Patents

Literature

64results about How to "Affect flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acidic, protein-containing drinks with improved sensory and functional characteristics

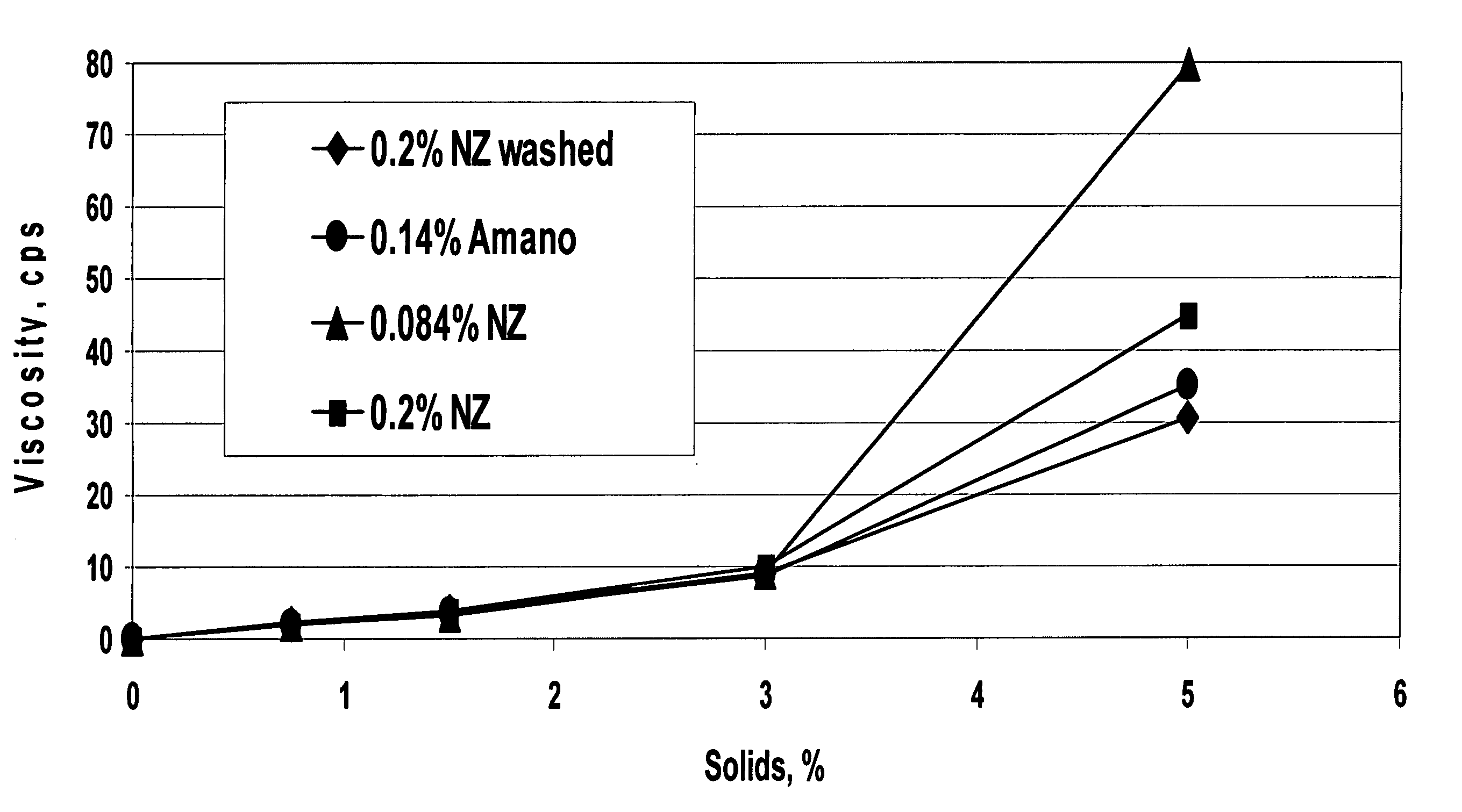

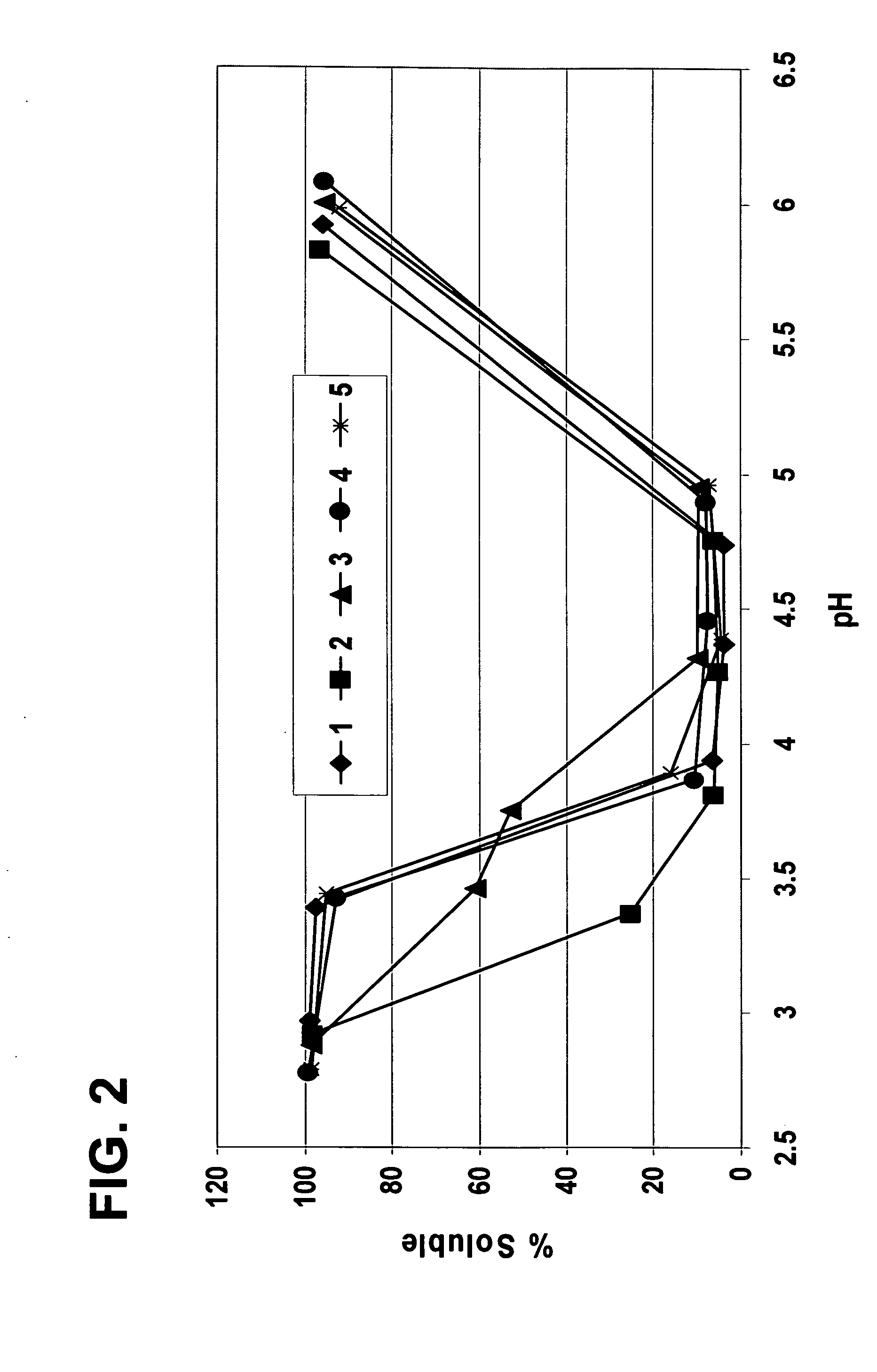

InactiveUS20070014910A1Improve suspendabilityWell flavorHydrolasesVegetable proteins working-upPlant proteinReduced viscosity

Processes for producing acidic, protein-containing drinks are disclosed. Specifically, the processes comprise producing acidic, protein-containing drinks comprising plant protein material. The acidic, protein-containing drinks have improved sensory and functional characteristics such as reduced viscosity, improved sedimentation rate, and improved mouthfeel.

Owner:ALTEMUELLER ANDREAS G +1

Pectin grain containing milk beverage and its production process

The pectin grain containing milk beverage contains milk product 30-60 weight portions, pectin grain 1-20 weight portions, sugar 4.0-15 weight portions, stabilizer 0.1-1.0 weight portions, edible essence 0.05-0.3 weight portions except water. The pectin grain is obtained through inoculating pyracetic bacillus to fruit juice, fermenting culture, taking upper fiber and crushing. The present invention provides the production of milk beverage containing pectin grain, especially coconut pectin grain.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

