Patents

Literature

114 results about "Freezing Point Temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The temperature at which a liquid freezes: The freezing point of water is 32°F, 0°C.

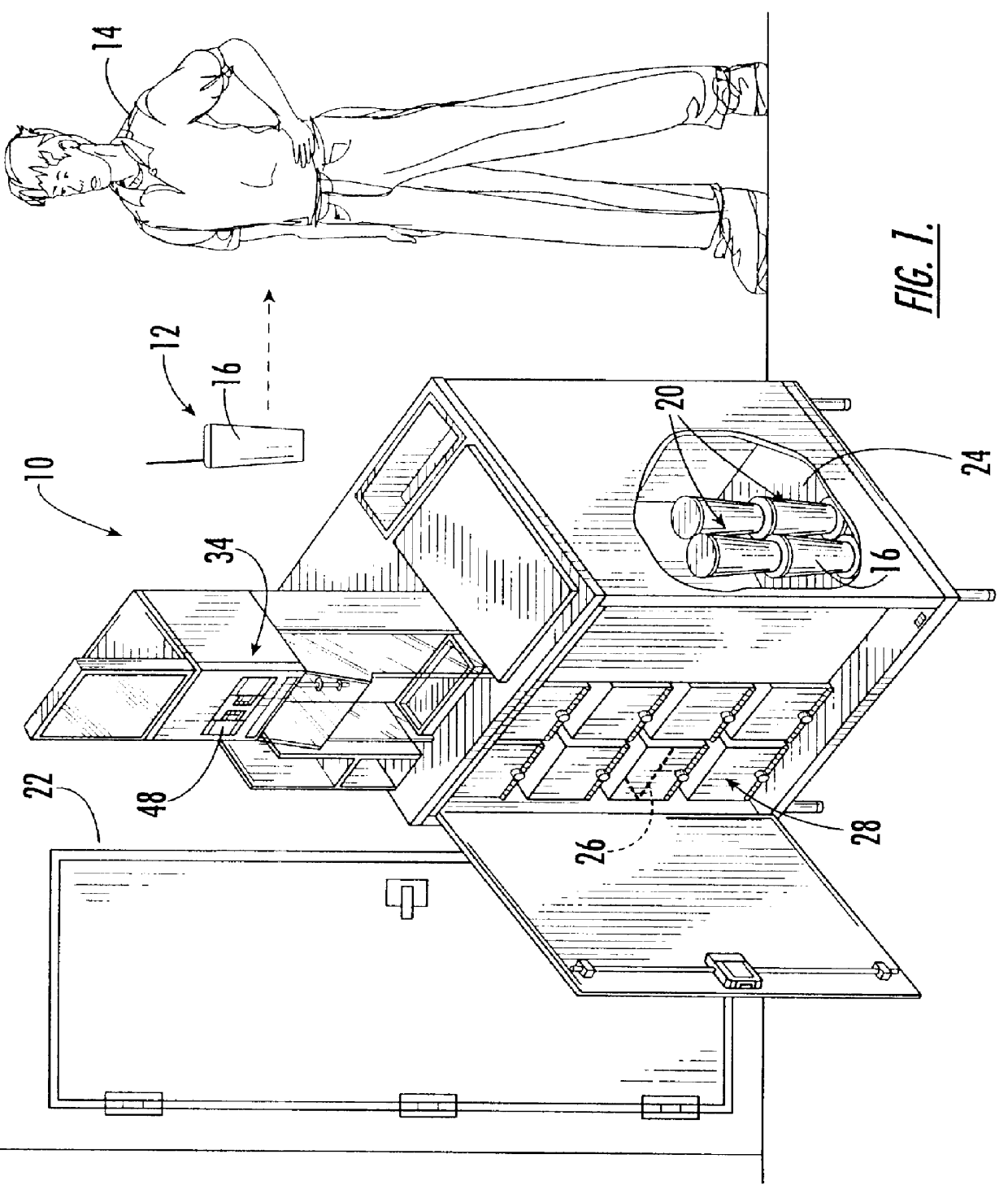

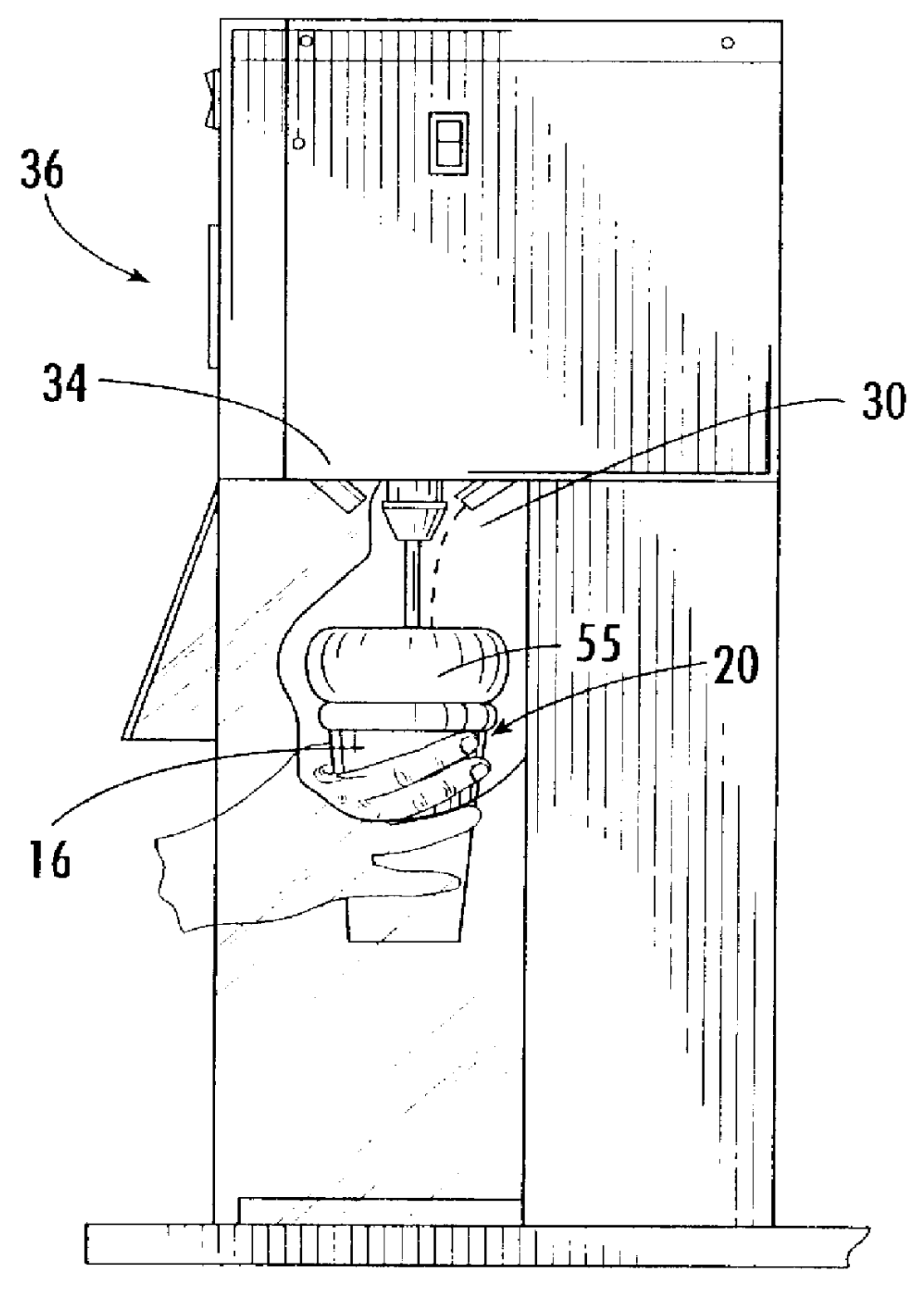

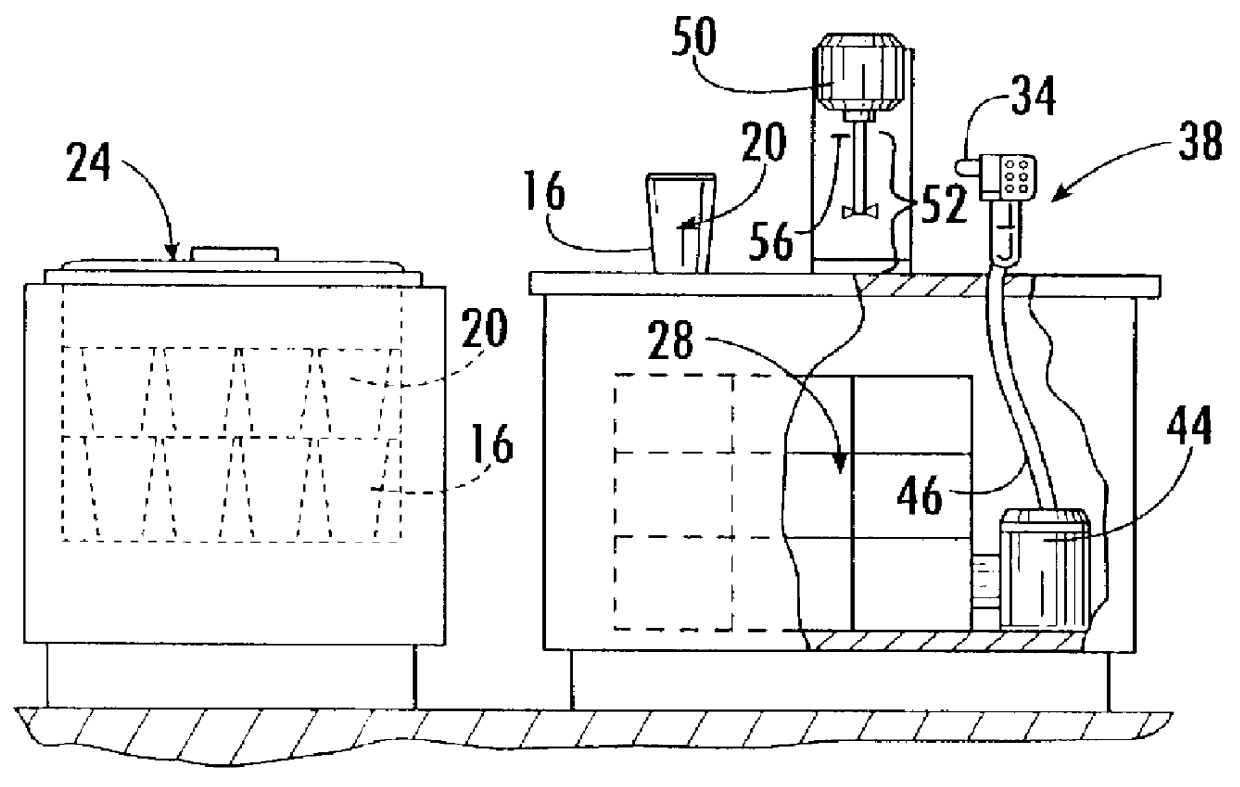

Method for preparing a slurried confection

InactiveUS6068875AMinimize storageImprove accessibilityMeat/fish preservationRotary stirring mixersFreezing Point TemperatureFlavor

A method for preparing a flavored slurried confection includes the use of a disposable serving container holding an individual serving of a neutral flavored mix which has a freezing point temperature lower than normally found for that of water. A large supply of the mix filled containers is stored in a storage freezer for maintaining the neutral flavored mix at a storage temperature, such as is typical of a food storage freezer for a restaurant. A desired quantity of the mix filled containers is then transferred from the storage freezer to a tempering freezer, generally close to a preparation and serving area, for maintaining the neutral flavored mix at a desirable blending temperature. The mix filled container is then removed from the tempering freezer for preparation of a flavored confection, such as a flavored shake. In preparing the flavored confection, a small quantity of a selected syrup is pumped from a selected bag-in-the-box styled carton into the mix filled container for blending the selected syrup with the neutral flavored mix while the mix remains chilled at the blending temperature. The small quantity of syrup adds provides the selected flavor to the neutral flavored mix for forming the flavored slurried confection which is then served within the disposable serving container.

