Patents

Literature

1568results about How to "Promote fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drill bit arcuate-shaped inserts with cutting edges and method of manufacture

InactiveUS7331410B2Extended bit lifeImprove abilitiesDrill bitsMetal-working drilling toolsStress relievingEngineering

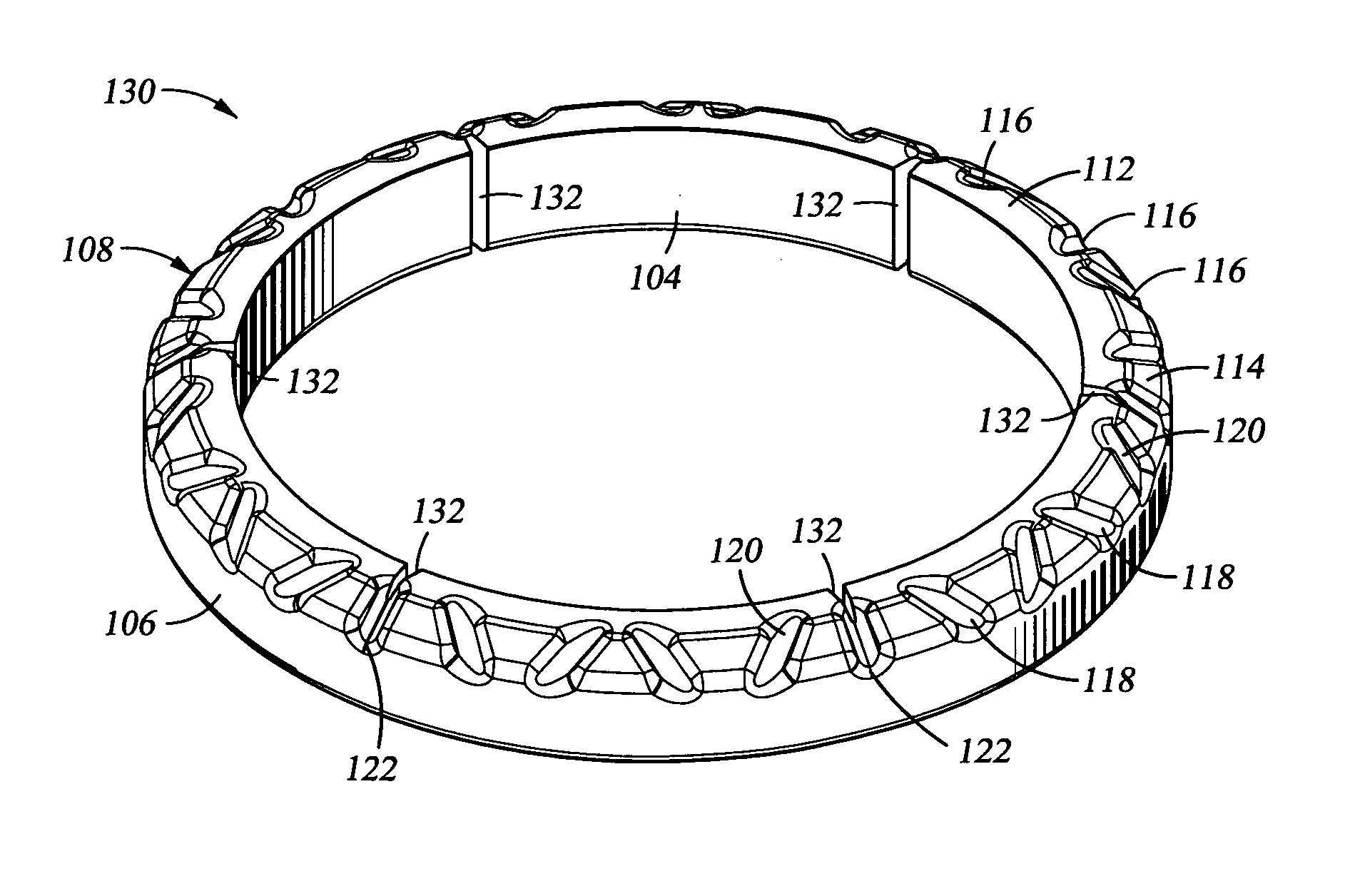

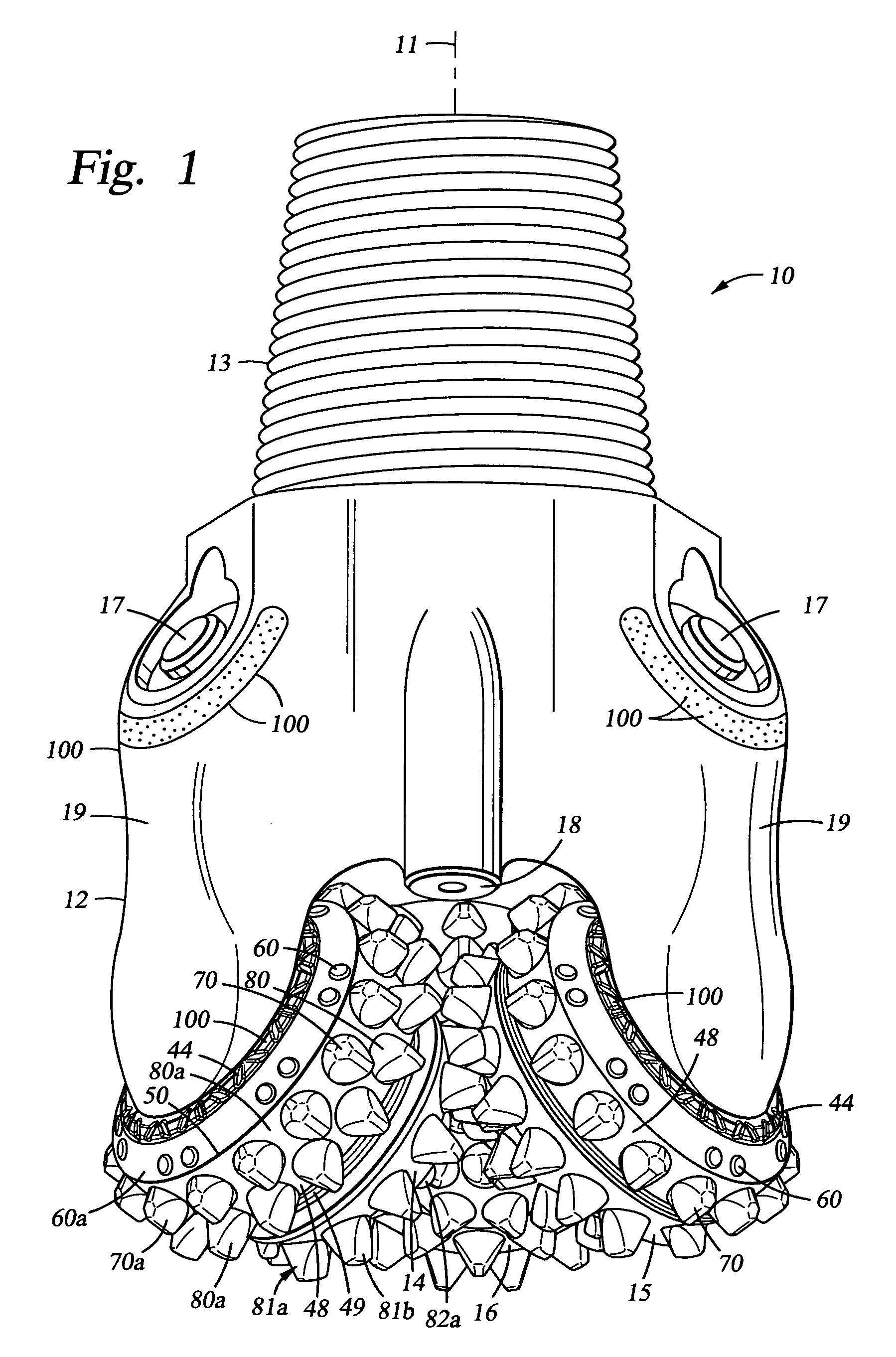

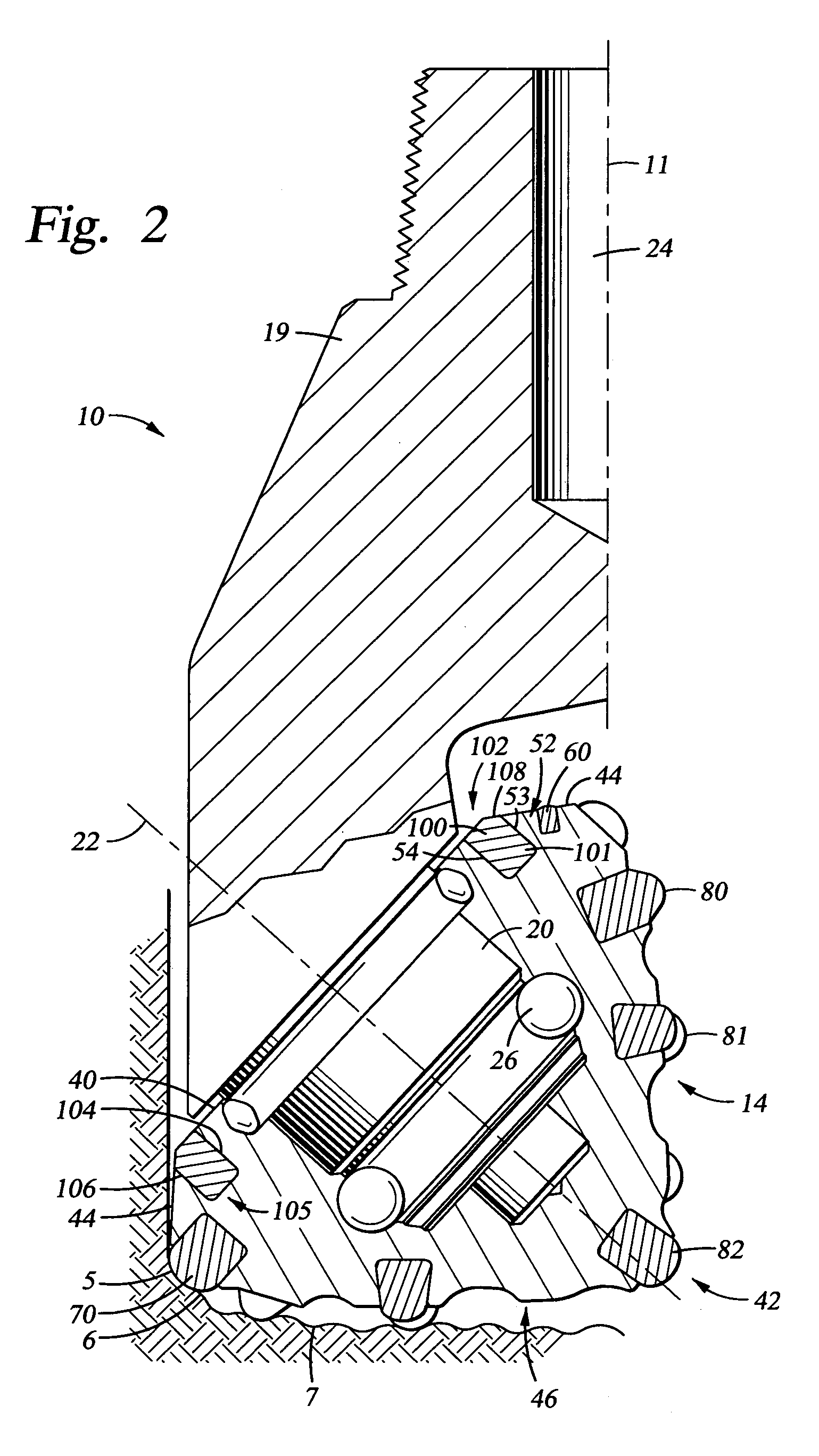

Disclosed are a variety of arcuate-shaped inserts for drill bits, and in particular, for placement in rolling cone cutters of drill bits. The arcuate inserts include 360° or ring-shaped inserts, as well as inserts of smaller arcuate length. The arcuate inserts are suitable for use in all surfaces of the rolling cone cutter, and in other locations in drill bits, and may have specialized cutting surfaces and material enhancements to enhance their cutting duty performance. Certain arcuate inserts may include stress relieving discontinuities such that, upon assembly into the cone or during drilling, the arcuate inserts may fragment in a controlled and predicted manner into shorter arcuate lengths.

Owner:SMITH INT INC

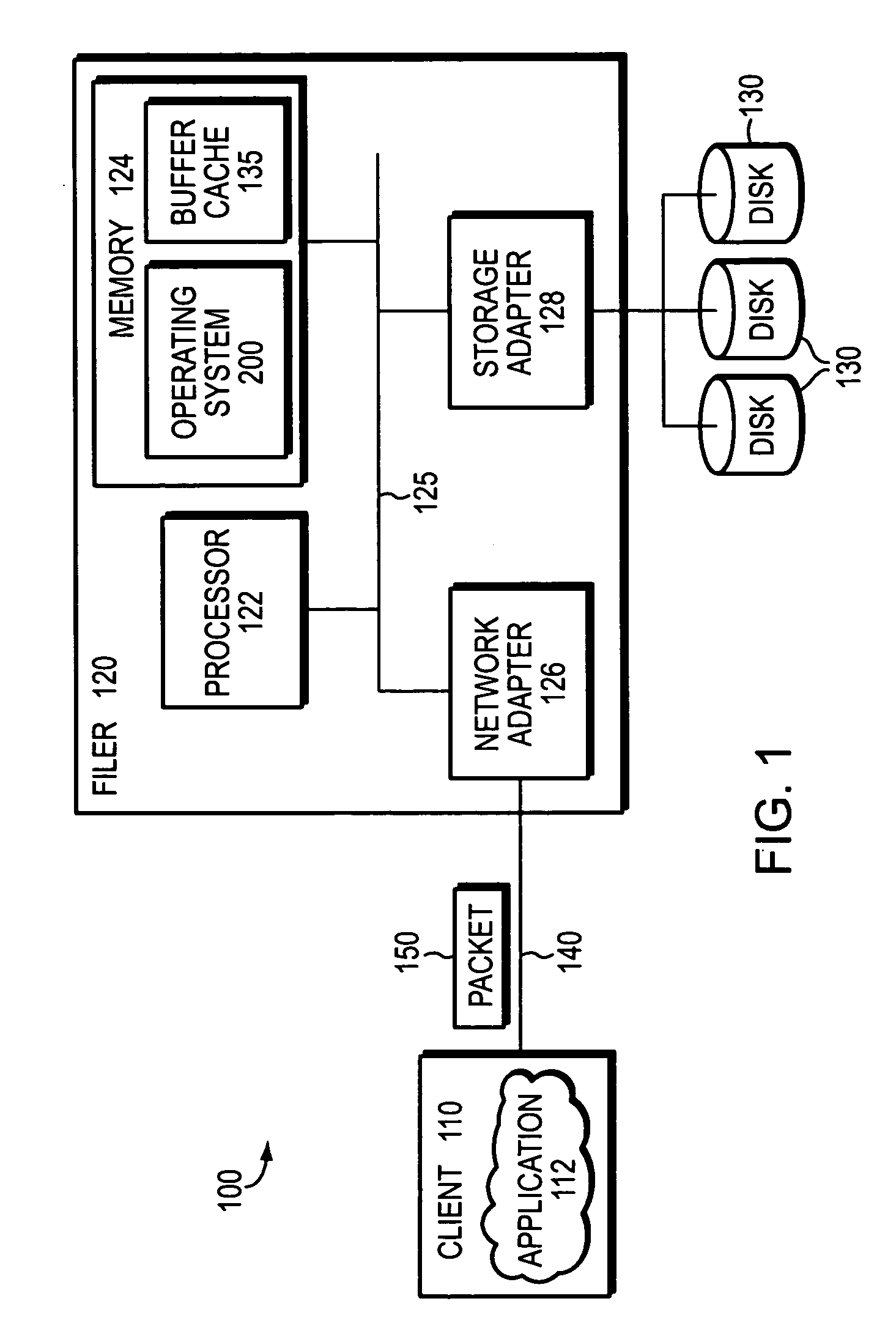

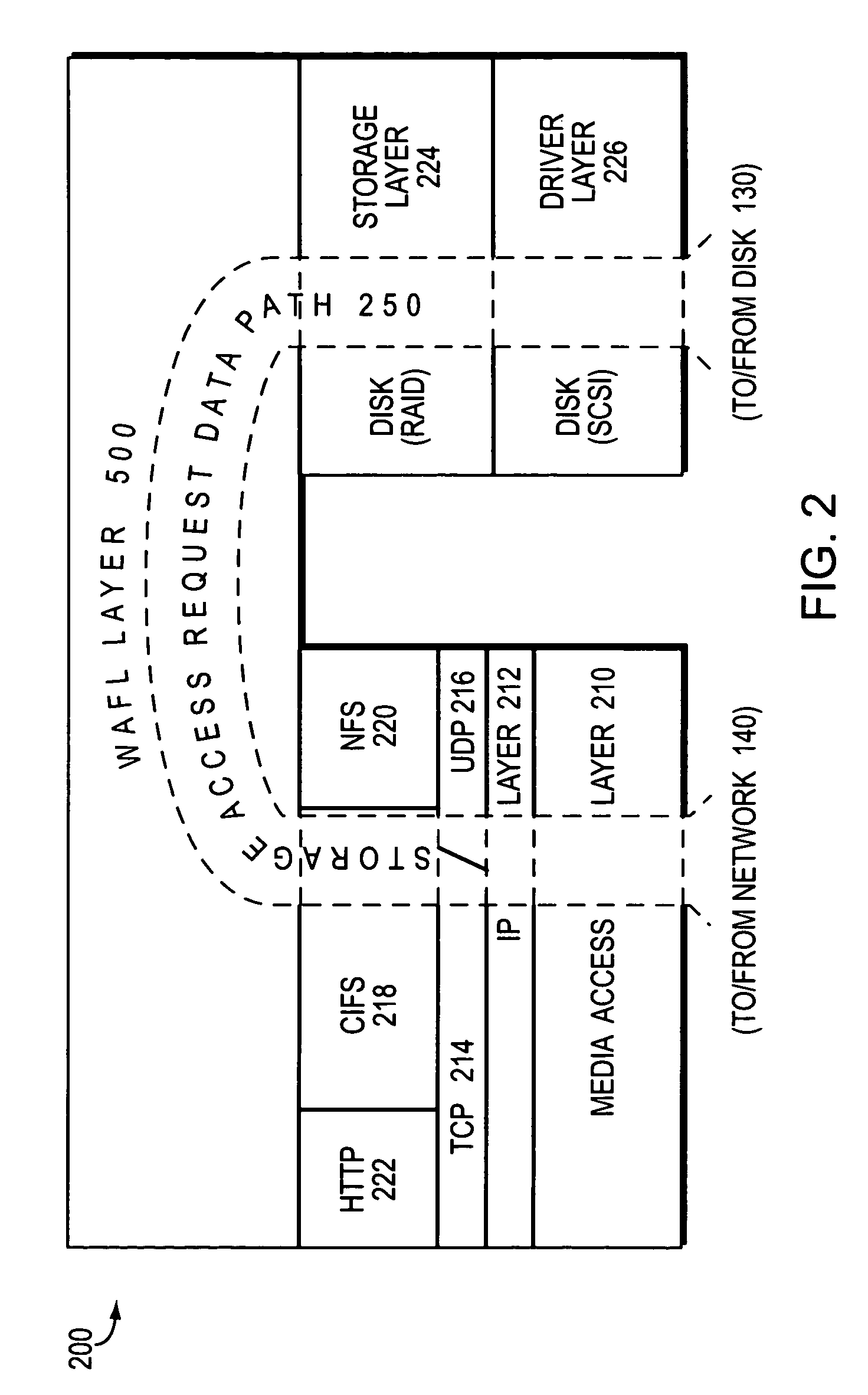

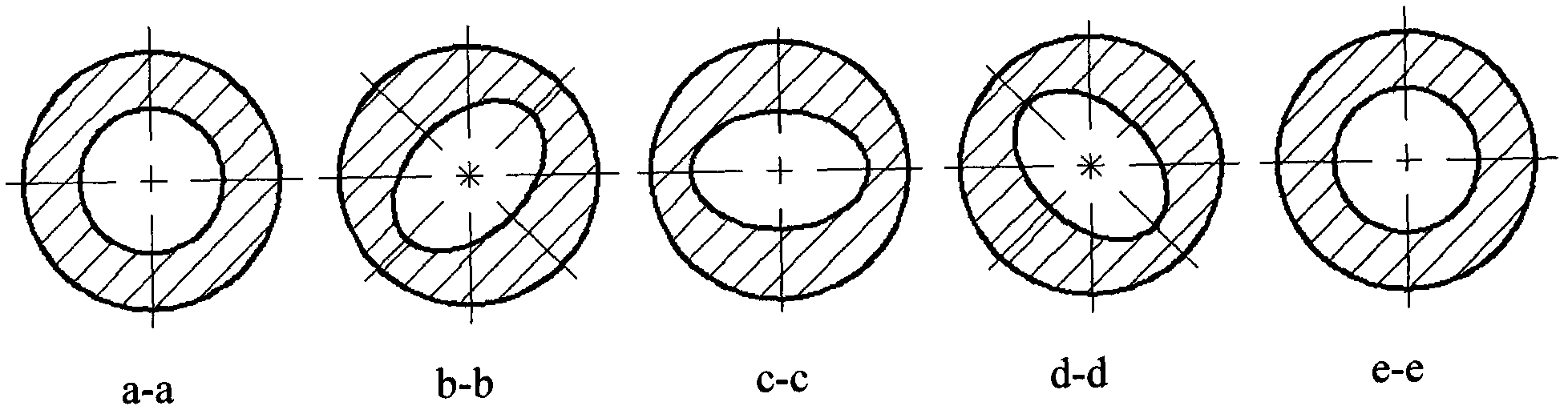

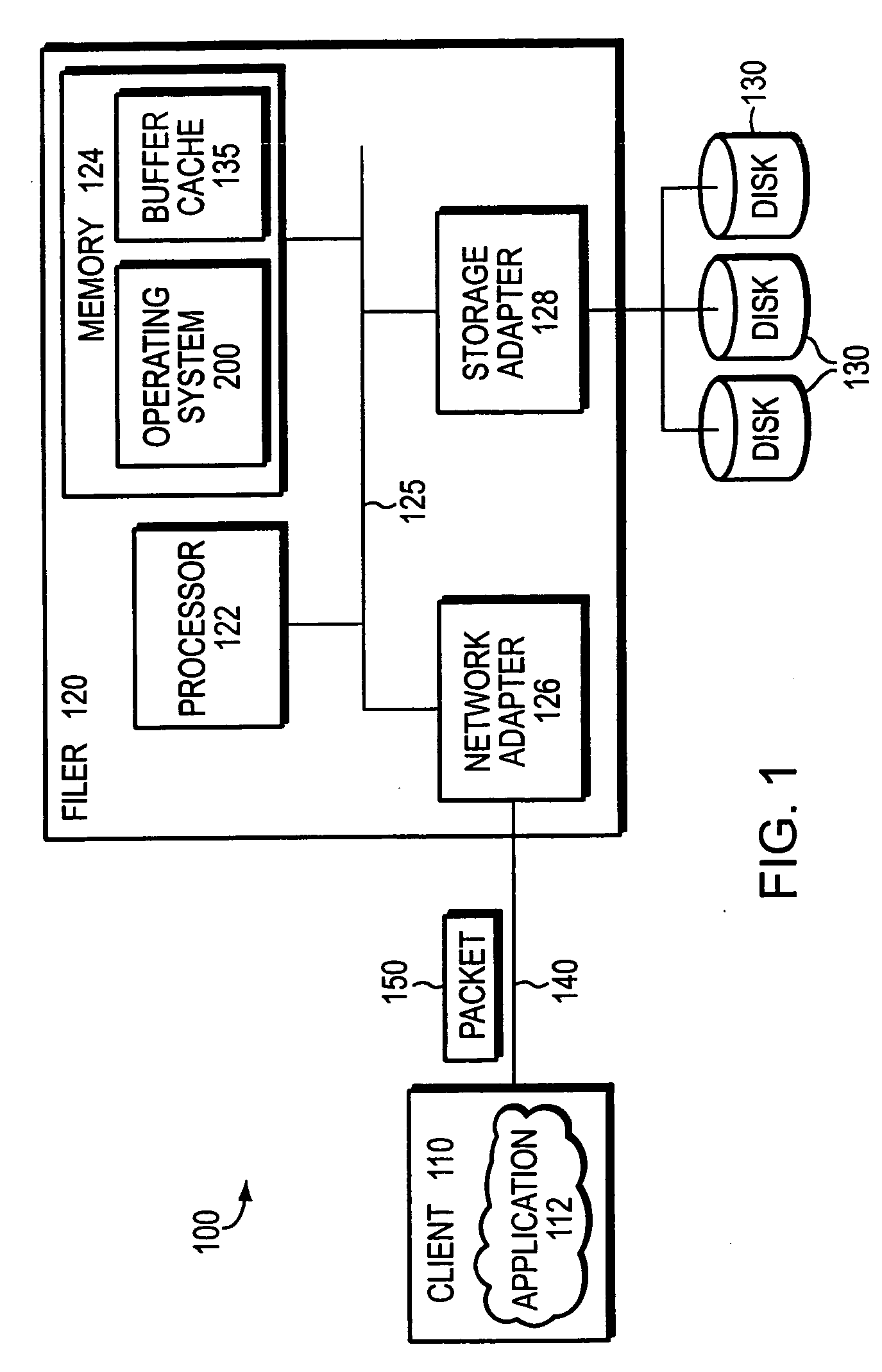

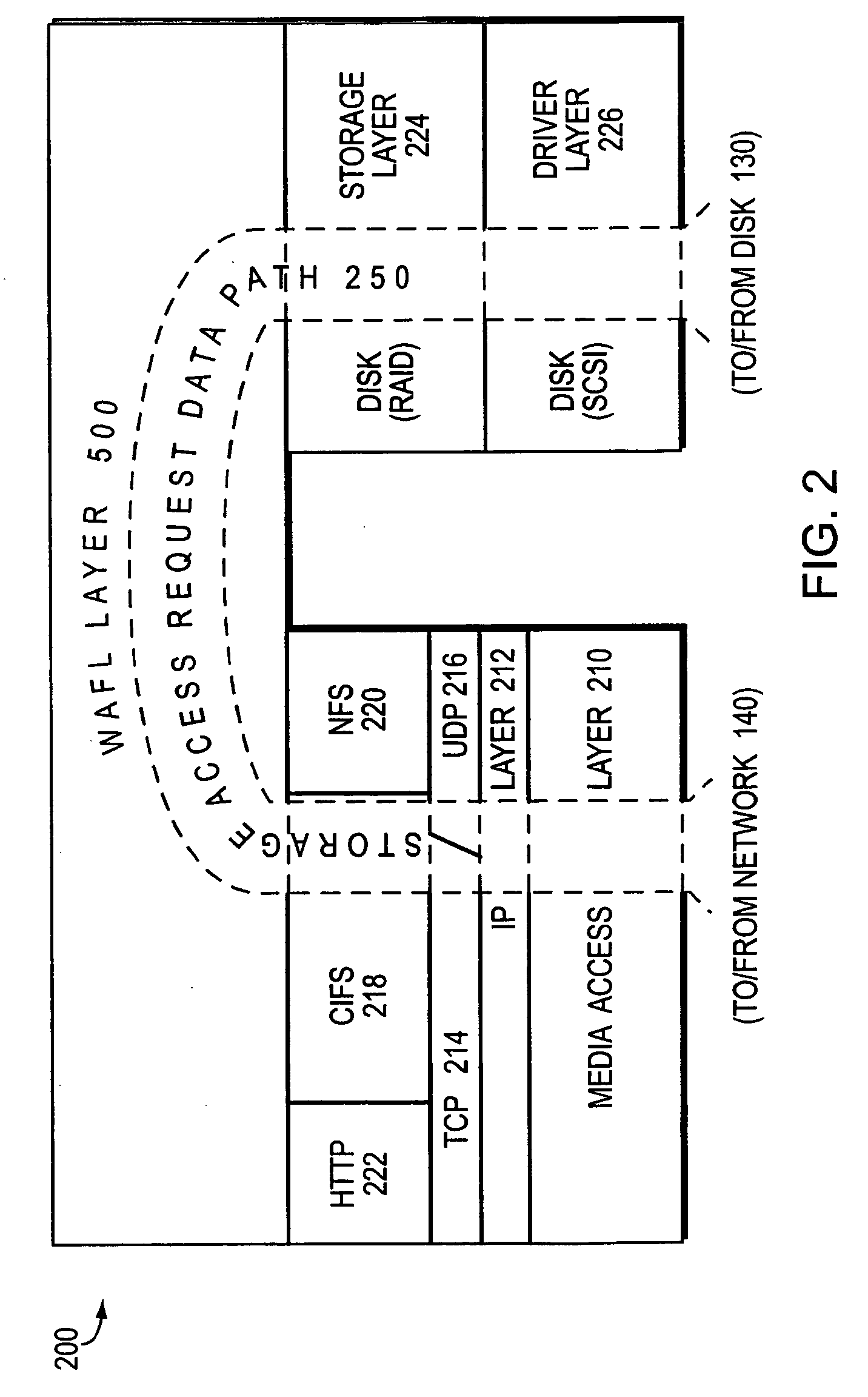

File system defragmentation technique via write allocation

InactiveUS6978283B1Efficiently relocatedPromote fragmentationDigital data information retrievalInput/output to record carriersComputer hardwareShard

