Engine correct-timing drive system mounting method and positioning tool

A drive system and installation method technology, applied in the direction of engine components, machines/engines, manufacturing tools, etc., can solve the problems of undiscovered installation methods and positioning tools, etc., and achieve the effect of simple tooling tools, accurate positioning, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

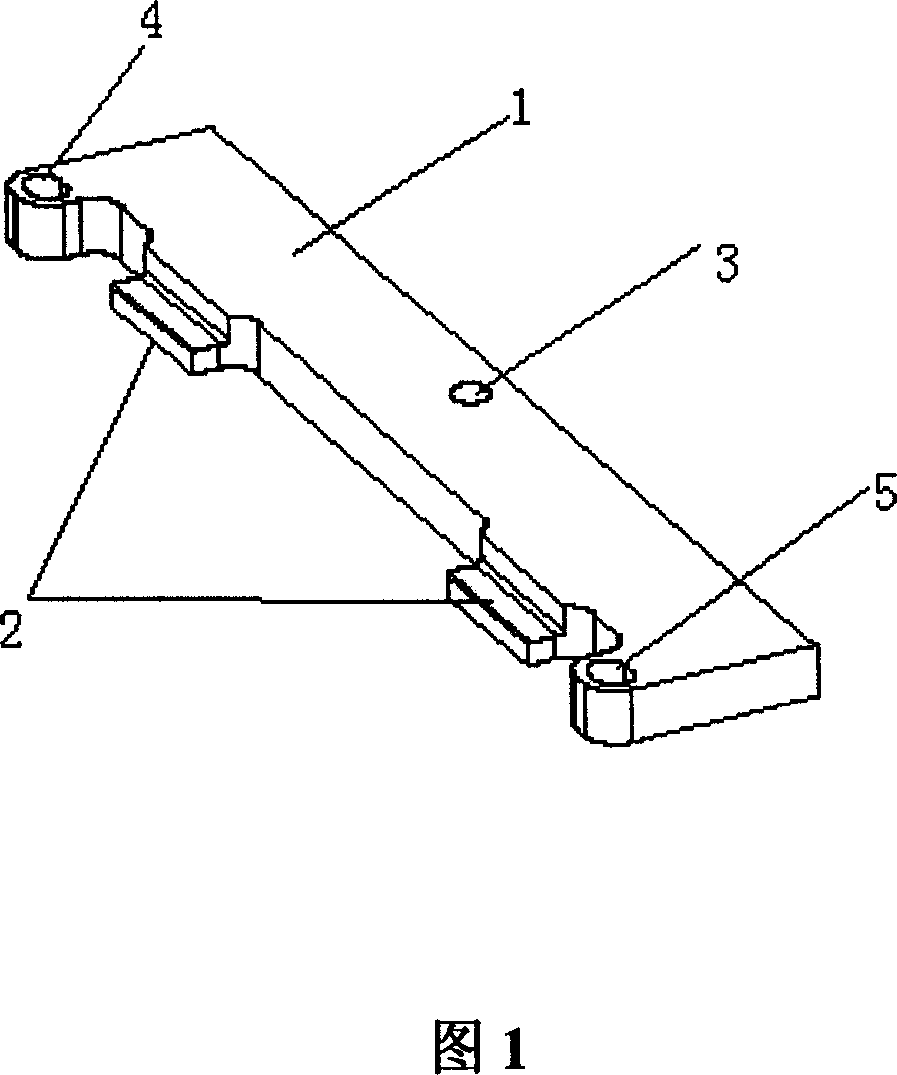

Image

Examples

Embodiment Construction

[0016] Embodiment of the installation method of the engine timing drive system:

[0017] (1) Rotate the crankshaft to a crankshaft angle of 270°, and then manually insert the crankshaft positioning pin (the positioning pin must match the crankshaft hole well);

[0018] (2) Put the timing gear on the crankshaft, tighten it to 130Nm with a 130Nm torque wrench, and then turn it clockwise for 65 degrees;

[0019] (3) Rotate the camshaft to a suitable position to insert the camshaft positioning tool (this positioning tool must match the slot on the camshaft perfectly). Use 3 pieces of M6x20 (5 +5 The tightening torque of Nm) bolts to fix the camshaft alignment tool;

[0020] (4) Put the camshaft timing gear on, insert the M12 bolt into the center screw hole of the timing gear and tighten it to 3Nm with a tool (make sure that the camshaft gear cannot shake after being fastened by the bolt);

[0021] (5) Install the tensioning wheel, and the fixing hook on the tensioning wheel mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com