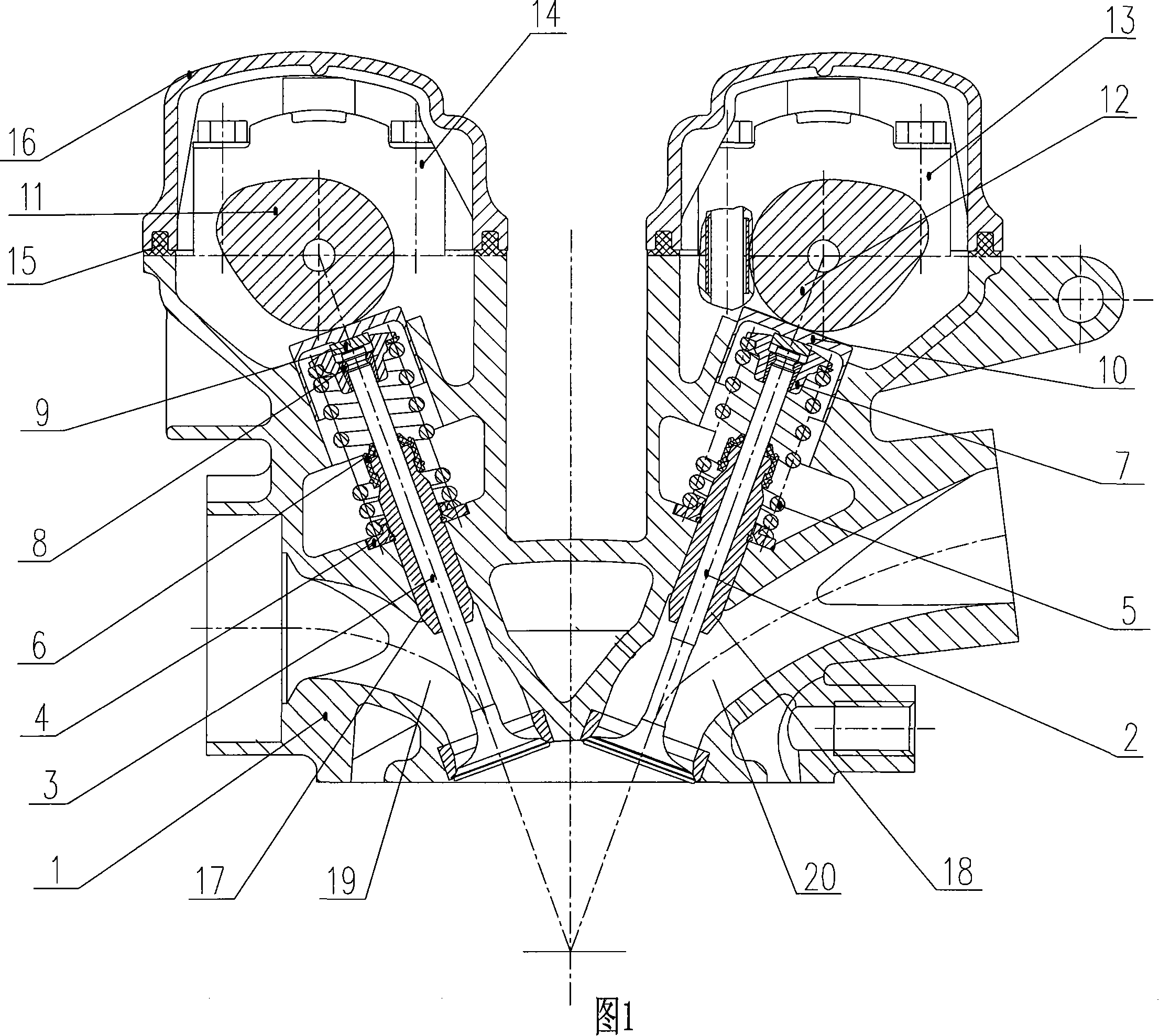

Double-overhead camshaft four-valve air distribution mechanism of motorcycle engine

InactiveCN101131107AReduce the cross-sectional areaStable jobCasingsValve drivesExhaust valveInlet valve

The present invention relates to gas distributing mechanism of engine, and is especially one kind of four-valve gas distributing mechanism with two top set cams mainly for 125-175 cc displacement engine of motorcycle and motor tricycle. The four-valve gas distributing mechanism includes one gas intake duct with intake valve and one exhaust duct with exhaust valve on the cylinder head. It features the intake valve and the exhaust valve with separate clamping slot in the bar end, the spring holders set in the clamping slots, the conic blocks between the spring holder and the bar end, and the valve springs in holder. The present invention can raise gas exchanging efficiency effectively for complete burning.