Owner:ARCHIBALD BROS FINE BEVERAINC

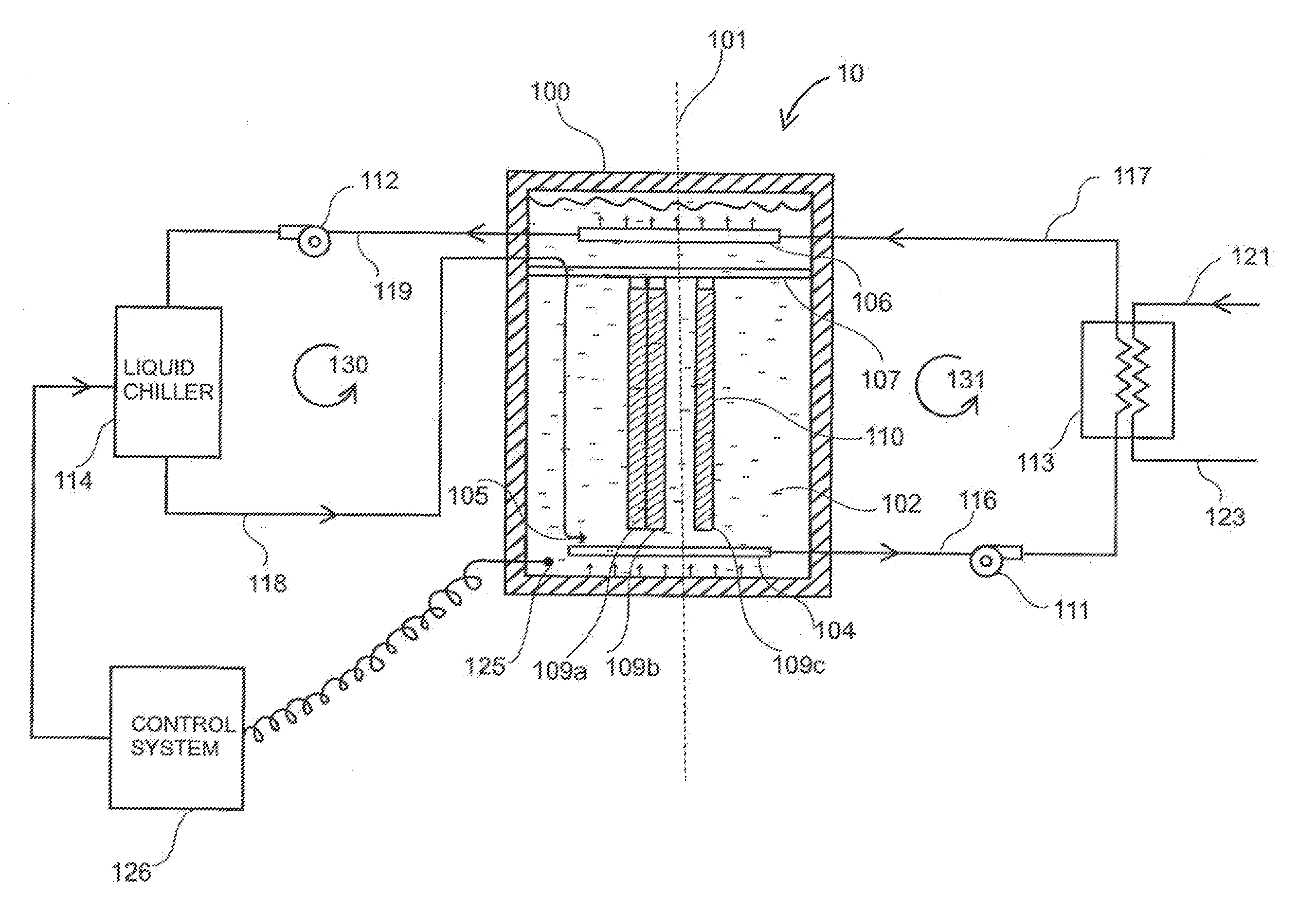

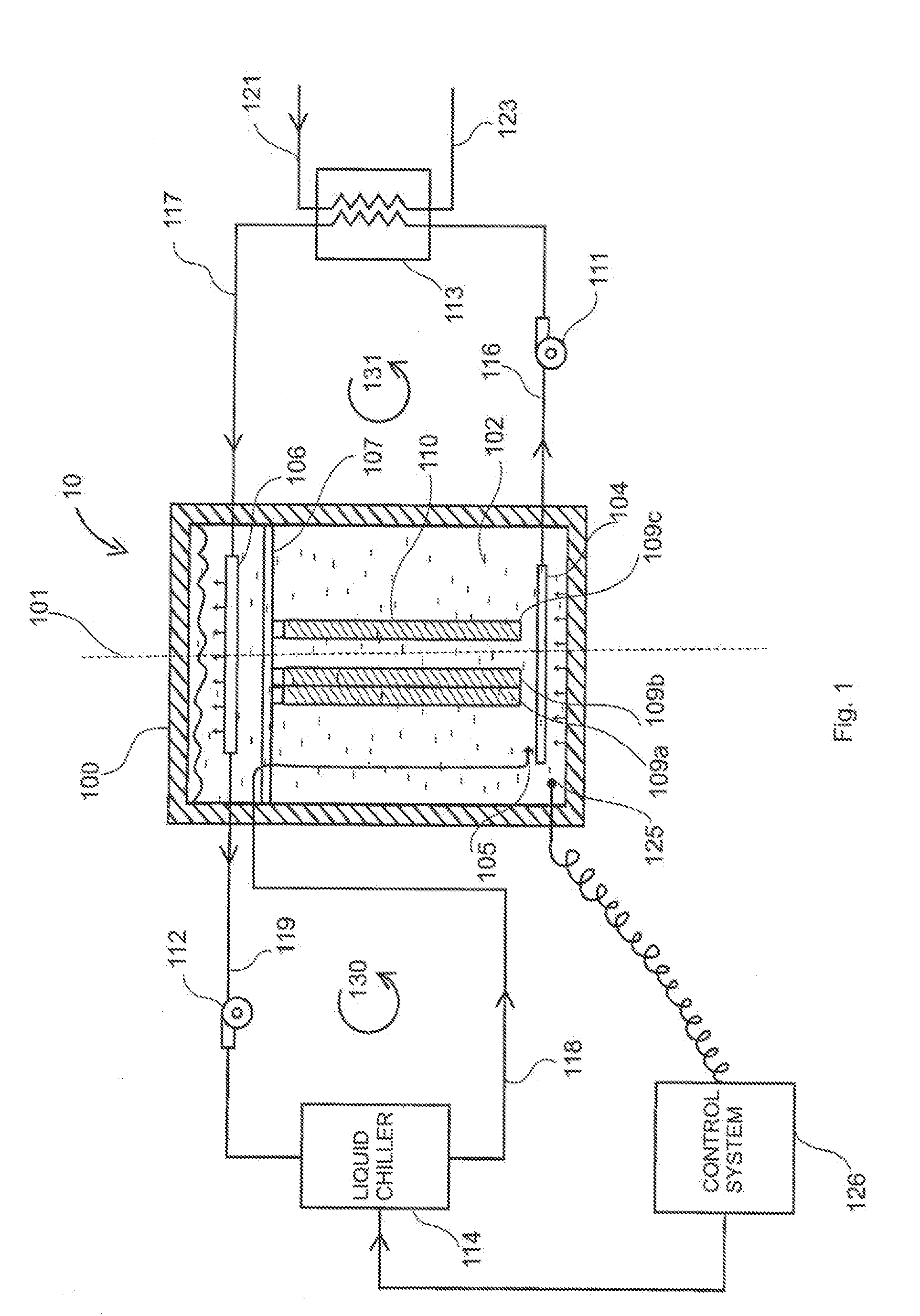

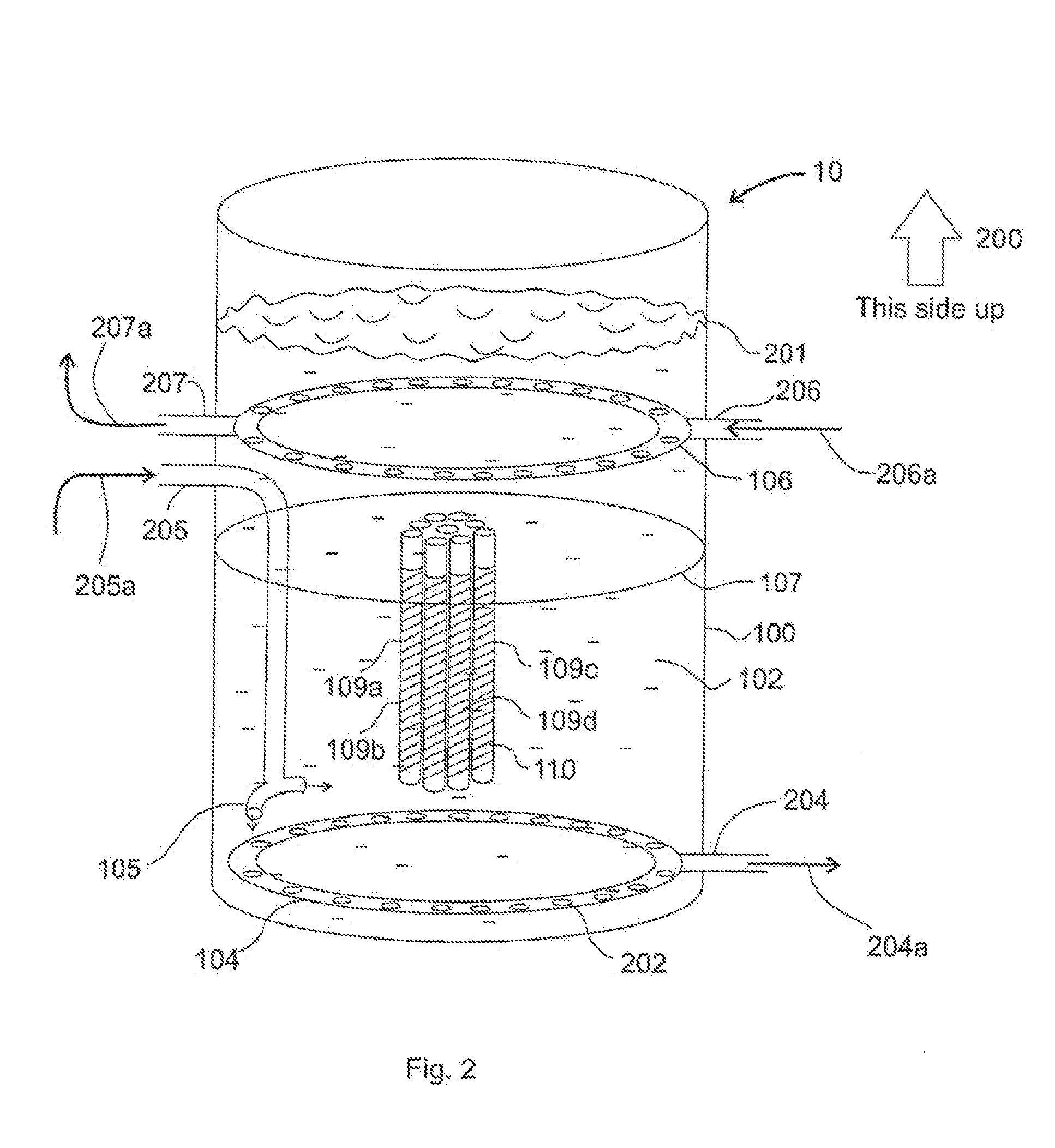

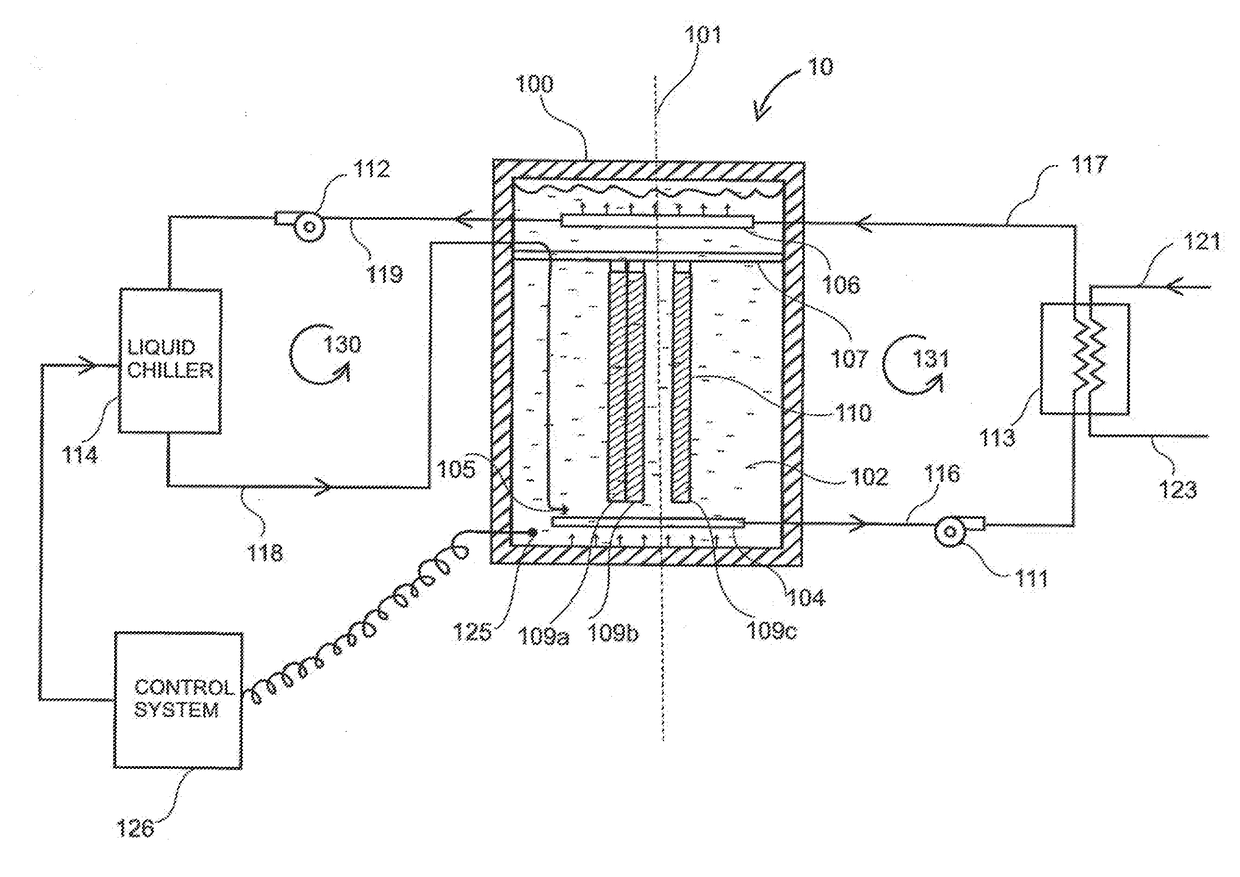

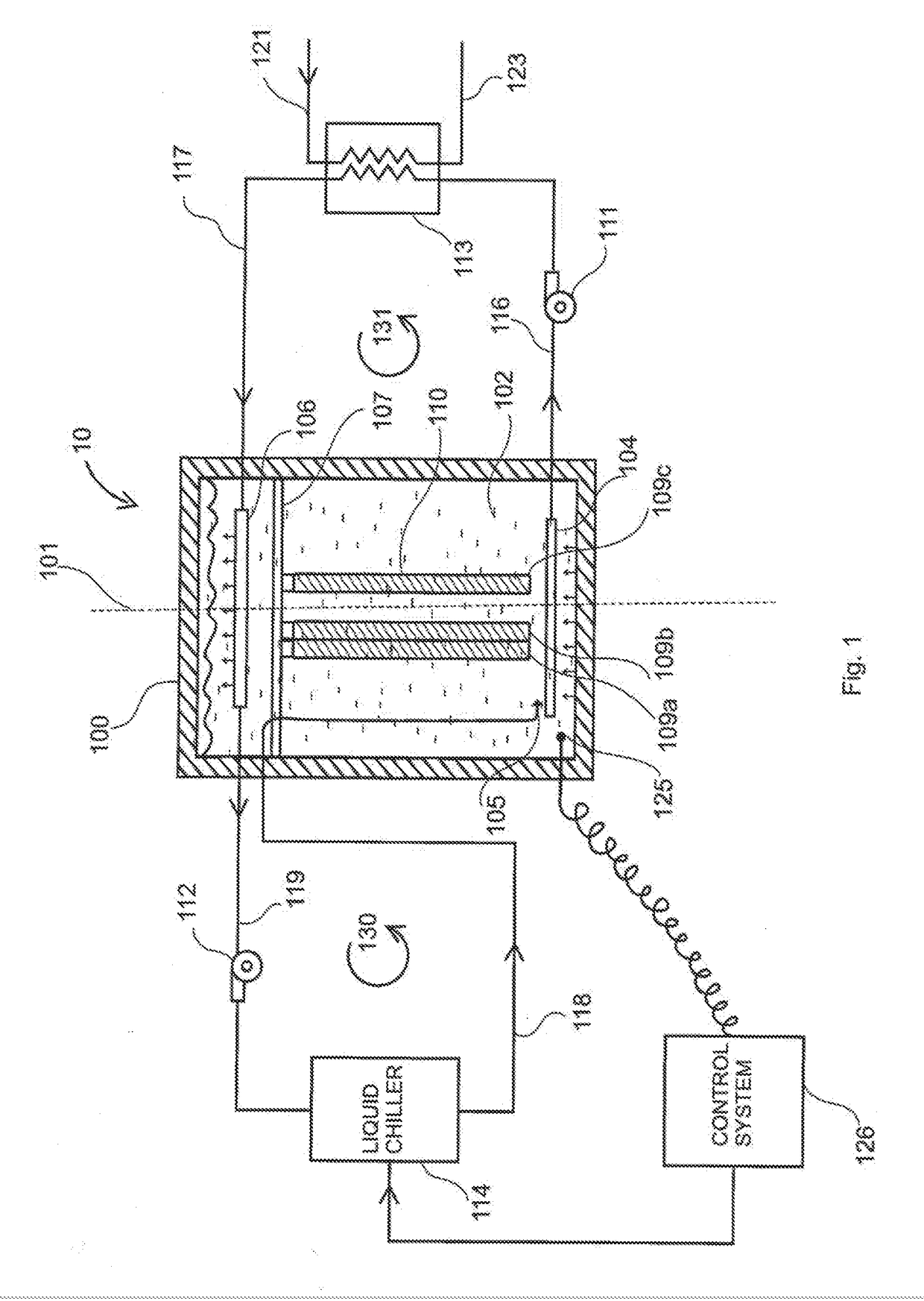

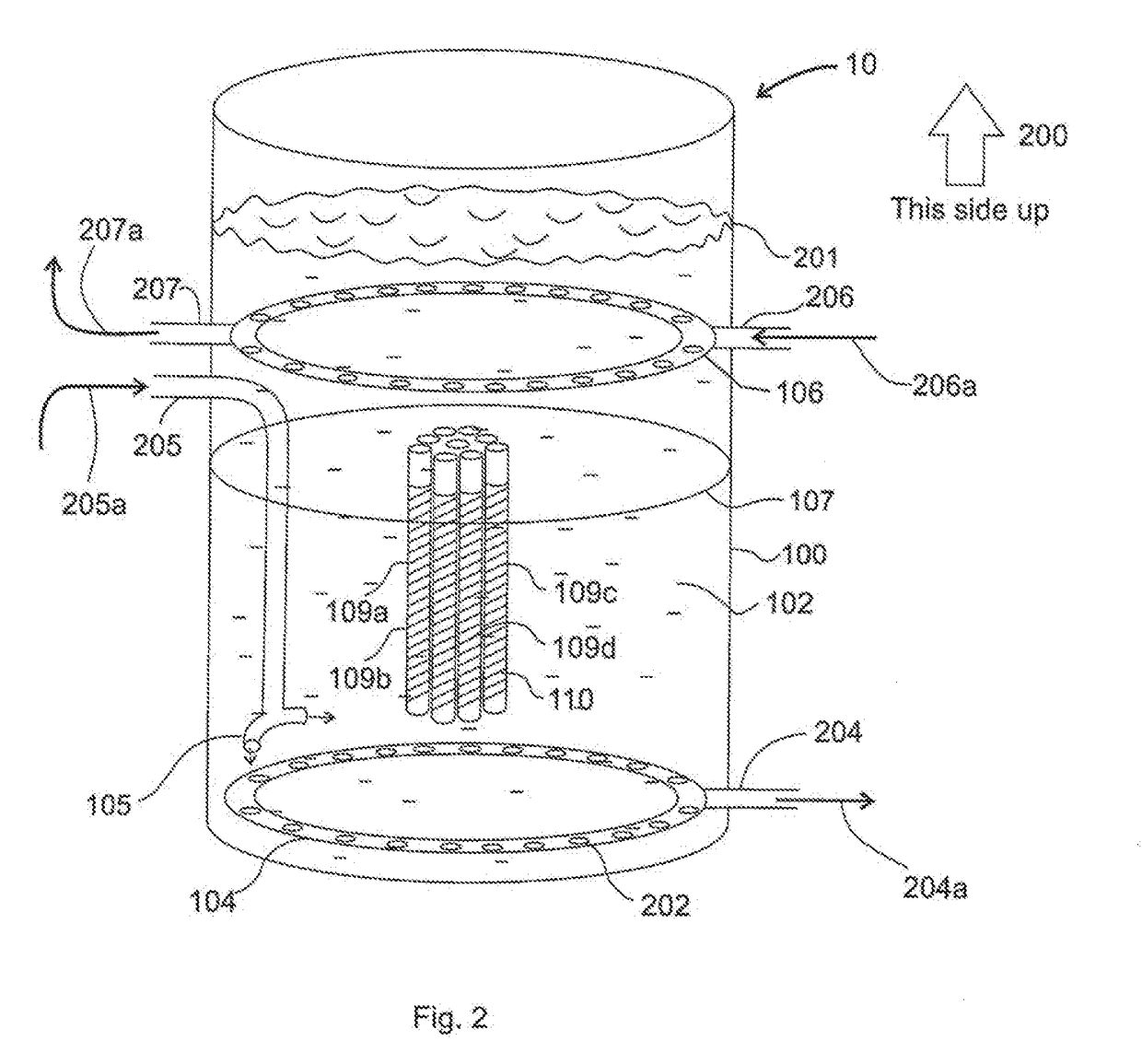

Thermal energy battery with enhanced heat exchange capability and modularity

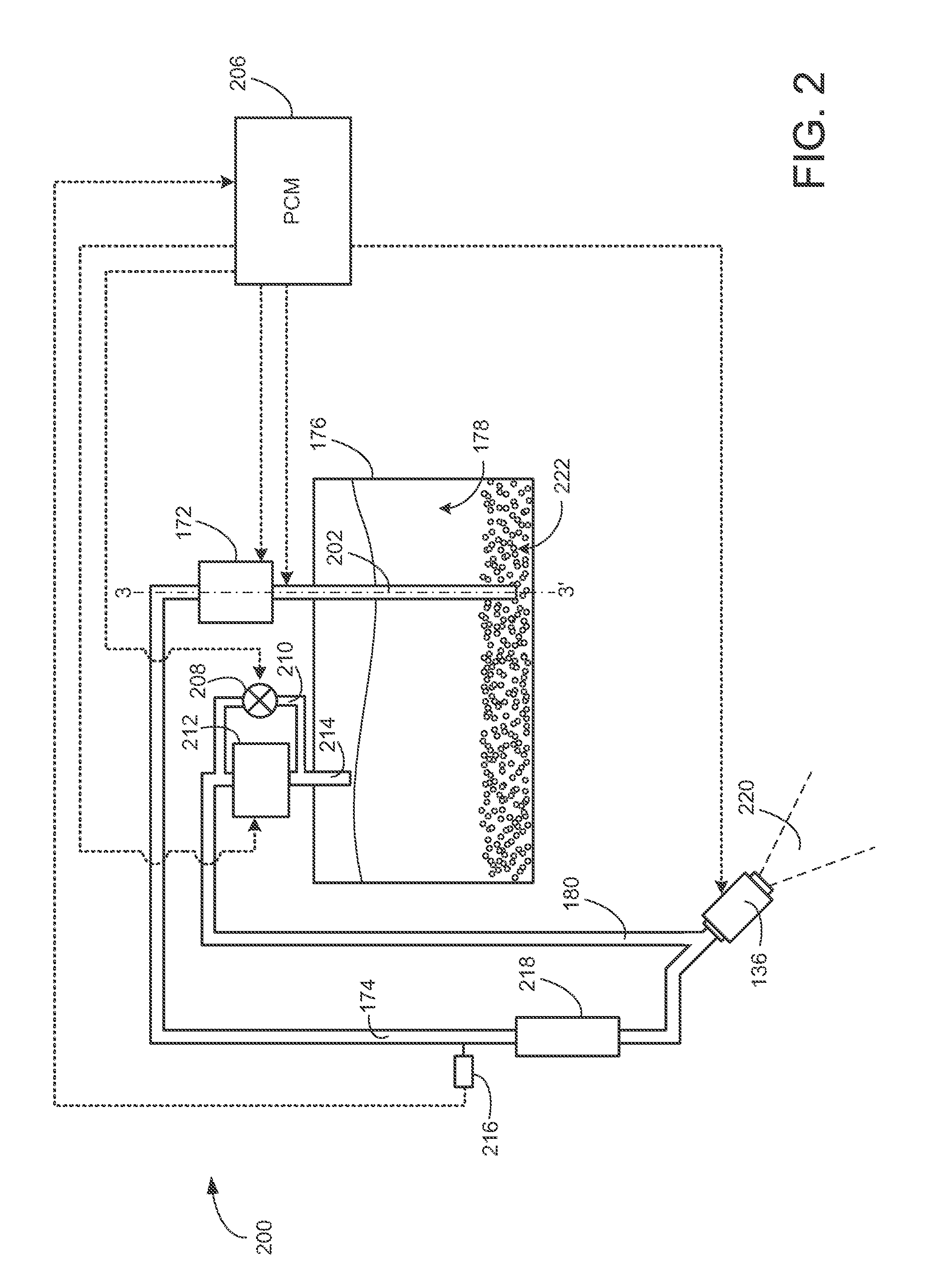

ActiveUS20140102662A1Improve heat exchange capacityConstant rate of dischargeHeat storage plantsMilk receptaclesFreezing Point TemperatureThermal energy

This invention provides a thermal energy battery having an insulated tank contains a multitude of densely packed plastic tubes filled with a phase-change material (PCM, such as ice) that changes from solid to liquid and vice-versa. Energy is stored when the PCM transitions from liquid to solid form, and released when the PCM transitions back from solid to liquid form. The tubes are arranged vertically, span the height of a well-insulated tank, and are immersed in heat transfer fluid (HTF) contained within the tank. The HTF is an aqueous solution with a freezing point temperature below the freezing point temperature of the chosen PCM. The HTF remains in liquid form at all times during the operation of the battery. Diffusers located allow the HTF to be extracted uniformly from the tank, pumped and cooled by a liquid chiller situated outside the tank and then and inserted back into the tank.

Owner:PROMETHEAN POWER SYST

Mining temperature reduction coolant and preparation method thereof

InactiveCN101824304AEnvironmentally friendlyIncrease elasticityHeat-exchange elementsFreezing Point TemperatureCross-link

The invention relates to a mining temperature reduction coolant and preparation method thereof. The invention takes macromolecular compound polyvinyl alcohol as basic raw material, cross-linking agent in certain proportion is added, wherein the cross-linking agent is 10% borax solution and the like; then freezing point temperature reduction auxiliary agent is added to prepare gel-like coolant, the prepared coolant is injected into a forming container and is frozen and formed in an icehouse the temperature of which is lower than minus 15 DEG C, and then the formed coolant is unfrozen at room temperature and is filled into a packaging bag. The mining temperature reduction coolant of the invention has the following characteristics: (1) elasticity and flexibility are good, comfortable sensation can be obtained when human body touches the coolant; (2) cold accumulation material has major latent heat of phase change and appropriate phase change temperature; (3) the coolant can be repeatedly used, can not be cataklastic, can not contract and can produce no separated water; (4) the coolant can be in close contact with human body when in use, and refrigeration effect can be fully played; (5) no toxin, odour or pollution is produced; (6) cold insulating plate and cold insulating bag of the outer packing of the coolant has the function of 'environmental protection and high efficiency cold insulation heat preservation'.

Owner:ANHUI PROVINCE COAL SCI RES INST

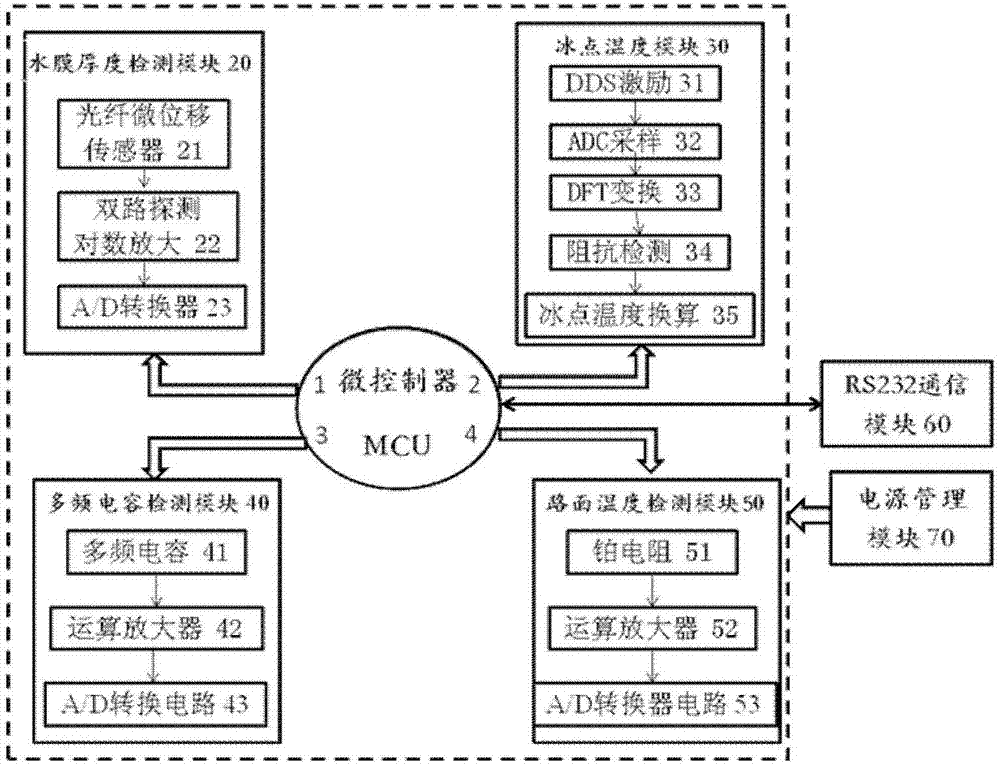

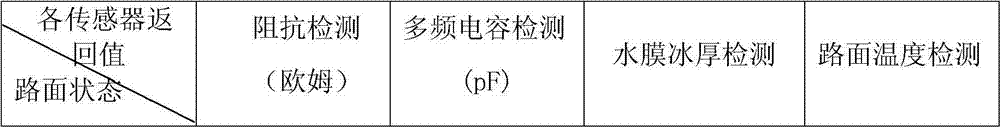

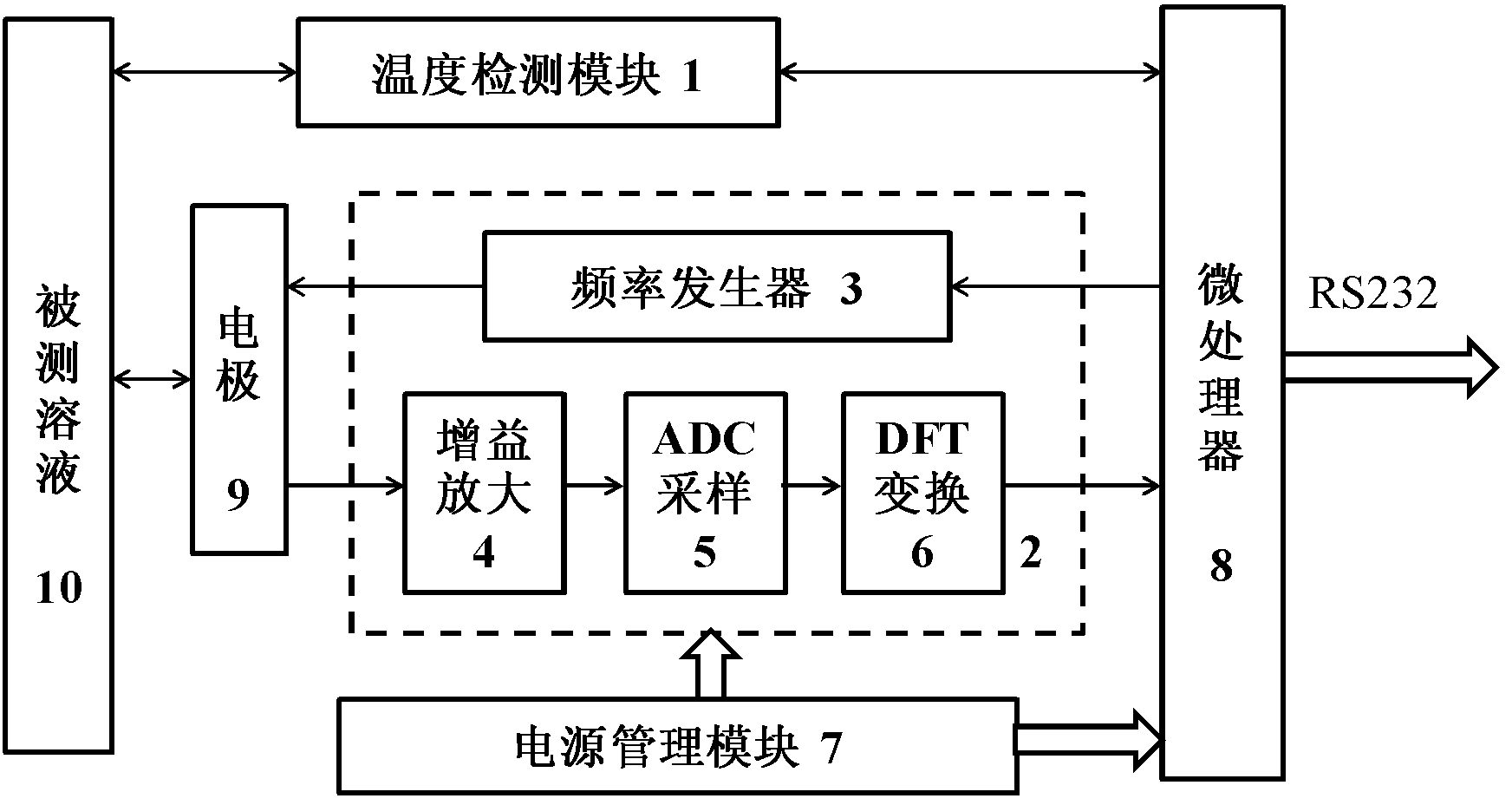

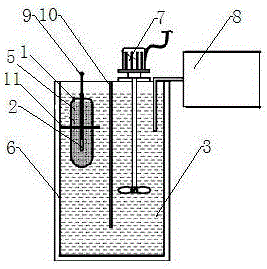

Contact type meteorological monitoring pavement sensor for road traffic

InactiveCN102830447AIndication of weather conditions using multiple variablesMicrocontrollerFreezing Point Temperature

A contact type meteorological monitoring pavement sensor for road traffic comprises a microcontroller, a water film thickness detecting module, a freezing point temperature module, a multi-frequency capacitance detecting module, a pavement temperature detecting module, an RS232 communication module and a power management module, wherein an input end of the water film thickness detecting module is connected with a first output end of the microcontroller; an input end of the freezing point temperature module is connected with a second output end of the microcontroller; an input end of the multi-frequency capacitance detecting module is connected with a third output end of the microcontroller; an input end of the pavement temperature detecting module is connected with a fourth output end of the microcontroller; the RS232 communication module is connected with the microcontroller; and the power management module respectively supplies power for the microcontroller, the water film thickness detecting module, the freezing point temperature module, the multi-frequency capacitance detecting module and the RS232 communication module. The contact type meteorological monitoring pavement sensor for road traffic has the advantages of comprehensive testing physical quantity and low cost.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

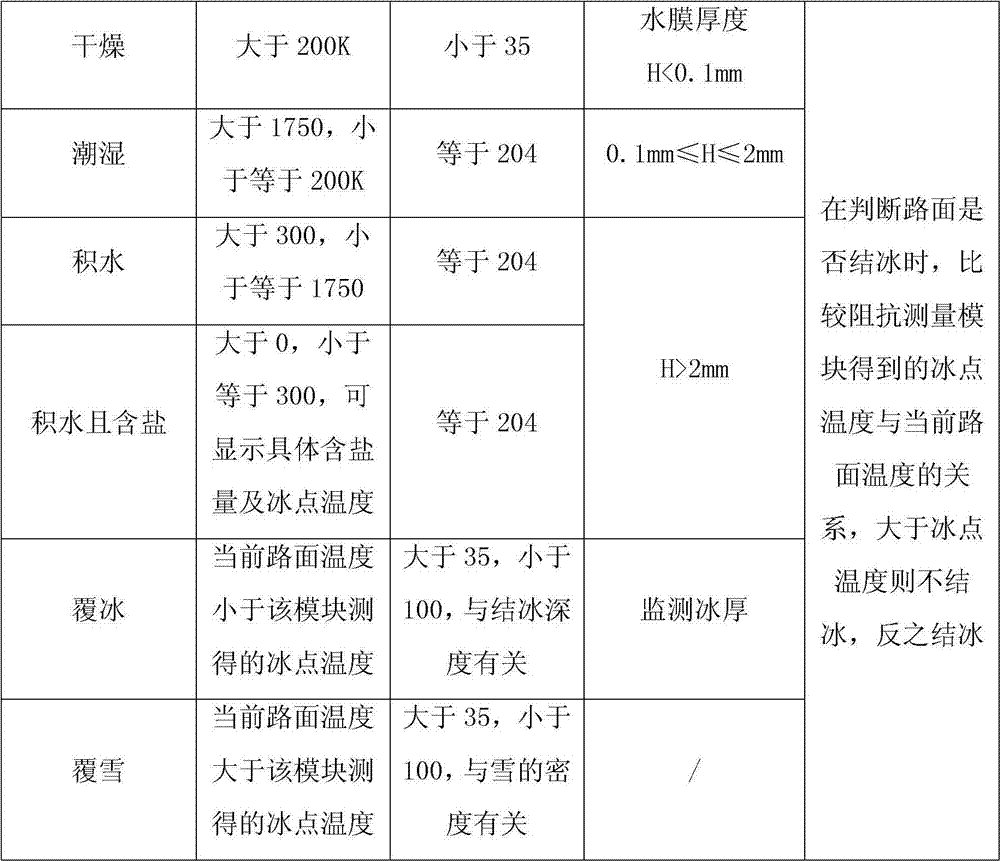

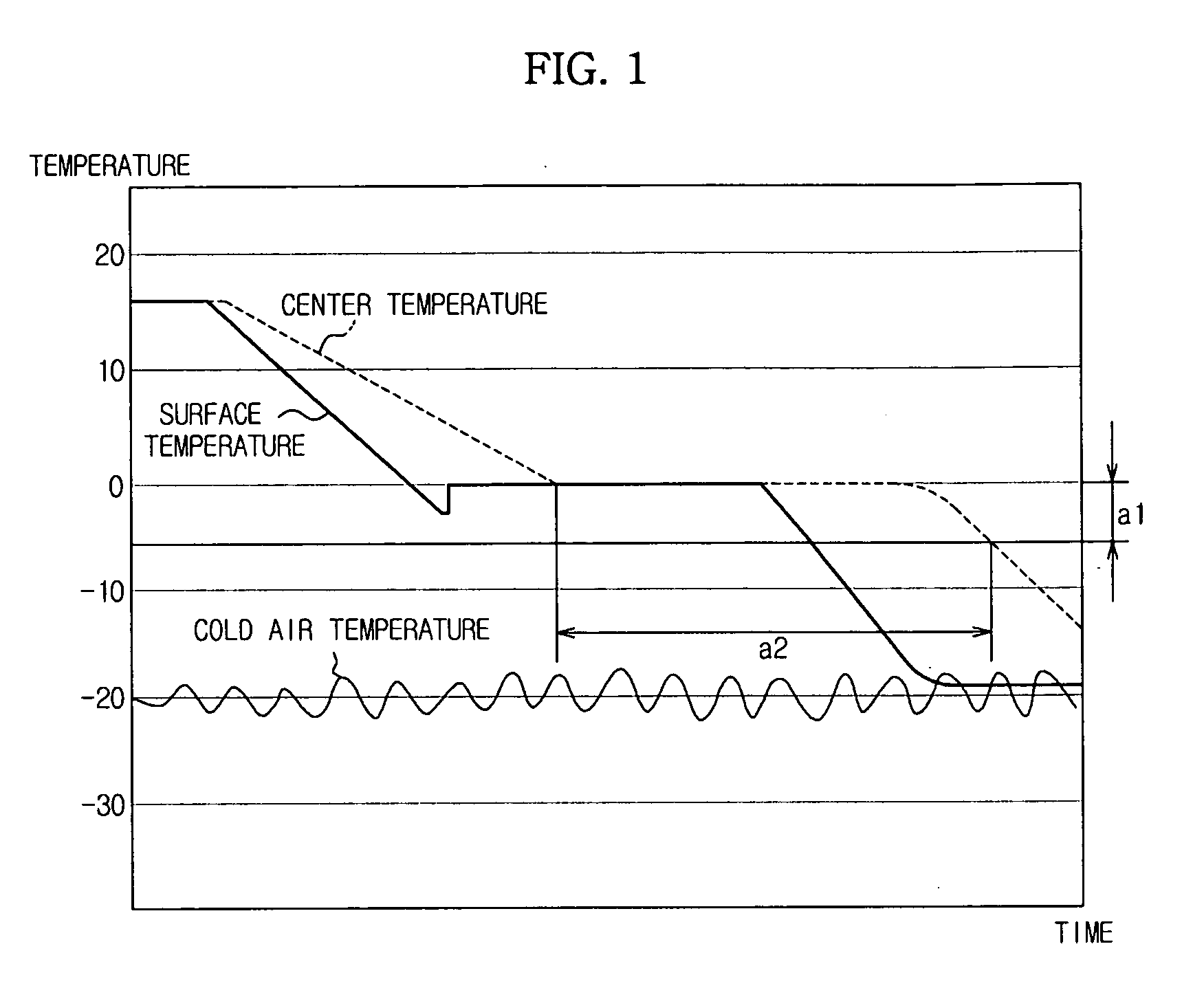

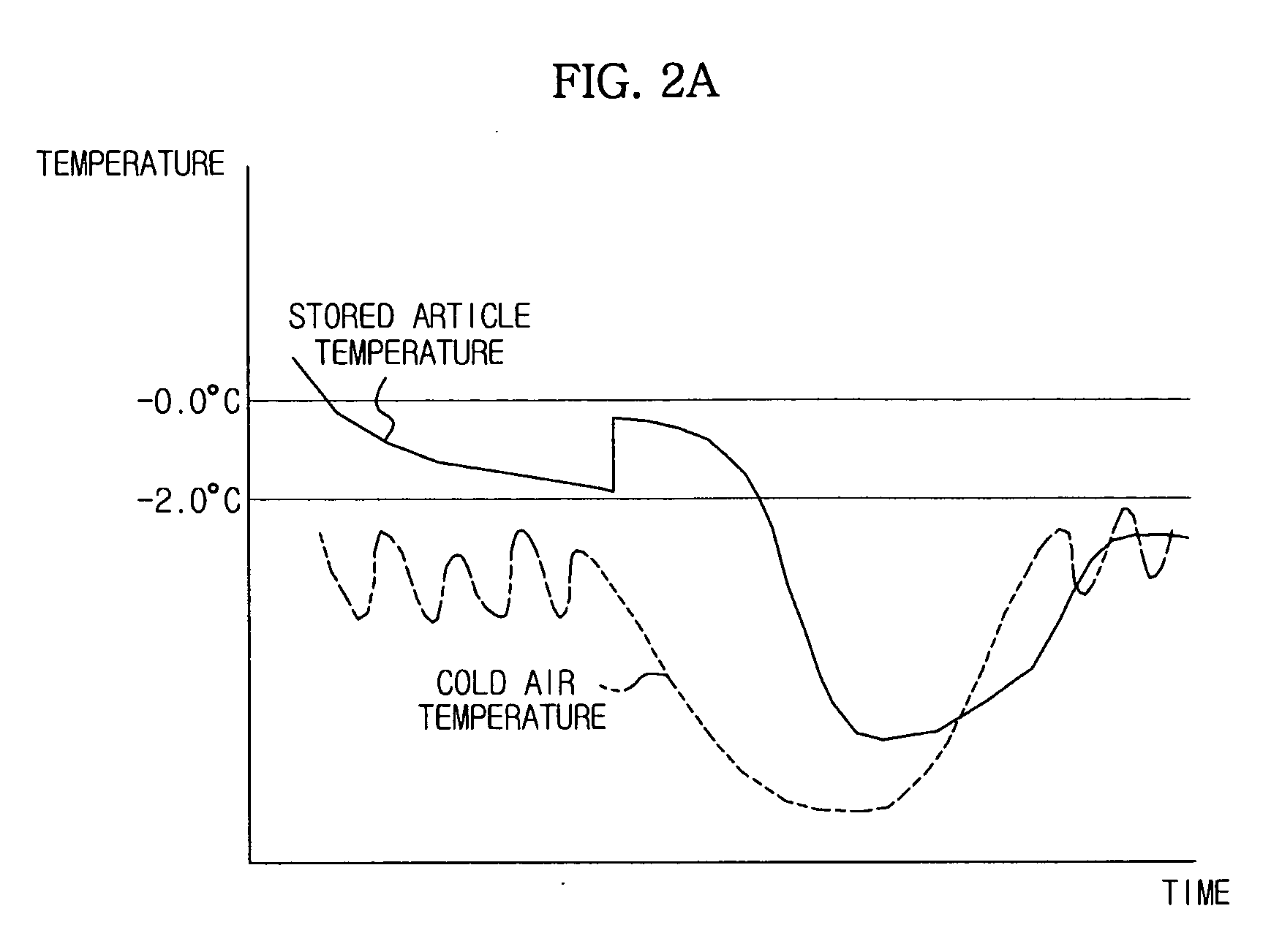

Refrigerating apparatus and method of controlling the same

InactiveUS20100332048A1Good frozen qualityLighting and heating apparatusDomestic refrigeratorsCold airSuper cooling

Disclosed herein are a refrigerating apparatus and a method of controlling the same. The method includes lowering a temperature in a storage chamber to a freezing point temperature zone by adjusting cold air supplied to the storage chamber, and lowering the temperature in the storage chamber to a temperature below a freezing point by increasing an amount of the cold air supplied to the storage chamber, when it is determined that a temperature of articles stored in the storage chamber is stabilized in the freezing point temperature zone by the cold air. When the surface temperature and the center temperature of the stored articles are cooled close to the freezing point and are then cooled again to the freezing temperature below the freezing point, super-cooling of the stored articles is carried out for a short time, the surfaces and the centers of the stored articles start to freeze simultaneously.

