Mining temperature reduction coolant and preparation method thereof

A cold storage agent and cooling agent technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of short cold storage time, high cost, harmful substances, etc., and achieve good flexibility, simple preparation, and large phase change The effect of latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The mine cooling and storage agent includes the following raw materials by weight:

[0023] 6 kg of polyvinyl alcohol, 15 kg of 10% borax solution, 4 kg of propylene glycol, and 75 kg of water.

[0024] The specific preparation and operation method of the cold storage agent is as follows:

[0025] a. According to the above formula, add polyvinyl alcohol and water into the container, and heat to 85~95℃ while stirring to melt the polyvinyl alcohol completely;

[0026] b. Stir the reaction vessel continuously, add freezing point cooling agent to make it evenly mixed;

[0027] c. Add 10% borax solution, stir until the mixture is uniform, and keep it at this temperature for 10 minutes to prepare the cold storage agent;

[0028] d. Pour the prepared cold storage agent into a forming container, freeze and shape it in an ice room below -15°C, then thaw the shaped cold storage agent at room temperature and fill it into the packaging bag to obtain the finished product.

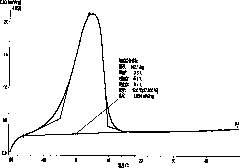

[0029] The initial m...

Embodiment 2

[0031] The mine cooling and storage agent includes the following raw materials by weight:

[0032] Polyvinyl alcohol 4kg, 10% borax solution 5kg, propylene glycol 4kg, water 87kg.

[0033] The specific preparation and operation method of the cold storage agent is the same as in Example 1.

[0034] The initial melting temperature of the cold storage agent is -3.6°C, and the latent heat of melting is 247.5J / g.

Embodiment 3

[0036] The mine cooling and storage agent includes the following raw materials by weight:

[0037] Polyvinyl alcohol 4kg, 10% borax solution 15kg, propylene glycol 8kg, water 73kg.

[0038] The specific preparation and operation method of the cold storage agent is the same as in Example 1.

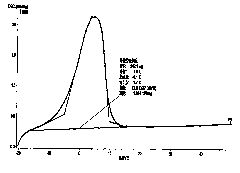

[0039] The initial melting temperature of the cold storage agent is -4.4°C, and the latent heat of melting is 225.5J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com