Patents

Literature

148 results about "Heavy duty diesel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

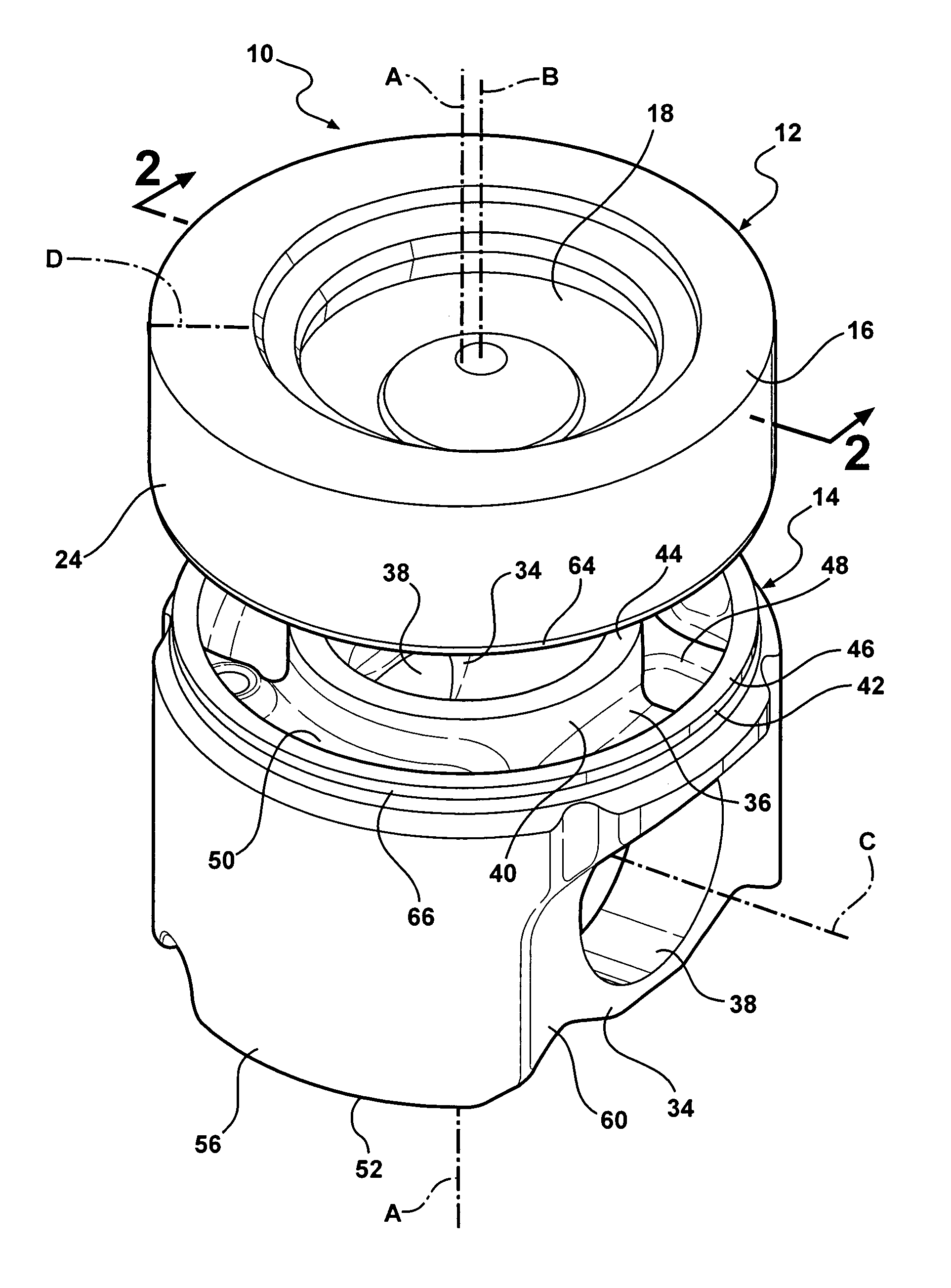

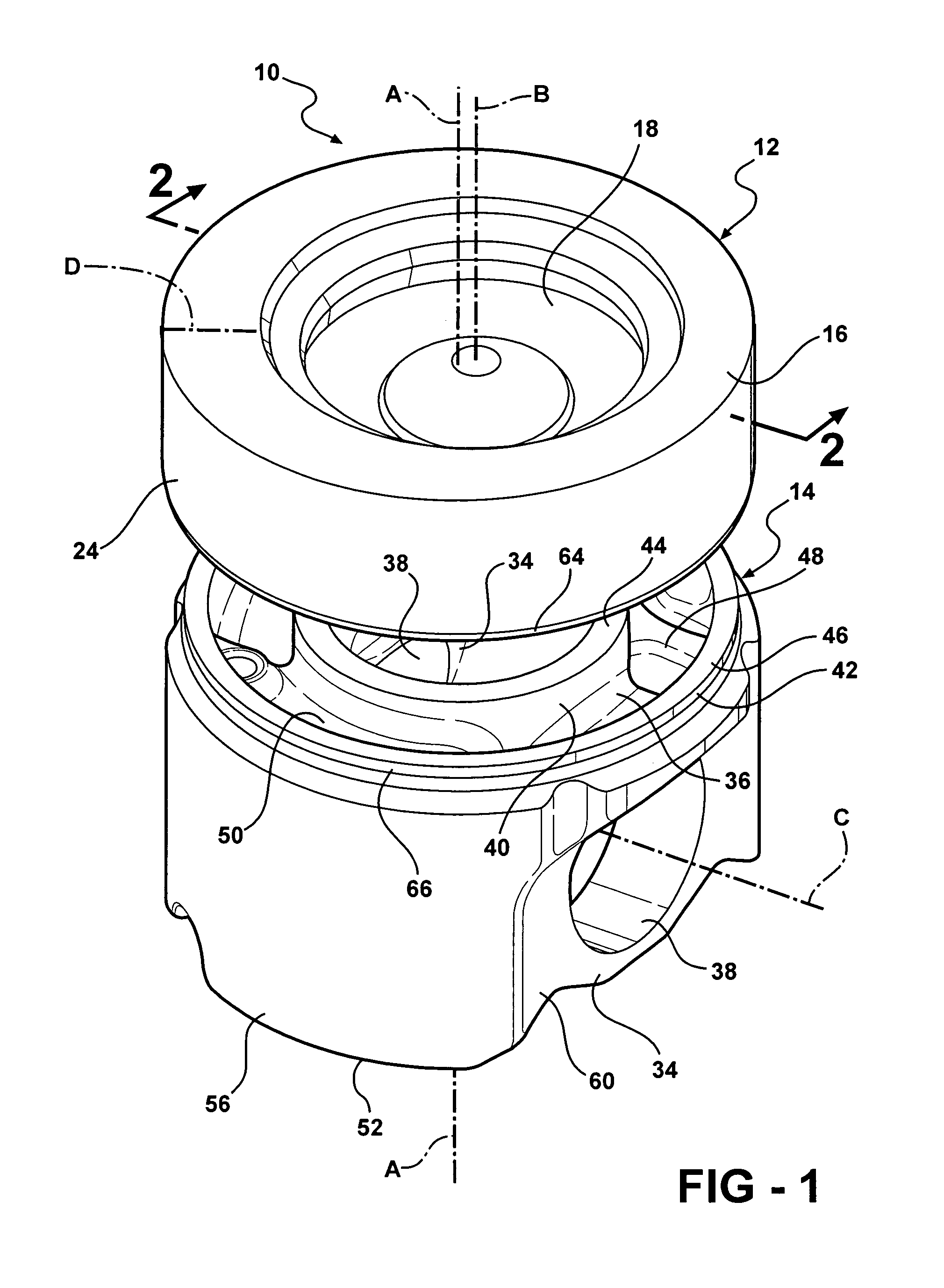

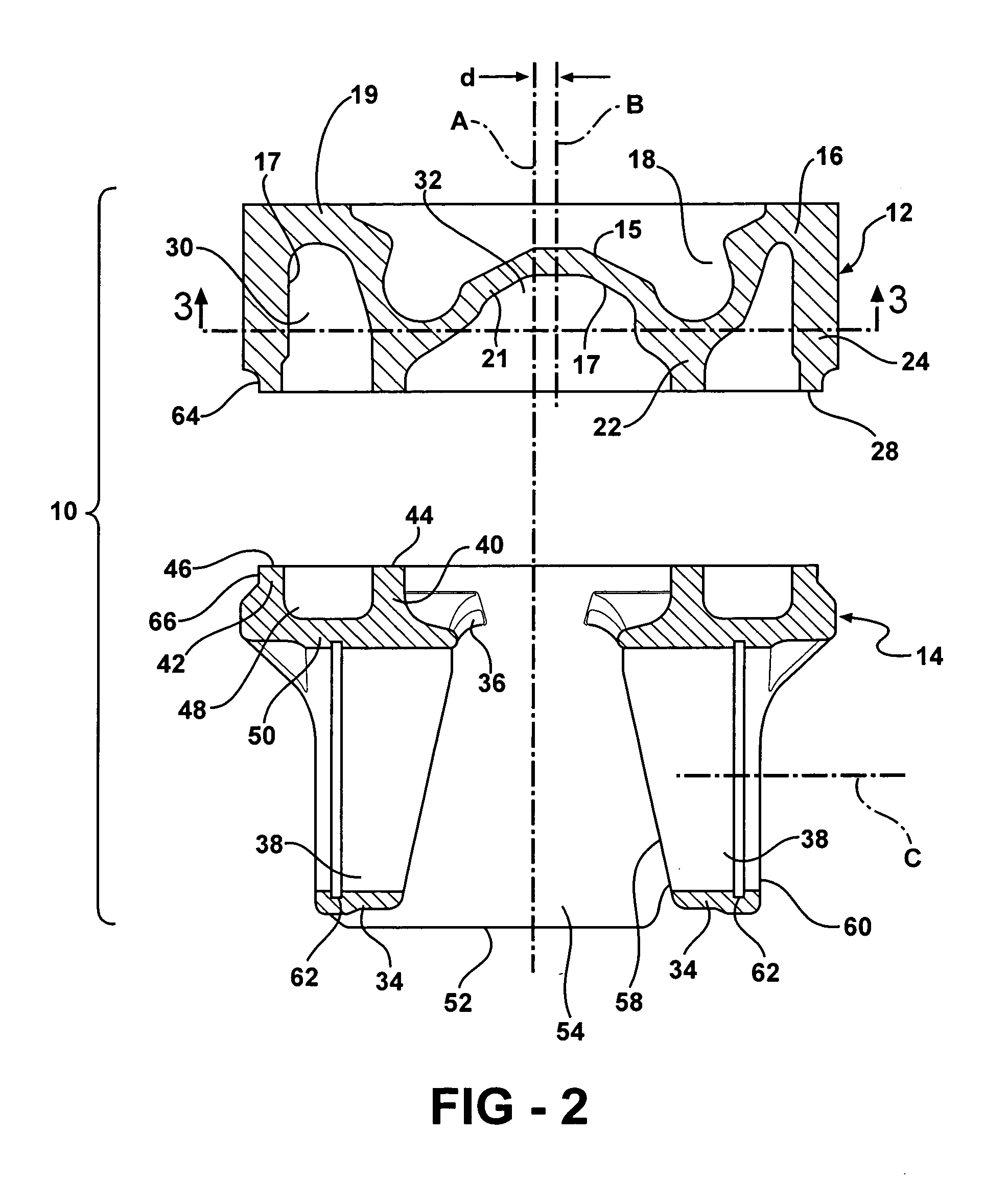

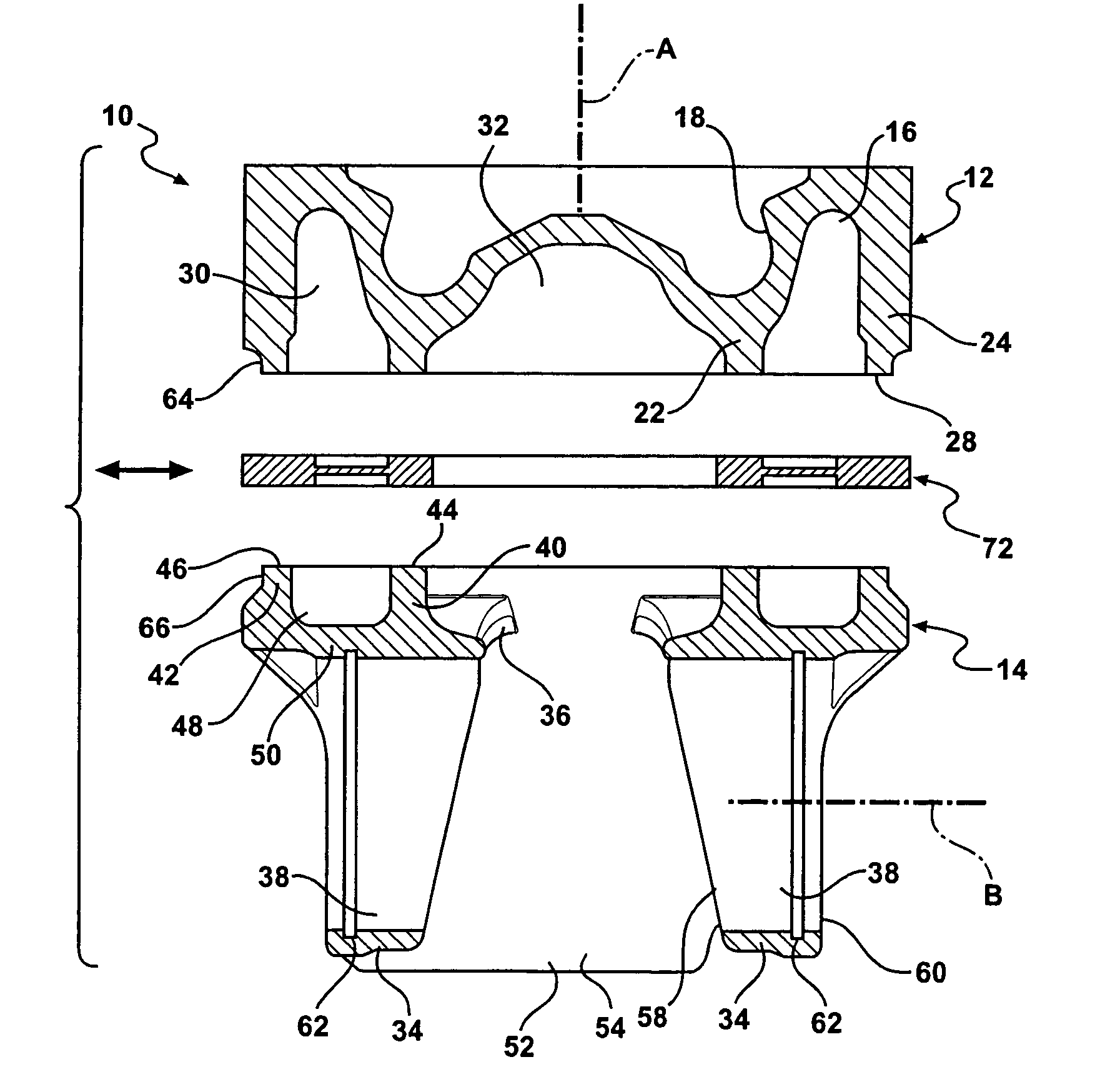

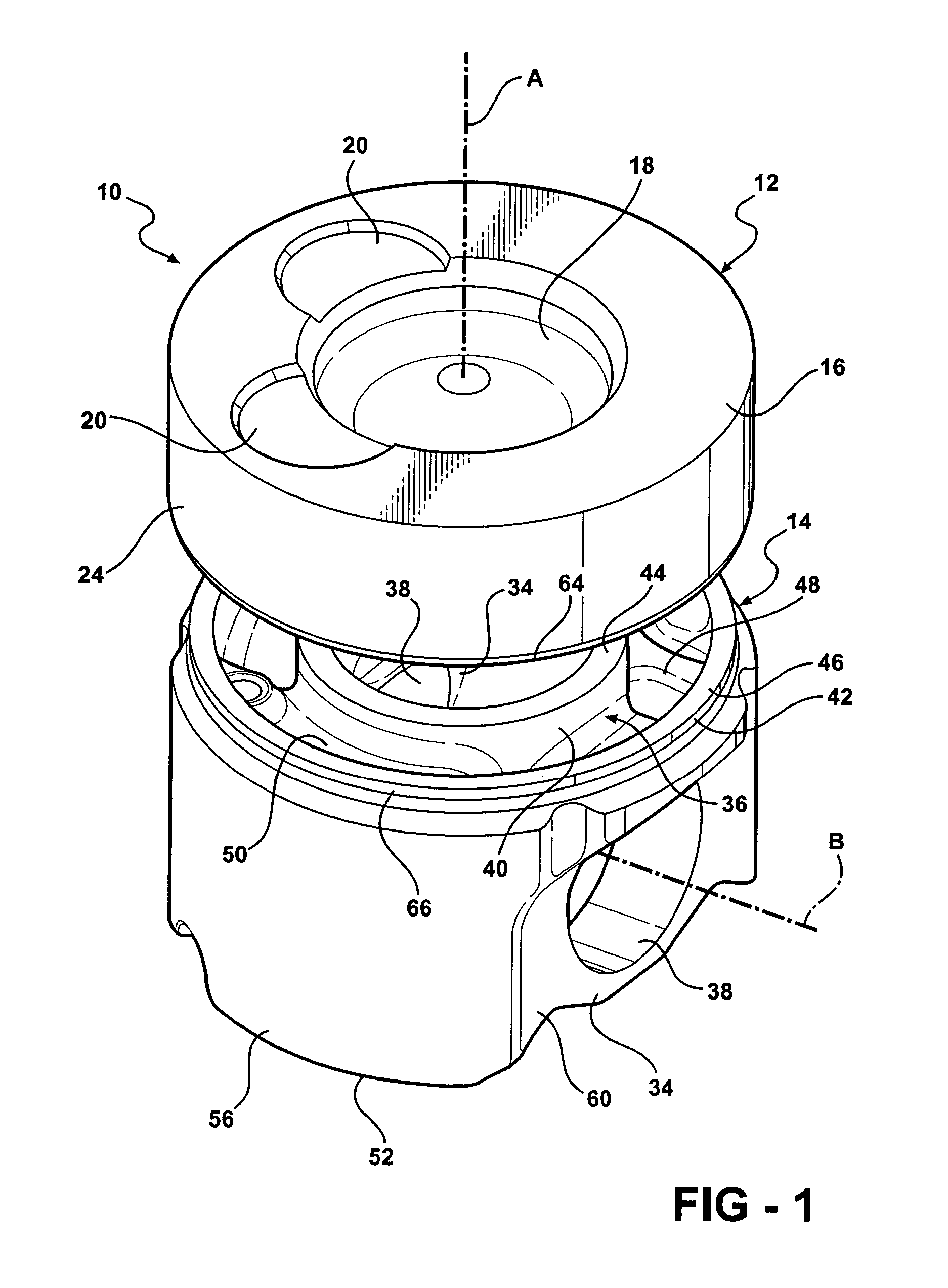

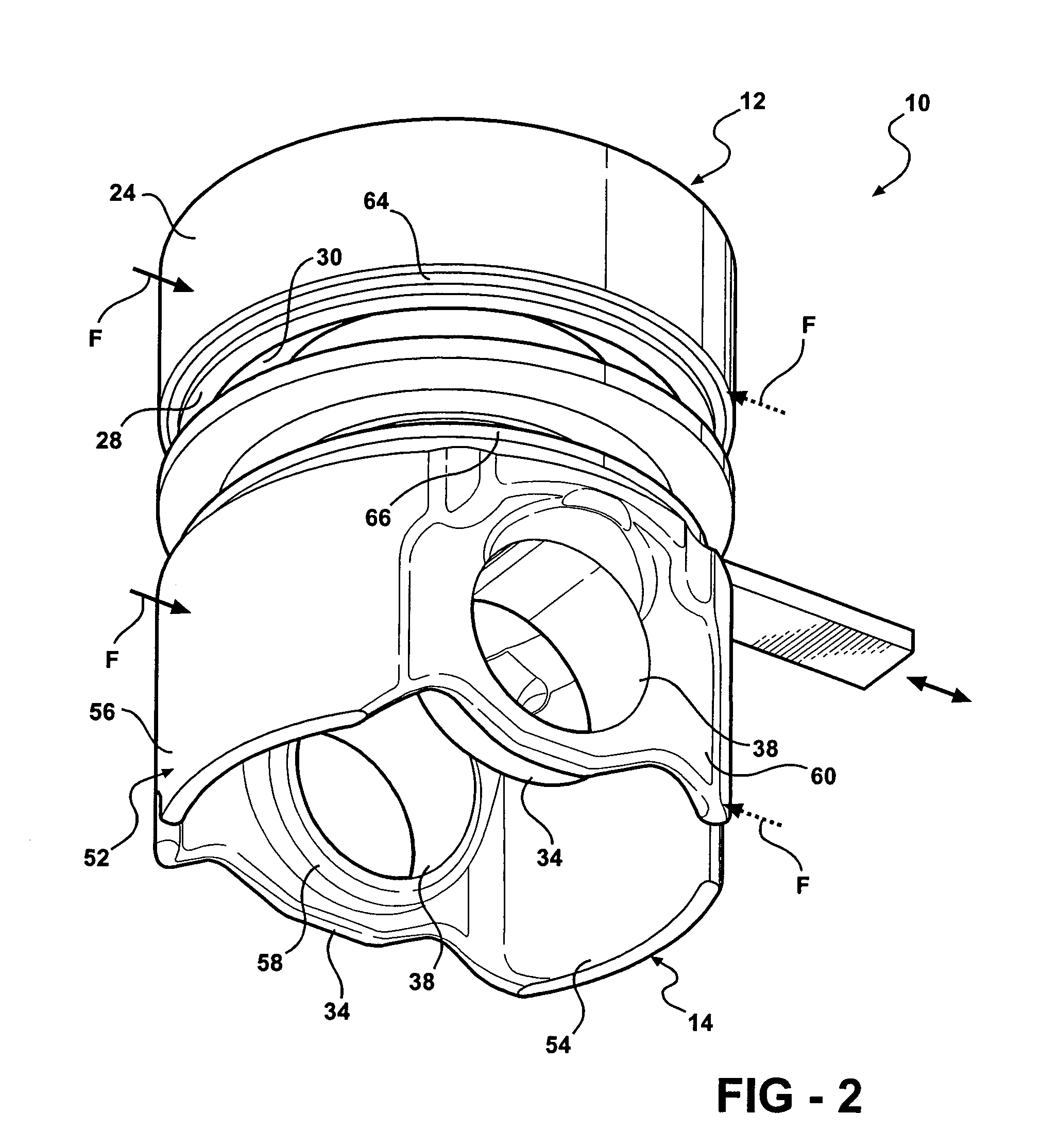

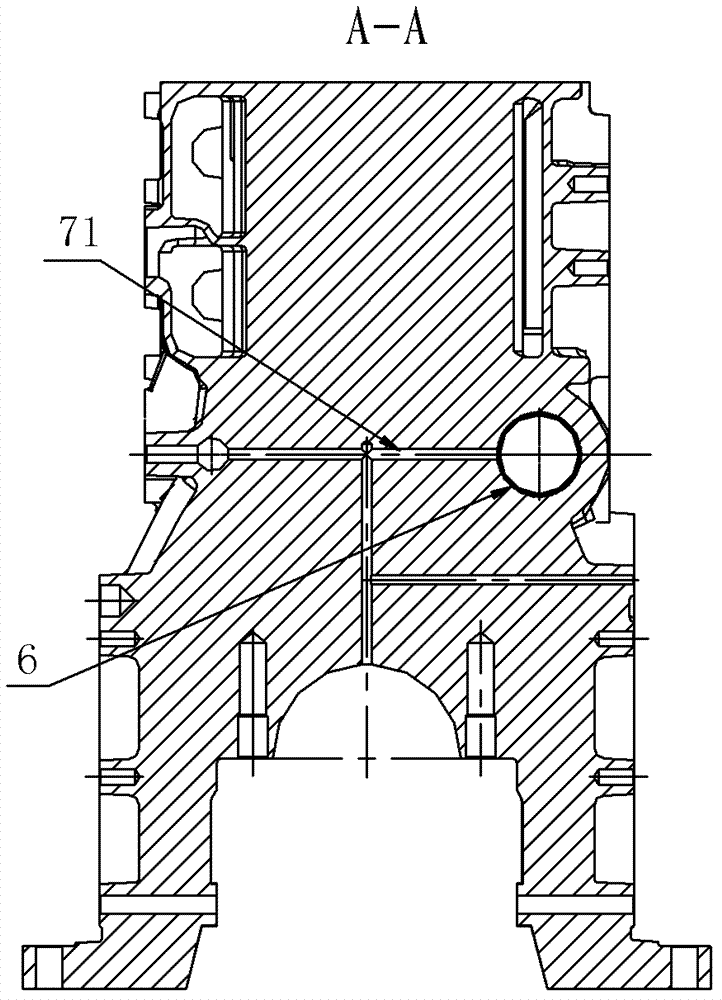

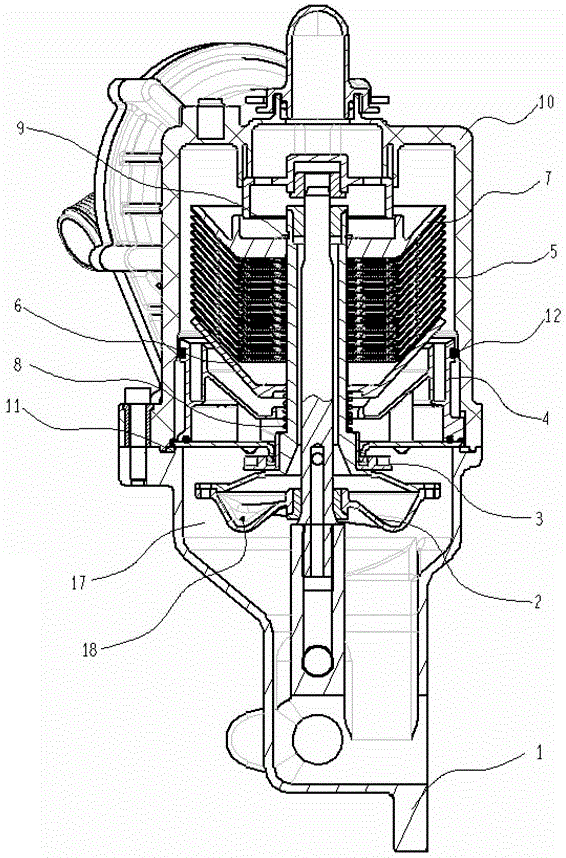

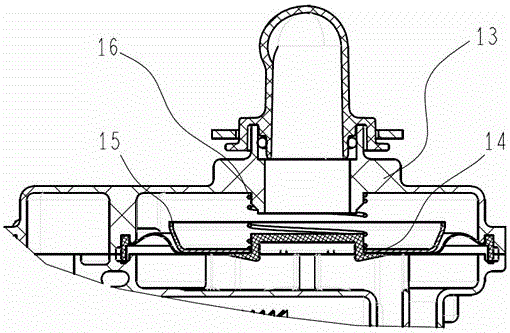

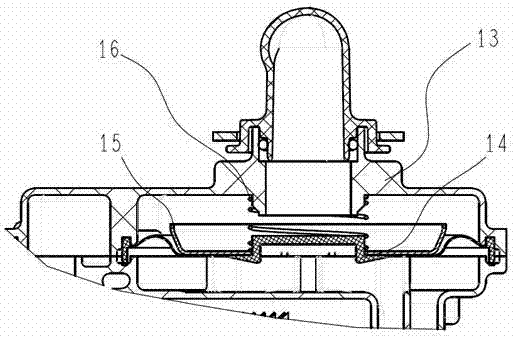

Piston and method of manufacture

A piston particularly adapted for heavy-duty diesel engine applications is fabricated from a separate head portion and base portion having circumferentially extending joining surfaces that are heated prior to bonding to an elevated temperature sufficient to enable bonding of the joining surfaces, and thereafter the joining surfaces brought into contact with one another and twisted to attain a permanent metallurgical weld at the interface of the joining surfaces. The head portion has an eccentric combustion bowl and crown. The joined head portion and base portion together form a monobloc piston having a closed gallery which is adapted to receive a cooling fluid, such as oil. The combustion bowl has a substantially uniform bowl sidewall thickness. The piston and method are particularly adopted for use with steel alloys and other high temperature metal alloys.

Owner:FEDERAL MOGUL WORLD WIDE