Owner:SAMSUNG ELECTRONICS CO LTD

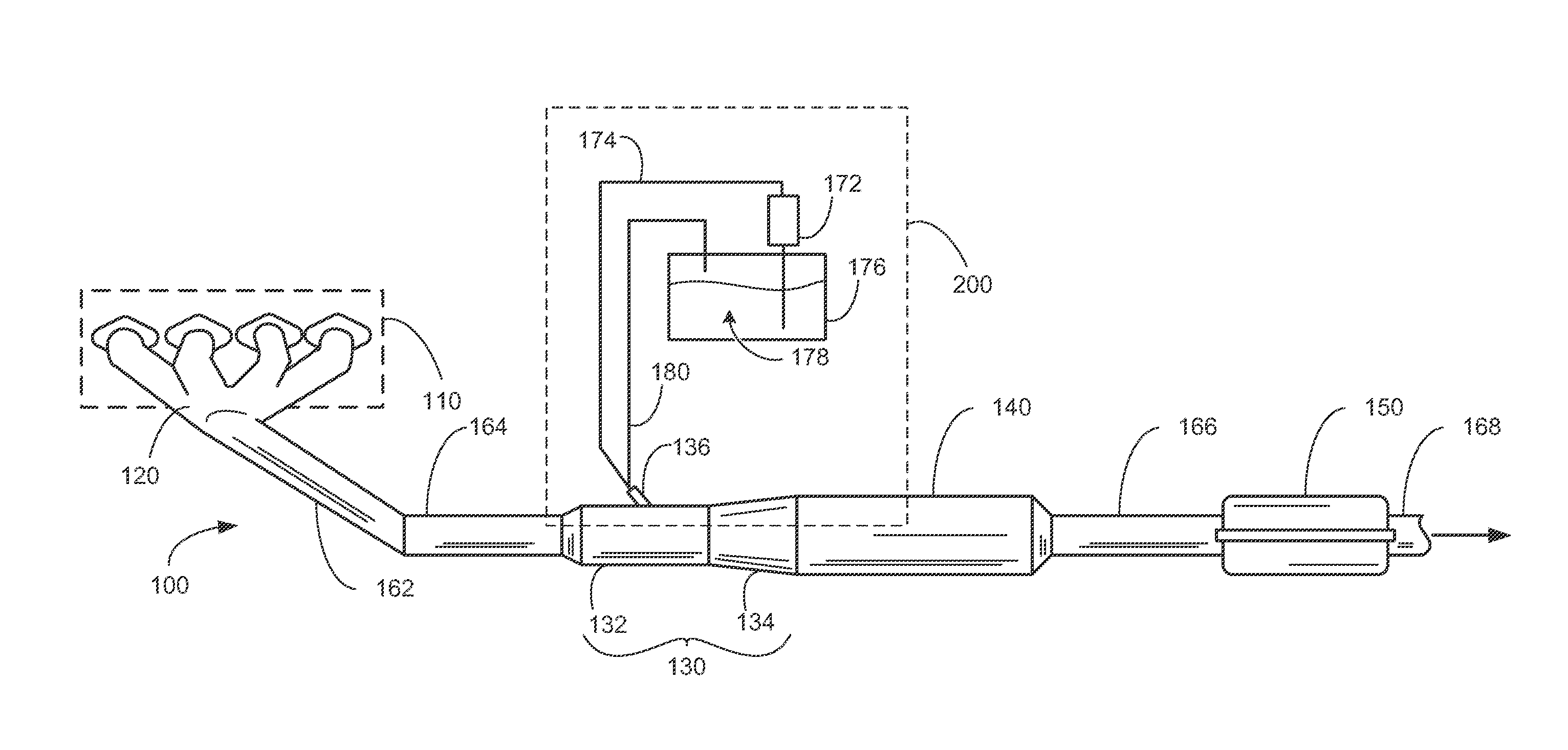

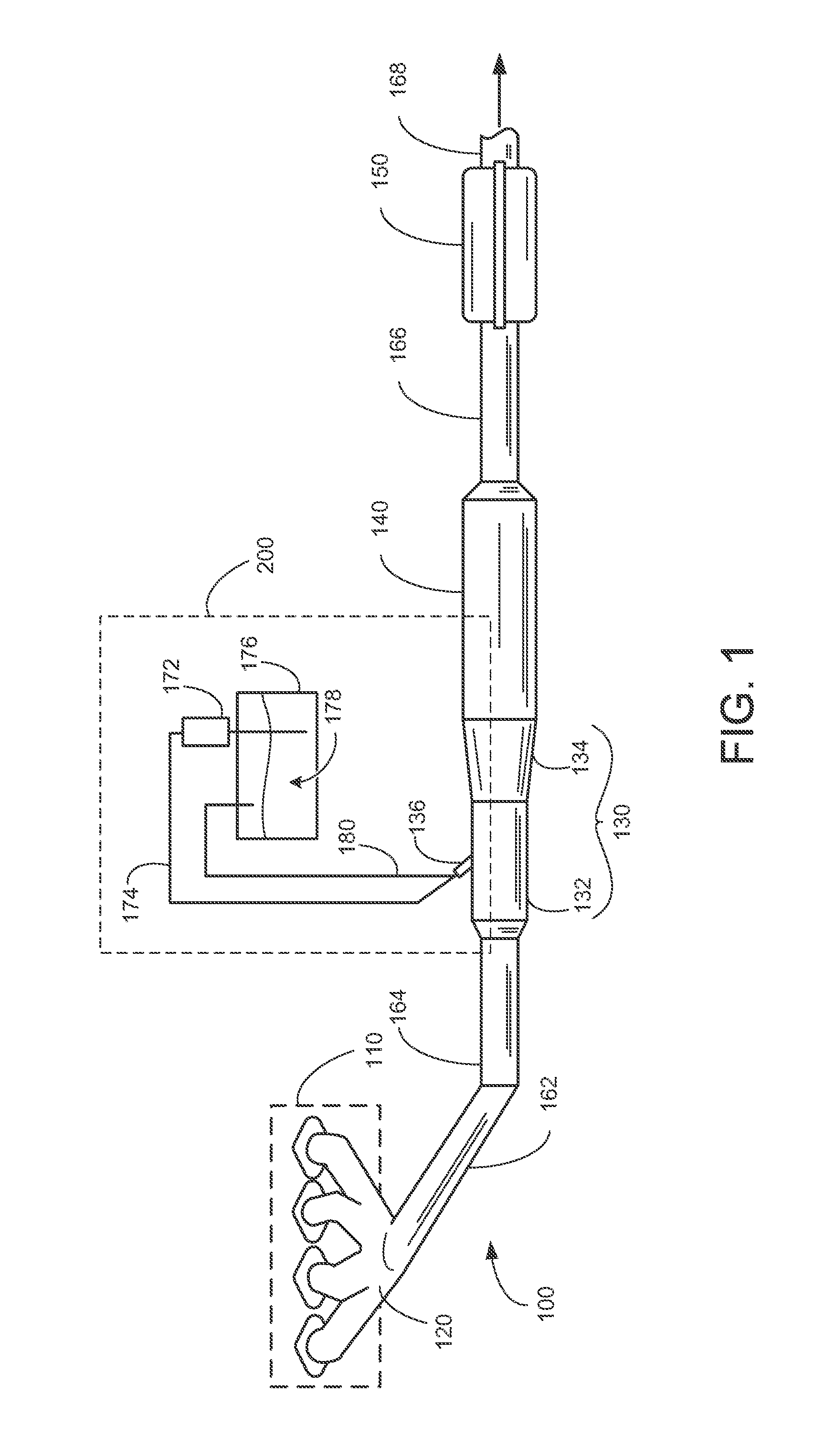

System and Method for Liquid Reductant Injection

InactiveUS20120260629A1Assure functionalityAssure survivabilityInternal combustion piston enginesExhaust apparatusFreezing Point TemperatureElectricity

A method for operating a liquid reductant injection system is provided. The method includes storing a reductant mixture of ethanol, water, and urea; drawing the stored mixture into an electrically heated pick-up tube for delivery via a delivery line to the exhaust by operating a pump in a first direction; and, clearing a return line that returns the stored mixture or the delivery line by operating the pump in a second, reverse, direction. In this way, by including ethanol in the reductant solution, a freezing point temperature of the liquid reductant may be reduced.

Owner:FORD GLOBAL TECH LLC

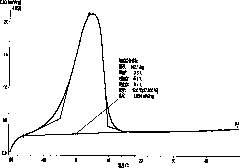

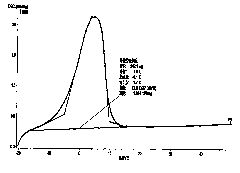

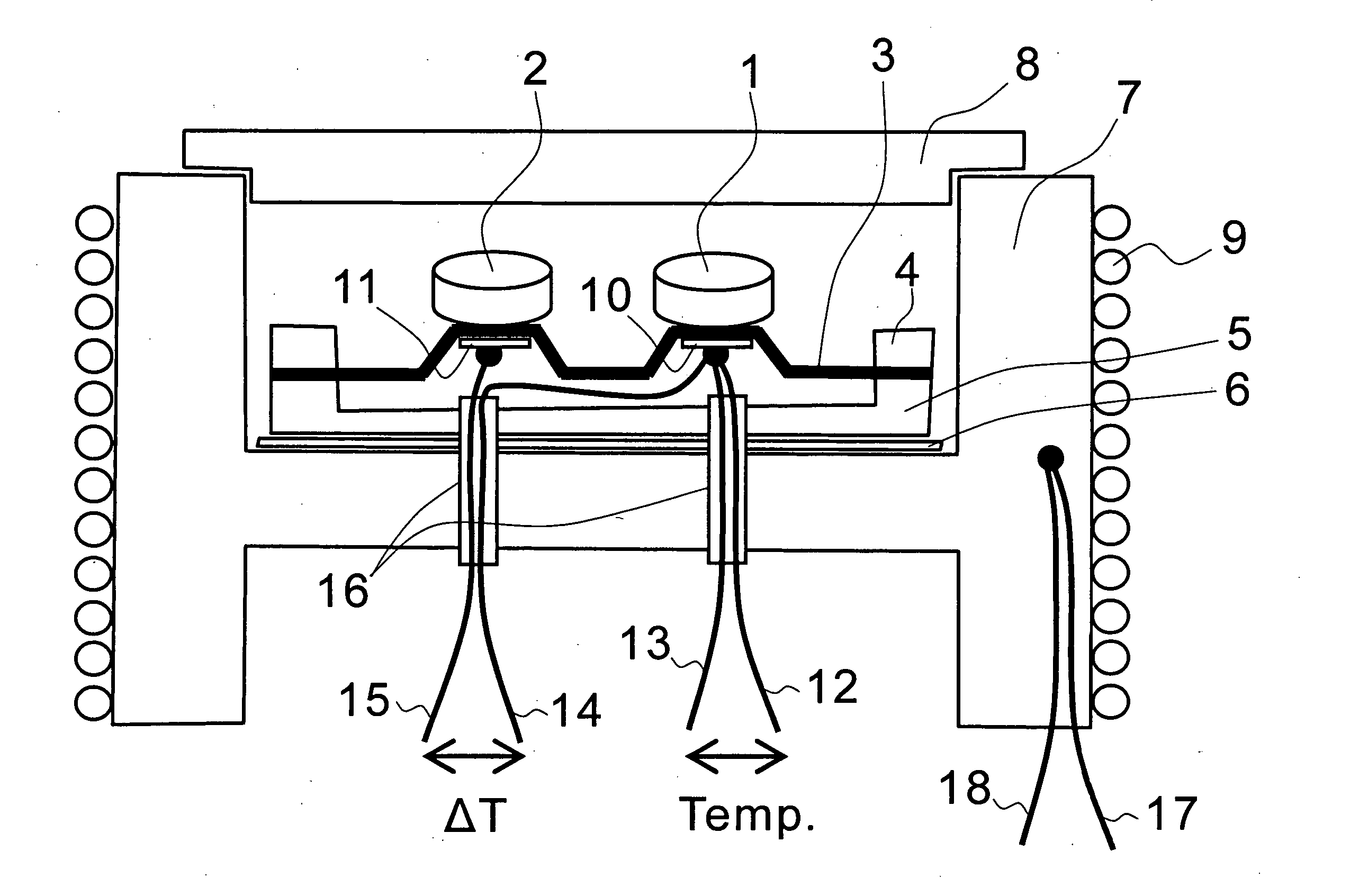

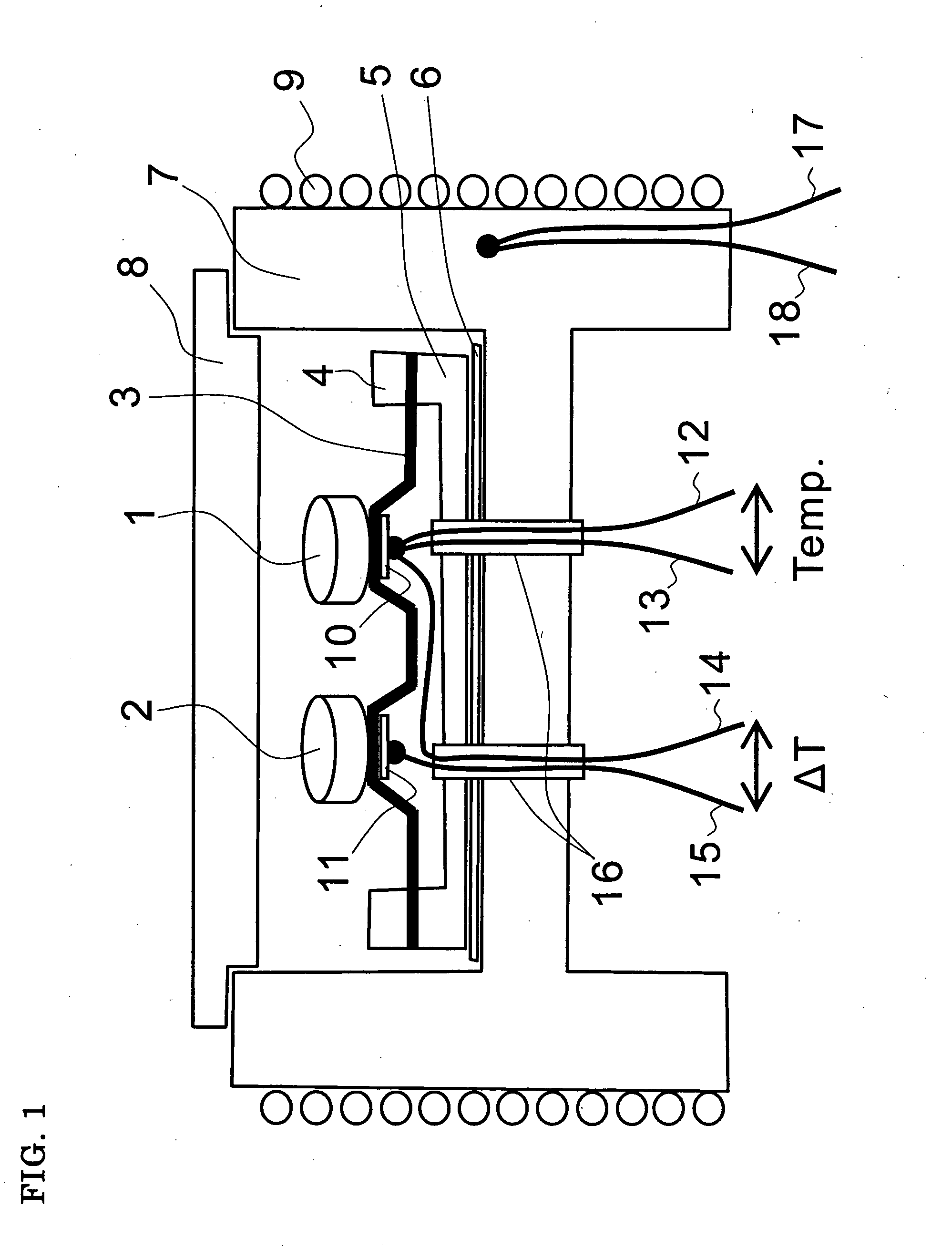

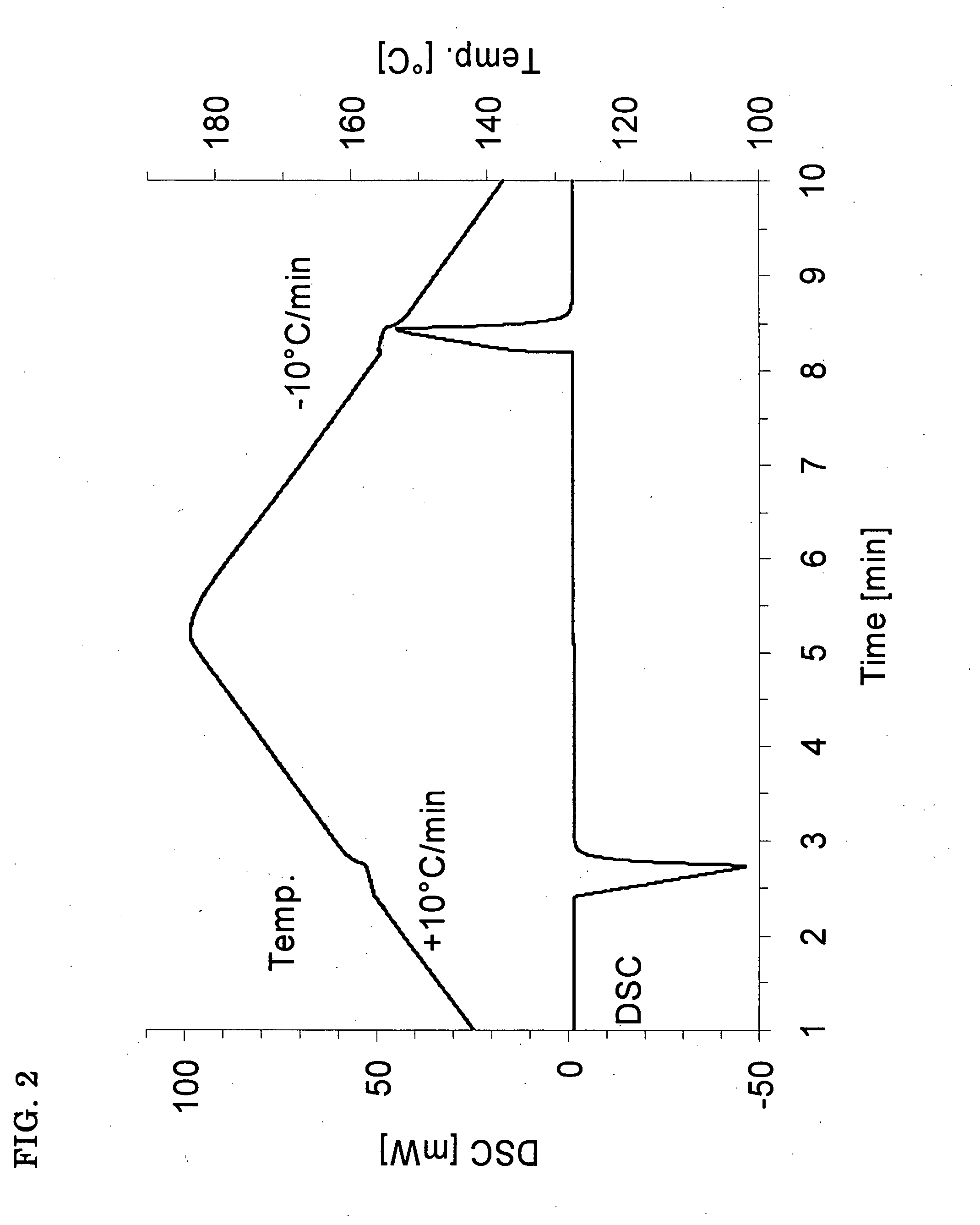

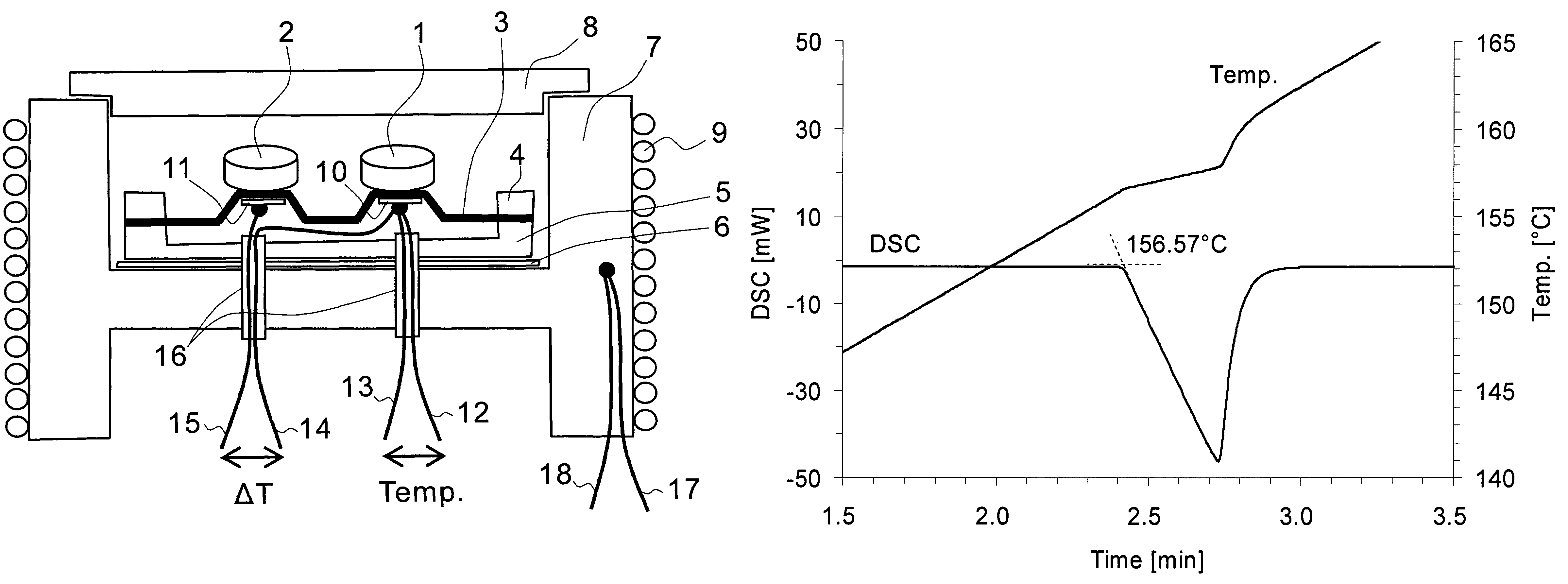

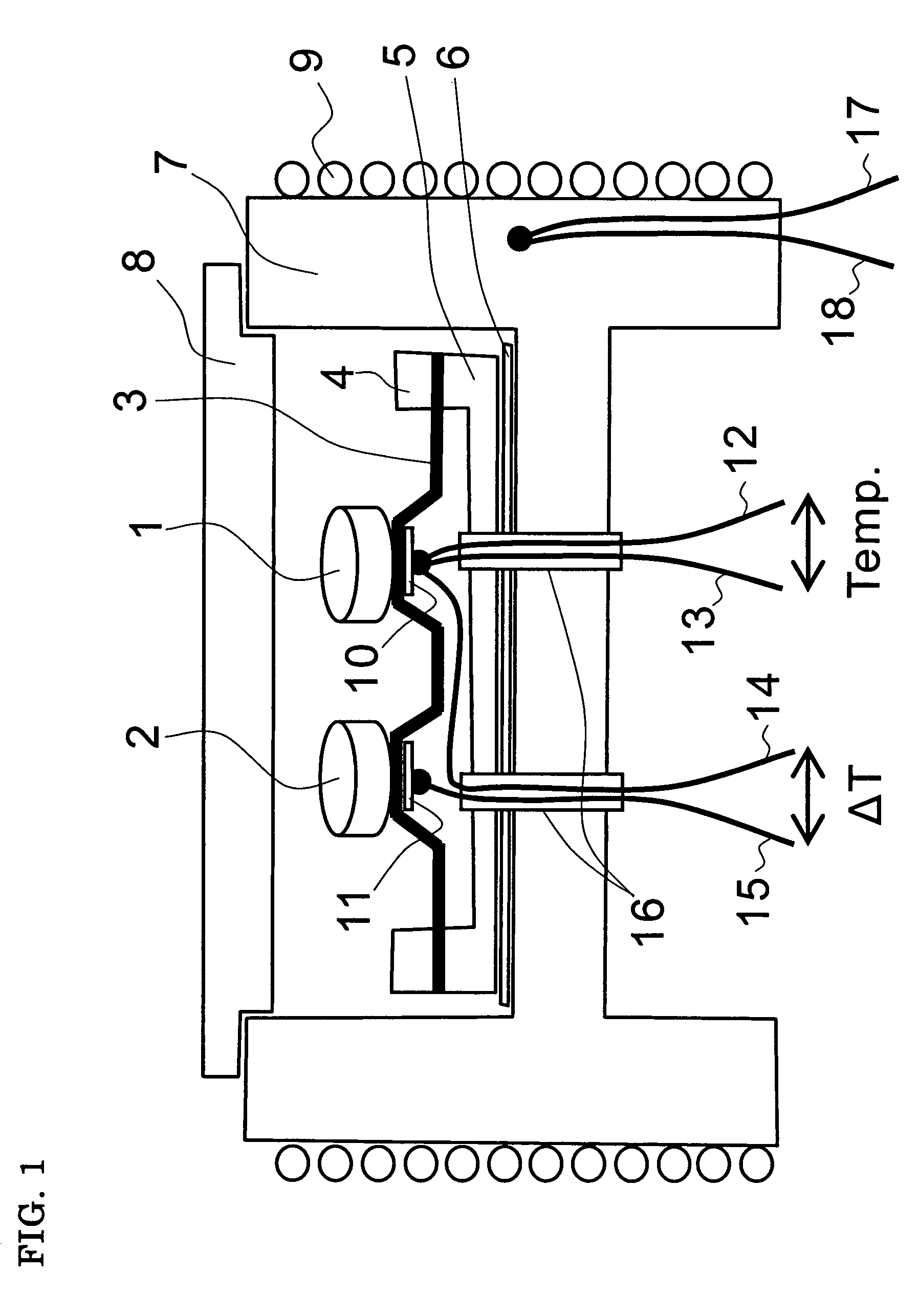

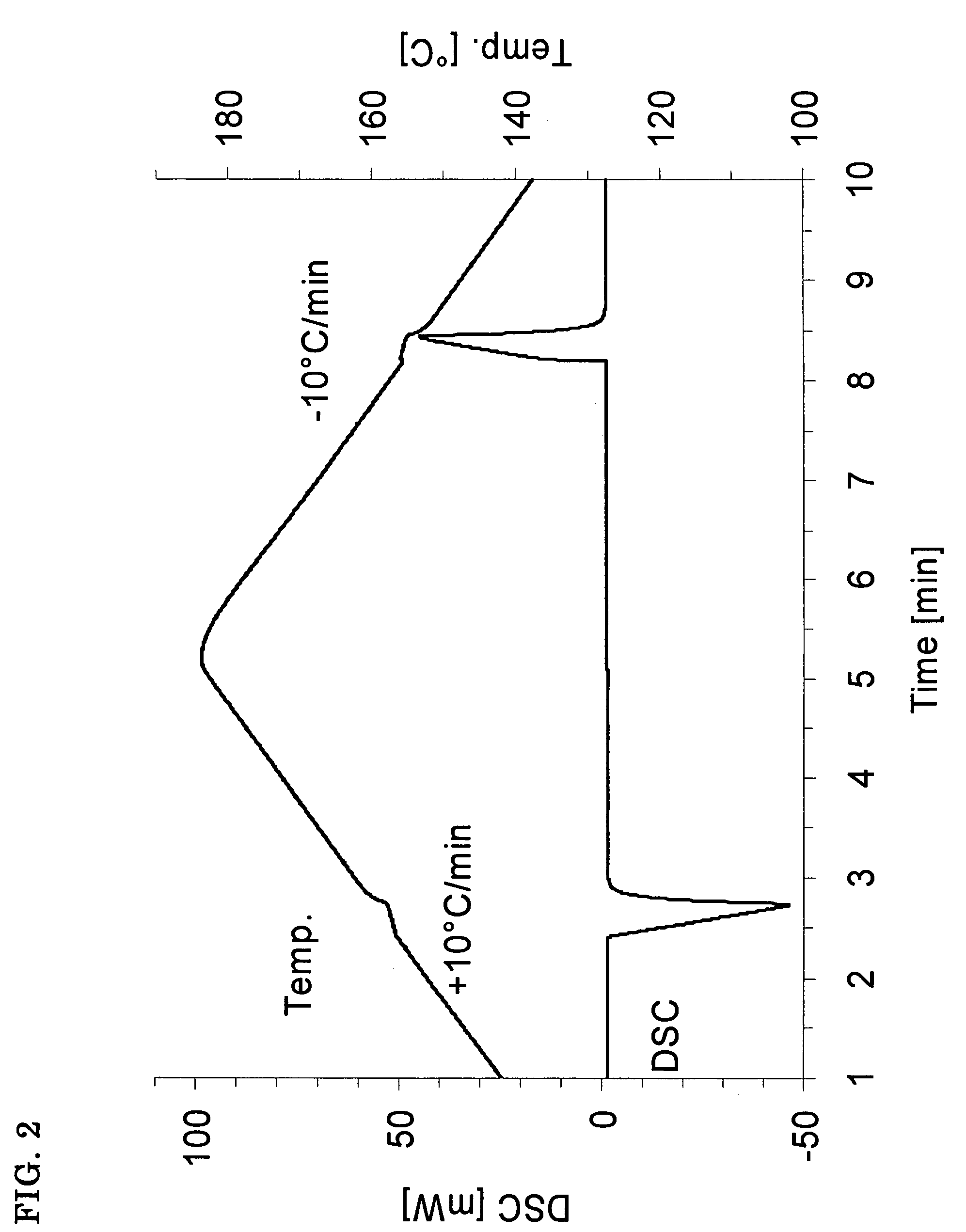

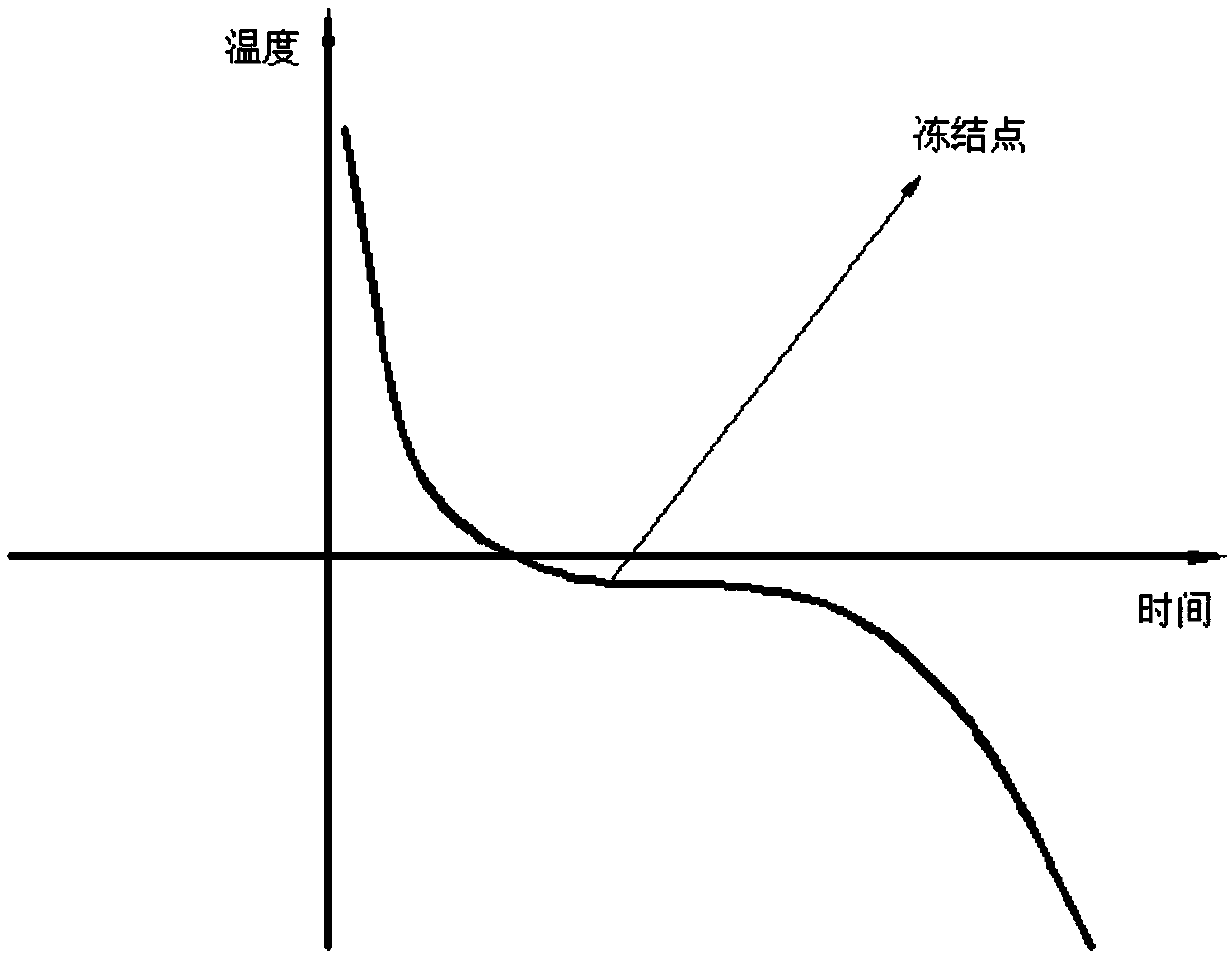

Freezing point temperature measuring method and temperature calibrating method in differential scanning calorimetry