Owner:张文宝

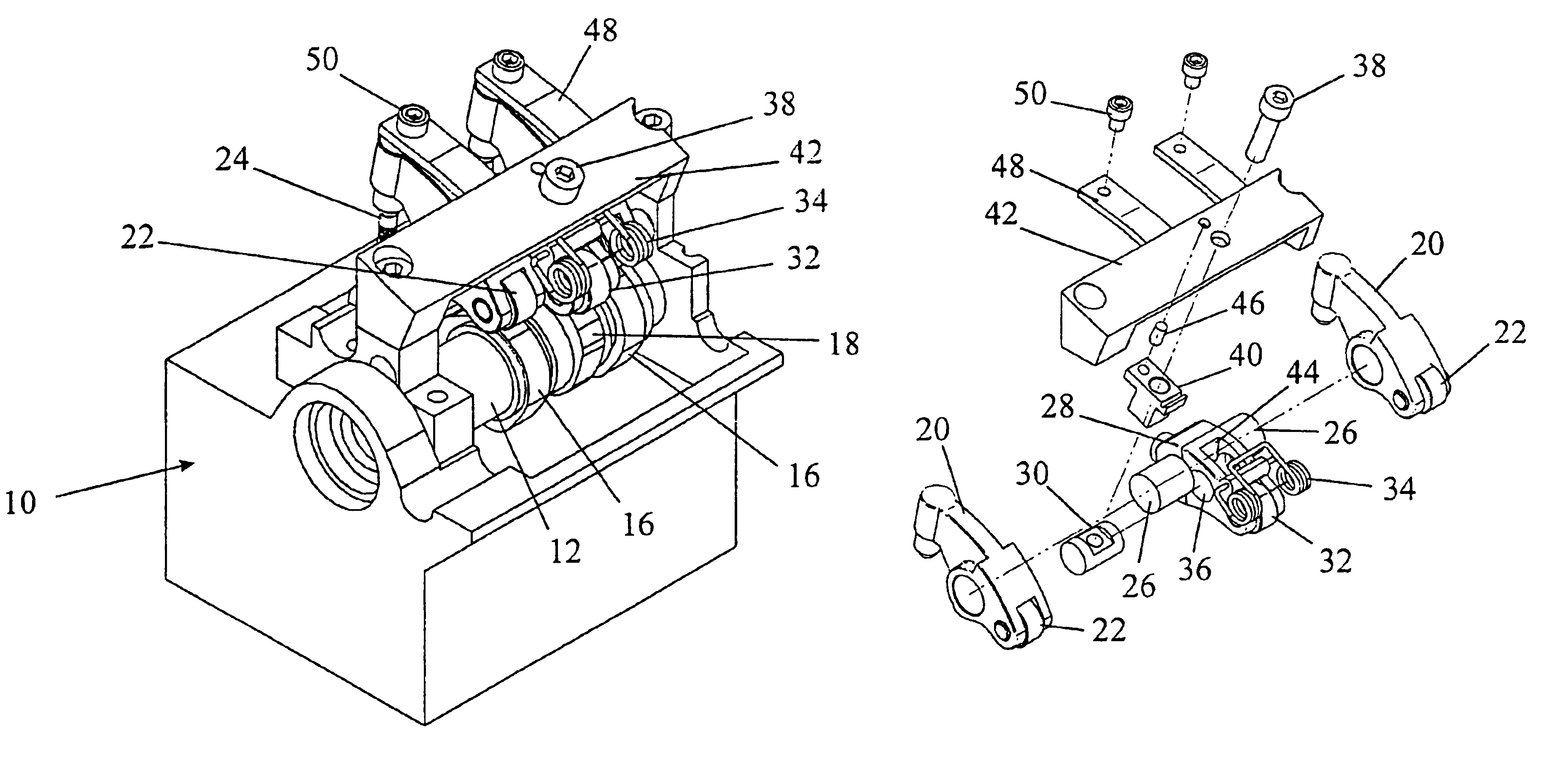

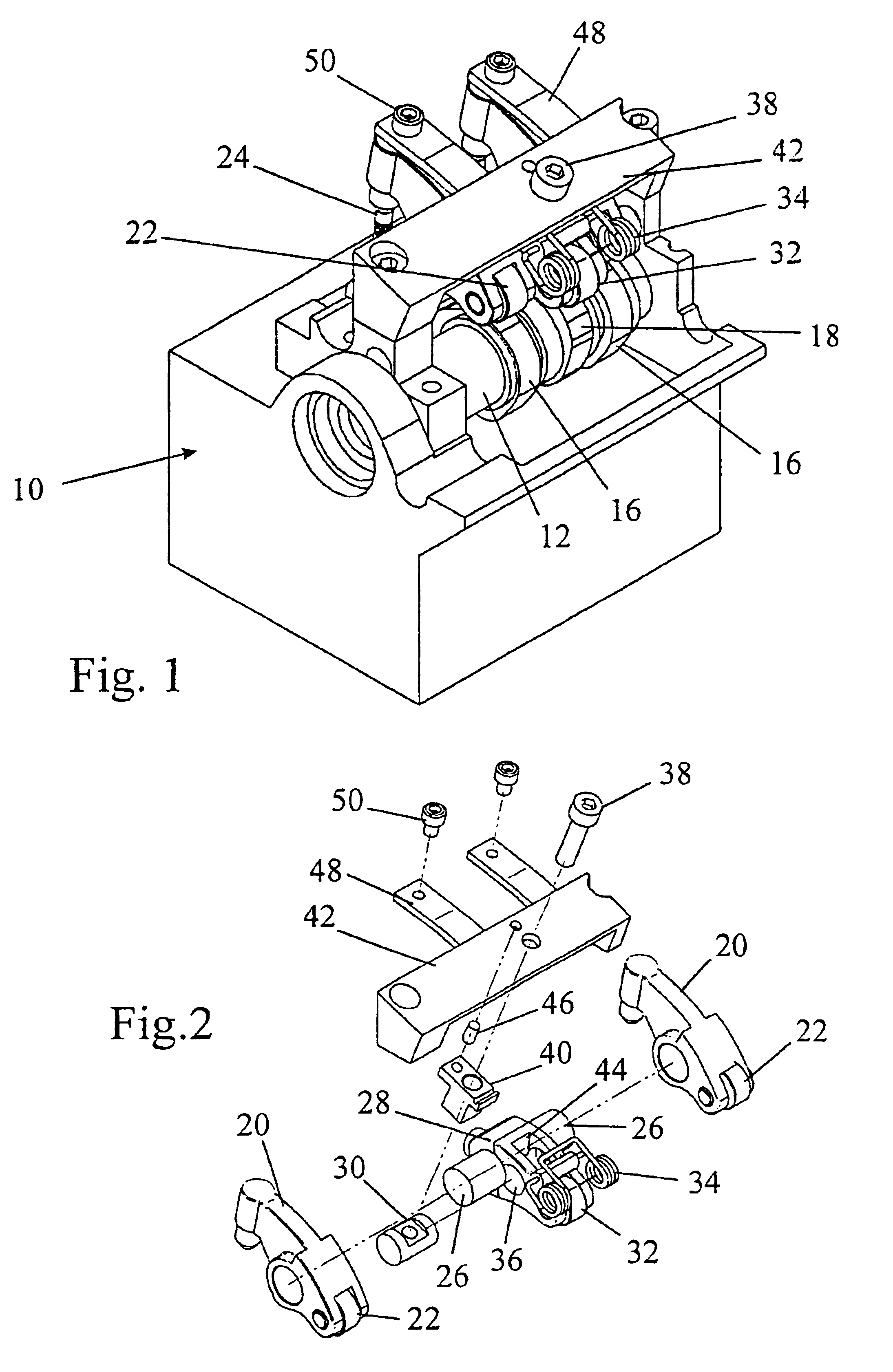

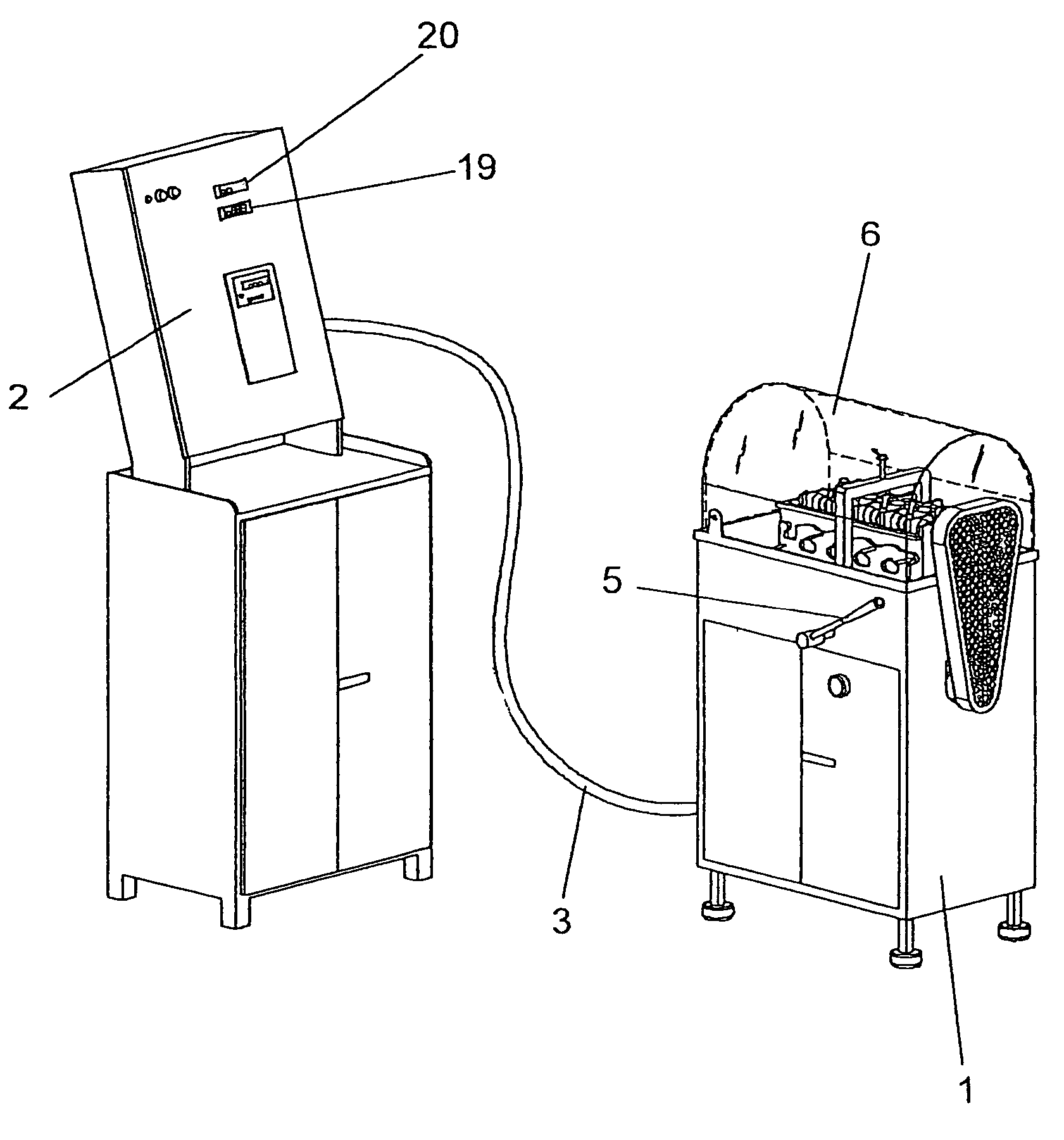

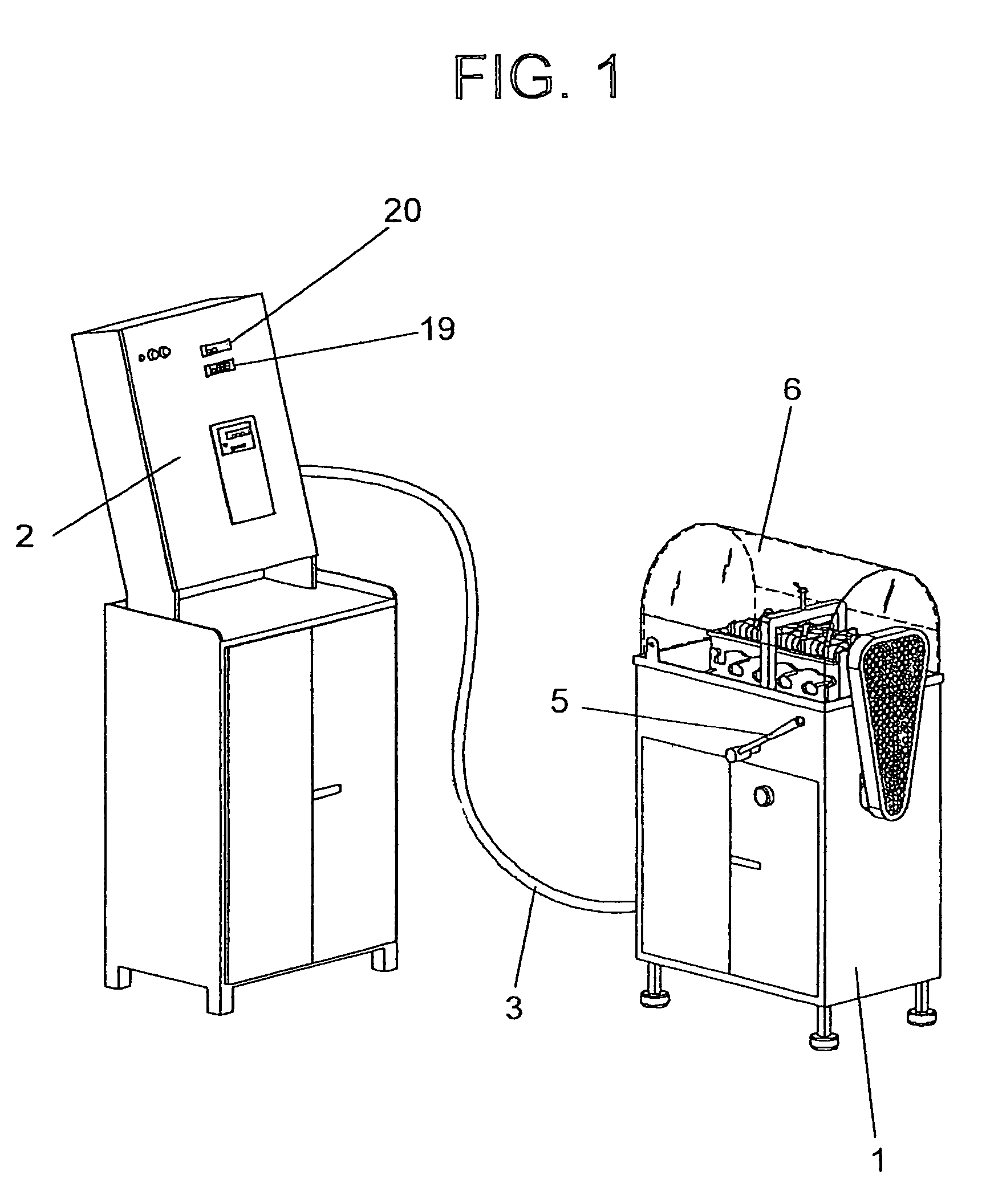

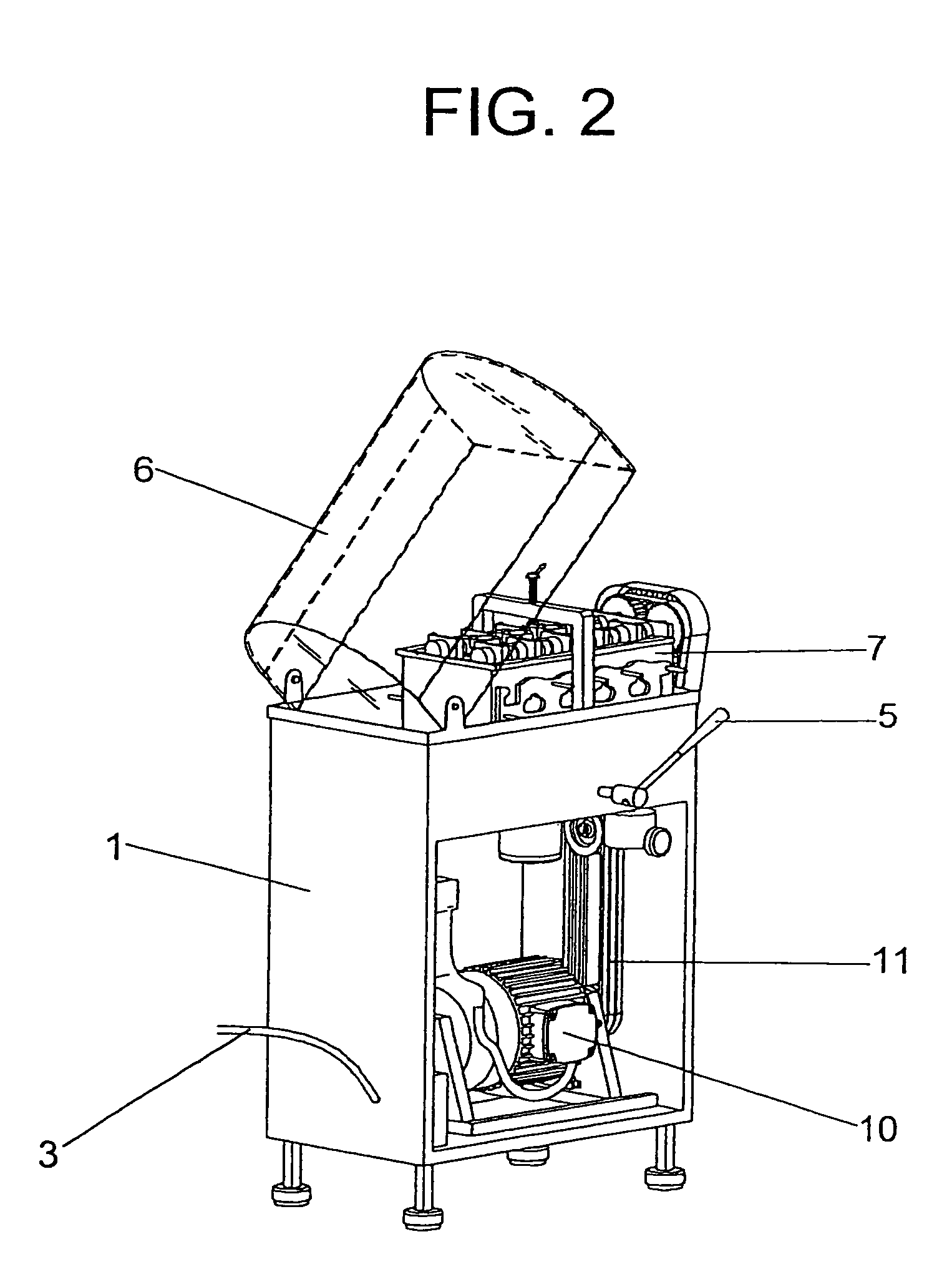

Dynamometric bench for headstocks with SOHC and DOHC type overhead camshaft for internal combustion engines

InactiveUS7152465B2Easy diagnosisEasy to processMachine gearing/transmission testingEngine testingElectrical conductorExternal combustion engine

Dynamometric bench for headstocks with SOHC and DOHC type overhead camshaft for internal combustion engines has a testing workbench connected to a monitoring and control panel such that the testing workbench comprised of a mobile platform, protected by a cover, where the headstock is placed, with an overhead camshaft gear directed towards the front of the equipment, thus allowing a grooved belt to pass through the testing workbench and is coupled to a synchronizer, at the same time is coupled to an electrical motor by other belts, such that in the interior and opposite part of the testing workbench an oil reservoir is available, coupled to a pump, that pressurizes the oil inside the headstock, when the system is turned on; at the other end of the electrical motor a charging cell is coupled, which at the same time is connected to an energized conductor, which sends measurement signals to the monitoring and control panel, composed of a digital counter in front and a digital acceleration control, that show the acceleration, a digital display, which present the friction force reading and the haul force reading and a digital manometer, that indicates the oil pressure.