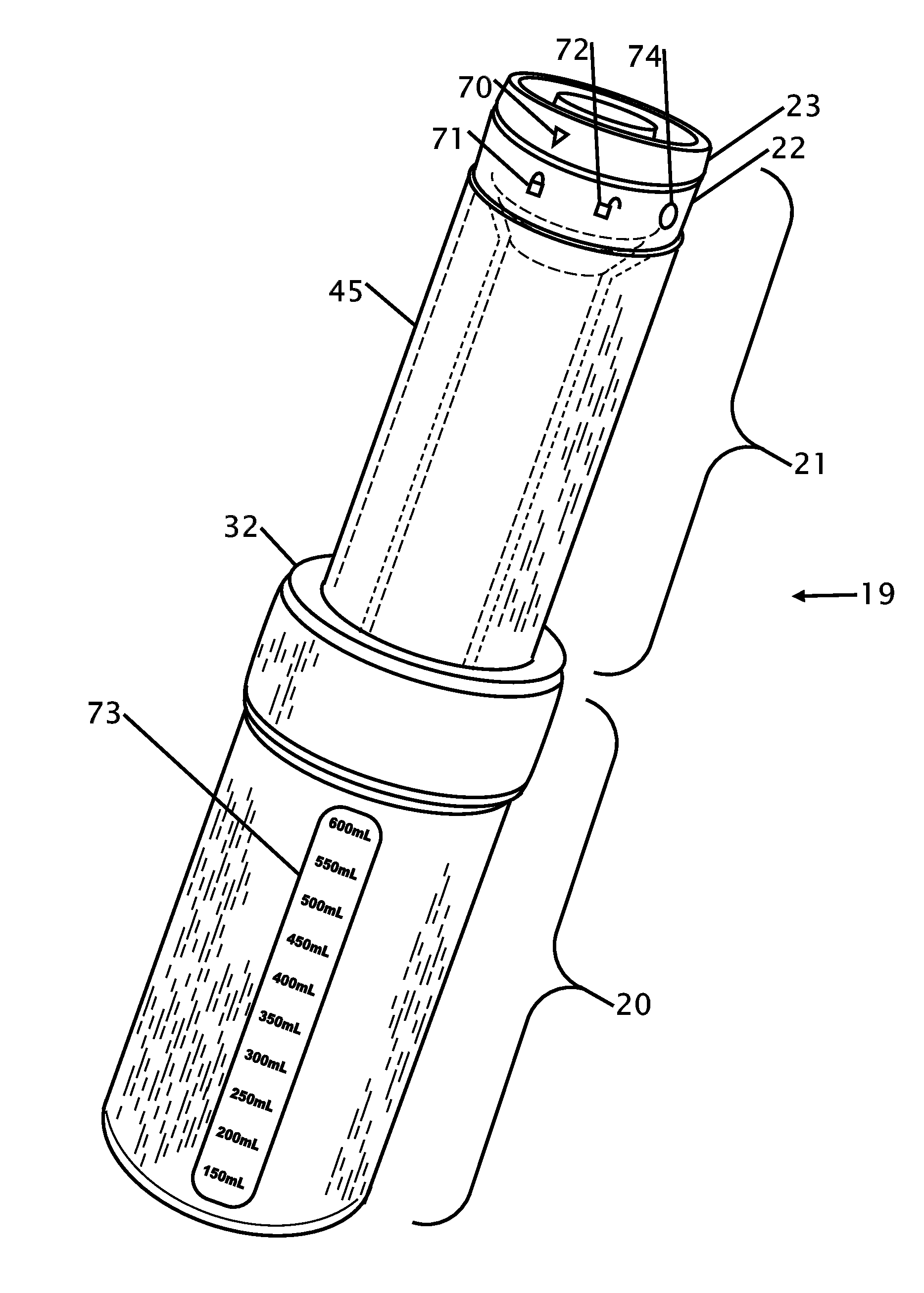

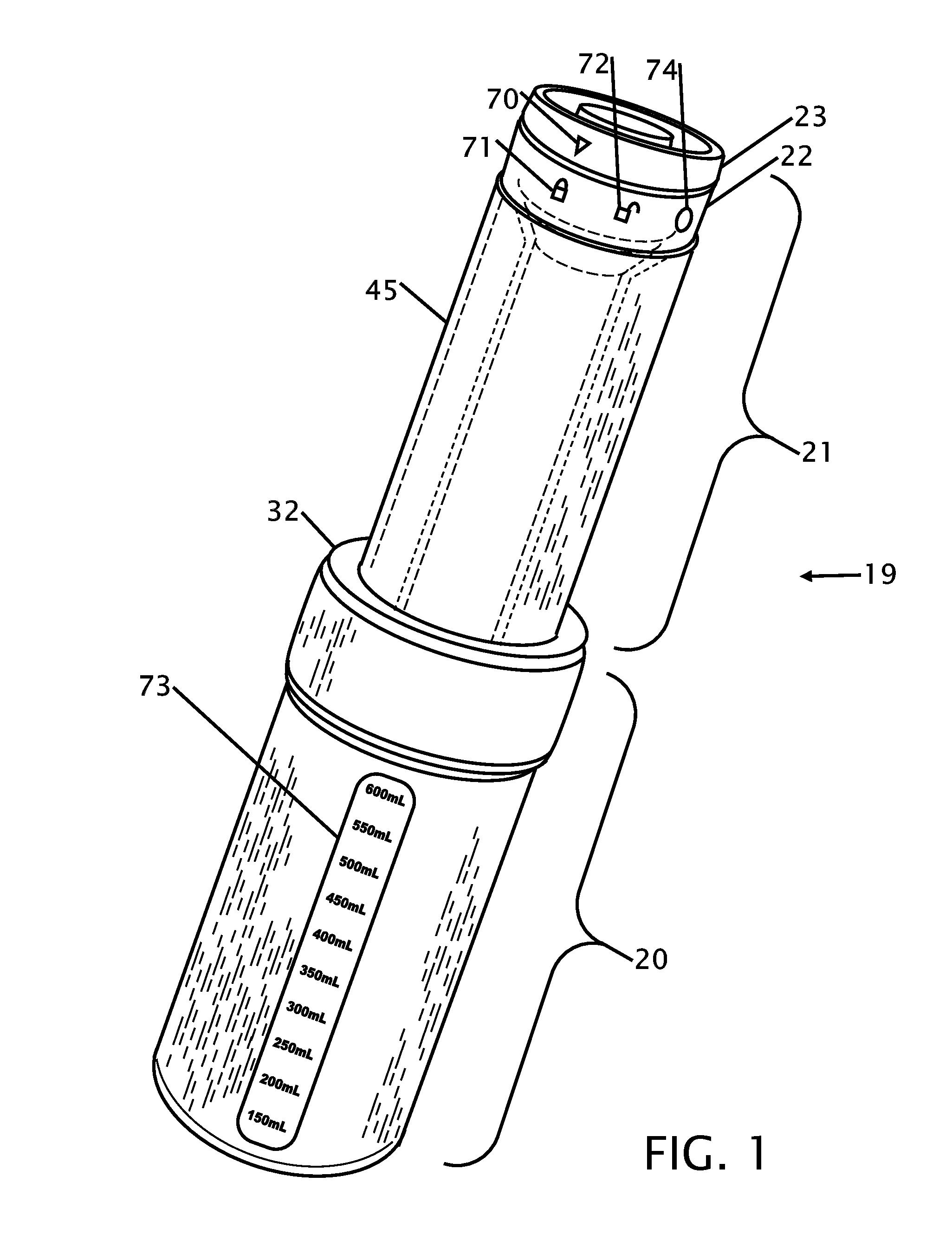

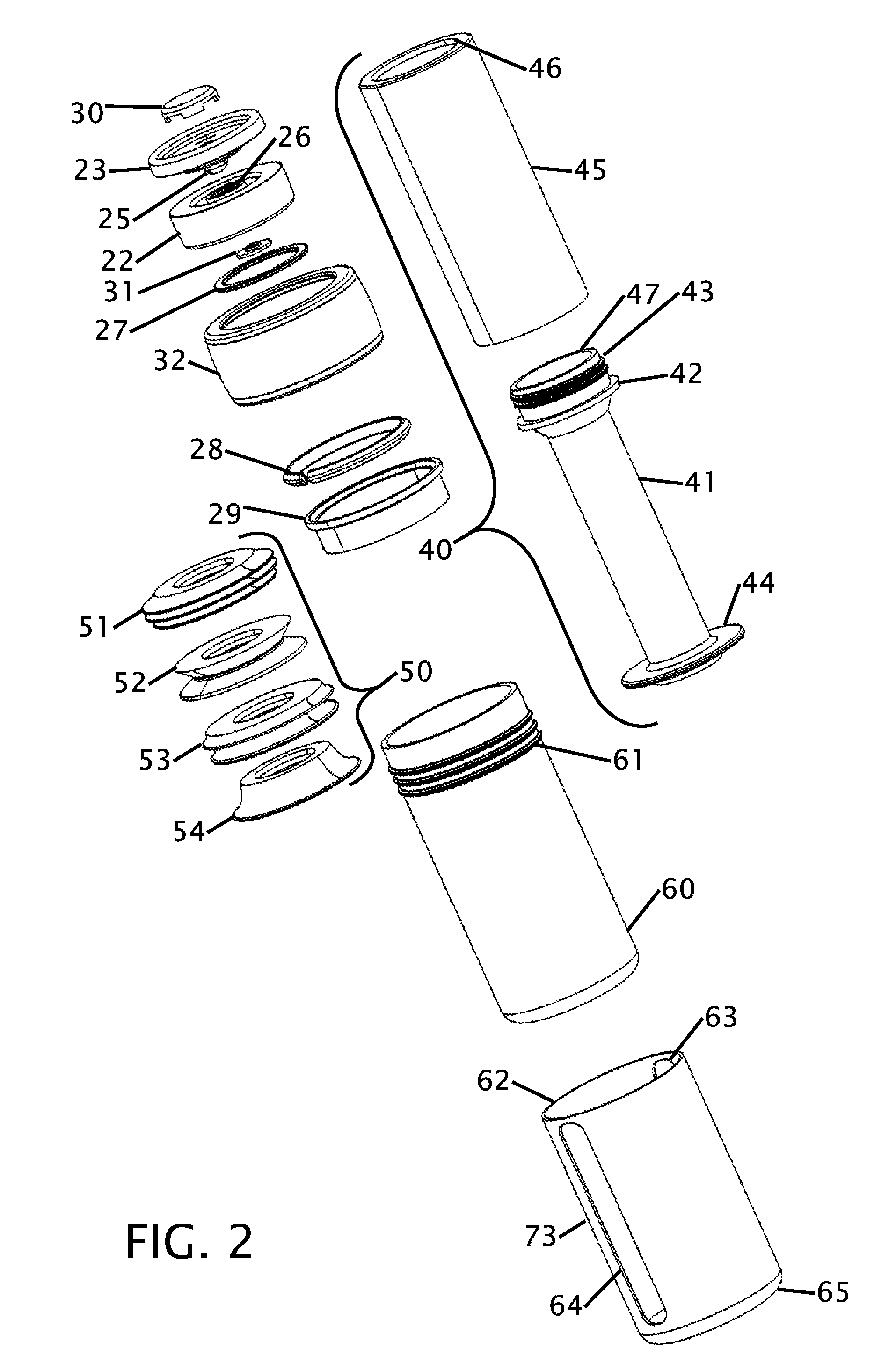

Adjustable Volume Rigid Container

InactiveUS20150344180A1Decrease and eliminate head spaceKeep for a long timeCapsClosure capsEngineeringMechanical engineering

Improvements in an adjustable volume rigid sided container are disclosed. The adjustable volume allows the container to reduce or eliminate air from within the container. As users consume a portion of the content of the container they reduce the internal volume. The container has an opening for delivery or pouring spout for delivery of the product and a cap that accommodates pouring, venting and close condition. The container has an adjustable connection between the container components.As the internal volume is adjusted the container collapses into a smaller size. Preferably the first component is larger diameter than a second component that is a smaller diameter and slides onto the larger first component. The components can be permanently sealed and disposable or can be designed to be completely taken apart where they can be placed into a dishwasher to be washed and or sterilized for future re-use.

Owner:SHAKOORI DIVANI SOHEIL

Production method of persimmon wine

ActiveCN102604778ABright colorThere is less mold on the surfaceMicroorganism based processesAlcoholic beverage preparationAlcoholEnzyme

The invention discloses a production method of persimmon wine, which comprises the following steps: 1) choosing fresh persimmons, spraying the surface of the fresh persimmons with an alcoholic solution, and sealing to thoroughly ripen and soften the persimmons; 2) breaking to obtain a persimmon pulp, adding sulfurous acid to sterilize, and then adding activated saccharomyces cerevisiae, activatedpectase and dissolved tartaric acid, and agitating uniformly and performing preliminary fermentation; 3) separating the preliminarily fermented persimmon pulp to obtain persimmon juice, and adding tartaric acid into the persimmon juice to adjust the pH value of the persimmon juice; 4) performing secondary fermentation; 5) adjusting the alcohol degree, the residual sugar, the total acid concentration and the concentration of free sulfur dioxide, and ageing; and 6) adjusting the concentration of free sulfur dioxide, filtering, sterilizing and filling to obtain the persimmon wine. According to the production method disclosed by the invention, white granulated sugar is not added in the fermentation process, and water is not additionally added in the whole production process, so that the fermented persimmon wine is intense in taste and balanced in wine, and in addition, the smell and the taste of the persimmon wine are enriched by using grape brandy to adjust the alcohol degree of the persimmon wine.

Owner:XIAN YUSHAN WINE ESTATE

Bakery product having excellent texture and taste and method of producing the same

InactiveUS20120076893A1Promote fermentationQuality improvementDough treatmentWort preparationFlavorRare sugar

An object of the present invention is to provide a bakery product which has a soft and moist texture, sweetly dissolves in the mouth, has a favorable flavor, and is well risen and a method of producing the same. Another object of the present invention is to provide a method of producing the same. By using raw material flour obtained by blending a rare sugar-containing isomerized sugar syrup or a rare sugar in wheat flour as a main raw material in the production of a bakery product, a bakery product to which softness, moistness, and a property of sweetly dissolving in the mouth is imparted is produced.

Owner:MATSUTANI CHEM INDS CO LTD

Method for effectively removing fishy smell of chub surimi

InactiveCN101695395AEffectively remove fishy smellRemove fishy smellFood preparationWater bathsAdditive ingredient

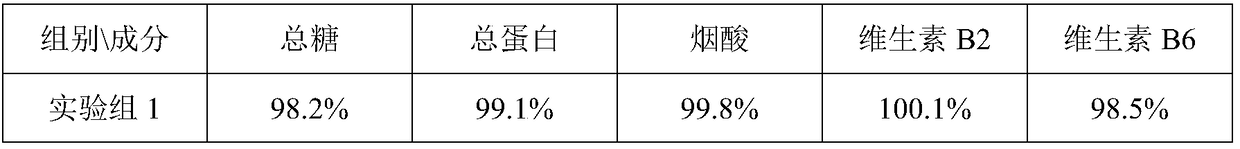

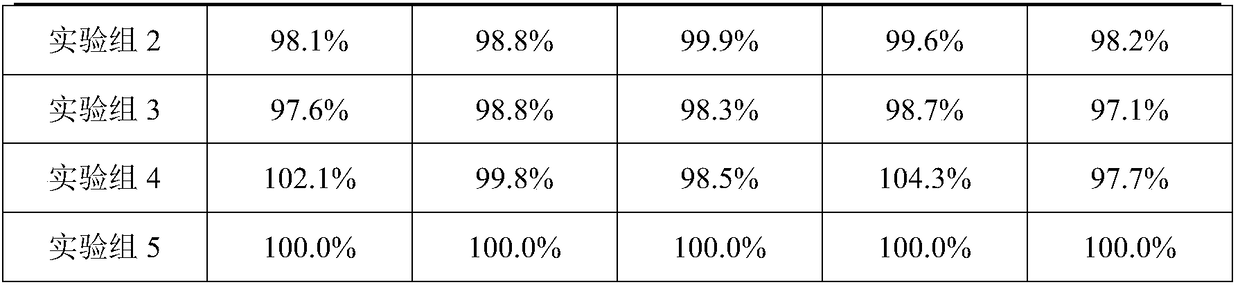

The invention relates to a method for effectively removing the fishy smell of chub surimi. The method comprises the steps of: temporarily feeding fresh chubs in aerated clean water for 12 hours, washing the chubs, then cutting off chub tails and bloodletting, removing scales, heads and internal organs of the chubs, then rinsing fish flesh by clean water, dehydrating the fish flesh, and then preparing the dehydrated fish flesh into surimi by a meat mincer; chopping up fresh fineleaf schizonepeta herb and gingers, then stirring the chopped fresh fineleaf schizonepeta herb and gingers by a juicing machine, and taking fineleaf schizonepeta herb juice and ginger juice for later use; and adding the fineleaf schizonepeta herb juice into the surimi, treating the surimi in a thermostat water bath, then adding tea polyphenol into the thermostat water bath, treating the surimi in the thermostat water bath for 50 minutes, or adding the ginger juice and cooking wine into the surimi, treating the surimi in the thermostat water bath, then adding the tea polyphenol into the thermostat water bath, and treating the surimi in the thermostat water bath to obtain the fishy smell-free chub surimi. In the method, combined fishy smell removing technique is adopted, and the removal ratios of a plurality of main components causing the fishy smell of the chub are close to 100 percent; and the water content, proteins, color and quality of nutrients such as amino acids of treated surimi products are hardly affected. The method has the advantages that: the operation is simple, used raw materials are edible additives, and no residue and pollution are caused; and the fishy smell of the chub is completely removed without affecting the chub flavor.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