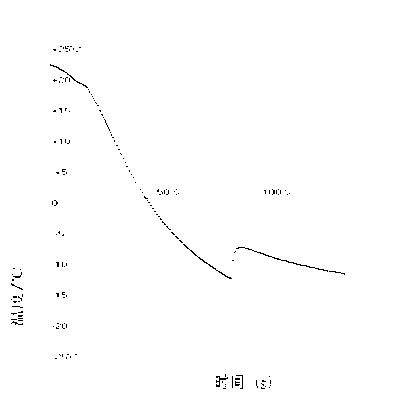

InactiveUS20070242722A1Accurate calculationMaterial heat developmentThermometer testing/calibrationFreezing Point TemperatureTemperature curve

It is discovered that a range of showing a state in which a sample is at a constant temperature at a freezing temperature by a latent heat can be specified from a result of a differential scanning calorimetry in a cooling procedure and a method of acquiring the freezing point of the sample from data in the range is shown. For example, an output temperature of an intersection constituted by a tangential line extrapolated from a DSC curve, an output temperature curve, and a base line or an extension of a range brought into a liquid state including a supercooled state is read, and a method of analyzing the DSC curve, the output temperature curve constituting the freezing point of the sample by a temperature of the intersection is discovered and adopted.

Owner:HITACHI HIGH TECH SCI CORP

Engine antifreeze composition

In general this invention relates to an antifreeze composition that can be used in the cooling systems of internal combustion engines, for example, in heavy-duty diesel engines, light duty trucks and cars. The antifreeze composition can be added to water or other suitable liquid coolant in the cooling system, to lower the freezing point temperature of the coolant and inhibit corrosion of metallic components associated with the cooling system. The antifreeze composition is particularly well suited, although not exclusively, for use with hard water. The antifreeze composition includes an organic acid component comprising adipic acid and at least one of benzoic acid and one or more C9-C12 dicarboxylic acid—or salts of these acids. The antifreeze composition also includes other anti-corrosive additive, for example, molybdate, nitrite, nitrate silicate azoles and a variety of buffer agents.

Owner:FLEETGUARD INC

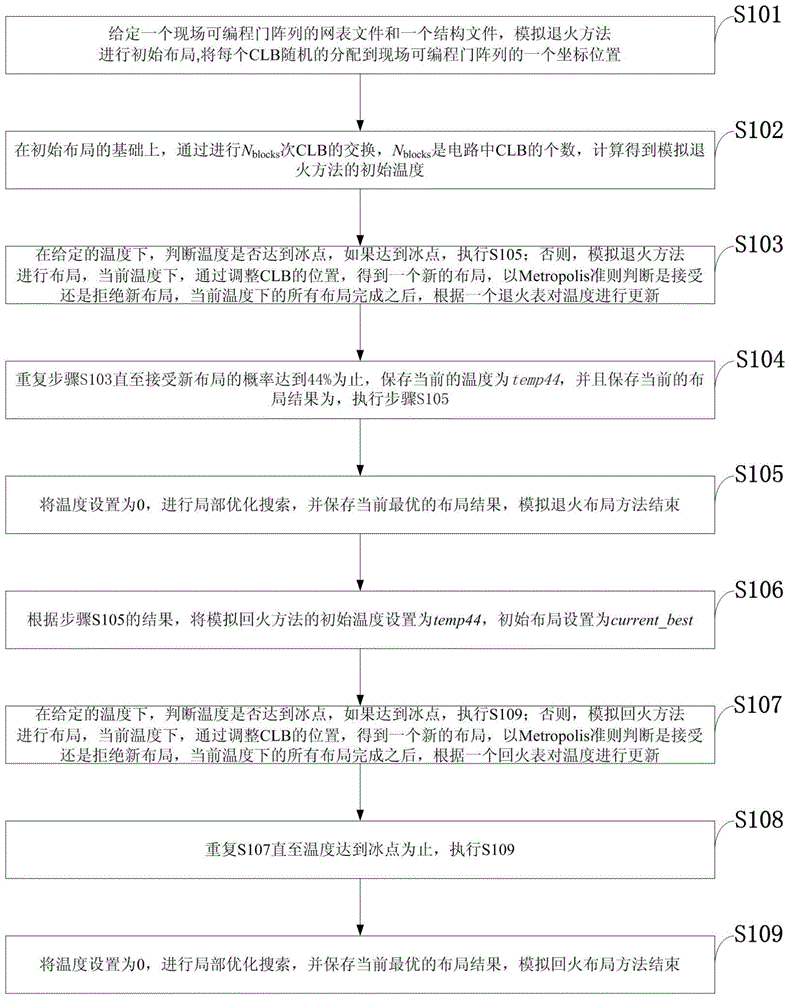

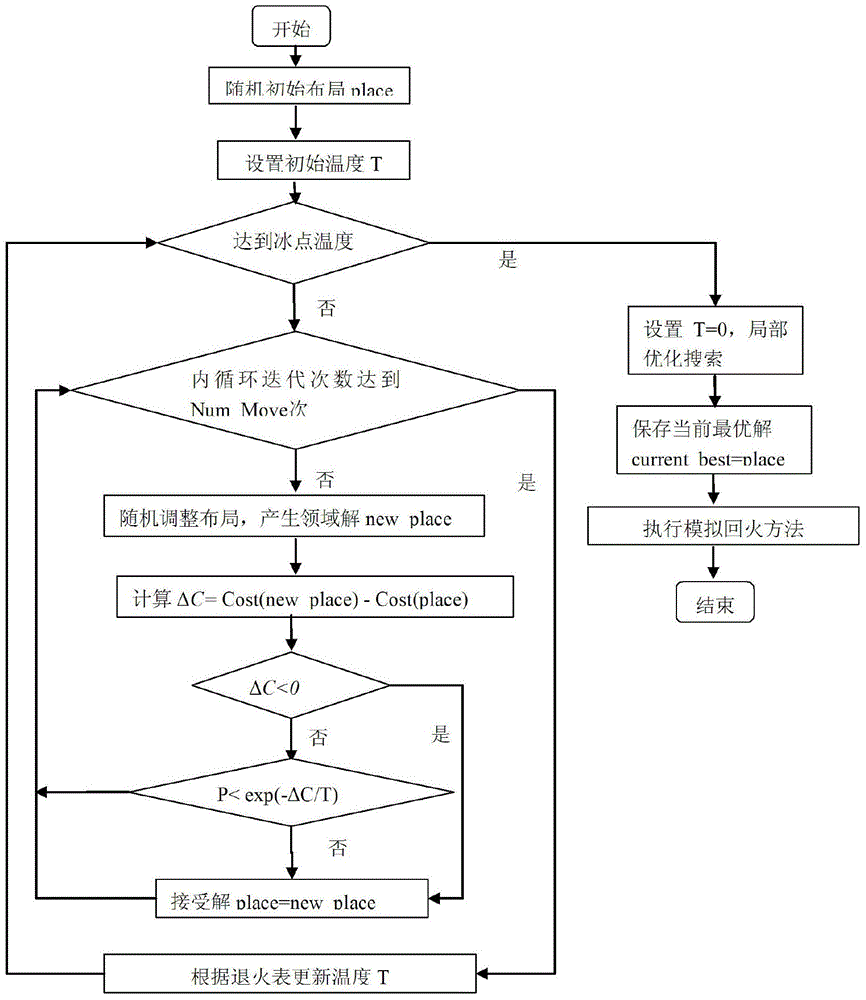

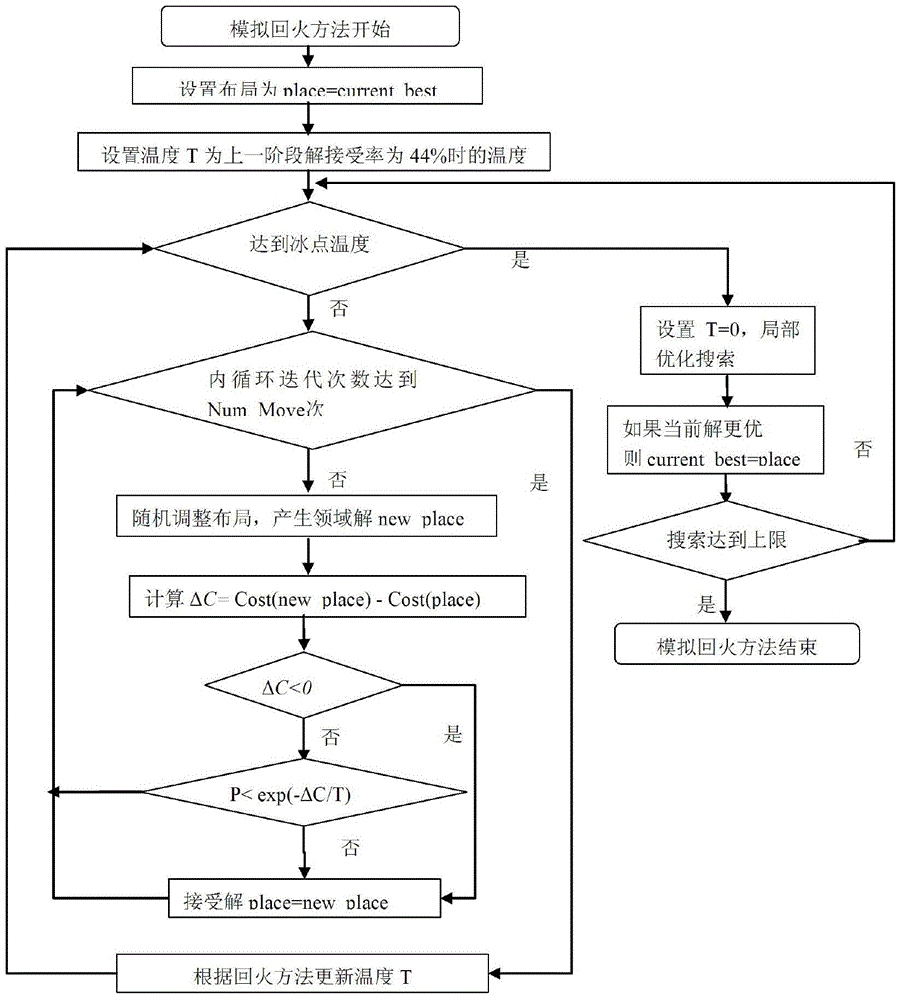

Field-programmable gate array (FPGA) layout method based on simulated annealing/tempering

ActiveCN103914587AImprove stabilityQuality improvementSpecial data processing applicationsFreezing Point TemperatureSimulation based

The invention discloses a field-programmable gate array (FPGA) layout method based on simulated annealing / tempering. A method of mixing simulated annealing and simulated tempering is used. Firstly, a traditional simulated annealing method is utilized to obtain a best solution current_best which can be found by simulated annealing, the temperature 44 DEG C (temp44) is recorded when the receiving rate of the solution is 44%, proper temperature gradient (t1, t2,```, tm) from temp44 to a freezing point temperature is established, then a tempering method is started to be simulated according to the temperature gradient, if a solution which is better than the current_best is found in the process, the solution better than the current_best replaces the current_best, and a finally obtained current_best is a required optimal solution. The FPGA layout method based on simulated annealing / tempering is applied to a layout tool of electronic design automation (EDA) software which supports FPGA development, a finally layout result is good in stability, meanwhile, the qualities of circuits can be improved, time delay of key routes is reduced, and a final distributed wire length is improved.

Owner:XIDIAN UNIV

Freezing point temperature measuring method and temperature calibrating method in differential scanning calorimetry

InactiveUS7547137B2Accurate calculationMaterial heat developmentThermometer testing/calibrationFreezing Point TemperatureCrossing point temperature

It is discovered that a range of showing a state in which a sample is at a constant temperature at a freezing temperature by a latent heat can be specified from a result of a differential scanning calorimetry in a cooling procedure and a method of acquiring the freezing point of the sample from data in the range is shown. For example, an output temperature of an intersection constituted by a tangential line extrapolated from a DSC curve, an output temperature curve, and a base line or an extension of a range brought into a liquid state including a supercooled state is read, and a method of analyzing the DSC curve, the output temperature curve constituting the freezing point of the sample by a temperature of the intersection is discovered and adopted.

Owner:HITACHI HIGH TECH SCI CORP

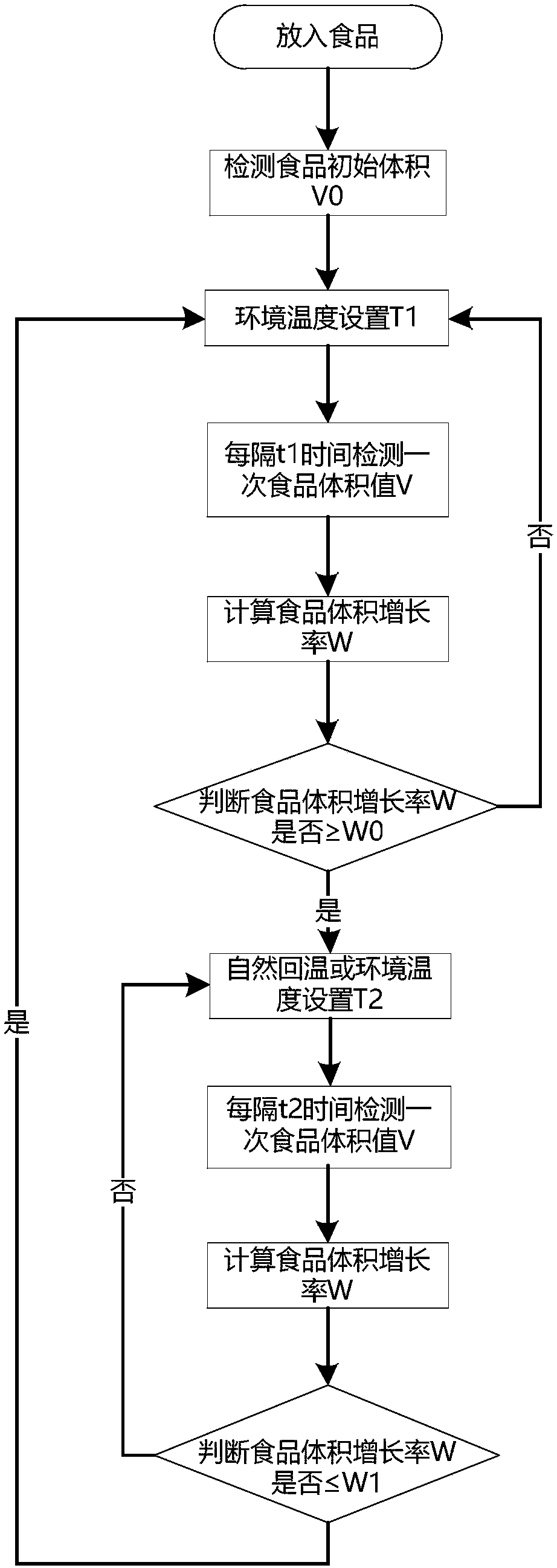

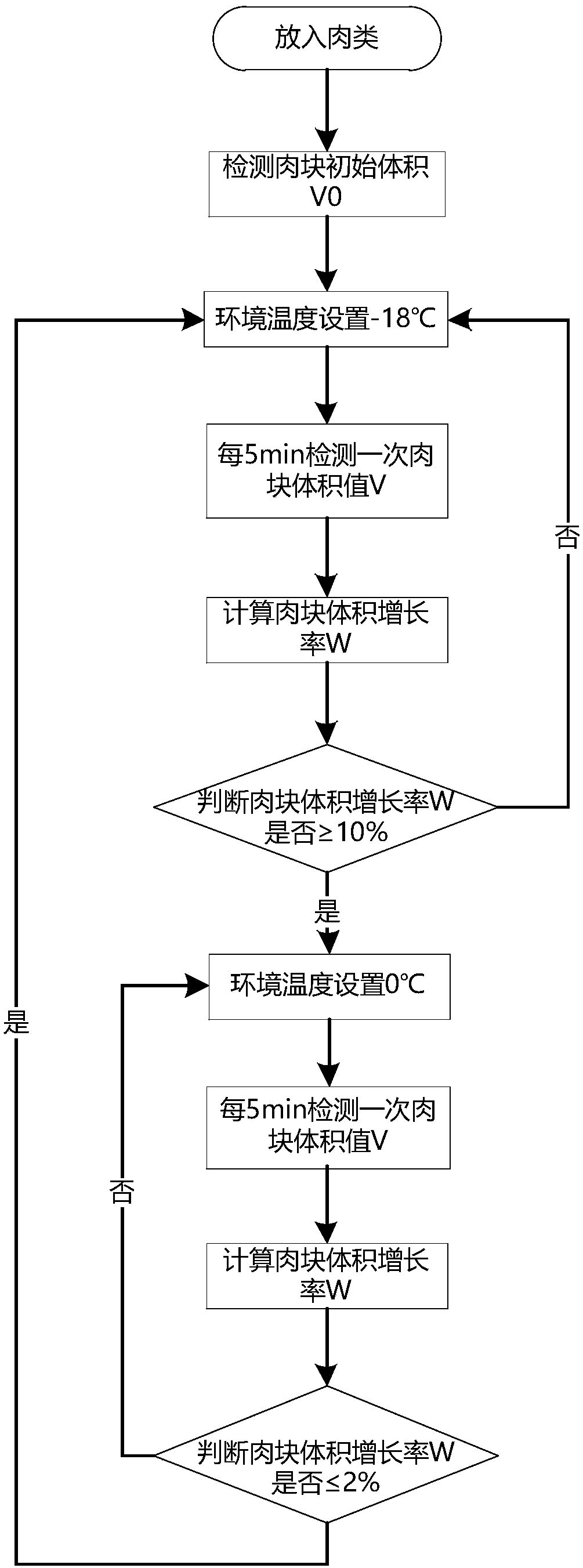

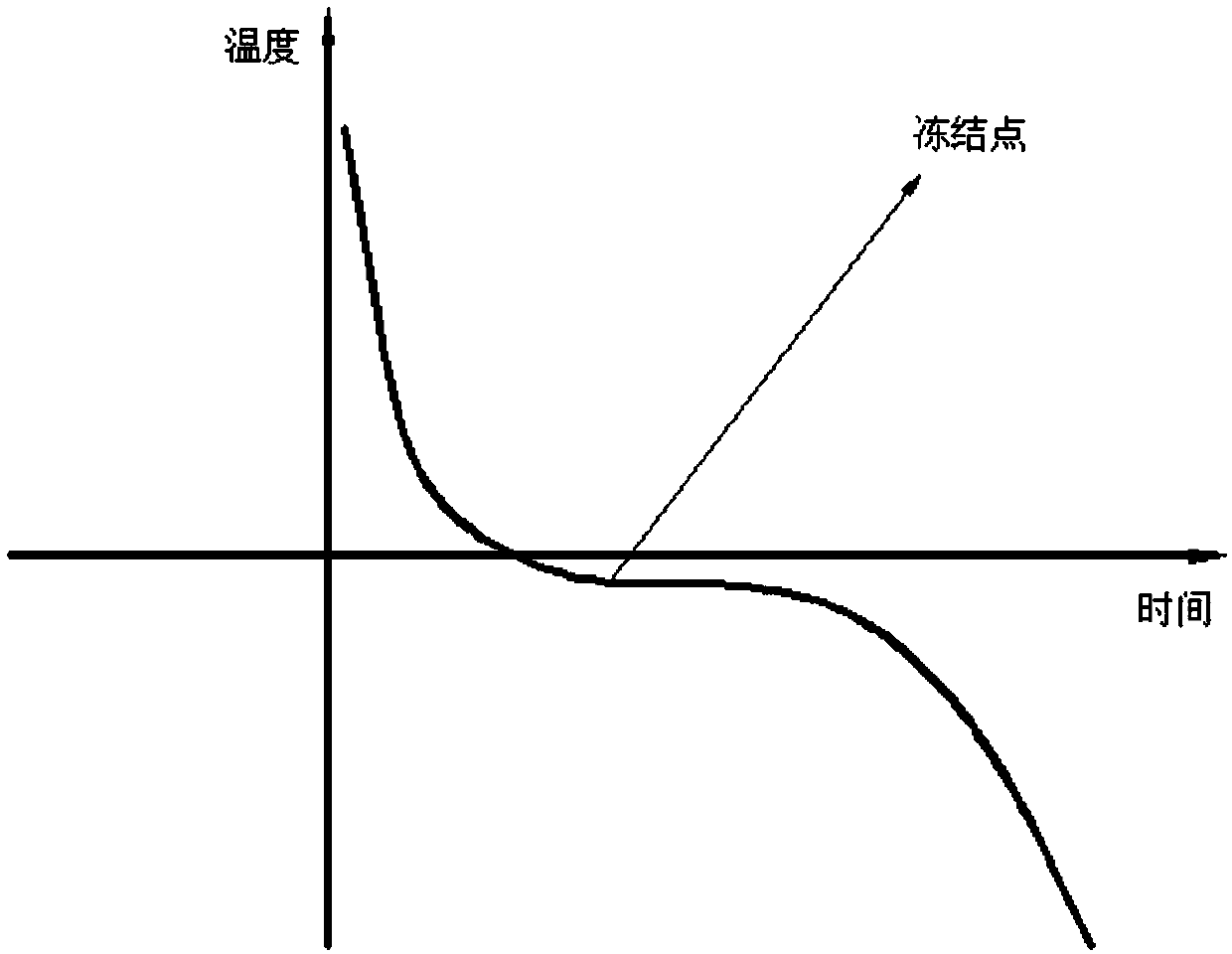

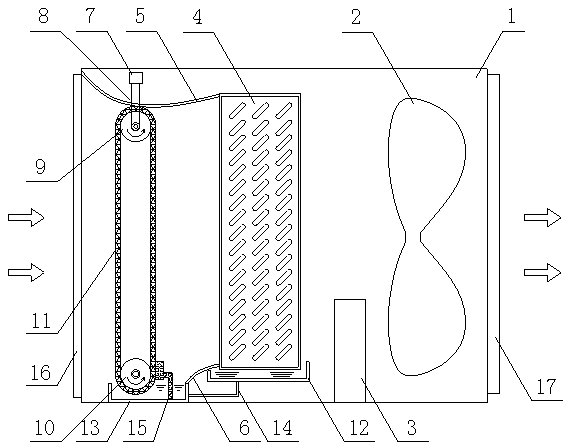

Method for judging freezing point according to food volume, controller and refrigeration equipment

InactiveCN107843062AGuaranteed not frozen freshStay Nutritious and TastyLighting and heating apparatusCooling fluid circulationFreezing Point TemperatureTemperature control

The invention relates to the field of refrigeration control, in particular to a method for judging a freezing point according to food volume, a controller and refrigeration equipment. According to themethod for judging the freezing point according to the food volume, the controller and the refrigeration equipment disclosed by the invention, whether food gets into a frozen state or not is judged by utilizing that the volume of the food is different at different temperature. Food temperature is controlled to be within a reasonable range by combining the volume change of the food with temperature control. If the food gets into the frozen state, the refrigeration equipment can enter a warming-up mode immediately to stop a process that water in the food continues to form ice crystals, so thatthe food cannot be frozen; when food temperature reaches a certain value, the food is cooled immediately; the cooling process and the warming-up process are repeated for multiple times in such a manner, so that the food temperature keeps at 0 DEG C to freezing point temperature most of the time or all the time, while the freezing point temperature is between -10 DEG C and 0 DEG C. The freezing point of the food is effectively judged by utilizing the change rate of the food volume; the volume change in the food and the temperature control are effectively controlled to reasonably control the food temperature to reach a critical state that the food is not frozen but fresh, and therefore the food is enabled to be not frozen but fresh, the fresh-keeping period is effectively prolonged, and thefood maintains nutritive and delicious.

