Car engine air valve variable phase device

A technology of automobile engine and valve, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

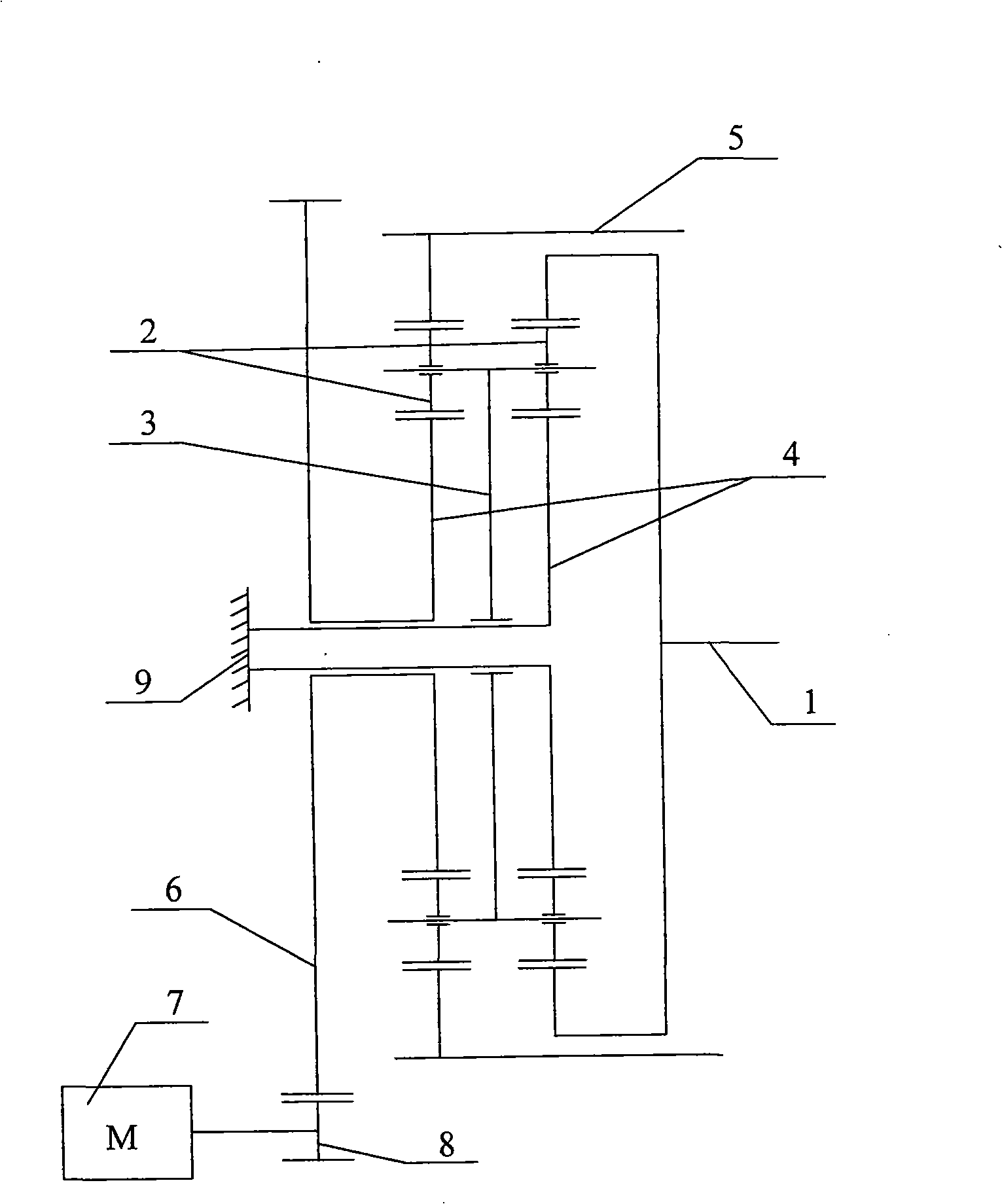

[0012] The invention adopts mechanical control, utilizes the working characteristics of the planetary gear, and forms the phase change of the ring gear and the planet carrier by controlling the rotation of the sun gear.

[0013] According to the accompanying drawings, the present invention includes a camshaft 1, and also includes two sets of planetary gears 2 and a sun gear 4, a planet carrier 3, a control adjustment wheel 6, a stepping motor 7 and a pulley 5. The camshaft pulley meshes internally with two sets of planetary gears, and the sun gear externally meshes with the left set of planetary gears is integrated with the control adjustment wheel. The rotating shaft of the planetary carrier of two groups of planetary gears is arranged on the axle that this sun gear connects engine casing 9, and the sun gear that meshes with the right side one group of planetary gears is fixed and stationary with respect to the engine casing, and the right side planetary gear The internally m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com