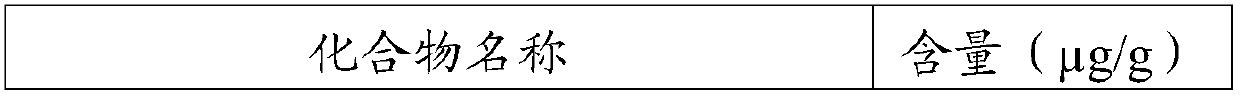

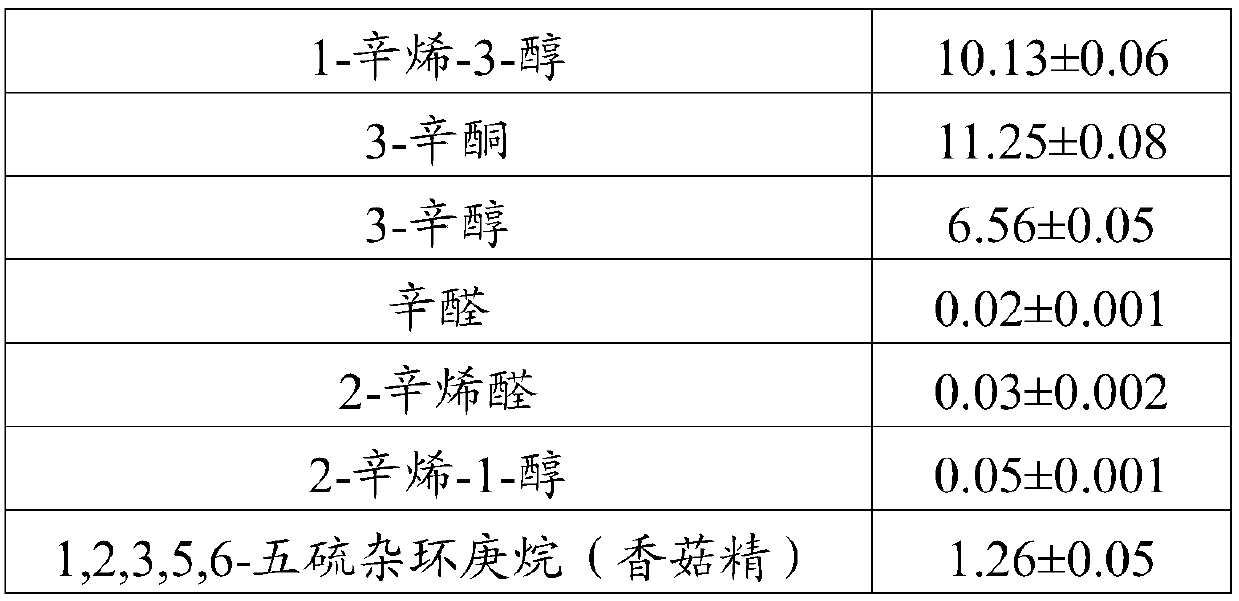

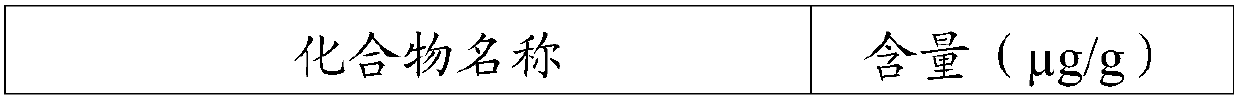

Preparation method of edible mushroom seasoning

InactiveCN109527505AAvoid the problem of difficulty in crushing evenlyPreserve the flavorFood preservationFood ingredient as taste affecting agentAdditive ingredientHydrolysate

The invention discloses a preparation method of an edible mushroom seasoning. The method comprises the following steps: S1, cutting of edible mushroom to form dices; S2, addition of water to the obtained edible mushroom, and crushing for obtaining a homogenate, wherein the homogenate can go through a 100-200 mesh sieve; S3, addition of one or more of papain, flavourzyme, cellulase and xylanase tothe homogenate to the homogenate, physical field processing, enzymatic hydrolysis, and passivation for obtaining an enzymatic hydrolysate; S4, addition of the enzymatic hydrolysate into a wall material solution to carry out embedding; and S5, drying for obtaining the seasoning. The preparation method makes flavor substances in the edible mushroom effectively reserved and fully released, develops the edible mushroom seasoning and ingredients with protruding flavor characteristics, ensures the quality of the edible mushroom seasoning and ingredients, establishes a high-efficiency and energy-saving production way, and meets the demands of consumers for all-natural healthy seasoning and the important direction of fine advanced processing of modern edible mushrooms.

Owner:DALIAN POLYTECHNIC UNIVERSITY

A brewing method of low-methanol-content Chinese date wine

ActiveCN106085699AIncrease contentIncrease the juice yieldAlcoholic beverage preparationPectin esteraseFruit juice

The invention relates to a brewing method of low-methanol-content Chinese date wine, and belongs to the technical field of brewing. The method includes sorting Chinese dates, cleaning, stoning, soaking with hot water, pulping, adding pectin esterase and cellulase, performing enzymatic hydrolysis, stirring and cooking in an air-lift combined mechanical manner, centrifuging, separating supernatant, adjusting the supernatant with white sugar and citric acid, sterilizing, inoculating, fermenting, clarifying, filtering, adding a clarifying agent, and aging by using an oak barrel. The method degrades cell walls of fruit tissues by using the pectin esterase and the cellulase, degrades polysaccharides to allow effective components inside the Chinese dates to dissolve out, and increases the content of juice nutrients and the juice yield. Through stirring and cooking in the air-lift combined mechanical manner, methanol produced by pectin substance zymolysis through the pectin esterase and methanol produced by other reasons are separated along with stirring, cooking and high-pressure air blowing, thus reducing the methanol content in Chinese date juice pulp.

Owner:河北九维生物科技开发有限公司

Method for moulding a food product

InactiveUS20090061059A1Reduce adhesionNoticeable off tasteFrozen sweetsConfectioneryShell moldingAqueous solution

A method for moulding a plastic food product comprising the steps of (a) pressing a moulding surface having a temperature of from −10° C. to −5O0C. against the food product to cause at least part of the product to take up the shape of the moulding surface; and (b) removing the moulding surface from the food product characterised in that in step (a) a layer of a frozen aqueous solution is present between the food product and the moulding surface, the solution having a Tg′ below −60° C. and a solute concentration of from 0.001 to 20% by weight.

Owner:CONOPCO INC D B A UNILEVER

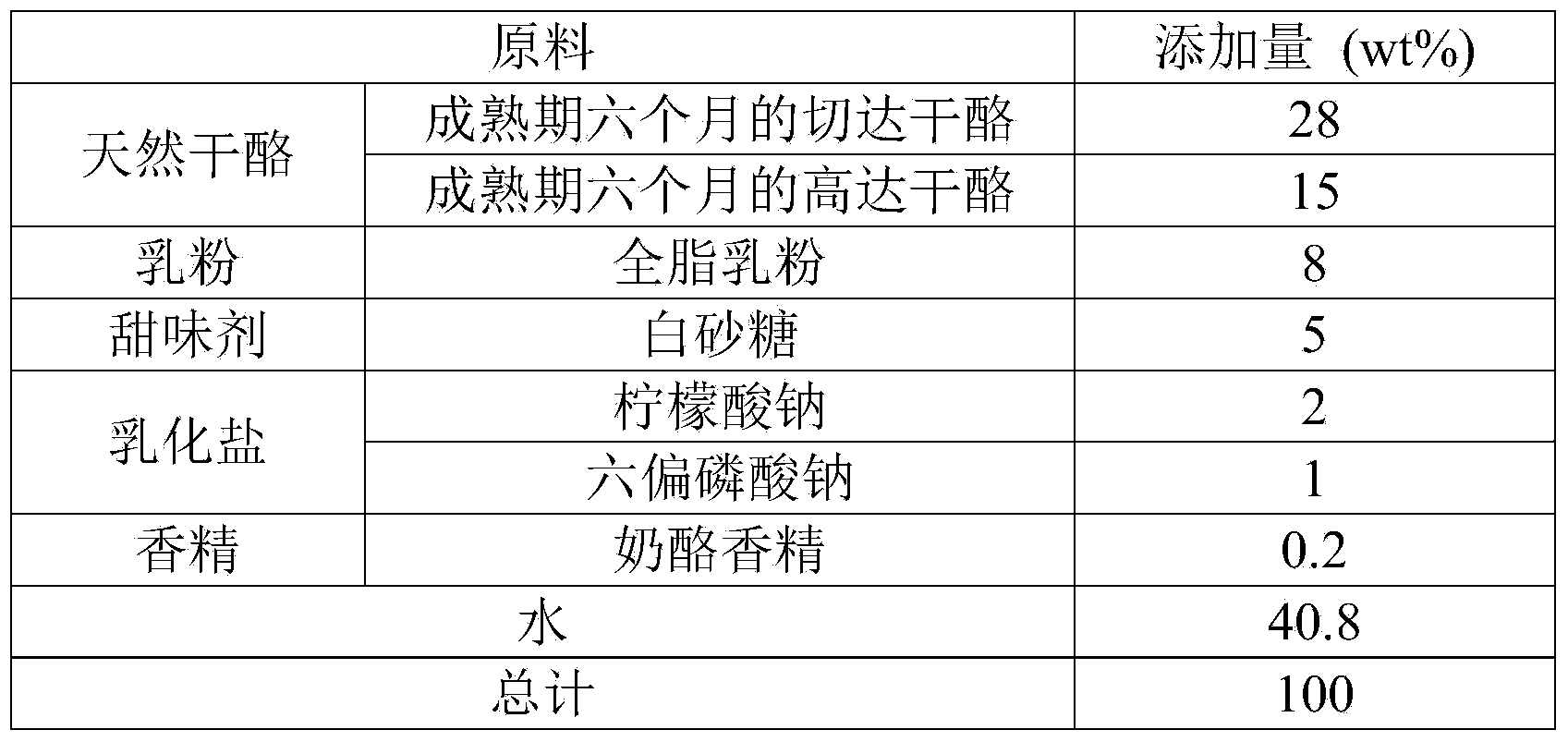

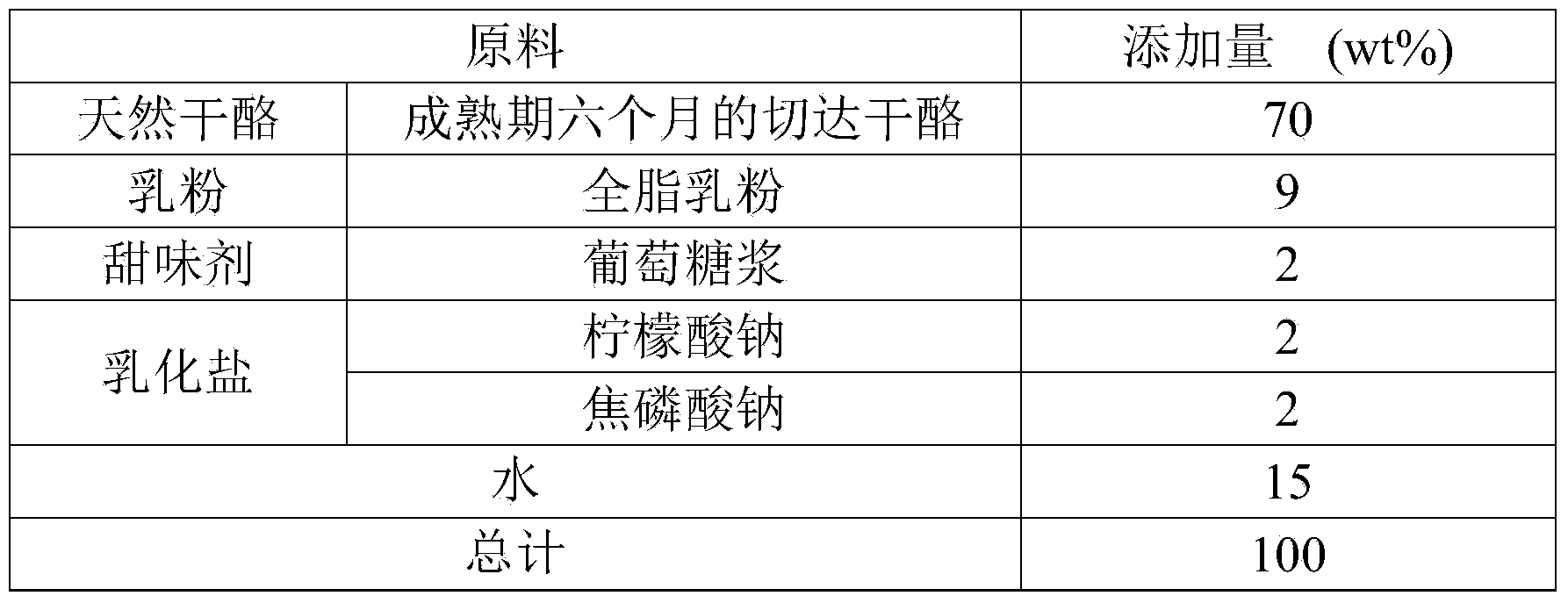

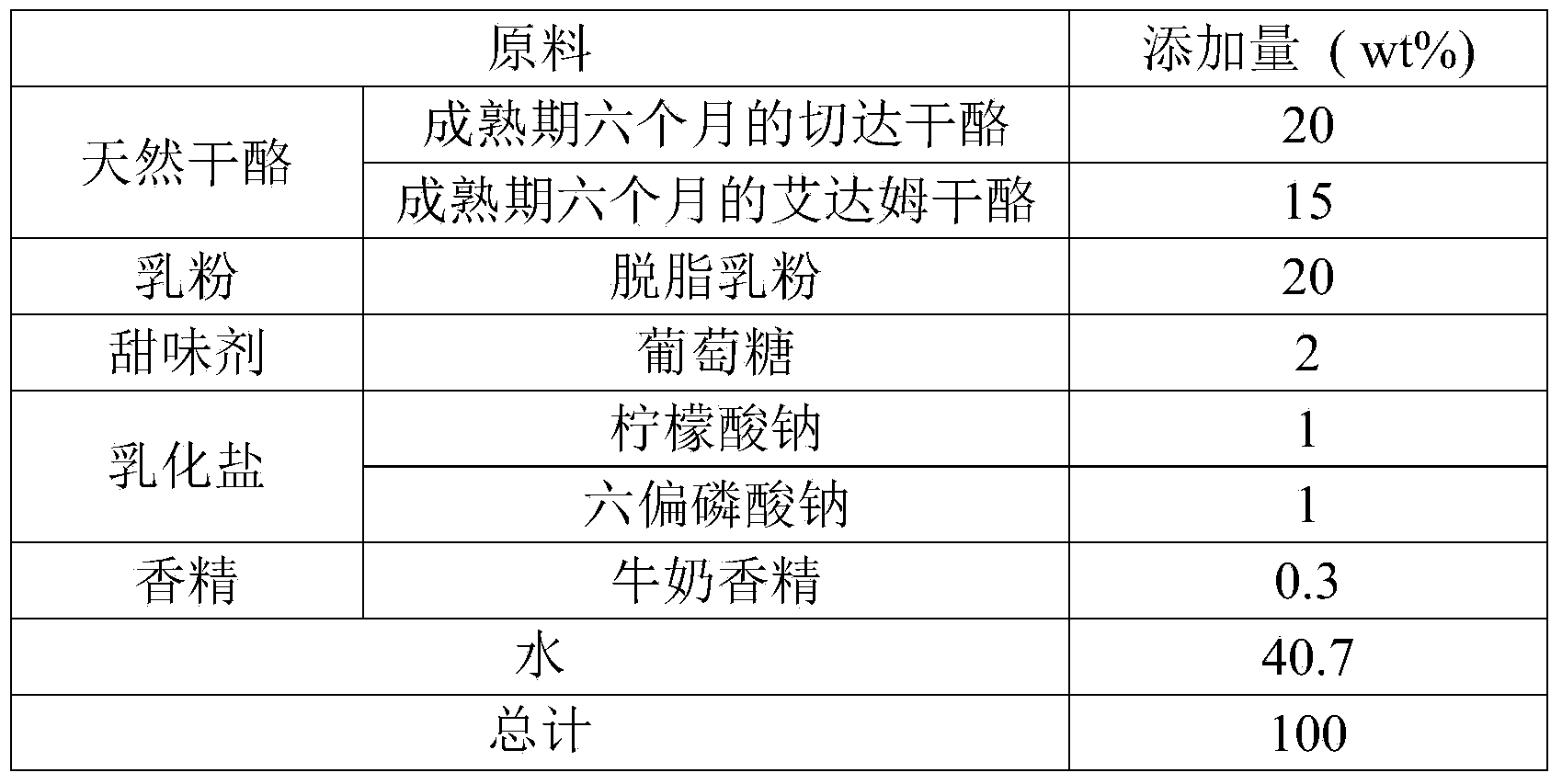

Preparation method for reproduced cheese preserved at normal temperature and product