Owner:NETWORK APPLIANCE INC

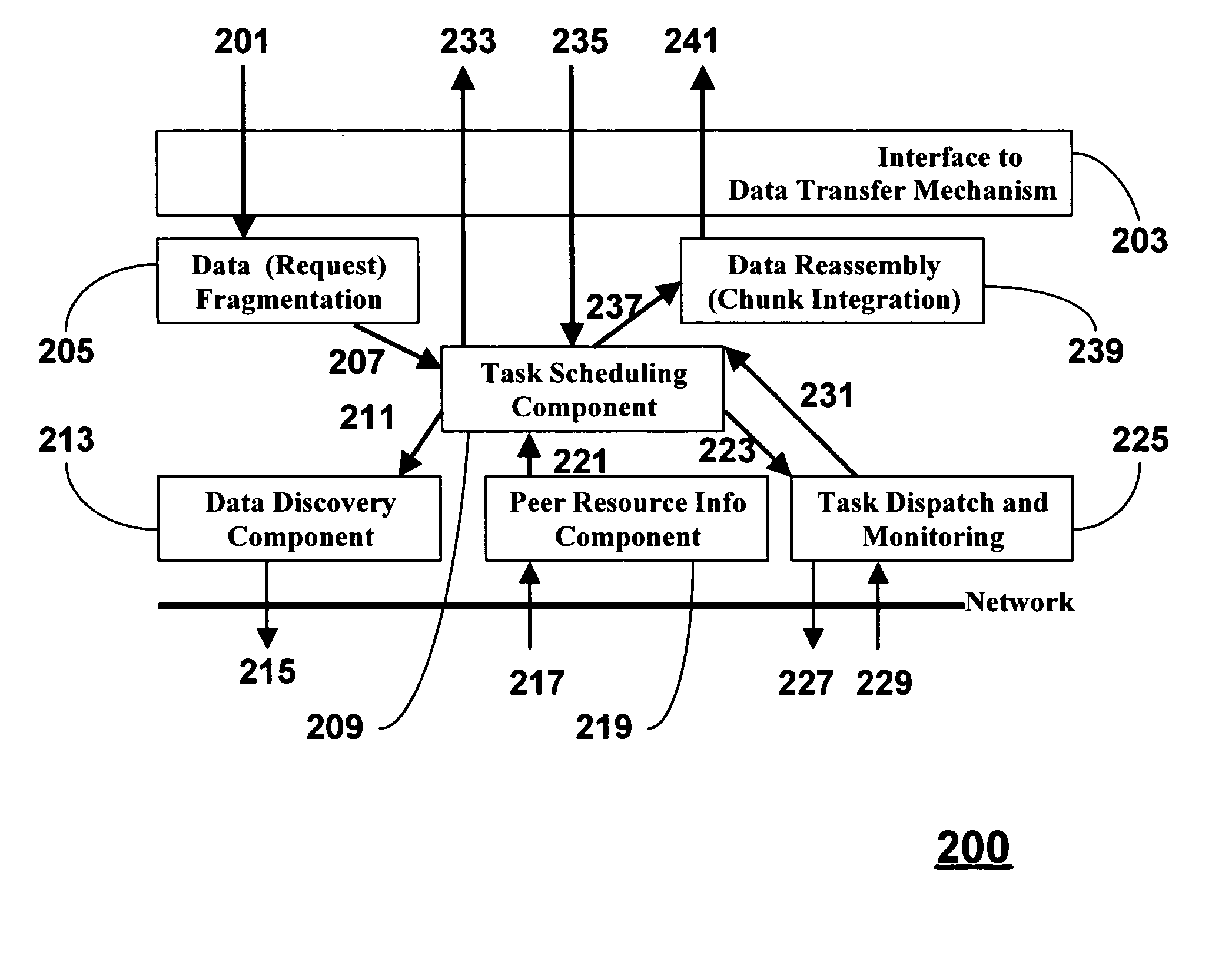

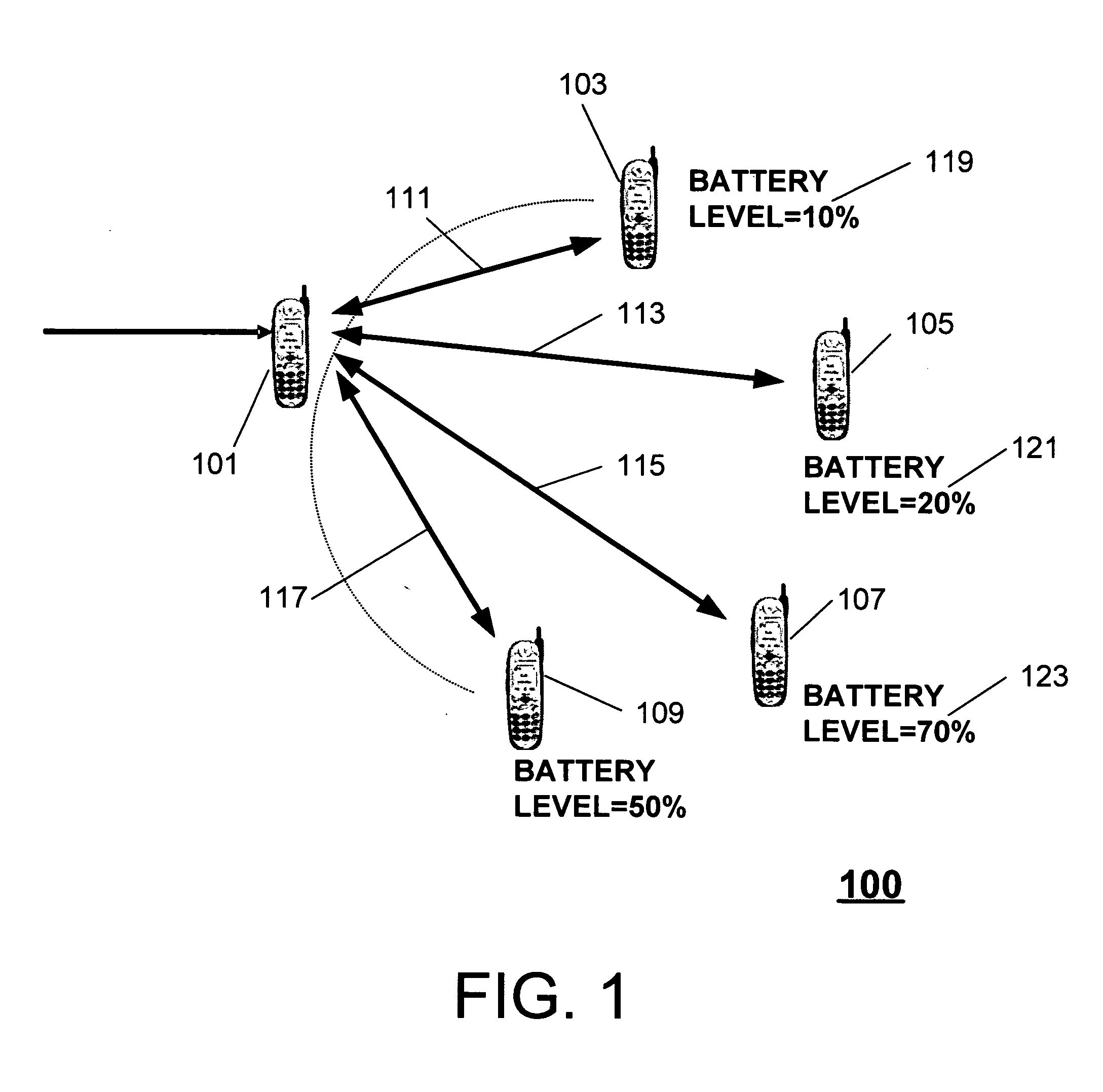

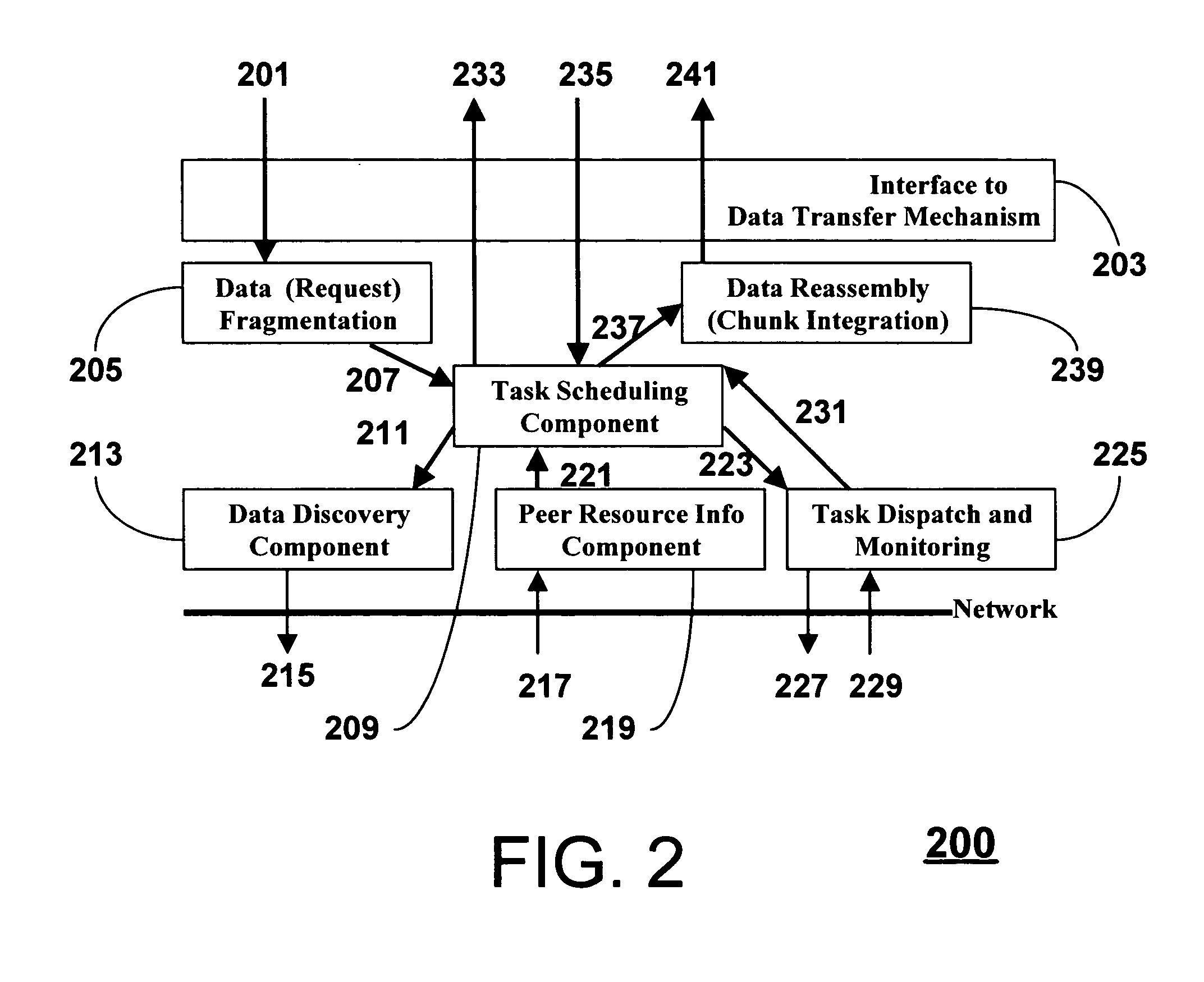

Device and method for transferring apportioned data in a mobile ad hoc network

InactiveUS20060095582A1Increase the number ofWeaken energyNetwork traffic/resource managementNetwork topologiesTransceiverSelf-organizing network

A wireless communication device (101) for communicating data portions of data over an ad hoc network is provided. The wireless communication device comprises a scheduling circuit (209), a transceiver (213, 219, 225) operating via a wireless link of the ad hoc network, and an integration circuit (239). The scheduling circuit is configured to identify a plurality of data portions to divide the data. The transceiver is configured to discover a plurality of remote devices having one or more data portions of the data and transmit a task associated with the one or more data portions of the data to the plurality of remote devices. The integration circuit is configured to assemble the plurality of data portions.