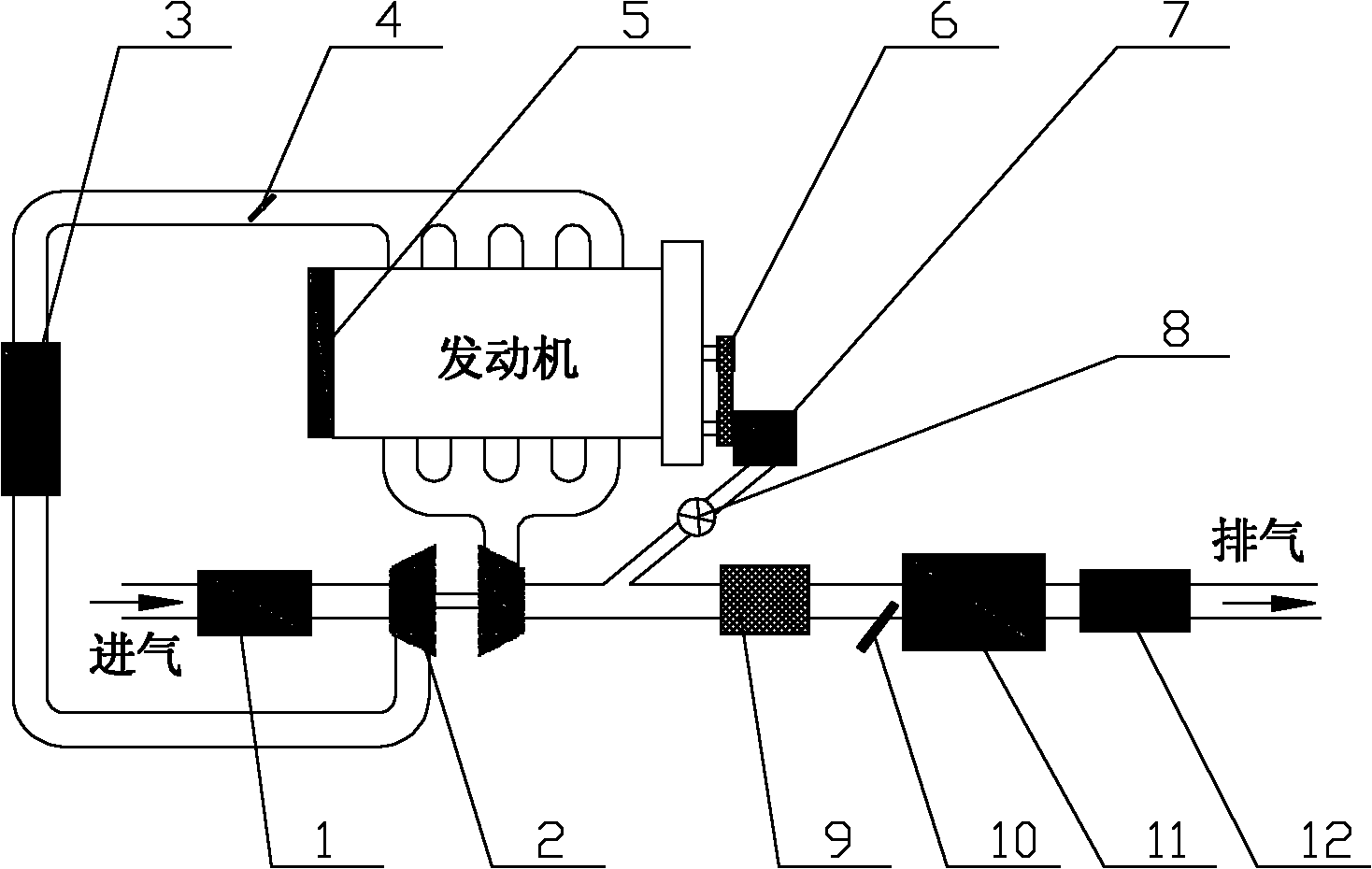

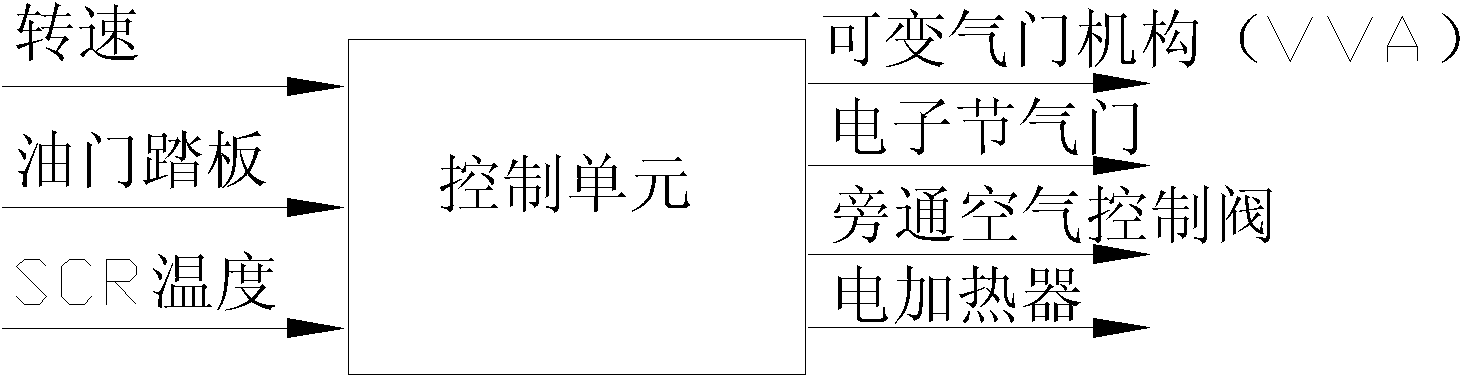

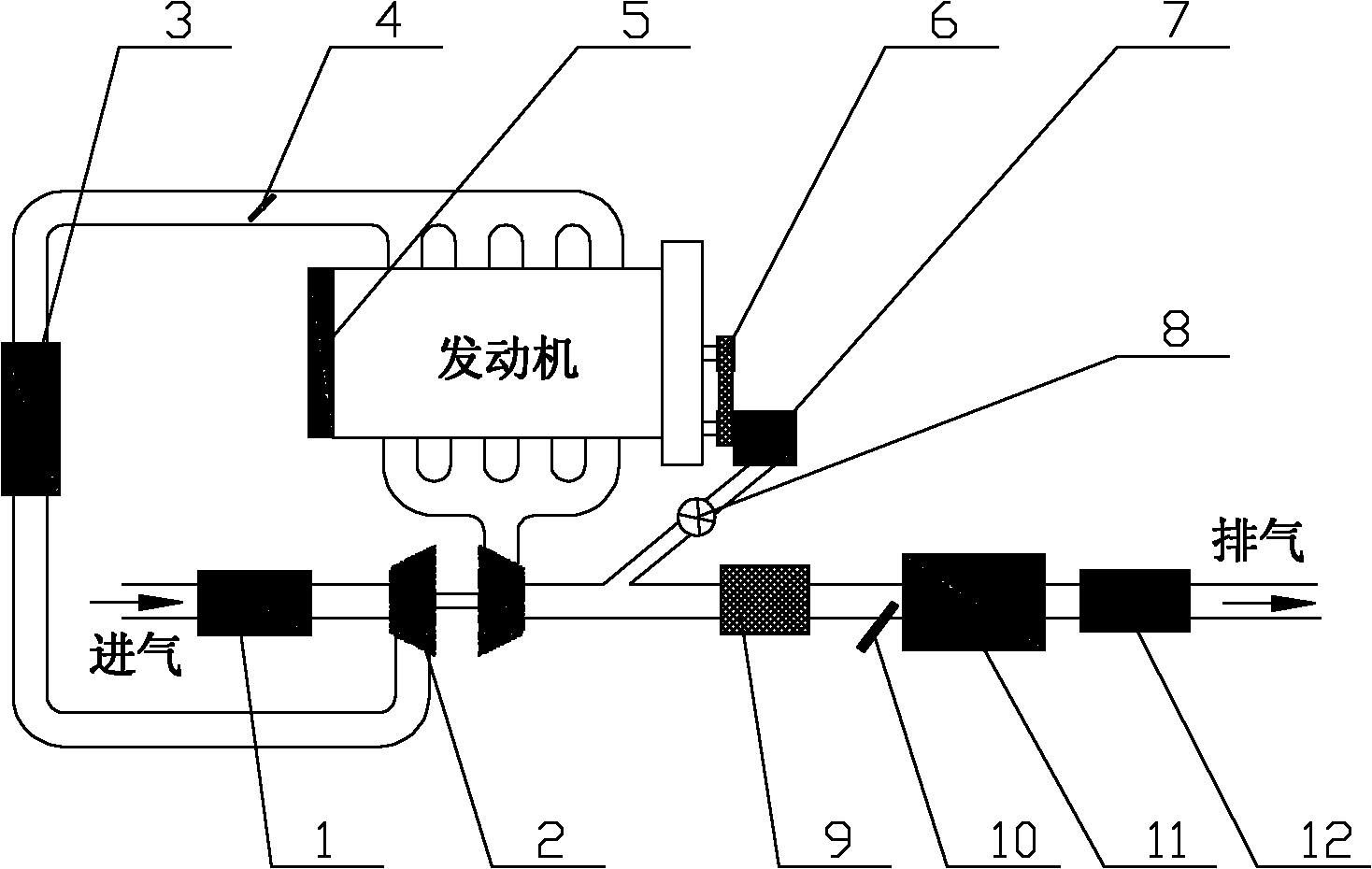

Method and device for achieving low emission of heavy-duty diesel engine through controlling exhaust temperature

ActiveCN102022214AReduce standby power consumptionMeet the requirements of remote workElectrical controlInternal combustion piston enginesTemperature controlCold air

The invention relates to emission control for a heavy-duty diesel engine. In order to provide a method and a device for achieving the low emission of the heavy-duty diesel engine through controlling exhaust temperature, the invention adopts an exhaust temperature control unit of the engine. The method comprises the following steps of: (1) respectively reading a rotate speed signal from an engine crankshaft sensor and a load signal from an accelerator pedal sensor by the exhaust temperature electric control unit of the engine; (2) controlling exhaust gas temperature according to the judged result of the step (1); (3) adopting an auxiliary heat preservation measure on an exhaust pipe except adopting variable valve actuation (VVA), an electronic throttle, cold air filling and the like to regulate the exhaust temperature; and (4) optimizing the burning process to increase the jet pressure of fuel, and adopting a flexibly variable jet control strategy. The invention is mainly applied to the emission control for the heavy-duty diesel engine.