Owner:HEFEI HUALING CO LTD +2

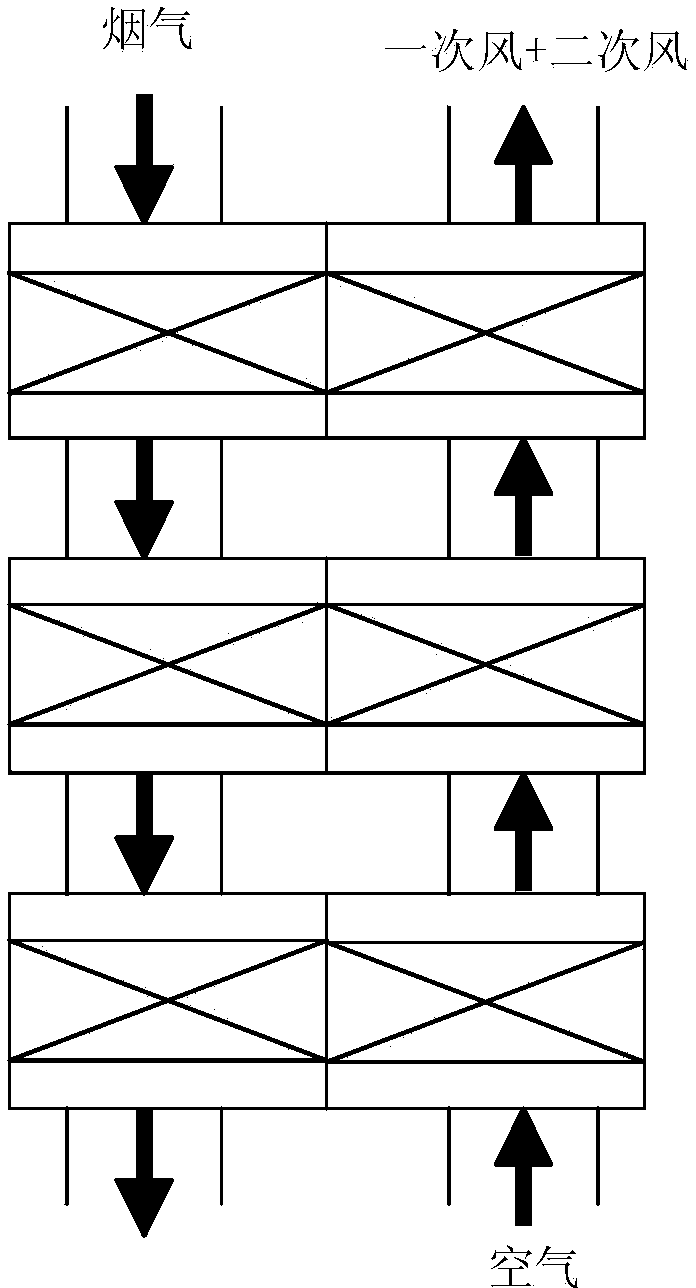

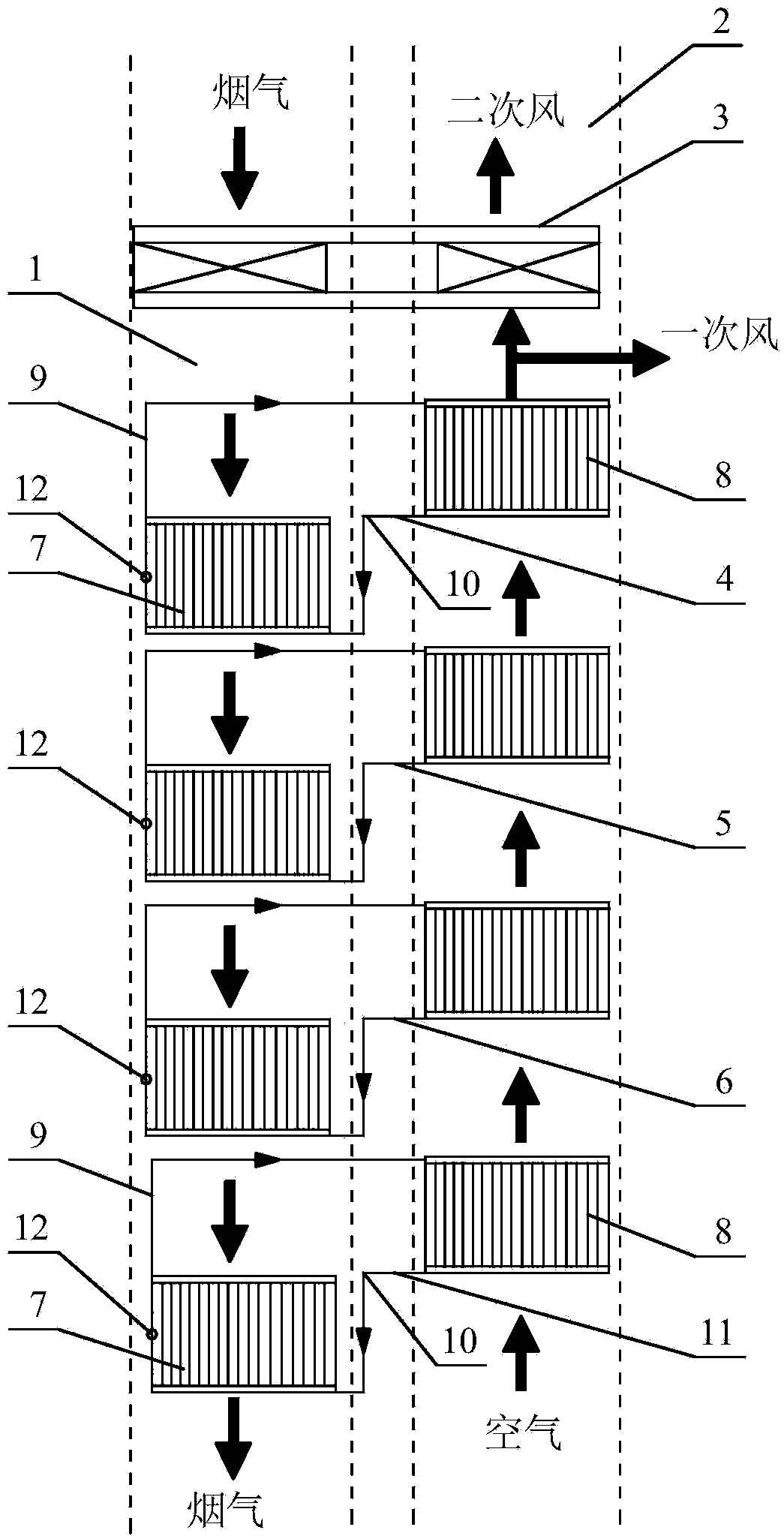

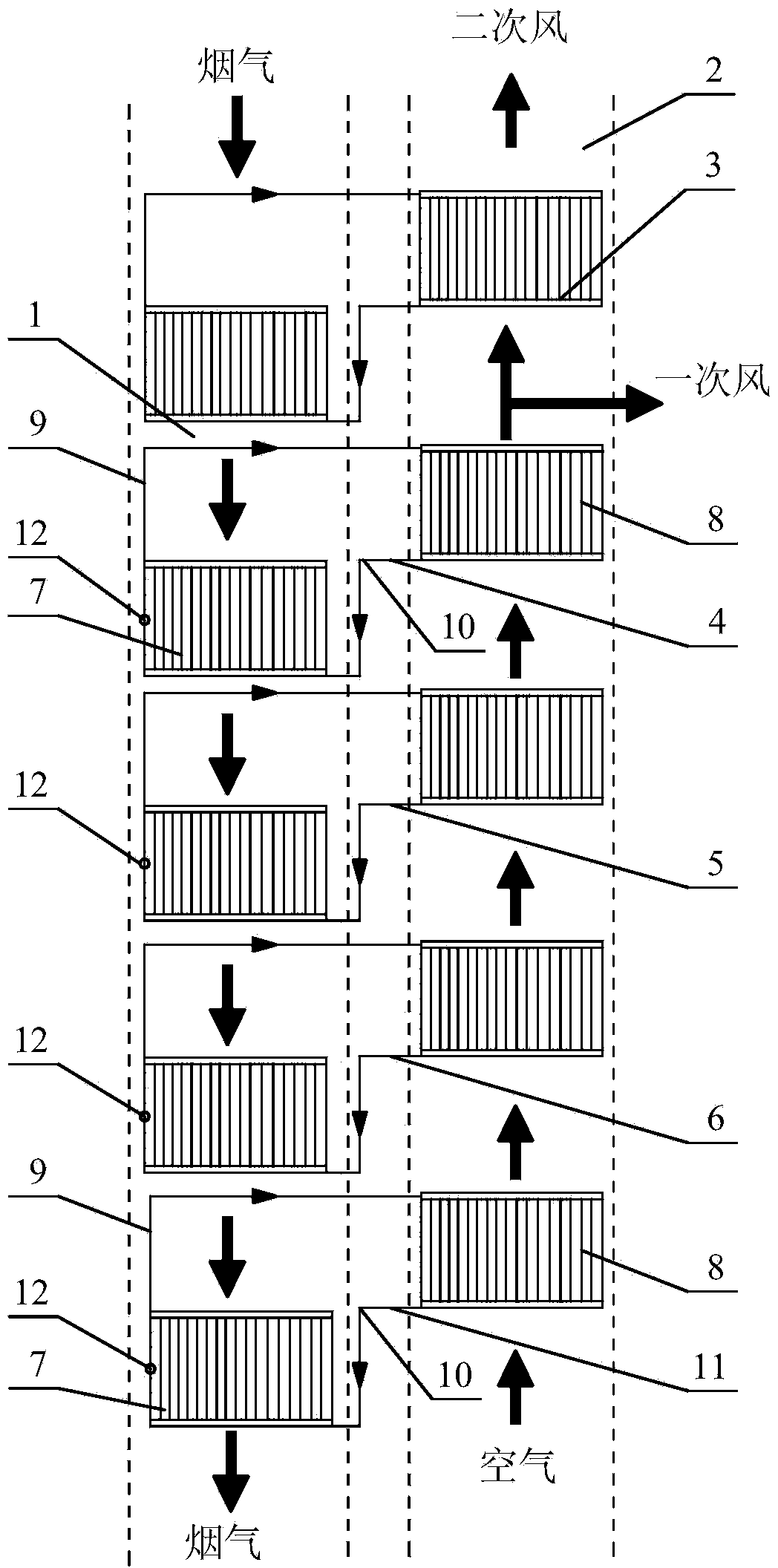

Combined air preheater suitable for SCR (Selective Catalytic Reduction) post-denitration, and anti-corrosion and anti-blocking method

InactiveCN103982906AEliminate the phenomenon of heating surfaceAvoid corrosionEmission preventionCorrosion preventionFreezing Point TemperatureAir preheater

The invention provides a combined air preheater suitable for SCR (Selective Catalytic Reduction) post-denitration, which comprises a flue and an air duct which are arranged downstream a denitration device, and also comprises a secondary air section, a primary air section, an ammonium bisulfate condensation resistant section and an ammonium bisulfate curing section which are sequentially arranged along the flue gas flowing direction, wherein the primary air section, the ammonium bisulfate condensation resistant section and the ammonium bisulfate curing section are phase change heat exchangers, and the phase change heat exchanger comprises a heat absorbing section positioned in the flue, a heat releasing section positioned in the air duct, and a riser and a downcomer which are used for connecting the heat absorbing section and the heat releasing section; the heat releasing section is higher than the heat absorbing section, and a circulating medium is arranged in the phase change heat exchanger; the wall surface temperature of the ammonium bisulfate condensation resistant section is higher than the dew-point temperature of ammonium bisulfate, and the wall surface temperature of the ammonium bisulfate curing section is lower than the freezing point temperature of ammonium bisulfate. The combined air preheater puts an end to the phenomenon that liquid ammonium bisulfate blocks the heating surface of the air preheater due to dust, and also effectively prevents the liquid ammonium bisulfate from corroding the air preheater.

Owner:HOTANT THERMAL TECH JIANGSU

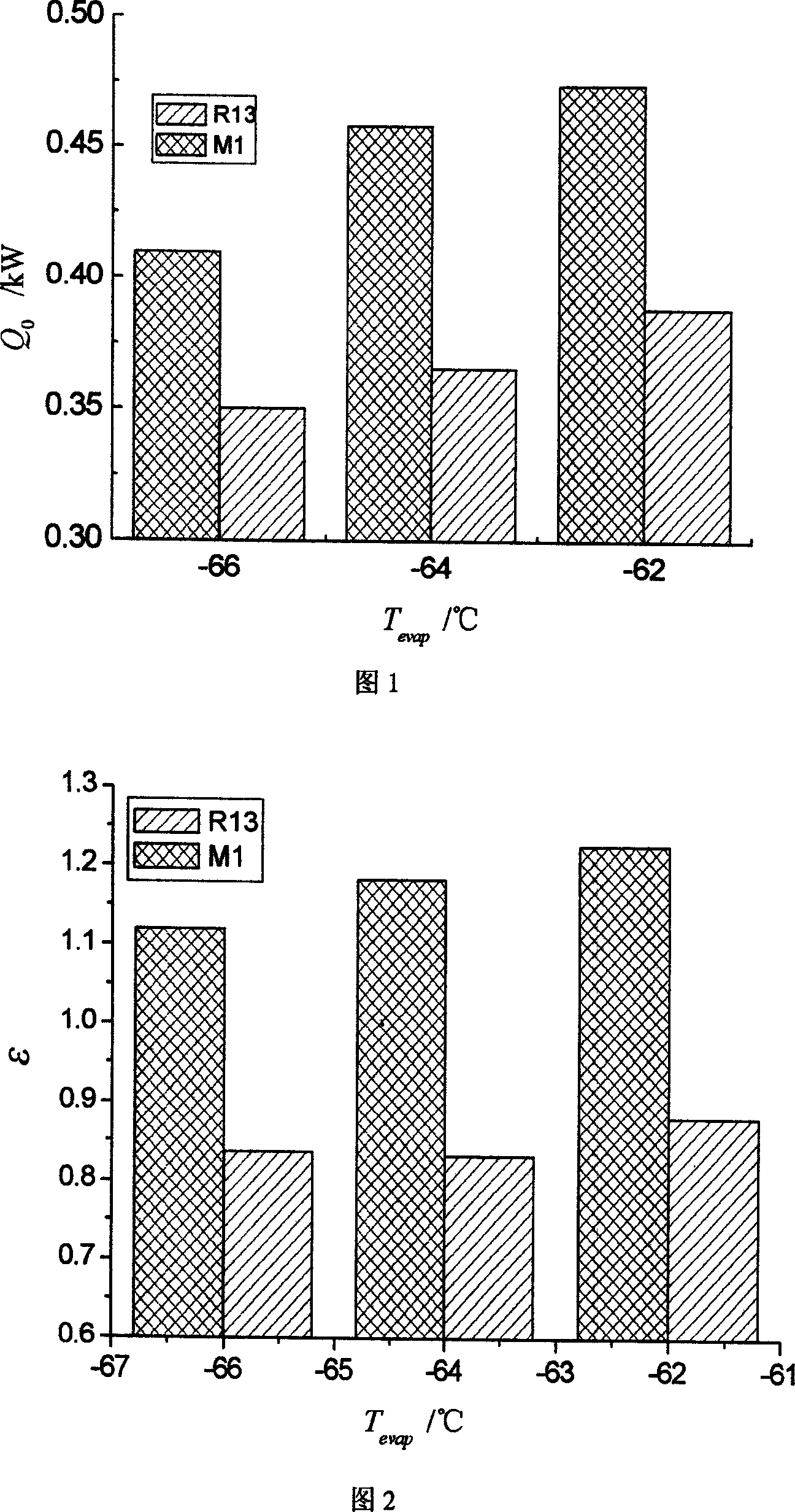

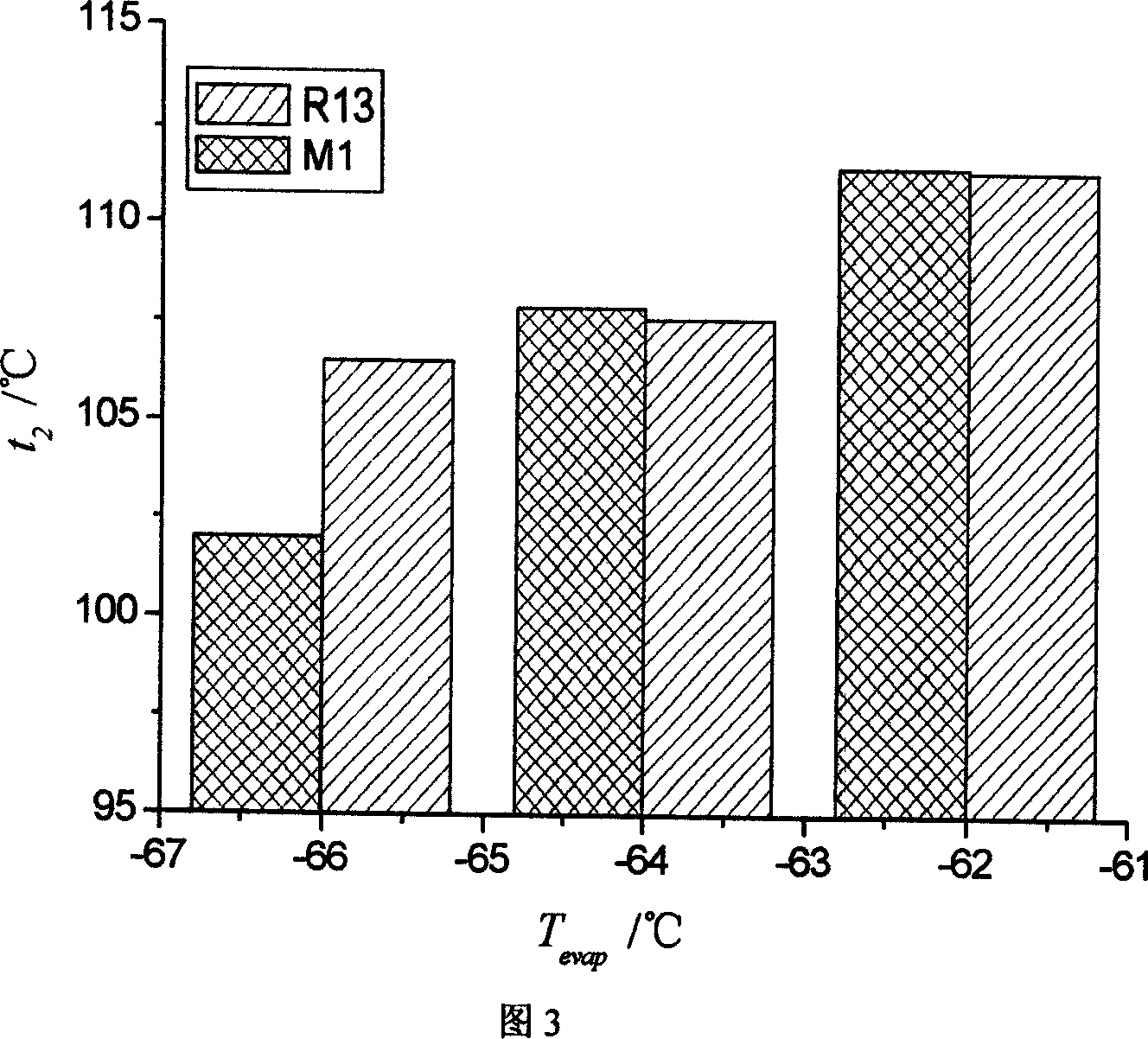

Refrigerant for refrigerating system low-temperature loop

InactiveCN101012367ALower freezing point temperatureLower saturation pressureHeat-exchange elementsFreezing Point TemperatureRefrigerant

The invention discloses a freezing agent of low-temperature circuit, which is characterized by the following: allocating raw material with 60-75% carbon dioxide and 25-40% propane; reducing coagulating point temperature and low-temperature saturated pressure of CO2 as well as combustibility and boiling-point temperature of propane (R290).

Owner:TIANJIN UNIV

Gas hydrate preparation method using phase-change heat transfer of oil wrapped water emulsion

InactiveCN105623767AIncreased hydration rateSolidificationLiquefactionFreezing Point TemperatureAdditive ingredient

The invention relates to a gas hydrate preparation method using phase-change heat transfer of oil wrapped water emulsion. The oil wrapped water emulsion is prepared from the following components in percentage by mass: 49.6 percent to 74.0 percent of an oil phase, 25.0 percent to 45.0 percent of water and 1 percent to 5.4 percent of a non-ionic surfactant. The gas hydrate preparation method comprises the following steps: preparing ingredients according to the raw materials; breaking the water phase into water drops with the size of 0.5 micron to 100 microns and dispersing into the oil phase through a high-speed shearing machine or dispersion equipment, so as to form emulsion, wherein a freezing point of the oil phase in the emulsion is lower than a freezing point temperature of the water; cooling the emulsion by adopting a cooling manner and keeping the temperature constant after the water in the emulsion is partially or wholly frozen into ice; enabling formed ice-containing slurry to be in sufficient contact with micro-molecular gas to perform hydration. According to the gas hydrate preparation method provided by the invention, hydration heat can be effectively removed in time by using fusion of the ice in a hydration process; under the condition that a cooling medium is not additionally introduced, the uniformity and stability of a hydration temperature can be kept, so that the generation speed of a hydrate is improved.

Owner:TIANJIN UNIV

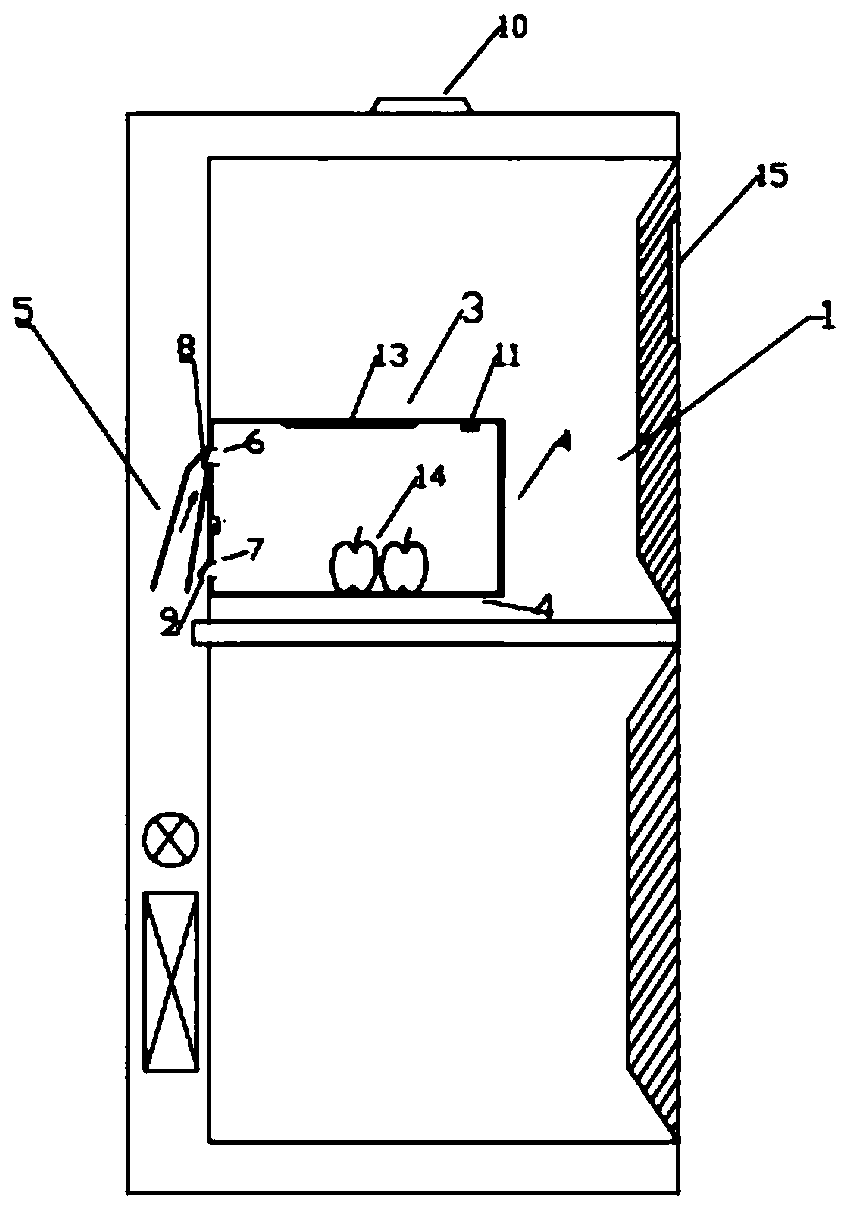

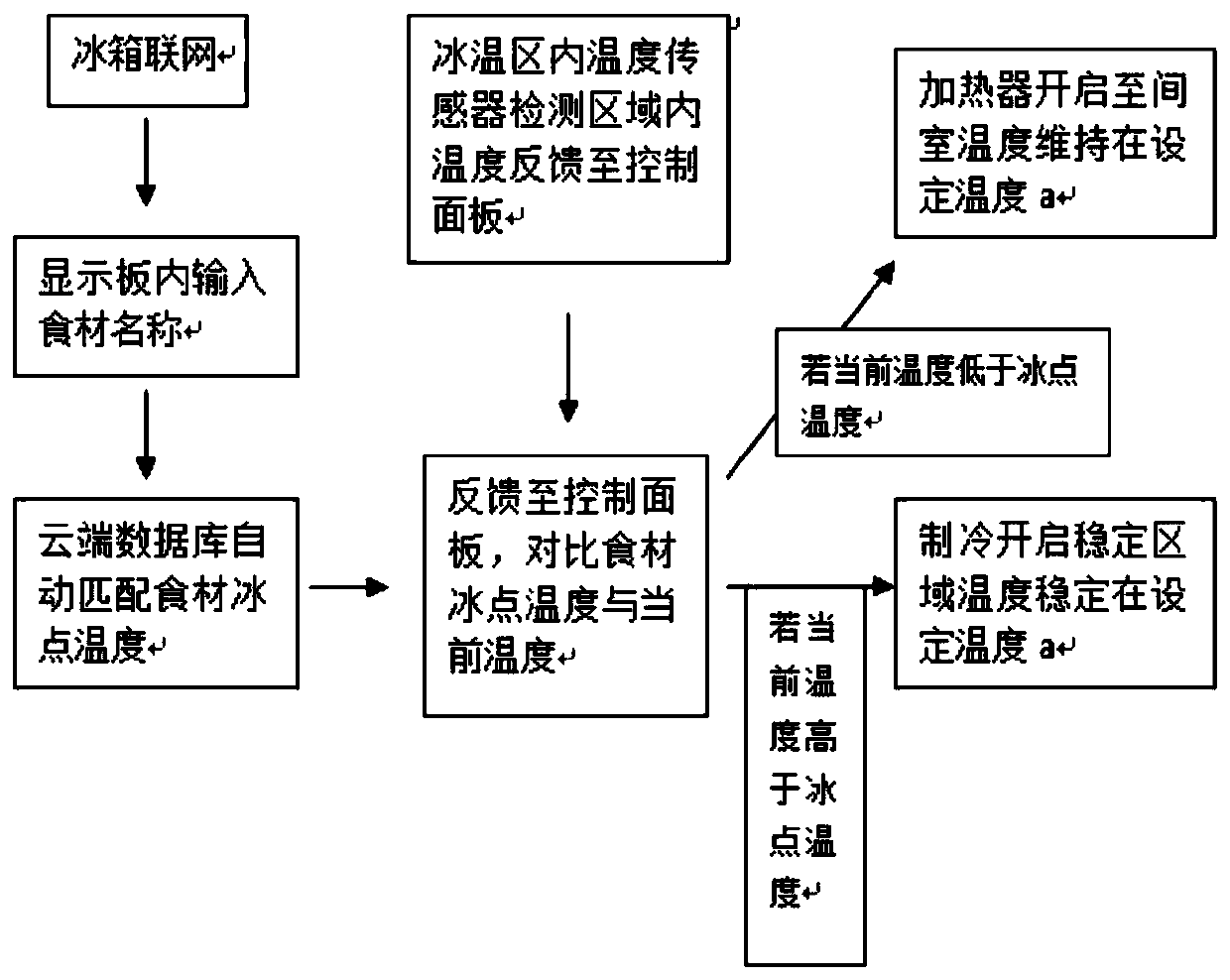

Control method of refrigerator with ice-temperature fresh-keeping function

InactiveCN110849067AAchieve exterminationReduced metabolic intensityLighting and heating apparatusCooling fluid circulationMicroorganismFreezing Point Temperature

The invention discloses a control method of a refrigerator with an ice-temperature fresh-keeping function, and relates to the technical field of intelligent refrigerators. The method comprises the following steps of S1, opening the refrigerator, and putting the food material to be preserved into an ice-temperature fresh-keeping area; S2, inputting the name of the food material through a display panel installed on the refrigerator, controlling the panel 0 to receive input data of the display panel, and acquiring freezing point temperature data of the food material in the cloud database througha built-in WIFI module; and S3, detecting the temperature in the ice-temperature fresh-keeping area to be fed back to the control panel through an infrared temperature sensor installed in the ice-temperature fresh-keeping area. According to the method, the fruits and vegetables are stored under the condition of near freezing point temperature, the reduction of metabolic strength and killing of microorganisms are realized, and the extension of the preservation period is finally realized.

