Liquefying method for compression cloud chamber

A liquid atomization and liquefaction device technology, applied in climate change adaptation, drinking water installations, climate sustainability, etc., can solve problems such as short sensitive time and long cycle period, and achieve extended equipment life, complete means, and significant progress and creative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

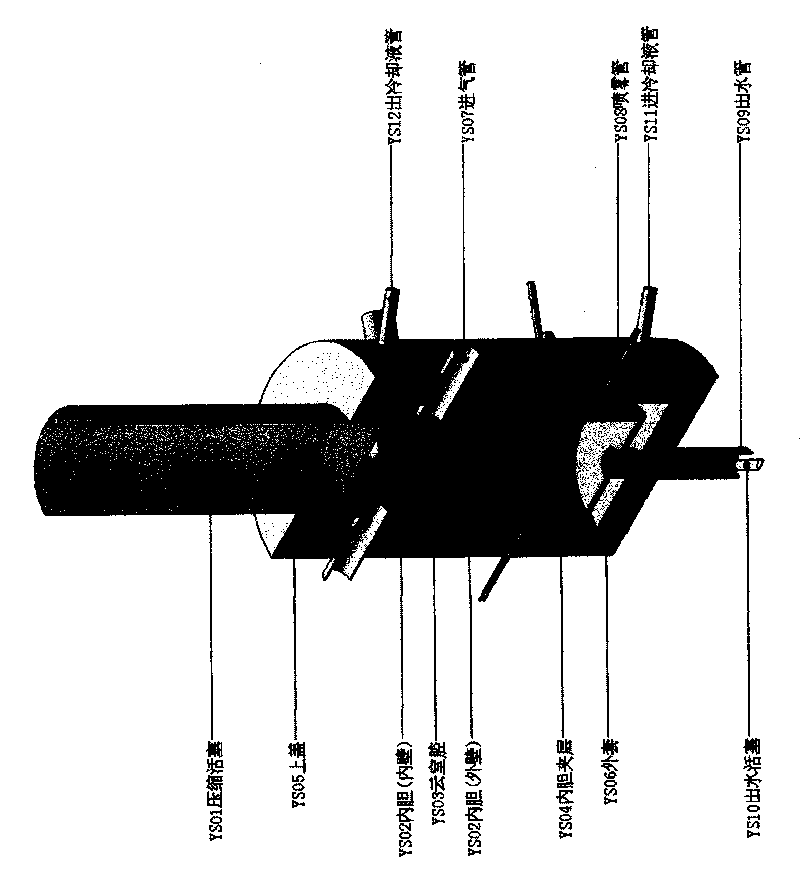

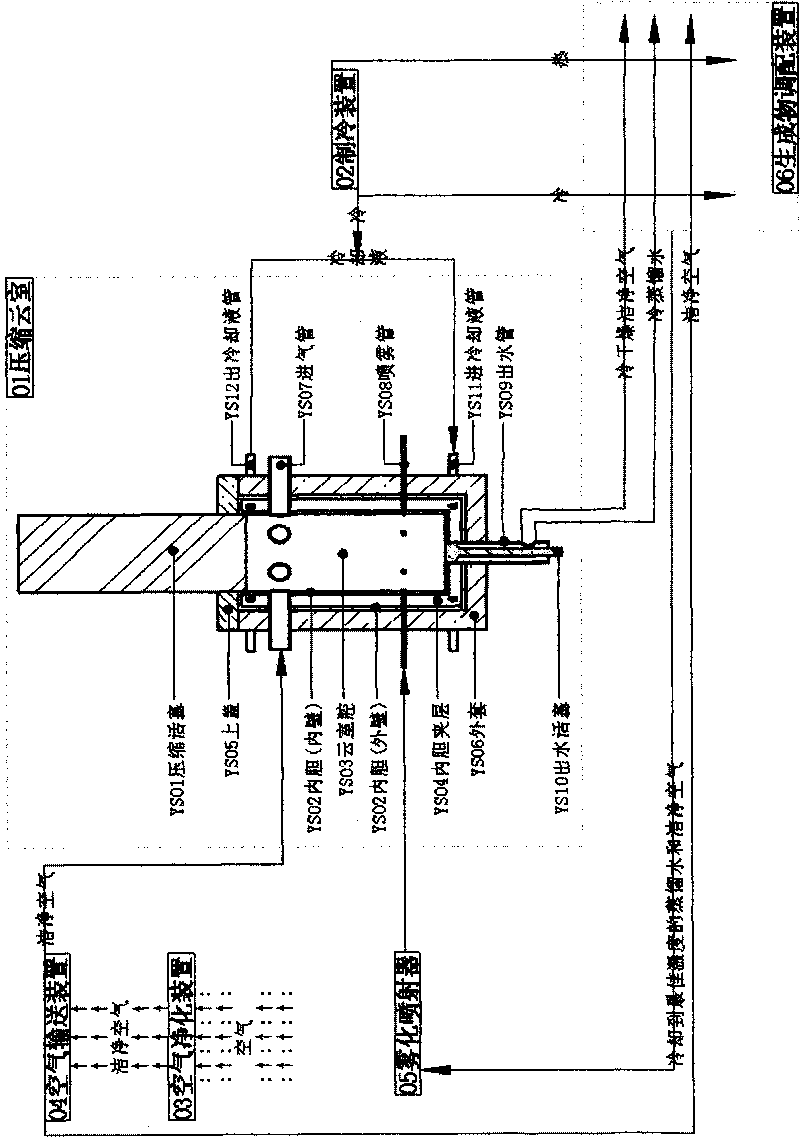

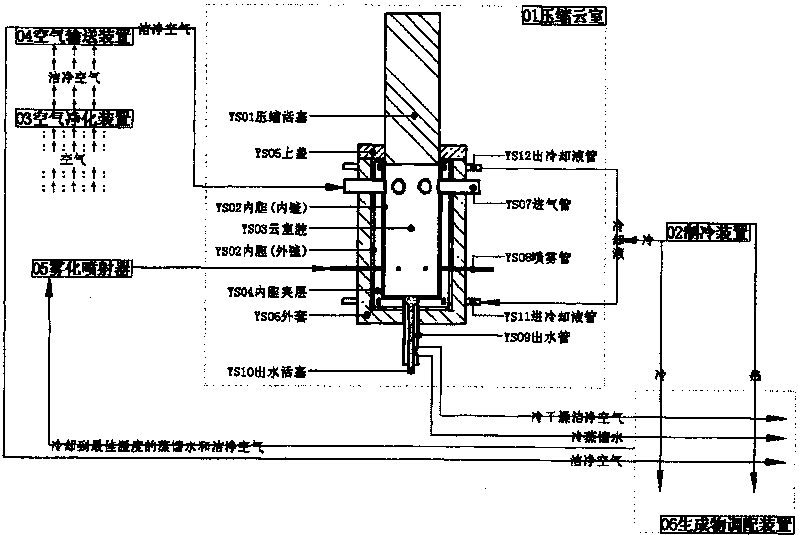

[0046] Next, taking a simple and intuitive structure as an example, the key device "01 compression cloud chamber" for implementing the present invention will be introduced:

[0047] The center of the "01 compression cloud chamber" is the "YS03 cloud chamber cavity" closed by the "YS01 compression piston" of heat-insulating material and the "YS02 liner" of heat-conducting material. Interlayer", heat insulation material "YS05 upper cover" and "YS06 jacket" cover the inner tank. A circle of "YS07 intake pipe" and a circle of "YS08 spray pipe" are inserted into the "YS03 cloud chamber chamber" from the side, and "YS09 outlet pipe" sandwiches the "YS10 water outlet piston" from below. A circle of "YS11 coolant inlet pipe" and a circle of "YS12 coolant outlet pipe" are inserted into the "YS04 liner interlayer" from the side.

[0048] Through the cooperation of the key device of the present invention and other auxiliary devices, the method of the present invention can be implemented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com