Owner:TIANJIN UNIV

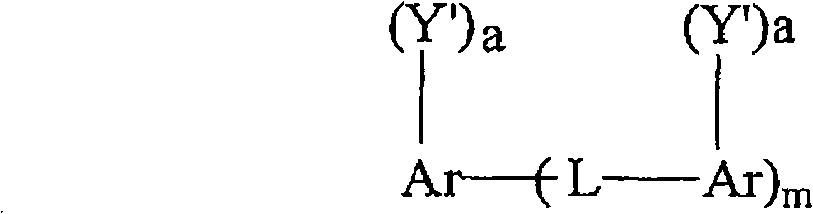

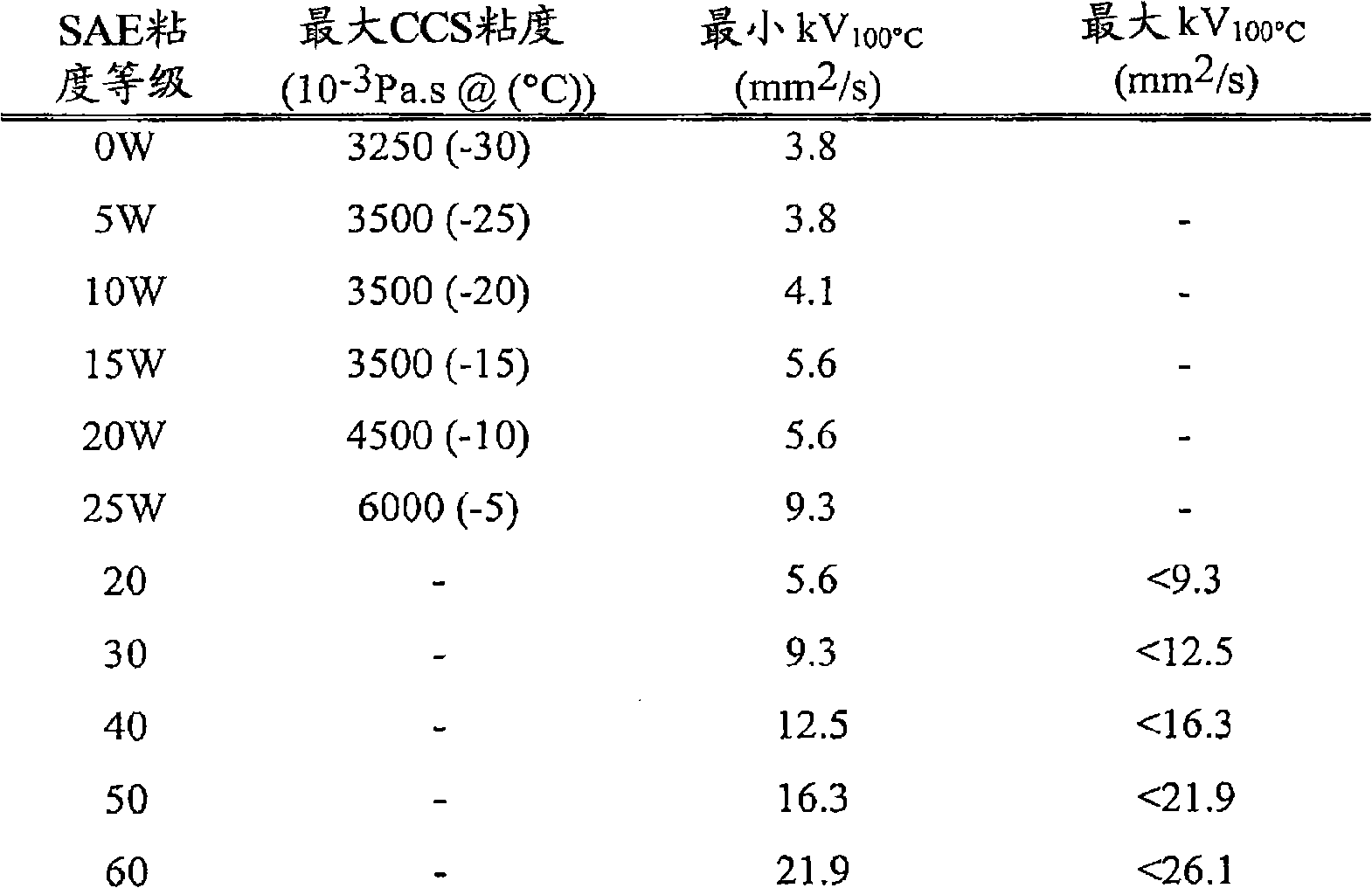

Lubricating Oil Composition

InactiveUS20090186784A1Improve fuel economyImprove wear performanceAdditivesBase-materialsChemical compositionCrankcase

SAE 0W and SAE 5W multigrade crankcase lubricating oil compositions for heavy duty diesel (HDD) engines meeting the performance requirements of at least one of the API CJ-4; API-CI-4, and / or ACEA A7 specifications, having a sulfated ash content of no greater than 1.0 mass %, a sulfur content of no greater than 0.4 mass %, and a phosphorus content of no greater than 0.12 mass %, formulated with a major amount of oil of lubricating viscosity including less than about 30 mass %, based on the total mass of oil of lubricating viscosity, of Group IV and / or Group V base stock, at least 0.3 mass %, of a non-hydrogenated olefin polymer; and greater than about 40 ppm, of boron.