The invention discloses a preparation method for reproduced cheese preserved at normal temperature and a product. The preparation method comprises the following steps: (1) mixing raw materials for reproduced cheese preserved at normal temperature, heating and evenly agitating to obtain feed liquid; (2) injecting the feed liquid into a die, cooling to room temperature and then primarily pre-freezing at -5 DEG C to -25 DEG C for 2-12 hours, demolding to obtain the reproduced cheese; (3) pre-freezing the reproduced cheese at -35 to -60 DEG C for 4-24 hours, so as to obtain pre-frozen reproduced cheese; (4) keeping the temperature of the pre-frozen reproduced cheese at 15-35 DEG C under the vacuum degree of 100-20Pa, wherein the thermal insulation time at least is the time required for cooling the center temperature of the pre-frozen reproduced cheese to 0 DEG C; and (5) heating up to 35-50 DEG C under the vacuum degree of 80-20Pa, and keeping the temperature for 4-10 hours. The reproduced cheese preserved at normal temperature prepared by the method can be preserved for over six months at normal temperature of 25 DEG C, and is good in flavor, mouthfeel and texture.

Owner:BRIGHT DAIRY & FOOD

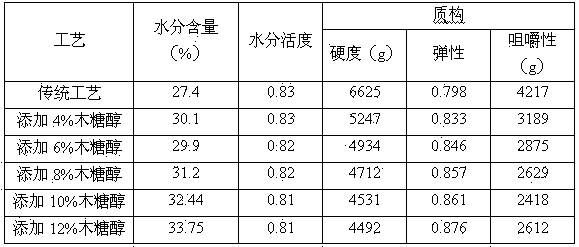

Method for improving texture of fermented sausage by virtue of xylitol

InactiveCN103892315AImprove qualityImprove storage effectFood ingredientsFood preparationFlavorWater activity

The invention discloses a method for improving the texture of a fermented sausage by virtue of xylitol, belonging to the technical field of meat product processing. The method comprises the following steps: adding 4%-12% of xylitol in a processing process, tumbling and salting in vacuum, fermenting, dewatering and drying. The quality of the fermented sausage is effectively improved; the texture quality of the fermented sausage is remarkably improved, the hardness is remarkably reduced, and the elasticity and the chewiness are remarkably improved under the circumstance that the preservation property, the color and the flavor of the fermented sausage are not affected. The method has the characteristics that part of free moisture is converted into bound water by virtue of a water retaining effect of a polyhydroxy structure in xylitol, and the water activity is reduced and the preservation property is improved under the circumstance that relatively high water content is kept. The obtained fermented sausage is fine in tissue, good in elasticity, bright in color, heavy in taste, unlikely to deteriorate during storage and long in shelf life more than 6 months.

Owner:JIANGNAN UNIV

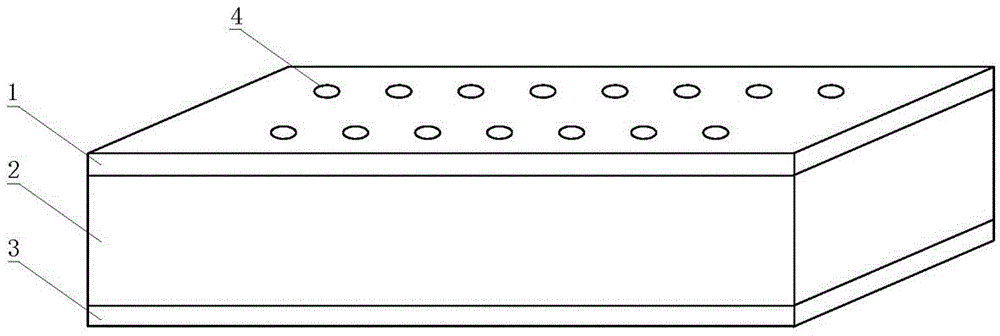

Microporous preservative BOPP film and preparation method thereof

ActiveCN106739358AReduce bacterial growthExtend shelf lifeFlexible coversWrappersPolypropyleneOptoelectronics

The invention provides a microporous preservative BOPP film, and belongs to the technical field of biaxially oriented polypropylene films. The microporous preservative BOPP film comprises an upper surface layer, a core layer and a lower surface layer, the upper surface layer is arranged on an upper surface of the core layer, the lower surface layer is arranged on a lower surface of the core layer, the microporous preservative BOPP film is characterized in that the upper surface layer is an anti-adhesion layer, a preset number of micropores formed by laser boring are uniformly formed in the surfaces of the upper surface layer and the lower surface layer, as the laser boring is added in the last procedure of film preparation in the preparation method, the process is simple, the control is accurate, the distances and sizes of the micropores can be adjusted, the prepared film has good air permeability and mechanical property, no micropore defective tearing is generated, and the microporous preservative BOPP film is suitable for averagely regulating and controlling the atmosphere in the package so as to play a better preservative effect.

Owner:山东顺凯复合材料有限公司

Rhizoma dioscoreae cloudy beverage and preparation method thereof

InactiveCN106962700AInhibits enzymatic browningInhibitory reactivityFood ingredient as antioxidantFood thermal treatmentCarboxymethyl celluloseFlavor

The invention provides a rhizoma dioscoreae cloudy beverage and a preparation method thereof. The beverage is prepared from, by mass, 88-94 parts of rhizoma dioscoreae pulp, 3-6 parts of purified water for drinking, 1-3 parts of white granulated sugar, 1-3 parts of trehalose, 0.1-0.25 part of D-erythorbic acid, 0.05-0.1 part of citric acid, 0.1-0.2 part of sodium carboxymethyl cellulose and 0.05-0.15 part of xanthan gum. The rhizoma dioscoreae pulp is prepared by peeling, slicing, color protecting, ageing and pulping of fresh rhizoma dioscoreae. The preparation method includes steps of mixing, homogenizing, filling, sterilizing and cooling. By the preparation method, a production process of the rhizoma dioscoreae cloudy beverage can be simplified, production cost is reduced, nutrients and flavor of rhizoma dioscoreae can be retained to the greatest extent, and white color, tender taste and high stability of products are realized.