Owner:CANDEO ZAURI

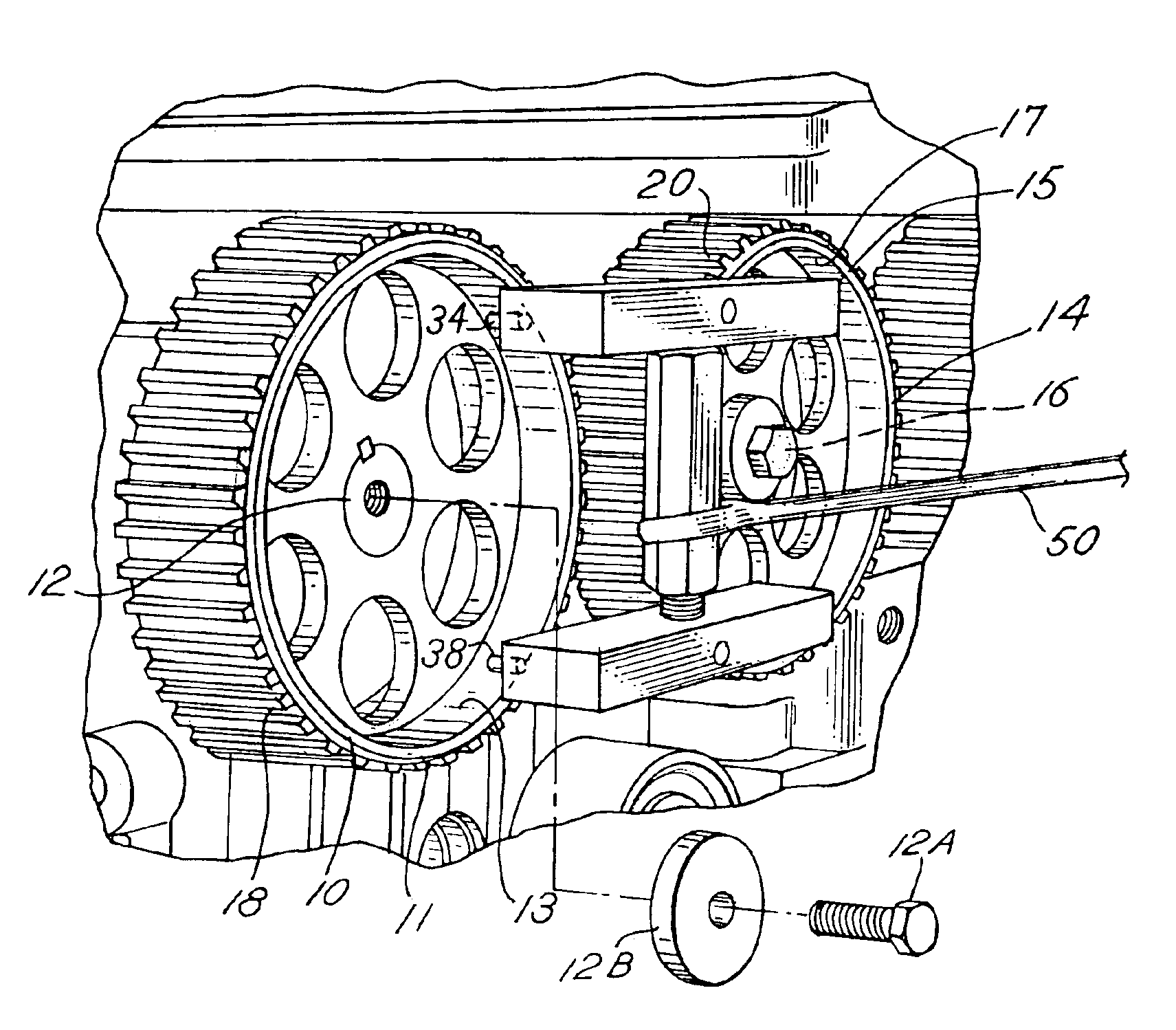

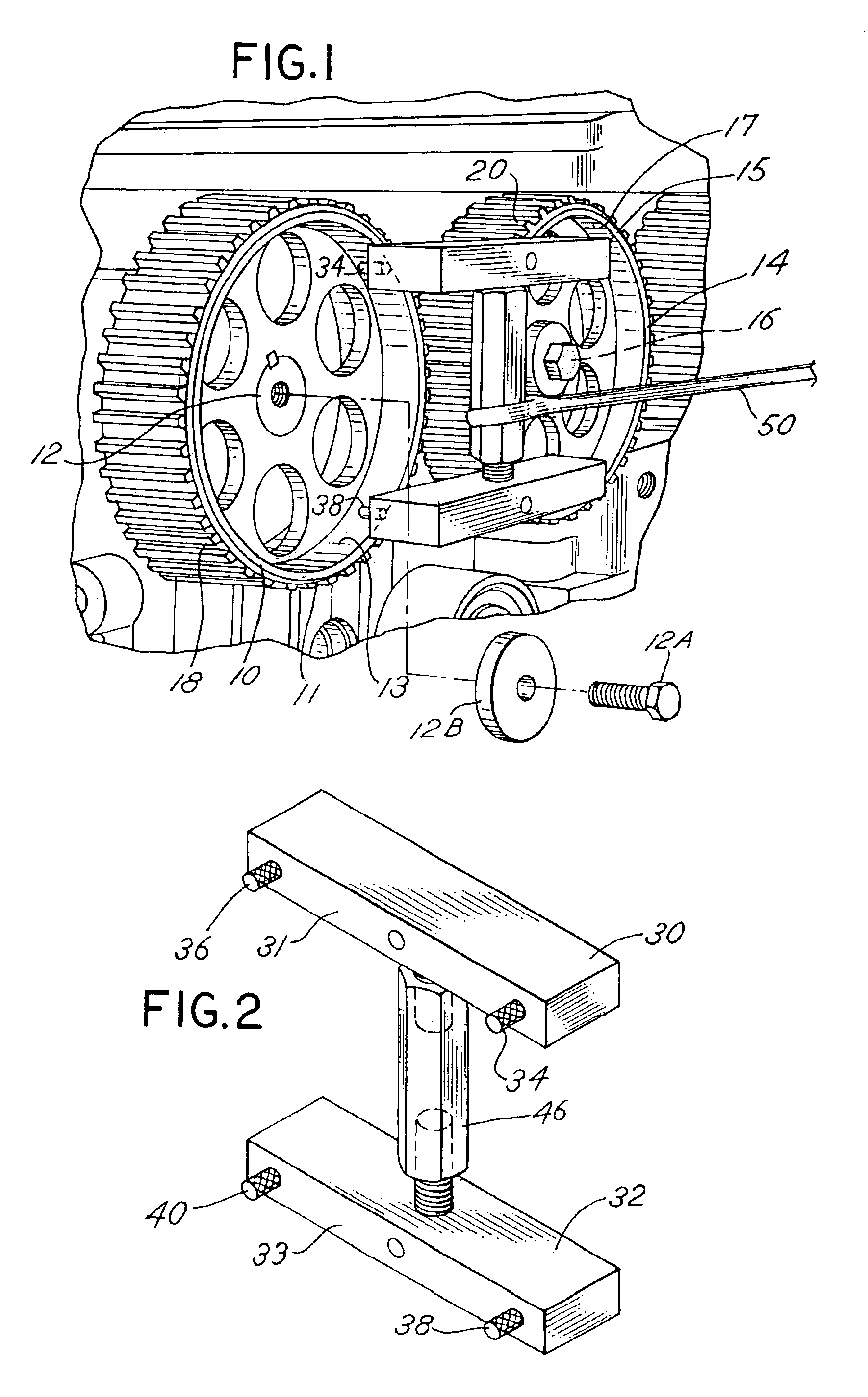

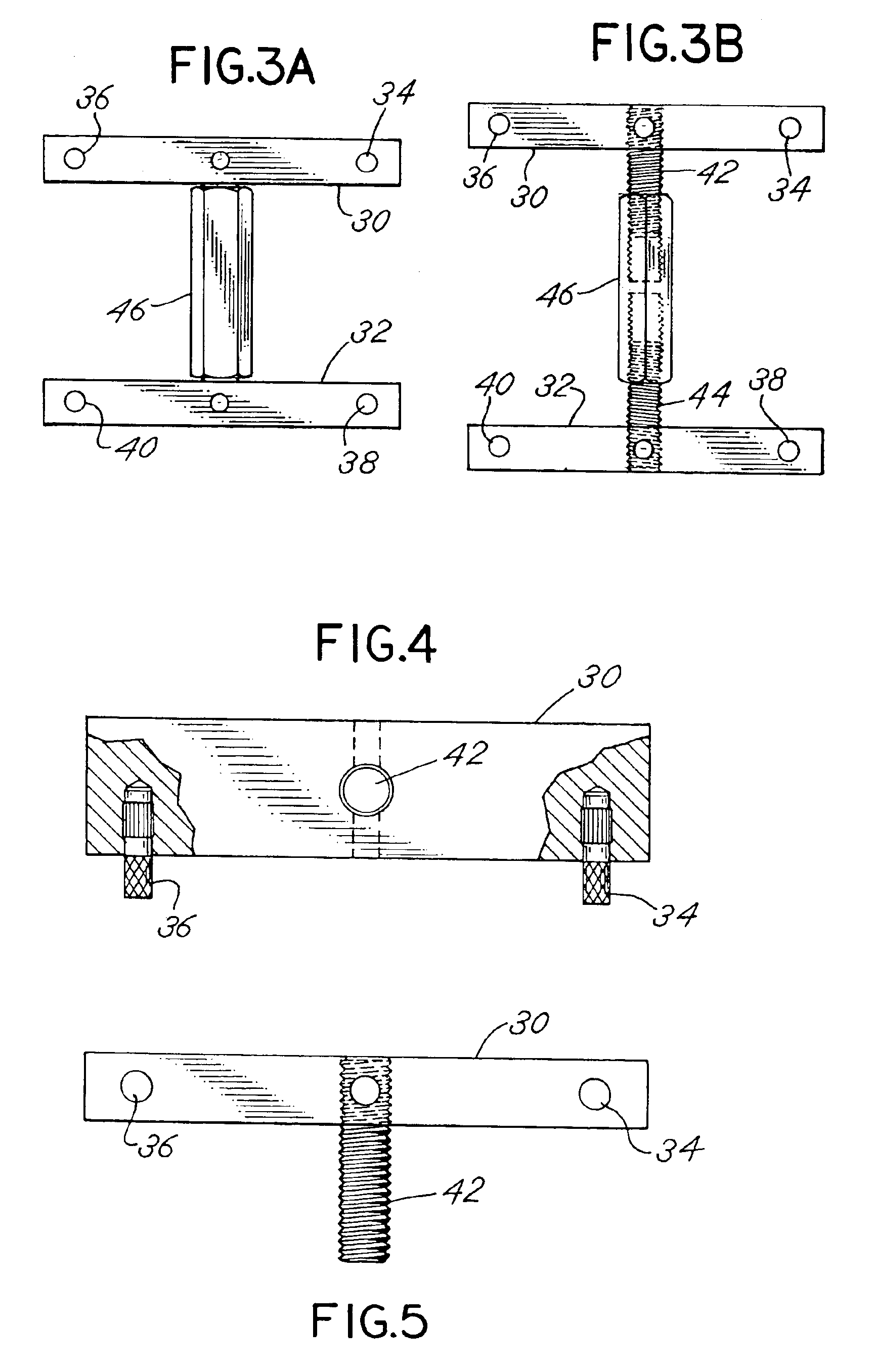

Method for locking dual overhead camshafts

InactiveUS6912768B2Increase frictionEasy to useMetal working apparatusPositioning apparatusGear wheelSprocket

A method for locking the sprockets or gears of a dual overhead camshaft engine in a fixed position includes two spaced bars with studs for engaging against the inside rim of the sprockets and a means for adjusting the spacing of the bars to frictionally maintain the sprockets in a locked position against the inside rims.

Owner:LISLE CORPORATION

Roller-type hydraulic rocking arm component

InactiveCN102733875ARealize air intakeRealize exhaust functionValve arrangementsLubrication of auxillariesEngineeringCam

The invention discloses a roller-type hydraulic rocking arm component. The structure is as follows: one end of a rocking arm is provided with a short shaft, a bearing is embedded outside the short shaft and into the roller, and the roller and a camshaft form a transmission pair; an oil duct is arranged in the rocking arm, the middle part of the rocking arm is provided with a rocking arm shaft, the other end of the rocking arm is provided with a plunger bushing, and a plunger, a check valve and a return spring are sequentially arranged in the plunger bushing; the upper end of the plunger bushing is provided with a plunger cover plate, and the plunger cover plate is provided with an oil return channel; and the plunger bushing is connected with a slider through a cutting sleeve, the slider closely contacts a valve bridge, and the valve bridge contacts a valve push rod mechanism. The invention is suitable for an overhead camshaft mechanism, and the structure is simplified since the valve support column, the push rod and other parts connected with the cam are reduced. The rocking arm forms a zero-clearance fit with the camshaft and the valve push rod, thereby lowering the noise. On the premise of enhancing the strength of the engine block, cylinder head and the like, the volume of the engine is reduced, so that the structure is more compact reasonable, and the economical efficiency and power performance of the engine are enhanced.

