Supercooling non-freezing storage control method and refrigerator

A storage method and supercooling technology, which can be used in cooling fluid circulation devices, household refrigeration devices, lighting and heating equipment, etc., and can solve the problems of food quality degradation and long thawing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Such as Figure 5 As shown, the present embodiment provides a supercooled non-freezing storage refrigerator, including:

[0056] The cooling chamber 2 is used for supercooling and not freezing preservation of the food put therein.

[0057] The refrigerating system 5 is used to produce cold air to refrigerate the cooling objects in the refrigerator, and specifically includes: a compressor 51, a condenser 52, an anti-condensation pipe 53, a drying filter 54, a freezing evaporator 55, and an air return pipe assembly 56. Example of a refrigeration system 5 such as Figure 4 shown.

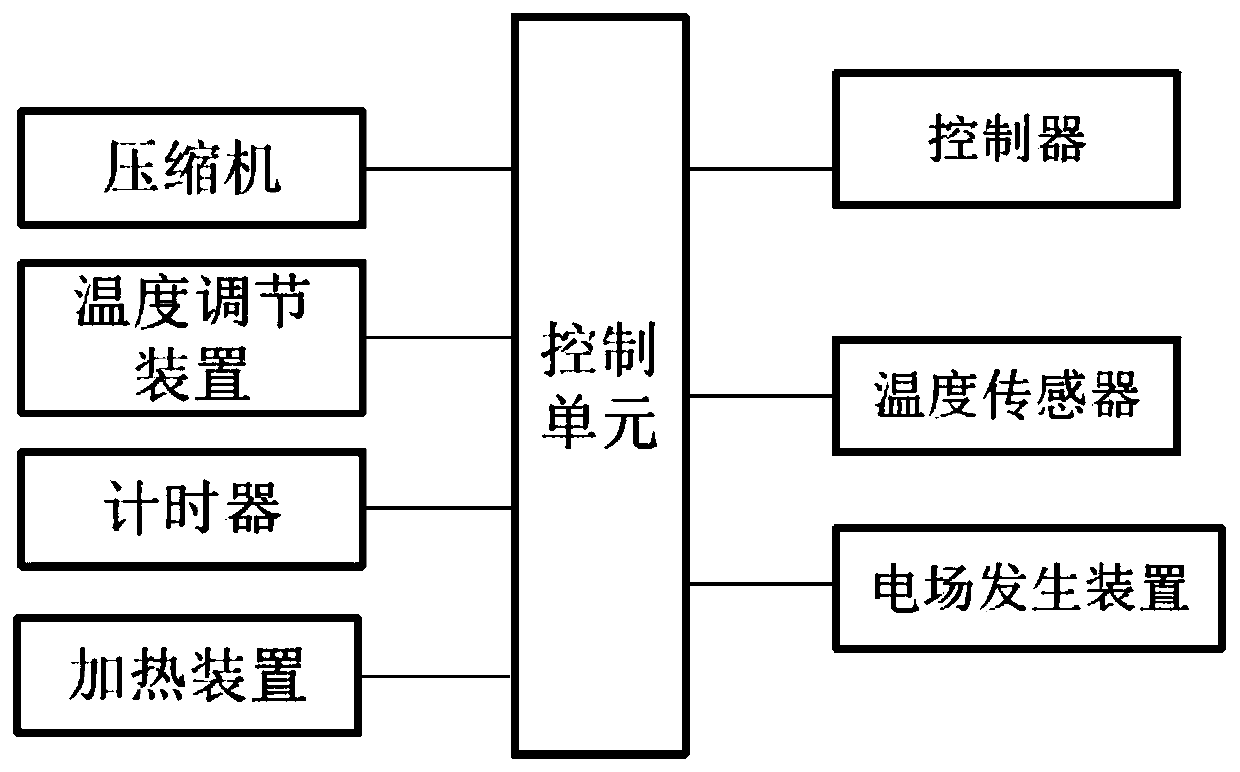

[0058] The control unit includes: a controller, a temperature regulating device, a temperature sensor 4, a timer, a heating device 6, and an electric field generating device 7, and is characterized in that: the controller is used to control other components of the control unit; the temperature regulating device is used for Adjust the temperature of the cooling chamber 2 to make it run accordi...

