Engine antifreeze composition

a technology of composition and engine, applied in the direction of heat exchange elements, chemical instruments and processes, etc., can solve the problems of loss of efficacy, inability to access suitable water for cooling system use, and inability to achieve the effects of reducing corrosion of metal surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

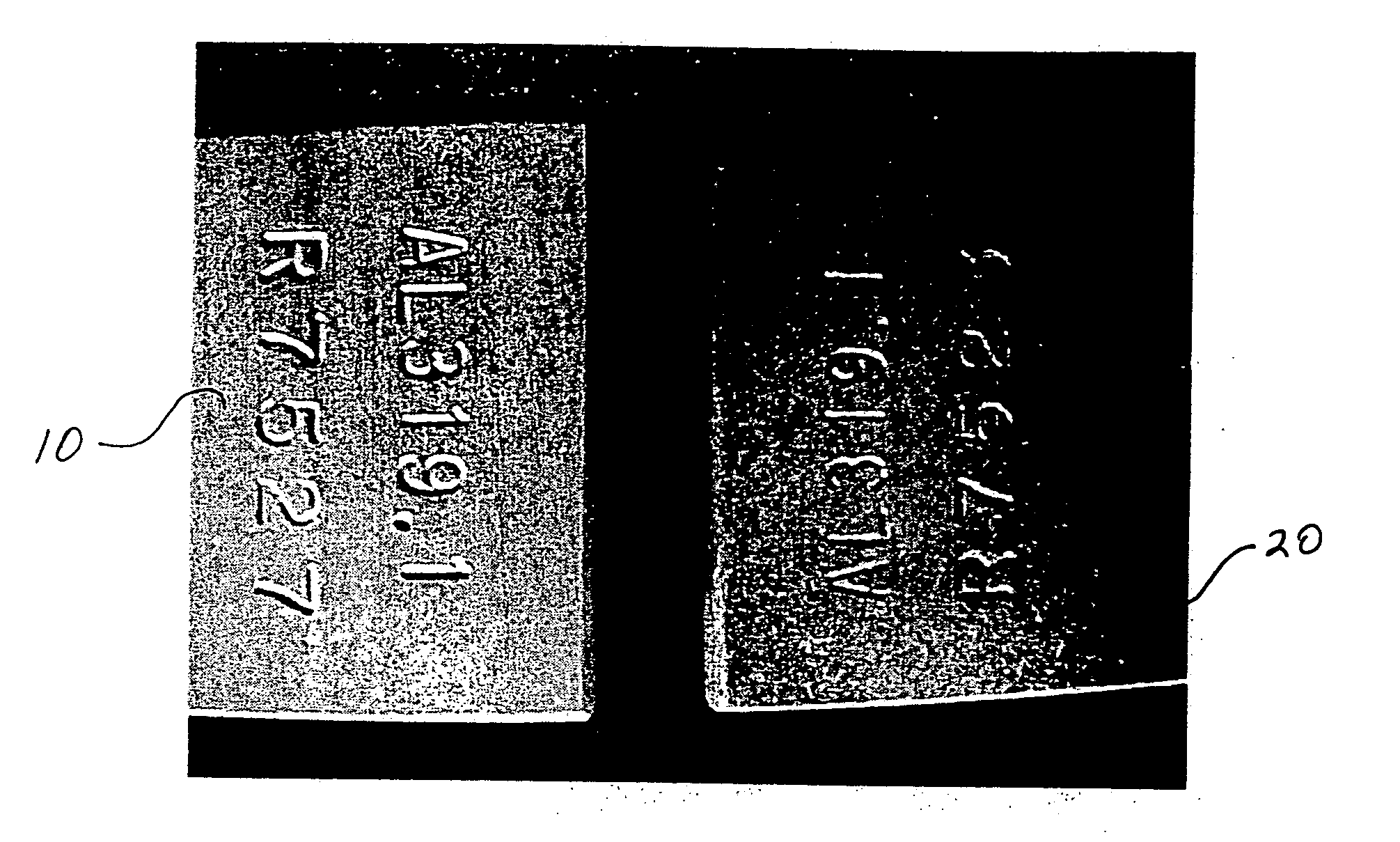

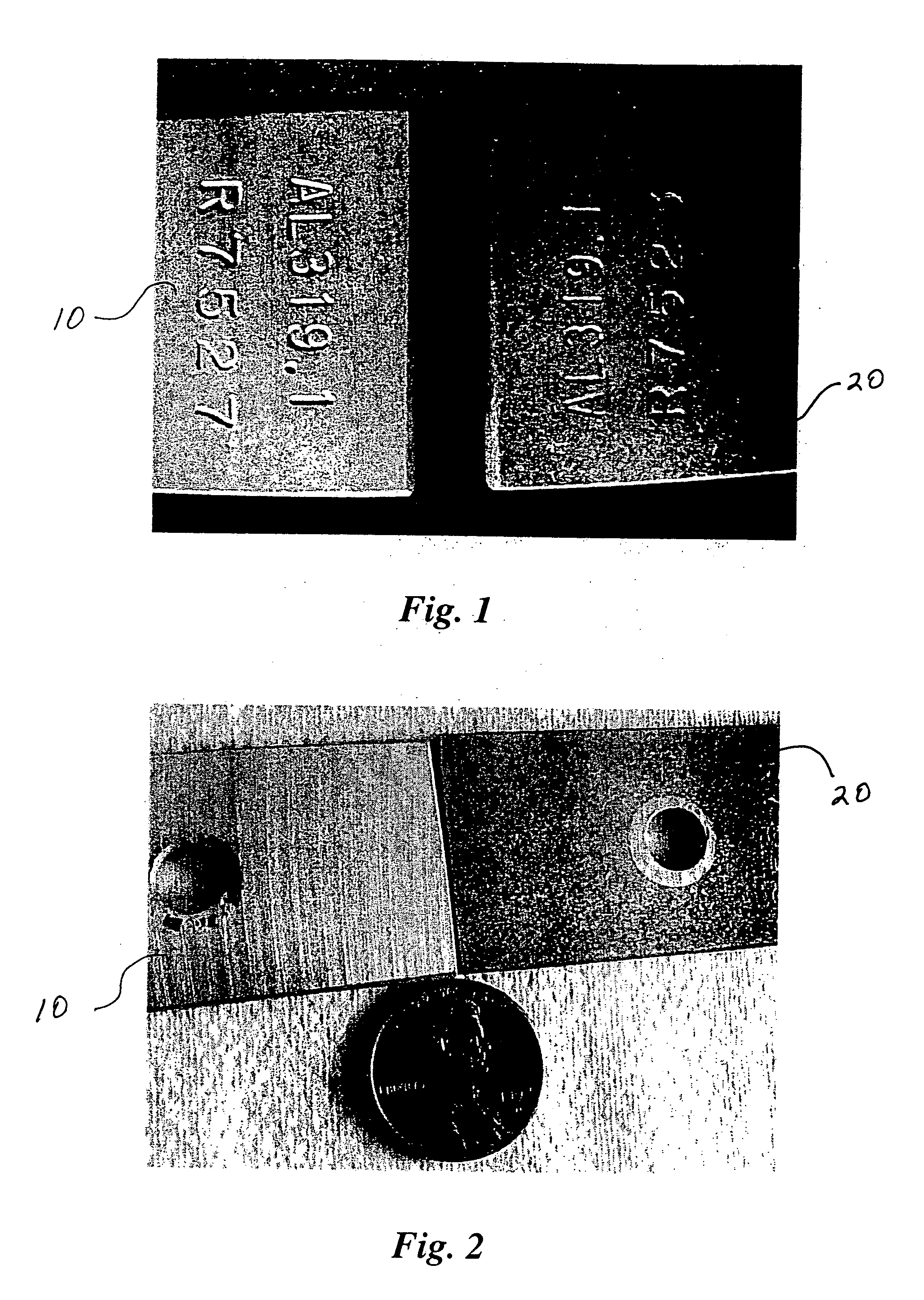

Image

Examples

example

[0036] Five coolant compositions listed as Examples 1-5 in Table 1 were prepared by combining the specific indicated components listed in the table in a fully formulated base antifreeze solution that included, in percent by weight based on the final total weight of the final antifreeze formulation, 95% ethylene glycol, sodium borate (0.20%); sodium molybdate (0.30%); mercaptobenzothiazole (MBT) (0.40%, 50% active); tolyltriazole (0.20%); sodium silicate (0.10%) as well as surfactants, scale inhibitors and defoamers (0.05%) to provide a concentrated coolant composition. Each of the concentrated coolant compositions was then diluted with water having a hardness of about 300 ppm and a pH between about 8.3 and about 8.5 to provide the coolant compositions listed as examples 1-5. These coolant compositions were then evaluated according to ASTM D-2809 Standard Text Method for Cavitation Corrosion and Corrosion and Erosion-Corrosion Bench Test described below.

TABLE 1*Concentrated Coolant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com