Owner:DIGGS NANCY Z +2

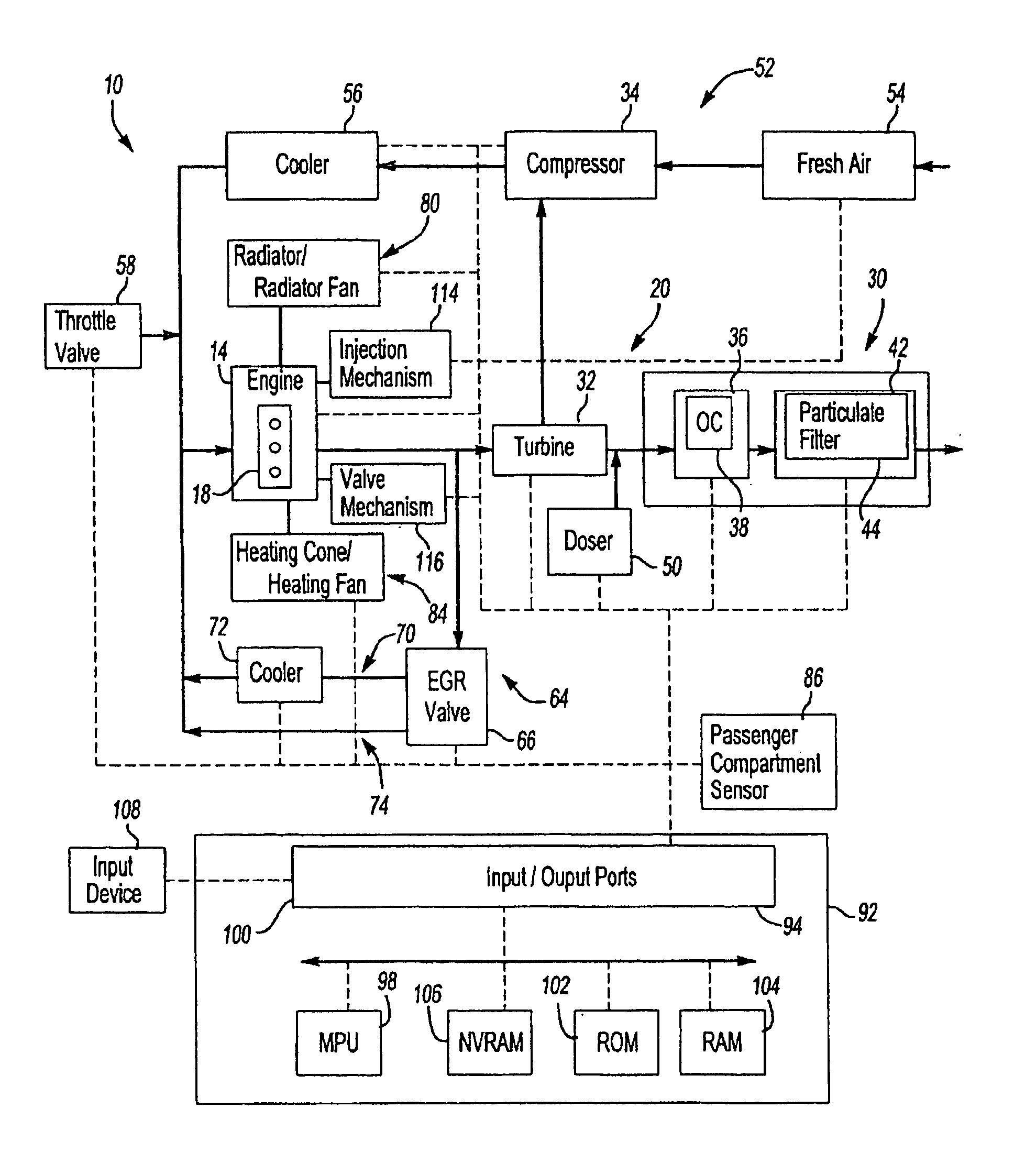

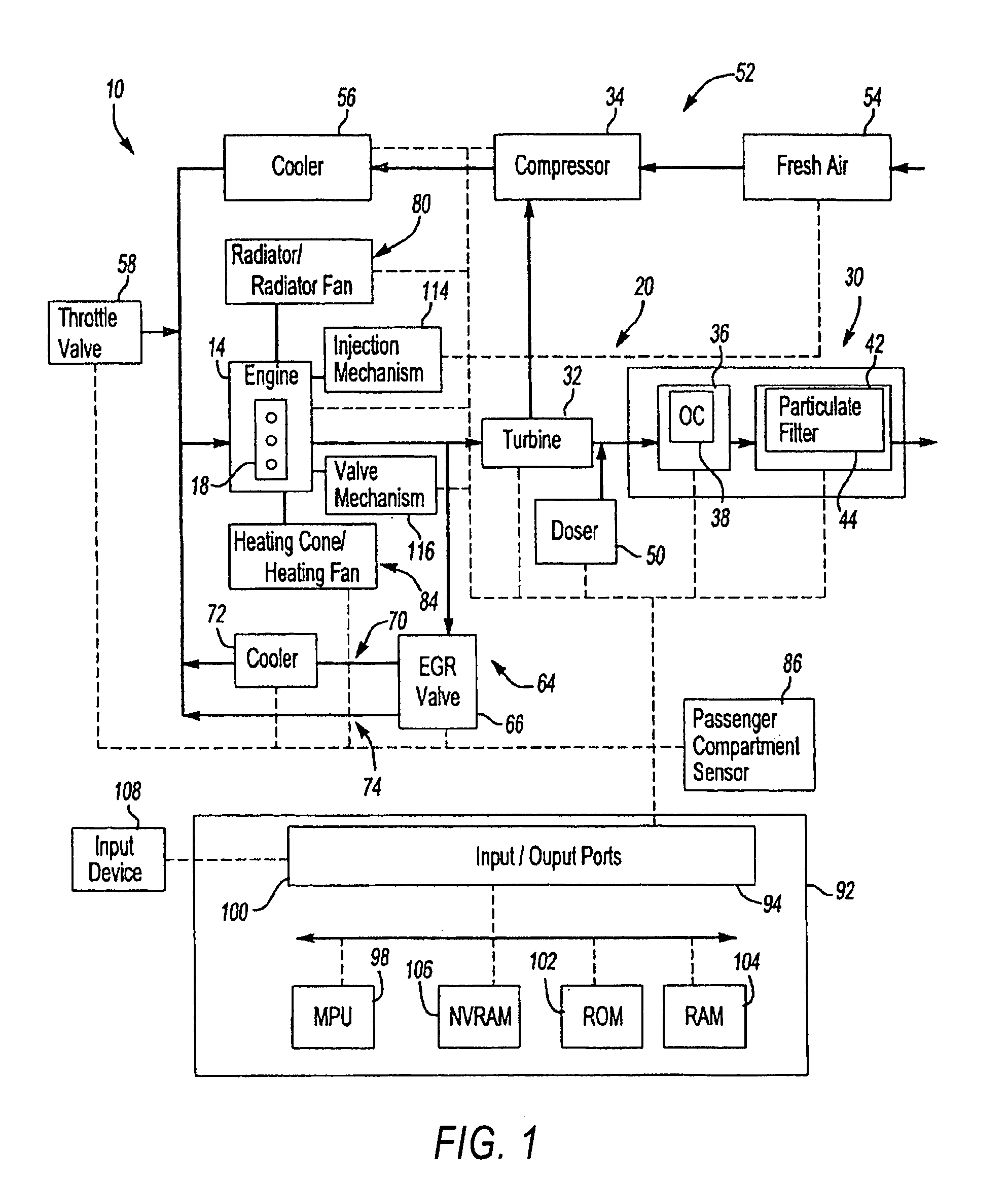

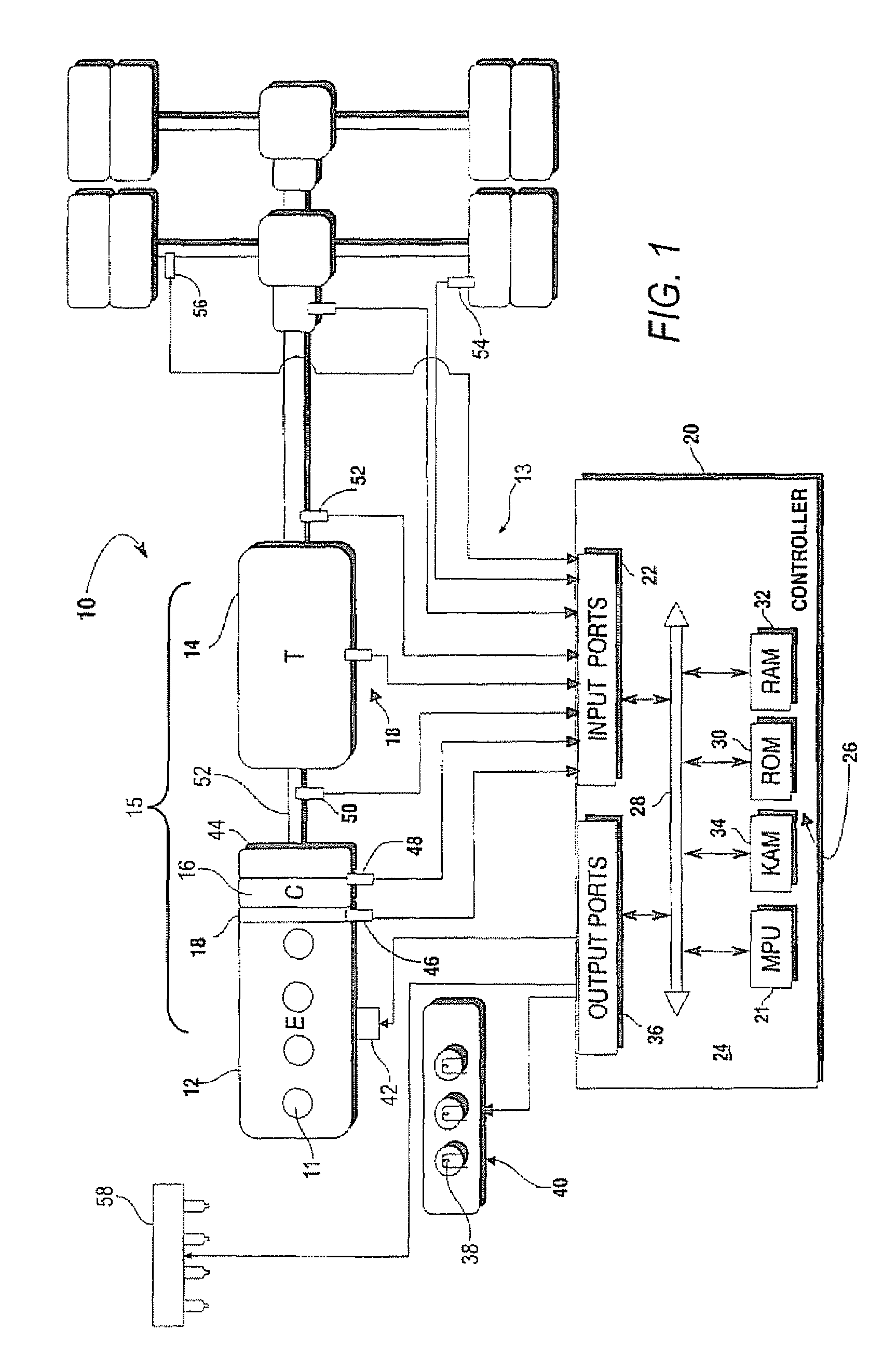

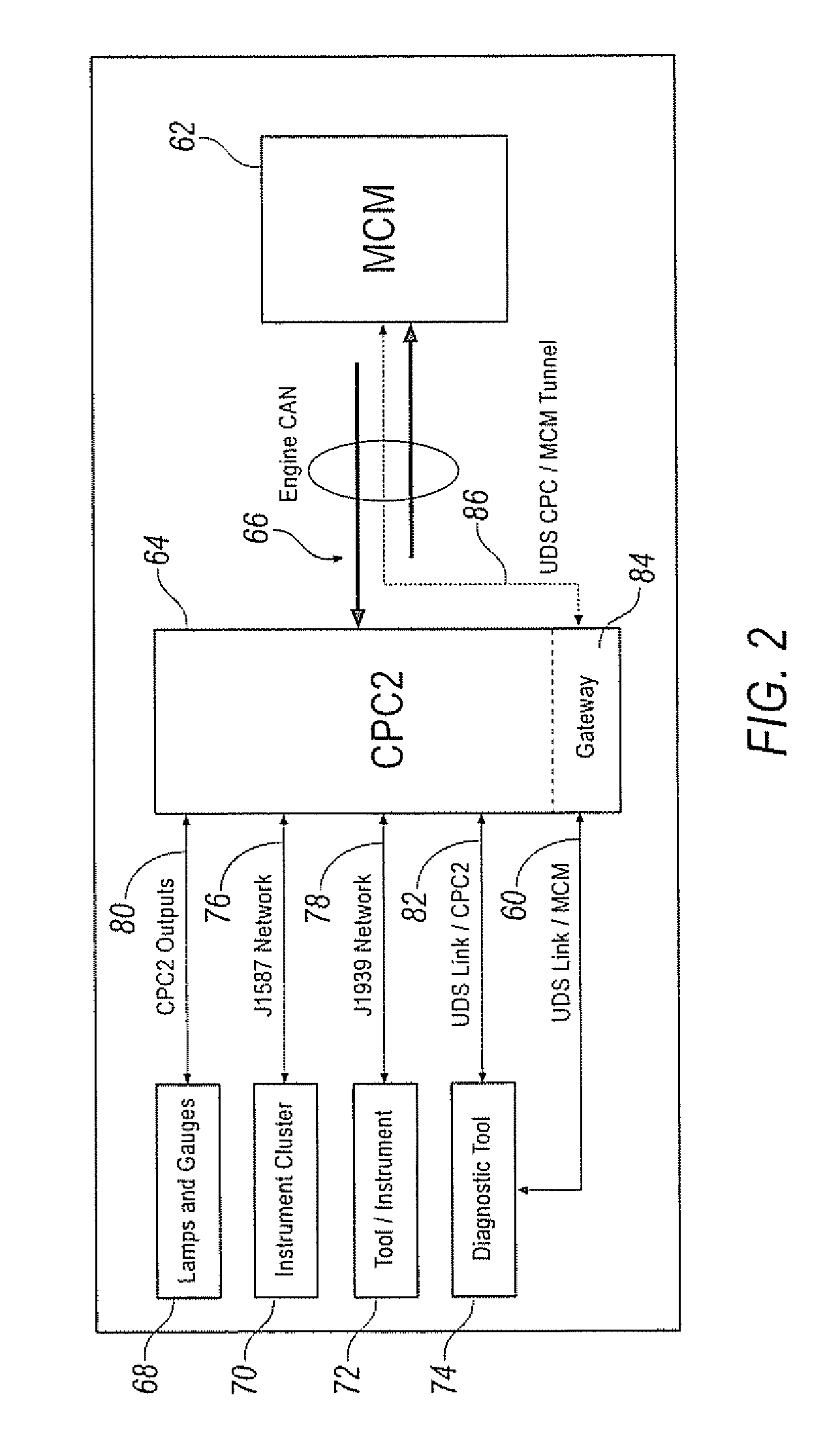

Method and system of diesel engine setpoint compensation for transient operation of a heavy duty diesel engine

InactiveUS7281518B1Improve transient emission controlEmission reductionElectrical controlInternal combustion piston enginesTurbochargerHeavy duty diesel

Method for controlling and improving the transient emissions of an electronically controlled heavy duty diesel engine having an ECM with memory, a turbocharger and an EGR system.

Owner:DETROIT DIESEL CORP

Piston and method of manufacture

InactiveUS7005620B2Minimize any variation in strength and integrityReduce compressionSoldering apparatusCombustion enginesEngineeringMechanical engineering

Owner:FEDERAL MOGUL WORLD WIDE LLC

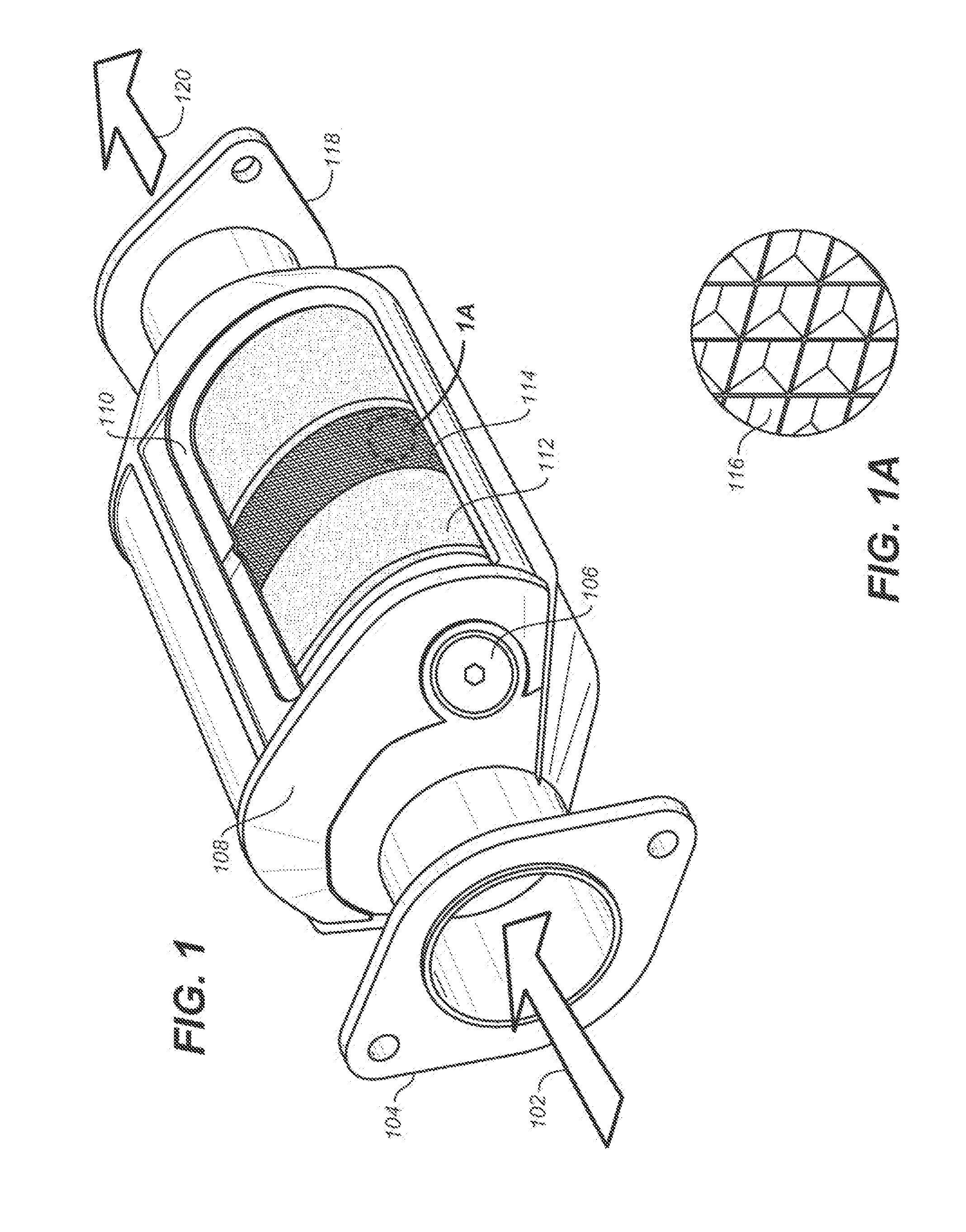

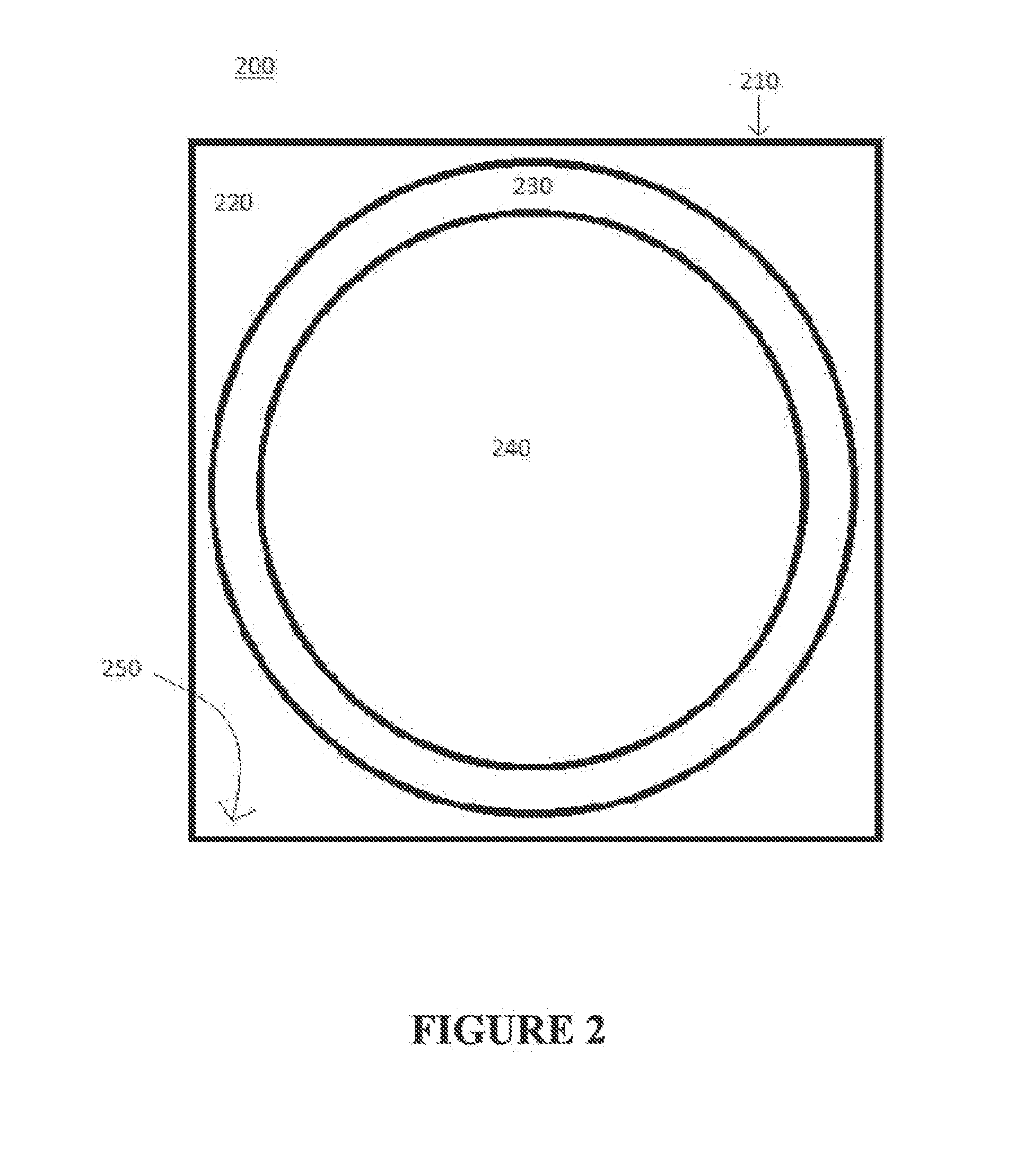

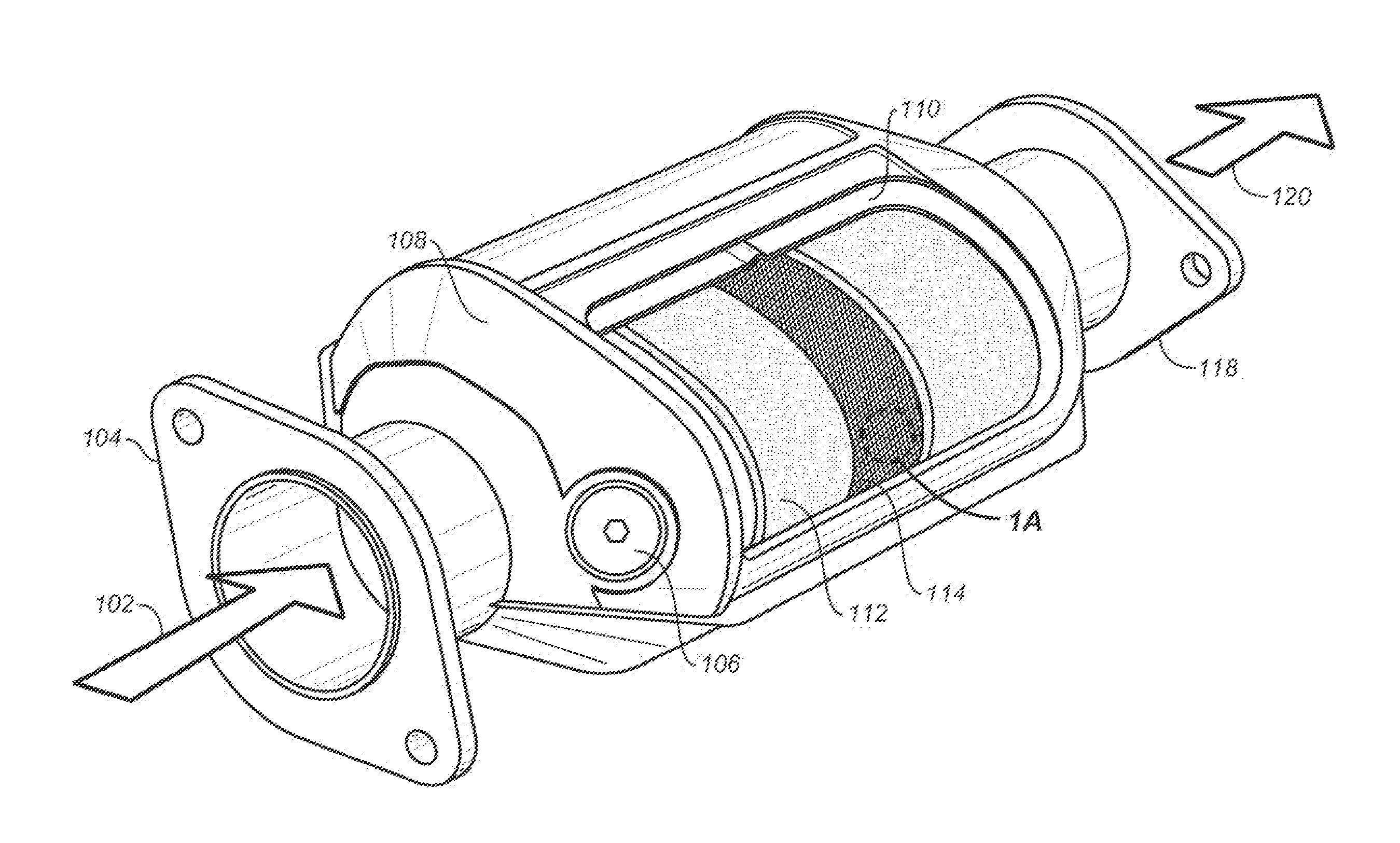

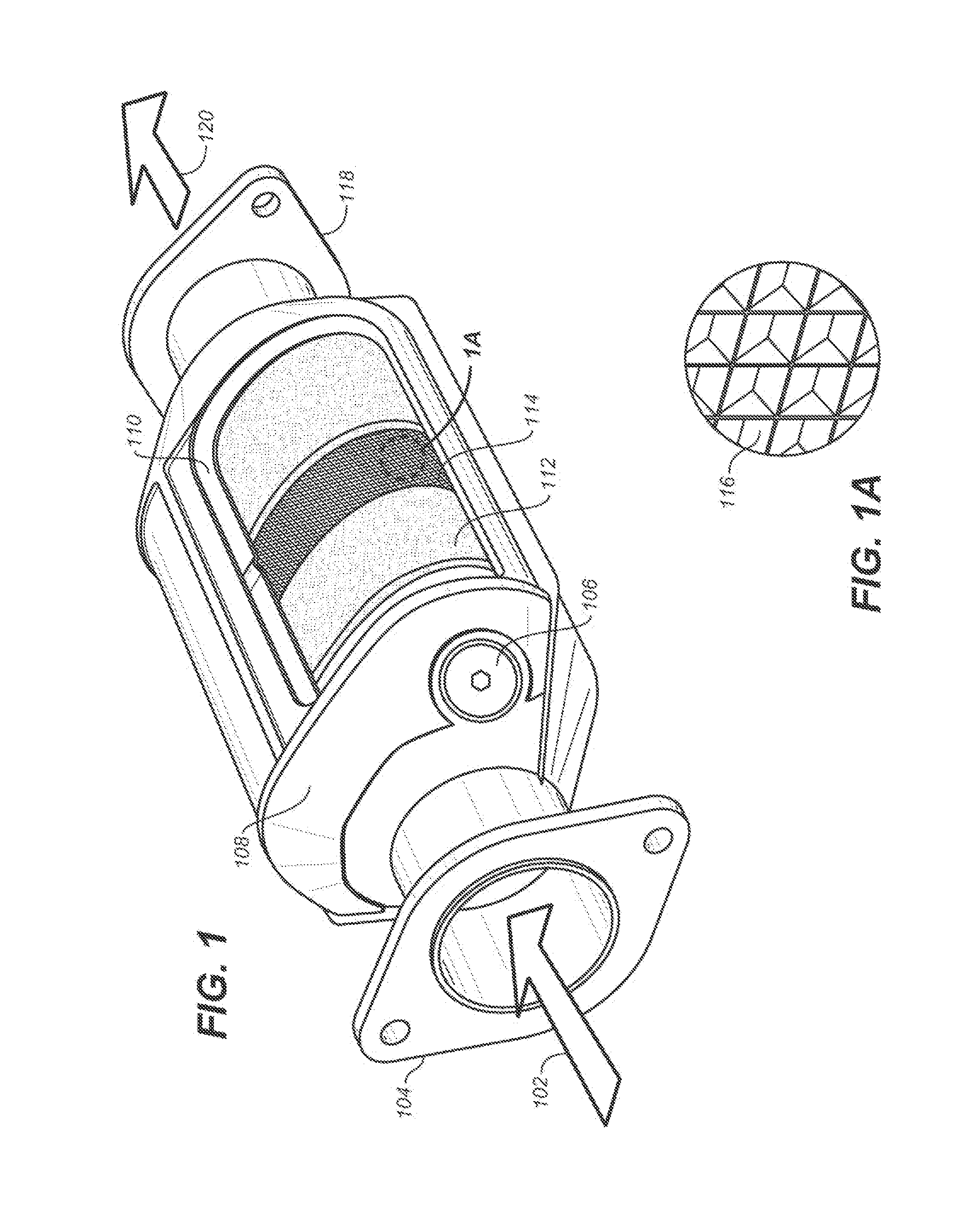

Catalyst design for heavy-duty diesel combustion engines

ActiveUS20150165434A1High catalytic efficiencyOptimizing Control ParametersInternal combustion piston enginesMolecular sieve catalystsCombustionHeavy duty diesel

Disclosed are washcoats, coated substrates formed from such washcoats, and catalytic converters for use in diesel applications, such as heavy duty diesel applications. Methods of preparing the coated substrates are also disclosed.