Owner:MOTOROLA MOBILITY LLC

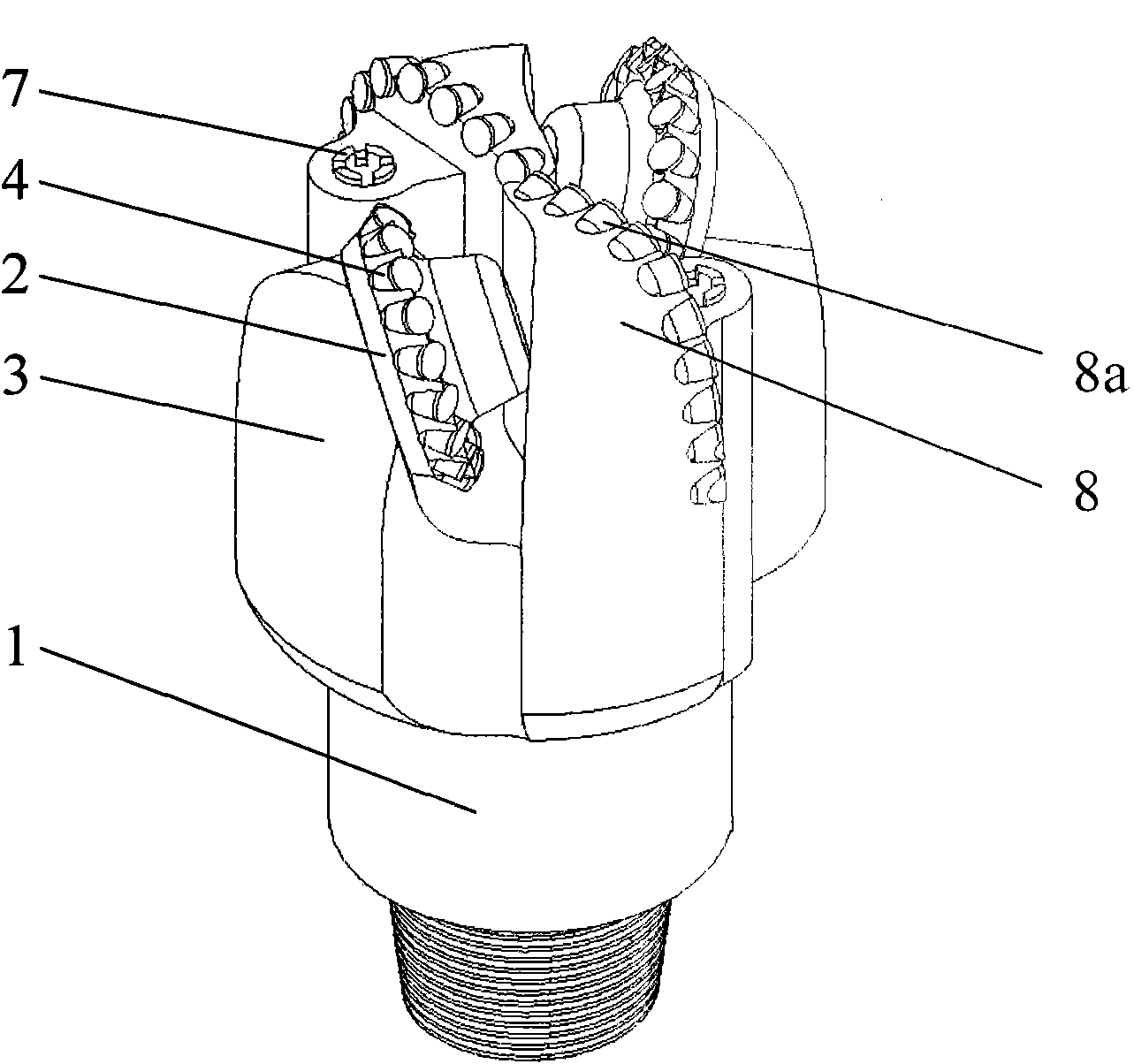

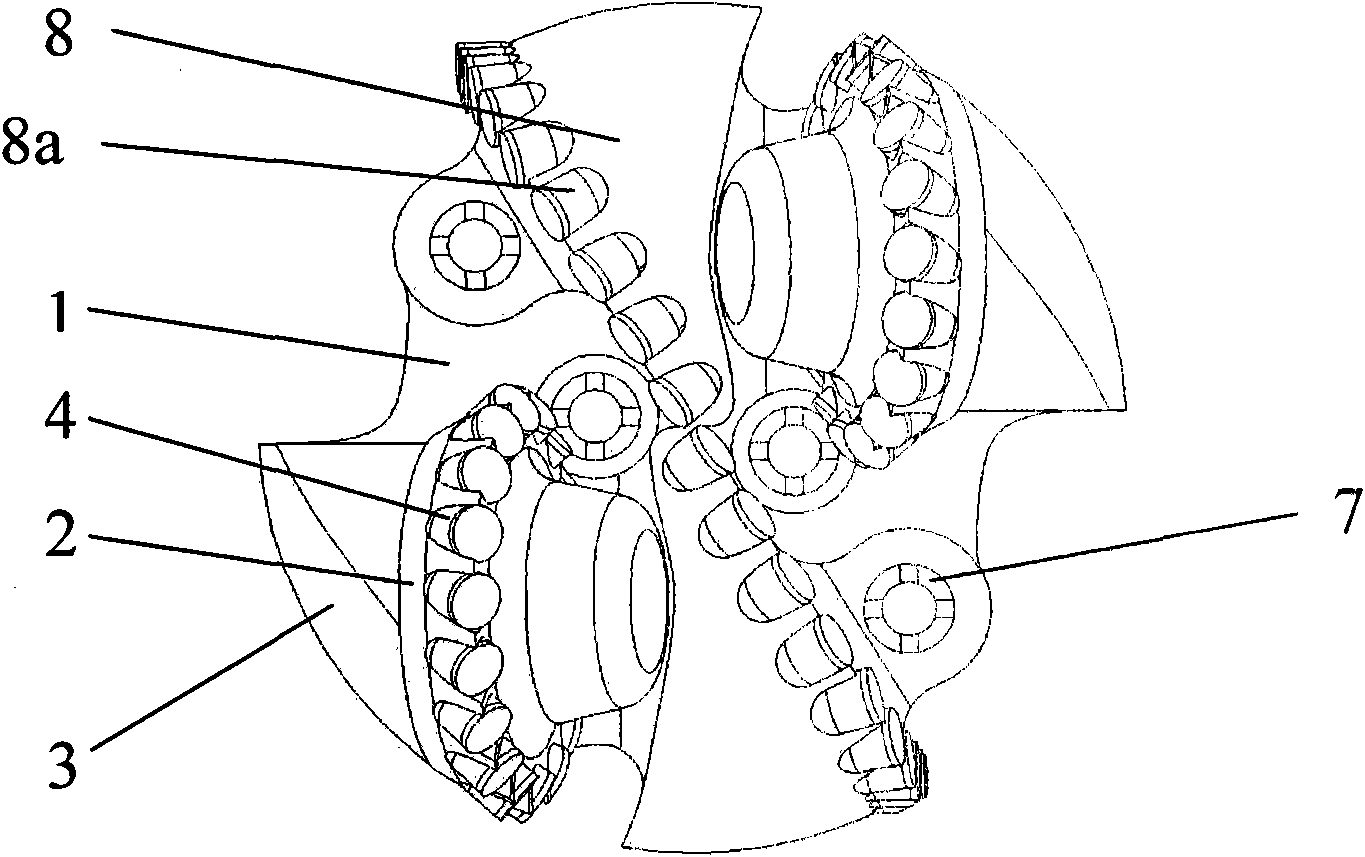

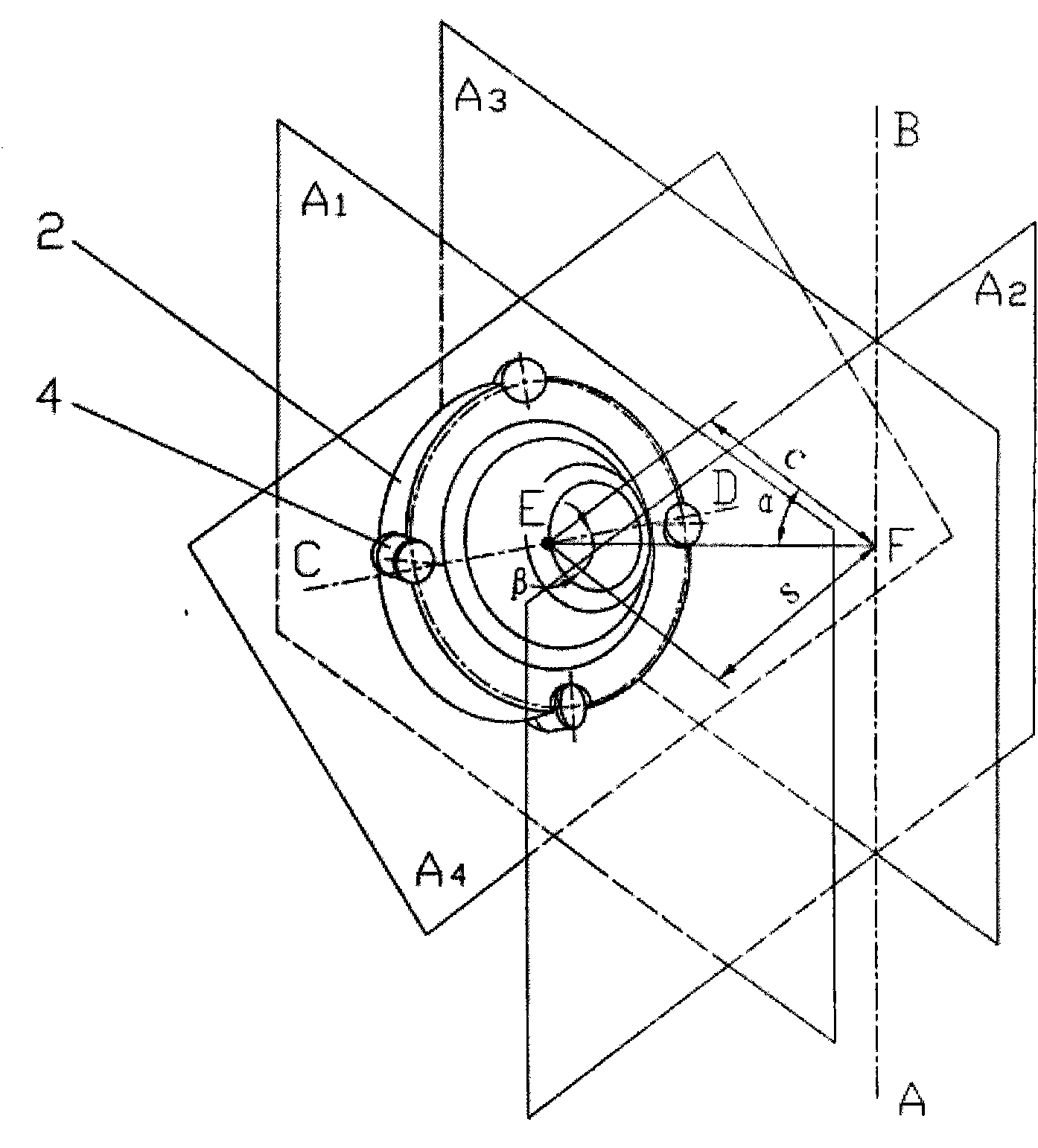

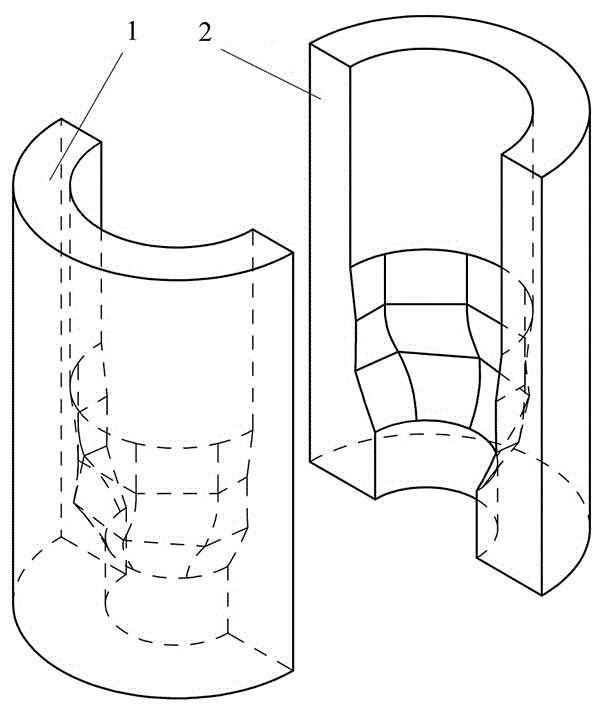

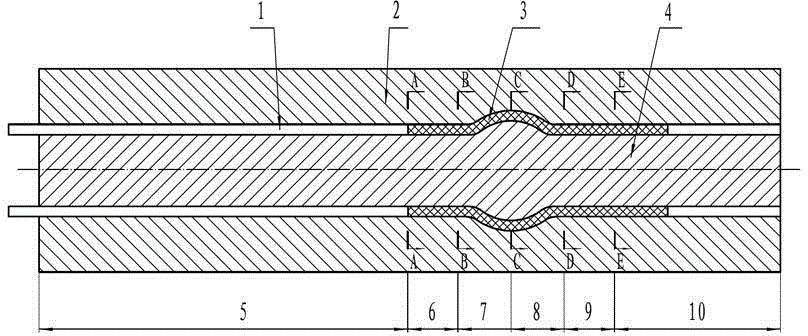

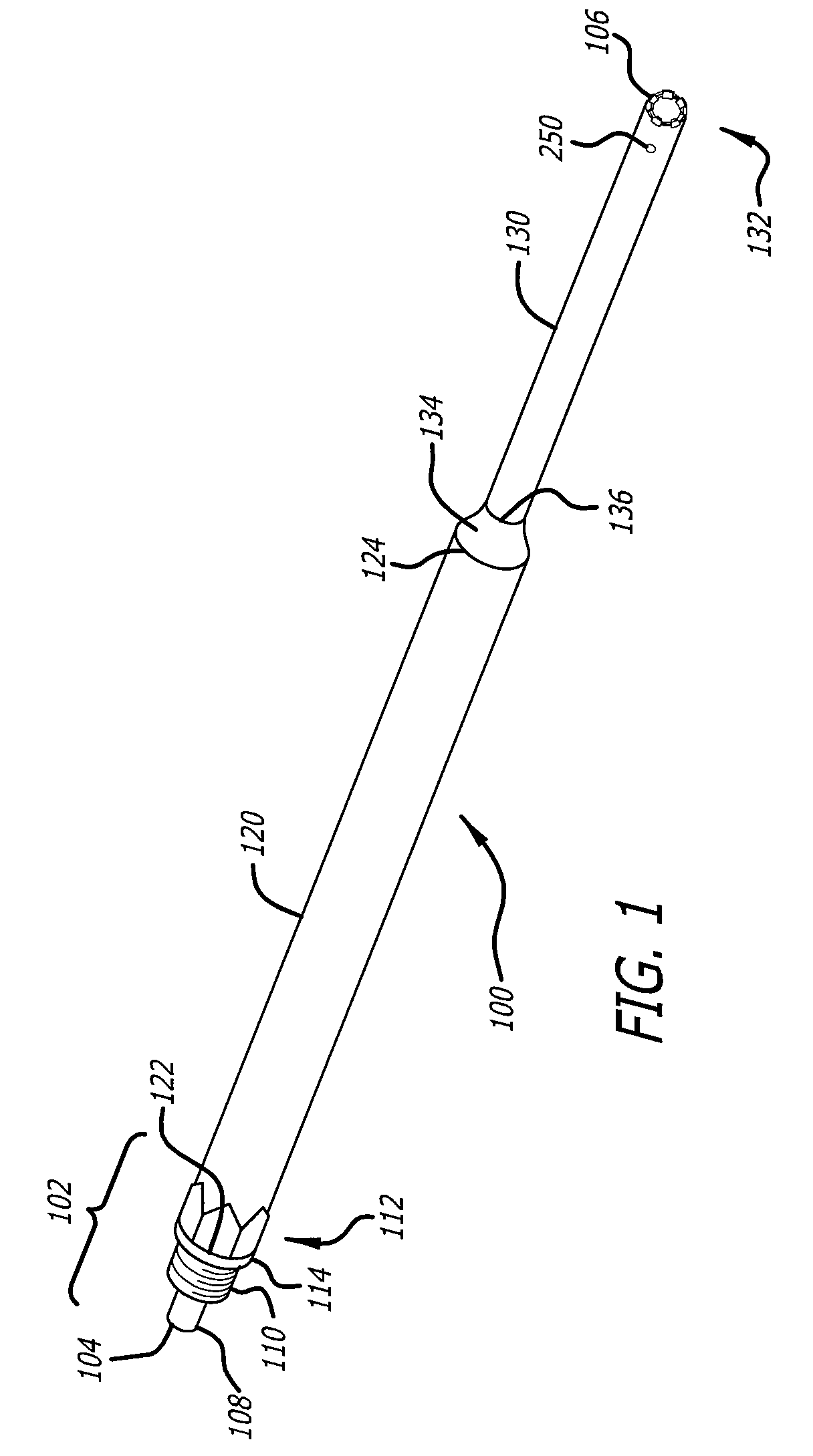

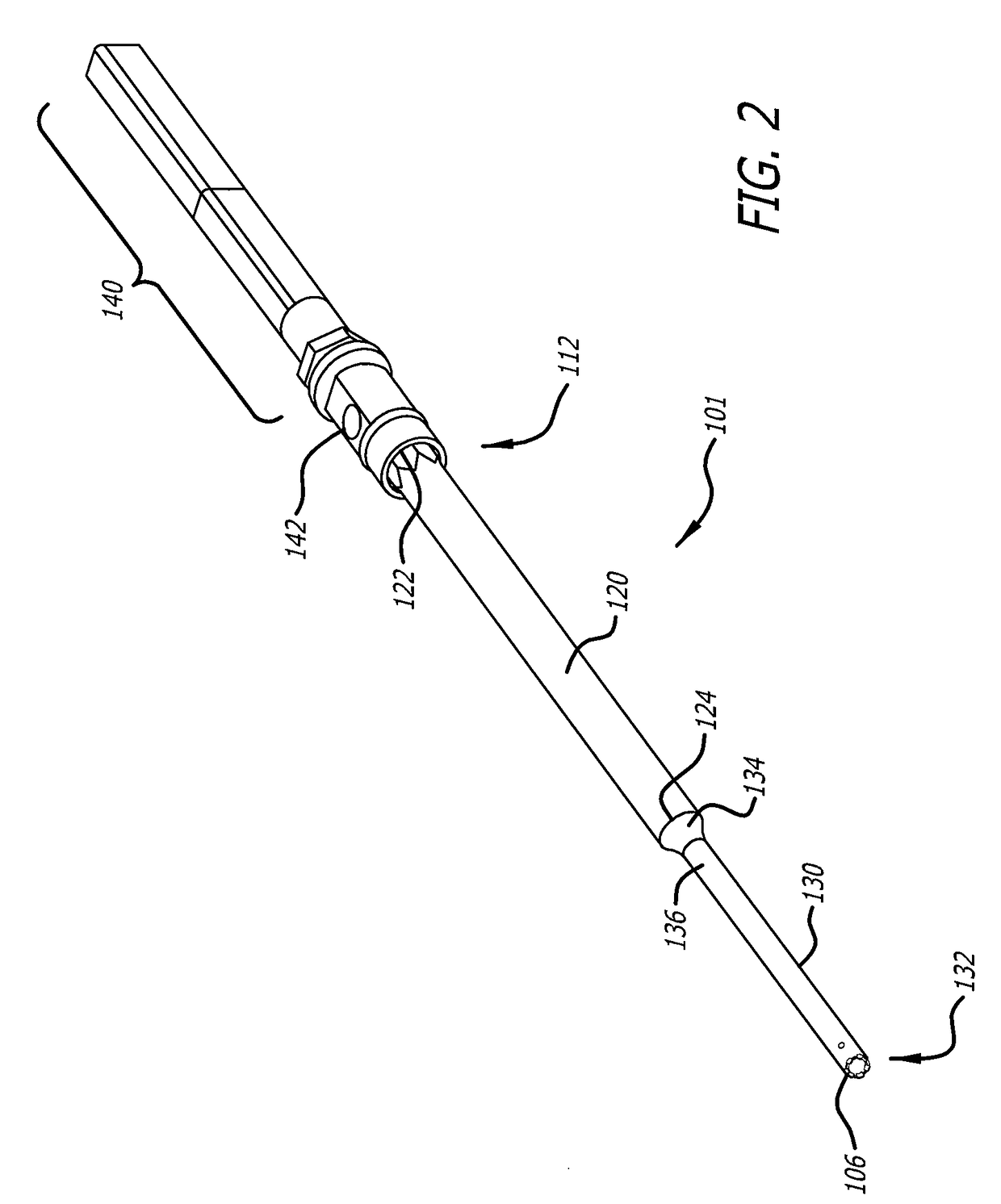

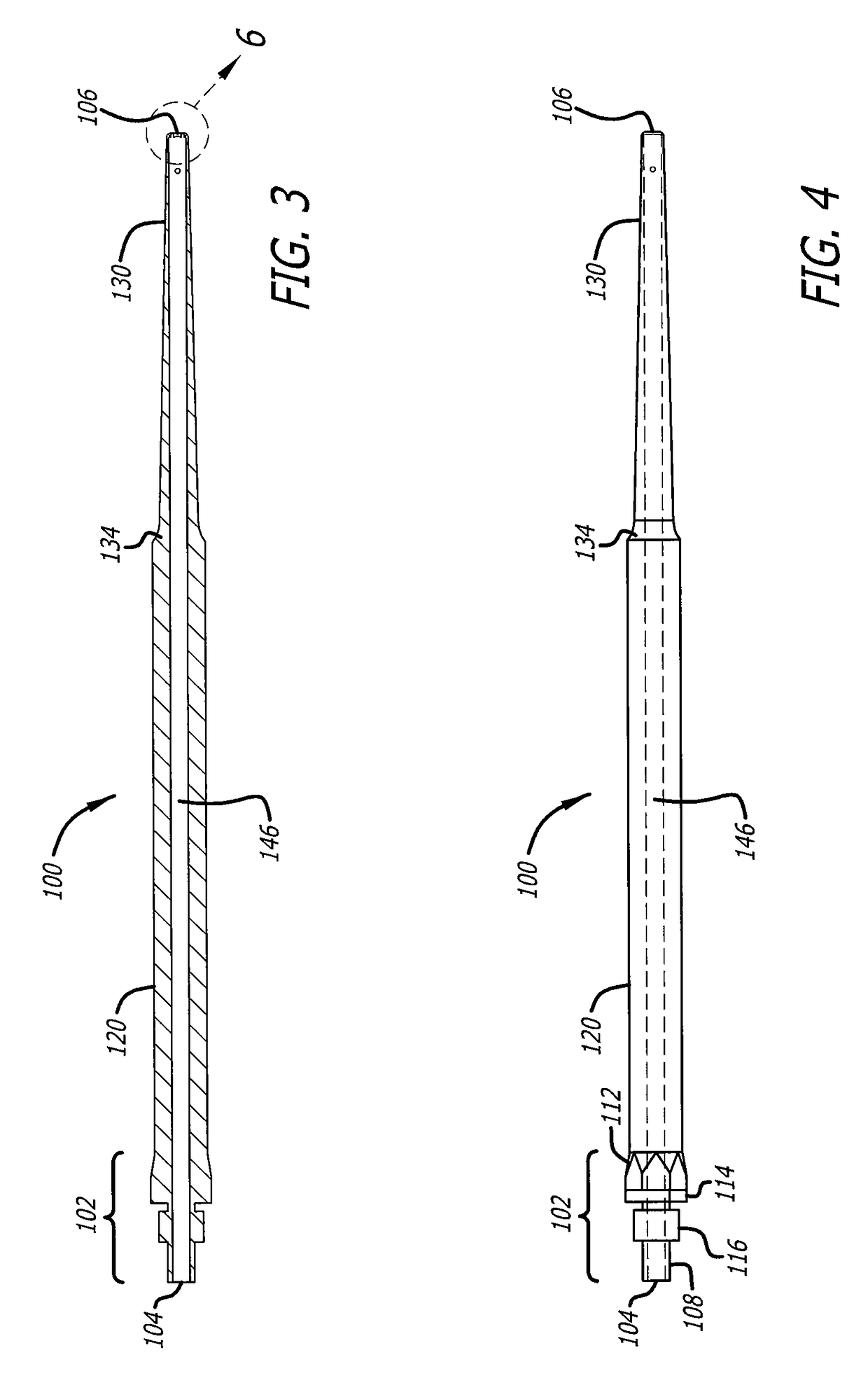

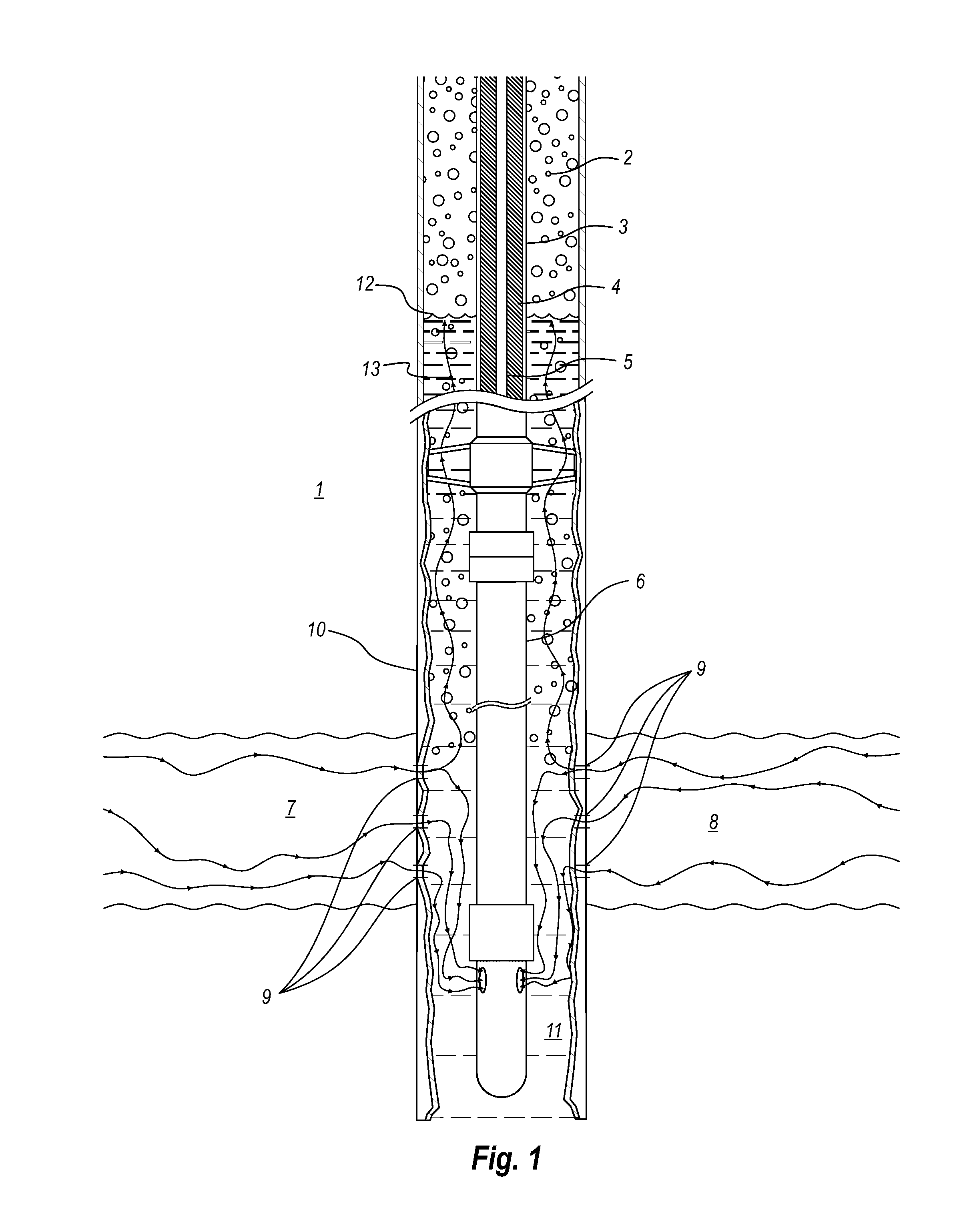

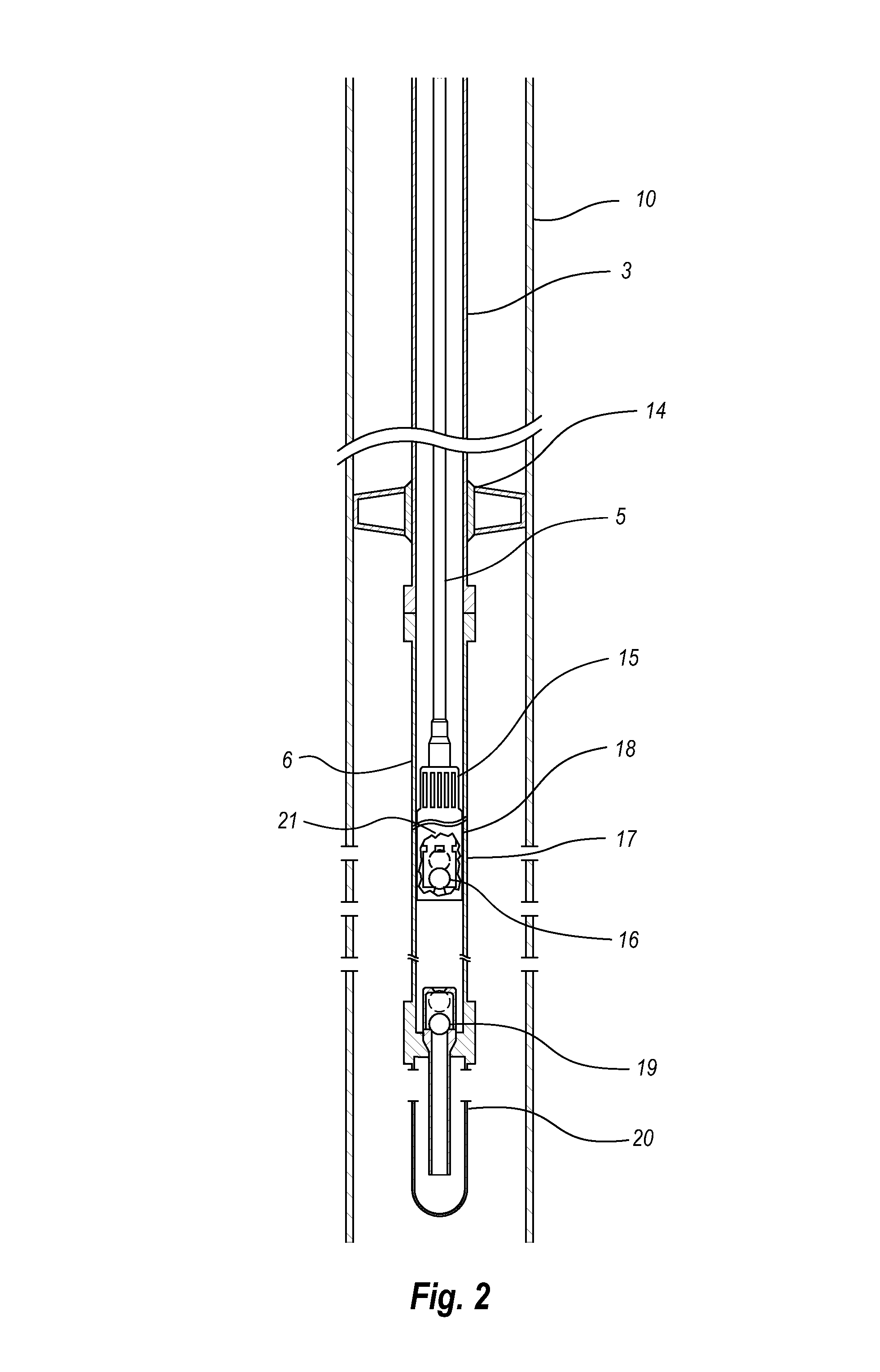

Combined drill breaking rocks by cutting method

ActiveCN101892810APromote fragmentationEffective intakeDrill bitsConstructionsWorking lifeCooling effect

The invention discloses a combined drill breaking rocks by a cutting method. The combined drill comprises a drill body (1) and a rotating wheel (2), wherein a wheel palm (3) is arranged on the drill body (1); the rotating wheel (2) is arranged on the shaft neck (6) of the wheel palm (3) and is in rotary connection with the wheel palm (3); an external row of cutting gear rings (4) are arranged on the rotating wheel (2); the deviation angle alpha of the rotating wheel (2) is in a range that the absolute value of alpha is more than or equal to 20 degrees and less than or equal to 90 degrees; and a fixed cutting structure (8) with fixed cutting teeth (8a) is arranged on the drill body (1). Cutting teeth on the rotating wheel break the rocks in an alternatively scraping mode and cooperates with the cutting teeth on the fixed cutting structure to form a net-like breaking region on the pit bottom rocks, so the combined drill has the advantages of high rock-breaking efficiency, uniform wear, good cooling effect, long service life of the teeth, long working life of the bearing and long service life of the drill.

Owner:CHENGDU WEIYI PETROLEUM TECH

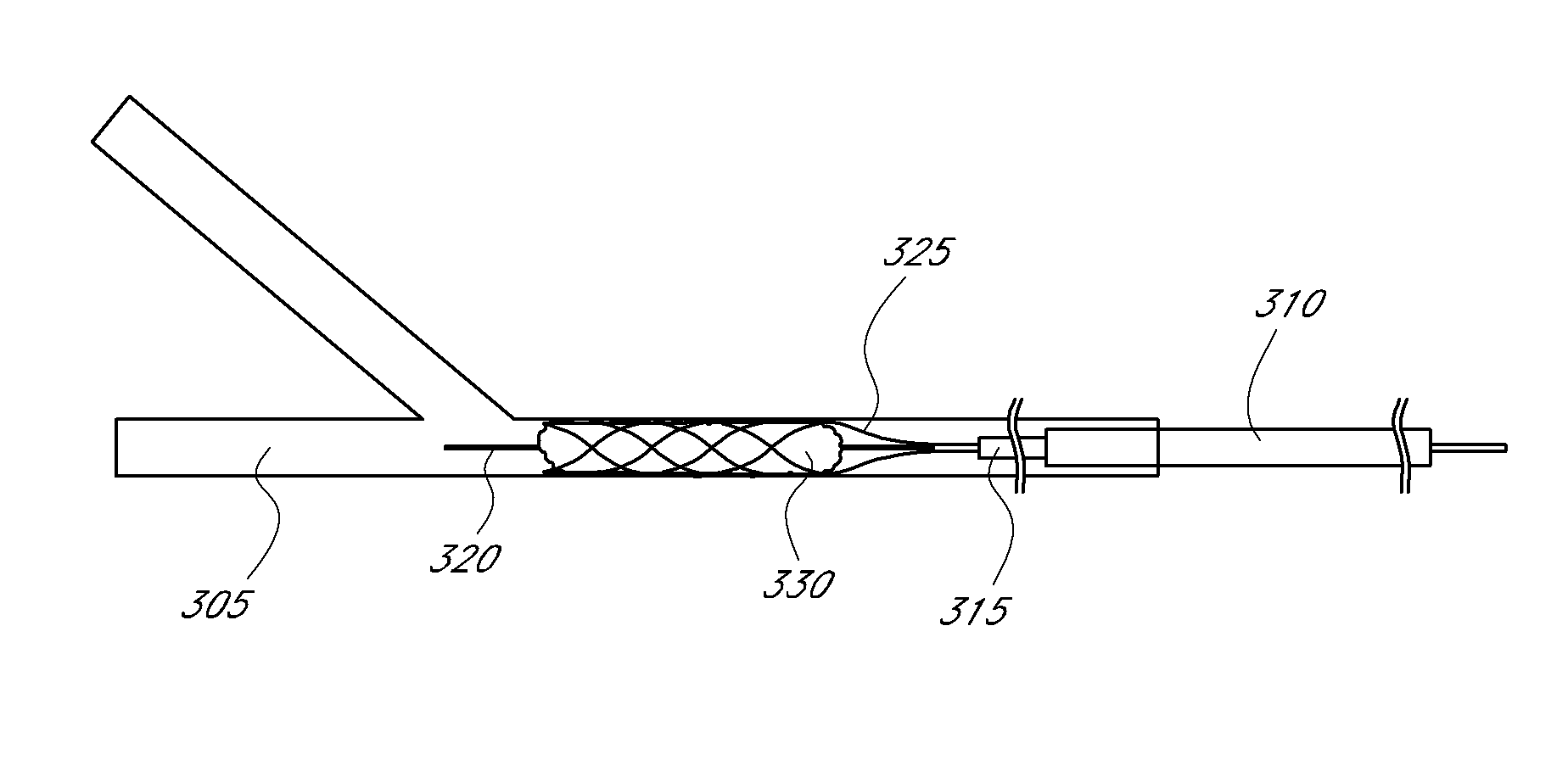

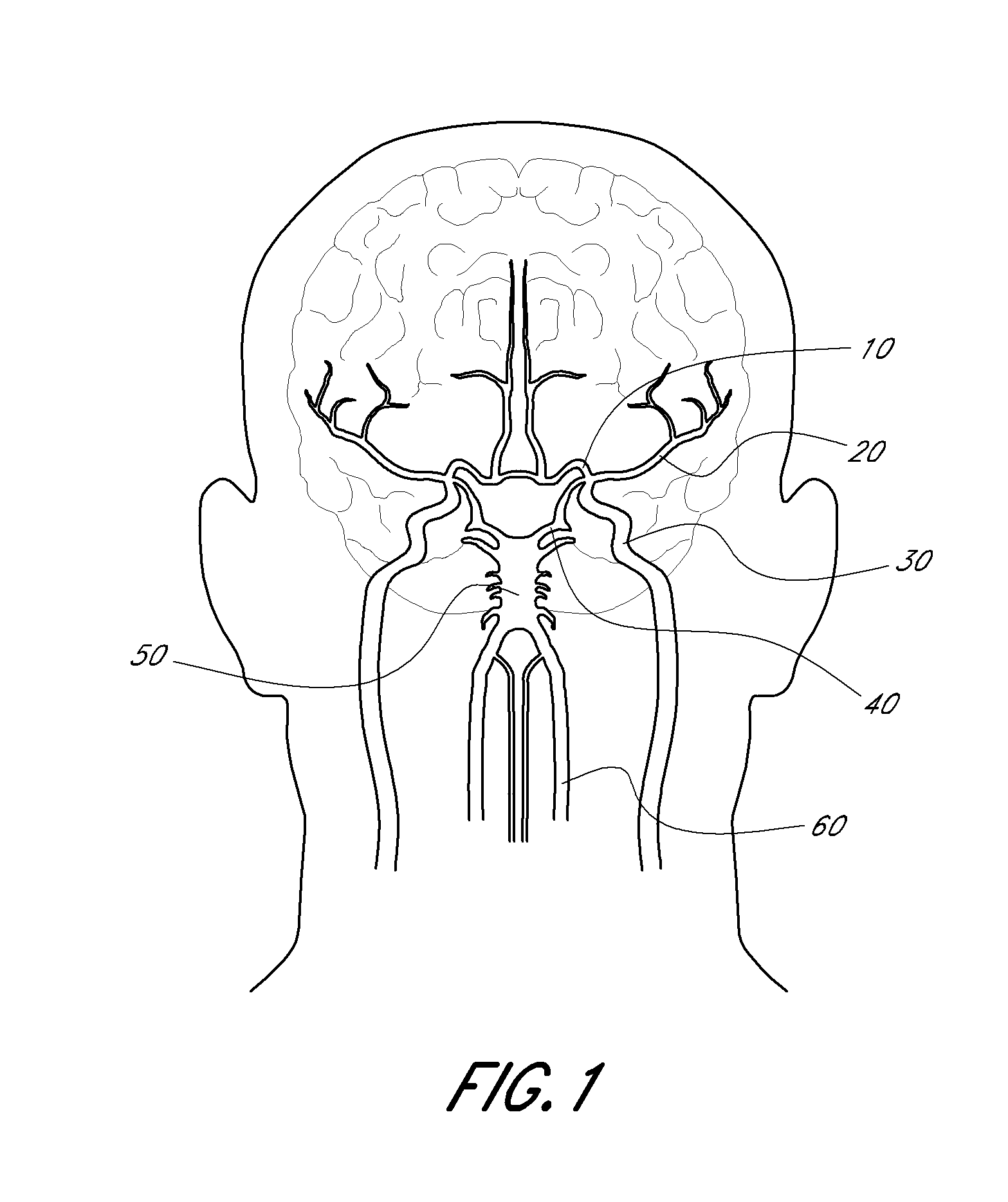

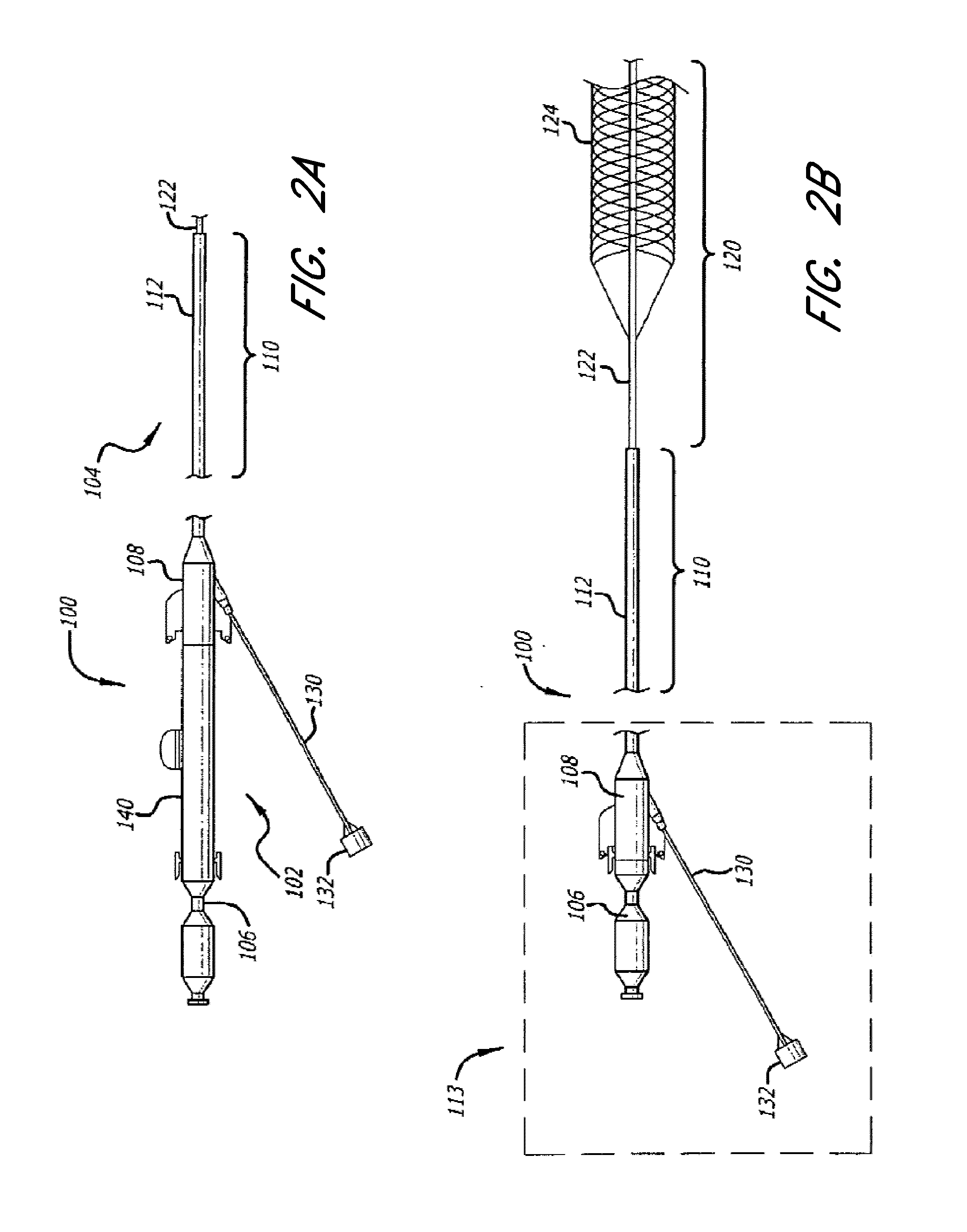

Thrombus management device

InactiveUS20120041475A1Facilitate natural lysis and fragmentationRestore blood flowStentsIncision instrumentsLysisDistal embolization

Systems, methods, and devices for the treatment of acute ischemic stroke that provide immediate blood flow restoration to a vessel occluded by a clot and, after reestablishing blood flow, address the clot itself. Immediate blood flow restoration advantageously can facilitate natural lysis of the clot and also can reduce or obviate the concern for distal embolization due to fragmentation of the clot. Several embodiments of the invention provide for progressive, or modular, treatment based upon the nature of the clot. For example, the progressive treatment can include immediate restoration of blood flow, in-situ clot management, and / or clot removal depending on the particular circumstances of the treatment. The in-situ clot management can include, for example, lysis, maceration, and / or removal.

