Multifunctional concrete structure endurance protective agent, preparation and application method thereof

A technology of concrete structure and durability, applied in the field of concrete protective agent, can solve the problems of single function and poor product stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

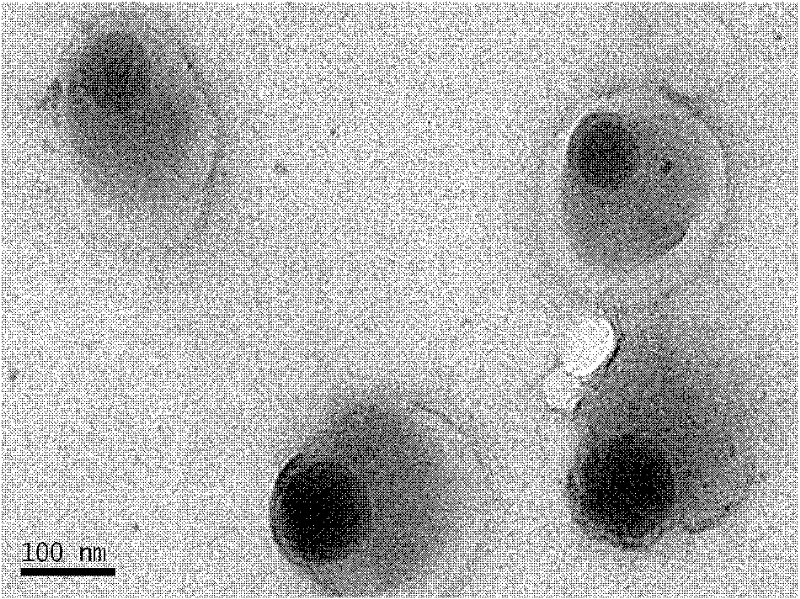

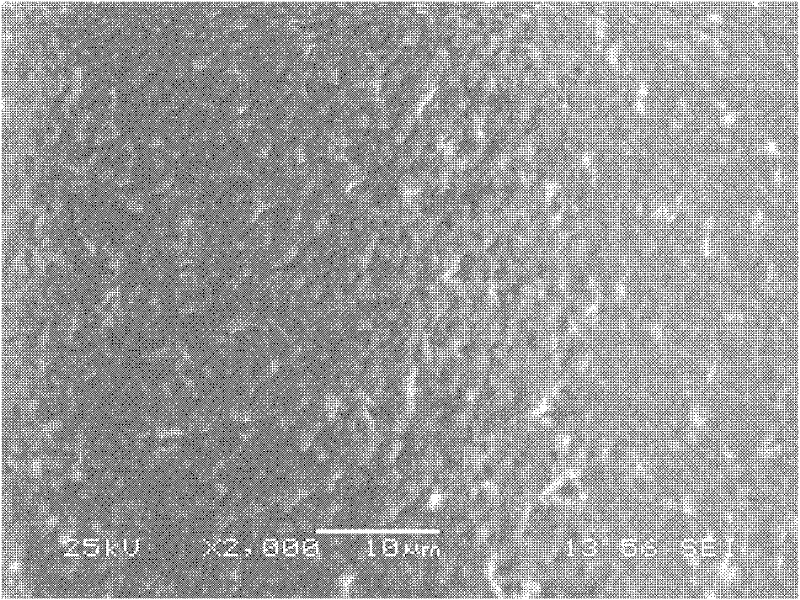

Embodiment 1

[0099] Mix 0.1 kg of aluminum isopropoxide, 0.3 kg of butyl titanate, 1.7 kg of tetraethyl silicate, and 6 kg of absolute ethanol, and put them into a separatory funnel for later use; mix 10 kg of absolute ethanol, 0.4 kg of distilled water Kilogram and 0.1 kilogram of ammoniacal liquor (mass fraction is 25%) join in the reactor that reflux condensing device and electric stirrer are housed, stir 1-2 hour with the speed of 150 rev / mins, mix homogeneously and heat up; When temperature rises to At 45-60°C, drop the organic alkoxide and ethanol mixture into the reactor, stir rapidly at 200 rpm, and react for 2-4 hours; slowly stir and age at room temperature for 24 hours to obtain the alcohol of inorganic nanomaterials Sol. Under the condition of low-speed stirring, add 0.18 kg of methacryloxypropyltrimethoxysilane dropwise into the alcohol sol of inorganic nanomaterials, react at room temperature for 22 hours, raise the temperature to 50°C and react at constant temperature for 2 ...

Embodiment 2

[0103] Synthesis and preparation of the organic / inorganic composite fluorosilicone acrylic polymer emulsion is the same as in Example 1.

[0104] 0.3 kg of sodium silicate, 1.2 kg of lithium silicate, 0.6 kg of sodium molybdate, 0.6 kg of sodium sulfate, 0.03 kg of nano-titanium dioxide, 0.02 kg of sodium tetraborate, and / or inorganic composite fluorosilicone acrylic polymer emulsion (solid content is about 18%) 75 kg and 20 kg of distilled water are added in a mixer with a stirrer. Then, the mixed solution of 0.3 kg of benzotriazole and 1 kg of absolute ethanol is added into the mixer, and mixed evenly at a speed of 100 rpm at room temperature, that is, a multi-functional concrete structure durable protective agent.

Embodiment 3

[0106] Synthesis and preparation of the organic / inorganic composite fluorosilicone acrylic polymer emulsion is the same as in Example 1.

[0107] 1 kg of sodium silicate, 0.9 kg of lithium silicate, 0.5 kg of sodium molybdate, 1 kg of sodium sulfate, 0.02 kg of nano-titanium dioxide, 0.03 kg of sodium tetraborate, and organic / inorganic composite fluorosilicone acrylic polymer emulsion (solid content is about 18%) 70 kg and 25 kg of distilled water are added in a mixer with a stirrer. Then, add 1.5 kg of dehydrated alcohol mixed solution with 0.2 kg of benzotriazole into the mixer, and mix evenly at a speed of 100 rpm at room temperature to obtain a multifunctional concrete structure durable protective agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com