Owner:SICHUAN UNIV

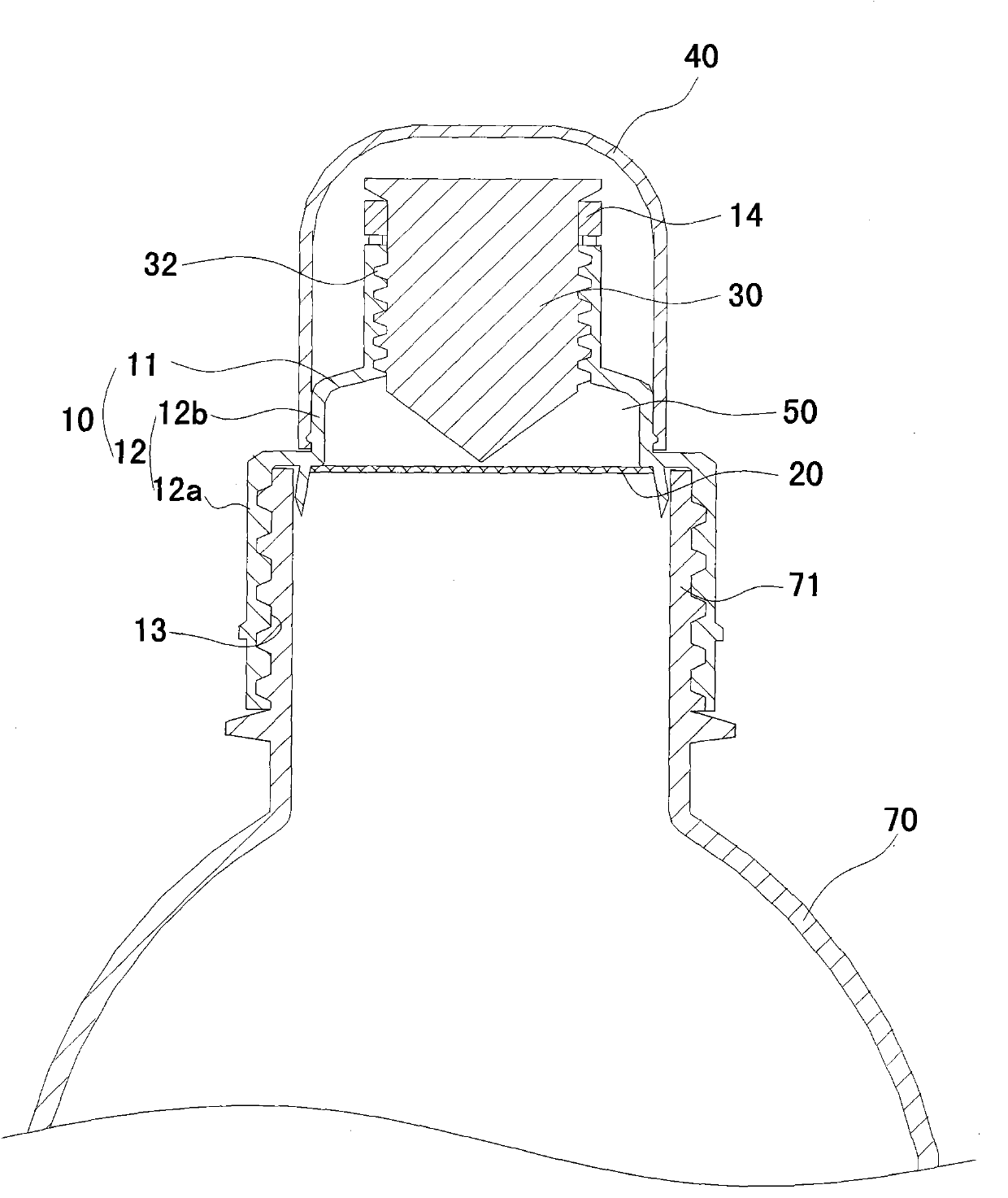

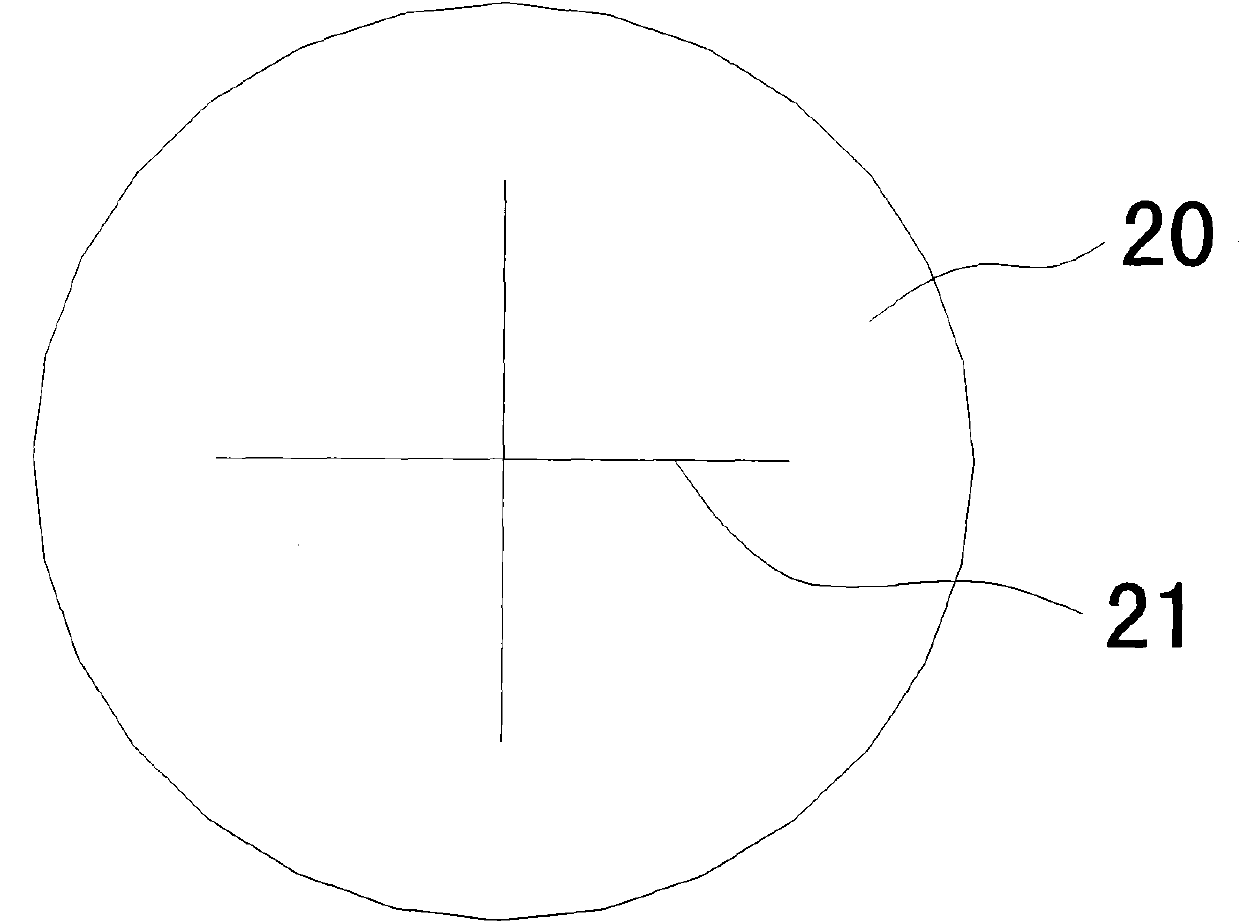

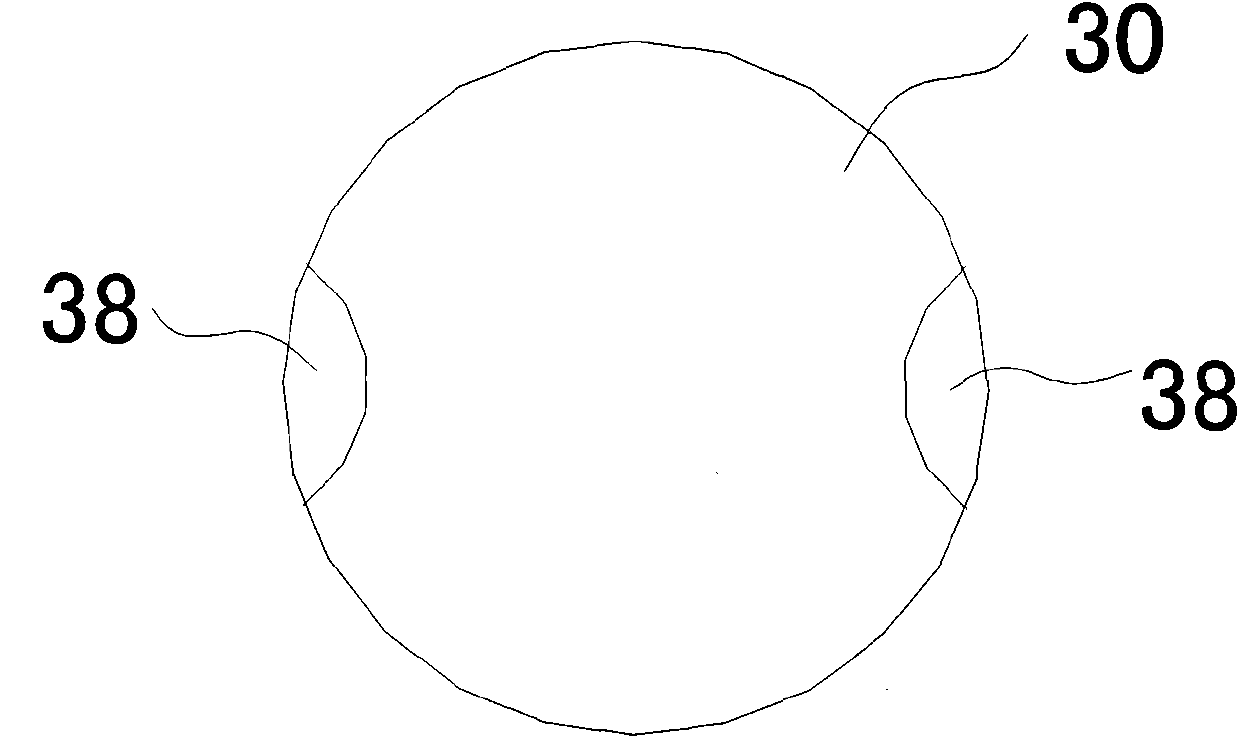

Bottle cap component and container bottle with same

InactiveCN103434745AAffect flavorImpact costClosure with auxillary devicesContainers with multiple articlesEngineeringScrew thread

The invention discloses a bottle cap component and a container bottle with the bottle cap component. The bottle cap component comprises a bottle cap body, the bottle cap body is provided with a top wall and a side wall, the bottle cap component further comprises a blocking sheet and an impaling piece, the blocking sheet is arranged in the bottle cap body, a containing cavity capable of containing additives is defined by the blocking sheet, the side wall and the top wall, a through hole is formed in the top wall, internal threads are arranged on the inner wall of the through hole, the impaling piece penetrates through the through hole to enter the containing cavity, external threads matched with the internal threads are arranged on the peripheral surface of the impaling piece, and an impaling portion is arranged at the lower end of the impaling piece. Before the bottle cap component is used, the additives are separated from solvents in the container bottle. When the bottle cap component needs to be used, the impaling piece is rotated and moves downwards relative to the bottle cap body, the blocking sheet is punctured by the impaling portion at the lower end of the impaling piece, and therefore the additives enter the solvents through the broken blocking sheet. Therefore, through the bottle cap component, the problems that when chemical additives are added, product flavor is influenced, cost is increased and health is harmed are avoided.