Owner:TYCO HEALTHCARE GRP LP

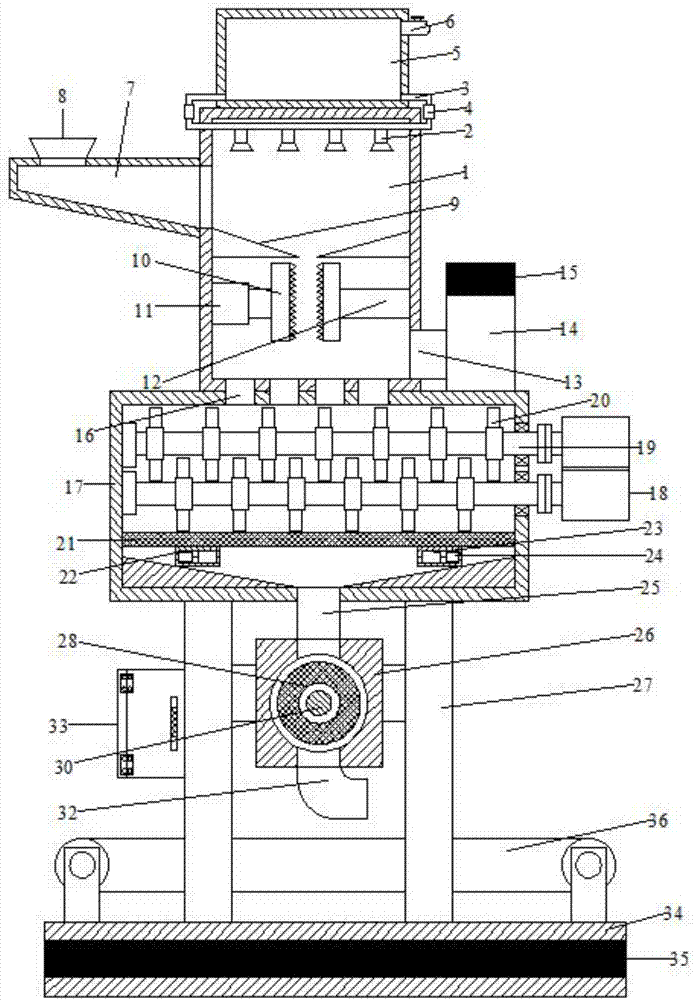

Construction waste treatment device

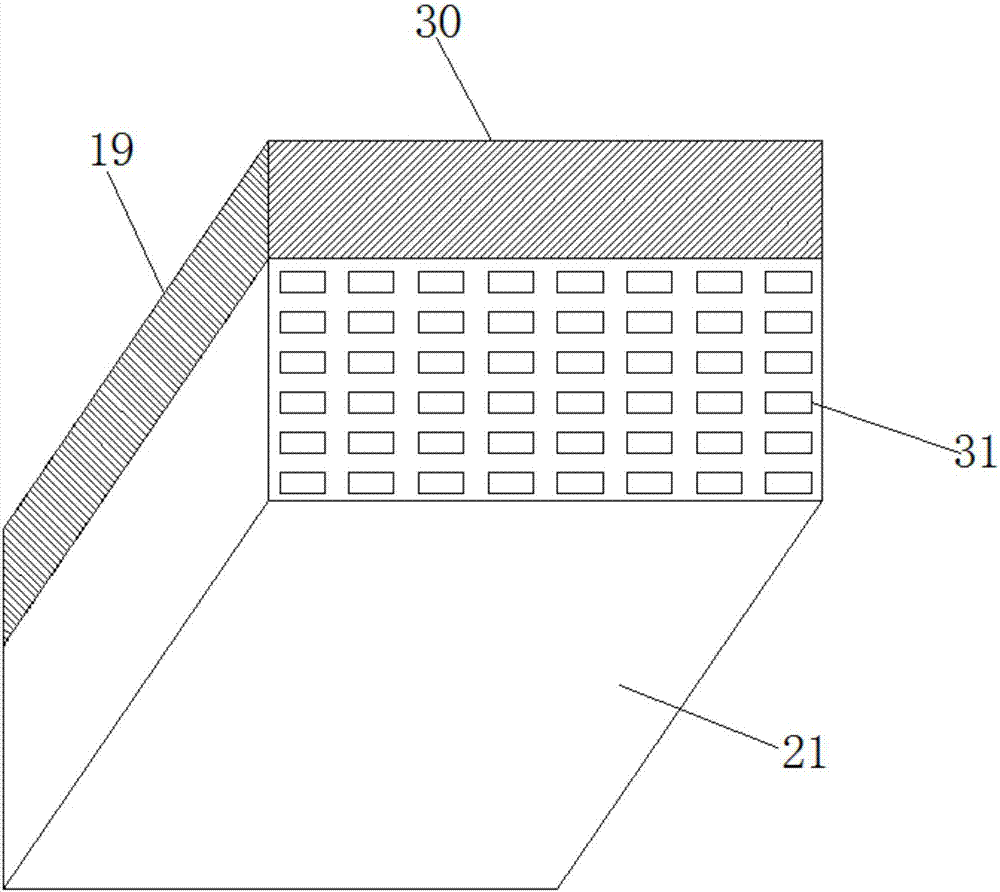

InactiveCN107214179AEfficient crushingPromote fragmentationConstruction waste recoverySolid waste disposalWater storageArchitectural engineering

The invention discloses a construction waste treatment device, which comprises a crushing chamber, an atomizing nozzle is arranged on the upper side of the crushing chamber, a water suction pipe is arranged on the upper side of the atomizing nozzle, a water storage chamber is arranged inside the upper end of the suction pipe, and a water storage chamber is arranged on the left upper side of the crushing chamber. There is a feeding pipe, the lower end of the right side of the feeding pipe is provided with a drainage plate, the lower side of the drainage plate is provided with a crushing plate, the lower left end of the crushing chamber is provided with a connecting pipe, the right side of the connecting pipe is provided with a rebar storage chamber, and the upper end of the rebar storage chamber is provided with a There is an electromagnet, there is a discharge port on the lower side of the crushing chamber, a crushing chamber is provided on the lower side of the discharge port, a screen is provided at the lower end of the crushing chamber, a discharge pipe is provided in the middle of the lower side of the crushing chamber, and a discharge pipe is provided on the lower side of the discharge pipe. There is a grinding chamber, the four corners of the lower side of the crushing chamber are provided with support columns, the lower side of the grinding chamber is provided with a discharge pipe, the lower side of the support column is provided with a base, the inside of the base is provided with a vibration-damping pad, and the upper middle of the base is provided with a pulley. The construction waste is crushed, separated, crushed, screened, ground and transported, which can effectively protect the environment and save resources.

Owner:彭利辉

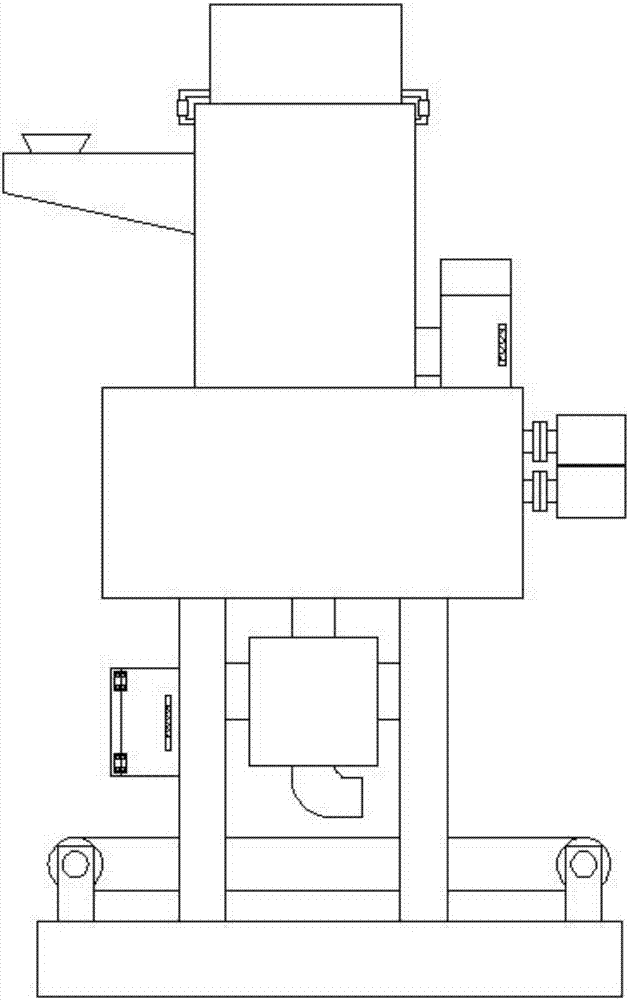

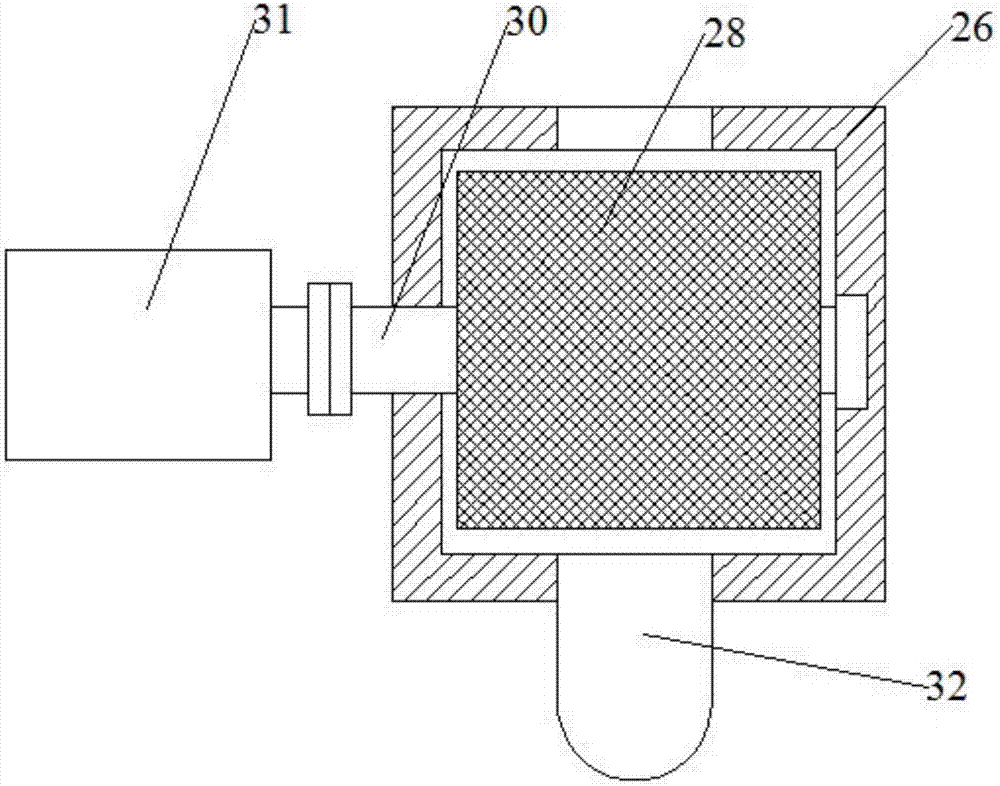

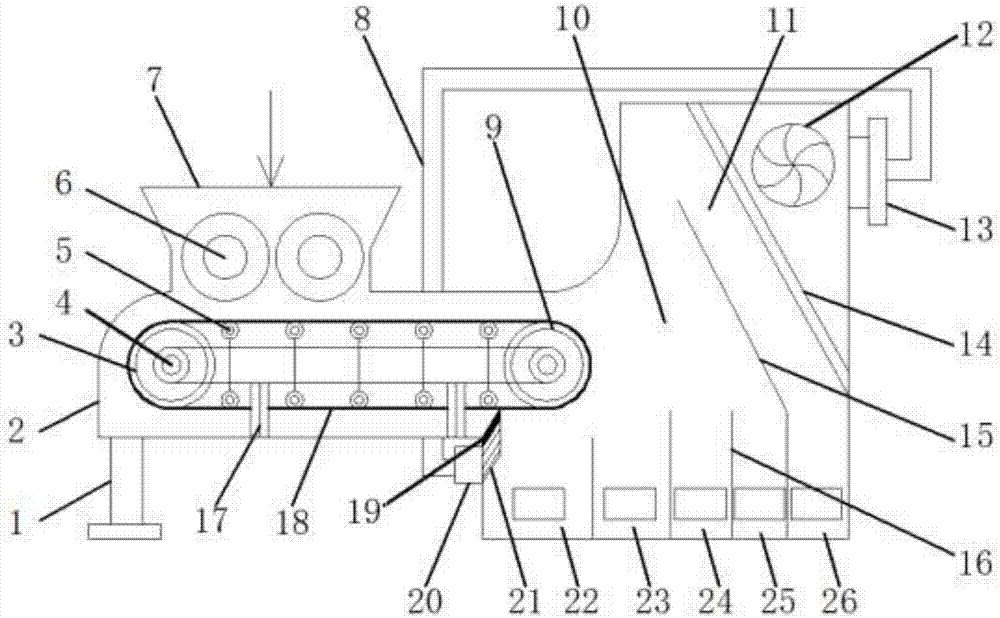

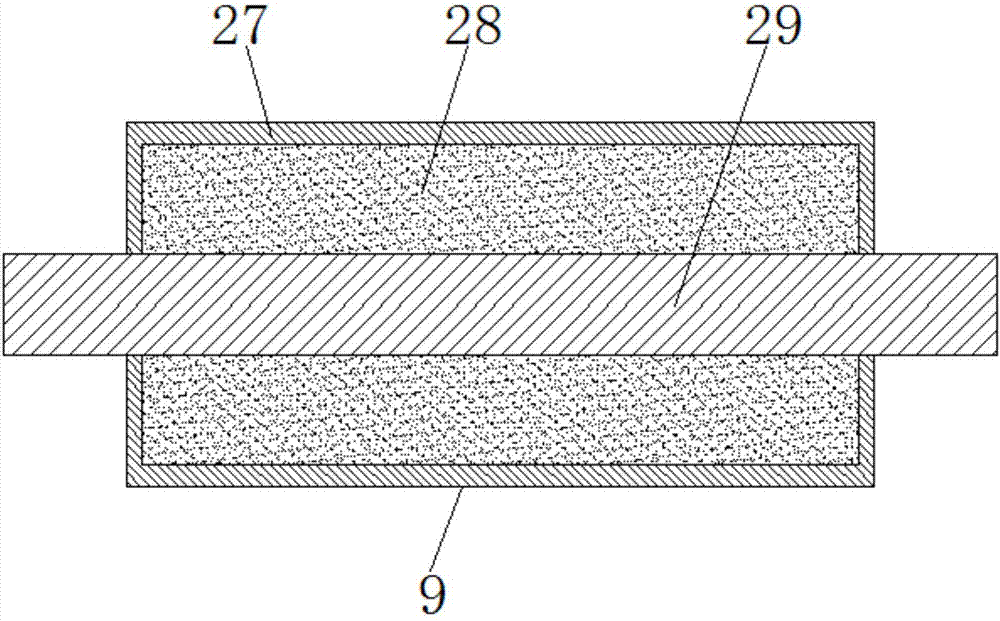

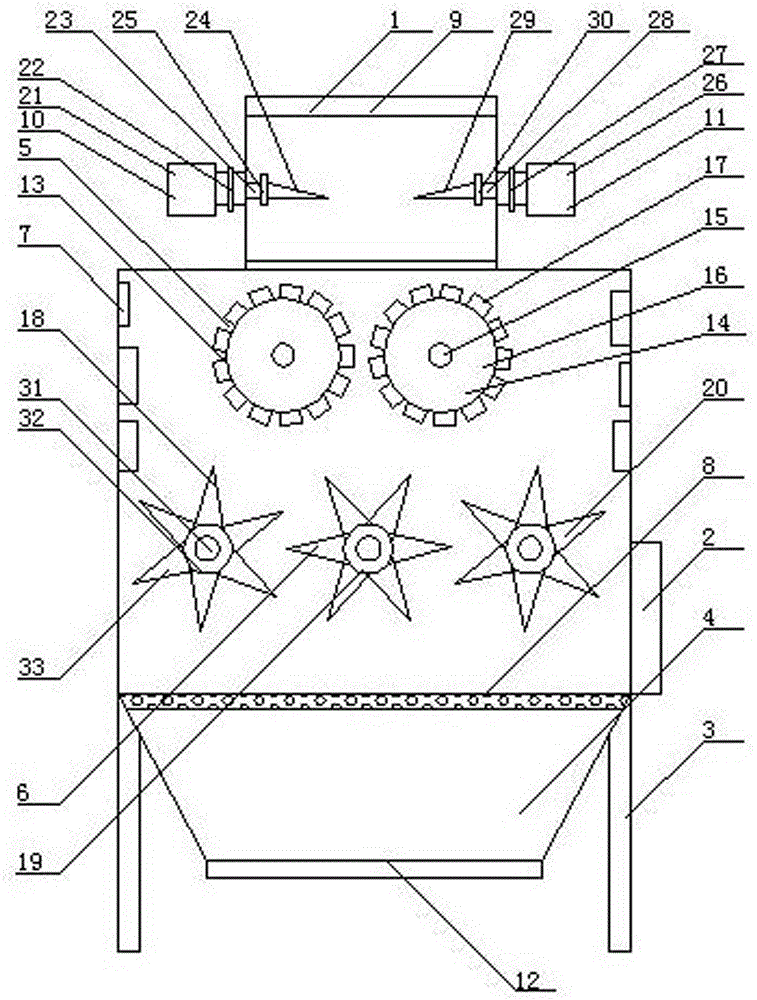

Transportation magnetic separation equipment for crushing and processing construction waste

InactiveCN107282175APromote fragmentationAchieve brokenGas current separationMagnetic separationSlagArchitectural engineering

The invention discloses a transportation magnetic separation equipment for crushing and processing construction waste, which comprises a frame, a transmission box, a magnetic separation roller and a conveyor belt. The transmission box is installed on the upper end of the frame, and a conveyor frame is installed inside the transmission box , a driving roller and a magnetic separation roller are installed on the conveyor frame, and a conveyor belt is set between the driving roller and the magnetic separation roller; the upper left end of the transmission box is welded with a construction waste adding bucket, and the bottom of the construction waste adding bucket is A crushing roller is installed inside; the right end of the conveyor belt is provided with a winnowing chamber, and the bottom side of the right end of the conveyor belt is installed in sequence from left to right with an iron collection box, a heavy material box, a light material box, a slag collection box and Dust settling box; it is convenient to add construction waste into the hopper and crush it through the two crushing rollers; the magnetic separation roller absorbs and screens the construction waste containing ferromagnetism to realize the crushing and transportation of construction waste , Removal of ferromagnetism, screening, separation and dust removal, the operation is convenient and quick.

Owner:寿涵红

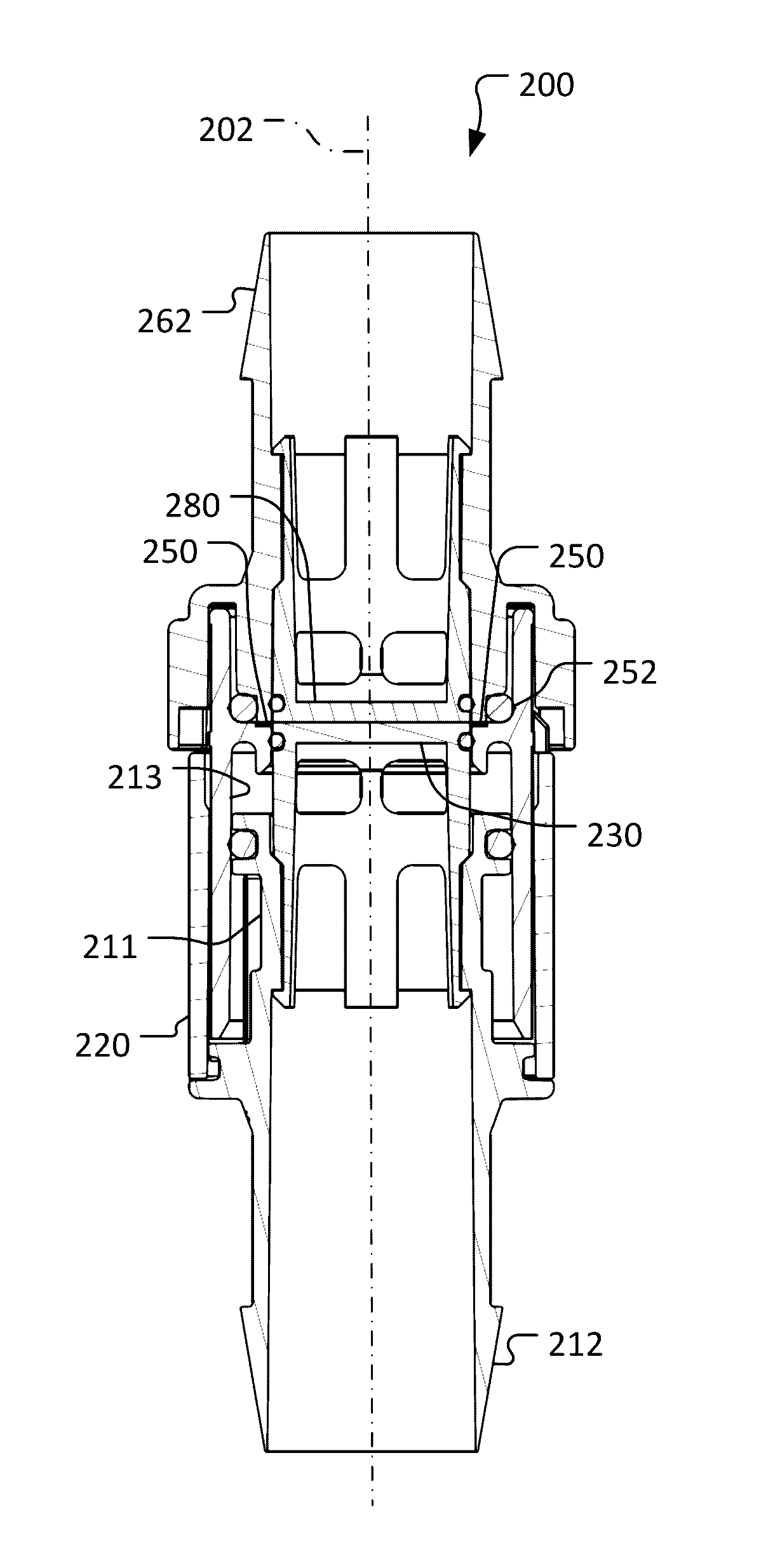

Piezoelectric two-phase flow ultrasonic atomization spraying nozzle

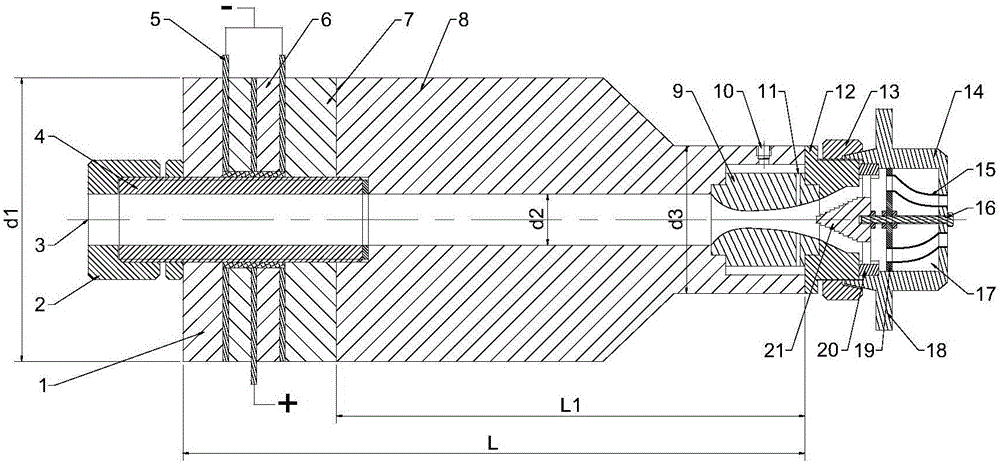

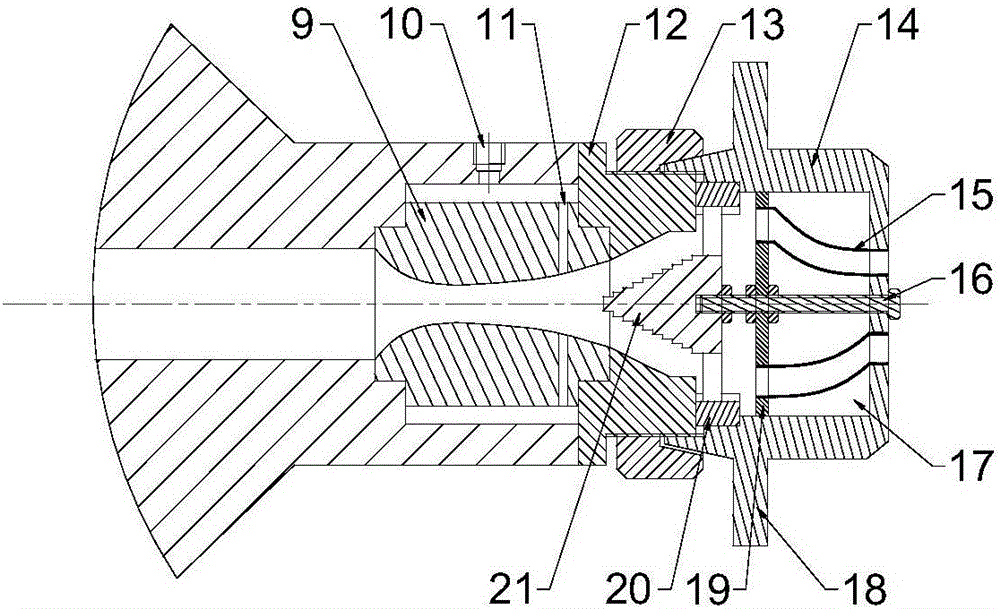

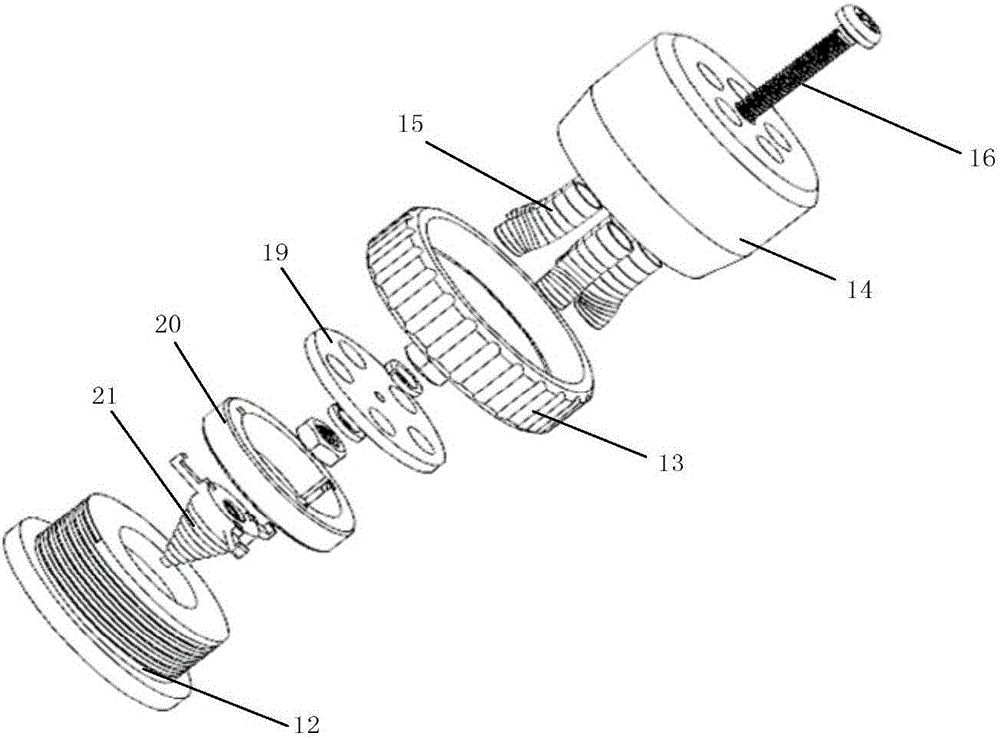

InactiveCN105834054ALarge amount of atomizationSmall dropletLiquid spraying apparatusElectricitySpray nozzle

The invention provides a piezoelectric two-phase flow ultrasonic atomization spraying nozzle. The piezoelectric two-phase flow ultrasonic atomization spraying nozzle comprises a piezoelectric vibrator, an amplitude-change pole, a second end cover and a first end cover; the piezoelectric vibrator and the amplitude-change pole are connected through a connecting bolt; an air inlet connector is installed at the tail of the connecting bolt; the second end cover is fixed to the front end of the amplitude-change pole; a laval type valve element is fixed into a step hole of the amplitude-change pole and a groove of the second end cover; a liquid inlet hole is formed in the hole wall face of the step hole of the amplitude-change pole; a plurality of flow guide holes are formed in the positions, close to an outlet, of the laval type valve element in the radial direction; the first end cover is threaded connection to the second end cover; a radial positioning ring is arranged at the position of a clamping groove in the back end of the first end cover; a step type taper valve is installed on the radial positioning ring; the step type taper valve and a vibration separating plate are connected through an adjusting bolt; a resonance chamber is formed between the vibration separating plate and the top end of the first end cover; and a plurality of flexible pipes are arranged in the resonance chamber. According to the piezoelectric two-phase flow ultrasonic atomization spraying nozzle, a large number of superfine fog drops are generated under the low-energy working condition, and the shortcoming that large pulverization amount, small grain size, low power dissipation and directed spraying cannot be considered at the same time through in the traditional technology is overcome.