Owner:UMICORE AG & CO KG +1

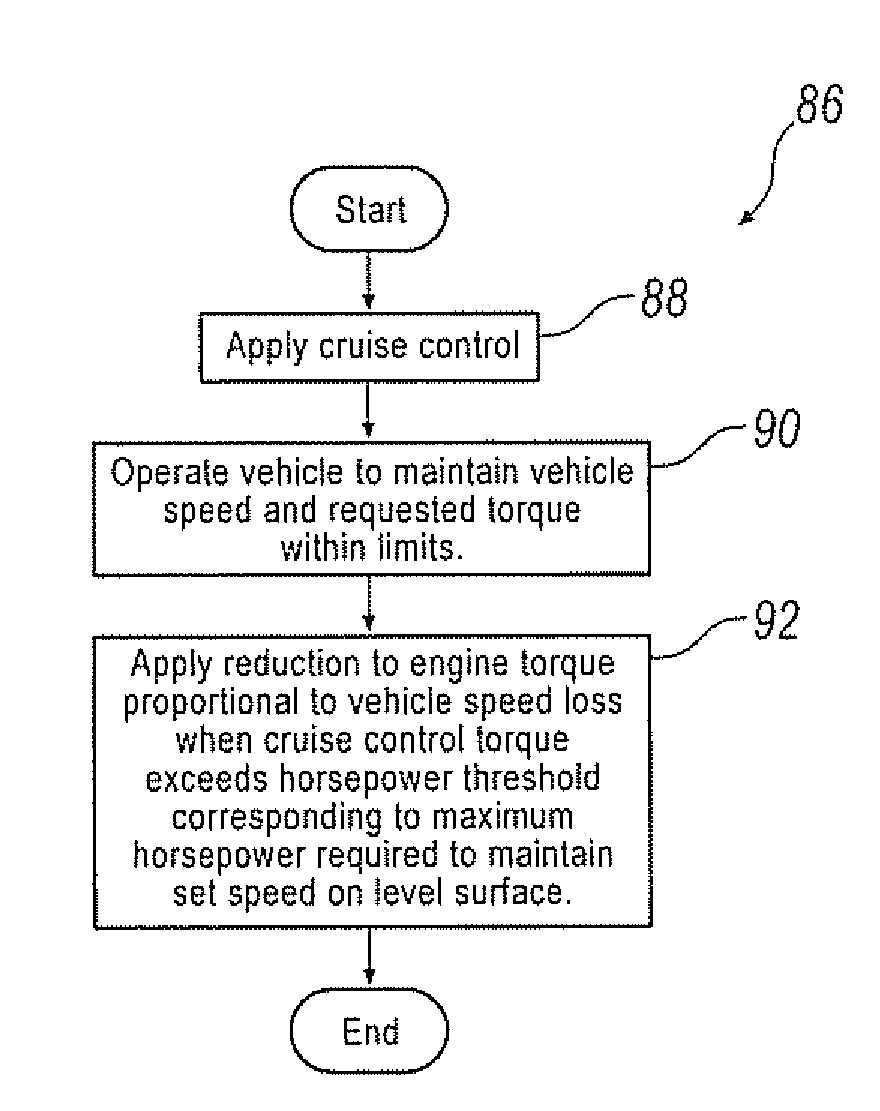

Method for optimizing cruise control fuel economy in heavy duty diesel engines

InactiveUS20090164081A1Digital data processing detailsExternal condition input parametersCruise controlInternal combustion engine

A method to operate a vehicle with an electronically controlled internal combustion engine equipped with an electronic control unit with memory and capable of operating the engine in a cruise control mode.

Owner:DETROIT DIESEL CORP

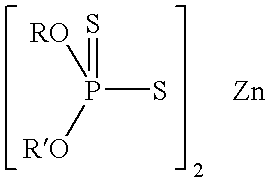

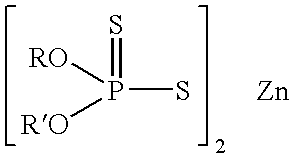

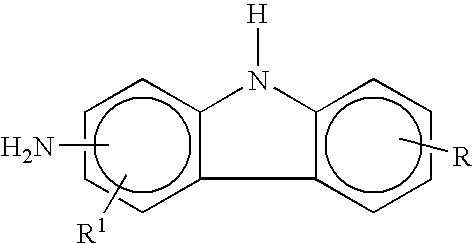

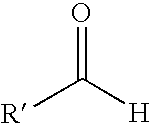

Low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition

ActiveUS20070111905A1Reduce the temperatureGuaranteed low temperature fluidityAdditivesAnti oxidantHeavy duty diesel

The present invention is directed to a low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity and (b) one or more dispersants (c) one or more anti-oxidants and (d) one or more ash-containing detergents, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.175 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to a low sulfur and low phosphorus heavy duty diesel engine lubricating oil composition comprising (a) an oil of lubricating viscosity (b) a borated dispersant and a non-borated dispersant (c) a molybdenum anti-oxidant and a phenolic anti-oxidant and (d) a low overbased calcium sulfonate and a high overbased calcium phenate, wherein the lubricating oil composition is essentially free of zinc di-alkyl di-thiophosphates and contains no more than 0.175 weight percent sulfur and provided the lubricating oil composition does not contain alkylated and non-alkylated aromatic amines and tri-nuclear molybdenum compounds. The present invention is also directed to method for lubricating a heavy duty diesel engines, which comprises lubricating the engine with a low sulfur and low phosphorus heavy duty diesel engine lubricating oil compositions of the present invention.

Owner:CHEVRON ORONITE CO LLC

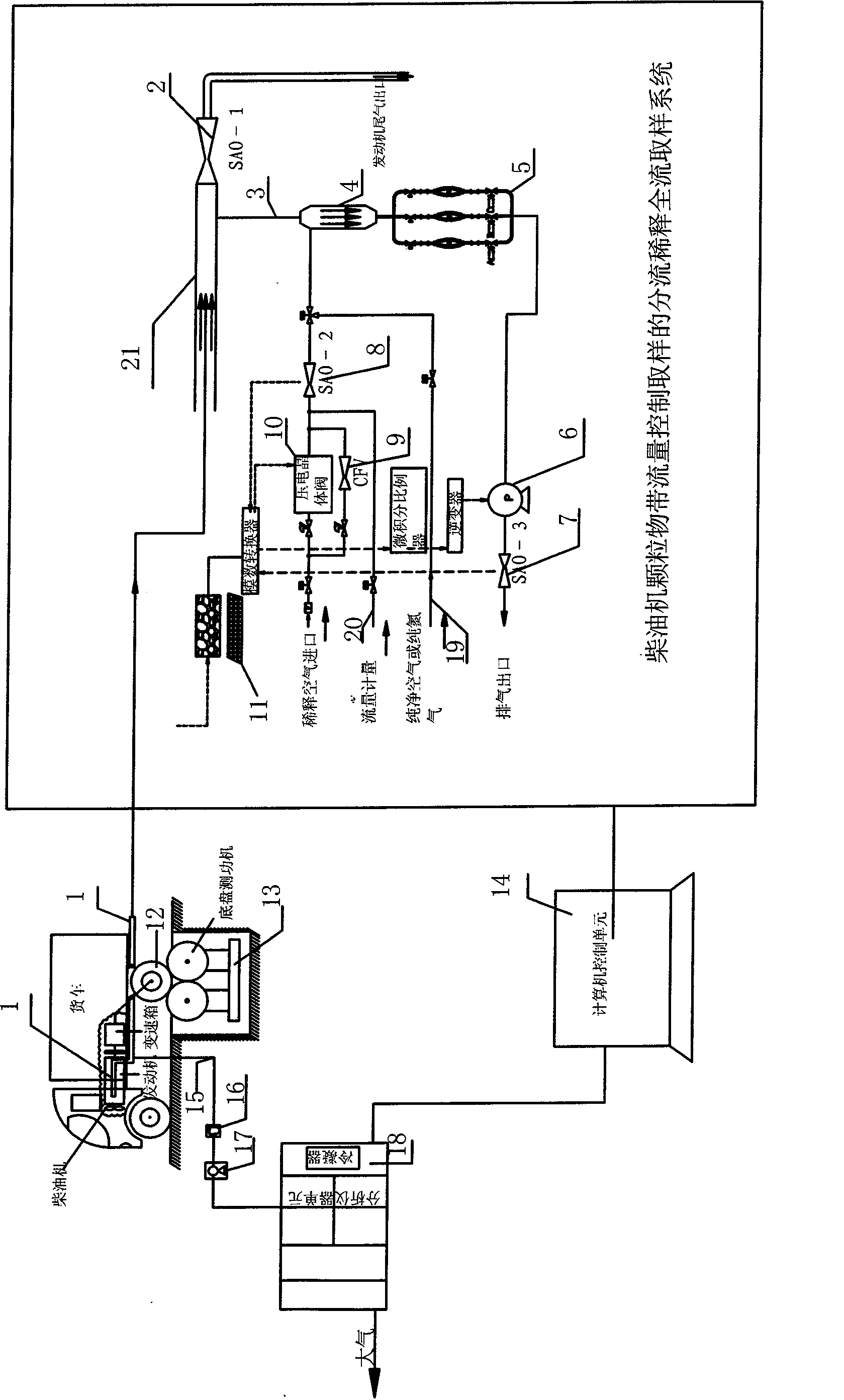

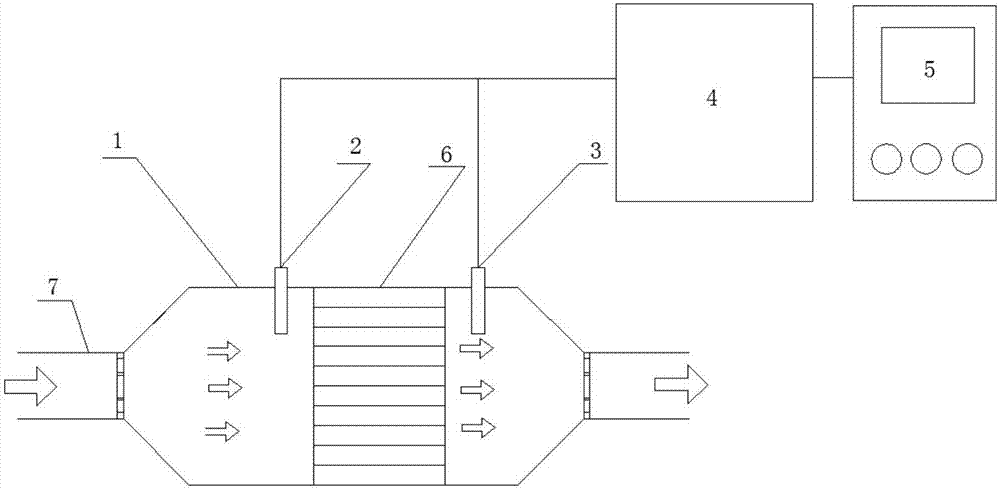

Exhaust pollutants measuring apparatus of heavy type diesel vehicle

ActiveCN101435827ASimple and fast operationEngine testingMaterial analysis by electric/magnetic meansParticulatesNational standard

The invention discloses a device for measuring exhaust contaminant of a heavy-duty diesel engine in operation. The device comprises a first subsonic venturi tube, an air and exhaust gas mixing tube, an outlet, a first pipeline, three particulate matter filtering brackets, a computer, a heating type filter and a heating pump which are sequentially connected, an analytic instrument unit and a computer control unit, wherein the outlet is provided a dilute air inlet pipeline of a second subsonic venturi tube and is communicated with the air and exhaust gas mixing tube; the first pipeline is sequentially provided with a fourth electromagnetic valve and a critical flow venturi tube and is in parallel arrangement with a dilute air inlet pipeline part provided with a first electromagnetic valve and the second subsonic venturi tube; the three particulate matter filtering brackets are in parallel connection with one another; and the computer control unit is used for calculating the emission value of the exhaust contaminant of the diesel engine. A result measured through the device can be compared with the prior result (g / kW.h) measured in delivery of the diesel engine; therefore, a relevant national standard can be also established; and the device is practical and simple in operation.

Owner:TIANJIN CPOWER TECH DEV CO LTD

Camshaft bush installation tool of heavy-duty diesel engine

ActiveCN102950453AGuaranteed installation phaseGuaranteed installation depthMetal working apparatusEngineeringHeavy duty diesel

The invention discloses a camshaft bush installation tool of a heavy-duty diesel engine. The camshaft bush installation tool of the heavy-duty diesel engine comprises a pressure lever and a guide sleeve sheathed with the pressure lever, wherein the pressure lever comprises a joint, a plunger chip, and a connecting pipe used for connecting the joint and the plunger chip, the joint is provided with a bush positioning part, and one end of the plunger chip is provided with a backstop bulge and a guide key arranged in a guide key slot extending along the axial direction; and the guide sleeve is internally provided with a guide slot, the pressure lever penetrates in the guide sleeve, and the guide key of the plunger chip extends into the guide slot of the guide sleeve, and is spaced by the backstop bulge. The installation phase and the installation depth of a camshaft bush on the diesel engine can be ensured by virtue of the camshaft bush installation tool of the heavy-duty diesel engine, so that the structure can greatly enhance the installation precision of the camshaft bush on the diesel engine, reduce the repeated operation and the camshaft bush scraped due to the poor installation precision of the camshaft bush, reduce the production cost and enhance the production efficiency.

Owner:GUANGXI YUCHAI MASCH CO LTD

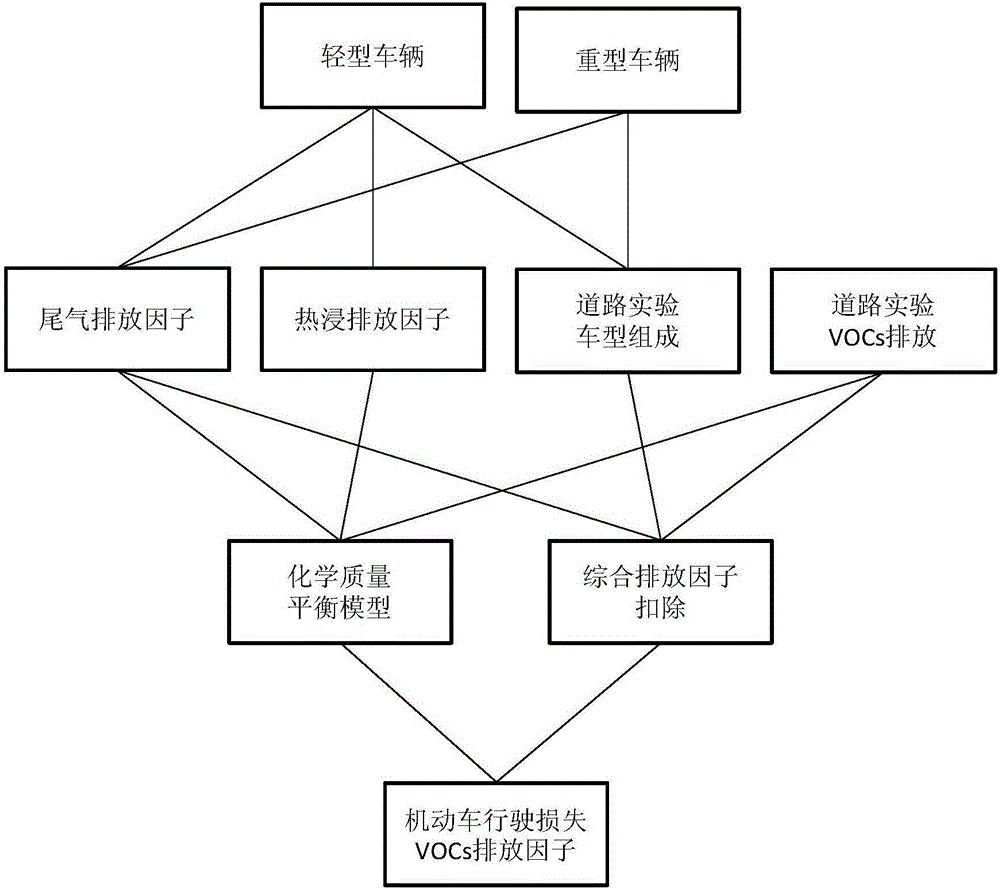

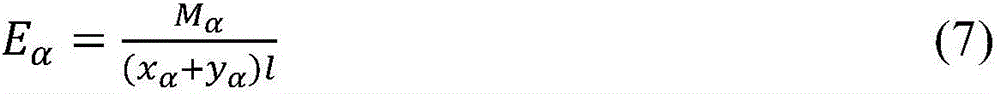

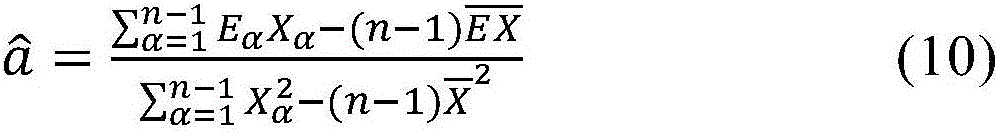

Vehicle evaporative emission operation loss VOCs emission factor measurement method

The invention discloses a vehicle evaporative emission operation loss VOCs emission factor measurement method. Based on serial applications of multiple modes, the operation loss emission can be indirectly and quantitatively judged. The method comprises steps of light-duty gasoline vehicle and heavy-duty diesel vehicle exhaust emission laboratory measurement, light-duty gasoline vehicle hot dipping emission VOCs emission factor laboratory measurement, actual road vehicle VOCs comprehensive emission factor tunnel measurement, VOCs species chemical composition analysis and model analysis. Based on the light-duty gasoline vehicle exhaust emission and hot dipping emission in a laboratory airtight cabin or a drum, a single process characteristic source spectrum is built. The model analysis comprises chemical mass balance model analysis and comprehensive emission factor deduction. Operation loss emission factors of a vehicle group in an actual road condition are finally built. The technology makes up for the existing lacked vehicle VOCs operation loss emission testing condition, emission errors caused by inconsistency between the experimental condition and the actual condition when the vehicle VOCs operation loss is tested in the laboratory in the past can be solved, and the vehicle VOCs operation loss emission factors can be accurately acquired.