Owner:ZHUHAI ZHONGFU IND GRP

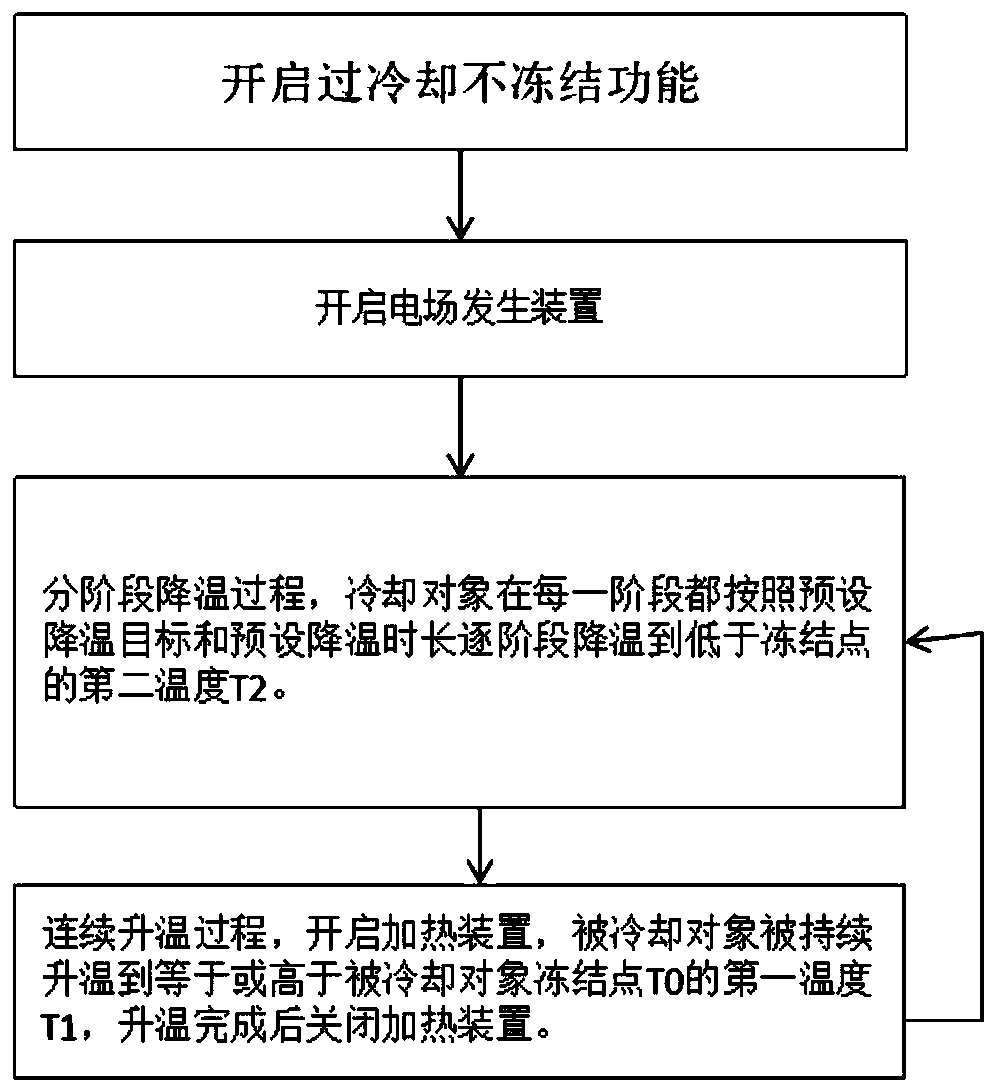

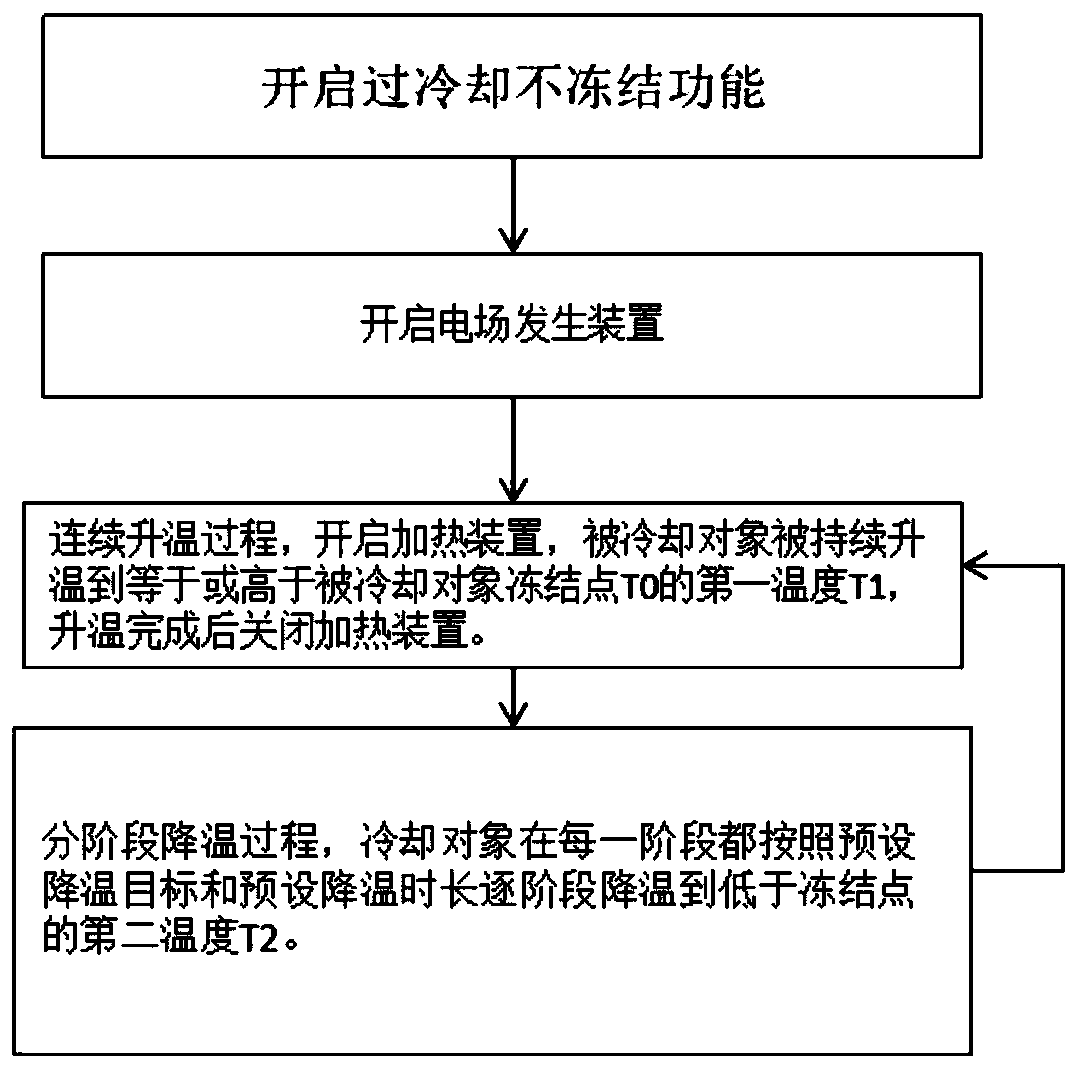

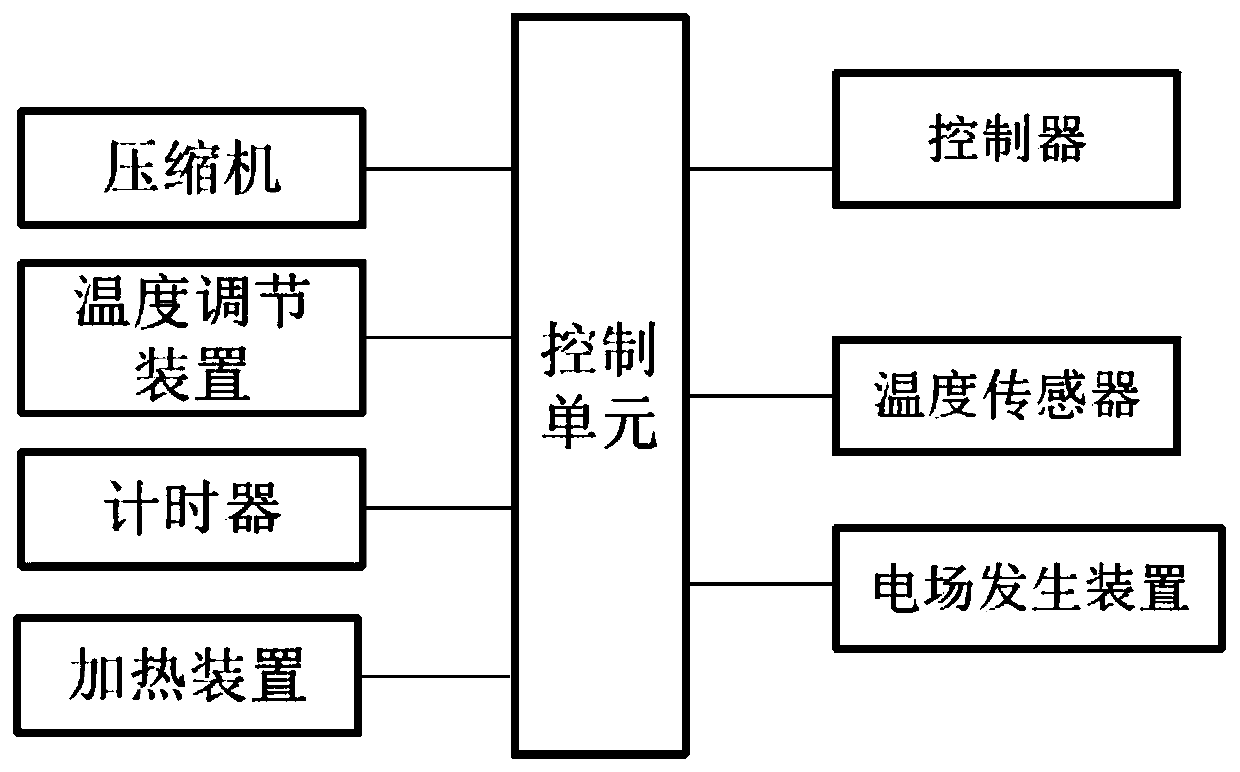

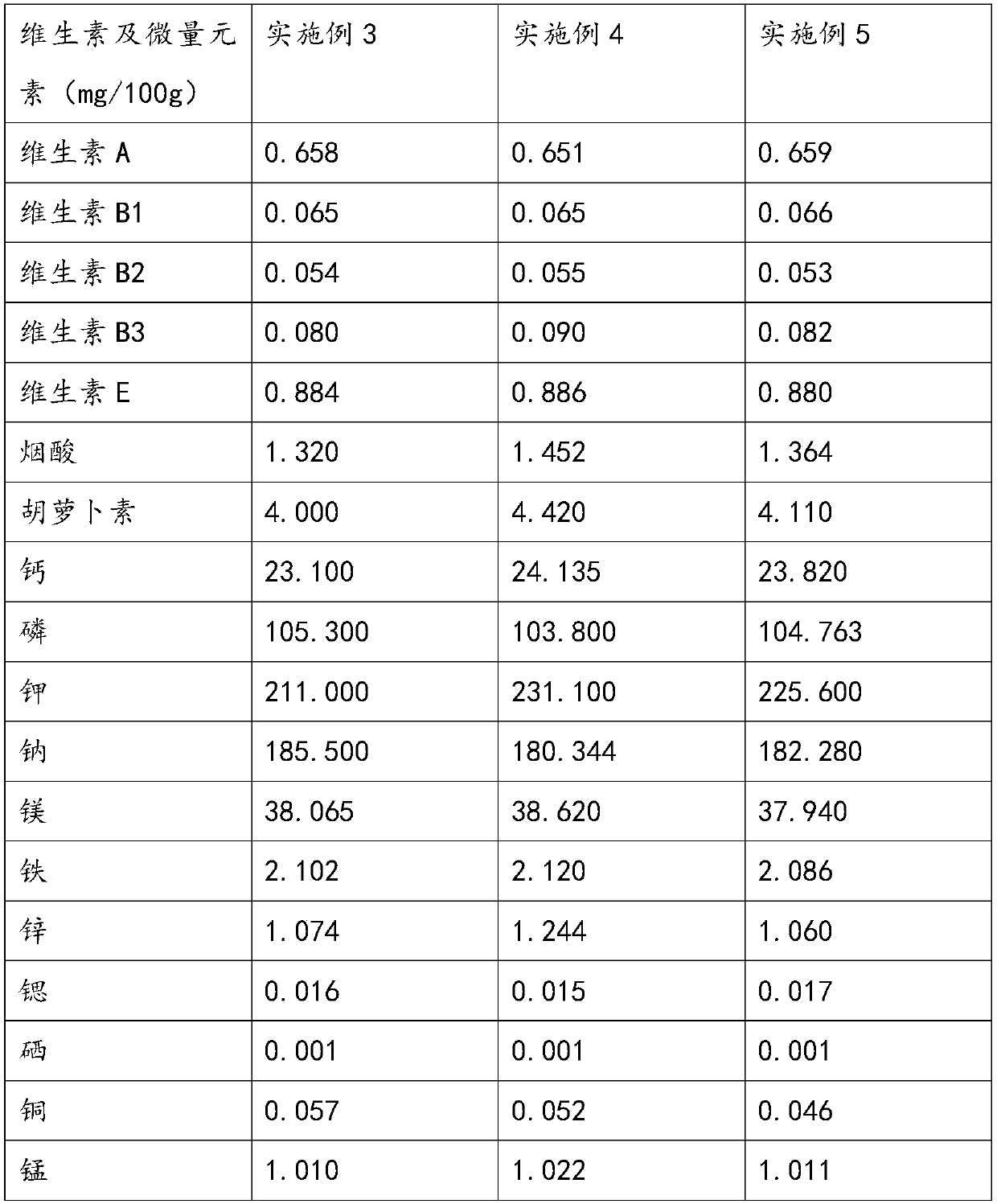

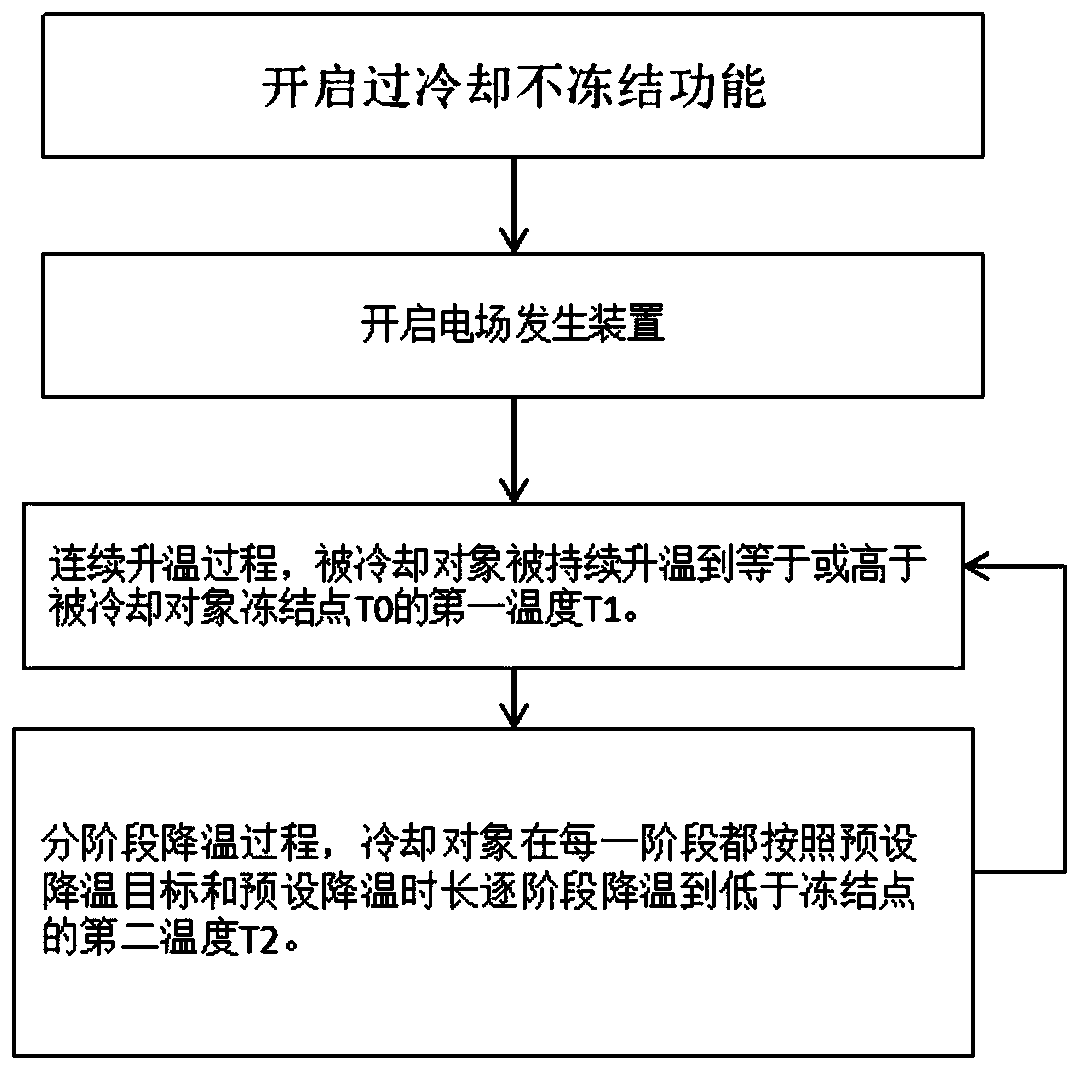

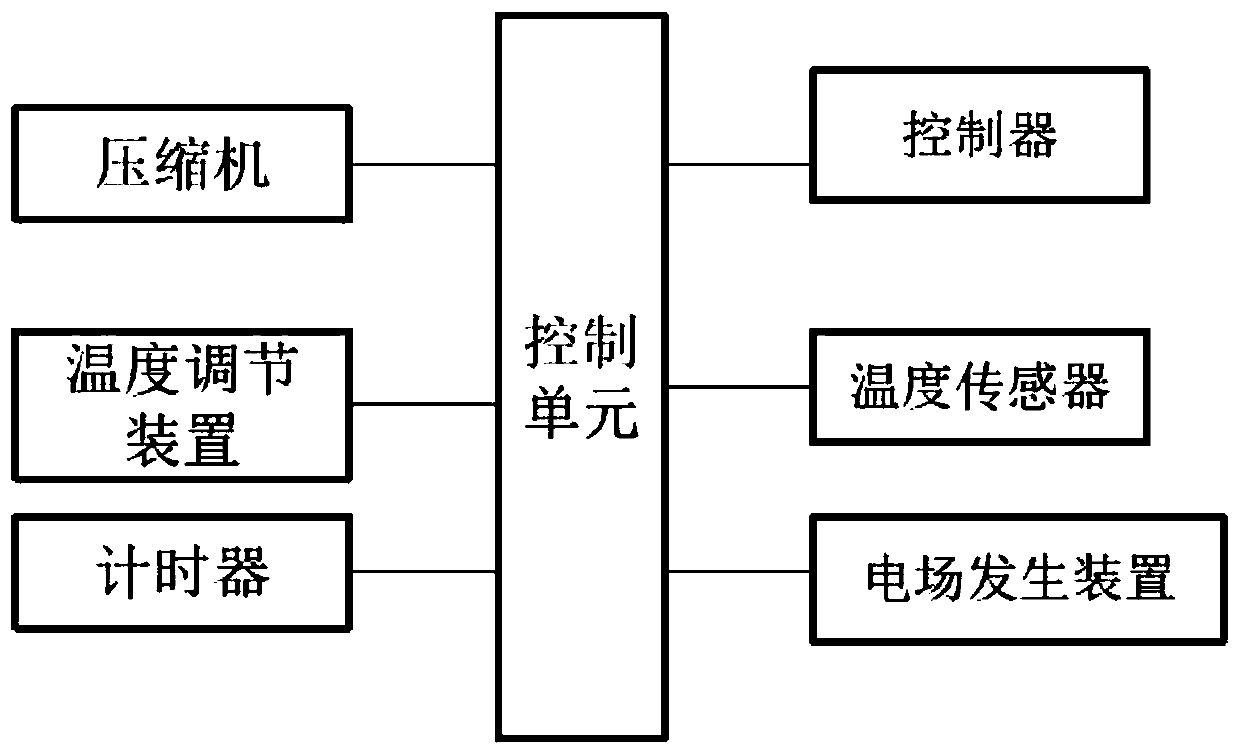

Supercooling non-freezing storage control method and refrigerator

PendingCN110906645AImprove qualityExtend freshnessLighting and heating apparatusCooling fluid circulationFreezing Point TemperatureThermodynamics

The invention relates to a supercooling non-freezing storage control method and a refrigerator. The method comprises the steps of turning on an electric field generating device to enable a cooled object to be in the electric field, and carrying out periodic heating and cooling control on the temperature of a cooling chamber, wherein staged step-by-step cooling is adopted in the cooling stage to reduce the temperature below a freezing point, the food is enabled to stably enter a supercooling state, the food is prevented from generating needle-like ice crystals due to freezing to damage the cellstructure, and the flavor of the food is further prevented from being damaged during thawing; and a heating device is turned on in the heating stage, the storage environment temperature of the food is continuously increased to be equal to or higher than the freezing point temperature by adopting a continuous heating mode, and the heating device is turned off after the heating is completed. Through continuous circulation of heating and cooling, the food is not frozen near the freezing point, and the fresh-keeping period of the food is prolonged.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD +1

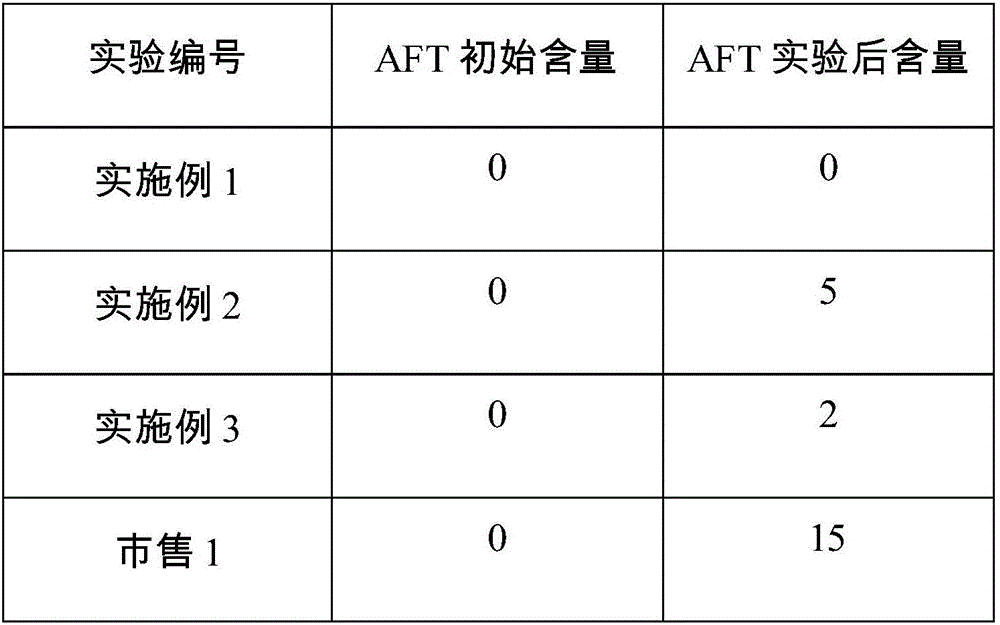

Process for producing flaxseed oil

InactiveCN105838498AHigh purityQuality improvementFatty-oils/fats refiningFatty-oils/fats productionFlavorOil and grease

The invention discloses a process for producing flaxseed oil, and belongs to the field of technologies for producing edible vegetable oil. The process includes a raw material processing stage, a squeezing post-processing stage and a crude oil post-processing stage. The process has the advantages that litsea cubeba oil is added into raw materials in the raw material processing stage, oil is subjected to adsorption processing in the squeezing post-processing stage, accordingly, aflatoxin in the oil can be effectively removed, generation of aflatoxin can be effectively inhibited in post-opening storage procedures, and the storage lives of oil products can be prolonged; the process is high in oil yield, the flaxseed oil produced by the aid of the process is high in purity and quality, and influence on flavor and the quality of grease can be prevented.