Owner:东风朝阳朝柴动力有限公司

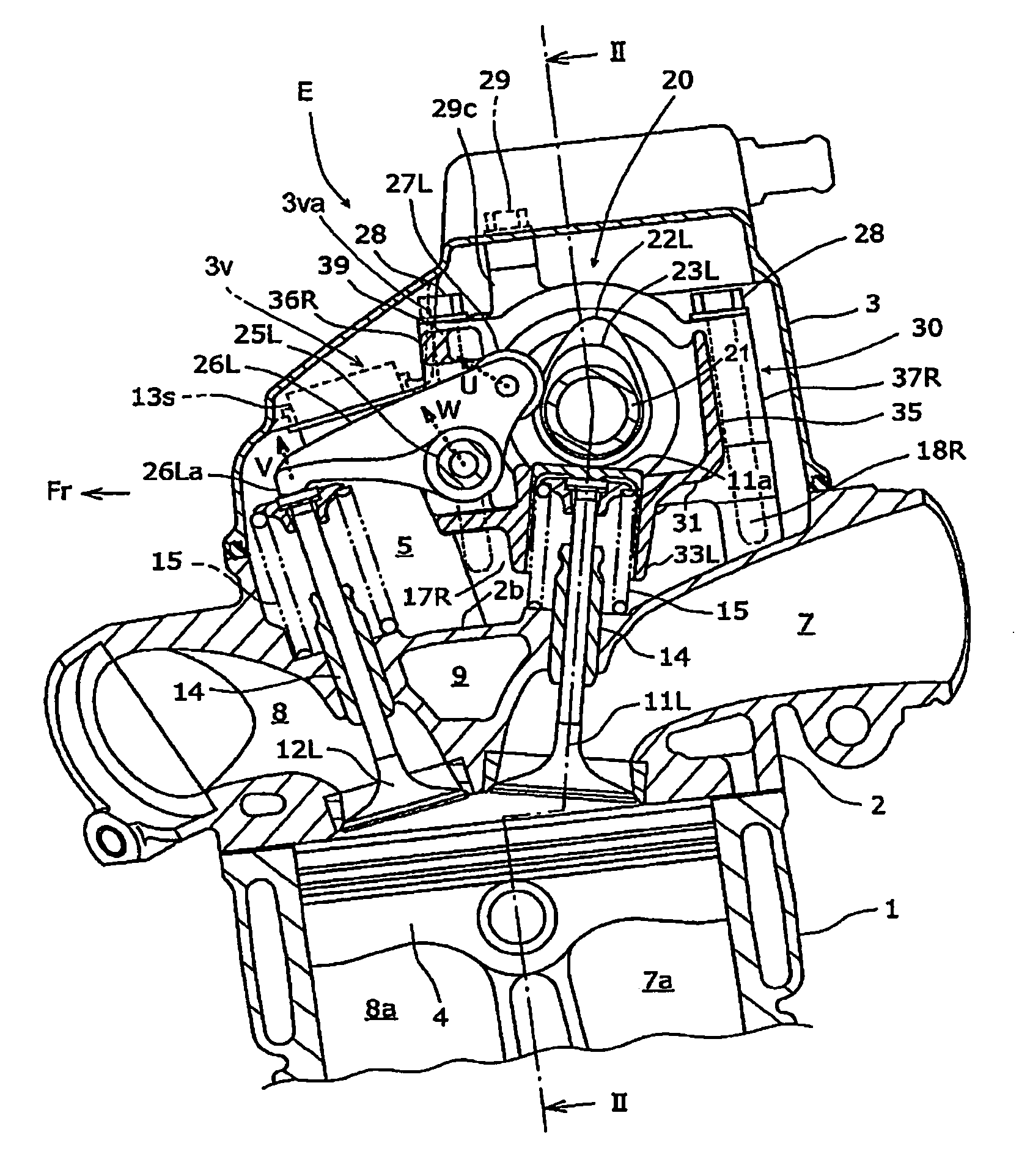

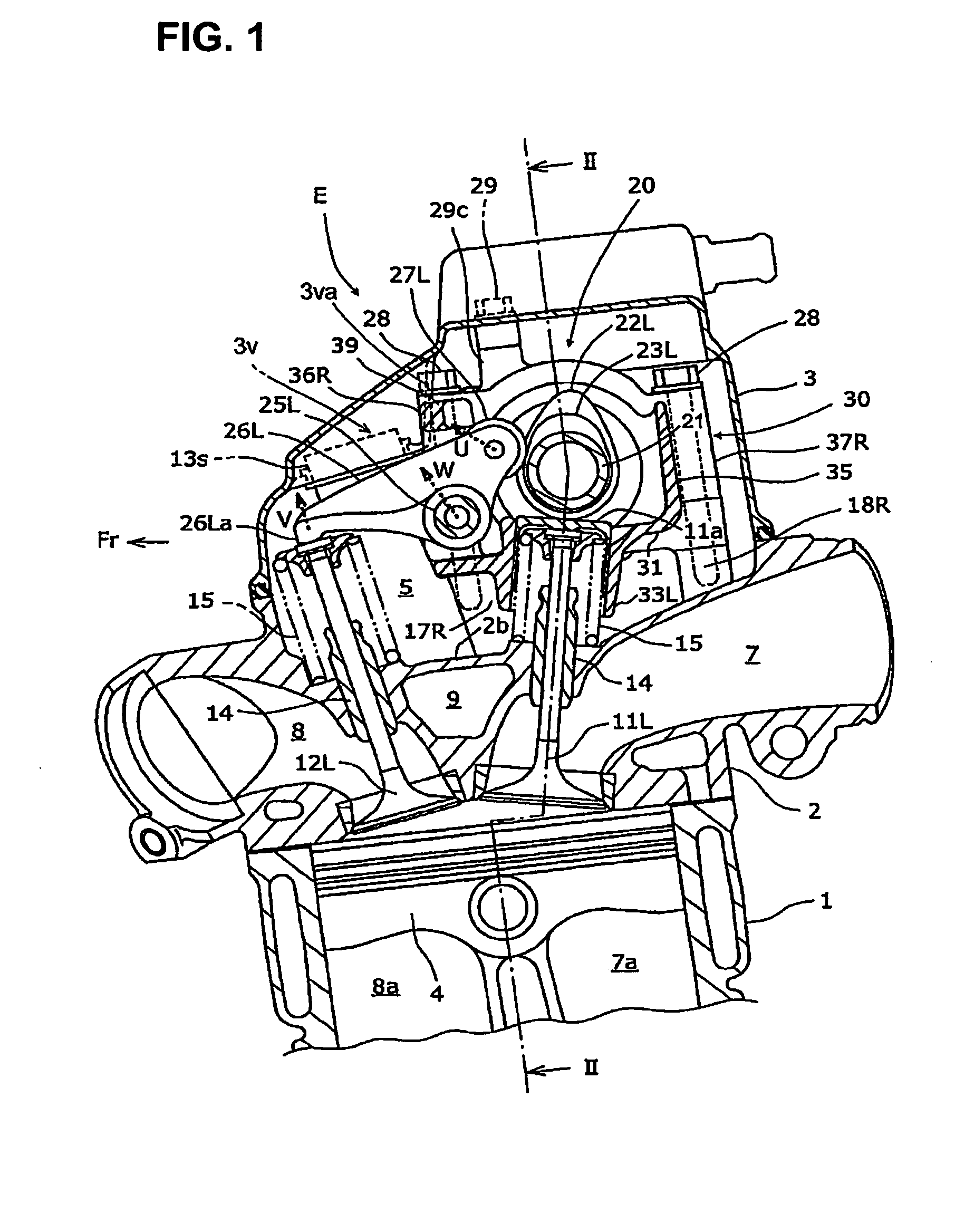

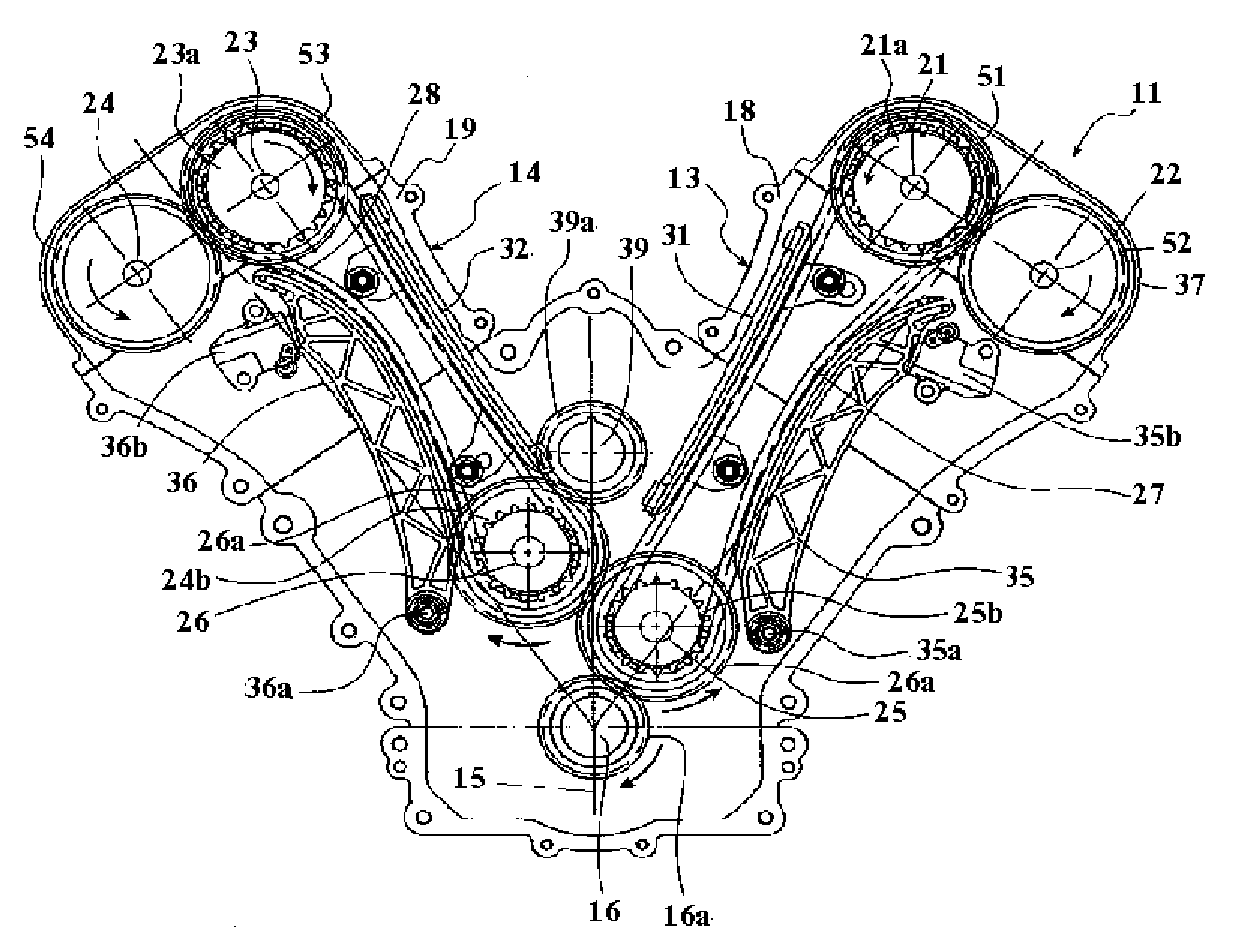

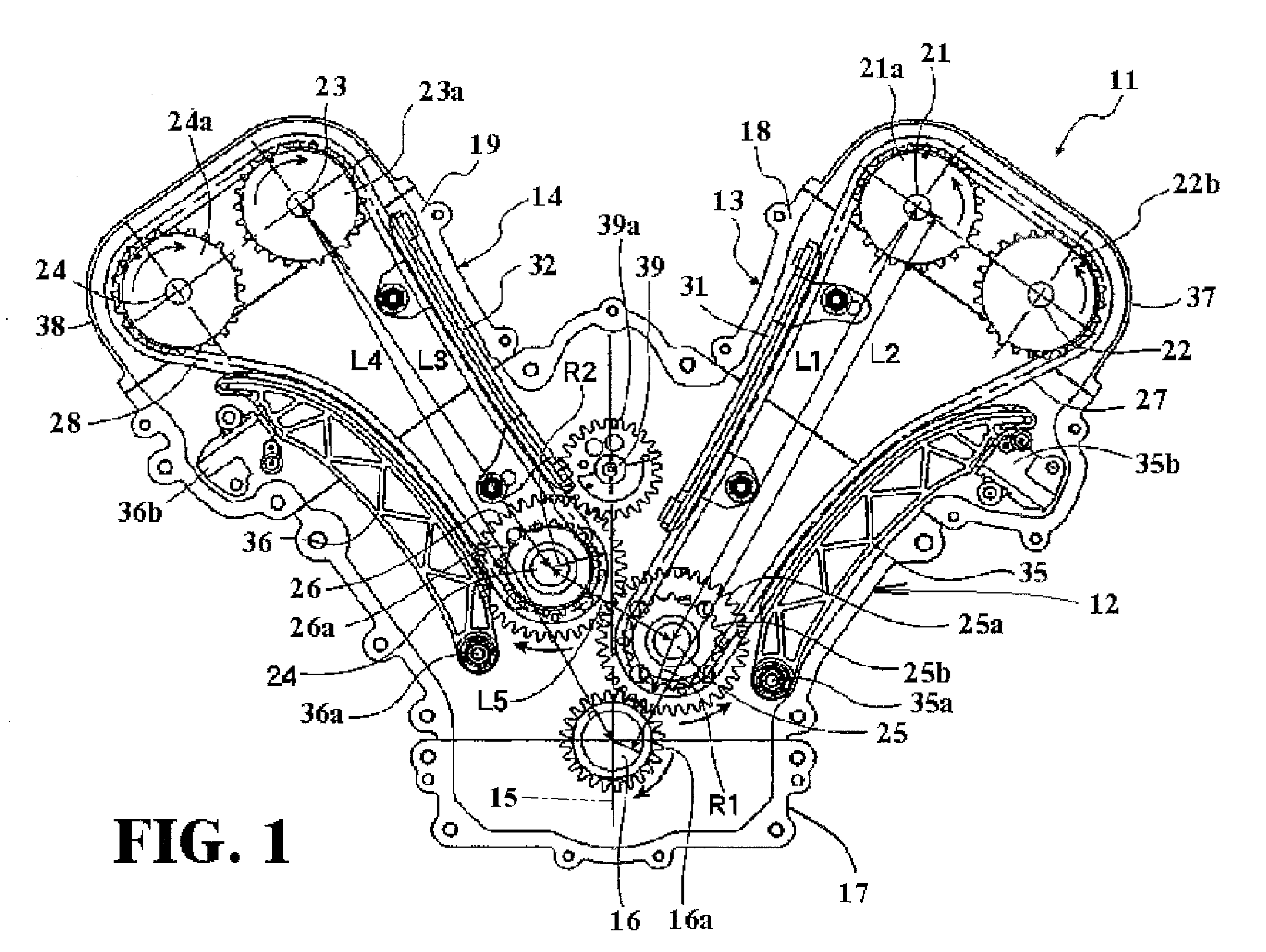

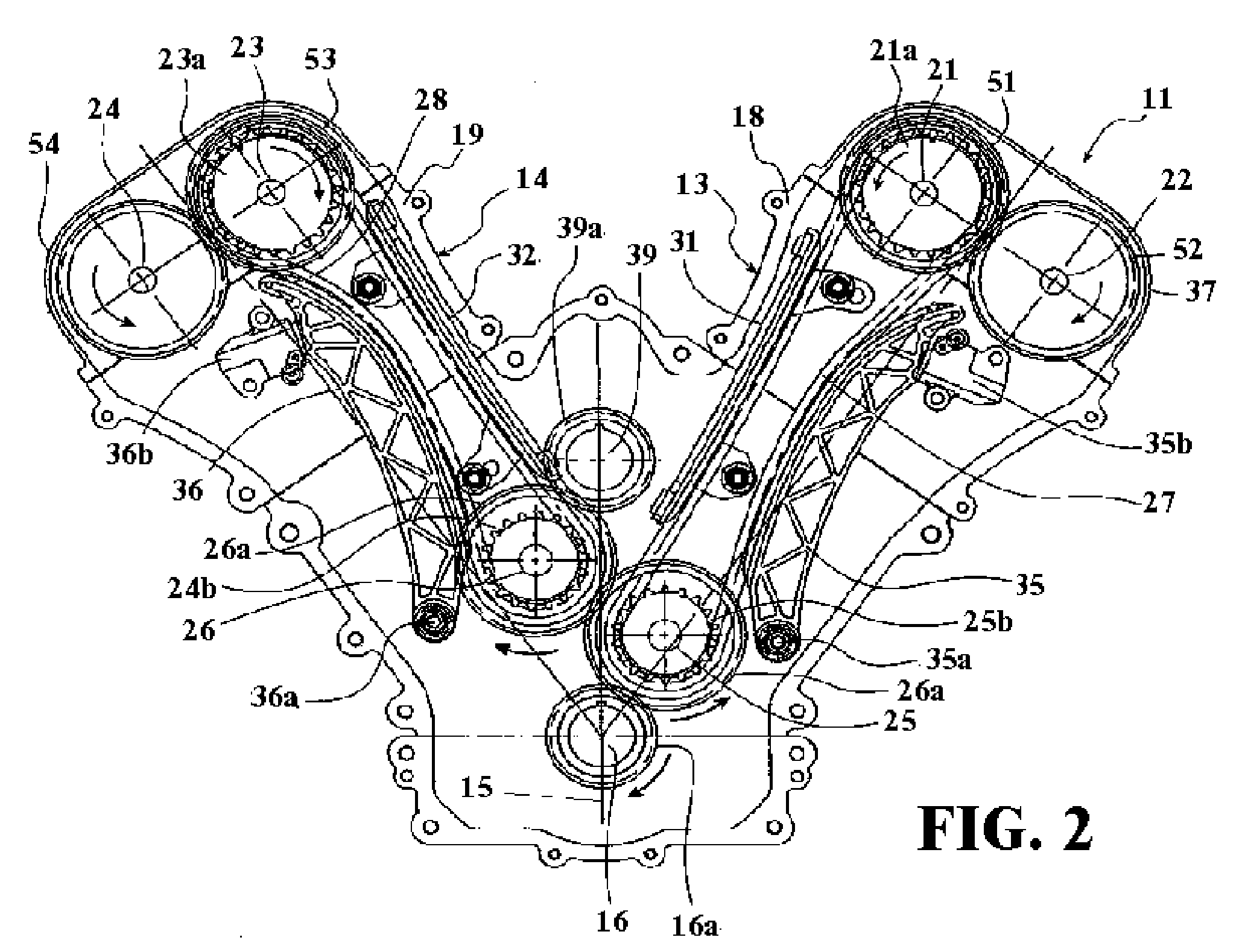

V type internal combustion engine

ActiveUS20060243236A1Transverse width can be reducedValve drivesGearingEngineeringInternal combustion engine

A number of embodiments of double overhead cam shaft V type engines wherein the drive arrangement for the camshafts permits not only a compact design but also one in which the timing loadings are decreased to improve engine life, performance and reduced servicing.

