Full-automatic jerky preparation equipment for biological food and jerky preparation method

A fully automatic, food technology, applied in meat processing equipment, food preservation, combustion methods, etc., can solve the problems of high requirements on individual ability and team ability, affecting the economic benefits of preparing jerky, and high cost of human resources. Achieve the effect of reducing labor consumption, facilitating flavor preservation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

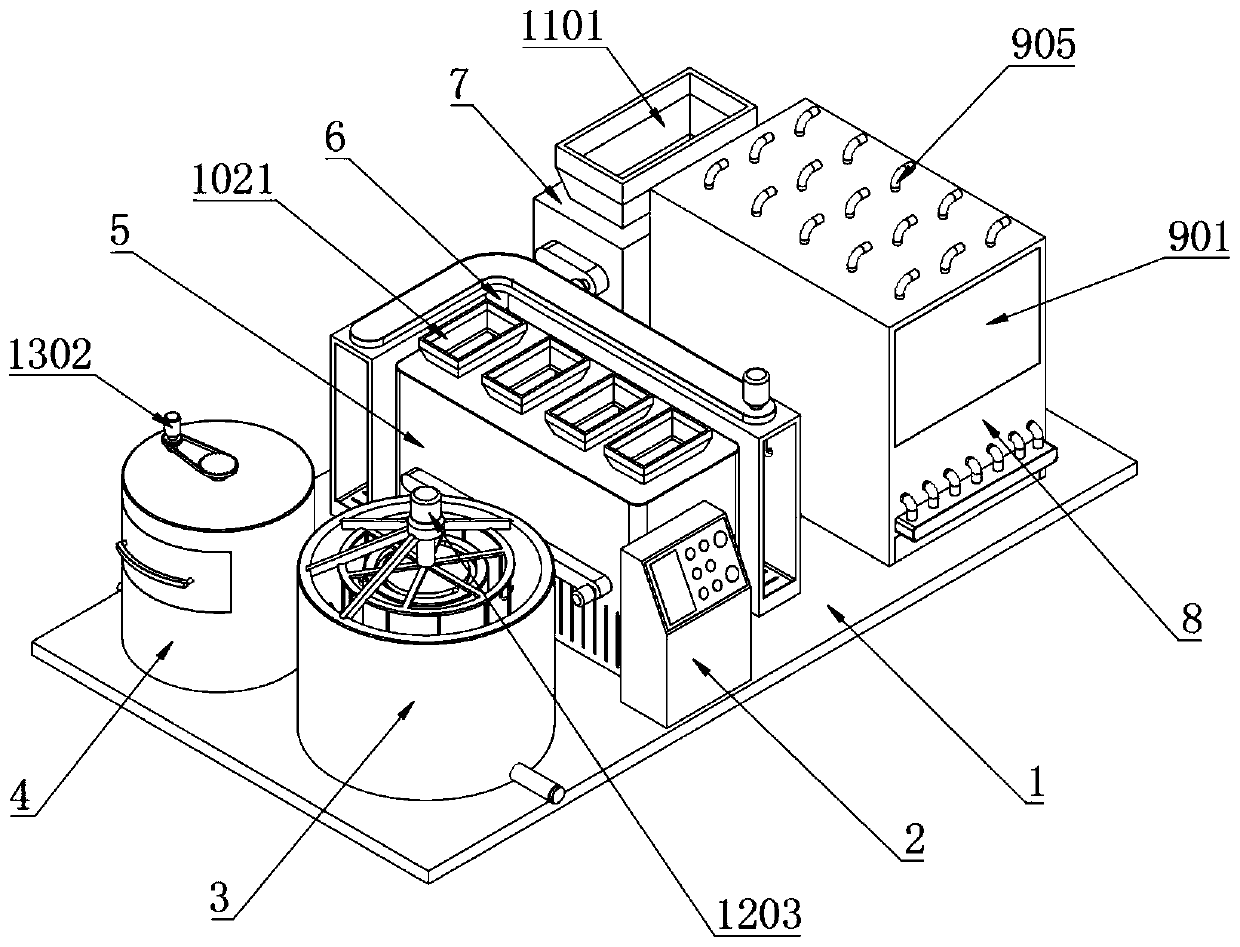