Owner:白雪

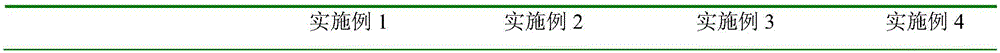

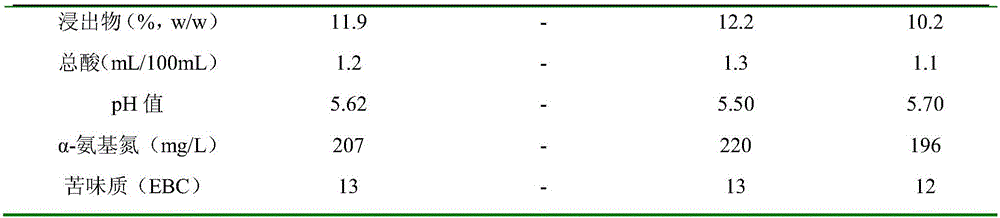

Brewing method of full-wheat-malt turbid beer

The invention relates to a brewing method of full-wheat-malt turbid beer. The turbid wheat beer is prepared from full wheat malt for the first time; the full-wheat-malt turbid beer, which is completely prepared from the wheat malt, is prepared by adding coarse bran which is more than 20 meshes in grain size as a filtering medium in a full-wheat-malt turbid beer brewing process; and the full-wheat-malt turbid beer is prepared by virtue of such steps as conducting crushing, conducting saccharifying, conducting filtering by virtue of a filtering tank, adding hops, conducting boiling, conducting cooling and filling oxygen, inoculating a wheat beer yeast, conducting temperature-controlled fermentation and the like; the full-wheat-malt turbid beer, which is brewed with the application of the method, is simple in filtering operation, mash can be completely filtered in one time, and the obtained wheat beer is pure in taste and coordinated in liquor body. The brewing method, which is free from additional filtering equipment in a brewing process, is low in raw material cost and low in power consumption. The obtained beer product is turbid in liquor body, lightly yellow, delicate and rich in foam, strong in foam retention, intense in fragrance and obvious in fermentation and bread aroma.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for processing normal-temperature circulating instant braised beef in sauce

InactiveCN106261850AExtended shelf lifeEase of industrial productionFood scienceUltra high pressureAdditive ingredient

The invention belongs to the technical field of meat product processing in the field of food processing and relates to a method for processing normal-temperature circulating instant braised beef in sauce. The method disclosed by the invention comprises the following steps: (1) cutting beef into beef cubes under freezing conditions, unfreezing and cleaning; (2) soaking the beef cubes in a salting solution for salting; (3) adding water and yellow wine into the salted beef cubes for stewing, stewing by big fire, removing floating blood foam, adding stewing ingredients, and continuously stewing; (4) cooling the stewed beef cubes to room temperature, and performing vacuum packaging by using a vacuum packaging bag; and (5) putting the packaged beef cubes into ultra-high pressure equipment, finishing the sterilization process, thereby obtaining the normal-temperature circulating instant braised beef in sauce. According to the invention, industrial production of the instant braised beef in sauce can be realized, the obtained beef product is sterilized in a temperature and pressure combined manner, the good flavor of the traditional instant braised beef in sauce is maintained to the greatest degree, the shelf life of the cooked beef is prolonged, and the circulation of the product in the market is promoted.

Owner:CHINA AGRI UNIV

Production technology of persimmon liquor

InactiveCN107674804AReduce the loss of nutrientsReduce astringencyAlcoholic beverage preparationMicroorganism based processesChemistrySaccharomyces cerevisiae

The invention discloses a production technology of persimmon liquor. The production technology comprises steps as follows: firstly, persimmon is treated, and the treatment process comprises followingsteps: fruit selection, freezing, getting warm again, beating, color protecting, composition adjusting, clarifying and filtering; secondly, saccharomyces cerevisiae is added for alcoholic fermentation, and new persimmon liquor is obtained after two-time fermentation and then is subjected to ageing; finally, the persimmon liquor obtained after ageing is subjected to after-treatment, and the after-treatment process comprises following steps: filtering, bottling, microwave sterilization and warehousing storage. According to the production technology of the persimmon liquor, tannin in persimmon juice is reduced in the persimmon treatment process, influence of tannin in the fermentation process is prevented, and pectin is reduced before fermentation, so that methanol in the persimmon liquor isreduced; besides, the persimmon liquor is soft, refreshing and mellow, has sweet flavor with the effect of moisturizing, tastes pure and further has higher yield.

Owner:雅安市八柿甜柿种植专业合作社

Method for Freezing a Food Product

InactiveUS20090081342A1Reduce adhesionNoticeable off tasteFrozen sweetsFood preservationAqueous solutionFood products

A method for freezing a food product comprising the steps of: (a) contacting the food product with a freezing surface, the freezing surface having a temperature of from −10° C. to −50° C.; and (b) removing the food product from the freezing surface, characterised in that in step (a) a layer of a frozen aqueous solution is present between the food product and the freezing surface, the solution having a Tg′ below −60° C. and a solute concentration of from 0.001 to 20% by weight.

Owner:CONOPCO INC D B A UNILEVER

Acid milk beverage and process for producing the same

ActiveUS8518465B2Improve securityStable conditionMilk preparationSugar food ingredientsSolid componentMaltitol

An acid milk beverage that without the use of conventionally employed various thickening stabilizers, excels in product quality stability, and that realizes good flavor and calorie suppression, being of light type; and a process for producing the same. There is provided an acid milk beverage characterized in that there are contained polydextrose and at least one glucide selected from the group (a) consisting of glucose, fructose, sugar, trehalose, maltose, erythritol, sorbitol, xylitol, maltitol, lactitol, palatinose and galactooligosaccharide, and that the sum of these soluble solid contents is in the range of 12.0 to 17.0 mass %, containing substantially none of thickening stabilizers. Further, there is provided a process for producing the acid milk beverage.

Owner:YAKULT HONSHA KK

Mulberry wine and method for making same

InactiveCN104962416AGrowth inhibitionImprove nutrient absorptionDigestive systemAlcoholic beverage preparationPassion fruitLycium chinense

The invention discloses mulberry wine. The mulberry wine comprises, by weight, 100-300 parts of mulberry fruits, 60-90 parts of passion fruits, 50-60 parts of cornel fruits, 10-20 parts of lemon, 20-30 parts of Barbary wolfberry fruits, 10-15 parts of honey, 5-10 parts of fresh jujube, 5-10 parts of sea buckthorn, 200-400 parts of fermented rice wine, 20-40 parts of mulberry leaves, 5-8 parts of lemongrass and 5-8 parts of rose. The invention further discloses a method for making the mulberry wine. The method includes smashing and sterilizing peel of the passion fruits, peel of the lemons, the mulberry leaves, the lemongrass, the rose, the fresh jujube and the sea buckthorn, then mixing the peel of the passion fruits, the peel of the lemon, the mulberry leaves, the lemongrass, the rose, the fresh jujube, the sea buckthorn and the fermented rice wine with one another to obtain a mixture and allowing the mixture to stand still for 15 days to obtain supernatant liquor A; cooking the mulberry fruits, then mixing the mulberry fruits, flesh of the passion fruits and flesh of the lemon with one another to obtain a mixture and then smashing and filtering the mixtures; mixing filter residue and the supernatant liquor A with each other to obtain a mixture, fermenting the mixture for 8 days to obtain supernatant liquor B; adding the honey and water into filter liquid and fermenting the filter liquid, the honey and the water for 10 days to obtain supernatant liquor C; mixing the supernatant liquor B and the supernatant liquor C with each other according to a weight ratio of 1:2-3 to obtain mixed liquid, storing the mixed liquid at low temperatures for 3 months and filtering the mixed liquid to obtain the mulberry wine. The mulberry wine and the method have the advantages that the mulberry wine tastes unique and has age defying and life prolonging healthcare functions.