Owner:YAMAHA MOTOR CO LTD

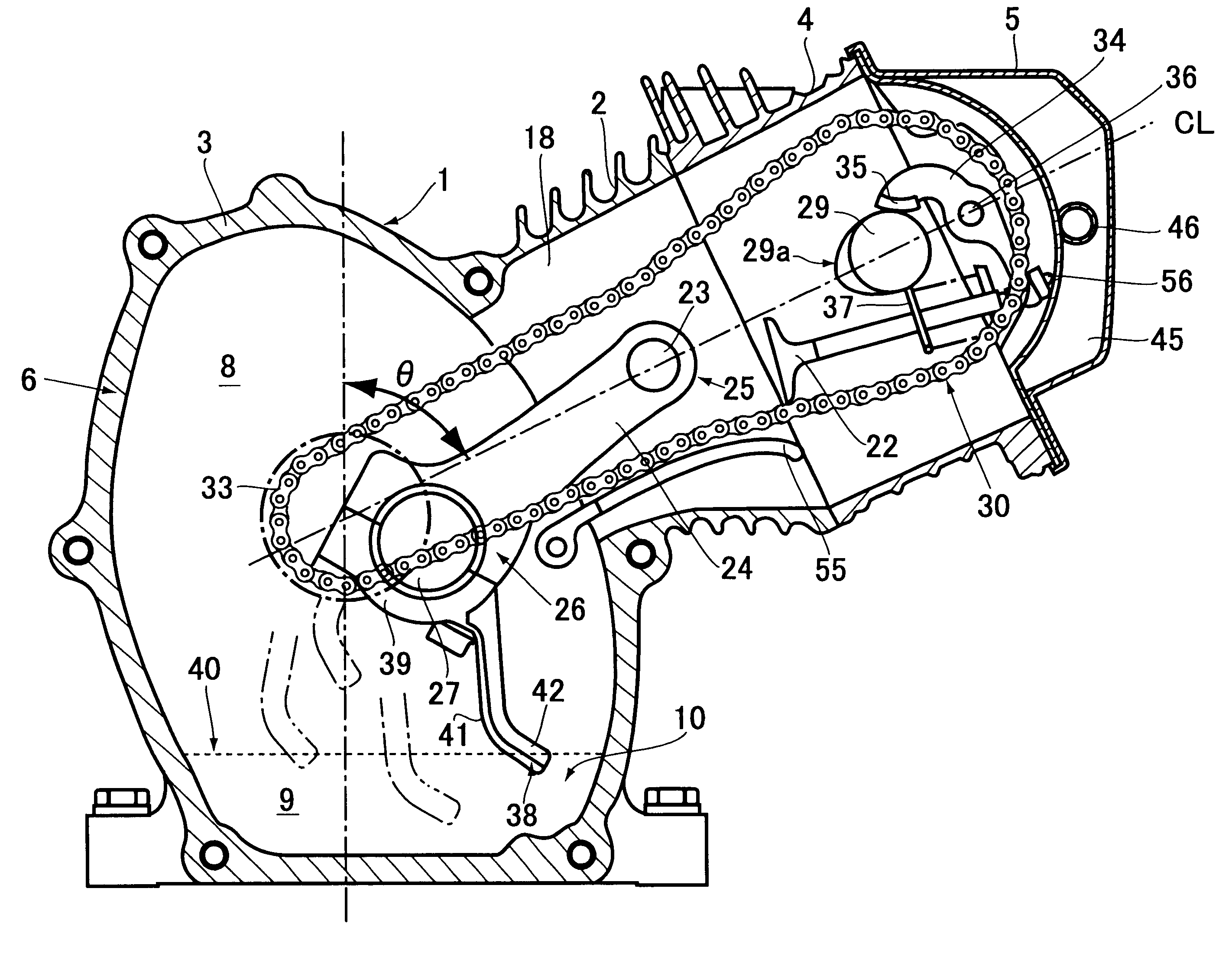

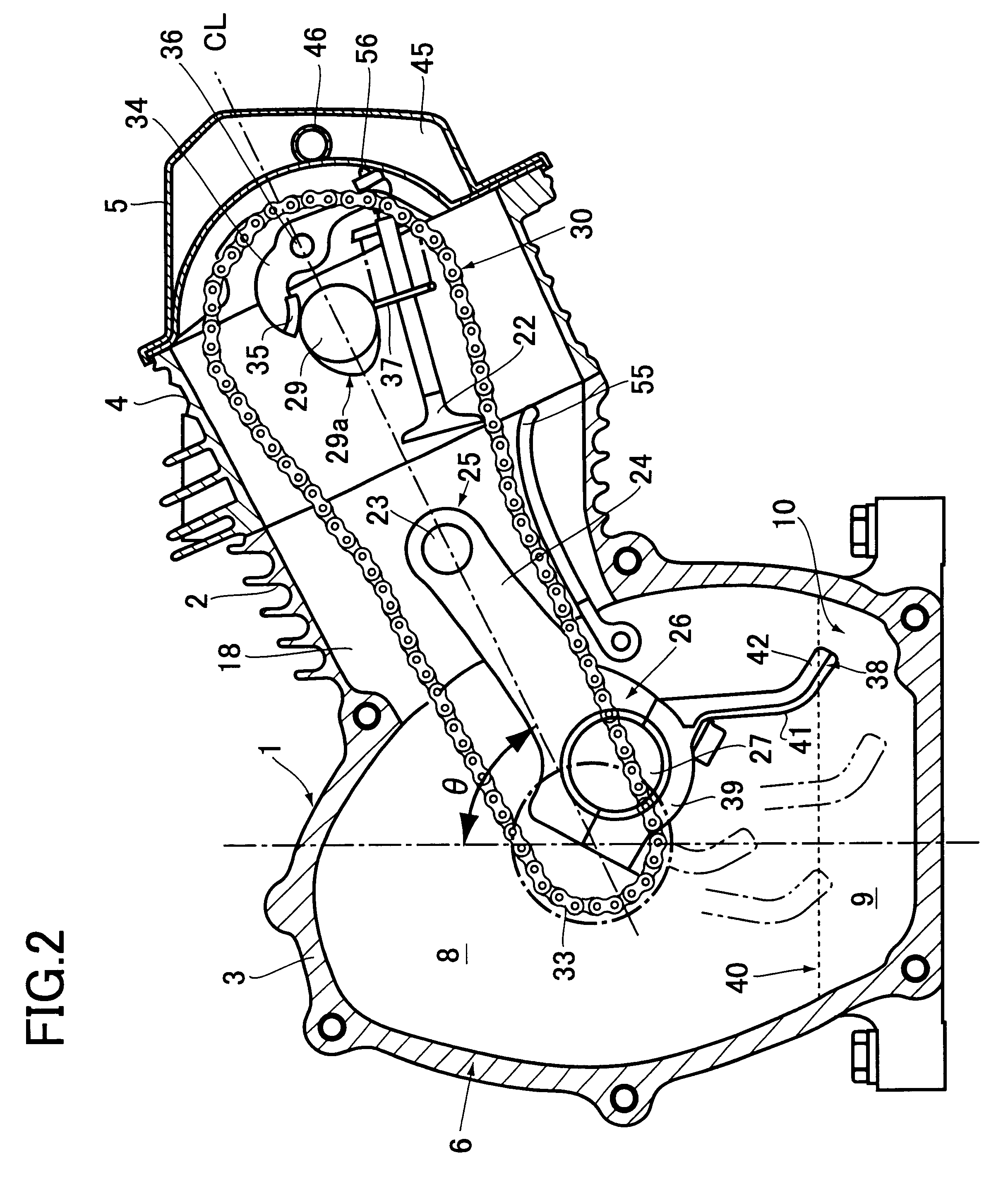

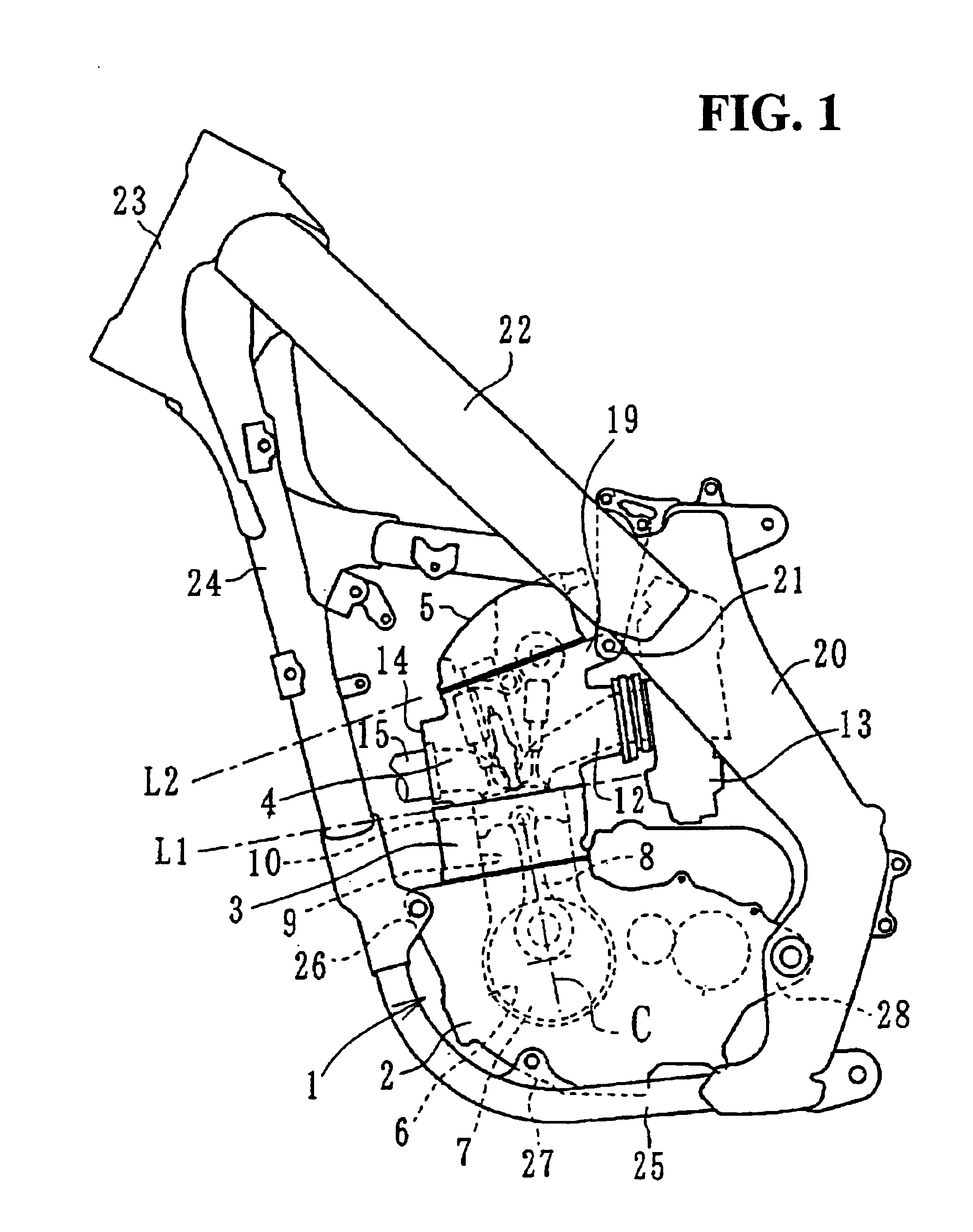

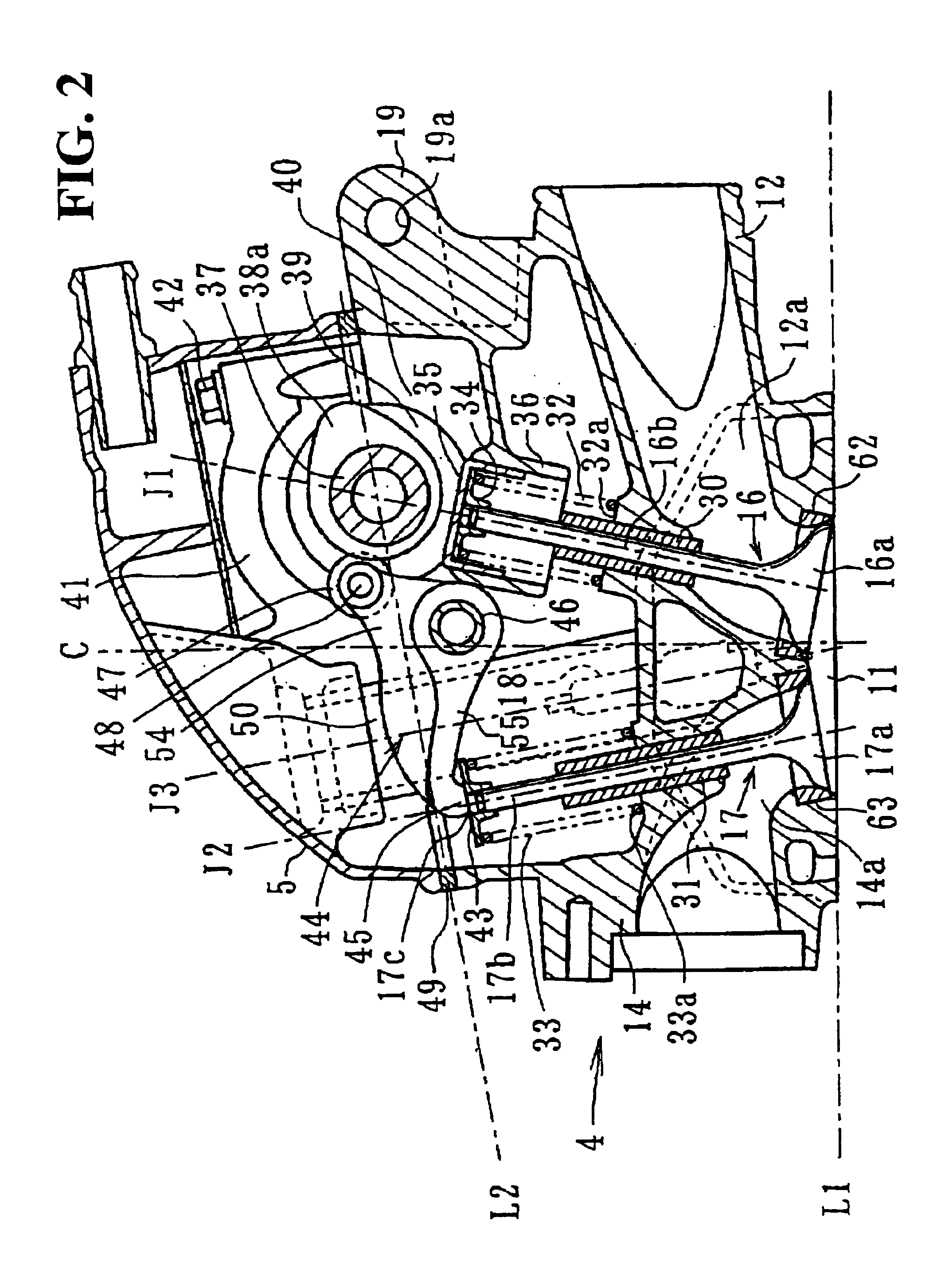

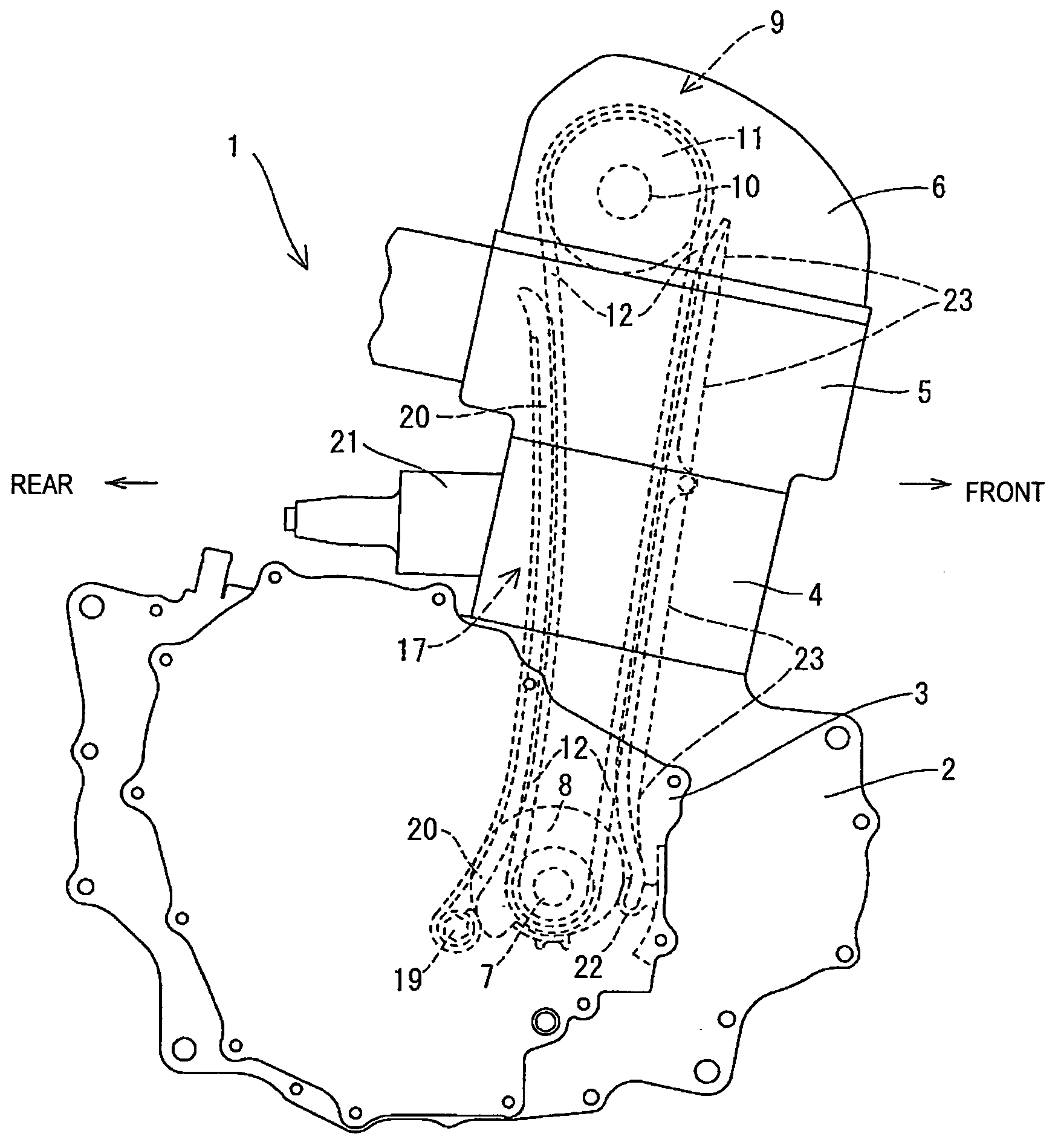

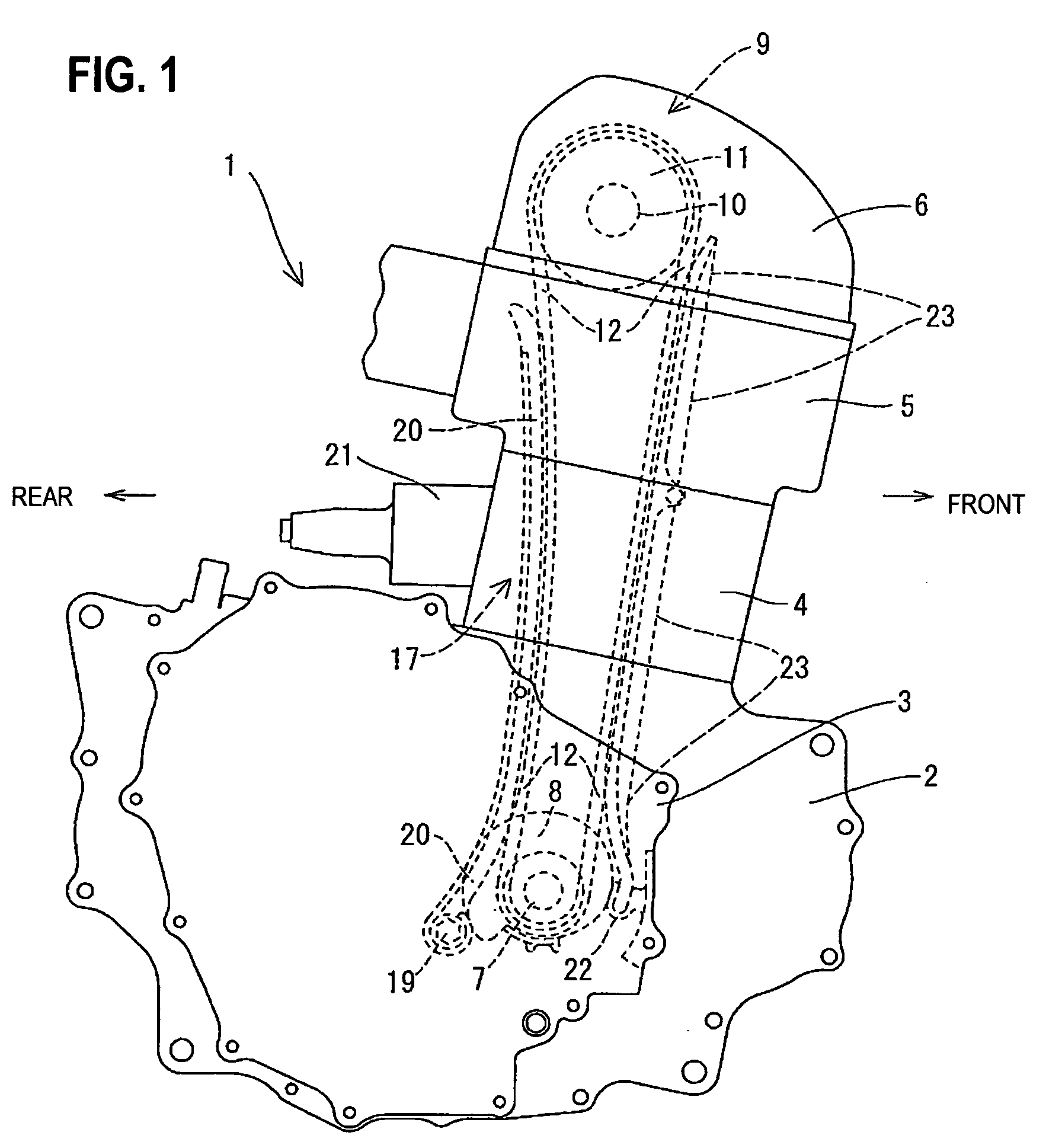

Crankcase structure for an overhead-camshaft internal combustion engine, and engine incorporating same

ActiveUS20090241892A1Increase stiffnessAvoid stress concentrationCasingsValve drivesEngineeringSprocket

An overhead-camshaft internal combustion engine having an outer wall of a crankcase provided adjacent a crankshaft, with a spiral-surfaced opening through which the crankshaft is passed. The outer crankcase wall is integrally provided with a loop guide engaging recess formed thereon. The loop guide engaging recess supports a base end portion of a loop guide for guiding an endless chain. A loop-retaining member for preventing the timing endless chain from dropping is arranged at a position on the lower side of a loop drive sprocket integrally formed at an end portion of the crankshaft.

Owner:HONDA MOTOR CO LTD

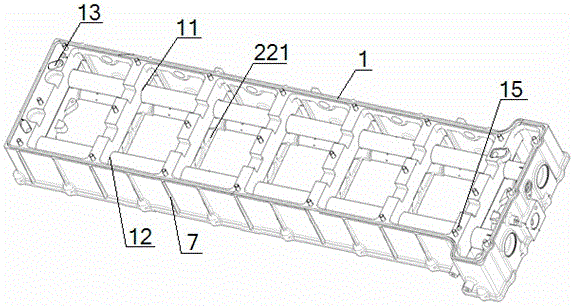

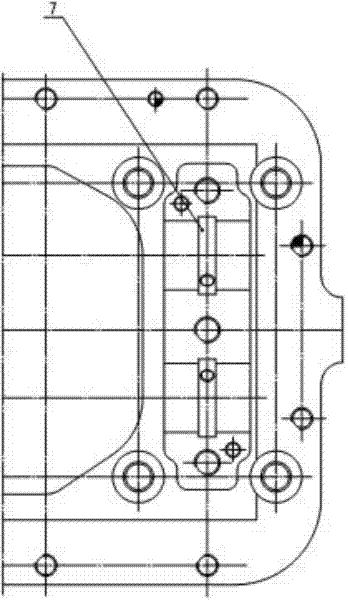

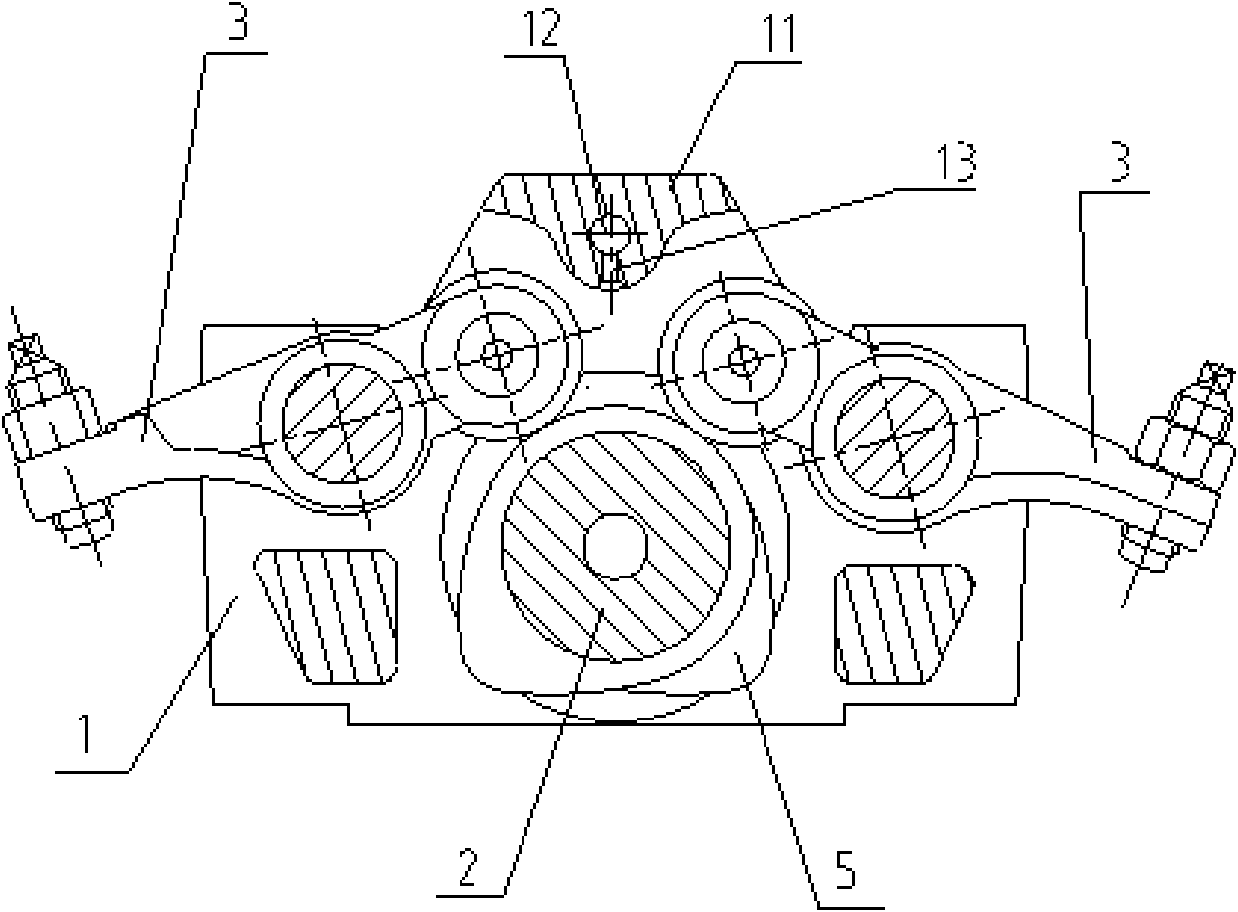

Cam shaft and rocker shaft supporting seat of overhead cam shaft type engine

InactiveCN102022150AHigh strengthSimple manufacturing processValve arrangementsMachines/enginesCross bridgeCam

The invention relates to a cam shaft and rocker shaft supporting seat of an overhead cam shaft type engine. The supporting seat (1) is an integrally formed member independent of a cylinder head and a cylinder cover; a rocker supporting seat hole and a cam shaft hole are formed on the supporting seat (1); bolt holes (4) of four corners of the supporting seat (1) correspond to the bolt hole positions on the cylinder head and the cylinder cover; a cross-bridge type connecting beam (11) is integrally formed on the upper end face of the supporting seat (1) and provided with a