Owner:CHANGHONG MEILING CO LTD

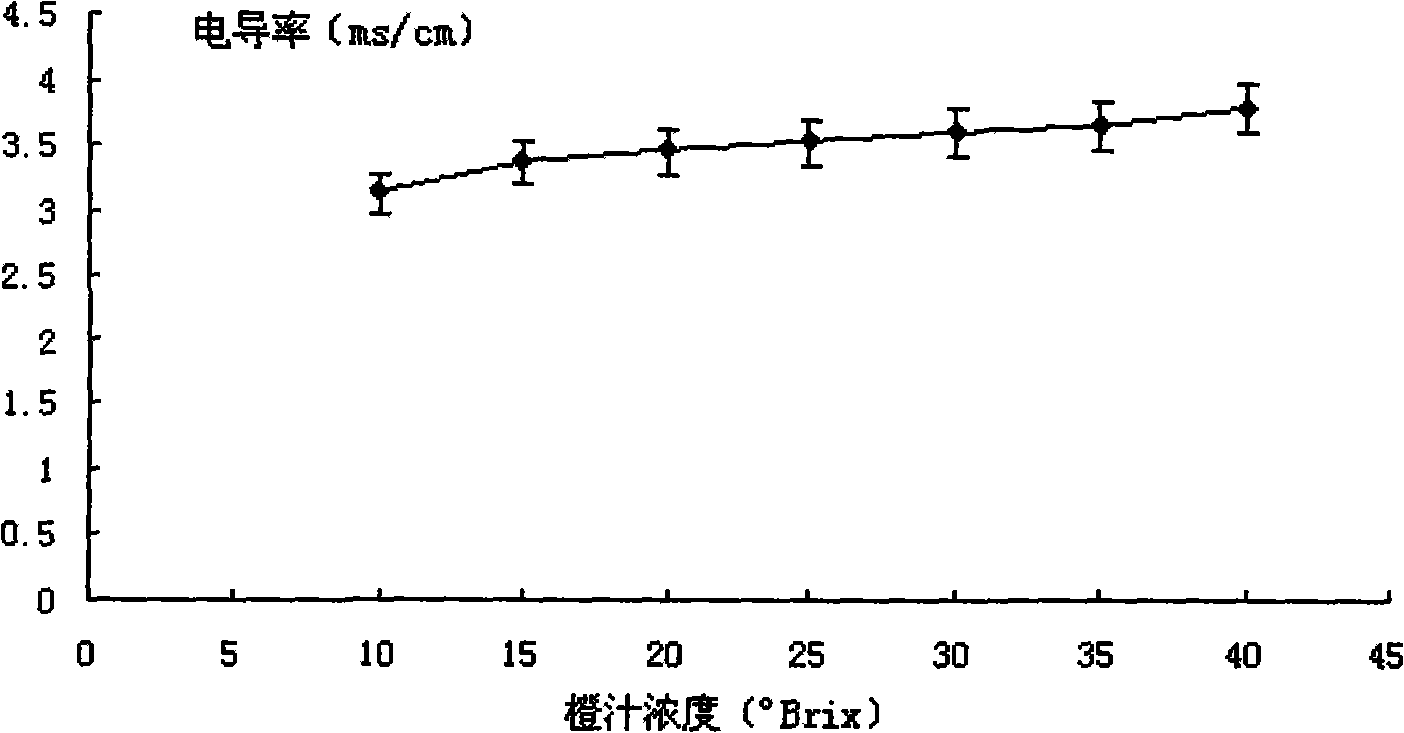

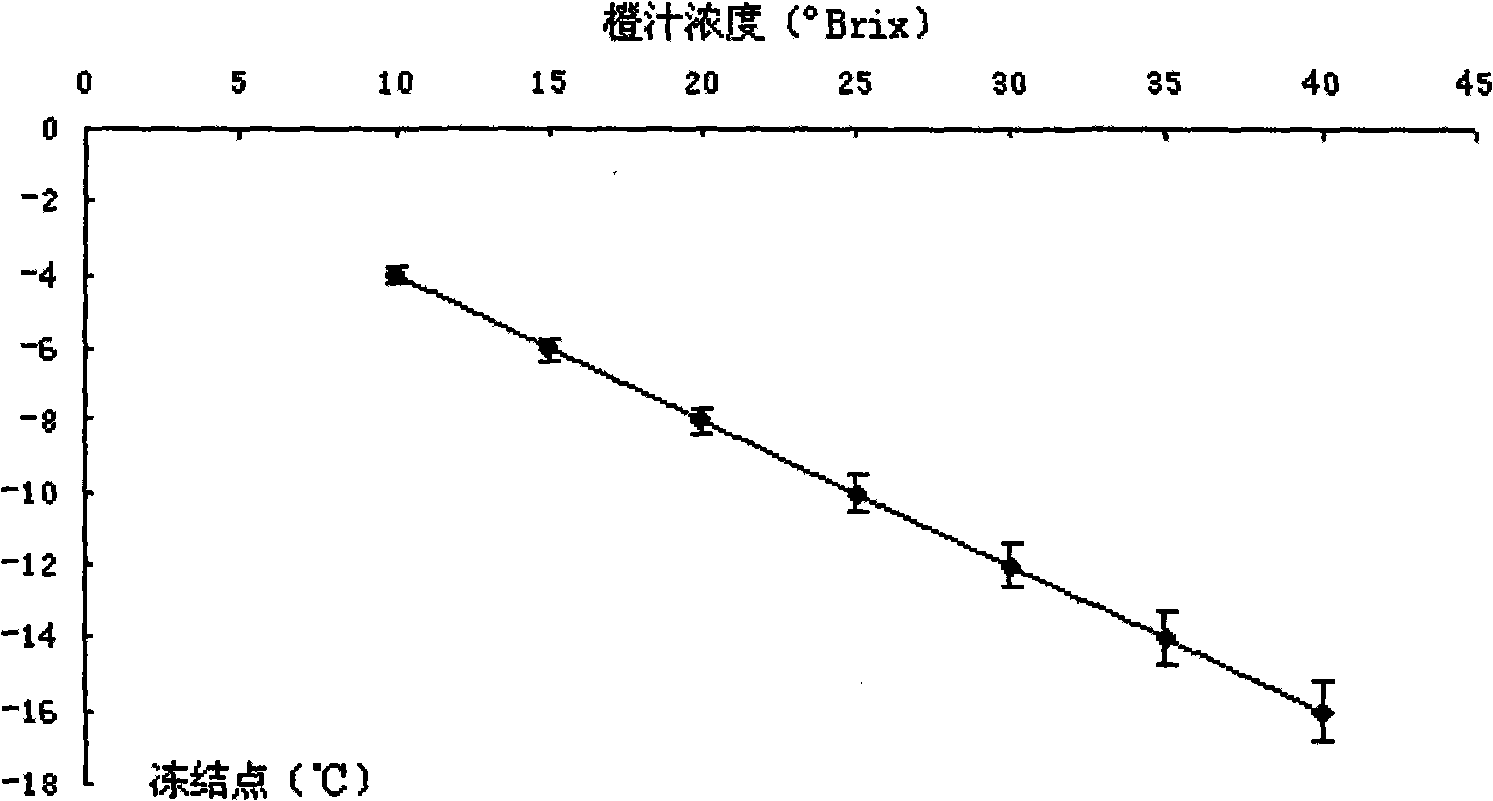

Liquid material low-temperature electric field bactericidal method

InactiveCN101297712AReduce conductivityFreezing point temperature dropMilk preservationFood preservationFreezing Point TemperatureBiochemical engineering

The invention relates to a method for the low-temperature electric field sterilization of liquid material, which is characterized in that: the liquid material is concentrated and cooled to the temperature between zero DEG C to the freezing point temperature of a concentrated liquid, and then sterilization treatment is carried out to the low-temperature concentrated liquid by the an electric field. The method for the low-temperature electric field sterilization of the liquid material can lower current generated by the liquid material in the electric field sterilization treatment process, thus not only ensuring effective sterilization and enzyme-killing effect, but also reducing energy consumption and temperature rise.

Owner:陈锦权

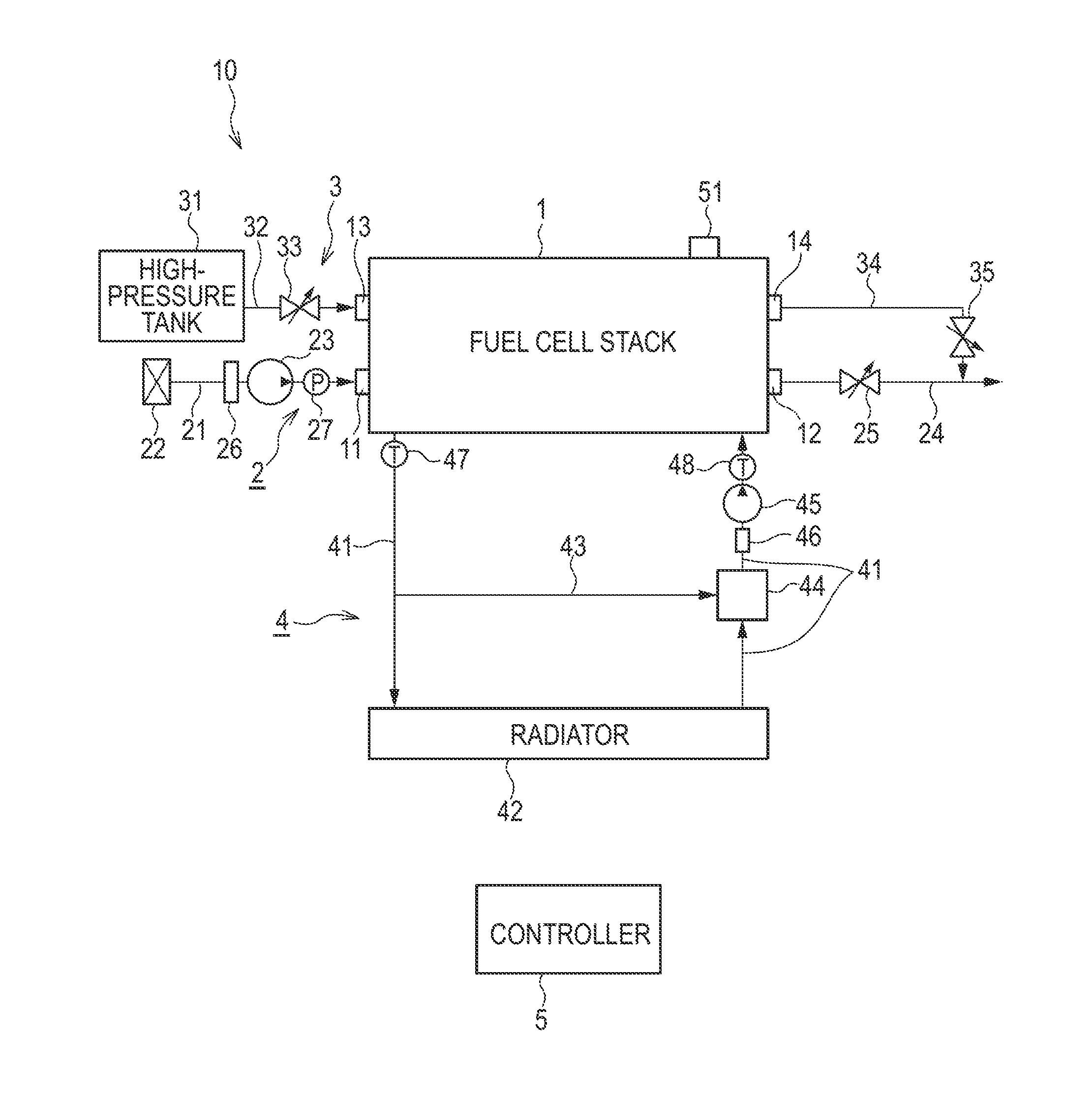

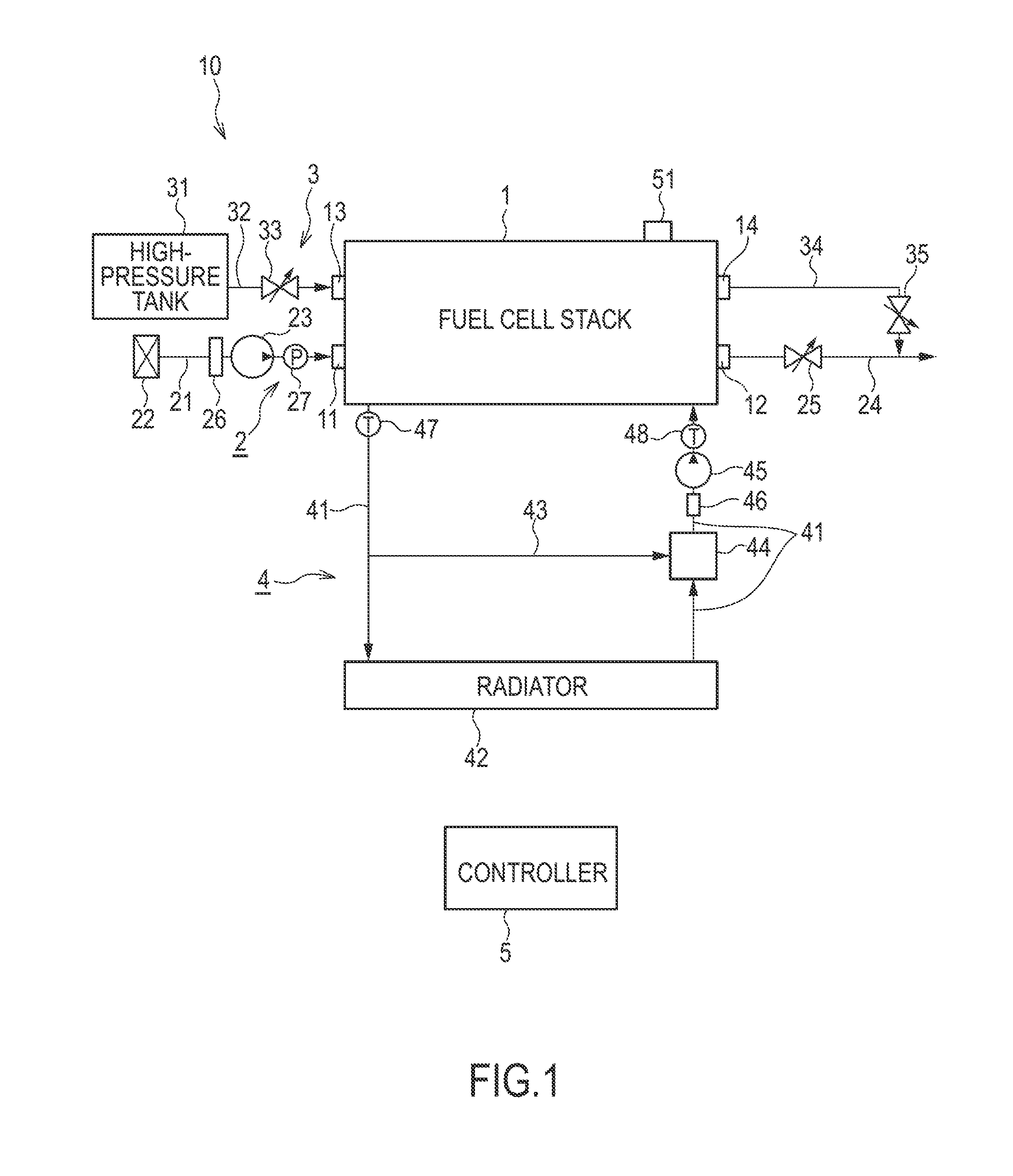

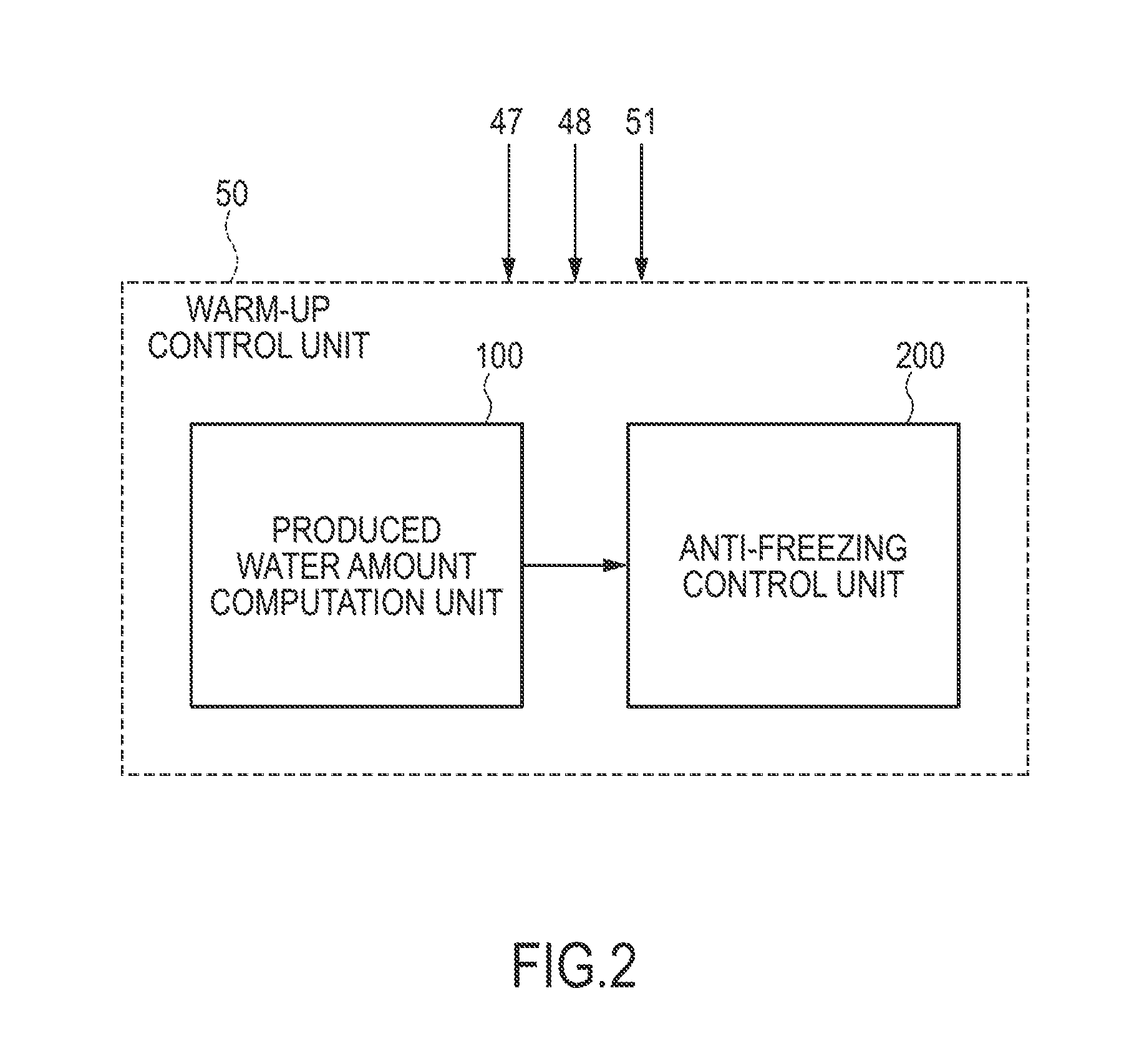

Fuel cell system and control method therefor

ActiveUS20150349360A1Prevent freezingIncrease power ratioFuel cell auxillariesMotive system fuel cellsFreezing Point TemperatureProduced water

A fuel cell system includes an auxiliary machine electrically connected to a fuel cell, the auxiliary machine being driven by power of the fuel cell, a heater electrically connected to the fuel cell, the heater being configured to heat cooling water supplied to the fuel cell, and a warm-up control unit configured to warm up the fuel cell itself by the supply of power to the auxiliary machine and the heater during start-up of the fuel cell below freezing point. The warm-up control unit includes a water amount computation unit configured to compute a produced water amount on the basis of a degree of wetness and a temperature of the fuel cell and a generated power of the fuel cell during warm-up, the produced water amount being a water amount produced in an electrolyte membrane until the temperature of the fuel cell increases to a freezing point temperature, and an anti-freezing control unit configured to increase a power ratio of power to the heater in regards to the auxiliary machine during the warm-up when the computed produced water amount is determined to be larger than a threshold value.

Owner:NISSAN MOTOR CO LTD

Paraffin rosin water plugging agent for water plugging of thick oil huff-puff well and water plugging construction method

ActiveCN102504779AHigh content of effective water blocking ingredientsIncreased blocking agent strengthDrilling compositionSealing/packingFreezing Point TemperatureParaffin wax

The invention provides a paraffin rosin water plugging agent for water plugging of a thick oil huff-puff well and a water plugging construction method. The water plugging agent for the water plugging of the thick oil huff-puff well is mixed liquid prepared by paraffin, rosin and water. The water plugging construction method of the thick oil huff-puff well comprises the steps that the paraffin-rosin mixed liquid water plugging agent provided by the invention is filled into a stratum to be treated for selective water plugging, and in addition, the temperature of the water plugging agent in the filling process is ensured to be higher than the freezing point temperature of the paraffin and the softening point temperature of the rosin. The technology provided by the invention is utilized, because the construction temperature during the water plugging agent filling is higher than the freezing point temperature of the paraffin and the softening point temperature of the rosin, water and solidcontent objects such as the paraffin, the rosin and the like form liquid-liquid mixed phases, and the liquid-liquid mixed phases can easily enter the deep part of the stratum; after the mixed phases are squeezed into the stratum, the paraffin and the rosin are crystallized and separated out along with the heat exchange when the temperature is lower than 55 DEG C, and the paraffin and the rosin are dissolved after meeting oil and are unchanged after meeting water, so the selective water plugging is realized; and simultaneously, the cold damage problem can be effectively avoided.

Owner:PETROCHINA CO LTD

Concentration system for water vapour energy latent heat feedback solution

PendingCN108721924ARealize the concentration cycleAvoid bloatingEvaporator accessoriesFreezing Point TemperatureEvaporation

The invention discloses a concentration system for a water vapour energy latent heat feedback solution. After a dilute solution from a water vapour energy heat source tower obtains water vapour latentheat through a heat exchanger, the dilute solution enters a solution negative-pressure evaporator to be concentrated to return to an evaporator so as to realize the concentration circulation of an antifreezing solution. Injected water vapour enters an injection circulation water tank to raise the temperature of circulating water, the circulating water of which the temperature is raised releases latent heat to the dilute solution in the heat exchanger to flow into an overflow box, a circulation process of the injected circulating water is realized, and meanwhile, a purpose that the dilute solution is concentrated and vapour latent heat is fed back to the solution is realized. Obviously, according to the concentration system, the heat of the circulating water is transferred to the dilute solution which leaves from the water vapour energy heat source tower through the heat exchanger to raise the temperature of the dilute solution so as to be favorable for improving evaporation and concentration efficiency, in addition, water vapour latent heat obtained after being lost is fed back to the solution again, the concentration of the antifreezing solution can be realized in an energy saving way, and therefore, and an event that solution is iced and swells to break an evaporator copper pipe since the freezing point temperature of the antifreezing solution rises is effectively avoided.

Owner:HUNAN DONGYOU WATER VAPOR ENERGY HEAT PUMP MFG CO LTD

Manufacturing method of sauce braised pork product

InactiveCN102793210AProduct temperature dropShorten the timeFood preparationFreezing Point TemperatureMicrowave oven

The invention discloses a manufacturing method of a sauce braised pork product, in particular a manufacturing method of the sauce braised pork product which can shorten food cooling time, rapidly cross a temperature interval in which microorganisms are easy to propagate, inhibit growth of the microorganisms to the utmost extent and maintain the original flavour of the product. The manufacturing method disclosed by the invention comprises the following steps of: cooking raw meat; rapidly cooling high-temperature cooked meat product and juice to a temperature close to a freezing point temperature, at which the cooked meat product is not frozen, under vacuum conditions from high temperature of 85-95 DEG C, draining the cooked meat product, and carrying out vacuum packaging. A vacuum packaged sauce spiced chicken product is stored in a refrigerator at the temperature of being from minus 2 DEG C to minus 3 DEG C, and the shelf life can be prolonged for 1.6-1.8 times compared with that of the conventionally processed sauce spiced meat product. The sauce braised pork product disclosed by the invention is only required to be heated in a microwave oven when the sauce braised pork product disclosed by the invention is eaten. The manufacturing method disclosed by the invention can combine vacuum cooling, vacuum packaging and ice-temperature storage, the original flavour of the product can be maintained, safety is high, and a soysauce-cooked pork product being more beneficial to health is provided for people. The technology disclosed by the invention has great benefit to food safety.