Owner:TSINGHUA UNIV

Catalyst design for heavy-duty diesel combustion engines

ActiveUS9427732B2High catalytic efficiencyOptimizing Control ParametersInternal combustion piston enginesMolecular sieve catalystsConvertersCatalytic transformation

Disclosed are washcoats, coated substrates formed from such washcoats, and catalytic converters for use in diesel applications, such as heavy duty diesel applications. Methods of preparing the coated substrates are also disclosed.

Owner:UMICORE AG & CO KG +1

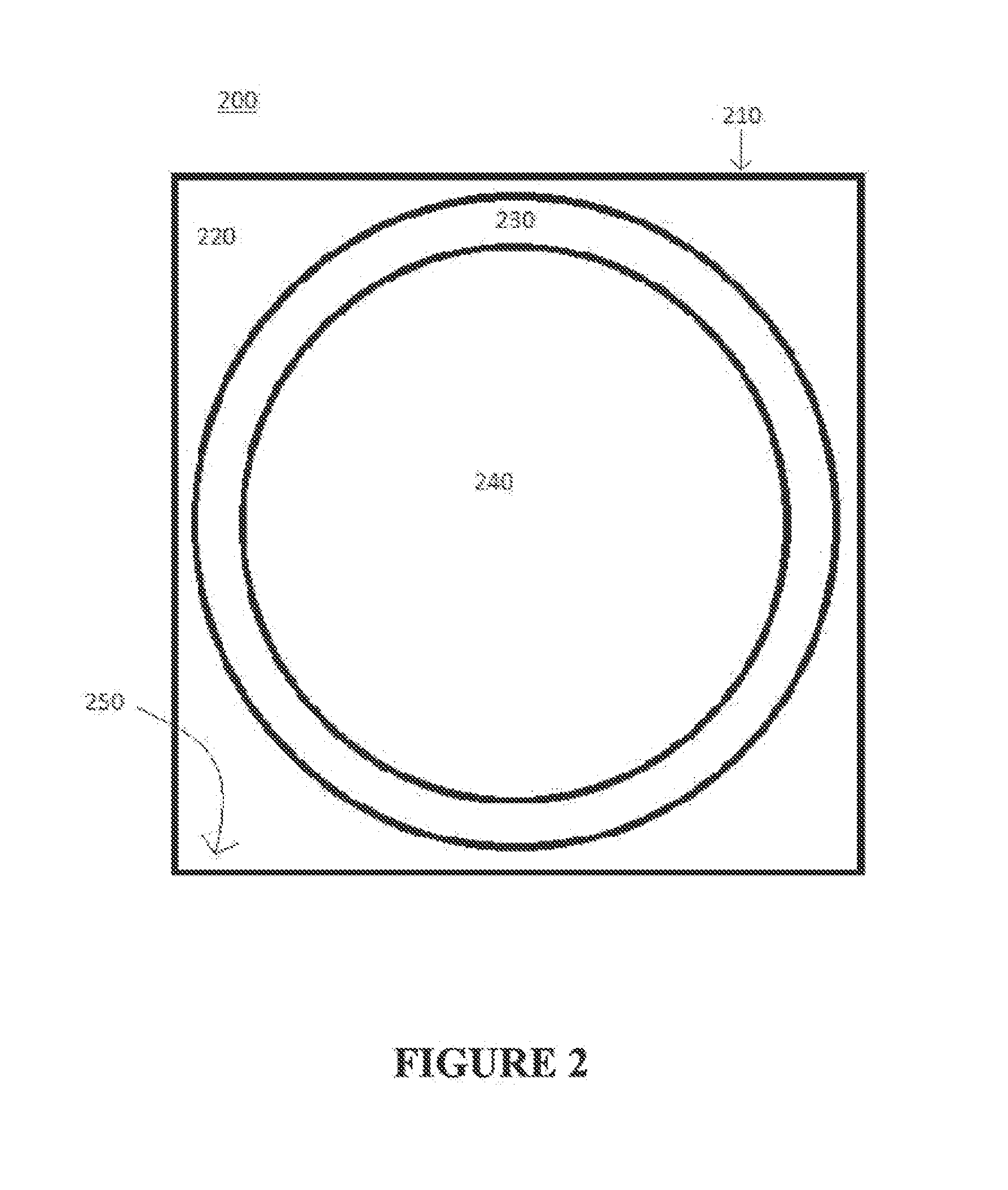

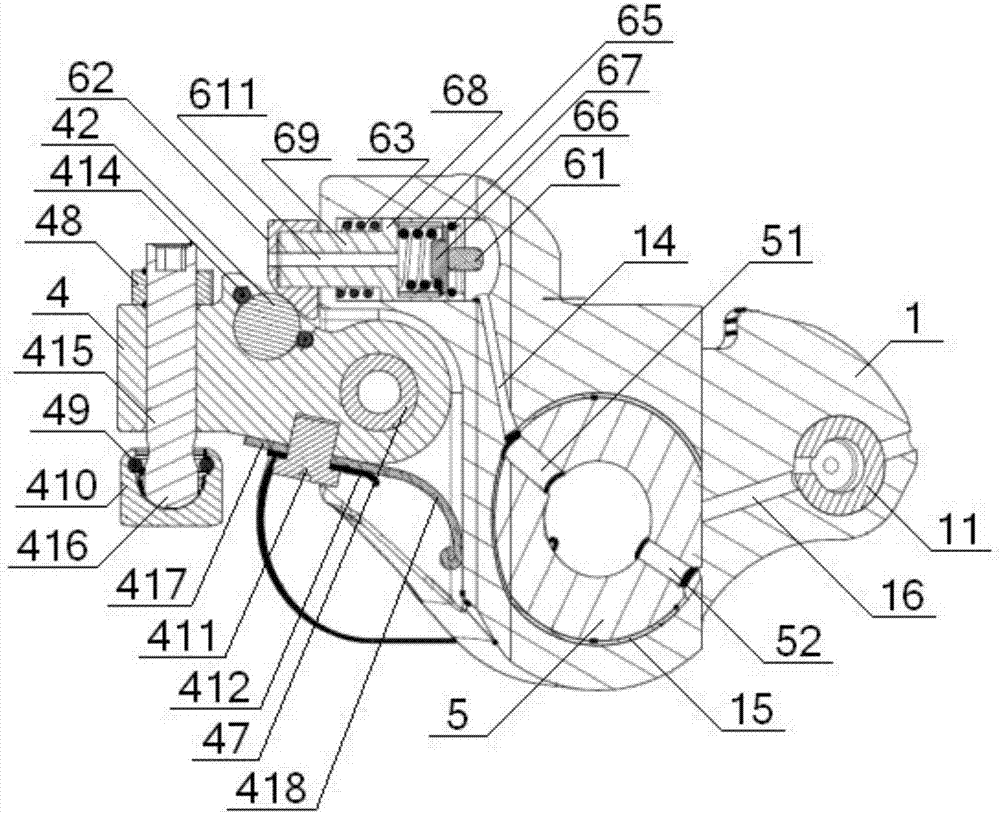

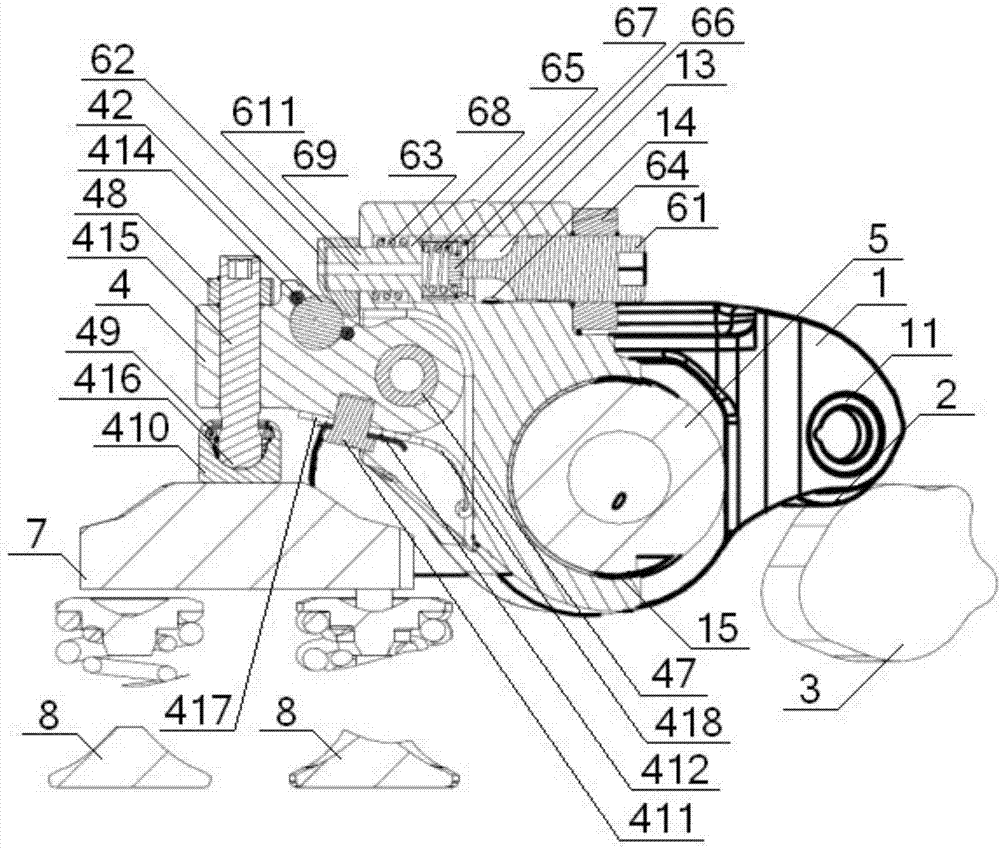

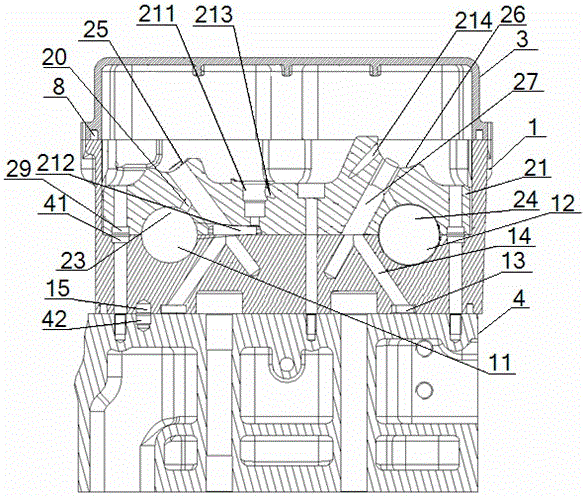

Heavy-duty diesel engine split type rocker arm brake mechanism for commercial vehicle

ActiveCN107143394AReduced processing performanceShorten the lengthValve arrangementsLubrication of auxillariesDieselingCam

A heavy-duty diesel engine split type rocker arm brake mechanism for a commercial vehicle comprises a rocker arm body, a swing mechanism and a hydraulic drive system; the rocker arm body is mounted on a rocker arm shaft through a main mounting hole, the swing mechanism comprises a swing head, a first adjusting bolt and a rolling column, the swing head is mounted on the rocker arm body, a sheet-shaped spring is arranged at the bottom of the swing head, and is pressed on the bottom of the rocker arm body, a ball head of the first adjusting bolt is mounted in a ball socket in an elephant foot shape, the hydraulic drive system comprises a hydraulic plunger with a return spring sleeved, a second adjusting bolt in contact with the hydraulic plunger and a rocker arm cam in threaded connection with the hydraulic plunger, the hydraulic plunger is mounted in a drive cavity of the rocker arm body, the rocker arm cam makes contact with the rolling column, a brake hydraulic oil way communicated with the main mounting hole, the drive cavity and a swing arm shaft hydraulic oil hole is arranged in the rocker arm body, and the heavy-duty diesel engine split type rocker arm brake mechanism is high in reliability, low in cost, high in lightweight degree, simple in structure, convenient to assemble and maintain and good in brake effect.

Owner:DONGFENG COMML VEHICLE CO LTD

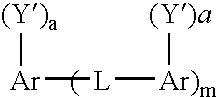

Lubricating Oil Compositions

A lubricating oil composition for internal combustion engines, particularly heavy duty diesel (HDD) engines, having reduced phosphorus, sulfur and sulfated ash contents that provide excellent piston cleanliness performance and contain an amount of phenate detergent that introduces a relatively large amount of phenate soap into the lubricating oil composition.

Owner:INFINEUM INT LTD

Lubricating oil compositions for inhibiting coolant-induced oil filter plugging

ActiveUS8093189B2Inhibits coolant-induced oil filter pluggingImprove pumping capacityLiquid carbonaceous fuelsAdditivesExhaust gas recirculationOrganic chemistry

Lubricating oil compositions are provided that inhibit coolant-induced oil filter plugging in heavy-duty diesel engines, and particularly CJ-4 and CI-4 PLUS compliant lubricating oil compositions that inhibit coolant-induced oil filter plugging in exhaust gas recirculation or recycle engines.

Owner:AFTON CHEMICAL

Detergent composition for a low sulfur, low sulfated ash and low phosphorus lubricating oil for heavy duty diesel engines

Owner:CHEVRON ORONITE TECH BV

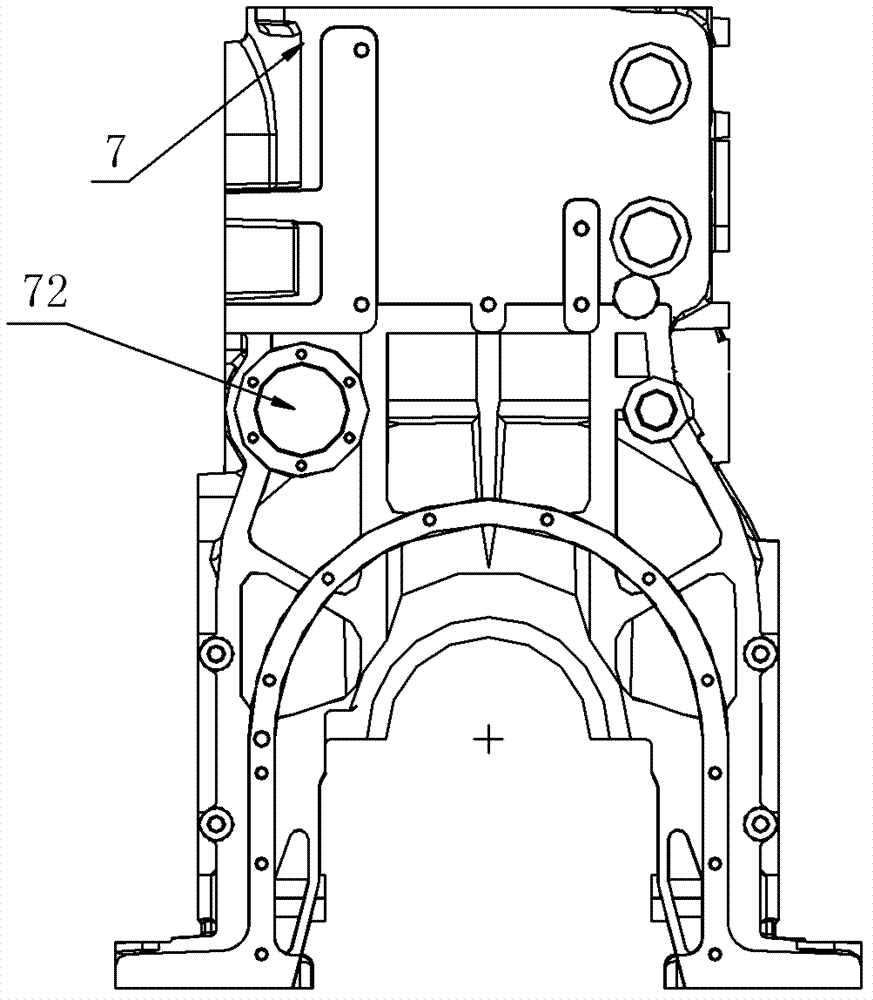

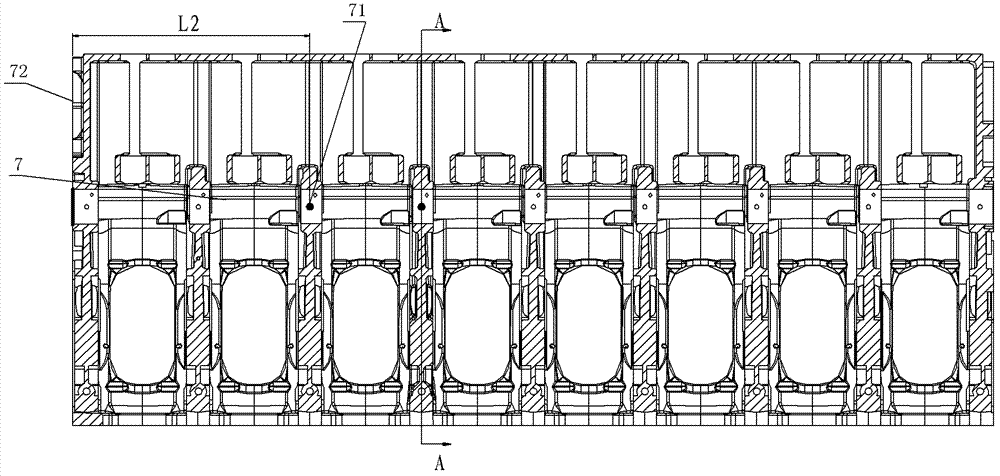

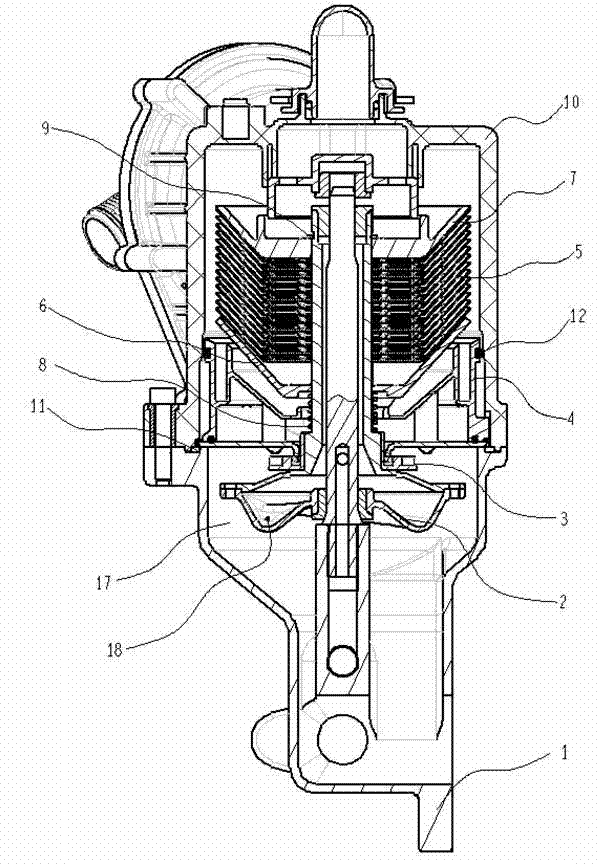

Active oil and gas separator

InactiveCN104265402BOptimize layoutReduce use costMachines/enginesCrankcase ventillationImpellerDrive shaft