branch oil passage (12) and an oil spray hole (13); a main oil passage on the supporting seat (1) is communicated with the oil spray hole (13) by the branch oil passage (12); and an oil outlet of the oil spray hole (13) is opposite to the position of a cam (5) on a cam shaft (2). In the supporting seat, the oil spray hole is not needed to be formed on the cylinder cover, so that the manufacturing process of the cylinder cover is simplified, and the supporting seat contributes to reducing the manufacturing cost of the cylinder cover.

Owner:CHONGQING LONCIN MOTOR

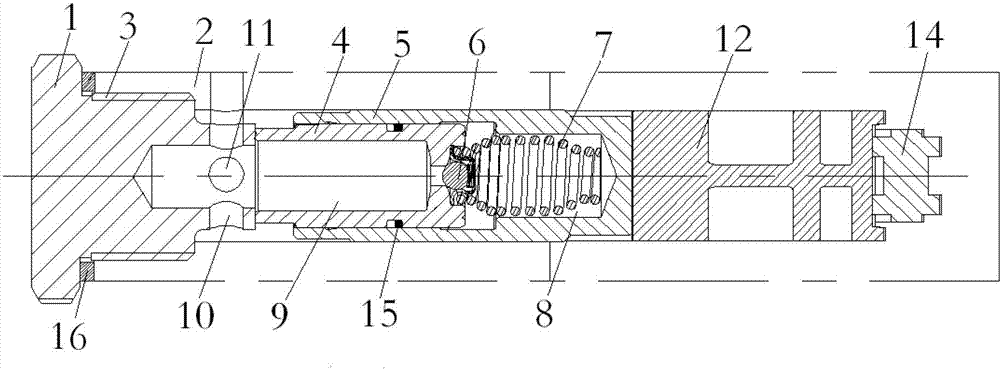

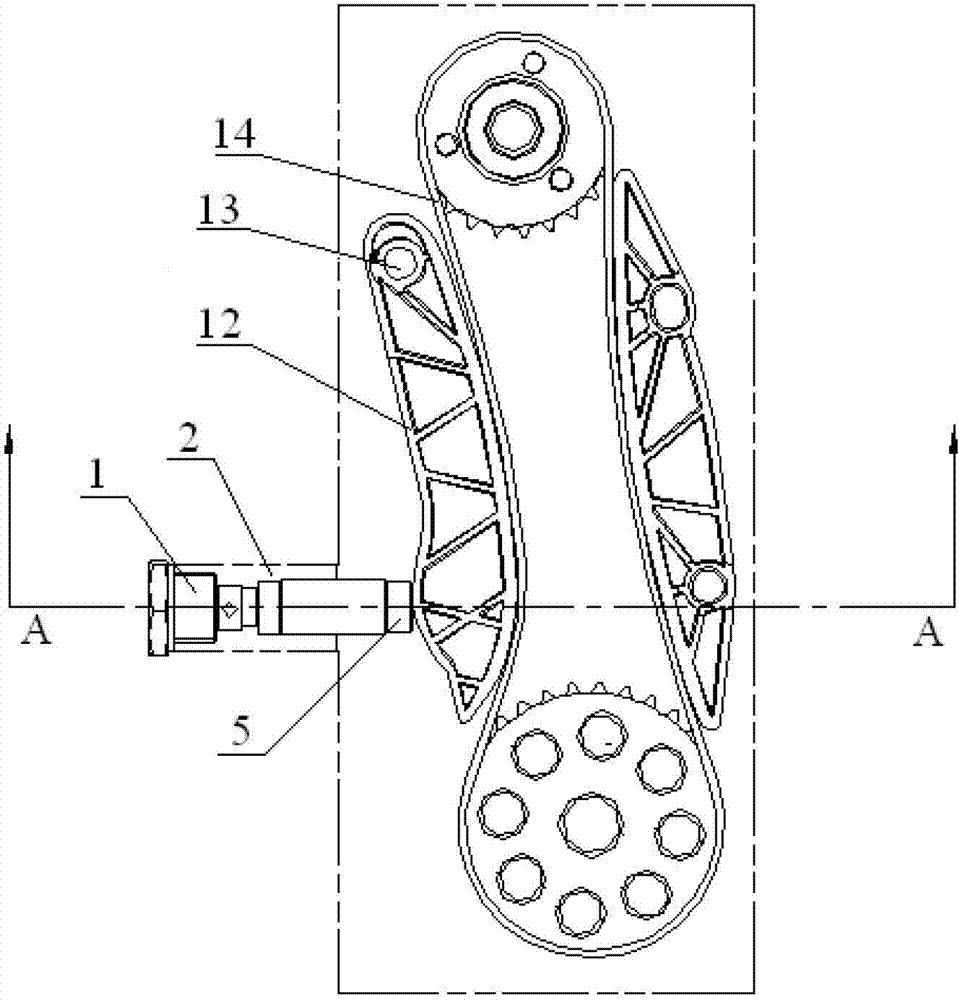

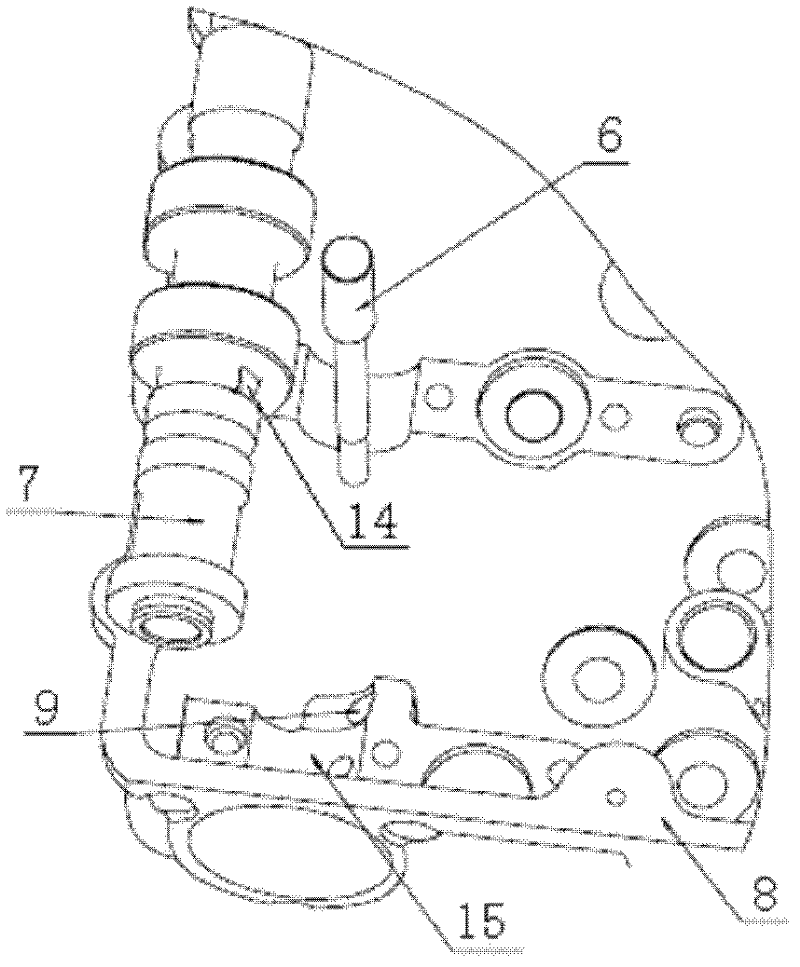

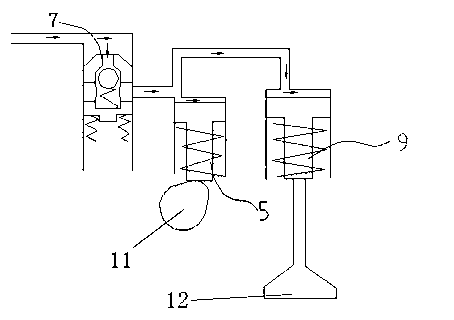

Hydraulic chain tensioner device

The invention discloses a hydraulic chain tensioner device. The structure is as follows: a tensioner fastening seat and a sprocket chamber are fastened and connected through threads, the forefront end of the tensioner fastening seat abuts against a plunger, and the plunger is arranged in a plunger bushing; a check valve and a return spring are sequentially arranged between the plunger and the plunger bushing, and the return spring is arranged in an oil storage chamber of the plunger bushing; a tensioner fastening seat oil chamber is communicated with a plunger oil chamber, and a transverse oil duct and a longitudinal oil duct are arranged in the tensioner fastening seat oil chamber; and a guide plate contacts the outer end of the plunger bushing and is fixed with the sprocket chamber through bolts, and a chain is arranged in a guide plate positioning groove. The device adopts sprocket drive, so the engine has the advantage of simple structure and compact layout. The tensioner can ensure the smooth sprocket drive, and has proper tension for the chain. The hydraulic chain drive can obviously reduce the noise. The invention is especially suitable for overhead camshaft engines, and has high popularization value.

