Lubricating oil composition

A technology of lubricating oil composition and olefin polymer, applied in lubricating composition, petroleum industry, additives, etc., can solve the problem of expensive base oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

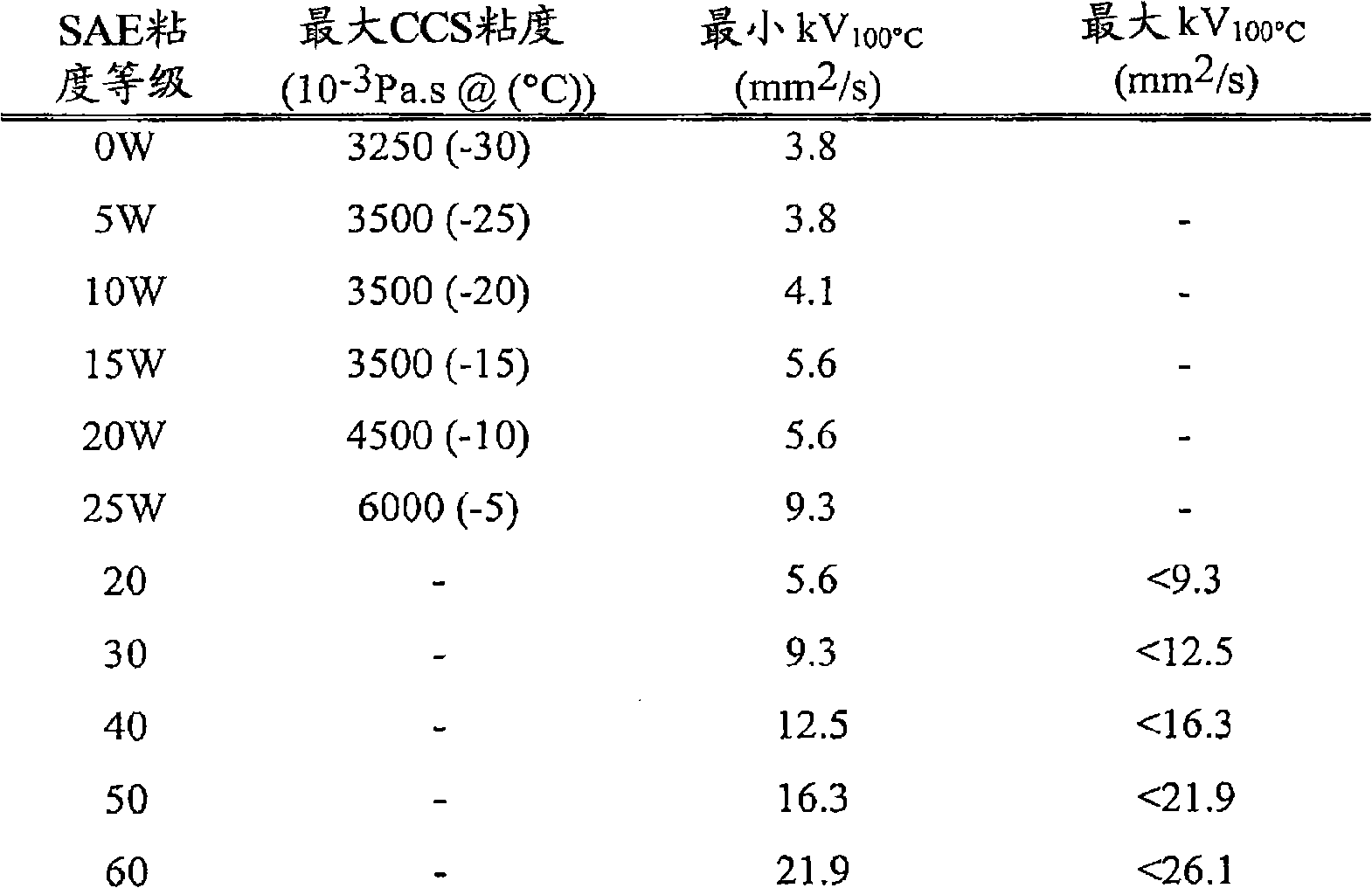

[0133] According to API CJ-4 and CI-4 specification (1.0 mass % SASH, 0.4 mass % sulfur and 0.12 mass % phosphorus), formulate SAE 5W40 grade lubricant in the blend of 4 cSt. and 6 cSt. III base oil, its Contains base oil, dispersant (combination of boronated and non-borated dispersant), detergent (combination of calcium phenate, calcium sulfonate and magnesium sulfonate detergent), ZDDP, soot dispersant, ashless Combination of sulfur phenolic antioxidant and amine antioxidant (total 0.7% by mass), molybdenum dithiocarbamate compound, viscosity modifier, pour point depressant and 1% by mass of polybutene (PIB) with Mn of 950 ). The resulting oil had a boron content of 65 ppm, a magnesium content of 1156 ppm, a molybdenum content of 44 ppm, a TBN of 9.9, and 79% of the TBN produced by the overbased detergent (52% of the composition's TBN) was cleaned by the overbased magnesium agent provided.

[0134] The wear of the valve train using the above lubricants was measured in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com