Owner:JIANGSU UNIV

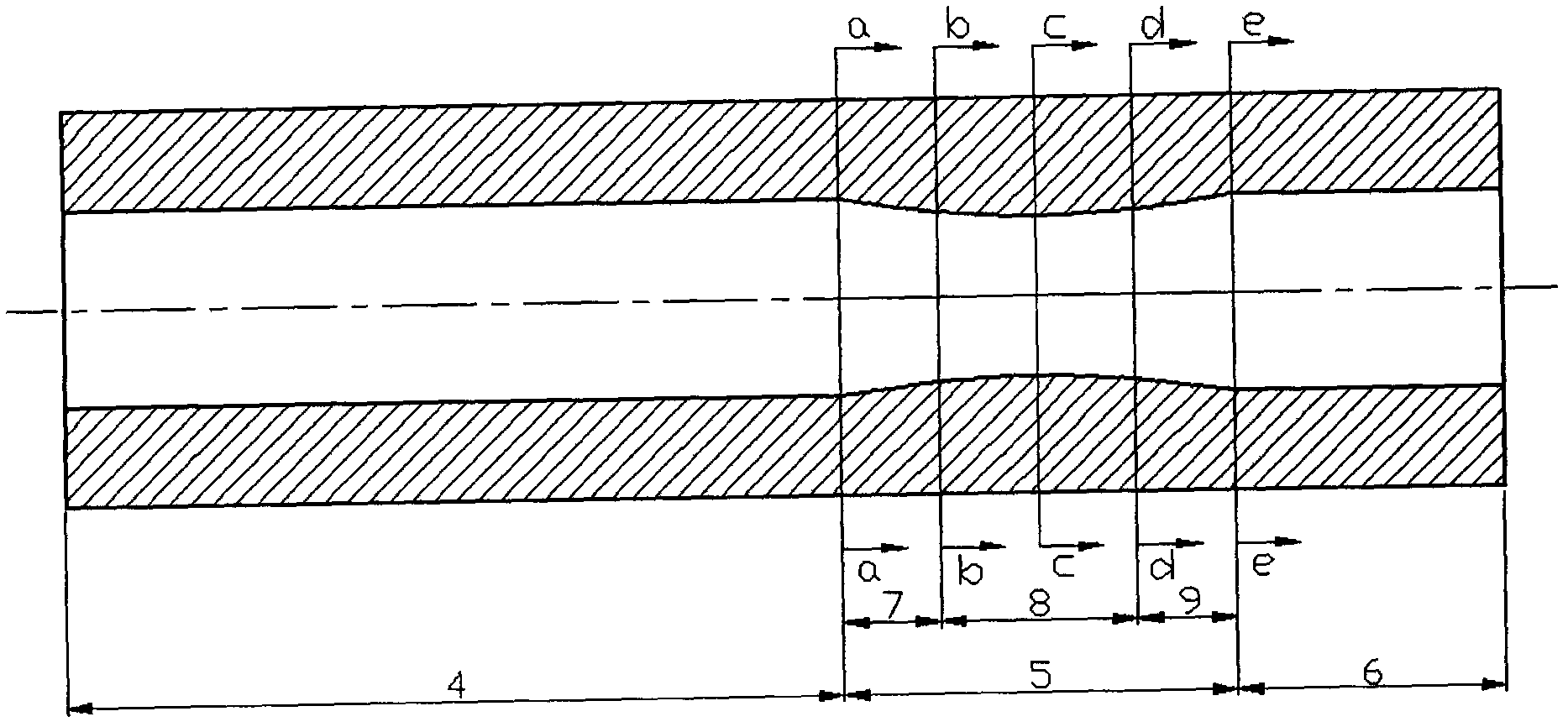

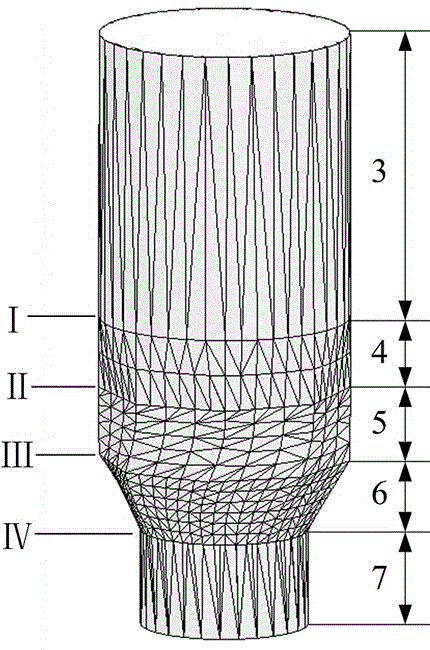

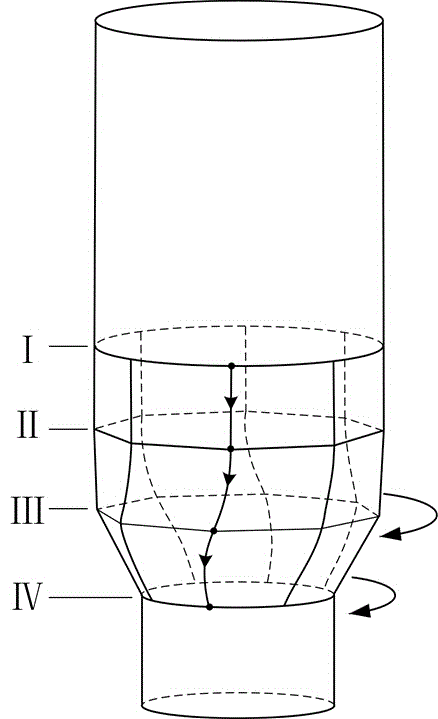

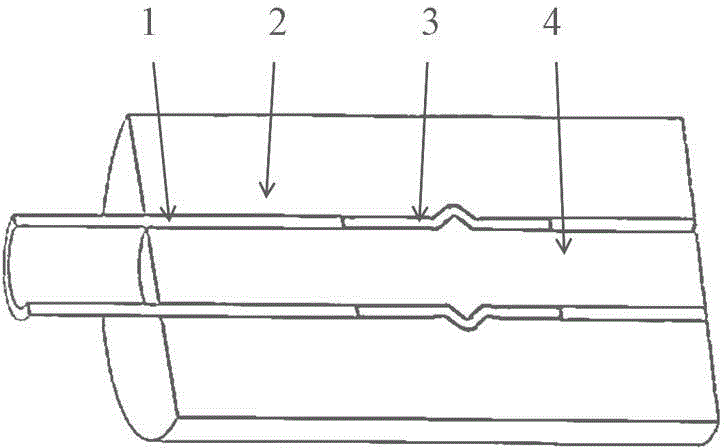

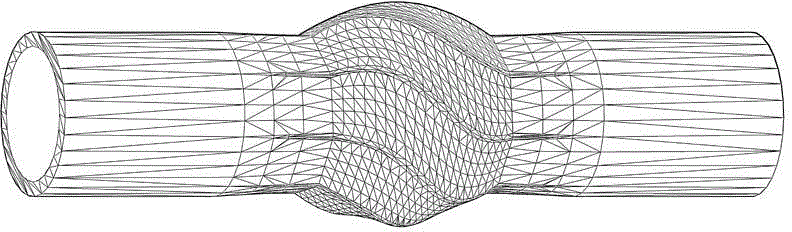

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Extraction method of microalga grease

InactiveCN103045352AImprove dissolution efficiencyHigh yieldFatty-oils/fats productionAlcoholOrganic solvent

The invention discloses an extraction method of microalga grease. The extraction method comprises the following steps of: (1) microalga cell collection: adjusting the pH value of a microalga culture solution to 11-12 at the later period of microalga cultivation, and collecting microalga cells in a centrifugal way; (2) microalga cell crushing: adding a C1-C6 short-chain alcohol solvent into microalga ooze obtained in the step (1), shaking and mixing the microalgae to be uniform, and then, carrying out cell breaking treatment on the microalgae; (3) grease extraction: adding one or more of organic solvents such as n-hexane and petroleum ether into a microalga cell breaking solution obtained in the step (2), and extracting the grease component in the cell breaking solution by using the organic solvents; and (4) solvent recovery: after the extraction reaction is ended, cooling the solvent to room temperature, standing for 10-30min, respectively extracting an organic solvent layer (oil phase) and a water layer (water phase), and recovering the organic solvents in the oil phase in a distillation way, and meanwhile, obtaining the microalga grease. The method has the advantages of simple operation process, short extraction time, low energy consumption, high microalga grease yield and the like and is suitable for directly extracting grease from alga ooze.

Owner:CHINA PETROLEUM & CHEM CORP +1

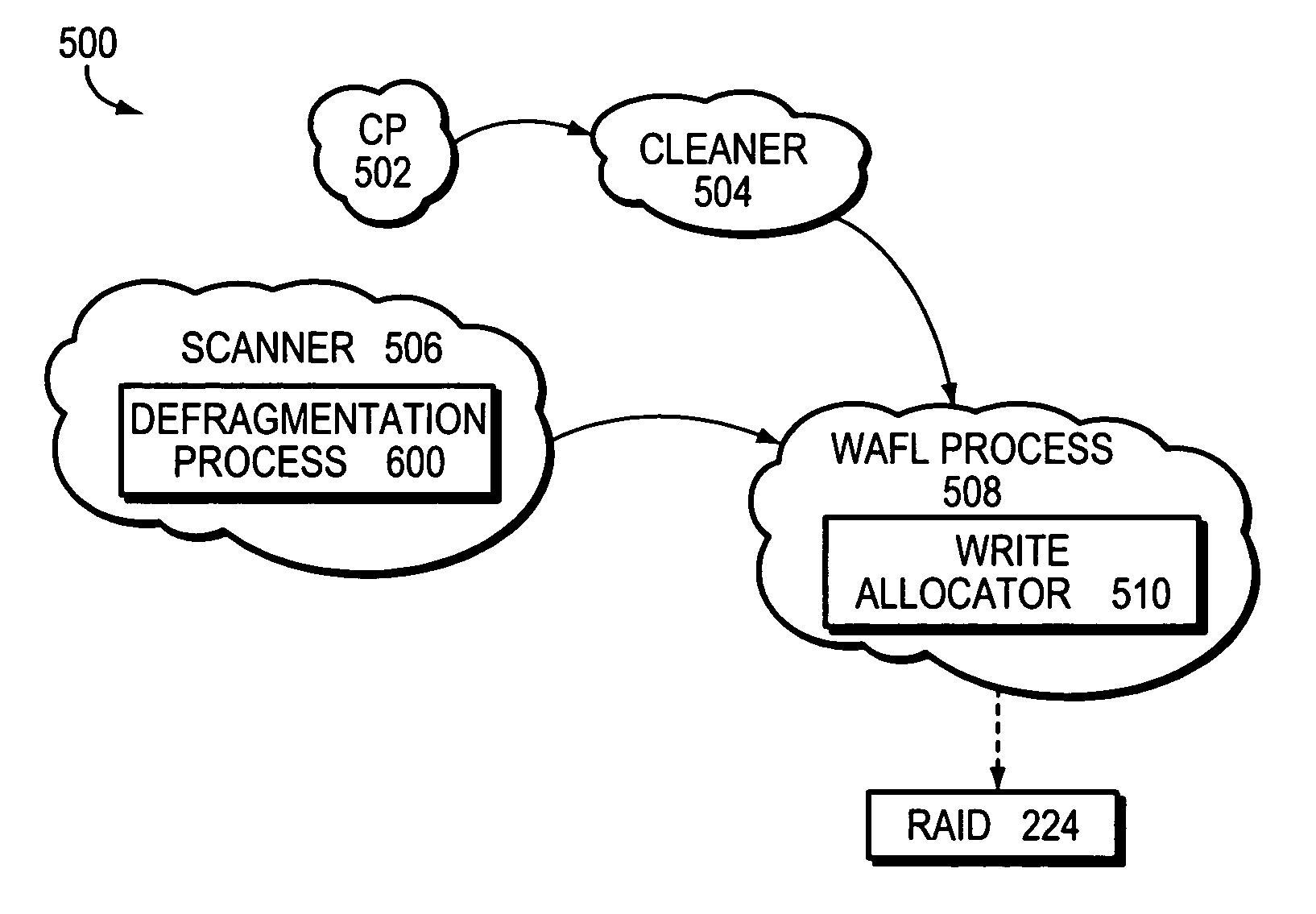

File system defragmentation technique via write allocation

InactiveUS20050187985A1Improved on-disk layoutReduces unnecessary disk input/output operationDigital data information retrievalData processing applicationsDisk layoutFile system fragmentation

A defragmentation technique determines the extent to which data blocks of a file are fragmented on disks of a computer and, in response, efficiently relocates those blocks if such relocation improves the on-disk layout of the file. Each indirect block of the file is examined and the current layout of the range of pointers referencing the data blocks is determined. In addition, the number of operations needed to retrieve those data blocks from disks is calculated. A potential new layout is then estimated based on an average fullness of the file system. If the potential new layout improves the fragmentation of the current layout, then the data blocks for that range are relocated, if there is sufficient free space on disk. Otherwise, the blocks are not relocated and the current on-disk layout of the file is maintained.

Owner:NETWORK APPLIANCE INC

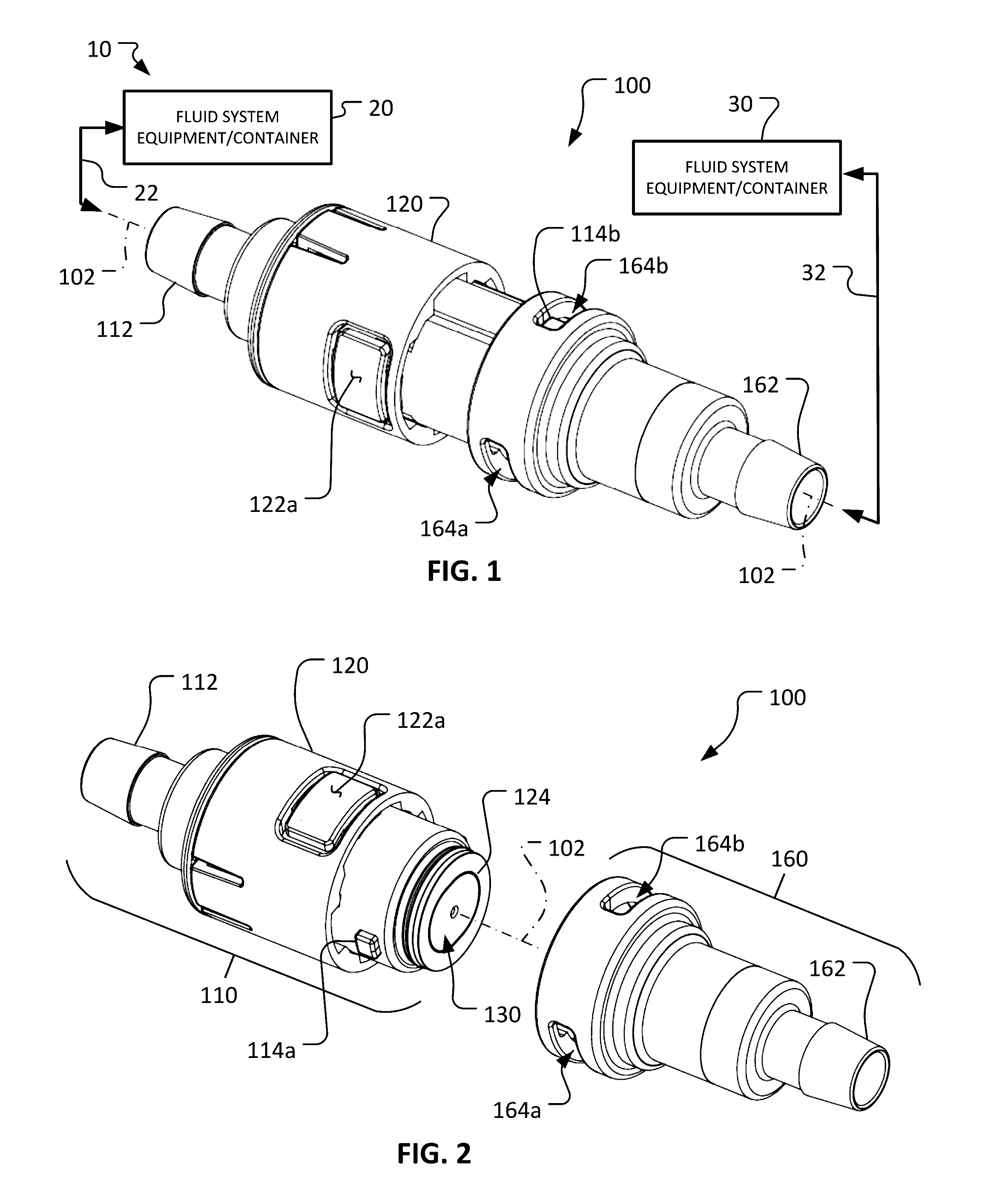

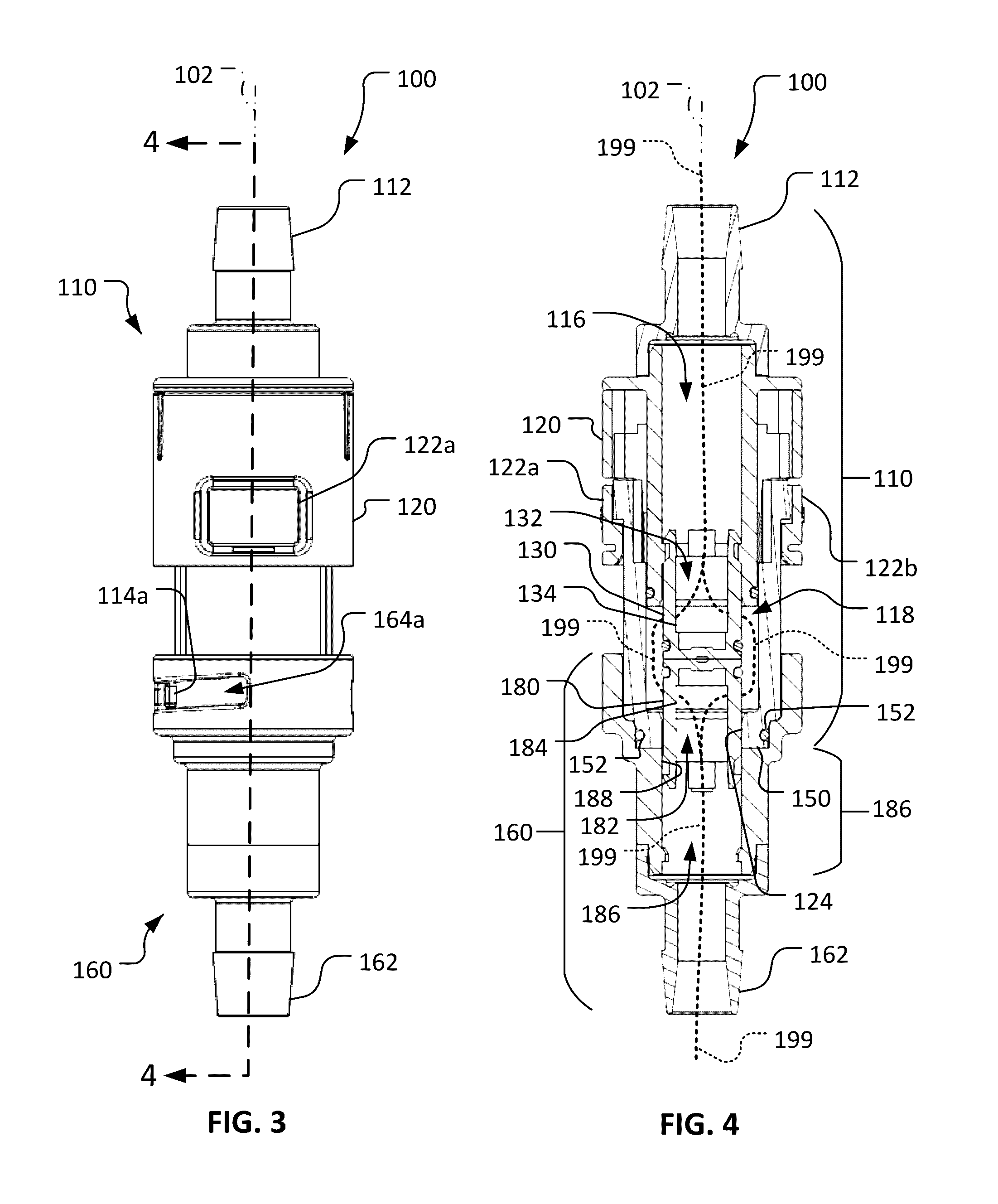

Single-use aseptic fluid couplings

ActiveUS20160305574A1Enhance characteristicMinimal instal stressValve arrangementsPipe couplingsSingle useBiomedical engineering

Some fluid coupling devices described herein are configured for use in fluid systems for purposes of providing a single-use, aseptic disconnection functionality that substantially prevents fluid spillage when being disconnected.

Owner:COLDER PRODS

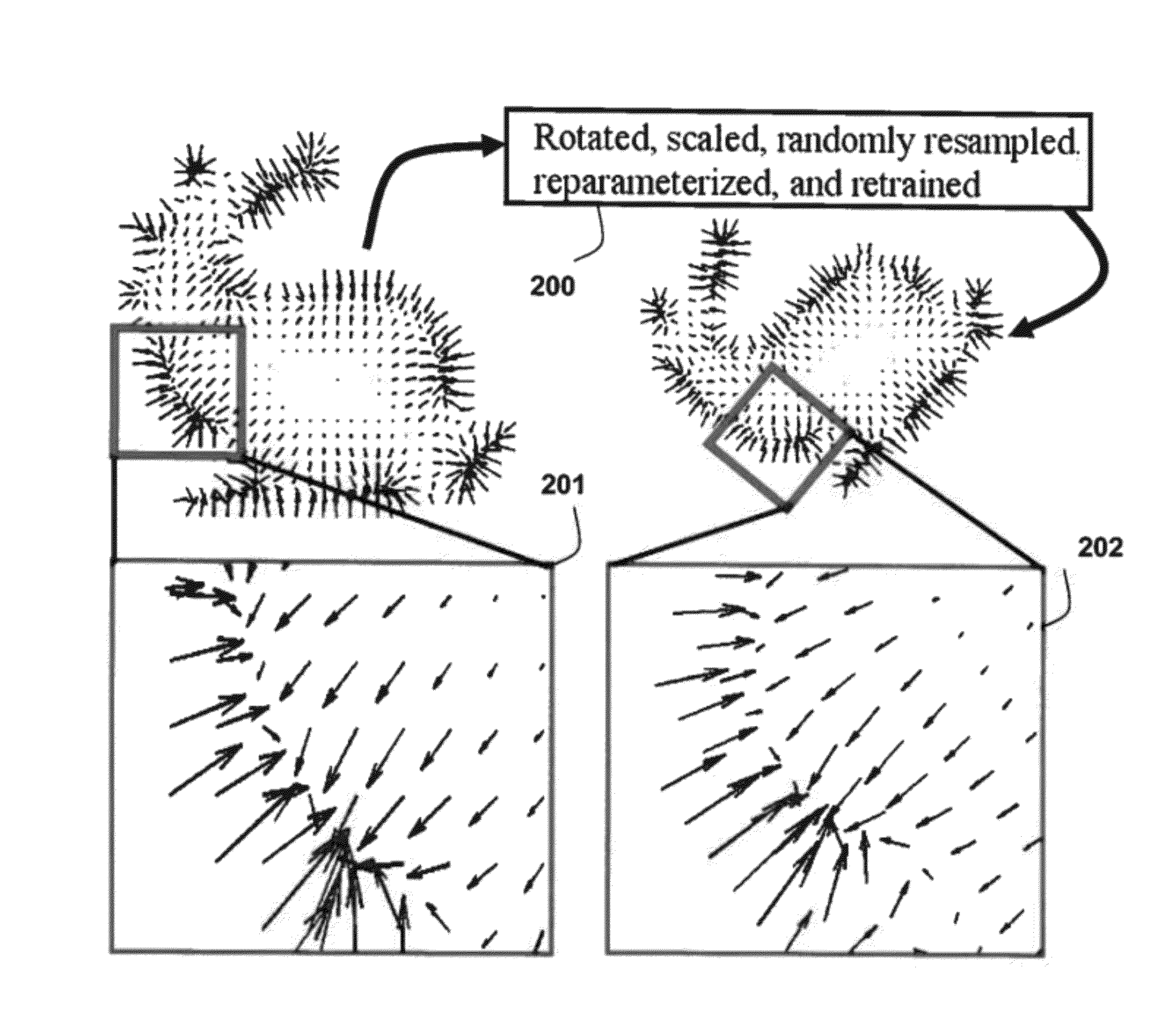

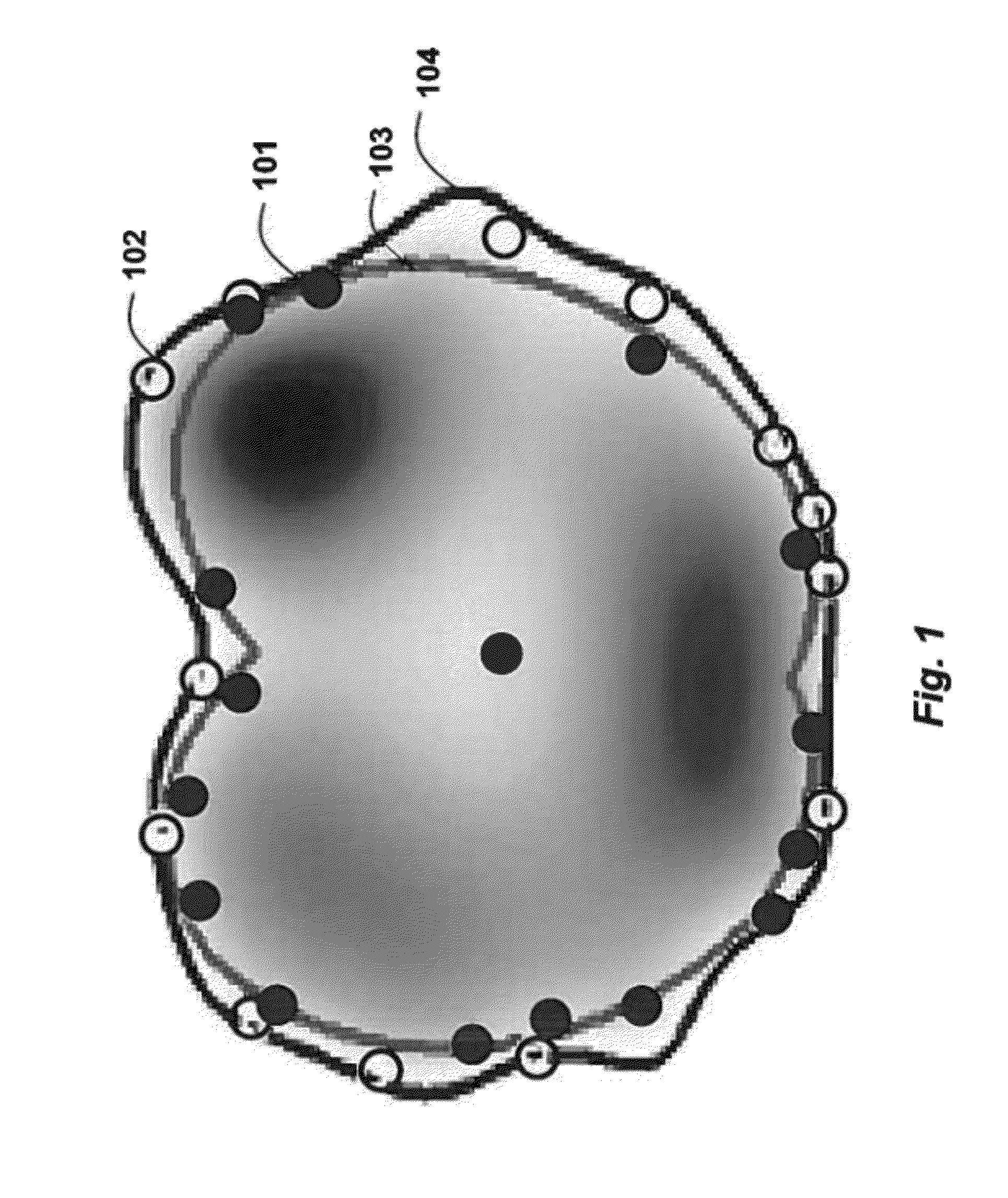

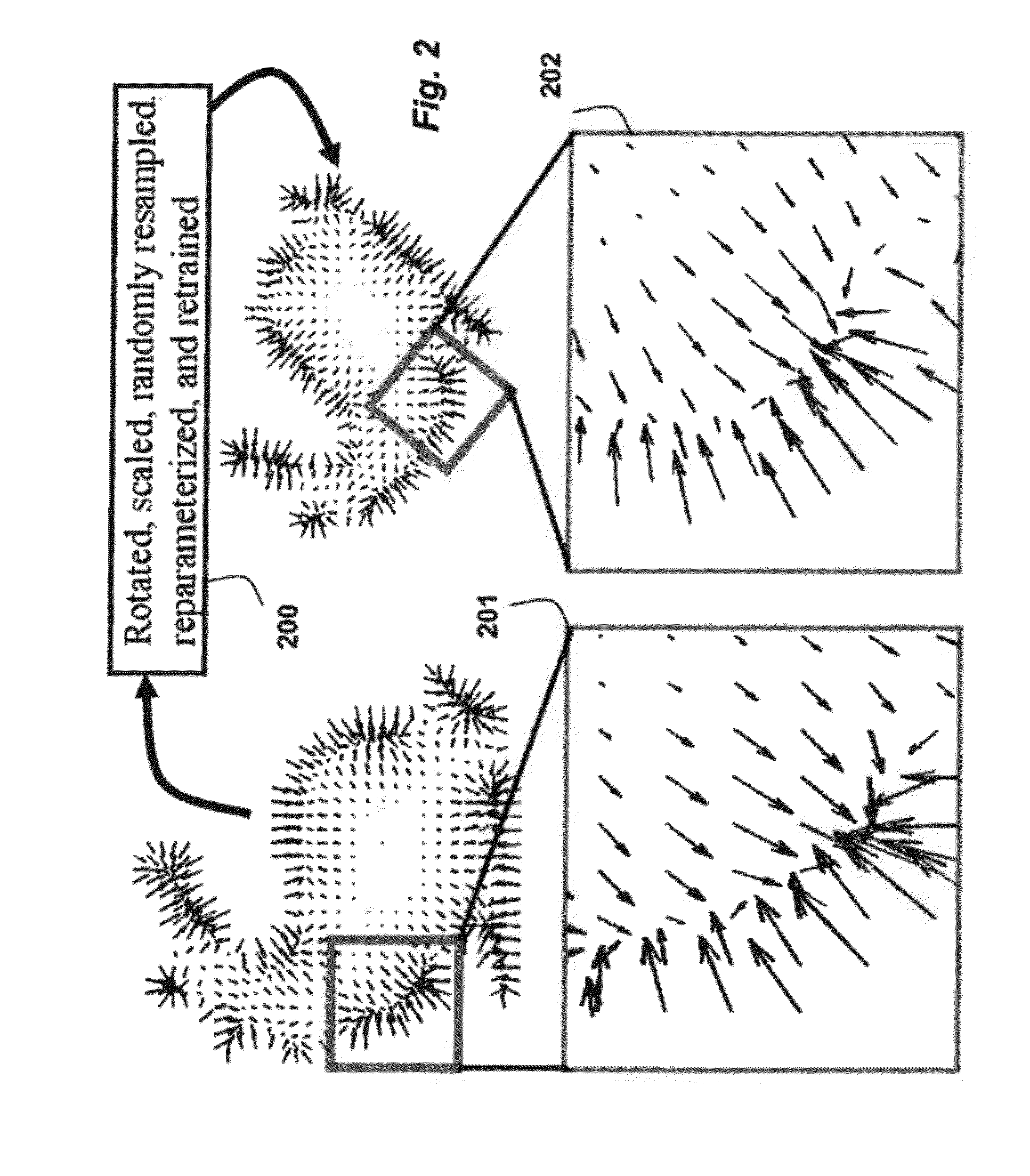

Representing Object Shapes Using Radial Basis Function Support Vector Machine Classification

InactiveUS20120207384A1Empowers the SVS representationData augmentationKernel methodsThree-dimensional object recognitionAlgorithmSupport vector machine classification

A shape of an object is represented by a set of points inside and outside the shape. A decision function is learned from the set of points an object. Feature points in the set of points are selected using the decision function, or a gradient of the decision function, and then a local descriptor is determined for each feature point.