Owner:符洁梅

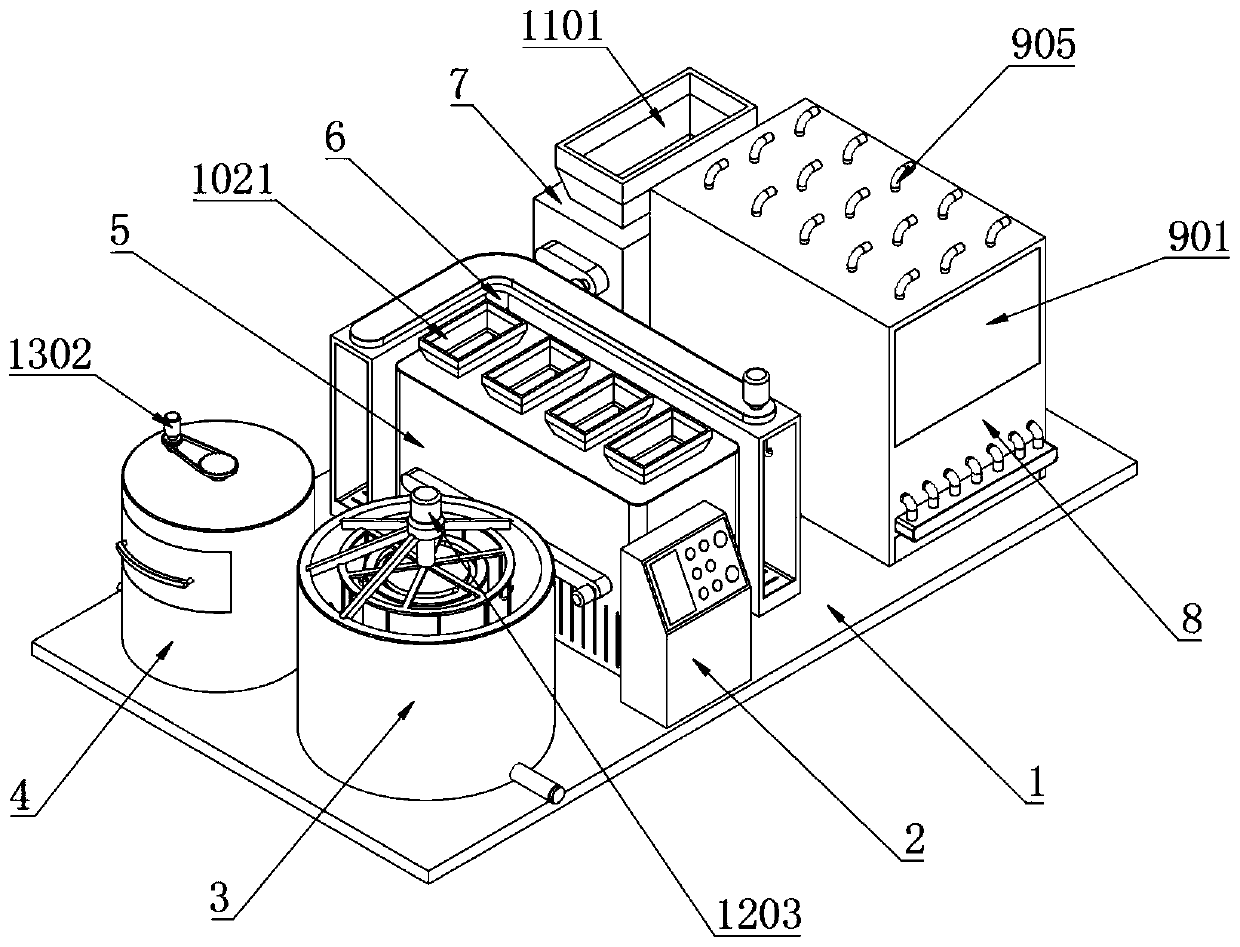

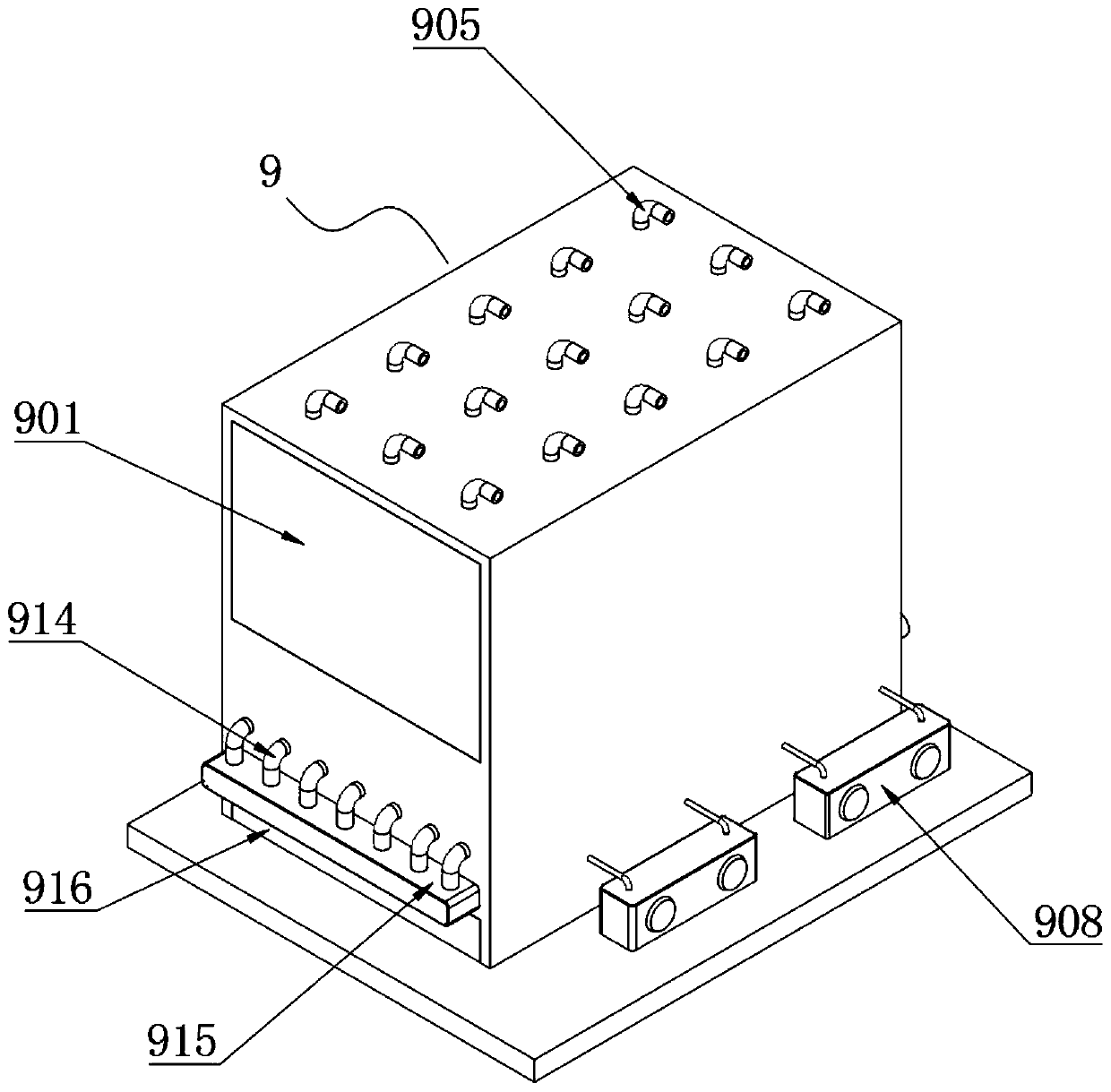

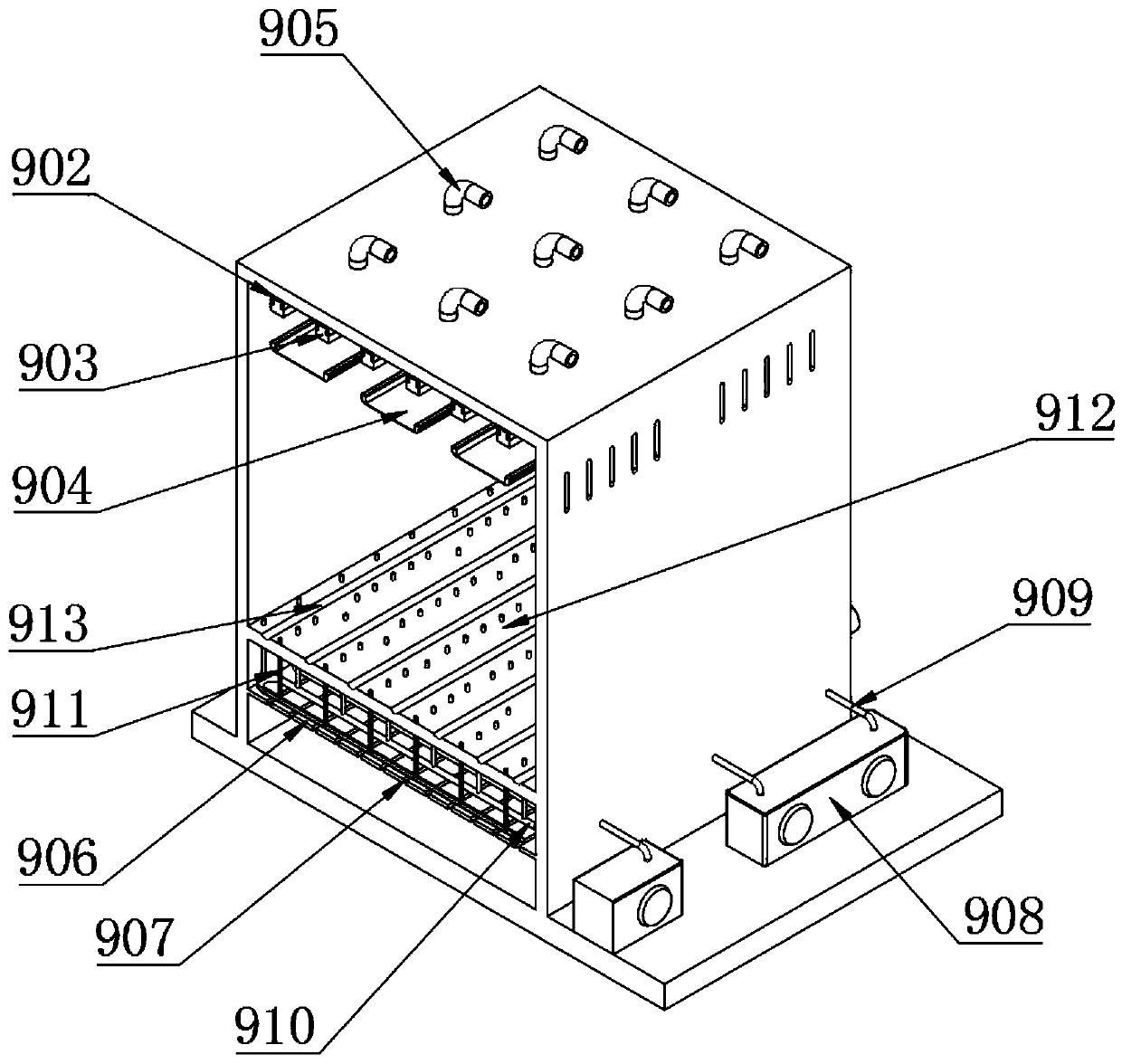

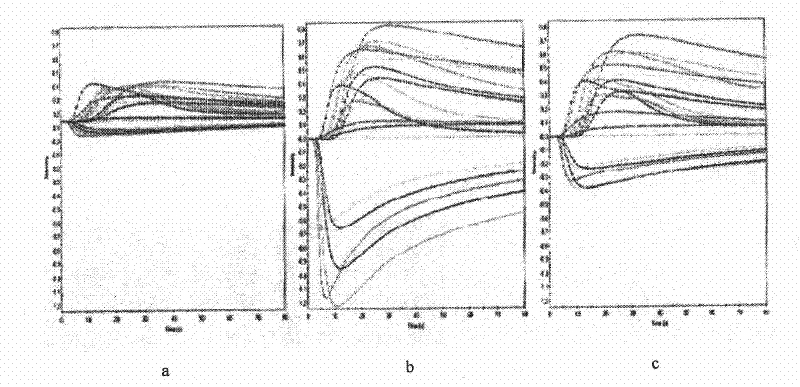

Full-automatic jerky preparation equipment for biological food and jerky preparation method

InactiveCN111480798AScientific and reasonable structureEasy to useDrying gas arrangementsFood coatingEngineeringDrive motor

The invention discloses full-automatic jerky preparation equipment for biological food and a jerky preparation method. The equipment includes a substrate; one side of the top end of the substrate is fixedly connected with a control cabinet; a cleaning bin is fixedly connected to the position, corresponding to one side of the control cabinet, of the top end of the substrate; a spin-drying bin is fixedly connected to the position, corresponding to one side of the cleaning bin, of the top end of the substrate; and a seasoning bin is fixedly connected to the position, corresponding to one side ofthe spin-drying bin, of the top end of the substrate. The structure is scientific and reasonable, and the equipment is safe and convenient to use; through the arrangement of a placing hopper, an air injection pump, an air injection pipe, a zigzag pipe and an exhaust pipe, biomass can be used for supplying heat to air-dry fresh meat, biomass combustion can be prevented from influencing the flavor of dried meat preparation, and the fresh meat air-drying efficiency is improved; seasonings can be uniformly sprayed on the surface of the fresh meat through the arrangement of a spreading hook, a driving motor, a transmission toothed chain and a spreading hanging plate, the manpower consumption required for dried meat preparation is reduced, and the time required for spraying the seasonings on thesurface of the fresh meat is shortened.

Owner:陈国全

Method for effectively removing fishy smell of chub surimi

InactiveCN101695395BImprove consistencyEffectively remove fishy smellFood preparationWater bathsAdditive ingredient

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Probiotic grapefruit passion fruit tea and preparation method thereof

InactiveCN108887438ADoes not affect normal passagePromote exchangeTea substituesMetabolitePropanoic acid

The invention provides a probiotic grapefruit passion fruit tea and a preparation method thereof. According to the technical scheme, a propionibacterium freudenreichii-pediococcus pentosaceus fermented product used for blending a beverage is prepared at first, viable bacteria are removed, and meanwhile, the main nutrition effect of probiotic metabolite is basically maintained. The amount of viablebacteria in fermentation liquor approaches to zero, so that the flavor of the beverage is not influenced by the microbial growth and metabolism after the fermentation liquor is mixed with the beverage. Besides, according to the invention, odor ingredients in the fermentation liquor are specifically treated, main acidic odor substances, such as lactic acid and propionic acid, are fully decomposed,and all the fermentation medium components are selected from natural plants, so that the propionibacterium freudenreichii-pediococcus pentosaceus fermented product used for blending the beverage almost has no negative influence on the flavor of the beverage. The probiotic grapefruit passion fruit tea prepared according to the invention keeps an excellent flavor, has a certain intestinal tract probiotic effect and has a bright popularizing prospect.

Owner:江西韩金实业有限公司

Acid milk beverage and process for producing the same

ActiveUS20090226566A1Excellent in safetyEnhance stabilityMilk preparationSugar food ingredientsPolydextroseMaltitol

An acid milk beverage that without the use of conventionally employed various thickening stabilizers, excels in product quality stability, and that realizes good flavor and calorie suppression, being of light type; and a process for producing the same. There is provided an acid milk beverage characterized in that there are contained polydextrose and at least one glucide selected from the group (a) consisting of glucose, fructose, sugar, trehalose, maltose, erythritol, sorbitol, xylitol, maltitol, lactitol, palatinose and galactooligosaccharide, and that the sum of these soluble solid contents is in the range of 12.0 to 17.0 mass %, containing substantially none of thickening stabilizers. Further, there is provided a process for producing the acid milk beverage.

Owner:YAKULT HONSHA KK

Cultivation method of tea leaves

InactiveCN107616054ALow costSimple stepsBiocideClimate change adaptationPlant cultivationAloe pearsonii

The invention discloses a cultivation method of tea leaves and relates to the technical field of plant cultivation. The method comprises the following steps that 1, first aloe is squeezed and separated to obtain aloe residues and aloe juice, and water is added into the aloe juice to obtain aloe water; 2, the aloe residues are applied to the periphery of tea trees; 3, after the tea trees are harvested or pruned, the aloe water is used for spraying. The problems of high cost and complex step in an existing pollution-free tea leaf cultivation method are solved.

Owner:三江侗族自治县布央茶业有限责任公司

Dampness-dispelling and fat-reducing healthcare vinegar beverage and preparation method thereof

InactiveCN107653173AGuaranteed sweetnessGuaranteed tasteAntibacterial agentsMetabolism disorderFlavorPreservative

The invention discloses a dampness-dispelling and fat-reducing healthcare vinegar beverage and a preparation method thereof. The dampness-dispelling and fat-reducing healthcare vinegar beverage is prepared from pure grain brewed edible vinegar, a mulberry normal juice, a longan normal juice, Semen Phaseoli, coix seeds, Poria cocos, Rhizoma Atractylodis Macrocephalae, mogroside, xylitol, Maotai-flavor liquor, honey, neotame, strontium-enriched water and a preservative according to a ratio of 800-1200 ml : 80-150 ml : 10-30 ml : 80-150 g : 40-60 g : 10-15 g : 10-15 g : 0.5-1 g : 15-25 g : 0.5-1ml : 30-60 ml : 0.02-0.05 g : 1000-1500 ml : 0.5-1 g. The healthcare vinegar beverage has strong dampness-dispelling and fat-reducing effects, and has abundant healthcare functions and good healthcareeffects.

Owner:王军

Production method of persimmon wine

ActiveCN102604778BBright colorThere is less mold on the surfaceMicroorganism based processesAlcoholic beverage preparationAlcoholEnzyme

Owner:XIAN YUSHAN WINE ESTATE

Supercooling non-freezing storage control method and refrigerator

InactiveCN110906659AImprove qualityExtend freshnessLighting and heating apparatusCooling fluid circulationFreezing Point TemperatureThermodynamics

The invention relates to a supercooling non-freezing storage control method and a refrigerator. The method comprises the steps of turning on an electric field generating device to enable a cooled object to be in the electric field, and carrying out periodic heating and cooling control on the temperature of a cooling chamber, wherein staged step-by-step cooling is adopted in the cooling stage to reduce the temperature below a freezing point, the cooled object is enabled to stably enter a supercooling state, the cooled object is prevented from generating needle-like ice crystals due to freezingto damage the cell structure, and the flavor of the cooled object is further prevented from being damaged during thawing; and the storage environment temperature of the cooled object is continuously increased to be equal to or higher than the freezing point temperature by adopting a continuous heating mode in the heating stage. Through continuous circulation of heating and cooling, the cooled object is not frozen near the freezing point, and the fresh-keeping period of the cooled object is prolonged.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com