Owner:CHINA FIRST AUTOMOBILE

Engine antifreeze composition

In general this invention relates to an antifreeze composition that can be used in the cooling systems of internal combustion engines, for example, in heavy-duty diesel engines, light duty trucks and cars. The antifreeze composition can be added to water or other suitable liquid coolant in the cooling system, to lower the freezing point temperature of the coolant and inhibit corrosion of metallic components associated with the cooling system. The antifreeze composition is particularly well suited, although not exclusively, for use with hard water. The antifreeze composition includes an organic acid component comprising adipic acid and at least one of benzoic acid and one or more C9-C12 dicarboxylic acid—or salts of these acids. The antifreeze composition also includes other anti-corrosive additive, for example, molybdate, nitrite, nitrate silicate azoles and a variety of buffer agents.

Owner:FLEETGUARD INC

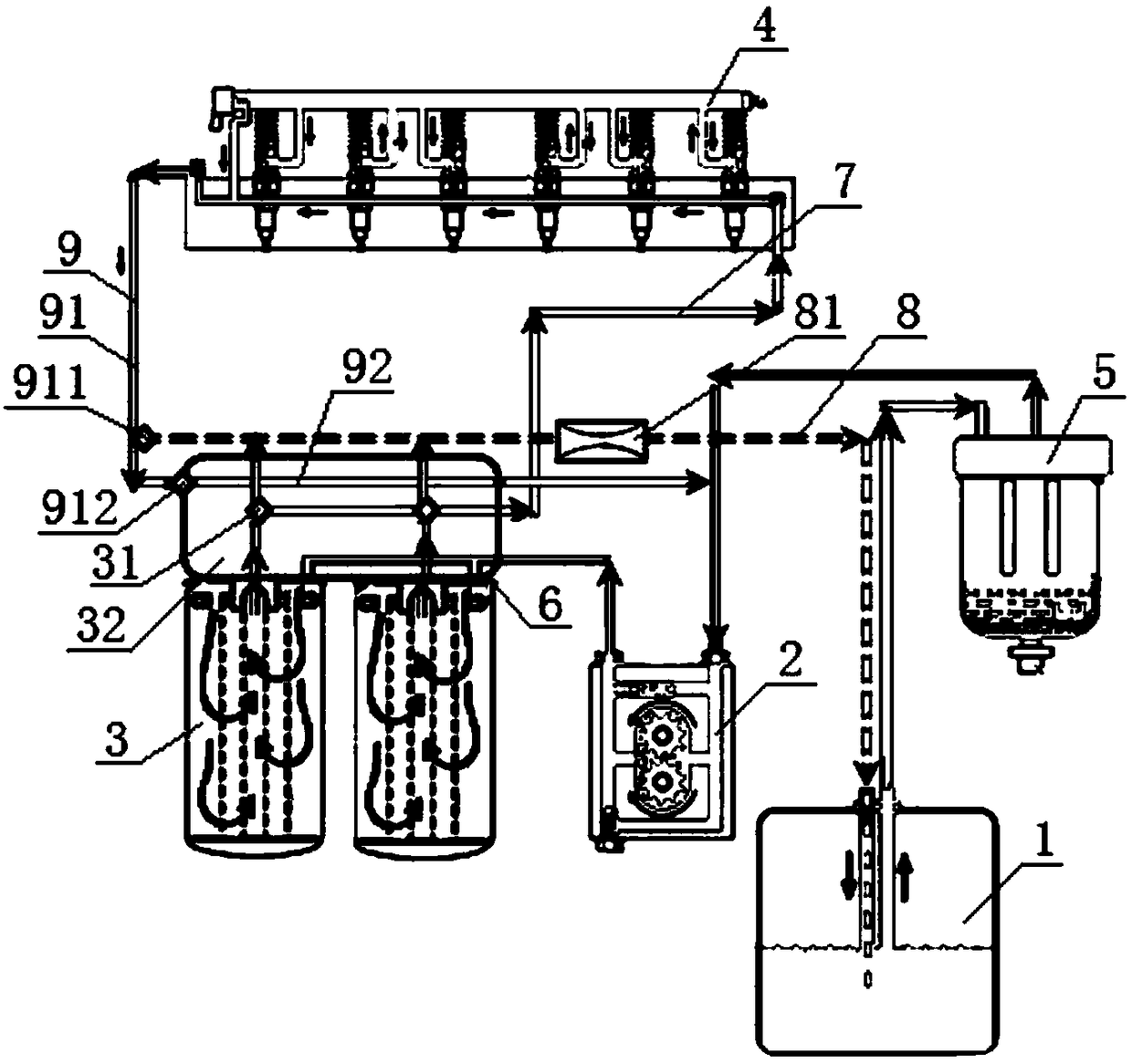

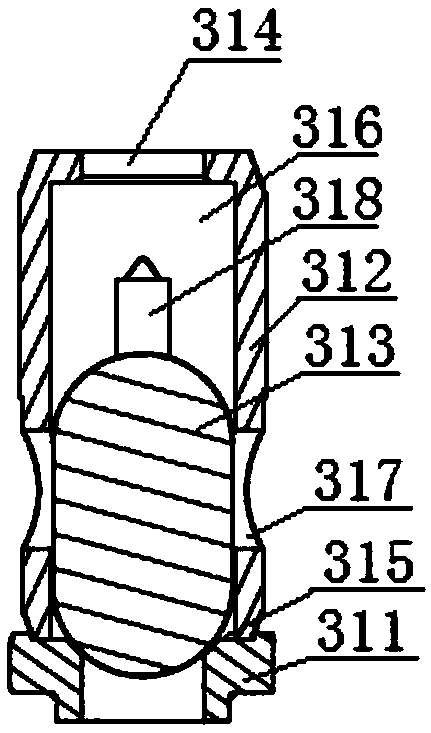

Fuel system of heavy-duty diesel engine

PendingCN108457781AAutomatic exhaustOutflow smoothlyMachines/enginesLiquid fuel feedersFuel tankFuel filter

A fuel system of a heavy-duty diesel engine comprises an oil tank, a low-pressure oil conveying pump, a fuel filter and a fuel injector assembly, wherein an automatic exhaust three-way valve is arranged on a base of the fuel filter, an inlet of the automatic exhaust three-way valve communicates with an oil outlet of the oil tank through a first oil path and the low-pressure oil conveying pump sequentially, a first outlet of the automatic exhaust three-way valve communicates with an oil inlet of the low-pressure oil conveying pump through a second oil path, the fuel ejector assembly and a fuelreturn pipeline, and a second outlet of the automatic exhaust three-way valve communicates with an oil inlet of the oil tank through an exhaust pipeline. Through the design, automatic exhaust of the engine in the running state is achieved, the filtering efficiency of the fuel filter is improved, and the service life of a prefilter is prolonged.

Owner:DONGFENG COMML VEHICLE CO LTD

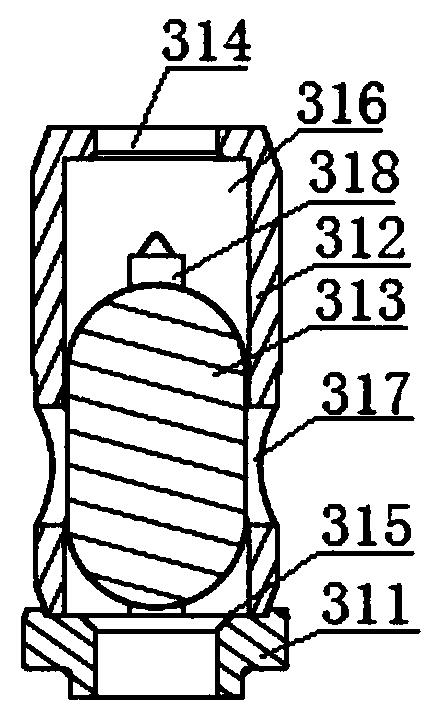

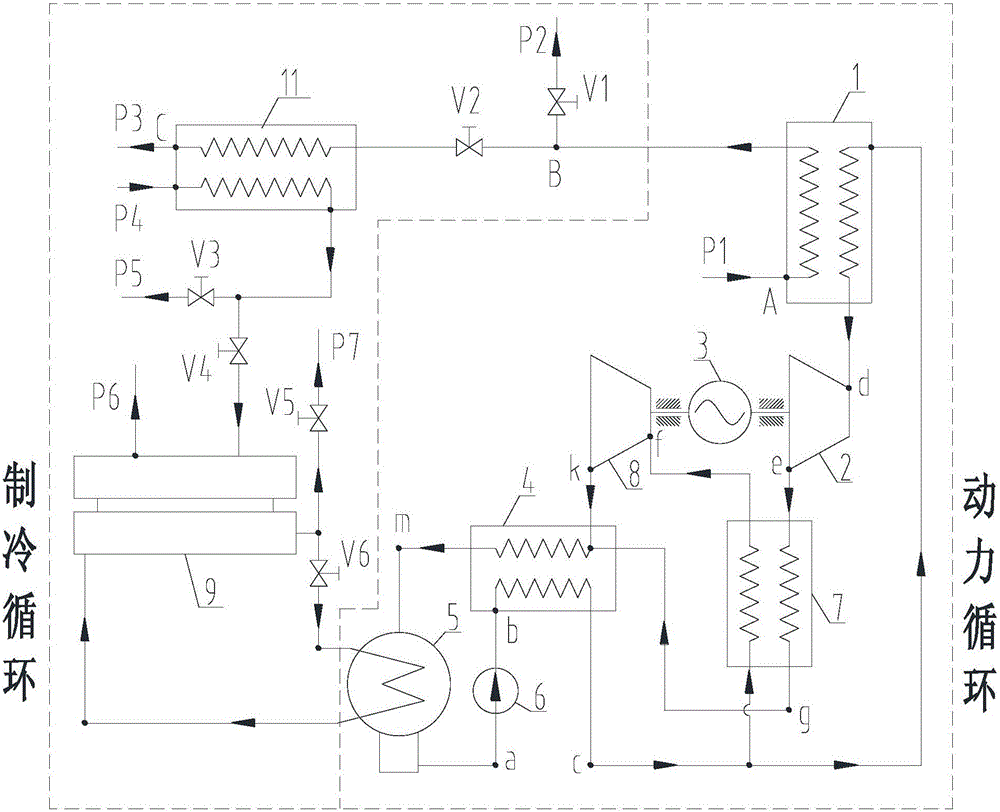

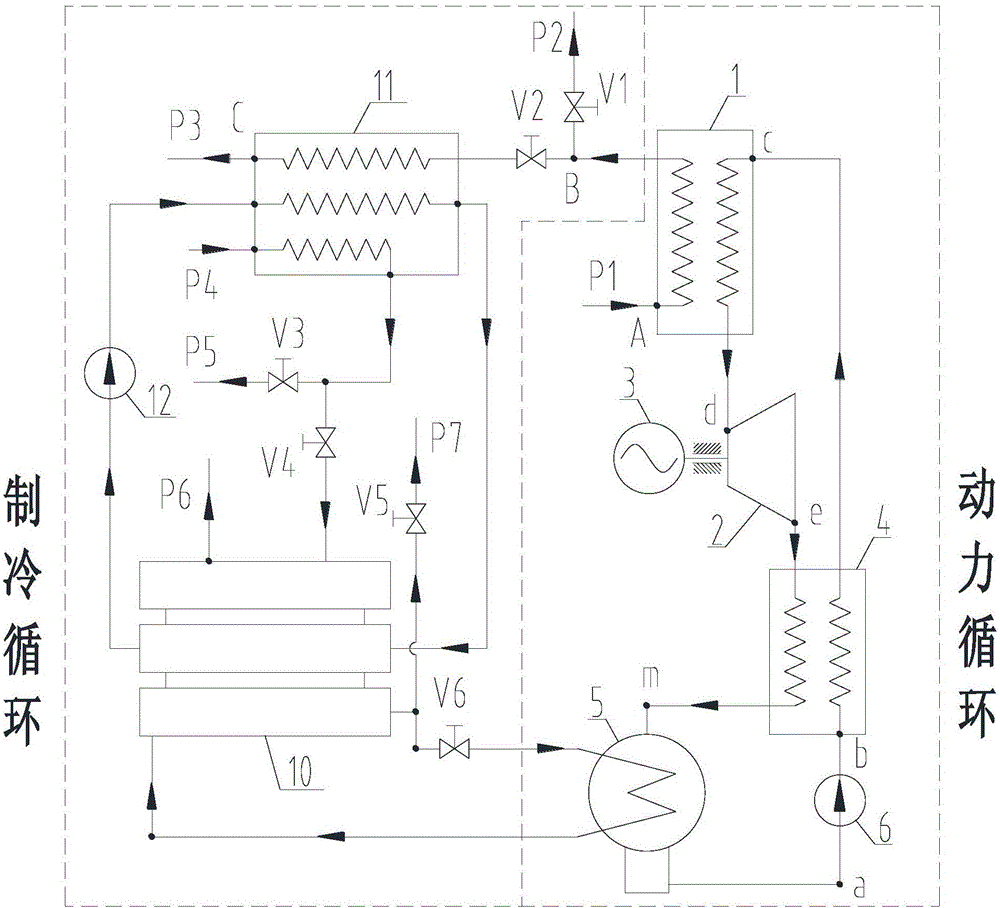

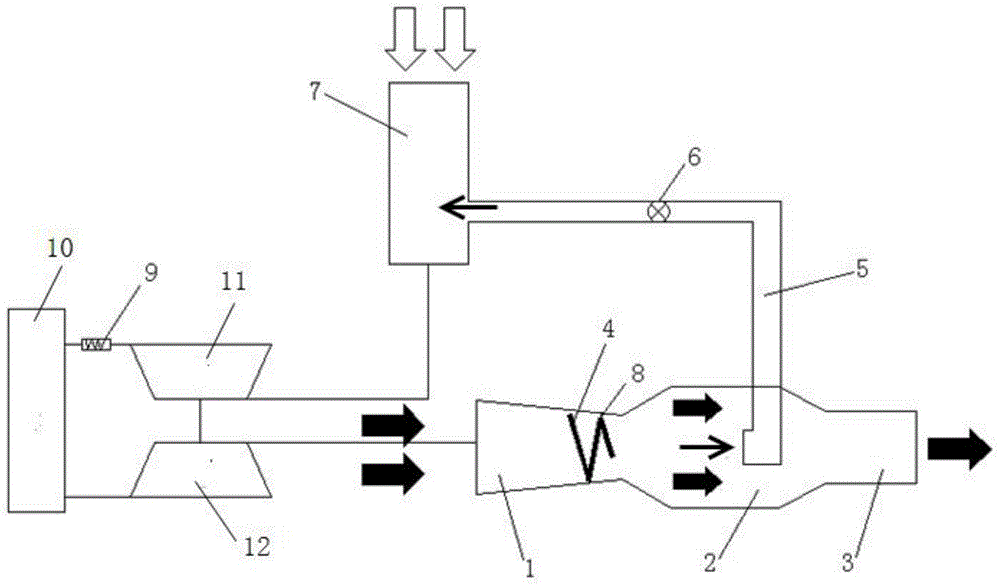

CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization

InactiveCN105804818AImprove fuel efficiencyImprove thermal power conversion efficiencyInternal combustion piston enginesSteam engine plantsFuel oilHigh pressure

The invention discloses a CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization. The CO2 Rankine cycle system is a special CO2 Rankine cycle system with CO2 serving as a working medium, waste heat of diesel engine high-temperature flue gas serving as a heat source, and a waste heat driving absorption refrigeration product of diesel engine cooling system hot water serving as a cold source. The CO2 Rankine cycle system is mainly composed of a flue gas waste heat exchanger, CO2 turbines, power equipment, a regenerator, a condenser, a high-pressure pump, a flue gas water heater and an absorption refrigerator. The characteristic that the condensation enthalpy of the CO2 working medium near the critical point is reduced is skillfully utilized; and the efficiency of conversion of heat into power is higher than that of an ORC cycle or other cycles and is obtained through a special cascade stage combined cycle formed by high and low grade waste heat, so that the fuel oil use ratio of a diesel engine is increased by 18%-25% or above. The CO2 Rankine cycle system for heavy-duty diesel engine waste heat gradient utilization is capable of achieving waste heat power generation / driving, heat supply and refrigeration poly-generation and has remarkable economic benefits, social benefits and application prospects.