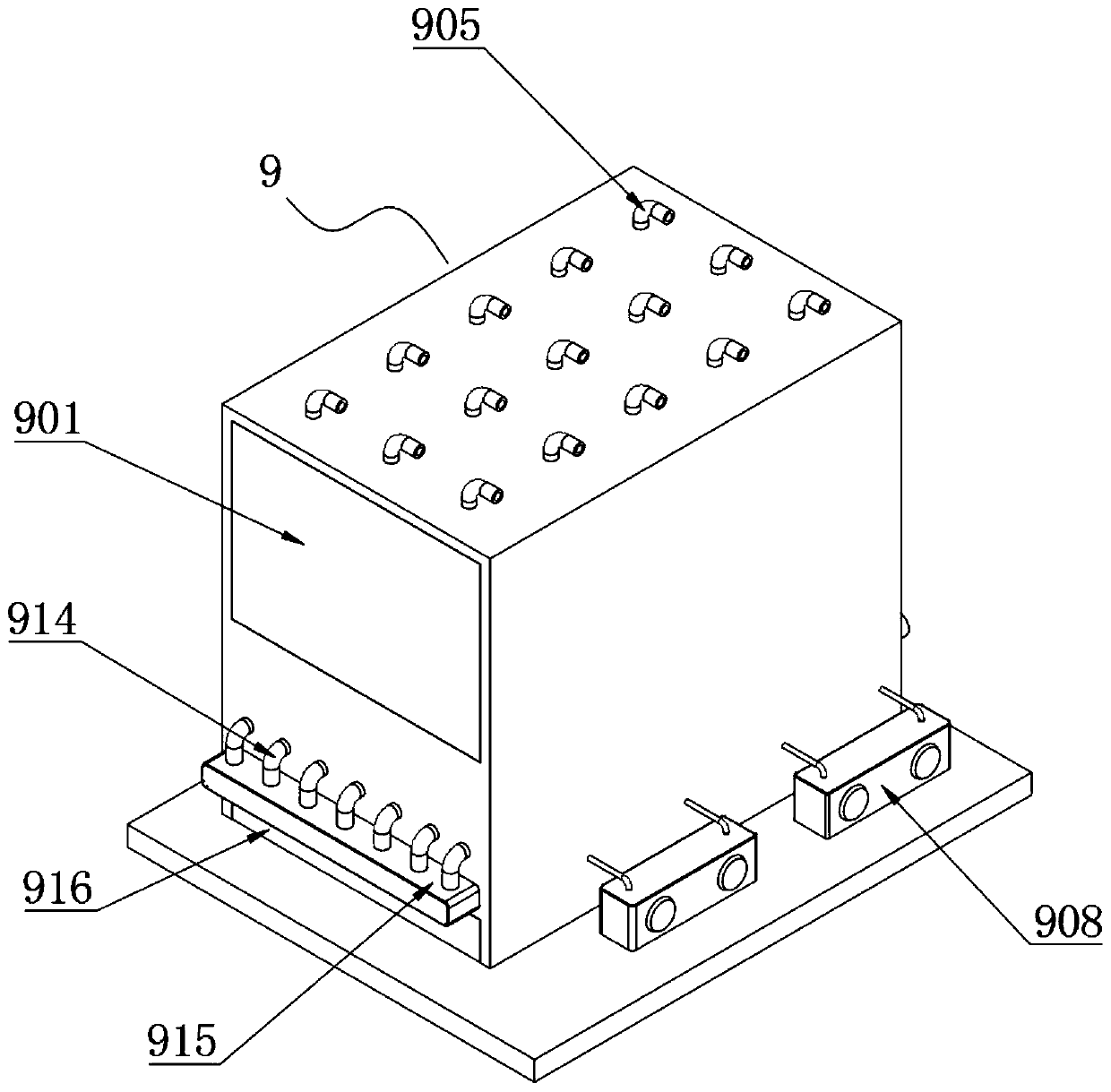

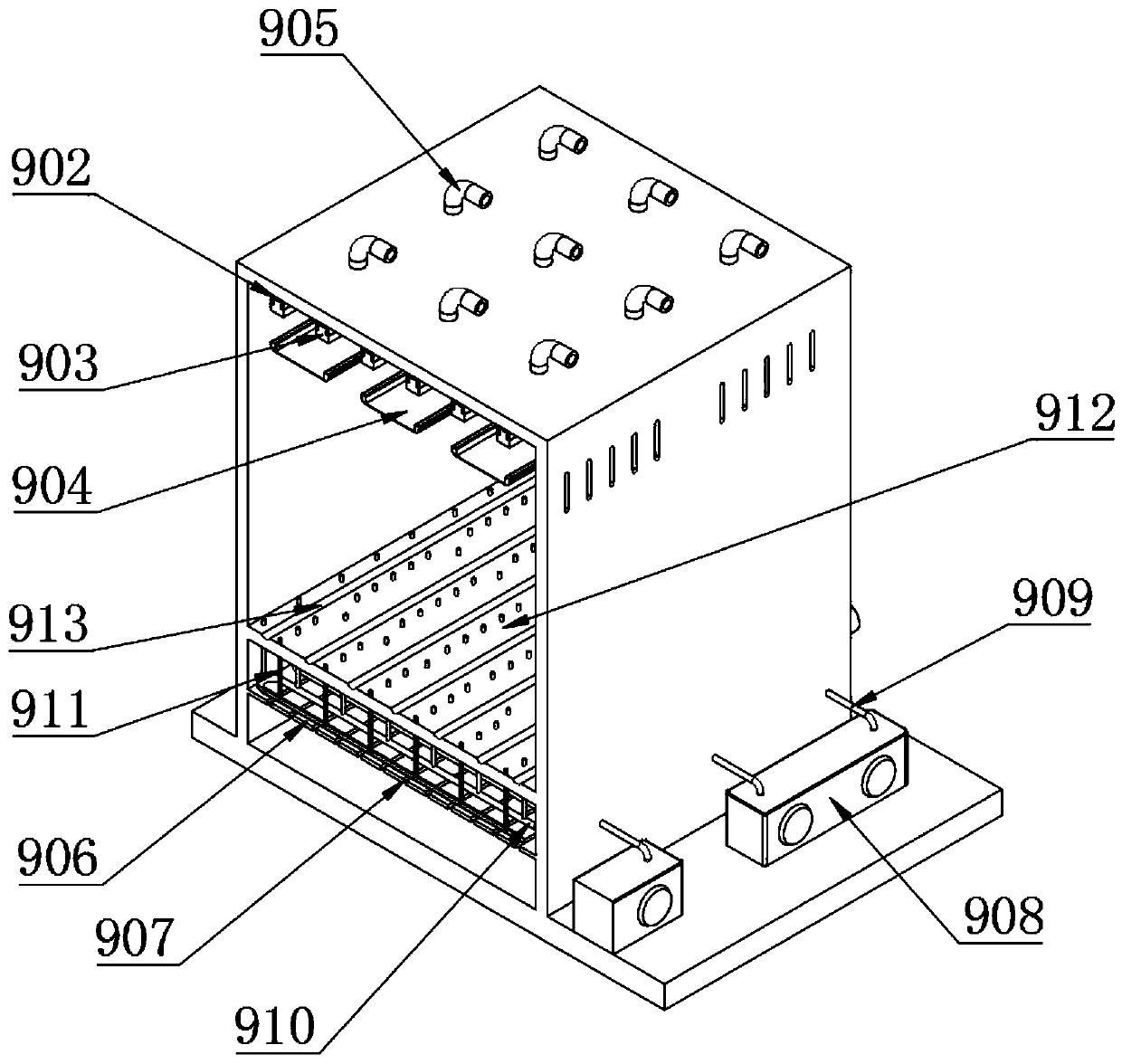

[0055] Example: such as Figure 1-14 As shown, the present invention provides a technical solution, a fully automatic jerky preparation equipment for biological food, including a substrate 1, the top side of the substrate 1 is fixedly connected to the control cabinet 2, and the top of the substrate 1 corresponds to the position on the side of the control cabinet 2 The cleaning chamber 3 is fixedly connected, the drying chamber 4 is fixedly connected to the top of the substrate 1 corresponding to the cleaning chamber 3 side, the seasoning chamber 5 is fixedly connected to the top of the substrate 1 corresponding to the drying chamber 4 side, and the substrate 1 The top corresponding to the side of the seasoning bin 5 is fixedly connected with the spreading bin 6, the top of the base plate 1 is fixedly connected with the crushing bin 7 at the position corresponding to the side of the sprinkling bin 6, and the top of the base plate 1 is fixed at the position corresponding to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com