Owner:MITSUBISHI ELECTRIC RES LAB INC

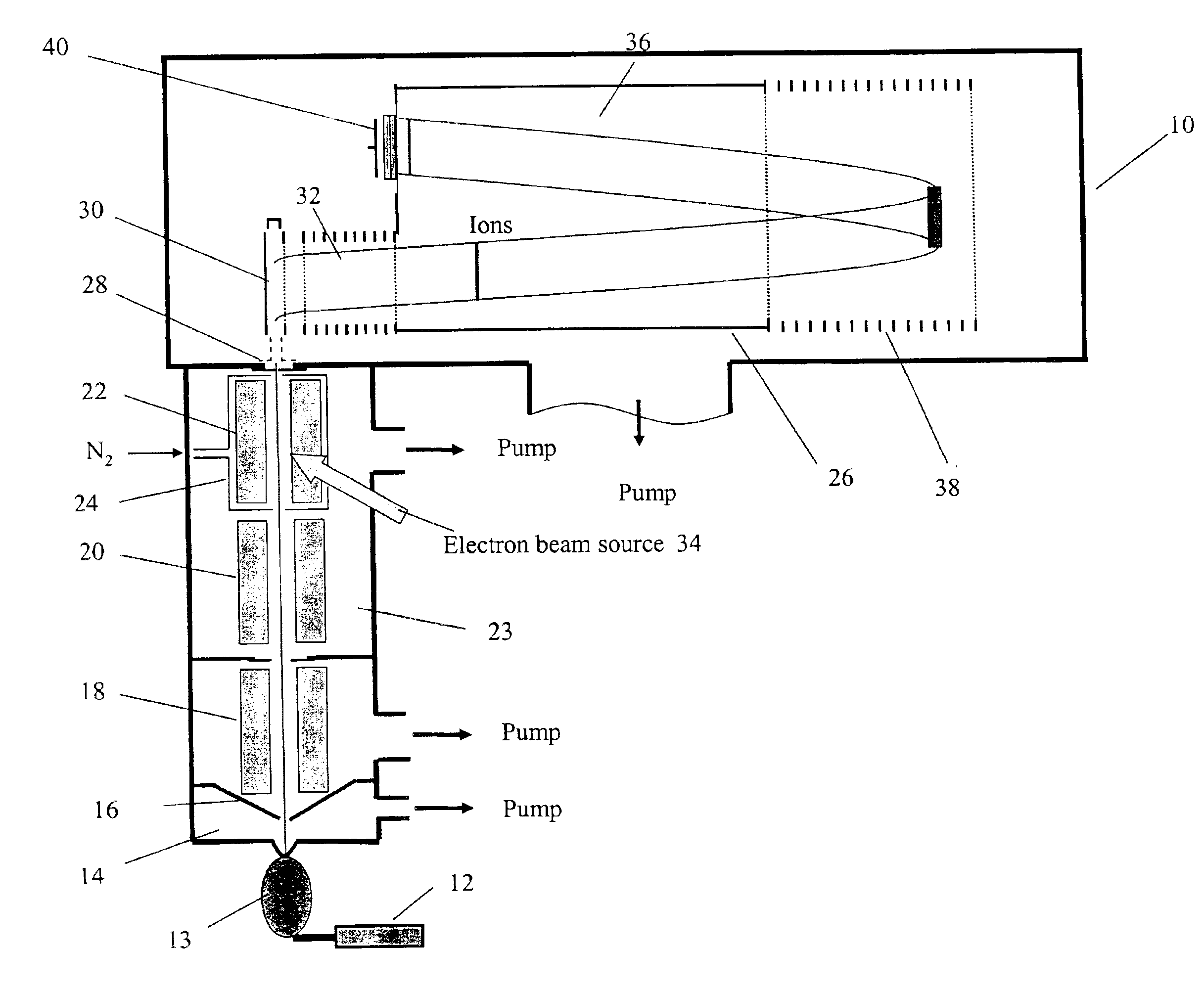

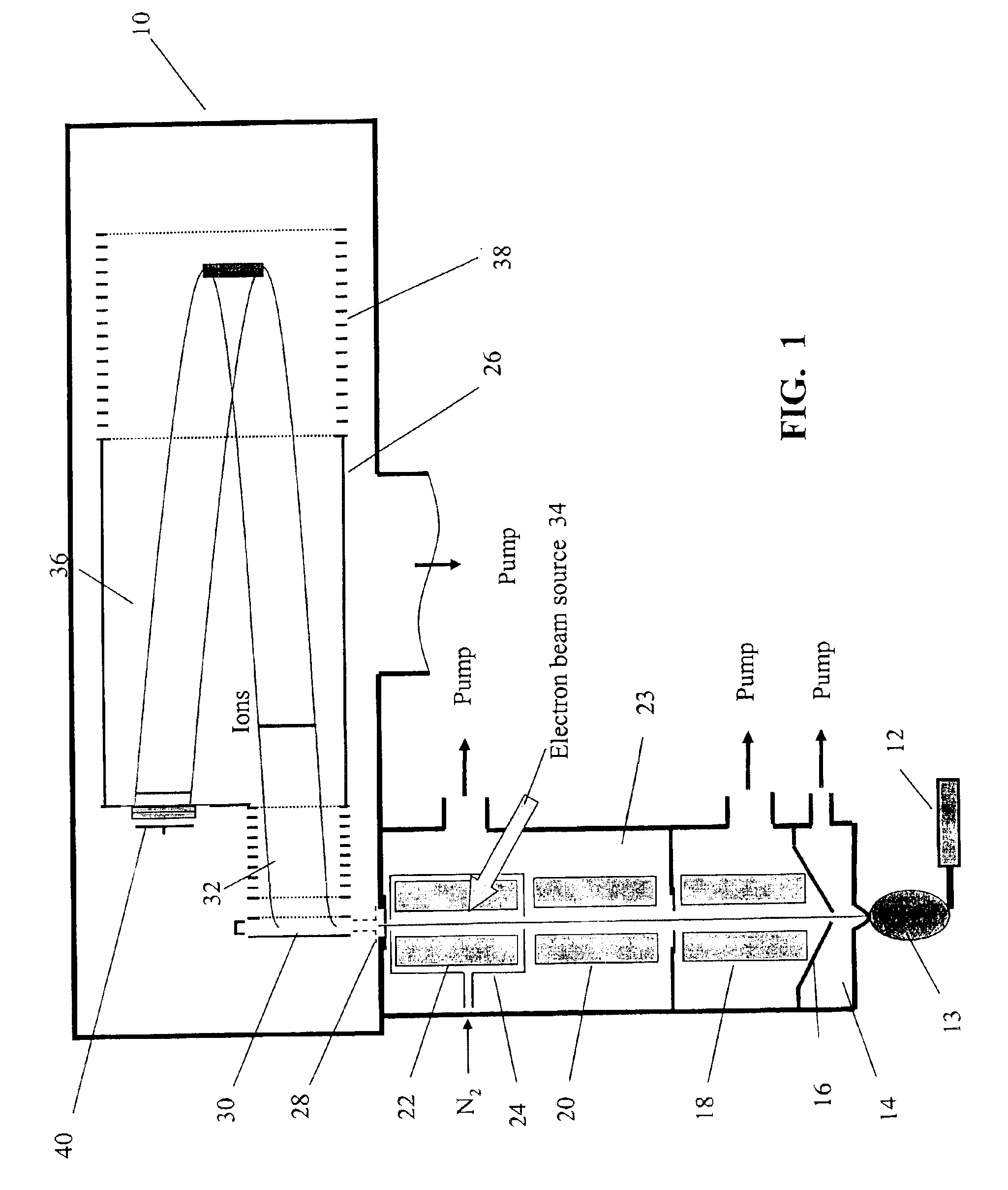

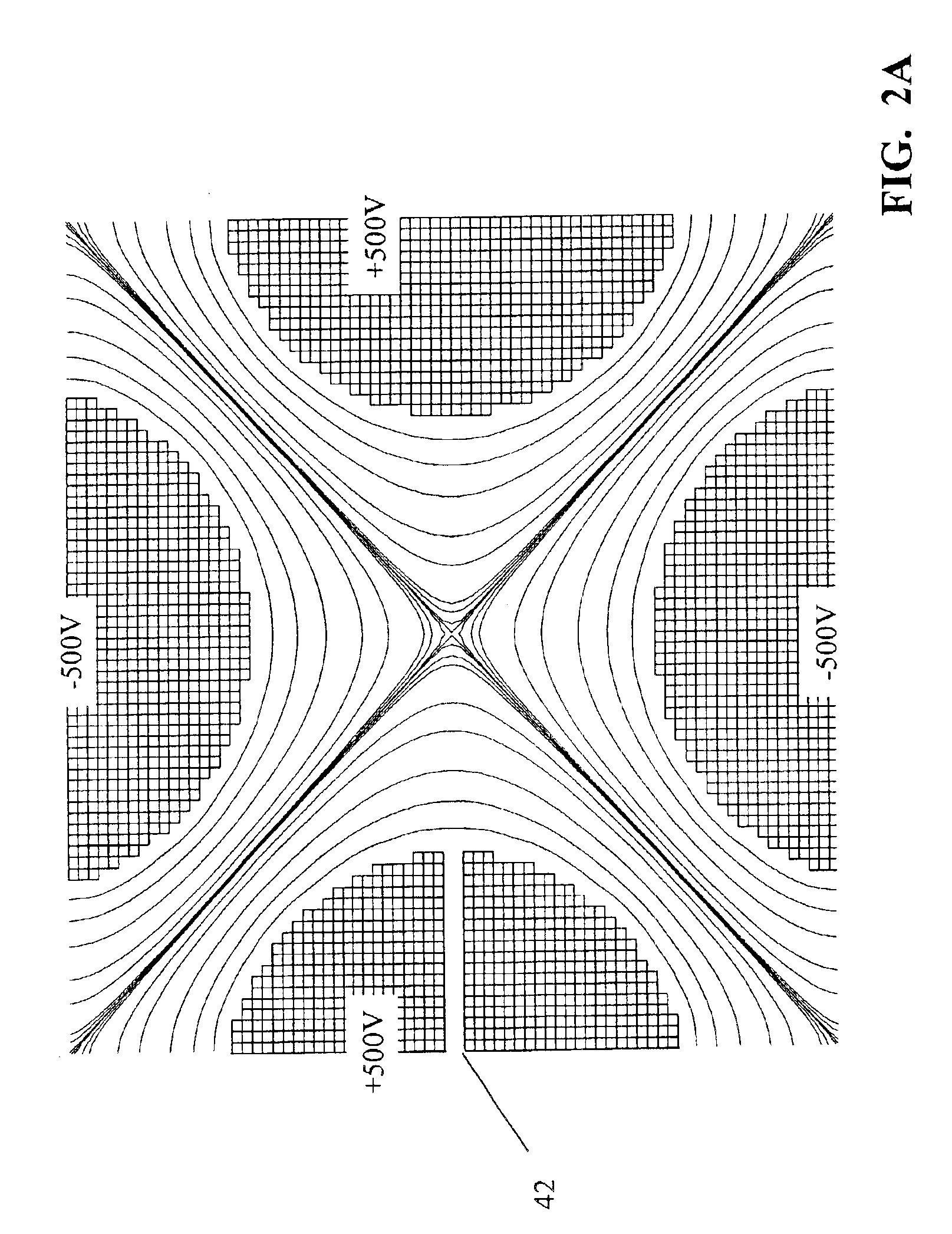

Method of ion fragmentation in a multipole ion guide of a tandem mass spectrometer

InactiveUS6858840B2Promote fragmentationImprovement in tandem mass spectrometry capabilityStability-of-path spectrometersTime-of-flight spectrometersElectron injectionIon beam

A system and method for mass analysis of an ion beam. The system includes a mass selector, at least one multipole ion guide, and a mass analyzer. In the system and method, precursor ions are selected with a desired mass to charge ratio. Electrons are injected into the multipole ion guide. The precursor ions are fragmented into product ions via electron capture dissociation from the injected electrons. The product ions are passed to a mass analyzer for a mass analysis.

Owner:SCI & ENG SERVICES

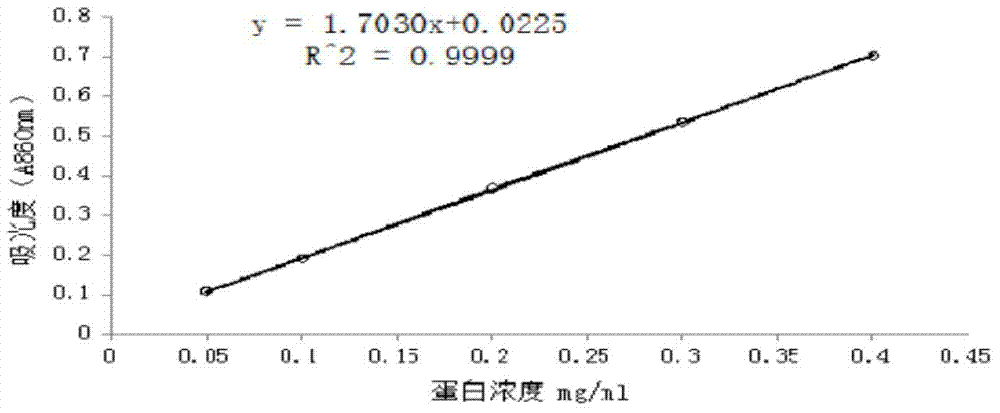

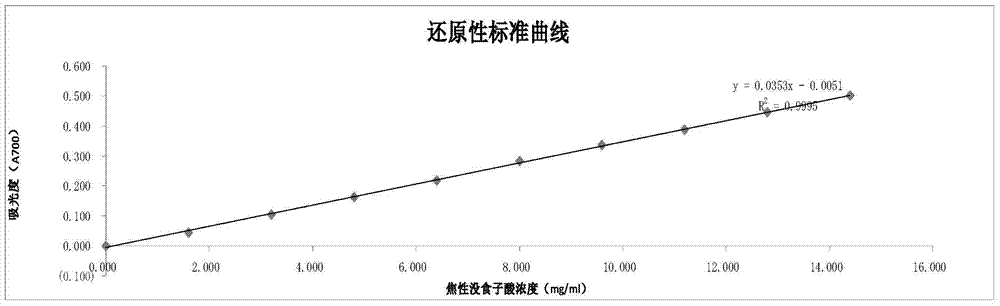

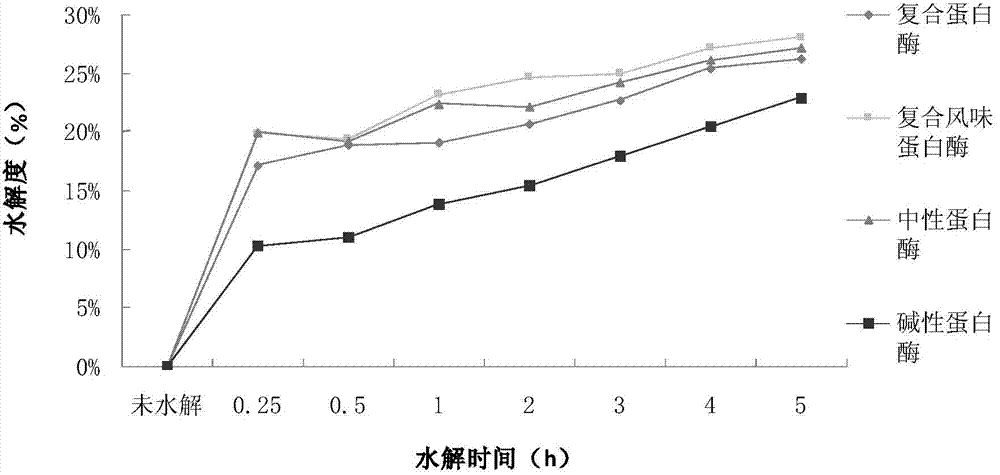

Preparation method for chlorella anti-oxidative peptide

ActiveCN104120160APromote fragmentationAvoid adverse effects such as nutrient lossMicroorganism based processesFermentationHydrolysateWater soluble

The invention discloses a preparation method for a chlorella anti-oxidative peptide. The preparation method is as follows: by taking chlorella as material, carrying out wall-breaking treatment on the chlorella to obtain soluble protein by utilizing a dilute alkali swelling-combined ultrasonic-wave process; and hydrolyzing the chlorella protein by a biological enzyme method to obtain the chlorella anti-oxidative peptide with remarkable anti-oxidative effect. The invention further discloses a treatment process combining ultralow temperature treatment, high pressure treatment with dilute alkali swelling and ultrasonic waves, which can improve yield of the water-soluble protein and can further improve anti-oxidative ability of hydrolysate. A product obtained by virtue of the preparation method disclosed by the invention is high in purity and strong in anti-oxidative activity.

Owner:安徽汉芳生物科技有限公司

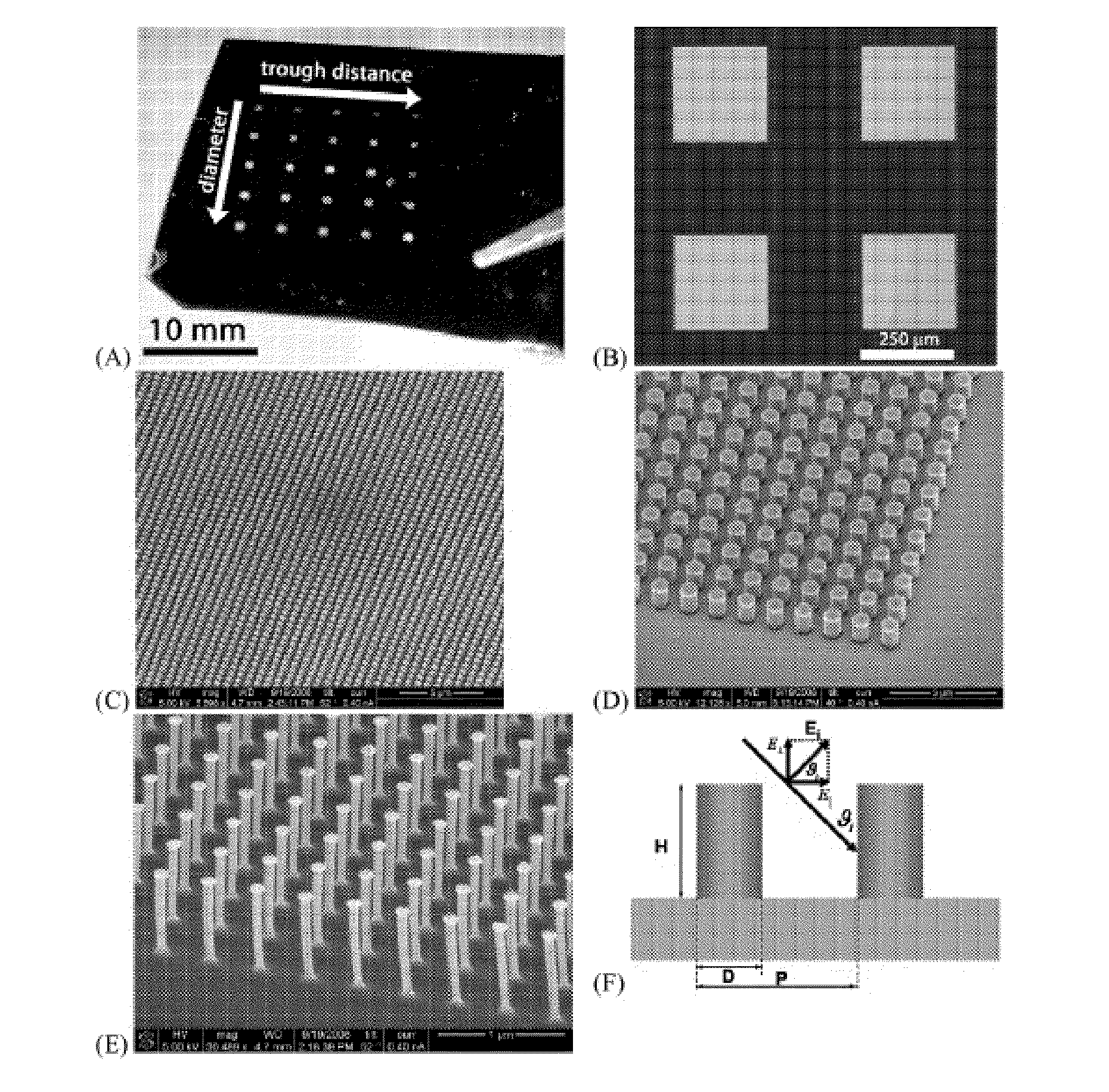

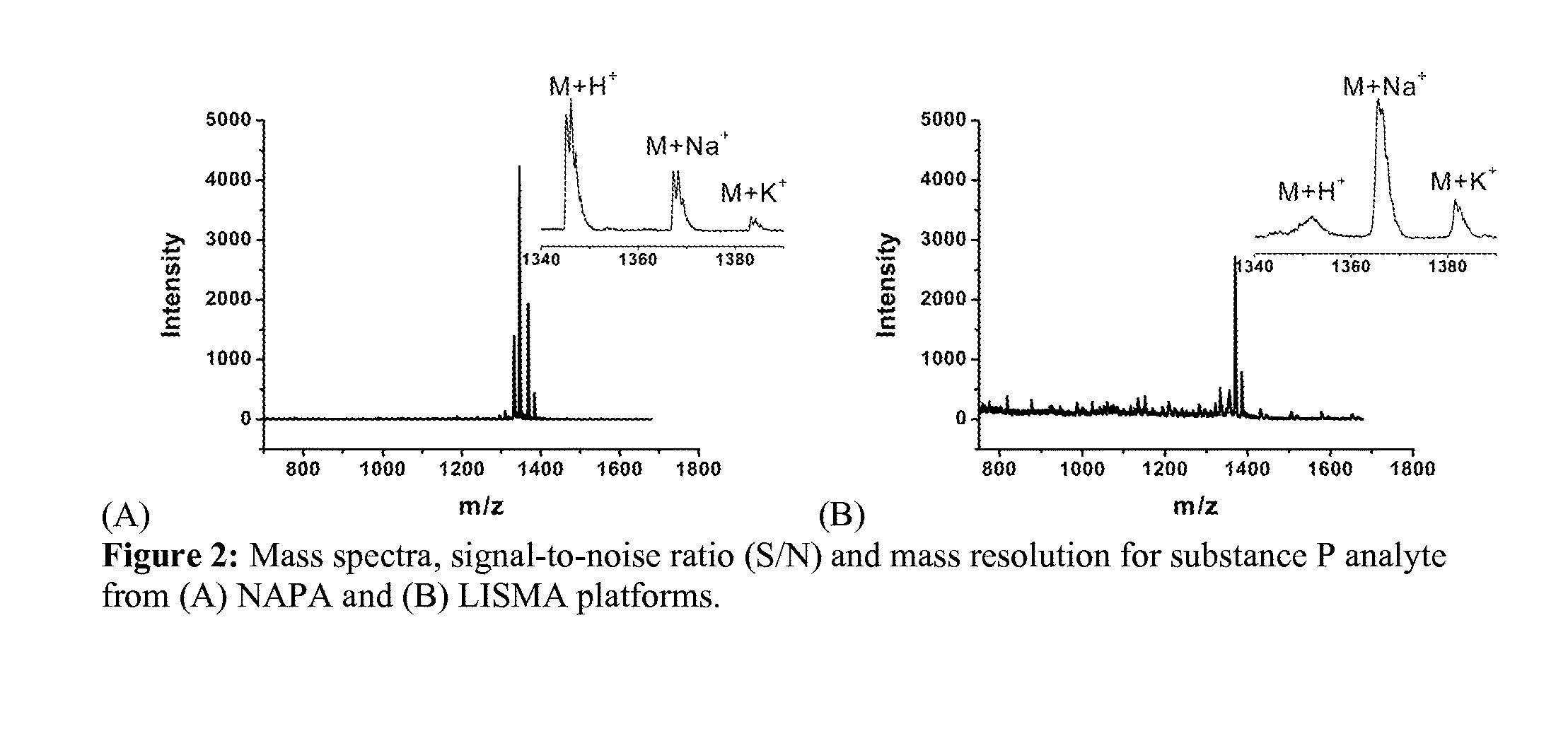

Tailored nanopost arrays (NAPA) for laser desorption ionization in mass spectrometry

ActiveUS20100323917A1Increased ion productionIncreased molecular fragmentationParticle separator tubesPV power plantsMass Spectrometry-Mass SpectrometryMass spectrometry imaging

The production and use of semiconducting nanopost arrays made by nanofabrication is described herein. These nanopost arrays (NAPA) provide improved laser ionization yields and controllable fragmentation with switching or modulation capabilities for mass spectrometric detection and identification of samples deposited on them.