Embodiment 2

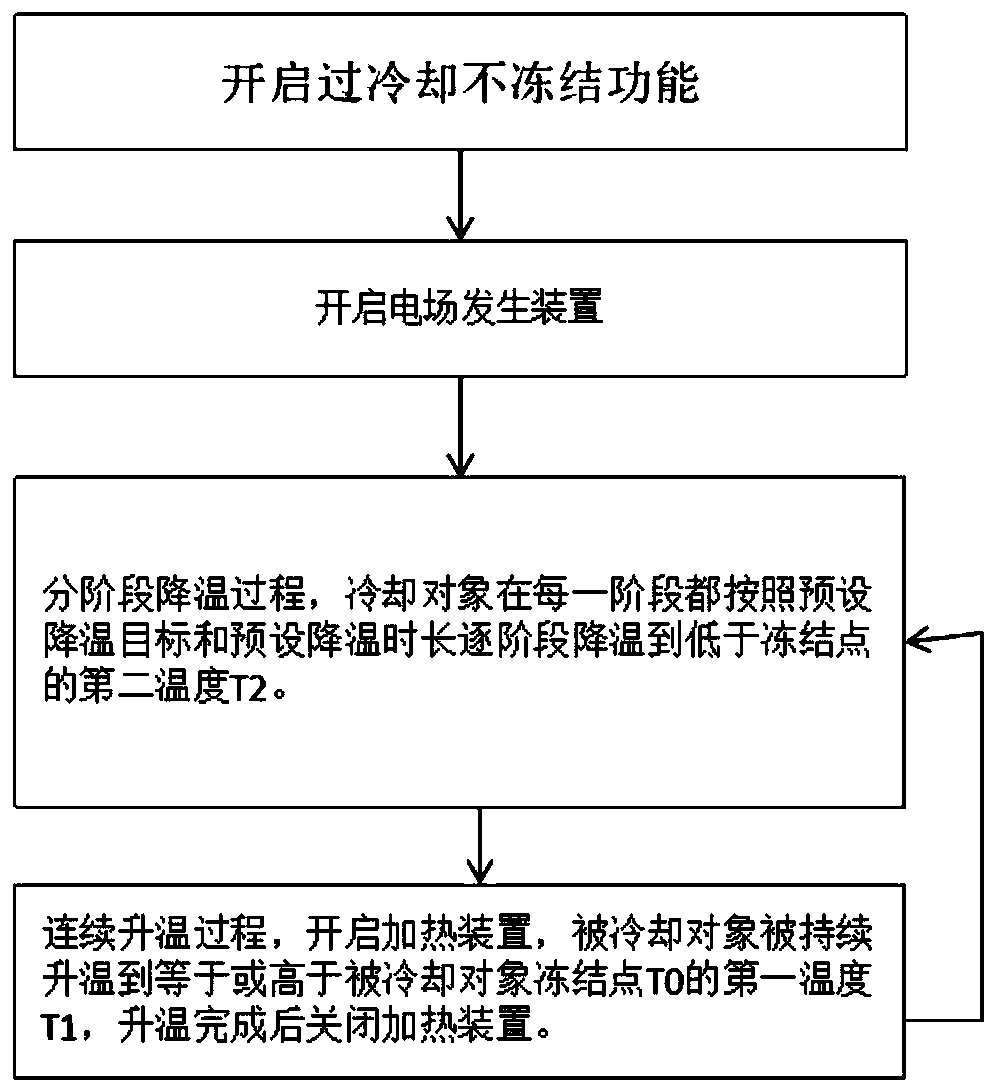

[0070] Attached below figure 1 The content of the specific embodiment of the present invention is described in detail: the electric field generating device 7 is turned on, and the food under the action of the electric field is controlled for cooling and heating. The cooling and heating control includes the following steps:

[0071] S1: the cooling process in stages, so that the cooling chamber is cooled step by step to the second temperature T2 lower than the freezing point T0 of the object to be cooled according to the preset cooling target and preset cooling time;

[0072] S2: In the continuous heating process, turn on the heating device 6 to continuously raise the temperature of the cooling chamber to the first temperature T1 equal to or higher than the freezing point T0 of the object to be cooled, and turn off the heating device 6 after the heating process is completed.

[0073] Wherein, T1>T2, the temperature range of T1 is 0°C to 10°C, the temperature range of T2 is -10°...