Owner:XI AN JIAOTONG UNIV

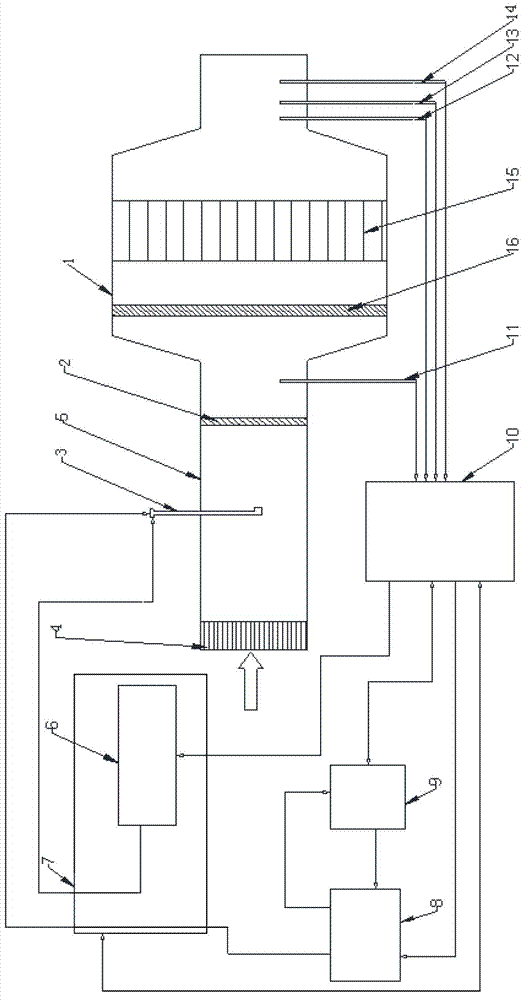

Particulate matter removing device of marine heavy-duty diesel engine EGR system

InactiveCN104791147AReduce pollutionReduce development costsNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesCombustion

The invention provides a particulate matter removing device of a marine heavy-duty diesel engine EGR system and relates to the technical field of internal combustion engines. The particulate matter removing device comprises a conical turbine air outlet pipe, a shuttle containing cavity, screw blades, an EGR pipeline and an EGR valve. The conical turbine air outlet pipe, the shuttle containing cavity and a rear exhaust pipe are sequentially connected. The screw blades are arranged in the conical turbine air outlet pipe to form a helical duct through a screw blade fixing support. An air inlet of the EGR pipeline is formed in the shuttle containing cavity, an air outlet of the EGR pipeline is formed in a front air inlet pipe. Clean tail gas can be used as an air source of the EGR system, and pollution of particulate matter to a gas compressor and an engine air inlet system is reduced. The particulate matter removing device is reasonable in design, simple in structure, and suitable for EGR low pressure loop connection methods.

Owner:SHANGHAI JIAO TONG UNIV

Non-automotive heavy-duty diesel engine SCR (semiconductor control rectifier) device and method

InactiveCN102817682ASolve the problem of uniform mixingPrevent proliferationInternal combustion piston enginesExhaust apparatusGas passingProcess engineering

The invention relates to a non-automotive heavy-duty diesel engine SCR (semiconductor control rectifier) device and method. The non-automotive heavy-duty diesel engine SCR device comprises a reactor in which a catalyst is arranged; a measuring unit which is connected with a system control device is arranged at an exit of the rear end of the catalyst in the reactor; the system control device is connected with a spray gun through a urea solution control device; an exit end of the spray gun is arranged at a front end of the catalyst in the reactor; the measuring unit comprises at least an NOX (nitric oxide) measuring unit; the urea solution control device comprises a urea pump and a urea tank which is connected with the urea pump, and a spraying device which is connected with the urea pump; the spraying device comprises at least two one-way valves which are connected with an air compressor and the urea pump respectively; the system control device is connected with a urea pump signal control end so as to output a urea solution output signal; and the spraying device is connected with the spray gun. The device provided by the invention is provided with the spraying device and the air compressor so as to solve the problem of uniformly mixing large capacity of urea water solution with tail gas and the problem of uniform diffusion of the mixed urea water solution and the tail gas passing through the catalyst.

Owner:陈志华

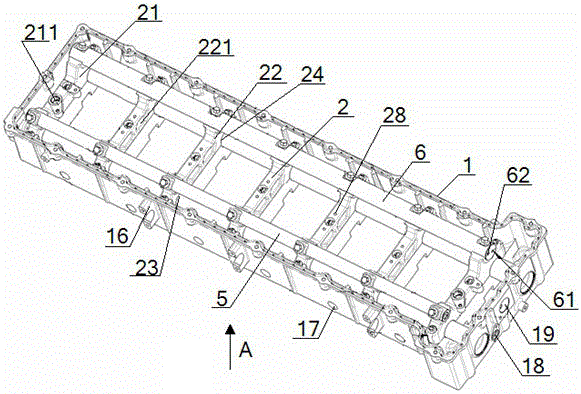

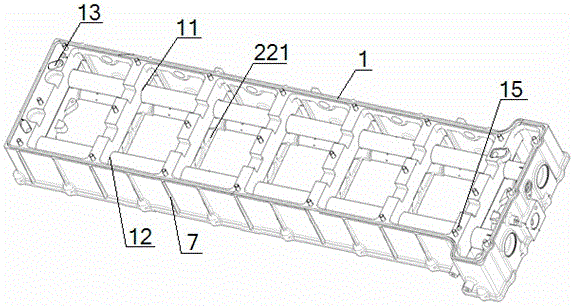

Rocker arm compartment assembly for heavy-duty diesel engine

ActiveCN104989546ARealize installation positioningReduce in quantityCasingsLubrication of auxillariesCamHeavy duty diesel

A rocker arm compartment assembly for a heavy-duty diesel engine comprises a rocker arm compartment and a cam bearing cap. The top of the rocker arm compartment is connected with a cylinder head cover. The bottom of the rocker arm compartment is connected with a cylinder head. A first intake camshaft installation groove and a first exhaust camshaft installation groove are symmetrically formed in the rocker arm compartment. The cam bearing cap comprises first cam bearing cap bodies and second cam bearing cap bodies. The top of each first cam bearing cap and the top of each second cam bearing cap are each provided with an intake rocker arm shaft installation arc surface matched with an intake rocker arm shaft and an exhaust rocker arm shaft installation arc surface matched with an exhaust rocker arm shaft. The bottom of each first cam bearing cap and the bottom of each second cam bearing cap are each provided with a second intake camshaft installation groove matched with the first intake camshaft installation groove and a second exhaust camshaft installation groove matched with the first exhaust camshaft installation groove. The rocker arm compartment assembly is applicable to the engine with double overhead camshafts and double rocker arm shafts; besides, part distribution is simplified while step-by-step braking of the engine is achieved.

Owner:DONGFENG COMML VEHICLE CO LTD

Lubricating oil composition

The invention relates to a lubricating oil composition, provides a SAE 0W and SAE 5W multigrade crankcase lubricating oil composition for heavy duty diesel (HDD) engines meeting the performance requirements of at least one of the API CJ-4; API-CI-4, and / or ACEA E7 specifications, having a sulfated ash content of no greater than 1.0 mass %, a sulfur content of no greater than 0.4 mass %, and a phosphorus content of no greater than 0.12 mass %, formulated with a major amount of oil of lubricating viscosity including less than about 30 mass %, based on the total mass of oil of lubricating viscosity, of Group IV and / or Group V base stock, at least 0.3 mass %, of a non-hydrogenated olefin polymer; and greater than about 40 ppm of boron.

Owner:INFINEUM INT LTD

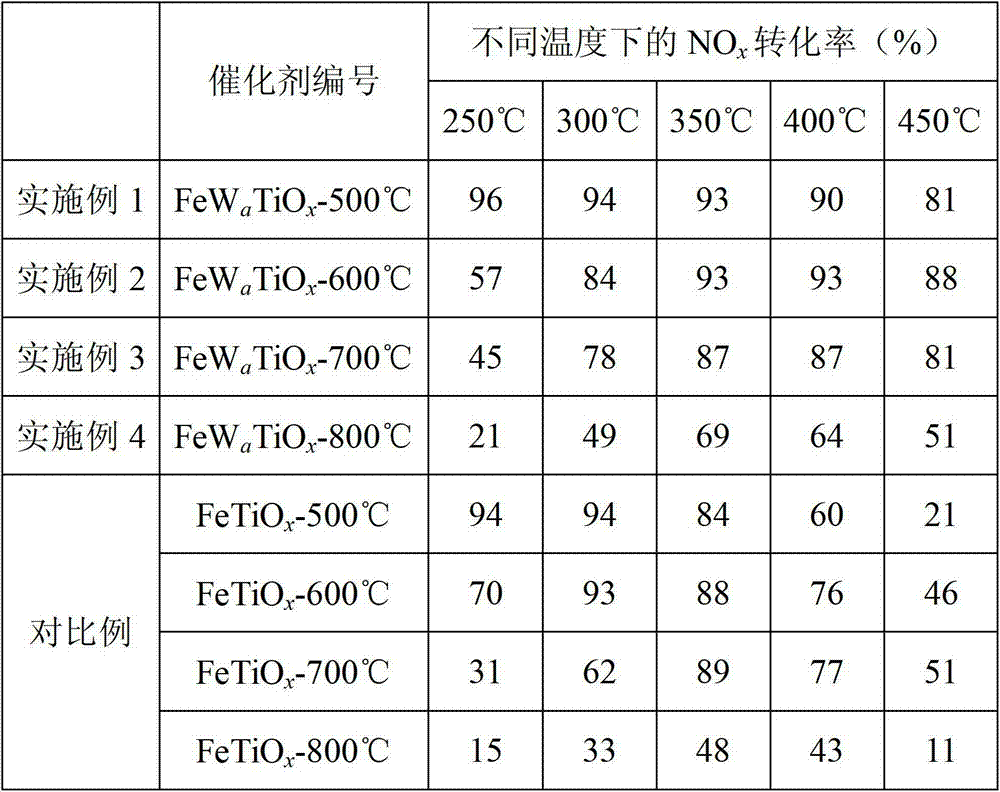

Iron-tungsten-titanium composite oxide catalyst, and preparation method and purpose thereof

ActiveCN103028420AGood dispersionOvercome CorrosivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationComposite oxide

The invention relates to iron-tungsten-titanium composite oxide catalyst. The catalyst has the chemical composition of FeWaTiOx, wherein a is greater than 0 and less than or equal to 1.6. The invention further discloses a preparation method of the catalyst, which comprises the following steps: (1), preparing the solutions of Fe source, W source and Ti source in the presence of oxalic acid, and mixing the solutions of Fe source, W source and Ti source to obtain a mixed solution; and (2), adding excessive urea precipitation agent into the mixed solution to ensure that ions can be fully deposited, and carrying out suction filtration, washing, drying and baking to obtained sedimentation products to obtain the iron-tungsten-titanium composite oxide catalyst. Compared with iron-tungsten-titanium composite oxide catalyst without adulteration, the iron-tungsten-titanium composite oxide NH3-SCR catalyst has an obviously improved high-temperature thermal stability, and is easier to apply to catalysis and decontamination of NOx in heavy duty diesel exhaust.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Active oil-gas separator

InactiveCN104265402AOptimize layoutReduce use costMachines/enginesCrankcase ventillationImpellerDrive shaft

The invention relates to an active oil-gas separator which is characterized in that the upper end of a base assembly is fixedly connected with an upper shell assembly, a sealing ring is arranged at the joint of the base assembly and the upper shell assembly, an inner cavity of the base assembly is an oil return cavity, a gas outlet cavity assembly is assembled at the lower end of an inner cavity of the upper shell assembly, a driving shaft assembly is vertically arranged in a cavity formed by the base assembly and the upper shell assembly, an auxiliary separating impeller is arranged on the portion of the driving shaft assembly positioned in the base assembly, an engine oil spraying hole is formed below the driving shaft assembly, a lamination lower body, a lamination and a lamination upper body sleeve the portion of the driving shaft assembly positioned in the upper shell assembly from bottom to top, the lamination lower body is limited by a limiting spring, the lamination upper body is limited by a clamping spring, a pressing plate is arranged in a side cover above the upper shell assembly, a diaphragm is arranged at the pressing plate, the maximum gap is kept between the diaphragm and a gas outlet, and the diaphragm is supported by a pressure adjusting valve spring. The active oil-gas separator can solve the problems that the overall engine performance and reliability of medium-duty and heavy duty diesel engines are reduced after a closed crankcase ventilation system is used.

Owner:CHINA FIRST AUTOMOBILE

Cylinder sleeve and surface treatment method of inner hole of cylinder sleeve

InactiveCN103834851AShorten break-in timeExtended service lifeSolid state diffusion coatingIncreasing energy efficiencyFriction effectHardness

The invention discloses a cylinder sleeve and a surface treatment method of the inner hole of the cylinder sleeve, and belongs to the field of manufacture of an internal combustion engine and parts thereof. The cylinder sleeve is prepared from a multicomponent low-alloy cast iron material which contains Cr, Mo, Cu and Ni; the inner surface of the cylinder sleeve comprises a hardened layer and a sulfurized layer, wherein the hardened layer is positioned at an inner side, and the sulfurized layer is positioned on a surface; the hardness of the hardened layer is 46-50HRC, and the thickness of the hardened layer is 0.4-2.6 mm; the thickness of the sulfurized layer is 0.001-0.005 mm, and the friction coefficient of the surface of the hardened layer is less than or equal to 0.05. The surface treatment method comprises the following steps of: carrying out quenching treatment and finish machining on the surface of the inner hole of the cylinder sleeve, and then carrying out sulfidization treatment. According to the cylinder sleeve produced by adopting the surface treatment method, the outer layer of the inner surface of the cylinder sleeve is the sulfurized layer which has an anti-friction effect, and the inner layer is an anti-abrasion layer which comprises acicular martensite and A type graphite and has higher hardness. The cylinder sleeve produced by adopting the surface treatment method can shorten the seating time of the cylinder sleeve, prolong the service life of the cylinder sleeve and is especially suitable for medium-duty and heavy-duty diesel engines.

Owner:SHIJIAZHUANG JINGANG KAIYUAN POWER SCI & TECH

Novel portable type diesel vehicle tail gas particulate road detection device and method

PendingCN107132161ARegulate Emission StandardsHigh precisionParticle suspension analysisWeighing by absorbing componentControl systemDisplay device

The invention relates to a novel portable type diesel vehicle tail gas particulate road detection device and a method. The novel portable type diesel vehicle tail gas particulate road detection device comprises a DPF (diesel particulate filter), a radio frequency generator, a radio frequency receiver, an integrated control system device and a display device, wherein a filter body is arranged in the DPF; the radio frequency generator and the radio frequency receiver are respectively connected with the integrated control system device, and the integrated control system device is connected with the display device; specifically, the integrated control system device is used for performing Fourier transformation on a signal received by the radio frequency receiver, and converting to obtain energy spectrum, so as to obtain resonance frequency; the obtained resonance frequency is found according to a function relationship of preset radio frequency resonance frequency and carbon content, so as to obtain value of carbon loading amount in the DPF. The novel portable type diesel vehicle tail gas particulate road detection device has the advantages that the content of carbon smoke particles in the diesel vehicle tail gas can be accurately measured, the device can be used for a traffic management department to detect whether the content of the particulate in the heavy-duty diesel vehicle tail gas exceeds standard or not in the road detection process, the device is cooperated with the issuing of national standard VI, and the emission standard of diesel vehicle particulate is further standardized.

Owner:ZHEJIANG UNIV

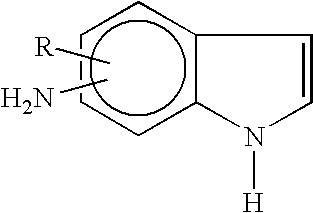

Method for improving fuel economy of a heavy duty diesel engine

InactiveUS20120247412A1Improve fuel economyFuel economy of heavyNon-fuel substance addition to fuelCombustion enginesDieselingControl theory

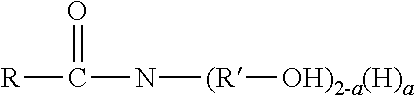

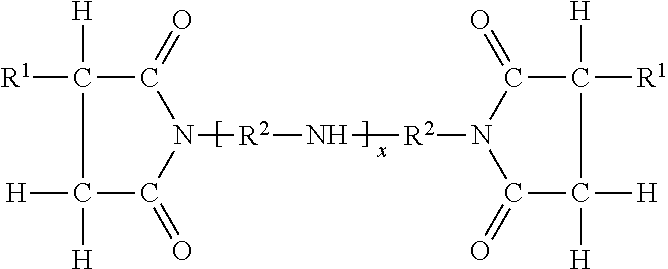

Disclosed is a method for improving the fuel economy of a heavy duty diesel engine which produces a heavily sooted lubricating oil composition during the engine's normal operation. The method involves introducing lubricating the heavy duty diesel engine with a heavy duty diesel engine lubricating oil composition comprising (a) a major amount of an oil of lubricating viscosity; and (b) a minor effective amount of an ashless friction modifier comprising a reaction product of a C4 to about C75 fatty acid ester and a mono- or dialkanolamine.

Owner:CHEVRON ORONITE CO LLC

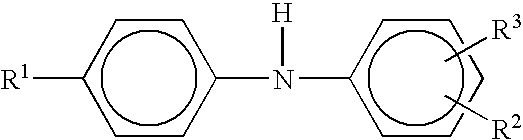

Anti-wear composition for low sulfur, low sulfated ash and low phosphorus lubricating oil composition for heavy duty diesel engines

InactiveUS20070049507A1Reduce particulate emissionsImprove detergencyLiquid carbonaceous fuelsAdditivesMannich condensationSulfur

The present invention is directed to a low sulfur, low sulfated ash and low phosphorus lubricating oil composition for low emission heavy duty diesel engines comprising (a) a major amount of an oil of lubricating viscosity and (b) at least 5 weight percent of an anti-wear additive composition comprising a metal salt of a Mannich condensation product based on the total weight of the lubricating oil. The present invention is also directed to a low sulfur, low sulfated ash and low phosphorus lubricating oil concentrate comprising (a) an oil of lubricating viscosity and (b) at least 5 weight percent of an anti-wear additive composition comprising a metal salt of a Mannich condensation product based on the total weight of the lubricating oil.

Owner:CHEVRON ORONITE TECH BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com