Owner:TIANJIN UNIV OF COMMERCE

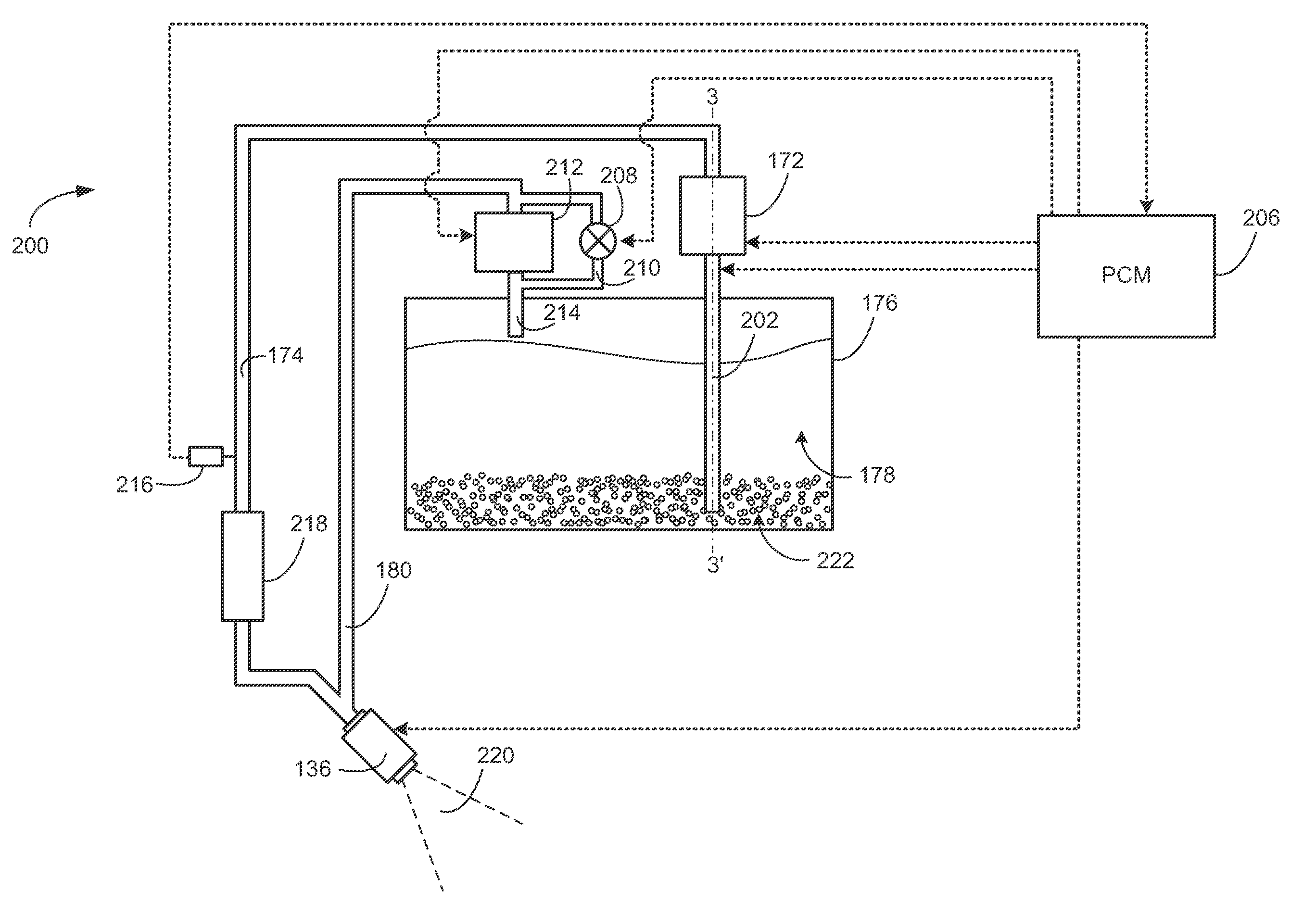

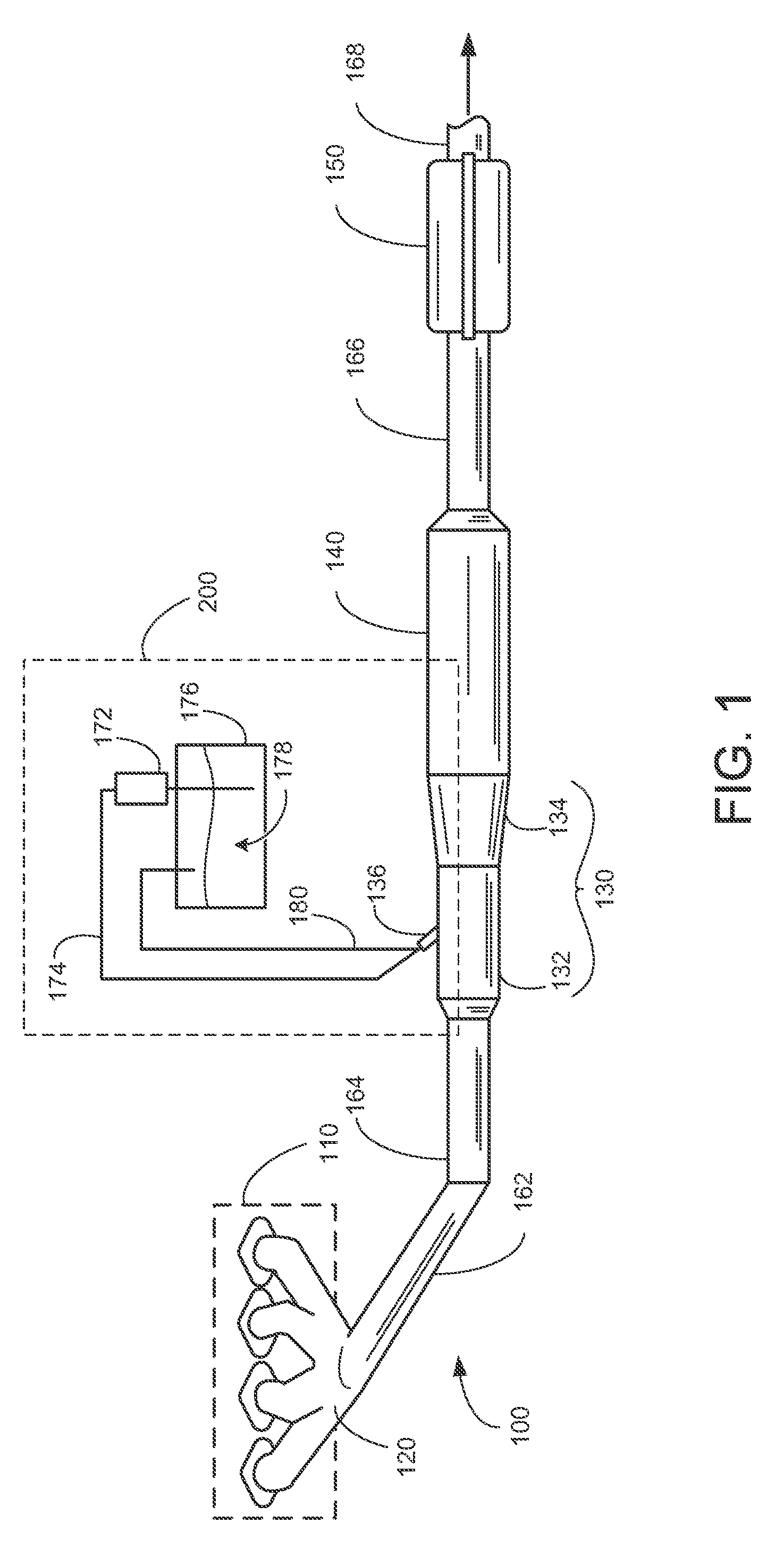

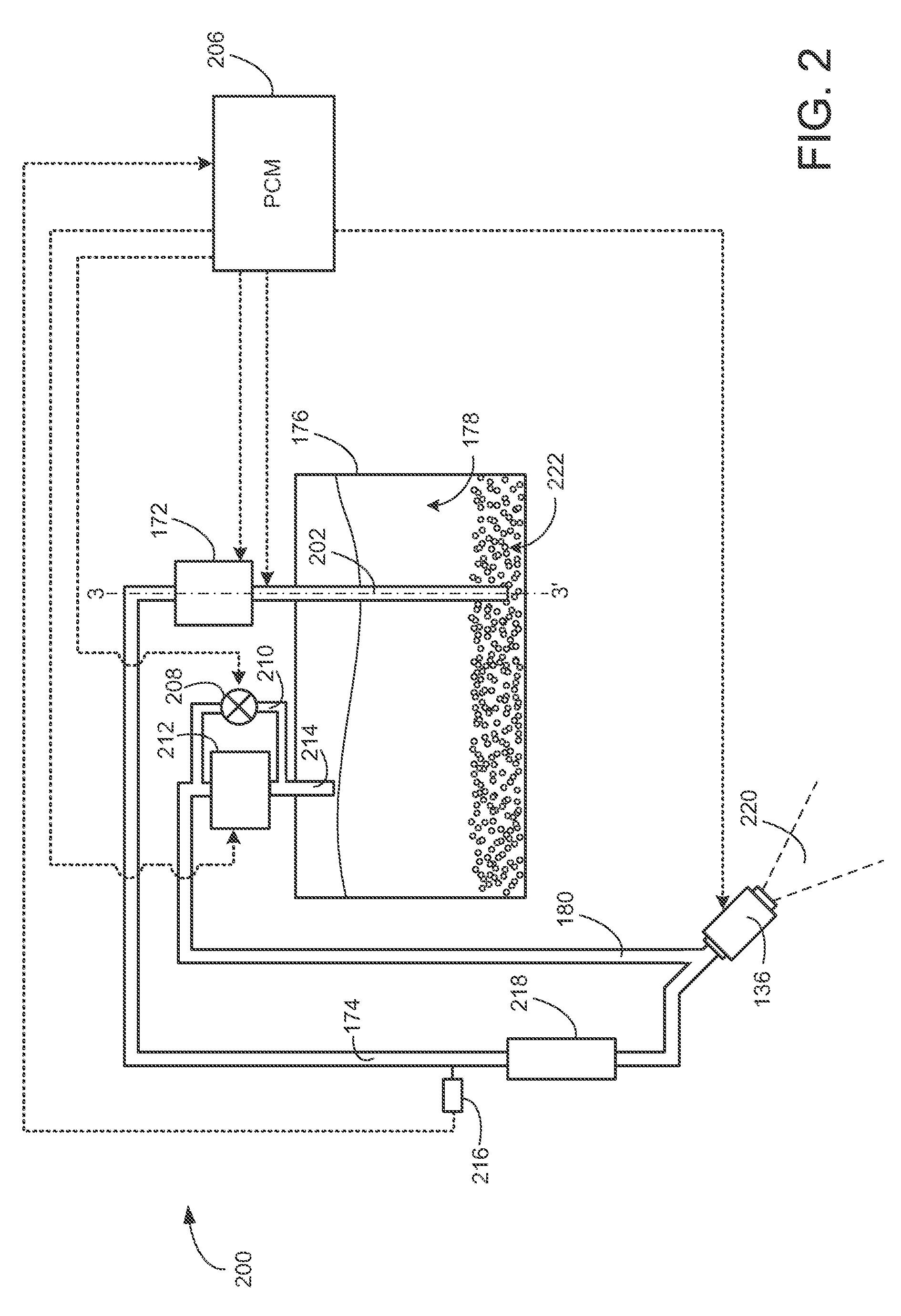

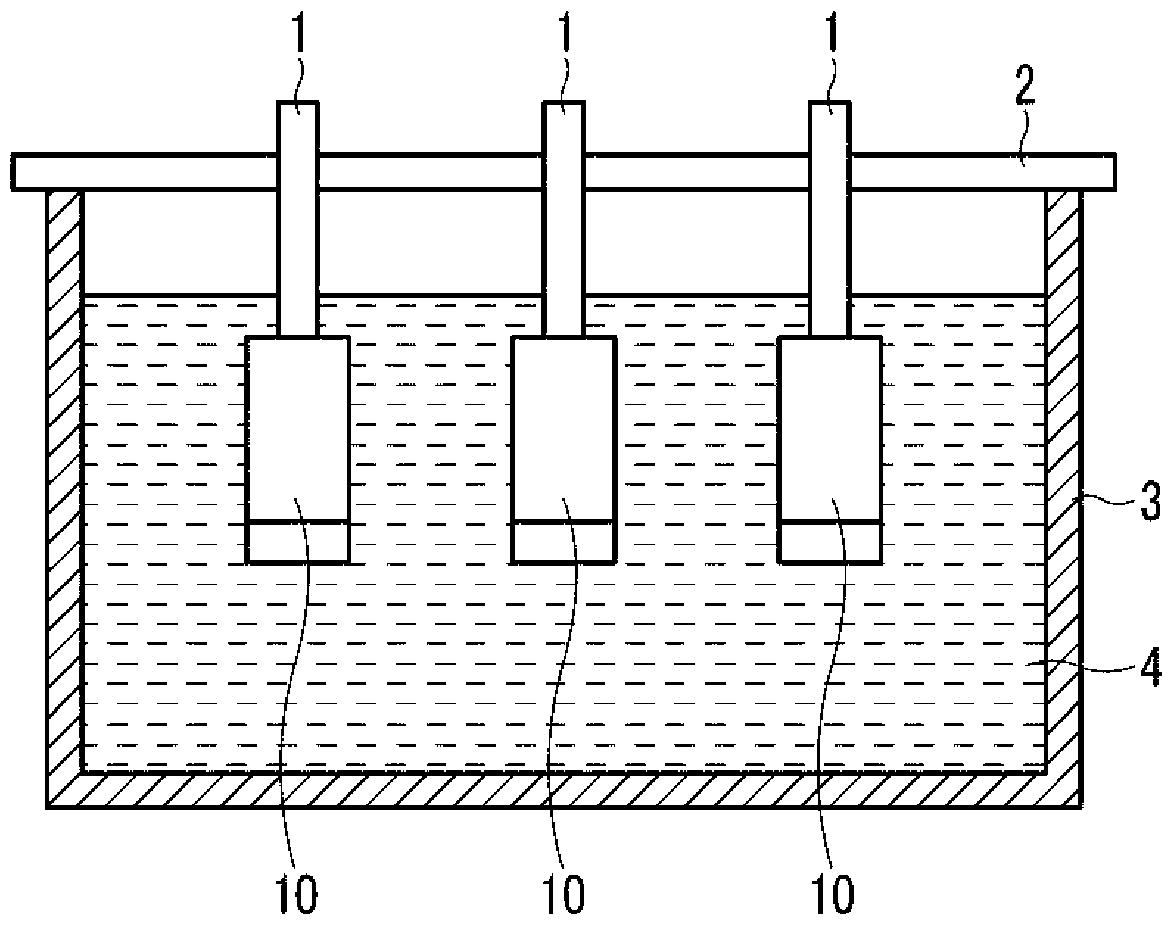

Thermal energy battery with enhanced heat exchange capability and modularity

ActiveUS20170205152A1Improve heat exchange capacityConstant rate of dischargeHeat storage plantsMilk receptaclesFreezing Point TemperatureThermal energy

This invention provides a thermal energy battery having an insulated tank contains a multitude of densely packed plastic tubes filled with a phase-change material (PCM, such as ice) that changes from solid to liquid and vice-versa. Energy is stored when the PCM transitions from liquid to solid form, and released when the PCM transitions back from solid to liquid form. The tubes are arranged vertically, span the height of a well-insulated tank, and are immersed in heat transfer fluid (HTF) contained within the tank. The HTF is an aqueous solution with a freezing point temperature below the freezing point temperature of the chosen PCM. The HTF remains in liquid form at all times during the operation of the battery. Diffusers located allow the HTF to be extracted uniformly from the tank, pumped and cooled by a liquid chiller situated outside the tank and then and inserted back into the tank.

Owner:PROMETHEAN POWER SYST

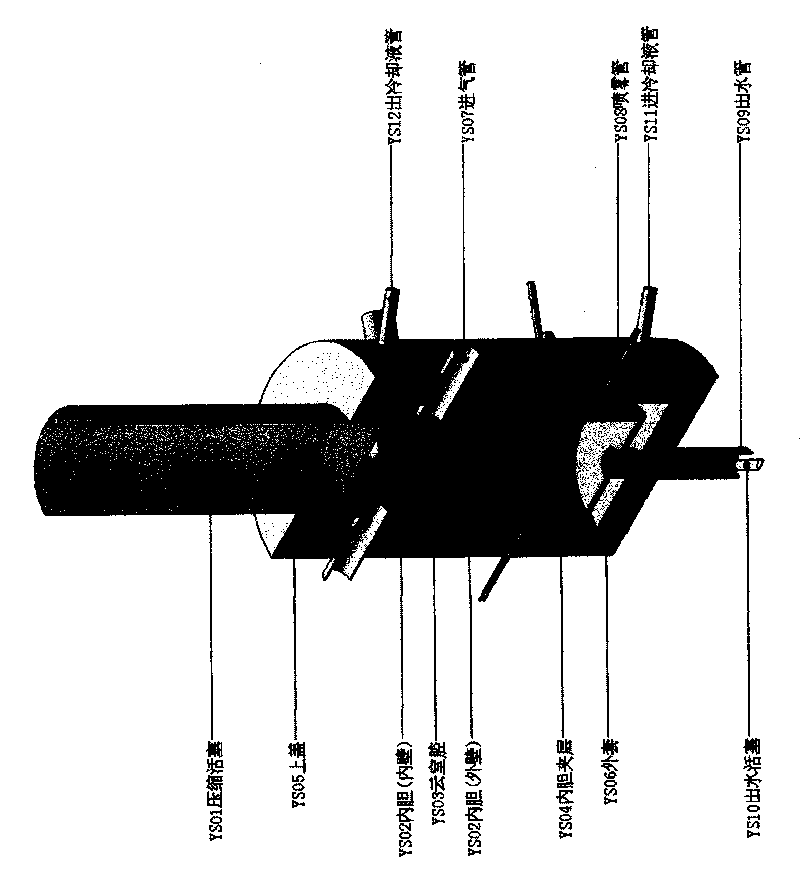

System and method for liquid reductant injection

InactiveUS8661785B2Assure functionalityAssure survivabilityInternal combustion piston enginesExhaust apparatusFreezing Point TemperatureElectricity

A method for operating a liquid reductant injection system is provided. The method includes storing a reductant mixture of ethanol, water, and urea; drawing the stored mixture into an electrically heated pick-up tube for delivery via a delivery line to the exhaust by operating a pump in a first direction; and, clearing a return line that returns the stored mixture or the delivery line by operating the pump in a second, reverse, direction. In this way, by including ethanol in the reductant solution, a freezing point temperature of the liquid reductant may be reduced.

Owner:FORD GLOBAL TECH LLC

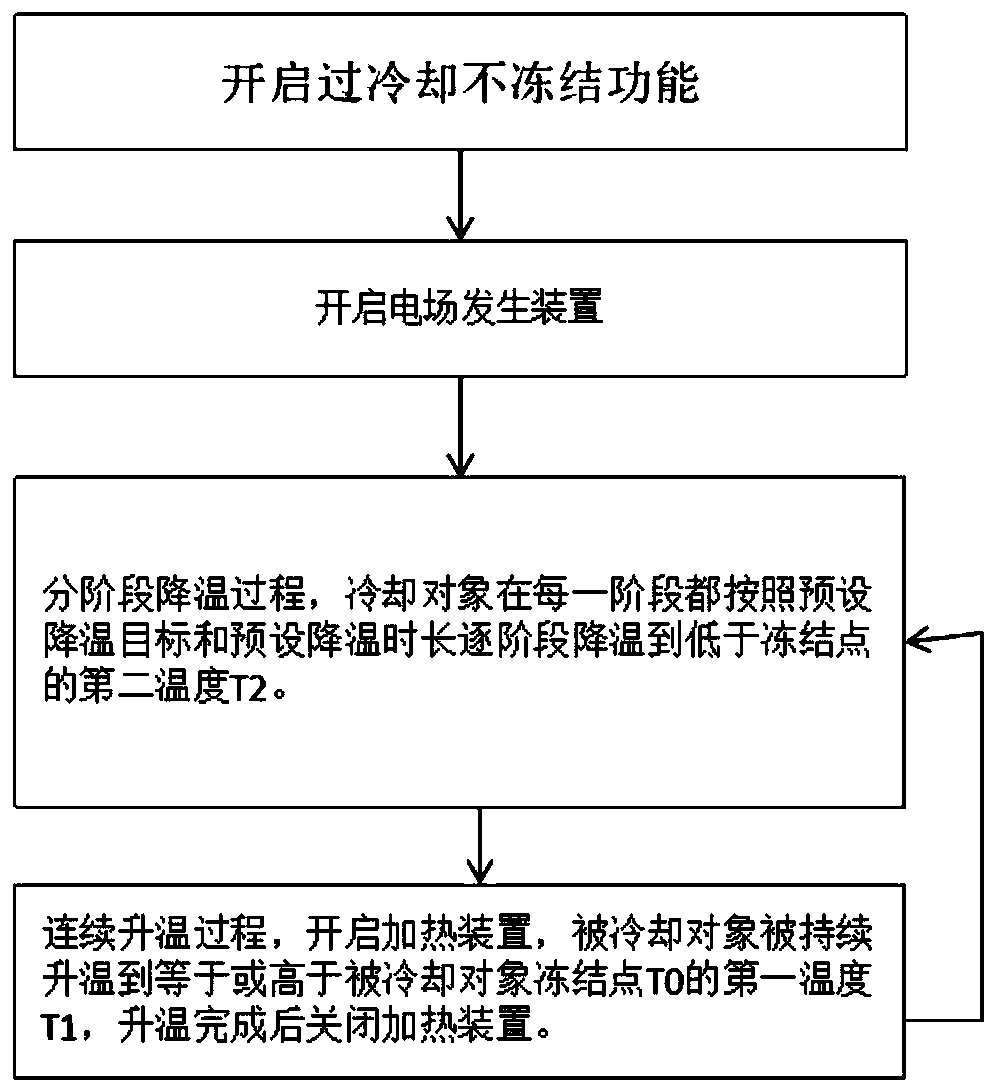

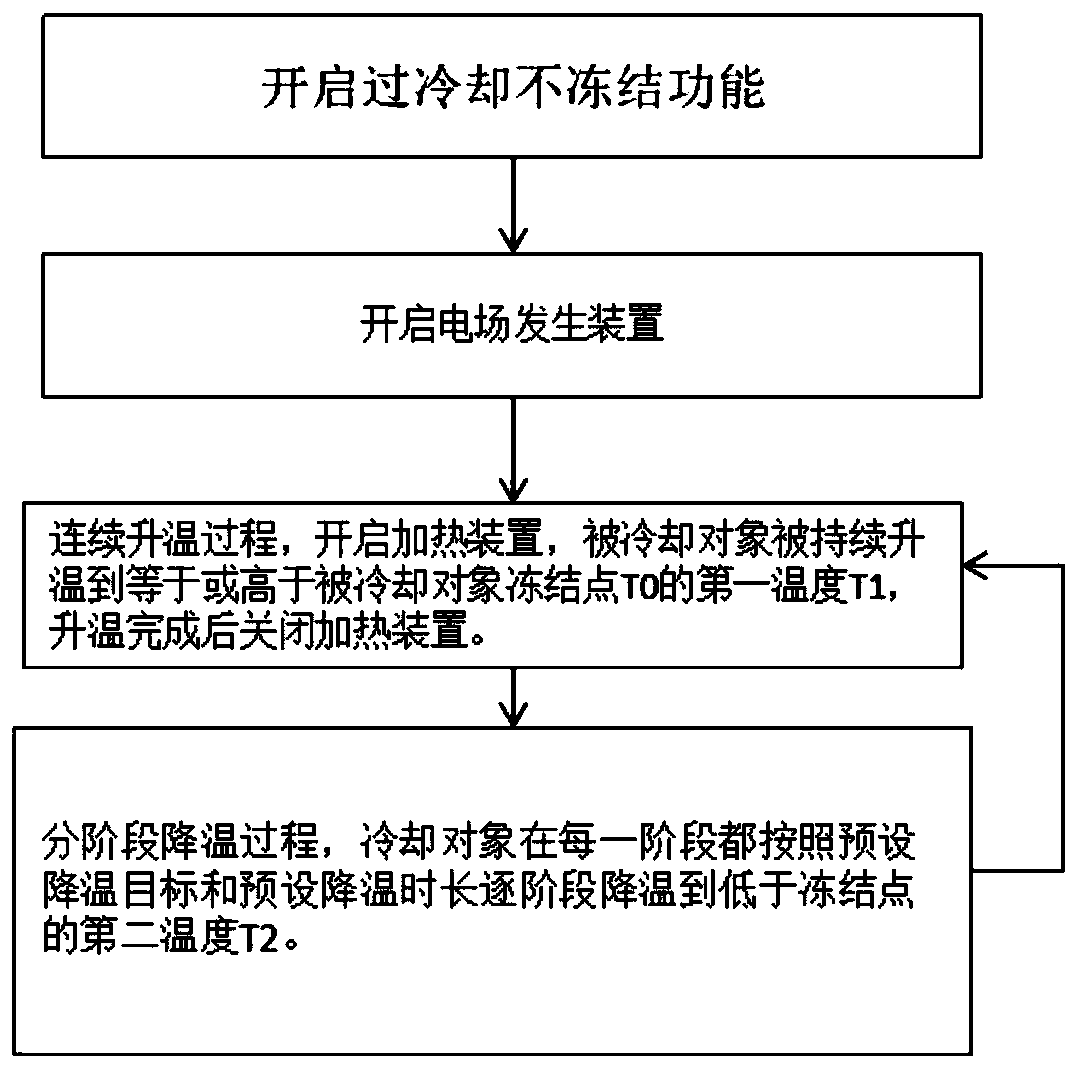

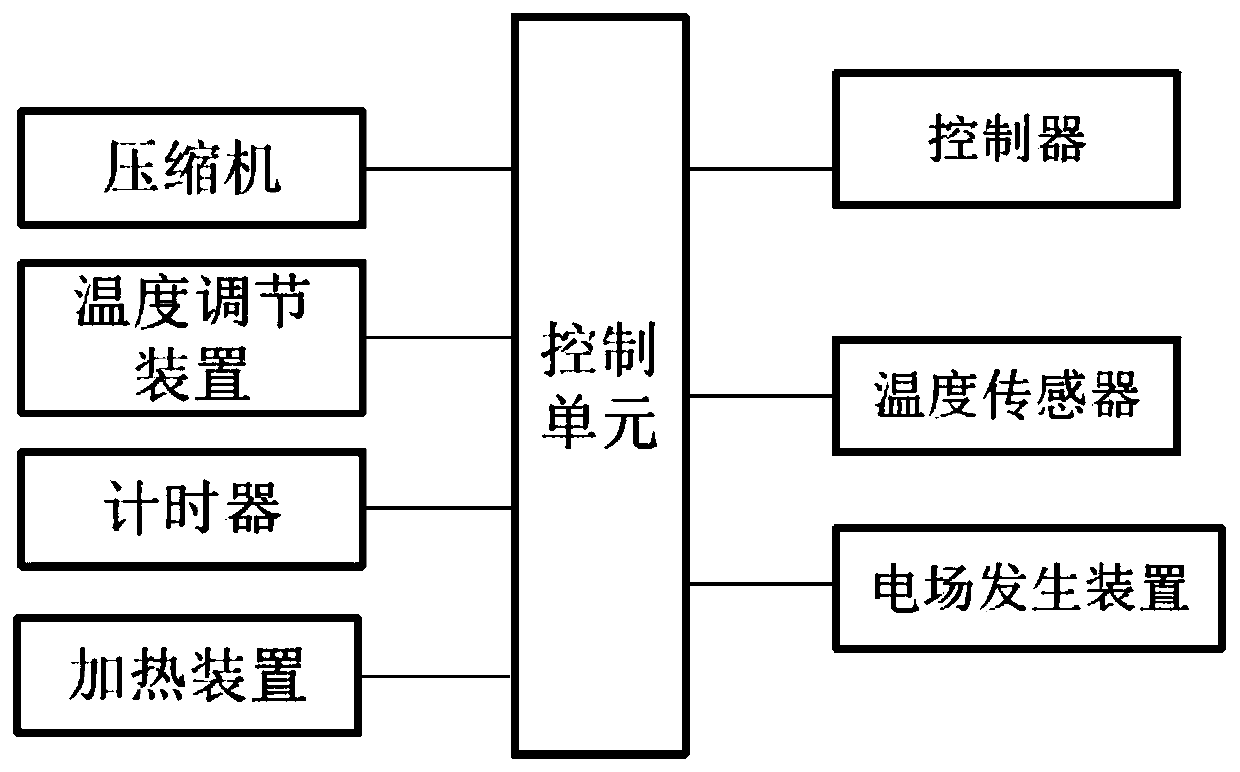

Supercooling non-freezing storage control method and refrigerator

PendingCN110906645AImprove qualityExtend freshnessLighting and heating apparatusCooling fluid circulationFreezing Point TemperatureThermodynamics

The invention relates to a supercooling non-freezing storage control method and a refrigerator. The method comprises the steps of turning on an electric field generating device to enable a cooled object to be in the electric field, and carrying out periodic heating and cooling control on the temperature of a cooling chamber, wherein staged step-by-step cooling is adopted in the cooling stage to reduce the temperature below a freezing point, the food is enabled to stably enter a supercooling state, the food is prevented from generating needle-like ice crystals due to freezing to damage the cellstructure, and the flavor of the food is further prevented from being damaged during thawing; and a heating device is turned on in the heating stage, the storage environment temperature of the food is continuously increased to be equal to or higher than the freezing point temperature by adopting a continuous heating mode, and the heating device is turned off after the heating is completed. Through continuous circulation of heating and cooling, the food is not frozen near the freezing point, and the fresh-keeping period of the food is prolonged.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD +1

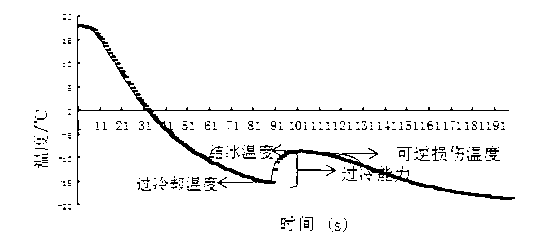

Method for discriminating cold resistance of peony tissue

InactiveCN103175859ADetermine cold toleranceSimple methodMaterial thermal analysisFreezing Point TemperaturePlant tissue

The invention belongs to the technical field of plant biology and specifically relates to a method for discriminating the cold resistance of a peony tissue. The method provided by the invention is capable of directly reflecting the adaptability and the buffering ability of the peony tissue to the low-temperature environment and the obvious degree of supercooling by measuring the freezing point temperature and the supercooling temperature of the peony plant tissue part and defining the difference between the freezing point temperature and the supercooling temperature as peony tissue supercooling ability (delta E). The greater the value of delta E is, the more obvious the supercooling phenomenon of the tissue is, the larger the temperature zone sensitive to low-temperature freezing injury is and the higher the adaptability of responding to a sudden low temperature is. The method provided by the invention is simple and convenient, and high in feasibility; and the method is capable of obtaining the supercooling point temperature and the freezing point temperature of the plant tissue from a temperature freezing curve, thereby providing convenient and accurate scientific basis for low-temperature safe storage and low-temperature freeze injury protection of peony.

Owner:HENAN UNIV OF SCI & TECH

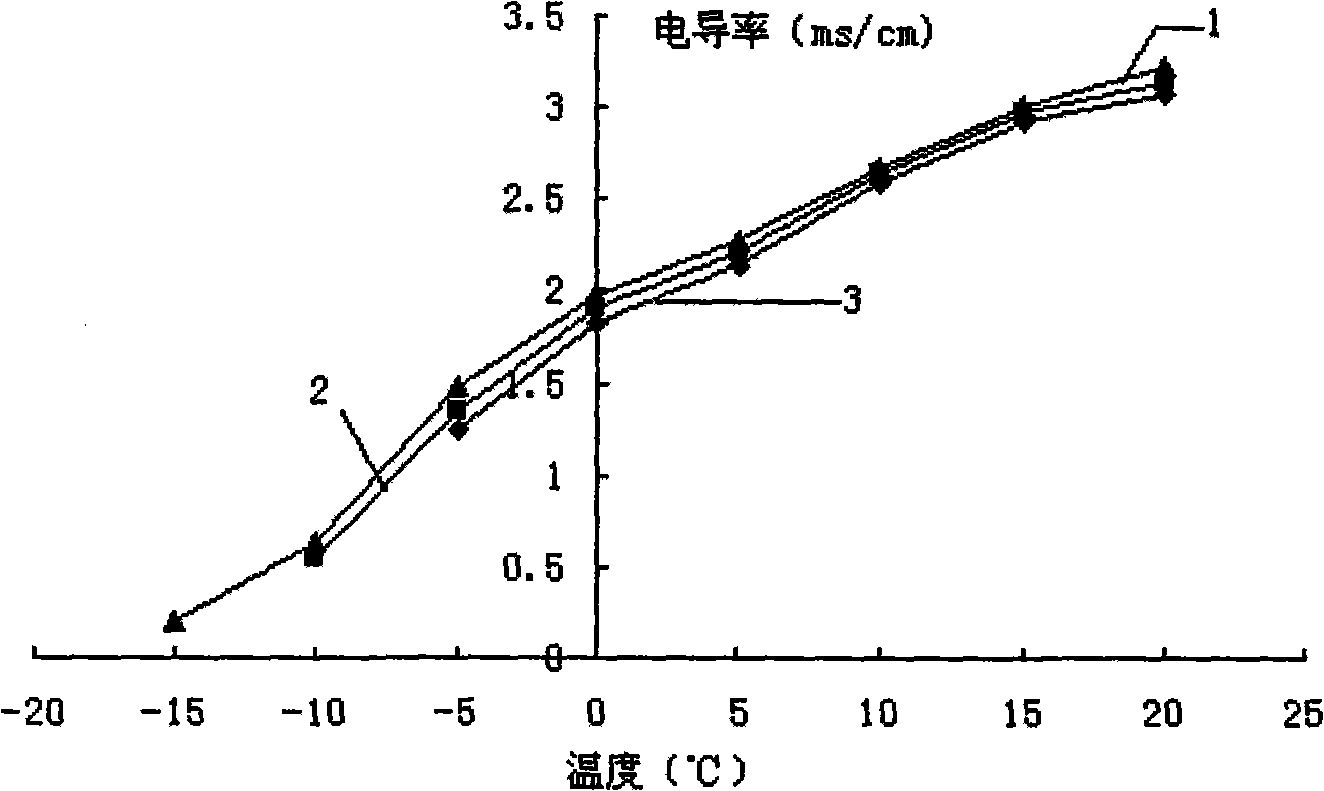

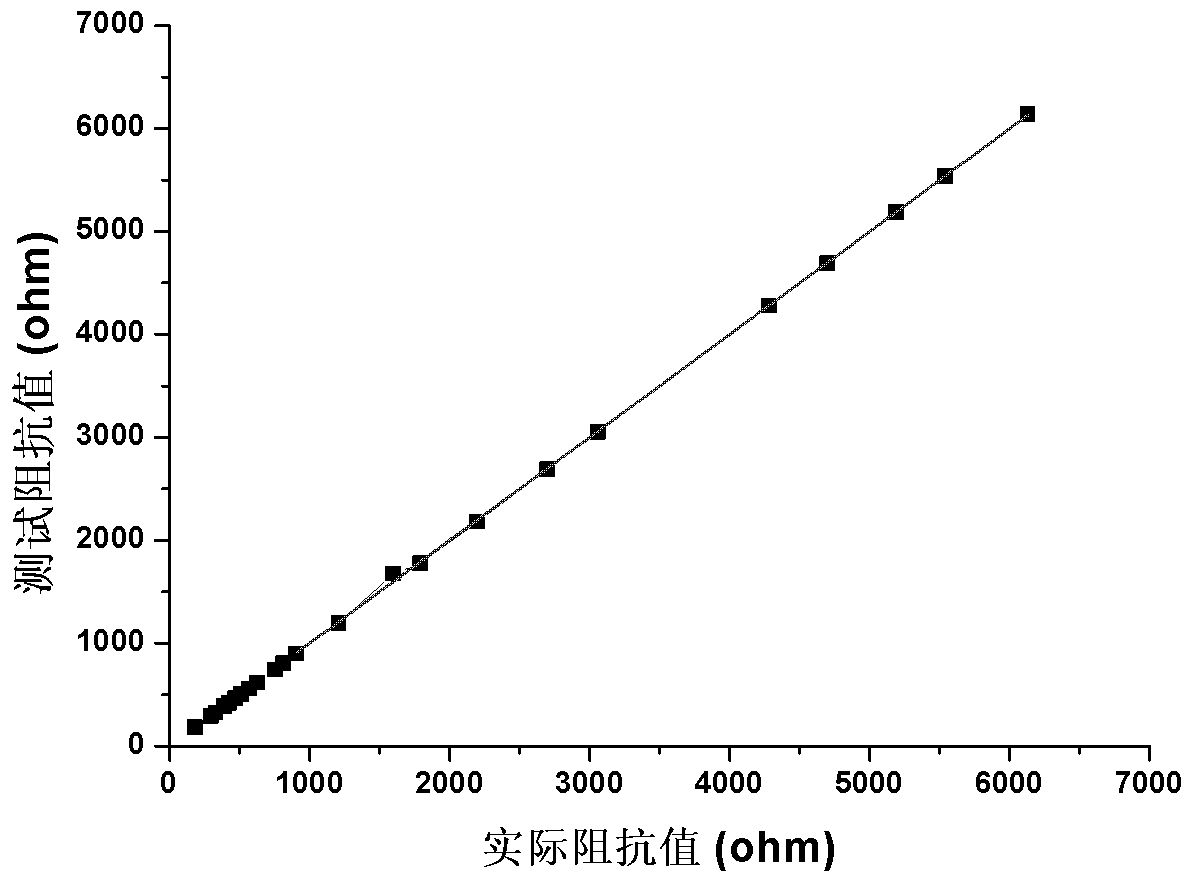

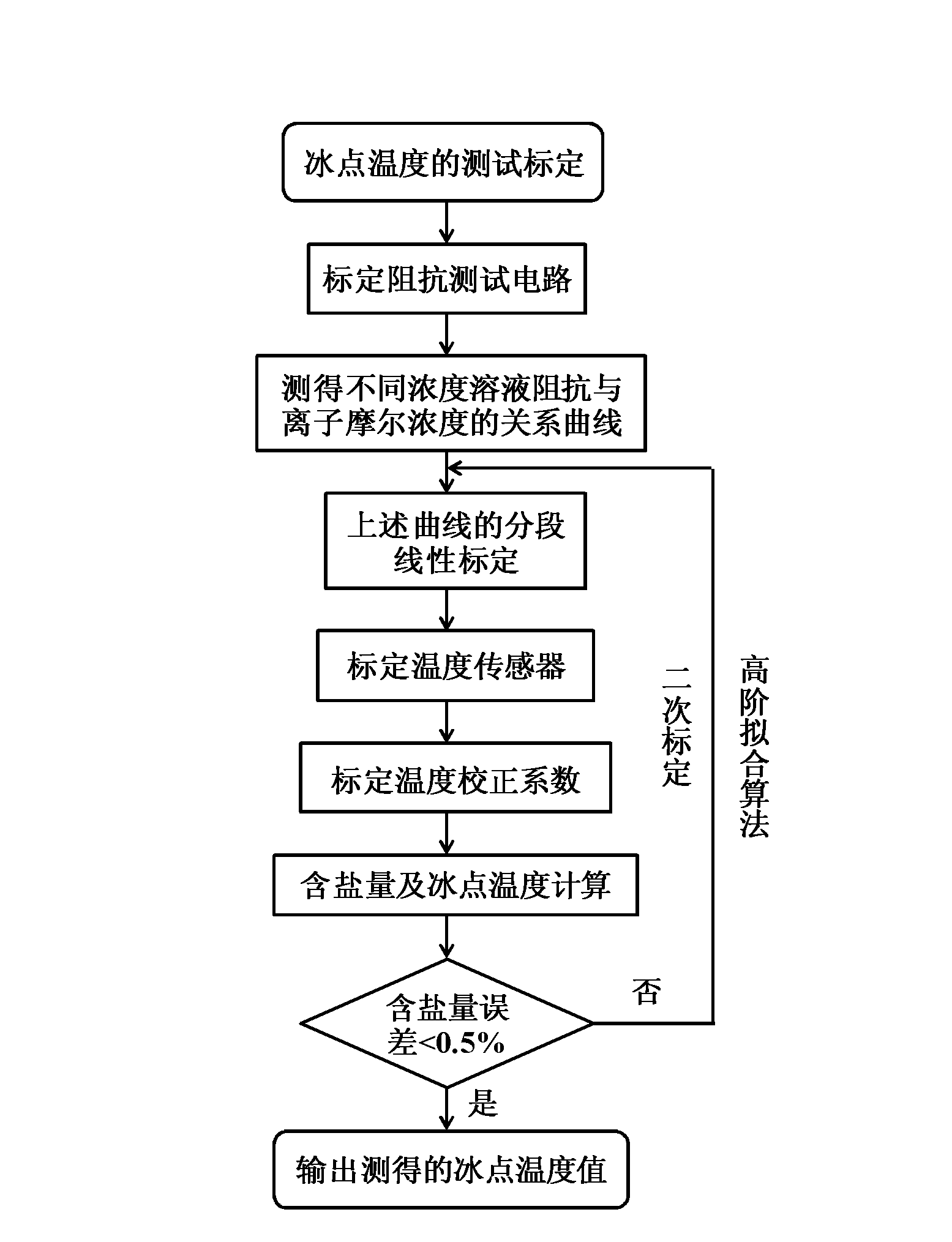

Road freezing point temperature testing system and method based on ion molar concentration monitoring