Embodiment 3

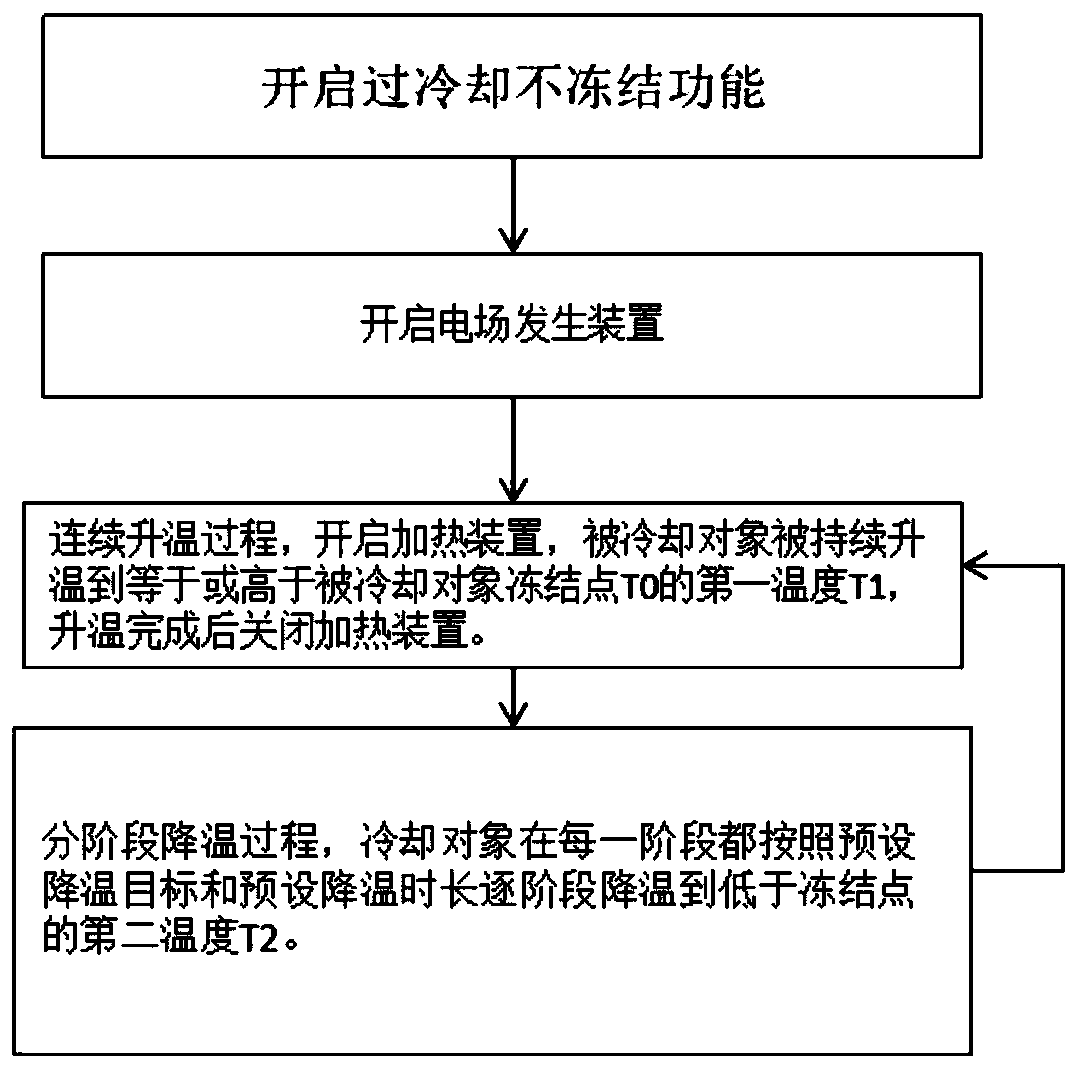

[0099] Such as figure 2 As shown, this embodiment provides another control method for supercooling without freezing storage. After the user puts the food into the cooling chamber 2 of the refrigerator, he turns on the electric field generator 7, so that the food is under the action of the electric field, and the infrared temperature in the cooling chamber 2 The sensor detects the surface temperature Ts of the food. If it detects that the surface temperature Ts of the food is equal to or lower than the second temperature T2, the refrigerator control unit controls the cooling chamber 2 to heat up first. Compared with Embodiment 2, the temperature rise program is executed first in this embodiment Re-execute the cooling program, and then enter the control cycle of heating and cooling, and the rest are the same as in Embodiment 2, and will not be repeated here. The temperature variation of present embodiment cooling chamber is as follows Figure 8 As shown, the temperature change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com