Owner:UT BATTELLE LLC +1

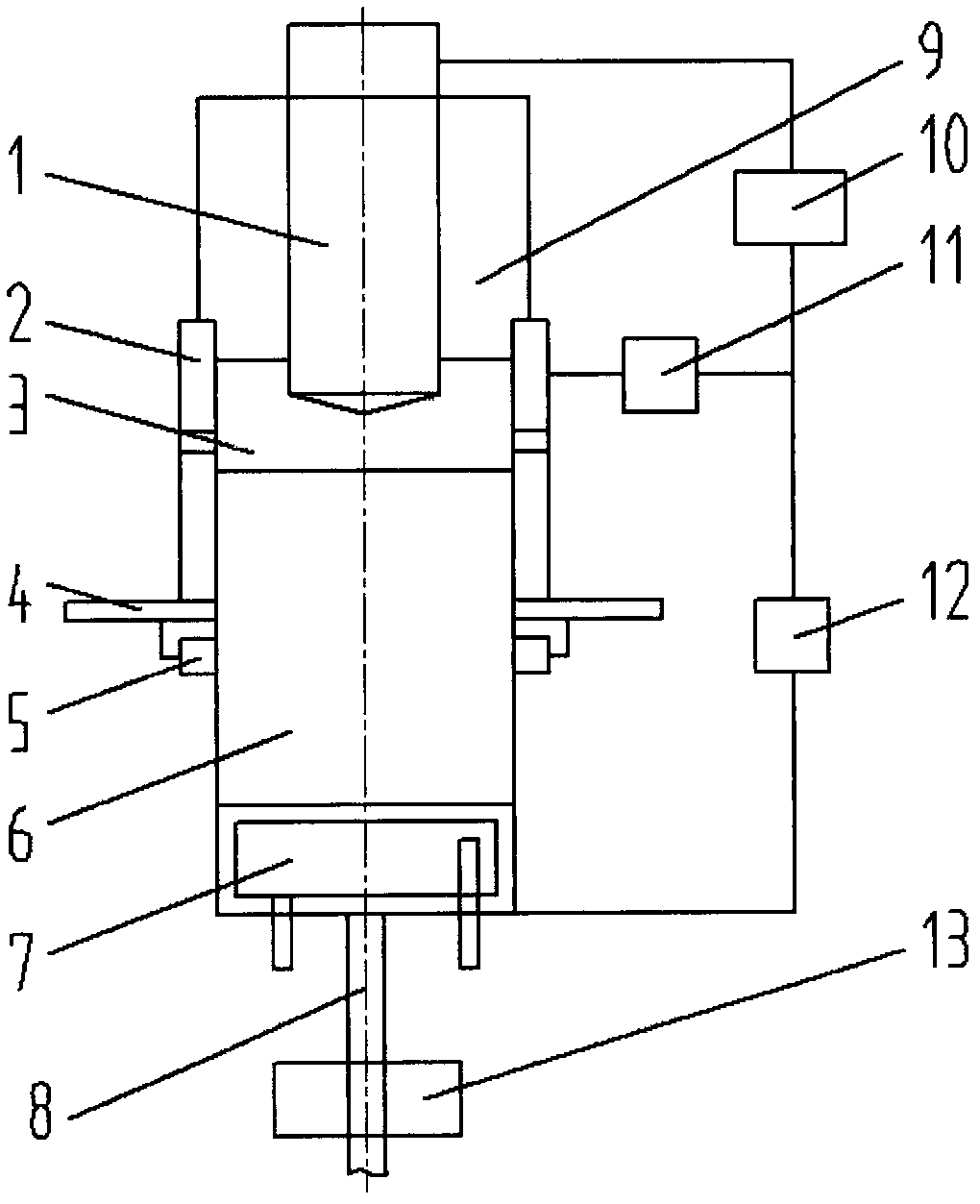

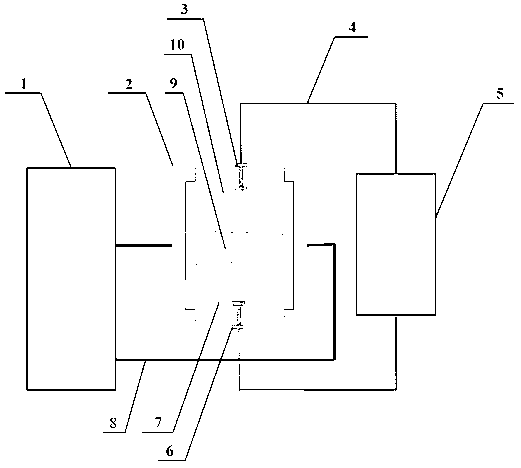

Vacuum/gas shield electroslag remelting continuous directional solidification device and method

ActiveCN102021348AEliminate aggregationEliminate coagulation and looseningElectricityHigh volume manufacturing

The invention relates to an electroslag remelting technique, in particular to a vacuum / gas shield electroslag remelting continuous directional solidification device and method. The device comprises a power supply, a consumable electrode (1), a water-cooling crystallizer (2) and a gas shield system, wherein the lower part of the water-cooling crystallizer (2) is provided with a water-cooling chassis (7) and a stripping device (13), and a two-circuit control mode is adopted by the consumable electrode (1) to make the stripping speed equivalent with the solidification speed of a cast ingot. The invention has simple operation and low cost, is convenient to control, can be used for producing large-dimension low-segregation directional solidification cast ingots and is suitable for mass production and application.

Owner:BEIJING CISRI GAONA TECH

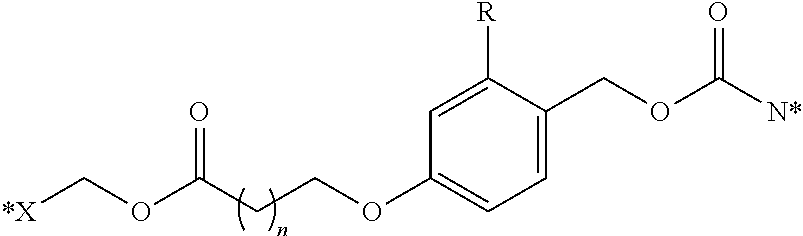

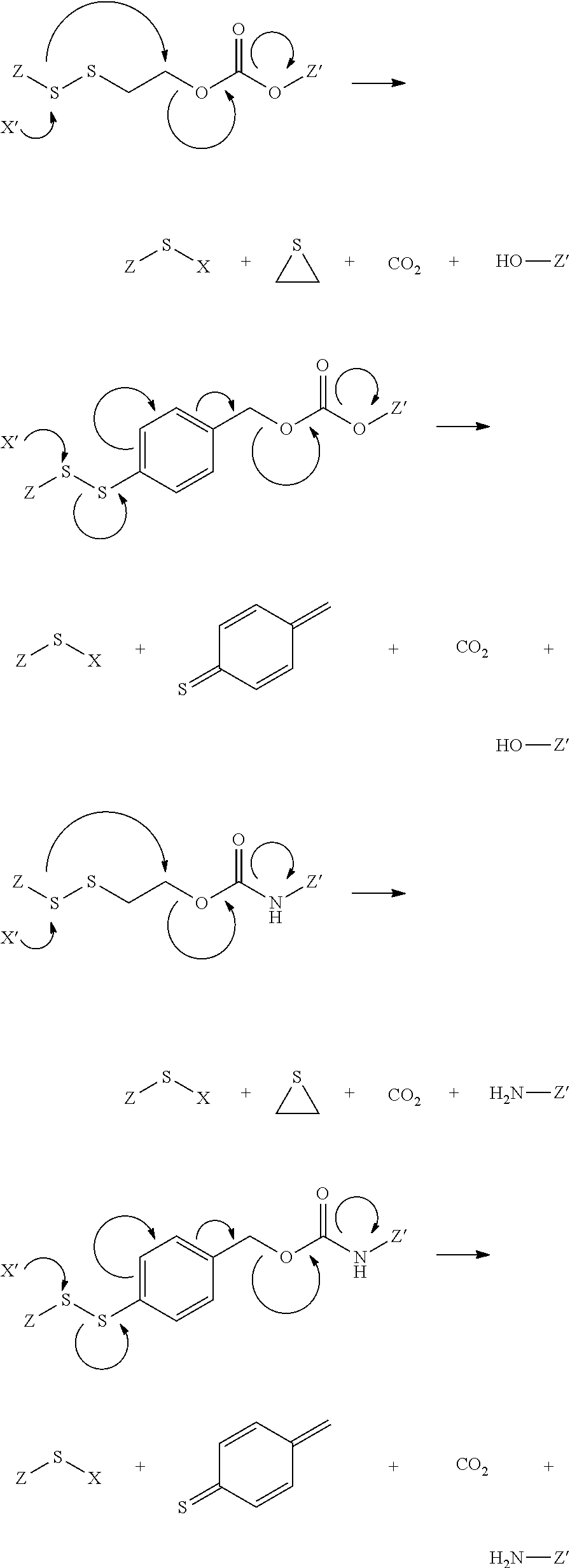

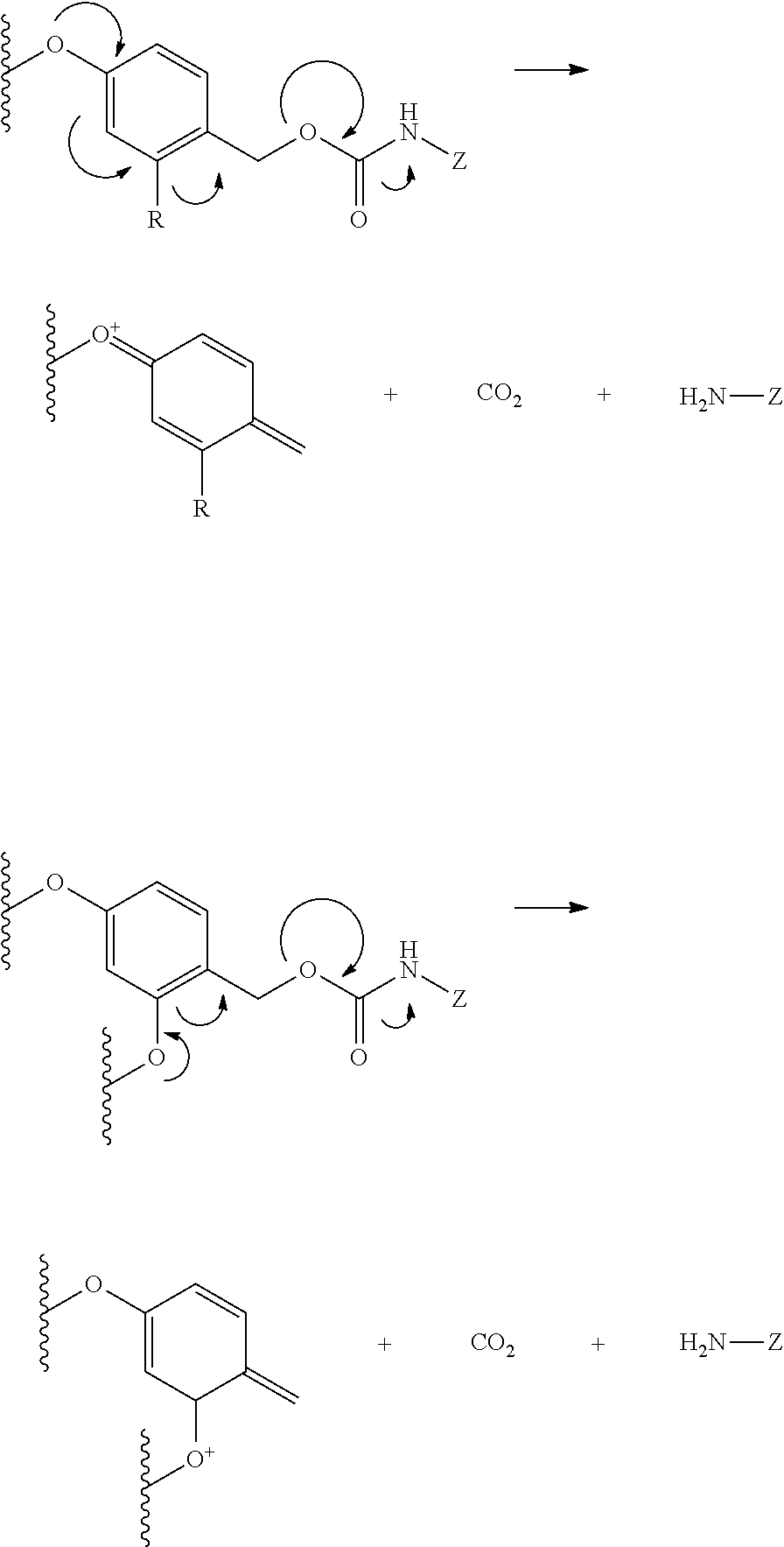

PSMA binding ligand-linker conjugates and methods for using

ActiveUS9951324B2Promoting extended conformationIncrease binding energyOrganic active ingredientsPeptide/protein ingredientsAntigenProstate specific membrane

Described herein are prostate specific membrane antigen (PSMA) binding conjugates that are useful for delivering therapeutic, diagnostic and imaging agents. Also described herein are pharmaceutical compositions containing them and methods of using the conjugates and compositions. Also described are processes for manufacture of the conjugates and the compositions containing them.

Owner:PURDUE RES FOUND INC

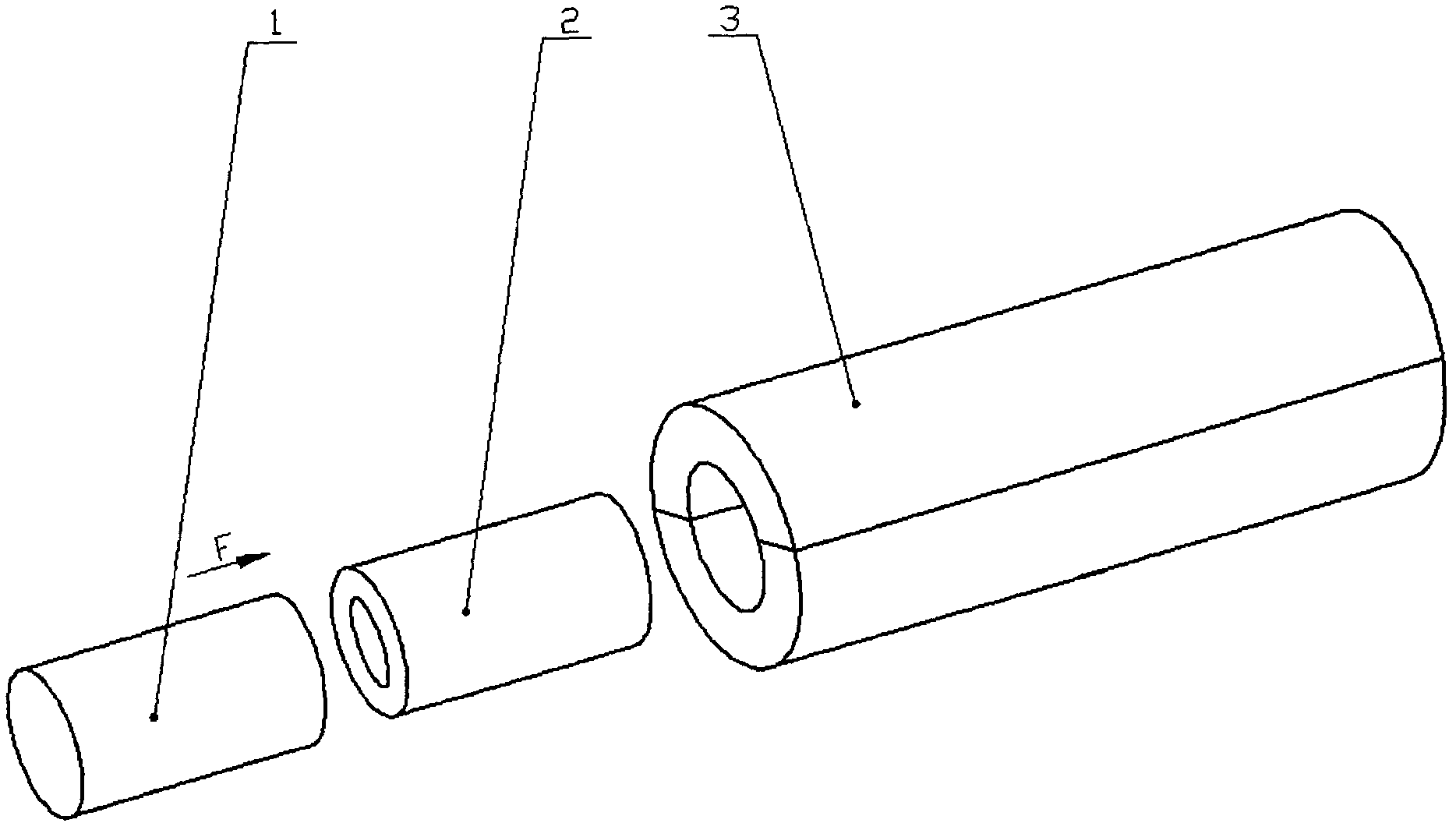

Twist extrusion forming die and twist extrusion forming method

The invention discloses a twist extrusion forming die and a twist extrusion forming method. The forming die comprises a first half die and a second half die, wherein the first half die and the second half die are tightly buckled through a bolt to form a cylinder, an extrusion die cavity is formed inside the cylinder, and a die joint of the first half die is fit and level with a die joint of the second half die; the extrusion die cavity is sequentially formed by a guide section, a large circular-regular octagonal transitional section, a regular octagonal twist section, an octagonal-small circular twist transitional section and an outlet section from an extrusion inlet to the lower side. The twist extrusion forming die has the advantages of good transformation effect, high speed and high efficiency, the weaknesses of the prior art such as non-uniformity in transformation and existence of transformation dead corner can be overcome, the stress distribution inside a material can be greatly improved, and the comprehensive performance of the material also can be improved.

Owner:TAIYUAN UNIV OF TECH

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

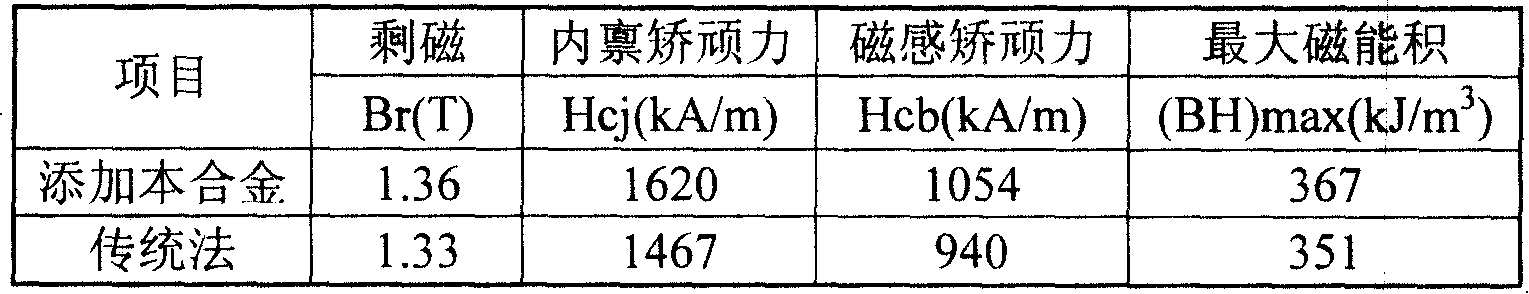

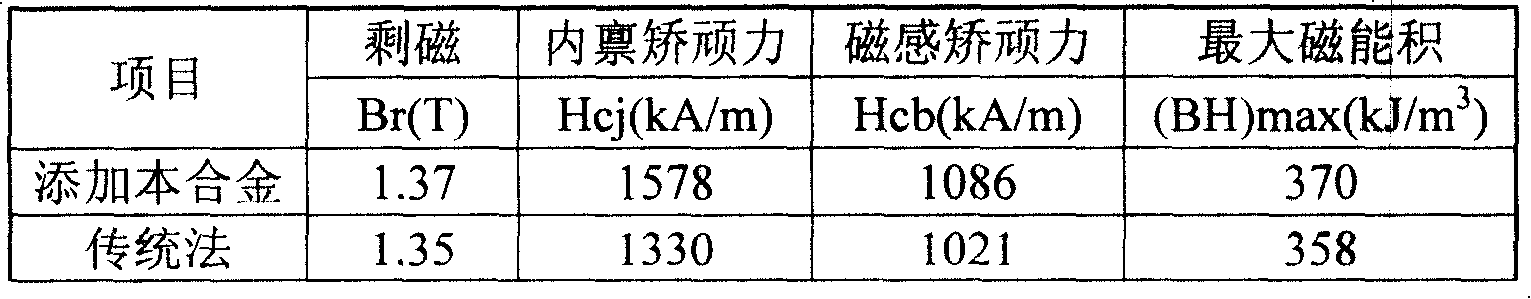

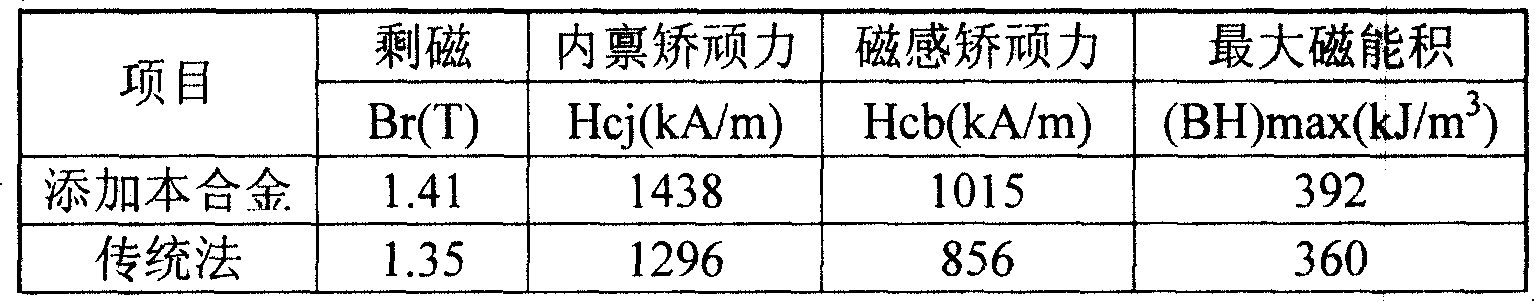

Rare earth alloy

InactiveCN101240392AImprove performancePrecise control of ingredientsMagnetic materialsRare earthAlloy

Owner:GRIREM ADVANCED MATERIALS CO LTD

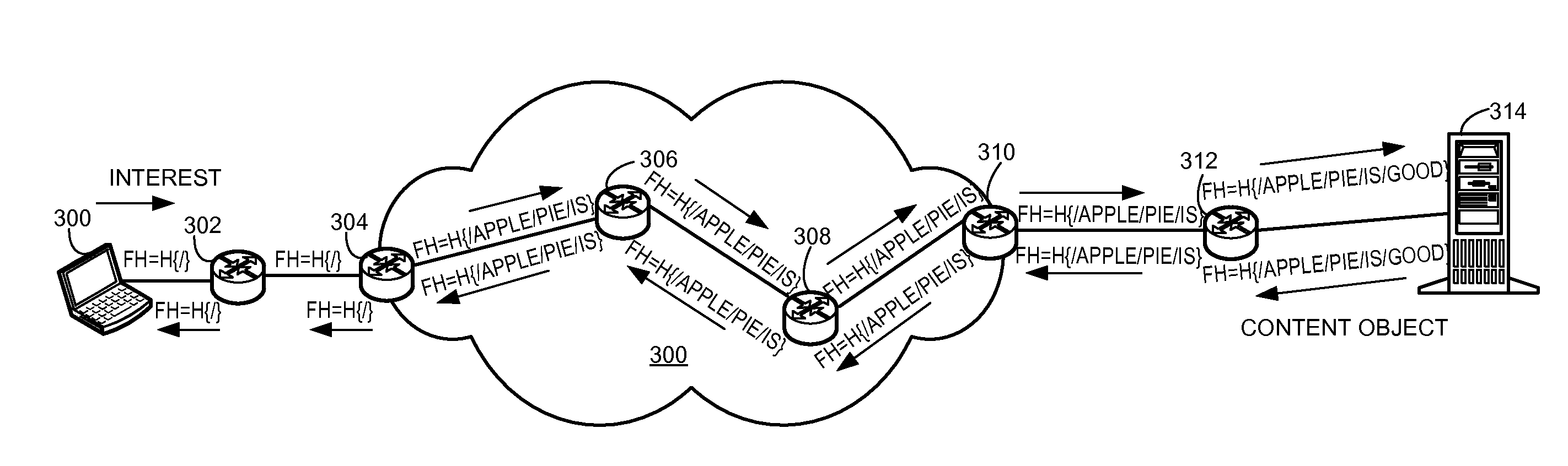

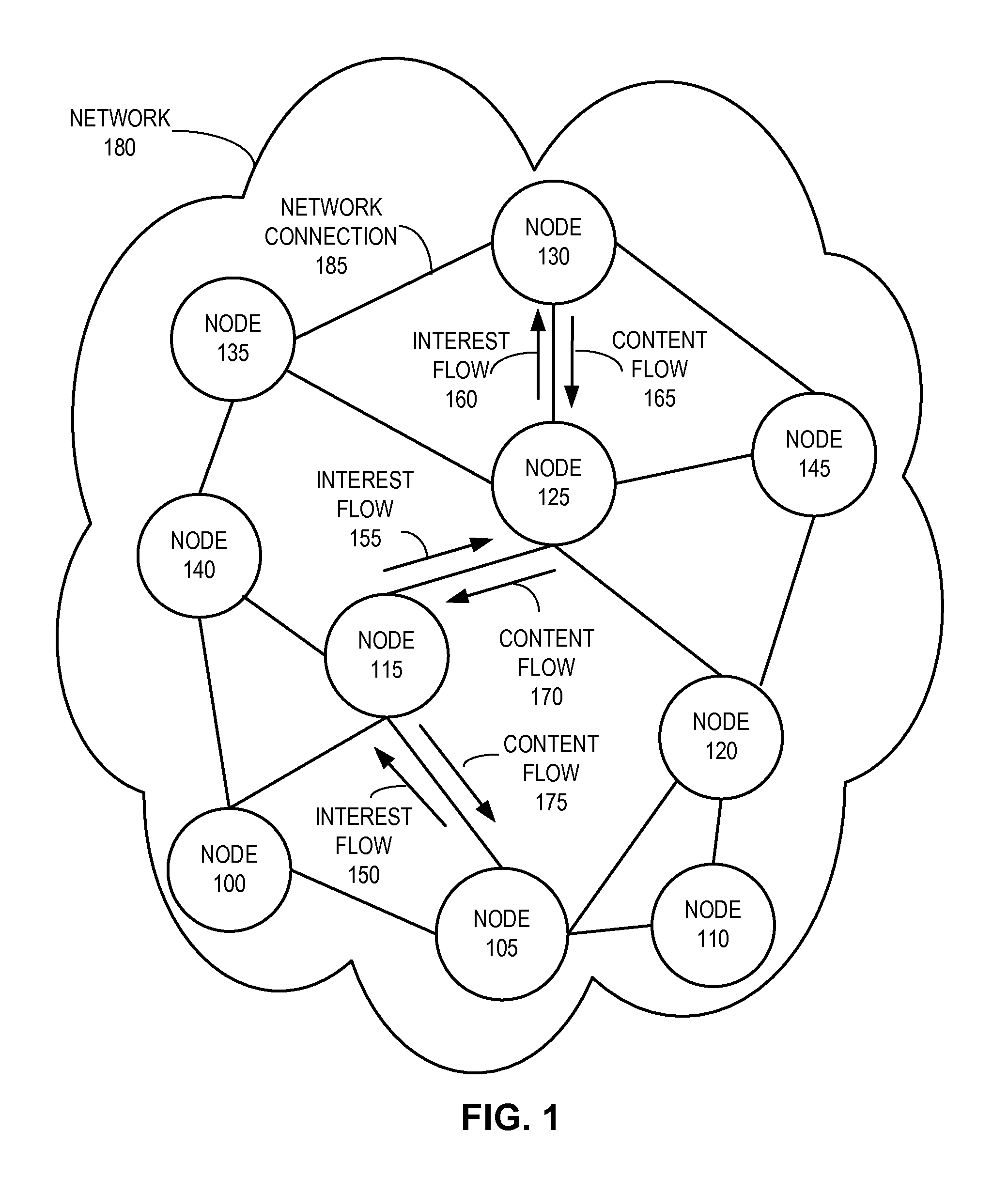

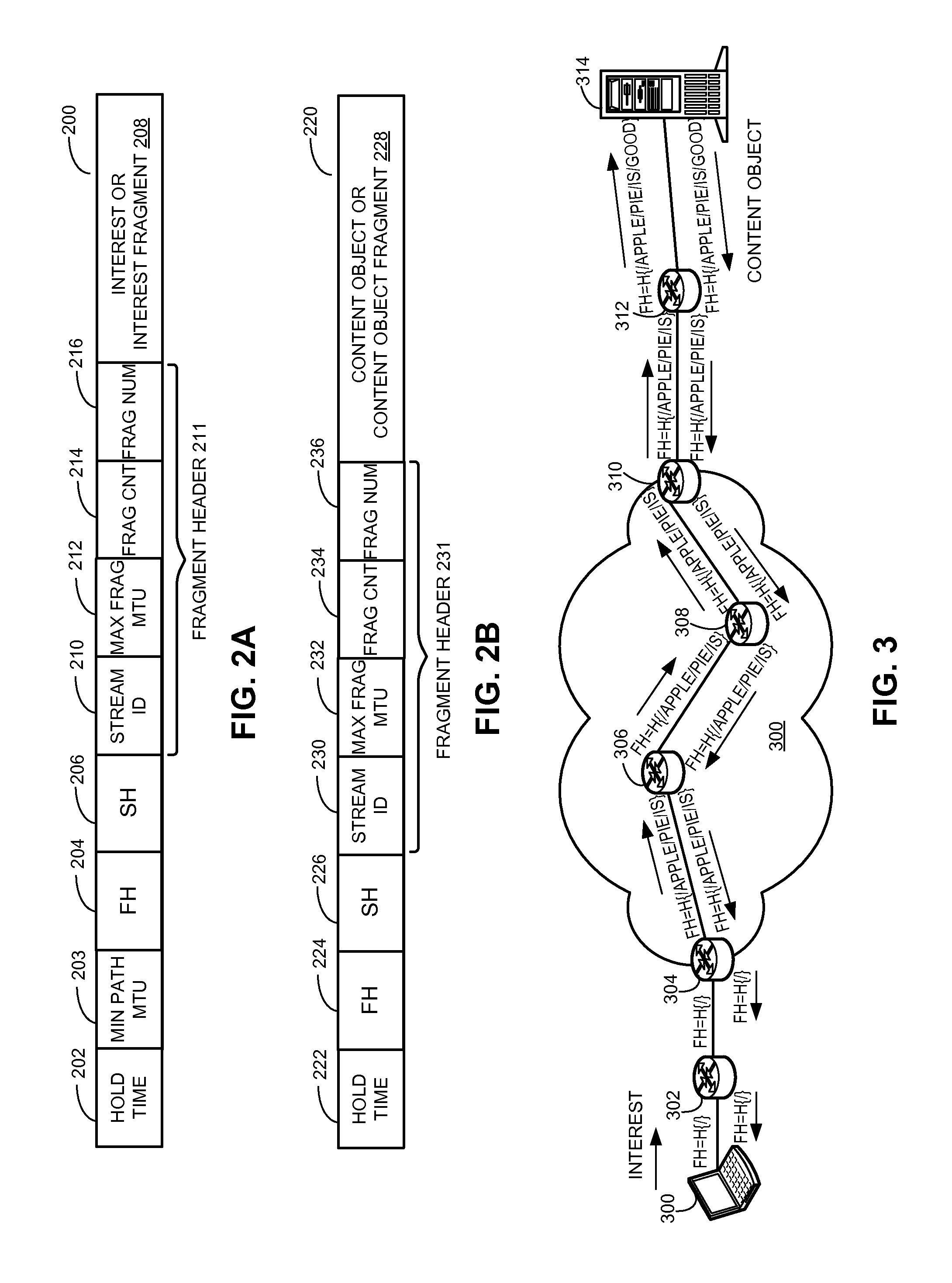

System and method for minimum path mtu discovery in content centric networks

ActiveUS20150117452A1Promote fragmentationData switching by path configurationContent centricVariable length

One embodiment of the present invention provides a system for facilitating fragmentation of packets with hierarchically structured variable-length identifiers (HSVLIs). During operation, the system receives an interest packet with an HSVLI corresponding to a piece of content. The system then identifies a minimum path maximum transmission unit (MTU) value carried in the packet. In response to the piece of content not being stored locally, the system then determines an egress port for the packet based on the HSVLI. The system further determines an MTU associated with the egress port. Subsequently, in response to the MTU associated with the egress port being less than the minimum path MTU value carried in the packet, the system updates the minimum path MTU value in the packet to the MTU value associated with the egress port.