Owner:东风朝阳朝柴动力有限公司

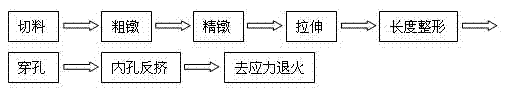

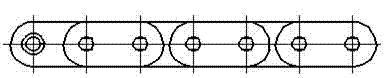

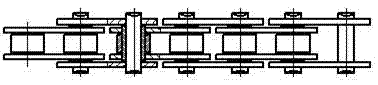

Timing chain of double VVT overhead camshaft engine for SUV and fabrication method

ActiveCN102926832AReduce stress concentrationImprove impact resistanceValve arrangementsSolid state diffusion coatingStress concentrationVariable valve timing

The invention relates to a timing chain of a double VVT (variable valve timing) overhead camshaft engine for an SUV (sports utility vehicle) and a fabrication method. When the maximum output power of the engine is 103kW, the maximum torque of the engine is 180N.m, the maximum crankshaft sprocket speed is 6000rpm, and the compacting moment of a camshaft is 28N.m, (1) the tensile strength of the timing chain is greater than or equal to 10kN and the circumferential tension is less than or equal to 1650N; (2) arc diameters of two ends of outer and inner chain plates of outer and inner chain links in a transmission chain of a timing system is 7.6max; two chain pin shaft holes with 8mm of a pitch are formed on each of the chain plates of the outer and inner chain links; the distance between every two holes is 8mm; and the internal distance between the two chain plates of the inner chain link is 4.6min. The method has the advantages that: firstly, the requirements that the tensile strength of the timing chain is greater than or equal to 10kN and the circumferential tension is less than or equal to 1650N are met; secondly, the pin shafts adopt 75 material and the surfaces of the pin shafts are strengthened by chroming; the tensile strength reaches 11-12kN; the requirements of the high-power and high-torque SUV and double VVT vehicle engine are met; thirdly, rollers are subjected to cold heading, thermal pretreatment ,quenching and tempering; the stress concentration of circumferential cracks is eliminated effectively; and the impact resistance is improved.

Owner:HANGZHOU CHIZHENG TECH

Timing positioning system device for top-mounted engine of camshaft

InactiveCN102493852APrecise gas distributionAccurate oil supplyValve arrangementsMachines/enginesEngineeringFlywheel

The invention discloses a timing positioning system device for a top-mounted engine of a camshaft, which is structurally characterized in that a crankshaft positioning rod penetrates through a positioning hole on a flywheel shell to be inserted in a positioning pin hole in a flywheel; and a camshaft positioning pin penetrates through the camshaft to be inserted in a cylinder cover positioning hole of a cylinder cover, transmission relation between the camshaft and a crankshaft is determined, and timing positioning during gas distribution of the engine and timing positioning of oil supply are completed. A crankshaft gear disc in a chain wheel system is assembled with the crankshaft; a camshaft gear disc is assembled with the camshaft; and an oil pump gear disc is assembled with a camshaft oil pump. A planar portion of the camshaft positioning pin is assembled with a positioning surface of the camshaft in a combined manner, and the purpose of limiting rotation of the camshaft is realized. The accurate timing positioning system is provided by the aid of the top-mounted camshaft and chain transmission, so that gas distribution of the engine and oil supply can be timely and accurate. Components match with the corresponding positioning holes, the step that meshing marks need to be aligned in conventional assembly is omitted, assembly process is simplified, and production efficiency is improved.

Owner:DONGFENG CHAOYANG DIESEL ENGINE

Diesel engine single overhead camshaft driven valve rocker mechanism

ActiveCN105569756AReduce the overall heightReduce widthValve arrangementsLubrication of auxillariesEngineeringCam

The invention discloses a diesel engine single overhead camshaft driven valve rocker mechanism. The mechanism comprises an exhaust rocker, an intake rocker, rocker ball heads, rocker ball head seats, a rocker shaft, rocker rolling pins, a rocker shaft seat and rocker rolling columns, wherein the rocker ball head seats sleeves the rocker ball heads; the threaded ends of the rocket ball heads are screwed in the threaded holes at the valve ends of the rockers; nuts are arranged at the tops of the threaded ends, exposed from the end faces of the rockers, of the rocker ball heads; the rocker rolling columns are arranged in slots at the cam ends of the rockers and are integrally connected with the rockers through the rocker rolling pins which are inserted in the inner holes at the cam ends of the rockers; a positioning pin is mounted on the bottom surface of the rocker shaft seat, an intake rocker mounting groove and an exhaust rocker mounting groove are milled in the top surface of the rocker shaft seat, and rocker shaft seat fixing bolts are arranged on the bottom surfaces of the grooves; the rocker shaft consists of a mounting boss in the middle and fixed shafts of the intake rocker and exhaust rocker at the two ends, and the both the two shaft ends are milled in the horizontal direction; the intake rocker and the exhaust rocker are respectively sleeved at two ends of the rocker shaft; and three bolts respectively penetrate through the two ends and the middle parts of the rocker shaft so as to fix the rocker shaft at the upper top surface of the rocker shaft seat and then the rocker shaft seat is positioned by the positioning pin.

Owner:FIRST TRACTOR

OHC overhead camshaft internal combustion enjine

To improve conventional structure that takes a lot of man-hours in manufacture since halved camshaft bearing holding parts are formed by using joint faces of separately produced members such as a cylinder head cover and a cylinder head to facilitate production of a bearing holding part and installation work of a camshaft, in an OHC type internal combustion engine whose rotating camshaft interlocked with a crankshaft is disposed on a cylinder head. A camshaft holder for holding the camshaft to be rotatable is produced separately from the cylinder head or cylinder head cover, and the camshaft holder is tightened together by stud bolts passing through a cylinder.

Owner:HONDA MOTOR CO LTD

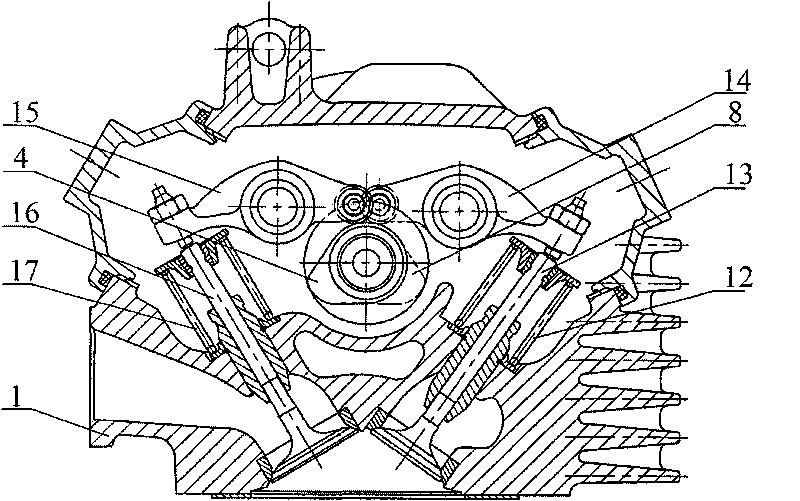

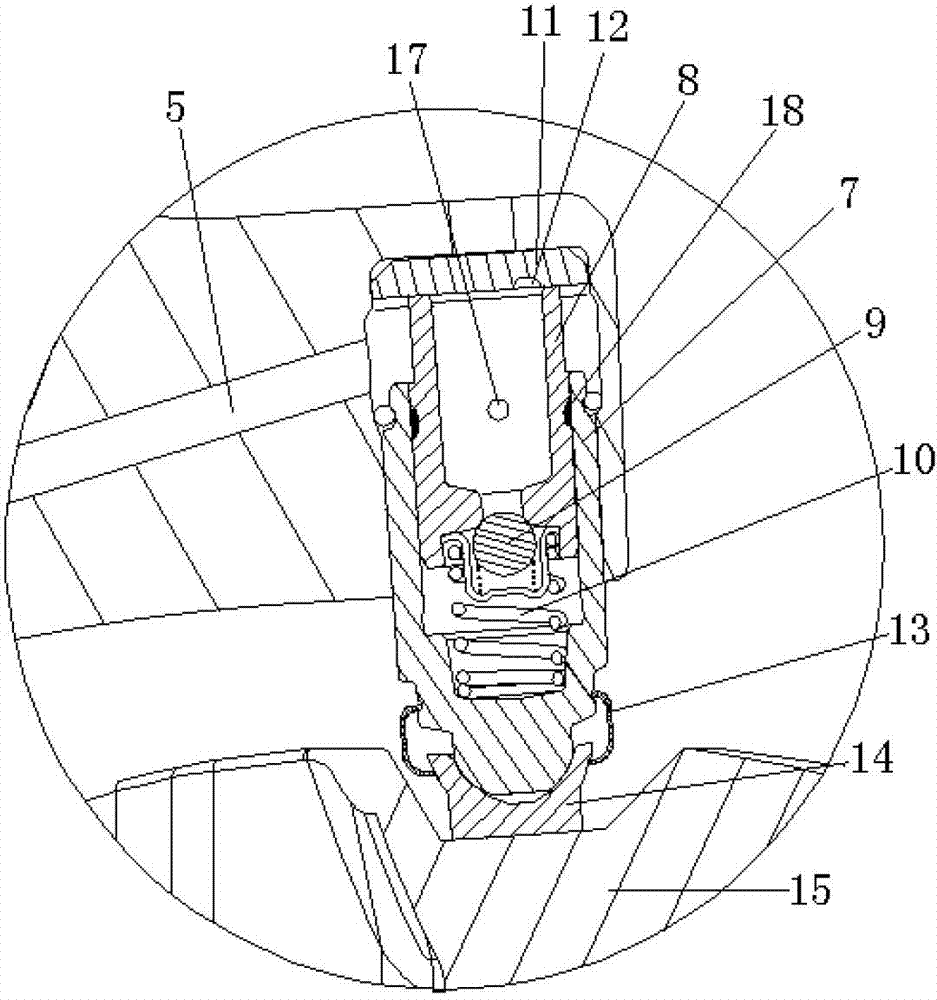

Rocker arm body capable of realizing braking function of engine

InactiveCN102937041AReasonable structureEasy to operateValve arrangementsMachines/enginesCamControl valves

The invention relates to a rocker arm body capable of realizing a braking function of an engine, which is characterized in that an air exhausting rocker arm is provided with a braking driving chamber, a control valve chamber and a braking driven chamber, wherein the braking driving chamber is internally provided with a braking driving valve; a braking driving valve resetting spring is sleeved on the driving valve; the control valve chamber is internally provided with a control valve; a control valve resetting spring is sleeved on the control valve; the braking driven chamber is internally provided with a braking driven valve; a driven valve resetting spring is sleeved on the braking driven valve; the braking driving valve works under the driving of a special cam; the braking driving chamber is located at the tail end of the air exhausting rocker arm; the control valve chamber is located above the braking driving chamber; the braking driven chamber is located at the front end of the air exhausting rocker arm; and the braking driving chamber, the control valve chamber and the braking driven chamber are communicated through an oil path on the air exhausting rocker arm. The braking of an independent cam type engine can be realized by using the engine, namely one special cam is used for engine braking, so as to realize the independent cam braking at an air inlet side by a cam shaft of a top-arranged cam shaft engine, and therefore, the braking power is improved.