ActiveCN103175860ASolve the freezing point temperature monitoring problemAchieve securityMaterial impedanceInvestigating phase/state changeFreezing Point TemperatureTemperature control

The invention discloses a road freezing point temperature testing system and method based on ion molar concentration monitoring. The testing method comprises the following steps of: measuring ion molar concentration by monitoring the impedance of a solution according to a linear monotonic relationship between a freezing point temperature of the solution and the ion molar concentration, and subsequently testing the current freezing point temperature of the solution by labeling and calibrating with combination of the current temperature of the solution. Compared with a conventional freezing point temperature testing method, the system is free of a solution refrigerating device and a temperature control unit and has a simple structure; and meanwhile, as a detection target is directly the ion molar concentration which affects the freezing point temperature of the solution, the freezing point temperature of a solution formed by mixing various solutes can be directly measured. The method can be applied to the measurement of the road freezing point temperature of traffic roads, so that the frozen states of roads in winter can be monitored, and the traffic is guided to ensure safety.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

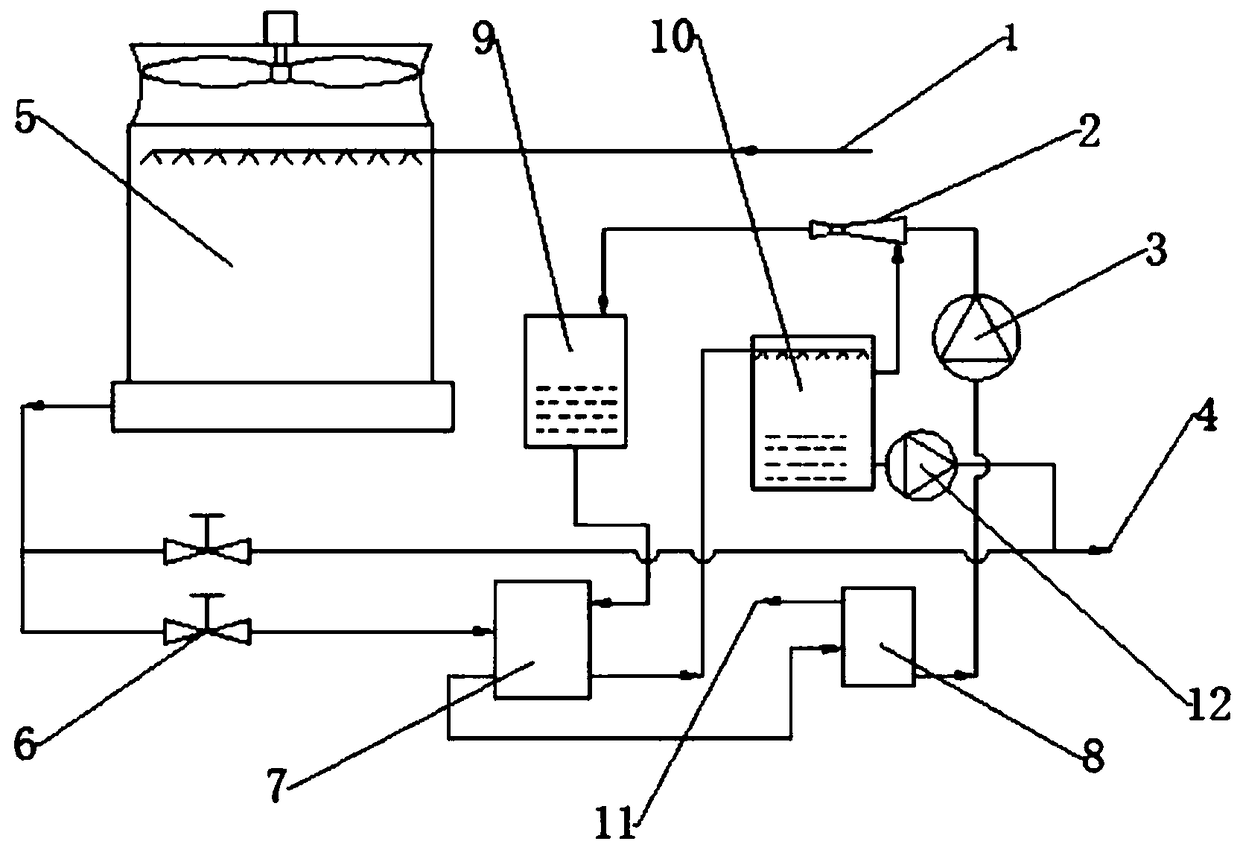

Pre-wetting type outdoor air conditioner

InactiveCN104697076ALower heat exchange temperatureReduce the temperatureCorrosion preventionSpace heating and ventilation detailsFreezing Point TemperatureSurface cleaning

The invention provides a pre-wetting type outdoor air conditioner and relates to the technical field of energy conservation and energy utilization, in particular to an outdoor air conditioner applied to the air conditioner industry. By means of combination of a pre-wetting cavity and a heat exchange cavity, in summer, outdoor air is pre-cooled through evaporation of water on a water filter screen before entering an outdoor surface air cooler, and therefore the condensation temperature of refrigerants in the surface air cooler is decreased, the surface heat exchange temperature of the surface air cooler can be lower than the dry-bulb temperature of the outdoor air, refrigeration efficiency is improved, and refrigeration power consumption is reduced; in winter, outdoor wet and cold air enters the outdoor surface air cooler by carrying anti-freezing solutions, the freezing point temperature of the surface of the surface air cooler is decreased, and therefore the frost formation frequency of the surface of the surface air cooler is reduced, the situation that a heat pump main engine shuts down due to defrosting is avoided, and heating efficiency is improved. Meanwhile, the water filter screen is used for filtering out dust and ash in air, cleanness of the outer surface of the surface air cooler is guaranteed, and heat exchange efficiency is improved.

Owner:黄国和

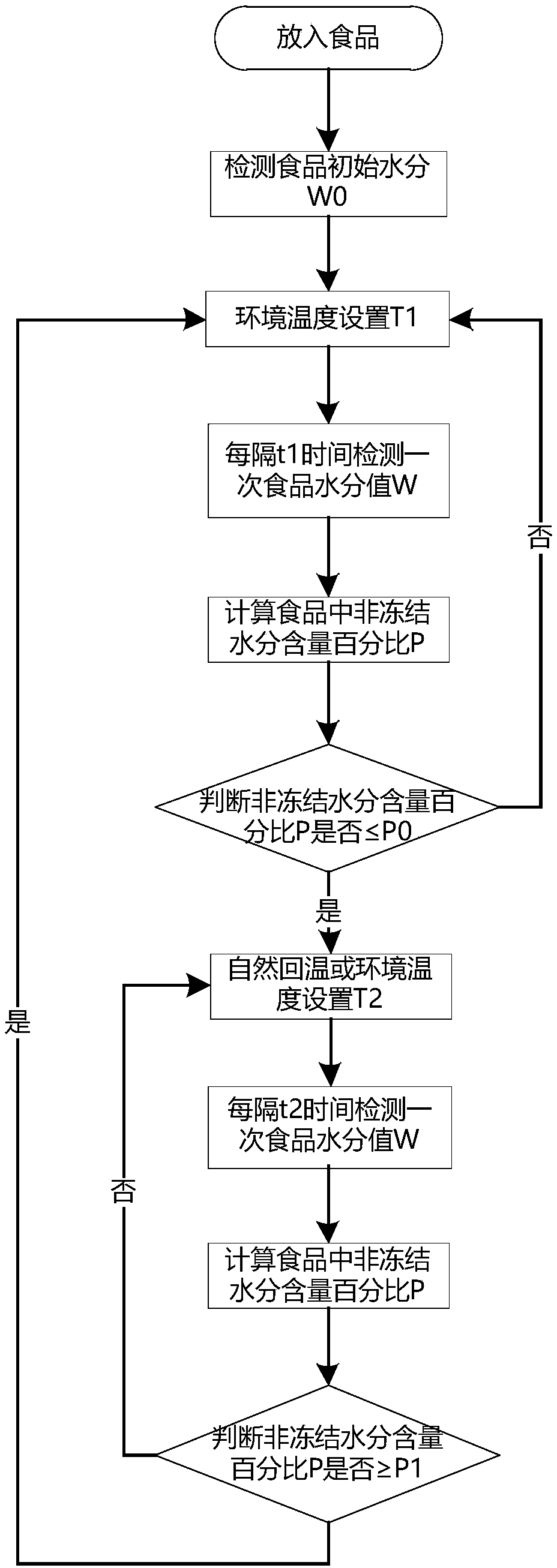

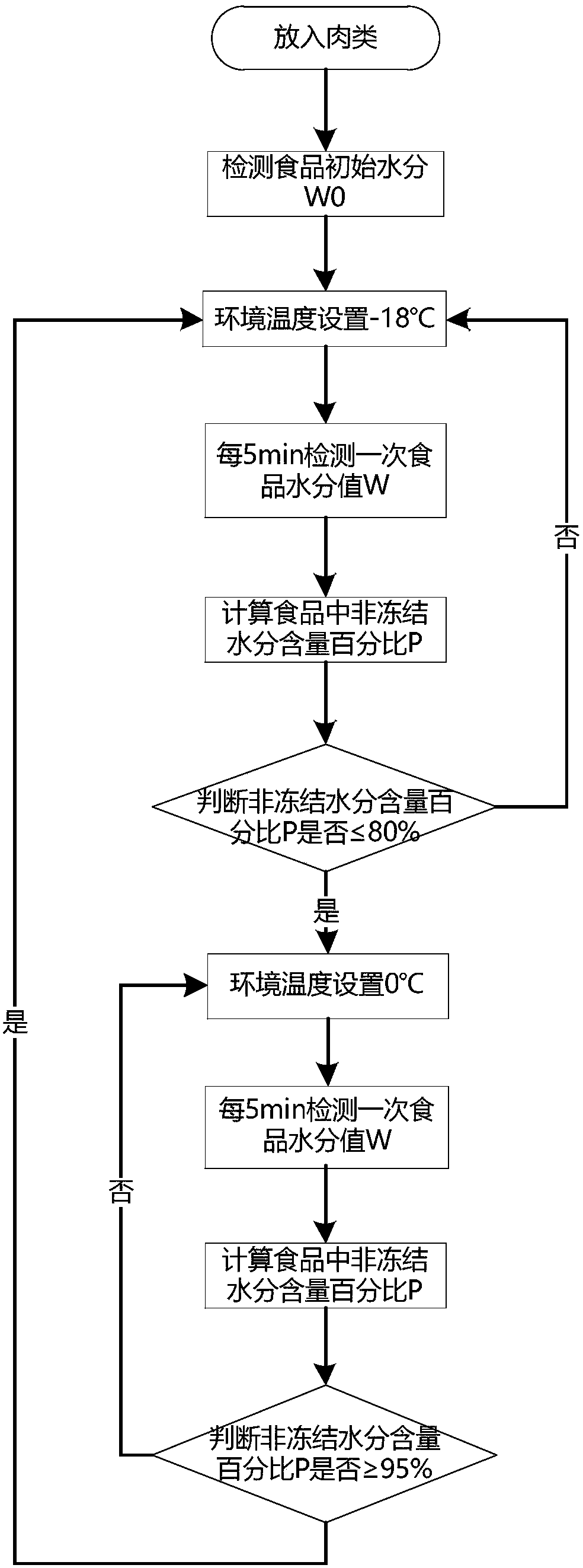

Method for determining freezing point based on unfrozen moisture of food, controller and refrigeration equipment

InactiveCN107727683AGuaranteed not frozen freshStay Nutritious and TastyInvestigating phase/state changeTemperature controlFreezing Point Temperature

The invention relates to the field of refrigeration control, in particular to a method for determining a freezing point based on unfrozen moisture of food, a controller and refrigeration equipment. According to the invention, different unfrozen moisture contents of the food at different temperatures are used to judge whether the food enters a frozen state or not. The unfrozen moisture is combinedwith temperature control to control food temperature within a reasonable range all the time. If the food enters the frozen state, a warming-up mode can be entered immediately to prevent water inside the food from forming ice crystals continuously, so that the food is not frozen, and when the temperature of the food reaches a certain value, the temperature is immediately lowered repeatedly for multiple times, the food temperature is kept to 0 DEG C to the freezing point temperature for most of the time or all the time, and the freezing point temperature is within minus 10 to 0 DEG C. The percentage content change rate of unfrozen water in the food is used to effectively determine the freezing point of the food, unfrozen moisture changes in the food are effectively combined with the temperature control, and the food temperature is reasonably controlled to reach a critical state in which the food is not frozen and fresh so as to ensure that the food is not frozen and fresh and prolong thepreservation period.

Owner:HEFEI HUALING CO LTD +2

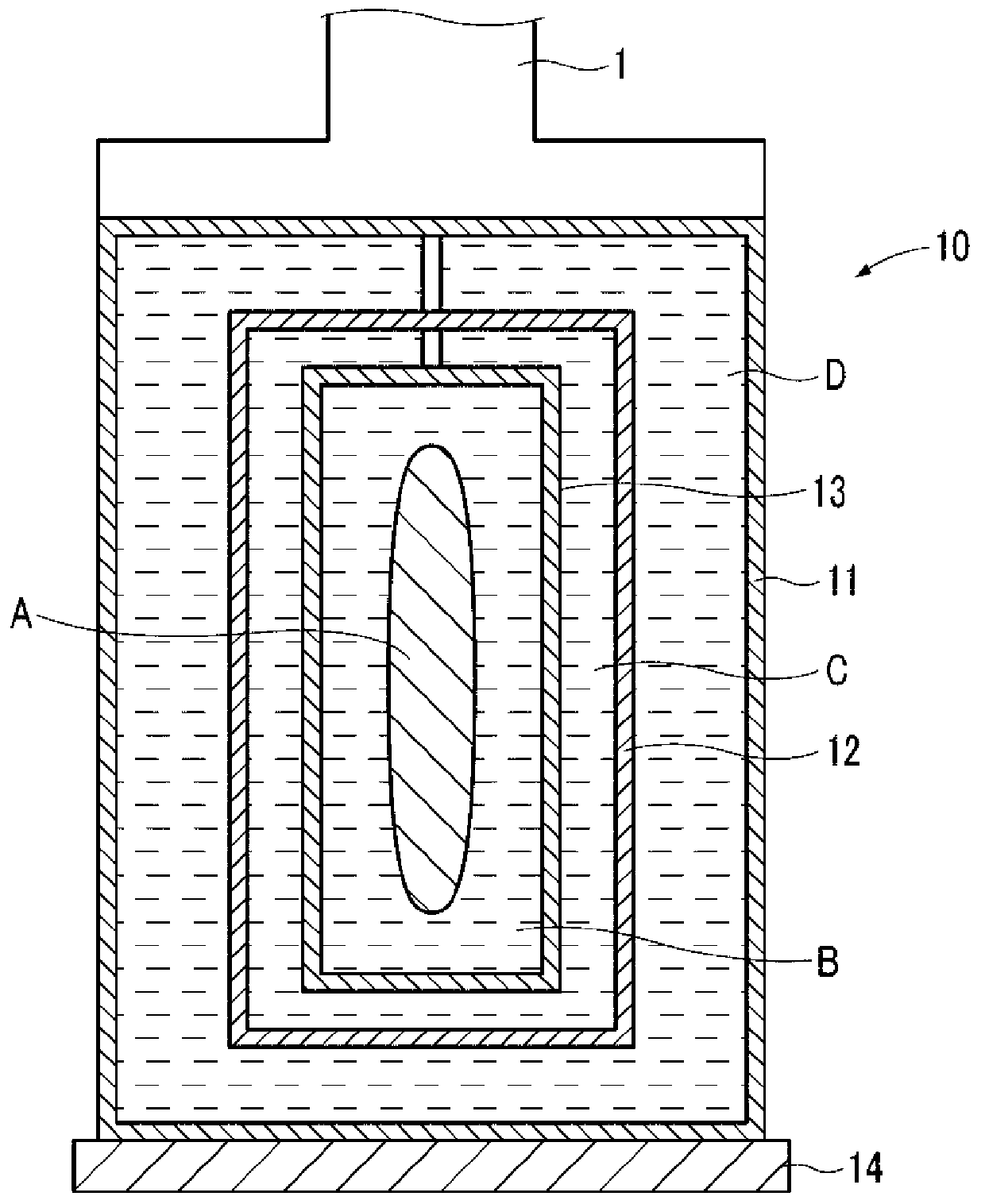

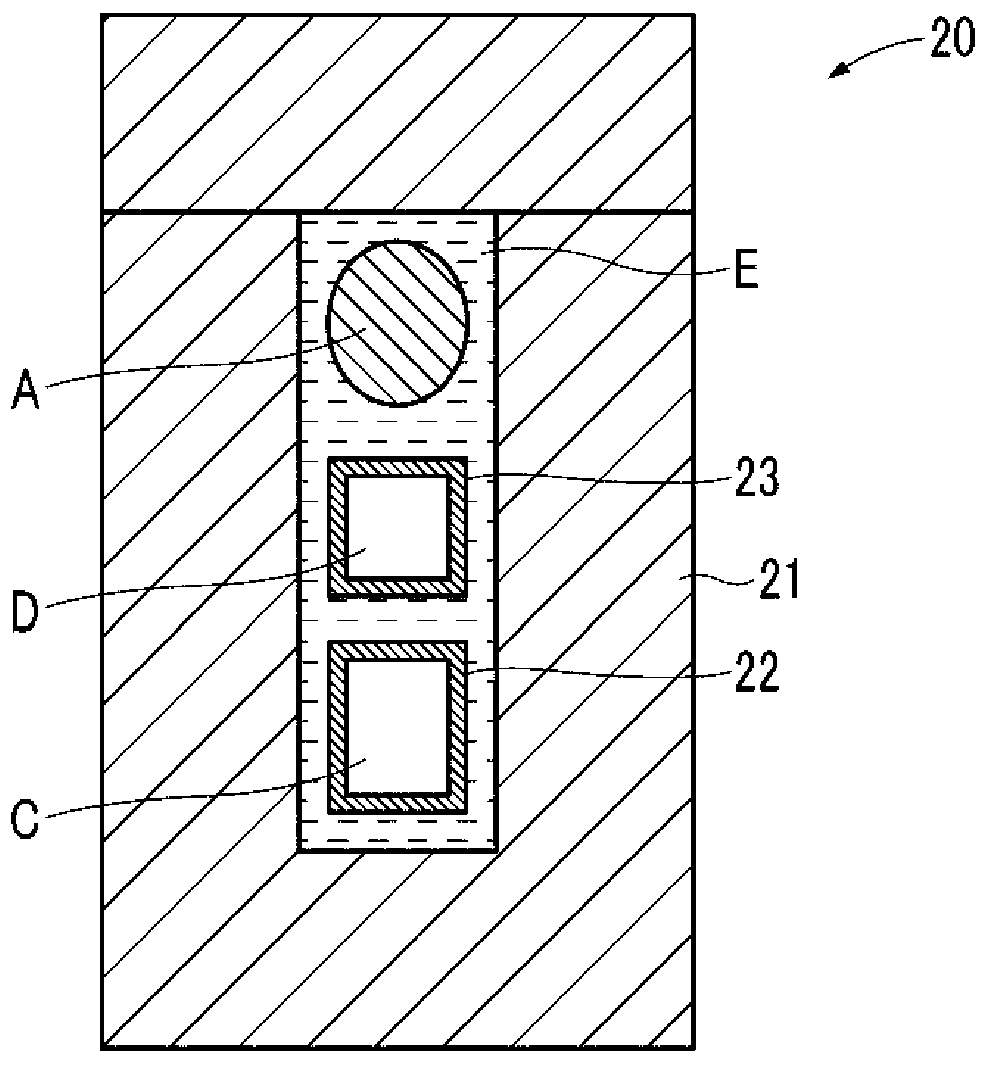

Low temperature storage method and low temperature storage container

InactiveCN103327839AWon't breakStable at low temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsFreezing Point TemperatureEngineering

A low temperature storage container (10) is sealed, after a stretchable middle bag (12) that makes a subject to be stored (A) exist therein and is filled with a liquid (C) having the compression rate larger than a liquid (D) and having the freezing point temperature lower than the liquid (D) is put into an outer container (11), and a space between the outer container (11) and the middle bag (12) is filled with the liquid (D) with the volume which is increased when freezing. Then, the low temperature storage container (10) is cooled, and the subject to be stored (A) is stored at the storage temperature that is the temperature between the freezing points of the liquid (C) and the liquid (D) and is lower than the freezing point temperature at atmospheric pressure of a liquid in the subject to be stored (A).

Owner:MITSUYA CO LTD +1

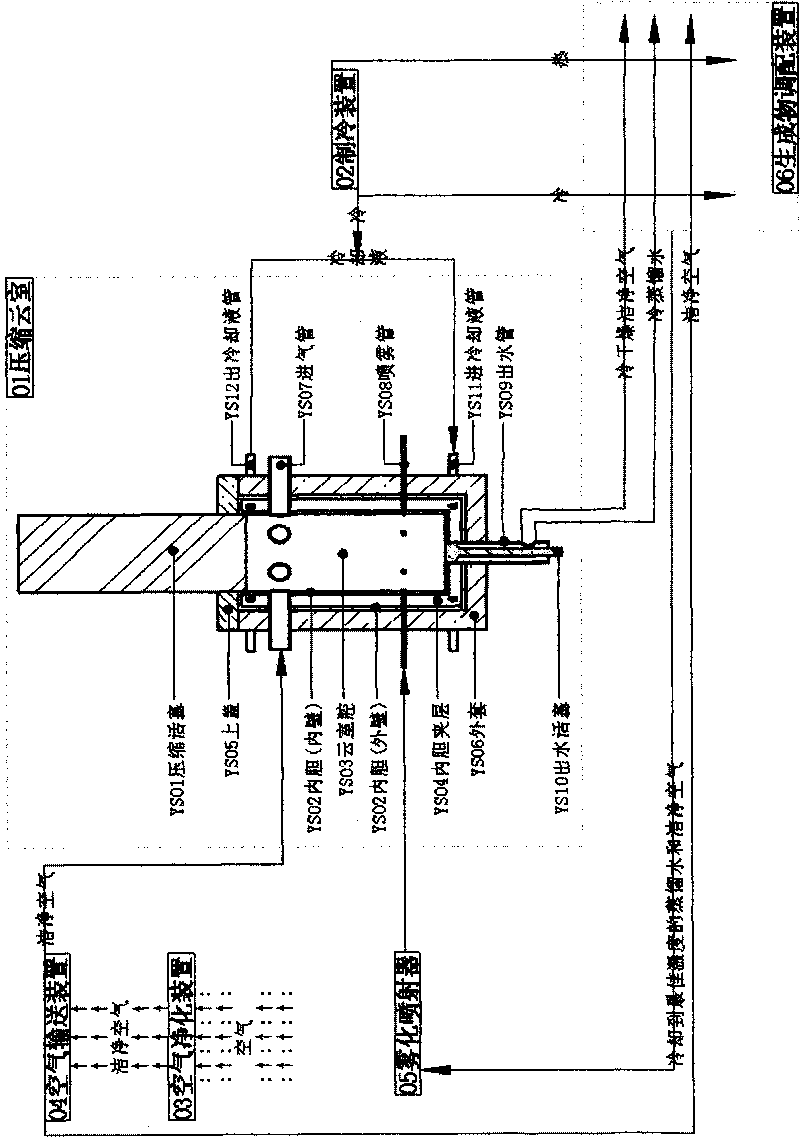

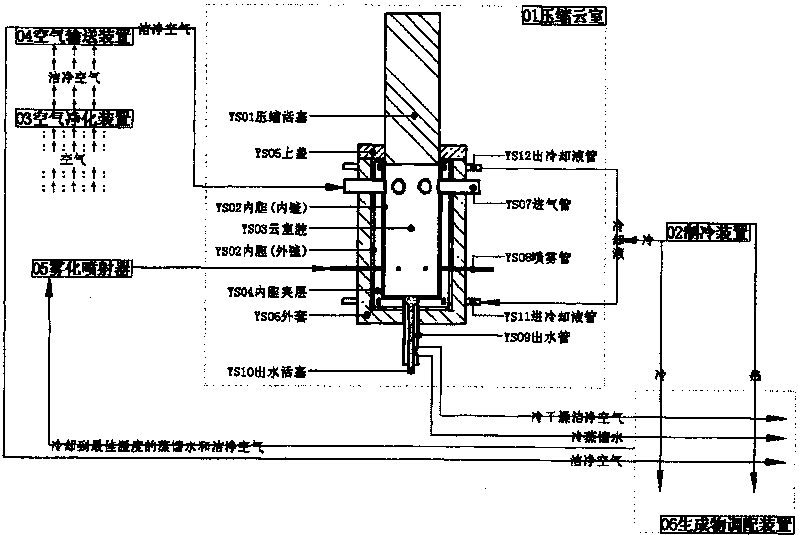

Liquefying method for compression cloud chamber

InactiveCN101725166AReduce manufacturing costReduce use costWater conservationDrinking water installationFreezing Point TemperatureWater vapor

The invention relates to a method and a device for liquefying with high purity, in particular to a method and a device for liquefying water vapor in the air and collecting the liquefied water vapor to prepare distilled water for drinking. In order to solve the problems of contradictions among liquefying purity, liquefying speed, liquefying proportion, liquefying energy consumption and liquefying cost and the like, the method increases the pressure of the purified air and lowers the temperature of the purified air at the same time through a system using a compression cloud chamber device as the core, and then atomizes and sprays the purified liquid at the same temperature to the pressed and cooled air by using the clear air at the temperature slightly lower than a freezing point so as to eliminate the contradictions in the liquefying process, shorten the process, improve the purity, speed and proportion, prolong the service life of the equipment and reduce the energy consumption and the cost.

Owner:张逸林

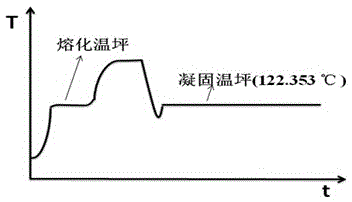

Method and device for temperature calibration by means of benzoic acid freezing point temperature level ground

ActiveCN105092096AImprove stabilityGood reproducibilityThermometer testing/calibrationFreezing Point TemperatureBenzoic acid

The invention belongs to the metering technology field, and concretely relates to a method for temperature calibration by means of a benzoic acid freezing point temperature level ground. The invention also relates to a device adopted by the above method. The method includes the steps of making a benzoic acid freezing point bottle and conducting temperature calibration. The device comprises a benzoic acid freezing point bottle and a benzoic acid freezing point reproduction storage device. The benzoic acid freezing point bottle and the benzoic acid freezing point reproduction storage device are combined together at about 122 DEG C to conduct temperature calibration by means of a benzoic acid freezing point temperature level ground. The beneficial effects of the invention are: firstly, the calibration accuracy is high, and secondly, good reliability is achieved. The method and the device are of practical significance in tracing a specific key temperature spot.

Owner:济南长峰致远仪表科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com