Owner:CISCO TECH INC

Biomass fuel crushing device

InactiveCN106732996AIncrease squeezePromote fragmentationGrain treatmentsPulp and paper industryCrusher

The invention discloses a biomass fuel crushing device which comprises a machine body; a feeding mechanism is arranged at the top end of the machine body; a discharge door is arranged at the lower end of the right side of the machine body; a supporting leg is arranged at each of the left side and the right side of the bottom end of the machine body; the bottom end of the machine body is equipped with a tapered discharge bin; a double-roller crusher is arranged at the upper end inside the machine body; a combined type crusher is arranged at the lower end inside the machine body; the upper ends of the left side and the right side inside the machine body are each provided with a plurality of irregular baffle plates; and the bottom end inside the machine body is equipped with a stainless steel filter screen. The biomass fuel crushing device disclosed by the invention solves the problems that biomass fuel crushing equipment in the prior art is low in crushing efficiency and is low in crushing speed. The biomass fuel crushing device adopts a multi-stage type crushing design, performs cutting, extruding and crushing and pulverizing treatment on biomass fuels, is high in crushing speed, is good in crushing effect, and is very convenient to charge and discharge.

Owner:南京恒誉名翔科技有限公司

Shear stress ultrasonic horn for ultrasonic surgical aspiration

An ultrasonic horn for use with an ultrasonic surgical hand piece including a resonator comprises a contacting annulus having a plurality of angled lands. The lands are alternated around the annulus such that adjacent lands have opposite angles. As a result of the adjacent angled lands, a shear stress field is developed in contacted tissue due to the promotion of refracted longitudinal ultrasonic waves propagating in different directions at the interface to the coupled tissue. The shear stress field enhances the fragmentation and removal rate of fibrous, elastic, and tenacious tissue. The horn is hollow permitting suction to be applied to the tissue for controlling tissue contact with the lands.

Owner:INTEGRA LIFESCI IRELAND

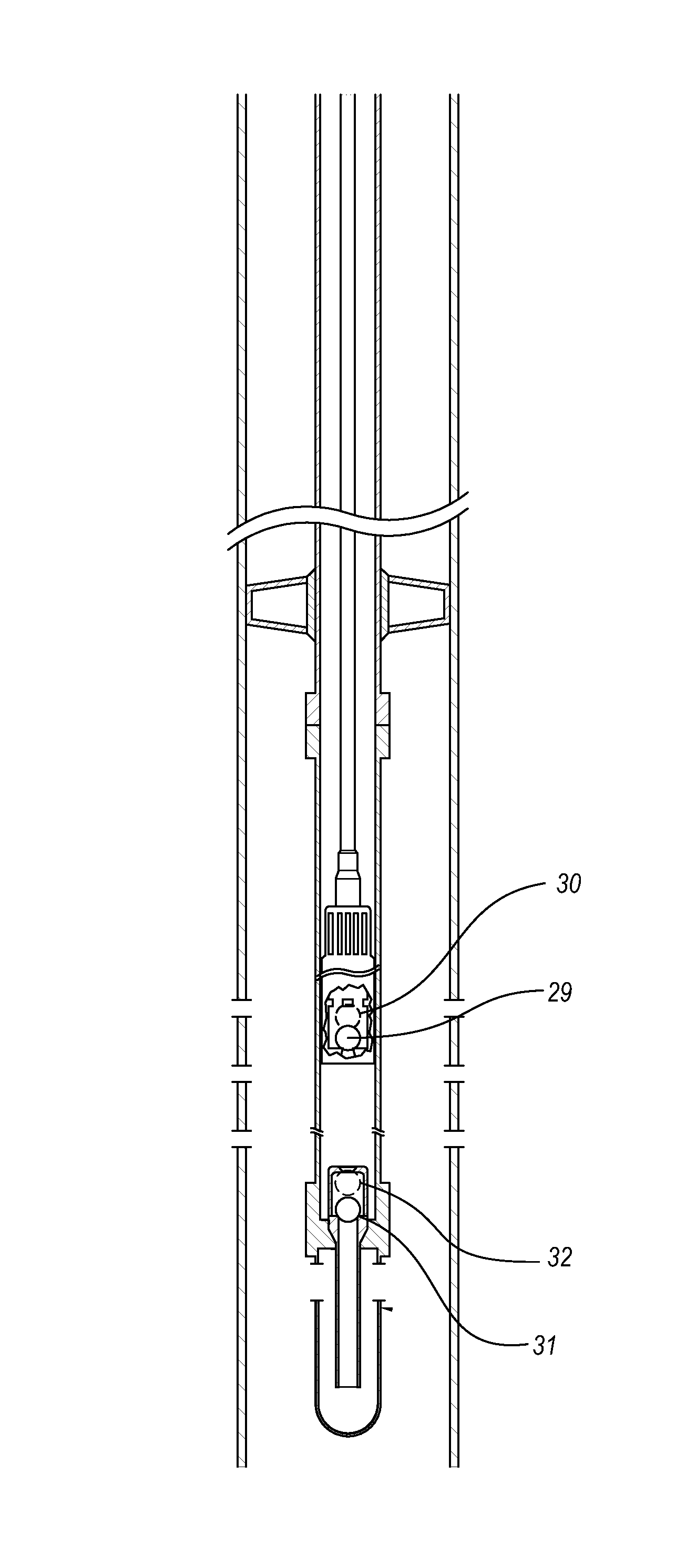

Method and apparatus for autonomous oil and gas well down-hole pump leakage testing

A method for autonomous testing of traveling valve assembly leakage and standing valve leakage for an oil or gas rod pumped well installation, and for autonomous adjustment of one or more pump operation characteristics based upon the autonomous test results. Traveling valve assembly leakage testing includes autonomous stopping and holding of the polished rod during an upstroke, autonomous determination of a rate of change in the polished rod load, and autonomous determination of a traveling valve leakage factor. Standing valve leakage testing includes autonomous stopping and holding of the polished rod stationary during a down stroke after weight transfer, autonomous determination of a rate of change in the polished rod load, and autonomous determination of a standing valve leakage factor.

Owner:RODMAX OIL & GAS

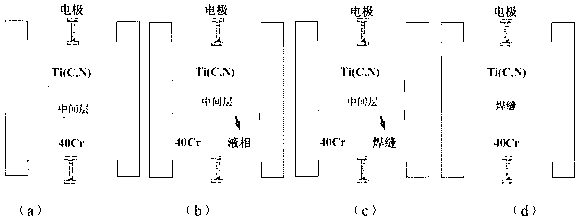

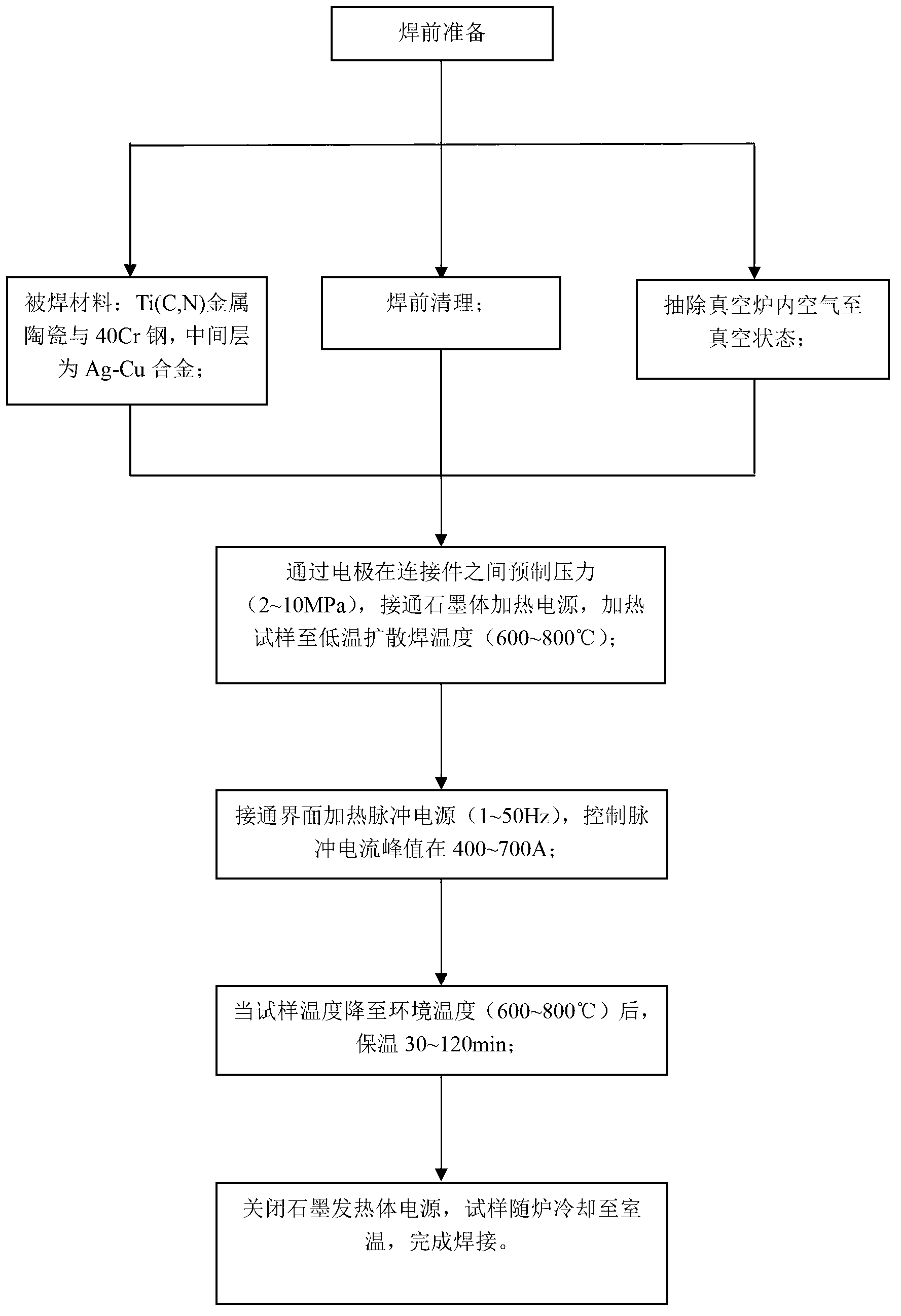

Low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating

ActiveCN102699520APromote fragmentationLow machining accuracy requirementsNon-electric welding apparatusRadiant heatPulse power supply

The invention discloses a low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating. The device comprises a graphite body heating power supply, a graphite body, electrodes, an interface heating pulse power supply and a sample. According to the method, graphite body radiant heat is mainly used, welding interface contact resistance heat and discharge heat are used as accessory, an original liquid phase is formed by the resistance heat and discharge heat which are formed at an interface to be connected by the pulse current, and diffusion welding is realized by virtue of less externally-applied extrusion force. The device and the method can be used for reducing the residual stress, obviously shortening the welding time, requiring smaller applied pressure and preventing workpieces from being subjected to serious deformation in a pressurization direction, are conductive to crushing oxidation films on the surfaces of materials and simultaneously can be used for reducing the material surface processing precision requirement; and the device disclosed by the invention is simple in process, smart in design and convenient in use, and can be widely applied to the diffusion welding of various nonmetals and metals.

Owner:JIANGSU UNIV OF SCI & TECH

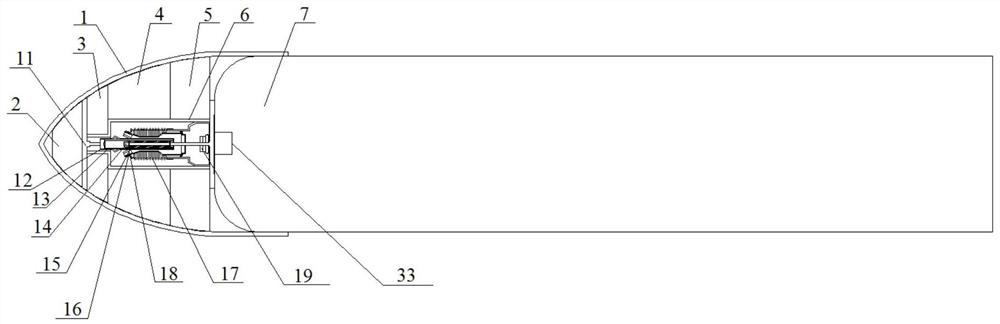

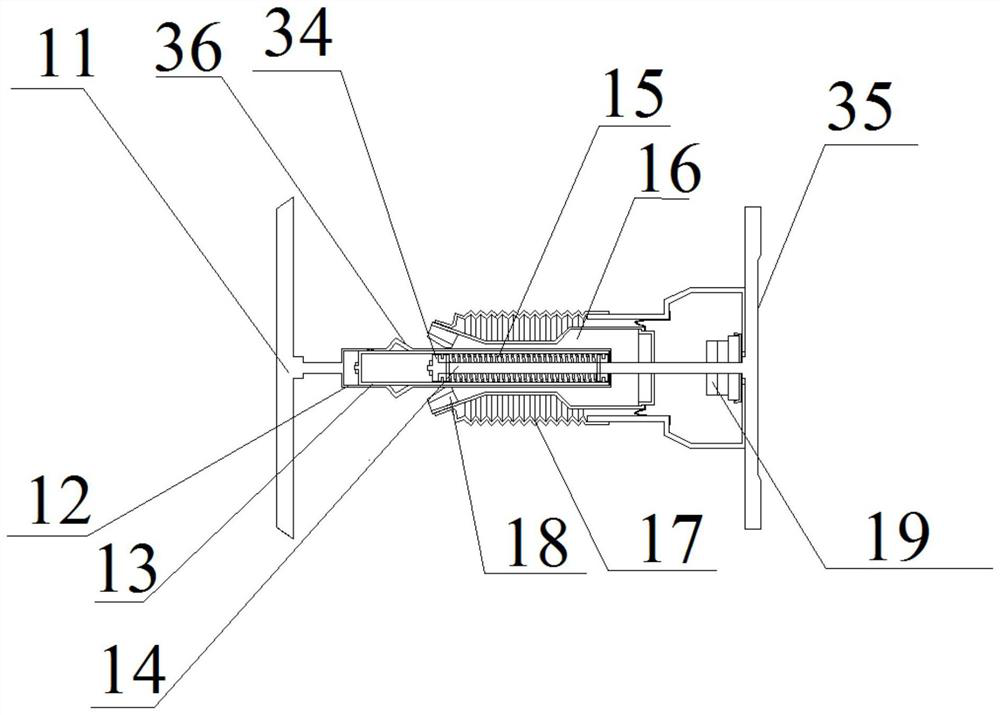

Composite load reduction device for high-speed water entry of aircraft body

ActiveCN112413038APowerful load reduction performanceEasy accessMarine torpedoesSlipwaysStructural engineeringWater entry

The invention provides a composite load reduction device for high-speed water entry of an aircraft body. The composite load reduction device comprises a fairing detachably connected to the head of a main projectile body, a cavitator and a damping device, wherein the cavitator and the damping device are arranged in the fairing; the damping device is arranged in the fairing and located between the cavitator and the main projectile body; and the damping device comprises a sealing pressure cylinder, a piston, a mounting seat, a piston rod, a tension spring, an air cavity and buffer air. The composite load reduction device is a buffer vibration reduction device which utilizes the pneumatic damping device and buffer foam for load reduction at the same time. Meanwhile, the pneumatic damping device and the buffer foam are utilized for buffering, and the composite load reduction device has higher load reduction performance.

Owner:DALIAN UNIV OF TECH

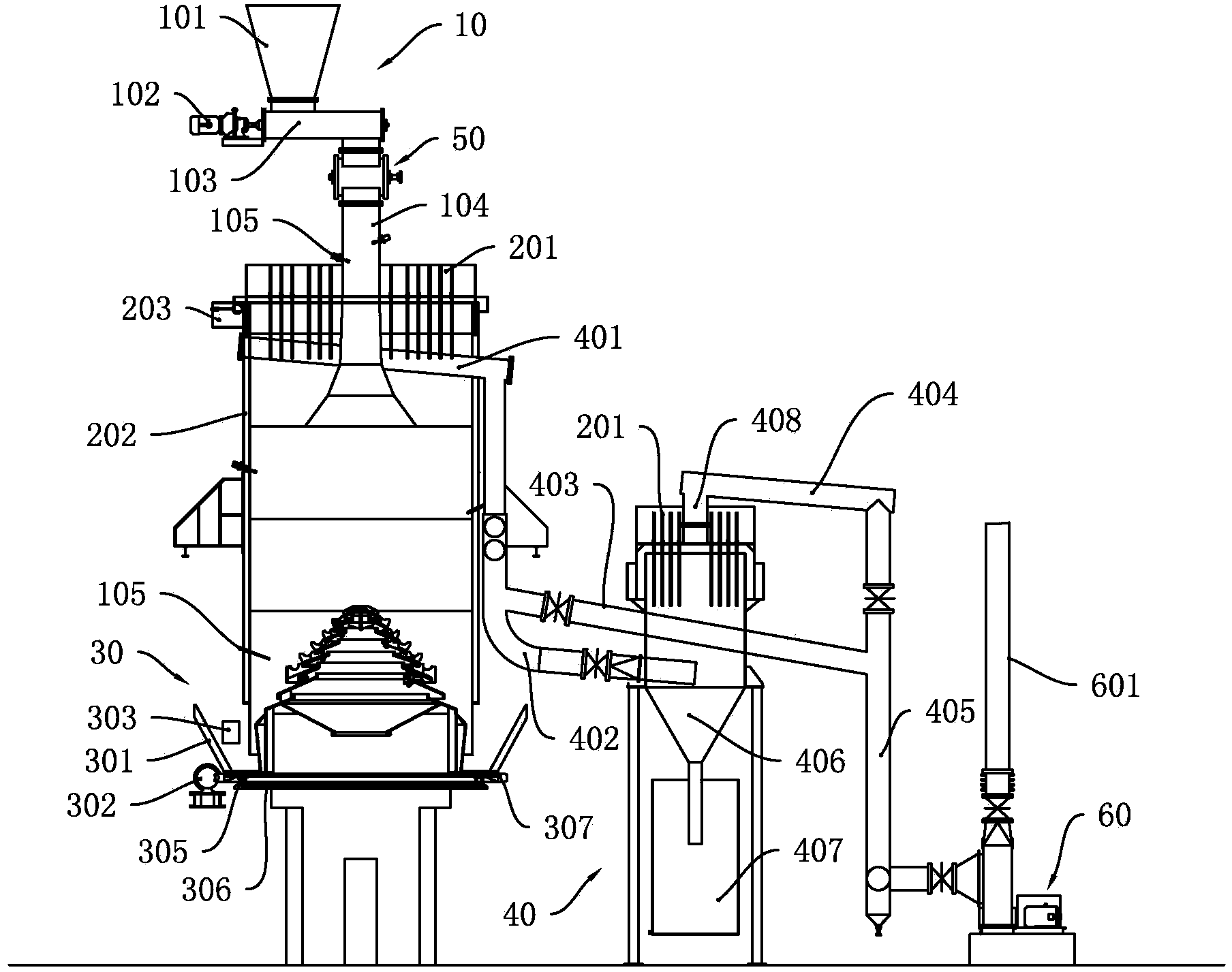

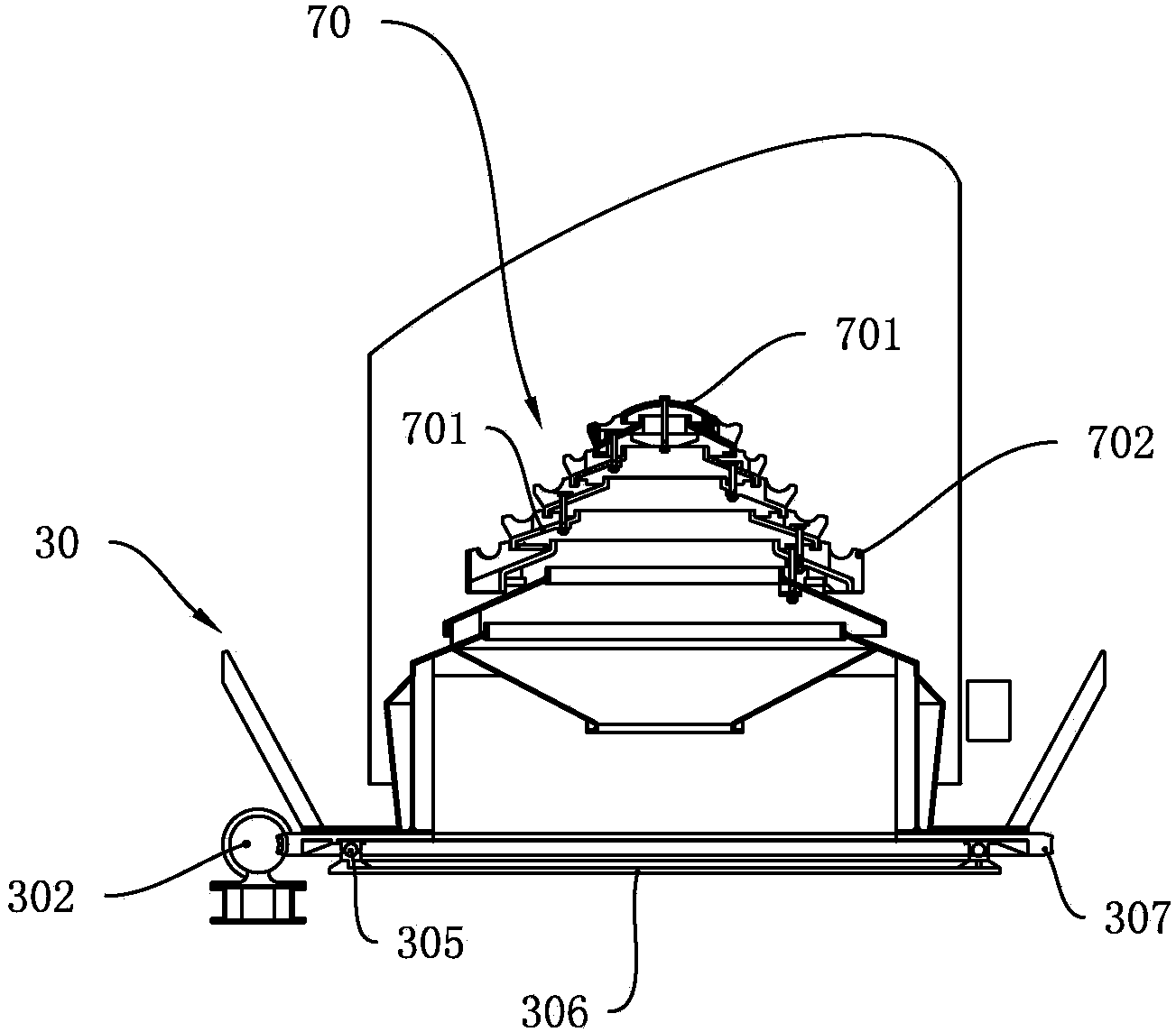

Tower type biomass gasifier

The invention discloses a tower type biomass gasifier. The tower type biomass gasifier comprises a gasifier body, a feeding device for conveying fed materials and an ash removing device arranged at the bottom of the gasifier body, as well as a driving system for driving the ash removing device to rotate, wherein a tower-shaped fire grate is supported on the inner side of the ash removing device; a plurality of heat pipes parallel to the axis of the gasifier body are arranged at the top of the inner side of the gasifier body; a gap is formed between the bottom of the gasifier body and the ash removing device, and the bottom of the gasifier body and the ash removing device are sealed by use of a liquid; the tower-shaped fire grate extends into the gasifier body and a gap is formed between the tower-shaped fire grate and the sidewall of the gasifier body. The tower type biomass gasifier further comprises a fan for blowing air into the tower-shaped fire grate. The tower type biomass gasifier has the advantages that slag can be quickly crushed, goes into the ash removing device and then is discharged from the ash removing device safely and efficiently, and partial tar can be separated from gas and is prevented from adhering to the pipelines of a combustion device.

Owner:广东宝杰环保科技有限公司

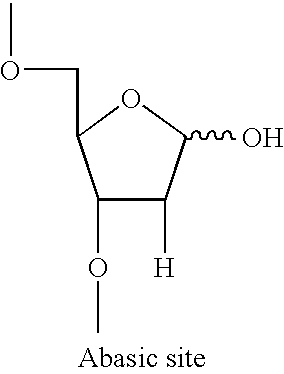

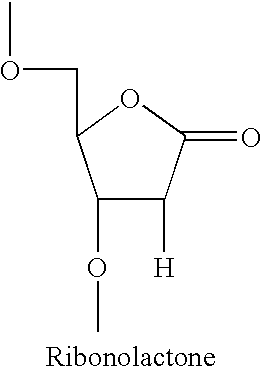

Method for labeling and fragmenting DNA

InactiveUS20030143555A1Promote fragmentationPromote generationSugar derivativesMicrobiological testing/measurementPhosphatePhosphoric acid

The invention relates to a method for labeling and fragmenting a single- or double-stranded deoxyribonucleic acid (DNA) comprising the following steps: chemically fragmenting the DNA by creating at least one abasic site on said DNA, attaching a marker to at least one of the fragments by means of a labeling reagent, said reagent covalently and predominantly coupling to at least one phosphate of said fragment. The invention finds a preferred application in the field of diagnosis.

Owner:MERIEUX BIO +2

Processing process of green tea capable of being brewed by cold water

ActiveCN103999956APromote fragmentationFacilitated releasePre-extraction tea treatmentQuick FreezeMicrowave

The invention discloses a processing process of green tea capable of being brewed by cold water. The processing process comprises the steps of fresh leaf picking, low-temperature quick freezing, microwave thawing water removing, first-step roasting leaf stir-frying, twisting, cooling, piling slight fermentation and drying, wherein in the low-temperature quick freezing step, picked fresh leaves are fast conveyed into a freezer and are fast frozen for 24 to 48 hours at -20 DEG C; in the microwave thawing water removing step, the fast frozen fresh leaves are flatly paved onto a conveying belt of a microwave water removing machine, the thickness is 2 to 4cm, and the microwave water removing machine is started for performing microwave water removing for 5 to 8 minutes until the water content of the fresh leaves is 70 to 75 percent; and in the piling slight fermentation step, the cooled twisted leaves are firstly subjected to piling, the weight in each pile is 30kg, each tea pile is sealed and covered by preservative films after the piling, and the twisted leaves are subjected to slight fermentation for 1 hours in sealed environment. The processing process has the advantages that the tippy quantity of the prepared tea is great, the taste is mellow, the mouth feeling is good, in addition, the cell fragmentation degree is high, and the fragmentation is sufficient, so the green tea is suitable for being brewed by the cold water; and the processing process is simple.

Owner:黄山紫霞茶业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com