Owner:CHINA FIRST AUTOMOBILE

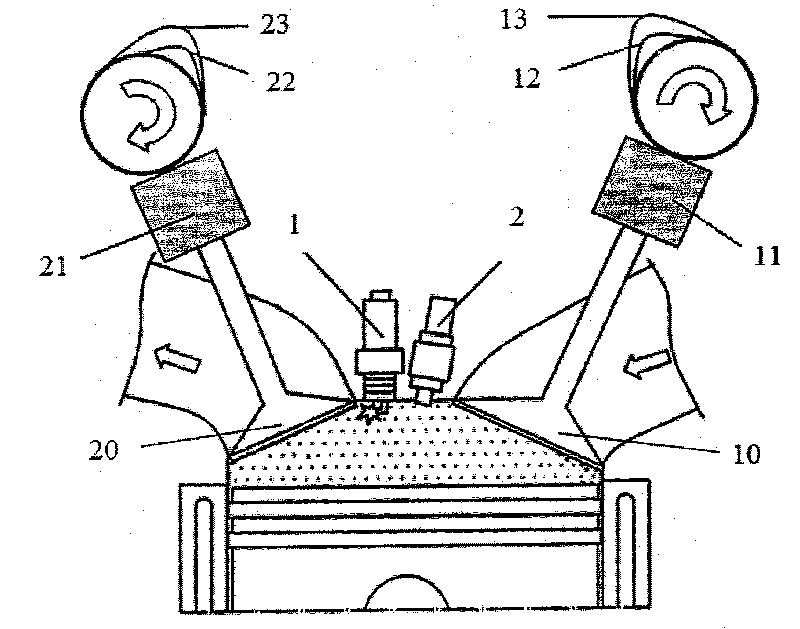

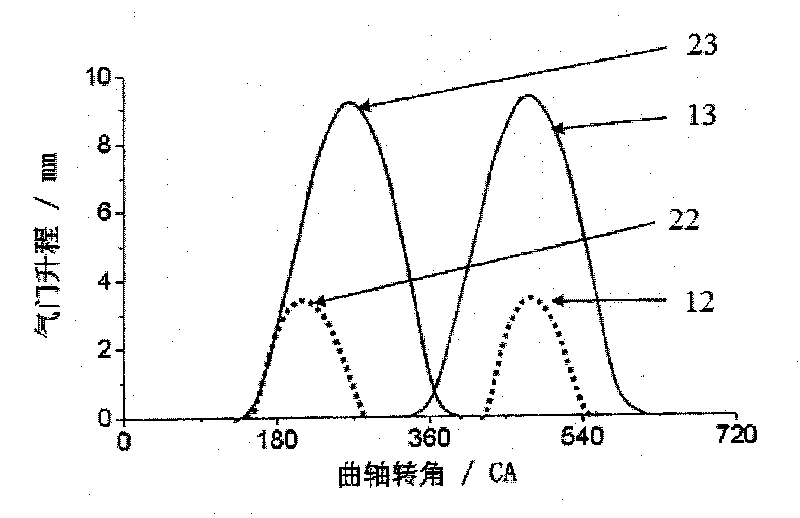

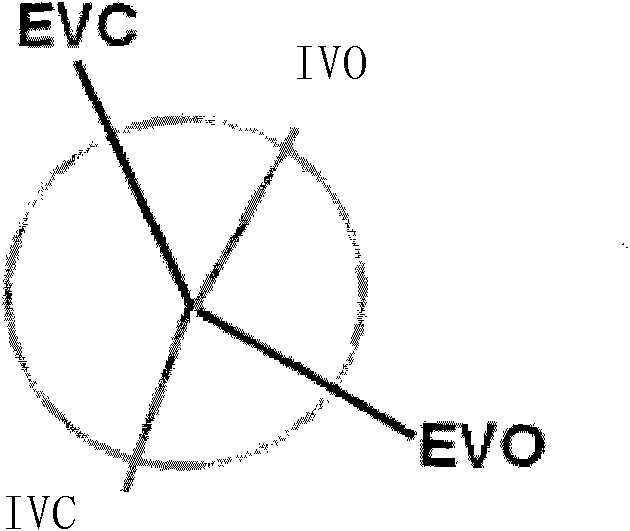

Two-stage variable compression ratio system of gasoline engine and control method thereof

InactiveCN101699040AImprove power densityReduce fuel consumptionValve arrangementsMachines/enginesHcci combustionDetonation

The invention relates to a two-stage variable compression ratio system of a gasoline engine and a control method thereof. On two overhead camshafts corresponding to an intake valve and an exhaust valve of the engine, a big cam and a small cam, which correspond to the intake valve and the exhaust valve of each cylinder are respectively arranged; an intake valve cam profile switching mechanism is arranged on the intake valve of each cylinder and is used for switching the big cam and the small cam of the intake valve, which correspond to the intake valve; and an exhaust valve cam profile switching mechanism is arranged on the exhaust valve of each cylinder and is used for switching the big cam and the small cam of the exhaust valve, which correspond to the exhaust valve. The system and the method have the advantages of quickly changing the compression ratio, realizing the switching between SI and HCCI combustion modes in an engine cycle, obtaining low oil consumption by adopting a high compression ratio when the engine has a medium or low load, and obtaining a high-power density by adopting a low compression ratio to avoid detonation when the engine has a high load.

Owner:TSINGHUA UNIV

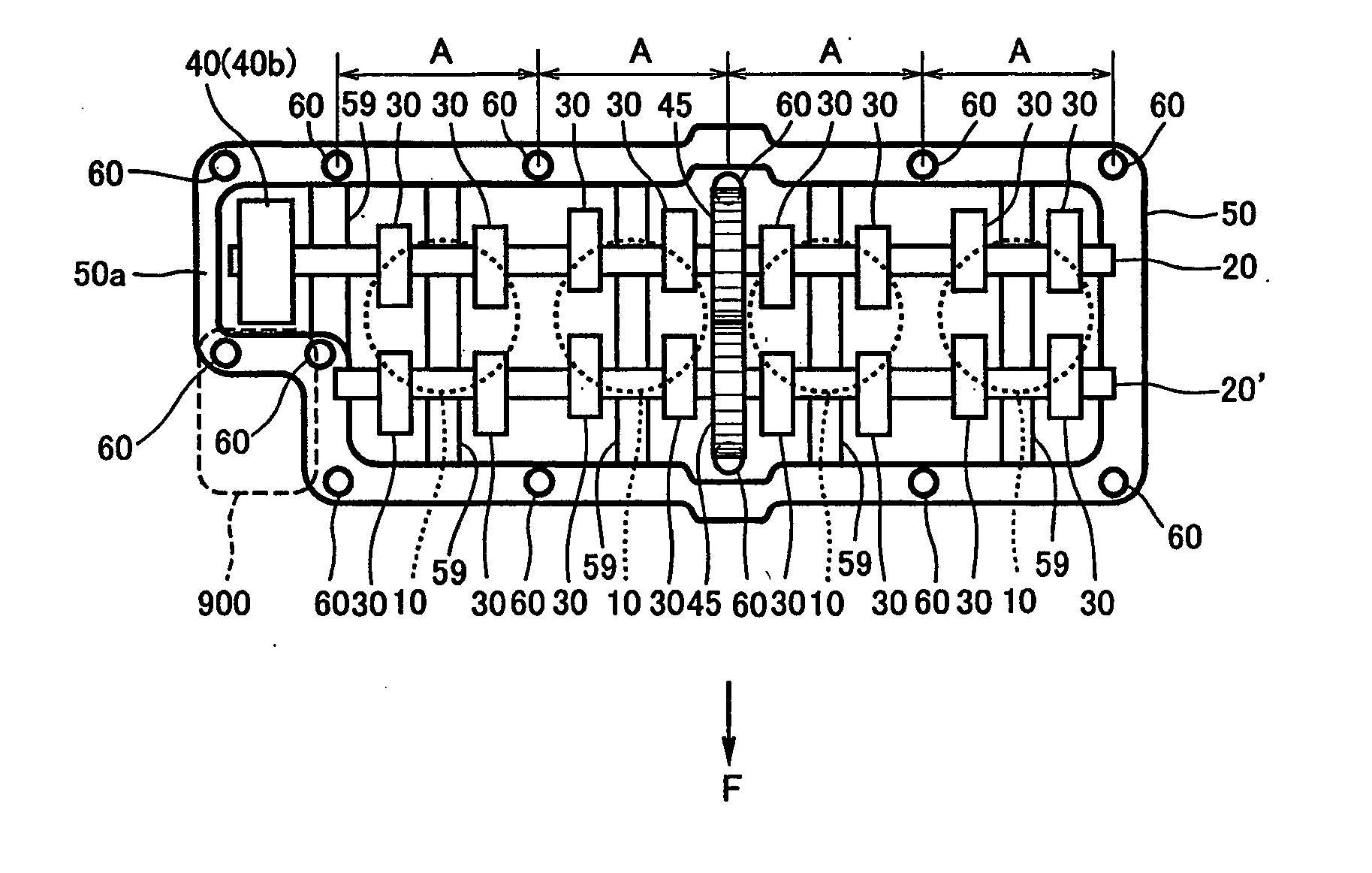

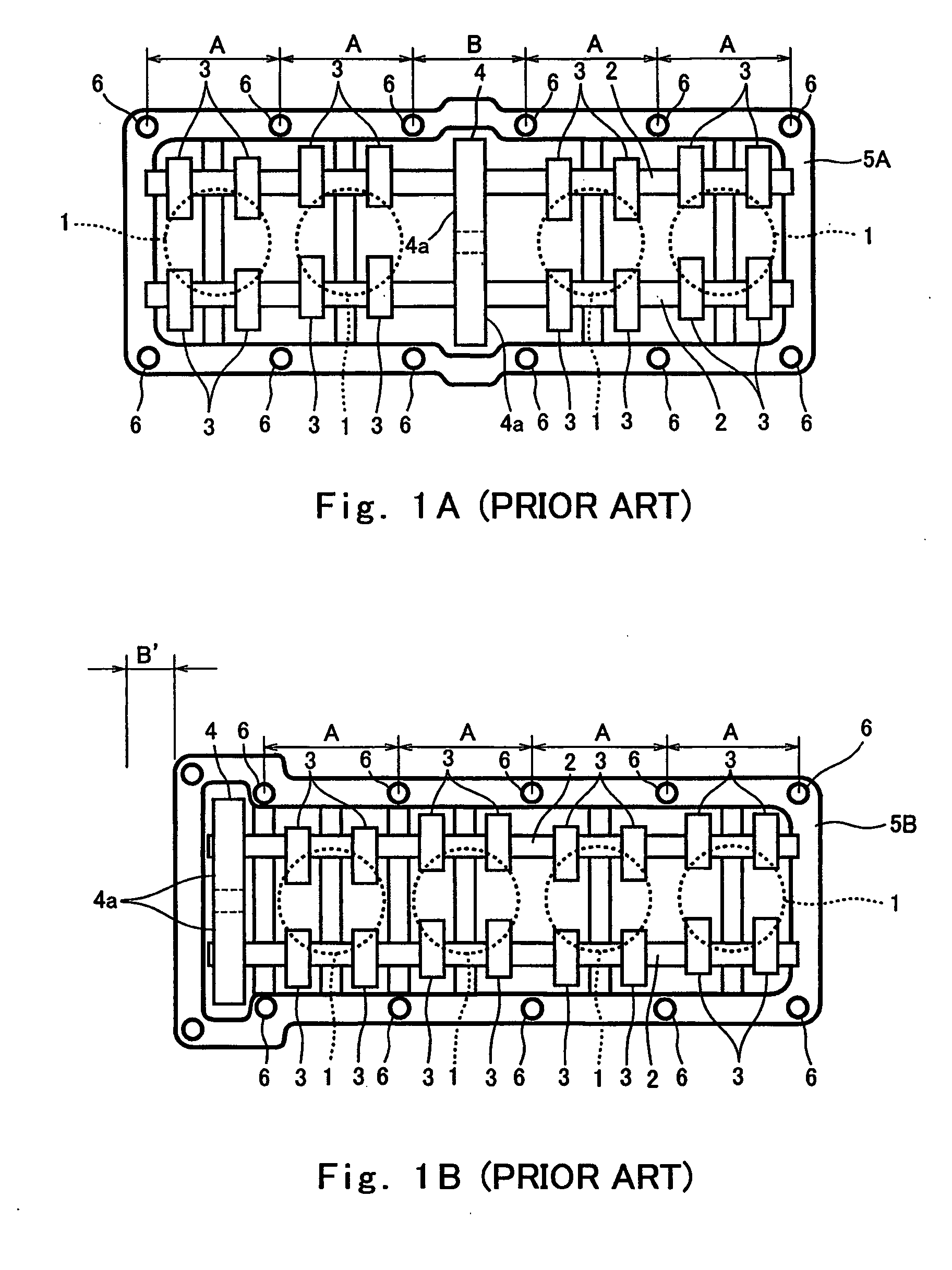

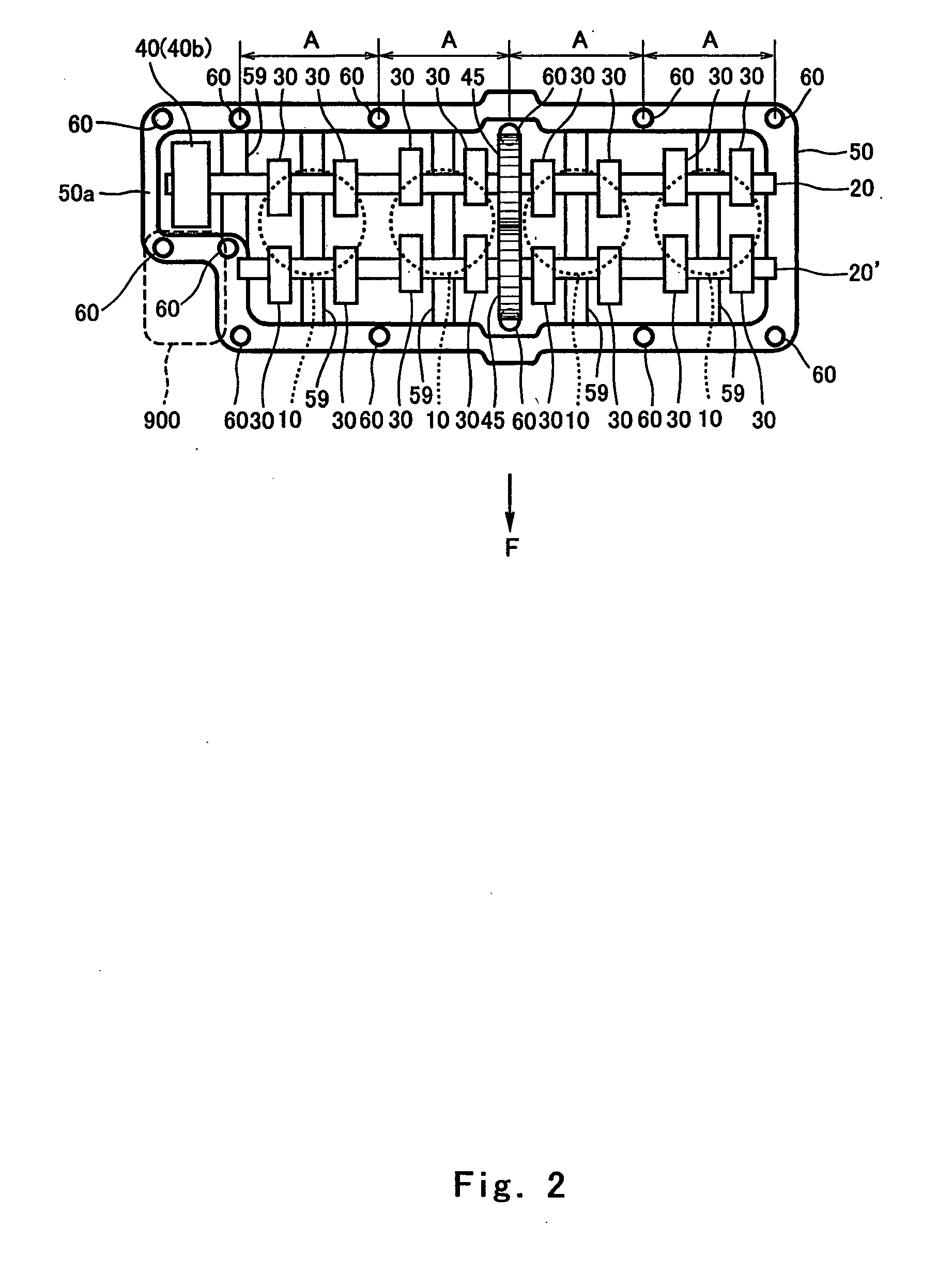

Engine and motorcycle

InactiveUS20080087246A1Avoiding increase in width of frameIncrease widthLubrication of auxillariesValve drivesExhaust valveEngineering

A multiple-cylinder DOHC engine, including a cylinder head block, a first camshaft that is mounted on the cylinder head block and is configured to drive one of an intake valve and an exhaust valve mounted on the cylinder head block, a second camshaft that is mounted on the cylinder head block and is configured to drive the other one of an intake valve and an exhaust valve, a camshaft drive system that is mounted at an end portion of the first camshaft in an axial direction thereof and is configured to drive the first camshaft, and a driving power transmission mechanism that is disposed at a center portion of the first and second camshafts in the axial direction to transmit a driving power from the first camshaft to the second camshaft.

Owner:KAWASAKI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com