Diesel engine single overhead camshaft driven valve rocker mechanism

A valve rocker arm, diesel engine technology, applied in the direction of machine/engine, valve device, mechanical equipment, etc., can solve the problem that cannot meet the high speed, high reinforcement of diesel engine, increase the height and width of the whole diesel engine, and the axial height and transverse direction of the mechanism. The problem of large width, etc., achieves the effect of compact structure, improved service life, and small size of the mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

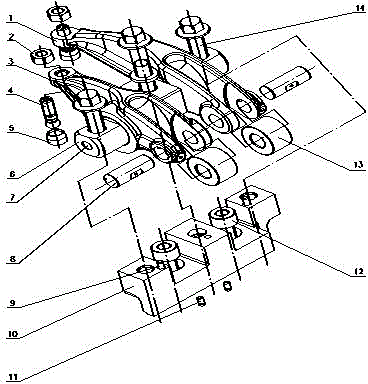

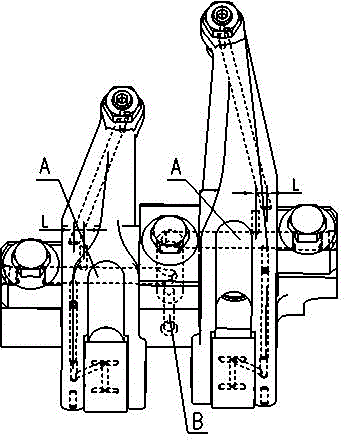

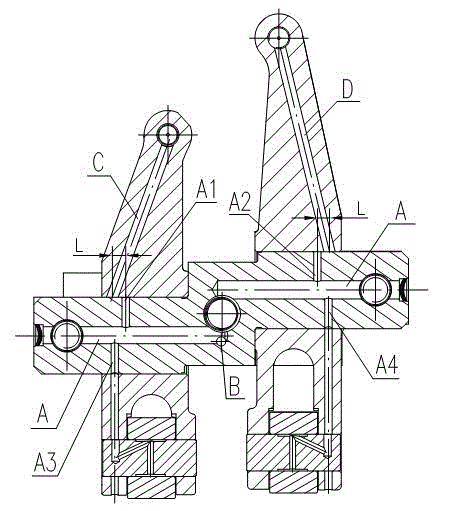

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1~3 As shown, the diesel engine overhead single camshaft drives the valve rocker arm mechanism, including: exhaust rocker arm 1, nut 2, intake rocker arm 3, rocker arm ball head 4, rocker arm ball head seat 5, rocker arm shaft 6, Plug piece 7, rocker arm rolling pin 8, first positioning pin 9, rocker arm shaft seat 10, second positioning pin 11, fixing screw 12, rocker arm roller 13 and bolt 14; rocker arm ball seat 5 is set on the rocker arm On the arm ball head 4, the top of the rocker ball head seat 5 is extruded with the shape of the rocker arm ball head 4, and the rocker arm ball head 4 can rotate freely in the rocker arm ball head seat 5. Screw the threaded end of the rocker ball head 4 into the threaded hole at the valve end of the rocker arm, and install the nut 2 on the top of the threaded end of the rocker ball head 4 where the end face of the rocker arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com